LG GR-P207, GR-C207, GR-B207, GR-L207 Service Manual

CAUTION

PLEASE READ CAREFULLY THE SAFETY PRECAUTIONS OF THIS BOOK

BEFORE CHECKING OR OPERATING THE REFRIGERATOR.

REFRIGERATOR

SERVICE MANUAL

Ref No :

GR-L207

Ref No :

GR-C207

Ref No :

GR-B207

Ref No :

GR-P207

http://biz.lgservice.com

WARNINGS AND PRECAUTIONS FOR SAFETY ................................................................................................................ 3

SPECIFICATIONS................................................................................................................................................................... 4

PARTS IDENTIFICATION ........................................................................................................................................................8

HOW TO INSTALL THE REFRIGERATOR .......................................................................................................................... 14

HOW TO ADJUST DOOR HEIGHT OF THE REFRIGERATOR ........................................................................................ 14

HOW TO INSTALL WATER PIPE........................................................................................................................................15

HOW TO CONTROL THE AMOUNT OF WATER SUPPLIED TO THE ICEMAKER ......................................................... 19

MICOM FUNCTION .............................................................................................................................................................. 21

EXPLATION FOR MICOM CIRCUIT..................................................................................................................................... 31

EXPLANATION FOR PWB CIRCUIT ................................................................................................................................. 31

COMPENSATION CIRCUIT FOR WEAK-COLD, OVER-COLD AT FREEZING ROOM.................................................... 60

PWB PARTS DRAWING AND LIST ................................................................................................................................... 61

PWB CIRCUIT DIAGRAM .................................................................................................................................................. 76

ICE MAKER AND DISPENSER WORKING PRINCIPLES AND REPAIR...........................................................................86

WORKING PRINCIPLES.................................................................................................................................................... 86

FUNCTION OF ICE MAKER .............................................................................................................................................. 87

ICE MAKER TROUBLESHOOTING................................................................................................................................... 90

ICE MAKER CIRCUITS...................................................................................................................................................... 91

CIRCUIT................................................................................................................................................................................ 93

TROUBLE DIAGNOSIS........................................................................................................................................................ 95

TROUBLE SHOOTING ...................................................................................................................................................... 95

FAULTS ............................................................................................................................................................................ 105

COOLING CYCLE HEAVY REPAIR ................................................................................................................................. 122

HOW TO DEAL WITH CLAIMS........................................................................................................................................ 129

HOW TO DISASSEMBLE AND ASSEMBLE..................................................................................................................... 134

DOOR............................................................................................................................................................................... 134

HANDLE ........................................................................................................................................................................... 135

SHROUD, GRILLE FAN ................................................................................................................................................... 135

ICEMAKER....................................................................................................................................................................... 135

DISPENSER..................................................................................................................................................................... 136

HOME BAR ...................................................................................................................................................................... 136

EXPLODED VIEW .............................................................................................................................................................. 139

REPLACEMENT PARTS LIST ........................................................................................................................................... 148

CONTENTS

- 2 -

Please observe the following safety precautions in order to

use safely and correctly the refrigerator and to prevent

accident and danger during repair.

1. Be care of an electric shock. Disconnect power cord

from wall outlet and wait for more than three minutes

before replacing PWB parts. Shut off the power

whenever replacing and repairing electric components.

2. When connecting power cord, please wait for more than

five minutes after power cord was disconnected from the

wall outlet.

3. Please check if the power plug is pressed down by the

refrigerator against the wall. If the power plug was

damaged, it may cause fire or electric shock.

4. If the wall outlet is over loaded, it may cause fire. Please

use its own individual electrical outlet for the refrigerator.

5. Please make sure the outlet is properly earthed,

particularly in wet or damp area.

6. Use standard electrical components when replacing

them.

7. Make sure the hook is correctly engaged.

Remove dust and foreign materials from the housing

and connecting parts.

8. Do not fray, damage, machine, heavily bend, pull out,

or twist the power cord.

9. Please check the evidence of moisture intrusion in the

electrical components. Replace the parts or mask it

with insulation tapes if moisture intrusion was

confirmed.

10. Do not touch the icemaker with hands or tools to

confirm the operation of geared motor.

11. Do not let the customers repair, disassemble, and

reconstruct the refrigerator for themselves. It may

cause accident, electric shock, or fire.

12. Do not store flammable materials such as ether,

benzene, alcohol, chemicals, gas, or medicine in the

refrigerator.

13. Do not put flower vase, cup, cosmetics, chemicals,

etc., or container with full of water on the top of the

refrigerator.

14. Do not put glass bottles with full of water into the

freezer. The contents shall freeze and break the glass

bottles.

15. When you scrap the refrigerator, please disconnect the

door gasket first and scrap it where children are not

accessible.

WARNINGS AND PRECAUTIONS FOR SAFETY

- 3 -

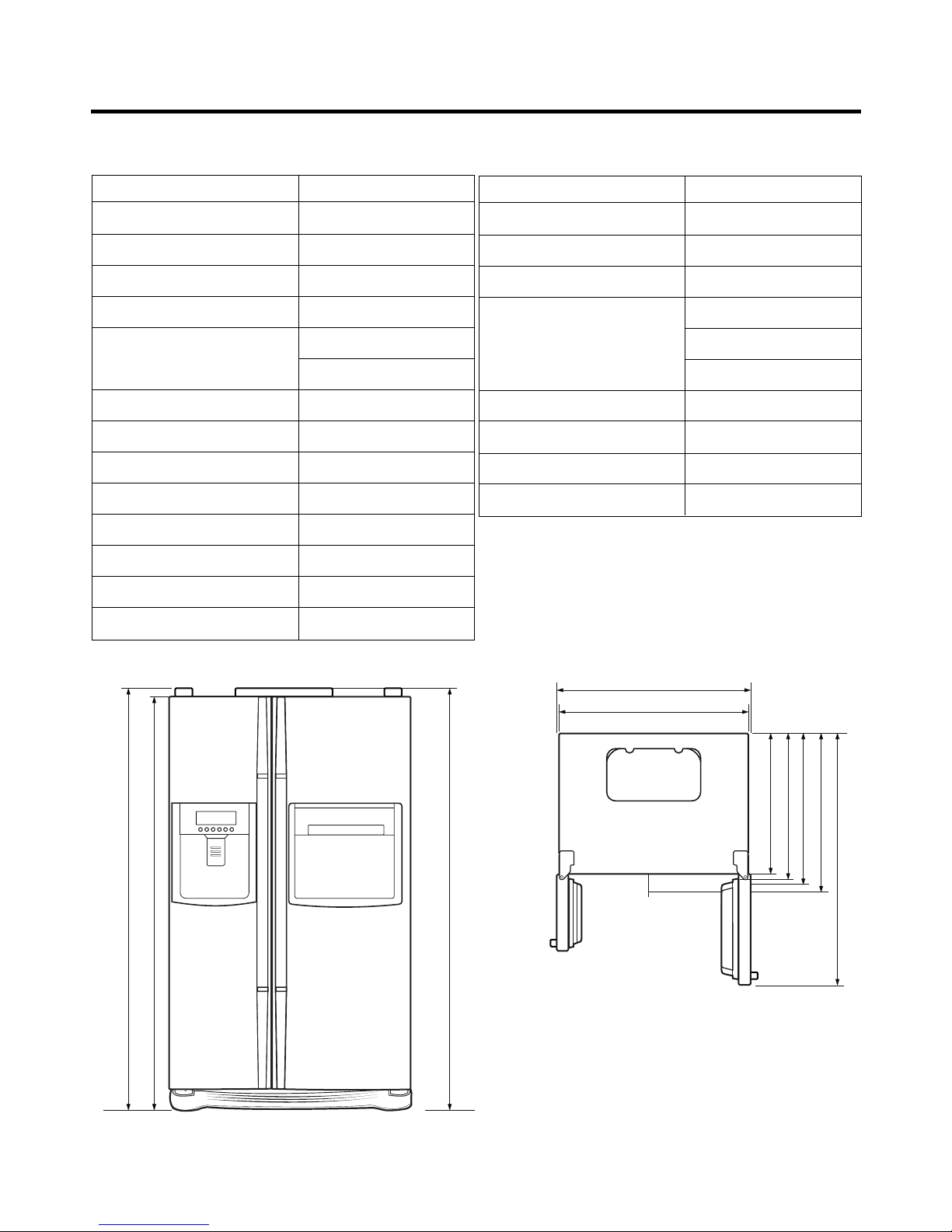

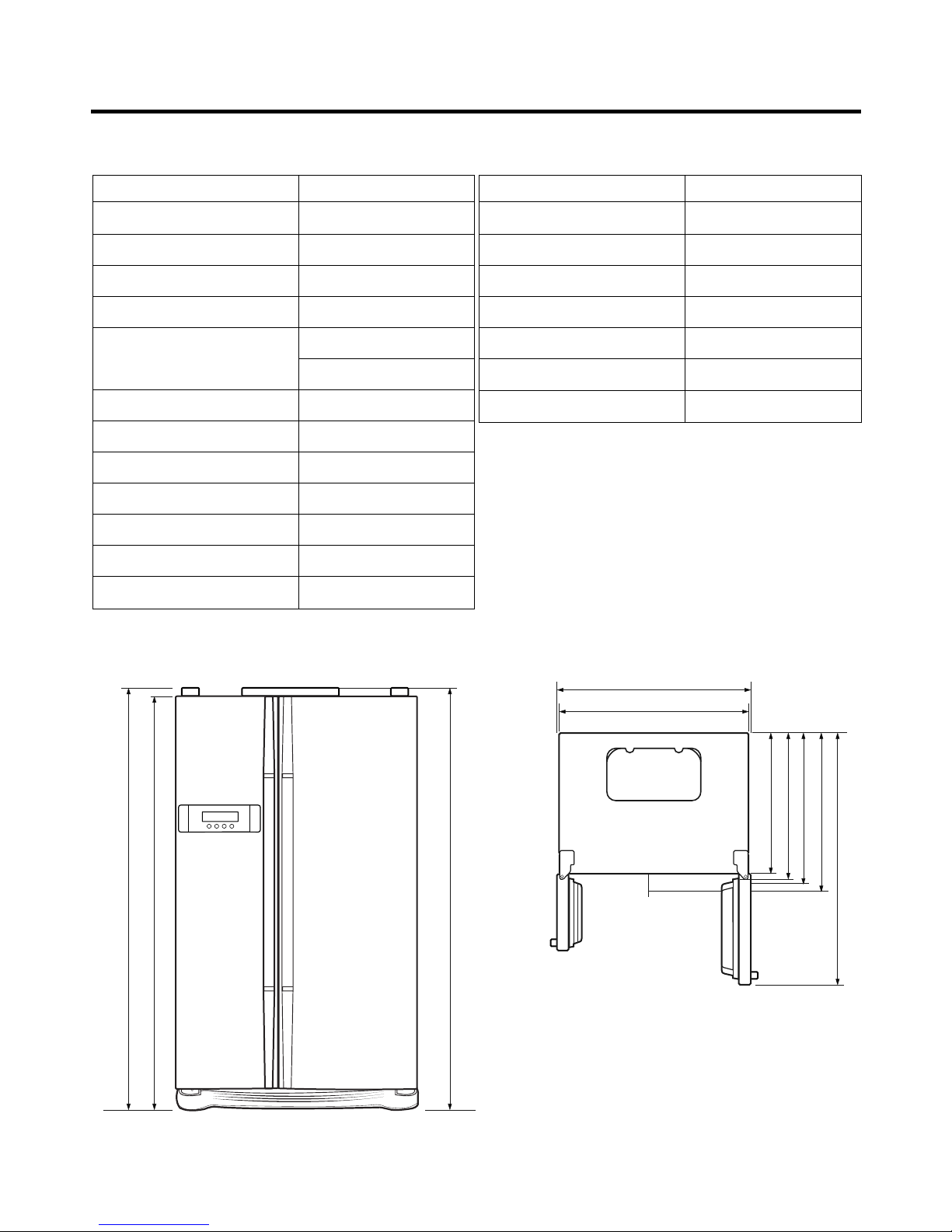

SPECIFICATIONS

- 4 -

ITEMS SPECIFICATIONS

DIMENSIONS (mm) 890(W)X725(D)X1750(H)

NET WEIGHT (kg) 121

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM Full Automatic

Heater Defrost

INSULATION Cyclo-Pentane

COMPRESSOR P.T.C. Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R134a (180g)

LUBRICATING OIL FREOL @10G (310 cc)

DRIER ID 0.83

CAPILLARY TUBE MOLECULAR SIEVE XH-7

1750

1720

1750

600

948

890

666

711

725

1133.5

<Front View> <Plane View>

1. Ref No. : GR-P207

ITEMS SPECIFICATIONS

FIRST DEFROST 4 - 5 Hours

DEFROST CYCLE 13 - 15 Hours

DEFROSTING DEVICE Heater, Sheath

ANTI SWEAT HEATER Dispenser Duct Door Heater

Dispenser Heater

Home Bar Heater

ANTI-FREEZING HEATER Damper Heater

FREEZER LAMP 40W (1 EA)

REFRIGERATOR LAMP 40W (1 EA)

DISPENSER LAMP 15W (1 EA)

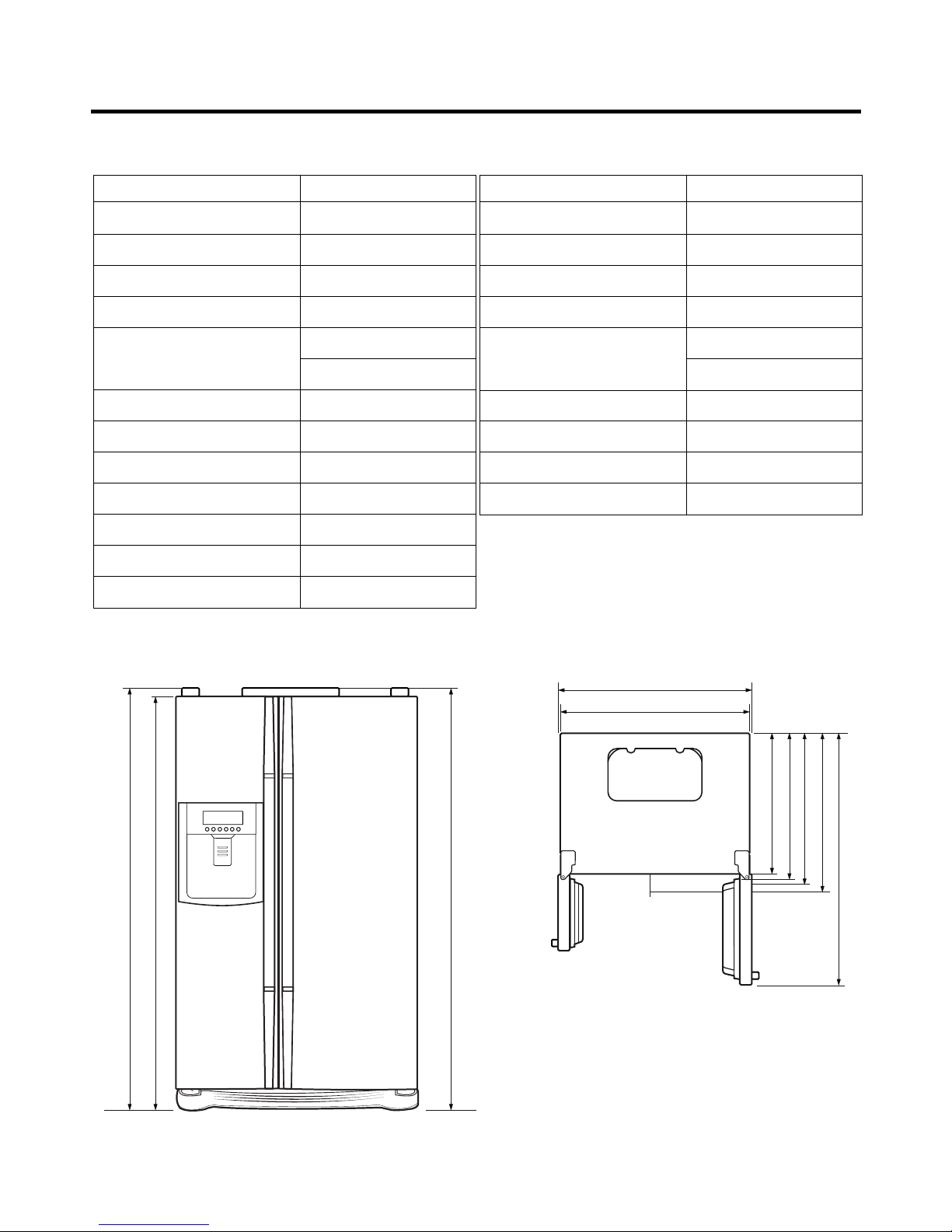

SPECIFICATIONS

- 5 -

ITEMS SPECIFICATIONS

DIMENSIONS (mm) 890(W)X725(D)X1750(H)

