Page 1

DLP PROJECTION TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : NB-04AA

MODEL : DU-52SZ61D

CANADA : http//biz.lgservice.com

USA : http//www.lgservice.com

: http//lgservice.com/techsup.html

Page 2

- 2 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

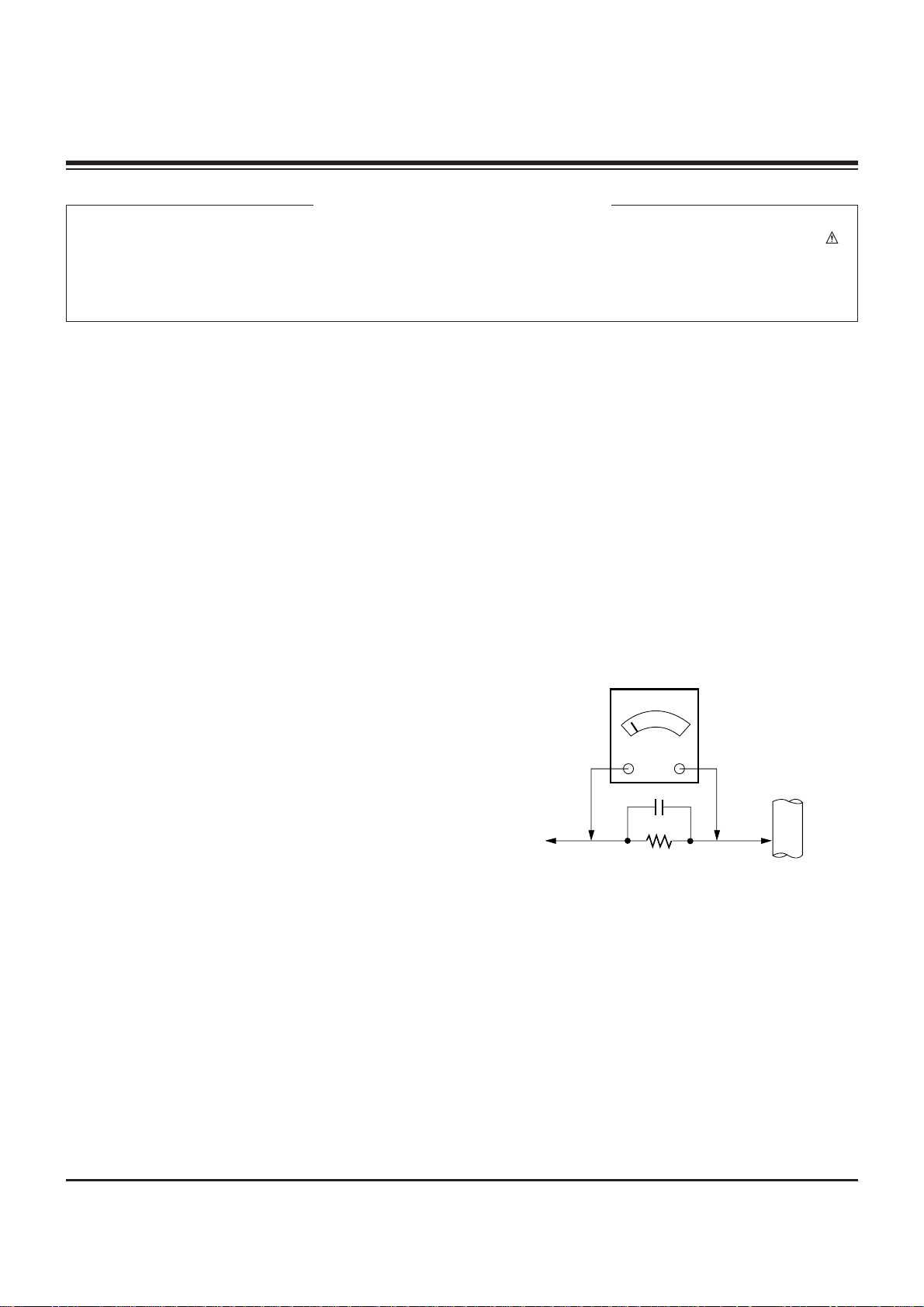

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 3

- 3 -

SPECIFICATIONS.................................................................4

DESCRIPTION OF CONTROLS...........................................5

ADJUSTMENT INSTRUCTION.............................................8

PRINTED CIRCUIT BOARDS.............................................21

BLOCK DIAGRAM...............................................................31

EXPLODED VIEW...............................................................32

EXPLODED VIEW PARTS LIST.........................................33

REPLACEMENT PARTS LIST............................................34

SCHEMATIC DIAGRAM..........................................................

TABLE OF CONTENTS

Page 4

- 4 -

• The specifications shown above may be changed without prior notice for quality improvement.

MODELS

AC120V, 60Hz

NTSC-M, ATSC

VHF 2 ~ 13, UHF 14 ~ 69, CATV 1 ~ 135, CADTV 1 ~ 135. DTV 2 ~ 69

75 Ω

Power requirement

Television System

Program Coverage

External Antenna Impedance

DU-52SZ51D / DU-52SZ61D

SPECIFICATIONS

Page 5

- 5 -

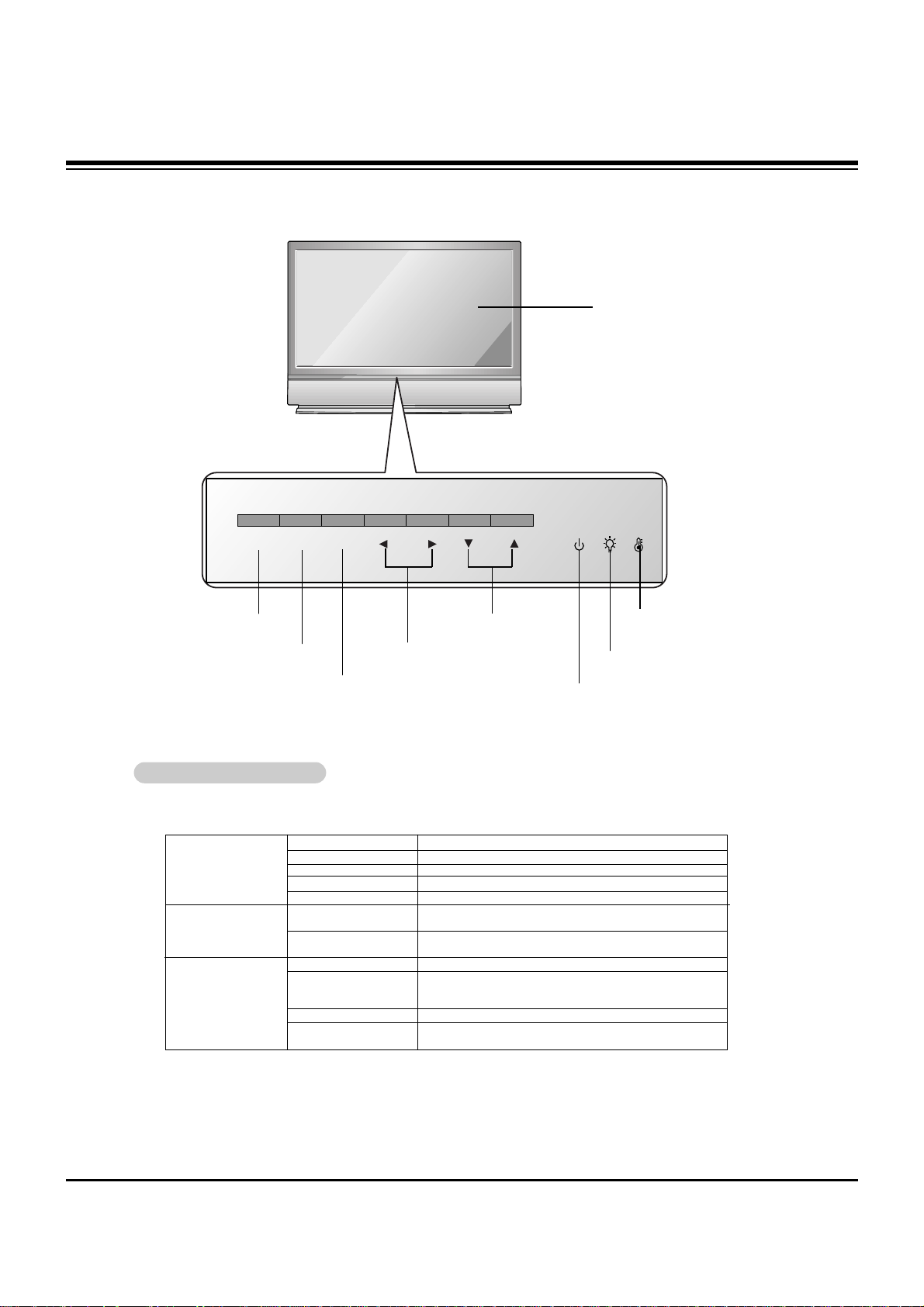

Controls

Controls

POWER TV GUIDE VOL CH

ENTER

POWER Button

VOLUME (

FF,GG

) Buttons

Remote Control Sensor

CHANNEL (EE, DD) Buttons

Operation Indicator

Lamp Indicator

Temperature Indicator

ENTER Button

TV GUIDE Button

Off Power Cord is not connected.

Red Power Cord is connected, TV is in standby mode.

Green TV turns on.

Red (flashing) Power Cord is connected, TV is in booting sequence.

Orange (flashing) Preparing operation in standby mode.

Orange Projection lamp is reaching the end of its life and needs to

be replaced with a new lamp. Contact your service center.

Red (flashing) There is a problem with the lamp or around it. Contact an

authorized service center.

Green (flashing) The lamp cover is not closed.

Orange The projection TV is overheating. Check the blocked vents

of the Projection TV and the accumulated dust in the dust

filter.

Red The projection TV shut down due to overheating.

Red (flashing) The projection TV shut down, check the cooling fan.

Contact your service center.

Operation Indicator

Lamp Indicator

Temperature Indicator

- Lamp indicator, operation indicator, and temperature indicator located below the front panel controls, reveal the

operating status of the DLP projection TV.

Function Status Indicators

Function Status Indicators

DESCRIPTION OF CONTROLS

Page 6

- 6 -

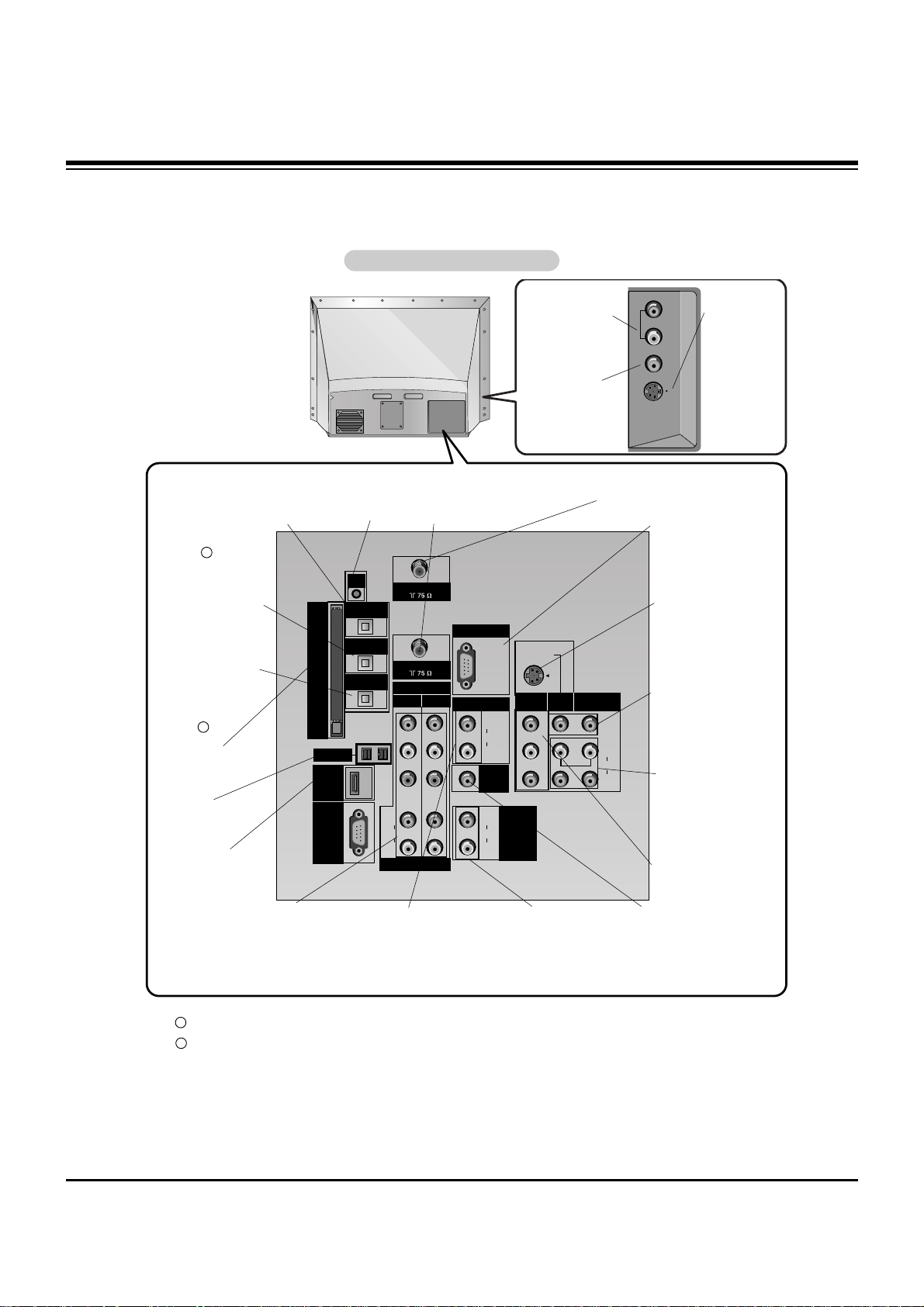

Connection Options

Connection Options

PC/DTV

(XGA

/480p

/720p

/1080i)

