Page 1

PORTABLE DVD

SERVICE MANUAL

MODEL : DP170

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

MODEL : DP170SERVICE MANUAL

P/NO : AFN30721334 MAY,2006

Page 2

1-1

CONTENTS

SECTION 1 . . . . SUMMARY

SECTION 2 . . . . EXPLODED VIEWS

SECTION 3 . . . . ELECTRICAL

SECTION 4 . . . . REPLACEMENT PARTS LIST

Page 3

1-2

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS ............. 1-3

SERVICING PRECAUTIONS................................................................................................... 1-4

SPECIFICATIONS ...................................................................................................................... 1-5

Page 4

1-3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILLNOT ONLY

VOID THE WARRANTY, BUT MAYLEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTYDAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METALSURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAG-

NITUDE TO CONSTITUTE ARISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALLTHEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

ATYOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLYRECOMMENDED FACTORYREPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS AFACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINSTTHE MOUNTING OF APRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLLA CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THATAFOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METALPART

Page 5

1-4

SERVICING PRECAUTIONS

CAUTION : Before servicing the PORTABLE DVD covered

by this service data and its supplements and addends, read

and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances create conflict between the following

servicing precautions and any of the safety precautions in

this publications, always follow the safety precautions.

Remembers Safety First:

General Servicing Precautions

1. Always unplug the PORTABLE DVD AC power cord from

the AC power source before:

(1)Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this PORTABLE DVD

or any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this PORTABLE DVD and/or

any of its electrical assemblies unless all solid-state

device heat sinks are cerrectly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grouned-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

Page 6

1-5

SPECIFICATIONS

[DVD player]

Power supply DC 9.5V (AC adapter terminal), DC 7.4V (Battery)

Power consumption 12 W with battery

Weight 12.6 ibs (0.66kg)(without battery pack)

External dimensions(W X D X H) (186 X 150 X 25mm)

Signal system NTSC

Laser Semiconductor laser, wavelength 650 nm (DVD),

780nm(CD)

Frequency range (audio) DVD linear sound:48KHZ sampling 4 HZ to 20KHZ

96KHZ sampling 4 HZ to 44 KHZ

Signal-to-noise ratio(audio) More than 95dB

Dynamic range(audio) More than 95dB

Harmonic distortion(audio) 0.08%

Operatingconditions(audio) Temperature: 41°F to 95°F, Operation status: Horizontal

[Connectors]

Video input/output(VIDEO IN/OUT) 1.0V(P-P),75R,negative sync ø3.5m X 1

Audio output (optical audio) Optical connector (ø3.5mm) X 1

Audio input/output 2.0Vrms (1 KHZ,0 dB), ø3.5m X 1

(AUDIO IN/OUT, analog audio)

Earphone terminal ø3.5mm stereo mini jack X 1

[Liquid Crystal Display]

Panel size 7 inches (16:9)

Projection system TN color transmission

Driving system TFT active matrix

[Supplied Accessories]

RC Aaudio/Video cable 1

AC Adapter (AD-DP40) 1

Power Cord 1

Battery Pack (DP-BT50) 1

Remote control 1

Battery for Remote control (Lithium) 1

Page 7

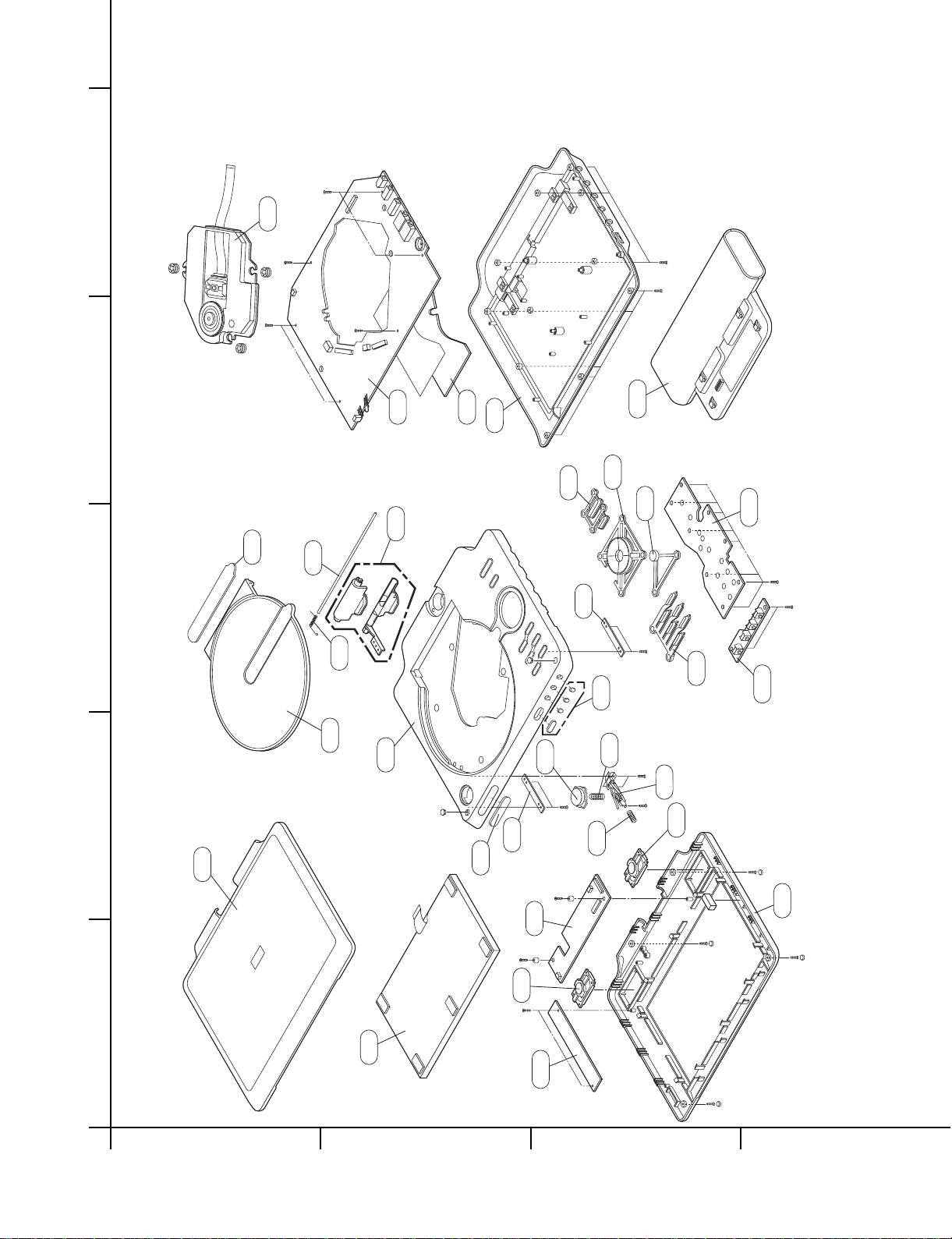

2-12-1

SECTION 2

EXPLODED VIEWS

CONTENTS

EXPLODED VIEWS.....................................................................................................................2-2

• CABINET AND MAIN FRAME SECTION ..................................................................................2-2

Page 8

2-22-2

EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION

A

5

4

3

2

1

BCD

A00

292

295

296

293

260

A46

278

A47

A42

281

275

267

275

A48

262

284

265

285

266

A44A

283

A45A

282

A46A

264

277

272

A51

LCD

277

A40

A49A

Page 9

3-1

SECTION 3

ELECTRICAL

CONTENTS

LCD PART ................................................................................................................3-2

LCD TROUBLE SHOOTING GUIDE .....................................................................3-3

LCD CIRCUIT DIAGRAMS ....................................................................................3-5

LCD BLOCK DIAGRAM........................................................................................3-9

LCD PRINTED CIRCUIT DIAGRAMS..................................................................3-10

MAIN PART ............................................................................................................3-11

MAIN ELECTRICAL TROUBLE SHOOTING GUIDE...........................................3-11

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING..............3-19

MAIN BLOCK DIAGRAMS...................................................................................3-28

MAIN CIRCUIT DIAGRAMS.................................................................................3-30

MAIN PRINTED CIRCUIT DIAGRAMS................................................................3-56

Page 10

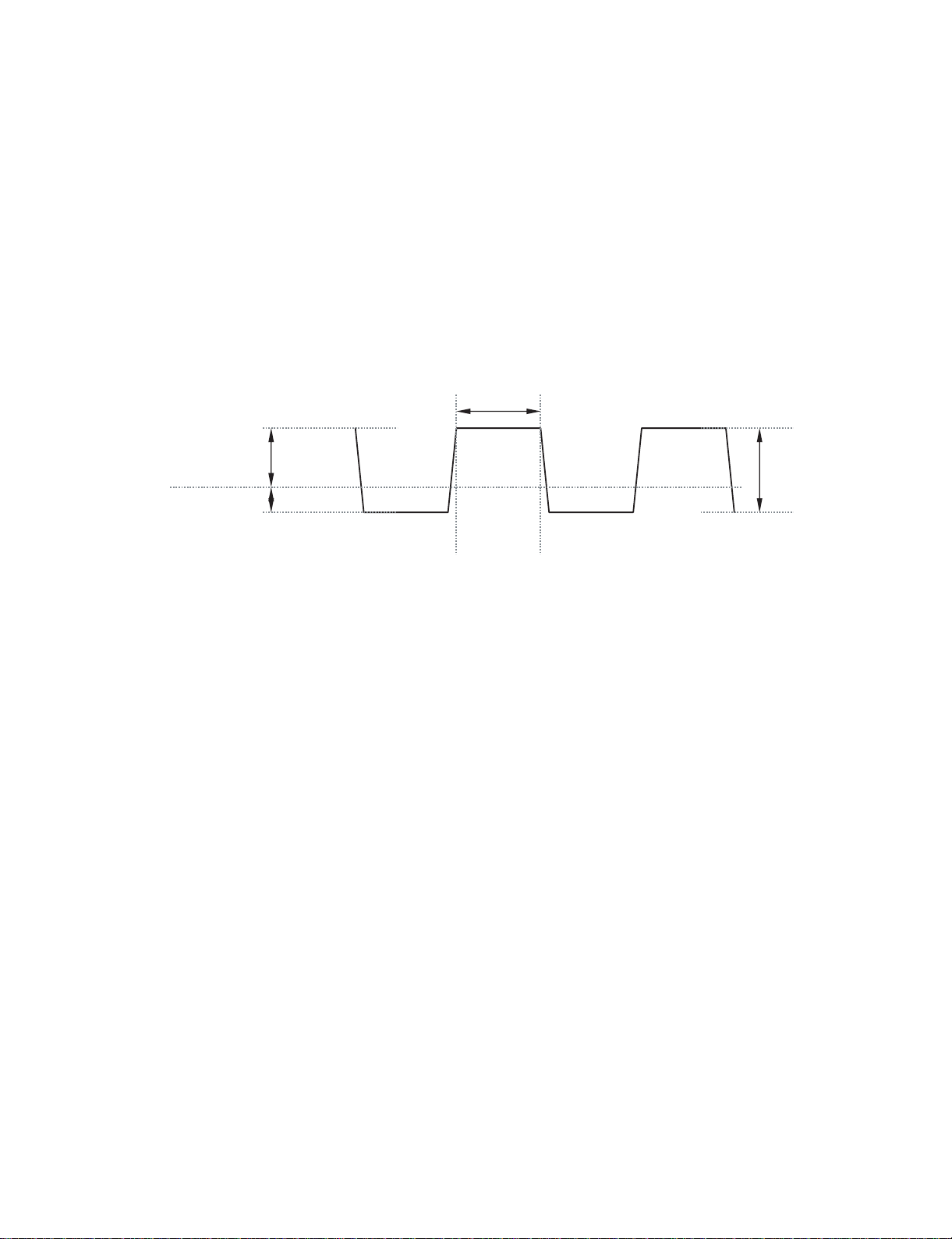

1) Power measuring

Measure each power after power supply.

