Page 1

IMPORTANT

Please read through this manual. It contains valuable

information about your air conditioner. This manual may

help save time and money by explaining proper product

maintenance and preventing improper use.

PRECAUTIONS

Pay close attention to precautions in order to prevent

potential hazards and damage from misuse or improper

installation. LG is not responsible for any damages caused

by misuse of the product.

LG

Low Static Hide Away Type Air Conditioner

OWNER'S & INSTALLATION

MANUAL

LG

P/No.: MFL62760202

Page 2

1.The following should be always observed for safety..............................

2. Installation of Indoor, Outdoor unit .........................................................

3. Connecting Pipes to the Indoor Unit .....................................................

4. Connecting Pipes to the Outdoor Unit ..................................................

5. IR Remote Sensor installation & operation detail.................................

6. Connecting Cables between Indoor Unit and Outdoor Unit ................

7. Air Purging of the Connecting Pipes and the Indoor Unit.................... 27

OUT-LINE OF INSTALLATION

Installation works Installation Parts Required tools

A)

B)

C)

D)

E)

F)

•

Four Type “A”

screws

•

Connecting cable

•

Level

•

Screw driver

•

Electric drill

•

Hole core drill (ø70mm)

1) Preparation of Piping...12

•

Pipes: Gas side

Liquid side

•

Insulated drain hose

•

Insulation materials

•

FlaringTools set

1) Connecting the pipes to

the Outdoor Unit ..........14

A) Circuit Breaker Detail......................16

•

Screw driver

•

Hexagonal Wrench (4mm/5mm)

•

Gas-leak Detector

2

4

3

12

14

14

16

Index Page No.

Selection of best location of indoor .....04

Ceiling dimension & Hanging blot detail........05

Filter convertible option.......06

Drain piping .........................07

Insulation of the piping & drain...08

Out door unit best location & piping ....10

B) Wiring diagram, wiring specification & interconnection

detail.................................. ................17

C) Outdoor Wire Routine & Pipe Routine.......25

8. Operating Instructions.................... ........................................................ 28

A) Indoor Unit, Outdoor Unit ...................... 28

B) Remote Control Preparation .. .............. 29

C) Remote Control Operations .. ............... 30

Page 3

3

1. The following should be always observed for safety

• Please report to or take consent by the supply authority before connecting to the system.

• Be sure to read "THE FOLLOWING SHOULD BE ALWAYS OBSERVED FOR SAFETY" before

installing the air conditioner.

• Be sure to observe the cautions specified here as they include important items related to safety.

• The indications and meanings are as follows.

• After reading this manual, be sure to keep it together with the owner's manual in an accessible

place.

Could lead to death, serious injury, etc.

Do not install it yourself (customer).

Perform the installation securely referring to the

installation manual.

Install the unit securely in a place which can bear the

weight of the unit.

Perform electrical work according to the installation

manual and be sure to use an exclusive circuit.

Attach the electrical part cover to the indoor unit and

the service panel to the outdoor unit securely.

Be sure to use the part provided or specified parts for

the installation work.

Check that the refrigerant gas do not leak after

installation is completed.

Perform the drainage/piping work securely

according to the installation manual.

Use the specified wires to connect the indoor and the

outdoor units securely and attach the wires firmly to

the terminal board connecting sections so the stress

of the wires is not applied to the sections.

• Incomplete installation could cause injury due to fire, electric shock,

the unit falling or a leakage of water. Consult the dealer from whom

you purchased the unit or special installer.

• Incomplete installation could cause a personal injury due to

fire, electric shock, the unit falling or a leakage of water.

• When installed in an insufficient strong place, the unit could fall

causing injured.

• Incomplete connecting and fixing could cause fire.

• If the capacity of the power circuit is insufficient or there is

incomplete electrical work, it could result in a fire or an electric

shock.

• The use of defective parts could cause an injury or leakage of

water due to a fire, electric shock, the unit falling, etc.

• If there is a defect in the drainage/piping work, water

could drop from the unit and household goods could be

wet and damaged.

Do not install the unit in a place where an

inflammable gas leaks.

• If gas leaks and accumulates in the area surrounding the unit, it

could cause an explosion.

• If the electrical part cover if the indoor unit and/or the service

panel if the outdoor unit are not attached securely, it could result

in a fire or electric shock due to dust, water, etc.

Could lead to serious injury in particular environments when operated incorrectly.

