LG DX535-JD, DX535 Service Manual

DLP PROJECTOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : FM73A

MODEL : DX535 DX535-JD

website:http://biz.LGservice.com

Internal Use Only

- 2 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

CONTENTS

CONTENTS.......................................................................................................2

SAFETY PRECAUTIONS .................................................................................3

REPLACING OF LAMP ....................................................................................4

SPECIFICATIONS.............................................................................................6

ADJUSTMENT INSTRUCTION.........................................................................8

BLOCK DIAGRAM..........................................................................................15

EXPLODED VIEW...........................................................................................16

EXPLODED VIEW PARTS LIST.....................................................................17

REPLACEMENT PARTS LIST........................................................................18

SVC. SHEET .......................................................................................................

PRINTED CIRCUIT BOARD ...............................................................................

- 3 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube. Do not

lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on positioin, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

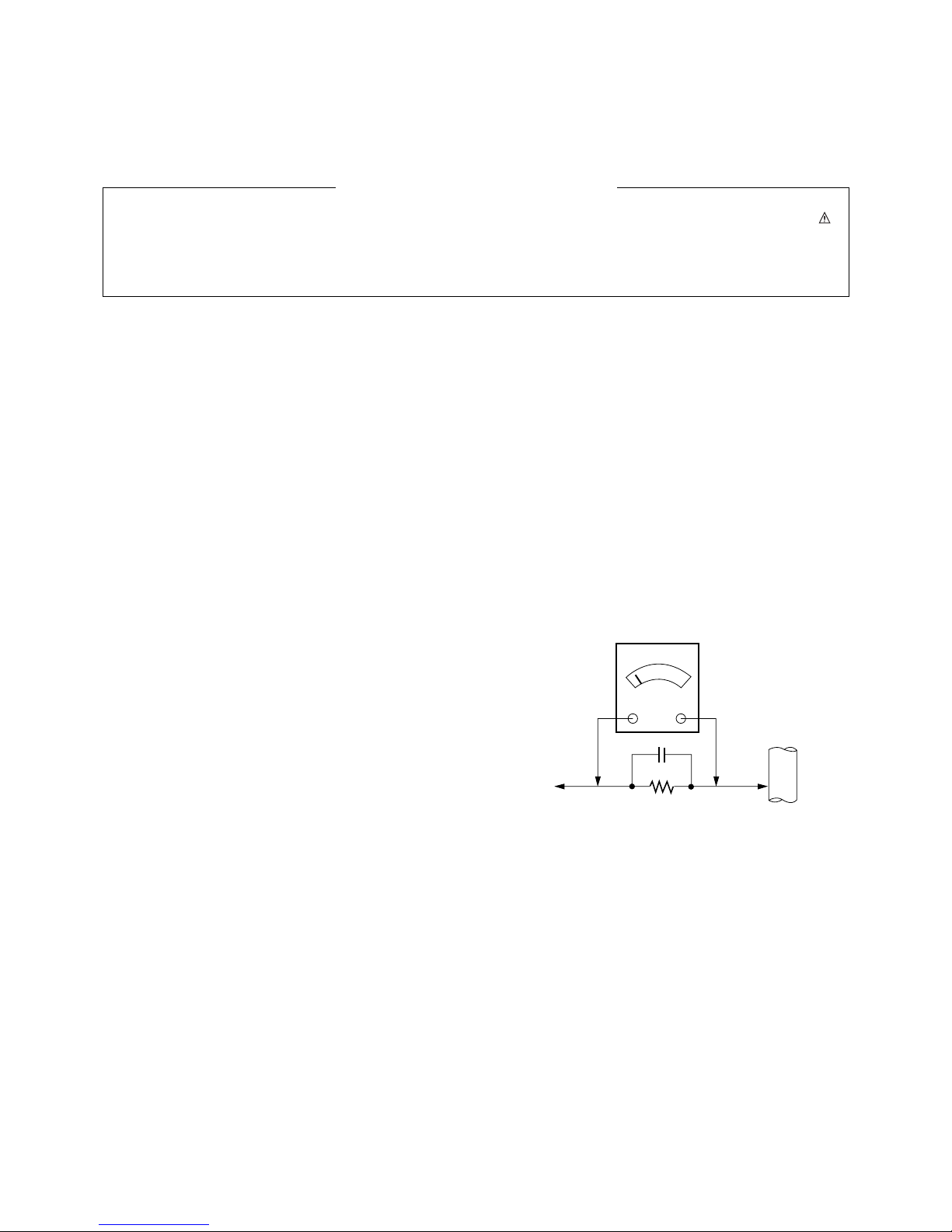

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each esposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

- 4 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Lamp Replacement

Be careful when replacing lamp

The change interval of lamp may depend on the use environment of Projector. You

can see the used lamp time in the CHECKING LAMP TIME section of the Menu

(page.25). You must replace the lamp when:

* The projected image gets darker or starts to deteriorate.

