Page 1

CAUTION

BEFORE SERVICING THE UNIT, READ THE "SAFETY

PRECAUTIONS" IN THIS MANUAL.

MODEL: GR-S552 / GR-S592

REFRIGERATOR

SERVICE MANUAL

http://biz.lgservice.com

Page 2

CONTENTS............................................................................................................................................................................. 2

SERVICING PRECAUTIONS.................................................................................................................................................. 3

SPECIFICATIONS................................................................................................................................................................... 4

PARTS IDENTIFICATION....................................................................................................................................................... 5

DISASSEMBLY.................................................................................................................................................................... 6-7

DOOR................................................................................................................................................................................... 6

DOOR SWITCH.................................................................................................................................................................... 6

FAN AND FAN MOTOR........................................................................................................................................................ 6

DEF' CONTROL ASM .......................................................................................................................................................... 7

LAMP.................................................................................................................................................................................... 7

CONTROL BOX-R................................................................................................................................................................ 7

ADJUSTMENT..................................................................................................................................................................... 8-9

COMPRESSOR.................................................................................................................................................................... 8

PTC-STARTER..................................................................................................................................................................... 8

OLP (OVER LOAD PROTECTOR)....................................................................................................................................... 9

CIRCUIT DIAGRAM................................................................................................................................................................ 9

TROUBLESHOOTING..................................................................................................................................................... 10-15

COMPRESSOR AND ELECTRIC COMPONENTS ........................................................................................................... 10

PTC AND OLP.................................................................................................................................................................... 11

ANOTHER ELECTRIC COMPONENT............................................................................................................................... 12

SERVICE DIAGNOSIS CHART.......................................................................................................................................... 13

REFRIGERATING CYCLE............................................................................................................................................ 14-15

DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM ................................................................................................ 16-32

EXPLODED VIEW & REPLACEMENT PARTS LIST.......................................................................................................... 33-

Please read the followings before servicing your refrigerator.

1. Check if an electric leakage occurs in the set.

2. To prevent electric shock, unplug prior to servicing.

3. In case of testing with power on, wear rubber gloves to

prevent electric shock.

4. If you use any appliances, check regular current, voltage

and capacity.

5. Don't touch metal products in cold freezer with wet hand.

It may cause frostbite.

6. Prevent water flowing to electric elements in mechanical

parts.

7. When you stand up during observing the lower part

with the upper door open, move with care to prevent

head wound which may happen by hitting the upper

door.

8. When sloping the set, remove any materials on the set,

especially thin plate type. (ex.: glass shelf or books.)

9. When servicing evaporator part, wear cotton gloves

without fail. It is to prevent wound by sharp fin of

evaporator.

10. Leave a breakage of refrigerating cycle to a heavy

service center. The gas in cycle inside may soil

ambient air.

SAFETY PRECAUTIONS

CONTENTS

- 2 -

Page 3

- 3 -

Air Recharging in Compressor

Test the refrigeration by connecting it electrically before

refilling operation. It is necessary to ascertain the function

of the motor-compressor and identify the defects

immediately. If the defects have been found, empty the old

system of eventual R-134a residue by breaking off the end

of the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an extension completely with male Hansen and

last, solder it to the same tube again. (Figure 2)

It is necessary to execute the soldering operation with

valve open so that the fumes caused by oil residue can

come out freely without blowholes between two tubes

during heating the point to be soldered.

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

Air evacuating from the system begins so soon as the

pump starts. The refrigeration system must be kept under

vacuum until the reading on the low-pressure gauge

indicates vacuum (0 absolute, -1 atm., -760 mm hg) in any

case it is advisable to keep the pump running for about 60

minutes. (Figure 3)

In case that a considerable leakage occurs and to stop the

vacuum pump will be necessary and add a small quantity

of Freon to the system, if vacuum should not be obtained

(pressure gauge can't fall to 1 atmosphere), start the

refrigeration unit and find the leakage with the special leakfinder. When the defective soldering point is visible, re-do it

after opening the extension tube valve and reestablishing

the normal outside pressure inside the group.

Because the melted alloy is sucked into the tubes and

block them, the pressure must be rebalanced when

vacuum is in the system in soldering. As soon as the

vacuum operation is over, add the quantity in grams of

R-134a to the refrigerant system. Remember that every

system has an exact quantity of R-134a with a tolerance of

±5 grams that can be added. (Figure 4)

Before performing this operation (if the vacuum pump and

refilling cylinder are connected), make sure that the valve

placed between the vacuum pump and refilling tube are

closed to keep the Freon for adding to the system. (Figure 5)

In addition, check the graduated scale on the cylinder for

the quantity of R-134a to be added, for example, if we

have 750 grams of Freon in the cylinder and must add 165

grams to the group, this amount will be reached when

R-134a has dropped to 585 grams, remembering that the

indicator shows a lower limit of meniscus. Do this after

choosing the scale corresponding to the gas pressure

different scales reported as the same gas pressure

indicated by the pressure gauge on the top of the column.

To make R-134a flow into the system, open the valve

placed at the base of the cylinder and connected to the

filling tube. The amount of Freon cannot be added to the

system all at once because it may cause a blocking of

motor-compressor. Therefore, proceed by adding original

quantity of about 20-30 grams and close the valve

immediately.

The pressure rises and the motor-compressor must start,

sucking the gas and making the pressure go down again.

Regulate the valve again, maintaining the same manner

until reaching to the quantity of R-134a established for the

system being charged. When the system is running, the

suction pressure must be stabilized between 0.10 to 0.4

atmosphere.

POINT TO BE

BROKEN

CHARGE TUBE

EXTENSION

FEMALE

HANSEN

MALE HANSEN

SOLDERING POINTSERVICE TUBE EXTENSION

Figure 1 Figure 2

TO THE VACUUM

PUMP

PRESSURE

GAUGE

Figure 3

TO THE R-134a CYLINDER

TO THE REFRIGERATION

SYSTEM

Figure 4

FILLING OR

CHARGE TUBE

VALVE TO BE OPENED

WHEN REFILLING

VALVE TO BE CLOSED

AFTER VACUUM

TO THE VACUUM PUMP

TO THE REFRIGERATION

SYSTEM

TO THE CHARGE

CYLINDER

Figure 5

SERVICING PRECAUTIONS

Page 4

- 4 -

ITEMS SPECIFICATIONS

FREEZER 114

NET CAPACITY

REFRIGERATOR 306

TOTAL 420

DIMENSIONS (mm) 755(W)

X

689(D)X1777(H)

NET WEIGHT (kg) 79

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

Full Automatic

DEFROSTING SYSTEM

Heater Defrost

OUT CASE Pre Coated Metal

INNER CASE A B S

INSULATION Polyurethane Foam

( l )

