Page 1

787LE Service Manual

1. PRECAUTION AND NOTICES------------------------------------------------------------------------------------- 1

1.1. SAFETY PRECAUTIONS ----------------------------------------------------------------------------------------1

1.2. PRODUCT SAFETY NOTICE----------------------------------------------------------------------------------- 1

1.3. SERVICE NOTES-------------------------------------------------------------------------------------------------- 1

2. SERVICE TOOL & EQUIPMENT REQUIRED----------------------------------------------------------2

3. SPECIFICATIONS----------------------------------------------------------------------------------------------------- 2~3

PRODUCT SPECIFICATIONS

3.1.

FACTORY SUPPORTING MODES

3.2.

3.3. D-SUB CONNECTOR -------------------------------------------------------------------------------------------- 3

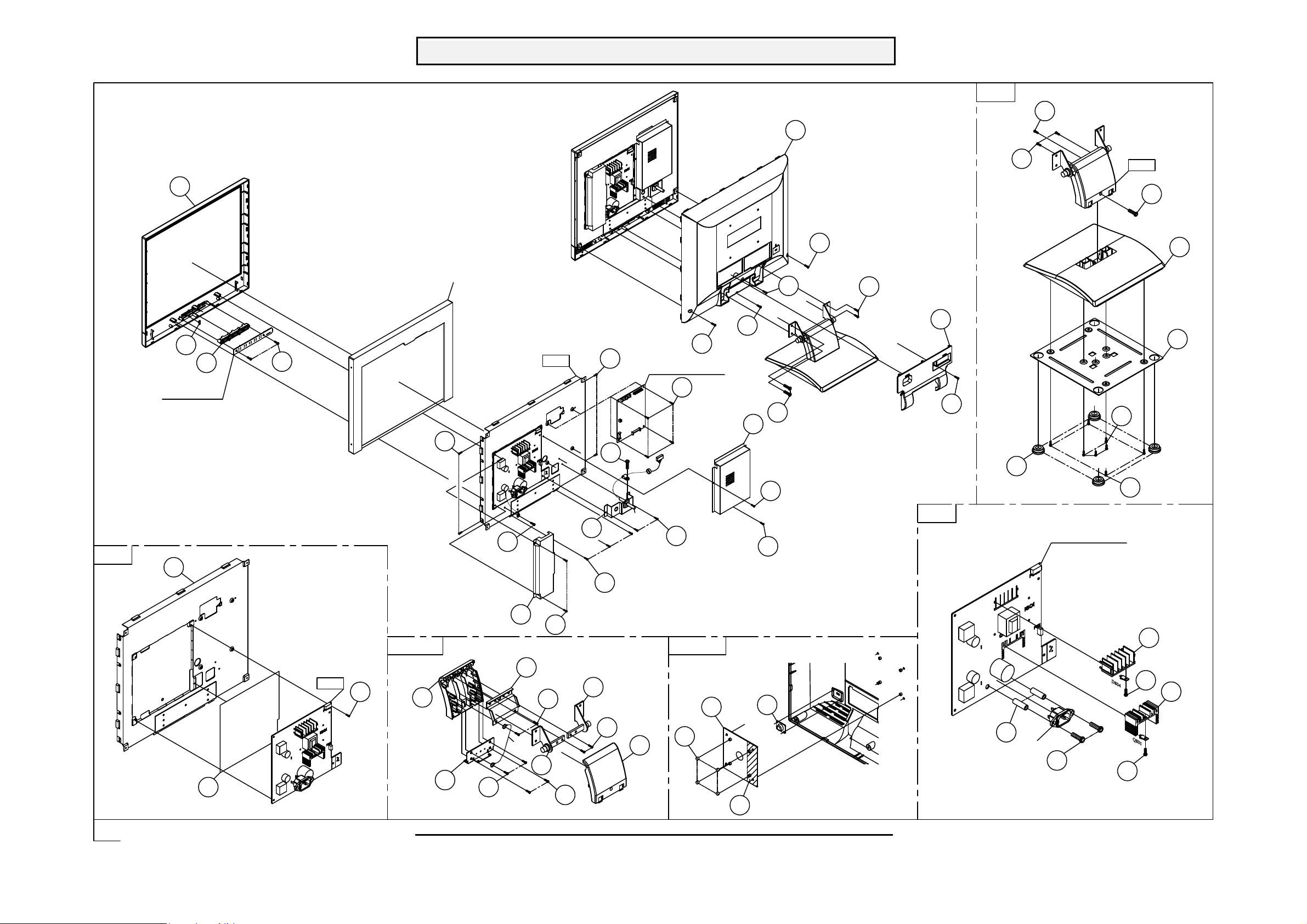

4. EXPLODED VIEW AND PARTS LIST --------------------------------------------------------------------------- 4~5

4.1. EXPLODED VIEW------------------------------------------------------------------------------------------------ 4

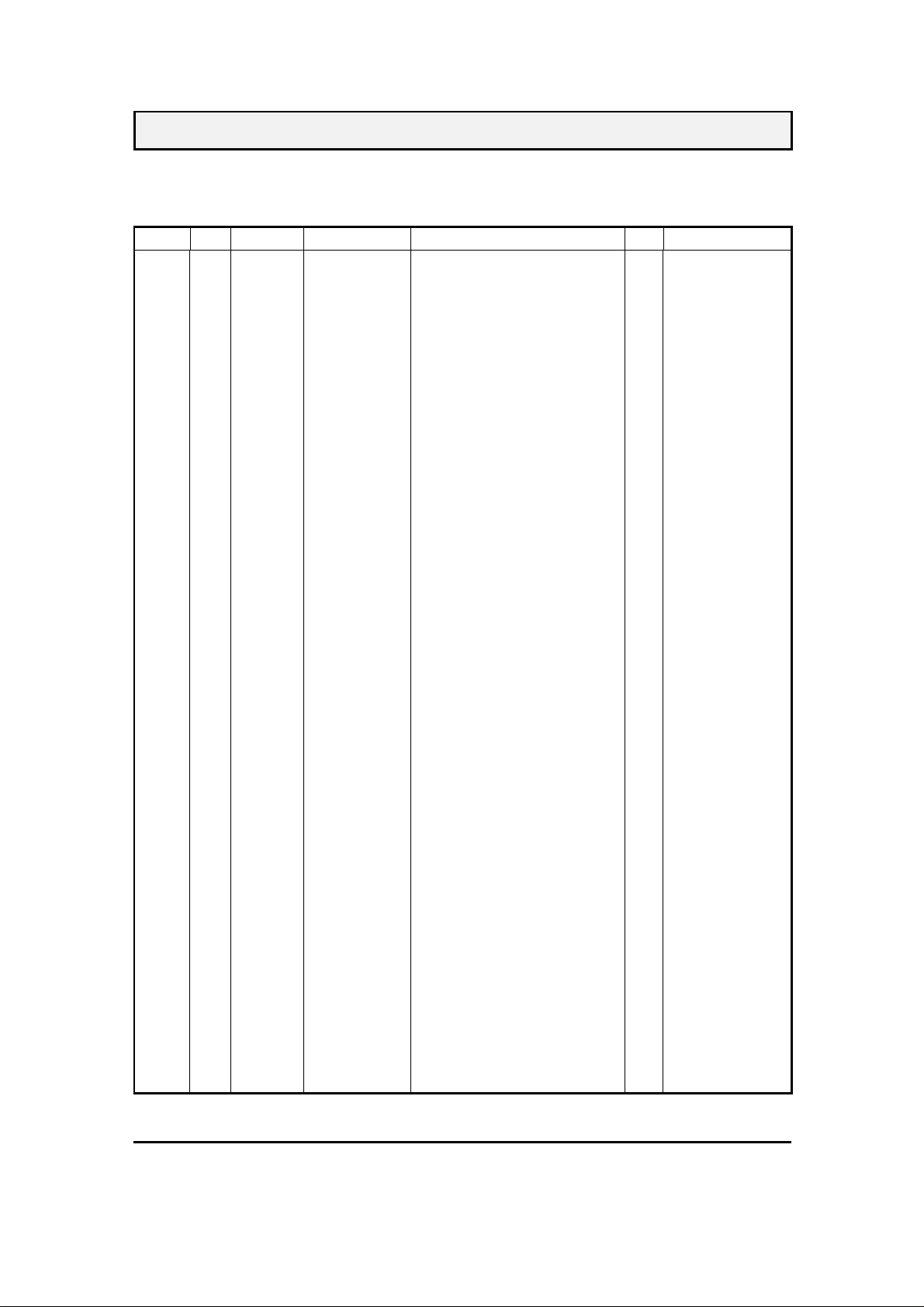

