Page 1

LG

Multi Type Air Conditioner

SERVICE MANUAL

LG

CAUTION

website http://www.lgservice.com

e-mail http://lgservice.com/techsup.html

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODEL

• Indoor Unit:

AMNH076LQL0

AMNH096LQL0

AMNH096LRL0

AMNH126LRL0

AMNH186LTL0

AMNH246LTL0

AMNH096AP*1

AMNH126AP*1

AMNH076DZ*0

AMNH096DU*0

AMNH126DU*0

• Outdoor Unit: A2UW146FA0

A2UW186FA0

A3UW186FA0

A3UW246FA0

A4UW246FA0

A4UW306FA0

A6UW406FA0

A7UW486FA0

A8UW566FA0

Room Type

Art Cool Type

Art Cool Deluxe Type

Duct Type 1 Way CST

AMNH096BTG0

AMNH126BTG0

AMNH186BTG0

AMNH096BPA0

AMNH126BPA0

AMNH186BHA0

AMNH246BHA0

AMNH306BGA0

AMNH366BGA0

AMNH096TCC0

AMNH126TCC0

4 Way CST

AMNH126TEC0

AMNH186TEC0

AMNH246TFC0

AMNH306TFC0

AMNH366TDC0

CVT

AMNH096VEA0

AMNH126VEA0

AMNH186VBA0

AMNH246VBA0

Page 2

2 Multi type Air Conditioner

Multi type Air Conditioner Service Manual

TABLE OF CONTENTS

Model Number Nomenclature....................................................................................................................3

Symbols Used in this Manual...................................................................................................................5

Safety Precautions......................................................................................................................................6

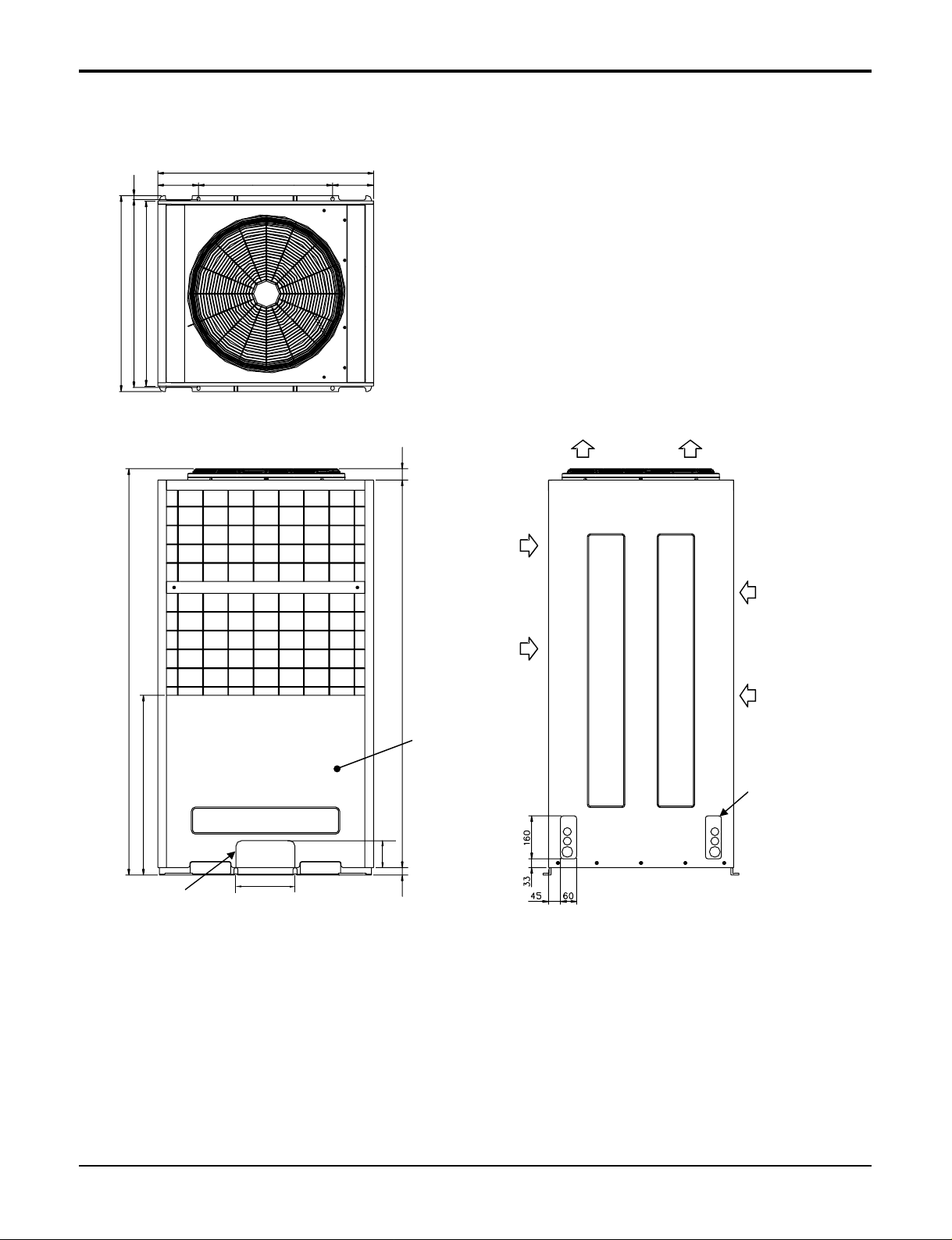

Dimensions................................................................................................................................................12

Indoor Unit.............................................................................................................................................12

Outdoor Unit...........................................................................................................................................20

Product Specifications ............................................................................................................................22

Installation.................................................................................................................................................28

Select the best location of indoor unit ....................................................................................................28

How to fix ...............................................................................................................................................31

Piping and Drainage of Indoor Unit........................................................................................................38

Connection of indoor unit piping.............................................................................................................39

Remote Controller Installation................................................................................................................62

Connecting Pipings and the cable to Outdoor unit.................................................................................64

Checking the Drainage and Pipe forming...............................................................................................66

Maximum Length of Pipe and Extra Charge of Refrigerant Charge.......................................................71

Test Running ..........................................................................................................................................78

System Layout and Piping Length..........................................................................................................81

Installation..............................................................................................................................................82

Installation of The Main Unit...................................................................................................................83

Connection of Piping..............................................................................................................................84

Connection of Wiring..............................................................................................................................85

Operation ..................................................................................................................................................86

Function of control..................................................................................................................................86

Function of Indoor Unit...........................................................................................................................91

Function of Outdoor Unit........................................................................................................................97

Remote Control Operation .....................................................................................................................98

Control Devices and Function...............................................................................................................106

Simple Central Control.........................................................................................................................106

Term of Each part and Function...........................................................................................................106

Electrical wiring ....................................................................................................................................107

Deluxe Central Control.........................................................................................................................113

Disassembly of the parts (Indoor unit) .................................................................................................119

Indoor unit ............................................................................................................................................119

Schematic Diagram.................................................................................................................................133

Electronic Control Device.....................................................................................................................133

Wiring Diagram.....................................................................................................................................142

Components Locations.........................................................................................................................146

Troubleshooting Guide...........................................................................................................................161

Refrigeration Cycle Diagram................................................................................................................161

Self-diagnosis Function........................................................................................................................166

Cycle Troubleshooting Guide................................................................................................................167

Electronic Parts Troubleshooting Guide...............................................................................................168

General Information..............................................................................................................................173

(3-way) Valve ...........................................................................................................................................189

Exploded View & Replacement Parts List ............................................................................................193

Indoor Unit ...........................................................................................................................................193

Outdoor Unit ........................................................................................................................................222

Page 3

Service Manual 3

Model Number Nomenclature

Model Number Nomenclature

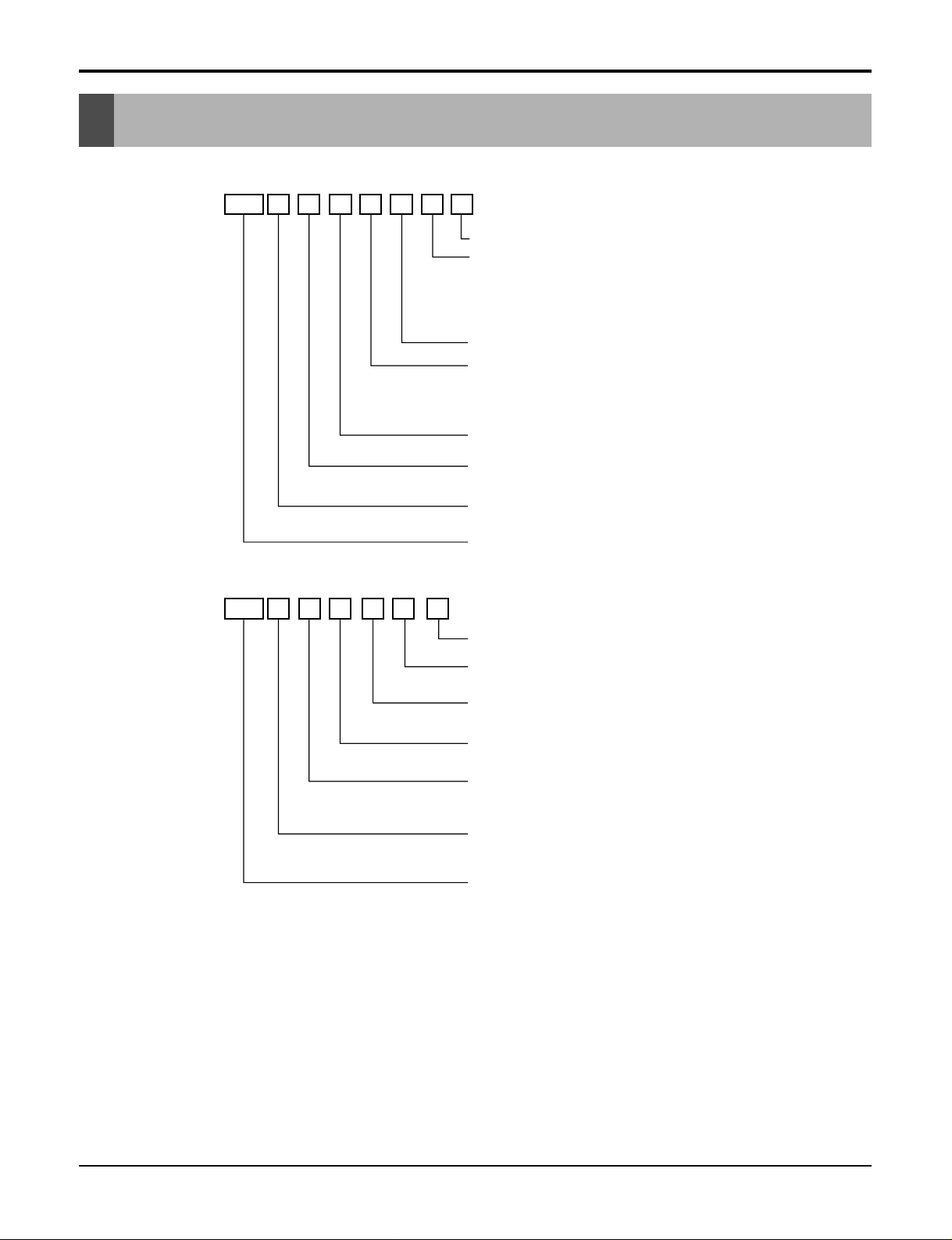

Indoor Unit

Outdoor Unit

AMN H 6

07

QLA0

Serial Number

A2U W 618 F A 0

Electrical Ratings

TPS Inverter Multi System Indoor Unit

Model Type

H : Heat Pump

Ex) 7,000 Btu/h '07', 18,000 Btu/h '18'

Nominal Cooling Capacity in Btu/h

Electrical Rating

6 : 1Ø, 220-240V, 50Hz

Chassis Name

Indoor Unit Type

L : Wall Mounted , A : ART COOL

D : ART COOL DELUXE, T : Ceiling Cassette

B : Ceiling Concealed Duct

V : Ceiling & Floor(Convertible)

Function

A : Basic, L : Nano Plasma + Auto Clean(Wall Mounted)

C: Plasma(Ceiling Cassette), G: Low Static Motor

ART COOL(DELUXE) Type Front Panel Color

B : Blue, D : Wood, M : Meta, R : Mirror, W : White

R410A

TPS Inverter Multi

System Outdoor Unit.

And No. of Connectable Indoor Units

Ex) A2U : Connectable max. 2 Indoor Units

A6U : Connectable max. 6 Indoor Units

Model Type

W : DC Inverter Heat Pump

Ex) 18,000 Btu/h '18', 48,000 Btu/h, '48'

Nominal Cooling Capacity in Btu/h

6 : 1Ø, 220-240V, 50Hz

8 : 3Ø, 380-415V, 50Hz

Multi Type

Function

A : Basic

F : Free Joint Multi Type

Serial Number

Page 4

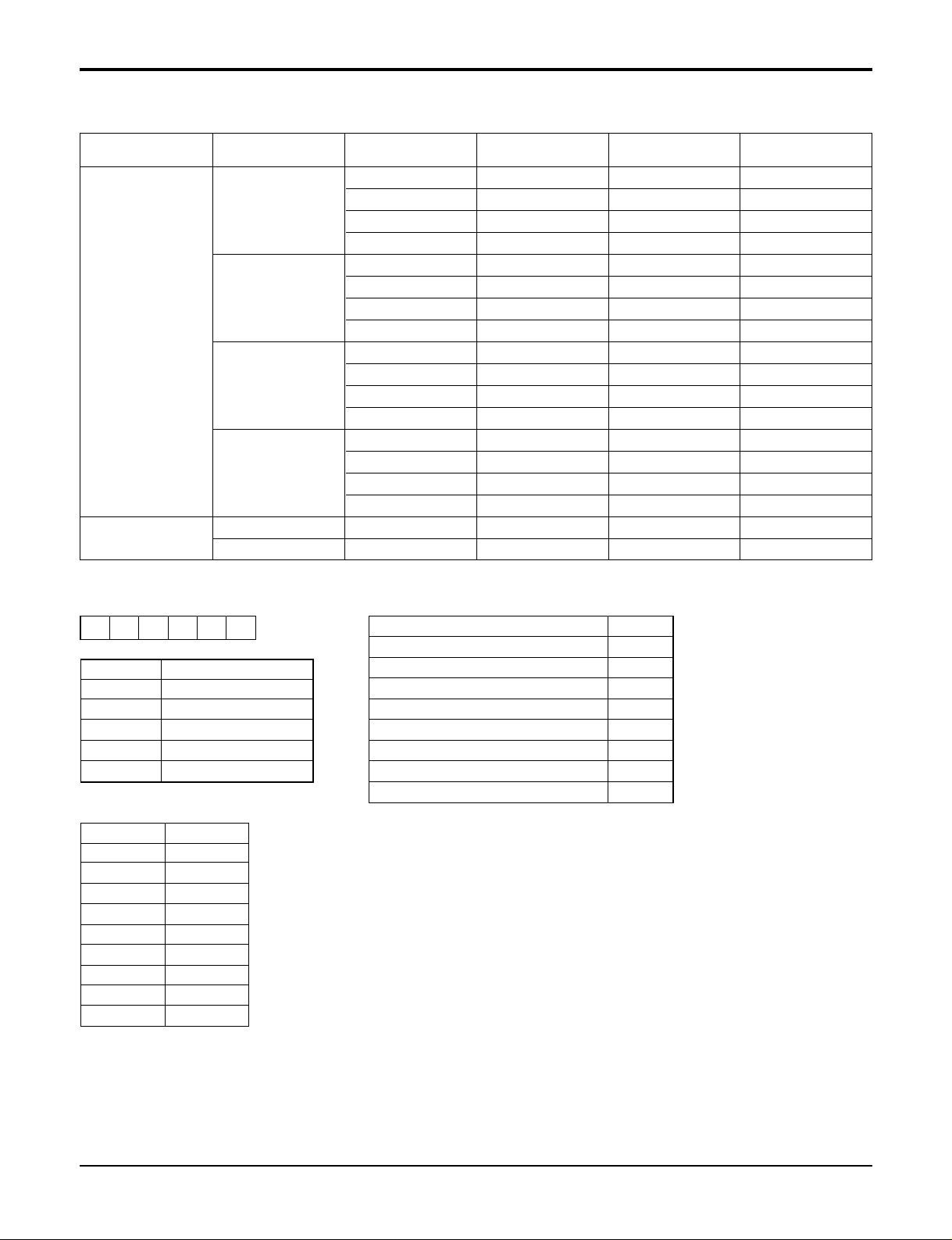

Model Number Nomenclature

Panel (Cassette, Built in Duct)

4 Multi type Air Conditioner

PT-CFA 3721A10072B 8435002992862 COOLING

TF

PT-CFC 3721A10072G 8435002992879 COOLING + PLASMA

PT-HFA 3821A10072A 8435002992886 HEATING

PT-HFC 3721A10072E 8435002992893 HEATING + PLASMA

PT-CCA 3721A10023Z 8435002994095 COOLING

TC

PT-CCC 3721A10023W 8435002994101 COOLING + PLASMA

PT-HCA 3721A10023Y 8435002994118 HEATING

CST PANEL

PT-HCC 3721A10023V 8435002994125 HEATING + PLASMA

PT-HEA 3721A10105A 8435002992978 HEATING

TE(family look)

PT-HEC 3721A10105B 8435002992985 HEATING + PLASMA

PT-CEA 3721A10105C 8435002992954 COOLING

PT-CEC 3721A10105D 8435002992961 COOLING + PLASMA

PT-HAD 3721A10106A 8435002994057 HEATING

TD(family look)

PT-HDC 3721A10106B 8435002994064 HEATING + PLASMA

PT-CDA 3721A10106C 8435002994071 COOLING

PT-CDC 3721A10106D 8435002994088 COOLING + PLASMA

BUILT IN DUCT

BP PB-HPA 3721A20168A 9K/12K

BQ PB-HQA 3721A20168B 18K/24K

Category CHASSIS PANEL NAME PANEL P/NO. SERIAL NO. Remark

123456

PT-HEA

Basic A

B

Plasma Filter C

D

Elevation Grille E

Elevation Grille + Plasma Filter F

TE/TB/TD Before 2003 : Basic 0

TE/TD Before 2003 : Plasma Filter 1

6. Function

5. Chassis Name

Function

Number Contents

1, 2 Panel for Cassette

34 Cooling/Heatpump

5 Chassis Name

6 Function

Chassis Abbrevation

TC C

TB B

TD D

TE E

TF F

TH H

TJ J

BP P

BQ Q

Page 5

Service Manual 5

Model Number Nomenclature

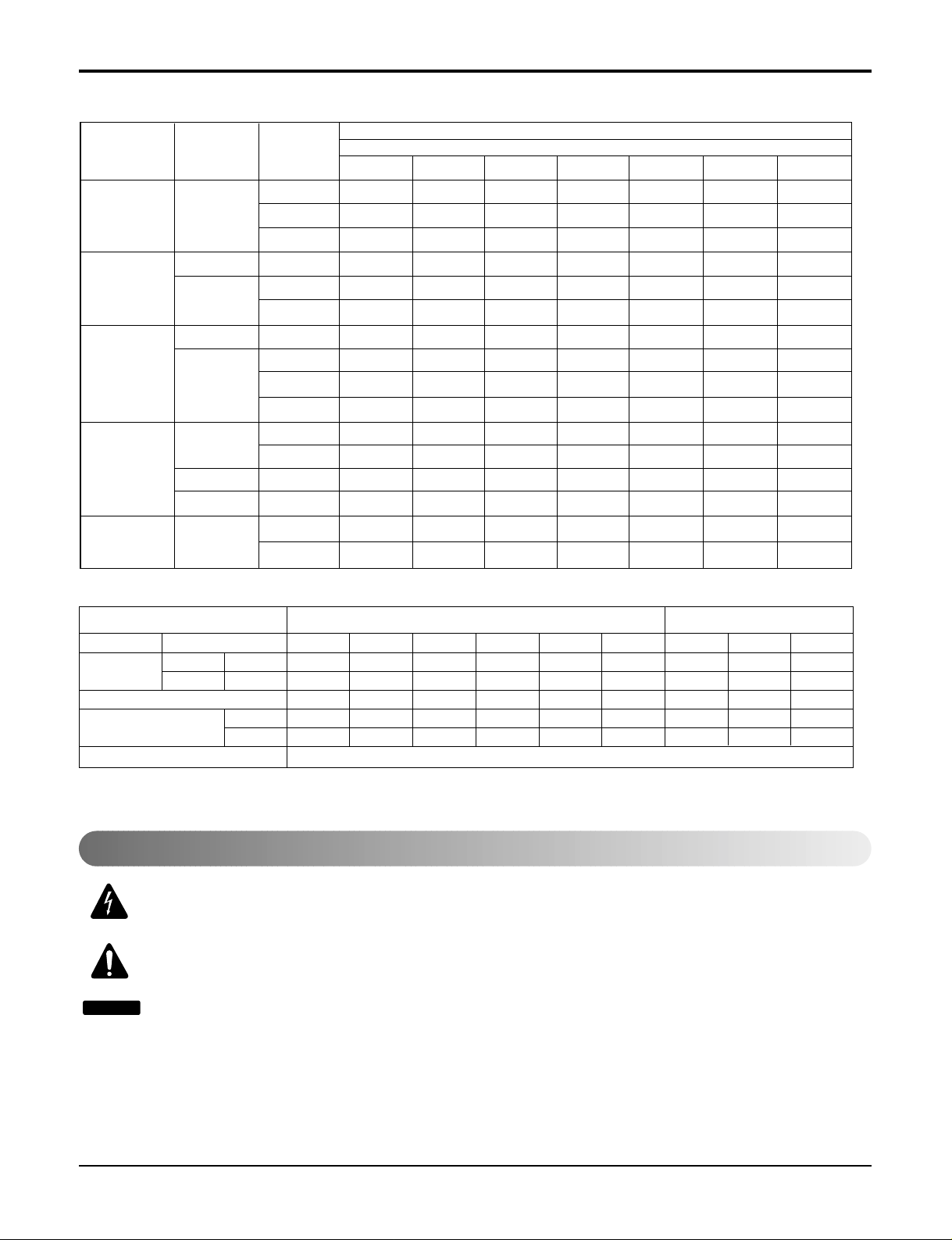

Indoor Units

Outdoor Units

2.1

(7000)

