LG GR-M712Y*A, GR-M652Y*X, GR-M712Y*Q, GR-B652Y*B, GR-B712Y*B Service Manual

...

REFRIGERATOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT, READ THE "SAFETY

PRECAUTIONS" IN THIS MANUAL.

MODEL : GR-M652Y*A/M712Y*A GR-M652Y*X/M712Y*X

GR-M652Y*Y/M712Y*Y GR-M652Y*Q/M712Y*Q

GR-B652Y*B/B712Y*B GR-B652Y*S/B712Y*S

GR-B652Y*Y/B712Y*Y GR-B652Y*Q/B712Y*Q

GR-B652Y*C/B712Y*C

- 1 -

CONTENTS

CONTENTS ............................................................................................................................................................................. 2

SERVICING PRECAUTIONS .................................................................................................................................................. 3

SPECIFICATIONS ............................................................................................................................................................... 4-5

PARTS IDENTIFICATION .................................................................................................................................................. 6-15

FEATURE CHART ........................................................................................................................................................... 6-15

WATER DISPENSER..................................................................................................................................................... 16-17

HOME BAR ....................................................................................................................................................................... 18

DISASSEMBLY ................................................................................................................................................................ 19-20

DOOR ................................................................................................................................................................................. 19

DOOR SWITCH .................................................................................................................................................................. 19

FAN AND FAN MOTOR ..................................................................................................................................................... 19

DEF' CONTROL ASM ........................................................................................................................................................ 20

LAMP ................................................................................................................................................................................. 20

CONTROL BOX-R ............................................................................................................................................................. 20

ADJUSTMENT ................................................................................................................................................................. 21-22

COMPRESSOR ................................................................................................................................................................. 21

PTC-STARTER .................................................................................................................................................................. 21

OLP (OVER LOAD PROTECTOR) .................................................................................................................................... 22

CIRCUIT DIAGRAM .............................................................................................................................................................. 23

TROUBLESHOOTING ..................................................................................................................................................... 24-29

COMPRESSOR AND ELECTRIC COMPONENTS ........................................................................................................... 24

PTC AND OLP ................................................................................................................................................................... 25

ANOTHER ELECTRIC COMPONENT .............................................................................................................................. 26

SERVICE DIAGNOSIS CHART ......................................................................................................................................... 27

REFRIGERATING CYCLE ........................................................................................................................................... 28-29

DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM ................................................................................................ 30-53

EXPLODED VIEW & REPLACEMENT PARTS LIST....................................................................................................... 54-65

SAFETY PRECAUTIONS

Please read the followings before servicing your refrigerator.

1. Check if an electric leakage occurs in the set.

2. To prevent electric shock, unplug prior to servicing.

3. In case of testing with power on, wear rubber gloves to

prevent electric shock.

4. If you use any appliances, check regular current, voltage

and capacity.

5. Don't touch metal products in cold freezer with wet hand.

It may cause frostbite.

6. Prevent water flowing to electric elements in mechanical

parts.

7. When you stand up during observing the lower part with

the upper door open, move with care to prevent head

wound which may happen by hitting the upper door.

8. When sloping the set, remove any materials on the set,

especially thin plate type. (ex.: glass shelf or books.)

9. When servicing evaporator part, wear cotton gloves

without fail. It is to prevent wound by sharp fin of

vaporator.

10.Leave a breakage of refrigerating cycle to a heavy

service center. The gas in cycle inside may soil ambient

air.

- 2 -

SERVICING PRECAUTIONS

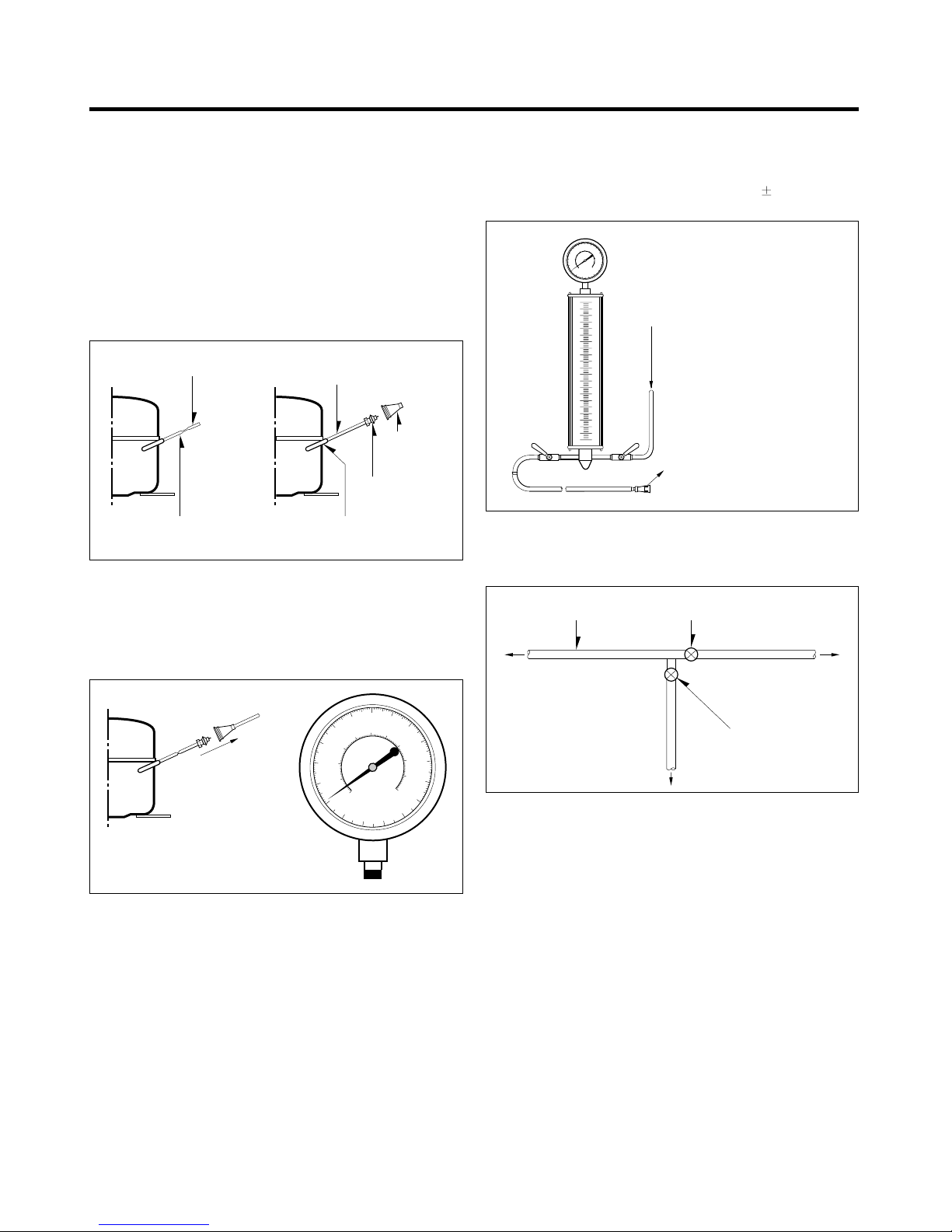

Air Recharging in Compressor

Test the refrigeration by connecting it electrically before

refilling operation. It is necessary to ascertain the function

of the motor-compressor and identify the defects

immediately. If the defects have been found, empty the old

system of eventual R-134a residue by breaking off the end

of the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an extension completely with male Hansen and

last, solder it to the same tube again. (Figure 2)

POINT TO BE

BROKEN

SERVICE TUBE EXTENSION SOLDERING POINT

CHARGE TUBE

EXTENSION

MALE HANSEN

FEMALE

HANSEN

Figure 1 Figure 2

It is necessary to execute the soldering operation with valve

open so that the fumes caused by oil residue can come out

freely without blowholes between two tubes during heating

the point to be soldered.

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

is over, add the quantity in grams of R-134a to the

refrigerant system. Remember that every system has an

exact quantity of R-134a with a tolerance of

5 grams that

can be added. (Figure 4)

TO THE R-134a CYLINDER

TO THE REFRIGERATION

SYSTEM

Figure 4

Before performing this operation (if the vacuum pump and

refilling cylinder are connected), make sure that the valve

placed between the vacuum pump and refilling tube are

closed to keep the Freon for adding to the system. (Figure 5)

FILLING OR

CHARGE TUBE

TO THE REFRIGERATION

SYSTEM

VALVE TO BE OPENED

WHEN REFILLING

TO THE CHARGE

CYLINDER

TO THE

VACUUM PUMP

PRESSURE

GAUGE

Air evacuating from the system begins so soon as the pump

starts. The refrigeration system must be kept under vacuum

until the reading on the low-pressure gauge indicates

vacuum (0 absolute, -1 atm., -760 mm hg) in any case it is

advisable to keep the pump running for about 60 minutes.

