Page 1

System

SERVICE MANUAL

System

Heat Pump Air Conditioner

SERVICE MANUAL

LG

MODELS: CRUN/CRNN Series

website http://www.lgservice.com

e-mail http://www.lgeservice.com/techsup.html

CAUTION

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

Page 2

2

Air Conditioner Service Manual

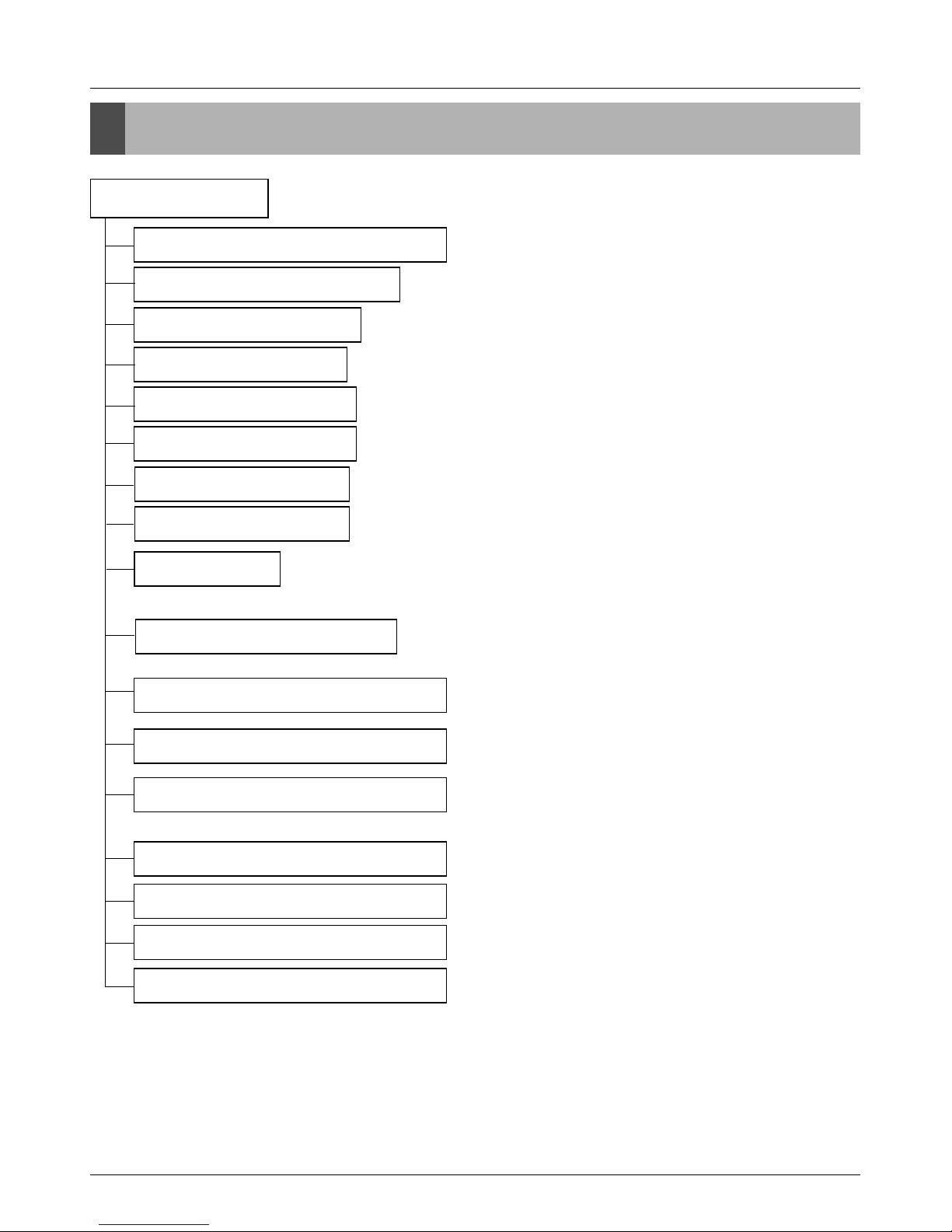

TABLE OF CONTENTS

Model Name Namerclature...........................................................................3

Model Names.................................................................................................4

Safety Precautions .......................................................................................5

Indoor Units.............................................................................................9

Ceiling Mounted Cassette Type (1 way)................................................10

Ceiling Mounted Cassette Type (4 way)................................................20

Ceiling Mounted Duct Type (High static)..............................................36

Ceiling Mounted Duct Type (Low static)...............................................48

Convertible Type.....................................................................................58

Wall Mounted Type..................................................................................77

Art Cool Type (Mirror).............................................................................93

Art Cool Type.........................................................................................111

Art Cool Type (Wide).............................................................................127

Flor Standing Type................................................................................144

Outdoor Units.....................................................................................154

Control Devices and Functions...........................................................182

Trouble Shooting Guide .......................................................................209

Appendix................................................................................................243

Page 3

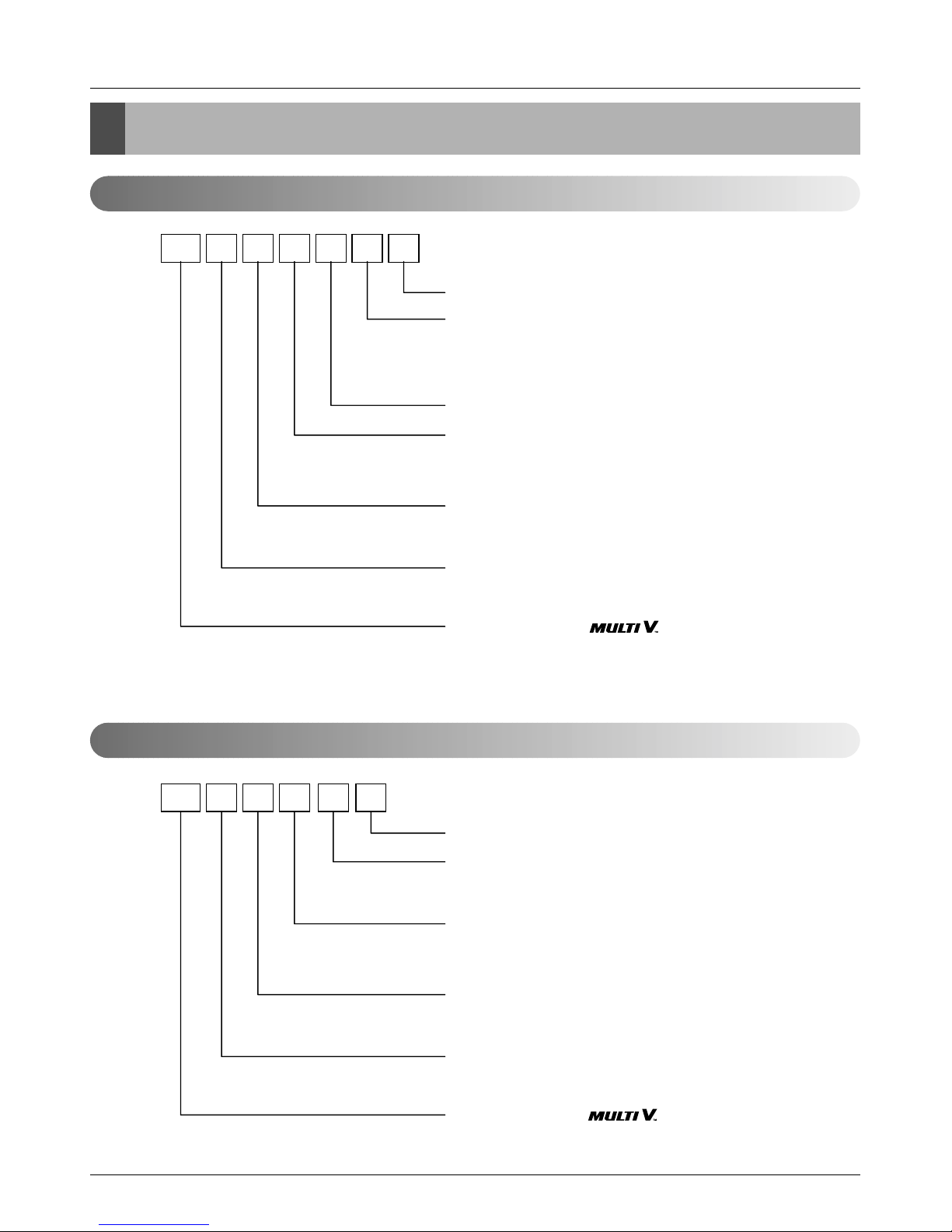

Model Name Nomenclature

Service Manual 3

CRN N 607 ASR 0

Serial Number

Combinations of functions

A: Basic Function

Art Cool Type Panel Color

B: Blue, C: Cherry, D: Wood, M: Metal

N: Walnut, R: Mirror, W: White, G: Gold

Chassis Name

Electrical Ratings

1: 1ø, 100V~115V, 60Hz, 2: 1ø, 220V~240V, 60Hz

6: 1ø, 220V~240V, 50Hz, 7: 1ø, 100V~115V, 50Hz

Total Cooling Capacity in Btu/h unit

Ex) 5,000 Btu/h ➞ ‘05’ , 18,000 Btu/h ➞ ‘18’

Combination of Inverter Type and

Cooling Only or Heat Pump or Heat Recovery

N: AC Inverter and H/P, V: AC Inverter and C/O

Indicates that this is

using the R-407C.

System indoor unit

CRU N 8100 T 0

Air Discharge Type

S: Side discharge

T: Top discharge

Serial Number

Electrical Ratings

8: 3ø, 380V~415V, 50Hz, 9: 3ø, 380V~415V, 60Hz

A: 3ø 220V, 50Hz, B: 3ø, 220V, 60Hz

C: 3ø, 440V~460V, 50Hz, D: 3ø, 440V~460V, 60Hz

Total Cooling Capacity in Horse Power(Hp) unit

Ex) 4.5 Hp ➞ ‘45’ , 10 Hp ➞ ‘100’

Combination of Inverter Type and

Cooling Only or Heat Pump or Heat Recovery

N: AC Inverter and H/P, V: AC Inverter and C/O

Indicates that this is System outdoor unit

using the R-407C.

Note: Suffix - Look: Wall Mounted Type

- Panel: Ceiling Mounted Cassette Type

Indoor Unit

Outdoor Unit

Page 4

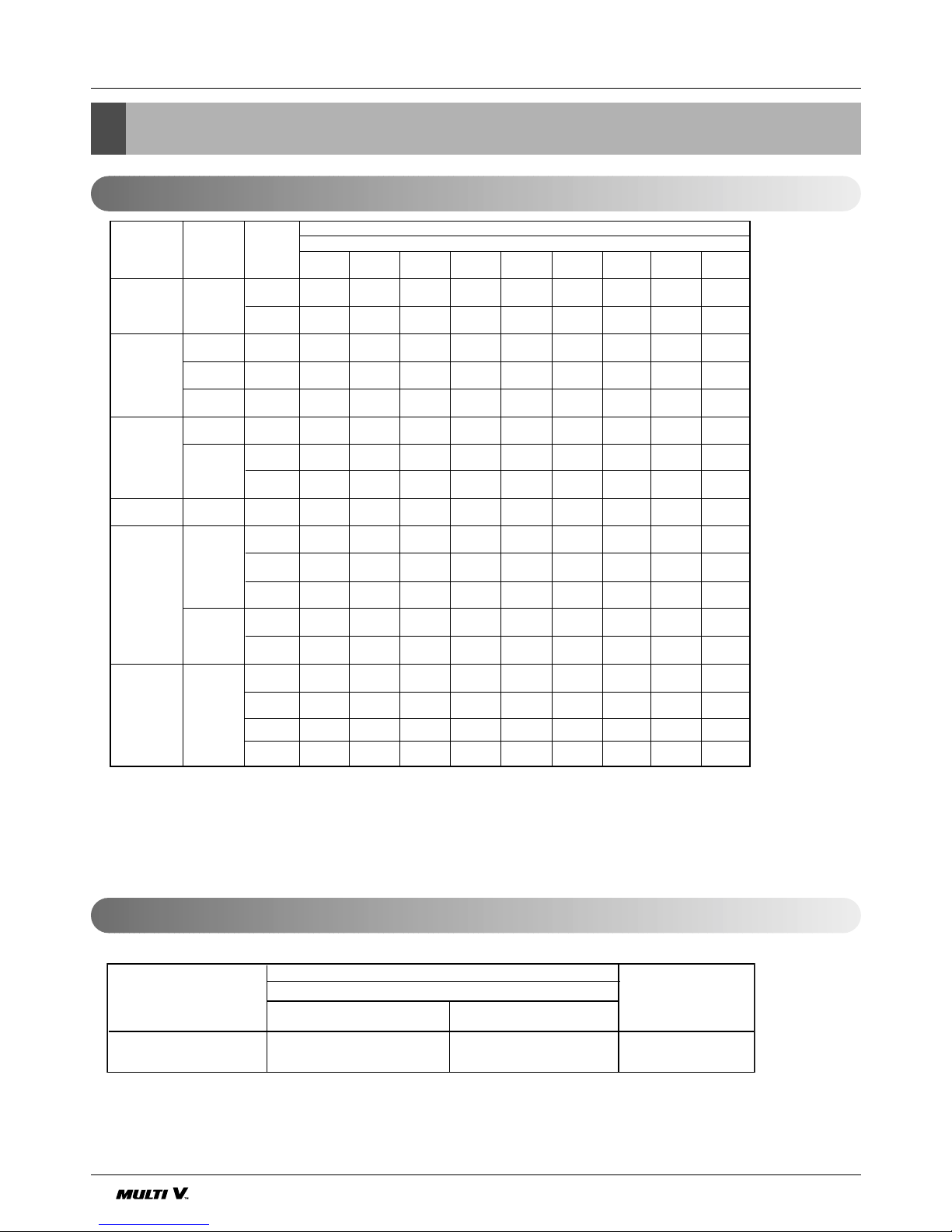

4

Model Names

Series

Model name

Power

Supply

Inverter Series

(Heat Pump)

4.5

(44,000)

Capacity, Hp(Btu/h)

10

(95,500)

CRUN

458S0

CRUN

1008T0

3ø, 4W,380V~415V,

50Hz

Category Type

Chassis

Name

Model Name

Capacity, kW(Btu/h)

Wall

Mounted

Type

General

SR

ST

2.1

(7,000)

CRNN

076SRA0

-

2.6

(9,000)

CRNN

096SRA0

-

3.5

(12,000)

CRNN

126SRA0

-

5.3

(18,000)

-

CRNN

186STA0

7.0

(24,000)

-

-

8.2

(28,000)

-

-

10.6

(36,000)

-

-

12.3

(42,000)

-

-

14.1

(48,000)

-

-

Art Cool

Mirror

SU

SP

CRNN

076SU*0

-

CRNN

096SU*0

CRNN

126SU*0

-

-

-

-

-

-

-

-

-

-

-

-

Art

Cool

CRNN

096SP*0

CRNN

126SP*0

SV

-

CRNN

186SV*0

CRNN

126SV*0

-----

Wide

-

Ceiling

Cassette

1 Way

TC

CRNN

076TCA0

CRNN

096TCA0

CRNN

126TCA0

------

TE

-

CRNN

186TEA0

-----

4 Way

-

CRNN

126TEA0

TD

--

CRNN

246TDA0

--

CRNN

286TDA0

CRNN

366TDA0

CRNN

426TDA0

CRNN

486TDA0

Ceiling

& Floor

Convertible

VB

-

CRNN

186VBA0

CRNN

246VBA0

------

Ceiling

Concealed

Duct

High

Static

BH

BG

BE

BN

Low

Static

BJ

-

CRNN

186BHA0

CRNN

246BHA0

--

-

-- -

CRNN

286BGA0

CRNN

366BGA0

----

-

-

CRNN

426BGA0

CRNN

486BEA0

---- ----

CRNN

076BNG0

--- -----

-

CRNN

096BJG0

CRNN

126BJG0

------

CAA

CBA

CCA

CDA

With

Case

CRNN

076CAA0

--------

CRNN

096CBA0

CRNN

126CBA0

CRNN

186CCA0

CRNN

246CDA0

---- --

Floor

Standing

Indoor Unit

Outdoor Unit

Page 5

Safety Precautions

Service Manual 5

Safety Precautions

To prevent indury to the user or other people and property damage the following instructions must be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the

following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Carefully read the labels affixed to the main unit.

Be sure not to do.

Be sure to follow the instruction.

This symbol indicates a part which must be grounded.

This symbol indicates that caution should be taken with rotating parts.

(This symbol is displayed on the main unit label.) <Color: Tellow>

This symbol indicates that the main switch must be turned off before service.

(This symbol is displayed on the main unit label.) <Color: Blue>

This symbol alerts you to the risk of electric shock.

(This symbol is displayed on the main unit label.) <Color: Yellow>

This symbol alerts you to the risk of hot surface.

(This symbol is displayed on the main unit label.) <Color: Yellow>

This symbol alerts you to hazards that could cause harmto the air conditioner.

NOTICE

This symbol indicates special notes.

ELV

Pay attention to electric shock.

And at servicing, please shut down the power supply for both of Indoor and Outdoor

Unit.

Page 6

6 Indoor Unit

Safety Precautions

Use the specified cables for wiring. Make the

connections securely so that the outside force

of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

Always use accessories specified by LG

Electronics.

- Ask an authorized technician to install the

accessories. Improper installation by the user

may result in water leakage, electric shock, or

fire.

Cautions before installation

Never repair the unit. If the air conditioner

must be repaired, consult the dealer.

- If the unit is repaired improperly, water leakage,

electric shock, or fire may result.

Do not touch the heat exchanger fins.

- Improper handling may result in injury.

If refrigerant gas leaks during service work,

ventilate the room.

- If the refrigerant gas comes into contact with a

flame, poisonous gases will be released.

