Page 1

ADJUSTMENT INSTRUCTION

These instructions are applied to only NC-5AA chassis.

Notes

1.So this is a hot chassis, you must be careful, and be caution

not to touch 1st and 2nd concurrently.

2.Adjustment must be done in the correct order.

3.Power supply of a SET which is adjusted is 100~240V

A.C./50~60Hz.

4.The receiver must be operated for about 30 minutes proir to

the adjustment.

CONTENTS

1) VIF, AFT and SIF Adjustment

2) Sound Multiplex Adjustment

3) FOCUS Adjustment

4) AGC Adjustment

4)-1 Picture AGC Adjustment

5) V-Size and V-Center Adjustment

6) Horizontal Size, Center and Side Pincushion Adjustment

7) Purity and Convergence Adjustment

8) White Balance Adjustment

9) SUB-Bright Adjustment

10) Vertical Center Adjustment

11) Horizontal Center Adjustment

1. VCO and AFT Adjustment

This Adjustment must be applied only to PCB Assy.

1.1. Necessary Instruments

1) Sweamer Generator : can sweep 35MHz~55MHz(over

120dBu)

2) PLUG in Unit : With PIF(45.75MHz), SIF(41.25MHz) Marker

3) Alignment Scope : X-Y mode, 10mV~20V Variable

4) D.C. Power Supply : 0~12V Variable

5) D.C. Power Supply : 13.5V±0.2V (over 300mA)