ITEMS SPECIFICATIONS

FREEZER 1 EA

REFRIGERATOR 2 EA

VEGETABLE TRAY Drawer Type

EGG TRAY 2 Pieces

ICE TRAY 2 Pieces (Plastic)

ICE BANK 1 Piece

COMPRESSOR P.T.C Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R-134a (135g)

DEFROSTING DEVICE HEATER

SHELF

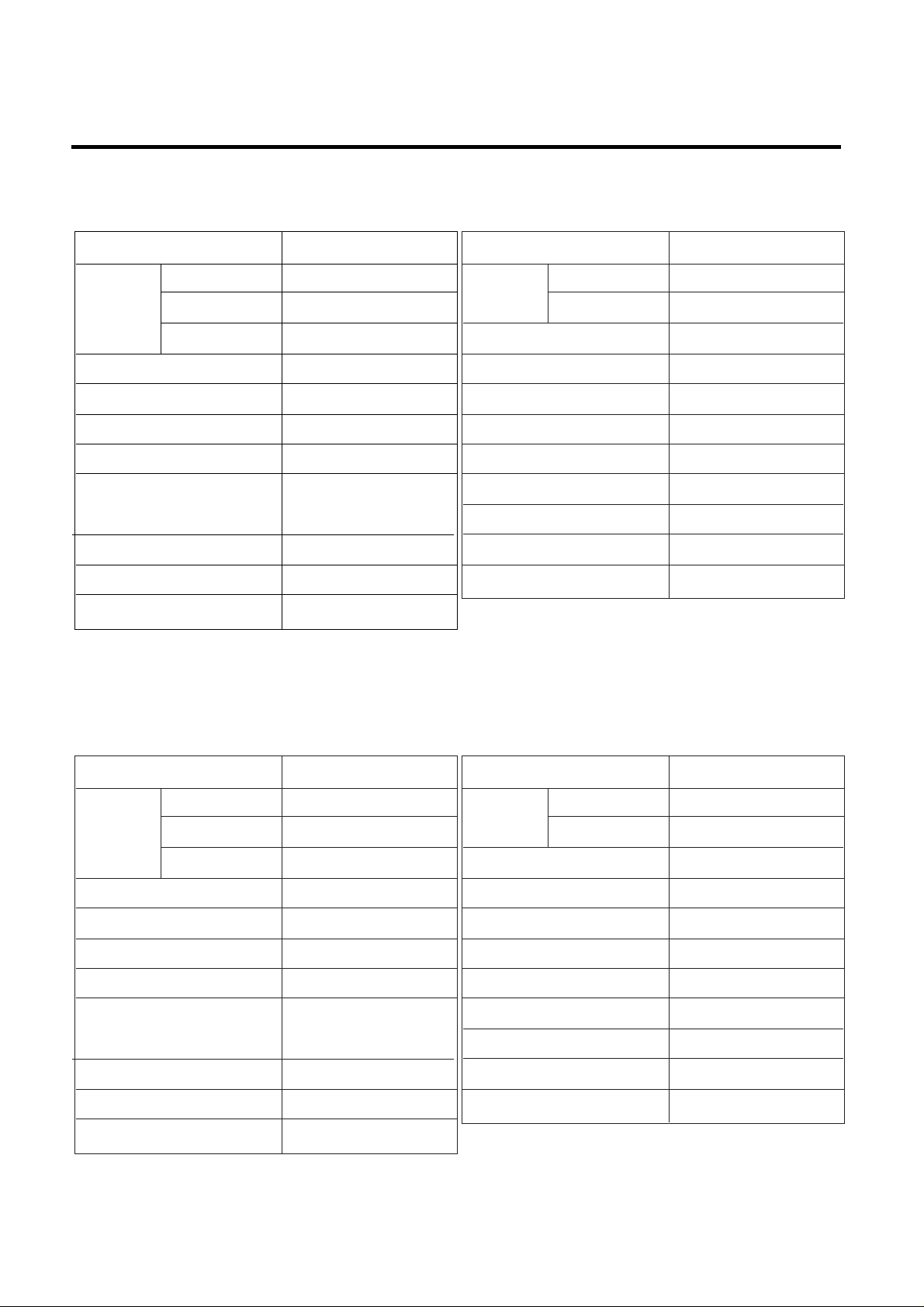

1. SPECIFICATIONS

1-1 GR-S552

ITEMS SPECIFICATIONS

FREEZER 126

NET CAPACITY

REFRIGERATOR 334

TOTAL 460

DIMENSIONS (mm) 755(W)

X

719(D)X1777(H)

NET WEIGHT (kg) 81

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

Full Automatic

DEFROSTING SYSTEM

Heater Defrost

OUT CASE Pre Coated Metal

INNER CASE A B S

INSULATION Polyurethane Foam

( l )

ITEMS SPECIFICATIONS

FREEZER 1 EA

REFRIGERATOR 2 EA

VEGETABLE TRAY Drawer Type

EGG TRAY 2 Pieces

ICE TRAY 2 Pieces (Plastic)

ICE BANK 1 Piece

COMPRESSOR P.T.C Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R-134a (135g)

DEFROSTING DEVICE HEATER

SHELF

1-2 GR-S592

Page 5

- 5 -

2-1 FEATURE CHART

NOTE : This is a basic model. The shape of refrigerator is subject to change.

2. PARTS IDENTIFICATION

Egg Storage Rack

Freezer Door Rack

Freezer Temperature

Control Dial

Leveling Screw

Vegetable Drawer

Used to keep fruits

and vegetables, etc.

fresh and crisp.

Shelves

Lamp

Fresh Meat

Base Cover

FREEZER

COMPARTMENT

Lamp

Shelf

Twisting Ice

Serve(Option)

or

General Type

Ice Making

Deodorizer

REFRIGERATOR

COMPARTMENT

Refrigerator

Temperature

Electronic Control

Page 6

- 6 -

3-1 DOOR

● Freezer Door

1. Remove the hinge cover by pulling it upwards.

2. Loosen hexagonal bolts fixing the upper hinge to the

body and lift the freezer door.

3. Pull out the door gasket to remove from the door foam

Ass'y.

● Refrigerator Door

1. Loosen hexagonal bolts fixing the lower hinge to the

body to remove the refrigerator door only.

2. Pull out the door gasket to remove from the door foam

Ass'y.

3-2 DOOR SWITCH

1. To remove the door switch, pull out it with a '—' type

driver as shown in (figure 9).

