Page 1

website http://biz.LGEservice.com

e-mail http://www.LGEservice.com/techsup.html

C D - RW/DVD-ROM DRIVE

S E RVICE MANUAL

MODEL: GCC-4520B

P/NO : 3828HS1041G

J u l y, 2003

Printed in Korea

MODEL : GCC-4520B

Page 2

TABLE OF CONTENTS

INTRODUCTION....................................................................................................................................................3

FEATURES............................................................................................................................................................3

SPECIFICATIONS.............................................................................................................................................4~5

LOCATION OF CUSTOMER CONTROLS........................................................................................................6~7

DISASSEMBLY.................................................................................................................................................8~9

1. CABINET and CIRCUIT BOARD DISASSEMBLY.........................................................................................8

1-1. Bottom Chassis.........................................................................................................................................8

1-2. Front Bezel Assy.......................................................................................................................................8

1-3. Cabinet and Main Circuit Board................................................................................................................8

2. MECHANISM ASSY DISASSEMBLY............................................................................................................8

2-1. Pick-up Unit...............................................................................................................................................8

2-2. Pick-up .....................................................................................................................................................9

GLOSSARY.........................................................................................................................................................10

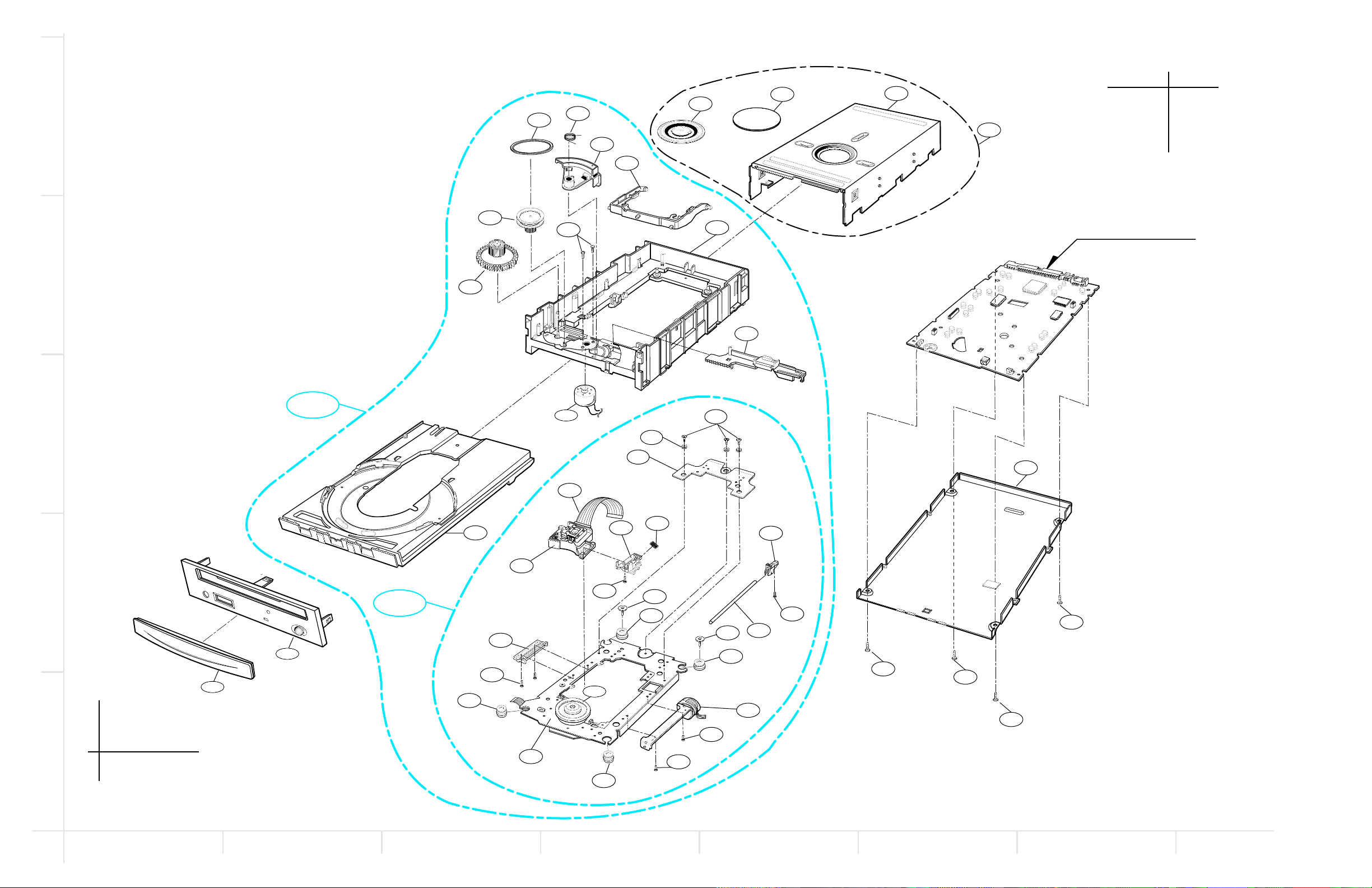

EXPLODED VIEW.........................................................................................................................................11~12

MECHANICAL REPLACEMENT PARTS LIST.............................................................................................13~14

THE DIFFERENCES OF CD-R/CD-RW DISCS AND GENERAL CD-ROM.......................................................15

1. Recording Layer...........................................................................................................................................15

2. Disc Specification.........................................................................................................................................15

3. Disc Materials...............................................................................................................................................16

4. Reading Process of Optical Disc..................................................................................................................17

5. Writing Process of CD-R Disc......................................................................................................................18

6. Writing Process of CD-RW Disc...................................................................................................................18

7. Organization of the PCA, PMA and Lead-in Area........................................................................................19

8. Function of PCA and PMA area...................................................................................................................20

9. OPC and ROPC...........................................................................................................................................20

10. Writing Process of DISC ............................................................................................................................21

11. Super link...................................................................................................................................................22

12. Zone CLV Recording..................................................................................................................................22

13. Optimum record speed...............................................................................................................................22

DVD & CD DATA PROCESSING..................................................................................................................23~26

1. Data Processing Flow..................................................................................................................................23

2. Copy Protection and Regional Code Management Block............................................................................24

3. About Prevention the DVD-ROm from to be copy........................................................................................25

4. About the DVD-ROM Regional Code...........................................................................................................26

INTERNAL STRUCTURE OF THE PICK-UP................................................................................................27~29

1. Block Diagram of the Pick-up.......................................................................................................................27

2. Pick up Pin Assignment ...............................................................................................................................28

3. Signal detection of the P/U...........................................................................................................................29

DESCRIPTION OF CIRCUIT.........................................................................................................................30~32

1. ALPC Circuit.................................................................................................................................................30

2. Focus/Tracking/Sled Servo Circuit...............................................................................................................31

3. Spindle Servo Circuit....................................................................................................................................32

MAJOR IC INTERNAL BLOCK DIAGRAM AND PIN DESCRIPTION.........................................................33~50

TROUBLESHOOTING GUIDE......................................................................................................................51~68

BLOCK DIAGRAM ..............................................................................................................................................69

CIRCUIT DIAGRAM ......................................................................................................................................70~72

PRINTED CIRCUIT BOARD DIAGRAM .......................................................................................................73~76

ELECTRICAL REPLACEMENT PARTS LIST....................................................................................................77

CAUTION - INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM.

Page 3

3

INTRODUCTION

FEATURES

1. General

1) Enhanced IDE interface.

2) Internal 5.25 inch, halfheight CD-RW/DVD-ROM Drive.

3) 2 Mbytes buffer memory(Super-LinkTMfunction embedded for Buffer underrun.)

4) Power loading and power ejecting of a disc. The disc can also be ejected manually.

5) Supports Power saving mode and Sleep mode.

6) Vertical and Horizontal operation.

7) Support Mt. Rainier function.

2. Supported disc formats

1) Reads and writes data in each CD-ROM, CD-ROMXA, CD-I FMV, Video CD, and CD-EXTRA

2) Reads data in Photo CD (Single and Multi session).

3) Reads and writes standard CD-DA.

4) Reads and writes CD-R discs conforming to “Orange Book Part 2”.

5) Reads and writes CD-RW discs conforming to “Orange Book Parts 3”.

6) Reads DVD-ROM, DVD-R/RW and DVD+RW discs.

3. Supported write method

1) Disc at once (DAO), Session at once (SAO), Track at once (TAO), Variable packet, Fixed packet, and

Multi-session.

4. Performance

1) Random average access time : 100ms(CD-ROM/R/RW), 120ms(DVD-ROM)

2) CD-R Record speed : 4X, 8X, 16X(CLV), 24X, 32X,40X(PCAV), 20~52X(Full CAV).

3) CD-RW Record speed : 4X, 10X,16X(CLV), 24X(PCAV).

4) Sustained Transfer rate : Max 7,800Kb/s (CD-ROM, Max 52X),

Max 21,600Kb/s (DVD-ROM, Max 16X)

5) PIO Mode 4

6) Multimedia MPC-3 Spec compliant.

7) Support CD-TEXT read.

5. Audio

1) Output 16 bit digital data over ATA interface.

2) Software Volume Control

3) Equipped with audio line output and headphone jack for audio CD playback.

4) Front panel Volume Control for Headphone Output.

This service manual provides a variety of service

information.

It contains the mechanical structure of the CDRW/DVD-ROM Drive and the electronic circuits in

schematic form. This CD-RW/DVD-ROM Drive

was manufactured and assembled under our strict

quality control standards and meets or exceeds

industry specifications and standards.

This CD-RW/DVD-ROM drive is an internal drive

unit designed for use with IBM PC, HP Vectra, or

compatible computer. It can write as much as 650

Mbytes of digital data into CD-R/RW disc, and can

read as much as 650 Mbytes of digital data stored

in a CD-ROM, CD-R and CD-RW disc.

This CD-RW/DVD-ROM Drive can easily meet the

upcoming MPC level 3 specification, and its

Enhanced Intelligent Device Electronics (E-IDE)

and ATAPI interface allows Plug and play

integration in the majority of today’s PCs without

the need of an additional interface card.

Page 4

4

SPECIFICATIONS

1. SYSTEM REQUIREMENTS

-CPU: IBM Compatible Pentium 350MHZ (or faster)

(For High speed, 500MHz or faster recommended.)

-64MB Memory or greater

2. SUPPORTING OPERATING SYSTEM

3. GENERAL

1) Host Interface.......................................................................................................................ATAPI compliant

2) Read Function

• Acceptable discs...............................................................CD-ROM Mode1 (basic format), CD-ROM XA

CD-Audio

Mixed Mode (Audio and Data Combined)

Photo-CD (Single and Multi-Session)

CD-I FMV, Video CD

CD-Plus/CD-Extra,

CD-R (Conforming to “Orange Book Part2”)

CD-RW (Conforming to “Orange Book Part3”)

DVD-Single/Dual, DVD-R/RW, DVD+RW

3) Write function

• Applied Format..................................................................CD-ROM Mode-1

CD-ROM XA

CD-Audio

Video CD, CD-I FMV

CD-Plus/CD-Extra,

• Writing Method..................................................................Disc at once(DAO)

Session at once(SAO)

Track at once(TAO)

Variable packet writing

Fixed packet writing

Multi-session

4) Cache memory (R/W) .........................................................2 Mbyte

5) Disc diameter......................................................................12cm/8cm

6) Data capacity (Yellow-Book)

• User Data/Block................................................................2,048 bytes/block (Mode 1 & Mode 2 Form 1)

2,336 bytes/block (Mode 2)

2,328 bytes/block (Mode 2 Form 2)

2,352 bytes/block (CD-DA)

DVD-ROM(Book A, B) 2,048 bytes/block

7) Rotational Speed

CD:

CD-Audio (Analog)..............................................................4X~10X(CAV) Approx.2,000 rpm

CD-Audio(Digital) ................................................................18X~40X(CAV) Approx.9,000 rpm

CD-R/RW data ....................................................................18X~40X(CAV) Approx.9,000 rpm

(After disc initialize, in pause state, press open button and hold 3 seconds or more will change drive

speed from 40X to 48X)

CD-ROM..............................................................................20X~52X(CAV) Approx.10,200 rpm

DVD:

Single layer (DATA).............................................................6.5X~16X(CAV) Approx.9,500 rpm

(MOVIE) ..........................................................3.3X~8X (CAV) Approx 4,600rpm

Dual layer............................................................................3.3X~8X(CAV) Approx.5,000 rpm

8) MTBF

• 120, 000 POH at an operating duty of 10% at room temperature.

• DOS 3.1 or Higher

• Windows ‘95/’98/’2000/ME/XP

• OS/2 Warp (Ver 3.0)

• Solaris Ver 2.4 or higher

• Linux Slackware Ver 2.3

• Windows NT 4.0 or later

Page 5

5

4. DRIVE PERFORMANCE

1) Data Transfer Rate

* Sustained Data Transfer Rate:

CD :

R/RW : 2,700 to 6,000 Kbytes/s (18X~40X CAV)

ROM : 3,000 to 7,800 Kbytes/s (20X~52X CAV)

DVD:

DUAL : 4,460 to 11,080 Kbytes/s (3.3X ~ 8X CAV)

SINGLE :

Data : 8,700 to 21,600 Kbytes/s (6.5X~16X CAV)

Movie : 4,460 to 10,800 Kbytes/s (3.3X ~ 8X CAV)

+R/RW, -R/RW : 3,370 to 8,100 Kbytes/s (2.5X ~6X CAV)

* Burst Data Transfer Rate (ATAPI)....................................16.67 Mbytes/sec (PIO Mode 4)

16.67 Mbytes/sec (MULTI-DMA Mode 2)

33.3 Mbytes/sec (UDMA Mode 2)

2) Average Access Time

Random Access Full Access

CD (R/RW/ROM) : 100ms (Typ) 160ms (Typ)

DVD (Single Layer) : 120ms (Typ) 200ms (Typ)

3) Data Buffer Capacity...........................................................2 Mbytes

5. POWER REQUIREMENTS

1) Voltage

+5 V DC with +5% tolerance, less than 100 mVp-p Ripple voltage

+12 V DC with +5% tolerance, less than 100 mVp-p Ripple voltage

2) Current

• Hold Track State ...............................................................+5V DC 1.3A, +12 V DC 1.3A (Max)

• Seeking & Spin up ............................................................+5V DC 1.3A, +12 V DC 1.3A (Max)