C83(-) : -14.5V, C82(+) : +15V,C100 : +7.5V,C97(+) : +5V,C43(+) : 3.3V

2) VCOM waveform adjustment

Adjust the VCOM level while changing the VR1 as below waveform by using the scope in the

C84.

3-2

Vcom Waveform

63.5

3Vp-p

GNDGND

LCD PART

63.5

µs

4.6V

0.7V

5.5.3Vp-p

Page 11

3-3

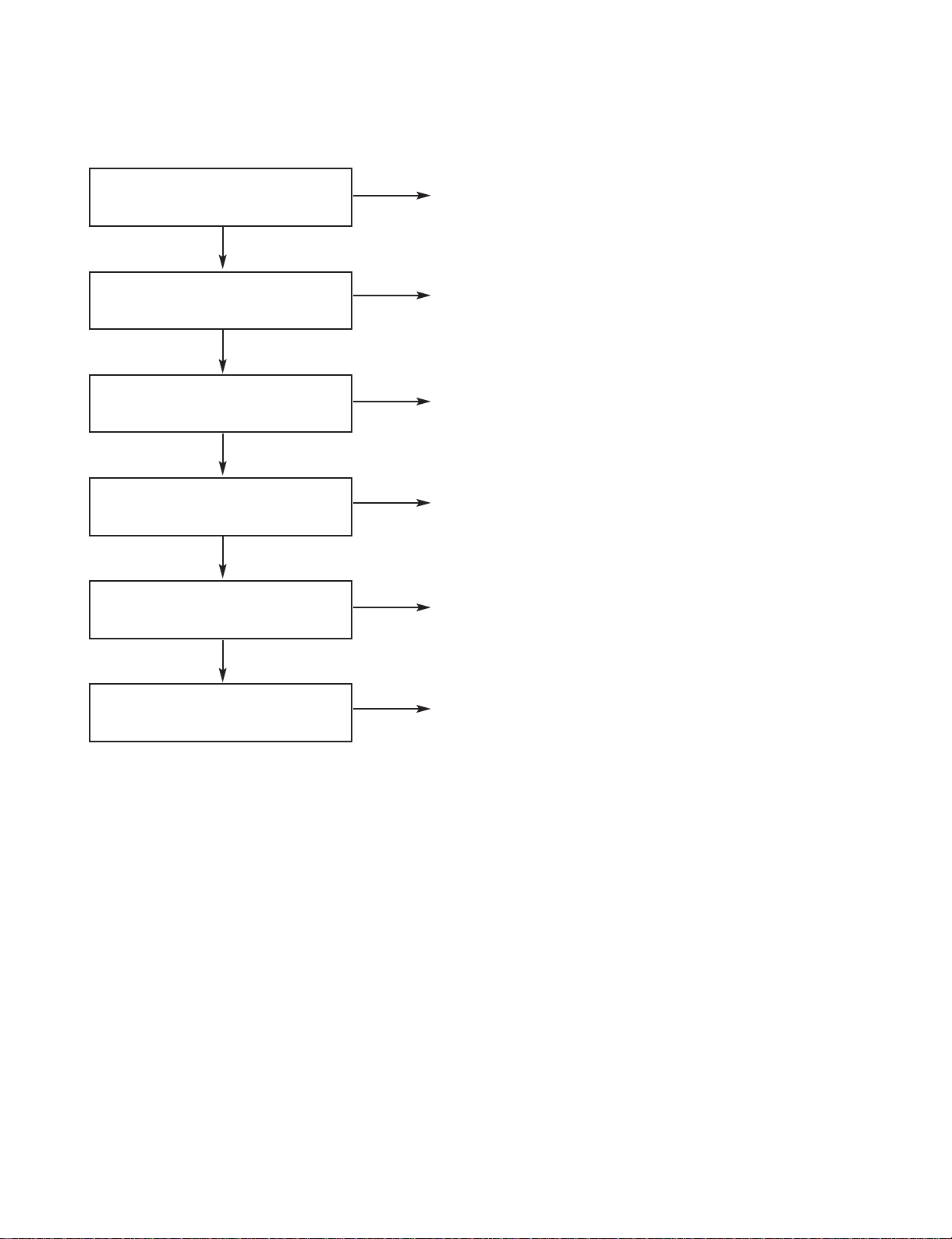

DESPLAY CONDITION? INVERTOR ABNORMAL

Appear shadow form

interference in black background

There is only bring light.(LCD B/D abnormal)

Fuse Replace

IC(U1) Check and Replace

D2 ,D3 ,D8 Check

Main B/D on located

IC(U6) Check and Replace

A/V IN S/W Check

IC(U2) Check and Replace

IC(U3) Check and Replace

FUSE NORMAL?

IC(U1) NORMAL OPERAE

7.5V,15V,-14.5V NORMAL?

+5V NORMAL?

Y/C DISPLAY SIGNAL?

R. G .B SIGNAL OUTPUT?

VCOM SIGNAL?(5.5VPP)

YES

YES

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

LCD TROUBLE SHOOTING GUIDE

Page 12

3-4

LCD MODE CONT SIGNAL?

ALL “LOW”(MORMAL CONDITION)?

MAIN B/D Check

Power source and D2,D3,U4 Check

TFT LCD PRESSURE VOLTAGE?

+15V,- 14.5V,+5V

TFT LCD NORMAL?

Replace

COLOR ADJUSTING NORMAL?

Readjust as adjustement standard

EACH CONNECTOR?

Replace and Reassemble

END

Replace

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

Page 13

3-5

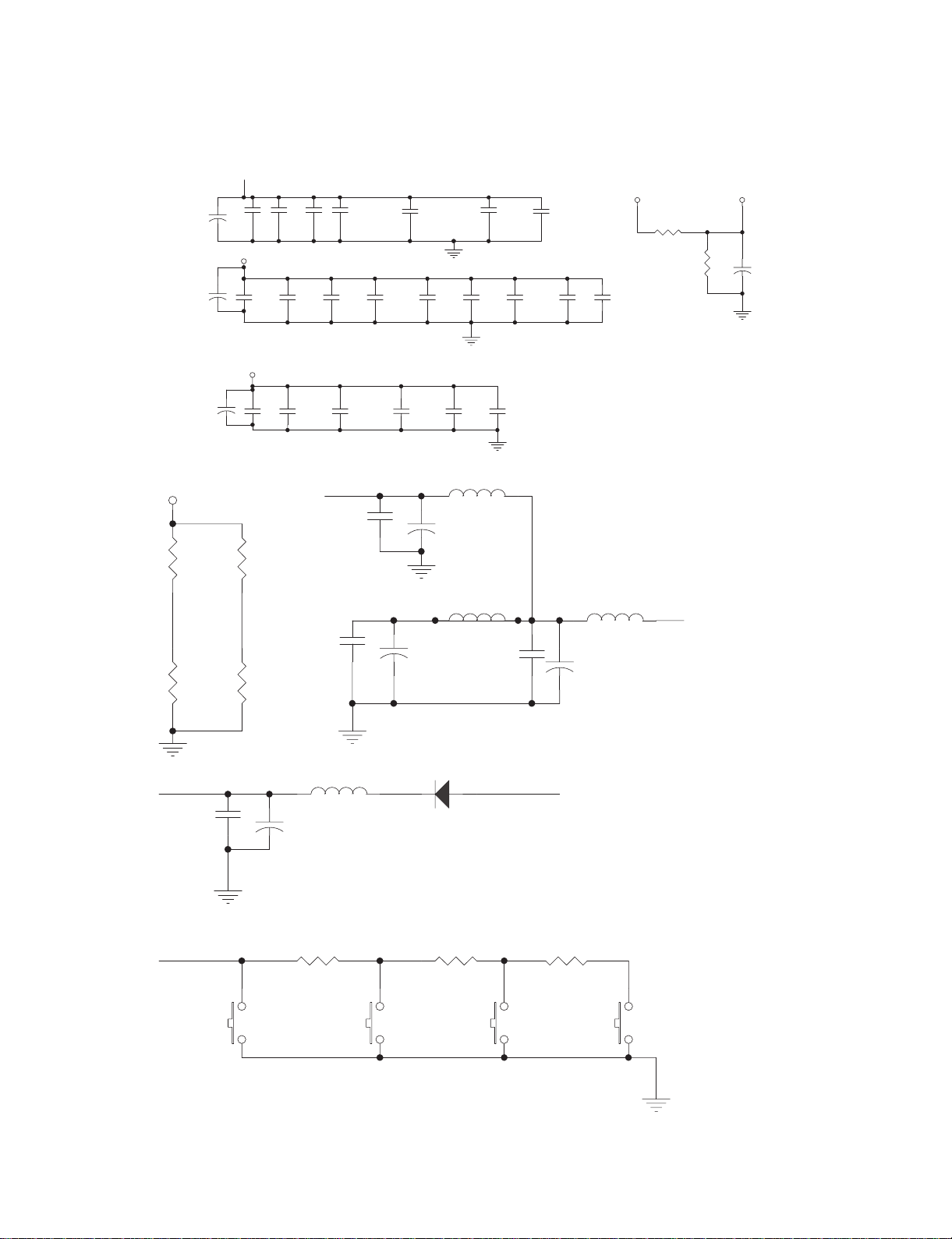

LCD CIRCUIT DIAGRAMS

L?

nc(1.6)

