Page 1

PORTABLE DVD

SERVICE MANUAL

MODEL: DP351G

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

MODEL: DP351G

SERVICE MANUAL

P/NO : AFN56903641

Website http://biz.lgservice.com

APRIL, 2008

Av. Sor Juana lnés de la Cruz No 555

Col. San Lorenzo

Tlalnepantla, Estado de México CP 54033

Tel. 321 19 00 Fax. 5 657549

Lada sin costo 01 800 50 481 00

Internal Use Only

Page 2

CONTENTS

SECTION 1.........SUMMARY

SECTION 2.........EXPLODED VIEWS

SECTION 3.........ELECTRICAL

SECTION 4.........REPLACEMENT PARTS LIST

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS .............................1-3

SERVICING PRECAUTIONS....................................................................................................................1-4

• GENERAL SERVICING PRECAUTIONS

• INSULATION CHECKING PRODEDURE

• ELECTROSTATICALLY SENSITIVE (ES) DEVICES

SPECIFICATIONS ........................................................................................................................................1-5

LGE Internal Use Only

1-2

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original design be

modified or altered without permission from LG Corporation. All components should be

replaced only with types identical to those in the original circuit and their physical

location, wiring and lead dress must conform to original layout upon completion of

repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are allowed

without prior approval by LG Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into the set

are not delayed until the new service literature is printed.

CAUTION

customized installations without manufacturer’s approval. Unauthorized modifications

will not only void the warranty, but may lead to property damage or user injury.

Service work should be performed only after you are thoroughly familiar with these

safety checks and servicing guidelines.

: Do not attempt to modify this product in any way. Never perform

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended to alert

the service personnel to important safety information in the service

literature.

The lightning flash with arrowhead symbol within an equilateral triangle

is intended to alert the service personnel to the presence of noninsulated

“dangerous voltage” that may be of sufficient magnitude to constitute a

risk of electric shock.

The pictorial representation of a fuse and its rating within an equilateral

triangle is intended to convey to the service personnel the following fuse

replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF

FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND RATING

AS MARKED NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock. After the

original service problem has been corrected, make a check of the following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

component shorts. This is especially important on items trans-ported to and from the

repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields, strain

reliefs, power supply cords, and other hardware have been reinstalled per the

original design. Be sure that the safety purpose of the polarized line plug has not

been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder splashes,

or sharp solder points. Be certain to remove all loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and components,

for frayed leads or damaged insulation (including the AC cord), and replace if

necessary.

5. No lead or component should touch a high current device or a resistor rated at 1 watt

or more. Lead tension around protruding metal surfaces must be avoided.

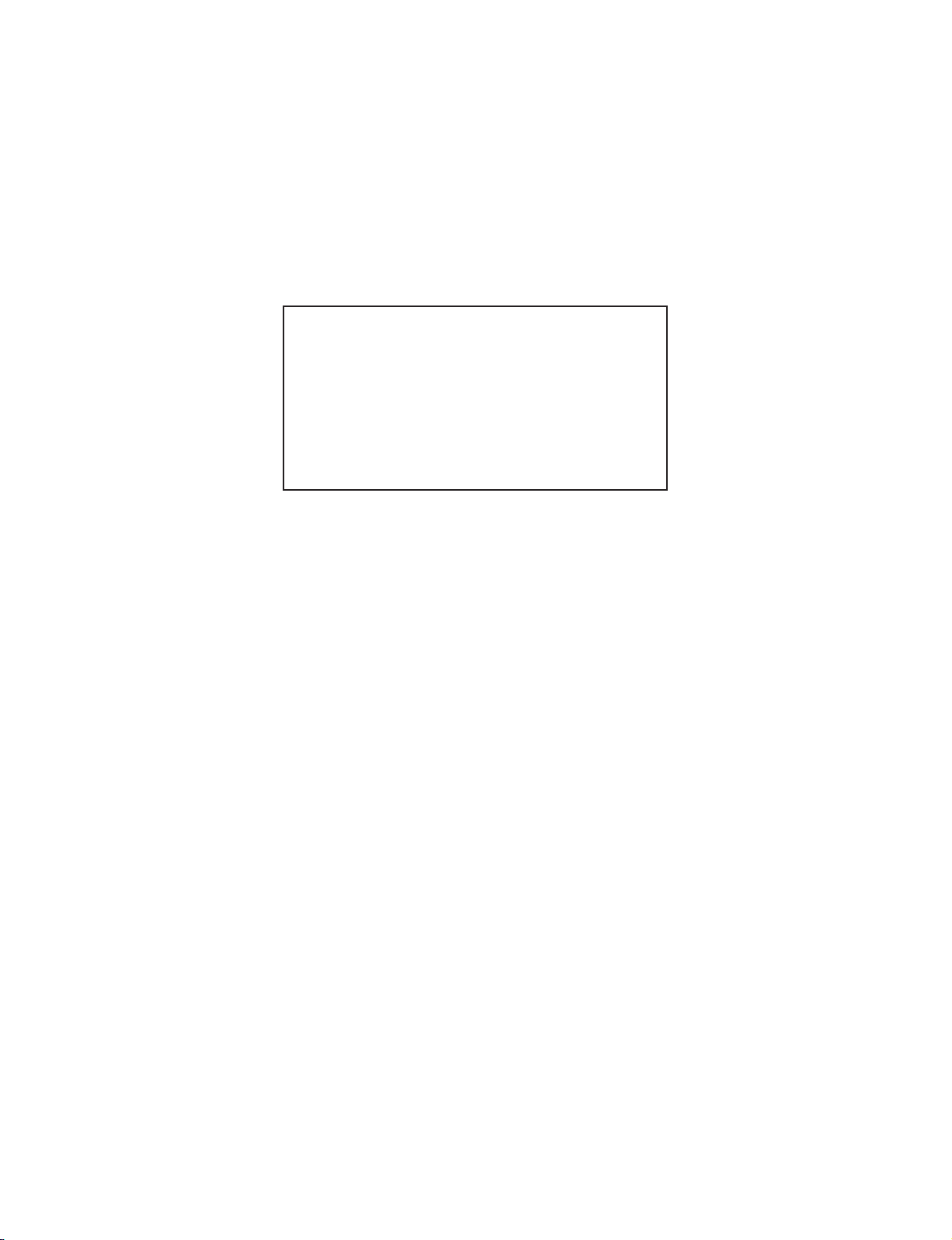

6. After reassembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals, handle

and screws) to be sure that set is safe to operate without danger of electrical shock.

DO NOT USE ALINE ISOLATION TRANSFORMER DURING THIS TEST. Use an

AC voltmeter having 5000 ohms per volt or more sensitivity in the following manner:

Connect a 1500 ohm, 10 watt resistor, paralleled by a .15 mfd 150V AC type

capacitor between a known good earth ground water pipe, conduit, etc.) and the

exposed metallic parts, one at a time. Measure the AC voltage across the

combination of 1500 ohm resistor and .15 mfd capacitor. Reverse the AC plug by

using a non-polarized adaptor and repeat AC voltage measurements for each

exposed metallic part. Voltage measured must not exceed 0.75 volts RMS. This

corresponds to 0.5 milliamp AC. Any value exceeding this limit constitutes a potential

shock hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting shelf

space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where dew is a

factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer should also

avoid the use of decorative scarves or other coverings that might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must follow

the factory-approved mounting instructions. A product mounted to a shelf or platform

must retain its original feet (or the equivalent thickness in spacers) to provide

adequate air flow across the bottom. Bolts or screws used for fasteners must not

touch any parts or wiring. Perform leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted

position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters across

thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous consequences to

home and family.

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1-3

LGE Internal Use Only

Page 5

SERVICING PRECAUTIONS

CAUTION: Before servicing the PORTABLE DVD covered by

this service data and its supplements and addends, read and

follow the SAFETY PRECAUTIONS. NOTE: if unforeseen

circumstances create conflict between the following servicing

precautions and any of the safety precautions in this

publication, always follow the safety precautions.

Remember Safety First :

General Servicing Precautions

1. Always unplug the PORTABLE DVD AC power cord from

the AC power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an

electrolytic capacitor.

Caution: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Do not spray chemicals on or near this PORTABLE DVD or

any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner, cottontipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this PORTABLE DVD and / or any

of its electrical assemblies unless all solid state device heat

sinks are correctly installed.

6. Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1Mohm.

Note 1: Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power

to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

an electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

LGE Internal Use Only

1-4

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 6

SPECIFICATIONS

• GENERAL

Power requirements DC 12V

Power consumption 12W

External Dimensions 202 x 39 x 164mm (W x H x D)

Net Weight (Approx.) 0.85kg

Operating temperature: 5ºC to 40ºC

Operating humidity 5% to 90%

Laser Semiconductor laser

Signal system NTSC

• CONNECTORS

Audio/Video Output ø3.5mm mini jack x 1

- Video: 1.0V(p-p), 75Ω, sync negative

- Audio: 1.5Vrms (1kHz, 0dB)

Earphone terminal ø3.5mm stereo mini jack x 1

• LIQUID CRYSTAL DISPLAY

Panel size 7 inches wide (diagonal)

Projection system R.G.B. stripe

Driving system TFT active matrix

Resolution 480 x 234 (WQVGA)

• SUPPLIED ACCESSORIES

- RCA Video/Audio cable

- AC Adapter (MPA-630)

- Automotive Adapter (DPDC1)

- Remote Control

- Battery for Remote Control (Lithium Battery)