*

The lamp indicator is red.

* The message “Replace the lamp” appears on the screen when turning the

projector on.

- Press the POWER button on the control panel or remote control to turn off power.

- If the operation indicator LED is orange and blinking, do not disconnect the main supply until the operation indicator LED

is lit up constantly (orange).

- Allow the lamp to cool for 1 hour before replacing it.

- Replace only with the same type lamp from an LG Electronics Service Center. Using another manufacturers lamp may

cause damage to the Projector and lamp.

- Pull out the lamp only when replacing the lamp.

- Keep the lamp unit out of reach of children. Keep the Lamp away from heat sources such as radiators, stoves etc.

- To reduce the risk of fire do not expose the lamp to liquids or foreign materials.

- Do not place the lamp near any heat source.

- Make sure the new lamp is securely tightened with screws. If not, the image may be dark or there could be an increased

risk of fire.

- Never touch the lamp unit glass otherwise image quality may be compromised or lamp life maybe reduced.

To obtain a replacement Lamp unit

Lamp model number is on page 37. Check the lamp model and then purchase it from an LG Electronics Service Center.

Using another manufacturers lamp may cause damage to the projector.

Lamp unit disposal

Dispose of the used lamp by returning it to the LG Electronics Service Center.

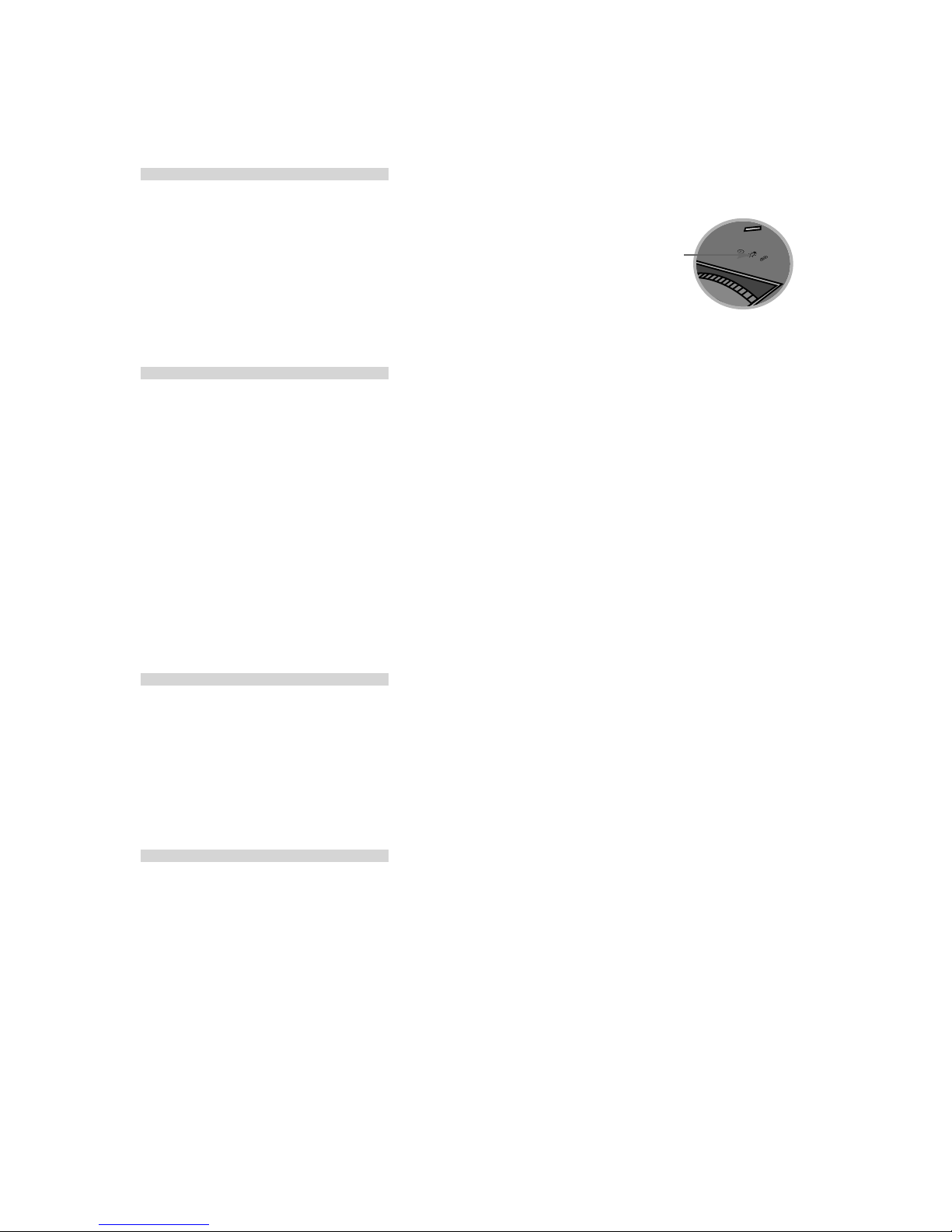

<Front panel of the Projector>

Lamp indicators

REPLACING OF LAMP

- 5 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

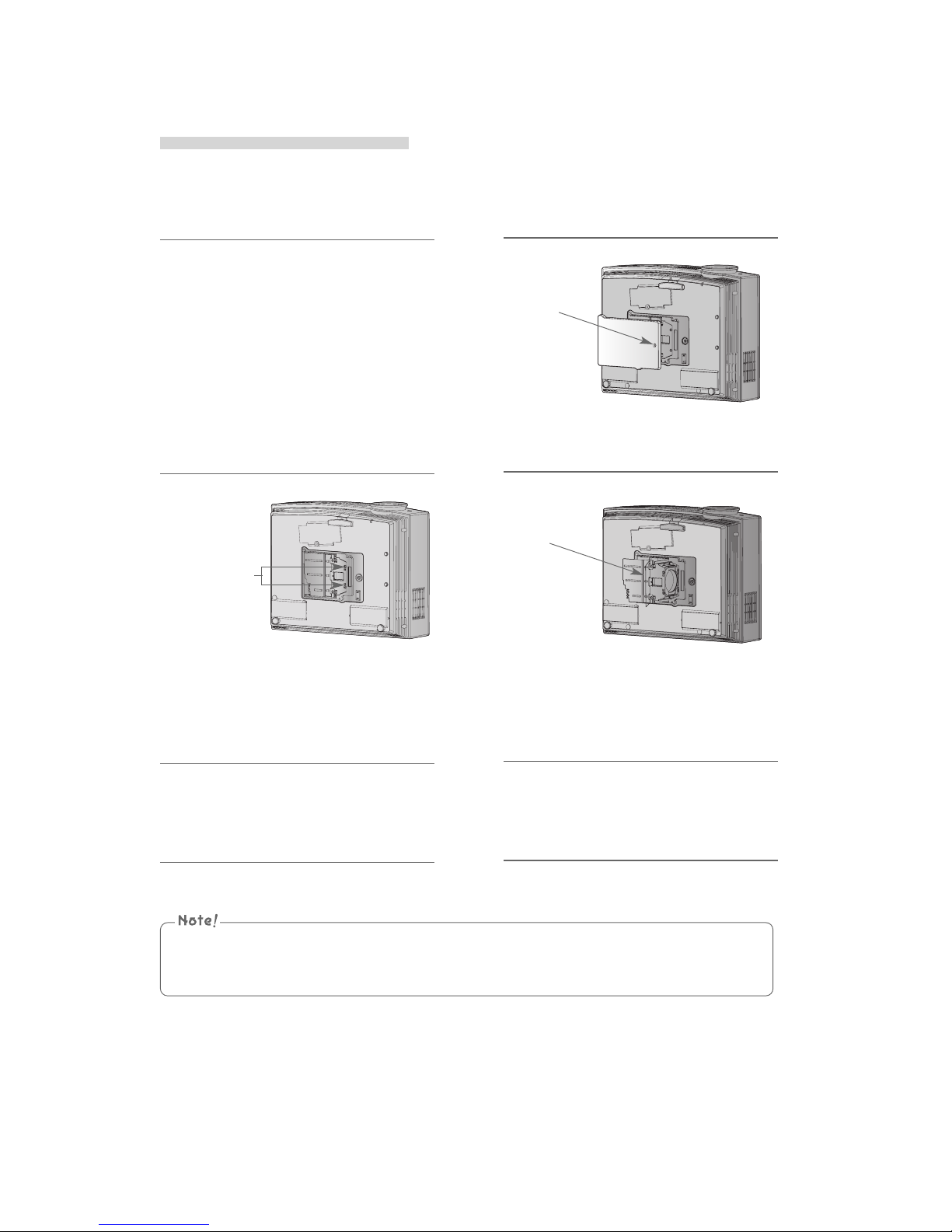

1

Turn off the projector and unplug the power cable.

