Page 1

System

Outdoor Unit

INSTALLATION MANUAL

LG

MODELS: ARUN Series ARUV Series

(1Ø, 220~240V, 50Hz / 1Ø, 220V, 60Hz)

website http://www.lgservice.com

IMPORTANT

• Please read this installation manual completely before

installing the product.

• Installation work must be performed in accordance with

the national wiring standards by authorized personnel

only.

• Please retain this installation manual for future reference

after reading it thoroughly.

R410A

ENGLISH ITALIANO ESPAÑOL FRANÇAIS DEUTSCH

PORTUGUESE

Page 2

2 Outdoor Unit

ARUN Series Outdoor Unit Installation Manual

TABLE OF CONTENTS

Safety Precautions.....................................................................................................3

Installation Process...................................................................................................7

Outdoor Units Information........................................................................................8

Before installation......................................................................................................9

Select the Best Location .........................................................................................10

Installation Space.....................................................................................................11

Installation................................................................................................................15

Refrigerant piping....................................................................................................18

Electrical Wiring.......................................................................................................37

Test Run....................................................................................................................52

Caution For Refrigerant Leak..................................................................................63

Installation guide at the seaside.............................................................................65

Page 3

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

■ Installation

Have all electric work done by a licensed

electrician according to "Electric Facility

Engineering Standard" and "Interior Wire

Regulations" and the instructions given in

this manual and always use a special circuit.

• If the power source capacity is inadequate or

electric work is performed improperly, electric

shock or fire may result.

Ask the dealer or an authorized technician to

install the air conditioner.

• Improper installation by the user may result in

water leakage, electric shock, or fire.

Always ground the product.

• There is risk of fire or electric shock.

Always intstall a dedicated circuit and breaker.

• Improper wiring or installation may cause fire or

electric shock.

ENGLISH

Installation Manual 3

For re-installation of the installed product,

always contact a dealer or an Authorized

Service Center.

• There is risk of fire, electric shock, explosion, or

injury.

Do not install, remove, or re-install the unit

by yourself (customer).

• There is risk of fire, electric shock, explosion, or

injury.

Do not store or use flammable gas or

combustibles near the air conditioner.

• There is risk of fire or failure of product.

Use the correctly rated breaker or fuse.

• There is risk of fire or electric shock.

Prepare for strong wind or earthquake and

install the unit at the specified place.

• Improper installation may cause the unit to

topple and result in injury.

Do not install the product on a defective

installation stand.

• It may cause injury, accident, or damage to the

product.

Page 4

Ventilate before operating air conditioner

when gas leaked out.

• It may cause explosion, fire, and burn.

Securely install the cover of control box and

the panel.

• If the cover and panel are not installed securely,

dust or water may enter the outdoor unit and fire

or electric shock may result.

If the air conditioner is installed in a small room, measures must be taken to prevent the

refrigerant concentration from exceeding the safety limit when the refrigerant leaks.

• Consult the dealer regarding the appropriate measures to prevent the safety limit from being

exceeded. Should the refrigerant leak and cause the safety limit to be exceeded, harzards due to lack

of oxygen in the room could result.

■ Operation

Do not damage or use an unspecified power

cord.

• There is risk of fire, electric shock, explosion, or

injury.

Use a dedicated outlet for this appliance.

• There is risk of fire or electrical shock.

Be cautious that water could not enter the

product.

• There is risk of fire, electric shock, or product

damage.

Do not touch the power switch with wet

hands.

• There is risk of fire, electric shock, explosion, or

injury.

4 Outdoor Unit

Safety Precautions

When installing and moving the air conditioner

to another site, do not charge it with a

different refrigerant from the refrigerant

specified on the unit.

• If a different refrigerant or air is mixed with the

original refrigerant, the refrigerant cycle may

malfunction and the unit may be damaged.

Do not reconstruct to change the settings of

the protection devices.

• If the pressure switch, thermal switch, or other

protection device is shorted and operated

forcibly, or parts other than those specified by

LGE are used, fire or explosion may result.

When the product is soaked (flooded or

submerged), contact an Authorized Service

Center.

• There is risk of fire or electric shock.

Be cautious not to touch the sharp edges

when installing.

• It may cause injury.

T ake care to ensure that nobody could step

on or fall onto the outdoor unit.

• This could result in personal injury and product

damage.

Do not open the inlet grille of the product

during operation. (Do not touch the

electrostatic filter, if the unit is so equipped.)

• There is risk of physical injury, electric shock, or

product failure.

Page 5

Installation Manual 5

ENGLISH

Safety Precautions

Use power cables of sufficient current

carrying capacity and rating.

• Cables that are too small may leak, generate

heat, and cause a fire.

Do not use the product for special purposes,

such as preserving foods, works of art, etc. It

is a consumer air conditioner, not a precision

refrigeration system.

• There is risk of damage or loss of property.

Keep the unit away from children. The heat

exchanger is very sharp.

• It can cause the injury, such as cutting the finger.

Also the damaged fin may result in degradation

of capacity.

When installting the unit in a hospital,

communication station, or similar place,

provide sufficient protection against noise.

•

The inverter equipment, private power generator,

high-frequency medical equipment, or radio

communication equipment may cause the air

conditioner to operate erroneously, or fail to

operate. On the other hand, the air conditioner may

affect such equipment by creating noise that

disturbs medical treatment or image broadcasting.

Do not install the product where it is exposed to sea wind (salt spray) directly.

• It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator fins,

could cause product malfunction or inefficient operation.

■ Installation

Always check for gas (refrigerant) leakage

after installation or repair of product.

• Low refrigerant levels may cause failure of

product.

Do not install the product where the noise or

hot air from the outdoor unit could damage

the neighborhoods.

• It may cause a problem for your neighbors.

Keep level even when installing the product.

• To avoid vibration or water leakage.

Do not install the unit where combustible gas

may leak.

• If the gas leaks and accumulates around the

unit, an explosion may result.

■ Operation

Do not use the air conditioner in special

environments.

• Oil, steam, sulfuric smoke, etc. can significantly

reduce the performance of the air conditioner or

damage its parts.

Do not block the inlet or outlet.

• It may cause failure of appliance or accident.

Make the connections securely so that the

outside force of the cable may not be applied

to the terminals.

• Inadequate connection and fastening may

generate heat and cause a fire.

Be sure the installation area does not

deteriorate with age.

• If the base collapses, the air conditioner could

fall with it, causing property damage, product

failure, or personal injury.

Page 6

6 Outdoor Unit

Safety Precautions

Install and insulate the drain hose to ensure that water is drained away properly based on the

installation manual.

• A bad connection may cause water leakage.

Be very careful about product transportation.

• Only one person should not carry the product if it weighs more than 20 kg.

• Some products use PP bands for packaging. Do not use any PP bands for a means of transportation.

It is dangerous.

• Do not touch the heat exchanger fins. Doing so may cut your fingers.

• When transporting the outdoor unit, suspending it at the specified positions on the unit base. Also

support the outdoor unit at four points so that it cannot slip sideways.

Safely dispose of the packing materials.

•

Packing materials, such as nails and other metal or

wooden parts, may cause stabs or other injuries.

•

Tear apart and throw away plastic packaging bags

so that children may not play with them. If children

play with a plastic bag which was not torn apart,

they face the risk of suffocation.

Turn on the power at least 6 hours before

starting operation.

• Starting operation immediately after turning on

the main power switch can result in severe

damage to internal parts. Keep the power switch

turned on during the operational season.

Do not touch any of the refrigerant piping

during and after operation.

• It can cause a burn or frostbite.

Do not operate the air conditioner with the

panels or guards removed.

• Rotating, hot, or high-voltage parts can cause

injuries.

Do not directly turn off the main power

switch after stopping operation.

• Wait at least 5 minutes before turning off the

main power switch. Otherwise it may result in

water leakage or other problems.

Auto-addressing should be done in condition of

connecting the power of all indoor and outdoour

units. Auto-addressing should also be done in

case of changing the indoor unit PCB.

Use a firm stool or ladder when cleaning or

maintaining the air conditioner.

• Be careful and avoid personal injury.

Do not insert hands or other objects through

the air inlet or outlet while the air conditioner

is plugged in.

• There are sharp and moving parts that could

cause personal injury.

Page 7

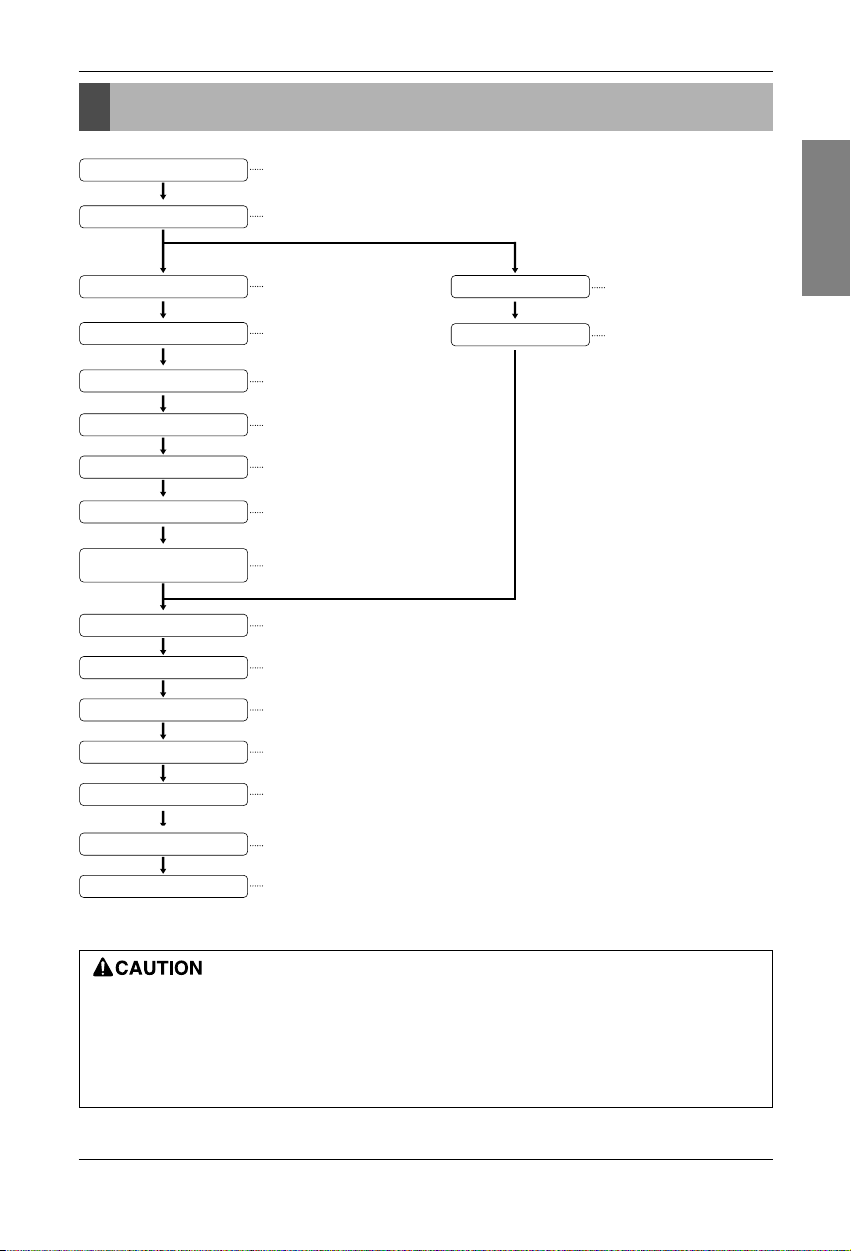

Installation

Installation Process

The foundation must be level even

Outdoor unit foundation work

Avoid short circuits and ensure

sufficient space is allowed for service

Installation of outdoor unit

Automatic addressing of indoor unit

In the final check for 24hours at 3.8 MPa(38.7 kgf/cm

2

) there must be no drop in pressure.

Airtight test

Multiple core cable must not be used.

(suitable cable should be selected)

Electrical work

(connection circuits and drive circuits)

Make sure no gaps are left where

the insulating materials are joined

Heat insulation work

Make sure airflow is sufficient

Duct work

Adjust to downward gradient

Drain pipe work

Special attention to dryness,

cleanness and tightness

Refrigerant piping work

Check model name to make

sure the fitting is made correctly

Installation of indoor unit

Take account of gradient

of drain piping

Sleeve and insert work

Make relationship between outdoor, indoor, remote controller, and option connections clear.