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1-5

LGE Internal Use Only

Page 7

MEMO

LGE Internal Use Only

1-6

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 8

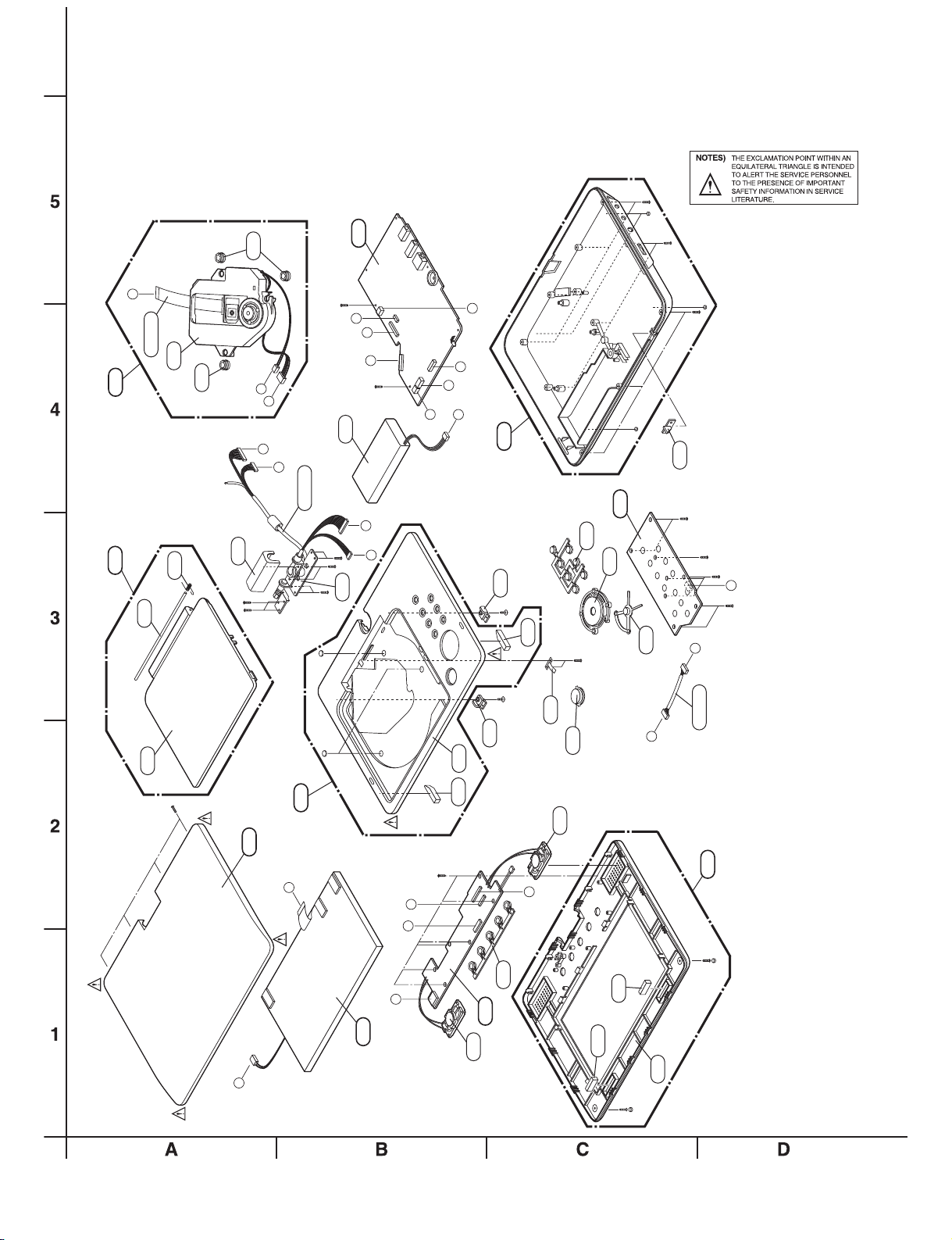

SECTION 2

EXPLODED VIEWS

CONTENTS

EXPLODED VIEWS .....................................................................................................................................2-2

1. CABINET AND MAIN FRAME SECTION ..................................................................................................2-2

2. PACKING ACCESSORY SECTION...........................................................................................................2-3

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2-1

LGE Internal Use Only

Page 9

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

A00

A53

L

CABLE3

295

263

296

262

297

262

A46

MAIN

K

J

L

C

B

09

J

K

8

2

CABLE

I

H

278

C

E

B

A

A

A44

289

A45

281

282

285

288

KEY

283

D

D

293

287

285

64

2

88

A43

A48

G

G

LCD PANEL

F

F

A40

2

H

LCD

253

A51

77

2

286

277

I

51A

2

E

251

CABLE1

A52

72

2

LGE Internal Use Only

2-2

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 10

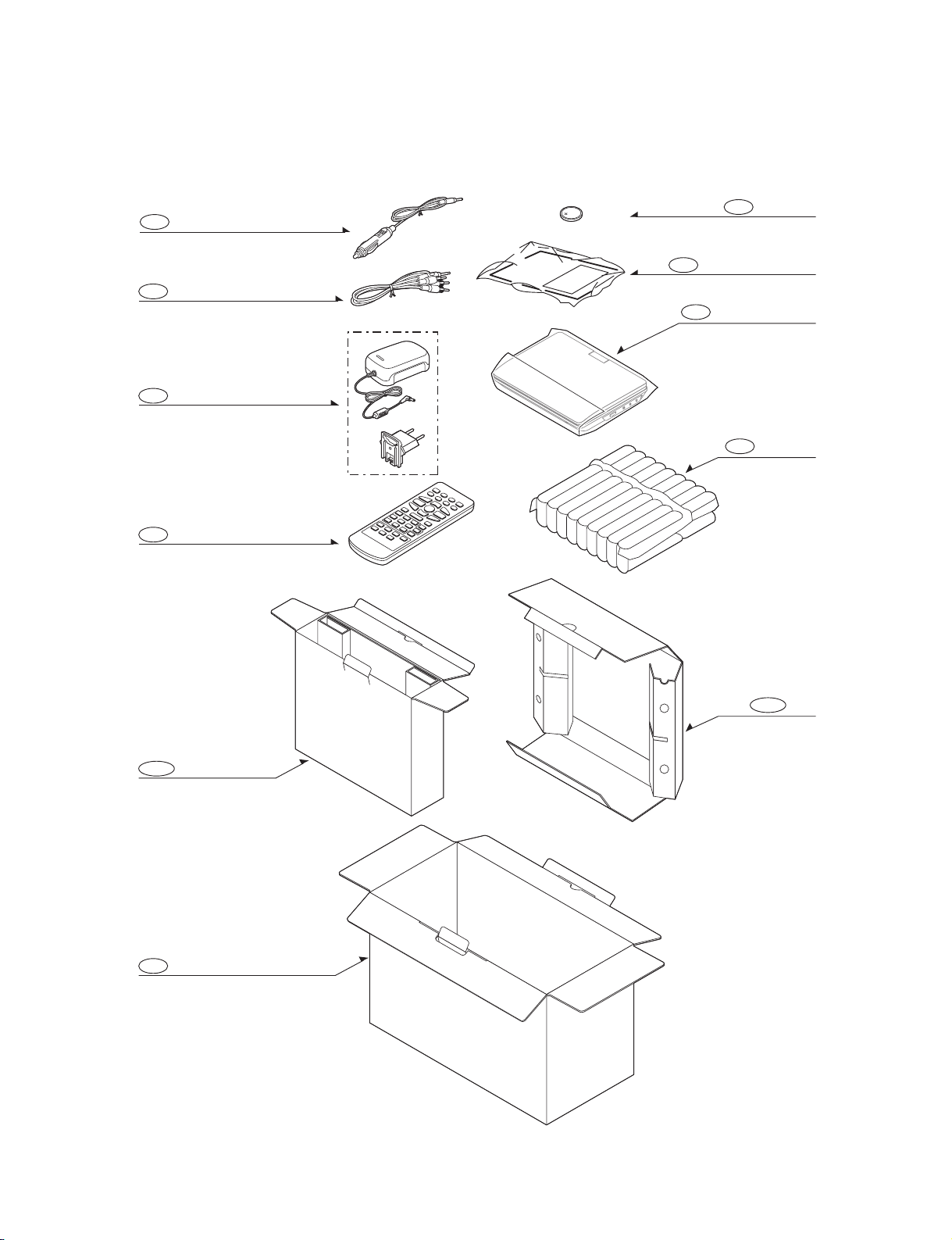

2. PACKING ACCESSORY SECTION

834

CABLE, CIGAR JACK

806

PLUG ASS'Y(RCA CABLE)

833

ADAPTER

900

REMOTE CONTROL

808

801

OWNER'S MANUAL

804

PACKING SHEET

803

BATTERY

PACKING

802A

802

BOX

BOX

802B

BOX

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2-3

LGE Internal Use Only

Page 11

MEMO

LGE Internal Use Only

2-4

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 12

SECTION 3

ELECTRICAL

CONTENTS

LCD PART ...................................................................................................................................................3-2

LCD ELECTRICAL TROUBLESHOOTING GUIDE .........................................................................3-2

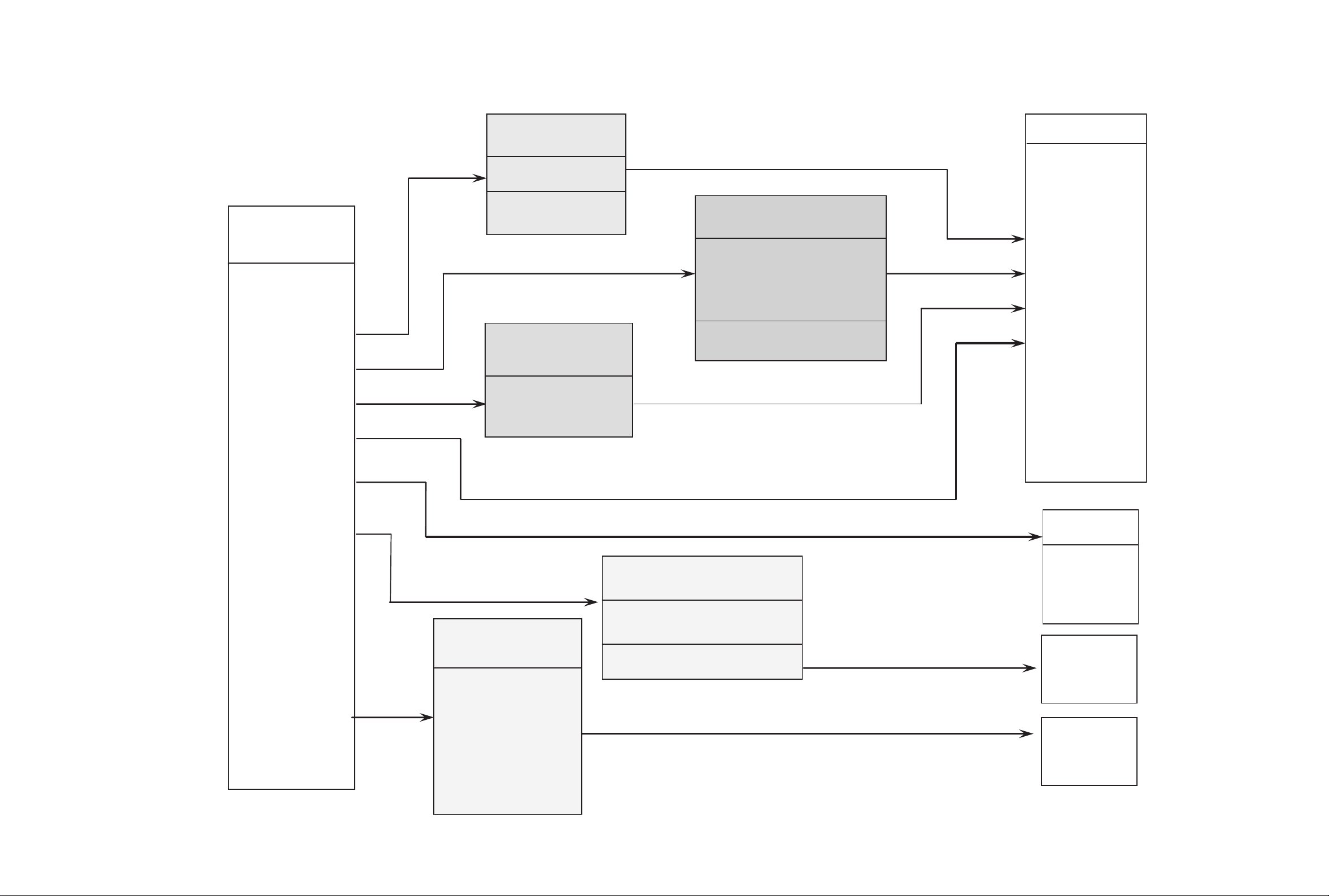

BLOCK DIAGRAM......................................................................................................................................3-3