6. AUDIO PERFORMANCE

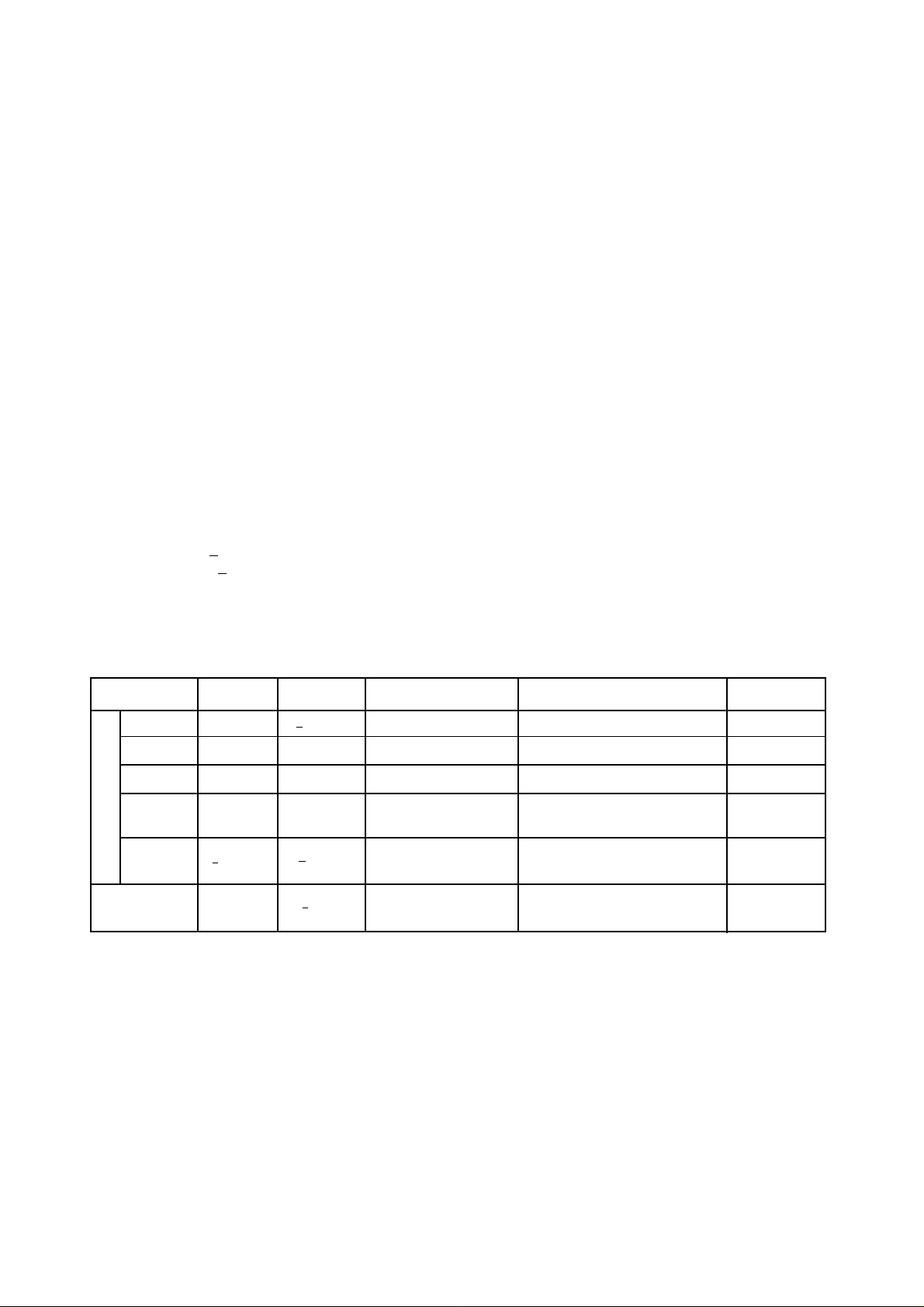

Item Typical Limit Test Signal Test Condition Note

Output Level

0.7 Vrms

+

10 % 1KHz 0 dB No Filter at 47 kΩ

S/N 80 dB 75 dB 1KHz 0 dB with IHF-A + 20KHz LPF at 47kΩ

THD 0.1 % 0.15 % 1KHz 0 dB with IHF-A + 20KHz LPF at 47kΩ

Channel

65 dB 60 dB 1KHz 0 dB with IHF-A + 20KHz LPF at 47kΩ

Separation

Frequency +

2dB

Response

H/P

Output Level

AUDIO OUT

+

3 dB 20Hz~18KHz 0 dB No Filter at 47 kΩ

0.6Vrms

+

20 % 1KHz 0dB No Filter H/P Volume MAX at 33 Ω

Page 6

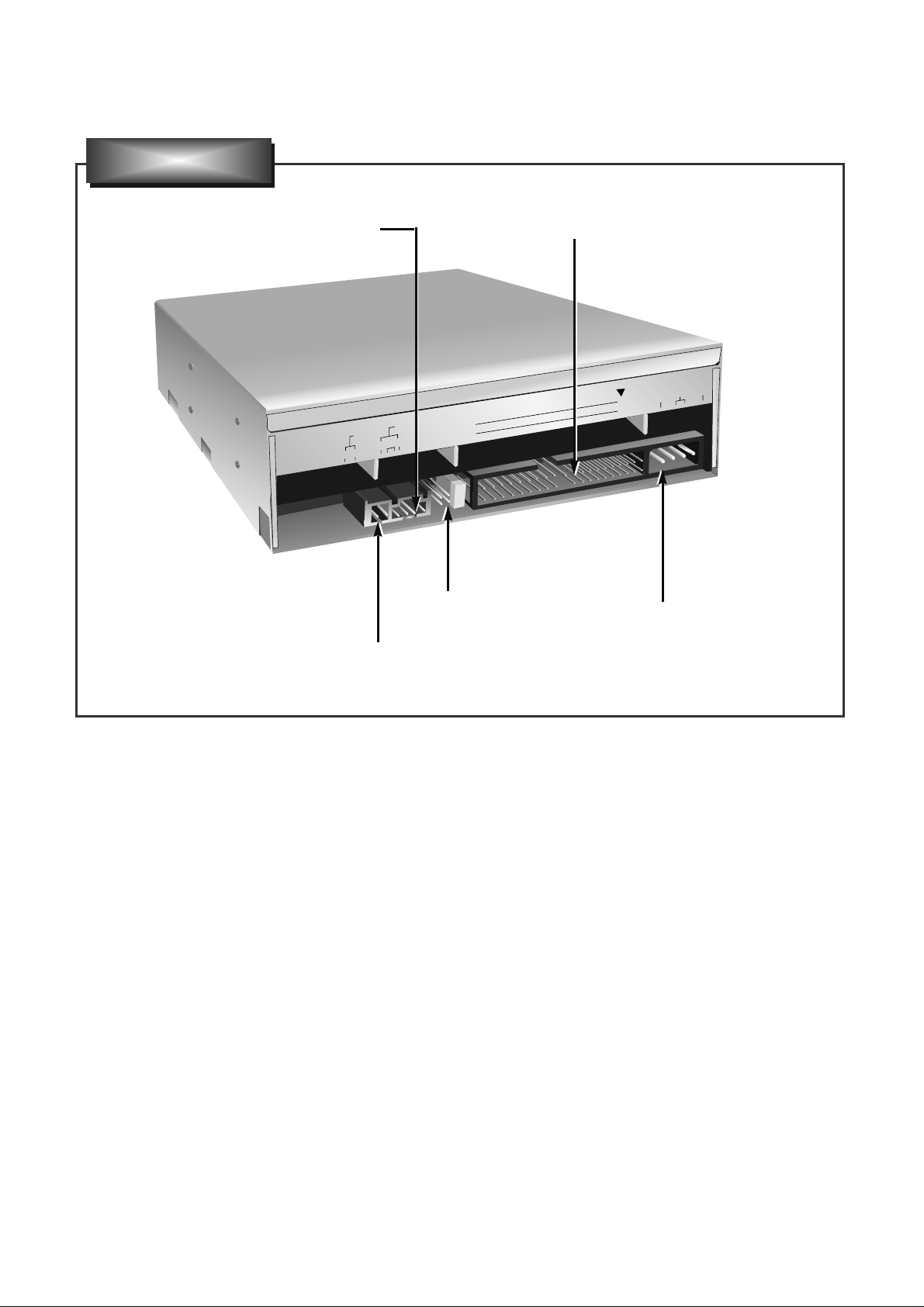

LOCA TION OF CUSTOMER CONTROLS

6

1. Disc tray

This is the tray for the disc. Place the disc on the

ejected disc tray, then lightly push the tray (or

push the eject button) and the CD will be loaded.

NOTE: Don’t pull out or push in the disc tray

forcibly. This might cause damage to the loading

section of the drive.

2. Stop/Eject button

This button is pressed to open the CD tray.

This button works only when power is supplied to

the drive.

If an Audio CD is playing, pressing this button will

stop it, and pressing it again will open the tray.

3. Emergency Eject Hole

Insert a paper clip here to eject the Disc tray

manually or when there is no power.

4. Volume control

This is used to adjust the output volume of the

headphone jack. It can’t be used to adjust the

output volume for the audio output connectors on

the rear panel.

NOTE : Turn the volume down before turning on

the power. Sudden loud noises can damage your

hearing.

5. Headphone jack

This jack is for connecting headphones or minispeakers.

6. Drive activity indicator

Two colored LED is used to indicate the operation

of CD-R/RW Drive.

Headphone Jack

Volume

Control

Drive Activity Indicators

Stop/Eject Button

Disc Tray

Emergency Eject Hole

Front Panel

Page 7

7

1. Power Connector

Connects to the power supply (5-and 12-V DC) of

the host computer.

NOTE : Be careful to connect with the proper

polarity. Connecting the wrong way may damage

the system (and is not guaranteed). Usually this

connector can only be attached one-way.

2. IDE Interface Connector

Connect to the IDE (Integrated Device

Electronics) Interface using a 40-pin flat IDE

cable.

NOTE : Do not connect or disconnect the cable

when the power is on, as this could cause a short

circuit and damage the system. Always turn the

power OFF when connecting or disconnecting the

cable.

3. Jumper Connector

This jumper determines whether the drive is

configured as a master or slave. Changing the

master-slave configuration takes effect after

power-on reset.

4. Analog Audio Output Connector

Provides output to a sound card (analog signal).

Generally you need this to play a regular audio

CD.

5. Digital Audio Output Connector

Provides output to a sound card (digital signal).

DIGITAL

AUDIO

ANALOG

AUDIO

INTERFACE

POW

ER

D G

39

40

1

+5

GND

+12

2

C S M

S L A

R G L

Digital Audio Output

Connector

Jumper Connector

Analog Audio Output Connector

IDE Interface Connector

Power Connector

Rear Panel

Page 8

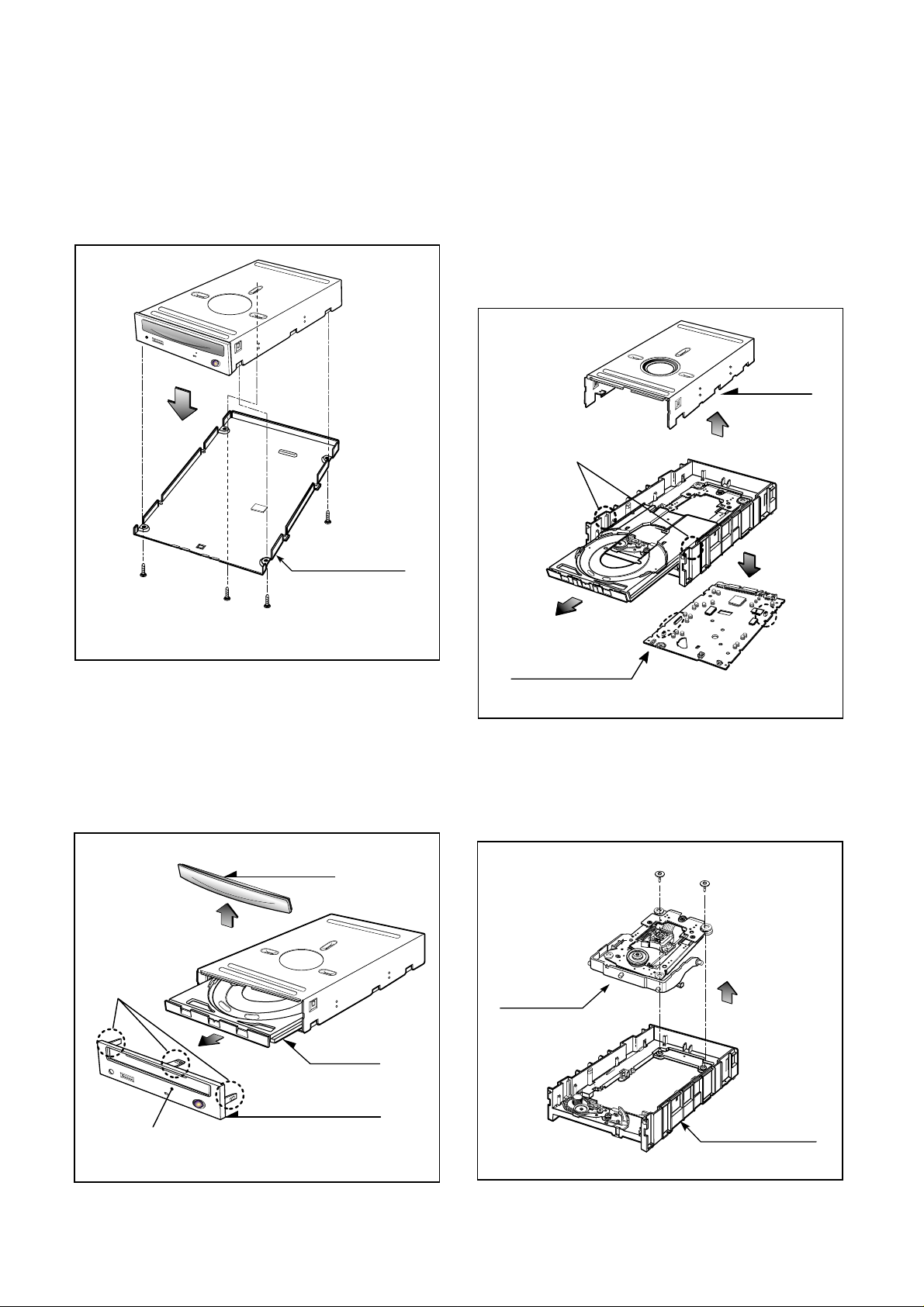

1. CABINET and CIRCUIT BOARD

DISASSEMBL Y

1-1. Bottom Chassis

A. Release 4 screws (A) and remove the Bottom Chassis

in the direction of arrow (1). (See Fig.1-1)

1-2. Front Bezel Assy

A. Insert and press a rod in the Emergency Eject

Hole and then the CD Tray will open in the direction

of arrow (2).

B. Remove the Tray Door in the direction of arrow

(3) by pushing the stoppers forward.

C. Release 3 stoppers and remove the Front Bezel Assy.

1-3. Cabinet and Main Circuit Board

A. Remove the Cabinet in the direction of arrow (4).

(See Fig. 1-3)

B. Release 2 hooks (a) and remove the CD Tray

drawing forward.

C. Remove the Main Circuit Board in the direction of

arrow (5).

D. At this time, be careful not to damage the 4

connectors, are positioned at left and bottom sides,

of the Main Circuit Board.