2.6

(9000)

3.5

(12000)

5.3

(18000)

7.0

(24000)

8.8

(30000)

10.6

(36000)

SQ

AMNH

076LQL0

AMNH

096LQL0

-- - - -

SR

-

AMNH

096LRL0

AMNH

126LRL0

----

ST

---

AMNH

186LTL0

AMNH

246LTC0

--

General

SP1

-

AMNN

096AP*1

AMNN

126AP*1

----

SZ

AMNH

076DZ*0

--- - - -

SU

-

AMNH

096DU*0

AMNH

126DU*0

----

1Way

TC

-

AMNH

096TCC0

AMNH

126TCC0

----

TE

--

AMNH

126TEC0

AMNH

186TEC0

-- -

TF

----

AMNH

246TFC0

AMNH

306TFC0

-

TD

------

AMNH

366TDC0

BH

---

AMNH

186BHA0

AMNH

246BHA0

--

BG

-----

AMNH

306BGA0

AMNH

366BGA0

Low

Static

BT

-

AMNH

096BTG0

AMNH

126BTG0

AMNH

186BTG0

-- -

Built in

BP

-

AMNH

096BPA0

AMNH

126BPA0

----

VE

-

AMNH

096VEA0

AMNH

126VEA0

----

VB

---

AMNH

186VBA0

AMNH

246VBA0

--

Chasiss

Model Name

Capacity, kW(Btu/h)

Wall

Mounted

General

Ceiling &

Floor

Convertible

Category Type

ART

COOL

Mirror

Ceiling

Cassette

4Way

Ceiling

Concealed

Duct

High

Static

Notes :

A2UW146FA0, A2UW186FA0 and A3UW186FA0 are not TPS inverter system but one inverter compressor system.

TPS Inverter Multi Series Multi Piping Type Distributor Type

Heat Pump Model Name

Rated Capacity Cooling kW(Btu/h)

Heating kW(Btu/h)

Number of Indoor Units to be Connected

Indoor Units kW

Connectable Capacity Btu/h

Power Supply

A2UW146FA0 A2UW186FA0 A3UW186FA0 A3UW246FA0 A4UW246FA0 A4UW306FA0 A6UW406FA0 A7UW486FA0 A8UW566FA0

4.7(1600) 5.3(18000) 5.3(18000) 7.0(24000) 7.0(24000) 8.8(30000) 11.7(40000) 14.0(48000) 16.4(56000)

5.3(1800) 6.3(21600) 6.3(21600) 8.2(28000) 8.2(28000) 10.1(34500) 13.5(46000) 16.2(55200) 18.9(64400)

Max.2 Units Max.2 Units Max.3 Units Max.3 Units Max.4 Units Max.4 Units Max.6 Units Max.7 Units Max.8 Units

2.1~6.2 2.1~7.0 2.1~7.0 2.1~9.7 2.1~9.7 2.1~11.4 4.7~15.2 5.6~18.3 6.6~21.3

7000~21000 7000~24000 7000~24000 7000~33000 7000~33000 7000~39000 16000~52000 19200~62400 22400~72800

1Ø, 220-240V, 50Hz

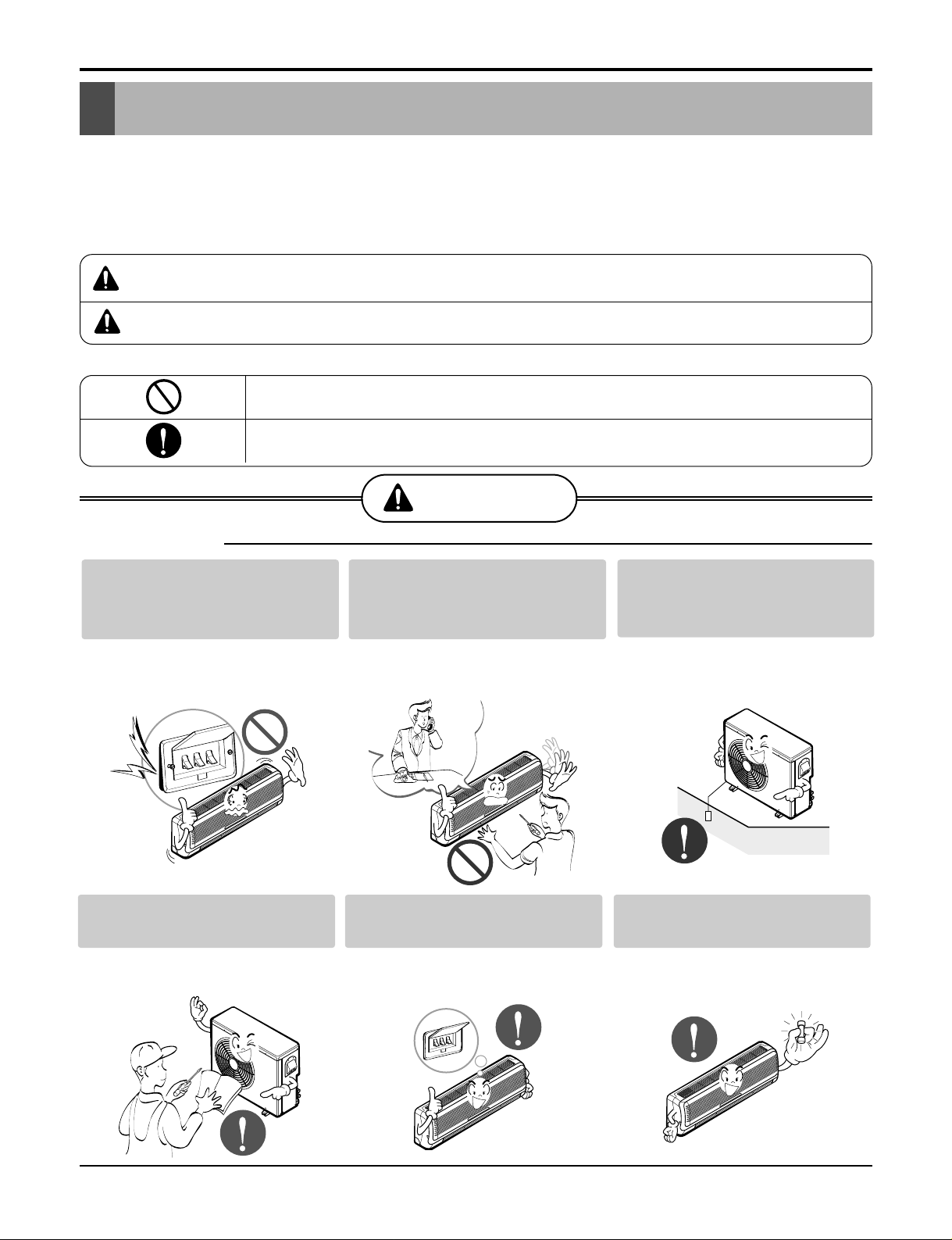

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

NOTICE

Symbols Used in this Manual

Page 6

6 Multi type Air Conditioner

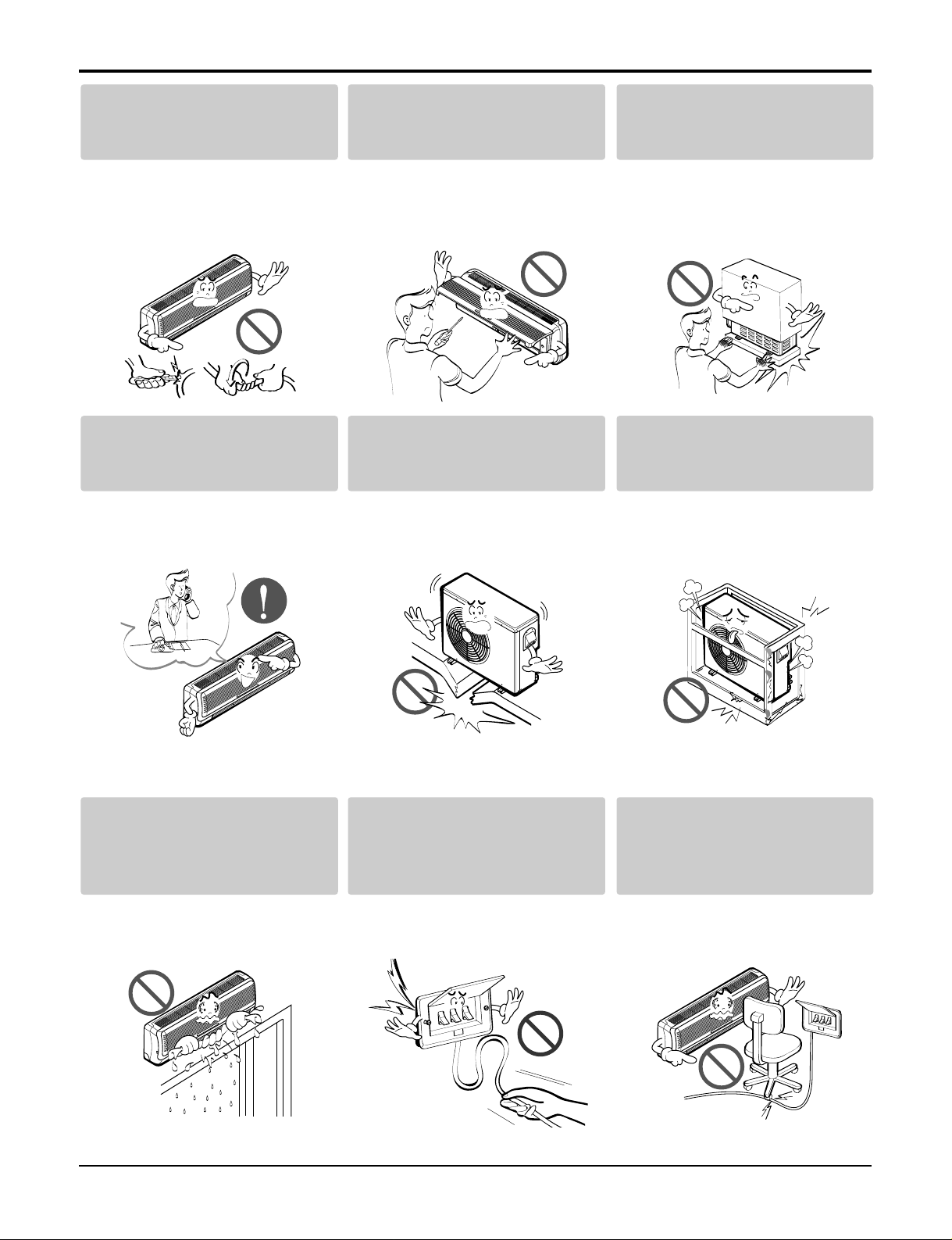

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

WARNING

■ Installation

Be sure not to do.

Be sure to follow the instruction.

Do not use a defective or underrated circuit breaker. Use this

appliance on a dedicated circuit.

• There is risk of fire or electric

shock.

For electrical work, contact the

dealer, seller, a qualified electrician,

or an Authorized Service Center

.

• Do not disassemble or repair the

product. There is risk of fire or

electric shock.

Always ground the product.

• There is risk of fire or electric

shock.

Install the panel and the cover

of control box securely.

• There is risk of fire or electric

shock.

Always install a dedicated circuit and breaker.

• Improper wiring or installation may

cause fire or electric shock

Use the correctly rated breaker or fuse.

• There is risk of fire or electric

shock.

WARNING

CAUTION

Page 7

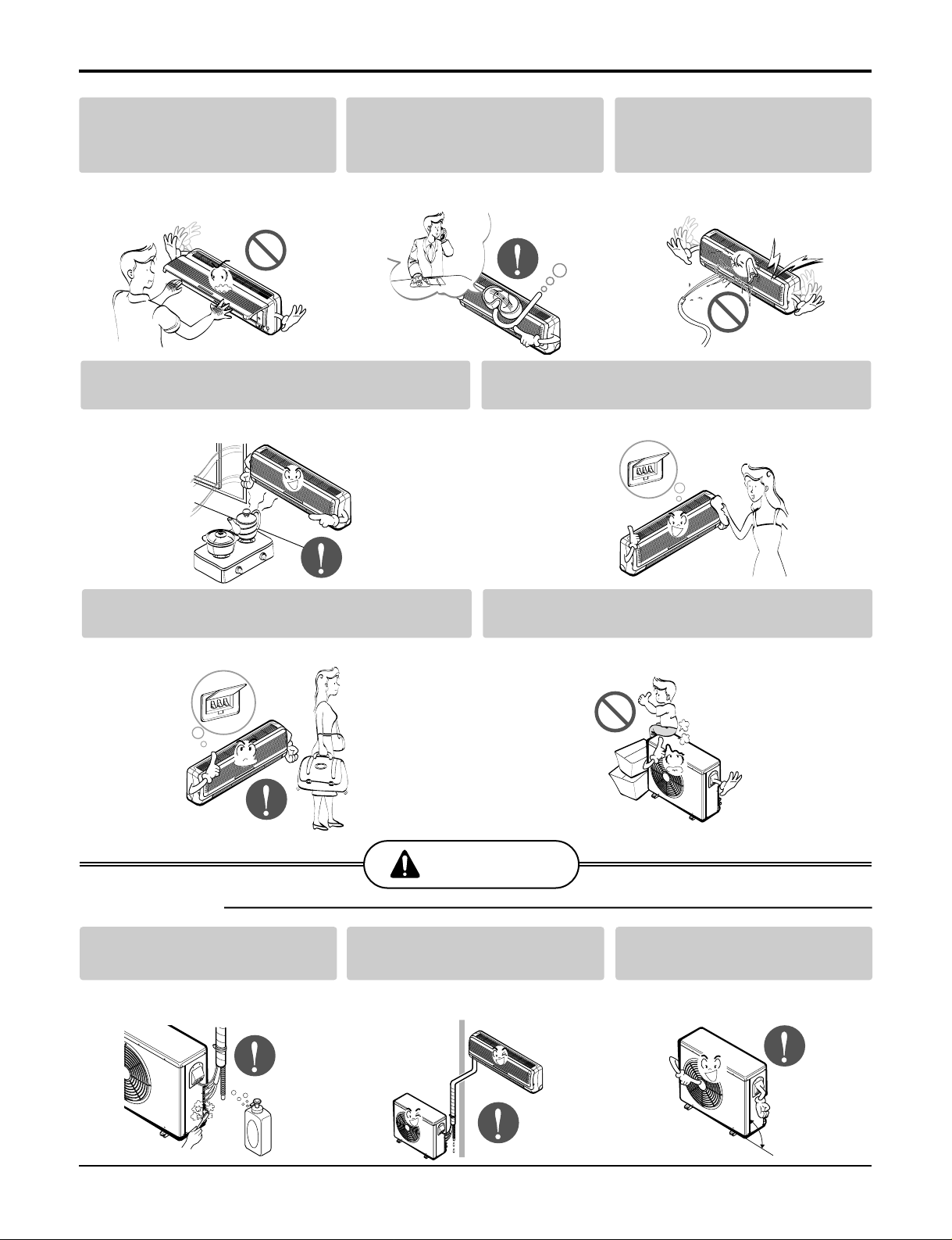

Service Manual 7

Safety Precautions

Do not modify or extend the

power cable.

• There is risk of fire or electric

shock.

Do not install, remove, or reinstall the unit by yourself

(customer).

• There is risk of fire, electric shock,

explosion, or injury.

Be cautious when unpacking

and installing the product.

• Sharp edges could cause injury.

Be especially careful of the case

edges and the fins on the condenser and evaporator.

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric shock,

explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or

damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air conditioner could fall with it, causing

property damage, product failure,

and personal injury.

Do not let the air conditioner

run for a long time when the

humidity is very high and a

door or a window is left open.

• Moisture may condense and wet or

damage furniture.

Take care to ensure that

power cable could not be

pulled out or damaged during

operation.

• There is risk of fire or electric

shock.

Do not place anything on the

power cable.

• There is risk of fire or electric

shock.

Page 8

8 Multi type Air Conditioner

Safety Precautions

Do not allow water to run into

electric parts.

• It may cause There is risk of fire,

failure of the product, or electric

shock.

Do not store or use flammable

gas or combustibles near the

product.

• There is risk of fire or failure of

product.

Do not use the product in a

tightly closed space for a long

time.

• Oxygen deficiency could occur.

When flammable gas leaks,

turn off the gas and open a

window for ventilation before

turn the product on.

• Do not use the telephone or turn

switches on or off. There is risk of

explosion or fire

If strange sounds, or small or

smoke comes from product.

Turn the breaker off or disconnect the power supply cable.

• There is risk of electric shock or

fire.

Stop operation and close the

window in storm or hurricane.

If possible, remove the product from the window before

the hurricane arrives.

• There is risk of property damage,

failure of product, or electric shock.

Do not plug or unplug the

power supply plug during

operation.

• There is risk of fire or electric

shock.

Do not touch(operate) the

product with wet hands.

• There is risk of fire or electrical

shock.

Do not place a heater or other

appliances near the power

cable.

• There is risk of fire and electric

shock.

