LG ARUM096BTE5, ARUM144BTE5, ARUM192BTE5, ARUM121BTE5, ARUM168BTE5 Installation Manual

...

INSTALLATION MANUAL

Variable Refrigerant Flow Outdoor Units

6.0 to 42.0 Tons

PROPRIETARY DATA NOTICE

This document, as well as all reports, illustrations, data, information,

and other materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc. only in confidence.

Do not throw away, destroy, or lose this manual.

Please read carefully and store in a safe place for future reference.

Content familiarity is required for proper installation.

The instructions included in this manual must be followed to prevent product malfunction, property damage, injury, or death to the user or

other people. Incorrect operation due to ignoring any instructions will cause harm or damage. The level of seriousness is classified by the

symbols described by the summary list of safety precautions on page 4.

For more technical materials such as submittals, catalogs, engineering,

owner’s, best practices, and service manuals, visit www.lghvac.com.

For continual product development, LG Electronics U.S.A., Inc. reserves the right to change specifications without notice.

© LG Electronics U.S.A., Inc.

TABLE OF CONTENTS

Safety Precautions ............................................................................. 4-7

Unit Nomenclature ................................................................................. 8

Outdoor Unit Specications ............................................................ 9-18

208-230V Outdoor Units ................................................................. 9-13

460V Outdoor Units ...................................................................... 14-18

Electrical Data ................................................................................. 19-20

208-230V Outdoor Unit Electrical Data ............................................. 19

460V Outdoor Unit Electrical Data ..................................................... 20