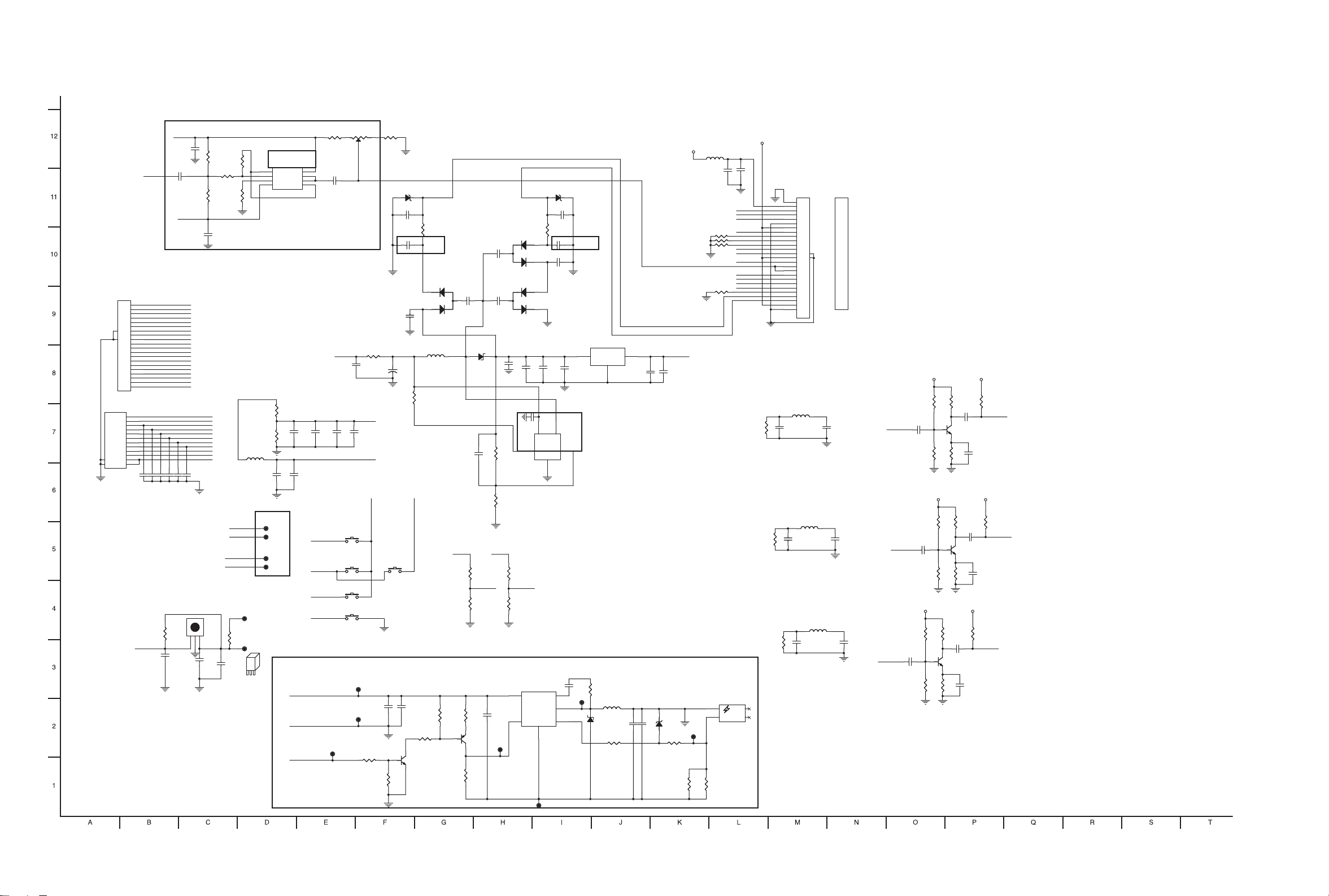

CIRCUIT DIAGRAM ...................................................................................................................................3-5

PRINTED CIRCUIT BOARD DIAGRAM..............................................................................................3-7

MAIN PART ...............................................................................................................................................3-11

MAIN ELECTRICAL TROUBLESHOOTING GUIDE .....................................................................3-11

1. DC-DC CONVERTER CIRCUIT...........................................................................................................3-11

2. MPEG CIRCUIT ...................................................................................................................................3-14

3. RF/SERVO CIRCUIT............................................................................................................................3-15

4. CHARGING CIRCUIT ..........................................................................................................................3-18

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING.................................3-19

1. SYSTEM 27MHz CLOCK, RESET & FLASH R/W SIGNAL ................................................................3-19

2. SDRAM CLOCK ...................................................................................................................................3-19

3. DISC TYPE JUDGEMENT WAVEFORM .............................................................................................3-20

4. FOCUS ON WAVEFORM.....................................................................................................................3-22

5. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)..............................................................3-22

6. TRACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING) ..................................................3-23

7. MT1389 AUDIO OPTICAL AND COAXIAL OUTPUT (ASPDIF) ..........................................................3-24

8. MT1389 VIDEO OUTPUT WAVEFORM ..............................................................................................3-24

9. AUDIO OUTPUT FROM AUDIO DAC ..................................................................................................3-25

WIRING CONNECTION DIAGRAMS..................................................................................................3-26

1. WIRING CONNECTION DIAGRAMS-1 ...............................................................................................3-26

2. WIRING CONNECTION DIAGRAMS-2 ...............................................................................................3-27

BLOCK DIAGRAMS.................................................................................................................................3-29

1. OVERALL BLOCK DIAGRAM..............................................................................................................3-29

2. POWER BLOCK DIAGRAM.................................................................................................................3-31

3. SERVO BLOCK DIAGRAM..................................................................................................................3-33

4. SYSTEM BLOCK DIAGRAM................................................................................................................3-35

5. AV BLOCK DIAGRAM ..........................................................................................................................3-37

CIRCUIT DIAGRAMS ..............................................................................................................................3-39

1. MPEG CIRCUIT DIAGRAM .................................................................................................................3-39

2. MEMORY CIRCUIT DIAGRAM............................................................................................................3-41

3. OPU & MOTOR CIRCUIT DIAGRAM ..................................................................................................3-43

4. AV CIRCUIT DIAGRAM........................................................................................................................3-45

5. CHARGE CIRCUIT DIAGRAM.............................................................................................................3-47

6. LCD I/F CIRCUIT DIAGRAM................................................................................................................3-49

7. KEY MENU CIRCUIT DIAGRAM .........................................................................................................3-51

• CIRCUIT VOLTAGE CHART ..............................................................................................................3-53

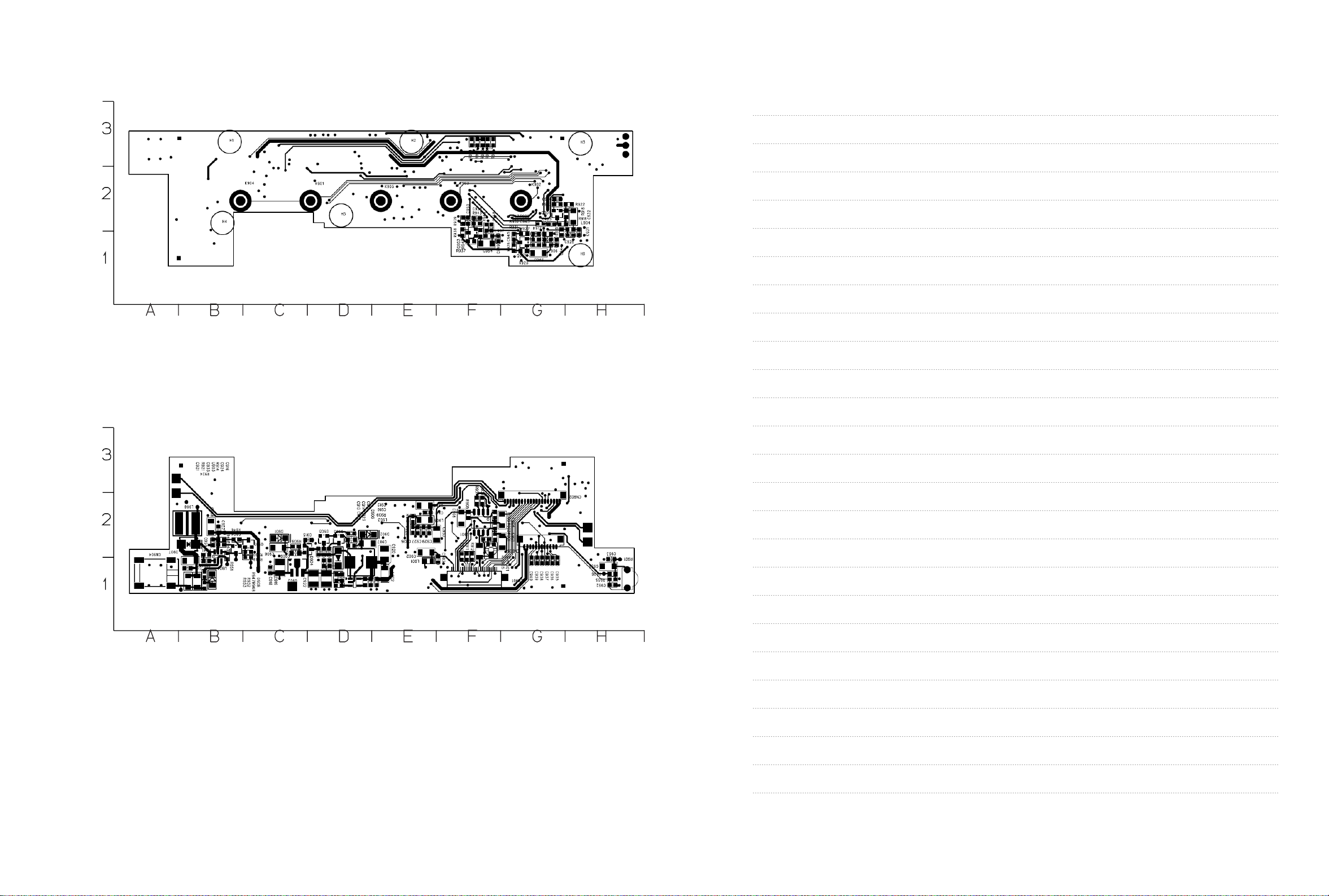

PRINTED CIRCUIT BOARD DIAGRAMS .........................................................................................3-57

