Page 1

INSTALLATION MANUAL

AIR CONDITIONER

• Please read this installation manual completely before installing the product.

• Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

• Please retain this installation manual for future reference after reading it

thoroughly.

P/NO : MFL42803109

www.lg.com

TYPE : Ceiling Concealed Duct - Low Static

ENGLISH

ITALIANO

ESPAÑOL

FRANÇAIS DEUTSCH

PORTUGUÊS

кмллдавьбхд

Page 2

2 Indoor Unit

Ceiling Concealed Duct - Low Static Type Indoor Unit Installation Manual

TABLE OF CONTENTS

❏ Four type "A" screws

❏ Connecting cable

❏ Pipes: Gas side

Liquid side

(Refer to Product

Data)

❏ Insulation materials

❏ Additional drain pipe

❏ Level gauge

❏ Screw driver

❏ Electric drill

❏ Hole core drill

❏ Flaring tool set

❏ Specified torque wrenches

(different depending on model No.)

❏ Spanner .......Half union

❏ A glass of water

❏ Screw driver

❏ Hexagonal wrench

❏ Gas-leak detector

❏ Vacuum pump

❏ Gauge manifold

❏ Owner's manual

❏ Thermometer

Safety Precautions.................3

Introduction.............................6

Installation

Selection of the best location

................................................7

Ceiling opening dimension

and hanging bolt location ......8

Indoor Unit Installation...........9

Wiring Connection .................9

Part name and functions .....10

Checking the Drainage........11

Installation of Wired

Remote Controller ...............15

Name and function of wired

remote controller(Accessory)

...17

Dip Switch Setting ...............18

Group Control Setting..........19

How to Set E.S.P? ................24

Installation Requirements

Required Parts Required Tools

Page 3

Installation Manual 3

ENGLISH

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be followed.

n Be sure to read before installing the air conditioner.

n Be sure to observe the cautions specified here as they include important items related to safety.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the

following indications.

n Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

n Installation

Do not use a defective or

underrated circuit breaker.

Use this appliance on a dedicated circuit.

• There is risk of fire or electric

shock.

For electrical work, contact

the dealer, seller, a qualified

electrician, or an Authorized

Service Center.

• Do not disassemble or repair

the product. There is risk of

fire or electric shock.

Always ground the product.

• There is risk of fire or electric

shock.

Install the panel and the

cover of control box securely.

• There is risk of fire or electric

shock.

Always install a dedicated

circuit and breaker.

• Improper wiring or installation

may cause fire or electric

shock.

Use the correctly rated breaker or fuse.

• There is risk of fire or electric

shock.

Page 4

4 Indoor Unit

Safety Precautions

n Operation

Do not modify or extend the

power cable.

• There is risk of fire or electric

shock.

Do not let the air conditioner

run for a long time when the

humidity is very high and a

door or a window is left open.

• Moisture may condense and

wet or damage furniture.

Be cautious when unpacking

and installing the product.

• Sharp edges could cause

injury. Be especially careful of

the case edges and the fins

on the condenser and evaporator.

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric

shock, explosion, or injury.

Do not install the product on

a defective installation stand.

• It may cause injury, accident,

or damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air

conditioner could fall with it,

causing property damage,

product failure, and personal

injury.

Do not store or use flammable gas or combustibles near the product.

• There is risk of fire or failure of product.

Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge.

Do not compress air or Oxygen and Do not use Flammable gases.

Otherwise, it may cause fire or explosion.

• There is the risk of death, injury, fire or explosion.

Page 5

ENGLISH

Installation Manual 5

Safety Precautions

n Installation

Always check for gas (refrigerant) leakage after installation or repair of product.

• Low refrigerant levels may

cause failure of product.

Install the drain hose to

ensure that water is drained

away properly.

• A bad connection may cause

water leakage.

Keep level even when

installing the product.

• To avoid vibration or water

leakage.

Do not install the product

where the noise or hot air from

the outdoor unit could damage the neighborhoods.

• It may cause a problem for

your neighbors.

Use two or more people to lift

and transport the product.

• Avoid personal injury.

Do not install the product

where it will be exposed to

sea wind (salt spray) directly.

• It may cause corrosion on the

product. Corrosion, particularly

on the condenser and evaporator fins, could cause product

malfunction or inefficient operation.

PTIf you eat the liquid from the batteries, brush your teeth and see doctor.

Do not use the remote if the batteries have leaked.

• The chemicals in batteries could cause burns or other health hazards.

