Page 1

INSTALLATION MANUAL

РУССКИЙ ЯЗЫК

ENGLISH

УКРАÏНСЬКА

ITALIANO

ҚАЗАҚ ТІЛІ

ESPAÑOL

БЕЛАРУСКАЯ МОВА

FRANÇAIS

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring standards by

authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

Convertible

Original instruction

[Representative] LG Electronics Inc. EU Representative : LG Electronics European Shared

Service Center B.V. Krijgsman 1, 1186 DM Amstelveen, The Netherlands

[Manufacturer] LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro, Seongsan-gu,

Changwon-si, Gyeongsangnam-do, KOREA

O‘ZBEK TILI

DEUTSCH

ΕΛΛΗΝΙΚΆ

ČEŠTINA

NEDERLANDS

POLSKI

LIMBA ROMÂNĂ

MFL68800312

Rev.00_052319

www.lg.com

Copyright © 2017 - 2019 LG Electronics Inc. All Rights Reserved.

Page 2

Table of Contents

TABLE OF CONTENTS

3 SAFETY PRECAUTIONS

9 INTRODUCTION

9 Symbols used in this Manual

9 Features

10 INSTALLATION

10 Installation Parts

10 Installation Tools

12 Wired remote controller installation

13 Installation Map

14 Select the best Location

14 Preparing Work for Installation

15 Mounting the installation plate(Wall Mounting)

15 Mounting the anchor Nut & Bolt(Ceiling Mounting)

17 Checking the Drainage

17 Panel Front Assembly

18 Flaring Work

19 Drill a Hole in the Wall

19 Connecting the Piping

21 Precautions when laying power wiring

21 Wiring Connection

23 DIP Switch Setting

24 Group Control Setting

29 Model Designation

29 Airborne Noise Emission

29 Limiting concentration

2 Indoor Unit

Page 3

Safety Precautions

The following symbols are displayed on indoor and outdoor units.

Safety Precautions

ENGLISH

Read the precautions in this manual

carefully before operating the unit.

This symbol indicates that the Operation

Manual should be read carefully.

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

WARNING

!

!

CAUTION

n Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

!

WARNING

This appliance is filled with flammable

refrigerant (R32)

This symbol indicates that a service

personnel should be handling this

equipment with reference to the

Installation Manual.

Installation

• Compliance with national gas regulations shall be observed.

• Do not use a defective or underrated circuit breaker. Use this appliance on a

dedicated circuit.

- There is risk of fire or electric shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized

Service Center.

- Do not disassemble or repair the product. There is risk of fire or electric shock.

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

Installation Manual 3

Page 4

Safety Precautions

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

• Do not install, remove, or re-install the unit by yourself (customer).

- There is risk of fire, electric shock, explosion, or injury.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the case edges and the fins

on the condenser and evaporator.

• For installation, always contact the dealer or an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the air conditioner could fall with it, causing property damage,

product failure, and personal injury.

• Do not turn on the breaker or power under condition that front panel, cabinet, top

cover, control box cover are removed or opened.

- Otherwise, it may cause fire, electric shock, explosion or death.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do

not compress air or Oxygen and Do not use Flammable gases. Otherwise, it may

cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

• Have all electric work done by a licensed electrician according to "Electric Facility

Engineering Standard" and "Interior Wire Regulations" and the instructions given in

this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is performed improperly,

electric shock or fire may result.

• Always intstall a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• The appliance shall be stored in a well-ventilated area where the room size

corresponds to the room area as specified for operation. (for R32)

• The appliance shall be stored in a room without continuously operating ignition

sources (for example: open flames, an operating gas appliance or an operating

electric heater.)

4 Indoor Unit

Page 5

Safety Precautions

• Keep any required ventilation openings clear of obstruction.

ENGLISH

• Mechanical connections shall be accessible for maintenance purposes.

• To prevent the mixing of different types of refrigerants, be sure to check the type of

refrigerant used in the outdoor unit.

Operation

• Do not let the air conditioner run for a long time when the humidity is very high and a

door or a window is left open.

- Moisture may condense and wet or damage furniture.

• Take care to ensure that power cable could not be pulled out or damaged during

operation.

- There is risk of fire or electric shock.

• Do not place anything on the power cable.

- There is risk of fire or electric shock.

• Do not plug or unplug the power supply plug during operation.

- There is risk of fire or electric shock.

• Do not touch(operate) the product with wet hands.

- There is risk of fire or electrical shock.

• Do not place a heater or other appliances near the power cable.

- There is risk of fire and electric shock.

• Do not allow water to run into electric parts.

- There is risk of fire, failure of the product, or electric shock.

• Do not store or use flammable gas or combustibles near the product.

- There is risk of fire or failure of product.

• Do not use the product in a tightly closed space for a long time.

- Oxygen deficiency could occur.

• When flammable gas leaks, turn off the gas and open a window for ventilation before

turn the product on.

- Do not use the telephone or turn switches on or off. There is risk of explosion or fire.

• If strange sounds, smell or smoke comes from product. Turn the breaker off or

disconnect the power supply cable.

- There is risk of electric shock or fire.

• Stop operation and close the window in storm or hurricane.

If possible, remove the product from the window before the hurricane arrives.

- There is risk of property damage, failure of product, or electric shock.