1. MAIN P.C.BOARD ................................................................................................................................3-57

2. KEY MENU P.C.BOARD ......................................................................................................................3-61

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-1

LGE Internal Use Only

Page 13

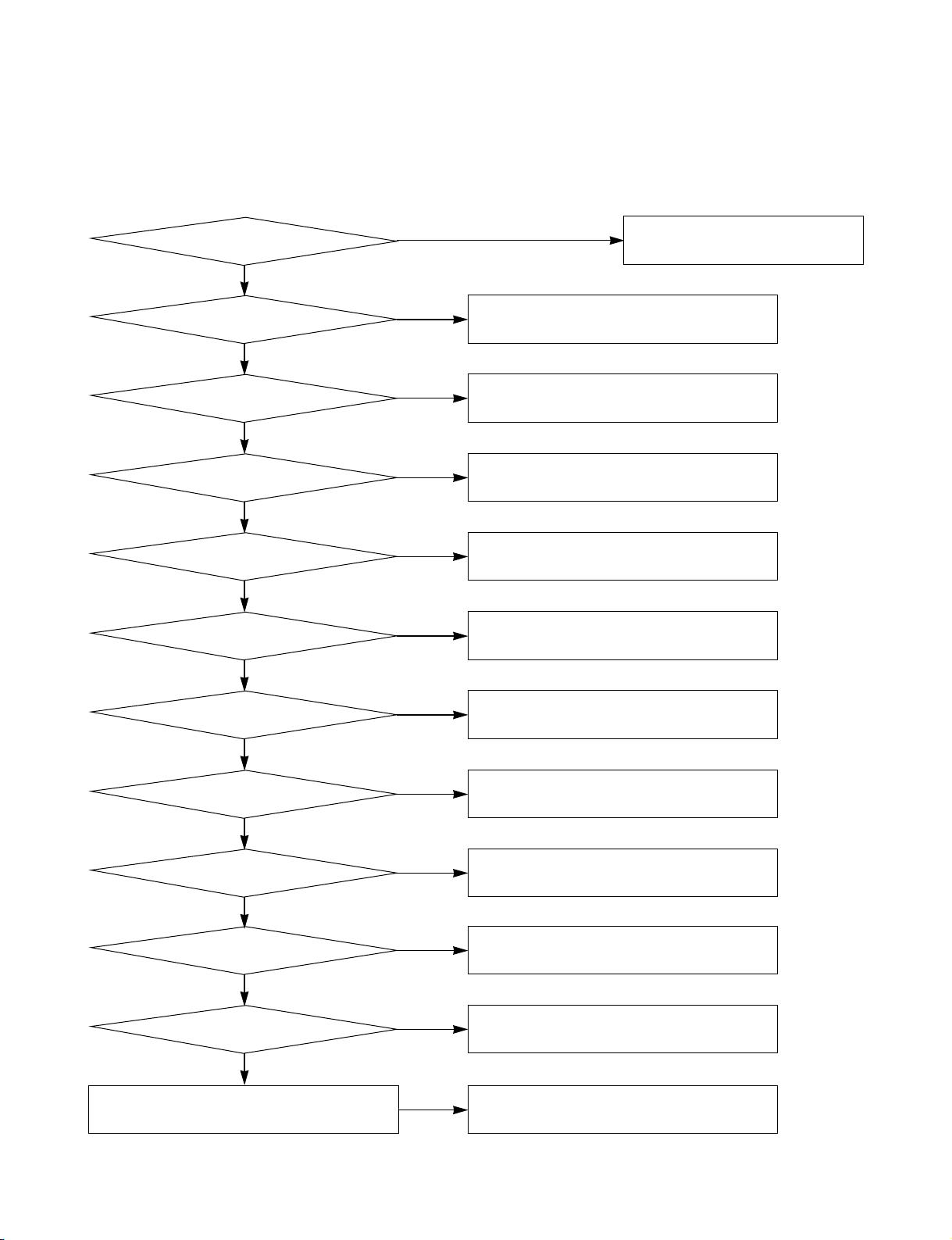

LCD PART

LCD ELECTRICAL TROUBLESHOOTING GUIDE

Appear shadow form

Display condition?

YES

interference in black background

NO

Inverter abnormal

Fuse normal? Fuse Replace

YES

+7.5V, 15V, -10V

YES

+5V normal?

YES

R G B signal output?

YES

VCOM signal?

(Vip 4.5)

YES

LCD MODE

CONT signal? All “LOW” (Normal

condition?)

YES

TFT LCD

pressure voltage? +3.3V, +5V,

+15V, -10V

YES

NO

NO

NO

NO

NO

NO

NO

D906, D901, D902

IC(U902) Check and Replace

Check and Replace

MPEG1389LP (Pin107, 108, 109)

IC(U901) Check and Replace

MAIN B/D Check

Power source and

L9020R, L901, D901, D902 check

TFT LCD normal?

adjusting normal?

Each connector?

LGE Internal Use Only

Color

END

YES

YES

YES

NO

NO

NO

NO

3-2

Replace

Readjust as adjustement standard

Replace and Reassemble

Replace

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 14

BLOCK DIAGRAM

Connector

(Main interface)

•STVR

•STVL

•CKV

•UND

•OEV

•VCOMO

•OEH

•STHL

•CPH1

•89P_R

•89P_G

•89P_B

•SP L-

•SP L+

•SP R-

•SP R+

•3.3V

•5VA

•VIN_6-12V

•PWRCTL_LCD

•IR

•KEY-PLAY

•DVD_KEY1

•DVD_KEY2

•DVD_KEY3

•DVD_KEY4

•DVD_KEY5

VCOM BLOCK

•VCOM

•UTC3308 IC

R/G/B Circuit

BLOCK

•ROUT

•GOUT

•BOUT

KEYPAD BLOCK

IR

KEY-PLAY

DVD_KEY1

DVD_KEY2

DVD_KEY3

DVD_KEY4

DVD_KEY5

LCD POWER BLOCK

•VGH (+15V)

•VGL (-10V)

•7.5V

•5V

•RCR2561 IC

INVERTER POWER BLOCK

•VIN_6-12V

•PWRCTL_LCD

•MP2359 IC

LCD PANEL

•VGH

•VGL

•STVR

•STVL

•CKV

•UND

•OEV

•VCOMO

•LNR

•MOD

•OEH

•STHL

•STHR

•CPH3

•CPH2

•CPH1

•89P_R

•89P_G

•89P_B

SPEAK

•SP L-

•SP L+

•SP R-

•SP R+

BACKLIGHT

KEY

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-3 3-4

LGE Internal Use Only

Page 15

CIRCUIT DIAGRAM

Friday, November 30, 2007Friday, November 30, 2007Friday, November 30, 2007

ROUT

BOUT

ROUT

BOUT

GOUT

STHR

OEH

STHL

OEV

UND

CKV

STVL

STVR

CPH1

LNR

+15V

+7.5V

IR

89L_B

5VA

DVD_KEY4

R_IN

89L_G

DVD_KEY1

KEY_PLAY

B_IN

IR

DVD_KEY2

G_IN

89L_R

-10V

GND

BIAS

89L_G

89L_B

GND

CPH1

STVL

STHL

LCD_3.3V

89L_R

OEV

VCOMO

5VA

GND

LCD_3.3V

CKV

OEH

SP_RSP_R+

DVD_KEY5

SP_L-

DVD_KEY3

SP_L+

5VD

5VD

7VD5

VCOMO

+7.5V

-10V

VCOM

VCOM

LCD_3.3V

R_IN

G_IN

GOUT

B_IN

KEY_PLAY

DVD_KEY1

DVD_KEY3

DVD_KEY5

DVD_KEY4

5VD

UND

5VD

LNR

DVD_KEY2

PWRCTL_LCD

SP_L-

SP_R+

SP_R-

SP_L+

VIN_6-12V

PWRCTL_LCD

GND

VIN_6-12V

GND

GND

5VD

LCD_3.3V

BIAS

BIAS

7VD5

7VD5

BIAS7VD5

Vdc

Vdc

Vdc

GND

CPH3

STHR

STHL

CKV

U/D

CPH1

VCOM

VCOM

OEV

VGL

VR

GND

VCC

VCC

L/R

VGH

VG

STVR

MOD

VB

AVSS

AVDD

CPH2

OEH

STVL

1.Ref

2.Anode

3.Cathode

123

89P VCOM DAC OUTPUT

Spec Sheet No.

DC TO DC

RCR2561

10

4

16

14

19

11

6

20

15

13

12

17

2

23

5

3

22

18

9

8

7

24

1

21

25

26

CPT CLAA070WA03

InnoLux AT070TN04

AUO A070FW03

Elite Star LR070WA01B

PVI PW070XU3

LED DRIVER

4 11.26

0603 to 0805(11.26)

0603 to 0805(11.26)

UTC3308

K905PLAYK905PLAY

1 2

D903

BAT54S

D903

BAT54S

3

2

1

C936ESD(15pF) C936ESD(15pF)

CN904

3.5-2P

CN904

3.5-2P

1

1

2

2

3

3

4

4

C953

104

C953

104

R935

4.7K

R935

4.7K

IR G VCC

IR901

HRM538CB5100 DIP

IR G VCC

IR901

HRM538CB5100 DIP

123

CN902

CON20_0.8MM

CN902

CON20_0.8MM

10

9

8

7

6

5

4

3

2

1

11

13

12

15

14

16

20

19

18

17

21

22

R919

160

R919

160

C940ESD(15pF) C940ESD(15pF)

K902NEXTK902NEXT

1 2

C938ESD(15pF) C938ESD(15pF)

C950 105C950 105

C954

10uF/16VC954 10uF/16V

R943

100/75

R943

100/75

C907

4.7u/25uFC907 4.7u/25uF

R927

47K

R927

47K

D901

D_15V

D901

D_15V

1 2

B

C

E

Q903

SMBT3904

B

C

E

Q903

SMBT3904

1

3 2

TP913TP913

C946

10uF/16VC946 10uF/16V

C961

104

C961

104

R928

160

R928

160

C924

105

C924

105

C919

22uF/16V

C919

22uF/16V

R952

6.8 1%

R952

6.8 1%

R911

0R911 0

R930

0R

R930

0R

R953

NC

R953

NC

C960

2.2uF/16V X5R

C960

2.2uF/16V X5R

C956

100pF

C956

100pF

R904

30K

R904

30K

R903

10K

R903

10K

D902

D_10V

D902

D_10V

1 2

R945

100K

R945

100K

D905

BAT54S

D905

BAT54S

3

2

1

R936

100

R936

100

R933

0R

R933

0R

C928

100pF

C928

100pFC927

104

C927

104

R950

5.6K

R950

5.6K

R926

430/270

R926

430/270

R944

10K

R944

10K

C947

100pF

C947

100pF

U901

NJM3414AM

U901

NJM3414AM

A OUT

1

A- IN

2

A+ IN

3

GND

4

B+ IN

5

B- IN

6

B OUT

7

V+

8

K901PLAUSEK901PLAUSE

1 2

TP912TP912

R939

47K

R939

47K

R946

10K

R946

10K

R913

NCR913 NC

R910

0R910 0

D906

1N5819

D906

1N5819

1 2

C930

22uF/10V

C930

22uF/10V

U904

MP2359DT

U904

MP2359DT

IN

5

EN

4

GND

2

BST

1

FB

3

SW

6

C934

100pF

C934

100pF

C923

104

C923

104

R905

10K

R905

10K

C913

104

C913

104

L902

0RL9020R

TP921TP921

C943

100pF

C943

100pF

TP918TP918

D908

D_13V

D908

D_13V

1 2

C959

334

C959

334

C951

10uF/16V

C951

10uF/16V

TP920TP920

R923

100/75

R923

100/75

C949

100pF

C949

100pF

D907

SS14

D907

SS14

1 2

C906 4.7u/25uFC906 4.7u/25uF

TP919TP919

R902

2KR902 2K

C941

104

C941

104

C917

105

C917

105

R912

NCR912 NC

C952

20pF

C952

20pF

U903

MP1540

U903

MP1540

IN

5SW1

EN

4

GND

2

FB

3

TP916TP916

C915

104

C915

104

L908

LSS57S30-330(33uH)L908LSS57S30-330(33uH)