Page 6

6 Indoor Unit

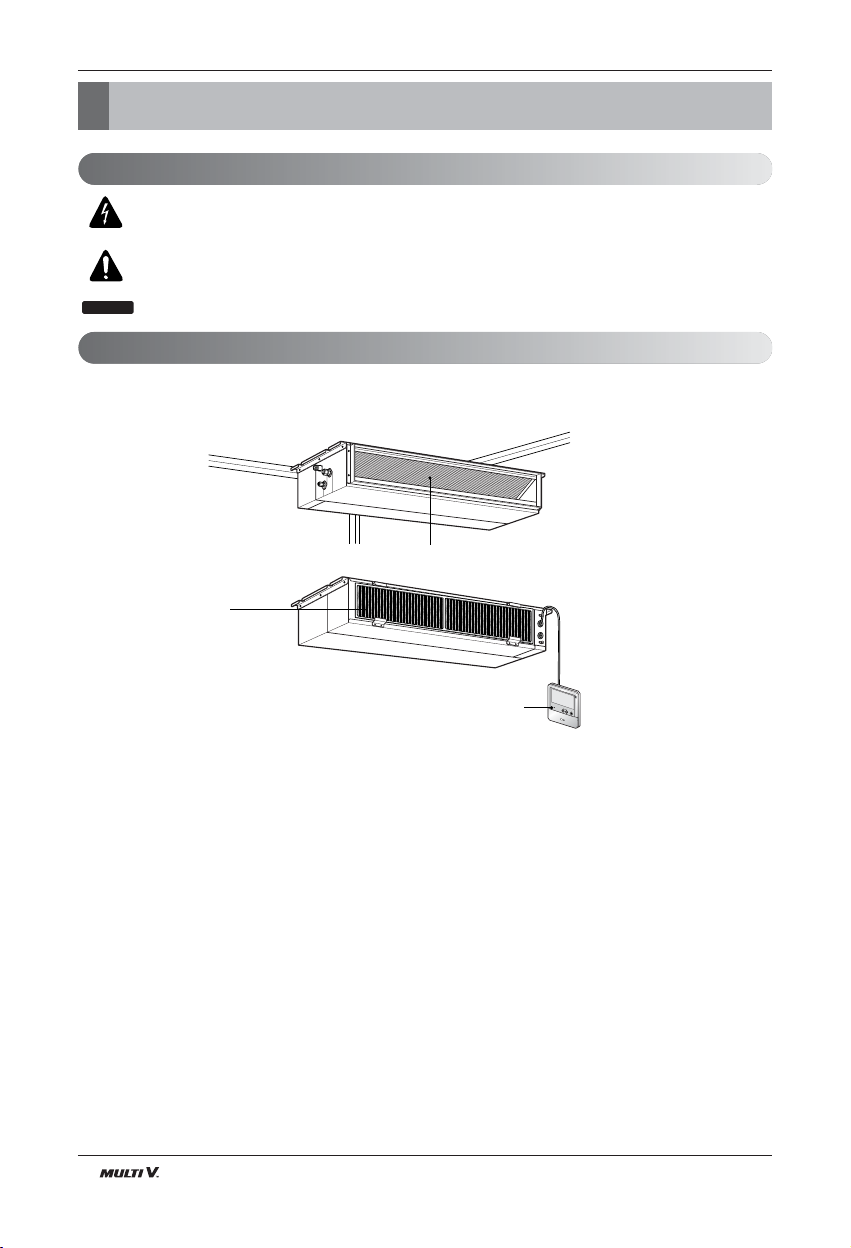

Introduction

Introduction

Air outlet vents

Air filters

Wired Remote Controller

R

e

m

o

t

e

C

o

n

t

r

o

l

l

e

r

TEMP

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

NOTICE

Symbols Used in this Manual

Features

Low static Duct type

Page 7

ENGLISH

Installation Manual 7

Installation

Installation

Indoor unit

Install the air conditioner in the location that satisfies the following conditions.

• The place shall easily bear a load exceeding four times the

indoor unitʼs weight.

• The place shall be able to inspect the unit as the figure.

• The place where the unit shall be leveled.

• The place shall easily connect with the outdoor unit.

• The place where the unit is not affected by an electrical

noise.

• The place where air circulation in the room will be good .

• There should not be any heat source or steam near the

unit

Confirm the positional relationship between the unit and

suspension bolts.

• Installation the ceiling opening to clean the filter or service

under the product.

