Page 1

LG Water Cooled Package

Air Conditioner

INSTALLATION MANUAL

LG

MODELS: AKWW0243AA0 AKWW0243YA0

AKWW0183AA0 AKWW0183YA0

AKWW0123AA0 AKWW0123YA0

AKWW0093AA0 AKWW0093YA0

website http://www.lgservice.com

e-mail http://www.lgeservice.com/techsup.html

IMPORTANT

• Please read this instruction sheet completely before

installing the product.

• When the power cord is damaged, replacement work shall

be performed by authorized personnel only.

• Installation work must be performed in accordance with

the national wiring standards by authorized personnel

only.

• Please retain this owner's manual for future reference after

reading it thoroughly.

ENGLISH FRANÇAIS ESPAÑOL

Page 2

2 Water Cooled Package

Single Split Wall Mounted Air Conditioner Installation Manual

TABLE OF CONTENTS

Safety Precautions............................3

Introduction ........................................8

Symbols Used in this Manual .........8

Features ...........................................8

Installation ........................................10

Installation Parts ............................10

Installation Tools ............................10

Weights / Clearance......................11

Installation ......................................13

Pre-Start-up Checklist ...................17

Maintenance ..................................18

❏ Panel, Return

❏ Grille, Discharge

❏ Hose, Flexible(1/2")

❏ Remote controller

❏ Screw driver

❏ Electric drill

❏ Specified torque wrenches

❏ Spanner

❏ Ohmmeter

❏ Ammeter

❏ Thermometer

❏ Horizontal meter

❏ Pipe wrench

Installation

Requirements

Required Parts Required Tools

Page 3

ENGLISH

IMPORTANT!

Please read this instruction sheet completely before installing the product.

CAUTION

:

Safety Precautions

NOTE TO INSTALLING DEALER

: The Owners Instructions and Warranty are to be given to

the owner or prominently displayed near the indoor

Furnace/Air Handler Unit.

When wiring:

Electrical shock can cause severe personal injury or death. Only a qualified,

experienced electrician should attempt to wire this system.

When transporting:

Be careful when picking up and moving the units. Get a partner to help, and bend your knees

when lifting to reduce strain on your back. Sharp edges or thin aluminum fins on the air conditioner

can cut your finger. Move the product more than two people, Improper moving may result in injury.

When servicing

WARNING

WARNING

WATER-SOURCE HEAT PUMP

INSTALLATION INSTRUCTIONS

• Turn the power OFF at the main power box(mains) before opening the unit to check or repair

electrical parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being serviced.

• Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is

an important part of your job to install or service the system so it operates safely and efficiently.

• Installation or repairs made by unqualified persons can result in hazards to you and others.

Installation MUST conform with local building codes or, in the absence of local codes, with the National

Electrical Code NFPA 70/ANSI C1-1993 or current edition and Canadian Electrical Code Part1 CSA

C.22.1.

• The information contained in the manual is intended for use by a qualified service technician familiar with

safety procedures and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction,

property damage, personal injury and/or death.

• Always wear safety eye wear and work gloves when installing equipment.

• Never assume electrical power is disconnected. Check with meter and equipment.

• Keep hands out of fan areas when power is connected to equipment.

• R-410A causes frostbite burns.

• R-410A is toxic when burned.

Improper installation, adjustment, alteration, service or maintenance can void the warranty.

The weight of the condensing unit requires caution and proper handling procedures when lifting

or moving to avoid personal injury. Use care to avoid contact with sharp or pointed edges.