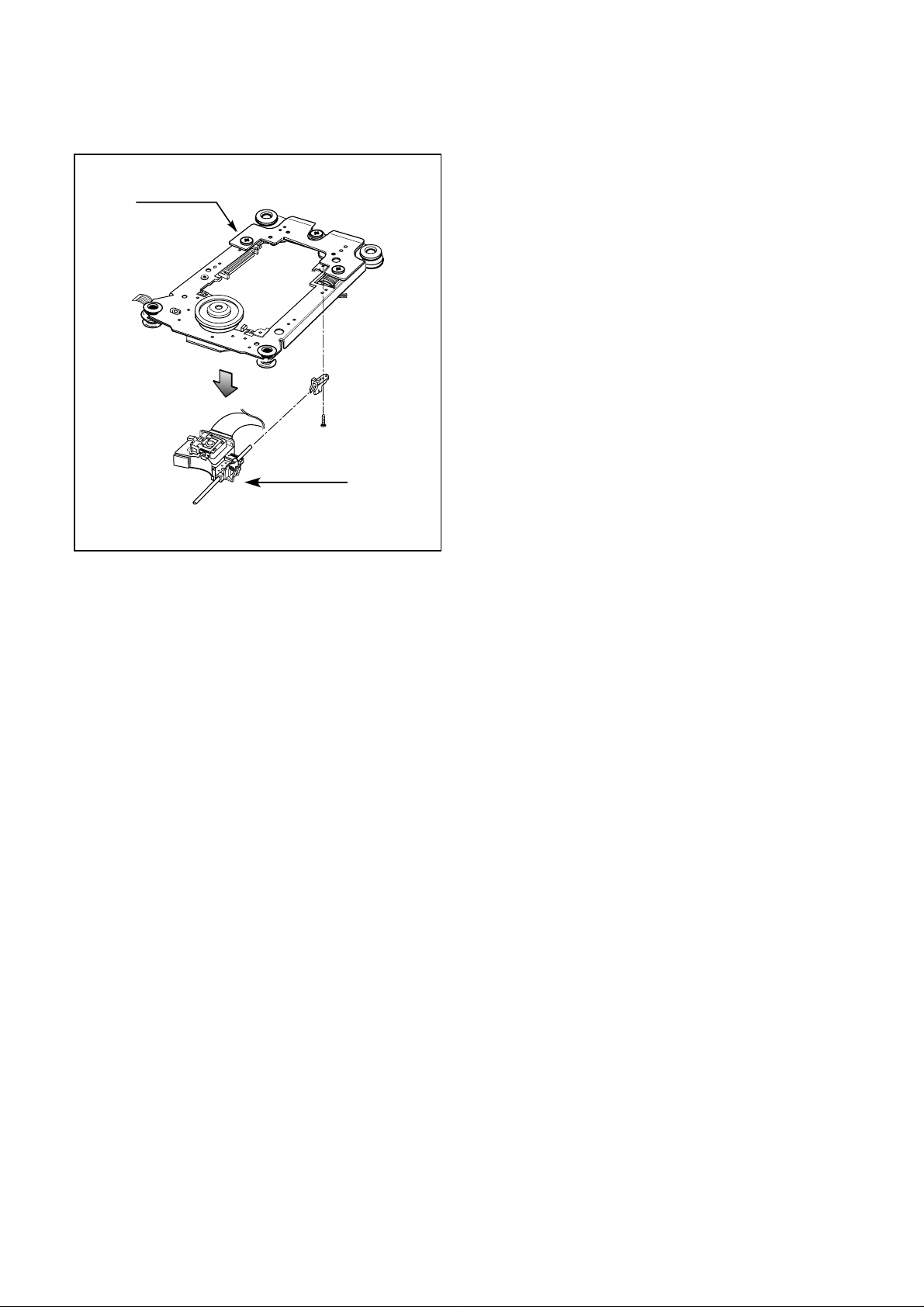

2. MECHANISM ASSY DISASSEMBL Y

2-1. Pick-up Unit

A. Release screws (B).

B. Separate the Pick-up Unit in the direction of arrow (6).

Main

Circuit Board

Cabinet

(4)

(5)

Hooks (a)

Fig. 1-1

Fig. 1-2

DISASSEMBLY

8

Fig. 1-3

Mechanism Assy

Pick-up Unit

(B)

(B)

(6)

Fig. 2-1

(1)

(A)

Bottom Chassis

(A)

(A)

(A)

Tray Door

(3)

Front Bezel Assy

CD Tray

Stoppers

Emergency Eject Hole

(2)

Page 9

2-2. Pick-up

A. Release 1 screw (C) and remove the Pick-up.

Pick-up Unit

Pick-up

(C)

Fig. 2-2

9

Page 10

030

PBM00 (MAIN C.B.A)

007

A02

A01

021

028

401

032

401

020

021

050

400

022

413

413

413

001

413

430

010

009

420

008

011

012

005

035

016

015

004

006

A B C D E F GH

1

2

3

4

5

003

002

013

452

029

031

027

026

033

025

430

419

020

449

023

014

11 12

EXPLODED VIEW

Page 11

ATIP Absolute Time in Pre-groove. With an additional modulation of the “Wobble”, the “Groove” contains a time

code information.

Wobble The pre-groove in the Disc is not a perfect spiral but is wobbled.

With : – A typical amplitude of 30 nm

– A spatial peried of 54~64 µm

CW Continuous Wave. The laser light output is at a constant level.

DOW Direct Over-Write. The action in which new information is recored over previously recorded information in

CD-RW disc.

Overwrite

The action in which new information is recorded over previously recorded information.

(Pre-)Groove

The guidance track in which clocking and time code information is stored by means of an FM

modulated wobble.

Land Land is characterized in the following way:

When radial signals are concerned,land is defined as the area between the grooves.

When HF signal are concerned,land is defined as the area between the marks(pits) in tangential

direction.

Hybrid Disc A Multisession disc of which the first Session is mastered. On a hybrid disc, recorded and

mastered information may co-exist.

Mastered Information,stored as pits on the disc during the manufacturing process of the disc.

Information (when making the master)

OPC Optimum Power Control. Procedure is determined optimum recording power according to CD-

R/RW Media in recording start step.

ROPC Running OPC. The purpose is to continuously adjust the writing power to the optimum power

that is required.

When the optimum power may change because of changed conditions of disc and change in

operating temperature.

Jitter The 16 value of the time variation between leading and trailing edges of a specific (I3 … I11) pit

or land as measured by Time Interval Analysis.

Deviation The difference between a fixed value of Pit length and Land length.

TOC Table Of Contents : in the Lead-in Area the subcode Q-channel contains information about the

Tracks on the disc.

Packet A method of writing data on a CD in small increments.

Writing Two kinds of packets can be written : Fixed-length and Variable-length.

Write The shape of the HF write signal used to modulate the power of the laser.

Strategy The Write Strategy must be used for recordings necessary for disc measurements.

Information Wobble, ATIP, Disc Identification, Write Power, Speed Range OPC Parameters, etc are

Area recorded in the Information area of CD-RW Disc

Finalization The action in which (partially) unrecorded or logically erased tracks are finished and the Lead-in

and/or Lead-out areas are recorded or overwritten with the appropriate TOC subcode.

Logical Erase

A method to remove information from a disc area by overwriting it with an EFM signal containing

mode 0 subcode

A logically erased area is equivalent to an unrecorded

Physical Erase

The action in which previously recorded information is erased by overwriting with a CW laser

output.

After a Physical Erase action, the erased area on the CD-RW disc is in the unrecorded state

again.

Session

An area on the disc consisting of a Lead-in area, a Program area, a lead-out area.

Multi session

A session that contains or can contain more than one session composed Lead-in and Lead-out

GLOSSARY

10

Page 12

15

The differences of CD-R/CD-RW discs and General CD-ROM

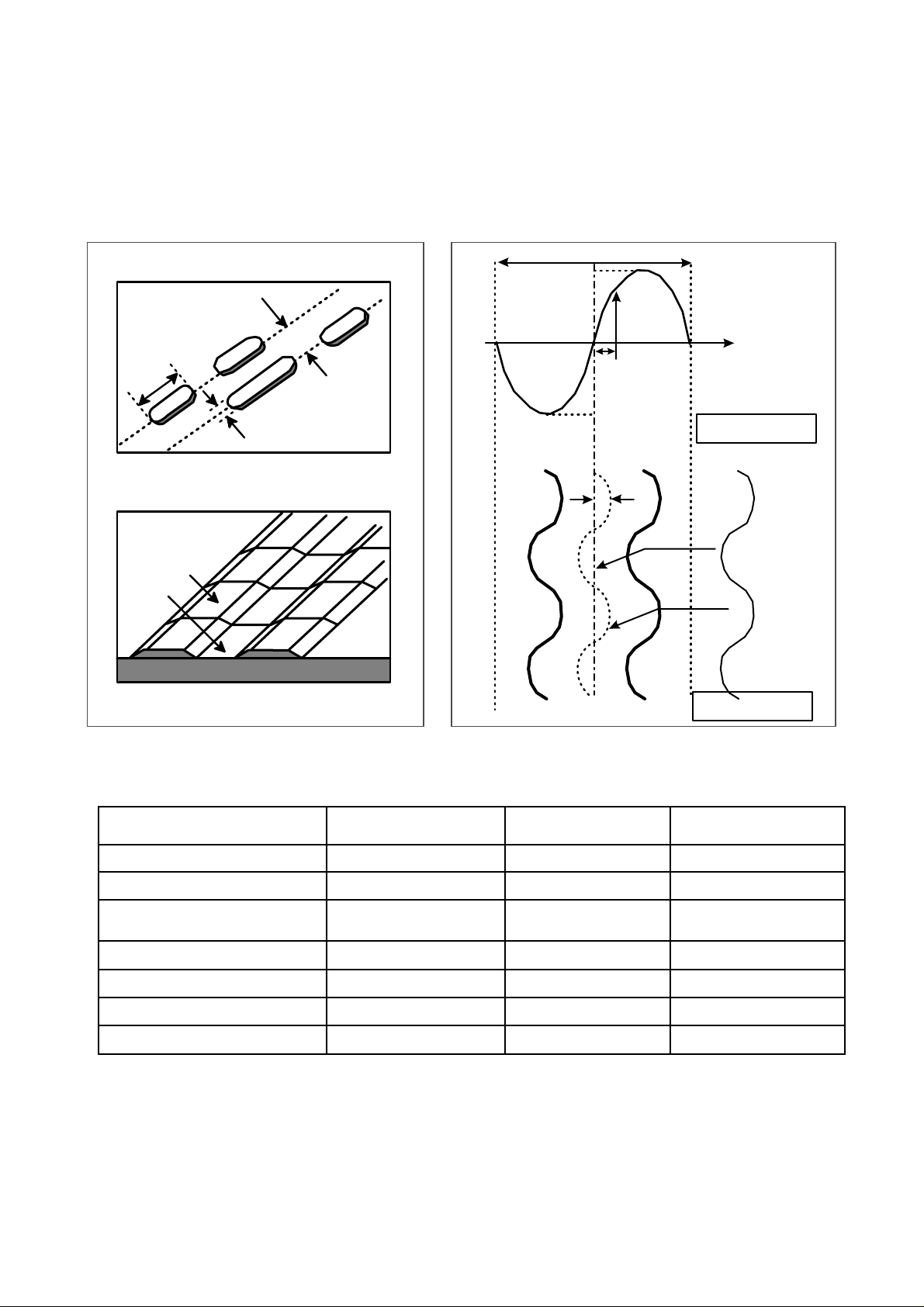

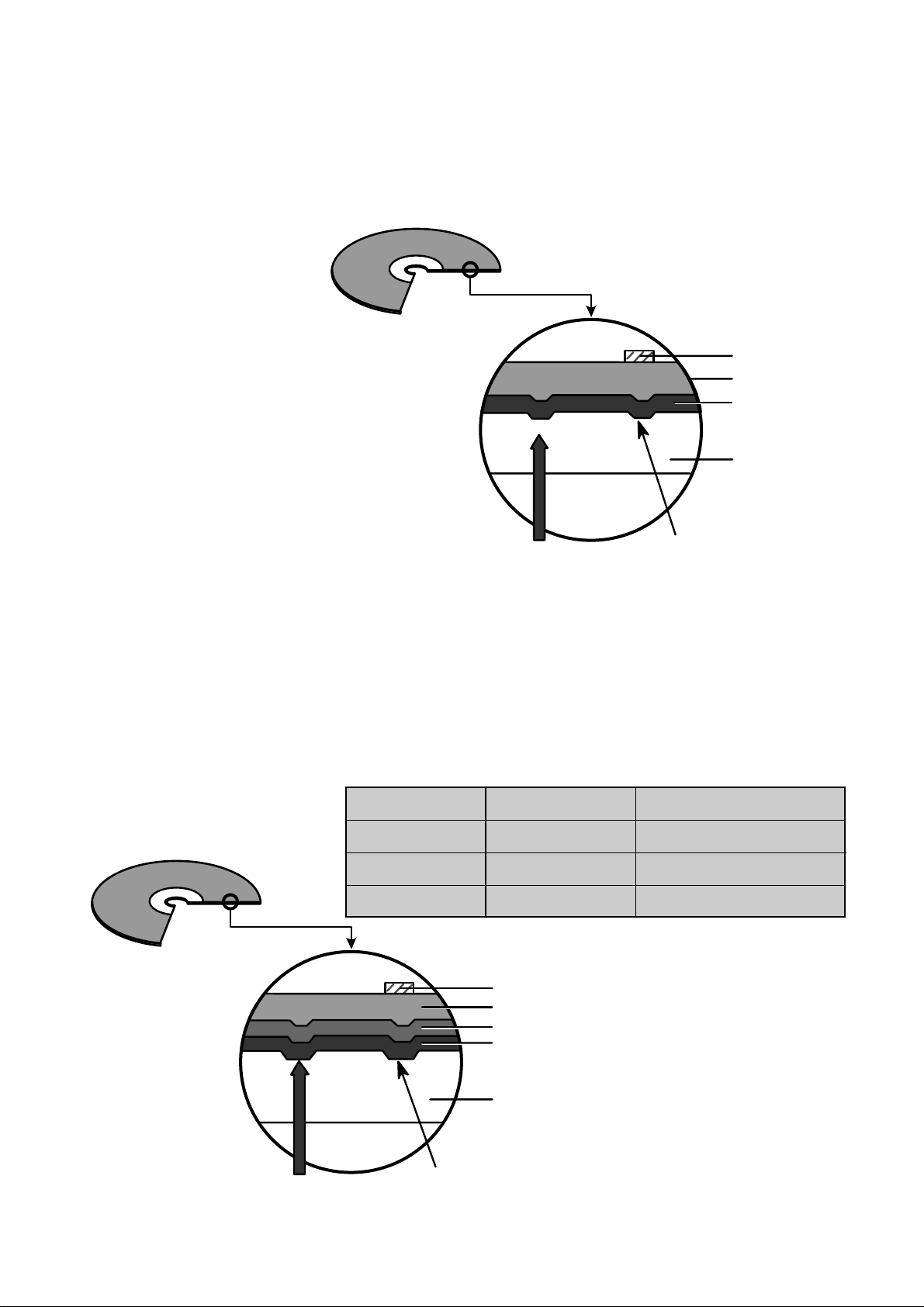

1.Recording Layer

Recordable CD has a wobbled pre-groove on the surface of disc for laser beam to follow track.

2.Disc Specification

Read-only Disc

CD-R and CD-RW Disc

3~1 1T

1.6um

0.4~0.5 um

(Pit)Groove

Land

Track pitch(p)

Radial Direction

Iw

A

O

a

a

Groove

Land

Radial Error Signal

The Groove wobble

Average center

Actual center

CD-ROM (READ-ONLY DISC)

a=30nm

ITEM CD-ROM CD-R CD-RW

Standard Yellow Book Orange Book II Orange Book III

Record Not available Write once Re-Writeable

Tracking Signal I11/Itop > 0.6 > 0.6 0.55 > M11> 0.70

(HF Modulation)

Read Laser Power(mW) < 0.5 mW < 0.7 mW < 1.0 mW

Jitter < 35 nsec < 35 nsec < 35 nsec

Reflectivity (R

top) 70 % 65 % 15 % ~ 25 %

Remark)

Write Laser Power(mW) 14-65 mW 6-45 mW

Page 13

16

3.Disc Materials

1) CD-ROM disc

Laser Beam

Groove

Substrate

(Polycarbonate)

Organic Dye Layer

Reflective Layer

Protective Layer

Label Printing

2) CD-R disc

Pigment Reflective Layer Color

Phtalocyanine Gold/Silver Yellow/White

Cyanine Gold/Silver Dark Green/Bright Green

Azo Gold/Silver Dark Blue

• It is composed of Silver _ colored aluminum plate and Reflective layer.