C45

0.1uF

33

1RP1

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

1RP2 33

FB1

300

FB2

nc

1C2

22P

nc

FB3

VDD22

+

C46

100uF/6.3V

L/R

U/D

STV2

1RP3

1 8

2 7

3 6

4 5

1C1

22P

1C3

22P

1 8

2 7

3 6

4 5

1RP4 33

33

OEV

CKV

OEH

VCOMO

STH1

STH2

CPH1

CPH2

CPH3

RSET

COMP

L7

VDD33

VDD33

AVSS33G

76

VDD33

AVSS

VDD33

AVSS33R

95

2735607789

91

3

VD3

VD33

VDD33

DPLLGND

GND

GND

25374851555879

VDD22

VDD25

VDD25

VDD25

POL/VCOM/HSO

GND

GND

GND

VDD25

VDD25

LP/OEH

STH1/HSO

STH2/DE

CPH1/LLCK1

CPH2/LLCK2

CPH3/LLCK3

GND

GND

GND

945961

DVDD

DVSS

VDT0

VDT1

VDT2

VDT3

VDT4

VDT5

VDT6

VDT7

VCLK

STV1

STV2

GCLK

RSET

COMP

96

AVDD

DPLLVC25

81

82

83

84

85

86

87

88

90

38

RL

39

UD

40

41

42

GOE

43

44

45

49

50

52

53

54

71

72

62

IOB

65

IOG

68

IOR

AVDD33

1791517236366697526475680465778

U2

AVDDB

AVDDB

AVDDG

AVDDG

AVDDR

VBIVALID/XbusRD

FIELD/XbusWR

AGNDB

AGNDB

32

33

AVDDR

AVDD33

AVDD33B

AVDD33G

AVDD33R

TERAWINS T100

AGNDG

AGNDG

AGNDR

AGNDR

AVSSD

AVSS33B

24

646770

S_Y

6

AC0/ACB0

5

3312

C67

0.1uF

S_C

AV

AC1/ACB1

4

AC2/ACB2

14

CVBS0/AY0

13

CVBS1/AY1

12

CVBS2/AY2

22

CVBS3/ACR0

21

CVBS4/ACR1

20

CVBS5/ACR2

3

CBMID

11

CGMID

19

CRMID

29

IICA3/SDA

30

SCANB/SCL

92

XTALI

93

XTALO

36

XCLK2MC

28

RSTB

31

CPUINT/SCANST

100

VREF

73

VREFIN

74

VREFOUT

99

FIB1

34

PWM

NC1

979828101618

NC2

C55

0.1uF

C54

0.1uF

CBMID

CGMID

R20

SDA

C62

22PF

VDD33

12

R29

4.7K

+

4.7uF/10V

SCL

R65

R66

TP1

C64

0.1uF

C68

C?

nc(104)

Y1

27MHZ

12

R24

C61

1M

1(22)PF

R30

RESET_T

33

R21

47uF/16V

12

33

33012

012

R25

33 12

+

C65

FB

C44

0.1uF

IOB

IOG

IOR

5VD

47uF/10V

C81

VCOMO

C92

+

10uF/16V

C80

0.1uF

R41

C84

10uF/16V

R47

10K

C103

470P

22K

VR1

3

+

VR50K

-15V

1 2

R44

1K

C91

+

VCOM

10u/16V

-15V

L17

10uH

C98

0.1uF

1

2

R52

150K

C104

18P

3

4 5

R54

U3

678

NJM3414AM

-I/P B

V+

O/P B

+I/P A

-I/P A

O/P A

GND+I/P B

123

4 5

R46

10K

R48

10K

R50

20K

3

1 2

VR2

VR50K

-10V

L14

0805

2.7uH

3VD3

R45

8.2K

VGOFF

R49

5.6K

EO

IN

SHDN

GND SW

4.7K

U5

C99

47uF/10V

FREQ

AAT1102

D2

+15V

16V

C82

4.7uF/25V

R42

10K

C85

1

1uF

C89

2

1

C95

0.1uF

L15

8

SS

7

6

VDD

3VD3

BAT54S

C102

27nF

D6

BAT54S

5.4uH

C87

3

0.1uF

C93

3

0.1uF

D8

2 1

1N5819

D4

1uF

2

C88

0.1uF

C94

0.1uF

D5

3

BAT54S

D7

3

BAT54S

C96

0.1u

R51

51k

R53

10k

-15V

7VD5

4.7uF/25V

R43

33

1C86 1uF

2

C90

1

2

U4

C100

47uF/16V

D3

15V

C83

1uF

3214

78L05

VOUTVIN

GND

TAB

47uF/10V

5VD

+

C97

C101

0.1uF

Page 14

3-6

-15V

5VD

GNDD

+7.5V

IOB

L13

L10

10uH IRON(1206)

L16

FB 10R

+15V

10uH IRON(1206)

C75

0.1uF

C78

+

10uF/10V

R38

75

10uH

C73

4.7uF/25V

+

C58

10u/16V

10u/25V

R34

39K

R39

10K

L12

C70

J1

+

+

GNDD

C74

0.1uF

C71

100n

GNDD

4K7

VDD33

VDD33

VCOM

VGL

STH1R55

R56

CPH3

4K7

CPH2

CPH1

OEH

R57 10K1 2

L/R

STH2

VG

VB

VGOFF

OEV

CKV

STV2

U/D

FB 10R(0603)

L11

D070L001-A01(Panel30Pin)

JP3

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SPR+

SPRSPL+

SPLGND

KEY

RESET_T

SDA

SCLVR

GND

SY

GND

SC

GND

CVBS

GND

3.3V

3VD3

5VD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

R+

RL+

LGND1

KEY

REST

SDA

SCL

GND2

SY

GND3

SC

GND4

CVBS_IN

GND5

3.3V-TFT

3.3V_T100

3.3V_AAT110

TFT5V

CON_20-A

2

BIAS

C63

1uF

100pF

C69

BIAS

R28

1M

C60

0.1uF

VG

R35

430

C77

1uF

R36

1M

C76

0.1uF

VB

C59

0.1uF

+7.5V

R26

39K

R27

430

31

Q3

2

2N3904

C79

R40

100pF

100

IOG

C66

10uF/10V

R31

75

+

R32

10K

31

Q2

2

2N3904

R33

100

L8 10uH

1206

+

47uF/16V

C47

IOR

+7.5V

C48

0.1uF

C53

10uF/10V

R12

75

BIAS

7VD5

C49

R9

39K

430

C52

1uF

R11

1M

0.1uFR10

VR

31

+

R13

10K

Q1

2

2N3904

R14

C56

100

100pF

Page 15

3-7

100uF/6.3V

100uF/6.3V

100uF/6.3V

C11

C26

C1

+

+

C2

AVDD33

+

0.1uF

VDD33

C12

0.1uF

C27

0.1uF

0.1uF

C4

0.1uF

C14

0.1uF

C5

0.1uF

C29

0.1uF

C3

C13

0.1uF

C28

0.1uF

C15

0.1uF

C30

0.1uF

C6

0.1uF

C16

0.1uF

C31

0.1uF

C17

0.1uF

C7

0.1uF

C32

0.1uF

C18

0.1uF

C8

0.1uF

C19

0.1uF

+7.5V BIAS

20K

R3

R4

10K

C20

0.1uF

+

C24

47uF/16V

VDD33

CGMID

VDD22

C33

0.1uF

R18

4.7K

R22

1K

R19

4.7K

CBMID

R23

1K

C39

0.1uF

L3 10uH

1206

+

C34

47uF/10V

VDD33

C35

0.1uF

+

47uF/10V

+

C40

47uF/10V

D1

IN5819

L4 10uH

1206

C36

L5 FB

1206

12

C41

0.1uF

+2.5V

+3.3V

AVDD33

L6 10uH

3.3V

1206

C43

+

47uF/6.3V

KEY

R15

1.2K(3.9K)

SW2

R16

2.7K(8.2K)

SW3

R17

4.7K(24K)

SW4SW1

Page 16

3-8

SY

SC

CVBS

0603

C22

680pF

L2 2.7uH

0603

C37

680pF

L9 2.7uH

0603

C50

680pF

C23

330pF

330pF

C51

330pF

R1

R7

R5

C21

R2

75

R6

75C38

R8

75

104

104

C25

C42

104

S_C

S_Y

AV

VDD33

SPL+

SPL-

SPR+

SPR-

C9

1uF

0

0

0

JP1

2

1

JP2

2

1

U1

CM1117SCM223 2.5V

PCBCOMPONENT_1

TAB

OUTIN

GND

1

AVDD33L1 2.7uH

C72

0.1uF

COMP

RSET

R37

1K

4

+2.5V

23

+

C10

47uF/6.3V

Page 17

3-9

LCD BLOCK DIAGRAM

OEH

OEV

STV

TFT LCD 7" WIDE

STH

CKV

VCOM

RGB

TERAMINS T100

15V -14.5V 7.5V 5V

INVERTER

DC-DC

CONV

SY

SC

CVBS

Page 18

3-10

LCD PRINTED CIRCUIT DIAGRAMS

( TOP VIEW )

( BOTTOM VIEW )

Page 19

3-11

MAIN ELECTRICAL TROUBLE SHOOTING GUIDE

1. Power (DC-DC Converter) Circuit

NO POWER ON

by ADAPTOR

Replace ADAPTOR

Is ADAPTOR OUT

9.5V.

A

Is1D3 OK.

NO

NO

Replace 1D3

NO

NO

YES

YES

YES

NO POWER ON by

BATTERY

Replace BATTERYIs BATTERY OK?

A

NO

YES

YES

A

YES

NO +3.3VNO +1.8V

Is IC(1U2)

3.3v OK?

Replace

IC(1U2).

Is 1Q3 3.3V

OK?

Replace

IC(1Q3).

NO LCD

POWER

NO +5V

Replace

IC(1U1)

Replace7L1

MAIN PART

Page 20

B. AUDIO OUT ABNORMAL C.VIDEO OUT ABNORMAL

D. AUDIO IN/SPEAKER ABNORMAL E. VIDEO IN ABNORMAL

AUDIO OUT

ABNORMAL

Check Audio Jack &

Mode

Check Signals from

MPEG

Check +9V

YES

YES

YES

YES

Replace IC(4U3)

VIDEO OUT

ABNORMAL

Check Video Jack &

Mode

Check IC(8U1)

Check Video signals

from MPEG

YES

YES

YES

Check LC Filter

YES

AUDIO IN/SPEAKER ABNORMAL

Check Audio Jack &

Mode S/W

Is Speakers OK

.Replace

Is 7J2 OK . Replace 7J2

Speakers

Replace IC(5U1)

VIDEO IN

ABNORMAL

Check Video Jack

& Mode

Check 7J2

Is 8Q1 OK .

Replace 8Q1

Refer to LCD part

3-12

Page 21

3-13

H. OPEN/CLOSE ABNORMAL

F. PICTURE ABNORMAL G. DISC ERROR

PICTURE ABNORMAL

Check the disc.

Check MPEG_CLK

Signal of MPEG part

Refer to Servo part

YES

YES

YES

YES

Check MPEG (IC 2U1)

If OK

YES(If OK)

YES(If OK)

YES(If OK)

YES(If OK)

YES(If OK)

YES

Replace B/D

DISC ERROR

Check Disc

Replace B/D

Refer to Servo part

YES

YES

YES

OPEN/CLOSE

ABNORMAL

Check 2SW1 switch

Refer to SERVO part.

Check IC(2U1) Pin 158

NO

Check the connectin of

MD.

YES

YES

Refer to SERVO part.

YES

Page 22

3-14

2. MPEG Circuit

Power is on

Does Logo appear

on the screen?

