Page 1

Internal use Only

D4A0081EDF1.C0AAWAA

LG Electronics Technical Service Manual

LED DOWNLIGHT(8W)

MODEL : D4A0081EDF1.C0AAWAA

D4A0083EDF1.C0AAWAA

D4A0085EDF1.C0AAWAA

D4A0081EDF2.C0AAWAA

D4A0083EDF2.C0AAWAA

D4A0085EDF2.C0AAWAA

Caution: Please carefully read the safety precautions within this manual

before operating the product

P/NO : Printed in Korea

Page 2

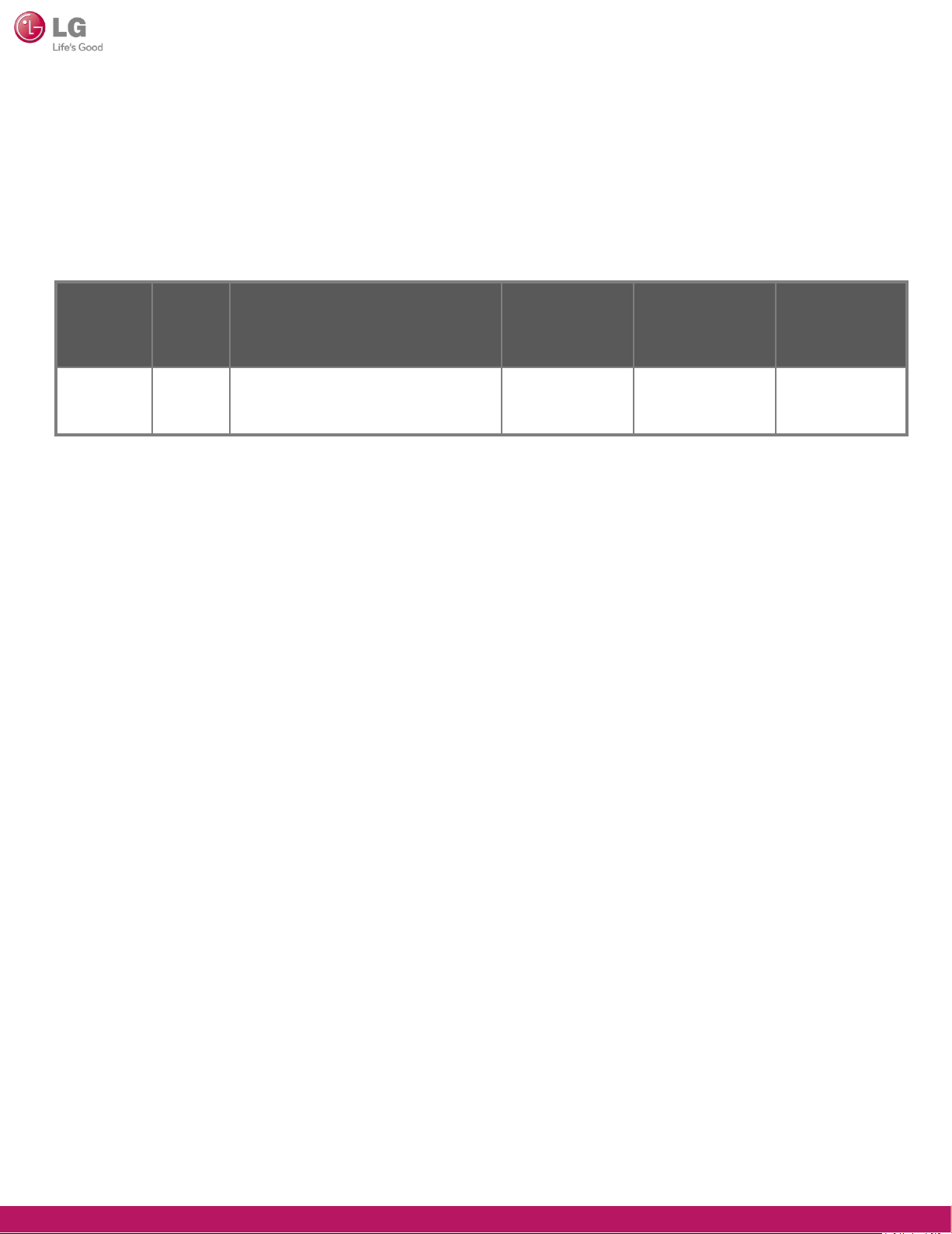

Revisions

• Established date : 2013. 07. 19

• Revised date : -

• Revision No. : 00

Revision

No.