Have all electric work done by a licensed

electrician according to "Electric Facility

Engineering Standard" and "Interior Wire

Regulations" and the instructions given in

this manual and always use a special circuit.

- If the power source capacity is inadequate or

electric work is performed improperly, electric

shock and fire may result.

Securely install the cover of control box and

the panel.

- If the cover and panel are not installed properly,

dust or water may enter the outdoor unit and fire

or electric shock may result.

When installing and moving the air conditioner to another site, do not charge it with a

refrigerant different from the refrigerant

(R407C) specified on the unit.

- If a different refrigerant or air is mixed with the

original refrigerant, the refrigerant cycle may

malfunction and the unit may be damaged.

If the air conditioner is installed in a small

room, measures must be taken to prevent the

refrigerant concentration from exceeding the

safety limit when the refrigerant leaks.

- Consult the dealer regarding the appropriate

measures to prevent the safety limit from being

exceeded. Should the refrigerant leak and cause

the safety limit to be exceeded, hazards due to

lack of oxygen in the room could result.

When moving and reinstalling the air conditioner, consult the dealer or an authorized

technician.

- If the air conditioner is installed improperly, water

leakage, electric shock, or fire may result.

Page 7

Safety Precautions

Service Manual 7

After completing service work, make sure

that refrigerant gas is not leaking.

- If the refrigerant gas leaks and is exposed to a

fan heater, stove, oven, or other heat source, it

may generate noxious gases.

Do not reconstruct or change the settings of

the protection devices.

- If the pressure switch, thermal switch, or other

protection device is shorted and operated

forcibly, or parts other than those specified by

LG Electronics are used, fire or explosion may

result.

Do not install the unit where combustible gas

may leak.

- If the gas leaks and accumulates around the

unit, an explosion may result.

Do not use the air conditioner where food,

pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly

reduce the performance of the air conditioner or

damage its parts.

Do not install the unit on a structure that may

cause leakage.

- When the room humidity exceeds 80% or when

the drain pipe is clogged, condensation may drip

from the indoor unit. Perform collective drainage

work together with the outdoor unit, as required.

Take measures to prevent children from

touching the unit.

- Injuries such as cuts could occur if a child

touches the surface of the fins on the heat

exchanger.

Cautions for electrical work and movement

Ground the unit.

- Do not connect the ground wire to gas or water

pipes, lightning rods, or telephone ground lines.

Improper grounding may result in electric shock.

Install the power cable so that tension is not

applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

Use power cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate

heat, and cause a fire.

Use only a circuit breaker and fuse of the

specified capacity.

- A fuse or circuit breaker of a larger capacity or a

steel or copper wire may result in a general unit

failure or fire.

Page 8

8 Indoor Unit

Safety Precautions

Do not wash the air conditioner units.

- Washing them may cause an electric shock.

Be careful that the installation base is not

damaged by long use.

- If the damage is left uncorrected, the unit may

fall and cause personal injury or property

damage.

Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not play with them. If children

play with a plastic bag which was not torn apart, they face the risk of suffocation.

Cautions before the test run

Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can result in severe damage to

internal parts. Keep the power switch turned on during the operational season.

Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause an electric shock.

Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes may be hot or cold, depending on the

condition of the refrigerant flowing through the refrigerant piping, compressor, and other refrigerant

cycle parts. Your hands may suffer burns or frost-bite if you touch the refrigerant pipes.

Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise, water leakage and trouble

may occur.

Page 9

Service Manual 9

Indoor Unit

Indoor Units

Page 10

10 Indoor Unit

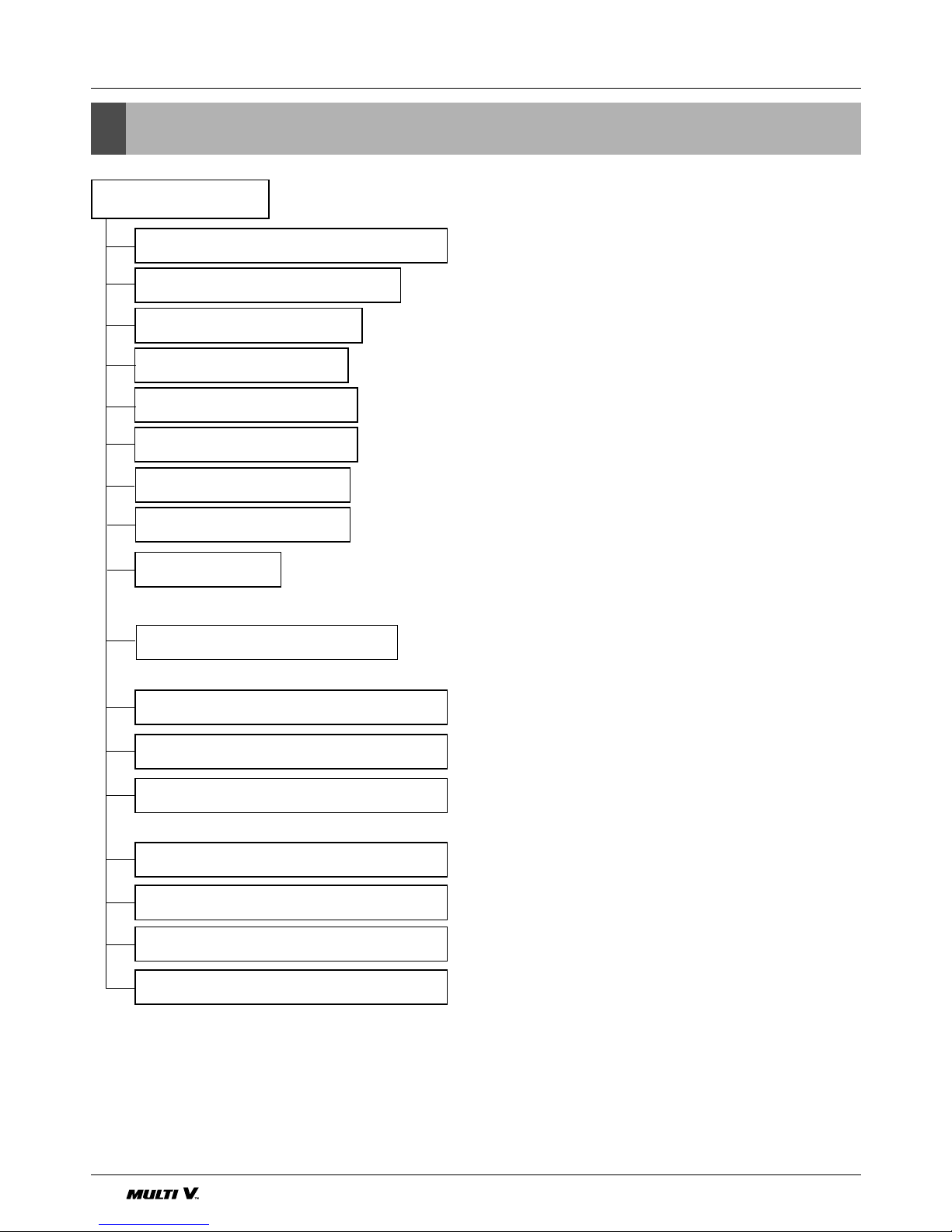

CRNN-TC

Ceiling Mounted Cassette Type (1Way)

1. Specifications.............................................................................11

2. Functions ....................................................................................12

3. Operation Details........................................................................13

4. Dimensional Drawings...............................................................15

5. Piping Diagrams.........................................................................16

6. Wiring Diagrams.........................................................................17

7. Exploded View............................................................................18

8. Replacement Parts List..............................................................19

Page 11

1. Specifications

Service Manual 11

Specifications

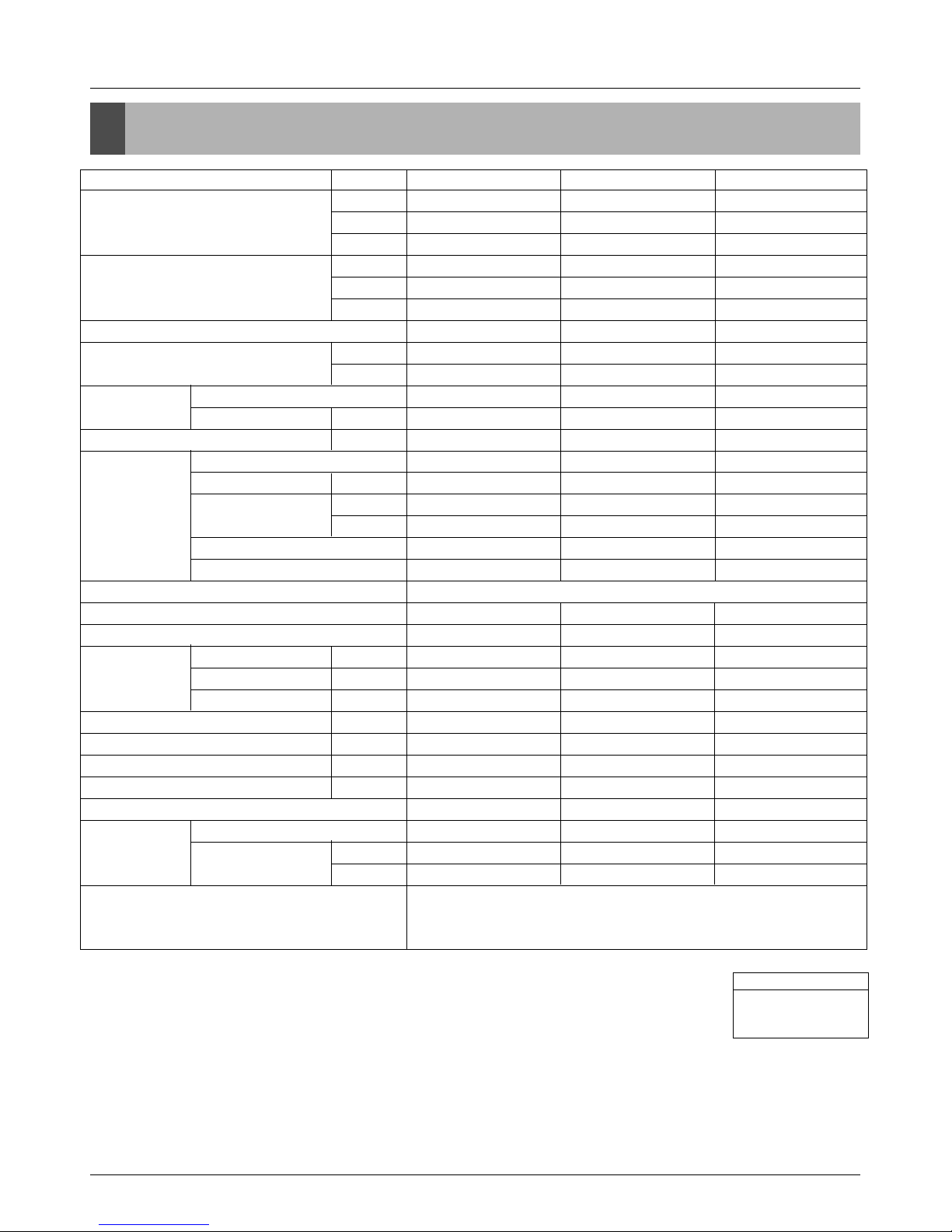

Model Unit

W

Cooling Capacity kcal/h

Btu/h

W

Heating Capacity kcal/h

Btu/h

Casing

Dimensions (W*H*D)

mm

inch

Coil

Rows x Columns x FPI

Face Area m

2

Moisture removal l/h.

Type

Fan

Motor Output x Number

W

Air Flow Rate(H/M/L)

cmm

cfm

Drive

Speed Control

Temperature Control

Sound Absorbing Thermal Insulation Material

Safety Device

Liquid Side mm(inch)

Pipe Connections

Gas Side mm(inch)

Drain Pipe(Internal Dia.)

mm

Net Weight kg(lbs)

Noise Level

(Sound Press,1.5m, H/M/L)

dB±3

Power Supply Ø,V,Hz

Power Cable

AWG#:P*mm

2

Refrigerant Control

Panel Color

Decoration Panel

Dimensions (W*H*D) mm

inch

Standard Accessories

CRNN076TCA0 CRNN096TCA0 CRNN126TCA0

2,100 2,600 3,500

1,806 2,235 3,009

7,165 8,871 11,942

2,363 2,925 3,938

2,031 2,515 3,385

8,061 9,980 13,435

Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

860*390*180 860*390*180 860*390*180

33.8*15.3*7.0 33.8*15.3*7.0 33.8*15.3*7.0

2 x 12 x 18 2 x 12 x 21 2 x 12 x 21

0.184 0.184 0.184

1.0 1.0 1.5

Cross Flow Fan Cross Flow Fan Cross Flow Fan

14 x 1 14 x 1 14 x 1

6/5/4 7/6/5 10/9/8

225/197/168 246/216/195 353/317/283

Direct Direct Direct

Phase Control Phase Control Phase Control

Microprocessor, Thermostat for cooling and heating

Foamed polystyrene Foamed polystyrene Foamed polystyrene

Fuse, Thermal Fuse for Fan Motor Fuse, Thermal Fuse for Fan Motor Fuse, Thermal Fuse for Fan Motor

6.35 (1/4) 6.35 (1/4) 6.35 (1/4)

12.7 (1/2) 12.7 (1/2) 12.7 (1/2)

25 25 25

17(37.5) 17(37.5) 17(37.5)

35/32/29 37/34/31 39/36/35

1,220~240,50 1,220~240,50 1,220~240,50

12:3*2.5 12:3*2.5 12:3*2.5

L.E.V L.E.V L.E.V

White White White

1050*480*30 1050*480*30 1050*480*30

41.3*18.9*1.2 41.3*18.9*1.2 41.3*18.9*1.2

Owner Manual, Installation Manual, Paper Pattern for Installation, Drain Hose, Clamp

Metal, Insulation for Fitting, Sealing Pads, Clamps, Screws, Washers, Positioning Jig

for Installation, Insulation for Hanger Bracket, Air Outlet Blocking Pad.

Notes:-

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5 m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

4. L.E.V. : Linear Expansion Valve

Conversion Formula

kcal/h = kW x 860

Btu/h = kW x 3414

cfm = m

3

/min x 35.3

Page 12

12 Indoor Unit

Functions

2. Functions

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Soft Dry Operation Mode

Airflow Direction Control

Deice (defrost) control (Heating)

Auto Restart

Hot-start Control (Heating)

• The indoor fan does not rotate until the evaporator piping temperature will be reached at 25°C.

Compact and light design

• To install a unit is very convenient because of smaller

size than textile.

Low noise

• The most advanced low-noise design.

• The adoption of turbo fan and round type heat exchang-

er give the quietest operation.

Long life filter

• Long life wrinkle(type) and washable and anti-bacteria

filter is adopted.

High head Drain pump

• Built-in drain pump automatically drains water.

• A standard drain-head height of up to 700mm is possible.

High-Ceiling corresponding Function

• According to the height of ceiling, the RPM of indoor fan

motor is selected to increase air reaching distance.

Central Control(Optional)

•

It is operating individually or totally by central control function.

• Room temperature sensor. (Thermistor)

•

Maintains the room temperature in accordance with the Setting temperature

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• Jet, High, Med, Low

• Intermittent operation of fan at low speed.

• The louver can be set at swing up and down automatically.

• Although the air-conditioner is turned off by a power failure, it is restarted auto-

matically previous operation mode after power supply.

• Both the indoor and outdoor fan stops during defrosting.

• Hot start after defrost ends.

Page 13

3. Operation Details

Service Manual 13

Operation Details

■ Time Delay Safety Control

• 5sec

Vertical louvers are delayed for 5 secs to be opened to prevent the frictional sound between louver and air

flow.

• 30sec The 4-way valve is ceased for 30sec. to prevent abnormal noise when the Heating operation is OFF or

switched to the other operation mode while compress is off.

While compressor is running, it takes 3~5 seconds to switch.

■ Auto Swing Control

• This function is to swing the louver up and down automatically.

■ Air-Filter Checking Control

• 'Filter' sign will appear on the remote controller display and main body display when an air-filter is polluted. Then

clean the air-filter referring to Owners Manual.

■ Soft-Dry Operation

• The indoor fan speed is automatically set to the low, and fan speed control is not available because of already being

set to the best speed for Dry Operation by microcontroller control.