Carefully place on a cushioned surface.

(Allow the lamp to cool for 1 hour before

removing the used lamp from the projector.)

2

Unscrew the screw from the lamp cover using a

screwdriver.

Lamp case screw

3

After lifting the lamp cover off, remove the two

retaining screws on the lamp case with a screwdriver.

4

Lift the lamp up from the projector.

5

Pull out the handle slowly and remove the lamp

case.

6

Insert the new lamp gently into the correct position.

Make sure it is inserted correctly.

7

Tighten the screws you removed in step 3.

(Make sure they are fixed firmly.)

8

Close the lamp cover and install the screws from

step 2 to install the cover.

(If the lamp cover is not installed correctly the unit will not

power on.)

Replacing the Lamp

Screws

Using another manufacturers lamp may cause damage to the projector or lamp.

Make sure the lamp cover is securely fastened. If the lamp cover is not installed correctly the unit will not power on.

If this fault persists contact an LG Authorized Service Center.

Knob

- 6 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

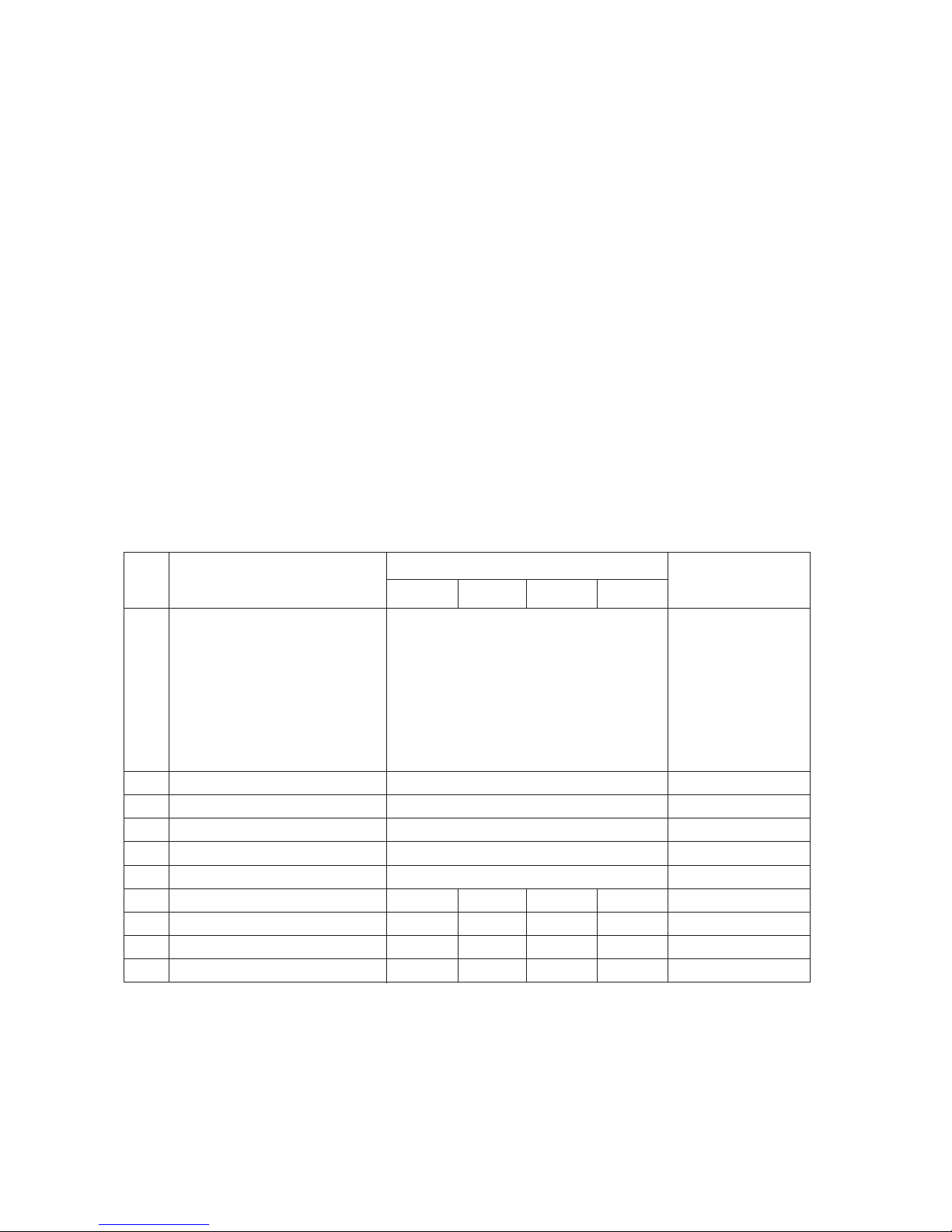

NOTE: Specifications and others are subject to change without notice for improvement

.

