LG Multi Type

Air Conditioner

(Ceiling Duct Type)

INSTALLATION MANUAL

LG

IMPORTANT

• Please read this installation manual completely before

installing the product.

• When the power cord is damaged, replacement work shall

be performed by authorized personnel only.

• Installation work must be performed in accordance with

the national wiring standards by authorized personnel

only.

• Please retain this installation manual for future reference after

reading it thoroughly.

website http://www.lgservice.com

e-mail http://lgservice.com/techsup.html

2 Multi Type Air Conditioner

Multi Type Air Conditioner Installation Manual

TABLE OF CONTENTS

Safety Precautions..............3

Introduction .........................6

Installation of Indoor...........7

Connecting Pipes to the

Indoor Unit.........................12

Connecting Pipes to the ..14

Checking the Drainage .....14

Connecting Cables

between Indoor Unit .........15

Group Control....................17

Two Thermistor system....17

E.S.P.(External Static

Pressure) Setting...............18

How to Set E.S.P? .............19

Installation

Requirements

Required Parts Required Tools

•

Four Type “A” screws

•

Connecting cable

•

Level

•

Screw driver

•

Electric drill

•

Hole core drill(ø70mm)

•

Pipes: Gas side ...........

1

/2",3/8"

Liquid side...........................

1

/4"

•

Insulated drain hose

•

Insulation materials

•

Flaring Tools set

•

Additional Drain hose

(Inner Dia...............25mm)

•

Screw driver

•

Hexagonal Wrench (4mm/5mm)

•

Gas-leak Detector

Safety Precautions

Installation Manual 3

To prevent injury to the user or other people and property damage, the following instructions must be

followed.

■ Be sure to read before installing the air conditioner.

■ Be sure to observe the cautions specified here as they include important items related to safety.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Installation

Be sure not to do.

Be sure to follow the instruction.

Safety Precautions

Do not use a defective or

underrated circuit breaker.

Use this appliance on a

dedicated circuit.

• There is risk of fire or electric

shock.

For electrical work, contact

the dealer, seller, a

qualified electrician, or an

Authorized Service Center.

• Do not disassemble or repair

the product. There is risk of

fire or electric shock.

Always ground the

product.

• There is risk of fire or electric

shock.

Install the panel and the

cover of control box

securely.

• There is risk of fire or electric

shock.

Always install a dedicated

circuit and breaker.

• Improper wiring or installation

may cause fire or electric

shock

Use the correctly rated

breaker or fuse.

• There is risk of fire or electric

shock.

Safety Precautions

■ Operation

4 Multi Type Air Conditioner

Do not modify or extend

the power cable.

• There is risk of fire or electric

shock.

Do not let the air

conditioner run for a long

time when the humidity is

very high and a door or a

window is left open.

• Moisture may condense and

wet or damage furniture.

Be cautious when

unpacking and installing

the product.

• Sharp edges could cause

injury.Be especially careful of

the case edges and the fins on

the condenser and evaporator.

For installation, always

contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric

shock, explosion, or injury.

Do not install the product

on a defective installation

stand.

• It may cause injury, accident,

or damage to the product.

Be sure the installation

area does not deteriorate

with age.

• If the base collapses, the air

conditioner could fall with it,

causing property damage,

product failure, and personal

injury.

Do not store or use flammable gas or combustibles near the product.

• There is risk of fire or failure of product.

Gasolin

Installation Manual 5

Safety Precautions

Always check for gas

(refrigerant) leakage after

installation or repair of

product.

• Low refrigerant levelsmay

cause failure of product.

Install the drain hose to

ensure that water is

drained away properly.

• A bad connection may cause

water leakage.

Keep level even when

installing the product.

• To avoid vibration or water

leakage.

Do not install the product

where the noise or hot air

from the outdoor unit could

damage the neighborhoods.

• It may cause a problem for

your neighbors.

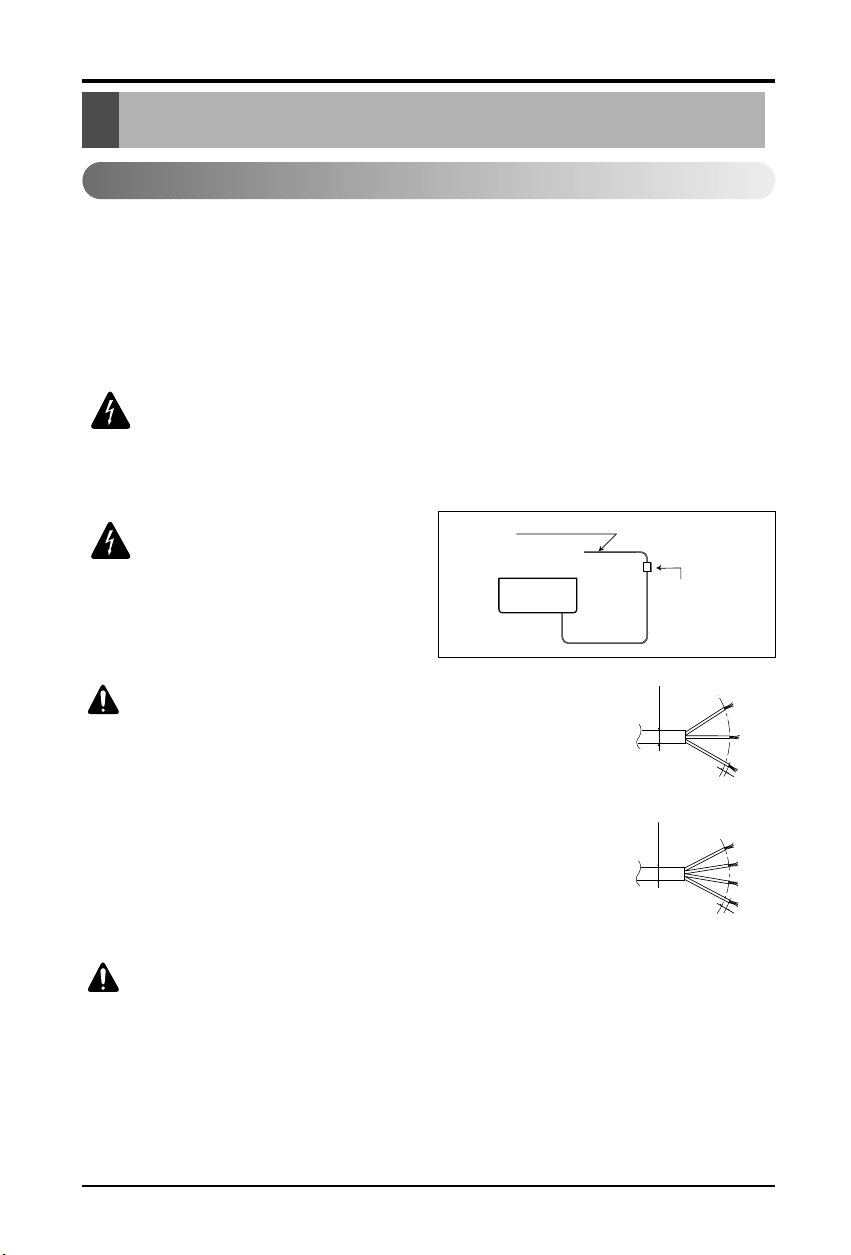

Use two or more people to

lift and transport the

product.

• Avoid personal injury.

Do not install the product

where it will be exposed to

sea wind (salt spray)

directly.

• It maycause corrosion on the

product. Corrosion,particularly

on thecondenser and evaporator

fins, could cause product

malfunction orinefficient

operation.