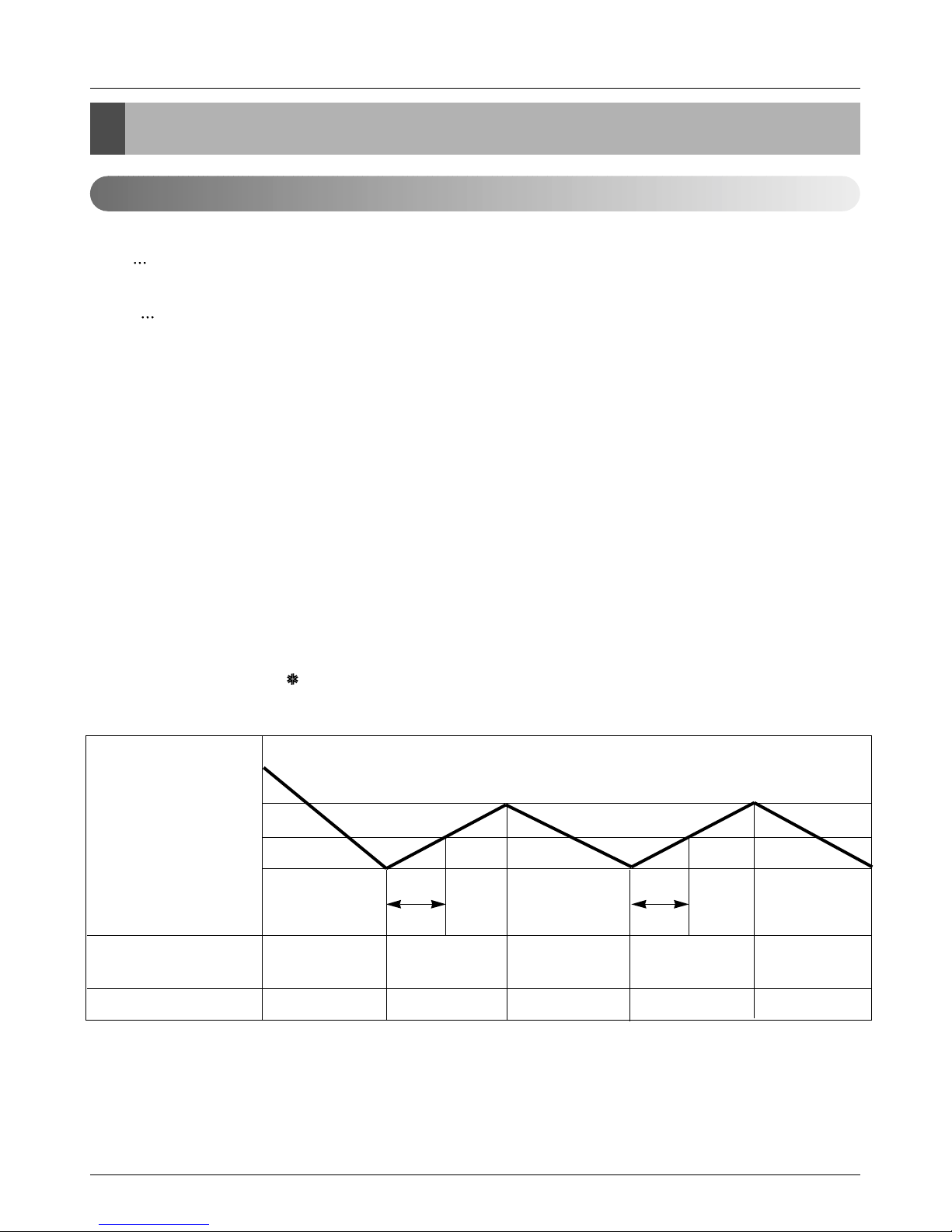

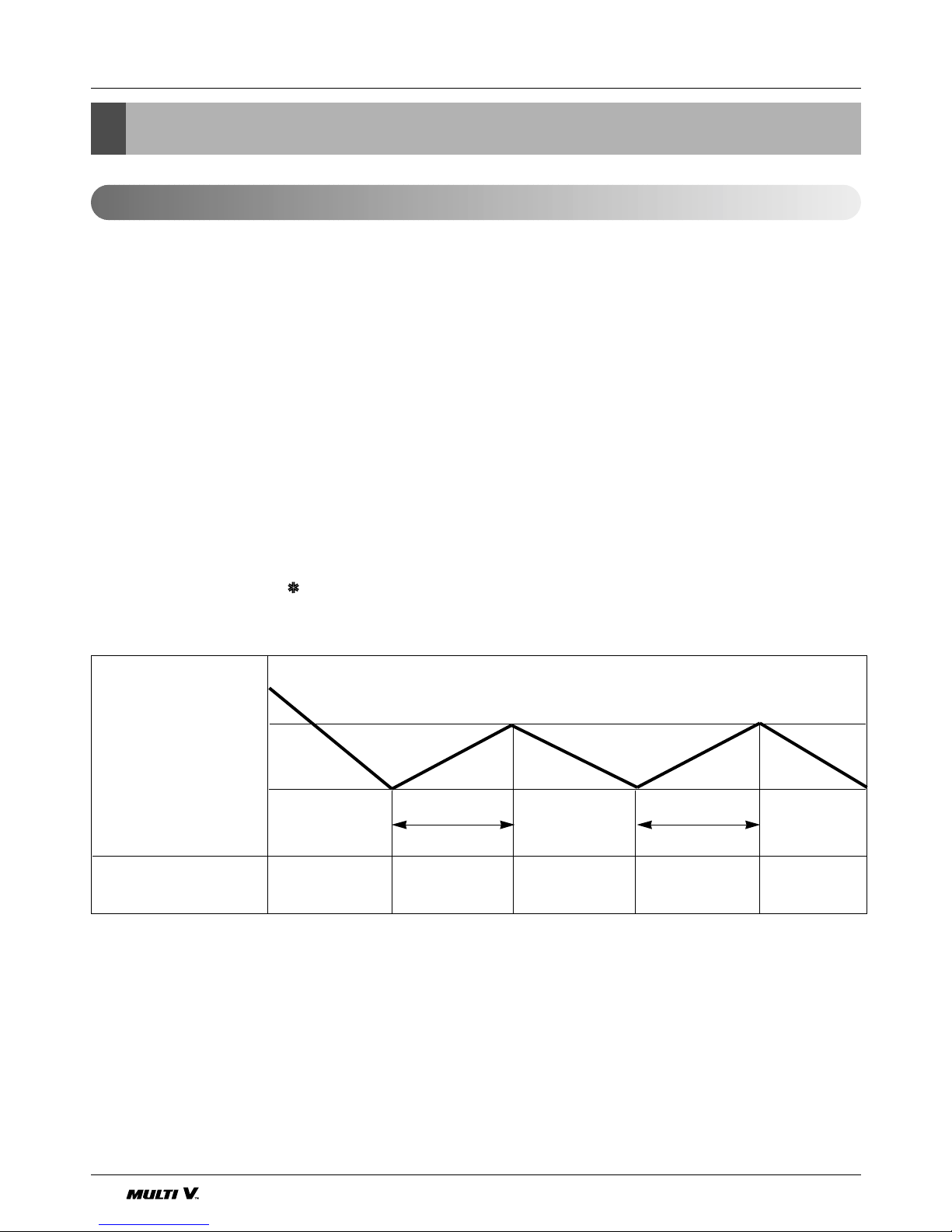

■ Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote con-

troller and the operation diagram is as follows.

Intake Air Temperature

SET TEMPERATURE +0.5°C

(COMP. ON)

SET TEMPERATURE

SET TEMPERATURE -0.5°C

(COMP. OFF)

Selected Selected Selected

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low

More than

3 minutes

More than

3 minutes

(1) The function of main control

Page 14

14 Indoor Unit

Operation Details

Intake Air Temperature.

Setting Temperature .+3°C

(Compressor OFF)

Setting Temperature

(Compressor ON)

INDOOR FAN

COMPRESSOR ON OFF ON OFF

A point; While the indoor Heat-Exchanger temperature is higher than 40°C fan operates at low speed,

when it becomes lower than 40˚C fan stops.

B point; When the indoor Heat-Exchanger temperature is higher than 42°C, fan operates at selected fan

speed, when it becomes lower than 39°C, the fan operates at low speed.

■ Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as follows.

(Hot Start)

Low

OFF

Selected

Fan Speed

minimum 3min

Selecting fan

speed

LowLowLow OFF OFF

minimum

10sec.

1min

A

A

minimum

1min.

minimum

10sec.

B

■ Hot-Start Control

• The indoor fan sdoes not rotate until the evaporator piping temperature reaches to 25°C.

• If the evaporator piping temperature drops below 22°C, indoor fan stops again.

• The operation diagram is as follows.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN

ON

OFF LOW

Selected

fan speed

22°C

25°C

Page 15

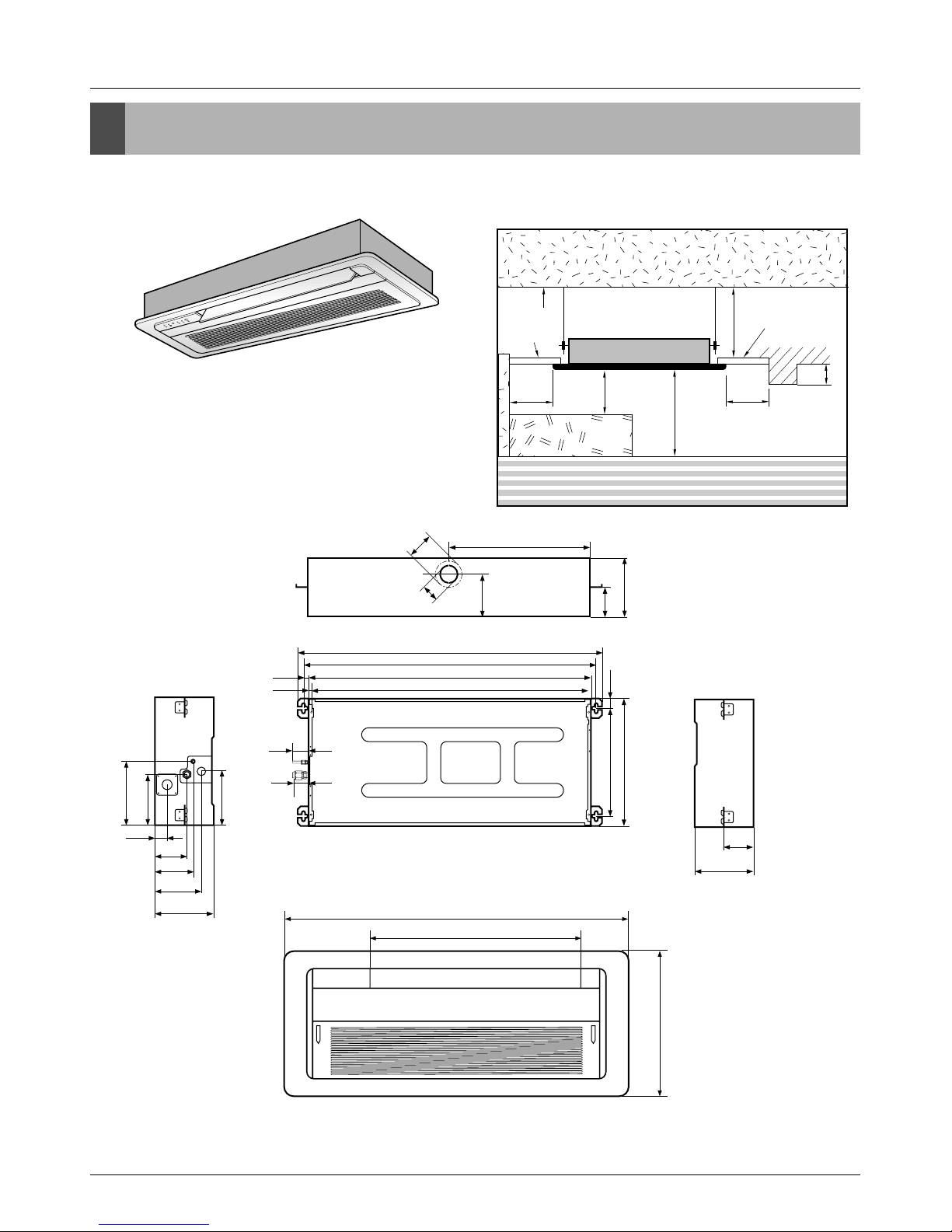

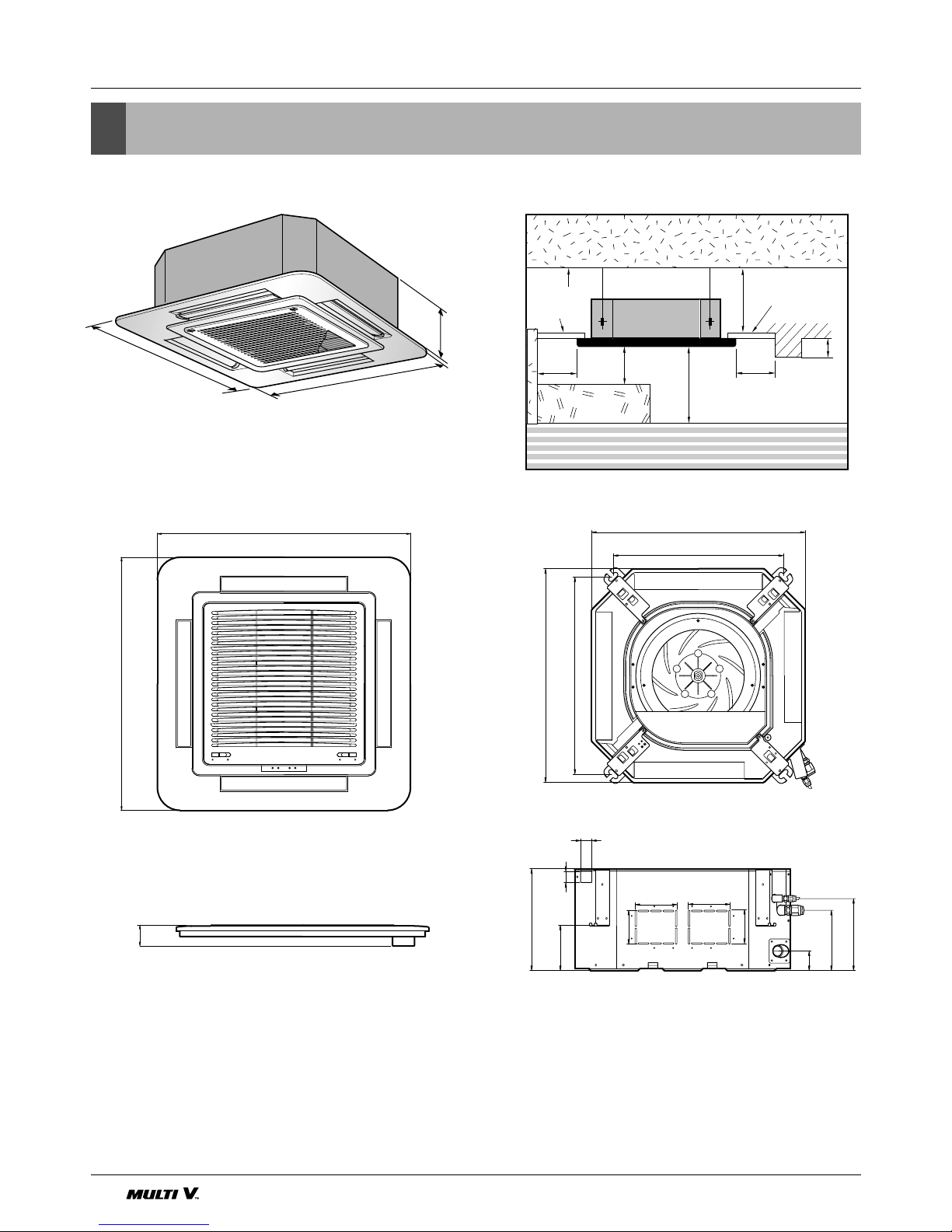

4. Dimensional Drawings

Service Manual 15

Dimensional Drawings

846

860

328.430.8

390

893.4

931.6

16.7

50

42.7

7

155

97.7

37

116.3

141.8

180

164

194.4

91.6

180

430

130

Ø80

Ø55

180

91.6

(Unit: mm)

Unit:cm

Ceiling

Ceiling Board

Ceiling Board

20 or more

Above 250

330 or less

100

or more

50 or

more

50 or

more

30 or less

Floor

694.5

1050

480

Page 16

16 Indoor Unit

Piping Diarams

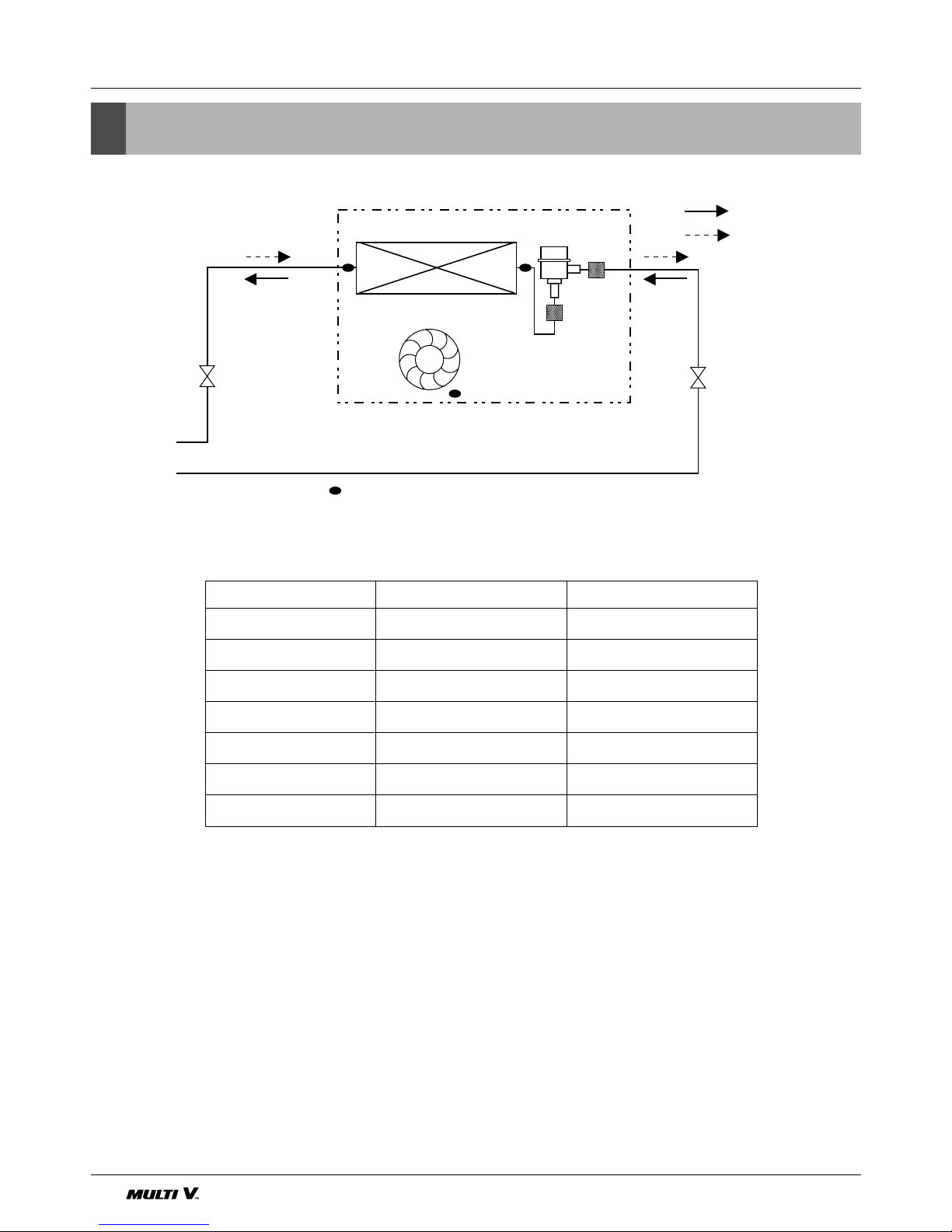

5. Piping Diagrams

: Thermistor

Heat Exchanger

C.F.F.

