Page 1

INSTALLATION MANUAL

AIR

CONDITIONER

ENGLISH

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

Ceiling Concealed Duct

Original instruction

MFL68821903

Rev.01_050819

Copyright © 2016 - 2019 LG Electronics Inc. All Rights Reserved.

www.lg.com

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS

3 Features

4 Safety Precautions

7 Installation

7 Selection of the best location

8 Ceiling dimension and hanging bolt location

9 Indoor Unit Installation

9 Wiring Connection

10 Checking the Drainage

11 Indoor Unit Drain Piping

13 DIP Switch Setting

14 Group Control Setting

19 Model Designation

19 Airborne Noise Emission

19 Limiting concentration

20 How to Set E.S.P?

2 Indoor Unit

Page 3

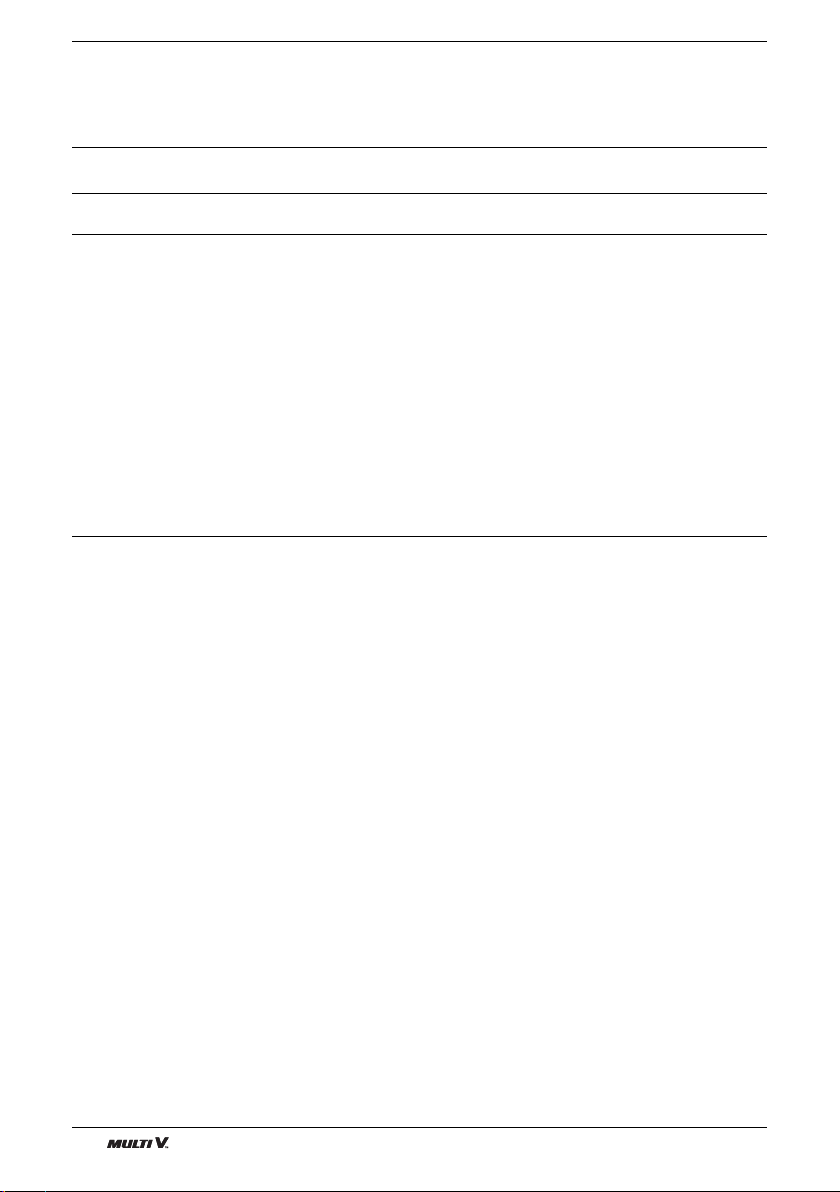

Features

Installation Tool

Name Drain hose Clamp metal

Quantity

1 EA 2 EA 8 EA 4 EA 1 SET

Air outlet vents

Washer for

hanging bracket

Air inlet vents

Clamp

(Tie Wrap)

Wired Remote Controller

(Optional)

Insulation for

fitting

• Owner's manual

•

Feature

(Other)

Installation manual

ENGLISH

Shape

for gas pipe

for liquid pipe

Installation Manual 3

Page 4

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be

followed.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

!

WARNING

!

CAUTION

n Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

!

WARNING

Installation

• Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated circuit.

- There is risk of fire or electric shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized Service Center.

- Do not disassemble or repair the product. There is risk of fire or electric shock.

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

• Do not install, remove, or re-install the unit by yourself (customer).

- There is risk of fire, electric shock, explosion, or injury.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the case edges and the fins on the condenser and

evaporator.

• For installation, always contact the dealer or an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the air conditioner could fall with it, causing property damage, product failure, and

personal injury.

• Do not turn on the breaker or power under condition that front panel, cabinet, top cover, control box cover

are removed or opened.

- Otherwise, it may cause fire, electric shock, explosion or death.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do not compress air or

Oxygen and Do not use Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

4 Indoor Unit

Page 5

Safety Precautions

ENGLISH

Operation

• Do not let the air conditioner run for a long time when the humidity is very high and a door or a window is left

open.

