LG AK-Q240BC01 INSTALLATION MANUAL

P/NO : MFL67445803

INSTALLATION MANUAL

SINGLE PACKAGE TYPE AIR CONDITIONER

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

www.lg.com

Copyright © 2012 - 2018 LG Electronics Inc. All Rights Reserved.

ENGLISH

ESPAÑOL

PORTUGUÊS

TIPS FOR SAVING ENERGY

2

ENGLISH

TIPS FOR SAVING ENERGY

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your air conditioner more efficiently by referring to the instructions

below:

• Do not cool excessively indoors. This may be harmful for your health and may consume more

electricity.

• Block sunlight with blinds or curtains while you are operating the air conditioner.

• Keep doors or windows closed tightly while you are operating the air conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Open windows regularly for ventilation as the indoor air quality may deteriorate if the air

conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block the

air flow or weaken the cooling / dehumidifying functions.

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE INSTALLING THE APPLIANCE.

Always comply with the following precautions to avoid dangerous situations and ensure peak

performance of your product.

WARNING

!

It can result in serious injury or death when the directions are ignored.

CAUTION

!

It can result in minor injury or product damage when the directions are ignored.

WARNING

!

• Installation or repairs made by unqualified persons can result in hazards to you and others.

• Installation shall be in accordance with national standards of electrical appliances.

• The information contained in the manual is intended for use by a qualified service technician

familiar with safety procedures and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment

malfunction, property damage, personal injury and/or death.

Installation

• Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated circuit.

- There is risk of fire or electric shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized Service Center.

- Do not disassemble or repair the product. There is risk of fire or electric shock.

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and circuit breaker.

- Improper wiring or installation may cause fire or electric shock

• Use the correctly rated circuit breaker or fuse.

- There is risk of fire or electric shock.

• Use the specified wires to connect the unit.

- There is risk of fire or electric shock.

• Do not install, remove, or re-install the unit by yourself (customer).

- There is risk of fire, electric shock, explosion, or injury.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the case edges and the fins on the

condenser and evaporator.

• For installation, always contact the dealer or an Authorized Service Center.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

3

ENGLISH

4

ENGLISH

• Be sure the installation area does not deteriorate with age.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do not compress

Operation

• Take care to ensure that power cable could not be pulled out or damaged during operation.

• Do not place anything on the power cable.

• Do not touch(operate) the product with wet hands.

• Do not place a heater or other appliances near the power cable.

• Do not allow water to run into electric parts.

• Do not store or use flammable gas or combustibles near the product.

• Do not use the product in a tightly closed space for a long time.

• When flammable gas leaks, turn off the gas and open a window for ventilation before turn the

• If strange sounds, or small or smoke comes from product. Turn the circuit breaker off or disconnect

• Stop operation and close the window in storm or hurricane. If possible, remove the product from the

• Do not open the panel of product during operation. (If the unit has the electrostatic filter, Do not

• When the product is soaked (flooded or submerged), contact an Authorized Service Center.

• Be cautious that water could not enter the product.

• Ventilate the product from time to time when operating it together with a stove, etc.

• Turn the main power off when cleaning or maintaining the product.

• When the product is not be used for a long time, turn off the circuit breaker.

IMPORTANT SAFETY INSTRUCTIONS

- If the base collapses, the air conditioner could fall with it, causing property damage, product failure,

and personal injury.

air or Oxygen and Do not use Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

- There is risk of fire or electric shock.

- There is risk of fire or electric shock.

- There is risk of fire or electrical shock.

- There is risk of fire and electric shock.

- It may cause failure of the product or electric shock.

- There is risk of fire or failure of product.

- Oxygen deficiency could occur.

product on.

- Do not use the telephone or turn switches on or off. There is risk of explosion or fire

the power supply cable.

- There is risk of electric shock or fire.

window before the hurricane arrives.

- There is risk of property damage, failure of product, or electric shock.

touch it.)

- There is risk of physical injury, electric shock, or product failure.

- There is risk of fire or electric shock.

- There is risk of fire, electric shock, or product damage.

- There is risk of fire or electric shock.

- There is risk of electric shock.

- There is risk of product damage or failure, or unintended operation.

IMPORTANT SAFETY INSTRUCTIONS

• Take care to ensure that nobody could step on or fall onto the unit.

- This could result in personal injury and product damage.

CAUTION

!

Installation

• Always check for gas (refrigerant) pressure after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Install the drain hose to ensure that water is drained away properly.

- A bad connection may cause water leakage.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Do not install the product where the noise or hot air from the outdoor unit could damage the

neighborhoods.

- It may cause a problem for your neighbors.