S-VIDEO

PR

PB

Y

MONO

CABLE

RGB INPUT

COMPONENT

INPUT2 INPUT1

DTV/DVD INPUT

RGB/DVI INPUT

(L)

(R)

AUDIO

(L)

(R)

AUDIO

VIDEO

(L)

(R)

AUDIO

(L)

(R)

AUDIO

AUDIO

CENTER

MODE IN

MONITOR

OUTPUT

VIDEO

INPUT2

VIDEO

INPUT1

DIGITAL AUDIO

OPTICAL INPUT1

(COMPONENT2)

DIGITAL AUDIO

OPTICAL INPUT2

(DVI)

IEEE1394

DIGITAL AUDIO

OPTICAL OUTPUT

ANTENNA

S-VIDEO

FRONT A/V

VIDEO

AUDIO

(R)

(L)/

MONO

Cable

CARD

HDMI/

DVI(VIDEO)

UPGRADE

PORT

VARIABLE

AUDIO OUT

G-LINK

Back Connection Panel

Back Connection Panel

ANTENNA Inputs

Connect antenna signals to the

TV directly .

DIGITALAUDIO OPTICAL

OUTPUT

Used to connect either an external amplifier, or add a subwoofer to your surround sound

system if it has a digital

audio optical input.

(Refer to )

MONITOR OUTPUT

Connect a second TV or

Monitor.

S-VIDEO In

A connection available

with some high-end

equipment that provides

even better picture quality for Video 2.

RGB/DVI INPUT

Connect the monitor

output connector from

a PC to the appropriate input port.

RGB Input

Connect the TV output

connector from a PC/DTV

to the appropriate input

port.

AUDIO CENTER MODE IN

Connect to external Dolby

Digital Center “preamp

output.”

VARIABLE AUDIO OUT

Used to connect either

an external amplifier, or

add a sub-woofer to your

surround sound system.

COMPONENT INPUT 1-2

Connect a component

video/audio device to these

jacks. Refer to your DVD

manual for further information.

VIDEO 1 or 2

Connects the video signals from various types

of equipment.

Left/Right AUDIO

Used for stereo sound

from various types of

equipment.

HDMI/DVI(VIDEO)

Connect a

HDMI/DVI(Video) signal

to this jack.

IEEE1394

Connect DVHS or

MicroMV to IEEE1394

Connector.

CableCARD

Used for CableCARD

received Cable Service

Provider.

CABLE Inputs

Connect cable signals to the

TV, either directly or through

your cable box.

LEFT/RIGHT AUDIO

Used for stereo

sound from various

types of equipment.

VIDEO

Connects the

video signals from

any piece of

equipment.

S-VIDEO

A connection

available on

some very

high-end equipment that provides better picture quality

than video

input.

G-LINK

Connect an

IR controller

to this jack.

DIGITALAUDIO OPTICAL INPUT1(COMPONENT2)

Connect digital audio

from the equipment

whose video is connected to COMPONENT 2.

DIGITALAUDIO OPTICAL INPUT2(DVI)

Connect digital audio

from the equipment

whose video is connected to

HDMI/DVI(VIDEO).

(Refer to )

Note: In standby mode, these port will not work.

If the video is connected through HDMI-TO-HDMI cable, you don’t need to connect digital audio. This port

is used only when the video connected through DVI-TO-HDMI cable.

1

2

1

2

DESCRIPTION OF CONTROLS

Page 7

- 7 -

LIGHT

TV/VIDEO

MODE

COMP/RGB/HDMI

MUTE

SURF

VOL CH

PGUP

PGDN

INFO

SAP

RATIO

CC

MENU

TV GUIDE

TIMER

EXIT

PLAY

PAUSE STOP

RECORD

PIP PIPCH- PIPCH+ PIPINPUT

ENTER

SIGNAL SWAP

REW FF

POWER

1394

FLASHBK

VIDEO

SOUND

ADJUST

FREEZE

DAY +

DAY -

SKIP

Remote Control Key Functions

Remote Control Key Functions

- When using the remote control, aim it at the remote control sensor on the TV.

VCR/DVD BUTTONS

Control some video cassette recorders or

DVD player ("RECORD" button is not available for DVD player.)

Selects the frequency setting in the recording: Once, Regulary, Weekly, Off.

RATIO

Changes the aspect ratio.

MODE

Selects the remote operating mode: TV,

VCR, DVD, CABLE, HDSTB or AUDIO.

Select other operating modes, for the

remote to operate external devices.

POWER

Turns your TV or any other programmed

equipment on or off, depending on mode.

1394

SURF

Use to scroll the Surf channel.

CC

Select a closed caption:

Off, CC1~4, Text1~4.

FLASHBK

Tunes to the last channel viewed.

CHANNEL UP/DOWN

Selects available channels found with EZ

scan.

PAGE UP/PAGE DOWN

Moves from one full set of screen information to the next one.

EXIT

Clears all on-screen displays and returns to

TV viewing from any menu.

TIMER

Lets you select the amount of time before

your TV turns itself off automatically.

PIP

Switches between PIP, POP (Picture-out-ofPicture) and Twin picture modes.

Switches the video window locking or

unlocking in the Listing Grid.

PIPCH-/PIPCH+

Changes to next higher/lower PIP channel.

PIP INPUT

Selects the input source for the sub picture.

SWAP

Exchanges the main/sub images in

PIP/Twin picture mode.

DAY+/DAY-

Moves forward or backward in 24 hour

increments in the Listings Grid.

LIGHT

Illuminates the remote control buttons.

TV/VIDEO

Selects: Antenna,Cable,Video1,2, Front

Video, Component 1-2, RGB-DTV (or RGB-

PC), HDMI/DVI input sources.

COMP/RGB/HDMI

Selects: Component 1-2, RGB-DTV (or RGB-

PC), HDMI/DVI input sources.

NUMBER buttons

DASH

Used to enter a program number for multiple

program channels such as 2-1,2-2,etc.

MUTE

Switches the sound on or off.

THUMBSTICK (Up/Down/Left/Right/ENTER)

Allows you to navigate the on-screen menus

and adjust the system settings to your pref-

erence.

VOLUME UP/DOWN

Increases/decreases the sound level.

SAP

Selects MTS sound: Mono, Stereo, and SAP

in Analog mode. Change the audio language

in DTV mode.

MENU

Brings up the main menu to the screen.

Enter or exit the panel menu in the Guide

Screen.

INFO

When you watch the TV, displays information

on top of the screen. Not available in

Component 1-2, RGB and HDMI/DVI mode.

TV GUIDE

Brings up the TV Guide On Screen system to

the screen.

VIDEO

Adjusts the factory preset picture

according to the viewing

environment.

ADJUST

Adjusts screen position, size, and

phase in PC mode.

SOUND

Selects the sound appropriate

for the program's character.

SIGNAL

Displays the digital signal strength.

FREEZE

Freezes the currently-viewed picture. Main pic-

ture is frozen in PIP/Twin picture mode.

DESCRIPTION OF CONTROLS

Page 8

- 8 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions apply to the DLP Projection (Chassis: NB04AA).

2. Notes

(1) Because this is not a hot chassis,it is not necessary to use

an isolation transformer. However, the use of an insolation

transformer will help protect test equipment.

(2) The adjustments must be performed in the correct

sequence.

(3) The adjustments must be performed in the condition of

25±5°C of temperature and 65±10% of relative humidity if

there is no other specific designation.

(4) The input voltage of the receiver must remain AC 110V,

60Hz.

(5) Unless stated otherwise, the set must be operated for at

least 5 minutes prior to adjustments.

The heat-run should be performed with a 100% white

pattern,but reception of a moving picture may also be

possible in unavoidable cases.

3. Composition of Adjustment Mode

(1) Adjustment modes are entered by pressing the ADJ key

on the Service Remote Control, after adjustments press

the ADJ key to exit.

(2) Initial Adjustment mode Menu is shown below. <Fig. 1>

(3) As shown <Fig. 1>, using the CH+ (

D), CH- (E) keys to

select an item, press the ENTER or VOLUME+ (

G) keys to

enter the appropriate item and begin adjustment.

(4) Change the value of adjustment with using the volume +(

G ),

volume -(

F) keys. To change adjustment item, use the

CH+ (

D), CH- (E) keys in EZ ADJ Mode.

(5) Press the ADJ key to exit, after adjustments.

(6) Preparation for Adjustment

1) Connect the power to TV Set and set “Power on”.

2) Allow set to Heat-Run for at least 5 minitues before

adjusting.

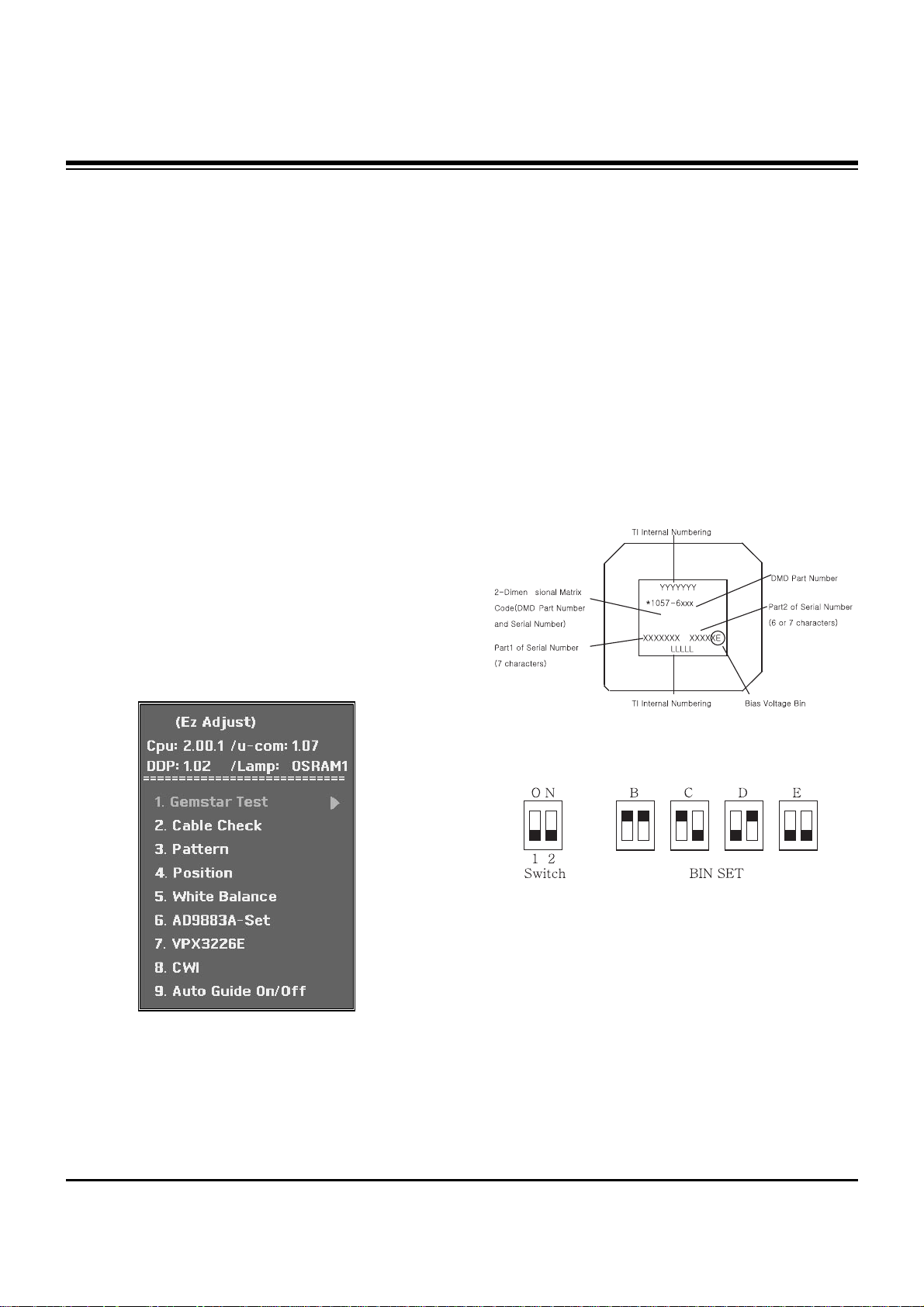

4. Driver Board Bin Setting

See Bias Voltage Bin on the DMD as shown <Fig. 2> and

adjust the switches on the lower Driver Board as shown <Fig.