- Moisture may condense and wet or damage furniture.

• Take care to ensure that power cable could not be pulled out or damaged during operation.

- There is risk of fire or electric shock.

• Do not place anything on the power cable.

- There is risk of fire or electric shock.

• Do not plug or unplug the power supply plug during operation.

- There is risk of fire or electric shock.

• Do not touch(operate) the product with wet hands.

- There is risk of fire or electrical shock.

• Do not place a heater or other appliances near the power cable.

- There is risk of fire and electric shock.

• Do not allow water to run into electric parts.

- It may cause There is risk of fire, failure of the product, or electric shock.

• Do not store or use flammable gas or combustibles near the product.

- There is risk of fire or failure of product.

• Do not use the product in a tightly closed space for a long time.

- Oxygen deficiency could occur.

• When flammable gas leaks, turn off the gas and open a window for ventilation before turn the product on.

- Do not use the telephone or turn switches on or off.

There is risk of explosion or fire.

• If strange sounds, smell or smoke comes from product. Turn the breaker off or disconnect the power supply

cable.

- There is risk of electric shock or fire.

• Stop operation and close the window in storm or hurricane. If possible, remove the product from the window

before the hurricane arrives.

- There is risk of property damage, failure of product, or electric shock.

• Do not open the inlet grille of the product during operation. (Do not touch the electrostatic filter, if the unit is

so equipped.)

- There is risk of physical injury, electric shock, or product failure.

• When the product is soaked (flooded or submerged), contact an Authorized Service Center.

- There is risk of fire or electric shock.

• Be cautious that water could not enter the product.

- There is risk of fire, electric shock, or product damage.

• Ventilate the product from time to time when operating it together with a stove, etc.

- There is risk of fire or electric shock.

• Turn the main power off when cleaning or maintaining the product.

- There is risk of electric shock.

• When the product is not be used for a long time, disconnect the power supply plug or turn off the breaker.

- There is risk of product damage or failure, or unintended operation.

• Take care to ensure that nobody could step on or fall onto the outdoor unit.

- This could result in personal injury and product damage.

!

CAUTION

Installation

• Always check for gas (refrigerant) leakage after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Install the drain hose to ensure that water is drained away properly.

- A bad connection may cause water leakage.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

Installation Manual 5

Page 6

Safety Precautions

• Do not install the product where the noise or hot air from the outdoor unit could damage the neighborhoods.

- It may cause a problem for your neighbors.

• Use two or more people to lift and transport the product.

- Avoid personal injury.

• Do not install the product where it will be exposed to sea wind (salt spray) directly.

- It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator fins, could

cause product malfunction or inefficient operation.

Operation

• Do not expose the skin directly to cool air for long periods of time. (Don't sit in the draft.)

- This could harm to your health.

• Do not use the product for special purposes, such as preserving foods, works of art, etc. It is a consumer air

conditioner, not a precision refrigeration system.

- There is risk of damage or loss of property.

• Do not block the inlet or outlet of air flow.

- It may cause product failure.

• Use a soft cloth to clean. Do not use harsh detergents, solvents, etc.

- There is risk of fire, electric shock, or damage to the plastic parts of the product.

• Do not touch the metal parts of the product when removing the air filter. They are very sharp!

- There is risk of personal injury.

• Do not step on or put anything on the product. (outdoor units)

- There is risk of personal injury and failure of product.

• Always insert the filter securely. Clean the filter every two weeks or more often if necessary.

- A dirty filter reduces the efficiency of the air conditioner and could cause product malfunction or damage.

• Do not insert hands or other objects through the air inlet or outlet while the product is operated.

- There are sharp and moving parts that could cause personal injury.

• Do not drink the water drained from the product.

- It is not sanitary and could cause serious health issues.

• Use a firm stool or ladder when cleaning or maintaining the product.

- Be careful and avoid personal injury.

• Replace the all batteries in the remote control with new ones of the same type. Do not mix old and new

batteries or different types of batteries.

- There is risk of fire or explosion.

• Do not recharge or disassemble the batteries. Do not dispose of batteries in a fire.

- They may burn or explode.

• If the liquid from the batteries gets onto your skin or clothes, wash it well with clean water. Do not use the

remote if the batteries have leaked.

- The chemicals in batteries could cause burns or other health hazards.

• If you eat the liquid from the batteries, brush your teeth and see doctor. Do not use the remote if the

batteries have leaked.

- The chemicals in batteries could cause burns or other health hazards.

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazrd.

• This equipment shall be provided with a supply conductor complying with the national regulation.

