LG KE-14P2G, KB-14P2G, KE-14P2P, KE-14P2S, KL-14P2B Service Manual

...

TVCR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : MV-995B

MODEL : KB/

KE/KL/KF-14P2B/G/P/S

MODEL :

KB/

KE/KL/KF-14P2BX/GX/PX/SX

MODEL : KB/KE/KL/KF-20/21P30X

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

SERVICE MANUAL MODEL:KE/KL/KF-14P2BX/21P30X

LG Electronics inc.

CHASSIS : MV-995B

MODEL : KB/KE/KL/KF-14P2B/G/P/S

MODEL : KB/KE/KL/KF-14P2BX/GX/PX/SX

MODEL : KB/KE/KL/KF-20/21P30X

CONTENT

SPECIFICATION ................................................1-2

SAFETY INSTRUCTIONS ............................ 1-3

SERVICING PRECAUTIONS ....................... 1-4

DESCRIPTION OF CONTROLS .................. 1-6

SECTION 1 SUMMARY

TVCR

SERVICE MANUAL

1-2

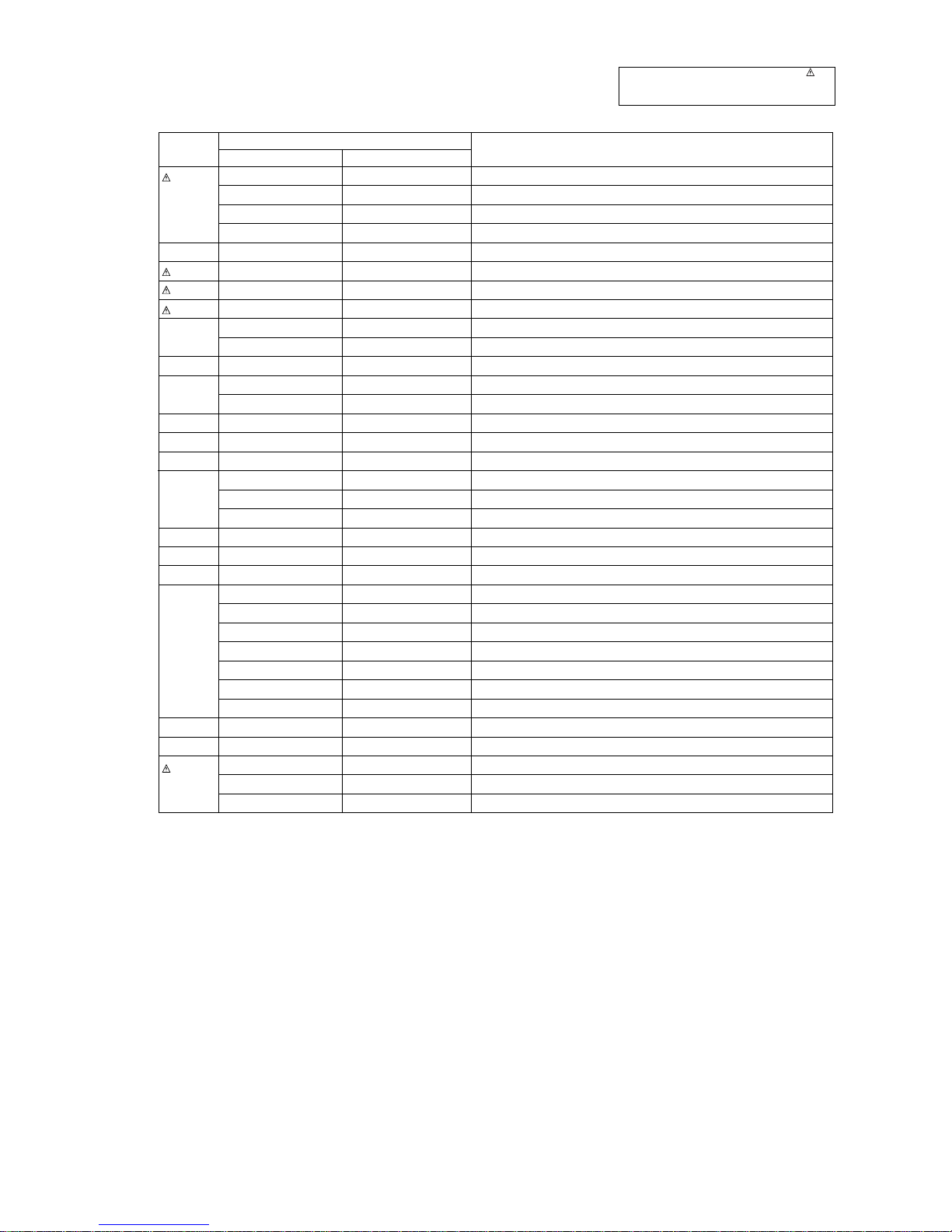

SPECIFICATIONS

Video

Video S

/

Video Re

Head Two

Tape S

Tape Fo

Timer Progr

Tape L

Input/

Audio

Audio Re

Head No

Input/

General

Power Source A

Power Consum

2

2

Channel

Tuning Syste

Antenna UH

Sound Output

Operat

Dimens

2

ABBREVIATIONS :

ADJ

AFC

AG

AM

CPT

DEF

DET

FBT

H.V

OSC

SEP Sep

SYNC

S.I.

V.I

H Ho

V V

I

OSD

SAP S

BPF B

ST Stereo

LPF L

DP D

DG

PLL P

AP

BM

BT

1-3

SAFETY PRECAUTIONS

Many el

the Sc

It is

prevent XDo not m

General Guidance

An lsola

the s

the A

as

pers

It wi

da

ina

If a

rep

When rep

Resi

Keep

Due to

extreme c

Do not

X-RAY Radiation

Warning:

To d

h

Ad

M

Th

23

29

If th

and

p

Before returning the receiver to the customer,

a

met

to be

el

Leakage Current Cold Check(Antenna Cold Check)

Wit

conne

Pl

ohm

ohm

antenn

If t

me

When

rea

An o

rece

Leakage Current Hot Check (See

Plug

Do not use a line Isolation Transformer during this check.

