LG 6RWU0-05A Engineering Product Data Book

6RWU0-05A

PTAC Type

(60Hz/R410A)

2

PTAC

PTAC

Introduction

Part 1 General information

1. Model line up ....................................................................................12

2. Nomenclature ...................................................................................13

3. Appearance.......................................................................................14

4. List of functions ...............................................................................15

5. Features ............................................................................................16

3

PTAC

Part 2 Product data

1 YA chassis ........................................................................................22

1.1 Features........................................................................................................22

1.2 List of functions.............................................................................................23

1.3 Specifications................................................................................................24

1.4 Dimensions ...................................................................................................30

1.5 Piping diagrams ............................................................................................31

1.6 Wiring diagrams............................................................................................33

1.7 Capacity tables .............................................................................................35

1.8 Electrical characteristics ...............................................................................43

1.9 Operation range............................................................................................44

2 Control Devices...............................................................................45

2.1 Electronic Controls........................................................................................45

1.10 Sound level test method...............................................................................44

4

PTAC

Part 3 Design and installation

1 General installation procedure........................................................51

2 Installation of unit.............................................................................52

2.1 Safety precautions.........................................................................................52

2.2 Points of explanation about operations .........................................................55

2.3 Selecting installation site for the unit .............................................................55

2.4 Installation of unit...........................................................................................56

2.5 Wall sleeve installation ..................................................................................58

5

PTAC

Part 4 Accessories

1 Controller accessories ....................................................................65

1.1 Hard Wire kit .................................................................................................65

1.2 Wired Wall Thermostat Connection Kit .........................................................67

2 Mechanical accessories ..................................................................68

2.1 Control Panel Key Lock ................................................................................68

2.2 Outer Grille ....................................................................................................69

2.3 Condensate Drain Kit ....................................................................................71

2.4 Leveling Legs ................................................................................................73

2.5 Sub Base ......................................................................................................74

2.6 Lateral Duct Accessory System ...................................................................76

2.7 Replacement Filter - 10 Pack ........................................................................79

2.8 Wall Sleeve ...................................................................................................79

2.9 Folding Wall Sleeve ......................................................................................79

2.10 Remote Escutcheon Kit – 10 pack ..............................................................80

2.11 Vent Filter ....................................................................................................81

3 Power cord accessories ...................................................................82

3.1 Power cord .....................................................................................................82

6 General information

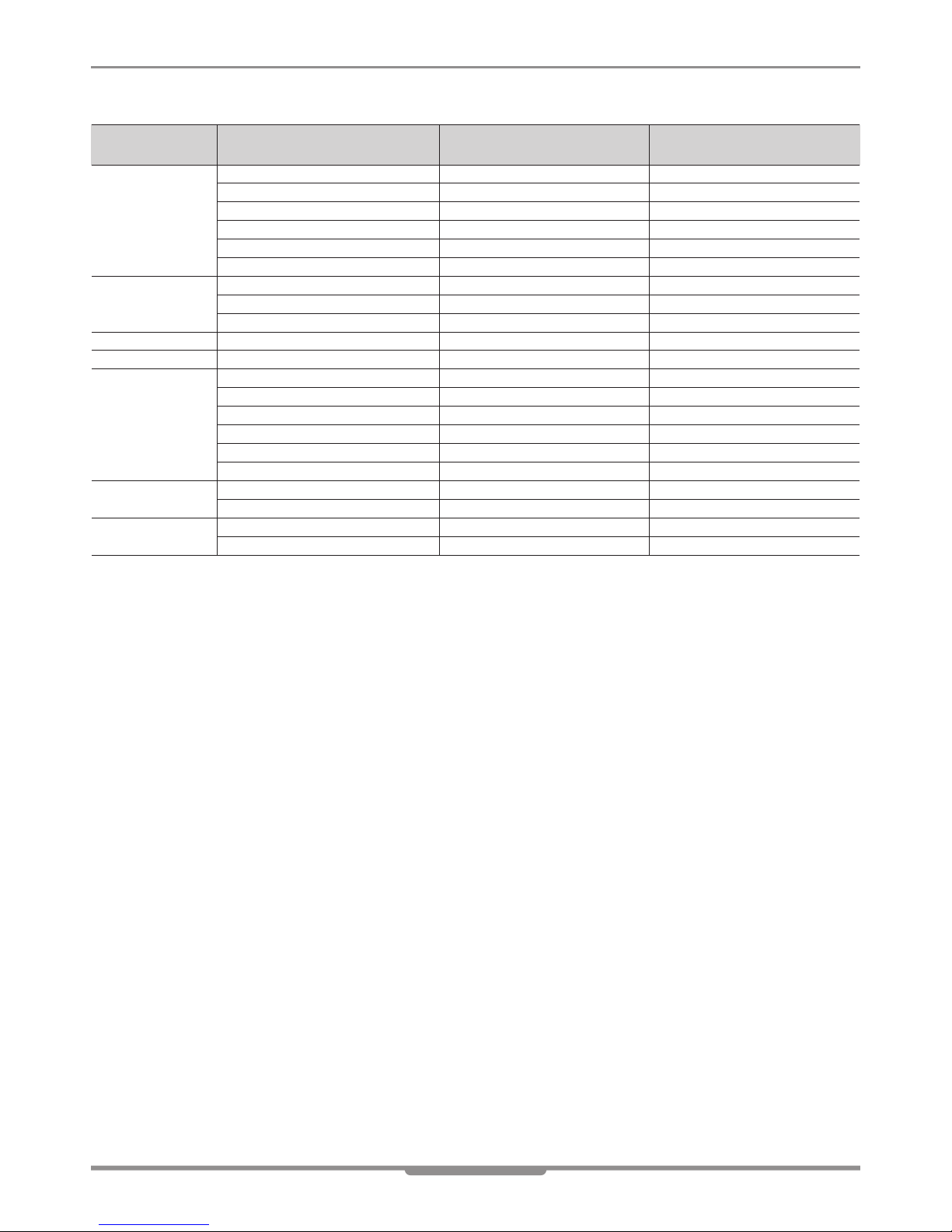

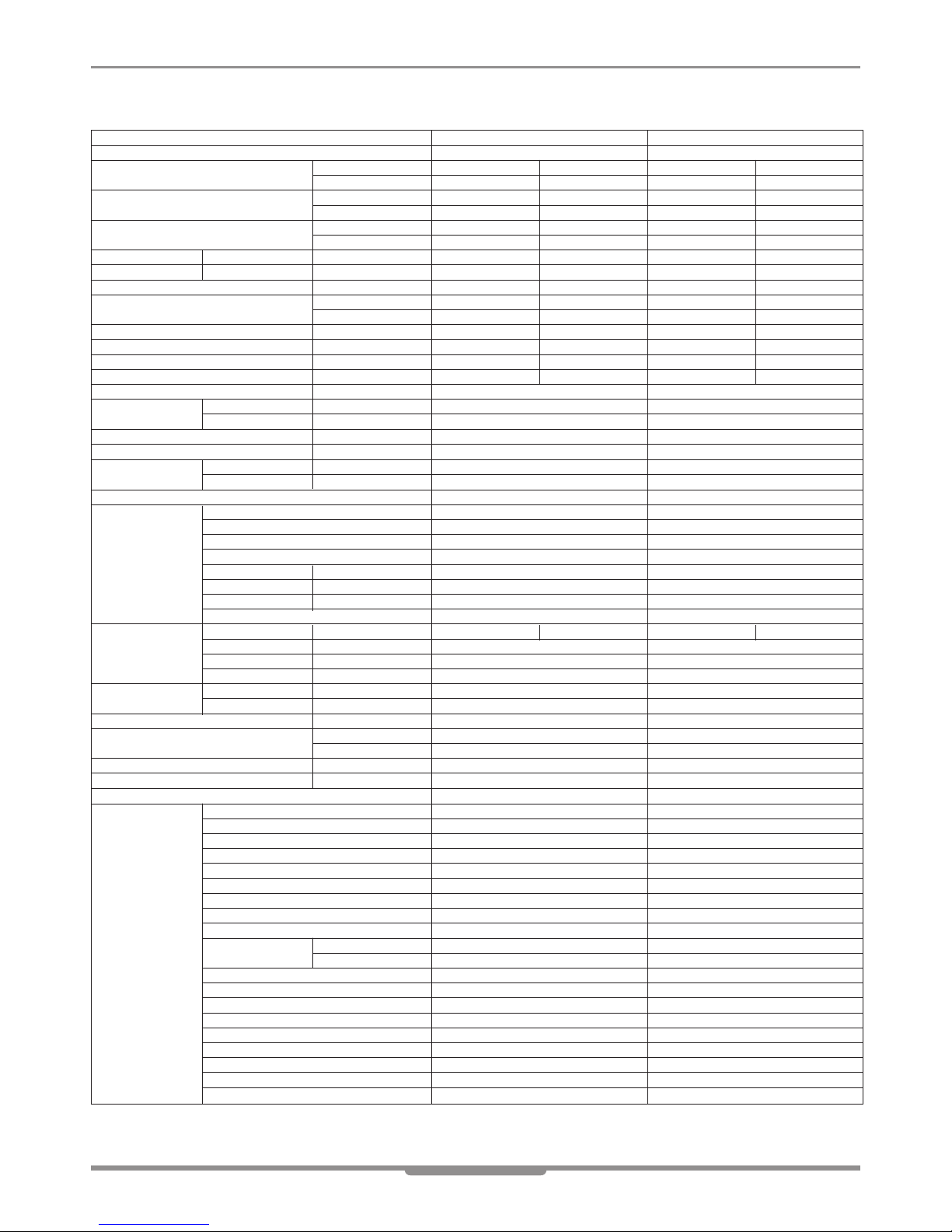

Test condition of International Standards

PTAC

6RWU0-05B

Test condition of International Standards

CLASSIFICATION

KSC ISO AHRI AHAM AS SSA

9306 5151 210/240 1861.1 385

Indoor

DB°C(°F) 27.0 27.0 26.7(80) 26.7(80) 27.0 29.0

Cooling WB°C(°F) 19.5 19.0 19.4(67) 19.4(67) 19.0 19.0

Capacity

Outdoor

DB°C(°F) 35.0 35.0 35.0(95) 35.0(95) 35.0 46.0

WB°C(°F) 24.0 24.0 23.9(75) 23.9(75) 24.0 24.0

Indoor

DB°C(°F) 20.0 20.0 21.1(70) 21.1(70) 21.0 21.0

