LG ACHH060LBAB Owner’s Manual

INSTALLATION &

OWNER’S MANUAL

www.lg.com

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring standards by authorized

personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

Please read this manual carefully before operating your set and retain it

for future reference.

[Representative] LG Electronics Inc. EU Representative : LG Electronics European Shared Service

Center B.V. Krijgsman 1, 1186 DM Amstelveen, The Netherlands

[Manufacturer] LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro, Seongsan-gu,

Changwon-si, Gyeongsangnam-do, KOREA

Air Cooled Liquid Chilling Package

ACHH Series

Original instruction

AIR

CONDITIONER

MFL67262615

Rev.01_120320

Copyright © 2018 - 2020 LG Electronics Inc. All Rights Reserved.

SVENSKA

ENGLISH

ITALIANO

NORSK

ESPAÑOL

DANSK

FRANÇAIS

DEUTSCH

ΕΛΛΗΝΙΚΆ

ČEŠTINA

NEDERLANDS

POLSKI

LIMBA ROMÂNĂ

TIPS FOR SAVING ENERGY

2

ENGLISH

TIPS FOR SAVING ENERGY

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your air conditioner more efficiently by referring to the instructions

below:

• Do not cool excessively indoors. This may be harmful for your health and may consume more

electricity.

• Block sunlight with blinds or curtains while you are operating the air conditioner.

• Keep doors or windows closed tightly while you are operating the air conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Open windows regularly for ventilation as the indoor air quality may deteriorate if the air conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block the

air flow or weaken the cooling / dehumidifying functions.

ENGLISH Disposal of your old appliance

1. This crossed-out wheeled bin symbol indicates that waste electrical and electronic products

(WEEE) should be disposed of separately from the municipal waste stream.

2. Old electrical products can contain hazardous substances so correct disposal of your old appli-

ance will help prevent potential negative consequences for the environment and human health.

Your old appliance may contain reusable parts that could be used to repair other products, and

other valuable materials that can be recycled to conserve limited resources.

3. You can take your appliance either to the shop where you purchased the product, or contact your

local government waste office for details of your nearest authorised WEEE collection point. For

the most up to date information for your country please see www.lg.com/global/recycling

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

IMPORTANT SAFETY INSTRUCTIONS

3

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid dangerous

situations and ensure peak performance of your product.

WARNING

!

It can result in serious injury or death when the directions are

ignored.

CAUTION

!

It can result in minor injury or product damage when the

directions are ignored.

WARNING

!

• Installation or repairs made by unqualified persons can result in

hazards to you and others.

• Installation of all field wiring and components MUST conform with

local building codes or, in the absence of local codes, with the

National Electrical Code 70 and the National Building Construction and

Safety Code or Canadian Electrical Code and National Building Code of

Canada.

• The information contained in the manual is intended for use by a

qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can

result in equipment malfunction, property damage, personal injury

and/or death.

ENGLISH

Installation

• Installation is to be performed by qualified personnel who are familiar

with local codes and regulations.

- There is risk of fire, electric shock, explosion, or injury.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• For re-installation of the installed product, always contact a dealer or

an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

IMPORTANT SAFETY INSTRUCTIONS

4

ENGLISH

• Do not install, remove, or re-install the unit by yourself (customer).

- There is risk of fire, electric shock, explosion, or injury.

• Prepare for strong wind or earthquake and install the unit at the

specified place.

- Improper installation may cause the unit to topple and result in injury.

• When installing and moving the Product to another site, do not charge

it with a different refrigerant from the refrigerant specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant,

the refrigerant cycle may malfunction and the unit may be damaged.

• Securely install the cover of control box and the panel.

- If the cover and panel are not installed securely, dust or water may

enter the outdoor unit and fire or electric shock may result.

• If the Product is installed in a small room, measures must be taken to

prevent the refrigerant concentration from exceeding the safety limit

when the refrigerant leaks.

- Consult the dealer regarding the appropriate measures to prevent

the safety limit from being exceeded. Should the refrigerant leak and

cause the safety limit to be exceeded, hazards due to lack of oxygen

in the room could result.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Have all electric work done by a licensed electrician according to

regulations and the instructions given in this manual and always use a

special circuit.

- If the power source capacity is inadequate or electric work is

performed improperly, electric shock or fire may result.

• There must be no obstruction above the unit.

- It would deflect discharge air downward where it could be re-

circulated back to the inlet of the condenser coil. The condenser fans

are propeller type and will not operate with ductwork on the fan

outlet.

• When transporting the product, use the forklift or spreader bar in

accordance with the manual.

- Arbitrarily moving the product can cause product damage or injury.

• When moving the product using the forklift, check the weight of the

chiller, size and length of the fork to select the appropriate equipment.

- It can cause damage or injury.

IMPORTANT SAFETY INSTRUCTIONS

5

ENGLISH

• When hanging the product on the hoist to move the chiller, make sure

that the load of the product is evenly distributed and leveled during

the move.

- It can cause damage or injury.

• When moving the product using the spreader bar, make sure to select

the spreader bar with material and size to sufficiently support the

strength spreader bar.

- Using inappropriate spreader bar can cause the product to fall and

cause injury due to the strength or size.

• Always ground the product.

- There is risk of fire or electric shock.

• Do not store or use flammable gas or combustibles near the Product.

- There is risk of fire or failure of product.

• Do not reconstruct to change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is

shorted and operated forcibly, or parts other than those specified by

LGE are used, fire or explosion may result.

• Ventilate before operating Product when gas leaked out.

- It may cause explosion, fire, and burn.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test

or air purge. Do not compress air or Oxygen and Do not use

Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

Use

• Do not damage or use an unspecified POWER CABLE.

- There is risk of fire, electric shock, explosion, or injury.

• Use a dedicated outlet for this appliance.

- There is risk of fire or electrical shock.

• Be cautious that water could not enter the Product.

- There is risk of fire, electric shock, or product damage.

• Do not touch the power switch with wet hands.

- There is risk of fire, electric shock, explosion, or injury.

• When installing and moving the Product to another site, do not charge

it with a different refrigerant from the refrigerant specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant,

the refrigerant cycle may malfunction and the unit may be damaged.

IMPORTANT SAFETY INSTRUCTIONS

6

ENGLISH

• When the product is soaked (flooded or submerged), contact an

Authorized Service Center.

- There is risk of fire or electric shock.

• Be cautious not to touch the sharp edges and coil.

- It may cause injury.

• Take care to ensure that nobody could step on or fall onto the outdoor

unit.

- This could result in personal injury and product damage.

• Do not open the inlet grille of the product during operation.

(Do not touch the electrostatic filter, if the unit is so equipped.)

- There is risk of physical injury, electric shock, or product failure.

• Be careful during valve checkout about hot gas line

- It may become hot enough to cause injury.

• Electric shock hazard. Can cause severe injury or death. Even when

power to the panel is off, output board could be connected to high

voltage.

• Electric shock hazard. Turn off all power before doing any service.

• Turn the main power off in case of installation or service.

CAUTION

!

Installation

• Always check for gas (refrigerant) leakage after installation or repair of

product.

- Low refrigerant levels may cause failure of product.

• Do not install the product where the noise or hot air from the outdoor

unit could damage the neighborhoods.

- It may cause a problem for your neighbors.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may

result.

• Do not install the product where it is exposed to sea wind (salt spray)

directly.

- It may cause corrosion on the product. Corrosion, particularly on the

condenser and evaporator fins, could cause product malfunction or

inefficient operation.

IMPORTANT SAFETY INSTRUCTIONS

7

ENGLISH

• When installing the unit in a hospital, communication station, or

similar place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency

medical equipment, or radio communication equipment may cause

the Product to operate erroneously, or fail to operate. On the other

hand, the Product may affect such equipment by creating noise that

disturbs medical treatment or image broadcasting.

• Use power cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Do not use the product for special purposes, such as preserving

foods, works of art, etc. It is a consumer Product, not a precision

refrigeration system.

- There is risk of damage or loss of property.

• Keep the unit away from children. The heat exchanger is very sharp.

- It can cause the injury, such as cutting the finger. Also the damaged

fin may result in degradation of capacity.

• The operator must provide protection against water circuit freezing on

all Product units.

- To prevent damage from freezing water.

• If anyone other than a licensed Professional installs, repairs, or alters

LG Electronics Air Conditioning Products, the warranty is voided.

- All costs associated with repair are then the full responsibility of the

owner.

• Do not install the unit in potentially explosive atmospheres.

Use

• Do not use the Product in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the

performance of the Product or damage its parts.

• Make the connections securely so that the outside force of the cable

may not be applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a

fire.

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the Product could fall with it, causing property

damage, product failure, or personal injury.

• Install and insulate the drain hose to ensure that water is drained

away properly based on the installation manual.

- A bad connection may cause water leakage.

IMPORTANT SAFETY INSTRUCTIONS

8

ENGLISH

• Be very careful about product transportation.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, suspending it at the specified

positions on the unit base. Also support the outdoor unit at four

points so that it cannot slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts,

may cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children

may not play with them. If children play with a plastic bag which was

not torn apart, they face the risk of suffocation.

• Turn on the power at least 6 hours before starting operation.

- Starting operation immediately after turning on the main power

switch can result in severe damage to internal parts. Keep the power

switch turned on during the operational season.

• Do not touch any of the refrigerant piping during and after operation.

- It can cause a burn or frostbite.

• Do not operate the Product with the panels or guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not directly turn off the main power switch after stopping

operation.

- Wait at least 5 minutes before turning off the main power switch.

Otherwise it may result in water leakage or other problems.

• When re-running the product after keep product long time in a low

temperature conditions, touch function may not work temporarily.

- Wait for a time. After time, product work normally.

• Do not insert hands or other objects through the air inlet or outlet

while the Product is plugged in.

- There are sharp and moving parts that could cause personal injury.

• Field wiring must be installed according to unit wiring diagram.

- It may cause serious electrical damage can occur.

• Do not use an automotive grade antifreeze. Industrial grade glycols

must be used. Automotive antifreeze contains inhibitors which will

cause plating on the copper tubes within the Product evaporator. The

type and handling of glycol used must be consistent with local codes.

• Electrical power must be applied to the compressor crankcase heaters

6 hours before starting unit to drive off refrigerant from the oil.

IMPORTANT SAFETY INSTRUCTIONS

9

ENGLISH

• Any changes to these parameters must be determined and

implemented by qualified personnel with a thorough understanding of

how these parameters affect the operation of the unit. Negligent or

improper adjustment of these controls can result in damage to the

unit or personal injury.