Conne

between

a

Me

volt

Reverse

volt

volt

c

In

pos

rep

Leakage Current Hot Check circuit

The

Hi

For

repl

th

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

1-4

CAUTION: Before s

ma

SAFETY PRECAUTIONS

on

NOTE:

If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

General Servicing Precautions

1.

p

a.

mod

b.

or oth

c.

Connectin

capacitor in the receiver.

CAUTION: A

pol

i

d.

2. T

hi

FET

Do not

3.

one end

aq

pi

touch

tube

pers

4. D

a

5.Unl

elec

the c

com

Ac

s

CAUTION: Th

Unles

of c

6. D

whi

eq

7.

elec

a

8. A

recei

p

Al

9.

service manual.

CAUTION: Do not

a

Electrostatically Sensitive (ES) Devices

Some s

easi

ca

typi

trans

fol

in

el

1.

or se

ele

ground.

av

remov

a

2. A

dev

a

exp

3.

E

4.U

so

generate

5.

ele

6. D

p

(Mo

ele

foi

7.

the

m

d

CAUTION:Be

c

8. M

rep

as

of your foot

ele

General Soldering Guidelines

1.

a

tem

2. U

co

3.

4. T

wire

Do not

5.

a.

(5

b.

c.

su

CAUTION: Work

c

6.

a.

tem

b.

ag

SERVICING PRECAUTIONS

1-5

c.

com

there onl

c

CAUTION: Work

b

d.

or sp

IC Remove/Replacement

Some c

whi

ci

tech

worki

sta

Removal

1.

gently p

s

2. D

type

rem

Replacement

1.

2. C

s

3.

(It

"Small-Signal" Discrete Transistor

Removal/Replacement

1.

cl

2. B

rem

3.

4. C

corres

cri

conta

Power Output, Transistor Device

Removal/Replacement

1.

2.Rem

3.

c

4.

5.

6.

Diode Removal/Replacement

1.

p

2. B

b

3.

around

4. Sec

5.

the two

and

Fuse and Conventional Resistor

Removal/Replacement

1.

h

2. S

notc

3

CAUTION: M

co

to p

Circuit Board Foil Repair

Ex

bo

bo

The

whenever

At IC Connections

To re

fol

p

c

1.

kn

nec

2. c

(if

3.

c

4. Rou

co

of the

c

At Other Connections

Use

p

invo

s

1.

Remove

h

2. T

p

d

3.

the n

the

C

CAUTION: Be

the

1-6

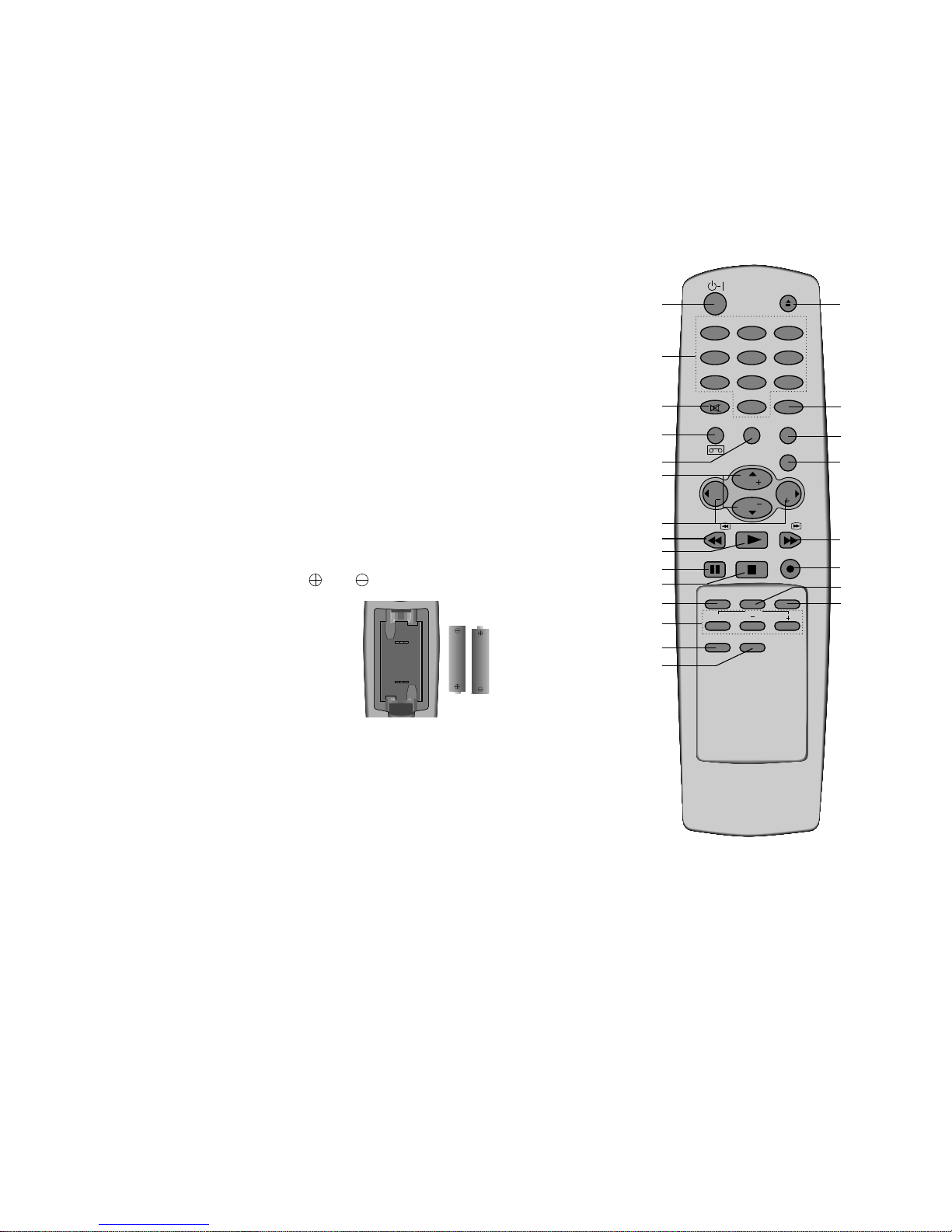

DESCRIPTION OF CONTROLS

All the functions can be controlled with the remote control handset.

Some functions can also be adjusted with the buttons on the front

panel of the set.