6 Indoor Unit

Page 7

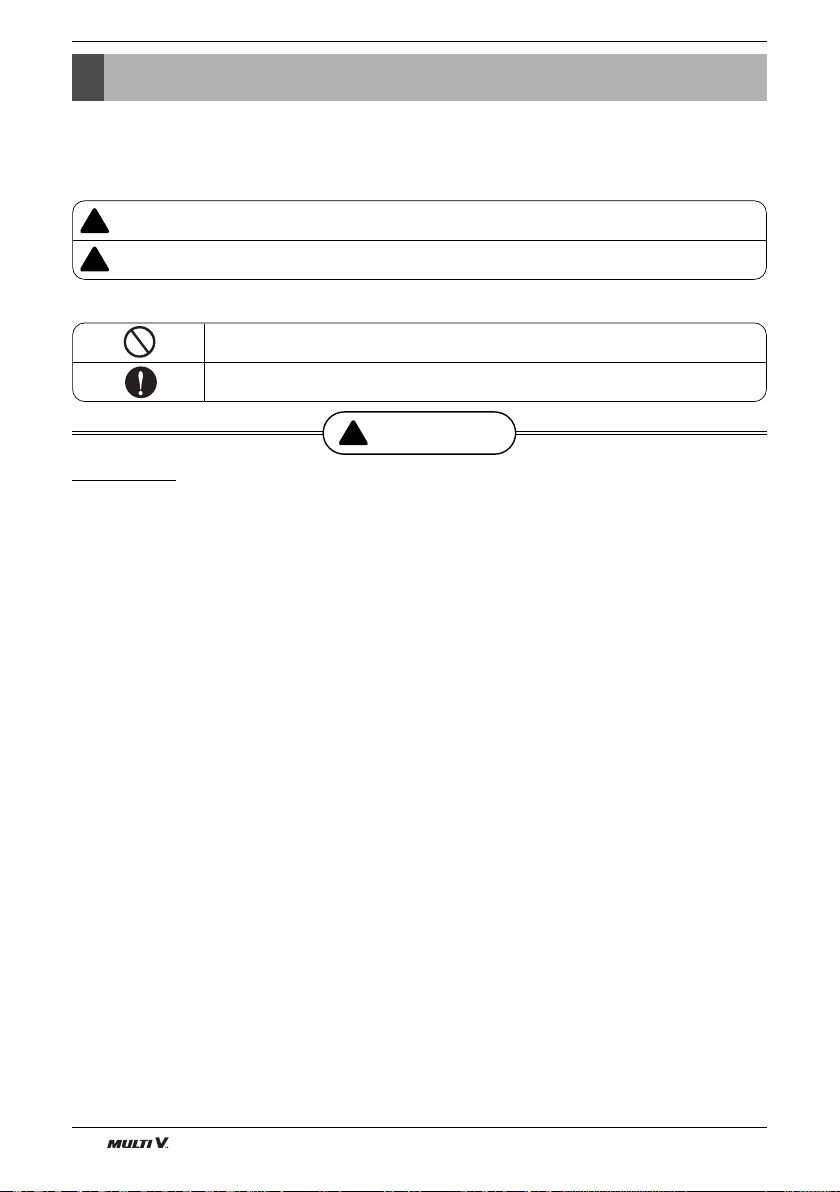

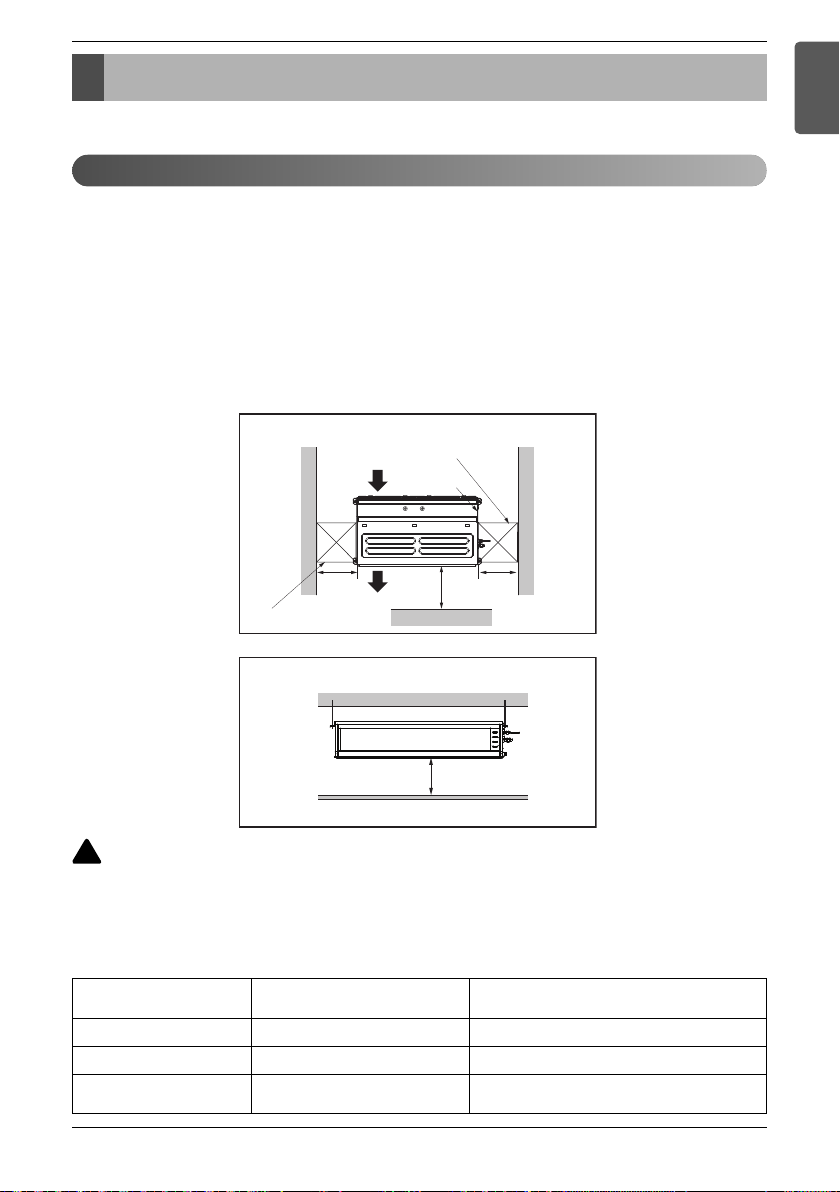

Front view (Unit: mm)

(Unit: mm)

Top view

Front

Inspection hole(1)

600 x 600

Inspection hole(2)

600 x 600

Control box

1 000

Air outlet vents

Air inlet vents

600

600

More than 20

Installation

Read completely, then follow step by step.