4.2. EXPLODED VIEW PARTS LIST-------------------------------------------------------------------------------- 5

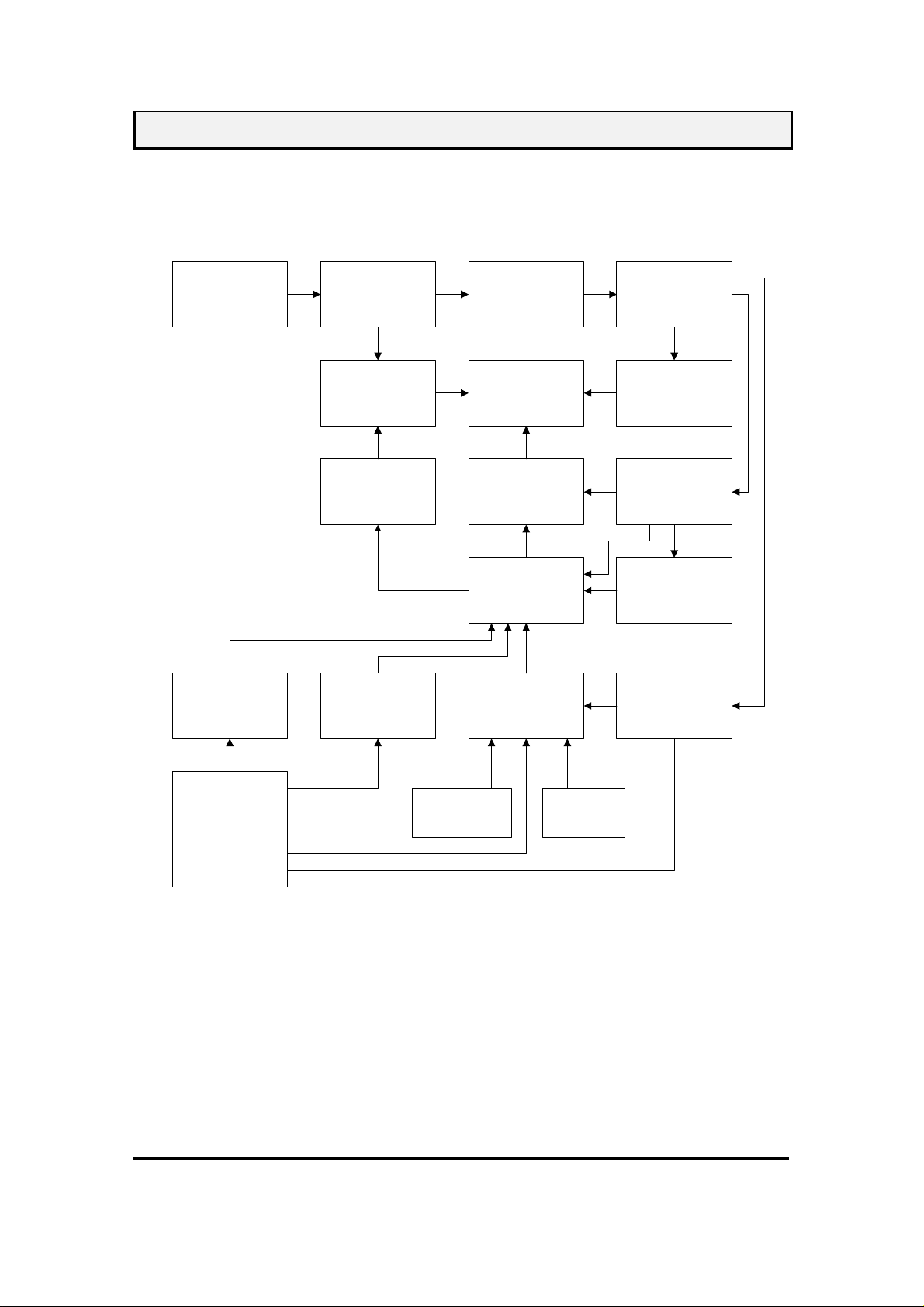

5. BLOCK DIAGRAM---------------------------------------------------------------------------------------------------- 6

6. SCHEMATIC DIAGRAM -------------------------------------------------------------------------------------------- 7~13

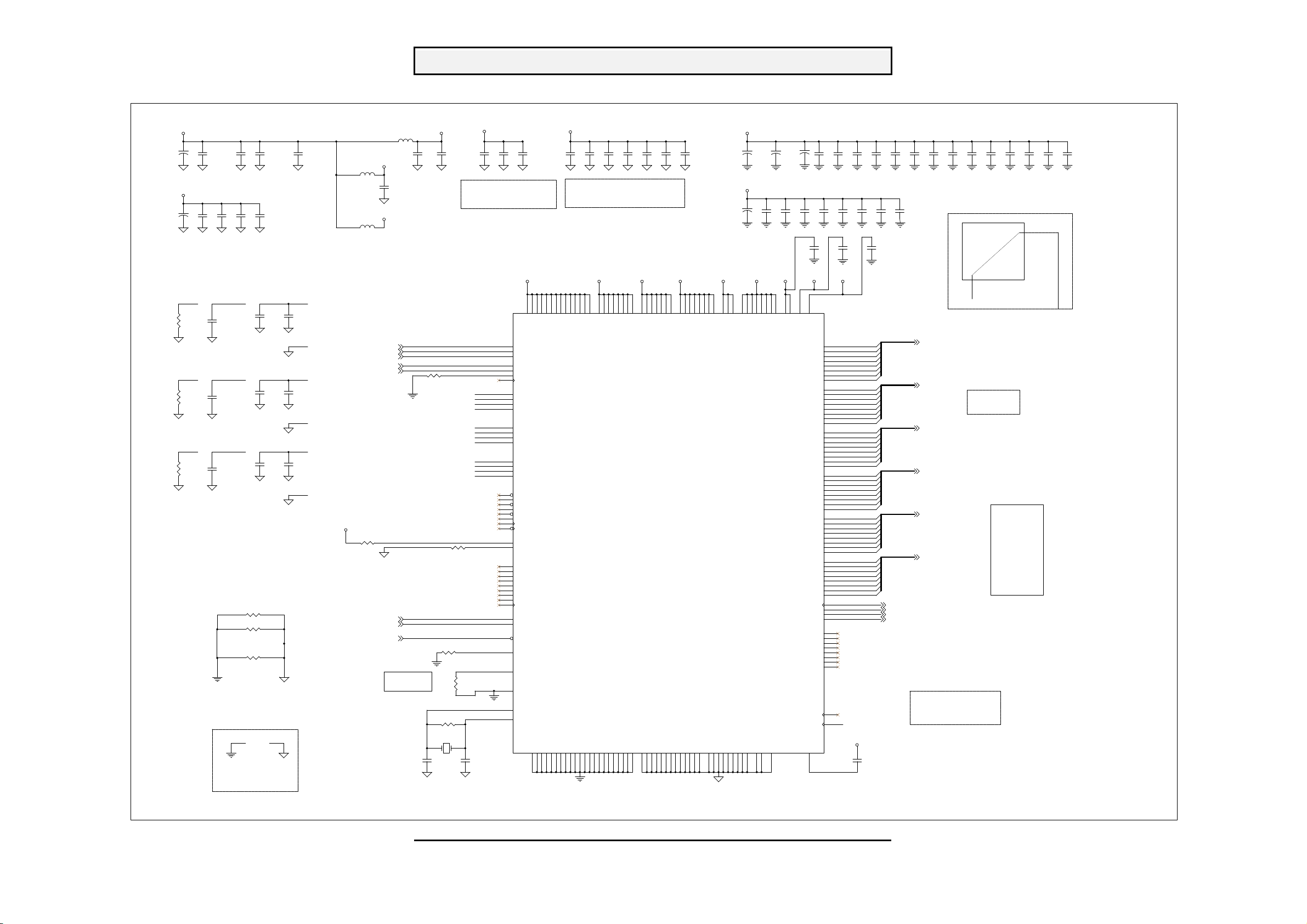

6.1. ADE------------------------------------------------------------------------------------------------------------------ 7

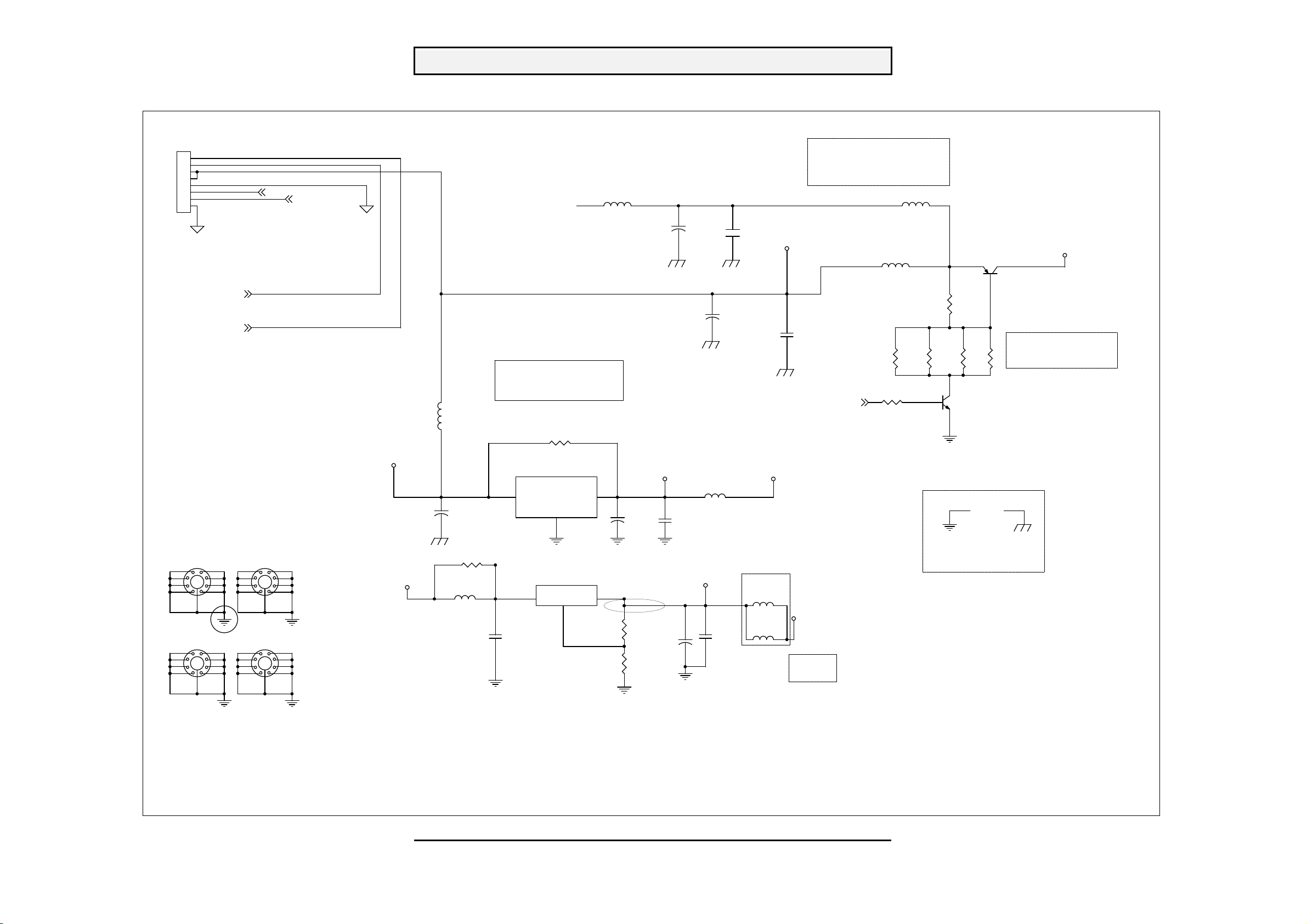

6.2. POWER ------------------------------------------------------------------------------------------------------------- 8

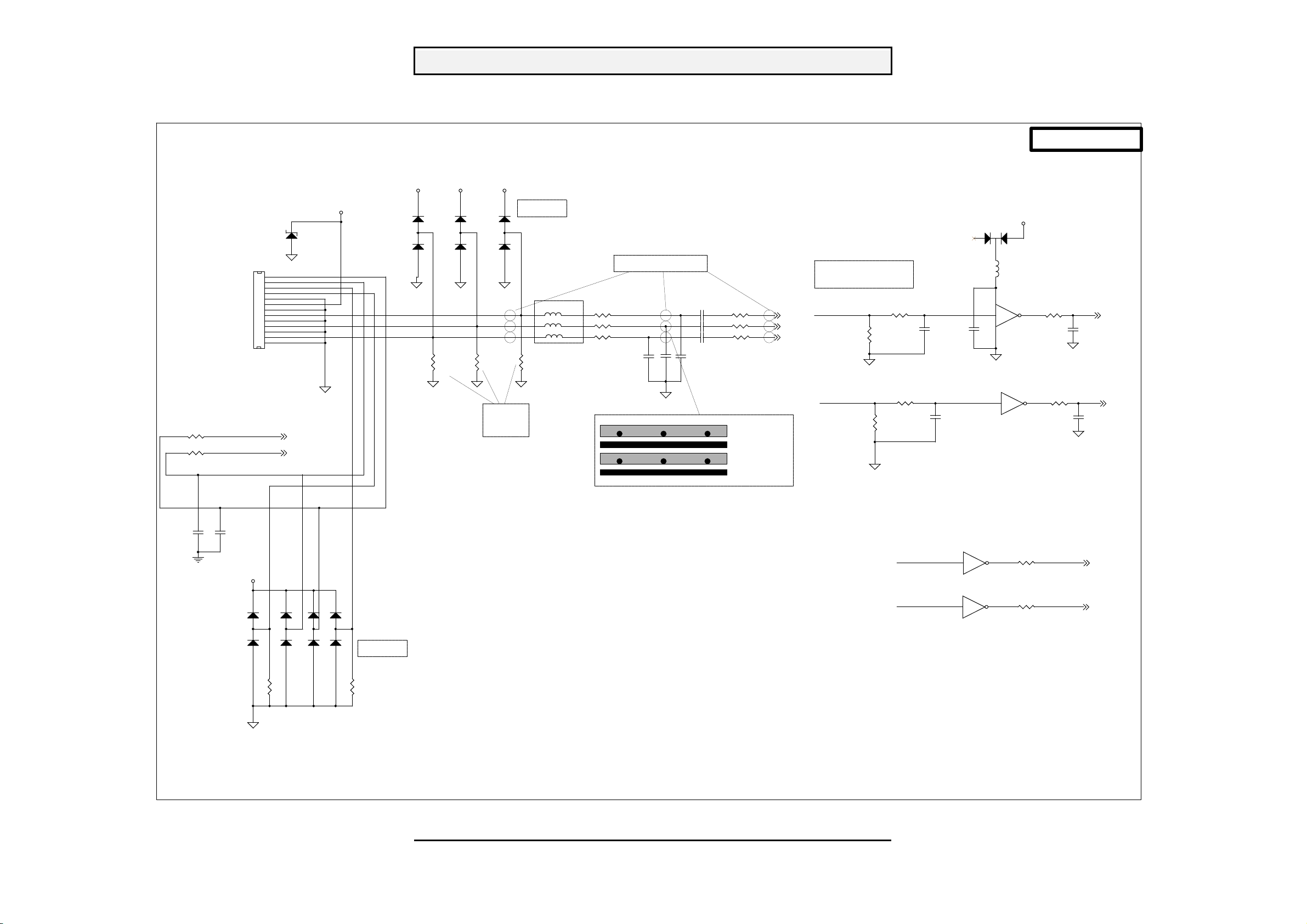

6.3. INPUT INTERFACE ----------------------------------------------------------------------------------------------9

6.4. OUTPUT INTERFACE -------------------------------------------------------------------------------------------10

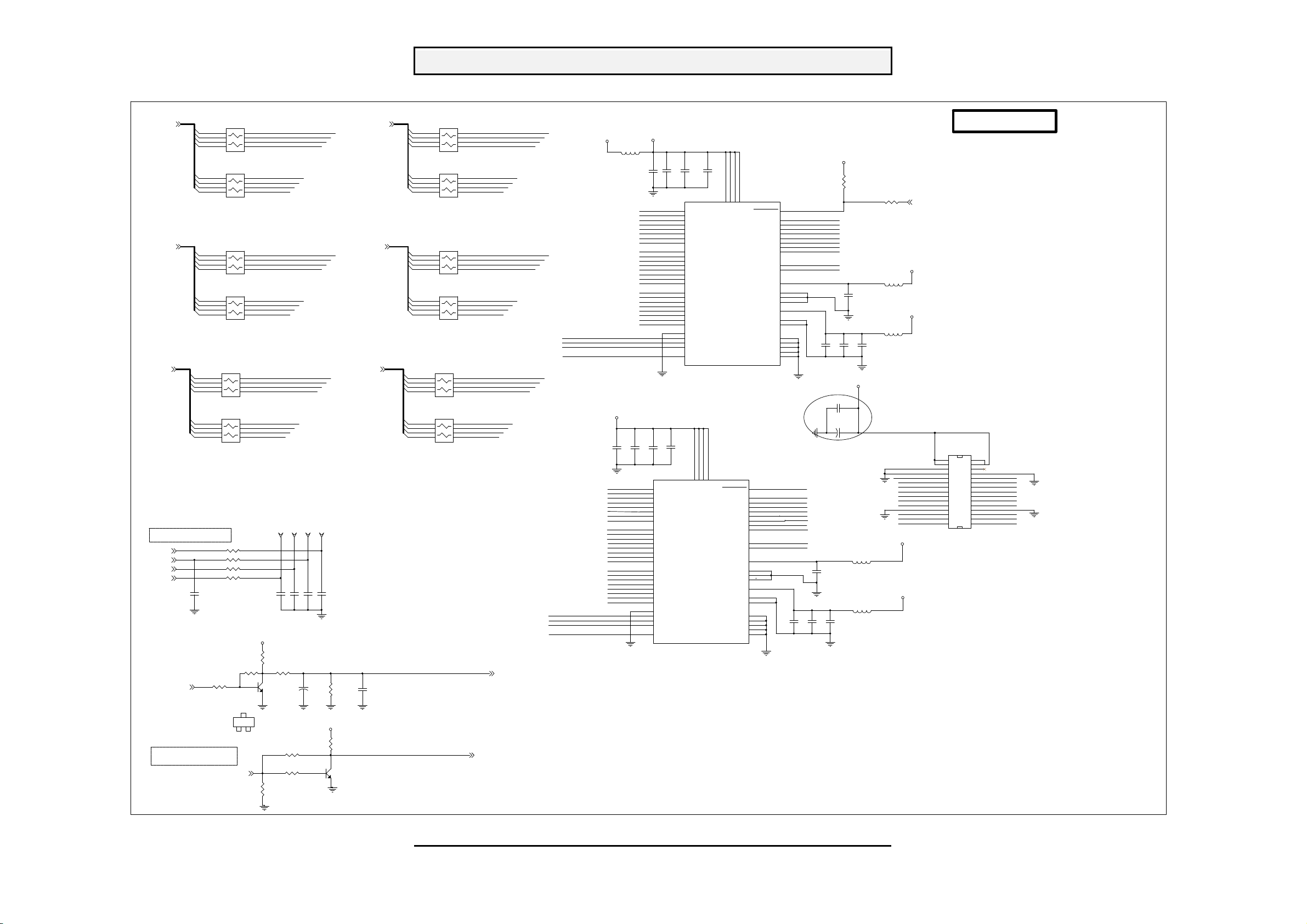

6.5. MICRO CONTROLLER ------------------------------------------------------------------------------------------ 11

6.6. POWER PCB ------------------------------------------------------------------------------------------------------- 12

