LG AVUQ18GJLA0, ABUQ18GHLA0, AUUQ21GH1, ATUQ21GPLE3, AVUQ21GJLA0 Service Manual

...

Air Conditioner

SVC MANUAL(General)

CAUTION

Before Servicing the unit, read the safety precautions in General SVC manual.

Only for authorized service personnel.

Internal Use Only

http://biz.lgservice.com

- 2 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Air Conditioner Service Manual

TABLE OF CONTENTS

Part 1 General Information ..........................................................................................................3

1. Safety Precautions........................................................................................................4

2. Model Line Up................................................................................................................7

3. Nomenclature ................................................................................................................9

Part 2 Functions & Controls......................................................................................................10

1. List of Functions & Accessory...................................................................................11

2. Air Flow .......................................................................................................................15

3. Air Purifying.................................................................................................................17

4. Installation Functions.................................................................................................18

5. Reliability .....................................................................................................................24

6. Convenience Functions & Controls .........................................................................25

7. Special Function & KIT...............................................................................................33

Part 3 Basic Control ..................................................................................................................36

1. Normal operation ........................................................................................................37

2 Compressor control ....................................................................................................37

3. EEV( Electronic Expansion Valve) control ...............................................................37

Part 4 Trouble Shooting Guide ...............................................................................................38

1. Self-diagnosis Function ............................................................................................39

2. Pump Down ................................................................................................................41

3. Evacuation (All amount of refrigerant leaked) ........................................................42

4. Gas Charging (After Evacuation)..............................................................................43

5. Cycle Part....................................................................................................................44

6. Electronic Parts..........................................................................................................45

- 3 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. Safety Precautions ............................................................................................................4

2. Model Line Up .....................................................................................................................7

3. Nomenclature....................................................................................................................10

Part 1 General Information

- 4 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 1 General Information

1. Safety Precautions

1.1 Cautions in Repair

To prevent injury to the user or other people and property damage, the following instructions must be followed.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the follow-

ing indications.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

n Meanings of symbols used in this manual are as shown below.

Be sure not to do.

Be sure to follow the instruction.

Dangerous Voltage

Be sure to disconnect the power cable plug from the plug socket before disassembling the equipment for a repair.Internal components and circuit boards are at

main potential when the equipment is connected to the power cables. This voltage is extremely dangerous and may cause death or severe injury if come in contact with it.

Do not touch the discharging refrigerant gas during the repair work.

The discharging refrigerant gas.The refrigerant gas can cause frostbite.

Release the refrigerant gas completely at a well-ventilated place first.

Otherwise, when the pipe is disconnected, refrigerant gas or refrigerating

machine oil discharges and it Can cause injury.

When the refrigerant gas leaks during work, execute ventilation. If the refrigerant

gas touches to a fire, poisonous gas generates. A case of leakage of the refrigerant and the closed room full with gas is dangerous because a shortage of oxygen

occurs. Be sure to execute ventilation.

When removing the front panel or cabinet, execute short-circuit and discharge

between high voltage capacitor terminals. If discharge is not executed, an electric

shock is caused by high voltage resulted in a death or injury.

Do not turn the air-conditioner ON or OFF by plugging or unplugging the power

plug. There is risk of fire or electrical shock.

- 5 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 1 General Information

Do not turn on the breaker under condition that front panel and cabinet are

removed.

Be sure to earth the air conditioner with an earthing conductor connected to the

earthing terminal.

Conduct repair works after checking that the refrigerating cycle section has

cooled down sufficiently. Otherwise, working on the unit, the hot refrigerating

cycle section can cause burns.

Do not tilt the unit when removing panels. Otherwise, the water inside the unit

can spill and wet floor.

Do not use the welder in a well-ventilated place. Using the welder in an enclosed

room can cause oxygen deficiency.

Be sure to turn off power switch before connect or disconnect connector, or parts

damage may be occurred.

Do not use a defective or underrated circuit breaker. Use the correctly rated

breaker and fuse. Otherwise there is a risk of fire or electric shock.

Install the panel and the cover of control box securely. Otherwise there is risk of

fire or electric shock due to dust, water etc.

Indoor/outdoor wiring connections must be secured tightly and the cable should

be routed properly so that there is no force pulling the cable from the connection

terminals. Improper or loose connections can cause heat generation or fire.

Do not touch, operate, or repaire the product with wet hands. Hoding the plug by

hand when taking out. Otherwise there is risk of electric shock or fire.

Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air

purge. Do not compress air or Oxygen and Do not use Flammable gases.

Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

- 6 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 1 General Information

1.2 Inspections after Repair

Check to see if the parts are mounted correctly and wires are connected.

Improper installation and connections can cause an electric shock or an injury.

Check the installation platform or frame has corroded. Corroded installation platform or frame can cause the unit to fall, resulting in injury.

Be sure to check the earth wire is correctly connected.

After the work has finished, be sure to do an insulation tset to check the resistance is 2[Mohm] or more between the charge section and the non-charge metal

section (Earth position). If the resistance value is low, a disaster such as a leak or

electric shock is caused at userʼs side.

Check the drainage of the indoor unit after the repair. If drainage is faulty the

water to enter the room and wet floor.

Check to see if the power cable plug is not dirty or loose. If the plug is dust or

loose it can cause an electrical shock or fire.

Do not use a joined power cable or extension cable, or share the same power

outlet with other electrical appliances. otherwise, it can cause an electrical shock,

excessive heat generation or fire.

Do not insert hands or other objects through the air inlet or outlet while the product is operating. There are sharp and moving parts that could cause personal

injury.