01 All New 2013.07.19 Hyojin Kim,

Scope Details of revision Revised date Prepared by

Research

Checked by

Document

Management

department

Engineer

-2-

LGE Internal Use Only

Page 3

Before the service

Safety precaution …..........…………………………………………………………………………………… 4

Model name nomenclature ……..………………………………………………………………………… 5

Product specification ………………………………………………………………………………………… 8

During the service

Exploded view ………………………………………………………………………… 10

Service part list …………..…………………………………………………………… 11

Installation environment ……………………………………………………………… 12

Installation method ……………………………………………….…………………… 13

Dimming cable connection … … … … … … … … … … … … … … … … 14

Dimming wiring diagram and capability … … … …… … … … … … … … 15

Incorrect application and use ...........………………………………………………… 16

Troubleshooting ...……………………………………………………………………… 17

Part replacement method …………………………………………………………….. 18

-3-

LGE Internal Use Only

Page 4

Safety Precautions

The meaning of the symbol expressed in this product and manual is as follows.

• The purpose of this symbol is to gain the attention of the user on items or operations that can

cause dangerous situations. To avoid dangerous situations, please read and follow the directions

with the symbol carefully.

• The purpose of this symbol is to show possible electric shock in specific conditions.

Can result in major injury or casualty (death) when the directions are violated.

Can result in minor injury or product damage when directions are violated.

• Do not twist or damage the power cable.

It can cause fire and electric shock.

• When repairing or installing the product, always make sure to turn off the power.

It can cause fire and electric shock.

• Do not connect the polarity of the power arbitrarily.

It can damage the product or cause a safety accident.

• Firmly fixate the product on the ceiling.

It can cause the product to fall down and cause an injury.

• Be careful not to drop or apply impact on the product.

It can cause product failure.

• When the product is turned on, do not directly stare into the lamp.

Strong light can cause visual disorder.

• Do not let any alien particles penetrate into the product, and if alien particles do penetrate

into the product, remove them.

It can cause a safety accident such as electric shock and product damage.

• Do not install the product where the ceiling is uneven.

It can cause the product to fall down, resulting in product damage and injury.

• If the lamp goes off abnormally after the product is installed, check the product according

to the troubleshooting procedure.

Disassembling the product arbitrarily can cause electric shock.

• Have two people install or repair the product if possible.

The product can fall over and cause an injury.

• After installing or repairing the product, make sure that the product is installed

correctly without any gap between the exterior surface and the ceiling. If there is a gap,

rotate the product to check the gap.

• After installing the product, check if there are any alien particles on the surface of the

product.

.

• Do not wipe the product with flammable substance such as alcohol, benzene and acetone

that can degrade the surface of the product.

