LG AB-H366GSA0 B36AH SG0, AB-H426GSA0 B42AH SG0, AB-H366GTA0 B36AHV SG0, AB-H246HTA0 B24AHV SH0, AB-H306GTA0 B30AHV SG0 Product Data

LG AIR CONDITIONERS

Ceiling Concealed Duct (50Hz, R410A)

Model:

AB-H366GSA0[B36AH SG0]

AB-H426GSA0[B42AH SG0]

AB-H246HTA0[B24AHV SH0]

AB-H306GTA0[B30AHV SG0]

AB-H366GTA0[B36AHV SG0]

5CSB0-02A

Replaces 5CSB0-01A

50Hz • R410A • Heat Pump

LG Airconditioners Product Data

Table of contents

Table of contents Pag e

1. Model Number Nomenclature .....................................................................................2

2. Feature & Benefits.......................................................................................................3

3. List of Functions ..........................................................................................................5

4. Specifications ..............................................................................................................7

5. Dimensional Drawings.................................................................................................9

6. Wiring Diagrams........................................................................................................13

7. Piping Diagrams ........................................................................................................16

8. Performance Data .....................................................................................................17

9. The Coefficient of Capacity Change..........................................................................21

10. Operation Limit ........................................................................................................22

11. E.S.P. Setting .........................................................................................23

12. Sound Levels...........................................................................................................26

13. Installation ...............................................................................................................27

14. Accessories .............................................................................................................32

15. Function of Remote Control ....................................................................................33

Ceiling Concealed Duct 1

50Hz • R410A • Heat Pump Model Number Nomenclature

1. Model Number Nomenclature

A B - H 4 2 6 G S A0

Serial Number

Functions

A : Basic

Outdoor Fan Discharge

S : Side Discharge T : Top Discharge

Chassis Name

H : BH Chassis G : BG Chassis

Electric Rating (Phase, Volts, Freq)

6:1Ø, 220V-240V, 50Hz

Nominal Cooling Capacity in Btu/h

Ex) 42 -> 42,000 Btu/h

Model Type

H : Heat Pump

Indicates that this is

the Ceiling Concealed Duct Type using R410A.

2 Ceiling Concealed Duct

50Hz • R410A • Heat Pump Features & Benefits

Inspection

Port

Indoor Unit

Ceiling

Canvas

Duct

Air Intake

Port

Ceiling

Board

Ceiling Board

Air Discharge

Port

Discharge

Flexible Duct

Intake

Duct

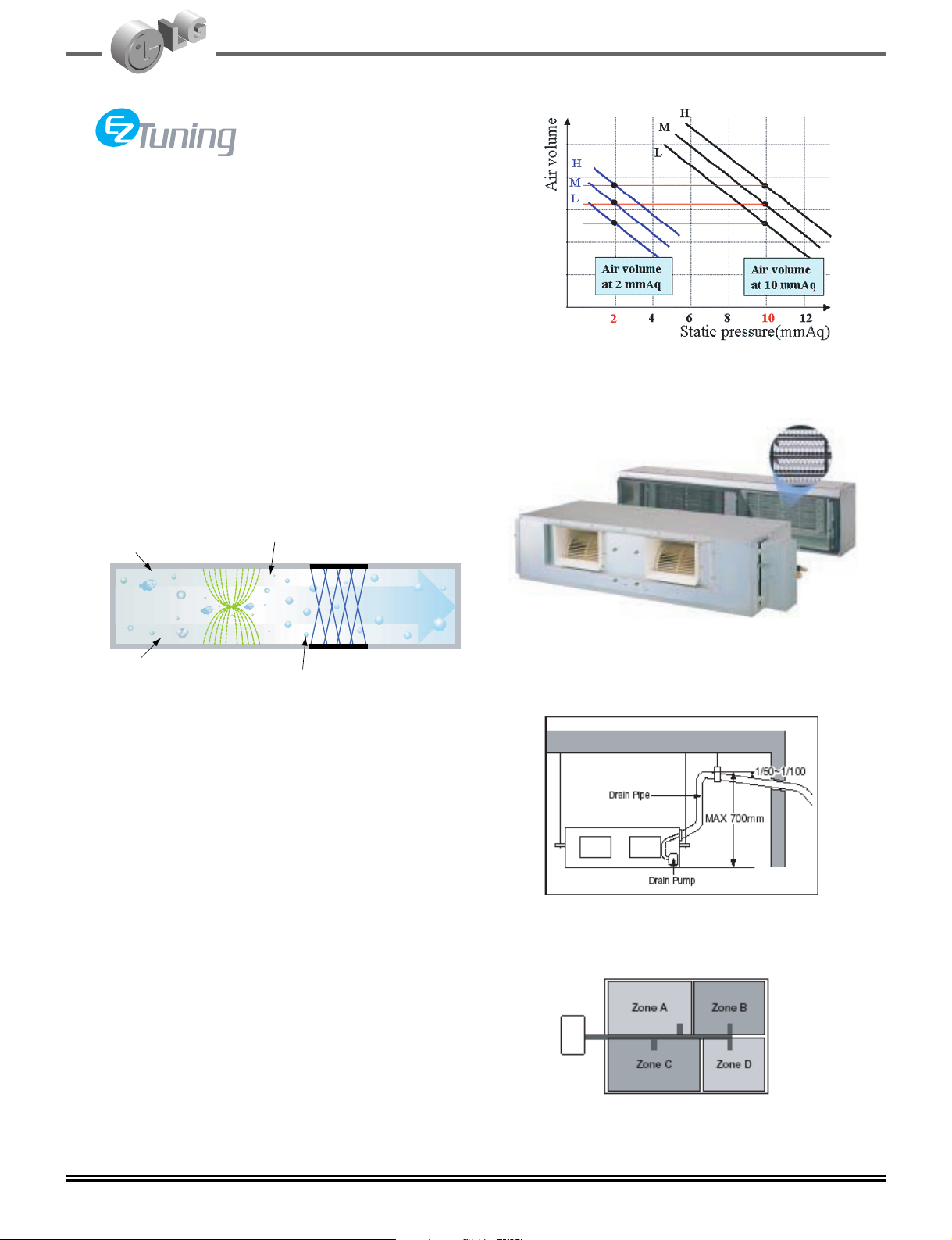

2. Features & Benefits

■ Easy Installation

• Compact & light design

• (Linear E.S.P Control)