• Don't use people to lift and transport the product.

- Avoid personal injury.

• Do not install the product where it will be exposed to sea wind (salt spray) directly.

- It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator

fins, could cause product malfunction or inefficient operation.

• Do not let the air conditioner run for a long time when the humidity is very high and a door or a

window is left open.

- Moisture may condense and wet or damage furniture.

Operation

• Do not expose the skin directly to cool air for long periods of time. (Don't sit in the draft.)

- This could harm to your health.

• Do not use the product for special purposes, such as preserving foods, works of art, etc. It is a

consumer air conditioner, not a precision refrigeration system.

- There is risk of damage or loss of property.

5

ENGLISH

TABLE OF CONTENTS

6

ENGLISH

TABLE OF CONTENTS

2 TIPS FOR SAVING ENERGY

3 IMPORTANT SAFETY INSTRUCTIONS

7 INTRODUCTION

7 Features (10 / 12.5 / 15 RT)

8 Features (20 / 23 / 25 RT)

9 DIMENSIONAL DATA(10 / 12.5 / 15 RT)

10 DIMENSIONAL DATA(20 / 23 / 25 RT)

11 INSTALLATION OF UNIT

11 Inspection

11 Location and Recommendations

12 Ductwork

12 Change Airflow

13 Condensate Drain Piping

13 Filter Installation

13 Down flow filter bracket installation guide

15 Installation of Remote Controller(Accessory)

19 Electronic Wiring

20 Field Wiring

24 Connect the cable to the Product

26 Dip Switch Setting in Indoor Main PCB

26 Group Control

27 Evaporator Fan Adjustment

28 Trial Run Mode

29 Self-Diagnosis Function

34 Starting the Unit

35

Final Installation Checklist and Maintenance

42 Installation guide at the seaside

INTRODUCTION

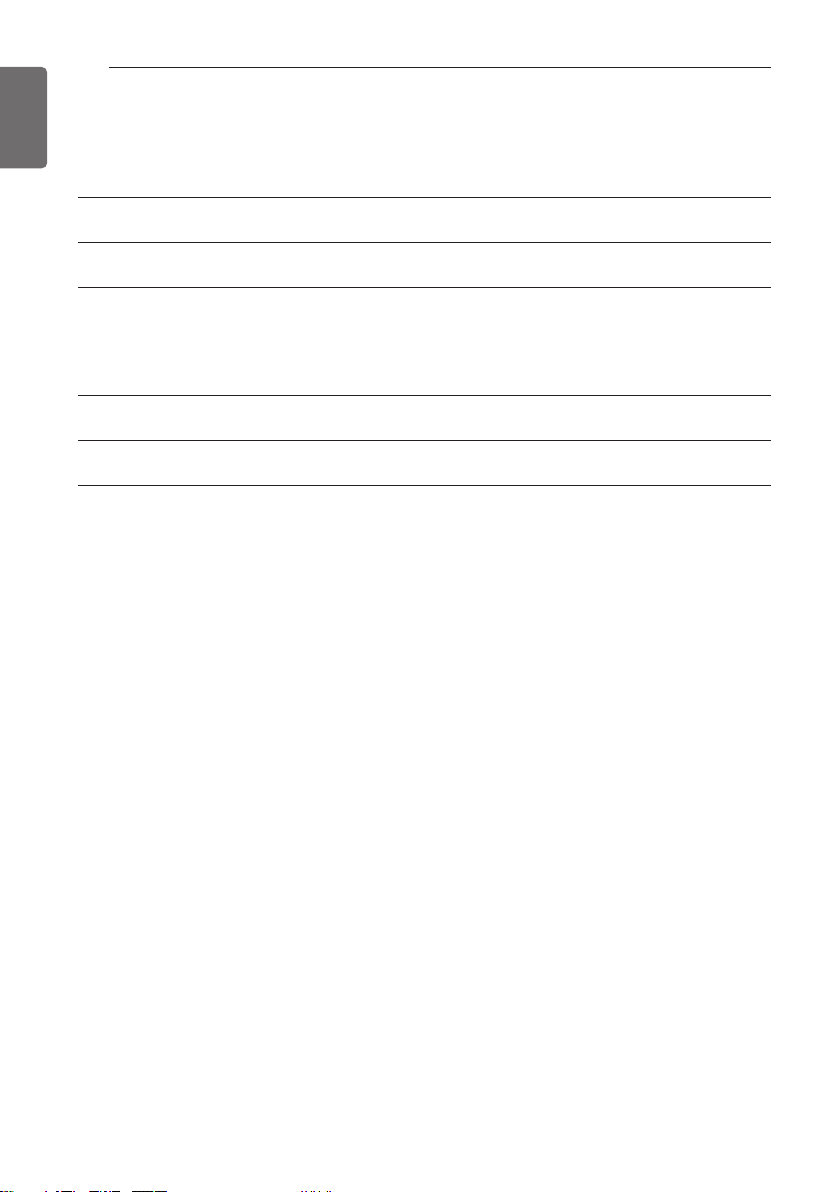

Features (10 / 12.5 / 15 RT)