6) Digital Multimeter

1.2. Preliminary Steps

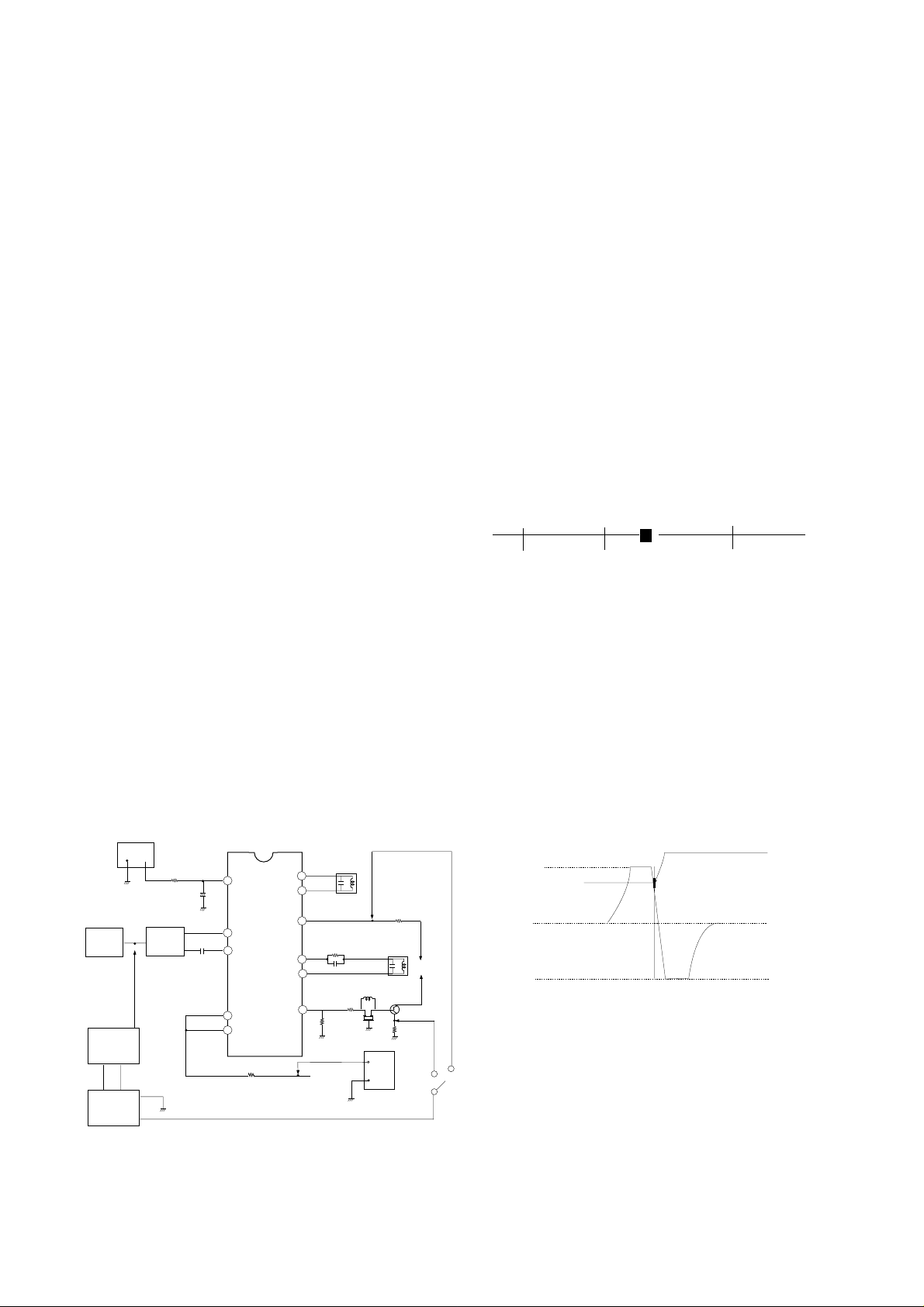

1) Connect the output of Sweamer Generator like <Fig 1>.

Here, set the output of Sweamer Gen. to 100±5dBu.

POWER

SUPPLY

-

TUNER

IF

SWEEMAR

GENERATOR

+

ALIGNMENT

SCOPE

TP2

+

SAW

FILTER

470/0.5W

7.5V

TP11

+

C122

2

C508

8

9

IC501

LA7674

11

14

R591

TP12

<Figure 1>

L501

VCO COIL

51

50

47

R520

46

C521

45

44

R518

TP4

R507

L506

AFT COIL

9V

Q503

R517

L503

Z502

TP3

L502

12.5V

+

POWER

-

SUPPLY

D502

+B

2) Connect H.Scope and Pulse output of Sweamer Generator

to H.Input and Marker input of Alignment Scope,

respectively.

3) Apply AGC Voltage(D.C.) to TP11 of IC201.(7.5±0.05V)

4) Apply B+ of IC201 to TP12 of R591.(12.0±0.1V)

5) Set VR526(AGC Adjustment) to mechanical center.

1.3. Adjustment

A. VCO

1) Set the vertical range of Alignment Scope to 1V/DIV and

CAL position, and, by applying D.C. 0~9V, do DC

Calibration to place D.C 4.5V point of waveform to center of

Screen.

2) Connect the Input terminal of Alignment Scope to

TP3(Video Detection Output), and set Vertical Variable

Switch to CAL position.

3) Apply AGC Voltage to TP11 of IC201 through 470§to be

7.5±0.05V

4) Adjust L501 so that BEAT appears on 45.75MHz Marker

like <Fig 2> If not, adjust again after attenuating output 10

~20dBu.

42.75

B. AFT

1) Connect the Input of Alignment Scope to TP4 with keeping

DC voltage of 2pin of IC201.

2) Keep the output of Sweamer Generator 100±5dBu.

3) Adjust L506 so that waveform of Alignment Scope to be

that of <Fig 3>.

4) Adjust Vertical Volume of Alignment Scope to place DC

level of waveform to center (4.5V) and 45.75MHz Marker to

7.5V¡0.5V.