Installation Manual 5

Page 6

Safety Precautions

• Do not open the inlet grill of the product during operation.

(Do not touch the electrostatic filter, if the unit is so equipped.)

- There is risk of physical injury, electric shock, or product failure.

• When the product is soaked (flooded or submerged), contact an Authorized Service

Center.

- There is risk of fire or electric shock.

• Be cautious that water could not enter the product.

- There is risk of fire, electric shock, or product damage.

• Ventilate the product from time to time when operating it together with a stove, etc.

- There is risk of fire or electric shock.

• Turn the main power off when cleaning or maintaining the product.

- There is risk of electric shock.

• When the product is not be used for a long time, disconnect the power supply plug or

turn off the breaker.

- There is risk of product damage or failure, or unintended operation.

• Take care to ensure that nobody could step on or fall onto the outdoor unit.

- This could result in personal injury and product damage.

• When mechanical connectors are reused indoors, sealing parts shall be renewed. (for

R32)

• When flared joints are reused indoors, the flare part shall be re-fabricated. (for R32)

• Periodic ( more than once/year ) cleaning of the dust or salt particles stuck on the heat

exchanger by using water.

• Do not use means to accelerate the defrosting process or to clean, other than those

recommended by the manufacturer.

• Do not pierce or burn refrigerant cycle part.

• Be aware that refrigerants may not contain an odour.

!

CAUTION

Installation

• Always check for gas (refrigerant) leakage after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Install the drain hose to ensure that water is drained away properly.

- A bad connection may cause water leakage.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

6 Indoor Unit

Page 7

Safety Precautions

• Do not install the product where the noise or hot air from the outdoor unit could

ENGLISH

damage the neighborhoods.

- It may cause a problem for your neighbors.

• Use two or more people to lift and transport the product.

- Avoid personal injury.

• Do not install the product where it will be exposed to sea wind (salt spray) directly.

- It may cause corrosion on the product. Corrosion, particularly on the condenser and

evaporator fins, could cause product malfunction or inefficient operation.

• Any person who is involved with working on or breaking into a refrigerant circuit should

hold a current valid certificate from an industry-accredited assessment authority, which

authorises their competence to handle refrigerants safely in accordance with an

industry recognised assessment specification. (for R32)

• The appliance shall be stored so as to prevent mechanical damage from occurring.

• Refrigerant tubing shall be protected or enclosed to avoid damage.

• Flexible refrigerant connectors (such as connecting lines between the indoor and

outdoor unit) that may be displaced during normal operations shall be protected

against mechanical damage.

• The installation of pipe-work shall be kept to a minimum.

• Pipe-work shall be protected from physical damage.

• A brazed, welded, or mechanical connection shall be made before opening the valves

to permit refrigerant to flow between the refrigerating system parts.

• Dismantling the unit, treatment of the refrigerant oil and eventual parts should be done

in accordance with local and national standards.

Operation

• Do not expose the skin directly to cool air for long periods of time. (Don't sit in the

draft.)

- This could harm to your health.

• Do not use the product for special purposes, such as preserving foods, works of art,

etc. It is a consumer air conditioner, not a precision refrigeration system.

- There is risk of damage or loss of property.

• Do not block the inlet or outlet of air flow.

- It may cause product failure.

• Use a soft cloth to clean. Do not use harsh detergents, solvents, etc.

- There is risk of fire, electric shock, or damage to the plastic parts of the product.

Installation Manual 7

Page 8

Safety Precautions

• Do not touch the metal parts of the product when removing the air filter. They are very

sharp!

- There is risk of personal injury.

• Do not step on or put anything on the product. (outdoor units)

- There is risk of personal injury and failure of product.

• Always insert the filter securely. Clean the filter every two weeks or more often if

necessary.

- A dirty filter reduces the efficiency of the air conditioner and could cause product

malfunction or damage.

• Do not insert hands or other objects through the air inlet or outlet while the product is

operated.

- There are sharp and moving parts that could cause personal injury.

• Do not drink the water drained from the product.

- It is not sanitary and could cause serious health issues.

• Use a firm stool or ladder when cleaning or maintaining the product.

- Be careful and avoid personal injury.

• Replace the all batteries in the remote control with new ones of the same type. Do not

mix old and new batteries or different types of batteries.

- There is risk of fire or explosion.

• Do not recharge or disassemble the batteries. Do not dispose of batteries in a fire.

- They may burn or explode.

• If the liquid from the batteries gets onto your skin or clothes, wash it well with clean

water. Do not use the remote if the batteries have leaked.

- The chemicals in batteries could cause burns or other health hazards.

• If you eat the liquid from the batteries, brush your teeth and see doctor. Do not use the

remote if the batteries have leaked.

- The chemicals in batteries could cause burns or other health hazards.

• Servicing shall only be performed as recommended by the equipment manufacturer.

Maintenance and repair requiring the assistance of other skilled personnel shall be

carried out under the supervision of the person competent in the use of flammable

refrigerants. (for R32)

• Means for disconnection must be incorporated in the fixed wiring in accordance with

the wiring rules.

• If the supply cord is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualified persons in order to avoid a hazard.

8 Indoor Unit

Page 9

NOTICE

Introduction

Symbols used in this Manual

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that may cause harm to the

air conditioner.

This symbol indicates special notes.