Do not block the inlet or outlet of air flow. It may cause product failure

- 7 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2. Model Line Up

Part 1 General Information

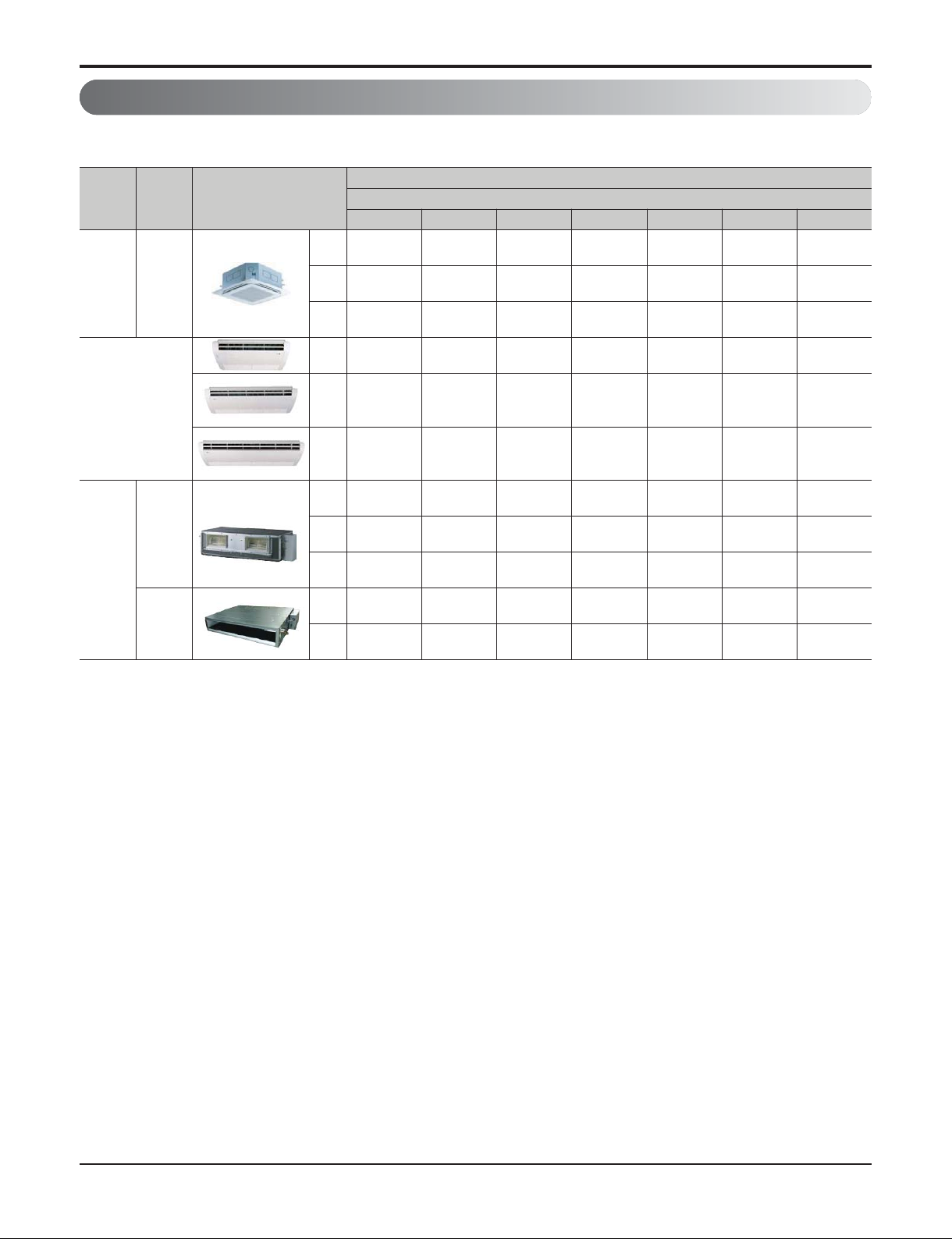

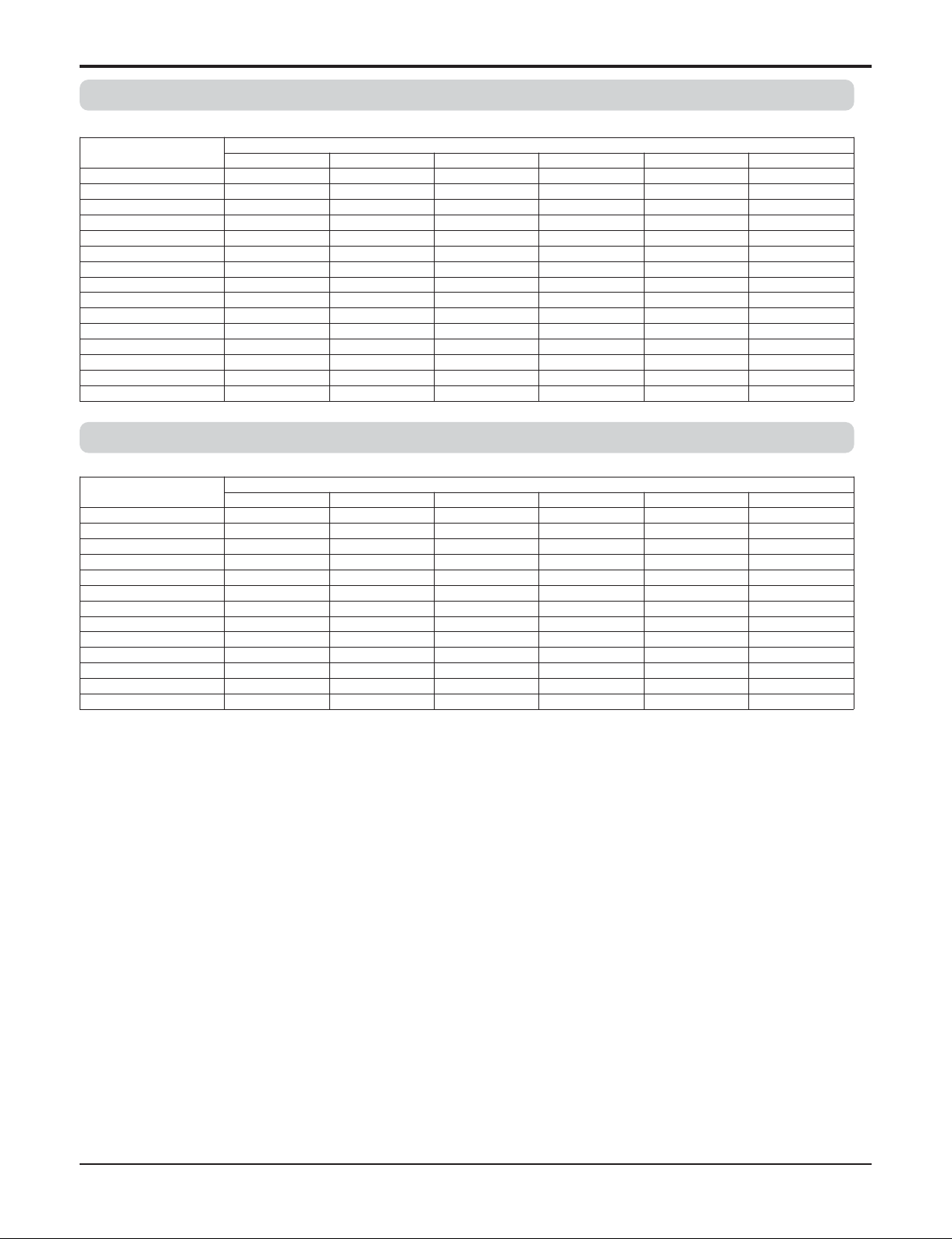

2.1 Indoor units

Category Type Chassis

Model Name

Capacity class, kW

5.0 6.0 7.0 10.5 12.5 14.1 15.8

Ceiling

cassette

4way

TP

ATNQ18GPLE3 ATNQ21GPLE3

TN

ATNQ24GNLE3

TM

ATNQ36GMLE3 ATNQ42GMLE3 ATUQ48GMLE3 ATUQ54GMLE3

Ceiling suspended

VJ

AVNQ18GJLA0 AVNQ21GJLA0 AVNQ24GJLA0

VK

AVNQ36GKLA0

VL

AVNQ42GLLA0 AVUQ48GLLA0 AVUQ54GLLA0

Ceiling

concealed

duct

High

static

pressure

BH

ABNQ18GHLA0 ABNQ21GHLA0

BG

ABNQ24GGLA0 ABNQ36GGLA0

BR

ABNQ42GRLA0 ABUQ48GRLA0 ABUQ54GRLA0

Low

static

pressure

L2

ABNQ18GL2A0 ABNQ21GL2A0

L3

ABNQ24GL3A0

- 8 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 1 General Information

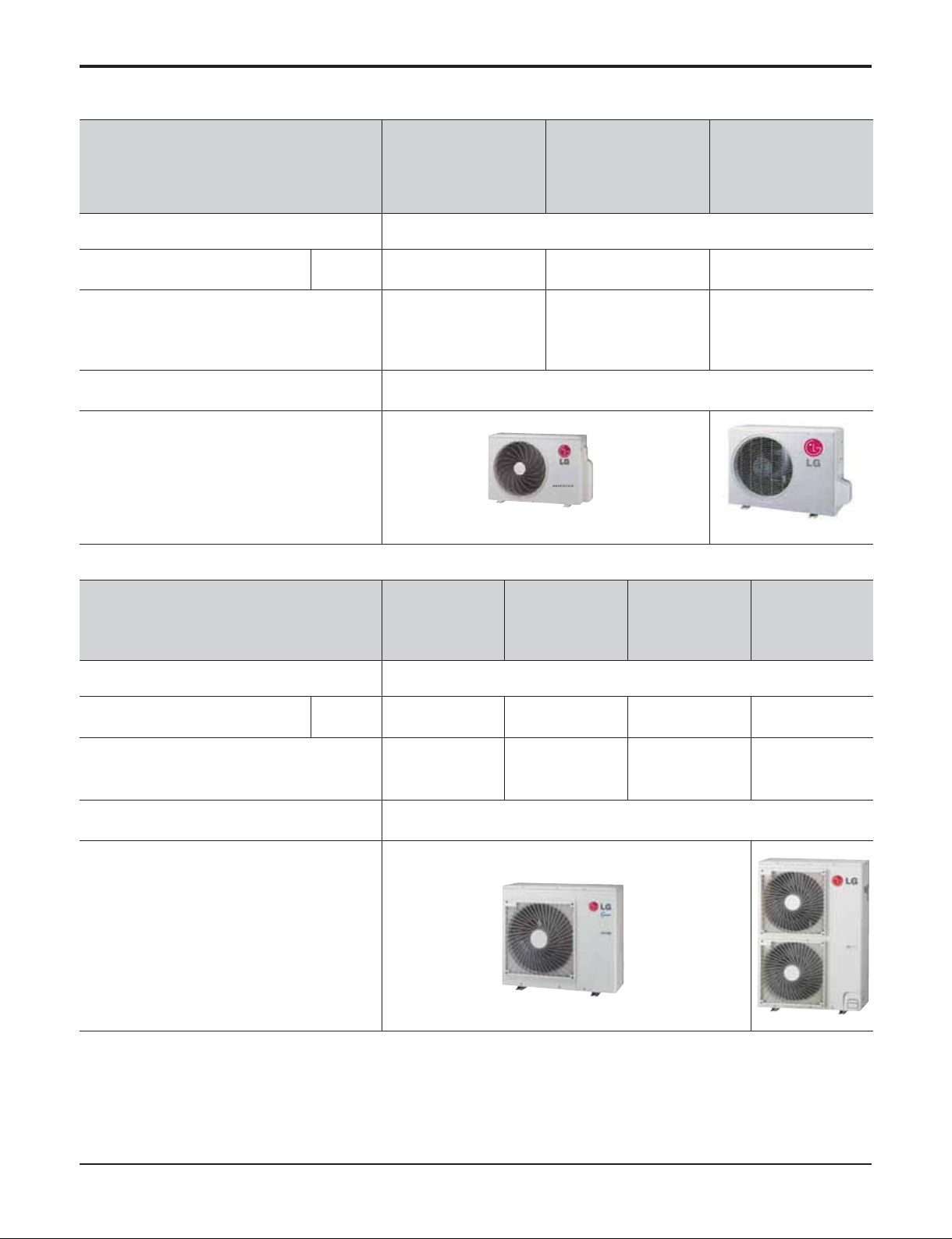

2.2 Outdoor units

Model Names

AUUQ18GH1

ATUQ18GPLE3

AVUQ18GJLA0

ABUQ18GHLA0

ABUQ18GL2A0

AUUQ21GH1

ATUQ21GPLE3

AVUQ21GJLA0

ABUQ21GHLA0

ABUQ21GL2A0

AUUQ24GH1

ATUQ24GNLE3

AVUQ24GJLA0

ABUQ24GGLA0

ABUQ24GL3A0

No. of connectable indoor units 1

Total capacity class index of

Connectable Indoor units

kW 5.0 6.0 7.0

Connectable indoor unit model names

ATNQ18GPLE3

AVNQ18GJLA0

ABNQ18GHLA0

ABNQ18GL2A0

ATNQ21GPLE3

AVNQ21GJLA0

ABNQ21GHLA0

ABNQ21GL2A0

ATNQ24GNLE3

AVNQ24GJLA0

ABNQ24GGLA0

ABNQ24GL3A0

Power supply

220-240V, 1Ø, 50Hz

220V, 1Ø, 60Hz

Chassis

Model Names

AUUQ36GH1

ATUQ36GMLE3

AVUQ36GKLA0

ABUQ36GGLA0

AUUQ42GH1

ATUQ42GMLE3

AVUQ42GLLA0

ABUQ42GRLA0

AUUQ48GH1

ATUQ48GMLE3

AVUQ48GLLA0

ABUQ48GRLA0

AUUQ54GH1

ATUQ54GMLE3

AVUQ54GLLA0

ABUQ54GRLA0

No. of connectable indoor units 1

Total capacity class index of

Connectable Indoor units

kW 10.5 12.5 14.1

15.8

Connectable indoor unit model names

ATNQ36GMLE3

AVNQ36GKLA0

ABNQ36GGLA0

ATNQ42GMLE3

AVNQ42GLLA0

ABNQ42GRLA0

ATUQ48GMLE3

AVUQ48GLLA0

ABUQ48GRLA0

ATUQ54GMLE3

AVUQ54GLLA0

ABUQ54GRLA0

Power supply

220-240V, 1Ø, 50Hz

220V, 1Ø, 60Hz

Chassis

- 9 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

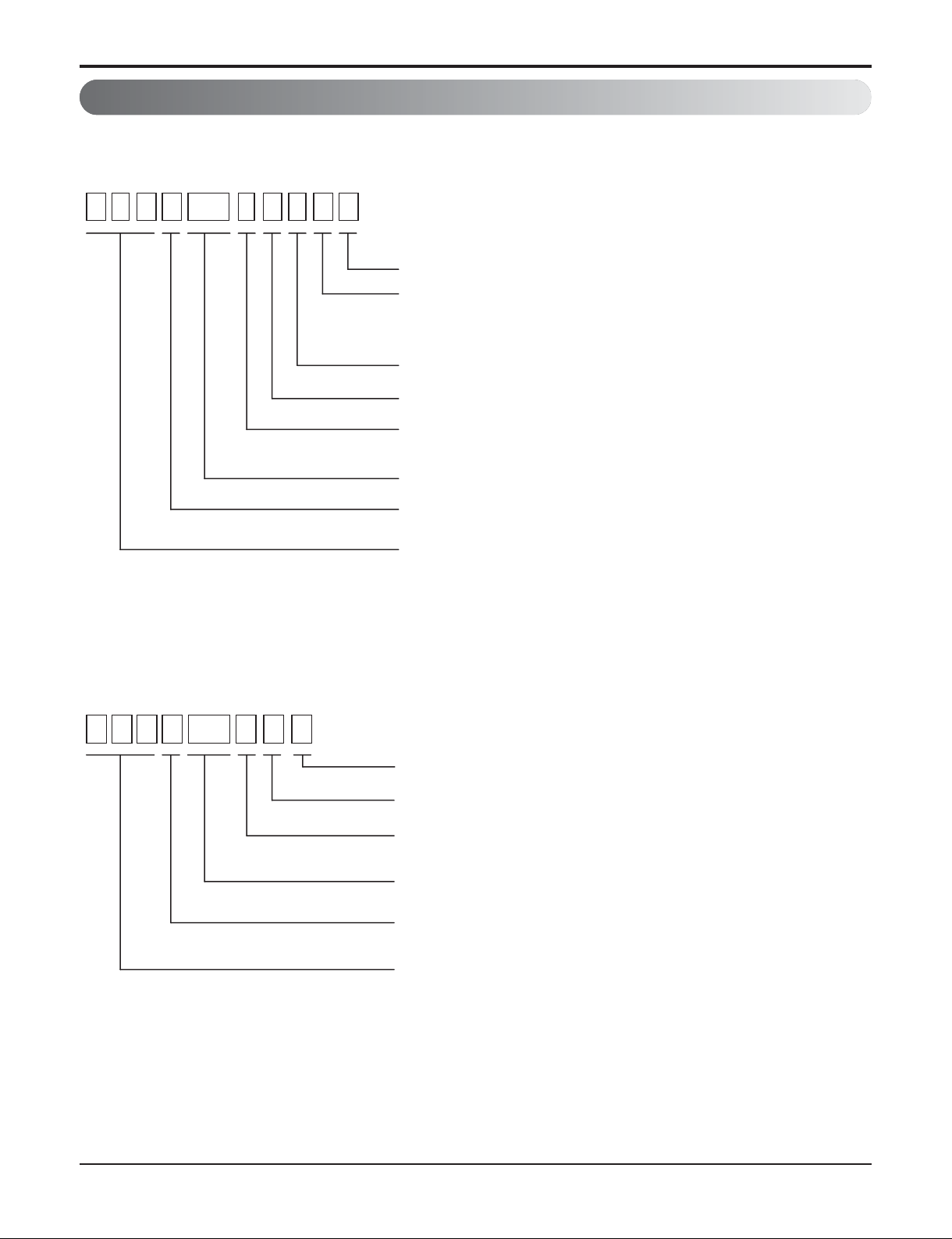

3. Nomenclature

3.1 Indoor Unit(Global)

Part 1 General Information

A T N Q24 G N L E 3

Serial Number

Functions

A : Basic

E : Elevation grille

Look : Basic

Chassis Name

Electrical Ratings

G : 220-240V, 1Ø, 50Hz / 220V, 1Ø, 60Hz

Capacity Code based on ‘kBtu/h’ units

A U U Q24 HG 1

Model Type

Q: Cooling Only

R410A Single A Indoor Unit

ATN : Ceiling cassette type indoor unit

AVN : Convertible, Ceiling and Floor type indoor unit

ABN : Ceiling concealed duct type indoor unit

Serial Number

High Efficiency model

Electrical Ratings

G : 220-240V, 1Ø, 50Hz / 220V, 1Ø, 60Hz

Capacity code

Model Type

Q : Cooling Only

R410A Single A Outdoor Unit

- 10 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

1. List of Functions & Accessory ......................................................................................11

2. Air flow ............................................................................................................................15

2.1 Auto swing (left & right)...............................................................................................15

2.2 Auto swing (up & down) ..............................................................................................15

2.3 Chaos swing (up/down)...............................................................................................15

2.4 Air flow step.................................................................................................................16

2.5 Chaos wind (auto wind)...............................................................................................16

2.6 Jet Cool Mode Operation ............................................................................................16

2.7 Swirl wind Swing .........................................................................................................16

3. Air purifying ....................................................................................................................17

3.1 PLASMA Air Purifying System ....................................................................................17

4. Installation Functions ....................................................................................................18

