LG DLGX7701KE User Manual

<![endif]>ESPAÑOL ENGLISH

OWNEr’S MANuAL

DRYER

Please read this owner’s manual thoroughly before operating and keep it handy for reference at all times.

DLEx7700*E DLGx7701*E

www.lg.com

MFL67731038 |

Copyright © 2015 - 2017 LG Electronics Inc. All Rights Reserved. |

2 TABLE OF CONTENTS

TABLE OF CONTENTS

3 |

IMPORTANT SAFETY INSTRUCTIONS |

39 |

Cycle Settings and Options |

||

39 |

Special Functions |

||||

|

|

||||

|

|

||||

3 |

WHAT TO DO IF YOU SMELL GAS |

40 |

Custom Program |

||

4 |

BASIC SAFETY PRECAUTIONS |

41 |

Steam Functions |

||

4 |

California Safe Drinking WATER and |

42 |

Steam Cycle Guide |

||

|

Toxic Enforcement Act |

|

|

|

|

5 |

GROUNDING INSTRUCTIONS |

43 |

SMART FUNCTIONS |

||

5 |

SAFETY INSTRUCTIONS FOR |

||||

|

|

|

|||

|

INSTALLATION |

|

43 Using the Tag On Function |

||

7 |

SAFETY INSTRUCTIONS FOR CONNECTING |

|

|||

|

44 Using Smart Diagnosis™ |

||||

|

ELECTRICITY |

|

|||

|

|

|

|

||

8 |

PRODUCT FEATURES |

45 |

MAINTENANCE |

||

|

|

|

|||

|

|

45 |

Regular Cleaning |

||

9 |

INTRODUCING YOUR DRYER |

||||

46 |

TROUBLESHOOTING |

||||

|

|

||||

9 |

Parts and Accessories |

|

|

|

|

46 |

Before Calling for Service |

||||

9 |

Two-Way Reversible Door |

||||

|

|

|

|||

10 |

Control Panel Features |

49 |

SPECIFICATIONS |

||

11 |

Display |

||||

|

|

|

|

|

|

12 INSTALLATION INSTRUCTIONS

50 WARRANTY

12Preview Installation Order

13Installation Location Requirements

13Clearances

14Leveling the Dryer

15Reversing the Door

21Installing the Side Vent Kit

22Venting the Dryer

24Connecting the Inlet Hose

25Connecting Gas Dryers

27Connecting Electric Dryers

32Special Requirements for Manufactured or Mobile Homes

32Final Installation Check

33Installation Test (Duct Check)

35 HOW TO USE

35Operating the Dryer

36Sorting Loads

36 Loading the Dryer

36Check the Lint Filter Before Every Load

36Using the Lid

37Using the LG EasyLoad™

38Cycle Guide

IMPORTANT SAFETY INSTRUCTIONS |

3 |

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

wWarning

For your safety, the information in this manual must be followed to minimize the risk of fire, explosion, or electric shock, or to prevent property damage, injury to persons, or death.

Your safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

w |

This is the safety alert symbol. |

This symbol alerts you to potential hazards that can kill or hurt you and others. |

All safety messages will follow the safety alert symbol and either the word DANGER, WARNING, or CAUTION. These words mean:

wDANGER

You will be killed or seriously injured if you don’t immediately follow instructions.

wWarning

You can be killed or seriously injured if you don’t follow instructions.

wcaution

You may be slightly injured or cause damage to the product if you do not follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

•Do not install a clothes dryer with flexible plastic venting materials. If flexible metal (foil type) duct is installed, it must be of a specific type identified by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting materials are known to collapse, be easily crushed, and trap lint.These conditions will obstruct clothes dryer airflow and increase the risk of fire.

•Install the clothes dryer according to the manufacturer’s instructions and local codes.

•Save these instructions.

wWarning

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death or property damage.

-Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any phone in your building.

•Clear the room, building or area of all occupants.

•Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

•If you cannot reach your gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer, service agency or the gas supplier.

<![endif]>ENGLISH

wWarning:This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

4 IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

wWarning

For your safety, the information in this manual must be followed to minimize the risk of fire, explosion, or electric shock, or to prevent property damage, injury to persons, or death.

BASIC SAFETY PRECAUTIONS

wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions,

including the following:

•Read all instructions before using the dryer.

•Before use, the dryer must be properly installed as described in this manual.

•Do not place items exposed to cooking oils in your dryer. Items contaminated with cooking oils may contribute to a chemical reaction that could cause a load to catch fire.

•Do not dry articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, drycleaning solvents, or other flammable or explosive substances as they give off vapors that could ignite or explode.

•Do not reach into the dryer if the drum or any other part is moving.

•Do not repair or replace any part of the dryer or attempt any servicing unless specifically

recommended in this owner’s manual or in published user-repair instructions that you understand and have the skills to carry out.

•Do not tamper with controls.

•Before the dryer is removed from service or discarded, remove the door to the drying compartment.

•Do not allow children to play on or in the dryer. Close supervision of children is necessary when the dryer is used near children.

•Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric softener or product.

•Do not use heat to dry articles containing foam rubber or similarly textured rubber-like materials.

•Keep area around the exhaust opening and adjacent surrounding areas free from the accumulation of lint, dust, and dirt.

•The interior of the dryer and exhaust vent should be cleaned periodically by qualified service personnel.

•Do not install or store the dryer where it will be exposed to the weather.

•Always check the inside of the dryer for foreign objects.

•Clean lint screen before or after each load.

•Do not store plastic, paper, or clothing that may burn or melt on top of the dryer during operation.

•Be careful when opening and closing the door. Fingers and hands can get caught in the door and cause injury if the door drops forward unexpectedly.

•Do not place heavy items on or lean against the top of the door when it is open.

•Do not attempt to pull the hamper door open more than 40 degrees.

•The dryer could tip forward, causing injury or damage.

•Do not place items on the top of the dryer.

•Certain internal parts are intentionally not grounded and may present a risk of electric shock only during servicing.

Service personnel - do not contact the following parts while the appliance is energized: valve, motor, control board, heater, generator.

California Safe Drinking WATER and Toxic Enforcement Act

This act requires the governor of California to publish a list of substances known to the state to cause cancer, birth defects, or other reproductive harm and requires businesses to warn customers of potential exposure to such substances.

Gas appliances can cause minor exposure to four of these substances, namely benzene, carbon monoxide, formaldehyde, and soot, caused primarily by the incomplete combustion of natural gas or LP fuels.

Properly adjusted dryers will minimize incomplete combustion. Exposure to these substances can be minimized further by properly venting the dryer to the outdoors.

IMPORTANT SAFETY INSTRUCTIONS |

5 |

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

wWarning

For your safety, the information in this manual must be followed to minimize the risk of fire, explosion, or electric shock, or to prevent property damage, injury to persons, or death.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current. This appliance must be

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided with the appliance. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

This appliance must be connected to a grounded metal, permanent wiring system or an equipment-grounding conductor must be run with the circuit conductors and connected to the equipment-grounding terminal or lead on the appliance.

Electric shock can result if the dryer is not properly grounded.

wWarning

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or service person if you are in doubt that the appliance is properly grounded.

SAFETY INSTRUCTIONS FOR INSTALLATION wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions,

including the following:

•Properly ground dryer to conform with all governing codes and ordinances. Follow details in the installation instructions. Electric shock can result if the dryer is not properly grounded.

•Before use, the dryer must be properly installed as described in this manual. Electric shock can result if the dryer is not properly grounded.

•Install and store the dryer where it will not be exposed to temperatures below freezing or exposed to the weather.

•All repairs and servicing must be performed by an authorized servicer unless specifically recommended in this owner’s manual. Use only authorized factory parts. Failure to follow this

warning can cause serious injury, fire, electric shock, or death.