(Prepare control circuit diagram)

Preparation of contract drawings

Indicate clearly who is to be responsible for switch settings

Determination of division work

The vacuum pump used must have a capacity of reaching at least 5 torr, more than 1 hour

Vacuum drying

Recharge correctly as calculated in this manual. and record the amount of added refrigerant

Additional charge of refrigerant

Make sure there are no gaps left between the facing materials used on the ceiling

Fit facing panels

Run each indoor unit in turn to make sure the pipe work has been fitted correctly

Test run adjustment

Explain the use of the system as clearly as possible to your customer and make sure all relevant

documentation is in order

Transfer to customer with explanation

Refer to automatic addressing flowchart

Preheat the crank case with the electrical heater for more than 6 hours.

(In case of outdoor temperature below 10℃)

• The above list indicates the order in which the individual work operations are normally carried out but this

order may be varied where local conditions warrants such change.

• The wall thickness of the piping should comply with the relevant local and national regulations for the

designed pressure 3.8MPa.

• Since R410A is a mixed refrigerant, the required additional refrigerant must be charged in its liquid state.(If the

refrigerant is charged in its gaseous state, its composition changes and the system will not work properly.)

ENGLISH

Installation Manual 7

Page 8

8 Outdoor Unit

Outdoor Units Information

Outdoor Units Information

CAUTION

Ratio of the connectable Indoor Units to the Outdoor: Within 50 ~ 130%

Ratio of running Indoor Units to the Outdoor: Within 10 ~ 100%

A combination operation over 100% cause to reduce each indoor unit capacity.

Power Supply: Outdoor Unit (1Ø, 220~240V, 50Hz/1Ø, 220V, 60Hz)

Connectable Indoor Unit

should be connected with 2 series indoor unit only.

Ex) ARNU07GSEA2

System(HP)

Model

Refrigerant

Product charge kg

CF(Correction Factor) kg

Max. Connectable No. of Indoor Units

Net Weight kg

Dimensions mm

(WxHxD) inch

Connecting Pipes

Liquid Pipes[mm(inch)]

Gas Pipes[mm(inch)]

456

ARUN40GS2 ARUN50GS2 ARUN60GS2

ARUV40GS2 ARUV50GS2 ARUV60GS2

3.7 3.7 3.7

-0.5 0 0

689

118 118 118

950x1,380x330 950x1,380x330 950x1,380x330

37.4x54.3x13 37.4x54.3x13 37.4x54.3x13

9.52(3/8) 9.52(3/8) 9.52(3/8)

15.88(5/8) 15.88(5/8) 19.05(3/4)

Page 9

ENGLISH

Installation Manual 9

Before Installation

Before Installation

• The refrigerant R410A has the property of higher operating pressure in comparison with R22.

Therefore, all materials have the characteristics of higher resisting pressure than R22 ones and this

characteristic should be also considered during the installation.

R410A is an azeotrope of R32 and R125 mixed at 50:50, so the ozone depletion potential (ODP) of R410A is

0. These days the developed countries have approved it as the environment-friendly refrigerant and

encouraged to use it widely to prevent environment pollution.

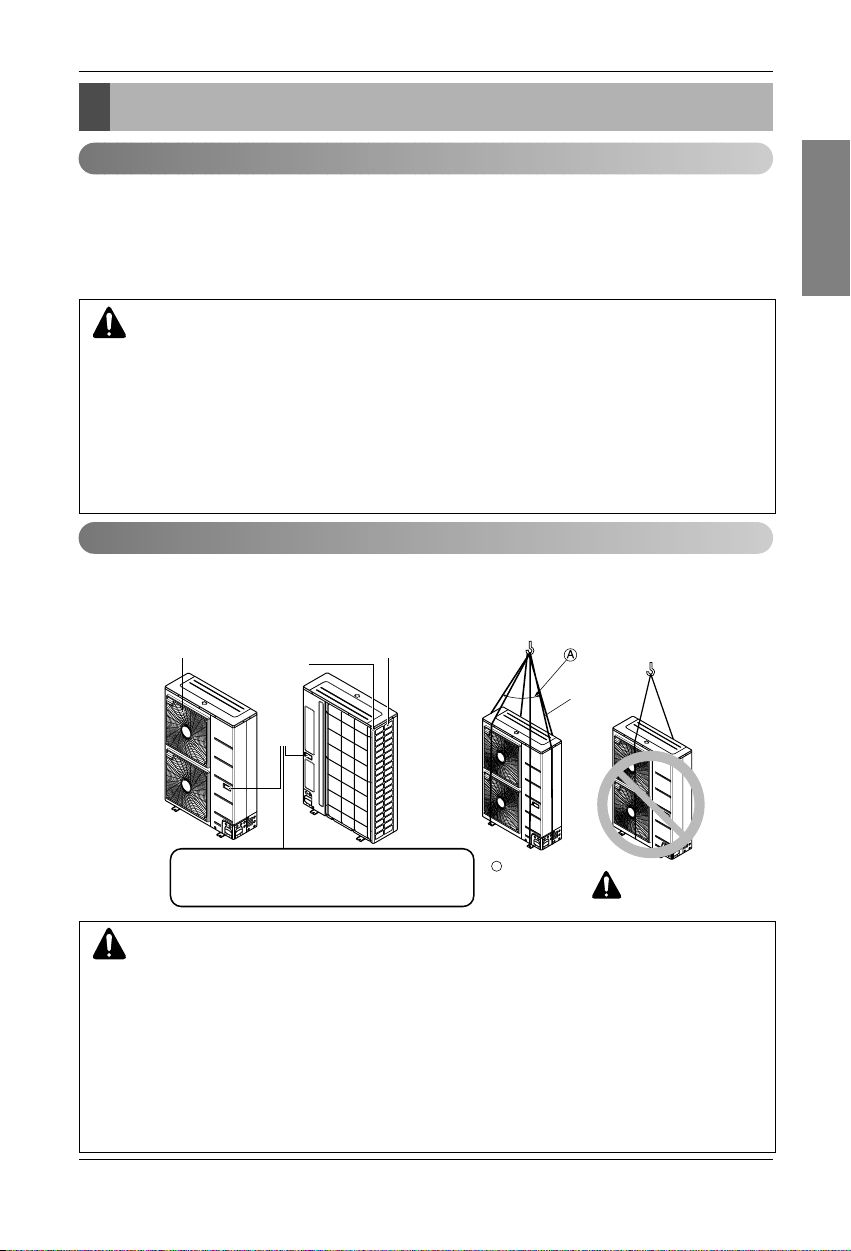

• When carrying the suspended, unit pass the ropes between legs of base panel under the unit.

• Always lift the unit with ropes attached at four points so that impact is not applied to the unit.

• Attach the ropes to the unit at an angle of 40° or less.

• Use only accessories and parts which are of the designated specification when installing.

CAUTION:

• The wall thickness of the piping should comply with the relevant local and national regulations for the designed

pressure 3.8MPa

• Since R410A is a mixed refrigerant, the required additional refrigerant must be charged in its liquid state.

• If the refrigerant is charged in its gaseous state, its composition changes and the system will not work properly.

• Do not place the refrigerant container under the direct rays of the sun to prevent it from exploding.

• For high-pressure refrigerant, any unapproved pipe must not be used.

• Do not heat pipes more than necessary to prevent them from softening.

• Be careful not to install wrongly to minimize economic loss because it is expensive in comparison with R22.

CAUTION:

Be very careful while carrying the product.

- Do not have only one person carry product if it is more than 20 kg.

- PP bands are used to pack some products. Do not use them as a mean for transportation because they are

dangerous.

- Do not touch heat exchanger fins with your bare hands. Otherwise you may get a cut in your hands.

- Tear plastic packaging bag and scrap it so that children cannot play with it Otherwise plastic packaging bag may

suffocate children to death.

- When carrying in Outdoor Unit, be sure to support it at four points. Carrying in and lifting with 3-point support may

make Outdoor Unit unstable, resulting in a fall.

Environment-friendly Alternative Refrigerant R410A

Transporting the Unit

Air outlet grille Intake hole

Corner

Sub line

Handle

Always hold the unit by the corners, as holding

it by the side intake holes on the casing may

cause them to deform.

A

40° or less

WARNING

Page 10

10 Outdoor Unit

Select the Best Location

Select the Best Location

1. Select space for installing outdoor unit, which will meet the following conditions:

• No direct thermal radiation from other heat sources

• No possibility of annoying neighbors by noise from unit

• No exposition to strong wind

• With strength which bears weight of unit

• Note that drain flows out of unit when heating

• With space for air passage and service work shown next

• Because of the possibility of fire, do not install unit to the space where generation, inflow, stagnation, and

leakage of combustible gas is expected.

• Avoid unit installation in a place where acidic solution and spray (sulfur) are often used.

• Do not use unit under any special environment where oil, steam and sulfuric gas exist.

• It is recommended to fence round the outdoor unit in order to prevent any person or animal from accessing

the outdoor unit.

• If installation site is area of heavy snowfall, then the following directions should be observed.

- Make the foundation as high as possible.

- Fit a snow protection hood.

2. Select installation location considering following conditions to avoid bad condition when additionally

performing defrost operation.

• Install the outdoor unit at a place well ventilated and having a lot of sunshine in case of installing the product

at a place with a high humidity in winter (near beach, coast, lake, etc).

(Ex) Rooftop where sunshine always shines.

• Performance of heating will be reduced and preheat time of the indoor unit may be lengthened in case of

installing the outdoor unit in winter at following location:

- Shade position with a narrow space

- Location with much moisture in neighboring floor.

- Location with much humidity around.

- Location where ventilation is good.

It is recommended to install the outdoor unit at a place with a lot of sunshine as possible as.

- Location where water gathers since the floor is not even.

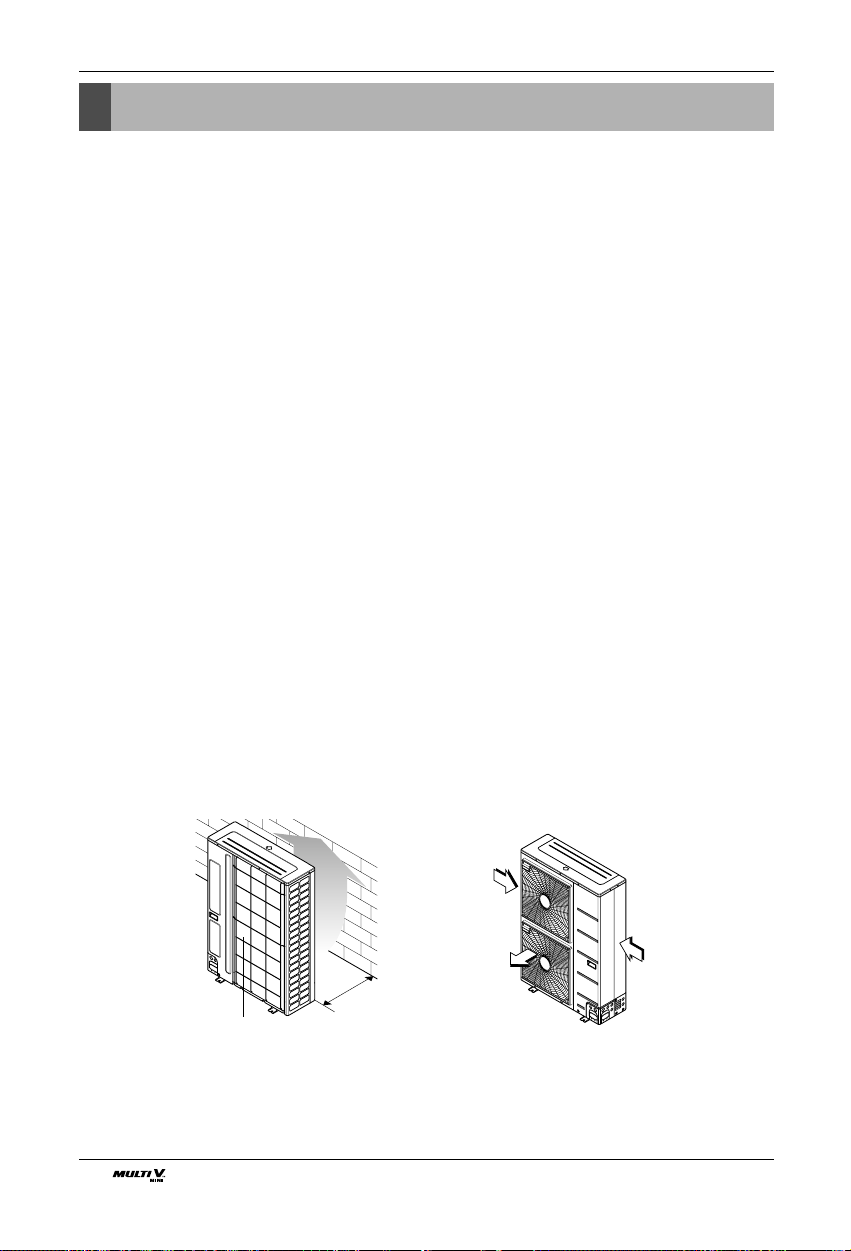

3. When installing the outdoor unit in a place that is constantly exposed to a strong wind like a coast or on a

high story of a building, secure a normal fan operation by using a duct or a wind shield.