4.1 E.S.P. (External Static Pressure) Setting ....................................................................18

4.2 High Ceiling operation.................................................................................................23

5. Reliability ........................................................................................................................24

5.1 Hot start.......................................................................................................................24

5.2 Self-diagnosis Function...............................................................................................24

6. Convenience Functions & Controls .............................................................................25

6.1 Cooling Operations .....................................................................................................25

6.2 Auto cleaning operation ..............................................................................................26

6.3 Auto changeover operation.........................................................................................26

6.4 Child Lock Function.....................................................................................................27

6.5 Group Control..............................................................................................................28

6.6 Sleep Timer Operation................................................................................................29

6.7 Timer(On/Off) ..............................................................................................................29

6.8 Weekly Program..........................................................................................................30

6.9 Two Thermistor Control...............................................................................................32

7. Special Function & KIT ..................................................................................................33

7.1 Low Ambient control....................................................................................................33

7.2 Space Control .............................................................................................................33

7.3 Auto Elevation Grille....................................................................................................33

Part 2 Functions & Controls

- 11 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

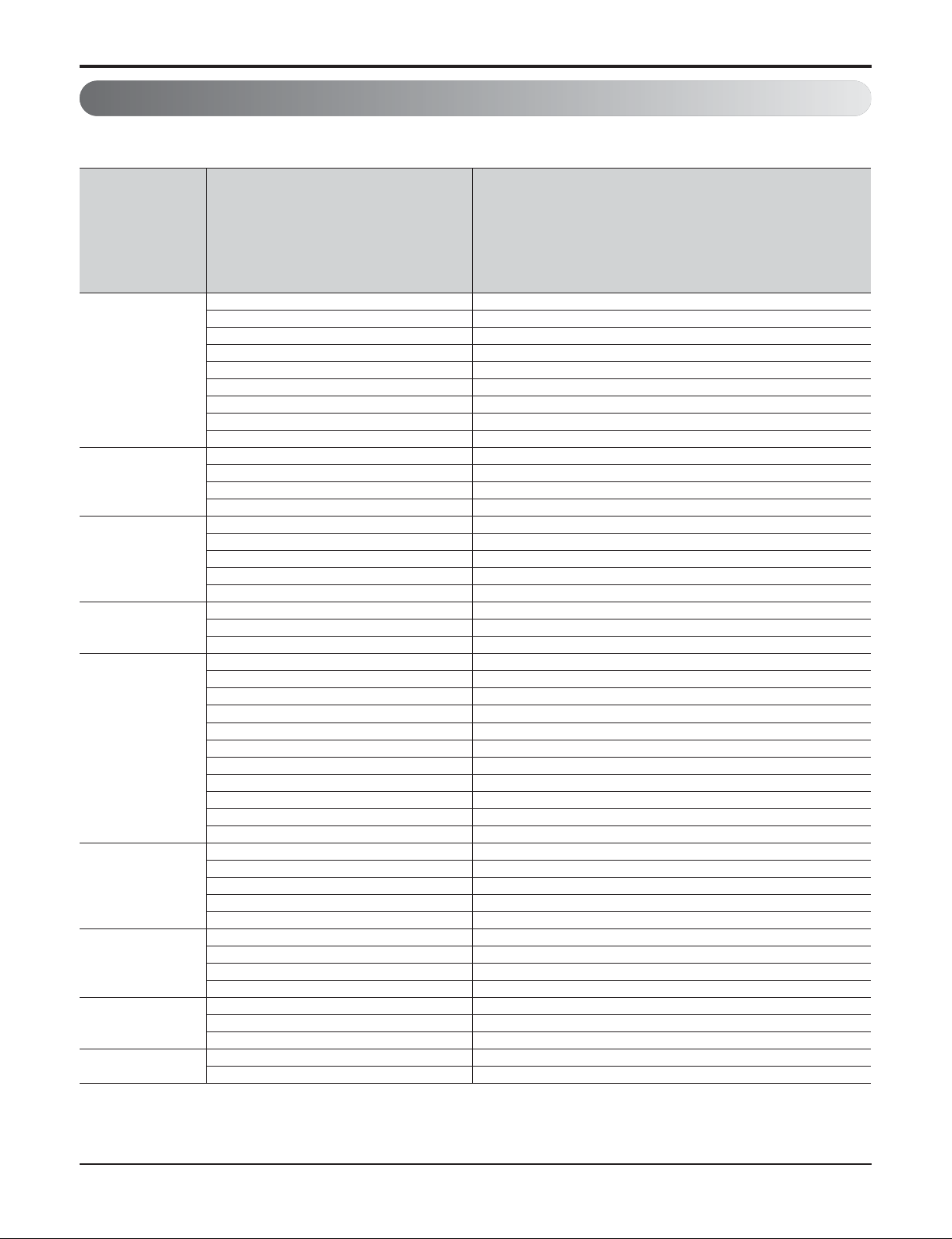

Category Functions

ATNQ18GPLE3

ATNQ21GPLE3

ATNQ24GNLE3

ATNQ36GMLE3

ATNQ42GMLE3

ATNQ48GMLE3

ATNQ54GMLE3

Air flow

Air supply outlet 4

Airflow direction control (left & right) X

Airflow direction control (up & down) Auto

Auto swing (left & right) X

Auto swing (up & down) O

Airflow steps (fan/cool/heat) 4 / 5 / 4

Chaos wind(auto wind) O

Jet cool/heat O / X

Swirl wind O

Air purifying

Triple filter (Deodorizing) X

Plasma air purifier PTPKM0

Allergy Safe filter X

Long-life prefilter (washable / anti-fungus) O

Installation

Drain pump O

E.S.P. control* X

Electric heater X

High ceiling operation* O

Auto Elevation Grille* PTEGM0

Reliability

Hot start O

Self diagnosis O

Soft dry operation O

Convenience

Auto changeover** O**

Auto cleaning X

Auto operation(artificial intelligence)** O**

Auto Restart O

Child lock* O

Forced operation O

Group control* O

Sleep mode O

Timer(on/off) O

Timer(weekly)* O

Two thermistor control* O

Individual

control

Wired remote controller O

Deluxe wired remote controller PQRCUDS0 / PQRCUDS0B / PQRCUDS0S

Simple wired remote controller PQRCVCL0Q / PQRCVCL0QW

Simple Wired remote controller(for hotel use)

PQRCHCA0Q / PQRCHCA0QW

Wireless remote controller PQWRHDF0

CAC network

function

General central controller (Non LGAP) X

Network Solution(LGAP) O

Dry contact PQDSA(1)/PQDSB(1) / PQDSBC

PI 485(for Indoor Unit) X

Special

function kit

Zone controller X

CTI(Communication transfer interface) X

Electronic thermostat X

Others

Remote temperature sensor PQRSTA0

Telecom shelter controller X

Part 2 Functions & Controls

1. List of Functions & Accessory

1. 4-Way Ceiling Cassette Indoor

- 12 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

2. Ceiling Concealed Duct Indoor

Category Functions

ABNQ18GHLA0, ABUQ18GL2A0

ABNQ21GHLA0, ABUQ21GL2A0

ABNQ24GGLA0, ABUQ24GL3A0

ABNQ36GGLA0

ABNQ42GRLA0

ABNQ48GRLA0

ABNQ54GRLA0

Air flow

Air supply outlet 2

Airflow direction control (left & right) X

Airflow direction control (up & down) X

Auto swing (left & right) X

Auto swing (up & down) X

Airflow steps (fan/cool/heat) 3 / 3 / 3

Chaos wind(auto wind) X

Jet cool/heat O / X

Swirl wind X

Air purifying

Triple filter (Deodorizing) X

Plasma air purifier X

Allergy Safe filter X

Long-life prefilter (washable / anti-fungus) O

Installation

Drain pump ABDPG

E.S.P. control* O

Electric heater X

High ceiling operation* X

Auto Elevation Grille* X

Reliability

Hot start O

Self diagnosis O

Soft dry operation O

Convenience

Auto changeover** O**

Auto cleaning X

Auto operation(artificial intelligence)** O**

Auto Restart O

Child lock* O

Forced operation X

Group control* O

Sleep mode X

Timer(on/off) O

Timer(weekly)* O

Two thermistor control* O

Individual

control

Standard Wired remote controller O

Deluxe wired remote controller X

Simple wired remote controller X

Simple Wired remote controller(for hotel use) X

Wireless remote controller X

CAC network

function

General central controller (Non LGAP) X

Network Solution(LGAP) O

Dry contact PQDSA(1)/PQDSB(1) / PQDSBC

PI 485(for Indoor Unit) X

Special

function kit

Zone controller ABZCA

CTI(Communication transfer interface) X

Electronic thermostat X

Others

Remote temperature sensor PQRSTA0

Telecom shelter controller X

- 13 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

3. Ceiling & floor

Type Ceiling Suspended

Category Functions

AVNQ18GJLA0

AVNQ21GJLA0

AVNQ24GJLA0

AVNQ36GKLA0

AVNQ42GLLA0

AVNQ48GLLA0

AVNQ54GLLA0

Air flow

Air supply outlet 1

Airflow direction control (left & right) Manual

Airflow direction control (up & down) Auto

Auto swing (left & right) X

Auto swing (up & down) O

Airflow steps (fan/cool/heat) 3 / 4 / 3

Chaos wind(auto wind) O

Jet cool/heat O / X

Swirl wind X

Air purifying

Triple filter (Deodorizing) X

Plasma air purifier X

Allergy Safe filter X

Long-life prefilter (washable / anti-fungus) O

Installation

Drain pump X

E.S.P. control* X

Electric heater X

High ceiling operation* O

Auto Elevation Grille* X

Reliability

Hot start O

Self diagnosis O

Soft dry operation O

Convenience

Auto changeover** O**

Auto cleaning X

Auto operation(artificial intelligence)** O**

Auto Restart O

Child lock* O

Forced operation O

Group control* O

Sleep mode O

Timer(on/off) O

Timer(weekly)* O

Two thermistor control* O

Individual

control

Wired remote controller PQRCVSL0/PQRCVSL0QW

Deluxe wired remote controller X

Simple wired remote controller X

Simple Wired remote controller(for hotel use)

X

Wireless remote controller O

Network

function

General central controller (Non LGAP) X

Network Solution(LGAP) O

Dry contact

PQDSA(1)/PQDSB(1) / PQDSBC

PI 485(for Indoor Unit) X

Special

function kit

Zone controller X

CTI(Communication transfer interface) X

Electronic thermostat X

Others

Remote temperature sensor PQRSTA0

Telecom shelter controller X

Part 2 Functions & Controls

- 14 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

4. Outdoor

Category Functions 5 / 6 kW

7 kW ↑

Reliability

Defrost / Deicing X X

High pressure switch X X

Low pressure switch X X

Phase protection X X

Restart delay (3-minutes) O O

Self diagnosis O O

Soft start O O

Test function O X

Convenience Night Silent Operation O O

network

function

Network solution(LGAP) X O

Device 5 / 6 kW

7 kW ↑

Central

Controller

Simple Controller X PQCSB101S0

Function controller X PQCSB101S0 + PQCSC101S0

Function Scheduler X PQCSB101S0 + PQCSD130A0

AC Ez X PQCSZ250S0

AC Smart ll X PQCSW320A1E

Option Kit (SD card type) X PQCSE341A0 / PQCSE342A0

ACP(Advanced Control Platform) X PQCPA11A0E / PQCPB11A0E

AC Manager X PQCSS520A0E

PI485 X PMNFP14A0 / PMNFP14A1

DO(Digital Output) Kit X PQNFP00T0

BNU (Building

Network Unit)

LONWORKS Gateway X PQNFB16A1

BACnet Gateway X PQNFB17B0

Installation

Y branch X X

Header branch X X

Air Guide X X

ODU Dry Contact X X

Low Ambient Kit O (Logical operation) O (Logical operation)