Heating WB°C(°F) 15.0 15.0 15.6(60) 15.6(60) 15.0 15.5

Capacity

Outdoor

DB°C(°F) 7.0 7.0 8.3(47) 8.3(47) 7.0 7.0

WB°C(°F) 6.0 6.0 6.1(43) 6.1(43) 6.0 6.0

Indoor

DB°C(°F) 32.0 32.0 26.7(80) 32.2(90) 32.0 29.0

Maximum

WB°C(°F) 23.0 23.0 19.4(67) 22.8(73) 23.0 19.0

Cooling

Outdoor

DB°C(°F) 43.0 43.0 46.1(115) 43.3(110) 43.0 54.0

Operating

WB°C(°F) 26.0 26.0 23.9(75) 25.6(78) 26.0 24.0

Indoor

DB°C(°F) 27.0 27.0 26.7(80) 26.7(80) - -

Maximum

WB°C(°F) 19.0 19.0 19.4(67) 22.8(73) - -

Heating

Outdoor

DB°C(°F) 21.0 24.0 23.9(75) 23.9(75) - -

Operating

WB°C(°F) 15.0 18.0 18.3(65) 18.3(65) - -

Enclosure

Indoor

DB°C(°F) 27.0 27.0 26.7(80) 26.7(80) 27.0 27.0

Sweat / WB°C(°F) 24.0 24.0 23.9(75) 23.9(75) 24.0 24.0

Condensate

Outdoor

DB°C(°F) 27.0 27.0 26.7(80) 26.7(80) 27.0 27.0

Disposal WB°C(°F) 24.0 24.0 23.9(75) 23.9(75) 24.0 24.0

Freeze-up/

Indoor

DB°C(°F) 21.0 21.0 19.4(67) 21.1(70) 21.0 21.0

Low

WB°C(°F) 15.0 15.0 13.9(57) 15.6(60) 16.0 16.0

Temperature

Outdoor

DB°C(°F) 21.0 21.0 19.4(67) 21.1(70) 21.0 21.0

WB°C(°F) 15.0 15.0 13.9(57) 15.6(60) 16.0 16.0

KS : Korea Standard AS : Australia Standard

ISO : International Standard Organization SSA : Saudi Arabian Standard

AHRI : Airconditioning, Heating & Refrigeration Institute

AHAM : Association of Home Appliance Manufacturers

In the table above, temperatures are expressed in Fahrenheit(°F) within parentheses only for ARI and AHAM standards.

General information 7

Introduction

PTAC

Introduction

Preface

Air Conditioning & Energy Solution Company

Packaged Terminal Air-Conditioners(PTAC) of LG is the best choice a customer can avail when it comes to a quiet environment. Ultra quiet operation is the hallmark of these Air-Conditioners of LG. This range of units is suitable for Hotels and

Healthcare applications. These units have extremely low noise levels and outstanding sound prevention ratings. Moreover,

these units have higher Energy ratings which results in excellent energy savings.

These units are also provided with unique features to provide better usability and easy installation for the user.

The capacity of these PTAC models ranges from 7,000 Btu/h to 15,000 Btu/h.

Some of the important features of this unit are as follows:-

Long term money saving: By providing features such as Gold Fin etc... to maintain the same performance throughout the life

of the Air-Conditioner.

Comfort : With features such as Wall Thermostat temperature control, Auto Restart, etc…, which gives ultimate comfort to

our customer.

These units are equipped with many standard and optional features for our customers. For details, please refer to the

detailed specification following this description.

6RWU0-05B

8 General information

Introduction

PTAC

6RWU0-05B

Publication History

Pub. No. Frequency Category Product name Refrigerant Notes Published in

6RWU0 - 01A 60Hz RAC PTAC R410A New Edition of PDB Apr.2010

6RWU0 - 01B

6RWU0 – 01C

60Hz RAC PTAC R410A Spec sheet update June.2010

60Hz RAC PTAC R410A Spec sheet update August. 2010

6RWU0 – 01D

60Hz RAC PTAC R410A Add Operation range Dec. 2010

6RWU0 – 02A

60Hz RAC PTAC R410A 2011 New line-up update

6RWU0 – 02B

60Hz RAC PTAC R410A Modified Capacity Table

Apr. 2011

Apr. 2012

6RWU0 – 02C

60Hz RAC PTAC R410A Spec Sheet Update

Apr. 2012

6RWU0-03A

60Hz RAC PTAC R410A 2013 Model Line Up

Mar, 2013

6RWU0-03B

60Hz RAC PTAC R410A Update additional accessories

Jun,2014

6RWU0-04A

60Hz RAC PTAC R410A 2016 Model Line UP

Jun,2016

6RWU0-04B

60Hz RAC PTAC R410A Spec Sheet Update

Feb,2017

6RWU0-05A

60Hz RAC PTAC R410A 2017 Model Line UP

Aug,2017

6RWU0-05B

60Hz RAC PTAC R410A Spec sheet update (add gross weight)

Nov,2017

General information 9

Introduction

PTAC

6RWU0-05B

Step by step air conditioner selection process (reference)

(1)

Calculate or obtain the maximum heat load for the area to be air conditioned.

(2)

(3)

1. Air conditioners should not be installed in areas where corrosive gases such as acid gas or

alkaline gas are present.

CAUTION

Selection of the control system

Remote Wall Thermostat Control

Front Desk Control

Specifications

Model features and functions

Air-flow and temperature distribution

Note :

Here in this PDB, the temperature units are generally expressed in Fahrenheit (°F) but for specific regions

please conform to local standards whenever necessary.

10 General information

PTAC

6RWU0-05B

General information 11

PTAC

Part 1 General information

1. Model line up .......................................................................................12

2. Nomenclature ......................................................................................13

3. Appearance..........................................................................................14

4. List of functions ..................................................................................15

5. Features ...............................................................................................16

12 General information

PTAC

6RWU0-05B

1. Model line up

Model line up

2.05(7) 2.64(9) 3.52(12) 4.4(15)

YA

Model names

Capacity, kW(kBtu/h)

Chassis

UYC073ALEU1(LP073CDUC)

UYH073ALEU1(LP073HDUC)

UYC093ALEU1(LP093CDUC)

Y4NZ09ANLD1 (LP093HDUC1)

UYC09EALE31(LP096CD3B)

UYH09EALE31(LP096HD3B)

UYC123ALEU1(LP123CDUC)

Y4NZ12ANLD1 (LP123HDUC1)

UYC12EALE31(LP126CD3B)

UYH12EALE31(LP126HD3B)

UYC153ALEU1(LP153CDUC)

UYH153ALEU1(LP153HDUC)