-4-

LGE Internal Use Only

Page 5

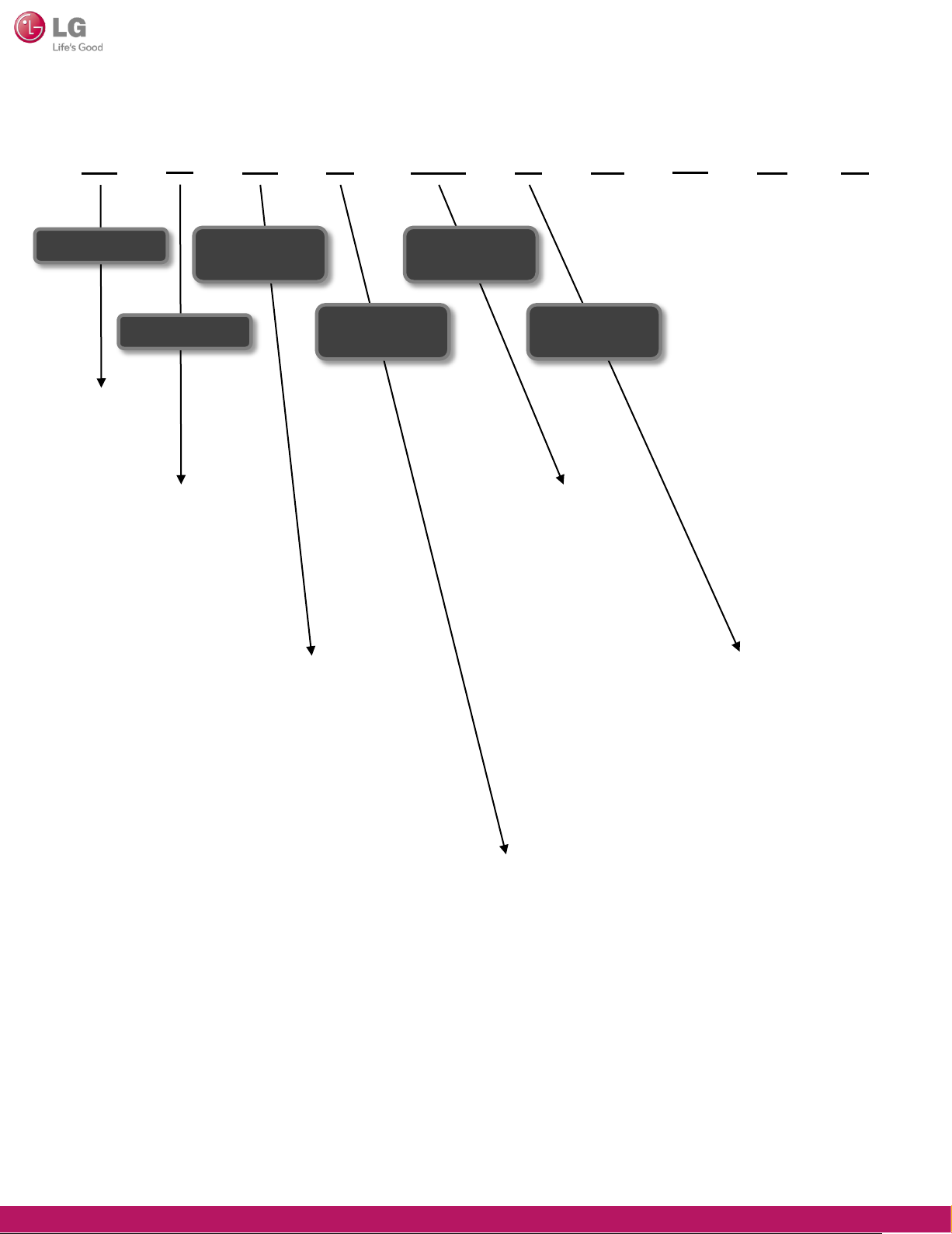

Model name nomenclature (Front)

Classification

DOWNLIGHT

4

Size

3 : 3”

4 : 4”

5 : 5”

6 : 6”

7 : 7”

8 : 8”

9 : 9”

A 0 08 1 F D E

Reflector /

Trim

Installation

Method

Power

Consumption

Color

Temperature

05 : 4.5W

13 : 13W

12 : 120W

D

1

A : White - White

B : White - Silver

C : White - Brushed Nickel

D : Haze Clear - White

E : Haze Clear - Silver

F : Haze Clear - Brushed Nickel

G : Clear - White

H : Clear - Silver

J : Clear - Brushed Nickel

0 : Commercial Power Wire Connection – Round Shape – Fixed Type

1 : Commercial Power Wire Connection – Round Shape – Swivel Type

2 : Commercial Power Wire Connection – Square Shape – Fixed Type

3 : Commercial Power Wire Connection – Square Shape – Swivel Type

0 : 2700K (2725±145)