WARNING

WARNING

CAUTION

CAUTION

Page 4

4

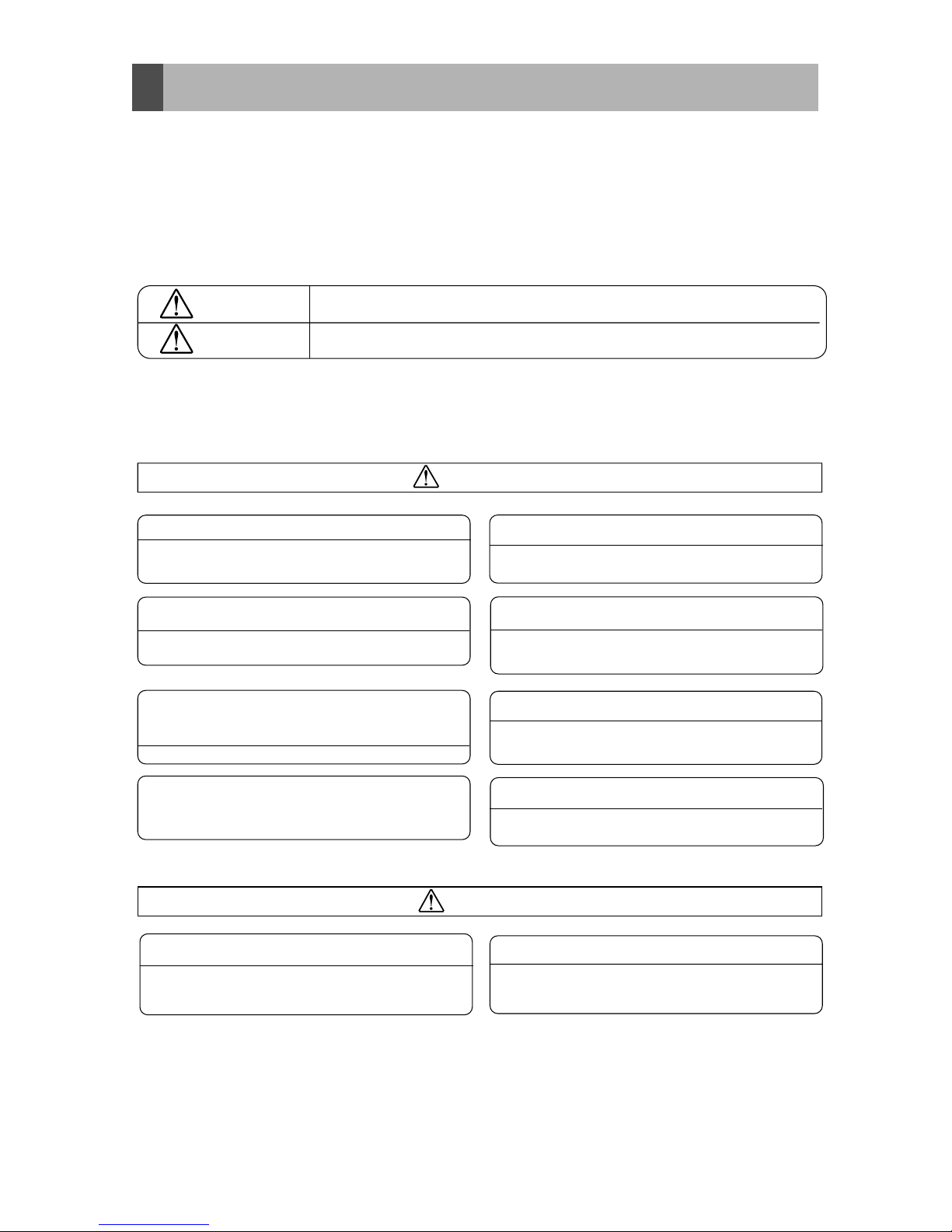

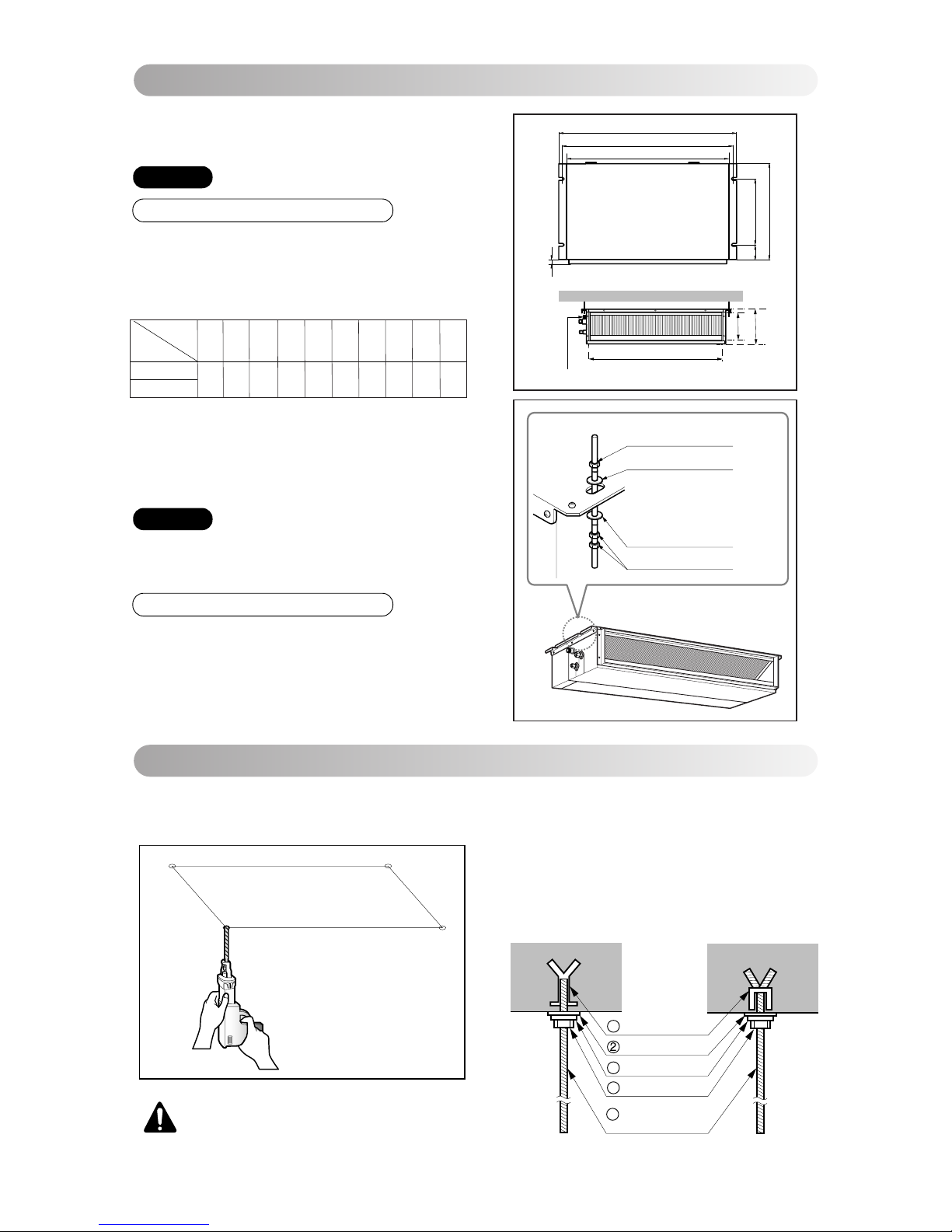

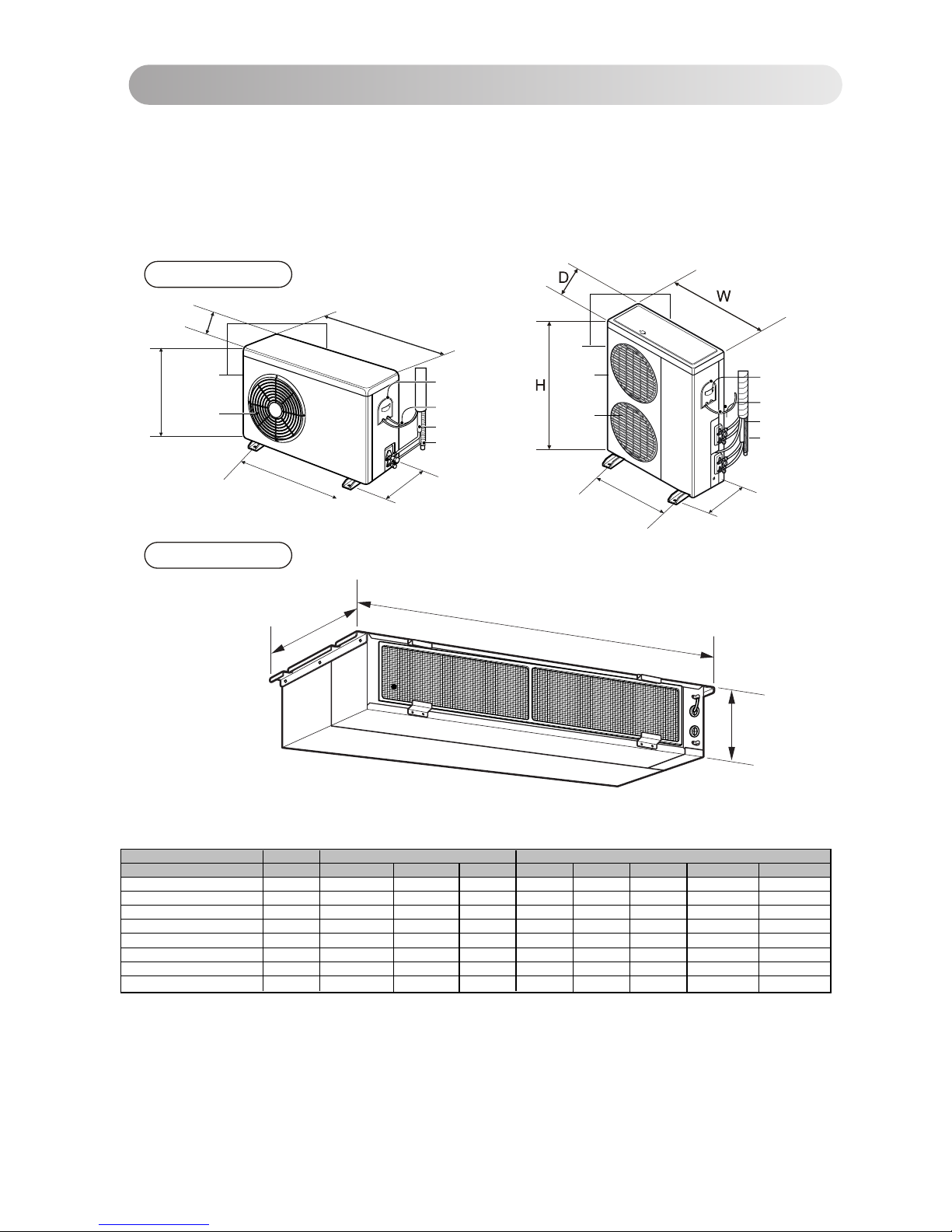

2). Installation of indoor & Outdoor.

Indoor unit

Install the air conditioner in the location that satisfies the following conditions.

• The place shall easily bear a load exceeding four times the

indoor unit’s weight.

• The place shall be able to inspect the unit as the figure.

• The place where the unit shall be leveled.

• The place shall easily connect with the outdoor unit.

• The place where the unit is not affected by an electrical

noise.

• The place where air circulation in the room will be good .

• There should not be any heat source or steam near the

unit

Confirm the positional relationship between the unit and

suspension bolts.

• Installation the ceiling opening to clean the filter or service

under the product.

A).Selection of the best location of Indoor

Inspection hole

(600 x 600)

Control box

H=20 or more

• Suitable dimension "H" is necessary to get a slooe

to drain as aiven in the fiaure

Side view

(unit: mm)

600600

A(Min)

B(Min)

Ceiling

Service Space

A

B

Capacity(Btu/h)

A

B

18/24/30k

600 1100

(Length: mm)

Low static Duct type

Minimum height for motor replacement.

Less than 20cm

Hole size should be

more than the size of IDU.

Insufficient space. Difficult for servicing

20cm to 100cm2

Sufficient space in the ceiling for servicing.

More than 100cm1

Remarks

Distance between

False ceiling & Actual ceiling

Number of

Inspection hole

[Inspection Hole Standard]

36/48/60k

Page 5

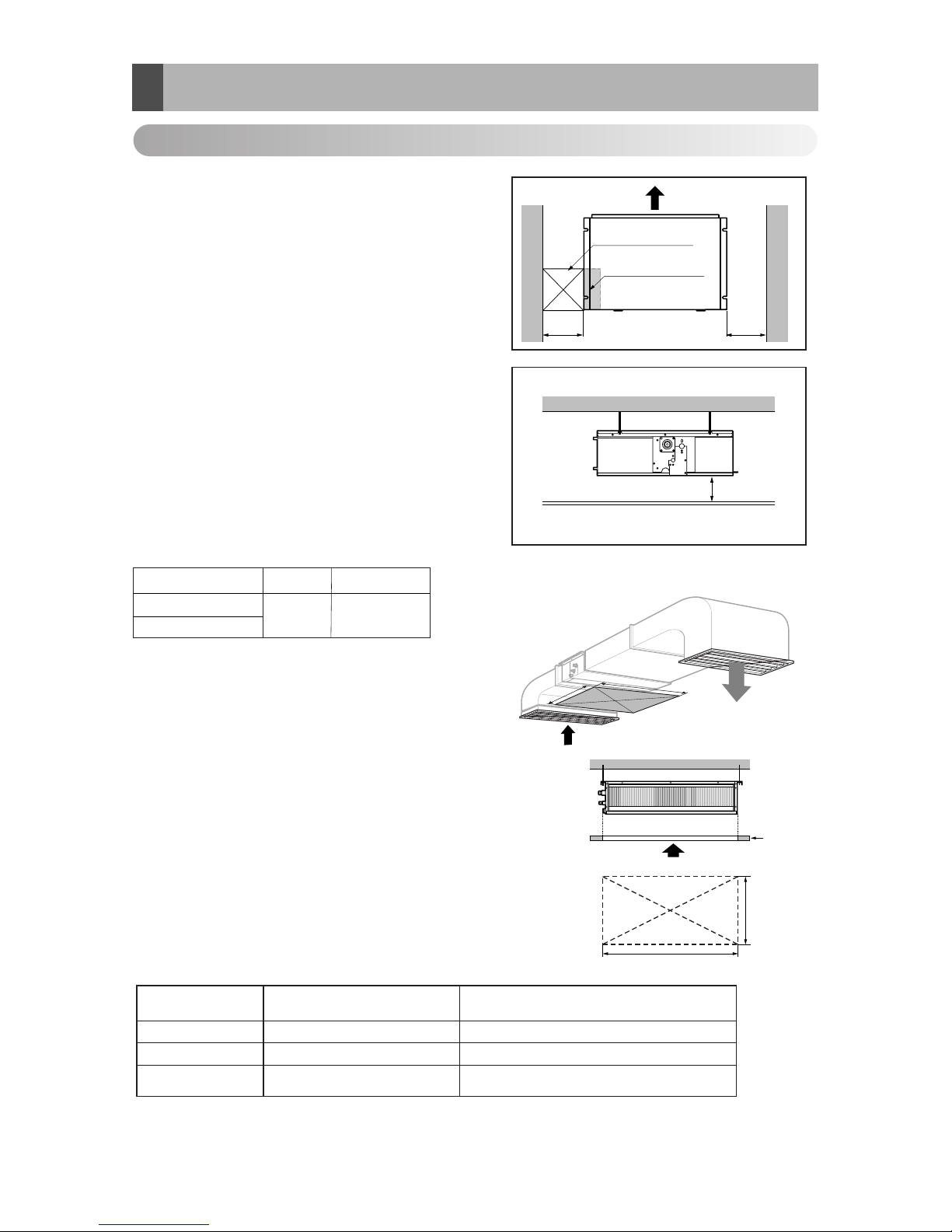

B).Ceiling dimension and hanging bolt location

Installation of Unit

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct to absorb

unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Install the unit leaning to a drainage hole side as a figure

for easy water drainage.

• A place where the unit will be leveled and that can support

the weight of the unit.

• A place where the unit can withstand its vibration.

• A place where service can be easily performed.

CASE 1

POSITION OF SUSPENSION BOLT

(Unit:mm)

18/24/30k BTU/h

1130 1180 383 575 93 190 21 1065 163 1100

Dimension

Capacity(Btu/h)

A B C D E F G H I J

CE

G

D

A

J

B

I

F

H

Drainage hole

Drain Pump use

M10 Nut

M10 washer

X 4

X 4

M10 Nut

M10 washer

X 4

X 8

CASE 2

POSITION OF CONSOLE BOLT

5

• Select and mark the position for fixing bolts.

• Drill the hole for set anchor on the face of ceiling.

• Insert the set anchor and washer onto the suspension bolts for locking the suspension bolts on the

ceiling.

•

Mount the suspension bolts to the set anchor firmly.

• Secure the installation plates onto the suspension

bolts (adjust level roughly) using nuts, washers

and spring washers.

1 Set anchor

Old building New building

Plate washer

3 Spring washer

4 Nut

5 Suspension

bolts

Indoor Unit Installation

CAUTION : Tighten the nut and bolt

to prevent unit falling.