Selection of the best location

Install the air conditioner in the location that satisfies the following conditions.

• The place shall easily bear a load exceeding four times the indoor unit’s weight.

• The place shall be able to inspect the unit as the figure.

• The place where the unit shall be leveled.

•

The place shall allow easy water drainage.

• The place shall easily connect with the outdoor unit.

• The place where the unit is not affected by an electrical noise.

• The place where air circulation in the room will be good .

• There should not be any heat source or steam near the unit.

Installation

ENGLISH

!

CAUTION

In case that the unit is installed near the sea, the installation parts may be corroded by

salt, The installation parts (and the unit) should be taken appropriate anti-corrosion

measures.

[Inspection Hole Standard]

Number of

inspection hole

1 More than 100 cm

false ceiling & actual ceiling

2 20 cm to 100 cm

Hole size should be more

than the size of IDU.

Distance between

Less than 20 cm

Remarks

Sufficient space in the ceiling for servicing.

Insufficient space. Difficult for servicing

Minimum height for motor replacement.

Installation Manual 7

Page 8

Installation

NOTICE

Ceiling dimension and hanging bolt location

n Installation of Unit

Install the unit above the ceiling correctly.

D

POSITION OF SUSPENSION BOLT

• Apply a joint-canvas between the unit and duct

to absorb unnecessary vibration.

• Install the unit leaning to a drainage hole side

as a figure for easy water drainage.

• A place where the unit will be leveled and that

can support the weight of the unit.

A place where the unit can withstand its vibration.

•

• A place where service can be easily performed.

E

C

J

A

B

I

F

H

G

Drain hole

M10 Nut

M10 washer

M10 washer

M10 Nut

Dimension

Chassis name

M1 933.4 971.6 619.2 700 30 270 15.2 858 201.4 900

M2 1 283.4 1 321.6 619.2 700 30 270 15.2 1 208 201.4 1 250

M3 1 283.4 1 321.6 619.2 700 30 360 15.2 1 208 291.4 1 250

A B C D E F G H I J

X 4

X 4

X 4

X 8

(Unit:mm)

• Throughly study the following installation locations:

1. In such places as restaurants and kitchens, considerable amount of oil steam and flour adhere to the fan, the fin of the heat

exchanger, resulting in heat exchange reduction, spraying, dispersing of water drops, etc. In these cases, take the following actions:

• Make sure that the ventilation fan for smoke-collecting hood on a cooking table has sufficient capacity so that it draws oily steam

which should not flow into the suction of the air conditioner.

• Make enough distance from a cooking room to install the air conditioner in such a place where it may not suck in oil steam.

2. Avoid installing air conditioner in such circumstances where cutting oil mist or iron powder is in suspension in factories, etc.

3. Avoid places where inflammable gas is generated, flows in, is stored or vented.

4. Avoid places where sulfurous acid gas or corrosive gas is generated.

5. Avoid places near high frequency generators.

8 Indoor Unit

Page 9

Indoor Unit Installation

Installation

ENGLISH

• Select and mark the position for fixing bolts.

Drill the hole for set anchor on the face of ceiling.

•

• Insert the set anchor and washer onto the

suspension bolts for locking the suspension

bolts on the ceiling.

Mount the suspension bolts to the set anchor firmly.

•

• Secure the installation plates onto the

suspension bolts (adjust level roughly) using

nuts, washers and spring washers.

Old building New building

1 Set anchor

2 Plate washer

3 Spring washer

4 Nut

!

CAUTION

Tighten the nut and bolt to prevent unit falling.

5 Suspension

bolts

Wiring Connection

Connect the wires to the terminals on the control board individually according to the outdoor unit connection.

• Ensure that the color of the wires of outdoor unit and the terminal No. are the same as those of indoor

unit respectively.

<M1 Chassis>

Terminal Block Indoor

1(L) 2(N)

INDOOR POWER INPUT

<M2/M3 Chassis>

Terminal Block Indoor

Terminal Block Indoor

34

GN/YL

Terminal Block Indoor

1(L) 2(N)

Outdoor unit

Indoor unit

ODU ODU

IDU IDU

Terminal Block Indoor

34

INTERNET

Outdoor unit

ODU ODU

Central controller

DRY1

DRY2

Indoor unit

INTERNET

IDU IDU

Outdoor unit

12V

GND

Central controller

DRY1

DRY2

GND

12V

Outdoor unit

INDOOR POWER INPUT

GN/YL

!

WARNING

Make sure that the screws of the terminal are free from looseness.