• Install the unit so that its discharge port faces to the wall of the building.

Keep a distance 500mm or more between the unit and the wall surface.

• Supposing the wind direction during the operation season of the air conditioner, install the unit so that the

discharge port is set at right angle to the wind direction.

Turn the air outlet side toward the building's wall,

fence or windbreak screen.

Set the outlet side at a right angle

to the direction of the wind.

Air inlet grille

500

Strong

wind

Strong

wind

Blown

air

Page 11

ENGLISH

Installation Manual 11

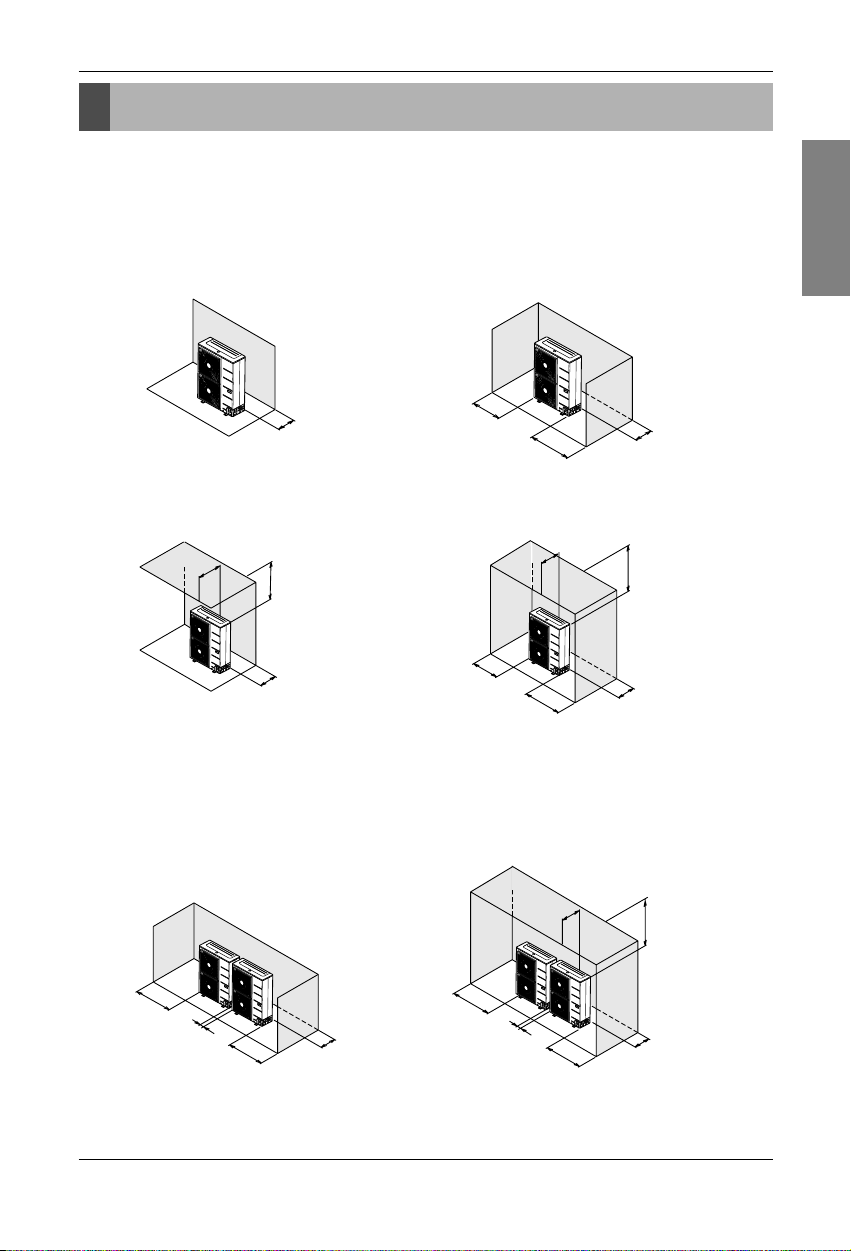

Installation Space

Installation Space

• The following values are the least space for installation.

If any service area is needed for service according to field circumstance, obtain enough service space.

• The unit of values is mm.

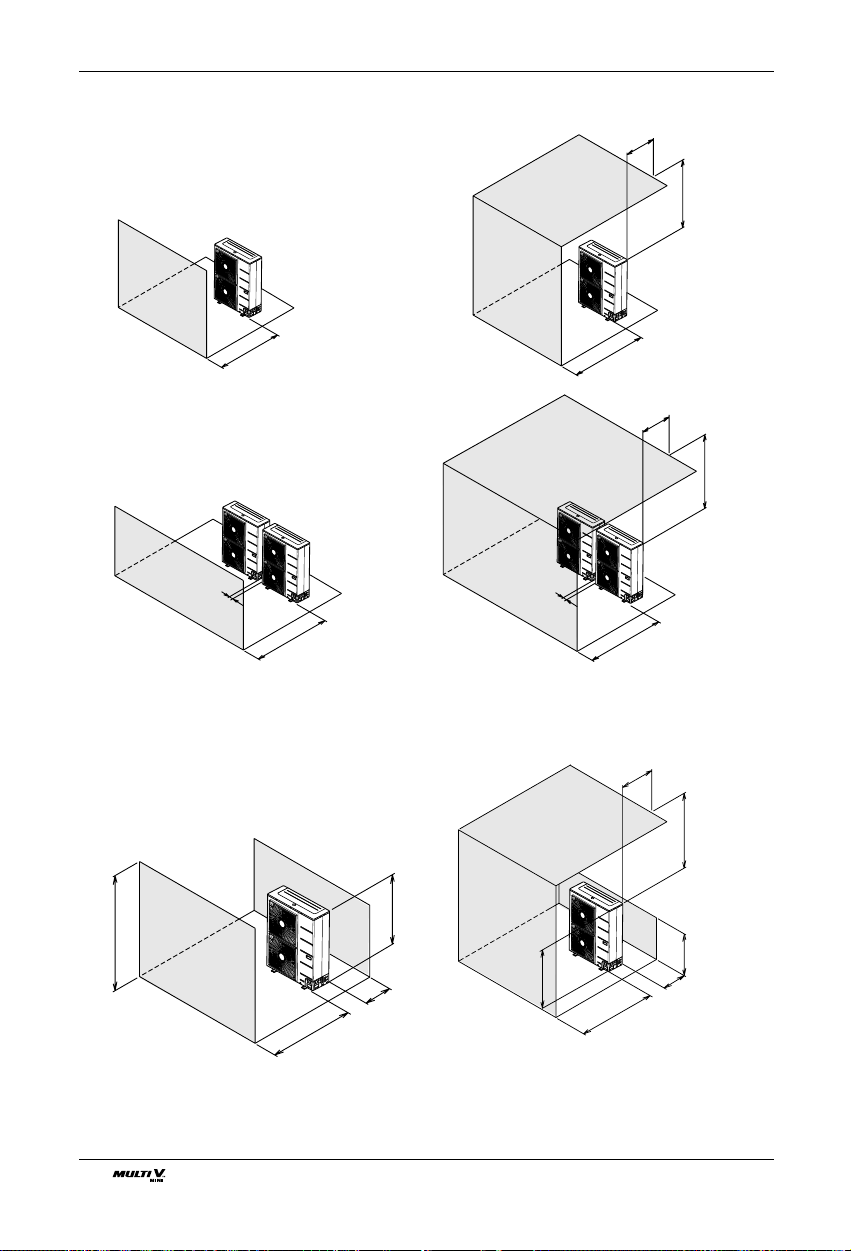

■ In case of obstacles on the suction side

1. Stand alone installation

2. Collective installation

100 or

more

100 or

500 or less

100 or

more

more

more

1000 or

150 or

more

100 or

more

150 or

more

500 or less

100 or

150 or

more

more

more

1000 or

[Unit:mm]

1000 or

more

100 or

more

200 or

more

300 or

more

1000 or

more

100 or

more

500 or less

200 or

more

more

1000 or

300 or

more

[Unit:mm]

Page 12

12 Outdoor Unit

Installation Space

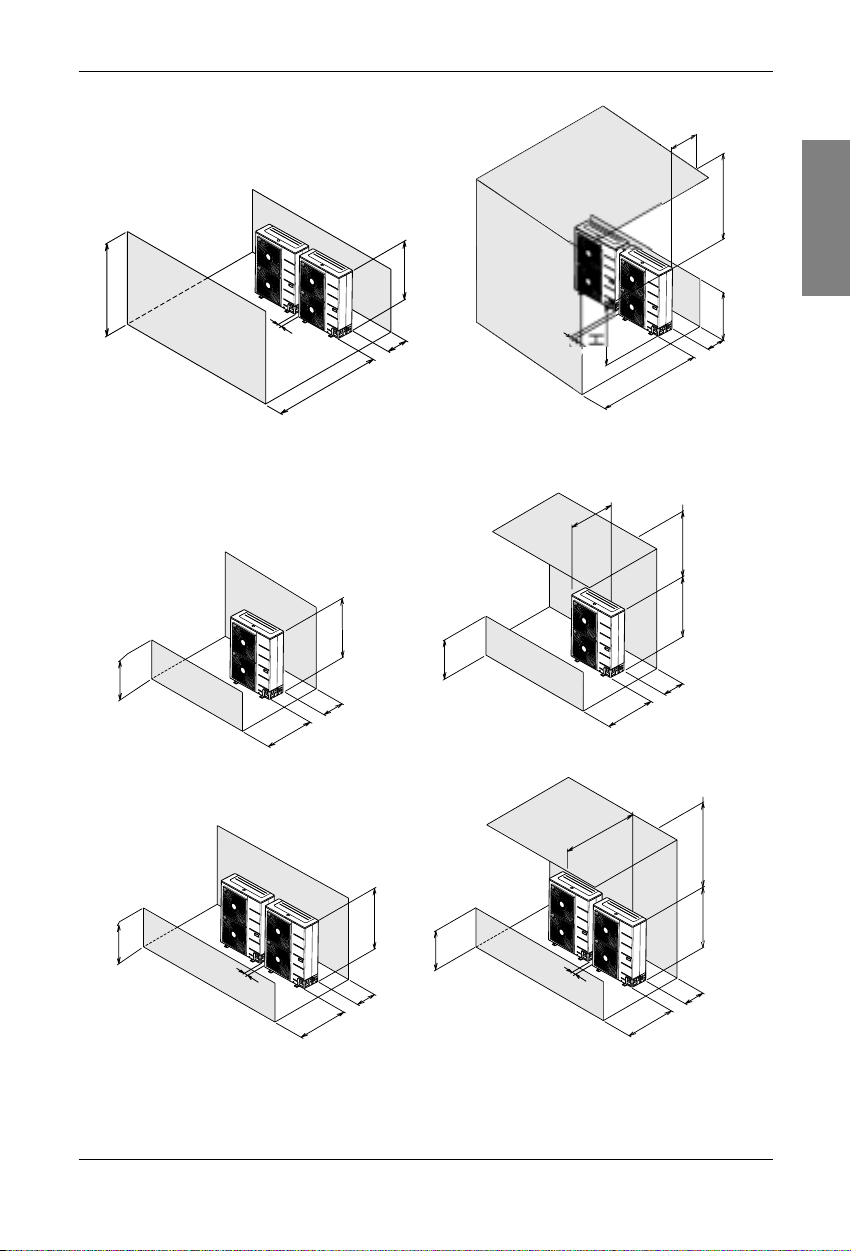

■ In case of obstacles on the discharge side

1. Stand alone installation

■ In case of obstacles on the suction and the discharge side

➲ Obstacle height of discharge side is higher than the unit

1. Stand alone installation

2. Collective installation

500 or less

more

1000 or

ore

500 or m

500 or m

100 or

m

ore

ore

1000 or m

100 or

m

ore

1000 or m

L > HL > H

H

L

H

100 or

more

500 or

more

ore

500 or less

500 or less

1000 or

ore

m

ore

250 or

ore

m

[Unit:mm]

1000 or

L

[Unit:mm]

1000 or more

more

Page 13

ENGLISH

Installation Manual 13

Installation Space

2. Collective installation

2. Collective installation

➲ Obstacle height of discharge side is lower than the unit

1. Stand alone installation

5

100 or more

L > H L > H

H

L

100 or more

more

1000 or

L

300 or

more

1000 or

more

500 or less

L ≤ HL ≤ H

H

L

L

100 or

more

500 or

more

500 or less

L ≤ HL ≤ H

H

L

100 or more

L

100 or more

1250 or more

300 or

1000 or

more

1000 or

H

more

300 or

more

[Unit:mm]

more

more

1000 or

H

1500 or

more

300 or

more

300 or

more

more

[Unit:mm]