• High head drain pump(700mm, Accessory)

■ Comfort & Reliability

• Low noise design

• 2-Thermistor control(Main body & Remote control)

• Zero stanby power consumption

■ Convenience

• Tele control(Accessory)

• LCD wired remote control

• Group control

• Zone control(Accessory)

• Central control(Accessory)

• Weekly progam

■ Cleanness

• Plasma air purifying system(Accessory)

• Hygienic and easy to clean filter

Easy Installation

Flexible Duct is easy to install, regardless of room

size or heater position.

It can be installed even in a limited space and saves

construction cost with slim thickness

Innovative Design of Fan and Housing System

Low Noise ! Easy Serviceability!

Plastic Fan and Housing Assembly

- Designed for low noise

- Designed to reduce weight

- Designed for easy service

This product guarantees lower sound level and gives

lesser service expenses.

Ceiling Concealed Duct 3

50Hz • R410A • Heat Pump Features & Benefits

+

+

+

+

Polluted Air

Purified fresh Air

+4.8KV discharge

Ionizer Photo-Catalyst Coated Mesh

Dust particles

Odour

Dust electrode discharge

Odour molecule

Generating plasma

LG’s High Technology provide Easy and Low cost Design

of Duct work

Generally, when External Static Pressure increases

air volume decreases. But by controlling the phase of

motor while installing the product E.S.P. is controlled

from 8~10 mmAq linearly. E.S.P. control provides

required constant air volume irrespective of ESP

change. Desired ESP can also be set through LCD

wired remote control. Setting of the desired ESP

gives required combination of ESP and airflow.

Plasma Air Purifying Kit (Accessory)

The PLASMA Air Purifying Function not only removes

microscopic contaminants and dust, but also removes

house mites, pollen, and pet fur helps to prevent

allergic diseases like asthma.

High Head Drain

Pump(Accessory:700mm)

In some of the places natural drainage is not possible. For such places drain pump is very useful. It

removes condensed water from the unit.

Zone Control(Accessory)

It controls the temperature of each zone. Opening or

closing of the damper is controlled by sensing the

temperature of each zone. In the cooling mode, if the

temperature of a particular zone is lower than set

temperature then the damper is closed. On the other

hand if the temperature of a particular zone is higher

than the set temperature, damper is opened to provide cooling to the zone and vice versa in the heating

mode.