L906

1.8uH

L906

1.8uH

C911

104

C911

104

R914

10K

R914

10K

R937

39k

R937

39k

TP909TP909

C921

22uF/16V

C921

22uF/16V

C935ESD(15pF) C935ESD(15pF)

C933

(NC)104

C933

(NC)104

C903

104

C903

104

D904

BAT54S

D904

BAT54S

3

2

1

C904 10uF/16VC904 10uF/16V

C937ESD(15pF) C937ESD(15pF)

C909 105C909 105

B

C

E

Q902

SMBT3904

B

C

E

Q902

SMBT3904

1

3 2

C925 105C925 105

C942

10uF/16V

C942

10uF/16V

TP914TP914

R915

39k

R915

39k

R942

10K

R942

10K

R916

430/270

R916

430/270

L903

6.8uHL903 6.8uH

R909

330

R909

330

R951

68K

R951

68K

R918

20K

R918

20K

C908

4.7uF/25V

C908

4.7uF/25V

R934

NC

R934

NC

L901

4.7uHL901 4.7uH

R917

47K

R917

47K

R908

TBD/10K

R908

TBD/10K

CN905

CON12_0.8MM

CN905

CON12_0.8MM

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

R925

39K

R925

39K

R932

100/75

R932

100/75

C916

104

C916

104

C955

103

C955

103

R901

6.8K

R901

6.8K

R940

160

R940

160

C926

104

C926

104

C902

10uF/16V

C902

10uF/16V

R931

10K

R931

10K

C905

10uF/16VC905 10uF/16V

R929

NC

R929

NC

B

C

E

Q901

SMBT3904

B

C

E

Q901

SMBT3904

1

3 2

R921

51K

R921

51K

TP915TP915

K904

STOPK904STOP

1 2

R906

20K

R906

20K

R938

430/270

R938

430/270

C929

104

C929

104

+

C920

47uF/10V

+

C920

47uF/10V

12

R948

1K

R948

1K

R907

10K

R907

10K

C948

100pF

C948

100pF

K903

PREK903PRE

1 2

C939ESD(15pF) C939ESD(15pF)

C944

100pF

C944

100pF

TP917TP917

R949

10K

R949

10K

C922

22uF/16V

C922

22uF/16V

U902

78L05

U902

78L05

GND

2

IN

3

OUT

1

TP911TP911

R922

10K

R922

10K

R941

0R

R941

0R

B

C

E

Q904

SMBT3906

B

C

E

Q904

SMBT3906

2 3

1

C957

104

C957

104

VR901

10K

VR901

10K

1

2

3

CN901

CON26_0.5MM

CN901

CON26_0.5MM

10

9

8

7

6

5

4

3

2

1

11

13

12

15

14

16

20

19

18

17

24

23

22

21

26

25

27

28

C932 10uF/16VC932 10uF/16VC931

100pF

C931

100pF

C912

105

C912

105

R920

10K

R920

10K

C958

2.2uF/16V X5R

C958

2.2uF/16V X5R

C914

104

C914

104

C910

105C910 105

B

C

E

Q905

SMBT3904

B

C

E

Q905

SMBT3904

1

3 2

R947

270K

R947

270K

R924

10K

R924

10K

C918

104

C918

104

C901

10uF/16V

C901

10uF/16V

TP910TP910

L905

4.7uHL905 4.7uH

L907

1.8uH

L907

1.8uH

C945

105C945 105

L904

1.8uH

L904

1.8uH

LGE Internal Use Only

3-5 3-6

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 16

PRINTED CIRCUIT BOARD DIAGRAM

(TOP VIEW)

MEMO

(BOTTOM VIEW)

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-7 3-8

LGE Internal Use Only

Page 17

MEMO MEMO

LGE Internal Use Only

3-9 3-10

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 18

MAIN PART

MAIN ELECTRICAL TROUBLESHOOTING GUIDE

1. DC-DC CONVERTER CIRCUIT

A. NO POWER ON BY ADAPTOR B. NO POWER ON BY BATTERY

No power on

by ADAPTOR

YES

Is ADAPTOR

out 12V?

YES

Is D606 OK?

No +18V

NO

NO

Replace ADAPTOR

Replace D606

No LCD_3.3V

No S3.3V

No power on

by BATTERY

YES

Is BATTERY OK?

No A+5V

No M5V

VCC_5V

NO

Replace BATTERY

No 5VA

Is U401

3.3V OK?

YES

Is U202 1.8V OK?

NO

Replace U401

NO

Replace U202

NO

Replace U401

NO

Replace U202

Is U401

5V OK?

YES

Is Q402 5V OK?

NO

Replace U401

Is U401

5V OK?

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-11

LGE Internal Use Only

Page 19

MAIN ELECTRICAL TROUBLESHOOTING GUIDE

C. AUDIO OUT ABNORMAL

Audio out abnormal

YES

Check Audio jack & mode

YES

Check A+5V

YES

Check signals from MPEG

YES

Replace IC(U502)

D. VIDEO OUT ABNORMAL

Video out abnormal

YES

Check Video jack & mode

YES

Check A+5V

YES

Check signals from MPEG

YES

Check IC(U502)

E. PICTURE ABNORMAL

Picture abnormal

YES

Check the disc.

YES

Refer to SERVO part

YES

Check DCLK signal of MPEG part

YES

Check MPEG (IC U201)

YES

Replace B/D

F. DISC ERROR

Disc error

YES

Check Disc

YES

Refer to SERVO part

YES

Replace B/D

LGE Internal Use Only

3-12

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 20

MAIN ELECTRICAL TROUBLESHOOTING GUIDE

G. OPEN/CLOSE ABNORMAL

OPEN/CLOSE abnormal

YES

Check SW201, SW202 switch

YES

Check IC(U201) Pin92

YES

Refer to SERVO part.

NO

Check the connectin of MD.

YES

Refer to SERVO part.

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-13

LGE Internal Use Only

Page 21

MAIN ELECTRICAL TROUBLESHOOTING GUIDE

2. MPEG CIRCUIT

Power is on

Does logo appear

on the screen?

YES

Does the

Video of the DVD Disc

play properly?

YES

Does the

Video of the video CD

play properly?

OPTION

If included VCD function.

NO

NO

YES

NO

Check power & clock.

YES

Is MPEG data

signal normal?

YES

Is error

signal normal?

Is MPEG data

signal normal?

NO

OK

NO

NO

Check CD/DVD DSP

output signal.

OK

Check MPEG Decoder

input signal.

Check CD/DVD DSP

output signal.

YES

Check MPEG Decoder

input signal.

Check CD/DVD DSP

output signal.

OK

Check MPEG Decoder

input signal.

the audio sound output

normally?

YES

LGE Internal Use Only

Does

END

NO

Is clock normal?

YES

Does the audio

signal output from MPEG

decoder?

YES

3-14

NO

NO

Copyright © 2008 LG Electronics. Inc. All right reserved.

Check clock signal

Check clock signal

Only for training and service purposes

Page 22

MAIN ELECTRICAL TROUBLESHOOTING GUIDE

3. RF/SERVO CIRCUIT

Put Disc in.

YES

Disc ID is correct?

YES

Does spindle rotate.

YES

Replace IC(U201)

NO

NO

NO

Laser off

Proper RFL signal

on MT1389?

YES

Check the RFL connection

between J401 and MT1389.

Proper DMSO signal

on MT1389

YES

Check the cable connection

between spindle and main PCBA.

NO

NO

Check the related circuit on

MT1389 RFL signal .

Check DMSO related circuit

on MT1389.

A

YES

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-15

LGE Internal Use Only

Page 23

MAIN ELECTRICAL TROUBLESHOOTING GUIDE

A

YES

Focus on OK.

YES

Track on OK.

NO

NO

Proper

signals on A, B, C, D

of MT1389

YES

Proper FEO signal

on MT1389.

YES

Check IC(U401)

Proper FEO signal

on MT1389.

YES

Properly TRSO signal

on MT1389.

YES

NO

NO

NO

NO

Check connections between

MT1389 and pick-up head.

Check the related circuit

on MT1389 FEO sugnal.

Check the related circuit

on MT1389

Check the TRSO connection

on MT1389 and motor dirver.

Disc is play?

B

LGE Internal Use Only

YES

YES

NO

T+ & T-

output properly.

YES

Check cable connection on

pick-up head.

YES

Check RF signal waveform.

3-16

Check the tracking control

amp circuit on motor driver.

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 24

MAIN ELECTRICAL TROUBLESHOOTING GUIDE

B

YES

Normal

Audio output when

disc playback.

YES

Normal

IR. VFD & Front pannel

key functions.

YES

NO

NO

Aout_L, Aout_R signal

Proper

on MTK1389

YES

Check Audio filter, amplify,

mute circuit.

Commu-

nications between

IR.VFD Front pannel key &

MT1389 & Front µ-com

is normally.

YES

NO

NO

NO

Check Aout_L related circuit

Aout_R

Check the related circuit of

Audio DAC.

Check communi cation lines

on MT1389

TEST END

NO

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Check the cable connection

on Front pannel.

3-17

LGE Internal Use Only

Page 25

MAIN ELECTRICAL TROUBLESHOOTING GUIDE

4. CHARGING CIRCUIT

No turn on Red LED Is 8.4V of J602_Pin3 OK?

NO

YES

Is L601 OK?

YES

Is IC(U601) OK?

YES

Is L602 OK?

YES

NO

NO

NO

Replace L601.

Replace IC(U601).

Replace L602.

Is IC(U603) OK?

NO

Replace IC(U603).