Gasolin

Page 9

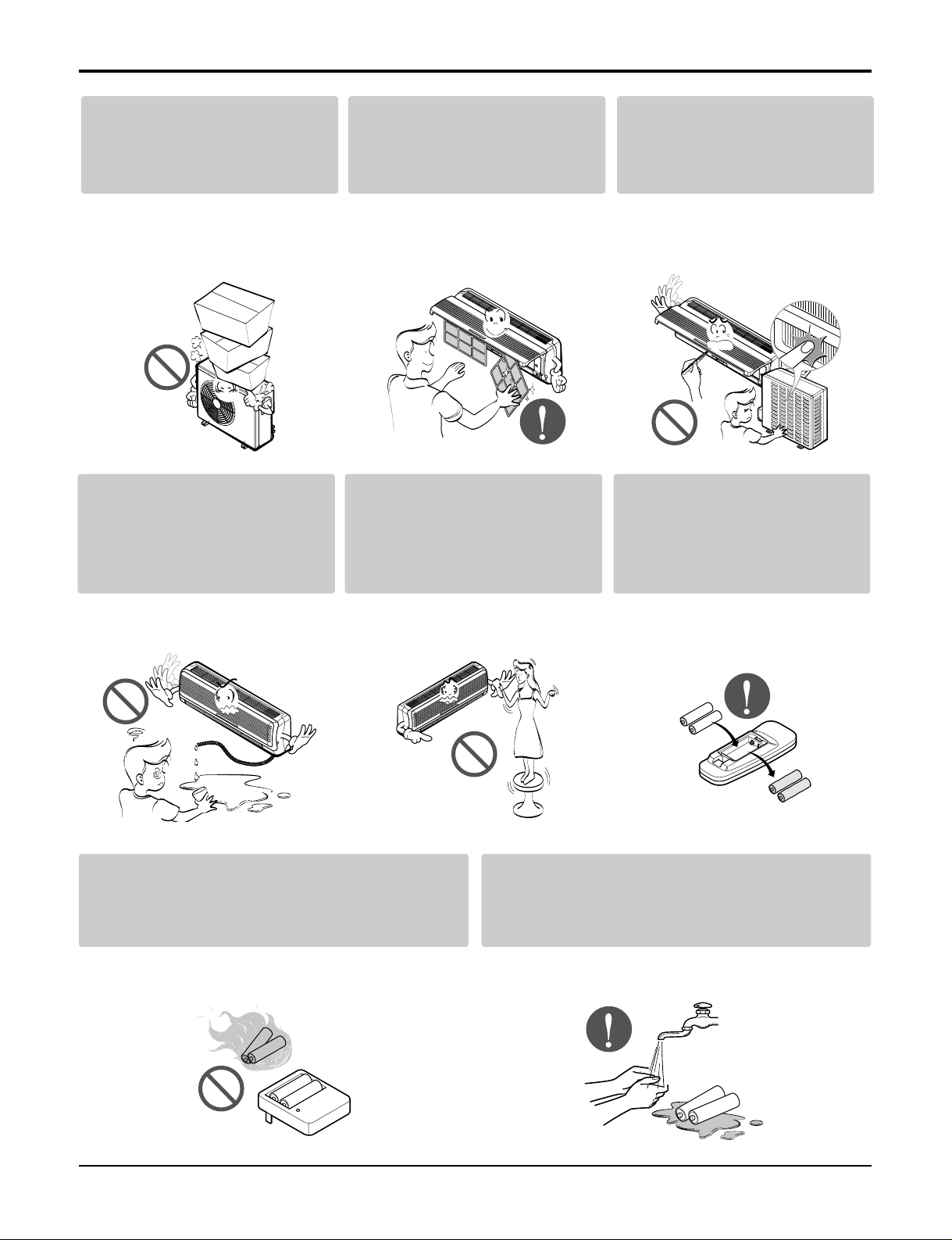

Service Manual 9

Safety Precautions

Do not open the inlet grill of the product

during operation. (Do not touch the electrostatic filter, if the unit is so equipped.)

• There is risk of physical injury,

electric shock, or product failure.

When the product is soaked

(flooded or submerged), contact

an Authorized Service Center.

• There is risk of fire or electric

shock.

Be cautious that water could

not enter the product.

• There is risk of fire, electric shock,

or product damage.

Ventilate the product from time to time when

operating it together with a stove, etc.

• There is risk of fire or electric shock.

Turn the main power off when cleaning or

maintaining the product.

• There is risk of electric shock.

When the product is not be used for a long time, disconnect the power supply plug or turn off the breaker.

• There is risk of product damage or failure, or unintended operation.

Take care to ensure that nobody could step on

or fall onto the outdoor unit.

• This could result in personal injury and product damage.

Always check for gas (refrigerant) leakage after installation or repair of product.

• Low refrigerant levels may cause

failure of product.

Install the drain hose to ensure that

water is drained away properly.

• A bad connection may cause water

leakage.

Keep level even when

installing the product.

• To avoid vibration or water leakage.

CAUTION

■ Installation

90°

Page 10

10 Multi type Air Conditioner

Do not block the inlet or outlet

of air flow.

• It may cause product failure.

Use a soft cloth to clean. Do

not use harsh detergents, solvents, etc.

• There is risk of fire, electric shock,

or damage to the plastic parts of

the product.

Do not touch the metal parts of

the product when removing the

air filter. They are very sharp!

• There is risk of personal injury.

Safety Precautions

Do not install the product

where the noise or hot air

from the outdoor unit could

damage the neighborhoods.

• It may cause a problem for your

neighbors.

Use two or more people to lift

and transport the product.

• Avoid personal injury.

Do not install the product

where it will be exposed to

sea wind (salt spray) directly.

• It may cause corrosion on the

product. Corrosion, particularly on

the condenser and evaporator fins,

could cause product malfunction or

inefficient operation.

Do not expose the skin directly to cool air for

long periods of time.

(Don't sit in the draft.)

• This could harm to your health.

Do not use the product for special purposes,

such as preserving foods, works of art, etc. It

is a consumer air conditioner, not a precision

refrigeration system.

• There is risk of damage or loss of property.

■ Operational

Wax

Thinner

Page 11

Service Manual 11

Do not step on or put anyting

on the product. (outdoor

units)

• There is risk of personal injury and

failure of product.

Always insert the filter securely. Clean the filter every two

weeks or more often if necessary.

• A dirty filter reduces the efficiency

of the air conditioner and could

cause product malfunction or damage.

Do not insert hands or other

objects through the air inlet or

outlet while the product is

operated.

• There are sharp and moving parts

that could cause personal injury.

Do not drink the water drained

from the product.

• It is not sanitary and could cause

serious health issues.

Use a firm stool or ladder

when cleaning or maintaining

the product.

• Be careful and avoid personal

injury.

Replace the all batteries in the

remote control with new ones

of the same type. Do not mix

old and new batteries or different types of batteries.

• There is risk of fire or explosion

Do not recharge or disassemble the batteries.

Do not dispose of batteries in a fire.

• They may burn or explode.

If the liquid from the batteries gets onto your

skin or clothes, wash it well with clean water.

Do not use the remote if the batteries have

leaked.

• The chemicals in batteries could cause burns or other

health hazards.

Safety Precautions

Page 12

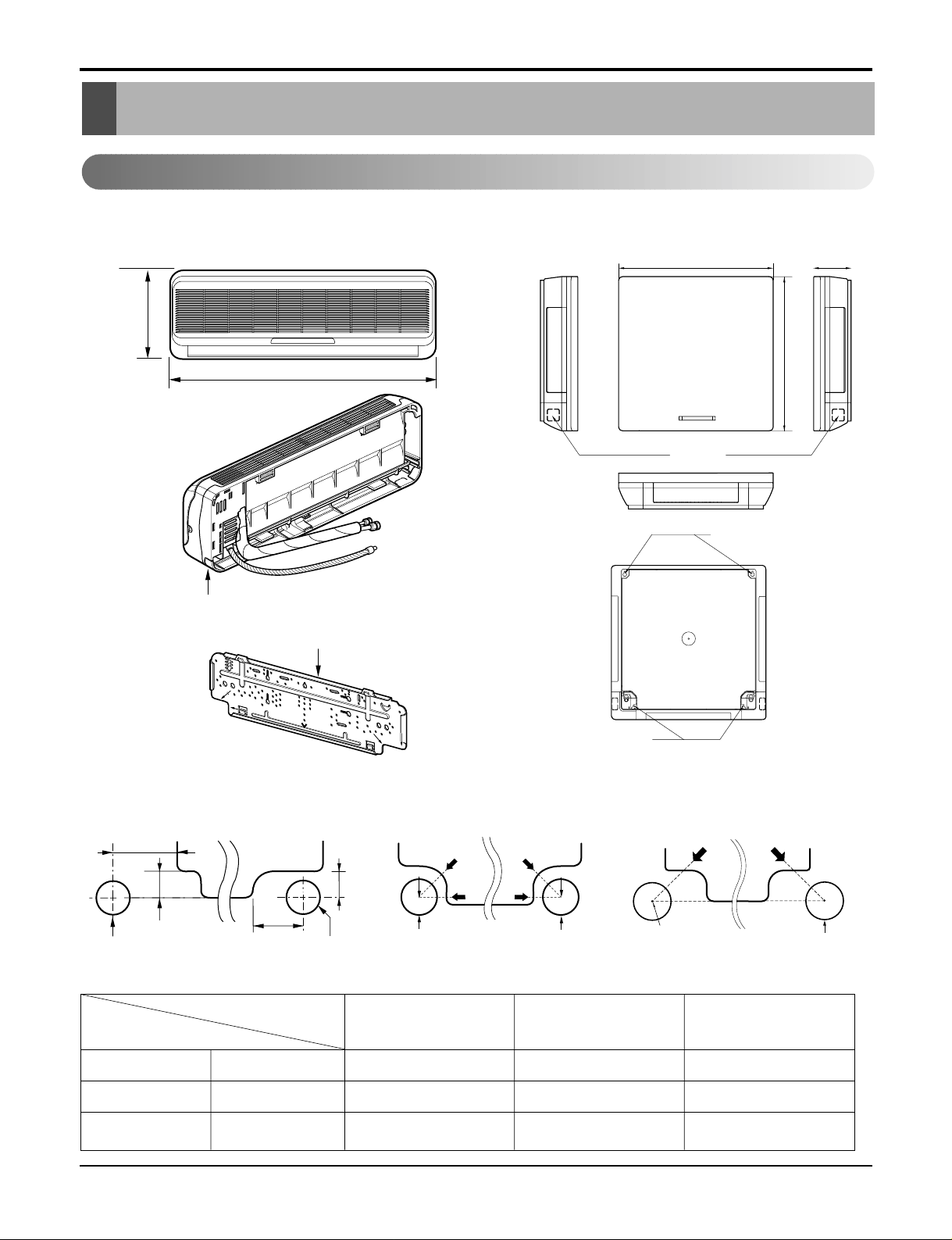

12 Multi type Air Conditioner

Dimensions

Dimensions

Indoor Unit

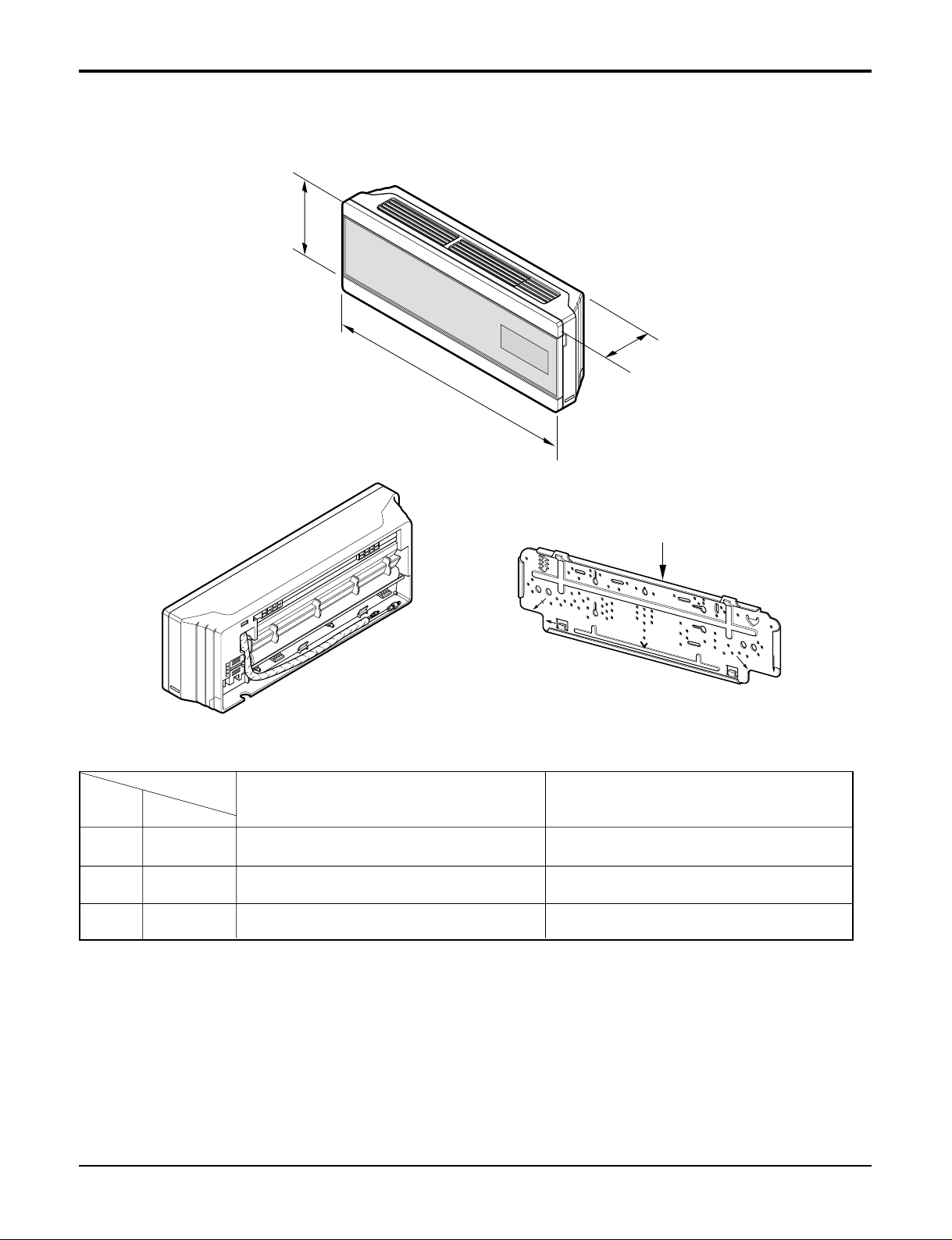

1. Split Type Indoor 2. Art Cool Type Indoor Unit

Installation plate

Right rear piping

Left rear piping

ø70mm

ø70mm

50mm

20mm

20mm

80mm

A

A

ø70mm

Center

Center

ø70mm

Left rear piping

Right rear piping

A

A

H

W

Tubing hole cover

Left rear piping Right rear piping

Hole Center

ø70mm

"D"

"C"

(7K, 9K) (9K, 12K) (18K, 24K)

Pipe Hole

Fix Hole

Hanger Hole

H

W

D

W mm 824 900 1,080

H mm 260 285 314

D mm 155 156 172

SQ

7K,9K

SR

9K, 12K

ST

18K, 24K

MODEL

DIM

Page 13

Service Manual 13

Dimensions

Installation plate

D

H

W

MODEL

DIM Unit

W mm 900 1030

H mm 272 290

D mm 135 153

SZ

7K

SU

9K, 12K

3. Art Cool Deluxe Type

Page 14

14 Multi type Air Conditioner

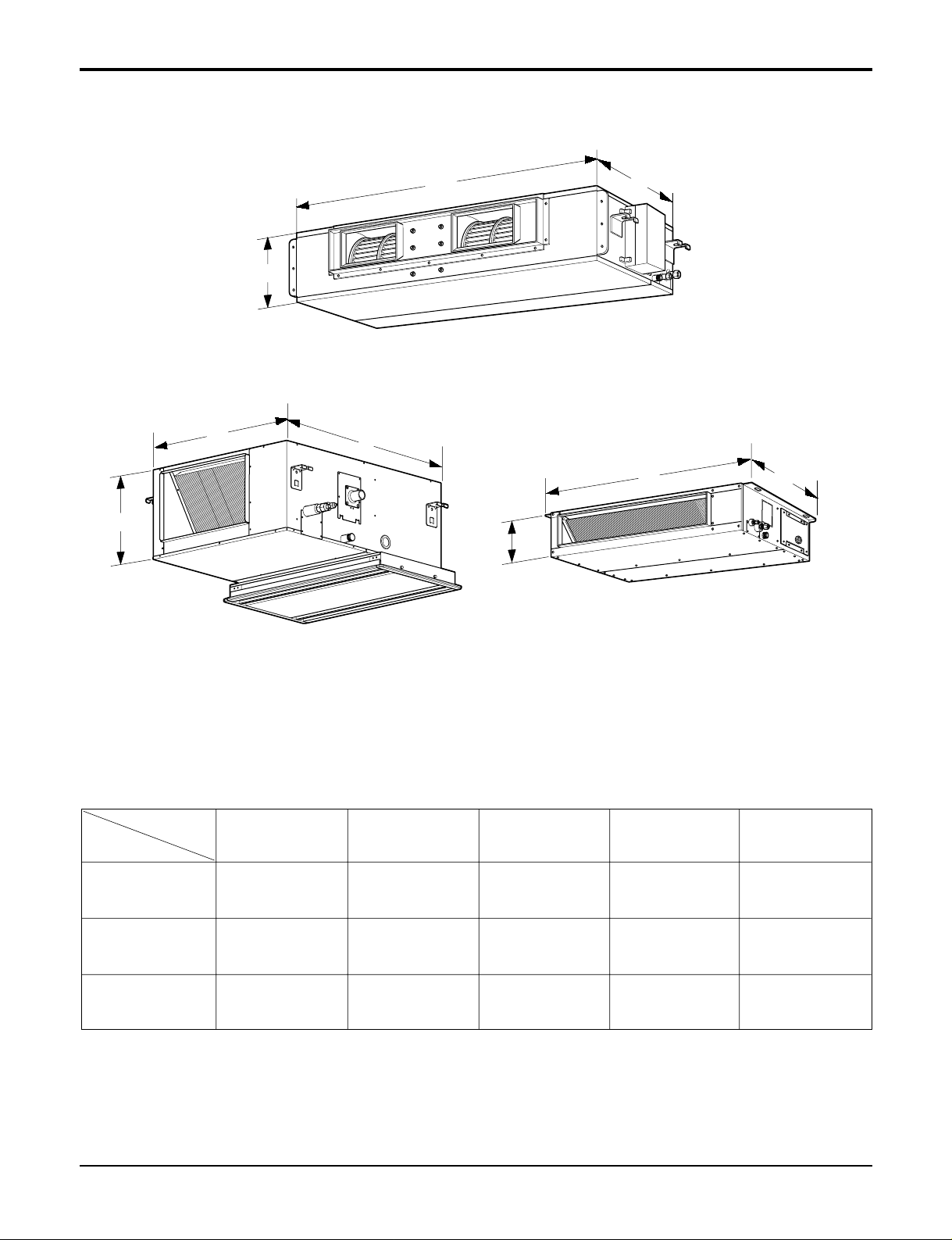

Dimensions

W

H

D

H

H

D

BH/BG

BP BT/BT1

W

W

D

MODEL

DIM

W(mm) 708 1060 880 1180 580

H(mm) 230 230 260 298 300

D(mm) 537 357 450 450 750

BT

9K/12K

BT1

18K

BH

18K/24K

BG

30K/36K

BP

9K/12K

4. Duct Type

Page 15

Service Manual 15

Dimensions

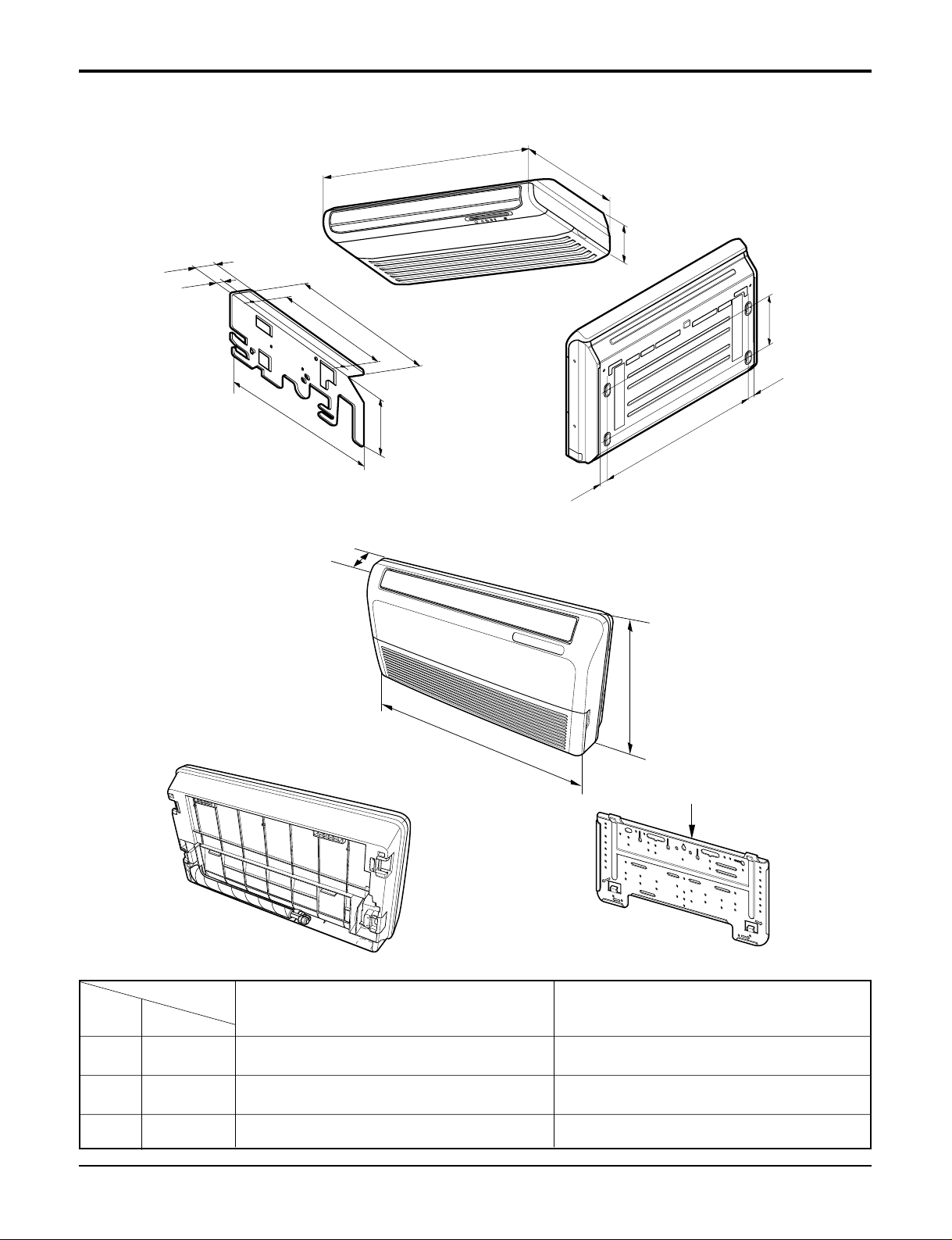

5. CVT Type

VE(9K/12K)

