LG DVD-5353 Service manual

3-43 3-44

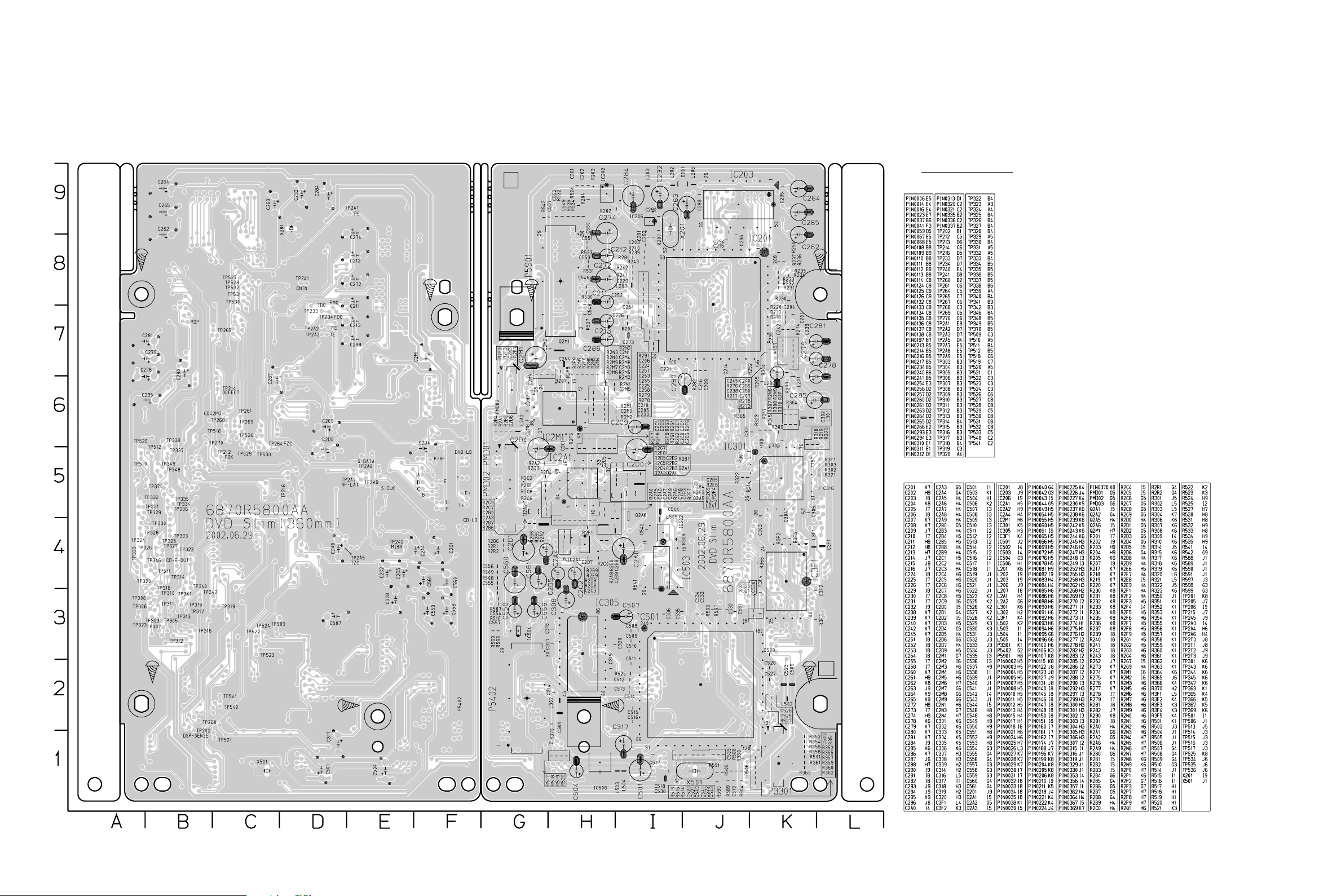

2. POWER, A/V, FRONT P.C.BOARD

LOCATION GUIDE