• Service on this equipment is to be performed by qualified refrigeration

personnel familiar with equipment operation, maintenance, correct

servicing procedures, and the safety hazards inherent in this work.

Causes for repeated tripping of equipment protection controls must

be investigated and corrected.

• Anyone servicing this equipment shall comply with the requirements

set forth by the EPA in regards to refrigerant reclamation and venting.

• This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

• This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by

children without supervision.

TABLE OF CONTENTS

10

ENGLISH

TABLE OF CONTENTS

2 TIPS FOR SAVING ENERGY

3 IMPORTANT SAFETY INSTRUCTIONS

11 PRODUCT INTRODUCTION

11 General information

21 CONTROL

21 Control panel configuration

25 Freezer address setting

26 Logging in to HMI

27 Introduction to HMI menu

42 Introduction to schedule menu

50 Introduction to record menu

52 View setting menu

70 FROM INSTALLATION TO TEST RUN

71 INSTALLATION

71 Selecting installation location

78 Transportation method and precaution

80 Installing chiller

83 Snow protection

84 Water pipe connection

90 Electric specification

91 Electric work

95 How to set control box address (Set cycle PCB address)

97 How to install HMI indoors

99 Unit Combination

100 How to set the main controller address

101 TEST RUN/ADDITIONAL FUNCTION

101 Test run

103 Additional function

105 SELF DIAGNOSIS FUNCTION

107 HEAT SOURCE WATER MANAGEMENT

107 Heat source water management

108 Heat source water quality management standard table

109 Water pipe side strainer

110 Actions for problems in the test operation

110 Plate type heat exchanger maintenance

111 Daily inspection management

113 TROUBLESHOOTING

123 APPENDIX

PRODUCT INTRODUCTION

PRODUCT INTRODUCTION

General information

Product information

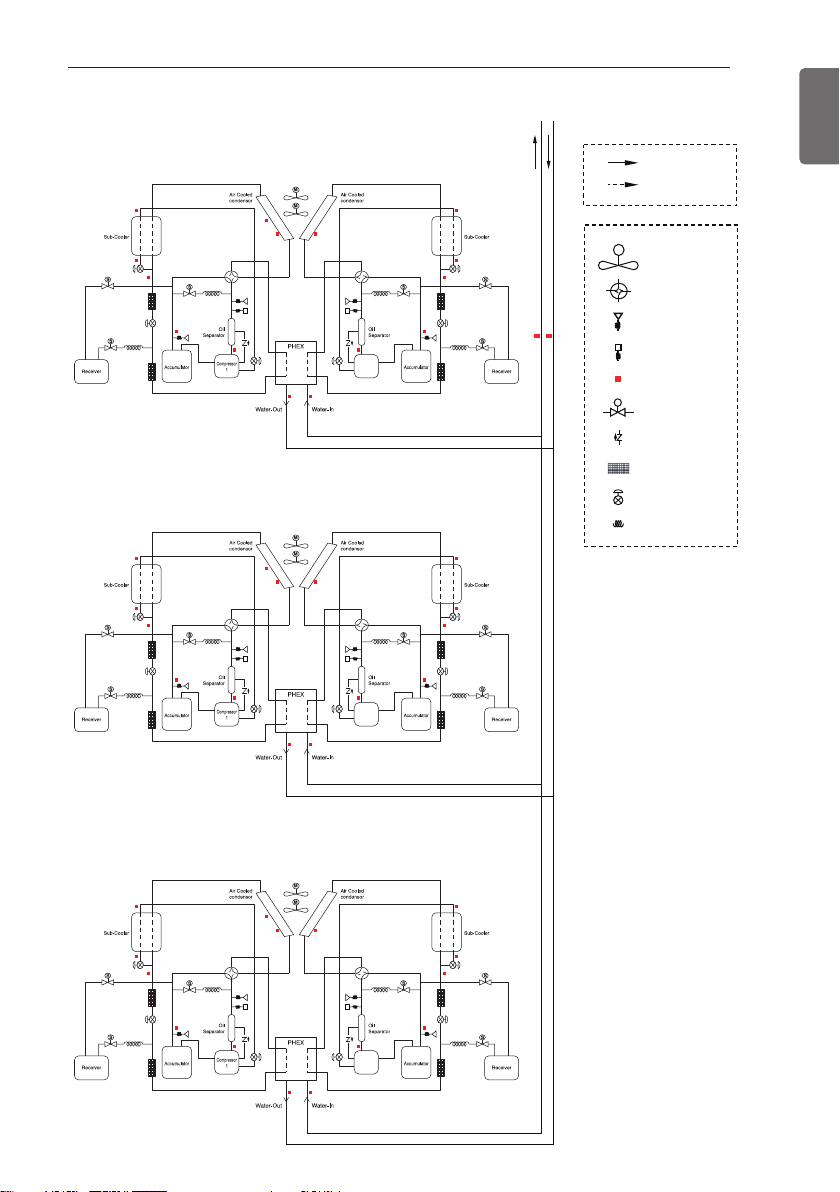

Inverter Scroll Chiller of LG Electronics provides cold water for cooling air conditioning system

using AHU or FCU etc. Air Cooled R410A Refrigerant Scroll Chiller ACHH Series designed for outdoors is a single unit product of modular type composed of scroll compressor, air cooled condenser, electronic expansion valve, evaporator and LG HMI (Human Machine Interface).

ACHH Series is composed of 2 inverter compressor to form independent refrigerant cycle and

one unit module can configure up to maximum of 3 refrigerantcycles and interlock of 5 modules

by using AC Smart controller and up to 10 modules by using ACP.

ACHH Series applies the inverter technology to the compressor and condenser fan motor for not

only high load but also highly efficient operation in all operating areas.

HMI controller of ACHH Series has the LG’s unique control logic to monitor all parameters controlling the operation. These parameters can be controlled to improve the operational efficiency

to continuously supply cold water by optimizing to the environment.

Each refrigerant cycle includes the check valve, electronic expansion valve, strainer and refrigerant charge valve. Evaporator connected to the cold water uses the plate type heat exchanger and

the condenser uses the air cooled fin and tube heat exchanger.

Inverter Scroll Chiller is a commercial/industrial product.

11

ENGLISH

ENGLISH

PRODUCT INTRODUCTION

12

Model naming convention

ACHH020 LB AB

Development number

Communication method : A = Modbus

Model type : A = Module model

Power

specification :

Cooling capacity (RT) : 060 = 60 RT

Compressor type :

H = Scroll(High pressure type)

Cooled type : A = Air cooled C/O

Product type : C = Chiller

Area of production Refrigerant :

A = South Korea R410A

B = Independent model

C = Slave model

L = 380~415 V/50,60 Hz/3 Ø

H = 460 V/60 Hz/3 Ø

040 = 40 RT

020 = 20 RT

H = Air cooled H/P

Airborne Noise Emission

The A-weighted sound power of this product is 93 dB.

** The noise level can vary depending on the site.

The figures quoted are emission level and are not necessarily safe working levels. Whilst there is

a correlation between the emission and exposure levels, this cannot be used reliably to determine whether or not further precautions are required. Factor that influence the actual level of

exposure of the workforce include the characteristics of the work room and the other sources of

noise, i.e. the number of equipment and other adjacent processes and the length of time for

which an operator exposed to the noise. Also, the permissible exposure level can vary from country to country. This information, however, will enable the user of the equipment to make a better

evaluation of the hazard and risk.

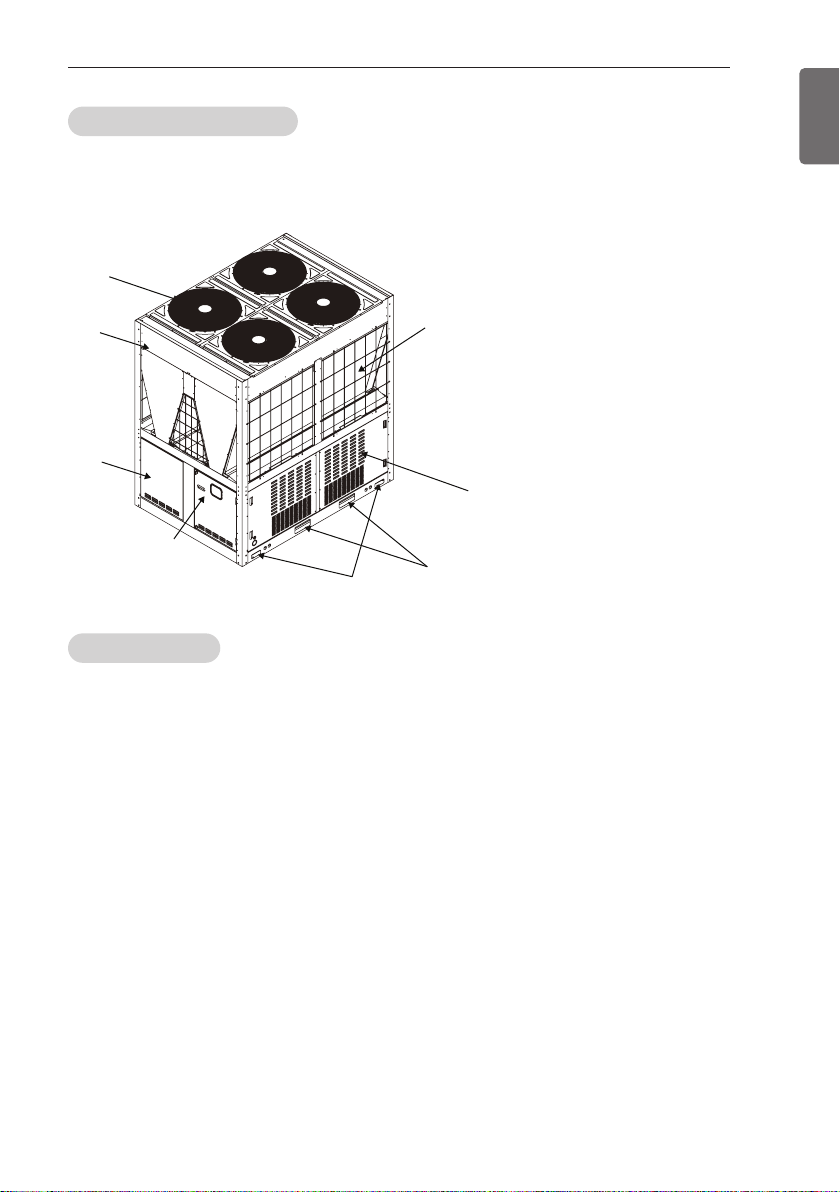

Product configuration

This chiller model is configured as shown below.