•To reduce the risk of electric shock, do not install the dryer in humid spaces. Failure to follow this warning can cause serious injury, fire, electric shock, or death.

•Connect to a properly rated, protected, and sized power circuit to avoid electrical overload. Improper power circuit can melt, creating electric shock and/or fire hazard.

•Remove all packing items and dispose of all shipping materials properly. Failure to do so can result in death, explosion, fire, or burns.

•Place dryer at least 18 inches above the floor for a garage installation. Failure to do so can result in death, explosion, fire, or burns.

•Keep all packaging from children. Packaging material can be dangerous for children. There is a risk of suffocation.

•Do not install near another source of heat such as a stove, cooking oven. Failure to do so can cause deform, smoke and fire.

•Do not place candles, smoking materials, or other flammables on top of the product. Dripping wax, smoke, or fire can result.

•Remove all protective vinyl film from the product.

Failure to do so can cause product damage, smoke or fire.

•Certain internal parts are intentionally not grounded and may present a risk of electric shock only during servicing.

Service personnel - do not contact the following parts while the appliance is energized: valve, motor, control board, heater, generator.

<![endif]>ENGLISH

6 IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

wWarning

For your safety, the information in this manual must be followed to minimize the risk of fire, explosion, or electric shock, or to prevent property damage, injury to persons, or death.

SAFETY INSTRUCTIONS FOR INSTALLATION

wWarning

To reduce the risk of injury to persons, follow all industry recommended safety procedures including the use of long sleeved gloves and safety glasses. Failure to follow all of the safety warnings in this manual could result in property damage, injury to persons, or death.

Exhaust/Ducting:

•Gas dryers MUST be exhausted to the outside.

Failure to follow these instructions can result in fire or death.

•The dryer exhaust system must be exhausted to the outside of the dwelling. If the dryer is not exhausted outdoors, some fine lint and large amounts of moisture will be expelled into the laundry area. An accumulation of lint in any area of the home can create a health and fire hazard.

•Use only rigid, semi-rigid, or flexible metal 4-inch diameter ductwork inside the dryer cabinet or for exhausting to the outside. Use of plastic or other combustible ductwork can cause a fire. Punctured ductwork can cause a fire if it collapses or becomes otherwise restricted in use or during installation.

•Ductwork is not provided with the dryer, and you should obtain the necessary ductwork locally.The end cap should have hinged dampers to prevent backdraft when the dryer is not in use. Failure to follow these instructions can result in fire or death.

•The exhaust duct must be 4 inches (10.2 cm) in diameter with no obstructions.The exhaust duct should be kept as short as possible. Make sure to clean any old ducts before installing your new

dryer. Failure to follow these instructions can result in fire or death.

•Rigid, semi-rigid, or flexible metal ducting is recommended for use between the dryer and the wall. All non-rigid metal transition duct must be UL-listed. Use of other materials for transition ducting could affect drying time. Failure to follow these instructions can result in fire or death.

•DO NOT use sheet metal screws or other fasteners which extend into the duct that could catch lint and reduce the efficiency of the exhaust system. Secure all joints with duct tape. For complete details, follow the Installation Instructions. Failure to follow these instructions can result in fire or death.

wWarning

Fire Hazard

Failure to follow safety warnings exactly could result in serious injury, death or property damage.

Do not install a booster fan in the exhaust duct.

Install all clothes dryers in accordance with the installation instructions of the manufacturer of the dryer.

IMPORTANT SAFETY INSTRUCTIONS |

7 |

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

wWarning

For your safety, the information in this manual must be followed to minimize the risk of fire, explosion, or electric shock, or to prevent property damage, injury to persons, or death.

SAFETY INSTRUCTIONS FOR CONNECTING ELECTRICITY

wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Do not, under any circumstances, cut or remove the ground prong from the power cord. To prevent injury to persons or damage to the dryer, the electrical power cord must be plugged into a properly grounded outlet.

•For personal safety, this dryer must be properly grounded. Failure to do so can result in electric shock or injury.

•Refer to the installation instructions in this manual for specific electrical requirements for your model.

Failure to follow these instructions can create an electric shock hazard and/or a fire hazard.

•This dryer must be plugged into a properly grounded outlet. Electric shock can result if the dryer is not properly grounded. Have the wall outlet and circuit checked by a qualified electrician to make sure the outlet is properly grounded.

Failure to follow these instructions can create an electric shock hazard and/or a fire hazard.

•The dryer should always be plugged into its own individual electrical outlet which has a voltage rating that matches the rating plate. This provides sparkling performance and also prevents overloading house wiring circuits which could cause a fire hazard from overheated wires.

•Never unplug your dryer by pulling on the power cord. Always grip plug firmly and pull straight out from the outlet. The power cord can be damaged, resulting in a risk of fire and electric shock.

•Repair or replace immediately all power cords that have become frayed or otherwise damaged. Do not use a cord that shows cracks or abrasion damage along its length or at either end. The power cord can melt, creating an electric shock and/or fire hazard.

•When installing or moving the dryer, be careful not to pinch, crush, or damage the power cord. This will prevent injury and prevent damage to the dryer from fire and electric shock.

<![endif]>ENGLISH

SAVETHESE INSTRUCTIONS

8 PRODUCT FEATURES

PRODUCT FEATURES

EASY-TO-USE CONTROL PANEL

Rotate the cycle selector knob to select the desired dry cycle. Add cycle options or adjust settings with the touch of a button.

TWO-WAY EASY-ACCESS REVERSIBLE DOOR

The LG EasyLoad™ can be tilted open from the top, hamper-style, allowing you to easily load the dryer without items falling on the floor. The door still swings open to provide easy access for unloading or loading of bulkier items. The door hinge can be reversed to adjust for installation location.

STEAM FUNCTIONS

LG’s steam technology allows you to inject fabrics with a swirling jet of hot steam to refresh clothes, reduce static. Simply select the Steam Fresh™ cycle, you can add a Steam option to selected cycles.

Flow Sense™ DUCT BLOCKAGE SENSING SYSTEM INDICATOR

The Flow Sense™ duct blockage sensing system detects and alerts you to restrictions in the installed household ductwork that reduce exhaust airflow through the dryer. If you see the alert: Clean or repair the ducts to remove the restrictions. Keep your ducts clean to help increase efficiency and reduce long drying times caused by blocked ducts.

Smart Diagnosis™

Should you experience any technical difficulty with your washing machine, it has the capability of transmitting data by phone to the Customer Information Center. The call center agent records the data transmitted from your machine and uses it to analyze the issue, providing a fast and effective diagnosis.

Tag On

The Tag On feature works on most smart phones equipped with the NFC function and based on the Android operating system (OS).

Using the LG Smart ThinQ application, the Tag On feature will allow you to diagnose your appliance, download new cycles by simply touching the smartphone to the Tag On logo of the appliance.

|

S |

E |

|

D |

|

I

G

N

Protocol P154

Sanitization Performance of Residential Clothes dryer

INTRODUCING YOUR DRYER |

9 |

INTRODUCING YOUR DRYER

Parts and Accessories

Parts

Control |

Reversible |

|

|

panel |

|

|

|

door |

Terminal |

|

|

|

|

||

|

|

block |

Power cord |

|

|

access panel |

|

|

|

location |

|

|

|

(Electric |

|

|

|

(Gas |

|

|

|

models) |

|

|

|

models) |

|

|

|

|

<![endif]>ENGLISH

Lint filter |

Gas |

Exhaust |

|

duct |

|||

Leveling |

connection |

||

outlet |

|||

location |

|||

feet |

|

||

(Gas models) |

|

||

|

|

||

Accessories |

Two-Way Reversible Door |

|

|

Included accessories |

|

|

|

|

Release |

|

Y connector |

Hose |

Safety Tether Kit |

Hamper door

Optional accessories

Drying rack |

Side vent kit |

(AHB73109001) |

(sold separately) |

|

Kit No. 383EEL9001B |

SafetyTether Kit |

|

Swing door

The LG EasyLoad™ feature allows you to open the dryer door from the top, hamper-style, when loading the dryer to help guide clothes into the drum and prevent them from falling onto the floor. When unloading the dryer or loading bulkier items, use the swing door for easy access to the drum. For more details on using the door, see page 37. For information on reversing the door swing, see page 15.