• Groove (Pit) of aluminum plate make a track.

• Laser wavelength : 780 nm, Laser Power (Read): 0.5mW

• Signal is detected by the

difference of reflective beam

intensity between “pit” and

“Land” on the disc.

• It is so-called WORM (Write Once Read Many) CD.

• It is composed of polycarbonate layer, Organic dye layer, Reflective layer, and Protective

layer.Gold/Silver Reflective layer is used to enhance the reflectivity

• According to the kinds of Organic dye layer, it is divided by Green CD, Gold CD, Blue CD.

• Laser Wavelength : 780 nm, Laser Power (read) : 0.7 mW

• Recording Power : 8x(14~20mW), 16x(25~35mW), 32x(40~50mW), 40x(45~55mW), 52x(50~65mW)

• When some part of dye layer is exposed to laser heat, it’s color changs black.Therefore, writing and

reading is enabled by the difference of reflectivity between changed part and unchanged part.

• Polycarbonate layer has Pre_Groove which make a Track.

Laser Beam

Pit

Substrate

(Polycarbonate)

Reflective Layer

Protective Layer

Label Printing

Page 14

17

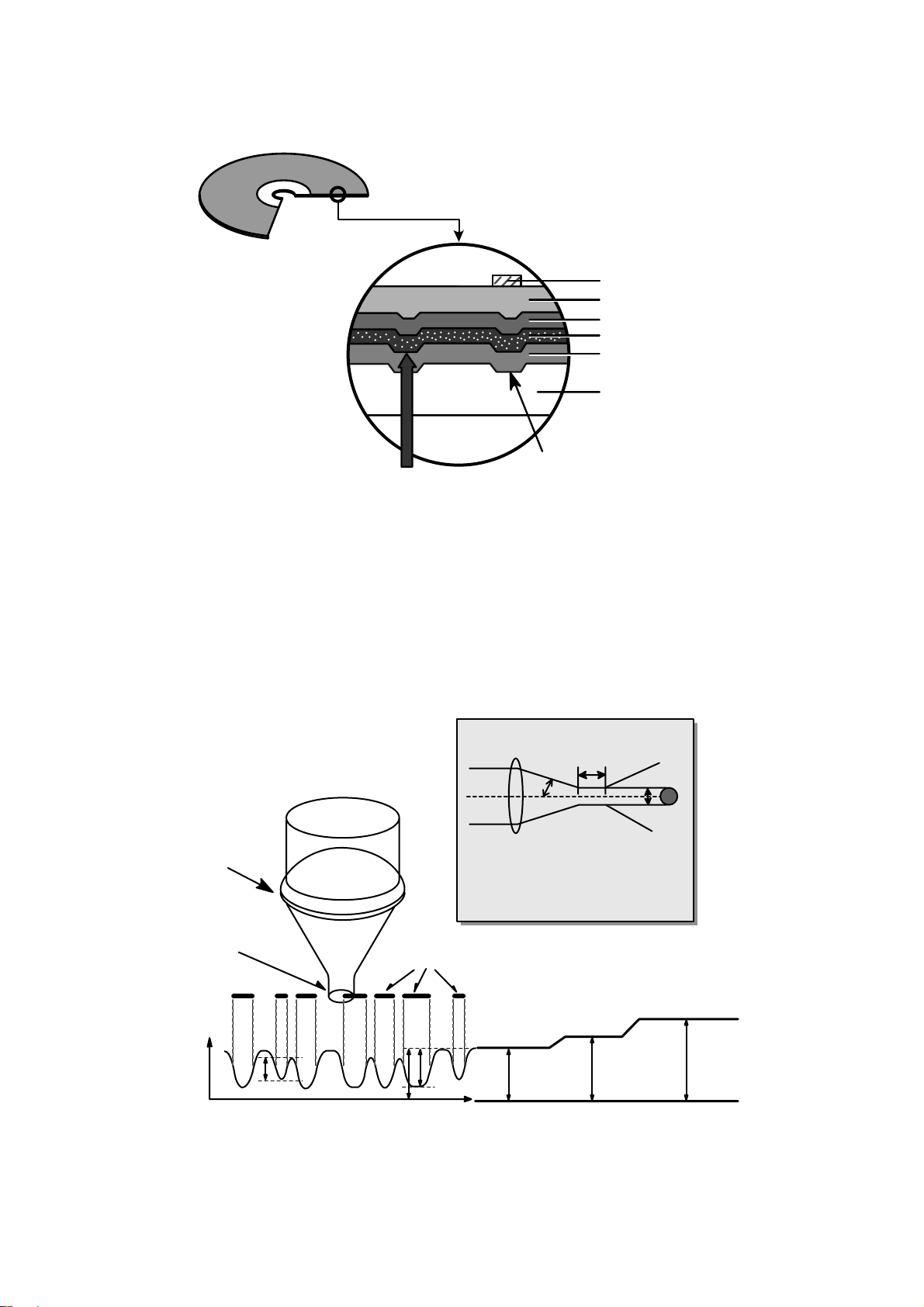

3) CD-RW Disc

4.

Reading process of Optical Disc

Laser Beam

Groove

Substrate

(Polycarbonate)

Recording Layer

Dielectric Layer(TL)

Dielectric Layer(UL)

Protective Layer

Label Printing

• It is composed of polycarbonate layer, alloy(silver, arsenic) layer, aluminum reflectivity layer, protective layer.

• An crystalized alloy layer is transformed into noncrystalized by the laser heat. Therefore, writing and reading

is enabled by the difference of reflectivity.

• It is possible to overwrite about 1000 times.

• Laser Wavelength : 780 nm, Laser Power (Read) : 1.0mW

• Recording Power : Erase (4~18mW), Write (6~45mW)

• When disc rewriting, new data is overwritten previously recorded data.

• Polycarbonate layer has a Pre-Groove which make a track.

Lens

H

D

Beam

Spot

Focusing

Lens

Laser Spot

at Constant

Read Intensity

Reflected

Light

Signal

Laser Spot

Position

(Time)

Previously Recorded Marks

Groove Land Mirror

I

3

I

top

I

11

I

G

I

L

I

0

Numerical aperture: NA=nsinθ,

n: Refractive index

Focus depth : H =

λ

/NA

laser spot diameter : D =

λ

/NA

2

θ

Page 15

18

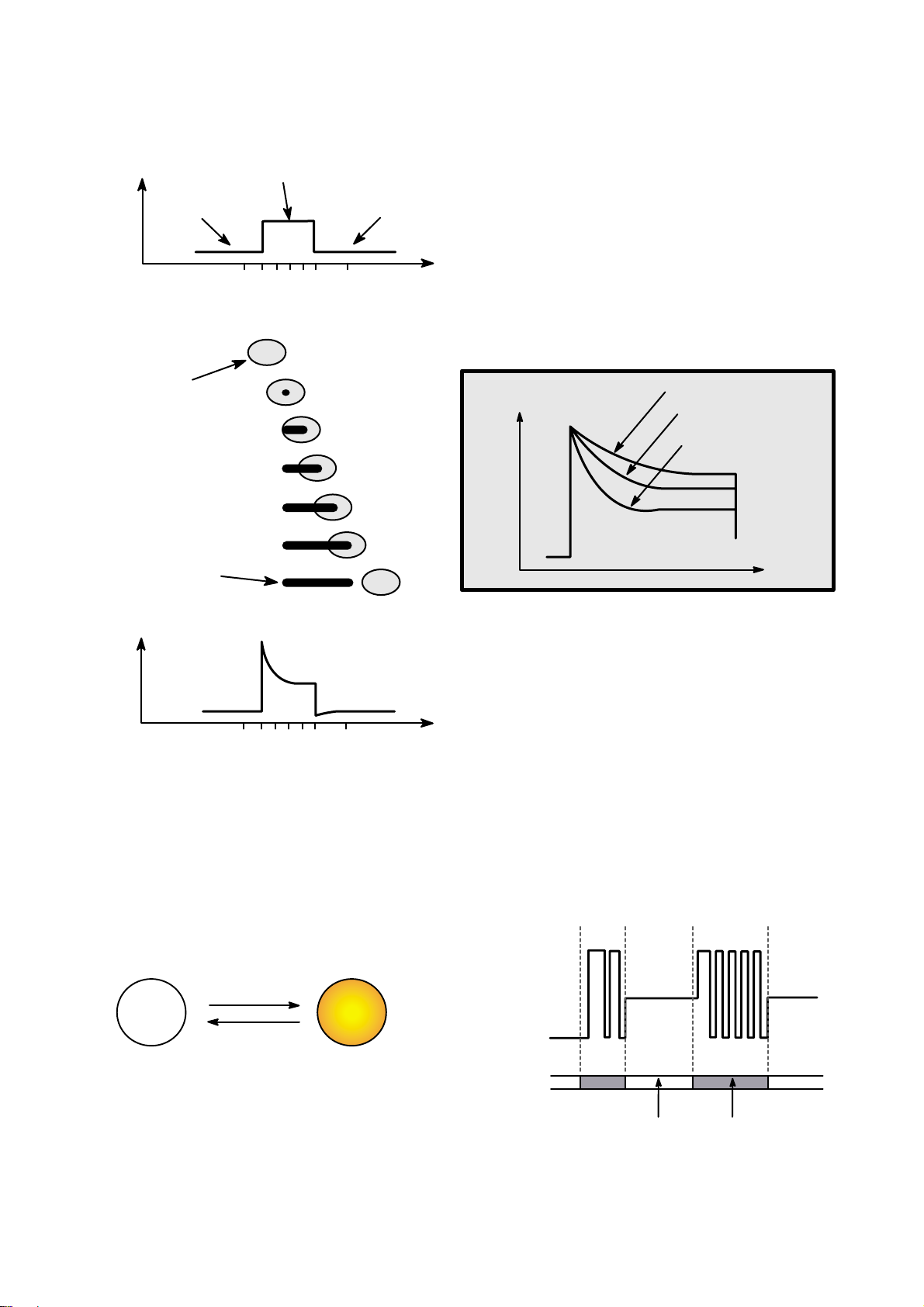

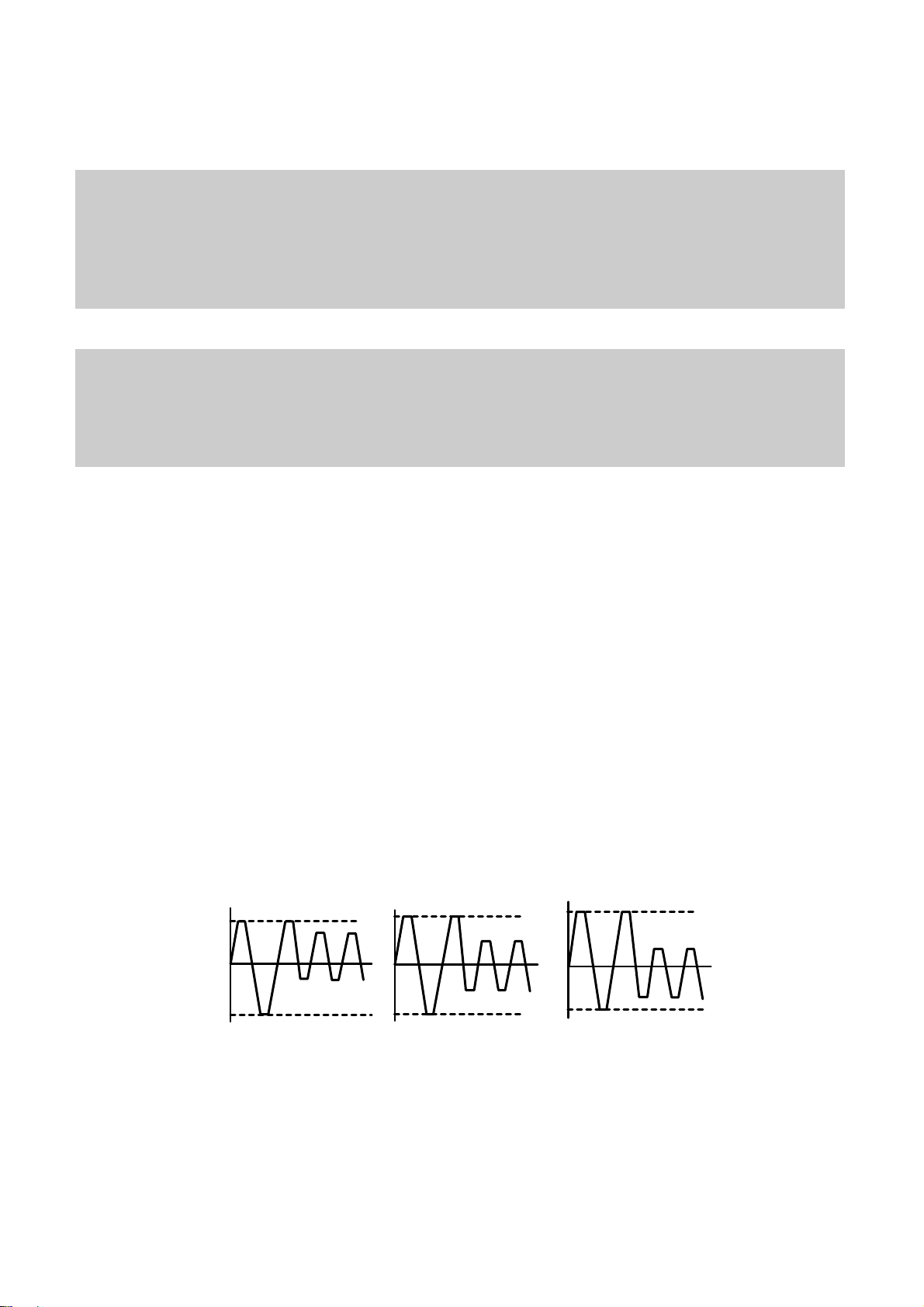

5.Writing Process of CD-R Disc

a b c d e f g

a

b

c

d

e

f

g

Incident

Laser

Power

(Read)

(Read)

(Write)

Laser Spot

Position

(Time)

a b c d e f g

Laser Spot

Position

(Time)

Laser

Spot

Recorded

Mark

Reflected

Light

Signal

Reflected

Light

Signal

Below "ORP"– Mark Too Short

At Optimum Record Power ("ORP")

Above "ORP" – Mark Too Long

Time

6.Writing process of CD-RW Disc

Write Power

Erase Power

Read Power

Groove

Crystal

Amorphous

Amorphous

Recorded state

(lower reflectivity)

Melting/

quenching

Heating/

gradual cooling

Crystal phase

Erased state

(higher reflectivity)

Page 16

19

7.Organization of the PCA, PMA and Lead-in Area

1) Layout of CD-ROM disc

Center hole Clamping and Label Area Information Area

Lead-in Area

Lead-in Area

Diameter 15 mm

Diameter 46 mm

Diameter 120 mm

Program Area

Read Only Disc

Lead-out Area

Program Area Lead-out Area

Center hole

Clamping and Label Area

Information Area

PCA PMA

Test Area Count Area

Diameter 15 mm

Diameter 45 mm

Diameter 120 mm

Unrecorded Disc

Tsl-00:35:65 Tsl-00:15:05

Tsl-00:13:25

Tsl

99:59:74

00:00:00

in out

Test Area : for performing OPC procedures.