Installation Manual 3

Page 4

4 Water Cooled Package

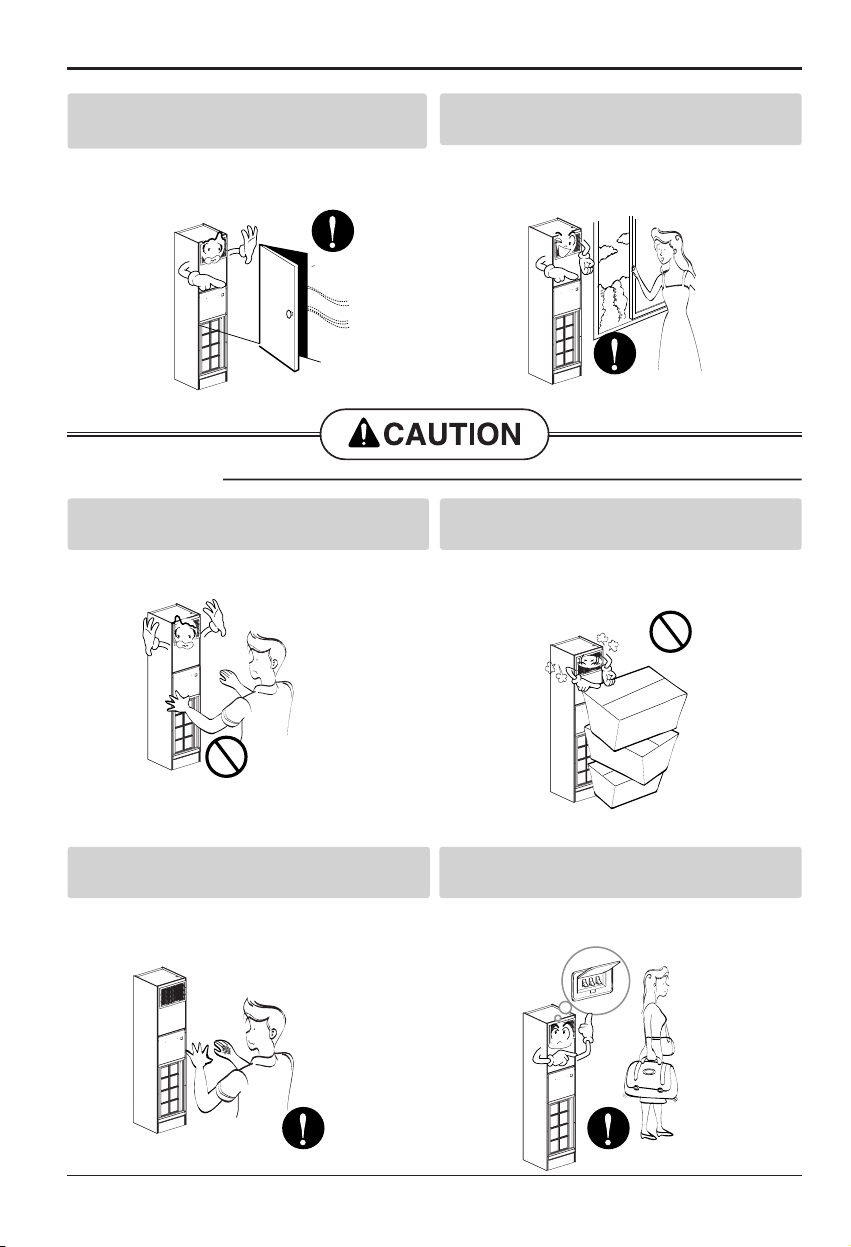

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Be sure to read before installing the air conditioner.

■ Be sure to observe the cautions specified here as they include important items related to safety.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Installation

Gasolin

Do not place the power cord near a heater.

• It may cause fire and electric shock.

(See features section)

Do not use the power cord near flammable

gas or combustibles such as gasoline,

benzene, thinner, etc.

• It may cause explosion or fire.

Do not disassemble or modify products.

• It may cause failure and electric shock.

(See features section)

Be sure not to do.

Be sure to follow the instruction.

Safety Precautions

Page 5

ENGLISH

Installation Manual 5

Safety Precautions

■ Operation

Plug in the power plug

properly.

• Otherwise, it will cause

electric shock or fire due to

heat generation or electric

shock.

Do not operate or stop the

unit by inserting or pulling

out the power plug.

• It will cause electric shock or

fire due to heat generation.

Do not damage or use an

unspecified power cord.

• It will cause electric shock or

fire.

Do not modify power cord

length.

• It will cause electric shock or

fire due to heat generation.

Always plug into a

grounded outlet.

• No grounding may cause

electric shock (See Installation

Manual).

Unplug the unit if strange

sounds, odors, or smoke

come from it.

• Otherwise it may cause fire

and electric shock accident.

ON

Do not operate with wet hands or in damp

environment.

• It will cause electric shock.

Do not allow water to run into electric parts.

• It will cause failure of machine or electric

shock.

Page 6

6 Water Cooled Package

■ Installation

Safety Precautions

Leave the door closed while the air

conditioner is running.

• It is not designed to cool the entire house.

Ventilate before operating air conditioner

when gas goes out.

• It may cause explosion, fire, and burn.

Never touch the metal parts of the unit

when removing the filter.

• They are sharp and may cause injury.

Do not block the inlet or outlet.

• It may cause failure of appliance or accident.

Be cautious not to touch the sharp edges

when installing.

• It may cause injury.

Turn off the main power switch when not

using it for a long time.

• Prevent accidental startup and the possibility of

injury.

Page 7

ENGLISH

Installation Manual 7

Safety Precautions

Do not place heavy object

on the power cord and take

care so that the cord should

not be pressed.