3>.

<Fig. 2> DMD Marking Locations

<Fig. 1> Adjustment Mode OSD

<Fig. 3> Driver Board Bin Setting

Page 9

- 9 -

ADJUSTMENT INSTRUCTIONS

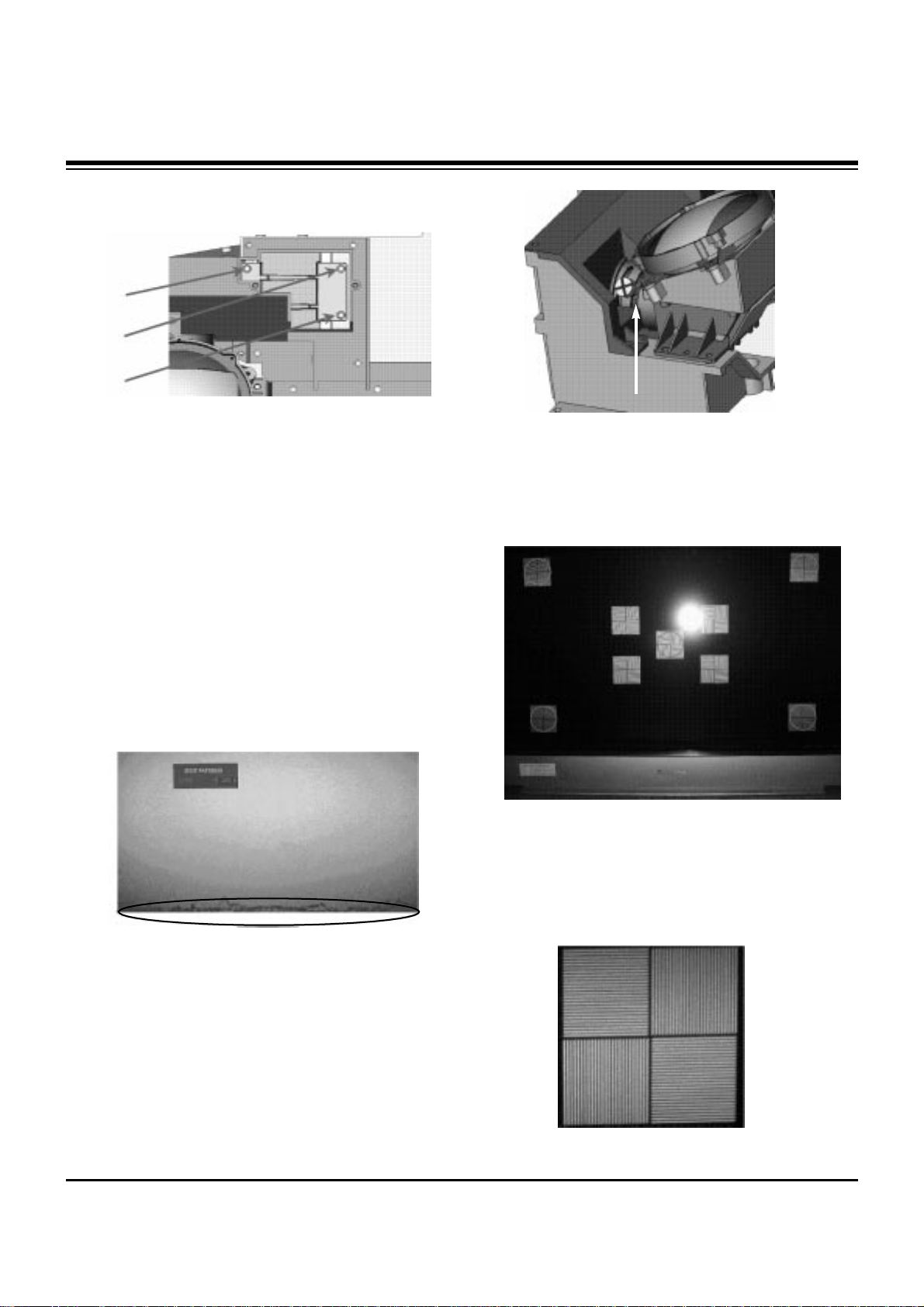

5. Adjusting the Optical Engine

(1) After placing the optical engine on the JIG, adjust

illuminator by adjuting the A, B, and C as shown <Fig. 4>.

1) Screen change when adjusting screw A

Tighten the screw: Upper/right illuminator are out of joint

Loosen the screw: Lower/left illuminator are out of joint

2) Screen change when adjusting screw B

Tighten the screw: Lower illuminator is out of joint

Loosen the screw: Upper illuminator is out of joint

3) Screen change when adjusting screw C

Tighten the screw: Upper/left illuminator are out of joint

Loosen the screw: Lower/right illuminator are out of joint

Check the spot (phenomenon such as Light tunnel exit) on the

edge of the white screen as shown <Fig. 5>.

(2) After adjusting the illuminator, adjust the focus by using the

focus adjustment screw of projection lens. After adjusting,

fasten the screw tighty and secure with sealer.

[ Note: The focus check point is not the screen center but the

upper/lower screen.

1) <Fig. 7> shows the pattern for focus adjustment

2) Adjust the 4 green ellipse so that all are in equal focus.

3) If you can’t check the DMD cell border at red center

position after adjustment, regard as NG.

4) <Fig. 8> shows the magnified pattern for checking the

focus adjustment

<Fig. 5>

<Fig. 6>

<Fig. 7>

<Fig. 8>

A

B

C

<Fig. 4>

Page 10

- 10 -

ADJUSTMENT INSTRUCTIONS

6. Caution for DMD

(Digital Micro-mirror Device)

6-1. Caution for DMD ESD

(1) Use a grounding strap to prevent ESD (Electrostatic

Dischage) damage when handing the DMD.

(2) Connect the grounding strap to a ground point on the

workbench.

(3) Keep the DMD in an ESD Safe container when not being

used or in transit.

(4) Wearing gloves will help prevent ESD damage and help

preserve the physical condition of the DMD.

(5) All work should be performed in a static free environment.

(6) Use caution and remove any dust particles on the DMD

front glass or back pins/pads.

6-2. Caution for DMD Cleaning

(1) Use caution to prevent scratches to the DMD glass.

(2) When DMD glass stains with dust, polish the front and

back DMD glass with soft cloth. Then, rotate the DMD 180

degrees and polish again.

(3) Do not use pressure when cleaning the DMD. The static

electricity and pollution can damage the DMD.

7. EDID(HDMI) Data Input

7-1. Required Test Equipment

(1) Jig for adjusting PC, DDC (PC serial to D-sub connection

device)

(2) S/W for writing DDC(EDID data write & read)

(3) D-sub terminal

(4) Jig for connecting EDID(HDMI) Cable

7-2. Adjustment Preparation and Setting of

Device

(1) Setup as in <Fig. 9> and turn on the PC & JIG.

(2) Operate the S/W for writing DDC(EDID data write & read)

(operated in DOS mode.)

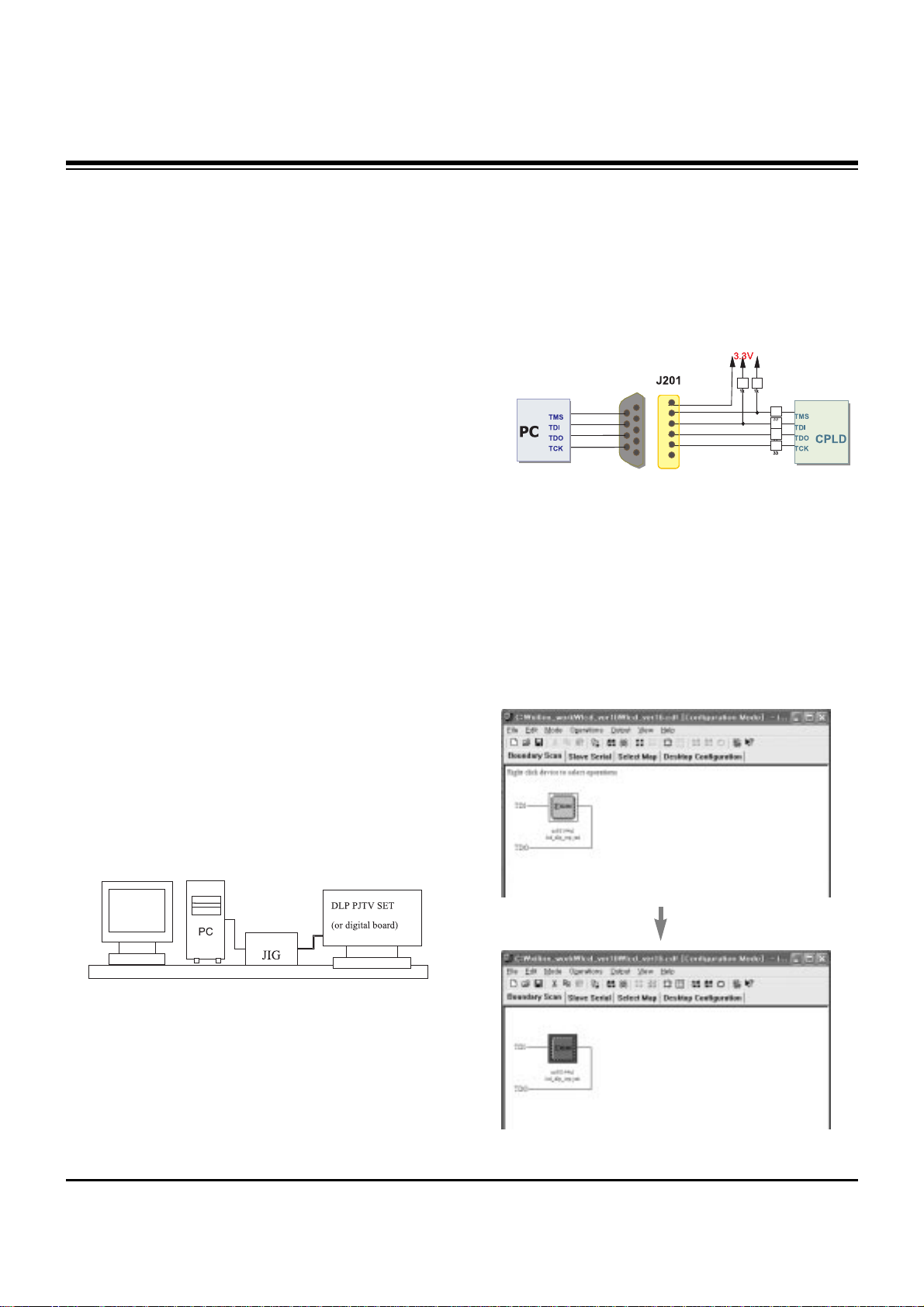

8. CPLD Download Work

8-1. Required Test Equipments &

Preparation for Adjustment

(1) Connect the PC and memory JIG as shown in <Fig. 10>.