• Communication and Power Cable

1. Communication Cable : CVV-SB 1.0~1.5x2C

2. Power Cable : H07RN-F 1.5x3C

Clamping of cables

1) Arrange 2 power cables on the control panel.

2) First, fasten the steel clamp with a screw to the inner boss of control panel.

3) For the cooling model, fix the other side of the clamp with a screw strongly. For the heat pump

model, put the 0.75mm

2

cable(thinner cable) on the clamp and tighten it with a plastic clamp to

the other boss of the control panel.

!

CAUTION

The Power cord connected to the unit should be selected according to the following

specifications.

Installation Manual 9

Page 10

Installation

Air outlet vents

Air filters

INSULATION, OTHERS

THERMAL INSULATION

INDOOR UNIT

Liquid pipe

Clamp for insulation

(Local supply)

Insulation

(Local supply)

Union for gas pipe

Checking the Drainage

1. Remove the Air Filter.

Insulate the joint and tubes completely.

All thermal insulation must comply with local requirement.

Refrigerant pipe and thermal

insulation(Local supply)

Thermal insulator for refrigerant pipe

(Local supply)

Hose clip for thermal insulator(Local supply)

Make sure that there is no clearance here.

Thermal insulator for

piping(Local supply)

Overlap with thermal

insulator for piping.

2. Check the drainage.

10 Indoor Unit

• Spray one or two glasses of water upon the

evaporator.

• Ensure that water flows drain hose of indoor

unit without any leakage.

Page 11

Installation

Maintenance

drain port

Upward

routing

not allowed

Pipe clamp

Indoor unit

1/50~1/100

MAX 700 mm

Feed water

Drain Pump

Drain pan

Flexible drain hose

(accessory)

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip (accessory)

1/50~1/100 slope

Hanger

distance

Hanger Bracket

Max 700 mm

Flexible drain hose

Insulation

Metal

clamp

Max 300 mm

1~15 m

!

CAUTION

1. Install declination of the indoor unit is very important for the drain of the duct type air

conditioner.

2. Minimum thickness of the insulation for the connecting pipe shall be 5 mm.

Front of view

• The unit must be horizontal or declined to the drain hose connected when finished installation.

Ceiling

1~3 mm

Drainage hole

Indoor Unit Drain Piping

•

Drain piping must have down-slope (1/50 to 1/100): be sure

not to provide up-and-down slope to prevent reversal flow.

• During drain piping connection, be careful not to exert

extra force on the drain port on the indoor unit.

• The outside diameter of the drain connection on the

indoor unit is 32 mm.

Piping material: Polyvinyl chloride pipe inner

diometes Ø 25 mm and pipe fittings

• Be sure to install heat insulation on the drain piping.

Heat insulation material: Polyethylene foam

with thickness more than 8 mm.

ENGLISH

Drain test

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

• Connect the main drain pipe to the exterior and leave

it provisionally until the test comes to an end.

• Feed water to the flexible drain hose and check the

piping for leakage.

• Be sure to check the drain pump for normal operation

and noise when electrical wiring is complete.

!

CAUTION

The supplied flexible drain hose should

not be strained. A strained hose may

cause leakage of water.

• When the test is complete, connect the flexible drain

hose to the drain port on the indoor unit.

Installation Manual 11

Page 12

Installation

!

CAUTION

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specialized for the air conditioner. As for the

method of wiring, be guided by the circuit diagram posted on the inside of control

box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screws which fasten the wiring in the casing of electrical fittings are liable to

come loose from vibrations to which the unit is subjected during the course of

transportation. Check them and make sure that they are all tightly fastened. (If they

are loose, it could give rise to burn-out of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated

voltage marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point, fuse breaking, disturbance

by the normal function of an overload protection device.

• Proper starting power is not given to the compressor.

HAND OVER

Teach the customer the operation and maintenance procedures, using the operation manual.

(air filter cleaning, temperature control, etc.)

12 Indoor Unit

Page 13

Installation

DIP Switch Setting

1. Indoor Unit

Function Description Setting Off Setting On Default

SW1 Communication N/A (Default) - - Off

SW2 Cycle N/A (Default) - - Off

SW3 Group Control

Dry Contact

SW4

Mode

SW5 Installation

SW6 Heater linkage N/A - - Off

Ventilator

linkage

Vane selection

SW7

(Console)

Region

selection

SW8 Etc. Spare - - Off

Selection of Master or

Slave

Selection of Dry

Contact Mode

Fan continuous

operation

Selection of Ventilator

linkage

Selection of up/down

side Vane

Selection tropical

region

Master Slave Off

Wired/Wireless remote

controller

selection of Manual or Auto

operation Mode

Continuous operation

Removal

Linkage Removal Working

Up side + Down side Vane

General model

Auto Off

- Off

Up side Vane

Only

Tropical

model

ENGLISH

Off

!

CAUTION

For Multi V Models, DIP switch 1, 2, 6, 8 must be set OFF.

2. Outdoor Unit

In case that the products meet specific conditions, “Auto addressing” function can start automatically

with the improved speed by turning the DIP switch #3 of the outdoor unit and resetting the power.

※ Specific conditions:

- All names of the indoor units are ARNU****4.

- The serial number of Multi V super IV (outdoor units) is after October 2013.