Count Area : to find the usable area immediately in T.A

Tsl : start time of the Lead-in Area, as encoded in ATIP

PMA : Program Memory Area

Disc Center

Disc Center

2) Layout of CD-R/RW disc

Page 17

20

8. Function of PCA and PMA area

1) PCA (Power Calibration Area)

• PCA area is used to determine the correct Laser Power for a disc.

– Method 1 : PCA area is divided by a track.

– Method 2 : The previous Calibration value is referred.

– Method 3 : ROPC is used to determine Laser Power value automatically in data writing.

• CD-R Disc can write maximum 99 Tracks but CD-RW Disc can write unlimited tracks because it has a rewritable

function.

2) PMA (Program Memory Area)

• It has a track information (track No, track Start/End time) of every track before writing completed.

– PMA area has the last written point and the next writable point of a disc.

– In case of CD to CD copy, some writer may not write PMA area.

* When Disc is Finalized,

PMA information is transferred to the Lead_In area so that general Driver can read it.

* Because PCA and PMA area exist before Lead-In area, General CD Player or CD-ROM Drive can’t read

these areas.

9. OPC and ROPC

1) OPC (Optimum Power Control)

• This is the first step of writing process, because CD writer has its own laser power value and media have different

writing characteristics,

– This is determined by the Writing characteristic, speed, temperature, and humidity.

– Laser wavelength is determined by the environmental temperature (775~795nm) and Optical Laser Power is

determined by the test and retry.

• Asymmetry and optimum writing Power

– EFM signal Asymmetry is determined by the writing power.

Therefore, Optical Power which has the same value to the preset power value can be estimated by measuring

HF signal Asymmetry on the PCA area.

• Measurement of Asymmetry

* Parameter setting (Beta) : Using AC coupled HF signal before equalization

Beta = (A1+A2)/(A1-A2)

Time

P << Po

Time

P = Po

HF Signal

A1

0

A2

Time

P >> Po

Page 18

21

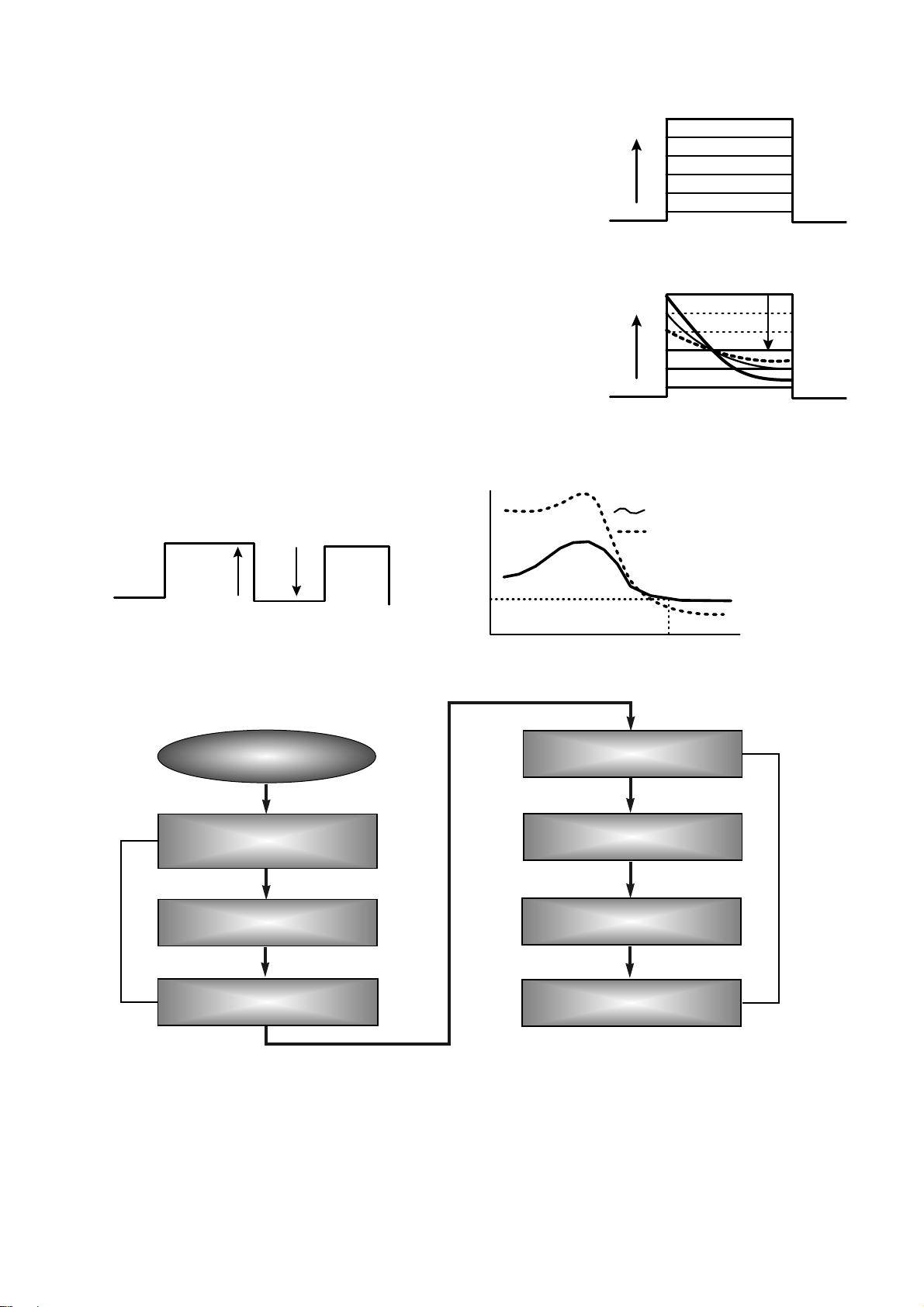

2) ROPC (Running Optimum Power Control)

• Variable primary factor of Optimum Power

– Change of Power sensitivity on the Disc. (limited to 0.05 *Po)

– Wavelength shift of the laser diode due to the operating temperature change.

– Change of the Spot aberration due to the Disc skew,

Substrate thickness, Defocus.

– Change of Disc or Optics conditions due to the long term OPC

==> It is necessary to adjust continuously to obtain the Optimum Power.

• Principle of Running OPC

– To meet the factors mentioned above,

a horizontal _ direction movement of a curve is uesd.

– Beta = f(B-level) = constant on the Recorded Disc

– Procedure of ROPC

a. Reference B-level is determined during OPC Procedure.

b. During Recording, B-level value is controlled to have a close

Reference B-level value.

c. Normalization of B-level is used to eliminate the effect of reflectivity fluctuation.

==> The reflected B-level value is normalized by the disc reflectivity itself.

CD-R/RW Media

Write Strategy

Determination

PCA Test Area

Program Area

PMA Area

Lead-In Area

Lead-out Area

OPC

PCA Count Area

ROPC

* Recording Capacity of CD-R/RW (74Minute Recording media)

• (2048 Byte/Sector) X (75 Sector/Second) X (60 Second/Minute) X 74 Minute

= 681,984,000 Bytes = 682 Mbytes

• But the actual recording capacity is about 650 Mbytes. (according to the ISO 9660 standard, approximately

30 Mbytes are used to make directory structure and volume names.)

Incident recording pulse

Reflected recording pulse

Sampled timing B

11T

Sample B-level (Write Power)

Level B

Sampled at timing B

Pwo decided by OPC

Recording Power

Level B with Pwo

normalized to recording power

Sample Disc Reflectivity

(Read power)

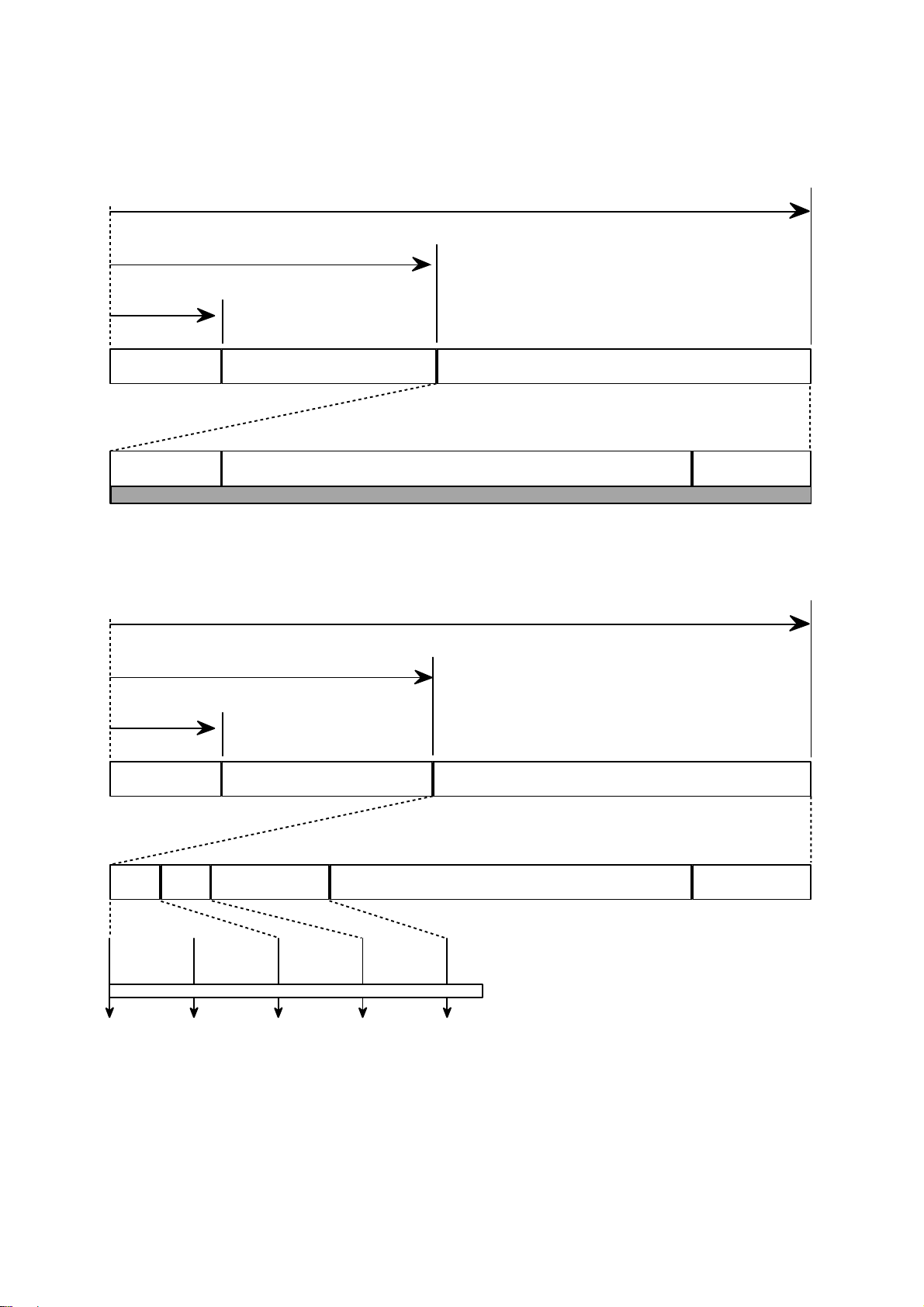

10. Writing Process of DISC

Page 19

22

11. Super Link

Super(SUPpressed Error Recording) link method is a new technology to link the interrupted recording by buffer

under run. When drive¡fls buffer will be under, the drive will stop recording and store the stop position. When

drive¡fls buffer receive data from HOST again, the drive will seek to the stop position of last recording and

continue writing. In the read procedure, the drive can not find any error in the linking area, the data or audio will

be regenerated perfectly.

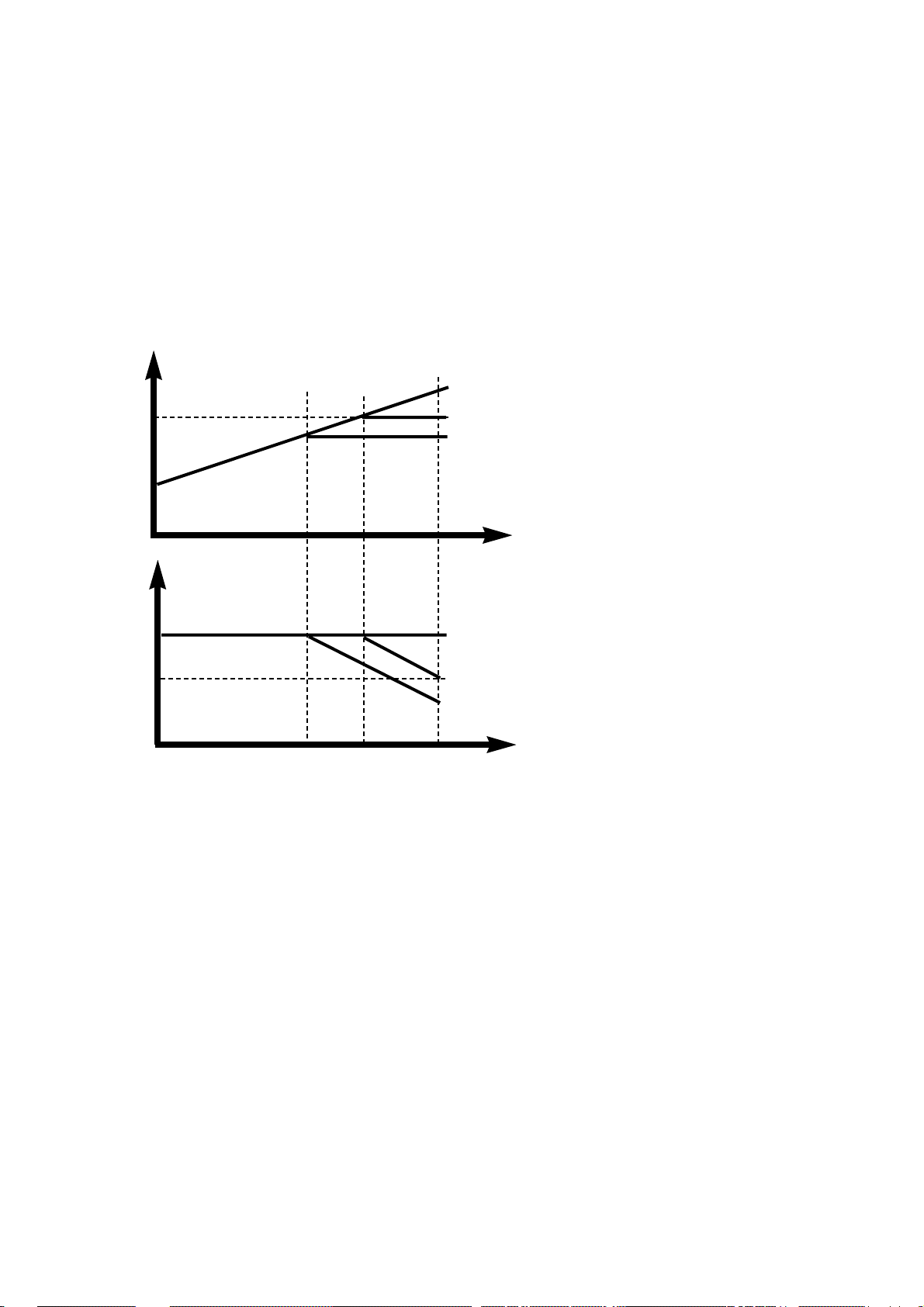

12. Partial CAV Recording

Intial RPM of 52x Full CAV Recording has been considered as 10,200 RPM, 20x to 52x.