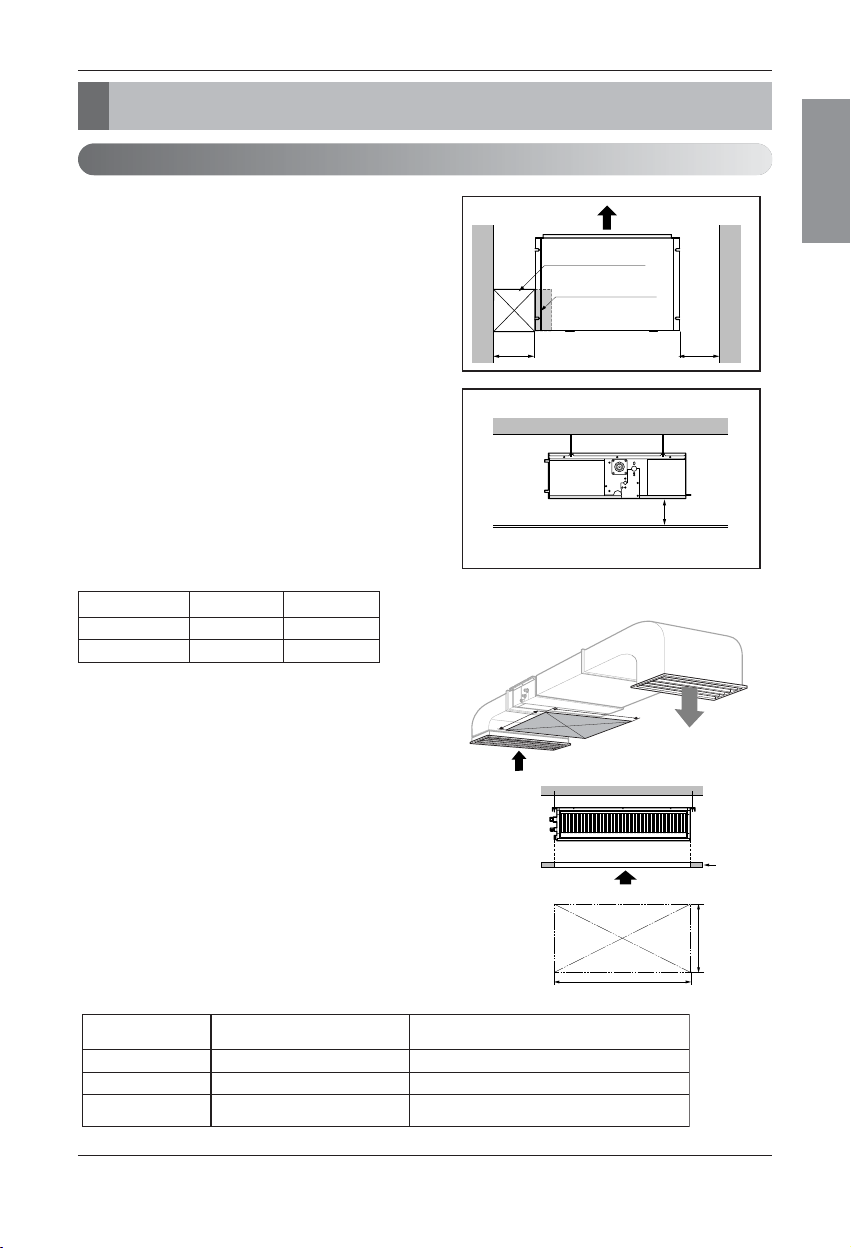

Selection of the best location

Inspection hole

(600 x 600)

Control box

H=20 or more

• Suitable dimension "H" is necessary to get a slooe

to drain as aiven in the fiaure

Side view

(unit: mm)

600600

A(Min)

B(Min)

Ceiling

Service Space

A

B

Capacity(Btu/h) A B

7/9/12/15k 600 900

18/24k 600 1100

(Length: mm)

Low static Duct type

Minimum height for motor replacement.

Less than 20cm

Hole size should be

more than the size of IDU.

Insufficient space. Difficult for servicing

20cm to 100cm2

Sufficient space in the ceiling for servicing.

More than 100cm1

Remarks

Distance between

False ceiling & Actual ceiling

Number of

Inspection hole

[Inspection Hole Standard]