1500 or

Page 14

14 Outdoor Unit

Installation Space

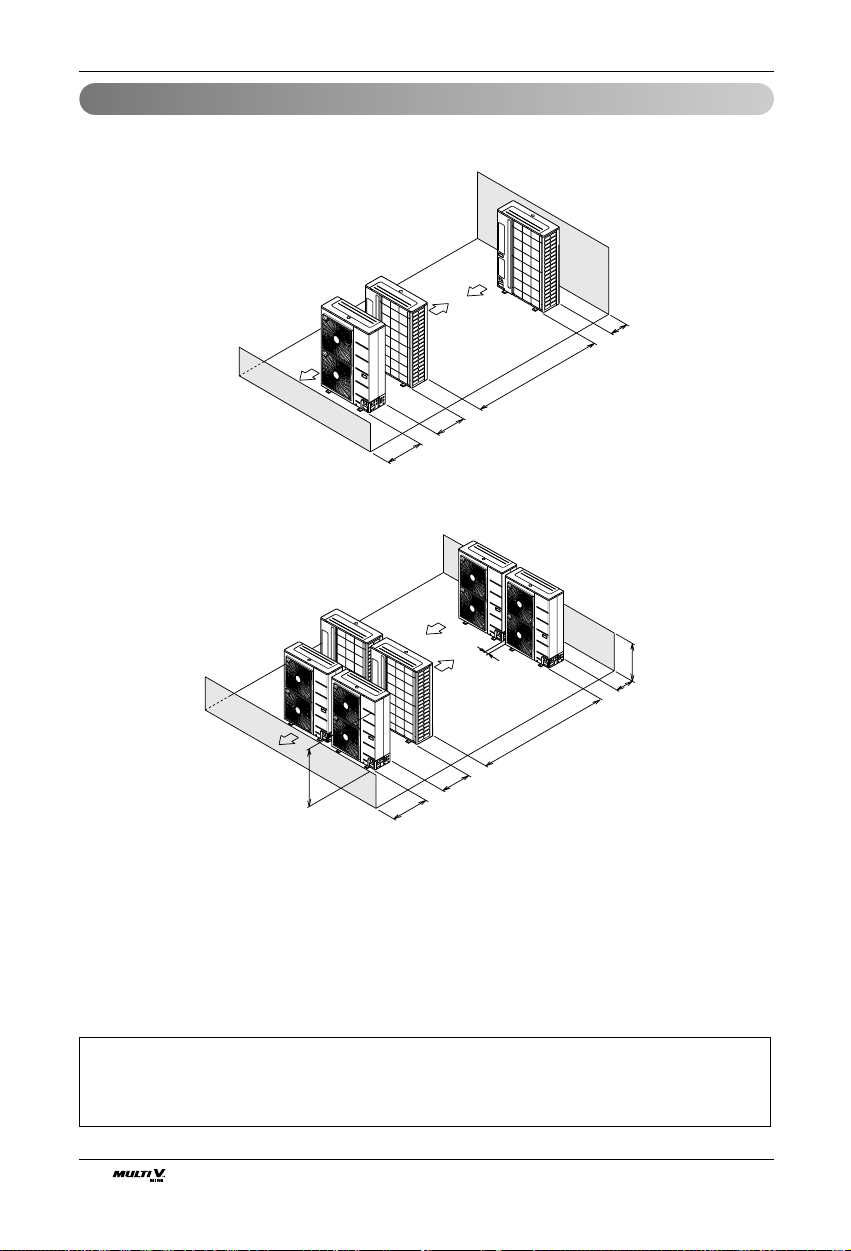

Collective / Continuous Installation for roof top use

Space required for collective installation and continuous installation: When installing several units, leave space

between each block as shown below considering passage for air and people.

1. One row of stand alone installation

2. Rows of collective installation (2 or more)

• L should be smaller than H

100 or

more

2000 or

more

200 or

more

1000 or

more

L

300 or

more

3000 or

more

H

600 or

more

1500 or

more

100 or

more

L ≤ H

[Unit:mm]

[Unit:mm]

Seasonal wind and cautions in winter

• Sufficient measures are required in a snow area or severe cold area in winter so that product can be operated well.

• Get ready for seasonal wind or snow in winter even in other areas.

• Install a suction and discharge duct not to let in snow or rain.

• Install the outdoor unit not to come in contact with snow directly. If snow piles up and freezes on the air suction hole,

the system may malfunction. If it is installed at snowy area, attach the hood to the system.

• Install the outdoor unit at the higher installation console by 50cm than the average snowfall (annual average snowfall) if

it is installed at the area with much snowfall.

1. The height of H frame must be more than 2 times the snowfall and its width shall not exceed the width of the

product. (If width of the frame is wider than that of the product, snow may accumulate)

2. Don't install the suction hole and discharge hole of the Outdoor Unit facing the seasonal wind.

Page 15

ENGLISH

Installation Manual 15

Installation

Installation

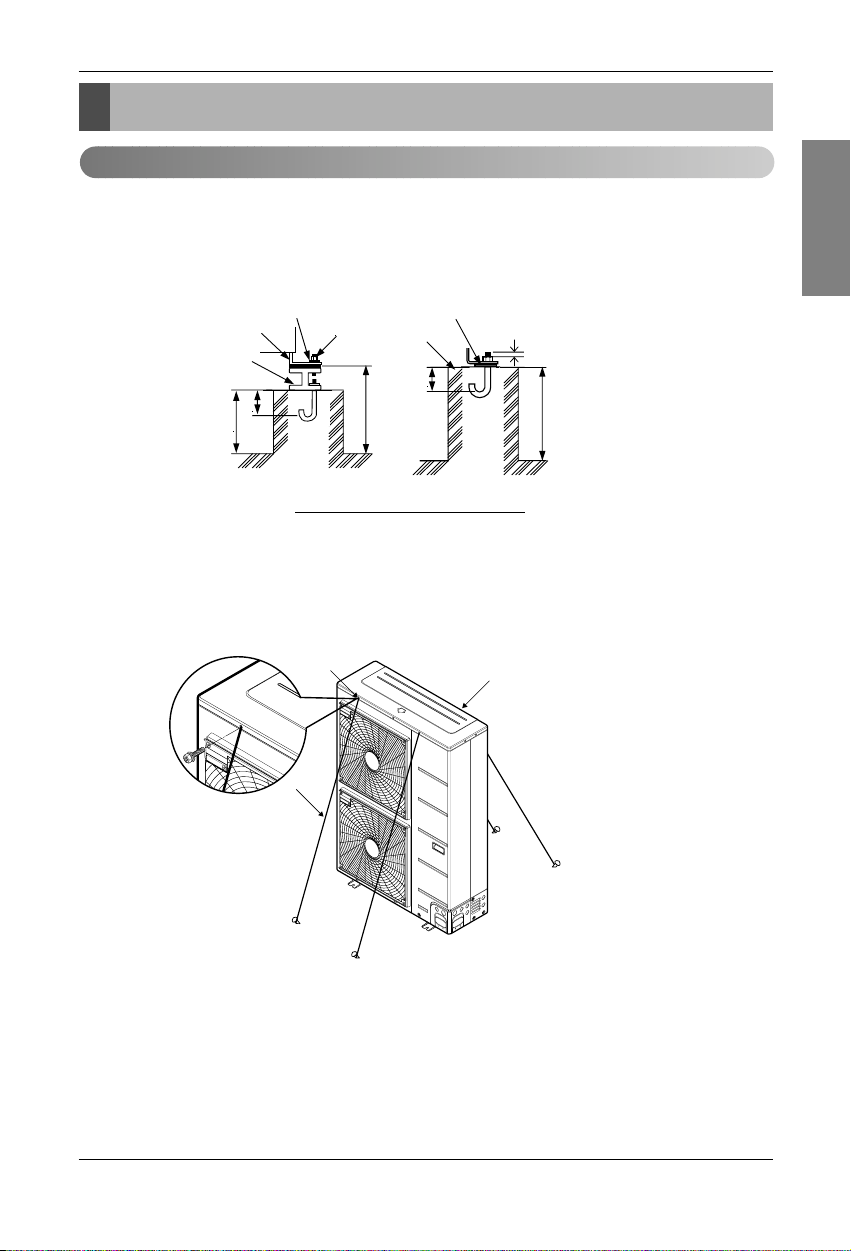

Foundation for Installation

• Check the strength and level of the installation ground so that the unit will not cause any operating vibration or

noise after installation.

• Fix the unit securely by means of the foundation bolts. (Prepare 4sets of M12 foundation bolts, nuts and

washers each which are available on the market.)

• It is best to screw in the foundation bolts until their length are 20mm from the foundation surface.

If it is necessary to prevent the unit from falling over, install as shown in the figure.

• Prepare all 4 wires as indicated in the drawing

• Unscrew the top plate at the 4 location indicated A and B

• Put the screws through the nooses and screw them back tight

A : Location of the 2 fixation holes on the front side of the unit

B : Location of the 2 fixation holes on the rear side of the unit

C : wires

[Unit:mm]

Foundation bolt executing method

200

Nut

75

75

200

Spring washer

Frame

Anti-vibration

materials

Four bolt are

required

3 thread ridges

H-Beam

Concrete

base

100

A

B

C

Page 16

16 Outdoor Unit

Installation

Preparation of Piping

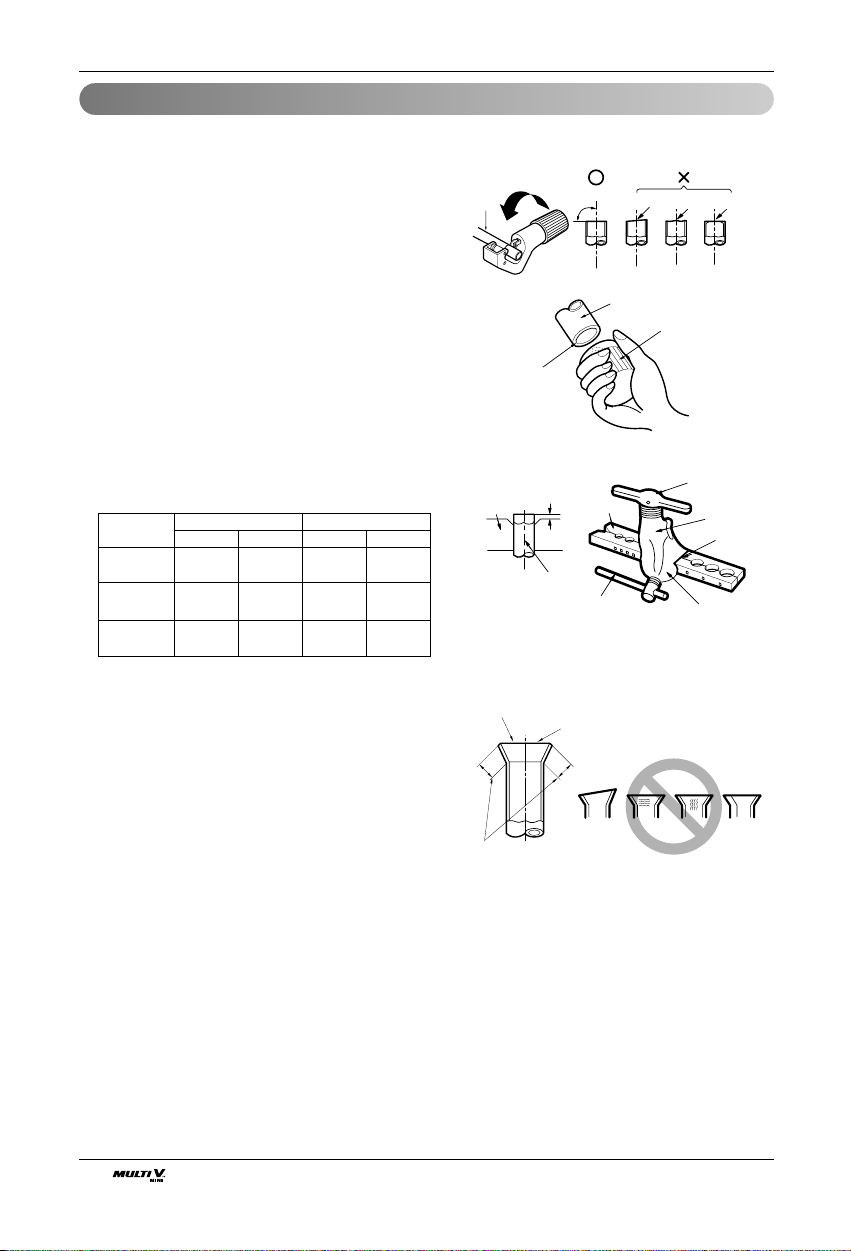

1) Cut the pipes and the cable.

■ Use the accessory piping kit or the pipes purchased

locally.