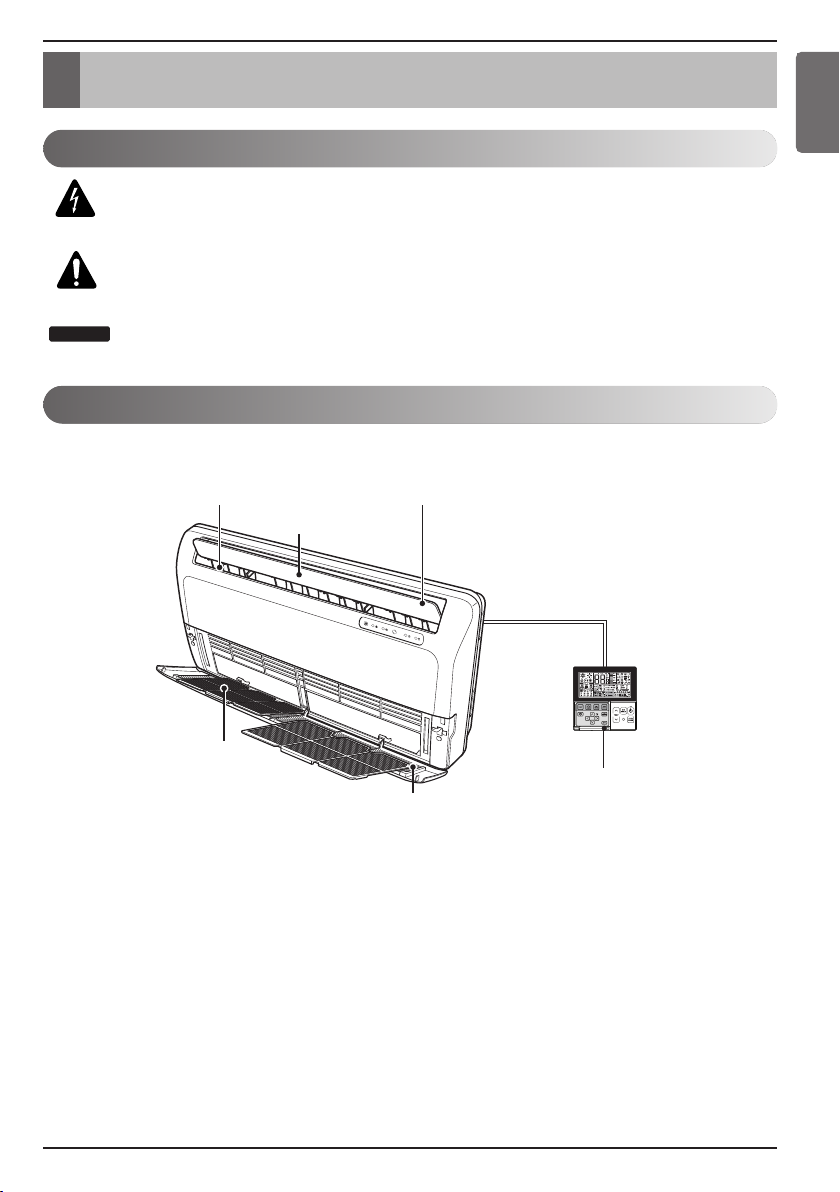

Features

Vertical louver Horizontal louver

Air outlet vent

Introduction

ENGLISH

Air filters

(behind front panel)

Air inlet vent

Remote Controller

(Accessory)

Installation Manual 9

Page 10

Installation

Installation

Read carefully, and then follow step by step.