This optional kit helps prevent the dryer tipping if children climb on the door or if someone should fall onto the door. It is recommended that you install this kit, depending on your situation, but it is not required. Follow the customer installation instructions included with the kit to properly install the kit. If you do not install the kit, store it out of reach of children.

NOTE

•Visit www.lg.com to purchase accessories.

•Contact LG Customer Service at 1-800-243-0000 (1-888-542-2623 in Canada) if any accessories are missing.

•For your safety and for extended product life, use only authorized components.The manufacturer is not responsible for product malfunction or accidents caused by the use of separately purchased unauthorized components or parts.

•The images in this owner’s manual may be different from the actual components and accessories, which are subject to change by the manufacturer without prior notice for product improvement purposes.

10 INTRODUCING YOUR DRYER

Control Panel Features

Following are instructions for starting and using your new dryer. Please refer to specific sections of this manual for more detailed information.

wWarning

To reduce the risk of fire, electric shock, or injury to persons, read this entire manual, including the Important Safety Instructions, before operating this dryer.

Operation

|

|

|

|

Button |

|

Description |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yy |

Power On/Off Button |

|

|

|

|

|

|

|

|

|

|

|

- Press to turn the dryer On. Press again to turn the dryer Off. |

|

|

|

|

|

|

|

|

|

|

|

NOTE : Pressing the On/Off button during a cycle cancels that cycle and any |

|

|

|

|

|

|

|

|

|

|

|

load settings are lost. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yy |

Cycle Selector Knob |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

- Turn this knob to select the desired cycle. Once the desired cycle has been |

|

|

|

|

|

|

|

|

|

|

|

selected, the standard presets are shown in the display. On Manual Dry cycles, |

|

|

|

|

|

|

|

|

|

|

|

these settings can be adjusted using the cycle modifier buttons any time |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

before starting the cycle. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yy |

Start/Pause Button |

|

|

|

|

|

|

|

|

|

|

|

- Press this button more than 0.4 seconds hold to start the selected cycle. If the dryer |

|

|

|

|

|

|

|

|

|

|

|

is running, use this button to pause the cycle without losing the current settings. |

|

|

|

|

|

|

|

|

|

|

|

NOTE : If you do not press the Start/Pause button to resume a cycle within four |

|

|

|

|

|

|

|

|

|

|

|

minutes, the dryer turns off automatically. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yy |

MoreTime/LessTime Buttons |

|

|

|

|

|

|

|

|

|

|

|

- To adjust the drying time, use these buttons with Manual Dry, Time Dry, and |

|

|

|

|

|

|

|

|

|

|

|

Steam Fresh™ cycles, as well as the Reduce Static and TurboSteam options. |

|

|

|

|

|

|

|

|

|

|

|

Press the More Time button to increase the selected manual cycle time by a |

|

|

|

|

|

|

|

|

|

|

|

minute; press LessTime to decrease the cycle time by a minute. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yy |

Cycle Modifier Buttons |

|

|

|

|

|

|

|

|

|

|

|

- Use these buttons to select the desired cycle settings for the selected cycle. |

|

|

|

|

|

|

|

|

|

|

|

The current settings are shown in the display. Press the button for that option |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

to view and select other settings. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yy |

Option Buttons |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

- The Option buttons allow you to select additional cycle options. Certain |

|

|

|

|

|

|

|

|

|

|

|

buttons also allow you to activate special functions by pressing and holding |

|

|

|

|

|

|

|

|

|

|

|

the button for three seconds. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yy |

Steam Functions |

|

|

|

|

|

|

|

|

|

|

|

- LG’s steam technology allows you to inject fabrics with a swirling jet of hot steam |

|

|

|

|

|

|

|

|

|

|

|

to refresh or sanitize clothes, or reduce static. Simply select the Steam Fresh™ or |

|

|

|

|

|

|

|

|

|

|

|

Steam Sanitary™ cycle. Or you can add a steam option to selected cycles. |

|

|

|

|

|

|

|

|

|

|

|

|

INTRODUCING YOUR DRYER 11

Display

The display shows the settings, estimated time remaining, options, and status messages for your dryer. When the dryer is turned on, the light in the display illuminates.

wWarning

To reduce the risk of fire, electric shock, or injury to persons, read this entire manual, including the Important Safety Instructions, before operating this dryer.

<![endif]>ENGLISH

Button |

Description |

|

|

yy |

EstimatedTime Remaining |

|

- When the Start/Pause button is pressed, the dryer displays the estimated |

|

(Sensor Dry) or set time (Time Dry) remaining, and begins tumbling. |

|

NOTE :The cycle time on Sensor Dry cycles may fluctuate as the dryer |

|

recalculates drying time for optimal results |

yy Cycle Completion Indicator with Check Filter Reminder

-This portion of the display shows which stage of the drying cycle is currently underway (Clean Filter, Drying, or Cooling).

yy Child Lock Indicator

-When Child Lock is set, the Child Lock indicator appears and all buttons are disabled except the Power button. This prevents children from changing settings while the dryer is operating

yy Clean Filter Reminder

-The display shows Clean Filter when the dryer is turned on as a reminder to check the filter. It turns off when the Start/Pause button is pressed.

yy Custom Program

-If you have a special combination of settings that you use frequently, you can save these settings as a Custom Program.

yy Flow Sense™ Duct Blockage Sensing System Indicator

- The Flow Sense™ duct blockage sensing system detects and alerts you to blockages in the ductwork that reduce exhaust flow from the dryer. This improves operating efficiency and helps minimize service calls, saving you money.

12 INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Preview Installation Order

Checking and choosing the |

Leveling the dryer |

Venting the dryer |

proper location |

|

|

120V 240V

Connecting gas dryers |

Connecting electric dryers |

Plugging in the power cord |

|

|

and grounding |

Press and hold |

|

Installation test |

Test run |

(Refer to page 33.) |

|

INSTALLATION INSTRUCTIONS 13

Installation Location Requirements

wWarning

Read all installation instructions completely before installing and operating your dryer! It is important that you review this entire manual before installing and using your dryer. Detailed instructions concerning electrical connections, gas connections, and exhaust requirements are provided on the following pages.

• A location that allows for proper exhaust installation. A |

• A sturdy floor to support the total dryer weight of 200 |

gas dryer must be exhausted to the outdoors. |

lbs (90.7 kg). The combined weight of a companion |

See Venting the dryer. |

appliance should also be considered. |

• A grounded electrical outlet located within 2 ft. |

• No other fuel-burning appliance can be installed in the |

(61 cm) of either side of the dryer. See Connecting |

same closet as a dryer. |

electric dryers. |

|

Do not operate your dryer at temperatures below 45°F (7°C). At lower temperatures, the dryer might not shut off at the end of an automatic cycle. This can result in longer drying times. The dryer must not be installed or stored in an area where it will be exposed to water and/or weather. Check code requirements. Some codes limit, or do not permit, installation of the dryer in garages, closets, mobile homes or sleeping quarters. Contact your local building inspector.

NOTE

NOTE

•Floor must be level, with a maximum slope of 1 inch (2.5 cm) under entire dryer. Clothes may not tumble properly, and automatic sensor cycles may not operate correctly if the dryer is not level.

•For a garage installation, you will need to place the dryer at least 18 inches (46 cm) above the floor. If using a pedestal, you will need 18 inches (46 cm) to the bottom of the dryer.

