P/NO : MFL63746203 (1005-REV00) Printed in Korea

COLOR MONITOR

SERVICE MANUAL

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS NO. : LM99G

MODEL: E2280V E2280V-PNV

Internal Use Only

- 2 -

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

CONTENTS

CONTENTS .............................................................................................. 2

PRECAUTION............................................................................................3

SERVICING PRECAUTIONS.....................................................................4

SPECIFICATIONS......................................................................................6

TIMING CHART .......................................................................................10

ADJUSTMENT .........................................................................................11

BLOCK DIAGRAM...................................................................................15

TROUBLE SHOOTING ............................................................................17

EXPLODED VIEW .................................................................................. 21

SVC. SHEET ...............................................................................................

- 3 -

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PRECAUTION

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD monitor that

are important for safety. These parts are marked on the

schematic diagram and the Exploded View. It is essential

that these critical parts should be replaced with the

manufacturer’s specified parts to prevent electric shock, fire or

other hazard.

• Do not modify original design without obtaining written

permission from manufacturer or you will void the original parts

and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE WITH

BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged in four

corners.

• Do not press on the panel, edge of the frame strongly or electric

shock as this will result in damage to the screen.

• Do not scratch or press on the panel with any sharp objects,

such as pencil or pen as this may result in damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

• Make certain that treatment person’s body are grounded

through wrist band.

• Do not leave the module in high temperature and in areas of

high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within the

module.

• If the surface of panel become dirty, please wipe it off with a

softmaterial. (Cleaning with a dirty or rough cloth may damage

the panel.)

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL) or LIPS

part, must disconnect the AC power because high voltage

appears at inverter circuit about 650Vrms.

• Handle with care wires or connectors of the inverter circuit. If

the wires are pressed cause short and may burn or take fire.

Leakage Current Hot Check Circuit

• Replaceable batteries

* CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN

INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE

INSTRUCTIONS

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

Ω

0.15uF

AC Volt-meter

Good Earth Ground

such as WATER PIPE,

To Instrument's

exposed

METALLIC PARTS

When 25A is impressed between Earth and 2nd Ground

for 1 second, Resistance must be less than 0.1

*Base on Adjustment standard

1.5 Kohm/10W

CONDUIT etc.

- 4 -

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or re-connecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) is opropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500ºF to 600ºF.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500ºF to 600ºF)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500ºF to 600ºF)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

- 5 -

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete TransistorRemoval/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