Front View

Air outlet vents

Drain Hole

INTRODUCTION

Return

SupplyMotor Access Panel

7

ENGLISH

Rear View

Control

access panel

Compressor

access panel

Air outlet

vents

Air intake vents

INTRODUCTION

8

ENGLISH

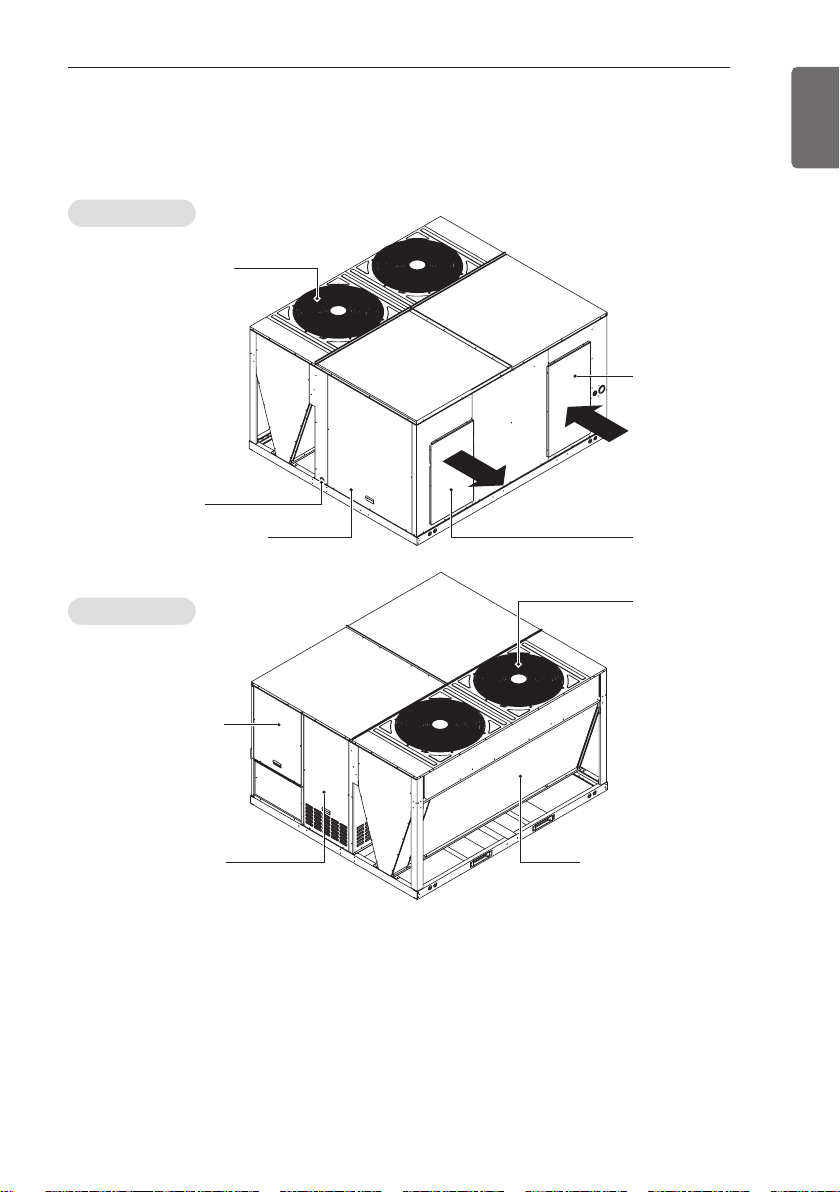

Features (20 / 23 / 25 RT)

