Page 1

INSTALLATION MANUAL

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

Ceiling Suspended Air Conditioner

Original instruction

P/NO : MFL67107610

REV.00_062816

www.lg.com

Page 2

TIPS FOR SAVING ENERGY

2

ENGLISH

TIPS FOR SAVING ENERGY

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your air conditioner more efficiently by referring to the instructions

below:

• Do not cool excessively indoors. This may be harmful for your health and may consume more

electricity.

• Block sunlight with blinds or curtains while you are operating the air conditioner.

• Keep doors or windows closed tightly while you are operating the air conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Open windows regularly for ventilation as the indoor air quality may deteriorate if the air conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block the

air flow or weaken the cooling / dehumidifying functions.

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

Page 3

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid dangerous situations and ensure peak

performance of your product

WARNING

!

It can result in serious injury or death when the directions are ignored

CAUTION

!

It can result in minor injury or product damage when the directions are ignored

WARNING

!

• Installation or repairs made by unqualified persons can result in hazards to you and others.

• Installation MUST conform with local building codes.

• The information contained in the manual is intended for use by a qualified service technician

familiar with safety procedures and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction, property damage, personal injury and/or death.

Installation

• Don’t use a power cord, a plug or a loose socket which is damaged.

- Otherwise, it may cause a fire or electrical shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized Service Center.

- Do not disassemble or repair the product. There is risk of fire or electric shock.

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

• Do not let the air conditioner run for a long time when the humidity is very high and a door or a window is left open.

- Moisture may condense and wet or damage furniture.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the case edges and the fins on the con-

denser and evaporator.

• For installation, always contact the dealer or an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

3

ENGLISH

Page 4

4

ENGLISH

Operation

Installation

IMPORTANT SAFETY INSTRUCTIONS

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the air conditioner could fall with it, causing property damage, product failure,

and personal injury.

• There is a risk of fire and explosion.

- Inert gas (nitrogen) should be used when you check plumbing leaks, cleaning or repairs of pipes

etc.

If you are using combustible gases including oxygen, product may have the risk of fires and explosions.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do not compress

air or Oxygen and do not use Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

• Do not store or use flammable gas or combustibles near the product.

- There is risk of fire or failure of product.

CAUTION

!

• Always check for gas (refrigerant) leakage after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Install the drain hose to ensure that water is drained away properly.

- A bad connection may cause water leakage.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Use two or more people to lift and transport the product.

- Avoid personal injury.

