Page 1

OWNER’S MANUAL

DRYER

ENGLISH ESpañoL

Read this owner’s manual thoroughly before operating the appliance

and keep it handy for reference at all times.

DLEX7900*E DLEX7800*E

DLGX7901*E DLGX7801*E

MFL70442605

Rev.03_021519

Copyright © 2019 LG Electronics Inc. All Rights Reserved.

www.lg.com

Page 2

2

TABLE OF CONTENTS

TABLE OF CONTENTS

PRODUCT FEATURES

3

SAFETY INSTRUCTIONS

4

5 IMPORTANT SAFETY INSTRUCTIONS

7 GROUNDING INSTRUCTIONS

PRODUCT OVERVIEW

8

8 Parts

8 Accessories

8 Safety Tether Kit

8 Two-Way Reversible Door (on some models)

INSTALLATION

9

9 Installation Overview

9 Product Specifications

10 Installation Location Requirements

10 Clearances

12 Leveling the Dryer

12 Reversing the Door

20 Installing the Side Vent Kit

21 Venting the Dryer

24 Connecting Gas Dryers

26 Connecting Electric Dryers

30 Final Installation Check

31 Installation Test (Duct Check)

SMART FUNCTIONS

44

44 LG SmartThinQ Application

47 Smart Diagnosis™ Function

MAINTENANCE

48

48 Regular Cleaning

TROUBLESHOOTING

49

49 FAQs: Frequently Asked Questions

49 User Support Videos

50 Before Calling for Service

WARRANTY (USA)

58

OPERATION

33

33 Using the Dryer

34 Check the Lint Filter Before Every Load

34 Sorting Loads

34 Loading the Dryer

35 Using the LG EasyLoad

36 Control Panel

38 Cycle Guide

40 Cycle Settings and Options

42 Steam Functions (Steam Models)

43 Steam Cycle Guide

TM

Page 3

PRODUCT FEATURES

C

E

R

T

I

F

I

E

D

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

D

E

S

I

G

N

T

I

F

3

PRODUCT FEATURES

Easy-to-Use Control Panel

An entire selection of user-friendly functions make operating the dryer easy.

Two-Way Easy-Access Reversing Door

The LG EasyLoad™ can be tilted open from the top, hamper-style, allowing you to easily load the dryer without items falling

on the floor. The door still swings open to provide easy access for unloading or loading of bulkier items. The door hinge can

be reversed to adjust to the installation location.

Steam Functions (Steam Models)

LG's steam technology allows you to inject fabrics with a swirling jet of steam to refresh clothes, reduce static, and make

ironing easier. Simply select the Steam Fresh™ cycle or Wrinkle Care cycle.

Flow Sense™ Duct Blockage Sensing System Indicator

The Flow Sense™ duct blockage sensing system detects and alerts you to restrictions in the installed household ductwork

that reduce exhaust airflow through the dryer. If you see the alert: Clean or repair the ducts to remove the restrictions. Keep

your ducts free of blockage to help increase efficiency and reduce long drying times caused by blocked ducts.

Smart Diagnosis™

Should you experience any technical difficulty with your dryer, it has the capability of transmitting data via your telephone

to the Customer Information Center. The call center agent records the data transmitted from your machine and uses it to

analyze the issue, providing a fast and effective diagnosis.

ENGLISH

SmartThinQ™

Download the new LG smart phone app to set options, self-diagnose and troubleshoot problems with the appliance, and

other useful features. This function uses Wi-Fi.

I

G

S

N

E

D

Protocol P154

Sanitization Performance of

C

E

D

R

E

I

Residential Clothes dryer

Page 4

4

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

Your safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance. Always read and

obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word DANGER, WARNING, or

CAUTION.

These words mean:

-

DANGER

You will be killed or seriously injured if you

do not

immediately follow instructions.

WARNING

CAUTION

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury,

and tell you what may happen if the instructions are not followed.

- You may be killed or seriously injured if you do not follow instructions.

- You may be slightly injured or cause damage to the product if you do not follow

instructions.

WARNING – Risk of Fire

Install the clothes dryer according to the manufacturer’s instructions and local codes.

Clothes dryer installation must be performed by a qualified installer.

•Do not install a clothes dryer with flexible plastic venting materials. If flexible metal (foil type) duct is installed,

it must be of a specific type identified by the appliance manufacturer as suitable for use with clothes dryers.

Flexible venting materials are known to collapse, be easily crushed, and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire.

•To reduce the risk of severe injury or death, follow all installation instructions.

•Save these instructions.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death or property damage.

—Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

—WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

—Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Page 5

SAFETY INSTRUCTIONS

5

IMPORTANT SAFETY INSTRUCTIONS

WARNING

To reduce the risk of fire, electric shock, or injury to persons when using your appliance, follow basic

precautions, including the following:

Installation

•Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint,

dust, and dirt.

•Do not install or store this appliance where it will be

exposed to the weather.

•Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause a

load to catch fire.

•Properly ground the dryer to conform with all

governing codes and ordinances. Follow the details

in the installation instructions. Electric shock may result

if the dryer is not properly grounded.

•Before use, the dryer must be properly installed as

described in this manual. Electric shock may result if

the dryer is not properly grounded.

•Install and store the dryer where it will not be exposed to

temperatures below freezing or exposed to the weather.

•All repairs and servicing must be performed by

authorized service personnel unless specifically

recommended in this Owner’s Manual. Use only

authorized factory parts. Failure to follow this warning

may result in serious injury, fire, electric shock, or death.

•To reduce the risk of electric shock, do not install

the dryer in humid spaces. Failure to follow this

warning may result in serious injury, fire, electric shock,

or death.

•Connect to a properly rated, protected, and sized

power circuit to avoid electrical overload. Improper

power circuits may melt, creating electric shock and/or

fire hazard.

•Remove all packing items and dispose of all

shipping materials properly. Failure to do so may

result in burns, fire, explosion, or death.

•Place the dryer at least 18-inch (45.7 cm) above the

floor for a garage installation. Failure to do so may

result in burns, fire, explosion, or death.

•Keep all packaging from children. Packaging material

can be dangerous for children. There is a risk of

suffocation.

•Do not install near another heat source such as a

stove, oven or heater. Failure to follow this warning

may result in product deformation, smoke, or fire.

•Do not place candles, smoking materials, or other

flammables on top of the product. Dripping wax, smoke,

or fire may result.

•Remove all protective vinyl film from the product.

Failure to do so may result in product damage, smoke,

or fire.

•Gas dryers MUST be exhausted to the outside.

Failure to follow these instructions may result in fire or

death.

•The dryer exhaust system must be exhausted to the

outside of the dwelling. If the dryer is not exhausted

outdoors, some fine lint and large amounts of moisture

will be expelled into the laundry area. An accumulation

of lint in any area of the home may create a health and

fire hazard.

•Use only rigid, semi-rigid or flexible metal 4-inch

(10.2 cm) diameter duct inside the dryer cabinet or

for exhausting to the outside. Use of plastic or other

combustible ductwork may cause fire. Punctured

ductwork may cause fire if it collapses or becomes

otherwise restricted in use or during installation.

•Ductwork is not provided with the dryer, and you

should obtain the necessary ductwork locally. The

end cap should have hinged dampers to prevent

backdraft when the dryer is not in use. Failure to

follow these instructions may result in fire or death.

•The exhaust duct must be 4-inch (10.2 cm) in

diameter with no obstructions. The exhaust duct

should be kept as short as possible. Make sure

to clean any old ducts before installing your new

dryer. Failure to follow these instructions may result in

fire or death.

•Rigid, semi-rigid or flexible metal ducting is

recommended for use between the dryer and the

wall. All non-rigid metal transition duct must be

UL-listed. Use of other materials for transition

duct could affect drying time. Failure to follow these

instructions may result in fire or death.

•Do not use sheet metal screws or other fasteners

which extend into the duct that could catch lint and

reduce the efficiency of the exhaust system. Secure

all joints with duct tape. For complete details, follow

the Installation Instructions. Failure to follow these

instructions may result in fire or death.

•Certain internal parts are intentionally not

gronunded and may present a risk of electronic

shock only during serving.

Service personnel - do not contact the following

parts while the appliance is energized: CONTROL

BOARD

ENGLISH

Page 6

6

SAFETY INSTRUCTIONS

Operation

•Read all instructions before using the appliance.

•Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other flammable

or explosive substances, as they give off vapors

that could ignite or explode.

•Do not reach into the appliance if the drum is

moving.

•Do not allow children to play on or in the appliance.

Close supervision of children is necessary when

the appliance is used near children.

•Do not use fabric softeners or products to eliminate

static unless recommended by the manufacturer of

the fabric softener or product.

•Do not use heat to dry articles containing foam

rubber or similarly textured rubber-like materials.

•Do not tamper with controls.

•Always check the inside of the dryer for foreign

objects. Failure to follow these instructions may

result in fire or death.

•Do not store plastic, paper, or clothing that may

burn or melt on top of the dryer during operation.

Failure to follow these instructions may result in fire

or death.

•Be careful when opening and closing the door.

Fingers and hands can get caught in the door and

cause injury if the door drops forward unexpectedly.

•Do not place heavy items on or lean against the

top of the door when it is open.

•Do not attempt to pull the hamper door open

more than 40 degrees.

•The dryer could tip forward, causing injury or

damage.

•Do not place items on the top of the dryer.

•Gas appliances can cause minor exposure to four

potentially hazardous substances, namely benzene,

carbon monoxide, formaldehyde, and soot, caused

primarily by the incomplete combustion of natural

gas or LP fuels.

•Properly adjusted dryers will minimize incomplete

combustion. Exposure to these substances can be

minimized further by properly venting the dryer to

the outdoors.

•Do not place items exposed to cooking oils in your

dryer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause

a load to catch fire. To reduce the risk of fire due

to contaminated loads, the final part of a tumble

dryer cycle occurs without heat (cool down period).

Avoid stopping a tumble dryer before the end of the

drying cycle unless all items are quickly removed

and spread out so that the heat is dissipated.

•Do not let children or pets climb inside the dryer

drum.

•Do not put living animals such as pets inside the

product.

•Do not put any part of your body, such as your

hands or feet, or metal objects under the product.

•Do not let your hand get pinched when opening or

closing the dryer door.

Steam (steam model):

•Do not open the dryer door during steam

cycles. Failure to follow these instructions may

result in a burn hazard.

•Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted

with gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode. Failure to

follow these instructions may result in fire or death.

•Do not fill the steam feeder with gasoline,

dry cleaning solvents, or other flammable or

explosive substances. Failure to follow these

instructions may result in fire or death.

•Do not touch the steam nozzle in the drum

during or after the steam cycles. Failure to follow

these instructions may result in a burn hazard.

•Do not fill the steam feeder with hot water (over

86 °F/30 °C). Failure to follow these instructions

may result in a burn hazard.

Maintenance

•Do not repair or replace any part of the appliance

or attempt any servicing unless specifically

recommended in the user maintenance instructions

or in published user-repair instructions that you

understand and have the skills to carry out.

•Clean the lint filter before or after each load.

•The interior of the appliance and exhaust duct

should be cleaned periodically by qualified service

personnel.

•Before the appliance is removed from service

or discarded, remove the door to the drying

compartment.

•Certain internal parts are intentionally not

gronunded and may present a risk of electronic

shock only during serving.

Service personnel - do not contact the following

parts while the appliance is energized: CONTROL

BOARD

WARNING

Fire Hazard

Failure to follow safety warnings exactly could

result in serious injury, death or property damage.

Do not install a booster fan in the exhaust duct.

Install all clothes dryers in accordance with the

installation instructions of the manufacturer of the

dryer.

SAVE THESE INSTRUCTIONS

Page 7

SAFETY INSTRUCTIONS

7

GROUNDING INSTRUCTIONS

WARNING

Improper connection of the equipment-grounding conductor may result in a risk of electric shock.

Check with a qualified electrician or service person if you are in doubt that the appliance is properly

grounded.

•This appliance must be grounded. In the event

of malfunction or breakdown, grounding will reduce

the risk of electric shock by providing a path of least

resistance for electric current.

•This appliance must be equipped with a cord

having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into

an appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

•Do not modify the plug. If it will not fit the outlet,

have a proper outlet installed by a qualified

electrician.

•This appliance must be connected to a

grounded metal, permanent wiring system or

an equipment-grounding conductor must be

run with the circuit conductors and connected

to the equipment-grounding terminal or lead

on the appliance. Electric shock may result if the

dryer is not properly grounded.

•The dryer should always be plugged into its

own individual electrical outlet which has a

voltage rating that matches the rating plate. This

provides the best performance and also prevents

overloading house wiring circuits which can cause

a fire hazard from overheated wires.

•Never unplug your dryer by pulling on the

power cord. Always grip the plug firmly and pull

straight out from the outlet. The power cord may

be damaged, resulting in a risk of fire and electric

shock.

•Repair or replace immediately all power

cords that have become frayed or otherwise

damaged. Do not use a cord that shows cracks

or abrasion damage along its length or at either

end. The power cord may melt, creating electric

shock and/or fire hazard.

•When installing or moving the dryer, be careful

not to pinch, crush, or damage the power cord.

This will prevent injury and damage to the dryer

from fire and electric shock.

•Do not, under any circumstances, cut or

remove the ground prong from the power cord.

To prevent personal injury or damage to the dryer,

the electrical power cord must be plugged into a

properly grounded outlet.

•For personal safety, this dryer must be properly

grounded. Failure to do so may result in electric

shock or injury.

•Refer to the installation instructions in this

manual for specific electrical requirements for

your model. Failure to follow these instructions

may create an electric shock hazard and/or a fire

hazard.

•This dryer must be plugged into a properly

grounded outlet. Electrical shock may result if

the dryer is not properly grounded. Have the

wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly

grounded. Failure to follow these instructions

may create an electric shock hazard and/or a fire

hazard.