- 15 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2. Air flow

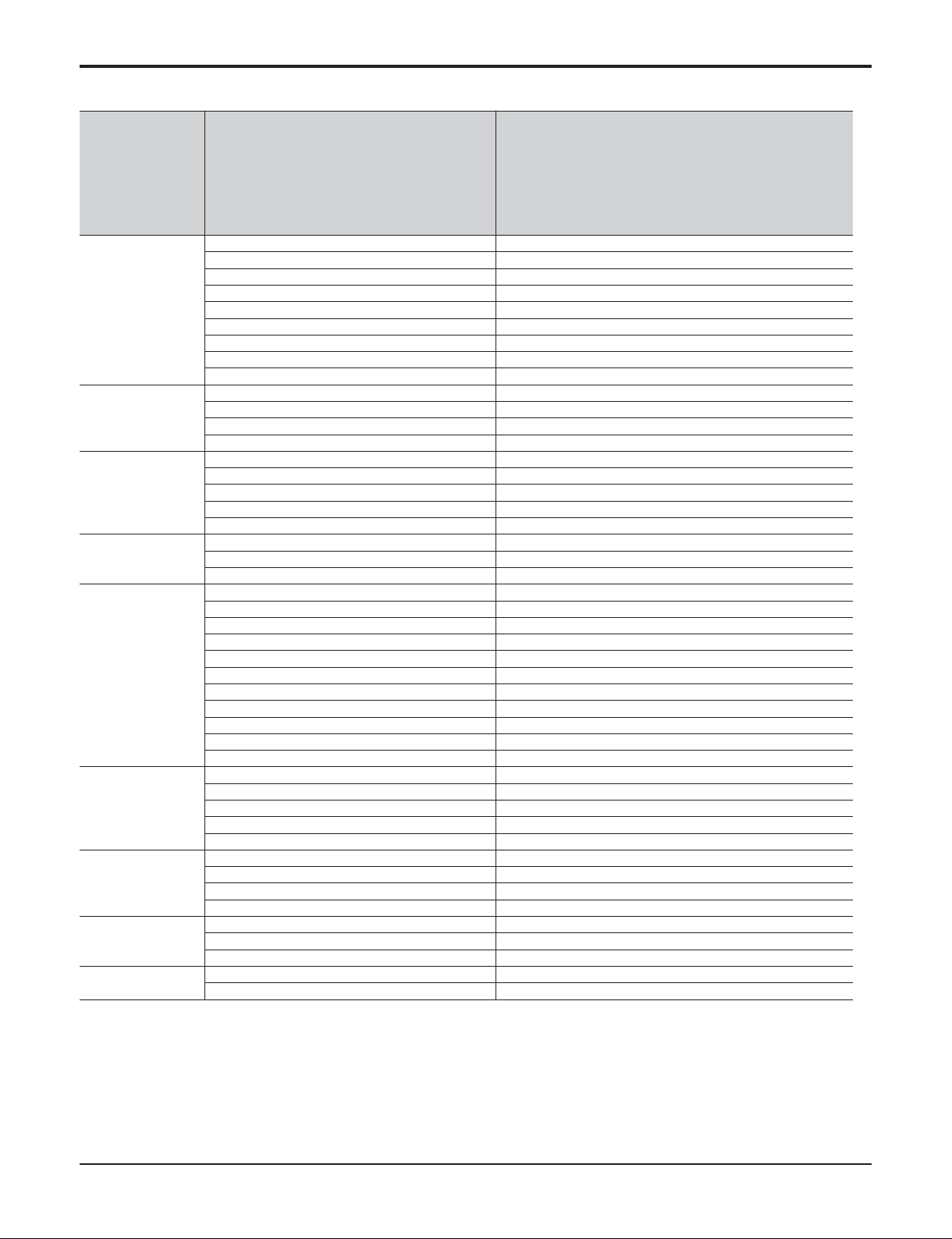

2.1 Auto swing (left & right)

• By the horizontal airflow direction control key input, the left/right louver automatically operates with the auto swing or it

is fixed to the desired direction.

2.2 Auto swing (up & down)

• By the auto swing key input, the upper/lower vane automatically operates with the auto swing or it is fixed to the

desired direction.

2.3 Chaos swing (up/down)

• By the Chaos swing key input, the upper/lower vane automatically operates with the chaos swing or it is fixed to the

desired direction.

NOTE: Some Models are different by swing width and swing pattern.

Part 2 Functions & Controls

RightLeft

110° ~ 120°

Close

110° ~ 120°

Open

CLOSED

Mode9

Mode8

Mode7

Mode6

Mode5

Mode4

Mode3

Mode2

110~120°

7~8°

OPEN

- 16 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

2.4 Air flow step

• Indoor fan motor control have 6 steps.

• Air volume is controlled "SH", "H", "Med", Low" by remote controller.

• "LL" step is selected automatically in Hot start operation.

2.5 Chaos wind (auto wind)

• When "Auto" step selected and then operated, the high, medium, or low speed of the airflow mode is operated for

2~15 sec. randomly by the Chaos Simulation

2.6 Jet Cool Mode Operation

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input.

When it is input while in the other mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min. at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C.

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then operated

in order that the air outflow could reach further.

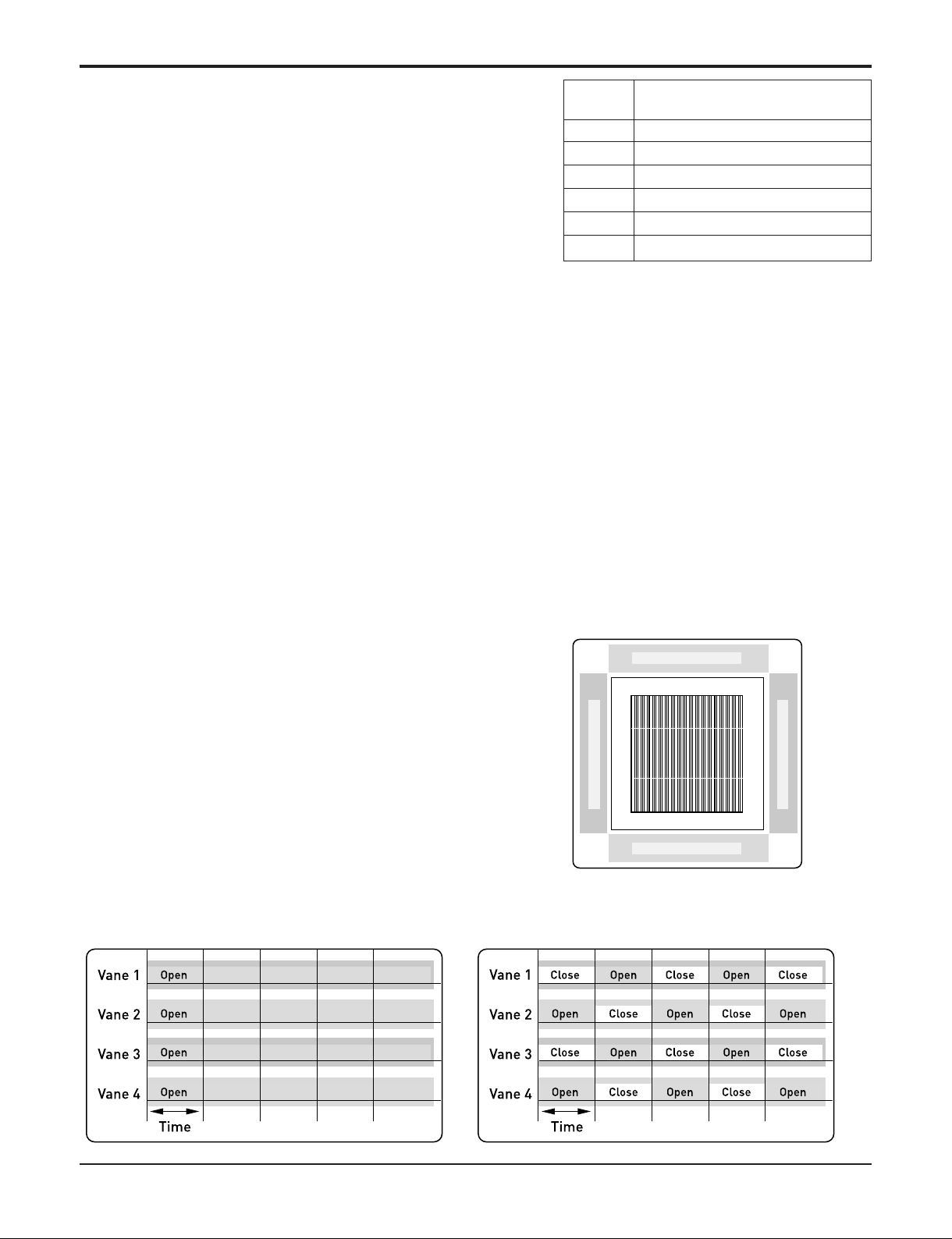

2.7 Swirl wind Swing

• It is the function for comfort cooling/heating operation.

• The diagonal two louvers are opened the more larger

than the other louvers. After one minute, it is opposite.

• Comparison of Air Flow Types

4-Open (conventional) Swirl Swing (New)

LL Very low, In heating mode

L Low

M Med

H High

SH Super high

Auto Chaos wind

Step Discription

Vane 4

Vane 2

Vane 1 Vane 3

- 17 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

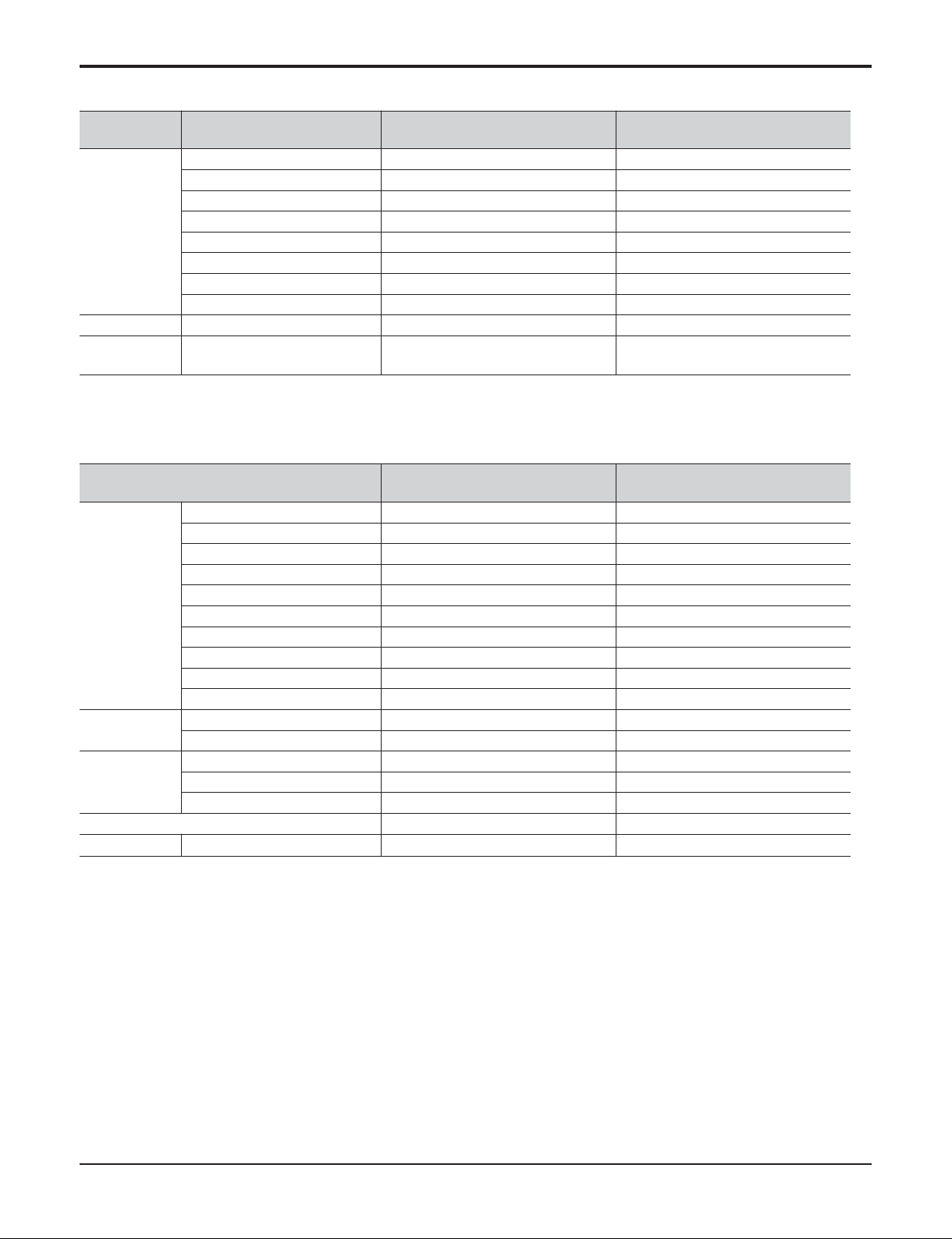

3.1 PLASMA Air Purifying System

The PLASMA Air Purifying System not only removes microscopic contaminants and dust, but also removes house

mites, pollen, and pet fur to help prevent allergic diseases like asthma. This filter that can be used over and over again

by simply washing with water.