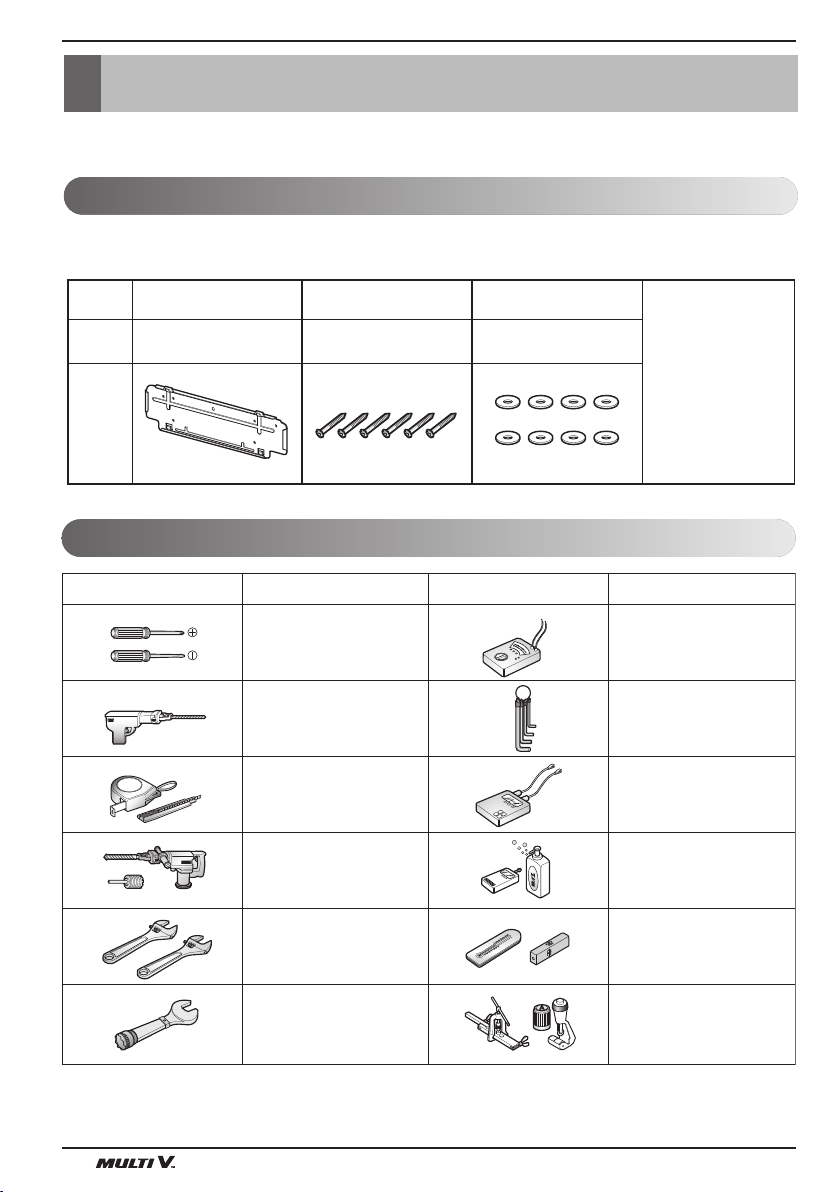

Installation Parts

Standard Accessories

Name

Quantity

Shape

Installation plate

Installation Tools

Figure FigureName

Measuring tape, Knife

Type "A" screw and

plastic anchor

Screw driver

Electric drill

Flat washer

6 EA1 EA

8 EA

Hexagonal wrench

(Other)

• Owner's manual

• Installation manual

• Drain Hose

• Wood screw for indoor

Name

Multi-meter

Ammeter

10 Indoor Unit

Hole core drill

Spanner

Torque wrench

Gas-leak detector

Thermometer,

Level

Flaring tool set

Page 11

Installation

Minimum floor area

(for R32)

ENGLISH

- The appliance shall be installed, operated and stored in a room with a floor area larger than the

minimum area.

- Use the graph of table to determine the minimum area.

Amin (m2)

- m : Total refrigerant amount in the system.

- Total refrigerant amount : factory refrigerant charge + additional refrigerant amount.

- Amin : minimum area for installation.

600

500

400

300

200

100

0

0 1.224 2 3 4 5 6 7 8

Floor standing

Wall mounted

Ceiling mounted

m (kg)

Floor location

m (kg) Amin (m

< 1.224

1.224

1.4 16.82

1.6 21.97

1.8 27.80

2.2 41.53

2.4 49.42

2.6 58.00

2.8 67.27

3.2 87.86

3.4 99.19

3.6 111.20

3.8 123.90

4.2 151.36

4.4 166.12

-

12.9

2 34.32

3 77.22

4 137.29

Floor location

2

m (kg) Amin (m

)

4.6 181.56

4.8 197.70

5 214.51

5.2 232.02

5.4 250.21

5.6 269.09

5.8 288.65

6 308.90

6.2 329.84

6.4 351.46

6.6 373.77

6.8 396.76

7 420.45

7.2 444.81

7.4 469.87

7.6 495.61

7.8 522.04

2

)

Wall mounted

m (kg) Amin (m

< 1.224

1.224

1.4 1.87

1.6 2.44

1.8 3.09

2.2 4.61

2.4 5.49

2.6 6.44

2.8 7.47

3.2 9.76

3.4 11.02

3.6 12.36

3.8 13.77

4.2 16.82

4.4 18.46

-

1.43

2 3.81

3 8.58

4 15.25

Wall mounted

2

m (kg) Amin (m

)

4.6 20.17

4.8 21.97

5 23.83

5.2 25.78

5.4 27.80

5.6 29.90

5.8 32.07

6 34.32

6.2 36.65

6.4 39.05

6.6 41.53

6.8 44.08

7 46.72

7.2 49.42

7.4 52.21

7.6 55.07

7.8 58.00

2

)

Ceiling Mounted

m (kg) Amin (m

< 1.224

1.224

1.4 1.25

1.6 1.63

1.8 2.07

2 2.55

2.2 3.09

2.4 3.68

2.6 4.31

2.8 5.00

3 5.74

3.2 6.54

3.4 7.38

3.6 8.27

3.8 9.22

4 10.21

4.2 11.26

4.4 12.36

2

-

0.956

Installation Manual 11

Ceiling Mounted

m (kg) Amin (m

)

4.6 13.50

4.8 14.70

5 15.96

5.2 17.26

5.4 18.61

5.6 20.01

5.8 21.47

6 22.98

6.2 24.53

6.4 26.14

6.6 27.80

6.8 29.51

7 31.27

7.2 33.09

7.4 34.95

7.6 36.86

7.8 38.83

2

)

Page 12

Installation

Wired remote controller installation

• Since the room temperature sensor is in the remote controller, the remote controller box should be installed in a place

away from direct sunlight, high humidity and direct supply of cold air to maintain proper space temperature.

Install the remote controller about 5 ft (1.5 m) above the floor in an area with good air circulation at an average

temperature.

Do not install the remote controller where it can be affected by:

- Drafts, or dead spots behind doors and in corners.