1 : 3000K (3045±175)

2 : 3500K (3465±245)

3 : 4000K (3985±275)

4 : 4500K (4503±243)

5 : 5000K (5028±283)

6 : 5700K (5665±355)

7 : 6500K (6530±510)

A : Adjustable Color Temperature

-5-

LGE Internal Use Only

Page 6

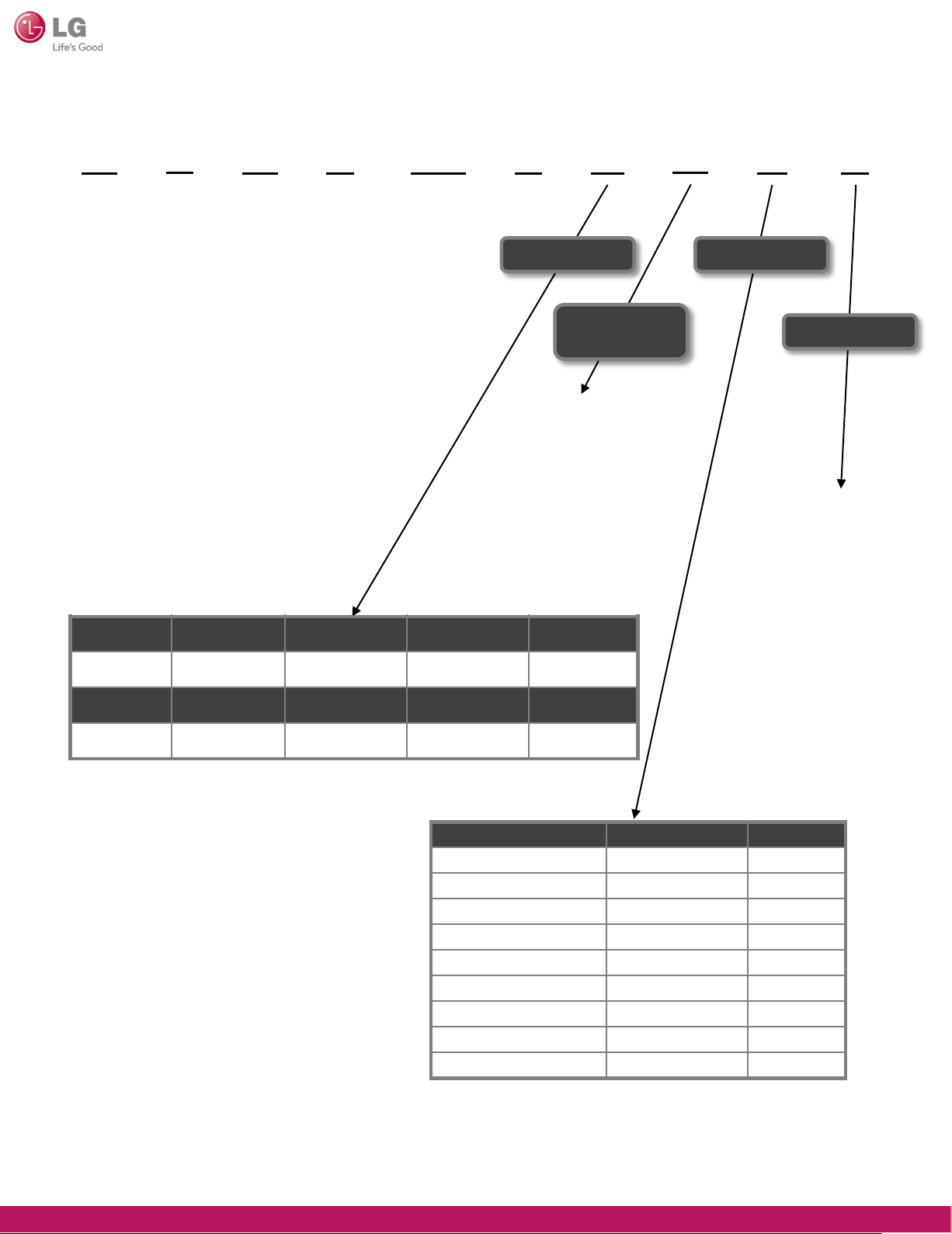

Model name nomenclature (Front)