4 Ceiling Concealed Duct

50Hz • R410A • Heat Pump List of Functions

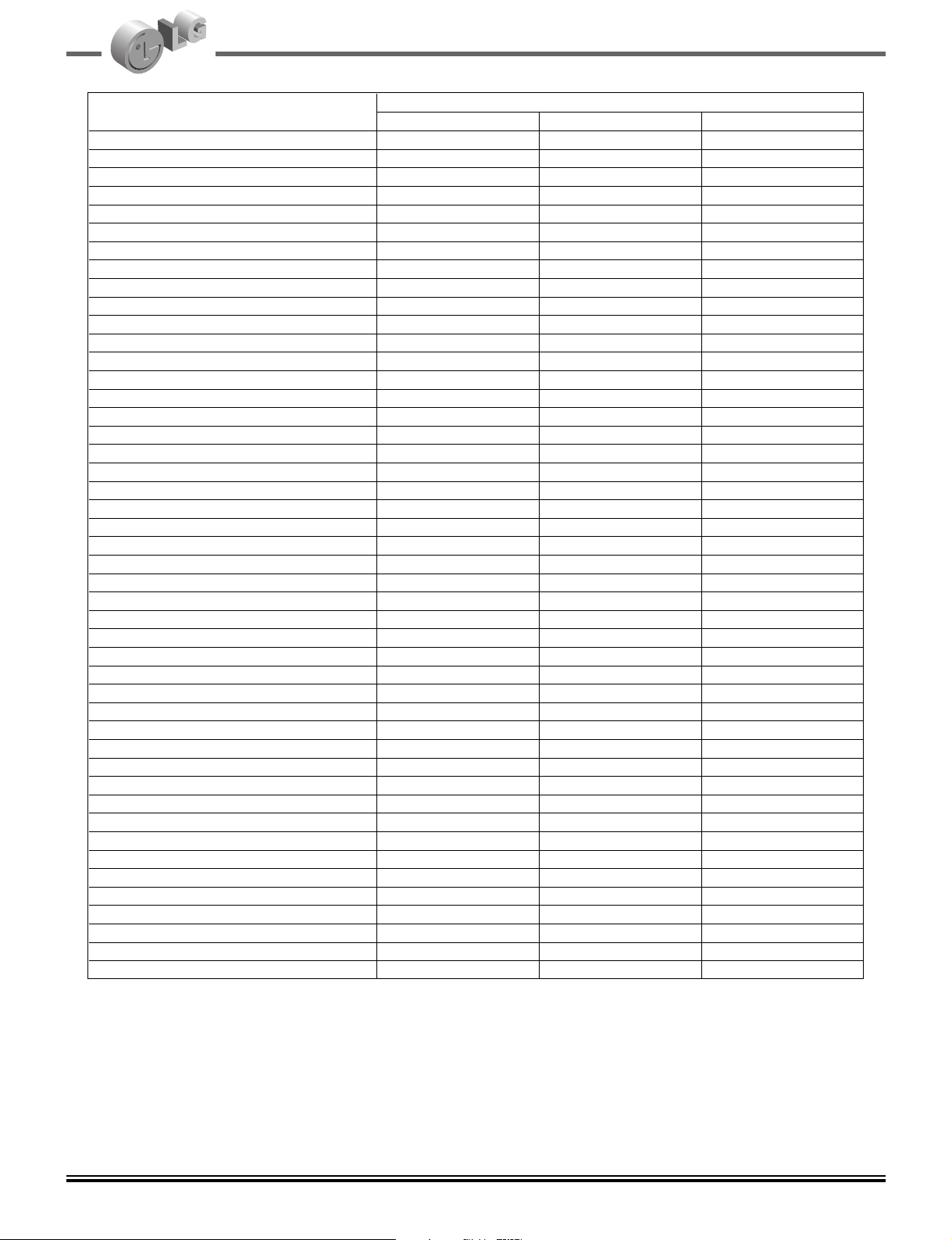

3. List of Functions

Function

Air Discharge outlet - Airflow Direction control (left & right) - Airflow Direction control (up & down) - Airflow Steps(Fan / Cool /Heat) 3/3/3 3/3/3

Auto Changeover O O

Auto Operation O O

Auto Restart Operation O O

Auto Swing - Central Control Accessory Accessory

CHAOS wind (Auto wind) - Child Lock Function O O

Cooling & Fan Operation(Cooling Only) - Coolling, Heating & Fan Operation(Heat Pump)

Defrost / Deicing O O

Deodorizing Filter - Drain Pump Accessory Accessory

E.S.P. Control O O

Electric Heater - Energy Saving Gold Fin(Outdoor Unit) Optional Optional

Environment Friendly Refrigerant O O

Fire Alarm Function - Forced Operation O O

Group Control O O

High Ceiling Operation - Hot Start O O

Jet Cool - Low Ambient Control Optional Optional

Plasma Air Purifier Accessory Accessory

Prefilter(Washable / Anti-fungus) O O

Self Diagnosis O O

Sleep Mode - Soft Dry Operation O O

Swirl Swing - Space Control - Tele Control Accessory Accessory

Temperature Control O O

Test Function O O

Time Delay Safety Function O O

Timer (weekly) O O

Timer (24 hr On/Off) O O

Two Thermistor Control O O

Wired LCD Remote Control O O

Wireless Remote Control Accessory Accessory

Zero Standby Power O O

Zone Control Accessory Accessory

AB-H366GSA0[B36AH SG0] AB-H426GSA0[B42AH SG0]

OO

Ceiling Concealed Duct

Notes :