NET WEIGHT (kg) 120

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM Full Automatic

Heater Defrost

INSULATION Cyclo-Pentane

COMPRESSOR P.T.C. Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R134a (180g)

LUBRICATING OIL FREOL @10G (310 cc)

DRIER ID 0.83

ITEMS SPECIFICATIONS

CAPILLARY TUBE MOLECULAR SIEVE XH-7

FIRST DEFROST 4 - 5 Hours

DEFROST CYCLE 13 - 15 Hours

DEFROSTING DEVICE Heater, Sheath

ANTI SWEAT HEATER Dispenser Duct Door Heater

Dispenser Heater

ANTI-FREEZING HEATER Damper Heater

FREEZER LAMP 40W (1 EA)

REFRIGERATOR LAMP 40W (1 EA)

DISPENSER LAMP 15W (1 EA)

1750

1720

1750

600

948

890

666

711

725

1133.5

<Front View> <Plane View>

2. Ref No. : GR-L207

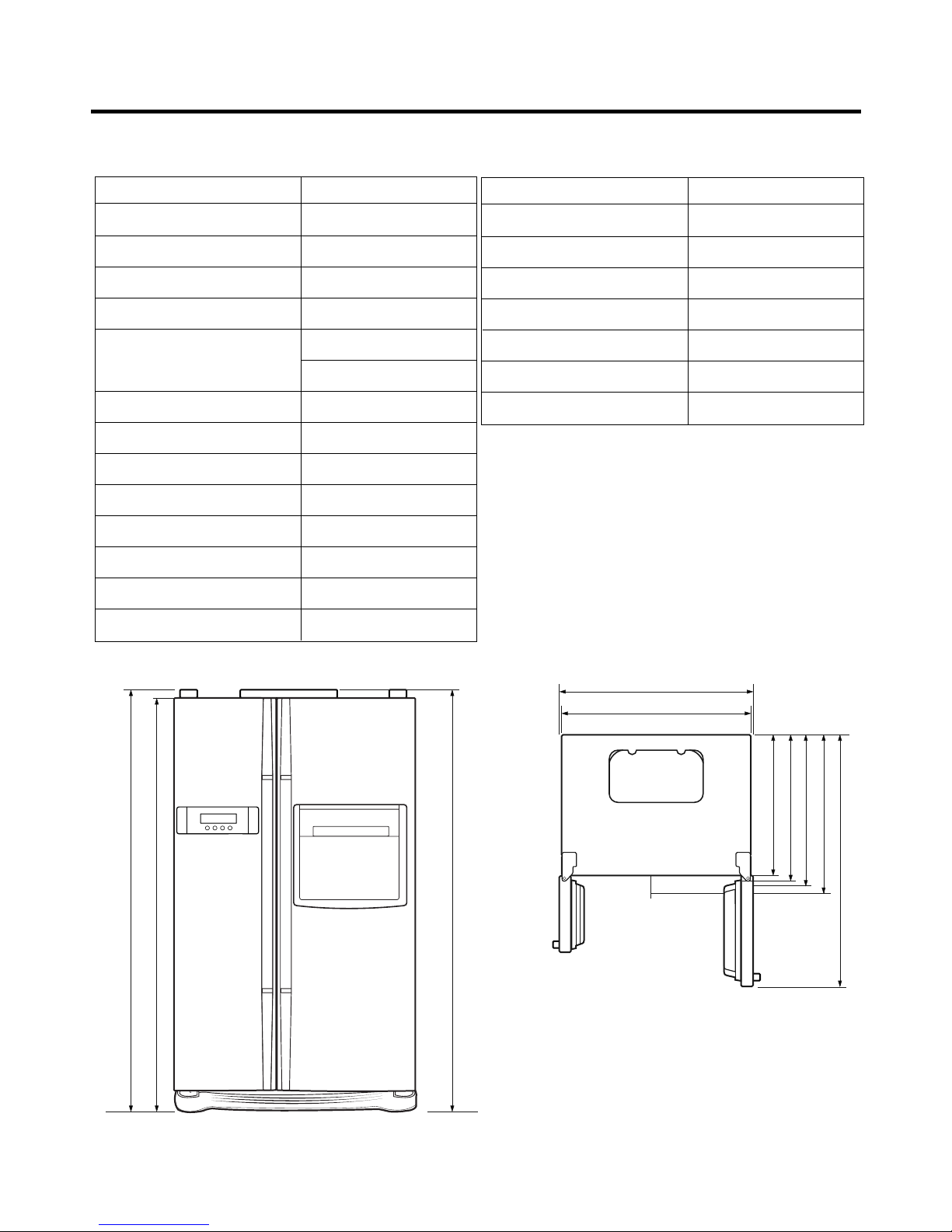

SPECIFICATIONS

- 6 -

ITEMS SPECIFICATIONS

DIMENSIONS (mm) 890(W)X725(D)X1750(H)

NET WEIGHT (kg) 107

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM Full Automatic

Heater Defrost

INSULATION Cyclo-Pentane

COMPRESSOR P.T.C. Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R134a (180g)

LUBRICATING OIL FREOL @10G (310 cc)

DRIER ID 0.83

CAPILLARY TUBE MOLECULAR SIEVE XH-7

1750

1720

1750

600

948

890

666

711

725

1133.5

<Front View> <Plane View>

3. Ref No. : GR-C207

ITEMS SPECIFICATIONS

FIRST DEFROST 4 - 5 Hours

DEFROST CYCLE 13 - 15 Hours

DEFROSTING DEVICE Heater, Sheath

ANTI SWEAT HEATER Home Bar Heater

ANTI-FREEZING HEATER Damper Heater

FREEZER LAMP 40W (1 EA)

REFRIGERATOR LAMP 40W (1 EA)

SPECIFICATIONS

- 7 -

ITEMS SPECIFICATIONS

DIMENSIONS (mm) 890(W)X725(D)X1750(H)

NET WEIGHT (kg) 106

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM Full Automatic

Heater Defrost

INSULATION Cyclo-Pentane

COMPRESSOR P.T.C. Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R134a (180g)

LUBRICATING OIL FREOL @10G (310 cc)

DRIER ID 0.83

ITEMS SPECIFICATIONS

CAPILLARY TUBE MOLECULAR SIEVE XH-7

FIRST DEFROST 4 - 5 Hours

DEFROST CYCLE 13 - 15 Hours

DEFROSTING DEVICE Heater, Sheath

ANTI-FREEZING HEATER Damper Heater

FREEZER LAMP 40W (1 EA)

REFRIGERATOR LAMP 40W (1 EA)

1750

1720

1750

600

948

890

666

711

725

1133.5

<Front View> <Plane View>

4. Ref No. : GR-B207

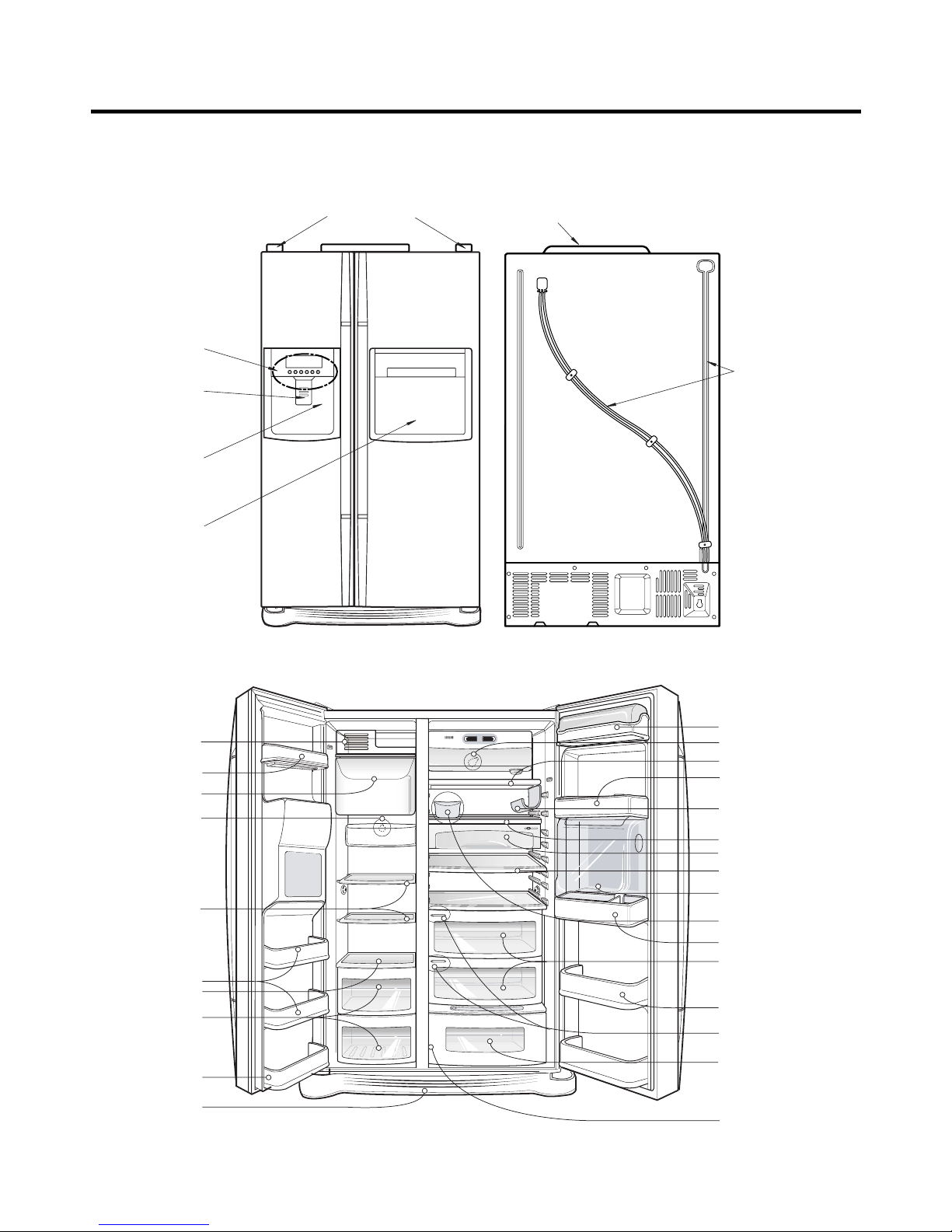

PARTS IDENTIFICATION

- 8 -

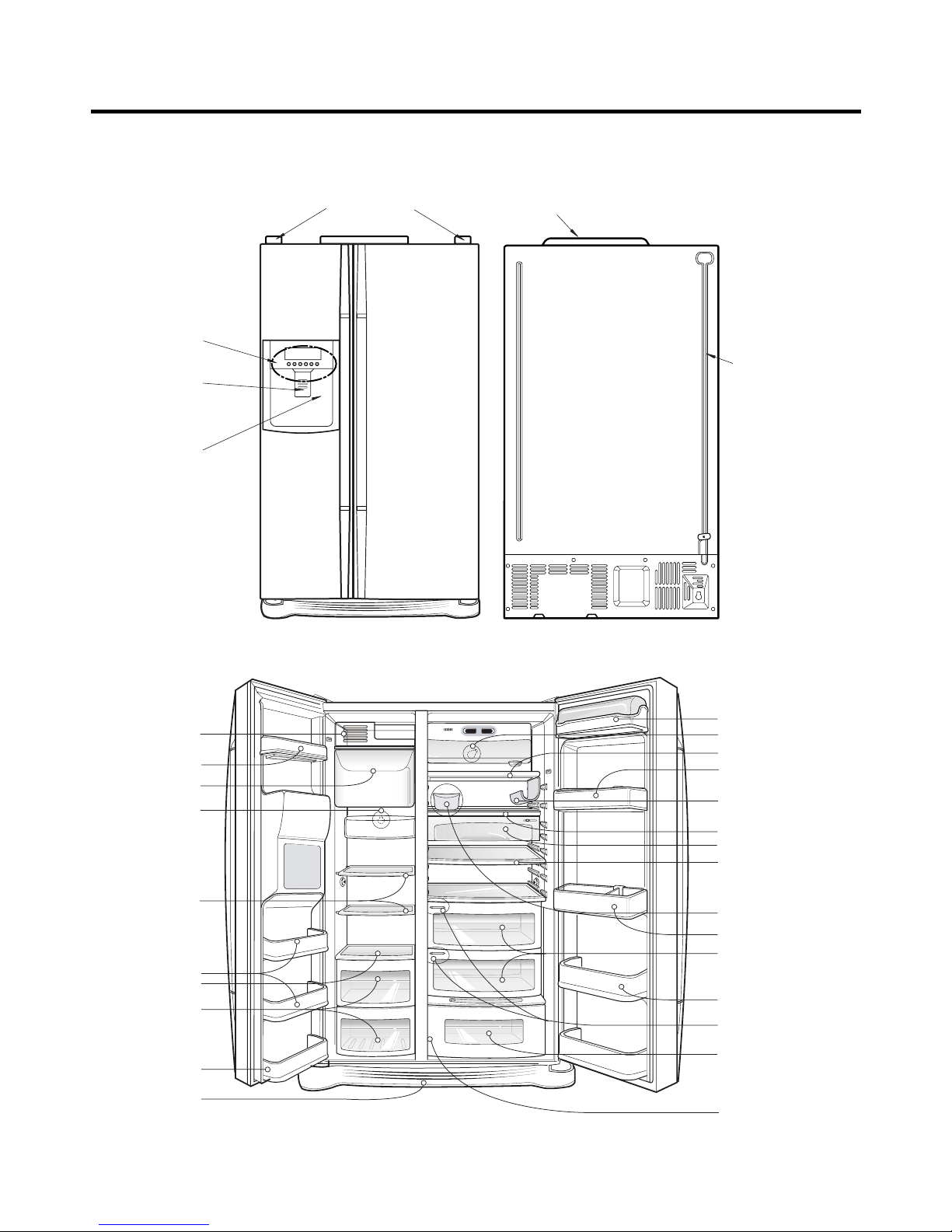

Cover Hinge

Home Bar

Frame Display

Cover PWB

Water Tube

Dispenser Lamp

Ice & Water

Dispenser Button

Freezer

compartment

Refrigerator

compartment

Milk product corner

Door rack

Space plus

Lamp

Automatic

ice maker

Shelf

(steel or glass)

Shelf

Door rack

Drawer

Door rack

Lower cover

Lamp

Shelf

Door rack

(1piece or 2piece)

Door rack

(1piece or 2piece)

Door rack

Shelf

Snack drawer (Optional)

Shelf(Folding or Normal)

*Refreshment center

(Optional)

Egg box

Vegetable drawer

(1 or 2)

*Miracle Zone (Optional)

Fresh compartment

(Optional)