3. Air purifying

Ionizer

Photo-Catalyst Coated Mesh

Dust particles

Odour

Dust electrode discharge

Odour molecule

Generating plasma

+

+

+

+

Polluted Air

Purified fresh Air

+4.8KV discharge

+

Part 2 Functions & Controls

- 18 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

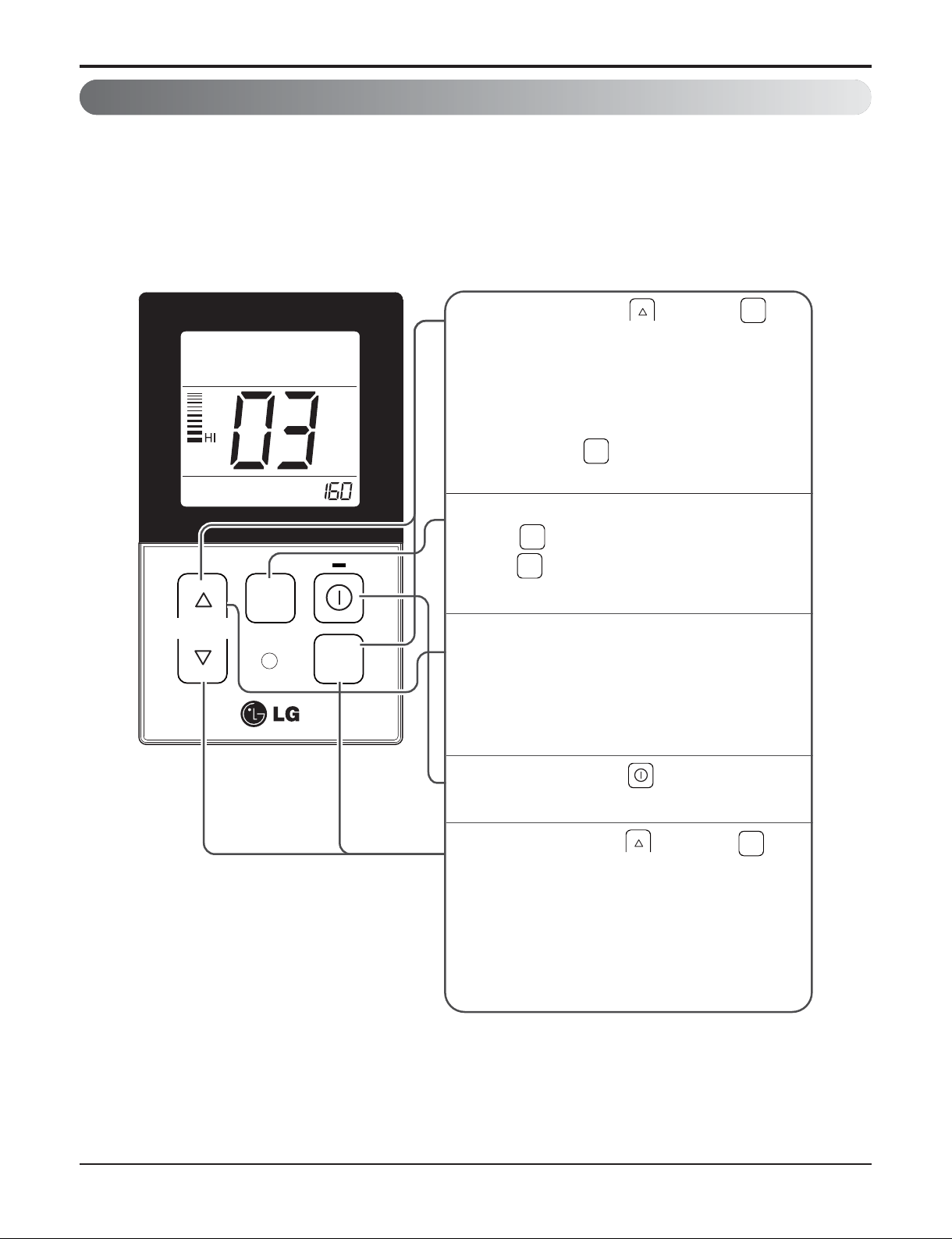

4.1 E.S.P. (External Static Pressure) Setting

4. Installation Functions

This is the function that decides the strength of the wind for each wind level and because this function is to make

the installation easier.

- If you set ESP incorrectly, the air conditioner may malfunction.

- This setting must be carried out by a certificated-technician.

- Precaution shall be taken not to alter the E.S.P value corresponded to each air flow section.

- E.S.P value can be varied according to the products.

- In the case of going to the next air flow rate stage by pressing the fan-speed button during the setup of the E.S.P

value, the E.S.P value of previous air flow rate will be maintained by remembering the E.S.P value prior to the

shift.

OPER

When pressing the button and

1

button simultaneously for more than 3

seconds, the system will be entered into the

installer setting mode.

- After entering into the installer setting

mode, select the E.S.P code value by

OPER

pressing the button.

MODE

* E.S.P code value : 03

MODE

TEMP

FAN

SPEED

OPER

MODE

Select the desired air flow rate with

2

FAN

SPEED

the button. Whenever pressing

FAN

the button, [Lo→Med→Hi] will be

SPEED

indicated.

Select the desired air flow rate value with

3

the temperature up(s), down(t) button.

* E.S.P value range : 0~255

- E.S.P value will be indicated at the upper

right section of the display window.

When pressing the button, currently

4

established E.S.P value will be set up.

When pressing the button and

5

button simultaneously for more than 3

OPER

MODE

seconds after the setting has been

completed, the setting mode will be released.

- If there isn’t any button input for more than

25 seconds, the installer setting mode will

also be released.

- 19 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

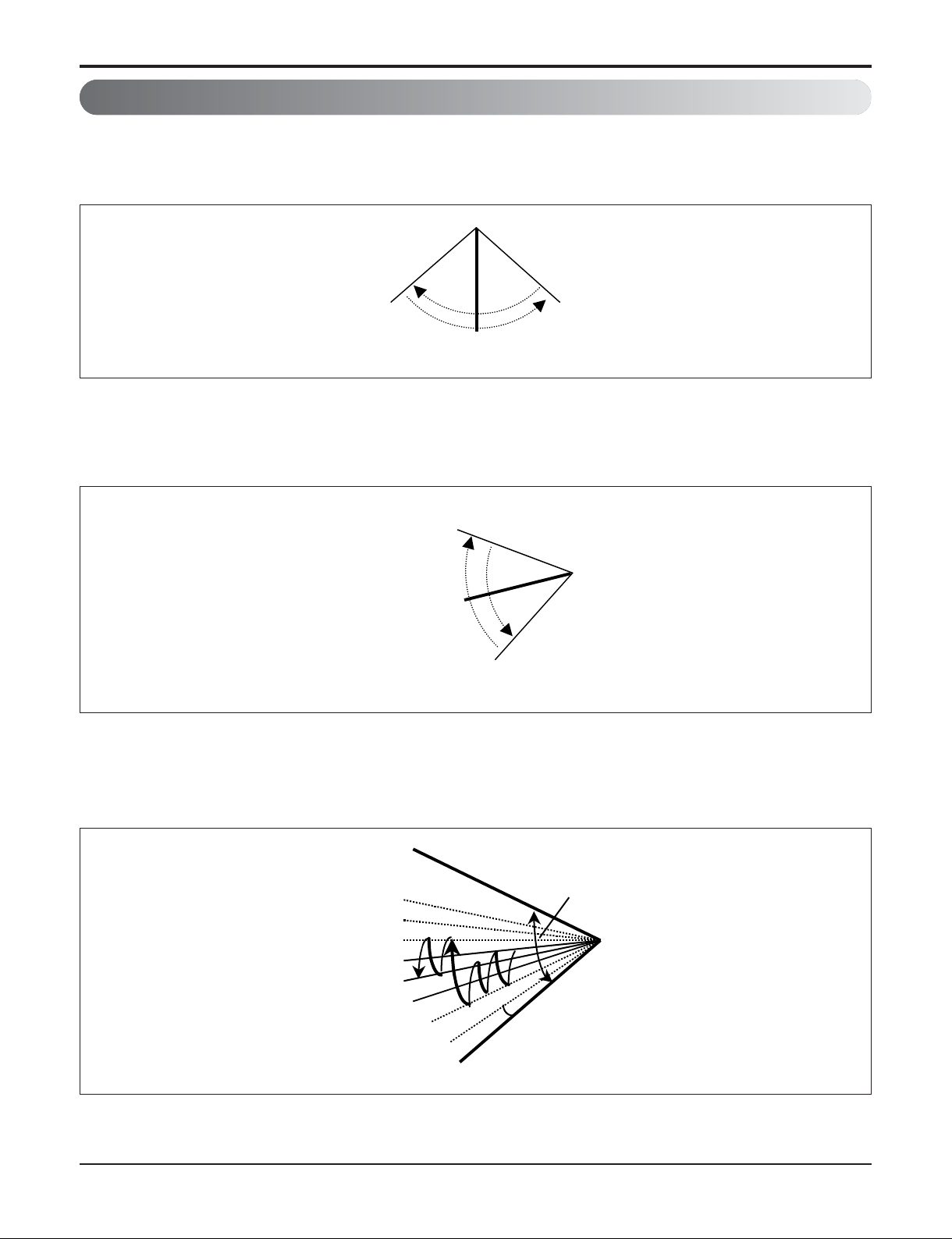

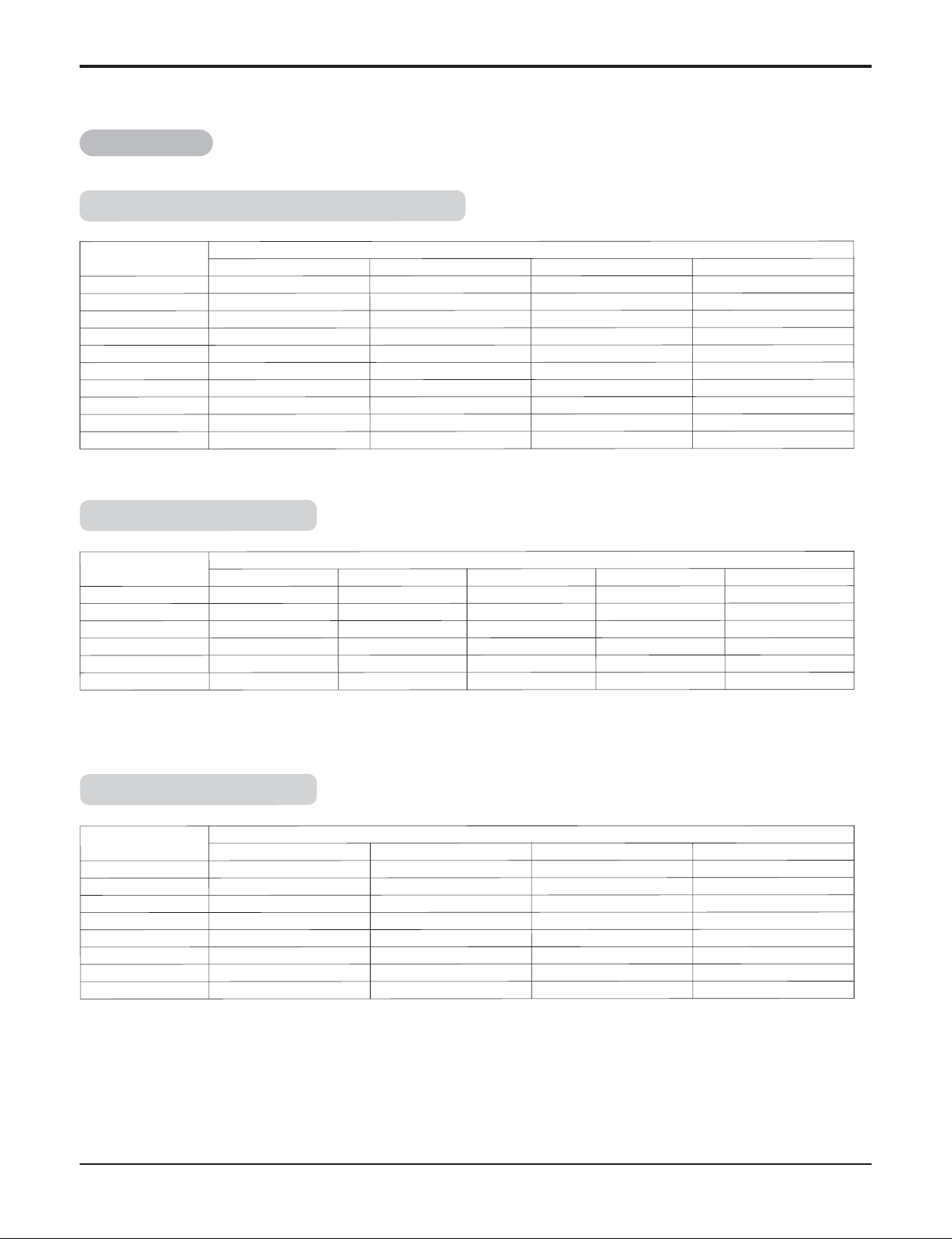

E.S.P. setting value (reference)

[ Notes ]

1. To get the desired Airflow & E.S.P. combination from the table set the matching value from the table. Value other than

that in table will not give the combinations of airflow & E.S.P. which are mentioned in the table.