1

PRODUCT INTRODUCTION

13

ENGLISH

5

4

3

6

2

8

7

Legend

1. Fan motor

2. Fin & tube heat exchanger

3. Main Controller box

4. Sub Controller box

5. Condenser cover

6. Rope support

7. Forklift groove

8. Side cover

Cooling cycle

ACHH Series uses the high pressure type scroll compressor, and the suction gas part is separated from the high pressure discharge part and the motor is installed on the low pressure gas part.

Space for motor and storage for refrigerant is secured in the low pressure gas part to increase

the reliability for the liquid compression.

Because the sucked refrigerant gas cools the motor and flows to the compressor, separate cooling device to cool the compressor is not required. Inside the system, oil to lubricate the compressor is mixed with the refrigerant to discharge both the oil and refrigerant during the operation.

Because the oil discharged from the compressor can reduce the heat transfer efficiency when

thick layer is built up on the inner walls of the condenser and evaporator, device to prevent the

refrigerant and oil to be discharged together is added to prevent this issue.

This lubrication system ensures longer life for the compressor, improves the sealing of the compression space and provides low noise operation.

As the air cooled fin and tube type heat exchanger, the condenser is composed of heat exchanger in V shape, and the electronic expansion valve is used for efficient control in all load conditions.

The controller used in the chiller is exclusively for LG and monitors various sensors installed on

the product to protect the product.

For continuous supply of cold and hot water, the product is equipped with maximum continuous

operational function and also provides precision control to supply accurate target amount of cold

and hot water.

But the protective devices will immediately stop the product when the product reaches abnormal

condition or area limit.

In case of an issue, the controller of the chiller will provide helpful diagnostic message to the

administrator.

PRODUCT INTRODUCTION

14

ENGLISH

Description of cooling cycle

The cooling cycle of ACHH Series can be described using the following Pressure – Enthalpy

chart.

①,②,③,④ and ⑤ in the following chart shows the conditions of the refrigerant. The refrigerant

comes into the compressor motor and cools the motor, and becomes overheated and moves to

the suction inlet of the compressor. The oil inside the compressor seals the gap between the

compressor scrolls and provides lubrication for the bearing to help the compression of the refrigerant. During this time, the refrigerant is compressed and is discharged to the air cooled condenser. (②) The compressed refrigerant passes through the air cooled condenser and exchanges

the heat with the outdoor air. The condensed refrigerant then passes the condenser to be overcooled. (② → ③ → ④). The refrigerant that passed through the condenser expands in the electronic expansion valve to flow to the evaporator. (④ → ⑤). The refrigerant is evaporated in the

plate type heat exchanger, the evaporator. (⑤ → ①) Liquid refrigerant of low temperature pressure passes through the evaporator to cool the water flowing into the evaporator and the refrigerant itself receives the heat to evaporate to gas condition. (①) The refrigerant continues to change

the phase and continuously repeats the cooling cycle. For heating, the refrigerant flows in the

reverse direction to provide hot water.

Pressure

ں

ڻ

ڹ

ڼ

ڸ

Enthalpy

Lubrication system

Oil is efficiently separated inside the scroll compressor and even when the cycle operates, most

of the oil remains inside the scroll compressor. Only part of the oil will be mixed with the refrigerant to be circulated within the cycle.

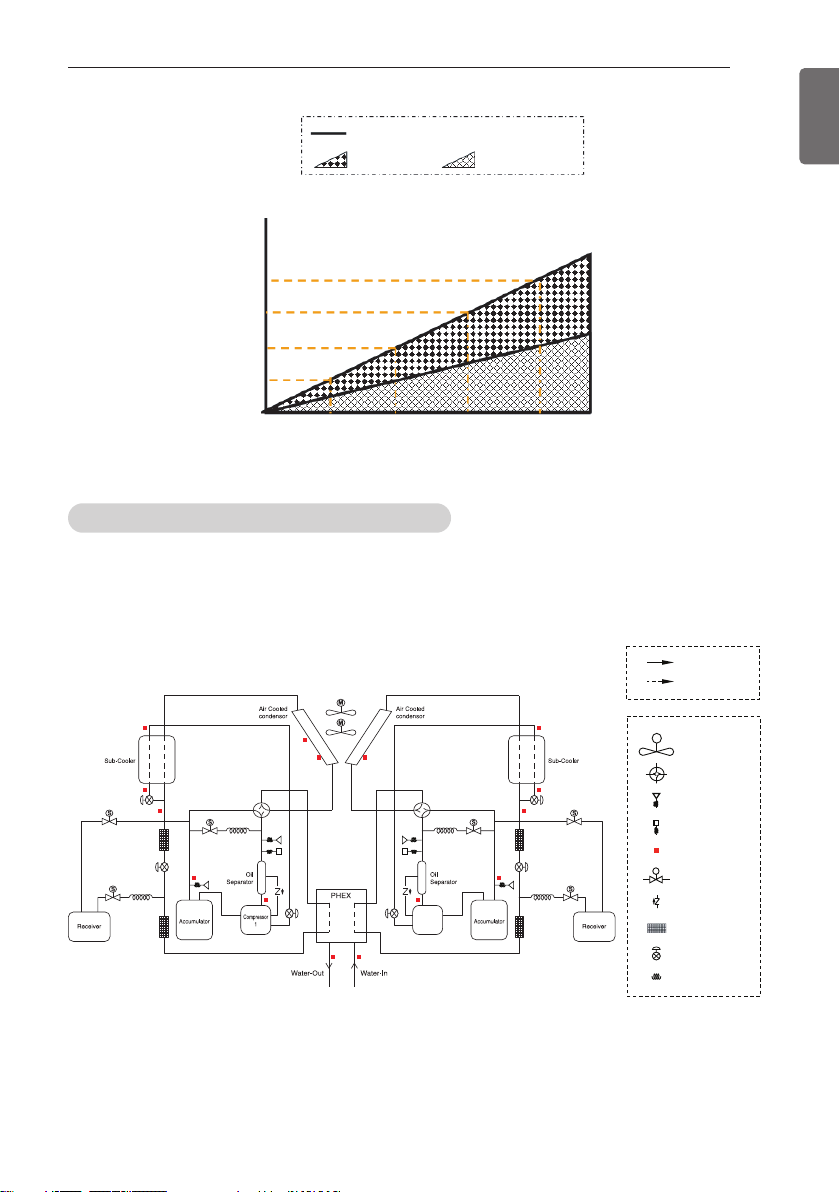

Partial load operation

Each cooling cycle operates independently and 1 cooling cycle is composed of 2 inverter com-

pressor as shown below.

2 Inverter compressors increase the RPM after staring to operate to gradually increase the cool-

ing capacity.

The user can operate the product smoothly at optimal condition by setting the cooling capacity

based on the linear control of LG Chiller Controller and the product has efficient partial load performance at any load.

Load (%)

Cooling capacity

Capacity (%)

Inverter

compressor 1

Capacity (%)

100 %

75 %

50 %

25 %

0 %

25 % 50 % 75 % 100 %

Cooling capacityStatic speed compressor 1

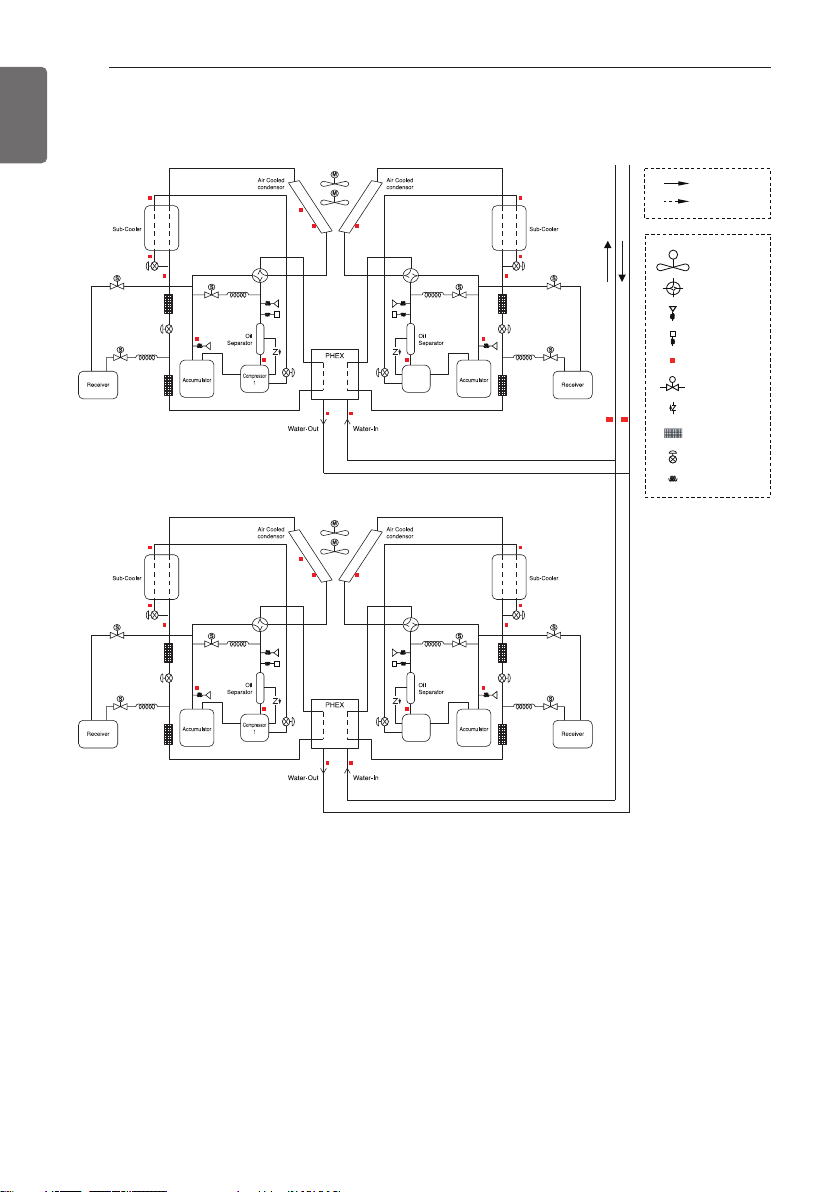

Cycle configuration and sensor location

This chiller model is configured as shown below.