(Figure 3)

In case that a considerable leakage occurs and to stop the

vacuum pump will be necessary and add a small quantity of

Freon to the system, if vacuum should not be obtained

(pressure gauge can't fall to 1 atmosphere), start the

refrigeration unit and find the leakage with the special leakfinder. When the defective soldering point is visible, re-do it

after opening the extension tube valve and reestablishing

the normal outside pressure inside the group.

Because the melted alloy is sucked into the tubes and block

them, the pressure must be rebalanced when vacuum is in

the system in soldering. As soon as the vacuum operation

Figure 3

VALVE TO BE CLOSED

AFTER VACUUM

TO THE VACUUM PUMP

Figure 5

In addition, check the graduated scale on the cylinder for

the quantity of R-134a to be added, for example, if we have

750 grams of Freon in the cylinder and must add 165 grams

to the group, this amount will be reached when R-134a has

dropped to 585 grams, remembering that the indicator

shows a lower limit of meniscus. Do this after choosing the

scale corresponding to the gas pressure different scales

reported as the same gas pressure indicated by the

pressure gauge on the top of the column.

To make R-134a flow into the system, open the valve

placed at the base of the cylinder and connected to the

filling tube. The amount of Freon cannot be added to the

system all at once because it may cause a blocking of

motor-compressor. Therefore, proceed by adding original

quantity of about 20-30 grams and close the valve

immediately.

The pressure rises and the motor-compressor must start,

sucking the gas and making the pressure go down again.

Regulate the valve again, maintaining the same manner

until reaching to the quantity of R-134a established for the

system being charged. When the system is running, the

suction pressure must be stabilized between 0.10 to 0.4

atmosphere.

- 3 -

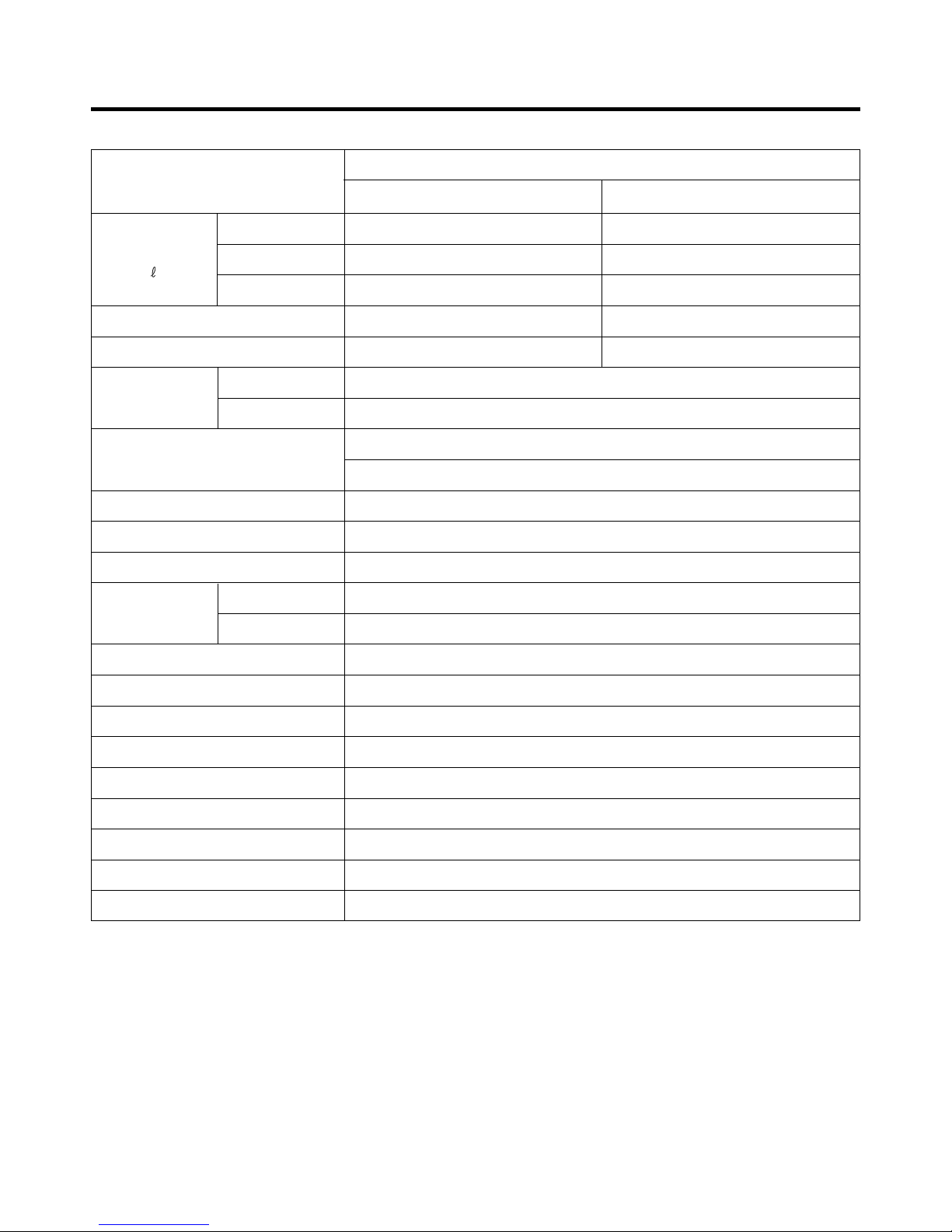

1. SPECIFICATIONS

ITEMS

FREEZER

NET CAPACITY

)

(

DIMENSIONS (mm)

NET WEIGHT (kg)

TEMPERATURE

CONTROL

DEFROSTING SYSTEM

OUT CASE

INNER CASE

INSULATION

SHELF

REFRIGERATOR

TOTAL

FREEZER

REFRIGERATOR

FREEZER

REFRIGERATOR

SPECIFICATIONS

GR-M712Y*A/ M712Y*X/ M712Y*Y,

GR-B712Y*Y/ B712Y*Q/ B712Y*C

157

409

566

860(W) X 750.5(D) X 1794(H)

97

Knob Dial

Micom Control

Full Automatic

Heater Defrost

Pre Coated Metal

Cyclo-Pentane Foam

2 EA/ 3EA(Option)

GR-B712Y*B/ B712Y*S

157

393

550

860(W) X 750.5(D) X 1794(H)

96

A B S

1 EA

VEGETABLE TRAY

EGG TRAY

ICE TRAY

ICE BANK

COMPRESSOR

EVAPORATOR

CONDENSER

REFRIGERANT

DEFROSTING DEVICE

Drawer Type

1 Piece

2 Piece

1 Piece

P.T.C Starting Type

Fin Tube Type

Wire Condenser / Screw Condenser

R134a (140g) / R600a (69g)