- Hot or cold air from ducts.

- Radiant heat from sun or appliances.

- Concealed pipes and chimneys.

- Uncontrolled areas such as an outside wall behind the remote controller.

- This remote controller is equipped with a seven segment LED. display. For proper display of the remote controller LED's,

the remote controller should be installed properly as shown in Fig.1.

(The standard height is 1.2~1.5 m from floor level.)

Remote Controller

no

TEMP

Remote Controller

no

TEMP

yes

TEMP

Remote Controller

5 feet

(1.5 m)

Fig.1 Typical locations for remote controller

nonono

12 Indoor Unit

Page 13

Installation

Installation parts you should purchase.

NOTICE

(Left and right

are identical)

(Left and right

are identical)

Sleeve

Bushing-Sleeve

Putty(Gum Type Sealer)

Bend the pipe as closely

on the wall as possible,

but be careful that it

doesn't break.

Vinyl tape (Wide)

• To carry out the drainage

test, remove the air filters

and pour water into the heat

exchanger.

• Apply after carrying out a

drainage test.

Saddle

There should be no space

between ceiling and the unit.

More than

200 mm

More than

200 mm

More than 50 mm

More than 50mm

Ceiling Mounting

Wall Mounting

Installation Map

ENGLISH

!

CAUTION

The Power cord connected to the unit should be selected according to the following

specifications.

Installation Manual 13

Page 14

Installation

NOTICE

Select the best Location

Indoor unit

1. Do not have any heat or steam near the unit.

2. Select a place where there are no obstacles

in front of the unit.

3. Make sure that condensation drainage can be

conveniently routed away.

4. Do not install near a doorway.

5. Ensure that the interval between a wall and

the left (or right) of the unit is more than

200 mm. The unit should be installed as low

as possible on the wall, allowing a minimum

of 50 mm from floor.

6. Use a stud finder to locate studs to prevent

unnecessary damage to the wall.

Preparing Work for Installation

Open panel front

1. Remove the five screws.

2. Release the claws in the 3 places indicated.

3. Pull up the Front Panel.

Cover pipe and cover side remove

1. Pull up the side cover of desired connecting

direction, then cover side is separated.

2. Pick the pipe hole of the side cover.

More than 200 mm

More than 200 mm

More than 50 mm

1

More than 200 mm

More than 50 mm

More than 200 mm

Claw

2

3

!

CAUTION

After removing the pipe hole, cut

the burr for safety.

When making pipe path through rear wall,

you don’t need to pick the pipe hole.

Drain hose junction

1. Remove the rubber stopple in the left side

drain hole. (Do not use the right side drain

hole)

2. Insert drain hose into the handle of drain pan,

and join drain hose and connecting hose

according to the figure by.

14 Indoor Unit

Page 15

Installation

Suspension bolt

piping hole

(Ø 45)

Mounting the installation plate(Wall Mounting)

The wall you select should be strong and solid

enough to prevent vibration

1. Mount the installation plate on the wall with

type "A" screws. If mounting the unit on a

concrete wall, use anchor bolts.

• Mount the installation plate horizontally by

aligning the centerline using a level.

2. Measure the wall and mark the centerline. It

is also important to use caution concerning

the location of the installation plate-routing

of the wiring to power outlets is through the

walls typically. Drilling the hole through the

wall for piping connections must be done

safely.

Type "A" screw

70

Ø 65 mm

Left rear piping

Installation Plate

Installation plate

120

more than 200

Floor

Mounting the anchor Nut & Bolt(Ceiling Mounting)

• Prepare 4 suspension bolts. (Each bolts length

should be same.)

• Measure and mark the position for the Suspension

bolts and the piping hole.

• Drill the hole for anchor nut on the ceiling.

• Insert the nuts and washer onto the suspension

bolts for locking the suspension bolts on the ceiling.

• Mount the suspension bolts to the anchor-nuts

firmly.

• Secure the hangers onto the Suspension bolts

(adjust level roughly.) using nuts, washers.

• Adjust a level with a level gauge on the direction of

left-right, back-forth by adjusting suspension bolts.

• Adjust a level on the direction of top-bottom by

adjusting supension bolts. Then the unit will be

declined to the bottomside so as to drain well.

!

CAUTION

Tighten the nut and bolt to prevent unit falling.

!

CAUTION

• When mechanical connectors are reused

indoors, sealing parts shall be renewed.

(for R32)

• When flared joints are reused indoors, the

flare part shall be re-fabricated. (for R32)

Anchor nut

Ceiling

Nut

Suspension

bolts

piping hole

piping hole

(Ø 45)

(Ø 45)

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Washer

40

820

Suspension bolt

Suspension bolt

Hangen

Ø 65 mm

Right rear piping

Suspension

bolts

Max.

12 mm

Washer

Flat washer for M10

(accessory)

Flat washer for M10

(accessory)

Nut

(W3/8 or M10)

70

235

Nut

Unit : mm

50

100

Reference

of piping

hole (Ø 45)

Unit : mm

ENGLISH

Installation Manual 15

Page 16

Installation

!

CAUTION

Installation Information For right piping. Follow the instruction below.

Good case

For left piping. Follow the instruction below.

