Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PD75A

MODEL : 60PF95 60PF95-ZA

website:http://biz.LGservice.com

Internal Use Only

Page 2

- 2 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ..........................................................................3

SPECIFICATION ........................................................................................4

ADJUSTMENT INSTRUCTION .................................................................7

TROUBLE SHOOTING ............................................................................11

BLOCK DIAGRAM...................................................................................20

EXPLODED VIEW .................................................................................. 22

EXPLODED VIEW PARTS LIST............................................................. 23

REPLACEMENT PARTS LIST ............................................................... 24

SVC. SHEET ...............................................................................................

PRINTED CIRCUIT DIAGRAM ....................................................................

Page 3

- 3 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

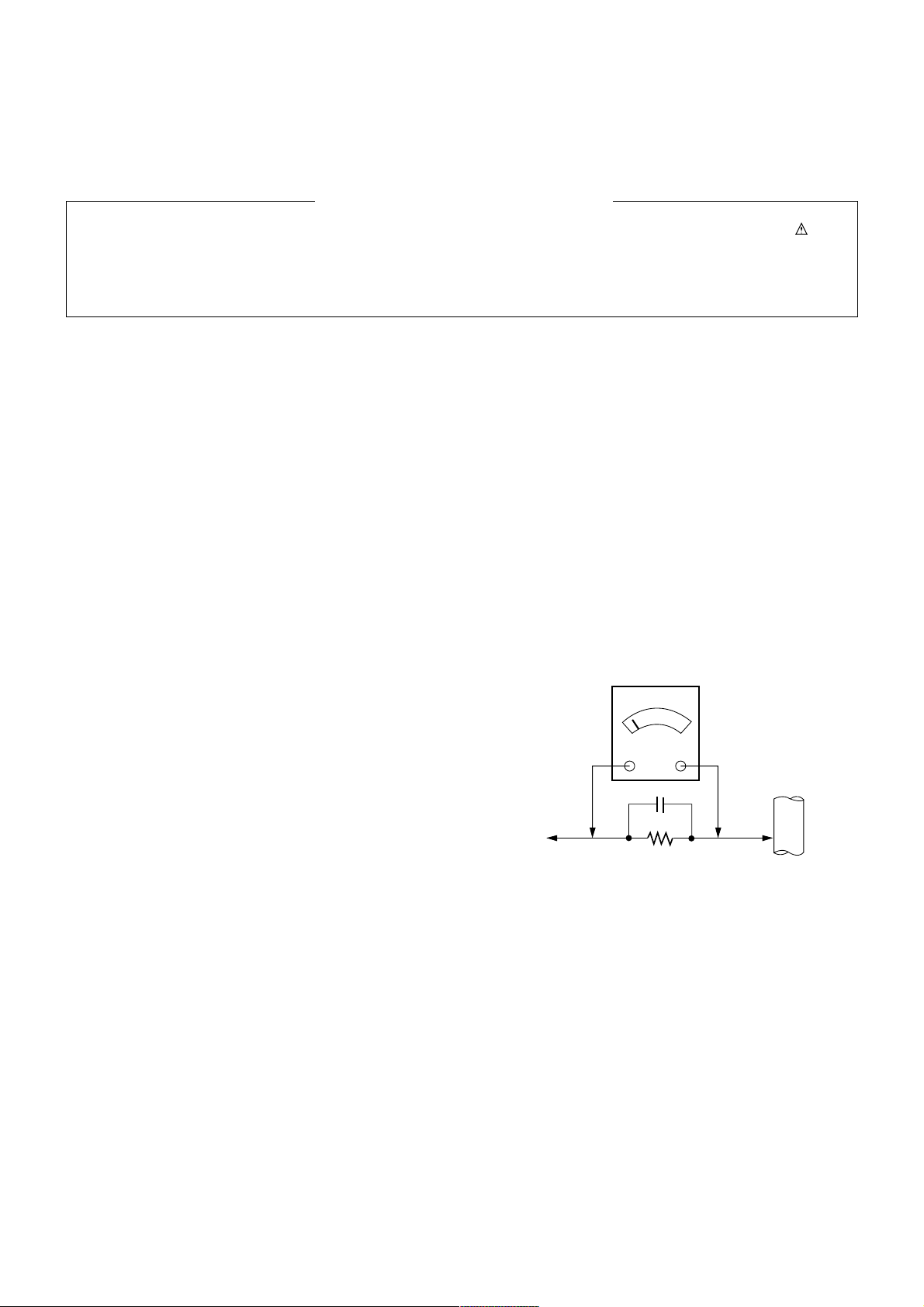

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to the 60” PLASMA TV used PD75A Chassis.

V Specification

Each part is tested as below without special appointment.

1) Temperature : 25±5°C (77±9°F), CST : 40±5

2) Relative Humidity: 65±10%

3) Power Voltage: Standard Input voltage (100-240V~, 50/60Hz)

* Standard Voltage of each product is marked by models.

4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with SBOM.

5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

1) Performance : LGE TV test method followed.