PRINTED CIRCUIT DIAGRAMS

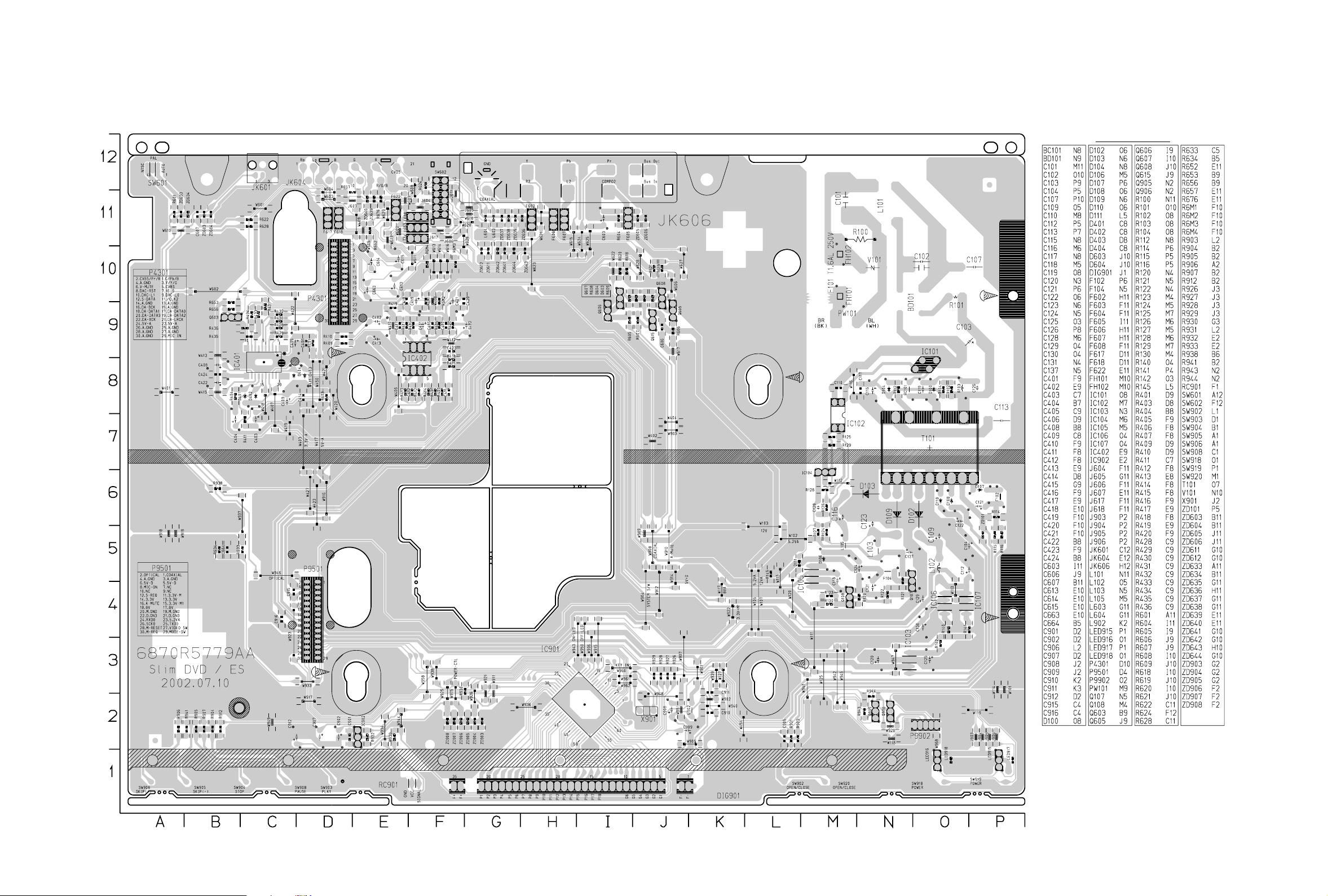

1. MAIN P.C.BOARD

LOCATION GUIDE

(TOP SIDE)

(BOTTOM SIDE)