6.7. INVERTER---------------------------------------------------------------------------------------------------------- 13

7. WORKING THEOREM----------------------------------------------------------------------------------------------- 14~19

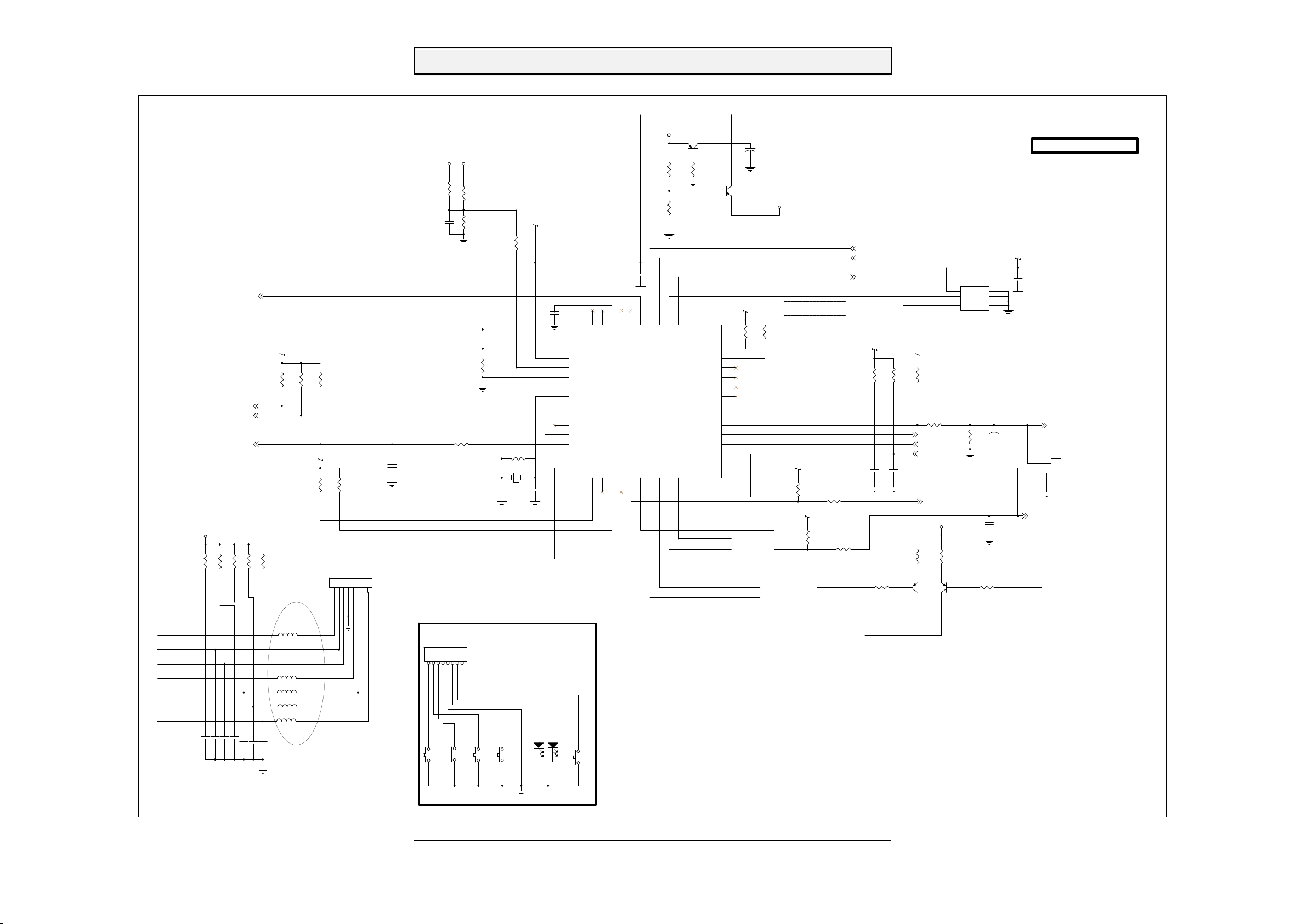

8. WIRING DIAGRAM--------------------------------------------------------------------------------------------------- 20

9. PCB LAYOUT----------------------------------------------------------------------------------------------------------- 21~26

9.1. MAIN PCB TOP VIEW ------------------------------------------------------------------------------------------- 21

9.2. MAIN PCB BOTTOM VIEW------------------------------------------------------------------------------------- 22

9.3. CON PCB TOP VIEW --------------------------------------------------------------------------------------------23

9.4. CON PCB BOTTOM VIEW --------------------------------------------------------------------------------------24

9.5. POWER PCB TOP VIEW ----------------------------------------------------------------------------------------25

9.6. POWER PCB BOTTOM VIEW---------------------------------------------------------------------------------- 26

10. TROUBLE SHOOTING FLOW CHART ------------------------------------------------------------------------- 27~30

10.1. NO POWER -------------------------------------------------------------------------------------------------------- 27

10.2. MCU NO FUNCTION --------------------------------------------------------------------------------------------28

10.3. NO DISPLAY------------------------------------------------------------------------------------------------------- 29

10.4. LOSE COLOR------------------------------------------------------------------------------------------------------ 30

11. ADJUSTMENT----------------------------------------------------------------------------------------------------------31~32

11.1. ADJUSTMENT CONDITIONS AND PRECAUTIONS-------------------------------------------------------31

11.2. MAIN ADJUSTMENTS------------------------------------------------------------------------------------------- 31

11.3. ALIGNMENT PROCEDURES----------------------------------------------------------------------------------- 31

12. ELECTRICAL PARTS LIST ---------------------------------------------------------------------------------------- 33~41

TABLE OF CONTENTS

PAGE

------------------------------------------------------------------------------ 2

------------------------------------------------------------------------ 3

8/25/2003

Page 2

787LE Service Manual

1. PRECAUTION AND NOTICES

1.1. SAFETY PRECAUTIONS

This monitor is manufactured and tested on a ground principle that a user's safety comes first.

However, improper use or installation may cause damage to the monitor as well as to the user.

Carefully go over the following WARNINGS before installing and keep this guide handy.

WARNINGS:

This monitor should be operated only at the correct power sources indicated on the label on

u

the rear end of the monitor. If you're unsure of the power supply in your residence, consult

your local dealer or power company.

Use only the special power adapter that comes with this monitor for power input.

u

Do not try to repair the monitor your self as it contains no user-serviceable parts. This

u

monitor should only be repaired by a qualified technician.

Do not remove the monitor cabinet. There is high-voltage parts inside that may cause

u

electric shock to human bodies, even when the power cord is unplugged.

Stop using the monitor if the cabinet is damaged. Have it checked by a service technacian.

u

Put your monitor only in a clean, dry environment. If it gets wet, unplug the power cable

u

immediately and consult your service technician.

Always unplug the monitor before cleaning it. Clean the cabinet with a clean, dry cloth.

u

Apply non-ammonia based cleaner onto the cloth, not directly onto the glass screen.

Keep the monitor away from magnetic objects, motors, TV sets, and transformer.

u

Do not place heavy objects on the monitor or power cord.

u

1.2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety visual inspections and

the protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher voltages, wattage, etc. Before replacing any of these components

read the parts list in this manual carefully. The use of substitute replacement parts which do not

have the same safety characteristics as specified in the parts list may create shock, fire, or other

hazards.

1.3. SERVICE NOTES

1. When replacing parts or circuit boards, clamp the lead wires around terminals before

soldering.

2. When replacing a high wattage resistor (more than 1W of metal oxide film resistor) in

circuit board, keep the resistor about 5mm away from circuit board.

3. Keep wires away from high voltage, high temperature components and sharp edges.

4. Keep wires in their original position so as to reduce interference.

5. Usage of this product please refer to also user's manual.

-1-

8/25/2003

Page 3

787LE Service Manual

2. SERVICE TOOL & EQUIPMENT REQUIRED

1. SIGNAL GEN.

2. MULTIMETER

3. OSCILLOSCOPE

4. SCREW DRIVER

5. IRON

6. ABSORBER

7. SOLDER

8. DUMMY LOAD (5ohm/200W)

3. SPECIFICATIONS

3.1. PRODUCT SPECIFICATIONS

LCD Panel 17.0" TFT

Power Management Energy Star compliant VESA

DPMS compatible

< 2W

Displayable Resolution SXGA 1280× 1024 (max.)

Pixel Dimension 0.264(H)× 0.264(V)mm

LCD Display Color 16.2M Color Max. (6bit+2FRC)

Viewing Angle CR≧10

Horizontal: -70°+70°

Vertical: -65°+65°

Tilt +90°, -5°

Contrast Ratio 400 : 1 (typ.)

Brightness 200 cd/ m2 (min.)

260 cd/m2 (typ.)

Response Time Tr: 9 ms Tf: 16ms

Active Display Area 339.5mm(H)× 272mm(V)

Temperature Operating: 0°C ~ +40°C

Storage: -20°C ~ +60°C

Compliance UL 1950, C-UL, EN60950, FCC-B, CE MARK,

TÜV/GS, TCO99, CB.

Power Input Voltage: 100~240 Vac

Consumption: 45 Watts (Max.)

-2-

8/25/2003

Page 4

787LE Service Manual

3.2. FACTORY SUPPORTING MODES

There are totally 35 timings mode that can be saved in memory by FIFO architecture.

This monitor can support VGA up to SXGA resolution.

There are some resolution example listed in lookup timing table.

Lookup timing table: 1.VGA 720× 400 (70Hz) mode

2.VGA 640× 480 (60Hz) mode

3.VESA 640× 480 (72Hz) mode

4.VESA 640× 480 (75Hz) mode

5.VESA 800× 600 (56Hz) mode

6.VESA 800× 600 (60Hz) mode

7.VESA 800× 600 (72Hz) mode

8.VESA 800× 600 (75Hz) mode

9.VESA 1024× 768 (60Hz) mode

10.VESA 1024× 768 (70Hz) mode

11.VESA 1024× 768 (75Hz) mode

12.VESA 1280× 1024 (60Hz) mode

13.VESA 1280× 1024 (75Hz) mode

14.VESA 1152× 864 (75Hz) mode

15.MAC 640× 480 (67Hz) mode

16.MAC 832× 624 (74.5Hz) mode

17.MAC 1152× 870 (75Hz) mode

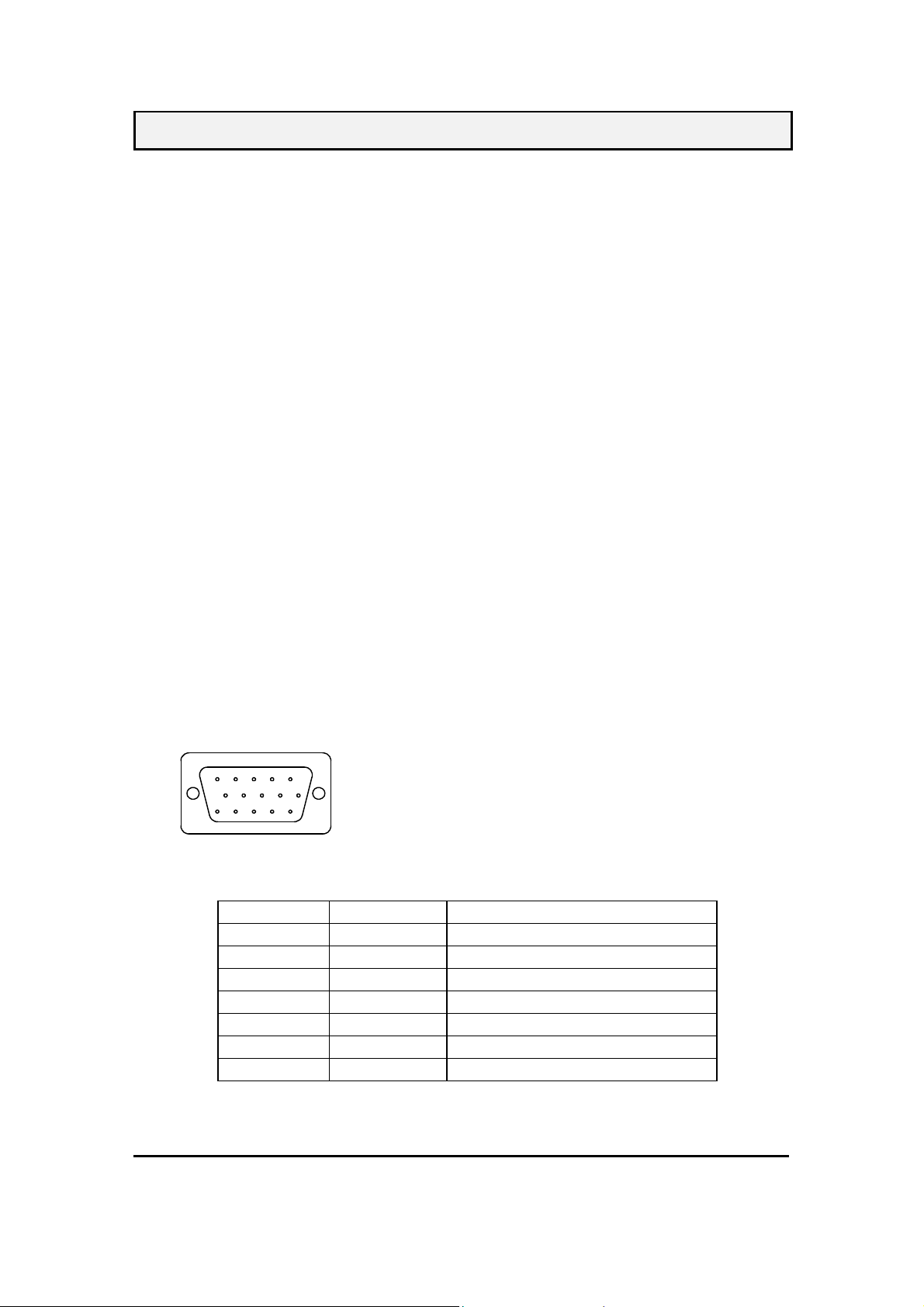

3.3. D-SUB CONNECTOR

D-SUB 15 PIN CONNECTOR

1 2 3 4 5

6 7 8 9 10

11 12 13 14 15

SIGNAL LEVEL

CONNECTOR SIGNAL DESCRIPTION

R RED 0.7vp-p(VIDEO)