2. Disconnect the lead wire from the switch.

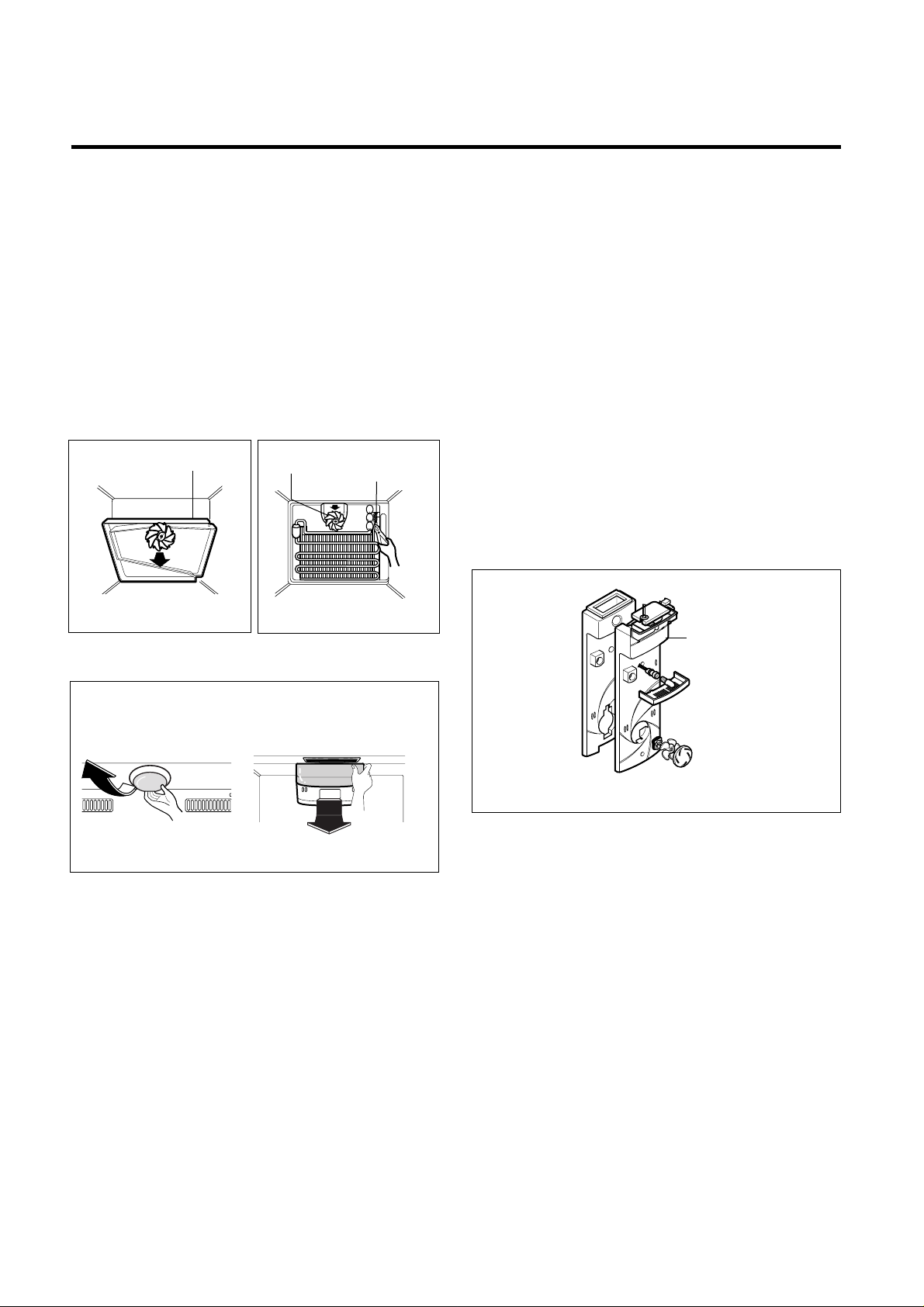

3-3 FAN AND FAN MOTOR

1. Remove the freezer shelf.

2. Remove the Cover Lamp-F and Case Lamp by

loosening 1 screw fixed to ceiling of Inner Case.

3. Remove the Grille by pulling it out.

4. Pull out the Shroud and remove the Fan Motor Assy by

loosening 2 screws.

5. Pull out the fan and, separate the Fan Motor, Brackets

and the Guide Fan.

BOLT

HINGE

HINGE COVER

Figure 6

GASKET

Figure 7

LOWER HINGE

BOLT

Figure 8

Figure 9

3. DISASSEMBLY

GUIDE FAN

FAN

SHROUD

GRILLE

FAN MOTOR

Figure 12

Figure 11

Page 7

- 7 -

3-4 DEF' CONTROL ASSY

Def control ASM consists of Defrost Sensor and FUSE–M.

Defrost

Sensor

functions to defrost automatically and it is

attached to the Evaporator and the metal side of the case

senses Temp.

Fuse-M is a kind of safety device for preventing overheating of the Heater when defrosting.

At the temperature of 77°C, it stops the emission of TEMP

from the Defrost Heater.

1. Pull out the shroud-F after removing the Grille Fan.

(Figure 13)

2. Separate the connectors connected with the Def Control

ASM and replace the Def Control ASM after cutting the

Tie Wrap. (Figure 14)

3-5 LAMP

3-5-1 Freezer room lamp

1. Unplug the power cord from the outlet.

2. Remove the room lamp lid by taking down while pulling

it forward with your hand after inserting finger into the

inside hole as shown in (figure 16).

3. Remove the lamp by turning it counterclockwise.

4. Assemble in reverse order of disassembly. Replacement

bulb must be the same specication as original.

3-5-2 Refrigerator room lamp

1. Unplug the power cord from the outlet.

2. Remove refrigerator shelves.

3. Remove the room lamp lid by taking down while pulling

forward with your hands as shown in (figure 17).

4. Turn the lamp counterclockwise.

5. Assemble in reverse order of disassembly. Replacement

bulb must be the same specification as original.

3-6 CONTROL BOX-R

1. First, remove all shelves in the refrigerator and Control

Box-R by loosening 1 screw.

2. Loosen 2 screws fixing the Control Box-R to the Inner

Case after detaching the cap screw.

3. Remove the Control Box-R by pulling it downward.

SHROUD-F

Figure 13

FAN

DEF CONTROL ASM

Figure 14

FREEZER ROOM LAMP REFRIGERATOR ROOM LAMP

Figure 16

Figure 17

MULTI FLOW

DUCT

Figure 18

Page 8

- 8 -

4-1 COMPRESSOR

4-1-1 Role

The compressor inhales low temperature and low pressure

gas evaporated from Evaporator of the Refrigerator, and

condenses this gas to high temperature and high pressure

gas, and then plays delivering role to Condenser.

4-1-2 Composition

The Compressor is Composed of Compressor Apparatus

compressing gas, Compressor Motor moving Compressor

Apparatus and Case protecting Compressor Apparatus

and Motor. There are PTC-Starter, and Over Load

Protector (OLP) in the Compressor outside.

On the other

hand, because the Compressor consists of 1/1000mm processing

precision components and is sealed after producing without dust

or humidity, deal and repair with care.

4-1-3 Note to Use

(1) Be careful not to allow over-voltage and over-current.