3-41 3-42

1-3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

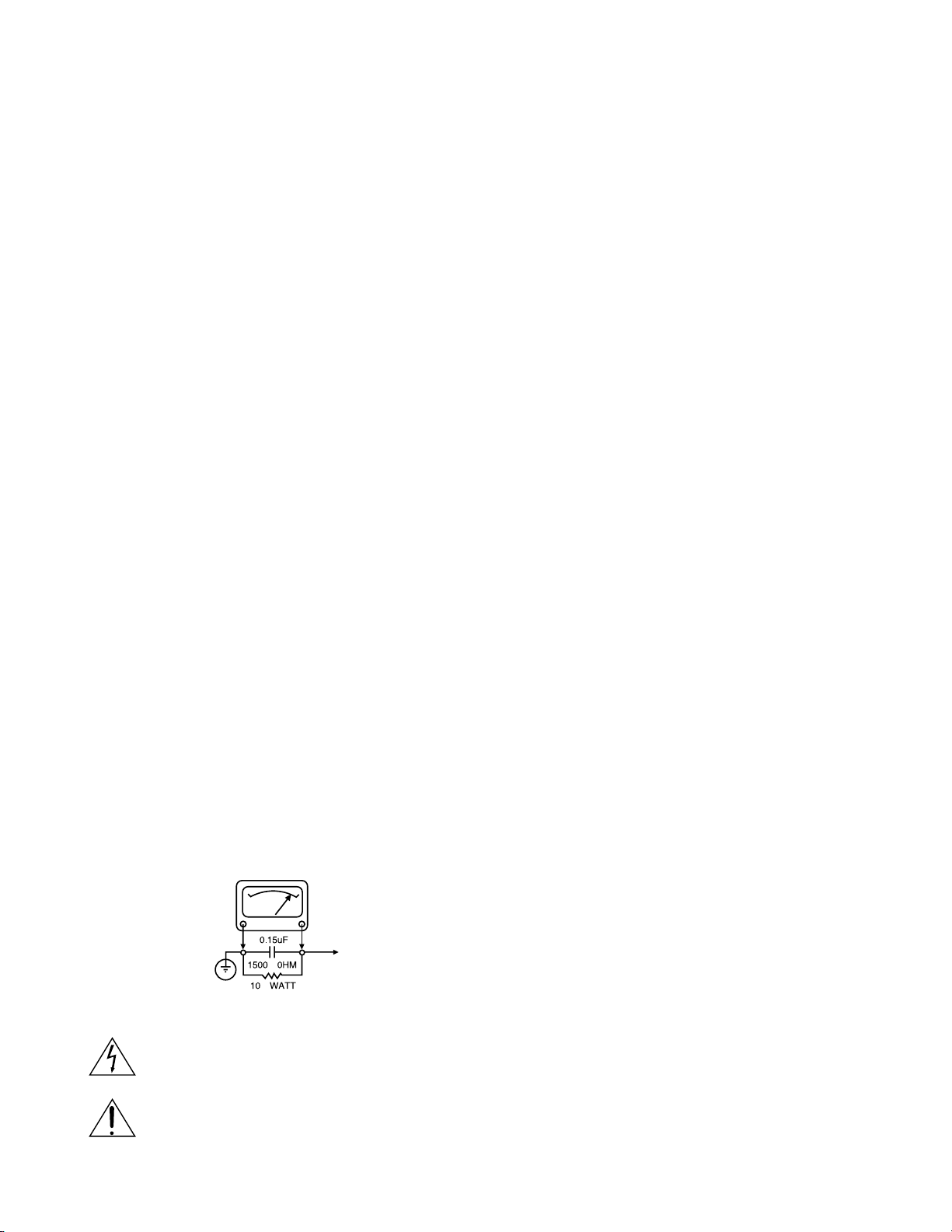

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAG-

NITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

1-4

SERVICING PRECAUTIONS

CAUTION : Before servicing the DVD covered by this service

data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remembers Safety First:

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this DVD or any of

its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this DVD and/or any of its

electrical assemblies unless all solid-state device heat

sinks are cerrectly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grouned-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