ENGLISH

Page 8

8

PRODUCT OVERVIEW

PRODUCT OVERVIEW

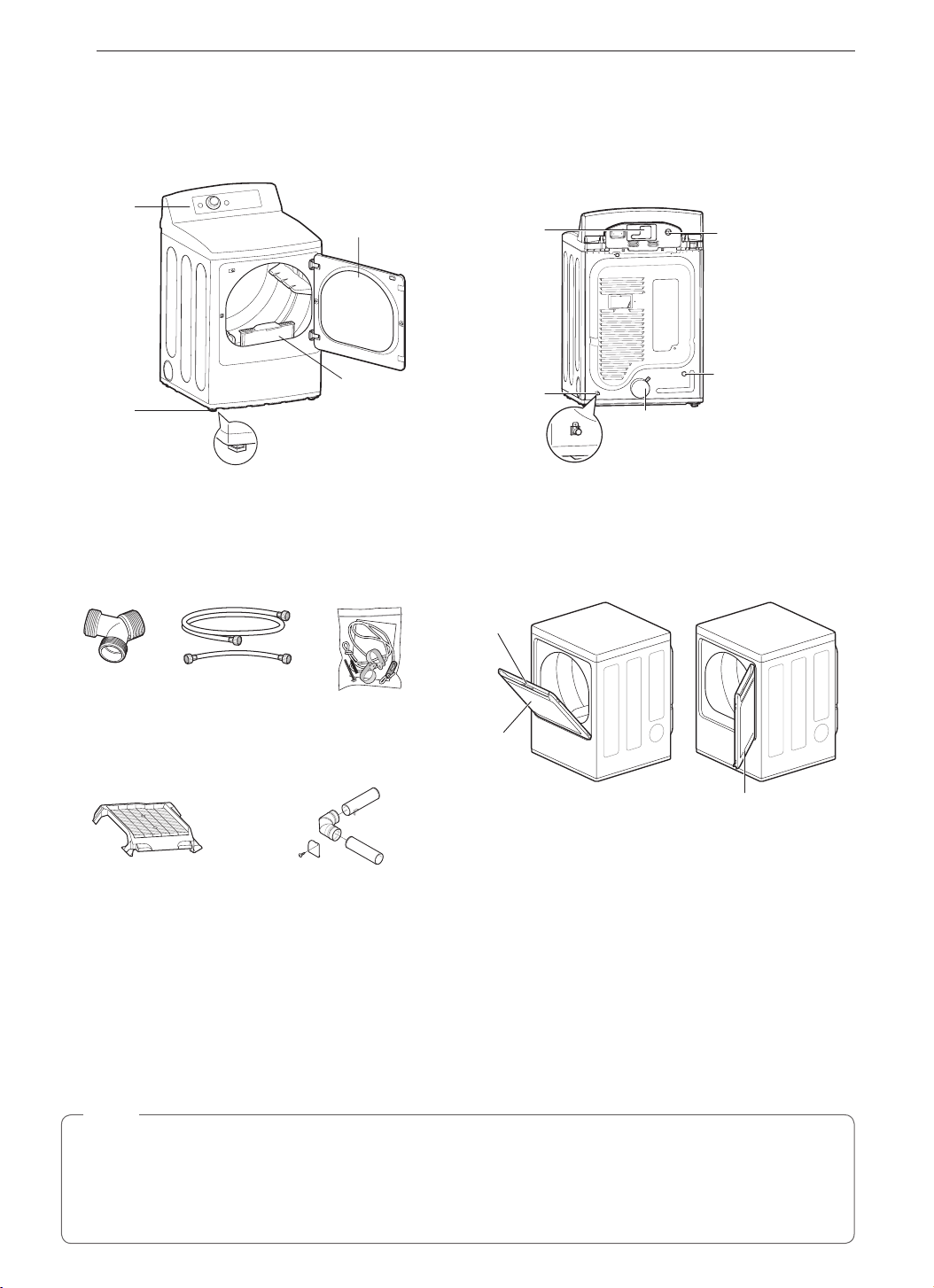

Parts

Control

panel

Leveling

feet

Accessories

Included Accessories

Y connector

(steam models)

Optional accessories

(steam models)

Hoses

Reversible

door

Lintlter

Safety Tether Kit

(on some models)

Terminal block

access panel

(electric models)

Gas connection

location

(gas models)

Exhaust duct

outlet

Power cord

location

(gas models)

Water inlet valve

(on some models)

Two-Way Reversible Door

(on some models)

Release

Hamper

door

Swing door

The LG EasyLoad™ feature allows you to open the

dryer door from the top, hamper-style, when loading the

Drying rack

(sold separately)

No. 3750EL0001C

Side vent kit

(sold separately)

Kit No. 383EEL9001B

dryer to help guide clothes into the drum and prevent

them from falling onto the floor. When unloading the

dryer or loading bulkier items, use the swing door for

easy access to the drum.

Safety Tether Kit

This optional kit helps prevent the dryer tipping if children climb on the door or if someone should fall onto the

door. It is recommended that you install this kit, depending on your situation, but it is not required. Follow the

customer installation instructions included with the kit to properly install the kit. If you do not install the kit, store it

out of reach of children.

NOTE

•For your safety and for extended product life, use only authorized components. The manufacturer is not

responsible for product malfunction or accidents caused by the use of separately purchased unauthorized

components or parts.

•The images in this guide may be different from the actual components and accessories, which are subject

to change by the manufacturer without prior notice for product improvement purposes.

Page 9

INSTALLATION

9

INSTALLATION

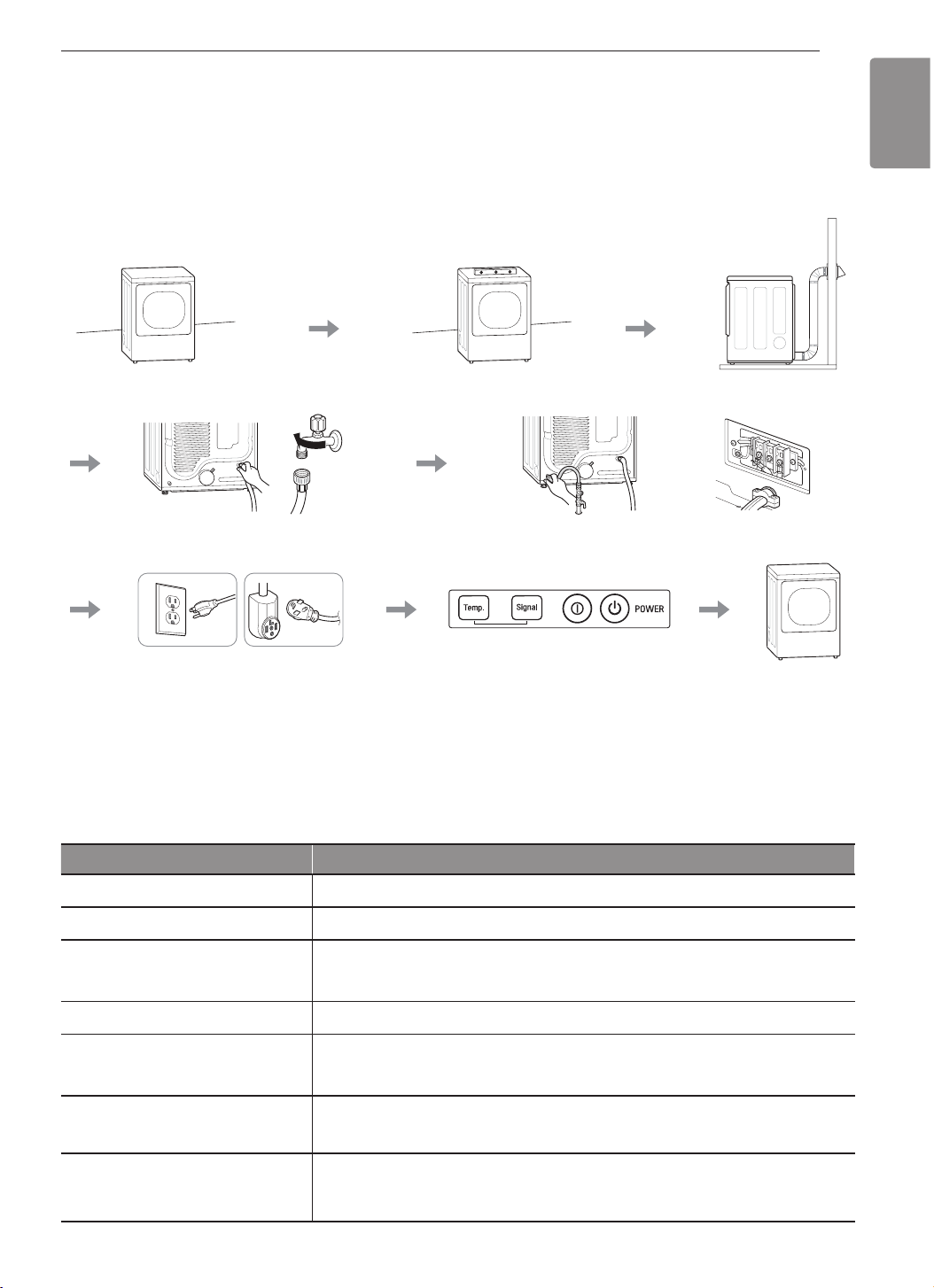

Installation Overview

Please read the following installation instructions first after purchasing this product or transporting it to another

location.

Check and choose

the proper location

Connect the inlet hose

(steam models)

Level the dryer

Connect gas dryers

Vent the dryer

Connect electric dryers

ENGLISH

Gas dryer Electric dryer

Plug in the power cord Installation test Test run

Product Specifications

The appearance and specifications listed in this manual may vary due to constant product improvements.

Dryer Models DLEX7900*E, DLEX7800*E, DLGX7901*E, DLGX7801*E

Description Steam Dryer

Electrical requirements Please refer to the rating label regarding detailed information.

Gas requirements

Max. water pressure 20–120 psi (138–827 kPa)

Dimensions

Net weight

Drying capacity

- Normal cycle

- Steam cycle

NG: 4–10.5-inch WC

LP: 8–13-inch WC

27” (W) X 29 1/2” (D) X 44 1/4” (H), 50 1/4” (D with door open)

68.6 cm (W) X 75.0 cm (D) X 112.3 cm (H), 127.5 cm (D with door open)

Gas dryer : 129.8 lb (58.9 kg)

Electric dryer : 124.8 lb (56.6 kg)

IEC 7.3 cu.ft. (22.5 lb/10.2 kg)

IEC 7.3 cu.ft.(8 lb/3.6 kg)

Page 10

10

INSTALLATION

Installation Location Requirements

WARNING

Read all installation instructions completely before installing and operating your dryer! It is important that you

review this entire manual before installing and using your dryer. Detailed instructions concerning electrical

connections, gas connections, and exhaust requirements are provided on the following pages.

The installation requires:

•A location that allows for proper exhaust installation. A gas dryer must be exhausted to the outdoors. See

Venting the Dryer.

•A grounded electrical outlet located within 2 ft. (61 cm) of either side of the dryer. See Connecting Electric

Dryers .

•A sturdy floor to support the total dryer weight of 200 lb (90.7 kg). The combined weight of a companion

appliance should also be considered.

•No other fuel-burning appliance can be installed in the same closet as a dryer.

Do not operate your dryer at temperatures below 45 °F (7 °C). At lower temperatures, the dryer might not shut off

at the end of an automatic cycle. This can result in longer drying times. The dryer must not be installed or stored

in an area where it will be exposed to water and/or weather. Check code requirements. Some codes limit, or do

not permit, installation of the dryer in garages, closets, mobile homes or sleeping quarters. Contact your local

building inspector.

NOTE

•The floor must be level, with a maximum slope of 1 inch (2.5 cm) under the entire dryer.

Clothes may not tumble properly, and automatic sensor cycles may not operate correctly if dryer is not

level.

•For a garage installation, you will need to place the dryer at least 18-inch (46 cm) above the floor. The

standard pedestal is 15-inch (38.1 cm). You will need 18-inch (46 cm) from the garage floor to the bottom

of the dryer.

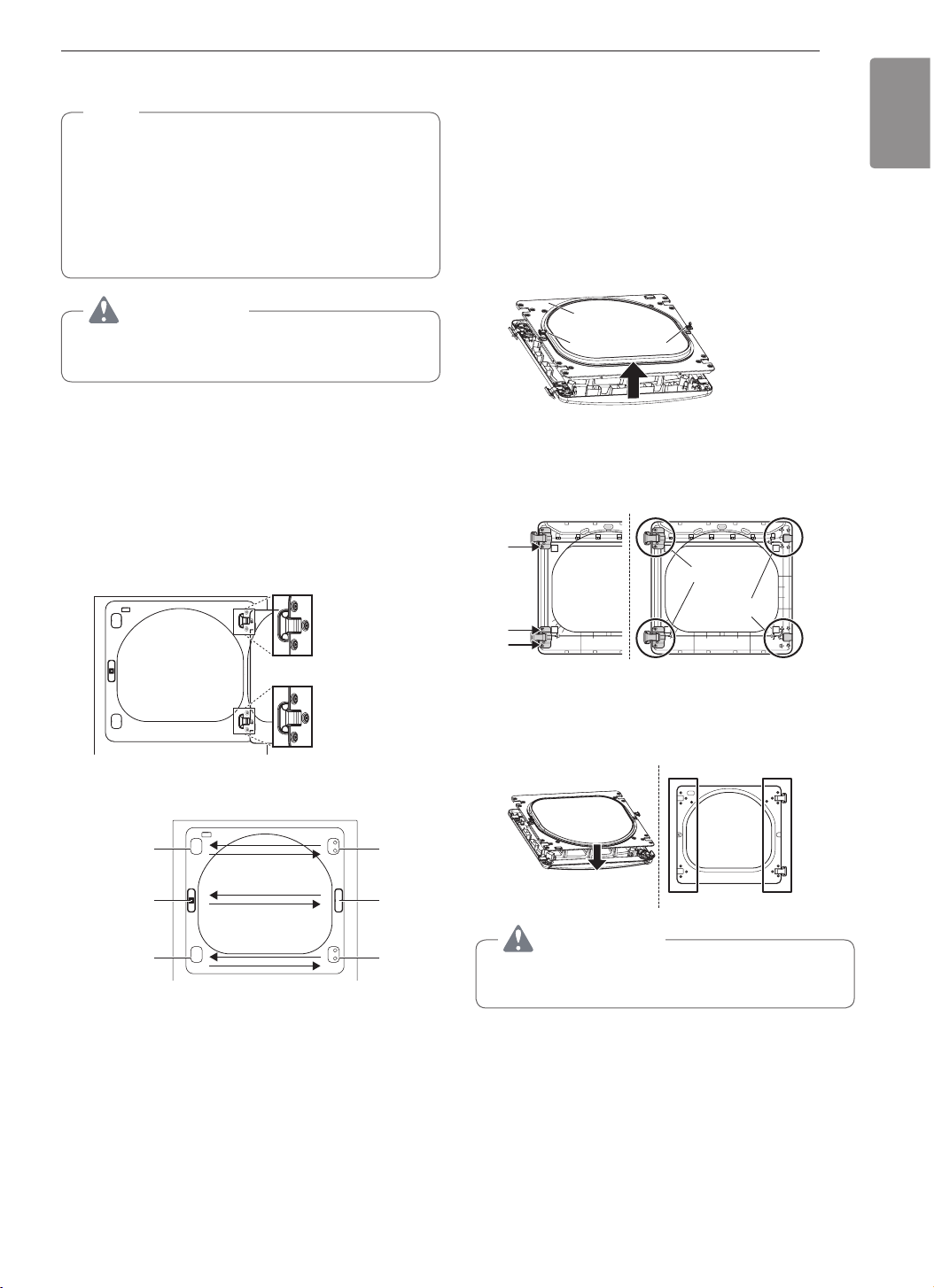

Clearances

Installation Spacing for Recessed Area or Closet Installation

The following spacing dimensions are recommended for this dryer. This dryer has been tested for clearances of

1 inch (2.5 cm) on the sides and rear. Recommended clearances should be considered for the following reasons:

•Additional clearances should be considered for ease of installation and servicing.