1. Press on the upper side of clamp. (Ⓐ)

2. Unfold the tubing to downward slowly. (Ⓑ)

3. Bend the tubing to the left side of chassis.

Bad case

1. Following bending type from right to

left could cause problem of pipe damage.

16 Indoor Unit

Page 17

Installation

Downward slope

Do not raise

Accumulated

drain water

Tip of drain hose

dipped in water

Air

Waving

Water

leakage

Water

leakage

Ditch

Less than

50 mm gap

Water

leakage

Checking the Drainage

1. Set the air direction louvers up-and-down to

the position(horizontally) by hand.

To check the drainage.

1. Pour a glass of water on the evaporator.

2. Ensure the water flows through the drain hose

of the indoor unit without any leakage and

goes out the drain exit.

n Checking the Drainage

1. Remove the Air Filter.

• To remove air filter, take hold of tab and pull

slightly upwards.

2. Check the drainage.

• Spray one or two glasses of water upon the

evaporator.

• Ensure that water flows drain hose of indoor

unit without any leakage.

Drain piping

1. The drain hose should point downward for

easy drain flow.

2. Do not make drain piping like the following.

ENGLISH

Panel Front Assembly

1. Suspend the hook of panel front in

the groove.

2. Press the panel front.

3. Screw up panel front.

1

2

3

Installation Manual 17

Page 18

Installation

Flaring Work

Main cause for gas leakage is due to defect in flaring work. Carry out correct flaring work in the

following procedure.

Cutting the pipes and the cable.

1. Use the piping kit accessory or the pipes

purchased locally.

2. Measure the distance between the indoor

and the outdoor unit.

3. Cut the pipes a little longer than measured

distance.

4. Cut the cable 1.5 m longer than the pipe

length.

Removing burrs

1. Completely remove all burrs from the cut

cross section of pipe/tube.

2. Put the end of the copper tube/pipe in a

downward direction as you remove burrs in

order to avoid dropping burrs into the tubing.

Copper

pipe

90°

Point down

Slanted Uneven Rough

Pipe

Reamer

Putting nut on

• Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after flaring work)

Flaring work

1. Firmly hold copper pipe in a die in the

dimension shown in the table below.

2. Carry out flaring work with the flaring tool.

Pipe diameter

inch (mm)

A inch (mm)

Wing nut type Clutch type

Ø 1/4 (Ø 6.35) 0.04~0.05 (1.1~1.3)

Ø 3/8 (Ø 9.52) 0.06~0.07 (1.5~1.7)

Ø 1/2 (Ø 12.7) 0.06~0.07 (1.6~1.8)

Ø 5/8 (Ø 15.88) 0.06~0.07 (1.6~1.8)

0~0.02

(0~0.5)

Ø 3/4 (Ø19.05) 0.07~0.08 (1.9~2.1)

Check

1. Compare the flared work with the figure by.

2. If a flared section is defective, cut it off and

do flaring work again.

Flare nut

Copper tube

<Wing nut type>

Smooth all round

Even length

all round

Bar

Copper pipe

<Clutch type>

Inside is shiny without scratches

= Improper flaring =

Inclined

Surface

Cracked Uneven

damaged

"A"

thickness

18 Indoor Unit

Page 19

Installation

Connecting pipe

Connecting

cable

Tape

Drain hose

Drill a Hole in the Wall

• Drill the piping hole with a Ø 65 mm hole core

drill. Drill the piping hole at either the right or

the left with the hole slightly slanted to the

outdoor side.

Indoor

WALL

Outdoor

5-7 mm

Connecting the Piping

Indoor

Preparing the indoor unit's piping and drain hose for installation through the wall.

1. Route the indoor tubing and the drain hose in

the direction of rear left or right

ENGLISH

(3/16"~5/16")

2. Tape the tubing, drain hose and the

connecting cable. Be sure that the drain hose

is located at the lowest side of the bundle.

Locating at the upper side can cause drain

pan to overflow inside the unit.

!

CAUTION

If the drain hose is routed inside the room, insulate the hose with an

insulation material* so that dripping from "sweating"(condensation) will

not damage furniture or floors.

*Foamed polyethylene or equivalent is recommended.

Installation Manual 19

Page 20

Installation

Connecting the piping with the indoor

unit and drain hose with drain pipe

1. Align the center of the pipings and sufficiently

tighten the flare nut by hand.

2. Tighten the flare nut with a wrench.

Indoor unit tubing Flare nut Pipings

Outside diameter Torque

mm inch kgf.m

Ø 6.35 1/4 1.8~2.5

Ø 9.52 3/8 3.4~4.2

Ø 12.7 1/2 5.5~6.6

Ø 15.88 5/8 6.3~8.2

Ø 19.05 3/4 9.9~12.1

3. When extending the drain hose at the indoor

unit, install the drain pipe.

Wrap the insulation material around

the connecting portion.

1. Overlap the connection pipe insulation

material and the indoor unit pipe insulation

material. Bind them together with vinyl tape

so that there may be no gap.

2. Wrap the area which accommodates the rear

piping housing section with vinyl tape.

Torque wrench

Indoor unit tubing

Drain pipe

Adhesive

Connection

pipe

Vinyl tape

(wide)

Connecting cable

Vinyl tape(narrow)

Plastic bands

Wrap with vinyl tape

Spanner (fixed)

Flare nut

Connection pipe

Indoor unit drain hose

Insulation material

Indoor

unit pipe

3. Bundle the piping and drain hose together by

wrapping them with vinyl tape over the range

within which they fit into the rear piping

housing section.