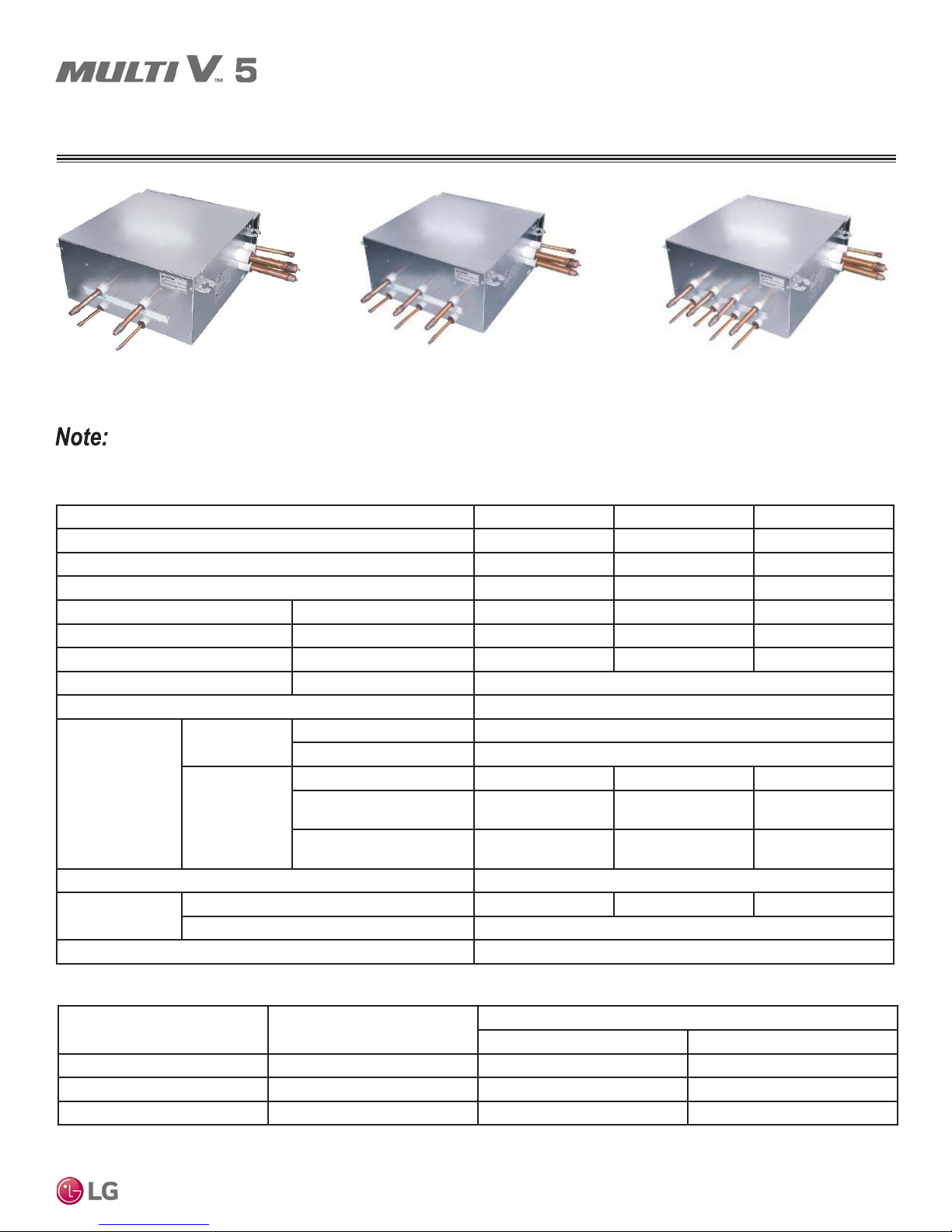

Heat Recovery Specications / Electrical Data ................................ 21

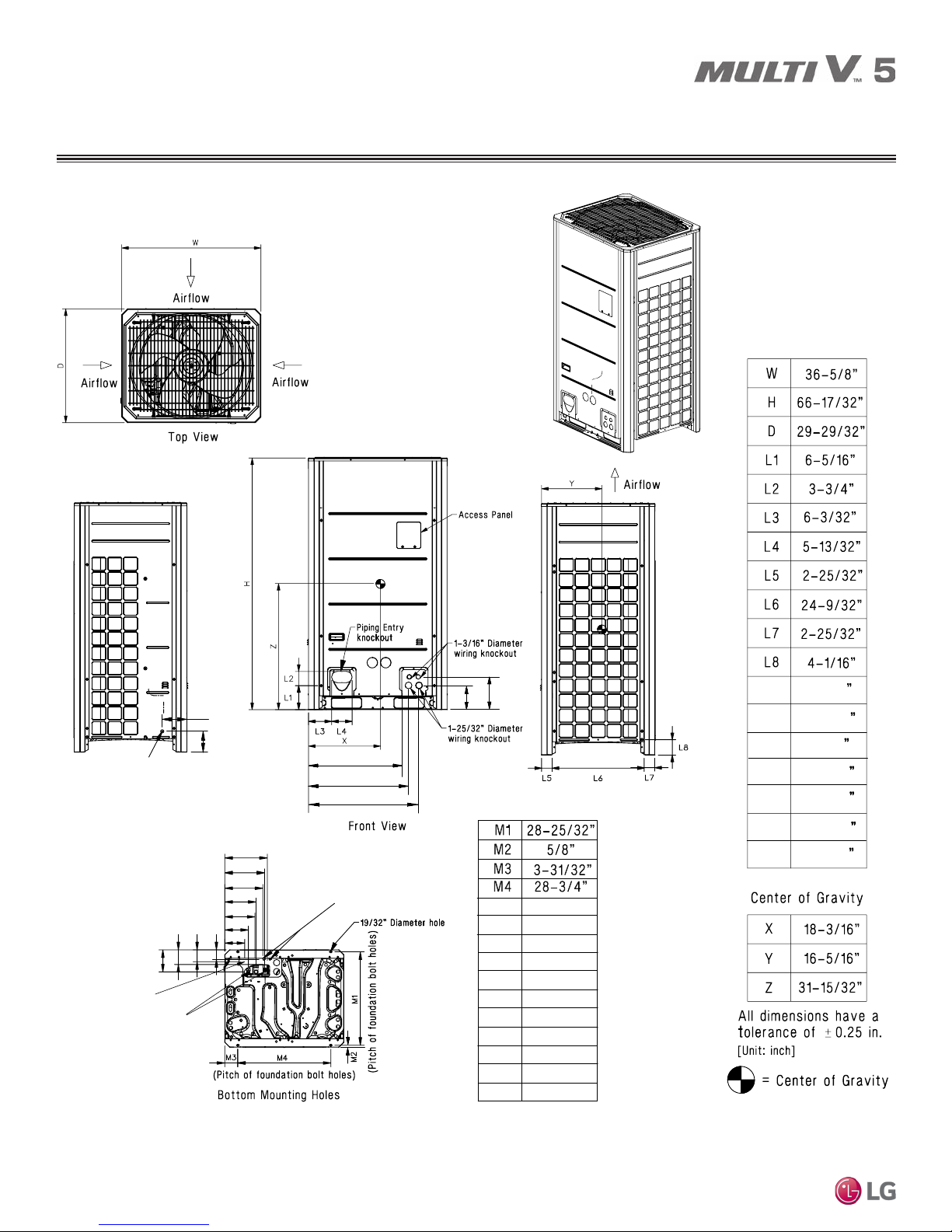

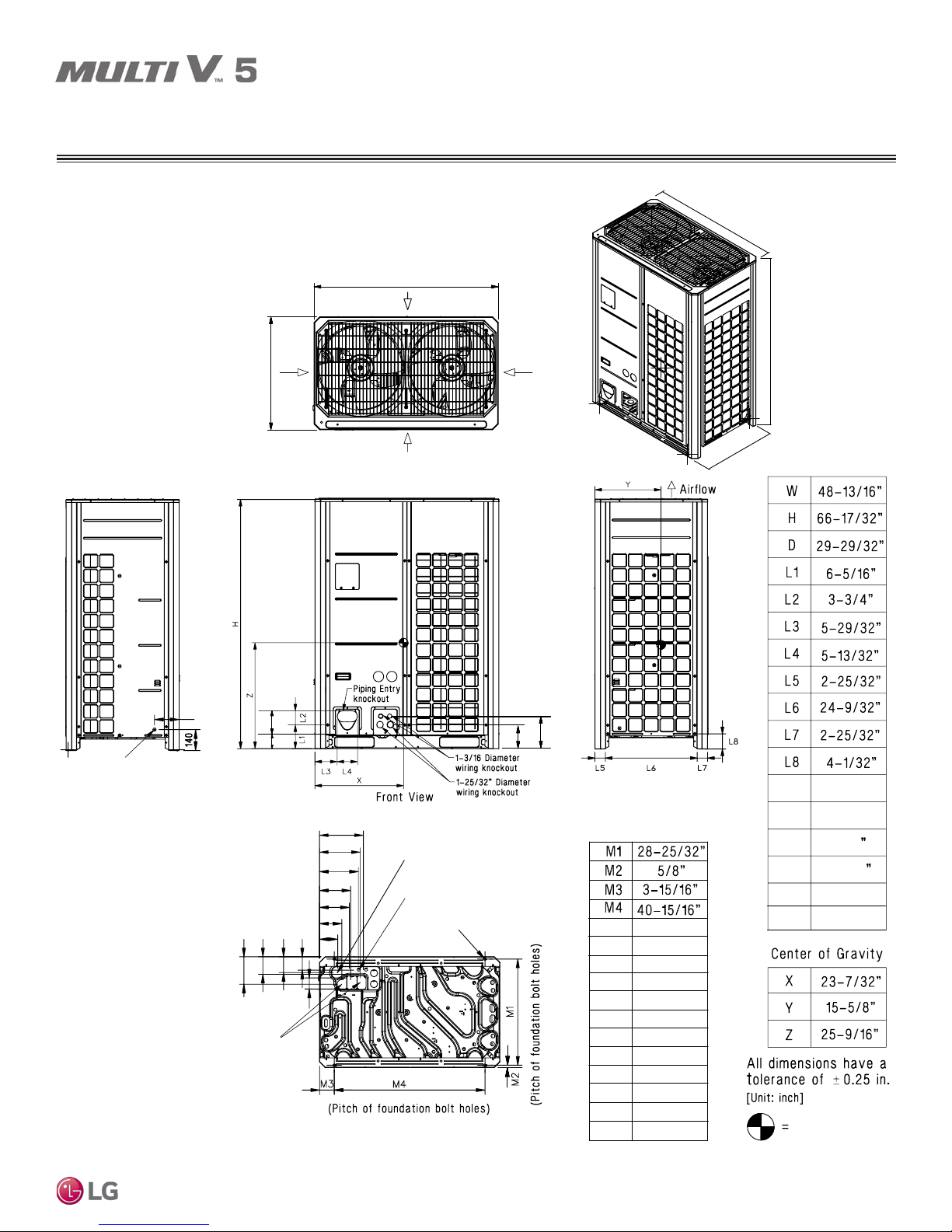

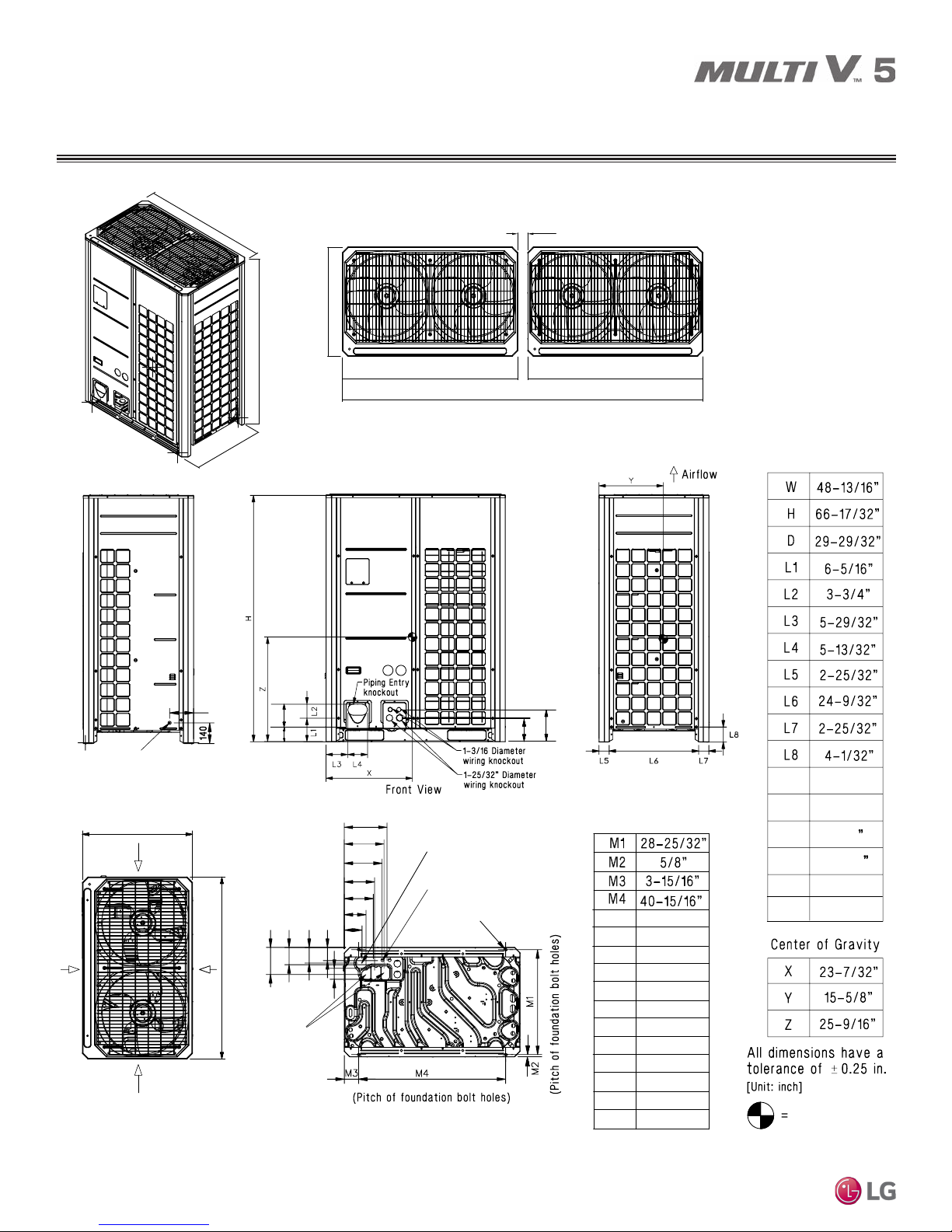

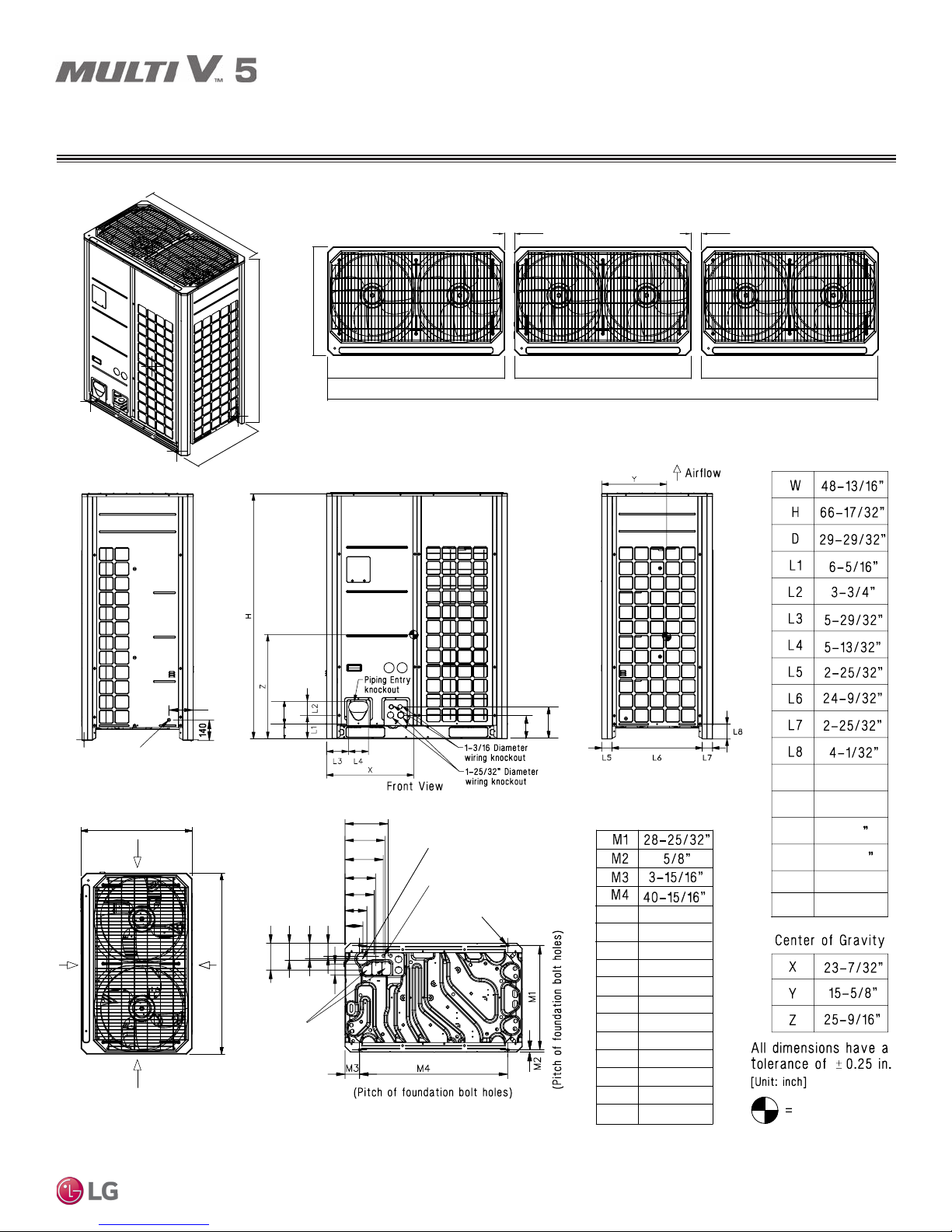

Outdoor Unit Dimensions .............................................................. 22-25

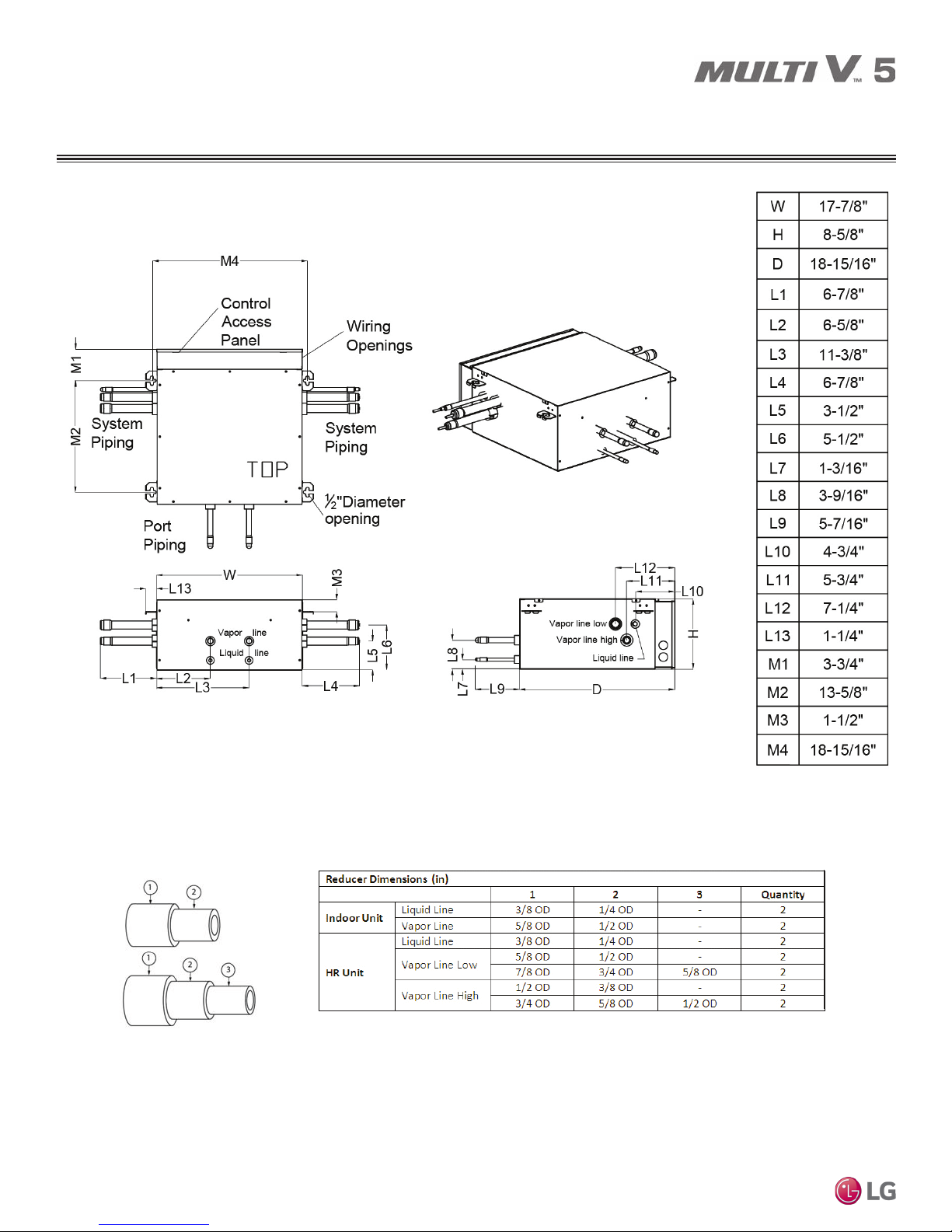

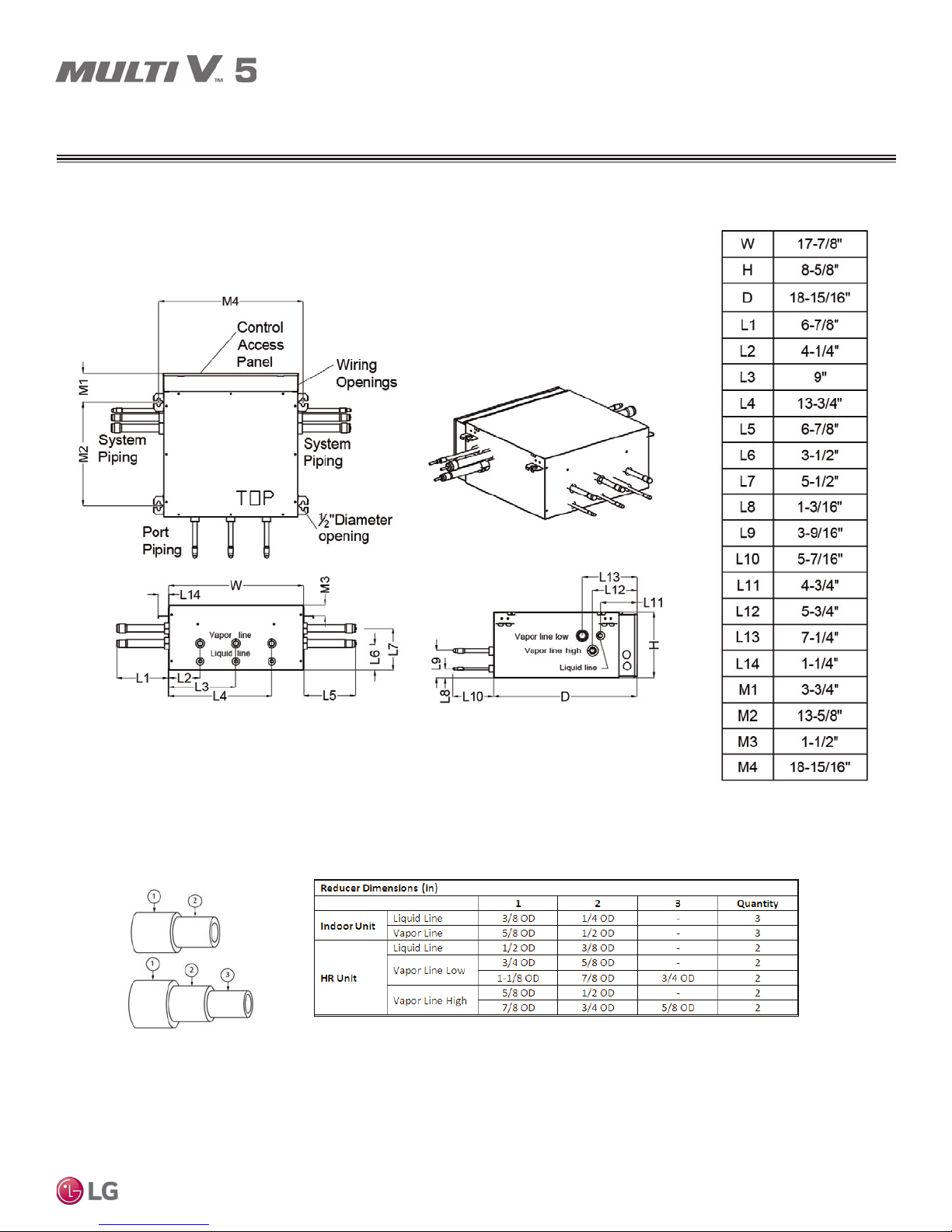

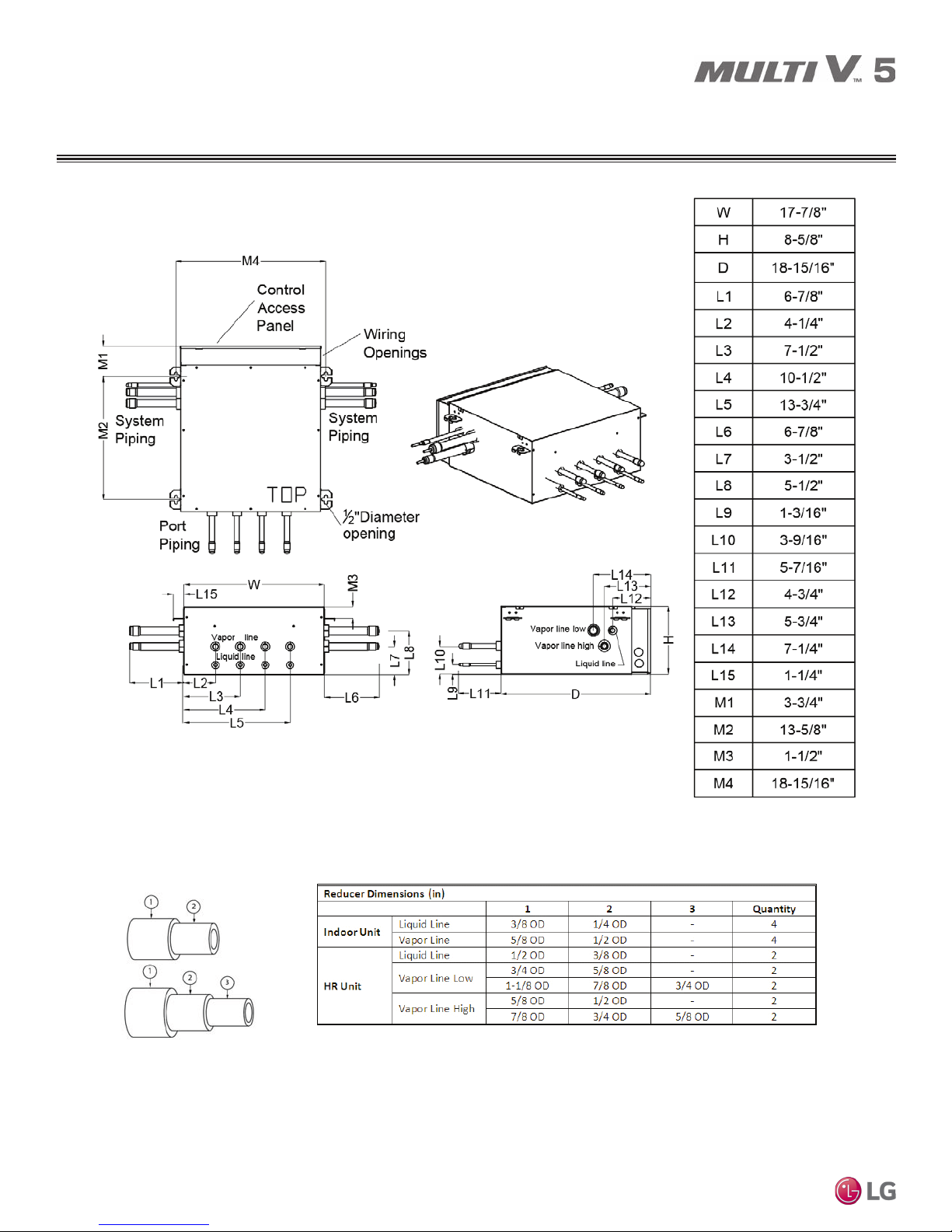

Heat Recovery Unit Dimensions ................................................... 26-28