1 UNIT

PRODUCT INTRODUCTION

Inverter

compressor 2

Load (%)

15

ENGLISH

Compressor

2

Cooling

Heating

M

Fan motor

4 way valve

Pressure sensor

Pressure switch

Temperature sensor

S

Solenoid valve

Check valve

Strainer

Electonic expantion

Valve

Expansion valve

ENGLISH

M

S

Cooling

Heating

Fan motor

4 way valve

Pressure sensor

Pressure switch

Solenoid valve

Check valve

Strainer

Electonic expantion

Valve

Expansion valve

Temperature sensor

Compressor

2

Compressor

2

PRODUCT INTRODUCTION

16

2 UNIT

Compressor

2

Compressor

2

Compressor

2

3 UNIT

PRODUCT INTRODUCTION

Cooling

Heating

M

Fan motor

4 way valve

Pressure sensor

Pressure switch

Temperature sensor

S

Solenoid valve

Check valve

Strainer

Electonic expantion

Valve

Expansion valve

17

ENGLISH

ENGLISH

PRODUCT INTRODUCTION

18

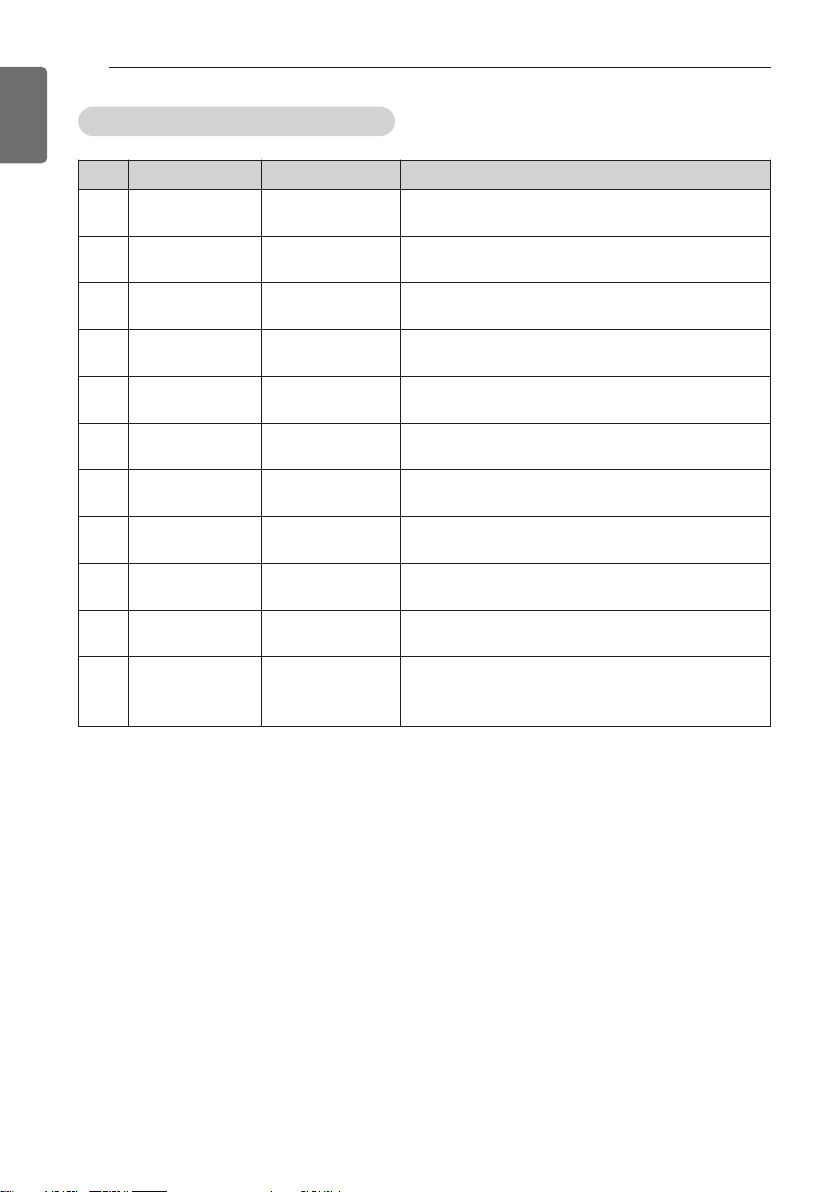

List of safety device and setting

No. Safety device Setting Function

High pressure

1

switch

2 Fuse

Compressor cir-

3

cuit breaker

Fan motor circuit

4

breaker

Discharge tem-

5

perature sensor

High pressure

6

sensor

Low pressure

7

sensor

Water pipe tem-

8

perature sensor

Reverse phase

9

detector

Liquid compres-

10

sor prevention

Compressor ratio

11

limit

3.8 MPa

250 V 5 A (Main)

250 V 15 A (INV)

35 A Measures and stops over-current per compressor

7 A Measures and stops over-current per motor

110 °C Stops compressor in stages

3 801 KPa

0.22 MPa

Off : 3 °C Prevent evaporator from freezing

-

-

9

Stops operation of the module when the pressure

is above the setting

Disconnects current when it exceeds the normal

value

Starts protective operation control to reduce the

cycle pressure

Starts protective operation control to raise the

cycle pressure

Compares the current of each phase and stops

when it is in reverse phase

Discharge over-heating level goes up to prevent

liquid compression

Compressor frequency is reduced when operating

at high compression ratio to prevent the internal

parts within the compressor from being damaged

PRODUCT INTRODUCTION

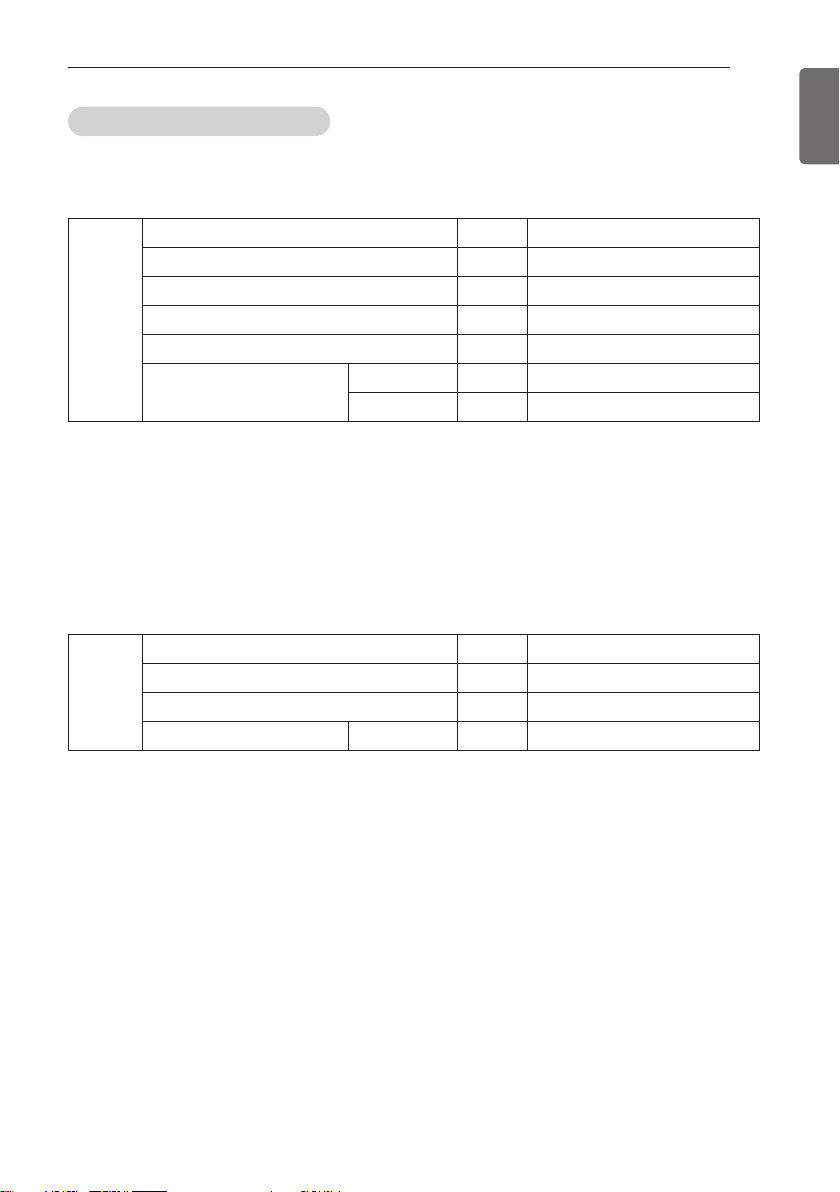

Operation range and limit

The following table shows the operation range of the product. Do not operate the product

exceeding the following operation range.

H/P

Voltage V 342~457

Cold water inlet temperature °C 8 or above

Operation

range

(1) Product performance range at rated condition is 20-100 %.

- Cooling rate condition: Outdoor temperature 35 °C, Water inlet temp. 12 °C. Water Outlet

temp. 7 °C

- Heating rate condition: Outdoor temperature 7 °C, Water inlet temp. 40 °C. Water Outlet

temp. 45 °C

(2) When running heating operating with outdoor temperature is less than 7 °C, Inlet water tem-

perature must be at least 20 °C.

C/O

Operation

range

(1) Product performance range at rated condition is 20-100 %.

- Cooling rate condition: Outdoor temperature 35 °C, Water inlet temp. 12 °C. Water Outlet