Heater

- 4 -

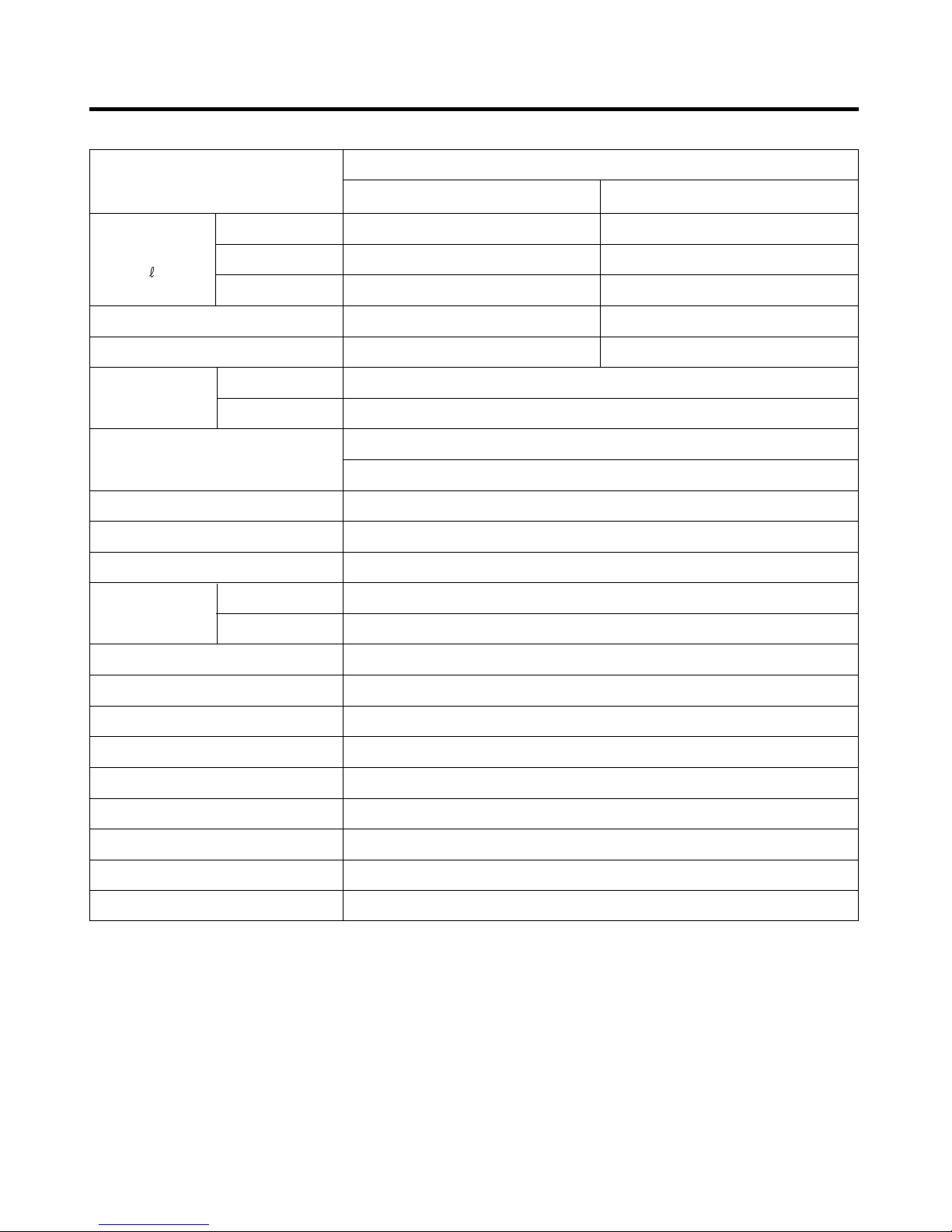

NET CAPACITY

)

(

ITEMS

FREEZER

REFRIGERATOR

TOTAL

SPECIFICATIONS

GR-M652Y*A/ M652Y*X/ M652Y*Y,

GR-B652Y*C/ B652Y*Y/ B652Y*Q

151

394

545

GR-B652Y*B/ B652Y*S

151

378

529

DIMENSIONS (mm)

NET WEIGHT (kg)

TEMPERATURE

CONTROL

DEFROSTING SYSTEM

OUT CASE

INNER CASE

INSULATION

SHELF

VEGETABLE TRAY

EGG TRAY

ICE TRAY

ICE BANK

FREEZER

REFRIGERATOR

FREEZER

REFRIGERATOR

860(W) X 730.5(D) X 1794(H)

95

Pre Coated Metal

Cyclo-Pentane Foam

2 EA/ 3EA(Option)

860(W) X 730.5(D) X 1794(H)

94

Knob Dial

Micom Control

Full Automatic

Heater Defrost

A B S

1 EA

Drawer Type

1 Piece

2 Pieces

1 Piece

COMPRESSOR

EVAPORATOR

CONDENSER

REFRIGERANT

DEFROSTING DEVICE

P.T.C Starting Type

Fin Tube Type

Wire Condenser / Screw Condenser

R134a (140g) / R600a (69g)