36/48/60k BTU/h

Page 6

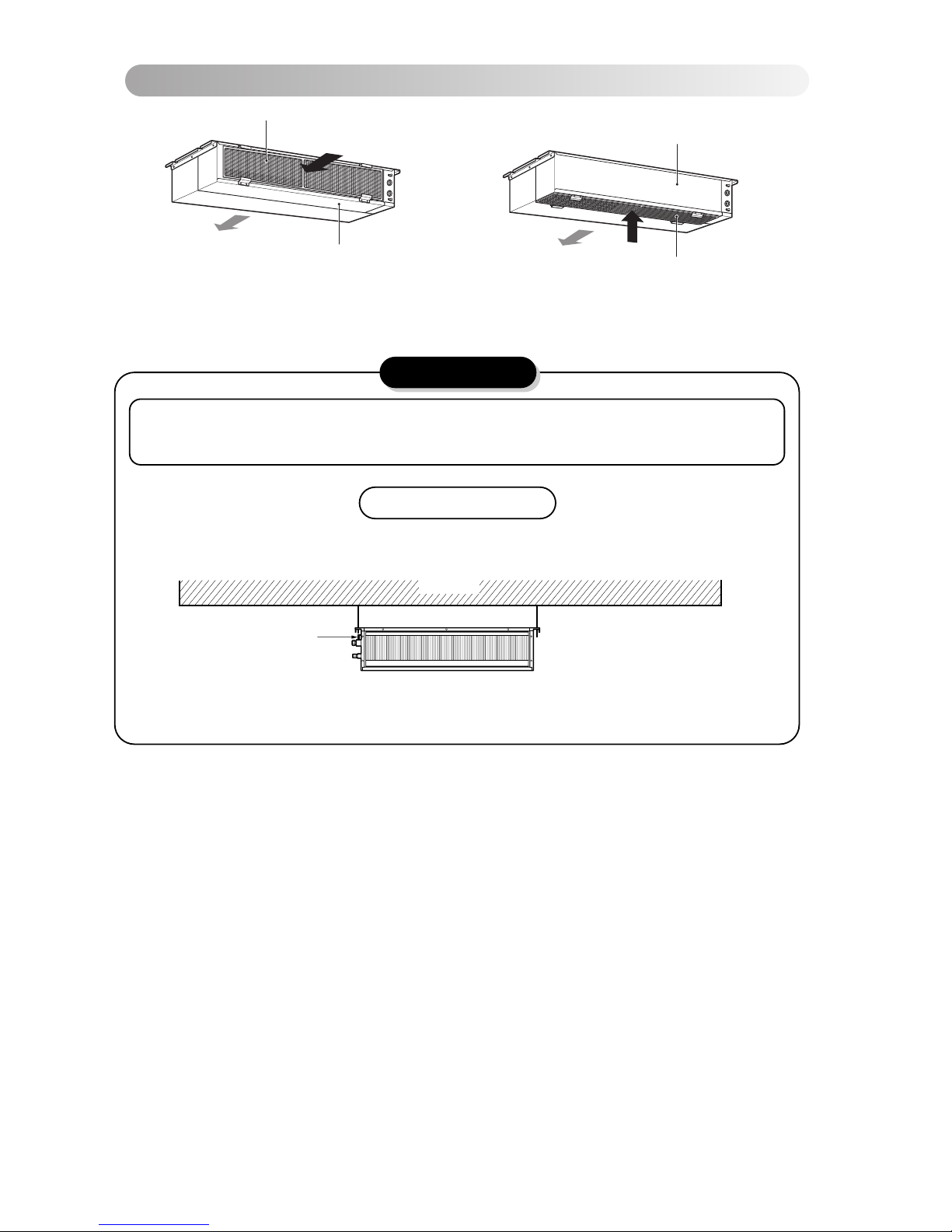

• Low static duct type in case of suction from back

side.

• Low static duct type in case of suction from bottom

side.

Air Filter

Air outlet

Panel Rear

Air outlet

Air Filter

Panel Rear

C).Filter convertible option.

6

CAUTION

Ceiling

Drain Pump use

Drainage hole

Front of view

1. Install declination of the indoor unit is very important for the drain of the duct type air conditioner.

2. Minimum thickness of the insulation for the connecting pipe shall be 19mm.

• The unit must be horizontal or declined to the drain hose connected when finished

installation.

Page 7

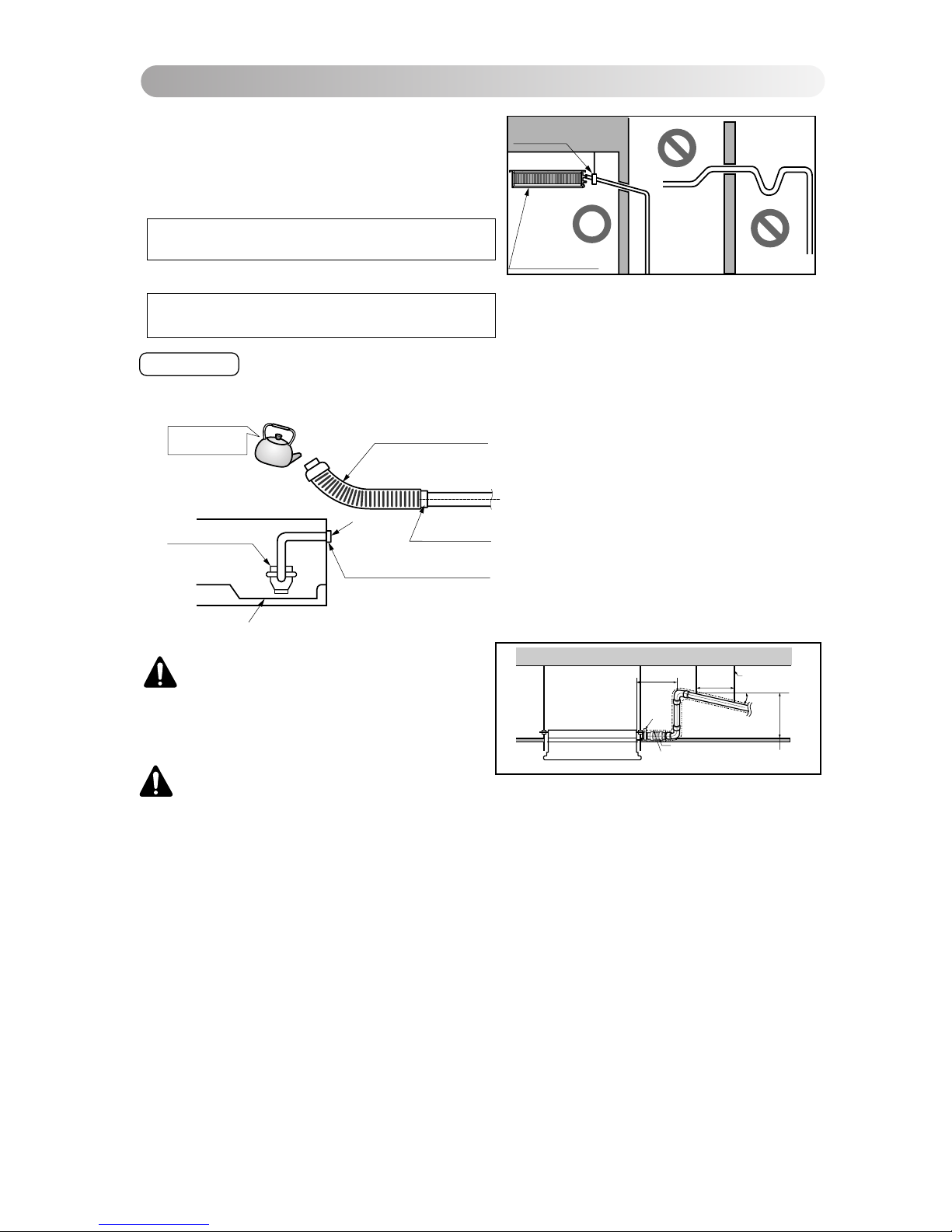

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

• Connect the main drain pipe to the exterior

an d leav e it pr ovisi o nally until the te st

comes to an end.

• Feed water to the flexible drain hose and

check the piping for leakage.

• Be sure to check the drain pump for normal

operating and noise when electrical wiring

is complete.

• When the test is comple te, connect the

flexible drain hose to the drain port on the

indoor unit.

Drain test

Feed water

Drain Pump

Drain pan

Flexible drain hose

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip

• Drain piping must have down-slope (1/50 to 1/100): be sure not to

provide up-and-down slope to prevent reversal flow.

• During drain piping connection, be careful not to exert extra force

on the drain port on the indoor unit.

• The outside diameter of the drain connection on the indoor unit is

32mm.

•

Be sure to install heat insulation on the drain piping.

Piping material: Polyvinyl chloride pipe VP-25 and

pipe fittings

Heat insulation material: Polyethylene foam with thickness more than 8 mm.

Upward

routing

not allowed

Pipe clamp

Maintenance

drain port

Indoor unit

D). Drain Piping

7

CAUTION:

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specialized for the air conditioner. As for the method of

wiring, be guided by the circuit diagram posted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screws which fasten the wiring in the casing of electrical fittings are liable to come loose

from vibrations to which the unit is subjected during the course of transportation. Check them

and make sure that they are all tightly fastened. (If they are loose, it could give rise to burn-out

of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage

1/50~1/100 slope

Hanger

distance

Hanger Bracket

Max 700mm

Flexible drain hose

Insulation

Metal

clamp

Max 300mm

1~15m

CAUTION : The supplied flexible drain

hose should not be curved, neither

screwed. The curved or screwed hose

may cause a leakage of water.

marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point, fuse breaking, disturbance by the normal function of an overload protection device.

• Proper starting power is not given to the compressor.

Page 8

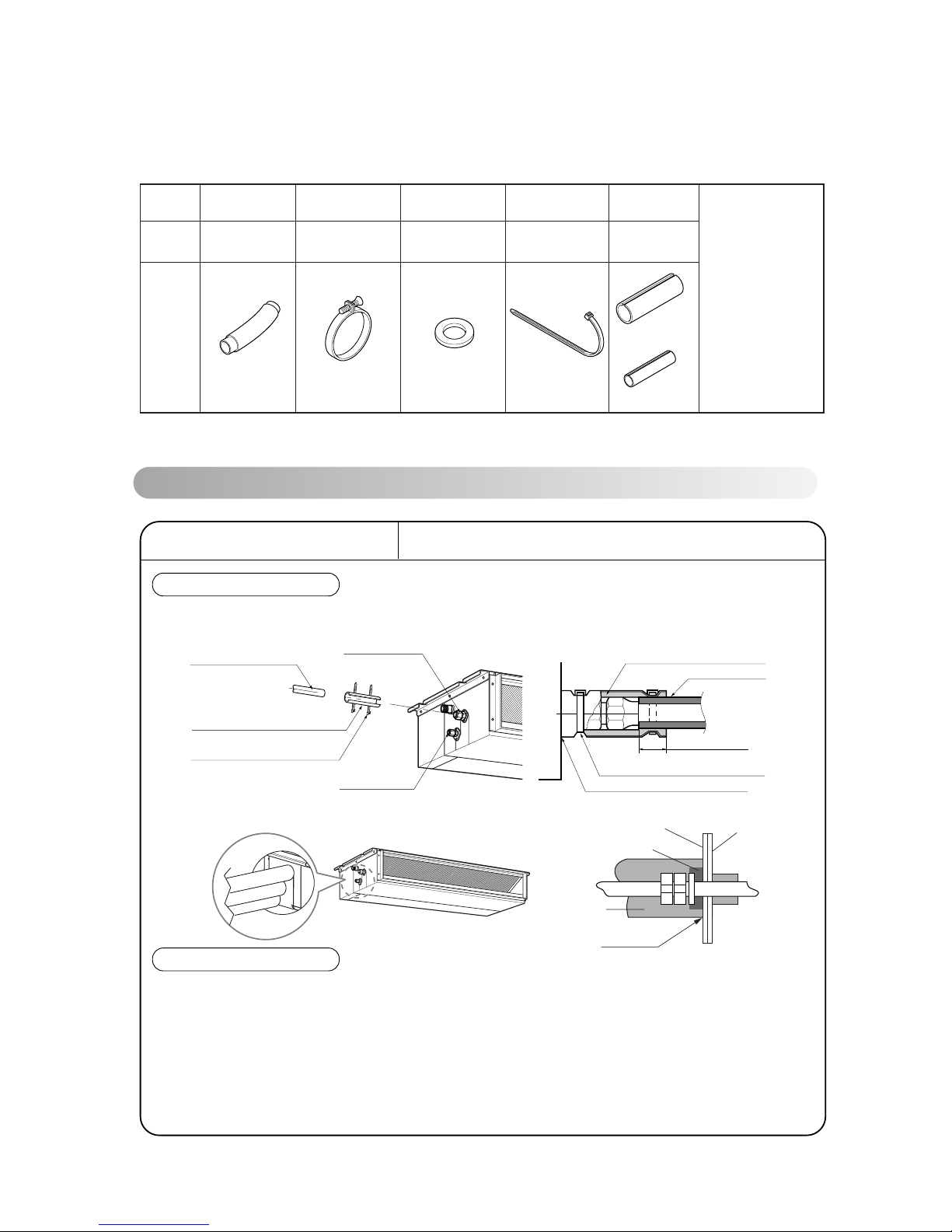

HAND OVER

Teach the customer the operation and maintenance procedures, using the operation manual.