LGE Internal Use Only

3-18

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 26

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 27MHz CLOCK, RESET & FLASH R/W SIGNAL

1) MT1379 main clock is at 27MHz (X201)

2. SDRAM CLOCK

1) MT1389 main clock is at 27MHz (R308)

DCLK=125MHz, Vp-p=3.7V

U301 PIN38

FIG 1-1

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

FIG 2-1

3-19

LGE Internal Use Only

Page 27

3. DISC TYPE JUDGEMENT WAVEFORM

F+(U401 PIN8)

FE(U201 PIN26)

RFL(U201 PIN21)

FIG 3-1

F+(U401 PIN8)

FE(U201 PIN26)

RFL(U201 PIN21)

LGE Internal Use Only

FIG 3-2

3-20

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 28

F+(U401 PIN8)

FE(U201 PIN26)

RFL(U201 PIN21)

FIG 3-3

F+(U401 PIN8)

FE(U201 PIN26)

RFL(U201 PIN21)

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

FIG 3-4

3-21

LGE Internal Use Only

Page 29

4. FOCUS ON WAVEFORM

FOSO(U401 PIN11)

F+(U401 PIN8)

F-(U401 PIN9)

FIG 4-1

5. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)

DMSO(U401 PIN12)

SP-(U401 PIN15)

SP+(U401 PIN14)

FIG 5-1

LGE Internal Use Only

3-22

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 30

6. TRACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING)

TE(U201 PIN27)

TRSO(U401 PIN23)

T-(U401 PIN18)

T+(U401 PIN17)

FIG 6-1

TE(U201 PIN27)

TRSO(U401 PIN23)

T-(U401 PIN18)

T+(U401 PIN17)

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

FIG 6-2

3-23

LGE Internal Use Only

Page 31

7. MT1389 AUDIO OPTICAL AND COAXIAL OUTPUT (ASPDIF)

ASDIF Vpp=2.5V

(U201 PIN208)

FIG 7-1

8. MT1389 VIDEO OUTPUT WAVEFORM

1) Full colorbar signal (CVBS)

(U501 PIN14)

LGE Internal Use Only

FIG 8-1

3-24

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 32

9. AUDIO OUTPUT FROM AUDIO DAC

1) Audio L/R

MR 1kHz 0dB

(JK601 PIN4, 5)

2) Audio related Signal

FIG 9-1

ASDATA3

ASDAT0(IC301 PIN3)

ABCK(IC301 PIN4)

ALRCK(IC5301 PIN5)

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

FIG 9-2

3-25

LGE Internal Use Only

Page 33

WIRING CONNECTION DIAGRAMS

MAIN PCB

LCD PCB

1. WIRING CONNECTION DIAGRAMS-1

MAIN PCB LCD PCB

(MAIN PCB <----> LCD PCB)

0.8-12Y-12Y-220mm

0.8-20Y-20Y-220mm

MAIN PCB

LCD PCB

LGE Internal Use Only

3-26

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 34

2. WIRING CONNECTION DIAGRAMS-2

MAIN PCB

KEY PCB

(MAIN PCB <----> KEY PCB)

KEY PCB

MAIN PCB

KEY PCB

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-27

1.0-10Y-10Y-80mm

LGE Internal Use Only

Page 35

MEMO

LGE Internal Use Only

3-28

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 36

BLOCK DIAGRAMS

1. OVERALL BLOCK DIAGRAM

DECK MECHANISM

SPINDLE

MOTOR

SLED

MOTO

M

M5V

MOTOR DRIVER

DC-DC BLOCK1

DISC

M

R

SL+,

SL-

AM5898N

SP+,

SP

-

PICK

UP

27MHz

LDO1,LDO2,IOA,V20

A,B,C,D,E,F,RFO,MDI1/2

F+,F-,

T+,T-

V1P4,FOSO,TRSO,FMSO,DMSO,STBY

VCC5V

5VA

2F2301P

A+5V

M5V

XI,X

TRO

PEN

LIMIT

OPO

OP-,OP+

O

3.3V/BAT_OUT

LCD PANEL

VCOMO,CPH1/2/3,

1.8V/3.3V

MOD,89P_R/G/B,

STHL/R, STVL/R,

OEH/V,LNR,UND,

CKV,PWRCTL_LCD

8/16/32MBit

FLASH

MEMORY

R#

A[0..21]

PCE#,PRD#,PW

MT1389LP

MPEG

AD[0..7]

3.3V3.3V

64MBit

SDRAM

MA[0..11], BA[0..1],

CS#,CAS#,RAS#,

WE#,DQM[0..1]

DCLK,DCKE

DQ[0..15]

AOUT_L/R

A_MUTE_SW

SP_M

UTE

CV

BS

A± 5V

NJM4580M

A+5V

PT2303

VOLUME

SP_L/R+/

SP_L/R-

/AV_JACK_I

-

N

AV OUT

SPK

H/

P

DC-DC BLOCK2

DC_IN

P+

BATTERY

P-

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SM9926K

APM4953K

3.3V

CM1117

V18

BAT_OUT

/M_RESET

STANDBY

AD_PR

PWM

AD_U

AD_T

AD_I

5VA

AD_K

KEY

REMOCON

RECEIVE

3-29 3-30

GT6312

IR

CH_SCS,

SCLK,

SDO

R

SDI

RED,

GREEN

Power,

Charge LE

D

LGE Internal Use Only

Page 37

2. POWER BLOCK DIAGRAM

t

Charge

AC/DC Adapter

DC Sense BAT Sense

GT6 312

12V in

Battery Charge Circuit

Charge Enable

BAT out

Charge

Thermister

Divide Divide

FET

BAT Con

SW (12V in)

5VA

5VA

M5V

Discharge

REMOCON

RECEIVER

Servo

LGE Internal Use Only

DC-DC

AM5898N

S/W

S/W

Reg

Standby

3-31 3-32

A+5V

3.3V

1.8V

RCR2561

LCD

Vcc

7.5V

-10V

15V

DV

Battery out

A+5V

Video

Audio

A+5V

3.3V

1.8

V

7.5V

-10V

15V

5VD

Copyright © 2008 LG Electronics. Inc. All right reserved.

System

LCD

Panel

Only for training and service purposes

Page 38

3. SERVO BLOCK DIAGRAM

ALPC

CDLD(LD01),DVDLD(LD02)

IOA

U201

Y201

27MHz

X-TA

L

PICK

UP

Stepping

Mote

r

LIMIT

FO+, FO-,

TR+, TR-

SL-,SL+

MDI1,MDI2

DVD : A,B,C,D,RF

CD : A,B,C,D,E,

F,RF

U401

MTK1389DE/LP

P-DVDPLAYER

ONE CHIP

FMSO,DMSO,FOSO,

TRSO,STBY,

V1P4

Spindle

Mote

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

AM5898N

Motor

SP-,SP+

r

OP+,OP-

OP

3-33 3-34

Driver

O

LGE Internal Use Only

Page 39

4. SYSTEM BLOCK DIAGRAM

SF_DO

System & AV Part

27MHz

1.8V/3.3V

3.3V

SF_DO

MT1389DE/LP

MPEG

IROUT

SF_DI

SF_CS

SF_CK

MA0~MA11,DBA0/1

DQ0~DQ15

DCLK,DCKE

CS#,CAS#,RAS#

WE#,DQM0,DQM1

DVD_K1,DVD_K2,DVD_K3,

DVD_K4,DVD_K5

16/32MBit

FLASH

MEMORY

3.3V

64MBit

SDRAM

2^14*2^8*16=64Mbit

LGE Internal Use Only

REMOCON

RECEIVER

IR

5VA

GT6312

RED,

GREEN

Power,

Charge LED

AD_KEY

3-35 3-36

KEY1

KEY2

LCD MODE,DISPLAY,SETUP,MENU

UP,DOWN,LEFT,RIGHT,ENTER

POWER,PLAY/PAUSE,REW,FF,STOP,

COLOR/BRIGHT

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 40

5. AV BLOCK DIAGRAM

GT

6312

1.8V/3.3V

5VA

GT

System & AV Part

6312

VIDEO ADC

2CH DAC

CVBS

A_MUTE_SW

AOUT_L/R

12V

NJM4580M

OP-AMP

VOLUME

SP_MUTE

A+5V

PT2303

VIDEO

< AV OUT >

AUDIO

SP_L+/L-

SPK

SP_R+/R-

SPK

MT1389DE/LP

MPEG

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SDA,SCL,

ML_OUT,MR_OUT

3-37 3-38

SP_L-/R-

SP_L-/R-

H/P JACK

H/P JACK

LGE Internal Use Only

Page 41

CIRCUIT DIAGRAMS

02.MPEG

LG & MALATA

Thursday, December 20, 2007

02.MPEG

LG & MALATA

Thursday, December 20, 2007

02.MPEG

LG & MALATA

Thursday, December 20, 2007

SDA

SCL

DCLK

DQM[0..1]

WE#

RAS#

MA[0..11]

CAS#

3.3V

GND

89L_B

89L_G

89L_R

CPH1

STHL

OEH

OEV

CKV

STVL

DQ[0..15]

AL

AR

IR_OUT

C

LDO1

D

LDO2

STBY

E

V1P4

F

RFO

DMSO

TRSO

FOSO

FMSO

IOA

MDI1

OPO

A

LIMIT

V20

OP-

B

DVD_SLEEP

CVBS

DVD_KEY1

DVD_KEY3

DVD_KEY2

DVD_KEY4

DVD_KEY5

DVD_KEY6

OP-

AVCM

RFVDD3

MA3

IR_OUT

AVDD33

LIMIT

V20

MA1

TRO

FOO

V1P4

FMO

DMO

FOSOFOSOFOSOFOSOFOSOFOSO

TRSOTRSOTRSOTRSOTRSOTRSO

DMSODMSODMSODMSODMSODMSO

FMSOFMSOFMSOFMSO

TRIN

MA0

TXD

RFO

FS

RXD

MA10

DVD_KEY5

DVD_KEY4

BA1

BA0

D

A

B

C

RAS#

STVL

AADVDD

CAS#

CKV

OPO

RFV18-1

WE#

AADVDD

MA4

MA11

APLLVDD3

MA5

DCLK

DQM1

MA6

MA7

SF_CS

SF_DO

SF_D

I

DACV

DD3

TXD

RXD

RFV18-1

RFV18-2

SF_CK

SC

L

SDA

DQ0

DQ1

DQ2DQ3

DACVDD3

DQ4

DQ5

ADACVD

D

DACVDD3

DVD_KEY

1

DQ

7

DQ6

DVD_KEY

2

DVD_KEY3

DQM

0

DQ

15DQ12

DQ13

DQ10

DQ11DQ

8

APLLVDD3

ADACVDD

MA9

MA8

DACVDD3

VCOMO

DQ

9

89L_G

DQ

14

F

89L_B

DVD_SL

EEP

89L_R

E

AL

AR

DVD_

KEY6

STHLOE

H

V1P4

DVD_KEY5

DVD_KEY6

DVD_KEY1

DVD_KEY2

DVD_KEY3

DVD_KEY4

VCOMO

SF_CS

SF_DI

SF_DO

SF_CK

MA2

FOO

XI

DMO

FG

TRO

RFVDD3

AVDD33

RFV18-2

IOA

XO

STBY

FMO

V20

V1P4

OEV

BA1

BA0OPO

OP+

OP+

TRIN

URST#

CP

H1

CVBS

XI XO

LDO1

LDO2

MDI1

URST#

DV33

DV33

V18

DV33

DV33 V18

V18

AVDD33

DV33

RFVDD3

DV33

AVDD33

DV33

AADVDD

V18

RFV18-1

RFV18-2

DV33

ADACVDD

APLLVDD3

DACVDD3

RFVDD3

RFV18-2

RFV18-1

3.3V

DV33

DV33

DV333.3V

3.3V

V18

DV33

V18

GND

3,4,5,6,7

3.3V

3.4,7

89L_B 7

89L_G 7

89L_R 7

CPH1 7

STHL 7

OEH

7

OEV 7

CKV

7

STVL

7

DQ[0..15]