Page 8

8 Indoor Unit

Installation

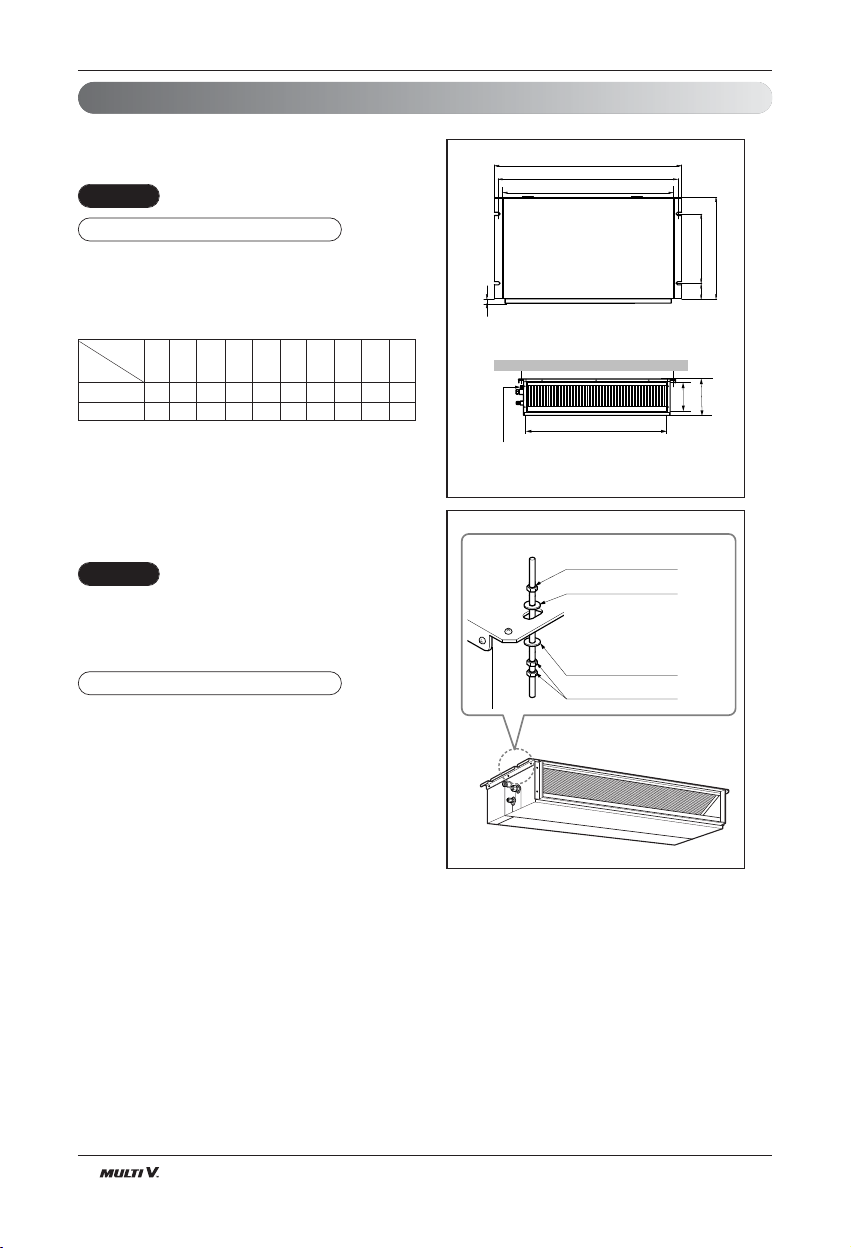

Ceiling dimension and hanging bolt location

Installation of Unit

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct to absorb

unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Install the unit leaning to a drainage hole side as a figure

for easy water drainage.

• A place where the unit will be leveled and that can support

the weight of the unit.

• A place where the unit can withstand its vibration.

• A place where service can be easily performed.

CASE 1

POSITION OF SUSPENSION BOLT

(Unit:mm)

7/9/12/15k BTU/h

850 900 383 575 93 190 21 795 163 820

18/24k BTU/h

1130 1180 383 575 93 190 21 1065 163 1100

Dimension

Capacity(Btu/h)