(2) Turn on JIG MAIN POWER SW.

(3) Turn on the PC and moniter, operate the device

programming software.

8-2. Adjustment Sequence

(1) Once the program is running, [OPTION MODE

SELECTION] is displayed in the window.

Check the “Load configuration File(.cdf, .pdr)” in this

window and click the finish button

(2) When the screen displays the open window, select the

suitable file(*.cdf) according to model.

(3) IC figure is change to green by clicking it.

(Refer to <Fig. 11>)

<Fig. 9> Device Setting Diagram of Input EDID Data

<Fig. 10 > How to connect the MEMORY JIG and PC

<Fig. 11>

Page 11

- 11 -

ADJUSTMENT INSTRUCTIONS

(4) Select program options.

(5) Check the [Erase before programming] and [Verify] menu

as shown <Fig. 12> and press the OK button.

(6) At this time, the download starts. The download will finish

in about 10 seconds.

9. Gemstar VBI Micom Download

9-1. Preparation for Adjustment

(1) As shown below, connect the MPLAB ICD2 equipment, PC

and Digital Connector.

(2) Turn on the MPLAB ICD2 POWER Supply.

(3) After turning on the PC and MONITOR, select the ‘MPLAB

IDE’ from the screen.

9-2. Adjustment Sequence

(1) Once the program is executed, select the MPLAB ICD2

from "Programmer -> Select Programmer".

(2) Select "Configure -> Select Device".

(3) When the "Select Device" window appears, select the

PIC18F1220 from "Device" and press OK.

(4) Select "Programmer -> Connect".

When connected with the Micom, the display message on

the Output window appears as below.

<Fig . 12>

+13V

CN1201

IC1204

VIB Micom

+5V

GND

Data

Clock

<Digital Board>

Connect the MPLAB ICD2 and connector of Digital Board

Connect the RS-232 or USB Cable

Connecting to MPLAB ICD 2

...Connected

Setting Vdd source to MPLAB ICD 2

Target Device PIC18F1220 found, revision = 0x4

...Reading ICD Product ID

Running ICD Self Test

...Passed

MPLAB ICD 2 Ready

Page 12

- 12 -

ADJUSTMENT INSTRUCTIONS

(5) Select "File -> Import", select the Work HEX file and open.

(6) Select "Programmer -> Program".

(7) Download begins and about 3 seconds later, the

"Programming succeeded" message is displayed on the

Output window and the Download process is ended.

Note: Step (6) is more convenient when using the short-cut icon.

10. Gemstar IR Micom Download

10-1. Preparation for Adjustment

(1) As shown below, connect the MPLAB ICD2 equipment, PC

and Digital Connector.

(2) Turn on the MPLAB ICD2 POWER Supply.

(3) After turning on the PC and MONITOR, select ‘MPLAB

IDE’ from the screen.

10-2. Adjustment Sequence

(1) When the program is executed, select MPLAB ICD2 from

"Programmer -> Select Programmer"

(2) Select "Configure -> Select Device".

(3) When the "Select Device" window appears, select

PIC18F242 from "Device" and press OK.

(4) Select "Programmer -> Connect".

+13V

CN1203

IC1205

IR Micom

+5V

GND

Data

Clock

<Digital Board>

Connect the MPLAB ICD2 and connector of Digital Board

Connect the RS-232 or USB Cable

Page 13

- 13 -

ADJUSTMENT INSTRUCTIONS

When connected with the Micom, the display message on

the Output window appears as below.

(5) Select "File -> Import", select the Work HEX file and open.

(6) Select "Programmer -> Program".

(7) Download begins and about 3 seconds later, the

"Programming succeeded" message is displayed on the

Output window and the Download process is ended.

Note: Step (6) is more convenient when using the short-cut icon.

11. POD Certificate Download &

IEEE1394(DTCP) Download

11-1. Preparation for Adjustment

(1) Connect the MEMORY JIG and PC.

(2) Turn on the JIG MAIN POWER SWITCH.

(3) After turning on the PC and MONITOR, execute the

‘Certificate Downloader v1.4’ from the screen.

11-2. Adjustment Sequence

(1) After opening the ‘Certificate Downloader v1.4’, enter

Connection set and set the as same below.

The port settings are determined by each PC's setup.

(2) Select ‘Connection’ and SET connected to RS-232C.

(3) After clicking "Enter", confirm that "Enter Password:"

appears.

(4) Click the "OpenFile - Download" button from CP Data

Download, ‘select the Private Key’ appears and click

ENTER.

Connecting to MPLAB ICD 2

...Connected

Setting Vdd source to MPLAB ICD 2

Target Device PIC18F242 found, revision = 0x7

...Reading ICD Product ID

Running ICD Self Test

...Passed

MPLAB ICD 2 Ready

Page 14

- 14 -

ADJUSTMENT INSTRUCTIONS

(5) After clicking ENTER, the ‘opens Private key' window

appears and select the Private key applied to the SET.

The Private Key file name is on the Label of the Digital

Board.

(6) When the Dialog window appears, click OK and the

write work will begin.

(7) When completed, click ‘CP Data Download: OK’

[ When ‘CP Data Download: OK’ does not appear, certificate

has not Download correctly.

SET is rebooted and certificate Download work must be

repeated.

(8) Now, you may begin IEEE1394 (DTCP) Download work.

Select the “DTCP.dat” file by pressing the ‘DTCP File

Open’ button.

(9) After opening the ‘DTCP.dat’ file, confirm the key list in the

DTCP Key List window.

(10) Select the desired item of DTCP key List.

When pressing ‘DTCP key writing’ button, the Progress

window will appear.

Page 15

- 15 -

ADJUSTMENT INSTRUCTIONS

(11) When completed, “DTCP key Download: OK" will display

in the Terminal window and the SET will reboot

automatically.

[ When process (11) malfunctions, it is not Download.

DTCP Download process start again from (8).

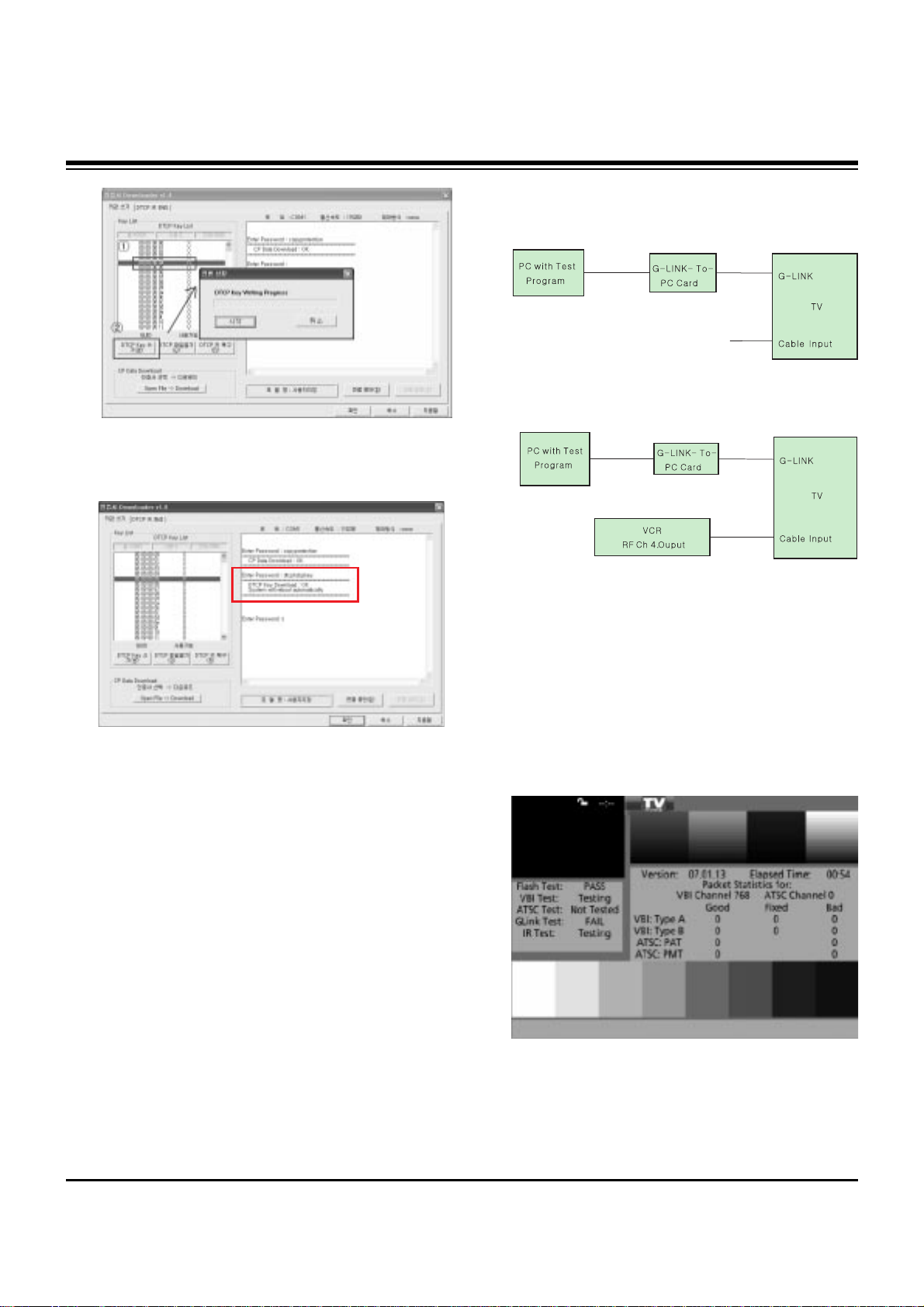

12. Gemstar Operation Confirmation

12-1. Required Test Equipment

(1) PC with Factory Test Program

(2) G-LINK-To-PC Card (Serial GLINK(CN1202))

(3) VBI Inserter (Norpak TES3) - Guide Data Discharge

Equipment

[ If the VBI Inserter(TES3) is not available, a VCR may be

used.

12-2. Preparation for Adjustments

(1) When using VBI Inserter(TES3): Signal uses Cable input

and set as below.

(2) When not using VBI Inserter(TES3): VCR uses Cable input

and set as below.

[ Factory Test S/W must be set to "GLinkTo PC Card" ON.

12-3. Adjustment Confirmation Work

(1) Turn on the TV and run Factory Test Program of PC.

[ Program only needs to run once, regardless of set quantity.

(2) Enter the EZ adjust menu by pressing Adjust on the

Service Remote Control (S R/C).

(3) Go to number 1 Gemstar and press Enter.

(4) TV set screen will appear as shown.

(5) Confrim that VBI Test, Glink Test and IR Test PASS from

the screen.