•Additional clearances might be required for wall, door and floor moldings.

•Additional clearances should be considered on all sides of the dryer to reduce noise transfer.

For closet installation, with a door, minimum ventilation openings in the top and bottom of the door are

required. Louvered doors with equivalent ventilation openings are acceptable.

•Companion appliance spacing should also be considered.

Page 11

INSTALLATION

11

Closet Ventilation Requirements

Closets with doors must have both an upper and lower vent to prevent heat and moisture buildup in the closet.

One upper vent opening with a minimum opening of 48 sq. in. (310 cm

2

) must be installed no lower than 6 feet

above the floor. One lower vent opening with a minimum opening of 24 sq. in. (155 cm2) must be installed no

more than one foot above the floor. Install vent grills in the door or cut down the door at the top and bottom to

form openings. Louvered doors with equivalent ventilation openings are also acceptable.

NOTE

There should be at least a little space around the dryer (or any other appliance) to eliminate the transfer of

vibration from one appliance to another. If there is enough vibration, it could cause appliances to make noise

or come into contact, causing paint damage and further increasing noise.

Installation Spacing for Recessed Area or Closet

3"

(7.6 cm)

14" max.*

(35.6 cm)

18" min.

(45.7 cm)

48 in.

(310 cm2)

2

24 in.

(155 cm2)

1

21

/4"

2

(54 cm)

ENGLISH

1

/2"

29

(75.0 cm)

1

/4"

50

(127.5 cm)

1"

(2.5 cm)

27"

(68.6 cm)

3"

(7.6 cm)

Closet Door Vent

Requirements

* Required spacing

** For side or bottom venting, 2-inch (5.1 cm) of spacing is allowed

Installation Spacing for Cabinet

For cabinet installation with a door, minimum ventilation openings in the top of the cabinet are required.

* Required spacing

7"* (17.8 cm)

7"* (17.8 cm)

1"

(2.5 cm)

5"

(12.7 cm)

*

1

/2"

29

(75.0 cm)

1"

*

(2.5 cm)

(2.5 cm)

1"

27"

(68.6 cm)

1"

(2.5 cm)

Page 12

12

INSTALLATION

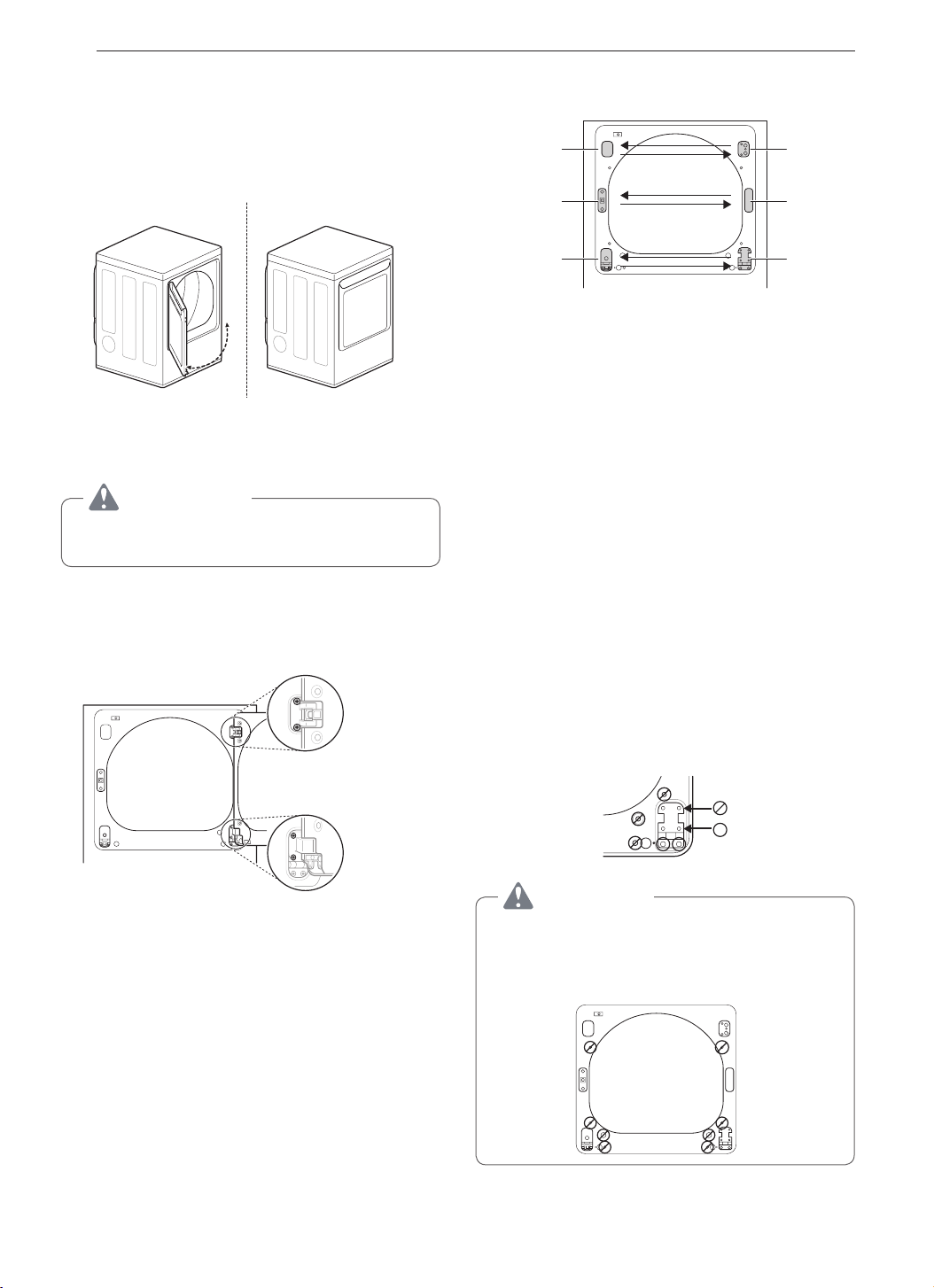

Leveling the Dryer

WARNING

To reduce the risk of injury to persons, adhere

to all industry recommended safety procedures

including the use of long-sleeved gloves and

safety glasses. Failure to follow this warning may

result in serious injury or death.

•The appliance is heavy. Two or more people

are required when installing the dryer. Failure to

follow this warning may result in serious injury

or death.

•To ensure that the dryer provides optimal drying

performance, it must be level. To minimize

vibration, noise, and unwanted movement, the

floor must be a perfectly level, solid surface.

NOTE

Adjust the leveling feet only as far as necessary

to level the dryer. Extending the leveling feet more

than necessary may cause the dryer to vibrate.

Position the dryer in the final location. Check

1

levelness of dryer from side to side. Repeat from

front to back

Place level here

Use an adjustable wrench to turn the leveling

2

feet. Unscrew the legs to raise the dryer or

screw in the legs to lower it. Raise or lower with

the leveling feet until the dryer is level from side

to side and front to back. Make sure that all four

leveling feet are in firm contact with the floor.

If you are installing the dryer on the optional pedestal,

you must use the leveling feet on the pedestal to level the

dryer. The dryer leveling feet should be fully retracted.

Reversing the Door

Before you Begin

NOTE

Service calls to reverse the door are not covered

under the product warranty.

•The door reversal process for the two-way door

is more complex than for a conventional dryer

door. Read through these instructions in their

entirety before beginning the process, in order to

gauge whether to have the procedure done by a

professional installer or service person.

•A support video is also provided at http://www.

lg.com/us/support/videos/video-tutorials-view,

How to Reverse the Door – LG EasyLoad™ Dryer.

Place level here

Not Level Not LevelLevel

Tools Required

•Phillips screwdriver

•Large flat blade screwdriver (recommended

for hinge screws if they are tight or your Phillips

screwdriver is worn)

•Small flat blade screwdriver (for lifting out parts)

WARNING

THE DRYER DOOR IS VERY LARGE AND

HEAVY. Failure to follow the instructions below

may result in damage to the dryer, property

damage or personal injury.

•To avoid damage to the dryer or the door,

support the door with a stool or box that fits

under the door, or have an assistant support

the weight of the door.

•Avoid dropping the door to avoid damage to the

door or the floor.

•Unplug the dryer or turn off power at the main

circuit breaker before beginning door reversal.

Page 13

INSTALLATION

13

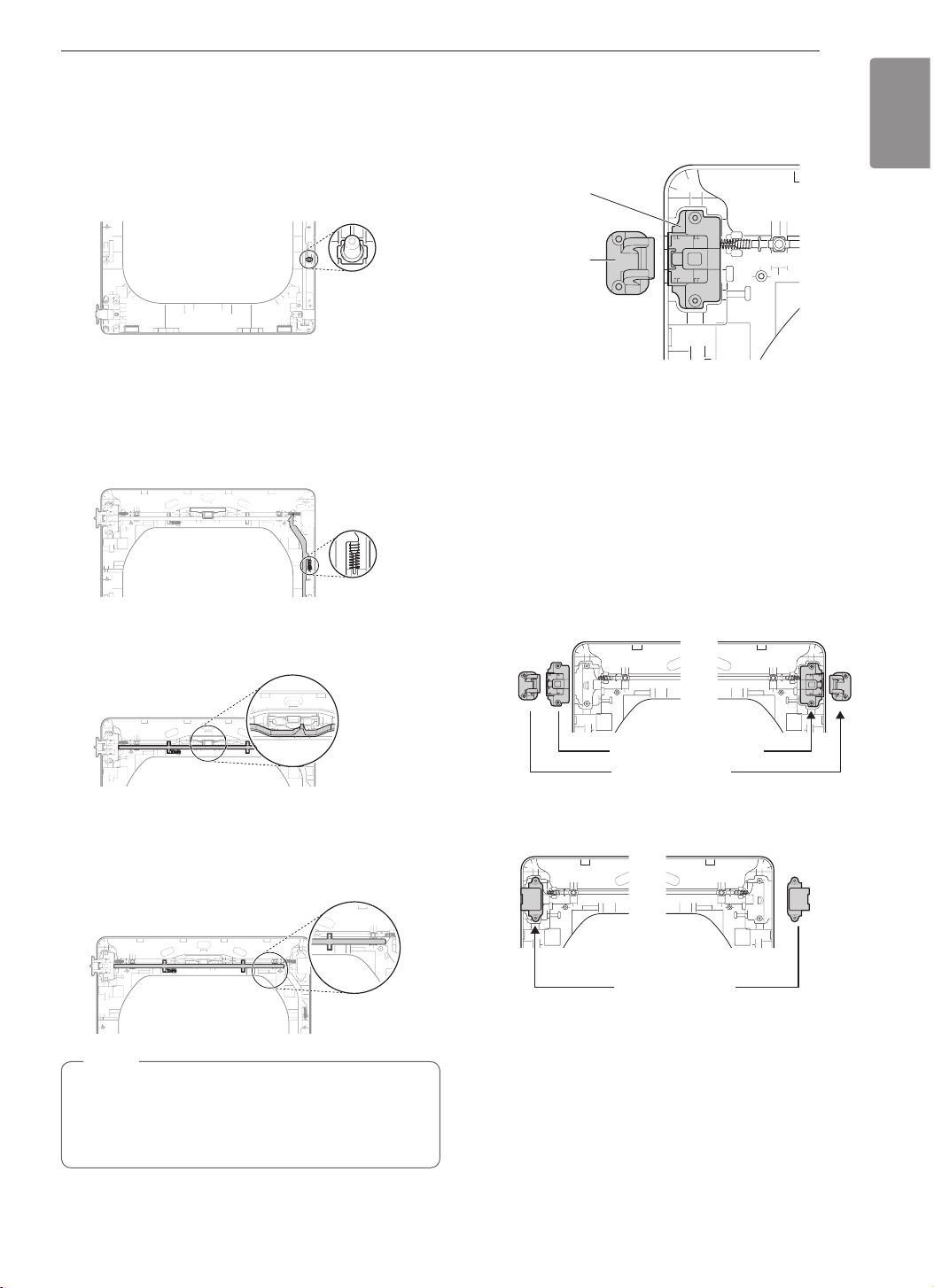

Door Reversal Instructions

NOTE

The instructions here are for changing the door

swing from a right to a left side hinge. If the

door has been reversed, and it is necessary to

change it back, use care when following these

instructions. Some of the illustrations and the left/

right references will be reversed, and you will

need to read the instructions carefully.

WARNING

Be sure to support the weight of the door before

removing the hinge screws.

Swing door

Open the door from the side so that the hinge

1

screws are accessible.

Remove the four hinge screws.