Front View

Air outlet vents

Drain Hole

Motor Access Panel

Rear View

Return

Supply

Air outlet

vents

Control

access panel

Compressor

access panel

Air intake vents

DIMENSIONAL DATA

RETURN

SUPPLY

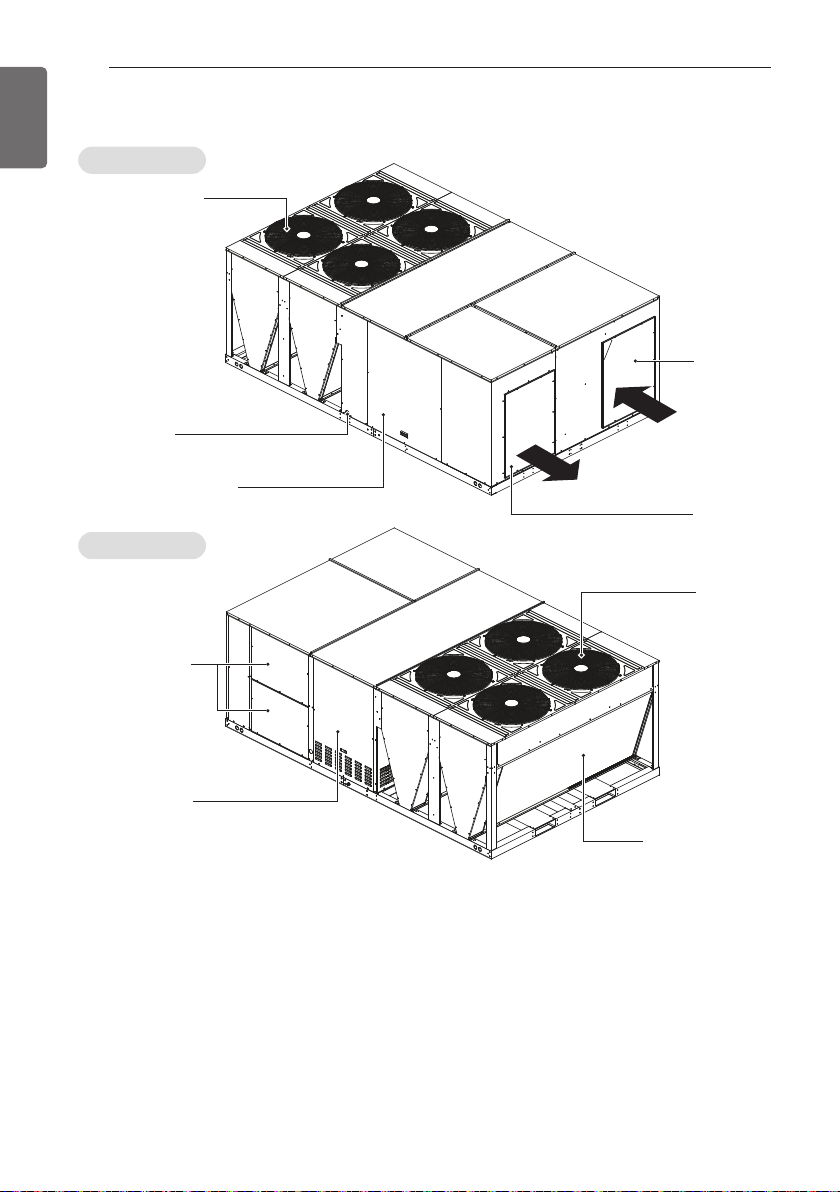

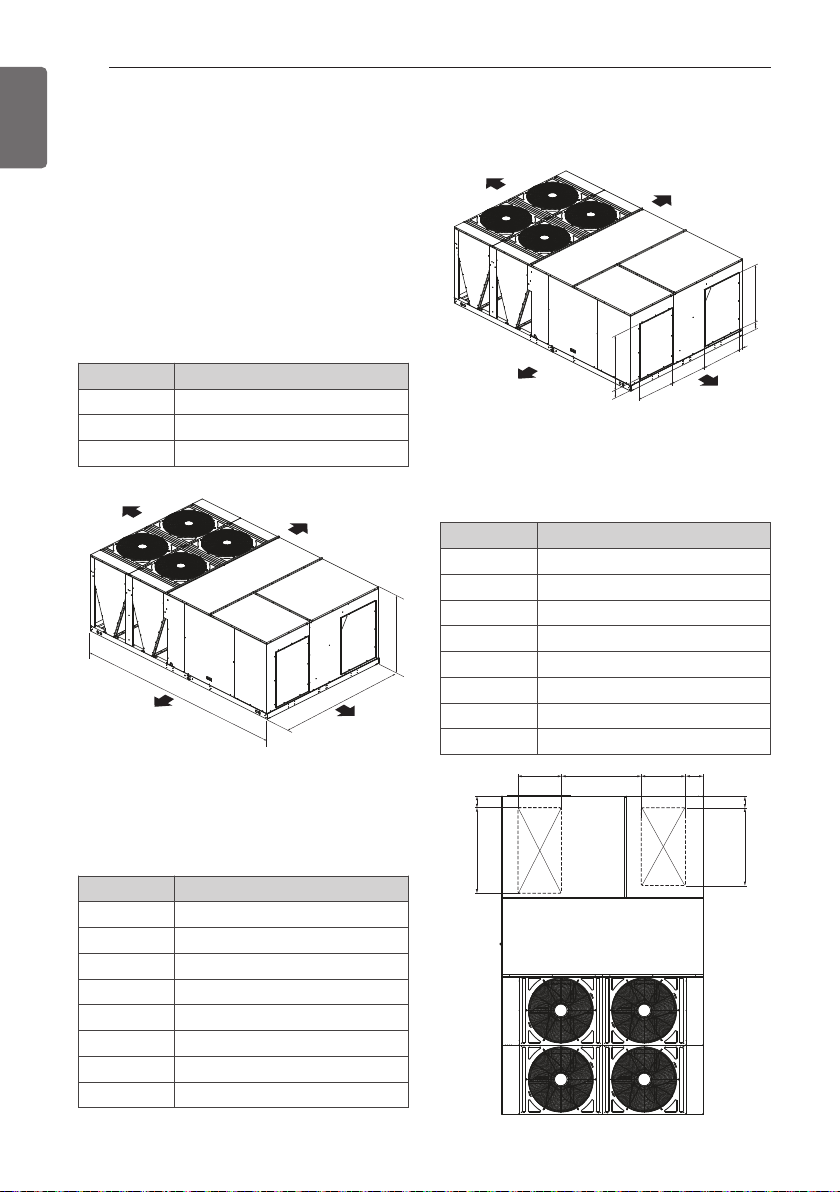

DIMENSIONAL DATA (10 / 12.5 / 15 RT)

9

ENGLISH

Single packaged cooling Units are designed

for outdoor mounting with vertical condenser

discharge. They can be located either at

ground level or on roof.

Each unit contains an operating charge of

Refrigerant as shipped.

Product Dimensions (Figure 1A)

[Unit : mm (inch)]

Tool 10 / 12.5 / 15 RT

A 1 237 (48-11/16)

B 2 230 (87-25/32)

C 1 958 (77-3/32)

D 36 (1-13/32)

E 60 (2-3/8)

CLEARANCE 860mm

C

CLEARANCE 1 160mm

CLEARANCE 1 160mm

E

D

B

CLEARANCE 860mm

Figure 1A

A

CLEARANCE 860mm

CLEARANCE 1 160

mm

H

G

CLEARANCE 1 160mm

C

B

A

CLEARANCE 860mm

DOWN FLOW APPLICATION

(Figure 1C)

Tool 10 / 12.5 / 15 RT

A 484 (19-1/16)

B 427 (16-13/16)

C 482 (18-31/32)

D 642 (25-9/32)

E 92 (3-5/8)

F 800 (31-1/2)

G 92 (3-5/8)

H 913 (35-15/16)

A

[Unit : mm (inch)]

BCD

F

E

D

Figure 1B

HORIZONTAL FLOW APPLICATION

(Figure 1B)

Tool 10 / 12.5 / 15 RT

A 484 (19-1/16)

B 864 (34-1/32)

C 482 (18-31/32)

D 206 (8-1/8)

E 126 (4-31/32)

F 913 (35-15/16)

G 130 (5-1/8)

H 800 (31-1/2)

[Unit : mm (inch)]