*

Conversion switch

(Meats/Vegetables)

(Optional)

* Optional

Humidity switch

*Wine holder

(Plastic or wire)

1. Ref No. : GR-P207(Internal Filter)

2. Ref No. : GR-P207(External Filter)

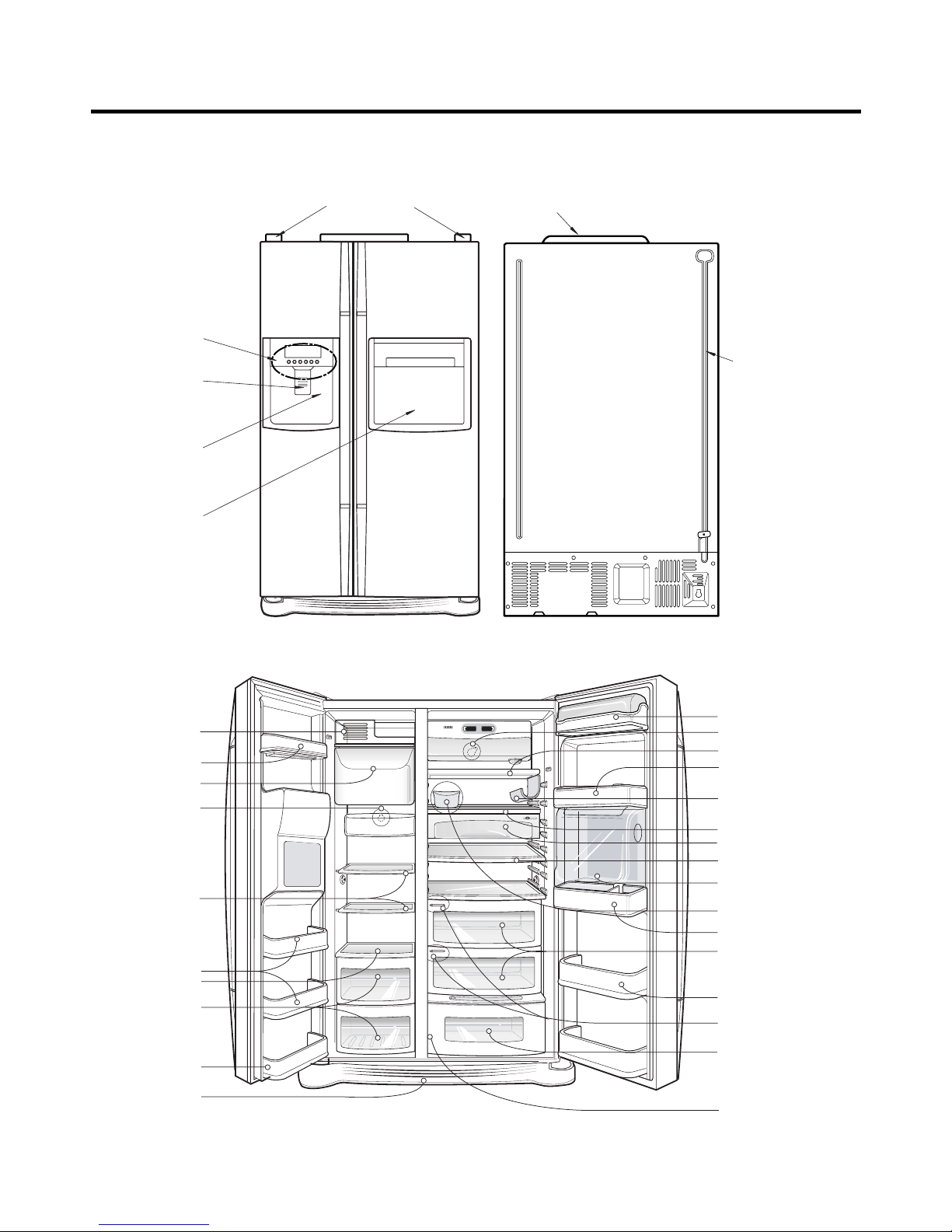

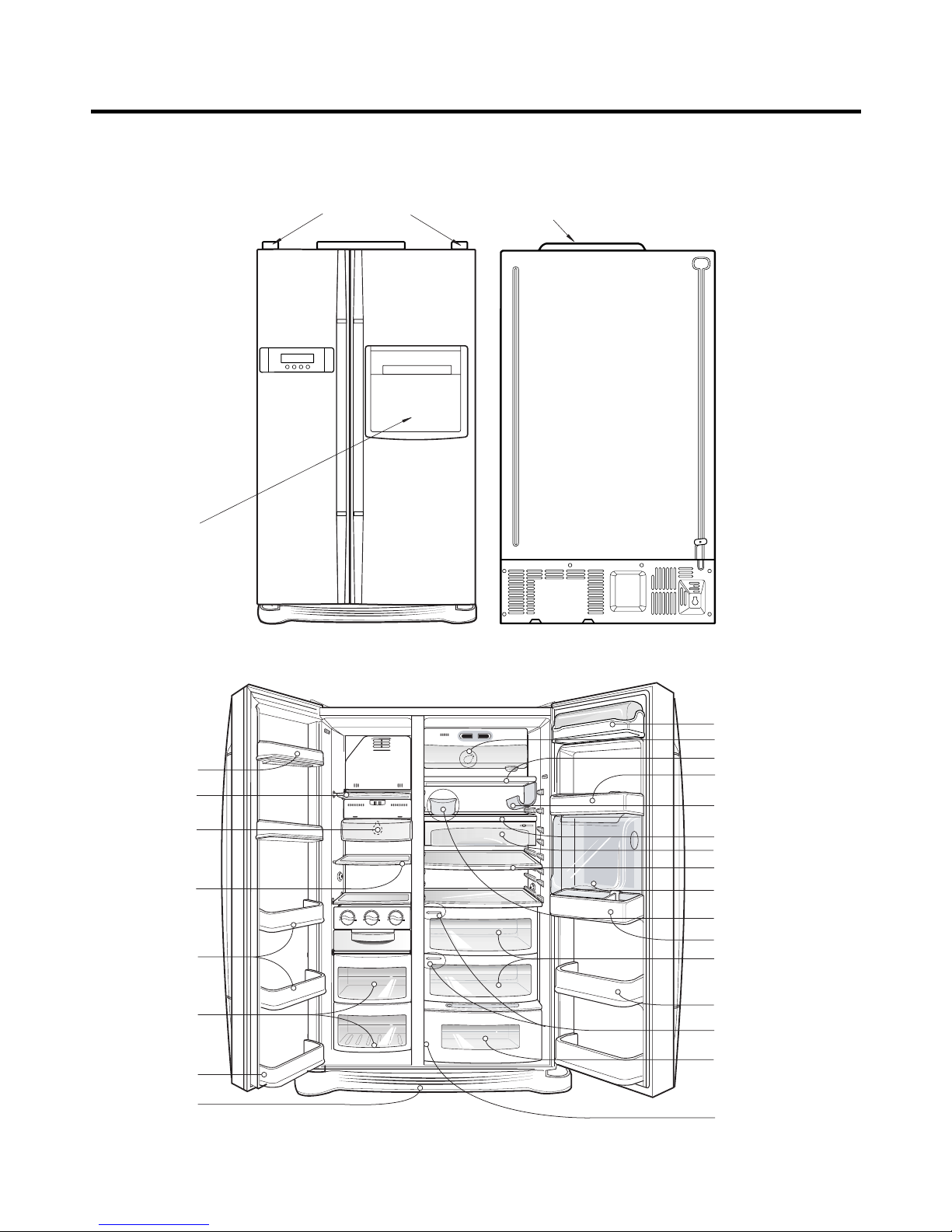

PARTS IDENTIFICATION

- 9 -

Freezer

compartment

Refrigerator

compartment

Milk product corner

Door rack

Space plus

Lamp

Automatic

ice maker

Shelf

(steel or glass)

Shelf

Door rack

Drawer

Door rack

Lower cover

Lamp

Shelf

Door rack

(1piece or 2piece)

Door rack

(1piece or 2piece)

Door rack

Shelf

Snack drawer (Optional)

Shelf(Folding or Normal)

*Refreshment center

(Optional)

Egg box

Vegetable drawer

(1 or 2)

*Miracle Zone (Optional)

Fresh compartment

(Optional)

*

Conversion switch

(Meats/Vegetables)

(Optional)

* Optional

Humidity switch

*Wine holder

(Plastic or wire)

Cover Hinge

Home Bar

Frame Display

Cover PWB

Water Tube

Dispenser Lamp

Ice & Water

Dispenser Button

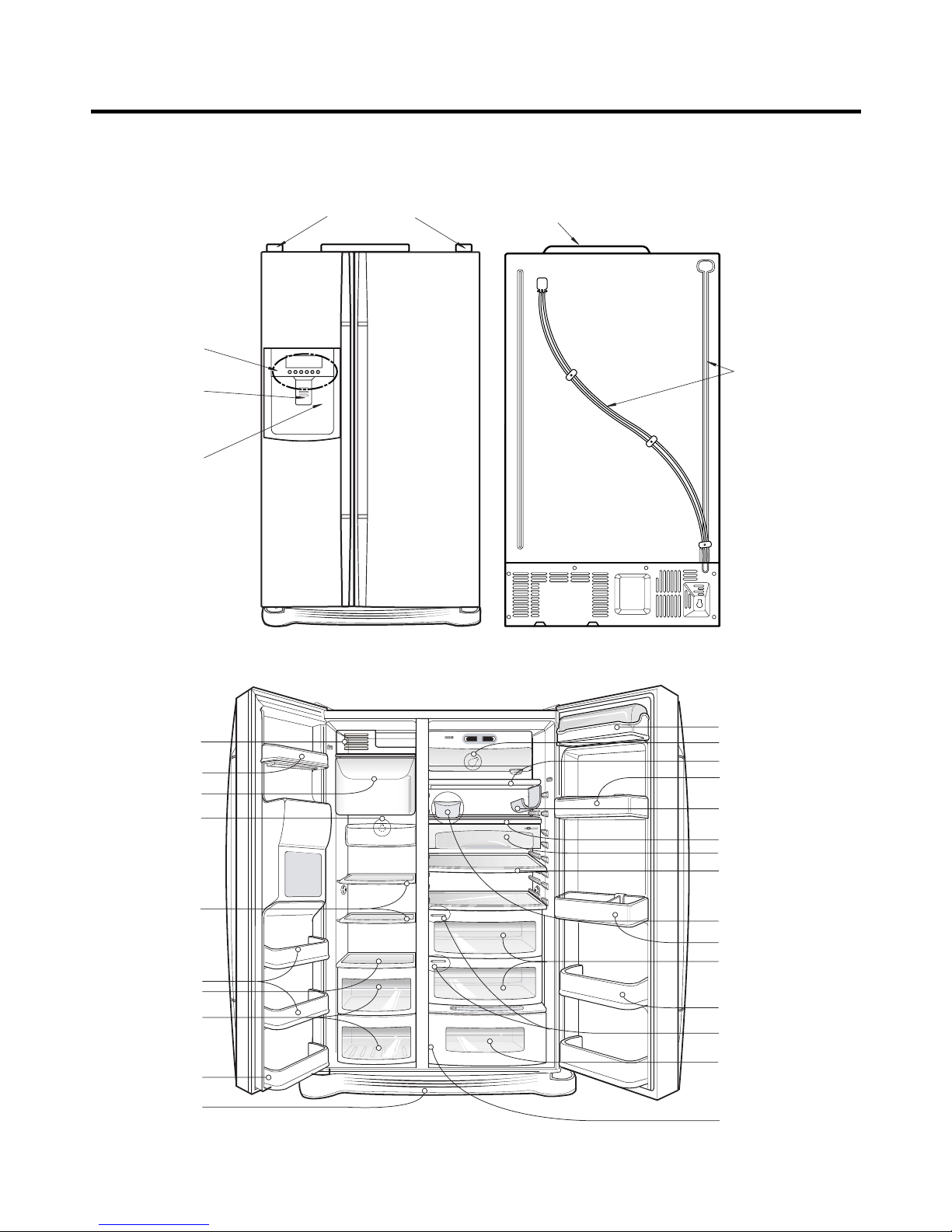

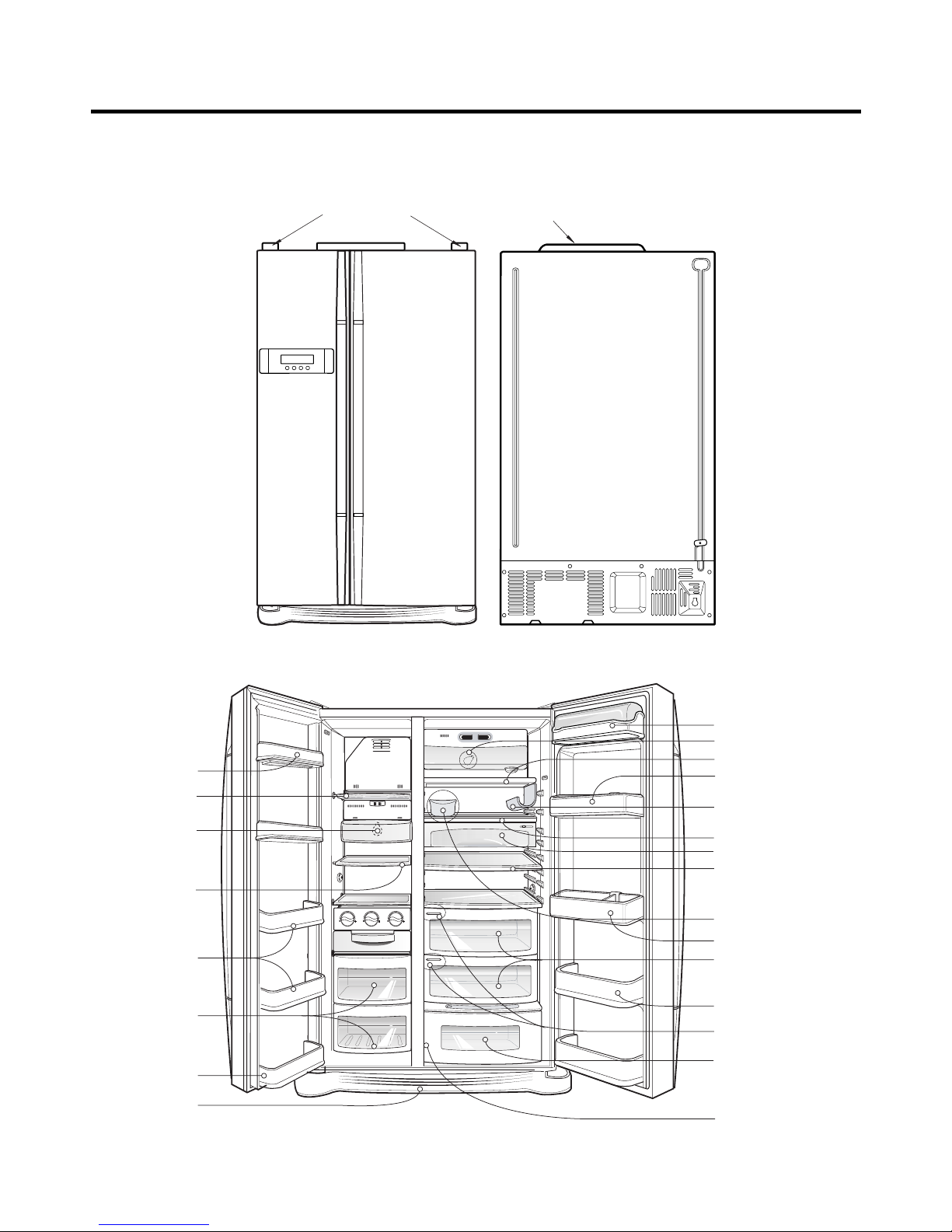

PARTS IDENTIFICATION

- 10 -

Freezer

compartment

Refrigerator

compartment

Milk product corner

Door rack

Space plus

Lamp

Automatic

ice maker

Shelf

(steel or glass)