lndoor unit

LEV

Filter

Filter

:Heating

:Cooling

Refrigerant pipe connection port diameter

Model

CRNN076TCA0

CRNN096TCA0

CRNN126TCA0

Gas

12.7(1/2)

Liquid

6.35(1/4)

[unit: mm(inch)]

Page 17

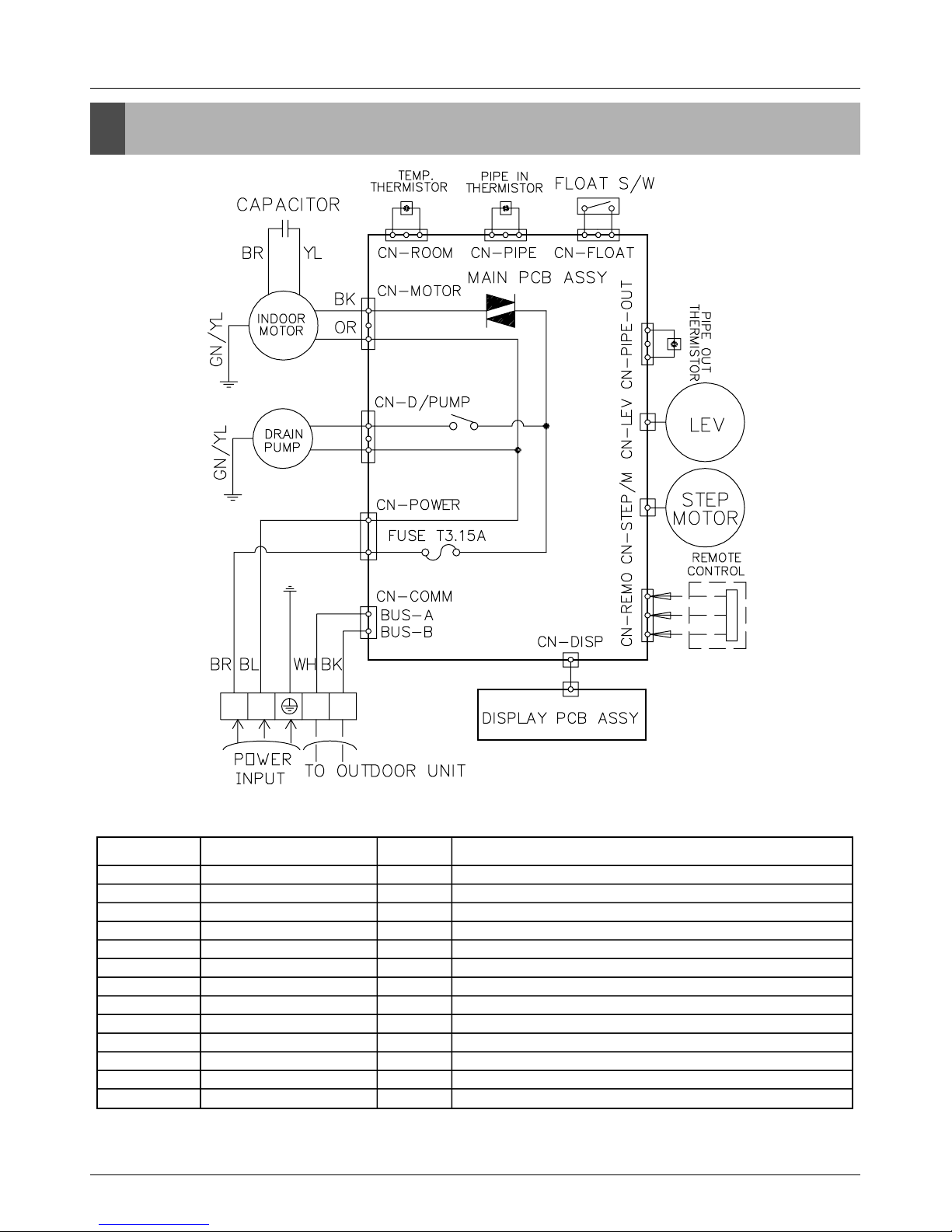

6. Wiring Diagrams

Service Manual 17

Wiring Diagrams

CN-POWER

CONNECTOR

NUMBER

CN-MOTOR2

CN-D/PUMP

CN-COMM

CN-DISP1

CN-LEV

CN-STEP/M1

CN-FLOAT

CN-PIPE

CN-PIPE/O

CN-ROOM

CN-REMO

CN-POWER

CN-MOTOR2

CN-COMM

CN-DISP1

CN-LEV

CN-STEP/M1

CN-PIPE

CN-PIPE/O

CN-ROOM

CN-REMO

AC POWER SUPPLY

AC FAN MOTOR OUTPUT

DRAIN PUMP OUTPUT

COMMUNICATION

DISPLAY

LEV OUTPUT

STEP MOTOR

FLOAT SWITCH INPUT

PIPE SENSOR

DISCHARGE PIPE SENSOR

ROOM SENSOR

REMOTE CONTROLLER

WHITE

YELLOW

WHITE

WHITE

WHITE

WHITE

WHITE

BLUE

WHITE

RED

BLUE

WHITE

AC POWER LINE INPUT FOR INDOOR CONTROLLER

MOTOR OUTPUT OF PHASE CONTROL

AC OUTPUT FOR DRAIN PUMP

COMMUNICATION BETWEEN INDOOR AND OUTDOOR

DISPLAY OF INDOOR STATUS

LEV CONTROL OUTPUT

STEP MOTOR OUTPUT

FLOAT SWITCH SENSING

PIPE THERMISTOR

DISCHARGE PIPE THERMISTOR

ROOM THERMISTOR

REMOTE CONTROL LINE

SPEC COLOR DESCRIPTION

CN-AIRC

AIR CLEAN WHITE AIR CLEAN SIGNAL

(Transmission)

2(N)1(L) 3 4

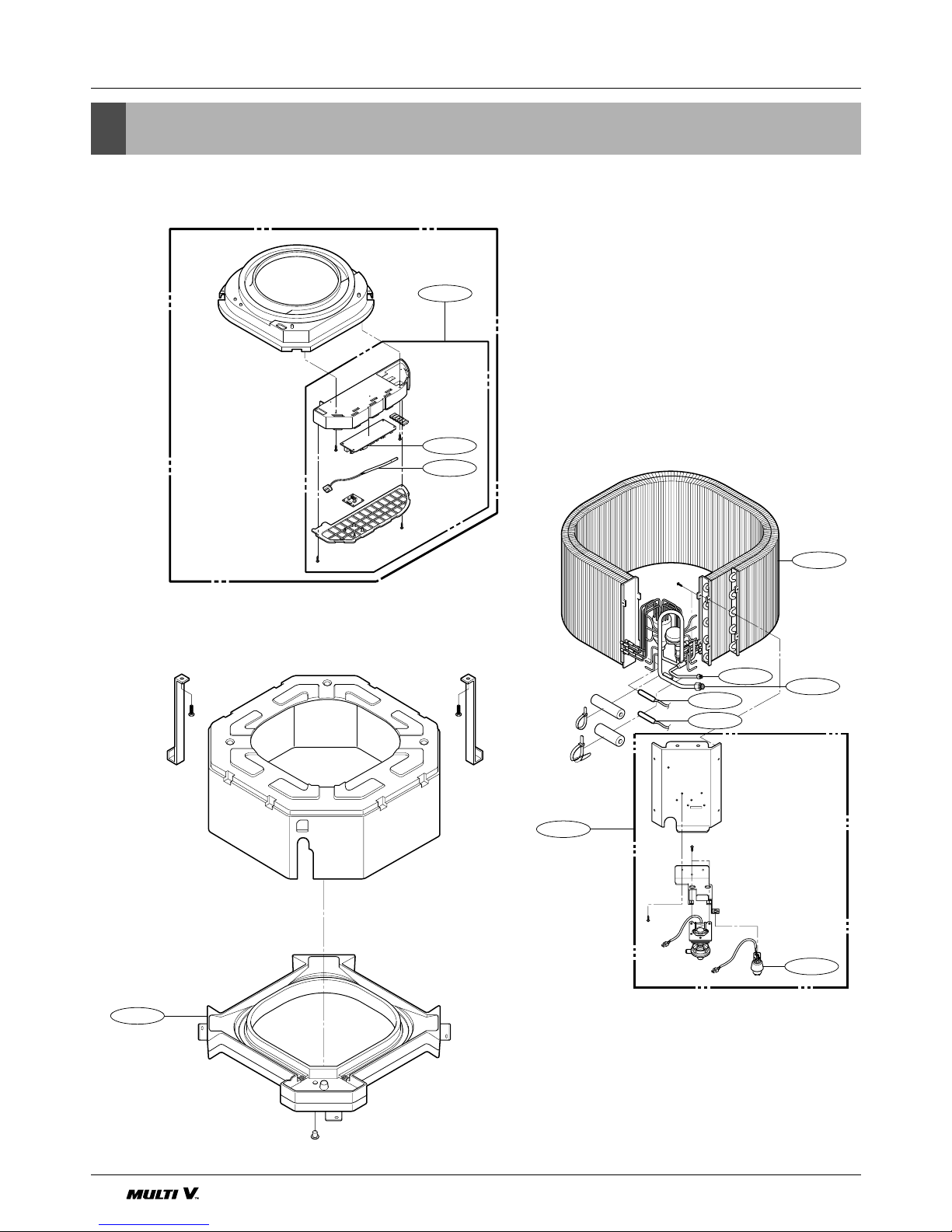

Page 18

18 Indoor Unit

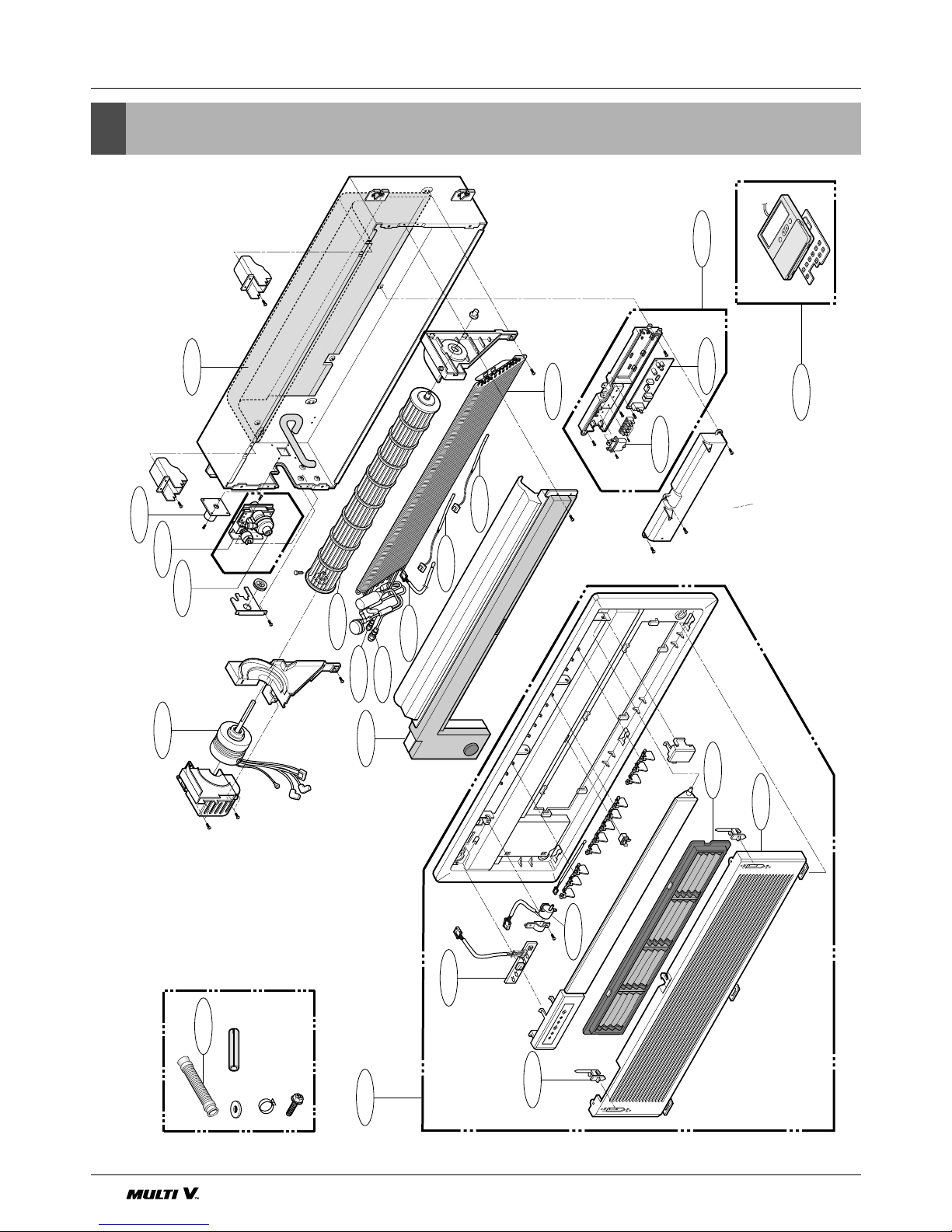

Exploded View

7. Exploded View

330870

158580

266012

359011

267110

352150-1

352150-2

137211

346810

130911

135802

268712

146811

435310

152312

354210

W0CZZ

268714

249951

352115

352116

Basic

263230-2

263230-1

263230-3

Page 19

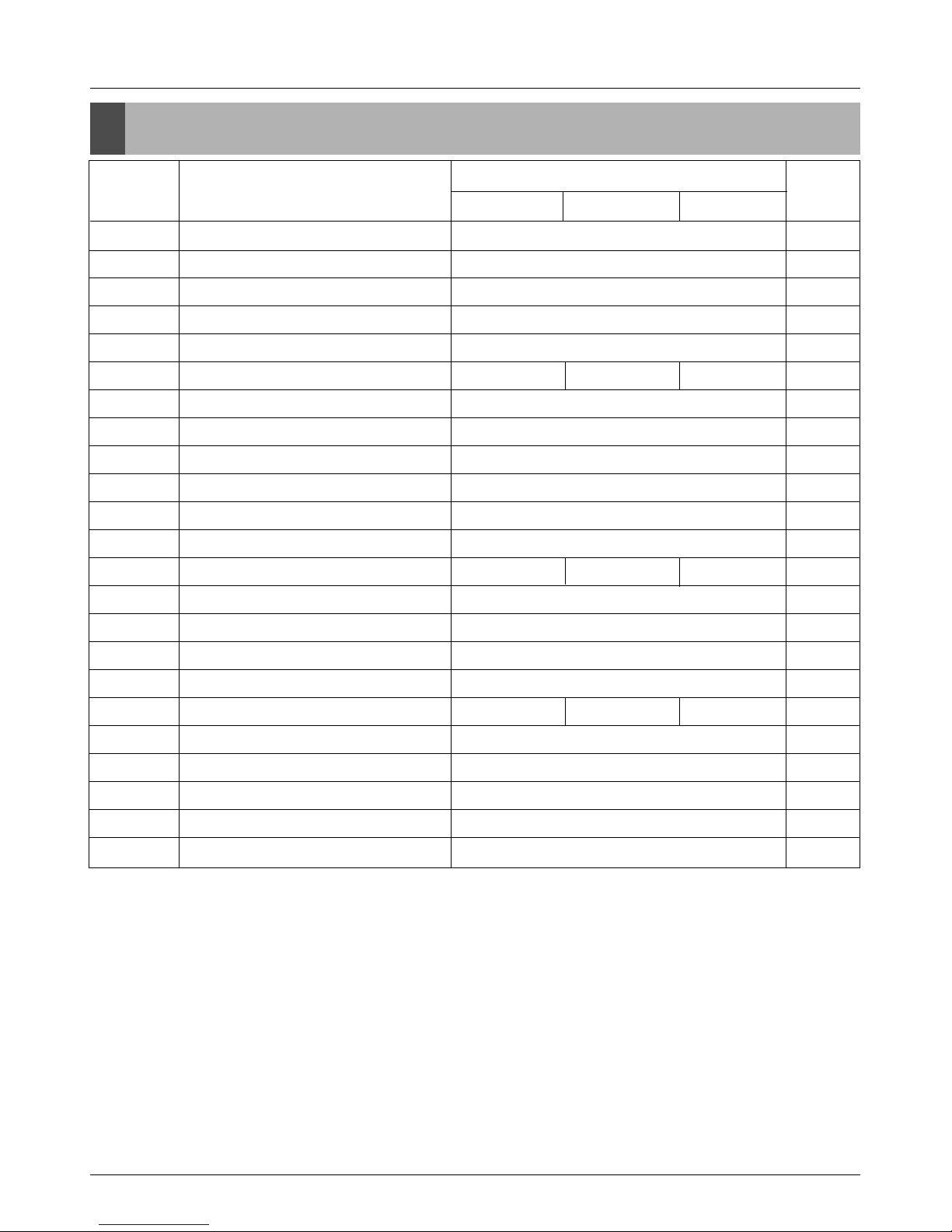

8. Replacement Parts List

Service Manual 19

Replacement Parts List

PART No.