■ Installation

90˚

6 Multi Type Air Conditioner

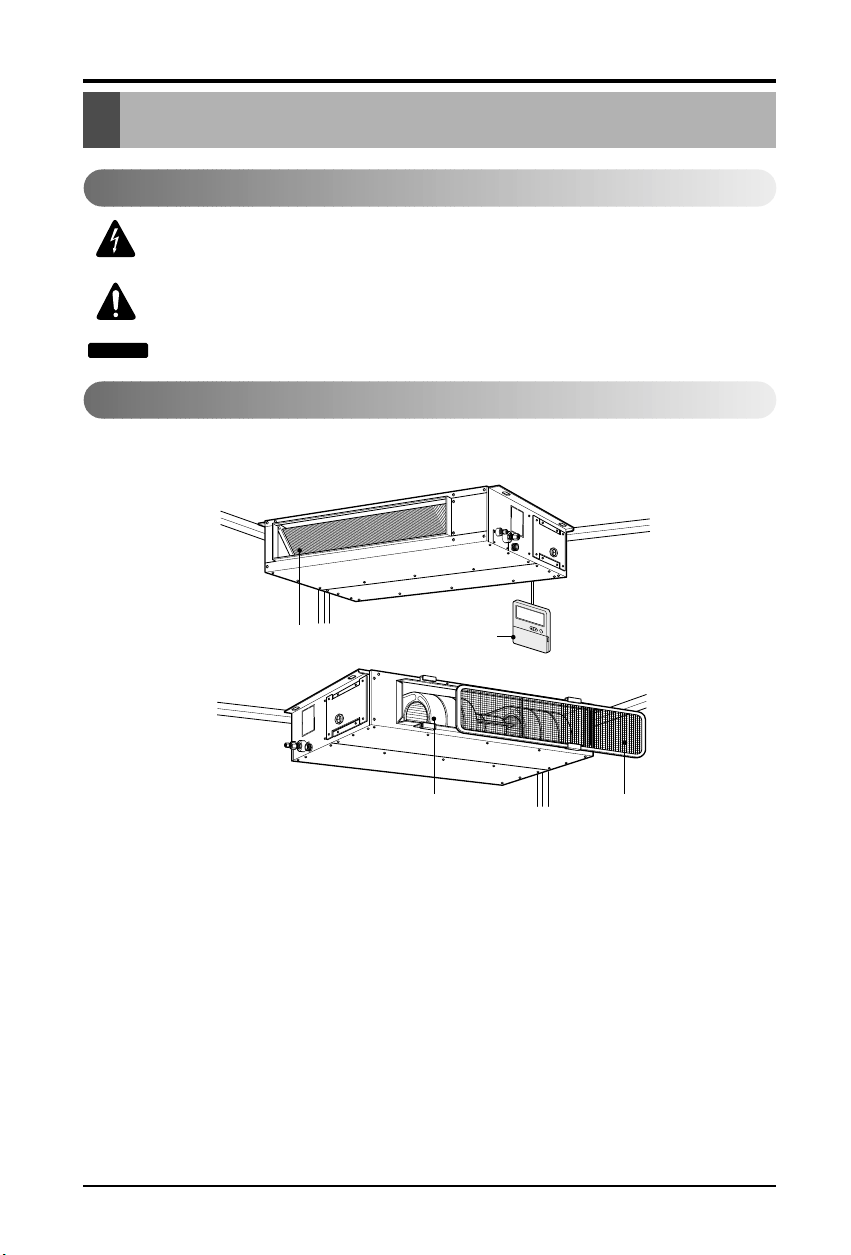

Introduction

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

NOTICE

Introduction

Symbols Used in this Manual

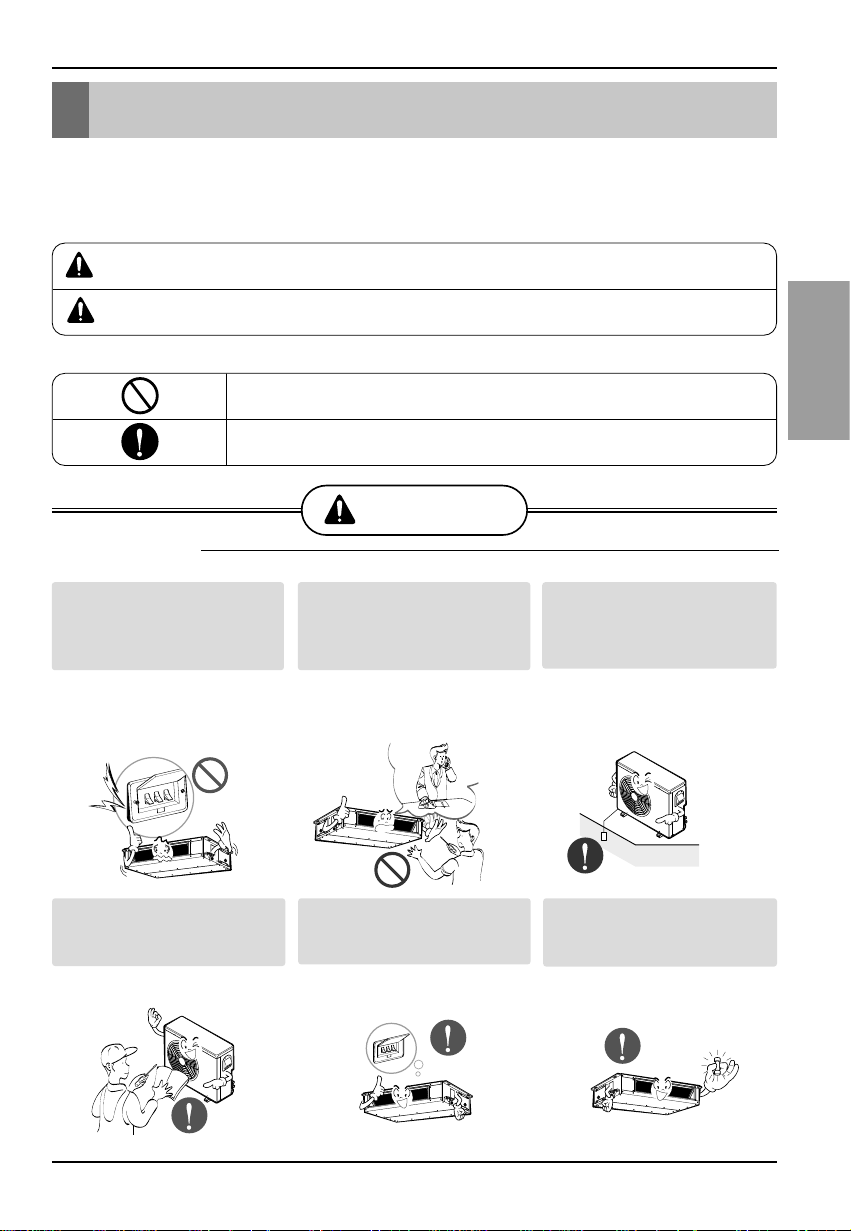

Features

Air filters

Air intake vents

Remote Controller

Air outlet vents

Installation Manual 7

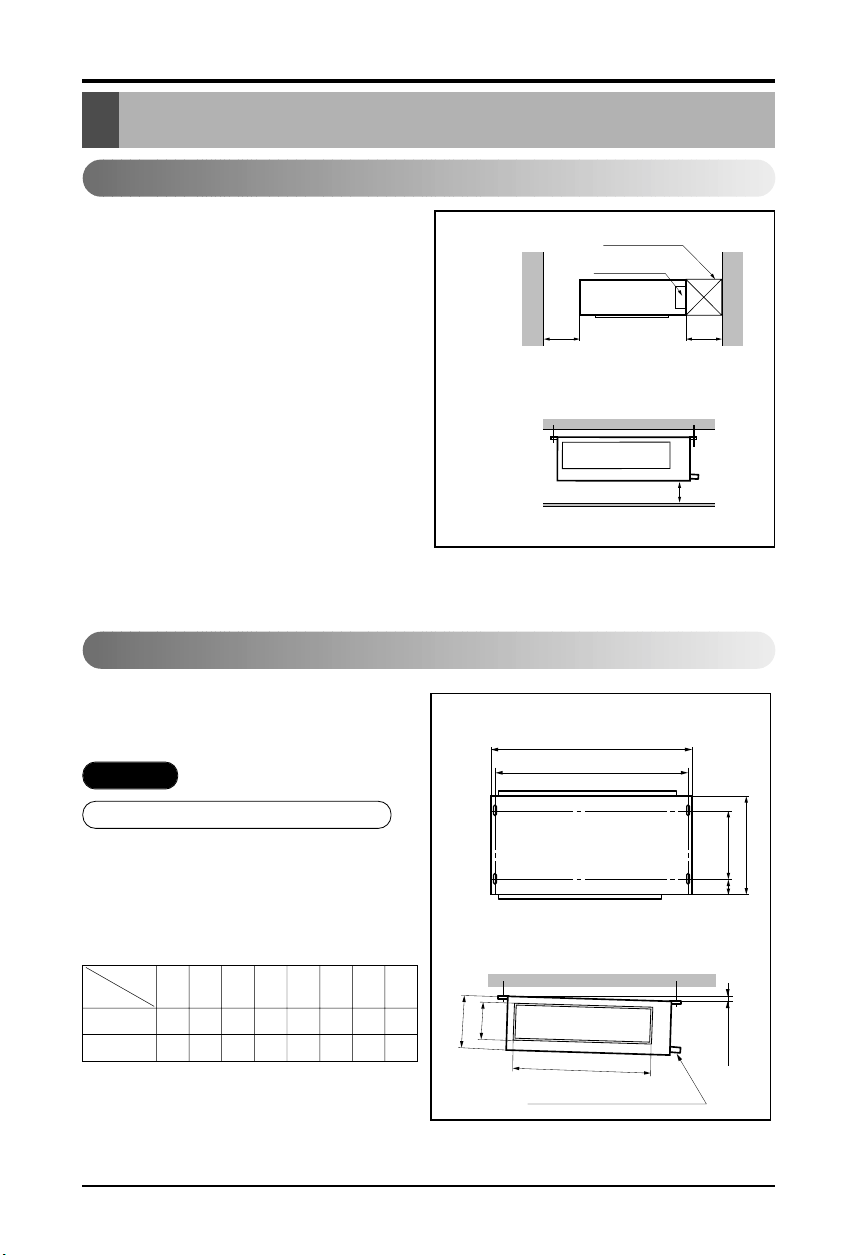

Installation of Indoor

Installation of Indoor

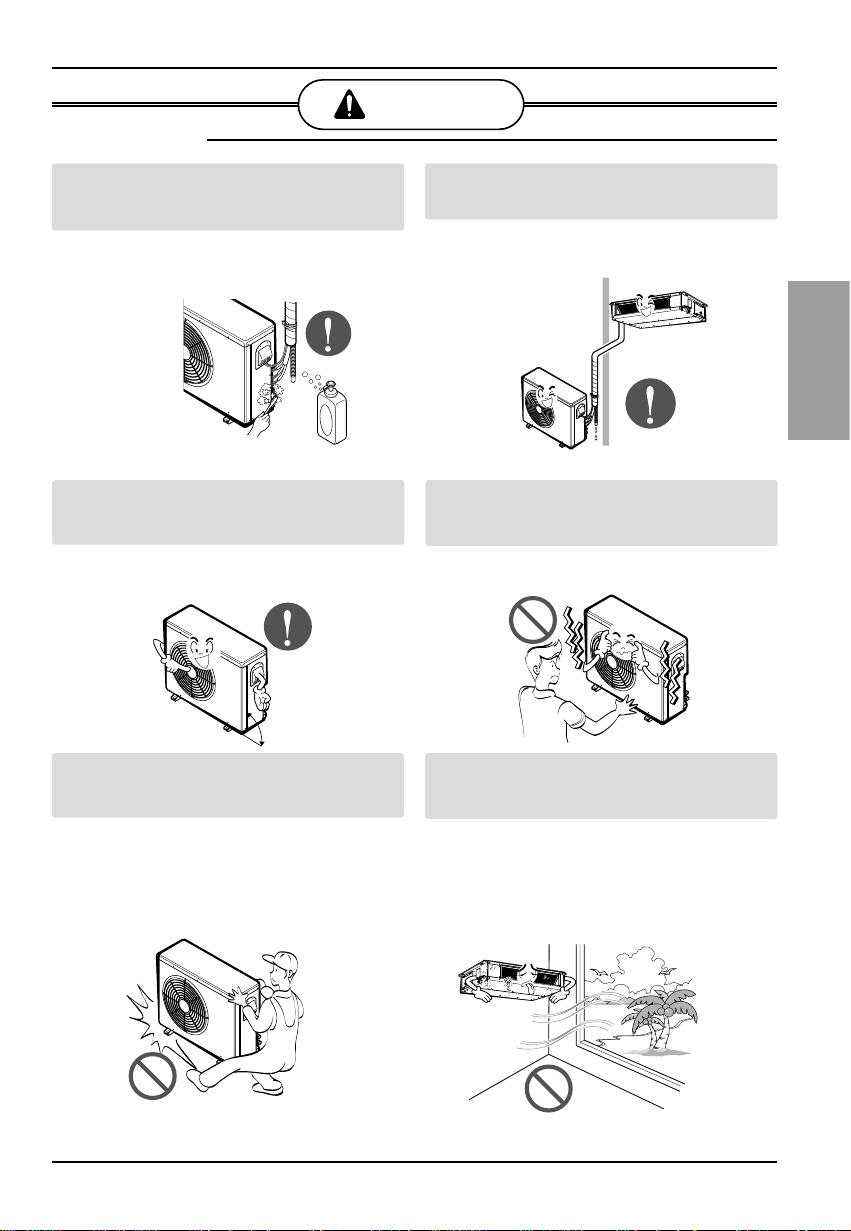

Selection of the best location

1) Indoor unit

Select location

Install the air conditioner in the location that

satisfies the following conditions.

• The place shall easily bear a load exceeding

four times the indoor unit’sweight.

• The place shall be able to inspect the unit as

the figure.

• The place where the unit shall be leveled.

• The place shall allow easy water

drainage.(Suitable dimension “H” is necessary

to get a slope to drain as figure.)

• The place shall easily connect with the

outdoor unit.

• The place where the unit is not affected by an

electrical noise.

• The place where air circulation in the room will

be good .

• There should not be any heat source or steam

near the unit

H

600600

Top view

(unit: mm)

Front view

Inspection hole

(600X600)

Control box

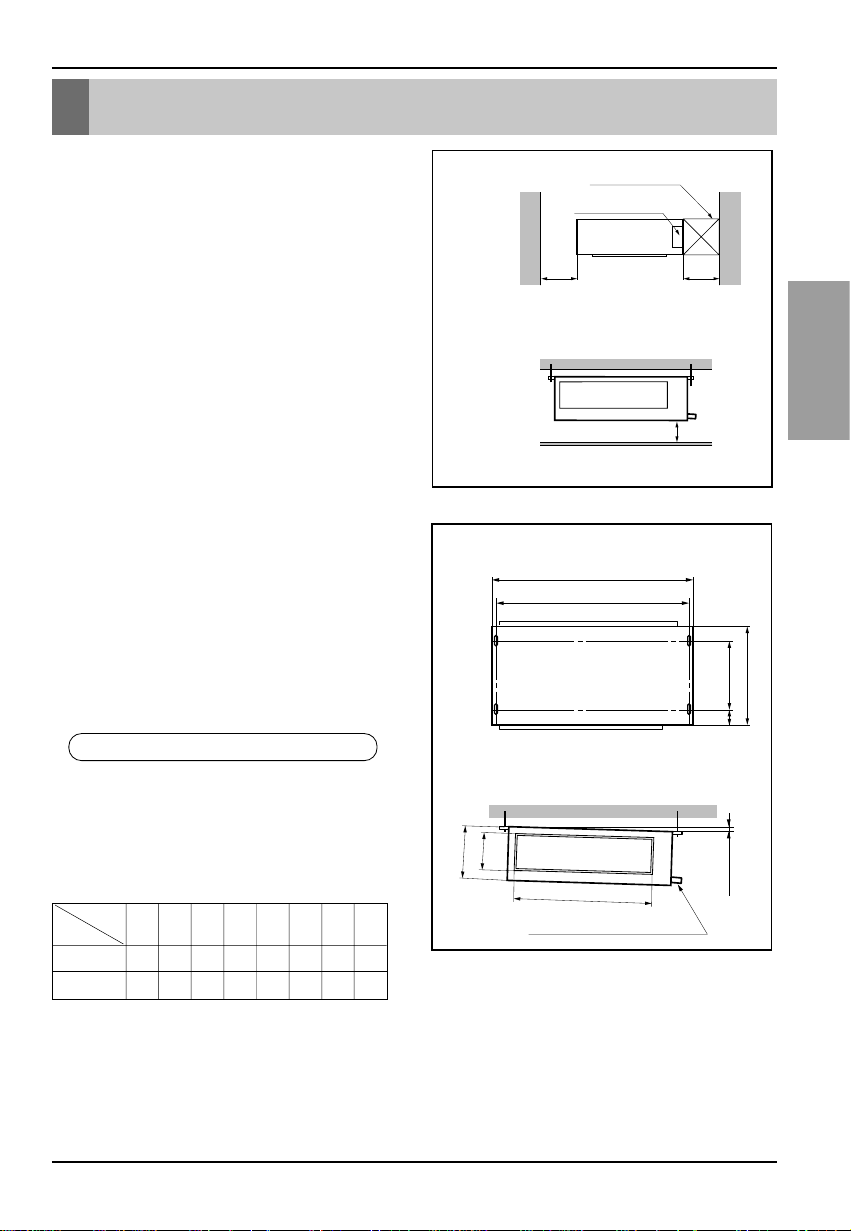

Indoor unit installation

■ Installation of Unit

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and

duct to absorb unnecessary vibration.

• Apply a filter Accessory at air return hole.

CASE 1

POSITION OF SUSPENSION BOLT

(Unit:mm)

9/12K 708 678 434 51 537 455 230 172

18K 1060 1030 434 51 535 805 230 175

Dimension

Capacity

ABCDEFGH

Drainage hole

A

B

CD

1-3 mm

F

H

G

E

8 Multi Type Air Conditioner

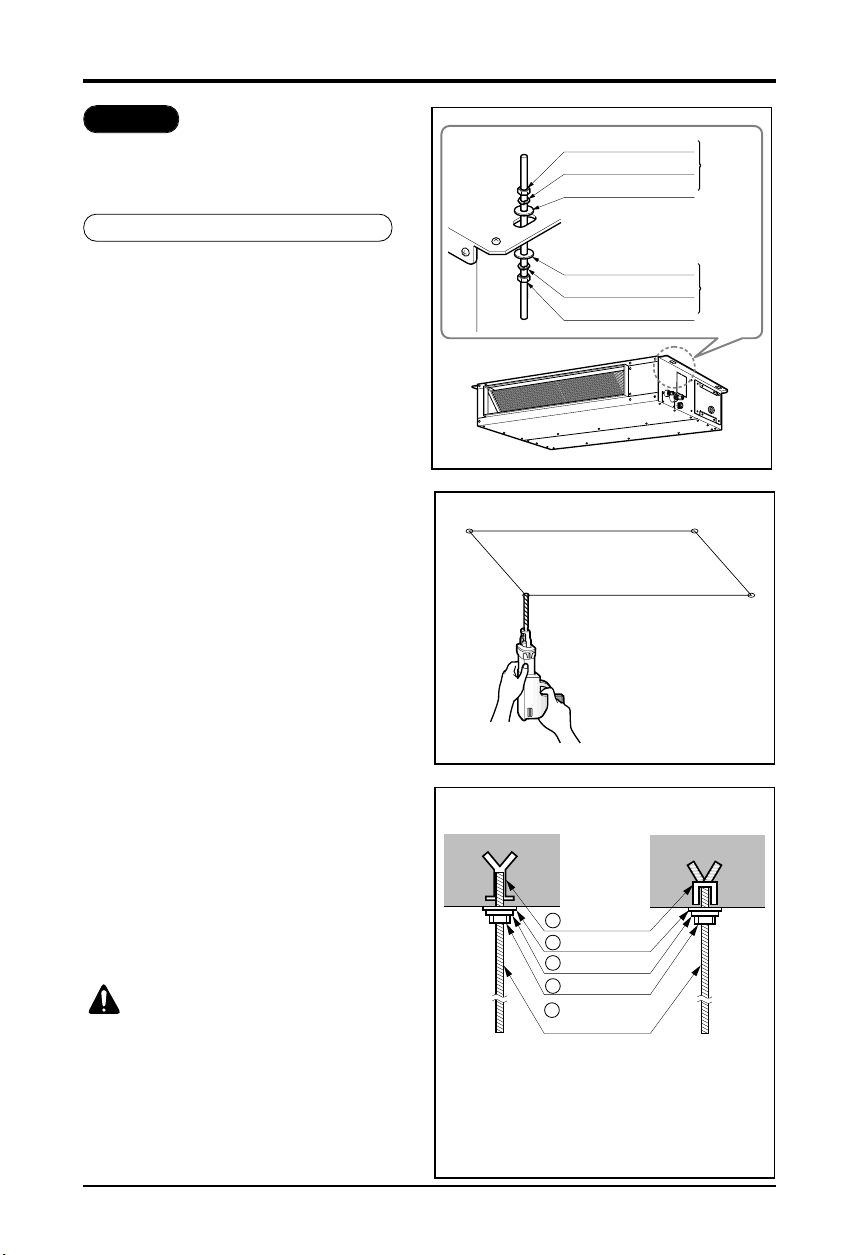

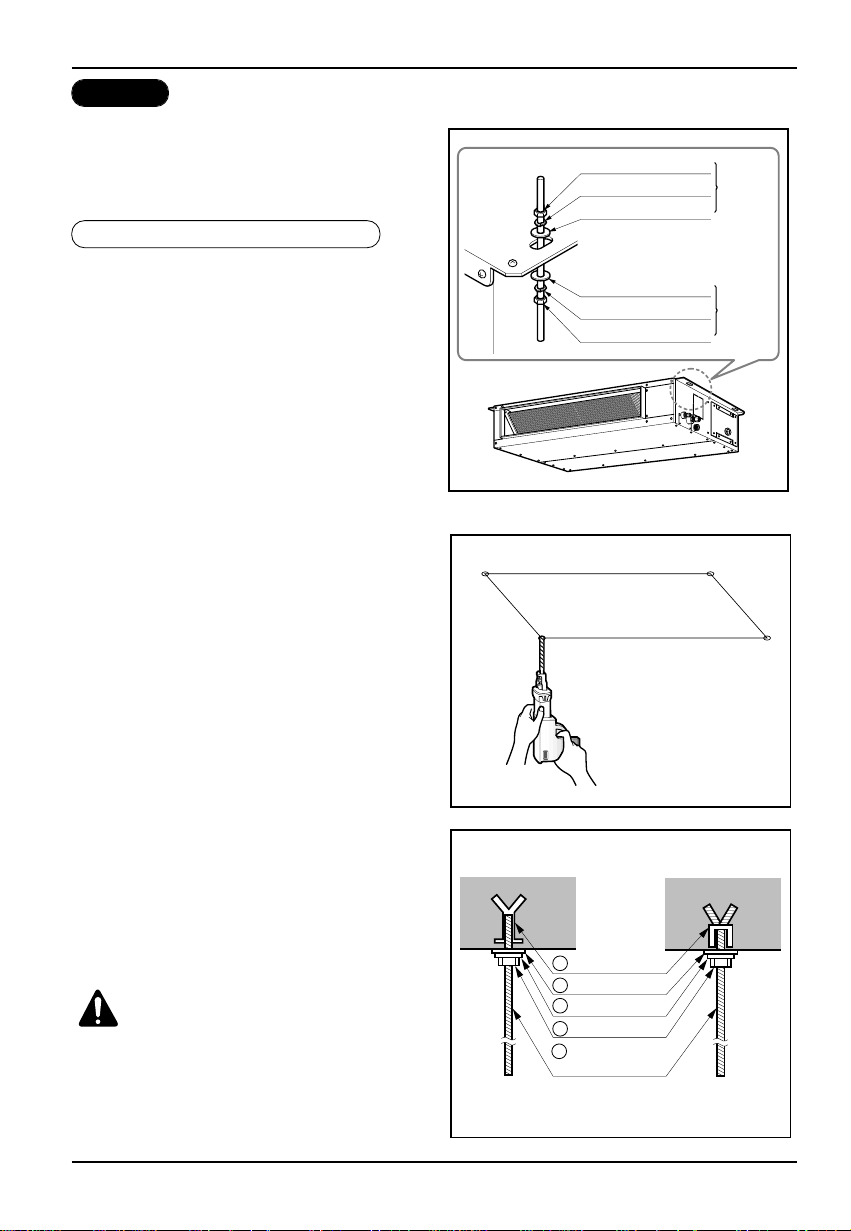

• Select and mark the position for fixing

bolts.

• Drill the hole for set anchor on the face of

ceiling.

• Insert the set anchor and washer onto the

suspension bolts for locking the

suspension bolts on the ceiling.

• Mount the suspension bolts to the set

anchor firmly.

• Secure the installation plates onto the

suspension bolts (adjust level roughly)

using nuts, washers and spring washers.