A Scope

This standard can be applied to the DLP Projector related to FM73A Chassis.

A Test Condition

1) Temperature: 25°C

±5°C (Only CST is 40°C ± 2°C )

2) Relative Humidity: 65

±10%

3) Power Voltage: Standard input voltage (100-240V~, 50/60Hz)

4) Use the parts only designated in B.O.M.,PARTS SPEC.,or drawings.

5) Follow each drawing or spec for spec and performance of parts,based upon P/N of B.O.M

6) Warm up TV set for more than 30min. before the measurement.

A Test and Inspection Method

1) Performance: Follow the Standard of LG TV test

2) RCA JACK performance: Follow the standard of LG

3) Standards of extra requirement

SAFETY: CB (EN55013),

Electric wave: CE (EN55020)

A General Specification

No. Item

Video input applicable system

Power

Input Voltage

Market

Screen size

Aspect ratio

Operating Temperature

Operating Humidity

Storage Temperature

Storage Humidity

1) NTSC M

2) NTSC 4.43

3) PAL

4) PAL M

5) PAL N

6) SECAM

7) NTSC-PB

SMPS

100V(-10%) - 240(+6%)V~, 50/60Hz

World wide

4:3

4:3

0

-20

40

75

60

85

deg

%

deg

%

3.579545 / 60Hz

4.433618 / 60Hz

4.433618 / 50Hz

3.575611 / 60Hz

3.582056 / 50Hz

4.286 / 50Hz

4.433618 / 60Hz

1

2

3

4

5

6

7

8

9

10

Specification

Min Typ Max Unit

Remark

SPECIFICATIONS

- 7 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

A Feature and Function

No. Item

REMOCON

DVI_D Input

RGB Input

RGB Output

Component input

Composite input

S-video input

USB Port

RS-232C Port

Local Key

Display mode

Sound

OSD Language

Source

APC

Contrast

Brightness

Sharpness

Color

Tint

Color R

Color G

NEC Code

1 Digital RGB

1 Separate

1 Separate

1 Y, P

B, PR

480i, 480p, 720p, 1080i, 576i,576p

1 480i, 576i

1 480i,576i

1

1

MENU, SOURCE, AUTO,

A OK, /(KEYSTONE+),

0

(KEYSTONE-), <, >, Power

4:3 & 16:9

No

Korean/ English/ Deutsch/ Italiano/ Espanol/

Chinese/ French/ Portugal/ Svenska/ Polish

RGB(Component)/ DVI/ Video/ S-Video

Clear/ Soft/ User

0

0

0

0

R50

0

0

LGE key

D-Sub 15 pin

D-Sub 15 pin

Through RCA to D-Sub Gender

RCA Jack(Yellow)

S-VIDEO jack

USB jack(only for download)

Control the SET w/PC

Video/ S-Video/ Component

Video/ S-Video/ Component

Video/ S-Video/ Component

RGB/DVI

RGB/DVI

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Specification

Min Typ Max

100

100

100

100

G50

100

100

Unit

Remark

- 8 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. Application Object

This instruction is for the application to the DLP Projector

(Chassis: FM73A).

2. Notes

(1) The power source insulation of this DLP Projector is not

charging type and you may not use the transformer for

insulation. It is advised to use an insulation transform

between the power supply cable and power input of the set

to protect the test equipment.

(2) The adjustment must be performed under the correct

sequence.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity.

(4) The set must be on for 5 minutes prior to any adjustment.

3. Composition of Adjustment Mode

(1) Select ‘Video mode’ as input source.

(2) Pressing the adjust key on the service remote will open or

close the service menu.

(3) Press the ADJ key to exit the service menu.

(4) Preparation for Adjustment

1) Power is connected in set to be power on.

2) Do heat run 5minutes.

4. Folding Mirror Adjustment

4-1. Illuminator Adjustment Sequence

After putting optical engine on JIG, check the mirror part.

Check the full white screen and make adjustments in the

following sequence.

(1) Up and Down Adjustment

1) Turn screw (A) up / down adjustment to the right and

mark where the image is aligned.

2) Turn screw (A) up / down adjustment to the left and

mark where the image is aligned.