2) Demanded other specification

Safety : CE, IEC specification

EMC : CE, IEC

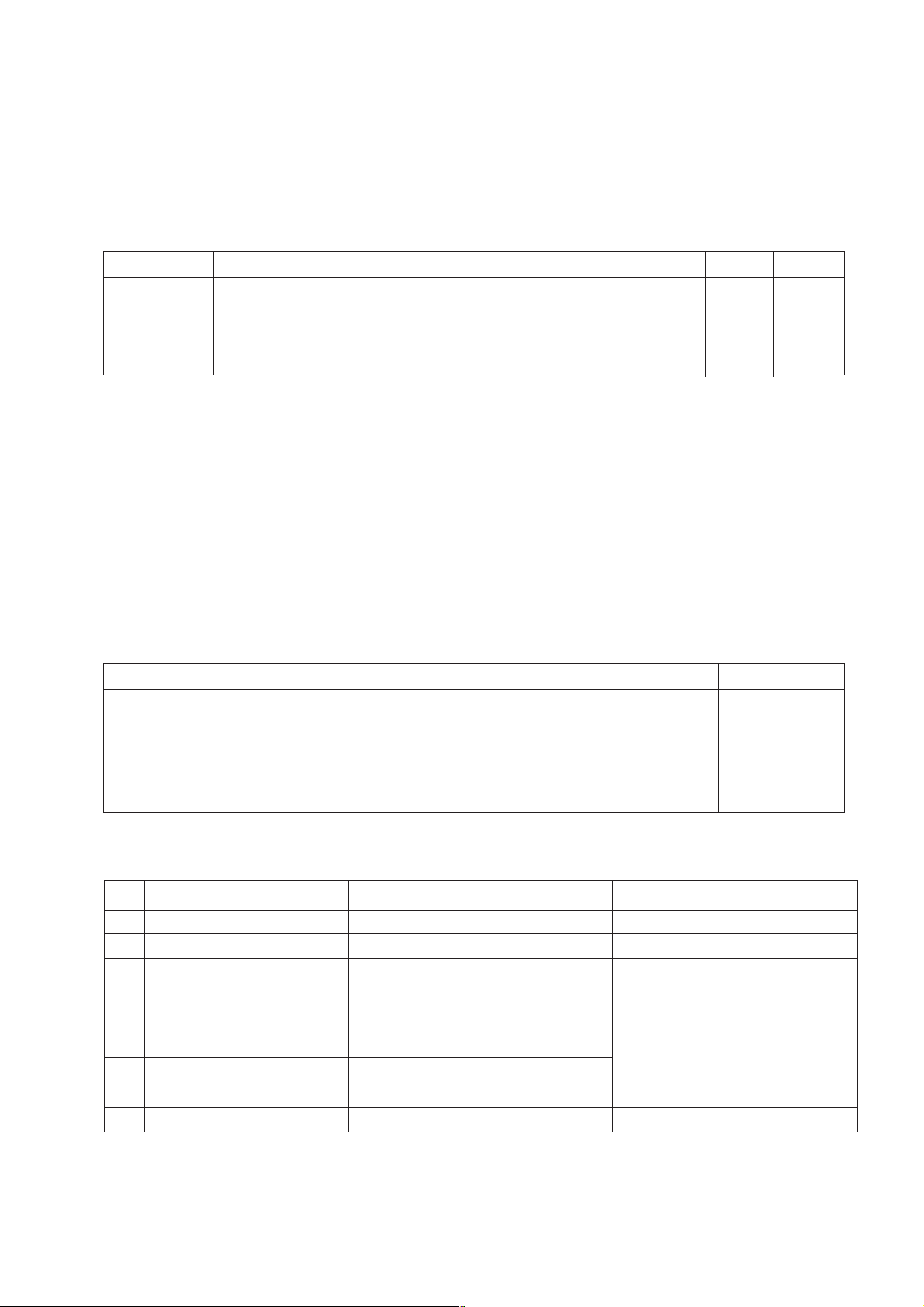

V General Specification ( 60” FHD Module)

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

No Item Specification Remark

60” Wide Color Display Module

16:9

PDP60H1,

RGB Closed Type, Glass Filter

1)Temp. : 0~60deg

2)Humidity : 20~80%

3)Temp. : -10~60deg

4)Humidity : 10~90%

100-240V~, 50/60Hz

Plasma Display Panel

LGE SPEC.

Maker : LG

Chassis

PD75A 60PF95

UK, German, Italy, France, Sweden, Finland, Spain,

Netherlands, Belgium, Luxemburg, Greece, Denmark,

Czech, Austria, Poland, Portugal, Norway, Rumania,

Hungary , Bulgaria, Croatia, Serbia, Swiss, Slovenia, Russia

LG

Model Name Market Brand Remark

60PF95

Safety : IEC/EN60065

EMI : EN55013

EMS : EN55020

UK, German, Italy, France, Sweden, Finland,

Spain, Netherlands, Belgium, Luxemburg,

Greece, Denmark, Czech, Austria, Poland,

Portugal, Norway, Rumania, Hungary , Bulgaria,

Croatia, Serbia, Swiss, Slovenia, Russia

Model ApplianceMarket

TEST

Remark

Page 5

- 5 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

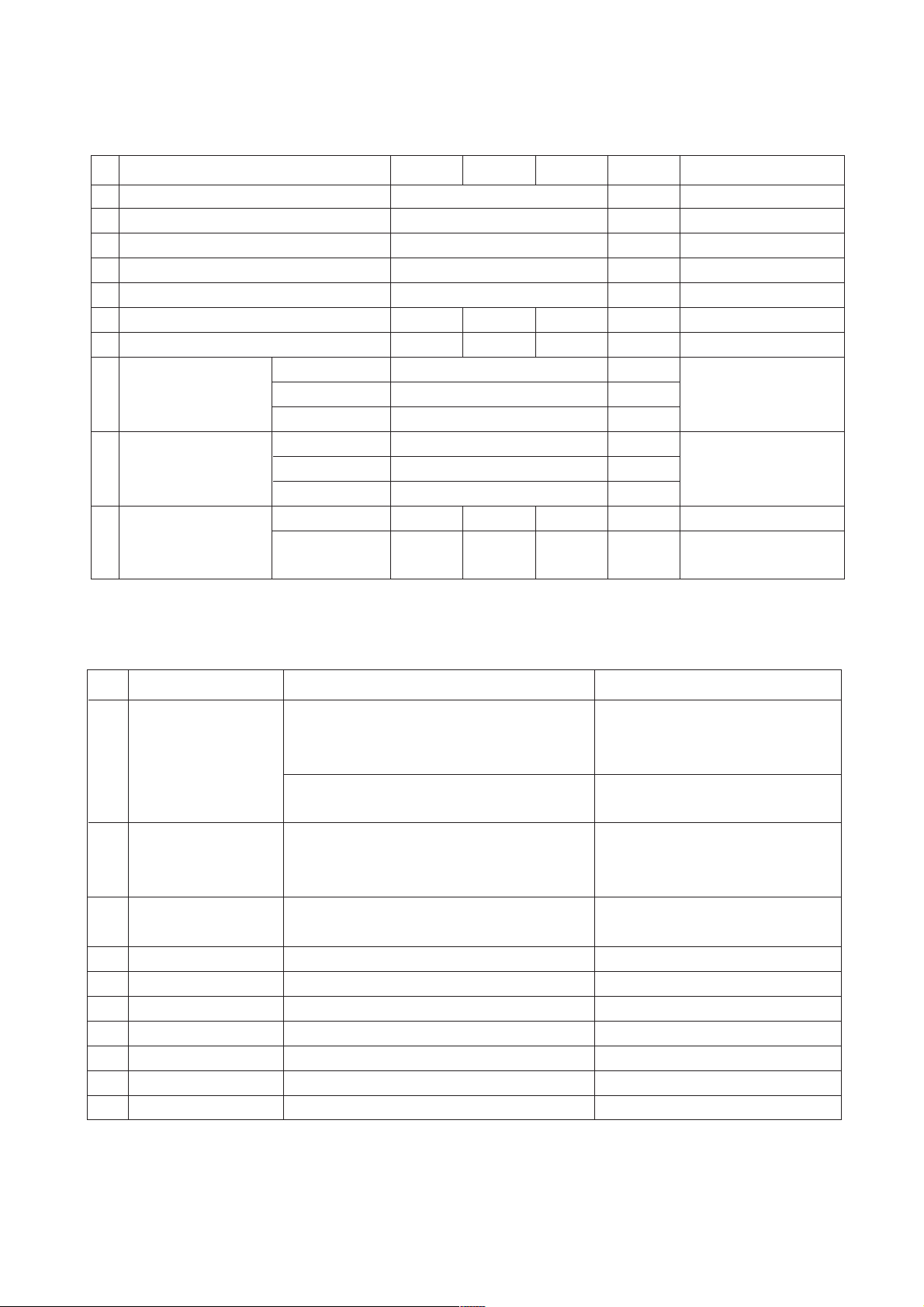

V Module Specification

V General Specification ( PDP60) - PDP Module

Market

Broadcasting system

Receiving system

Scart Jack (2EA)

Video Input (1EA)

S-Video Input (1EA)

Component Input (1EA)

RGB Input(1EA)

HDMI Input(2EA)

Audio Input (3EA)

1

2

3

4

5

6

7

8

9

10

No Item Specification Remark

UK, German, Italy, France, Sweden, Finland, Spain,

Netherlands, Belgium, Luxemburg, Greece,

Denmark, Czech, Austria

Poland, Portugal, Norway, Rumania, Hungary ,

Bulgaria, Croatia, Serbia, Swiss, Slovenia, Russia

1) PAL-BG/I / I’/ DK

2) SECAM-L/L’