Shelf

Door rack

Drawer

Door rack

Lower cover

Lamp

Shelf

Door rack

(1piece or 2piece)

Door rack

(1piece or 2piece)

Door rack

Shelf

Snack drawer (Optional)

Shelf(Folding or Normal)

Egg box

Vegetable drawer

(1 or 2)

*Miracle Zone (Optional)

Fresh compartment

(Optional)

*

Conversion switch

(Meats/Vegetables)

(Optional)

* Optional

Humidity switch

*Wine holder

(Plastic or wire)

Cover PWB

Water Tube

Cover Hinge

Frame Display

Dispenser Lamp

Ice & Water

Dispenser Button

3. Ref No. : GR-L207(Internal Filter)

4. Ref No. : GR-L207(External Filter)

PARTS IDENTIFICATION

- 11 -

Freezer

compartment

Refrigerator

compartment

Milk product corner

Door rack

Space plus

Lamp

Automatic

ice maker

Shelf

(steel or glass)

Shelf

Door rack

Drawer

Door rack

Lower cover

Lamp

Shelf

Door rack

(1piece or 2piece)

Door rack

(1piece or 2piece)

Door rack

Shelf

Snack drawer (Optional)

Shelf(Folding or Normal)

Egg box

Vegetable drawer

(1 or 2)

*Miracle Zone (Optional)

Fresh compartment

(Optional)

*

Conversion switch

(Meats/Vegetables)

(Optional)

* Optional

Humidity switch

*Wine holder

(Plastic or wire)

Cover PWB

Water Tube

Cover Hinge

Frame Display

Dispenser Lamp

Ice & Water

Dispenser Button

PARTS IDENTIFICATION

- 12 -

Freezer

compartment

Refrigerator

compartment

Door rack

Cover, Lamp-F

Shelf-F

Shelf-F

Door rack

Drawer

Door rack

Lower cover

compartment

Refrigerator

compartment

Milk product corner

Lamp

Shelf

Door rack

(1piece or 2piece)

Door rack

(1piece or 2piece)

Door rack

Shelf

Snack drawer (Optional)

Shelf(Folding or Normal)

Egg box

Vegetable drawer

(1 or 2)

*Miracle Zone (Optional)

Fresh compartment

(Optional)

*

Conversion switch

(Meats/Vegetables)

(Optional)

* Optional

Humidity switch

*Wine holder

(Plastic or wire)

*Refreshment center

(Optional)

Cover Hinge

Home Bar

Cover PWB

1. Ref No. : GR-C207

PARTS IDENTIFICATION

- 13 -

Freezer

compartment

Refrigerator

compartment

Door rack

Cover, Lamp-F

Shelf-F

Shelf-F

Door rack

Drawer

Door rack

Lower cover

compartment

Refrigerator

compartment

Milk product corner

Lamp

Shelf

Door rack

(1piece or 2piece)

Door rack

(1piece or 2piece)

Door rack

Shelf

Snack drawer (Optional)

Shelf(Folding or Normal)

Egg box

Vegetable drawer

(1 or 2)

*Miracle Zone (Optional)

Fresh compartment

(Optional)

*

Conversion switch

(Meats/Vegetables)

(Optional)

* Optional

Humidity switch

*Wine holder

(Plastic or wire)

Cover Hinge

Cover PWB

2. Ref No. : GR-B207

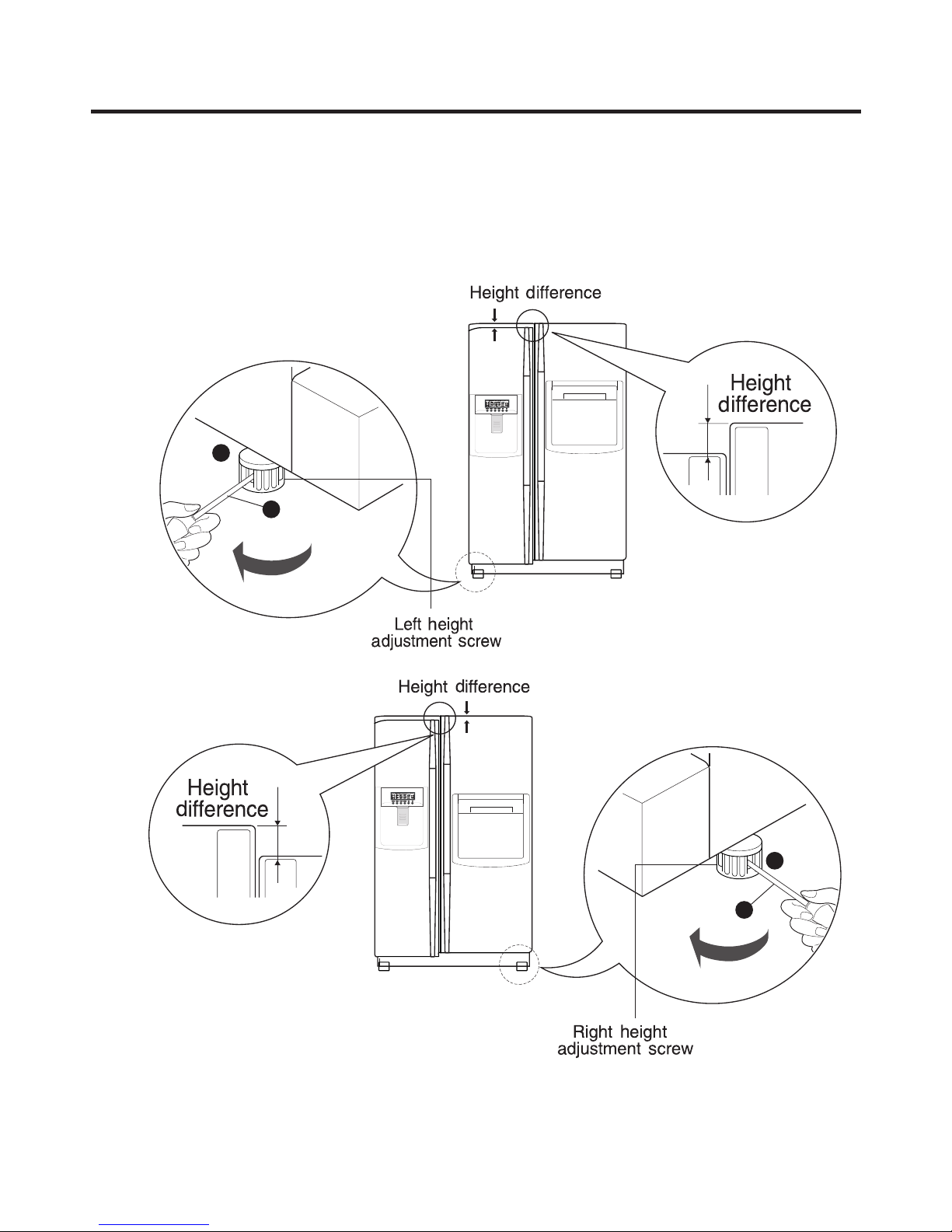

1. How to Adjust Door Height of Refrigerator

■ Make the refrigerator level first. (If the refrigerator is not installed on the flat floor, the height of freezer and refrigerator

door may not be the same.)

1. If the height of freezer door is lower than that of

refrigerator compartment :

2. If the height of freezer door is higher than that of

refrigerator compartment :

Insert a driver into the groove of adjusting screw

and rotate driver in arrow direction (clockwise) until the

refrigerator becomes horizontal.

Insert a driver into the groove of adjusting screw

and rotate driver in arrow direction (clockwise) until the

refrigerator becomes horizontal.

HOW TO INSTALL REFRIGERATOR

- 14 -

1

1

2

2

Adjusting

Adjusting

Driver

Driver

2. How to Install Water Pipe

■ Before Installation

1. The icemaker requires the water pressure of 1.5 -

8.5kgf/cm

2

. (It is acceptable if city water fills a cup of

180cc with water for 3 seconds)

2. Install booster pump where the city water pressure is

below 1.5kgf/cm

2

for normal operation of water and ice

dispenser.

3. The total length of water pipe shall be less than 12m. Do

not bend the pipe at right angle. If the length is more

than 12m, there will be troubles on water supply due to

water pressure drop.

4. Please install water pipe where there is no heat around.

2-1. When connecting directly to the water tap.

■ Please confirm the following installation parts.

HOW TO INSTALL REFRIGERATOR

- 15 -

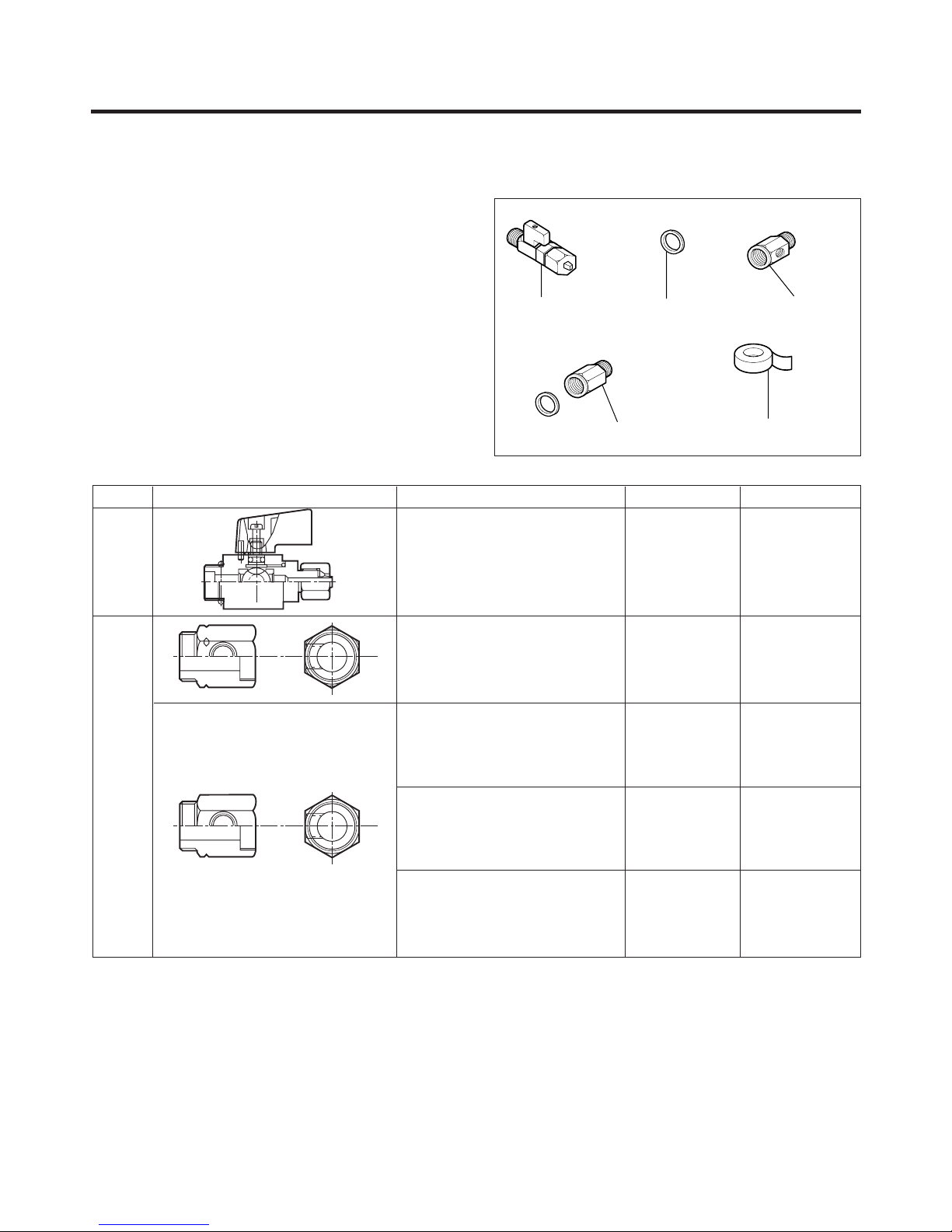

Class. Shape and Spec. Nomenclature P/No Remarks

Valve Feed 5221JA3001A Common Use

Connector, (MECH) Pipe 4932JA3003A

Conversion Connector(3/4") 6631JA3004A

No Holes

Balance Conector(3/4") 6631JA3004B

Packing(ø24x3t) 3920JA3001B

Connector, (MECH) Pipe 4932JA3003B

Conversion Connector(W25) 6631JA3004C

No Holes

Balance Conectoor(W25) 6631JA3004D

Packing(ø23x3t) 3920JA3001A

Connector, (MECH) Pipe 4932JA3003C

Conversion Connector(W28) 6631JA3004E

No Holes

Balance Conector(W28) 6631JA3004F

Packing(ø26x3t) 3920JA3001C

Connector, (MECH) Pipe 4932JA3003D

Conversion Connector(1/2") 6631JA3004G No Holes

Balance Conector(1/2") 6631JA3004H

Packing(ø19x3t) 3920JA3001D

Convertible

Water

Valve

Water

Connector

Valve Feed Rubber, Packing Connector, Pipe

Tape, TeflonConnector, Pipe

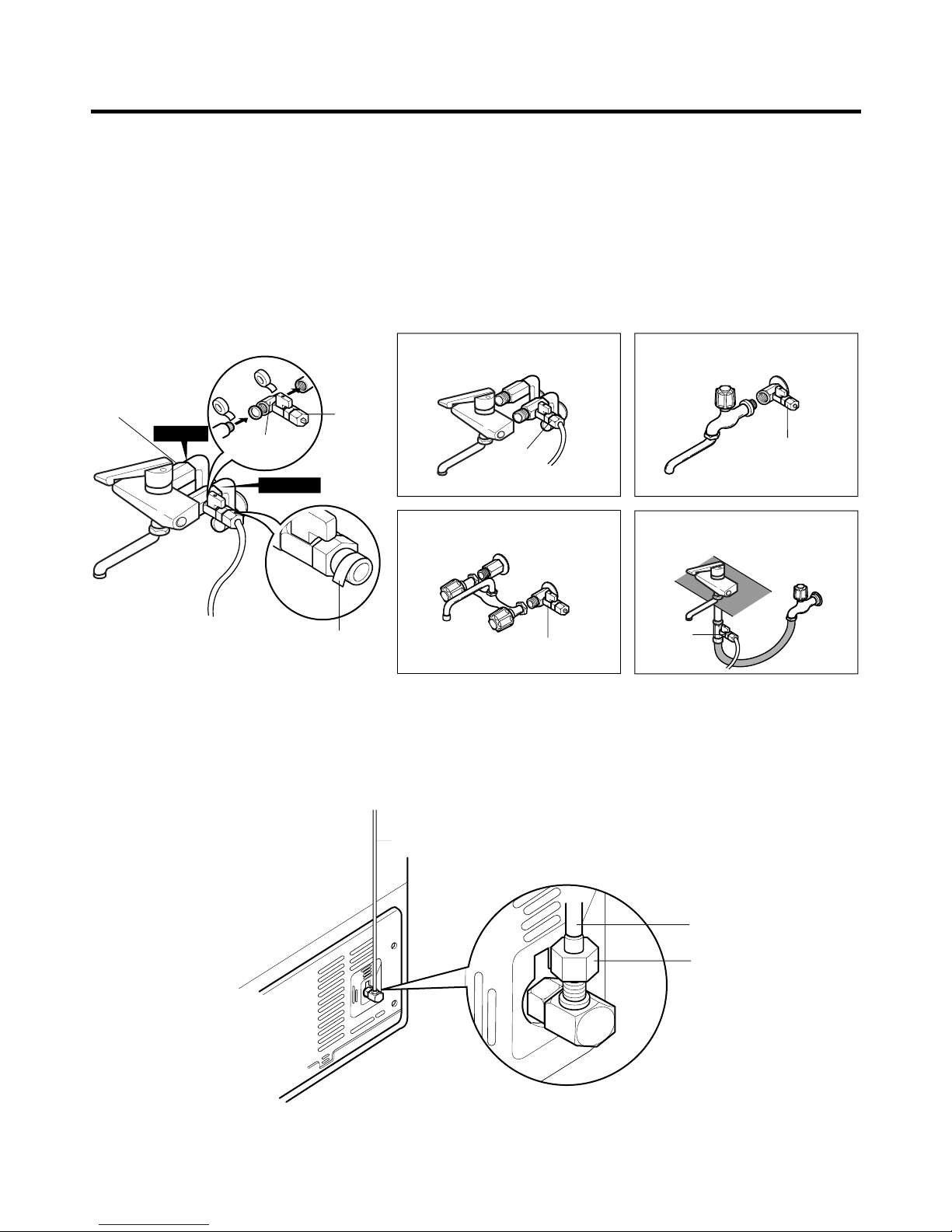

1. Connection of Pipe Connector A and B.

1) Turn off main valve of water pipe.