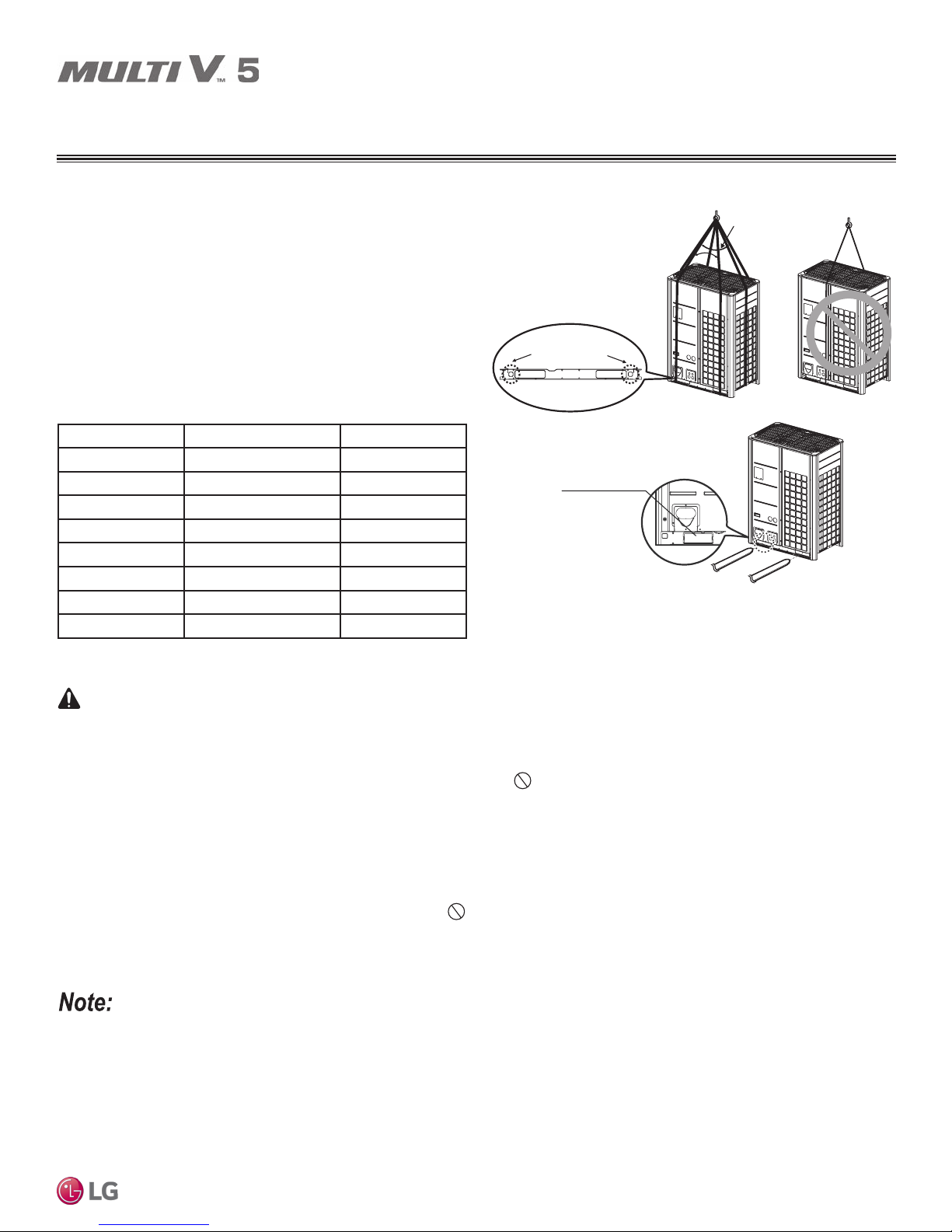

Transporting / Lifting .......................................................................... 29

Placement Considerations ............................................................ 30-37

Selecting the Best Location for the Outdoor Unit(s) ..................... 30-31

Outdoor Unit Clearance Requirements ............................................. 32

Installing Outdoor Units Indoors ................................................... 33-34

Installing and Setting Outdoor Units in Dual /

Triple Frame Systems ........................................................................ 35

Selecting the Best Location / Clearance Requirements for the

Heat Recovery Unit(s) .................................................................. 36-37

Mounting / Anchoring the Outdoor Unit(s) ...................................38-39

Mounting / Anchoring the Heat Recovery Unit(s) ............................. 40

General Refrigerant Piping System Information ......................... 41-53

LG Air Conditioner Technical Solution (LATS) ..............................41-42

Refrigerant Safety Standards / Device

Connection Limitations ...................................................................... 43

Selecting Copper Piping .................................................................... 44

Copper Expansion and Contraction .............................................. 45-47

Piping Handling ................................................................................. 48

Refrigerant System Engineering ................................................... 49-51

Flaring and Brazing Procedures ................................................... 52-53

Installing for Heat Pump Operation .............................................. 54-67

Indoor Unit Y-Branch Kits.............................................................. 54-55

Outdoor Unit Y-Branch Kits ........................................................... 56-57

Header Kits ................................................................................... 58-59

Sample Layouts ............................................................................ 60-63

Piping Connections / Pipe Routes ..................................................... 64

Knock Outs ....................................................................................... 65

Removing the Leak Prevention Caps ................................................ 66

Service Ports ..................................................................................... 67

Installing for Heat Recovery Operation ........................................ 68-89

Indoor Unit Y-Branch Kits.............................................................. 68-69

Outdoor Unit Y-Branch Kits ........................................................... 70-71

Header Kits ................................................................................... 72-73

Heat Recovery Units ..................................................................... 74-79

Sample Layouts ............................................................................ 80-85

Piping Connections / Pipe Routes ..................................................... 86

Knock Outs ....................................................................................... 87

Removing the Leak Prevention Caps ................................................ 88

Service Ports ..................................................................................... 89

Refrigerant Piping for Separated Outdoor Units ......................... 90-92

Insulation ......................................................................................... 93-95

Electrical ........................................................................................ 96-110

General Information ...................................................................... 96-97

Power Wiring and Communication Cable Terminations ................ 98-99

Power Wiring and Communication Cable Connections ................... 100

Power Wiring and Communication Cable

System Layout ................................................................................. 101

Power Supply / Power Wiring Specications ............................ 102-105

Communication Cable Specications ....................................... 106-110

Pre-Commissioning .....................................................................111-157

Triple Leak / Pressure Check ....................................................111- 113

Triple Evacuation Procedure .....................................................114-116

Vacuum Mode (Option) .....................................................................117

Pre-commissioning Start / Outdoor Unit

DIP Switch Settings ..........................................................................118

DIP Switch Settings for Use With Gen 4 Indoor Units ......................119

Setting the Optional Modes ...................................................... 120-134

Self Diagnostics Check .................................................................... 135

Indoor Unit Auto Addressing ..................................................... 136-138

Group Controlling Indoor Units ........................................................ 138

Central Control ......................................................................... 139-141

Addressing with Heat Recovery Units ...................................... 141-153

Temperature Sensing Location ................................................. 154-155

Setting External Static Pressure ............................................... 155-156

Package Pre-commissioning Documents /

Initiate a Request ............................................................................. 157

Error Codes ................................................................................. 159-168

LG Monitoring View (LGMV) Diagnostic Software .................. 169-170

Maintenance Recommendations ...................................................... 171

Checklists .................................................................................... 172-182

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

3

DANGER

WARNING

CAUTION

SAFETY PRECAUTIONS

DANGER

WARNING

The instructions below must be followed to prevent product malfunction, property damage, injury or death to the user or other people. Incorrect operation due to ignoring any instructions will cause harm or damage. The level of seriousness is classified by the symbols described

below.

TABLE OF SYMBOLS

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This symbol indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action that should not be performed.

INSTALLATION

Do not store or use ammable gas or combustibles near

the unit.

There is risk of re, explosion, and physical injury or death.

Do not install, remove, or re-install the unit by yourself

(end user). Ask the dealer or an LG trained technician to

install the unit.

Improper installation by the user may result in re, explosion, electric

shock, physical injury or death.

For replacement of an installed unit, always contact an LG

trained service provider.

There is risk of re, electric shock, explosion, and physical injury or

death.

MULTI V 5 Outdoor Unit Installation Manual

Wear protective gloves when handling equipment. Sharp

edges may cause personal injury.

Do not change the settings of the protection devices.

If the protection devices have been bypassed or are forced to operate

improperly, or parts other than those specied by LG are used, there is

risk of re, electric shock, explosion, and physical injury or death.

Replace all control box and panel covers.

If cover panels are not securely installed, dust, water, and animals may

enter the outdoor unit, causing re, electric shock, and physical injury or

death.

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Exposure to high concentration levels of refrigerant gas may lead to

illness or death.

Do not supply power to the unit until all wiring and piping

are completed or reconnected and checked.

There is risk of physical injury or death due to electric shock.

If the air conditioner is installed in a small space, take

measures to prevent the refrigerant concentration from

exceeding safety limits in the event of a refrigerant leak.

Consult the latest edition of American Society of Heating,

Refrigerating, and Air Conditioning Engineers (ASHRAE) Standard 15.

If the refrigerant leaks and safety limits are exceeded, it could result in

personal injuries or death from oxygen depletion.

The heat recovery unit must be installed indoors; do not

install the heat recovery unit in a highly humid environment.

There is risk of physical injury or death due to electric shock.

Dispose of the packing materials safely.

• Packing materials, such as nails and other metal or wooden parts,

may cause puncture wounds or other injuries.

• Tear apart and throw away plastic packaging bags so that children

may not play with them and risk suffocation and death.

Install the unit considering the potential for strong winds or

earthquakes.

Improper installation may cause the unit to fall over, resulting in physical

injury or death.

Install the unit in a safe location where nobody can step, fall

onto it, or place objects on it.

defective stand.

It may result in an accident that causes physical injury or death.

Do not install the unit on a

Periodically check that the outdoor frame is not damaged.

There is a risk of explosion, physical injury, or death.

4

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

SAFETY PRECAUTIONS

CAUTION

WARNING

Properly insulate all cold surfaces to prevent “sweating.”

Cold surfaces such as uninsulated piping can generate condensate that could drip, causing a slippery surface that creates a risk of slipping, falling,

and personal injury.

Be very careful when transporting the product. There is a risk of the product falling and causing physical injury.

• Use appropriate moving equipment to transport each frame; ensure the equipment is capable of supporting the weights listed.

• Some products use polypropylene bands for packaging. Do not use polypropylene bands to lift the unit.

• Suspend the outdoor unit from the base at specified positions (at a minimum of six [6] points) to avoid slippage from rigging apparatus.

LG Electronics U.S.A., Inc., is not responsible for any piping

calculations, refrigerant leaks, degradation of performance,

or any other potential problems or damages as a result of

interconnecting piping, their joint connections, isolation

valves, introduced debris inside the piping system, or other

problems caused by the interconnecting piping system.

Do not install the product where it is exposed directly to

ocean winds.

Sea salt in the air may cause the product to corrode. Corrosion,

particularly on the condenser and evaporator ns, could cause product

malfunction or inefcient operation.

When installing the outdoor unit in a low-lying area, or a location that is not level, use a raised concrete pad or concrete

blocks to provide a solid, level foundation.

This prevents water damage and abnormal vibration.

Properly insulate all cold surfaces to prevent “sweating.”

Cold surfaces such as uninsulated piping can generate condensate that

may drip and cause a slippery surface condition and / or water damage

to walls.

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Low refrigerant levels may cause product failure.

Do not make refrigerant substitutions. Use R410A only.

If a different refrigerant is used, or air mixes with original refrigerant, the

unit will malfunction and damage will occur.

Keep the unit upright during installation to avoid vibration or

water leakage.

When installing the unit in a hospital, mechanical room, or

similar electromagnetic eld (EMF) sensitive environment,

provide sufcient protection against electrical noise.

Inverter equipment, power generators, high-frequency medical equipment or radio communication equipment may cause the air conditioner

to operate improperly. The unit may also affect such equipment by

creating electrical noise that disturbs medical treatment or image broadcasting.

The heat recovery box must be installed indoors; do not

install the heat recovery box in a highly humid environment.

There is risk of product failure and property damage.

When connecting refrigerant piping, remember to allow for

pipe expansion.

Improper piping installation may cause system malfunction.

Do not install the outdoor unit or heat recovery unit in a

noise-sensitive area.

Take appropriate actions at the end of HVAC equipment life

to recover, recycle, reclaim, or destroy R410A refrigerant

according to applicable U.S. Environmental Protection

Agency (EPA) rules.

Periodically check that the outdoor frame is not damaged.

There is a risk of equipment damage.

Safety Precautions

Do not store or use ammable gas / combustibles near

the unit.

There is a risk of product failure.

Do not use the product for mission critical or special purpose applications such as preserving foods, works of art, or

other precision air conditioning applications. The equipment

is designed to provide comfort cooling and heating.

There is risk of property damage.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Install the unit in a safe location where no one can step on or

fall onto it.

Do not install the unit on a defective stand.

There is a risk of unit and property damage.

Install the drain hose to ensure adequate drainage.

There is a risk of water leakage and property damage.

5

SAFETY PRECAUTIONS

DANGER

WARNING

WIRING

High voltage electricity is required to operate this system.

Adhere to the U.S. National Electric Codes (NEC) and these

instructions when wiring.

Improper connections and inadequate grounding can cause accidental

injury or death.

Always ground the unit following local, state, and NEC codes.

There is risk of re, electric shock, and physical injury or death.

Turn the power off at the nearest disconnect before servicing

the equipment.

Electrical shock can cause physical injury or death.

The information contained in this manual is intended for use

by an industry-qualied, experienced, trained electrician

familiar with the NEC who is equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in this manual can

result in personal injury or death.

All electric work must be performed by a licensed electrician

and conform to local building codes or, in the absence of

local codes, with the NEC, and the instructions given in this

manual.

If the power source capacity is inadequate or the electric work is not

performed properly, it may result in re, electric shock, physical injury or

death.

MULTI V 5 Outdoor Unit Installation Manual

Refer to local, state, and federal codes, and use power wires

of sufcient current capacity and rating.

Wires that are too small may generate heat and cause a re, and physical injury or death.

Properly size all circuit breakers or fuses.

There is risk of re, electric shock, explosion, physical injury or death.

Do not share the electrical circuit with other devices.

There is risk of re, electric shock, and physical injury or death due to

heat generation.

Do not use damaged or loose power wiring. Do not

modify or extend the outdoor unit’s power wiring. Ensure that

the power wiring will not be pulled nor weight be placed on

the power wiring during operation.

There is risk of re, electric shock, and physical injury or death.

Secure all eld wiring connections with appropriate wire

strain relief.

Improperly securing wires will create undue stress on equipment power

connections. Inadequate connections may generate heat, cause a re,

and physical injury or death.