4

A 0 08 1 F D E

Beam Angle

LED PKG

Maker

A : Cree

B : LiteOn

C : Citizen

D : Innotek

E : Lumileds

F : ILJIN

G : LG Chem

U : UOT- ALEF

H : Seoul Semi

D

Rated Voltage

1

Serial Number

0~9 : Applied according to

the sequential

development

history

Angle[˚] 2Θ½≤20 20<2Θ½ ≤40 40<2Θ½ ≤60 60<2Θ½ ≤80

Model Code A B C D

Angle[˚] 80<2Θ½≤100 100<2Θ½≤120 120<2Θ½≤140 140<2Θ½

Model Code E F G H

Voltage (VAC) Hz Model Code

100V 50/60Hz common A

110V 50/60Hz common B

120V 50/60Hz common C

220V 50/60Hz common D

230V 50/60Hz common E

100 - 240V 50/60Hz common F

220 - 240V 50/60Hz common G

120 - 277V 50/60Hz common H

277V 50/60Hz common J

-6-

LGE Internal Use Only

Page 7

Model name nomenclature (Back)

O

1. Area

2. Branch

CODE Type Language

1 Area English

2 Branch English

AA C W

3,4. Business Type

5. Exterior color

Description

Each area represents a letter written in English should

A : Korea

B : North America

C : Europe

D : Asia

Area (Branch) a letter written in English indicating the referred patients

K : Korea Branch

E ; Middle Southern America

F : Middle East / Africa

6,7. Certification

AA

3, 4

5

6, 7 Certification Number

Business

Type

Exterior

Color

number

English

00 : B2C / B2B / B2G

01 : B2C / B2B

02 : B2G

03 : B2C

04 : B2B

Appearance (body parts) referred to the color of the English abbreviation If you

duplicate the colors indicated with different alphabet letter.

A : Brown

B : Blue

E : Beige

L : Black

P : Pink

R : Red

01 : High Efficiency (Only Korea)

02 : KS (Only Korea)

03 : KC (Only Korea)

04 : High Efficiency / KS (Only Korea)

S : Silver

T : Titan

W : White

X : Bordeaux Purple

0 : No Color

-7-

LGE Internal Use Only

Page 8

Product specification

General specification

This specification applies to all LED flat light models.

1. Electric specification (4” 8W)

Item

Input voltage

(V, rms)

Input current

(A, rms)

Input power

(W, rms)

Input frequency

(Hz)

Test

Min. Typ. Max. Criteria

Conditions

AC 100 230 240

AC 0.027 0.034 0.096

AC (All) 7.2 8 8.64

AC 47 50 53

Rated voltage 10% (230V)

Criteria : 8W + 8%, -10%

Rated Frequency ± 3 Hz

Power factor

Output voltage

(V, rms)

Output current

(A, rms)

Output power

(W, rms)

Efficiency

(%)

AC 0.85

DC 28.00 29.50 30.68

DC 0.191 0.205 0.219

DC 5.34 6.04 6.71

AC (All) 75

Rated Voltage : AC 230V, 50Hz

By LED PKG characteristics change

(bin mixing 4%)

Converter output Tolerance 7%

-8-

LGE Internal Use Only

Page 9

2. Product specification

Classification 4 inch Unit

Watts 8 W

Light Output 520 540 560 lm

Lumens per Watt 65 67 70 lm/W

Light Color 3000 4000 5000 K

Color Accuracy (CRI) > 80

Beam Angle 100 ⁰(angle)

Size

Ф120 ⅹ 88(H)

Product Weight 358 g

AC 230

Input Voltage

(AC 100 – 240)

Input Frequency 50 Hz

Method of Power Input Single Phase Three Wiring System

Dimming 0 - 10V

Operating Temperature -20 ~ 50

mm

V

℃

Power Factor (PF) > 0.85

-9-

LGE Internal Use Only

Page 10

Exploded view

Screw,Machine

Y62708802

V62332001

V62332002

V62332003

SMPS,AC/DC

Screw,Machine

Heat Sink

Spring,Locker

-10-

Case,Body

Cover,Optic

Cover,Guide

LGE Internal Use Only

Page 11

Service Part List

No. Name Applicable model Part No.