E

F

RETURN

RETURN

SUPPLY

SUPPLY

TOP VIEW

HG

Figure 1C

DIMENSIONAL DATA

RETURN

SUPPLY

10

ENGLISH

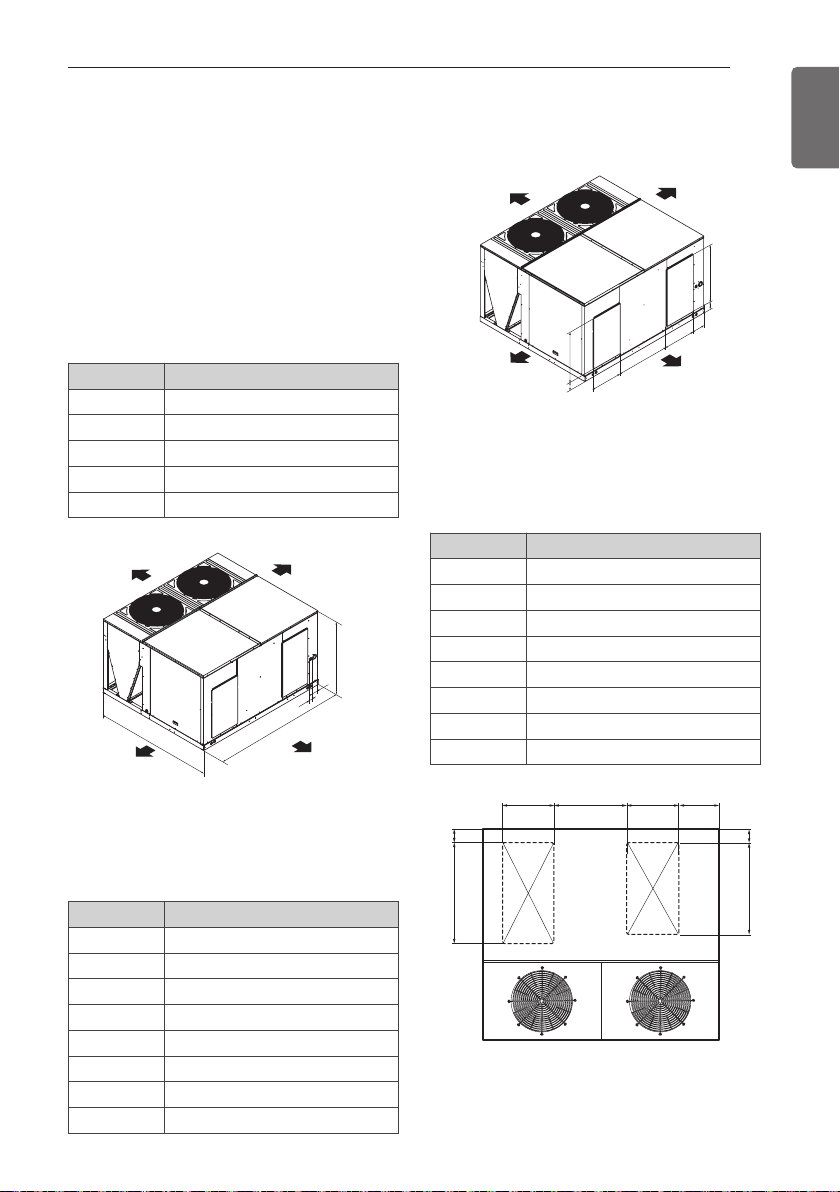

DIMENSIONAL DATA (20 / 23 / 25 RT)

Single packaged cooling Units are designed

for outdoor mounting with vertical condenser

discharge. They can be located either at

ground level or on roof.

Each unit contains an operating charge of

Refrigerant as shipped.

Product Dimensions (Figure 1A)

[Unit : mm (inch)]

Tool 20 / 23 / 25 RT

A 1 242 (48-29/32)

B 2 230 (87-25/32)

C 3 520 (138-19/32)

CLEARANCE 860mm

C

CLEARANCE 1 160mm

CLEARANCE 1 160mm

B

CLEARANCE 860mm

HORIZONTAL FLOW APPLICATION

(Figure 1B)

[Unit : mm (inch)]

Tool 20 / 23 / 25 RT

A 616 (24-1/4)

B 678 (26-11/16)

C 655 (25-25/32)

D 60 (2-3/8)

E 125 (4-29/32)

F 882 (34-23/32)

G 115 (4-17/32)

H 860 (33-27/32)

Figure 1A

CLEARANCE 860mm

H

CLEARANCE 1 160mm

G

DOWN FLOW APPLICATION

(Figure 1C)

Tool 20 / 23 / 25 RT

A 655 (25-25/32)

B 457 (18)

A

C 616 (24-1/4)

D 196 (7-23/32)

E 116 (4-9/16)

F 882 (34-23/32)

G 116 (4-9/16)

H 860 (33-27/32)

A

BCD

E

F

RETURN

RETURN

TOP VIEW

CLEARANCE 1 160mm

B

A

CLEARANCE 860mm

Figure 1B

[Unit : mm (inch)]

SUPPLY

SUPPLY

Figure 1C

F

E

D

C

HG

INSTALLATION OF UNIT

INSTALLATION OF UNIT

11

ENGLISH

Inspection

1 Check for damage after unit is unloaded.

Report promptly, to the carrier, any

damage found to unit. Do not drop unit.

2 Check the unit nameplate to determine if

the unit voltage is correct for the

application. Determine if adequate

electrical power is available. Refer to the

application specifications.

3 Check to be sure the refrigerant charge

has been retained during shipment.

Access to 1/4" flare pressure taps may be

gained by removing compressor

compartment access panel.

Location and

Recommendations

Unit Support

If unit is to be roof mounted check building

codes for weight distribution requirements.

Location and Clearances

Installation of unit should conform to local

building codes and the National Electrical Code.