Ensure the system is connected to a dedicated power source

that provides adequate power.

If the power source capacity is inadequate or the electric work is not

performed properly, it may result in re, electric shock, physical injury or

death.

Properly tighten all power connections.

Loose wiring may overheat at connection points, causing a re, physical

injury or death.

Do not change the settings of the protection devices.

If the protection devices have been bypassed or is forced to operate

improperly, or parts other than those specied by LG are used, there is

risk of re, electric shock, explosion, and physical injury or death.

Do not supply power to the unit until all electrical wiring,

controls wiring, piping, installation, and refrigerant system

evacuation are completed.

The system may malfunction.

6

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

The information contained in this manual is intended for use

by an industry-qualied, experienced, licensed electrician

familiar with the NEC who is equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in this manual can

result in equipment malfunction and property damage.

OPERATION

DANGER

WARNING

CAUTION

SAFETY PRECAUTIONS

Do not provide power to or operate the unit if it is ooded

or submerged.

There is risk of re, electric shock, physical injury or death.

Use a dedicated breaker for this product.

There is risk of re, electric shock, physical injury or death.

Do not operate the disconnect switch with wet hands.

There is risk of re, electric shock, physical injury or death.

Periodically verify the equipment mounts have not

deteriorated.

Use inert (nitrogen) gas when performing leak tests or air

purges.

gases.

Do not use compressed air, oxygen, or ammable

Using these substances may cause re, explosion, and physical injury

or death.

If refrigerant leaks out, ventilate the area before operating the

unit.

If the unit is mounted in an enclosed, low-lying, or poorly ventilated area,

and the system develops a refrigerant leak, it may cause a re, electric

shock, explosion, physical injury or death.

If the base collapses, the unit could fall and cause physical injury or death.

Do not allow water, dirt, or animals to enter the unit.

There is risk of re, electric shock, physical injury or death.

Do not operate the unit with the panel(s) or protective

cover(s) removed; keep ngers and clothing away from

moving parts.

Do not touch the refrigerant piping during or after

operation.

It can cause burns or frostbite.

Do not open the inlet during operation.

There is risk of electric shock, physical injury or death.

The rotating, hot, cold, and high-voltage parts of the unit can cause

physical injury or death.

To avoid physical injury, use caution when cleaning or servicing the air conditioner.

There is risk of electric shock, physical injury or death.

Safety Precautions

Clean up the site after servicing is nished, and check that

no metal scraps, screws, or bits of wiring have been left

inside or surrounding the unit.

Do not use the product for mission critical or special purpose applications such as preserving food, works of art, or

other precision air conditioning applications. The equipment

is designed to provide comfort cooling and heating.

There is risk of property damage.

Do not allow water, dirt, or animals to enter the unit.

There is risk of unit failure.

Do not open the inlet during operation.

There is risk of unit failure.

Do not operate the unit with the panel(s) or protective

cover(s) removed; keep ngers and clothing away from

moving parts.

Non-secured covers can result in malfunction due to dust or water in the

service panel.

Periodically verify the equipment mounts have not

deteriorated.

If the base collapses, the unit could fall and cause property damage or

product failure.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Use only a soft cloth to clean the air conditioner. Do not

use wax, thinner, or strong detergents.

Strong cleaning products may damage the surface of the air conditioner,

or may cause its appearance to deteriorate.

Provide power to the outdoor unit to warn the compressor

crankcase at least six (6) hours before operation begins.

Starting operation with a cold compressor sump(s) may result in severe

bearing damage to the compressor(s). Keep the power switch on during

the operational season.

Do not turn off the main power switch after operation has

been stopped.

Wait at least ve (5) minutes before turning off the main power switch,

otherwise it may result in product malfunction.

Do not block the inlet or outlet.

Unit may malfunction.

Auto-addressing should be performed after connecting the

power of all indoor and outdoor units.

Auto-addressing should also be performed after servicing an indoor unit.

7

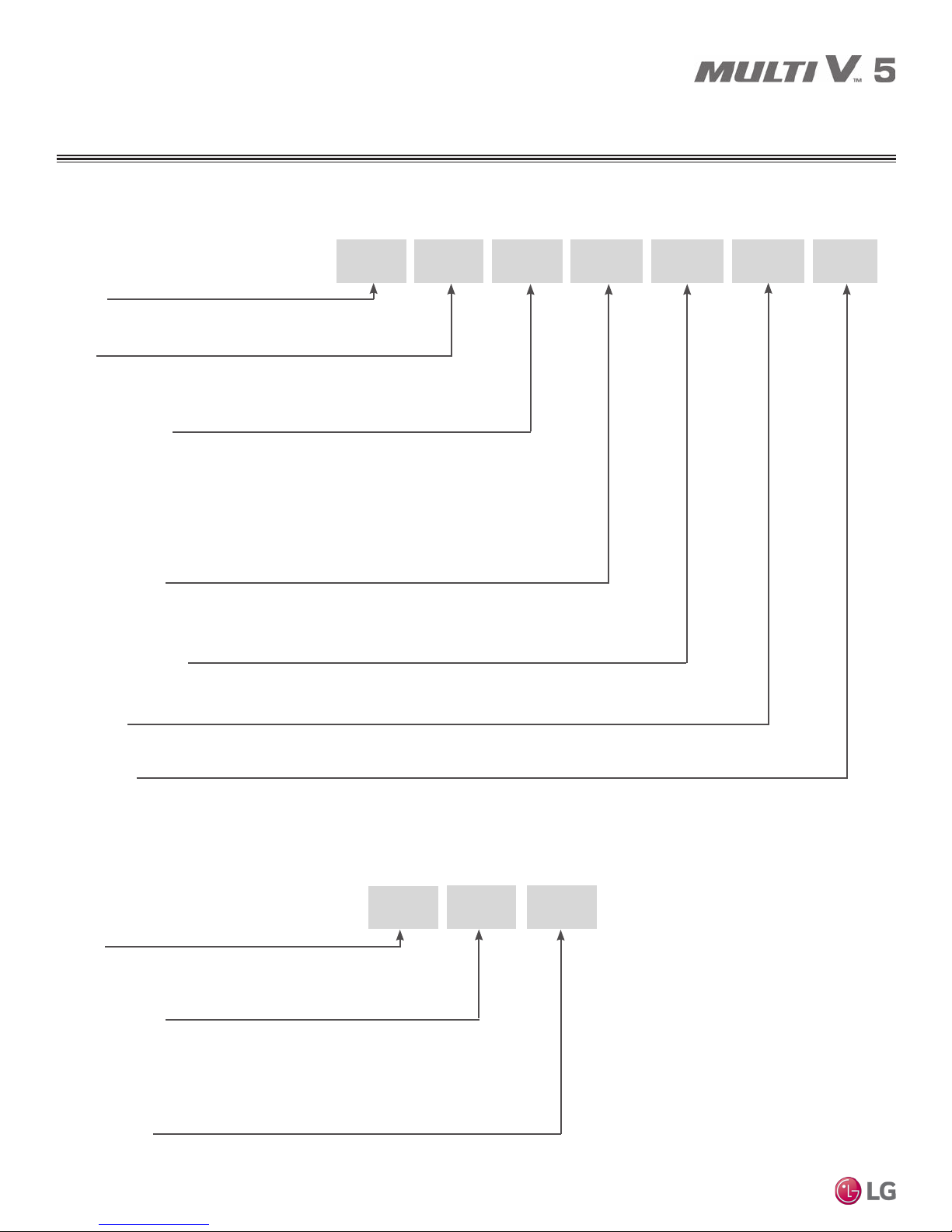

UNIT NOMENCLATURE

Outdoor Units and Heat Recovery Units

Outdoor Units (ODU)

Family

ARU = Multi V Outdoor Unit (Refrigerant R410A)

Type

M = Combination (Heat Pump or Heat Recovery)

Nominal Capacity

(Nominal cooling capacity in Btu/h)

072 = 72,000

096 = 96,000

121 = 121,000

144 = 144,000

168 = 168,000

Electrical Ratings

B = 208–230V/60Hz/3Ph

D = 460V/60Hz/3Ph

Airflow Configuration

T = Top Discharge

192 = 192,000

216 = 216,000

241 = 240,000

264 = 264,000

288 = 288,000

312/313 = 312,000

336/337 = 336,000

360 = 360,000

384 = 384,000

408 = 408,000

ARU

M 072 B T

432 = 432,000

456 = 456,000

480 = 480,000

504 = 504,000

E

5

Efficiency

E = High Efficiency

Generation

5 = Fifth

MULTI V 5 Outdoor Unit Installation Manual

Heat Recovery Units (HRU)

PRHR

Family

PRHR = Multi V Heat Recovery (HR) unit (Refrigerant R410A)