3

SDA

3

SCL

3

MA[0..11]

3

RAS#

3

WE#

3

CAS#

3

DCLK

3

DQM[0..1] 3

AR

5

AL

5

IR_OUT

6

V20

4

V1P4

4

STBY

4

DMSO 4

FOSO

4

TRSO

4

FMSO

4

OPO

4

LIMIT

4

IOA

4

LDO1

4

LDO2

4

A4

B4

C4

D4

E4

F4

RFO

4

MDI1

4

OP-

4

DVD_SLEEP

7

CVBS

5

DVD_KEY6

7

DVD_KEY1

7

DVD_KEY3

7

DVD_KEY4

7

DVD_KEY2

7

DVD_KEY5

7

VCOMO

7

SF_CS

3

SF_DI

3

SF_CK 3

SF_DO

3

BA1

3

BA0

3

OP+

4

AUDIO INTERFACE

MEMORY

POWER

CONTRL

IIC

FLASH

SERVO I/F

DVD_KEY

10K C TO 4.7K(11.21)

R259 0R259 0

L213

10uH

L213

10uH

C211 4.7uFC211 4.7uF

B

C

E

Q202

3904

B

C

E

Q202

3904

1

3 2

C221

0.1uF

C221

0.1uF

L208

47uH/NC L20847uH/NC

R229

10KR229 10K

C204

1000pF/NC

C204

1000pF/NC

+

CE206

10uF/16V

+

CE206

10uF/16V

12

R209 0R209 0

R202

0RR202 0R

C209

120pF/NC

C209

120pF/NC

R268

0R268 0

MT1389LP

U201

MT1389L/SMD

LQFP-128

MT1389LP

U201

MT1389L/SMD

LQFP-128

RFA

1

RFB

2

RFC

3

RFD

4

RFE

5

RFF

6

AVDD18_2

7

AVDD33_1

8

XTALI

9

XTALO

10

AGND33

11

V20

12

V14

13

REXT

14

MDI1

15

MDI2

16

LDO1

17

MDILDO2

18

AVDD33_2

19

DMO

20

FMO

21

TRAY_OPEN

22

TRAY_CLOSE

23

TRO

24

FOO

25

PG/GPIO2

26

USB_DP

27

USB_DM

28

VDD33_USB

29

VSS33_USB

30

PAD_VRT

31

VDD18_USB

32

GPIO3/INT#

33

GPIO434GPIO635SF_CS_36SF_DO37SF_DI38SF_CK39UP1_6/SCL40UP1_7/SDA41ICE42PRST#43IR44RD045RD146RD247RD348RD449DVDD3350RD551RD652RD753DVDD1854DQM055RD1556RD1457RD1358RD1259DVSS3360RD1161RD1062RD963RD8

64

VOE/GPIO15

96

VCK/GPIO14

95

VSTU/GPIO13

94

SPDIF/GPIO12

93

HSTR/11

92

LR/GPIO10

91

DVDD18

90

UD/GPIO9

89

VSTD/GPIO8

88

GPIO7/CKE

87

RA3

86

RA2

85

DVDD33

84

RA1

83

RA0

82

RA10

81

BA1

80

DVSS18

79

BA0

78

RAS#

77

CAS#

76

RWE#

75

RA4

74

RA5

73

RA6

72

RA7

71

RA8

70

RA9

69

DVDD33

68

RA11

67

RCLK

66

DQM1

65

HCK/GPIO18

99

HSTL/GPIO17

98

HOE/GPIO16

97

RFH/OPINN

128

RFG/OPINP

127

RFIN/OPOUT

126

RFIP

125

AGND18

124

AVDD18_1

123

ADACVDD2

122

ADACVDD1

121

AL/GPIO1

120

AVCM

119

AR/GPIO0

118

ADACVSS

117

APLLCAP

116

APLLVDD

115

AADVDD

114

AKIN1/GPIO21/Audio_mute

113

ADVCM/GPIO20

112

AKIN2/GPIO19/Audio_mute

111

AADVSS

110R109B108G107

DACVDDA

106

DACVDDB

105

CVBS

104

DACVSSC

103FS102

VREF

101

DACVDDC

100

C202

330pF

C202

330pF

R269

0

R269

0

C218

0.1uF

C218

0.1uF

L209

2.7uH/NC

L209

2.7uH/NC

R216

15KR216 15K

RN201

10Kx4RN20110Kx4

1 8

2 7

3 6

4 5

L211

CBV160808A471B

L211

CBV160808A471B

1 2

L204

FB(50)

L204

FB(50)

1 2

L21047uH L21047uH

C227

0.1uF

C227

0.1uF

C207

0.015uF

C207

0.015uF

C201

0.1uF

C201

0.1uF

R206

0R206 0

C226

0.1uF

C226

0.1uF

R225

3.3K

R225

3.3K

C228 1uFC228 1uF

C224

0.1uF

C224

0.1uF

R221

27KR221 27K

C203

0.1uF

C203

0.1uF

R226

15K

R226

15K

R224

3.3K

R224

3.3K

C215

0.1uF

C215

0.1uF

C239

1uF

C239

1uF

C216

0.1uF

C216

0.1uF

C208 0.1uFC208 0.1uF

D201

1N4148/NC

D201

1N4148/NC

1 2

C205

0.1uF

C205

0.1uF

R208

0R208 0

C232

27pF

C232

27pF

C222 1500pFC222 1500pF

R213 5.1KR213 5.1K

J201

CON4_2.0MM_DIP

J201

CON4_2.0MM_DIP

1

2

3

4

C214 220pFC214 220pF

+

CE213

22uF/16V

+

CE213

22uF/16V

12

R220 4.7kR220 4.7k

+

CE207

47uF/6.3v

+

CE207

47uF/6.3v

12

C230 0.1uFC230 0.1uF

C220

10uF/10V

C220

10uF/10V

C235

0.1uF

C235

0.1uF

C213

0.1uF

C213

0.1uF

R230

330R230 330

L207

FB(1206)

L207

FB(1206)

1 2

R211 15KR211 15K

R219

10K

R219

10K

L212

FB(

600)

L212

FB(600)

1 2

+

CE204

10uF/16V

+

CE204

10uF/16V

12

+

CE208

100uF/6.3V

+

CE208

100uF/6.3V

12

R217 10kR217 10k

C210

6800pF

C210

6800pF

C241

180pF

C241

180pF

C219

0.1uF

C219

0.1uF

C217

NCC217 NC

R212

0R212 0

L205

FB(50)

L205

FB(50)

1 2

+

CE205

100uF/6.3V

+

CE205

100uF/6.3V

12

R218

10K

R218

10K

L215

10uH

L215

10uH

R228

0R228 0

L206

FB(50)

L206

FB(50)

1 2

R201 100KR201 100K

C233

6800pF

C233

6800pF

C225

0.1uF

C225

0.1uF

R205

10

R205

10

R236

22K

R236

22K

C234

0.1uF

C234

0.1uF

U202

CM1117SCM233

SOT223

U202

CM1117SCM233

SOT223

OUT

2

IN

3

ADJ

1

TAB

4

C223

0.1uF

C223

0.1uF

SW201

SW212

SW201

SW212

1 4

2 3

C238

0.1uF

C238

0.1uF

R235

4.7K

R235

4.7K

L214

10uH

L214

10uH

C229

330pF

C229

330pF

R210

0R210 0

C206

0.1uF

C206

0.1uF

R222

0R222 0

C231

0.1uF

C231

0.1uF

R203

0RR203 0R

R233

0R/NCR233 0R/NC

+

CE201

100uF/6.3V

+

CE201

100uF/6.3V

1 2

Y201

27M

Y201

27M

1 2

3

R207 10R207 10

+

CE202

100uF/6.3v

+

CE202

100uF/6.3v

12

SW202

SW212

SW202

SW212

1 4

2 3

L203 FB(50)L203 FB(50)

1 2

R204

560R 1%

R204

560R 1%

+

CE203

100uF/6.3v

+

CE203

100uF/6.3v

12

L202

FB(50)

L202

FB(50)

1 2

+

CE211

220uF/6.3v

+

CE211

220uF/6.3v

12

R232 0R232 0

+

CE209

100uF/6.3V

+

CE209

100uF/6.3V

12

R234 0R/NCR234 0R/NC

L201

FB(50)

L201

FB(50)

1 2

+

CE212

220uF/6.3v

+

CE212

220uF/6.3v

12

C212

27pF

C212

27pF

B

C

E

Q201

3904

B

C

E

Q201

3904

1

3 2

C236

0.1uF

C236

0.1uF

R223

680

R223

680

R249 2KR249 2K

R214

27KR214 27K

1. MPEG CIRCUIT DIAGRAM

LGE Internal Use Only

3-39 3-40

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 42

2. MEMORY CIRCUIT DIAGRAM

MA0

SF_CS

BA1

DQ[0..15]

DQM[0..1]

MA[0..11]

SCL

SDA

WE#

DCLK

CAS#

RAS#

BA0

3.3V

SF_CK

SF_CS

SF_DO

SF_DI

SDCLK

DQM1

DRAS#

MA5

MA9

DQ0

SDCKE

MA10

DCAS#

DQ9

DCAS#

DBA1

BA1

DRAS#

DQ1

MA8

DCS#

DQ11

DQ15

BA0

MA6

CAS#

SDCKE MA7

WE#

MA4

DQ3

DQ5

DWE#

MA11

DCLK

RAS#

DBA0

MA1

DQ2

DQ7

MA2

DQ10DCS#

DQ8

DBA0

SDCLK

DBA1

DQ4

MA3

DWE#

DQM0

DQ14

DQ6

DQ13

DQ12

GND

SF_CK

SF_DI

SF_CS

SF_DO

SD33

SD33

SD33

SD33

SD33

SD33

3.3V SD33

SD33

SD33

BA1

3

WE#

3

DCLK

3

CAS#

3

RAS#

3

DQM[0..1]