General information 13

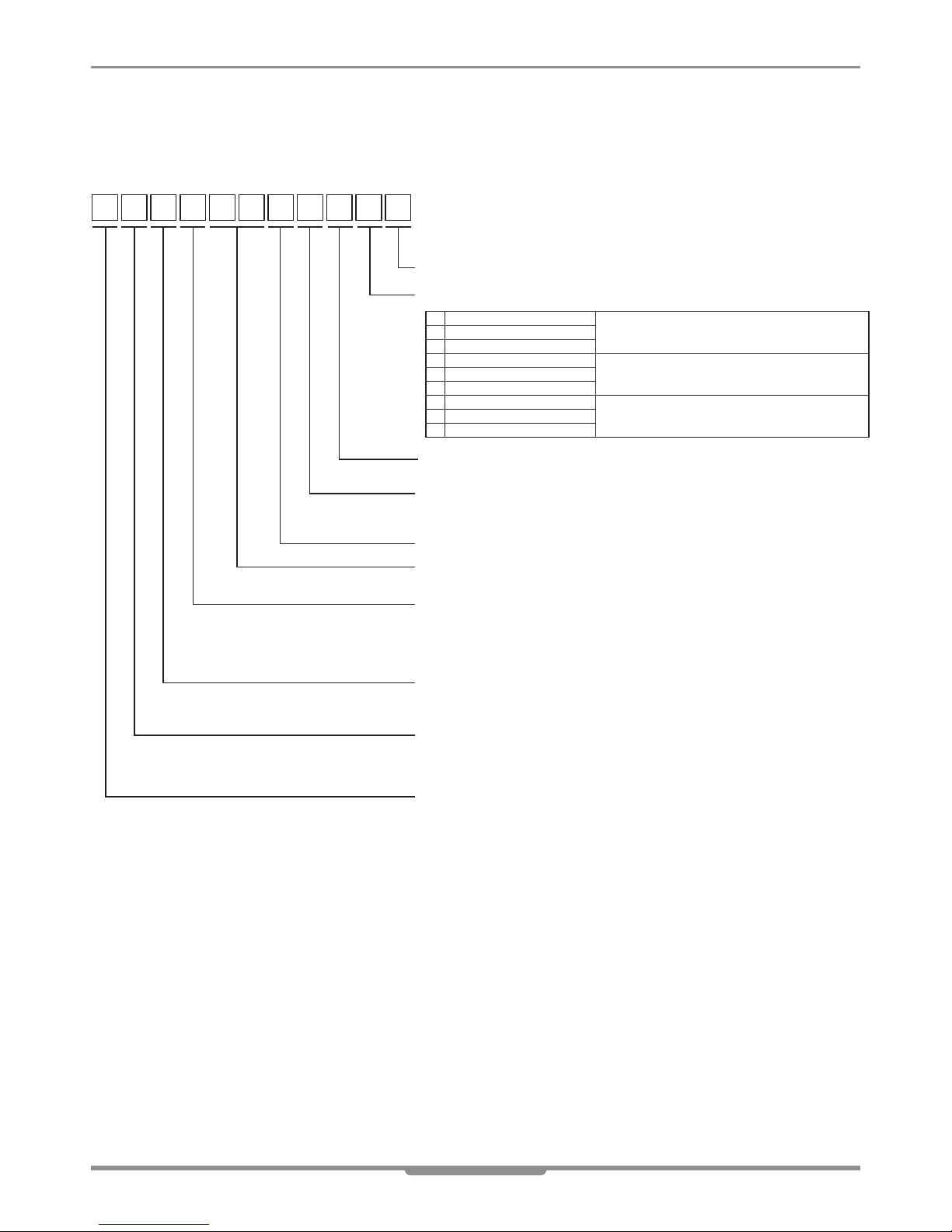

2. Nomenclature

PTAC

6RWU0-05B Nomenclature

Global standard

[New version]

Y 4 N Z 0 9 A N L D 1

Model Development serial number.

Function

Production type

Chassis : A – YA chassis.

Capacity

N: In house

S: Outsourcing

Look

L: LG Brand

Operation type

Set Type

N: Indoor unit

M: Mock-up

2: R22

3: R32

4: R410A

C: C/O

H: H/P

Q: DC Inverter C/O

M: DC Inverter H/P Multi-Comp atible

X: C/O + E/Heater

Z: H/P + E/Heater

W: DC Inverter H/P

Product

Production Center, Refrigerant

W: Window Air Conditioner

Y: Packaged Terminal Air Conditioner

X: Through the Wall Air Conditioner

E: Casement Air Conditioner

U: SPVU Air Conditioner

L: Console Air Conditioner

Q: Low Profile Air Conditioner

P: Portable Air Conditioner

Ex) 07 -> 7,000 Btu/h Class

A

B

C

D

E

F

G

H

J

2kW~5kW (Universal Heater)

2kW

3kW

2kW~5kW (Universal Heater)

2kW

3kW

2kW~5kW (Universal Heater)

2kW

3kW

Fan Mode + Auto Restart + Evaporator Frost Control +

Freeze Room Protection + 4-Way Cooling

Fan Mode + Auto Restart + Evaporator Frost Control +

Freeze Room Protection + 4-Way Cooling +

Target Temp. display

Fan Mode + Auto Restart + Evaporator Frost Control +

Freeze Room Protection + 4-Way Cooling +

Condensate Pump

Note :

The old version Nomenclature at the page 83 of this book.

14 General information

PTAC

6RWU0-05B

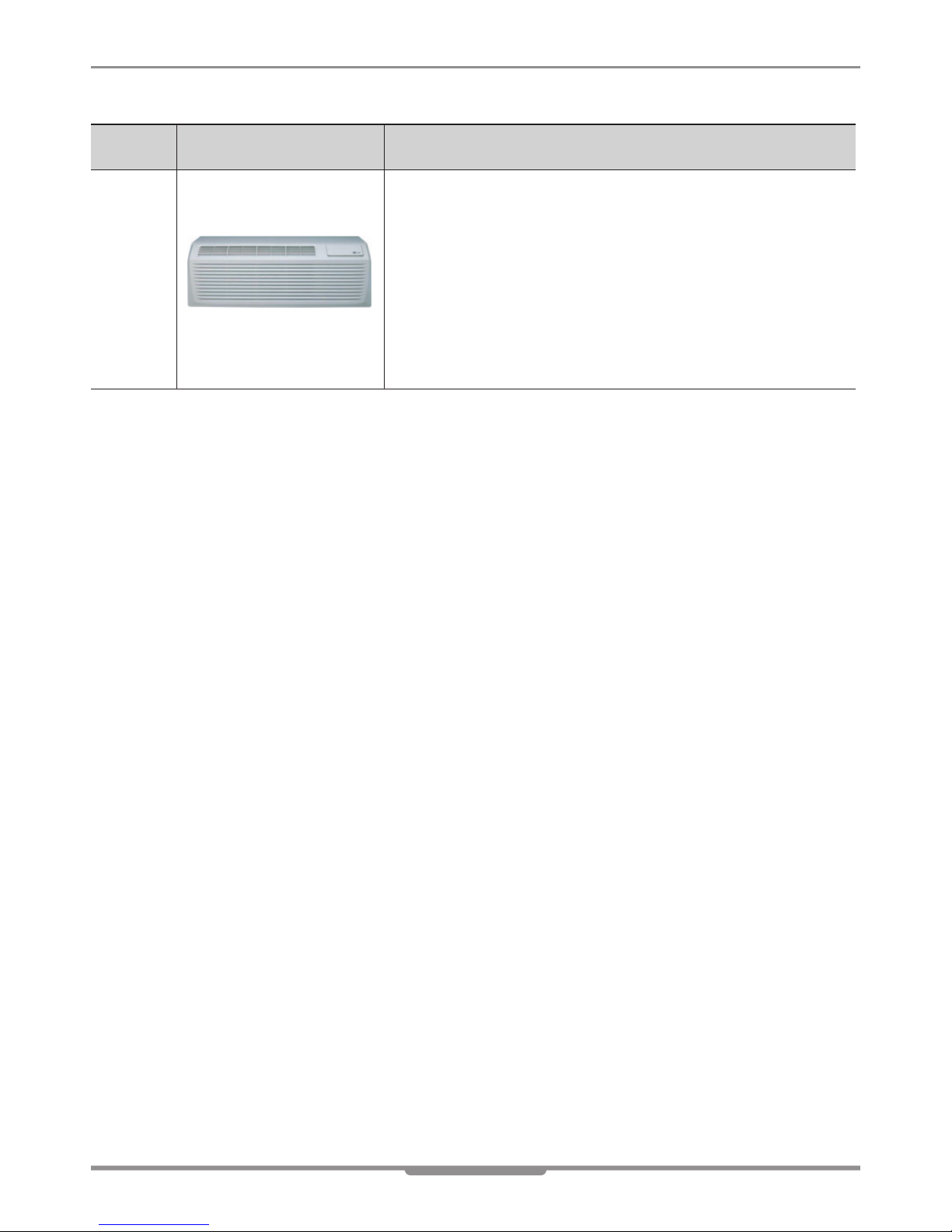

3. Appearance

Chassis Unit Models

YA

UYC073ALEU1(LP073CDUC)

UYH073ALEU1(LP073HDUC)

UYC093ALEU1(LP093CDUC)

Y4NZ09ANLD1 (LP093HDUC1)

UYC09EALE31(LP096CD3B)

UYH09EALE31(LP096HD3B)

UYC123ALEU1(LP123CDUC)

Y4NZ12ANLD1 (LP123HDUC1)

UYC12EALE31(LP126CD3B)

UYH12EALE31(LP126HD3B)

UYC153ALEU1(LP153CDUC)

UYH153ALEU1(LP153HDUC)