Remote control handset

Before you use the remote control handset, please install the

batteries. See the next page.

1. r-I (POWER)

switches the set on from standby or off to standby.

2. NUMBER BUTTONS

switch the set on from standby or directly select a number.

3. MUTE

switches the sound on or off.

4. TIMER PROG

displays the timer programme recording menu.

5. CLEAR/RESET

resets the tape counter or clears a data in the Timer

programme

menu.

6.

D

/

E

(PROGRAMME UP/DOWN)

switches the set on from standby.

selects a programme or a menu item.

7.

F/G

(VOLUME UP/DOWN)

adjusts the volume.

adjusts menu settings.

8. REW (REWIND/REVIEW)

rewinds the tape at high speed in the stop mode.

reviews fast the tape during playback.

9. PLAY

plays back the tape at normal speed.

10. PAUSE/STILL

stops the tape temporarily during recording.

displays a still picture during playback.

11. STOP

stops the tape during playback or recording.

12. SLEEP

sets the sleep timer.

13. TRK AUTO, +/-

adjust the picture automatically or manually during playback.

14. CLOCK/COUNT

displays the current time or tape counter.

15. SP/LP

selects a recording tape speed SP or LP.

16. TELETEXT BUTTONS (option)

These buttons are used for teletext.

For further details, see the ‘Teletext’ section.

OK

PR

VOL

PR

VOL

PLAY

P/STILL STOP

REC/ITR

REW/

FF/

SLEEP

AUTO

CLOCK/COUNT

TRK

SYSTEM Q.VIEW

SP/LP

?

TEXT

i

0

MUTE

TV/AV

MENU

CLEAR/RESETTIMER PROG

1

2 3

4

5 6

7

8 9

EJECT

1

3

4

5

6

7

8

12

13

15

16

10

2

9

11

14

(With TELETEXT)

17

18

19

21

23

22

24

20

1-7

Battery installation

The remote control handset is powered by two AA type batteries.

To load the batteries, turn the handset over and slide open the

battery compartment. Install two batteries as indicated by the

polarity symbols( and ) marked inside the compartment.

Note : To avoid damage from possible battery leakage, remove the

batteries if you do not plan to use the remote control handset for an

extended period of time.

17. EJECT

ejects the tape.

18. TV/AV

selects a TV or AV mode.

19. MENU

selects a menu.

20. OK

accepts your selection or displays the current mode.

21. FF (FAST FORWARD/CUE)

winds the tape forward at high speed in the stop mode.

fast forward playback.

22. REC/ITR

starts a manual recording or instant timer recording.

23. SYSTEM

selects the desired VCR colour system.

24. QUICK VIEW

returns to the previously viewed programme.

OK

PR

VOL

PR

VOL

PLAY

P/STILL STOP

REC/ITR

REW/

FF/

SLEEP

AUTO

CLOCK/COUNT

TRK

SYSTEM Q.VIEW

SP/LP

0

MUTE

TV/AV

MENU

CLEAR/RESETTIMER PROG

1

2 3

4

5 6

7

8 9

EJECT

1

3

4

5

6

7

8

12

13

10

2

9

11

14

15

(Without TELETEXT)

17

18

19

21

23

22

24

20

1-8

1. MAIN POWER (ON/OFF)

switches the set on or off.

Note : One power line lives even when the

main power is off.

2. POWER (r-I)

switches the set on from standby or off to

standby.

3. REMOTE CONTROL SENSOR

4. AUDIO/VIDEO IN SOCKETS (AV2)

Connect the audio/video out sockets of the

external VCR to these sockets.

5. REC/ITR

starts a manual recording or instant timer

recording.

6. PLAY

plays back the tape at normal speed.

7. PAUSE/STILL (option)

stops the tape temporarily during recording.

displays a still picture during playback.

8. MENU (option)

selects a menu.

9. STANDBY INDICATOR

illuminates red brightly when the set is in

standby mode.

dims red when the set is switched on.

10. TIMER REC INDICATOR

illuminates red when the timer programme is

set for recording.

11. VOLUME UP/DOWN

adjusts the volume.

adjusts menu settings.

12. PROGRAMME UP/DOWN

switches the set on from standby.

selects a programme or a menu item.

13. CASSETTE COMPARTMENT

To insert a video cassette tape here.

14. REC/ITR INDICATOR

illuminates red during recording.

15. REW (REWIND/REVIEW)

rewinds the tape at high speed in the stop

mode.

reviews fast the tape during playback.

16. FF (FAST FORWARD/CUE)

winds the tape forward at high speed in the

stop mode.

fast forward playback.

17. STOP/EJECT

stops the tape during playback or recording

or ejects the tape.

18. OK (option)

accepts your selection or displays the current

mode.

19. TAPE-IN INDICATOR (option)

illuminates green while a video cassette tape

is inserted.

20. HEADPHONE SOCKET (option)

connect the headphone plug to this socket.

Note : In some models, you might drop the set if

you move it only with the handle on the top of the

set. So you can should support the bottom of the

set at the same time.