Heater

- 5 -

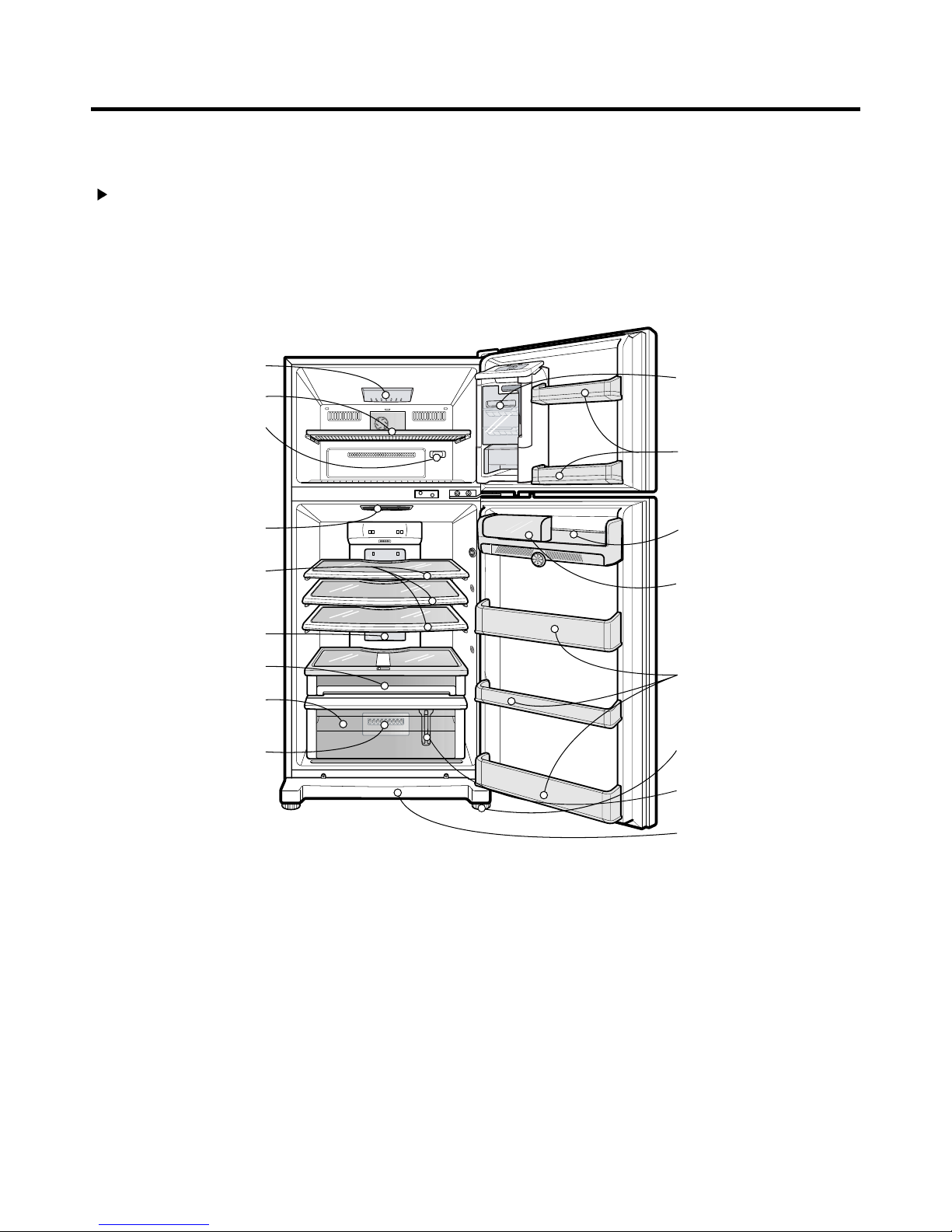

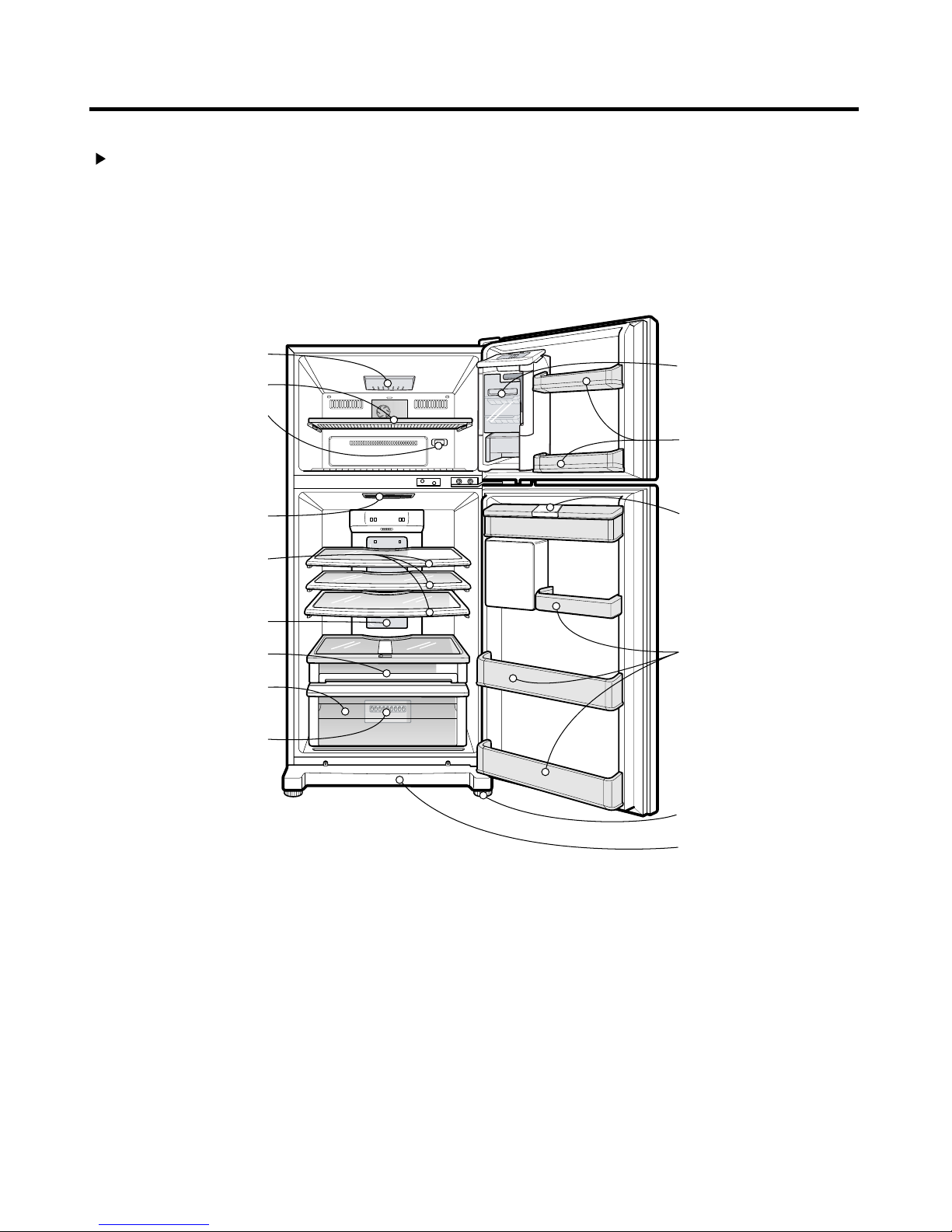

2. PARTS IDENTIFICATION

2-1. FEATURE CHART

GR-M652Y*A/M712Y*A, GR-M652Y*X/M712Y*X

FREEZER

COMPARTMENT

Lamp

Shelf

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

In-Door Ice

Maker

Freezer Door Rack

Egg Storage Rack

Dairy Corner

Lamp

Convertible Room

Vegetable Drawer

Vita Light

Refrigerator Door

Rack

Levelling Screw

Vegetable Partitioner

(Optional)

Base Cover

NOTE : This guide covers several different models.The refrigerator you have

purchased may have some or all of the features shown above.