Number of Ports

02 = Two Ports

03 = Three Ports

04 = Four Ports

Series Number

2A = Series Number

02 2A

8

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

SPECIFICATIONS

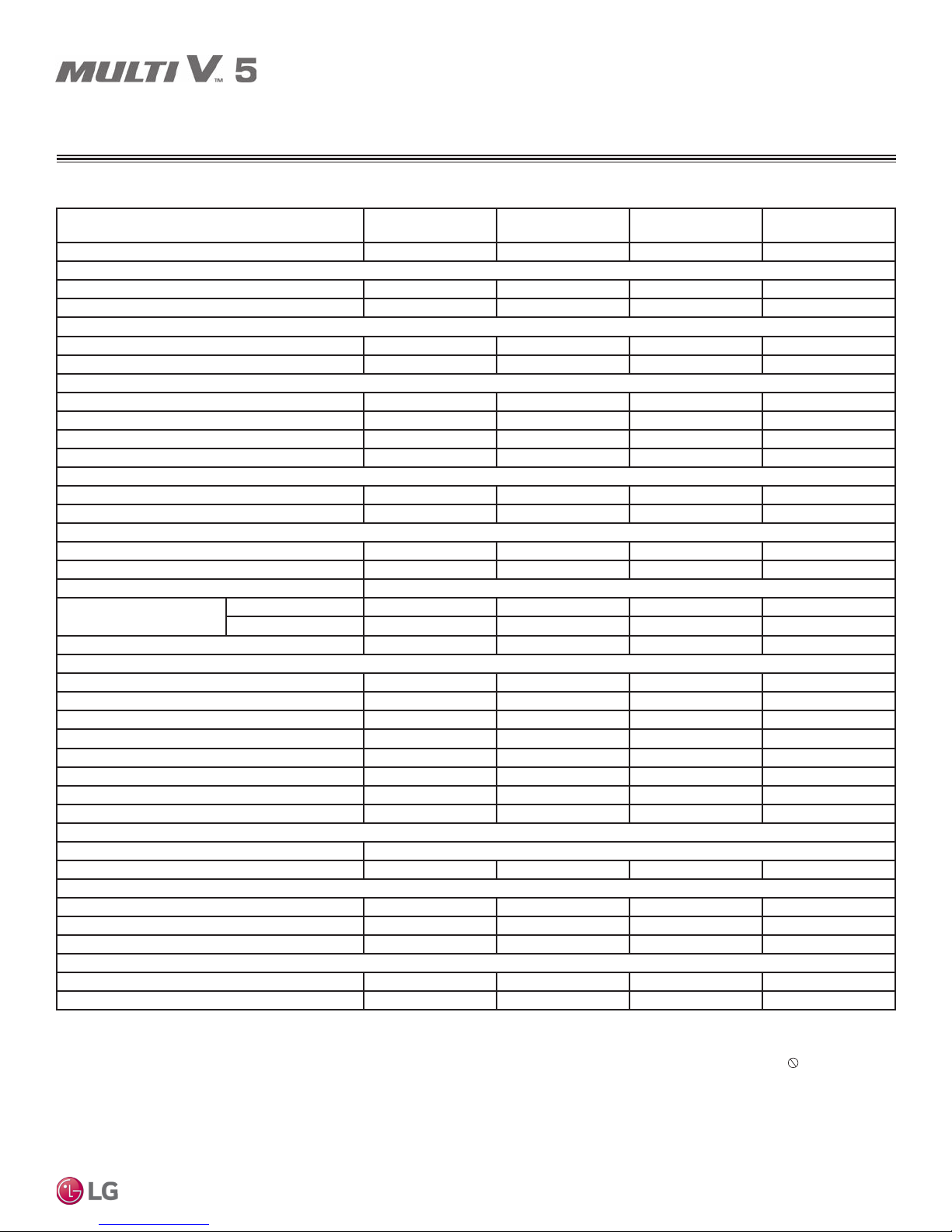

208-230V Outdoor Units

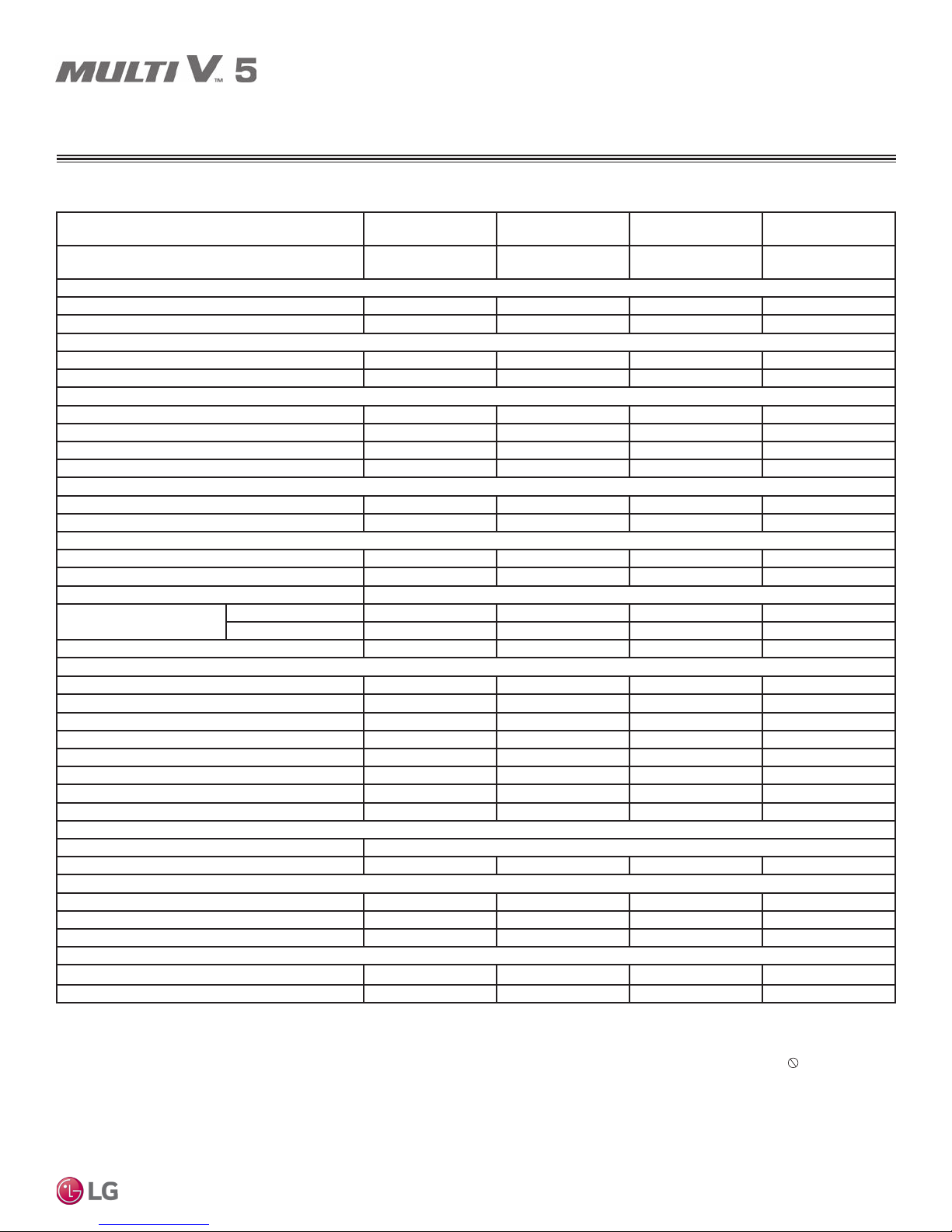

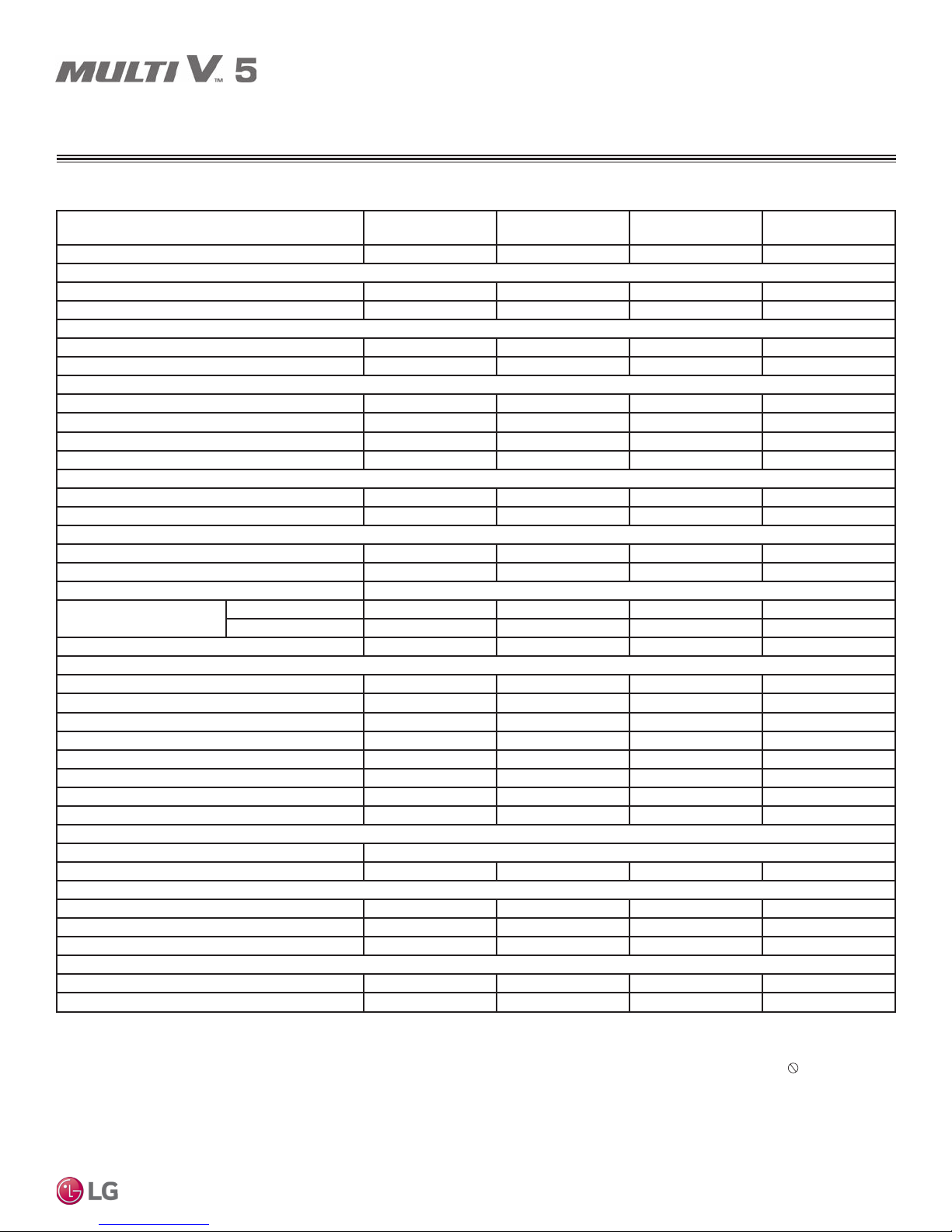

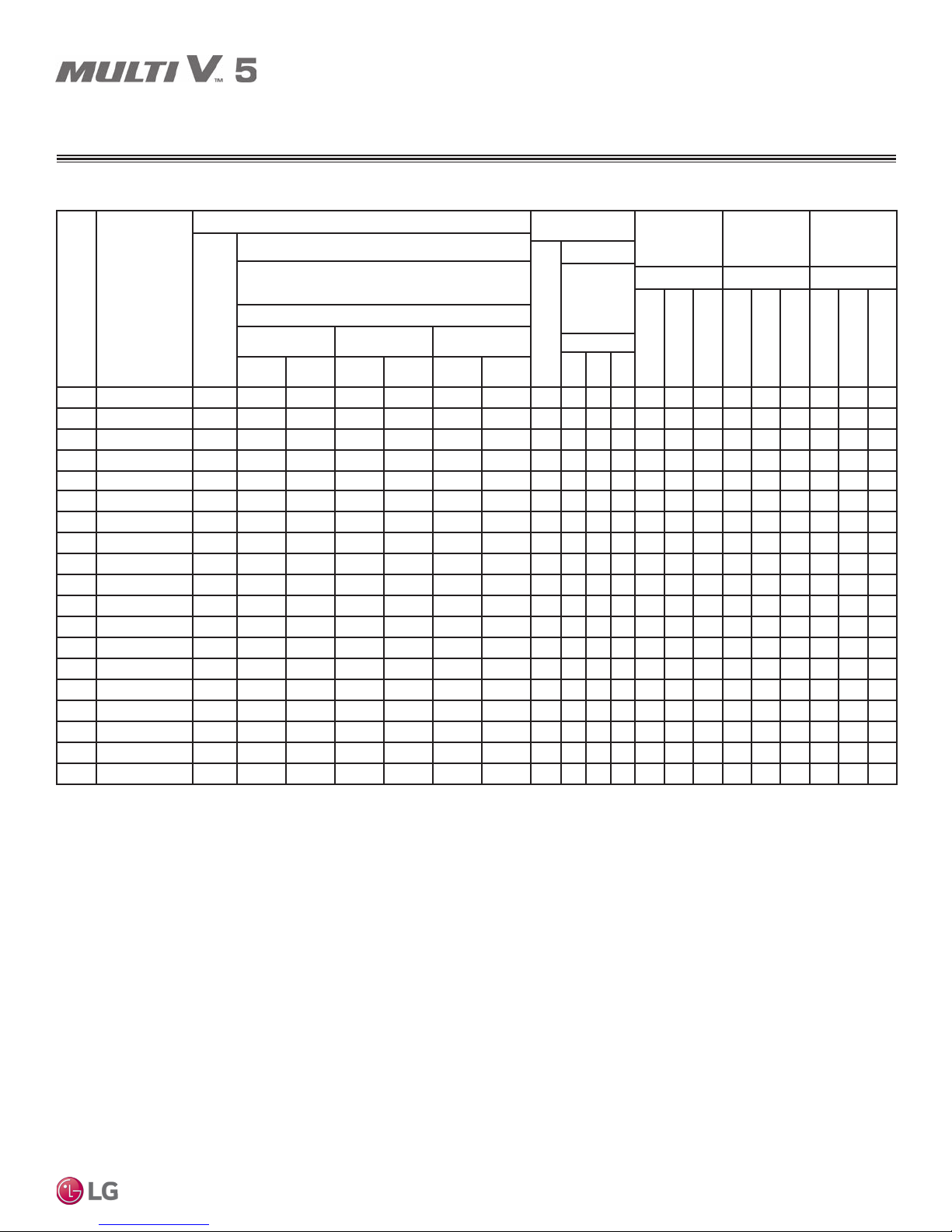

Table 1: Single Frame 208-230V Outdoor Units.

Unit Model Number

ARUM072BTE5

6.0 Ton

Individual Component Model Numbers - - - -

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

1

2

72,000 96,000 120,000 144,000

69,000 92,000 114,000 138,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

1

2

81,000 108,000 135,000 162,000

77,000 103,000 129,000 154,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 1 HSS DC Scroll x 1 HSS DC Scroll x 1 HSS DC Scroll x 2

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 1.5 x 1 0.9 x 2 0.9 x 2 0.9 x 2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,000 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,000 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 8,470 11,300 11,300 11,300

Unit Data

Refrigerant Type R410A R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 14.3 23.2 23.2 26.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

3

4

13 16 20 24

58.0 58.0 59.0 60.0

Net Unit Weight (lbs.) 430 507 507 639

Shipping Weight (lbs.) 452 534 534 666

Communication Cables

5,6

2 x 18 2 x 18 2 x 18 2 x 18

Heat Exchanger

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 2 / 17 2 / 17 2 / 17 3 / 17

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 3/8 Braze 3/8 Braze 1/2 Braze 1/2 Braze

Low Pressure Vapor Line Connection (in., OD) 3/4 Braze 7/8 Braze 1-1/8 Braze 1-1/8 Braze

High Pressure Vapor Line Connection (in., OD) 5/8 Braze 3/4 Braze 3/4 Braze 7/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 3/8 Braze 3/8 Braze 1/2 Braze 1/2 Braze

Vapor Line Connection (in., OD) 3/4 Braze 7/8 Braze 1-1/8 Braze 1-1/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

ARUM096BTE5

8.0 Ton

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only.

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 19 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM121BTE5