CAUTION: Tighten the nut and bolt

to prevent unit falling

1 Set anchor

Old building New building

2 Plate washer

3 Spring washer

4 Nut

5 Suspension

bolts

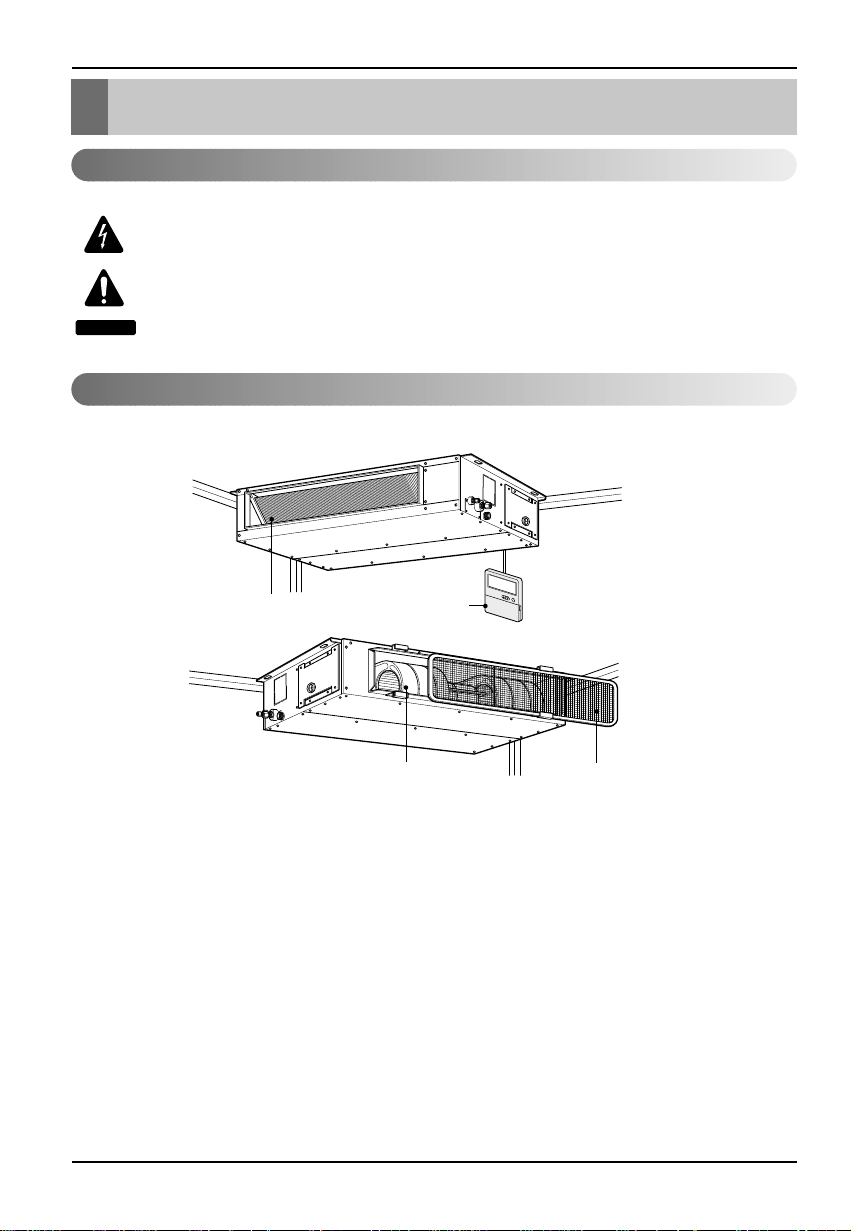

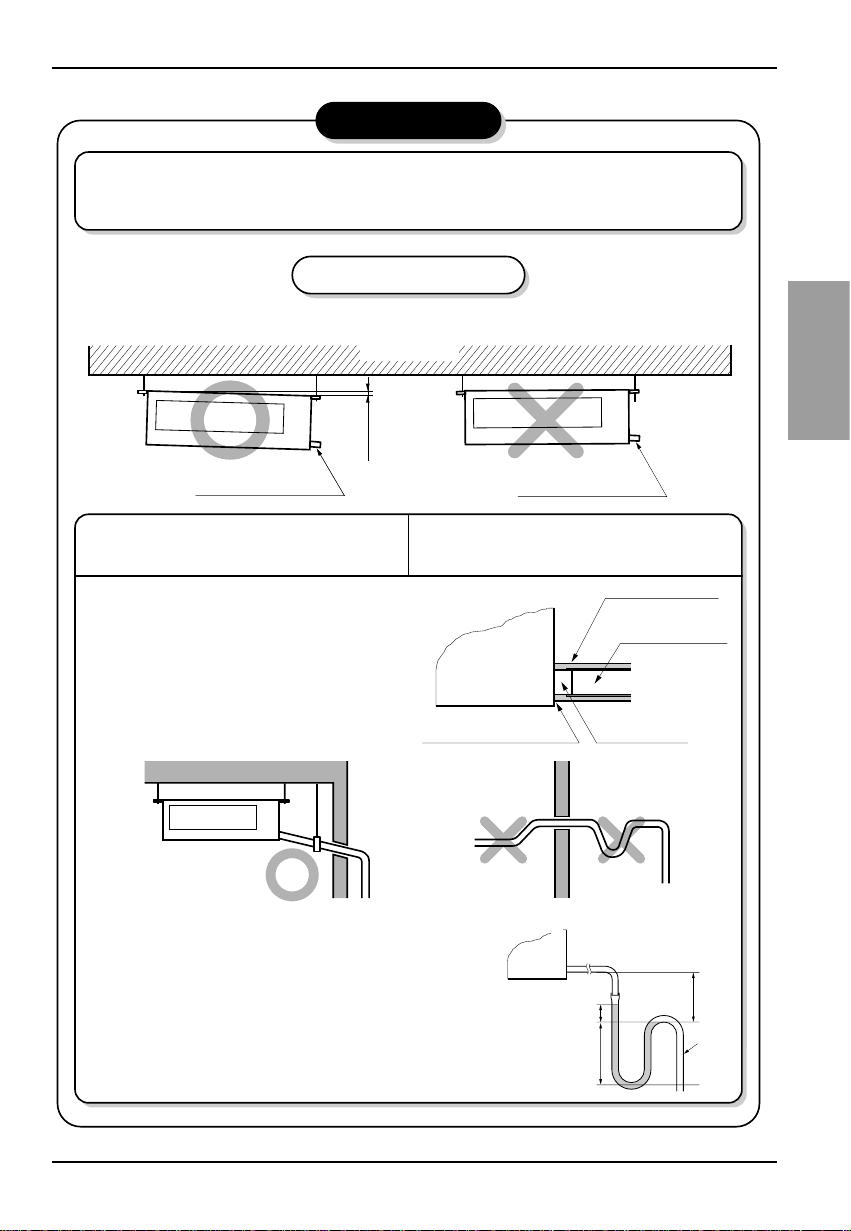

Installation of Indoor

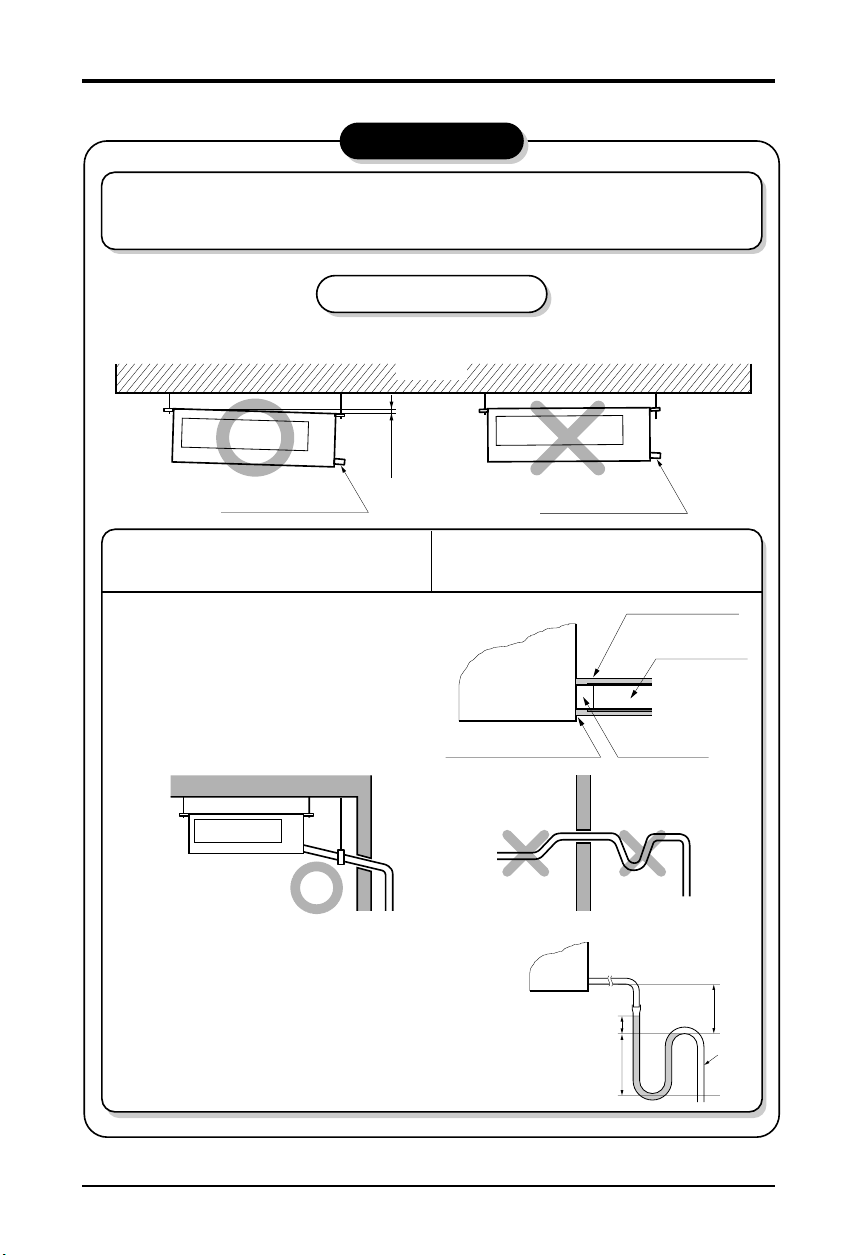

• Install the unit leaning to a drainage hole

side as a figure for easy water drainage.

• A place where the unit will be leveled and

that can support the weight of the unit.

• A place where the unit can withstand its

vibration.

• A place where service can be easily

performed.

CASE 2

POSITION OF CONSOLE BOLT

M10 Nut

M10 SP. washer

M10 washer

X 4

X 4

(Local

supply)

X 4

M10 Nut

M10 SP. washer

M10 washer

X 4

X 4

(Local

supply)

X 4

Installation Manual 9

Installation of Indoor

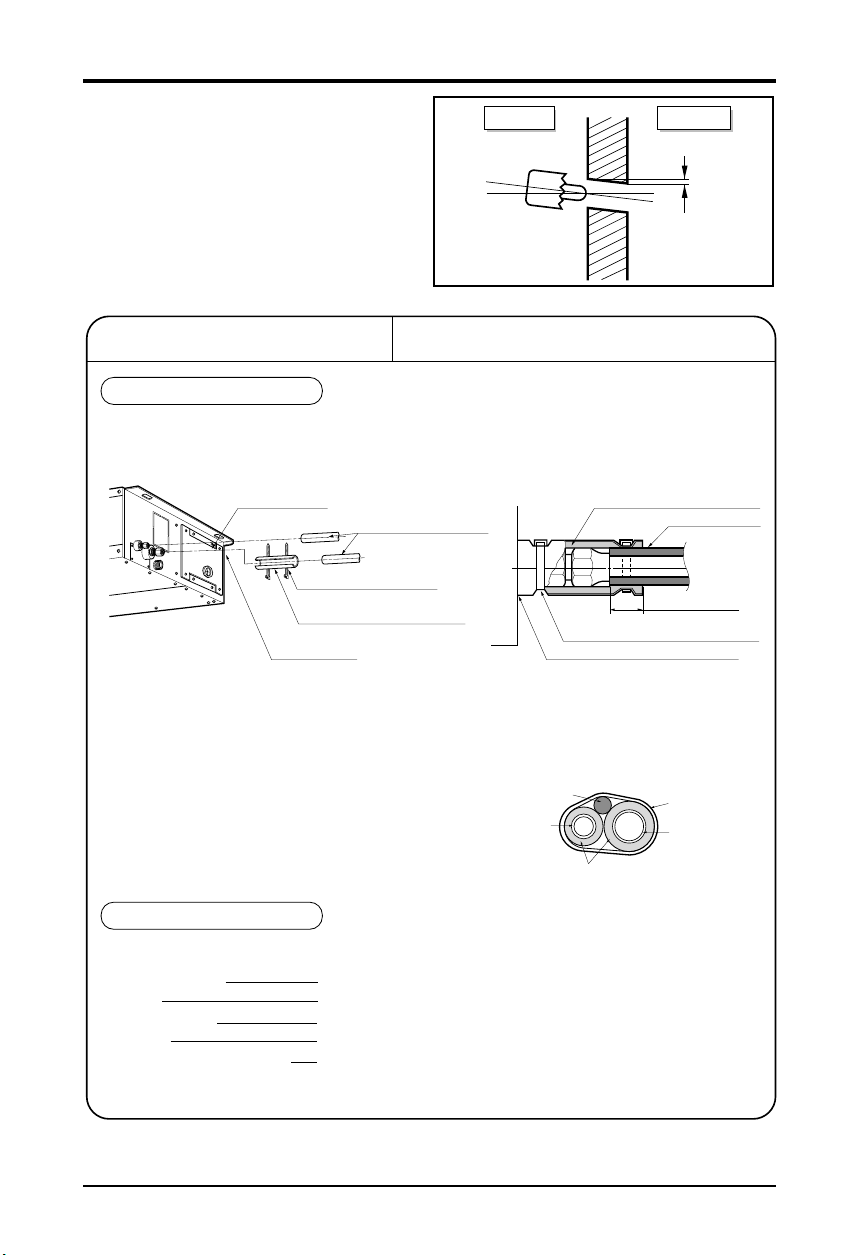

Ceiling

CAUTION

1~3mm

Drainage hole

Drainage hole

U-Trap

B

C

A ≥ 70mm

B ≥ 2C

C ≥ 2 x SP

SP = External Pressure

(mmAq)

Ex) External Pressure

= 10mmAq

A ≥ 70mm

B ≥ 40mm

C ≥ 20mm

A

Make sure to be closed.

Unit

Drainage pipe

(Local supply)

Thermal insulator

(Local supply)

Drainage hole

CAUTION FOR GRADIENT OF

UNIT AND DRAIN PIPING

Lay the drain hose with a downward

inclination so water will drain out.

Front of view

• Always lay the drain with downward

inclination (1/50 to 1/100).

Prevent any upward flow or reverse flow

in any part.

• 5mm or thicker formed thermal insulator

shall always be provided for the drain

pipe.

• Install the P-Trap (or U-Trap) to prevent

a water leakage caused by the blocking

of intake air filter.

Applied U-TrapDimension

1. Install declination of the indoor unit is very important for the drain of the duct type air

conditioner.

2. Minimum thickness of the insulation for the connecting pipe shall be 5mm.

• The unit must be horizontal or declined to the drain hose connected when finished

installation.

CORRECT

CORRECT

INCORRECT

INCORRECT

• Upward routing not

allowed

10 Multi Type Air Conditioner

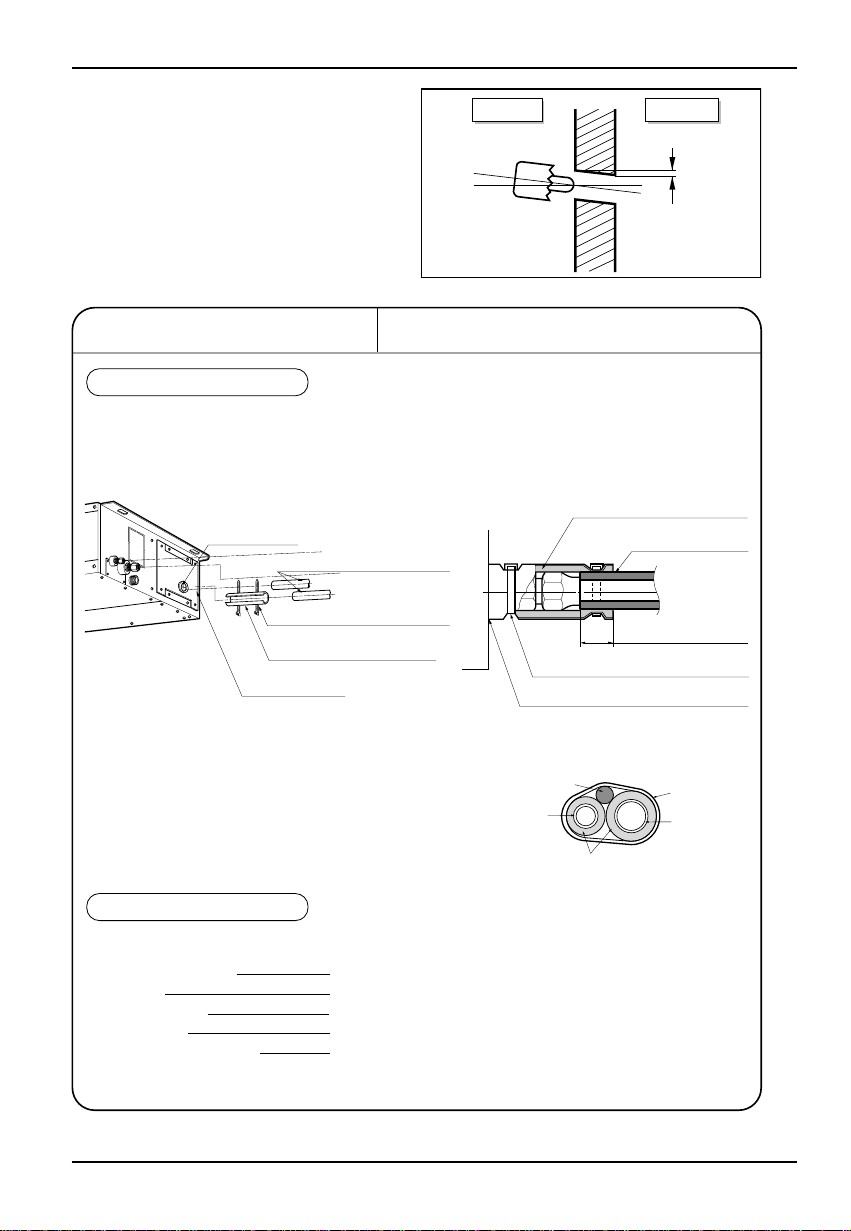

• Drill the piping hole with 70mm dia, hole

core drill.