VB(18K/24K)

R

Installation plate

D

W

H

250mm

36mm

36mm

1076mm

(Rear Side)

63mm

38mm

175mm

(Installation Plate)

392m

m

265m

m

468mm

D

W

H

MODEL

DIM Unit

W mm 900 1200

H mm 285 615

D mm 156 205

VE

9K/12K

VB

18K/24K

Page 16

16 Multi type Air Conditioner

Dimensions

694.5

1050

480

846

860

328.430.8

390

893.4

931.6

16.7

50

42.7

7

155

97.7

37

116.3

141.8

180

164

194.4

91.6

180

430

130

Ø80

Ø55

180

91.6

1,000 (Ceiling opening)

931.6

893.4 (Hanging bolt)

328.4 (Hanging bolt)

860

390

30.8

430 (Ceiling opening)

4

5

6

3

2

1

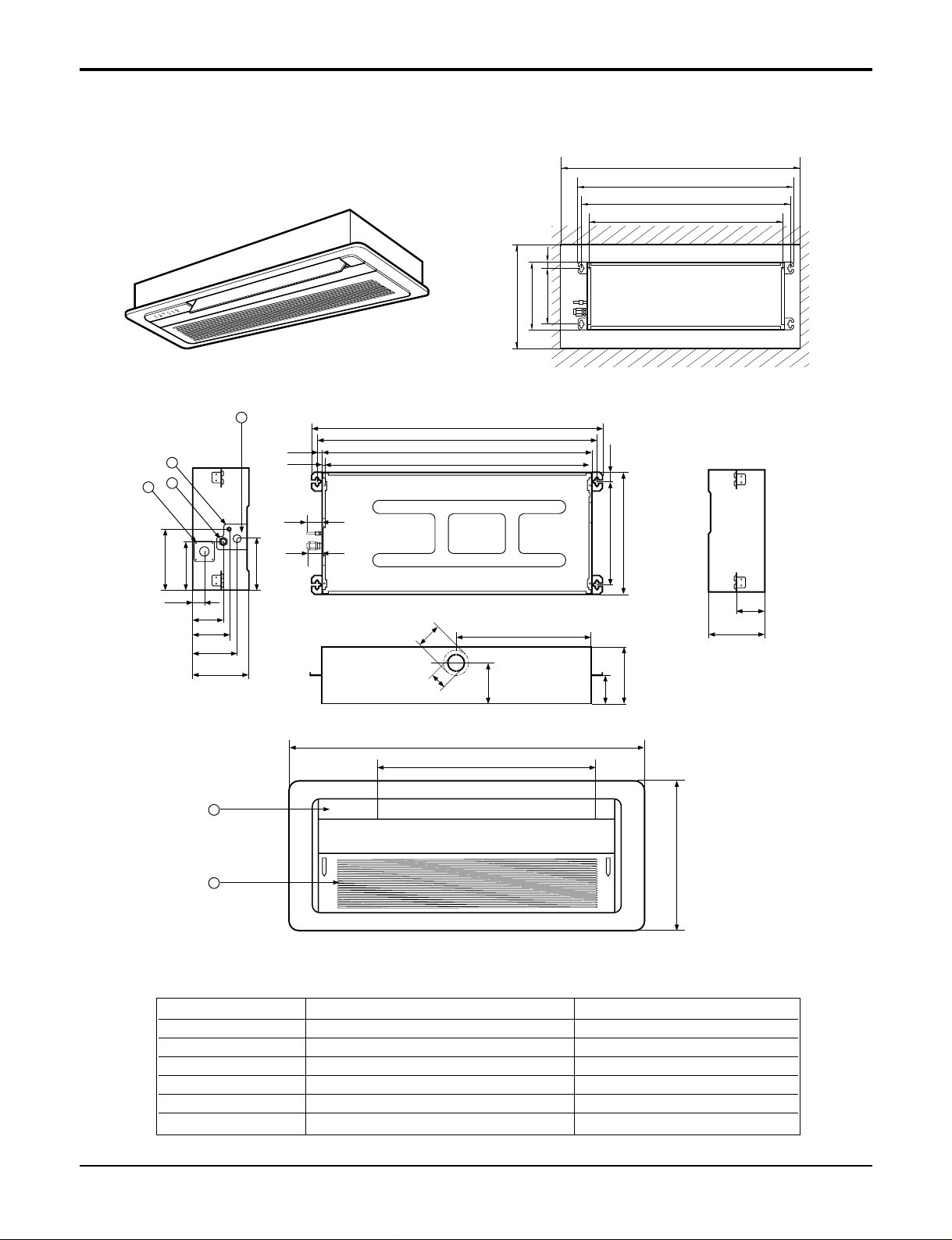

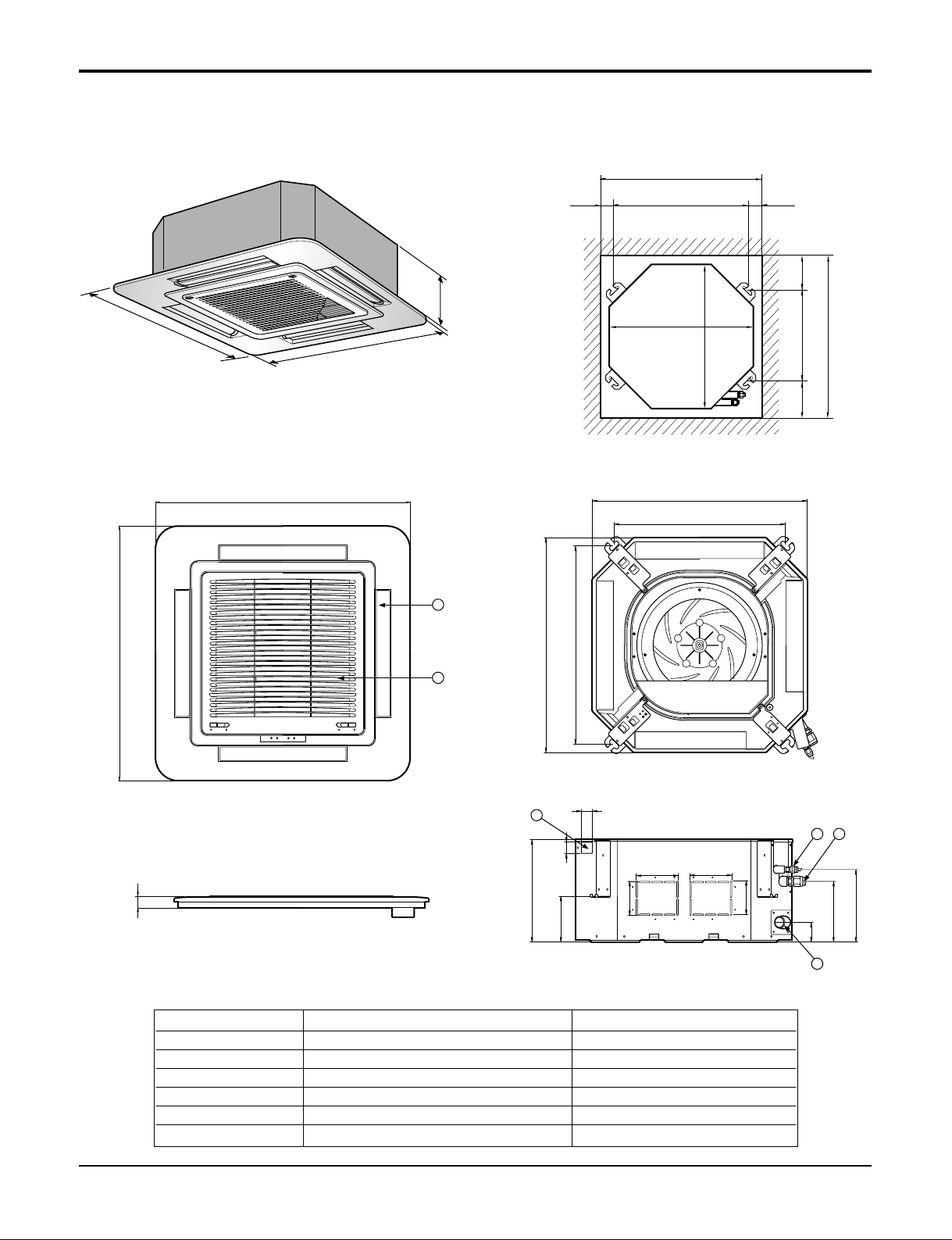

6. CST Type - TC (9K/12K)6. CST Type - TC (9K/12K)

(unit : mm)

Number Name Descripition

1 Liquid pipe connection ø6.35 flare

2 Gas pipe connection ø9.52 flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grill

6 Air suction grill

Page 17

Service Manual 17

CLOSE OPEN OPEN CLOSE

269

670

30

570

269

190.5

160

52

90

90

120.4

30

521

670

570

450

40

110 110

670

670

4

132

5

6

Unit:mm

570 Unit size

570 Unit size

450 (Hanging bolt)

7575

600 (Ceiling opening)

600 (Ceiling opening)

521(Hanging bolt)

39.5

39.5

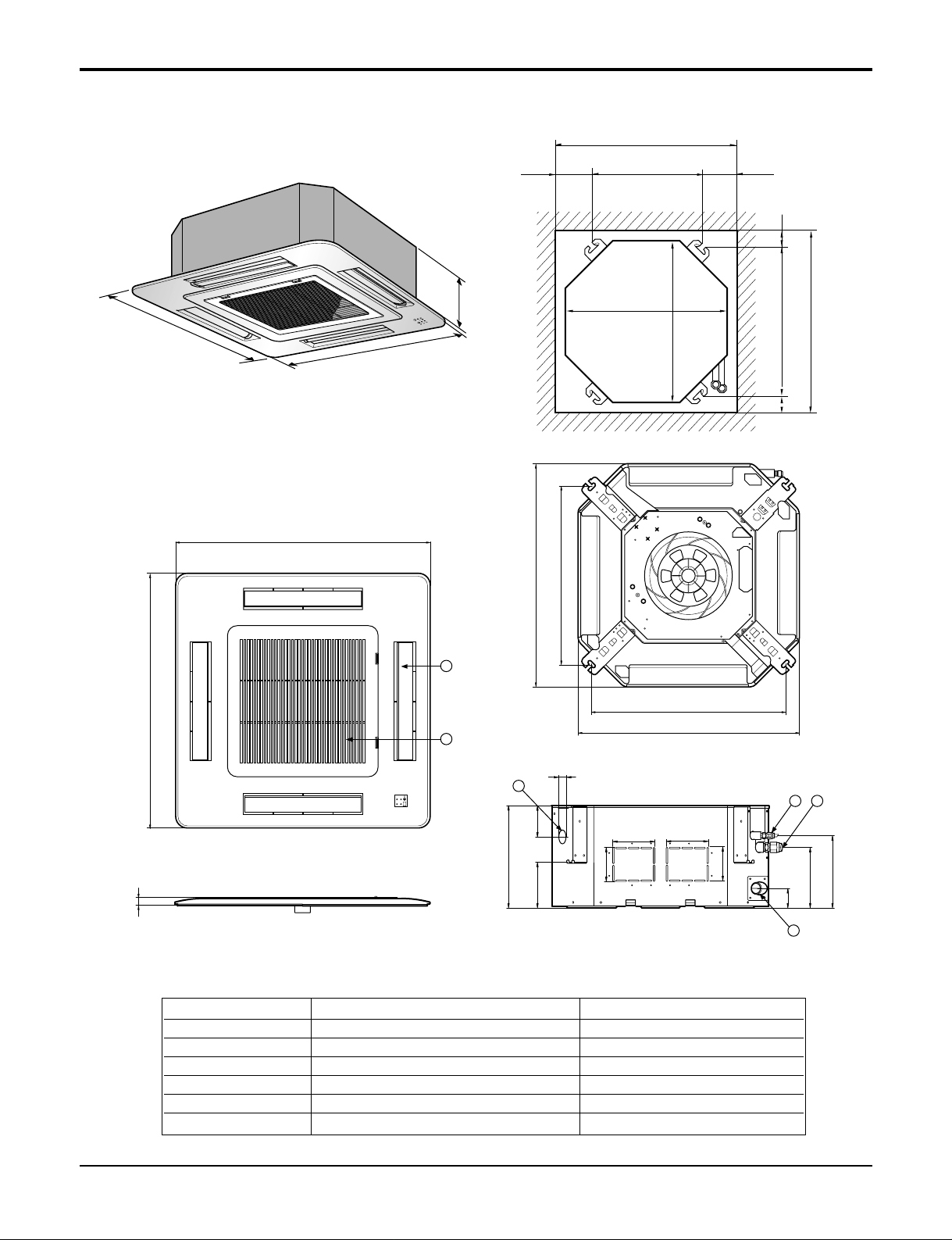

7. CST Type - TE (12K/18K)

Dimensions

(unit : mm)

Number Name Descripition

1 Liquid pipe connection ø6.35 flare

2 Gas pipe connection

12k: ø9.52, 18k: ø12.7 flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grill

6 Air suction grill

Page 18

18 Multi type Air Conditioner

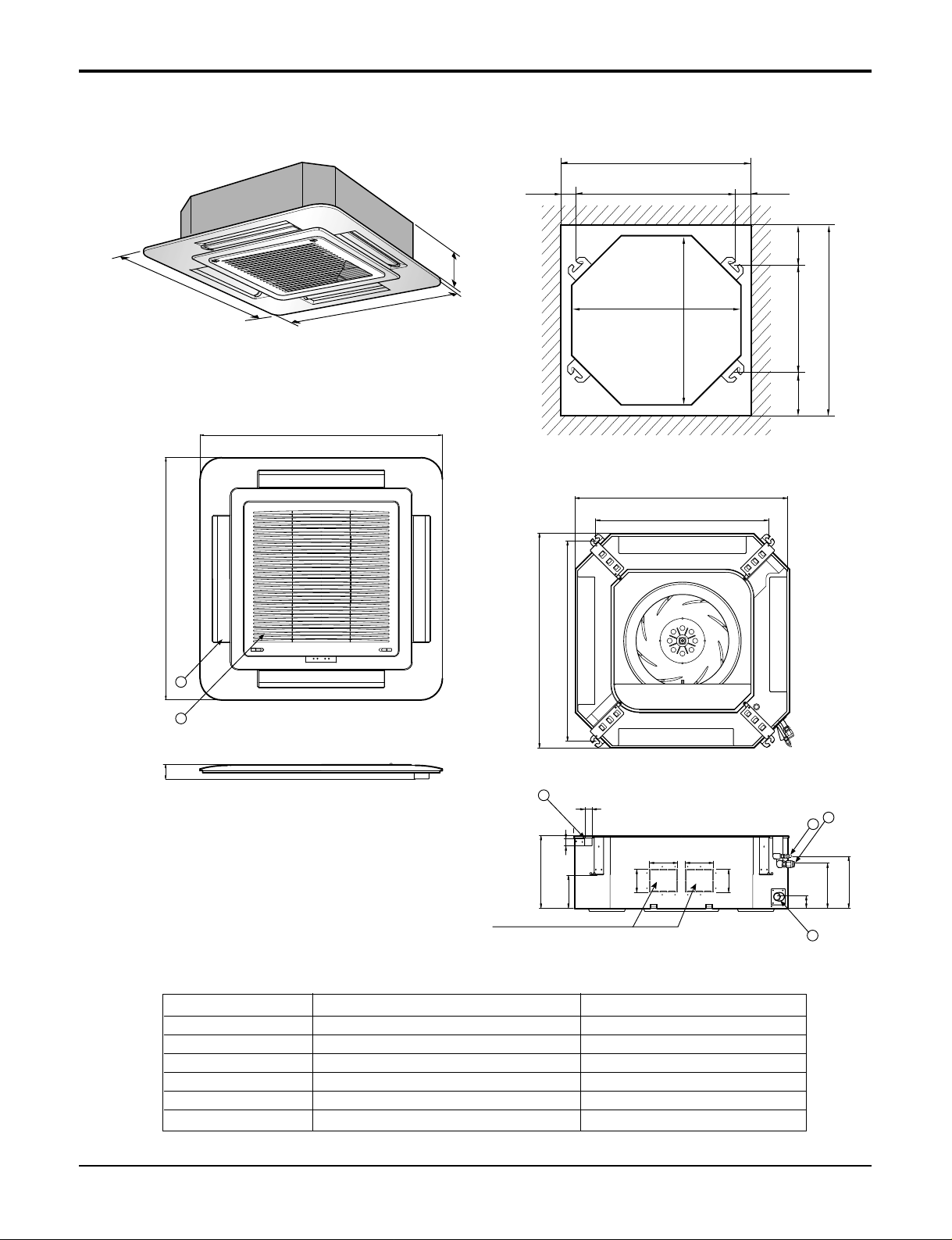

8. CST Type - TF (24K/30K)

292

850

850

850

850

744

658

572

744

292

212

150

54

90

90

192 117

70

110 110

4

132

5

6

Unit:mm

744 Unit size

744 Unit size

658 (Hanging bolt)

6666

790 (Ceiling opening)

790 (Ceiling opening)

572(Hanging bolt)

109

109

30

(unit : mm)

Number Name Descripition

1 Liquid pipe connection ø6.35 flare

2 Gas pipe connection

ø12.7 flare-24K, ø15.88 flare-30K

3 Drain pipe connection

4 Power supply connection

5 Air discharge grill

6 Air suction grill

Dimensions

Page 19

Service Manual 19

9. CST Type - TD(36K)

288

950

950

950

950

290

210.5

180

52

140

40

110

30

90

90

110

55

840

785

840

678

Fresh Air Inlet

Unit:mm

840 Unit size

840 Unit size

672 (Hanging bolt)

101.5101.5

875 (Ceiling opening)

875 (Ceiling opening)

785 (Hanging bolt)

45

45

4

5

6

1

3

2

Dimensions

(unit : mm)