10.0 Ton

ARUM144BTE5

12.0 Ton

Do not ground the

Product Data

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

9

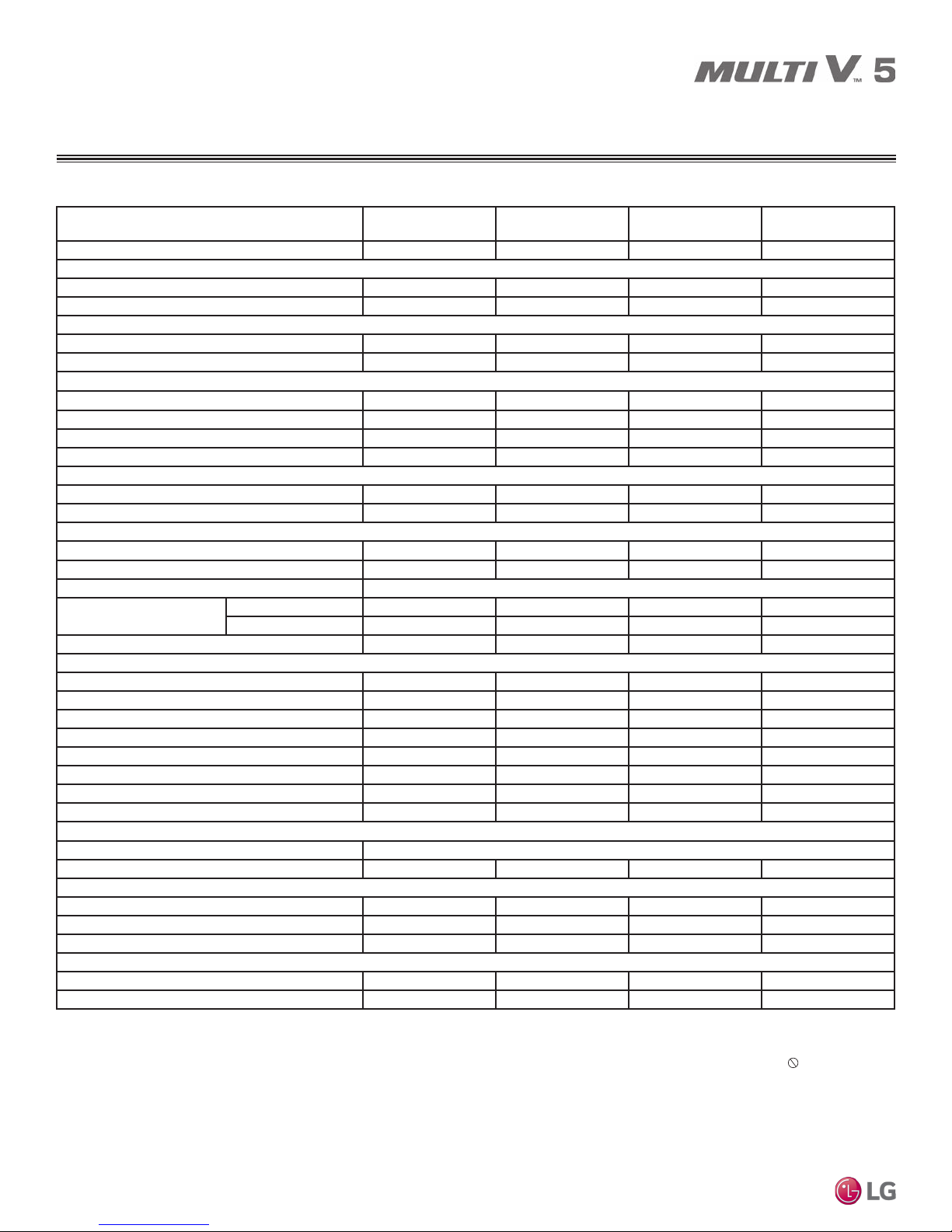

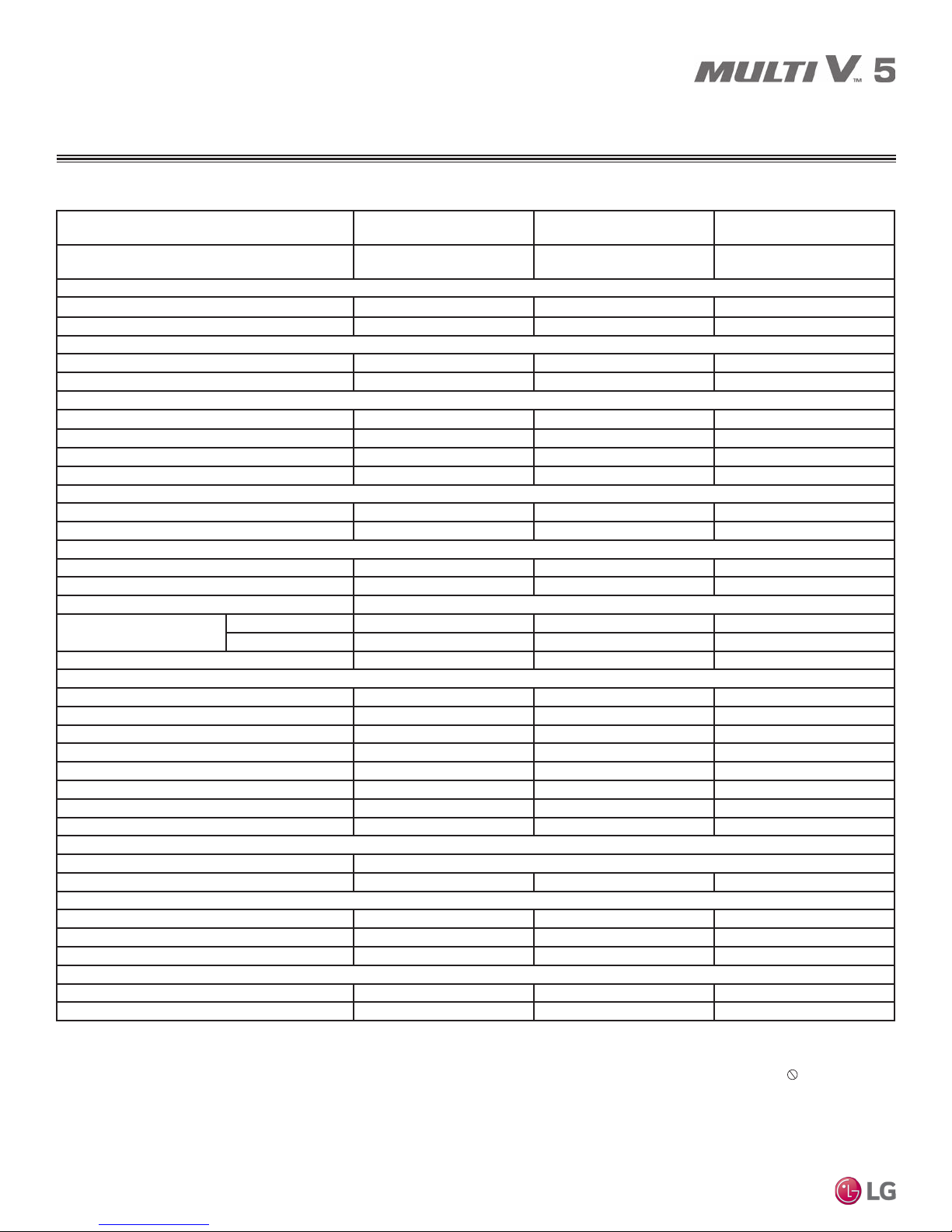

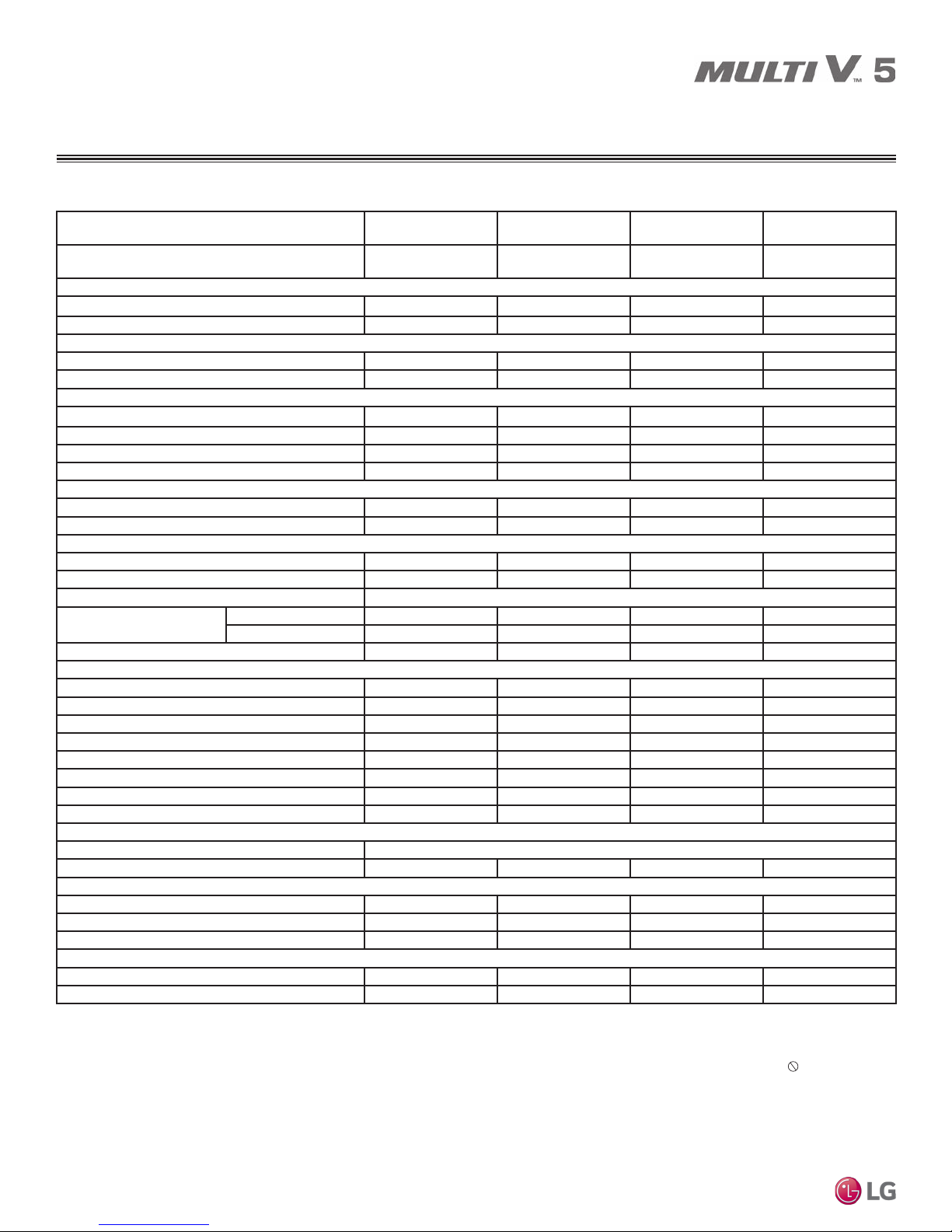

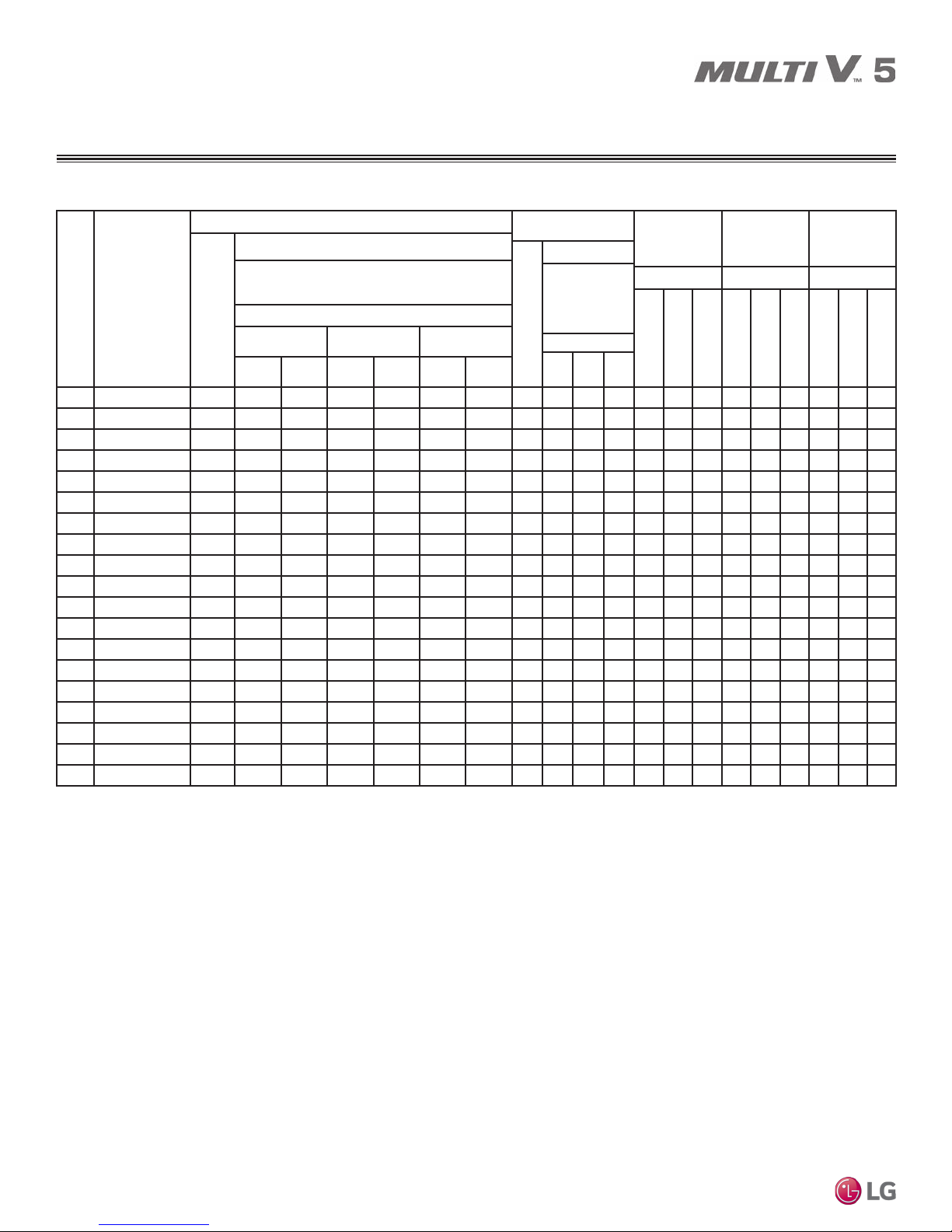

SPECIFICATIONS

208 / 230V Outdoor Units

Table 2: Single Frame 208-230V Outdoor Units, continued.

Unit Model Number

ARUM168BTE5

14.0 Ton

Individual Component Model Numbers - - - -

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

1

2

168,000 192,000 216,000 240,000

160,000 184,000 206,000 222,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

1

2

189,000 216,000 243,000 243,000

180,000 206,000 230,000 230,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 2 HSS DC Scroll x 2 HSS DC Scroll x 2 HSS DC Scroll x 2

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 0.9 x 2 0.9 x 2 0.9 x 2 0.90 x 2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,150 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,150 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 11,300 11,300 11,300 11,300

Unit Data

Refrigerant Type R410A R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 26.5 30.9 37.5 37.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

3

4

29 32 35 39

61.0 62.0 64.0 65.0

Net Unit Weight (lbs.) 639 659 666 666

Shipping Weight (lbs.) 666 688 694 694

Communication Cables

MULTI V 5 Outdoor Unit Installation Manual

Heat Exchanger

5,6

2 x 18 2 x 18 2 x 18 2 x 18

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 3 / 17 3 / 17 3 / 17 3 / 17

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 5/8 Braze 5/8 Braze 5/8 Braze 5/8 Braze

Low Pressure Vapor Line Connection (in., OD) 1-1/8 Braze 1-1/8 Braze 1-1/8 Braze 1-3/8 Braze

High Pressure Vapor Line Connection (in., OD) 7/8 Braze 1-1/8 Braze 1-1/8 Braze 1-1/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 5/8 Braze 5/8 Braze 5/8 Braze 5/8 Braze

Vapor Line Connection (in., OD) 1-1/8 Braze 1-1/8 Braze 1-1/8 Braze 1-3/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

ARUM192BTE5

16.0 Ton

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only.

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 19 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM216BTE5

18.0 Ton

ARUM241BTE5

20.0 Ton

Do not ground the

10

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

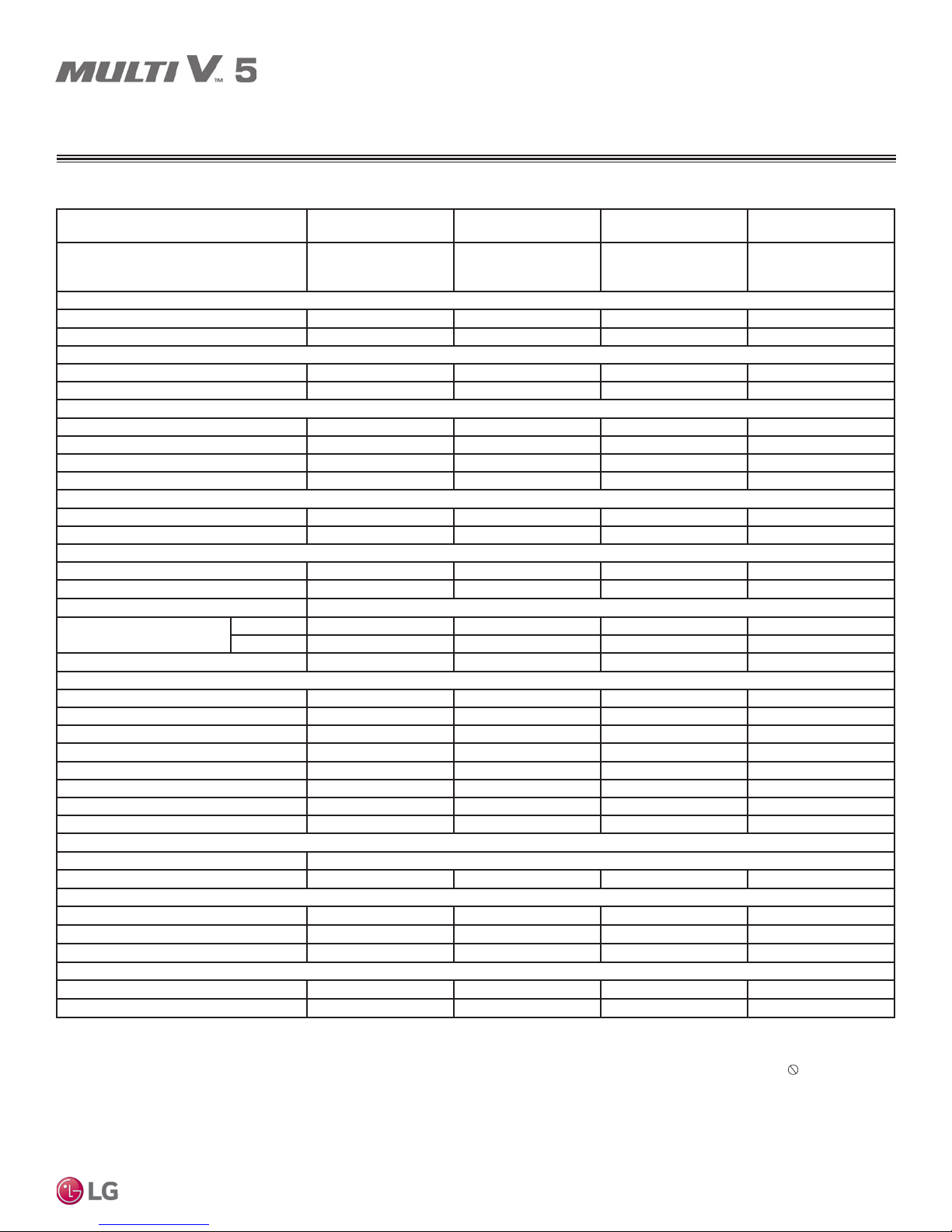

SPECIFICATIONS

208-230V Outdoor Units

Table 3: Dual Frame 208-230V Outdoor Units.