YES

Does the

Video of the DVD Disc

play properly?

YES

Does the

Video of the video

CD play properly?

YES

NO

NO

YES

NO

Check power & clock.

Is MPEG data signal normal?

Is error signal normal?

Is MPEG data signal normal?

YES

YES

YES

NO

OK

NO

NO

Check CD/DVD DSP output

signal.

OK

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

OK

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

OK

OPTION

If included VCD function.

Does the audio sound

output normally?

YES

END

NO

Is Clock normal?

YES

Does the audio

signal output from MPEG

decoder?

YES

Check MPEG Decoder input

signal.

NO

Check clock signal

Check clock signal

Page 23

3-15

3. RF/Servo Circuit

Put disc in.

Disc ID is correct?

Does spindle rotate.

Check the RFL connection

between 2J3 and MT1389.

Proper RFL signal on

MT1389?

Laser off

Proper DMSO signal on

MT1389

Check DMSO related circuit

on MT1389.

Replace IC(5U1)

Check the cable connection

between spindle and main PCBA.

D

A.

Check the related circuit on

MT1389 RFL signal .

NONO

NO

NO

NO

YES

YESYES

YES YES

YES

Page 24

3-16

D

Focus ON OK.

Proper FEO signal on

MT1389.

Proper signals on A, B, C,

D of MT1389

Check IC(2U1) IC

Track On OK.

Proper FEO signal on

MT1389.

ProperlyTRSOsignaL on

MT1389.

Disc is play ?

E

B.

Check connections between

MT1389 and pick-up head.

NO

Check the related circuit

on MT1389 FEO sugnal .

Check the related circuit on

MT1389

Check the TRSO connection

on MT1389 and motor dirver.

T+ & T- output properly.

Check cable connection on

pick-up head.

Check RF signal waveform.

Check the tracking control

amp circuit on motor driver.

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

Page 25

3-17

E

Normal Audio output

when disc playback.

Normal Audio DAC out. (4U3)

Audio DAC received correct

data stream.

Check Audio filter, amplify,

mute circuit.

Normal IR. VFD & Front

pannel key functions.

TEST END

Communications between IR.VFD

Front pannel key & MT1389 &

Front u-com is normally.

Check the cable connection

on Front pannel.

C.

Check connection between

MT1389 & Audio DAC. (Check

VRST#, ACLK, ABCK, ASDA T3)

NO

Check the related circuit of

Audio DAC.

Check communi cation lines

On MT1389

NO

NO

NO

NO

YES

YES

YES

YES

YES

Page 26

3-18

No turn on Red LED

Is 9U1 OK?

Is 8.4V of 9J1_Pin4 OK?

NO

Replace 9U1.

NO

Replace IC(9U4).

NO

Replace 9L1.

NO

Replace IC(9U3).

NO

YES

Is IC9U4)OK?

YES

Is 9L1, OK?

YES

Is IC(9U3) OK?

YES

* Chargeing Circuit

Page 27

3-19

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 27MHz CLOCK,RESET,FLASH R/W SIGNAL

1) MT1389 main clock is at 27MHz(X500)

3.8V, 27MHz

FIG 1-1

2. SDRAM CLOCK

1) MT1389 main clock is at 27MHz(X501)

(IC500 PIN 229, 228)

DCLK = 93MHz, Vp-p=2.2, Vmax=2.7V

FIG 2-1

Page 28

3-20

3. DISC TYPE JUDGEMENT WAVEFORM

F+(IC200 PIN 24)

FE(IC500 PIN 31)

RFL(IC500 PIN 6)

FIG 3-1

F+(IC200 PIN 24)

FE(IC500 PIN 31)

RFL(IC500 PIN 6)

FIG 3-2

Page 29

3-21

F+(IC200 PIN 24)

FE(IC500 PIN 31)

RFL(IC500 PIN 6)

FIG 3-3

F+(IC200 PIN 24)

FE(IC500 PIN 31)

RFL(IC500 PIN 6)

FIG 3-4

Page 30

3-22

4. FOCUS ON WAVEFORM

FE(IC500 PIN 31)

FOSO(IC200 PIN9)

F+(IC200 PIN 24)

F-(IC200 PIN 23)

FIG 4-1

FE(IC500 PIN 31)

FOSO(IC200 PIN9)

F+(IC200 PIN 24)

F-(IC200 PIN 23)

FIG 4-2

Page 31

3-23

5. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)

DMSO(1.4V/1.8V)

(IC501 PIN 18)

SP-(3.6V/2.4V)

(IC202 PIN 10)

SP+(3.6V/4.8V)

(IC202 PIN 11)

FIG 5-1

6. TRACKING CONTROL RELATED SIGNAL(System checking)

TE(IC500 PIN 32)

TRSO(IC200 PIN 8)

T-(IC200 PIN 20)

T+(IC200 PIN 19)

FIG 6-1

Page 32

3-24

7. RF WAVEFORM

RFOP(2.3V/1.1V)

(IC500 PIN 25)

RFON(0.8V/2.0V)

(IC500 PIN 26)

FIG 7-1

TE(IC500 PIN 32)

TRSO(IC200 PIN 8)

T-(IC200 PIN 20)

T+(IC200 PIN 19)

FIG 6-2

Page 33

3-25

8. MT1389 AUDIO OPTICAL AND COAXIAL OUTPUT (ASPDIF)

(IC500 PIN 225)

FIG 8-1

9. MT1389 VIDEO OUTPUT WAVEFORM

1) Full colorbar signal(CVBS)

(IC604 PIN 23)

FIG 9-1

Page 34

3-26

2) Y

(IC604 PIN 21)

FIG 9-2

3) C

(IC604 PIN 26)

FIG 93

Page 35

3-27

10. AUDIO OUTPUT FROM AUDIO DAC

1) Audio L/R

FIG 10-1

(JK601 PIN 4,5)

2) Audio related Signal

ASDAT0(IC301 PIN 3)

ABCK(IC301 PIN 4)

ALRCK(IC5301 PIN 5)

ASDAT 0

FIG 10-2

Page 36

3-28

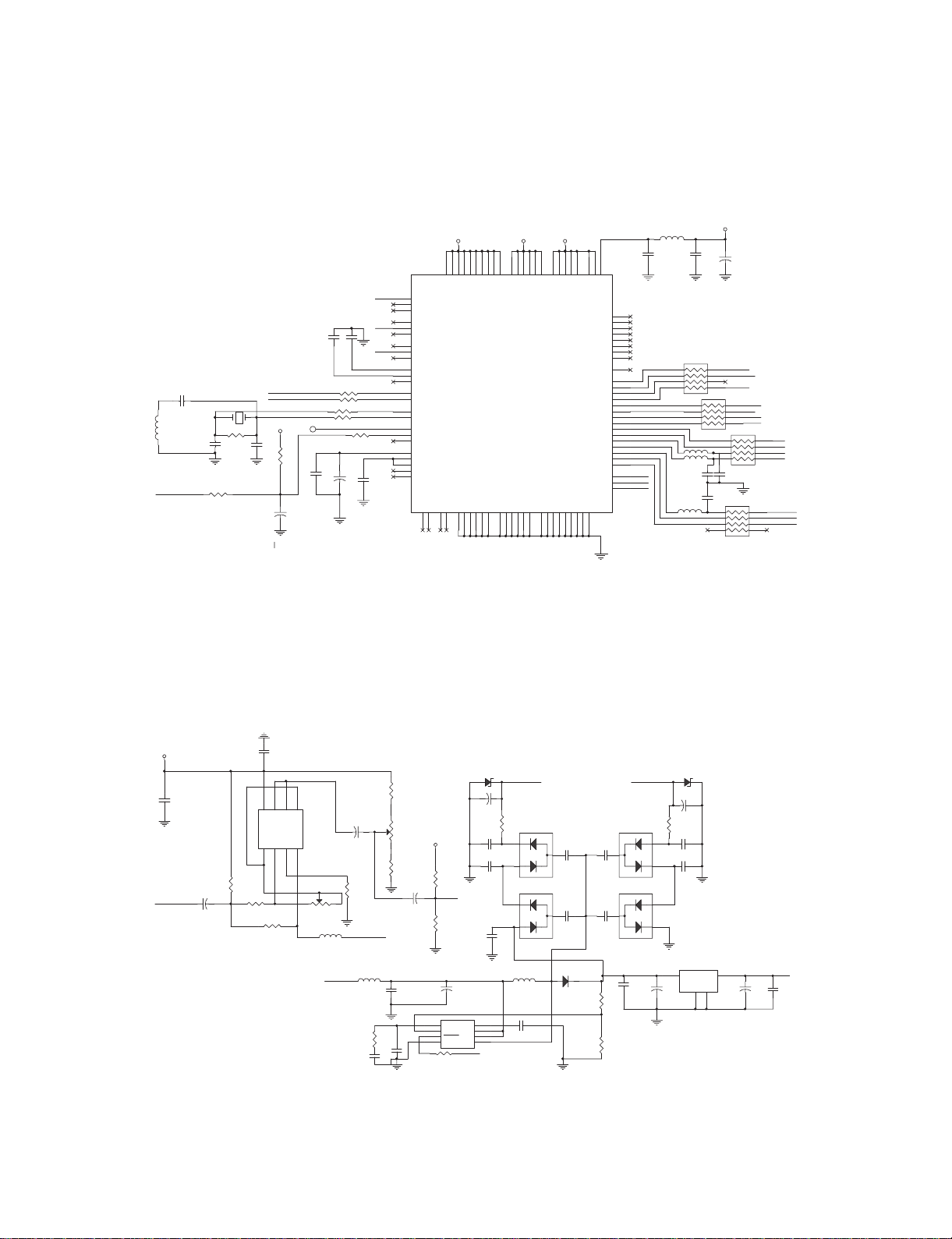

MAIN BLOCK DIAGRAMS

1. OVERALL BLOCK DIAGRAM

P

B

CVBS JACK

HP JACK

HP JACK

OPTI-A_OUT

LCD

BLOCK

MPEG

}

HP_SENSE

SP_L+/-,SP_R+/-

SP_AMP_EN

MUTE_FM

BF1_FM_CS

VIDEO_IO_CON

AUDIO_CD_CON

VFD_TXD

VFD_SCK

U603

MPEG

U306

FRONTA_SP_AMP_EN

MPEG /SP_MUTE

47U/6.3V

U502

U501

TPA6011

U303

NJU4052BV

U302

NJM4580M

U301

CS4391

U503

S24C021CS

DQ[00:15]

MA[00:11 ]

M12264164A-7T

BA[0:1]

AD[0:7]

A[00:20]