9V

8V

AFT

0V

2. SIF Adjustment

VCO

2.1. Necessary Instruments

1) Sweamer Generator : can sweep 3~6MHz

2) Plug In Unit : with 4.5MHz Marker

3) Alignment Scope : X-Y mode(can measurable 10mV~

20Vp-p)

4) DC Power Supply : 13.5V, over 300mA

5) DC Power Supply : 0~12V variable

f (MHz)

45.0 47.25

45.75MHz

(Turn L105 so that the position of Beat

is same with 45.75MHz Marker)

<Figure 2>

45.75 MARKER

<Figure 3>

- 1-

Page 2

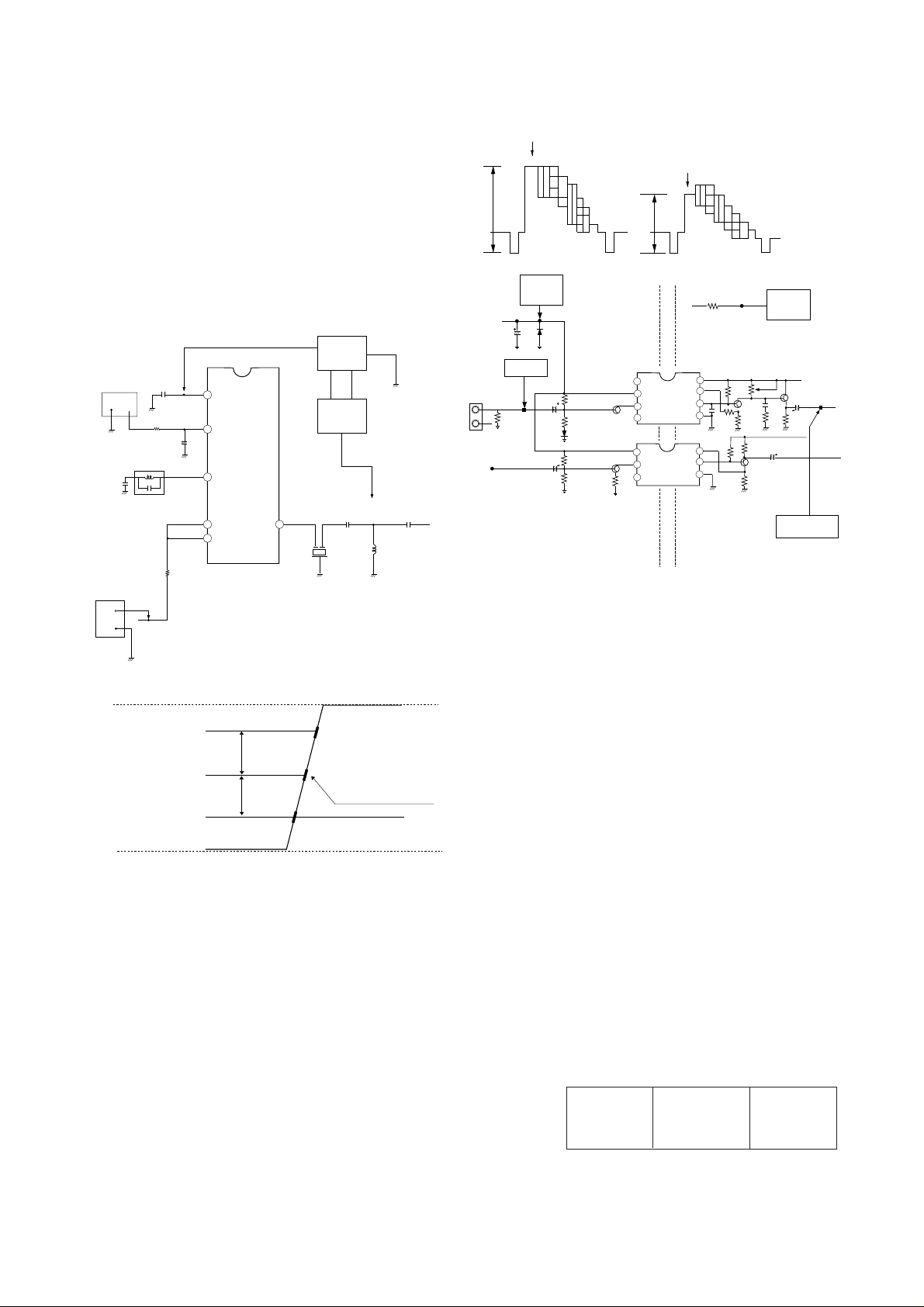

2.2. Adjustment

1) Connect Sweamer Generator and Alignment Scope the

same method of VIF adjustment.