Front panel

AV2

ON/OFF

VOL

PR

REC/ITR REW/ PLAY FF/ P/STILL STOP/EJECT MENU OK

VIDEO- IN -AUDIO

STAND-BY TAPE-IN TIMER REC

,,,,,,,,,,,,,,,,,

,,,,,

REC/iTR REW/

PLAY

FF/

P/STILL

STOP/EJECT

MENU

OK

VOL

PR

STAND-BY

TAPE-IN

TMER REC

ON/OFF

AV2

VIDEO- IN -AUDIO

20

20

4

14

13 15 16 17

1918

1

3 5 6 7 8

9

10 11

12

2 4

ON/OFF

/

VOL PR

STOP/EJECT REW/

PLAY FF/

REC/ITR

AV2

AUDIO

VIDEO

H/P

REC TIMER REC STAND-BY

IN

13 15 16

10 43

1

11

12

17 6 5

14

9

20

2

ON/OFF

VOL PR

STOP/EJECT REW/

PLAY FF/

REC/ITR

REC TIMER-REC STAND-BY

13 15 16

103

1

11

12

17 6 5

14

9 202

14

13 15 16 17

1918

1

3 5 6 7 8

9

10 11

12

2 4

CHASSIS : MV-995B

MODEL : KB/KE/KL/KF-14P2B/G/P/S

MODEL : KB/KE/KL/KF-14P2BX/GX/PX/SX

MODEL : KB/KE/KL/KF-20/21P30X

CONTENT

EXPLODED VIEW .............................................2-2

EXPLODED VIEW PARTS LIST..................2-3

DISASSEMBLY INSTRUCTIONS

..................2-6

SECTION 2 DISASSEMBLY PART

TVCR

SERVICE MANUAL

2-2

EXPLODED VIEW:14P2

330

340

320

315

300

120

501

520

310

943

400

603

610

601

602

121

A00

174

913

510

112

153

170

150

2-3

EXPLODED VIEW PARTS LIST

LOCA. NO PART NO DESCRIPTIONS

112 2055-00744L CPT SET A34KPU02XX 00N7ND

2055-00744K CPT SET A34KPU02XX 00L7ND * MOS-BWT

2055-00744M CPT SET A34KPU02XX 00P7ND * NAGHI

2055-00745J CPT SET A34KPU02XX 00S7ND * LGEAP

120 6400VA0019B SPEAKER,G9050402(C93H)8 OHM

121 4810V00205A BRACKET,SPK

150 150-D02B COIL,DEGAUSSING,CU 14” 42T 5.7 OHM

153 153-113V DY,DCAD2-14SNAB

170 170-A01E LEAD SET,CPT EARTH

300 3091V00251G CABINET ASSY(BLUE)

3091V00251C CABINET ASSY(GREEN)

3091V00251F CABINET ASSY(SILVER)

3091V00251H CABINET ASSY(PINK)

310 5020V00382A BUTTON,CONTROL

315 3580V00014J DOOR,CST(BLUE)

3580V00014K DOOR,CST(PINK)

3580V00014T DOOR,CST(SILVER)

3580V00014W DOOR,CST(GREEN)

320 320-075B SPRING,KNOB

330 5020V00381A BUTTON,POWER

340 5020V00383A BUTTON,CONTROL

400 3809V00185B BACK COVER ASSY(GREEN)

3809V00185C BACK COVER ASSY(BLUE,SCART)

3809V00185E BACK COVER ASSY(SILVER,SCART)

3809V00185F BACK COVER ASSY(BLUE,PHONO)

3809V00185D BACK COVER ASSY(PINK,SCART)

3809V00185G BACK COVER ASSY(PINK,PHONO)

501 4810V00012A BRACKET,SMPS

520 6871VDM105A PWB ASSY,MAIN2 14”,NARROW

601 4810V00195C BRACKET,MAIN

602 4814V00158B SHIELD,BOTTOM

603 4814V00157E SHIELD,TOP CASE

610 6871VMM449A PWB ASSY,MAIN KE,E/D/F,W/TXT,SCART

6871VMM449B PWB ASSY,MAIN KE,E/D/F,W/O TXT,SCART

6871VMM449C PWB ASSY,MAIN KL,E/D/F,W/O TXT,SCART

6871VMM449D PWB ASSY,MAIN KE,E/I/S,W/TXT,SCART

6871VMM449H PWB ASSY,MAIN KF,E/RUS,W/O TXT,PHONO

6871VMM449M PWB ASSY,MAIN KB,E/D/F,W/O TXT,PHONO

913 332-057A SCREW ASSY,HEXAGON HEAD

943 1PTF0403116 SCREW,TAP TITE D4.0 L16.0

A00 6721R-0105B DECK ASSY,D33(TV-33A2OMO 1KT2,2HD,NP

P801 174-009V CORD,POWER(W/HOLD,HOUSING)L=400,4.0

174-224G CORD,POWER H03VVH2-F

174-222W CORD,POWER

The components identified by mark is

critical for safety.

Replace only with part number specified.

330

320

315

603

610

601

602

A00

501

520

P801

913

510

112

153

170

150

310

943

400

120

EXPLODED VIEW:20/21P30X

2-4

2-5

112 2055-01221L - CPT

2055-01221K 2424GDA80AV CPT *MOS-BWT

2055-01221S 2424GDA80AB CPT *LGESW ,A.E.C,LGEGF

2055-01221Q 2426GDA80AG CPT *LGEAP

120 120-D44D 120-D44D SPEAKER,16OHM 3W/5

150 150-D02M 150-D02M COIL,DEGAUSSING

153 153-276A 6150Z-1023A DY

170 170-A01F 170-A01F LEAD SET,CPT EARTH

300 3091V00268C - CABINET ASSY(W/O SECAM)

3091V00268D 3091V00269D CABINET ASSY(W/SECAM)

310 5020V00401B 5020V00399A BUTTON,CONTROL

315 3580V00014Y - DOOR,CST,W/O SECAM

3580V00014S 3580V00014S DOOR,CST,W/SECAM

330 5020V00402A 5020V00400A BUTTON,POWER

400 3809V00195C 3809V00195C BACK COVER ASSY

501 4810V00206B 4810V00206B BRACKET,SMPS

520 6871VDM105B 6871VDM105C PWB ASSY,MAIN2 CKD ,NARROW

6871VDM105E 6871VDM105F PWB ASSY,MAIN2 CKD KF-

6871VDM105L 6871VDM105M PWB ASSY,MAIN2 CKD KB-

601 4810V00195A 4810V00195A BRACKET,MAIN

602 4814V00158B 4814V00158B SHIELD,BOTTOM

603 4814V00157F 4814V00157F SHIELD,TOP CASE

610 6871VMM449A - PWB ASSY,MAIN PAL E/D/F,W/TXT

6871VMM449B 6871VMM449B PWB ASSY,MAIN PAL E/D/F,W/O TXT

6871VMM449C 6871VMM449C PWB ASSY,MAIN PAL E/D/F,W/O TXT

6871VMM449F - PWB ASSY,MAIN PAL E/D/F,W/TXT

6871VMM449H 6871VMM449H PWB ASSY,MAIN PAL E/RUS,W/O TXT

6871VMM449K 6871VMM449K PWB ASSY,MAIN KF E/D/F,W/O TXT

6871VMM449L 6871VMM449L PWB ASSY,MAIN KF E/D/F,W/TXT

913 332-057B 332-057B SCREW ASSY,HEXAGON HEAD

943 1PTF0403116 1PTF0403116 SCREW,TAP TITE D4 L16

P801 174-224G 174-224G POWER CORD

174-009Q 174-009Q POWER CORD

174-222W 174-222W POWER CORD

LOCA. NO

20” 21”

PART NO

DESCRIPTIONS

EXPLODED VIEW PARTS LIST

The components identified by mark is

critical for safety.