2) Disconnect water tap from piping by loosening nuts.

3) Connect pipe connector A and B to piping after sealing

the pipe connector with sealing tapes.

4) Connect feed valve to pipe connector A.

5) If there is only one tap water pipe, connect pipe

connector A only and install feed pipe.

2. Water Supply

1) After the installation of feed water, plug the refrigerator

to the earthered wall outlet, press the water dispenser

button for 2 - 3 minutes, and confirm that the water

comes out.

Caution : • Feed pipe should be connected to cold water

line. If it is connected to hot water line, trouble

may occur.

• Please check rubber packing when connecting

feed pipe.

2) Check leakage at connecting part, then arrange water

tube and locate the refrigerator at its regular place if

there is no leaking.

HOW TO INSTALL REFRIGERATOR

- 16 -

Single Lever Type Faucet

(general)

Feed

Valve

General Type

Feed

Valve

Two Hands Type Faucet Single Lever Type Faucet (one

hole, tech type and hand spray)

Feed

Valve

Feed

Valve

Pipe Connector B

Hot Water

Pipe Connector A

Feed

Valve

Cold Water

How to wind

Sealing Tapes.

Water Tube

Water Tube

Nut

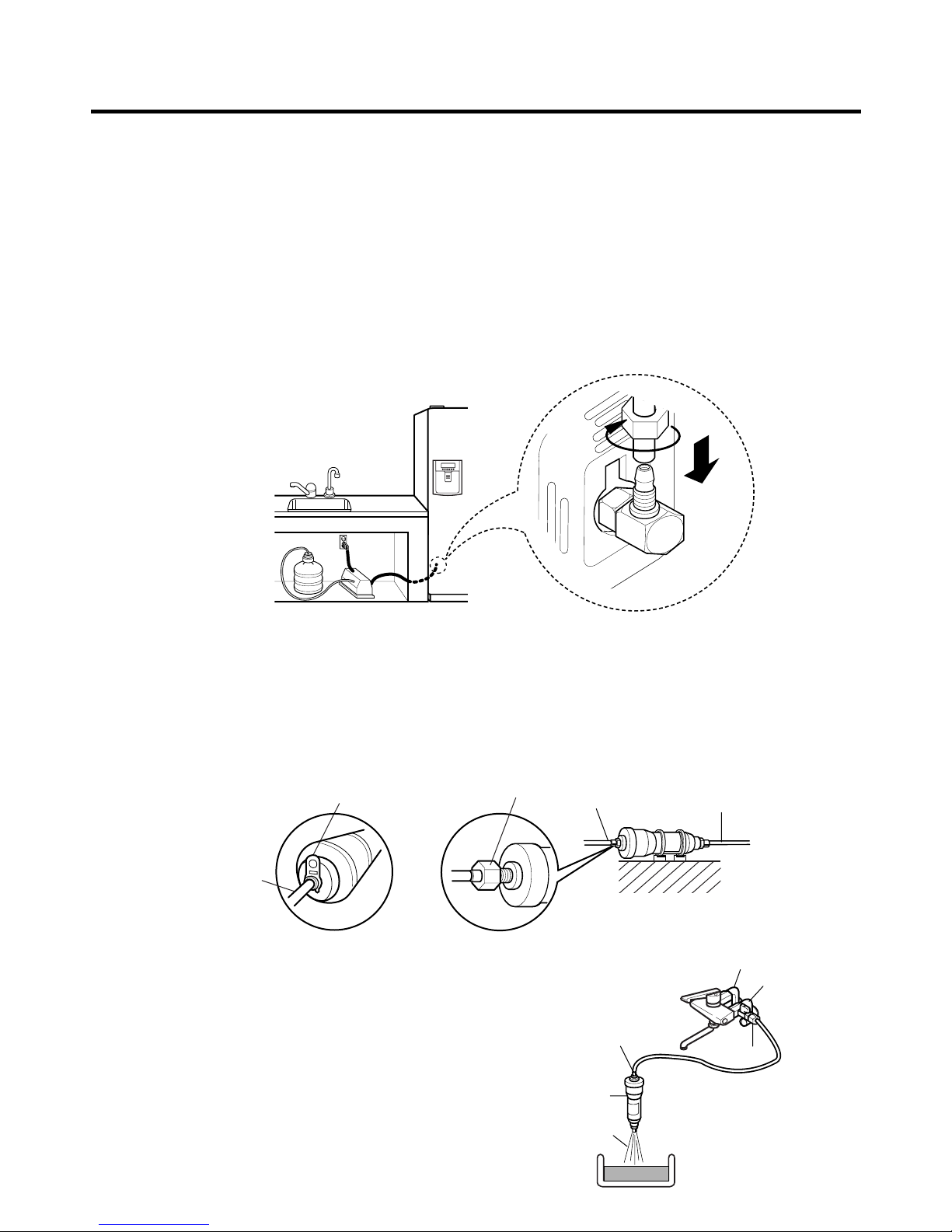

3. When customer uses bottled water.

*If customer wants to use bottled water, extra pump should be installed as shown below.

1. The pump system should not be on the floor (it may cause noise and vibration). Securely fasten the inlet and outlet

nuts of pump.

2. If there is any leakage after installation, cut the water tube at right angle and reassemble.

3. When put the water tube end into the bottle, leave a clearance between bottle bottom and water tube end.

4 Check water coming out and any leakage.

Caution : • If feed tube is more than 4m, less water will come out due to pressure drops.

• Use standard feed tube to prevent leaking.

■ Outternal Filter

1. Filter Fixation

1) There are two types of filter. One is nut type and the other is connector type.

2) Connect feed tube to the filter outlet and water valve connecting tube.

3) Fix the filter at proper place around the sink where it is easy to replace the filter and to receive the cleaning water.

Please consider the length of tube shall be less than 8m when locating filter.

2. Filter Cleaning

1) Connect feed tube to the inlet of feed valve and filter.

2) Clean the main valve and feed valve with water for at

least one minute until clean water comes out.

HOW TO INSTALL REFRIGERATOR

- 17 -

Water Tube

or

Nut

Nut

Inlet

Outlet

Connector Type Nut Type

Water

Filter

Filter Inlet

Feed Valve

Hot Water

Cold Water

■ Install Water Filter (Applicable to some models only)

■ Before Installing water filter

1. Before installing the filter, take out the top shelf of the

refrigerator after tilting it to the direction () and lifting it

to the direction () and move it to the lower part.

2. Remove the lamp cover by pressing the protrusion

under the cover and pulling the cover to the front.

■ Installing water filter

1. Initial installation of water filter

Remove the filter substitute cap by turning it

counterclockwise () by 90 degrees and pulling it down.

Note : Keep it safe to use it later when you do not use the

filter.

Remove the red cap from the filter and attach the

sticker. Insert the upper part of the filter () after

aligning with the guideline marked on the control box,

and fasten it by turning it clockwise by 90 degrees.

Note : Check that the guideline and the fastening

indication line are aligned.

2. Replacement of water filter

While holding the lower part of the filter, turn it

counterclockwise () by 90 degrees and pull it down.

Note : Check that the guideline and the loosening

indication line are aligned.

■ After installing water filter

Reassemble the lamp cover and the top shelf of the

refrigerator. To place the top shelf of the refrigerator, raise

the front part of the shelf a bit so that the hook of the shelf

is fit into the groove.

In order to clean the water filter system, drain water for

about 3 min.

Note : Then open the door of the refrigerator and check for

water droppings on the shelf under the filter.

Control box

Aligning with the guide line

and the fastening indication line

Aligning with the guide line

and the loosening indication line

Control box

Separation

of red cap

Adhesion

sticker

Substitute

cap

HOW TO INSTALL REFRIGERATOR

- 18 -

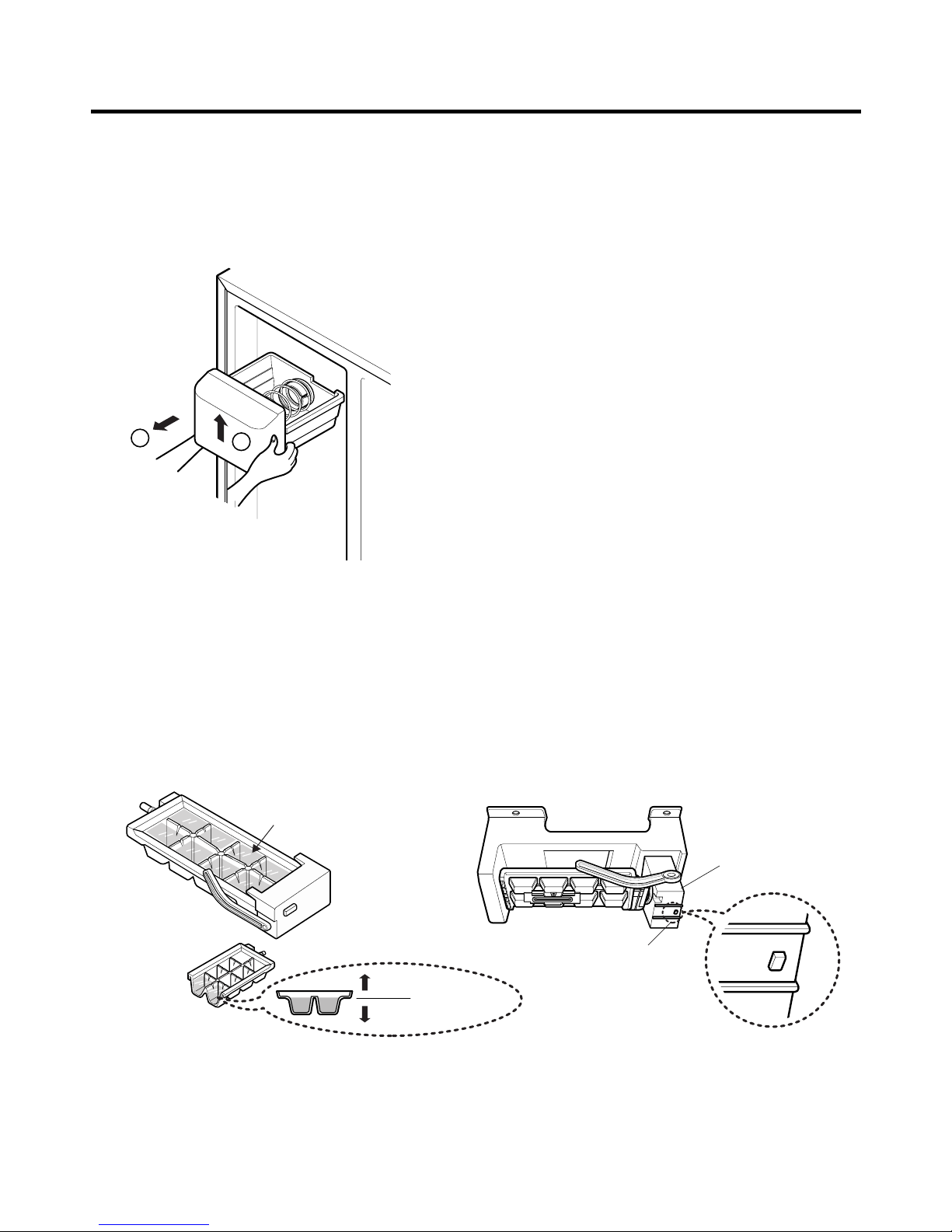

3. How to Control the Amount of Water Supplied to Icemaker.

3-1. Confirm the amount of water supplied to the icemaker.

1. Lift and pull out the space plus in the upper part of the freezer compartment.

2. Pull out the ice bank in the upper part of the freezer compartment.

Caution : • Do not put hands or tools into the chute to confirm

the operation of geared motor.

it may damage refrigerator or hurt hands.)

• Check the operation of motor with its operation

noise.

2. Apply electricity after connecting water pipe.

1) Press test switch under the icemaker for two seconds as shown below.

2) The bell rings(ding~dong) and ice tray rotates and water comes out from the icemaker water tube.

3) The water shall be supplied two or three times into the tray. The amount of water supplied for each time is small.

Put a water container under the ice tray and press test switch.

4) When ice tray rotates, the water in it will spill. Collect the spilt water and throw away into the sink.

5) When ice tray has finished rotation, water comes out from the water tube. Confirm the amounts of water in the ice tray.

(refer to fig. The optimum amount of water is 110cc)

* It is acceptable if the adjusted level of water is a bit smaller than optimum level.

HOW TO INSTALL REFRIGERATOR

- 19 -

2

1

Test Switch

Confirm the amount

of water

Ice maker

Too much

Too little

Optimum level

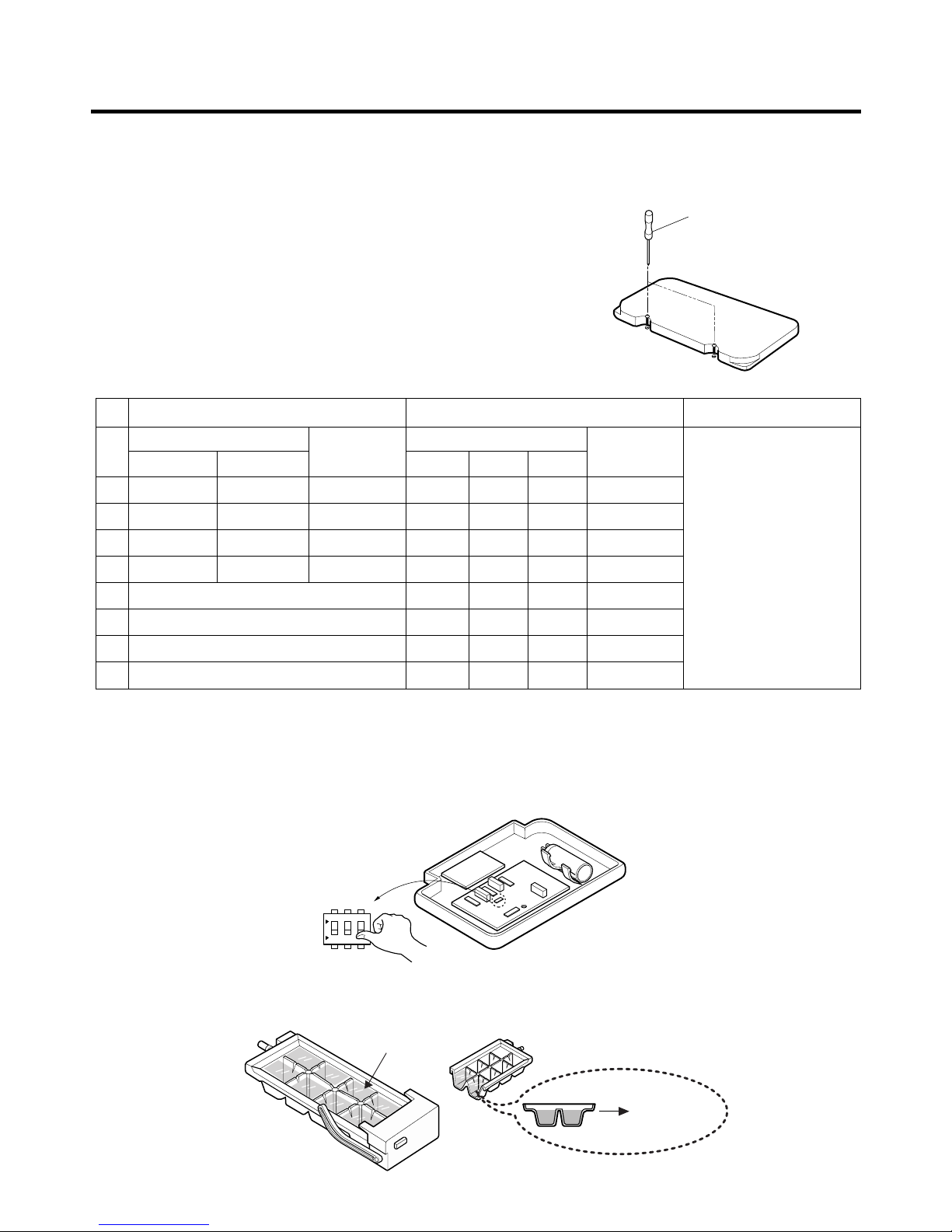

3-2. Control the amount of water supplied to the icemaker.