2. Table data is based at 230V. According to the fluctuation of voltage, air flow rate varies.

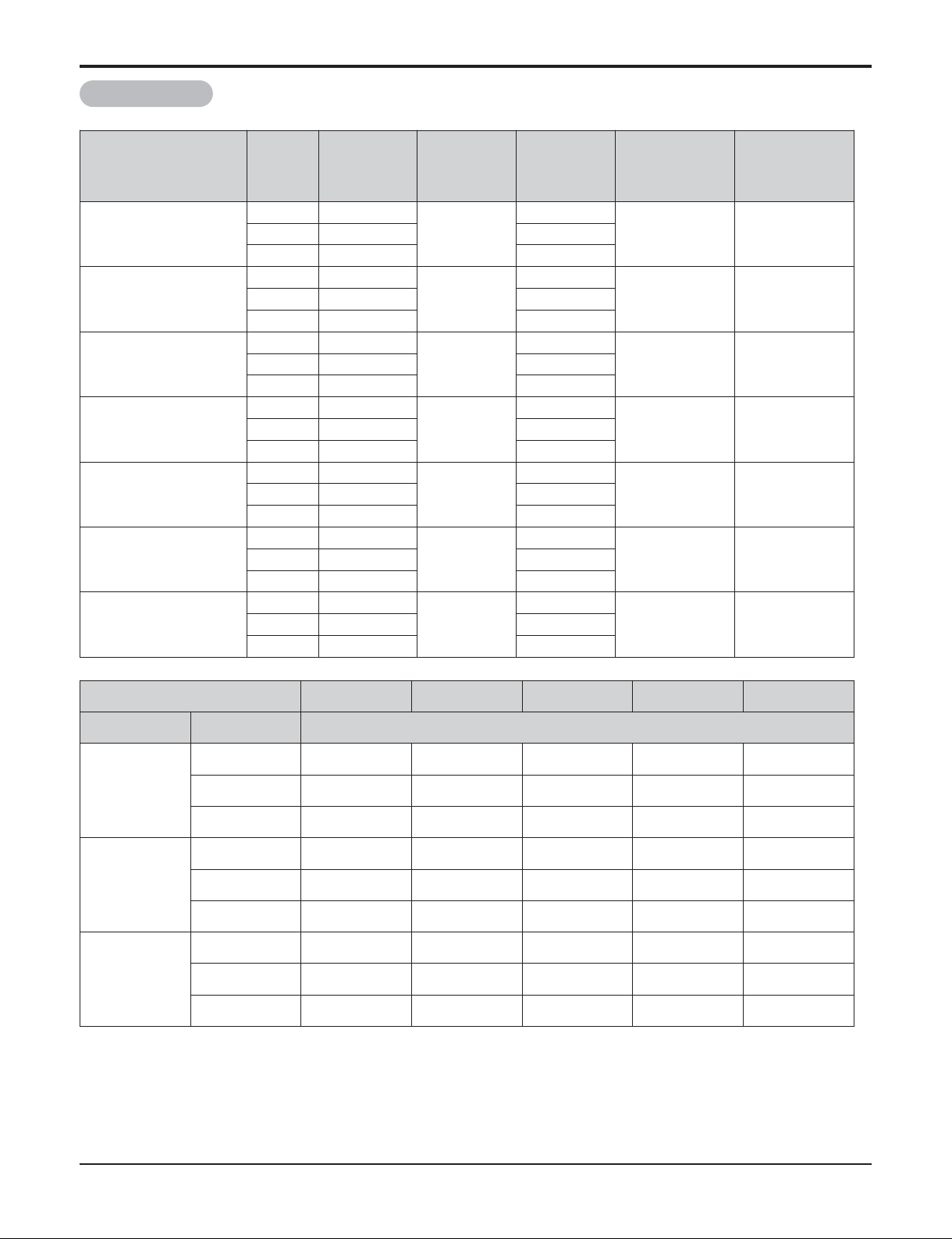

Table 1

Part 2 Functions & Controls

Setting Value

Static Pressure[mmAq(Pa)]

2.5(25) 4(39) 6(59) 8(78)

100 12.8 - - 105 13.9 - - 110 15.2 12.7 - 115 16.5 14.0 - 120 17.8 15.3 12.7 125 - 16.5 14.0 130 - 17.8 15.3 12.6

135 - - 16.5 13.5

140 - - 17.5 14.5

145 - - - 16.5

(Unit: CMM)

(Unit: CMM)

Setting Value

Static Pressure[mmAq(Pa)]

4(49) 6(59) 8(78) 10(98)

100 20.8 - - 105 23.2 19.5 - 110 26.0 21.5 - 115 - 23.5 19.1 120 - 26.3 21.6 125 - - 24.0 19.9

130 - - 27.0 22.7

135 - - - 25.9

(Unit: CMM)

Models : ABNQ18GHLA0, ABNQ21GHLA0

Models :

ABNQ24GGLA0

Models :

ABNQ36GGLA0

Setting Value

Static Pressure[mmAq(Pa)]

6(59) 8(78) 10(98) 12(118) 14(137)

80 14.8 - - - -

90 19.0 14.4 - - 100 23.3 19.7 13.9 - 110 26.9 24.3 19.8 14.1 120 31.2 28.2 25.2 20.1 14.4

130 34.9 32.4 29.5 25.4 20.5

- 20 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

Setting Value

Static Pressure[mmAq(Pa)]

6(59) 8(78) 10(98) 12(118)

85 31.5 - - 90 36.3 29.8 - 95 41.3 34.5 28.4 -

100 45.4 39.7 33.5 27.3

105 - 44.1 38.6 33.1

110 - - 44.2 38.9

115 - - - 44.7

(Unit: CMM)

Setting Value

Static Pressure[mmAq(Pa)]

6(59) 8(78) 10(98) 12(118)

85 31.5 - - 90 36.3 29.8 - 95 41.3 34.5 28.4 -

100 45.4 39.7 33.5 27.3

105 - 44.1 38.6 33.1

110 - - 44.2 38.9

115 - - - 44.7

(Unit: CMM)

Setting Value

Static Pressure[mmAq(Pa)]

6(59) 8(78) 10(98) 12(118) 14(137)

95 41.3 - - - -

100 45.4 39.7 - - 105 49.5 44.1 38.6 - 110 - 48.5 44.2 38.9 115 - - 49.8 44.7 42.2

120 - - - 50.5 48.1

(Unit: CMM)

Models :

ABNQ42GRLA0

Models :

ABNQ48GRLA0

Models :

ABNQ54GRLA0

※ ABNQ42GRLA0 / ABNQ48GRLA0 As far as possible do not set ESP 82,83

- 21 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

Models: ABNQ18GL2A0 / ABNQ21GL2A0

Models: ABNQ24GL3A0

Setting Value

Static Pressure(mmAq(Pa))

0 (0) 1 (10) 2 (20) 3 (30) 4 (40) 5 (50)

75 6.50 - - - - 80 7.34 6.70 - - - 85 8.20 7.55 6.69 - - 90 9.07 8.43 7.56 6.47 - 95 9.96 9.32 8.45 7.36 - -

100 10.87 10.22 9.36 8.27 6.96 105 11.79 11.15 10.28 9.19 7.89 6.35

110 12.73 12.09 11.22 10.14 8.83 7.30

115 13.69 13.05 12.18 11.09 9.78 8.25

120 14.67 14.02 13.16 12.07 10.76 9.23

125 15.66 15.01 14.15 13.06 11.75 10.22

130 16.67 16.02 15.16 14.07 12.76 11.23

135 - - 16.18 15.10 13.79 12.26

140 - - - 16.14 14.83 13.30

145 - - - - 15.89 14.36

(Unit : CMM)

(Unit : CMM)

Setting Value

Static Pressure(mmAq(Pa))

0 (0) 1 (10) 2 (20) 3 (30) 4 (40) 5 (50)

85 10.19 - - - - 90 12.18 10.71 11.09 - - 95 13.81 12.34 12.19 - - -

100 15.16 13.69 13.38 10.71 - 105 16.30 14.83 14.36 11.85 - 110 17.31 15.85 15.23 12.86 10.97 115 18.27 16.80 16.07 13.82 11.93 120 19.26 17.79 16.93 14.80 12.91 10.49

125 20.34 18.87 17.89 15.88 13.99 11.57

130 21.60 20.13 19.01 17.14 15.25 12.83

135 - 21.64 20.36 18.66 16.76 14.35

140 - - 22.01 20.50 18.61 16.19

145 - - - 22.75 20.86 18.44

Note :

1. The above table shows the correlation between the air rates and E.S.P.

- 22 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

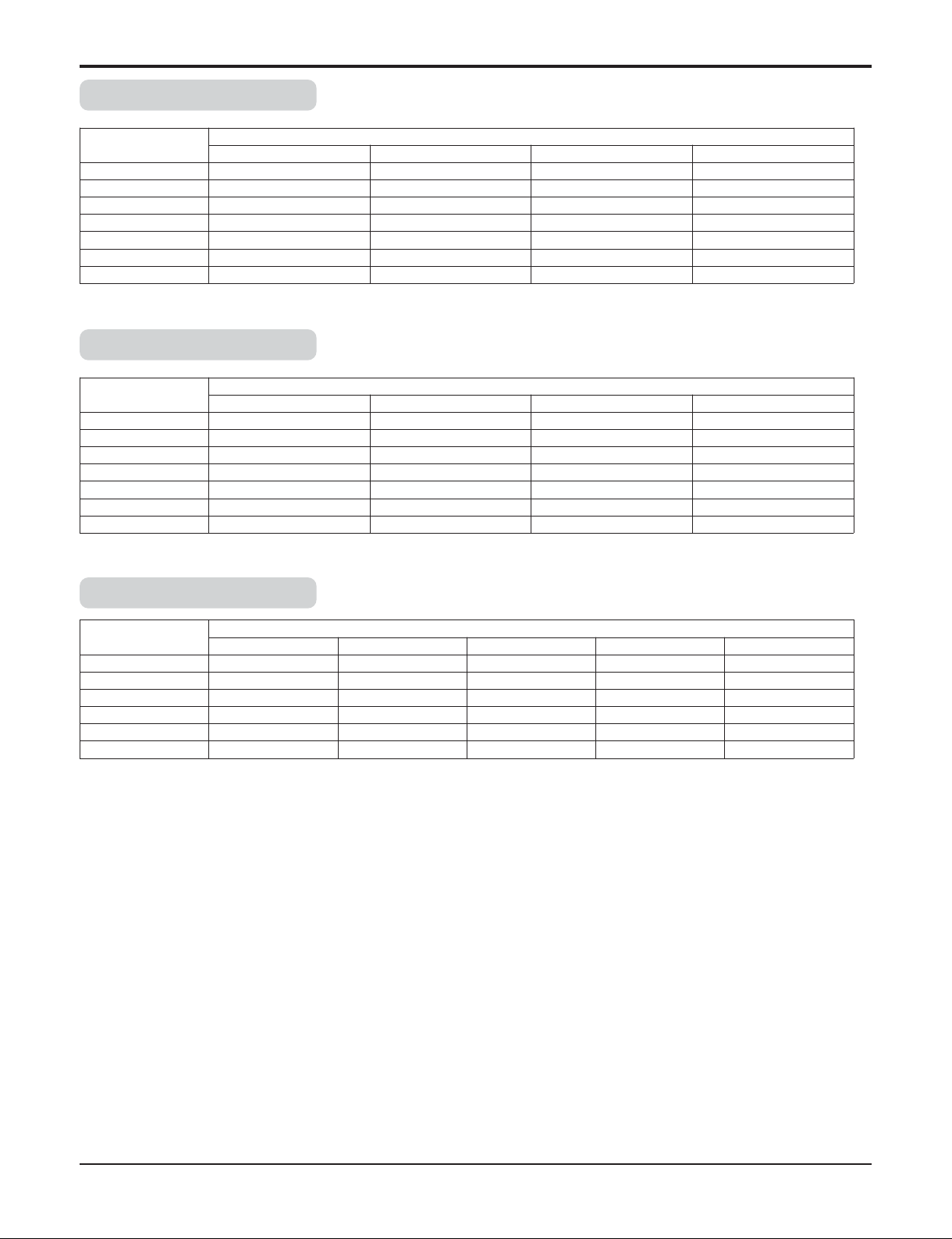

Part 2 Functions & Controls

Table 2

Model Mode Set value

Standard ESP

(mmAq(Pa))

CMM

Lower Limit of

External Static

Pressure

(mmAq(Pa))

Upper Limit of

External Static

Pressure

(mmAq(Pa))

ABNQ18GHLA0

Hi

8 (78)

16.5

2.5(25) 8 (78)Mid 14.5

Low 13.0

ABNQ21GHLA0

Hi

8 (78)

16.5

2.5(25) 8 (78)Mid 14.5

Low 13.0

ABNQ24GGLA0

Hi

8 (78)

16.5

2.5(25) 8 (78)Mid 14.5

Low 13.0

ABNQ36GGLA0

Hi

10 (98)

32.0

4.0(39) 10 (98)Mid 29.0

Low 26.0

ABNQ42GRLA0

Hi

10 (98)

28.0

5.0(49) 10 (98)Mid 26.0

Low 32.0

ABNQ48GRLA0

Hi

10 (98)

40.0

5.0(49) 10 (98)Mid 35.0

Low 30.0

ABNQ54GRLA0

Hi

10 (98)

50.0

5.0(49) 10 (98)Mid 45.0

Low 40.0

1450

1400

1340

1450

1400

1340

1270

1210

1090

1370

1310

1260

1060

1020

990

1100

1060

1030

1240

1200

1150

[Notes]

1. To get the desired Airflow & E.S.P. combination from the table set the matching value from the table. Value other than

that in table will not give the combinations of airflow & E.S.P. which are mentioned in the table.