26V160TE-70

A,B,C,D,RFIP,TNI,TPI

MDI1,SUBA,SUBB

LD01,LD02,IOA,V20

+15V ,-14.5V,+7.5V,A_5V,LCDPWR

FRONT

BLOCK

CVBS

MT1389

U2

TERAWINS T100

/A_MUTE

SY

SC

BAT7.6V

POWER

S-8232A

LFT

U703

SI443 5

U701

SI4435

PWM

BATERY BLOCK

27MHz

27MHz

MPEG/DSP/RF

POWER DC+9.5V

FRONT

}BATTERY/

BAT7.6V

DCPWR

DC+9.5V

U304

NJM4580M

ACLK

ABCK

ASDAT0

VRST#

SC L

SDA

DCLK

DCKE

DQM[ 0:1]

CS#

RAS#

CAS#

WE#

U500

PC E#

PRD#

PWR#

/M_RESET

C391,C392,

C393,C394

A_VIDEO_IO_CON

A_AUDIO_CD_CON

{

FRONT

74VHCT541

BAT_SENCE,DC_SENCE

U702

BAT_SE NSE

DC_SENSE

AUDIO

}

FM

}

FM_MUTE

FM_CS

FM_SCK

FM_TXD

A_VIDEO_IO_CON

A_AUDIO_CK_CON

A_SP_AMP_EN

AV FD_TXK

AVFD_SCK

AVFD_CS

SAM_I,SAM_U

U 601

Q602

RC601

TSOP6238

DC+9.5V

GT631 2(CLV2.0)

MPEG

FRONT

A-5V

U104

PWRCTL_5V

PWRCTL_3.3 V

BD6111FV

A+5V

E+5V

S+5 V

LED

5MHz

KEY_M

2N3904

-14.5V

+15V

+7.5V

U5

AAT1102

D+1.8V

D+3.3V

A+3.3V

DISCI

UP

PICK

M

SPINDLE

MOTOR

DECK MECHANISM

MOTOR

STEPPING

M

#

V,HV+/-,W,HW+/U,HU+/-

FO+,FO-,TR+,TR-

STEP1+/-,STEP2+/-

DMSO,FG

U202

BA5954

STB Y,V 1P4

FOSO,TRSO,FMSOB,

TRAY_OPEN_SW

U201

BA5954

TRAY_OPEN_SW2

OWER

Q107

SI4435DY

LCD_OPEN

POWER

JACK

LOCK

U105

BA9701

U101

MP1410

U102

MP1410

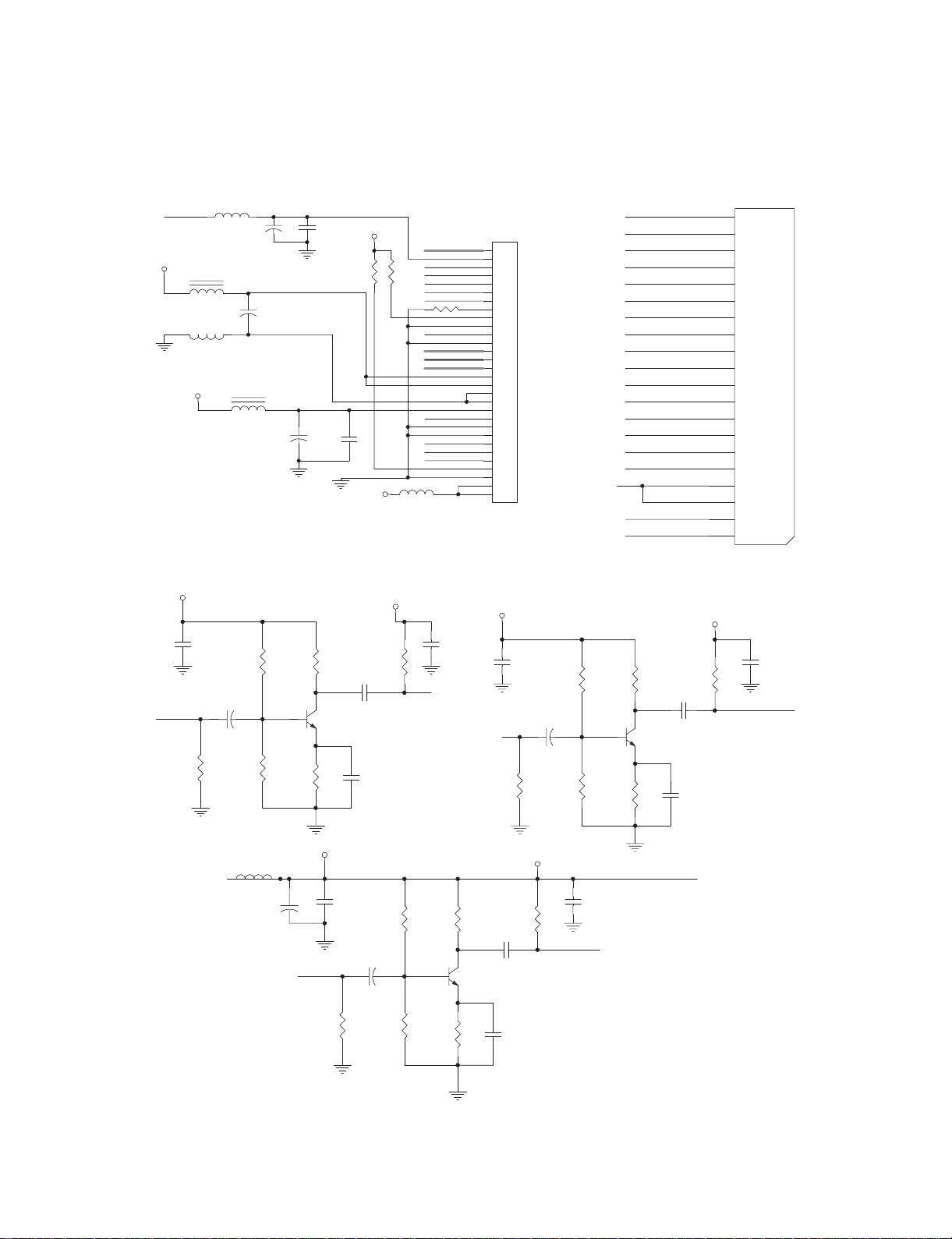

Page 37

3-29

2. POWER(DC-DC CONVERTER)BLOCK DIAGRAM

D

CPWR

E+5V S+5V A+5V A-5V D+3.3V A+3.3V D+1.8V +15V

U104

BD6111FV

U105

RT9701

U5

AAT1102

-14.5V

7.5V

U101

MP1410

Q107

SI4435DY

From AC Adapter 9.5v

U102

MP1410

From BATTERY 7.6V

U701

SI4435DY

To BATTERY

U702

GT6312

CH_EN

PWRCTL_3.3V

PWRCTL_5V

Page 38

Page 39

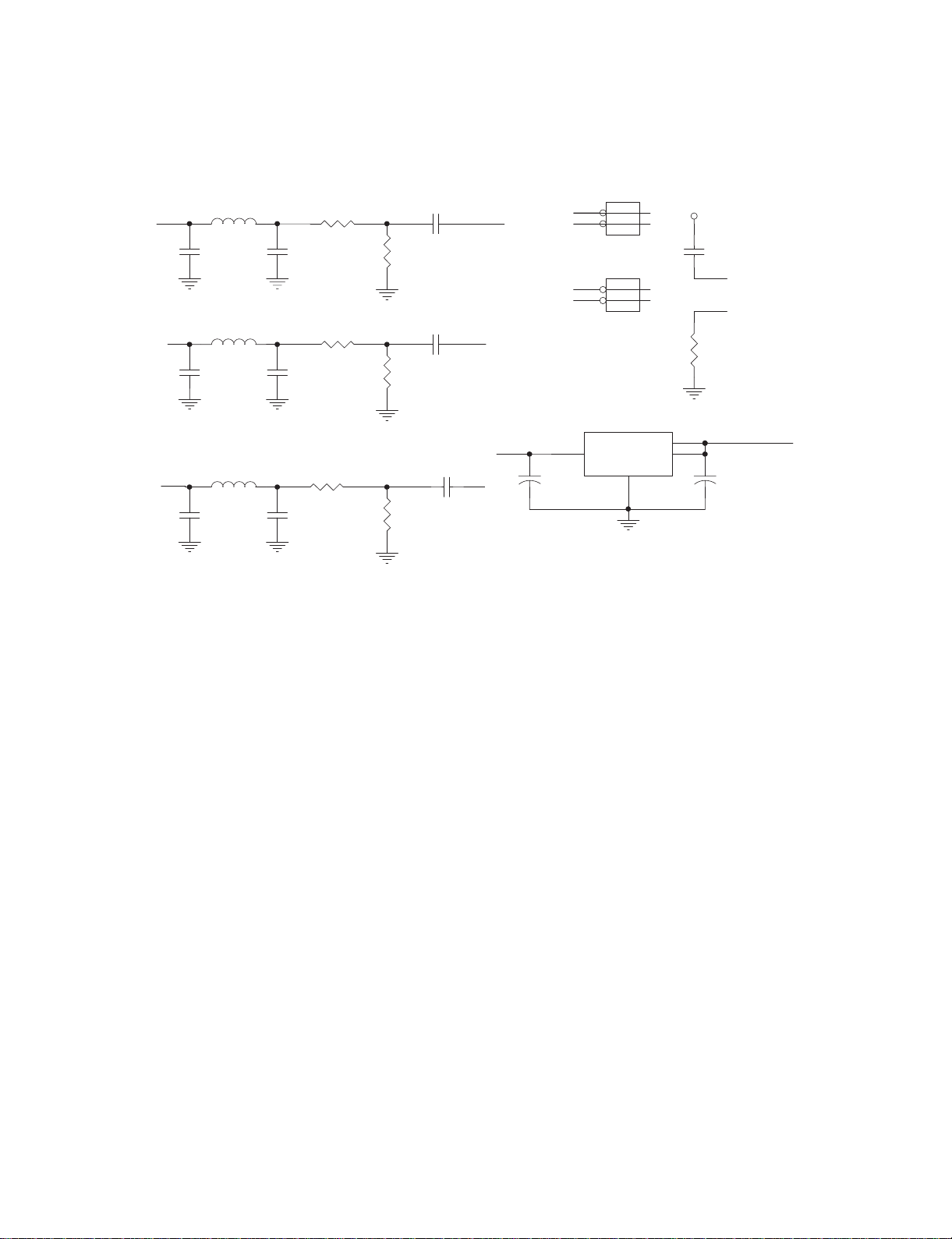

3-30 3-31

MAIN CIRCUIT DIAGRAMS

1. MAIN POWER CIRCUIT DIAGRAM

C

2N3904

SOT23

1

2

EB

3

Audio DAC

RFV33

Audio -5V

DVDD3

AVDD5

OP AMP.

Laser Diode 3.3V

DV33

Audio 5V

SD33

DEVICE

Servo 3.3V

AV33

Digital 3.3V

MT1389E

OP AMP.