DIP switch 7 segment

Outdoor Unit PCB Outdoor Unit DIP Switch

Installation Manual 13

Page 14

Installation

Group Control Setting

1. Group Control 1

n Wired remote controller 1 + Standard Indoor Units

Master Slave Slave Slave

Master

n DIP Switch in PCB

¿ Master Setting

- No. 3 Off

Display Error Message

Indoor Unit DIP Switch

or

Only connect serial signal and GND lines

between indoor units.

¡ Slave Setting

- No. 3 On

LGAP Network System

GND

Signal

12 V

Some products have no DIP switch on PCB. It is possible to set indoor units to Master or Slave by

using the wireless remote controller instead of DIP switch.

For the details of the setting, please refer to the manual of the wireless remote controller.

1. It is possible to 16 indoor units(Max.) by one wired remote controller.

Set only one indoor unit to Master, set the others to Slave.

2. It is possible to connect with every type of indoor units.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

- The Master indoor unit is possible to recognize Dry Contact and Central Controller only.

5. In case that any error occurs at indoor unit, the error code is displayed on the wired remote

controller.

It is possible to control the other indoor units except the error units.

14 Indoor Unit

Page 15

h It is possible to connect indoor units since Feb. 2009.

h It can be the cause of malfuctions when there is no setting of master and slave.

h In case of Group Control, it is possible to use following functions.

- Selection of operation, stop or mode

- Temperature setting and room temperature check

- Current time change

- Control of flow rate (High/Middle/Low)

- Reservation settings

It is not possible to use some functions.

2. Group Control 2

n Wired remote controllers + Standard Indoor Units

Installation

ENGLISH

or

Master Master Slave Slave

Donʼt connect serial 12V line

Display Error Message

Master Master

LGAP Network System

GND

Signal

12 V

h It is possible to control 16 indoor units(Max.) with the master wired remote control.

h Other than those, it is same with the Group Control 1.

Installation Manual 15

Page 16

Installation

3. Group Control 3

n Mixture connection with indoor units and Fresh Air Intake Unit

LGAP Network System

Slave

FAU

Master

Master

FAU

Slave

or

Master

MN

Display Error Message

Master Master

Display Error Message

h In case of connecting with standard indoor unit and Fresh Air Intake Unit, separate Fresh Air

Intake Unit with standard units. (N, M ≤ 16) (Because setting temperature are different.)

h Other than those, it is same with Group Control 1.

FAU

Standard Standard

FAU FAU

FAU

Standard Standard

GND

Signal

12 V

16 Indoor Unit

* FAU : Fresh Air Intake Unit

Standard: Standard Indoor Unit

Page 17

4. 2 Remote Control

n Wired remote controller 2 + Indoor unit 1

Installation

ENGLISH

LGAP Network System

Slave

GND

Signal

12 V

Master

Master

Display Error Message

Slave

Slave

or

Slave

1. It is possible to connect two wired remote controllers (Max.) with one indoor unit.

Set only one indoor unit to Master, set the others to Slave.

Set only one wired remote controller to Master, set the others to Slave.

2. Every types of indoor unit is possible to connect two remote controller.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

5. In case that any error occurs at indoor unit, the error code is displayed on the wired

remote controller.

6. There isnʼt limits of indoor unit function.

Installation Manual 17

Page 18

Installation

5. Accessories for group control setting

It is possible to set group control by using below accessories.

Indoor unit 2 EA + Wired remote controller 1 EA

h

PZCWRCG3 cable used for connection

Mas te r

!

CAUTION

• Apply totally enclosed noncombustible conduit in case of local building code Requiring plenum

cable usage.

Slave

PZCWRCG3

Mas ter

Indoor unit 1 EA + Wired remote controller 2 EA

h

PZCWRC2 cable used for connection

PZCWRC2

Mas ter S lave

18 Indoor Unit

Page 19

ARN U G28 AM2 4

Serial Number

Chassis Name

Electrical Ratings

1 : 1Ø, 115 V, 60 Hz

6 : 1Ø, 220 - 240 V, 50 Hz

3 : 1Ø, 208/230 V, 60 Hz

2 : 1Ø, 220 V, 60 Hz

7 : 1Ø, 100 V, 50/60 Hz

G

: 1Ø, 220 - 240 V, 50 Hz/1Ø, 220 V, 60 Hz

Total Cooling Capacity in Btu/h

EX) 5 000 Btu/h ➝ '05' 18 000 Btu/h ➝ '18'

Combination of Inverter Type and Cooling Only or Heat Pump

N : AC Inverter and H/P V : AC Inverter and C/O

U : DC Inverter and H/P and C/O

System with Indoor Unit using R410A

❈ LGETA : U Ex) URN

Combinations of functions

A : Basic function L : Neo Plasma(Wall Mounted)

C : Plasma(Ceiling Cassette) B : High Static

G : Low Static K : High Sensible Heat

U : Floor Standing without Case

SE/S8 - R : Mirror V : Silver B : Blue(ART COOL Type Panel Clolr)

SF - E : Red V : Silver G : Gold 1 : Kiss (Photo changeable)

Q : Console Z : Fresh Air Intake Unit

Model Designation

Airborne Noise Emission

The A-weighted sound pressure emitted by this product is below 70 dB.

