LG FLATRON L3000A Service Manual

L3000A

COLOR MONIT OR

SER VICE MANUAL

CHASSIS NO. : CL-36

F ACTORY MODEL: L3000AL

MODEL: L3000A (L3000AL-AL), (L3000AL-SL)

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

1. LCD CHARACTERISTICS

Type : TFT Color LCD Module

Size : 30inch

Pixel Pitch : 0.5025 x 0.1675 x RGB

Color Depth : 8-bit, 16,777,216 colors

Electrical Interface : LVDS

Active Display Area : 643.2mm x 385.92mm

Surface Treatment : Anti-Glare, Hard Coating(3H)

Operating Mode : Normally Black

Backlight Unit : 16-CCFL (Cold Cathode

Fluorescent Lamp)

2. OPTICAL CHARACTERISTICS

2-1. Viewing Angle by Contrast Ratio

≥

10

Left : -80° min., -85°(Typ)

Right : +80° min., +85°(Typ)

Top : +80° min., +85°(Typ)

Bottom : -80° min., -85°(Typ)

2-2. Luminance : 350(min), 414(Typ)

2-3. Contrast Ratio : 2300(min), 350(Typ)

3. SIGNAL (Refer to the Timing Chart)

3-1. Video Input

1)Signal Input : 15pin D-sub Connector/ S-video,

RCA

2)Input Form : RGB Analog(0.7Vp-p/75ohm), CVBS,

Digital, Y/C

3)Resolution(max) : Analog -1280 x 1024

@60Hz

Digital -1024 x 768@75Hz

3-2. Audio Signal

1) Input: PC : 700mVrms

VCR: 450mVrms

DVD: 450mVrms

3-3. Sync Input

Horizontal : 30 ~ 66kHz(Digital: 30~63kHz)

Vertical : 56 ~ 85Hz

Input Form : Separate, TTL,

Positive/Negative Digital, SOG

4. POWER SUPPLY

4-1. Power Adaptor

Input : AC 100~240V, 50/60Hz , 2.0A

Output : DC 5V 0.9A, DC12V 1.5A

DC18V 1.0A, DC24V 5.0A

4-2. Power Consumption

5. ENVIRONMENT

6-1. Operating Temperature: 10°C~35°C (50°F~95°F)

(Ambient)

6-2. Relative Humidity : 10%~80%

(Non-condensing)

6-3. MTBF : 30,000 Hours(Typ.)

6. DIMENSIONS (with TILT/SWIVEL)

Width : 734 mm (28.90'')

Depth : 487 mm (19.17')

Height : 96 mm (3.78'')

7. WEIGHT (with TILT/SWIVEL)

Net. Weight : 18.0kg (39.68 lbs)

Gross Weight : 22.0kg (48.51 lbs)

CONTENTS

SPECIFICATIONS

- 2 -

SPECIFICATIONS ................................................... 2

PRECAUTIONS ....................................................... 4

TIMING CHART ....................................................... 5

OPERATING INSTRUCTIONS ................................ 6

WIRING DIAGRAM ................................................. 9

BLOCK DIAGRAM ................................................. 10

DESCRIPTION OF BLOCK DIAGRAM...................11

ADJUSTMENT ...................................................... 13

TROUBLESHOOTING GUIDE .............................. 14

PRINTED CIRCUIT BOARD................................... 19

EXPLODED VIEW...................................................22

REPLACEMENT PARTS LIST ...............................24

PIN CONFIGURATION............................................31

SCHEMATIC DIAGRAM......................................... 35

MODE

POWER ON (NORMAL)

STAND-BY

SUSPEND

DPM OFF

POWER OFF

H/V SYNC

ON/ON

OFF/ON

ON/OFF

OFF/OFF

-

POWER CONSUMPTION

less than 165 W

less than 5 W

less than 5 W

less than 5 W

less than 1 W

LED COLOR

GREEN

AMBER

AMBER

AMBER

OFF

VIDEO

ACTIVE

OFF

OFF

OFF

-

Signal Connector Pin Assignment

Pin Signal (DVI-D)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

T. M. D. S. Data2T. M. D. S. Data2+

T. M. D. S. Data2/4 Shield

T. M. D. S. Data4T. M. D. S. Data4+

DDC Clock

DDC Data

Analog Vertical Sync.

T. M. D. S. Data1T. M. D. S. Data1+

T. M. D. S. Data1/3 Shield

T. M. D. S. Data3T. M. D. S. Data3+

+5V Power

Ground

(return for +5V,

H. Sync. and V. Sync.)

Pin Signal (DVI-D)

1

8

9

17

24

16

16

17

18

19

20

21

22

23

24

Hot Plug Detect

T. M. D. S. Data0T. M. D. S. Data0+

T. M. D. S. Data0/5 Shield

T. M. D. S. Data5T. M. D. S. Data5+

T. M. D. S. Clock Shield

T. M. D. S. Clock+

T. M. D. S. Clock-

T. M. D. S. (Transition Minimized Differential Signaling)

• DVI-D Connector (Digital)

- 4 -

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD

monitor that are important for safety. These parts are

marked on the schematic diagram and the

replacement parts list. It is essential that these critical

parts should be replaced with the manufacturer’s

specified parts to prevent electric shock, fire or other

hazard.