(air filter cleaning, temperature control, etc.)

4 EA

Name

Quantity

Shape

for gas pipe

for liquid pipe

Clamp metal

2 EA

Insulation for

fitting

1 SET

Drain hose

1 EA

Clamp

(Tie Wrap)

8 EA

Washer for

hanging backet

(Other)

Standard Accessories

• Owner's manual

• Installation manual

8

INSULATION, OTHERS

Insulate the joint and tubes completely.

All thermal insulation must comply with local requirement.

INDOOR UNIT

After all workings are finished, check the working and operation.

• Air distribution ............... Is the air circulation good?

• Drain ............................. Is the drainage smoothly and no sweating?

• Gas leakage ................. Is the piping connection correctly?

• Wiring ........................... Is the wiring connection correctly?

• Lock-bolt ....................... Is the lock-bolt of compressor loosened?

• Insulation Is the unit fully insulated?

• Ground Is the unit safely grounded?

THERMAL INSULATION

TEST AND CHECK

Make sure that there is no clearance here.

Overlap with thermal

insulator for piping.

Thermal insulator for refrigerant pipe

(Local supply)

Thermal insulator for

piping(Local supply)

Hose clip for thermal insulator(Local supply)

Union for gas pipe

Refrigerant pipe and thermal

insulator(Local supply)

Union for liquid pipe

Thermal insulator for refrigerant pipe

(Local supply)

Hose clip for thermal insulator

(Local supply)

Felt

Rubber

Insulation

No clearance

Cabinet

E). Insulation of the Piping & Drain

Page 9

9

B

e

n

z

e

n

e

S

C

O

U

R

I

N

G

C

L

B

A

R

G

E

R

S

I

N

N

E

R

Care and maintenance

Indoor Unit

Caution: Before performing any maintenance, turn off the main power to the system.

Grille, Case, and Remote Control

Turn the system off before cleaning. To clean,

wipe with a soft, dry cloth. Do not use bleach or

abrasives.

Note:

Supply power must be disconnected before

cleaning the indoor unit.

Never use any of the followings:

• Water hotter than 40°C

Could cause deformation and/or

discoloration.

• Volatile substances

Could damage the surfaces

of the air conditioner.

Clean the filter with a vacuum or warm, soapy

water.

• If very dirty, wash with a solution of

detergent in lukewarm water.

• If hot water (50°C or more) is used, filter

may be deformed.

After washing with water, dry well in the shade.

Re-install the air filter.

Air Filter

The air filters behind Indoor unit

(the suction side) should be checked and cleaned

once every 2 weeks or more often if necessary.

1

2

3

Indoor Unit Dimensions (mm)

CE

G

D

A

J

B

I

F

H

Drainage hole

Drain Pump use

(Unit:mm)

18/24/30k BTU/h

1130 1180 383 575 93 190 21 1065 163 1100

Dimension

Capacity(Btu/h)

A B C D E F G H I J

36/48/60k BTU/h

Page 10

10

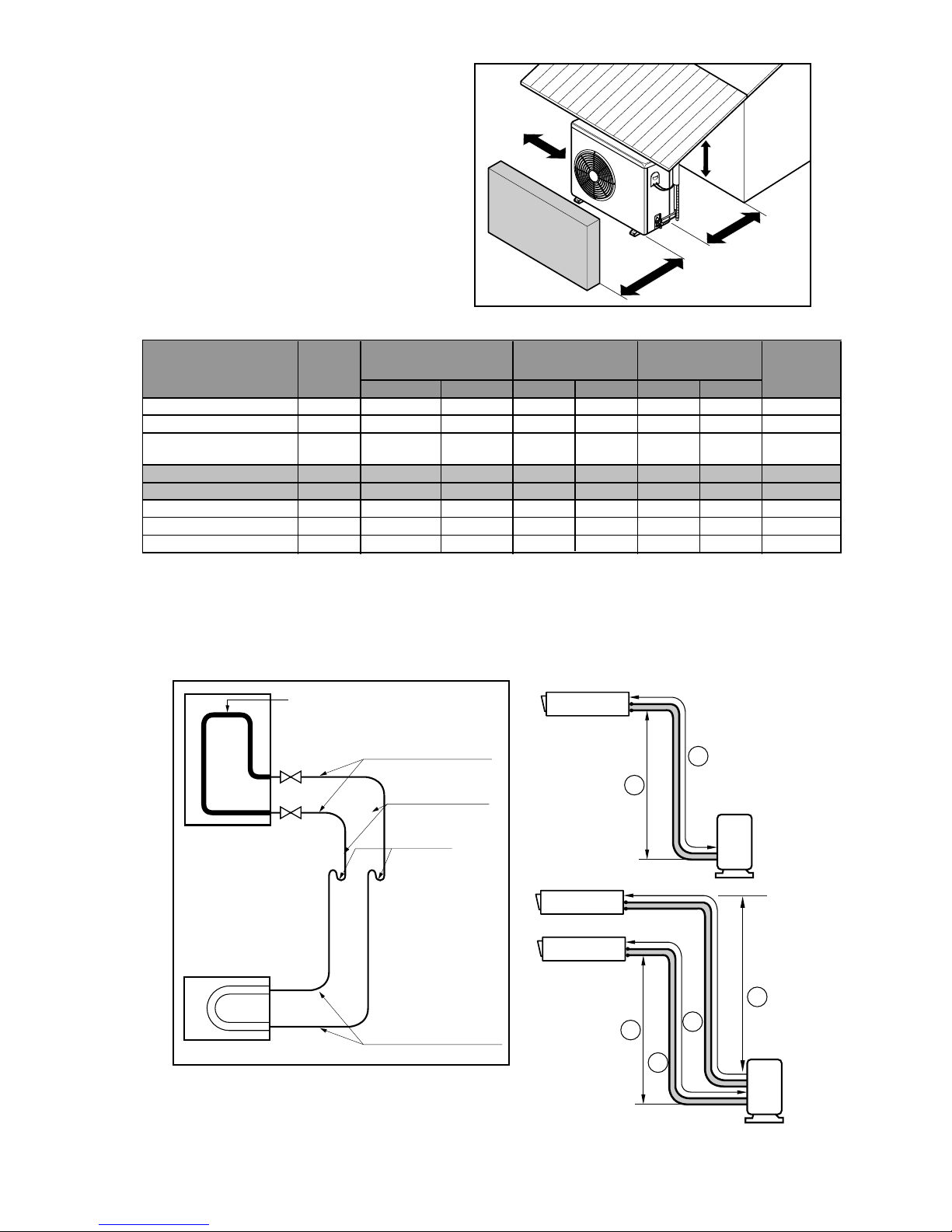

F). Outdoor Unit best location & piping.

The heat exchanger coils and panel vents of the

outdoor unit should be checked regularly. If clogged

with dirt or soot, the heat exchanger and panel vents

may be professionally steam cleaned.

Note:

Dirty or clogged coils will reduce the operating

efficiency of the system and cause higher

operating costs.

Outdoor Unit

Indoor Unit

Outdoor Unit

(Side)

(Rear)

Air outlet

vents

Air intake

vents

Connecting Wire

Connection Pipe

Drain Hose

Control Cover

H

D

W

W

H

D

L2

L1

(Rear)

(Side)

Air outlet

vents

Air intake

vents

L1

L2

Connecting Wire

Connection Pipe

Drain Hose

Control Cover

Model Capacity Indoor dimension Outdoor Dimnesion

W D H W D H L1 L2

LB-B2156QC

1.5 TR

1180 575 190 800 260 555 590 305

LB-B2206QC

2 TR

1180 575 190 800 260 555 590 305

LB-B2256QC / LB-B2258QC

2.5 TR

1180 575 190 870 320 655 545 350

JB-B2156QC

1.5 TR

1180 575 190 870 320 655 545 350

JB-B2258QC

2.5 TR

1180 575 190 870 320 800 545 350

LMA36B2ALI

1.5x2 TR

1180 575 190 870 320 655 545 350

LMA48B2ALI

2.0x2 TR

1180 575 190 906 406 1135 606 465

LMA60B2ALI

2.5x2 TR

1180 575 190 906 406 1135 606 465

Page 11

>>Outdoor unit space requirement.

•If an awning is built over the unit to prevent

direct sunlight or rain exposure, be careful

that heat radiation f rom t he condenser is not

restricted.

• There should not be any animals or plants

which could be aff ected by hot air

discharged.

• Ensure the spaces indicated by arrows f rom

the w all, ceiling, f ence or other obstacles.

>>Piping length and the elevation

More than

50cm

More than

50cm

More than

100cm

Sunroof

Fence or

obstacles

• Capacity is based on standard length and maximu m allowance

length is on the basis of reliability .

• Oil trap should be installed every 5 meters.

• If 18K model is installed at a distance of 15m, 150g of refrigerant

should be added [(15-5) x 15g = 150g].