3) Turn screw (A) up / down adjustment to the right / left

and mark where the image is aligned. Fix the

adjustment screw in position.

(2) Left and Right Adjustment 1

1) Turn screw (B)Left / Right adjustment to the right and

mark where the image is aligned.

2) Turn screw (B) Left / Right adjustment to the left and

mark where the image is aligned.

3) Turn screw (B)Left / Right adjustment to the right / left

and mark where the image is aligned. Fix the

adjustment screw in position.

(3) Left and Right Adjustment 2

1) Turn screw (C)up / down adjustment to the right and

mark where the image is aligned.

2) Turn screw (C) up / down adjustment to the left and

mark where the image is aligned.

3) Turn screw (C)up / down adjustment to the right / left

and mark where the image is aligned. Fix the

adjustment screw in position.

(4) Final Adjustment

Fix the adjustment screw in position. (1), (2), (3)

adjustment twice and find the optimum position. Check the

image with the naked eye for optimum alignment.

ADJUSTMENT INSTRUCTION

Top and bottom

adjustment screw A

Left and right

adjustment screw C

Left and right

adjustment screw B

<Fig. 1> Illuminator Adjustment Part by Folding Mirror

Step 1 Step 2 Step 3

<Fig. 2> Illuminator Up / Down Adjustment Sequence

Step 1 Step 2 Step 3

<Fig. 3> Illuminator Left/Right Adjustment Sequence 1

Step 1 Step 2 Step 3

<Fig. 4> Illuminator Left/Right Adjustment Sequence 2

- 9 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

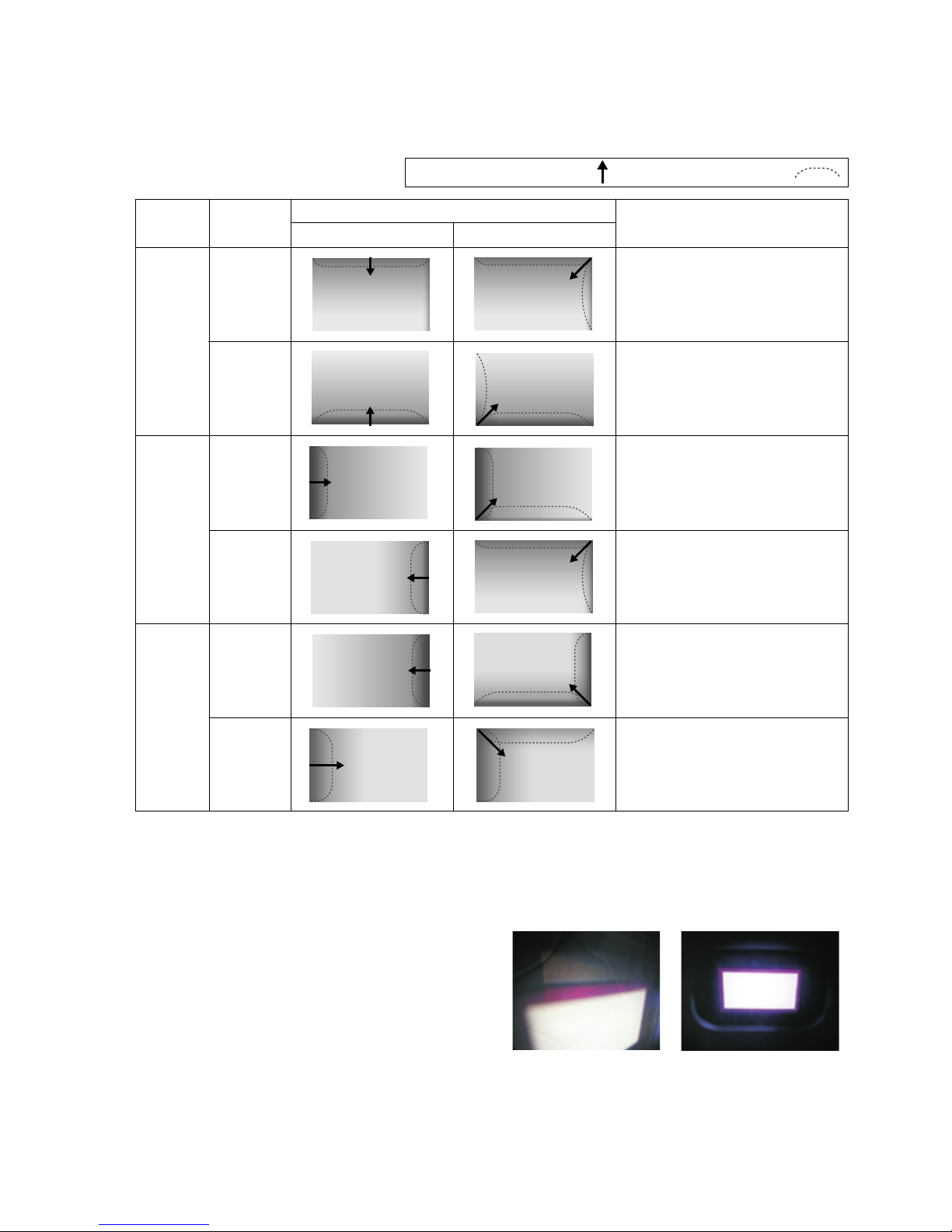

Up/down

screw A

Right

(tighten

direction)

Adjustment

part

Screen state

Initial state State after adjusting

Screw

direction

Description

At first, upside illuminator goes down

and right illuminator also goes down in

detail.

Left

(loosen

direction)

At first, downside illuminator goes

down and left illuminator also goes

down.

left/right

screw B

Right

(tighten

direction)