CRNN076TCA0 CRNN096TCA0 CRNN126TCA0

130911 CABINET ASSEMBLY,INDOOR 3091A10024A R

146811 MOTOR ASSEMBLY,STEP 4681AR2727G R

152312 FILTER ASSEMBLY,AIR CLEANER 5231A10003A R

158580 PUMP ASSEMBLY,WATER 5859A10001A R

137211

PANEL ASSEMBLY,FRONT(INDOOR)

3721A10023Y R

249951

CONTROL BOX ASSEMBLY,INDOOR

4995A10024Q 4995A10024R 4995A10024X R

263230-1 THERMISTOR ASSEMBLY(ROOM) 6323AQ3214P R

263230-2 THERMISTOR ASSEMBLY(PIPE-IN) 6323AQ3226E R

263230-3

THERMISTOR ASSEMBLY(PIPE-OUT)

6323AQ3226V R

266012 SWITCH ASSEMBLY,FLOAT 6601A20001E R

267110

REMOTE CONTROLLER ASSEMBLY

6711A10002A R

268712 PWB(PCB) ASSEMBLY,DISPLAY 6871A20096B R

268714 PWB(PCB) ASSEMBLY,MAIN 6871A10089A 6871A10089B 6871A10089C R

330870 DRAIN PAN ASSEMBLY 3087A10005A R

346810 MOTOR ASSEMBLY,AC 4681A20003V R

352115 TUBE ASSEMBLY,EVAPORATOR IN 5211A10303A R

352116

TUBE ASSEMBLY,EVAPORATOR OUT

5211A20230D R

354210 EVAPORATOR ASSEMBLY,FIRST 5421A10011B 5421A10011A 5421A10011A R

359011 FAN ASSY,CROSS FLOW 5901AR2441A R

435310 GRILLE ASSEMBLY,INLET 3531A10062D R

W0CZZ CAPACITOR,DRAWING 3H00671E R

352150-1 DRAIN TUBE ASSEMBLY 5251AP2984A R

352150-2 DRAIN ASSEMBLY,TUBE 5251A20001A R

LOCATION No.

DESCRIPTION

REMARK

Page 20

20 Indoor Unit

1. Specifications.............................................................................21

2. Functions ....................................................................................23

3. Operation Details........................................................................24

4. Dimensional Drawings...............................................................26

5. Piping Diagrams.........................................................................28

6. Wiring Diagrams.........................................................................29

7. Exploded View............................................................................30

8. Replacement Parts List..............................................................34

CRNN-TE / CRNN-TD

Ceiling Mounted Cassette Type (4Way)

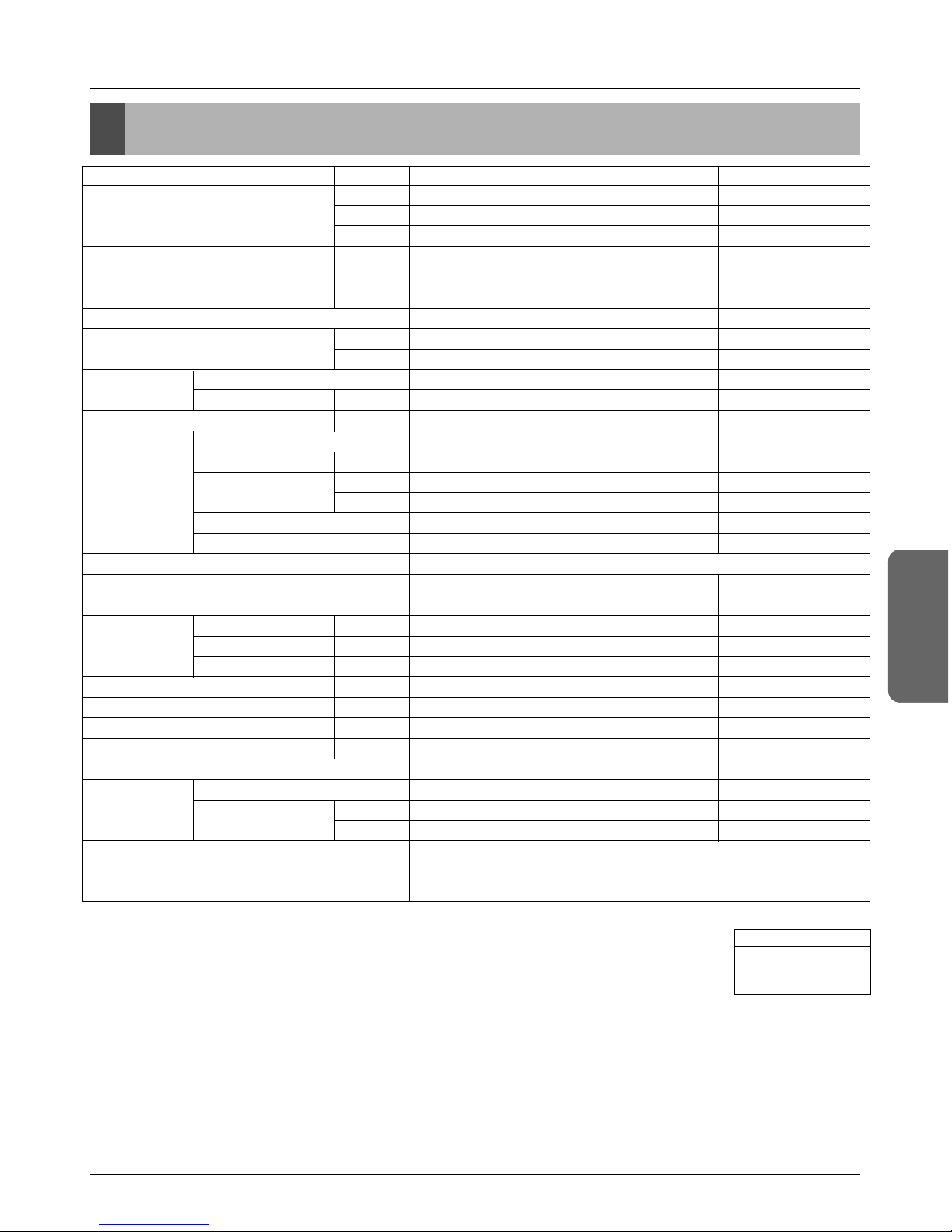

Page 21

Service Manual 21

Specifications

1. Specifications

Indoor Unit

Cassette-4way

Model Unit

W

Cooling Capacity kcal/h

Btu/h

Kw

Heating Capacity kcal/h

Btu/h

Casing

Dimensions (W*H*D)

mm

inch

Coil

Rows x Columns x FPI

Face Area m

2

Moisture removal l/h.

Type

Fan

Motor Output x Number

W

Air Flow Rate(H/M/L) cmm

cfm

Drive

Speed Control

Temperature Control

Sound Absorbing Thermal Insulation Material

Safety Device

Liquid Side mm(inch)

Pipe Connections

Gas Side mm(inch)

Drain Pipe(Internal Dia.)

mm

Net Weight kg(lbs)

Noise Level

(Sound Press,1.5m, H/M/L)

dB±3

Power Supply Ø,V,Hz

Power Cable

AWG#:P*mm

2

Refrigerant Control

Panel Color

Decoration Panel

Dimensions (W*H*D) mm

inch

Standard Accessories

CRNN126TEA0 CRNN186TEA0 CRNN246TDA0

3,500 5,300 7,000

3,009 4,557 6,019

11,942 18,084 23,885

3,938 5,963 7,875

3,385 5,127 6,771

13,435 20,345 26,870

Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

570*570*269 570*570*269 840*840*288

22.4*22.4*10.5 22.4*22.4*10.5 33.0*33.0*11.3

2*11*19 2*11*21 2*12*21

0.274 0.274 2*0.22

1.0 1.9 4.02

Turbo Fan Turbo Fan Turbo Fan

20 22.4 52.5

11 / 10 / 9 13 / 12 / 10 19 / 17 / 15

353/317/283 459/423/353 670/600/530

Direct Direct Direct

Phase control Phase control Phase control

Microprocessor, Thermostat for cooling and heating

Foamed polystyrene Foamed polystyrene Foamed polystyrene

Fuse, Thermal Fuse for Fan Motor Fuse, Thermal Fuse for Fan Motor Fuse, Thermal Fuse for Fan Motor

6.35 (1/4) 9.52 (3/8) 9.52 (3/8)

12.7 (1/2) 15.88 (5/8) 15.88 (5/8)

25 25 25

19(41.9) 19(41.9) 32(70.5)

38 / 35 / 32 41 / 39 / 37 36 / 34 / 32

1,220~240,50 1,220~240,50 1,220~240,50

12:3*2.5 12:3*2.5 12:3*2.5

L.E.V L.E.V L.E.V

White White White

670*670*30 670*670*30 950*950*30

26.4*26.4*1.2 26.4*26.4*1.2 37.4*37.4*1.2

Owner Manual, Installation Manual, Paper Pattern for Installation, Drain

Hose, Clamp Metal, Washer fixing Plate, Sealing Pads, Clamps, Screws,

Washer for Hanging Bracket, Insulation for Fitting

Notes:-

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5 m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

4. L.E.V. : Linear Expansion Valve

Conversion Formula

kcal/h = kW x 860

Btu/h = kW x 3414

cfm = m

3

/min x 35.3

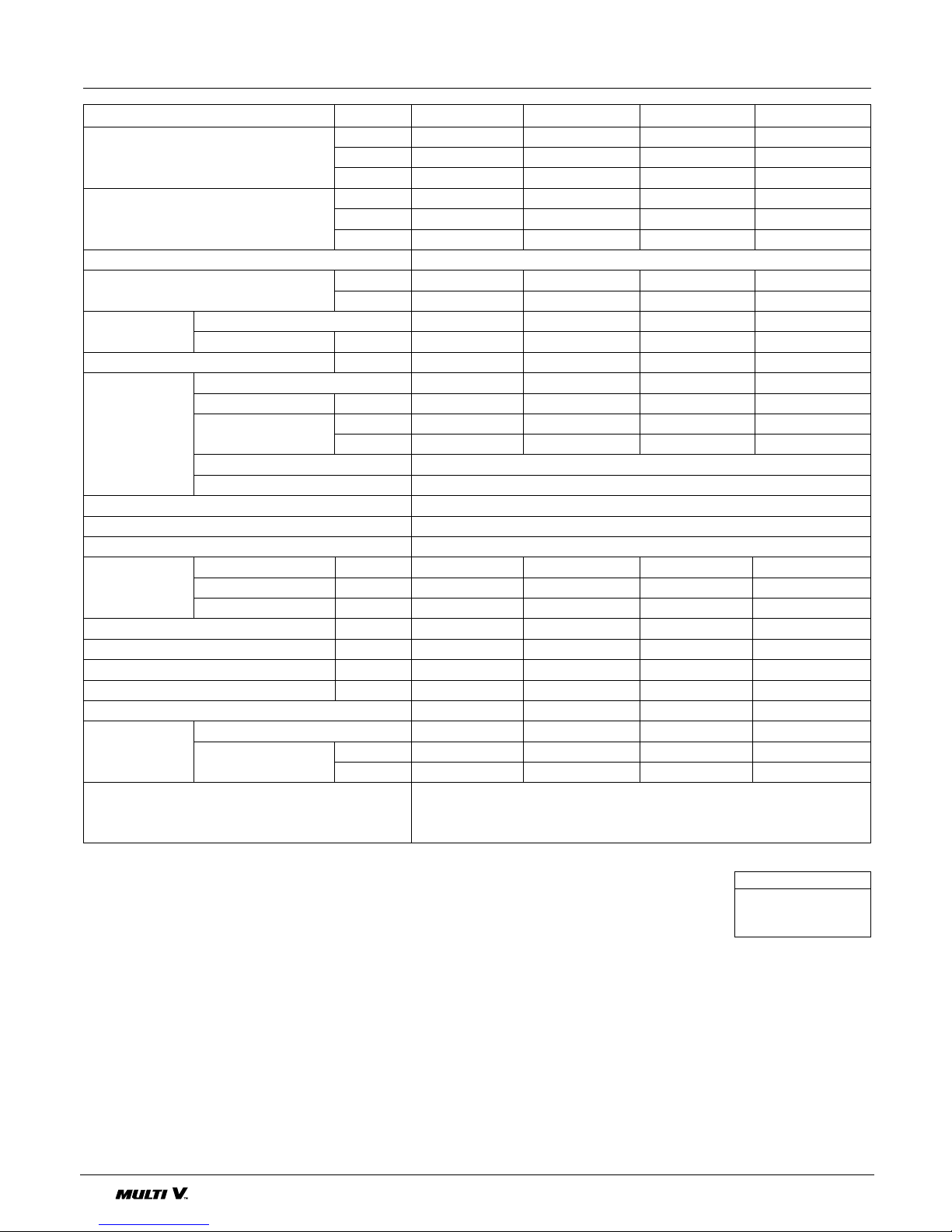

Page 22

22 Indoor Unit

Specifications

Model Unit

W

Cooling Capacity kcal/h

Btu/h

W

Heating Capacity kcal/h

Btu/h

Casing

Dimensions (W*H*D)

mm

inch

Coil

Rows x Columns x FPI

Face Area m

2

Moisture removal l/h.

Type

Fan

Motor Output x Number

W

Air Flow Rate(H/M/L) cmm

cfm

Drive

Speed control

Temperature Control

Sound Absorbing Thermal Insulation Material

Safety Device

Liquid Side mm(inch)

Pipe Connections

Gas Side mm(inch)

Drain Pipe(Internal Dia.)

mm

Net Weight kg(lbs)

Noise Level

(Sound Press,1.5m, H/M/L)

dBA±3

Power Supply Ø,V,Hz

Power Cable

AWG#:P*mm

2

Refrigerant Control

Panel Color

Decoration Panel

Dimensions (W*H*D) mm

inch

Standard Accessories

Owner Manual, Installation Manual, Paper Pattern for Installation, Drain Hose,

Clamp Metal, Washer fixing Plate, Sealing Pads, Clamps, Screws, Washer for

Hanging Bracket, Insulation for Fitting

CRNN286TDA0 CRNN366TDA0 CRNN426TDA0 CRNN486TDA0

8,200 10,600 12,300 14,100

7,052 9,116 10,578 12,126

27,995 36,168 41,992 48,137

9,225 11,925 13,838 15,863

7,934 10,253 11,040 13,156

31,494 40,689 43,829 54,156

Galvanized Steel Plate

840*840*288 840*840*288 840*840*288 840*840*288

33.0*33.0*11.3 33.0*33.0*11.3 33.0*33.0*11.3 33.0*33.0*11.3

2*11*21 2*11*21 2*11*21 2*11*21

2*0.26 2*0.26 2*0.26 2*0.26

4.2 5.0 5.2 5.5

Turbo Fan Turbo Fan Turbo Fan Turbo Fan

52.5 52.5 52.5 52.5

21 / 19 / 17 25 / 23 / 21 27 / 25 / 22 30 / 28 / 26

741/670/600 883/812/742 953/883/777 1,059/988/918

Direct

Phase control

Microprocessor, Thermostat for cooling and heating

Foamed polystyrene

Fuse, Thermal Fuse for Fan Motor

9.52 (3/8) 9.52 (3/8) 9.52 (3/8) 9.52 (3/8)

15.88 (5/8) 19.05(3/4) 19.05(3/4) 19.05(3/4)

25 25 25 25

32(70.5) 32(70.5) 32(70.5) 32(70.5)

42/40/38 43/41/39 44/42/40 45/43/41

1,220~240,50 1,220~240,50 1,220~240,50 1,220~240,50

12:3*2.5 12:3*2.5 12:3*2.5 12:3*2.5

L.E.V L.E.V L.E.V L.E.V

White White White White

950*950*30 950*950*30 950*950*30 950*950*30

37.4*37.4*1.2 37.4*37.4*1.2 37.4*37.4*1.2 37.4*37.4*1.2

Notes:-

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5 m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

4. L.E.V. : Linear Expansion Valve

Conversion Formula

kcal/h = kW x 860

Btu/h = kW x 3414

cfm = m3/min x 35.3

Page 23

Service Manual 23

Functions

2. Functions

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Soft Dry Operation Mode

Airflow Direction Control

Deice (defrost) control (Heating)

Auto Restart

Hot-start Control (Heating)

• The indoor fan does not rotate until the evaporator piping temperature will be reached at 25°C.

Compact and light design

• To install a unit is very convenient because of smaller

size than textile.

Low noise

• The most advanced low-noise design.

• The adoption of turbo fan and round type heat exchang-

er give the quietest operation.

Long life filter

• Long life wrinkle(type) and washable and anti-bacteria

filter is adopted.

High head Drain pump

• Built-in drain pump automatically drains water.

• A standard drain-head height of up to 700mm is possible.

High-Ceiling corresponding Function

• According to the height of ceiling, the RPM of indoor fan

motor is selected to increase air reaching distance.

Central Control(Optional)

•

It is operating individually or totally by central control function.

• Room temperature sensor. (Thermistor)

•

Maintains the room temperature in accordance with the Setting Temperature.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• Jet, High, Med, Low

• Intermittent operation of fan at low speed.

• The louver can be set at swing up and down automatically.

• Although the air-conditioner is turned off by a power failure, it is restarted auto-

matically previous operation mode after power supply.

• Both the indoor and outdoor fan stops during defrosting.

• Hot start after defrost ends.

Page 24

24 Indoor Unit

Operation detail

3. Operation detail

■ Time Delay Safety Control

• 5 sec

...

Vertical air flow direction control louvers open in 5 seconds to prevent noise between louvers and wind.

• 5 sec

...

The 4-way valve is ceased for 5 sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode when compress is off.

While compressor is running, it takes 3~5 seconds to switch.