2

While supporting the door, remove the four hinge

screws, two from each hinge. Set the door aside

face down on a protected surface to prevent

damage to the door or the work surface.

c. Remove the hinge cover by gently prying it up

with a flat blade screwdriver, being careful not

to scratch the paint. Rotate the hinge cover

180 degrees and install it on the opposite side,

where the hinge was attached.

With the door on a protected surface, remove all

4

screws on each side of the door and lift off the

inner door frame using a flat blade screwdriver.

Remove the latch hook and blank and install

them on the opposite side.

Inner door

frame

Blank

Latch hook

Remove the 4 screws securing the hinges to

5

the door frame. Remove the two plastic cover

caps. Reinstall the hinges and cover caps on the

opposite sides from which they were removed.

Hinge

assembly

Cover cap

ENGLISH

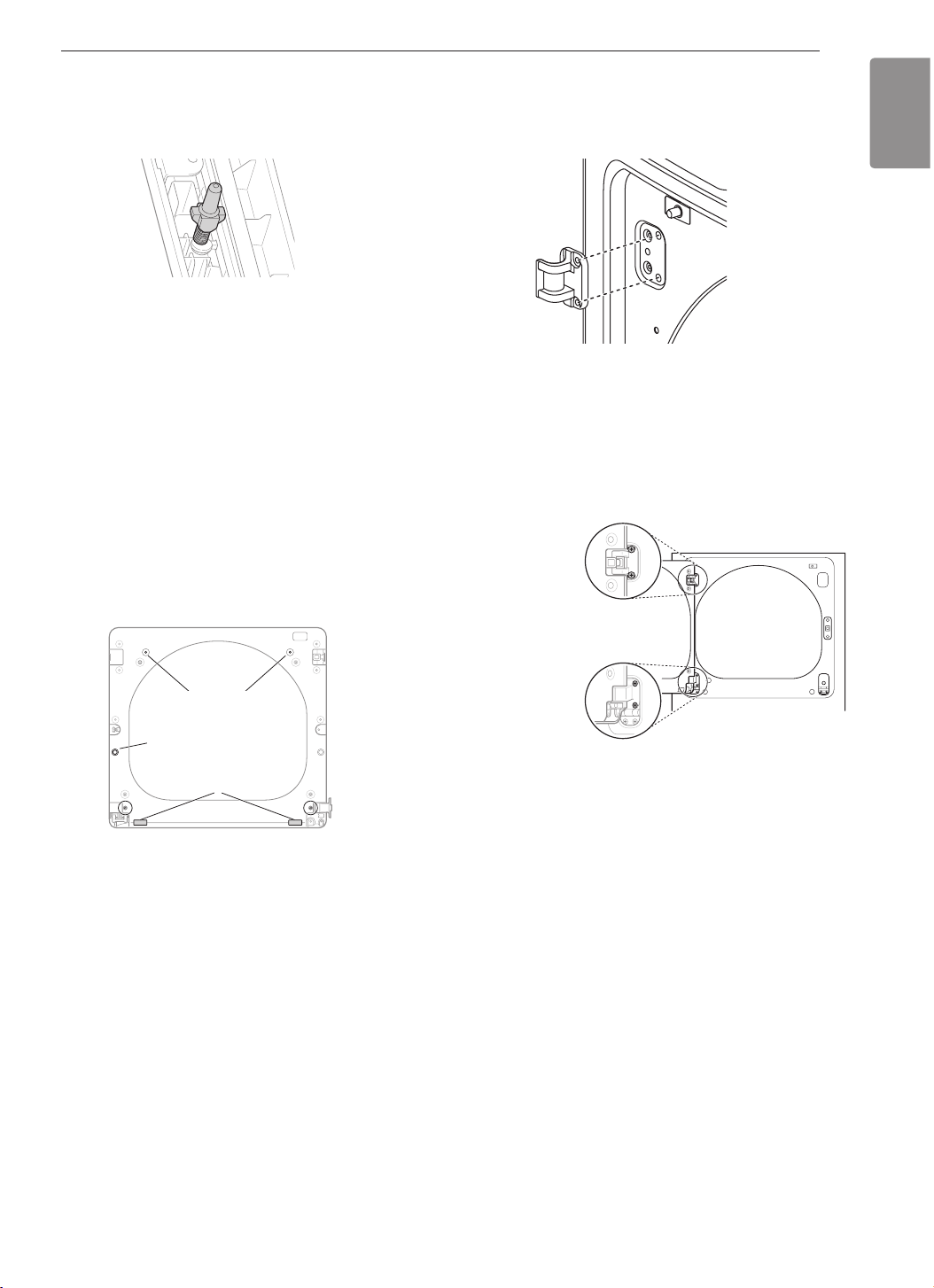

Reverse the components on the cabinet.

3

hinge

cover

latch

mechanism

hinge

cover

a. Use a Phillips screwdriver to remove the two

screws and the latch mechanism on the front

panel of the cabinet.

b. Remove the latch hole cover by gently prying it

up with a flat blade screwdriver, being careful

not to scratch the paint. Install the latch hole

cover on the opposite side, where the latch

mechanism was removed. Install the latch

mechanism in the position from which you

removed the latch hole cover, using the two

screws removed in step a.

hinge

latch

hole

cover

hinge

With the hinges and cover caps in the new

6

locations, remount the inner door frame onto the

outer door frame with the screws removed in

step 4 above.

WARNING

Be sure to support the weight of the door before

installing the hinge screws.

Page 14

14

INSTALLATION

Reinstall the door.

7

While supporting the door, install the four hinge

screws removed in step 2. Test the swing of

the door to make sure the hinges and latch are

properly aligned and that the door opens, closes

and latches properly in both directions.

Swing

Door

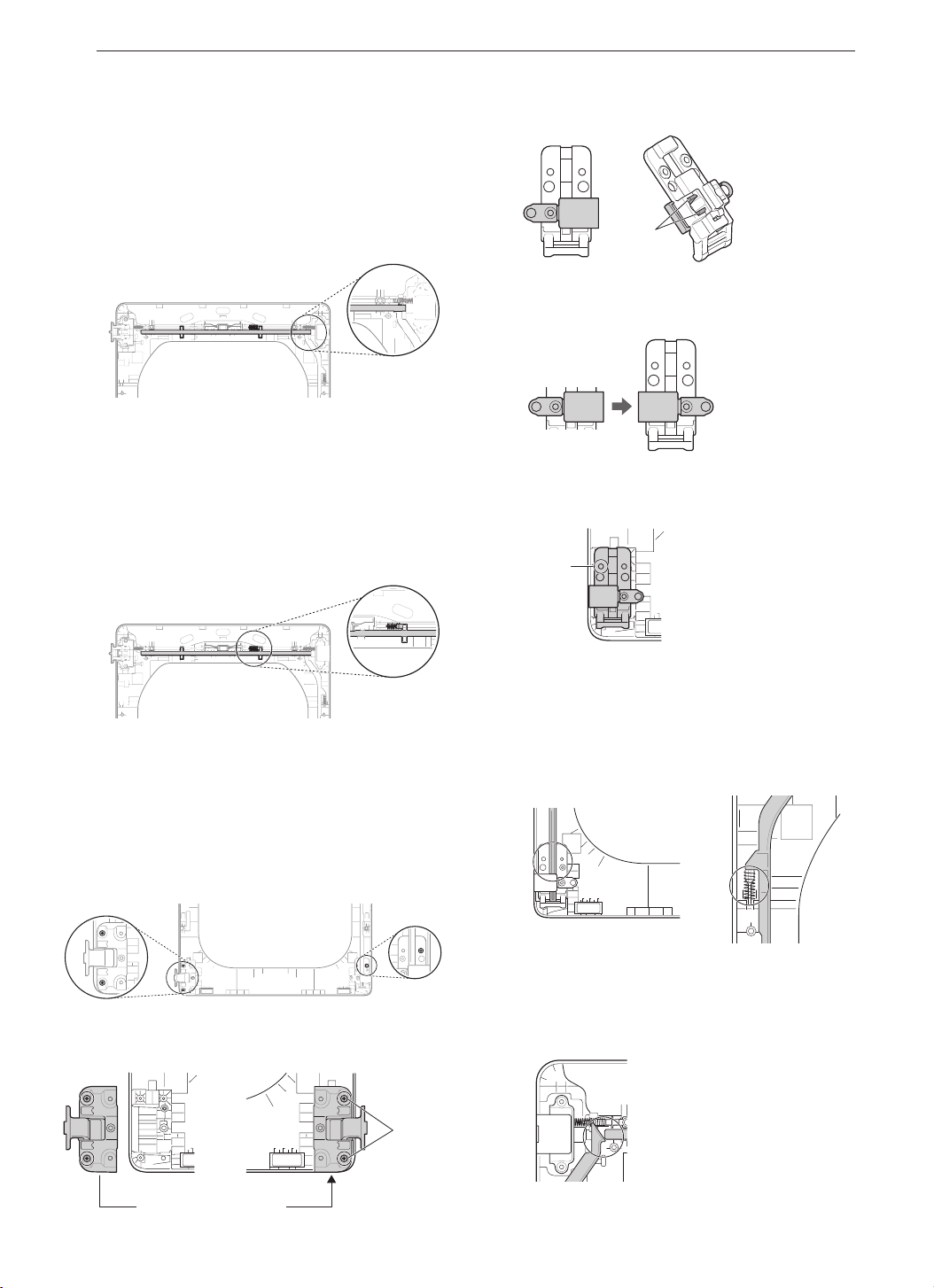

Easy load door (on some models)

WARNING

Be sure to support the weight of the door before

installing the hinge screws.

ON THE CABINET :

Open the door from the side so that the hinge

1

screws are accessible.

Two large

screws

Reverse the components on the cabinet.

3

Hinge

cover

latch

mechanism

Hinge

a. Use a Phillips screwdriver to remove the two

screws and the latch mechanism on the front

panel of the cabinet.

b. Remove the latch hole cover by gently prying it

up with a flat blade screwdriver, being careful

not to scratch the paint. Install the latch hole

cover on the opposite side, where the latch

mechanism was removed. Install the latch

mechanism in the position from which you

removed the latch hole cover, using the two

screws removed in step a.

c. Remove the hinge cover by gently prying it up

with a flat blade screwdriver, being careful not

to scratch the paint. Rotate the hinge cover

180 degrees and install it on the opposite side,

where the upper hinge was attached.

d. Reverse the hinge and the hinge bracket at

the bottom of the cabinet. Remove the two

screws from the hinge bracket at the bottom

right and remove the hinge bracket. Remove

the lower of the two screws behind the hinge

bracket. Do NOT remove the upper screw

behind the hinge bracket. Set the parts aside.

Upper

hinge

Latch

hole

cover

Hinge

bracket

Two small

screws

Remove the four hinge screws

2

While supporting the door, remove the four hinge

screws, two from each hinge. Set the door aside

face down on a protected surface to prevent

damage to the door or the work surface.

CAUTION

Do NOT remove any of the eight screws on the

face of the cabinet (marked below). Doing so

could result in damage to the dryer and the need

for a service call to repair the dryer.

Page 15

INSTALLATION

15

e. Remove the three screws on the hinge at the

bottom left. Remove the hinge and reinstall it

on the right side. The top screw will occupy

the hole where you removed the screw behind

the hinge bracket in step d.

f. Install the hinge bracket removed in step d on

the bottom left side, first installing one screw

behind the hinge bracket.

Cabinet Reversal complete

hinge

cover

latch hole

cover

hinge

bracket

latch

mechanism

hinge

ON THE DOOR:

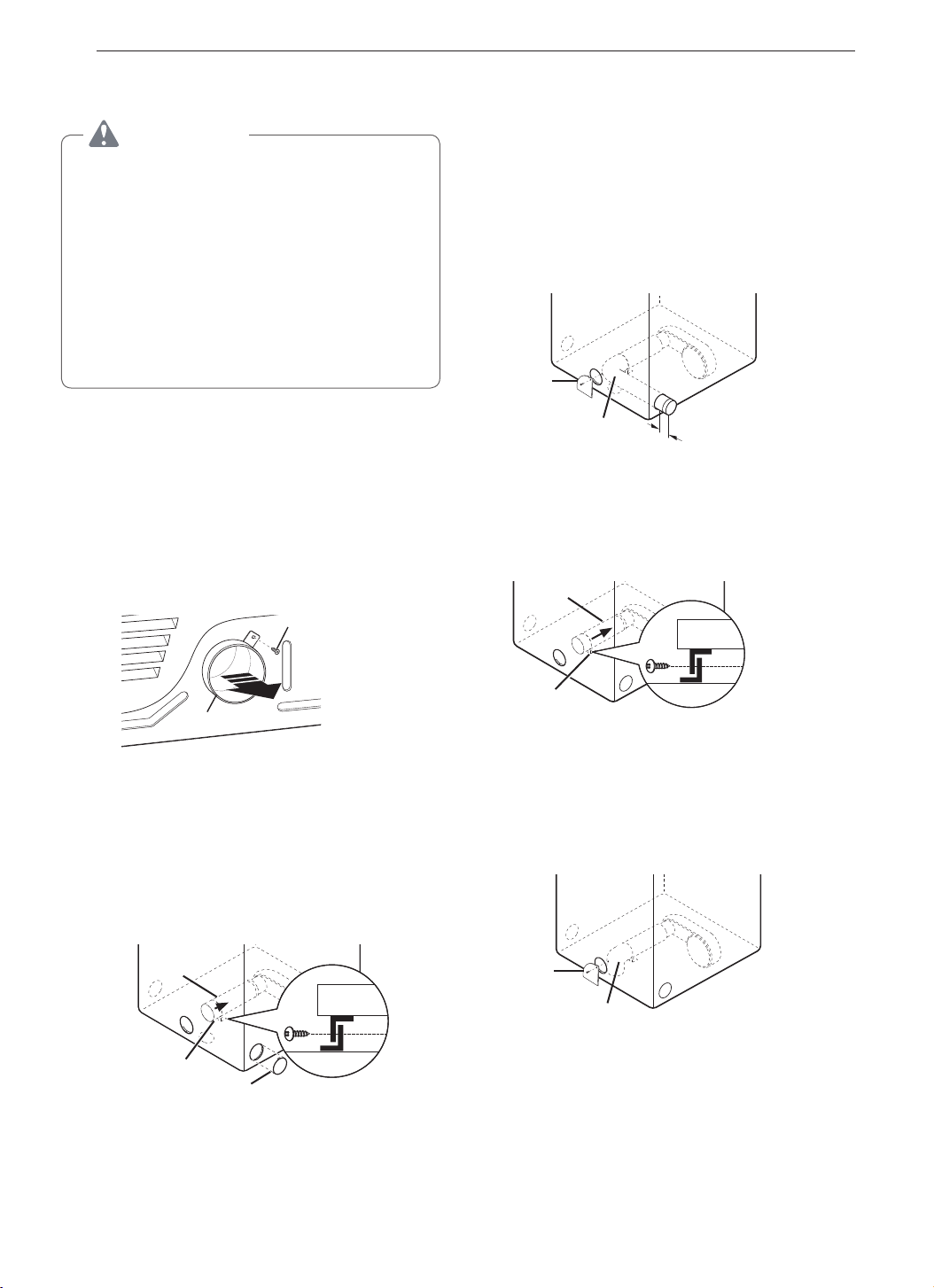

Lift off the door cover.