Replace only with part number specified.

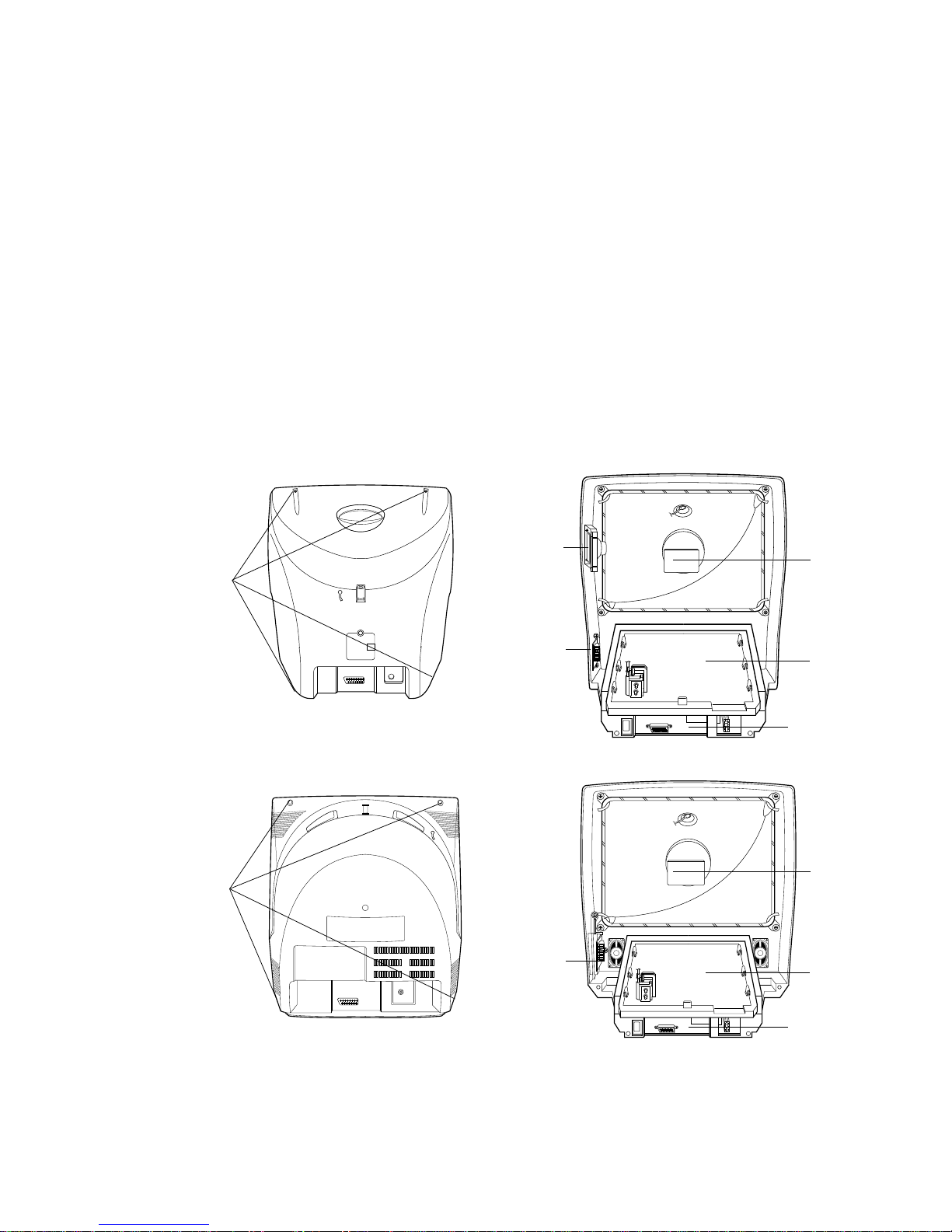

DISASSEMBLY INSTRUCTIONS

2-6

1. Back Cover Removal

Remove th

sepa

hol

2. Main 2 PCB Removal

Gra

3. Main Chassis Removal

1)

c

2)G

4. Speaker Assembly Removal

1)

c

2)

5. CPT REMOVAL

1

C

2)P

3

4)

PICTURE TUBE HANDLING CAUTION

Due to

c

p

TH

or s

result

pers

Fig. 2-1

Fig. 2-2

CPT

Board

Remove

Screws

Remove

Screws

Main 2

PCB

Side AV

PCB

Main chassis

CPT

Board

Main 2

PCB

Side AV

PCB

Main chassis

Speaker

MODEL:14P2

MODEL:20/21P30X

CHASSIS : MV-995B

MODEL : KB/KE/KL/KF-14P2B/G/P/S

MODEL : KB/KE/KL/KF-14P2BX/GX/PX/SX

MODEL : KB/KE/KL/KF-20/21P30X

CONTENT

PURITY & CONVERGENCE ADJUSTMENT

........3-2

ADJUSTMENT INSTRUCTIONS .................3-5

BLOCK DIAGRAM ..............................................3-7

WIRING DIAGRAM ........................................ 3-10

TROUBLESHOOTING CHARTS .................3-11

COMPONENT LOCATION GUIDE.............3-16

PRINTED CIRCUIT BOARDS .......................3-17

SECTION 3 ELECTRICAL PART

TVCR

SERVICE MANUAL

3-2

PURITY & CONVERGENCE ADJUSTMENT

Caution:

Convergence and Purity have been factory aligned. Do not

attempt to tamper with these alignments.

However, the effects of adjacent receiver components, or

replacement of picture tube or deflection yoke may require the

need to readjust purity any convergence.

¡ Purity Adjustment

This procedure DOES NOT apply to bonded yoke and picture

tube assemblies.