■ Auto Swing Control

• This function is to swing the louver up and down automatically.

■ Soft-Dry Operation

• The indoor fan speed is automatically set to the low, so the shift of the indoor fan speed is impossible because of

already being set to the best speed for Dry Operation by microcontroller control.

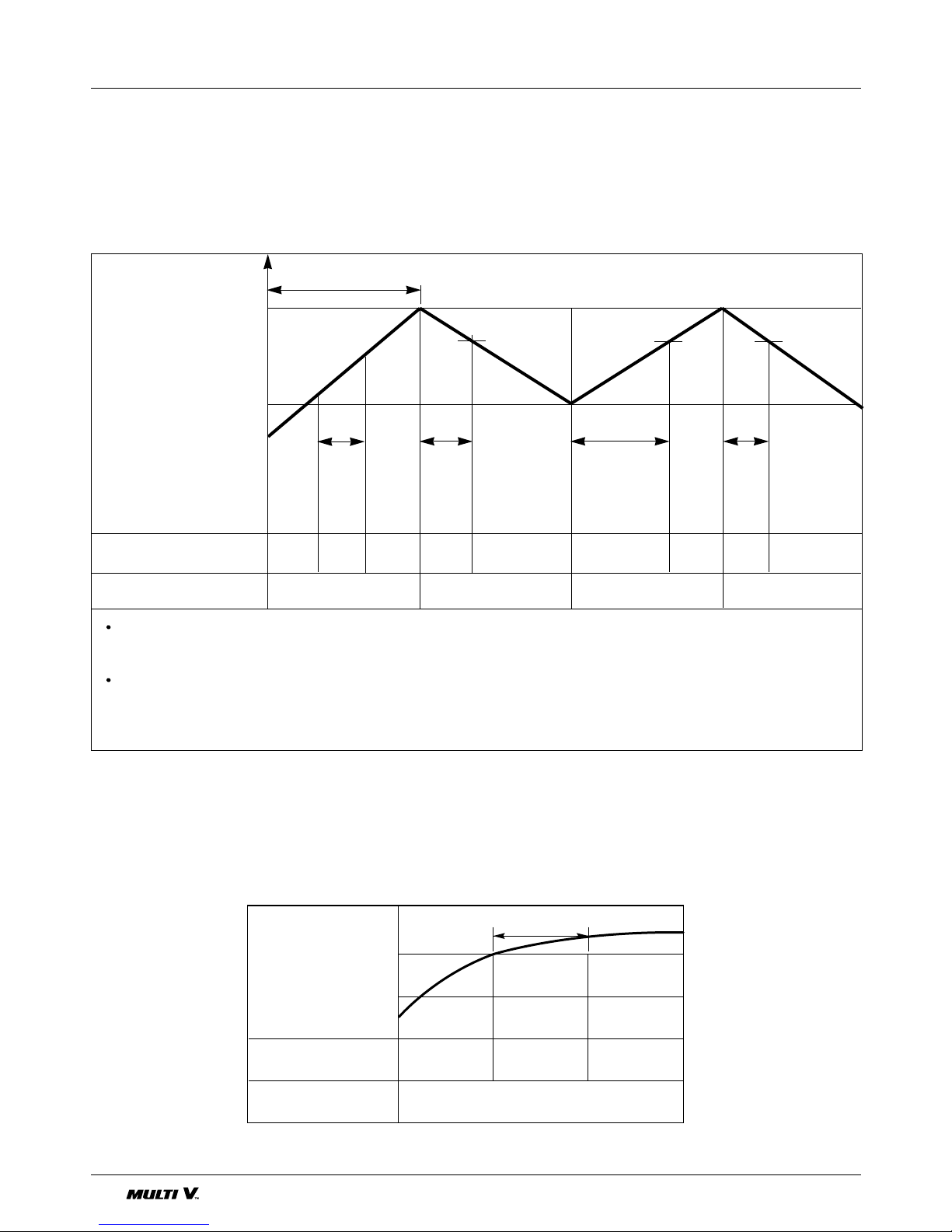

■ Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote con-

troller and the operation diagram is as following

Intake Air Temperature

COMP. ON

(SET TEMPERATURE +0.5°C)

COMP. OFF

(SET TEMPERATURE -0.5°C)

More than More than

3 minutes 3 minutes

Selecting Selecting Selecting

fan speed fan speed fan speed

INDOOR FAN Low Low

(1) The function of main control

Page 25

Service Manual 25

Operation detail

Intake Air temperature

Setting Temperature .+3°C

(Compressor OFF)

Setting Temperature

(Compressor ON)

INDOOR FAN Low OFF Low Low OFF

■ Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

Hot Start

Low

Selecting

Fan Speed

minimum 3min

Selecting fan

speed

minimum

10sec.

1min

AA

minimum

1min.

minimum

10sec.

B

■ Hot-start Control

The indoor fan does no rotate until the evaporator piping temperature will be reached to 25°C.

The operation diagram is as following.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN OFF LOW

Selected Fan

ON

22°C

25°C

• A point; While the indoor Heat-Exchanger temperature is higher than 40°C fan operates at low speed,

when it becomes lower than 40˚C fan stops.

• B point; When the indoor Heat-Exchanger temperature is higher than 31°C, fan operates at selected fan

speed, when it becomes lower than 31°C, the fan operates at low speed for 10sec, after 10sec, it

operates at selected fan speed.

Page 26

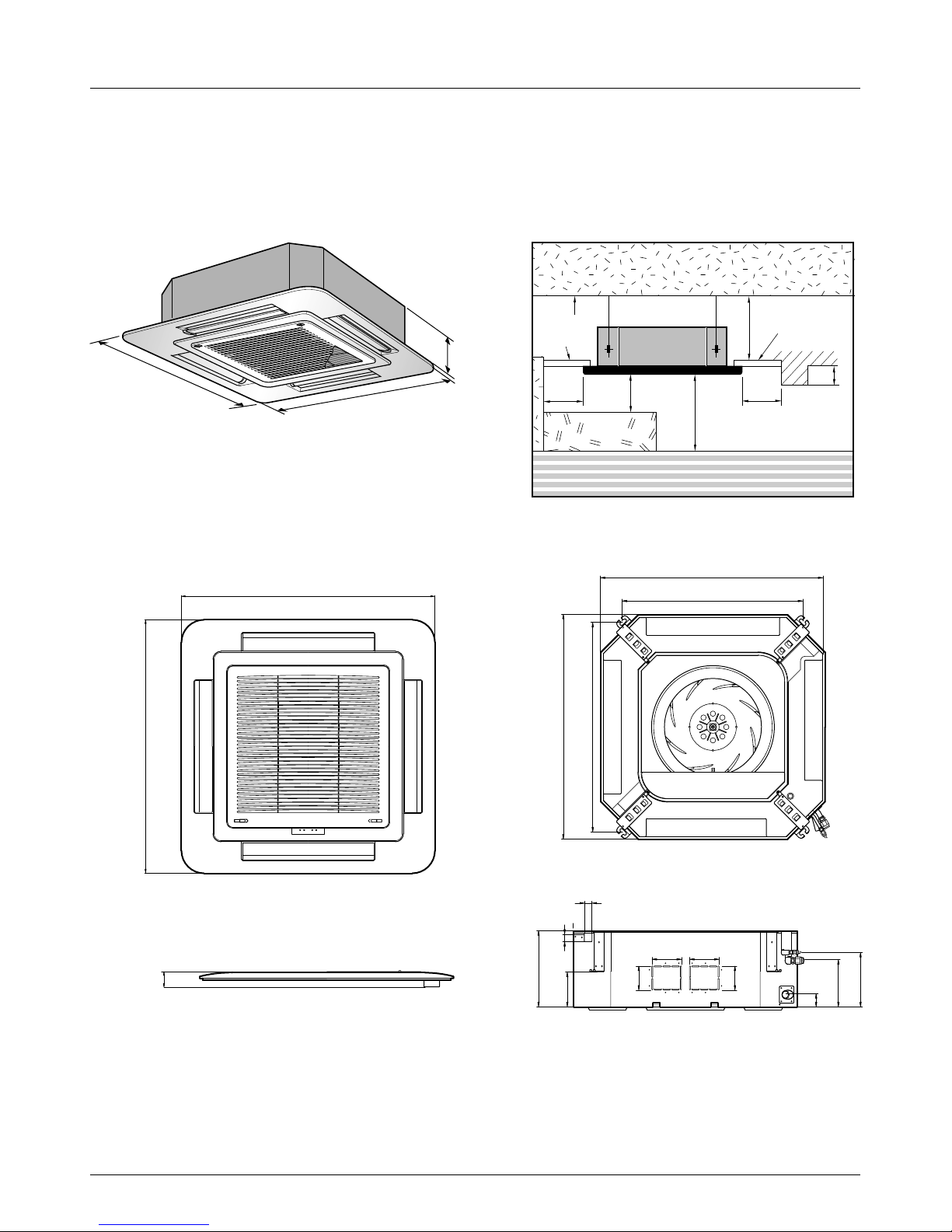

26 Indoor Unit

Dimensional Drawings

4. Dimensional Drawings

CRNN126TEA0, CRNN186TEA0,

269

670

55

570

269

190.5

160

52

90

90

120.4

30

521

670

570

450

40

110 110

670

670

CLOSE OPEN OPEN CLOSE

Unit:cm

Ceiling

Ceiling Board

Ceiling Board

30 or more

Above 250

330 or less

100

or more

50 or

more

50 or

more

30 or less

Floor

(unit:mm)

Page 27

Service Manual 27

Dimensional Drawings

CRNN246TDA0, CRNN286TDA0, CRNN366TDA0

CRNN426TDA0, CRNN486TDA0

290

950

950

950

950

290

210.5

180

52

140

40

110

30

90

90

110

55

840

785

840

678

Unit:cm

Ceiling

Ceiling Board

Ceiling Board

30 or more

Above 250

330 or less

100

or more

50 or

more

50 or

more

30 or less

Floor

(unit:mm)

Page 28

28 Indoor Unit

Piping Diagrams

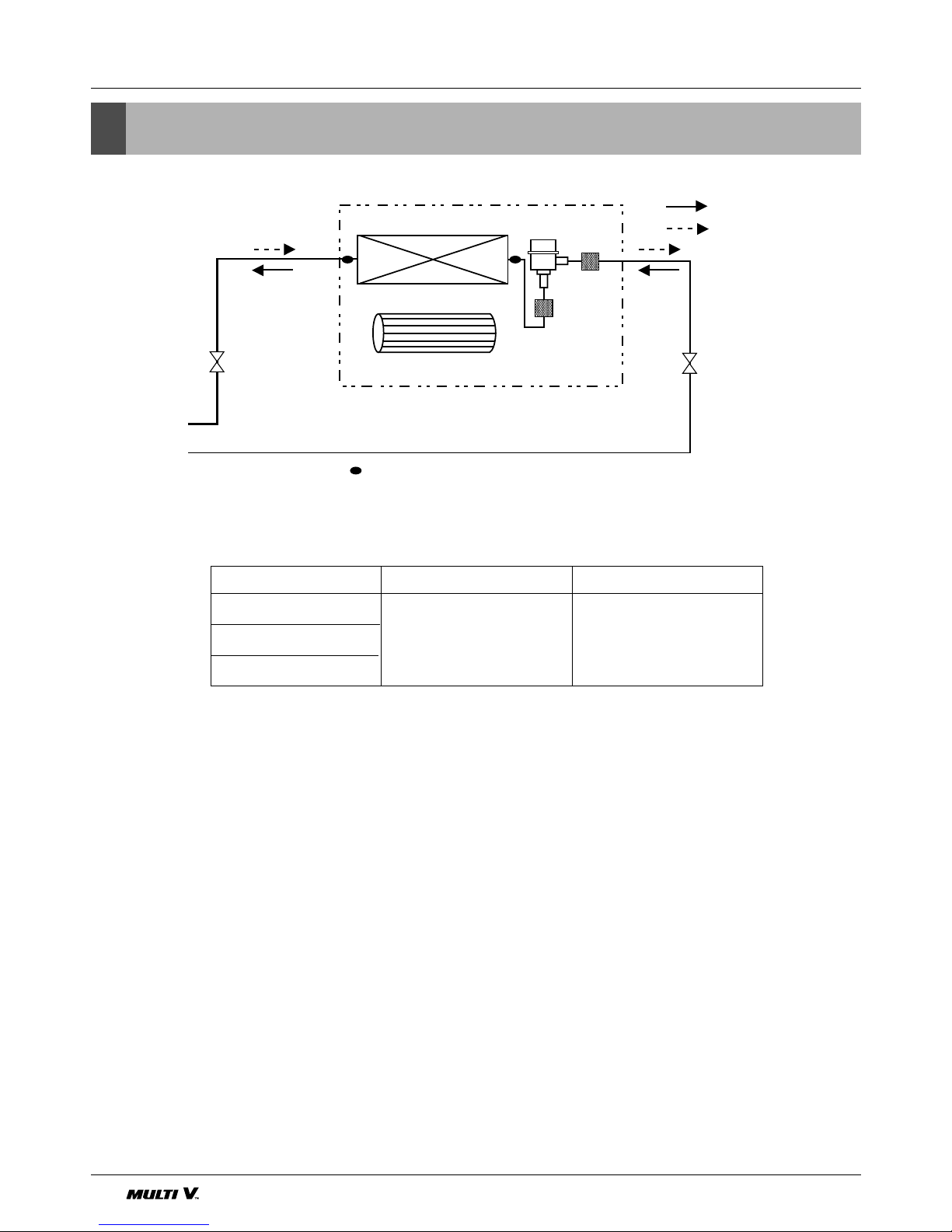

5. Piping Diagrams

Heat Exchanger

Turbo Fan

lndoor unit

LEV

:Heating

:Cooling

Filter

Filter

: Thermistor

Refrigerant pipe connection port diameter

Model

CRNN126TEA0

CRNN186TEA0

CRNN246TDA0

CRNN286TDA0

CRNN366TDA0

CRNN426TDA0

CRNN486TDA0

Gas

12.7(1/2)

15.88(5/8)

15.88(5/8)

15.88(5/8)

19.05(3/4)

19.05(3/4)

19.05(3/4)

Liquid

6.35(1/4)

9.52(3/8)

9.52(3/8)

9.52(3/8)

9.52(3/8)

9.52(3/8)

9.52(3/8)

[unit: mm(inch)]

Page 29

Service Manual 29

Wiring Diagrams

6. Wiring Diagrams

CN-POWER

CONNECTOR

NUMBER

CN-MOTOR2

CN-D/PUMP

CN-COMM

CN-DISP1

CN-LEV

CN-STEP/M1

CN-FLOAT

CN-PIPE

CN-PIPE/O

CN-ROOM

CN-REMO

CN-POWER

CN-MOTOR2

CN-COMM

CN-DISP1

CN-LEV

CN-STEP/M1

CN-PIPE

CN-PIPE/O

CN-ROOM

CN-REMO

AC POWER SUPPLY

AC FAN MOTOR OUTPUT

DRAIN PUMP OUTPUT

COMMUNICATION

DISPLAY

LEV OUTPUT

STEP MOTOR

FLOAT SWITCH INPUT

PIPE SENSOR

DISCHARGE PIPE SENSOR

ROOM SENSOR

REMOTE CONTROLLER

WHITE

YELLOW

WHITE

WHITE

WHITE

WHITE

WHITE

BLUE

WHITE

RED

BLUE

WHITE

AC POWER LINE INPUT FOR INDOOR CONTROLLER

MOTOR OUTPUT OF PHASE CONTROL

AC OUTPUT FOR DRAIN PUMP

COMMUNICATION BETWEEN INDOOR AND OUTDOOR

DISPLAY OF INDOOR STATUS

LEV CONTROL OUTPUT

STEP MOTOR OUTPUT

FLOAT SWITCH SENSING

PIPE THERMISTOR

DISCHARGE PIPE THERMISTOR

ROOM THERMISTOR

REMOTE CONTROL LINE

SPEC COLOR DESCRIPTION

CN-AIRC

AIR CLEAN WHITE AIR CLEAN SIGNAL

(Transmission)

1(L)

2(N)

34

Page 30

30 Indoor Unit

Explodede View

7. Exploded View

CRNN126TEA0, CRNN186TEA0

354211

266012

352115

352118

330870

158591

249951

268714

263230-1

263230-2

263230-3

Page 31

Service Manual 31

Explodede View

346810

130411

359011

152312

W0CZZ

267110

352150-1

140570

268712

146811

352150-2

130911-1

137211

130911-2

135802

Page 32

32 Indoor Unit

Explodede View

130411

354211-2

330870

263230-2

352118

266012

55211G

249951

263230-1

352114

158591

268714

263230-3

249951

354211-1

CRNN246TDA0, CRNN286TDA0, CRNN366TDA0, CRNN426TDA0, CRNN486TDA0

Page 33

Service Manual 33

Explodede View

130411

346810

152312

135314

135802

352150

359012

130911-2

130913-1

152510

140570

W0CZZ

146811

137211

267110

268712

130911-1

130913-2

Page 34

34 Indoor Unit

Replacement Parts List

8. Replacement Parts List

CRNN126TEA0 CRNN186TEA0

130411 BASE ASSY,WELD[INDOOR] 3041A10013A R

130911-1 CABINET ASSEMBLY,INDOOR 3091A10023C R

130911-2 CABINET ASSEMBLY,INDOOR 3091A10023D R

135802 DOOR 3580A20005A R

137211 PANEL ASSY,FRONT(INDOOR) 3721A10021A R

140570 LOCKER 4056A20001A R

146811 MOTOR ASSY,STEP 4681AP2968D R

152312 FILTER ASSY,AIR CLEANER 5231A10005A R

158591 PUMP ASSEMBLY,WATER 5859A20001H R

249951 CONTROL BOX ASSEMBLY,INDOOR 4995A10083A 4995A10083B R

263230-1 THERMISTOR ASSEMBLY(ROOM) 6323AQ3214B R

263230-2 THERMISTOR ASSEMBLY(PIPE-IN) 6323A30002B R

263230-3 THERMISTOR ASSEMBLY(PIPE-OUT) 6323AQ3226R R

266012 SWITCH ASSY,FLOAT 6601A20001F R

267110 REMOTE CONTROLLER ASSEMBLY 6711A10002A R

268712 PWB(PCB) ASSY,DISPLAY 6871A20096C R

268714 PWB(PCB) ASSEMBLY,MAIN 6871A10089D 6871A10089E R

330870 DRAIN PAN ASSEMBLY 3087A10002A R

346810 MOTOR ASSEMBLY,SINGLE 4681AC2026E 4681AC2026D R

352115 TUBE ASSEMBLY,EVAPORATOR IN 5211A10335B 5211A10335A R

352118 TUBE ASSEMBLY,MENIFOLD(INDOOR) 5211A20241N 5211A20241P R

354211 EVAPORATOR ASSY,BENDING 5421A10006A 5421A10006B R

359011 FAN,TURBO 5900A10004A R

W0CZZ CAPACITOR,DRAWING 3H00660N R

352150-1 DRAIN TUBE ASSEMBLY 5251AP2984A R

352150-2 DRAIN ASSEMBLY,TUBE 5251A20002A R

PART NO.