• There is danger of fire or

electric shock.

If water enters the product,

turn off the the power switch

of the main body of appliance.

Contact service center after

taking the power-plug out from

the socket.

Do not clean the air

conditioner with water.

• Water may enter the unit and

degrade the insulation. It may

cause an electric shock.

Turn off the power and

breaker firstly when

cleansing the unit.

• Since the fan rotates at high

speed during operation, it may

cause injury.

Do not put a pet or house

plant where it will be

exposed to direct air flow.

• This could injure the pet or

plant.

Do not use this appliance

for special purposes such

as pets, foods, precision

machinery, or objects of art.

• It is an air conditioner, not a

precision refrigeration system.

Always insert the filter

securely.

Clean it every two weeks.

• Operation without filters will

cause failure.

Use a soft cloth to clean. Do

not use wax, thinner, or a

strong detergent.

• The appearance of the air

conditioner may deteriorate,

change color, or develop

surface flaws.

Do not drink water drained

from air conditioner. / Do

not direct airflow at room

occupants only.

• It contains containments and

will make you sick. / This

could damage your health.

Wax

Thinner

Page 8

8 Water Cooled Package

Introduction

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

NOTICE

Introduction

Symbols Used in this Manual

Features

AKWW0243AA0 AKWW0243YA0

AKWW0183AA0 AKWW0183YA0

AKWW0123AA0 AKWW0123YA0

AKWW0093AA0 AKWW0093YA0

Page 9

ENGLISH

Installation Manual 9

CAUTION

Be cautious not to touch the sharp edges when installing It may cause

injury

Introduction

L2

L1

Page 10

10 Water Cooled Package

Introduction

1.6

AKWW0243AA0 / AKWW0183AA0 / AKWW0123AA0 / AKWW0093AA0

AKWW0243YA0 / AKWW0183YA0 / AKWW0123YA0 / AKWW0093YA0

20

20

1.6

16.7 1.6

5.1

10.2

16.7

84.7

3.7 12.6 3.7

49.45.9

35.43.2

(Unit:inch)

(Unit:inch)

18.8

17.5

49

18.3

18.7

Page 11

ENGLISH

Installation Manual 11

Installation

Hose, Flexible(2EA)

Grille, Discharge(1EA)

Remote controller (1set)

Panel, Return(1EA)

Figure FigureName

Screw driver

Electric drill

Spanner

Torque wrench

Tefron Tape

Ohmmeter

Ammeter

Thermometer,

Horizontal meter

Name

1/2" 24"

1/2" 24"

21.9

52.6

2

49.4

8.7

3.1

28.5

3.1

9.1

1.6 18.7 1.6

(Unit: inch) (Unit: inch)

18

11.8

1.8

1.7

3.93.9

4.7 8.5

❈ Recommended to use part supplied by LG ❈ Recommended to use part supplied by LG

❈ Recommended to

use part supplied by LG

❈ Not supplied by LG

Installation Parts(Option)

Installation Tools

Installation

Read completely, then follow step by step.

Page 12

12 Water Cooled Package

Installation

Weights / Clearance

- Improper Unit Lift

Test lift unit approximately 24 inches to verify proper center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to properly lift unit could result in death or serious injury or

possible equipment or property-only damage.

- Unit Location and Clearances

Locate the unit in an indoor area. The ambient temperature surrounding the unit must not be less than 45°F.

Do not locate the unit in areas subject to freezing.

Attention should be given to service clearance and technician safety.

The unit chassis should be easily removed from the cabinet in all applications.

There must be enough space for service personnel to perform maintenance or repair.

Provide sufficient room to make water, and electrical connection(s).

Local and national codes should be followed in providing electrical power connections.

See below figure for mechanical clearances.

Model Name(Cabinet) Shipping Weight(lb/kg) Unit Weight(lb/kg)

171/78 139/63

171/78 139/63

171/78 139/63

171/78 139/63

Model Name(Chassis) Shipping Weight(lb/kg) Unit Weight(lb/kg)

161/73 135/61

161/73 135/61

161/73 135/61

161/73 135/61

AKWW0243AA0

AKWW0183AA0

AKWW0123AA0

AKWW0093AA0

AKWW0243YA0

AKWW0183YA0

AKWW0123YA0

AKWW0093YA0

ALLOW 36" (914 mm)

AT UNIT FRONT FOR

CHASSIS REMOVAL

Page 13

ENGLISH

Installation Manual 13

Installation

RETURN-AIR OPENING

FLANGE ON CABINET

RETURN-AIR OPENING

FLANGE ON CABINET

2 X 4 STUD

A

B

SHEET ROCK

OPENING

TOP VIEW

SIDE VIEW

CABINET

B

2 1/4"