** The noise level can vary depending on the site.

The figures quoted are emission level and are not necessarily safe working levels. Whilst there is a

correlation between the emission and exposure levels, this cannot be used reliably to determine

whether or not further precautions are required. Factor that influence the actual level of exposure of the

workforce include the characteristics of the work room and the other sources of noise, i.e. the number

of equipment and other adjacent processes and the length of time for which an operator exposed to the

noise. Also, the permissible exposure level can vary from country to country. This information, however,

will enable the user of the equipment to make a better evaluation of the hazard and risk.

Limiting concentration

Limiting concentration is the limit of Freon gas concentration where immediate measures can be

taken without hurting human body when refrigerant leaks in the air. The limiting concentration shall

be described in the unit of kg/m

n Calculate refrigerant concentration

Refrigerant concentration =

Installation

3

(Freon gas weight per unit air volume) for facilitating calculation

Limiting concentration : 0.44 kg/m3(R410A)

Total amount of replenished refrigerant in refrigerant facility (kg)

Capacity of smallest room where indoor unit is installed (m

Installation Manual 19

3

)

ENGLISH

Page 20

How to Set E.S.P?

How to Set E.S.P?

ARNU**GM1A4 (** : 07, 09, 12, 15, 18)

Setting

value

70 11.3 - - - ---75 12.8 - - - ---80 14.4 11.4 - - ---85 15.9 13.2 10.2 - ---90 17.5 15.0 12.0 - ----

95 19.0 16.7 13.7 10.7 ---100 20.6 18.5 15.5 12.5 ---105 22.1 20.3 17.3 14.3 11.1 - - 110 23.7 22.1 19.0 16.1 13.1 10.0 - 115 - 23.8 20.8 17.9 15.1 12.2 - 120 - - 22.6 19.7 17.1 14.3 11.3 125 - - - 21.5 19.1 16.5 13.6 11.9

130 - - - 23.3 21.2 18.7 15.8 14.3

135 - - - - 23.2 20.8 18.0 16.7

140 - - - - - 23.0 20.3 19.1

145 - - - - - - 22.5 21.5

150 - - - - - - - 23.8

2.5(25) 4(39) 6(59) 8(78) 10(98) 12(118) 14(137) 15(147)

Static Pressure (mmAq(Pa))

ARNU**GM1A4 (** : 24)

Setting

value

85 16.8 14.6 - - ----

90 18.1 15.9 - - ----

95 19.4 17.2 15.0 - ---100 20.7 18.5 16.3 13.9 ---105 22.0 19.8 17.7 15.3 13.0 - - 110 23.3 21.1 19.1 16.8 14.6 - - 115 24.6 22.4 20.5 18.3 16.3 14.2 - 120 25.9 23.7 21.8 19.7 17.9 15.9 13.3 125 - 25.1 23.2 21.2 19.6 17.5 15.2 14.6

130 - - 24.6 22.7 21.2 19.2 17.1 16.3

135 - - - 24.2 22.9 20.9 19.0 18.1

140 - - - - 24.5 22.6 20.9 19.9

2.5(25) 4(39) 6(59) 8(78) 10(98) 12(118) 14(137) 15(147)

Static Pressure (mmAq(Pa))

ARNU**GM2A4 (** : 07, 09, 12, 15)

Setting

value

654.7------70 10.3 ------75 15.0 ------80 19.0 7.6 -----85 24.9 13.8 4.9 ----90 27.6 20.4 7.8 -----

95 30.4 24.4 15.7 5.2 ---100 33.1 28.7 20.8 9.2 3.8 - - 105 35.9 31.7 24.1 17.5 6.7 - - -

110 38.6 34.7 30.5 22.2 11.5 5.5 - -

115 40.1 37.8 33.8 27.9 20.2 9.1 - 120 - 39.1 37.1 31.4 24.6 17.9 7.5 125 - - 38.5 35.0 30.1 21.2 11.0 6.7

130 - - - 37.1 32.0 27.6 15.6 10.0

135----36.8 31.5 24.3 16.2

140----40.5 35.9 29.8 22.4

145-----39.9 34.9 27.8

150------39.4 34.2

155-------37.1

Note: 1. The above table shows the correlation between the air rates and E.S.P.

2. Make sure to check and adjust E.S.P (external static pressure) value after the installation of the product.

4(39) 6(59) 8(78) 10(98) 12(118) 14(137) 16(157) 18(177)

Otherwise, there is a risk of weak cooling/heating and condensed water discharge/drop.

Static Pressure (mmAq(Pa))

(Unit: CMM)

(Unit: CMM)

(Unit: CMM)

20 Indoor Unit

Page 21

How to Set E.S.P?

ARNU**GM2A4 (** : 28, 36)

Setting

value

4(39) 6(59) 8(78) 10(98) 12(118) 14(137) 16(157) 18(177)

654.7------70 10.3 ------75 15.0 ------80 19.0 7.6 - - - - - 85 24.9 13.8 4.9 - - - - 90 27.6 20.4 7.8 - - - - -

95 30.4 24.4 15.7 5.2 - - - 100 33.1 28.7 20.8 9.2 3.8 - - 105 35.9 31.7 24.1 17.5 6.7 - - 110 38.6 34.7 30.5 22.2 11.5 5.5 - 115 40.1 37.8 33.8 27.9 20.2 9.1 - 120 - 39.1 37.1 31.4 24.6 17.9 7.5 125 - - 38.5 35.0 30.1 21.2 11.0 6.7