Number Name Descripition

1 Liquid pipe connection ø6.35 flare

2 Gas pipe connection ø15.88 flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grill

6 Air suction grill

Page 20

20 Multi type Air Conditioner

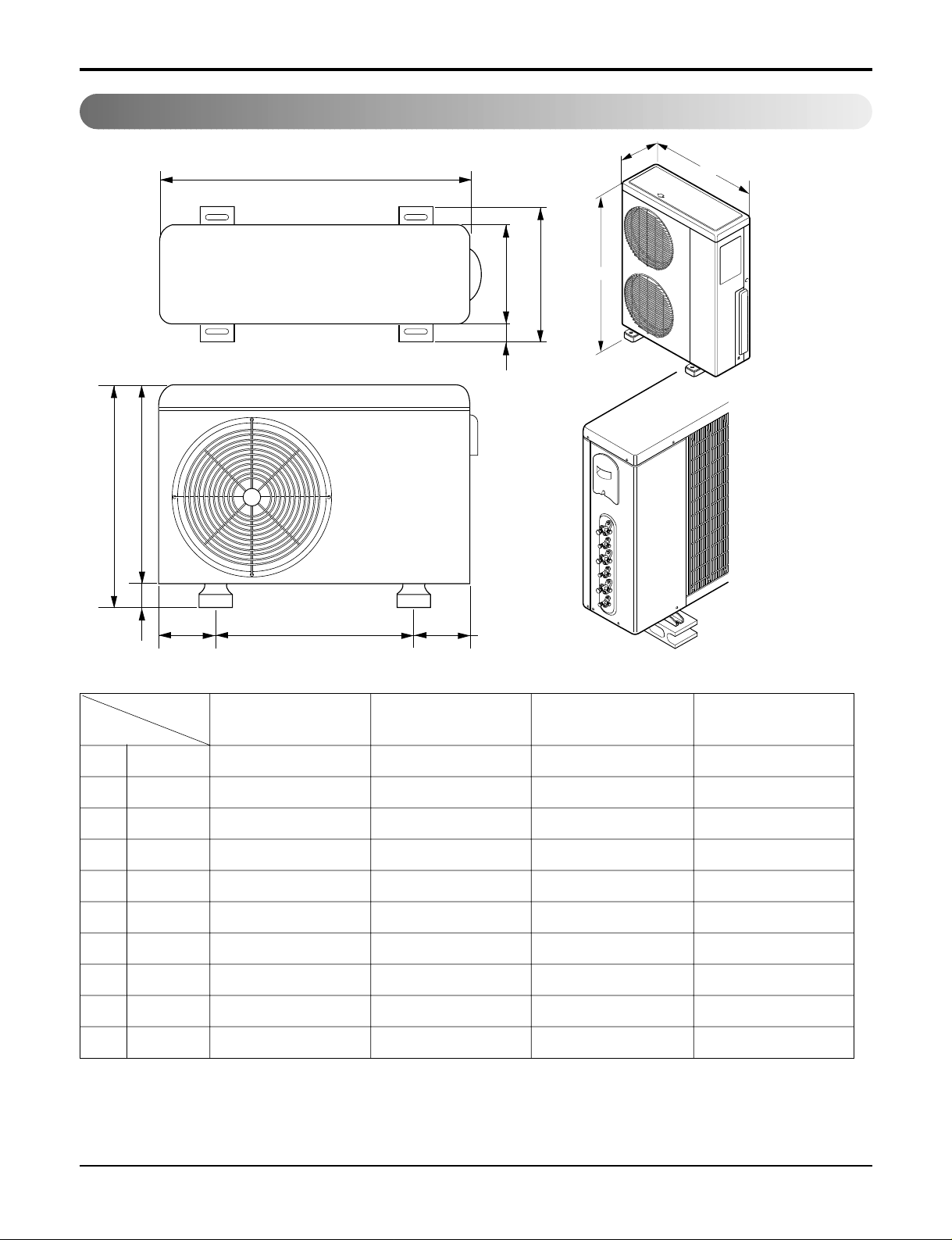

Outdoor Unit

W

D

L1

L2

L4

L3

H

L7L5L6

D

W

H

W mm 870 870 870 900

H mm 655 800 1060 1165

D mm 320 320 320 370

L1 mm 370 370 360 460

L2 mm 25 25 20 45

L3 mm 775 775 1040 1135

L4 mm 25 25 20 30

L5 mm 546 546 550 550

L6 mm 160 160 160 175

L7 mm 160 160 165 175

18K 24K 30K 40K

MODEL

DIM

30K/40K

18K/24K

Dimensions

Page 21

Service Manual 21

Dimensions

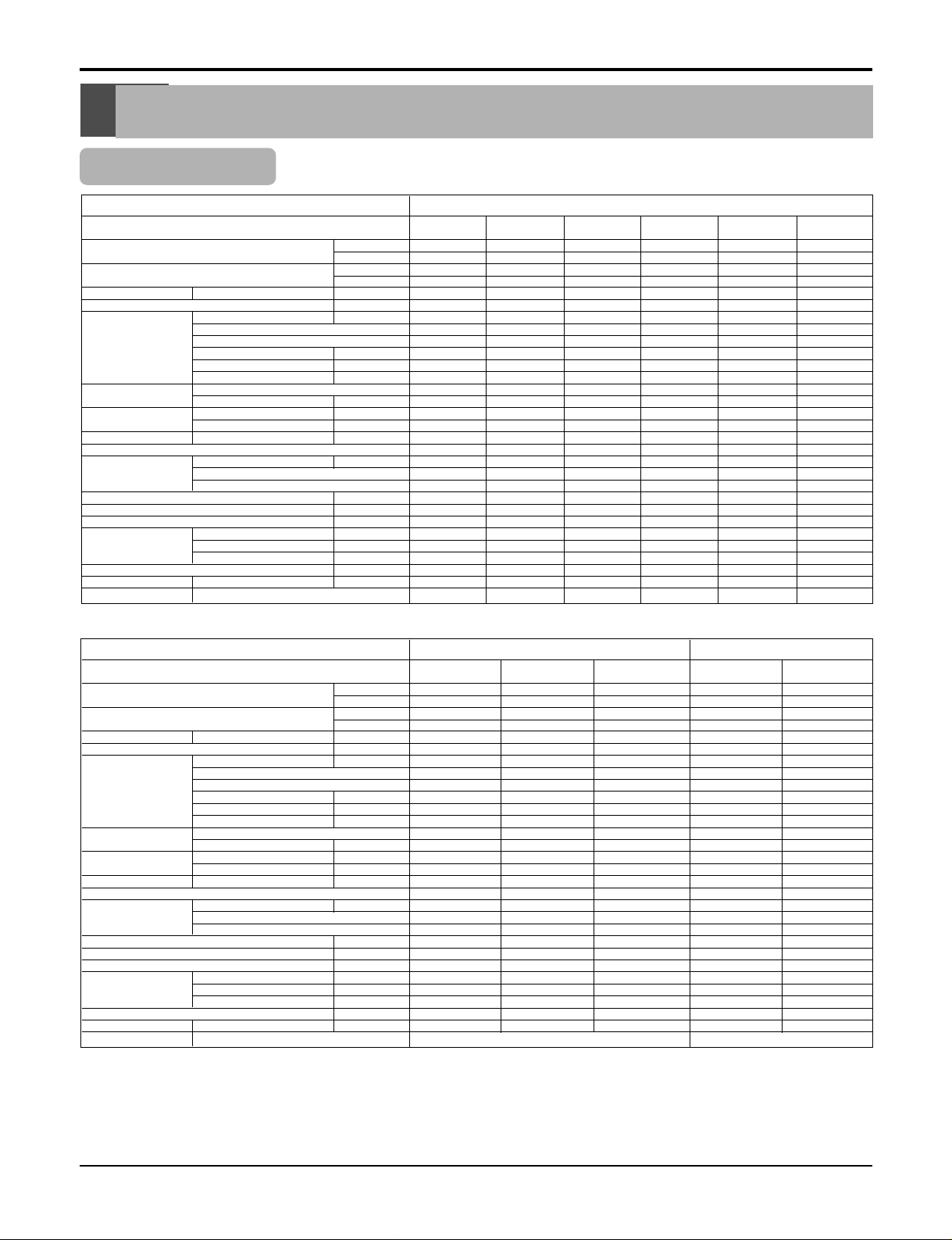

A7UW486FA0/A8UW566FA0

806

15

730

690

700(bolt hole)

153

500(bolt hole)

153

1512

670

220

Knockout hole

(For the control wiring, the power supply,

refrigerant connecting pipe)

40

144428

Service Panel

100

Air outlet

Air

inlet

Air

inlet

Knockout hole

(For the control wiring,

the power supply,

refrigerant connecting

pipe)

(Unit : mm)

Page 22

22 Multi type Air Conditioner

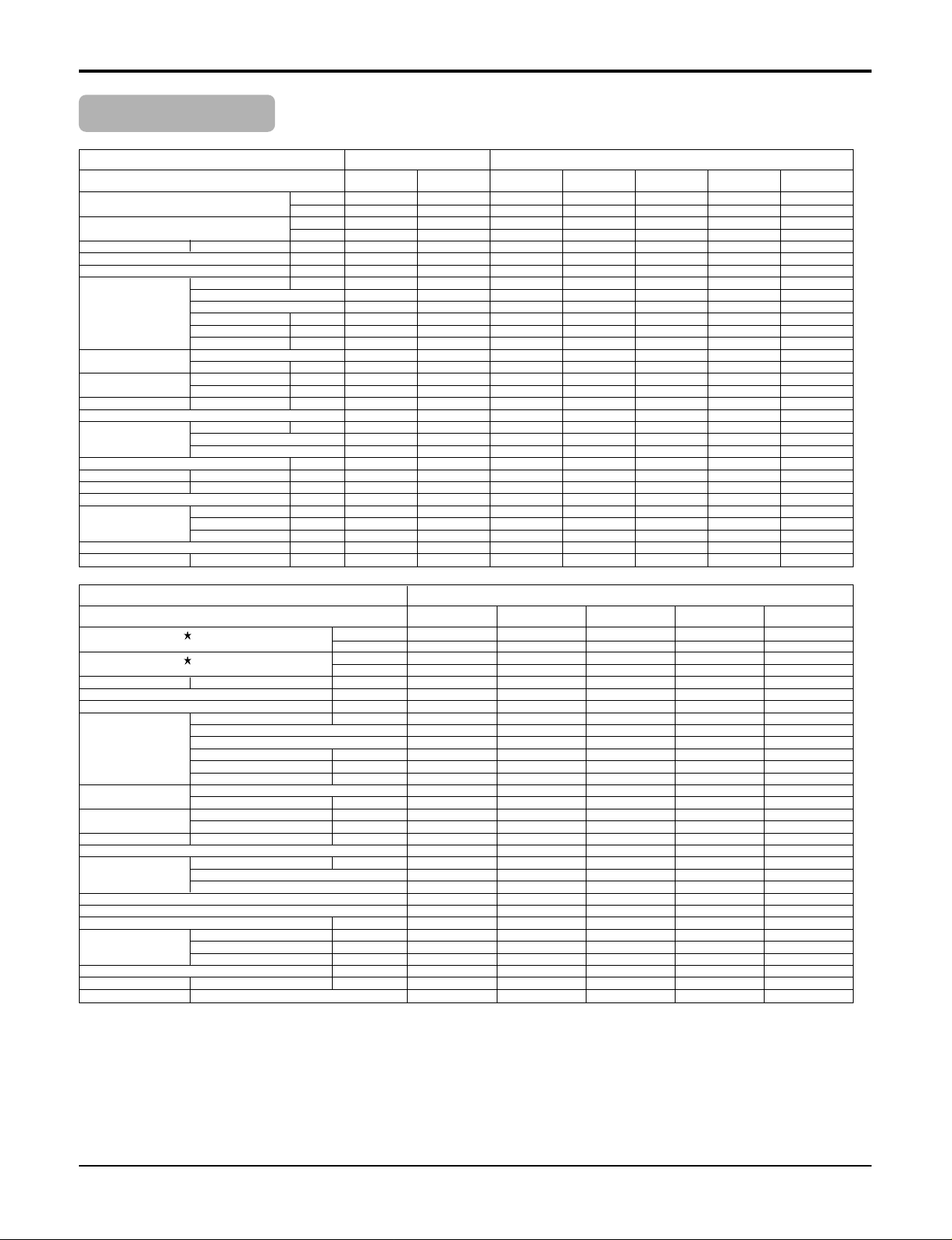

Product Specifications

Product Specifications

Indoor Unit

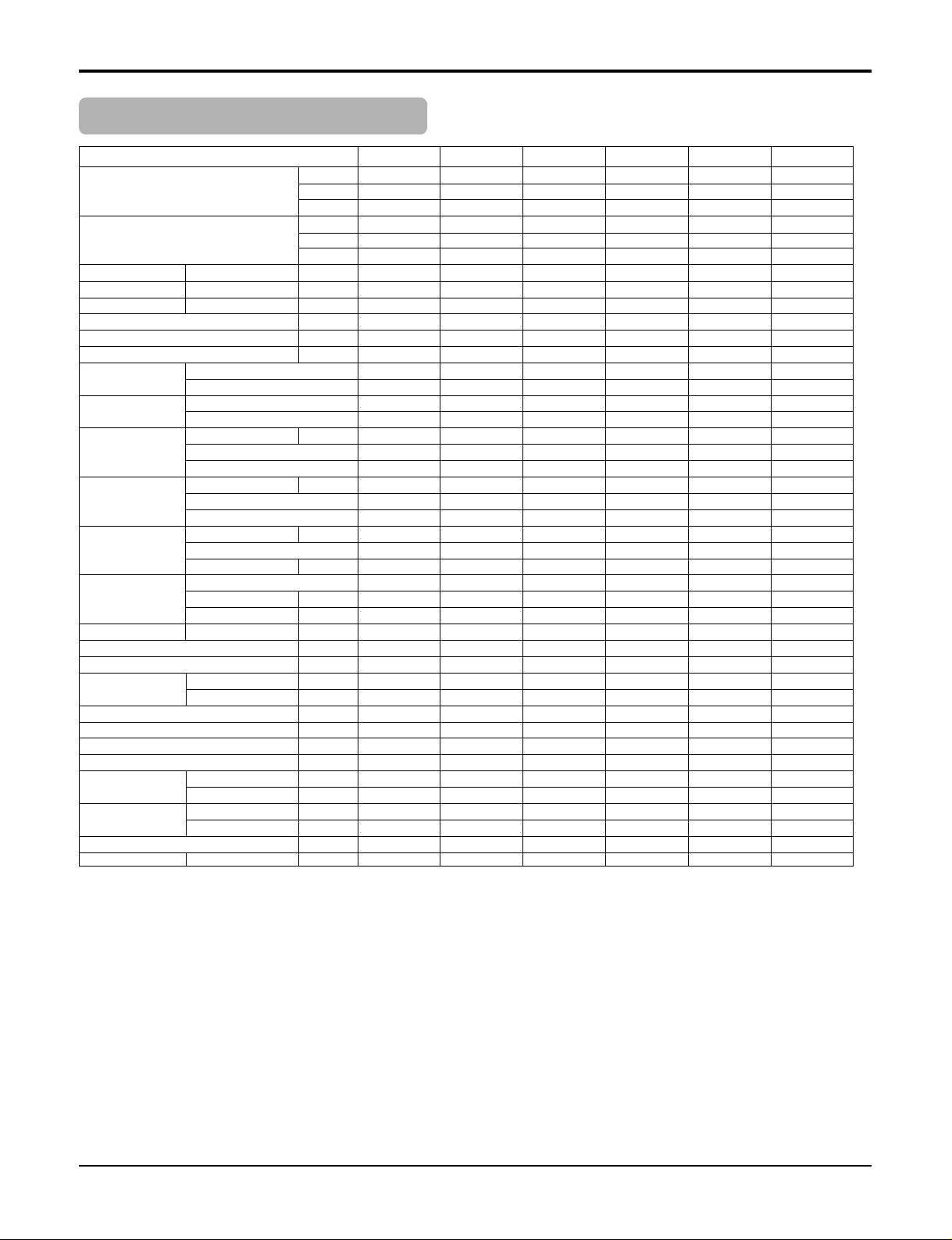

Rated Cooling Capacity ★ kcal/hr(W)

Btu/hr

Rated Heating Capacity ★ kcal/hr(W)

Btu/hr

Air Circulation H/M/L

CMM(CFM)

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without S/Parts 20/40ft

Front Panel Color "★" Position

Wall Mounted

AMNH076LQL0 AMNH096LQL0 AMNH096LRL0 AMNH126LRL0 AMNH186LTL0 AMNH246LTL0

Indoor Unit Type

Model

1764(2051) 2267(2638) 2267(2638) 3024(3515) 4536(5275) 5544(6446)

7000 9000 9000 12000 18000 22000

2016(2343) 2520(2929) 2520(2929) 3326(3867) 4990(5803) 6099(7091)

8000 10000 10000 13200 19800 24200

5.5(194) 8.5(300) 8.5(300) 9.0(318) 13(459) 14(494)

18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30

8.4 8.4 14.4 14.4 22 29

IC-8415LG62A IC-8415LG62A IC-8420LG48A IC-8420LG48A AMR-023E2 AMR-023E5

44 44 46

25 25 37 37 54 59

0.11 0.11 0.16 0.16 0.21 0.21

0.9 / 400 0.9 / 400 0.9 / 400 0.9 / 400 2.0 / 370 2.0 / 370

Cross Flow Fan Cross Flow Fan Cross Flow Fan Cross Flow Fan Cross Flow Fan Cross Flow Fan

1/3.43(87) 1/3.43(87) 1/3.43(87) 1/3.43(87) 1/3.74(95) 1/3.74(95)

1080 / 970 / 880 1170 / 1100 / 1020 1200/1100/1000 1290 / 1200 / 1120 1140 / 1040 / 940 1260 / 1140 / 1000

1080 / 970 / 880 1170 / 1100 / 1020 1200/1100/1000 1290 / 1200 / 1120 1140 / 1040 / 940 1260 / 1140 / 1000

35 / 32 / 29 37 / 33 / 31 35 / 33 / 31 39 / 36 / 34 42 / 39 / 36 46 / 43 / 39

Thermistor Thermistor Thermistor Thermistor Thermistor Thermistor

0.197(5.0) 0.197(5.0) 0.197(5.0) 0.197(5.0) 0.276(7.0) 0.276(7.0)

19 19 20 20 20 20

2R,10C 2R,10C 2R,12C 2R,12C 2R,13C 2R,13C

1.0 1.2 1.4 1.8 2.0 2.5

32.4*10.2*6.1(824*260*155) 32.4*10.2*6.1(824*260*155) 35.4*11.2*6.1(900*285*156) 35.4*11.2*6.1(900*285*156) 42.9*12.4*6.8(1090*314*172) 42.9*12.4*6.8(1090*314*172)

7(15.4) 7(15.4) 8(17.6) 8(17.6) 12(26.5) 12(26.5)

1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35)

3/8 (9.52) 3/8 (9.52) 3/8 (9.52) 3/8 (9.52) 1/2 (12.7) 1/2 (12.7)

20 20 20 20 20 20

35.4*9.2*13.4(900*233*340) 35.4*9.2*13.4(900*233*340) 38.4*9.2*14.6(976*233*372) 38.4*9.2*14.6(976*233*372) 45.9*10.0*15.3(1165*255*388) 45.9*10.0*15.3(1165*255*388)

354/774 (360/780) 354/774 (360/780) 338/714 (340/720) 338/714 (340/720) 264/536 (270/540) 264/536 (270/540)

Morning Beige Morning Beige Morning Beige Morning Beige Morning Beige Morning Beige

Rated Cooling Capacity ★ kcal/hr(W)

Btu/hr

Rated Heating Capacity ★ kcal/hr(W)

Btu/hr

Air Circulation H/M/L

CMM(CFM)

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without S/Parts 20/40ft

Front Panel Color "★" Position

ART COOL DELUXE ART COOL

AMNH076DZ*0 AMNH096DU*0 AMNH126DU*0 AMNH096AP*1 AMNH126AP*1

Indoor Unit Type

Model

1764(2051) 2267(2638) 2772(3224) 2267(2638) 2772(3224)

7000 9000 12000 9000 12000

1940(2257) 2495(2901) 3049(3546) 2520(2929) 3049(3546)

8000 10000 13200 10000 13200

5.5(194) 8.5(300) 9.0(318) 7.5(264) 8.5(300)

18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30

4.7 7.8 7.8 24 24

OBM-1547P2 OBM-1547P2 OBM-1547P2 SIC-39CV-D828-1 SIC-39CV-D828-1

444 88

27 40 40 18 18

0.12 0.18 0.18 0.08 0.08

0.9/400 0.9/400 0.9/400 - -

Cross Flow Fan Cross Flow Fan Cross Flow Fan Turbo Fan Turbo Fan

1/3.43(87) 1/3.43(87) 1/3.43(87) 1/24.32(617.7) 1/24.32(617.7)

1330/1230/1130 1320/1220/1120 1400/1300/1200 510/350/290 560/460/360

1330/1230/1130 1320/1220/1120 1400/1300/1200 510/350/290 560/460/360

35 / 32 / 29 37 / 33 / 31 39 / 36 / 34 38 / 35 /32 43 / 40 / 33

Thermistor Thermistor Thermistor Thermistor Thermistor

0.197(5.0) 0.197(5.0) 0.197(5.0) 0.197(5.0) 0.197(5.0)

19 19 19 20 20

2R,12C 2R,12C 2R,12C 2R,20C 2R,20C

1.0 1.2 1.5 1 1.2

42.9*12.4*6.8(1090*314*172) 35.4*10.7*5.3(900*272*135) 40.6*11.4*6.0(1030*290*153) 22.4*22.4*5.4 (570*568*137) 22.4*22.4*5.4 (570*568*137)