Appearance

General information 15

PTAC

6RWU0-05B

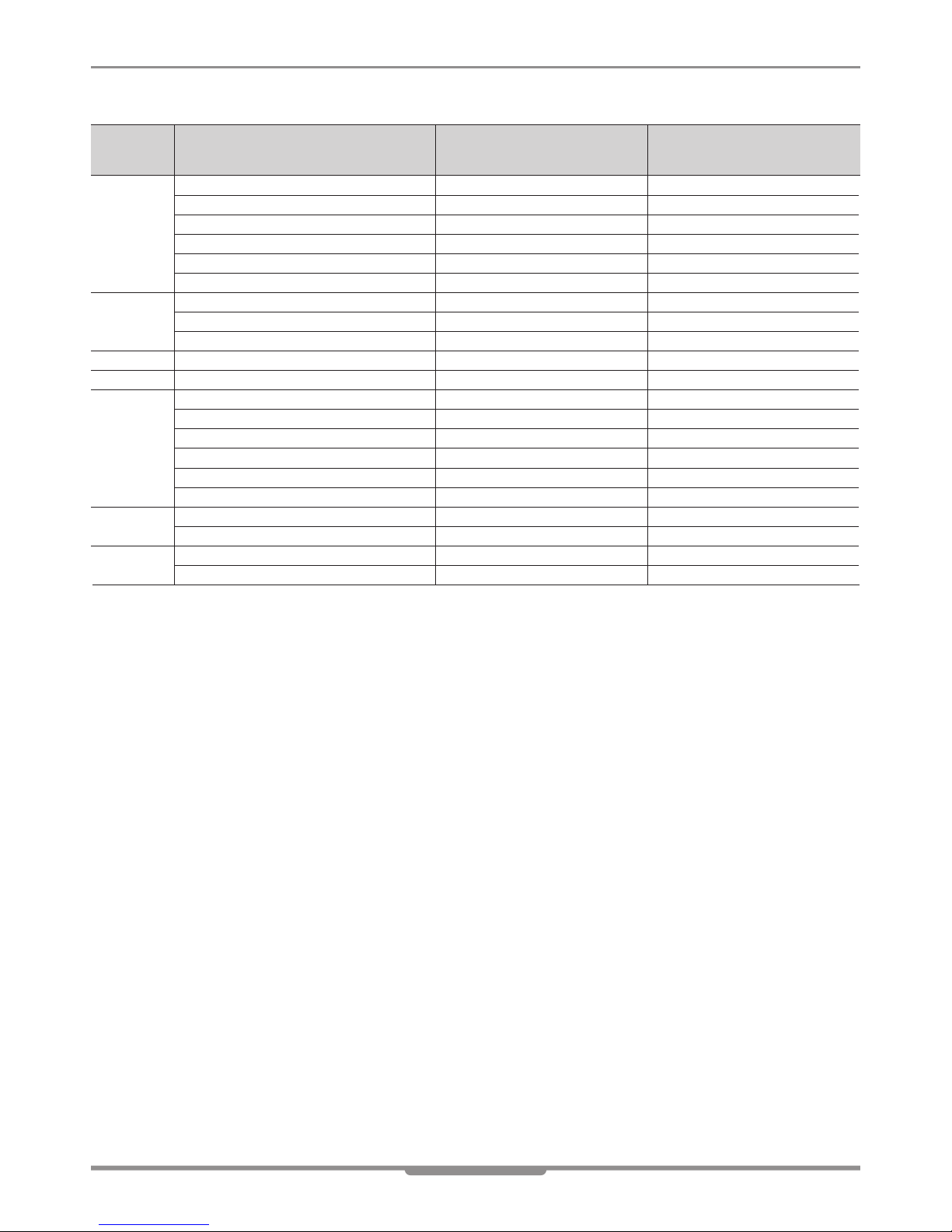

4. List of functions

Function

Category

PTAC Type

Cooling only Models

PTAC Type

Heat Pump Models

Air discharge type Top discharge Top discharge

Airflow direction control (up & down) Manual Manual

Airflow direction control (left & right) - Auto swing - Airflow steps (fan/cool/heat) 2/2/2 2/2/2

Airflow Direction 2 way 2 way

Deodorizing filter - Plasma air filter - Air filter (washable / anti-fungus) O O

Electric heater (operation) O O

Hot start - Auto restart operation O O

Micom control O O

Air ventilation O O

Forced operation - Sleep mode - Timer O O

Wired remote control O O

Wireless remote control O O

Energy save mode O O

Thermistor O O

O : applied

- : not applied

Air flow

Air purifying

Installation

Reliability

Convenience

Individual

control

Others

List of functions

16 General information

PTAC

6RWU0-05B

5. Features

The following features can be found in PTAC (Packaged Terminal Air-Conditioners) :-

n 2 -Way Air Flow Direction

n Washable Filters

n Low Noise at High Air Volume

n High Efficiency Compressor

n Energy Saver Mode

n Timer

n Electric Heater

n Defrost Control

n Air Ventilation

n Energy saving Anti-corrosion treated Fins

n Infinite Impulse Response(IIR)

n Compressor Restart Delay

n Fan Only Setting

n Indoor Fan Speed Setting

n Two Fan Motors

n LED Diagnostics and Self Diagnostics

n Indoor Room Freeze Protection

n Compressor Overload Protection

n Outdoor Air Temperature Switchover

n Temperature Limits

n Condensate Drain Valve

n Quick Heater Recovery

n Reverse Cycle Defrosting (PTHP’s only)

n

High Temperature Heat Pump Operation Protection

n Remote Thermostat Control

n Slinger Technology

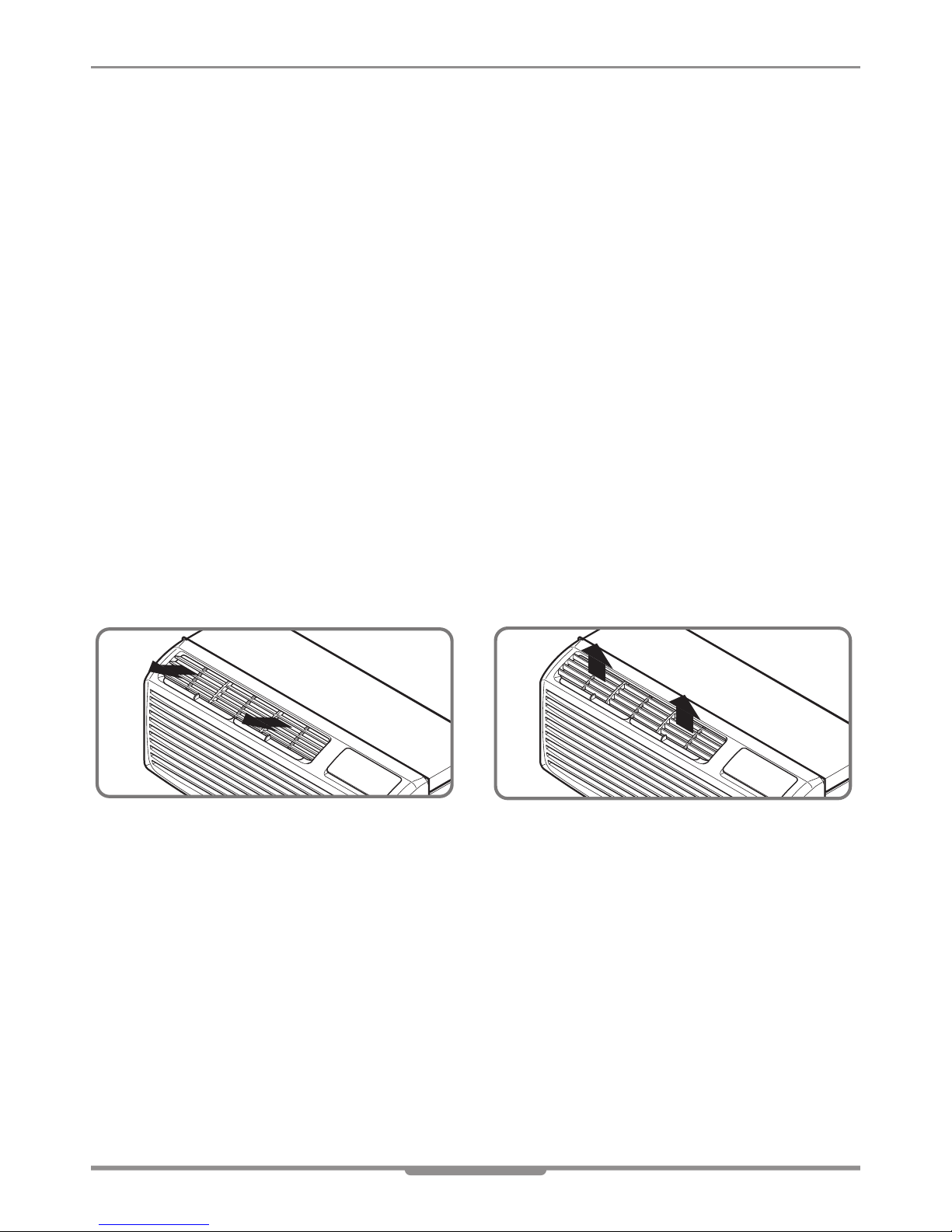

2 -Way Air Flow Direction

Air Flow can be adjusted by changing the direction of the air conditioner’s louvers at an angle of 15-40° off vertical to attain the

desired level of comfort and convenience. This can also increase the cooling efficiency of the air conditioner.

In order to attain maximum cooling efficiency, adjust the louvers so that they face upwards.