• Do not modify original design without obtaining written

permission from manufacturer or you will void the

original parts and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE

WITH BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged

in four corners.

• Do not press on the panel, edge of the frame strongly

or electric shock as this will result in damage to the

screen.

• Do not scratch or press on the panel with any sharp

objects, such as pencil or pen as this may result in

damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

• Make certain that treatment person’s body are

grounded through wrist band.

• Do not leave the module in high temperature and in

areas of high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within

the module.

• If the surface of panel become dirty, please wipe it off

with a softmaterial. (Cleaning with a dirty or rough cloth

may damage the panel.)

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL) or

inverter circuit, must disconnect the AC adapter

because high voltage appears at inverter circuit about

650Vrms.

• Handle with care wires or connectors of the inverter

circuit. If the wires are pressed cause short and may

burn or take fire.

PRECAUTION

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

TIMING CHART

- 5 -

VIDEO

SYNC

B

D

C

F

E

A

<< Dot Clock (MHz), Horizontal Frequency (kHz), Vertical Frequency (Hz), Horizontal etc... (µs), Vertical etc... (ms) >>

H + 31.469 800 640 16 96 48

V – 70.8 449 350 37 2 60

H – 43.269 832 640 56 56 80

V – 85.0 509 480 1 3 25

H – 31.469 800 640 16 96 48

V – 59.94 525 480 10 2 33

H – 37.5 840 640 16 64 120

V – 75 500 480 1 3 16

H – 31.468 900 720 18 108 54

V + 70.8 449 400 12 2 35

H + 37.879 1056 800 40 128 88

V + 60.317 628 600 1 4 23

H + 46.875 1056 800 16 80 160

V + 75.0 625 600 1 3 21

H + 53.674 1048 800 32 64 152

V + 85.061 631 600 1 3 27

H+/– 49.725 1152 832 32 64 224

V+/– 74.55 667 624 1 3 39

H – 48.363 1344 1024 24 136 160

V – 60.0 806 768 3 6 29

H – 60.123 1312 1024 16 96 176

V – 75.029 800 768 1 3 28

H + 63.981 1688 1280 48 112 248

V + 60.02 1066 1024 1 3 38

H + 47.7 1680 1280 66 134 200

V + 60 795 768 1 3 23

Mode

H/V

Sort

1

2

3

4

5

6

7

8

9

10

11

12

13

25.175

28.321

25.175

31.5

36.0

40.0

49.5

56.25

57.283

65.0

78.75

108.0

80.14

640x350

70Hz

640x480

85Hz

640x480

60Hz

640x480

75Hz

720x400

70Hz

800x600

60Hz

800x600

75Hz

800x600

85Hz

832x624

75Hz

1024x768

60Hz

1024x768

75Hz

1280x1024

60Hz

1280x768

60Hz

Sync

Polarity

Frequency

Dot

Clock

Total Period

(E)

Video Active Time

(A)

Sync Duration

(D)

Back Porch

(F)

Front Porch

(C)