2) Connect the output of Sweamer Generator to TP5 like <Fig 4 >.

3) Connect the Input of Alignment Scope to TP6.

4) Apply AGC voltage of IC201 to TP11(7.5±0.05V).

5) Apply B+ of IC201 to TP12.

6) Adjust L502 S-shaped waveform of Alignment Scope to be

that of <Fig 5>.

Adjust (A=B)

Because 4.5MHz Marker doesn’t with horizontal line, apply

(a) marker(4.5MHz) to be the center of (b), (c)Markers.

100% WHITE

75% WHITE

A

B

DC POWER

SUPPLY

DC 12V

TP13

R591

TP12

<Figure 6>

DC POWER

SUPPLY

DC 12.5V

12.5V

POWER

SUPPLY

9V

A = B

+B

POWER

-

+

ALIGNMENT

SCOPE

TP6

7.5V

TP11

+

C508

1

2

4

11

14

IC501

LA7674

SWEEMAR

GENERATOR

TP5

45

C515

C516

Z501

SUPPLY

C509

+

470/0.5W

L502

SIF COIL

R591

-

TP12

C206

ZD201

PATTERN

A/V IN

VIDEO

SOUND

R609

GENERATOR

TP8

A

R210

1

2

Q206

IC202

C204

C507

3

4

1

Q603

2

IC601

3

COLD

8

7

6

5

8

7

6

HOT

VR202

Q201

R618

Q601

Q202

L201

C510

OSCILLOSCOPE

C201

6.0MHz

VIDEO

SOUND

TP10

D

<Figure 7>

3.3 Adjustment

Adjust VR202 to get Luminance signal(Color Bar) level like

below. ( Refer to <Fig 6> )

1) White 100% modulated 1.78±0.1Vp-p

<Figure 4>

2) White 75% modulated 1.46±0.1Vp-p

4. Automatic Gain Control(AGC) Adjustment

4.1Turn on a SET and receive Digital Pattern of 65¡1dB through

A

(b)

(a)

B

4.5 MARKER

75§Ant. terminal.

4.2 Connect DMM(Digital Multi-Meter) to J27.

4.3 Adjust VR101 to read 5.7±0.05V of DMM.

(Where, you can set proper AGC voltage according to signal

condition.)

0V

(c)

<Figure 5>

3. Composite Video Signal Adjustment

3.1.Necessary Instruments

1) Pattern Generator : PM5518(PHILIPS) or Equivalents

7 Step Color Bar Pattern with 75§out

2) Oscilloscope : VP-5650A or Equivalents

can measure over 1.0Vp-p

Vertical Freq. : over 4MHz

3) DC Power Supply : 12.2±0.2V/400mA 2EA

3.2. Preliminary Steps

1) Connect the output of Pattern Generator to TP8 like <Fig 7>.

Where, the output of Pattern Generator is 1.0Vp-p.(Point

position “A”)

2) Connect DC Power Supply to TP12 and TP13.

Where, devide Ground of TP12 and TP13(HOT/COLD).

3) Connect probe to TP10(point “D”).