2-2

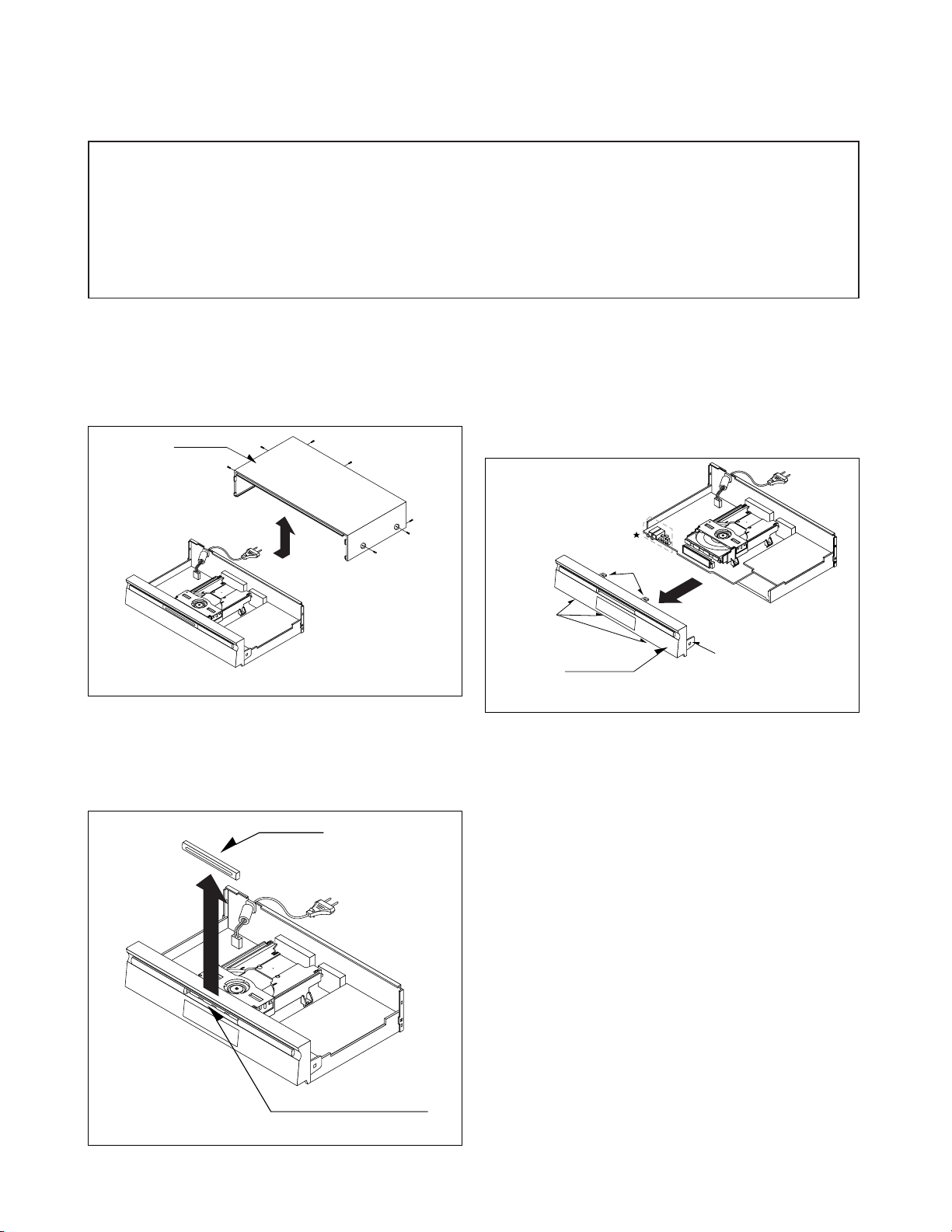

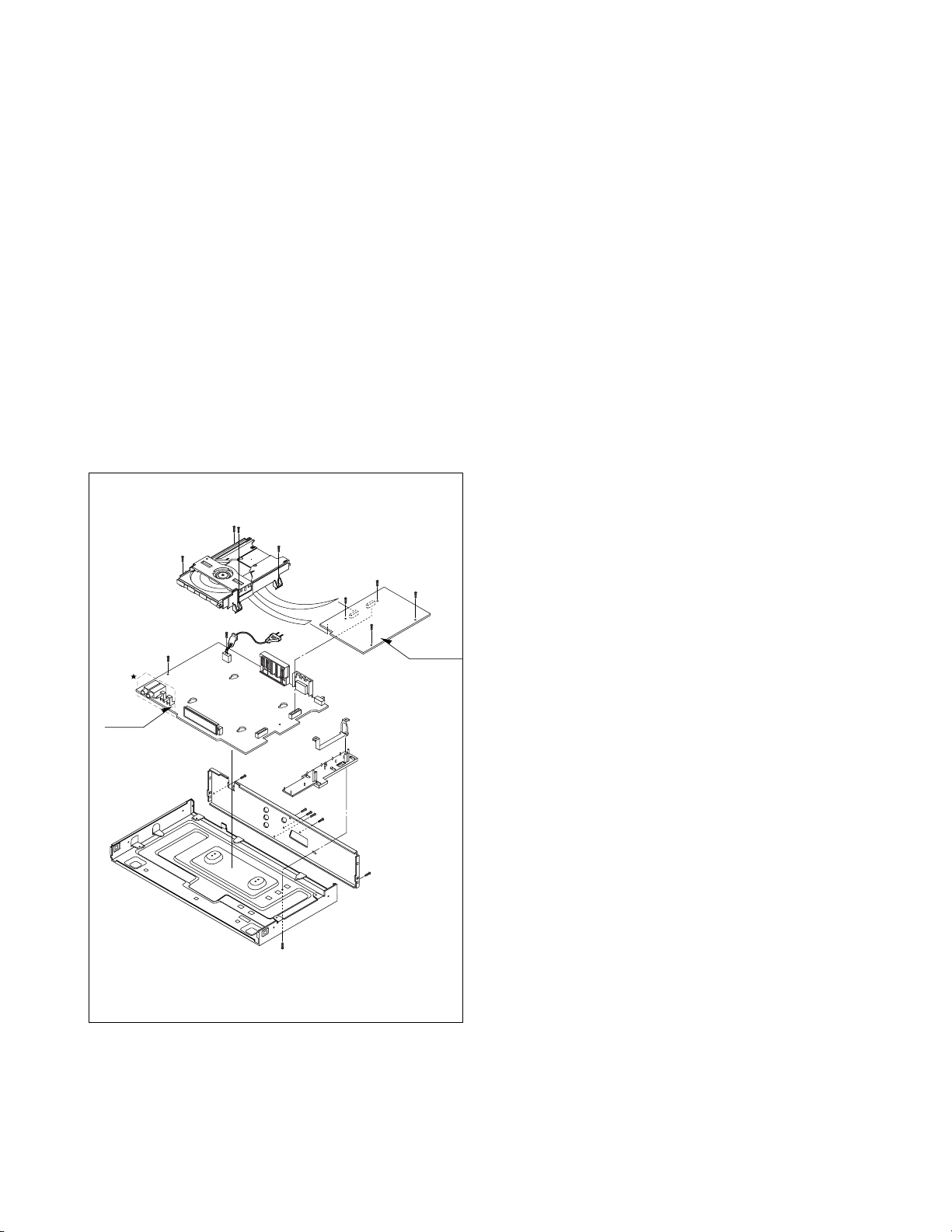

DISASSEMBLY

CAUTION BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily and damaged, so do not forget to take a

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screw driver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded parts and fine pitch screws used to secure

metal parts. If they are used improperly, the screw holes will be easily damaged and the parts can not be fixed.

(A)

(A)

(A)

(A)

(A)

Top Case

(A)

(A)

Tray Door

Disc Tray

Fig. 2-3

Stopper

Stopper

Stopper

Front Panel

OPTIONAL

PART

CABINET DISASSEMBLY

1. Top Case

1. Release 7 screws (A). (See Fig. 2-1)

2. Lift the top case with holding the back of it,

and remove it in the direction of the arrow

Fig. 2-1

Fig. 2-2

Fig. 2-3

3. Front Panel

1. Eject the disc tray. (See Fig. 2-2)

2. Remove the tray door. (See Fig. 2-2)

3. Pull the front panel toward you while pressing

7 stoppers to disengage, and remove the front

panel. (See Fig. 2-3)

2.Tray Door

1.Eject the disc tray.

2.Lift up the tray door in the direction of the

arrow.

2-3

OPTIONAL

PART

Interface

Board

Main Circu

Board

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(C)

Fig. 2-4

1. Disassembling of Main Circuit Board

and Interface Board

1. Remove the top case.(See Fig. 2-1)

2. Remove 14 screw (B).

3. Remove the Deck from Main Circuit Board.

4. Remove Main Circuit Board from Interface Board.

5. Remove 2 screw (C).

6. Remove Interface Board from the chassis.

CIRCUIT BOARD DISASSEMBLY

Note: Before removing the main circuit board, be sure to shortcircuit the laserdiode output land.

After replacing the main circuit board, open the land after inserting the flexible connector.

(Refer to Mechanism Disassembly)