Audio 3.3V

MT1389E

SDRAM

VCC

A+5V Audio +5V

TYPE

V18

NAME

Digital 3.3V

Digital 5V SUPPLY

Audio DAC

MT1389E

A-5V

Digital 1.8V

1

2

C

BE

2N3906

3

1C3 1C10

FB:0.92 V

FB:0.92 V

INDEX&POWER

VCC_5V

DVD_5V

BAT_OUT

V18

DV33

SD33

RFV33

STANDBY

POWER_DET1

AUDIO_5V

9V_IN

BAT_OUT

V+5V

LCD_5V

9V_IN

DVD_5V

POWER_DET2

LCD_3V3

POWER_DET2

POWER_DET1

POWER_DVD

A+5V

A-5V

RFV33

SD33

DV33

STANDBY

A-5V

A+5V

V+5V

POWER_DVD

LCD_3V3

VCC_3V3

V18

LCD_5V

STANDBY

AUDIO_5VV+5V

POWER_DVD

BAT_OUT GND

VCC_5V

BAT_OUT

VCC_5V

VCC_5V

DVD_5V

VCC_3V3

VCC_3V3

DVD_3V3

DVD_3V3

DVD_3V3

VCC_3V3

DVD_3V3

POWER_DET1

6

VCC_5V

4,6

DVD_5V

2,4

V18

2

DV33

2

SD33

3

RFV33

2

STANDBY

6

AUDIO_5V

4,5,8

9V_IN

9

BAT_OUT

4,7,9

LCD_3V3

7

POWER_DET2

6

POWER_DVD

4,6

A+5V

4

A-5V 4

LCD_5V

7

GND

2,3,4,5,6,7,8,9,10

VCC_3V3

6

DVD_3V3

2,3

1C7

0.22uF(224)

1D4

OPEN(SMBJ26A)

1 2

1R4 5.6K

1R7

10K/1%

1TP

7

1C8

103

1C24

0.1uF

1C4

0.1uF

1TP2

0

1R11

6.2K

1TP3

4

1C26

0.1uF

1C14

0.1uF

1R13

47K

1R10

12K

1R1 100

K

1TP3

2

1L4

0805

1C22

0.1uF

1TP2

7

1TP1

0

1C27

OPEN(1uF)

1TP3

3

1TP

6

1R8

2K

1R5

39K

1CE14

100uF/6.3V

1TP3

5 1R23 330

1C25

0.22uF(224)

1TP1

4

1Q2

3904

1

3 2

-

+

1U3B

LM

393

5

6

7

84

1TP26

1C30

0.1uF

1Q1

AF2301P

1

3 2

1TP2

9

1TP3

0

1Q4

3904

1

3 2

1C15

0.1uF 1TP9

1C23

0.1uF

1TP

3

1R2

10K

1U1

MP1411

1

2

3

4

6

7

8

9

5

10

NC

BS

NC

IN

GND

FB

COMP

EN

SW

SS

1C1

103

1CE18

220uF/10V

1FB6

50

1FB7

FB/1206

1R14

5.1K

1Q6

390

4

1

3 2

1FB1 10uH

1C16

0.1uF

1TP2

2

+

1U3A

LM

393

3

2

1

8 4

1CE13

100uF/16V

1CE1

220uF/16V

1CE9

100uF/16V

1CE19

100uF/10V

1U4

CM1117SCM223 1.8V

SOT22

3

23

1

4

OUTIN

GND

TAB

1TP1

6

1TP2

8

1C5

3.9nF

1R12

10K

1TP3

1

1U2

MP

1411

1

2

3

4

6

7

8

9

5

10

NC

BS

NC

IN

GND

FB

COMP

EN

SW

SS

1TP3

6

1L3

OPEN(10uH)

1CE7

47uF/25V

1TP1

7

1C17

0.1uF

1D3

SS24

1 2

1R26

2K

1R9

24K

1TP1

2

1R24

10K

1C13

0.22uF(224)

1C32

0.1uF

1C19

0.22uF(224)

1C18

0.1uF

1TP

1

1C2

0.22uF(224)

1U5

OPEN(TPS60400

)

1

5

2

3

4

OUT

Cfly+

IN

Cfly-

GND

1L1

22uH

1Q3

AF2301P

1

3 2

1TP2

3

1CE8

100uF/16V

1FB2

FB/1206

1FB3

50

1R25

5.1K

1FB4

50

1R6

10K

1D2

SS24

1CE17

OPEN(10uF/10V)

1TP1

9

1CE10

100uF/6.3V

1C21

0.22uF(224)

1C9

0.22uF(224)

1C3

0.22uF(224)

1TP1

3

1TP1

1

1TP2

4

1FB8

OPEN(50)

1D1

SS24

1R15

2K

1R17

12K

1R19

10K

1C31

0.1uF

1CE11

100uF/6.3V

1TP

2

1R22

620

1R16

2K

1CE3

220uF/6.3V

1L2

22uH

1C11

3.9nF

1CE4

100uF/25V

1CE2

100uF/25V

1TP1

8

1CE16

OPEN(10uF/10V)