3 1/2"

±3/8"

3 1/2" ±3/8"

1 1/2" X 2 3/8"

FLOOR

SHEETROCK

SHEETROCK

RETURN AIR

DOOR FRAME

RETURN AIR

DOOR FRAME

1" X 1" CLOSED

CELL INSULATION

1" X 1" CLOSED

CELL INSULATION

3 1/2"

±3/8"

1 1/4"

+1/2"/-0"'

1 1/4"

+1/2"/-0"

A

1" X 1" CLOSED

CELL INSULATION

1" X 1" CLOSED

CELL INSULATION

2" X 4"

STUD

2" X 4" STUD

RETURN AIR OPENING

FLANGE ON CABINET

RETURN AIR OPENING

FLANGE ON CABINET

SHEETROCK

SHEETROCK

RETURN AIR

DOOR FLANGE

CABINET

CABINET

Finished wall and framing should not

touch the unit cabinetry.

NOTE

AB

21.3(542) 52.9(1344)

21.3(542) 52.9(1344)

21.3(542) 52.9(1344)

21.3(542) 52.9(1344)

Unit: inch(mm)

Page 14

14 Water Cooled Package

Installation

Unit Placement

Unit placement

If unit cabinet assembly includes factory provided risers, and "no" field provided between-the-floor

riser extensions, please move to Step 1.

Note: Risers are designed to accommodate a maximum of 1 1/2" to 3" expansion and contraction.

If the total calculated riser expansion exceeds 3", expansion devices must be field provided.

If unit cabinet assembly includes factory provided risers and field provided between-the floor riser

extensions are required, install the extensions before installing the cabinet.

1. Install drain valve, shut-off balancing valves, flow indicators and drain at the base of each supply

and return riser to enable system flushing at start-up, balancing and service maintenance.

2. Lift cabinet into space while aligning it into the 3"swage of the riser below.

Note: Take extra care as not to scrape or dent risers during positioning. The riser should fall

approximately 2" into the 3" swage. This will allow for the variation in floor-to-floor dimensions,

and keep the riser joints from bottoming out.

3. Level the cabinet

4. Plum bribers in two planes to as sure proper unit operation and condensate drainage.

5. Anchor all units into place.

6. For field provided risers, center the supply/return stubou is into the unit expansion slots. The

stubou is ahold be perpendicular to the cabinet panel.

7. Verify all risers are vertical and that they penetrate the swaged joint at least 1". Riser should not

be allowed to bottom out.

8. Braze riser joints. Sot solder or low-temperature alloys should not be used in this application.

9. If risers are field provided, it is recommended that the risers be anchored to the building structure

with a minimum of one contact point. For expansion and contraction reasons, do not fasten risers

rigidly to the building.

10. Seal access holes made through the cabinet for piping with suitable material to help eliminate

air leakage.

3" Swage

Floor

Stacking illustration

Floor

Page 15

ENGLISH

Installation Manual 15

Installation

Cleaning and Flushing the Water Loop

Water Connection

For vibration isolation, it is recommended that flexible steel braided hoses be in stalled instead of

hard piping between the vertical risers and the unit chassis.

Supply Grille installation

1. Install the supply grille(s) into the cabinet discharge opening. Insure there are no air gaps

between the cabinet supply air and the grille. This helps prevent recirculation of supply air into the

return air opening behind the drywall.

2. Secure grille(s) into the drywall via two screws.

Cleaning and flushing the Water Loop

After the piping system is complete, the flexible hose connector should be doubled back to

complete the water circuit external to the unit (avoiding trash settle-ut in the condenser). An extra

pipe may be necessary to connect the hose kits. See page 15 for antifreeze/water mixture by

volume.

3. Water circulation system should be filled with clean water using the water make up connections.

Note: Air vents should be opened during filling.

4. With the air vents closed, start the circulating pump and then crack the air vents to bled off the

trapped air, assuring circulation through all components of the system.

Note: Make up water must be available to the system to replace the volume formerly occupied by

the air that is bled off.

5. With the air vented and the water circulating, the entire system should be checked for leaks with

repairs made as required.

6. Operate the supplementary heat system making checks per manufacturer's instructions. During

this operation, visual checks should be made for leaks that may have occurred due to increased

heat. Repair as required.

7. Open the system at the lowest point for the initial blow down (making sure the make up water is

equal to the water being dumped). Continue blow down until the water leaving the drain runs

clear, but not less than 2 hours.