40° 15°

Features

General information 17

PTAC

6RWU0-05B

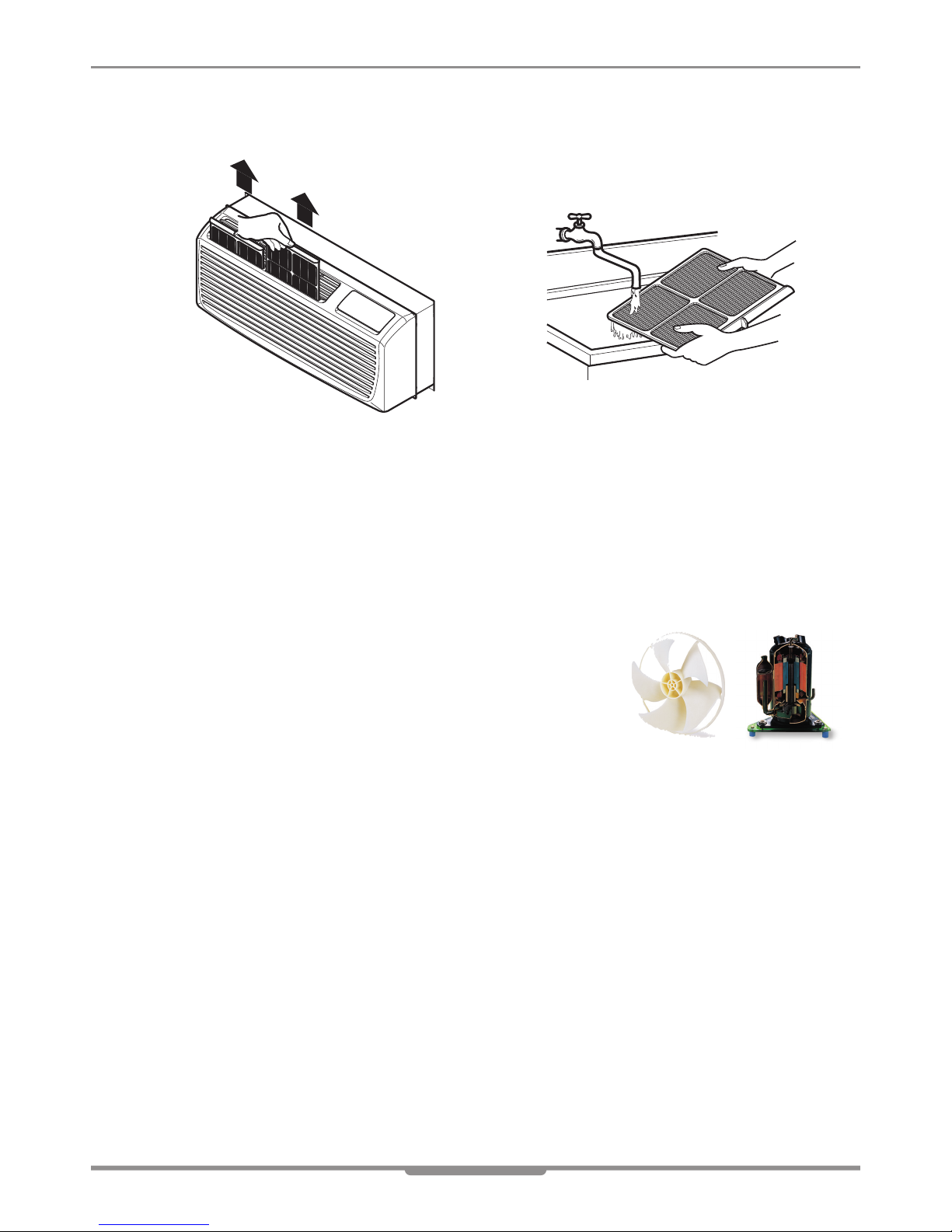

Washable Filters

The Unit uses two filters on the indoor side which can be slide easily. These filters can be taken out without removing the

Front Grille and then cleaned by washing or brushing.

The filters should be checked and cleaned every two(2) weeks or as necessary to maintain the optimal performance of the

air conditioner depending upon the region and purpose of application.

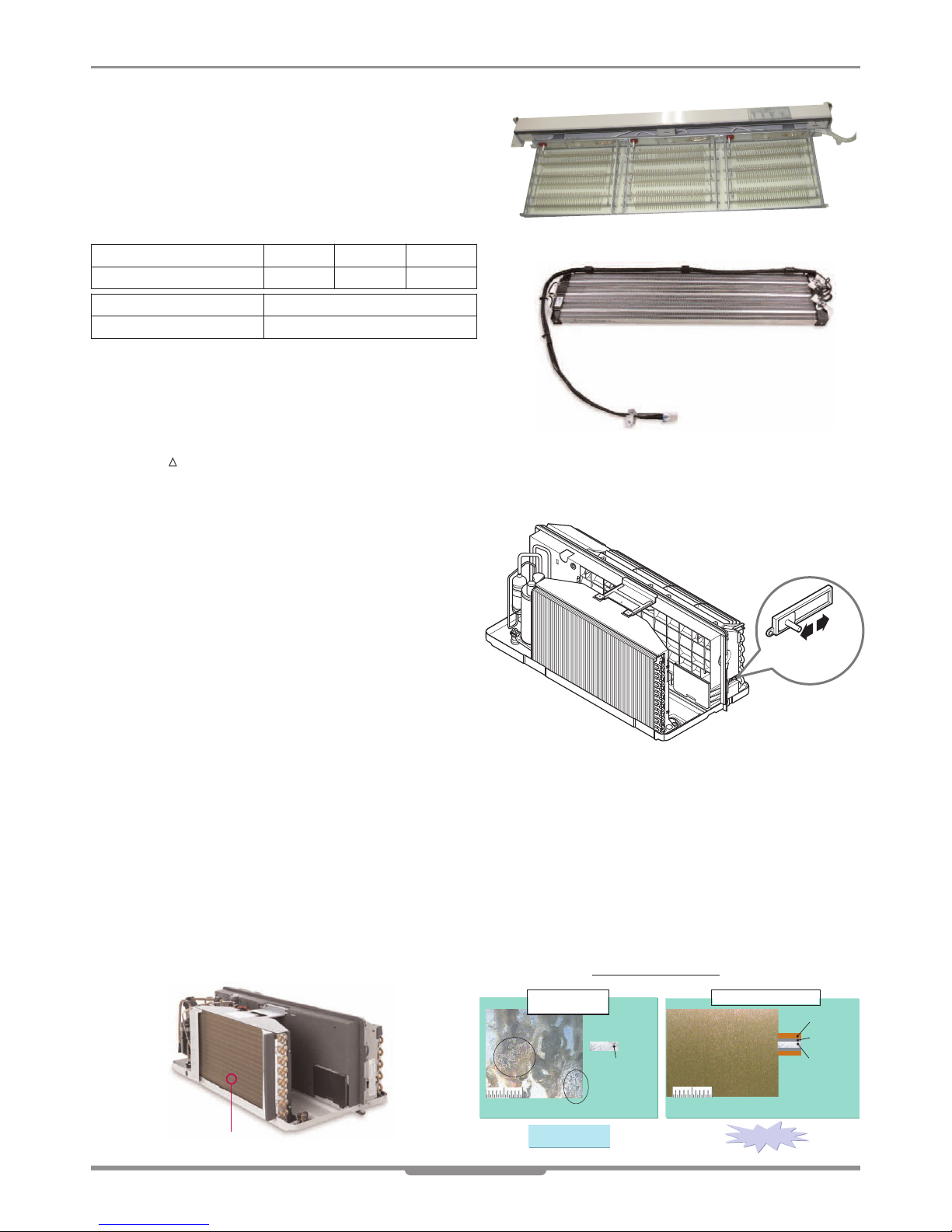

Low Noise at High Air Volume

New Blowers and Fans which are bigger and stronger than earlier ones operate at low rpm’s and have higher efficiency.

High Efficiency Compressor

LG Rotary compressors have low noise, low vibration and higher efficiency and

reliability.

Energy save mode

This feature employs a programmable logic which enables the unit to minimize power consumption. When the switch is activated in the “on” position, the Indoor fan turns off as soon as the compressor stops running. And in the “off” mode, the

indoor fan runs continuously even if the compressor stops running.

Timer

By this feature we can set the operating time of the air conditioner from one(1) hour up to a time of 12 hours. In the “Off”

mode, the Air Conditioner stops operating after the set time, while in the “On” mode, the Air Conditioner timer can be set so

that the unit starts operating at the desired time.

Features

18 General information

PTAC

6RWU0-05B

Electric Heater

Electric heaters are used in cold regions when instant heating is

required in the room.

In such cases, electric heaters are preferred over heat pump models which

sometimes require long times to achieve the desired heating effect.

Electric Heater are of two types – Coil Heater (265 V) and PTC

Heater (208-230 V) With different heater capacity according to models.

Defrost Control

When the unit starts operating in the heating mode outdoor unit

start freezing, to protect from freezing, Defrost Control is used.

Defrost operation take place when pipe temperature reaches

-1℃(30℉),

Type/Capacity

2.5kW 3kW 5kW

Coil Heater

(265 V)

-

9K 12K

-

Type/Capacity

2.4kW / 3.3kW / 4.7kW

PTC Heater

(208-230 V)

7K 9K 12K 15K

T(OD air temp – OD pipe temp)≥12 ℃ (54℉).

Defrost condition operates minimum 3minutes and maximum 9minutes for complete one cycle.

Air Ventilation

Air ventilation is carried out by means of a ventilation lever from

time to time to induct outside air into the room. For the air conditioner to maintain the best cooling conditions, the lever must be

in the closed position.

Energy saving Gold Fin

Heat exchangers are coated with anti-corrosive and Hydrophilic layers. It prevents the corrosion of heat exchanger.

Fins remain new for a long time and the efficiency of the heat exchanger remains constant thereby saving power and

maintenance cost.

Fig : Coil Heater

Fig : PTC Heater

Features

VENT

OPEN

VENT

CLOSE

Gold Fin Anti-Corrosive Treatment:

Salt Spray Test Result : After 360 hours

[ Test Standard: ASTM B-117, KS D 9502 ]

[ Aluminum]

10 mm

Pitting Corrosion

Uncoated

Aluminum

10 mm

Anti Corrosion Gold Fin

Hydrophilic

layer

Aluminum

Anticorrosion

layer

Anti Corrosion Gold Fin

• Pitting corrosion

on the surface

No corrosion

Fig : PTC Heater

General information 19

PTAC

6RWU0-05B

Infinite Impulse Response (IIR)

The IIR function senses the temperature several times per second and make micro adjustments accordingly.

Compressor Restart Delay

This feature extends the overall life of the compressor by preventing the short cycling of the air-conditioner. When the compressor restarts, LG PTAC is designed to give it a minimum of three minutes to have a time of equalizing the refrigerant

pressures for optimizing the cycle.

Fan Only Setting

When the Fan only setting is made, only the fan on the indoor side operates while the compressor stops operating and the

unit ceases to run in the Cooling or the Heating mode.