The instrument should be at room temperature (60 degrees F or

above) for six (6) hours and be operating at low beam current

(dark background) for approximately 20 to 30 minutes before

performing purity adjustments.

CAUTION: Do not remove any trim magnets that may be

attached to the bell of the picture tube.

1. Remove the AC power and disconnect the internal

degaussing coil.

2. Remove the yoke from the neck of the picture tube.

3. If the yoke has the tape version beam bender, remove it and

replace it with a adjustable type beam bender (follow the

instructions provided with the new beam bender)

4. Replace the yoke on the picture tube neck, temporarily

remove the three (3) rubber wedges from the bell of the

picture tube and then slide the yoke completely forward.

5. Reconnect the internal degaussing coil.

6. Position the beam bender locking rings at the 9 o'clock

position and the other three pairs of tabs (2,4 and 6 pole

magnets) at the 12 o'clock position.

7. Perform the following steps, in the order given, to prepare the

receiver for the purity adjustment procedure.

a. Face the receiver in the "magnetic north" direction.

b. Externally degauss the receiver screen with the television

power turned off.

c. Turn the television on for approximately 10 seconds to

perform internal degaussing and then turn the TV off.

d. Unplug the internal degaussing coil. This allows the

thermistor to cool down while you are performing the purity

adjustment. DO NOT MOVE THE RECEIVER FROM ITS

"MAGNETIC NORTH" POSITION.

e. Turn the receiver on and obtain a red raster by increasing

the red bias control (CW) and decreasing the bias controls

for the remaining two colors (CCW).

f. Attach two round magnets on the picture tube screen at 3

o'clock and 9 o'clock positions, approximately one (1) inch

from the edge of the mask (use double-sided tape).

DEFLECTION YOKE

PURITY &CONVERGENCE

MAGNET ASSEMBLY

RUBBER

WEDGES

GLASS CLOTH TAPE

PURITY MAGNET

6-POLE

4-POLE

4-POLE

MAGNET

CONVERGENCE MAGNET ASSEMBLY

6-POLE

MAGNES

PURITY MAGNET(2-POLE)

X-AXIS YOKE

POSITIONING

(L/R PURITY)

6-POLE

MAGNETS

CONVERGENCE MAGNET ASSEMBLY

3-3

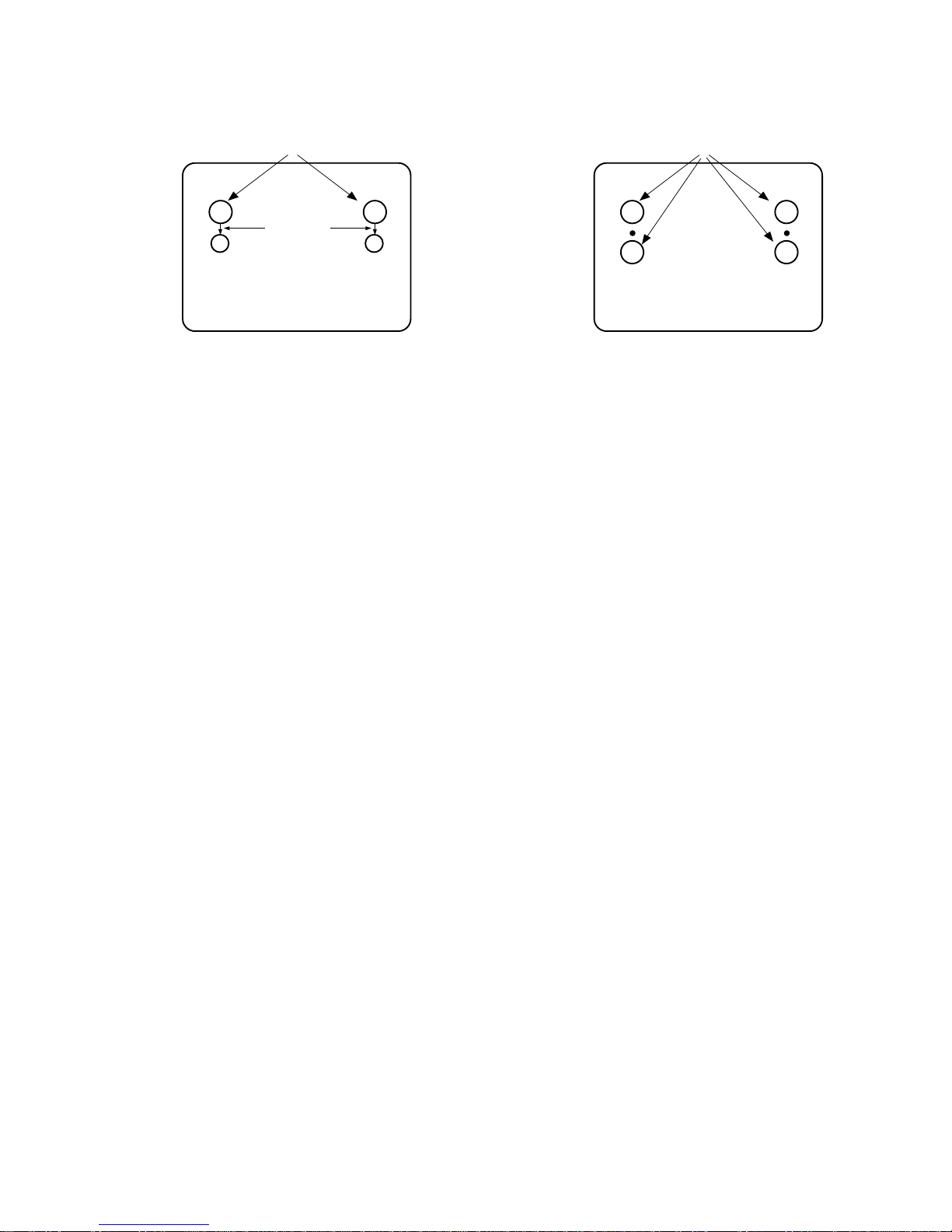

8. Referring to above, perform the following two steps:

a. Adjust the yoke Z-axis to obtain equal blue circles.

b. Adjust the appropriate beam bender tabs to obtain correct

purity (four equal circles).

9. After correct purity is set, tighten the yoke clamp screw and

remove the two screen magnets.