20 Indoor Unit

Pipe

Drain hose

Pipe

Vinyl tape(narrow)

Wrap with vinyl tape

Vinyl tape(wide)

Page 21

Installation

Terminal block of indoor unit

Terminal block of outdoor unit

1(L) 2(N) 3 4

Indoor power input

IDU IDU

Outdoor unit

Indoor unit

Central controller

SODU SODU

DRY1

DRY2

GND

INTERNET

12 V

Round pressure terminal

Power cable

Precautions when laying power wiring

Use round pressure terminals for connections to the power terminal block.

When none are available, follow the instructions below.

• Do not connect wiring of different thicknesses to the power terminal block. (Slack in the power

wiring may cause abnormal heat.)

• When connecting wiring which is the same thickness, do as shown in the figure below.

!

CAUTION

Make sure that the screws of the terminal are free from looseness.

ENGLISH

Wiring Connection

• Connect the cable to the indoor unit by connecting the wires to the terminals on the control

board individually according to the outdoor unit connection. (Ensure that the color of the wires of

the outdoor unit and the terminal No. are the same as those of the indoor unit.)

The earth wire should be longer than the common wires.

• When installing, refer to the circuit diagram on the Control Box of Indoor Unit.

• When installing, refer to the wiring diagram on the Control Cover Inside Outdoor Unit.

Installation Manual 21

Page 22

Installation

Air

Conditioner

Main power source

Connection Terminal

2

1.5 mm

L

N

G

1.5 mm

1.5 mm

2

• The capacity of connection terminal should be over 250 V 20 A. And when

2

connecting the power line and communication line between indoor units,

you are advised to use the connection terminal.

• When you are not able to use the connection terminal, fix each power

line/communication line by using the clamp cord attached in the product,

together with the clamp cord and screw in the accessories.

Please consider the all

connected capacity of

indoor units.

!

CAUTION

• The above circuit diagram is subject to change without notice.

• Be sure to connect wires according to the wiring diagram.

• Connect the wires firmly, so that not to be pulled out easily.

• Connect the wires according to color codes by referring the wiring diagram.

!

CAUTION

If a power plug is not to be used, provide a

circuit breaker between power source and

the unit as shown below.

Circuit Breaker

Use a circuit

breaker or time

delay fuse.

!

CAUTION

After the confirmation of the above conditions,

prepare the wiring as follows:

1) Never fail to have an individual power circuit specifically for the air conditioner. As for the method

of wiring, be guided by the circuit diagram posted on the inside of control cover.

2) The screws which fasten the wiring in the casing of electrical fittings are liable to come loose

from vibrations to which the unit is subjected during the course of transportation. Check them

and make sure that they are all tightly fastened. (If they are loose, it could cause burn-out of the

wires.)

3) Specification of power source.

4) Confirm that electrical capacity is sufficient.

5) See to that the starting voltage is maintained at more than 90 percent of the rated voltage marked

on the name plate.

6) Confirm that the cable thickness is as specified in the power source specification.

(Particularly note the relation between cable length and thickness.)

7) Always install an earth leakage circuit breaker where it is wet or moist.

8) The following would be caused by voltage drop.

• Vibration of a magnetic switch, which will damage the contact point, fuse breaking, disturbance of the

normal function of the overload protection device.

9) The means for disconnection from a power

supply shall be incorporated in the fixed wiring and have an air gap contact separation of at least

3mm in each active(phase) conductors.

22 Indoor Unit

Page 23

Installation

DIP Switch Setting

BLDC

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

For Multi V Models, DIP switch 1, 2, 6, 8 must be set OFF.

Function

Communication

Cycle

Group Control

Dry Contact Mode

Install

Heater linkage

Ventilator linkage

-

!

CAUTION

Description

Selection of Communication or Non-communication

Selection of C/O or H/P

Selection of Master or Slave

Selection of Dry Contact Mode

Selection of Ceiling or Floor

Selection of Heater linkage

Selection of Ventilator linkage

-

Setting Off

Communication

Heat Pump

Master

Variable

Ceiling

Linkage Removal

Linkage Removal

Non-communication

-

Setting On

Cooling Only

Slave

Auto

Floor

Working

Working

-

ENGLISH

Default

Off

Off

Off

Off

Off

Off

Off

Off

Installation Manual 23

Page 24

Installation

Group Control Setting

1. Group Control 1

n Wired remote controller 1 + Indoor units

LGAP Network System

Master

Master

Slave

Display Error Message

Slave

Only connect serial signal and GND lines

between slave indoor unit

Slave

GND

Signal

12 V

n DIP Switch in PCB (Cassette and Duct Type indoor units)

Master Setting Slave Setting

- No. 3 Off - No. 3 On

1. It is possible to 16 indoor units(Max) by one wired remote controller.

Set only one indoor unit to Master, set the others to Slave.

2. It is possible to connect with every type of indoor units.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

- The Master indoor unit is possible to recognize Dry Contact and Central Controller only.

- In case of Central controller and Group controller at the same time, it is possible to connect standard 2

series indoor units or later since Feb. 2009.

- In case of Central controller setting, the Central controller can control indoor units after setting only the

address of master indoor unit.