Input Signal

Page 16

- 16 -

ADJUSTMENT INSTRUCTIONS

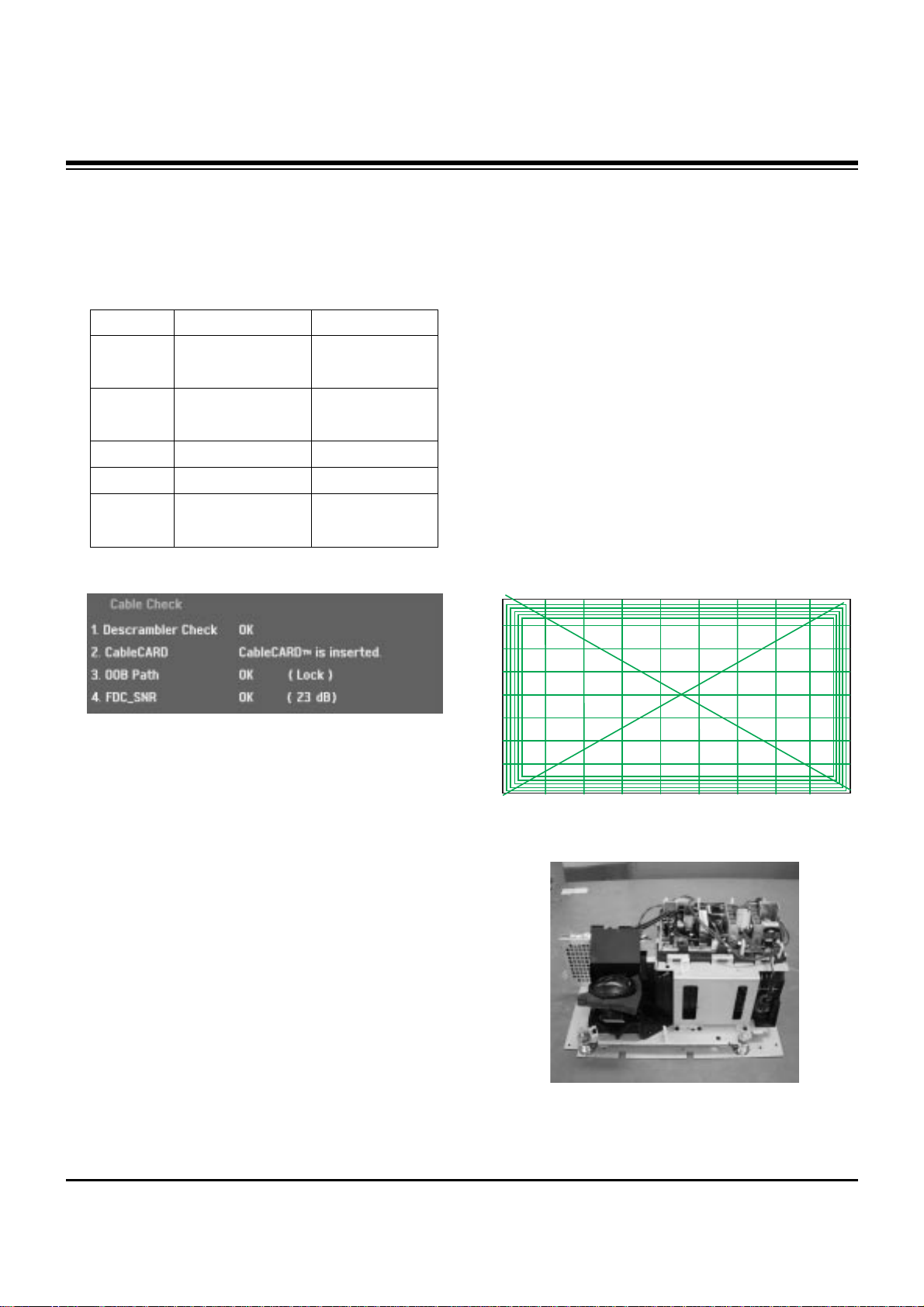

13. Cable Operation Confirmation

(1) Confirm that the Cable Card is inserted in the slot.

(2) Enter the EZ adjust menu by pressing Adjust on the

Service Remote Control (S R/C).

(3) Go to number 2 Cable Check and press the Right key (

G) .

(4) Confirm items below..

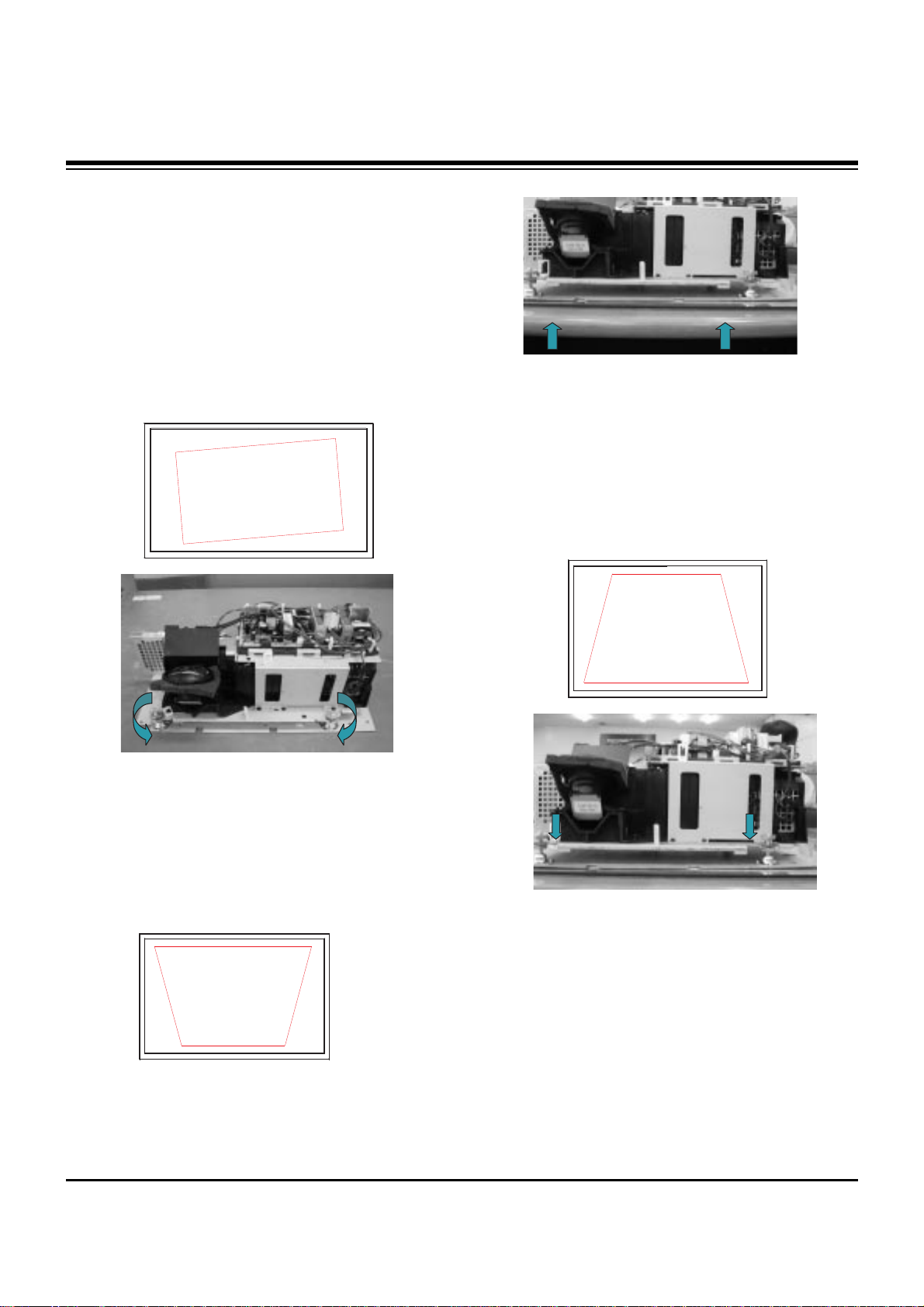

14. Tilt & Keystone Adjustment

14-1. Required Test Equipment

(1) Hardware: Six angle wrenches, Spanner, and Screwdriver

(2) PC to output XGA signal

(3) Service Remote Control

14-2. Preparation for Adjustment

(1) Engine Fix Knob will be able to adjust, Lower Back Cover

does not close.

(2) After Set turn on, select the adjustment pattern come out

from screen using EYE Key on the Service Remote Control .

14-3. Adjustment

(1) After Engine to be completely affixed in the adjustment

Knob pillar from TV front, sees camera sheds light TV

Screen and Keystone & Tilt confirm from back side.

(2) Keystone adjust moving to upper, lower with Top, Bottom

adjustment BOLT and Tilt adjust moving to left, right with

Engine Base.

(3) Both sides Adjustment Knob and Top Mirror adjust to be

Tilt and Keystone is Max and Min difference 4mm.

(4) After adjustment completed, Engine fixes with Top fixation

BOLT.

Name

Descrambler

Check

CableCARD

OOB Path

FDC_SNR

Video Signal

Normal

OK

CableCARD

TM

is inserted.

OK(Lock)

OK(20dB above)

Normal Screen

Defective

Not OK

CableCARD

TM

is removed.

Not OK(Unlock)

Not OK(20dB under)

Black Screen

(No Picture)

<Tilt & Keystone Adjustment Pattern>

<DLP Engine>

Page 17

- 17 -

ADJUSTMENT INSTRUCTIONS

14-4. It followed in Screen Condition,

Projector Lens Direction

(1) When the upper portion of the screen is larger than the

bottom: Adjust Projection lens upward

(2) When the upper portion of the screen is smaller than the

bottom: Adjust Projection lens downward

14-5. It followed in Screen Form,

Adjustment Method

(1) When the screen is rotated: Rotate the Engine to adjust

1) Badness Type: Tilt Badness

2) Adjustment Method:

Engine Base rotate with the left/right and fix the

horizontality horizontal line of Cross Pattern

(2) In case of the upper screen size is large bottom screen

size than: upward projector

1) Badness Type: Keystone Badness

2) Adjustment Method:

The Engine Base front part raises at upper direction and

projection lens to be downward projector.

Bottom screen size a lot, fix the top/bottom screen size to

be same as.

(3) In case of

the upper screen size is

smaller

bottom screen

size than:

downward projector

1) Badness Type: Keystone Badness

2) Adjustment Method:

The Engine Base front part down at bottom direction

and projection lens to be upward projector.

Top screen size a lot, fix the top/bottom screen size to

be same as.

Page 18

- 18 -

ADJUSTMENT INSTRUCTIONS

15. Screen Position Adjustment

15-1. Required Test Equipment

Service Remote Control

15-2. Horizontal Position Adjustment

(1) Press ADJ key on the remote control to enter the

adjustment mode.

(2) Select POSITION in the adjustment menu.

(3) The adjustment pattern below appears.

(4) Select the H_position with CHANNEL key.

(5) Change data with using the VOLUME keys on the remote

control in order adjust left/right screen semmetry.

(6) If symptom is out of adjustable range: N.G.

(7) After adjustment is completed, recieve NTSC-M Digital

Pattern and check the adjusment level.

15-3. Vertical Position Adjustment

(1) Select V_position with CHANNEL key. (V: 15)

(2) Change data with using the VOLUME keys on the remote

control in order to adjust up/downscreen semmetry.

(3) If symptom is out of adjustable range: N.G.

16. Component AD9883A Offset/

Gain Adjustment

16-1. Required Test Equipment

Service Remote Control, 801GF/802F Pattern Generator

16-2. Preparation for Adjustment

(1) Connect power and turn TV set on.

(2) Perform Heat-Run for at least 5 minutes.

(3) Select Component Input.

(4) Receive the 720P/60Hz, HozTVBar Pattern of 801GF/802F.

16-3. Offset/ Gain Adjustment

(1) Press ADJ key on the Remote Control to enter the

adjustment mode after more than 10 seconds of receiving

the signal.

(2) Adjustment is automatic by pressing the VOLUME+ (

G)

key in AD9883A-SET item of adjustment menu.

“Gain/Offset Adjust” will apeear on the OSD for a short

time during adjustment.

(3) After adjustment, “End of AD9883 Adjust” appears and

press the ADJ key to exit.

<Pattern for Screen Adjustment>

Adjustment

Adjustment

<720P/60Hz HozTVBar Pattern>

Page 19

- 19 -

ADJUSTMENT INSTRUCTIONS

17. White Balance Adjustment

17-1. Required Test Equipment

CA110 or CA210

17-2. White base value (Medium)

x = 0.283¡ 0.01, y = 0.297¡ 0.01

17-3. Adjustment

(1) Install the equipment(CA110 or CA210) be 20cm away

from screen center.

(2) Select White balance by pressing ADJ Mode Key on

Remote control.

(3) Warm(6500

cK) : x = 0.313, y = 0.329

1) R Gain 107 fixation

2) Adjust white balance changing G, B gain.

3) Offset fixation R/G/B --> -20, -20, -20

(4) Medium(9300cK) : x = 0.283, y = 0.297

1) R Gain 107 fixation

2) Adjust white balance changing G, B gain.

3) Offset fixation R/G/B --> -20, -20, -20

(5) Cool(12000cK) : x = 0.275, y = 0.277

1) R Gain 107 fixation

2) Adjust white balance changing G, B gain.

3) Offset fixation R/G/B --> -20, -20, -20

* Reference : Gamma table -> 1

Brightness -> 200Level

Spoke Func. -> 0

R/G/B offset -> Fix to -20 without MODE

18. CWI Adjustment

18-1. Required Test Equipments

Service Remote Control

18-2. Preparation for Adjustment

(1) Connect power and turn the TV set on.