10. Remove the AC power and rotate the receiver 180 degrees

(facing "magnetic south").

11. Reconnect the internal degaussing coil.

12. Turn the receiver on for 10 seconds (make sure the receiver

came on) to perform internal degaussing, and then turn the

receiver off.

13. Unplug the internal degaussing coil.

14. Turn on the receiver and check the purity by holding one (1)

round magnet at the 3 o'clock and a second round magnet at

9 o'clock position. If purity is not satisfactory, repeat steps 8

through 14.

15. Turn off the receiver and reconnect the internal degaussing

coil.

¡ Convergence Adjustment

Caution: This procedure DOES NOT apply to bonded yoke and

picture tube assemblies.

Do not use screen magnets during this adjustment

procedure. Use of screen magnets will cause an

incorrect display.

1. Remove AC power and disconnect the internal degaussing

coil.

2. Apply AC Power and set the brightness to the Picture Reset

condition. Set the Color control to minimum.

3. Apply 8V to the pin.

4. Adjust the Red, Green and Blue Bias controls to get a dim

white line.

5. Remove the AC power and 8V from the pin.

6. Reconnect the internal degaussing coil and apply AC power.

7. Turn the receiver on for 10 seconds to perform internal

degaussing and then turn the receiver off again.

8. Unplug the internal degaussing-coil.

9. Turn on the receiver, connect a signal generator to the VHF

antenna terminal and apply a crosshatch signal.

Caution: During the convergence adjustment procedure, be

very careful not to disturb the purity adjustment tabs

are accidentally move, purity should be confirmed

before proceeding with the convergence adjustments.

Note:

Make sure the focus is set correctly on this instrument

before proceeding with the following adjustment.

10. Converge the red and blue vertical lines to the green vertical

line at the center of the screen by performing the following

steps (below TABLE).

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in opposite directions from the 12 o'clock

position to converge the red and blue vertical lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in opposite directions form the 12 o'clock

position to converge the red and blue (now purple)

vertical lines with the green vertical line.

11. Converge the red and blue horizontal with the green line at

the center of the screen by performing the following steps.

(below TABLE)

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in the same direction (keep the spacing

between the two tabs the same) to converge the red and

blue horizontal lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in same direction (keep the spacing

between the two tabs the same) to converge the red and

blue (now purple) horizontal lines with the green

horizontal line.

c. Secure the tabs previsouly adjusted by locking them in

place with the locking tabs on the beam bender.

MAGNETS

RED RED

1.ADJUST YOKE Z-AXIS FIRST

TO GET EQUAL BLUE

COLOR CIRCLES

2 .ADJUST BEAM BENDER 2 POLE

MAGNET TO GET FOUR EQUAL

COLOR CIRCLES

3-4

RING

PAIRS

4

POLE

ROTATION DIRECTION

OF BOTH TABS

OPPOSITE

SAME

OPPOSITE

SAME

MOVEMENT OF RED

AND BLUE BEAMS

B B

RR

OR

OR

B R B R

OR

B

R

B

R

B R

OR

B

R

6

POLE

12. While watching the 6 o'clock positions on the screen, rock the

front of the yoke in a vertical (up/down) direction to converge

the red and blue vertical lines. (Fig upper left)

13. Temporarily place a rubber wedge at the 12 o'clock position

to hold the vertical position or the yoke.

14.

Check the 3 o'clock and 9 o'clock areas to confirm that the red

and blue horizontal lines are converged.

If the lines are not converged, slightly offset the vertical tilt of the

yoke (move the rubber wedge if necessary) to equally balance the

convergence error of the horizontal lines at 3 o'clock and 9 o'clock

and the vertical lines at 6 o'clock and 12 o'clock.

15. Place a 1.5 inch piece of glass tape over the rubber foot at

the rear of the 12 o'clock wedge.

16. While watching the 6 o'clock and 12 o'clock areas of the

screen, rock the front of the yoke in the horizontal (left to

right) motion to converge the red and blue horizontal lines.

(Fig. upper right)

17. Temporarily place a rubber wedge at the 5 o'clock and 7

o'clock positions to hold the horizontal position of the yoke.

18. Check the 3 o'clock and 9 o'clock areas to confirm that the

red and blue vertical lines are converged. If the lines are not

converged, slightly offset the horizontal tilt of the yoke (move

the temporary rubber wedges if necessary) to equally

balance the convergence error of the horizontal lines at 6

o'clock and 12 o'clock and the vertical lines at 3 o'clock and 9

o'clock.

19. Using a round magnet confirm purity at the center, right and

left sides and corners. See Purity Adjustment Procedure.

20. Reconfirm convergence and apply a 1.5 inch piece of glass

tape over the rubber foot at the rear of the 5 o'clock and the 7

o'clock wedges.

RED

BLUE

RED BLUE

BLUE

RED

GREEN

GREEN

BLUE RED

GREEN

GREEN

ADJUSTMENT

VIEWING

AREA

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

ADJUSTMENT

VIEWING

AREA

RED

RED

GREEN

TV

SCREEN

LEET/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF

THE RED AND BLUE RASTERS

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

LEFT/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF THE

RED AND BLUE RASTERS

3-5

ADJUSTMENT INSTRUCTIONS

Notes;

(Ad

1.

when s

d

2. T

5

3.