8.1(17.9) 9.5(20.9) 9.5(20.9) 9(19.84) 9(19.84)

1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35)

3/8(9.52) 3/8(9.52) 3/8(9.52) 3/8 (9.52) 3/8(9.52)

20 20 20 20 20

38.8*8.7*14.3(985*220*363) 44.0*8.9*14.8(1117*225*377) 44.0*8.9*14.8(1117*225*377) 25.7*25.2*8.5(653*641*216) 25.7*25.2*8.5(653*641*216)

340/720 324/684 324/684 239/539 239/539

R:Mirror, M:Metal, N:Walnut, W:White, B:Blue, C:Cherry M:Metal, B:Blue, D:Wood

Note : 1.★See the page "Combination Table"

2. Due to our policy of innovation some specifications may be changed without notification.

Page 23

Service Manual 23

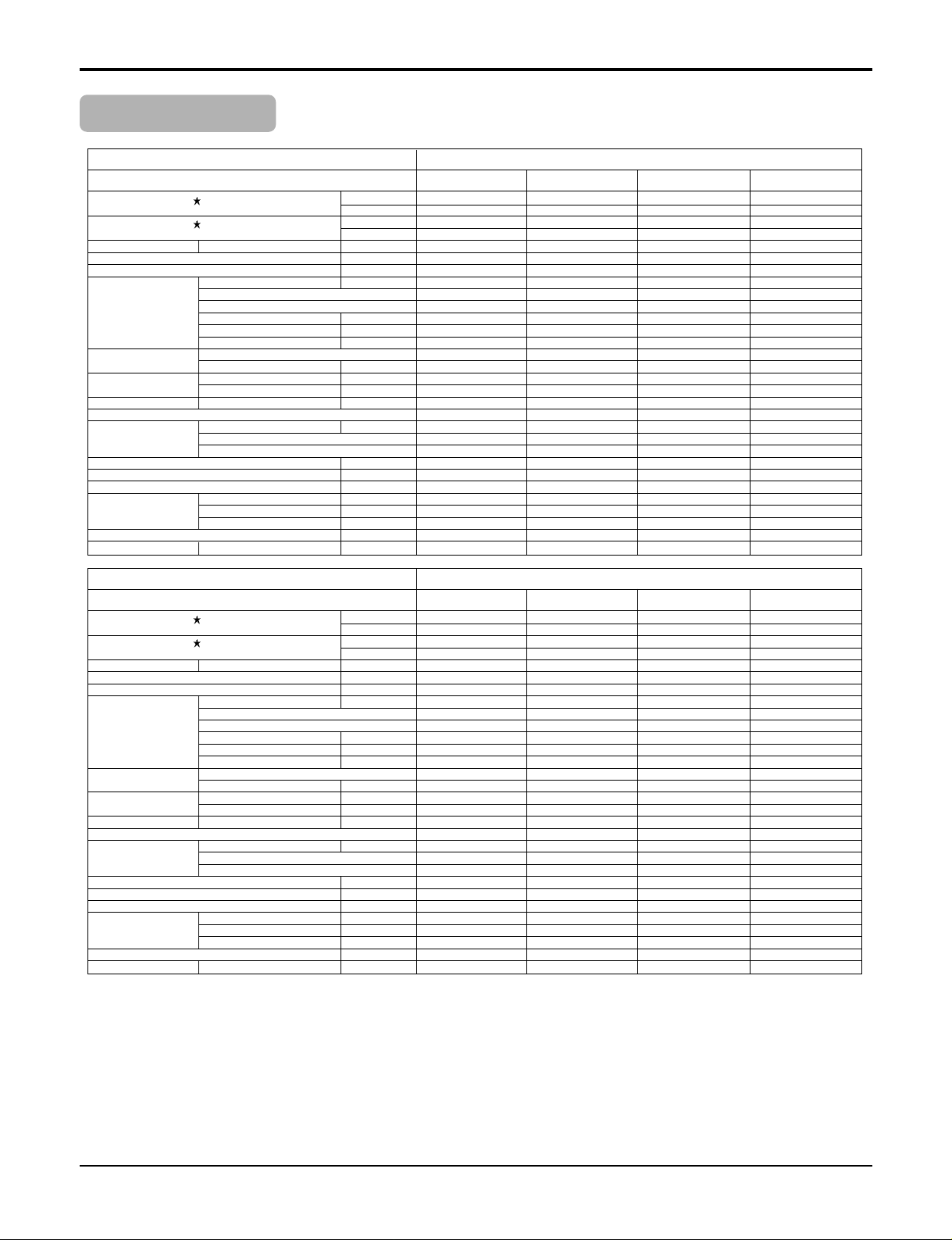

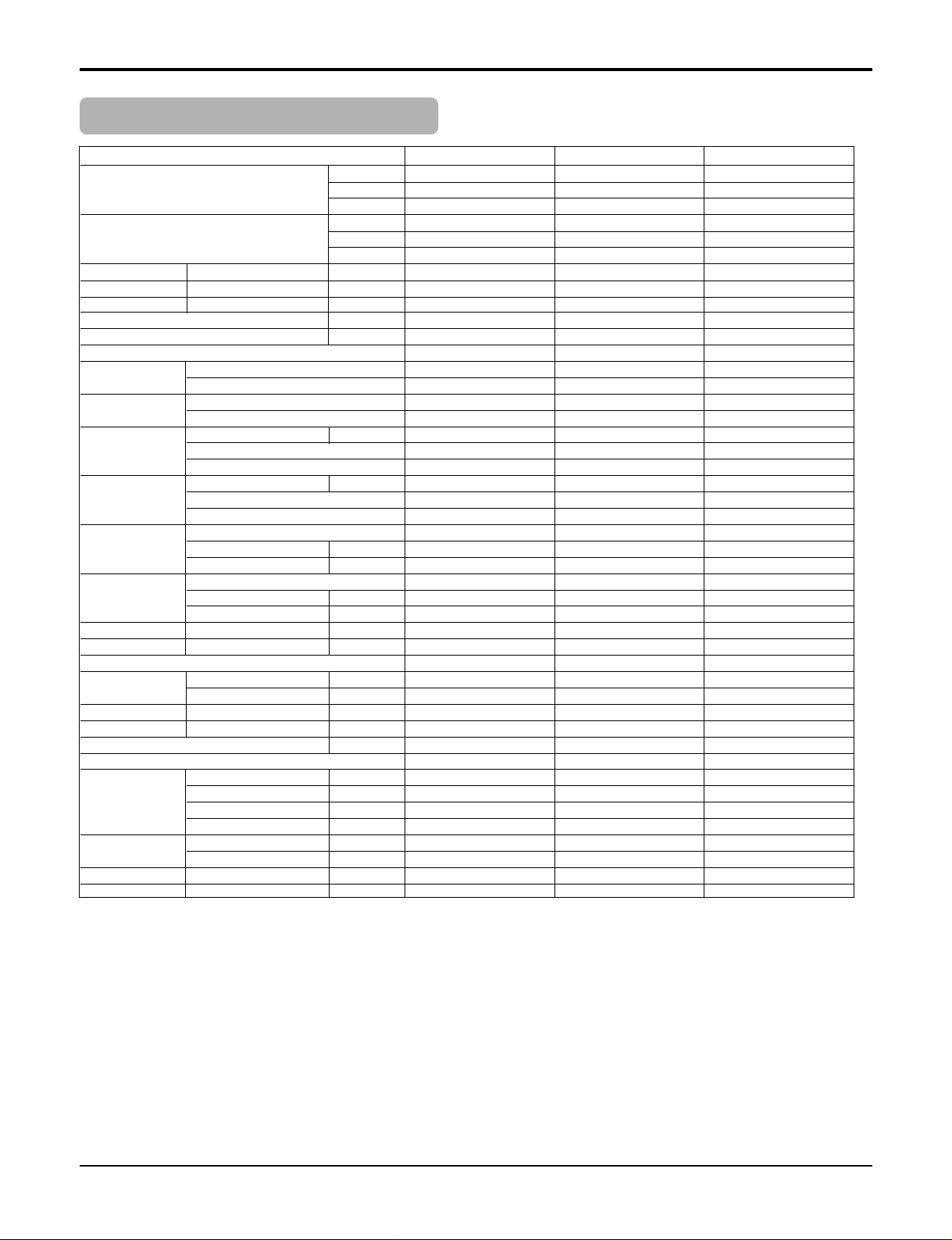

Product Specifications

Indoor Unit

2267(2638) 3024(3515) 3024(3515) 4536(5275) 6048(7033) 7056(8206) 9072(10551)

9000 12000 12000 18000 24000 28000 36000

2520(2929) 3326(3867) 3326(3867) 4990(5803) 6653(7736) 7761(9027) 9979(11600)

10000 13200 13200 19800 26400 30800 39600

9(317) 10(353) 11(353) 13(459)

15/14/13(53/494/459)

18(636)

25/23/21(883/812/742)

-------

18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30

14 14 18.4 22.4 40.3 45 52.5

AMR-023E7 AMR-023E7 IC-9630LGAE IC-9630LGAC OBM-350292 OBM-401592 IC-1630LGPJ

4466666

50 50 75 90 121 146 175

0.56 0.56 0.35 0.75 0.53 0.67 0.8

0.9/400 0.9/400 2.5/440 2.5/440 4/440 4/440 4/450

Cross Flow Fan Cross Flow Fan Turbo Fan Turbo Fan Turbo Fan Turbo Fan Turbo Fan

1/4(102) 1/4(102) 1/13.0(330) 1/13.0(330) 1/15.0(382) 1/15.0(382) 1/15.0(382)

900 / 800 / 700 1000 / 900 / 800 670 / 620 / 550 720 / 670 / 620 600/540480 660/590/530 550/510/470

900 / 800 / 700 1000 / 900 / 800 670 / 620 / 550 720 / 670 / 620 600/540480 660/590/530 550/510/470

35 /32 / 28 37 / 33 / 29 38 / 35 / 32 41 /39 / 37 43/41/39 44/41/39 40/38/36

Thermistor Thermistor Thermistor Thermistor Thermistor Thermistor Thermistor

0.275(7) 0.275(7) 0.275(7) 0.275(7) 0.275(7) 0.275(7) 0.275(7)

18 18 19 19 21 21 21

2R11C 2R11C 2R11C 2R11C 2R12C 2R12C 2R12C

1.2 1.5 1.2 2.4 3 3.5 4

33.8*15.3*7(860*390*190) 33.8*15.3*7(860*390*190) 22.4*10.5*22.4 (570*269*570) 22.4*10.5*22.4 (570*269*570) 29.3*11.5*29.4 (744*292*744) 29.3*11.5*29.4 (744*292*744) 33.0*33.0*11.3(840*840*288)

41.3*18.9*1.2(1050*480*30) 41.3*18.9*1.2(1050*480*30) 26.4*26.4*1.2(670*670*30) 26.4*26.4*1.2(670*670*30) 33.5*33.5*1.2(850*850*30) 33.5*33.5*1.2(850*850*30) 37.4*37.4*1.2(950*950*30)

22(48.5) 22(48.5) 19(41.9) 19(41.9) 24(52.9) 24(52.9) 32(70.5)

1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35)

3/8(9.52) 3/8(9.52) 3/8(9.52) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

32 32 32 32 32 32 32

38.6*10.0*18.1 38.6*10.0*18.1(980*255*460) 25.2*13.0*25.2(640*330*640) 25.2*13.0*25.2(640*330*640) 32.6*14.4*32.6 (828*365*828) 32.6*14.4*32.6 (828*365*828) 36.4*13.8*36.4(925*350*925)

263/539 263/539 189/378 189/378 84/168 84/168 30/64(36/72)

Rated Cooling Capacity ★ kcal/hr(W)

Btu/hr

Rated Heating Capacity ★ kcal/hr(W)

Btu/hr

Air Circulation H/M/L

CMM(CFM)

External Static Pressure mmAq

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) Indoor inch(mm)

Panel inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without S/Parts 20/40ft

Ceiling Cassette - 1way Ceiling Cassette - 4way

AMNH096TCC0 AMNH126TCC0 AMNH126TEC0 AMNH186TEC0 AMNH246TFC0 AMNH306TFC0 AMNH366TDC0

Indoor Unit Type

Model

Rated Cooling Capacity kcal/hr(W)

Btu/hr

Rated Heating Capacity kcal/hr(W)

Btu/hr

Air Circulation H/M/L

CMM(CFM)

External Static Pressure mmAq

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without S/Parts 20/40ft

Front Panel Color "*" Position

2268(2637) 3024(3516) 4536(5274) 2268(2637) 3024(3516)

9000 12000 18000 9000 12000

2520(2930) 3326(3868) 4990(5802) 2520(2930) 3326(3868)

10000 13000 19800 10000 13200

8/7/6(282/246/211) 10/9/8(352/317/282) 13.5/12/10(477/424/353) 11.5/10/8.5 11.5/10/8.5

22244

18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 18~30

35 35 47 118 118

YDK110-35-4L YDK110-35-4L YSK110-70-4L IC-13450LG31A IC-13450LG31A

44444

68 68 126 180 180

0.31 0.31 0.58 4.3 4.3

2.5/400 2.5/400 2.5/370 6/370 6/370

Sirocco Fan Sirocco Fan Sirocco Fan Sirocco Fan Sirocco Fan

1/7.8(197) 1/7.8(197) 2/7.8(197) 1/Ø177 1/Ø177

930/840/810 950/850/780 1000/900/800 1125/990/870 1125/990/870

930/840/810 950/850/780 1000/900/800 1125/900/870 1125/990/870

34/32/30 37/34/31 38/36/34 38/36/34 38/36/34

Thermistor Thermistor Thermistor Thermistor Thermistor

0.276(7.0) 0.276(7.0) 0.276(7.0) 0.276(7.0) 0.276(7.0)

18 18 18 18 18

2R,12C 3R,12C 2R, 12C 2R14C 3R14C

1 1.2 2 1.6 2

25.6*9.0*21.1(650*230*535) 25.6*9.0*21.1(650*230*535) 39.4*9.0*21.1(1000*230*535) 750*300*580(695*56.5*396) 750*300*580(695*56.5*396)

22(48.5) 22(48.5) 29(63.9) 30(6) 30(6)

1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4(6.35) 1/4(6.35)

3/8 (9.52) 3/8 (9.52) 1/2 (12.7) 3/8(9.52) 3/8(9.52)

25.4 25.4 25.4 25.4(OD) 25.4(OD)

29.9*24.6*11.8(760*625*300) 29.9*24.6*11.8(760*625*300) 29.9*24.6*11.8(760*625*300) 845*370*760(735*90*435) 845*370*760(735*90*435)

172/356 172/356 123/251 228/468 228/468

- - - NOBEL WHITE NOBEL WHITE

Ceiling Concealed Duct

AMNH096BTG0 AMNH126BTG0 AMNH186BTG0 AMNH096BPA0 AMNH126BPA0

Indoor Unit Type

Model

Note : 1.★See the page "Combination Table"

2. Due to our policy of innovation some specifications may be changed without notification.

Page 24

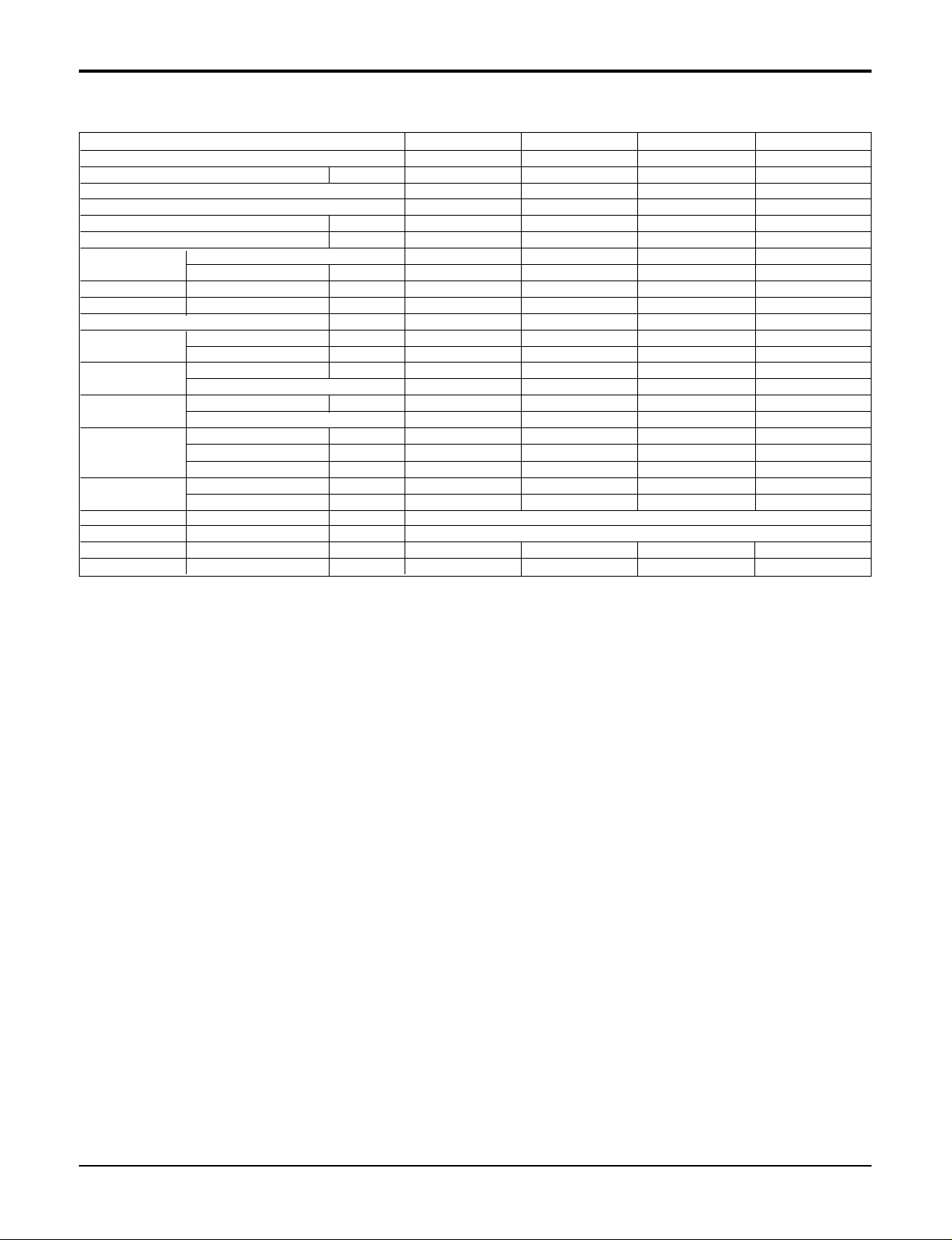

24 Multi type Air Conditioner

Product Specifications

Indoor Unit

Rated Cooling Capacity kcal/hr(W)

Btu/hr

Rated Heating Capacity kcal/hr(W)

Btu/hr

Air Circulation H/M/L

CMM(CFM)

External Static Pressure mmAq

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without S/Parts 20/40ft

Ceiling & Floor(Convertible)

AMNH096VEA0 AMNH126VEA0 AMNH186VBA0 AMNH246VBA0

Indoor Unit Type

Model

2268(2637) 3024(3516) 4536(5274) 6048(7032)

9000 12000 18000 24000

2520(2930) 3326(3867) 4990(5801) 6350(7384)

10000 132000 19800 25200

7.8/6.4/5.0(276/226/177) 10.0/8.3/6.5(353/293/230) 135./12/11(477/424/388) 15/13.5/12(530/477/424)

--- -

18-30/16-30 18-30/16-30 18~30 / 16~30 18~30 / 16~30

14.5 17.5 30 35

IC-18422LG31B IC-18422LG31A IC-9430LGCM IC-9430LGCM

444 4

35 43 53 63

0.18 0.23 0.23 0.27

1.5/370 1.5/370 1.5/370 1.5/370

Cross Flow Fan Cross Flow Fan Cross Flow Fan Cross Flow Fan

1/3.7(95) 1/3.7(95) 1/3.1(80) 1/3.1(80)

960/870/760 1240/1120/900 1090/990/890 1160/1060/960

960/870/760 1240/1120/900 1090/990/890 1160/1060/960

36/32/28 40/36/31 43 / 40 / 37 45 / 42 / 39

Thermistor Thermistor Thermistor Thermistor

0.197(5) 0.197(5) 0.275(7) 0.275(7)

20 20 18 20

2R 12C 2R 12C 2R 12C 2R 14C

1 1.2 2.3 3.2

35.4*7.9*19.3 (900*200*490) 35.4*7.9*19.3 (900*200*490) 47.24*24.21*8.07(1200*615*205) 47.24*24.21*8.07(1200*615*205)