- 6 -

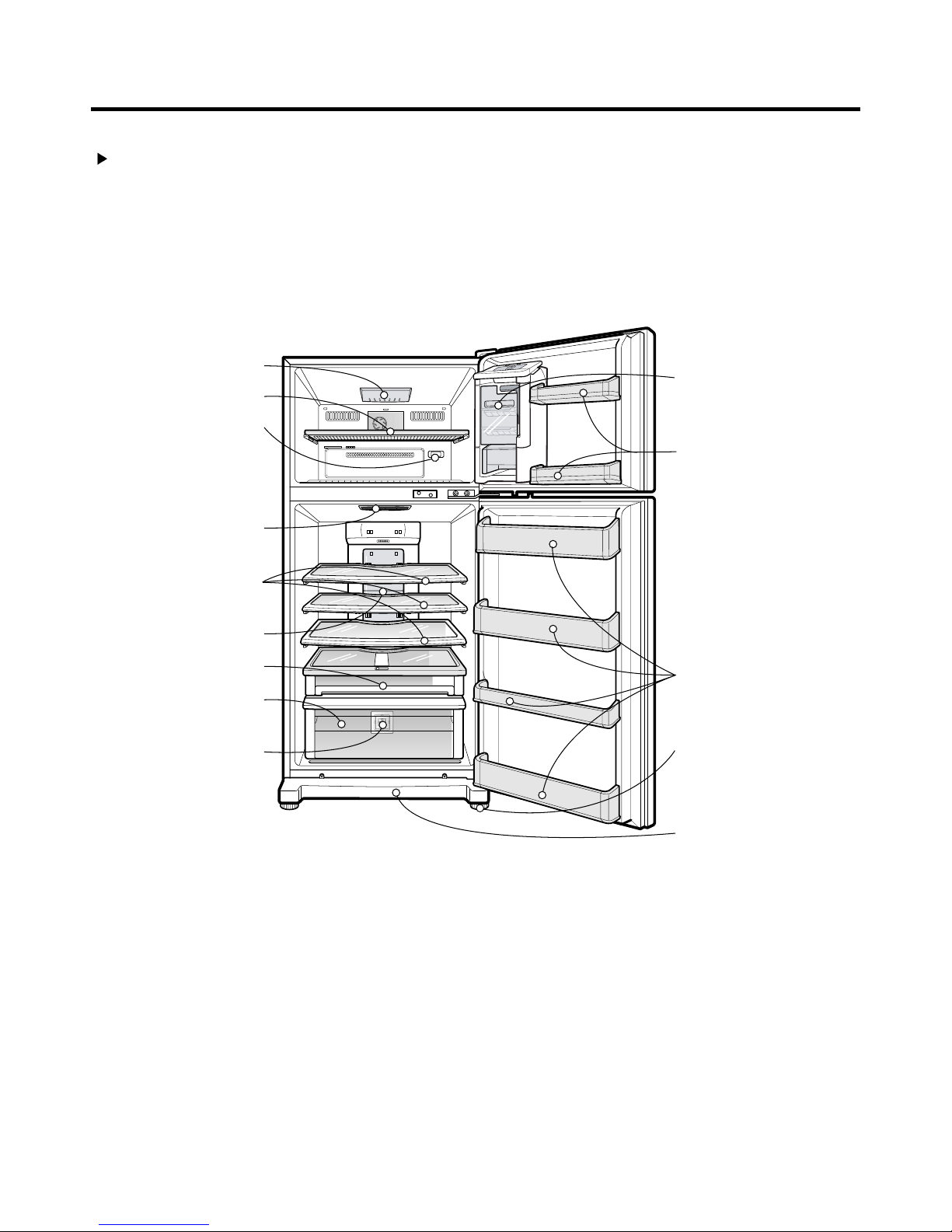

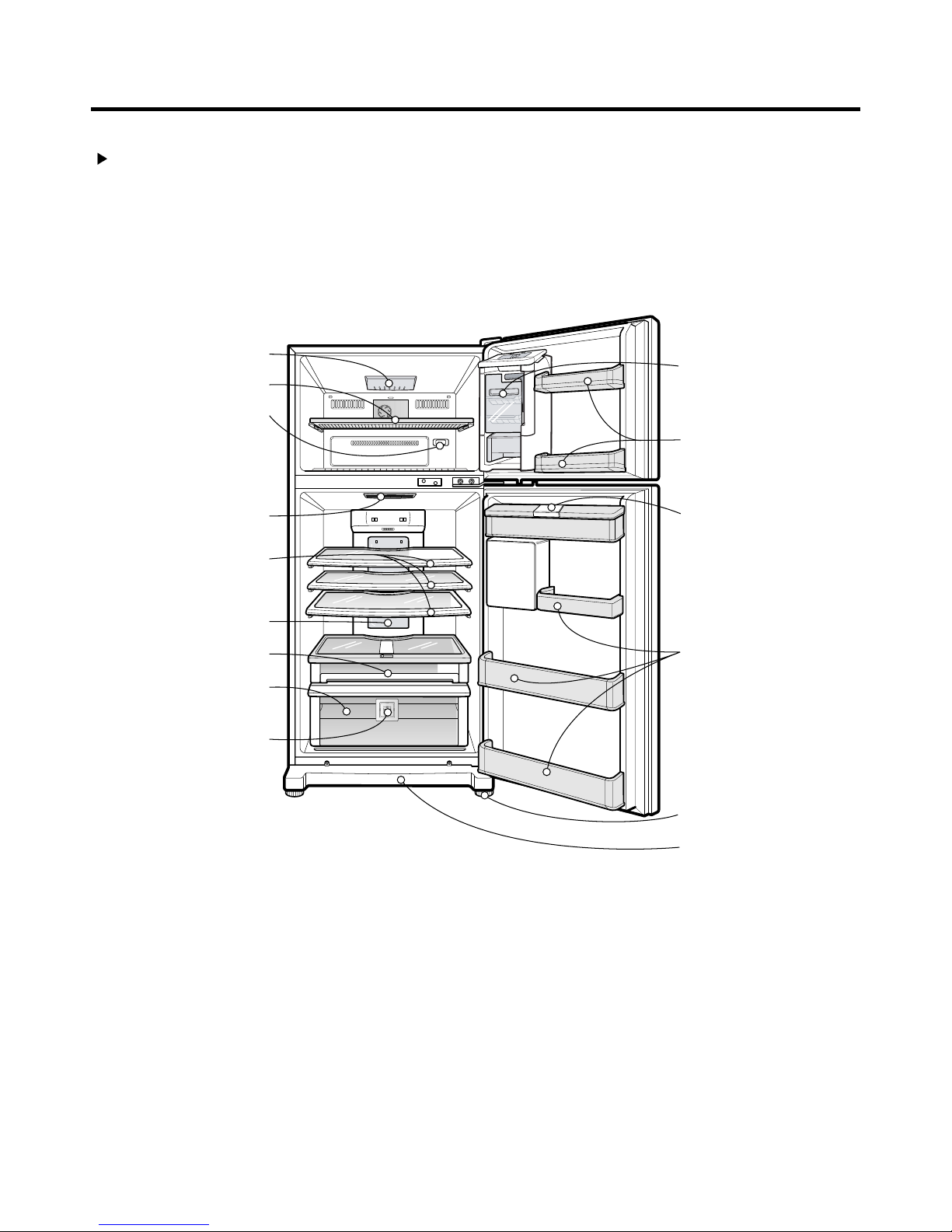

GR-M652Y*Y/M712Y*Y

FREEZER

COMPARTMENT

Lamp

Shelf

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

Lamp

Convertible Room

Vegetable Drawer

Vitamin Kit(optional)

In-Door Ice

Maker

Freezer Door Rack

Egg Storage Rack

Dairy Corner

Refrigerator Door

Rack

Levelling Screw

NOTE : This guide covers several different models.The refrigerator you have

Base Cover

purchased may have some or all of the features shown above.