(2) Using the remote control, enter from ADJUST to CWI.

(Base value: 160)

18-3. Adjustment

(1) Using the Volume key, adjust CWI to the left/right.

(2) As adjustment, check the appearance noise in the TEST

Pattern.

Setting the value reduced 3~4 step at a GREEN noise

disappearing spot.

(3) Using CH UP/DOWN key of the Remote Control, enter the

RED PATTERN.

(4) Check the RED Pattern to uniform. After checking unless

abnormality do OK.

[ As temperature is different sensitivity, change angle of the

color wheel. At this time, the adjustment is done because color

may be changed.

(color wheel index)

CWI

160

<TEST Pattern: Lamp Gray Pattern>

(color wheel index)

CWI

162

starting point of noise

(appearance GREEN)

(color wheel index)

CWI

160

<TEST Pattern: RED Pattern>

Page 20

- 20 -

ADJUSTMENT INSTRUCTIONS

19. Main/Sub Contrast Adjustment

Adjust which it sees last prosecuting attorney time the screen

contrast difference.

Basically the letter does with the fact that the character and

distinction become.

19-1. Preparation for Adjustment

(1) Receive signal(RF 06Ch.) on the Main/Sub screen in twin

picture mode.

(2) Set Picture control to “CLEAR”.

19-2. Adjustment

(1) Main Screen Adjustment

1) Select the VPX3226 by pressing “ADJ” key on the

Service Remote Control.

2) Select Contrast(m) in adjustment menu using CH +/keys and adjust using VOL +/- keys. (Initial data: 32)

(2) Sub Screen Adjustment

1) Select the VPX3226 by pressing “ADJ” key on the

Service Remote Control.

2) Select Contrast(s) of adjustment item using CH +/-keys

and adjust using VOL +/- keys. (Initial data: 32)

19-3. Overseas Factory Production

Contrast Adjustment Method

Adjust which it sees last prosecuting attorney time the screen

contrast difference.

(1) Do the same method as above method.

(2) Make the as same below pattern in VHF 6CH using RF

MODULATOR and PATTERN GENERATOR.

(3) Adjust to become dividing 15 and 16 Gray of Main/Sub

screen .

(4) Adjust to be identical Main/Sub contrast of MAX 16Gray.

(5) Make the adjustment pattern as below.

<16Gray Scale/H Pattern>

Page 21

- 21 -

PRINTED CIRCUIT BOARD

MAIN(TOP)

Page 22

- 22 -

PRINTED CIRCUIT BOARD

MAIN(BOTTOM)

Page 23

- 23 -

PRINTED CIRCUIT BOARD

TUNER(TOP)

Page 24

- 24 -

PRINTED CIRCUIT BOARD

TUNER(BOTTOM)

Page 25

- 25 -

PRINTED CIRCUIT BOARD

DIGITAL(TOP)

Page 26

- 26 -

PRINTED CIRCUIT BOARD

DIGITAL(BOTTOM)

Page 27

- 27 -

PRINTED CIRCUIT BOARD

DRIVER(TOP)

DRIVER(BOTTOM)

Page 28

- 28 -

PRINTED CIRCUIT BOARD

SMPS

LINE FILTER

Page 29

- 29 -

PRINTED CIRCUIT BOARD

CONTROL(TOP)

CONTROL(BOTTOM)

PRE-AMP SIDE A/V

CASE DET

INTERFACE

COLOR WHEEL

Page 30

- 30 -

PRINTED CIRCUIT BOARD

LED(TOP)

LED(BOTTOM)

COMPONENT(TOP)

COMPONENT(BOTTOM)

Page 31

- 31 -

BLOCK DIAGRAM

Page 32

- 32 -

EXPLODED VIEW

410

680

681

401

403

402

404

700

630

420

640

641

602

622

623

174

502

530

590

601

600

570

572

571

612

620

610

611

621

720

411

310

308

309

305

660

121

300

650

301

120

302

430

434

431

433

432

670

520

540

501

550

624

560

503

400

Page 33

- 33 -

EXPLODED VIEW PARTS LIST

120 6400WESC01A SPEAKER,WOOFER C080P23K1450 ESTEC WOOFER 8OHM 15/25W 84DB 80 NON

121 6400DESA01A SPEAKER,TWEETER D016D01K1450 8HMOHM 15/25W 85DB 50 NON

174 6410VUH004A POWER CORD,UL/CSA3000MM 3P 3000MM HUG BLACK 500MH 7A

300 3091V00552C CABINET ASSEMBLY,DU-52SZ61D STEREO NB04AA FULL

301 5020V00870B BUTTON,CONTROL DN-52SZ60D ABS, HF-380 7KEY .

302 4811V00049C BRACKET ASSEMBLY,SPEAKER DU-52SZ61D NB04AA GRILLE,LG BRAND

305 3351V00007A SCREEN ASSEMBLY,RN-52SZ30H 1178*670*3.6 LCD TYPE

308 4980V00890B SUPPORTER,SCREEN SECC(EGI) SIDE(CUSHION),RN-52SZ50H

309 4980V00889B SUPPORTER,SCREEN EGI BOTTOM(CUSHION),RN-52SZ50H

310 4980V00888B SUPPORTER,SCREEN SECC(EGI) TOP

400 3809V00361F BACK COVER ASSEMBLY,RU-52SZ61D NON ZENITH

401 3550V00269D COVER,LAMP RU-44SZ51D PC-ABS FAN 7S00115A

402 3550V00322D COVER,LAMP RU-52SZ51D HIPS 40AF SIDE

403 3110V00307B CASE,LAMP DUCT DLP 52SZ60H PC-ABS .

404 4980V00885E SUPPORTER,BACK COVER SECC(EGI) FRONT,RN-52SZ50H

410 3809V00362F BACK COVER ASSEMBLY,RU-52SZ51D NON ZENITH

411 3550V00321C COVER,LAMP RU-52SZ51D HIPS 40AF ZENITH

420 3550V00365C COVER ASSY,RU-52SZ51D ABS, AF-303S DUST

430 5018V00067D MIRROR,REFLECTION SSC(SAMSUNG CORNING) 0000 1172(H1)*590(H2)*604(V1)*3T .

431 4810V01112A BRACKET,SUPPORTER TN-56SZ70LR NB037A NON MIRROR SIDE, LEFT

432 4980V00883C SUPPORTER,MIRROR AL TOP

433 4980V00884C SUPPORTER,MIRROR AL BOTTOM

434 4810V01113A BRACKET,SUPPORTER TN-56SZ70LR NB037A NON MIRROR SIDE, RIGHT

501 3210V00165B FRAME,ABS, AF-303S RN-48SZ40H MAIN CHASSIS

502 3210V00191A FRAME,CHASSIS HIPS 40AF DN-44SZ60D SMPS

503 4811V00135A BRACKET ASSEMBLY,REAR AV DU-52SZ62D NB04AA .

520 6871VMMR77A PCB ASSEMBLY,MAIN NB-04AA DU-44/52SZ60D

530 6871VPMA54A PCB ASSEMBLY,POWER SMPS NB-04AA DLP M/I

540 6871VSMS02A PCB ASSEMBLY,SUB TUNER NB03KB CABLE READY

550 6871VSMS01C PCB ASSEMBLY,SUB DIGITAL NB04AA DU-52SZ62D

560 6871VSMU24F PCB ASSEMBLY,SUB NB04AA DU-52SZ61D COMP M/I ASSY

570 6871VSMB50F PCB ASSEMBLY,SUB NB04AA DRIVER(DU-52SZ61D)

571 4814V00434B SHIELD ASSY,DN-44SZ60D NB03KB SUS ,SHIELD CASE DRIVE BOTTOM

572 4814V00394B SHIELD,COVER DN-44SZ60D NB03KB AL DRIVER FRONT DLP720P SHIELD CASE

590 6871VSMV52B PCB ASSEMBLY,SUB L/F NB037B TU-62SZ72D LINE-FILTER M/I

600 3141VSN906A CHASSIS ASSEMBLY,SUB NB03KB DU-44/52SZ60D

601 4980V00886B SUPPORTER,SMPS SECC(EGI) DLP

602 4980V00816C SUPPORTER,OPTICAL EGI DN-44SZ50D ENGINE BASE

610 6912B22007A LAMP,HIGH PRESSURE MECURY UHP 120W 1.0 PH E23 PHILIPS 120V 1A 25KV

611 4814V00396B SHIELD,COVER DN-44SZ60D NB03KB SECC(EGI) COVER,LAMP.DLP720P-ENGINE

612 4930V00301A HOLDER,PC+GF30% LAMP

620 5900V12001B FAN,DC G1225S12B2 DONGYANG 120*120*25 12V 1000RPM 9-14V L1000MM

621 4810V00813A BRACKET,FIXER RN-44SZ50H NB03JA ABS, AF-303S FAN HOLDER

622 5900V06006A FAN,DC F6025S12B2 DONGYANG 60*60*25 12V 2000RPM 9-14V L650MM

623 4980V00813B SUPPORTER,FAN SPCC(CR) ,DN-44SZ60H

624 5900V06006B FAN,DC F6025S12B2 DONGYANG 60*60*25 12V 2000RPM 9-14V L350MM

630 6871VSN221J PCB ASSEMBLY,SUB NB04AA PRE-AMP, DU-52SZ61D

640 6316000007A BALLAST,EUC-120P/H11 PHILIPS 20KV

641 4810V00659A BRACKET,BALLAST RE-44SZ20 NON ABS NON

650 6871VSMV96B PCB ASSEMBLY,SUB NB03KB TACT S/W

660 6871VSMV95D PCB ASSEMBLY,SUB LED MB03CC M/I ASSY FOR CHINA

670 6871VSME03K PCB ASSEMBLY,SUB NB04AA CASE S/W, DU-52SZ61D

680 6871VSN220D PCB ASSEMBLY,SUB NB037A TN-56SZ70LR SIDE AV M/I

681 3500V00061M BOARD ASSY,RU-44SZ51D NB03JC FRONT A/V

700 6871VSMY69A PCB ASSEMBLY,SUB INTER MB03CC M/I ASSY FOR CHINA

720 6871VSMW40E PCB ASSEMBLY,SUB SENSOR MB03CC HD2 7SEGMENT SENSOR B/D

No. Part No.