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS

5

ENGLISH

2

TIPS FOR SAVING EN-

ERGY

3

IMPORTANT SAFETY INSTRUCTIONS

6

PRODUCT PARTS

INSTALLATION TOOLS

6

7

INSTALLATION

7 Select the best Location

8

THE INDOOR UNIT IN-

STALLATION

9 Open side-cover

10 Mounting the anchor nut and bolt

12 Indoor unit drain piping

12 Drain piping

12 Drain test

13 Heat insulation

Connecting Cables to the indoor unit

13

13 Flaring Work

16 Wiring Connection

17 DIP Switch Setting

18 Group Control Setting

23 Model Designation

23 Airborne Noise Emission

23 Limiting concentration

Page 6

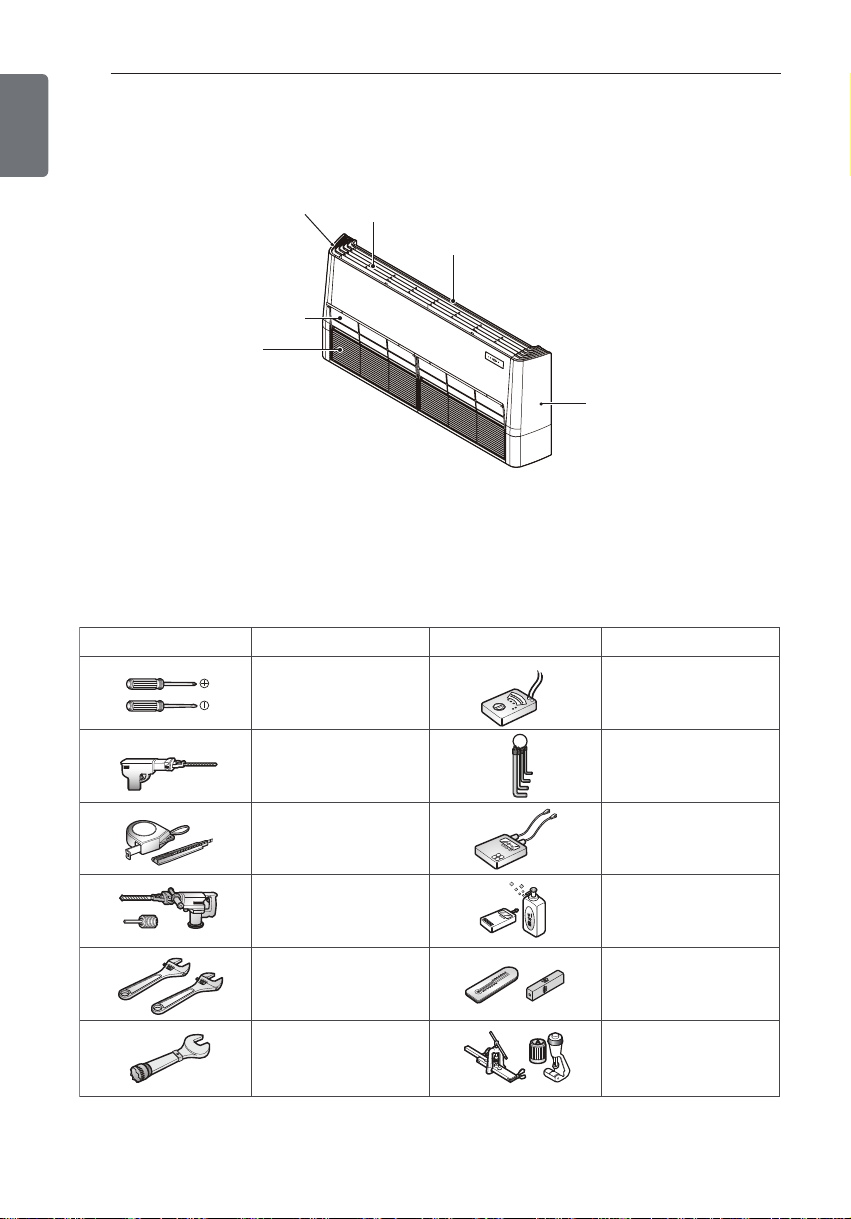

PRODUCT PARTS

6

ENGLISH

PRODUCT PARTS

Right side cover

Air filters

(behind inlet grille)

Air inlet vent

(inlet grille)