O:Basic

Optional : Factory-Installed

Accessory : Field-Installed

- : Not available on this system

Ceiling Concealed Duct 5

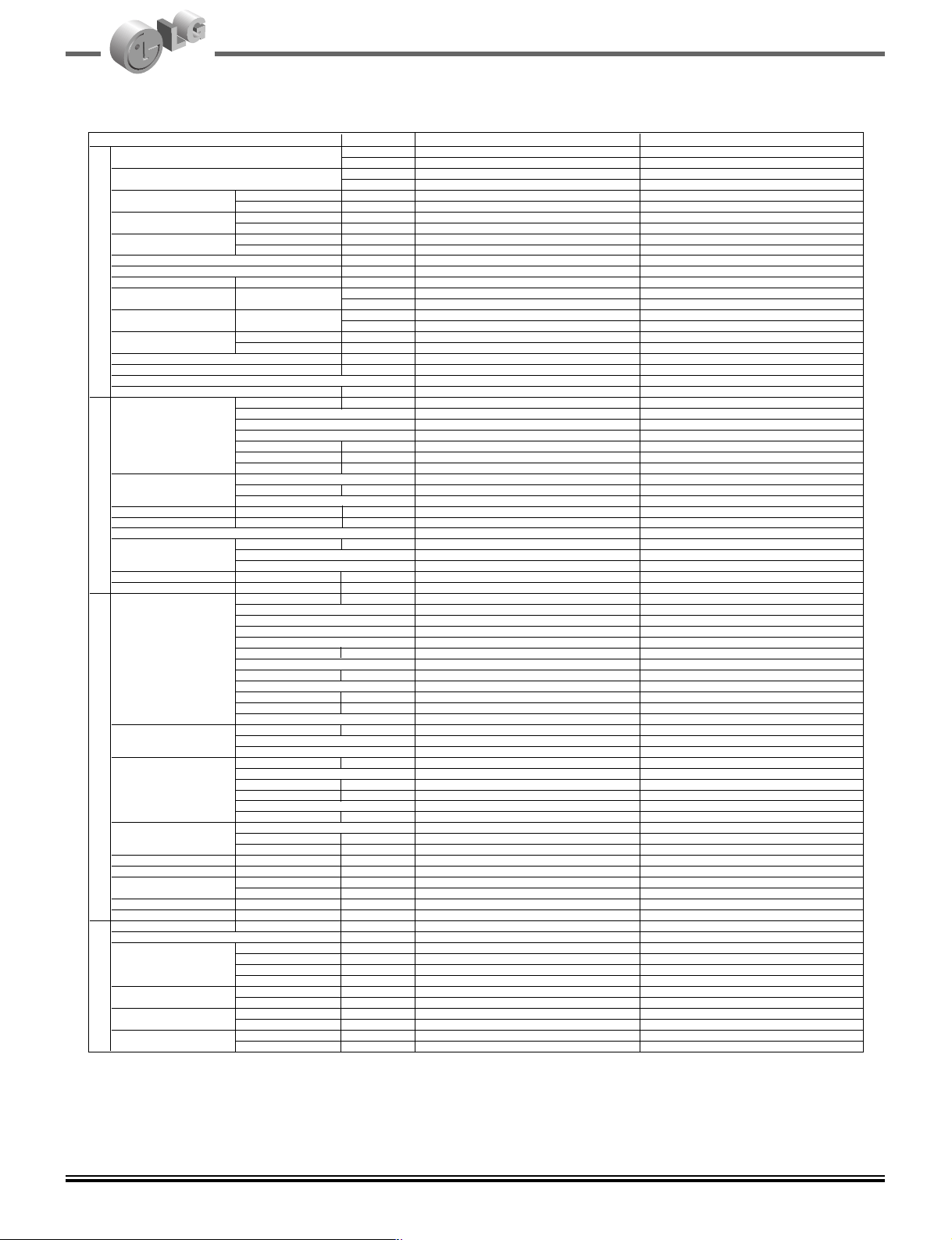

50Hz • R410A • Heat Pump List of Functions

Function

Air Discharge outlet - - Airflow Direction control (left & right) - - Airflow Direction control (up & down) - - Airflow Steps(Fan / Cool /Heat) 3/3/3 3/3/3 3/3/3

Auto Changeover O O O

Auto Operation O O O

Auto Restart Operation O O O

Auto Swing - - Central Control Accessory Accessory Accessory

CHAOS wind (Auto wind) - - Child Lock Function O O O

Cooling & Fan Operation O O O

Coolling, Heating & Fan Operation - - Defrost / Deicing O O O

Deodorizing Filter - - Drain Pump Accessory Accessory Accessory

E.S.P. Control O O O

Electric Heater - - Energy Saving Gold Fin O O O

Environment Friendly Refrigerant O O O

Fire Alarm Function - - Forced Operation O O O

Group Control O O O

High Ceiling Operation - - HotStart OOO

JetCool --Low Ambient Control Optional Optional Optional

Plasma Air Purifier Accessory Accessory Accessory

Prefilter(Washable / Anti-fungus) O O O

Restart Delay (3-minutes) O O O

Self Diagnosis O O O

Sleep Mode - - Soft Dry Operation O O O

Space Control - - SwirlSwing --Tele Control Accessory Accessory Accessory

Temperature Control O O O

Test Function O O O

Time Delay Safety Function O O O

Timer(weekly) OOO

Timer (24 hr On/Off) O O O

Two Thermistor Control O O O

Wired LCD Remote Controller O O O

Wireless Remote Controller Accessory Accessory Accessory

Zero Standby Power O O O

Zone Control Accessory Accessory Accessory

Notes :

O:Basic

Optional : Factory-Installed

Accessory : Field-Installed

- : Not available on this system

AB-H246HTA0[B24AHV SH0] AB-H306GTA0[B30AHV SG0] AB-H366GTA0[B36AHV SG0]