• Piping hole should be slightly slant to the

outdoor side.

INSULATION, OTHERS

Insulate the joint and tubes completely.

All thermal insulation must comply with local requirement.

INDOOR UNIT

REFRIGERANT PIPE

• Insulate and tape both the gas pipe and

liquid pipe.

■ After all workings are finished, check the working and operation.

• Air distribution Is the air circulation good?

• Drain Is the drainage smoothly and no sweating?

• Gas leakage Is the piping connection correctly?

• Wiring Is the wiring connection correctly?

• Service ValveLock-bolt Is the lock-bolt of Service Valve loosened?

THERMAL INSULATION

TEST AND CHECK

Make sure that there is no clearance here.

Overlap with thermal

insulator for piping.

Thermal insulator for refrigerant pipe

(Local supply)

Thermal insulator for

piping(Local supply)

Hose clip for thermal insulator(Local supply)

Union for liquid pipe

Refrigerant pipe and thermal

insulator(Local supply)

Union for gas pipe

Thermal insulator for refrigerant pipe

(Local supply)

Hose clip for thermal insulator

(Local supply)

Power cable

Liquid pipe

Thermal insulator

Gas pipe

Tape

Installation of Indoor

Indoor Outdoor

WALL

5~7mm

Installation Manual 11

Installation of Indoor

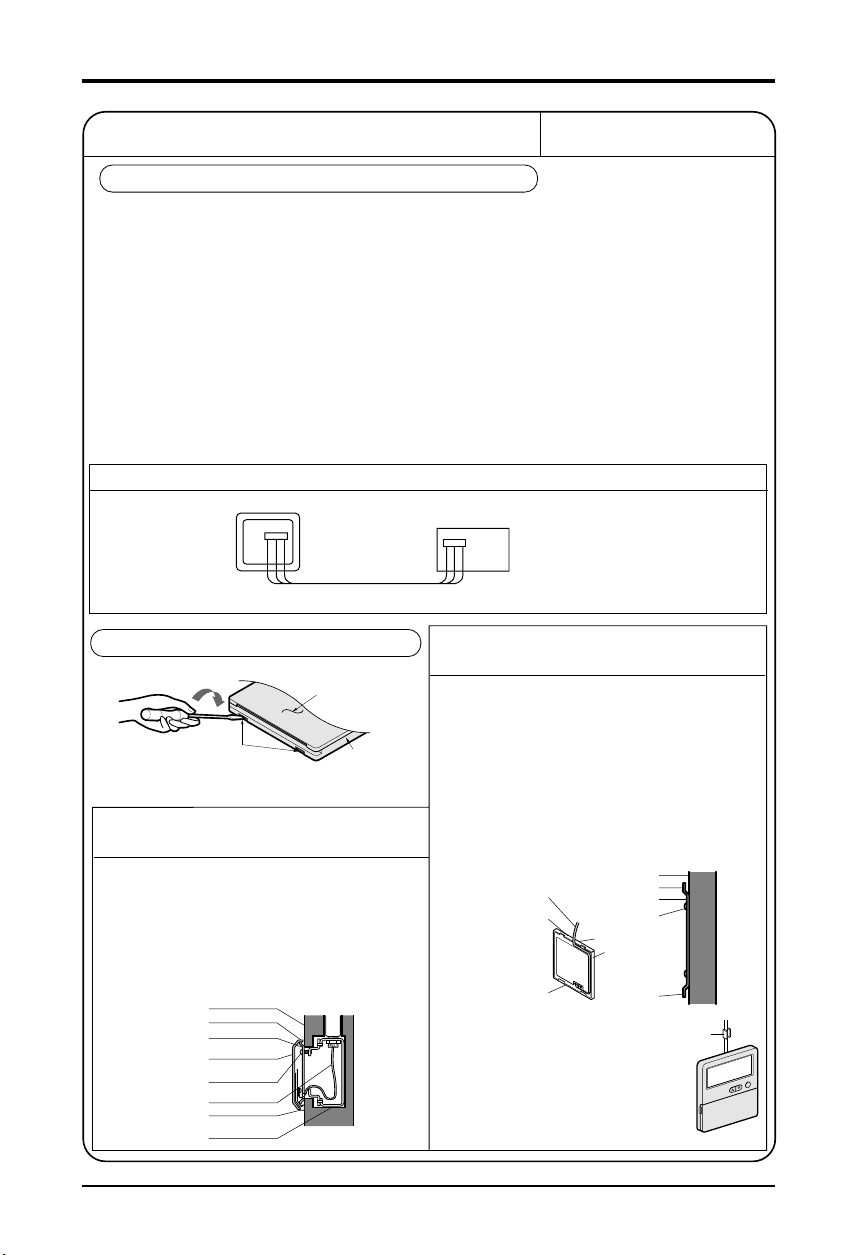

INSTALLATION OF REMOTE CONTROLLER

Install the remote control box

and cord correctly.

• Although the room temperature sensor is in the indoor unit, the remote control box should

be installed in such places away from direct sunlight and high humidity.

INSTALLATION OF THE REMOTE CONTROLLER

• Select places that is not splashed by

water.

• Select control position after receiving

customer approval.

• The room temperature sensor of the

thermostat for temperature control is built

in the indoor unit.

• This remote controller equipped with

liquid crystal display. If this position is

higher or lower,display is difficult to see.

(The standard height is 1.2~1.5m high)

ROUTING OF THE REMOTE CONTROL CORD

• Keep the remote control cord away from

the refrigerant piping and the drain

piping.

• To protect the remote control cord from

electrical noise, place the cord at least

5cm away from other power cables.

(Audio equipment, Television set, etc)

• If the remote control cord is secured to a

wall, provide a trap at the top of the cord

to prevent water droplets from running.

POINT OF REMOTE CONTROLLER INSTALLATION

DISASSEMBLING THE REMOTE CONTROLLER

ELECTRICAL WIRING TO THE INDOOR UNIT

FIXING OF REMOTE

CONTROL CORD

1. Fix the cord clamps on the wall

by ø3 tapping screws(Local supply).

2. Fix the remote control cord.

PROCEDURE OF INSTALLATION

1. Fix the under plate on the switch box by

screws(Local supply). In this case, fit the under

plate on the wall, and be careful of deformation.

2. Receive the remote control cord in the switch box.

3. Hook the remote control unit on the under plate.

WHEN THE REMOTE CONTROLLER IS

INSTALLED WITH THE CORD BURIED.

PROCEDURE OF INSTALLATION

1. Fix the under plate on thewall by self tapping

screws (accessory).

2.Makeaslit(PartA)atthetopsideoftheremote

controller by nipper.

3.Rout the cord as shown in the following figure. In

this case, push the cord into the around of

case(Part B).

4. Hook the remote control unit on the under plate.

WHEN THE REMOTE CONTROLLER IS

INSTALLED WITH THE CORD EXPOSED.

Remote controller

CN REMO

If the length of the cord exceeds 50m, use a wire size greater than 0.5mm

The maximum length of the cord is 100m.

(Main board)

CN REMO

Make sure that wire and terminal

numbers are matched on unit side

and remote controller side.

2

.

Front case

lo

w

e

r p

a

rt

Remote

control

box body

Lever carefully

the box open

using a screw

driver, etc.

T

h

e

Face of wall

Upper notch

Under plate

Remote

control unit

Screw

(Local supply)

Remote

control cord

Lower notch

Switch box

(Local supply)

Remote

control cord

(Part A)

Remote

control unit

Face of wall

Upper notch

Under plate

Tapping screw

(Local supply)

Upper flange

Push hand

(Part B)

Lower notch

Cord

clamp

12 Multi Type Air Conditioner

Connecting Pipes to the Indoor Unit

Connecting Pipes to the Indoor Unit

Preparation of Piping

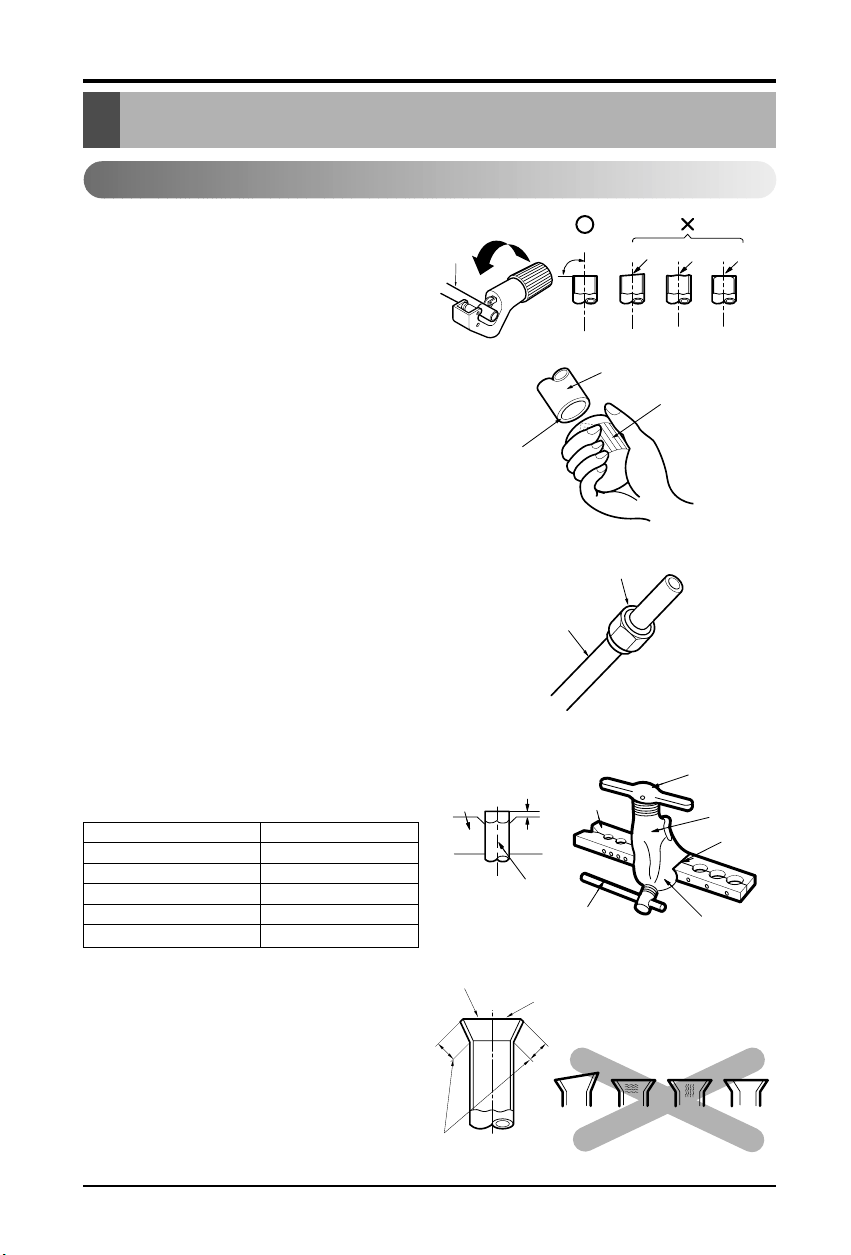

Main cause of gas leakage is defect in flaring

work. Carry out correct flaring work in the

following procedure.

1) Cut the pipes and the cable.

■ Use the accessory piping kit or the pipes

purchased locally.

■ Measure the distance between the indoor

and the outdoor unit.

■ Cut the pipes a little longer than

measured distance.

■ Cut the cable 1.5m longer than the pipe

length.

2) Burrs removal

■ Completely remove all burrs from the cut

cross section of pipe/tube.

■ Put the end of the copper tube/pipe to

downward direction as you remove burrs

in order to avoid to let burrs drop in the

tubing.

3) Putting nut on

■ Remove flare nuts attached to indoor and

outdoor units, than put them on pipe/tube

having completed burr removal.

(Not possible to put them on after flaring

work)

4) Flaring work

■ Carry out flaring work using flaring tool

as shown below.

Firmly hold copper tube in a bar(or die) as

indicated dimension in the table above.

5) Check

■ Compare the flared work with figure.

■ If flare is noted to be defective, cut off the

flared section and do flaring work again.

Copper

tube

90°

Slanted Uneven Rough

Pipe

Reamer

Point down

Flare nut

Copper tube

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shining without scratches.

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Outside Diameter "A"

1/4" 0~0.5

3/8" 0.5~0.8

1/2" 0.5~0.8

5/8" 0.8~1.0

3/4" 1.0~1.3

Installation Manual 13

Connecting Pipes to the Indoor Unit

6) Pipe bending

Annealed copper pipe with small diameter (ø6.35 or ø9.52) can be easily bent manually. In

this case, secure large R(radius) for the bend section and gradually bend pipe. If annealed

copper pipe is large in diameter (ø15.88 or ø19.05), bend pipe with bender. Use bender

appropriate for the pipe diameter.

7)

Brazing

In refrigerant piping, bending (in particular, acute bending) must be minimized to reduce

piping resistance. Bending is, however, necessary in some places by virtue of the installation

position of devices auxiliary to the packaged air conditioner,or of the building structure,

piping distance or finishing appearance. If a more acute bend is required than that attainable

by pipe bender,perform brazing using ready-made elbow. Aside from this function, brazing

also serves to connect straight pipes, generally using ready-made sockets. While brazing,

protect piping against heat with wet cloth to avoid damaging valve packing or burning

thermal insulator with burner heat. While brazing, blow inert gas (nitrogen gas or carbonic

gas) to prevent formation of oxidation film in copper piping; otherwise, the refrigerant circuit

will clog. The blowing of nitrogen gas (or carbonic gas) through 3-way valves is described in

the following:

8)

Refrigerant piping(Flare piping)

When connecting piping, be sure to keep piping dry(keep piping awayfrom water), clean

(keep piping away from dust) and airtight (avoid refrigerant leakage).

When connecting piping on rainy days or making a through-hole in wall, take due care to

prevent water or plaster from entering piping.

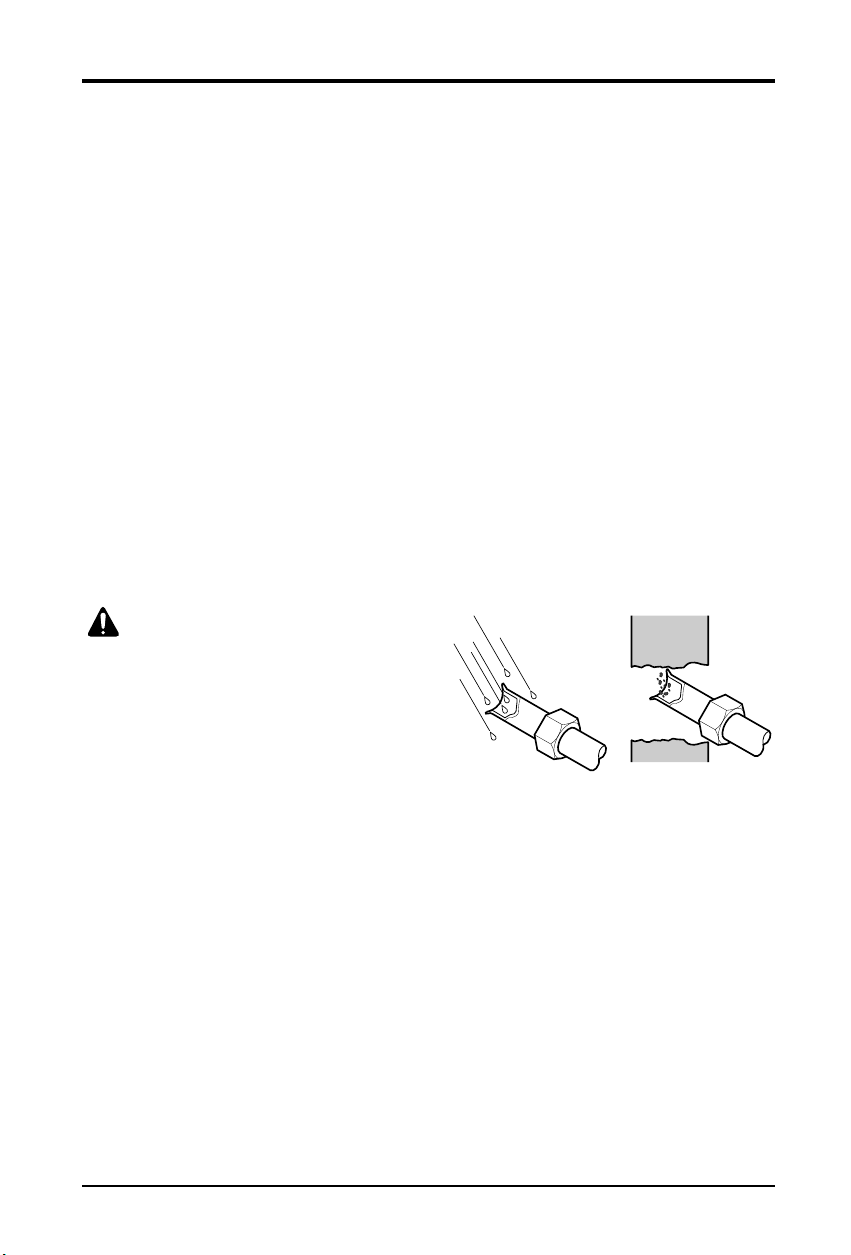

CAUTION: This procedure is

designed to prevent formation of

oxidation film by filling piping with

inert gas. Note that excessive gas

pressure will generate pinholes at

brazed points.