Description

Page 34

- 34 -

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC403

IC403

IC404

IC405

IC405

IC406

IC406

IC407

IC408

IC409

IC409

IC410

IC413

IC414

IC415

IC5

IC500

IC500

IC501

IC502

IC502

IC600

IC601

IC601

IC601

IC602

IC603

IC700

IC701

IC701

IC702

IC702

IC703

IC704

IC705

IC800

IC800

IC801

IC801

IC802

IC803

IC804

IC805

IC806

IC807

IC808

IC810

IC811

0IMMRSS041D

0ISH302122A

0ISH052100C

0ISH323422A

0ICTMLG013A

0ISH323422A

0INA562300A

0ISJ156612A

0ISS780500F

0IKE781200P

0IKE780500P

0ISH052100C

0IKE780900M

0IMCRFA009A

0ISH052100C

0IFA754207A

0IMCRFA013A

0IPRPTI001A

0ITO741570C

0ICB841500B

0IZZVF0020B

0ILNRMN005A

0IMCRMN012A

0IMCRNS006A

0ILNRMN005A

0IFA754207A

0ISS455880A

0IMCRTI011A

0IMCRXL004A

0IMMRAL015C

0IMCRTI019A

0IMCRFA003A

0ILNRID002A

0ILNRID002A

0IMCRAL006A

0IMCRSJ001A

0IMMRSS053B

0ICTMLG014B

0IMCRTI014A

0IMCRSG007A

0IMCRSG008A

0IMCRSG008A

0IMCRMX001A

0IMCRSG008A

0IMCRMX001A

0IMCRSG008A

0IMCRSJ001A

0IMCRON002A

K4S641632H-TL75 54P

PQ30RV21 TO-220

PQ05RD21 4SIP

PQ3RF23 4P(TO-220) 3.3V

LGDT1901A 24P

PQ3RF23 4P(TO-220) 3.3V

CLC5623IMX 14P

SC15661T-2.5TR 3P TO-220-3L

KA7805

KIA7812API TO220 ST 3P 12V

KIA78L05BP(AT) 3P 5V,150MA

PQ05RD21 4SIP

KIA7809API TO220 ST 3P 9V

KA78M08RTM 2P

PQ05RD21 4SIP

KA75420ZTA 3P,TO-92 TP 4.2V

74LCX244MTC 20P

TFP401PZP 100 DIGITAL RECEIVER

TC74LCX157FT 16P

CS8415A-CZR 28P 96KHZ DIGITAL AUDIO

X1272-0346 251P HD2

VPX3226E 44 VIDEO PIXEL DECODER

MSP4450G QA B8 80P MULTI SOUND

LM4765T 15P AUDIO POWER AMP

VPX3226E 44 VIDEO PIXEL DECODER

KA75420ZTA 3P,TO-92 TP 4.2V

KA4558D 8SOP OP AMP

2503227-001(DDP1010) 529P

XC95288XL-10TQ144C 144P

AT49BV8192A-90TI 48P

TFP410 64P

KA2903 8SOP

IDTQS4A210Q IDT 16P

IDTQS4A210Q IDT 16P

AT24C16AN-10SI-2.7 8P

SC1565IST-1.8 3P SOT223

K4R271669F-TCS8 54P

LGDT3302S 100P

CDCR83 24P

74VIT125CTR 5P S0T323-5L

74LX1G14CTR 5P SOT323-5L

74LX1G14CTR 5P SOT323-5L

MAX708SCSA 8P

74LX1G14CTR 5P SOT323-5L

MAX708SCSA 8P

74LX1G14CTR 5P SOT323-5L

SC1565IST-1.8 3P SOT223

MC33262P 8P

LOCA. NO PART NO DESCRIPTION

IC1

IC1

IC1

IC100

IC1000

IC1000

IC1001

IC1002

IC1004

IC1008

IC101

IC102

IC103

IC1101

IC1102

IC1105

IC1200

IC1200

IC1202

IC1202

IC1203

IC1204

IC1205

IC1301

IC151

IC152

IC152

IC1602

IC2

IC200

IC201

IC202

IC203

IC204

IC206

IC207

IC208

IC208

IC300

IC301

IC4

IC400

IC401

IC401

IC402

IC402

0IZZVC0119A

0IMCRSH003A

0IPRPTO002A

0IKE702900G

0IMCRTI025A

0IMI623200B

0IPRPFA006A

0IPRPFA007A

0IMMRNE002A

0IMI623200B

0ITK118100B

0ISTLPH026A

0IMCRBM003A

0ICTMLG017A

0IMCRLT002A

0IMCRFA013A

0IMCRSO008A

0IMCRMT003A

0IMO744053B

0IMO744053B

0IPMGNS026A

0IMCRMP006A

0IMCRMP007A

0ICTMLG018A

0IMCRTI035A

0IMCRFA004A

0ISS455880A

0ISH052100C

0IFA754207A

0IMCRAL021A

0IMMRHY015B

0IMMRHY015B

0IMMRAM006B

0IMMRAM006B

0IMCRSG010A

0IMCRPH026A

0ISO206900A

0IMO744053B

0IMCRSJ001A

0ICTMLG009A

0IMCRAL006A

0IMMRSS041D

0ISH122100B

0IMMRSS041D

0ISH302122A

0IMMRSS041D

M37272E8A(OTP) DIP 42P

GP2S40 4P

TC7S14F(T5L,T) 5P

KIA7029AF SOT-89 TP 2.9V

TSB43CA42GGW 176P

M62320FP 16P

RC1117S33T SOT-223 R/TP 3.3VOLT

RC1117S25T SOT-223 R/TP 2.5VOLT

UPD64083GF3BA 100

M62320FP 16P

TK11840L 8P SOT23L DC-DC CONVERTER

74LVC14APW 14PIN

IBM25PPC405CR-3BC200C

LGDT3502B 208P/PBGA

LCT1470CS8 8P

74LCX244MTC 20P

CXA2151Q 48P

MM1108XFFE 8P

MC74HC4053DW 16SOP 3*2CH.MUX

MC74HC4053DW 16SOP 3*2CH.MUX

LM311MX 8P

PIC18F1220T-I/SO 28P

PIC18F242T-I/SO 18P

LGDP4410 176P

TL592B-8DR 8P VIDEO AMPLIFIER

KA2904DTF 8SOP R/TP OP-AMP

KA4558D 8SOP OP AMP

PQ05RD21 4SIP

KA75420ZTA 3P,TO-92 TP 4.2V

AT24C512W-10SI-2.7 8P

HY57V281620HCT-H 54P

HY57V281620HCT-H 54P

AM29DL640H90EI 48P

AM29DL640H90EI 48P

ST3232CDR 16 R/TP RS232

PCA9516PW 16P

CXA2069Q QFP64 I2C BUS AV S/W

MC74HC4053DW 16SOP 3*2CH.MUX

SC1565IST-1.8 3P SOT223

LGDT1102 HD2 SBGA-432PIN

AT24C16AN-10SI-2.7 8P

K4S641632H-TL75 54P

PQ12RD21 4SIP

K4S641632H-TL75 54P

PQ30RV21 TO-220

K4S641632H-TL75 54P

IC

RUN DATE : 2004.8.30

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 35

- 35 -

LOCA. NO PART NO DESCRIPTION

IC820

IC831

IC832

IC841

IC845

IC900

IC900

IC901

IC901

IC905

IC906

IC907

IC908

IC909

IC910

IC903

IC904

IC905

Q1000

Q1001

Q1001

Q1002

Q1002

Q1003

Q1003

Q1004

Q1004

Q1005

Q1005

Q1006

Q1007

Q1008

Q1009

Q101

Q1010

Q1011

Q1012

Q1013

Q1014

Q1015

Q1016

Q1017

Q102

Q107

Q109

Q1200

Q1200

Q1201

Q1202

0ISK666813A

0ISK615311B

0ISH817300B

0ISH817300B

0IMCRKE003B

0IMCRAD002A

0IMCRTI012B

0IMCRTI013A

0IMCRS5005A

0IMMRAL014B

0IMCRSG007A

0IMCRSG008A

0IMCRSG008A

0IMCRSG008B

0IMCRSG007A

0TFFC80015A

0TFFC80015A

0TFFC80015A

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TRKE80038A

0TR387500AA

0TR387500AA

0TR387500AA

0TRKE80046A

0TR387500AA

0TR387500AA

STR-F6668B(LF1352) 5PIN

STR-G6153T(LF1101) 5PIN

PC817XF3 4D PHOTO COUPLER

PC817XF3 4D PHOTO COUPLER

KIA78R12API 4P TO-220IS

AD9883AKST-110 80P DIGITAL BOARD

2503253-0003(DAD1000-3) 80P

SNSH6742CFA0PA(P32J6742PAG) 64P

SIL9993CTG100 100P

AT24C02N-10SI-2.7 8P

74VIT125CTR 5P S0T323-5L

74LX1G14CTR 5P SOT323-5L

74LX1G14CTR 5P SOT323-5L

74LX1G07CTR 5P SOT323-5L

74VIT125CTR 5P S0T323-5L

FDS6930A 8P O-8 30V 5.5A

FDS6930A 8P SO-8 30V 5.5A

FDS6930A 8P SO-8 30V 5.5A

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

KTC3552T-RTK SOT-23F 50V 3A

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

2N3904S SOT23 60V 200MA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

LOCA. NO PART NO DESCRIPTION

Q1202

Q1203

Q1203

Q1204

Q1205

Q1206

Q1206

Q1207

Q1208

Q1209

Q1210

Q1213

Q1214

Q1215

Q1216

Q1217

Q1218

Q1219

Q2

Q201

Q202

Q203

Q204

Q205

Q206

Q207

Q208

Q209

Q210

Q211

Q3

Q403

Q5

Q6

Q601

Q601

Q602

Q602

Q602

Q603

Q604

Q605

Q605

Q605

Q614

Q615

Q616

Q617

Q618

Q801

Q802

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR390609DC

0TR387500AA

0TR387500AA

0TR150400BA

0TR102009AG

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TRKE80038A

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR322709AA

0TR322709AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR102008AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

2N3906S-RTK SOT23

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP KRC102S SOT-23

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

KTC3552T-RTK SOT-23F 50V 3A

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

KTC3227-Y,TP(KTC1627A),KEC

KTC3227-Y,TP(KTC1627A),KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

KRA102S SOT23

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

REPLACEMENT PARTS LIST

TRANSISTOR

Page 36

- 36 -

LOCA. NO PART NO DESCRIPTION

Q810

Q841

Q842

Q851

Q900

Q901

Q902

Q903

Q904

D1

D101

D1201

D1202

D1203

D1204

D1205

D2

D200

D201

D3

D403

D404

D430

D431

D432

D433

D434

D435

D436

D437

D438

D439

D5

D6

D601

D603

D605

D606

D607

D801

D810

D811

D820

D821

D822

D832

D833

D834

D841

0TF283700AA

0TR945009AA

0TR322709AA

0TR945009AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR830009BA

0TR830009BA

0DD184009AA

0DD184009AA

0DRSE00038A

0DRSE00038A

0DRSE00038A

0DD184009AA

0DD184009AA

0DD184009AA

0DRSE00038A

0DRSE00038A

0DD226239AA

0DS113379BA

0DD184009AA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD606000AA

0DD100009AM

0DR260001AA

0DD100009AM

0DD100009AM

0DD100009AM

0DR010009AA

0DD100009AM

0DD260000BB

0DD100009AP

2SK2837 500V 20A TO3P

KSC945C-Y TO92 50V 150MA

KTC3227-Y,TP(KTC1627A)

KSC945C-Y TO92 50V 150MA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

BSS83

BSS83

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

SDC15 SOT23 12.8V

SDC15 SOT23 12.8V

SDC15 SOT23 12.8V

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

SDC15 SOT23 12.8V

SDC15 SOT23 12.8V

CHIP KDS226 SOT-23

1SS133 T-72 DO34 90V

KDS184S CHIP 85V 300MA

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

RBV606 600V 6A

EU1ZV(1)

FMG-26S TO220 600V 6A

EU1ZV(1) TP SANKEN

EU1ZV(1) TP SANKEN

EU1ZV(1) TP SANKEN

EG01C 1000V 0.5A 10A

EU1ZV(1) TP SANKEN

BRIDGE D2SBA60(STK)

EG1ZV(1)