DESCRIPTION

REMARK

LOCATION

NO.

Page 35

Service Manual 35

Replacement Parts List

CRNN246TDA0 CRNN286TDA0 CRNN366TDA0 CRNN426TDA0 CRNN486TDA0

354211-1 EVAPORATOR ASSY 5421A10016A R

354211-2 EVAPORATOR ASSY 5421A10016B R

352118

TUBE ASSEMBLY, MENIFOLD (INDOOR)

5211A20251B R

TUBE ASSEMBLY, MENIFOLD (INDOOR)

5211A20251H 5211A20251G R

352114 TUBE ASSEMBLY, DISTRIBUTOR 5211A10299A R

55211G TUBE ASSEMBLY, EXPANSION 5211A10298A R

158591 PUMP ASSEMBLY, WATER 5859A20001D R

266012 SWITCH ASSY, FLOAT 6601A20001F R

330870 DRAIN PAN ASSY 3087A100006A R

249951 CONTROL BOX ASSY

4995A20268X 4995A20268Y 4995A20268A 4995A20268Z 4995A10106L

R

268714 PWB(PCB) ASSY, MAIN

6871A10089F

F6871A10089G

6871A10089H 6871A10089S 6871A10089T

R

130411 BASE ASSY, WELD INDOOR 3041A10016A R

346810 MOTOR ASSY, INDOOR 4681A20006J 4681A20006H R

359012 FAN,TURBO 5900A10003B R

140570 LOCKER 4056A20001B R

130911-1 CABINET ASSY, INDOOR 3091A10031A R

130911-2 CABINET ASSY, INDOOR 3091A10031B R

130913-1 CABINET ASSEMBLY, WELD 3091A10030A R

130913-2 CABINET ASSEMBLY, WELD 3091A10030B R

152510 DRAIN ASSY, TUBE 5251A20002B R

352150 DRAIN TUBE ASSY 5251AP2984A R

137211 PANEL ASSY, FRONT(INDOOR) 3721A10025A R

135314 GRILLE INLET 3530A10062A R

146811 MOTOR ASSY, STEP 4681A20055A R

268712 PWB(PCB) ASSY, DISPLAY 6871A20096C R

152312 FILTER ASSY 5231A10004A R

135802 DOOR LOCK 3580A20005A R

267110 WIRED REMOTE CONTROLLER 6711A10002A R

263230-1 THERMISTOR ASSY(PIPE-IN) 6323A30002A R

263230-2 THERMISTOR ASSY(PIPE-OUT) 6323AQ3226T R

263230-3 THERMISTOR ASSY(ROOM) 6323A30004C R

W0CZZ CAPACITOR 3H00660M 2A00986D R

PART NO.

DESCRIPTION

REMARK

LOCATION

NO.

Page 36

36 Indoor Unit

1. Specifications.............................................................................37

2. Functions ....................................................................................39

3. Operation Details........................................................................40

4. Dimensional Drawings...............................................................42

5. Piping Diagrams.........................................................................43

6. Wiring Diagrams.........................................................................44

7. Exploded View............................................................................45

8. Replacement Parts List..............................................................47

CRNN-BH / CRNN-BG / CRNN-BE

Ceiling Concealed Duct Type (High static)

Page 37

Service Manual 37

Specifications

1. Specifi cations

Notes:-

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5 m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

4. L.E.V. : Linear Expansion Valve

Conversion Formula

kcal/h = kW x 860

Btu/h = kW x 3414

cfm = m

3

/min x 35.3

Model Unit

W

Cooling Capacity kcal/h

Btu/h

W

Heating Capacity kcal/h

Btu/h

Casing

Dimensions (W*H*D)

mm

inch

Coil

Rows x Columns x FPI

Face Area m

2

Moisture removal l/h.

Type

Fan

Motor Output x Number

W

Air Flow Rate(H/M/L) cmm

cfm

External Static Pressure

Pa

Drive

Speed control

Temperature Control

Sound Absorbing Thermal Insulation Material

Safety Device

Liquid Side mm(inch)

Pipe Connections

Gas Side mm(inch)

Drain Pipe(Internal Dia.)

mm

Net Weight kg(lbs)

Noise Level

(Sound Press,1.5m, H/M/L)

dBA±3

Power Supply Ø,V,Hz

Power Cable

AWG#:P*mm

2

Refrigerant Control

Standard Accessories

CRNN186BHA0 CRNN246BHA0 CRNN286BGA0

5,300 7,000 8,200

4,557 6,019 7,052

18,084 23,885 27,995

5,963 7,875 9.255

5,127 6,771 7,933

20,345 26,870 31,494

Galvanized Steel Plate

880*260*450 880*260*450 1,180*298*450

34.6*10.2*17.7 34.6*10.2*17.7 46.4*11.7*17.7

2*10*21 3*10*21 3*12*21

0.15 0.15 0.20

2.0 2.5 3.0

Sirocco Fan Sirocco Fan Sirocco Fan

118 118 272

16.5 / 14.5 / 13 18 / 16.5 / 14 30 / 27 / 25

583 / 512 / 459 636 / 583 / 494 1,059 / 953 / 882

78.5 58.8 78.5

Direct

Phase control

Microprocessor, Thermostat for cooling and heating

Foamed polystyrene

Fuse, Thermal Fuse for Fan Motor

9.52 (3/8) 9.52 (3/8) 9.52 (3/8)

15.88 (5/8) 15.88 (5/8) 15.88 (5/8)

25 25 25

34(74.9) 35(77.2) 38(83.8)

36 / 34 / 32 38 / 35 / 32 40 / 38 / 36

1,220~240,50 1,220~240,50 1,220~240,50

12:3*2.5 12:3*2.5 12:3*2.5

L.E.V L.E.V L.E.V

Owner Manual, Installation Manual, Drain Hose, Clamp Metal, Insulation

for Fitting, Sealing Pads, Clamps, Screws

Page 38

38 Indoor Unit

Specifications

Model Unit

W

Cooling Capacity kcal/h

Btu/h

W

Heating Capacity kcal/h

Btu/h

Casing

Dimensions (W*H*D)

mm

inch

Coil

Rows x Columns x FPI

Face Area m

2

Moisture removal l/h.

Type

Fan

Motor Output x Number

W

Air Flow Rate(H/M/L) cmm

cfm

External Static Pressure

Pa

Drive

Speed control

Temperature Control

Sound Absorbing Thermal Insulation Material

Safety Device

Liquid Side mm(inch)

Pipe Connections

Gas Side mm(inch)

Drain Pipe(Internal Dia.)

mm

Net Weight kg(lbs)

Noise Level

(Sound Press,1.5m, H/M/L)

dBA±3

Power Supply Ø,V,Hz

Power Cable

AWG#:P*mm

2

Refrigerant Control

Standard Accessories

CRNN366BGA0 CRNN426BGA0 CRNN486BEA0

10,600 12,300 14,100

9,116 10,578 12,126

36,188 41,992 48,137

11,925 13,837 15,885

10,255 11,900 13,661

40,712 47,410 54,231

Galvanized Steel Plate

1,180*298*450 1,230*370*680 1,230*370*680

46.4*11.7*17.7 48.4*14.6*26.8 48.4*14.6*26.8

3*12*21 3*14*17 3*14*17

0.20 0.55 0.25

3.5 5.0 6.0

Sirocco Fan Sirocco Fan Sirocco Fan

272 391 391

32/29/26.5 38/34/28 40/36/30

1,130/1,024/936 1,341/1,200/988 1,413/1,271/1,059

78.5 78.5 98.1

Direct

Phase control Steps control

Microprocessor, Thermostat for cooling and heating

Foamed polystyrene

Fuse, Thermal Fuse for Fan Motor

9.52(3/8) 9.52(3/8) 9.52(3/8)

19.05(3/4) 19.05(3/4) 19.05(3/4)

25 25 25

38(83.8) 70(154.3) 70(154.3)

44/42/40 46/44/42 48/46/44

1,220~240,50 1,220~240,50 1,220~240,50

12:3*2.5 12:3*2.5 12:3*2.5

L.E.V L.E.V L.E.V

Owner Manual, Installation Manual, Drain Hose, Clamp Metal, Insulation for

Fitting, Sealing Pads, Clamps, Screws

Notes:-

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5 m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

4. L.E.V. : Linear Expansion Valve

Conversion Formula

kcal/h = kW x 860

Btu/h = kW x 3414

cfm = m3/min x 35.3

Page 39

Service Manual 39

2. Functions

Functions

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Soft Dry Operation Mode

Deice (defrost) control (Heating)

Auto Restart

Hot-start Control (Heating)

• The indoor fan does not rotate until the evaporator piping

temperature reaches 25°C.

High head height Drain pump

• A standard drain-head height of up to 700mm is possible.

Central Control(Optional)

•

It is operating individually or totally by central control function.

•

Both the indoor and outdoor fan stops during defrosting.

•

The indoor fan stops until the evaporator pipe temperature will be reached

at 28°C.

• Room temperature sensor. (Thermistor)

•

Maintains the room temperature in accordance with the Setting Temperature.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low

• Intermittent operation of fan at low speed.

• Although the air-conditioner is turned off by a power failure, it is restarted auto-

matically previous operation mode after power supply.

• Both the indoor and outdoor fan stops during defrosting.

• Hot start after defrost ends.

Defrost(Deice) control (Heating)

Hot-start Control (Heating)

Page 40

40 Indoor Unit

Operation Details

3. Operation Details

■ Time Delay safety Control

• 30sec

...

The 4-way valve is ceased for 30sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode while compress is off.

While compressor is running, it takes 3~5 seconds to switch to another mode.

■ Soft-Dry Operation

• The indoor fan speed is automatically set to the low, so the shift of the indoor fan speed is impossible because of

already being set to the best speed for Dry Operation by microcontroller control.

■ Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote controller and the operation diagram is as following.

Intake Air Temperature

SET TEMPERATURE +0.5°C

(COMP. ON)

SET TEMPERATURE -0.5°C

(COMP. OFF)

More than More than

3 minutes 3 minutes

Selecting Selecting Selecting

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low

(1) The function of main control

Page 41

Service Manual 41

Operation Details

Intake Air Temperature

Setting Temperature +3°C

(Compressor OFF)

Setting Temperature

(Compressor ON)

INDOOR FAN Low OFF Low Low OFF

COMPRESSOR ON OFF ON OFF

• A point; While the indoor Heat-Exchanger temperature is higher than 40°C fan operates at low speed,

when it becomes lower than 40˚C fan stops.

• B point; When the indoor Heat-Exchanger temperature is higher than 42°C, fan operates at seleted fan

speed, when it becomes lower than 39°C, the fan operates at low speed.

■ Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

Hot Start

Low

Selecting

Fan Speed

minimum 3min

Selecting fan

speed

minimum

10sec.

1min

AA

minimum

10sec.

B

■ Hot-Start Control

• The indoor fan does not rotate until the evaporator piping temperature reaches 25°C.

• The operation diagram is as following.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN

ON

22°C

: Selected Fan : Low Fan : Fan Stop

25°C

Page 42

42 Indoor Unit

Dimensional Drawings

4. Dimensional Drawings

Top view

(unit: mm)

H

Front view

600600

Front

Inspection hole

(600X600)

Control box

1000

l

i

h

j

k

A

H

CD

EF

B

(G)

ab c d

K

J

fe

C D E F (G) H J K a b c d e f h i j k l

355 45.5 450 30 87 750 163 260 61.5 243 212.3 243 110 130 52 66 81 30 158.5

355 45.5 450 30 87 830 186 298 229.5 243 232 243 116 160 53 59 81 19 158.5

570.5 54 680 30 120 1006 294 370 253.5 253 217 253 152 186 42 143 82 50 172

Model A B

186/246BH 932 882

286/366/426BG 1232 1182

486BE 1292 1230

(Unit: mm)

Page 43

Service Manual 43

5. Piping Diagrams

Piping Diagrams

Heat Exchanger

Sirocco Fan

lndoor unit

LEV

:Heating

:Cooling

Filter

Filter

: Thermistor

Refrigerant pipe connection port diameter

Model

CRNN186BHA0

CRNN246BHA0

CRNN286BGA0

CRNN366BGA0

CRNN426BGA0

CRNN486BEA0

Gas

15.88(5/8)

19.05(3/4)

19.05(3/4)

9.52(3/8)

9.52(3/8)

Liquid

9.52(3/8)

[unit: mm(inch)]

Page 44

44 Indoor Unit

Wiring Diagrams

6. Wiring Diagrams

CN-POWER

CONNECTOR

NUMBER

CN-MOTOR2

CN-D/PUMP

CN-COMM

CN-LEV

CN-FLOAT

CN-PIPE

CN-PIPE/O

CN-ROOM

CN-REMO

CN-POWER

CN-MOTOR2

CN-D/PUMP

CN-COMM

CN-LEV

CN-FLOAT

CN-PIPE

CN-PIPE/O

CN-ROOM

CN-REMO

AC POWER SUPPLY

AC FAN MOTOR OUTPUT

DRAIN PUMP OUTPUT

COMMUNICATION

LEV OUTPUT

FLOAT SWITCH INPUT

PIPE SENSOR

DISCHARGE PIPE SENSOR

ROOM SENSOR

REMOTE CONTROLLER

WHITE

YELLOW

WHITE

WHITE

WHITE

BLUE

WHITE

RED

BLUE

WHITE

AC POWER LINE INPUT FOR INDOOR CONTROLLER

MOTOR OUTPUT OF PHASE CONTROL

AC OUTPUT FOR DRAIN PUMP

COMMUNICATION BETWEEN INDOOR AND OUTDOOR

LEV CONTROL OUTPUT

FLOAT SWITCH SENSING

PIPE THERMISTOR

DISCHARGE PIPE THERMISTOR

ROOM THERMISTOR

REMOTE CONTROL LINE

SPEC COLOR DESCRIPTION

CN-AIRC AIR CLEAN WHITE AIR CLEAN SIGNAL

(Transmission)

32(N)1(L) 4

Page 45

Service Manual 45

7. Exploded View

Exploded View

346810

359012

354210

55211G

152302

352118

330870

W0CZZ

268714

249951

336610-2

267110

263230-2

263230-1

336610-1

158591

263230-3

• CRNN186BHA0

• CRNN246BHA0

• CRNN286BGA0

• CRNN366BGA0

• CRNN426BGA0

Page 46

46 Indoor Unit

Exploded View

330870

152302

268714

35211C-2

35211C-1

267110

249951

346810

336610-1

336610-2

359012-2

359012-1

354210

352118

W0CZZ

263230-2

263230-3

158591

55211G

263230-1

• CRNN486BEA0

Page 47

Service Manual 47

Replacement Parts List

8. Replacement Parts List

152302 FILTER(MECH),A/C 5230A30001M 5230A30001M R

152302 FILTER(MECH), A/C 5230A30001M R

158591 PUMP ASSEMBLY, WATER 5859A20002A R

249951 CONTROL BOX ASSEMBLY, INDOOR 4995A20164M 4995A20164L R

263230-1 THERMISTOR ASSEMBLY(ROOM) 6323AQ3214E R

263230-2 THERMISTOR ASSEMBLY(PIPE-IN) 6323AQ3226G R

263230-3 THERMISTOR ASSEMBLY(PIPE-OUT) 6323AQ3226W R

266012 SWITCH ASSEMBLY, FLOAT 6601A20001E R

267110 REMOTE CONTROLLER ASSEMBLY 6711A20043D R

268714 PWB(PCB) ASSEMBLY, MAIN 6871A10089J 6871A10089K R

330870 DRAIN PAN ASSEMBLY 3087A10008D R

336610-1 HOUSING(MECH), WRAPPER 3660A20017A R

336610-2 HOUSING(MECH), WRAPPER 3660A20018A R

346810 MOTOR ASEMBLY, INDOOR 4681A10013C R

352118 TUBE ASSEMBLY, MENIFOLD(INDOOR) 5211A20465D R

354210 EVAPORATOR ASSEMBLY, FIRST 5421A20100A 5421A20100B R

359012 FAN ASSEMBLY, BLOWER 5901A10026A R

352115 TUBE ASSEMBLY, EVAPORATOR IN 5211A10305B 5211A10305A R

W0CZZ CAPACITOR, DRAWING 2A00986D R

CRNN186BHA0 CRNN246BHA0

DESCRIPTION

LOCATION

No.

Part No.