8. Shut down pumps and supplementary heat system. Reconnect the hoses placing the water-to

refrigerant heat exchanger in the water circulating system.

Note: Vents should be open when the pumps and supplementary heat system are shut down.

Flushing the water loop

Page 16

16 Water Cooled Package

Installation

Connect the cable

CAUTION:The power cord connected to the unit should be complied with the

following specifications.

Connect the cable to the unit by connecting the wires to the terminals on the control board

individually according to the unit connection.

The earth wire should be longer than the common wires.

The circuit diagram is not subject to change without notice.

When installing, refer to the wiring diagram behind the panel front of Unit.

CAUTION:

• The diagram is not subject to change without notice.

• Be sure to connect wires according to the wiring diagram.

• Connect the wires firmly, so that not to be pulled out easily.

• Connect the wires according to color codes by referring the wiring diagram.

RECOMMAND: Provide a circuit

breaker between power source

and the unit as shown below.

RECOMMAND:

The power cord connected to the unit should be complied with

the following specifications (ETL recognized and CSA certified).

The power connecting cable connected to the indoor and outdoor unit should be

complied with the following specifications (ETL recognized and CSA certified).

Air

Conditioner

Main power source

Circuit Breaker

Use a circuit breaker

or time delay fuse.

RECOMMAND:

When using the separate wire as the power cord, please fix the

separate wire into the control box panel by using tie wrap as the fixture.

Model

AKWW0243YA0

AKWW0183YA0

AKWW0123YA0

Min.Thickness

Main/Earth

0.005/0.005

(inch2)

AWG

12

12

14

14

Circuit breaker

(NFB)

25A

20A0.005/0.005

15A0.003/0.003

15A0.003/0.003AKWW0093YA0

Leak current circuit breaker

(ELB)

25A 100mmA 0.1sec

20A 100mmA 0.1sec

15A 100mmA 0.1sec

15A 100mmA 0.1sec

AKWW0123YA0

AKWW0093YA0

Line voltage (208~230V)

AWG14

GN/YL

20mm

AKWW0183YA0

AKWW0243YA0

Line voltage (208~230V)

AWG12 (Allowable temperature

to the wire rated at least 90C˚)

GN/YL

20mm

AWG18

Low voltage (below 40V)

GN/YL

20mm

Page 17

ENGLISH

Installation Manual 17

Installation

How to connect the Power cable

Remove the case of Manual controllers switch

1.Connect the power cable to the right side of manual controllers switch via clamp cord

2. Put the earth with grounding screw

3. Connect the lead wire from manual controllers switch to terminal block in control box refer to the

wiring diagram

L1

L2

Manual controllers

switch

L1 L2

Power cable

L1 L2

Earth cable

Page 18

18 Water Cooled Package

Installation

WARNING: Loose wiring may

cause the terminal to overheat or

result in unit malfunction. A fire

hazard may also exist.Therefore,

be sure all wiring is tightly

connected.

When connecting each power wire to the

corresponding terminal, follow instructions "How

to connect wiring to the terminals" and fasten

the wire tightly with the fixing screw of the

terminal plate.

How to connect wiring to the

terminals and the manual controllers

switch

For strand wiring

(1) Cut the wire end with a wire cutter or wire-

cutting pliers, then strip the insulation to

expose the strand wiring about 10mm(3/8").

(2) Using a screwdriver, remove the terminal

screw(s) on the terminal (manual controllers

switch) plate.

(3) Using a round terminal fastener or pliers,

securely clamp each stripped wire end with

a round terminal.

(4) Position the round terminal wire, and replace

and tighten the terminal screw using a

screwdriver.

Connection method of the connecting cable(Example)

High voltage

Low voltage

Strip 10mm(3/8")

Round

terminal

Connecting cable

Loosening the

terminal block

screw

Fastening the

wire tightly

Strand wire

Connecting cable

Loosening the

terminal block

screw

Fastening the

wire tightly

Page 19

ENGLISH

Installation Manual 19

Installation

How to connect the drain hose

To check the drainage.

1. Pour a glass of water on the evaporator.

2. Ensure the water flows through the drain

hose of the unit without any leakage and

goes out the drain exit.

When extending the drain hose at the unit,

install the drain pipe.

Drain piping

1. The drain hose should point downward for

easy drain flow.