3) DVB-T

Analog : Upper Heterodyne

Digital : COFDM

PAL, SECAM

PAL, SECAM, NTSC

PAL, SECAM, NTSC

Y/Cb/Cr, Y/Pb/Pr

RGB-PC

HDMI-DTV & SOUND

PC Audio, Component, AV

Analog Only

Scart 2 Jack : MNT / DTV output

4 System : PAL, SECAM, NTSC, PAL60

4 System : PAL, SECAM, NTSC, PAL60

L/R Input

Display area

Outline dimension

Number of Pixels

Cell pitch

Pixel type

Weight(net)

Weight(gross)

Operation Environment Temperature

Humidity

Pressure

Storage Environment Temperature

Humidity

Pressure

Image stick minimization Start time

mode Low Brightness

Arrival Time

1324.8 (H) * 745.2(V) °æ0.5

1408 (W) x 828 (H) x 70 (D) °æ1

1920 (H) x 1080(V)

230um (H) x 690um (V)

RGB closed type

32 33 34

119 120 121

0 ~ 60

20 ~ 80

800 ~ 1100

-10 ~ 60

10 ~ 90

700 ~ 1100

4.5 5 5.5

14 15 16

1

2

3

4

5

6

7

8

9

10

No Item Remark

1Pixel=3RGB Cells

Net 1EA

12EA 1Box

Altitude : 0 to 2000M

Altitude : 0 to 3000M

mm

mm

um

Kg

Kg

deg

%

hPa

deg

%

hPa

min

min

Min Typ Max Unit

Page 6

- 6 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

V FHD Module ( Glass Filter, 60Hz- This data at 50Hz is about 80% level of 60Hz data )

White peak brightness

White average brightness

Brightness uniformity

Color Coordinate White X

Y

Color coordinate uniformity

Contrast ratio at dark room 60Hz

Color Temperature Cool

Medium

Warm

Color pull in Range PAL

NTSC

Color killer Sensitivity

300

45

-15

0.261

0.268

-0.02

2500 :1

10000

8300

5500

-500

-500

-80

380

55

0

0.276

0.283

Average

3000 :1

11000

9300

6500

-

-

+15

0.291

0.298

+0.02

12000

10300

7500

+500

+500

1

2

3

4

5

6

7

8

9

No Item Remark

(*) Peak Brightness Mode

- 1/100 white window pattern

(Typically 1% window size)

- 100 IRE (255 Gray)

- Picture : Dynamic (cool)

- Input : HDMI-PC (1920x1080 60Hz)

* Peak Brightness Condition may

Slightly different between Sets.

- Full White Pattern

- 100 IRE (255 Gray)

- Picture : Dynamic (cool)

- Full White Pattern

- 85 IRE (216 Gray)

- Picture : Dynamic (cool)

- Full White Pattern

- 85 IRE (216 Gray)

- Picture : Dynamic (cool)

- 85IRE Full White Pattern

- Picture : Dynamic (cool)

- 1/100 white window pattern

- 100 IRE (255 Gray)

- Picture : Dynamic (cool)

- Input : HDMI-PC (1920x1080 60Hz)

- Full White Pattern

- 85 IRE (216 Gray)

- Picture : Dynamic (cool)

cd/m

2

cd/m

2

%

Hz

Hz

dBm

Min Typ Max Unit

Page 7

- 7 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Object

These instructions are applied all of the 60” PLASMA TV,

PD75A Chassis.

2. Note

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100-240V~,

50/60Hz.

(5) Before adjustment, execute Heat Run for 15 minutes.

O After RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

O Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

* Set is activated HEAT-RUN without signal generator in

this mode.

* Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses to check PANEL.

3. Adjustment items

3-1. PCB assembly adjustment items

(1) Channel memory.

- Recovery the channel memory by adjust R/C.

3-2. SET assembly adjustment items

(1) Adjustment of POWER PCB assembly voltage.

(2) DDC Data input.

(3) Auto AV(CVBS) Color Balance.

(4) Auto Component Color Balance adjust.

- standard equipment : 802F Pattern Generator. Master

Pattern Generator(MSPG-925, etc) or same product.

(5) Auto RGB Color Balance adjustment

- standard equipment : PC Pattern Generator(VG828,

VG854, 801GF, MSP3240A) or same product.

(6) Factoring Option Data input.

4. Channel memory Setting Method

: You can set channel memory by R/C for adjustment.

1) Press ADJ key on R/C for adjustment.

2) Press ENTER key on “System Control3”.

3) Press VOL + key on “Channel Recover”.

5. PCMCIA CARD Checking Method

: You must adjust DTV 29 Channel and insert PCMCIA CARD

to socket.

1) If PCMCIA CARD works normally, normal signals display

on screen. But it works abnormally, “No CA module” words

display on screen.