ABCDEFGHI J

CE

G

D

A

J

B

I

F

H

Drainage hole

Drain Pump use

M10 Nut

M10 washer

X 4

X 4

M10 Nut

M10 washer

X 4

X 8

CASE 2

POSITION OF CONSOLE BOLT

Page 9

ENGLISH

Installation Manual 9

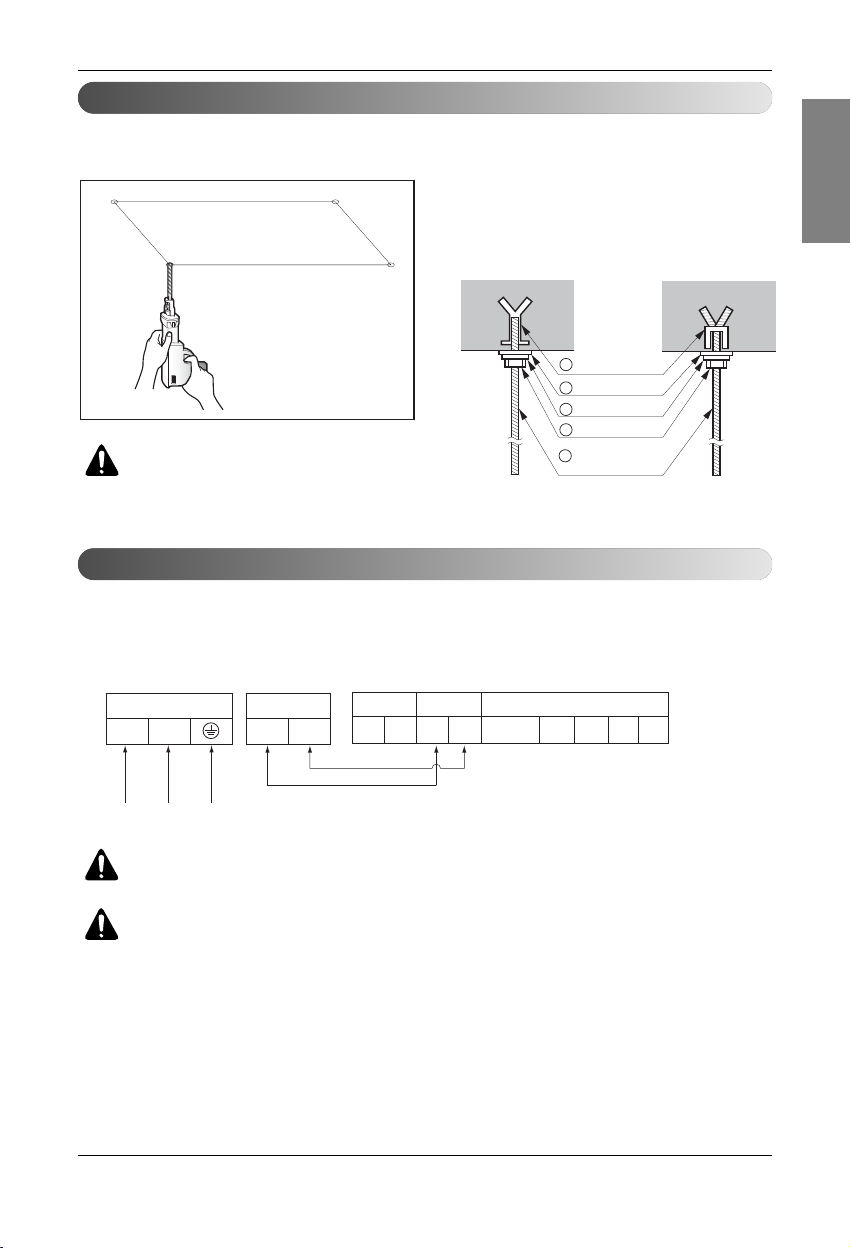

Installation

• Select and mark the position for fixing bolts.

• Drill the hole for set anchor on the face of ceiling.

• Insert the set anchor and washer onto the suspension bolts for locking the suspension bolts on the

ceiling.

•

Mount the suspension bolts to the set anchor firmly.

• Secure the installation plates onto the suspension

bolts (adjust level roughly) using nuts, washers

and spring washers.

Connect the wires to the terminals on the control board individually according to the outdoor unit connection.

• Ensure that the color of the wires of outdoor unit and the terminal No. are the same as those of indoor unit respectively.

Wiring Connection

Indoor Unit Installation

CAUTION : Tighten the nut and bolt

to prevent unit falling.

B1/B2 Series

WARNING : Make sure that the screws of the terminal are free from looseness.

CAUTION : The Power cord connected to the unit should be selected according

to the following specifications.

Old building New building

1 Set anchor

2 Plate washer

3 Spring washer

4 Nut

5 Suspension

bolts

Terminal Block Indoor

INDOOR POWER INPUT

Terminal Block Indoor

34L(L1) N(L2)

Outdoor unit

SODU SODU

Indoor unit

IDU IDU

Central controller

INTERNET

DRY1

DRY2

GND

12V

Outdoor unit

Page 10

10 Indoor Unit

Installation

• Low static duct type in case of suction from back

side.

• Low static duct type in case of suction from bottom

side.

Air Filter

Air outlet

Panel Rear

Air outlet

Air Filter

Panel Rear

Part name and functions

Page 11

ENGLISH

Installation Manual 11

Installation

1. Remove the Air Filter.

2. Check the drainage.

• Spray one or two glasses of water upon the

evaporator.

• Ensure that water flows drain hose of indoor

unit without any leakage.

Checking the Drainage

INSULATION, OTHERS

Insulate the joint and tubes completely.

All thermal insulation must comply with local requirement.

INDOOR UNIT

■ After all workings are finished, check the working and operation.

• Air distribution ............... Is the air circulation good?

• Drain ............................. Is the drainage smoothly and no sweating?

• Gas leakage ................. Is the piping connection correctly?

• Wiring ........................... Is the wiring connection correctly?

• Lock-bolt ....................... Is the lock-bolt of compressor loosened?

• Insulation Is the unit fully insulated?

• Ground Is the unit safely grounded?

THERMAL INSULATION

TEST AND CHECK

Make sure that there is no clearance here.

Overlap with thermal

insulator for piping.

Thermal insulator for refrigerant pipe

(Local supply)

Thermal insulator for

piping(Local supply)

Hose clip for thermal insulator(Local supply)

Union for gas pipe

Refrigerant pipe and thermal

insulator(Local supply)

Union for liquid pipe

Thermal insulator for refrigerant pipe

(Local supply)

Hose clip for thermal insulator

(Local supply)

Felt

Rubber

Insulation

No clearance

Cabinet

Page 12

12 Indoor Unit

Installation

CAUTION

Ceiling

Drain Pump use

Drainage hole

Front of view

1. Install declination of the indoor unit is very important for the drain of the duct type air conditioner.

2. Minimum thickness of the insulation for the connecting pipe shall be 19mm.

• The unit must be horizontal or declined to the drain hose connected when finished

installation.

• Drain piping must have down-slope (1/50 to 1/100): be sure not to

provide up-and-down slope to prevent reversal flow.

• During drain piping connection, be careful not to exert extra force

on the drain port on the indoor unit.