(Nitrogen gas: Supply pressure

0.05~0.1kg/cm2G)

When supplying inert gas, be sure

to open one end of piping.

Water enters Plaster enters

14 Multi Type Air Conditioner

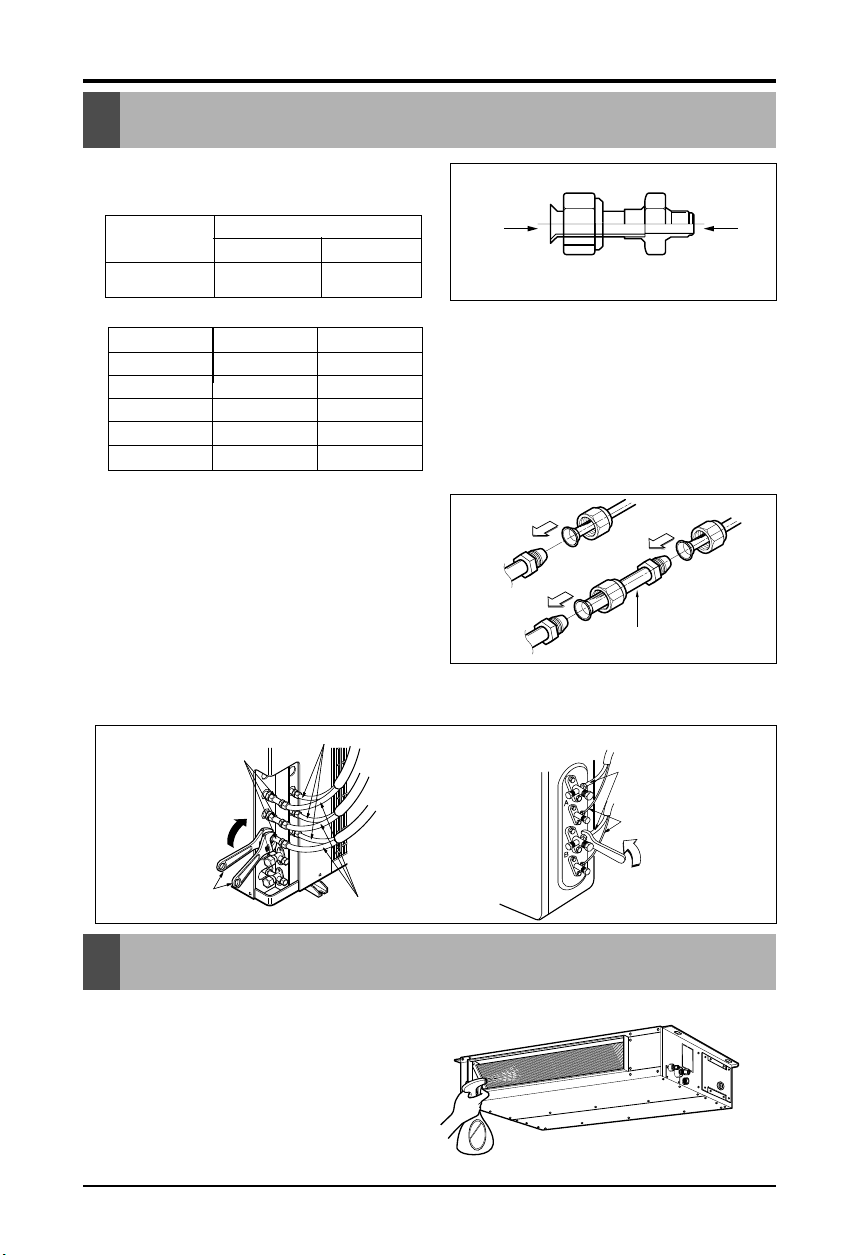

1) Checking the Drainage

1. Check the drainage.

• Spray one or two glasses of water upon

the evaporator.

• Ensure that water flows drain hose of

indoor unit without any leakage.

1. When piping installation work you

must be used the connector.

2. Align the center of the pipings and

sufficiently tighten the flare nut by

hand

3. Finally, tighten the flare nut with

torque wrench until the wrench

clicks.

■ When tightening the flare nut with torque

wrench, ensure the direction for tightening

follows the arrow on the wrench.

Connecting Pipes to the Outdoor Unit

Connecting Pipes to the Outdoor Unit

Checking the Drainage

Indoor Units Gas side Liquid side

7K Ø9.52(3/8") Ø6.35(1/4")

9K Ø9.52(3/8") Ø6.35(1/4")

12K Ø9.52(3/8") Ø6.35(1/4")

18K Ø12.7(1/2") Ø6.35(1/4")

24K Ø12.7(1/2") Ø6.35(1/4")

Indoor Units

Gas

AB

Ø9.52 Ø12.7

A

B

*Connecting pipe size

Outdoor unit Outdoor unit

Connector

Liquid side piping

A-UNIT

B-UNIT

C-UNIT

Connector

A-UNIT

Gas side piping

B-UNIT

Liquid side piping

Torque

wrench

Torque wrench

Gas side piping

Installation Manual 15

Connecting Cables between Indoor Unit and Outdoor Unit

Connecting Cables between Indoor Unit

2) Clamping of cables

1) Arrange 2 power cables on the control panel.

2) First, fasten the steel clamp with a screw to the inner boss of control panel.

3) For the cooling model, fix the other side of the clamp with a screw strongly.

For the heat pump model, put the 0.75mm2cable(thinner cable) on the clamp and tighten it

with a plastic clamp to the other boss of the control panel.

4) In Australia, the length of powersupply cord measured from the entryof the power supply

cord to the middle of live pin on the power plug should be over 1.8m.

WARNING: Make sure that the screws of the terminal are free from looseness.

CAUTION: The power cord connected to the outdoor

unit should be complied with the following

specifications (Rubber insulation, type H05RN-F

approved by HAR or SAA).

The connecting cable connected to the indoor and

outdoor unit should be complied with the following

specifications (Rubber insulation, type H07RN-F

approved by HAR or SAA).

NORMAL

CROSS-SECTIONAL

AREA 2.5mm

2

ø8.5mm

GN/YL

20mm

NORMAL

CROSS-SECTIONAL

AREA 0.75mm

2

ø7.5mm

GN/YL

20mm

Connect the cable to the indoor unit by connecting the wires to the terminals on the

control board individually according to the outdoor unit connection. (Ensure that the color

of the wires of the outdoor unit and the terminal No. are the same as those of the indoor unit.)

The earth wire should be longer than the common wires.

The circuit diagram is not subject to change without notice.

When installing, refer to the circuit diagram behind the panel front of Indoor Unit the

wiring diagram on the Control Cover Inside Outdoor Unit.

Connect the cable to the Indoor unit.

CAUTION:

• The circuit diagram is not subject to change without notice.

• Be sure to connect wires according to the wiring diagram.

• Connect the wires firmly, so that not to be pulled out easily.

• Connect the wires according to color codes by referring the wiring diagram.

Air

Conditioner

Main power source

Circuit Breaker

Use a circuit breaker

or time delay fuse.

CAUTION: Provide a circuit

breaker between power source

and the unit as shown below.

16 Multi Type Air Conditioner

Connecting Cables between Indoor Unit

CAUTION:

After the confirmation of the above conditions, prepare the wiring as follows:

1. Never fail to have an individual power specialized for the air conditioner. As for the

method of wiring, be guided by the circuit diagram pasted on the inside of control box

cover.

2. Provide a circuit breaker switch between power source and the unit.

3. The screw which fasten the wiring in the casing of electrical fittings are liable to come

loose from vibrations to which the unit is subjected during the course of

transportation. Check them and make sure that they are all tightly fastened. (If they

are loose, it could give rise to burn-out of the wires.)

4. Specification of power source

5. Confirm that electrical capacity is sufficient.

6. Be sure that the starting voltage is maintained at more than 90 percent of the rated

voltage marked on the name plate.

7. Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8. Never fail to equip a leakage breaker where it is wet or moist.

9. The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point there of, fuse breaking,

disturbance to the normal function of a overload protection device.

• Proper starting power is not given to the compressor.

Installation Manual 17

Air Purging of the Connecting Pipes and the Indoor Unit

Group Control

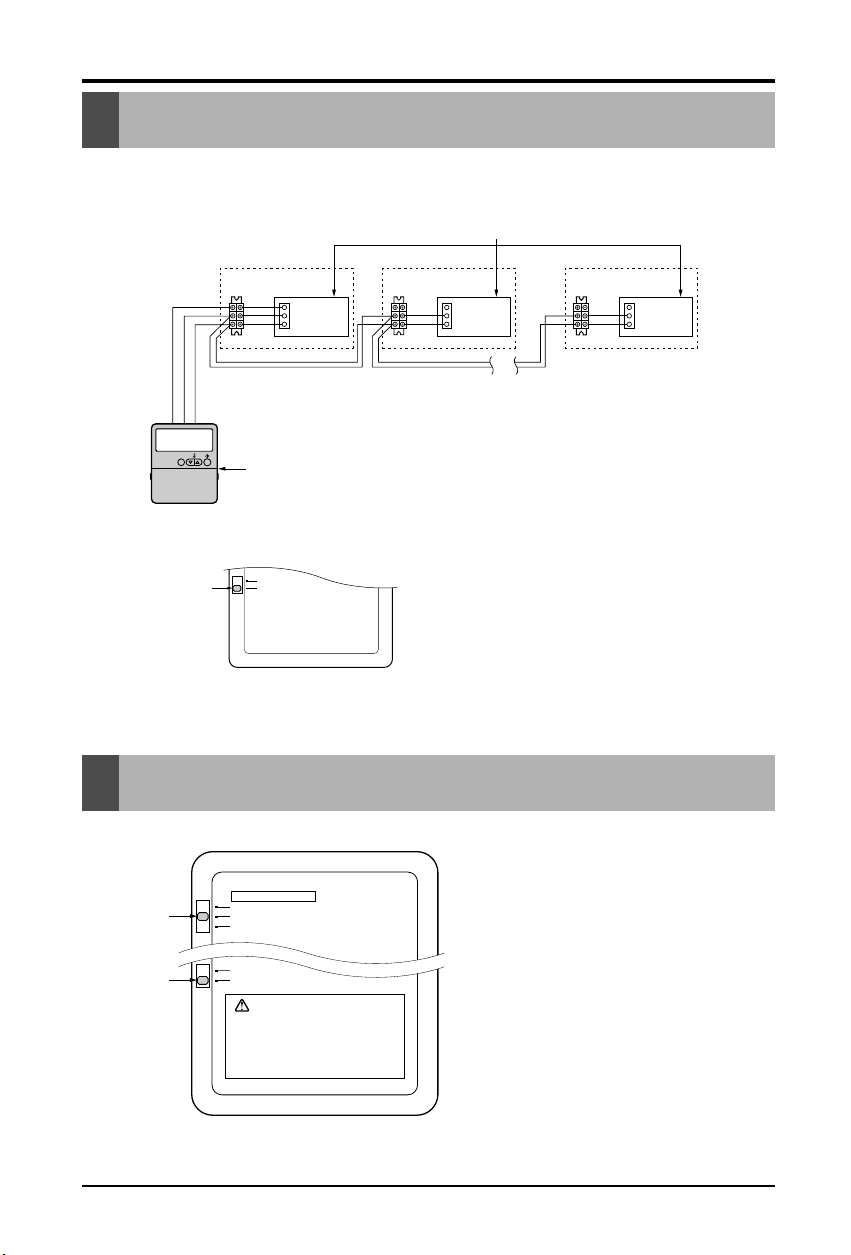

Two Thermistor system

It operates maximum 16 Units by only one Wired Remote Controller,

and each Unit starts sequentially to prevent overcurrent.

• Open the rear cover of Remote

Controller to set up the mode.

•

Selectable options are three as follows

.

- Remo: Sensing the room Temperature.

- Indoor Unit: Sensing the intake air into

indoor Unit.

- 2 TH: Sensing the lower temperature of

the two thermistors.

• To set up the mode, adjust the slide

switch to desired mode position on

installing.

Operation unit

ZONE

1234

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no.Time

Off

01 03 0507 09 11 13 15 1719 21 23

Indoor Unit 1

Terminal(Local Supply)

Block

Terminal(Local Supply)

Block

Terminal(Local Supply)

Block

Main PCB

#1

Main PCB

#2

Main PCB

#16

Wired Remote Controller

(Standard)

Indoor Unit 2

Main PCB

Indoor Unit 16

Connector

RED(12V)

YL(SIGNAL)

BR(GND)

RED(12V)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

Connecting Cable(Local Supply)

Connector Connector

....

....

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

Remote

Controller

PCB

Single

Group

Slide Switch2

Slide Switch1

Remo.

Room Temp . Sensing

Indoor Unit

2 TH(Remo.+Indoor)

• On installing, don't impact to the PCB

and LCD display.

• Don't remove the protection sheet.

• Use the specified screw.

• On installing, turn off the main power.

CAUTION

Single

Group

Slide Switch2

• Using the supplied Wired Remote Controller,

wire them like above.

• Move slide switch2 to "Group" position.

• Ensure that the color of wire.

18 Multi Type Air Conditioner

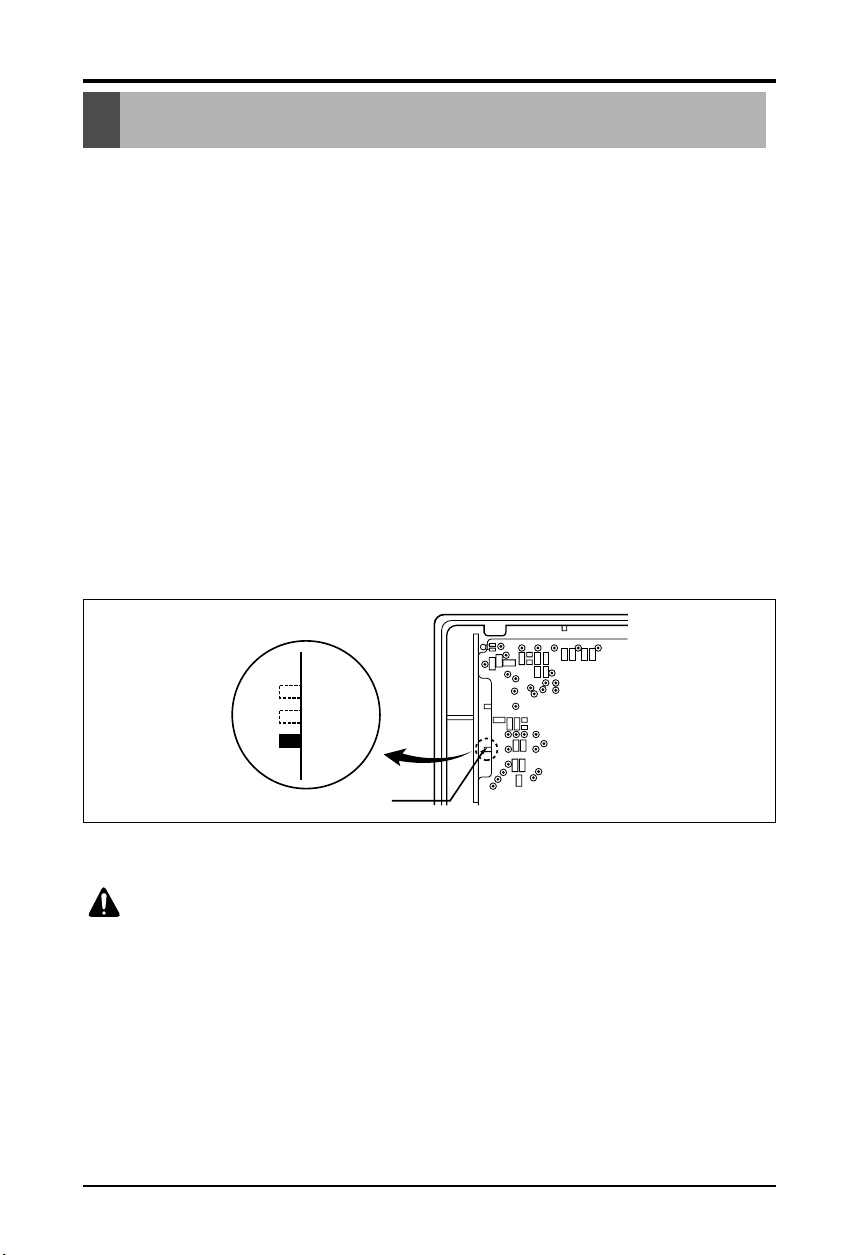

E.S.P.(External Static Pressure) Setting

(1) Open the rear cover of the wired remote-controller to set the mode.

(2) Select one of three selectable modes as follows.

■ Without Zone System

1. PositionV-H, F-H:

• This position sets the maximum E.S.P as a default set.

2. PositionV-L:

• This position sets the minimum E.S.P as a default set.