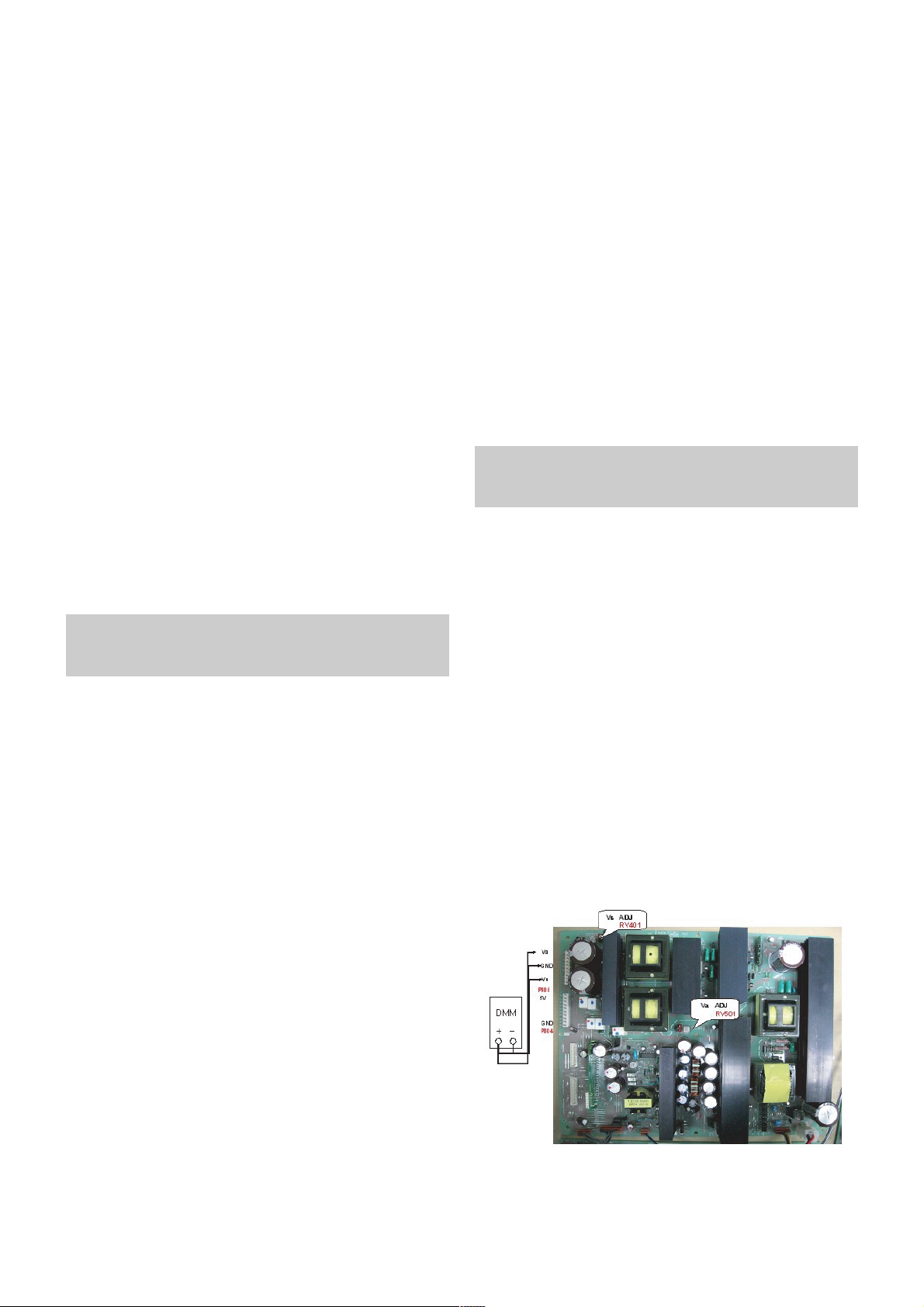

6. POWER PCB Assy Voltage

Adjustments (Va, Vs Voltage adjustments)

6-1. Test Equipment : D.M.M. 1EA

6-2.Connection Diagram for Measuring

: refer to Fig.1

6-3. Adjustment Method

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P805, connect

- terminal to GND pin of P805.

3) After turning RV501, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805, connect

– terminal to GND pin of P805.

2) After turning RV401, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

If you turn on a still screen more than 20 minutes (Especially

Digital pattern, Cross Hatch Pattern), an afterimage may occur

in the black level part of the screen.

Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

(Fig.1) Connection diagram of power adjustment for measuring

Page 8

7. EDID

7-1. EDID Data

7-2. Data

(1) ANALOG(128Byte).

(2) HDMI1(256Byte).

=> Detail EDID Options are below([1],[2],[3],[4],[5])

1.[1]-Product ID

2. [2]-Serial No : Controlled on production line.

3. [3]-Month, Year : Controlled on production line.

ex) Monthly: '09' => '09'

Year : '2006' => '10'

4. [4]-Model Name : model name.

5. [5]-Checksum (7EH) -> Changeable by total EDID data.

8. ADC Calibration

9. Adjustment of AV Color Balance

9-1. Required Equipment

(1) Remote controller for adjustment.

(2) MSPG-925FS Pattern Generator. (Which has Video

Signal: 7 Color Bar Pattern shown in Fig.2)

-> Model: 202 / Pattern: 65

- Case 1) EC and FC model use PAL-BGDHI

(composite signal)

9-2. Method of Auto RF/ AV/ S-Video Color

Balance (PAL_BGDHI)

(1) Input the Video Signal: 7 Color Bar signal into AV3.

(2) Set the PSM to Dynamic mode in the Picture menu.

(3) Press IN-START key on R/C for adjustment.

(4) Press the

G(Vol. +) key to operate the set, then it

becomes automatically.

(5) After downloading complete, the ‘OK’ word appears.

(6) Auto-RGB OK means the adjustment is completed.

- 8 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Item

Manufacturer ID

Version

Revision

Condition

GSM

Digital : 1

Digital : 3

Hex Data

1E6D

01

03

For RGB EDID

D-sub to D-sub

For HDMI EDID

DVI-D to HDMI or HDMI to HDMI

1

2

3

4

5

1

2

3

4

5

5

* Use the proper signal cable for EDID Download.

- Analog EDID : Pin3 exists.

- Digital EDID : Pin3 exists.

*

Never connect HDMI & DVI-D & DVI-A Cable at the same time.

* Use the proper cables below for EDID Writing.

60PF95

Product ID

Product IDModel Name

EDID table

67C3

68C3

Hex

C367

C368

Dec

50023

50024

Analog

Digital

60PF95

000000FC003630504639350A202020202020

Model Name Model Name(Hex)

MSPG925FS

Component RGB-PCAVADC

Model : 3

(1024*768 60Hz)

Pattern : 65

Model:215(720P)

Pattern : 65

* 720P/50Hz

7 Color Bar

PAL

INPUT SELECT AV3

Model : 202

(PAL-BGDHI)

Pattern : 65

* PAL 7 Color Bar

- System control RS-232 Host should be “PC“ for adjustment.

(Fig.2)

Page 9

- 9 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

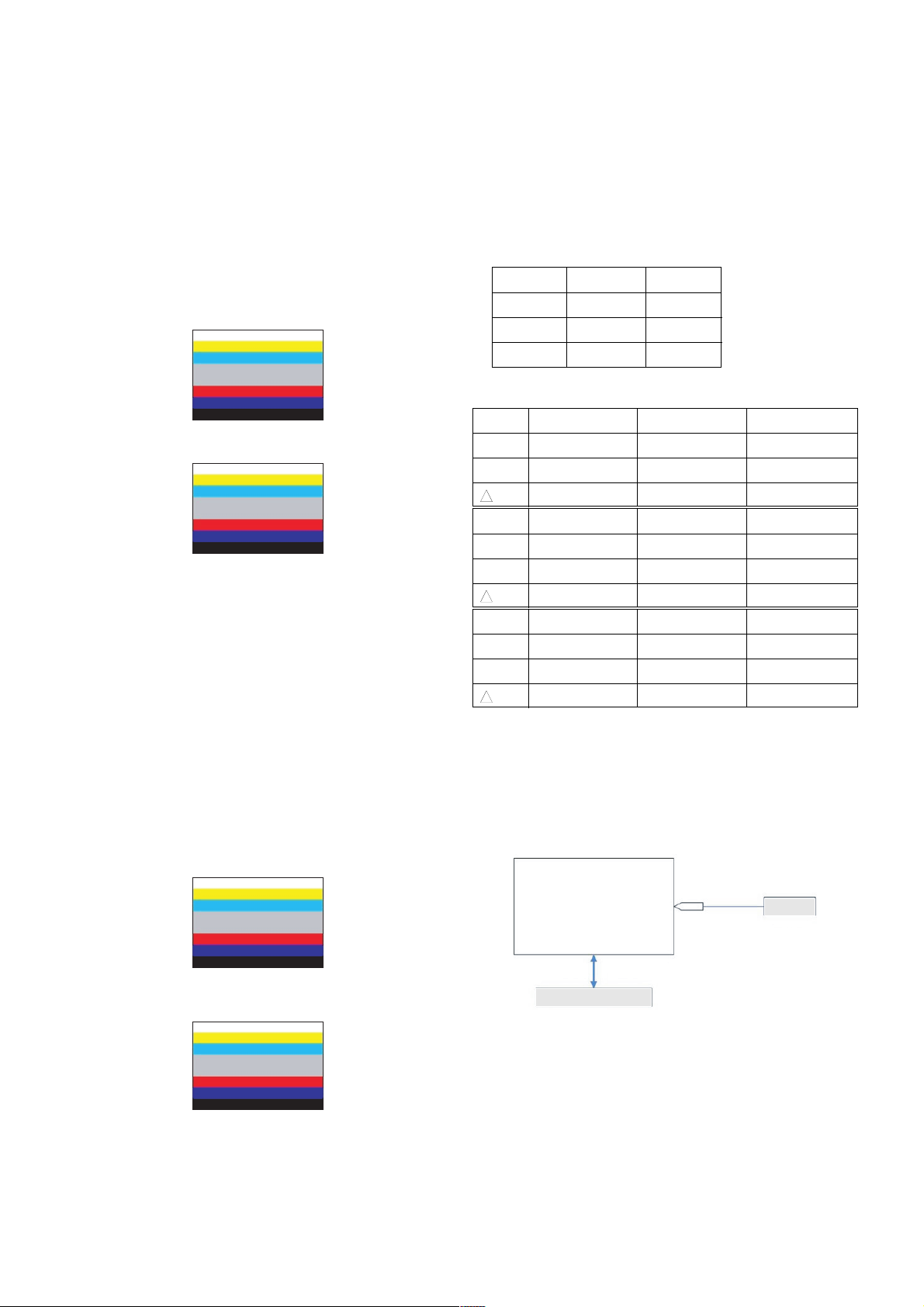

10. Adjustment of Component

10-1. Required Equipment

(1) Remote controller for adjustment.