10cm

Gas Liquid standard Max standard Max

1.5 TR 1/2" 1/4" 7.5 30 5 15 R-22 15gm

2 TR 5/8" 1/4" 7.5 30 5 15 R-22 20gm

2.5 TR 5/8" 3/8" 7.5 30 5 15 R-22 25gm

LB-B2156QC

LB-B2206QC

Length(A meter)

Model

Additional

Gas Charge

Pipi Sizes

( Dia In Inch)

Capacity

Elevation(B meter)

1.5 TR 5/8" 3/8" 7.5 80 5 35 R-410 30gmJB-B2156QC

JB-B2258QC 2.5 TR 5/8" 3/8" 7.5 80 5 35 R-410 30gm

11

LB-B2256QC/

LB-B2258QC

LMA36B2ALI 1.5x2 TR 1/2" x 2 1/4"x2 5 30 15 R-22 15gm

LMA48B2ALI 2.0x2 TR 5/8" x 2 1/4"x2 5 30 15 R-22 20gm

LMA60B2ALI 2.5x2 TR 5/8" x 2 3/8"x2 5 30 15 R-22 25gm

5

5

5

Indoor unit

Outdoor unit

B

A

U-Trap

Use seamless pipe

Flared connection (union)

Flared connections

Outdoor

Factory charged gas

Indoor

(Service valves)

Indoor unit

Outdoor unit

B

A

B

A

Page 12

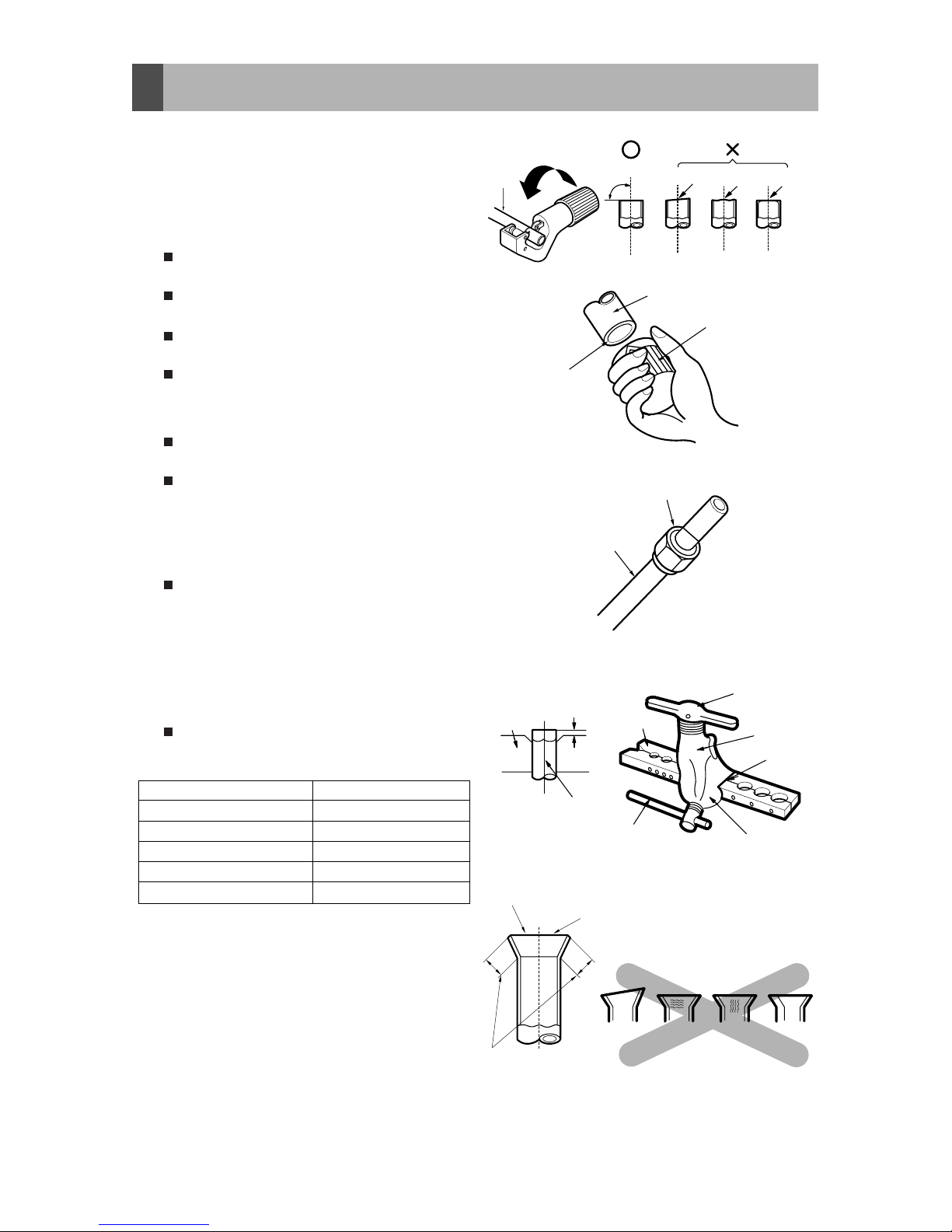

3-1. Preparation of Piping

3. Connecting Pipes to the Indoor Unit

Main cause of gas leakage is defect in

flaring work. Carry out correct flaring work

in the following procedure.

1) Cut the pipes and the cable.

Use the accessory piping kit or the pipes

purchased locally.

Measure the distance between the

indoor and the outdoor unit.

Cut the pipes a little longer than

measured distance.

Cut the cable 1.5m longer than the pipe

length.

2) Burrs removal

Completely remove all burrs from the cut

cross section of pipe/tube.

Put the end of the copper tube/pipe to

downward direction as you remove burrs

in order to avoid to let burrs drop in the

tubing.

3) Putting nut on

Remove flare nuts attached to indoor

and outdoor units, than put them on

pipe/tube having completed burr

removal.

(Not possible to put them on after flaring

work)

4) Flaring work

Carry out flaring work using flaring tool

as shown below.

Firmly hold copper tube in a bar(or die) as

indicated dimension in the table above.

5) Check

Compare the flared work with figure.

If flare is noted to be defective, cut off

the flared section and do flaring work

again.

Copper

tube

90

Slanted Uneven Rough

Pipe

Reamer

Point down

Flare nut

Copper tube

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shining without scratches.

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Outside Diameter "A"

1/4" 0~0.5

3/8" 0.5~0.8

1/2" 0.5~0.8

5/8" 0.8~1.0

3/4" 1.0~1.3

12

Page 13

6) Pipe bending

Annealed copper pipe with small diameter (ø6.35 or ø9.52) can be easily bent manually. In

this case, secure large R(radius) for the bend section and gradually bend pipe. If annealed

copper pipe is large in diameter (ø12.7, ø15.88 or ø19.05), bend pipe with bender. Use bender

appropriate for the pipe diameter.

7)

Brazing

In refrigerant piping, bending (in particular, acute bending) must be minimized to reduce

piping resistance. Bending is, however, necessary in some places by virtue of the installation

position of devices

or of

the building structure, piping distance or finishing appearance.

Perform brazing using ready-made elbow. Aside from this function, brazing

perform brazing using ready-made elbow. Aside from this function, brazing

also serves to connect straight pipes, generally using ready-made sockets. While brazing,

protect piping against heat with wet cloth to avoid damaging valve packing or burning

thermal insulator with burner heat. While brazing, blow inert gas (nitrogen gas or carbonic

gas) to prevent formation of oxidation film in copper piping; otherwise, the refrigerant circuit

will clog. The blowing of nitrogen gas (or carbonic gas) through 3-way valves is described in

the following:

8)

Refrigerant piping(Flare piping)

When connecting piping, be sure to keep piping dry(keep piping away from water), clean

(keep piping away from dust) and airtight (avoid refrigerant leakage).

When connecting piping on rainy days or making a through-hole in wall, take due care to

prevent water or plaster from entering piping.

CAUTION

a. This procedure is designed to prevent

formation of oxidation film by filling piping

with inert gas. Note that excessive gas

pressure will generate pinholes at brazed

points.

(Nitrogen gas: Supply pressure

2

0.05~0.1kg/cm

G)

b. When supplying inert gas, be sure to open

one end of piping.

Water enters Plaster enters

13

Page 14

1) Connecting the pipes to the

Outdoor unit

1. Al ign the center of the pipin g s and

sufficiently tighten the flare nut with

fingers.

2. Finally, tightenthe flare nut with torque

wrenchuntilthe wrenchclicks.

• When tightening the flare nut with torque

wrench, ensure the direction for

tightening follows the arrow on the

wrench.

4. Connecting Pipes to the Outdoor Unit

Torque wrench

Outdoor unit

Gas side piping

(Bigger Dia.)

Liquid side piping

(Smaller Dia.)

Pipe size Torque

1/4" 1.8kg.m

3/8" 4.2kg.m

1/2" 5.5kg.m

5/8" 6.6kg.m

3/4" 6.6kg.m

5. IR Remote Sensor Installation & Operation

14

•

Install the IR remote sensor about 6 feet above the floor in an area with good air circulation at an average temperature.

Do not install the IR remote sensor where it can be affected by:

- Drafts, or dead spots behind doors and in corners.

- Hot or cold air from ducts.

- Radiant heat from sun or appliances.

- Concealed pipes and chimneys.

- Uncontrolled areas such as an outside wall

behind the remote controller.

- This IR remote sensor is equipped with

LED display and ON/OFF button. For proper

display of the IR remote sensor

The IR remote sensor should be installed

properly as shown in Fig.1.

(The standard height is 6 feet from floor

level.)

R

e

m

o

t

e

C

o

n

t

r

o

l

l

e

r

T

E

M

P

6feet

no

no

no

Remote Controller

TEMP

Fig.1 Typical locations for IR Remote Sensor

LG

COMP

POWER

FILTER

TIMER

ON/OFF

yes-Optional

Remote Controller

TEMP

yes

Page 15

Installation of IR Remote Sensor

15

1. Connect the IR sensor cable

to the CN-DISPLAY connector

of main PCB Assy.

2. Fix the rear side of the installation board with

the screw.

3. Now attach the IR PCB Assy at the rear

side of installation board.

When disassemble the IR remote sensor

from the installation board, use the driver as

shown in the right picture and insert it into the

hole with the arrow. And when you pull the driver

in the front direction, the IR remote sensor

will be separated.

The IR sensor cable is connected as factory default.

Fixate the IR Remote

Sensor cable to

the guide slot.

Use the screws

for fixate the unit

firmly on the wall.

Installation board

<Front side of

installation board>

<Rear side of

installation board>

Bottom

Wall

Side

Wall

Side

Wall

Side

Wall

Side

Wall

Side

Do not install the cable to be 10m or above.

(It can cause communication error.)

• When installing the extension cable, check the connecting direction of the connector of the IR remote sensor side

and the product side for correct installation.

• If you install the extension cable in the opposite direction, the connector will not be connected.

• Specification of extension cable: AWG 26 (2sim 7shield) or above

Guide slot

Page 16

6). Connecting Cable between Indoor and Outdoor Unit

Perform the electrical wiring work according to

the electrical wiring connection.

• All wiring must comply with local

requirements.

• Select a power source that is capable of

supplying the current required by the air

conditioner.

• Use a recognized circuit breaker

between the power source and the unit.

A disconnection device to adequately

disconnect all supply lines must be

fitted.

• Capacity of circuit breaker

Outdoor

Indoor

Main

power source

Switch box

Circuit Breaker

• Warranty will be null & void if wiring is

not as per installation instructions.