Resolution

OPERATING INSTRUCTIONS

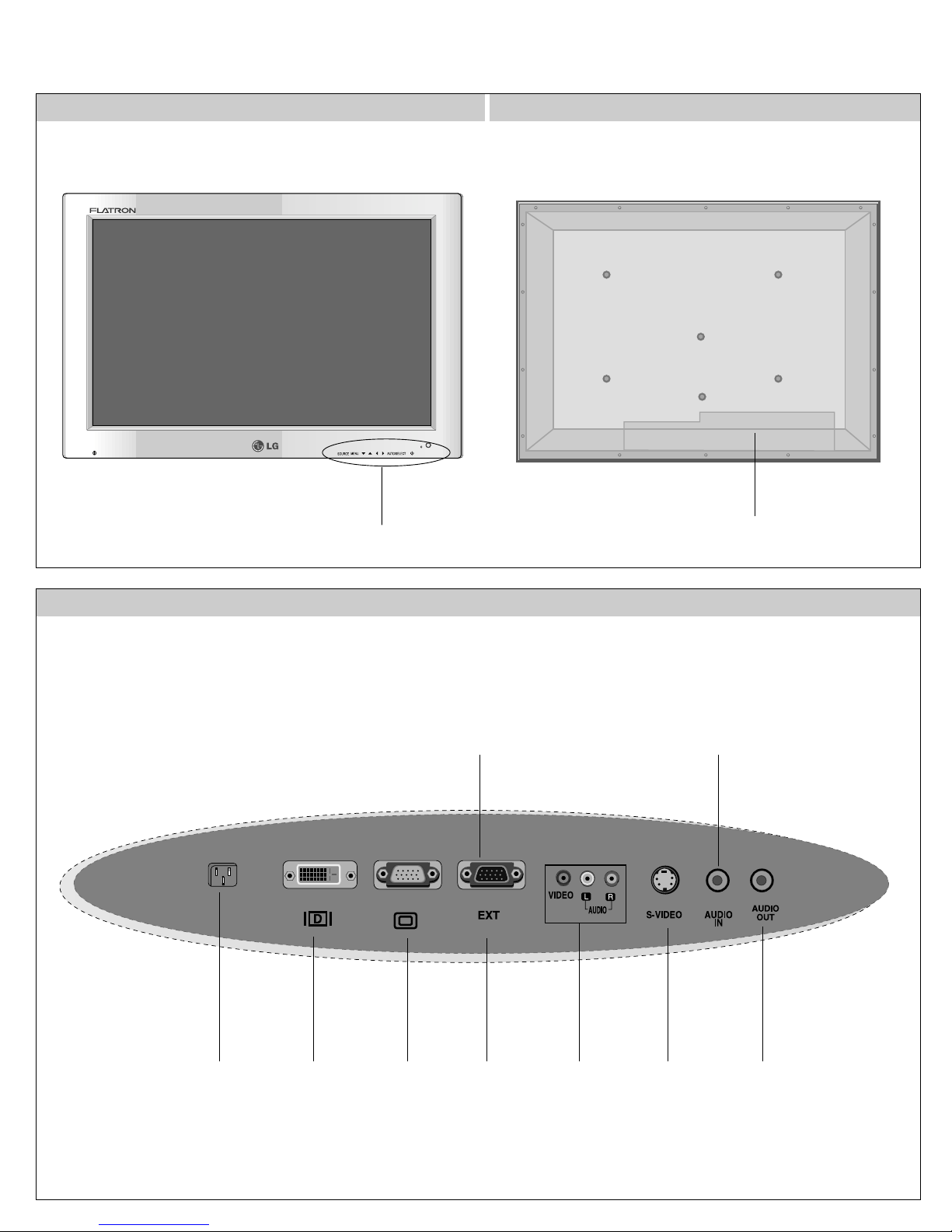

L3000A

FRONT VIEW

Front Control Panel

REAR VIEW

Rear View Pannel

REAR VIEW CONNECTOR PANEL

Factory adjustment

or AS Port

AUDIO

Input

Power

Cord

DVI-D

Connector

D-Sub

Connector

D-Sub

Connector

RCA Cable

Connector

S-Video

Connector

AUDIO

Output

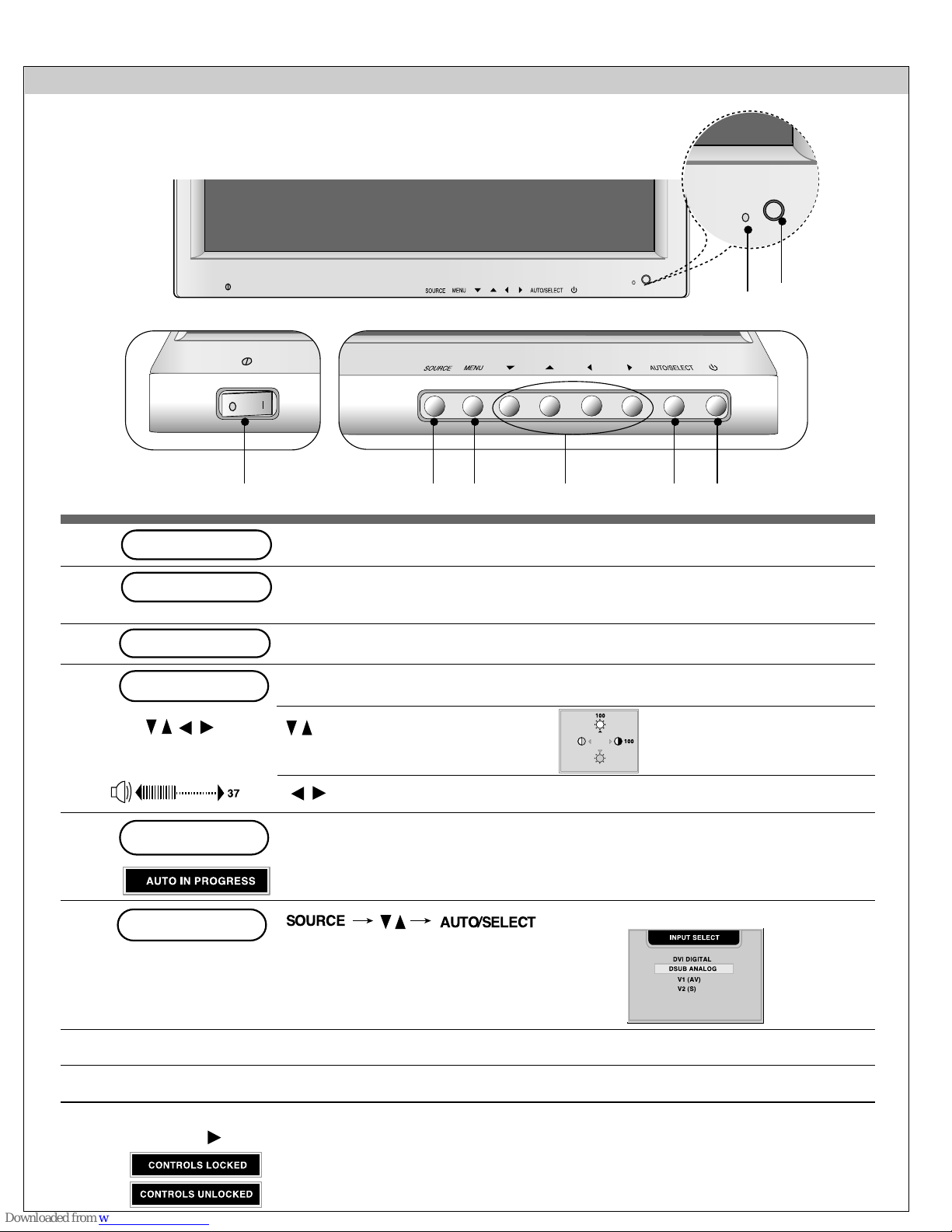

OPERATING INSTRUCTIONS

AUTO/SELECT

SOURCE

Front Control Panel

7

2

1

2

3

4

5

6

Power Button

Power (DPMS)

Indicator

MENU Button

Buttons

OSD

AUTO/SELECT Button

SOURCE

Button

1568 3 4

• Use this button to turn the display on or off.

• This Indicator lights up green when the display operates normally. If the display is in

DPM (Energy Saving) mode, this indicator color changes to amber.

• Use this button to enter or exit the On Screen Display.

•

Use these buttons to choose or adjust items in the On Screen Display.

•

Bring up Contrast and

Brightness adjustment.

Use these buttons to decrease or increase the volume level.

•Use this button to enter a selection in the On Screen Display.

•When adjusting your display settings, always press the AUTO/SELECT button before

entering the On Screen Display(OSD). This will automatically adjust your display image

to the ideal settings for the current screen resolution size (display mode).

• Use this button to select an input signal.

• DVI DIGITAL: DVI digital signal

• DSUB ANALOG: 15-pin D-sub analog signal

• V1 (AV): Composite video

• V2 (S): S video

Remote Control Sensor

7

8

Power On/Off switch

CONTROLS LOCKED/UNLOCKED :

MENU and

This function allows you to secure the current control settings, so that they cannot be

inadvertently changed. Press and hold the MENU button and button for 3 seconds: the

message “CONTROLS LOCKED” appears.

You can unlock the OSD controls at any time by pushing the MENU button and

button for 3 seconds:

the message “CONTROLS UNLOCKED” will appear.