- 6 -

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SPECIFICATIONS

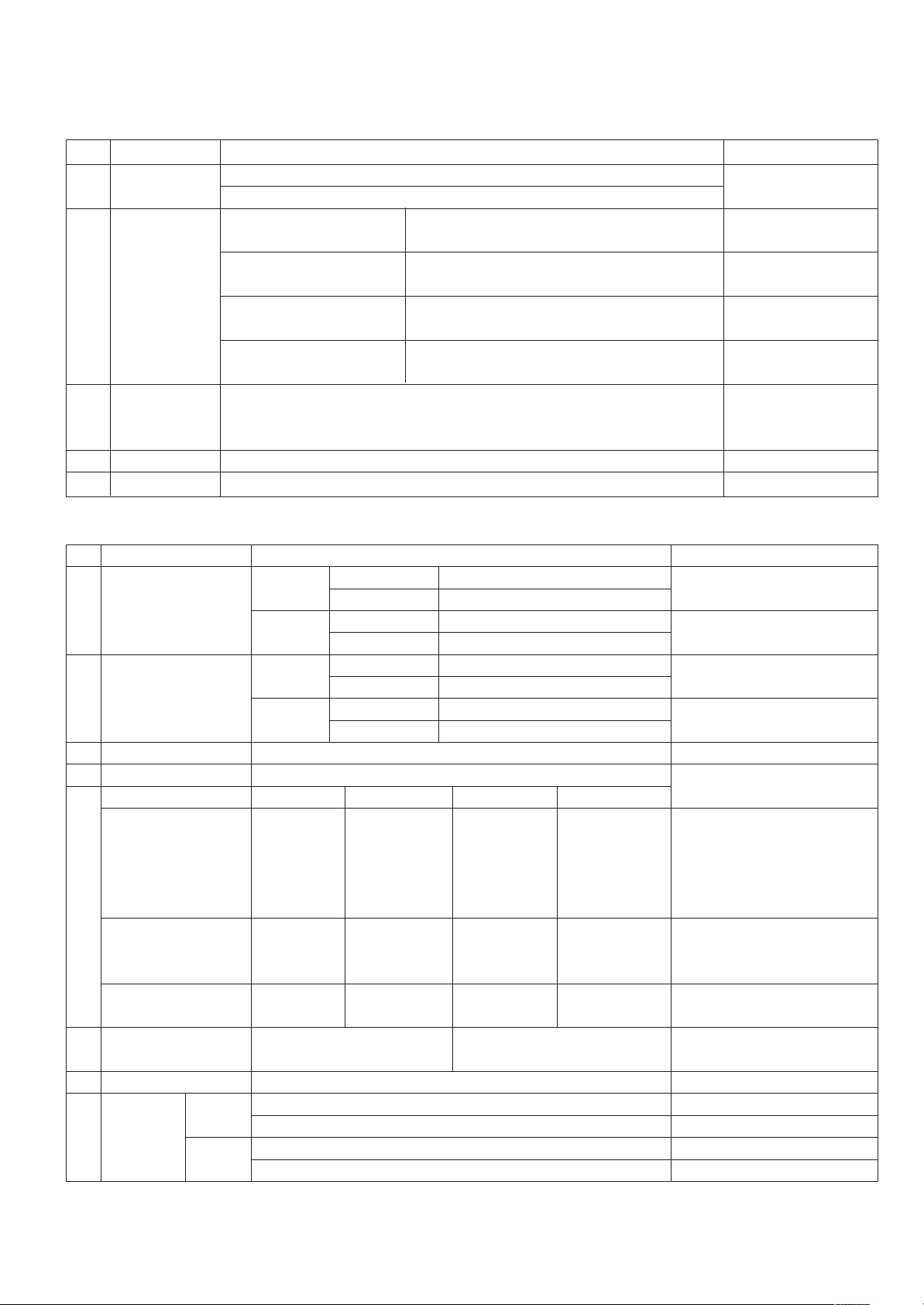

1. General Specification

No Item Content Remark

1 Customer BRAND

2 User Model Name E2280V

3 Sale region Refer to Suffix standard

4 Feature 55 cm (21.5 inch) White LED Wide LCD MONITOR

5 Chassis Name LM99G

External SW &Adj. Menu, Smart+, Super+ Resolution, Auto, Input, Exit, Power

6 General

Scope Function OSD, Control lock, 1 Analog/1 DVI/ 1 HDMI, Headphone out, sRGB,

HDCP, F-engine, Super+ Resolution, Galaxy Lighting

Length : 1.5 m ± 0.05 m

7 Power Cord Shape : Wall-out

Color : Black

Length : 1.8 m 68509F0003A

Signal Cable Shape : Detachable Type

(D-SUB) Color : Black

Pin : Triple Row, 15 Pin D-Sub

8 Cable Length : 2.0 m

DVI Shape : Detachable Type

Color : Black 68509J0004A

Pin : Triple Row, 18-Position DVI-D

9 Adapter Input: AC100 - 240V 50Hz ~ 60 Hz,1.0A Max, Output: DC 12V 3A Lienchang 36W

No Item Content Remark

Width (W) Length (D) Height (H)

1 Product

Before Packing 516.2 mm 194.5 mm 426.9 mm

With stand

Dimension

After Packing 59.3 cm 47.3 cm 14.5 cm

2 Product Only SET 3.7 kg

Weight With BOX 5.0 kg

3 Container Individual or 20ft 40ft

Loading Palletizing Indi. Wooden Indi. Wooden

Quantity 600 736 1320 1520

Type Stand Base detachable

4 Stand Size (W x D x H) 232.5 x 194.5 x 34.4

Assy Tilt Degree -5° (

±

3 ) ~ 10° (±3)