(2) No Strike

If applying forcible power or strike (dropping or careless

dealing), poor operation and noise may occur.

(3) Use proper electric components appropriate to the

Compressor.

(4) Note to Keep Compressor.

If Compressor gets wet in the rain and rust in the pin of

Hermetic Terminal, poor operation and poor contact

may cause.

(5) Be careful that dust, humidity, and flux due to welding

don't inflow in Compressor inside in replacing

Compressor. Dust, humidity, and flux due to welding

which inflows to Cylinder may cause lock and noise.

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is no-contact

semiconductor starting device which uses ceramic

material and the material consists of BaTiO

3.

(2) The higher the temperature is, the higher resistance

value becomes . These features are used as starting

device of Motor.

4-2-2 Role of PTC-Starter

(1) PTC is attached to Hermetic Compressor used for

Refrigerator, Show Case and starts Motor.

(2) Compressor for household refrigerator applies single-

phase induction Motor.

For normal operation of single-phase induction motor, in

the starting operation flows in both main coil and subcoil. After the starting is over, the current is cut off in

subcoil. The proper features of PTC play the above all

roles. So, PTC is used as a starting device of motor.

4-2-3 PTC-Applied Circuit Diagram

● According to Starting Method of Motor

4-2-4 Motor Restarting and PTC Cooling

(1) For restarting after power off during normal

Compressor Motor operation, plug the power cord after

5 min. for pressure balance of Refrigerating Cycle and

PTC cooling.

(2) During normal operation of Compressor Motor, PTC

elements generate heat continuously. Therefore,

if PTC isn't cooled for a while after power off, Motor

can't operate again.

4-2-5 Relation of PTC-Starter and OLP

(1) If power off during operation of Compressor and power

on before PTC is cooled, (instant shut-off within 2 min.

or reconnect a power plug due to misconnecting),

PTC isn't cooled and a resistance value grows. As a

result, current can't flow to the sub-coil and Motor can't

operate and OLP operates by flowing over current in

only main-coil.

(2) While the OLP repeats on and off operation about 3-5

times, PTC is cooled and Compressor Motor performs

normal operation.

If OLP doesn't operate when PTC is not cooled,

Compressor Motor is worn away and causes circuitshort and fire. Therefore, use a proper fixed OLP

without fail.

4-2-6 Note to Use PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) No Strike

Don't apply a forcible power or strike.

(3) Keep apart from any liquid.

If liquid such as oil or water inflows into PTC,

PTC materials it may break due to insulation

breakdown of material itself.

(4) Don't change PTC at your convenience.

Don't disassemble PTC and mold. If damaging to

outside of PTC-starter, resistance value alters and poor

starting of compressor motor may cause.

(5) Use a properly fixed PTC.

PTC STARTER

HERMETIC

TERMINAL

COMPRESSOR

MOTOR

C

M

S

M

3

6

5

S

PTC

OVERLOAD PROTECTOR

RSIR

Figure 20

4. ADJUSTMENT

Page 9

- 9 -

4-3 OLP (OVER LOAD PROTECTOR)

4-3-1 Definition of OLP

(1) OLP (OVER LOAD PROTECTOR) is attached to

Hermetic Compressor and protects Motor by cutting off

current in Compressor Motor by Bimetal in the OLP in

case of over-rising temperature.

(2) When over-voltage flows to Compressor motor, Bimetal

works by heating the heater inside OLP,

and OLP protects Motor by cutting off current which

flows to Compressor Motor.

4-3-2 Role of OLP

(1) OLP is attached to Hermetic Compressor used to

Refrigerator and Show Case and prevents Motor Coil

from being started in the Compressor.

(2) Do not turn the Adjust Screw of OLP in any way for

normal operation of OLP.

(Composition and connection Diagram of OLP)

5. CIRCUIT DIAGRAM

CONTACTING

POINT

COVER

BIMETAL

CONTACTING

POINT

HEATER

TERMINALS

ADJUST

SCREW

HEATER

BIMETAL

Figure 21

NOTE : 1. This is a basic diagram and specifications vary in different localities.

Page 10

- 10 -

6-1 COMPRESSOR AND ELECTRIC COMPONENTS

6. TROUBLESHOOTING

1

2

3

4

5

2

5

5

3

5

4

5

5

1

43

YES

YES

YES

YES

NO

NO

YES

YES

YES

NO

NO

NO

Power Source.

Remove the PTC-Starter

from the Compressor

and measure the voltage

between Terminal C of

Compressor and

Terminals 5 or 6 of PTC.

No Voltage.

(Rating Voltage

±10%)?

Replace OLP.

Reconnect.

Replace

PTC-Starter.

Replace OLP.

O.K.

Check connection

condition.

OLP disconnected?

Advise the customer

to use a regular

Trans.

Replace Compressor.

OLP works within

30 sec. in forcible

OLP operation by

turning instant power

on and off.

Components start in

the voltage of Rating

Voltage ±10%

below.

Applied voltage isn't

in the range of Rating

Voltage ±10%.

Check the resistance

among M-C, S-C and

M-S in Motor

Compressor.

Check the resistance

of two terminals in

PTC-Starter.

Check if applying

a regular OLP.

Measure minimum

starting voltage after 5

min. for balancing cycle

pressure and cooling

the PTC.

Check the

resistance of

Motor

Compressor.

Check the

resistance of

PTC-Starter.

Check OLP.

Check

starting state.