■ With Zone System

1. PositionV-H:

• Maximum E.S.P setting & Fan speed is varied according to the state of dampers by micom.

2. PositionF-H:

• Maximum E.S.P setting & Fan speed doesn't vary according to the opening & Closing of dampers.

3. PositionV-L:

• Minimum E.S.P setting & Fan speed is varied according to the state of dampers by micom.

*Maximum : 3mmAq

Minimum : All-0mmAq

(3) Move the slide switch to set position.

(4) Close the rear cover and check if it works normally.

TH

R14H

SW TH

REMO

MAIN

2TH

OP7

R18H

R17H

OP6

LO

STAND

SW HIGH

HI

R03S

C070

R04S

R02S

R01S

OP3

OP2 OP1

R19H

R11H

R13H R12H

OP5R16H OP4

R15H

CO1H

V-L

V-H

F-H

Slide switch for ceiling height

CAUTION: Select the position after checking duct work and E.S.P of the unit.

Maunfactured in the position F-H.

E.S.P.(External Static Pressure) Setting

Installation Manual 19

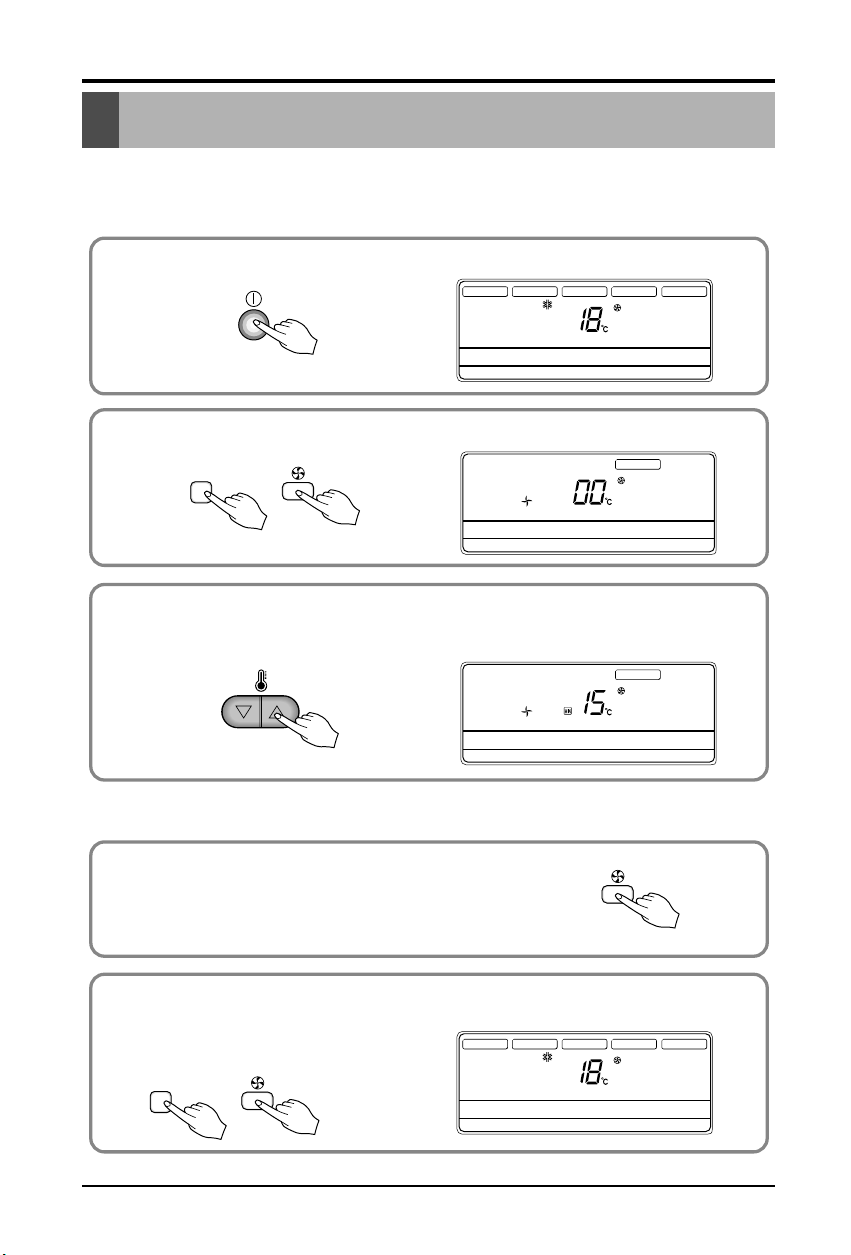

How to Set E.S.P?

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

1234

OPERATION

FAN SPEED

SUB FUNCTION

SET TEMP

HI

AUTO SWING

Time

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

1234

OPERATION

FAN SPEED

SUB FUNCTION

SET TEMP

HI

AUTO SWING

Time

Time

SUB FUNCTION

SET TEMP

OPERATIONAUTO SWING

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

1234

FAN SPEED

HI

Time

SUB FUNCTION

SET TEMP

OPERATIONAUTO SWING

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

134

FAN SPEED

HI

2

Timer

1

2

3

5

4

Timer

Procedure of RPM change:

Ex) External Static pressure is 1mmAq for "9k"

• To protect the unit, compressor is designed to be off during E.S.P. setting.

Push the "On/Off" button.

The unit will start.

Push the "Timer" and "Wind" button simultaneously for more then 3 seconds.

Push the "Up" of "Down" button for E.S.P adjustment.

And, adjust the number which you want.(In this example, the number is "215". Refer to the

table 1 on the next page.)

Shift the fan speed mode bypressing the fan speed button.

And then, Adjust numbers of next steps by repeating the stage 3.

(In this example, the numbers are "235" and "250" respectly)

Push the "Timer" and "Wind" button simultaneously for more than 3 seconds.

Then, Wind Data is memorized by the EEPROM of the main PCB.

Note: The range of selection is from 1~254. Since, the display is two Digit only.

If the range selection is above100 then the third digit will appear in the screen as shown.

How to Set E.S.P?

20 Multi Type Air Conditioner

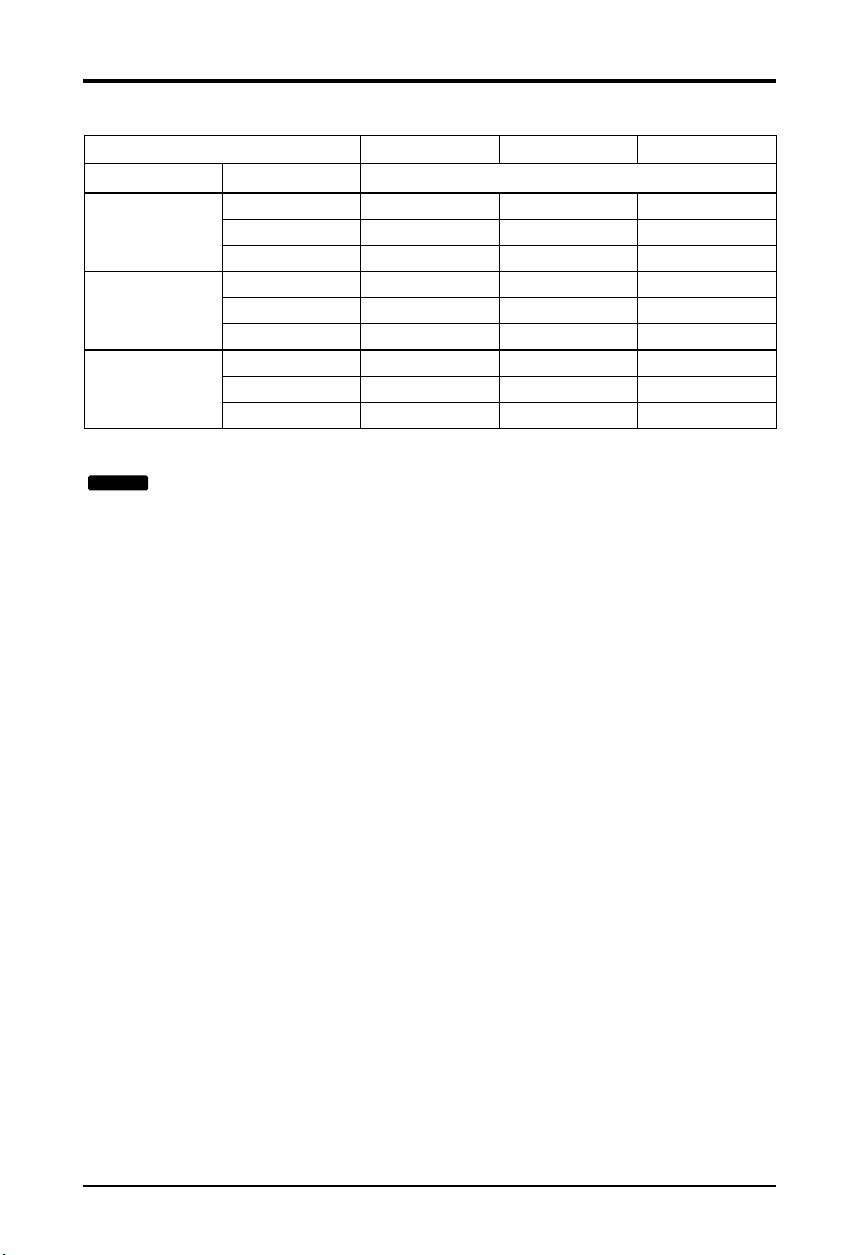

Static Pressure(mmAq)

Setting Value

012

Ca(Btu/h) Step(Hi/Med/Lo)

8 CMM 220 215 210

9k 7 CMM 240 235 230

6 CMM 255 250 245

10 CMM 175 170 150

12k 9CMM 200 190 185

8 CMM 220 215 210

14 CMM 170 150 130

18k 13 CMM 185 165 145

12 CMM 200 180 160

[Table. 1]

: 1. Be sure to set the value refering table 1. Unexpected set value will cause

mal-function.

2. Table 1 is based at 230V. According to the fluctuation of voltage, air flow

rate varies.

NOTICE

How to Set E.S.P?

ITALIANOITALIANO

LG

Condizionatore d’aria di tipo da

controsoffitto a socmparsa

MANUALE D’INSTALLAZIONE

IMPORTANTE

• Leggere questo manuale d’istruzioni prima di installare il

condizionatore d’aria.

• Il lavoro d’installazione deve essere eseguito conformemente

alla normativa vigente sugli impianti elettrici, solo da

personale tecnico autorizzato.

• Dopo averlo letto dettagliatamente, conservare questo

manuale come riferimento per il futuro

2 Climatizzatore tipo da controsoffitto a socmparsa

Climatizzatore tipo da controsoffitto a socmparsa Manuale d’installazione

INDICE

Precauzioni di sicurezza.............................................3

Introduzione.................................................................6

Installazione dellunità Intern......................................7

Collegamento dei tubi al Gruppo Interno...............12

Collegamento dei tubi al Gruppo Esterno..............14

Controllo dello Scarico.............................................14

Collegamento del cavo tra unità interna e unità

esterna........................................................................15

Controllo di gruppo...................................................17

Sistema a due termistori ..........................................17

Comment régler E.S.P (Pression statique externe....

....................................................................................18

Impostazione P.S.E (Pressione Statica Esterna)? ....

....................................................................................19

❏ Indicatore di livello

❏ Cacciavite

❏ Trapano elettrico

❏ Trapano per carotaggio (ø 70 mm)

❏ Metro orizzontale

❏ Setdistrumentipersvasatura

❏ Coppie di serraggio specificate

1,8 kgm, 4,2 kgm, 5,5 kgm, 6,6 kgm

(differenti a seconda del n°.di modello)

❏ Chiave.............Semi-raccordo

❏ Un bicchiere d'acqua

❏ Cacciavite

❏ Chiave esagonale (4mm/5mm)

❏ Rilevatore di fughe di gas

❏ Pompa a vuoto

❏ Manometro

❏ Manuale dell’utente

❏ Termometro

❏ Supporto del telecomando

Requisiti di installazione

Elementi richiesti

Precauzioni di sicurezza

Manuale d’installazione

3

ITALIANO

Per evitare infortuni dell'utente o altre persone e danni alle cose, attenersi alle seguenti

istruzioni.

■

L’uso errato causato dalla mancata osservanza delle istruzioni può causare danni o lesioni.

L’importanza è classificata dalle seguenti indicazioni.

■ Il significato dei simboli utilizzati in questo manuale è spiegato di seguito.

Questo simbolo indica la possibilità di decesso o di grave infortunio.

Questo simbolo indica la possibilità di infortunio o danni alle cose.

ATTENZIONE

Azione/operazione da non fare.

Attenersi alle istruzioni.

Precauzioni di sicurezza

■ Installazione

Installare il pannello e il

coperchio della scatola di

controllo in modo sicuro.

• Vi è il rischio di scosse elettriche o

incendio.

Installare sempre un

interruttore automatico e

circuito dedicato

• L'errato cablaggio o installazione può

causare incendi o scosse elettriche.

Utilizzare fusibili o interruttori

automatici di giusta tensione.

• Vi e il rischio di scosse elettriche o

incendio.

Non utilizzare interruttori automatici

difettosi o di potenza inferiore.

Utilizzare questa apparecchiatura su

un circuito dedicato.

• Vi è il rischio di scosse elettriche o

incendio.

Per i collegamenti elettrici, rivolgersi

al rivenditore, a un elettricista

qualificato o a un centro di

assistenza autorizzato.

• Non smontare o tentare di riparare il

prodotto.Vi è il rischio di scosse

elettriche o incendio.

Il prodotto deve essere sempre

provvisto di messa a terra.

• Vi è il rischio di scosse elettriche o

incendio.

ATTENZIONE

AVVISO

4 Climatizzatore tipo da controsoffitto a socmparsa

Precauzioni di sicurezza

Nonmodificareoprolungareilcavodi

alimentazione.

• Vi è il rischio di scosse elettriche o incendio.

Disimballare e installare il prodotto con

attenzione.

•

I bordi taglienti possono causare infortuni. Fare

particolare attenzione ai bordi del contenitore e

alle alette del condensatore e dell'evaporatore.

Per l'installazione, rivolgersi sempre al

rivenditore o a un centro di assistenza

autorizzato.

• Vi è il rischio di scosse elettriche, incendio,

esplosione o lesioni.

Non installare il prodotto su supporti di

installazione difettosi.

• Ciò potrebbe causare infortuni, incidenti o

danni al prodotto.

Accertarsi che l'area di installazione non sia

soggetta a deterioramento nel tempo.

•

Se la base si rompe, l’unità può cadere con essa,

causando infortuni a persone, guasti al prodotto o danni

alle cose.

Non utilizzare il prodotto troppo a lungo in

ambienti molto umidi e con una finestra o una

porta aperta.

• L’umidità potrebbe condensarsi e bagnare o

danneggiare i mobili.

Non conservare o utilizzare gas infiammabili o combustibili in prossimità del prodotto.

• Vi è il rischio di incendio o guasti al prodotto.

■ Funzionamento

asolin

G

Manuale d’installazione

5

ITALIANO

Precauzioni di sicurezza

Dopo l'installazione o la riparazione del

prodotto, verificare sempre che non vi siano

perdite di gas (refrigerante).

• Livelli bassi di refrigerante potrebbero

causare guasti al prodotto.

Installare il tubo flessibile di scarico in modo da

garantire uno scarico corretto e sicuro.

• Un errato collegamento può causare perdite

d’acqua.

Installare il prodotto allineandolo in modo

uniforme.

• Per evitare perdite d'acqua.

Non installare il prodotto in modo che il rumore

ol’aria calda provenienti dall’unità esterna

possano causare danni ai vicini.

• Ciò potrebbe causare problemi con i vicini.

Per sollevare e trasportare il prodotto sono

consigliabili due persone.

• Evitare lesioni personali.

Non installare il prodotto in luoghi esposti

direttamente al vento di mare (spruzzi di sale).

• Ciò potrebbe causare corrosioni al prodotto.

La corrosione, in particolare sul condensatore

e sulle alette dell’evaporatore, può causare

malfunzionamenti o inefficienza.

AVVISO

■ Installazione

90˚

6 Climatizzatore tipo da controsoffitto a socmparsa

Introduzione

Simboli usati in questo manuale

Questo simbolo segnala il rischio di scossa elettrica.

Questo simbolo segnala i pericoli che potrebbero causare danni al

condizionatore d'aria.

Questo simbolo indica note speciali

AVVISO

Caratteristiche

Filtri aria

Prese d’aria di uscita

Prese d’aria di entrata

Telecomando

Introduzione

Installazione dellunità Interna

Manuale d’installazione

7

ITALIANO

Installazione dellunità Interna

1. Selezione della migliore posizione

1) Gruppo Interno

Selezione della posizione

Installare il condizionatore d’aria nel punto che soddisfa le

seguenti condizioni.

•

Il punto può facilmente sostenere quattro volte il peso del

gruppo interno.

•

In questo punto sarà agevole ispezionare il gruppo come

indicato dall’illustrazione.

•

Un punto in cui il gruppo sarà messo a livello.

•

Un punto che permetta un agevole scarico dell’acqua. (Le

dimensioni idonee “H” sono necessarie per ottenere una

curva per scaricare come dall’illustrazione.