Caution : • Please unplug the power cord from the wall outlet and wait for more than three minutes before disconnecting

PWB cover as 310V is applied in the control panel.

1. Disconnect PWB cover from the upper part of the refrigerator.

2. Adjust the amount of water supplied by using DIP switch.

■ Water Supplying Time Control Option

1) The water supplying time is set at five seconds when the refrigerator is delivered.

2) The amount of water supplied depends on the setting time and water pressure (city water pressure).

3) If ice cube is too small, increase the water supplying time. This happens when too small water is supplied into the ice tray.

4) If ice cube sticks together, decrease the water supplying time. This happens when too much water is supplied into the ice tray.

Caution : When adjusting the amount of water supplied, adjust step by step. Otherwise the water may spill over.

3. When adjustment of control switch for the amount of water supplied is complete, check the level of water in the ice tray.

HOW TO INSTALL REFRIGERATOR

- 20 -

(+) Driver

1

ON

Switch ON

Switch OFF

23

Confirm the amount

of water

Optimum level

* The quantity of water

supplied depends on DIP

switch setting conditions

and water pressure as it

is a direct tap water

connection type. (the

water supplied is

generally 80 cc to 120 cc)

* DIP switch is on the main

PWB.

TYPE-3(Dot-LED) TYPE-2(Bar-LED) TYPE-1(88-LED)

No

DIP SWITCH SETTING

S1 S2

DIP SWITCH SETTING

S1 S2 S3

1

2

3

4

5

6

7

8

OFF OFF 6.5 SEC

ON OFF 5.5 SEC

OFF ON 7.5 SEC

ON ON 8.5 SEC

OFF OFF OFF 6.5 SEC

ON OFF OFF 5.5 SEC

OFF ON OFF 6 SEC

ON ON OFF 7 SEC

OFF OFF ON 7.5 SEC

ON OFF ON 8 SEC

OFF ON ON 9 SEC

ON ON ON 10 SEC

WATER

SUPPLY TIME

WATER

SUPPLY TIME

REMARKS

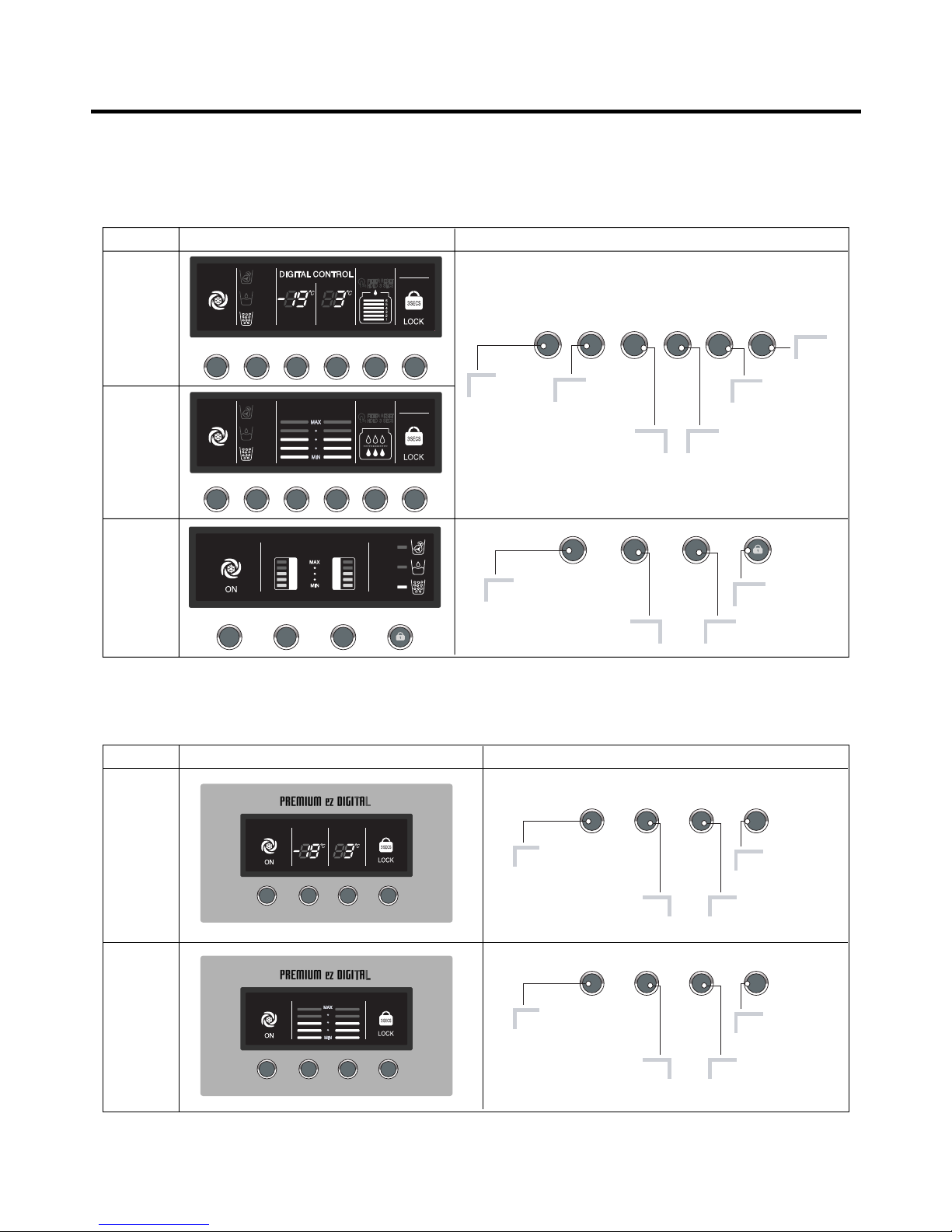

1. Monitor Panel

1-1. GR-P207, GR-L207

1-2. GR-C207, B207

MICOM FUNCTION

- 21 -

Optional Function display board Description

Type-1

(88-LED)

Type-2

(Bar-LED)

Type-3

(Dot-LED)

Type-1

(88-LED)

Type-2

(Bar-LED)

Optional Function display board Description

EXPRESS FRZ DISPENSER FREEZER REFRIGERATOR FILTER LOCK

DISPENSER

Lock: Hold 3 Secs

EXPRESS FRZ FREEZER REFRIGERATOR

CUBE

WATER

CRUSH

FRZ TEMP REF TEMP

EXPRESS FRZ

Express freezer.

Dispenser

selection button.

Lock button.

Filter reset button.

Temperature adjustment button

for refrigerator compartment.

Temperature adjustment button

for freezer compartment.

EXPRESS FRZ DISPENSER FREEZER REFRIGERATOR FILTER LOCK

Express freezer.

Dispenser

selection button.

Temperature adjustment button

for refrigerator compartment.

Temperature adjustment button

for freezer compartment.

EXPRESS FRZ DISPENSER

Lock: Hold 3 Secs

FREEZER REFRIGERATOR

Express freezer.

Lock button.

Temperature adjustment button

for refrigerator compartment.

Temperature adjustment button

for freezer compartment.

EXPRESS FRZ LOCKFREEZER REFRIGERATOR

Express freezer.

Lock button.

Temperature adjustment button

for refrigerator compartment.

Temperature adjustment button

for freezer compartment.

EXPRESS FRZ LOCKFREEZER REFRIGERATOR

EXPRESS FRZ

CHILD LOCK

LOCKEXPRESS FRZ FREEZER REFRIGERATOR

FRZ TEMP REF TEMP

EXPRESS FRZ

CHILD LOCK

LOCKEXPRESS FRZ FREEZER REFRIGERATOR

FRZ TEMP REF TEMP

FRZ TEMP REF TEMP

FILTER STATUS DISPENSER

BUTTON

EXPRESS

FRZ

ON

CUBE

WATER

CRUSH

EXPRESS FRZ DISPENSER FREEZER REFRIGERATOR FILTER LOCK

EXPRESS

FRZ

CUBE

WATER

CRUSH FRZ TEMP REF TEMP

FILTER STATUS DISPENSER

BUTTON

ON

1-3. Display Second Function

1. Buzzer sound mute Mode

The buzzer sound is set to OFF.

It activates by sounding the recognition sound of “Ding~” after pressing and holding “Express FRZ” button more than 5

seconds. It inactivates when resetting the mode power.

2. Display Power saving Mode

It places display in standby mode until door is opened.

Press “Freezer” and “Express FRZ” buttons simultaneously to turn all leds become ON and then OFF with the recognition

sound of “Ding~” after 5 seconds. (Be sure not to press only one button to work.)

Once the mode activates, the display is always OFF. Until door is opened or display button is pressed. When 30 seconds

has elapsed after closing door or pressing button, the display turns OFF. To deactivate this mode is same as the

activation methods. The mode inactivates when resetting the power.

3. Exhibition Mode

This function is available when exhibiting a refrigerator in the shopping moll.

Function is inserted with recognition sound “Ding ~” if pressing both the “Express FRZ” button and the “REFRIGERATOR”

button at the same time for more than 5 seconds. If function is inserted, all basic refreezing functions at the R/F room and

the Storage room (COMP, F-FAN, C-FAN) turns off and the display normally operates. However, the dispenser function

normally operates.

The DEMO stops if pressing the button during DISPLAY DEMO, DEMO stops and the display normally operates but

performs DEMO operation again if not pressing the button again for more than 30 seconds (DEMO: Display scenario

when using the display).

Release method is same as input method.

The mode is released if power is reset.

MICOM FUNCTION

- 22 -

EXPRESS FRZ DISPENSER FREEZER REFRIGERATOR FILTER LOCK

EXPRESS

FRZ

CUBE

WATER

CRUSH FRZ TEMP REF TEMP

FILTER STATUS DISPENSER

BUTTON

ON

Express freezer.

Dispenser

selection button.

Lock button.

Filter reset button.

Temperature adjustment button

for refrigerator compartment.

Temperature adjustment button

for freezer compartment.

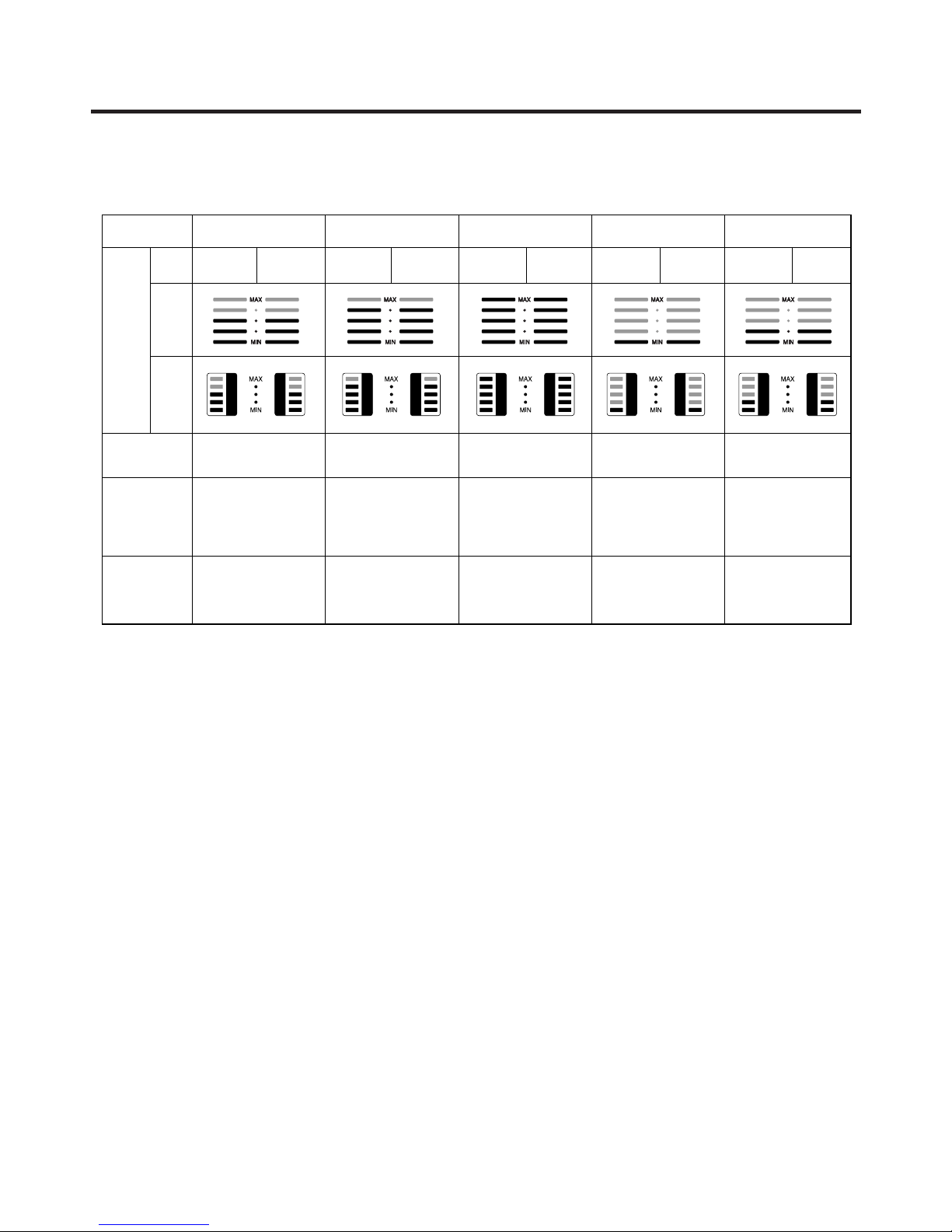

2. Description of Function

2-1. Funnction of Temperature Selection

* The temperature can vary ±3 °C depending on the load condition. *( ) : 127V/60Hz, 110~115V/60Hz, 115V/60Hz Rating ONLY.

*< > : TAIBEI

1. When power is initially applied or reapplied after power cut, “Medium” is automatically selected.

2. When the temperature selection switch in the freezer and refrigerator compartments is pressed, the light is on in the

following sequence:

"Middle" ➝ "Middle Strong" ➝ "Strong" ➝ "Weak" ➝ "Middle Weak"

3. The temperature setting condition of freezer and refrigerator compartments shall not be indicate in the standard model

(GR-P207, GR-L207, GR-C207, GR-B207) when refrigerator or home bar door is closed.