Ceiling Concealed Duct

6 Ceiling Concealed Duct

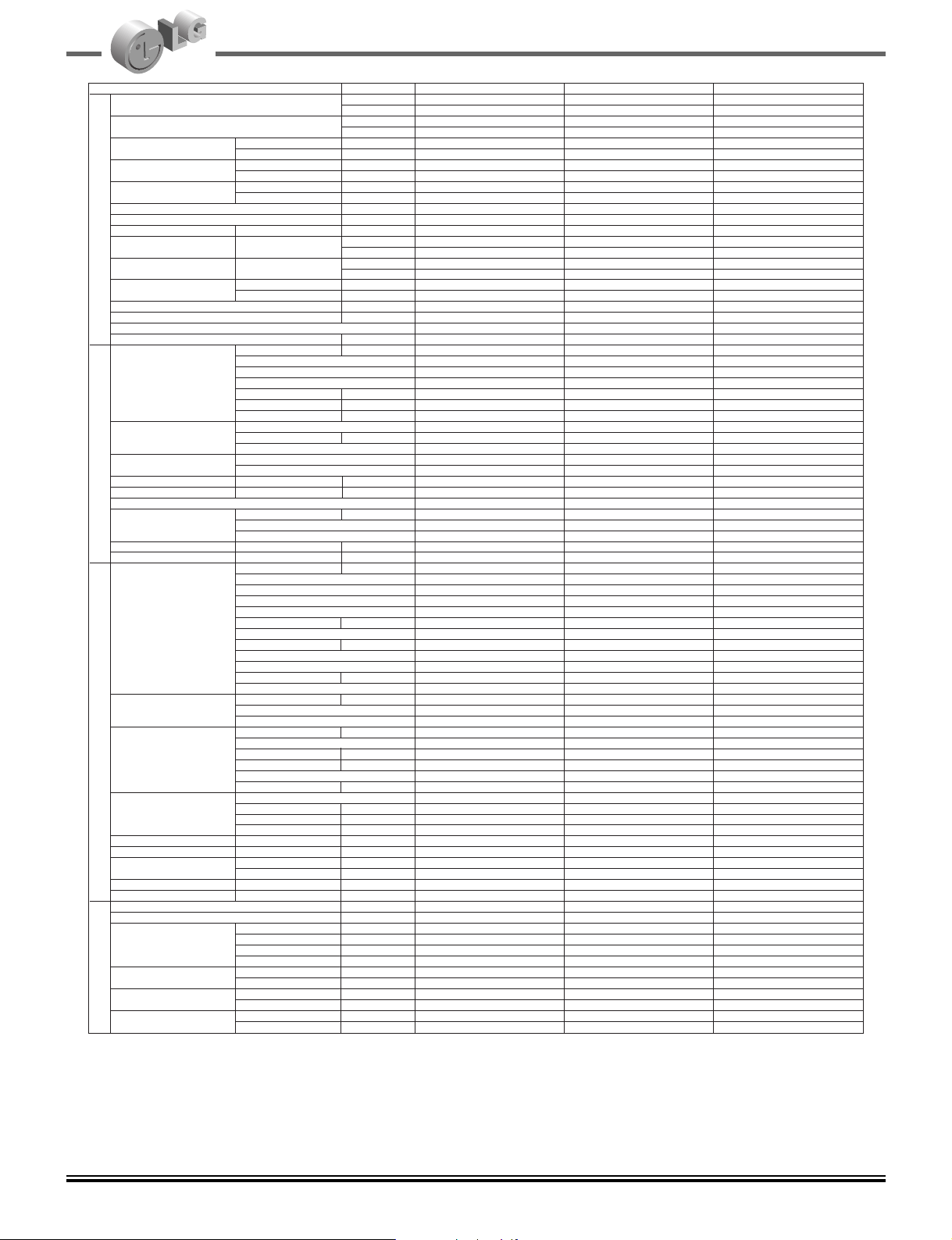

50Hz • R410A • Heat Pump50Hz • R410A • Heat Pump Specifications

4. Specifications

Cooling Capacity

Heating Capacity

Input

Running Current

Starting Current

Power Supply Ø,V,Hz

Power Factor %

Electric Heater (Optional) KW

GeneralIndoorOutdoor

E.E.R Cooling

C.O.P Heating

Setting Temperature Range

Dehumidification Rate l/h

External Static Pressure mm Aq

Refrigerant Control Type

Refrigerant charge g(oz),type

Indoor Fan motor No. of Poles

Indoor Fan No. Used / Diameter EA/ (mm)

Air Circulation Indoor(H/M/L) CMM(CFM)

Noise Level (SoundPress,1m) Indoor(H/M/L) dB(A)±3

Temperature Controller

Indoor Coil Fins per inch

Dimensions (W*H*D) Indoor inch(mm)

Net Weight indoor kg(lbs)

Compressor

Outdoor Coil Fins per inch

Outdoor Fan motor

Outdoor Fan No. Used / Diameter EA/ mm

Air Circulation Outdoor CMM(CFM)

Noise Level (SoundPress,1m) Outdoor dB(A)±3

SVC Valve

Dimensions (W*H*D) Outdoor inch(mm)

Net Weight Outdoor kg(lbs)

Power Supply Cable No.* mm

Connecting Cable No.* mm

Connecting Tube Gas Side inch(mm)

(Ø Socket Flare) Length, std m

Other

Drain Hose

Packing Dimension Indoor inch(mm)

(W*H*D) Outdoor inch(mm)

Stuffing Quantity

Item Unit

Cooling W

Heating W

Cooling A

Heating A

Cooling A

Heating A

Cool °C

Heat °C

Output W

Type

Model

Input W

Running Current A

Capacitor µF/Vac

Type

Motor Step

Tube Size (OD) inch(mm)

No of Rows & Column

Locked Rotor Amp. A

Type

Quantity

Model

Maker

Capacity kcal/h(Btu/h)

Motor Type

Motor Input W

Oil Type

Oil Charge cc

PTCR Ω

O.L.P Type(model name)

Tube Size (OD) inch(mm)

No of Rows & Column

Output W

Model

Input W

Running Current A

No.ofPoles

Capacitor µF/Vac

Type

Discharge Side/top

Liquid inch(mm)

Gas inch(mm)

Liquid Side inch(mm)

Max length/Elevation m

Inner diameter(Ø)mm

Outer diameter(Ø)mm

With S/Parts 20/40ft

Without S/Parts 20/40ft

kcal/h(W)

kcal/h(W)

kcal/hW(W/W)

Btu/hW

W/W(kcal/hW)

Btu/hW

Btu/h

Btu/h

AB-H366GSA0[B36AH SG0] AB-H426GSA0[B42AH SG0]

9072(10550) 10457(12162)

36,000 41,500

9702(11300) 11087(12895)

38,500 44,000

3,900 4,600

3,600 4,500

17.5 21.0

16.0 20.0

68.0 125.0

65.0 125.0

1,220-240,50 1,220-240,50

97.5 97

--

2.33(2.71) 2.27(2.65)

9.23 9.02

3.15(2.71) 2.87(2.46)

10.69 9.78

18~30 18~30

16~30 16~30

3.3 3.5

88

Capillary Tube Capillary Tube

2400(84.7),R410A 3500(123.43),R410A

272 272

condenser inducted condenser inducted

IC-13450LG13A IC-13450LG13A

44

323 323

1.42 1.42

6/370 6/370

Sirocco Fan Sirocco Fan

2/Ø177 2/Ø177

32/29/26.5(1130/1024/936) 32/29/26.5(1130/1024/936)

46.4*11.7 *17.71(1180*298*450) 46.4*11.7 *17.71(1180*298*450)

34.3*41.7*12.6(870*1060*320) 35.4*45.8*14.5(900*1165*370)

2

2

56.5*14.8*23.0(1435*375*585) 56.5*14.8*23.0(1435*375*585)

41.1*44.9*17.3(1045*1140*440) 41.7*48.0*18.3(1060*1220*465)

33

42/40/38 42/40/38

Thermistor Thermistor

0.275(7.0) 0.275(7.0)

21 21

3R12C 3R12C

38(83.8) 38(83.8)

43/43 62/43

Rotary Rotary/Rotary

21/1

GJ222PAC GP290PAD/GJ222PAB

LG LG/LG

4687(18600)*2 6250(24800)/4685(18600)

PSC PSC

1867*2 2150/1560

FVC68D FVC68D/FVC68D

700*2 1130/500

--

Internal Internal

0.275(7) 0.375(9.52)

18 18

2R48C 2R44C

47.2 129

OBM-3018P2 OBM-4006P2

107.5 151

0.48 0.63

46

2/400 6/370

Propeller Propeller

2/16.5(420) 2/18.1(460)

Side Discharge Side Discharge

30(1060)*2 53(1872) *2

58 62

1/4(6.35) 3/8(9.52)

5/8(15.88) 5/8(19.05)

75(165.3) 90(198.4)

3*5.5 3*5.5

5*0.75 5*0.75

1/4(6.35) 3/8(9.52)

5/8(15.88) 3/4(19.05)

7.5 7.5

50/30 50/30

22.6 22.6

25.4 25.4

30/64 27/55

34/70 27/55

Notes: 1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19 °C(66.2°F) WB Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 35 °C(95°F) DB /24 °C(75.2°F) WB - Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5m - Interconnecting Piping Length 7.5 m

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

- Level Difference of Zero. - Level Difference of Zero.