■ Measure the distance between the indoor and the

outdoor unit.

■ Cut the pipes a little longer than measured distance.

■ Cut the cable 1.5m longer than the pipe length.

2) Burrs removal

■ Completely remove all burrs from the cut cross section

of pipe/tube.

■ Put the end of the copper tube/pipe to downward

direction as you remove burrs in order to avoid to let

burrs drop in the tubing.

3) Flaring work

■ Carry out flaring work using flaring tool as shown right.

Firmly hold copper tube in a bar(or die) as indicated

dimension in the table above.

4) Check

■ Compare the flared work with figure right.

■ If flare is noted to be defective, cut off the flared section

and do flaring work again.

Main cause of gas leakage is defect in flaring work. Carry out correct flaring work in the following procedure.

Pipe "A "

Gas Liquid Gas Liquid

<5.6(19,100) 12.7(1/2) 6.35(1/4)

1.6~1.8 1.1~1.3

(0.63~0.71) (0.43~0.51)

<16.0(54,600) 15.88(5/8) 9.52(3/8)

1.6~1.8 1.5~1.7

(0.63~0.71) (0.59~0.67)

<22.4(76,400) 9.52(3/4) 9.52(3/8)

1.9~2.1 1.5~1.7

(0.75~0.83) (0.59~0.67)

Indoor unit

[kW(Btu/h]

Copper

tube

90°

Slanted Uneven Rough

Pipe

Reamer

Point down

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shining without scratches.

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Unit : mm(inch)

Page 17

ENGLISH

Installation Manual 17

Installation

1. Use the heat insulation material for the refrigerant piping which has an excellent heat-resistance (over

120°C).

2. Precautions in high humidity circumstance:

This air conditioner has been tested according to the

"ISO Conditions with Mist" and confirmed that there is

not any default. However, if it is operated for a long

time in high humid atmosphere (dew point

temperature: more than 23°C), water drops are liable

to fall. In this case, add heat insulation material

according to the following procedure:

• Heat insulation material to be prepared... EPDM

(Ethylene Propylene Diene Methylene)-over 120°C

the heat-resistance temperature.

• Add the insulation over 10mm thickness at high humidity environment.

Indoor unit

Thermal insulator

(accessory)

Fastening band

(accessory)

Refrigerant piping

HEAT INSULATION

Precautions when connecting pipes

• See the following table for flare part machining dimensions.

• When connecting the flare nuts, apply refrigerant oil to the inside and outside of the flares and turn them three

or four times at first. (Use ester oil or ether oil.)

• See the following table for tightening torque.(Applying too much torque may cause the flares to crack.)

• After all the piping has been connected, use nitrogen to perform a gas leak check.

CAUTION

Always use a charge hose for service port connection.

After tightening the cap, check that no refrigerant leaks are

present.

When loosening a flare nut, always use two wrenches in

combination, When connecting the piping, always use a spanner

and torque wrench in combination to tighten the flare nut.

When connecting a flare nut, coat the flare(inner and outer faces)

with oil for R410A(PVE) and hand tighten the nut 3 to 4 turns as

the initial tightening.

FLARE SHAPE and FLARE NUT TIGHTENING TORQUE

90°

±2

4

5°

±2

A

R=0.4~0.8

Pipe size Tightening Torque(kgf·cm) A(mm) flare shape

9.52 340~420 12.6~13.0

12.7 550~660 15.8~16.2

15.88 630~820 19.0~19.4

Union

Page 18

18 Outdoor Unit

Refrigerant Piping

Refrigerant Piping

■ Connecting the pipes to the outdoor unit

1. Liquid pipe

• Align the center of the pipings and sufficiently tighten

the flare nut with fingers.

• Finally, tighten the flare nut with torque wrench until

the wrench clicks.

- When tightening the flare nut with torque wrench,

ensure the direction for tightening follows the arrow

on the wrench.

■

Possible direction for field piping

• For the units with capacity more than 42 kBtu/h, the

installation piping is connectable in four directions.(refer

to figure 1)

• When connecting in a downward direction, knock out the

knockout hole of the base pan.

(refer to figure 2)

■ Preventing foreign objects from

entering (Figure3)

• Plug the pipe through-holes with putty or insulation

material(procured locally)to stop up all gaps,as shown in

the figure 3.

• Insects or small animals entering the outdoor unit may

cause a short circuit in the electrical box.

2. Gas pipe

• Braze suitable field piping with service valve of gas pipe.

<Gas pipe>

<Liquid pipe>

Torque wrench

Wet towel

Gas side piping

(Bigger Dia.)

Liquid side piping

(Smaller Dia.)

mm inch kgf.m

Ø9.52 3/8 3.4~4.2

Outside diameter Torque

CAUTION

Take care so that there is no thermal damage on the service valves of the outdoor unit.

(Especially packing part of service port.) Wrap the service valve with a wet towel when brazing it as shown figure above.

CAUTION

• Make sure that pipe doesn't contact with the compressor terminal cover

and comp bolt.

• Always insulate the liquid and gas-side field piping and branch.

<Figure 1>

<Figure 3>

Backward

Downward

Forward

<Figure 2>

Sideways

Knock-out Base pan

Putty or insulating material

(produced locally)

Connecting wire

Drain hose

Connection pipe

Page 19

ENGLISH

Installation Manual 19

Refrigerant Piping

Cautions for Handling Service Valve

How to Use the Shut-Off Valve

CAUTION

Make sure to keep the valve open during operation

• The service valves are closed at shipment from the factory

The names of parts of the service valve are

shown in the figure.

• since the side boards may be deformed if only a torque wrench is used when loosening or tightening flare nuts,

always lock the shut-off valve with a wrench and then use a torque wrench.

Do not place wrenches on the valve cover.

Do not apply force on the valve cover, this may result in a refrigerant leak.

Use hexagonal wrenches 4mm or 6mm

• Opening the valve

1. Place the hexagon wrench on the valve bar and turn counter-clockwise.

2. Stop when the valve bar no longer turns. It is now open.

• Closing the valve

1. Place the hexagon wrench on the valve bar and turn clockwise.

2. Stop when the valve bar no longer turns. It is now closed.

1. Service point

2. Shut-off Valve

3. Filed piping connection

4. Valve cover

1. Spanner

2. Torque wrench

1

2

4

2

3

1

Direction to open

<Liquid pipe>

Direction to open

<Gas pipe>

Page 20

20 Outdoor Unit

Refrigerant Piping

To Outdoor Unit

Sealed Piping

A

A

B

A

B

1. Use the following materials for refrigerant piping.

• Material: Seamless phosphorous deoxidized copper pipe

• Wall thickness : Comply with the relevant local and national regulations for the designed pressure

3.8MPa. We recommend the following table as the minimum wall thickness.

2. Commercially available piping often contains dust and other materials. Always blow it clean with a dry inert

gas.

3. Use care to prevent dust, water or other contaminants from entering the piping during installation.

4. Reduce the number of bending portions as much as possible, and make bending radius as big as possible.

5. Always use the branch piping set shown below, which are sold separately.

6. If the diameters of the branch piping of the designated refrigerant piping differs, use a pipe cutter to cut

the connecting section and then use an adapter for connecting different diameters to connect the piping.

7. Always observe the restrictions on the refrigerant piping (such as rated length, difference in height, and

piping diameter).

Failure to do so can result in equipment failure or a decline in heating/cooling performance.

8. A second branch cannot be made after a header. (These are shown by .)

9. The Multi V will stop due to an abnormality like excessive or insufficient refrigerant. At such a time, always

properly charge the unit. When servicing, always check the notes concerning both the piping length and

the amount of additional refrigerant.

10. Never use refrigerant to perform an air purge. Always evacuate using a vacuum pump.

11. Always insulate the piping properly. Insufficient insulation will result in a decline in heating/cooling

performance, drip of condensate and other such problems.

12. When connecting the refrigerant piping, make sure the service valves of the Outdoor Unit is completely

closed (the factory setting) and do not operate it until the refrigerant piping for the Outdoor and Indoor

Units has been connected, a refrigerant leakage test has been performed and the evacuation process

has been completed.

13. Always blow nitrogen into pipe which is brazed. Always use a non-oxidizing brazing material for brazing

the parts and do not use flux. If not, oxidized film can cause clogging or damage to the compressor unit

and flux can harm the copper piping or refrigerant oil.

Caution

ARBLN01621 ARBLN03321 ARBL054 ARBL057 ARBL1010

ARBLN07121 ARBLN14521 ARBL104 ARBL107 ARBL2010

Y branch

Header

4 branch 7 branch 10 branch

0.99

22.2

1.1

31.8

1.21

34.9

1.35

38.1

1.43

41.3

0.99

28.58

0.99

25.4

0.99

19.05

0.99

15.88

0.8

12.7

0.8

9.52

0.8

6.35

Minimum

thickness [mm]

Outer diameter

[mm]

Page 21

ENGLISH

Installation Manual 21

Refrigerant Piping

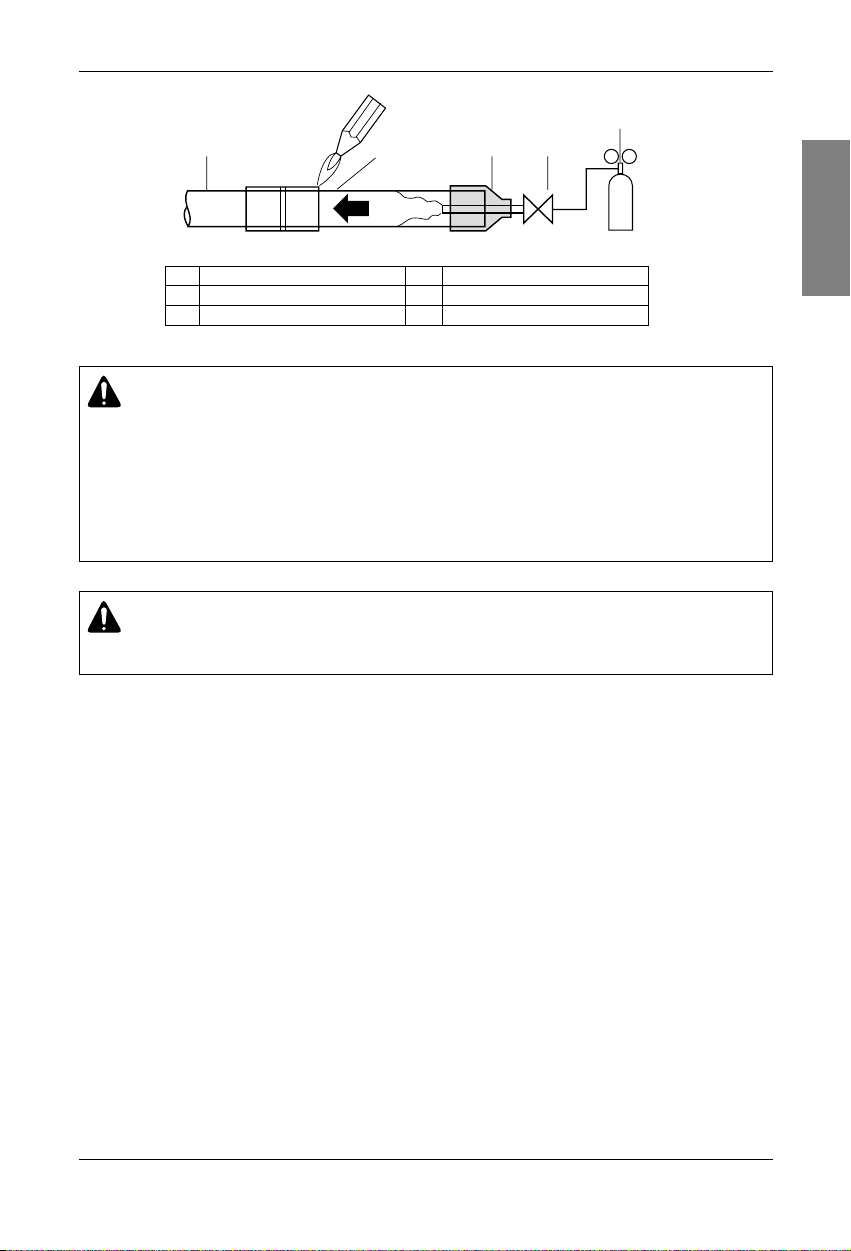

WARNING

When installing and moving the air conditioner to another site, be sure to make recharge refrigerant

after perfect evacuation.

- If a different refrigerant or air is mixed with the original refrigerant, the refrigerant cycle may malfunction and

the unit may be damaged.

- After selecting diameter of the refrigerant pipe to suit total capacity of the indoor unit connected after

branching, use an appropriate branch pipe set according to the pipe diameter of the indoor unit and the

installation pipe drawing.

WARNING

Do not use anti-oxidants when brazing the pipe joints. Residue can clog pipes and break equipment.