Louver

INSTALLATION TOOLS

Screw driver

Electric drill

Air outlet vent

erugiFerugiF Name

Left side cover

Name

Multi-meter

Hexagonal wrench

Measuring tape, Knife

Hole core drill

Spanner

Torque wrench

Ammeter

Gas-leak detector

Thermometer,

Level

Flaring tool set

Page 7

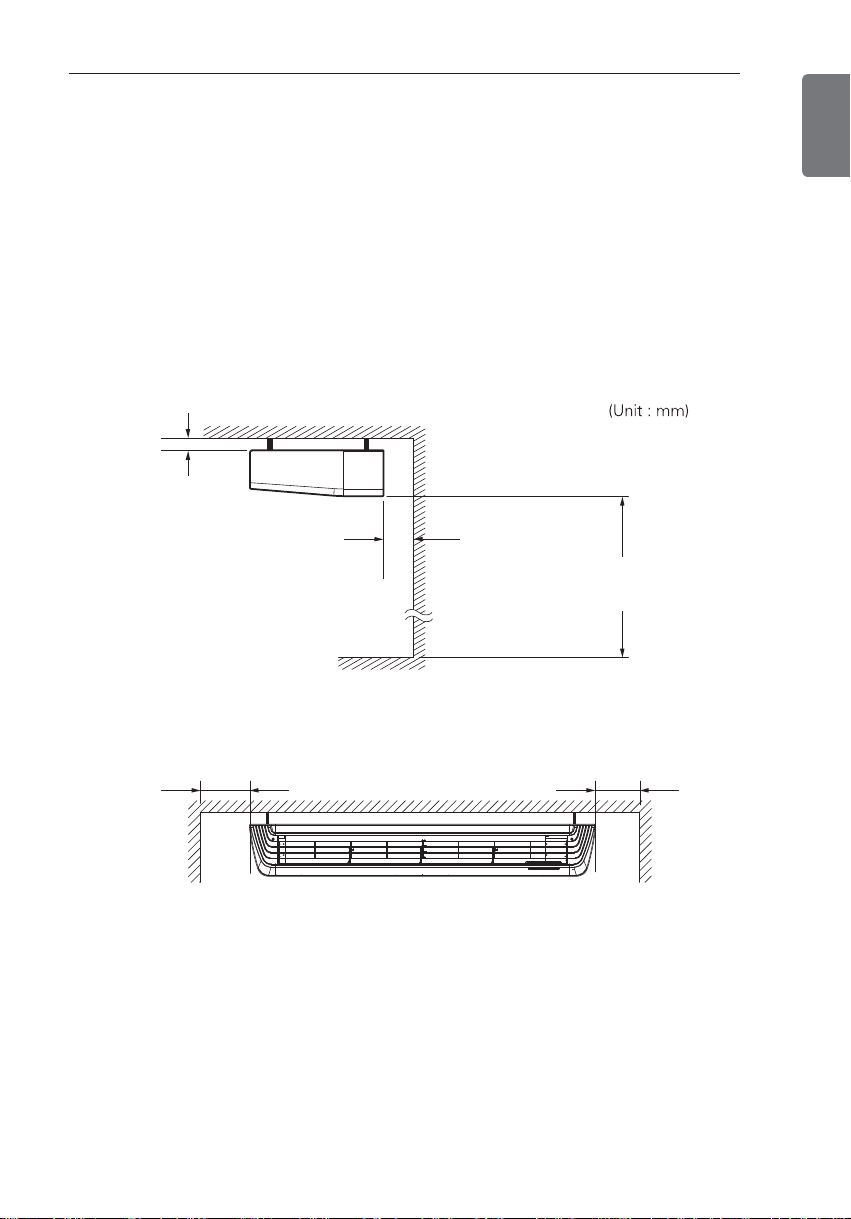

INSTALLATION MAP

INSTALLATION

Select the best Location

- There should not be any heat source or steam near the unit.

- There should not be any obstacles to prevent the air circulation.

- A place where air circulation in the room will be good.

- A place where drainage can be easily obtained.

- A place where noise prevention is taken into consideration.

- Do not install the unit near the door way.

- Ensure the spaces indicated by arrows from the wall, ceiling, or other obstacles.

- The indoor unit must keep the maintenance space.

10 (13/32)

or more

300 (11 – 13/16)

or more

2500 (98 – 3/7)