Clearances

|

14" max.* |

|

|

|

(7.6 cm) |

|

|

|

|

|

|

|

|

|

(35.6 cm) |

|

|

|

|

|

23" |

13 2⁄4" |

|

|

|

|

|

(35.2 cm) |

|

|

|

|

|

|

(58.5 cm) |

|

|

|

|

|

|

|

|

52 3⁄4" |

|

|

45 1⁄8" |

|

|

|

(134 cm) |

|

|

|

|

|

|

|

|

|

(114.6 cm) |

|

|

31 2⁄4" |

5"** |

|

29" |

|

Closet Door Vent |

|

(79.5 cm) |

(12.7 cm) |

(2.5 cm) |

(73.6 cm) |

(2.5 cm) |

|

|

54 2⁄4" |

|

|

|

(7.6 cm) |

Requirements |

|

(138 cm) |

|

|

|

|

|

Installation Spacing For Recessed Area Or Closet Installation

The following spacing dimensions are recommended for this dryer. This dryer has been tested for clearances of

1 inch(2.5 cm) on the sides and rear. Recommended spacing should be considered for the following reasons:

•Additional spacing should be considered for ease of installation and servicing.

•Additional clearances might be required for wall, door and floor moldings.

NOTE

NOTE

•Additional spacing should be considered on all sides of the dryer to reduce noise transfer.

For closet installation, with a door, minimum ventilation openings in the top and bottom of the door are required. Louvered doors with equivalent ventilation openings are acceptable.

•Companion appliance spacing should also be considered.

<![endif]>ENGLISH

There should be at least a little space around the dryer (or any other appliance) to eliminate the transfer of vibration from one to the other. An appliance that vibrates too much can make noise or shift against another appliance, causing paint damage and additional noise.

14 INSTALLATION INSTRUCTIONS

Clearances (cont.)

Recommended Installation Spacing For Cabinet Installation

• For cabinet installation with a door, minimum ventilation openings in the top of the cabinet are required.

*Required spacing

**For side or bottom venting,

2 inches (5.1 cm) clearance is allowed.

7"* (17.8 cm) 7"* (17.8 cm)

7"* (17.8 cm) 7"* (17.8 cm)

5"* |

312⁄4" |

1"* |

1" |

|

|

|

29" |

|

|

|

1" |

(12.7 cm) (79.5 cm) |

(2.5 cm) |

(2.5 cm) |

(73.6 cm) |

|

(2.5 cm) |

||||||

Leveling the Dryer

wWarning

•To reduce the risk of injury to persons, adhere to all industryrecommendedsafetyproceduresincluding the use of long-sleeved gloves and safety glasses.

Failure to follow this warning can cause serious injury or death.

•The appliances are heavy. Two or more people are required when installing the dryer. Failure to follow this warning can cause serious injury or death.

To ensure that the dryer provides optimal drying performance, it must be level. To minimize vibration, noise, and unwanted movement, the floor must be a perfectly level, solid surface.

NOTE

NOTE

Adjust the leveling feet only as far as necessary to level the dryer. Extending the leveling feet more than necessary can cause the dryer to vibrate.

1.Position the dryer in the final location. Place a level across the top of the dryer.

•All four leveling feet must rest solidly on the floor.

Gently push on the top corners of the dryer to make sure that the dryer does not rock from corner to corner.

If you are installing the dryer on the optional pedestal, you must use the leveling feet on the pedestal to level the dryer. The dryer leveling feet should be fully retracted.

2.Use an adjustable wrench to turn the leveling feet.

Turn clockwise to raise the dryer or counterclockwise to lower it. Raise or lower the leveling feet until dryer is level from side to side and front to back.

Make sure that all four leveling feet are in firm contact with the floor.

Level |

Leveling Feet

Leveling Feet

INSTALLATION INSTRUCTIONS 15

Reversing the Door

Before you begin

NOTE

NOTE

The door reversal procedure for the two-way door is far more complex than for a conventional dryer

door. It is recommended that you read through these instructions in their entirety before beginning the process, in order to gauge whether you prefer to have the procedure done by a professional installer or service person.

The door reversal procedure consists of four main parts:

•Removing and reinstalling the door and hinges (steps 1, 2 and 20)

•Removing and reversing components on the dryer cabinet (step 3)

•Removing and reversing components on the door cover (steps 4 and 5)

•Removing and reversing components inside the door (steps 6 through 19).

Tools Required

•Phillips screwdriver

•Large flat blade screwdriver (recommended for hinge screws if they are tight or your Phillips screwdriver is worn)

•Small flat blade screwdriver (for lifting out parts)

wWarning

•THE DRYER DOOR ISVERY LARGE AND HEAVY. Failure to follow the instructions below can result in damage to the dryer, property damage or personal injury.

•To avoid damage to the dryer or the door, support the door with a stool or box that fits under the door, or have an assistant support the weight of the door.

•Avoid dropping the door to avoid damage to the door or the floor.

•Unplug the dryer or turn off power at the main circuit breaker before beginning door reversal.

Instructions

NOTE

NOTE

The instructions here are for changing the door swing from a right to a left side hinge. If the door has been reversed, and it is necessary to change it back, use care when following these instructions. Some of

the illustrations and the left/right references will be reversed, and you will need to read the instructions carefully.

wWarning

Be sure to support the weight of the door before removing the hinge screws.

1.Open the door from the side so that the hinge screws are accessible.

Two large screws

Two small screws

2.Remove the four hinge screws.

While supporting the door, remove the four hinge screws, two from each hinge. Set the door aside face down on a protected surface to prevent damage to the door or the work surface.

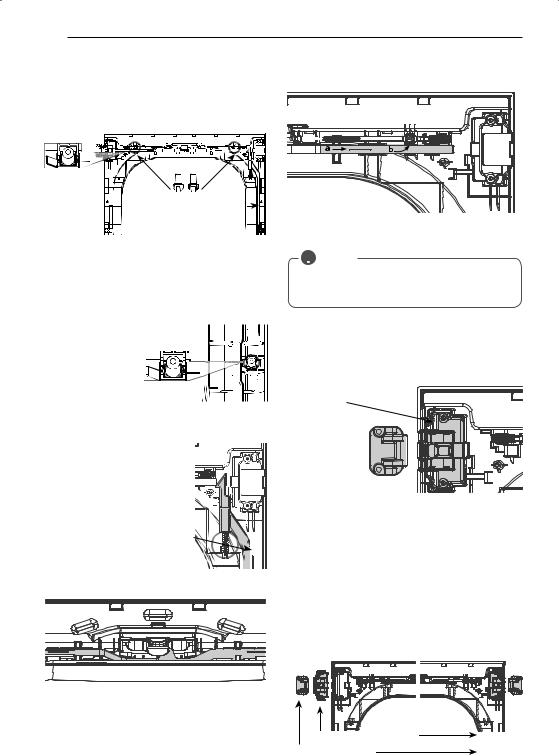

3.Reverse the components on the cabinet.

a.Use a Phillips screwdriver to remove the two screws and the latch mechanism on the front panel of the cabinet.

hinge |

upper |

|

cover |

hinge |

|

latch |

latch hole |

|

mechanism |

cover |

|

hinge |

hinge |

|

bracket |

||

|

b.Remove the latch hole cover by gently prying it up with a flat blade screwdriver, being careful not to scratch the paint. Install the latch hole cover on the opposite side, where the latch mechanism was

removed. Install the latch mechanism in the position from which you removed the latch hole cover, using the two screws removed in step a.

c.Remove the hinge cover by gently prying it up with a flat blade screwdriver, being careful not to scratch the paint. Rotate the hinge cover 180 degrees and install it on the opposite side, where the upper hinge was attached.