1 Refrigerant piping 4 Taping

2 Pipe to be brazed 5 Valve

3 Nitrogen 6 Pressure-reducing valve

6

1

2

45

3

Page 22

22 Outdoor Unit

Refrigerant Piping

Selection of Refrigerant Piping

Selection of pipe sizeName

Size of main pipe

Pipe size of between branching sections

Connecting pipe size of indoor unit

Piping partsNo.

Outdoor unit

1st branching section

Branching section

Branching section

Branching section

Indoor unit

Main pipe

Branching pipe

Indoor unit

connecting pipe

Outdoor unit capacity type

Liquid pipe Gas pipe

[mm(inch)] [mm(inch)]

4 HP Ø9.52(3/8) Ø15.88(5/8)

5 HP Ø9.52(3/8) Ø15.88(5/8)

6 HP Ø9.52(3/8) Ø19.05(3/4)

Indoor unit capacity[kW(Btu/h)]

Liquid pipe Gas pipe

[mm(inch)] [mm(inch)]

≤ 5.6(19,100) Ø6.35(1/4) Ø12.7(1/2)

< 16.0(54,000) Ø9.52(3/8) Ø15.88(5/8)

Indoor unit capacity[kW(Btu/h)]

Liquid pipe Gas pipe

[mm(inch)] [mm(inch)]

≤ 5.6(19,100) Ø6.35(1/4) Ø12.7(1/2)

< 16.0(54,600) Ø9.52(3/8) Ø15.88(5/8)

< 22.4(76,400) Ø9.52(3/8) Ø19.05(3/4)

Outdoor unit

Gas pipe

Main pipe

Liquid pipe

Branching

Branching

pipe

pipe

Indoor unit

Page 23

ENGLISH

Installation Manual 23

Refrigerant Piping

Allowable Length/Height Difference of Refrigerant Piping

■ Y Branch Method

Example : 5 Indoor Units connected

: Outdoor Unit

: 1st branch (Y branch)

: Indoor Units

L150m

H 50m

l 40m

➲ Total pipe length = A+B+C+D+a+b+c+d+e ≤ 300m

Longest pipe length Equivalent pipe length

A+B+C+D+e ≤ 150m * A+B+C+D+e ≤ 175m

Longest pipe length after 1st branch

B+C+D+e ≤ 40m

Difference in height(Outdoor Unit ↔ Indoor Unit)

H ≤ 50m ( 40m : Outdoor Unit is lower than Indoor Units)

Difference in height (Indoor Unit ↔ Indoor Unit)

h ≤ 15m

L

l

H

h

• * :

Assume equivalent pipe length of Y branch to be 0.5m, that of header to be 1m, calculation purpose

• ** : Indoor Unit should be installed at lower position than the header

Page 24

24 Outdoor Unit

Refrigerant Piping

■ Header Method

Example : 6 Indoor Units connected

: Outdoor Unit

: 1st branch

: Indoor Units

: Sealed piping

L 150m

H 50m

40m

WARNING

Pipe length after header branching (a~f)

It is recommended that difference in length of the pipes connected to the Indoor Units is

minimized. Performance difference between Indoor Units may occur.

• * :

Assume equivalent pipe length of Y branch to be 0.5m, that of header to be 1m, calculation purpose

• ** : Indoor Unit should be installed at lower position than the header

Longest pipe length * Equivalent pipe length

A+f ≤ 150m A+f ≤ 175m

Longest pipe length after 1st branch

f ≤ 40m

Difference in height(Outdoor Unit ↔ Indoor Unit)

H ≤ 50m (40m : Outdoor Unit is lower)**

Difference in height (Indoor Unit ↔ Indoor Unit)

h ≤ 15m

L

l

H

h

➲ Total pipe length = A+a+b+c+d+e+f ≤ 300m

Page 25

ENGLISH

Installation Manual 25

Refrigerant Piping

■ Combination of Y branch/header method

Example : 5 Indoor Units connected

: Outdoor Unit

: 1st branch (Y branch)

: Y branch

: Indoor Unit

: Header

: Sealed piping

L 150m

40m

H 50m

Branch pipe can not be used after header

➲ Refrigerant pipe diameter from branch to branch (B,C)

➲ Total pipe length = A+B+C+a+b+c+d+e ≤ 300m

Longest pipe length * Equivalent pipe length

A+B+b ≤ 150m A+B+b ≤ 175m

Longest pipe length after 1st branch

B+b ≤ 40m

Difference in height(Outdoor Unit ↔ Indoor Unit)

H ≤ 50m (40m : Outdoor Unit is lower than Indoor Units)**

Difference in height (Indoor Unit ↔ Indoor Unit)

h ≤ 15m

L

l

H

h

Downward Indoor Unit total capacity

[kW(Btu/h)]

≤5.6(19,100) Ø6.35(1/4) Ø12.7(1/2)

<16(54,600) Ø9.52(3/8) Ø15.88(5/8)

<22.4(76,400) Ø9.52(3/8) Ø19.05(3/4)

Liquid pipe

[mm(inch)]

Gas pipe

[mm(inch)]

• * :

Assume equivalent pipe length of Y branch to be 0.5m, that of header to be 1m, calculation purpose

• ** : Indoor Unit should be installed at lower position than the header

WARNING

It is recommended that difference of piping length for pipes connected to the Indoor Unit is

minimized. Performance difference between Indoor Units may occur.

Page 26

26 Outdoor Unit

Refrigerant Piping

1. Normal condition

The calculation of the additional charge should take into account the length of pipe.

Example : 5 HP

Additional charge amount R (kg)

= (Lx x 0.022kg/m) + (Ly x 0.061kg/m) + Correction factor

= (12 x 0.022kg/m) + (28 x 0.061kg/m) + 0

= 1.972

Lx : Real total length of liquid pipe Ø6.35(m)

Ly : Real total length of liquid pipe Ø9.52(m)

L1

L2 L3

abcd

Ø6.35:5m

d

Ø6.35:4m

c

Ø6.35:3m

b

Ø9.52:3m

a

Ø9.52:5m

L3

Ø9.52:10m

L2

Ø9.52:10m

L1

The Amount of Refrigerant

2. Special condition

In case of the No. of CST TQ/RAC SE/ARTCOOL SF models are over than 50% of the connected indoor units

when the total No. of connected indoor units are over than 50% of the max. connectable indoor units.

■ Additional refrigerant charging amount (kg) :

= (A x + B x ß) - (AVG x ß)

• A = Total No. of TQ,SE and SF Indoor units, = 0.5

• B = Total No. of except TQ,SE and SF Indoor units, ß = 0.3

• AVG = 50% of Max. No. of connectable Indoor units.

Example)

1) Installation Information

- Outdoor unit : 6HP

- Total indoor units : 6 units (TQ 3 units, SE 2 units, BH 1 unit)

2) Information from PDB

- Max. No. of connectable indoor units : 10 units

- Calculated additional refrigerant amount = 2 kg :

3) Indoor refrigerant charging amount

= (5 units x 0.5+1 unit x 0.3) - (5 units x 0.3) = 1.3 kg :

Revised the total additional charging amount = = 2 kg +1.3 kg

= 3.3 kg

Product Charge(kg)

A

Additional charge (kg)

B

Total liquid pipe (m)

=

Additional refrigerant charge

x

amount per liquid pipe 1m

(Table 1)

Correction Factor (kg)

+

(Table 2)

Total amount(kg)

+=

A B

Table 1

Pipe diameter at

liquid side (mm)

Additiona

refrigerantl

amount (kg/m)

Ø22.2Ø19.05Ø15.88Ø12.7Ø9.52Ø6.35

0.3540.2660.1730.1180.0610.022

Table 2

HP

PRODUCT CHARGE

CF

-0.5

5

4

3.7

3.7

0

Total amount(kg)

+=

AB+C

6

3.7

0

Page 27

ENGLISH

Installation Manual 27

Refrigerant Piping

WARNING

Regulation for refrigerant leakage

: the amount of refrigerant leakage should satisfy the following equation for human safety.

If the above equation can not be satisfied, then follow the following steps.

- Selection of air conditioning system: select one of the next

1. Installation of effective opening part

2. Reconfirmation of Outdoor Unit capacity and piping length

3. Reduction of the amount of refrigerant

4. Installation of 2 or more security device (alarm for gas leakage)

- Change Indoor Unit type

: installation position should be over 2m from the floor (Wall mounted type → Cassette type)

- Adoption of ventilation system

: choose ordinary ventilation system or building ventilation system

- Limitation in piping work

: Prepare for earthquake and thermal stress

WARNING

Refer to model information since the CF Value of correction factor differs depending on model.

CAUTION

If a negative result is obtained from the calculation, no refrigerant needs to be added.

Total amount of refrigerant in the system

0.44 ( kg / m3)

Volume of the room at which Indoor Unit of the least capacity is installed

Page 28

28 Outdoor Unit

Refrigerant Piping

1. Line Distribution

2. Vertical Distribution

Ensure that the branch pipes are attached vertically.

3. The others

Header

1st

1st

1st

Main pipe

Distribution

2nd

2nd

3rd

2nd

Main pipe

Distribution

1st

3rd

3rd main pipe distribution

2nd

Distribution Method

Page 29

ENGLISH

Installation Manual 29

Refrigerant Piping

Branch Pipe Fitting

Y branch

A

B

To Outdoor Unit

To Branch Piping or Indoor Unit

A

B

Facing

upwards

Facing

downwards

Within ± 3° Within ± 3°

Viewed from point A

in direction of arrow

Horizontal

plane

Within +/- 10°

A

A

B

Header

To outdoor unit

To indoor unit

A

B

C

• Ensure that the branch pipes are attached horizontally or vertically (see the diagram below.)

• When the number of pipes to be connected is

smaller than the number of header branches,

install a cap to the unconnected branches.

• The indoor unit having larger capacity must be

installed closer to

than smaller one.

• If the diameter of the refrigerant piping selected

by the procedures described is different from

the size of the joint,

the connecting section

should be cut with a pipe cutter.

Pipe cutter

Page 30

30 Outdoor Unit

Refrigerant Piping

• When the number of indoor units to be connected to the branch pipes is less than the number of branch

pipes available for connection then cap pipes should be fitted to the surplus branches.

• Fit branch pipe lie in a horizontal plane.

• Header should be insulated with the insulator in each kit.

• Joints between branch and pipe should be sealed with the tape included in each kit.

• Any cap pipe should be insulated using the insulator provided with each kit and then taped as described

above.

B

Pinched pipe

Horizontal plane

View from point B in the direction of the arrow

Insulate the header using

the insulation

material attached to the

branch pipe kit

as shown in the figure.

Insulator

Insulator of field pipe

Tape

Tape

Cap pipe

Insulator for cap pipe

Page 31

ENGLISH

Installation Manual 31

Refrigerant Piping

1. Y Branch

Selection of Y Branch and Header

Models Gas pipe Liquid pipe

ARBLN01621

ARBLN03321

ARBLN07121

I.D. 15.88

O.D19.05

I.D31.8

I.D31.8

I.D. 12.7

I.D22.2

I.D25.4

I.D22.2

I.D19.05

I.D28.58

O.D22.2

I.D28.58

I.D25.4

I.D22.2

O.D19.05

I.D12.7

I.D12.7

I.D15.88

I.D15.88

O.D19.05

I.D19.05

I.D19.05

I.D. 15.88

I.D22.2

I.D15.88

I.D22.2

I.D. 15.88

I.D19.05

I.D12.7

I.D19.05

I.D15.88

I.D12.7

I.D28.58

I.D12.7

I.D6.35

I.D12.7

I.D12.7

I.D19.05

O.D12.7

I.D9.52

I.D9.52

I.D15.88

I.D9.52

I.D6.35

[unit:mm]

I.D6.35

I.D9.52

I.D6.35

I.D9.52

I.D6.35

I.D9.52

I.D12.7

I.D15.88

I.D15.88

O.D12.7

I.D12.7

I.D19.05

I.D19.05

I.D6.35

I.D12.7

I.D12.7

I.D9.52

I.D9.52

I.D34.9

O.D38.1

O.D28.58

I.D38.1

I.D34.9

I.D22.2

I.D28.58

I.D28.58

I.D22.2

I.D19.05

ARBLN14521

O.D22.2

I.D19.05

I.D34.9

I.D15.88

I.D12.7

I.D41.3

I.D38.1

2 X

I.D41.3

O.D15.88

For example. Indicated Ø9.52 is the outer diameter(O.D..) of field jointed piping