- 7 -

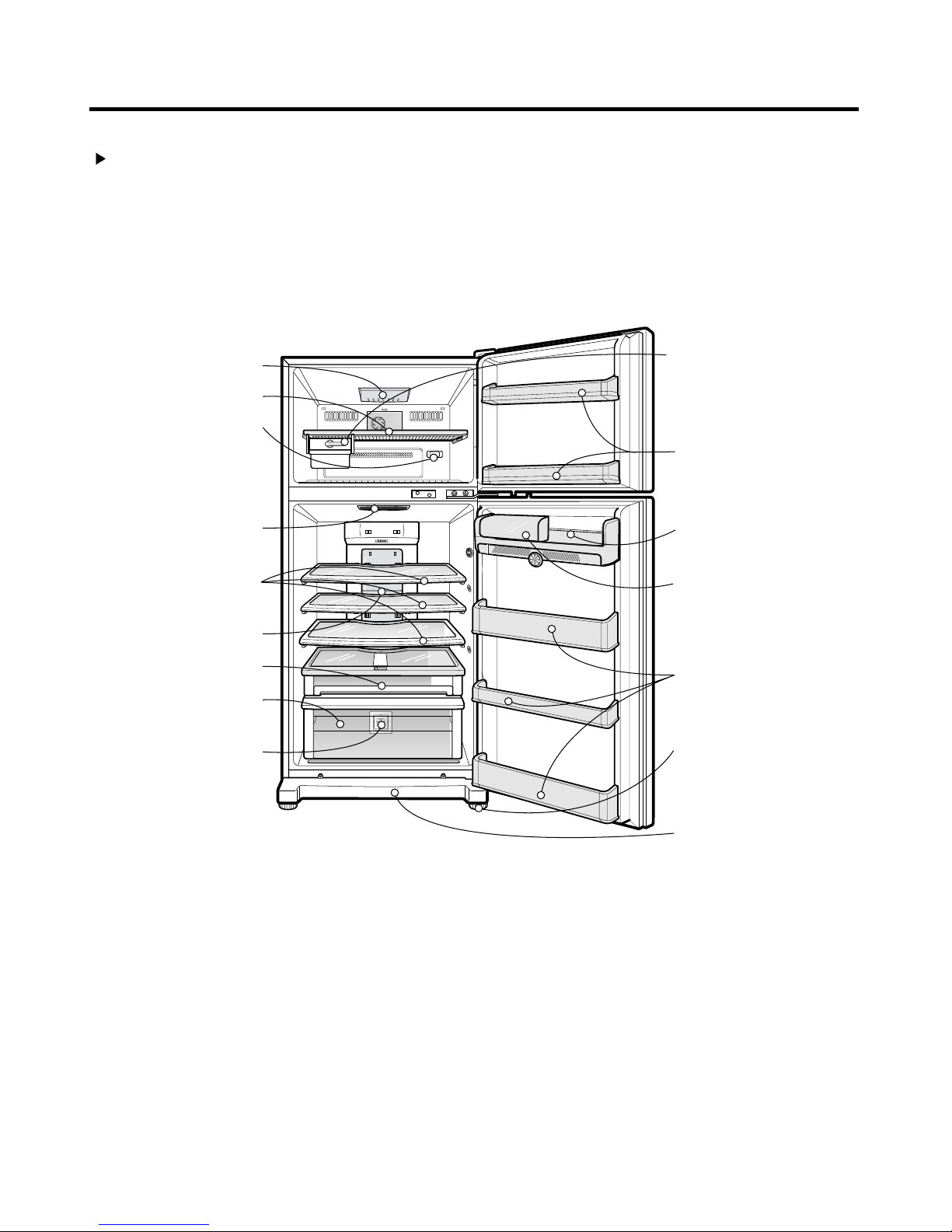

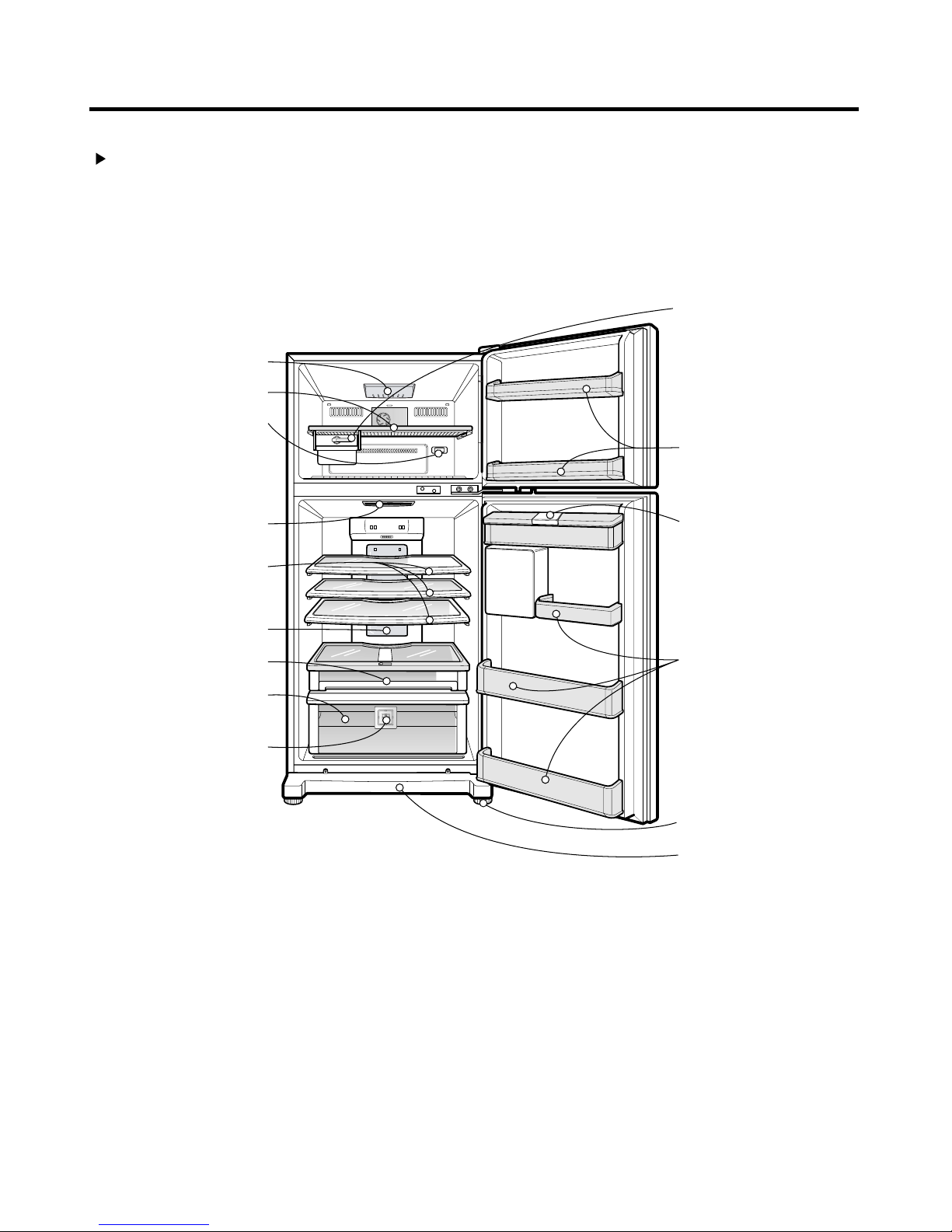

GR-B652Y*Y/B712Y*Y

FREEZER

COMPARTMENT

Lamp

Shelf

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

Lamp

Convertible Room

Vegetable Drawer

Vitamin Kit(optional)

In-Door Ice

Maker

Freezer Door Rack

Refrigerator Door

Rack

Levelling Screw

NOTE : This guide covers several different models.The refrigerator you have

Base Cover

purchased may have some or all of the features shown above.

- 8 -

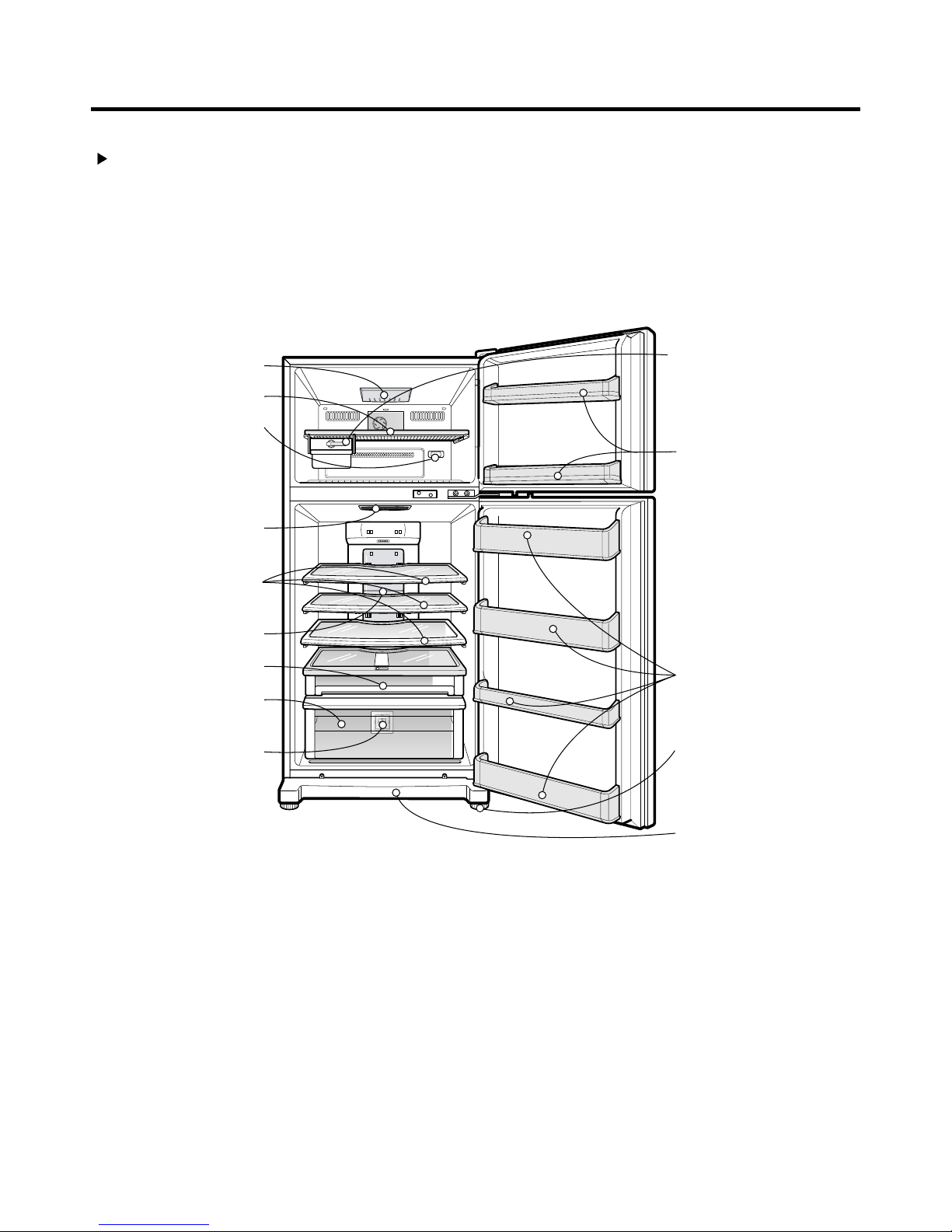

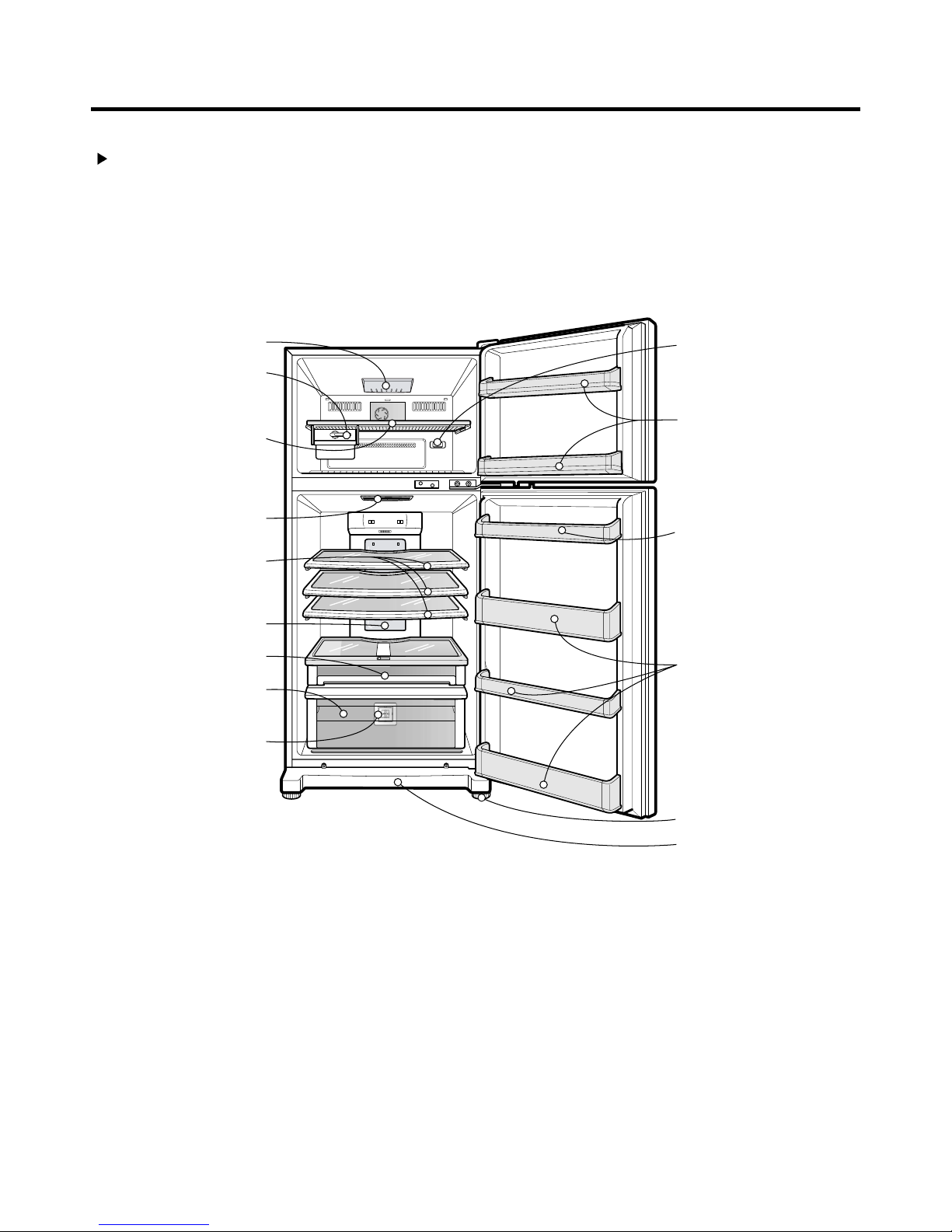

GR-M652Y*Q/M712Y*Q

FREEZER

COMPARTMENT

Lamp

Shelf

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Twigting Ice Serve

Freezer Door Rack

Egg Storage Rack

Shelves

(Optional)

Lamp

Convertible Room

Vegetable Drawer

Vitamin Kit(optional)

Dairy Corner

Refrigerator Door

Rack

Levelling Screw

Base Cover

NOTE : This guide covers several different models.The refrigerator you have

purchased may have some or all of the features shown above.