MICOM FUNCTION

- 23 -

Division Power Initially On 1st Press 2nd Press 3th Press 4th Press

Type-1

(88-LED)

Type-2

(Bar-LED)

Type-3

(Dot-LED)

-

19 °C 3 °C

-

22°C 2 °C

-

23 °C 0 °C

-

15 °C 6 °C

-

17 °C 4 °C

Change

of

Indication

Lamp

Temperature

Control

Middle Middle Strong Strong Weak Middle Weak

-19 °C

(-18 °C)

<-19 °C>

3 °C

<2 °C>

1.5 °C

<1 °C>

0 °C

<0 °C>

6 °C

<4.5 °C>

4.5 °C

<3 °C>

-21 °C

(-21 °C)

<-21 °C>

-23 °C

(-22 °C)

<-22 °C>

-15 °C

<-16.5 °C>

-17 °C

<-18 °C>

Freezer

Control

Refrigeration

Control

2-2. Automatic ice maker

• The automatic ice maker can automatically make 8 pieces of ice cube at a time, 80 pieces a day. But these quantities may

be varied according to various conditions including how many times the refrigerator door opens and closes.

• Ice making stops when the ice storage bin is full.

• If you don’t want to use automatic ice-maker, change the ice-maker switch to ON-OFF.

If you want to use automatic ice-maker again, change the switch to OFF-ON.

NOTE : It is normal that a noise is produced when ice made is dropped into the ice storage bin.

2-3. When ice maker does not operate smoothly

Ice is lumped together

• When ice is lumped together, take the ice lumps out of the ice storage bin, break them into small pieces, and then place

them into the ice storage bin again.

• When the ice maker produces too small or lumped together ice, the amount of water supplied to the ice maker need to

adjusted. Contact the service center.

✻ If ice is not used frequently, it may lump together.

Power failure

• Ice may drop into the freezer compartment. Take the ice storage bin out and discard all the ice then dry it and place it

back. After the machine is powered again, crushed ice will be automatically selected.

The unit is newly installed

• It takes about 12 hours for a newly installed refrigerator to make ice in the freezer compartment.

2-4. Express freezing

1. Express freezing is function to improve cooling speed of the freezing room by consecutively operating compressors and

freezing room fan.

2. Express freezing is released if power failure occurs and then returns to the original status.

3. Temperature setting is not changed even if selecting the express freezing.

4. The change of temperature setting at the freezing room or the cold storage room is allowed with express freezing

selected and prrocessed.

5. The cold storage room operates the status currently set with Express freezing selected and procesed.

6. If selecting the Express freezing, the Express freezing function is released after continuously operating compressor and

freezing room fan.

7. If frost removal starting time is arrived during Express freezing, Express freezing operation is done only for the remaining

time after completion of frost removal when the Express freezing operation time passes 90 minutes. If passing 90

minutes, Express freezing operation is done only for 2 hours after completion of frost removal.

8. If pressing Express freezing button during frost removal, the Express freezing LED is turned on but if pressing the

Express freezing, compressor operates after the remaining time has passed.

9. If selection Express freezing within 7 minutes (delay for 7 minutes of compressor) after the compressor stops,

compressor operates after the remaining time has passed.

10. The freezing room fan motor operates at the high speed of RPM during operation of Express freezing.

MICOM FUNCTION

- 24 -

2-5. Control of variable type of freezing room fan

1. To increase cooling speed and load response speed, MICOM variably controls freezing room fan motor at the high speed

of RPM and standard RPM.

2. MICOM only operates in the input of initial power or special freezing operation or load response operation for the high

speed of RPM and operates in the standard RPM in other general operation.

3. If opening doors of freezing / cold storage room or home bar while fan motor in the freezing room operates, the freezing

room fan motor normally operates (If being operated in the high speed of RPM, it converts operation to the standard

RPM). However, if opening doors of freezing room or home bar, the freezing room fan motor stops.

4. As for monitoring of BLDC fan motor error in the freezing room, MICOM immediately stops the fan motor by determining

that the BLDC fan motor is locked or poor if there would be position signal for more than 65 seconds at the BLDC motor.

Then it displays failure (refer to failure diagnosis function table) at the display part of refrigerator, performs re-operation in

the cycle of 30 minutes. If normal operation is performed, poor status is released and refrigerator returns to the initial

status (reset).

2-6. Control of M/C room fan motor

1. The M/C room fan motor performs ON/OFF control by linking with the COMP.

2. It controls at the single RPM without varying RPM.

3. Failure sensing method is same as in fan motor of freezing fan motor (refer to failure diagnosis function table for failure

display).

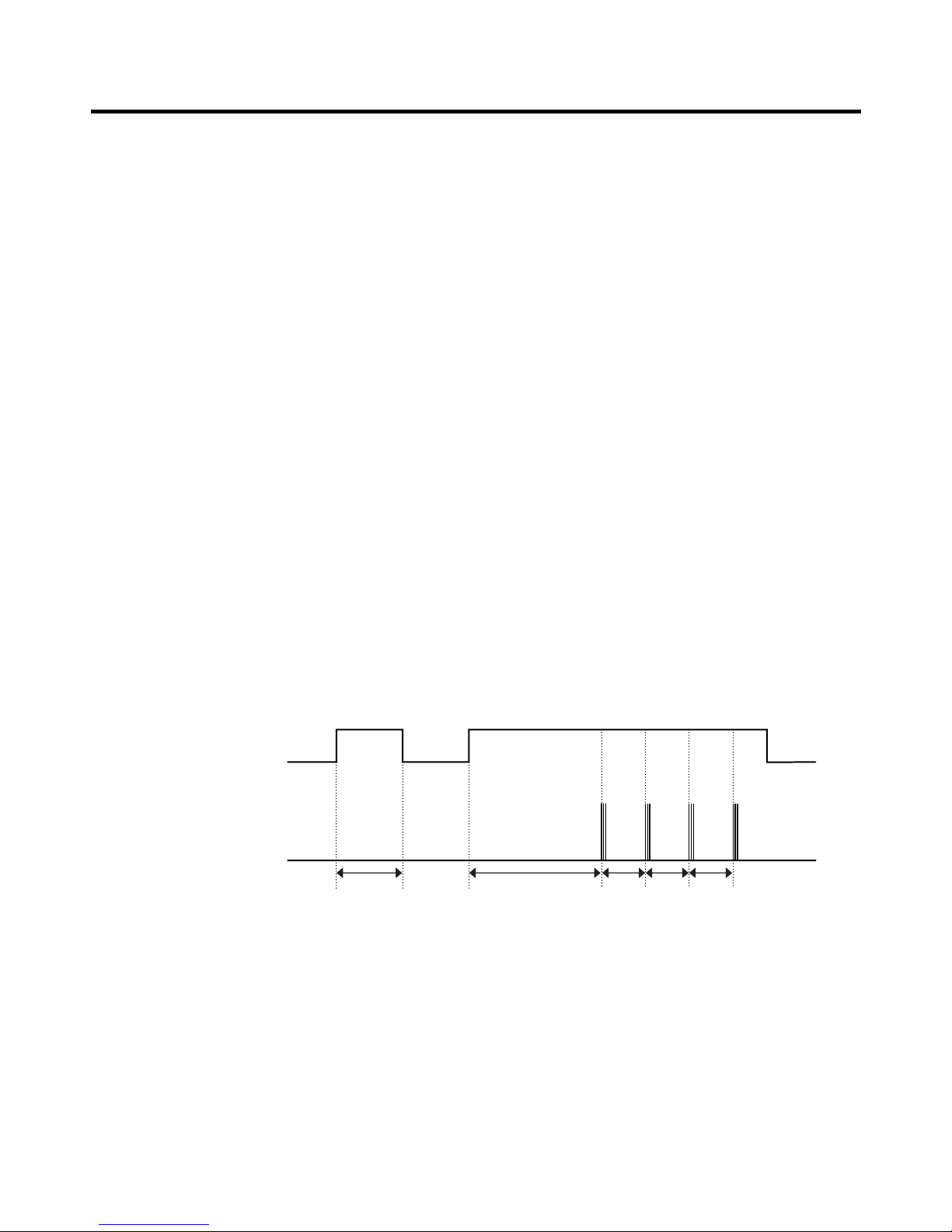

2-7. Door opening alarm

1. Buzzer generates alarm sound if doors are not closed even when more than a minute consecutively has passed with

doors of freezing / cold storage room or home bar opened.

2. Buzzer rings three times in the interval of 0.5 second after the first one-minute has passed after doors are opened and

then repeats three times of On/Off alarm in the cycle of every 30 seconds.

3. If all the doors of freezing / cold storage room or home bar are closed during door open alarm, alarm is immediately

released.

2-8. Ringing of button selection buzzer

1. If pressing the front display button, “Ding ~ “ sound rings.

2-9. Ringing of compulsory operation, compulsory frost removal buzzer

1. If pressing the test button in the main PCB, “Phi ~ “ sound rings.

2. In selecting compulsory operation, alarm sound is repeated and completed in the cycle of On for 0.2 second and Off for

1.8 second three times.

3. In selecting compulsory frost removal, alarm sound is repeated and completed in the cycle of On for 0.2 second , Off for

0.2 second, On for 0.2 second and Off for 1.4 second three times.

MICOM FUNCTION

- 25 -

Doors of freezing /

cold storage room

or home bar

BUZZER

Closing

Opening

Within

a minute

A minute

30

seconds30seconds30seconds

Opening

Closing Closing

3 Times 3 Times 3 Times 3 Times

2-10. Frost removal function

1. Frost removal is performed whenever total operation time of compressor becomes 7 ~ 7.5 hour.

2. In providing initial power (or returning power failure), frost removal starts whenever total operation time of compressor

becomes 4 ~ 4.5 hour.

3. Frost removal is completed if temperature of a frost removal sensor becomes more than 5°C after starting frost removal.

Poor frost removal is not displaced if it does not arrive at 5°C even if two hours have passed after starting frost removal.

4. No removal is done if frost removal sensor becomes poor (snapping or short-circuit).

2-11. Sequential operation of built-in product

Built-in products such as compressor, frost removal heater, freezing room fan, Cooling Fan and step motor damper are

sequentially operated as follows for preventing noise and part damage occurred due to simultaneous operation of a lot of

parts in applying initial power and completing test.

MICOM FUNCTION

- 26 -

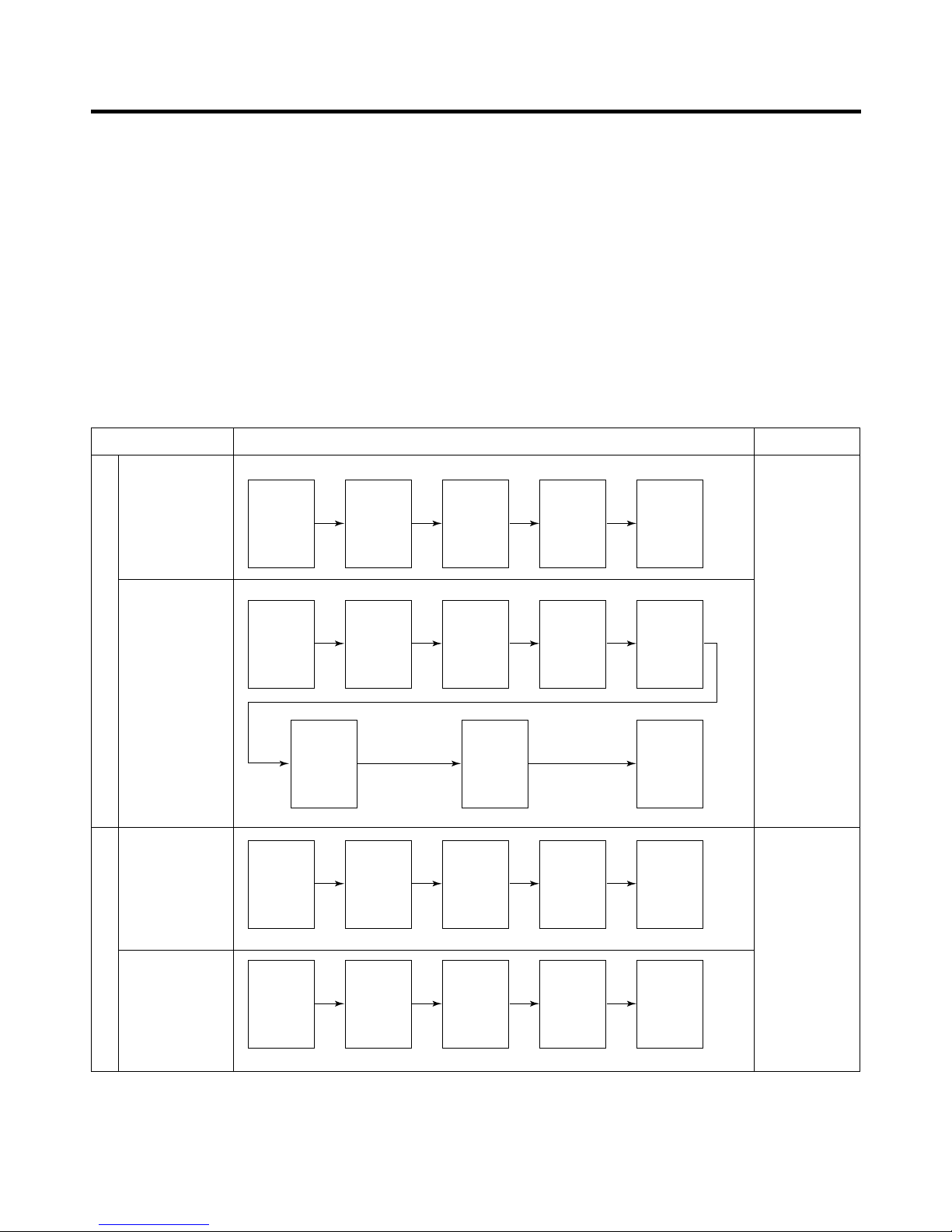

Function Load Operation Sequence Remark

In applying Initial power TEST MODE

When temperature

of a frost removal

sensor becomes

more than 45°C

(In purchase,

movement)

If error occurs

during operation,

initial operation is

not done.

If pressing switch

once more in the

test mode 2 or

temperature of a

frost removal

sensor is more

than 5°C, it

immediately

returns to the test

mode for initial

operation

(COMP operates

after 7 minutes).

When

temperature of a

frost removal

sensor becomes

less than 45°C

(In power failure,

service)

Test mode 1

(Compulsory

function)

Test mode 2

(Compulsory frost

removal)

POWER

ON

COMP

ON

COMP

ON

F-FAN

&

C-FAN

ON

F-FAN

&

C-FAN

ON

F-FAN

&

C-FAN

ON

F-FAN

&

C-FAN

OFF

STEP

MOTOR

DAMPER

ON

STEP

MOTOR

DAMPER

OPEN

STEP

MOTOR

DAMPER

CLOSE

HOME

BAR

HEATER

ON

POWER

ON

FROST

REMOVAL

HEATER

ON

HOME

BAR/

PIPE

HEATER

OFF

HOME

BAR/

PIPE

HEATER

ON

TEST

S/W

(Press

Once)

COMP

ON

TEST

S/W

(Press

2 times)

COMP

OFF

0.5

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.5

sec.

8

sec.

0.3

sec.

5

sec.

FROST

REMOVAL

HEATER

OFF

FROST

REMOVAL

HEATER

ON

WATER

SUPPLY

&

DISPENSE

HEATER

ON

5

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

5.6

sec.