or more

7

ENGLISH

Floor

700(27 – 9/16) or more 700(27 – 9/16) or more

Page 8

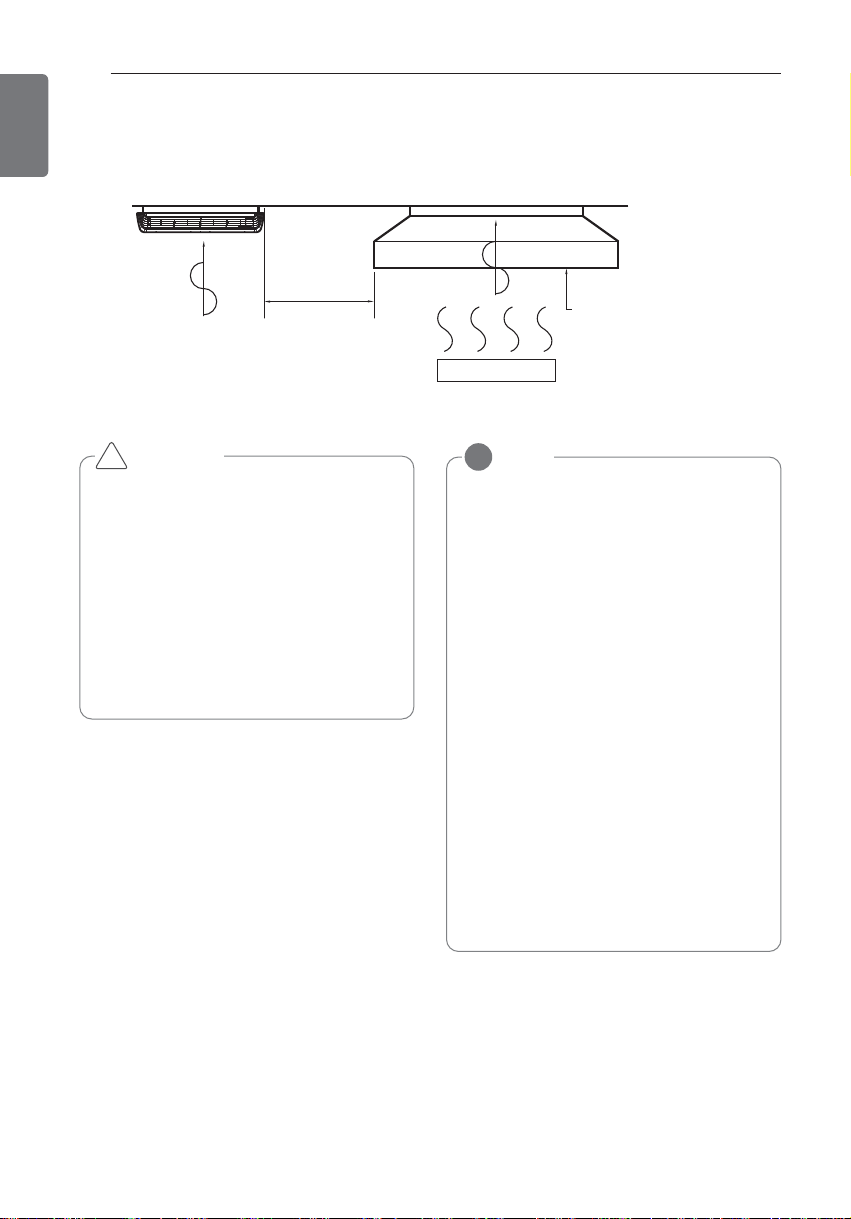

THE INDOOR UNIT INSTALLATION

8

ENGLISH

THE INDOOR UNIT INSTALLATION

Air conditioner

Take enough

distance

Cooking table

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

CAUTION

!

• Install the unit horizontally using a level

gauge.

• During the installation, care should be

taken not to damage electric wires.

• Select and mark the position for fixing

bolts and piping hole.

• Decide the position for fixing bolts

slightly tilted to the drain direction after

considering the direction of drain hose.

• Drill the hole for anchor bolt on the ceiling.

NOTE

!

• Avoid the following installation location.

1. Such places as restaurants and kitchen

where considerable amount of oil

steam and flour is generated.

These may cause heat exchange efficiency reduction, or water drops, drain

pump mal-function.

In these cases, take the following actions;

• Make sure that ventilation fan is enough

to cover all noxious gases from this

place.

• Ensure enough distance from the cook-

ing room to install the air conditioner in

such a place where it may not suck oily

steam.

2. Avoid installng air conditioner in such

places where cooking oil or iron powder is generated.

3. Avoid places where inflammable gas is

generated.

4. Avoid place where noxious gas is generated.

5. Avoid places near high frequency generators.

Page 9

Open side-cover

Step 1

THE INDOOR UNIT INSTALLATION

- Remove paper bracket from side-cover.

9

ENGLISH

- Remove two screws from side-cover.

Step 2

Right side cover

Left side

Backside

Backside

- Unlock side-cover from side-panel slightly

(Tap the side-cover with your palm on the

backside)

cover

Step 4

- Knock out the pipe hole from the left sidecover with nipper/plier.

CAUTION

!

Hold the side-cover with other hand while

tapping to prevent it to fall down.