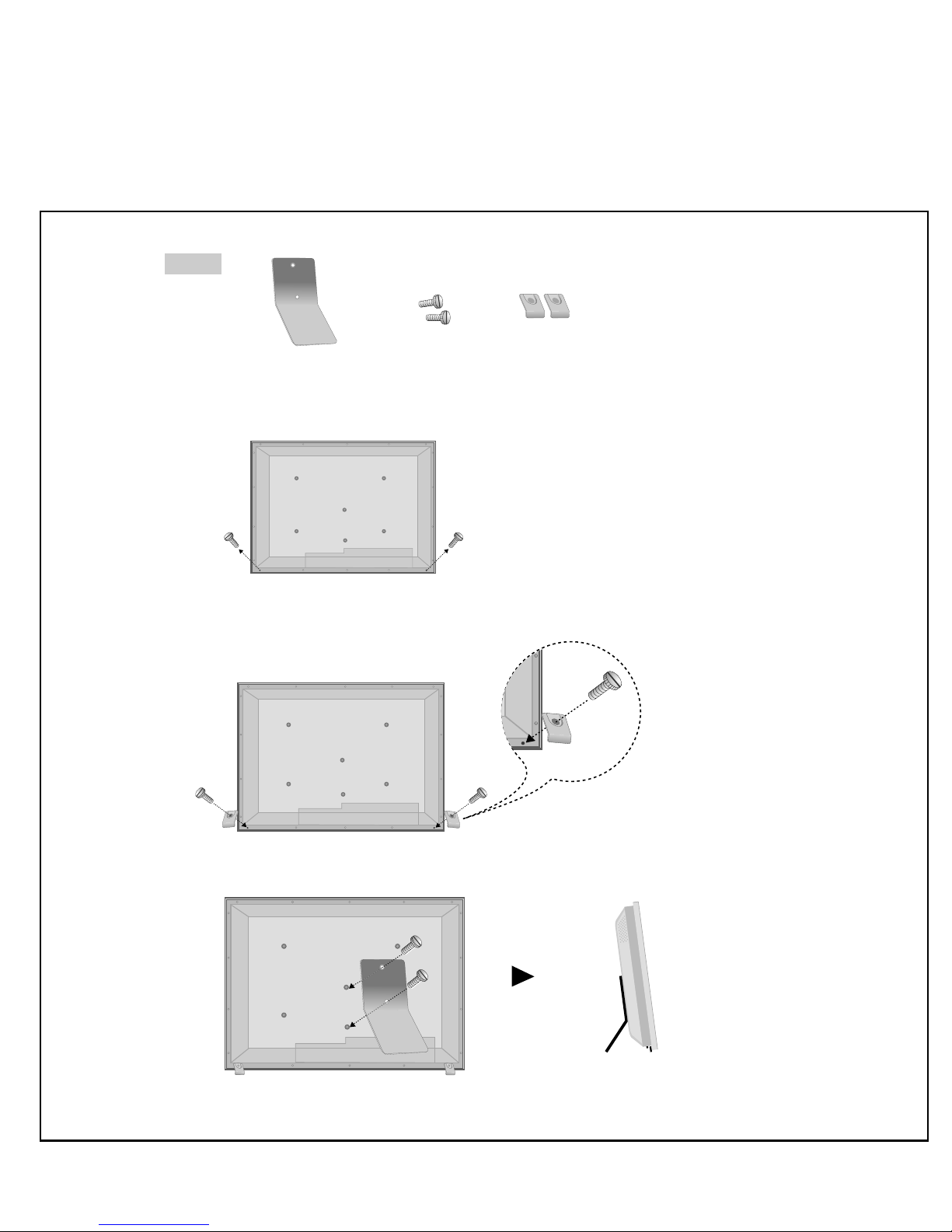

Attaching temporary stand

Follow below procedures to temporarily use the display on the floor.

First, check if the following parts are all present.

Parts

Temporary Stand Screws Bottom Rubbers

1. Take out 2 screws from the rear of the display.

2. As shown in the diagram, place the bottom rubbers where you took out the 2

screws and then secure them with those 2 screws.

3. Attach the temporary stand as shown.

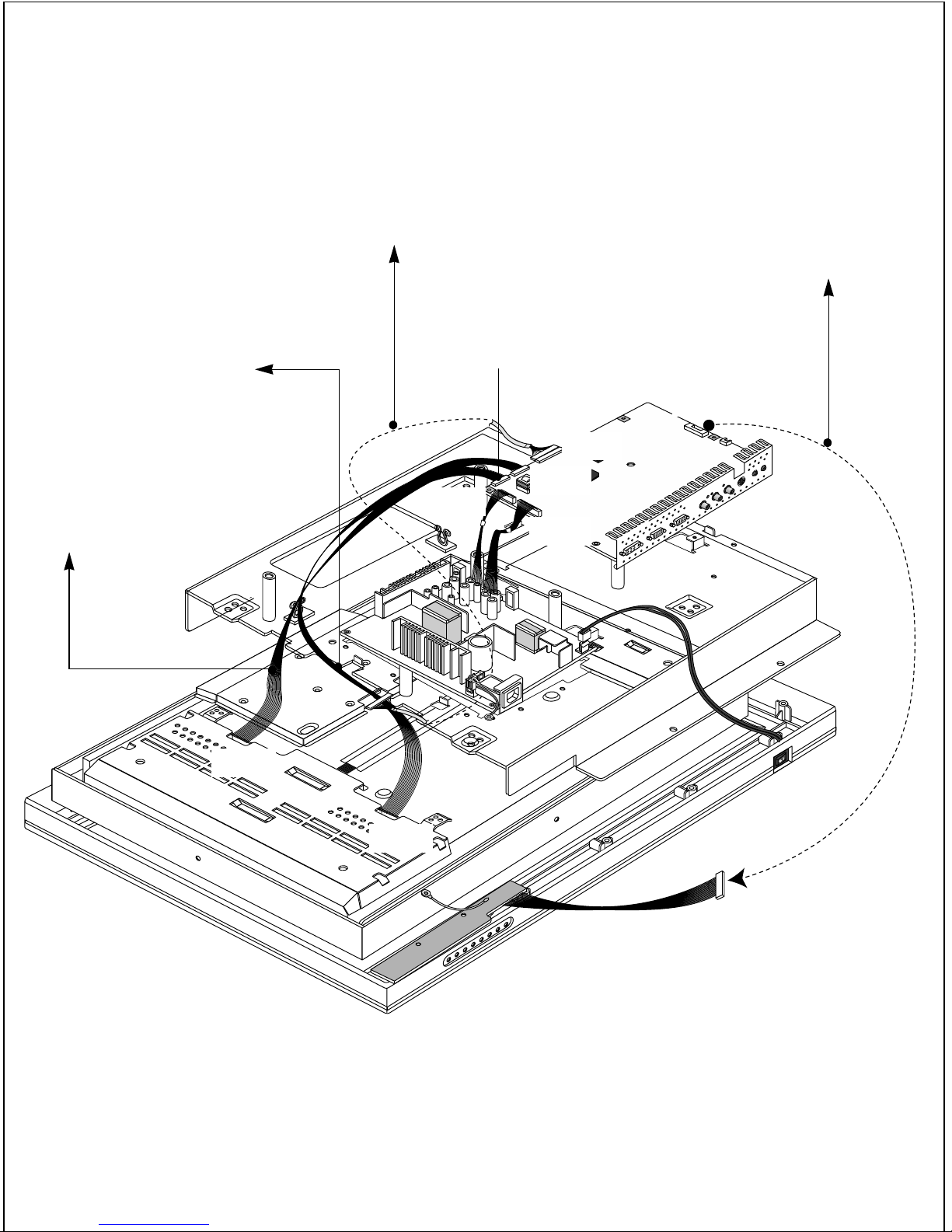

CN1

CN1

J710

J19

J703

J706

J704

J705

Connector Ass’y P/N:

6631T11016A

Connector Ass’y P/N:

6631T20020P

Connector Ass’y P/N:

6631T12002P

Connector Ass’y P/N:

6631T12002N

DVI-D

D-SUB

CVBS

L

R

PC L/R

Video

Decoder

(SAA7114H)

Deinterlacer

(SDA9400)

YUV

Flash

Memory

(M29W800DT)

EEPROM

Y/C

YUV

Multi-

plexer

(74LVC257)

H V Sync

H V Sync

GVS

GHS

Video Signal

GVS

GHS

Sync_ Sel

Sync_ Sel

3.3V

3.3V

3.3V

NCTL_SCL

NCTL_SDA

GREF

GREF

3.3V

5V

8V

3.3V

3.3V

2.5V

3.3V

3.3V

Buffer

(74LVC541ct)

RDN CS0N

Data

(PWD

0...7

)

Key_Data

(0...15)

CS0N

RDN

CS1N

Data

(PWD 0 ..7)

(PWA 0 ..19)

ROMOE

ROMWE

ROMWE

ROMOE

I/O expander

(74LVC273D)

Control Signals

TMDSTX_PDNN

TMDSRX_PDNN

R,G,B

Even

R,G,B

Odd

RGB

Digital

Signal

Even

Input Selection

Format Converter Circuit

Odd

ADC

(AD9883-140)

R,G,B

differential

Video Signal

Processor

(PW166B-20T)

Analo g

Switch

(BA7657F)

TMDS

Receiver

(SIL161A)

Control Board

Line-out L

Line-out R

Audio

Processor

(MSP3420G)

LCD

Module

LVDS

Transm itter

(THC63LVDM83R)