temp. 7 °C

Cold water outlet temperature °C 4 ~ 20

Heat water inlet temperature °C 25 ~ 52

Heat water outlet temperature °C 30 ~ 55

Outdoor temperature

Voltage V 342~457

Cold water inlet temperature °C 8 or above

Cold water outlet temperature °C 4 ~ 20

Outdoor temperature Cooling °C -15 ~ 48

Cooling °C -15 ~ 48

Heating °C -30 ~ 35

19

ENGLISH

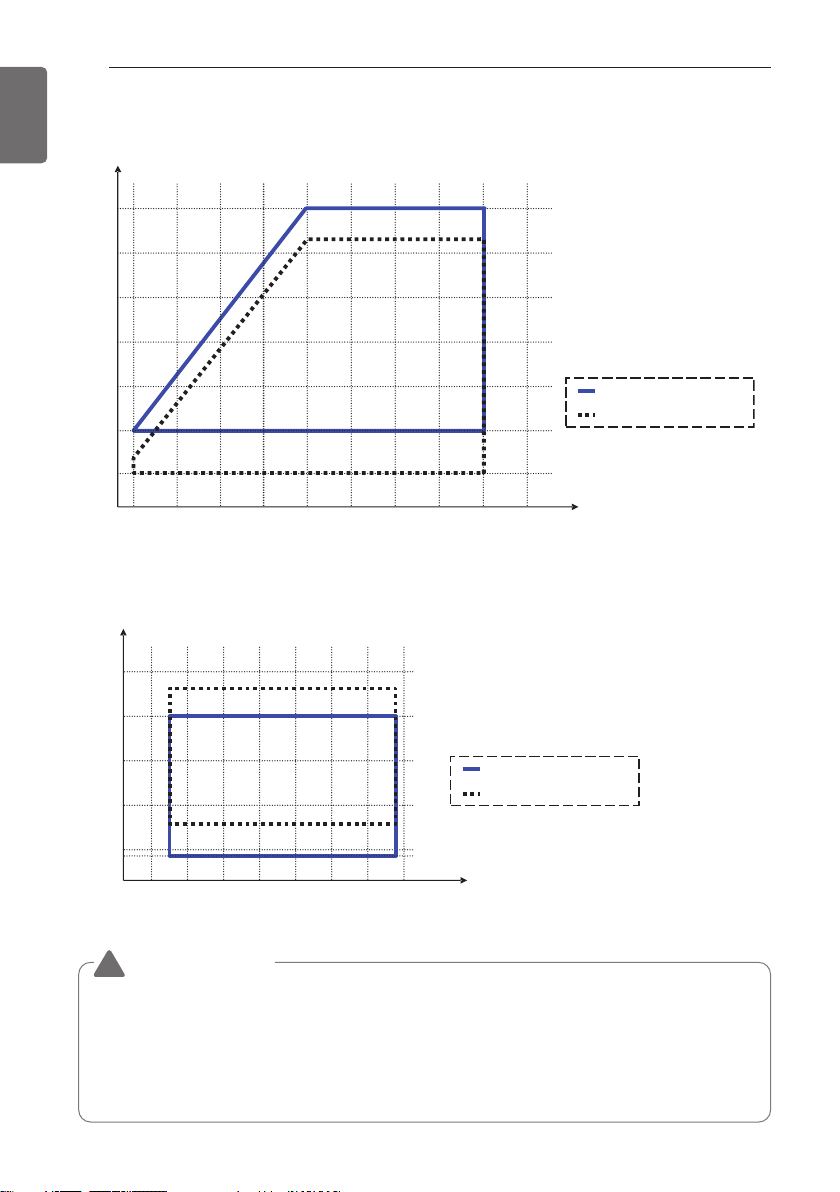

PRODUCT INTRODUCTION

Outdoor temperature

Water temperature

Outlet water temperature

Inlet water temperature

-20 °C -10 °C 0 °C 10 °C 20 °C 30 °C 40 °C 50 °C

10 °C

15 °C

20 °C

25 °C

5 °C

4 °C

48 °C

8 °C

-15°C-20°C-25°C-30°C -5°C 5°C 15°C 25°C 35°C 45°C Outdoor temperature

40°C

45°C

50°C

55°C

35°C

25°C

30°C

Water temperature

42°C

52°C

26°C

Outlet water temperature

Inlet water temperature

20

ENGLISH

Operation range of heating mode

Operation range of cooling mode

CAUTION

!

When running cooling operation with outdoor temperature is less than -10 °C, depending on

inlet temperature, the product does not operate normally, or can take a long time for running.

In this case, Please running operation After raising the inlet temperature by circulating load

water.

Please add antifreeze when operating at ambient temperature less than 5 °C. (There is a risk

of freeze.)

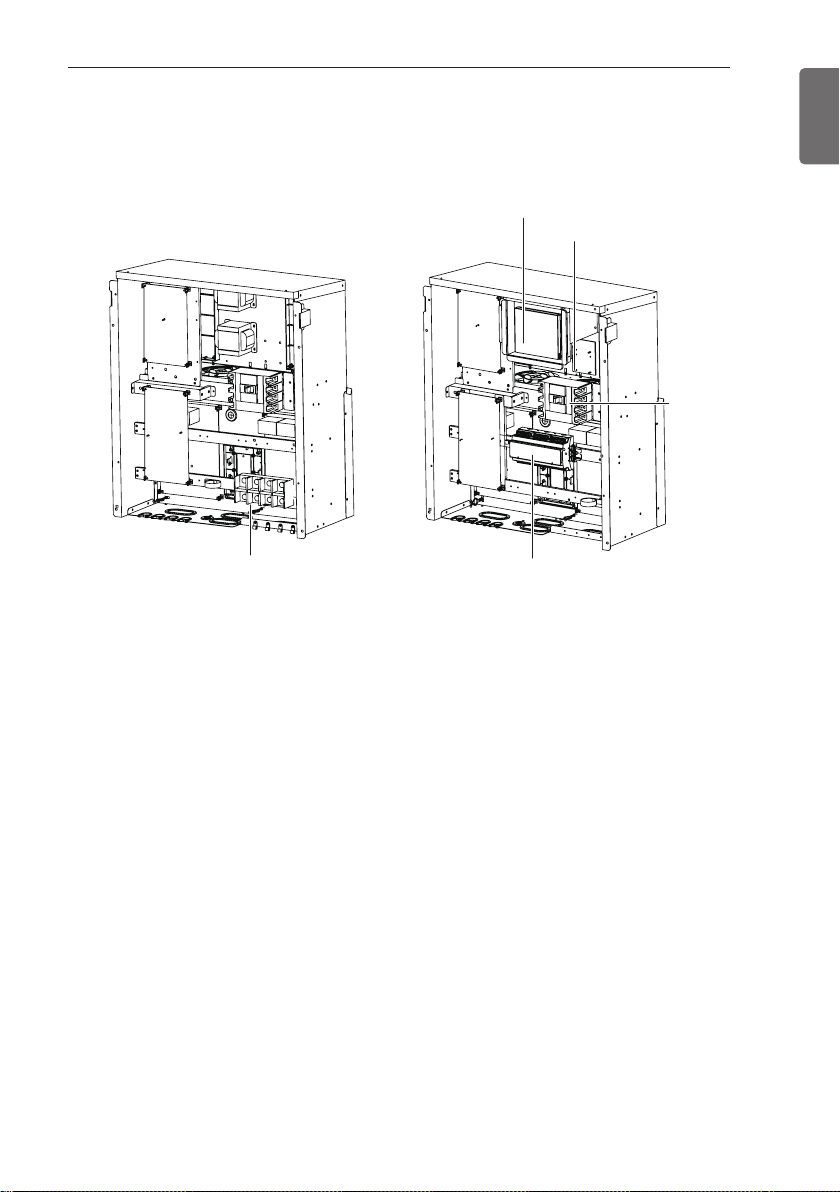

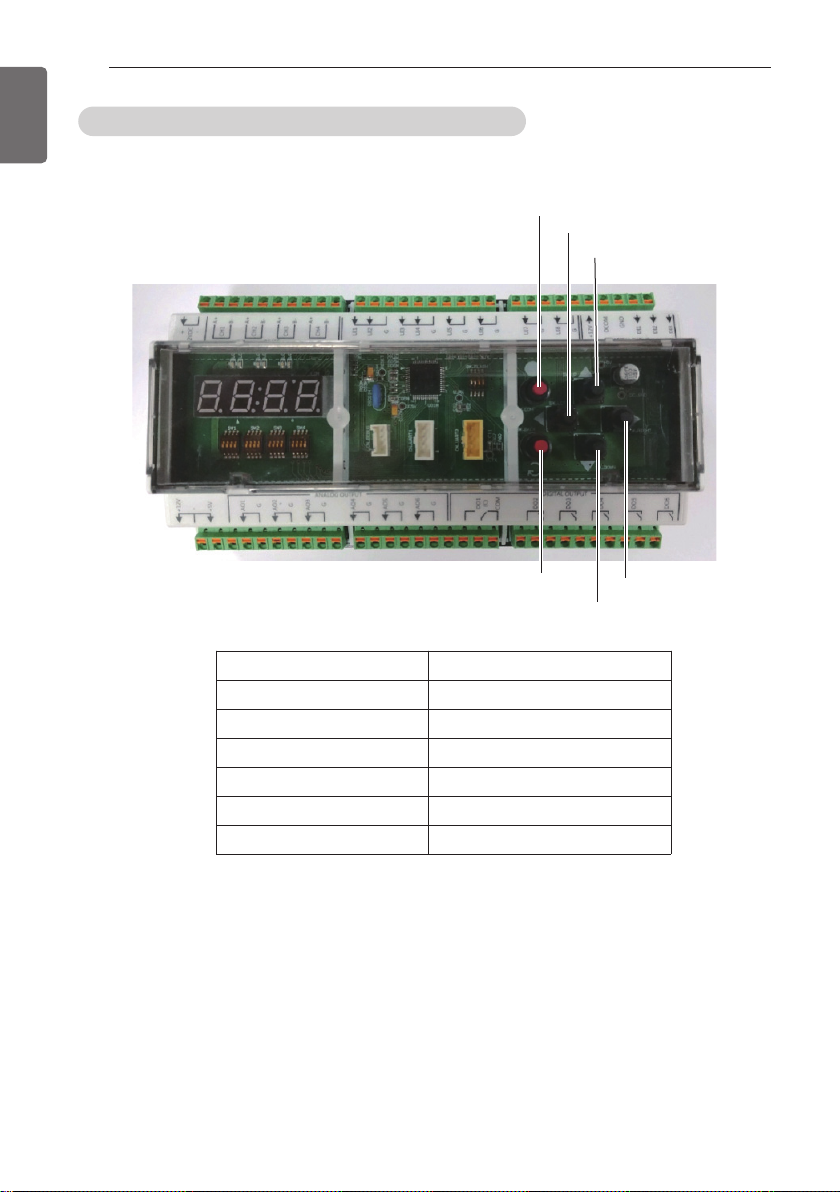

CONTROL

Control panel configuration

HMI

Power supply

CONTROL

MCCB

21

ENGLISH

Terminal block

Sub Control Box Main Control Box

<Inside control panel>

• HMI (Human Machine Interface)

This is for basic product setting and command, and shows the information of product and each

cycle.

• Main controller

This controls the input/output port and the communication with each cycle.

• Power supply

This supplies the power to the HMI.

• MCCB (Molded Case Circuit Breaker)

This shuts off the overcurrent.

• Terminal block

This is the terminal block that receives the main power externally.