- Slave indoor unit will be operated like master indoor unit.

- Slave indoor unit can not be individually controlled by Central controller.

- Some remote controller can’t perform with Dry Contact and Central controller at the same time.

So contact us further information about it.

24 Indoor Unit

Page 25

Installation

5. In case of any error occurs at indoor unit, display on the wired remote controller.

Exception of the error indoor unit, an individual indoor unit control possibility.

6. In case of Group Control, it is possible to use following functions.

- Selection of operation options (operation/stop/mode/set temperature)

- Control of flow rate (High/Middle/Low)

- It is not possible at some functions.

h Master/Slave setting of indoor units be set possible using a PCB DIP Switch.

h It is possible to connect indoor units since Feb. 2009. In the other cases, please contact LGE.

h It can be the cause of malfuctions when there is no setting of master and slave.

2. Group Control 2

LGAP Network System

Master

Donʼt connect serial 12 V line

Master

Slave

Slave

GND

Signal

12 V

ENGLISH

Display Error Message

Master

Master

h It is possible to control N indoor units by wired remote controller M units. (M+N ≤ 17 Units)

Other than those, it is same with the Group Control 1.

Installation Manual 25

Page 26

Installation

3. Group Control 3

n Mixture connection with indoor units and Fresh Air Intake Unit

LGAP Network System

FAU

Master

Master

FAU

Slave

Display Error Message

Master

Master

Slave

GND

Signal

12 V

h In case of connecting with standard indoor unit and Fresh Intake Unit, separate Fresh Air

Intake Unit with standard units. (Because setting temperature are different.)

h Other than those, it is same with Group Control 1.

FAU

Standard Standard

FAU

Standard Standard

FAUFAU

* FAU : Fresh Air Intake Unit

Standard: Standard Indoor Unit

26 Indoor Unit

Page 27

Installation

4. 2 Remote Control

n Wired remote controller 2 + Indoor unit 1

LGAP Network System

Master

Display Error

Message

Master

1. It is possible to connect two wired remote controllers with one indoor unit.

2. Every types of indoor unit is possible to connect two remote controller.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

5. In case of any error occurs at indoor unit, display on the wired remote controller.

6. There isnʼt limits of indoor unit function.

h Maximum 2 wired remote controllers can be connected with 1 indoor unit.

Slave

ENGLISH

Installation Manual 27

Page 28

Installation

Slave

Master

Master

PZCWRCG3

Master Slave

PZCWRC2

5. Accessories for group control setting

It is possible to set group control by using below accessories.

Indoor unit 2 EA + Wired remote controller Indoor unit 1 EA + Wired remote controller 2 EA

h PZCWRCG3 cable used for connection h PZCWRC2 cable used for connection

28 Indoor Unit

Page 29

Installation

Model Designation

ARN U G12 AVE 4

Airborne Noise Emission

Serial Number

Combinations of functions

A : Basic function L : Neo Plasma(Wall Mounted)

C : Plasma(Ceiling Cassette)

G : Low Static K : High Sensible Heat

U : Floor Standing without Case

SE/S8 - R : Mirror V : Silver B : Blue(ART COOL Type Panel Clolr)

SF - E : Red V : Silver G : Gold 1 : Kiss (Photo changeable)

Q : Console Z : Fresh Air Intake Unit

Chassis Name

Electrical Ratings

1 : 1Ø, 115 V, 60 Hz

6 : 1Ø, 220 - 240 V, 50 Hz

3 : 1Ø, 208/230 V, 60 Hz

Total Cooling Capacity in Btu/h

EX) 5 000 Btu/h ➝ '05' 18 000 Btu/h ➝ '18'

Combination of Inverter Type and Cooling Only or Heat Pump

N : AC Inverter and H/P V : AC Inverter and C/O

U : DC Inverter and H/P and C/O

System with Indoor Unit using R32/R410A

2 : 1Ø, 220 V, 60 Hz

7 : 1Ø, 100 V, 50/60 Hz

G :

1Ø, 220 - 240 V, 50 Hz/1Ø, 220 V, 60 Hz

ENGLISH

The A-weighted sound pressure emitted by this product is below 70 dB.

** The noise level can vary depending on the site.

The figures quoted are emission level and are not necessarily safe working levels. Whilst there is a

correlation between the emission and exposure levels, this cannot be used reliably to determine

whether or not further precautions are required. Factor that influence the actual level of exposure of

the workforce include the characteristics of the work room and the other sources of noise, i.e. the

number of equipment and other adjacent processes and the length of time for which an operator

exposed to the noise. Also, the permissible exposure level can vary from country to country. This

information, however, will enable the user of the equipment to make a better evaluation of the hazard

and risk.

Limiting concentration

Limiting concentration is the limit of Freon gas concentration where immediate measures can be

taken without hurting human body when refrigerant leaks in the air. The limiting concentration shall

be described in the unit of kg/m

n Calculate refrigerant concentration

Refrigerant concentration =

3

(Freon gas weight per unit air volume) for facilitating calculation

Limiting concentration : 0.44 kg/m3(R410A)

Total amount of replenished refrigerant in refrigerant facility (kg)

Capacity of smallest room where indoor unit is installed (m

3

)

Installation Manual 29

Page 30

30 Indoor Unit

Page 31

Loading...

Loading...