Indoor Fan Speed Setting

The Indoor fan can run at HIGH or LOW speed for either COOLING or HEATING operation.

Two Fan Motors

The air conditioning unit has dual BLDC motor, one is for indoor fan and other one for outdoor fan for providing a quiet operation and maximum efficiency.

LED Diagnostics and Self Diagnostics

LED Diagnostics feature indicates the problem by its easy to read diagnostics, when the unit does not operate properly. For

example, one blink every 2 seconds indicates compressor failure.

While Self Diagnostics feature is used in micom models and it indicates the problem by displaying a set of error codes.

Indoor Room Freeze Protection

When the unit senses the room temperature to be less than 40˚ F, the unit activates the fan motor and either the electric

resistance heater or the hydronic heater, to prevent the pipes or fixtures from freezing. This also overrides the front desk

control of the unit mounted controls or the wall mounted controls.

Compressor Overload Protection

This feature prevents damage of the compressor by sensing the indoor coil temperature during the heating mode. If the

indoor coil temperature is over 54℃(130℉), the outdoor fan is switched off and it operates again only when the temperature

drops below 49℃(120℉).

Features

20 General information

PTAC

6RWU0-05B

Outdoor Air Temperature Switchover

For Heat pump models during the heating mode, if outdoor temp below 33℉(0.6 ℃), the Comp. is OFF and Heating Mode

is operated by Heater. If outdoor temp reaches 38 ℉(3.3 ℃) Comp. and Heater on/off controlling based on the indoor temp.

However, during normal Heating mode restoration, if in the state of ON, the Heater will continue to operate until desired

temp + 0.5 ℉ and above is reached before being turned OFF. If the Heater is at off state, it remained OFF until Comp. on

condition (desired temp -1.5 ℉ and below) is reached.

Temperature Limits

The unit is programmed to provide both heating and cooling temperature limits by dip switches on the control panel. The

limits are from 54 °F ~ 86 °F (12.2 °C ~ 30 °C). These temperature limits help to prevent overheating and overcooling thereby reducing the energy costs.

Condensate Drain Valve

The most widely used method of disposing of heat pump condensate is with a temperature-activated drain valve. This is a

device mounted in the base pan of a heat pump unit with a bellows that expands on temperature rise and contracts with

temperature drop. A shaft with a rubber plug on the end is connected to the bellows. When the outdoor temperature remains

above a certain temperature, the bellows is expanded and the plug fits tightly into a hole in the bottom, or base pan, of the

unit. When the plug is blocking the hole, as it should be during cooling operation, the condensate water is contained in the

base pan. At temperatures when heating is required, the bellows contracts, the rubber plug is retracted from the hole and

the heat pump condensate water is allowed to drain into the wall case. The valve is fully open at approximately 45 °F.

Quick Heater Recovery

The unit is designed to operate the electric heater so as to warm the room to the desired temperature set point as soon as the Heat

Pump cycle operates. This feature has an advantage of reducing the time to reach the desired temperature for better comfort.

Reverse Cycle Defrosting – PTHP Only

This feature enables the unit to activate the reverse cycle defrost so as to prevent the formation of ice on the outdoor unit,

which is exposed to cold environment. Formation of ice reduces the airflow through the coil and hence the efficiency of the

air conditioning unit. The LG PTHP employs an active reverse cycle defrost function to melt the ice off the outdoor coil for

ensuring room comfort conditions and savings from extended operation.

High Temperature Heat Pump Operation Protection

When the unit operates at high outdoor temperature conditions during the cooling cycle, this feature switches off the compressor to prevent damage.

Remote Thermostat Control

The PTAC air conditioning unit is designed and built to be operated by a wired or wireless remote mounted thermostat if

desired. The unit has a built-in low voltage power source which can accommodate any of the thermostat choices – manual,

auto changeover or programmable. A remote thermostat can also be added to any unit.

Slinger Technology

The PTAC air conditioner is equipped with an outdoor fan includes outer ring that takes condensate water during cooling

operation from the base pan and dispense it through the condenser, increasing the unit’s efficiency.

Features

21 Product Data

PTAC

6RWU0-05B

Part 2 Product data

1 YA chassis ...........................................................................................22

1.1 Features ...........................................................................................................22

1.2 List of functions ................................................................................................23

1.3 Specifications ...................................................................................................24

1.4 Dimensions .......................................................................................................30

1.5 Piping diagrams................................................................................................31

1.6 Wiring diagrams................................................................................................33

1.7 Capacity tables ..................................................................................................35

1.8 Electrical characteristics ....................................................................................43

1.9 Operation range.................................................................................................44

2 Control Devices..................................................................................45

2.1 Electronic Controls ...........................................................................................45

1.10 Sound level test method...................................................................................44

Product Data 22

YA Chassis

PTAC

6RWU0-05B

1. YA Chassis

Models :

1.1 Features

2 -Way Air Flow Direction

Washable Filters

Low Noise at High Air Volume

High Efficiency Compressor

Energy Saver Mode

Timer

Electric Heater

Defrost Control

Air Ventilation

Energy saving Anti-corrosion treated Fins

Infinite Impulse Response(IIR)

Compressor Restart Delay

Fan only Setting

Indoor Fan Speed Setting

Two Fan Motors

LED Diagnostics and Self Diagnostics

Indoor Room Freeze Protection

Compressor Overload Protection

Outdoor Air Temperature Switchover

Temperature Limits

Condensate Drain Valve

Quick Heater Recovery

Reverse Cycle Defrosting (PTHP’s only)

High Temperature Heat Pump operation Protection

Remote Thermostat Control

Slinger Technology

UYC073ALEU1(LP073CDUC)

UYH073ALEU1(LP073HDUC)

UYC093ALEU1(LP093CDUC)

Y4NZ09ANLD1(LP093HDUC1)

UYC09EALE31(LP096CD3B)

UYH09EALE31(LP096HD3B)

UYC123ALEU1(LP123CDUC)

Y4NZ12ANLD1(LP123HDUC1)

UYC12EALE31(LP126CD3B)

UYH12EALE31(LP126HD3B)

UYC153ALEU1(LP153CDUC)

UYH153ALEU1(LP153HDUC)

23 Product Data

PTAC

6RWU0-05BYA Chassis

1.2 List of functions

Air flow Air discharge type

Airflow direction control (up & down)

Airflow direction control (left & right)

Auto swing

Airflow steps (fan/cool/heat)

Airflow Direction

Air purifying Deodorizing filter

Plasma air filter

Air filter (washable / anti-fungus)

Installation Electric heater (operation)

Reliability Hot start

Convenience Auto restart operation

Micom control

Air ventilation

Forced operation

Sleep mode

Timer

Individual control Wired remote control

Wireless remote control

Others Energy saver mode

Thermistor

Top discharge Top discharge

Manual

Manual

- -

- 2/2/2 2/2/2

2 way 2 way

- -

- -

O O

O O

- -

O O

O O

O O

- -

- -

O O

O O

O O

O O

O O

FunctionCategory

PTAC

Cooling only Models

PTAC

Heat Pump Models

Note :