Page 11

- 11 -

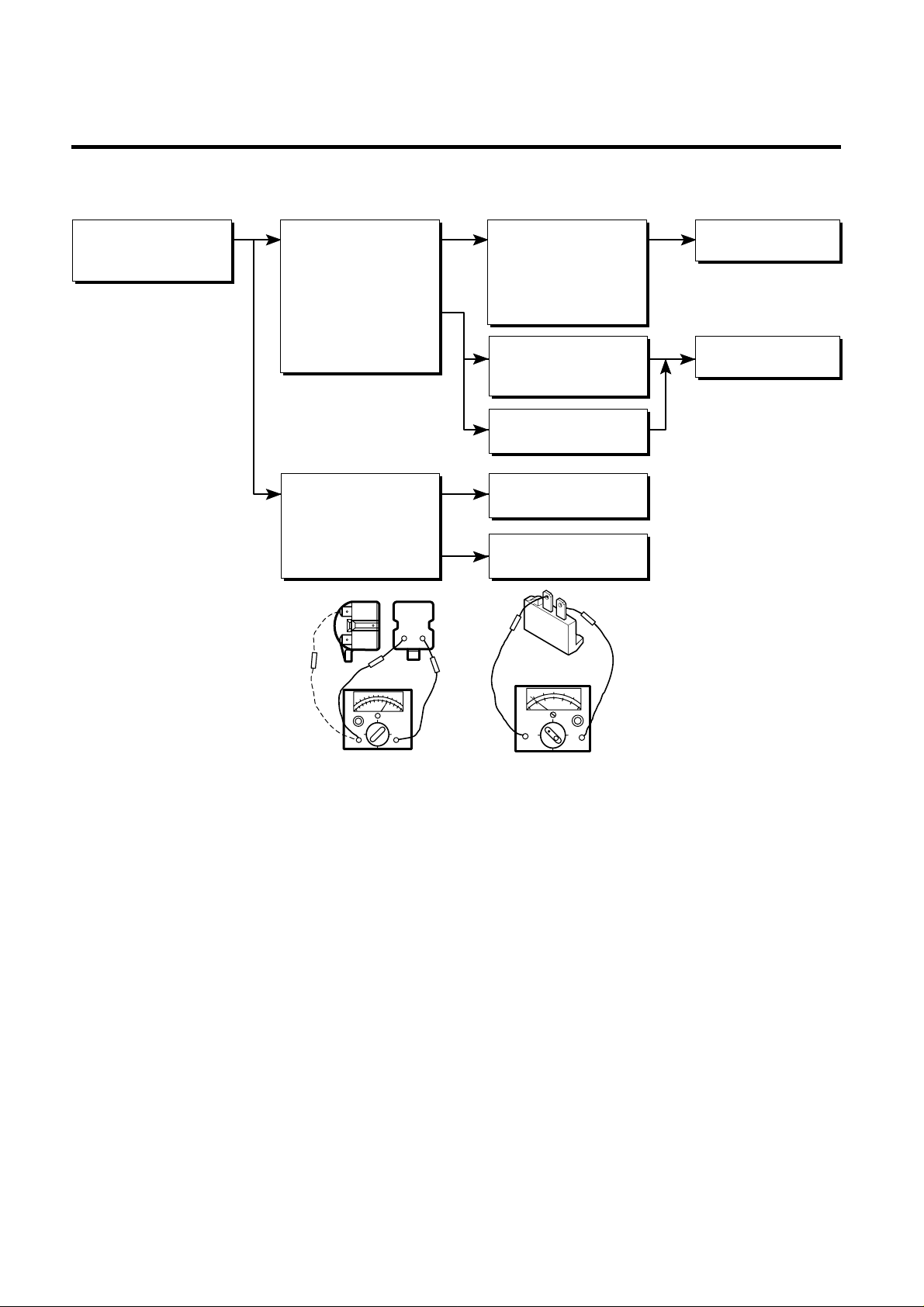

6-2 PTC AND OLP

65

3

4

YES

NO

Normal operation of

Compressor is

impossible or poor.

Separate the PTC from

Compressor and

measure the resistance

between No. 5 and 6

(only RSIR Type) or No.

4 and 5 of PTC with a

Tester or Whistone

Bridge. (Figure 22)

Separate the OLP

from Compressor and

check resistance

value between two

terminals of OLP with

a Tester. (Figure 23)

Observation value is

220V/50Hz : 47Ω ± 30%

220 - 240V/50Hz : 47Ω ±30%

110 -115V/60Hz : 6.8Ω ± 30%

220V/60Hz : 47Ω ± 30%

127V/60Hz : 22Ω ± 30%

The resistance value is

0 or several

hundreds Ω.

The value is ∞.

Check another

electric components.

Replace OLP.

Check another

electric components.

Replace

PTC.

Figure 23

Figure 22

Page 12

- 12 -

6-3 ANOTHER ELECTRIC COMPONENTS

▼ Cooling is impossible

Compressor

doesn't run.

Running state of

Compressor is poor.

Check a starting

voltage.

Check if current flows to

the following

components.

a. Thermistor

b. Starting devices

c. OLP

d. Compressor coil

e. Circuit Parts

Low voltage.

Poor contacting.

Shorted or broken.

Poor contacting

or shorted.

Coil shorted.

Poor contacting

or shorted.

Poor contacting

and broken.

Shorted.

Lack of capacity.

Coil of motor

Compressor.

Replace

the compressor.

Replace

each component.

Raise the voltage.

Replace

each component.

Cause.

Check if current flows

to starting devices.

Check current flowing

in sub-coil of

Compressor.

Check capacity of OLP.

The items described

above are normal.

▼ Cooling ability is poor

Fan motor

doesn't run.

Much frost are sticked

to the EVAPORATOR.

Poor contacting.

Coil is shorted.

Shorted.

Replace

each component.

Replace

each component.

Replace

each component.

Check current flowing

in door S/W.

Check current flowing

in the Fan Motor.

Check current flowing

of the following

components.

• Def. Sensor

• FUSE-M

Check current flowing

of the following

components.

• Sheath Heater

Page 13

- 13 -

COMPLAINT POINTS TO BE CHECKED REMEDY

Cooling is • Is the power cord unplugged from the outlet? • Plug to the outlet.

impossible. • Check if the power S/W is set to OFF. • Set the switch to ON.

• Check if the fuse of power S/W is shorted. • Replace a regular fuse.

• Measure the voltage of power outlet. • If voltage is low, wire newly.

Cooling ability • Check if the set is placed close to wall. • Place the set with the space of about 10cm.

is poor. • Check if the set is placed close to stove, gas • Place the set apart from these heat

• cooker and direct rays. • appliances.

• Is the ambient temperature high or • Make the ambient temperature below.

• the room door closed?

• Check if putting in hot foods. • Put in foods after they get cold.

• Did you open the door of the set too often • Don't open the door too often and close

• or check if the door is closed up? • it firmly.

• Check if the Control is set to "Min". • Set the control to mid-position.

Foods in the • Are foods placed in cooling air outlet? • Place foods in high temperature section.

Refrigerator • (Front Part)

are frozen. • Check if the Display LED is set to "Max". • Set the Display LED to "Mid".

• Is the ambient temperature below 5°C? • Set the Display LED to "Min".

Dew or ice • Is watery foods kept? • Seal up watery foods with wrap.

forms in the • Check if putting in hot foods. • Put in foods after they get cold.

chamber of • Did you open the door of the set too • Don't open the door too often and close

the set. • often or check if the door is closed up. • it firmly.

Dew forms • Check if ambient temperature and humidity • Wipe dew with a dry cloth. This happening

in the Out Case. of surroumcling air are high. • is solved in low temperature and humidity

• naturally.

• Is the gap in the door packed? • Fill up the gap.

Abnormal • Is the set positioned in a firm and even place? • Adjust the Adjust Screw, and position

noise generates. • in the firm place.

• Does any unnecessary objects exist • Remove the objects.

• in the back side of the set?

• Check if the Drip Tray is not firmly fixed. • Fix it firmly on an original position.

• Check if the cover of mechanical room • Place the cover at an original position.

• in below and front side is taken out.

To close the door • Check if the door packing becomes dirty • Clean the door packing.

is not handy. • by filth such as juice.