Ceiling Concealed Duct 7

50Hz • R410A • Heat Pump Specifications

Cooling Capacity kcal/h(W)

Heating Capacity kcal/h(W)

Input Cooling W

Running Current Cooling A

Starting Current Cooling A

Power Supply Ø,V,Hz

Power Factor %

Electric Heater ( Optional ) KW

GeneralIndoorOutdoor

E.E.R Cooling kcal/hrW(W/W)

C.O.P Heating kcal/hrW(W/W)

Setting Temperature Range Cool °C

Dehumidification Rate l/h

External Static Pressure mm Aq

Refrigerant Control Type

Refrigerant charge g(oz),type

Indoor Fan motor Output W

Indoor Fan Type

Indoor Fan RPM Cooling(H/M/L)

Air Circulation Indoor(H/M/L) CMM(CFM)

Noise Level (SoundPress,1m) Indoor(H/M/L) dB(A)±3

Temperature Controller

Indoor Coil Tube Size (OD) inch(mm)

Dimensions (W*H*D) Indoor inch(mm)

Net Weight indoor kg(lbs)

Compressor Locked Rotor Amp. A

Outdoor Coil Tube Size (OD) inch(mm)

Outdoor Fan motor Output W

Outdoor Fan Type

Air Circulation Outdoor CMM(CFM)

Noise Level (SoundPress,1m) Outdoor dB(A)±3

SVC Valve Liquid inch(mm)

Dimensions (W*H*D) Outdoor inch(mm)

Net Weight Outdoor kg(lbs)

Power Supply Cable No.* mm

Connecting Cable No.* mm

Connecting Tube Liquid Side inch(mm)

(Ø. Socket Flare) Gas Side inch(mm)

Drain Hose In diameter mm

Other

Packing Dimension (W*H*D) Indoor inch(mm)

Stuffing Quantity With S/Parts 20/40ft

Notes: 1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19 °C(66.2°F) WB Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 35 °C(95°F) DB /24 °C(75.2°F) WB - Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

- Interconnecting Piping Length 7.5m - Interconnecting Piping Length 7.5 m

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

- Level Difference of Zero. - Level Difference of Zero.

Item Unit

Btu/h

Btu/h

Heating W

Heating A

Heating A

Btu/hW

Btu/hW

Heat °C

Type

Model

No.ofPoles

Input W

Running Current A

Capacitor µF/Vac

No. Used / Diameter EA/ (mm)

Motor Step

Heating(H/M/L)

Fins per inch

No of Rows & Column

Type

Quantity

Model

maker

Capacity kcal/hr(Btu/h)

Motor Type

Motor Input W

Oil Type

Oil Charge CC

PTCR _

O.L.P Type(model name)

Fins per inch

No of Rows & Column

Model

Input W

Running Current A

No.ofPoles

Capacitor µF/Vac

No. Used / Diameter EA/ inch(mm)

Discharge Side / Top

Speed rpm

Gas

Length, std m

Max length/Elevation m

Out diameter mm

Outdoor inch(mm)

Without S/Parts 20/40ft

AB-H246HTA0[B24AHV SH0] AB-H306GTA0[B30AHV SG0] AB-H366GTA0[B36AHV SG0]

5,795(6,740) 8063(9378) 8568(9964)

23,000 32,000 34000

6,551(7,619) 9449(10990) 9828(11430)

26,000 37,500 39000

2,500 3,300 3450

2,700 3,400 3550

11.0 15.1 15.5

12.0 16.0 16

48.0 125.0 125

46.0 125.0 125

1,220-240,50 1,220-240,50 1,220-240,50

---

---

2.32(2.70) 2.44(2.84) 2.48(2.89)

9.21 9.69 9.9

2.42(2.82) 2.78(3.23) 2.77(3.22)

9.62 11.02 10.99

18~30 18~30 18~30

16~30 16~30 16~30

2.64 3.2 3.3

688

Capillary Tube Capillary Tube Capillary Tube

2930(103.4) , R410a 2600(91.7),R410A 2600(91.7),R410A

118 272 272

condenser inducted condenser inducted condenser inducted

IC-13450LG13C IC-13450LG13A IC-13450LG13A

444

180 323 323

0.92 1.42 1.42

6/370 6/370 6/370

Sirocco Fan Sirocco Fan Sirocco Fan

2/Ø177 2/Ø177 2/Ø177

333

1127/1037/937 1384(High) 1384(High)

1127/1037/937 1384(High) 1384(High)

18/16.5/14(636/583/494) 32/29/26.5(1130/1024/936) 32/29/26.5(1130/1024/936)

37/35/33 42/40/38 42/40/38

Thermistor Thermistor Thermistor

0.275(7.0) 0.275(7.0) 0.275(7.0)

21 21 21

3R 10C 3R 12C 3R 12C

34.6/10.2/17.7(880*260*450) 46.4*11.7 *17.71(1180*298*450) 46.4*11.7 *17.71(1180*298*450)

34(74.9) 38(83.8) 38(83.8)

62 88/96 88/96

Rotary Rotary Rotary

111

GP290PAC NN40VAAMT NN40VAAMT

6,225(24,700)/6,275(24,900) 8770(34802)/8860(35158) 8770(34802)/8860(35158)