Unit Model Number

Individual Component Model Numbers

ARUM264BTE5

22.0 Ton

ARUM096BTE5 +

ARUM168BTE5

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

1

2

264,000 288,000 312,000 336,000

252,000 276,000 298,000 320,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

1

2

297,000 324,000 351,000 378,000

283,000 309,000 333,000 359,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 3 HSS DC Scroll x 3 HSS DC Scroll x 3 HSS DC Scroll x 3

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,150 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,150 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 22,600 22,600 22,600 22,600

Unit Data

Refrigerant Type R410A R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 23.2 + 26.5 23.2 + 30.9 23.2 + 37.5 23.2 + 37.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

3

4

42 45 52 55

63.0 63.0 65.0 65.0

Net Unit Weight (lbs.) 507 + 639 507 + 659 507 + 666 507 + 666

Shipping Weight (lbs.) 534 + 666 534 + 688 534 + 694 534 + 694

Communication Cables

5,6

2 x 18 2 x 18 2 x 18 2 x 18

Heat Exchanger

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 2 / 17 + 3 / 17 2 / 17 + 3 / 17 2 / 17 + 3 / 17 2 / 17 + 3 / 17

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 3/8 & 5/8 Braze 3/8 & 5/8 Braze 3/8 & 5/8 Braze 1/2 & 5/8 Braze

Low Pressure Vapor Line Connection (in., OD) 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

High Pressure Vapor Line Connection (in., OD) 3/4 & 7/8 Braze 3/4 & 1-1/8 Braze 3/4 & 1-1/8 Braze 3/4 & 1-1/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 3/8 & 5/8 Braze 3/8 & 5/8 Braze 3/8 & 5/8 Braze 1/2 & 5/8 Braze

Vapor Line Connection (in., OD) 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

ARUM288BTE5

24.0 Ton

ARUM096BTE5 +

ARUM192BTE5

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only.

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 19 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM312BTE5

26.0 Ton

ARUM096BTE5 +

ARUM216BTE5

ARUM336BTE5

28.0 Ton

ARUM121BTE5 +

ARUM216BTE5

Do not ground the

Product Data

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

11

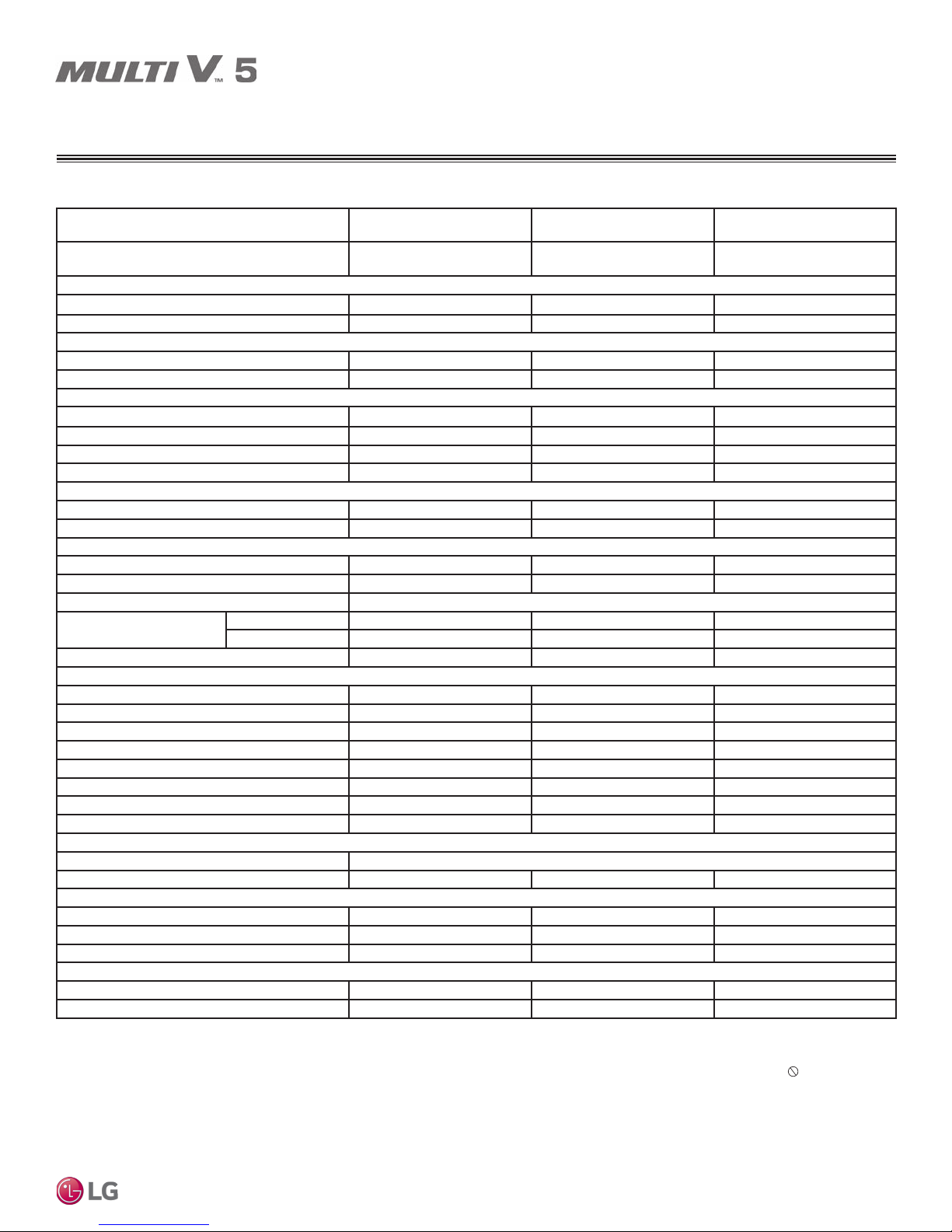

SPECIFICATIONS

208-230V Outdoor Units

Table 4: Dual Frame 208-230V Outdoor Units, continued.

Combination Unit Model Number

Individual Component Model Numbers

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 4 HSS DC Scroll x 4 HSS DC Scroll x 4

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Maximum Air Volume (CFM) 22,600 22,600 22,600

Unit Data

Refrigerant Type R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 26.5 + 37.5 26.5 + 37.5 30.9 + 37.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

4

Net Unit Weight (lbs.) 639 + 666 639 + 666 659 + 666

Shipping Weight (lbs.) 666 + 694 666 + 694 688 + 694

MULTI V 5 Outdoor Unit Installation Manual

Communication Cables

5,6

Heat Exchanger

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 3 / 17 x 2 3 / 17 x 2 3 / 17 x 2

Piping for Heat Recovery Operation

Liquid Line Connection (in., OD) 1/2 & 5/8 Braze 5/8 & 5/8 Braze 5/8 & 5/8 Braze

Low Pressure Vapor Line Connection (in., OD) 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

High Pressure Vapor Line Connection (in., OD) 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

Piping for Heat Pump Operation

Liquid Line Connection (in., OD) 1/2 & 5/8 Braze 5/8 & 5/8 Braze 5/8 & 5/8 Braze

Vapor Line Connection (in., OD) 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

12

1

2

1

2

Cooling 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,150 80 - 1,150 80 - 1,150

3

7

7

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ARUM360BTE5

30.0 Ton

ARUM144BTE5 +

ARUM216BTE5

ARUM384BTE5

32.0 Ton

ARUM168BTE5 +

ARUM216BTE5

ARUM192BTE5 +

360,000 384,000 408,000

344,000 366,000 390,000

405,000 432,000 459,000

384,000 410,000 436,000

58 61 64

66.0 66.0 66.0

2 x 18 2 x 18 2 x 18

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only. Do not ground the

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 19 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM408BTE5

34.0 Ton

ARUM216BTE5

SPECIFICATIONS

208-230V Outdoor Unit

Table 5: Triple Frame 208-230V Outdoor Units.

Combination Unit Model Number

ARUM432BTE5

36.0 Ton

ARUM121BTE5 +

Individual Component Model Numbers

ARUM121BTE5 +

ARUM192BTE5

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

1

2

432,000 456,000 480,000 504,000

412,000 434,000 458,000 480,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

1

2

486,000 513,000 540,000 567,000

460,000 488,000 513,000 539,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 4 HSS DC Scroll x 4 HSS DC Scroll x 5 HSS DC Scroll x 5

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 0.90x2 + 0.90x2 + 0.90x2 0.90x2 + 0.90x2 + 0.90x2 0.90x2 + 0.90x2 + 0.90x2 0.90x2 + 0.90x2 + 0.90x2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,150 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,150 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 33,900 33,900 33,900 33,900

Unit Data

Refrigerant Type R410A R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 23.2 + 23.2 + 30.9 23.2 + 23.2 + 37.5 23.2 + 26.5 + 37.5 23.2 + 26.5 + 37.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

3

4

64 64 64 64

66.0 66.0 67.0 67.0

Net Unit Weight (lbs.) 507 + 507 + 659 507 + 507 + 666 507 + 639 + 666 507 + 639 + 666

Shipping Weight (lbs.) 534 + 534 + 688 534 + 534 + 694 534 + 666 + 694 534 + 666 + 694

Communication Cables

5,6

2 x 18 2 x 18 2 x 18 2 x 18

Heat Exchanger

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 2/17 x 2 + 3/17 2 / 17 x 2 + 3 / 17 2 / 17 + 3 / 17 x 2 2 / 17 + 3 / 17 x 2

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 1/2 & 1/2 & 5/8 Braze 1/2 & 1/2 & 5/8 Braze 1/2 & 1/2 & 5/8 Braze 1/2 & 5/8 & 5/8 Braze

Low Pressure Vapor Line Conn. (in., OD) 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze

High Pressure Vapor Line Conn. (in., OD) 3/4 & 3/4 & 1-1/8 Braze 3/4 & 3/4 & 1-1/8 Braze 3/4 & 7/8 & 1-1/8 Braze 3/4 & 7/8 & 1-1/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 1/2 + 1/2 + 5/8 Braze 1/2 & 1/2 & 5/8 Braze 1/2 & 1/2 & 5/8 Braze 1/2 & 5/8 & 5/8 Braze

Vapor Line Connection (in., OD) 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

ARUM456BTE5

38.0 Ton

ARUM121BTE5 +

ARUM121BTE5 +

ARUM216BTE5

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only. Do not ground the

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 19 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM480BTE5