Select a location that will permit unobstructed

airflow into the condenser coil and away from

the fan discharge and permit unobstructed

service access into the compressor

compartment. Suggested airflow clearances and

service clearances are given in Figure 1.

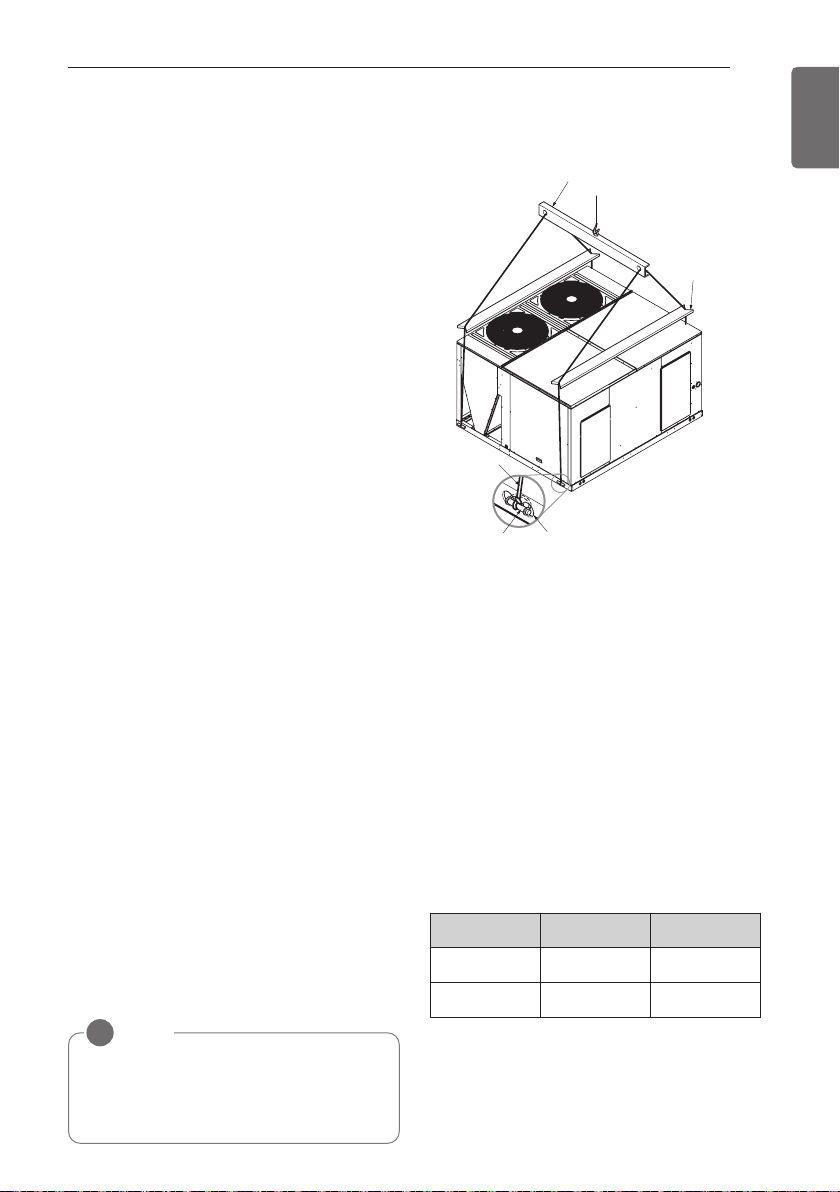

Placing and Rigging

Rig the unit using either belt or cable slings.

The sling eyelet must be placed through the

lifting holes in the base rail of the unit. The

point where the slings meet the lifting eyelet

should be at least 1.8m above the unit. Use

spreader bars to prevent excessive pressure

on the top of the unit during lifting.

NOTE

!

• The use of "spreader bars" is required

when hoisting the unit (prevents

damage to sides and top). Top crating

can be used as spreader bars.

Lifting Beam

Recommended

Rigging Method

Spreader Bar

Cable

or Chain

Clevis

Holes in Base

Rail

Figure 2

Roof Mounted Unit

On new roofs, the curb should be welded

directly to the roof deck. For existing

construction, nailers must be installed under

the curb if welding is not possible. Be sure

attach the down flow ductwork to the curb

before setting unit in place.

When installing the unit, it must be level to

insure proper condensate flow from the unit

drain pan.

Slab Mount

"For ground level installation, the unit base

should be adequately supported and hold the

unit near level. The installation must meet the

guidelines set forth in local codes."