At first, left illuminator goes down and

downside illuminator also goes down.

Left

(loosen

direction)

At first, right illuminator goes down and

upside illuminator also goes down.

left/right

screw C

Right

(tighten

direction)

At first, left illuminator goes down and

downside illuminator also goes down.

Left

(loosen

direction)

At first, right illuminator goes down and

upside illuminator also goes down.

4-2. Illuminator Phenomenon Adjustment

Illuminator goes down direction Illuminator goes down area

4-3. Coherent Light Source Adjustment

(1) Coherent light source specification

: 50% of center black brightness

(Refer to product specification)

==> Same specification applied for coherent light source

of <Fig. 5> type

(2) Optical axis

: Adjust so that it is set at the center.

[ Do not tilt the optical axis adjustment to improve the

coherent light source

<Fig. 5> Coherent Light Source

5. Caution for DMD

(Digital Micro-mirror Device)

5-1. Caution for DMD ESD

(1) Connector the grounding to prevent a damage of ESD

(Electrostatic Discharge) when handing the DMD.

(2) Wear a wrist strap to connect the ESD grounding in flesh

necessarily.

(3) Connect the ESD ground to workstation and an electric

conductor.

(4) Save the DMD after getting rid of a static electricity. Keep

it at an exclusive case when moving it When grounding,

open the case.

(5) Put on gloves for preventing static electricity.

(6) All work is done at static free location. Attach the tape or

remove a dust on the DMD front or DMD back pin

5-2. Caution for DMD Clean

(1) Follow the procedure and caution to prevent the screen

from being scratched.

(2) When DMD glass stains with dust, polish the front and

back DMD glass with soft cloth. Then, do it again after

rotating 180 degree the DMD. If necessary, keep under

observation.

(3) Don’t clean the DMD with the high pressure. The static

electricity and pressure will damage the DMD.