130 - - - 37.1 32.0 27.6 15.6 10.0

135 - - - - 36.8 31.5 24.3 16.2

140 - - - - 40.5 35.9 29.8 22.4

145-----39.9 34.9 27.8

150------39.4 34.2

155-------37.1

Static Pressure (mmAq(Pa))

(Unit: CMM)

ENGLISH

ARNU**GM2A4 (** : 42)

Setting

value

4(39) 6(59) 8(78) 10(98) 12(118) 14(137) 16(157) 18(177)

Static Pressure (mmAq(Pa))

(Unit: CMM)

90 23.0 -------

95 25.9 19.1 - - - - - 100 28.6 23.3 - - - - - 105 31.4 26.4 19.6 - - - - -

110 34.2 29.9 24.2 - - - - -

115 36.6 32.7 28.8 21.7 - - - 120 39.2 35.7 31.8 26.2 19.6 - - 125 41.7 38.5 34.8 30.8 24.3 - - 130 44.0 41.2 37.7 34.1 29.0 22.3 - 135 - 43.8 40.7 37.4 32.6 27.5 20.5 140 - - 43.5 40.4 37.2 32.6 25.8 19.9

145 - - - 43.4 41.6 37.4 30.7 24.6

150----43.4 42.3 35.4 29.4

155-----43.7 37.5 32.7

ARNU**GM3A4 (** : 18, 24, 28)

Setting value

70 25.2 -------75 30.4 21.4 ------80 35.0 27.2 18.5 -----85 39.8 35.4 24.6 -----90 44.3 40.1 31.5 22.7 ----

95 49.3 44.8 36.8 28.8 21.4 ---100 53.0 49.4 44.6 35.4 27.7 ---105 57.2 54.1 49.2 43.0 35.0 26.5 - - 110 - 58.8 53.9 47.9 42.4 33.8 24.3 14.8 115 - - 58.6 52.9 47.8 42.5 31.4 20.3 18.3

120 - - - 57.8 53.1 48.2 39.2 30.2 24.6

125-----49.4 43.1 36.7 33.1

130-----52.7 48.6 44.4 39.6

135-------50.2 45.2

Note: 1. The above table shows the correlation between the air rates and E.S.P.

2. Make sure to check and adjust E.S.P (external static pressure) value after the installation of the product.

4(39) 6(59) 8(78) 10(98) 12(118) 14(137) 16(157) 18(177) 20(196)

Otherwise, there is a risk of weak cooling/heating and condensed water discharge/drop.

Static Pressure (mmAq(Pa))

(Unit: CMM)

Installation Manual 21

Page 22

How to Set E.S.P?

ARNU**GM3A4 (** : 48, 54)

Setting value

70 25.1 - - - - - -

75 29.5 26.1 - - - - -

80 34.0 30.8 25.9 - - - -

85 38.4 35.4 30.6 32.2 - - -

90 42.9 40.1 35.2 28.1 21.0 - -

95 47.3 44.8 39.9 33.1 26.3 19.5 100 51.8 49.4 44.6 38.0 31.7 25.2 22.6

105 56.2 54.1 49.2 43.0 37.1 31.0 28.5

110 - 58.8 53.9 47.9 42.4 36.7 34.4

115 - - 58.6 52.9 47.8 42.5 40.3

120 - - - 57.8 53.1 48.2 46.1

125----54.2 49.4 47.3

5(49) 6(59) 8(78) 10(98) 12(118) 14(137) 15(147)

Static Pressure (mmAq(Pa))

(Unit: CMM)

ARNU**GM3B4 (** : 48, 54)

Setting value

70 25.2 --------

75 30.4 21.4 -------

80 35.0 27.2 18.5 ------

85 39.8 35.4 24.6 ------

90 44.3 40.1 31.5 22.7 -----

95 49.3 44.8 36.8 28.8 21.4 ---100 53.0 49.4 44.6 35.4 27.7 ---105 57.2 54.1 49.2 43.0 35.0 26.5 - - 110 - 58.8 53.9 47.9 42.4 33.8 24.3 14.8 115 - - 58.6 52.9 47.8 42.5 31.4 20.3 18.3

120 - - - 57.8 53.1 48.2 39.2 30.2 24.6

125-----49.4 43.1 36.7 33.1

130-----52.7 48.6 44.4 39.6

135------ 55.3 50.2 45.2

4(39) 6(59) 8(78) 10(98) 12(118) 14(137) 16(157) 18(177) 20(196)

ARNU**GM3A4 (** : 60)

Setting value

70

75

80

85

90

95

100

105

110

115

120

125

5(49) 6(59) 8(78) 10(98)

25.1 - - -

29.5 26.1 - -

34.0 30.8 25.9 -

38.4 35.4 30.6 32.2

42.9 40.1 35.2 28.1

47.3 44.8 39.9 33.1

51.8 49.4 44.6 38.0

56.2 54.1 49.2 43.0

Static Pressure (mmAq(Pa))

- 58.8 53.9 47.9

- - 58.6 52.9

- - - 57.8

----

Static Pressure (mmAq(Pa))

(Unit: CMM)

(Unit: CMM)

Note: 1. The above table shows the correlation between the air rates and E.S.P.

2. Make sure to check and adjust E.S.P (external static pressure) value after the installation of the product.

Otherwise, there is a risk of weak cooling/heating and condensed water discharge/drop.

22 Indoor Unit

Loading...

Loading...