13. Optimum record speed

1. All media do not support 52 x Record by media quality.

Even though a CD-R can be recorded by 52x, there is a possibility to occur recording fail during record,

especially in high speed write. Before recording, Drive decides write speed by test. During the high speed

write, Drive checks the record status and control the optimum record speed not to occur record fail. We call

it as ‘Optimum record speed’.

2. During the record, Drive check the ATIP and Servo error. Drive thinks the current record status is unstable,

stops record and decreases a record speed for getting stable record.

( 52x ---> 40x ---> 32x ---> 24x )

1. Micro processor calculates RPM of

Spindle motor by FG signal comes from

Drive IC.

2. Partial CAV : Reference Speed : 52X,

40X, 32x

3. The position of CAV mode is changed

CLV mode, RPM will be reduced.

4. The write power between each

recording speed is changed.

Data

Transfer

Rate

20x

CAV

52x CAV

40x PCAV

32x PCAV

Time

52x CAV

40x PCAV

32x PCAV

0

24min 47min 80min Time

RPM

10,200

8000

Page 20

23

DVD & CD DATA PROCESSING

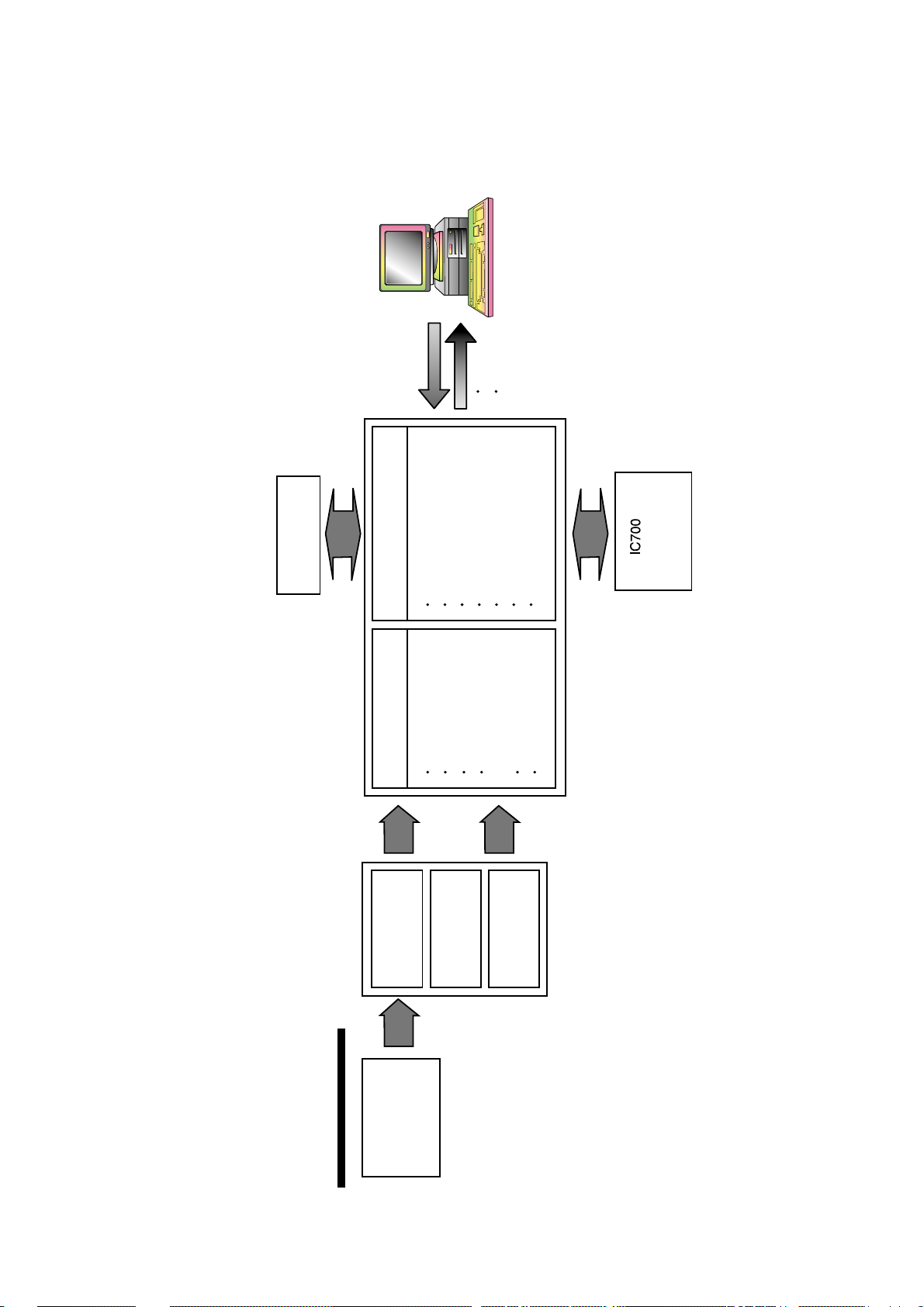

1.Data Processing Flow

Command

Data

Status

RF EQ & AGC

SERVO

DSP

Encoder & Decoder & CSS

RF data slice EFM demodulator

CiRC error correction

Audio DAC

C3 decoder

Buffer/Memory controller

CSS controller

Atapi interface control

Data PLL

Servo ADC

Focus/tracking

control output

Sled control output

CAV Spindle control

P-up

Unit

IC200

RF AMP

(MT1616E)

CD

DVD

IC100

(MT1618E)

TE/CSO GEN

FE GEN

IC500 DRAM

Flash ROM

IC100

(MT1628E)

Page 21

24

MT1628E

HOST DVD

PLAYER

(MPEG2 B/D)

Scrambled MPEG Data

Change the "KEY"

KEY Management Control

2. Copy Protection and Regional Code Management Block

Block Diagram

Brief Process

1. Regional Code for DVD Disc

– DVD-ROM drive transfers the regional code of the control data to host by the command of host, the DVD

player of host reads the regional code, and plays title in the case of allowed regional code only.

2. Management of DVD Disc for the scrambled of data

(1) DVD-ROM and DVD player of host generate the “KEY 1” respectively, transfer to opposite part, the

“KEY 2” is received, recognizes the data transfer or not with this value, and generates the bus key

encoded the data.

(2) Encoded “Disc Key” and “Title Key” host is transfer with the bus Key.

(3) DVD player of host reads the key value, and uses the value to restore the scrambled data.

* Refer to the next page for the details.

Page 22

25

3. About Prevention the DVD-ROM from to be copy

A data is able to encode and record in the disc, if a copyright holder wants to prevent the disc from copying.

In case of a disc enhanced movie of 3 titles......

DISC KEY (2048 Bytes) is used to encode the whole contents in the disc and TITLE

KEY (5 Bytes) is used to encode the title respectively.

So, the data is encoded and stored in a disc through the unknown algorithms

with a disc key and title key. (At this time, the disc key and title key are stored

in a disc.)

…As above, the disc is able to copy when the disc key and title key are

opened.

Then, ROM-DRIVE encodes the disc key and title key and transfers to MPEG2 board.

If you want to play the disc prevented from the copy......

First of all, ROM-DRIVE and MPEG-2 board identify with each other through the procedure as described

below.

1. Drive and host gives and takes the ID of 2bit. This ID is AGID (Authentication Grant ID).

The various decoder boards are attached to the host, in these, AGID sets the MPEG-2 board and drive.

2. After the AGID is set, MPEG-2 board generates the challenge key (10 Byte) and transfers to drive. The

board and drive generate key 1 (5Byte) with the challenge key respectively. (Of course, the Algorithm

generating the key 1 is not known.)

3. Compare with the generated key 1, if it corresponds each other, the first step of authentication is

completed. This is a course to identify the MPEG-2 board with a drive.

4. The second step of authentication is a course to identify a drive with the MPEG-2 board.

The dirve generates a challenge key and transfers it to the MPEG-2 board. The dirve and MPEG-2 board

generate the key 2 (5Byte) with the challenge key, compare with each other, and if it corresponds and the

secondary step of authentication is completed.

5. As above, the identification is completed.

6. The dirve and MPEG-2 board generate the Bus key with the key 1 and key 2 and own it.

7. Dirve encodes the disc key and title key with this Bus key and transfers to the MPEG-2 board.

8. The MPEG-2 board reads the encoded disc key and title key with the Bus key only.

9. MPEG-2 board lets data read from the drive to decode with the read disc key and title key and makes into

the video signal by decoding.

ROM-DRIVE

AGID

HOST

MPEG-2

BOARD

Challenge key

encoded disc key, title key

Page 23

26

4.About the DVD-ROM Regional Code

DISC ROM - DRIVE MPEG-2 BOARD VGA CARD

MONITOR

1

CAN

U.S.A

MIX

CUB

BHS

PRI. VIR

1

BMG

GRL

2

2

ZAF

ISO

SWZ

FIN

POI

FST

LTU

BIR

UKR

TUR

FGY

JRN

TKM

AFG

PAK

CHN

MMR

MNG

RUS

KOR

JPN

HKG

MAC

TWN

PHL

6

3

2

1

5

5

4

1

MDI

MNP

GUM

PLW

PNG

NZL

AUS

4

The disc has

the regional

code of 8 bit.

Example)

The disc

manufactured

in the U.S.A,

has the

number one.

Transfer to

MPEG-2 board

reading the

regional code.

Receiving

data from the

MPEG-2

board and

output

through the

monitor

If the board is setting to the regional

code 1 for the U.S.A. ...

Check the received regional code to

number 1, all or not, transfer the

data to VGA card in accordance with

only a case among the three case.

Regional code

Page 24

INTERNAL STRUCTURE OF THE PICK-UP

1.Block Diagram of the PICK-UP

27

ACZ1007Y-301-B

L1

C14

38k

VR2

DW

C

A9

R13

R12

R11

R10

R5R4R3

R2 2.2K

2.2K

2.2K

2.2K

O

O

O

O

A3

RF- SW

RF+ EF3

EF2 C

BVC

A VCC

EF1 D

EF4 GND

PH974

78

91011

12

13

14

C11

C4 C5 C6 C7

C9

CD LD

G

A2

LD PD

C10

1n

R8

R9

NCP15XH1D3J03

O

R7

C8

3.9K

0.1u

R6

AK8911

PNA4SB7F

ACTUATOR

TILT- J1-40

TILT+ J1-39

T- J1-38

T+ J1-37

F- J1-36

F+ J1-35

GND(FM) J1-34

FM J1-33

VREF(FM) J1-32

OSCEN J1-31

ENABLE J1-30

EDIS J1-29

RDIS J1-28

W2DIS J1-27

W1DIS J1-26

GND(LD_HF) J1-25

W2SET J1-24

W1SET J1-23

ESET J1-22

RSET J1-21

TEMP J1-20

Vcc(HF) J1-19

Vcc(LD, FM) J1-18

VR J1-17

PD J1-16

LD J1-15

Vcc(OEIC) J1-14

GND(OEIC) J1-13

RF- J1-12

RF+ J1-11

EF2 J1-10

B J1-9

A J1-8

EF1 J1-7

EF4 J1-6

C J1-5

D J1-4

EF3 J1-3

SW J1-2

Vc(OEIC) J1-1

A1

A7

220p 220p 220p 220p

2.7K

0.1u

1234567

16151413121110

9

8

DR14

22

R1

VR1

470

CW

RDIS EDIS

RSET VDD

ESET LD

FADJ VSS

W1SET AADJ

W2SET ENABLE

W1DIS OSCEN

W2DIS

GND

34

25

1

C3C2

0.1u 0.1u

6

IVOT

VREF IN

VCC OUT

VOD

0.1u

0.1u

C12

65432

1

R15

o

3

A8

HFM-1001

4

GND

VCC

GND GND

LD

GND

5

6

2

1

C13

0.1u

DVD LD

LD

PD

0.1u

Page 25

2.Pick up Pin Assignment

28

No. Signal Name I/O Signal Description

1 Vc(OEIC) I reference voltage input for OEIC (+2.3V)

2 SW I gain swich for signal OEIC output (Gain 8.7dB)

3 EF3 O signal OEIC output EF3

4 D O signal OEIC output D

5 C O signal OEIC output C

6 EF4 O signal OEIC output EF4

7 EF1 O signal OEIC output EF1

8 A O signal OEIC output A

9 B O signal OEIC output B

10 EF2 O signal OEIC output EF2

11 RF+ O signal OEIC output RF+

12 RF- O signal OEIC output RF13 GND(OEIC) ground connection for OEIC

14 Vcc(OEIC) I Power supply for HF signal and OEIC

15 LD I input current for driving Laser Diode

16 PD O output current of Laser Diode power monitor for APC amplifier

17 VR O output voltage of controlling signal level of Laser Diode for APC

18 VCC(LD.FM) I power supply for LD (+5V) and FM

19 VCC(HF) I power supply for HF (+5V)

20 TEMP O output voltage for controlling temperature

21 RSET I input voltage for current amplifier

22 ESET I input voltage for current amplifier

23 W1SET I input voltage for current amplifier

24 W2SET I input voltage for current amplifier

25 GND(LD, HF) ground connection for LD-IC and HF signal

26 W1DIS I Digital control of channel W1SET (low active)

27 W2DIS I Digital control of channel W2SET (low active)

28 RDIS I Digital control of channel RSET (low active)

29 EDIS I Digital control of channel ESET (low active)

30 ENABLE I Enables output current (high active)

31 OSCEN I Oscilator shutdown (OSCEN Low=oscillator off, Floats Low)

32 VREF(FM) I reference voltage input for FM

33 FM O APC amplifier output

34 GND(FM) ground connection for FM

35 AF+ I focusing Actuator drive signal +

36 AF- I focusing Actuator drive signal 37 TR+ I tracking Actuator drive singal +

38 TR- I tracking Actuator drive signal 39 TILT+ I Tilting Actuator drive signal +

40 TILT- I Tilting Actuator drive signal -

ENBLE RDIS EDIS W1DIS W2DIS

0XXXX

11111

10111

11011

11101

11110

ENBLE RDIS EDIS W1DIS W2DIS OSCEN OSCILATOR

0XXX XXOFF

1 1 1 1 1 X OFF

1000 00OFF

1000 01 ON

IOUT CONTROL

OSCILLATOR CONTROL

X : Don’t care

Page 26

3.Signal detection of the P/U

1) Focus Error Signal ==> (A+C)-(B+D)

This signal is generated in RF IC (IC200 : MT1616E) and controls the pick-up’s up and down to focus on

Disc.

2) Tracking Error Signal (DPP Method) ==> {(A+D)-(B+C)}- k x {(EF1+EF4)-(EF2+EF3)}

This signal is generated in RF IC (IC200 : MT1616E) and controls the pick-up’s left and right shift to find

to track on Disc.

3) RF Signal ==> (A+B+C+D)

This signal is converted to DATA signal in DSP IC (IC100 : MT1628E).