•

Un punto in cui sia agevole effettuare il collegamento con

il gruppo esterno.

•

Un punto in cui il gruppo non sia influenzato da rumore

elettrico.

•

Un punto in cui la circolazione di aria nella stanza sia

buona.

•

L’assenza di fonti di calore o vapore nelle vicinanze del

gruppo.

2.Installazione del Gruppo Interno

■ Installazione del Gruppo

Installare correttamente sul soffitto

• Applicare un giunto gommato tra gruppo e

conduttura al fine di assorbire le vibrazioni

inutili.

• Applicare un accessorio filtro sul foro di

ritorno dell’aria

H

600600

Vista superiore

(unità: mm)

Vista frontale

Foro di ispezione

(600X600)

Scatola di controllo

POSIZIONE DEL BULLONE DI SOSPENSIONE

(Unit:mm)

Foro di scarico

A

B

CD

1-3 mm

F

H

G

E

9/12K 708 678 434 51 537 455 230 172

18K 1060 1030 434 51 535 805 230 175

Dimensioni

Capacità

ABCDEFGH

8 Climatizzatore tipo da controsoffitto a socmparsa

Installazione dellunità Interna

• Installare il gruppo in pendenza verso il

foro di scarico come indicato dalla figura

per facilitare lo scarico dell’acqua.

• Un punto dove il gruppo è a livello e può

sostenere il peso del gruppo.

• Un punto in cui il gruppo può sostenere

le vibrazioni

• Un punto che sia facile da raggiungere

per la manutenzione.

CASO 2

POSIZIONE DEL BULLONE DELLA CONSOLLE

Dado

M10

Dado

M10

Rondella Dist M10 SP

Rondella Dist. M10

Rondella M10

Rondella M10

X 4

X 4

(Fornitura

locale)

(Fornitura

locale)

X 4

X 4

X 4

X 4

1 Ancoraggio

Costruzione

vecchia

Costruzione

nuova

2 Rondella piastra

3 Rondella elastica

4 Dado

5 Bullone di

sospensione

• Selezionare e contrassegnare la

posizione di fissaggio dei bulloni.

• Praticare un foro per inserire gli

ancoraggi sul soffitto.

• Inserire l’ancoraggio e la rondella sui

bulloni di sospensione per bloccare i

bulloni di sospensione al soffitto.

• Montare i bulloni di sospensione per

ancorare saldamente.

• Fissare le piastre di installazione sui

bulloni di sospensione (regolare il livello

a occhio) usando dadi, rondelle e

rondelle elastiche.

AVVISO

: Stringere il dado e bullone per evitare

la caduta del gruppo.

Manuale d’installazione

9

ITALIANO

Installazione dellunità Interna

SOFFITTO

ATTENZIONE

Foro di scarico

Foro di scarico

Sifone a U

B

C

A ≥ 70mm

B ≥ 2C

C ≥ 2 x SP

SP = Pressione esterna

(mmAq)

Es) Pressione esterna

= 10mmAq

A ≥ 70mm

B ≥ 40mm

C ≥ 20mm

A

Verificare che sia chiuso

Gruppo

Foro di scarico

ATTENZIONE PER LA PENDENZA

DI UNITÀTUBATURA DI SCARICO

Disporre il tubo flessibile di scarico con

una inclinazione verso il basso per facilitare

los carico dell'acqua.

Tubo di scarico

(Fornitura locale)

Isolatore termico

(Fornitura locale)

1~3mm

Vista di fronte

• Disporre sempre lo scarico con una

inclinazione verso il basso (1/50 a

1/100).

Impedire qualsiasi scorrimento verso

l’alto o inverso in qualsiasi punto.

• Il tubo di scarico deve essere sempre

fornito di isolamento termico sagomato

dello spessore di 5mm o superiore.

• Installare il sifone intercettatore a

P (o sifone a U) per prevenire le

perdite di acqua provocate dal

blocco del filtro di aspirazione.

1. La pendenza di installazione del gruppo interno è importante per lo scarico del

condizionatore d’aria del tipo a condotti.

2. Lo spessore minimo dell’isolamento dei tubi di collegamento deve essere di 5 mm.

• Il gruppo deve essere orizzontale o in pendenza verso il tubo di scarico collegato ad

installazione terminata.

CORRETTO

CORRETTO

SCORRETTO

Dimensioni applicate sifone a U

SCORRETTO

• La disposizione del

tubo verso lalto non

è permessa.

10 Climatizzatore tipo da controsoffitto a socmparsa

Installazione dellunità Interna

• Praticare un foro per i tubi con una punta

di 70mm di dia metro.

• Il foro per la tubatura deve essere

leggermente inclinato verso il basso dal

lato esterno.

ISOLAMENTO, ALTRO

Isolare completamente i raccordi ed i tubi.

Tutto l’isolamento termico deve essere conforme ai requisiti

locali.

GRUPPO INTERNO

Tubo refrigerante

Isolare con nastro sia le condutture del

gas che le condutture del liquido.

■ Una volta finito il lavoro, controllare il funzionamento e l’operazione.

• Distribuzione aria La circolazione dell’aria è soddisfacente?

• Scarico Lo scarico è dolce e senza trasudamento?

• Fughe di gas I collegamenti dei tubi sono corretti?

• Cablaggio Le connessioni dei cavi sono corrette?

• Bullone di bloccaggio Il bullone di bloccaggio del compressore è allentato?

ISOLAMENTOTERMICO

COMPROBACIONES

Assicurarsi che non ci sia luce in questa posizione.

Parte sovrapposta con

isolatore termico per tubature

(Fornitura locale)

Isolatore termico per tubo refrigerante

(fornitura locale)

Isolatore termico per tubi

(fornitura locale)

Morsetto per tubo flessibile per isolatore termico

(fornitura locale)

Raccordo per tubo del liquido

Tubo refrigerante e isolatore termico

(fornitura locale)

Raccordo per tubo gas

Isolatore termico per tubo

refrigerante (fornitura locale)

Morsetto per tubo flessibile per isolatore

termico (fornitura locale)

Cavo di alimentazione

Tubo liquido

Isolatore termico

Tubo gas

Nastro

Interno Esterno

MURO

5~7mm

Manuale d’installazione

11

ITALIANO

Installazione dellunità Interna

INSTALLAZIONE DELLA SCATOLA DEL TELECOMANDO

Installare correttamente il cavo e la

scatola di controllo del telecomando.

• Nonostante nel gruppo interno sia presente un sensore della temperatura dell’ambiente, la scatola

del telecomando deve essere installata in punti lontani dalla luce diretta del sole o di alta umidità.

INSTALLAZIONE DELLA SCATOLA DEL TELECOMANDO

• Selezionare punti che non siano sottoposti agli

schizzi d’acqua

• Selezionare una posizione per il controllo dopo

avere ricevuto l’approvazione del cliente.

• Il sensore della temperatura dell’ambiente del

termostato per il controllo della temperatura è

inserito nel gruppo interno.

• Il telecomando è fornito di display a cristalli

liquidi. Se la posizione è troppo alta o troppo

bassa il display sarà difficile da vedere.

(L’altezza standard è 1,2-1,5 m di altezza)

DISPOSIZIONE DEL CAVO DEL TELECOMANDO

• Tenere il cavo del telecomando lontano

dalle tubature refrigeranti e le tubature

di scarico.

• Per schermare il cavo del telecomando

da rumore elettrico, disporre il cavo a 5

cm da altri cavi di alimentazione.

(Attrezzature audio, televisore ecc.)

• Se il cavo del telecomando viene fissato

ad un muro inserire un separatore nella

sezione superiore del cavo per evitare lo

sgocciolare di acqua.

PUNTO DI INSTALLAZIONE DEL TELECOMANDO

SMONTAGGIO DEL TELECOMANDO

CABLAGGIO ELETTRICO DEL GRUPPO INTERNO

FISSAGGIO DEL

CAVO DEL TELECOMANDO

1. Fissare le reggette del cavo sul muro

usando viti autofilettanti del 3ÿ

(fornitura locale)

2. Fissare il cavo del telecomando.

PROCEDURE DI INSTALLAZIONE

1. Fissare la sottopiastra sulla scatola degli interruttori con

delle viti (fornitura locale). In questo caso inserire la

piastra sul muro facendo attenzione a non deformarla.

2. Infilare il cavo del telecomando nella scatola degli

interruttori.

3. Agganciare l’unità del telecomando sulla sottopiastra.

NEL CASO DI INSTALLAZIONE DI SCATOLA DEL

TELECOMANDO CON CAVO INCASSATO

PROCEDURE DI INSTALLAZIONE

1. Fissare la sottopiastra al muro con viti

autofilettanti.

2. Praticare una fessura (Parte A) sul lato

superiore della scatola del telecomando con

una tenaglia.

3. Far passare il cavo come indicato nella figura

che segue. In questo caso premere il cavo

intorno alla scatola (Parte B)

4. Agganciare l’unità del telecomando sulla

sottopiastra

NEL CASO DI INSTALLAZIONE DI SCATOLA

DEL TELECOMANDO CON CAVO A VISTA

Telecomando

CN REMO

Se la lunghezza del cavo supera 50m, usare un filo con sezione superiore a 0,5mm

La lunghezza massima del cavo è 100 m.

(Pannello principale)

CN REMO

Verificare che i numeri di filo e

di terminale siano combinati sul

lato unità e sul lato telecomando.

2

Scatola frontale

io

n

e

in

fe

rio

re

Corpo scatola del

telecomando.

Fare leva con attenzione

usando un cacciavite

per aprire la scatola

S

e

z

Parete

Dentellatura superiore

Sottopiastra

Unità telecomando

Vite (fornitura locale)

Cavo del telecomando

Dentellatura inferiore

Scatola interruttore

Parete

Sottopiastra

Vite autofilettante

(Fornitura locale)

Flangia superiore

Premere

(Parte B)

Dentellatura

inferiore

Morsetto

per cavo

(Parte A)

Unità di

telecomando

Dentellatura Superiore

Cavo del

telecomando

12 Climatizzatore tipo da controsoffitto a socmparsa

Preparazione dei tubi

Collegamento dei tubi al Gruppo Interno

Collegamento dei tubi al Gruppo Interno

La causa principale delle fughe di gas sono difetti

nel lavoro di svasatura. Effettuare correttamente il

lavoro di svasatura seguendo queste istruzioni.

1) Tagliare il tubo e il cavo

■

Usare il corredo per tubi accessorio o i

tubi acquistati localmente.

■

Misurare la distanza tra gruppo interno e

gruppo esterno.

■

Tagliare i tubi in lunghezza leggermente

superiore a quella misurata.

■

Tagliare il cavo 1,5 m più lungo della

lunghezza del tubo.

2) Rimozione delle bavature

■

Rimuovere completamente le bavature

dalla sezione tagliata del tubo.

■

Volgere l’estremità del tubo di rame

verso il basso per evitare la caduta

delle bavature all’interno dei tubi.

3) Inserimento del dado

■

Rimuovere i dadi svasati collegati ai

gruppi interno ed esterno, poi inserirli

sul tubo dopo avere terminato la

rimozione delle bavature. (Non è

possibile inserirli dopo aver effettuato il

lavoro di svasatura.

4) Lavoro di Svasatura

■

Usare l’arnese di svasatura indicato

sotto per effettuare il lavoro di svasatura.

Tenere ben saldo il tubo di rame in una

barra o forma come indicato nella tabella

delle dimensioni riportata in precedenza.

5) Controllo

■

Confrontare il lavoro di svasatura con

l’illustrazione.

■

Se la svasatura sembra difettosa , tagliare

la sezione svasata e rifare la svasatura.

Tubo di rame

90°

Inclinato Impari Grezzo

Tubo

Alesatore

Punta verso

il basso

Dado svasato

Tubo di rame

Barra

Tubo di rame

Manico del morsetto

Freccia rossa

Cono

Morsetto

Manico

Barra

"A"

Inclinato

L'interno lucido senza graffi.

Liscio per tutta la circonferenza

Lunghezza uguale

per tutta la circonferenza

Superficie

danneggiata

Spaccato Spessore

irregolare

=

Svasatura scorretta =

Diametro esterno

"A"

1/4" 0~0.5

3/8" 0.5~0.8

1/2" 0.5~0.8

5/8" 0.8~1.0

3/4" 1.0~1.3

Manuale d’installazione

13

ITALIANO

Collegamento dei tubi al Gruppo Interno

6) Piegatura dei tubi

I tubi di rame ricotto di piccolo diametro (ø 6,35 0 ø 9,52) possono essere facilmente piegati

manualmente. In questo caso fermare un R (raggio) ampio per la sezione da piegare e

piegare gradualmente il tubo. Se il tubo di rame ricotto è di diametro grande (ø 15,88 o

ø 19,05) piegare il tubo con un piegatubi. Usare il piegatubi adeguato al diametro del tubo.

7) Brasatura

Nelle tubature del refrigerante la piegatura deve essere minimizzata (ed in particolare

piegature ad angoli acuti) al fine di ridurre la resistenza delle tubature. Comunque, la

piegatura è necessaria in alcuni punti a causa della posizione di dispositivi ausiliari al

condizionatore d’aria o struttura dell’edificio, distanza delle tubature o aspetto finito. Se

viene richiesta una piegatura maggiore a quella ottenibile con un piegatubi, effettuare la

brasatura utilizzando un gomito già preparato. Oltre a questa funzione la brasatura serve

per collegare tubi diritti usando, generalmente, innesti già preparati. Durante la brasatura

proteggere il tubo dal calore con uno straccio bagnato per evitare danni alla guarnitura della

valvola o bruciare l’isolatore termico con il calore della fiaccola. Durante la brasatura

soffiare gas inerte (azoto o carbonio) per impedire la formazione di una pellicola di

ossidazione nelle tubature di rame; in caso contrario il refrigerante si intaserebbe. La

soffiatura dell’azoto (carbonio) attraverso le valvole a tre vie è descritta di seguito.

8) Tubature del refrigerante (tubature svasate)

Nel collegamento dei tubi, mantenere i tubi asciutti (tenere i tubi lontani dall’acqua) puliti

(tenere lontano dalla polvere) e tenuta stagna (evitare perdite di refrigerante). Evitare che

entrino acqua o polvere nel condizionatore se esso viene collegato in un giorno di pioggia o

se viene effettuato un buco passante nella parete.

AVVISO

a. Questa procedura è stata studiata per

impedire la formazione della pellicola di

ossidazione riempiendo i tubi con gas

inerte. Notare che una pressione eccessiva

di gas genera punture di spillo nei punti

brasati.

(Azoto: pressione di alimentazione 0,050,1kg/cm2G)

b.Nel alimentare gas inerte mantenere

aperta un’estremità del tubature.

Acqua entra Intonaco entra

1. Quando l'installazione di trasportare a mezzo

di tubazioni lo lavora deve essere usato il

connettore.

Dimensioni del raccordo

2. Allineare il centro dei tubi e stringere

sufficientemente il dado svasato con le dita.

3. Infine stringere il dado svasato con una

chiave torsiometrica fino a quando non si

sente lo scatto della chiave.

■ Nello stringere il dado svasato con la chiave

torsiometrica assicurarsi che la direzione di

serraggio corrisponda alla freccia sulla

chiave.

14 Climatizzatore tipo da controsoffitto a socmparsa

Collegamento dei tubi al Gruppo Esterno

A

B

Gas

AB

Ø9.52 Ø12.7

Gruppo

Interno

Collegamento dei tubi al Gruppo Esterno

Controllo dello Scarico

1. Controllo dello scarico

• Spruzzare uno o due bicchieri d’acqua

sull’evaporatore.

• Assicurarsi che l’acqua scorra nel tubo

flessibile di scarico senza perdite.

Gruppo Interno Gas Liquido

7K Ø9.52(3/8") Ø6.35(1/4")

9K Ø9.52(3/8") Ø6.35(1/4")

12K Ø9.52(3/8") Ø6.35(1/4")

18K Ø12.7(1/2") Ø6.35(1/4")

24K Ø12.7(1/2") Ø6.35(1/4")

Connector

Gruppo Esterno Gruppo Esterno

Chiave torsiometrica

Connector

Tubature lato liquido

Tubature lato gas

A-UNIT

B-UNIT

C-UNIT

A-UNIT

Tubature lato gas

B-UNIT

Tubature lato liquido

Chiave torsiometrica

Collegamento del cavo tra unità interna e unità esterna

Manuale d’installazione

15

ITALIANO

Collegamento del cavo tra unità interna e unità esterna

Collegare il cavo all’unità interna collegando i fili ai terminali situati sulla scheda di controllo secondo il

collegamento all’unità esterna. Accertarsi che il colore dei fili dell’unità esterna e i numeri dei terminali siano

uguali a quelli dell’unità interna.

Il filo di terra deve essere più lungo degli altri.

Il suddetto schema dei circuiti è soggetto a modifiche senza preavviso.

Durante l'installazione, fare riferimento allo schema dei circuiti dietro il pannello frantale dell'unità

interna.

Collegamento del cavo all'unità interna.

AVVISO:

• Il suddetto schema dei circuiti è soggetto a modifiche senza preavviso.

• Accertarsi di collegare i fili secondo lo schema di cablaggio.

• Collegare i fili in modo sicuro, in modo che non possano essere facilmente rimossi.