OTHER

LOAD

OFF

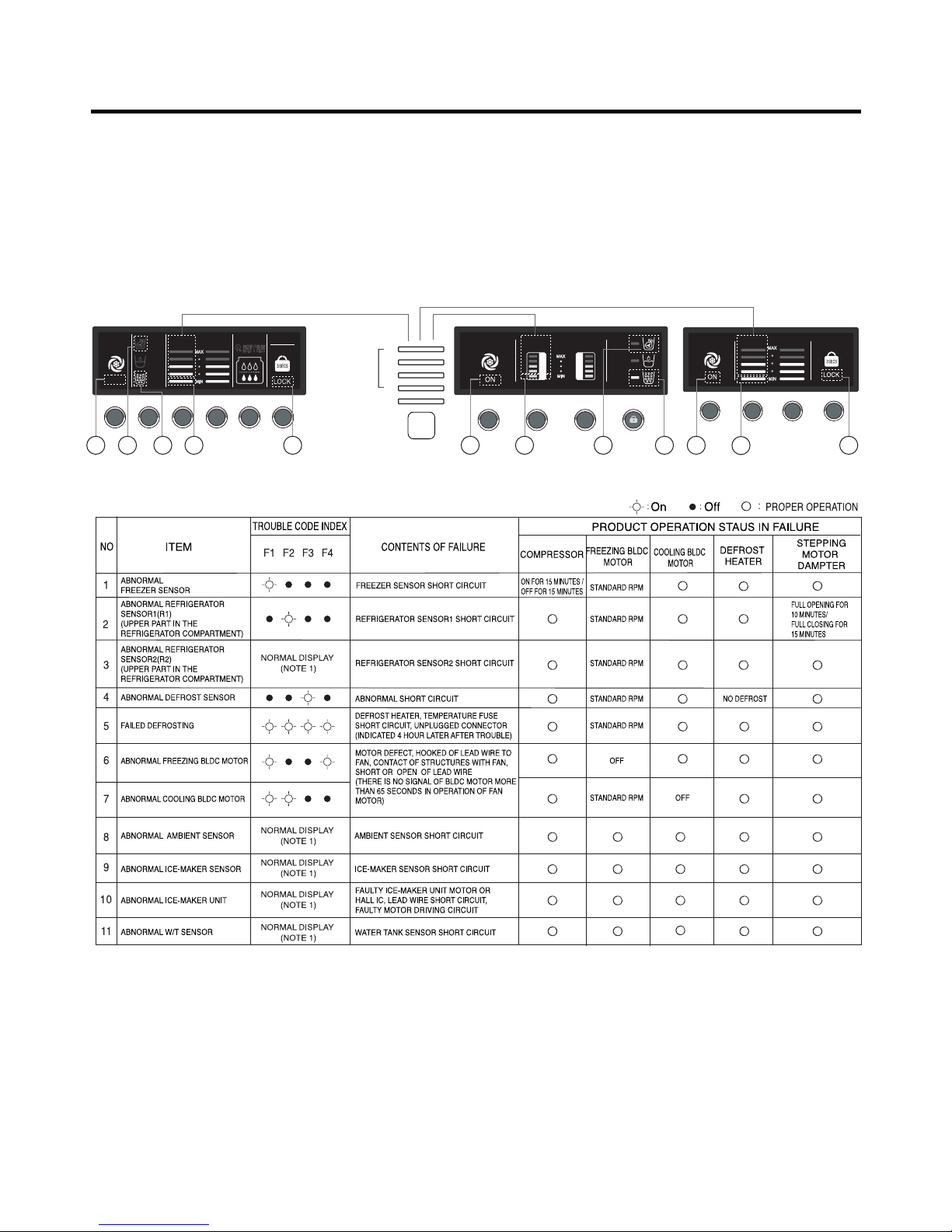

2-12. Function of Trouble Diagnosis(88-LED)

1. Failure diagnosis function is function to facilitate service when nonconforming matters affecting performance of product

during use of product.

2. In occurrence of failure, pressing the function adjustment button does not perform function and only alarm sound (“Ding~”) rings.

3. If nonconforming matters occurred are released during display of failure code, MICOM returns to the original state (Reset).

4. Failure code is displayed on the display part of setting temperature for the freezing room and the display part of setting

temperature for the cold storage room of LED, which are placed at the display part of a refrigerator. All the LED graphics

other than a failure code are turned off.

✽ In display of the failure mode, all LEDs of setting temperature for freezing/ setting temperature for cold storage are turned

off (excluding Note1 and Note2).

MICOM FUNCTION

- 27 -

EXPRESS FRZ

CHILD LOCK

LOCKEXPRESS FRZ FREEZER REFRIGERATOR

FRZ TEMP REF TEMP

EXPRESS FRZ DISPENSER FREEZER REFRIGERATOR FILTER LOCK

EXPRESS

FRZ

CUBE

WATER

CRUSH FRZ TEMP REF TEMP

FILTER STATUS DISPENSER

BUTTON

ON

C

E F A B D

Failure Code Display Part

C A B D

Failure Code Display Part

●● : Normal Operation

1

2

3

4

5

6

7

8

9

10

11

Er FS

Er rS

Setting temperature

display (Note 2)

Er dS

Er dH

Er FF

Er CF

Er CO

Setting temperature

display (Note 1)

Setting temperature

display (Note 2)

Setting temperature

display (Note 2)

Failure code display part

Setting

temperature

for freezing

Setting

temperature for

cold storage

No. Item

Contents of failure

Freezer

Fan

Compressor

Stepping

motor damper

Defrost

Heater

M/C room

Fan

Product operation status in failure

Failure of freezer

sensor

Failure of refrigerator

sensor 1

Failure of refrigerator

sensor 2

Failure of frost

removal sensor

Poor of frost

removal

Failure of BLDC FAN

at freezing room

Failure of BLDC FAN

at machine room

Failure of

Communication

Failure of

Outside Sensor

Failure of ice

removal sensor

Failure of ice

maker unit

Snapping or short-circuit of

freezer sensor

Snapping or short-circuit of

refrigerator sensor 1

Snapping or short-circuit of

refrigerator sensor 2

Snapping or short-circuit of frost

removal sensor

Snapping of frost removal heater

or temperature fuse, pull-out of

connector (indicated minimum 4

hours after failure occurs)

Poor motor, hooking of wires to

fan. Contact of structures to Fan.

Snapping or short-circuit of L/wire

(if there is no fan motor signal for

more than 115 seconds in

operation of fan motor

Connection between main PCB

and display PCB. Snapping or

short-circuit of L/wire.

Transmission between main PCB

and display PCB. Poor TR and

receiving part.

Snapping or short-circuit of outside

temperature perceiving sensor

Snapping or short-circuit of icemaking sensor

Poor motor or Hall IC within ice-maker

unit. Snapping or short-circuit of

L/Wire. Poor main PCB drive circuit.

Standard

RPM

Standard

RPM

Standard

RPM

Standard

RPM

Standard

RPM

OFF

Standard

RPM

Standard

RPM

●●

●●

●●

●●

●●

●●

●●

●●

●●

OFF

●●

●●

●●

●●

ON for 15minutes

OFF for 15minutes

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

No frost

removal

●●

●●

●●

●●

●●

●●

●●

●●

Open for 10munutes,

closing for 15 minutes

●●

●●

●●

●●

●●

●●

●●

●●

●●

MICOM FUNCTION

- 28 -

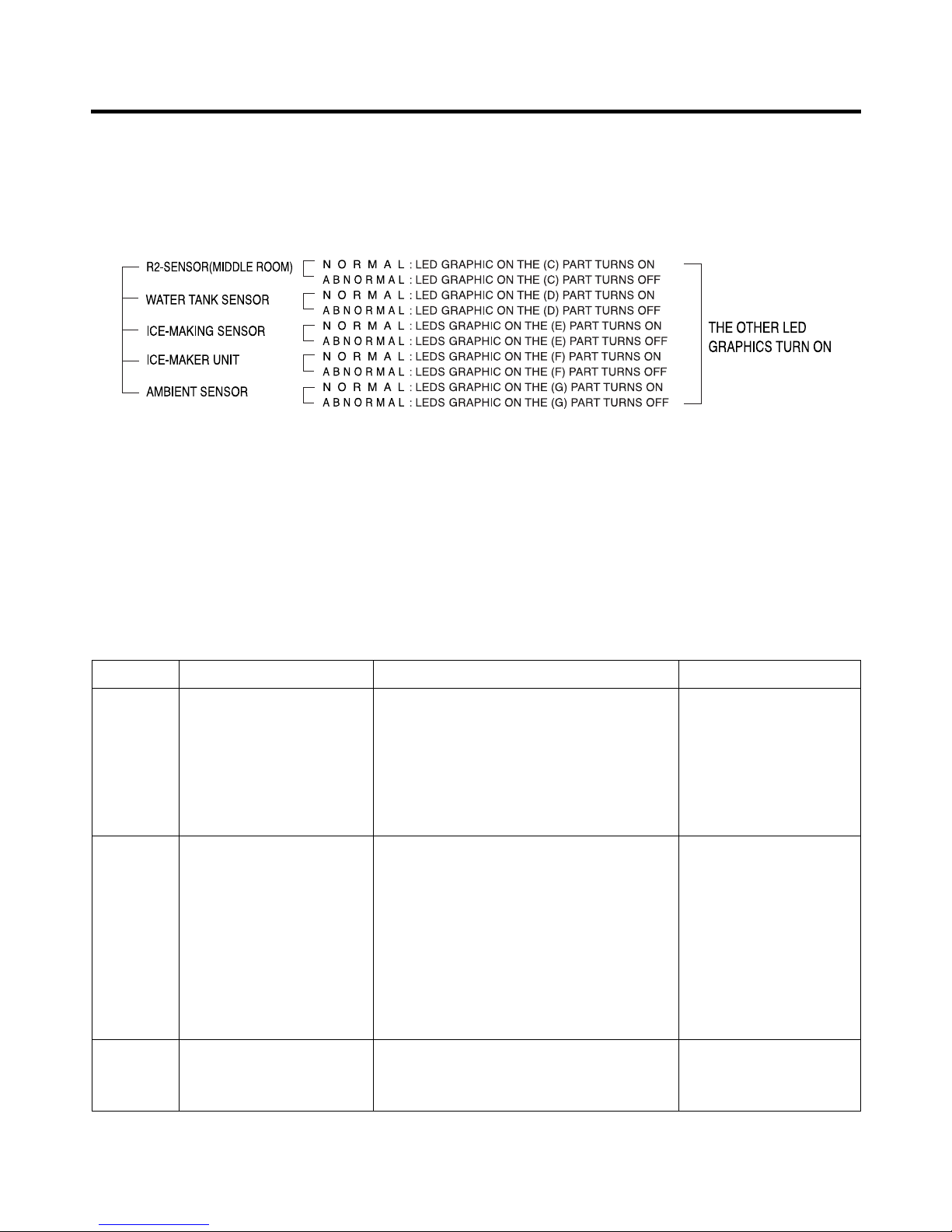

2-13. Function of Trouble Diagnosis(Bar-LED, Dot-LED)

1. Function of trouble diagnosis is to make the repair service easy when the refrigerator is out of order during service.

2. The function control button does not work but the recognition sound is heard when the refrigerator is out of order.

3. It returns to normal conditions when trouble code led is off. (reset)

4. Trouble code is indicated by the freezing temperature indicator led in the refrigerator display. All leds except trouble code

are off.

DISPENSER

Lock: Hold 3 Secs

EXPRESS FRZ FREEZER REFRIGERATOR

CUBE

WATER

CRUSH

FRZ TEMP REF TEMP

EXPRESS FRZ

EXPRESS FRZ DISPENSER FREEZER REFRIGERATOR FILTER LOCK

FRZ TEMP REF TEMP

FILTER STATUS DISPENSER

BUTTON

EXPRESS

FRZ

ON

CUBE

WATER

CRUSH

EXPRESS FRZ

CHILD LOCK

LOCKEXPRESS FRZ FREEZER REFRIGERATOR

FRZ TEMP REF TEMP

C C E FE F G GD C D

FRZ

TEMP

Trouble Code

Index

Trouble Code Trouble Code

Trouble Code

F4

F3

F2

F1

G

Note1) In error of outside sensor, setting temperature for freezing/ cold storage is normally displayed and indicated “Er” on

the outside temperature display part (normally displayed except for the outside temperature display part).

Note2) Nonconforming contents of poor R2 sensor, ice-making sensor and ice-making kit are displayed in LED check, not

indicated on the failure display part (when pressing freezing temperature adjustment button and special freezing

button for a second or more).

2-14. Test Function

1. The purpose of test function is to check function of the PWB and product and to search for the failure part at the failure

status.

2. Test button is placed on the main PCB of refrigerator (test switch), and the test mode will be finished after maximum 2

hours irrespective of test mode and then is reset to the normal status.

3. Function adjustment button is not perceived during performance of test mode but only warning sounds ring.

4. In finishing test mode, always pull the power cord out and then plug-in it again for the normal state.

5. If nonconforming contents such as sensor failure are found during performance of test mode, release the test mode and

display the failure code.

6. Even if pressing the test button during failure code display, test mode will not be performed.

Test 1

Test 2

Normal

Status

Mode Manipulation Content Remarks

Press test button once

(freezing force mode)

Press test button once at

the test mode 1 status

(compulsory frost removal

mode)

Press test button once at

the test mode 2 status

(freezing force mode)

1. Continuous operation of compressor

2. Continuous operation of freezing room fan

(high speed RPM) and M/C room fan

3. Frost removal heater OFF

4. Full opening status (baffle opened) status of

electronic step motor damper

5. All display LED graphics - ON.

1. Compressor OFF

2. Freezing room fan and M/C room fan is

turned off.

3. Frost removal heater ON

4. Full closing status (baffle closed) status of

electronic step motor damper

5. All display LED graphics - OFF

(88LED: Except for (A)22 (B)22 LEDs

Bar, Dot LED: Except for only middle Notch

Bar Graphics)

Return to the initial status.

Freezing room fan is

turned off in door open.

Compressor is operated

after 7 minutes.

MICOM FUNCTION

- 29 -

* LED check function- When freezer and refrigerator temperature control buttons are pressed for more than 1 second at the

same time, all LEDS on the display are on. And it returns to the normal conditions when the buttons are released.

* Check of freezer fan rpm variation- Freezer fan speed changes from high speed to standard speed and vice versa for 30

seconds whenever freezer and refrigerator temperature control buttons are pressed at the same time for more than 1

second when freezer fan is in operation and returns to the previous rpm.

2-15. Functions of Ice Dispenser and Water Dispenser

1. Ice and cold water are available without opening refrigerator door.

2. The desired ice (crushed or cube) or cold water are dispensed when dispenser press button (rubber button) is pressed

after selection of ice or cold water. When ice is selected, duct door opens by electric solenoid when dispenser press

switch is pressed. When dispenser press switch is released, duct door closes after it opens for 5 seconds.

3. Ice and water dispensing function stops when freezer door is open.

4. Geared motor and solenoid are automatically off if there is no signal after 3 minutes when ice (crushed and cube) or

water is selected and dispenser switch is pressed down. Solenoid (duct door) stops after 5 seconds when solenoid is off.

(in order to protect short circuit from solenoid heat generation)

5. Dispenser Lamp On/Off Function. The dispenser lamp shall be on or off whenever dispenser button is pressed or

released, respectively after selection of ice (crushed or cube) or water.

6. Water/Crushed Ice/Cube Ice Selection function

1) It is to select water/crushed ice/cube ice by user from the function control part and it will be indicated and selected by

pressing button.

2) Crushed ice is automatically selected when power is initially on.

3) When crushed ice is selected and its button is pressed, geared motor operates and crushed ice is dispensed.

4) When cube ice is selected and its button is pressed, geared motor and ice solenoid operate and cube ice is dispensed.

7. Function of Water Dispenser

1) When user selects water in the function control parts, it is indicated in the LED and water is selected.

2) Water dispenser is a direct tap water connection type. The water solenoid valve on the right of machine room opens

and water dispenses when user selects water and presses button.

MICOM FUNCTION

- 30 -

Loading...

Loading...