• Is the set positioned in a firm and even place? • Position in the firm place and adjust the

• Adjust Screw.

• Is too much food putted in the set? • Keep foods not to reach the door.

Ice and foods • Check if the inside of the set becomes dirty. • Clean the inside of the set.

smell unpleasant. • Did you keep smelly foods without wraping? • Wrap smelly foods.

• It smells plastic. • The new products smell plastic, but it is

• removed after 1-2 weeks.

● In addition to the items described left, refer to the followings to solve the complaint.

Check if dew forms in

the Freezer.

Replace the

Components of

defrosting circuit.

Check Refrigerating

Cycle.

Check the

Thermistor

Defrosting

is poor.

The cycle

is faulty.

Repair the cycle.

Replace the

Thermistor.

The operation of

the Thermistor is

poor.

6-4 SERVICE DIAGNOSIS CHART

Page 14

- 14 -

6-5 REFRIGERATING CYCLE

▼ Troubleshooting Chart

▼ Leakage Detection

Observe discharging point of refrigerant which may be in oil discharging part in compressor and hole of evaporator.

YES

YES

Whether Compressor

runs or not.

Whether frost

forms or not in

Evaporator.

Observe the discharging

amount of Refrigerant.

Inject Refrigerant to

Compressor and check

cooling operation.

Clogged by dust. Gas leakage.

Faulty

Compressor.

Moisture Clog.

Whether oil leaks

or not.

Normal formed frost

Normal amount

No or much amount

(Check the leakage point)

Normal formed

frost in Evaporator

No frost or forms

in inlet only

Check Comprossor

PARTIAL Freezer and Low flowing sound of A little high • A little Refrigerant

LEAKAGE Refrigerator Refrigerant is heard and more than • discharges.

don't get cold frost forms in inlet only ambient • Normal cooling is possible

normally. temperature. • when injecting Refrigerant

• of regular amount.

WHOLE Freezer and Flowing sound of Refrigerant Equal to ambient • No discharging of Refrigerant.

LEAKAGE Refrigerator is not heard and frost isn't temperature. • Normal cooling is possible

don't get cold formed. • when injecting Refrigerant

at all. • of regular amount.

PARTIAL Freeze room and Flowing sound of Refrigerant A little high • Normal discharging of

CLOG Refrigerator is heard and frost forms more than • refrigerant.

don't get cold in inlet only. ambient • The capillary tube is faulty.

normally. temperature.

WHOLE Freezer and Flowing sound of Refrigerant Equal to ambient • Normal discharging of

CLOG Refrigerator is not heard and frost isn't temperature. • Refrigerant.

don't get cold. formed.

MOISTURE Cooling operation Flowing sound of Refrigerant Low than • Cooling operation restarts

CLOG stops periodically. is not heard and frost melts. ambient • when heating the inlet of

temperature • capillary tube.

COMP- Freezer and Low flowing sound of A little high • The pressure of high

RESSION Refrigerator Refrigerant is heard and than ambient • pressure part in

don't get cold. frost forms in inlet only. temperature. • compressor is low.

NO COMP- No compressing Flowing sound of Refrigerant Equal to ambient • No pressure of high pressure

RESSION operation. is not heard and no frost. temperature. • part in compressor.

CAUSE

TEMPERATURE

OF THE

COMPRESSOR

REMARKS

STATE OF

THE SET

STATE OF THE

EVAPORATOR

LEAKAGE

CLOGGED BY DUST

DEFECTIVE

COMPRESSION

Page 15

- 15 -

NO. ITEMS CONTENTS AND SPECIFICATIONS REMARKS

WELDING (1) H 30

ROD (1) • Chemical Ingredients • Recommend H34 containing 34% Ag in the

(1) • Ag: 30%, Cu: 27%, Zn: 23%, Cd: 20% • Service Center.

(1) • Brazing Temperature: 710~840°C

(2) Bcup-2

(1) • Chemical Ingredients

(1) • Cu: About 93%

(1) • P: 6.8~7.5%

(1) • The rest: within 0.2%

(1) • Brazing Temperature: 735~840°C

FLUX (1) • Ingredients and how to make • Make amount for only a day. (1)

(1) ••Borax 30% • Holding period: 1 day

(1) ••Borax 35% • Close the cover of container to prevent dust

(1) • Fluoridation kalium: 35% • putting in the FLUX.

(1) • Water: 4% • Keep it in a stainless steel container.

(1) • Mix the above ingredients and boil until

(1) • they are transformed into liquid.

DRIER (1) Assemble the drier within 30min. • Don't keep the drier in a outdoor because

ASM (1) after unpacking. • humidity damages to it.

(2) Keep the unpacked drier at the temperature

of 80~100°C.

VACUUM (1) When measuring with pirant Vacuum • Apply M/C Vacuum Gauge without fail.

(1 )gauge of charging M/C, vacuum • Perform vacuum operation until a proper

(1 )degree is within 1 Torr. • vacuum degree is built up.

(2) If the vacuum degree of the cycle inside is • If a proper vacuum degree isn't built up,•

(2) 10 Torr. below for low pressure and 20 Torr. • check the leakage from

(2) for high pressure, it says no vacuum • the Cycle Pipe line part and

(2) leakage state. • Quick Coupler Connecting part.

(3) Vacuum degree of vacuum pump must be

(3) 0.05 Torr. below after 5 min.

(4) Vacuum degree must be same to the

value described item (2) above for more than

20 min.

(1) The pressure of dry air must be more

than 12~16Kg/cm

2

(2) Temperature must be more than

-20~-70°C.

(3) Keep the pressure to 12~6Kg/cm

2

also

(3) when substituting dry air for Nitrogen Gas.

NIPPLE (1) Check if gas leaks with soapy water. • Check if gas leaks from connecting part of

AND (2) Replace Quick Coupler in case of leakage. • Coupler.

COUPLER

PIPE (1)• Put all Joint Pipe in a clean box and

(1)• cover tightly with the lid so that dust or

(1)• humidity is not inserted.

1

2

3

4

5

6

7

DRY AND

AIR

NITROGEN

GAS

▼ General Control of Refrigerating Cycle

Page 16

The following description is basically for GR-S552/GR-S592. For the other models, refer to the diagram of the entire PCB

circuit.

7-1 FUNCTION

7-1-1 FUNCTION

1. When the appliance is plugged in, it is set to ‘Medium’. Each time the button is pushed, it is set to

‘Medium’→‘Medium/High’→‘High’→‘Low’→‘Medium/Low’→‘Medium’ in order.

2. When the power is initially applied or restored after a power failure, it is automatically set to ‘Medium’.

7-1-2 CONTROL OF VARIABLE SPEED FAN IN THE FREEZER COMPARTMENT

1. Fan motor in the freezer compartment shall change from standard to high speed rpm in order to increase cooling speed

and load corresponding speed.