Model Capacity 1 Phase 3 Phase

LB-B2156QC 25 NA

LB-B2206QC 25 NA

LB-B2256QC 32 NA

LB-B2258QC NA 20

JB-B2156QC 25 NA

JB-B2258QC

1.5 TR

2 TR

2.5 TR

2.5 TR

1.5 TR

2.5 TR NA 20

A) Circuit Breaker Detail

LMA36B2ALI 1.5x2 TR 20 x 2 NA

LMA48B2ALI 2.0x2 TR NA

LMA60B2ALI 2.5x2 TR NA 32

Outdoor

Indoor

Main

power source

Circuit Breaker

Circuit Breaker

20 x 2

16

Page 17

Indoor Wiring Diagram :

Model :

LB-B2156QC /

LB-B2206QC /

LB-B2256QC /

LB-B2258QC /

LMA36B2ALI /

LMA48B2ALI /

LMA60B2ALI

(R-22 Gas Charge

Model)

TO

INDOOR

INPUT MAINS/SUPPLY

(1ø,230V)

L N E L N

S

1 2 3 4 5 6

RD

BK

A1

A2

L1

L2

T1

T2

Magnetic

Contractor

BK

RD

BK

WH

T/B

Out

Motor

GR

OR

COMP

RD

C

S

R

BK

YL

H

F

C

3854A20298J

OUTDOOR WIRING DIAGRAM

FROM

INDOOR

RD

GR

BK

BK

BL

Outdoor Wiring Diagram :

Model :

LB-B2256QC

(R-22 Gas

Charge Model)

B) Wiring Diagram

Model : LB-B2258QC

(R-22 Gas charge Model)

3854A20298Q

In door & Out door connection detail

INDOOR OUTDOOR

Terminal No.

1

2

3

7

8

PHASE IN (R)

PHASE IN (S)

PHASE IN (T)

NEUTRAL IN

GND IN

1

2

3

4

5

6

9

10

11

PHASE

NEUTRAL

COMP

GND

PHASE

NEUTRAL

COMP

GND

3ø415 V

Power Supply

NORMAL CROSS-SECTIONAL AREA

WIRE NO. SPECIFICATION

1,2,3,7 & 8

9,10 & 11

2

3.5 mm

2

1.25 mm

5 CORE

3 CORE

T1

T2

T3

RD WH BK

COMP

L1 L2 L3

A2

A1

T1 T2 T3

Magnetic

Contactor

BL

YL

RD

RD

18 15

BL

YL

RD

RD

BK

TERMINAL A

1R2S3

T

MOTOR

1

ORANGE

CAPACITOR 1

YELLOW

BK

TERMINAL C

TERMINAL B

7

NGL

8910 11 12

From Indoor

Signal

(3ø, 415V)

Power Supply

3ø 415V

Power Supply

OUTDOOR WIRING DIAGRAM

BLACK

To Indoor

(1ø, 230V)

BK

L3 L2 L1

3ø, MONTORING RELAY

BK

RD

N

S

Model :

LB-B2156QC /

LB-B2206QC

(R-22 Gas

Charge Model)

TO

INDOOR

INPUT MAINS/SUPPLY

(1ø,230V)

L N E L N

S

1(L)

4 5 6

RD

BK

0

1

2

6

4

8

Power

Relay

BK

RD

YL

WH

T/B

Out

Motor

GR

BL

COMP

RD

C

S

R

BK

RD

H

F

C

3854A20298U

OUTDOOR WIRING DIAGRAM

FROM

INDOOR

RD

GR/YL

BK

BK

BR

2(N)

17

NOTE : Connect IR PCB Assy. at CN-DISP of PCB Assy.

Page 18

Outdoor Wiring Diagram :

Model : LMA36B2ALI (R-22 Gas Charge Model)

Outdoor Wiring Diagram :

Model : LMA48B2ALI (R-22 Gas Charge Model)

Outdoor Wiring Diagram :

Model : LMA60B2ALI (R-22 Gas Charge Model)

C

S

R

FAN

MOTOR

R

S

C

COMP. 2

OR

BK

5

RD

BR

BK

RD

RD

RD

COMP. 1

S

R

C

WH

RD

RD

OR

TB

1

CAP 1

BK

HCF

BL

BL

BK

RD

WH

TB

2

CAP 2

H

C

F

RD/BR

BK/BL

RD/BR

BK/BL

8 2 0

1

6 4

L1 N1

RD/BR

BK/BLRDBK

SIGNAL

(1ø, 230V)

INPUT MAINS SUPPLY UNIT 1

TO INDOOR

UNIT 1

OUTDOOR WIRING DIAGRAM

(1ø, 230V)

INPUT MAINS SUPPLY UNIT 2

RD/BR

BK/BL

N2

L2

8 2 0

1

46

3854A20298X

CAP3

GR

1 2 3 4 5 6

RDBKSIGNAL

TO INDOOR

UNIT 2

RD/BR

BK/BL

BK/BL

RD/BR

BK/BL

RD

GR

BK/BL

BK/BL

RD/BR

RD

BK/BL

RD/BR

3854A20298Y

FAN

MOTOR2

R

C

S

OR

YL

RD

H

C F

CAP 2

BK

BK

R

S

COMP. 2

C

WH

TB4

BK

TB3

RD

RD

RD

8 2 0

146

BK

BK

BR

GR/YL

BK

RD

TERMINAL

BLOCK (B)

7 8 9 10 11 12

RD/BR

BK/BL

GREEN

RD

BK

SIGNAL

(1Ø, 230V)

INPUT MAINS SUPPLY

TO INDOOR

FAN

MOTOR1

R

C

S

OR

YL

RD

H

C F

CAP 1

BK

BK

R

S

COMP. 1

C

WH

TB2

BK

TB1

RD

RD

RD

8 2 0

146

BK

BK

BR

GR/YL

BK

RD

TERMINAL

BLOCK (A)

1 2 3 4 5 6

RD/BR

BK/BL

GREEN

RD

BK

SIGNAL

(1Ø, 230V)

INPUT MAINS SUPPLY

TO INDOOR

OUTDOOR WIRING DIAGRAM

OUTDOOR WIRING DIAGRAM

TERMINAL (A)TERMINAL (B)

12

B

3Ø415 V

POWER SUPPLY

NGY R

TO

INDOOR 1

1Ø230 V

4

6

5

23 1

911 1078

BK

28

3

2

1

YL

27

BK

20

RD

BK

20

5

4

L1

15

RD

28

BL

L3

25

BL

6

L2

18

21

21

BL YL RD

A2

A1

BL

WH

BK

V

COMP(2)

W

WH

COMP(1)

BK

V

W

U

RD

Magnetic

Contactor

L1 L2

Magnetic

Contactor

L1 L21L3

2

L3

RD

U

RD

T3

11

11

BK

9

T1

BL8YL

T2

YLT2BLT1RD

T3

7

Magnetic Contactor(1)

Magnetic Contactor(2)

A1

A2

GN/YL

3ø MONITORING

RELAY

BK

GND

BLACK

MOTOR MOTOR

1

2

C

S

R

C

S

YELLOW

YELLOW

ORANGE

ORANGE

BLACK

CAPACITOR1CAPACITOR

2

BK11BK

11

1

2

BK

9

7

BR

7

BR

R

3

4

28

BK

GN/YL

FROM

INDOOR

SIGNAL 2

TO

INDOOR 2

1Ø230 V

FROM

INDOOR

SIGNAL 1

S2

N2 P2S1N1 P1

G

3854A20298T

18

Page 19

3854A20298K

CN-FLOAT

CONTROLLER

CN-PIPE/IN

RY-D/PUMP

FUSE 250V

3.15A

CN-POWER

RD

BL

BR

BK

CN-VM

CN-PTC

FROM OUTDOOR

CN-DISP

CN-DISPLAY

NOTE: 1) For ANONE1 Model Suffix, CN-DISP is Optional.

2) For ANONE2 Model Suffix, WIRED REMOTE CONTROLLER

& DRAIN PUMP is Optional.

SENSOR

JUMPER

SENSOR

ASSY.

Indoor Wiring Diagram :

Model : JB-B2156QC (R410 Gas Charge Model)

Outdoor Wiring Diagram :

Model : JB-B2156QC (R410 Gas Charge Model)

1ph 230V

To

Indoor

3 2 1

GR

BR

BL

HP

SWITCH

4 5 6 78 9

BR

GR

GR

BL

BR

BL

BL

BR

BL

Magnetic

Contactor

A1

A2

L1

L2

T1

T2

BK

T/B1BKT/B2

WH

OUT

MOTOR

OR(GR)

GR

C

S

R

RD

COMP

YL

BK

H

C

F

OUTDOOR WIRING DIAGRAM

3854A20372B

FUSE

19

NOTE : Connect IR PCB Assy. at CN-DISP of PCB Assy.

Page 20

3854A20298K

CN-FLOAT

CONTROLLER

CN-PIPE/IN

RY-D/PUMP

FUSE 250V

3.15A

CN-POWER

RD

BL

BR

BK

CN-VM

CN-PTC

FROM OUTDOOR

CN-DISP

CN-DISPLAY

NOTE: 1) For ANONE1 Model Suffix, CN-DISP is Optional.

2) For ANONE2 Model Suffix, WIRED REMOTE CONTROLLER

& DRAIN PUMP is Optional.

SENSOR

JUMPER

SENSOR

ASSY.

Indoor Wiring Diagram :

Model : JB-B2258QC (R410 Gas Charge Model)

Outdoor Wiring Diagram :

Model : JB-B2258QC (R410 Gas Charge Model)

TERMINAL

B

L N

G

S

N

To Indoor

(1Ø,230V)

From Indoor

R

S

213 6

54 1

2 3

T

TERMINAL A

3Ø 415V

Power Supply

R

D

WH

BK

T2

COMP

T1

T

3

T2

Magnetic

Contactor

L1T1L2

L3

T3

A1

A2

TERMINAL C

MOTOR

1

ORANGE

CAPACITOR

YELLOW

RD

RD

BK

RD

Y

L

BL

BK

YL

BL

3854A20396B

RD

BL

RD

RD

RD

BK

BK

3ø MONITORING

RELAY

1518

L1L2L3

34

34

RD

RD

35

HP

SWITCHLPSWITCH

20

NOTE : Connect IR PCB Assy. at CN-DISP of PCB Assy.

Page 21

21

Connecting Cables between Indoor and Outdoor Unit

1) Connecting cables to the Indoor Unit

Connect the wires to the terminals on the control board individually according to the

outdoor unit connection.

Ensure that the color of the wires of outdoor unit and the terminal No. are the same as

those of indoor unit respectively

2) Clamping of cables

1) Arrange 2 power cables on the control panel.

2) First, fasten the steel clamp with a screw to the inner boss of control panel.

3) For the cooling model, fix the other side of the clamp with a screw strongly.

The power cord connected to the outdoor unit should be

with the following specifications

If the supply cord is damaged, it must be replaced by a special cord or assembly availible from the manufacturer of its service agent.

The connecting cable connected to the indoor and outdoor

unit should be with the following specifications

CAUTION

20mm

G

N/YL

NORMAL

CROSS-SECTIONAL

AREA

1.25mm

2

(18/24K)

20mm

GND

Capacity

18/24

K BTU/h

1 Phase

2.5mm

2

NORMAL CROSS-SECTIONAL AREA

Make sure that the screws of the terminal are free from looseness.

WARNING

18/24/30K BTU/h

Applied Model:- LB-B2156QC,LB-B2206QC,LB-B2256QC, JB-B2156QC.

1) Input 1-phase power supply into outdoor & wire specification.

1

2

GND

L N GND

Outdoor terminal block

2) For connection between of Indoor and Outdoor unit & wire specifiacation

Indoor terminal block

1 2

GND

3

4

5

GND

6

Outdoor terminal block

RD BK GND BR

Wire specification.