- 9 -

GR-B652Y*Q/B712Y*Q

FREEZER

COMPARTMENT

Lamp

Shelf

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

Twigting Ice Serve

Freezer Door Rack

Lamp

Convertible Room

Vegetable Drawer

Vitamin Kit(optional)

Refrigerator Door

Rack

Levelling Screw

Base Cover

NOTE : This guide covers several different models.The refrigerator you have

purchased may have some or all of the features shown above.

- 10 -

GR-B652Y*B/B712Y*B

FREEZER

COMPARTMENT

Lamp

Shelf

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

Lamp

Convertible Room

Vegetable Drawer

Vita Light

In-Door Ice

Maker

Freezer Door Rack

Water Tank

Refrigerator Door

Rack

NOTE : This guide covers several different models.The refrigerator you have

Levelling Screw

Base Cover

purchased may have some or all of the features shown above.

- 11 -

GR-B652Y*S/B712Y*S

FREEZER

COMPARTMENT

Lamp

Shelf

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

Lamp

Convertible Room

Vegetable Drawer

Vitamin Kit(optional)

In-Door Ice

Maker

Freezer Door Rack

Water Tank

Refrigerator Door

Rack

NOTE : This guide covers several different models.The refrigerator you have

Levelling Screw

Base Cover

purchased may have some or all of the features shown above.

- 12 -

GR-B652Y*P/B712Y*P

FREEZER

COMPARTMENT

Lamp

Shelf

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

Lamp

Convertible Room

Vegetable Drawer

Vitamin Kit(optional)

Twigting Ice Serve

Freezer Door Rack

Water Tank

Refrigerator Door

Rack

NOTE : This guide covers several different models.The refrigerator you have

Levelling Screw

Base Cover

purchased may have some or all of the features shown above.

- 13 -

GR-B652Y*C/B712Y*C

FREEZER

COMPARTMENT

Lamp

Twigting Ice Serve

Shelf

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

Freezer Temperature

Control Dial

Freezer Door Rack

Egg Storage Rack

Lamp

Convertible Room

Vegetable Drawer

Vitamin Kit(optional)

Refrigerator Door

Rack

Levelling Screw

Base Cover

NOTE : This guide covers several different models.The refrigerator you have

purchased may have some or all of the features shown above.

- 14 -

GR-M652Y*C/M712Y*C

FREEZER

COMPARTMENT

Lamp

Twigting Ice Serve

Shelf

REFRIGERATOR

COMPARTMENT

Deodorizer

(Optional)

Shelves

(Optional)

Freezer Temperature

Control Dial

Freezer Door Rack

Egg Storage Rack

Dairy Corner

Lamp

Convertible Room

Vegetable Drawer

Vitamin Kit(optional)

Refrigerator Door

Rack

Levelling Screw

Base Cover

NOTE : This guide covers several different models.The refrigerator you have

purchased may have some or all of the features shown above.

- 15 -

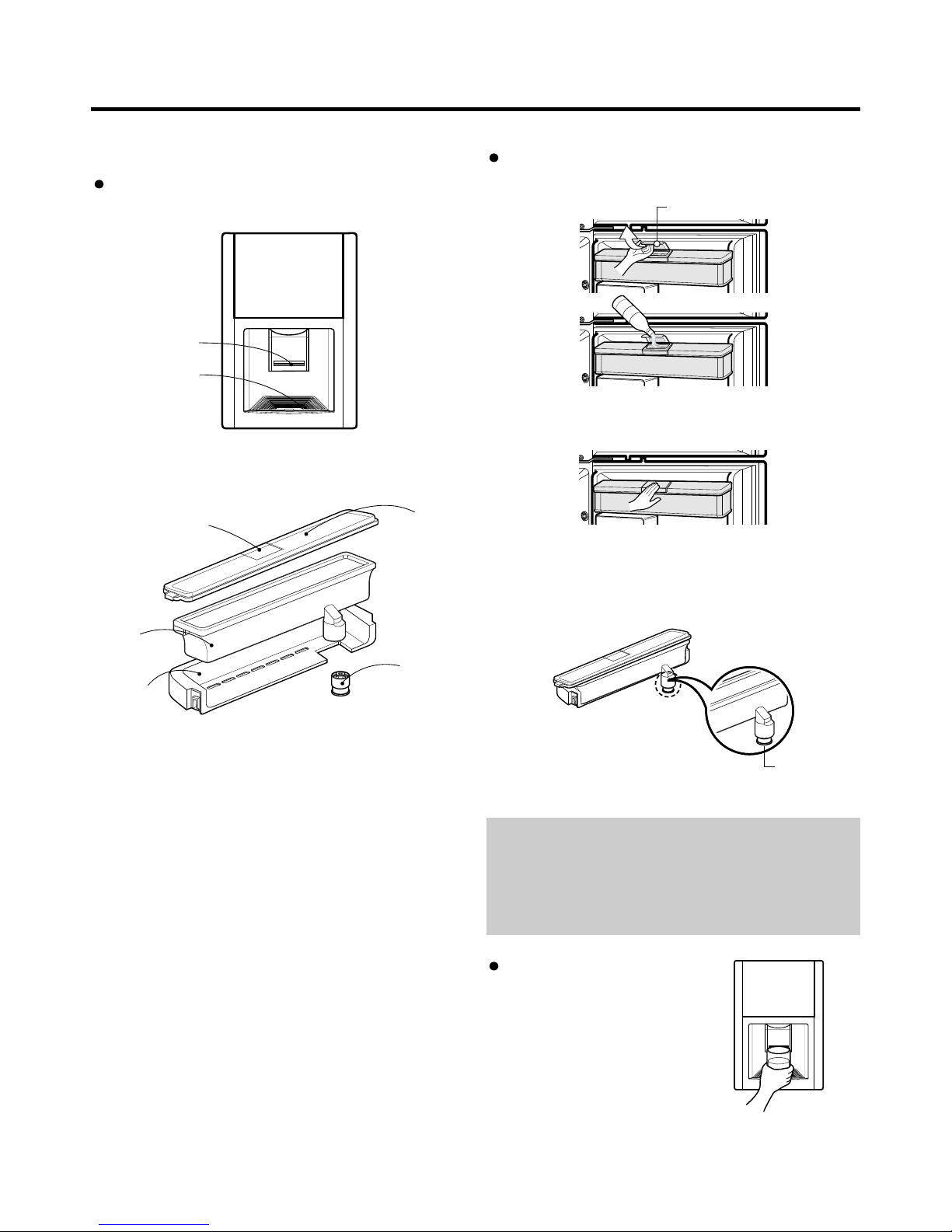

2-2 WATER DISPENSER

Putting The Water In The Water Tank

Features 1. Open the cover cap and pour water into the water tank.

Cover Cap

DISPENSER

PAD

GRILLE

2. Close the cover cap.

WATER

TANK

REFRIG

ERATOR

DOOR

RACK

Cover Cap

Tank

Cover

3. Make sure that the valve under the water tank is in

position. Push the connecting part into the hole.

VALVE

WATER TANK

VALVE

CAUTION

1. Do not use anything other than water including soft

drinks, milk and juices.

2. Hot water needs to be cooled before being put in the

water tank.

Drinking

1. Press the dispenser pad

with the glass.

2. The water is released when

the dispenser pad is

pressed. The pad returns to

its original position when

the glass is removed, and

the water stops its flow.