3

SCL

2

SDA

2

DQ[0..15]

3

MA[0..11]

3

BA0

3

3.3V

2,4,7

SF_CK

2

SF_CS

2

SF_DO

2

SF_DI

2

GND 2,4,5,6,7

DRAM

IIC

SDRAM

4Mb/8Mb

S-FLASH

S-FLASH

R315 0R315 0

C305

0.1uF

C305

0.1uF

R312

0R312 0

C303

0.1uF

C303

0.1uF

C302

0.1uF

C302

0.1uF

U302

AT25FS040/EN25B80

U302

AT25FS040/EN25B80

CS#

1

DO

2

WP#

3

VSS

4

DI

5

CLK

6

HOLD#

7

VCC

8

R310

NCR310 NC

R311

10KR311 10K

R302

10KR302 10K

RN301

33x4

RN301

33x4

1 8

2 7

3 6

4 5

C309

0.1uF

C309

0.1uF

R314

0R314 0

L301

FB(50)L301 FB(50)

1 2

C304

0.1uF

C304

0.1uF

C308

0.1uF

C308

0.1uF

C306

0.1uF

C306

0.1uF

C307

0.1uF

C307

0.1uF

R303

150R303 150

R307

10KR307 10K

+

CE301

47uF/10V

+

CE301

47uF/10V

12

R301 10KR301 10K

R313

0R313 0

U301

HY57V641620

U301

HY57V641620

A0

23

A1

24

A2

25

A3

26

A4

29

A5

30

A6

31

A7

32

A8

33

A9

34

A10/AP

22

A11

35

BA0/A13

20

BA1/A12

21

CLK

38

CKE

37

CS

19

RAS

18

CAS

17

WE

16

DQML

15

DQMH

39

NC1

36

NC2

40

VSS

54

VSS

41

VSS

28

DQ0

2

DQ1

4

DQ2

5

DQ3

7

DQ4

8

DQ5

10

DQ6

11

DQ7

13

DQ8

42

DQ9

44

DQ10

45

DQ11

47

DQ12

48

DQ13

50

DQ14

51

DQ15

53

VCC

1

VCC

14

VCC

27

VCCQ

3

VCCQ

9

VCCQ

43

VCCQ

49

VSSQ

6

VSSQ

12

VSSQ

46

VSSQ

52

R306

10KR306 10K

C301

0.1uF

C301

0.1uF

R304

33R304 33

R305

33R305 33

03.MEMORY

LG & MALATA

Thursday, December 20, 2007

03.MEMORY

LG & MALATA

Thursday, December 20, 2007

03.MEMORY

LG & MALATA

Thursday, December 20, 2007

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-41 3-42

LGE Internal Use Only

Page 43

3. OPU & MOTOR CIRCUIT DIAGRAM

04.OPU & MOTOR

LG & MALATA

Thursday, December 20, 2007

04.OPU & MOTOR

LG & MALATA

Thursday, December 20, 2007

04.OPU & MOTOR

LG & MALATA

Thursday, December 20, 2007

LDO1

V1P4

TRSO

C

LDO2

OPO

D

V20

LIMIT

STBY

DMSO

RFO

E

FOSO

MDI1

A

F-

F+

T+

T-

D

B

E

GND

FMSO

F

OP-

B

F+

F-

CT1

FMSO

TRSO

STBY

V1P4

CT1

3.3V

A+5V

BAT_OUT

IOA

GND

LIMIT

OP+

V1P4

SP-

OP-

SL+

SL-

SP-A

SP+

C

A

VR_CD

VR_DVD

LD_CD

MDI1

STANDBY

STANDBY

V20

F

IOA

VCC_5V

OPO

LCD_3.3V

5VA

MDI1

OPO

SP- OP-

SP+

SP-A

T-

SP-

SP+

DMSO

FOSO

T+

SLSL+

OP+

IOA

VCC_5V

RFO

STANDBY

LDO1

LDO2

LD_DVD

VCC_5V

BAT_OUT

M5V

M5V

3.3V

BAT_OUT

BAT_OUT

M5V

BAT_OUT

BAT_OUT

S3.3V3.3V

BAT_OUT

M5V

M5V

VCC_5V

M5VVCC_5V

A+5V

LCD_3.3V

S3.3V

5VA

S3.3V

S3.3V

S3.3V

LDO1

2

V1P4

2

TRSO

2

C2

LDO2

2

OPO

2

D2

LIMIT

2

DMSO

2

RFO

2

E2

FOSO

2

MDI1

2

A2

FMSO

2

F2

OP-

2

B2

3.3V

2,3,7

A+5V

5

BAT_OUT

5,6,7

IOA

2

GND

2,3,5,6,7

STBY

2

STANDBY

6

V20

2

VCC_5V

7

LCD_3.3V

7

5VA

6,7

OP+ 2

SERVO I/F

OFF-PAGE CONNECTION

5V Power for Video Buffer & Motor Driver & OPU

3

2SB1132

1

C2EB

ADD(11.26)

ADD(11.29)

R415 15R415 15

J401

HEADER 24 SMD0.5 TOP

CON24_0.5MM

J401

HEADER 24 SMD0.5 TOP

CON24_0.5MM

10

9

8

7

6

5

4

3

2

1

11

13

12

15

14

16

20

19

18

17

24

23

22

21

25

26

L409

47uH(LH)

L409

47uH(LH)

B

C

E

Q412

3906

B

C

E

Q412

3906

2 3

1

+

CE415

47uF/6.3v

+

CE415

47uF/6.3v

12

Q411

2SB1132

Q411

2SB1132

1

23

+

CE410

220uF/10V

+

CE410

220uF/10V

12

R401 10kR401 10k

R448

10KR448 10K

R459

100KR459 100K

C430

0.1uFC430 0.1uF

R409

750

R409

750

R453 10KR453 10K

C426

0.1uF

C426

0.1uF

R438

20KR438 20K

R406

150K/NC

R406

150K/NC

C411

1uF

C411

1uF

R430

0.11%R430 0.11%

R442

0

R442

0

J402

2x1 W/HOUSING

CON2_2.0MM_DIP_B

J402

2x1 W/HOUSING

CON2_2.0MM_DIP_B

2

1

D

S

G

Q410

AO3409

P-CHANNEL

D

S

G

Q410

AO3409

P-CHANNEL

1

32

R427 0.1 1%R427 0.1 1%

B

C

E

Q413

3906

B

C

E

Q413

3906

23

1

C420

0.1uF

C420

0.1uF

L407

FB(50)

L407

FB(50)

R423

10KR423 10K

R418

3.6K 1%R418 3.6K 1%

R461

47K/NC

R461

47K/NC

C419

1000pF

C419

1000pF

R462

10K

R462

10K

R447

10KR447 10K

C417

68pFC417 68pF

R454

100KR454 100K

R407

2K 1%R407 2K 1%

R443

0/NC

R443

0/NC

R416

100R416 100

+

CE417

220uF/6.3v

+

CE417

220uF/6.3v

1 2

R463

10K

R463

10K

L412

47

UH(

L412

47UH(

1 2

D401

1N5819

D401

1N5819

1 2

+

CE406

100uF/10V

+

CE406

100uF/10V

12

L410

FB(50)

L410

FB(50)

C409

0.1uF

C409

0.1uF

U401

AM5898N

U401

AM5898N

EN2

1

GND

35

VCC1

10

VINSL+

12

COMP2

3

CT2

2

VOSP-

21

PVCC2

7

VOSL+

14

MGND

13

PGND1

26

PGND

25

GND

36

COMP1

30

MUTE

33

PVCC1

6

SW2

4

IPK2

5

BIAS

34

VOFC-

9

VINFC

11

VINTK

23

VCC2

24

VINSP

22

SW1

29

IPK1

28

CT1

31

EN1

32

VOFC+

8

PGND2

27

VOSL-

15

MGND

16

VOTK+

17

VOSP+

20

MGND

19

VOTK-

18

C402

2200pF/NC

C402

2200pF/NC

B

C

E

Q407

3906

B

C

E

Q407

3906

2 3

1

C435

0.1uF

C435

0.1uF

C410

0.1uF

C410

0.1uF

L403

50

L403

50

1 2

R455

0

R455

0

J403

4x1 W/HOUSING

J403

4x1 W/HOUSING

1

2

3

4

C421

0.1uF

C421

0.1uF

C415

1000pF

C415

1000pF

+

CE402

47uF/10V

+

CE402

47uF/10V

12

+

CE403

47uF/10V

+

CE403

47uF/10V

12

R464 0R464 0

D403

BAT54CD403BAT54C

3

2

1

C425

0.1uF

C425

0.1uF

C416

68pFC416 68pF

B

C

E

Q415

2N3904

B

C

E

Q415

2N3904

1

3 2

R413

680K

R413

680K

C408

0.1uF

C408

0.1uF

R437

4.7K

R437

4.7K

C428

0.1uF

C428

0.1uF

+

CE416

100uF/10V

+

CE416

100uF/10V

12

R412

1/NC

R412

1/NC

R441

10kR441 10k

+

CE412

220uF/10V

+

CE412

220uF/10V

12

R405

27K

R405

27K

C423

2200pF/NCC423 2200pF/NC

R408

33R408 33

C414

0.1uF

C414

0.1uF

R460

10K/NC

R460

10K/NC

C434

0.1uF

C434

0.1uF

B

C

E

Q409

2N3904

B

C

E

Q409

2N3904

1

3 2

R456

10K

R456

10K

G

S

D

Q418

2SK3018

G

S

D

Q418

2SK3018

1

2 3

R420 680KR420 680K

R402

20KR402 20K

R410

10KR410 10K

R432

10KR432 10K

C401

0.1uF

C401

0.1uF

R421

4.7R421 4.7

C433

0.1uF

C433

0.1uF

R424

4.7R424 4.7

R449

150K/NC

R449

150K/NC

C418

0.1uF

C418

0.1uF

R434

0R434 0

C436

NC

C436

NC

R404

680K/NCR404 680K/NC

C413

NC

C413

NC

R426

51K

R426

51K

R433

0R433 0

R425

1R

R425

1R

L404

10uH

L404

10uH

1 2

C429

0.1uF

C429

0.1uF

R452

OPEN

R452

OPEN

Q414

2SB1132

Q414

2SB1132

1

2 3

L408

47uH(LH)

L408

47uH(LH)

G

S

D

Q417

2SK3018

G

S

D

Q417

2SK3018

1

2 3

+

CE418

47uF/6.3v

+

CE418

47uF/6.3v

12

R465 NCR465 NC

R428

NCR428 NC

L414

10uH

L414

10uH

R422

6.8K

R422

6.8K

D

S

G

Q408

AO3409

P-CHANNEL

D

S

G

Q408

AO3409

P-CHANNEL

1

3 2

C431

NC

C431

NC

R450

1.2K 1%R450 1.2K 1%

D

S

G

Q402

AF2301P/RCR1521SI

P-CHANNEL

D

S

G