• The outside diameter of the drain connection on the indoor unit is

32mm.

•

Be sure to install heat insulation on the drain piping.

Piping material: Polyvinyl chloride pipe VP-25 and

pipe fittings

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

• Connect the main drain pipe to the exterior

and leave it provisionally until the test

comes to an end.

• Feed water to the flexible drain hose and

check the piping for leakage.

• Be sure to check the drain pump for normal

operating and noise when electrical wiring

is complete.

• When the test is complete, connect the

flexible drain hose to the drain port on the

indoor unit.

Heat insulation material: Polyethylene foam with thickness more than 8 mm.

Drain test

Upward

routing

not allowed

Pipe clamp

Maintenance

drain port

Indoor unit

Feed water

Drain Pump

Drain pan

Flexible drain hose

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip

Drain Piping

Page 13

Installation Manual 13

ENGLISH

Installation

CAUTION:

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specialized for the air conditioner. As for the method of

wiring, be guided by the circuit diagram posted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screws which fasten the wiring in the casing of electrical fittings are liable to come loose

from vibrations to which the unit is subjected during the course of transportation. Check them

and make sure that they are all tightly fastened. (If they are loose, it could give rise to burn-out

of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage

marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point, fuse breaking, disturbance by the nor-

mal function of an overload protection device.

• Proper starting power is not given to the compressor.

HAND OVER

Teach the customer the operation and maintenance procedures, using the operation manual.

(air filter cleaning, temperature control, etc.)

1/50~1/100 slope

Hanger

distance

Hanger Bracket

Max 700mm

Flexible drain hose

Insulation

Metal

clamp

Max 300mm

1~15m

CAUTION : The supplied flexible drain

hose should not be curved, neither

screwed. The curved or screwed hose

may cause a leakage of water.

4 EA

Name

Quantity

Shape

for gas pipe

for liquid pipe

Clamp metal

2 EA

Insulation for

fitting

1 SET

Drain hose

1 EA

Clamp

(Tie Wrap)

8 EA

Washer for

hanging backet

(Other)

Standard Accessories

• Owner's manual

• Installation manual

Page 14

14 Indoor Unit

WIERED REMOTE CONTROLLER INSTALLATION

• Since the room temperature sensor is in the remote controller, the remote controller box should be installed in a place

away from direct sunlight, high humidity and direct supply of cold air to maintain proper space temperature.

Install the remote controller about 5ft(1.5m) above the floor in an area with good air circulation at an average temperature.

Do not install the remote controller where it can be affected by:

- Drafts, or dead spots behind doors and in corners.

- Hot or cold air from ducts.

- Radiant heat from sun or appliances.

- Concealed pipes and chimneys.

- Uncontrolled areas such as an outside wall behind the remote controller.

- This remote controller is equipped with a seven segment LED. display. For proper display of the remote controller

LED's, the remote controller should be installed properly as shown in Fig.1.

(The standard height is 1.2~1.5 m from floor level.)

R

e

m

o

t

e

C

o

n

t

r

o

l

l

e

r

T

E

M

P

5feet

(1.5meters)

no

no

no

yes

Remote Controller

TEMP

Remote Controller

TEMP

Fig.1 Typical locations for remote controller

Installation

Page 15

Installation Manual 15

Installation

ENGLISH

Installation of Wired Remote Controller

1. Please fix tightly using provided screw after placing remote controller setup board on the place where

you like to setup.

- Please set it up not to bend because poor setup could take place if setup board bends.

Please set up remote controller board fit to the reclamation box if there is a reclamation box.

2. Can set up Wired remote controller cable into three directions.

- Setup direction: the surface of wall reclamation, upper, right

- If setting up remote controller cable into upper and right side, please set up after removing remote controller

cable guide groove.

❈

Remove guide groove with long nose.

①

Reclamation to the surface of the wall

②

Upper part guide groove

③

Right part guide groove

Wall

Side

Wall

Side

Wall

Side

Wall

Side

<Connecting order>

<Separating order>

3. Please fix remote controller upper part into the

setup board attached to the surface of the wall, as

the picture below, and then, connect with setup

board by pressing lower part.

- Please connect not to make a gap at the remote controller and setup boardʼs upper and lower, right and left

part.

When separating remote controller from setup

board, as the picture below, after inserting into the

lower separating hole using screw driver and then,

spinning clockwise, remote controller is separated.

- There are two separating holes. Please individually

separate one at a time.

- Please be careful not to damage the inside

components when separating.

2

3

1

2

3

<Wire guide grooves>

Page 16

16 Indoor Unit

Installation

4. Please connect indoor unit and remote controller using connection cable.

5. Please use extension cable if the distance between wired remote controller and indoor unit is more

than 10m.

Please check if connector is normally connected.

Connecting cable

Indoor

Unit side

When installing the wired remote controller, do not bury it in the wall.

(It can cause damage in the temperature sensor.)

Do not install the cable to be 50m or above.