29

Pick-Up module

Photo Diode

Tracking

Focusing

Infrared Iaser

k[(F+H) - (E+G)]

(A+D) - (B+C)

(A+D) - (B+C) - k[(F+H) - (E+G)]

Offset

TE

Tp

Sub2

Main

Tp/2

Sub1

T rac k Center

F,E

D,C

A,B

H,G

Page 27

DESCRIPTION OF CIRCUIT

1. ALPC (Automatic Laser Power Control) Circuit

1-1. Block Diagram

30

MT1628E

Write

Strategy

Write

S/H Signal

Micro

Processor

IC 100

CN 101

IC200 (

MT1616E)

Optical

Pick-up

LPC-711A

LD

Drive

33 114

113

FPDO

FPDOLP

10523

VWDC1O

VWDC1

10624

VWDC2O

VWDC2

61 177

WLDON

59

179

RLDON

10421

VRDCO

RREF

VRDC

58

181

RFPDSH

S/H &

VRDCG &

Level Shift

60

S/H &

VWDC1G &

Level Shift

VWDC1

DAC

& Gain

WFPDSH

178

WDAC2

&

Amplifier

WDAC1

& x1/x2

RDAC

VRDC

DAC

& Gain

32 112

FVREF

+

-

-

+

1-2. APC (Automatic Power Control) Block

APC (Automatic Power Control) function in CD-R/RW analog front-end is used for constant power level control

purpose. Based on the accurate power sensor (FMD) in PUH, APC feedback loop maintains constant power level against

laser diode’s temperature variation.

There are three power control loops in MT1616, two for CD and one for DVD, which are used with different combination

for different applications. Generally, the first APC loop is used for read-power control. The second APC loop is used for write

(erase) power control for CD-R (CD-RW) disc. And the third APC loop is used for DVD read power control.

Owing to the small signal level in read-power control mode, the first APC loop amplifies (x5/x10/x15/x20) the FMD

signal (FPDO) to enhance the accuracy of read power control. The register VRDCG[1:0] is used to adjust the gain of FMD

signal. The registers RDAC[7:0] and VBDAC[7:0] will set the read power level at the built-in 8-bit DAC (RDAC). The second

APC loop is used for high power control. The built-in 10-bits DAC(WDAC1) is used to set the wanted power level. And the

register VWDC1G is employed to adjust the gain of FMD signal.

The following potentiometers (VRDCDAC, VWDC1DAC, and VWDC2DAC) and amplifiers (VRDCDAG, VWDC1DAG,

and WDAC2G) are used to set the wanted levels of VRDCO, VWDC1O, and VWDC2O. Moreover, the input source of the

VWDC2O path can be fed from the output of VWDC1O or directly programmed by the built-in 10-bit DAC (VWDC2DAC).

Moreover, the input signal FPDO (form CD FMD) after low-pass filtering $ amplification (x1 or x2) will send the

MPXOUT2 for monitoring.

Furthermore, the third loop is used for DVD read power control loop. Read power level is adjusted by the RREF voltage

set in the first APC loop.

Page 28

2. Focus/Tracking/Sled Servo Circuit

2-1. Focus, T racking & Sled Servo Process

31

Focus, Tracking Servo

C

B

D

A

F1

F2

F4

F3

E1

E2

E4

E3

Pick- up

A,B,C,D,E, F,G,H

A,B,C,D

Focus Error

Detector

Track Error

Detector

A,B,C,D

E,F,G,H

IC200 MT1616E

FE

TE

TE FE

A/D

PARALLEL

DIGITAL

COMPENSATOR

DAC

SLED

COMPENSATOR

PWM

FMSO

FMSO2

IC100

Servo Control

MT1618E

Tracking x5

Focus x5

Tracking Focus ing

Actuator

FOSO

TRSO

F+

F-

T+

T-

Sled Control

M

Stepping Control

Logic

SL1+

IC300

M63028FP

SL1SL2SL2+

IC300 M63028FP

27 12

28 13

18

14

1

2

MT1628E

Page 29

3. Spindle Servo Circuit

3-1. Spindle Servo Process

3-2. Spindle Servo

Spindle servo is as followings;

1)Wobble CLV x4, x8, x10,x16, x24, x32,x40 : Blank area in CD-R, CD-RW.

2)CD 10x CAV: Eccentric CD-R/RW, Video CD, CD-Audio Analog.

3)CD 40x CAV: Recorded area in CD-R/RW, CD-Adio Digital.

4) CD 52x CAV : CD-ROM

5) DVD 6x CAV: DVD+RW, DVD-R, DVD-RW

6)DVD 8x CAV: Dual Layer DVD-ROM, Single Layer DVD-ROM(Movie)

– Spindle Servo is controlled by IC100(MT1628E) and servo signal is output via DMO (pin 17).

7) DVD 16x CAV : Single Layer DVD-ROM (Data)

32

A

B

DC

E1 E2

E4 E3

F1 F2

F4 F3

Pick- up

IC200 MT1616E

Wobble Signal

Generator

RF

SRF

EFM

WOBSI

Decode PLL

Frequency

Controller

CD-DSP/SERVO

LOCK

DEFS

MOTOR SPEE D

CONTROLLER

174

FILTER

TON

DMSO

ATIP CLV, FG

Level Shift

Hall Sensor

M

Spindle Motor

SPNON

SPNFG

REVDEF

IC100 MT1618E

IC301 HD153704

CD WOBBLE CLV

FG CAV 40X

6

8

IC300 M63028FP

40

65

17

55

6364

MT1628E

48X

Page 30

MAJOR IC INTERNAL BLOCK DIAGRAM AND PIN DESCRIPTION

IC200 (MT1616E) : RF AMP

Pin Assignment

33

ATFG

GIO2

EEP_CS

EEP_SCLK

EEP_SDATA

DRVOUT0

DRVOUT1

DRVOUT2

FR

LIMIT#

LED2

LED1

TRAYIN#

TRAYOUT#

ENBL

GIO1

SUBGND1

AVSS3

AGC3C

AGC2C

AGC1C

AVDD3

AVDD6

VREF

V14

V28

VHAVC

VFVREF

AVSS6

MPXOUT2

MPXOUT1

RRFXLP

AUX1

AUX2

DVDMDI

DVDLDO

VDAC0

VDAC1

OSCL1CP

OSCL1CN

RFAGCI

RFAGCU

RFAGC

EQBIAS

AVSS4

RFON

RFOP

AVDD4

RFIN

RFIP

AVDD7

DVDA

DVDB

DVDC

DVDD

AVSS7

RRFSUM

AVDD5

RRF/WRF

AVSS5

WRFSUM

HTRLP

AVDD1

INA

INB

INC

IND

HAVC

AVSS1

TRINA

TRINB

TRINC

TRIND

INE

INF

ING

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

GIO3

XRST#

WBLCLK

WLDON/IDGATE

WFPDSH

RLDON/UDGATE

RFPDSH

H11T/VF013

DVSS1

MCLK

DVDD1

XLAT

SCLK

SD ATA

ASPREQ

LRFZC/BLANK

DVDD2

SRVSH

HTRC/PHTO

WBLSH

DVSS2

GIO4

RFSUBO

SUBGND2

OSCL2CP

OSCL2CN

AVSS2

VRDC0

VWDC1O

VWDC2O

AVDD2

VRDCN

VRDC

VWDC1N

VWDC1

FVREF

FPDOLP

FPDO

SHBC

SHPC

PHTIN

DFCTLP

SBAD/RFLVL

TEIN

TE

CE

FE

DRCO2

DRCO

FOIN

FOIP

INH

64636261605958575655545352515049484746

45

44

43

424140

39

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

MT1616

COMBI RF IC

Page 31

Block Diagram

34

RRFSUM

RRF/WRF

VRDCO

VWDC1O

VWDC2O

VRDC

FPDOLP

RFON

RFAGCI

RFIN

RFIP

RFAGCU

RFAGC

RFOP

EQBIAS

OSCL1CP

OSCL1CN

OSCL2 CP

OSCL2 CN

A

B

C

D

HAVC

SERVO

&

Detection

A

B

C

D

HAVC

GAINUP

RRFXLP

RRFX

GAINUP

A

B

C

D

HAVC

RRF

APC

RFZC1

MCLK

MPX1

MPX2

VCON

RRFX

ADBCO

BC O

ADO

FPDOX

TELP

MPPO

SPPO

DRCO

RFRP

MPX1

TZC

MPX2

MPX1

P/H

B/H

x1

ASH

BSH

DSH

ESH

CSH

FSH

GSH

HSH

MPX2

MPX2B

VRDCB

VWDC1B

WREF1

RREF

WRFSH

AUX1

AUX2

ADBCO

ADO

BC O

SF E O

MPPO

SBADO

SPPO

S/H

&

MATRIX

RECDIN

TE

FE

CE

TESTM2

SBADOLP

VCON

MPXOUT2

MPXOUT1

MPX2B

ATFG

AGC3C

AGC2C

AGC1C

WBLCLK

VREFMPX

TESTM1

D RCSO

DRCMO

RRFX LP

H11T/VFO1 3

ATIP/

Wobble

10-Bit

ADC

SBAD/RFLVL

AUX2

AUX1

WRFSUM

FE

DRCO2

CE

TE

SBAD/RFLVL

TEIN

DEFECT

RFZC1

TZC

DFCTLP

FOIP

FOIN

HAVC

WBLSH

SRVSH

DRCO

MFEO

LRFZC/BLANK

SHPC

SHBC

PHTIN

HTRC/PHTO

HTRLP

VWDC1

VWDC1N

FPDO

FVREF

VRDCN

DVDLDO

DVDMDI

RFPDSH

WFPDSH

RLDON/UDGATE

WLDON/IDGATE

WRF

AVDD1

AVSS1

AVDD2

AVSS2

AVDD3

AVSS3

AVDD4

AVSS4

AVDD5

AVSS5

AVDD6

AVSS6

AVDD7

AVSS7

DVDD1

DVSS1

DVDD2

DVSS2

DVDD

SUBGND1/2

Voltage

Ref & DAC

DPFO

DPFO

DVDC

DVDB

DVDA

TRINA

TRINB

TRINC

TRIND

RFSUBO

DIG.

REG.

ING

INC

INB

INA

IND

INE

INH

INF

DPD

EQRF RRF

ROPC

DEFECT

RFRPLP

ATFMX

FPDO

ADO

DPFO

HRFRP

WRFX

MDG/LDO

GDAC0

HTRL PA

FELP

DFCTIN

HTE

VRDCO

VWDC1O

VWDC2O

BCO

TRAYOUT#

TRAYIN#

LED1

LED2

LIMIT#

FR

DRVOUT2

DRVOUT1

DRVOUT0

EEP_SDATA

EEP_SCLK

EEP_CS

ENBL

ASPREQ

GIO1~GIO4

General

I/O

SDATA

XLAT

SCLK

XRST#

VDA C1

VDAC0

VRE F

VFVREF

V14

VHA VC

V28

Page 32

35

• Pin Description

Pin

Numbers

Symbol Type Description

RF Signals & S/H Control Pulses

9 HAVC Analog Output Decoupling Pin for Reference Voltage of Main and Sub Beams

13 INA Analog Input Input of Main Beam Signal (A)

12 INB Analog Input Input of Main Beam Signal (B)

11 INC Analog Input Input of Main Beam Signal (C)

10 IND Analog Input Input of Main Beam Signal (D)

3 INE Analog Input Input of Sub-Beam Signal (E)

2 IN F Analog Input Input of Sub-Beam Signal (F)

1 IN G Analog Input Input of Sub-Beam Signal (G)

128 INH Analog Input Input of Sub-Beam Signal (H)

27 RFIP Analog Input Differential Input of AC Coupling RF SUM Signal (Positive)

28 RFIN Analog Input Differential Input of AC Coupling RF SUM Signal (Negative)

20 RRFSUM Analog Input DC Input of RRF SUM signal for CD

16 WRFSUM Analog Input DC Input of WRF SUM signal for CD

25 DVDA Analog Input Input of AC coupled DVD RF signal (A)

24 DVDB Analog Input Input of AC coupled DVD RF signal (B)

23 DVDC Analog Input Input of AC coupled DVD RF signal (C)

22 DVDD Analog Input Input of AC coupled DVD RF signal (D)

7 TRINA Analog Input Input of Tracking Signal (A)

6 TRINB Analog Input Input of Tracking Signal (B)

5 TRINC Analog Input Input of Tracking Signal (C)

4 TRIND Analog Input Input of Tracking Signal (D)

127 FOIP Analog Input Input of Focusing Signal (Positive)

126 FOIN Analog Input Input of Focusing Signal (Negative)

47 SRVSH

Digital Input (TTL),

SMT

S/H Control Pulse of Main and Side Beam Signals

45 WBLSH

Digital Input (TTL),

SMT

S/H Control Pulse of Wobble Signal

Focus/Tracking Error & Servo Control Signals

125 DRCO Analog Output Output of Differential Radial Contrast (DRC) Signal

124 DRCO2 Analog Input Re-Input of Differential Radial Contrast (DRC) Signal

123 FE Analog Output Output of Focusing Error (FE) Signal

121 TE Analog Output Output of Tracking Error (TE) Signal

122 CE Analog Output Output of Center Error (CE) Signal

119 SBAD /RFLVL Analog Output

(1). Output of SBAD Signal

(2). RF Level Output

120 TEIN Analog Input Input of Out-of-Track Detection Circuit

118 DFCTLP Analog Output Low Pass Filter Capacitor Connecting for DEFECT Detection

116 SHPC Analog Output External Capacitor Connection for Peak Hold of RFRP Signal

115 SHBC Analog Output External Capacitor Connection for Bottom Hold of RFRP Signal

42 RFSUBO Analog Output Header Push-Pull RF Output Signal

49 LRFZC/BLANK

4 mA Driving

(1). Output of RF Zero Crossing Binary Signal

(2). Output of Blank Signal

117 PHTIN Analog Input Input of Comparator for Photo Interrupt Signal

15 HTRLP Analog Output Low Pass Filter Capacitor Connecting for HTRC Detection

Digital Output (TTL),

Page 33

36

Pin

Numbers

Symbol Type Description

46 HTRC/PHTO

Digital Output (TTL),

4 mA Driving

(1). High Speed Track Counting Digital Output

(2). Output of Photo Interrupt Signal

EQRF Circuits

33 EQBIAS Analog Output External Bias Connection for Circuits in EQRF Block

38 OSCL1CP Analog Output

External Capacitor Connection of Offset Cancellation Loop1 for

VGA in EQRF Block (Positive)

37 OSCL1CN Analog Output

External Capacitor Connection of Offset Cancellation Loop1 for

VGA in EQRF block (Negative)

36 RFAGCI Analog Output RF AGC Loop Capacitor Connecting for DVD-RAM

35 RFAGCU Analog Output RF AGC Loop Capacitor Connecting for DVD-RAM

34 RFAGC Analog Output External Capacitor Connection for RF AGC in EQRF Block

30 RFOP Analog Output Differential Output of RF Signal (Positive)

31 RFON Analog Output Differential Output of RF Signal (Negative)

40 OSCL2CP Analog Output

External Capacitor Connection of Offset Cancellation Loop2 for

Equalizer Output (Positive)

39 OSCL2CN Analog Output

External Capacitor Connection of Offset Cancellation Loop2 for

Equalizer Output (Negative)

RRF & ROPC (Running OPC) Related Signals

18 RRF/WRF Analog Output Output of Read RF (RRF) or Write RF (WRF) Signal

96 RRFXLP Analog Output Low Pass Output of RRF Signal

57 H11T/VFO13

Digital Input (TTL),

SMT

(1). S/H Control Pulse of WRF Signal

(2). DVD-RAM Header Signal

ATIP (Absolute Time In Pre-groove)