O : applied

- : not applied

Product Data 24

PTAC

6RWU0-05B YA Chassis

1.3 Specifications

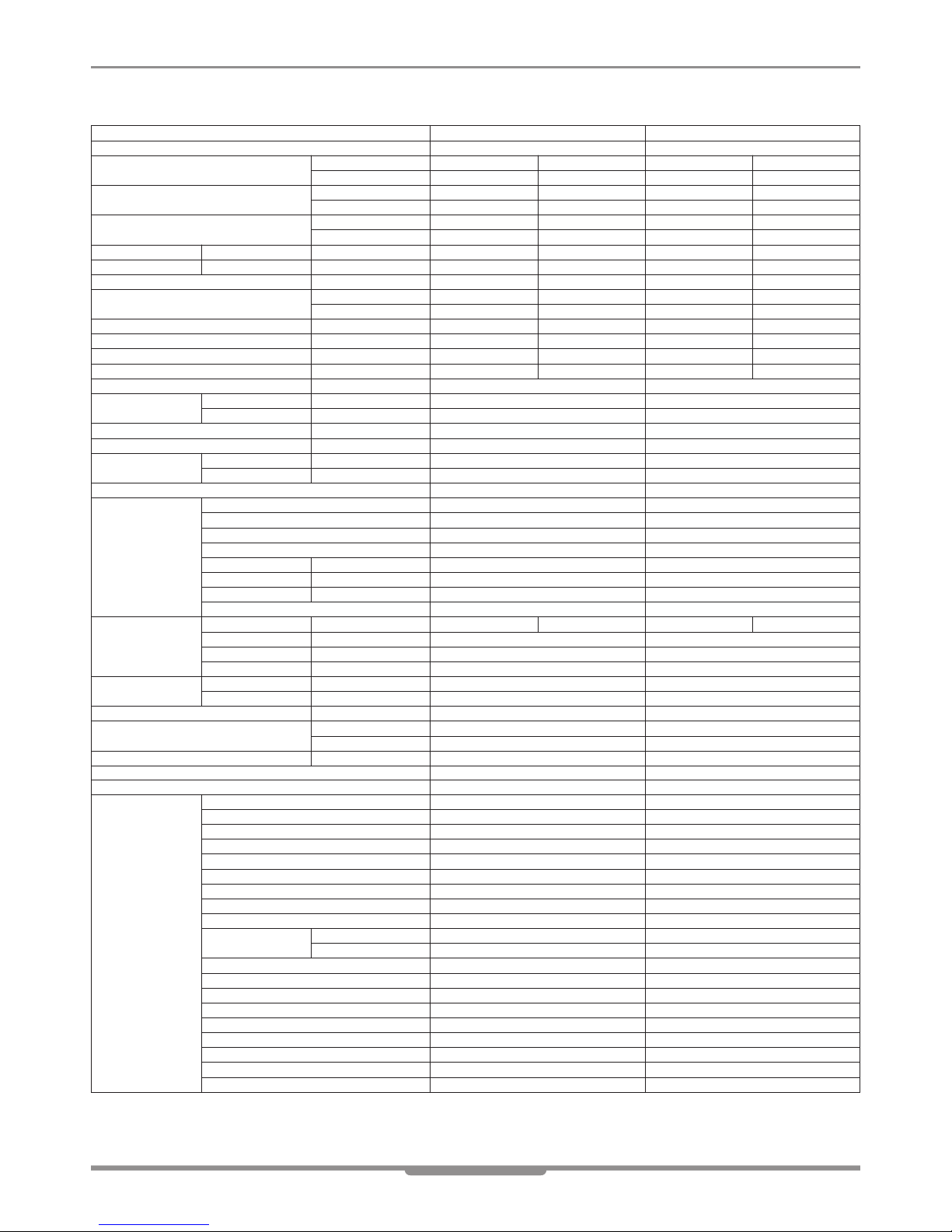

208-230V COOLING ONLY MODELS

Note : -

○ : applied

- : not applied

Buyer Models

LG Models

Cooling Capacity

kW

Btu/h.

Heating Capacity ( for Heat Pump models)

kW

Btu/h.

Electric Heater capacity

kW

Btu/h.

Power Input Cooling/Heating W

Running Current Cooling/Heating A

Electric Heater Current A

EER

W/W

Btu/h.W

COP W/W

Power Supply Ø / V / Hz

Power Factor %

MCA A

MOP A

Air Flow Rate

Ventilation (Outside Air Intake)

Indoor,Max(H/L) m3/ min(CFM)

Outdoor,Max m3/ min(CFM)

m

3

/ min(CFM)

Dehumidification pts/h

Sound Level

Indoor,H/M/L dB(A)±3

Outdoor,Max dB(A)±3

Refrigerant & Charge g(oz)

Compressor

Type

Model

Motor Type

Oil Type

Oil Charge cc

Capacitor µF

RLA/LRA A

O.L.P Name

Fan

Type(In/Out)

Motor Type(In/Out)

FLA(In/Out) A

Motor Output(In/Out) W

Heat Exchanger

Evaporator Rows * Column * FPI

Condensor Rows * Column * FPI

Power Supply Cable (Power Cord) No.*mm

2

Dimensions ( W * H * D)

mm

inch

Net Weight

kg(lbs)

Tool Code(Chassis)

Features

Operating Range Voltage (Min/Max)

Temperature Control

Energy Saver Mode

Prefilter(washable/anti-fungus)

Plasma Filter

Steps, Fan/Cool/Heat

Airflow Direction Control(up&down)

Airflow Direction Control(left&right)

Remote Control

Setting Temperature

Range

Cooling

Heating

Auto Operation (Micom Control)

Panel Touch Type

Timer

Air Discharge

Air-Ventilation

Deice Control(Defrost)

Hot Start

Cabinet Type(Chassis Type)

Special Function

LP073CDUC LP093CDUC

UYC073ALEU1 UYC093ALEU1

2.08 2.14 2.73 2.78

7,100 7,300 9,300 9,500

- - - -

- - - -

2.3/3.2/4.6 2.4/3.3/4.7

7,800/10,900/15,700 8,100/11,200/16,000

535 550 730 745

2.7 2.5 3.7 3.4

11.2/15.5/22.3 10.5/14.5/20.6

3.90 3.90 3.72 3.72

13.3 13.3 12.7 12.7

- - - -

1 / 208 / 60 1 / 230 / 60 1 / 208 / 60 1 / 230 / 60

95 96 95 95

14.5/19.8/28.3 13.6/18.6/26.2

15/20/30

2.3/3.2/4.6 2.4/3.3/4.7

7,800/10,900/15,700 8,100/11,200/16,000

11.2/15.5/22.3 10.5/14.5/20.6

14.5/19.8/28.3 13.6/18.6/26.2

15/20/30

7.6(270)/6.3(225) 7.6(270)/6.3(225)

17(600) 17(600)

1.42(50) 1.70(60)

1.7 2.6

45/-/43 46/-/44

61 61

R410A, 740(26.1) R410A,600(21.2)

Rotary(Non Tropical) Rotary(Non Tropical)

GA060KAA GA080KBA

PSC PSC

POE(RB68A)orPVE(FVC68D) POE(RB68A)orPVE(FVC68D)

310 230

15 25

2.9/16 3.7/19

B120-160-241E B145-155-241E

Cross Flow Fan Axial Fan Cross Flow Fan Axial Fan

BLCD / BLCD BLCD / BLCD

0.36/0.36 0.36/0.36

20/65 26/66

2R *12C *18FPI 2R *10C *19FPI

3R *17C *20FPI 3R *17C *20FPI

3 * 2.1 3 * 2.1

1,066*406*505 1,066*406*505

42*16*19-7/8 42*16*19-7/8

43(95) 43(95)

Gross Weight

kg(lbs)

49(108) 49(108)

YA YA

187/253 187/253

Thermistor Thermistor

OO

OO

--

2/2/2 2/2/2

Manual Manual

--

Wall Thermostat Wall Thermostat

54℉ ~ 86℉(12.2℃ ~ 30℃) 54℉ ~ 86℉(12.2℃ ~ 30℃)

54℉ ~ 86℉(12.2℃ ~ 30℃) 54℉ ~ 86℉(12.2℃ ~ 30℃)

OO

Micom Micom

12h, On/Off 12h, On/Off

Top Top

OO

--

--

Slide In-Out Slide In-Out

Electric Heater Electric Heater

25 Product Data

PTAC

6RWU0-05BYA Chassis

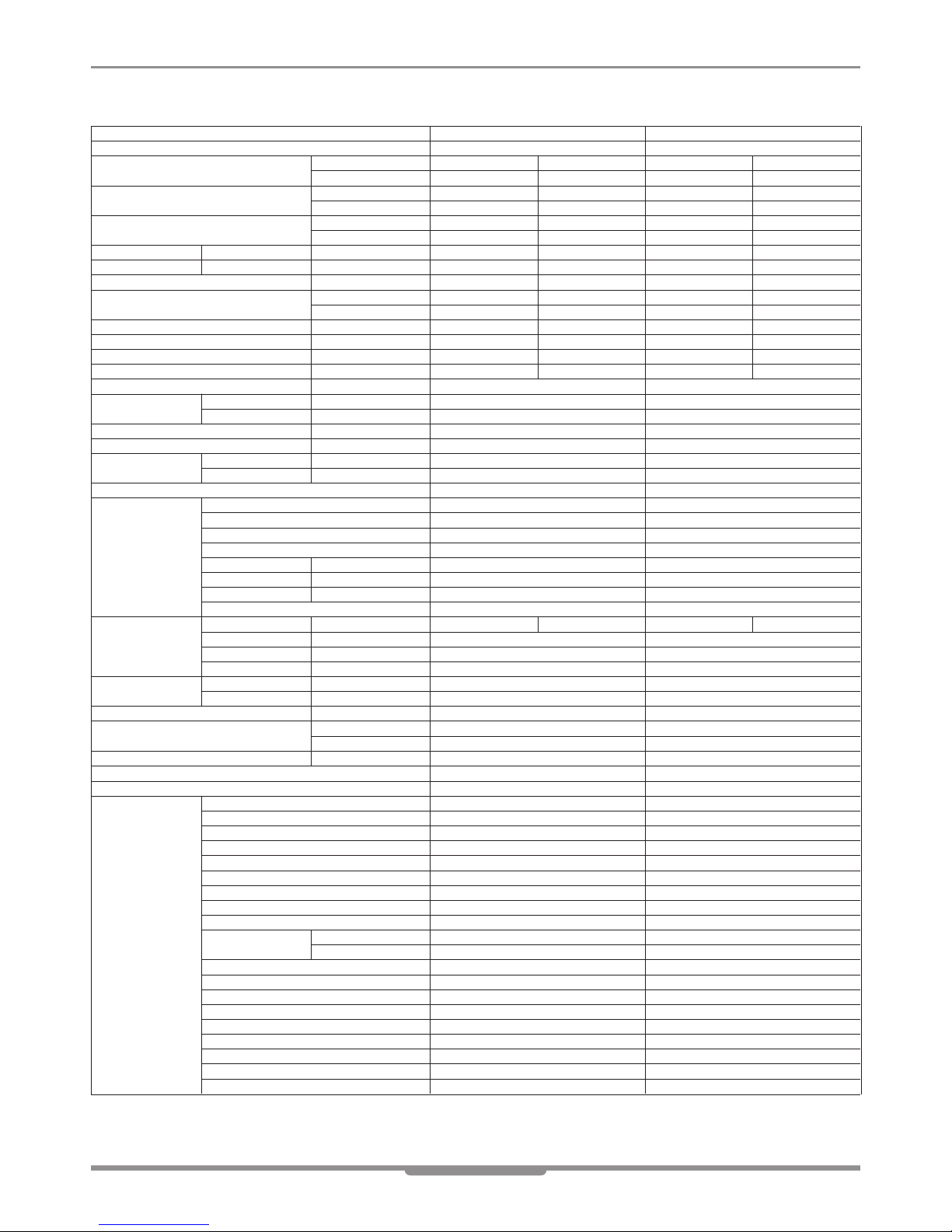

Note : -

○ : applied

- : not applied

Buyer Models

LG Models

Cooling Capacity

kW

Btu/h.