Page 10

Chassis Code

VM1 ARNU**GV1A4 1018 355

Page 11

THE INDOOR UNIT INSTALLATION

Ceiling

10~20 mm

Ceiling

5~10 mm

CAUTION

!

Installation information for declination

- Install declination of the indoor unit is very important for the drain of the convertible type air

conditioner.

- Minimum thickness of the insulation for the connecting pipe shall be 10 mm.

- If the Installation Plates are fixed to horizontal line, the indoor unit after installing will be declined to the bottomside.

Front of view

- The unit must be horizontal or inclined at angle.

- The inclination should be less than or equal to 1° or in between 10 to 20 mm inclined in drain

direction as shown in fig.

11

ENGLISH

Side of view

- The unit must be inclined to the bottomside of the unit when finished installation.

Page 12

Page 13

Page 14

14

ENGLISH

THE INDOOR UNIT INSTALLATION

Putting nut on

- Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after finishing

flare work)

Flare nut

Copper tube

Flaring work

Firmly hold copper pipe in a bar with the di-

1

mension shown in below table table

below.

2

Carry out flaring work with the flaring tool.

Outside diameter

mm inch mm

Ø6.35 1/4 1.1~1.3

Ø9.52 3/8 1.5~1.7

Ø12.7 1/2 1.6~1.8

Ø15.88 5/8 1.6~1.8

Ø19.05 3/4 1.9~2.1

Bar

"A"

Bar

A

Handle

Yoke

Cone

Check

Compare the flared work with the figure

1

by.

2

If a flared section is defective, cut it off

and do flaring work again.

Smooth all round

Inside is shiny without scratches

= Improper flaring =

Surface

Even length

all round

Inclined

damaged

Cracked Uneven

Connecting the installation pipe

and drain hose to the indoor unit.

1

Align the center of the pipes and sufficiently tighten the flare nut by hand

Indoor unit tubing Flare nut Pipes

2

Tighten the flare nut with a wrench

Outside diameter

mm inch kgf.m

Ø6.35 1/4 1.8~2.5

Ø9.52 3/8 3.4~4.2

Ø12.7 1/2 5.5~6.5

Ø15.88 5/8 6.3~8.2

Ø19.05 3/4 9.9~12.1

Torque

Open-end wrench

(fixed)

thickness

Copper pipe

Clamp handle

Red arrow mark

Wrench

Indoor unit tubing

Flare nut

Connection

pipe

Page 15

THE INDOOR UNIT INSTALLATION

Gas Pipe

Liquid Pipe

Cutting Line

Cutting Line

Good Case Bad Case

* Tubing cutting line have to be upward.

Vinyl tape(narrow)

Connection pipe

Connecting cable

Vinyl tape (wide)

Wrap with vinyl tape

Indoor unit pipe

Pipe

15

ENGLISH

When needed to extend the drain hose of

3

indoor unit, assembly the drain pipe as

shown on the drawing

Drain pipe

Indoor unit drain hose

Vinyl tape(narrow)

Adhesive

Wrap the insulation material

around the connecting portion.

Overlap the connection pipe insulation ma-

1

terial and the indoor unit pipe insulation

material. Bind them together with vinyl

tape so that there may be no gap.

Insulation material

2

Set the tubing cutting line upward.

Wrap the area which accommodates the

rear piping housing section with vinyl tape.

Bundle the piping and drain hose together

3

by wrapping them with vinyl tape sufficient

enough to cover where they fit into the

rear piping housing section.

Wrap with vinyl tape

Pipe

Drain hose

Vinyl tape(wide)

Page 16

-B -A

• The connecting cable:connected to the indoor and outdoor unit

should be complied with the following specifications(Rubber

insulation, type H07RN-F approved by HAR or SAA).

• If the supply cord is damaged, it must be replaced by a special

cord or assembly available from the manufacturer of its service agent.

NORMAL

CROSS-SECTIONAL

AREA 1.0-1.5mm

2

Page 17

Position

Selection of installation

position

ARNU******4

(outdoor units) should be after October 2013.