Tilt force 0.7 kg ~ 1.7 kg

5 Appearance General Refer to Standard of LG(56)G2-1011

2. Mechanical specification

- 7 -

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

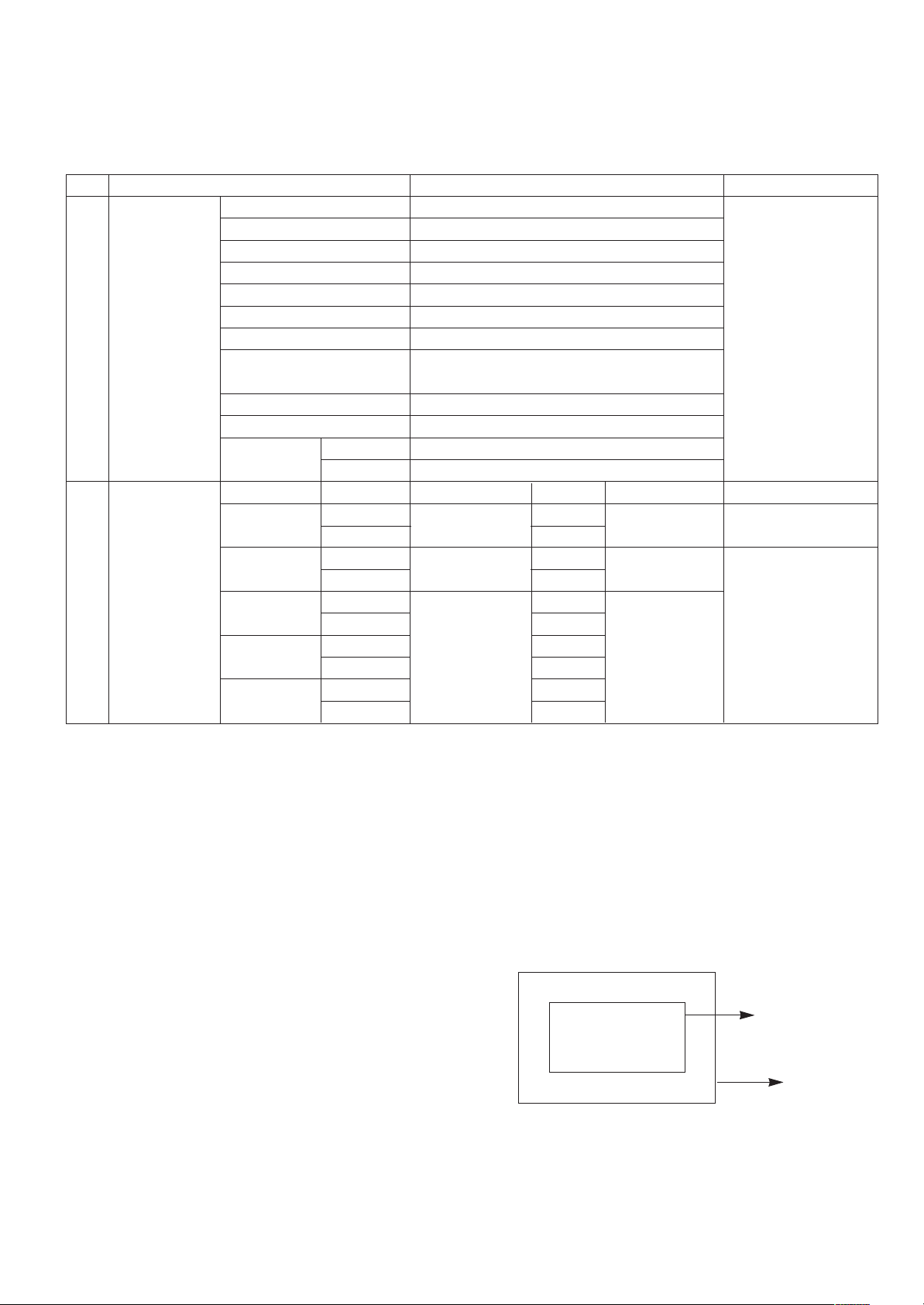

3. Optical Character

No Item Criteria Remark

1 Viewing Angle Horizontal(R/L) : + 85° / - 85° (Typ.)

<CR ≥10> Vertical(Top/Bottom) : + 75° / - 85° (Typ.)

2 Luminance Average Luminance (cd/m

2

) 150(Typ.) sRGB

(Typ

±

30 )

Average Luminance (cd/m

2

) 180(min), 200(Typ.) 6500K

(Full white pattern, 0.7V)

Average Luminance (cd/m

2

) 140 (Min.) 9300K

(Full white pattern, 0.7V)

Luminance

Uniformity 75%(Min.)