1 LED Assembly

D4A0081EDF1.C0AAWAA

D4A0083EDF1.C0AAWAA

D4A0085EDF1.C0AAWAA

D4A0081EDF2.C0AAWAA

D4A0083EDF2.C0AAWAA

D4A0085EDF2.C0AAWAA

D4A0081EDF1.C0AAWAA

EAV62332001

EAV62332002

EAV62332003

EAV62332001

EAV62332002

EAV62332003

2 SMPS, AC/DC

D4A0083EDF1.C0AAWAA

D4A0085EDF1.C0AAWAA

EAY62708802

D4A0081EDF2.C0AAWAA

D4A0083EDF2.C0AAWAA

D4A0085EDF2.C0AAWAA

-11-

LGE Internal Use Only

Page 12

Installation environment

[●:can be installed, ▲: contact manufacturer, X: can not be installed]

Classification 8W

Temperate range (℃) -20 ~ 50℃

Installation

environment

Humidity range (%)

Indoor installation (Fixed facing downward)

Working plant

Indoor gymnasium

Warehouse building

High rise building (Indoor)

Large building (Indoor)

Open square, playground

Park

Large billboard

95% RH <

●

●

●

●

●

●

-

-

-

Large wall

Bridge

Hot and humid environment

Location where gas is used

Location with vibration

Location with metallic dust

Area difficult for A/S

Wireless LAN

-12-

-

-

▲

X

▲

▲

▲

●

LGE Internal Use Only

Page 13

Installation method

-13-

LGE Internal Use Only

Page 14

Dimming Cable Connection

-14-

LGE Internal Use Only

Page 15

Dimming Wiring Diagram and Capability

-15-

LGE Internal Use Only

Page 16

Incorrect Application and Use

※ The following lists incorrect applications/uses.

Please be careful during installation and use in following cases as they can result

in electric shock, injury or skin burn.

No. Incorrect application and use Expected risk

Using product after there was an impact to the product, for example, from dropping

1

Using the product after configuring below the rated current capacity

2

Using the product after disassembling or reconfiguring the product arbitrarily

3

Installing the product in an environment where water can penetrate into the product

Using for underwater lighting purpose

4

(Underwater view, search light, fishing, promotional event etc.)

Using the product without sufficiently drying or repairing the product

5

after the product has been submersed in water

Using the product with excessive power voltage variance. (±10% or more)

6

Fire / Electric shock

Fire / Electric shock

Fire / Electric shock

Electric shock

Fire / Electric shock

Fire / Electric shock

7

8

9

10

11

12

13

14

15

16

17

Using the product with only the power cable connected and without grounding

the product properly

Using the product with excessively bent or damaged power cord

Do not insert pin, coin or metallic wire into the interior/exterior holes on the casing

Using the product while exposed to flammable material nearby

Disassembling the product while in use

Repairing and disassembling the product by unqualified technician

When cleaning, repairing or brushing the product without disconnecting the power

Using for purposes other than lighting. (Heating food, drying clothes, heating etc.)

Moving the product by holding parts other than the main unit.

(Moving the product by holding the reflector etc.)