G GREEN 0.7vp-p(VIDEO)

B BLUE 0.7vp-p(VIDEO)

H H/SYNC TTL positive or negative

V V/SYNC TTL positive or negative

SDA DDC1/2B TTL

SCL DDC1/2B TTL

1.R 6.GND 11.GND

2.G 7.GND 12.SDA

3.B 8.GND 13.H.SYNC

4.GND 9. +5V 14.V.SYNC

5.GND 10.GND 15.SCL

-3-

8/25/2003

Page 5

FIG.1

4.1. Exploded View

787LE Service Manual

5B11

2C01

1F01

1F02

1F03

KEYPAD PCB ASS'Y

1F12

X2

1F04

V901

X2

FIG.4

1F04

1F23

X2

1F29

MAIN PCB ASS'Y

X4

1F14

TO: MAIN PCB

P104

1F28

1F18

1F25

1F26

X2

1F29

1F25

X2

2C02

1F30

5B10 X2

5B15

X4

5B14

FIG.3

5B16

5B01

5B12

X4

FIG.4

1F05

1F08

FIG.2

1F15

FIG.3

5B02

5B07

5B08

1F24

X2

1F19

P983

5B03

5B08

5B05

1F17

X2

5B06

X2

X2

1F07

5B04

1F10

5B10

X3

X2

P961

5B09

X2

1F17

NOTE.1

2C05

X4

2C03

2C04

1F20

1F20

2C06

FIG.2

9R01

X2

POWER PCB ASS'Y

P951

9S01

X2

5B13

9S03

X4

9H02

9S02

9H03

-4-

8/25/2003

Page 6

787LE Service Manual

4.2. EXPLODED VIEW PARTS LIST

Ref. No. Source Part No. DESCRIPTION SPECIFICATION Q‘TY REMARK

1F01 2024262953 FRONT BEZEL LG ABS+PC PS-7604B MT11010 1

1F02 2053753001 LED INDIC.-PWR JT178L/LEP PMMA 94HB 1

1F03 2044262202 FUNCTION KEY JT178L ABS 94V0 PS-7604B 1

1F04 2082730062 SCREW,BND+ M3X6(BND+) 4

1F05 2071966800 METAL FITTG JT178L/SECC 0.8MM PANEL-178K77 1

1F07 2071966200 METAL FITTG JT178K77 SECC T=1.0MM(I/0) 1

1F08 2072454600 INSULATOR MYLAR(168*168T=0.5)MM(94V0) 1

1F10 2084740102 SCREW,BND T+ M4X10(BND T+) 3

1F12 2084730082 SCREW,BND T+ M3X8(BND T+) 2

1F14 2082630062 SCREW M3X6 P=0.5 4

1F15 2082630062 SCREW M3X6 P=0.5 1

1F17 2082630062 SCREW M3X6 P=0.5 4

1F18 2071666100 SHIELD PLATE JT178K77 SPTE T=0.3MM(MAIN) 1

1F19 2071667500 SHIELD PLATE JT178L/SPTE T:0.3MM(INVERTER) 1

1F20 2082630062 SCREW M3X6 P=0.5 2

1F23 2081430082 SCREW,(WASH) M3X8 P=0.5(TOOTH,WASHER) 1

1F24 2085740062 SCREW,B OTW+ B,OTW+,M4x6 1

1F25 2087340086 SCREW,B SPW+ M4X8 B SPW+ ö3.96 NYLON 4

1F26 2082740082 SCREW,BND+ M4X8(BND+) 1

1F28 2084740102 SCREW,BND T+ M4X10(BND T+) 1

1F29 2082630064 SCREW M3X6 P=0.6 BLACK 2

1F30 2082630064 SCREW M3X6 P=0.6 BLACK 1

2C01 2022259707 CABI BACK 787LE/ABS+PC BACK C LG LOGO 1

2C02 2027257503 DUST COVER JT178L/ABS+PC BLACK C 1

2C03 2071863900 BRACKET,FIX JT178L/SECC 1.0T KEWSINGTON 1

2C04 2072457100 INSULATOR PC BLACK 94V0 T=0.5 1

2C05 2072455300 INSULATOR SILICON RUBBER ö6.5Xö9.0 4

2C06 2071958300 METAL FITTG VE170 KENSINGTON 1

5B01 2028255202 STAND JT178L ABS 94HB BLACK C 1

5B02 2027255802 DUST COVER JT178L ABS 94HB BLACK C 1

5B03 2071962700 METAL FITTG JT178L SECC 1.5T HINGE(UP) 1

5B04 2106655100 HINGE JT178L(L) 0~90' 1

5B05 2106655200 HINGE JT178L(R) 0~90' 1

5B06 2084740082 SCREW,BND T+ M4X8(BND T+) 2

5B07 2071962800 METAL FITTG JT178L SECC 1.5T H1NGE (DOWN) 1

5B08 2084740082 SCREW,BND T+ M4X8(BND T+) 4

5B09 2027255902 DUST COVER JT178L/ABS 94HB BLACK C 1

5B10 2085740122 SCREW,B OTW+ SCREW B OTW+ M4X12 4

5B11 2084740102 SCREW,BND T+ M4X10(BND T+) 1

5B12 2071966700 METAL FITTG JT178L SECC 1.5T (STAND) 1

5B13 2084740082 SCREW,BND T+ M4X8(BND T+) 4

5B14 2082740122 SCREW,BND+ M4X12 (BND+) 4

5B15 2039802303 FOOT PAD VA520 CR420xö16.5x5.8 BLACK 4

5B16 2082630062 SCREW M3X6 P=0.5 1

9H02 2072259700 HEAT SINK JT178K77 44WX27LX20H 1

9H03 2072259600 HEAT SINK JT178K77 45WX20LX20H 1

9R01 2063252000 SPACER SUPPORT NYLON 66 94V2 15.87*06.6*42.5 2

9S01 2083730102 SCREW,BND T+ SCREW BND T+ 2

9S02 2084730082 SCREW,BND T+ M3X8(BND T+) 1

9S03 2084730082 SCREW,BND T+ M3X8(BND T+) 1

-5-

9/24/2003

Page 7

5. BLOCK DIAGRAM

787LE Service Manual

AC INPUT

100V ~ 220V

SYNC

I105

SW power supply

12V

I801

INVERTER

I901

P102

Q101,Q104

R.G.B INPUT

DC-DC

I804

PANEL

DISPLAY

LVDS

I106,I107

SCALAR

I101

MCU

I108,DDC

5V

VLCD

Q102

3.3V

I103

1.8V

I104

5V MCU

Q107,Q108

H,V SYNC

VGA INPUT

P104

SCL,SDA

VGA 5V

EEPROM

I109

-6-

OSC

X101

8/25/2003

Page 8

6. Schematic Diagrams

6.1. ADE

787LE Service Manual

AVDD_1.8

C101

47uF/16V

C148

47uF/16V

C102

0.1uF

AVDD_3.3

C150

C149

0.1uF

0.1uF

REFR

REFG

REFCR

R102

15K 1%

0603

R104

15K 1%

0603

REFB

R106

15K 1%

0603

C155

0.1uF

0603

REFCG

C158

0.1uF

0603

REFCB

C161

0.1uF

0603

INTERNAL ADC REFERENCE RESISTORS AND

DECOUPLING CAPACITORS. PLACE THESE

COMPONENTS CLOSE TO THEIR RESPECTIVE

PINS

DGND

AGND and DGND are isolated,

not completely separated

Place near PAD1

C104

0.1uF

C151

0.1uF

R201 0R 0805

R202 0R 0805

R204 0R 0805

DGND

C105

0.1uF

C152

0.1uF

REFPR

C153

0.47uF

0603

REFPG

C156

0.47uF

0603

REFPB

C159

0.47uF

0603

AGND

AGND

C154

100pF

REFMR

C157

100pF

0603

REFMG

C160

100pF

0603

REFMB

C107

0.1uF

BEAD120R

RVDD_3.3

L101

1 2

0805

L103

1 2

0805

BEAD100R

R101

NC

ADE-RESET#[6]

BEAD120R

XVDD_1.8

LVDD_1.8

AHSYNC[4]

AVSYNC[4]

ADE-SCL[6]

ADE-SDA[6]

L102

1 2

0805

C138

0.1uF

0603

INR[4]

ING[4]

INB[4]

XCLK_EN

0:xclk o/p disable

1:xclk o/p active

C162

22pF

0603

C109

0.1uF

0603

R187

0603

PVDD_1.8

C110

0.1uF

0603

0R

R108 NC

R188

0R

0603

R110

0R

0603

R111

1M0603

X101

27MHz Crystal

AVDD_1.8

C111

0.1uF

0603

PLACE CAPACITORS C111, C112,

AND C113 ON PINS 14, 38, AND 42,

RESPECTIVELY

(TMDS power supply pins)

REFR OGA1

REFCR

REFPR

REFMR

REFG

REFCG

REFPG

REFMG

REFB

REFCB

REFPB

REFMB

C163

22pF

0603

C113

C112

1nF

0.1uF

DVDD_1.8 AVDD_1.8

I101

92

INR

80

ING

68

INB

55

HSYNC

54

VSYNC

53

CSYNC

183

CLKIN

87

REFR

95

REFCR

89

REFPR

88

REFMR

75

REFG

83

REFCG

77

REFPG

76

REFMG

63

REFB

71

REFCB

65

REFPB

64

REFMB

16

RX2M

17

RX2P

20

RX1M

21

RX1P

23

RX0M

24

RX0P

27

RXCP

28

RXCM

30

REXT

36

RBIAS

7

YUV0

6

YUV1

5

YUV2

4

YUV3

3

YUV4

2

YUV5

1

YUV6

208

YUV7

8

YUVCLK

203

SCL

204

SDA

207

RESETN

184

TCON_IN

206

XCLK_EN

99

TST_SCAN

48

XTAL_IN

49

XTAL_OUT

9

DVDD18

DGND DVDD18

10 11

121

123

140

DVDD18

DVDD18

DGND

DGND

12

100

105

AVDD_3.3

C114

10nF

0603

142

164

DVDD18

DVDD18

DVDD18

DGND

DGND

DGND

112

122

C115

C116

100pF

0.1uF

PLACE CAPACITORS C114, C115, C116, C117,

C118, C119, AND C120 ON PINS 15, 19, 22, 25,

29, (31 & 32), AND 40, RESPECTIVELY

(TMDS power supply pins)

DVDD_3.3 PVDD_1.8AVDD_3.3 AVDD_3.3

166

178

180

191

193

199

201

101

111

125

134

148

158

172

DVDD18

DVDD18

DVDD18

DVDD18

DVDD18

DVDD18

DVDD18

DVDD33

DVDD33

DVDD33

DVDD33

DVDD33

DVDD33

DGND

DGND

DGND

DNGD

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

124

135

141

143

149

159

165

167

173

179

181

186

192

194

200

DVDD_1.8

C123

C122

C118

C119

AVDD18

AVDD18

AVDD18

0.1uF

58596970818293

AVDD18

AVDD18

C120

10nF

AVDD33

AVDD33

AVDD33

AVDD33

C117

1nF

10nF

AVDD_1.8 LVDD_1.8 XVDD_1.8

185

61737485869798

AVDD18

AVDD18

DVDD33

DVDD33

ADE3XXX

PQFP208

DGND

DGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

202

56576062666772787984909196

C121

47uF/16V

DVDD_3.3

C139

47uF/16V

143842

15192225293132

94

AVDD33

AVDD33

AVDD33

AVDD33

RVDD18

RVDD18

RVDD18

RVDD33

RGND

RGND

RGND

RGND

RGND

RGND

RGND

AGND

1318263334353739414345

RGND

47uF/16V

RVDD33

RVDD33

RVDD33

RGND

PGND

C140

0.1uF

40

RVDD33

RVDD33

RVDD33

PGND

XGND

47

47uF/16V

C141

0.1uF

44

46

PVDD18

RVDD33

51

LVDD18

PVDD18

TCON0

TCON1

TCON2

TCON3

TCON4

TCON5

TCON6

TCON7

CLKOUT

C142

0.1uF

10uF/10V

ORA0

ORA1

ORA2

ORA3

ORA4

ORA5

ORA6

ORA7

OGA0

OGA1

OGA2

OGA3

OGA4

OGA5

OGA6

OGA7

OBA0

OBA1

OBA2

OBA3

OBA4

OBA5

OBA6

OBA7

ORB0

ORB1

ORB2

ORB3

ORB4

ORB5

ORB6

ORB7

OGB0

OGB1

OGB2

OGB3

OGB4

OGB5

OGB6

OGB7

OBB0

OBB1

OBB2

OBB3

OBB4

OBB5

OBB6

OBB7

OCLK

XCLK

C232

50

XVDD18

ODE

OHS

OVS

LGND

52

C124

0.1uF

C143

0.1uF

133

132

131

130

129

128

127

126

120

119

118

117

116

115

114

113

110

109

108

107

106

104

103

102

177

176

175

174

171

170

169

168

163

162

161

160

157

156

155

154

153

152

151

150

147

146

145

144

138

136

137

139

198

197

196

195

190

189

188

187

205

182

C125

0.1uF

C144

0.1uF

C233

1uF

ORA0

ORA1

ORA2

ORA3

ORA4

ORA5

ORA6

ORA7

OGA0

OGA2

OGA3

OGA4

OGA5

OGA6

OGA7

OBA0

OBA1

OBA2

OBA3

OBA4

OBA5

OBA6

OBA7

ORB0

ORB1

ORB2

ORB3

ORB4

ORB5

ORB6

ORB7

OGB0

OGB1

OGB2

OGB3

OGB4

OGB5

OGB6

OGB7

OBB0

OBB1

OBB2

OBB3

OBB4

OBB5

OBB6

OBB7

LVDD_1.8

C126

0.1uF

C164

0.1uF

0603

C145

0.1uF

C234

1uF

C127

0.1uF

C146

0.1uF

OCLK [5]