1R21

2K

1FB9

FB/1206

1C20

0.1uF

1R18

47K

1FB5

50

1TP

4

1C10

0.1uF

+

1C28

100uF/6.3V

1CE5

220uF/25V

1J1

POWERJACK

1

3

2

1Q5

AF2301P

1

3 2

1C6

OPEN

1TP2

5

1R20

5.1K

1R3

10K/1%

1CE20

NC

+

1CE15

100uF/6.3V

1C12

OPEN

1TP

5

1CE12

100uF/16V

1TP

8

1TP2

1

1C29

0.1uF

1TP1

5

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Page 40

3-32 3-33

2. SERVO CIRCUIT DIAGRAM_1

C

MEMORY

AUDIO INTERFACE

Very Important to

reduce Noise

EB

2SB1132

13

HITACHI HOP120 0

2

EMI

2C54 closed to Pin18 6

VIDEO INTERFACE

IIC

C

FLASH

RS-232

DVD_KEY

RF&MEPG

SDA

PWR#

DCKE

AL

DQ3

ALRCK

V1P4

A14

DQ14

DV33DV33

FMSO

RFV18

A19

WE#

SL+

A10

SL-

FOSO

AD0

DQ0

XOO

AD4

DQ1

A7

V18

XO

LIMIT

RAS#

DQM1

APLLVDD3

DVD_Y

OP+

IR_OUT

CAS#

MA8

DQ7

DMSO

V1P4

A17

JITFO

MA6

A8

DQ0

TXD

V1P4

DVD_C

TRIN

ASDAT0

DQ12

LDO2

DQ13

DQ15

A4

DVD_C

OP-

V18

DCLK

RFVDD3

MA1

AD6

DVD_5V

DVD_KEY6

LDO1

SL-

V18

ADIN

A12

AL

A18

FMSO

CS#

DQ7

MA2

LDO_AV33

V1P4

DCLK

DQ10

DQ2

MA10

AD3

A11

DQ10

DQ3

FMO

V18

DQM0

URST#

ADIN

DQ2

URST#

JITFN

F

MA6

SPDIF

V2P8

MA5

V18

GND

STBY

V20

BA1

A3

ASPDIF

RFV33

A8

RFVDD3

DQ12

MA7

SCL

DCKE

A14

OP-

A11

DV33

AR

DACVDD3

AD7

DQ6

AD1

A20

A17

CAS#

A19

XOO

LIMIT

FOO

CVBS

AR

PRD#

WE#

A15

MA10

XII

DQ9

DQ1

A

MA9

A13

AD5

A12

DQ5

A1

AD7

SP-

V1P4

MA1

VREF1

PLLVDD3

OPO

AD4

DMO

A13

TRO

A2

MA4

BA1

XI

ADACVDD3

V1P4

IR_OUT

A2

DMSO

FOO

JITFN

B

A7

SDA

A5

A9

DACVDD3

A10

TRSO

TxD

DVD_SLEEP

DQ5

A4

A16

SP-

A3

AD0

DQ4

PWR#

V2P8

DACVDD3DACVDD3

DVD_Y

MA3

PCE#

DQ15

FOSO

DVD_5V

OP+

MA8

DQM0

A21

AD2

DV33

ABCK

A6

RFV33

STBY

SP+

RFVDD3

IOA

DQ6

AD6

DV33

RAS#

PRD#

APLLVDD3

TRIN

RFVDD3

BA0

A

TRSO

MA11MA11

A18

C

MA11

DQ13

A1

MA4

SCL

DV33

FMO

E

DV33DV33DV33DV33DV33DV33

B

DQ11

A6

SL+

MA0

A16

RxD

DVD_KEY4

DACVDD3

DV33

ACLK

DQ4

MA3

OPO

AD3

A15

XII

ASPDIF

RXD

PCE#

DQ14

LDO1

LDO2

AD2

ACLK

DQM1

DVD_3V3

A20

DVD_KEY5

DQ9

AD1

D

V1P4

DMO

PLLVDD3

DVD_5V

MA9

ADACVDD3

AD5

LDO_AV33

DQ11

D

DQ8

DV33

CS#

JITFO

C

DV33

CVBS

MA0

DQ8

RFVDD3

TEZISLV

MA7

A9

A0

BA0

MA5

A5

DV33

V18

MA2

SP+

TRO

RFV18

DVD_KEY4

DVD_KEY1

DVD_KEY2

DVD_KEY4

DVD_KEY1

DVD_KEY3

DVD_KEY6

DVD_KEY3

DVD_KEY5

DVD_KEY2

DVD_KEY6

DVD_KEY5

DVD_KEY3

DVD_KEY2

DVD_KEY1

DVD_SLEEP

ABCK

ACLK

ASDAT0

ALRCK

A21

A0

DVD_3V3

T+

MDI1

RFO

B

RFO

FF+

F

D

AVCC2

MDI2

V20

A

T-

V20

E

GND

LD-CD

MDI2

AVCC2

IOA

RFV33

LD-DVD

C

GND

GND

GND

MDI1

DQ0

3

CAS#

3

WE#

3

DQ14

3

RAS# 3

DQ15

3

DQ12

3

PRD#

3

DQ10

3

DQ3

3

DQ8

3

IR_OUT

6

AR

4

DVD_5V

1,4

DCKE

3

CS#

3

ASPDIF

4

DQ13

3

PWR#

3

DQ11

3

CVBS

8

V18

1

PCE#

3

AL

4

DCLK

3

DVD_Y

7

SCL

3

DVD_C

7

A1

3

DV33

1,3,

A14

3

RFV33

1

A4

3

A12

3

A2

3

A10

3

A9

3

A0

3

AD1

3

A20

3

A17

3

DQM1

3

A7

3

A15

3

A5

3

SDA

3

A13

3

MA2

3

A3

3

A11

3

AD4

3

MA0

3

AD2

3

BA0

3

AD0

3

A18

3

A8

3

MA10

3

A16

3

A6

3

MA8

3

MA5

3

AD7

3

MA3

3

AD5

3

MA1

3

AD3

3

BA1

3

DQ1

3

A19

3

MA11

3

DQ6

3

MA9

3

MA6

3

DQM0

3

MA7

3

MA4

3

AD6

3

DQ4

3

DQ9

3

DQ5

3

DQ2

3

DQ7

3

DVD_KEY6

9

DVD_KEY3

9

DVD_KEY1

9

DVD_KEY4

9

DVD_KEY2

9

DVD_KEY5

9

DVD_SLEEP

6

ASDAT0

4

ABCK 4

ACLK

4

ALRCK

4

A21

3

GND

2,3,4,5,6,7,8,9,10

DVD_3V3

1

AVCC1

AVCC1

MO_VCC

RFV33

LDO_AV33

MO_VCC

MO_VCC

DV33

2C47 1uF

2C3

22pF

2C5

0.1uF

2C83

0.1uF

2RN1

10Kx4

1 8

2 7

3 6

4 5

2C19

330pF

2C84

150pF

2C17 0.1uF

2R4 0

2TP3

4

2C74

0.1uF

2R13

150K

2TP32

URST#

2L7

FB

2TP1

8

2L1

FB

2C43

6800pF

2C38

0.1uF

2TP2

0

2C29

0.1uF

2R16 15K

2C77

0.1uF

+

2C35

100uF/6.3V

2R20

6.8

2R11

15K

2R14

150K

2TP3

8

2R40

1

2TP3

9

+

2C37

100uF/6.3V

2R50

10

2R41

1

2C15

1500pF

2C81

0.1uF

2TP1

3

2R19

1

2C68

NC

2L6

FB

2C20

330pF

2TP

2

2R32

68K

2C21

0.1uF

2C75

0.1uF

2Q1

3906

1

32

2C58

0.1uF

2C88

0.1uF

2C41

0.1uF

MT1389D

2U1

MT1389D

MT1389D

2

210

3

4

5

1

212

213

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

216

28

27

30

29

32

31

43

26

25

33

34

35

36

42

41

45

39

40

46

38

37

65646261605958

52

81

77

7655747372

71

63

83

53

54

70

57

82

75

66

6880695667

8485868788899091929394

95

106

96

97

204

205

9899100

101

102

103

104

105

107

108

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

137

138

136

135

134

133

132

131

130

129

128

126

127

125

124

123

122

121

120

118

119

117

116

115

114

113

111

112

110

109

209

21524214

191

190

198

197

208

207

196

211

206

203

201

202

200

199

194

195

192

184

185

182

181

180

179

186

178

177

175

173

174

164

171

170

169

168

172

167

166

165

163

193

44

47

48

49

50

51

78

79

176

183

188

189

187

DVDA

CRTPLP

DVDB

DVDC

DVDD

AGND

OSP

OSN

DVDRFIP

DVDRFIN

MA

MB

MC

MD

SA

SB

SC

SD

CDFON

CDFOP

TNI

TPI

MDI1

MDI2

LDO2

LDO1

AVDD3

V2REFO

SGND

VREFO

V20

TEO

FEO

FG/ADIN1

RFLVL/RFON

CSO/RFOP

TEZISLV

OP_OUT

OP_INN

OP_INP

FOO

TRO

GPIO1

TROPENPWM

PWMOUT1/ADIN0

GPIO2

FMO

DMO

HIGHA4

HIGHA5

HIGHA7

DVDD3

A16

IOWR#

DVDD3

IOA6

AD6

AD2

AD1

IOA18

DVSS

IOOE#

IOA1

DVSS

HIGHA6

ALE

IOA7

HIGHA0

IOCS#

IOA19

IOA21

AD0

HIGHA3

HIGHA1

AD5

IOA20

DVSS

HIGHA2

DVDD18

AD7

A17

DVDD3

IOA0

UWR#

URD#

UP1_2

UP1_3

GPIO6

UP1_4

UP1_5IRUP1_6

DVSS

ADCVDD3

ADCVSS

UP1_7

UP3_0

UP3_1

UP3_4

UP3_5

GPIO7

ICE

PRST#

INT0#

DVDD3

ACLK

ABCK

DVSS

GPIO5

GPIO4

GPIO3

DVDD18

RA4

RA5

RA6

RA7

DVDD3

RA8

RA9

RA11

CKE

RCLK

DVSS

RA3

DVSS

RA2

RA1

RA0

RA10

BA1

DVDD3

BA0

RCS#

RAS#

DVDD18

CAS#

RWE#

DVSS

DQM1

RD8

RD10

RD9

RD11

RD12

DVDD3

RD13

RD14

DVSS

RD0

RD15

RD1

RD2

DVSS

RD3

RD4

RD6

RD5

RD7

DQM0

HRFZC

IREF

SVDD3

RFGC

RFGND18

ADACGND

IDACEXLP

PLLVSS

RFRPAC

RFRPDC

JITFN

RFGND

RFVDD3

LPFOP

LPFIP

LPFIN

LPFON

PLLVDD3

XTALI

JITFO

RFVDD18

APLLCAP

APLLVSS

R

B

DACVSSA

G

ADACVDD3

DACVDDA

DACVSSB

CVBS

FS

DACVSSC

ASDATA0

DACVDDC

SPDIF

MC_DATA

DVDD3

VREF

ASDATA3

ASDATA2

ASDATA1

ALRCK

XTALO

GPIO0

IOA2

DVDD18

IOA3

IOA4

IOA5

AD3

AD4

DACVDDB

APLLVDD3

VCM

AL

AR

2L2

3.3UH

2C78

0.1uF

2TP

9

2L8

FB

2U2

AT565

4

1

9

10

12

3

2

15

7

14

13

21

19

20

24

27

6

4

5

28

8

11

17

18

16

23

22

25

26

2930

VINFC

PVCC1

PGND

VOSL+

CF2

CF1

VOTK+

VNFFC

VOFC+

VOFC-

PVCC2

PGND

VNFTK

CTK2

BIAS

VOSL

VINSL+

VINSL-

STBY

VCC

VOSL-

VOLD+

VOLD-

VOTK-

VINLD

PREGND

CTK1

VINTK

G1

G2

2C76

0.1uF

TOP

2J3

HEADER 24 SMD0.5 TOP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2R5

0

2C24

0.1uF

2R34

10k

2R31

0

2TP3

7

2R15

680K

2C49

0.1uF

2C1

390pF

2TP

1

2C69

NC

+

2C57

100uF/10V

2C53

OPEN

2C60

15PF(ESD)

2C8

0.1uF

+

2C4

100uF/6.3V

2C52

1uf

2TP

7

2R35

4.7

2C28 0.047uF

2Y1 C27MHz

1 2

3

2TP8

2R17

33R

+

2C59

10uF/25V

2C45

0.1uF

2TP2

1

+

2C63

47uF/10V

2R37

10k

2TP3

5

2C26

2200pF

2L11

10uH

2R38

10k

2SW2

1 4

2 3

2TP4

2C80

0.1uF

2SW1

1 4

2 3

+

2C87

47uF/10V

2C42

0.1uF

2C73

0.1uF

2C10 0.1uF

2C18

1000pF

2C9

0.1uF

2TP

6

2C66

NC

2R51

10

2C86

0.1uF

2C62

0.1uF

2D1

1N4148

2TP

5

2C54

1uF

2TP2

8

2TP1

9

2R49

0

2R18

OPEN

2R12

10K

2C23

1pF(TDK)

2C51

1uF

+

2C39

220uF/6.3V

2C40

0.1uF

2TP1

1

2C72

0.1uF

2R23

10K

2C79

0.1uF

2L10

10uH

2C7

2200pF

2C71

0.1uF

2R39

1

2R33

10k

2TP3

1

2C25

0.01uF

2C12 0.47uF

2TP41

+

2C36

100uF/6.3V

2C67

NC

2C11 20pF

2TP12

2C55

0.1uF

2R2

0

2Q6

2SB1132

1

32

2J2

2x1 W/HOUSING

CON2_2.0_DIP_B

1

2

2TP25

2R24

0

2C2

22pF

2TP4

0

2Q4

3904

1

3 2

2R9

100K

2TP16

2R44

20K

2C34

0.1uF

2C27 0.047uF

2TP17

2J1

4x1 W/HOUSING

1

2

3

4

+

2C6

100uF/6.3V

2L4

10uH(10R)

R0805

2C48

1uF

2TP2

4

2C44

0.1uF

2C50

1uF

2TP2

3

2C61

0.1uF

2C65

NC

2Q5

2SB1132

1

3 2

2TP42

2R21

560

2L9

FB

2C70

NC

2R3

750K

2R48

10K

2C22

0.015uF

+

2C13

100uF/6.3V

2R7

0

2R22

10K

2C82

0.1uF

+

2C64

47uF/10V

2TP3

3

+

2C14

10uF/25V

2TP2

2

2J4

4x1 W/HOUSING

1

2

3

4

2TP

3

2C24

0.1uF

2R10

33K

2TP3

6

2R6

680K

2C300.1uF

2R47

10K

2C31

0.1uF

+

2C46

220uF/6.3V

+

2C33

100uF/6.3V

2C16

2200pF

2L3

FB

2R36

4.7

2R1

100K

2TP1

0

2R42

1

2L5

FB

2C85

150pF

2TP1

5

2R46

20K

2C320.1uF

2TP14

2R43

10K

2R8

33K

+

2C25

220uF/6.3V

2R45

20K

2C56

0.1uF

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Page 41

3-34 3-35

3. SERVO CIRCUIT DIAGRAM_2

TSOP 48 pin

IIC

DRAM

FLASH

8M 16M 32M

FLASH

3CE1 1CE16 3U2

SD33 7 0.1uF

SDRAM & FLASH

DQ[0..15]

AD[0..7]

BA[0..1]

DQM[0..1]

MA[0..11]

A[0..21]

A9

A3

AD3

A1

A19

A4

AD6

AD1

A17

A16

A13

A14

AD0

A2

A6

A8

A18

AD7

A7

AD5

A12

A15

A10

AD2

AD4

A11

A5

A0

SD33

RAS#

PCE#

CAS#

PRD#

DCKE

SDA

DCLK

SCL

PWR#

CS#

WE#

CS#

WE#

DRAS#

DCS#

DCAS#

BA0

DCKE

BA1

SDCKE

DBA0

DBA1

SDCLK

DBA1

DQ3

DQ8

DQ5

DQ14

MA11

DRAS#

MA2

DQ15

MA5

DQ10

DQ0

MA4

DQ13

MA8

DBA0

DQ4

DQM1

DCS#

DQ2

DQ9

SDCLK

MA9

DQ11

MA3

MA6

DQM0

MA7

MA0

DCAS#

DWE#

MA10

SDCKE

DQ6

DQ7

DQ12

DQ1

MA1

A20 AA20

PCE#

PRD#

AA20

PWR#

DV33

VCC_5V

DVD_5V

DVD_3V3

SD33

CAS#

A21 AA21

AA21

GND

DVD_3V3

GND

DCLK

RAS#

SCL

DWE#

SDA

SDA

2

DQM[0..1]

2

BA[0..1]

2

WE#

2

PCE#

2

CAS#

2AD[0..7]2

CS#

2

DCKE

2

PRD#

2

SCL

2

DCLK

2

PWR#

2

MA[0..11]

2

DQ[0..15]

2

RAS#

2

A[0..21]