(2) MSPG-925FS Pattern Generator. (Which has 720p/50Hz

YPbPr output Pattern shown in Fig.3)

-> Model : 215 / Pattern : 65

10-2. Method of Auto Component Color Balance

(1) Input the Component 720p/50Hz 7 Color Bar(MSPG-

925FS model:215, pattern:65) signal into Component.

(2) Set the PSM to Dynamic mode in the Picture menu.

(3) Press IN-START key on R/C for adjustment.

(4) Press the

G(Vol. +) key to operate the set, then it becomes

automatically.

(5) After downloading complete, the ‘OK’ word appears.

(6) Auto-RGB OK means the adjustment is completed.

11. Adjustment of RGB

11-1. Required Equipment

(1) Remote controller for adjustment.

(2) MSPG-925FS Pattern Generator ( Which has XGA

[1024*768] 60Hz 1/2 black & white pattern shown in Fig.4 )

11-2. Method of Auto RGB Color Balance

(1) Input the PC 1024x768 @ 60Hz 1/2 black & white pattern

(MSPG-925FS, Model:3, Pattern:65) into RGB.

(using D-sub to D-sub cable)

(2) Set the PSM to Dynamic mode in the Picture menu.

(3) Press IN-START key on R/C for adjustment.

(4) Press the G(Vol. +) key to operate the set, then it becomes

automatically.

(5) After downloading complete, the ‘OK’ word appears.

(6) Auto-RGB OK means the adjustment is completed.

12. Adjustment of White Balance

12-1. Required Equipment

(1)

Color Analyzer.(CS-100, CA-100+(CH 10), CA-210(CH 10))

* Please adjust CA-210, CA-100+ by CS-1000 before

measuring.

W Color temperature standards according to CSM and Module.

W

White balance adjustment coordinate and color temperature.

* PC(for communication through RS-232C)

-> UART Baud rate : 115200 bps

12-2. Connection Picture of the Measuring

Instrument(On Automatic control)

(1) Inside PATTERN is used when W/B is controlled. Connect

to auto controller or push control R/C IN-START -> Enter

the mode of White-Balance, the pattern will come out.

12-3. Auto-control interface and directions

(1) Adjust in the place where the influx of light like floodlight

around is blocked.(illumination is less than 10ux)

(2) Measure and adjust after sticking the Color Analyzer(CA-

100+, CA210) to the side of the module.

(3) Aging time : keep white pattern using inside pattern.

(Fig.3)

(Fig.4)

(Fig.5) Auto AV(CVBS) Color Balance Test Pattern

Full White Pattern

RS-232C Communication

CA-210

Color

ANALYZER

TYPE : CA-210

PLASMA Remark

11000K

9300K

6500K

Cool

Normal

Warm

CSM

CS-1000 CA-100(CH 10) CA-210(CH 10)

0.276 ± 0.002

0.283 ± 0.002

0.000

0.276 ± 0.002

0.283 ± 0.002

0.000

0.276

0.283

0.000

x

y

uv

Cool

CS-1000 CA-100(CH 10) CA-210(CH 10)

0.285 ± 0.002

0.293 ± 0.002

0.000

0.285 ± 0.002

0.293 ± 0.002

0.000

0.285

0.293

0.000

x

y

uv

Medium

CS-1000 CA-100(CH 10) CA-210(CH 10)

0.313 ± 0.002

0.329 ± 0.002

0.003

0.313 ± 0.002

0.329 ± 0.002

0.003

0.313

0.329

0.003

x

y

uv

Warm

Page 10

- 10 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

V Auto adjustment Map(RS-232C)

13. Adjustment of White Balance

(Manual white Balance)

V One of R Gain/ G Gain/ B Gain should be kept on 80, and

others are controlled lowering from 80

(1) Press ‘power on’ of the control R/C, set heat run to white

by pressing and heat run over 15 minutes.(Set: RS-232

Host: PC, Baud Rate: 115200bps, Download: Cortez)

(2) Zero Calibrate CA-100+, and stick the sensor to the center

of PDP module surface when you adjust.

(3) Double click In-start key on Controlling R/C and get in

‘white balance’.

(4) Set test-pattern on and display inside pattern. Control is

carried out on three color temperature, COOL, MEDIUM,

WARM. (Control is carried out three times.)

(5) When the R/G/B GAIN is 80 on OSD, it is the FULL

DYNAMIC Range of the Module. In order to control white

balance without the saturation of FULL DYNAMIC Range

and DATA, one of R Gain / G Gain / B Gain should be kept

on 80, and other two is controlled lowering from 80.

* Color Temperature: Cool, Medium, Warm

(1) When R GAIN is set to 80

- Control G GAIN and B GAIN by lowering from 80.

(2) When B GAIN is set to 80

- Control R GAIN and G GAIN by lowering from 80.

(3) When G GAIN is set to 80

- Control R GAIN and B GAIN by lowering from 192.

One of R Gain / G Gain / B Gain should be kept on 80, and

adjust other two lower than 80.

(When R/G/B GAIN are all 80, it is the FULL DYNAMIC

Range of Module)

14. Input the Shipping Option Data

1) Push the IN-START key in a Adjust Remocon.

2) Input the Option Number that was specified in the BOM, into

the Shipping area.

3) The work is finished, Push

V Key.

15. Set Information(Serial No& Model name)

15-1.