<![endif]>ENGLISH

16 INSTALLATION INSTRUCTIONS

Reversing the Door (continued)

hinge |

upper |

|

cover |

hinge |

|

latch |

latch hole |

|

mechanism |

cover |

|

hinge |

hinge |

|

bracket |

||

|

d.Reverse the hinge and the hinge bracket at the bottom of the cabinet. Remove the two screws from the hinge bracket at bottom right and remove the hinge bracket.

Remove the lower of the two screws behind the hinge bracket. Do NOT remove the upper screw behind the hinge bracket. Set the parts aside.

NOTE

NOTE

Do NOT remove any of the eight screws on the face of the cabinet (marked with  below). Doing so could result in damage to the dryer and the need for a service call to repair the dryer.

below). Doing so could result in damage to the dryer and the need for a service call to repair the dryer.

e.Remove the three screws on the hinge at bottom left. Remove the

hinge and reinstall it on the right side. The top screw occupies the hole where you removed the screw behind the hinge bracket in step d.

f.Install the hinge bracket removed in step d on the bottom left side, first installing one screw behind the hinge bracket.

ON THE DOOR:

4.Lift off the door cover.

With the door laid inside facing up on a protected surface, remove the 12 screws on the inside of the door. Carefully lift off the door cover with the help of a small flat blade screwdriver inserted in the upper corner (circled below).

wWarning

The edges of the door cover may be sharp. Take care when handling, or wear gloves to avoid injury.

twelve screws

Hole |

interlock |

plug |

button |

5.Switch the door strike and the blank cover.

Remove the four screws on the door cover that secure the door strike and the blank cover.

Switch the door strike and the blank cover, installing them on the opposite sides from which they were removed.

long screw |

short |

|

screws |

||

|

||

blank cover |

door strike |

Gently pry out the hole plug on the side of the door cover and install it in the hole on the opposite side.

hole plug

Set the door cover aside.

INSTALLATION INSTRUCTIONS 17

Reversing the Door (continued)

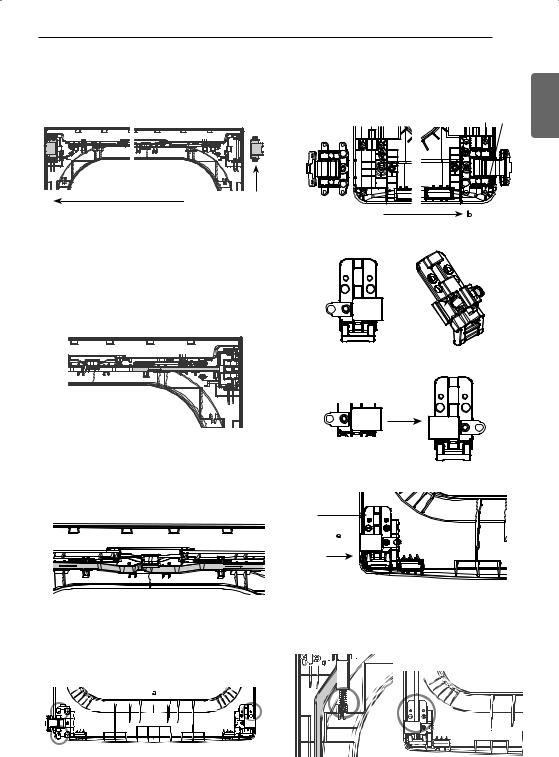

6. Reverse the components inside the door. |

<![if ! IE]> <![endif]>ENGLISH |

|

You will now be removing and reversing various components inside the door. See below for a detailed diagram |

||

|

||

and identification of the inner structure and parts of the door. (The diagram shows the “before view” of the door, |

|

|

with the default set-up for a right side hinge swing. After following these instructions, your door should be a |

|

|

mirror image of the illustration.) |

|

Inner Structure of Door (before reversing - right hinge swing)

Top interlock buttons |

inner lock rods |

upper hinge |

|

assembly |

|

upper hinge |

upper hinge |

pivot |

filler |

|

top lock rod |

side lock rod

glass

Side Interlock button

|

lower hinge |

|

lower |

filler |

|

lower |

||

hinge |

||

hinge |

||

assembly |

||

bracket |

||

|

||

|

bumpers |

interlock buttons |

lower hinge filler |

side lock rod |

top lock rod |

inner lock rods |

lower hinge bracket |

Hole plug |

lower hinge assembly |

18 INSTALLATION INSTRUCTIONS

Reversing the Door (continued)

7.Lift out the two top interlock buttons.

Lift out the two grey interlock buttons from the top of the outer door and set them aside for later use.

interlock buttons

side lock rod

8.Lift out the grey interlock button in the side of the door.

Make sure to remove the spring with the interlock button and to keep the two together. Set the interlock button aside. Do not confuse with interlock buttons from the top of the outer door.

9.Remove the side lock rod.

Remove the side lock rod from the lower hinge bracket by lifting

the top end of the rod and sliding it toward the top of the door. The spring should remain attached to the lock rod. Set the lock rod aside.

Spring

10. Remove the top lock rod.

a.Slide the lock rod to the right to remove it from the hinge assembly on the left side.

b.While sliding the lock rod right, lift the right end up and out of the guides.

NOTE

NOTE

Do not remove the two inner lock rods (see page 17) located underneath the top lock rod. They do NOT need to be reversed

11.Remove the upper hinge pivot.

Once the top lock rod has been removed, the hinge pivot can easily be removed from the hinge assembly on the upper left and set aside.

upper hinge assembly

upper hinge  pivot

pivot

12.Reverse the upper hinge assembly and hinge filler.

Lift out the upper hinge filler (on the right) and set it aside.

Carefully lift the upper hinge assembly (on the left) out of the outer door frame, using a small flat blade screwdriver if necessary. Rotate the hinge assembly

180 degrees and install it on the upper right side of the outer door. You will need to press firmly to install the hinge assembly.

The hinge pivot removed in step 11 will be installed later.

upper hinge assembly

upper hinge pivot

INSTALLATION INSTRUCTIONS 19

Reversing the Door (continued)

Now rotate the hinge filler 180 degrees and install it on the upper left side of the door.

upper hinge filler

13.Reinstall the top lock rod.

Rotate the top lock rod (removed in step 10) 180 degrees end for end from its original position and reinstall it. The spring should now be to the right of center, with the spring on the side of the rod facing the top of the door.

a.Insert the right end of the lock rod into the right hinge assembly. Make sure the rod is aligned with the guides in the door panel.

b.Lower the rod into position, sliding it to bypass the center handle, making sure to align the lock rod with the guides all the way across the door panel. When released, the lock rod should slide completely into the hinge assembly on the right. Slide the

lock rod back and forth to make sure it is correctly positioned in the guides and slides easily.

14.Reverse the lower hinge bracket and hinge assembly.

a.Remove the screw from the lower hinge bracket (on the right) and lift the hinge bracket out. Set it aside. Remove the two screws from the lower hinge assembly on the bottom left and lift the hinge assembly out.

b.Rotate the lower hinge assembly 180 degrees and install it on the right side using the two screws

removed in step a. |

screws |

lower hinge assembly

c.Flip over the lower hinge bracket and release the tabs on the back locking the hinge filler to the hinge bracket.

tabs

d.Rotate the hinge filler 180 degrees and snap it back onto the FRONT of the hinge bracket facing in the opposite direction.

e.Mount the lower hinge bracket and the filler on the left side of the door with the screw removed in step a.

screw

15.Install the side lock rod.

Flip the side lock rod over and install it on the opposite side. Insert the lower end into the left hinge and lower the rod into the guides on the door while compressing the spring inside the recess.

<![endif]>ENGLISH

20 INSTALLATION INSTRUCTIONS

Reversing the Door (continued)

Make sure the top of the side lock rod is beside the top lock rod and the two do not overlap each other, so the two rods can interact correctly. If they are not aligned properly, the door will not operate properly.

interlock buttons

bumpers

16.Reinstall the top interlock buttons.