I.D15.88

I.D22.2

O.D15.88

O.D19.05

I.D9.52

I.D22.2

I.D19.05

O.D12.7

I.D19.05

I.D22.2

I.D12.7

I.D19.05

I.D15.88

I.D12.7

I.D15.88

I.D6.35

I.D9.52

Page 32

32 Outdoor Unit

Refrigerant Piping

2. Header

I.D Ø15.88

I.D Ø12.7

I.D Ø15.88

I.D Ø12.7

I.D Ø19.05

O.D Ø19.05

I.D Ø15.88

I.D Ø12.7

I.D Ø9.52

I.D Ø9.52

I.D Ø6.35

I.D Ø6.35

I.D Ø12.7

O.D Ø12.7 I.D Ø9.52

I.D Ø15.88

I.D Ø12.7

I.D Ø15.88

I.D Ø12.7

I.D Ø19.05

O.D Ø19.05

I.D Ø15.88

I.D Ø12.7

I.D Ø9.52

I.D Ø6.35

I.D Ø9.52

I.D Ø6.35

I.D Ø12.7

O.D Ø12.7 I.D Ø9.52

I.D Ø15.88

I.D Ø12.7

I.D Ø28.58

I.D Ø19.05

I.D Ø15.88

O.D Ø28.58

I.D Ø22.2

I.D Ø25.4

I.D Ø9.52

I.D Ø6.35

I.D Ø9.52

I.D Ø12.7

I.D Ø6.35

O.D Ø12.7

I.D Ø9.52

I.D Ø15.88

I.D Ø12.7

I.D Ø28.58

I.D Ø19.05

I.D Ø15.88

O.D Ø28.58

I.D Ø22.2

I.D Ø25.4

I.D Ø9.52

I.D Ø6.35

I.D Ø9.52

I.D Ø12.7

I.D Ø6.35

O.D Ø12.7

I.D Ø9.52

I.D Ø15.88

I.D Ø12.7

I.D Ø28.58

I.D Ø19.05

I.D Ø15.88

O.D Ø28.58

I.D Ø22.2

I.D Ø25.4

I.D Ø9.52I.D Ø6.35

I.D Ø9.52

I.D Ø12.7

I.D Ø6.35

O.D Ø12.7 I.D Ø9.52

I.D Ø15.88

I.D Ø15.88

I.D Ø19.05

I.D Ø31.8

I.D Ø38.1

I.D Ø12.7

O.D Ø38.1

I.D Ø34.9

I.D Ø28.58

I.D Ø6.35

I.D Ø9.52

I.D Ø9.52 I.D Ø6.35

I.D Ø15.88

I.D Ø19.05

O.D Ø19.05 I.D Ø15.88

[unit:mm]

4 branch

ARBL054

7 branch

ARBL057

4 branch

ARBL104

7 branch

ARBL107

10 branch

ARBL1010

10 branch

ARBL2010

Models Gas pipe Liquid pipe

Page 33

ENGLISH

Installation Manual 33

Refrigerant Piping

Thermal Insulation of Refrigerant Piping

Heat

insulation

material

Outer

covering

Adhesive + Heat - resistant polyethylene foam +

Adhesive tape

Indoor Vinyl tape

Floor exposed

Water-proof hemp cloth + Bronze asphalt

Outdoor

Water-proof hemp cloth + Zinc plate + Oily paint

Note:

When using polyethylene cover as covering material, asphalt roofing shall not be required.

• Do not insulate gas or low pressure pipe and liquid or high

pressure pipe together.

• Be sure to fully insulate connecting portion.

Liquid pipe

Gas pipe

Power lines

Finishing tape

Insulating material

Bad example

Good example

These parts are not insulated.

B A C

A

B

C

A

C

D

E

A

B

C

D

E

Communication lines

F

Liquid pipe

Communication lines

Communication lines

Separation

Gas pipe

Power lines

Insulating material

A

B

C

D

E

A

A

B

F

Heat insulation material

Pipe

Outer covering

(Wind the connection part and cutting part of

heat insulation material with a finishing tape.)

Power lines

E

D

D

B

A

C

Be sure to give insulation work to refrigerant piping by covering liquid pipe and gas pipe separately with

enough thickness heat-resistant polyethylene, so that no gap is observed in the joint between indoor unit and

insulating material, and insulating materials themselves. When insulation work is insufficient, there is a

possibility of condensation drip, etc. Pay special attention to insulation work to ceiling plenum.

1m1m

A

B

D

F

G

B

G

D

B

H

I

J

A

E

B

I

A

B

D

C

Inner wall (concealed)

Floor (fireproofing)

Penetrating portion on fire

limit and boundary wall

Roof pipe shaft

Outer wall Outer wall (exposed)

Penetrations

Sleeve

Heat insulating material

Lagging

Caulking material

Band

Waterproofing layer

Sleeve with edge

Lagging material

Mortar or other incombustible caulking

Incombustible heat insulation material

When filling a gap with mortar, cover the

penetration part with steel plate so that

the insulation material will not be caved in.

For this part, use incombustible materials

for both insulation and covering.(Vinyl

covering should not be used.)

Page 34

34 Outdoor Unit

Refrigerant Piping

CAUTION

To prevent the nitrogen from entering the refrigeration system in the liquid state, the top of the cylinder must

be at higher position than the bottom when you pressurize the system.

Usually the cylinder is used in a vertical standing position.

Leak Test and Vacuum Drying

1. Leak test

Leak test should be m

ade by pressurizing nitrogen gas to 3.8 MPa(38.7kgf/cm2). If the pressure does not drop for

24 hours, the system passes the test. If the pressure drops, check where the nitrogen leaks. For the test method,

refer to the following figure. (Make a test with the service valves closed. Be also sure to pressurize liquid pipe, gas

pipe and high/low pressure common pipe)

The test result can be judged good if the pressure has not be reduced after leaving for about one day after

completion of nitrogen gas pressurization.

During this test, set DIP switch as Vacuum Mode.

Note:

If the ambient temperature differs between the time when pressure is applied and when the pressure drop is

checked, apply the following correction factor

There is a pressure change of approximately 0.1 kg/cm2(0.01 MPa) for each 1°C of temperature difference.

Correction= (Temp. at the time of pressurization – Temp. at the time of check) X 0.1

For example: Temperature at the time of pressurization (3.8 MPa) is 27 °C

24 hour later: 3.73 MPa, 20°C

In this case the pressure drop of 0.07 is because of temperature drop

And hence there is no leakage in pipe occurred.

Nitrogen gas

cylinder

Liquide pipe

Gas pipe

Page 35

ENGLISH

Installation Manual 35

Refrigerant Piping

2. Vacuum

Vacuum drying should be made from the service port provided on the outdoor unit’s service valve to the

vacuum pump commonly used for liquid pipe, gas pipe. Vaccum of the pipe and the indoor units should be

made from the port of the outdoor unit's service valve with the service valve closed.

* Never perform air purging using refrigerant.

• Vacuum drying: Use a vacuum pump that can evacuate to -100.7kPa (5 Torr, -755mmHg).

1) Evacuate the system from the liquid and gas pipes with a vacuum pump for over 2 hrs and bring the

system to -100.7kPa.

After maintaining system under that condition for over 1 hr, confirm the vacuum gauge rises. The system

may contain moisture or leak.

2) Following should be executed if there is a possibility of moisture remaining inside the pipe.

(Rainwater may enter the pipe during work in the rainy season or over a long period of time)

After evacuating the system for 2 hrs, give pressure to the system to 0.05MPa(vacuum break) with

nitrogen gas and then evacuate it again with the vacuum pump for 1hr to -100.7kPa(vacuum drying). If the

system cannot be evacuated to -100.7kPa within 2 hrs, repeat the steps of vacuum break and its drying.

Finally, check if the vacuum gauge does not rise or not, after maintaining the system in vacuum for 1 hr.

WARNING

• If the primary charging is not performed after vacuum, wet air may go into the outdoor unit. If air is mixed with the

refrigerant, the refrigerant cycle may malfunction and the unit may be damaged.

• Charging of refrigerant while the compressor is working is prohibited. Otherwise, liquid may go into the

compressor. It may cause faults of the compressor.

• Use a gravimeter accurate to 0.1kg.

• If other refrigerants are mixed in the original refrigerant, a refrigerant cycle may cause malfunction or damage.

• Add accurate refrigerant quantity via calculation.

Too much or too little refrigerant may cause problems

• Repeated on and off of the indoor units without charging refrigerant may cause faults of EEV.

• Since R410A is a mixed refrigerant, the required additional refrigerant must be charged in its liquid state. If the

refrigerant is charged in its gaseous state, its composition changes and the system will not work properly.

Vacuum pump

Liquide pipe

Gas pipe

Page 36

36 Outdoor Unit

Refrigerant Piping

CAUTION

Never charge the refrigerant with service valves closed and unit stopped.

If charging is carried out with service valves closed and unit stopped, the compressor will be damaged when unit

starts to run, and the unit will display ch26 error.

If trying to keep running under this condition, compressor will be broken.

3. Refrigerant charging

Follow following procedure to charge the refrigerant.

1. Open all service valves

2. Run the unit with cooling mode

3. Charging the refrigerant to gas service valve during operation.

Charging during

cooling operation

Refrigerant

cylinder

Open Open

Liquide pipe

Gas pipe

Page 37

ENGLISH

Installation Manual 37

Electrical Wiring

Electrical Wiring

CAUTION

Be sure to connect the Outdoor Unit to earth. Do not connect earth line to any gas pipe, water pipe,

lightening rod or telephone earth line. If earth is incomplete, it may cause an electric shock.

WARNING

Be sure to have authorized electrical engineers do the electric work using special circuits in

accordance with regulations and this installation manual. If power supply circuit has a lack of

capacity or electric work deficiency, it may cause an electric shock or fire.

1. Caution

1) Follow ordinance of your governmental organization for technical standard related to electrical equipment,

wiring regulations and guidance of each electric power company.

2) Install the Outdoor Unit communication line away from the power source wiring so that it is not affected by

electric noise from the power source. (Do not run it through the same conduit.)

3) Be sure to provide designated grounding work to Outdoor Unit.

4) Give some allowance to wiring for electrical part box of Indoor and Outdoor Units, because the box is

sometimes removed at the time of service work.

5) Never connect the main power source to terminal block of communication line. If connected, electrical parts

will be burnt out.

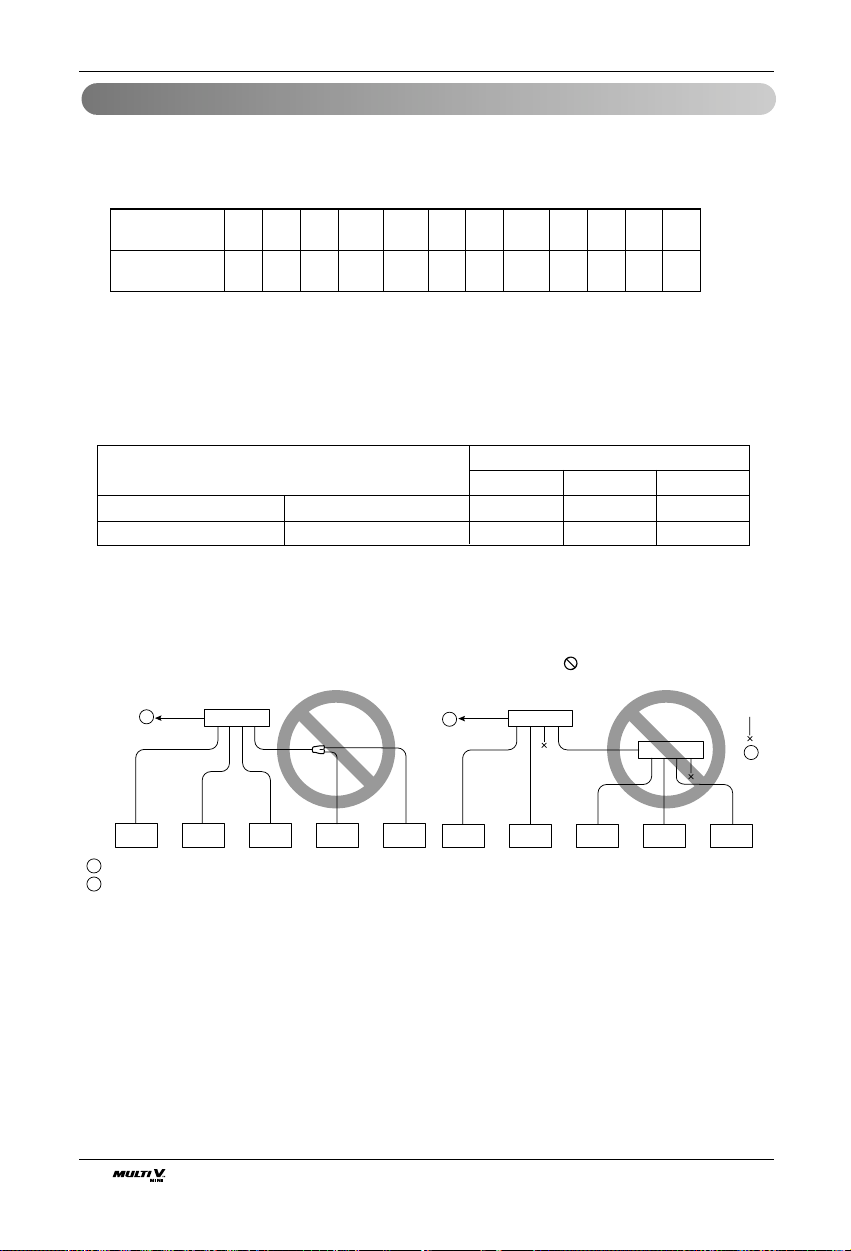

6) Use 2-core shield cable for communication line.(O mark in the figure below) If communication lines of

different systems are wired with the same multiplecore cable, the resultant poor transmitting and receiving will

cause erroneous operations. ( mark in the figure below)

7) Only the communication line specified should be connected to the terminal block for Outdoor Unit

transmission.