2. Table data is based at 230V. According to the fluctuation of voltage, air flow rate varies.

Static pressure(mmAq) 0 1 2 3 4

Model Step(Hi/Mid/Low) Setting value

ABNQ18GL2A0

15 CMM 90 97 105 114 122

12.5 CMM 82 90 99 109 119

10 CMM 75 84 93 103 114

ABNQ21GL2A0

17.5 CMM 90 97 105 114 122

14 CMM 82 90 99 109 119

12 CMM 75 84 93 103 114

ABNQ24GL3A0

20 CMM 110 117 125 129 -

16 CMM 100 107 115 121 127

12 CMM 90 97 105 114 122

- 23 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

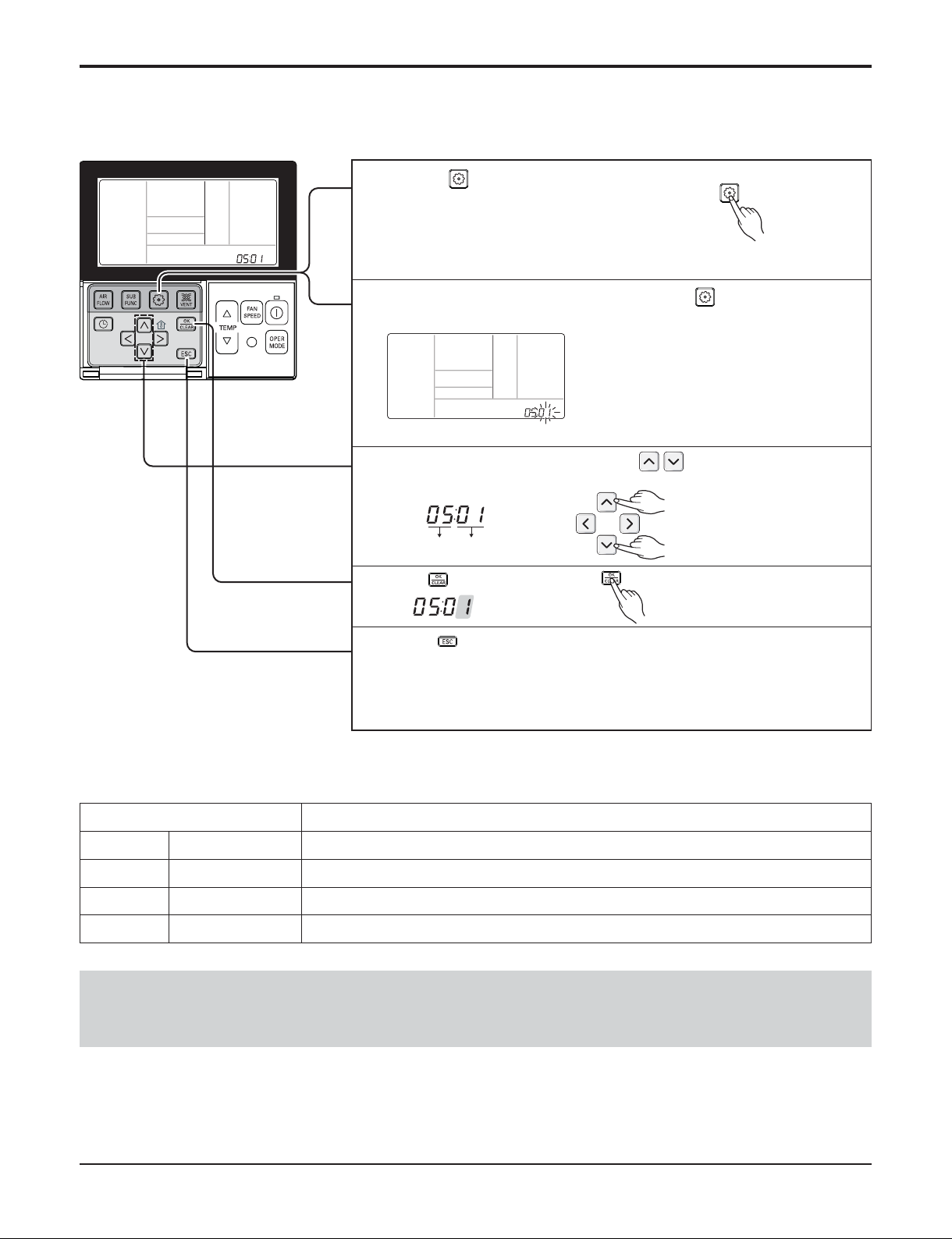

4.2 High Ceiling operation

Function Code Thermistor setting

Select ceiling height value by pressing button. (01:Low,

02:Medium, 03:High, 04:Very high)

3

Press button to save.

4

5

If moving to ceiling height selection menu by pressing button,

it indicates as picture below.

2

If pressing button long for 3 seconds, it enters into

remote controller setter setup mode.

- If pressing once shortly, it enters into user setup mode.

Please press more than 3 seconds for sure.

1

Pressing button will exit settings mode.

❈ After setup, it automatically gets out of setup mode if there is no button input

for 25 seconds.

❈ When exiting without pressing set button, the manipulated value is not

reflected.

This function is to adjust FAN Airflow rate according to ceiling height (For ceiling type product)

• Ceiling height setting is available only for some products.

• Ceiling height of ʻVery highʼ function may not exist depending on the indoor unit.

• Refer to the product manual for more details.

<Ceiling Height Selection Table>

Ceiling Height Level Description

01 Low Decrease the indoor airflow rate 1 step from standard level

02 Medium Set the indoor airflow rate as standard level

03 High Increase indoor airflow rate 1 step from standard level

04 Very high Increase indoor airflow rate 2 steps from standard level

- 24 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

5.1 Self-diagnosis Function

• The air conditioner installed can self-diagnosed its error status and then transmits the result to the central control.

Therefore, a rapid countermeasure against failure of the air conditioner allows easy management and increases the

usage life of air conditioner.

• Refer to trouble shooting guide.

5.2 Soft dry operation

• When the dehumidification operation input by the remote control is received, the intake air temperature is detected and

the setting temp is automatically set according to the intake air temperature.

• While compressor off, the indoor fan repeats low airflow speed and stop.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidification operation and 4-min compressor off repeat.

Compressor ON Temp. ‘ Setting Temp+0.5°C

Compressor OFF Temp. ‘ Setting Temp-0.5°C

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

5. Reliability

Intake air Temp. Setting Temp.

26°C ≤ intake air temp. 25°C

24°C ≤ intake air temp.< 26°C intake air temp. -1°C

22°C ≤ intake air temp. < 24°C intake air temp. -0.5°C

18°C ≤ intake air temp. < 22°C intake air temp.

intake air temp. < 18°C 18°C

- 25 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

6.1 Cooling Operations

6.1.1 Cooling Mode

• Operating frequency of compressor depends on the load condition, like the difference between the room temp. and

the set temp., frequency restrictions.

• If the compressor operates at some frequency, the operating frequency of compressor cannot be changed within 30

seconds. ( not emergency conditions)

• Compressor turned off when

- intake air temperature is in between ±0.5°C of the setting temp. limit for three minutes continuously.

- intake air temperature reaches below 1.0°C of the temperature of setting temp..

• Compressors three minutes time delay.

- After compressor off, the compressor can restart minimum 3 minutes later.

6. Convenience Functions & Controls

Part 2 Functions & Controls

- 26 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

6.3 Auto restart Operation

• Whenever there is electricity failure to the unit, and after resumption of the power, unit will start in the same mode prior

to the power failure. Memorized condition are on / off condition, operating mode (cooling/ heating), set temperature and

fan speed. The unit will memorize the above conditions and start with same memorized condition.

6.2 Auto cleaning operation

• Function used to perform Self Cleaning to prevent the Unit from Fungus and bad odor.

• Used after the Cooling Operation before turning the unit off, clean the Evaporator and keep it dry for the next operation.

• The function is easy to operate as it is accessed through the Remote controller.

Unit

Operation

ON

OFF

Comp.

Indoor

Fan

ON

OFF

ON

OFF

Setting step

OFFL Low

Setting step

(Cooling Only)

Part 2 Functions & Controls

- 27 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

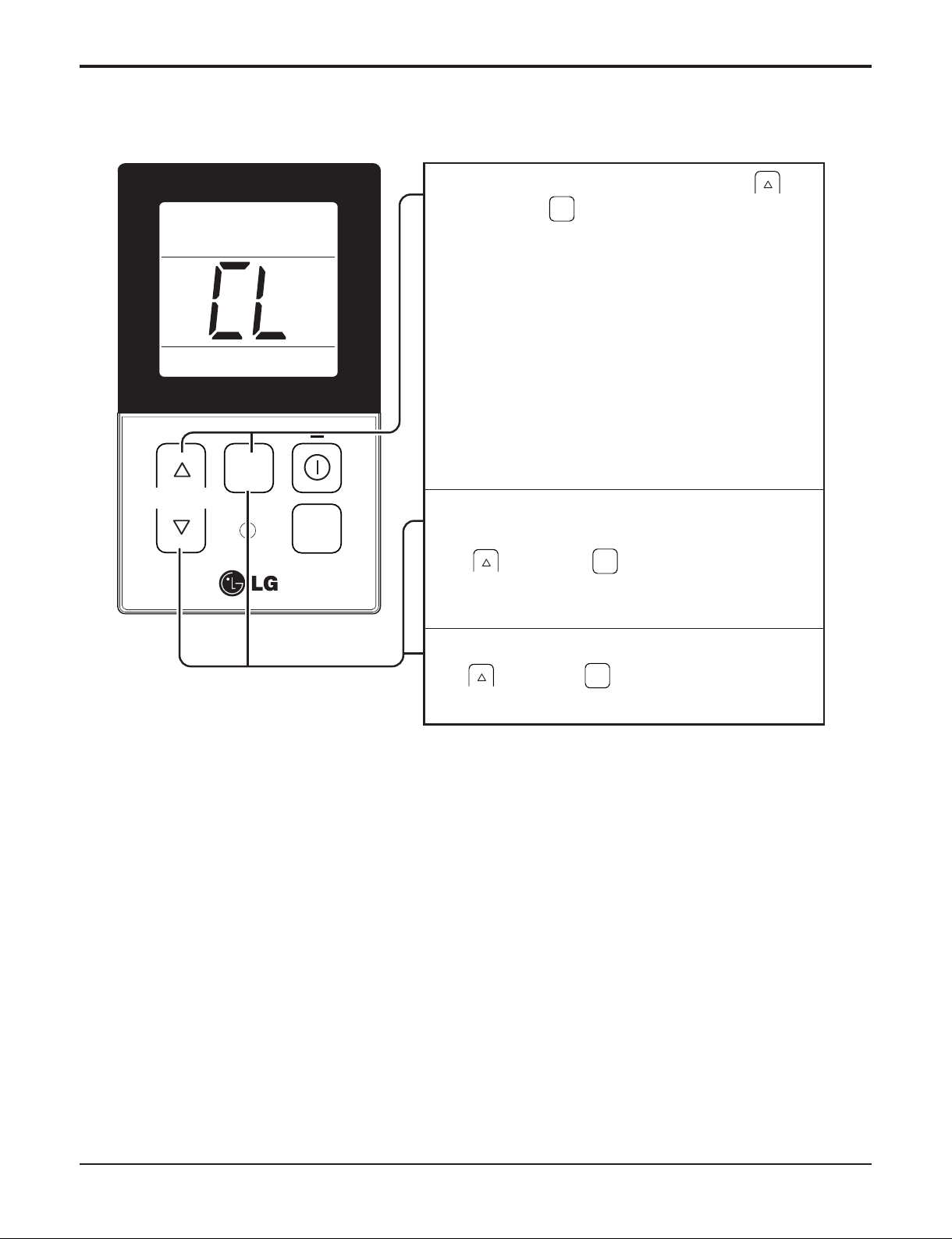

6.4 Child Lock Function

It is the function to use preventing children or others from careless using.