Reinstall the top gray interlock buttons removed in step 7, one on each side of the outer door panel.

17.Reinstall the side interlock button.

Reinstall the side interlock button removed in step 8.

Center the spring in the compartment and insert the interlock button on top of it.

18.Reinstall the door cover.

Clean the glass on the door and door cover, if necessary.

Make sure the three gray interlock buttons are properly installed and that the top and side lock rods are properly aligned where they meet. Carefully lower the door cover into place, aligning the holes in the cover with the interlock buttons on the top and side and the bumpers on the bottom. Take care not to dislodge the lock rods while mounting the door cover. Once the door cover is in place, secure it with the 12 screws removed in step 4.

The ten similar screws go around the top and sides of the door cover. Make sure to install the two different screws on the bottom edge, in the locations marked below

19.Now,pickuptheupperhingepivotremovedearlierand rotateit180degrees.Press in the side interlock button on the left side and hold it down while you press the hinge pivot into the hinge assembly on the top right side. If the door has been reassembled correctly, the lock rod will slide back easily and lock the pivot in place. The door is now ready to remount on the opposite side of the dryer.

wWarning

Be sure to support the weight of the door before installing the hinge screws.

20.Reinstallthedoor.

While supporting the door, install the four hinge screws removedinstep2.Testtheswingofthedoortomakesure the hinges and latch are properly aligned and that the door opens, closes and latches properly in both directions.

Two large screws

Two small screws

If the door doesn’t operate smoothly, remove the door and then the door cover to check that the lock rods and interlock buttons are properly mounted and aligned.

The interlock buttons should be oriented correctly and operating smoothly. The interlock rods should be in the proper position and should not overlap at the contact point.(Seesteps13-15.)

If the door is damaged, or if the door does not work after reassembly,contactthecallcenterat1-800-243-0000.

Installing the Side Vent Kit

wWarning

•Use a heavy metal vent.

•Do not use plastic or thin foil duct.

•Clean old ducts before installing this dryer.

•To reduce the risk of injury to persons, adhere to all industry recommended safety procedures including the use of long sleeved gloves and safety glasses.

•Failure to follow all of the safety warnings in this manual could result in property damage, injury to persons, or death.

Your new dryer is shipped to vent to the rear. It can also be configured to vent to the bottom or side (right-side venting is not available on gas models).

An adapter kit, part number 383EEL9001B, may be purchased from your LG retailer. This kit contains the necessary duct components to change the dryer vent location.

1.Remove the rear exhaust duct retaining screw. Pull out the exhaust duct.

Retaining

Screw

Rear

Exhaust Duct

OPTION 1: SIDEVENTING

2.Press the tabs on the knockout and carefully remove the knockout for the desired vent opening (rightside venting is not available on gas models). Press the adapter duct onto the blower housing and secure to the base of the dryer as shown.

Adapter

Duct

Bracket

Knockout

INSTALLATION INSTRUCTIONS 21

3.Preassemble a 4-inch (10.2 cm) elbow to the next 4-inch (10.2 cm) duct section, and secure all joints with duct tape. Be sure that the male end of the elbow faces AWAY from the dryer. Insert the elbow/duct assembly through the side opening and press it onto the adapter duct. Secure it in place with duct tape.

Be sure that the male end of the duct protrudes 12⁄4 inches (3.8 cm) to connect the remaining ductwork.

Attach the cover plate to the back of the dryer with the included screw.

Cover

Plate

Elbow |

12⁄4” |

|

(3.8 cm) |

OPTION 2: BOTTOMVENTING

2.Press the adapter duct onto the blower housing and secure to the base of the dryer as shown.

Adapter

Duct

Bracket

3.Insert the 4-inch (10.2 cm) elbow through the rear opening and press it onto the adapter duct. Be sure that the male end of the elbow faces down through the hole in the bottom of the dryer. Secure it in place with duct tape. Attach the cover plate to the back of the dryer with the included screw.

Cover

Plate

Elbow

<![endif]>ENGLISH

22 INSTALLATION INSTRUCTIONS

Venting the Dryer

wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Do not crush or collapse ductwork. Failure to follow these instructions can result in fire or death.

•Do not allow ductwork to rest on or contact sharp objects. Failure to follow these instructions can result in fire or death.

•If connecting to existing ductwork, make sure it is suitable and clean before installing the dryer.

Failure to follow these instructions can result in fire or death.

•Venting must conform to local building codes.

Failure to follow these instructions can result in fire or death.

•Gas dryers MUST exhaust to the outdoors. Failure to follow these instructions can result in fire or death.

•Use only 4-inch (10.2 cm) rigid, semi-rigid, or flexible metal ductwork inside the dryer cabinet and for venting outside. Failure to follow these instructions can result in fire or death.

•To reduce the risk of fire, combustion, or accumulation of combustible gases, DO NOT exhaust dryerair into an enclosedand unventilated area, such as an attic, wall, ceiling, crawl space, chimney,gasvent,orconcealedspaceofabuilding.

Failure to follow these instructions can result in fire or death.

•To reduce the risk of fire, DO NOT exhaust the dryer with plastic or thin foil ducting. Failure to follow these instructions can result in fire or death.

•The exhaust duct must be 4 inches (10.2 cm) in diameter with no obstructions.The exhaust duct should be kept as short as possible. Make sure to clean any old ducts before installing your new

dryer. Failure to follow these instructions can result in fire or death.

•Rigid, semi-rigid, or flexible metal ducting is recommended for use between the dryer and the wall. All non-rigid metal transition duct must be UL-listed. Use of other materials for transition ducting could affect drying time. Failure to follow these instructions can result in fire or death.

•DO NOT use sheet metal screws or other fasteners which extend into the duct that could catch lint and reduce the effi ciency of the exhaust system. Secure all joints with duct tape. Failure to follow these instructions can result in fire or death.

•Ductwork is not provided with the dryer.You should obtain the necessary ductwork locally.The end cap should have hinged dampers to prevent backdraft when the dryer is not in use. Failure to follow these instructions can result in fire or death.

•The total length of flexible metal duct shall not exceed 8 ft. (2.4 m).

•In Canada, only those foil-type flexible ducts, if any, specifically identified for use with the

appliance by the manufacturer shall be used. In the United States, only those foil-type flexible ducts, if any, specifically identified for use with the appliance by the manufacturer and that comply with the Outline for

Clothes DryerTransition Duct, Subject 2158A, shall be used.

INSTALLATION INSTRUCTIONS 23

Venting the Dryer (cont.)

Ductwork |

|

|

|

|

Number Of |

MaximumLengthOf |

Correct Venting |

Wall Cap Type |

90° Elbows |

4-inchDiameter |

|

|

|

RigidMetalDuct |

|

Recommended |

0 |

65 ft. (19.8 m) |

|

|

1 |

55 ft. (16.8 m) |

|

4” |

2 |

47 ft. (14.3 m) |

|

(10.2 cm) |

|

||

|

3 |

36 ft. (11.0 m) |

|

4” |

4 |

28 ft. (8.5 m) |

|

(10.2 cm) |

|

||

Use only for |

0 |

55 ft. (16.8 m) |

|

short run |

1 |

47 ft. (14.3 m ) |

|

installations |

|

||

|

2 |

41 ft. (12.5 m) |

|

|

3 |

30 ft. (9.1 m) |

|

22/4” |

4 |

|

|

(6.35 cm) |

22 ft. (6.7 m) |

|

|

|

Incorrect Venting |

||

|

|

|

NOTE

NOTE

Deduct 6 ft. (1.8 m) for each additional elbow. It is not recommended to use more than four 90° elbows.

Routing and Connecting Ductwork

NOTE

NOTE

Follow the guidelines below to maximize drying performance and reduce lint buildup and condensation in the ductwork.

Ductwork and fittings are NOT included and must be purchased separately.