4

With the door laid inside facing up on a protected

surface, remove the twelve screws on the inside

of the door. Carefully lift off the door cover with

the help of a small flat blade screwdriver inserted

in the upper corner (circled below).

Switch the door strike and the blank cover.

5

Remove the two screws on the door cover that

secure the door strike.

Switch the door strike and the blank cover,

installing them on the opposite sides from which

they were removed.

Short

screws

Blank cover Door strike

Pull

Raise

Remove blank cover

Gently pry out the hole plug on the side of

the door cover and install it in the hole on the

opposite side.

ENGLISH

Long

screw

WARNING

The edges of the door cover may be sharp. Take

care when handling, or wear gloves to avoid

injury.

Twelve screws

Hole

plug

Side

Interlock

button

Hole

plug

Set the door cover aside.

Page 16

16

INSTALLATION

Reverse the components inside the door.

6

You will now be removing and reversing various components inside the door. See below for a detailed

diagram and identification of the inner structure and parts of the door. (The diagram shows the “before view”

of the door, with the default set-up for a right side hinge swing. After following these instructions, your door

should be a mirror image of the illustration.)

Inner lock rodsTop interlock buttons

Upper

hinge

assembly

Upper

hinge

pivot

Top lock rod

Side lock rod

Glass

Upper

hingelter

Lower

hinge

assembly

Interlock buttons

Bumpers

Lowhingeller

Side Interlock button

Side lock rod

Lower

hingeller

Lower

hinge

bracket

Top lock rod

Inner lock rods

Upper hinge assembly Upper hinge pivot Upperhingeller

Lower hinge bracket

Hole plug

Lower hinge assembly

Page 17

INSTALLATION

17

Lift out the gray interlock button in the side

7

of the door.

Make sure to remove the spring with the

interlock button and to keep the two together.

Set the interlock button aside. Do not confuse

these with the interlock buttons from the top of

the outer door.

Remove the side lock rod.

8

Remove the side lock rod from the lower hinge

bracket by lifting the top end of the rod and

sliding it toward the top of the door. The spring

should remain attached to the lock rod. Set the

lock rod aside.

Spring

Remove the top lock rod.

9

Remove the upper hinge pivot.

10

Once the top lock rod has been removed, the

hinge pivot can easily be removed from the

hinge assembly on the upper left and set aside.

Upper hinge

assembly

Upper

hinge

pivot

Reverse the upper hinge assembly and

11

hinge filler.

Lift out the upper hinge filler (on the right) and

set it aside.

Carefully lift the upper hinge assembly (on the

left) out of the outer door frame, using a small

flat blade screwdriver if necessary. Rotate

the hinge assembly 180 degrees and install it

on the upper right side of the outer door. You

will need to press firmly to install the hinge

assembly.

The hinge pivot removed in step 11 will be

installed later.

ENGLISH

a. Slide the lock rod to the right to remove it from

the hinge assembly on the left side.

b. While sliding the lock rod right, lift the right end

up and out of the guides.

NOTE

Do not remove the two inner lock rods and

two interlock buttons (see page 16) located

underneath the top lock rod. They do NOT need

to be reversed.

Upper hinge assembly

Upper hinge pivot

Now rotate the hinge filler 180 degrees and

install it on the upper left side of the door.

Upperhingeller

Page 18

18

INSTALLATION

Reinstall the top lock rod.

12

Rotate the top lock rod (removed in step 10)

180 degrees end for end from its original

position and reinstall it. The spring should now

be to the right of center, with the spring on the

side of the rod facing the top of the door.

a. Insert the right end of the lock rod into the

right hinge assembly. Make sure the rod is

aligned with the guides in the door panel.

b. Lower the rod into position, sliding it to

bypass the center handle, making sure to

align the lock rod with the guides all the

way across the door panel. When released,

the lock rod should slide completely into

the hinge assembly on the right. Slide the

lock rod back and forth to make sure it is

correctly positioned in the guides and slides

easily.

c. Flip over the lower hinge bracket and

release the tabs on the back locking the

hinge filler to the hinge bracket.

Tab

d. Rotate the hinge 180 degrees and snap

it back onto the front of the hinge bracket

facing in the opposite direction.

e. Mount the lower hinge bracket and the filler

on the left side of the door with the screw

removed in step a.

Screw

Reverse the lower hinge bracket and hinge

13

assembly.

a. Remove the screw from the lower hinge

bracket (on the right) and lift the hinge

bracket out. Set it aside. Remove the two

screws from the lower hinge assembly on

the bottom left and lift the hinge assembly

out.

b. Rotate the lower hinge assembly 180

degrees and install it on the right side using

the two screws removed in step a.

Screws

Install the side lock rod.

14

Flip the side lock rod over and install it on the

opposite side. Insert the lower end into the left

hinge and lower the rod into the guides on the

door while compressing the spring inside the

recess.

Make sure the top of the side lock rod is

beside the top lock rod and the two do not

overlap each other, so the two rods can

interact correctly. If they are not aligned

properly, the door will not operate properly.

Lower hinge assembly

Page 19

INSTALLATION

19

Reinstall the side interlock button.

15

Reinstall the side interlock button removed in

step 7. Center the spring in the compartment

and insert the interlock button on top of it.

Reinstall the door cover.

16

Clean the glass on the door and door cover, if

necessary.

Make sure the three gray interlock buttons

are properly installed and that the top and

side lock rods are properly aligned where

they meet. Carefully lower the door cover into

place, aligning the holes in the cover with

the interlock buttons on the top and side and

the bumpers on the bottom. Take care not to

dislodge the lock rods while mounting the door

cover. Once the door cover is in place, secure

it with the 12 screws removed in step 4. The

ten similar screws go around the top and sides

of the door cover. Make sure to install the two

different screws on the bottom edge, in the

locations marked below.

Now, pick up the upper hinge pivot

17

removed earlier and rotate it 180 degrees.

Install the hinge on the top left side of the

cabinet.

Reinstall the door.

18

Press in the side interlock button on the left

side and hold it down while you press the

hinge pivot into the hinge assembly on the top

right side. If the door has been reassembled

correctly, the lock rod will slide back easily and

lock the pivot in place. The door is now ready

to remount on the opposite side of the dryer.

Two

large

screws

ENGLISH

Side

interlock

button

Interlock

buttons

Bumpers

Two

small

screws

While supporting the door, install the two small

hinge screws removed in step 2. Test the

swing of the door to make sure the hinges and

latch are properly aligned and that the door

opens, closes and latches properly in both

directions.

If the door doesn’t operate smoothly, remove

the door and then the door cover to check

that the lock rods and interlock buttons are

properly mounted and aligned.

The interlock buttons should be oriented

correctly and operating smoothly. The interlock

rods should be in the proper position and

should not overlap at the contact point. (See

steps 15-17.)

If the door is damaged, or if the door does not

work after reassembly, contact the call center

at 1-800-243-0000.

Page 20

20

INSTALLATION

Installing the Side Vent Kit

WARNING

•Use a heavy metal vent.

•Do not use plastic or thin foil ducts.

•Clean old ducts before installing this dryer.

•To reduce the risk of injury to persons, adhere

to all industry recommended safety procedures

including the use of long-sleeved gloves and

safety glasses.

•Failure to follow all of the safety warnings in this

manual could result in property damage, injury

to persons, or death.

Your new dryer is shipped to vent to the rear. It can

also be configured to vent to the bottom or side (rightside venting is not available on gas models).

An adapter kit, part number 383EEL9001B, may be

purchased from your LG retailer. This kit contains the

necessary duct components to change the dryer vent

location.

Remove the rear exhaust duct retaining screw.

1

Pull out the exhaust duct.

Retaining Screw

Preassemble a 4-inch (10.2 cm) elbow to the

3

next 4-inch (10.2 cm) duct section, and secure

all joints with duct tape. Be sure that the male

end of the elbow faces AWAY from the dryer.

Insert the elbow/duct assembly through the

side opening and press it onto the adapter duct.

Secure it in place with duct tape. Be sure that

the male end of the duct protrudes 1½-inch (3.8

cm) to connect the remaining ductwork. Attach

the cover plate to the back of the dryer with the

included screw.

Cover

Plate

Elbow

"

1

½

(3.8 cm)

Option 2: Bottom Venting

Press the adapter duct onto the blower housing

2

and secure it to the base of the dryer as shown.

Adapter

Duct

Rear Exhaust

Duct

Option 1: Side Venting

Press the tabs on the knockout and carefully

2

remove the knockout for the desired vent

opening (right-side venting is not available on

gas models). Press the adapter duct onto the

blower housing and secure to the base of the

dryer as shown.

Adapter

Duct

Bracket

Knockout

Bracket

Insert the 4-inch (10.2 cm) elbow through the

3

rear opening and press it onto the adapter duct.

Be sure that the male end of the elbow faces

down through the hole in the bottom of the

dryer. Secure it in place with duct tape. Attach

the cover plate to the back of the dryer with the

included screw.

Cover

Plate

Elbow

Page 21

INSTALLATION

21

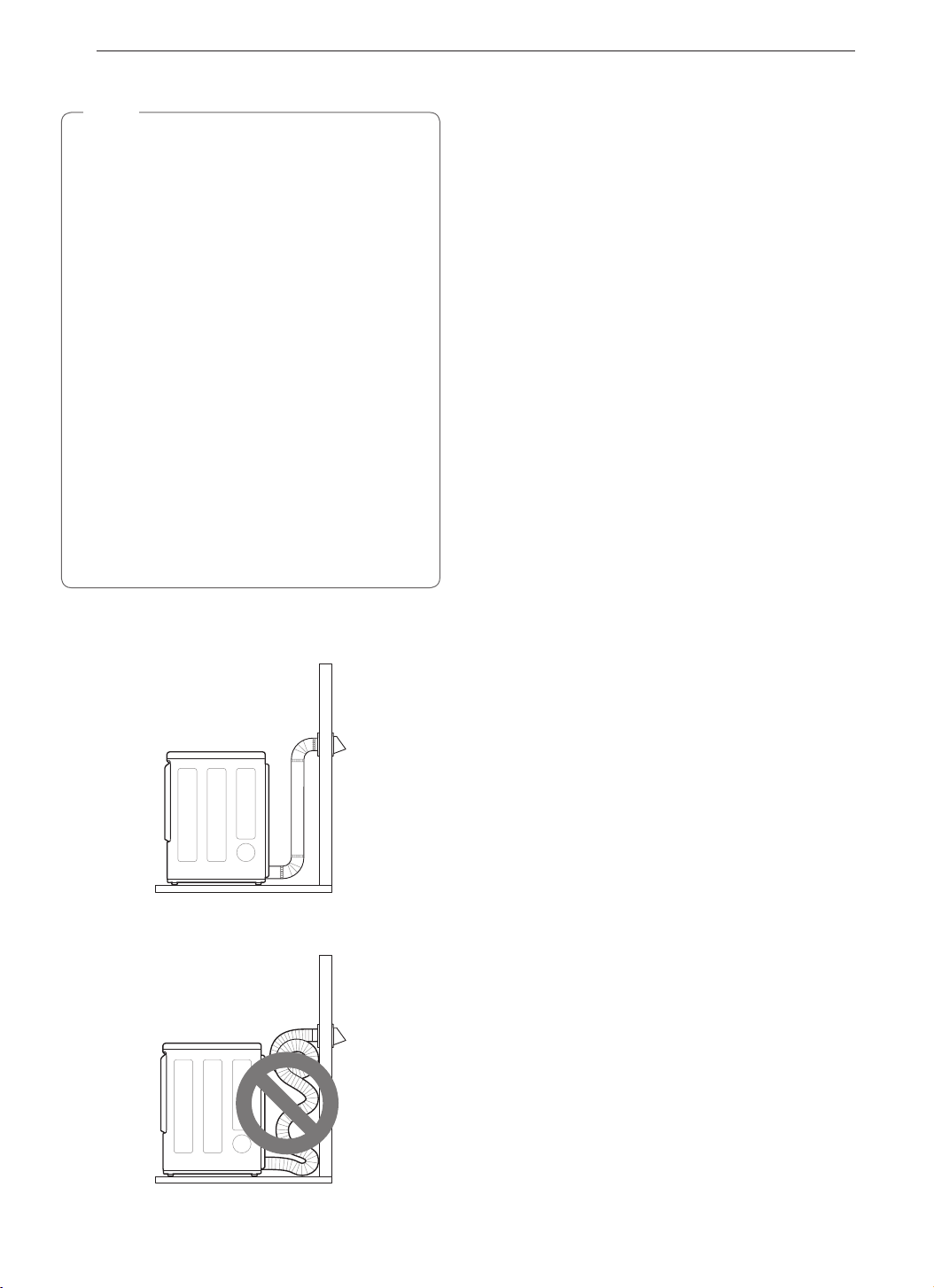

Venting the Dryer

WARNING

To reduce the risk of fire or explosion, electric

shock, property damage, injury to persons or

death when using this appliance, follow basic

safety precautions, including the following:

•Do not crush or collapse ductwork. Failure to

follow these instructions may result in fire or death.

•Do not allow ductwork to rest on or contact

sharp objects. Failure to follow these instructions

may result in fire or death.