Main controller

ENGLISH

CONTROL

22

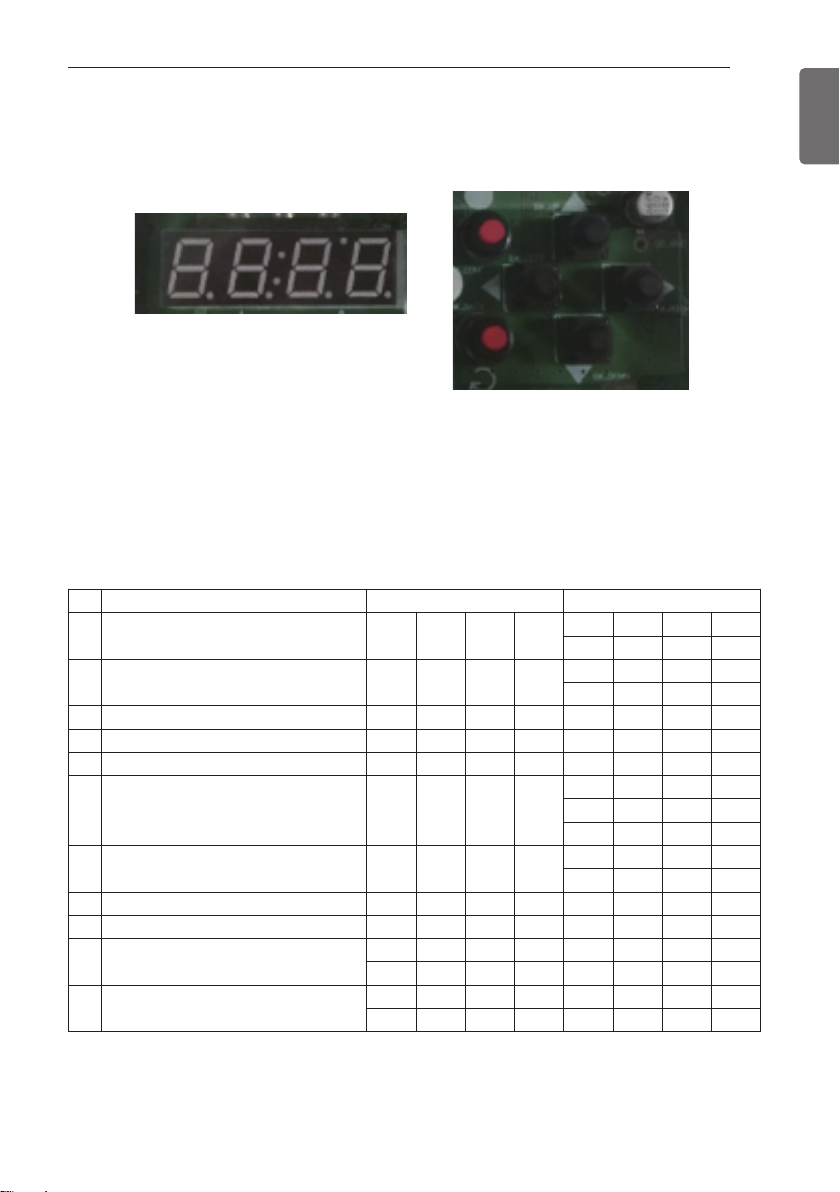

Chiller controller rotary, DIP switch setting

Switch location

SW_COMF

SW_LEFT

SW_UP

SW_BACK

Name Description

SW_RIGHT Changes the setting.

SW_UP Moves the screen.

SW_LEFT Changes the setting.

SW_DOWN Moves the screen.

SW_COMF Sets the selected function.

SW_BACK Moves to the previous step.

Chiller Controller includes the buttons described above so that the following functions are available for setting without HMI.

SW_RIGHT

SW_DOWN

CONTROL

Option Setting

Press SW_COMF Button to move to O Level Setting Screen.

<Screen>

<Button>

Press Up or Down (▲▼) Button to go to a desired function.

If the desired function shows, press SW_COMF Button.

Then, the Screen moves to 1 Level Setting.

Press Left or Right (◀▶) Buttons to go to a desired function. And Press SW_COMF Button to

set the function.

To go to the previous, press SW_BACK Button.

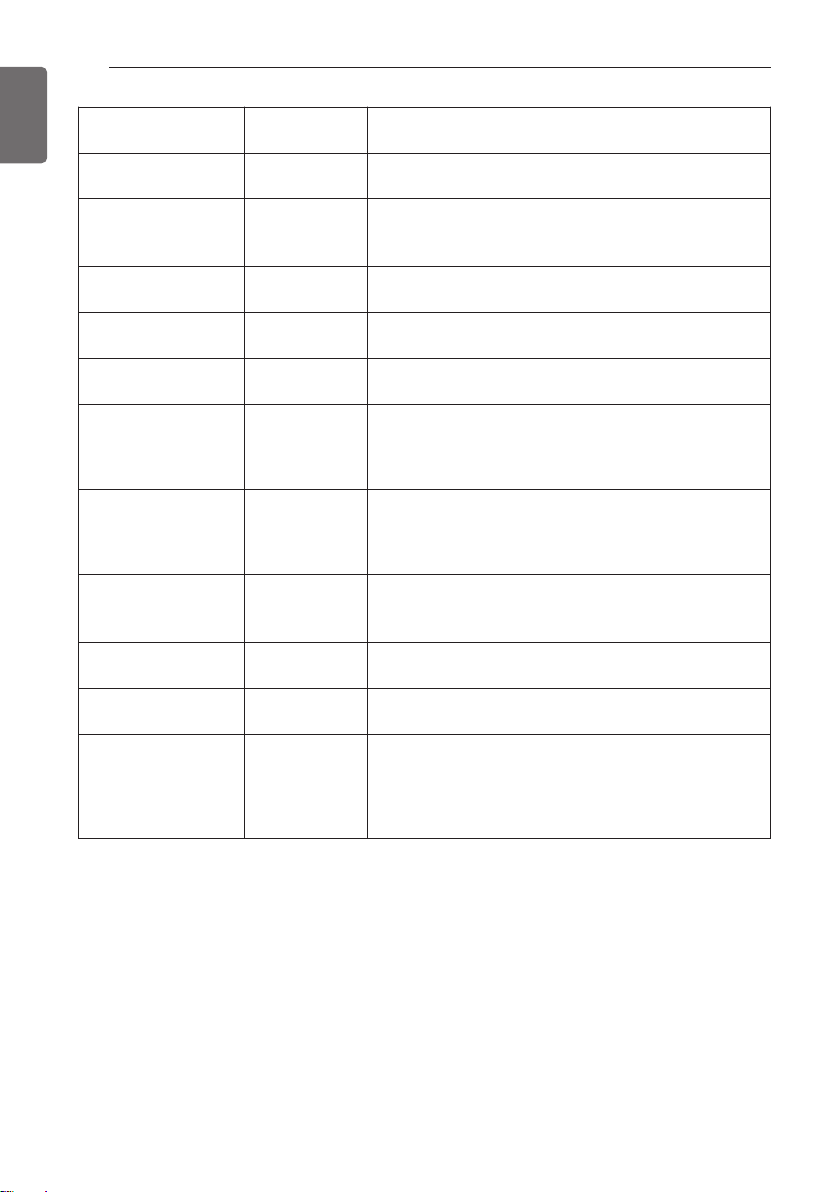

Description Screen Displays(0 Level) Screen Displays(1 Level)

1 Start/Stop O P E R

2 Cooling/Heating C Y C L

3 Cooling setpoint temperature C - T E 7

4 Heating setpoint temperature H - T E 4 5

5 Load outflow Temperature

6 Control Mode S Y S 1

7 Remote Mode S Y S 2

8 Central Control Address A D D R 1

9 Maximum Operation Frequency H I - R 1 1 0

10 Capacity of product

11 Version

HP4 0

CO4 0

10

SV10

RUN

STOP

HEAT

COOL

LOC

DIST

SCHE

CONT

BUS

23

ENGLISH

ENGLISH

CONTROL

24

Description

Start/Stop RUN /STOP

Cooling/Heating HEAT/COOL

Cooling setpoint tem-

perature

Heating setpoint tem-

perature

Load outflow water

Temperature

Control Mode LOC/DIST/SCHE

Remote Mode CONT/BUS

Central Control

Address

Maximum Operation

Frequency

Capacity of product -

Version -

Screen Display

(1 Level)

110

Detail Description

Set RUN to operate the product and STOP to stop the

operation.

Sets the product’s Cooling/Heating Operation Mode.

COOL selects Cooling Mode and HEAT selects Heating Mode.

7 Sets Cooling Target Temperature. (4 °C~ 20 °C)

45 Sets Heating Target Temperature.(30 °C~ 55 °C)

-

1

Shows the temperature value of Load outflow water.

(Specified in 0 Level)

Set’s the product’s Control Mode. In LOC, the product

control is available with HMI and Chiller Controller.

DIST refers Remote Control Mode. In SCHE, the product is controlled following the schedule set at HMI.

Sets how to set in Remote Mode. CONT enables the

product’s operation mode by simple switch contacts.

BUS enables the control on the entire product through

communication from other communication devices.

The product address can be set for communication

with other communication devices. The address can

be set by selecting values from 1-247.

Sets the Maximum Operation Frequency.(70 Hz~130

Hz)

Shows the current Capacity of product.

(Specifies in 0 Level)

Shows the program information of Chiller Controller

installed in the current product as Version. Version

information is subjected to change for improvement of

the product performance or the quality improvement.

(Specifies in 0 Level)