•Use 4-inch (10.2 cm) diameter rigid, semi-rigid, or flexible metal ductwork.

•The exhaust duct run should be as short as possible.

•Use as few elbow joints as possible.

•The male end of each section of exhaust duct must point away from the dryer.

•Use duct tape on all duct joints.

•Insulate ductwork that runs through unheated areas in order to reduce condensation and lint buildup on duct surfaces.

•Incorrect or inadequate exhaust systems are not covered by the dryer warranty. Failures or poor performance caused by such exhaust systems will not be covered by the dryer warranty.

<![endif]>ENGLISH

24 INSTALLATION INSTRUCTIONS

Connecting the Inlet Hose

The dryer must be connected to the cold water tap using the new water supply hose. Do not reuse old hoses.

NOTE

NOTE

•Water supply pressure must be between 20 psi and 120 psi (138–827 kPa).

•Do not strip or cross-thread when connecting inlet hose to the valve.

•If the water supply pressure is more than 120 psi (827 kPa), a pressure reducing valve must be installed.

•Periodically check the condition of the hose and replace the hose if necessary.

•Replace inlet hoses after five years of use to reduce the risk of hose failure.

•Record hose installation or replacement dates on the hoses for future reference.

1.Check the rubber seal in the inlet hose. Two rubber seals are supplied with each inlet hose. They are used for preventing water leaks. Make sure the connection to the cold water tap is tight.

Hose

connector

connector

Rubber

seal

Y connector

2. Check the installation type.

Short |

Long |

hose |

hose |

Y connector |

|

WITH WASHER |

WITHOUT WASHER |

Connect all water supply hoses tightly by hand and then tighten another 2/3 turn with pliers.

WITH WASHER: When connecting the dryer to the same faucet as a washer.

a.Shut off the cold water tap and remove the washer hose.

b.Connect the short hose to the Y-connector using one of the rubber seals.

c.Connect the other end of the short hose to the cold water faucet.

d.Connect the long dryer hose to one side of theY-connector and connect the washer hose to the other side.

WITHOUT WASHER: If the dryer does not share the

cold water tap with a washer.

a.Connect the straight end of the long hose to the cold water faucet.

NOTE

NOTE

•Before connecting the water line to the dryer, flush several gallons of water into a drain or bucket. This will help prevent foreign particles such as sand and scale from clogging the dryer inlet valve.

•Do not overtighten. Damage to the coupling can result.

3. Connect the hose to the dryer.

•Connect the water supply hose to the dryer inlet valve tightly by hand and then tighten another 2/3 turn with pliers.

Make sure that there are no kinks in the hoses and that they are not crushed.

4. Turn on the cold water faucet.

5.Check for leaks at the Y-connector (if used) and in all hoses.

NOTE

NOTE

•If any leaks are found, shut off the water faucet, remove the hose and check the condition of the rubber seals.

INSTALLATION INSTRUCTIONS 25

Connecting Gas Dryers

wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Gas supply requirements:

As shipped from the factory, this dryer is configured for use with natural gas. It can be converted for use with LP (Liquefied Propane) gas. Gas pressure must not exceed 13 inches of water column.

•A qualified service or gas company technician must connect the dryer to the gas service.

Failure to do so can result in fire, explosion, or death.

•Isolate the dryer from the gas supply system by closing its individual manual shutoff valve during any pressure testing of the gas supply. Failure to do so can result in fire, explosion, or death.

•Supply line requirements:

Your laundry room must have a rigid gas supply line to your dryer. In the United States, an individual manual shutoff valve MUST be installed within at least 6 ft. (1.8 m) of the dryer, in accordance with the National Fuel Gas Code

ANSI Z223.1 or Canadian gas installation code CSA B149.1. A 1⁄ - inch NPT pipe plug must be installed.

Failure to do so can result in fire, explosion, death.

•If using a rigid pipe, the rigid pipe should be ½ - inch IPS. If acceptable under local codes and ordinances and when acceptable to your gas

supplier, 3⁄ - inch approved tubing may be used where lengths are less than 20 ft. (6.1 m). Larger tubing should be used for lengths in excess of 20 ft. (6.1 m). Failure to do so can result in fire, explosion, or death.

Electrical requirements for gas models only

wWarning

•Connect the dryer to the type of gas shown on the nameplate. Failure to do so can result in fire, explosion, or death.

•To prevent contamination of the gas valve, purge the gas supply of air and sediment before connecting the gas supply to the dryer. Before tightening the connection between the gas supply and the dryer, purge remaining air until the odor of gas is detected. Failure to do so can result in fire, explosion, or death.

•DO NOT use an open flame to inspect for gas leaks. Use a noncorrosive leak-detection fluid. Failure to do so can result in fire, explosion, or death.

•Use only a new AGAor CSA-certified gas supply line with flexible stainless steel connectors. Failure to do so can result in fire, explosion, or death.

•Securely tighten all gas connections. Failure to do so can result in fire, explosion, or death.

•DO NOT attempt any disassembly of the dryer; any disassembly requires the attention and tools of an authorized and qualified service person or company. Failure to do so can result in fire, explosion, or death.

•Use a pipe-joint compound that is insoluble in Liquefied Petroleum (LP) gas on all pipe threads.

Failure to do so can result in fire, explosion, or death.

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. Failure to follow this warning can result in fire, explosion, or death.

•For personal safety, this dryer must be properly grounded. Failure to follow this warning can result in fire, explosion, or death.

wWarning

ELECTRIC SHOCK HAZARD

Failure to follow safety warnings could result in serious injury or death.

This dryer is equipped with a three-prong grounding plug for protection against shock hazard and should be plugged directly into a properly grounded threeprong receptacle. Do not cut or remove the grounding prong from this plug.

•This dryer must be plugged into a 60 Hz, 120 VAC, grounded outlet protected by a 15-ampere fuse or circuit breaker. Failure to follow this warning can result in fire, explosion, or death.

•Where a standard 2-prong wall outlet is encountered, it is your personal responsibility and obligation to have it replaced with a properly grounded 3-prong wall outlet. Failure to follow this warning can result in fire, explosion, or death.

<![endif]>ENGLISH

26 INSTALLATION INSTRUCTIONS

Connecting Gas Dryers (cont.)

wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Installation and service must be performed by a qualified installer, service agency, or the gas

supplier. Failure to do so can result in fire, explosion, or death.

•Use only a new stainless steel flexible connector and a new AGA-certified connector. Failure to do so can result in fire, explosion, or death.

•A gas shutoff valve must be installed within 6 ft. (1.8 m) of the dryer. Failure to do so can result in fire, explosion, or death.

•The dryer is configured for Natural Gas when shipped from the factory. Make sure that the dryer is equipped with the correct burner orifice for the type of gas being used (Natural Gas or Liquefied Petroleum). Failure to do so can result in fire, explosion, or death.

•If necessary, the correct orifice (For the LP orifice kit, order part number 383EEL3002D) should be installed by a qualified technician and the change should be noted on the dryer. Failure to do so can result in fire, explosion, or death.

•All connections must be in accordance with local codes and regulations. Failure to do so can result in fire, explosion, or death.

•Gas dryers MUST exhaust to the outdoors. Failure to do so can result in fire, explosion, or death.

Connecting the gas supply

1.Make sure that the gas supply to the laundry room is turned OFF. Confirm that the type of gas available in

your laundry room is appropriate for the dryer. The dryer is prepared for Natural Gas with a 3⁄ - inch NPT gas connection.

2.Remove the shipping cap from the gas connection at the back of the dryer. Be careful not to damage the threads of the gas connector when removing the shipping cap.

3.Connect the dryer to your laundry room’s gas supply using a new flexible stainless steel connector with a 3⁄ - inch NPT fitting.