Electrical Wiring

Page 38

38 Outdoor Unit

Electrical Wiring

Remote

control

Remote

control

Remote

control

Remote

control

Indoor

Unit

Outdoor Unit

Outdoor Unit

Outdoor Unit

Outdoor Unit

Indoor

Unit

Remote

control

Remote

control

Indoor

Unit

Indoor

Unit

Remote

control

Remote

control

Indoor

Unit

Indoor

Unit

Indoor

Unit

Indoor

Unit

2-Core Shield Cable Multi-Core Cable

CAUTION

• This product have reversed phase protection detector that only works when the power is turned on.

If there exists black out or the power goes on and off which the product is operating, attach a

reversed phase protection circuit locally. running the product in reversed phase may break the

compressor and other parts.

• Use the 2-core shield cables for communication lines. Never use them together with power cables.

• The conductive shielding layer of cable should be grounded to the metal part of both units.

• Never use multi-core cable

• As this unit is equipped with an inverter, to install a phase leading capacitor not only will deteriorate

power factor improvement effect, but also may cause capacitor abnormal heating. Therefore, never

install a phase leading capacitor.

• Make sure that the power unbalance ratio is not greater than 2%. If it is greater, the unit’s lifespan

will be reduced.

• Introducing with a missing N-phase or with a mistaken N-phase will break the equipment.

Page 39

ENGLISH

Installation Manual 39

Electrical Wiring

2. Communication and Power Lines

1) Communication cable

• Types : shielding wire CVVS or CPEVS

• Cross section : over 1.25mm

2

• Insulation material : PVC

• Maximum allowable temperature: 60°C

• Maximum allowable line length: 300m

2) Remote control cable

• Types : 3-core cable

3) Simple central control cable

• Types : 4-core cable (Shielding wire)

• Cross section : over 0.75mm

2

• Insulation material : PVC

4) Separation of communication and power lines

• If communication and power lines are run alongside each other then there is a strong likelihood of

operational faults developing due to interference in the signal wiring caused by electrostatic and

electromagnetic coupling.

The tables below indicates our recommendation as to appropriate spacing of communication and power

lines where these are to be run side by side

Note:

1. The figures are based on assumed length of parallel cabling up to 100m. For length in excess of 100m

the figures will have to be recalculated in direct proportion to the additional length of line involved.

2. If the power supply waveform continues to exhibit some distortion the recommended spacing in the

table should be increased.

• If the lines are laid inside conduits then the following point must also be taken into account when grouping

various lines together for introduction into the conduits

• Power lines(including power supply to air conditioner) and signal lines must not be laid inside the same

• In the same way, when grouping the lines power and signal lines should not be bunched together.

Current capacity of power line Spacing

10A 300mm

50A 500mm

100A 1000mm

Exceed 100A 1500mm

100V or more

CAUTION

• If apparatus is not properly earthed then there is always a risk of electric shocks, the earthing of the

apparatus must be carried out by a qualified person.

• Use a power wire pipe for the power wiring.

Page 40

40 Outdoor Unit

Electrical Wiring

Outdoor unit (1Ø, 220~240V, 50Hz / 1Ø, 220V, 60Hz), Indoor unit (1Ø, 220V, 50Hz/60Hz)

1. Separate power supply lines for the indoor units from outdoor unit.

2. Bear in mind ambient conditions (ambient temperature,direct sunlight, rain water,etc.) when

proceeding with the wiring and connections.

3. The wire size is the minimum value for metal conduit wiring. The power cord size should be 1 rank

thicker taking into account the line voltage drops. Make sure the power-supply voltage does not drop

more than 10%.

4. Specific wiring requirements should adhere to the wiring regulations of the region.

5. Power supply cords of parts of appliances for outdoor use should not be lighter than polychloroprene

sheathed flexible cord.

6. Don't install an individual switch or electrical outlet to disconnect each of indoor unit separately from

the power supply.

WARNING

• Follow ordinance of your governmental organization for technical standard related to electrical equipment, wiring

regulations and guidance of each electric power company.

• Make sure to use specified wires for connections so that no external force is imparted to terminal connections. If

connections are not fixed firmly, it may cause heating or fire.

• Make sure to use the appropriate type of overcurrent protection switch. Note that generated overcurrent may include

some amount of direct current.

CAUTION

•

Some installation site may require attachment of an earth leakage breaker. If no earth leakage breaker is installed, it may

cause an electric shock.

•

Do not use anything other than breaker and fuse with correct capacity. Using fuse and wire or copper wire with too large

capacity may cause a malfunction of unit or fire.

Wiring of Main Power Supply and Equipment Capacity

Page 41

ENGLISH

Installation Manual 41

Electrical Wiring

When none are available, follow the instructions below.

• Do not connect wiring of different thicknesses to the power terminal block. (Slack in the power wiring

may cause abnormal heat.)

• When connecting wiring which is the same thickness, do as shown in the figure below.

• For wiring, use the designated power wire and connect firmly, then secure to prevent outside pressure

being exerted on the terminal block.

• Use an appropriate screwdriver for tightening the terinal screws. A screwdriver with a small head will

strip the head and make proper tighterning impossible.

• Over-tightening the terminal screws may break them.

◆ Precautions when laying power wiring

◆ How to connect wiring

1. Connect power supply wire to terminal block of control case

using clamps on the supporter and control case as shown figure

right.

2. Connect communication wire to main PCB terminal block using

clamps on the supporter and main PCB case as shown figure

right.

Round pressure terminal

Power wire

Use round pressure terminals for connections to the power terminal block.

Page 42

42 Outdoor Unit

Electrical Wiring

Example Connection of Communication Cable

1. 50Hz

■ 1 Outdoor Unit - 1Ø, 220~240V

3 4 34

: Single phase of power supply line(L, N)

: Communication line (3 line): Wired remote control

: Communication line (2 shield line):

Between Indoor Unit and Outdoor Unit

The GND terminal is a '–' terminal for the central controller, not Ground Line

Between Indoor and Outdoor unit

IDUSODU DRY1 DRY2 GND

INTERNET

BA

12V

BABA

1 Phase 2 Wires

Power supply

50Hz 220~240V

Power supply

1 Phase 50Hz

220~240V

Power supply switch

(Switch fuse : ELCB)

Power supply switch

(Switch fuse)

(Main Switch)

Pull Box(Installer Option)

34

WARNING

• Indoor Unit ground Lines are required for preventing electrical shock accident during current leakage,

communication disorder by noise effect and motor current leakage (without connection to pipe).

• Don't install an individual switch or electrical outlet to disconnect each of indoor unit separately from the

power supply.

• Install the main switch that can interrupt all the power sources in an integrated manner because this system

consists of the equipment utilizing the multiple power sources.

• If there exists the possibility of reversed phase, lose phase, momentary blackout or the power goes on and off

while the product is operating, attach a reversed phase protection circuit locally.

Running the product in reversed phase may break the compressor and other parts.

Page 43

ENGLISH

Installation Manual 43

Electrical Wiring

2. 60Hz

■ 1 Outdoor Unit - 1Ø, 220V

The GND terminal is a '–' terminal for the central controller, not Ground Line

Between Indoor and Outdoor unit

IDUSODU DRY1 DRY2 GND

INTERNET

BA

12V

BABA

1 Phase 2 Wires

Power supply

60Hz 220~240V

Power supply

1 Phase 60Hz

220V

Power supply switch

(Switch fuse : ELCB)

Power supply switch

(Switch fuse)

(Main Switch)

34 34 34

Pull Box(Installer Option)

: Single phase of power supply line(L, N)

: Communication line (3 line): Wired remote control

: Communication line (2 shield line):

Between Indoor Unit and Outdoor Unit

WARNING

• Indoor Unit ground Lines are required for preventing electrical shock accident during current leakage,

communication disorder by noise effect and motor current leakage (without connection to pipe).

• Don't install an individual switch or electrical outlet to disconnect each of indoor unit separately from the

power supply.

• Install the main switch that can interrupt all the power sources in an integrated manner because this system

consists of the equipment utilizing the multiple power sources.

• If there exists the possibility of reversed phase, lose phase, momentary blackout or the power goes on and

off while the product is operating, attach a reversed phase protection circuit locally.

Running the product in reversed phase may break the compressor and other parts.

Page 44

Electrical Wiring

44 Outdoor Unit

■ Example Connection of Communication Cable

[BUS type]

• Connection of communication cable must be installed like below figure between indoor unit to outdoor

unit.

[STAR type]

• Abnormal operation can be caused by communication defect, when connection of communication

cable is installed like below figure(STAR type).

Page 45

Electrical Wiring

ENGLISH

Installation Manual 45

■ Location of setting Switch

Main PCB

SW01B

(DIP S/W)

SW02B

(DIP S/W)

7 - Segment

SW02V

Auto addressing

SW01V

Data confirm

DIP Switch Setting

■ Checking according to dip switch setting

1. You can check the setting values of the outdoor unit from the 7 segment LED.

The dip switch setting should be changed when the power is OFF.

2. It checks whether the input is properly performed without the bad contact of the dip switch or not

■ Checking the setting of the unit

The number is sequentially appeared at the 7 segment in 5 seconds after applying the power. This

number represents the setting condition. & model code ➔ total capacity ➔ 2 ➔ 25 ➔ model type

1 ~255 : model code

4~6HP : HP numbers

No display : cooling only 2 : heat pump

25 : normal

120 : Model type(Mini, 1Ø 220V) 121 : Model type(Mini, 3Ø 380V)

Example) 5HP, R410A

121 ➔ 5 ➔ 2 ➔ 25 ➔ 120

CAUTION

Product may not properly operate if the relevant DIP switch is not properly setup.

Model Code

Model Code Unit (HP) Ref.

120 4

121 5 R410A

122 6

Page 46

Electrical Wiring

46 Outdoor Unit

■ Setting the DIP switch

• Set the dip switch with the power turned off. If y ou change the setting when the power is on, the changed

setting is not applied immediately. The changed setting is applied at the moment that the power is on.

• Instant indoor unit checking, data display mode, and forced oil collecting operation are used when theunits

are running. If you don't have to use those functions after using them, restore the dip switch setting.

1. Settings of outdoor unit

Standard

Short Pipe

Length

Long Pipe Length

Refrigerant Auto

Charging

Refrigerant

Checking

SW01B Setting

ON

ON

1234567ON1234567

1234567ON1234567

1234567 891011121314

1234567 891011121314

ON

ON

1234567ON1234567

1234567ON1234567

1234567 891011121314

1234567 891011121314

ON

ON

1234567ON1234567

1234567ON1234567

1234567 891011121314

1234567 891011121314

ON

ON

1234567ON1234567

1234567ON1234567

1234567 891011121314

1234567 891011121314

ON

ON

1234567ON1234567

1234567ON1234567

1234567 891011121314

1234567 891011121314

RemarksSW02B SettingFunction SW01B Setting RemarksSW02B SettingFunction

Power reset is

necessary

Factory Setting

Power reset is

necessary

-Cooling T arget Pressure

: Standard+39

-Heating T arget Pressure

: Standard-131

Power reset is

necessary

-Cooling T arget Pressure

: Standard-39

-Heating T arget Pressure

: Standard+131

Dip SW setting

+ Black button

(SW01V)

Dip SW setting

+ Black button

(SW01V)

ON

ON

Cool/Heat

Selector

1234567ON1234567

1234567ON1234567

1234567 891011121314

* In long piping mode, power consumption will be increased.

Power reset is necessary

Optional device

Page 47

Electrical Wiring

ENGLISH

Installation Manual 47

Snow

Note: Oil collecting operation is default function which operates after every six hours.

• To enable forced operation of this function change the dip switch setting. And after using, make sure to

restore the dip switch setting.

Forced

Defrosting

Night Silent

Operation

Pump Down

Pump Out

Forced Oil Return

Vacuum Mode

SW01B Setting RemarksSW02B SettingFunction SW01B Setting RemarksSW02B SettingFunction

ON

ON

1234567ON1234567