2. High speed rpm is only used for the initial power application and load corresponding operation. But standard rpm is used

in the general working condition.

3. When the door of freezer room or refrigerator room is opened, the fan motor is stoped immediately, then when the door is

closed, the fan motor is operated.

7-1-3 CONTROL OF DOUBLE COOLING FAN IN THE REFRIGERATOR COMPARTMENT

1. To raise the refrigerating speed, fan motor in the refrigerator compartment is operated when the door of freezer room or

refrigerator room is opened and then closed.

2. The fan motor is stoped after 20 sec. When the door is dosed.

7. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM

- 16 -

Temp

Control

Low MediumMedium/Low Medium/High High

TEMP(°C)

ROOM

6 4.5 2.5 0.5 -1

REFRIGERATOR

Page 17

7-1-4 DEFROSTING

1. The defrosting is performed each time when the total running time of the compressor reaches 7 hours.

2. After the power is turned on (or restored after a power failure), the defrosting starts when the total running time of the

compressor reaches 4 hours.

3. When the temperature of the defrosting sensor reaches 10 °C or above, the defrosting stops. If the temperature does not

reach 10 °C in 2 hours after the defrosting starts, the defrosting error code is displayed.

(Refer to 7-1-6 Error Diagnostic Mode.)

4. With the defective defrosting sensor (cut or short-circuited wire), the defrosting will not be performed.

7-1-5 SEQUENTIAL OPERATION OF ELECTRIC COMPONENTS

The electric components, such as the comp, defrosting heater, and cooling fan, start sequentially to avoid the noise and

damage to the part, which may result from the simultaneous start of various components on turning the power on or after

the completion of a test.

Condition of Operation Operating Sequence

If the temp of the defrosting

sensor is 45 °C or above

(For the initial use after the

purchase or grounding)

If the temp of the defrosting

sensor is below 45 °C

(After a power failure or SVC)

- 17 -

POWER in 0.5 sec COMP & COOLING FAN

ON ON

POWER in 0.5 sec DEFROSTING in 10 sec DEFROSTING

ON HEATER ON HEATER OFF

in 0.5 sec COMP & COOLING FAN

ON

When the power is turned on

Page 18

7-1-6 ERROR DIAGNOSTIC MODE

1. The error diagnostic mode allows the SVC when a fault that may affect the performance of the product occurs while

operating the product.

2. Even if the function control button is pushed when an error occurs, the function will not be performed.

3. When the error is cleared while the error code is displayed due to a fault, the appliance returns to the normal condition

(Reset).

4. The error code is displayed by the refrigerator temp indication LED on the display of the refrigerator while the remaining

LEDs are off.

- 18 -

R1 R2 R3 R4

NO Error

Error Code Display

Cause

State of Operation with Error

R1 R2 R3 R4

Comp / Cooling fan

Defrosting heater

: ON : OFF

1.

2.

3.

Faulty refrigerator(R)

sensor (on the control

box of the refrigerator)

Faulty defrosting sensor

Defrosting failure

Cut or short-circuited wire of

refrigerator sensor

Cut or short-circuited wire of

defrosting sensor

Cut or disconnected wire of

defrosting heater or temperature

fuse(indicated at least 2 hours

later after the error occurs)

15 min ON/

15 min OFF

No defrosting

Page 19

7-2 PCB FUNCTION

7-2-1 POWER CIRCUIT

The secondary part of the TRANS is composed of the power supply for the display and relay drive (12Vdc) and that for the

MICOM and IC (5Vdc).

The voltage for each part is as follows.

VA1 is a part for preventing the over voltage and noise. When 385V or higher power is applied, the inside elements are

short-circuited and broken, resulting in the blowout of the fuse in order to protect the elements of the secondary part of the

TRANS.

- 19 -

PART VA 1 CE 2 CE3

VOLTAGE 220 Vac 12 Vdc 5 Vdc

Page 20

7-2-2 OSCILLATION CIRCUIT

This circuit is to generate the base clock for calculating time and the synchro clock for transmitting data from and to the

inside logic elements of the IC1(MICOM). Be sure to use the authentic parts since the calculating time by the IC1 may be

changed or it will not work if the OSC1 SPEC is changed.

7-2-3 RESET CIRCUIT

The RESET circuit is for allowing all the functions to start at the initial conditions by initializing various parts including the

RAM inside the MICOM (IC1) when the power is initially supplied or the power supply to the MICOM is restored after a

momentary power failure. For the initial 10ms of power supply, ‘LOW’ voltage is applied to the MICOM RESET terminal.

During a normal operation, 5V is applied to the RESET terminal. (If a trouble occurs in the RESET IC, the MICOM will not

work.)

- 20 -

Page 21

7-2-4 LOAD DRIVE CIRCUIT

1. Load Drive Condition Check

- 21 -

Load Type

Measurement Location (IC5) No. 16 No. 13 No. 15 No. 14 No. 12

ON 1V or below

Condition

OFF 12V

Comp

Defrosting

Heater

Freezer Fan Motor

High RPM

Fan Motor (R-Fan)

Standard RPM

Double Cooling

Page 22

7-2-5 TEMPERATURE SENSOR CIRCUIT

The upper CIRCUIT reads REFRIGERATOR temperature and DEF-SENSOR temperature for defrosting into MICOM.

OPENING or SHORT state of each TEMPERATURE SENSOR are as follows.

7-2-6 DOOR OPEN DETECTION CIRCUIT

- 22 -

SENSOR CHECK POINT NORMAL(-30 °C ~ 50 °C)

SHORT-CIRCUITED

OPEN

Refrigerator Sensor POINT Voltage

0.5 V ~ 4.5 V 0 V 5 V

Defrosting Sensor POINT Voltage

A

B

Closed 0V

Open 5V

Measurement Location

Freezer / Refrigerator Door

(Pin No.13)

Page 23

- 23 -

7-2-7 TEMPERATURE COMPENSATION & OVERCOOLING/UNDERCOOLING COMPENSATION CIRCUIT

1. Refrigerator Temperature Compensation

➧ Table of Temperature Compensation by adjusting the resistance (Difference with the current temperature)

E.g.) If the refrigerator compensation resistance (RCR1) is changed from 10K (the current resistance) to 18K

(the adjustment resistance), the temperature of the refrigerator rises +1.0 °C.

Refrigerator

Resistance Temperature Remark

(RCR1) Compensation

180 KΩ +2.5 °C Compensation by

56 KΩ +2.0 °C

raising the

33 KΩ +1.5 °C

temperature

18 KΩ +1.0 °C

12 KΩ +0.5 °C

10 KΩ 0 °C

Standard Temperature

8.2 KΩ -0.5 °C Compensation by

5.6 KΩ -1.0 °C

lowering the

3.3 KΩ -1.5 °C

temperature

2 KΩ -2.0 °C

470 Ω -2.5 °C

Page 24

7-2-8 KEY BUTTON INPUT & DISPLAY LIGHT ON CIRCUIT

➧ The circuit shown above is to determine whether a function control key on the operation display is pushed and to turn on

the corresponding function indication LED. The drive type is the scan type.