Ceiling Bottom

Page 18

THE INDOOR UNIT INSTALLATION

Wired remote controller 1 + Standard Indoor Units

DIP Switch in PCB

18

ENGLISH

Group Control Setting

Group Control 1

■

Master Slave Slave Slave

LGAP Network System

or

GND

Signal

12 V

Only connect serial signal and

GND lines between indoor units.

② Slave Setting

- No. 3 On

■

① Master Setting

- No. 3 Off

Display Error Message

Master

Indoor Unit DIP Switch

Some products have no DIP switch on PCB. It is possible to set indoor units to Master or Slave

by using the wireless remote controller instead of DIP switch.

For the details of the setting, please refer to the manual of the wireless remote controller.

1. It is possible to 16 indoor units(Max.) by one wired remote controller.

Set only one indoor unit to Master, set the others to Slave.

2. It is possible to connect with every type of indoor units.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

- The Master indoor unit is possible to recognize Dry Contact and Central Controller only.

5. In case that any error occurs at indoor unit, the error code is displayed on the wired remote

controller.

It is possible to control the other indoor units except the error units.

Page 19

THE INDOOR UNIT INSTALLATION

Wired remote controllers + Standard Indoor Units

* It is possible to connect indoor units since Feb. 2009.

* It can be the cause of malfuctions when there is no setting of master and slave.

* In case of Group Control, it is possible to use following functions.

- Selection of operation, stop or mode

- Temperature setting and room temperature check

- Current time change

- Control of flow rate (High/Middle/Low)

- Reservation settings

- It is not possible at some functions.

Group Control 2

■

LGAP Network System

or

19

ENGLISH

Master

Master

Donʼt connect serial 12V line

Display Error Message

SlaveMaster

Slave

Slave

* It is possible to control 16 indoor units(Max.) with the master wired remote control.

* Other than those, it is same with the Group Control 1.

GND

Signal

12 V

Page 20

THE INDOOR UNIT INSTALLATION

Mixture connection with indoor units and Fresh Air Intake Unit

20

ENGLISH

Group Control 3

■

LGAP Network System

Slave

Display Error Message

GND

Signal

12 V

M

FAU

Master

Master

FAU

Slave

Display Error Message

or

Master

N

Master

* In case of connecting with standard indoor unit and Fresh Air Intake Unit, separate Fresh Air In-

take Unit with standard units. (N, M ≤ 16) (Because setting temperature are different.)

* Other than those, it is same with Group Control 1.

FAU

Standard Standard

FAU FAU

FAU

Standard Standard

* FAU : Fresh Air Intake Unit

Standard: Standard Indoor Unit

Page 21

2 Remote Control

Wired remote controller 2 + Indoor unit 1

■

THE INDOOR UNIT INSTALLATION

21

ENGLISH

LGAP Network System

Slave

GND

Signal

12 V

Master

Master

Display Error Message

Slave

Slave

or

Slave

1. It is possible to connect two wired remote controllers (Max.) with one indoor unit.

Set only one indoor unit to Master, set the others to Slave.

Set only one wired remote controller to Master, set the others to Slave.

2. Every types of indoor unit is possible to connect two remote controller.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

5. In case that any error occurs at indoor unit, the error code is displayed on the wired remote

controller.

6. There isn't limits of indoor unit function.

Page 22

THE INDOOR UNIT INSTALLATION

Indoor unit 2 EA +Wired remote controller Indoor unit 1 EA +Wired remote controller 2EA

22

ENGLISH

Accessories for group control setting

It is possible to set group control by using below accessories.

* PZCWRCG3 cable used for connection * PZCWRC2 cable used for connection

PZCWRCG3

Master

Slave

PZCWRC2

Master Slave

Master

CAUTION

!

Apply totally enclosed noncombustible conduit in case of local building code Requiring plenum

cable usage.

Page 23

48,000 48 36,000 36

Page 24

24

ENGLISH

Page 25

LG Electronics European Shared Service Center B.V.

Krijgsman 1, 1186 DM Amstelveen, The Netherlands

LG Electronics Tianjin Appliances Co.,Ltd.

No.09, JinWei Road, BeiChen District,Tianjin, China.

Loading...

Loading...