CONTROL

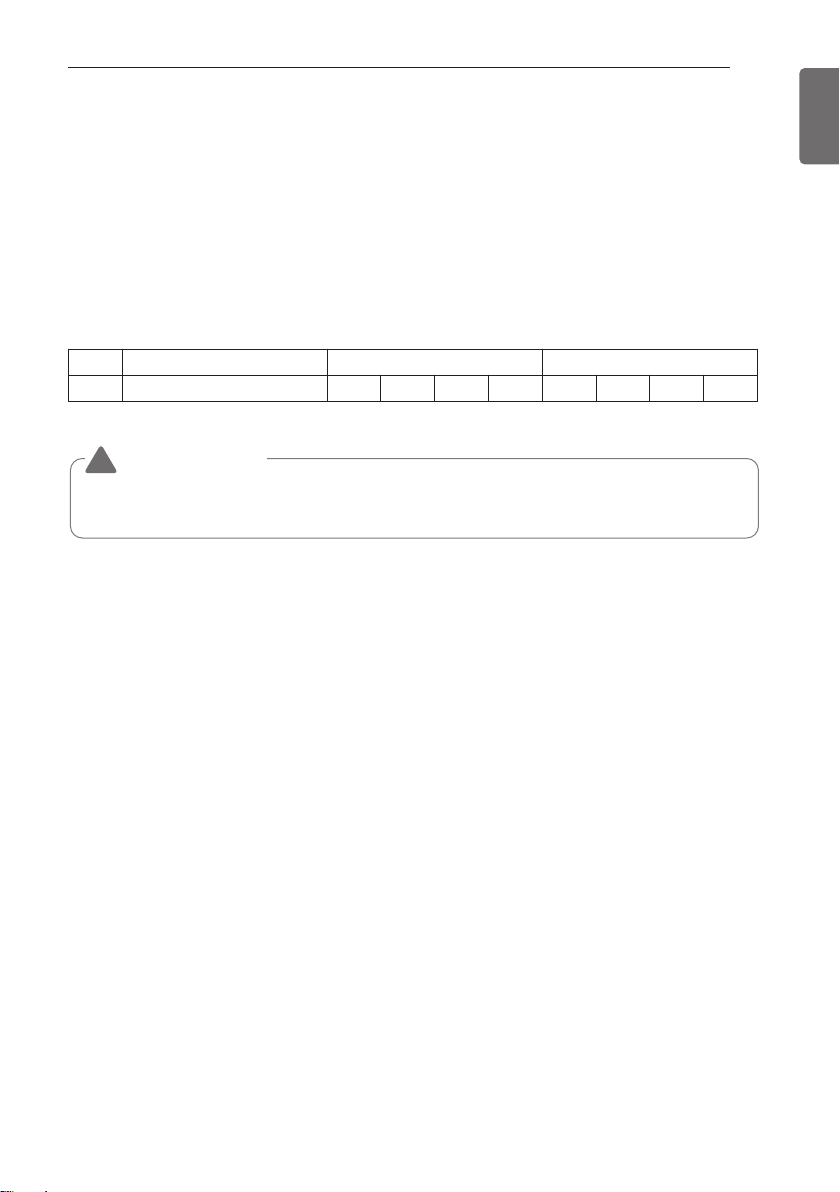

Freezer address setting

Address setting of product should be set from HMI and Main Controller and if 2 addresses doesn’t match each other, HMI communication error will occur.

• Main Controller address setting

Press down direction and right direction button (▼▶) at the same time.

When FN01 appears, press SW_CONF button.

Select desired address using left and right button (◀▶) and address will be set if press

SW_CONF button. If you don’t want, please press SW_CONF button.

Description Screen Displays(0 Lever) Screen Displays(1 Lever)

1 Chiller Address F N 0 2 1

CAUTION

!

• If Main Controller address doesn’t match HMI address, Error will occur. (please refer to control>freezer interlocking control about HMI address setting)

25

ENGLISH

CONTROL

26

ENGLISH

Logging in to HMI

This chapter will explain about the composition of each screen in HMI, detail functions, and operation methods. When power is applied to HMI, HMI automatically operates. When HMI starts,

Home screen appears.

CAUTION

!

When HMI is installed indoors, the guaranteed communication distance is 500 m.

- Guaranteed communication distance of HMI: 500 m

(But, when connected indoor, the end resistance (100-200 Ω) must be installed at the terminal connected to HMI for smooth communication. In this case, if the installation location of

the Unit is different from that of HMI, the maximum permitted connection distance of the

communication cable between the two locations is displayed.)

CONTROL

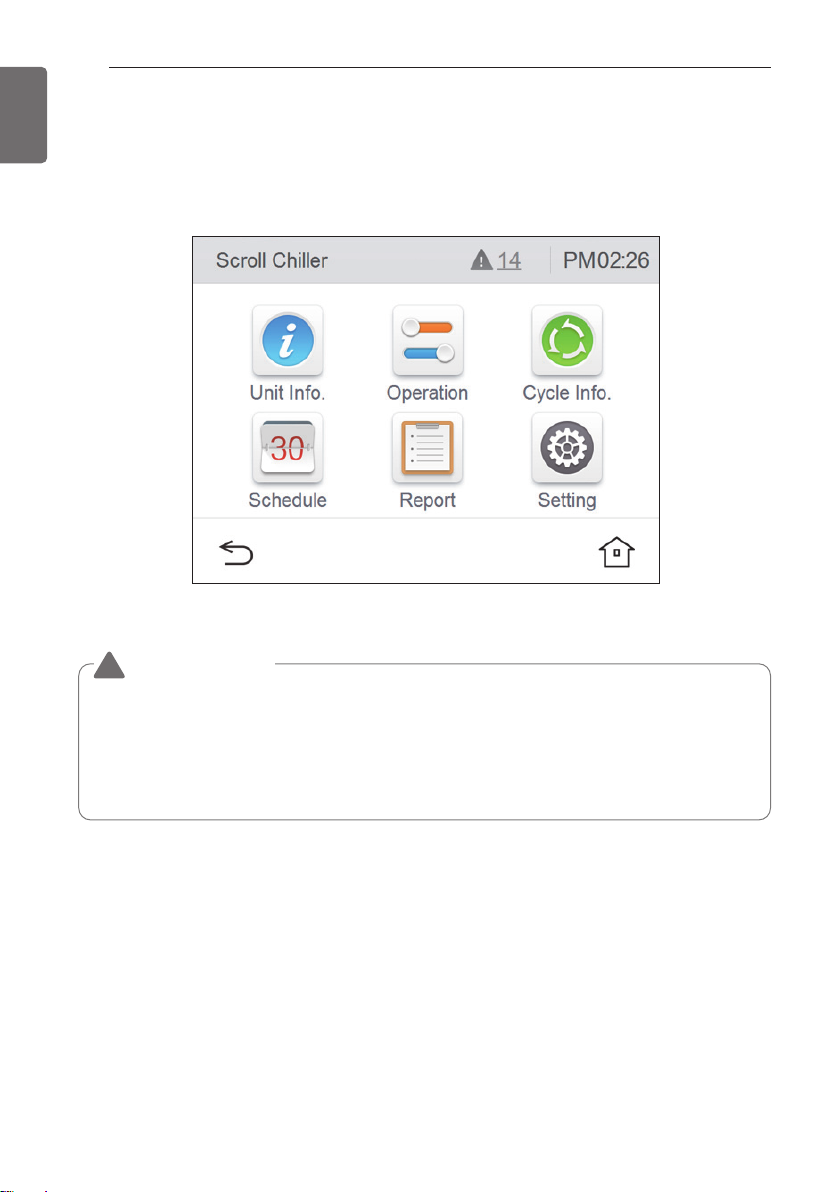

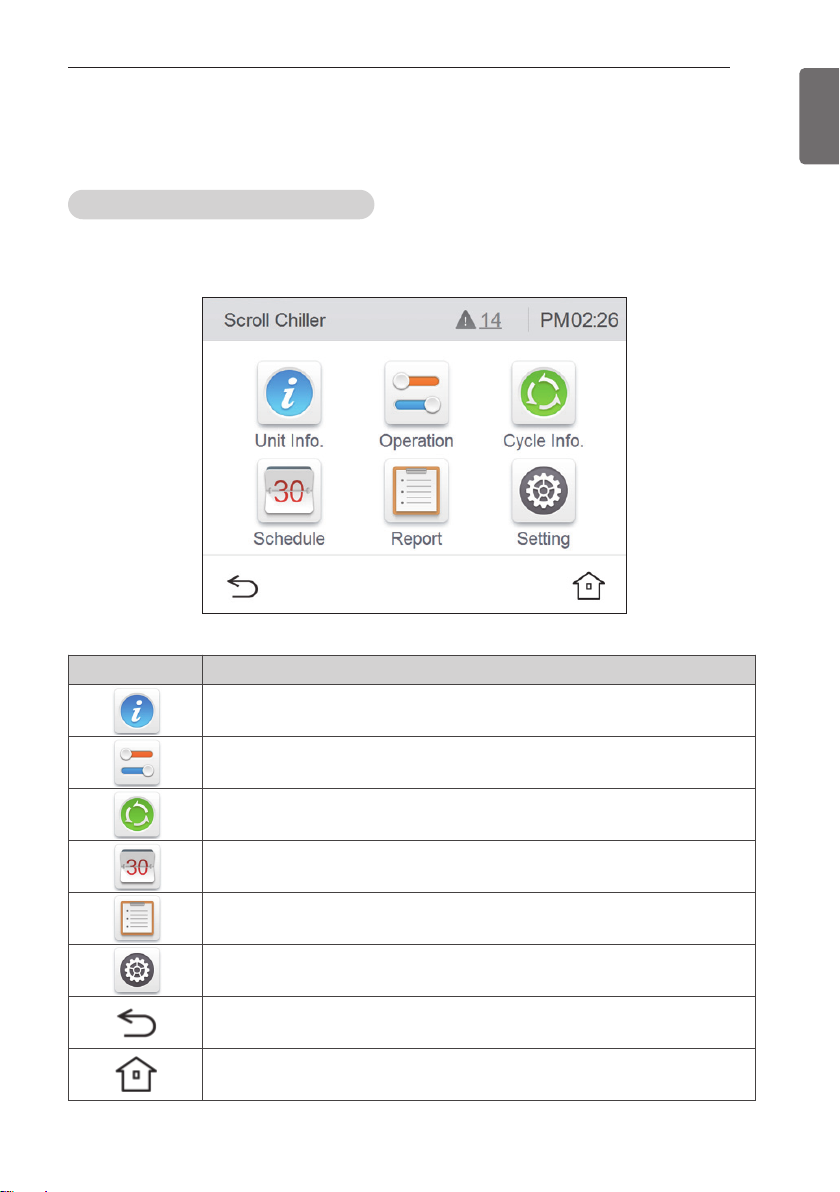

Introduction to HMI menu

This chapter describes the HMI menus to know to operate the product and how the screen is

configured.

HMI main screen configuration

After logging in to HMI, the system view screen that shows the common information of the

product is displayed as shown below.

27

ENGLISH

Icon Description

You can see the load water temperature, pump/flow amount status, and system information.

It sets the Start/Stop, Set Temperature, Operation Mode (Only for Heatpump

Model), control mode, max. operation frequency, and demand control ratio are set.

It checks the individual cycle’s operation information.

It checks the set schedule.

It checks the occurred error history.

It sets the installer setting, screen setting, and system setting.

It returns to the previous menu.

Home screen appears.