Part 2 Functions & Controls

During the operation, when pressing the

1

button and button for approx. 3

seconds, the ‘Child Lock’ Function can be

used.

- At the time of initial setting of the ‘Child Lock’,

the ‘CL’ Will be indicated approx. 3 seconds at

the temperature Display section before

resuming to the previous mode. After the

setting of the ‘CL’, if another button is setup,

the button can not be recognized as the ‘CL’ is

indicated at the temperature display section for

FA N

SPEED

TEMP

OPER

MODE

approx. 3 seconds.

If the ‘CL’ function is wanted to be used under

2

the operation standby state, press the

button and Button for approx.

3 seconds under the standby mode state and

the system will be the ‘CL’ state.

FAN

SPEED

FAN

SPEED

As for the releasing method, when pressing the

3

Button and button for approx. 3

FAN

SPEED

seconds, the ‘CL’ function can be released.

- 28 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

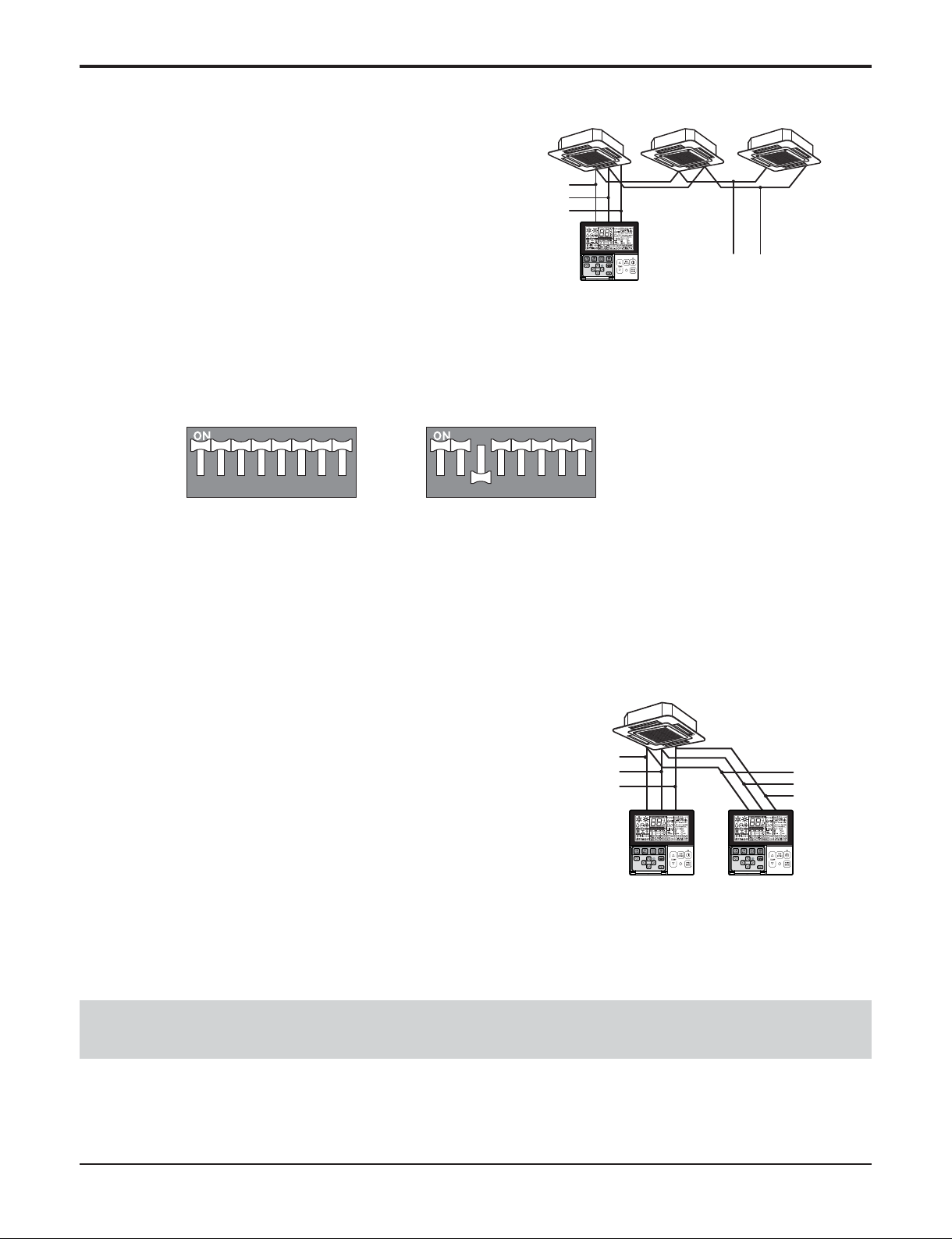

6.5 Group Control

GND

GND

12V

Signal wire

Signal wire

GND

12V

B Y R B Y R

MASTER SLAVE

Signal wire

GND

12V

Signal wire

1. When installing more than 2 units of air conditioner to

one wired remote controller, please connect as the

right figure.

• If it is not event communication indoor unit, set the unit

as slave.

• Check for event communication through the product

manual.

2. When installing more than 2 wired remote controllers to one

air conditioner, please connect as the right picture.

• When installing more than 2 units of wired remote controller to one

air conditioner, set one wired remote controller as master and the

others all as slaves, as shown in the right picture.

• You cannot control the group as shown in the right for some prod-

ucts.

•

Refer to the product manual for more detail.

When controlling multiple indoor units with event communication function with one remote controller, you must change the

master/slave setting from the indoor unit.

- Indoor units, the master/slave configuration of the product after completion of indoor unit power ʻOFFʼ and then ʻONʼ the

power after 1 minutes elapsed sign up.

- For ceiling type cassette and duct product group, change the switch setting of the indoor PCB.

- For wall-mount type and stand type product, change the master/slave setting with the wireless remote controller. (Refer to

wireless remote controller manual for detail)

h When installing 2 remote controllers to one indoor unit with event communication function, set the master/slave of the

remote controller. (Refer to remote controller master/slave selection)

When controlling the group, some functions excluding basic operation setting, fan level Min/Mid/Max, remote controller

lock setting and time setting may be limited.

<When simultaneously connecting

2 sets of wired remote controller>

• When controlling in groups, set the master/slaver of the remote controller. Refer to Installer setting section on how to set master/slave for more detail.

12345678 12345678

#3 switch OFF: Master

(Factory default setting)

#3 switch ON: Slave

Part 2 Functions & Controls

- 29 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

6.6 Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in appliance

operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature increases by

1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to the low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to the medium.

6.7 Timer(On/Off)

6.7.1 On-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance starts to operate.

• The timer LED is on when the on-timer is input. It is off when the time set by the timer is reached.

• If the appliance is operating at the time set by the timer, the operation continues.

While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature.

6.7.2 Off-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance stops operating.

• The timer LED is on when the off-timer is input. It is off when the time set by the timer is reached.

• If the appliance is on pause at the time set by the timer, the pause continues.

Part 2 Functions & Controls

- 30 -

Copyright ©2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

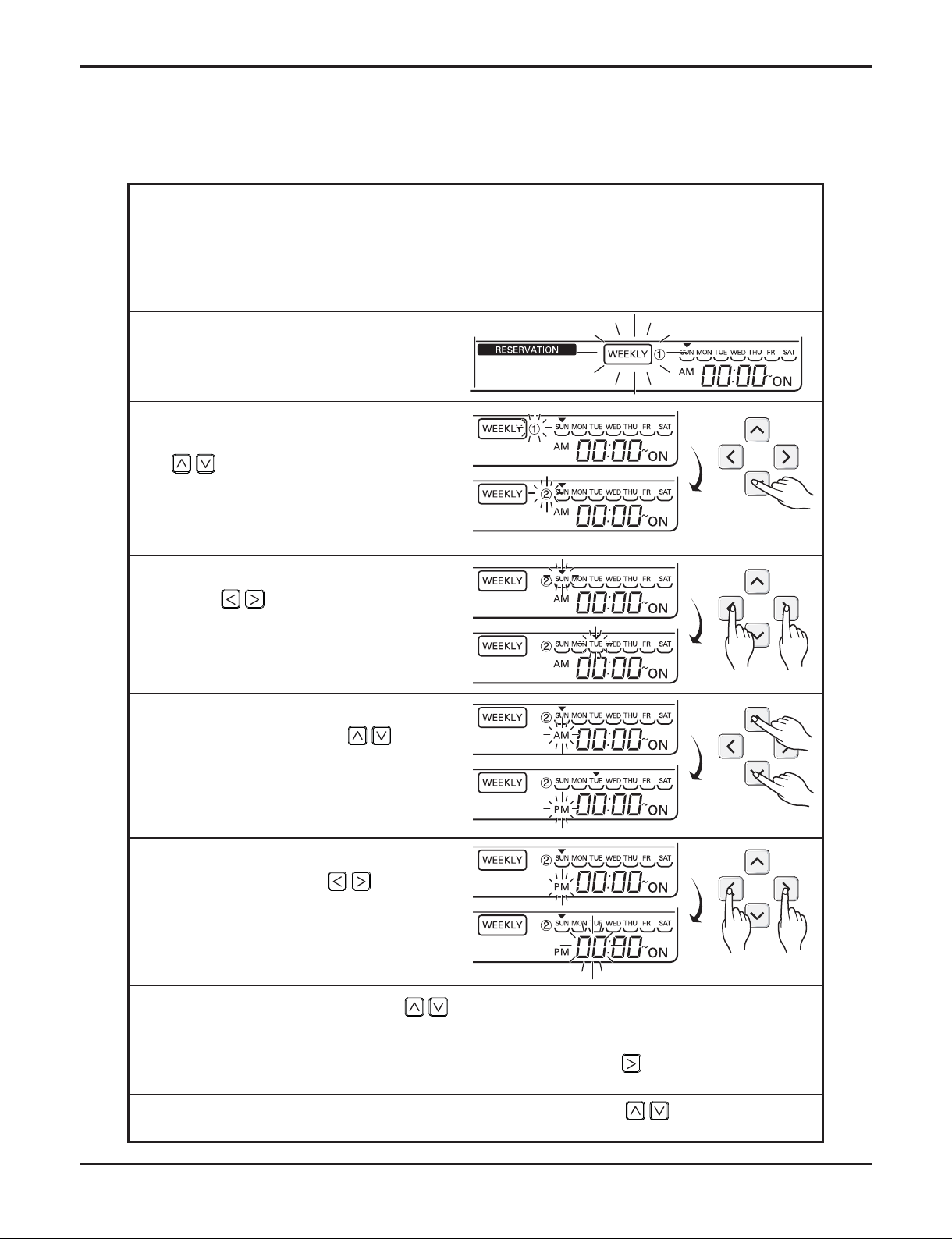

6.8 Weekly Program

You can set the daily reservation in weekly unit.

Weekly reservation keeps operating until before you cancel it once you setup

Part 2 Functions & Controls

Please move to reservation setup mode by pressing reservation button.

1

❈ You can setup two weekly reservations for one day, and up to fourteen

reservations for a week.

For example, to setup (Tuesday morning 11:30 turned on ~ afternoon 12:30

turned off), you setup in order below.

Please move to 'weekly' by

2

repeatedly pressing reservation

button. 'Weekly' blinks at this time.

Please select weekly reservation or

3

weekly reservation ¡ by using

button.

❈ You can setup two reservations,

weekly reservation 1 and weekly

reservation 2, for a day.

Please move to 'date' setup part by

4

using button. If 'date'

indication blinks, please setup date.

You can setup date from Monday to

Sunday.

Please move to 'AM/PM' setup part

5

of turning on by using button.

Please move to 'hour' setup part of

6

turning on by using button.

- It is the part to setup the time at

which air-conditioner is turned on.

Please change time by using button.

7

- You can setup hour 0~12.

Please move to 'minute' setup part of turning on by using button.

8

If 'minute' indication blinks, please setup 'minute' by using button

9

Loading...

Loading...