(It can cause communication error.)

• When installing the extension cable, check the connecting direction of the connector of the

remote controller side and the product side for correct installation.

• If you install the extension cable in the opposite direction, the connector will not be connected.

• Specification of extension cable: 2547 1007 22# 2 core 3 shield 5 or above.

Page 17

Installation Manual 17

Installation

ENGLISH

Name and function of wired remote controller(Accessory)

※ Some functions may not be operated and displayed depending on the product type.

※ It will display strange value to the room temperature if wired remote controller is not connected.

Model : PQRCVSL0 (Black Color)

PQRCVSL0QW (White Color)

1. Operation indication screen

2. Set temperature button

•

It will set not room temperature but outlet air temperature.

3. Fan speed button

• Fan Speed have 3 Steps.

• Middle and Low step is same

4. ON/OFF button

5. Opration mode selection button

6. Wireless remote controller receiver

• Some products don't receive the wireless signals.

7. Air flow button

8. Subfunction button

9. Function setting button

10. Ventilation button

11. Reservation

12. Up,down,left,right button

• To check the indoor temperature, press button.

13. Room temperature button

• Displays only the room temperature of the remote

controller perception.

• There is no control of room temperature.

• In case of fresh air intake unit, displays only the

temperature around remote controller.

14. Setting/Cancel button

15. Exit button

1

10

9

8

7

11

12

13

14

15

2

3

4

5

6

Please attach the inform label inside of the door.

Please choose proper language depend on your

country.

Page 18

18 Indoor Unit

Installation

Dip Switch Setting

For Multi V Models, Dip switch 1, 2, 6, 8 must be set OFF.

Function Description Setting Off Setting On Default

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

Communication

Cycle

Group Control

Dry Contact Mode

Installation

Heater linkage

Ventilator linkage

Vane selection

(Console)

Region selection

Etc.

N/A (Default)

N/A (Default)

Selection of Master or Slave

Selection of Dry Contact

Mode

Fan continuous operation

N/A

Selection of Ventilator link-

age

Selection of up/down side

Vane

Selection tropical region

Spare

-

-

Master

Wired/Wireless remote

controller

Selection of Manual or Auto

operation Mode

Continuous operation Removall

-

Linkage Removal

Up side + Down side Vane

General model

-

-

-

Slave

Auto

-

-

Working

Up side Vane

Only

Tropical model

-

Off

Off

Off

Off

Off

Off

Off

Off

Page 19

Installation Manual 19

Installation

ENGLISH

Group Control Setting

Wired remote controller 1 + Standard Indoor Units

Dip Switch in PCB (Cassette and Duct Type indoor units)

1. It is possible to 16 indoor units(Max) by one wired remote controller.

Set only one indoor unit to Master, set the others to Slave.

2. It is possible to connect with every type of indoor units.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

GND

Signal

12 V

Master

Slave

Slave

Slave

Master

Display Error Message

Only connect serial signal and GND lines

between slave indoor unit

LGAP Network System

- No. 3 Off - No. 3 On

- The Master indoor unit is possible to recognize Dry Contact and Central Controller only.

- In case of Central controller and Group controller at the same time, it is possible to connect

standard 2series indoor units or later since Feb. 2009.

- In case of Central controller setting, the Central controller can control indoor units after

setting only the address of master indoor unit.

- Slave indoor unit will be operated like master indoor unit.

- Slave indoor unit can not be individually controlled by Central controller.

- Some remote controller can’t perform with Dry Contact and Central controller at the same

time. So contact us further information about it.

1. Group Control 1

Page 20

20 Indoor Unit

Installation

2. Group Control 2

5. In case of any error occurs at indoor unit, display on the wired remote controller.

Exception of the error indoor unit, an individual indoor unit control possibility.

6. In case of Group Control, it is possible to use following functions.

- Selection of operation options (operation/stop/mode/set temperature)

- Control of flow rate (High/Middle/Low)

- It is not possible at some functions.

Master/Slave setting of indoor units be set possible using a PCB Dip Switch.

It is possible to connect indoor units since Feb. 2009.

In the other cases, please contact LGE.

It can be the cause of malfuctions when there is no setting of master and slave.

2. Group Control 2

Wired remote controllers + Standard Indoor Units

LGAP Network System

Master

Master

Slave

Donʼt connect serial 12V line

Display Error Message

Slave

Slave

Slave

GND

Signal

12 V

It is possible to control N indoor units by wired remote controller M units. (M+N≤17 Units)

Set only one indoor unit to Master, set the others to Slave.

Set only one wired remote controller to Master, set the others to Slave.

Other than those, it is same with the Group Control 1.

Page 21

Installation Manual 21

Installation

ENGLISH

Mixture connection with indoor units and Fresh Air Intake Unit

In case of connecting with standard indoor unit and Fresh Intake Unit, separate Fresh Air Intake

Unit with standard units.

(Because setting temperature are different.)

Other than those, it is same with Group Control 1.