Wire specification.

Model Capacity 1 Phase No of core

LB-B2156QC 1.5 tr 1.5 mm2 4

LB-B2206QC 2 TR 1.5 mm2 4

LB-B2256QC 2.5 TR 1.5 mm2 4

JB-B2156QC 1.5 TR 1.5 mm2 4

Model Capacity

1 Phase

mm2 * core

LB-B2156QC 1.5 tr 2.5 mm2*3

LB-B2206QC 2 TR 2.5 mm2*3

LB-B2256QC 2.5 TR 2.5 mm2*3

JB-B2156QC 1.5 TR 2.5 mm2*3

Note : GND = Ground Earthing

1 2

GND

3

5

6

4

7

RD BK GND BR

A) LB-B2156QC, LB-B2206QC, LB-B2256QC B) JB-B2156QC

Page 22

22

1) Connecting cables to the indoor Unit

Connect the wires to the terminals on the control board individually according to the

outdoor unit connection.

Ensure that the color of the wires of outdoor unit and the terminal No. are the same as

those of indoor unit respectively.

2) Clamping of cables

1) Arrange 2 power cables on the control panel.

2) First, fasten the steel clamp with a screw to the inner boss of control panel.

3) For the cooling model, fix the other side of the clamp with a screw strongly.

The power cord connected to the outdoor unit should be

with the following specifications

If the supply cord is damaged, it must be replaced by a special cord or assembly availible from the manufacturer of its service agent.

The connecting cable connected to the indoor and outdoor

unit should be with the following specifications

CAUTION

Capacity

30K BTU/h

3 Phase

2.5mm

2

NORMAL CROSS-SECTIONAL AREA

Make sure that the screws of the terminal are free from looseness.

WARNING

1) Input 3-phase power supply into outdoor, cable specification 4 core 2.5 sq mm2 & Separable

Earthing Wire.

1

2

3

R Y

GND

2) For connection between of Indoor and Outdoor unit & wire specification 4 core , 1.25 sq mm2 .

Outdoor terminal block

2 3 4 5

1 2 3 GND

Terminal B

Indoor terminal block

RD BK BR GND

30K BTU/h

Applied Model:- JB-B2258QC / LB-B2258QC.

Outdoor terminal block B

5 6

Outdoor terminal block A

Connecting Cables between Indoor and Outdoor Unit

B

NORMAL

CROSS-SECTIONAL

AREA

1.25mm

2

(30K)

20mm

GND

20mm

N

Note : GND = Ground Earthing

Note : GND = Ground Earthing

JB-B2258QC LB-B2258QC

R Y

Outdoor terminal block B

7 8

Outdoor terminal block A

B

GNDN

JB-B2258QC

8 9 10 11

1 2 3

GND

Terminal B

GND RD BK BR

LB-B2258QC

1 2 3

Page 23

23

Connecting Cables between Indoor and Outdoor Unit

1) Connecting cables to the Indoor Unit

Connect the wires to the terminals on the control board individually according to the

outdoor unit connection.

Ensure that the color of the wires of outdoor unit and the terminal No. are the same as

those of indoor unit respectively

2) Clamping of cables

1) Arrange 2 power cables on the control panel.

2) First, fasten the steel clamp with a screw to the inner boss of control panel.

3) For the cooling model, fix the other side of the clamp with a screw strongly.

The power cord connected to the outdoor unit should be

with the following specifications

If the supply cord is damaged, it must be replaced by a special cord or assembly availible from the manufacturer of its service agent.

The connecting cable connected to the indoor and outdoor

unit should be with the following specifications

CAUTION

20mm

G

N/YL

NORMAL

CROSS-SECTIONAL

AREA

1.25mm

2

(36/48K)

20mm

GND

Capacity

36/48

K BTU/h

1 Phase

2.5mm

2

NORMAL CROSS-SECTIONAL AREA

Make sure that the screws of the terminal are free from looseness.

WARNING

36/48K BTU/h

Applied Model:- LMA36B2ALI, LMA48B2ALI

1) Input 1-phase power supply into outdoor & wire specification.

2) For connection between of Indoor and Outdoor unit & wire specification

Indoor terminal block

1

2

3

1

2

3

Outdoor terminal block

RD BK BR

Wire specification.

Model Capacity 1 Phase No of core

LMA36B2ALI 1.5 TR x 2 1.5 mm2 4

LMA48B2ALI 2 TR x 2 1.5 mm2 4

Note : GND = Ground Earthing

A) LMA36B2ALI

2

1

N L GND

Outdoor terminal block

Wire specification.

Model Capacity

1 Phase

mm2 * core

LMA36B2ALI 1.5TR x 2 2.5 mm2*3

LMA48B2ALI 2TR x 2 2.5 mm2*3

2

1

NLGND

Unit-1 Unit-2

10

11

L N GND

3

2

GNDNL

Unit-1 Unit-2

1 12

GND

1

2

3

3

4

5

6

B) LMA48B2ALI

GND

1

2

3

9

10

11

12

GND

Unit-1

Unit-1

1 2 3

4 5 6

BR

BK

RD

GND

Unit-2

Unit-2

Unit-1 Unit-2

Unit-1 Unit-2

A) LMA36B2ALI B) LMA48B2ALI

RD BK BR RD BK BR

Page 24

24

1) Connecting cables to the indoor Unit

Connect the wires to the terminals on the control board individually according to the

outdoor unit connection.

Ensure that the color of the wires of outdoor unit and the terminal No. are the same as

those of indoor unit respectively.

2) Clamping of cables

1) Arrange 2 power cables on the control panel.

2) First, fasten the steel clamp with a screw to the inner boss of control panel.

3) For the cooling model, fix the other side of the clamp with a screw strongly.

The power cord connected to the outdoor unit should be

with the following specifications

If the supply cord is damaged, it must be replaced by a special cord or assembly availible from the manufacturer of its service agent.

The connecting cable connected to the indoor and outdoor

unit should be with the following specifications

CAUTION

Capacity

60K BTU/h

3 Phase

2.5mm

2

NORMAL CROSS-SECTIONAL AREA

Make sure that the screws of the terminal are free from looseness.

WARNING

1) Input 3-phase power supply into outdoor, cable specification 4 core 2.5 sq mm2 & Separable

Earthing Wire.

2) For connection between of Indoor and Outdoor unit & wire specification 4 core , 1.25 sq mm2 .

60K BTU/h

Applied Model:- LMA60B2ALI

Connecting Cables between Indoor and Outdoor Unit

NORMAL

CROSS-SECTIONAL

AREA

1.25mm

2

(60K)

20mm

GND

20mm

Note : GND = Ground Earthing

LMA60B2ALI

Outdoor terminal block

Note : GND = Ground Earthing

3 2 1

4

B Y RNGND

5

Indoor terminal block

1 2 3

12 11 10

Outdoor terminal block

BR

GND

Unit-2 Unit-1

Unit-2 Unit-1

BK RD

321

789

RD

GND

BKBR

Page 25

1. Remove the Cover control from the unit

by loosening a screw.

Connect the wires to the terminals on

the control board individually as

following.

2. Secure the cable onto the control board

with the holder (clamper).

3. Refix the cover control to the original

position with the screw.

25

CAUTION

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specialized for the air conditioner. As for the method

of wiring, be guided by the circuit diagram pasted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screw which fasten the wiring in the casing of electrical fittings are liable to come

loose from vibrations to which the unit is subjected during the course of transportation.

Check them and make sure that they are all tightly fastened. (If they are loose, it could give

rise to burn-out of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage

marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point there of, fuse breaking,

disturbance to the normal function of a overload protection device.

• Proper starting power is not given to the compressor.

Cord Clamper

Power supply

cord

Cover control

Terminal block

Outdoor unit

Over 5mm

C) Outdoor Wiring Routine and Pipe Routine

Page 26

>> Piping Routine

1. Wrap the connecting portion of indoor

unit with the Insulation material and

secure it with two Plastic Bands. (for the

right pipings)

• If you want to connect an additional drain

hose, the end of the drain-outlet should

keep distance from the ground. (Do not

dip it into water, and fix it on the wall to

avoid swinging in the wind.)

2. Tape t h e Pipin g s, drain h os e and

Connecting Cable from bottom to top.

3. Form the pipings gathered by taping

along the exterior wall and fix it onto the

wall by saddle or equivalent.

2. Tape the Pipings and Connecting cable

from bottom to top.

3. Form the pipings gathered by taping

along the exterior wall, and make the

trap prevent water from entering into the

room.

4. Fix the pipings onto the wall by saddle

or equivalent.

26

In case of the Outdoor unit being installed

below position of the Indoor unit.

In case of the Outdoor Unit being installed

above position of the Indoor Unit.

Trap is required to prevent water from entering

into electrical parts.

Seal a small opening

around the pipings

with gum type sealer.

Drain hose

Taping

Pipings

Connecting

cable

Power supply

cord

Seal a small opening

around the pipings

with gum type sealer.

Trap

Page 27

7. Air Purging of the Connecting Pipes and the Indoor Unit

27

Indoor unit

Liquid side

Outdoor unit

OPEN CLOSE

Vaccum pump

Gas side

Closed

Closed

2-way valve/

3-way valve

3-way

valve

The air which contains moisture remaining in the refrigeration cycle may cause a malfunction

on the compressor.

1. Confirm that both the liquid side valve and the gas side valve are set to the closed position.

2. After connecting the piping, check the joints for gas leakage with gas leak detector.

3. Remove the service port nut, and connect the gauge manifold and the vacuum pump to the

service port by the charge hose.

4. Vacuum the indoor unit and the connecting pipes until the pressure in them lowers to below 76cmHg.

5. Remove the valve stem nuts, and fully open the stems of the 2-way and 3-way valves with a

hexagon wrench.

6. Tighten the valve stem nuts of the 2-way valve and 3-way valve.

7. Disconnect the charge hose and fit the nut to the service port.

(Tightening torque: 1.8kg.m)

Page 28

8. Operating Instructions

A) Indoor Unit, Outdoor Unit

Outdoor Unit

Air Intake

(side, rear)

Connecting Wire

Drain Hose

Power Wire

Connection Tube

Air Outlet

Vents

Cooling model: Low static Type Air Conditioner for cooling

Wired Remote

Controller (Optional)

Operation Indication Lamps

Wireless Remote Receiver & Controller

(Standard)

6

LG

COMP

POWER

FILTER

TIMER

ON/OFF

4

2

5

3

1

Signal Recepter

28

LG

COMP

POWER

FILTER

TIMER

ON/OFF

Forced Operation : Use the ON/OFF button when remote control is not available.

TIMER

: Lights up during timer operation.

Signal Receptor

: Receives the signal from remote control (signal receiving sound:

switch on)

one long beep)

FILTER SIGN

: Lights up after 240 hours from the time of first power on operation.

1

2

3

4

COMP

ON/OFF

: Lights up during outdoor operation (i.e. when compressor

: Lights up during system operation.

5

6

Page 29

B) Remote Control Preparation

29

Page 30

C) Remote Control Operations

The remote control transmits the signals to the system.

Features of the Remote Control- Door Closed

1

START/STOP BUTTON

Operation starts when this button is

pressed and stops when the button is

pressed again.

2

OPERATION MODE

SELECTION BUTTON

Used to select the operation mode.