- 24 -

Page 25

- 25 -

7-3 RESISTANCE SPECIFICATION OF SENSOR

• The resistance of SENSOR has ±5% common difference.

• Measure the resistance of SENSOR after leaving it over 3 minutes in measuring temperature.

This postponing is necessary because of perceiving speed.

• Measure the F-SENSOR, SUPER FROST SENSOR, R1, R2-SENSOR after disconnect CON5 of PWB ASSY, MAIN.

TEMPERATURE SENSOR RESISTANCE OF REFRIGERATOR

(DEFROST) SENSOR

- 20 ˚C 77 KΩ

- 15 ˚C 60 KΩ

- 10 ˚C 47.3 KΩ

- 5 ˚C 38.4 KΩ

0 ˚C 30 KΩ

+ 5 ˚C 24.1 KΩ

+ 10 ˚C 19.5 KΩ

+ 15 ˚C 15.9 KΩ

+ 20 ˚C 13 KΩ

+ 25 ˚C 11 KΩ

+ 30 ˚C 8.9 KΩ

+ 40 ˚C 6.2 KΩ

+ 50 ˚C 4.3 KΩ

Page 26

- 26 -

7-4 TROUBLE SHOOTING

• Replace PCB when no trouble after checking the contents of trouble.

CLASSIFICATION

STATE OF TROUBLE

POINT BE CHECKED CHECKING METHOD CONTENT REMEDY

POWER SOURCE 1. All the DISPLAY 1. FREEZER/ FREEZER/REFRIGERATOR POWER SOURCE is poor Certify Fuse.

is poor LED OFF REFRIGERATOR DOOR OPEN Certify outlet Voltage.

2. DISPLAY LED 2. LAMP is dim. CHECK with the naked. Applied voltage mistake Use boosting TRANS.

represents abnormal 3. The connection of Certify connection of CONNECTOR connection Reconnect CONNECTOR.

operation. CONNECTOR of MAIN PWB. CONNECTOR. is poor.

TRANS FUSE open. Replace TRANS.

COOLING is poor NO COOLING 1. COMPRESSOR operates? Check the MAIN PCB. COMPRESSOR lock or Replace COMPRESSOR.

blocked.

OLP, PTC is poor. Replace OLP, PTC.

COMPRESSOR RELAY is Replace MAIN PWB RY1

poor

THE CONNECTING WIRE Certify the black wire of MAIN

is poor. PWB CONNECTOR (CON1)

2. Whether refrigerant leaks or Measure the amount of frost Refrigerant leakage. Remedy the leaking part

leaks or not. sticking on EVA and the and reaching Refrigerant.

surface temperature of

condenser pipe.

FREEZER 1. Whether FAN MOTOR Check the MAIN PCB. FAN MOTOR is poor Replace FAN MOTOR.

TEMPERATURE is poor operates or not. DOOR LINE contact. Replace DOOR LINER.

CONETTING WIRE is poor. Certify MOTOR and the

connection of the black wire

of MAIN PWB CONNECTOR.

(CON1)

2. DEFROSTING normal? Certify the amount of frost DEFROSTING is poor. See the DEFROSTING

sticking on EVA. trouble.

3. SENSOR normal? Check resistance the SENSOR RESISTANCE is Replace SENSOR

SENSOR in the poor.

Refrigerator

Page 27

- 27 -

CLASSIFICATION

STATE OF TROUBLE

POINT BE CHECKED CHECKING METHOD CONTENT REMEDY

COOLING is poor. REFRIGERATOR 1. FREEZER TEMPERATURE See "FREEZER Certify the attaching state

TEMPERATURE is is normal? TEMPERATURE is poor". of DOOR.

poor. 2. Cool air of FAN MOTOR is Certify the amount of cool air FAN MOTOR is poor. Replace FAN MOTOR.

is sufficient? and its speed touching check Passage of cool air blocking. Remove impurities.

supplied into

REFRIGERATOR EVA frozen. See "DEFROSTING is poor".

DEFROSTING is NO DEFROSTING. 1. HEATER emit heat? Check the MAIN PCB. HEATER disconnection. Replace HEATER.

poor.

TEMPERATURE FUSE Replace TEMPERATURE

disconnection. FUSE.

Connection is poor. Certify EVA connection and

wire of MAIN PWB

CONNECTOR (CON1)

DEF-SENSOR is poor. Replace DEF-SENSOR.

HEATER RELAY is poor. Replace RY4 of MAIN PWB.

2. DRAIN PIPE blocking? Certify DRAIN PIPE. DRAIN PIPE blocking. Remove ice and impurities.

Certify HEATER PLATE

resistance.

3. Remain ice at Certify the attaching Attaching is poor. Reassemble DEF-SENSOR.

DEFROSTING? of DEF-SENSOR.

Certify the attaching DOOR sticking is poor. Reassemble DOOR.

state(gap) of FREEZER/ Replace GASKET.

REFRIGERATOR DOOR.

Page 28

7-5 MAIN PWB ASS'Y AND PARTS LIST

7-5-1 MAIN PWB ASS'Y

- 28 -

1. R-B52DZ/R-B55DZ

Page 29

7-5-2 REPLACEMENT PARTS LIST

- 29 -

Page 30

7-5-3 PWB ASS'Y, DISPLAY AND PARTS LIST

- 30 -

Page 31

7-6 PWB DIAGRAM

- 31 -

Page 32

- 32 -

Page 33

- 33 -

8. EXPLODED VIEW

104A

106A

310A

308A

314A

307A

309A

312A

328B

315A

281C

281B

281A

282A

282B

103C

318A

317A

304A

323B

328A

329C

420A

319A

105A

315B

327A

315C

319C

106A

283B

120A

158F

329D

409B

158C

410J

158A

158B

409A

401A

301A

418A

406B

103B

103A

410G*

410H*

501A

501F

411A

501K

324A

129A

▼ The parts of refrigerator and the shape of each part are subject to change in different localities.

*

: optional parts

Page 34

*

: optional parts

- 34 -

151A

151A

155K

154A

233B

*

149C

*

149C

*

140A

*

149A

241A

205A

or

205A

or

241D

241C

235A

205A

205A

*

131A

405C

404A

405C 405A

*

131C

233A

230A

203A

200A

201A

*

136A

*

136B

*

136N

*

136P

*

136Q

*

136R

241A

210A

210B

243A

243B

231A

*

149B

*

125A

*

125A

*

131A

*

125A

*

125H

*

149A

234B

*

149B

*

212G

329A

212C

212A

244A

244C

330B

332A

Loading...

Loading...