LOCA. NO PART NO DESCRIPTION

D845

D881

D881

D881

D881

D891

D901

D901

D902

D903

D904

D905

D906

D907

D908

D909

IC1001

IC1002

IC1002

ZD01

ZD1

ZD10

ZD2

ZD201

ZD202

ZD203

ZD204

ZD3

ZD4

ZD5

ZD6

ZD601

ZD602

ZD602

ZD603

ZD841

ZD851

ZD9

C1

C1000

C1001

C1002

C1003

C1004

C1005

C1006

C1007

C1008

C1009

0DD414809ED

0DD120000BB

0DRSA00170A

0DD420000BB

0DD220000AC

0DD220000AC

0DRON00088A

0DD184009AA

0DRON00088A

0DRON00088A

0DRON00088A

0DRON00088A

0DSON00028A

0DRON00098A

0DZGS00108A

0DRGS00328A

0DRSE00018A

3720V00232A

0DRSE00018A

0DR050008AA

0DZ620009BB

0DZ620009BB

0DZ620009BB

0DZ560009CF

0DZ560009CF

0DZ560009CF

0DZ560009CF

0DZ620009BB

0DZ620009BB

0DZ620009BB

0DZ620009BB

0DD414809ED

0DD414809ED

0DR050008AA

0DR050008AA

0DZ620009BB

0DZ620009BB

0DZ620009BB

0CE476DF618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CC180CKH1A

0CC180CKH1A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

1N4148 TP GRANDE

FML-G12S

FML-G14S TO220 400V

D4L20U

FML-G22S TO220 200V

FML-G22S TO220 200V

BAT54SWT1 60V 3A 4A .SEC .A

KDS184S CHIP 85V 300MA

BAT54SWT1 60V 3A 4A .SEC .A

BAT54SWT1 60V 3A 4A .SEC .A

BAT54SWT1 60V 3A 4A .SEC .A

BAT54SWT1 60V 3A 4A .SEC .A

BAV99RWT1 SC-75 70V 215MA

MBRD320RL SC-75 30V 150MA

ZENERS,SMZJ3793B

SS26 DO-214AC 60V 2A

SRV05-4.TC SOT23-6L 5V

LED ASSEMBLY

SRV05-4.TC SOT23-6L 5V

SD05.TC SOD323 5V

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ5.6B

ZENERS,MTZJ5.6B

ZENERS,MTZJ5.6B

ZENERS,MTZJ5.6B

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

1N4148 TP GRANDE

1N4148 TP GRANDE

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

47UF STD 16V M

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

18PF 1608 50V 5%

18PF 1608 50V 5%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

REPLACEMENT PARTS LIST

CAPACITOR

DIODE

Page 37

- 37 -

LOCA. NO PART NO DESCRIPTION

C1010

C1011

C1011

C1012

C1013

C1013

C1014

C1015

C1016

C1017

C1018

C1019

C1019

C102

C1020

C1021

C1022

C1023

C1023

C1024

C1027

C1028

C1029

C103

C1030

C1035

C1036

C1039

C104

C1042

C1049

C105

C1055

C106

C1060

C108

C108

C108

C109

C109

C11

C110

C110

C111

C111

C111

C1112

C1113

C1115

C1117

C1119

0CK104CF56A

0CE476VF6DC

0CK104CF56A

0CK104CF56A

0CE476VF6DC

0CK104CF56A

0CK104CF56A

0CK105DF64A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE105VK6DC

0CK104CF56A

0CK104CF56A

0CE476VF6DC

0CK104CF56A

0CK104CF56A

0CE227SC6DC

0CK104CF56A

0CK104CF56A

0CK271CK46A

0CK271CK46A

0CK105DF64A

0CK104CF56A

0CK105DF64A

0CE106VF6DC

0CE106VF6DC

0CE227SC6DC

0CK683CKG6A

0CE106VF6DC

0CE106VF6DC

0CE476VF6DC

0CE106VF6DC

0CE476VK6DC

0CE476SF6DC

0CE106VF6DC

0CE476DD618

0CS335EFKDC

0CE476DD618

0CK104CF56A

0CE226VF6DC

0CE476VK6DC

0CE476DK618

0CE476VF6DC

0CE476DD618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0.1UF 1608 16V 10%

47UF MV 16V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

47UF MV 16V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

1UF 2012 16V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

1UF MV 50V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

47UF MV 16V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

220UF MVG 6.3V M

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

270PF 1608 50V 5%

270PF 1608 50V 5%

1UF 2012 16V 20%

0.1UF 1608 16V 10%

1UF 2012 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

220UF MVG 6.3V M

0.068UF 1608 50V 10%,-10%

10UF MV 16V 20%

10UF MV 16V 20%

47UF MV 16V 20%

10UF MV 16V 20%

47UF MV 50V 20%

47UF MVG 16V M

10UF MV 16V 20%

47UF STD 10V 20%

3.3UF 3216 16V 20%,-20%

47UF STD 10V 20%

0.1UF 1608 16V 10%

22UF MV 16V 20%

47UF MV 50V 20%

47UF STD 50V M

47UF MV 16V 20%

47UF STD 10V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

LOCA. NO PART NO DESCRIPTION

C112

C1120

C1121

C1122

C1123

C1124

C1125

C1126

C1127

C1128

C113

C1137

C1138

C114

C1140

C1141

C1142

C1144

C1149

C115

C1150

C116

C1161

C1163

C1164

C1165

C1167

C1168

C1169

C117

C1170

C1171

C1172

C1173

C118

C119

C120

C1201

C1202

C1202

C1203

C1204

C1204

C1205

C1206

C1207

C1208

C1208

C1209

C121

C121

0CK104CF56A

0CK104CF56A

0CC200CK41A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CC200CK41A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK103CK56A

0CS336IDKDC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK102CK56A

0CK102CK56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CC100CK11A

0CC100CK11A

0CC470CK41A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE106VF6DC

0CE106VF6DC

0CK392CK56A

0CK104CF56A

0CE106VF6DC

0CC561CK41A

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CC561CK41A

0CE106VF6DC

0CE476DD618

0CK104CF56A

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

20PF 1608 50V 5%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

20PF 1608 50V 5%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.01UF 1608 50V 10%

33UF 6032 10V 20%,-20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

1000PF 1608 50V 0.1

1000PF 1608 50V 0.1

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

10PF 1608 50V 0.5 PF

10PF 1608 50V 0.5 PF

47PF 1608 50V 5%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

10UF MV 16V 20%

10UF MV 16V 20%

3900PF 1608 50V 10%

0.1UF 1608 16V 10%

10UF MV 16V 20%

560PF 1608 50V 5%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

560PF 1608 50V 5%

10UF MV 16V 20%

47UF STD 10V 20%

0.1UF 1608 16V 10%

REPLACEMENT PARTS LIST

Page 38

- 38 -

LOCA. NO PART NO DESCRIPTION

C1215

C1216

C1217

C1218

C1221

C1222

C1224

C123

C1231

C1234

C1236

C1237

C124

C1241

C1243

C1244

C1245

C1246

C1247

C1248

C1249

C1250

C1250

C1251

C1251

C1252

C1253

C1254

C1256

C126

C127

C128

C128

C129

C130

C130

C1302

C1304

C1306

C1307

C1308

C1309

C131

C131

C1311

C1312

C1313

C1314

C1315

C1316

C1317

0CC471CK41A

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CK271CK46A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE476VF6DC

0CK102CK56A

0CE105VK6DC

0CK104CF56A

0CK104CF56A

0CC101CK41A

0CC101CK41A

0CC101CK41A

0CK104CF56A

0CC101CK41A

0CC180CKH1A

0CC180CKH1A

0CE105VK6DC

0CC200CK41A

0CE105VK6DC

0CC200CK41A

0CC200CK41A

0CC200CK41A

0CC200CK41A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE476VK6DC

0CK104CF56A

0CK104CF56A

181-064P

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE476VK6DC

0CS336IDKDC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

470PF 1608 50V 5%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

270PF 1608 50V 5%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

47UF MV 16V 20%

1000PF 1608 50V 0.1

1UF MV 50V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

100PF 1608 50V 5%

100PF 1608 50V 5%

100PF 1608 50V 5%

0.1UF 1608 16V 10%

100PF 1608 50V 5%

18PF 1608 50V 5%

18PF 1608 50V 5%

1UF MV 50V 20%

20PF 1608 50V 5%

1UF MV 50V 20%

20PF 1608 50V 5%

20PF 1608 50V 5%

20PF 1608 50V 5%

20PF 1608 50V 5%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

47UF MV 50V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

10UF 0 16V K CA TP 5

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

47UF MV 50V 20%

33UF 6032 10V 20%,-20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

LOCA. NO PART NO DESCRIPTION

C1318

C1319

C1320

C1321

C1322

C1323

C1324

C133

C137

C140

C142

C143

C15

C158

C16

C160

C1620

C1621

C2

C20

C200

C201

C202

C202

C203

C203

C204

C204

C205

C205

C206

C207

C208

C208

C209

C209

C210

C210

C211

C212

C212

C213

C214

C215

C216

C216

C217

C217

C218

C218

C219

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE476VH6DC

0CK104CF56A

0CE475WJ6DC

0CE475WJ6DC

0CE475WJ6DC

0CE105VK6DC

0CE226VF6DC

0CE476VF6DC

0CE226VF6DC

0CE107VF6DC

0CE107VF6DC

0CN1030F679

0CE105VK6DC

0CK104CF56A

0CK104CF56A

0CK105DF64A

0CK104CF56A

0CK105DF64A

0CK104CF56A

0CE105VK6DC

0CK104CF56A

0CE105VK6DC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK105DF64A

0CK104CF56A

0CE105VK6DC

0CK104CF56A

0CK105DF64A

0CK104CF56A

0CK104CF56A

0CE105VK6DC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK105DF64A

0CE105VK6DC

0CK104CF56A

0CK105DF64A

0CK104CF56A

0CE105VK6DC

0CK104CF56A

0CK104CF56A

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

47UF MV 25V 20%

0.1UF 1608 16V 10%

4.7UF MVK 35V 20%

4.7UF MVK 35V 20%

4.7UF MVK 35V 20%

1UF MV 50V 20%

22UF MV 16V 20%

47UF MV 16V 20%

22UF MV 16V 20%

100UF MV 16V 20%

100UF MV 16V 20%

10000P 16V M Y

1UF MV 50V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

1UF 2012 16V 20%

0.1UF 1608 16V 10%

1UF 2012 16V 20%

0.1UF 1608 16V 10%

1UF MV 50V 20%

0.1UF 1608 16V 10%

1UF MV 50V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

1UF 2012 16V 20%

0.1UF 1608 16V 10%

1UF MV 50V 20%

0.1UF 1608 16V 10%

1UF 2012 16V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

1UF MV 50V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

1UF 2012 16V 20%

1UF MV 50V 20%

0.1UF 1608 16V 10%

1UF 2012 16V 20%

0.1UF 1608 16V 10%

1UF MV 50V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

REPLACEMENT PARTS LIST

Page 39

- 39 -

LOCA. NO PART NO DESCRIPTION

C222

C223

C225

C226

C227

C227

C229

C230

C231

C231

C236

C247

C260

C261

C262

C29

C3

C300

C301

C302

C303

C304

C305

C306

C307

C308

C309

C310

C311

C312

C313

C314

C315

C316

C317

C318

C319

C320

C321

C322

C323

C324

C325

C326

C327

C328

C329

C330

C331

C332

C333

0CE105VK6DC

0CE105VK6DC

0CK104CF56A

0CC331CK41A

0CE226VF6DC

0CC331CK41A

0CK104CF56A

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0CK105DF64A

0CE227VF6DC

0CE475WJ6DC

0CE475WJ6DC

0CE227VF6DC

0CE105VK6DC

0CE476VF6DC

0CS336IDKDC

0CK104CF56A

0CK104CF56A

0CS336IDKDC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

1UF MV 50V 20%

1UF MV 50V 20%

0.1UF 1608 16V 10%

330PF 1608 50V 5%

22UF MV 16V 20%

330PF 1608 50V 5%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

100UF MVG 16V M

0.1UF 1608 16V 10%

1UF 2012 16V 20%

220UF MV 16V 20%

4.7UF MVK 35V 20%

4.7UF MVK 35V 20%

220UF MV 16V 20%

1UF MV 50V 20%

47UF MV 16V 20%

33UF 6032 10V 20%,-20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

33UF 6032 10V 20%,-20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

LOCA. NO PART NO DESCRIPTION

C334

C335

C336

C337

C338

C339

C340

C341

C342

C343

C344

C345

C346

C347

C348

C349

C350

C351

C352

C353

C354

C355

C356

C357

C358

C359

C360

C361

C362

C363

C364

C365

C366

C367

C368

C369

C370

C371

C372

C373

C374

C375

C376

C377

C378

C379

C380

C381

C382

C383

C400

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

REPLACEMENT PARTS LIST

Page 40

- 40 -

LOCA. NO PART NO DESCRIPTION

C401

C402

C403

C404

C405

C406

C406

C407

C407

C408

C408

C409

C409

C410

C410

C411

C411

C412

C412

C413

C414

C415

C416

C417

C418

C419

C420

C421

C422

C423

C424

C425

C425

C426

C426

C427

C427

C428

C430

C431

C432

C433

C434

C435

C435

C436

C437

C437

C438

C440

C443

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE227VF6DC

0CK104CF56A

0CE107VH6DC

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0CE476VF6DC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE227DD618

0CK104CF56A

0CE227DD618

0CK104CF56A

0CE227DD618

0CK104CF56A

0CE227DD618

0CK104CF56A

0CE107DH618

0CE107DD618

0CE107DD618

0CE227DD618

0CE227DD618

0CK104CF56A

0CK104CF56A

0CE227DD618

0CK104CF56A

0CE107DH618

0CK104CF56A

0CC560CK41A

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

220UF MV 16V 20%

0.1UF 1608 16V 10%

100UF MV 25V 20%

0.1UF 1608 16V 10%

100UF MVG 16V M

0.1UF 1608 16V 10%

100UF MVG 16V M

0.1UF 1608 16V 10%

100UF MVG 16V M

0.1UF 1608 16V 10%

100UF MVG 16V M

0.1UF 1608 16V 10%

47UF MV 16V 20%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

0.1UF 1608 16V 10%

220UF STD 10V M

0.1UF 1608 16V 10%

220UF STD 10V M

0.1UF 1608 16V 10%

220UF STD 10V M