Moving the product carelessly without considering the weight

Using the product near the heating device

Electric shock

Fire / Electric shock

Fire / Electric shock

Fire / Electric shock

Fire / Electric shock

Fire / Electric shock

Electric shock

Fire / Electric shock

Injury

Injury

Fire / Explosion

18

19

20

21

Using the product in frequently flooding location

Using the product with the power cord arbitrarily cut

Installing and using the product in a humid or wet location

Using the product underwater

-16-

Electric shock

Fire / Electric shock

Fire / Electric shock

Electric shock

LGE Internal Use Only

Page 17

Troubleshooting

No. Problem Checkpoint Resolution

1 Lighting does not work

or flickers

2 Cannot adjust

the brightness

3 Gap between product

and ceiling after

the installation

① Check AC power cable

② Check DC power cable connection

③ Check after replacing LED assembly

④ Check after replacing SMPS

⑤ If abnormal after checking above

① Check connector for dimming

connection

② Check 0~10V interface cable

③ Check after replacing SMPS

④ If abnormal after checking above

① Check if inner side of the ceiling

where product is assembled is even

② Check if the spring is missing

from the heat sink

• Connect the power

• Connect the DC power cable

• Replace LED assembly

• Replace SMPS

• Replace product

• Replace connector for dimming

connection

• Replace 0~10V interface cable

• Replace SMPS

• Request to replace dimmer

• Rotate product to move spring

to location without gap

• After disassembling the product,

reinstall the product after assembling

the spring on the heat sink

4 Weld line or alien

particle is visible on the

surface of cover and

guide after the

installation

5 Hot spot is visible

③ Check if the tension of the spring

is sufficient

④ Check the deformation of cover

and guide

⑤ If abnormal after checking above

① Check the surface of the product

(Scratch, flow mark etc.)

① Check after replacing cover and optic

② Check after replacing LED assembly

③ If abnormal after checking above

※ SMPS is supplied by LG and is replaced on 1:1 product basis.

• Replace spring

• Replace cover and guide

• Connect facility personnel

or call center

• Replace cover and guide

• Replace cover and optic

• Replace LED assembly

• Replace product

-17-

LGE Internal Use Only

Page 18

Part replacement method

Part Picture Direction

SMPS

Case, Body

Cover, Optic

Cover, Guide

Spring

①

①,②,③

①

②

③,④

⑥,⑦,⑧,⑨

④

⑤

① Use electric or manual driver to loosen 2 M3*6

machine screws assembled on SMPS and heat sink.

② Replace the SMPS.

① Use the electric driver to loosen the M3*30

tapping screw assembled on the heat sink

and main unit (Case body, cover guide).

(M3*30 4 screws)

② Disassemble the heat sink from the case body.

③ Disassemble the case body from the cover guide.

④ Disassemble the cover optic from the cover guide.

⑤ Remove the part to replace and replace it with a new part.

⑥ Place the cover optic on the cover guide.

⑦ Place the case body on the cover guide.

⑧ Align the case body groove to that of the heat sink

and place the heat sink on top of the case body.

⑨ Use the electric or manual driver to tighten the M3*30

tapping screw to assemble the heat sink and main unit

(Case body, cover guide). (M3*30 4 screws)

① Use the electric driver to loosen the M3*30 tapping screw

assembled on the heat sink and main unit

(Case body, cover guide). (M3*30 3 screws)

② Disassemble the heat sink from the case body.

③ Separate the heat sink and the spring, and replace

the spring. (2 springs)

④ Align the case body groove to that of the heat sink

and place the heat sink on top of the case body.

⑤ Use the electric or manual driver to tighten the M3*30

tapping screw to assemble the heat sink and main unit

(Case body, cover guide). (M3*30 4 screws)

LED Assembly

Base Assembly,

Rear

①,②,③

①,②,③,④

① Use the electric driver to loosen the M3*30 tapping screw

assembled on the heat sink and main unit

(Case body, cover guide). (M3*30 4 screws)

② Disassemble the heat sink from the case body

③ Disassemble the LED PCB from the heat sink.

(M2*4 4 locations)

④ Replace the LED PCB with a new one. If the insulator is

damaged, replace it as well.

① Use the electric driver to loosen the M3*30 tapping screw

assembled on the heat sink and main unit

(Case body, cover guide). (M3*30 4 screws)

② Disassemble the heat sink from the case body.

③ Disassemble the LED PCB from the heat sink.

(M2*4 4 locations)

④ Replace heat sink, bush or insulator with a new part.

-18-

LGE Internal Use Only

Loading...

Loading...