ROOM TEMPERATURE

SETTING BUTTONS

Used to select the room temperature.

3

Operation Mode

Cooling Operation

Auto Operation

Healthy Dehumidification Operation

Cooling Operation

Auto Operation

Healthy Dehumidification Operation

Heating Operation

(Cooling Model) (Heat Pump Model)

* Your unit shall have either Type A or Type B Remote Control.

ON

Signal transmitter

Flip-up door

(closed)

2

4

5 1

3

ON

Signal transmitter

Flip-up door

(closed)

2

4

5 1

3

JET COOL

A/SWING

POWER

TEMP

FAN SPEED

MODE

TYPE A TYPE B

66

30

4

INDOOR FAN SPEED

SELECTOR

Used to select fan speed in four steps

low, medium, high, or CHAOS.

JET COOL

Used to start or stop the speed

cooling. (Speed cooling operates

super high fan speed in cooling mode).

5

AIR SWING BUTTON

Used to stop or start louver movement and

set the desired up/down airflow direction.

6

For low static duct unit, CHAOS speed is not available.

For low static duct unit, JET COOL function is not available.

For low static , is not available.duct unit AIR SWING function

Page 31

Features of the Remote Control- Door Opened

1

ON/OFF TIMER BUTTONS

Used to set the time of starting and stopping

operation.

2

TIME SETTING BUTTONS

Used to adjust the time, (See page 38)

TIMER SET/CANCEL BUTTONS

Used to set the timer when the desired time is

obtained and to cancel the Timer operation.

(See page 38)

3

4

SLEEP MODE AUTO BUTTON

Used to set Sleep Mode Auto operation.

(See page 38)

AIR CIRCULATION BUTTON

Used to circulate the room air without cooling

or heating. (See page 39)

5

ROOM TEMPERATURE

CHECKING BUTTON

Used to check the room temperature.

6

7

88

RESET BUTTON

Used prior to resetting time or after replacing

batteries.

ON

OFF

CANCEL

SET

3

4

6

1

2

7

5

Flip-up door

(opened)

Signal

transmitter

3

4

6

1

2

7

5

Flip-up door

(opened)

Signal

transmitter

JET COOL

A/SWING

POWER

TEMP

FAN SPEED

MODE SLEEP CANCEL

TIMERON OFF SET

FAN ROOM

TIMER

8

8

2ndF BUTTON

Used prior to using modes printed in blue at

the bottom of buttons.(See page 37)

31

Page 32

ON

Cooling

To lower the temperature

To raise the temperature

Press the Start/Stop button.

The unit will respond with

a beep.

Open the door of the remote controller. To select Cooling

Operation, press the Operation Mode Selection button.

Each time the button is pressed, the operation mode is

shifted in the direction of the arrow.

Close the door of the remote controller. Set the temperature

lower than the room temperature. The temperature can be

set within a range of 18°C~30°C at intervals of 1°C.

Set the fan speed again with the door

of the remote controller still closed.

You can select the fan speed in 3

steps-low, medium, & high.

Each time the button is pressed, the

fan speed mode is shifted.

1

2

3

4

Cooling operation

A/SWING

POWER

TEMP

FAN SPEED

JET COOL

ON

MODE

Healthy

Dehumidification

Heating

(Heat pump model only)

Auto

32

CHAOS speed is not available for low static duct unit.

*

Page 33

Cooling

Healthy

Dehumidification

Auto

Heating

(Heat pump model only)

To lower the temperature

To raise the temperature

Press the Start/Stop button.

The unit will respond with

a beep.

Open the door of the remote controller. To select Auto

Operation, press the operation mode selection button.

Each time the button is pressed, the operation mode is

shifted in the direction of the arrow.

The temperature and fan speed are automatically set by the

electronic controls based on the actual room temperature. If

you want to change the set temperature, press the Room

Temperature Setting buttons. The cooler or warmer you feel,

the more times (up to two times) you should press the button.

The set temperature will be changed automatically.

During Auto Operation

You cannot control the indoor fan speed. It has already been set by the Fuzzy rule.

If the system is not operating as desired, manually switch to another mode. The system will not

automatically switch from the cooling mode to the heating mode, or from heating mode to cooling

mode, it must be done by manually resetting.

1

2

3

A/SWING

POWER

TEMP

FAN SPEED

JET COOL

ON

MODE

ON

33

Auto operation (Optional)

CHAOS speed is not available for low static duct unit.

*

Page 34

Cooling

Press the Start/Stop button.

The unit will respond with

a beep.

Open the door of the remote controller. To select Healthy

Dehumidification Operation, press the Operation Mode

Selection button.

Each time the button is pressed, the operation mode is

shifted in the direction of the arrow.

1

2

Set the fan speed again with the door

of the remote controller still closed.

You can select the fan speed in 3

steps-low, medium, high. Each time

the button is pressed, the fan

speed mode is shifted.

3

Healthy dehumidification operation

During Healthy Dehumidification Operation

If you select the dehumidification mode on the operation selection button, the product starts to run the

dehumidification function. It automatically sets the room temp. and airflow volume to the best condition

for dehumidification, based on the sensed current room temp.

In this case, however, the setting temp. is not displayed on the remote controller and you are not able to

control the room temp. either.

During the healthy dehumidification function, the airflow volume is automatically set according to the

optimization algorithm responding to the current room temp. status, so that the room condition is kept

healthy and comfortable even in the very humid season.

A/SWING

POWER

TEMP

FAN SPEED

JET COOL

ON

MODE

ON

Healthy

Dehumidification

Heating

(Heat pump model only)

Auto

34

CHAOS speed is not available for low static duct unit.

*

Page 35

Cooling

Press the Start/Stop button.

The unit will respond with

a beep.

Open the door of the remote controller. To select Heating

Operation, press the Operation Mode Selection button.

Each time the button is pressed, the operation mode is

shifted in the direction of the arrow.

To lower the temperature

To raise the temperature

Close the door of the remote controller.

Set the temperature higher than the room temperature.

The temperature can be set within a range of 18°C~30°C at

intervals of 1°C.

Set the fan speed again with the door of the

remote controller still closed. You can

select the fan speed in Three steps–low,

medium, & high. Each time the button is

pressed, the fan speed mode is shifted.

1

2

3

4

ON

ON

MODE

A/SWING

POWER

TEMP

FAN SPEED

JET COOL

Healthy

Dehumidification

Heating

(Heat pump model only)

Auto

35

Heating operation (Heat pump model only)

Page 36

or or

During the JET COOL function at any moment, the A/C starts to blow the cool air at extremely

high speed for 30 minutes setting the room temp. automatically to 180C. It is especially used to

cool the room temp. quickly in a hot summer.

In heat pump mode or auto changeover mode, however, the JET COOL function is not available.

In order to return to the normal cooling mode from the JET COOL mode, just press the operation

mode selection button, airflow volume selection, temp. setting button or the JET COOL button

again.

NOTICE

Press the Start/Stop button.

The unit will respond with

a beep.

Press the Jet Cool button to operate

the speed cooling mode and the unit

will operate at super high fan speed

on cooling mode for 30 minutes.

To cancel the Jet Cool mode, press the Jet Cool buttons,

1

2

3

A/SWING

POWER

TEMP

FAN SPEED

JET COOL

JET COOL function is not available for LS duct models.

36

The fan speed button or the room temperature setting

button again and the unit will operate at high fan speed

on cooling mode.

Jet cool operation (optional)

Page 37

2nd F operation

Press the Start/Stop button.

The unit will respond with

a beep.

Open the door of the remote controller and press the 2nd

Function button to operate functions printed blue color under

buttons.

(Check the indication of 2nd function on the display of the

remote controller.)

2nd function disappears in a short time automatically or when

the button is pressed again.

1

2

3

For more details, refer to functions next pages.

JET COOL

A/SWING

POWER

TEMP

FAN SPEED

MODE SLEEP CANCEL

TIMERON OFF SET

FAN ROOM

TIMER

ON

OFF

CANCEL

SET

37

Page 38

Delay OFF Timer Delay ON Timer Delay OFF and ON Timer Delay ON and OFF Timer

Sleep mode

1. Press the Sleep Mode Auto button to set the time you want the unit to stop automatically.

2. The Timer is programmed in one-hour increments by pressing the Sleep Mode Auto button 1 to 7 times. The

sleep mode is available for 1 to 7 times. To alter the time period in steps of 1 hour, press the Sleep Mode

Button while aiming at air conditioner.

3. Make sure the Sleep Mode Auto LED lights up.

To cancel the Sleep Mode, press the sleep Mode Auto button several times until the star

( ) disappears from the operation display.

The Sleep Mode will be operated at slow fan speed (cooling)

or medium fan speed (heat pump only) for

a comfortable sleep.

NOTICE

Setting the time

1. Time can be set only when you press the Reset button. Having replacing the batteries,

you should press the reset buttons to reset the time. Press the Start/Stop button.

2. Press 2nd F button and check if 2nd F icon is on.

3. Press the Time Setting buttons until the desired time is set.

4. Press the Timer SET button.

Check the indicator for A.M. and P.M.

NOTICE

1. Make sure the time is set correctly on the display of the remote controller.

2. Press 2nd F button.

3. Press the ON/OFF Timer buttons to turn Timer on or off.

4. Press the Time Setting buttons until the desired time is set.

5. To set the selected time, press the Timer setting button aiming the remote controller at the

signal receptor.

To cancel the timer setting

Check if 2nd F icon is off.

Press the Timer Cancel button aiming the remote controller at the signal receptor.

(The timer lamp on the air conditioner and the display will go out.)

Delay start/Pre-set stop

Select one of the following four types of operation.

NOTICE

with the unit running

CANCEL

SET

CANCEL

SET

CANCEL

SET

Additional Features

SLEEP

POWER

TIMER

ON

OFF

TIMER

TIMER

38

Page 39

Fan speed is on low. Fan speed is on medium. Fan speed is on high.CHAOS Air

Air circulation mode

Circulates the room air without cooling or heating.

1. Press the Start/Stop button. the unit will respond with a beep.

2. Open the door on the remote control. Press the Air Circulation button. Close the door on the remote control.

Now each time that you press the Indoor Fan Speed Selector button, the fan speed is shifted from low to

CHAOS and back to low again.

(Function not Available)

39

Forced operation

Press the ON/OFF button on IR PCB

Assembly for 3 seconds, once you listen

beep sound remove your hand.

Note :1) Forced operation button location

varies with model.

Use for ON/OFF the unit in case

of remote misplace.

LG

COMP

POWER

FILTER

TIMER

ON/OFF

Error Diagnosis

Sr.

No.

ERROR CODE DIAGNOSIS

1

2

3

4

5

CH-01

CH-02

CH-05

CH-04

Check room thermistor

Check pipe thermistor (CN-Pipe/In)

Check Option PCB (EPROM)

Check float sensor / Jumper

DESCRIPTION

Recover after 5 seconds of operation when respective

thermistor healthy

Recover after 3 seconds of operation when respective

thermistor healthy

Check Interconnection of Option PCB and Power Reset

Recover after 4 minutes of operation when float sensor /

Jumper healthy

CH-09

Check Dipswitch setting and Power Reset

Check Dipswitch comm (Yes/No)

Page 40

Loading...

Loading...