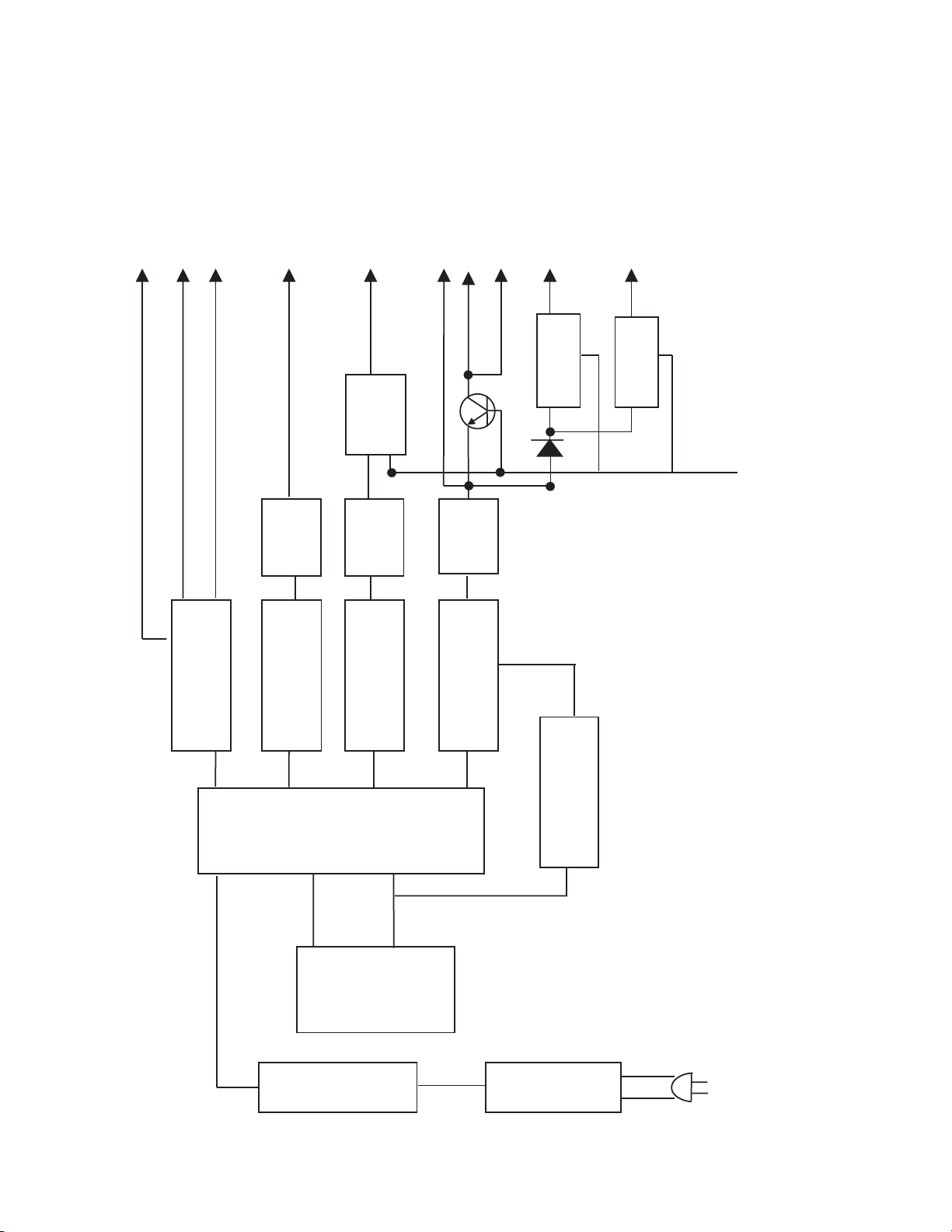

2. Power(SMPS) Block Diagram

5V_D

5V_A

-24VA

F+

RECTIFIER

LINE FIL TER

SWITCHING TR

TRANS

FEED B.

REG(8V)

8V

5.2VA

F-

RECTIFIER(FLD )

RECTIFIER(9V)

RECTIFIER(5.2V)

LPF

LPF

RECTIFIER(14V)

LPF

12VA

AC90~240V

PWR ON/OFF

REG(3.3V)

REG(3.3V)