ODE

OHS

OVS

C128

C129

0.1uF

0.1uF

C147

0.1uF

0805

ORA[7:0] [5]

OGA[7:0] [5]

OBA[7:0] [5]

ORB[7:0] [5]

OGB[7:0]

OBB[7:0] [5]

[5]

[5]

[5]

Indicate Pin# at every 5/10 pins

5 : short line

10 : long line

1,53,105 &157 should be

labeled

C131

C130

0.1uF

0.1uF

ADE3000

1 52

[5]

C133

C132

0.1uF

0.1uF

GND splitting

* Same VIA #

* Similar

length

C134

0.1uF

AGND

104

RB

GB

BB

Sync

RA

GA

BA

C135

0.1uF

DGND

C136

0.1uF

C137

0.1uF

-7-

9/24/2003

Page 9

6.2. Power

787LE Service Manual

P101

ON/OFF

1

BRIGHT

2

5V

3

4

GND

5

MUTE

6

VOLUM

7

8

[6]

ON/OFF

[6]

BRIGHT

PAD4

1

2

3

4 5

9

PAD2

1

2

3

4 5

9

8

7

6

8

7

6

MUTE 3

PAD5

1

2

3

4 5

9

PAD3

1

2

3

4 5

9

VOLUM 3

8

7

6

8

7

6

+5V

470uF/25V

DVDD_3.3

C170

L107

0.47/2W

1 2

0.47/2W

R256

L130

NC

1206

C178

0.1uF

0603

I103

RA:AMC7585-3.3ST

RB:AIC1084-33CM

R254

NC

I103

3

AIC1084

INPUT

OUTPUT

GND

1

I104 RC1117-ADJ

ADJ

VOUTVIN

SOT223

1

12V

249 1%

NC

2

23

R121

0603

L104

470uF/16V

C176

330uF/16V

Copper plate

Min : 10 x 10

mm

R120

0603

560

47uF/16V

DVDD_3.3

C177

0.1uF

C179

C165

NC

C171

1 2

DVDD_1.8

12

+

L119

BEAD60R

1206

C180

0.1uF

0603

C242

NC

AVDD_3.3

1206

L132

1 2

BEAD60R

L131

1 2

BEAD60R

1206

5V

CPT 18" USE L105 ONLY

AU 17",CMO 17",SANYO 18"

USE L106 ONLY

PAN 12V

L106

BEAD60R

1206

C174

NC

[6]

PANELPOWER

AVDD_1.8

R115

330

R119

2.2K

1Amax

NC

L105

1206

R116

330

Q102

KSB772

R113

10K

R118

R117

330

330

Q103

MMBT3904

DGND

DGND

PGND and DGND are isolated,

not completely separated

VLCD

CPT 18" R115,R116,R117,R118

USE 1.6K

-8-

9/24/2003

Page 10

6.3. Input Interface

787LE Service Manual

INPUT INTERFACE

AVDD_3.3AVDD_3.3 AVDD_3.3

R134

47

0603

R135 100

0603

P104

10

11

12

13

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

D120

ZD5V6

1 2

DB15-SCL

DB15-SDA

DB15-AVSYNC

DB15-AHSYNC

VGA_5V

BLUE

GREEN

RED

DDC-SCL [6]

DDC-SDA[6]

VGA_5V

D103

1N4148

D106

1N4148

D104

1N4148

1 2

D107

1N4148

1 2

R128

75

0603

D105

1N4148

1 2

D108

1N4148

1 2

R129

75

0603

R128-130

Place at

CN side

Place near CN

1 2

1 2

L120

0603 0R

1 2

L121

0603 0R

1 2

L122

0603 0R

1 2

L120,L121,L122 change to 0R

R130

75

0603

Guraded by AGND All the way

(From CN to ADE) & >= 12mil

0603

R122 100

100

R125

R127 100

C187

C188

NC

NC

0603

0603

C182 0.1uF

C183 0.1uF

C186 0.1uF

0603

C189

NC

0603

R197

0R 0603

R198

0R 0603

R1990R0603

AGND

R/G/B

INB

ING

INR

AHSYNC is important signal

First Priority with Least VIA

TOP side ONLY

DB15-AHSYNC

[2]

[2]

[2]

DB15-AVSYNC

R126

33K/NC

0603

R133

33K/NC

0603

R123

330

0603

R131

330

0603

RC-AHSYNC

C240

C184

NC

0.1uF

0603

0603

RC-AVSYNC

C190

NC

0603

AVDD_3.3

23

D119

BAT54C

1

SOT-23

L127

BEAD120R

0805

1 2

I105F

14

13 12

7

74LVC14

SO-14

I105E

14

11 10

7

74LVC14

SO-14

R124

0603

22

R132

0603

AHSYNC [2]

C185

22P

0603

C191

22P

0603

AVSYNC [2]

22

AGND

Add VIA on AGND

every 10mm

C192

47p

C193

NC

D110

NC

D114

ZD5.6V

AVDD_3.3

1 2

1 2

R139

10K

0603

D111

NC

1 2

D115

ZD5.6V

1 2

D112

NC

1 2

D116

ZD5.6V

1 2

D113

NC

1 2

D117

ZD5.6V

1 2

Analog Input (VGA)

Place near CN

R140

10K

0603

RC-AVSYNC

RC-AHSYNC

I105A

14

1 2

7

74LVC14

SO-14

I105B

14

3 4

7

74LVC14

SO-14

R137

MCU_VS

100 0603

R138

MCU_CS

100 0603

-9-

9/24/2003

Page 11

6.4. Output Interface

787LE Service Manual

ORA[7:0][2]

OGA[7:0][2]

OBA[7:0][2]

These are CRITICAL signal

NO VIA is allowed

OVS[2]

OCLK[2]

OHS[2]

ODE[2]

BRIGHTNESS[6]

BLON pin : Reset HIGH

Place Q104 if inverter is Low active

Place R180 if inverter is High active

C210

CAP/NC

0603

OBA0

OBA1

OBA2

OBA3

OBA4

OBA5

OBA6

OBA7

OCLK

OHS

ODE

OVS

ORA0

ORA1

ORA2

ORA3

ORA4

ORA5

ORA6

ORA7

OGA0

OGA1

OGA2

OGA3

OGA4

OGA5

OGA6

OGA7

1

2

3

4

1

2

3

4

R147 22

R148 22

R149 22

R151 22

R157

4.7K

0603

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

RP09

RP8SF

RP11

RP8SF

RP01

RP8SF

RP03

RP8SF

RP05

RP8SF

RP07

RP8SF

22R

22R

[6]

22R

22R

22R

22R

MMBT3904

BLON

3 2

8

7

6

5

8

7

6

5

0603

0603

0603

0603

0603

R251

SOT-23

1

Q104

MMBT3904

ORB[7:0][2]

OGB[7:0][2]

OBB[7:0][2]

C215

0.1uF

0603

RA0

8

RA1

7

RA2

6

RA3

5

RA4

8

RA5

7

RA6

6

RA7

5

GA0

8

GA1

7

GA2

6

GA3

5

GA4

8

GA5 GB5

7

GA6

6

GA7

5

BA0

BA1

BA2

BA3

BA4

BA5

BA6

TP12

1

FPVS

FPCLK

FPHS

FPDE

C211

CAP/NC

0603

+5V

R155

1K

0603

R156

1

Q101

2

MMBT3904

R160

NC

0603

2.2K

NC

3

0603

C212

0603

NC

0603

R159

TP13

R174

4.7K

0603

1

TP14

C213

0603

+

10uF/16V

1

C241

TP15

C214

0603

3

SOT-23

1

R252

NC

0603

+5V

R158

4.7K

0603

1

2

OBB0

OBB1

OBB2

OBB3

OBB4

OBB5

OBB6

OBB7

ORB0

ORB1

ORB2

ORB3

ORB4

ORB5

ORB6

ORB7

OGB0

OGB1

OGB2

OGB3

OGB4

OGB5

OGB6

OGB7

1

2

3

4

1

2

3

4

RP02

1

2

3

4

22R

RP8SF

RP04

1

2

3

4

22R

RP8SF

RP06

1

2

3

4

22R

RP8SF

RP08

1

2

3

4

22R

RP8SF

RP10

8

7

6

5

22R

RP8SF

RP12

8

7

6

5

22R

RP8SF

RB0

8

RB1

7

RB2

6

RB3

5

RB4

8

RB5

7

RB6

6

RB7

5

GB0

8

GB1

7

GB2

6

GB3

5

GB4

8

7

GB6

6

GB7

5

FPHS

FPVS

FPDE

DVDD_3.3

FPCLK

BB0

BB1

BB2

BB3

BB4

BB5

BB6

BB7BA7

FPHS

FPVS

FPDE

VCC_LVDS

RB6

RB7

RB0

RB1

RB2

RB3

RB4

RB5

GB6

GB7

GB0

GB1

GB2

GB3

GB4

GB5

BB6

BB7

BB0

BB1

BB2

BB3

BB4

BB5

FPCLK

0603

L123

BEAD60

1206

C202

0.1uF

C203

0.1uF

0603

RA6

RA7

RA0

RA1

RA2

RA3

RA4

RA5

GA6

GA7

GA0

GA1

GA2

GA3

GA4

GA5

BA6

BA7

BA0

BA1

BA2

BA3

BA4

BA5

50

51

52

54

55

56

10

11

12

14

16

18

15

19

20

22

23

24

25

27

28

30

31

VCC_LVDS

C194

0.1uF

0603

C204

0.1uF

0603

TXIN27

2

TXIN5

TXIN0

TXIN1

TXIN2

TXIN3

TXIN4

3

TXIN6

8

TXIN10

TXIN11

4

TXIN7

6

TXIN8

7

TXIN9

TXIN12

TXIN13

TXIN14

TXIN16

TXIN17

TXIN15

TXIN18

TXIN19

TXIN20

TXIN21

TXIN22

TXIN23

TXIN24

TXIN25

TXIN26

TXCLKIN

C195

0.1uF

0603

50

51

52

54

55

56

10

11

12

14

16

18

15

19

20

22

23

24

25

27

28

30

31

C205

0.1uF

0603

2

3

8

4

6

7

C196

0.1uF

0603

TXIN27

TXIN5

TXIN0

TXIN1

TXIN2

TXIN3

TXIN4

TXIN6

TXIN10

TXIN11

TXIN7

TXIN8

TXIN9

TXIN12

TXIN13

TXIN14

TXIN16

TXIN17

TXIN15

TXIN18

TXIN19

TXIN20

TXIN21

TXIN22

TXIN23

TXIN24

TXIN25

TXIN26

TXCLKIN

1917

VVV

I107

CS5824

TSSOP56

C197

0.1uF

0603

26

V

TXCLKOUT-

TXCLKOUT+

1917

VVV

I106

CS5824

TSSOP56

PWRDWN

TXOUT0-

TXOUT0+

TXOUT1-

TXOUT1+

TXOUT2-

TXOUT2+

TXOUT3-

TXOUT3+

LVDSVCC

LVDSGND

LVDSGND

LVDSGND

PLLVCC

PLLGND

PLLGND

GND

GND

GND

GND

GND

26

V

PWRDWN

TXOUT0-

TXOUT0+

TXOUT1-

TXOUT1+

TXOUT2-

TXOUT2+

TXOUT3-

TXOUT3+

TXCLKOUT-

TXCLKOUT+

LVDSVCC

LVDSGND

LVDSGND

LVDSGND

PLLVCC

PLLGND

PLLGND

GND

GND

GND

GND

GND

32

48

TXB1

47

46

45

42

41

38

37

40

39

44

49

43

36

34

35

33

53

29

21

13

5

LVDSPDN

TXB0

TXB2

TXB3

TXB4

TXB5

TXB6

TXB7

TXB8

TXB9

DVDD_3.3

R141

10K

0603

LVDSPDN

32

TXA0

48

TXA1

47

TXA2

46

TXA3

45

TXA4

42

TXA5

41

TXA6

38

TXA7

37

TXA8

40

TXA9

39

R142 0R

44

49

43

36

34

35

33

53

29

21

13

5

C199

0.1uF

0603

C200

10nF

0603

C198

0.1uF

0603

C201

1nF

0603

0603

L110

BEAD120R

0805

L111

BEAD120R

0805

LVDS_STBY[6]