2. Do not make drain piping.

main drain pipe

Drain hose

Vinyl tape

Adhesive

Downward slope

Unit drain hose

(narrow)

Water

leakage

Do not raise

Water

leakage

Accumulated

drain water

Air

Waving

Water

leakage

Tip of drain hose

dipped in water

Ditch

Less than

50mm gap

Page 20

20 Water Cooled Package

Installation

How to connect the water hose

Remove the cover of front panel

Connect supply and return water hoses refer to the label index

Water OutWater Out

Water Out

Water In

Water In

Wrench

Pipe(Water in,out)

Hose, flexible

Nut,hose

Open-end wrench (fixed)

Page 21

ENGLISH

Installation Manual 21

Installation

How to connect the remote controller lead wire

1. Remove the cover of front panel

2. Remove the cover of control box

3. Connect remote controller lead wire to the indoor PCB via hole on the control box refer to

the Wiring diagram

Conduit

Remote

controller

leadwire

L1 L2

Page 22

22 Water Cooled Package

Installation

1

Put the installation paper on the place and determine the

position and height of the fixing screws of the wired

remote controller.

• Refer to the printed side of the installation paper.

2

Plug the connecting cable into the indoor unit.

• The product is being shipped with the cable connected

only to the remote controller.

Fix the connecting cable with the cable rack.

3

Remove the installation paper before installing

the remote controller so that it can fit at the

right place.

* Do not embed the remote controller into the wall.

(It may cause the breakdown of the temperature sensor.)

* If you want to install a number of remote controller at the same place in a vertical line, install

them at regular intervals of 2cm. (It may cause the breakdown of the temperature sensor.)

* Do not install the cable with a distance of 50 m or longer. (This can cause communication

error.)

* When installing the cable, check whether the connector between the remote controller ands

the product is installed properly. The connector will not be connected when installed in

opposite sides.

Remote Controller Installation method

❏ Supply the power after connecting wired remote controller.

When you need to change wired remote controller, switch off the main power and change it.

If the wired remote controller is changed before switching off the main power, the option function

of the indoor unit can't be used. (option function like "slo" fan speed selection)

The position of the fixing screws

Main

indoor unit

CN-M CN-ZONEC

J15

C01K

IC01A

CN-DISP

LO1K

J14

CN-REMO

Red Yellow Brown

C07D

LO1D

LO2K

Side of

remote Controller

Side of

Indoor Unit

Fixing the

remote controller

Main frame

2cm

Page 23

ENGLISH

Installation Manual 23

Installation

How to install the chassis to the cabinet

1. Assemble the cover of control box

2. Assemble the chassis to the

cabinet by sliding

3. Assemble the cover of front panel

4. Assemble the filter to the front of

evaporator

5. Assemble the return panel to the

cabinet mating to hinge

Page 24

24 Water Cooled Package

Installation

Installation

- General Installation Checks

The checklist below is a summary of the steps required to successfully install a unit. This checklist is

intended to acquaint the installing personnel with procedures required in the installation process.

It does not replace the detailed instructions called out in the applicable sections of this manual.

1. Remove packaging and inspect the unit. Check the unit for shipping damage and material shortage; file a

freight claim and notify appropriate sales representation.

The unit cabinet is packaged in a cardboard.

The chassis sits inside a cardboard tray with an upper box for protection.

2. Verify the correct model, options and voltage from the unit nameplate.

3. Verify the installation location of the unit will provide the required clearance for proper operation.

4. Remove refrigeration access panel and inspect the unit. Be certain the refrigerant tubing has clearance

from adjacent parts.

- Hazardous Voltage

Disconnect all electric power, including remote disconnects and discharge all motor start/run capacitors

before servicing. Follow proper lockout/tagout procedures to ensure the power can not be inadvertently

energized. Failure to disconnect power before servicing could result in death or serious injury.The

transformer is located in the chassis control box.

- Main Electrical

1. Verify the power supply complies with the unit nameplate specifications.

2. Inspect all control panel components; tighten any loose connections.

3. Connect properly sized and protected power supply wiring to a field-supplied/installed disconnect switch

and to the unit power block in the unit's cabinet control box for equipment.

4. Install proper grounding wires to an earth ground.

All field-installed wiring must comply with NEC and applicable local codes.

- Low Voltage Wiring (AC & DC) Requirements

Connect properly sized control wiring to the proper termination points between the field supplied thermostat

and the terminal plug in the equipment's junction box.

- Field Installed Power Wiring

Power wiring to the equipment must conform to National and Local Electric Codes (NEC) by a professional

electrician.

- Live Electrical Components

During installation, testing, servicing and troubleshooting of this product, it may be necessary to work with

live electrical components. Have a qualified licensed electrician or other individual who has been properly

NOTE

NOTE

Page 25

ENGLISH

Installation Manual 25

Installation

trained in handling live electrical components perform these tasks. Failure to follow all electrical safety

precautions when exposed to live electrical components could result in death or serious injury. Verify that

the power supply available is compatible with the unit's nameplate. Use only copper conductors to connect

the power supply to the unit.