Setting up ‘Tool OPTION1,2’

(After setting white balance, this is set)

(1) Press ADJ Key in the R/C for adjustment

(2) Insert Option value by a number key

(3) Press the Enter Button

15-2. Check the serial number & Model Name

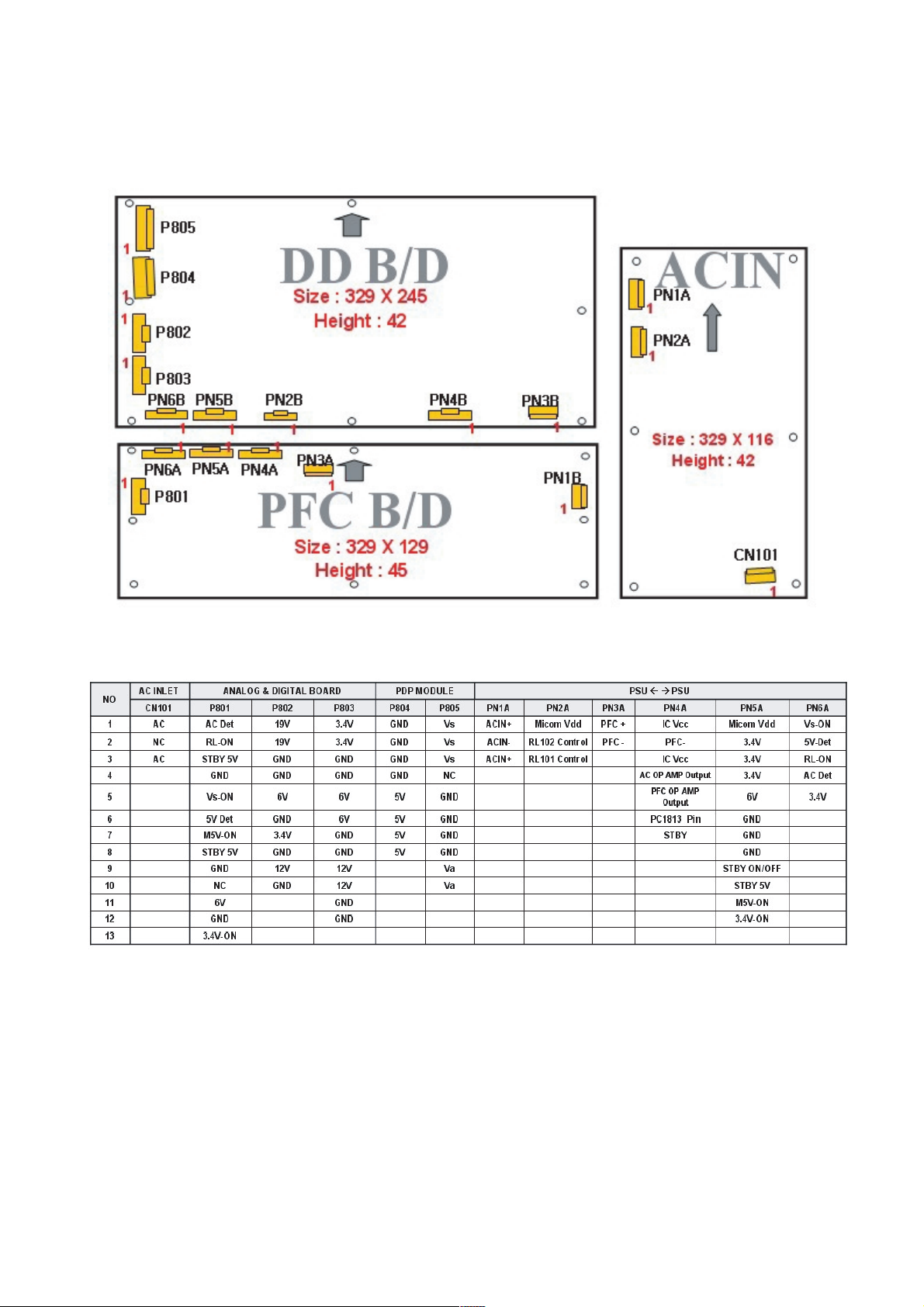

(1) Push the menu button in DTV mode.

- Select the SETUP-> Diagnostics -> To set.

(2) Check the Serial Number.

16. Set factoring condition

(1) This Adjustment is setting factory shipment mode.

(2) Push the IN-STOP key of adjustment remote controller

before the factory shipment.

Type

Baud Rate

115200

Index

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Data bit

8

Cmd1 Cmd2

ja

jb

jc

jd

je

jf

Stop bit

1

Parity

NONE

PD75A/C

Protocol

Setting

Data Min Value

00(00)

00(00)

00(00)

00(00)

00(00)

00(00)

Max Value

128(80)

128(80)

128(80)

128(80)

128(80)

128(80)