REMARKS

152302 FILTER(MECH), A/C 5230A30001L R

158591 PUMP ASSEMBLY, WATER 5859A20002A R

249951 CONTROL BOX ASSEMBLY, INDOOR 4995A10127F 4995A10127G 4995A10127H R

263230-1 THERMISTOR ASSEMBLY(ROOM) 6323A30004D R

263230-2 THERMISTOR ASSEMBLY(PIPE-IN) 6323AQ3226G R

263230-3 THERMISTOR ASSEMBLY(PIPE-OUT) 6323AQ3226W R

266012 SWITCH ASSEMBLY, FLOAT 6601A20001E R

267110 REMOTE CONTROLLER ASSEMBLY 6711A20043D R

268714 PWB(PCB) ASSEMBLY, MAIN 6871A10089U 6871A10089L 6871A10089V R

330870 DRAIN PAN ASSEMBLY 3087A10008C R

336610-1 HOUSING(MECH), WRAPPER 3660A20019A R

336610-2 HOUSING(MECH), WRAPPER 3660A20020A R

346810 MOTOR ASEMBLY, INDOOR 4681A10013A R

352118 TUBE ASSEMBLY, MENIFOLD(INDOOR) 5211A20416G 5211A20416H R

354210 EVAPORATOR ASSEMBLY, FIRST 5421A10027C R

359012 FAN ASSEMBLY, BLOWER 5901A10026A R

55211G TUBE ASSEMBLY, EXPANSION 5211A10426A R

W0CZZ CAPACITOR, DRAWING 2A00986D R

CRNN286BGA0 CRNN366BGA0 CRNN426BGA0

DESCRIPTION

Part No.

REMARKS

152302 FILTER(MECH), A/C 5230A30001A R

158591 PUMP ASSEMBLY, WATER 5859A10002A R

249951 CONTROL BOX ASSEMBLY, INDOOR 4995A10127J R

263230-1 THERMISTOR ASSEMBLY(ROOM) 6323A30004D R

263230-2 THERMISTOR ASSEMBLY(PIPE-IN) 6323AQ3226G R

263230-3 THERMISTOR ASSEMBLY(PIPE-OUT) 6323AQ3226W R

266012 SWITCH ASSEMBLY, FLOAT 6601A20001E R

267110 REMOTE CONTROLLER ASSEMBLY 6711A10002D R

268714 PWB(PCB) ASSEMBLY, MAIN 6871A10089W R

330870 DRAIN PAN ASSEMBLY 3087A20023A R

336610-1 HOUSING(MECH), WRAPPER 3661A20009E R

336610-2 HOUSING(MECH), WRAPPER 3661A20009F R

346810 MOTOR ASEMBLY, INDOOR 4681A20005K R

352118 TUBE ASSEMBLY, MENIFOLD(INDOOR) 5211A30076B R

354210 EVAPORATOR ASSEMBLY, FIRST 5421A20008A R

359012-1 FAN ASSEMBLY, BLOWER 5901A10015E R

359012-2 FAN ASSEMBLY, BLOWER 5901A10015F R

55211G TUBE ASSEMBLY, EXPANSION 5211A10416A R

W0CZZ CAPACITOR, DRAWING 0CZZA20001C R

35211C-1 TUBE ASSEMBLY,DISCHARGE(IN) 5211A30077A R

35211C-2 TUBE ASSEMBLY,DISCHARGE(OUT) 5211A30094B R

CRNN486BEA0

DESCRIPTION

Part No.

REMARKS

LOCATION

No.

LOCATION

No.

Page 48

48 Indoor Unit

1. Specifications.............................................................................49

2. Functions ....................................................................................50

3. Operation Details........................................................................51

4. Dimensional Drawings...............................................................53

5. Piping Diagrams.........................................................................54

6. Wiring Diagrams.........................................................................55

7. Exploded View............................................................................56

8. Replacement Parts List..............................................................57

CRNN-BN / CRNN-BJ

Ceiling Concealed Duct Type (Low static)

Page 49

Service Manual 49

Specifications

1. Specifications

Notes:-

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5 m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

4. L.E.V. : Linear Expansion Valve

Conversion Formula

kcal/h = kW x 860

Btu/h = kW x 3414

cfm = m

3

/min x 35.3

Model Unit

W

Cooling Capacity kcal/h

Btu/h

W

Heating Capacity kcal/h

Btu/h

Casing

Dimensions (W*H*D) mm

inch

Coil

Rows*Steps*Fin Pitch

inch

Moisture removal l/h

Fan Model

Type

Motor Output

W

Air Flow Rate(H/M/L) CMM

CFM

External Static Pressure

Pa

Drive

Speed control

Temperature Control

Sound Absorbing Thermal Insulation Material

Safety Device

Pipe Connections

Liquid Side mm(inch)

Gas Side mm(inch)

Drain Pipe(Internal Dia.)

mm

Net Weight kg(lbs)

Noise Level(SoundPress,1.5m,H/M/L) dBA±3

Power Supply Ø,V,Hz

Power Cable

AWG#:P*mm

2

Refrigerant Control

Standard Accessories

CRNN076BNG0 CRNN096BJG0 CRNN126BJG0

2,100 2,600 3,500

1,806 2,235 3,009

7,165 8,871 11,942

2,363 2,925 3,923

2,031 2,515 3,385

8,061 9,980 13,435

Galvanized Steel Plate

783*220*520 873*220*520 873*220*520

30.8*8.7*20.5 34.3*8.7*20.5 34.3*8.7*20.5

2*9*14 2*9*14 2*9*14

1.0 1.0 1.5

D-7K D-9K D-12K

Sirocco Fan Sirocco Fan Sirocco Fan

13 17 20

6.4/5.9/5.4 7.0/6.5/6.0 10.2/9.2/8.2

226/208/191 247/230/212 360/325/290

00 0

Direct

Steps Control

Microprocessor,Thermistat for cooling and heating

Foamed polystyrene

Fuse,Thermal Fuse for Fan Motor

6.35(1/4) 6.35(1/4) 6.35(1/4)

12.7(1/2) 12.7(1/2) 12.7(1/2)

25 25 25

23(50.7) 24(52.9) 24(52.9)

36/34/32 37/35/33 38/36/34

1,220~240,50 1,220~240,50 1,220~240,50

12:3 * 2.5 12:3 * 2.5 12:3 * 2.5

LEV LEV LEV

Owner's Manual, Installation Manual, Drain Hose, Clamp Metal, Insulation for

Fitting, Sealing Pads, Clamps, Screws

Page 50

50 Indoor Unit

Functions

2. Functions

Indoor Unit

Duct-Low

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Soft Dry Operation Mode

Deice (defrost) control (Heating)

Auto Restart

Hot-start Control (Heating)

• The indoor fan does not rotate until the evaporator piping

temperature reaches 25°C.

High head height Drain pump

• A standard drain-head height of up to 700mm is possible.

Central Control(Optional)

•

It is operating individually or totally by central control function.

• Room temperature sensor. (Thermistor)

•

Maintains the room temperature in accordance with the Setting Temperature.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low

• Intermittent operation of fan at low speed.

• Although the air-conditioner is turned off by a power failure, it is restarted auto-

matically previous operation mode after power supply.

• Both the indoor and outdoor fan stops during defrosting.

• Hot start after defrost ends.

Page 51

Service Manual 51

3. Operation Details

■ Time Delay safety Control

• 30sec

...

The 4-way valve is ceased for 30sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode while compress is off.

While compressor is running, it takes 3~5 seconds to switch to another mode.

■ Soft-Dry Operation

• The indoor fan speed is automatically set to the low, so the shift of the indoor fan speed is impossible because of

already being set to the best speed for Dry Operation by microcontroller control.

■ Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote controller and the operation diagram is as following.

Intake Air Temperature

SET TEMPERATURE +0.5°C

(COMP. ON)

SET TEMPERATURE -0.5°C

(COMP. OFF)

More than More than

3 minutes 3 minutes

Selecting Selecting Selecting

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low

(1) The function of main control

Functions

Page 52

52 Indoor Unit

Operation Details

Intake Air Temperature

Setting Temperature +3°C

(Compressor OFF)

Setting Temperature

(Compressor ON)

INDOOR FAN Low OFF Low Low OFF

COMPRESSOR ON OFF ON OFF

• A point; While the indoor Heat-Exchanger temperature is higher than 40°C fan operates at low speed,

when it becomes lower than 40˚C fan stops.

• B point; When the indoor Heat-Exchanger temperature is higher than 42°C, fan operates at seleted fan

speed, when it becomes lower than 39°C, the fan operates at low speed.

■ Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

Hot Start

Low

Selecting

Fan Speed

minimum 3min

Selecting fan

speed

minimum

10sec.

1min

AA

minimum

10sec.

B

■ Hot-Start Control

• The indoor fan does not rotate until the evaporator piping temperature reaches 25°C.

• The operation diagram is as following.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN

ON

22°C

: Selected Fan : Low Fan : Fan Stop

25°C

Page 53

Service Manual 53

Dimensional Drawings

4. Dimensional Drawings

H

Front view

Top view

(unit: mm)

600600

Front

Inspection hole

(600X600)

1000

Control box

B

A

C

D

EF

G

H

J

Model A B C D E F G H J

CRNN076BNG0 783 667 300 100 500 20 639 120 220

CRNN096BJG0 873 767 300 100 500 20 729 120 220

CRNN126BJG0

873 767 300 100 500 20 729 120 220

Page 54

54 Indoor Unit

Piping Diagrams

5. Piping Diagrams

Heat Exchanger

Sirocco Fan

lndoor unit

LEV

:Heating

:Cooling

Filter

Filter

: Thermistor

Refrigerant pipe connection port diameter

Model

CRNN076BNG0

CRNN096BJG0

CRNN126BJG0

Gas

Ø12.7(1/2)

Liquid

Ø6.35(1/4)

[unit: mm(inch)]

Page 55

Service Manual 55

Wiring Diagrams

6. Wiring Diagrams

CN-PIPE/O

(Transmission)

CN-POWER

CONNECTOR

NUMBER

CN-MOTOR2

CN-D/PUMP

CN-COMM

CN-LEV

CN-FLOAT

CN-PIPE

CN-PIPE/O

CN-ROOM

CN-REMO

CN-POWER

CN-MOTOR2

CN-D/PUMP

CN-COMM

CN-LEV

CN-FLOAT

CN-PIPE

CN-PIPE/O

CN-ROOM

CN-REMO

AC POWER SUPPLY

AC FAN MOTOR OUTPUT

DRAIN PUMP OUTPUT

COMMUNICATION

LEV OUTPUT

FLOAT SWITCH INPUT

PIPE SENSOR

DISCHARGE PIPE SENSOR

ROOM SENSOR

REMOTE CONTROLLER

WHITE

YELLOW

WHITE

WHITE

WHITE

BLUE

WHITE

RED

BLUE

WHITE

AC POWER LINE INPUT FOR INDOOR CONTROLLER

MOTOR OUTPUT OF PHASE CONTROL

AC OUTPUT FOR DRAIN PUMP

COMMUNICATION BETWEEN INDOOR AND OUTDOOR

LEV CONTROL OUTPUT

FLOAT SWITCH SENSING

PIPE THERMISTOR

DISCHARGE PIPE THERMISTOR

ROOM THERMISTOR

REMOTE CONTROL LINE

SPEC COLOR DESCRIPTION

CN-AIRC AIR CLEAN WHITE AIR CLEAN SIGNAL

Page 56

56 Indoor Unit

7. Exploded View

152302

268714

158591

135500-2

359012

267110

147901

249951

336610

137214

354210

437214

346810

137213-1

137213-2

263230-1

263230-2

263230-3

135500-1

330870

Exploded View

Page 57

Service Manual 57

Replacement Parts List

8. Replacement Parts List

135500-1 COVER 3550A20214A 3550A20214B 3550A20214B R

135500-2 COVER 3550A20215A 3550A20215A 3550A20215A R

137213-1 PANEL ASSEMBLY,SIDE 3721A20136A 3721A20136A 3721A20136A R

137213-2 PANEL ASSEMBLY,SIDE 3721A20136B 3721A20136B 3721A20136B R

137214 PANEL ASSEMBLY,UPPER 3721A20135A 3721A20135B 3721A20135B R

147901 BARRIER,INDOOR 4790A20043A 4790A20043B 4790A20043B R

152302 FILTER(MECH),A/C 5230A30009A 5230A30009B 5230A30009B R

158591 PUMP ASSEMBLY,WATER 5859A20002B 5859A20002B 5859A20002B R

249951 CONTROL BOX ASSEMBLY,INDOOR 4995A20297A 4995A20297B 4995A20297C R

263230-1 THERMISTOR ASSEMBLY(ROOM) 6323A30004E 6323A30004E 6323A30004E R

263230-2 THERMISTOR ASSEMBLY(PIPE-IN) 6323A30002A 6323A30002A 6323A30002A R

263230-3 THERMISTOR ASSEMBLY(PIPE-OUT) 6323AQ3226T 6323AQ3226T 6323AQ3226T R

267110 REMOTE CONTROLLER ASSEMBLY 6711A10002D 6711A10002D 6711A10002D R

268714 PWB(PCB) ASSEMBLY,MAIN 6871A10108A 6871A10108B 6871A10108C R

330870 DRAIN PAN ASSEMBLY 3087A20019A 3087A20019B 3087A20019B R

336610 HOUSING ASSEMBLY (MECH) 3661A20022A 3661A20023A 3661A20023A R

346810 MOTOR ASSEMBLY,INDOOR 4681A20100A 4681A20100B 4681A20100C R

354210 EVAPORATOR ASSEMBLY,FIRST 5421A20147A 5421A20147B 5421A20147B R

359012 FAN ASSEMBLY,BLOWER 5901A20027A 5901A20027B 5901A20027B R

437214 PANEL ASSEMBLY,BASE 3721A20137A 3721A20137B 3721A20137B R

CRNN076BNG0 CRNN096BJG0 CRNN126BJG0

LOCATION No.

DESCRIPTION

PART NO.

REMARKS

Page 58

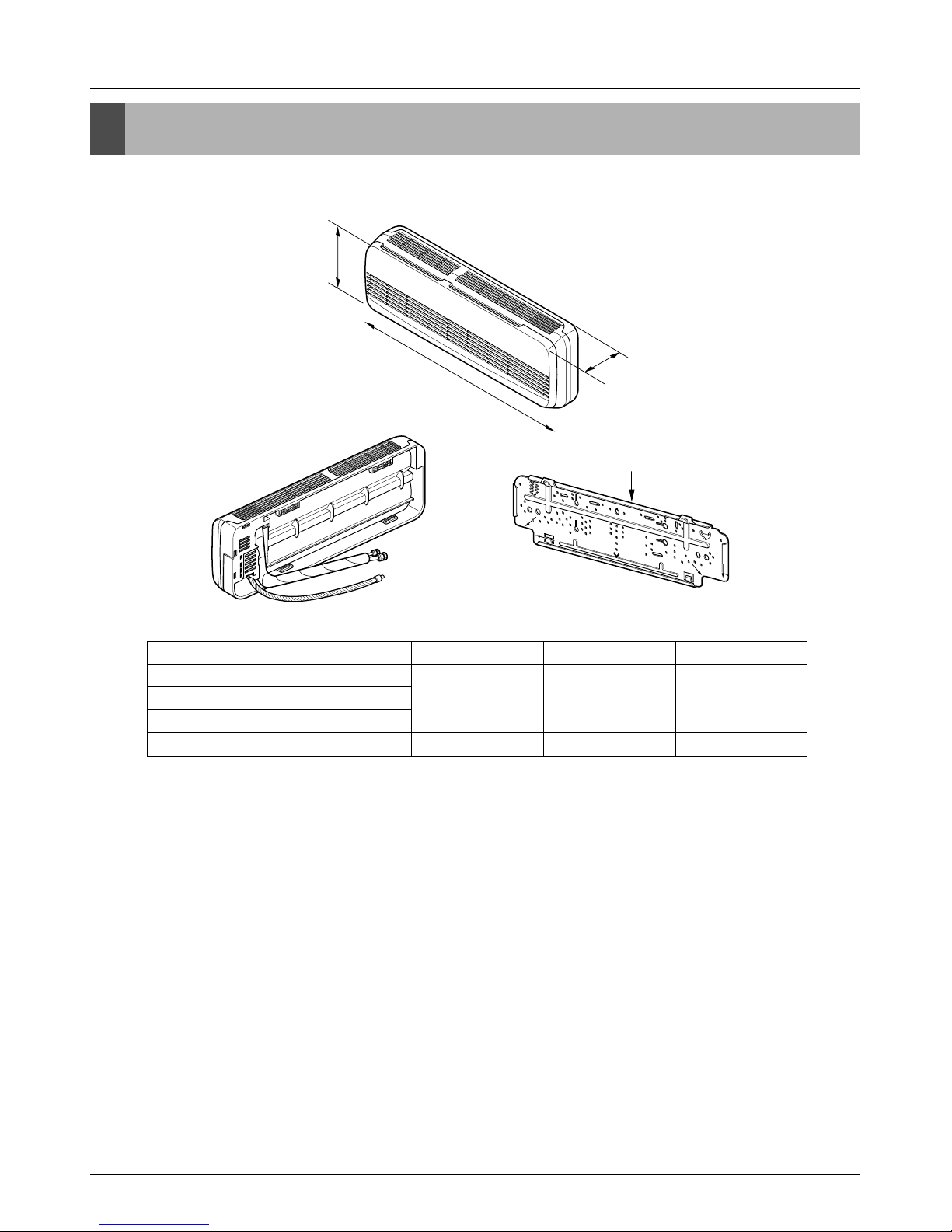

58 Indoor Unit

Indoor Unit

Convertible

1. Specification...............................................................................59

2. Installstion...................................................................................60

3. Operation Details........................................................................61

4. Display Function .............................................................................67

5. Dimensional Drawings...............................................................68

6. Piping Diagrams.........................................................................69

7. Wiring Diagrams.........................................................................70

8. Disassembly of the parts ................................................................71

9. Exploded View..................................................................................75

10. Replacement Parts List............................................................76

CRNN-VB

Convertible Type