- Use Copper Conductors Only

Unit terminals are not designed to accept other types of conductors. Failure to use copper conductors may

result in equipment damage. Main Unit Power Wiring A field supplied disconnect switch must be installed at

or near the unit in accordance with the National Electric Code (NEC latest edition).

- Return Air (hinged) Acoustical Door

The hinged acoustical door is recessed into the wall so that the door is flush with the surface of the wall.

The opening through the wall for the door assembly must be centered with the return-air opening of the unit

cabinet. For full installing instructions of the return-air acoustical door.

- Drywall Installation

Before installing drywall around cabinet. Cover the cabinet supply and return openings with plastic or

cardboard to help prevent dust or construction debris from reaching unit components. Warranties will be

voided if paint or foreign debris is allowed to contaminate internal unit components. The location of the

drywall may be dependent upon the type of return air access design. Units that contain a field provided

return air access assembly, contractor must calculate location of drywall to allow for frame mounting.

- Units utilizing Hinged Acoustic Door Assembly

1. Locate the side studs a minimum of 1 1/4-inches and a maximum of 1 3/8-inches from the cabinet to the

side of the stud. This critical dimension, combined with "distance between studs" is used to determine the

side-to-side opening for the door, dimension A.The distances provided in the table are a "minimum"

dimension. Allow 3 1/2-inches from the front of the cabinet to the sheet rock surface, Top View.

2. The height of the door assembly must be positioned to recess the door 2 1/4-inches from the cabinet's

return-air opening, Side View blow-up.

3. Locate dimensions A and B for sheet rock opening size. The position of the sheet rock opening must be

centered side-to-side with the return-air opening in the cabinet. Ensure the bottom of the sheet rock

opening is 2 1/4-inches below the return-air opening in the cabinet. This allows the door recess to rest on

the bottom of the sheet rock opening for proper vertical placement of the door.

4. Place the door frame into the sheet rock opening. A positive seal is critical between the back of the door

frame and the front of the cabinet. Ensure that the gasket material seals properly.

When placing the sheet rock panel, make certain the opening for the door is centered with the return-air

opening in the cabinet (±1/8").

NOTE

Page 26

26 Water Cooled Package

Installation

- Chassis Installation

1. Connect water coil pipe to the system with a flexible steel hose assembly.

2. Verify that the shut-off/balancing valve in the return line/supply line are closed.

3. Place shut-off valves in appropriate location (see sticker on the equipment for best placement

recommendation) to allow chassis to slide easily in/out of unit cabinetry.

4. Flush system. See Cleaning and Flushing the Water Loop for flushing instructions.

5. Open the unit water valves and check piping for leaks.

6. Connect electrical to unit chassis via the quick connect mating plugs.

Four plugs are included (motor, optional condensate overflow, power and thermostat).

7. Slide chassis into the cabinet. Center the chassis left to right to minimize sound transmission.

8. Verify unit's air filter is properly place in the chassis filter rack.

9. Install cabinet's front cover to the hinged door.

10. Ensure the gasket material creates a positive seal around the entire coil to avoid coil bypass. If a field

supplied door is used, ensure the front cover is attached to the building structure and not the unit

cabinet.

- Supply Grille Installation

1. Install the supply grille(s) into the cabinet discharge opening. Insure there are no air gaps between

thecabinet supply air and the grille. This helps prevent recirculation of supply air into the return air

opening behind the drywall.

2. Secure grille(s) into the drywall via two screws.

- Cleaning and Flushing the Water Loop

1. After the piping system is complete, the flexible hose connectors should be doubled back to complete the

water circuit external to the unit (avoiding trash settle-out in the condenser). An extra pipe may be

necessary to connect the hose kits. See next page for antifreeze/water mixture by volume.

2. Water circulation system should be filled with clean water using the water make up connections.

Air vents should be opened during filling.

3. With the air vents closed, start the circulating pump and then crack the air vents to bleed off the trapped

air, assuring circulation through all components of the system.

Make up water must be available to the system to replace the volume formerly occupied by the air that is

bled off.

4. With the air vented and the water circulating, the entire system should be checked for leaks with repairs

made as required.

5. Operate the supplementary heat system making checks per manufacturer's instructions. During this

operation, visual checks should be made for leaks that may have occurred due to increased heat. Repair

as required.

6. Open the system at the lowest point for the initial blow down (making sure the make up water is equal to

the water being dumped). Continue blow down until the water leaving the drain runs clear, but not less

than 2 hours.