12(26.5) 12(26.5) 30(66.1) 30(66.1)

1/4 (6.35) 1/4 (6.35) 1/4(6.35) 1/4(6.35)

3/8 (9.52) 3/8 (9.52) 1/2(12.7) 1/2(12.7)

20 20 20 20

38.2*11.2*22.2 (970*285*565) 38.2*11.2*22.2 (970*285*565) 50*10.9*27(1272*278*686) 50*10.9*27(1272*278*686)

189/383 189/383 102/219 102/219

Rated Cooling Capacity kcal/hr(W)

Btu/hr

Rated Heating Capacity kcal/hr(W)

Btu/hr

Air Circulation H/M/L

CMM(CFM)

External Static Pressure mmAq

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without S/Parts 20/40ft

Ceiling Concealed Duct

AMNH186BHA0 AMNH246BHA0 AMNH306BGA0 AMNH366BGA0

Indoor Unit Type

Model

4536(5275) 6048(7034) 7560(8792) 9072(10551)

18000 24000 30000 36000

4990(5803) 6653(7737) 8316(9671) 9979(11606)

19800 26400 33000 39600

16.5/14.5/13(583/512/459) 18/16.5/14(636/583/494) 28/25/23(989/883/812) 32/29/26.5(1130/1024/936)

888 8

18~30 / 16~30 18~30 / 16~30 18~30 / 16~30 18~30 / 16~30

118 118 124 272

IC-13450LG13C IC-13450LG13C IC-13450LG13J IC-13450LG13A

444 4

180 180 250 323

0.92 0.92 1.1 1.42

6/370 6/370 6/370 6/370

Sirocco Fan Sirocco Fan Sirocco Fan Sirocco Fan

2/6.97(177) 2/6.97(177) 2/6.97(177) 2/6.97(177)

1356/-/1270 1417/1350/1255 1415/1360/1290 1415/1360/1290

1356/-/1270 1417/1350/1255 1415/1360/1290 1415/1360/1290

36/34/32 37/35/33 40/38/36 42/40/38

Thermistor Thermistor Thermistor Thermistor

0.275(7) 0.275(7) 0.275(7) 0.275(7)

21 21 21 21

3R10C 3R10C 3R 12C 3R 12C

2.0 2.5 3 3.5

34.6*10.2*17.7 (880*260*450) 34.6*10.2*17.7 (880*260*450) 46.4*11.7*17.7(1180*298*450) 46.4*11.7*17.7(1180*298*450)

35(77.2) 35(77.2) 38(83.8) 38(83.8)

1/4(6.35) 1/4(6.35) 1/4(6.35) 1/4(6.35)

1/2(12.7) 1/2(12.7) 5/8(15.88) 5/8(15.88)

25.4(OD) 25.4(OD) 25.4(OD) 25.4(OD)

44.7*13.4*23.0(1135*340*585) 44.7*13.4*23.0(1135*340*585) 18.5*14.8*23.0(1435*375*585) 18.5*14.8*23.0(1435*375*585)

120/252 120/252 95/191 95/191

Note : 1.★See the page "Combination Table"

2. Due to our policy of innovation some specifications may be changed without notification.

Page 25

Service Manual 25

Outdoor Unit - Multiple piping models

Product Specifications

Notes: 1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB - Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5m - Interconnecting Piping Length 7.5 m

- Level Difference of Zero. - Level Difference of Zero.

2. Capacities are Net Capacities.

3.

★

: See the page "Combination Table"

4. Due to our policy of innovation some specifications may be changed without notification.

Model

Cooling Capacity ★ kcal/hr

W

Btu/hr

Heating Capacity ★ kcal/hr

W

Btu/hr

Input ★ Cooling/Heating W

Running Current ★ Cooling/Heating A

Starting Current Cooling/Heating A

Power Supply Ø,V,Hz

Power Factor %

Max. Number of Connectable Indoor Units %

Compressor Type

(Invertor) O.L.P Type(model name)

Compressor Type

(Constant) O.L.P Type(model name)

Refrigerant Charge g(oz), type

Type

Control

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column/No.

Fan Motor Model W

Output

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Discharge Side / Top

Air Circulation CMM(CFM)

Noise Level(Sound Press,1m) dBA

Defrosting

SVC Valve Liquid inch(mm)

Gas inch(mm)

Dimensions (W*H*D) inch(mm)

Net Weight kg(lbs)

Power Supply Cable No.* mm

2

Interunit Cable No.* mm

2

Max. Interunit

Total of Each Room m

Piping Length

For One Room m

Max. Installation Indoor Unit~Outdoor Unit m

Height Difference Indoor Unit~Indoor Unit m

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity Without S/Parts 20/40ft

1159~4031 1159~5443 1159~5443 1159~7257 1159~7257 1159~9072

1348~4688 1348~6330 1348~6330 1348~8,440 1348~8,440 1348~10549

4600~16000 4600~21600 4600~21600 4600~28800 4600~28800 4600~36000

1210~4535 1210~6249 1210~6249 1210~8063 1210~8063 2116~10332

1407~5274 1407~7268 1407~7268 1407~9376 1407~9376 2461~12014

4800~18000 4800~24800 4800~24800 4800~32000 4800~32000 8,400~41,000

380~1450/450~1350 420~2400/480~2600 420~2400/480~2600 440~2970/560~2950 440~2970/560~2950 450~3580/620~3580

1.6~6.5/2.0~5.8 3.5~11.5/4~12 3.5~11.5/4~12 3.08~13.0/4.6~12.9 3.08~13.0/4.6~12.9 3.2~15.7/4.6~15.7

111282828

1,220~240,50 1,220~240,50 1,220~240,50 1,220~240,50 1,220~240,50 1,220~240,50

94~98 94~98 94~98 94~98 94~98 95~98

223344

e-Scroll e-Scroll e-Scroll e-Scroll e-Scroll e-Scroll

------

- - - Rotary Rotary Rotary

- - - MRA99150-9090 MRA99150-9090 INTERNAL

1650(59.97) at 7.5m 1650(59.97) at 7.5m 1650(59.97) at 7.5m 1950(68.78) at 7.5m 1950(68.78) at 7.5m 2500(88.18) at 7.5m

R-410A R-410A R-410A R-410A R-410A R-410A

L.E.V L.E.V L.E.V L.E.V L.E.V L.E.V

0.276(7.0) 0.276(7.0) 0.276(7.0) 0.276(7.0) 0.276(7.0) 0.276(7.0)

18 18 18 18 18 18

1R,28C 2R,28C 2R,28C 2R,36C 2R,36C 2R,48C

IC28640LG28S IC28640LG28S IC28640LG28S IC28640LG28J IC28640LG28J IC9625LGSY

120 120 120 130 130 65 * 2

6/370 6/370 6/370 6/370 6/370 2.0/370

Propeller Propeller Propeller Propeller Propeller Propeller

1/18.1(460) 1/18.1(460) 1/18.1(460) 1/18.1(460) 1/18.1(460) 2/16.5(420)

Side Discharge Side Discharge Side Discharge Side Discharge Side Discharge Side Discharge

49(1730) 49(1730) 49(1730) 53(1872) 53(1872) 31(1094)*2

50/47 51/48 51/48 51/48 51/48 50/46

Invertion cycle Invertion cycle Invertion cycle Invertion cycle Invertion cycle Invertion cycle

1/4 (6.35)*2EA 1/4 (6.35)*2EA 1/4 (6.35)*3EA 1/4 (6.35)*3EA 1/4 (6.35)*4EA 1/4 (6.35)*4EA

3/8 (9.52)*2EA 3/8 (9.52)*2EA 3/8 (9.52)*3EA 3/8 (9.52)*3EA 3/8 (9.52)*4EA 3/8 (9.52)*4EA

34.3*31.5*12.6 (870*800*320) 34.3*31.5*12.6 (870*800*320) 34.3*31.5*12.6 (870*800*320) 34.3*31.5*12.6 (870*808*320) 34.3*31.5*12.6 (870*808*320) 34.3*31.5*12.6 (870*1038*320)

52(115) 57(125.6) 75(165) 75(165) 75(165) 84(185)

3*3.5 3*3.5 3*3.5 3*2.5 3*2.5 3*2.5

4*0.75 (Includes earth) 4*0.75 (Includes earth) 4*0.75 (Includes earth) 4*0.75 (Includes earth) 4*0.75 (Includes earth) 4*0.75 (Includes earth)

40 40 40 50 50 70

25 25 25 25 25 25

15 15 15 15 15 15

7.5 7.5 7.5 7.5 7.5 7.5

34.2*25.8*12.6(870*655*320) 34.2*25.8*12.6(870*655*320) 34.2*25.8*12.6(870*655*320) 40.1*34.2*17.3 (1020*870*440) 40.1*34.2*17.3 (1020*870*440) 40.1*34.2*17.3 (1045*1140*440)

81/171 81/171 81/171 54/114 54/114 51/111

A2UW146FA0 A2UW186FA0 A3UW186FA0 A3UW246FA0 A4UW246FA0 A4UW306FA0

Page 26

26 Multi type Air Conditioner

Product Specifications

Notes: 1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB - Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5m - Interconnecting Piping Length 7.5 m

- Level Difference of Zero. - Level Difference of Zero.

2. Capacities are Net Capacities.

3.

★

: See the page "Combination Table"

4. Due to our policy of innovation some specifications may be changed without notification.

Model

Cooling Capacity★ kcal/hr

W

Btu/hr

Heating Capacity★ W(kcal/hr)

Btu/hr

Input★ Cooling/Heating W

Running Current★ Cooling/Heating A

Starting Current Cooling/Heating A

Power Supply Ø,V,Hz

Power Factor %

Max. Number of Connectable Indoor Units

Compresso Type

(Invertor) O.L.P Type(model name)

Compressor Type

(Constant) O.L.P Type(model name)

Refrigerant charge Charge g(oz)

Type

Control

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column/No.

Fan motor Model

Output W

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Discharge Side / Top

Air Circulation Outdoor CMM(CFM)

Noise Level Sound Press,1m dB(A)±1

Defrosting

SVC Valve Liquid inch(mm)

Gas inch(mm)

Dimensions W*H*D inch(mm)

Net Weight Outdoor kg(lbs)

Power Supply Cable No.* mm

2

Interunit Cable

Max. Interunit

Total Piping m

Piping Length

Total Main Piping m

Total Branch Piping m

For One Room m

Max. Installation Indoor Unit~Outdoor Unit m

Height Difference Indoor Unit~Indoor Unit m

Packing Dimension W*H*D inch(mm)

Stuffing Quantity With(Without) S/Parts 20/40ft

4032~12095 4032~14515 4032~16934

4689~14067 4689~16878 4689~19691

16,000~48,000 16000~57600 16000~67250

4838~13356 4838~16027 4848~19051

5627~15533 5627~18636 5627~22152

19,200~53,000 19200~63600 19200~75600

1695~4980/2343~4600 750~5810/1450~5830 750~6600/1550~6800

7.9~22/10.5~20.6 3.4~26/6.6~24.3 3.4~29.6/7.1~30.5

67 43 74

1,220~240,50 1,220~240,50 1,220~240,50

87.1~99.4 90~97 90~97

67 8

e-Scroll e-Scroll e-Scroll

Internal Internal Internal

Rotary Rotary Rotary

Internal Internal Internal

4100(144.6) at 5m 7100(250.4) at 5m 7100(250.4) at 5m

R-410A R-410A R-410A

L.E.V L.E.V L.E.V

0.276(7.0) 0.276(7.0) 0.276(7.0)

18 18 18

2R,52C

IC28640LG28J ARE676E01 ARE676E01

120 * 2 270 270

6/370 10/370 10/370

Propeller Propeller Propeller

1/18.1(460) 1/20.7(526) 1/20.7(526)

Side Discharge Top discharge Top discharge

53(1872) *2 90(3179) 90(3179)

60/-/57 59/56 59/56

Invertion cycle Invertion cycle Invertion cycle

3/8 (9.52) 3/8(9.52) 3/8(9.52)

3/4 (19.05) 3/4 (19.05) 3/4 (19.05)

35.4*45.8*14.5 (900*1,165*370) 31.7*59.5*28.7(806*1512*730) 31.7*59.5*28.7(806*1512*730)

110(242) 110(242) 120(264)

3*5.0 3*5.0 3*5.0

4*0.75 (Includes earth) 4*0.75 (Includes earth) 4*0.75 (Includes earth)

100 110 120

50 50 50

50 60 70

15 15 15

30 30 30

10 10 10

40.6*47.7*17.1 (1032*1212*436) 33.9*61.0*28.7(860*1550*730) 33.9*61.0*28.7(860*1550*730)

22/48

A6UW406FA0 A7UW486FA0 A8UW566FA0

Outdoor Unit - Distributor type models

Page 27

Service Manual 27

Model

Connectable Indoor Units

Combination(Min~Max.) Btu/h

Casing color

Powre Source

Power Consumption W

Runing Current A

Refrigerant type

charge kg

Dimensions W*H*D mm

Packing Dimension W*H*D mm

Net Weight kg

Connecting Cable Direction Indoor Unit No. * mm

2

Direction Outdoor Unit No. * mm

2

Piping Connection Liquid inch(mm)

(Main) Gas

Piping Connection Liquid inch(mm)

(Indoor Unit) Gas

Piping length Total m

(Max.) Outdoor ↔ BD m

BD ↔ Indoor m

Piping Elevation Outdoor ↔ Indoor m

(Max.) Indoor ↔ Indoor m

Drain hose

Heat Insulation

Accessories Hanger EA

Screw EA

1~4 1~3 1~2 1~3

7,000~24,000 7,000~24,000 7,000~24,000 7,000~36,000

----

Ø1 , 50/60Hz ,220~240/220V Ø1 , 50/60Hz ,220~240/220V Ø1 , 50/60Hz ,220~240/220V Ø1 , 50/60Hz ,220~240/220V

10 10 10 10

0.05 0.05 0.05 0.05

R410A R410A R410A R410A

---302*143*252 302*143*252 302*143*252 302*143*252

422*202*300 422*202*300 422*202*300 422*202*300

5555

4*0.75 (Includes earth) 4*0.76 (Includes earth) 4*0.77 (Includes earth) 4*0.77 (Includes earth)

4*0.75 (Includes earth) 4*0.76 (Includes earth) 4*0.77 (Includes earth) 4*0.77 (Includes earth)

3/4(19.05) 3/4(19.05) 3/4(19.05) 3/4(19.05)

3/8 (9.52) 3/8 (9.52) 3/8 (9.52) 3/8 (9.52)

1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35)

3/8 (9.52) 3/8 (9.52) 3/8 (9.52) 3/8 (9.52)

100 100 100 100

40 40 40 40

20 20 20 20

30 30 30 30

10 10 10 10

Not available

Both Liquid and Gas pipes

4444

8888

PMBD3640 PMBD3630 PMBD3620 PMBD7230

LG Branch Distributor

Product Specifications

Page 28

28 Multi type Air Conditioner

Installation

Installation

Read completely, then follow step by step.

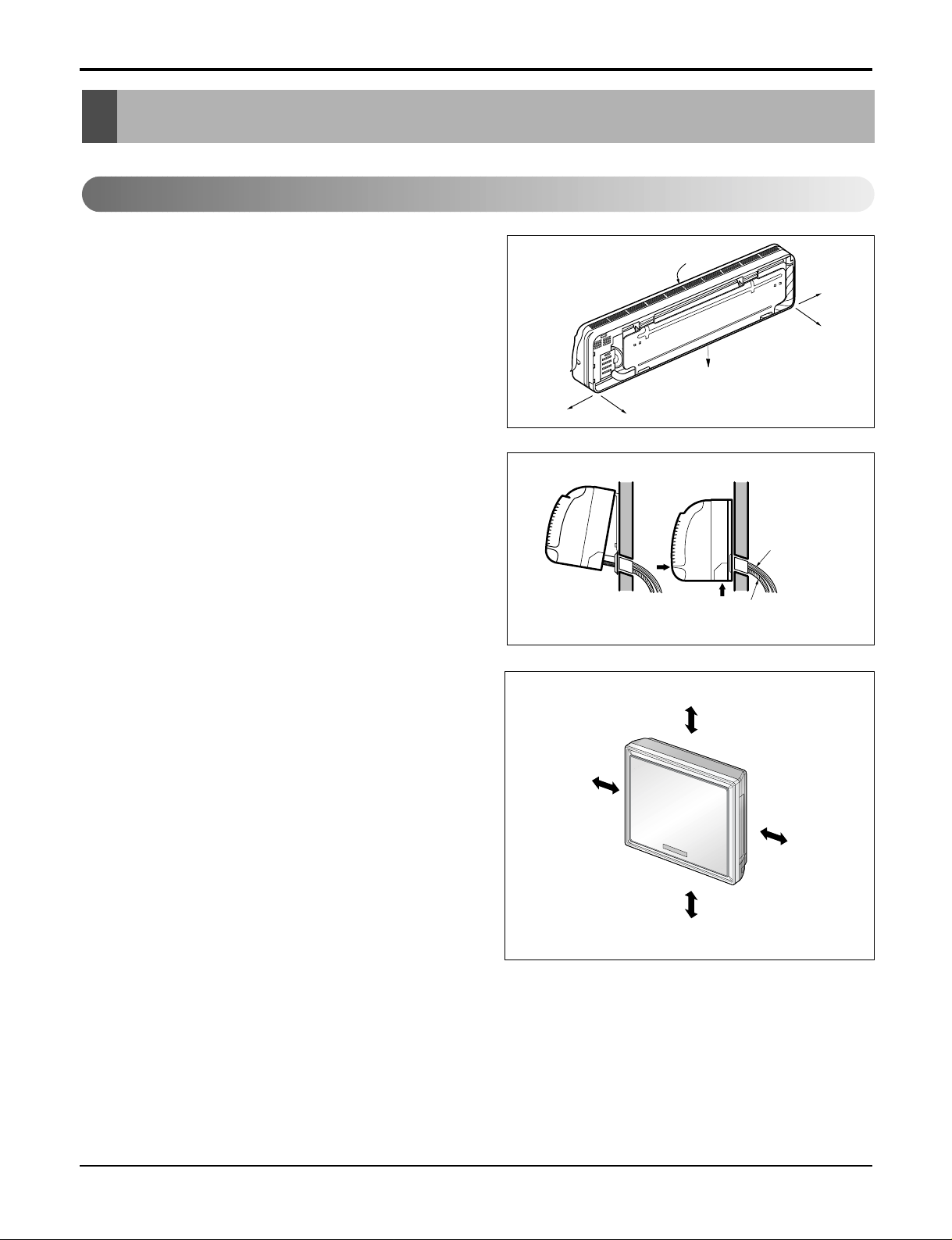

Select the best location of indoor unit

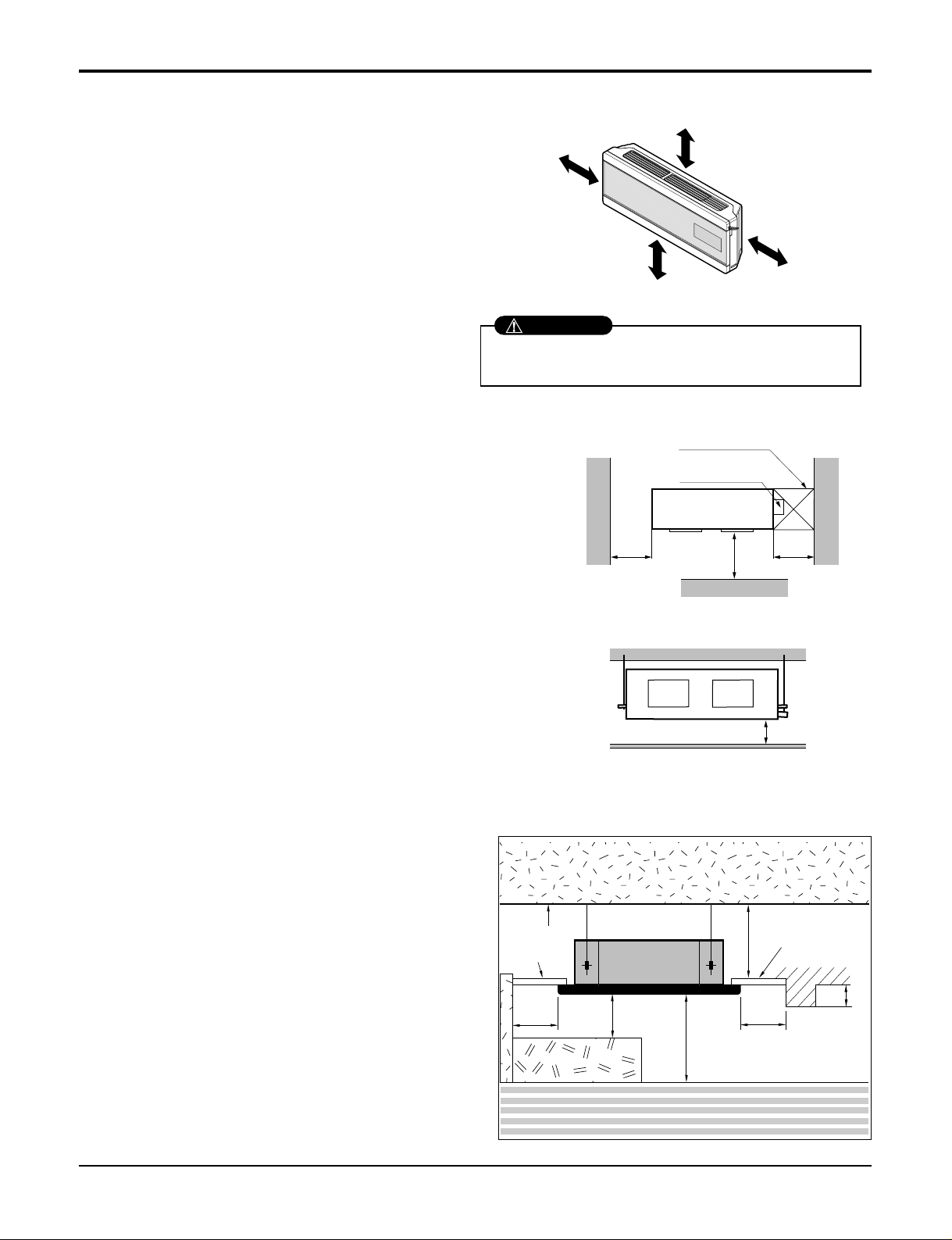

Front

Right Rear right

Rear left

Down right

Left

1. Split Type Indoor Unit

• There should not be any heat source or steam near the

unit.