•If connecting to existing ductwork, make sure it

is suitable and clean before installing the dryer.

Failure to follow these instructions may result in fire

or death.

•Venting must conform to local building codes.

Failure to follow these instructions may result in fire

or death.

•Gas dryers MUST exhaust to the outdoors.

Failure to follow these instructions may result in fire

or death.

•Use only 4-inch (10.2 cm) rigid, semi-rigid or

flexible metal ductwork inside the dryer cabinet

and for venting outside. Failure to follow these

instructions may result in fire or death.

•To reduce the risk of fire, combustion, or

accumulation of combustible gases, DO

NOT exhaust dryer air into an enclosed and

unventilated area, such as an attic, wall, ceiling,

crawl space, chimney, gas vent, or concealed

space of a building. Failure to follow these

instructions may result in fire or death.

•To reduce the risk of fire, DO NOT exhaust the

dryer with plastic or thin foil ducting. Failure to

follow these instructions may result in fire or death.

•The exhaust duct must be 4-inch (10.2 cm) in

diameter with no obstructions. The exhaust

duct should be kept as short as possible. Make

sure to clean any old ducts before installing

your new dryer. Failure to follow these instructions

may result in fire or death.

•Rigid, semi-rigid or flexible metal ducting is

recommended for use between the dryer and

the wall. All non-rigid metal transition duct

must be UL-listed. Use of other materials for

transition duct could affect drying time. Failure

to follow these instructions may result in fire or

death.

•DO NOT use sheet metal screws or other

fasteners which extend into the duct that

could catch lint and reduce the efficiency of

the exhaust system. Secure all joints with duct

tape. Failure to follow these instructions may result

in fire or death.

•Do not exceed the recommended duct length

limitations noted in the chart. Failure to follow

these instructions may result in extended drying

times, fire or death.

•Ductwork is not provided with the dryer. You

should obtain the necessary ductwork locally.

The vent hood should have hinged dampers to

prevent backdraft when the dryer is not in use.

Failure to follow these instructions may result in fire

or death.

•The total length of flexible metal duct must not

exceed 8 ft. (2.4 m).

•In Canada, only those foil-type flexible ducts,

if any, specifically identified for use with the

appliance by the manufacturer should be used.

In the United States, only those foil-type flexible

ducts, if any, specifically identified for use with the

appliance by the manufacturer and that comply

with the Outline for Clothes Dryer Transition Duct,

Subject 2158A, should be used.

Ductwork

Number

Wall Cap Type

of 90°

Elbows

Recommended

0 65 ft.(19.8 m)

1 55 ft.(16.8 m)

4"

(10.2 cm)

4"

(10.2 cm)

Use only for

short run

installations

2 47 ft.(14.3 m)

3 36 ft.(11.0 m)

4 28 ft.(8.5 m)

0 55 ft.(16.8 m)

1 47 ft.(14.3 m)

2 41 ft.(12.5 m)

21/2"

(6.35 cm)

3 30 ft.(9.1 m)

4 22 ft.(6.7 m)

NOTE

Deduct 6 ft. (1.8 m) for each additional elbow. Do

not use more than four 90° elbows.

Maximum length

of 4-inch (10.2 cm)

diameter rigid metal

duct

ENGLISH

Page 22

22

INSTALLATION

Routing And Connecting Ductwork

NOTE

Follow the guidelines below to maximize drying

performance and reduce lint buildup and

condensation in the ductwork. Ductwork and

fittings are NOT included and must be purchased

separately.

•Use 4-inch (10.2 cm) diameter rigid, semi-rigid

or flexible metal ductwork.

•The exhaust duct run should be as short as

possible.

•Use as few elbow joints as possible.

•The male end of each section of exhaust duct

must point away from the dryer.

•Use duct tape on all duct joints.

•Insulate ductwork that runs through unheated

areas in order to reduce condensation and lint

buildup on duct surfaces.

•Incorrect or inadequate exhaust systems

are not covered by the dryer warranty. Dryer

failures or service required because of such

exhaust systems will not be covered by the

dryer warranty.

Correct Venting

Incorrect Venting

Page 23

INSTALLATION

23

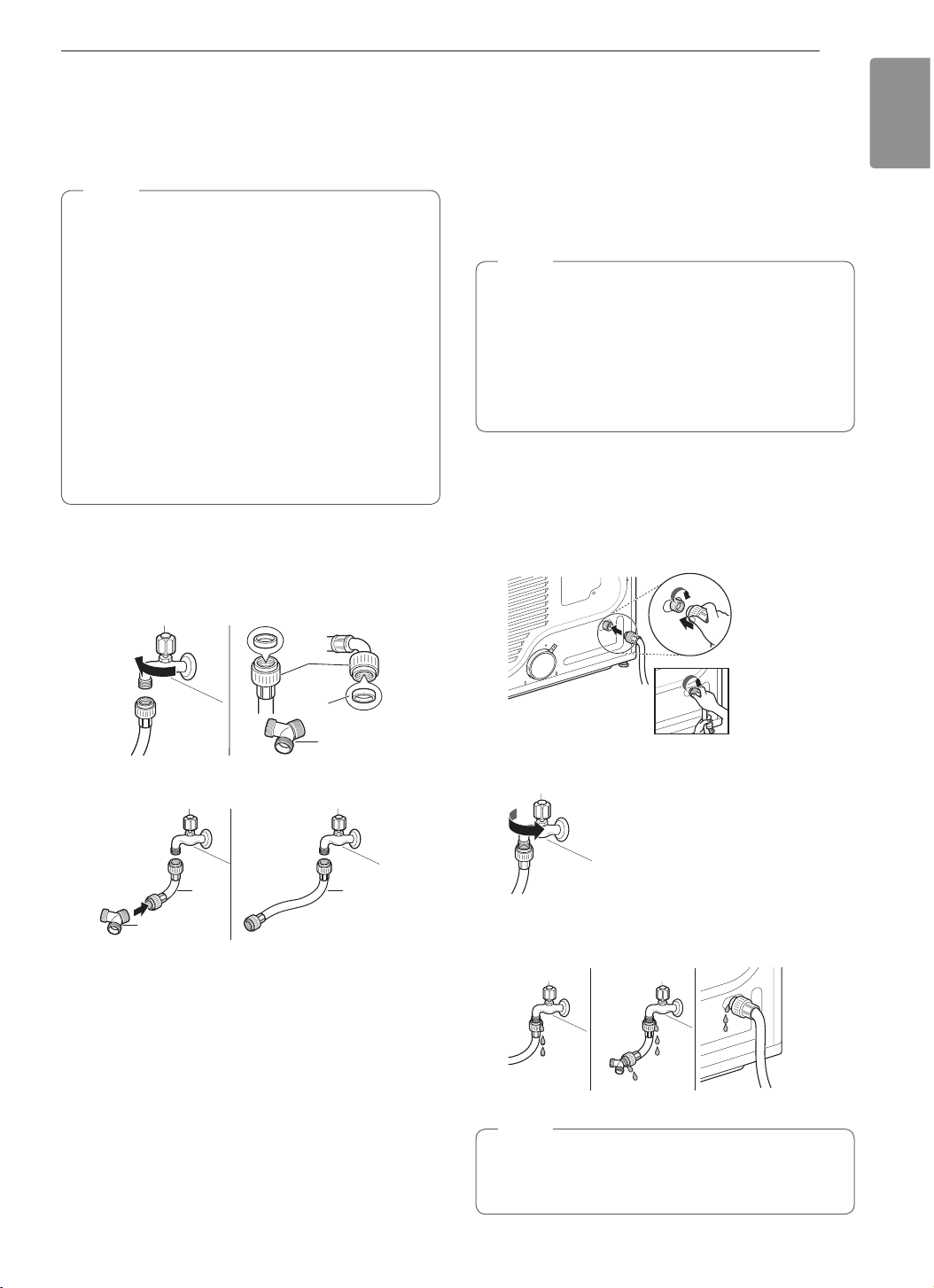

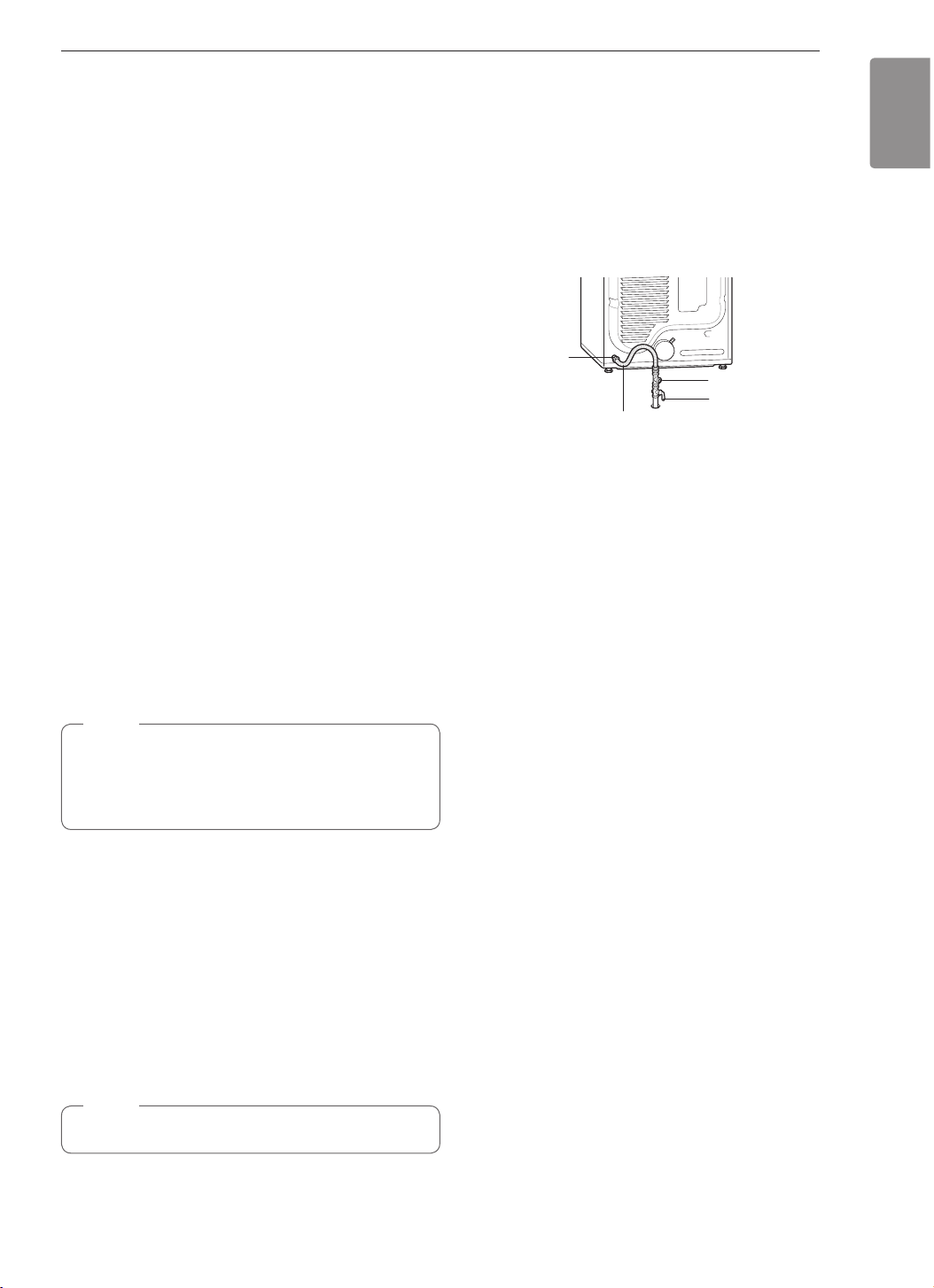

Connecting the Inlet Hose

(Steam Models)

The dryer must be connected to the cold water tap

using a new water supply hose. Do not use old hoses.

NOTE

•Water supply pressure must be between 20

and 120 psi (138—827 kPa) .

•Do not strip or cross-thread when connecting

the inlet hose to the valve.

•If the water supply pressure is more than 800

kPa, a pressure-reducing valve should be

installed.

•Periodically check the condition of the hose and

replace the hose if necessary.

•Replace inlet hoses after 5 years of use to

reduce the risk of hose failure.

•Record hose installation or replacement dates

on the hoses for future reference.

Check the rubber seal at each end of the inlet

1

hoses. Two rubber seals are supplied with each

inlet hose. They are used for preventing water

leaks. Make sure the connection to the cold

water tap is tight.

d. Connect the long dryer hose to one side of the

Y-connector and connect the washer hose to the

other side.

WITHOUT WASHER: If the dryer does not share

the cold water tap with a washer.

a. Connect the straight end of the long hose to the

cold water faucet.

NOTE

•Before connecting the water line to the dryer,

flush several gallons of water into a drain or

bucket. This will help prevent foreign particles

such as sand and scale from clogging the dryer

inlet valve.

•Do not overtighten. Damage to the coupling

may result.

Connect the hose to the dryer. Connect the

3

water supply hose to the dryer inlet valve tightly

by hand and then tighten another 2/3 turn with

pliers.

Make sure that there are no kinks in the hoses

and that they are not crushed.

ENGLISH

Hose

connector

Rubber

seal

Y connector

Check the installation type.

2

Short

hose

Y connector

WITH WASHER WITHOUT WASHER

Connect all water supply hoses tightly by hand

and then tighten another 2/3 turn with pliers.

WITH WASHER: When connecting the dryer to the

same faucet as a washer.

a. Shut off the cold water tap and remove the washer

hose.

b. Connect the short hose to the Y-connector using

one of the rubber seals.

c. Connect the other end of the short hose to the cold

water faucet.

Long

hose

Turn on the cold water faucet.

4

Check for leaks at the Y-connector (if used) and

5

in all hoses.

NOTE

•If any leaks are found, shut off the water faucet,

remove the hose and check the condition of the

rubber seal.

Page 24

24

INSTALLATION

Connecting Gas Dryers

WARNING

To reduce the risk of fire or explosion, electric

shock, property damage, injury to persons, or

death when using this appliance, follow basic

safety precautions.

Gas Supply Requirements

•As shipped from the factory, this dryer is

configured for use with natural gas (NG). It can

be converted for use with propane (LP) gas.