3 Contrast Ratio Module: 700(Min), 1000(Typ)

DFC : 5,000,000:1 (Min.)

(F-engine Movie mode)

4 Response Time On/off:5ms(TYP)

5 Light Leakage Condition: Do not visible at 300 Lux

4. Engineering Specification

1 Supported Sync. Type Separate Sync., Digital

2 Operating Frequency Analog/ Horizontal 30 ~ 83kHz

Vertical 56 ~ 75 Hz

HDMI Horizontal 30 ~ 83kHz

Vertical 56 ~ 61 Hz

3 Resolution Analog/ Max. 1920 x 1080 @ 60 Hz

Digital Recommend 1920 x 1080 @ 60 Hz

HDMI Max. 1920 x 1080 @ 60 Hz

Recommend 1920 x 1080 @ 60 Hz

4 Input Voltage Voltage : 100 – 240 V ac, 50 Hz or 60 Hz

5 Inrush Current Cold Start : 50 A, Hot : 120 A

Operating Condition Sync(H/V) Video LED Wattage

Test condition

27 W (Max.)

1. 1920 x 1080 @ 60 Hz

6 On Mode On/On Active Purple

25W (Typ.)

2. burst pattern

3. 100 V - 240 V

4. After aging 30 min

Off/On Purple 1W under

Sleep Mode On/Off Off blinking (Dsub,DVI)

Off/Off

1.2W under(HDMI)

Off Mode

- - Off 0.5 W under

(Power switch off)

7 MTBF

50,000 HRS with 90% Lamp Life : 30,000 Hours(Min.)

Confidence level

8 Using Altitude 5,000 m (for Reliability) 3,000 m (for FOS)

Temperature 10°C ~ 35°C

9 Environment

0perating

Humidity 10 % ~ 80 %

Condition

Storage

Temperature -20°C ~ 60°C non-condensing

Humidity 5% ~ 90% non-condensing

No Item Content Remark

Maker LGD

Type TFT Color LCD Module

Active Display Area 546.86 mm (21.53 inch) diagonal

Pixel Pitch [mm] 0.248(H) x 0.248(V)

1 LCD Module Electrical Interface 2ch-LVDS

Feature

Color Depth

8-bit with A-FRC, 16,7M colors

Size [mm] 495.6(H) x 292.2(V) x 14.5(D)

Surface Treatment Hard coating(3H) &

Anti-Glare

Operating Mode

Transmissive mode, Normally White

Back light Unit White LED

R/T Typical Rise Time: 1.3, Fall Time: 3.7

Max. Rise Time: 2.6, Fall Time: 7.4

Minimum Normal Maximum

White Wx 0.283

Wy

Typ-0.03

0.298

Typ+0.03 9300K

2 CIE Color White Wu’ 0.313

Coordinates Wv’

Typ-0.03

0.329

Typ+0.03

Red Rx 0.631

Ry 0.349 6500K

Green Gx Typ-0.03 0.341 Typ+0.03

Gy 0.622

Blue Bx 0.152

By 0.058

- 8 -

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

5. LCD Panel Characteristic

(1) Standard Measurement Condition

• Ambient Luminance Level : dark ( < 10 lux)

• Ambient Temperature : Normal Temperature(10ºC ~ 25ºC)

• warm-up Time : More than 30 min (at Full White Pattern)

• Input Signal : VESA 1920X1080 @60 Hz

• Contrast : 70

• Brightness : Max. 100

• 6500K : Color Temperature Setting is 6500 K( if it’s not special specification)

• Clock/Clock Phase : The Best Setting

(2) Another Spec.: Product Specification Standard( LG(55)G1-1034 )

(3) Cosmetic Spec. : LCD Module IIS Spec.

6.1 Display Area

1) Active Display Area of the LCD Monitor Should be within Cabinet’s Bezel.

2) Distance Difference between Active Area and Bezel

| A-B|<1.0 mm , | C-D|<1.0 mm

A: The Distance from The Left of Active Area to the Bezel

B: The Distance from The Right of Active Area to the Bezel

C: The Distance from The Top of Active Area to the Bezel

D: The Distance from The Bottom of Active Area to the Bezel

C

B

D

A

Active Area

Bezel

Loading...

Loading...