- 2-

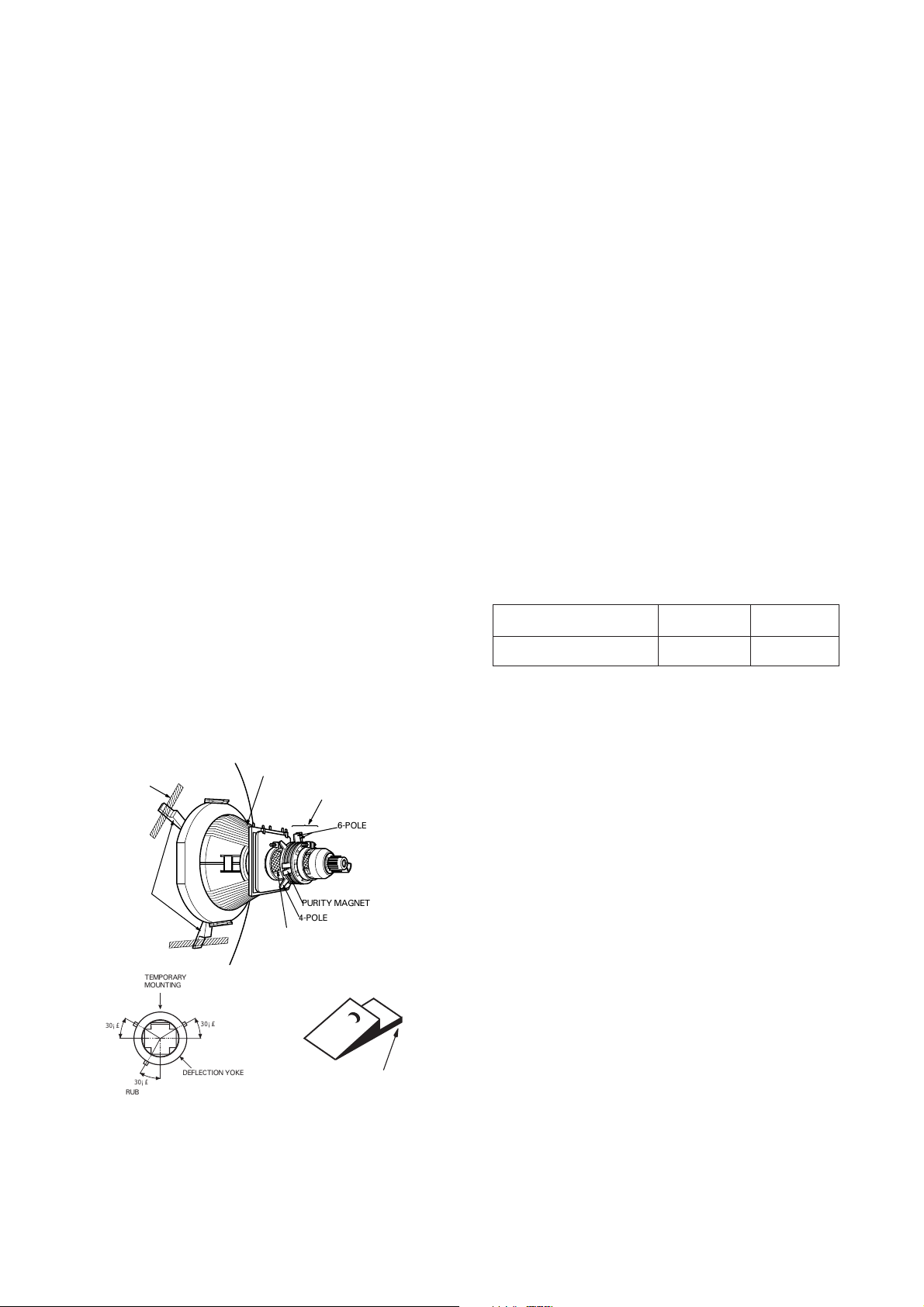

5. Purity and Convergence Adjustment

This adjustment should be made when a complete re-alignment

is required or a new picture tube is installed.

5.1 Purity Adjustment

5.1.1 Necessary instruments and Preliminary steps

1) Pattern Generator : 216/1 or Equivalents

2) Degauss CPT and Cabinet with Degaussing coil.

3) Maximize Contrast level.

4) Pre-adjust the DY.

5.1.2 Adjustment

1) Receive Raster signal(Red).

2) Push the DY to get Picture like <Fig 8>.

3) Adjust 2-pole magnet to place RED center of screen

orthogonally.

B

<Figure 8>

RG

Page 3

4) Pre-fix 2-pole magnet after adjustment with Lock Ring.