• Collegare i fili secondo i codici colore indicati sullo schema di cablaggio.

AVVISO: Se non si utilizza una

presa di alimentazione, prevedere

un interruttore di circuito tra

l'alimentazioneel'unità,come

mostrato di seguito.

AVVISO:Ilcavodialimentazione

collegato all’unità“A” deve essere

conforme alle seguenti specifiche (Tipo

“B” approvatodaHARoSAA).

Il cavo di collegamento

dell’alimentazione collegato all’unità

esterna e interna deve essere conforme

alle seguenti specifiche (Tipo “B”

approvato da HAR o SAA).

AVVISO:

Verificare che le viti del terminale non

siano allentate.

2) Bloccaggio dei Cavi

1) Sistemare 2 cavi sul pannello di controllo.

2) Prima fissare il morsetto di acciaio con una vite alla borchia interna del pannello di controllo.

3) Nel modello refrigerante fissare saldamente l’altra estremità del morsetto. Nel modello con pompa

calore inserire il cavo da 0,75mm2 (cavo più fine) sul morsetto e stringere con il morsetto di plastica

all’altra borchia del pannello di controllo.

4) In Australia la lunghezza del cavo di alimentazione misurata dall’entrata del cavo di alimentazione alla

metà del terminale sotto tensione della spina di corrente deve essere superiore a 1,8 m.

Condizionatore

d'aria

Sorgente di alimentazione principale

Interruttore di circuito

Utilizzare un interruttore di

circuito o un fusibile di tipo

ritardato.

ø8.5mm

GN/YL

AREA NORMALE

IN SEZIONE

TRASVERSALE

2

2.5mm

20m

m

ø7.5mm

G

N/YL

AREA NORMALE

IN SEZIONE

TRASVERSALE

2

0.75mm

20m

m

16 Climatizzatore tipo da controsoffitto a socmparsa

Collegamento del cavo tra unità interna e unità esterna

AVVERTENZA: dopo che le precedenti condizioni sono state soddisfate,

preparare il cablaggio rispettando quanto segue.

1. Usare sempre un circuito d’alimentazione specifico dedicato al condizionatore d’aria. Come

visto per il metodo di cablaggio, seguire come guida lo schema circuitale riportato

internamente al coperchio del vano elettrico.

2. Serrare fermamente le viti dei terminali elettrici in modo da evitare che si allentino. Dopo avere

serrato le viti, tirare leggermente i fili elettrici per accettarsi che siano collegati fermamente. (Se

le viti si allentano, l'unità non funzionerà normalmente e i cablaggi potrebbero usurarsi per

fusione.) Specifiche della sorgente di alimentazione.

3. Accertarsi che la sorgente elettrica abbia la capacità richiesta.

4. Prendere le necessarie misure affinché durante la fase di avviamento la tensione si mantenga a

livelli superiori rispetto al 90 percento del valore nominale riportato sulla targhetta del prodotto

5. Accertarsi che lo spessore del cavo sia conforme a quanto indicato nella specifica della

sorgente di alimentazione. (In particolare, prendere nota della relazione tra lunghezza del cavo e

spessore).

6. Non installare mai un interruttore automatico salvavita in aree bagne o umide.

7. Eventuali cadute di tensione causerebbero le seguenti situazioni :

• Vibrazioni degli interruttori magnetici che danneggerebbero i punti di contatto, rottura dei fusibili,

disturbi del funzionamento di sovraccarico.

8. I sistemi di sconnessione dell’alimentazione devono essere incorporati in un cablaggio fisso e

prevedere una distanza di separazione in aria di almeno 3 mm tra ciascun conduttore (fase)

attivo

Controllo di gruppo

Manuale d’installazione

17

ITALIANO

Controllo di gruppo

Sistema a due termistori

Gestisce un massimo di 16 unità con un solo telecomando cablato, e ciascuna unità viene

avviata sequenzialmente per prevenire le sovratensioni.

• Aprire il coperchio posteriore del

telecomando per impostare il modo.

• Le opzioni che possono essere selezionate

sono le seguenti tre:

- Remo: Rilebamento della temperatura

della stanza

- Unità interna:Rilevazione dell'aria in

aspirazione dell'unità interna

-2 TH: Rilevazione della temperatura più

bassa dei due termistori.

• Per impostare il modo, regolare l'interruttore

a slitta nella posizione desiderata per

l'installazione.

Telecomando

PCB

Operation unit

ZONE

1234

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no.Time

Off

01 03 0507 09 11 13 15 1719 21 23

Unità interna 1

Terminale(formitura locale)

Block

Terminale(formitura locale)

Block

Terminale(formitura locale)

Block

Main PCB

#1

Main PCB

#2

Main PCB

#16

Telecomando cablato

Unità interna 2

Main PCB

Unità interna 16

Connettore

RED(12V)

YL(SIGNAL)

BR(GND)

RED(12V)

YL(SIGNAL)

BR(GND)

Cavo di collegamento(Fornitura locale)

Connettore Connettore

....

....

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

Interruttore

a slitta 2

Singolo

Gruppo

Interruttore

a slitta 1

Interruttore

a slitta 2

Remo.

Temperatura ambiente Sensore remoto

Unità interna

2 TH(Remo.+Interno)

• Nell'installazione non sottoporre a colpi

il PCB ed ik display LCD.

• Non rimuovere il foglio di protezione.

• Usard la vite specificata.

• Per installare, staccare la corrente

di rete.

PERICOLO

Singolo

Gruppo

• Uso del telecomando cablato fornito in dotazione,

eseguire i collegamenti come segue.

• Spostare il selettore 2 nella posizione "GROUP”

• Assicurarsi che il colore del filo.

18 Climatizzatore tipo da controsoffitto a socmparsa

Comment régler E.S.P (Pression statique externe)

(1) Aprire il coperchio posteriore del telecomando per impostare il modo.

(2) Selezionare uno dei tre modi selezionabili come segue.

■

Senza sistema a zone

1. Posizione V-H, F-H:

• Questa posizione imposta la P.S.E massima come impostazione di base (Pressione Statica Esterna).

2. Posizione V-L:

• Questa posizione imposta come impostazione di base la P.S.E minima

■

Con sistema a zone

1. Posizione V-H

• L’impostazione massima P.S.E e la velocità del ventilatore viene modificata da Micom sulla base dello stato

degli smorzatori.

2. Posizione F-H

• L’impostazione massima P.S.E e la velocità del ventilatore non viene modificata sulla base dell’apertura e

chiusura degli smorzatori.

3. Posizione V-L

• L’impostazione minima P.S.E e la velocità del ventilatore viene modificata da Micom sulla base dello stato

degli smorzatori.

* Massimo: 3mmAq

Minimo:Tutti - 0mmAq

(3) Spostare il selettore per impostare la posizione.

(4) Chiudere il coperchio posteriore ed assicurarsi che funzioni normalmente.

TH

R14H

SW TH

REMO

MAIN

2TH

OP7

R18H

R17H

OP6

LO

STAND

SW HIGH

HI

R03S

C070

R04S

R02S

R01S

OP3

OP2 OP1

R19H

R11H

R13H R12H

OP5R16H OP4

R15H

CO1H

V-L

V-H

F-H

Slide switch for ceiling height

AVVERTENZA

• Selezionare la posizione dopo avere verificato le condizioni dei condotti e la P.S:E dell’unità.

• Prodotto con la posizione F-H.

Comment régler E.S.P (Pression statique externe)

Manuale d’installazione

19

ITALIANO

Impostazione P.S.E (Pressione Statica Esterna)?

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

1234

OPERATION

FAN SPEED

SUB FUNCTION

SET TEMP

HI

AUTO SWING

Time

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

1234

OPERATION

FAN SPEED

SUB FUNCTION

SET TEMP

HI

AUTO SWING

Time

Time

SUB FUNCTION

SET TEMP

OPERATIONAUTO SWING

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

1234

FAN SPEED

HI

Time

SUB FUNCTION

SET TEMP

OPERATIONAUTO SWING

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

134

FAN SPEED

HI

2

Timer

1

2

3

5

4

Timer

Modifica del RPM:

Ex) Per il modello "9k", la Pressione Statica Esterna (E.S.P) è 1mmAq

• Per proteggere l’unità, il compressore è stato progettato per restare spento durante le

impostazioni E.S.P.

Premere il tasto "On/Off".

L'Unità entra in funzione.

Premere contemporaneamente i tasti "Timer" e "Wind" per più di tre secondi.

Premere i tasti "Up" (Alto) o "Down" (Basso) per regolare l'E.S.P.

Impostare il numero desiderato.

(In questo esempio, il numero è "215".)

Modificare la velocità del ventilatore premendo il tasto Velocità.

Regolare quindi i numeri dei passi seguenti ripetendo la

procedura del passo 3.

(In questo esempio, i numeri sono rispettivamente "235" e "250".)

Premere contemporaneamente i tasti "Timer" e "Wind" per più di 3 secondi.

I dati Wind vengono memorizzati dall'EEPROM del PCB principale.

Nota: La gamma selezionabile è 1~254. Dato che il display visualizza solo due cifre, se il numero

selezionato supera i 100 la terza cifra apparirà sullo schermo nel modo qui indicato.

20 Climatizzatore tipo da controsoffitto a socmparsa

[Tabella.1]

Nota: 1. |Impostare il valore facendo riferimento alla tabella 1.

L’impostazione di un valore non previsto causerà un cattivo funzionamento

2. La tabella 1 è basata a 230V. Secondo la fluttuazione della tensione, varia la portata del flusso

d’aria.

La Pressione statica(mmAq)

Che il regolando Valore

012

Modellare il Nome

Il passo (ciao/il Med/il Lo)

8 CMM 220 215 210

9k 7 CMM 240 235 230

6 CMM 255 250 245

10 CMM 175 170 150

12k 9 CMM 200 190 185

8 CMM 220 215 210

14 CMM 170 150 130

18k 13 CMM 185 165 145

12 CMM 200 180 160

ESPAÑOLESPAÑOL

LG

Aire acondicionado

de

canalización de techo

MANUAL DE INSTALACIÓN

IMPORTANTE

• Lea este manual de instrucciones completamente antes de

instalar el producto.

• El trabajo de instalación debe realizarse de acuerdo con el

Reglamento Eléctrico nacional y únicamente por personal

autorizado.

• Después de leer completamente este manual de instalación,

guárdelo para futuras consultas.

2 Aire acondicionado de Tipo Cassete

Aire acondicionado de Tipo Cassete Manual de instalación

ÍNDICE

Precauciones de seguridad .......................................3

Introducción.................................................................6

Instalación de la unidad interior................................7

Conexión de los conductos a la unidad interior....12

Conexión de los conductos a la unidad exterior...14

Comprobación del desagü.......................................14

Conexión del cable situado entre la unidad interior

ylaexterio.................................................................15

Control de grupo.......................................................17

Sistema de dos termistores.....................................17

Establecimiento de la E.S.P (External Static

Pressure, Presión estática externa)........................18

Establecimiento de la E.S.P (External Static

Pressure, Presión estática externa)?......................19

❏ Calibre de nivel

❏ Destornillador

❏ Taladro eléctrico

❏ Taladradora (ø70mm)

❏ Metro horizontal

❏ Kit de herramientas para abocinado

❏ Llaves de apriete del par especificado

1,8 kg-m, 4,2 kg-m, 5,5 kg-m, 6,6 kg-m

(diferentes dependiendo del número del modelo)

❏ Llave inglesa.......Media unión

❏ Un vaso de agua

❏ Destornillador

❏ Llave hexagonal de apriete (4mm)

❏ Detector de escape de gases

❏ Bombadevacío

❏ Colector

❏ Manual del usuario

❏ Termómetro

❏ Soporte para el mando a distancia

Requisitos de instalación

Herramientas necesarias

Precauciones de seguridad

Manual de instalación

3

ESPAÑOL

Para evitar lesiones al usuario o a otras personas y daños a la propiedad, siga estas

instrucciones.

■

Una operaci’on incorrecta por ignorar las instrucciones provocará lesiones o daños. La

seriedad se clasifica por las siguientes indicaciones.

■ Significados de los símbolos utilizados en este manual.

Este símbolo indica la posibilidad de muerte o de seria lesión.

Este símbolo indica sólo la posibilidad de lesión o daño a la propiedad.

ADVERTENCIA

Prohibido.

Recuerde seguir las instrucciones.

Precauciones de seguridad

■ Instalación

No utilice un interruptor automático

defectuoso o de valor nominal inferior

al correspondiente. Utilice un circuito

específico para este aparato.

• Existe riesgo de incendio o

descarga eléctrica.

Para trabajos eléctricos, póngase en

contacto con el distribuidor, vendedor,

técnicocualificadoocentrode

asistencia técnica autorizado.

• No desmonte ni repare el

aparato.Existe riesgo de

incendio o descarga eléctrica.

Realice siempre la conexión

del aparato a tierra.

• Existe riesgo de incendio o

descarga eléctrica.

Instale correctamente el

panel y la cubierta de la

cajadecontrol.

• Existe riesgo de incendio o

descarga eléctrica.

Instale siempre un circuito y

un interruptor específico.

• Un cableado o instalación

inadecuados pueden provocar

un incendio o una descarga

eléctrica.

Utilice el interruptor o

fusible de valor nominal

adecuado.

• Existe riesgo de incendio o

descarga eléctrica.

ADVERTENCIA

PRECAUCIÓN

4 Aire acondicionado de Tipo Cassete

Precauciones de seguridad

No modifique ni extienda el cable de

alimentación.

• Existe riesgo de incendio o descarga

eléctrica.

Tenga cuidado al desembalar e instalar el

aparato.

•

Los bordes afilados podrían provocar lesiones.

Tenga especial cuidado con los bordes de la caja

y las aletas del condensador y evaporador.

Para la instalación, póngase en contacto

siempre con su vendedor o centro de

asistencia técnica autorizado.

• Existe riesgo de incendio, descarga

eléctrica, explosión o lesiones.

No instale el aparato en una superficie de

instalación insegura.

• Podría causar lesiones, accidentes o daños

en el aparato.

Asegúrese de que el soporte de instalaciónno

se deteriora con el tiempo.

•

Si el soporte cae, el aire acondicionado también puede

caer, causando daños materiales, avería del aparato y

lesiones personales.

No deje funcionando el aire acondicionado

durante mucho tiempo cuando la humedad sea

muy alta y haya una puerta o ventana abierta.

• Podría condensarse la humedad y mojar o

dañar el mobiliario.

No almacene ni utilice gas inflamable o

combustibles cerca del aparato.

• Existe riesgo de incendio o avería del

aparato.

■ Operación

Gasolin

Manual de instalación

5

ESPAÑOL

Precauciones de seguridad

Compruebe siempre las fugas de gas

(refrigerante) despuésdelainstalacióno

reparación del aparato.

• Niveles bajos de refrigerante pueden

producir una avería del aparato.

Instale la manguera de drenaje para asegurarse

de que el agua se drena correctamente.

• Una mala conexión puede causar fugas de

agua.

Instale el aparato bien nivelado.

• Para evitar las vibraciones o fugas de agua.

No instale el aparato donde el ruido o el aire

caliente de la unidad exterior pueda molestar a

los vecinos.

• Podría tener problemas con los vecinos.

Levante y transporte el aparato entre dos o más

personas.

• Evite lesiones personales.

No instale el aparato donde quede expuesto

directamente al viento del mar (rocío salino).

• Podría causar corrosión en el aparato. La

corrosión, particularmente en las aletas del

condensador y del evaporador, podría causar

un funcionamiento defectuoso del aparato o

un funcionamiento ineficaz.

PRECAUCIÓN

■ Instalación

90˚

6 Aire acondicionado de Tipo Cassete

Introducción

Este símbolo le avisa del riesgo de descarga eléctrica.

Este símbolo le avisa de riesgos que pueden producir daños al

aire acondicionado.

Este símbolo indica notas especiales.

AVISO

Introducción

Símbolos utilizados en este manual

Características

Filtros de aire

Salida de aire

Toma de aire

Control remoto

Manual de instalación

7

ESPAÑOL

Instalación de la unidad interior

Instalación de la unidad interior

1) Unidad interior

Seleccione la ubicación

Instale el equipo de aire acondicionado en el lugar que

cumpla con las siguientes condiciones.

•

El lugar deberá poder sostener fácilmente una carga

cuatro veces superior al peso de la unidad interior.

•

El lugar deberá permitir la inspección de la unidad tal

como se muestra en la figura.

•

El lugar donde la unidad deberá ser nivelada.

•

El lugar deberá tener un acceso fácil a un desagüe.

(Es necesaria una altura para conseguir un desnivel

de desagüe tal como se muestra en la figura.)

•

El lugar donde conecta fácilmente a la unidad exterior.

•

El lugar no deberá estar afectado por interferencias

eléctricas.

•

El lugar permitirá una buena circulacióndelaireporla

habitación.

•

No deberá hallarse ninguna fuente de calor ni vapor

cerca de la unidad.

■ Instalación de la unidad

Instale la unidad sobre el techo

correctamente.

• Aplique una goma de juntas entre la unidad

y las conducciones para absorber las

vibraciones innecesarias.

• Aplique un accesorio de filtro en el retorno

de aire.