85 AGC1C Analog Output External Capacitor Connection of AGC1 in ATIP Block

84 AGC2C Analog Output External Capacitor Connection of AGC2 in ATIP Block

83 AGC3C Analog Output External Capacitor Connection of AGC3 in ATIP Block

65 ATFG

4 mA Driving

Digital Output of Wobble Signal after Slicing

62 WBLCLK

Digital Input (TTL),

SMT

External Clock Input for Wobble BPF (SCF)

APC (Auto Power Control for Laser)

114 FPDO Analog Input Laser Power Monitor Input for CD APC

113 FPDOLP Analog Output Low Pass Output of FPDO Signal

112 FVREF Analog Input Reference Voltage of CD APC Loops

59

RLDON/

UDGATE

Digital Input (TTL)

(1). Laser Diode Control for CD-ROM/R/RW Read Mode

(2). Control Signal for DVD-RAM Read

61

WLDON/

IDGATE

Digital Input (TTL)

(1). Laser Diode Control for CD-R/RW Write Mode

(2). Control Signal for DVD-RAM Read

58 RFPDSH

Digital Input (TTL),

SMT

S/H Control Pulse for CD-ROM/R/RW Read APC

60 WFPDSH

Digital Input (TTL),

SMT

S/H Control Pulse for CD-R/RW Write APC

108 VRDCN Analog Input Vin(-) of Midcourse Amplifier for CD Read APC Loop

109 VRDC Analog Output Midcourse Output of Laser Diode Control in CD Read Mode

104 VRDCO Analog Output Output Voltage of Laser Diode Control in CD Read APC

110 VWDC1N Analog Input Vin(- ) of Midcourse Amplifier for CD-R/RW Write APC

Digital Output (TTL),

Page 34

37

Pin

Numbers

Symbol Type Description

111 VWDC1 Analog Output Midcourse Output of Laser Diode Control in CD-R/RW Write APC

105 VWDC1O Analog Output Output Voltage 1 of Laser Diode Control in CD-R/RW Write APC

106 VWDC2O Analog Output Output Voltage 2 of Laser Diode Control in CD-R/RW Write APC

99 DVDMDI Analog Input Laser Power Monitor Input for DVD APC

100 DVDLDO An alog Output Laser Driver Output of DVD APC

Reference Voltages & DACs

91 VHAVC Analog Output Output of Voltage Reference (2.0V/2.1V/2.2V/2.5V)

88 VREF Analog Output Decoupling Pin for Internal Voltage Reference (2.0V)

89 V14 Analog Output Output of Voltage Reference (1.4V)

90 V28 Analog Output Output of Voltage Reference (2.8V)

92 VFVREF Analog Output Output of Voltage Reference (2.5V/2.7V/2.8V/3.0V)

101 VDAC0 Analog I/O Output General 8-Bit DAC

102 VDAC1 Analog Output Output of General 10-Bit DAC

MPXOUT (Multiplexer Circuit for Various Signals) and Testing Interface

97 AUX1 Analog Input Auxiliary Input 1 for Signal Monitoring

98 AUX2 Analog Input Auxiliary Input 2 for Signal Monitoring

95 MPXOUT1 Analog Output Multiplexer Output 1 for Signal Monitoring

94 MPXOUT2 Analog Output Multiplexer Output 2 for Signal Monitoring

Serial Interface & Other Digital Control Signals

50 ASPREQ

4 mA Driving

ASP Request Signal Output to MT1618 for Sending Control Signals

via Serial Interface.

52 SCLK

Digital Input (TTL),

SMT

Clock Input for Register Setting

51 SDATA

Digital I/O (TTL),

4 mA Driving

Data Input/Output for Register Setting

53 XLAT

Digital Input (TTL),

SMT

Latch Input for Register Setting

63 XRST#

Digital Input (TTL),

SMT

Digital Input for Register Resetting, Active Low.

55 MCLK

Digital Input (TTL),

SMT

Digital Input of Main Clock

77 TRAYIN#

Digital Input (TTL),

50K Pull-Up, SMT

Tray_is_in Input, A Logical Low Indicates the Tray is IN.

Feedback Flag is from Tray Connector.

78 TRAYOUT#

Digital Input (TTL),

50K Pull-Up, SMT

Tray_is_out Input. A Logical Low Indicates the Tray is OUT.

Feedback Flag is from Tray Connector.

74 LIMIT#

Digital Input (TTL),

50K Pull-Up, SMT

Sledge Inner Limit Input, Active Low.

73 FR

Digital Input (TTL),

SMT

Spindle Motor Reverse Detection Input.

76 LED1

4 mA Driving

LED Control Output. Initial 0 Output.

75 LED2

4 mA Driving

LED Control Output. Initial 0 Output.

72 DRVOUT2

4 mA Driving

Motor Drive Control Signal-2. Initial 0 Output.

71 DRVOUT1

4 mA Driving

Motor Drive Control Signal-1. Initial 0 Output.

70 DRVOUT0

4 mA Driving

Motor Drive Control Signal-0. Initial 1 Output.

Digital Output (TTL),

Digital Output (TTL),

Digital Output (TTL),

Digital Output (TTL),

Digital Output (TTL),

Digital Output (TTL),

Page 35

38

Pin

Numbers

Symbol Type Description

67 EEP_CS

Digital Output (TTL),

4 mA Driving

EEPROM Chip Select Output.

68 EEP_SCLK

4 mA Driving

EEPROM Transmit Clock Output.

69 EEP_SDATA

Digital I/O (TTL),

50K Pull-Down,

4mA Driving

EEPROM Transmit Data Input/Output.

79 ENBL

Digital Output (TTL),

4 mA Driving

Laser Diode Enable Signal Output.

80 GIO1

Digital I/O (TTL),

50K Pull-Up,

4 mA Driving

General I/O 1 for Mass Production Use (Initial Input Mode)

66 GIO2

Digital I/O (TTL),

50K Pull-Up,

4 mA Driving

General I/O 2 for Mass Production Use (Initial Input Mode)

64 GIO3

Digital I/O (TTL),

50K Pull-Up,

4 mA Driving

General I/O 3 for Mass Production Use (Initial Input Mode)

43

GIO4

Digital I/O (TTL),

50K Pull-Up,

4 mA Driving

General I/O 4 for Mass Production Use (Initial Input Mode)

Power Supplies

81 SUBGND1 Analog Ground Ground Pin for Substrate Bias of Internal Digital Circuitry

41 SUBGND2 Analog Ground Ground Pin for Substrate Bias of Internal Digital Circuitry

14 AVDD1 Analog Power Power Pin for Internal Analog Circuitry (5V)

8 AVSS1 Analog Ground Ground Pin for Internal Analog Circuitry

107 AVDD2 Analog Power Power Pin for Internal Analog Circuitry(5V)

103 AVSS2 Analog Ground Ground Pin for Internal Analog Circuitry

86 AVDD3 Analog Power Power Pin for Internal Analog Circuitry (5V)

82 AVSS3 Analog Ground Ground Pin for Internal Analog Circuitry

29 AVDD4 Analog Power Power Pin for Internal Analog Circuitry (5V)

32 AVSS4 Analog Ground Ground Pin for Internal Analog Circuitry

19 AVDD5 Analog Power Power Pin for Internal Analog Circuitry (5V)

17 AVSS5 Analog Ground Ground Pin for Internal Analog Circuitry

87 AVDD6 Analog Power Power Pin for Internal Analog Circuitry (5V)

93 AVSS6 Analog Ground Ground Pin for Internal Analog Circuitry

26 AVDD7 Analog Power Power Pin for Internal Analog Circuitry (5V)

21 AVSS7 Analog Ground Ground Pin for Internal Analog Circuitry

54 DVDD1 Digital Power Power Pin for Internal Digital Circuitry (5V)

56 DVSS1 Digital Ground Ground Pin for Internal Digital Circuitry

48 DVDD2 Digital Power Power Pin for Digital I/O Pads Buffer Circuitry (5V)

44 DVSS2 Digital Ground Ground Pin for Digital I/O Pads Buffer Circuitry

Digital Output (TTL),

Page 36

IC100 (MT1628E) : Encoder, Decoder & DSP Signal Processor

Pin Diagram

39

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

IREF

PLLVSS

LPIOP

LPIOP

LPFON

LPFIP

LPFIN

LPFOP

JITFO

JITFN

PLLVDD33

FOO

TRO

FMO2

PWMOUT

DVDD25

DMO

FMO

TRAYPWM

FG

DVSS

EJECT#

PLAY#

UP3_0

UP3_1

UP3_2

DVDD33

UP3_3

UP3_6

UP3_7

DVSS

WXR

ODON

OSCEN

CMOD

CFREQ

DVDD25

UA0

UA1

DVSS

UA2

UA3

UA4

UA5

UA6

UA7

UALE

DVDD33(4)

UP2_4

UP2_7

UP1_0

EFMPLLVSS

EFMLPFGND

EFMVCOCIN

IPLLVSS

HD9

HD5

HD10

HD4

DVDD33(4)

HD11

HD3

DVSS

HD12

HD2

HD13

HD1

HD14

HD0

HD15

DMARQ

DIOW#

DIOR#

IORDY

DVDD33

DMACK#

INTRQ

DVSS

IOCS16#

HA1

DVDD25

PDIAG#

HA0

DVSS

HA2

CS1FX#

CS3FX#

DASP#

DEVSEL

DACVDD33

RQ

DACVREF

LO

DACVSS

ADGO

RA4

RA5

RA6

RA7

RA8

RA9

RA11

CKE

CLK

CASH#/RWEH#

DVDD33

RD8

RD9

54

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

RFIP

RFIN

RFDTSLVN

SCOP

SCON

RFDTSLVP

ADCVDD33

AMOP

RFLEVEL

FEI

CSO

TEI

TEZISLV

RFSUBI

ADIN

ADCVSS

AMON

PWM2VREF

PWMVREF

DVDD33

GIO3

WBLSH

HRFZC

SRVSH

LRFZC/BLANK

ASPREQ

XD ATA

DVDD33

XCLK

XLAT#

DVDD25

XTALI

XTALO

DVSS

H11T/FO13

RFPDSH

DVSS

RLDON/ICE

WFPDSH

WLDON/1DGATE

WBLCLK

XRST#

WBLSI

PRST

TEST

HRST#

GIO2

GIO1

GIO0

HD7

HD8

DVDDSS

HD8

IPLLVDD33

EFMPLLVDD33

UP1_2

FLASH_WE#

DVDD33

UP1_1

UP2_6

DVSS

UP2_5

UP2_0

UP2_1

UP2_3

UPSEN#

UP2_2

FLASH_CS#

UP0_7

UP0_6

UP0_5

UP0_4

UP0_3

UP0_2

UP0_1

UP0_0

RA3

RA2

RA1

DVDD33

RA0

RA10

DVDD25

BA1

BA0

DVSS

ROE#

RAS#

DVSS

CASL#

RWE#

DQML

RD7

RD6

DVDD33(4)

RD5

RD4

RD3

RD2

RD1

RD0

RD15

RD14

RD13

DVSS

RD12

RD11

RD10

216

215

214

213

212

211

210

209

208

207

206

205

204

203

202

201

200

199

198

197

196

195

194

193

192

191

190

189

188

187

186

185

184

183

182

181

180

179

178

177

176

175

174

173

172

171

170

169

168

167

166

165

164

163

555657585960616263646566676869707172737475767778798081828384858687888990919293949596979899

100

101

102

103

104

105

106

107

108

MT1618

MT1628E

Page 37

Functional Block Diagram

40

Data

Slicer

Data

PLL

Sync.

Protection

PWM

DAC

RFZC/

TEZC

Circuit

Servo

ADC

RDM &

PWM DAC

ASP

Control

Interface

OPC/ROPC

Computation

Unit

Laser Power

Control

Logic

Time to

Digital

Converter

Audio/Effect

Interface

CDROM

High-speed

Audio Playback

Host

Data

FIFO

ATAPI

Packet

FIFO

3K

SRAM

Key/LED

Interface

Host Interface

8032

Micro-controller

Audio DAC

Audio

Digital Out

Servo

DSP

CLV/CAV

Controller

CIRC/RSPC

Error Corrector

Wobble

Spindle

Control

Wobble Signal

Interface Logic

EFMPLL

(efmclk

synthesizer)

Reset

logic

TEST

H11T

SRVSH

WBLSH

RFPDSH

WFPDSH

WLDON

RLDON

ODON

OSCEN

CMOD

CFREQ

WXR

EFMPLLVSS

EFMLPFGND

EFMVCOIN

EFMPLLVDD33

WBLCLK

WBLS1

RFSUB1

RFIP

RFIN

WBLS1

SCOP

RFDTSLVN

RFDTSLVP

PLLVDD33

IREF

LPFIN

LPFIP

PLLVSS

JITFN

LPFON

LPFOP

LPION

LPIOP

JITFO

DMO

FG

TEZISLV

TEI

HRFZC

ADCVDD33

FEI

TEI

CSO

RPLEVEL

ADCVSS

FOO

TRO

FMO

FMO2

PWMOUT

PWM2VREF

PWMVREF

XRST#

XLCK

XLAT#

XDATA

GIO

LO

DACVREF

RO

DACVDD33

DACVSS

ADGO

HD[15:0]

PDIAG#

DASP#

HRST#

DIOW#

DIOR#

MACK#

HA[2:0]

CS1FX#

CS3FX#

DMARQ

IORDY

INTRQ

IOCS16#

UPSEN#

UP3_2/UNIT0#

UP3_3/UINT1#

UALE

UP0[7:0]/UAD[7:0]

UP2_7-UP2_0

UP3_5-UP3_4

UP3_1-UP3_0

UP3_6/UWR#

UP3_7/URD#

UA[7:0]

UA16/UP1_0

UA17/UP1_1

UA18/UP1_2

PRST#

XTALO

XTALI

IPLLVDD33

IPLLVSS

RD(15:0)

RA(11:0)

RAS#

CASL#

CASH#/RWEH#

RWE#

ROE#

CLK

CKE

DQML

BA(1:0)

EJECT#/STOP#

PLAY#/PAUSE#

system

clock

System

Clock

Generator

Servo

status

detection

circuit

CIRC Encoder

EFM modulation

Subcode generator

DMU

C3

Encoder

C3

Decoder

CDROM

Sync.

Detection

Descrambler

ATIP Sync Protection &

CRC check &

Target MSF Search

FM Demodulator

& Bi-Phase data

Demodulator

Buffer

Memory

Controller

Write Strategy

Interface Logic

EFM/EFM+

Demodulator

Subcode/ID

Demodjlator

Page 38

Pin description

41

Pin Numbers

Symbol Type Description

Data PLL Interface (11)

11 PLLVDD33 Power Power for data PLL and related analog circuitry.

10 JITFN Analog Input The input terminal of RF jitter meter.

9 JITFO Analog Output The output terminal of RF jitter meter.

8 LPFOP Analog Output The positive output of loop filter amplifier.

7 LPFIN Analog Input The negative input terminal of loop filter amplifier.

6 LPFIP Analog Input The positive input terminal of loop filter amplifier.

5 LPFON Analaog Ouptut The negative ouotput of loop filter amplifier.

4 LPION Analog Output The negative output of VCO integrator.

3 LPIOP Analog Output The positive output of VCO integrator.

2 PLLVSS Ground Ground pin for data PLL and related analog circuitry.