op

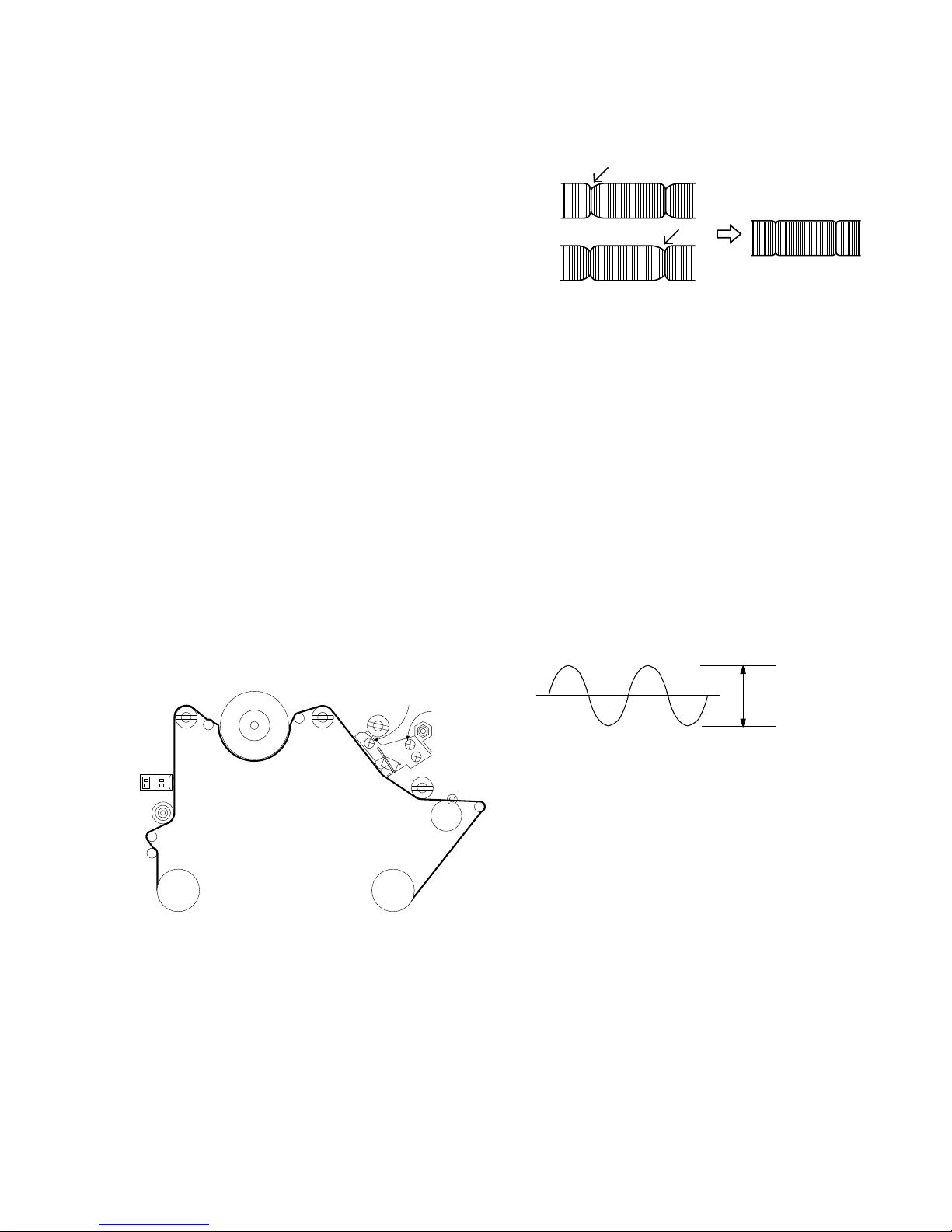

1. DECK ADJUSTMENT

1. Deck Transit System Adjustment

1-1. Necessary Instruments

1

2)

3

4)

(P2,

5)

1-2.Preliminary Steps

1)

PCB. Trigger on this channel.

2)C

PCB.

3

4)Wh

TRK

tra

5)

step

1-3. RF linearity check and adjustment

1)

m

2)C

by p

1-4. X-Distance Adjustment

1

RF

2)C

pre

CAUTION: I

the

(

1-5. Audio Level Check and Adjustment

1

to J

res

2)P

an

the

3

6

2. CIRCUIT ADJUSTMENT

1. PG Adjustment

1-1. Necessary Instruments

1

2)

3

1-2.Adjustment

1

2)C

M

O

3

the

4)

b

DRUM

P2

FE HEAD

P1

ARM

TENSION

P0

SUPPLY

REEL

TAKE-UP

REEL

PINCH

ROLLER

TAPE

CAPSTAN

T/UP

ARM

P4

A/C

HEAD

P3

X-DISTANCE

ADJUST SCREW

AZIMUTH

SCREW

CONE POINT

SCREW

A/C HEAD

HEIGHT ADJUST NUT

<A

P2 POST ADJUST

P2

P3

P3 POST ADJUST

<

Adjust waveform

<

3-6

3. Focus Voltage Adjustment

1)

2)Pres

c

3)

4. Screen Adjustment

1)

2)

3)

4)A

¡

HHooww ttoo ggeett iinnttoo SSVVCC mmooddee wwhheenn yyoouu ddoonn''tt hhaavvee SSVVCC

RReemmoottee CCoonnttrroolllleerr..

PPuusshh tthhee ""OOKK"" KKeeyy oonn tthhee uusseerr''ss RReemmoottee CCoonnttrroolllleerr aanndd llooccaall

""OOKK"" bbuuttttoonn aatt tthhee ssaammee ttiimmee..

5. SIF Adjustment

1)

2)

3)

6. RF AGC Adjustment

1)

2)C

3)

into SV

4)

b

7. White Balance Adjustment

1

wh

2)

3

i

4)

Press

¡ G

8 Deflection Data Adjustment

1

2)Pr

se

3

4)

5) Vertical SLOPE adjustment

¤ Sel

¤Ł Pre

the

6) Vertical amplitude adjustment

¤ Sel

¤Ł Pre

l

of

7) Vertical Shift Adjustment

¤ Sel

¤Ł Pre

wit

8) Horizontal Shift Adjustment

¤ Sel

¤Ł Pre

wit

9) Vertical S-Correction Adjustment

¤ Sel

¤Ł Pres

Pattern

Adjust Period

<Adjust Waveform>

* CAUTION:

MODEL

Electric fields strength

AGC Voltage

65dBu

¡ 0.2dBu

2.3

¡ 0.1Vdc

65dBu

¡ 0.2dBu

2.1¡ 0.1Vdc

KL/KF/KE KI

V

140V

GND

Black Level (DC)

3-7

BLOCK DIAGRAM

VCD BLOCK DIAGRAM

3-8

VIDEO/AUDIO BLOCK DIAGRAM

3-9

3-10

WIRING DIAGRAM

TOUCH .

P805

P805

1

P708

1

P602

P804

P03

P01

P02

P708

P602

P805

P804

P708

P102

P702

P703

P901A

SMPS PWB

P802

P103

P100

CPT PWB

Loading...

Loading...