24.6/27.7/22.7(626*703*576) 28*32.6*27(712*828*687) 28*32.6*27(712*828*687)

2

2

44.7*13.4*22.2(1135*340*565) 56.5*14.8*23.0(1435*375*585) 56.5*14.8*23.0(1435*375*585)

27.9*29.3*26.0(710*745*660) 31.1*35.0*30.1(790*890*765) 31.1*35.0*30.1(790*890*765)

LG SIAM SIAM

PSC PSC PSC

2,470/2,541 3430/3530 3430/3530

FVC68D MEL 56 MEL 56

1130±10 1300 1300

---

Internal Internal Internal

0.275(7.0) 0.275(7) 0.275(7)

18 18 18

1R(2R) 30C 2R34C 2R34C

90 189 189

IC-14654 LG97C IC-13670LG39D IC-13670LG39D

168 280 280

0.74 1.28 1.28

666

6.0/370 6/370 6/370

Propeller Propeller Propeller

1/16.5(420) 1/20.7(526) 1/20.7(526)

Top Discharge Top Discharge Top Discharge

900 930 930

55(1,940) 92(3245) 92(3245)

60 68 68

1/4(6.35) 1/4(6.35) 1/4(6.35)

1/2(12.7) 5/8(15.88) 5/8(15.88)

60(132.3) 75(165.3) 75(165.3)

3*5.5 3*5.5 3*5.5

5*1.25 5*1.25 5*1.25

1/4(6.35) 1/4(6.35) 1/4(6.35)

1/2(12.7) 5/8(15.88) 5/8(15.88)