Model

Name

60PF95

Tool

Option1

2379 1977 0 14 2 1 192

Tool

Option2

Area

Option

Option1 Option2 Option3 Option4

Page 11

- 11 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

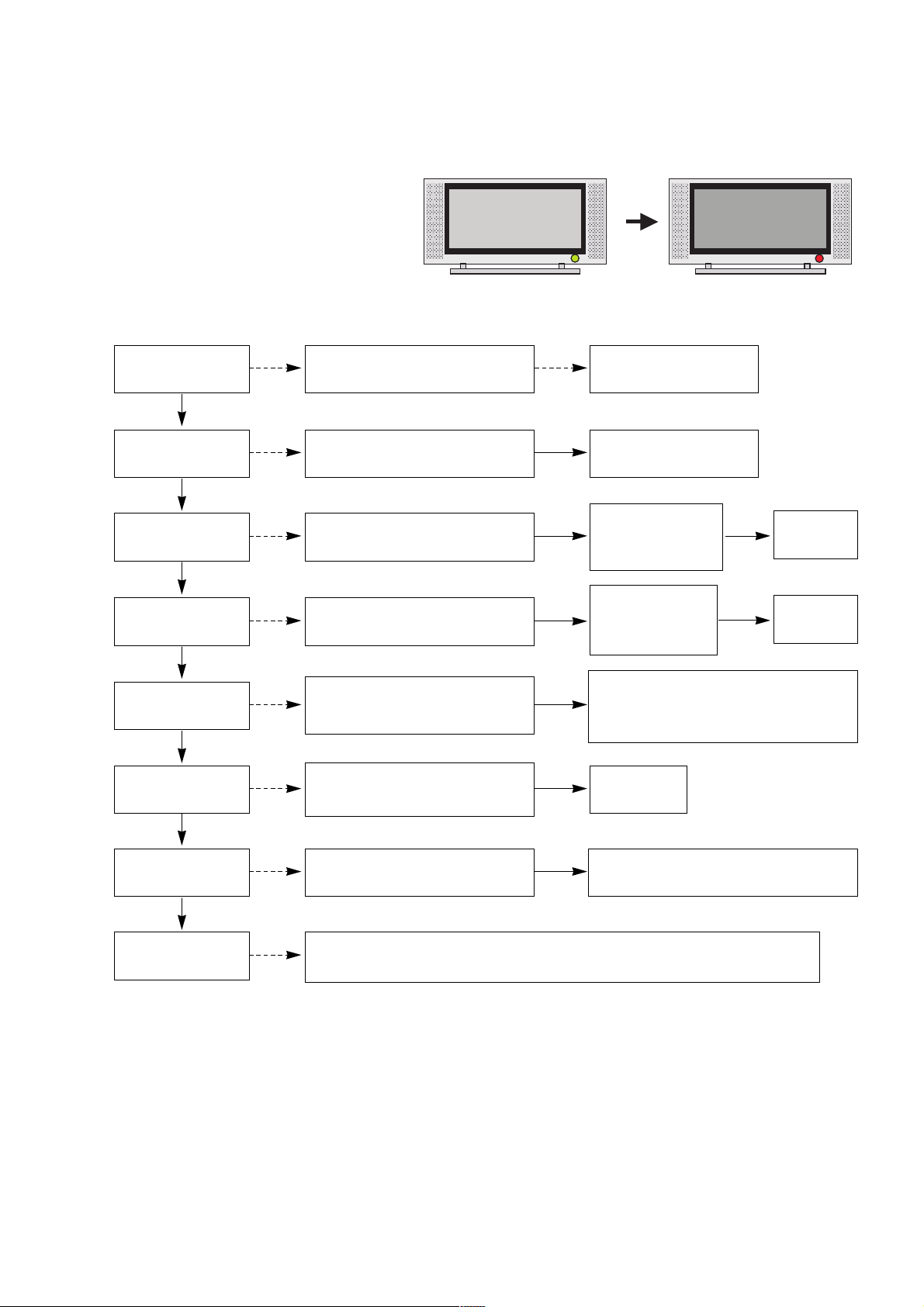

TROUBLE SHOOTING GUIDE

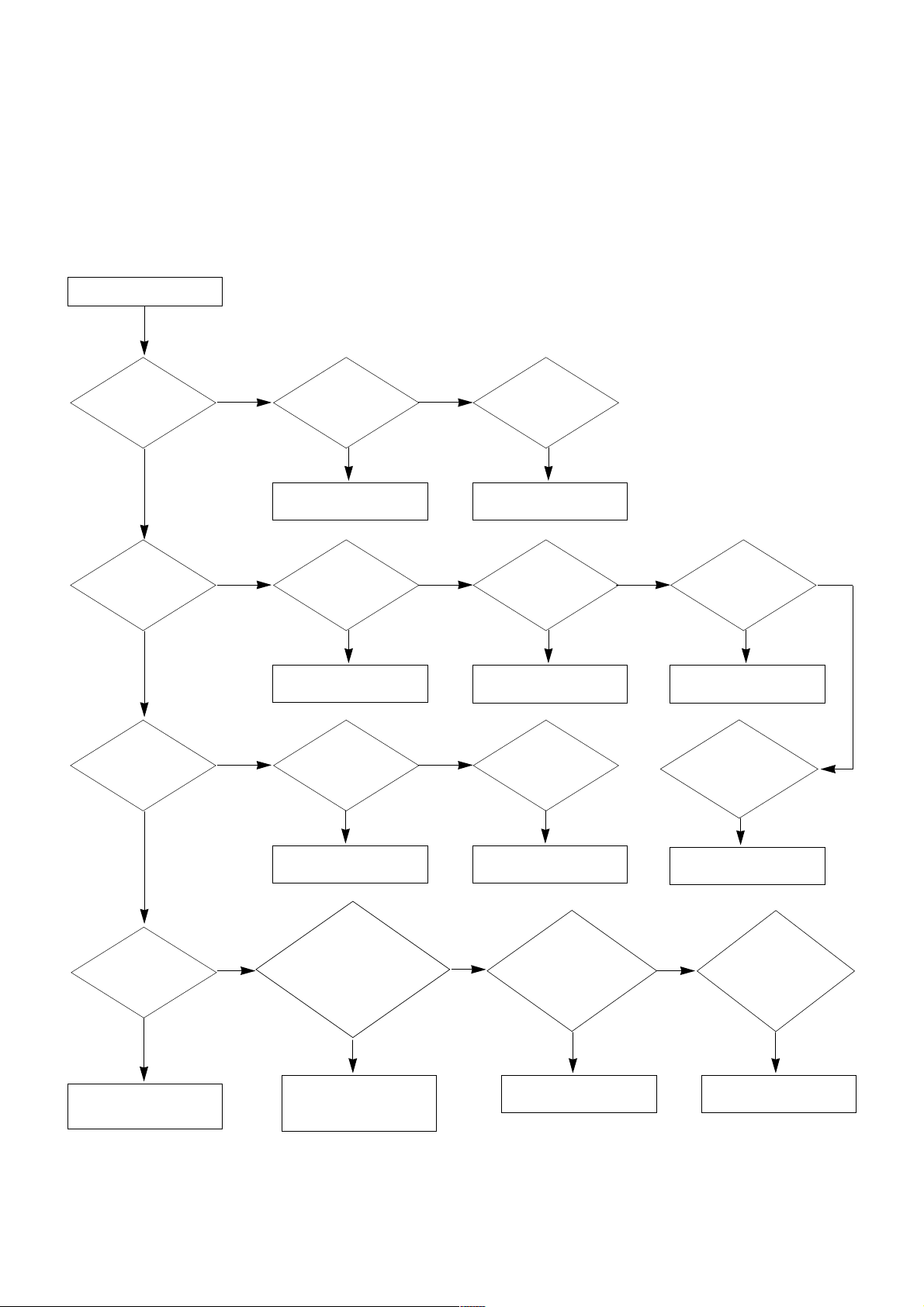

1. Power Board

1-1. The full flowchart for the voltage output

Start check

Manufacture’s model

passage

1. Check the Power Off

status.

Does the whole

screen appear?

Is it

identical to when the

power is off?

No

Yes

No

Yes

Yes

Yes

Yes

2. Check the Interface

signal status.

Is the Interface

signal operating?

Yes

3. Check the St-by 5V

signal circuit.

Does the

low pressure output

appear?

Does the

St-by 5V signal

appear?

No

No

Yes

4. Check the 5V Monitor

signal circuit.

Does the

5V Monitor signal

appear?

No

7. Check the VSC Vs-ON

signal

Does the

high tension output

appear?

Does the

VSC signal Vs-ON

appear?

No

No

Does the

high tension

output voltage

occur?

When

removing the Y B/D

Module input connector,

does output voltage

drop?

When the

Y, Z B/D Module

input connector, does Power

Board high tension

output voltage drop?

No No No

9. Check the Power

Board Output high

tension circuit

Yes

10. Check the Z B/D

Module output circuit

Yes

When

removing the Z B/D

Module input connector,

does output voltage

drop?

11. Check the Y B/D

Module output circuit

Yes

Yes

8. Check the Vs, Va

voltage output circuit.

Does the

Vs, Va voltage output

appear?

No

Yes

Yes

5. Check the VSC RL-ON

signal.

Does the

VSC signal RL-ON

appear?

No

6. Check the VSC low

pressure output

Does the

VSC low pressure

output appear?