Gas pressure must not exceed 8-inch (20.3 cm)

water column for NG, or 13-inch (33 cm) water

column for LP.

•A qualified service or gas company technician

must connect the dryer to the gas service.

Failure to follow these instructions may result

in fire, explosion, or death.

•Isolate the dryer from the gas supply system

by closing its individual manual shutoff valve

during any pressure testing of the gas supply.

Failure to do so may result in fire, explosion, or

death.

•Supply line requirements: Your laundry room

must have a rigid gas supply line to your dryer.

In the United States, an individual manual

shutoff valve MUST be installed within at least

6 ft. (1.8 m) of the dryer, in accordance with

the National Fuel Gas Code ANSI Z223.1 or

Canadian gas installation code CSA B149.1.

A 1/8-inch (0.3 cm) NPT pipe plug must be

installed. Failure to do so may result in fire,

explosion, or death.

•If using a rigid pipe, the rigid pipe should be ½

inch IPS. If acceptable under local codes and

ordinances and when acceptable to your gas

supplier, 3/8-inch (1 cm) approved tubing may

be used where lengths are less than 20 ft. (6.1

m). Larger tubing should be used for lengths

in excess of 20 ft. (6.1 m). Failure to do so may

result in fire, explosion, or death.

•Connect the dryer to the type of gas shown on

the nameplate. Failure to do so may result in fire,

explosion, or death.

•To prevent contamination of the gas valve,

purge the gas supply of air and sediment before

connecting the gas supply to the dryer. Before

tightening the connection between the gas

supply and the dryer, purge remaining air until

the odor of gas is detected. Failure to do so may

result in fire, explosion, or death.

•DO NOT use an open flame to inspect for gas

leaks. Use a noncorrosive leak detection fluid.

Failure to do so may result in fire, explosion, or

death.

•Use only a new AGA- or CSA-certified gas

supply line with flexible stainless steel

connectors. Failure to do so may result in fire,

explosion, or death.

•Securely tighten all gas connections. Failure to

do so may result in fire, explosion, or death.

•Use Teflon tape or a pipe-joint compound

that is insoluble in propane (LP) gas on all

pipe threads. Failure to do so may result in fire,

explosion, or death.

•DO NOT attempt any disassembly of the dryer;

disassembly requires the attention and tools of

an authorized and qualified service technician

or company. Failure to follow this warning may

result in fire, explosion, or death.

Electrical Requirements for Gas

Models Only

•Do not, under any circumstances, cut or remove

the third (ground) prong from the power cord.

Failure to follow this warning may result in fire,

explosion, or death.

•For personal safety, this dryer must be properly

grounded. Failure to follow this warning may result

in fire, explosion, or death.

•This dryer must be plugged into a 120-VAC, 60-

Hz. grounded outlet protected by a 15-ampere

fuse or circuit breaker. Failure to follow this

warning may result in fire, explosion, or death.

•Where a standard 2-prong wall outlet is

encountered, it is your personal responsibility

and obligation to have it replaced with a

properly grounded 3-prong wall outlet. Failure to

follow this warning may result in fire, explosion, or

death.

Plug dryer into a 120 VAC,

Plug dryer into a

60 Hz grounded 3-prong

outlet.

WARNING

ELECTRIC SHOCK HAZARD

Failure to follow safety warnings could result in

serious injury or death.

This dryer is equipped with a three-prong

grounding plug for protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle. Do not

cut or remove the grounding prong from this plug.

Page 25

INSTALLATION

25

Connecting the Gas Supply

•Installation and service must be performed

by a qualified installer, service agency, or the

gas supplier. Failure to do so may result in fire,

explosion, or death.

•Use only a new stainless steel flexible

connector and a new AGA-certified connector.

Failure to do so may result in fire, explosion, or

death.

•A gas shutoff valve must be installed within 6 ft.

(1.8 m) of the dryer. Failure to do so may result in

fire, explosion, or death.

•The dryer is configured for natural gas when

shipped from the factory. Make sure that the

dryer is equipped with the correct burner nozzle

for the type of gas being used (natural gas or

propane gas). Failure to do so may result in fire,

explosion, or death.

•If necessary, the correct nozzle (for the LP

nozzle kit, order part number 383EEL3002D)

should be installed by a qualified technician

and the change should be noted on the dryer.

Failure to do so may result in fire, explosion, or

death.

•All connections must be in accordance with

local codes and regulations. Failure to do so may

result in fire, explosion, or death.

•Gas dryers MUST exhaust to the outdoors.

Failure to do so may result in fire, explosion, or

death.

Securely tighten all connections between the

4

dryer and your laundry room’s gas supply.

Turn on your laundry room’s gas supply.

5

Check all pipe connections (both internal and

6

external) for gas leaks with a noncorrosive leakdetection fluid.

Proceed to Venting the Dryer.

7

3/8"

NPT gas

Connection

AGA/CSA-Certied

Stainless Steel

Flexible Connector

1/8" NPT Pipe Plug

Gas Supply Shutoff

Valve

High-altitude Installations

The BTU rating of this dryer is AGA-certified for

elevations below 10,000 feet.

If your gas dryer is being installed at an elevation

above 10,000 feet, it must be derated by a qualified

technician or gas supplier.

ENGLISH

NOTE

This dryer is configured from the factory for

natural gas (NG). If the dryer is to be used with

propane (LP) gas, it must be converted by a

qualified service technician.

Make sure that the gas supply to the laundry

1

room is turned OFF and the dryer is unplugged.

Confirm that the type of gas available in your

laundry room is appropriate for the dryer.

Remove the shipping cap from the gas fitting at

2

the back of the dryer. Be careful not to damage

the threads of the gas connector when removing

the shipping cap.

Connect the dryer to your laundry room’s gas

3

supply using a new flexible stainless steel

connector with a 3/8-inch NPT fitting.

NOTE

DO NOT use old connectors.

Page 26

26

INSTALLATION

Connecting Electric Dryers

Electrical Requirements for Electric

Models Only

WARNING

To help prevent fire, electric shock, serious injury,

or death, the wiring and grounding must conform

to the latest edition of the National Electrical

Code, ANSI/NFPA 70 and all applicable local

regulations. Please contact a qualified electrician

to check your home’s wiring and fuses to ensure

that your home has adequate electrical power to

operate the dryer.

•This dryer must be connected to a grounded

metal, permanent wiring system, or an

equipment-grounding conductor must be run

with the circuit conductors and connected

to the equipment-grounding terminal or lead

on the dryer. Failure to do so may result in fire,

explosion, or death.

•The dryer has its own terminal block that must

be connected to a separate 240 VAC, 60-Hertz,

single-phase circuit, fused at 30 amperes (the

circuit must be fused on both sides of the

line). ELECTRICAL SERVICE FOR THE DRYER

SHOULD BE OF THE MAXIMUM RATE VOLTAGE

LISTED ON THE NAMEPLATE. DO NOT

CONNECT THE DRYER TO 110-, 115-, OR 120VOLT CIRCUIT. Failure to follow these instructions

may result in fire, explosion, or death.

•If the branch circuit to dryer is 15 ft. (4.5

m) or less in length, use UL (Underwriters

Laboratories) listed No.-10 AWG wire (copper

wire only), or as required by local codes. If

over 15 ft. (4.5 m), use UL-listed No.-8 AWG

wire (copper wire only), or as required by local

codes. Allow sufficient slack in wiring so the

dryer can be moved from its normal location

when necessary. Failure to do so may result in

fire, explosion, or death.

•The power cord (pigtail) connection between

the wall receptacle and the dryer terminal block

IS NOT supplied with the dryer. Type of pigtail

and gauge of wire must conform to local codes

and with instructions on the following pages.

Failure to follow these instructions may result in

fire, explosion, or death.

•A 4-wire connection is required for all mobile

and manufactured home installations, as well

as all new construction after January 1, 1996.

A 4-wire connection must be used where local

codes do not permit grounding through the

neutral wire. Failure to do so may result in fire,

explosion, or death.

•Do not modify the plug and internal wire provided

with the dryer.

•The dryer should be connected to a 4-hole outlet.

•If the plug does not fit the outlet, a proper outlet will

need to be installed by a qualified electrician.

Special Electrical Requirements for

Mobile or Manufactured Homes

•Any installation in a manufactured or mobile

home must comply with the Manufactured Home

Construction and Safety Standards Title 24 CFR,

Part 3280 or Standard CAN/ CSA Z240 MH and

local codes and ordinances. If you are uncertain

whether your proposed installation will comply with

these standards, please contact a service and

installation professional for assistance.

•A 4-wire connection is required for all mobile

and manufactured home installations, as well

as all new construction after January 1, 1996.

Failure to do so may result in fire, explosion, or

death.

•A gas dryer must be permanently attached to the

floor.

•The electrical connection for an electric dryer must

be a 4-wire connection. More detailed information

concerning the electrical connection is provided in

the section Connecting Electric Dryers.

•To reduce the risk of combustion and fire, the dryer

must be vented to the outside.

•DO NOT vent the dryer under a manufactured

home or mobile home.

•Electric dryers may be vented to the outside using

the back, left, right, or bottom panel.

•Gas dryers may be vented to the outside using the

back, left, or bottom panel. Gas dryers may not

be vented to the outside using the right side panel

because of the burner housing.

•The dryer exhaust duct must be affixed securely to

the manufactured or mobile home structure, and

the exhaust duct must be made of a material that

will resist fire and combustion. It is recommended

that you use a rigid, semi-rigid or flexible metal

duct.

•DO NOT connect the dryer exhaust duct to any

other duct, vent, chimney, or other exhaust duct.

•Make sure the dryer has adequate access to

outside fresh air to ensure proper operation. The

opening for outside fresh air must be at least 25 sq.

in (163 cm

•It is important that the clearance of the duct from

any combustible construction be at least 2-inch

(5 cm), and when venting the dryer to the outdoors,

the dryer should be installed with a clearance of at

least 1 inch (2.5 cm) at the sides and back of the

dryer.

•Please be aware that venting materials are not

supplied with the dryer. You must obtain the venting

materials necessary for proper installation.

2

).

Page 27

INSTALLATION

27

WARNING

Connect the power cord to the terminal block.

Each colored wire should be connected to the

same color screw. Wire color indicated on manual

is connected to the same color screw in the block.

Failure to follow these instructions may result in a

short or overload.

Grounding through the neutral conductor is

prohibited for: (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and

(4) areas where local codes prohibit grounding

through the neutral conductor.