VCC_LVDS

VCC_LVDS

VLCD

C169

0.1uF

C166

+

330uF/16V

GND

TXB0

TXB2

TXB4

TXB8

TXB6

TXA0

TXA2

GND

TXA4

TXA8

TXA6

VCC_LVDS

L112

C206

BEAD120R

0805

0.1uF

0603

VCC_LVDS

L113

C207

0.1uF

0603

C208

10nF

0603

C209

1nF

0603

BEAD120R

0805

OUTPUT INTERFACE

P105

1

2

1

2

3

4

3

4

6

5

6

7

19

16

13

11

9

30

28

17

26

23

21

CONN 15x2

5

7

9

11

13

15

17

19

21

23

25

27

29

GND

14

8

18

10

TXB3

15

12

12

14

TXB9

10

16

18

20

22

24

26

28

30

TXB7

8

TXA1

29

27

GND

24

25

TXA9

22

20

THE 6 PIN PCB MUST

CANCER DELETE

TXB1

TXB5

TXA3

TXA5

TXA7

BRIGHT [3]

ACTVE LOW

ON/0FF [3]

-10-

9/24/2003

Page 12

6.5. MICROCONTROLLER

[3]

PANELPOWER

R178

3.3K

0603

ADE-SDA

[2]

ADE-SCL

[2]

ADE-RESET#[2]

+5V

R194

R193

POWER

LED_ORG

LED_GRN

MENU

UP

DOWN

ENTER

OSD Control

Panel

Interface

R192

3.3K

0603

C225NC

3.3K

0603

R195

R196

3.3K

3.3K

3.3K

0603

0603

0603

L114 BEAD600R

L115 BEAD600R

L116 BEAD600R

L117 BEAD600R

L118 BEAD600R

C226NC

C228NC

C227

C229NC

C230NC

NC

C231NC

R179

3.3K

0603

R180

NC

0603

+5V_MCU

R182

3.3K

0603

I/O KEY PORT

P103 CON8

CW5

787LE Service Manual

+5V

Q107

MMBT3906

C239

/STANDBY

WP

+5V_MCU

47uF

R168

100K

0603

BRIGHTNESS

RXD

TXD

VGA 5V

Write Protect (H:protect)

R169

10K

0603

+5V_MCU

* From 7414

MCU_VS

MCU_CS

LVDS_STBY

[4]

SCL

SDA

I109

24C16

DIP8

VCC

TEST

SCL

SDA

GND

1

A0

2

A1

3

A2

4

8

7

6

5

EEPROM

+5V_MCU

R175

4.7K

0603

R176

4.7K

0603

+5V_MCU+5V_MCU

R243

NC

0603

POWER

ENTER

2.2K

0603

BRIGHTNESS

DDC-SCL

R200

VOLUME

R244

[4]

2.2K

DDC-SDA

C220

NC

R242

0603

100

0603

100

0603

R165

LED_GRN

LED_ORG

R245

NC

0603

R246

+5V_MCU

R241

NC

0603

LED-GREENLED-GREEN LED-ORANGE

10k

0603

C221

33pF

0603

Q105

MMBT3906

R185

680

0603

BLON

+5V

Backlite ON

R186

680

0603

Q106

MMBT3906

C244

NC

0603

R167

0603

MUTE

10k

+12V

R183

3.3K

0603

ADE-SDA

ADE-SCL

ADE-RESET#

C238

0.1uF

0603

C216

0.1uF

0603

R253

0603

5V

R210

1k

R161

0

NC

0603

R162

R220

1K

0603

NC

0603

22pF

R177

0603

C222

0603

1K

C219

0.1uF

0603

R181

0603

X102

12MHz Crystal

R190

100

0603

1M

+5V_MCU

C218

0.1uF

0603

C223

22pF

0603

7

RST

8

VDD

9

P6.3/AD3

10

VSS

11

X2

12

X1

13

ISDA/P3.4/T0

14

ISCL/P3.5/T1

15

STOUT/P4.2

16

P6.2/AD2/HLFHI

17

P1.0

C217

0.1uF

0603

1

2

3

4

5

6

NC

NC

VDD3

DA0/P5.0

DA2/P5.2

DA1/P5.1

44

VSYNC

43

HSYNC

I108

MTV312M44PLCC

P1.1

P3.2/INT0

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

1819202122232425262728

R212

10K

41

42

DA3/P5.3

P6.1/AD1

DA4/P5.4

P6.0/AD0

R211

1.5K

MMBT3906

40

DA5/P5.5

DA8/HLFHO

DA9/HALFV

HBLANK/P4.1

VBLANK/P4.0

DA7/HCLAMP

DA6/P5.6

P6.7/DA13

P6.6/DA12

P6.5/DA11

P6.4/DA10

HSCL/P3.0/Rxd

HSDA/P3.1/Txd

Q108

39

38

37

36

35

34

33

32

31

30

29

SCL

SDA

MENU

UP

DOWN

8

1234567

LED-ORANGE

CW3

CW6

CW7

CW1

CW2

CW4

P701

8 HEADER

DOWN

S705

1234567

1

UP

S703

S702

PWR/SW

PSM/LED

PWR/LED

KEY PAD

GREEN

S704

ORANGE

D701

S706

8

2

MICROCONTROLLER

+5V_MCU

C224

0.1uF

0603

MUTE

VOLUME

P106

1

2

3

NC

C243

10u /50V

-11-

9/24/2003

Page 13

6.6. POWER PCB

787LE Service Manual

D805 2A07

R840

D807 2A07

10 3A

D810 2A07

D813 2A07

C802

4700PF

Y1

C824

0.22UF

C811

0.1uF

L805

ET-20

R833

470K

R801

470K

C801

0.22UF

R803

NC

F801

2.5A/250V

L

R

G

P801

AC IN 100-240V

C803

4700PF

Y1

C808

100uF/25V

C804

22nF

R820

47K

R818

68K

Q804

2SC945

100K/1W

+

C812

120uF/400V

TEA1533AP

1

Vcc

+

2

GND

3

Ctrl

4 5

DEMSense

R821

39K 1%

R823

1K

7A3(6.8V)

R804

I801

Drain

HVS

Driver

D801

1N4148

D808

Q803

2SC945

10nF/630V

R802

100K/1W

D802

1H7G

8

7

6

R816

10K 1%

2SC2120

D809

15-2

C806

R807 10

R806 470

C805

1000PF

R814 33K1%R822 200K 1%

Q802

R819

4K7

R805

1

D806

1H5G

+

C810

22uF/25V

C823

4700PF

Y1

PQ-2620

1

2

3

5

6

L802

BEAD

Q801

A09N70I

R826 12K

C807 22nF

D803

1U5G

D811

1U5G

4

R817

4K7

3

T801

C809

220PF 1KV

I802

TLP721F

I803

TL431

C832

470nF

10-12

7-9

R810

0.15/2W

R809

9K1 1%

1

2

+

C831

1uF/50V

C822

22nF

D804

FCH30A15

R813

100

C818

220PF

R865

10K 1%

+

C821

1500UF/16V

R815 120

C819

2200PF

C820

0.1UF

R812

2.43K 1%

I804 L4973

20

Sync

19

SS

18

V5.1

17

Gnd

16

Gnd

15

Gnd

14

Gnd

13

Vfb

12

COMP

L809

BEAD

Out

Out

Vcc

Vcc

1

2

3

4

5

6

7

8

9

1011

OSC

Gnd

Gnd

Gnd

Gnd

BootINH

C829

680UF/16V

R808 150 1%

L804

+

5UH

C813

1500UF/16V

R811

9.1K 1%

C828

220nF

+

+

C816

1500UF/16V

C814

2.7nF

R824

20K 1%

C830

680uF/16V

C833

680uF/16V

+

D814

6V2

L812

115uH

+

D812

SR560

C826

680uF/16V

L806

28UH

TO Inverter

L810

+

BEAD

TO Inveter

L803

BEAD

TO Inverter

TO Inverter

8

ON/OFF

7

Brigntness

6

5V

5

5V

4

GND

3

Standby

2

Volume

1

GND

P802

TO Audio

TO Audio

TO Audio

L811

NC

1

12V

2

GND

P805

-12-

9/24/2003

Page 14

6.7. INVERTER

787LE Service Manual

12V

C918

220uF/25V

5V

C815

220uF/16V

Brightness

R902 39K 1%

ON/OFF

C903 1uF

C905 0.1UF

C902 0.1UF

C906 0.47uF

C932

0.1uF

+

+

+

R905

10K

10uF/50V

+

R906 NC

C908

0.01UF

C901 220uF/25V

R933

100K

R904

R901

47K 1%

15

C917

C907 4.7uF/16V

10 11

C909

1500PF

Q905

2N7000

R934

220K

R903

51.1k 1%

C904

1uF/50V

1

CTIMR

2

OVP

3

ENA

4

SST

5

VDDA

6

GNDA

7

REF

8

RT1

9

FB

CMPNDR_D

I901 OZ960

Q906

2N7000

C933

0.1uF

+

NDR_B

PDR_A

CT

RT

PGND

LCT

DIM

LPWM

PDR_C

D920

9.1V

R932

10K

20

19

18

17

16

15

14

13

12

R909

10K

C913

47nF

R926

4.7

R925

4.7

C912 220PF

R908 62K 1%

C911

0.01UF

R907 27K

R931 4.7

R930 4.7

D919

5.6V

D918 SS14

4 5

3

2

1

D921 SS14

R915 10K

D908 5.6V

C910

47nF

Q903

2SC945

C914

2.2uF

G1D1

S1

D1

G2

D2

S2

D2

C915

2.2uF

6

7

8

I902

AOP600

D922 SS14

4 5

G1D1

3

S1

2

G2

1

S2

D923 SS14

R927

100K

R923

39K

D1

D2

D2

6

7

8

2 8

5 9

L901

EEL-19

24:2400

2 8

5 9

L903

EEL-19

24:2400

I903

AOP600

Q901

2N7000

Q902

2N7000

D905

1N4148

R914

1M

D910

1N4148

D911

1N4148

R919

51K

R921

1M

R922

1M

D904

1N4148

C928

5PF 3KV

C929

8200PF

C930

5PF 3KV

C931

8200PF

D916

1N4148

C926

0.1uF

D917

1N4148

C927

0.1uF

C919

1

47PF 3KV

3

C920 47PF 3KV

R912

499 1%

D914

1N4148

C924 47PF 3KV

C925

47PF 3KV

1N4148

R920

10K

L904

EE-8.3

1

3

R917

499 1%

D915

270 1%

2

4

D906

1N4148

R913

270 1%

L905

EE-8.3

1N4148

R918

2

4

D912

4

3

2

1

D907

1N4148

4

3

2

1

D913

1N4148

P901

H

H

NC

L

P906

H

H

NC

L

R916

390K

C916

0.1uF

Q904

2SA733

-13-

9/24/2003

Page 15

787LE Service Manual

7. WORKING THEOREM

A. DC-DC CONVERTER

This brick convert is the 12V input voltage to 5V output for panel use and system controller use .

It consists of a PWM IC (L4973 I804), flywheel diode (D812 SR560), buck choke (L812) and

capacitor C826.

I804 (L4973) is a PWM generator working at 200KHz.

5V Out put at 2,3 pin

VCC 12V In put at 8 pin

B. Scaling controller

The ADC is to convert RGB analog signal to digital signal that scaling chip can acknowledge.

The HSYNC input receives a logic signal and provides the frequency reference for pixel clock

generation.

The scaling IC is to converts the input signal ranging from VGA to SXGA into SXGA resolution

that panel can acknowledge.

The scaling IC is to converts the input signal ranging from VGA to SXGA into SXGA resolution

that panel can acknowledge.

When power is first applied, the ADE3XXX is asynchronously reset from a pin. The uC typically

programs the ADE3XXX with a number of default values and sets up the ADE3XXX to identify

activity on any of the input pins. All preconfigured values and RAMs, such as DVI settings,

line-lock PLL settings, video input modes (YUV), OSD characters, LCD timing values (output

sequencer), scale kernels, gamma curves, sRGB color warp, APC dithering, output pin

configuration (OMUX), etc. can be preloaded into the ADE3XXX.

The typical end state is that the ADE3XXX is initialized into a low power mode, ready to turn

active once the power button is pressed. activity detect When the monitor has been powered on,

the inputs can be monitored for active video sources. Based on the activity monitors, the uC

chooses an input or power down state.

SMEAS 40 sync / timing measurement Once an input source is selected, all available information

on frequencies and line/pixel counts is measured for the selected source and made available to the

uC.

SMEAS 40 mode set Once the uC has determined the matching video mode or calculated a video

mode using a GTF algorithm, the datapath is programmed to drive the flat panel. Clock

frequencies for the internal memory and datapath are also set at this time. autotune When the uC

calls for an autotune, the uC sets up an iterative loop to search for the best phase, gain, offset, etc.

At each step of the loop, the uC kicks off a test in which the ADE3XXX which performs extensive

statistical analysis of the incoming data stream. The results of the analysis are made available to

the uC which is responsible for the optimization algorithmSRT digital contrast / brightness In

response to user OSD control, the uC can program single 8b registers that set brightness and

contrast for each color channel independently.

SRGB 80 white point control In response to user OSD control, the uC can program three 8b

registers that set the white point for the output.

SRGB 80 gamma adjustment The uC can program the gamma RAMs to implement 10b accurate

color transformations.

GAMMA 92 sRGB control The SRGB block allows simple, intuitive color control with just a few

registers.

SRGB 80 pattern generation For production testing, the ADE3XXX can be programmed by the uC

to output a wide set of test patterns.

PGEN 74 flicker reduction For smart panel applications, the uC can set up the flicker detection

block to report any correlation with the polarity inversion signal. The uC can then change the

polarity inversion to a non-correlating pattern to eliminate flicker.

HDCP The ADE3XXX contains the BlockCipher and Decryption functions - interactions over

DDC are managed by the uC for maximum flexibility. The uC models the slow (frame rate, e.g.