4.Securely tighten all connections between the dryer and your laundry room’s gas supply. Turn on your laundry room’s gas supply and check all pipe

connections (both internal and external) for gas leaks with a noncorrosive leak-detection fluid.

Electrical connection

3/8” NPT Gas

Connection

AGA/CSA-Certified Stainless Steel Flexible Connector

Plug dryer into a 120 VAC, 60 Hz grounded 3-prong outlet.

1/8” NPT Pipe

Plug

Gas Supply

Gas Supply

Shutoff Valve

High-altitude installations

The BTU rating of this dryer is AGA-certified for elevations below 10,000 feet.

If your gas dryer is being installed at an elevation above

10,000 feet, it must be derated by a qualified technician or gas supplier.

INSTALLATION INSTRUCTIONS 27

Connecting Electric Dryers

wWarning

To help prevent fire, electric shock, serious injury, or death, the wiring and grounding must conform to the latest edition of the National Electrical Code,

ANSI/NFPA 70 and all applicable local regulations.

Please contact a qualified electrician to check your home’s wiring and fuses to ensure that your home has adequate electrical power to operate the dryer.

Electrical requirements for electric models only

wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

• This dryer must be connected to a grounded metal, permanent wiring system, or an equipmentgrounding conductor must be run with the circuit conductors and connected to the equipmentgrounding terminal or lead on the dryer. Failure to do so can result in fire, explosion, or death.

•The dryer has its own terminal block that must be connected to a separate 240 VAC, 60-Hertz, single-phase circuit, fused at 30 amperes (the circuit must be fused on both sides of the line).

ELECTRICAL SERVICE FOR THE DRYER SHOULD BE OF THE MAXIMUM RATE VOLTAGE LISTED ON THE NAMEPLATE. DO NOT CONNECT DRYER TO 110-, 115-, OR 120-VOLT CIRCUIT. Failure to follow these instructions can result in fire, explosion, or death.

•If branch circuit to dryer is 15 ft. (4.5 m) or less in length, use UL (Underwriters Laboratories) listed No.-10 AWG wire (copper wire only), or as required by local codes. If over 15 ft. (4.5 m), use UL-listed No.-8 AWG wire (copper wire only), or as required by local codes. Allow sufficient slack in wiring

so dryer can be moved from its normal location when necessary. Failure to do so can result in fire, explosion, or death.

•The power cord (pigtail) connection between wall receptacle and dryer terminal block IS NOT supplied with dryer. Type of pigtail and gauge of wire must conform to local codes and with instructions on the following pages. Failure to follow these instructions can result in fire, explosion, or death.

•A 4-wire connection is required for all mobile and manufactured home installations, as well as all new construction after January 1, 1996. A 4-wire connection must be used where local codes do not permit grounding through the neutral wire. Failure to do so can result in fire, explosion, or death.

wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Do not modify the plug and internal wire provided with the dryer.

•The dryer should be connected to 4-hole outlet.

•If it does not fit the outlet, a proper outlet will need to be installed by a qualified electrician.

wWarning

To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Any installation in a manufactured or mobile home must comply with the Manufactured Home Construction and Safety Standards Title 24 CFR, Part 3280 or Standard CAN/ CSA Z240 MH and local codes and ordinances.

•A 4-wire connection is required for all mobile and manufactured home installations, as well as all new construction after January 1, 1996. Failure to do so can result in fire, explosion, or death.

<![endif]>ENGLISH

28 INSTALLATION INSTRUCTIONS

Connecting Electric Dryers (cont.) USA only

wWarning

• Connect the power cord to the terminal block.

Connect each power cord wire to the terminal block screw that has the same colored wire. For example, connect the black power cord wire to the terminal block screw with the black wire. Failure to follow these instructions may result in a short, overload, fire or death.

• Grounding through the neutral conductor is prohibited for: (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and

(4) areas where local codes prohibit grounding through the neutral conductor.

Four-wire connection for electric dryers: Power cord

•A 4-wire connection is required for all mobile and manufactured home installations, as well as all new construction after January 1, 1996.

•A UL-listed strain relief is required.

1.Remove the terminal block access cover on the upper back of the dryer. Install a UL-listed strain relief into the power cord through-hole; then thread a UL-listed,

30 A, 240 V, 4-wire, #10 AWG-minimum copper conductor power cord through the strain relief.

Terminal

Block

UL-Listed

Strain Relief

UL-Listed

4-Wire Power

Cord

•Use a 30 A, 240 V, UL-listed power cord with #10 AWG-minimum copper conductor and closed loop or forked terminals with upturned ends.

2.Transfer the dryer’s ground wire from behind the green ground screw to the center screw of the terminal block. Attach the two hot leads of the power cord to the outer terminal block screws. Attach the white neutral wire to the center terminal block screw. Attach the power cord ground wire to the green ground screw. Tighten alL screws securely. Reinstall the terminal block access cover.

Hot |

Neutral |

|

(Black) |

(White) |

|

Ground |

Hot |

|

(Red) |

||

Screw |

||

|

|

White Wire |

|

moved from |

Power Cord |

Ground Screw |

|

|

Ground Wire |

|

INSTALLATION INSTRUCTIONS 29

Connecting Electric Dryers (cont.)

USA only

wWarning

•Connect the power cord to the terminal block. Connect each power cord wire to the terminal block screw that has the same colored wire. For example, connect the black power cord wire to the terminal block screw with the black wire.

Failure to follow these instructions may result in a short, overload, fire or death.

•Grounding through the neutral conductor is prohibited for: (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and

(4) areas where local codes prohibit grounding through the neutral conductor.

•Use UL-listed 4-wire #10 AWG-minimum copper conductor cable.

•Allow at least 5 ft. (1.5 m) length to allow for removal and reinstallation of the dryer.

3.Transfer the dryer’s ground wire from behind the green ground screw to the center screw of the terminal block. Attach the two hot leads of the power cable to the outer terminal block screws. Attach the white neutral wire to the center terminal block screw. Attach the power cable ground wire to the green ground screw. Tighten aLl screws securely. Reinstall the terminal block access cover.

Four-wire connection for electric dryers: Direct wire

•A 4-wire connection is required for all mobile and manufactured home installations, as well as all new construction after January 1, 1996.

•A UL-listed strain relief is required.

1.Remove 5 inches (12.7 cm) of the outer covering from the wire. Remove 5 inches of insulation from the ground wire. Cut off approximately 12⁄4 inches (3.8 cm) from the other three wires and strip 1 inch (2.5 cm) insulation from each wire. Bend the ends of the three shorter wires into a hook shape.

1" (2.5 cm)

Hot |

Neutral |

|

(Black) |

(White) |

|

Ground |

Hot |

|

(Red) |

||

Screw |

||

|

|

White Wire |

|

moved from |

Power Cord |

Ground Screw |

|

|

Ground Wire |

|

Ground Wire

5" (12.7 cm)

2.Remove the terminal block access cover on the upper back of the dryer. Install a UL-listed strain relief into the power cord through-hole; then thread the power cable prepared in Step 1 through the strain relief.

Terminal

Block

Block

UL-Listed

Strain Relief

<![endif]>ENGLISH

UL-Listed 4-Wire

Power Cord

30 INSTALLATION INSTRUCTIONS

Connecting Electric Dryers (cont.) USA only

wWarning

•Connect the power cord to the terminal block. Connect each power cord wire to the terminal block screw that has the same colored wire. For example, connect the black power cord wire to the terminal block screw with the black wire. Failure to follow these instructions may result in a short, overload, fire or death.

•Grounding through the neutral conductor is prohibited for: (1) new branch-circuit installations,

(2)mobile homes, (3) recreational vehicles, and

(4)areas where local codes prohibit grounding through the neutral conductor.

Three-wire connection for electric dryers: Power cord

•A 3-wire connection is NOT permitted on new construction after January 1, 1996.

•A UL-listed strain relief is required.