3.3V_M1

3.3V/3.3V_M

DV5000's/DV6000's

3-14

3-15

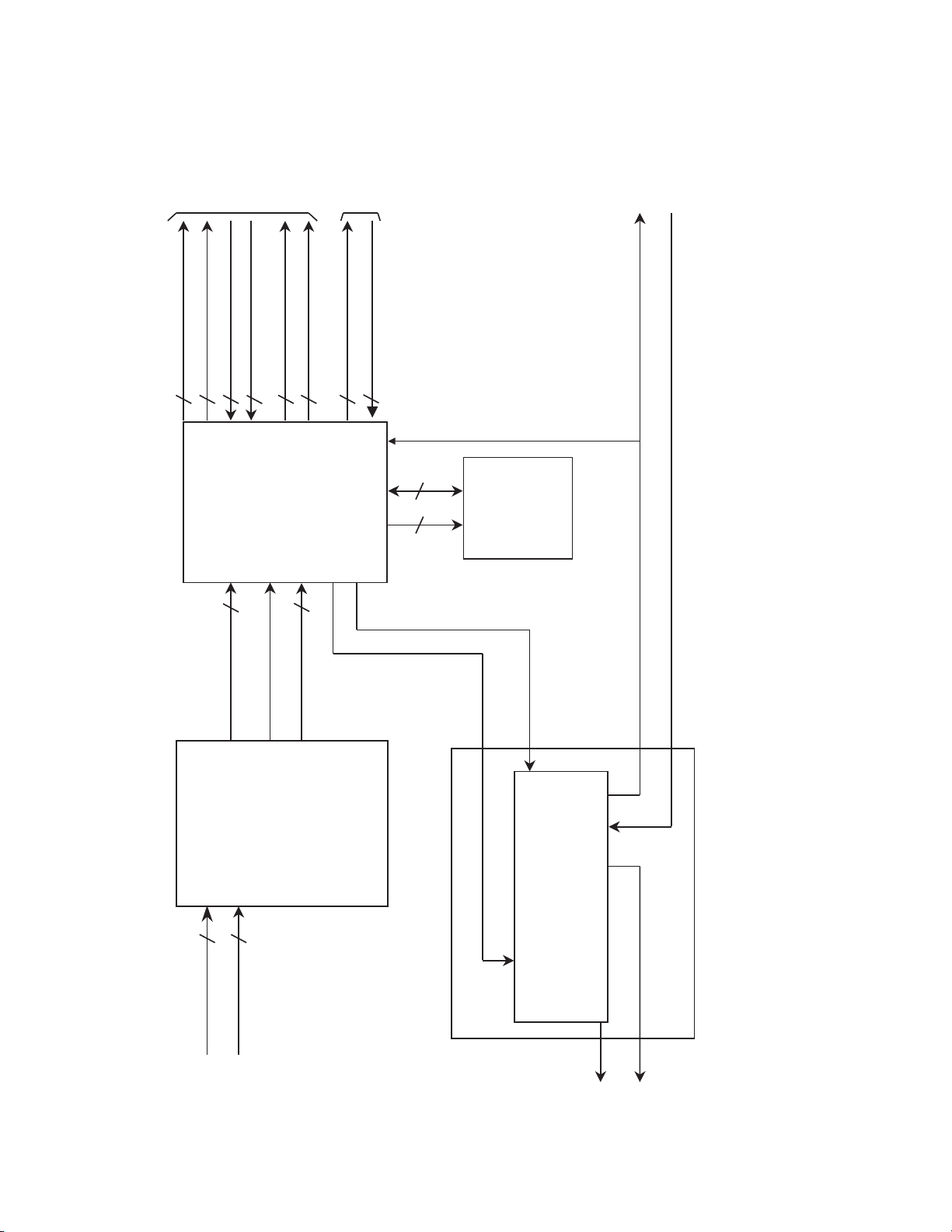

8

SENS, FOK, SLD_FG,

MSDAT0, DEFECT,DSP_SENSE

IC2M1

KA3082

SpindleMotor, LoadingMotor,

Actuator Driver

CD: A,B,C,D / E, F

4

4

MIRR,TZC

8

5

3

3

SQSO, SQCK,

SCOR

SCOR

6

XL AT , S_CL K, S_DA TA

UCOM

I/F

focu

s, track

ing, l

oa

di ng,

sled

Spi ndle

M/D

PICK

UP

MCK

IC206

HDC25D811

CD / DVD DSP

DVD SERVO

IC2A1

HD153702TF

RF Signal

Process or

FDO,TDO,FMO

Load open/cl ose(l oadi ng control)

UCOM

I/F

DVD: A,B,C,D,

FE,TE,PI,SBADD

4

DVD/CD RF

IC203

1M x 16bit

SDRAM

16

9

ICADDR[ 0:8]

ICDAT A[ 00:15]

DO[0:7]

AO[0 :5]

DVD_DATA[0:7]