2

VCC_5V

1,4,6

DVD_5V

1,2,4

DVD_3V3

1,2

SD33

1

GND

1,2,4,5,6,7,8,9,10

SD33

SD33

SD33

DV33

FLASH_VCC

FLASH_VCC

FLASH_VCC

DV33

FLASH_VCCDV33

3TP1

3TP2

8

3R1

1K

3C3

0.1uF

3TP1

1

3TP2

1

3C9

0.1uF

3C7

0.1uF

3R4

33

3TP2

5

3R6

150

3TP1

2

3TP1

3

3R2

1K

3C13

0.1uF

3C2

0.1uF

3TP3

6

3TP3

0

3C6

0.1uF

3R9

10

3TP4

3RN1

33x4

1 8

2 7

3 6

4 5

3TP2

7

3TP3

8

3TP1

5

3TP2

0

3C1

0.1uF

3TP3

2

3TP6

3TP1

0

+

3CE1

100uF/6.3V

3U1

EEPROM 24C16

SOP8

1

2

3

4 5

6

7

8

NC

NC

NC

GND SDA

SCL

WP

VCC

3C5

0.1uF

3C10

ope

n

3TP1

4

3TP2

2

3TP1

7

3TP9

3C12

0.1uF

3TP7

3TP2

9

3TP1

9 3L1

FB

3TP3

3

3TP2

6

3TP1

6

3C4

0.1uF

3TP5

3TP2

4

3U3

STM29W160/MX29LV800(

160)

25

24

23

22

21

20

19

18

8

10

28

47

16

29

31

33

35

7

26

38

40

42

44

30

32

14

36

39

41

43

45

37

27

11

9

34

46

6

4

5

3

2

1

48

17

12

A0

A1

A2

A3

A4

A5

A6

A7

A8

A20

OE

BYTE

A18

D0

D1

D2

D3

A9

CE

D4

D5

D6

D7

D8

D9

WP/ACC

D11

D12

D13

D14

D15

VCC

GND1

WE

A19

D10

GND2

A10

A12

A11

A13

A14

A15

A16

A17

RESET

3R10

10k

3TP2

3

3C8

0.1uF

3TP8

3TP3

4

3TP2

3C11

0.1uF

3R5

33

3TP1

8

3U2

ESMT M12L64164A

TSOP5

4

1

2

4

12

5

7

9

8

10

46

11

13

15

16

17

18

19

35

22

23

24

25

26

14

41

29

30

31

32

33

34

36

37

38

39

40

43

42

44

52

45

47

49

48

50

51

53

54

20

21

3

6

27

28

VCC

DQ0

DQ1

VSSQ

DQ2

DQ3

VCCQ

DQ4

DQ5

VSSQ

DQ6

DQ7

DQML

WE

CAS

RAS

CS

A11

A10/AP

A0

A1

A2

A3

VCC

VSS

A4

A5

A6

A7

A8

A9

NC

CKE

CLK

DQMH

NC

VCCQ

DQ8

DQ9

VSSQ

DQ10

DQ11

VCCQ

DQ12

DQ13

DQ14

DQ15

VSS

BA0/A13

BA1/A12

VCCQ

VSSQ

VCC

VSS

3TP3

1

3TP3

3R8

33

3R3

33

3R7

33

3TP3

7

3TP3

5

+

3CE2

100uF/10V

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Page 42

3-36 3-37

4. AUDIO CIRCUIT DIAGRAM_1

SOP8

SPDIF Interface

OPTICAL

AUDIO

BAT_OUT

4558_VCC

VER

MR_OUT

DVD_5V

ML_OUT

ML_IN/OUT

ML_OUT

DAC_ML

A-5V

AVCC

MUTE

MUTE

BAT_OUT

MUTE

A+5V

ABCK

SBCLK

DAC_ML

SLRCK

SACLK

DAC_MR

SLRCK

SBCLK

SDAT0

SDAT0

SACLK

MR_IN/OUT

MR_IN/OUT

SPDIF_VCCSPDIF_VCCSPDIF_VCCSPDIF_VCCSPDIF_VCCSPDIF_VCC

ASPDIF

ML_IN/OUT

AUDIO_5V

447_5V

MCU_MUTE

L_SPEAKER

R_SPEAKER

L_SPEAKER

R_SPEAKER

POWER_DVD

VER 4558_VCC

A-5V

DVD_5V

AR

AL

ASPDIF

ALRCK

ABCK

ACLK

ASDAT0

AR

AL

POWER_DVD

A-5V

A+5V

AUDIO_5V

GND

A_MUTE

4344_5V

DAC_MR

AVCC

AV_IN/OUT_DET

MCU_MUTE

ALRCK

ACLK

ASDAT0

4344_5V

GND

MR_OUT

AV_IN/OUT_DET

AUDIO_5V

MUTE

AL

2

AUDIO_5V

1,5,8

BAT_OUT

1,7,9

A-5V

1

DVD_5V

1,2

AR

2

POWER_DVD

1,6

A+5V

1

R_SPEAKER

5

L_SPEAKER

5

ASPDIF

2

ALRCK

2

ABCK

2

ACLK

2

ASDAT0

2

GND

1,2,3,5,6,7,8,9,10

A_MUTE

5

AV_IN/OUT_DET

8

MCU_MUTE

2

MUTE

5

4T

P19

4TP

4

4Q6

3906

4D2

NC(D4148)

1 2

4TP29

4T

P17

4R33

NC(7.5K)

4U2 78L0

5

2

13

GND

VOUTVIN

4Q3

3906

4T

P40

4Q4

390

4

3 2

1

4L2

10uH

+

4CE6 10uF/25V

4FB1

OPEN(50)

4T

P9

4R27

100K

4R38

NC(100K)

4T

P35

4R42

0

4C7

22p

4R30

10K

4T

P7

4T

P32

4R5

8.2k

4FB2 50

4R11

4.7K

4T

P24

+

4CE4

100uF/16V

4R10

04R9

100K

4R28

20K

4C14

OPEN(12pF)

4TP15

4R12

OPEN(100K)

4R41

10K

Drive IC

LED

4J1

GP1FD310TP

5

4

3

6

8

7

2

1

+

4CE7

10uF/25V

4R24

47K

4T

P5

4C4

0.1uF

4C12

56pF

4R19

12k

4C3

22p

4R4

NC-0

4T

P34

4T

P16

4U3

CS4344

1

2

3

4

6

7

8

9

5

10

SDATA

SCLK

LRCK

MCLK

FILT

AOUTL

GND

VA

VQ

AOUTR

4R8

OPEN(180K)

4Q1

3904

1

3 2

+

4CE12

NC(47U/10V)

4T

P26

+

4CE3

47uF/10V

4R21

4.7K

4CE5

47UF/10V

4CE10

10uF/25V

4T

P3

4C17

0.1uF

4D3

NC(D4148)

1 2

4L1

OPEN(10uH)

4T

P2

4Q8

NC(3906)

1

32

4R18

NC-0

+

-

4U1B

NJM4558

5

6

7

8 4

4D1

NC(D4148)

1 2

4T

P38

4R3

10k

4R14

8K2

4C8

2000pF

4T

P25

4R23

5.1k

4R1

0

4R16

10

K

4T

P27

4R40

100k

4R29

4.7K

4C18

OPEN(104)

4Q9

390

6

1

32

4TP13

4T

P28

+

4CE11

NC(220uF/10V)

4D4

1N4148

1 2

4C9

0.1uF

4C5

0.1u

4Q7

390

4

1

3 2

4TP20

4R34

NC(100K)

4R36

NC(470R)

4C11

56pF

+

4CE14

10uF/25V

4T

P14

+

-

4U1A

NJM4558

3

2

1

8 4

4R7

100

4C2

2000pF

4C1

220pF

4T

P30

4T

P39

4T

P21

4Q5

3904

1

3 2

4R31

5.1K

4R26

OPEN(180K)

4T

P1

+

4CE2

10uF/25V

4C15

OPEN(12pF)

4R22

8.2k

4C16

OPEN(12pF)

+

4CE9

100uF/10V

+

4CE13

4.7uF/16V

4C6

220pF

4T

P10

4R2

12k

4R25

100

4R39

4.7k

4T

P22

4T

P31

4R17

4.7K

4R15

4.7K

4T

P8

4R32

2K

4T

P12

+

4CE1 10uF/25V

4T

P18

4R13

10K

4C13

OPEN(12pF)

4L3 FB

4L4

FB

4T

P6

4R6

5.1k

4C10

0.1uF

4CE8

10uF/25V

4T

P23

4R35

10

4T

P37

4T

P33

4R20

10k

4Q2

390

6

4RN1

33x4

1 8

2 7

3 6

4 5

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Page 43

3-38 3-39

5. AUDIO CIRCUIT DIAGRAM_2

PT2303

05 TPA0102

SPR+

L_SPEAKER

AUDIO_5V

R_SPEAKER

SPRSPL+

SPL-

SPL-

PH_ON

R_SPEAKER L_SPEAKER

R_HP_IN

MUTE

L_HP_IN

MUTE

AUDIO_5V

0102_CTRL

MUTE

PH_ON

PH_ON

MUTE

AUDIO_5V

L_HP_IN

SPR-

SPL+

R_HP_IN

SPL-

SPR+

SPR-

SPL-

GND

SPR-

SE/BTL

0102_CTRL

SE/BTL

AUDIO_5V

1,4,8

SPL-

7

SPL+

7

L_SPEAKER

4

R_SPEAKER

4

SPR+

7

SPR-

7

0102_CTRL

GND

1,2,3,4,6,7,8,9,10

MUTE

4

+

5CE2

100uF/10V

5C9

0.1UF

5R9

100K

5L1

100

5R7

100K

5D1

1N4148

1 2

5TP17

+

5C4 1UF/50V

5R21

1K

5R20

330

+

5CE3

100uF/10V

5R3

10K

5C1

C

5T

P15

5T

P18

5T

P6

5T

P25

+

5C3 1UF/50V

5J2

PHONEJACK

3

6

5

4

2

1

7

8

5J1

PHONEJACK

3

6

5

4

2

1

7

8

5R5

1K

5CE1

22UF/16V

5C8

0.1uF

5T

P19

5R4

10K

5Q2

3904

1

3 2

5R1

47k

1

5R6 1K

5T

P27

5TP13

5Q7

390

4

1

32

5R11 100

5R19

10k

1

+

5CE5

10uF/25V

5TP

7

+

5CE4

10uF/25V

5T

P20

5R10

100

5C2

C

5Q5

3904

1

32

5R15

4.7K

5Q3

390

4

1

3 2

5CE6

22UF/16V

5R14

4.7K

5T

P14

5R8

100K

5T

P23

5R18

10k

1

5Q4

390

4

1

3 2

5TP12

5R12

4.7K

5R13

4.7K

5Q1

3904

1

3 2

5R17 4.7K

5U1

PT2303

1

2

9

4

11

6

7

8

14

10

12

16

13

5

15

3

Shutdown

GND

+IN2

VDD