NOTE

NOTE

NOTE

Page 27

ENGLISH

Installation Manual 27

Installation

7. Shut down pumps and supplementary heat system. Reconnect the hoses placing the water-to-refrigerant

heat

exchanger in the water circulating system.

Vents should be open when the pumps and supplementary heat system are shut down.

- Using Antifreeze

In areas of the country where entering water temperatures drop below 45°F or where piping is being run

through areas subject to freezing, the loop must be freeze protected by using an approved antifreeze

solution to prevent loop water from freezing inside the heat exchanger. Methanol and glycols are the most

commonly used antifreeze solutions. Consult your geothermal unit supplier for locally approved solutions in

your area. Propylene glycol is not recommended in installations where the water temperature are expected

to fall below 30°F. At extreme temperatures, the viscosity increases to the point where normal loop

circulating pumps may not maintain proper flow. If propylene glycol is the only locally approved solution for

anti-freeze, good engineering practices should be used to achieve the desired flow. Calculate the

approximate volume of water in the system by using the requirements detailed in the following table, Water

Volume. Add three gallons to this total to allow for the water contained in the hose kit and geothermal unit.

Type of Antifreeze

Minimum Temperature for Freeze Protection

10°F15°F20°F25°F30°F

Methanol 25% 21% 16% 10% 3%

Propylene Glycol - - - - 6%

Before energizing the unit, the following system devices must be checked:

• Is the high voltage power supply correct and in accordance with the nameplate ratings?

• Is the field wiring and circuit protection the correct size?

• Is the low voltage control circuit wiring correct per the unit wiring diagram?

• Is the piping system clean/complete and correct? (A recommendation of all system flushing o debris from

the water-to-refrigerant heat exchanger, along with air purging from the water-to-refrigerant heat

exchanger be done in accordance with the Closed-Loop Source Heat Pump Systems Installation Guide).

• Is vibration isolation provided? (i.e. unit isolation pad, hose kits)

• Is unit serviceable? (See clearance specifications).

• Are the low/high-side pressure temperature caps secure and in place?

• Are all the unit access panels secure and in place?

• Is the thermostat in the OFF position?

• Is the water flow established and circulating through all the units?

• Is the duct work (if required) correctly sized, run, taped, insulated and weather proofed with proper unit

arrangement?

• Is the condensate line properly sized, run, trapped and pitched?

• Does the indoor blower turn freely without rubbing?

• Has all work been done in accordance with applicable local and national codes?

• Has heat transfer fluid been added in the proper mix to prevent freezing in closed system application?

• Have the chassis isolation rails been released?

• Is there a good seal between the front air panel and the coil?

Pre-Start-up Checklist

NOTE

Page 28

28 Water Cooled Package

Installation

Maintenance

- Preventive Maintenance

Maintenance on the unit is simplified with the following preventive suggestions: Filter maintenance must be

performed to assure proper operation of the equipment. Filters should be inspected at least every three

months, and replaced when it is evident they are dirty.

Check the contactors and relays within the control panel at least once a year. It is good practice to check

the tightness of the various wiring connections within the control panel. A strainer (60 mesh or greater) must

be used on an open loop system to keep debris from entering the unit heat exchanger and to ensure a

clean system. For units on well water, it is important to check the cleanliness of the water-to-refrigerant heat

exchanger. Should it become contaminated with dirt and scaling as a result of bad water, the heat

exchanger will have to be back flushed and cleaned with a chemical that will remove the scale. This service

should be performed by an experienced service person.

- Hazardous Chemicals

Coil cleaning agents can be either acidic or highly alkaline. Handle chemical carefully. Proper handling

should include goggles or face shield, chemical resistant gloves, boots, apron or suit as required. For

personal safety, refer to the cleaning agent manufacturers Materials Safety Data Sheet and follow all

recommended safe handling practices. Failure to follow all safety instructions could result in death or serious

injury. It should be noted that the water quality should be checked periodically. See the following water

quality table.

Scaling Calcium and magnesium(total hardness) Less than 350 ppm

pH 7 ~ 9.5

Hydrogen Sulfide Less than 1 ppm

Corrosion

Sulfates Less than 25 ppm

Chlorides Less than 125 ppm

Carbon Dioxide Less than 75 ppm

Total dissolved solids(TDS) Less than 1000 ppm

Biological Growth Iron Bacteria Low

Erosion Suspended Solids Low

Cooling Heating

Air 64.4~89.6 50~69.8

Water 59~104 59~104

Operating range (unit : Fahrenheit, °F)

Page 29

P/No.: MFL30215306

Loading...

Loading...