60Hz) authentication handshaking and state machine whereas the ADE3XXX handles the fast (line

rate, e.g. 50kHz) decryption state machine.

HDCP 34 backlight control The ADE3XXX provides two PWM outputs for direct control of the

-14-

8/25/2003

Page 16

787LE Service Manual

power components in a typical backlight. The uC sets up the registers and enables the function.

PWM 97

Table 1: Pin Description

Pin # Name Type Description

1 YUV6 Input TV Video input port: Data 6

2 YUV5 Input TV Video input port: Data 5

3 YUV4 Input TV Video input port: Data 4

4 YUV3 Input TV Video input port: Data 3

5 YUV2 Input TV Video input port: Data 2

6 YUV1 Input TV Video input port: Data 1

7 YUV0 Input TV Video input port: Data 0

8 YUVCLK Input TV Video input port: Clock

9 DVDD18 Power Digital 1.8V VDD

10 DGND Power Digital Ground

11 DVDD18 Power Digital 1.8V VDD

12 DGND Power Digital Ground

13 AGND Power Analog Ground

14 AVDD18 Power Analog 1.8V VDD

15 AVDD33 Power Analog 3.3V VDD

16 RX2M Input DVI Receiver Channel 2 MINUS input (RED)

17 RX2P Input DVI Receiver Channel 2 PLUS input (RED)

18 AGND Power Analog Ground

19 AVDD33 Power Analog 3.3V VDD

20 RX1M Input DVI Receiver Channel 1 MINUS input (GREEN)

21 RX1P Input DVI Receiver Channel 1 PLUS input (GREEN)

22 AVDD33 Power Analog 3.3V VDD

23 RX0M Input DVI Receiver Channel 0 MINUS input (BLUE)

24 RX0P Input DVI Receiver Channel 0 PLUS input (BLUE)

25 AVDD33 Power Analog 3.3V VDD

26 AGND Power Analog Ground

27 RXCP Input DVI Receiver Clock Channel PLUS input

28 RXCM Input DVI Receiver Clock Channel MINUS input

29 AVDD33 Power Analog 3.3V VDD

30 REXT Passive 1% 475 Ohm resistor to Analog 3.3V VDD

31 AVDD33 Power Analog 3.3V VDD

32 AVDD33 Power Analog 3.3V VDD

33 AGND Power Analog Ground

34 AGND Power Analog Ground

35 AGND Power Analog Ground

36 RBIAS Passive 1% 2.0 kOhm resistor to Analog Ground

37 AGND Power Analog Ground

38 AVDD18 Power Analog 1.8V VDD

39 AGND Power Analog Ground

40 AVDD33 Power Analog 3.3V VDD

41 AGND Power Analog Ground

42 AVDD18 Power Analog 1.8V VDD

43 AGND Power Analog Ground

44 AVDD18 Power Analog 1.8V VDD

45 AGND Power Analog Ground

46 AVDD18 Power Analog 1.8V VDD

47 XGND Power Crystal Oscillator Ground

48 XTAL_IN Input Crystal Oscillator input

49 XTAL_OUT Output Crystal Oscillator output

50 XVDD18 Power Crystal Oscillator 1.8V VDD

51 LVDD18 Power Line Lock PLL 1.8V VDD

52 LGND Power Line Lock PLL Ground

-15-

8/25/2003

Page 17

787LE Service Manual

53 CSYNC Input Composite Sync Input - for Sync On Green

54 VSYNC Input Vertical Sync Input

55 HSYNC Input Horizontal (or Composite) Sync Input

56 AGND Power Analog Ground

57 AGND Power Analog Ground

58 AVDD33 Power Analog 3.3V VDD

59 AVDD33 Power Analog 3.3V VDD

60 AGND Power Analog Ground

61 AVDD18 Power Analog 1.8V VDD

62 AGND Power Analog Ground

63 REFB Passive 1% 15.0 kOhm resistor to Analog Ground

64 REFMB Passive connect to Analog Ground

65 REFPB Passive 470nF capacitor to Analog Ground

66 AGND Power Analog Ground

67 AGND Power Analog Ground

68 INB Input Analog Video Port: Blue Channel input

69 AVDD33 Power Analog 3.3V VDD

70 AVDD33 Power Analog 3.3V VDD

71 REFCB Passive 100nF capacitor to Analog Ground

72 AGND Power Analog Ground

73 AVDD18 Power Analog 1.8V VDD

74 AVDD18 Power Analog 1.8V VDD

75 REFG Passive 1% 15.0 kOhm resistor to Analog Ground

76 REFMG Passive connect to Analog Ground

77 REFPG Passive 470nF capacitor to Analog Ground

78 AGND Power Analog Ground

79 AGND Power Analog Ground

80 ING Input Analog Video Port: Green Channel input

81 AVDD33 Power Analog 3.3V VDD

82 AVDD33 Power Analog 3.3V VDD

83 REFCG Passive 100nF capacitor to Analog Ground

84 AGND Power Analog Ground

85 AVDD18 Power Analog 1.8V VDD

86 AVDD18 Power Analog 1.8V VDD

87 REFR Passive 1% 15.0 kOhm resistor to Analog Ground

88 REFMR Passive connect to Analog Ground

89 REFPR Passive 470nF capacitor to Analog Ground

90 AGND Power Analog Ground

91 AGND Power Analog Ground

92 INR Input Analog Video Port: Red Channel input

93 AVDD33 Power Analog 3.3V VDD

94 AVDD33 Power Analog 3.3V VDD

95 REFCR Passive 100nF capacitor to Analog Ground

96 AGND Power Analog Ground

97 AVDD18 Power Analog 1.8V VDD

98 AVDD18 Power Analog 1.8V VDD

99 TST_SCAN Input connect to Digital Ground

100 DGND Power Digital Ground

101 DVDD33 Power Digital 3.3V VDD

102 OBA7 Output Output Port A: Blue Data 7

103 OBA6 Output Output Port A: Blue Data 6

104 OBA5 Output Output Port A: Blue Data 5

105 DGND Power Digital Ground

106 OBA4 Output Output Port A: Blue Data 4

107 OBA3 Output Output Port A: Blue Data 3

108 OBA2 Output Output Port A: Blue Data 2

109 OBA1 Output Output Port A: Blue Data 1

-16-

8/25/2003

Page 18

787LE Service Manual

110 OBA0 Output Output Port A: Blue Data 0

111 DVDD33 Power Digital 3.3V VDD

112 DGND Power Digital Ground

113 OGA7 Output Output Port A: Green Data 7

114 OGA6 Output Output Port A: Green Data 6

115 OGA5 Output Output Port A: Green Data 5

116 OGA4 Output Output Port A: Green Data 4

117 OGA3 Output Output Port A: Green Data 3

118 OGA2 Output Output Port A: Green Data 2

119 OGA1 Output Output Port A: Green Data 1

120 OGA0 Output Output Port A: Green Data 0

121 DVDD18 Power Digital 1.8V VDD

122 DGND Power Digital Ground

123 DVDD18 Power Digital 1.8V VDD

124 DGND Power Digital Ground

125 DVDD33 Power Digital 3.3V VDD

126 ORA7 Output Output Port A: Red Data 7

127 ORA6 Output Output Port A: Red Data 6

128 ORA5 Output Output Port A: Red Data 5

129 ORA4 Output Output Port A: Red Data 4

130 ORA3 Output Output Port A: Red Data 3

131 ORA2 Output Output Port A: Red Data 2

132 ORA1 Output Output Port A: Red Data 1

133 ORA0 Output Output Port A: Red Data 0

134 DVDD33 Power Digital 3.3V VDD

135 DGND Power Digital Ground

136 ODE Output Output Data Enable

137 OHS Output Output Horizontal Sync

138 OCLK Output Output Clock

139 OVS Output Output Vertical Sync

140 DVDD18 Power Digital 1.8V VDD

141 DGND Power Digital Ground

142 DVDD18 Power Digital 1.8V VDD

143 DGND Power Digital Ground

144 OBB7 Output Output Port B: Blue Data 7

145 OBB6 Output Output Port B: Blue Data 6

146 OBB5 Output Output Port B: Blue Data 5

147 OBB4 Output Output Port B: Blue Data 4

148 DVDD33 Power Digital 3.3V VDD

149 DGND Power Digital Ground

150 OBB3 Output Output Port B: Blue Data 3

151 OBB2 Output Output Port B: Blue Data 2

152 OBB1 Output Output Port B: Blue Data 1

153 OBB0 Output Output Port B: Blue Data 0

154 OGB7 Output Output Port B: Green Data 7

155 OGB6 Output Output Port B: Green Data 6

156 OGB5 Output Output Port B: Green Data 5

157 OGB4 Output Output Port B: Green Data 4

158 DVDD33 Power Digital 3.3V VDD

159 DGND Power Digital Ground

160 OGB3 Output Output Port B: Green Data 3

161 OGB2 Output Output Port B: Green Data 2

162 OGB1 Output Output Port B: Green Data 1

163 OGB0 Output Output Port B: Green Data 0

164 DVDD18 Power Digital 1.8V VDD

165 DGND Power Digital Ground

166 DVDD18 Power Digital 1.8V VDD

-17-

8/25/2003

Page 19

787LE Service Manual

167 DGND Power Digital Ground

168 ORB7 Output Output Port B: Red Data 7

169 ORB6 Output Output Port B: Red Data 6

170 ORB5 Output Output Port B: Red Data 5

171 ORB4 Output Output Port B: Red Data 4

172 DVDD33 Power Digital 3.3V VDD

173 DGND Power Digital Ground

174 ORB3 Output Output Port B: Red Data 3

175 ORB2 Output Output Port B: Red Data 2

176 ORB1 Output Output Port B: Red Data 1

177 ORB0 Output Output Port B: Red Data 0

178 DVDD18 Power Digital 1.8V VDD

179 DGND Power Digital Ground

180 DVDD18 Power Digital 1.8V VDD

181 DGND Power Digital Ground

182 CLKOUT Output not to be connected - reserved

183 CLKIN Input to be connected to Digital Ground - reserved

185 DVDD33 Power Digital 3.3V VDD

186 DGND Power Digital Ground

191 DVDD18 Power Digital 1.8V VDD

192 DGND Power Digital Ground

193 DVDD18 Power Digital 1.8V VDD

194 DGND Power Digital Ground

199 DVDD18 Power Digital 1.8V VDD

200 DGND Power Digital Ground

201 DVDD18 Power Digital 1.8V VDD

202 DGND Power Digital Ground

203 SCL Input I2C Clock

204 SDA Open Drai

205 XCLK Output Crystal clock buffered output

206 XCLK_EN Input Crystal clock output enable

0 : xclk output disabled

1 : xclk output active

207 RESETN Input Reset input, Active Low

MTV312M64

The MTV312M micro-controller is an 8051 CPU core embedded device especially tailored for

CRT/LCD

Monitor applications. It includes an 8051 CPU core, 1024-byte SRAM, 14 built-in PWM DACs,

VESA DDC interface, 4-channel A/D converter, and a 64K-byte internal program Flash-ROM.

A “CMOS output pin” means it can sink and drive at least 4mA current. It is not recommended to

use such

pin as input function.

A “open drain pin” means it can sink at least 4mA current but only drive 10~20uA to VDD. It can

be used as input or output function and needs an external pull up resistor.

A “8051 standard pin” is a pseudo open drain pin. It can sink at least 4mA current when output is

at low level, and drives at least 4mA current for 160nS when output transits from low to high, then

keeps driving at 100uA to maintain the pin at high level. It can be used as input or output function.

It needs an external pull up resistor when driving heavy load device.

POWER CONFIGURATION

The MTV312M can work on 5V or 3.3V power supply system.

In 5V power system, the VDD pin is connected to 5V power and the VDD3 needs an external

capacitor, all

output pins can swing from 0~5V, input pins can accept 0~5V input range.

And ADC conversion range is 5V. However, X1 and X2 pins must be kept below 3.3V.

-18-

8/25/2003

Page 20

787LE Service Manual

In 3.3V power system, the VDD and VDD3 are connected to 3.3V power, all output pins swing

from 0~3.3V, HSYNC, VSYNC and open drain pin can accept 0~5V input range, other pins must

be kept below 3.3V. And the ADC conversion range is 3.3V.