GND

Signal

12 V

LGAP Network System

Display Error Message

FAU

Master

FAU

Slave

Master

Master

Master

Slave

FAU

Standard Standard

FAU FAU

Standard Standard

FAU

* FAU : Fresh Air Intake Unit

Standard: Standard Indoor Unit

3. Group Control 3

Page 22

22 Indoor Unit

Installation

Wired remote controller 2 + Indoor unit 1

1. It is possible to connect two wired remote controllers with one indoor unit.

2. Every types of indoor unit is possible to connect two remote controller.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

5. In case of any error occurs at indoor unit, display on the wired remote controller.

6. There isnʼt limits of indoor unit function.

LGAP Network System

Display Error Message

Master

Master

Slave

❈ Maximum 2wired remote controllers can be connected with 1 indoor unit.

4. 2 Remote Control

Page 23

Installation Manual 23

Installation

ENGLISH

Slave

Mas te r

Mas ter

PZCWRCG3

Mas ter S lave

PZCWRC2

Indoor unit 2 EA +Wired remote controller

❈ PZCWRCG3 cable used for connection ❈ PZCWRC2 cable used for connection

Indoor unit 1 EA +Wired remote controller 2EA

It is possible to set group control by using below accessories.

5. Accessories for group control setting

Page 24

24 Indoor Unit

How to Set E.S.P?

How to Set E.S.P?

• If you set ESP incorrectly, the air conditioner may malfunction.

• This setting must be carried out by a certificated-technician.

This is the function that decides the strength of the wind for each wind level and because this function is

to make the installation easier.

•

When setting ESP value on the product without very weak wind or power wind function, it may not

work.

If pressing button long for 3

1

seconds, it enters into remote

controller setter setup mode.

- If pressing once shortly, it enters

into user setup mode. Please press

more than 3 seconds for sure.

If entering into ESP setup mode by using

2

button, it indicates as the picture

below.

ESP step

Function Code ESP value

Function code,

ESP code

ESP value

Select ESP fan step by pressing

3

button. (01: very low, 02: low, 03:

medium, 04: high, 05: power)

Move to ESP value setting by pressing

4

button.

(It is 000 when delivering

from the warehouse.)

Press button to setup ESP value.

5

(It is possible to setup ESP

value from 1 to 255, and 1 is

the smallest and 255 is the

biggest.)

Page 25

Installation Manual 25

ENGLISH

How to Set E.S.P?

• Please be careful not to change the ESP value for each fan step.

• It does not work to setup ESP value for very low/power step for some products.

• ESP value is available for specific range belongs to the product.

Select ESP fan step again by using

6

button and setup ESP value, as No. 4

and 5, that corresponds each wind flow

Press button to save.

7

Press button to exit.

8

❈ After setup, it automatically gets out of

setup mode if there is no button input

for 25 seconds.

Function code,

ESP code

ESP value

❈ When exiting without pressing set

button, the manipulated value is not

reflected.

Page 26

26 Indoor Unit

How to Set E.S.P?

Note :

1. The above table shows the correlation between the air rates and E.S.P.

Setting Value

60 6.02 2.25 0.61 - 65 6.95 3.32 0.73 0.54 0.48

70 7.69 5.16 1.19 0.65 0.56

75 8.46 6.93 2.42 0.77 0.63

80 9.5 7.37 3.4 0.87 0.72

85 10.35 8.72 5.33 1.35 0.88

90 10.81 9.66 6.75 3.15 0.98

95 11.57 10.31 8.56 4.73 1.03

100 12.58 11.22 9.75 7.46 2.31

105 13.31 12.27 10.89 8.64 5.01

110 14.2 13.24 12.15 10.49 7.7

115 14.82 13.92 12.64 11.16 9.48

0(0) 1(10) 2(20) 3(30) 4(40)

Static Pressure(mmAq(Pa))

Setting Value

65 10.07 6.9 0.82 - -

70 11.39 8.49 2.2 - -

75 12.01 9.79 4.2 - -

80 13.21 11.03 5.92 0.92 -

85 14.24 12.36 9.41 2.1 -

90 15.04 13.34 10.8 5.29 1.01

95 16.02 14.63 12.5 7.59 1.34

100 17.11 15.56 13.66 11.53 5.35

105 17.99 16.53 15.17 12.35 7.67

110 19.04 17.71 16.22 14.23 10.45

115 19.77 18.62 17.1 15.23 13.25

120 20.94 19.92 18.56 16.98 14.66

125 21.97 20.56 19.25 17.68 16.06

130 22.83 21.98 20.75 19.32 17.73

0(0) 1(10) 2(20) 3(30) 4(40)

Static Pressure(mmAq(Pa))

ARNU07GB1G2, ARNU09GB1G2, ARNU12GB1G2, ARNU15GB1G2

ARNU18GB2G2, ARNU24GB2G2

(Unit: CMM)

(Unit: CMM)

Page 27

Loading...

Loading...