40.0 Ton

ARUM121BTE5 +

ARUM144BTE5 +

ARUM216BTE5

ARUM504BTE5

42.0 Ton

ARUM121BTE5 +

ARUM168BTE5 +

ARUM216BTE5

Product Data

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

13

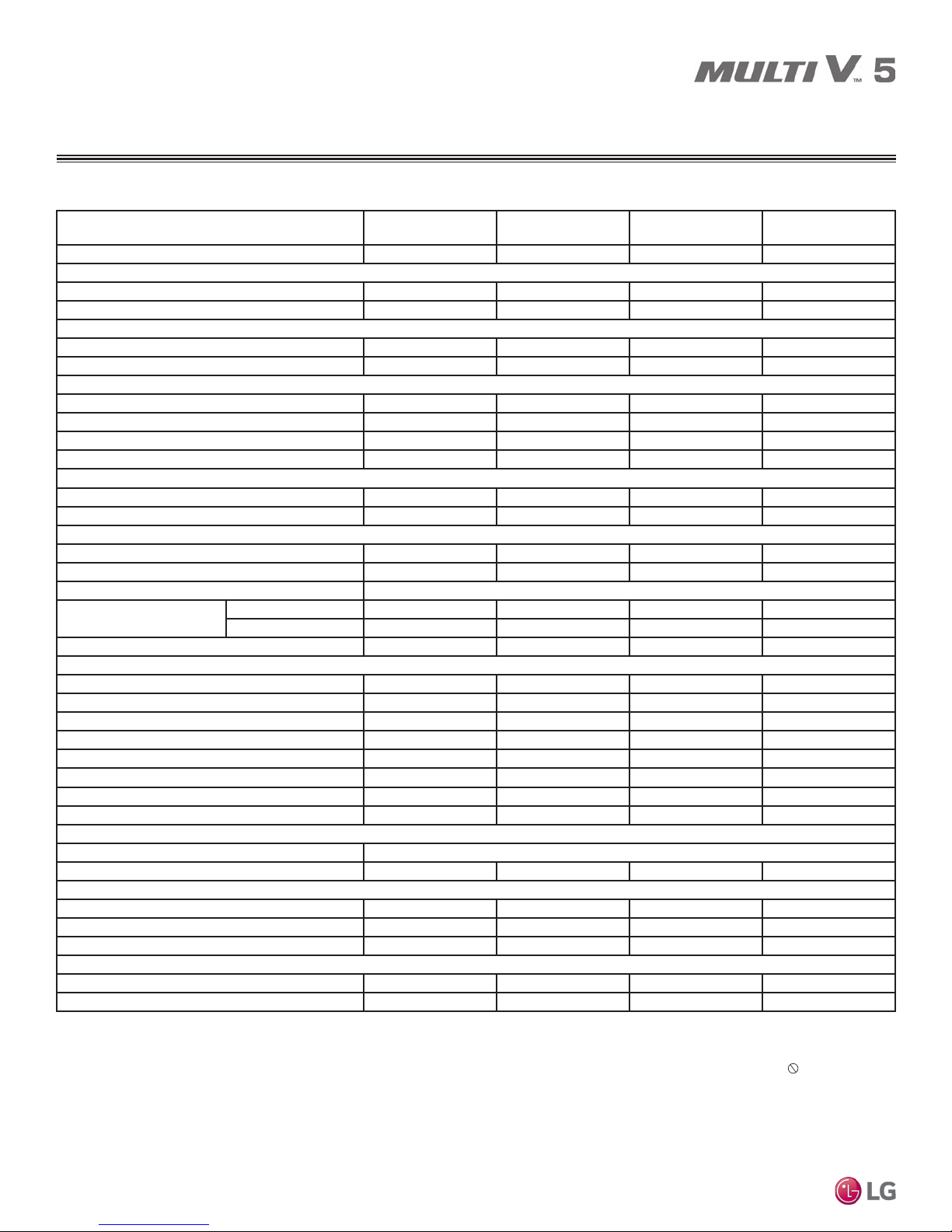

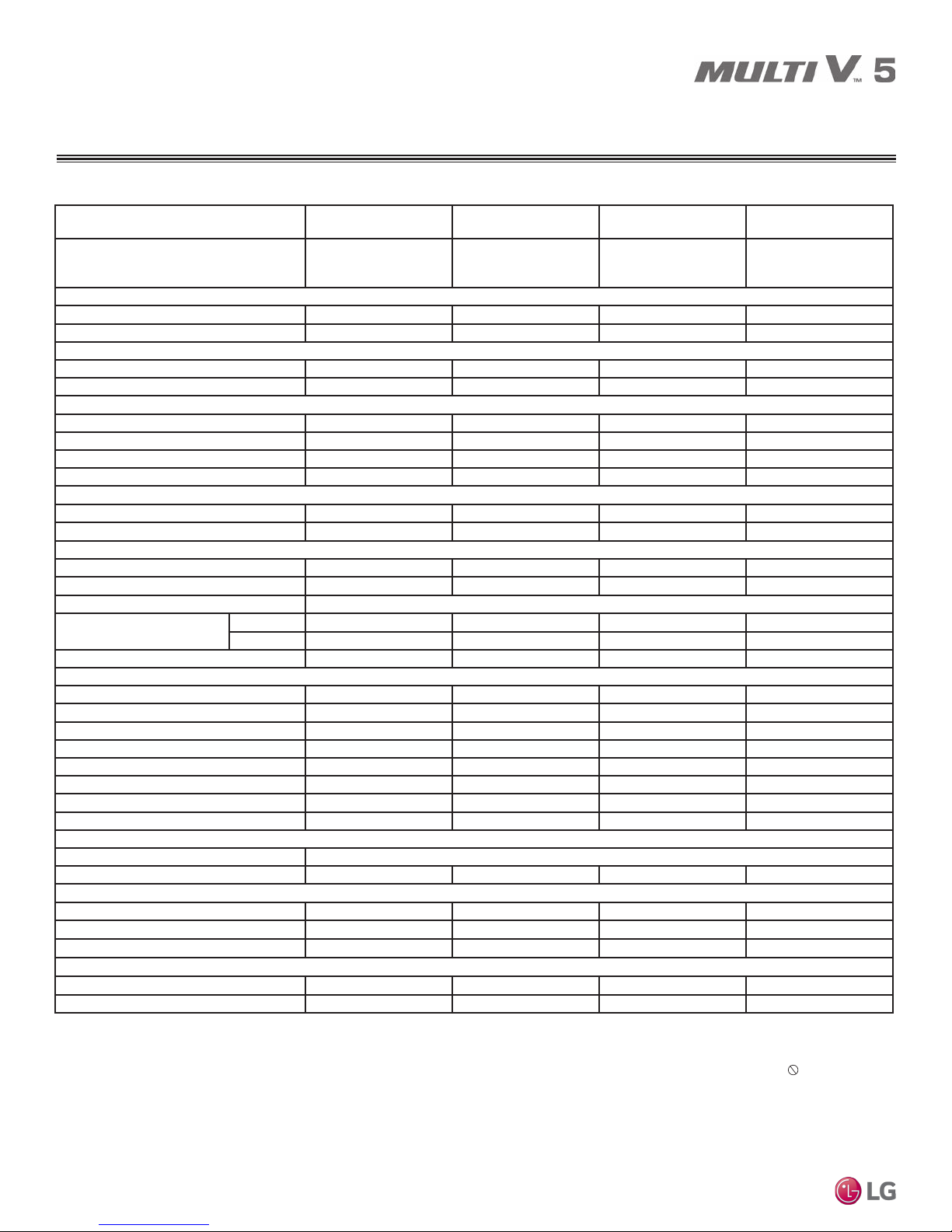

SPECIFICATIONS

460V Outdoor Units

Table 6: Single Frame 460V Outdoor Units.

Unit Model Number

ARUM072DTE5

6.0 Ton

Individual Component Model Numbers - - - -

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

1

2

72,000 96,000 120,000 144,000

69,000 92,000 114,000 138,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

1

2

81,000 108,000 135,000 162,000

77,000 103,000 129,000 154,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 1 HSS DC Scroll x 1 HSS DC Scroll x 1 HSS DC Scroll x 2

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 1.2 x 1 0.9 x 2 0.9 x 2 0.9 x 2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,000 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,000 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 8,470 11,300 11,300 11,300

Unit Data

Refrigerant Type R410A R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 14.3 23.2 23.2 26.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

3

4

13 16 20 24

58.0 58.0 59.0 60.0

Net Unit Weight (lbs.) 430 507 507 639

Shipping Weight (lbs.) 452 534 534 666

Communication Cables

MULTI V 5 Outdoor Unit Installation Manual

Heat Exchanger

5,6

2 x 18 2 x 18 2 x 18 2 x 18

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 2 / 17 2 / 17 2 / 17 3 / 17

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 3/8 Braze 3/8 Braze 1/2 Braze 1/2 Braze

Low Pressure Vapor Line Connection (in., OD) 3/4 Braze 7/8 Braze 1-1/8 Braze 1-1/8 Braze

High Pressure Vapor Line Connection (in., OD) 5/8 Braze 3/4 Braze 3/4 Braze 7/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 3/8 Braze 3/8 Braze 1/2 Braze 1/2 Braze

Vapor Line Connection (in., OD) 3/4 Braze 7/8 Braze 1-1/8 Braze 1-1/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

ARUM096DTE5

8.0 Ton

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only. Do not ground the

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 20 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM121DTE5

10.0 Ton

ARUM144DTE5

12.0 Ton

14

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

SPECIFICATIONS

460V Outdoor Units

Table 7: Single Frame 460V Outdoor Units, continued.

Unit Model Number

ARUM168DTE5

14.0 Ton

Individual Component Model Numbers - - - -

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

1

2

168,000 192,000 216,000 240,000

160,000 184,000 206,000 222,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

1

2

189,000 216,000 243,000 243,000

180,000 206,000 230,000 230,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 2 HSS DC Scroll x 2 HSS DC Scroll x 2 HSS DC Scroll x 2

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 0.9 x 2 0.9 x 2 0.9 x 2 0.9 x 2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,150 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,150 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 11,300 11,300 11,300 11,300

Unit Data

Refrigerant Type R410A R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 26.5 30.9 37.5 37.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

3

4

29 32 35 39

61.0 62.0 64.0 65.0

Net Unit Weight (lbs.) 639 659 666 666

Shipping Weight (lbs.) 666 688 694 694

Communication Cables

5,6

2 x 18 2 x 18 2 x 18 2 x 18

Heat Exchanger

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 3 / 17 3 / 17 3 / 17 3 / 17

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 5/8 Braze 5/8 Braze 5/8 Braze 5/8 Braze

Low Pressure Vapor Line Connection (in., OD) 1-1/8 Braze 1-1/8 Braze 1-1/8 Braze 1-3/8 Braze

High Pressure Vapor Line Connection (in., OD) 7/8 Braze 1-1/8 Braze 1-1/8 Braze 1-1/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 5/8 Braze 5/8 Braze 5/8 Braze 5/8 Braze

Vapor Line Connection (in., OD) 1-1/8 Braze 1-1/8 Braze 1-1/8 Braze 1-3/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

ARUM192DTE5

16.0 Ton

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only. Do not ground the

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 20 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM216DTE5

18.0 Ton

ARUM241DTE5

20.0 Ton

Product Data

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

15

SPECIFICATIONS

460V Outdoor Units

Table 8: Dual Frame 460V Outdoor Units.

Combination Unit Model Number

Individual Component Model Numbers

ARUM264DTE5

22.0 Ton

ARUM096DTE5 +

ARUM168DTE5

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

2

1

264,000 288,000 312,000 336,000

252,000 276,000 298,000 320,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

1

2

297,000 324,000 351,000 378,000

283,000 309,000 333,000 359,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 3 HSS DC Scroll x 3 HSS DC Scroll x 3 HSS DC Scroll x 3

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,150 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,150 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 22,600 22,600 22,600 22,600

Unit Data

Refrigerant Type R410A R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 23.2 + 26.5 23.2 + 30.9 23.2 + 37.5 23.2 + 37.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

3

4

42 45 52 55

63.0 63.0 65.0 65.0

Net Unit Weight (lbs.) 507 + 639 507 + 659 507 + 666 507 + 666

Shipping Weight (lbs.) 534 + 666 534 + 688 534 + 694 534 + 694

Communication Cables

MULTI V 5 Outdoor Unit Installation Manual

Heat Exchanger

5,6

2 x 18 2 x 18 2 x 18 2 x 18

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 2 / 17 + 3 / 17 2 / 17 + 3 / 17 2 / 17 + 3 / 17 2 / 17 + 3 / 17

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 3/8 & 5/8 Braze 3/8 & 5/8 Braze 3/8 & 5/8 Braze 1/2 & 5/8 Braze

Low Pressure Vapor Line Connection (in., OD) 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

High Pressure Vapor Line Connection (in., OD) 3/4 & 7/8 Braze 3/4 & 1-1/8 Braze 3/4 & 1-1/8 Braze 3/4 & 1-1/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 3/8 & 5/8 Braze 3/8 & 5/8 Braze 3/8 & 5/8 Braze 1/2 & 5/8 Braze

Vapor Line Connection (in., OD) 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

ARUM288DTE5

24.0 Ton

ARUM096DTE5 +

ARUM192DTE5

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only. Do not ground the

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 20 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM312DTE5

26.0 Ton

ARUM096DTE5 +

ARUM216DTE5

ARUM336DTE5

ARUM121DTE5 +

ARUM216DTE5

28.0 Ton

16

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

SPECIFICATIONS

460V Outdoor Units

Table 9: Dual Frame 460V Outdoor Units, continued.

Combination Unit Model Number

Individual Component Model Numbers

ARUM360DTE5

30.0 Ton

ARUM144DTE5 +

ARUM216DTE5

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

2

1

360,000 384,000 408,000

344,000 366,000 390,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

2

1

405,000 432,000 459,000

384,000 410,000 436,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 4 HSS DC Scroll x 4 HSS DC Scroll x 4

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2 0.90 x 2 + 0.90 x 2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 22,600 22,600 22,600

Unit Data

Refrigerant Type R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 26.5 + 37.5 26.5 + 37.5 30.9 + 37.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

4

3

58 61 64

66.0 66.0 66.0

Net Unit Weight (lbs.) 639 + 666 639 + 666 659 + 666

Shipping Weight (lbs.) 666 + 694 666 + 694 688 + 694

Communication Cables

5,6

2 x 18 2 x 18 2 x 18

Heat Exchanger

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 3 / 17 x 2 3 / 17 x 2 3 / 17 x 2

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 1/2 & 5/8 Braze 5/8 & 5/8 Braze 5/8 & 5/8 Braze

Low Pressure Vapor Line Connection (in., OD) 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

High Pressure Vapor Line Connection (in., OD) 7/8 & 1-1/8 Braze 7/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 1/2 & 5/8 Braze 5/8 & 5/8 Braze 5/8 & 5/8 Braze

Vapor Line Connection (in., OD) 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only. Do not ground the

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 20 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM384DTE5

32.0 Ton

ARUM168DTE5 +

ARUM216DTE5

ARUM408DTE5

34.0 Ton

ARUM192DTE5 +

ARUM216DTE5

Product Data

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

17

SPECIFICATIONS

460V Outdoor Units

Table 10: Triple Frame 460V Outdoor Units.

Combination Unit Model Number

ARUM432DTE5

36.0 Ton

ARUM121DTE5 +

Individual Component Model Numbers

ARUM121DTE5 +

ARUM192DTE5

Cooling Performance

Nominal Cooling Capacity (Btu/h)

Rated Cooling Capacity (Btu/h)

1

2

432,000 456,000 480,000 504,000

412,000 434,000 458,000 480,000

Heating Performance

Nominal Heating Capacity (Btu/h)

Rated Heating Capacity (Btu/h)

1

2

486,000 513,000 540,000 567,000

460,000 488,000 513,000 539,000

Operating Range

Cooling (°F DB) 5 to 122 5 to 122 5 to 122 5 to 122

Heating (°F WB) -13 to +61 -13 to +61 -13 to +61 -13 to +61

Synchronous — Cooling Based (°F DB) 14 to 81 14 to 81 14 to 81 14 to 81

Synchronous — Heating Based (°F WB) 14 to 61 14 to 61 14 to 61 14 to 61

Compressor

Inverter Quantity HSS DC Scroll x 4 HSS DC Scroll x 4 HSS DC Scroll x 5 HSS DC Scroll x 5

Oil/Type PVE / FVC68D PVE / FVC68D PVE / FVC68D PVE / FVC68D

Fan (Top Discharge)

Type Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty. 0.90x2 + 0.90x2 + 0.90x2 0.90x2 + 0.90x2 + 0.90x2 0.90x2 + 0.90x2 + 0.90x2 0.90x2 + 0.90x2 + 0.90x2

Motor/Drive Brushless Digitally Controlled / Direct

Operating Range (RPM)

Cooling 0 - 1,150 0 - 1,150 0 - 1,150 0 - 1,150

Heating 80 - 1,150 80 - 1,150 80 - 1,150 80 - 1,150

Maximum Air Volume (CFM) 33,900 33,900 33,900 33,900

Unit Data

Refrigerant Type R410A R410A R410A R410A

Refrigerant Control/Location EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit EEV / Indoor Unit

Factory Charge lbs. of R410A 23.2 + 23.2 + 30.9 23.2 + 23.2 + 37.5 23.2 + 26.5 + 37.5 23.2 + 26.5 + 37.5

Max. No. Indoor Units/System

Sound Pressure dB(A)

3

4

64 64 64 64

66.0 66.0 67.0 67.0

Net Unit Weight (lbs.) 507 + 507 + 659 507 + 507 + 666 507 + 639 + 666 507 + 639 + 666

Shipping Weight (lbs.) 534 + 534 + 688 534 + 534 + 694 534 + 666 + 694 534 + 666 + 694

Communication Cables

MULTI V 5 Outdoor Unit Installation Manual

5,6

2 x 18 2 x 18 2 x 18 2 x 18

Heat Exchanger

Material and Fin Coating Copper Tube / Aluminum Fin and Black Coated Fin™ / Hydrophilic

Rows / Fins per inch 2/17 x 2 + 3/17 2 / 17 x 2 + 3 / 17 2 / 17 + 3 / 17 x 2 2 / 17 + 3 / 17 x 2

Piping for Heat Recovery Operation

7

Liquid Line Connection (in., OD) 1/2 & 1/2 & 5/8 Braze 1/2 & 1/2 & 5/8 Braze 1/2 & 1/2 & 5/8 Braze 1/2 & 5/8 & 5/8 Braze

Low Pressure Vapor Line Conn. (in., OD) 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze

High Pressure Vapor Line Conn. (in., OD) 3/4 & 3/4 & 1-1/8 Braze 3/4 & 3/4 & 1-1/8 Braze 3/4 & 7/8 & 1-1/8 Braze 3/4 & 7/8 & 1-1/8 Braze

Piping for Heat Pump Operation

7

Liquid Line Connection (in., OD) 1/2 & 1/2 & 5/8 Braze 1/2 & 1/2 & 5/8 Braze 1/2 & 1/2 & 5/8 Braze 1/2 & 5/8 & 5/8 Braze

Vapor Line Connection (in., OD) 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze 1-1/8 & 1-1/8 & 1-1/8 Braze

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level

with 25 ft. of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

2

Rated capacity is certied under AHRI Standard 1230. See www.ahrinet.org for information.

3

The System Combination Ratio must be between 50–130%.

ARUM456DTE5

38.0 Ton

ARUM121DTE5 +

ARUM121DTE5 +

ARUM216DTE5

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

5

Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs /

HRUs to be 18 AWG, 2-conductor, twisted, stranded, shielded. Ensure the communication

cable shield is properly grounded to the Master ODU chassis only. Do not ground the

ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all

applicable local and national codes.

6

Power wiring is eld provided, solid or stranded, and must comply with the applicable

local and national codes. See page 20 for detailed electrical data.

7

LG requires that LATS software be used on all projects to ensure correct line sizing.

Designer must verify the shop drawing design against the as built design using LATS.

Contractor must also use LG manufactured Y-Branch and Header Kits only.

ARUM480DTE5

40.0 Ton

ARUM121DTE5 +

ARUM144DTE5 +

ARUM216DTE5

ARUM504DTE5

ARUM121DTE5 +

ARUM168DTE5 +

ARUM216DTE5

42.0 Ton

18