Net Weight kg lbs

10/12.5/15RT 550 1 212

20/23/25RT 1 040 2 293

12

ENGLISH

INSTALLATION OF UNIT

Ductwork

Ductwork construction guidelines

Connections to the unit should be made with

76mm(3’) canvas connectors to minimize

noise and vibration transmission.

Elbows with turning vanes or splitters are

recommended to minimize air noise and

resistance.

The first elbow in the ductwork leaving the

unit should be no closer than three times

blower diameter to avoid turbulence and back

pressure.

Attaching Horizontal Ductwork to

the Unit

All conditioned air ductwork should be

insulated to minimize heating and cooling duct

losses. Use minimum of 50mm(2’) of

insulation with a vapor barrier. The outside

ductwork must be weather proofed between

the unit and the building.

When attaching ductwork to a horizontal unit,

provide a flexible water tight connection to

prevent noise transmission from the unit to

the ducts. The flexible connection must be

indoors and molded out of heavy canvas.

NOTE

!

• Do not draw the canvas taut between

the solid ducts.

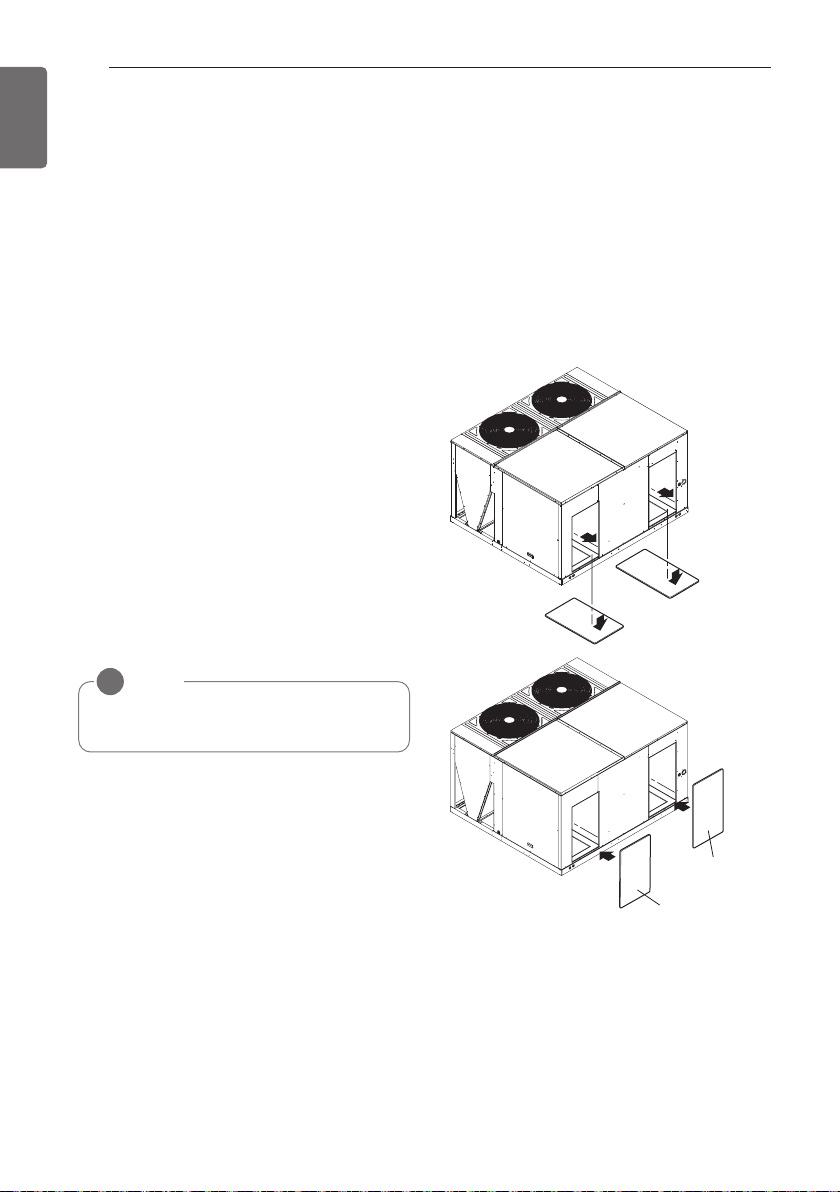

Change Airflow

Horizontal flow to Down flow Conversion

1 Remove the covers from the down flow

openings on the base panel by unscrewing

as shown.

2 Close the horizontal Supply and Return

openings on the front panel by attaching

the covers firmly on to it which are

removed from the down flow openings.

* Cover assembly should be assembled as

insulation being downward.

(1)

(2)

Return cover

Supply cover

Figure 3

Loading...

Loading...