Ready

Power Block

12V

5V

3.3V

24V,18V,12V,5V

Input

from Power B/d

8V

2.5V

12V

PCB_PWR

INV_PWR

LCM_PWR

- 11 -

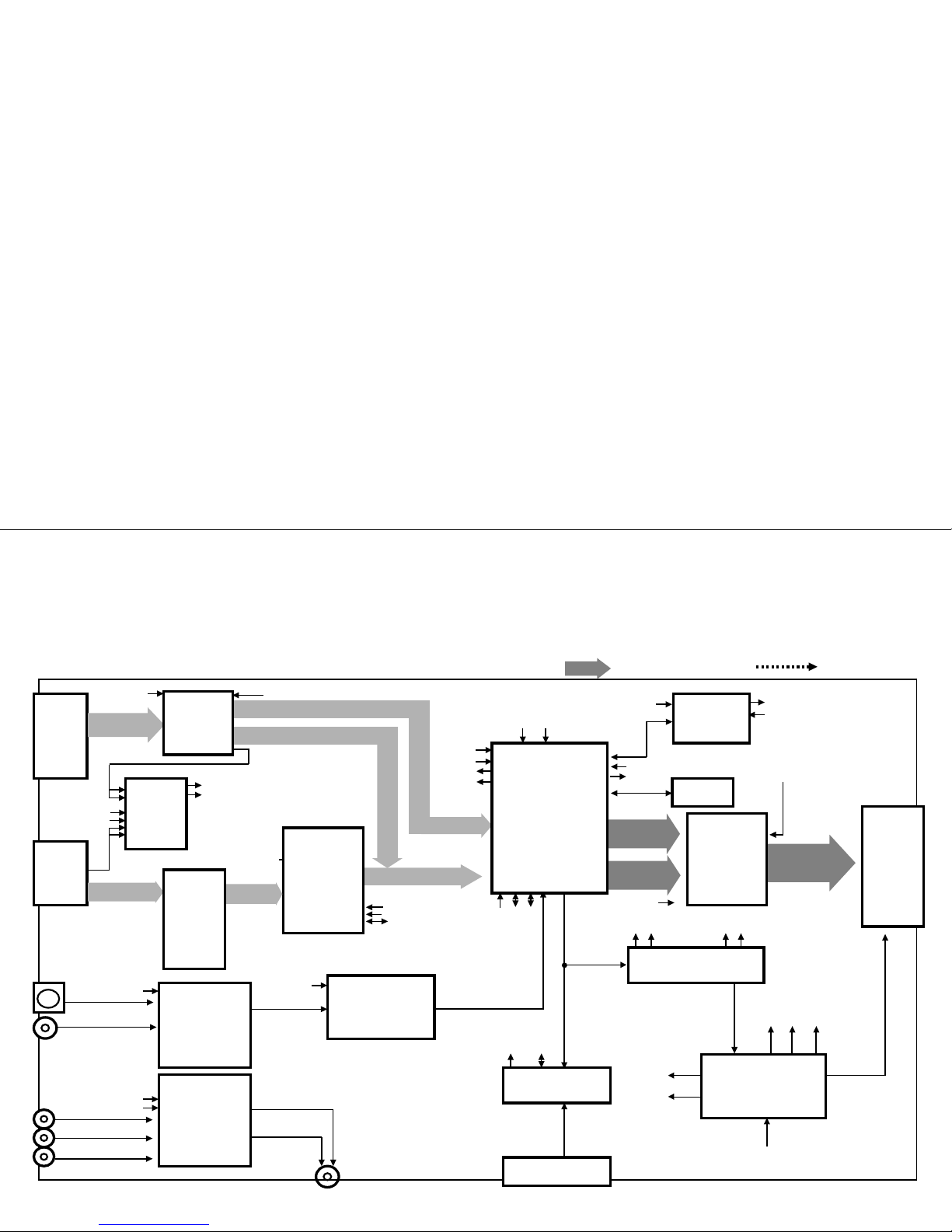

DESCRIPTION OF BLOCK DIAGRAM

1. Input Selection Circuit

This block is composed of 74LVC257(U5) and peripheral devices.

There are two inputs, Analog and Digital H/V Sync.

LVC257 IC chooses one input and outputs selected input through sync selection pin (Pin 1).

2. A/D Converter

This block is composed of AD9883 (U4) and peripheral devices.

AD9883 includes A/D converter, Pre-amp, and PLL.

The Analog RGB signal (0.7Vp-p) is input to R,G,B port of AD9883(U4).

Input signal is amplified, phase locked , A/D converted in 8bits digital signal by this IC(U4), and sent to the Digital

video signal to PW166B-20T.

U4 makes clock for PW166B-20T(U8).

3. TMDS PanelLink Receiver

This Block is composed of SiI161B (U201) and peripheral devices.

This IC decodes PanelLink Digital Input signal(TMDS) from DVI-D Pin (J18) and make 8bit digital RGB signal with

Digital EVEN/ODD format to PW166B-20T(U8).

4. DDC controller

This block is composed of PW166B-20T(U8) and peripheral devices.

PW166B-20T controls peripheral devices through IIC line.

Major functions are (1) to control Flash memory through DDC-SCLA, DDC-SDAA of D-sub And (2) to store EDID

data in the EEPROM (U17, U30)

5. Video Decoder

This block is composed of SAA7114H (U7) and peripheral devices.

PW166B-20T controls this IC through IIC Line.

This IC analyzes input signal of CVBS, Y/C and outputs analyzed signal (8bit interlace signal) to De-interlace block.

Analyzed signal has video control signals like Contrast, Brightness, Sharpness, Color, tint signals Including Adaptive

Comb Filter.

6. Audio Decoder

This block is composed of MSP3420G (U49) and peripheral devices.

PW166B-20T controls this IC through IIC Line.

This IC analyzes Audio input signal through A/V Jack and PC audio.

And output the analyzed signals

7. De-interlace

This block is composed of SDA9400 (U16) and peripheral devices.

PW166B-20T (U8) controls this IC through IIC Line.

And this IC convert 8 Bit Interlaced Y/UV signal to De-interlace signal.

It outputs converted signal to Format Converter (PW166B-20T).

8. Format Converter(Scaler)

This block is composed of PW166B-20T (U8), M29W800DT (U19) and peripheral devices.

MICOM in PW166B-20T (U7) processes outputs of A/D Converter and TMDS Receiver,

De-interlace output and output processed 48 Bit Digital signal to TMDS Transmitter.

PW166B-20T is Format Converter IC that receives Digital signal and outputs proper frame signal to LCD Module

Timing(1280x768,WXGA).

9. PanelLink Circuit

TMDS Transmitter (THC63LVDM83R, U401) is the IC that receives output digital signal of PW166B-20T (U8) and

output to LCD Module.

The signal format is Panel-link.

LCD Module has Panel-link receiver that is same output of PW166B-20T.

This is the best for reduction EMI problem and the number of pin connector.

- 12 -

10. DC/DC Converter block

DC/DC Converters convert the input 12V, 24V to proper 2.5V, 3.3V, 5V, 8V for main control system.

For shooting heat trouble, we use the DC/DC converting IC.

11. Power Supply Block

This Block generates DC Voltages(5V, 12V, 18V and 24V) to Main Control system from AC Power(100-240 V, 50/60

Hz, 1.0 A).

This Circuit contains PFC(Power Factor correction) circuit.

The Minimum of Power efficiency is about 75%.