Heating Capacity ( for Heat Pump models)

kW

Btu/h.

Electric Heater capacity

kW

Btu/h.

Power Input Cooling/Heating W

Running Current Cooling/Heating A

Electric Heater Current A

EER

W/W

Btu/h.W

COP W/W

Power Supply Ø / V / Hz

Power Factor %

MCA A

MOP A

Air Flow Rate

Indoor,Max(H/L) m3/ min(CFM)

Outdoor,Max m3/ min(CFM)

Dehumidification pts/h

Sound Level

Indoor,H/M/L dB(A)±3

Outdoor,Max dB(A)±3

Refrigerant & Charge g(oz)

Compressor

Type

Model

Motor Type

Oil Type

Oil Charge cc

Capacitor µF

RLA/LRA A

O.L.P Name

Fan

Type(In/Out)

Motor Type(In/Out)

FLA(In/Out) A

Motor Output(In/Out) W

Heat Exchanger

Evaporator Rows * Column * FPI

Condensor Rows * Column * FPI

Power Supply Cable (Power Cord) No.*mm

2

Dimensions ( W * H * D)

mm

inch

Net Weight kg(lbs)

Tool Code(Chassis)

Features

Operating Range Voltage (Min/Max)

Temperature Control

Energy Saver Mode

Prefilter(washable/anti-fungus)

Plasma Filter

Steps, Fan/Cool/Heat

Airflow Direction Control(up&down)

Airflow Direction Control(left&right)

Remote Control

Setting Temperature

Range

Cooling

Heating

Auto Operation (Micom Control)

Panel Touch Type

Timer

Air Discharge

Air-Ventilation

Deice Control(Defrost)

Hot Start

Cabinet Type(Chassis Type)

Special Function

LP123CDUC LP153CDUC

UYC123ALEU1 UYC153ALEU1

3.52 3.58 4.37 4.43

12,000 12,200 14,900 15,100

- - - -

- - - -

2.3/3.2/4.6 2.4/3.3/4.7

7,800/10,900/15,700 8,100/11,200/16,000

1,005 1,025 1,330 1,345

5.1 4.7 6.6 6.1

11.2/15.5/22.3 10.5/14.5/20.6

3.49 3.49 3.28 3.28

11.9 11.9 11.2 11.2

- - - -

1 / 208 / 60 1 / 230 / 60 1 / 208 / 60 1 / 230 / 60

95 95 97 96

14.5/19.8/28.3 13.6/18.6/26.2

15/20/30

2.3/3.2/4.6 2.4/3.3/4.7

7,800/10,900/15,700 8,100/11,200/16,000

11.2/15.5/22.3 10.5/14.5/20.6

14.5/19.8/28.3 13.6/18.6/26.2

15/20/30

11.9(420)/10.0(353) 11.9(420)/10.0(353)

20(706) 20(706)

Ventilation (Outside Air Intake)

m3/ min(CFM)

1.98(70) 1.98(70)

3.0 4.3

50/-/48 51/-/49

63 64

R410A, 610(21.5) R410A, 910(31.2)

Rotary(Non Tropical) Rotary(Non Tropical)

PA108M1C PA140M2C

PSC PSC

ESTER OIL VG74 ESTER OIL VG74

350 440

35 45

5.0/27 6.55/38.6

BF910-MA INTERNAL

Cross Flow Fan Axial Fan Cross Flow Fan Axial Fan

BLCD / BLCD BLCD / BLCD

0.36/0.36 0.36/0.36

41/74 41/74

2R *10C *19FPI 2R *10C *19FPI

3R *17C *20FPI 3R *17C *20FPI

3 * 2.1 3 * 2.1

1,066*406*505 1,066*406*505

42*16*19-7/8 42*16*19-7/8

45(99) 52(115)

Gross Weight kg(lbs)

51(112) 58(128)

YA YA

187/253 187/253

Thermistor Thermistor

OO

OO

--

2/2/2 2/2/2

Manual Manual

--

Wall Thermostat Wall Thermostat

54℉ ~ 86℉(12.2℃ ~ 30℃) 54℉ ~ 86℉(12.2℃ ~ 30℃)

54℉ ~ 86℉(12.2℃ ~ 30℃) 54℉ ~ 86℉(12.2℃ ~ 30℃)

OO

Micom Micom

12h, On/Off 12h, On/Off

Top Top

OO

--

--

Slide In-Out Slide In-Out

Electric Heater Electric Heater

Product Data 26

YA Chassis

PTAC

6RWU0-05B

Note : -

○ : applied

- : not applied

208-230V HEAT PUMP MODELS

Buyer Models

LG Models

Cooling Capacity

kW

Btu/h.

Heating Capacity ( for Heat Pump models)

kW

Btu/h.

Electric Heater capacity

kW

Btu/h.

Power Input Cooling/Heating W

Running Current Cooling/Heating A

Electric Heater Current A

EER

W/W

Btu/h.W

COP W/W

Power Supply Ø / V / Hz

Power Factor %

MCA A

MOP A

Air Flow Rate

Ventilation (Outside Air Intake)

Indoor,Max(H/L) m3/ min(CFM)

Outdoor,Max m3/ min(CFM)

Dehumidification pts/h

Sound Level

Indoor,H/M/L dB(A)±3

Outdoor,Max dB(A)±3

Refrigerant & Charge g(oz)

Compressor

Type

Model

Motor Type

Oil Type

Oil Charge cc

Capacitor µF

RLA/LRA A

O.L.P Name

Fan

Type(In/Out)

Motor Type(In/Out)

FLA(In/Out) A

Motor Output(In/Out) W

Heat Exchanger

Evaporator Rows * Column * FPI

Condensor Rows * Column * FPI

Power Supply Cable (Power Cord) No.*mm

2

Dimensions ( W * H * D)

mm

inch

Net Weight kg(lbs)

Tool Code(Chassis)

Features

Operating Range Voltage (Min/Max)

Temperature Control

Energy Saver Mode

Prefilter(washable/anti-fungus)

Plasma Filter

Steps, Fan/Cool/Heat

Airflow Direction Control(up&down)

Airflow Direction Control(left&right)

Remote Control

Setting Temperature

Range

Cooling

Heating

Auto Operation (Micom Control)

Panel Touch Type

Timer

Air Discharge

Air-Ventilation

Deice Control(Defrost)

Hot Start

Cabinet Type(Chassis Type)

Special Function

LP073HDUC LP093HDUC1

UYH073ALEU1 Y4NZ09ANLD1

2.08 2.14 2.93 2.99

7,100 7,300 10,000 10,200

1.82 1.88 2.52 2.58

6,200 6,400 8,600 8,800

2.3/3.2/4.6 2.4/3.3/4.7

7,800/10,900/15,700 8,100/11,200/16,000

535/500 550/520 800/720 820/735

2.7/2.6 2.5/2.4 4.0/3.5 3.7/3.2

11.2/15.5/22.3 10.5/14.5/20.6

10.5/14.5/20.6

3.90 3.90 3.63 3.63

13.3 13.3 12.4 12.4

3.6 3.6 3.5 3.5

1 / 208 / 60 1 / 230 / 60 1 / 208 / 60 1 / 230 / 60

95 96 96 97

14.5/19.8/28.3 13.6/18.6/26.2

15/20/30

2.3/3.2/4.6 2.4/3.3/4.7

7,800/10,900/15,700 8,100/11,200/16,000

14.5/19.8/28.3 13.6/18.6/26.2

15/20/30

7.6(270)/6.3(225) 7.6(270)/6.3(225)

17(600) 17(600)

m3/ min(CFM)

1.42(50) 1.70(60)

1.7 2.6

45/-/43 46/-/44

61 61

R410A, 740(26.1) R410A, 850(30.0)

Rotary(Non Tropical) Rotary(Non Tropical)

GA060KAA GKS094KBC

PSC PSC

POE(RB68A)orPVE(FVC68D) POE(RB68A)orPVE(FVC68D)

310 280

15 35

2.9/16 4.3/26

B120-160-241E B195-140-241E

Cross Flow Fan Axial Fan Cross Flow Fan Axial Fan

BLCD / BLCD BLCD / BLCD

0.36/0.36 0.36/0.36

20/65 26/66

2R *12C *18FPI 2R *10C *19FPI

3R *17C *20FPI 3R *17C *20FPI

3 * 2.1 3 * 2.1

1,066*406*505 1,066*406*505

42*16*19-7/8 42*16*19-7/8

43(95) 47(104)

Gross Weight kg(lbs)

49(108) 53(117)

YA YA

187/253 187/253

Thermistor Thermistor

OO

OO

--

2/2/2 2/2/2

Manual Manual

--

Wall Thermostat Wall Thermostat

54℉ ~ 86℉(12.2℃ ~ 30℃) 54℉ ~ 86℉(12.2℃ ~ 30℃)

54℉ ~ 86℉(12.2℃ ~ 30℃) 54℉ ~ 86℉(12.2℃ ~ 30℃)

OO

Micom Micom

12h, On/Off 12h, On/Off

Top Top

OO

--

--

Slide In-Out Slide In-Out

Electric Heater Electric Heater

11.2/15.5/22.3

Loading...

Loading...