7.5 7.5 7.5

50/30 50/30 50/30

22.6 22.6 22.6

25.4 25.4 25.4

45/96 30/66 30/66

41/86 27/58 27/58

8 Ceiling Concealed Duct

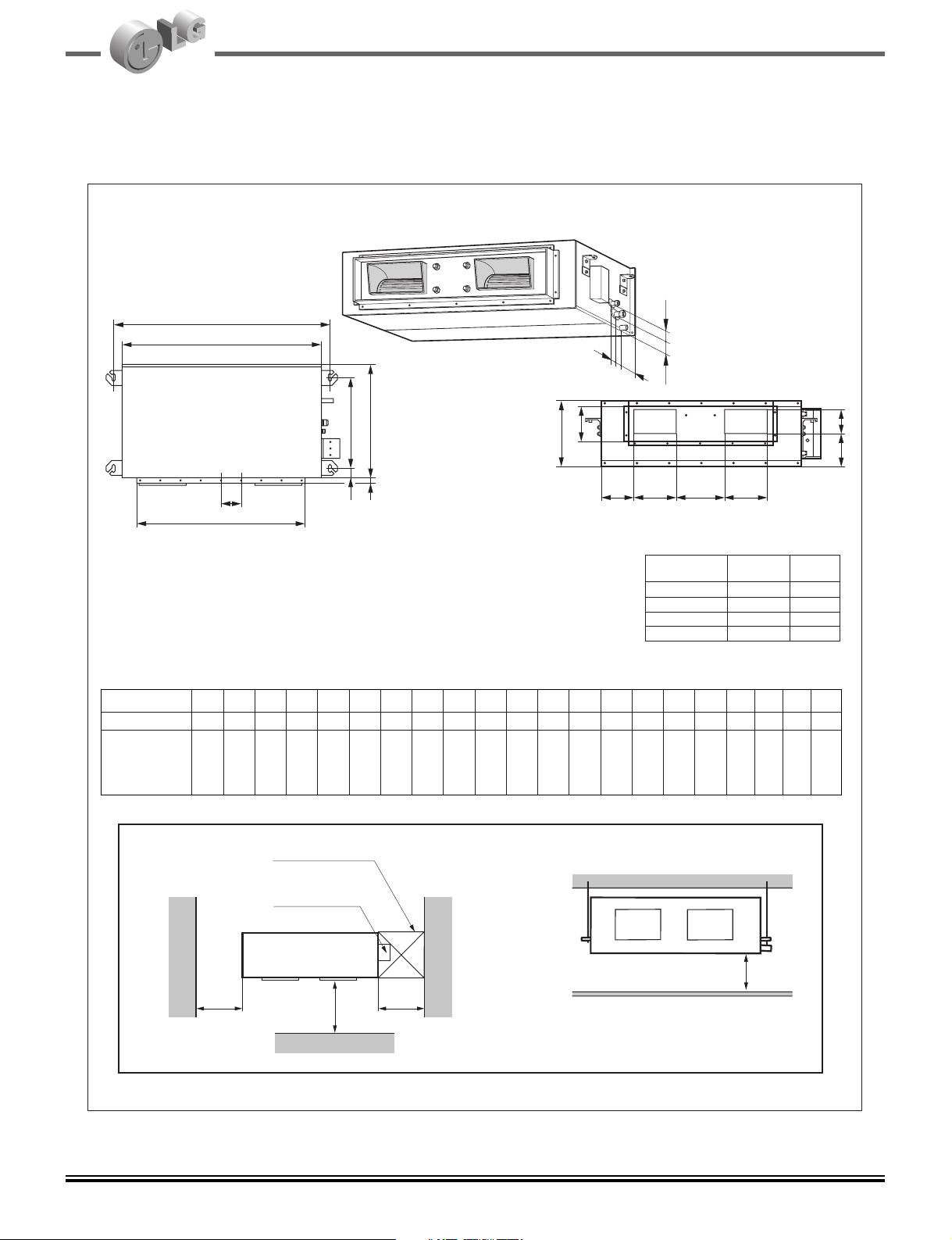

50Hz • R410A • Heat Pump50Hz • R410A • Heat Pump Dimensional Drawings

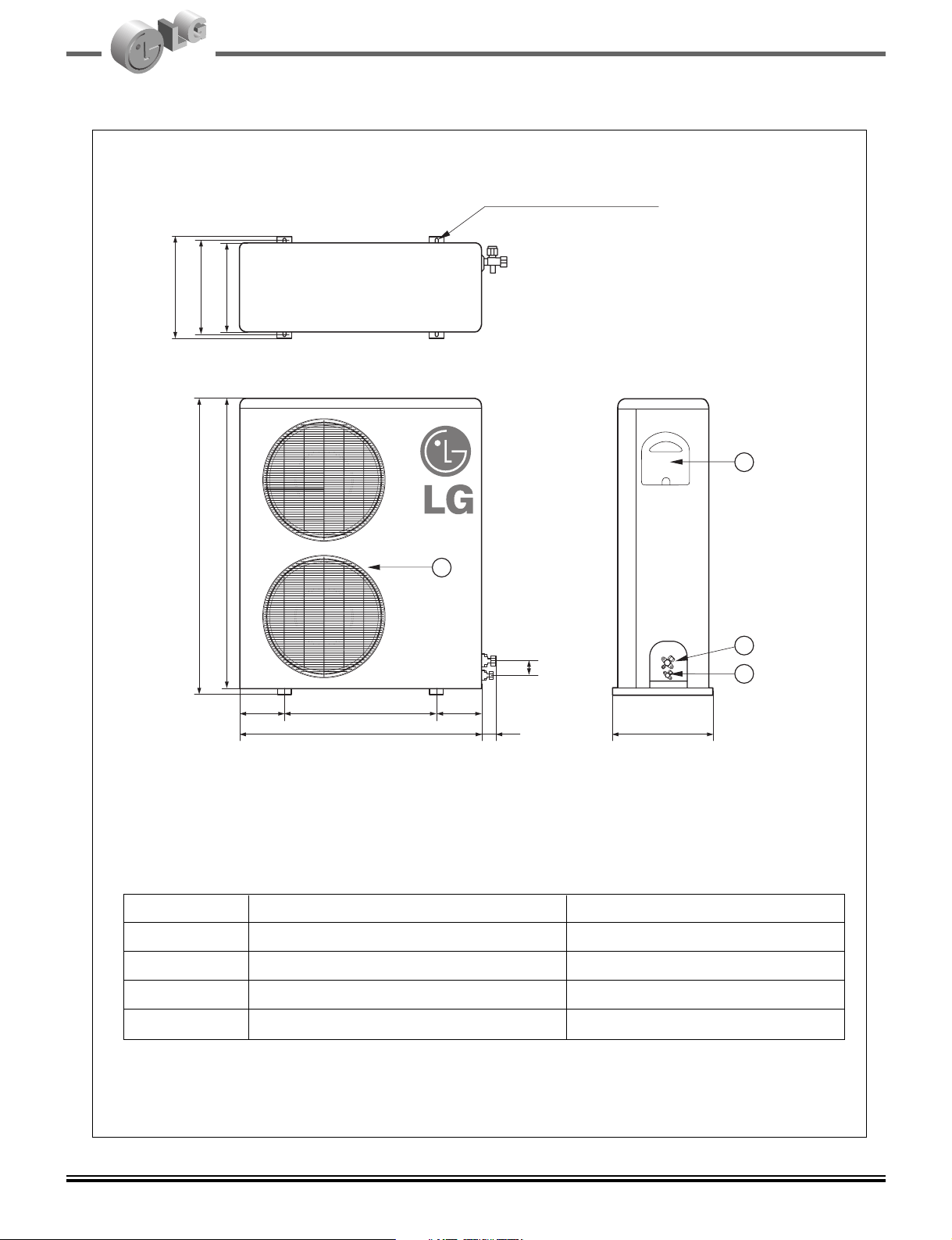

5. Dimensional Drawings

5.1 Indoor Unit

AB-H36(42)6GSA0[B36AH SG0, B42AH SG0], AB-H30(36)6GTA0[B30AHV SG0, B36AHV SG0],

AB-H246HTA0[B24AHV SH0]

Capacity A B

AB-H246HTA0[B24AHV SH0]

AB-H306GTA0[B30AHV SG0]

AB-H366GTA0[B36AHV SG0]

AB-H366GSA0[B36AH SG0]

AB-H426GSA0[B42AH SG0]

1232 1180

A

B

(G)

H

932 880

k

h

i

l

j

EF

CD

CDE F(G)H J K a b c d e f h i j k l

355 45.5 450 30 87 750 163 260 61.5 243 212.3 243 110 130 52 66 81 30 158.5

355 45.5 450 30 87 830 186 298 229.5 243 232 243 116 160 53 59 81 19 158.5

J

K

ab c d

Note:

1. Pipe Specification(mm)

GasLiquidModel

24k

30k

36k

42k

Ø6.35

Ø6.35

Ø6.35

Ø9.52

Ø12.7

Ø15.88

Ø15.88

Ø19.05

(Unit: mm)

f

e

Top view

(unit: mm)

Inspection hole

(600X600)

Control box

1000

Front

Front view

H

600600

※Suitable dimension "H" is necessary

to get a slope to drain as figure.

Ceiling Concealed Duct 9

50Hz • R410A • Heat Pump50Hz • R410A • Heat Pump Dimensional Drawings

5.2 Outdoor Unit

AB-H366GSA0[B36AH SG0]

360

340

320

4-holes for anchor bolts

4

1060

1030

870

Number Name Descripition

1 Liquid side service valve(mm) Ø6.35

2 Gas side service valve(mm) Ø15.88

3 Air discharge grill

3

2

76.5

160160 550

64

320

1

(Unit: mm)

4 Control Cover

10 Ceiling Concealed Duct

Loading...

Loading...