- 13 -

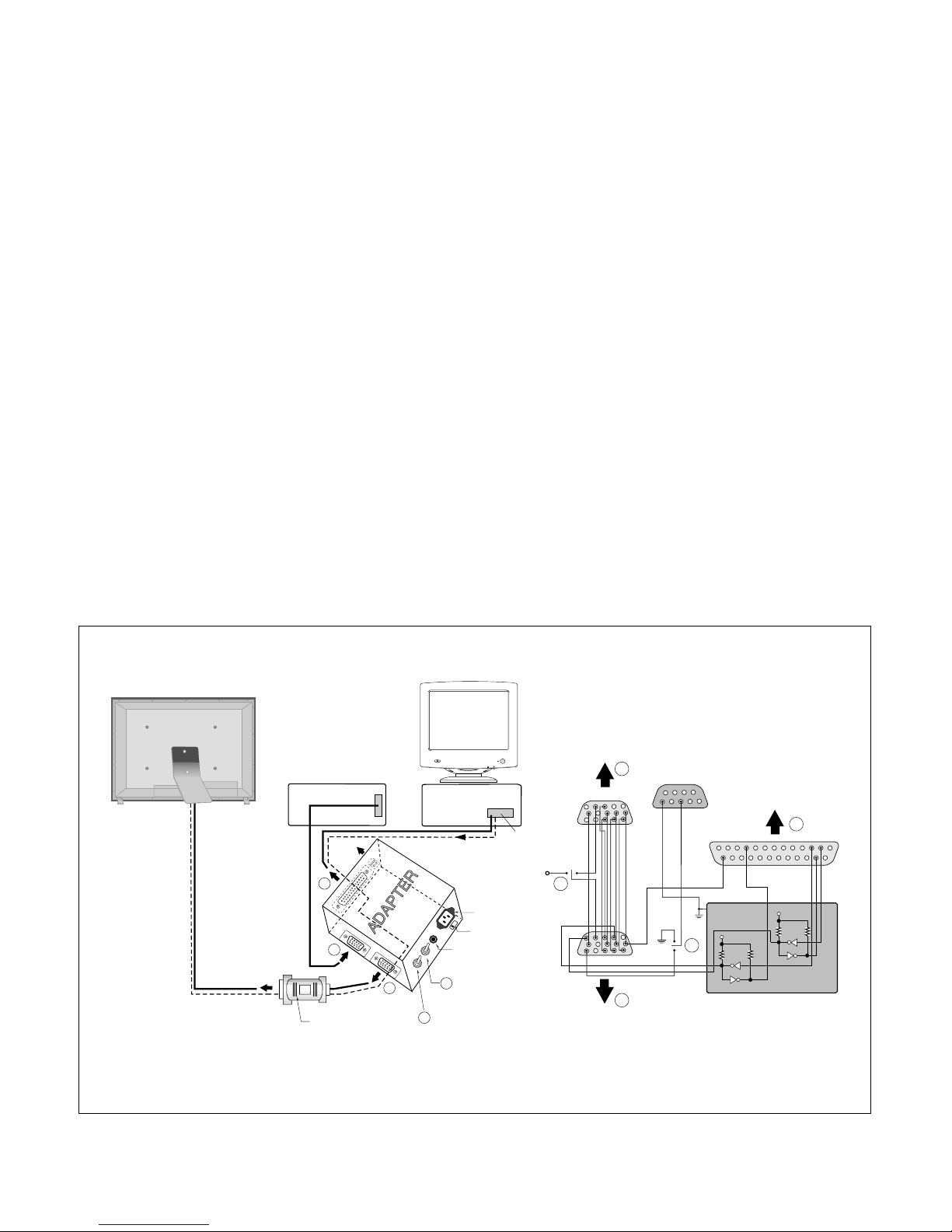

ADJUSTMENT

DVI-D Connector

220

IBM

Compatible PC

Parallel Port

Power inlet (required)

Power LED

ST Switch

Power Select Switch

(110V/220V)

Control Line

Not used

RS232C

PARALLEL

V-SYNC

POWER

ST

VGS

MONITOR

E

V-Sync On/Off Switch

(Switch must be ON.)

F

A

B

C

5V

E

F

A

B

C

15

10

5

5

69

1

1

1

14

13

25

6

5V

5V

4.7K

4.7K

4.7K

74LS06

74LS06

OFF ON

OFF

ON

11

Figure 1. Cable Connection

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several minor adjustment may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

• Alignment appliances and tools.

- IBM compatible PC

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- Oscilloscope.

- White Balance Meter. (CA-110)

1. Adjustment for Factory Preset Mode

No read to adjust FOS data for Factory Preset Mode.

2. Adjustment for White Balance

1) Set External Bright to MAX position and Contrast to

MAX position.

2) Display Color 0,0 pattern at Mode 15.

3) Press Menu key, Vp key, Right key of Remote

controller or Menu Buttons in sequence.

4) Select “WHITE BALANCE ADJUST” and Press SET

key.

5) After “INPUT WHITE PATTERN” message, Display

Color 15, 0 pattern at Mode 15.

6) No attempt to manually adjust, BIAS and Drive data

is automatically adjustde and saved to the EEPROM.

7) After “OK” message, Press SET KEY.

8) Select “SERVICE MODE EXIT” and Press SET KEY.

3. DDC Data Write Procedure-Analog

1) Use this procedure only when there is some

problem on Analog EDID data.

2) Run alignment program for LM805L on the IBM

compatible PC.

3) Select EEPROM

→ Analog EDID write command

and Enter.

4) This will write the Analog EDID data to EEPROM.

4. DDC Data Write Procedure-Digital

1) Use this procedure only when there is some

problem on Digital EDID data.

2) Run alignment program for LM805L on the IBM

compatible PC.

3) Select EEPROM → Digital EDID write command

and Enter.

4) This will write the Digital EDID data to EEPROM.

Loading...

Loading...