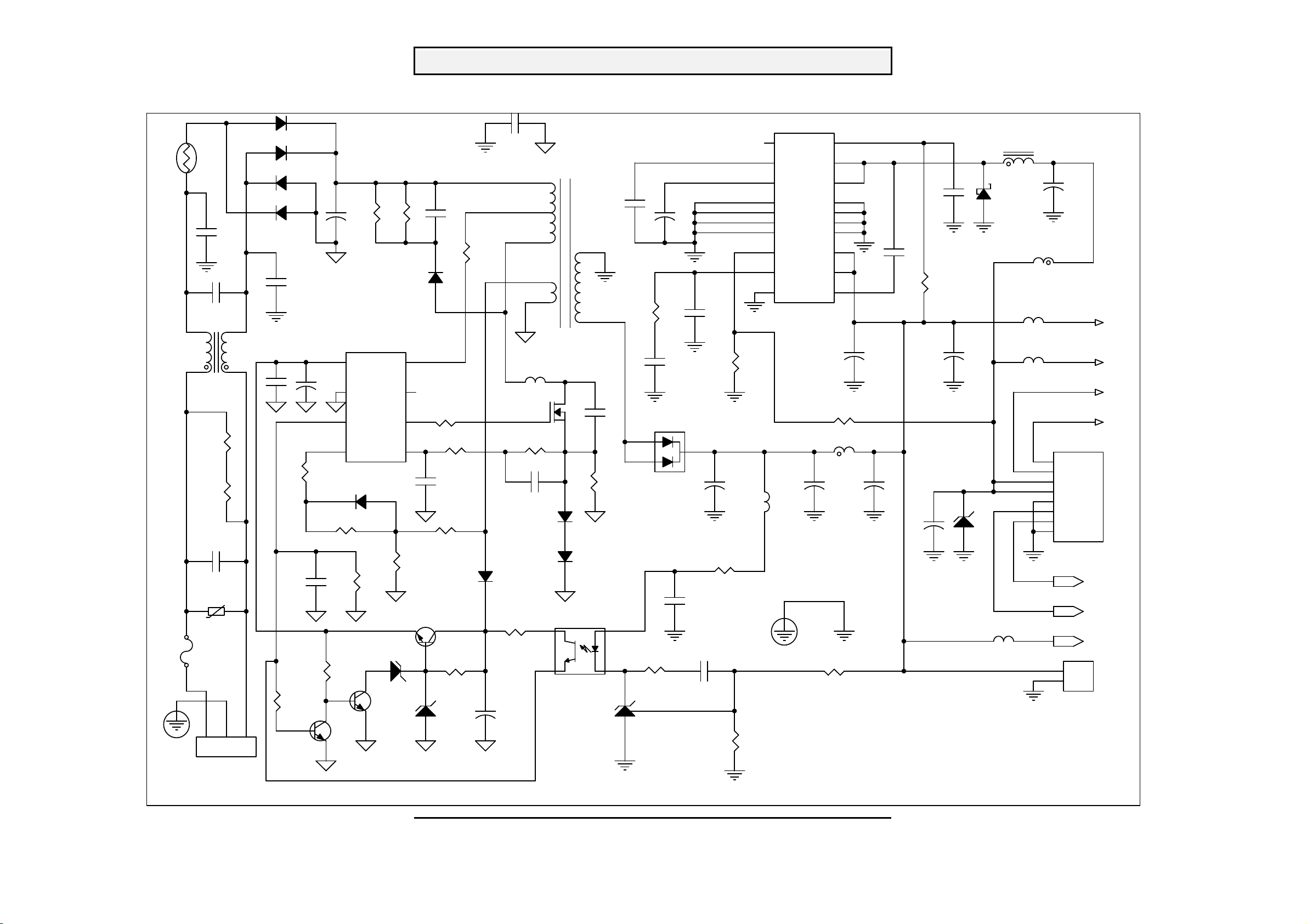

INVERTER

In order to drive the CCFLs embedded in the panel module, there is a half bridge inverter to

convert by the controller.

The input 12V up to hundreds of AC voltage output.

The inverter is formed by symmetric in order to drive the separate lamp modules.

The input stage consists of a PWM controller, half bridge inverter, and switching MOSFET to

convert DC input into AC output.

The output stage consists of a tuning capacitor, coupling capacitor, transformer, push-pull

MOSFET pair to boost AC output up to hundreds of voltage.

And one resister is serial to lamp for output voltage feedback.

There are two signal to control the inverter which come from system.

Logic “high” level which send to I901 is turn on the inverter.

BRI signal control brightness by DC level which was integral from PWM signal.

-19-

8/25/2003

Page 21

8. Wiring Diagram

787LE Service Manual

LCD PANEL

P981

P901

POWER PCB

P906

TO:METAL FITTG

GND

P802

P601

P953

P701

P701

KEYPAD PCB

P101 P105

MAIN PCB

P103

P104

P961

I/O CABLE

-20-

8/25/2003

Page 22

9. PCB Layout

9.1. MAIN PCB TOP VIEW

787LE Service Manual

-21-

8/25/2003

Page 23

9.2. MAIN PCB BOTTOM VIEW

787LE Service Manual

-22-

8/25/2003

Page 24

9.3. CON PCB TOP VIEW

787LE Service Manual

-23-

8/25/2003

Page 25

9.4. CON PCB BOTTOM VIEW

787LE Service Manual

-24-

8/25/2003

Page 26

9.5. POWER PCB TOP VIEW

787LE Service Manual

-25-

8/25/2003

Page 27

9.6. POWER PCB BOTTOM VIEW

787LE Service Manual

-26-

8/25/2003

Page 28

787LE Service Manual

10. TROUBLE SHOOTING FLOW CHART

10.1. NO POWER

POWER

STAR

Check

12V O/P

D804

Check F801

D805,D807

D810,D813

Check

I801

,Q801

STAR

12V

Check

5V O/P

C826

Check

I804

D812

P802 5,6 PIN

5V

12V

Check

Check

P901,P906

Check I101

L901,L903

L904,L905

D918,D922

Check

I901

MAIN PCB

PANEL

CHECK

MAIN PCB

5V OK?

Y

3.3V OK?

Y

1.8V OK?

N

N

N

CHECK

POWER PCB

OK?

CHECK

I103,

SUROUND CAP

BEAD OK?

CHECK

I104,

SUROUND CAP

BEAD OK?

-27-

CHECK

I106,I107

SUROUND CAP

OK?

CHECK

I101,

SUROUND CAP

BEAD OK?

8/25/2003

Page 29

10.2. MCU NO FUNCTION

787LE Service Manual

CHECK

C239

MCU 5V

OK?

Y

CHECK

I108 PIN7,PIN9

5V?

Y

CHECK

12MHz PIN11,PIN12

OK?

Y

CHECK

PIN13,PIN14

CLOCK OK?

N

N

N

N

CHECK

Q108,Q107

OK?

CHECK

R190,C219

OK?

CHECK

X102,C222,C223

OK?

CHECK

I108 TO I101

OK?

Y

CHECK

I108,EVERY TWO

PIN SHORT?

N

CHECK

KEYPAD P103

OK?

-28-

8/25/2003

Page 30

10.3. NO DISPLAY

787LE Service Manual

Power Key Work

OK?

Y

Check

H V sync

Y

Check R.G.B

DATA

Y

Check

X101,X102

Y

Check I101

OCLK,ODE,

OVS,OHS

N

N

N

N

N

Check

Keypad

Check

I105

CHECK

I/O cable

Check

C162,C163,

C222,C223

Check

ADE SCL,SDA

N

N

N

R197,R198,R199

N

N

Check

5V MCU

Check

P104

Check

Check

I104,I103

Check

I108,SCL,SDA

N

N

N

N

N

Check

I108

Check

I/O cable

Check

I101

Check

Avdd 1.8V,3.3V

Check

I109,SCL,SDA

Y

Check

I106,I107

N

Check

Q102

N

Check

INVERTER

N

Check

PANEL

-29-

8/25/2003

Page 31

10.4. LOSE COLOR

787LE Service Manual

Some bits

Lost

Y

Check

RP01~RP12

I106 poor

soldering

P105

soldering

N

N

I101 or R-pack

soldering

Y

I107 poor

soldering

Lose color

R or G or B

Y

Check

P104

Pin 8,10,12

Y

Check

L120,121,122

R122,125,127

Y

I101

fail or poor

soldering

N

N

Check

Sign Cable

Check

C182,183,186

R197,198,199

-30-

8/25/2003

Page 32

787LE Service Manual

1

2

2

11. ADJUSTMENT

11.1. ADJUSTMENT CONDITIONS AND PRECAUTIONS

1. Approximately 30 minutes should be allowed for warm up before proceeding.

2. Adjustments should be undertaken only on those necessary elements since most of them

have been carefully preset at the factory.

3. ESD protection is needed before adjustment.

11.2. MAIN ADJUSTMENTS

1. WHITE BALANCE FUNCTION KEY

2. GEOMETRY FUNCTION KEY

NO. FUNCTION DESIGNATION

11.3. ALIGNMENT PROCEDURES

Adjustment Conditions and Precautions:

(A). Power supply voltage:

AC 110/120V±10% 60 Hz±5%, AC 220/240V±10% 50 Hz±5%.

(B). Warm up time:

The display must be power ON for at least 30 minutes at full white pattern before

starting alignments.

This is especially critical in color temperature and white balance adjustments.

(C). Signals: reference the front detail specifications and timing table.

Video : reference the front detail specifications.

1. Adjustment of White Balance:

A. TIMING: 1280x1024 64KHz/60Hz.

B. PATTERN: 5 Blocks.

C. LCD MONITOR set to 1280x1024 80K/75Hz BURN IN and warm up over 30 minutes.

D. CA110 color analizer at the center of screen and along a perpendicular to the screen at

20cm from the display.

E. Power turn off, Press

LED ison, release

(Fig.1)

“▲” and “ ”

“▼” and “ ”

-31-

and turn on power at the same time after power

key, Then press “ ” key go to factory mode.

(Fig.1)

8/25/2003

Page 33

787LE Service Manual

2

2

2

2 1 2 2 1

F. Adjust Color Temperature:

(1) EEPROM INIT (5 BLOCKS):

Press “▼” key move cursor to EEPROM INIT, Press key then monitor will

INIT ADC value.

(2) Press “▲” key move cursor to “White Balance”, Press key do white balance

adjustment.

(3) Press “▼” key move cursor to “Color Temerature Adjust”, Press key, Then

OSD will display Fig.2

(4) 9300K verify: move cursor to 9300K Press key.

Press “▼” ,“▲” key adjust R.G.B value

x=0.283 ±0.03

y=0.298 ±0.03

Press key return to Fig.2

(5) 6500K verify: Repeat (4) press “▼” ,“▲” move cursor to 6500K press key

x=0.310 ±0.03

y=0.330 ±0.03

Y≧200 cd/m2

(6) Press key go back to Fig.2, Then press key return to Fig.1, Power key

OFF/ON quit factory mode.

G. Color Temperature & Luminance Verify:

BRIGHTNESS MAX, CONTRAST MAX

9300K: x=0.283 ±0.03 y=0.298 ±0.03

6500K: x=0.310 ±0.03 y=0.330 ±0.03 Y≧200 cd/m2

2. Geometry:

(a). Set cross-hatch pattern and preset timing as timing table listed.

(b). Change to each mode in turn and wait for the monitor finish auto-alignment and save

process before change to next mode.

(c). Until all of modes are agjusted, exit OSD menu and press PWR OFF to exit factory

mode.

(Fig.2)

-32-

8/25/2003

Page 34

787LE Service Manual

12. ELECTRICAL PARTS LIST

When you place a parts order, be sure to indicate the following data on the order:

l Location No.

l Parts No.

l Description

LOC NO. SOURCE PART NO. DESCRIPTION SPECIFICATION REMARK

MAIN P.C.BOARD

C101 2333347613 CAP,ELE 105'C EC 47u/ 16V 5*11 P=2.5

C102 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C104 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C105 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C107 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C109 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C110 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C111 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C112 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C113 2346110296 CAP,CHIP 125'C CS 0603/X7R/50V 1000p K

C114 2346110396 CAP,CHIP 125'C CS 0603/X7R/50V 0.01u K

C115 2341110196 CAP,CHIP 125'C CS 0603/COG/50V 100p J

C116 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C117 2346110296 CAP,CHIP 125'C CS 0603/X7R/50V 1000p K

C118 2346110396 CAP,CHIP 125'C CS 0603/X7R/50V 0.01u K

C119 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C120 2346110396 CAP,CHIP 125'C CS 0603/X7R/50V 0.01u K

C121 2333347613 CAP,ELE 105'C EC 47u/ 16V 5*11 P=2.5

C122 2333347613 CAP,ELE 105'C EC 47u/ 16V 5*11 P=2.5

C123 2333347613 CAP,ELE 105'C EC 47u/ 16V 5*11 P=2.5

C124 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C125 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C126 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C127 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C128 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C129 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C130 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C131 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C132 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C133 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C134 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C135 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C136 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C137 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C138 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C139 2333347613 CAP,ELE 105'C EC 47u/ 16V 5*11 P=2.5

C140 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C141 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C142 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C143 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C144 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C145 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C146 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C147 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C148 2333347613 CAP,ELE 105'C EC 47u/ 16V 5*11 P=2.5

C149 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C150 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C151 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C152 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C153 2346747496 CAP,CHIP 85'C CS 0603/Y5V/16V 0.47u Z

C154 2341110196 CAP,CHIP 125'C CS 0603/COG/50V 100p J

C155 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C156 2346747496 CAP,CHIP 85'C CS 0603/Y5V/16V 0.47u Z

C157 2341110196 CAP,CHIP 125'C CS 0603/COG/50V 100p J

C158 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

-33-

9/24/2003

Page 35

787LE Service Manual

LOC NO. SOURCE PART NO. DESCRIPTION SPECIFICATION REMARK

C159 2346747496 CAP,CHIP 85'C CS 0603/Y5V/16V 0.47u Z

C160 2341110196 CAP,CHIP 125'C CS 0603/COG/50V 100p J

C161 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C162 2341122096 CAP,CHIP 125'C CS 0603/COG/50V 22p J

C163 2341122096 CAP,CHIP 125'C CS 0603/COG/50V 22p J

C164 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C166 2333333791 CAP,ELE 105'C EC 330u/ 16V 8*11 P=5.0

C169 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C170 2333447791 CAP,ELE 105'C EC 470u/ 25V 10*13.0 P=5.0

C171 2333347791 CAP,ELE 105'C EC 470u/ 16V 10*12.5 P=5.0

C176 2333333791 CAP,ELE 105'C EC 330u/ 16V 8*11 P=5.0

C177 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C178 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C179 2333347613 CAP,ELE 105'C EC 47u/ 16V 5*11 P=2.5

C180 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C182 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C183 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C185 2341122096 CAP,CHIP 125'C CS 0603/COG/50V 22p J

C186 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C191 2341122096 CAP,CHIP 125'C CS 0603/COG/50V 22p J

C192 2341147096 CAP,CHIP 125'C CS 0603/COG/50V 47p J

C194 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C195 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C196 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C197 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C198 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C199 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C200 2346110396 CAP,CHIP 125'C CS 0603/X7R/50V 0.01u K

C201 2346110296 CAP,CHIP 125'C CS 0603/X7R/50V 1000p K

C202 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z

C203 2346410496 CAP,CHIP 85'C CS 0603/Y5V/50V 0.1u Z