CONTROL

28

ENGLISH

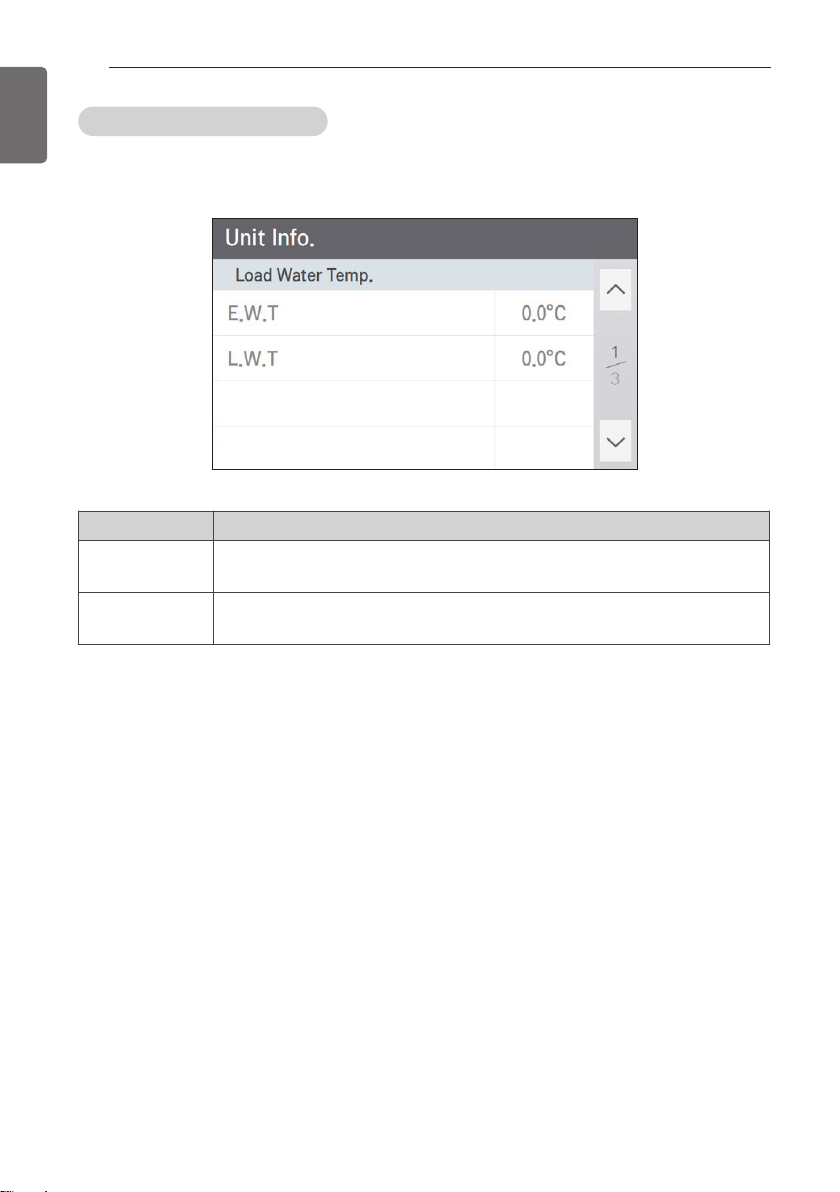

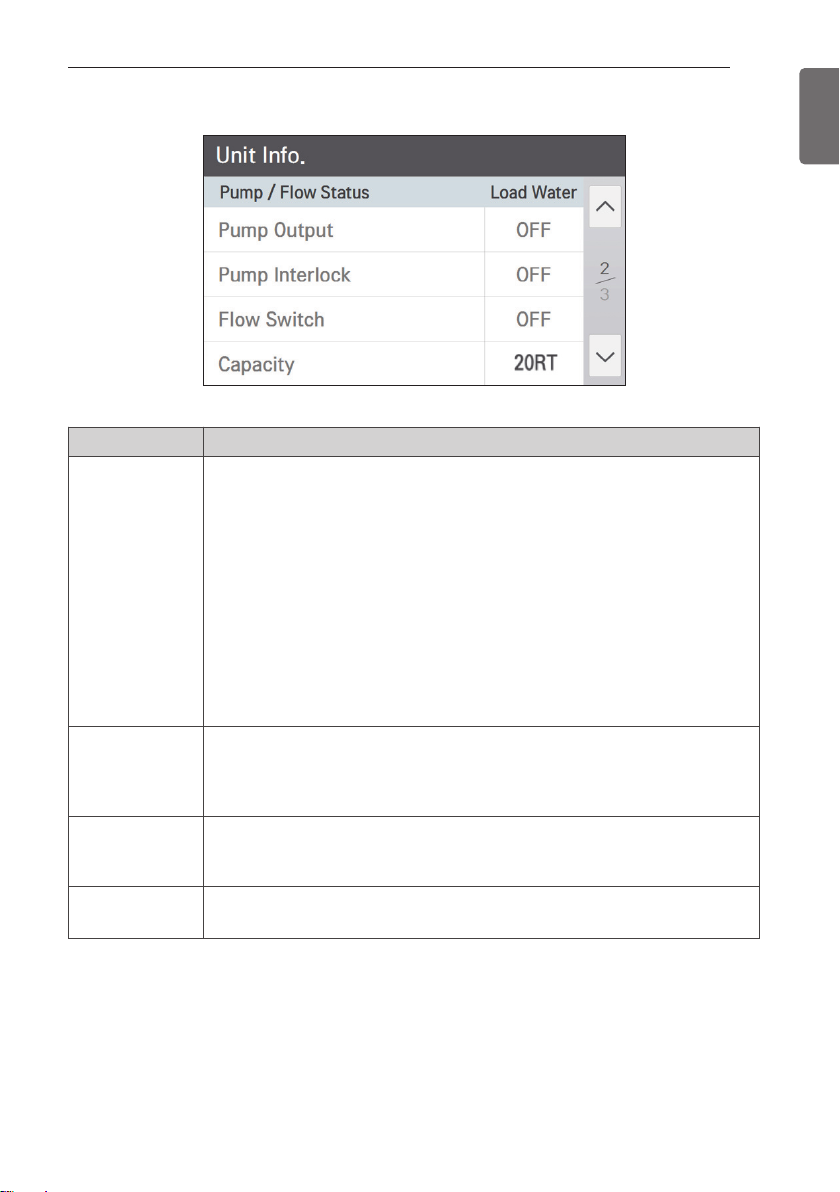

View chiller information

Chiller information is composed of the load water temperature, pump/flow amount status, and

system information.

• Load water temperature screen

Icon Description

E.W.T It shows the common load entering water temperature value.

L.W.T It shows the common load leaving water temperature value.

• Pump/flow amount status screen

Icon Description

If it is in operation, it always maintains ON, and when the product operation is

stopped, the freeze and burst mode is applied, and the freeze and burst prevention

mode operates as follows.

According to the outdoor air temperature condition, the load water pump repeats

operation ON and OFF.

Pump Output

Outdoor air temperature < 1 °C → always “ON”

1 °C ≤ outdoor air temperature < 5 °C → 2 min. operation and 18 min. stop

Outdoor air temperature ≥ 5 °C → operation “OFF”

The freeze and burst prevention mode is possible when the pump is connected, and

to interface with the pump, Pump Output connect shall be connected, and to check

whether the pump operates, Pump Interlock connector shall be connected.

(For the connector connection method, refer to the connection diagram.)

CONTROL

29

ENGLISH

It receives the status of the load water pump output through the external signal con-

Pump Interlock

Flow Switch

Capacity It shows the capacity of the device.

tact point of the pump.

(When the product is in operation, the pump output shall maintain “ON” state, and

otherwise, alarm will occur.)

It shows the current load water’s flow amount switch status value.

(When the product is in operation, the pump output shall maintain “ON” state, and

otherwise, alarm will occur.)

CONTROL

30

ENGLISH

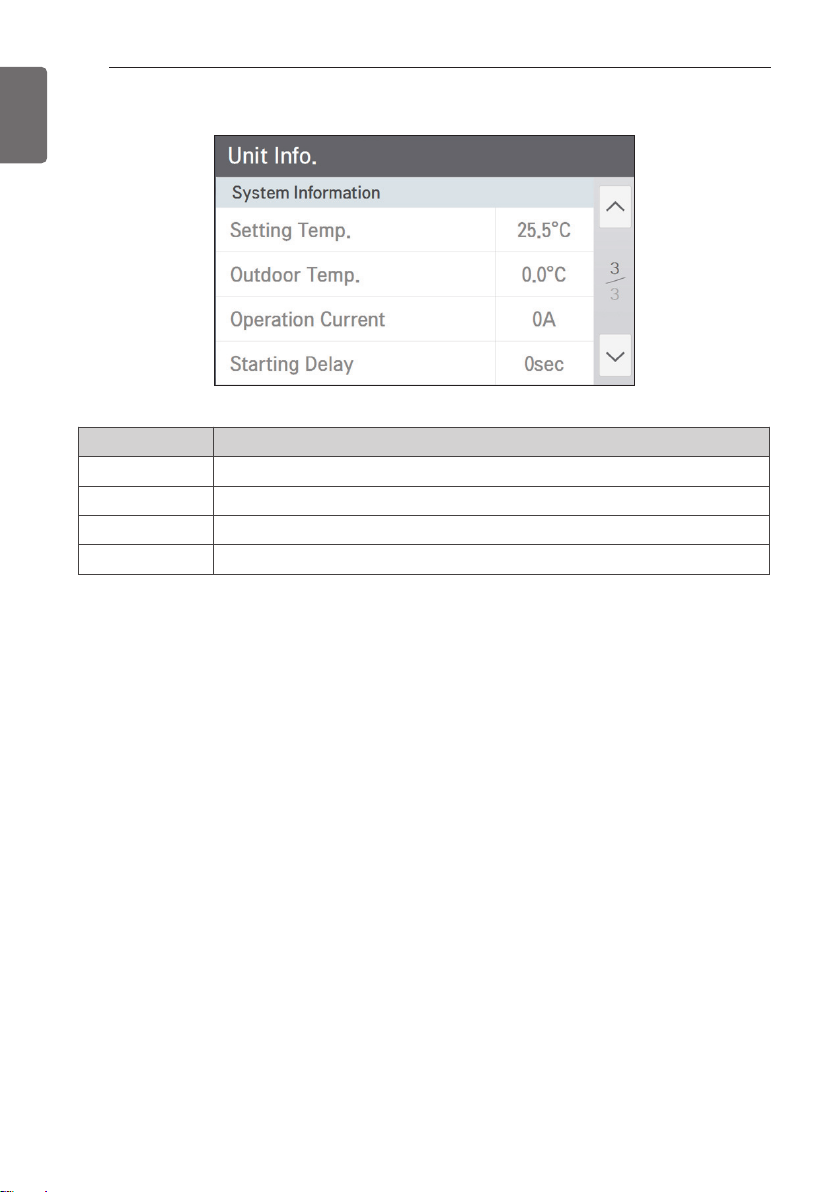

• System information screen

Icon Description

Setting Temp. It shows the set temperature for the current operation mode.

Outdoor Temp. It shows the current outdoor air temperature value.

Operation Current It shows the operation compressor’s overall operation current value.

Starting Delay It shows the time of the standby state before starting the product.

Loading...

Loading...