• There should not be any obstacles to prevent the air

circulation.

• A place where air circulation in the room will be good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into considera-

tion.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the wall,

ceiling, fence, or other obstacles.

2. Art Cool Type Indoor Unit

• Do not have any heat or steam near the unit.

• Select a place where there are no obstacles in front

of the unit.

• Make sure that condensation drainage can be conveniently routed away.

Do not install near a doorway.

• Ensure that the space around the left and right of the

unit is more than 50cm. The unit should be installed

as high on the wall as possible, allowing a minimum

of 10cm from ceiling.

• Use a stud finder to locate studs to prevent unnecessary damage to the wall.

Connecting

cable

Drain hose

More than 10cm

More than 50cm

More than 50cm

More than 2m

Page 29

Service Manual 29

3. Art Cool Deluxe Type Indoor unit

• Do not have any heat or steam near the unit.

• Select a place where there are no obstacles in front of the

unit.

• Make sure that condensation drainage can be conveniently

routed away.

Do not install near a doorway.

• Ensure that the space around the left and right of the unit is

more than 20cm. The unit should be installed as high on the

wall as possible, allowing a minimum of 30cm from ceiling.

• Use a stud finder to locate studs to prevent unnecessary

damage to the wall.

4. Duct Type Indoor Unit

Install the air conditioner in the location that satisfies the

following conditions.

• The place shall easily bear a load exceeding four times

the indoor unit’s weight.

• The place shall be able to inspect the unit as the figure.

• The place where the unit shall be leveled.

• The place shall allow easy water drainage.(Suitable

dimension “H” is necessary to get a slope to drain as figure.)

• The place shall easily connect with the outdoor unit.

• The place where the unit is not affected by an electrical

noise.

• The place where air circulation in the room will be good .

• There should not be any heat source or steam near the

unit

5. CST Type Indoor Unit

• There should not be any heat source or steam near the

unit.

• There should not be any obstacles to the air circulation.

• A place where air circulation in the room will be good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into considera-

tion.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the wall,

ceiling, or other obstacles.

• The indoor unit must have the maintenance space

around.

Unit:cm

Ceiling

Ceiling Board

Ceiling Board

30 or more

Above 250

330 or less

100

or more

50 or

more

50 or

more

30 or less

Floor

Installation

More than 20cm

More than 30cm

More than 2.3m

More than 30cm

Install the indoor unit on the wall where the height

from the floors more than 2.3 meters.

CAUTION

H

600600

Top view

(unit: mm)

Front view

Front

Inspection hole

(600X600)

Control box

1000

Page 30

30 Multi type Air Conditioner

Installation

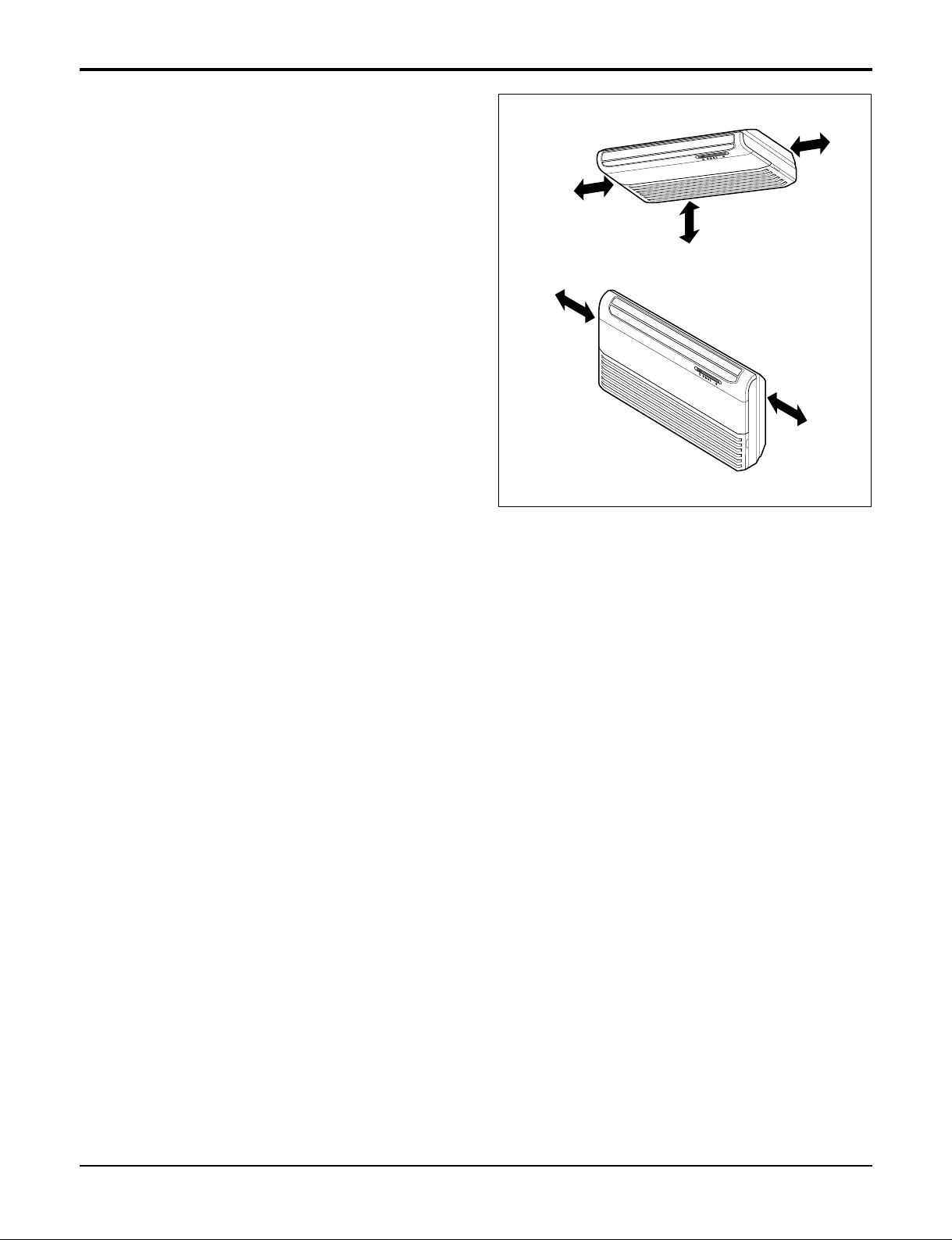

6. CVT Type Indoor Unit

• There should not be any heat source or steam near

the unit.

• There should not be any obstacles to prevent the air

circulation.

• A place where air circulation in the room will be good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into consid-

eration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the wall,

ceiling, or other obstacles.

More than

20cm

More than eye-level

More than

20cm

R

R

More than

20cm

More than

20cm

(Ceiling installation)

(Floor/Wall installation)

Page 31

Service Manual 31

Installation

1. Room Type Indoor Unit Installation

The mounting wall should be strong and solid

enough to protect it from the vibration.

1) Mount the installation plate on the wall with

four Type "A" screws.

(If mounting the unit on the concrete wall, consider using anchor bolts.)

• Always mount the Installation plate horizontally

by aligning the marking-off line by means of the

thread and a level.

2) Drill the piping hole with 70mm dia. holecore

drill.

• Line according to the arrows marked on lower

the left and the rght side of the Installation Plate.

The meeting point of the extended line is the

center of the hole.

• Drill the piping hole at either the right or the left

and the hole should be slightly slant to the outdoor side.

Installation Plate

marking-off line

Thread

Weight

Type "A" screw

The lower left and the right side of

Installation Plate

How to fix

C

D

Ø70mm

Left rear piping Right rear piping

CHASSIS

(Grade)

SR(9/12k)

ST(18/24k)

Installation plate

Distance(mm)

BCA

12

0

A

8075SQ(7/9k)

210105

B

Ø70mm

D

12

4020400

0

Page 32

32 Multi type Air Conditioner

Installation

2. Art Cool Type Indoor Unit

The wall you select should be strong and solid enough

to prevent vibration

1) Open panel front

• First,Pull the grille bottom, then remove screws

(2 pieces), and close grille bottom again.

• The moment of lifting the both lower parts of panel

front, you can hear sound this panel came out, In

this time panel front is separated

• After pull down this panel a bit, and separate connecting wire with product.

2) Cover pipe and cover side remove

• Remove two screws(for fixing cover pipe)

• Pull up the cover side of desired connecting direc-

tion, then cover side is separated.

• In case connecting direction is left or right, path

through the hole of cover side.

NOTE: When connecting pipe path through rear

wall, don’t remove the hole.

3) Drain hose junction

• Remove the rubber stopple of desired drain direction.

• As the following picture, Insert drain hose in the handle of drain pan, and join drain hose and connecting

hose.

Panel Front

Connector

Pipe hole

CAUTION: After removing the pipe

hole, cut the burr for safety.

Page 33

Service Manual 33

Installation

■ Sticking the installation guide map and

fixing Indoor unit

■ Drill a hole in the wall

• Drill the piping hole with a ø50mm hole core drill. Drill

the piping hole at either the right or the left with the hole

slightly slanted to the outdoor side.

Plastic anchors

INSTALLATION GUIDE MAP

10m

m

INSTALLA TION GU

INSTAIIATION GUIDE MAP

INSTALLATION GUIDE MAP

1. Put an Installation Guide Map on the desired

surface.

2. Make a hole with diameter of 6mm and depth of

30-35mm when piercing a screw point.

3. Drive the fore plastic anchors into drilled points.

4. Hang the hole of product at the upper screws.

(In this time, Remove the map)

(Falling attention)

5. Check the fixed product with light power.

6. Look at suited horizon by horizontal meter on

the horizontal setting line, and Fix lightly the

map by adhesive tape.

7. Drill the piercing part for connecting pipe as

diameter 50mm. (In case of piercing rear surface)

Refer to No. 5 on this page when making a hole in the wall.

8. First, Drive the two points of the upper parts by

screws. (Leave 10mm for hanging product)

9. Drive the lower parts after facing the hole of

product with plastic anchors, and fix completely

the upper screws.

In case of nothing wrong in the matter,

connect the pipe and the wire.

(Installation manual reference)

Horizontality

IN

S

T

A

L

L

A

T

IO

N

G

U

ID

E

M

A

P

Plastic anchors

IN

S

T

A

L

L

A

T

IO

N

G

U

ID

E

M

A

P

Hanger hole

(Rear side of

product)

5-7mm

(0.2~0.3")

Indoor

WALL

Outdoor

Page 34

34 Multi type Air Conditioner

Installation

3. Art Cool Deluxe Type Indoor Unit

The wall you select should be strong and solid enough

to prevent vibration

1) Mount the installation plate on the wall with four

type A screws. If mounting the unit on a concrete

wall, use anchor bolts.

• Mount the installation plate horizontally by aligning

the centerline using a level.

2) Measure the wall and mark the centerline. It is

also important to use caution concerning the

location of the installation plate-routing of the

wiring to power outlets is through the walls typically. Drilling the hole through the wall for piping

connections must be done safely.

3). Drill a hole in the wall

• Drill the piping hole with a ø70mm hole core drill. Drill

the piping hole at either the right or the left with the

hole slightly slanted to the outdoor side.

Installation Plate

Type "A" screw

5-7mm

(3/16"~5/16")

Indoor

WALL

Outdoor

Installation plate

Ø70mm

Left rear piping Right rear piping

C

D

B

A

Ø70mm

Left rear piping Right rear piping

B

A

D

C

Installation plate

ABCD

SU

92 44 67 44

(9k, 12k)

SZ

35 33 156 33

(7k)

CHASSIS

(Grade)

Distance (mm)

(SU)

(SZ)

Page 35

Service Manual 35

Installation

4. Duct Type Indoor Unit

- BH/BG chassis

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct to

absorb unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Install the unit leaning to a drainage hole side as a

figure for easy water drainage.

• A place where the unit will be leveled and that can

support the weight of the unit.

• A place where the unit can withstand its vibration.

• A place where service can be easily performed.

CASE 1

POSITION OF SUSPENSION BOLT

CASE 2

POSITION OF CONSOLE BOLT

(Unit:mm)

Drainage hole

M10 Nut

M10 SP. washer

M10 washer

X 4

X 4

(Local

supply)

X 4

M10 Nut

M10 SP. washer

M10 washer

X 4

X 4

(Local

supply)

X 4

A

B

C

1-3 mm

D

(G)

H

I

EF

NOTE:

• Throughly study the following installation locations:

1. In such places as restaurants and kitchens, considerable

amount of oil steam and flour adhere to the fan, the fin of

the heat exchanger, resulting in heat exchange reduction,

spraying, dispersing of water drops, etc.

In these cases, take the following actions:

• Make sure that the ventilation fan for smoke-collecting

hood on a cooking table has sufficient capacity so that

it draws oily steam which should not flow into the suction of the air conditioner.

• Make enough distance from a cooking room to install

the air conditioner in such a place where it may not

suck in oil steam.

2. Avoid installing air conditioner in such circumstances

where cutting oil mist or iron powder is in suspension in

factories, etc.

3. Avoid places where inflammable gas is generated, flows

in, is stored or vented.

4. Avoid places where sulfurous acid gas or corrosive gas

is generated.

5. Avoid places near high frequency generators.

932 880 355 45.5 450 30 87 750 163

1232 1180 355 45.5 450 30 87 830 186

Dimension

18k, 24k

30k, 36k

Capacity

A B C D E F (G) H I

Page 36

36 Multi type Air Conditioner

Installation

- BT chassis

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct to

absorb unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Install the unit leaning to a drainage hole side as a

figure for easy water drainage.

• A place where the unit will be leveled and that can

support the weight of the unit.

• A place where the unit can withstand its vibration.

• A place where service can be easily performed.

CASE 1

POSITION OF SUSPENSION BOLT

CASE 2

POSITION OF CONSOLE BOLT

(Unit:mm)

Drainage hole

M10 Nut

M10 SP. washer

M10 washer

X 4

X 4

(Local

supply)

X 4

M10 Nut

M10 SP. washer

M10 washer

X 4

X 4

(Local

supply)

X 4

A

B

CD

1-3 mm

F

H

G

E

9/12K 708 678 434 51 537 455 230 172

18K 1060 1030 434 51 535 805 230 175

Dimension

Capacity

ABCDEFGH

Page 37

Service Manual 37

Installation

- BP chassis

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct to

absorb unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Install the unit leaning to a drainage hole side as a

figure for easy water drainage.

• A place where the unit will be leveled and that can

support the weight of the unit.

• A place where the unit can withstand its vibration.

• A place where service can be easily performed.

CASE 1

POSITION OF SUSPENSION BOLT

POSITION OF CONSOLE BOLT

(Unit:mm)

C

B

A

D

G

H

F

E

Drainage hole

1-3 mm

H

I

Dimension

Capacity

9k/12k BTU/h

633 580 695 660 750 45 369 797 20 232 372

ABCDEFGHI JK

CASE 2

M10 Nut

M10 SP. washer

M10 washer

M10 washer

M10 SP. washer

M10 Nut

X 4

X 4

X 4

X 4

X 4

X 4

(Local

supply)

(Local

supply)

Page 38

38 Multi type Air Conditioner

Installation

1. Preparation of pipings

1) Cut the pipes and the cable.

• Use the accessory piping kit or the pipes purchased locally.

• Measure the distance between the indoor and

the outdoor unit.

• Cut the pipes a little longer than the measured

distance.

• Cut the cable 1.5m longer than the length of the

pipe.

2) Remove burrs.

• Remove burrs from cut edges of pipes.

• Turn the pipe end toward down to avoid the

metal powder entering the pipe.

3) Flaring the pipes.

• Insert the flare nuts, mounted on the connection

ports of both indoor and outdoor unit, onto the

copper pipes. Some refrgerant gas may leak,

when the flare nuts are removed from the indoor

unit, as some gas is charged to prevent the

inside of the pipe from rusting.

• Fit the copper pipe end into the Bar of flare tool

about 0~0.5mm higher. (See illustration)

• Flare the pipe ends.

4) Tape the flaring portion to protect it from the

dust or damages.

90

Slanted

Pipe cutter

Rough

"A"

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Bar

Yoke

Handle

"

A": ø15.88 mm (5/8")→0~1.0 mm

ø12.7 mm (1/2")

→

0~0.5 mm

ø9.52 mm (3/8")

→

0~0.5 mm

ø6.35 mm (1/4")

→

0~0.5 mm

Piping and Drainage of Indoor Unit

CAUTION: If burrs are not removed,

they may cause a gas leakage.

When properly flared, the internal surface flare will

evenly shine and be of even thickness.

Since the flare part comes into contact with the connectors, carefully check the flare finish.

Pipe

Reamer

Point down

Inclined Cracked Uneven

= Improper flaring =

Surface

damaged

thickness

Page 39

Service Manual 39

Installation

1. Split Type Indoor Unit

• Preparing the indoor unit's piping and drain hose

for installation through the wall.

• Remove the plastic tubing retainer(see illustration

below) and pull the tubing and drain hose away

from chassis.

• Replace the plastic tubing holder in the original

position.

1. Route the indoor tubing and the drain hose in the

direction of rear left.

2. Insert the connecting cable into the indoor unit

from the outdoor unit through the piping hole.

• Do not connect the cable to the indoor unit.

• Make a small loop with the cable for easy connec-

tion later.

3.

Tape the tubing, drain hose and the connecting

cable. Be sure that the drain hose is located at the

lowest side of the bundle. Locating at the upper side

can cause drain pan to overflow inside the unit.

NOTE: If the drain hose is routed inside the room,

insulate the hose with an insulation material* so that

dripping from "sweating"(condensation) will not

damage furniture or floors.

*

Foamed polyethylene or equivalent is recommended.

4. Indoor unit installation

• Hook the indoor unit onto the upper portion of the

installation plate.(Engage the two hooks of the

rear top of the indoor unit with the upper edge of

the installation plate.) Ensure that the hooks are

properly seated on the installation plate by moving

it left and right.

Press the lower left and right sides of the unit

against the installation plate until the hooks engage

into their slots(clicking sound).

5. Connecting the pipings to the indoor unit and

drain hose to drain pipe.

• Align the center of the pipings and sufficiently

tighten the flare nut by hand.

CAUTION

When install, make sure that the

remaining parts must be removed

clearly so as not to damage the

piping and drain hose, especially

power cord and connecting cable.

For left rear piping

Connection of indoor unit piping

Loop

Tubing holder

To remove the holder,

press the bottom of

2

chassis near the holder