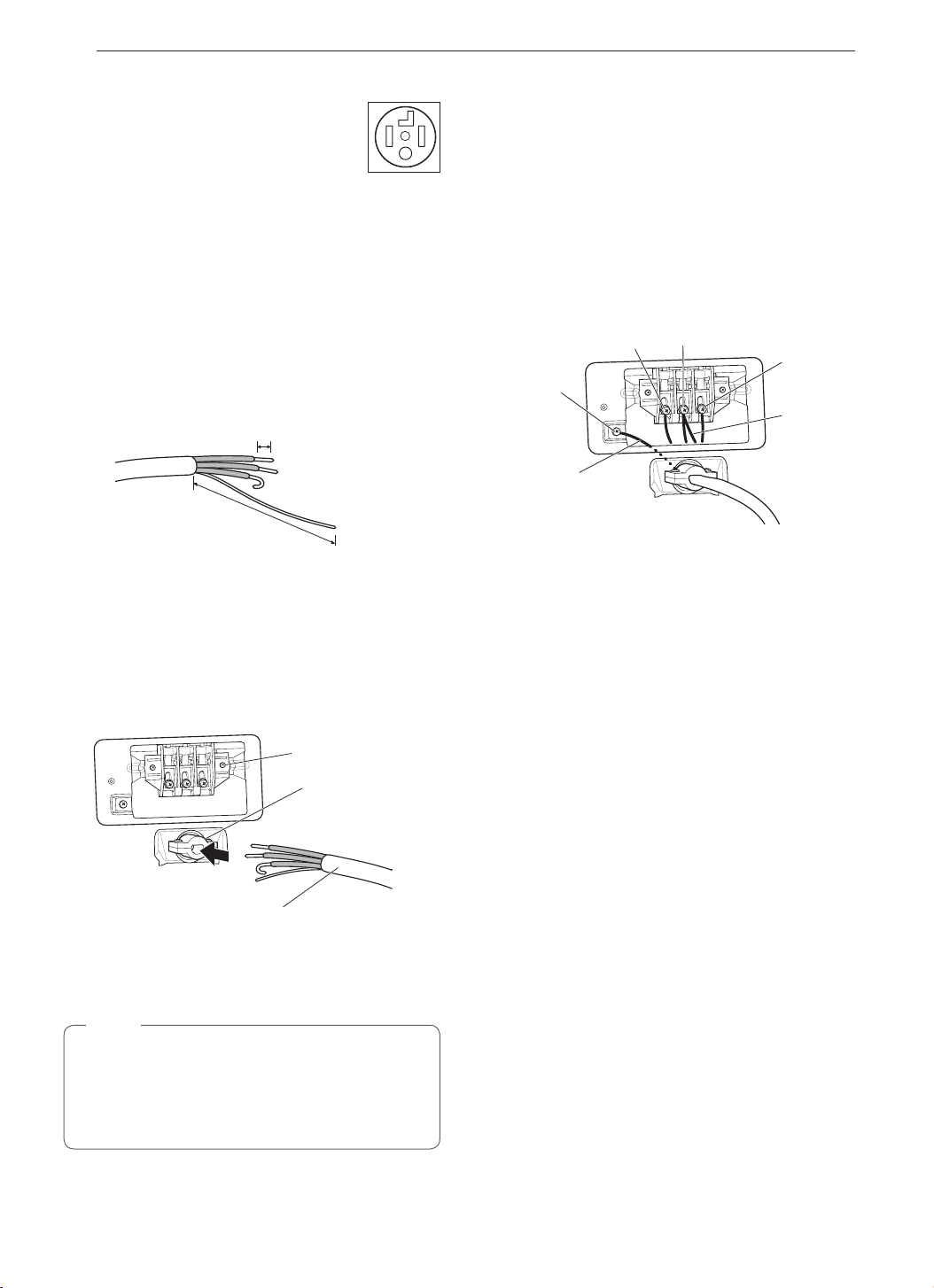

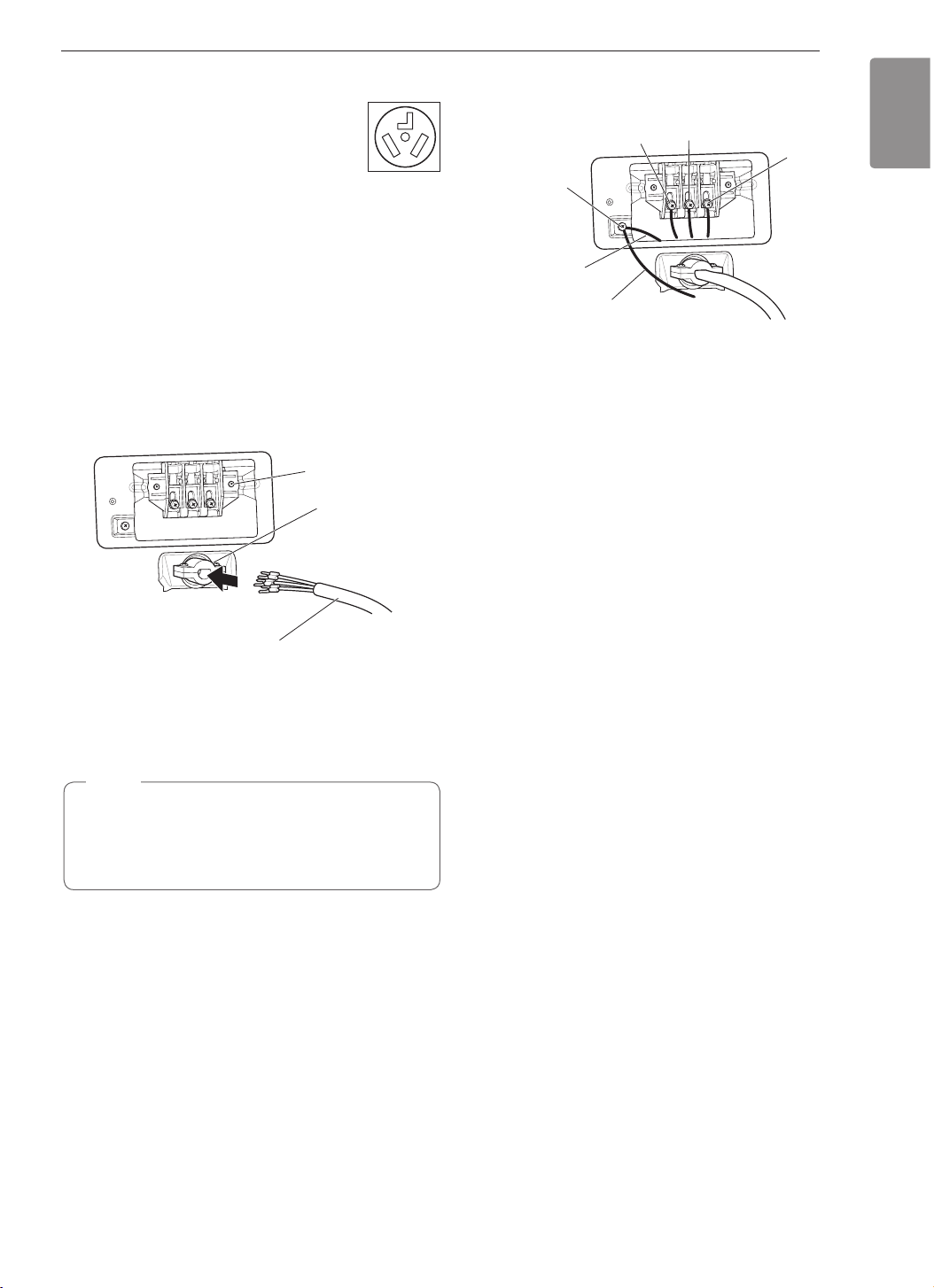

Four-Wire Power Cord

•A 4-wire connection is required for

all mobile and manufactured home

installations, as well as all new

construction after January 1, 1996.

•A UL-listed strain relief is required.

•Use a 30-amp, 240-volt, 4-wire, UL-listed power

cord with #10 AWG-minimum copper conductor and

closed loop or forked terminals with upturned ends.

Attach the two hot leads of the power cord to the

5

outer terminal block screws.

Attach the white neutral wire to the center screw

6

of the terminal block.

Attach the power cord ground wire to the green

7

ground screw.

Tighten all screws securely.

8

Reinstall the terminal block access cover.

9

Hot

(Black)

Ground

Screw

Power Cord

Ground Wire

Neutral

(White)

Hot

(Red)

White Wire

moved from

Ground

Screw

ENGLISH

Remove the terminal block access cover on the

1

upper back of the dryer.

Install a UL-listed strain relief into the power cord

2

through-hole.

Thread a 30-amp, 240-volt, 4-wire, UL-listed

3

power cord with #10 AWG-minimum copper

conductor through the strain relief.

Terminal Block

UL-Listed

Strain Relief

UL-Listed 4-Wire Power Cord

Transfer the dryer’s ground wire from behind the

4

green ground screw to the center screw of the

terminal block.

NOTE

This dryer is supplied with the neutral wire

grounded. This white ground wire MUST BE

MOVED to the neutral terminal when a 4-wire

cord is to be used, or where grounding through

the neutral conductor is prohibited.

Page 28

28

INSTALLATION

Four-Wire Direct Wire

•A 4-wire connection is required for

all mobile and manufactured home

installations, as well as all new

construction after January 1, 1996.

•A UL-listed strain relief is required.

•Use UL-listed 4-wire #10 AWG-minimum copper

conductor cable. Allow at least 5 ft. (1.5 m) of wire

to allow for removal and reinstallation of the dryer.

Remove 5-inch (12.7 cm) of the outer covering

1

from the wire. Remove 5-inch (12.7 cm)

of insulation from the ground wire. Cut off

approximately 1½-inch (3.8 cm) from the other

three wires and strip 1 inch (2.5 cm) insulation

from each wire. Bend the ends of the three

shorter wires into a hook shape.

1" (2.5 cm)

Ground Wire

5"

(12.7 cm)

Remove the terminal block access cover on the

2

upper back of the dryer.

Attach the two hot leads of the power cord to the

6

outer terminal block screws.

Attach the white neutral wire to the center screw

7

of the terminal block.

Attach the power cord ground wire to the green

8

ground screw.

Tighten all screws securely.

9

Reinstall the terminal block access cover.

10

Hot

(Black)

Ground

Screw

Power Cord

Ground Wire

Neutral

(White)

Hot

(Red)

White Wire

moved from

Ground

Screw

Install a UL-listed strain relief into the power cord

3

through-hole.

Thread the 4-wire #10 AWG-minimum copper

4

power cable prepared in step 1 through the

strain relief.

Terminal Block

UL-Listed

Strain Relief

UL-Listed 4-Wire Power Cord

Transfer the dryer’s ground wire from behind the

5

green ground screw to the center screw of the

terminal block.

NOTE

This dryer is supplied with the neutral wire

grounded. This white ground wire MUST BE

MOVED to the neutral terminal when a 4-wire

cord is to be used, or where grounding through

the neutral conductor is prohibited.

Page 29

INSTALLATION

29

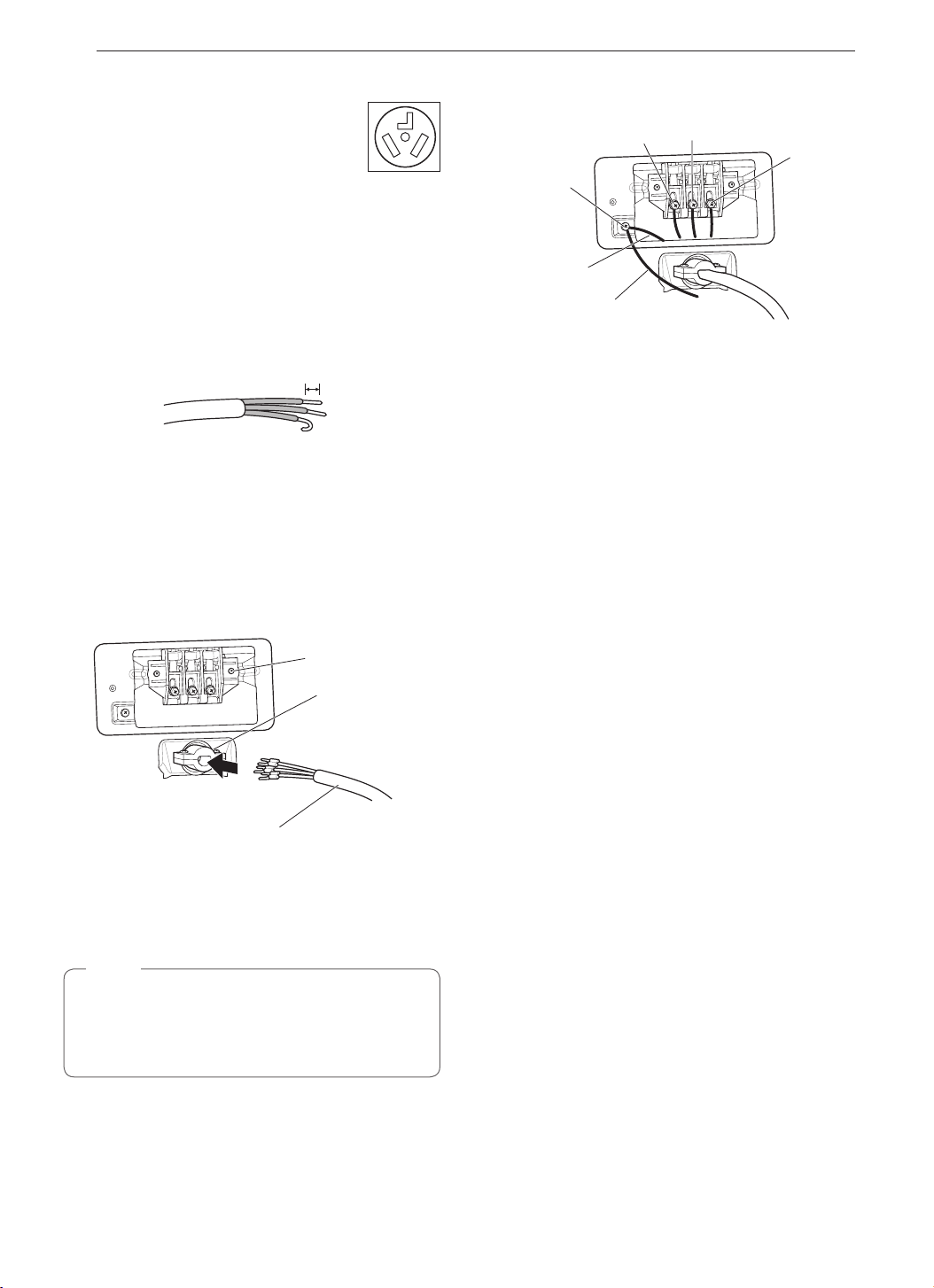

Three-Wire Power Cord

•A 3-wire connection is NOT permitted

on new construction after January 1,

1996.

•A UL-listed strain relief is required.

•Use a 30-amp, 240-volt, 3-wire, UL-listed power

cord with #10 AWG-minimum copper conductor and

closed loop or forked terminals with upturned ends.

Remove the terminal block access cover on the

1

upper back of the dryer.

Install a UL-listed strain relief into the power cord

2

through-hole.

Thread a 30-amp, 240-volt, 3-wire, UL-listed

3

power cord with #10 AWG-minimum copper

conductor through the strain relief.

Terminal Block

UL-Listed

Strain Relief

Reinstall the terminal block access cover.

8

Neutral

(White)

Ground

Screw

White Wire

from Dryer

harness

Hot

(Black)

External Ground

Wire (If required

by local codes)

ENGLISH

Hot

(Red)

UL-Listed 3-Wire Power Cord

Attach the two hot leads (black and red) of the

4

power cord to the outer terminal block screws.

Attach the neutral (white) wire to the center

5

terminal block screw.

NOTE

The dryer is supplied with the neutral conductor

grounded. If a 3-wire cord is to be used and is

allowed, make sure the white neutral grounding

wire is connected to the green ground screw.

Connect the external ground (if required by local

6

codes) to the green ground screw.

Tighten all screws securely.

7

Page 30

30

INSTALLATION

Three-Wire Direct Wire

•A 3-wire connection is NOT permitted

on new construction after January 1,

1996.

•A UL-listed strain relief is required.

•Use UL-listed 3-wire, #10 AWG-minimum copper

conductor cable. Allow at least 5 ft. (1.5 m) length

to allow for removal and installation of dryer.

Remove 3½-inch (8.9 cm) of the outer covering

1

from the wire. Strip 1 inch (2.5 cm) insulation

from each wire. Bend the ends of the three wires

into a hook shape.

1" (2.5 cm)

Remove the terminal block access cover on the

2

upper back of the dryer.

Install a UL-listed strain relief into the power cord

3

through-hole.

Thread the 3-wire, #10 AWG-minimum copper

4

conductor power cable prepared in step 1

through the strain relief.

Terminal

Block

UL-Listed

Strain Relief

Reinstall the terminal block access cover.

9

Ground

Screw

White Wire

from Dryer

harness

Hot

(Black)

External Ground

Wire (If required by

local codes)

Neutral

(White)

Hot

(Red)

Final Installation Check

Once you have completed the installation of the dryer

and it is in its final location, confirm proper operation

with the following tests and Installation Test (Duct

Check) on the following page.

Testing Dryer Heating

GAS MODELS

Close the dryer door, press the POWER button to turn

the dryer on, and start the dryer on a heat setting.

When the dryer starts, the igniter should ignite the

main burner.

UL-Listed 3-Wire Power Cord

Attach the two hot leads (black and red) of the

5

power cord to the outer terminal block screws.

Attach the neutral (white) wire to the center

6

terminal block screw.

NOTE

The dryer is supplied with the neutral conductor

grounded. If a 3-wire cord is to be used and is

allowed, make sure the white neutral grounding

wire is connected to the green ground screw.

Connect the external ground (if required by local

7