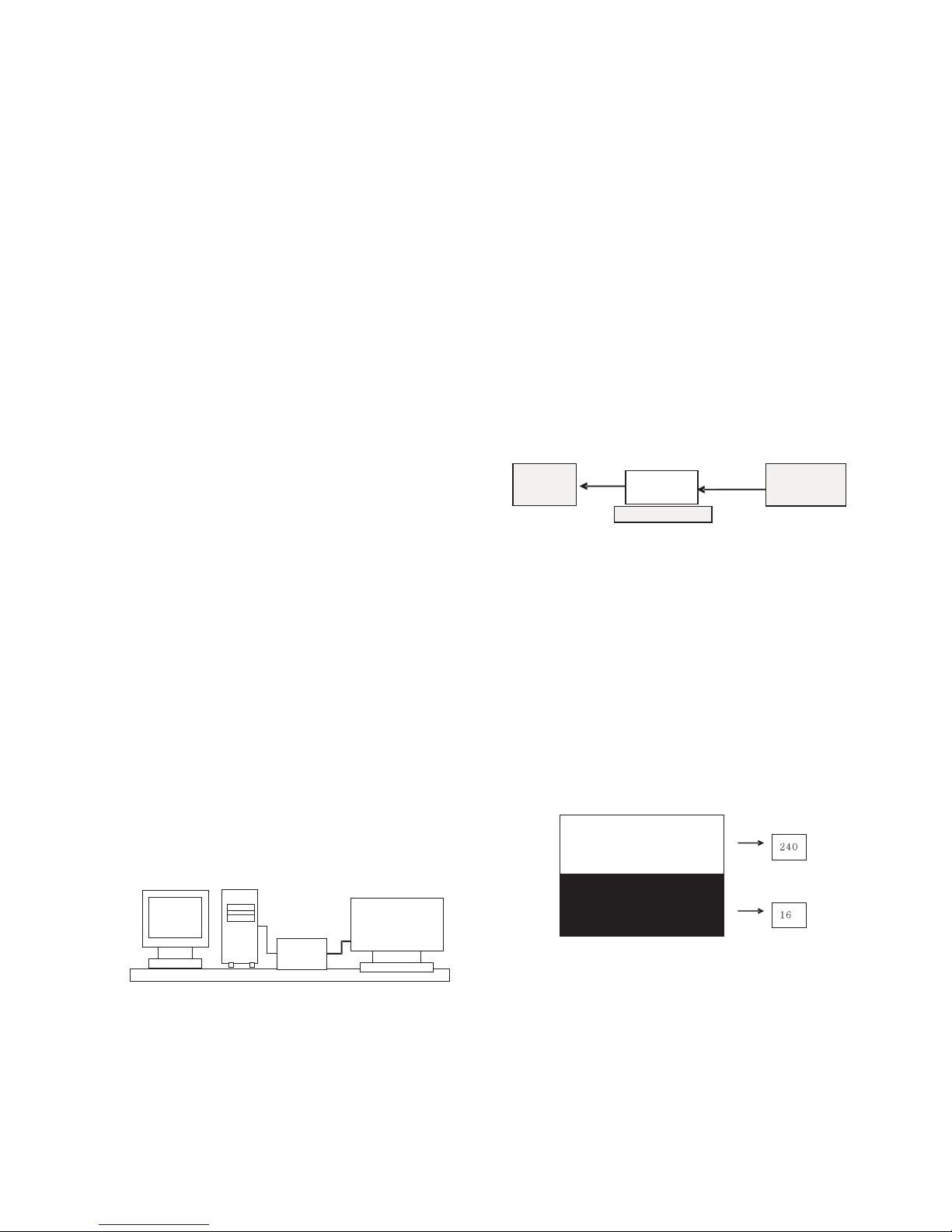

6. EDID Data input

6-1. Required Test Equipment

(1) PC, DDC adjustment Jig(PC serial to D-sub connection

machinery)

(2) DDC record S/W (EDID Data Write & Read)

(3) D-sub terminal, DVI_D

6-2.

Preparation for Adjustment & Setting

of the device

(1) Set like <Fig. 6>, PC and JIG

(2) Press “FRONT-AV” key of the adjustment remote

controller to release EDID Write Protection.

(3) Practice of DDC record S/W(EDID Data Write & Read)

(4) Make sure that the OK signal and the checksum are equal

to the values given at the record file.

(5) When any fail is occurred at the DDC record S/W, because

the EDID Write Protection may not be released, perform

(2) ~ (4) again.

7. Check the EDID

(1) Configure the equipment same to <Fig. 6>.

(2) Select [Read Data & Verify] of the DDC record S/W.

- Be sure that it is not [Write Data & Verify] of the substrate

adjustment.

(3) Make sure that the OK signal and the checksum are equal

to the values given at the record file.

- Because it is the process to read and check the EDID, it

is not necessary to release the EDID Write Protection.

8. RGB Offset/Gain Adjustment

8-1. Required Test Equipment

(1) Pattern Generator 1EA(Analog RGB)

(2) Remote control 1EA

8-2. Setting of the Device

Set the equipment as <Fig. 7>.

8-3. Preparation for Adjustment

(1) Connect the Pattern Generator as shown at <Fig. 6>

Device Setting Diagram.

(2) Set the output of the Pattern Generator to XGA 60Hz.

(1024 X 768 60Hz)

(3) Press the ‘Select Input’ key to select the RGB input.

8-4. Sequence of Adjustment

(It is entered into No. 99 pattern (pattern created: OPT->

199.127.0.16.240))

(1) Select the ‘white/black pattern’ of <Fig. 8> as the pattern

of Pattern Generator. (XGA 60Hz)

(2) Select ADJ -> 2. RGB Gain/Offset ->

A (Enter) -> G (Vol+)

at the adjustment remote controller.

(The actual adjustment is automatically performed by the

system Micom.)

- 10 -

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PC

JI G

DLP PJTR SET

<Fig. 6> Device setting diagram for EDID data input

SCREEN

Projector

RGB

PC Pattern

Generator

<Fig. 7> Device Setting Diagram for RGB offset/gain

Adjustment

<Fig. 8> White/Black Pattern

Loading...

Loading...