- 16 -

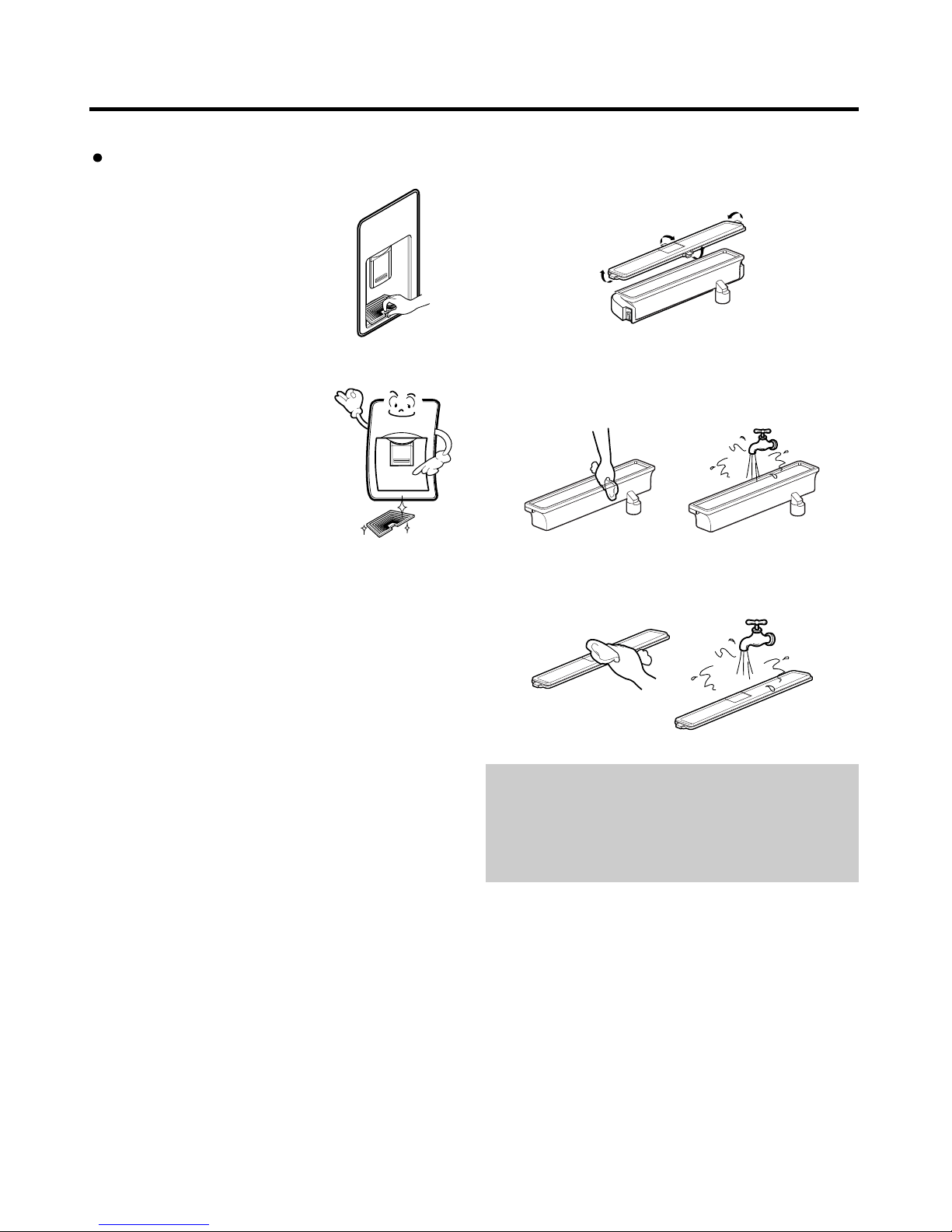

Cleaning

Grille and Drip Tray

1. Remove with the grille.

2. Wash the grille with a mild

detergent and rinse

thoroughly.

Water Tank

1. Remove the Cover.

2. Clean the inside and outside of the water tank with

dishwashing detergent and rinse thoroughly under

running water.

3. Clean the tank cover with dishwashing detergent and

rinse thoronghly under running water.

CAUTION

1. Use lukewarm water when cleaning.

2. Do not use anything other than water. If it is used with

soft drinks, put water in the water tank and discharge

three or four cups of water shortly.

- 17 -

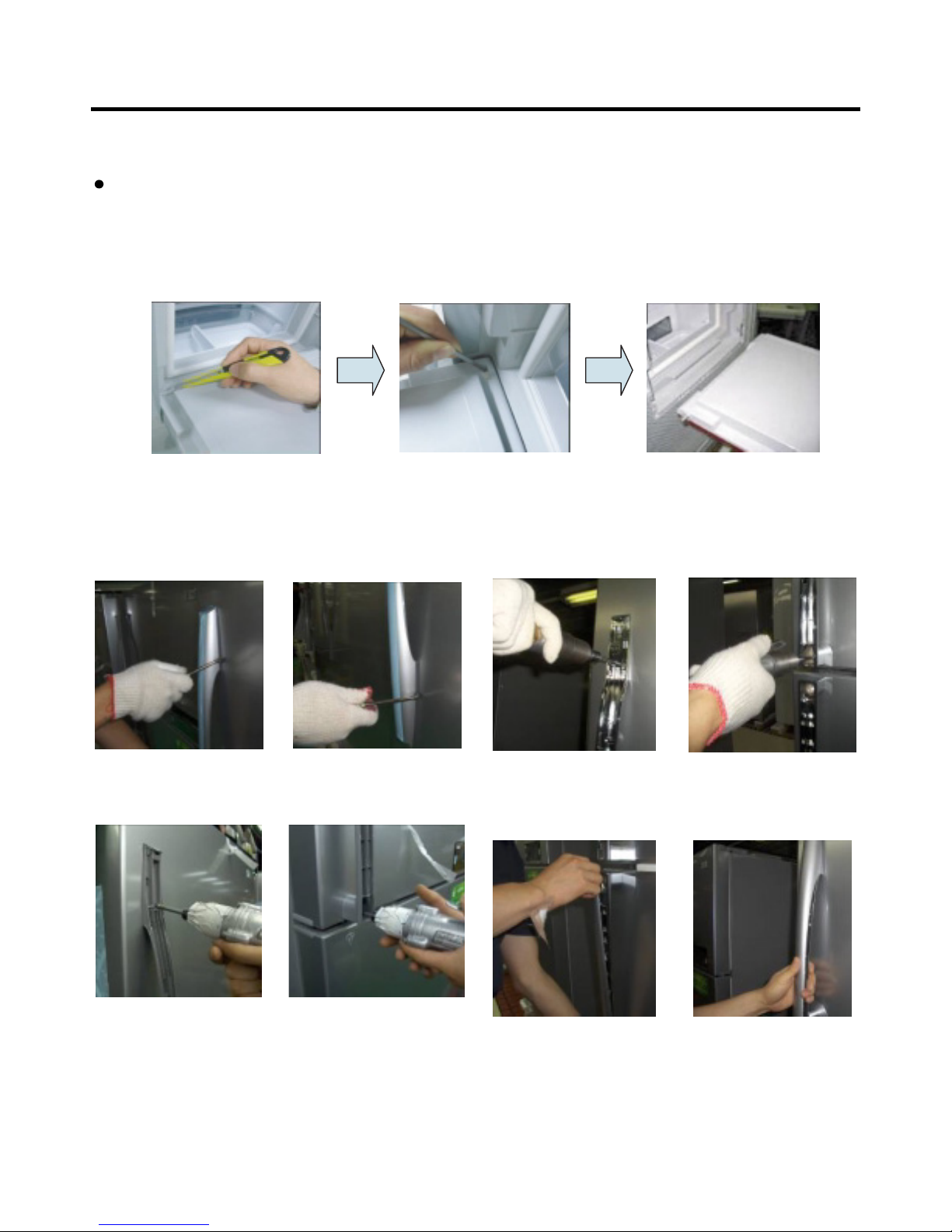

2-3 HOME BAR

How to disassemble and assemble the ice access door (H/BAR Door)

1) Open the ice access door to carefully remove left rubber packing.

2) While pressing the hinge separated using a pointed tool (driver, drill), move it to the right and carefully separate the ice

access door.

3) The assembly is made in reverse order.

1) 2) 3)

2-4 HOW TO DISASSEMBLE AND ASSEMBLE HANDLE

1. Disassemble the handle, deco and handle, base

1) Remove handle, deco by pulling it out with tooling.

2. Assemble the new handle, deco and handle, base

1) Assemble new handle, base by tightening 3 screws.

Freezer handle

2) Remove handle, base by loosening 3 screws.

Upper (1 screw)

Refrigerator handle

Upper (1 screw) Lower (2 screws)

2) Assemble handle, deco by pushing it after inserting

upper and lower part first.

Lower (2 screws)

- 18 -

Loading...

Loading...