,,,,,

5) Pull the DY back slowly to get uniformly RED picture and fix

it.

5.2 Convergence Adjustment

5.2.1 Necessary Instruments

1) Pattern Generator : 216/1 or Equivalents

2) Degaussing coil

5.2.2 Preliminary Steps

1) Do this adjustment after operating the SET more than 30

minutes.

2) Degauss CPT and Cabinet with Degaussing coil.

3) Receive Cross hatch pattern.

4) Adjust Contrast and Bright properly.

5) Untighten half-fixed Magnet Assy lock ring

5.2.3 Adjustment

A. Center(Static) Convergence Adjustment

1) Unify Red and Blue vertical lines at center of screen by

varying the angle of two tabs of 4-pole magnet.

2) Rotate tab with sustaining the angle of item 1) and unify

Red and Blue vertical lines at center of screen.

3) Unify Red,Blue and Green vertical lines by adjusting two

tab2 of 6-pole magnet.

4) Rotate tab with sustaining the angle of item 3) and unify

Red,Blue and Green vertical lines.

5) To get more detail adjustment repeat 1),2) with

remembering changes of Red,Blue and Green.

6) Fix magnet assy lock ring.

B. Dynamic Convergence Adjustment

1) Prepare bonded rubber wedge.

2) Adhere rubber wedge to “A” part halfly.

(Don’t remove paper of bonding part.)

3) Move the DY every direction to get best convergence in

every corner.

4) Adhere rubber wedge to bottom of CPT.(Refer <Fig 9>).

5) After checking the locatons of 3 wedges and check

Convergence.

6) Paint white lacquer on DY fixing nut and magnet.

ADHESIVE TAPE

RUBBER

WEDGES

TEMPORARY

MOUNTING

DEFLECTION YOKE

PURITY &CONVERGENCE

MAGNET ASSEMBLY

,,,

,,

,,

,,,

PURITY MAGNET

4-POLE

GLASS CLOTH TAPE

6-POLE

6. White Balance

6.1 White Balance Adjustment

6.1.1 Necessary Instrument

1) White BAlance Meter

6.1.2 Preliminary Steps

1) Do this adjustment after operating the SET more than 30

minutes.

2) Receive Standard White pattern.

3) Adjust under “APC ON” condition.

4) Turn Screen VR CCW.

5) Set Red driver(VR571) and Blue driver(VR572) to

mechanical center.

6) Set Red Bias(VR574) ,Blue Bias(VR575) and Green

Bias(VR573) to 1/3 point to Clock-wise from full CCW.

7) Set SVC SW to “SVC” to get Horizontal line.

6.1.3 Adjustment

1) Turn screen VR slowly to see first horizontal line on screen

2) Make horizontal line white with 2 Bias VRs which aren’t

displayed in 1).

3) Vary screen VR to get very dim horizontal line.

4) Set SVC SW to “Normal” position.

5) Receive adjustment signal-White in upper and Black in

Lower.

6) Vary Red driver(VR571) and Blue driver(VR572) to get

White screen in White.

7) Vary Bias and Drivers to get the best screen in White and

Black.

8) Check adjustment condition with White Balance Meter.

9) Refer below for Adjustment

Color Temperature

10,000K

High Light : 40fl

Low Right : 4fl

X

0.281

Y

0.288

7. Focus Adjustment

1) Receive Digital pattern.

2) Set screen conditon to “APC ON”.

3) Turn Focus VR to get the best condition in center and

every corner.

8. Sub-Bright Adjustment

1) Receive Digital pattern.

2) Do this adjustment after operating the SET more than 30

minutes.

3) After selecting Sub-mode with SVC Remocon and vary to

distinguish 4 and 5 step of Gray scale.

9. Vertical Size Adjustment

1) Receive Digital pattern and set screen conditon to “APC

ON”.

2) Vary Vertical Size adjustment VR(VR301) to reach inner

circle of large circle to edge of frame.