MON,MDP

SPINDLE_FG

MPEG

I/F

2

DSP_CS, /WR, /RD

3

8

DV5000's/DV6000's

3. RF/CD DSP/DVD DSP/DVD SERVO Block Diagram

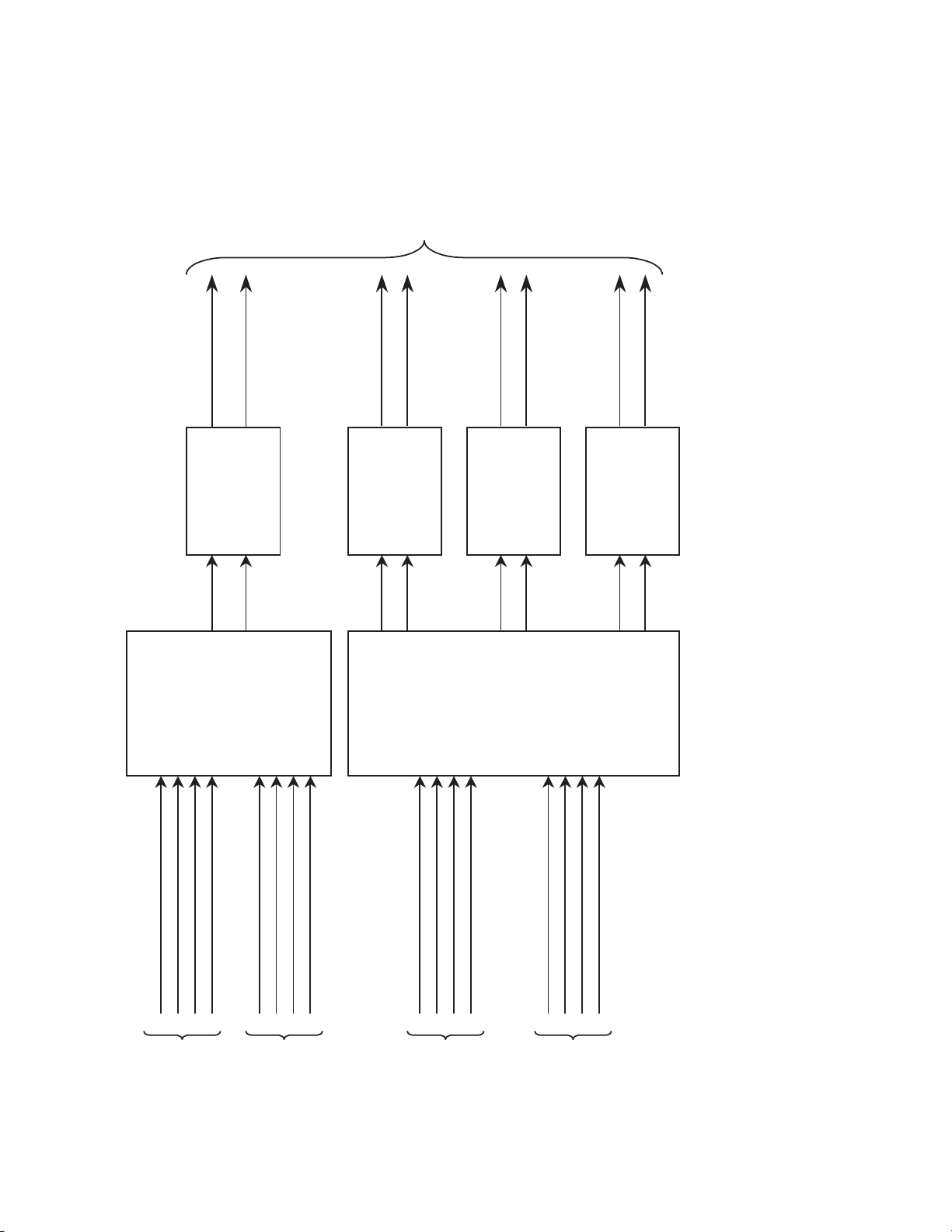

4. Audio Block Diagram

IC401

CS4932

Aud

i

o DAC

IC402

LPF & Bu ff

er

Buff

er

Buff

er

Buff

er

K

A

5532

OP AMP

DAC_RST

S_DAT A

S_CL K

DAC_L 0

DA_L RCK

DA_DAT A0

DA_BCK

DA_X CK

FL

FR

RL

RR

WOOFER

CENTER

L

R

U-COM

I/F

IC452

LPF &

KA 5532

OP AMP

IC453

LPF &

KA 5532

OP AMP

IC454

LPF &

KA 5532

OP AMP

IC451

PCM1603K Y

Aud io DAC

(5.1CH)

FL

FR

RL

RR

WOOFER

CENTER

L

R

A/V

JACK

I/F

DAC_RST

S_DATA

S_CL K

DAC_L 1

DA_L RCK

DA_DAT A[1: 3]

DA_BCK

DA_X CK

MPEG

I/F

MPEG

I/F

U-COM

I/F

DV5000's/DV6000's

3-16

3-17

5. MPEG & MEMORY Block Diagram

IC501

PANTERA-2

LE/PLUS

IC301

XC9572VL

CPLD

I/O PORT 72

IC304

SDRAM

16/32BIT

64M

IC502

93C46

EEPROM

IC3F1

FL A SH

MEMORY

AD[0 :7]

8

DSP

I/F

DVD[0:7]

8

LA [0:3]

4

SCLK,SDATA

SQCK,SQS0

REQP

SDCL K1,PSYNC

DSP_INT

SENSE

/DSP_CS

AD[04:21]

RF &

MOTOR

I/F

MIRR

LDON

SCLK,SDATA

EE_CS

F_IN

32

MD[ 00:31]

MCLK2

CKE

MA [00:10]

MA 12,13

/CS0

/RAS/

/CAS

/WE

/DQM[0:3]

SPINDLE_FG

ALE

AD[ 04:19]

16

LADD[04:19]

16

LA [0:3]

4

AD[ 00:15]

16

AUDIO

I/F

DA_DAT A[0:3}

DA_BCK,DA_LRCK,DA_XCK

4

DAC_L 0,DAC_L1

DAC_RST

A/V

JACK

I/F

C/R(B)

CVBS/G(R)

Y/B (G)

CVBS

V_MUTE,16:9

ZISENB

/RD

/PWED

IC301

DV5000's/DV6000's

6. KARAOKE Block Diagram(KARAOKE MODEL ONLY)

3-18

Microphone1

Microphone

Signal

PREAMP

(BA3308)

AMP

(KIA4558)

AUDIO

ADC

(CS5331)

DVD DSP

(P-Processor)

MPEG

(NS)

AUDIO

DAC

(

CS4392)

Microphone1

1 The unit turns to KARAOKE MODE with ou-screen lyrics display and melody sound when it play backs

VCD or DVD KARAOKE DISC.

2. IF a microphone is connected at this time, MICON recoguizes the connection and prepares the compo-

sition of external voice and internal melody.

3. The week signal of the microphone is converted to the digital signal after voice output that has passed

through PREAMP(BA3308) and AMP(KIA4558) passes through(CS5331) that is Audio ADC(Analog to

Digital convertor).

4. This digital signal enters NS that is MPEG IC and is added to the output of DVD DSP (Processor)

5. This mixed signal is output to AV JACK after passing through AUDIO DAC(CS4392).

(Block Digram)

Loading...

Loading...