30¡£

RUBBER WEDGES

LOCATION

30¡£

30¡£

DEFLECTION YOKE

<Figure 9>

ADHESIVE

10. Vertical Center Adjustment

1) Receive Digital pattern and set screen condition to “APC

ON”.

2) Adjust the center of screen with SVC SW(SW301) to place

center.

11. Horizontal Center Adjustment

1) Receive Digital pattern and set screen condition to “APC

ON”.

2) Adjust the center of screen with VR505 to place center.

- 3-

Page 4

- 1 -

BLOCK DIAGRM

TUNER

HOT

COLD

TU100

IC2

D801

IC301

IC801

RL801

D/G

COIL

IC1

PA1

5V 12V 33V

LOCK

CLOCK

DATA

CS

35

3

1

2

5

39 41

SDA/SCL

R, G, B, Ys

Q806

Q10

Q401

Q402

1877

H. D. T

Q805

TMP67CC31

IC501

8

9

50

51

45

46

44

48

T402

FBT

1

3

40

34

6

21

23 28

LA7674

SMPS TRANS

TX

IC601

PRE-AMP

EEPROM

12V

R-Y, B-Y, G-Y

5V

24V

180V

STR50092K

PWR

Q11

FBP

FROM FBT

H.Vcc of

IC501

AFT

HV

Z101

VIF

SIF

VCO

AFT

SHARP

BRI

COLOR

TINT

CONT

PRE-AMP.

Q102

SIF-IN

DET-OUT

SFE4.5

TPS4.5

SP

AUDIO IN VIDEO IN

2 12

IC602

CPT

1 4

T403

-Y

TDA

2006

IC202

Q208

Q603

3

2

9

5

6

10

HT

24V

12V

FBP

B+

COL

CPT

TO IC1

TO CPT

TO T403

CPT

JA001

PCB

13

26

D/G

3

1

6

5

8

Page 5

- 1 -

1. No Raster

Check if FBT PIN3 is 112V.

Check Power circuit

IC801 and its peripheral

circuit.

Check R410,D811

Check IC501 and its

peripheral circuit.

Check the IC602.

Check IC501 and its

peripheral sound

circuit.

Replace the

defective parts.

Check the position

of SW201 and

Heater and High voltage.

Check if the voltage of IC601

Pin2 is 12V DC.

Replace the

defective

parts.

2. No Sound

Does T402(FBT)

oscillate?

Check each

+B voltages.

(12V,24V,180V)

Check

FR526,D503,FR315,

D303,FR528,D504 and their

peripheral

circuit.

Check if the

voltage of IC501 Pin30

is 7.5V?

Check

if the H-Osc. circuit of

IC501 operates.

Check

if there is a click

sound touching the pin3

of IC602 by a screw-

driver.

Check

if there is a click

sound touching pin1 or

6 of IC501 by a screw-

driver.

Check

C817, D817.

Is there

DC voltage at + terminal

of C801.

Check

F801,R801 and

rectification

circuit.

Check

AC input.

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NG

NG

NG

NG

NG

OK

OK

OK

TROUBLESHOOTING HINTS

Page 6

- 2 -

Check the DC voltage of

IC01 pin25 and peripherals.

Replace IC01.

Check C554, ZD506 and the

pheripherals.

Check

PIF,AFT circuitry.

Check Q2,L2, C14 & C15

Replace

IC01.

3. On-Screen is not displayed

YES

Does

YES

YES

YES

NO

No

NO

NO

Do H-Pulse

and V-Pulse appear at

IC01 Pin26 and 27. And does

oscillation wave at IC01

pins 28 and 29?

When

channel selection

knob is turned for TV signal

reception does AFT signal appear

at IC501 Pin47? Does 1

to 9V change

appear?

Does on

screen character pulse

appear at IC01

pin22, 23, 24?

4. Inoperative AFT

Does

H-sync pulse

appear at IC01

pin 36?

Does

DC voltage of IC501

pin 18 be "0" V?

Page 7

Loading...

Loading...