No

Page 12

- 12 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

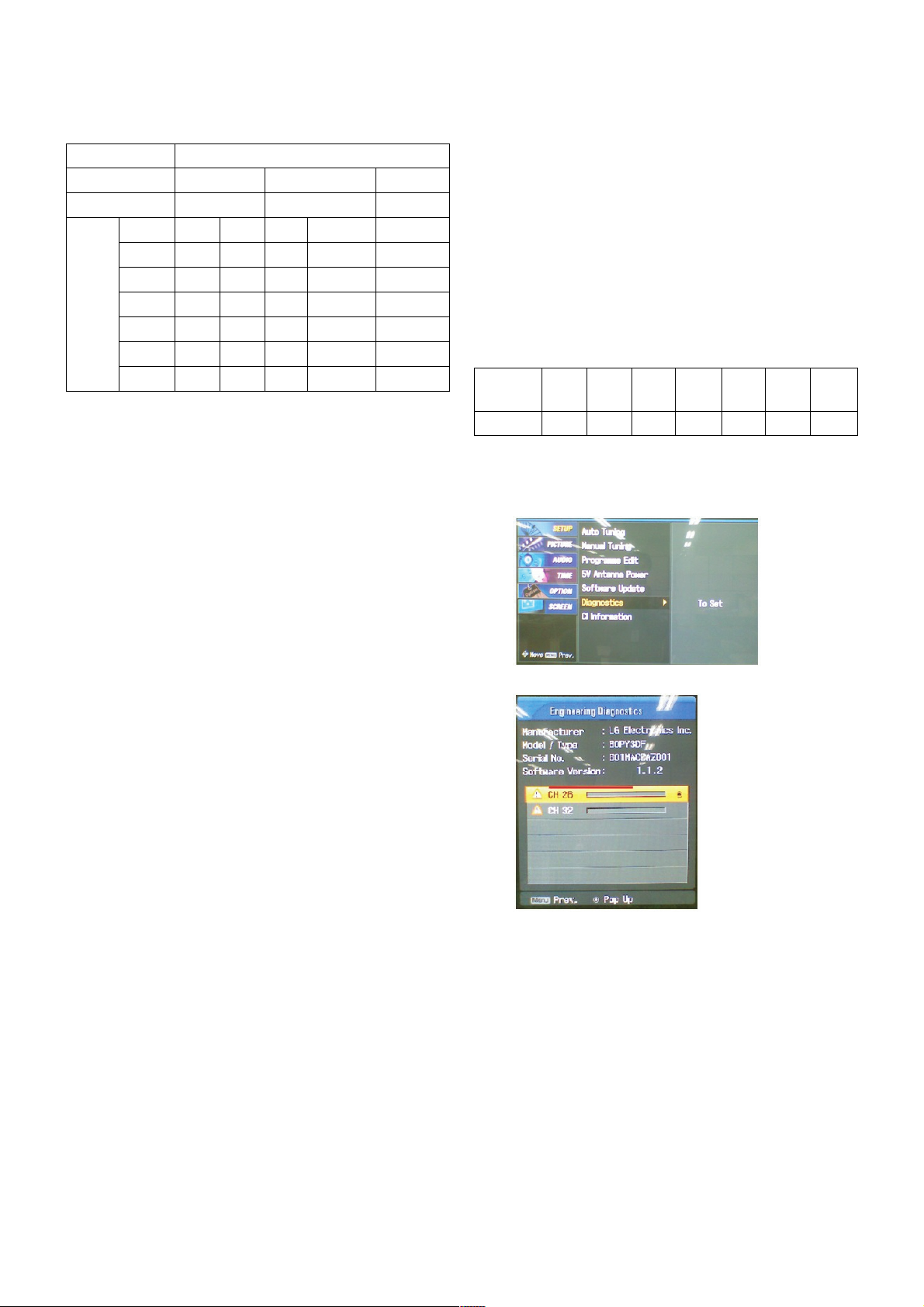

1-2. 60” Power Board Structure ( LGIT )

(1) Pin Layout

(2) Pin Spec

Page 13

- 13 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

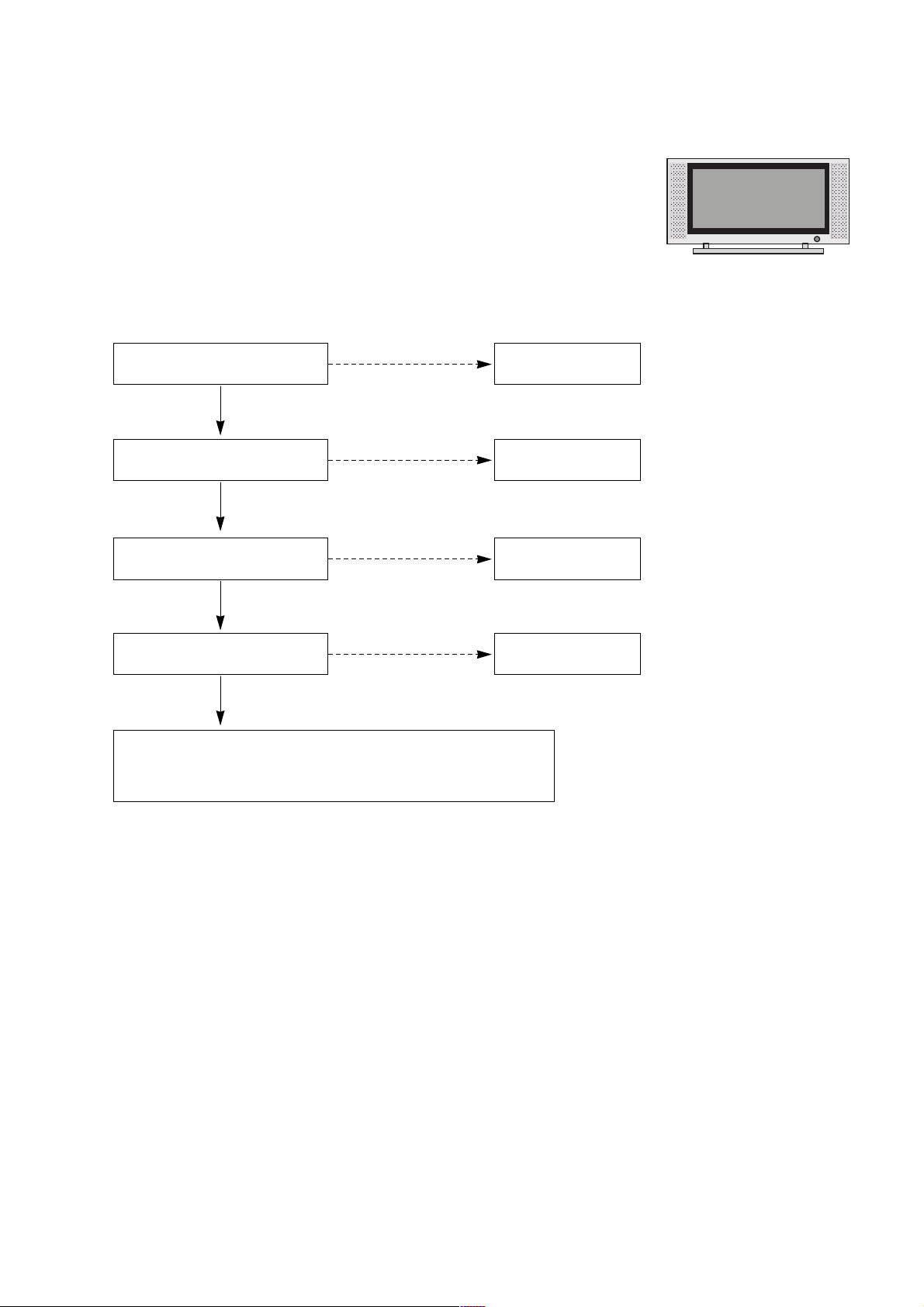

2. No Power

(1) Symptom

1) Does not minute discharge at module.

2) Non does not come into the front LED.

(2) Procedure check

Is the power cord plugged in? Plug in the power cord.

Yes

No

Is the Line Filter and Power

Board Cable connected?

Connect the Cable.

Yes

No

Is the appropriate Fuse(F101) on

the Power Board?

Replace the Fuse.

Yes

No

Is the Power Board and 13P of

VSC Board Cable connected?

Connect the Cable.

Yes

No

After removing the cables, connect them to the Power Board(except the

SC101 connection cable), and change the AC voltage marking to manual.

When ST-BY 5V does not operate, replace the Power Board.

Page 14

- 14 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3. Protect Mode

(1) Symptom

1) After lighting up once, it does not discharge

minutely from module.

2) The rely falls.(there is an audible “click”)

3) The color of the front LED turns from green to red.

(2) Procedure check

Is the Power Board

normal ?

Replace the Power Board.

Is the output Low/High voltage normal

except for Stand-by 5V?

Yes

No

No

Is the each connector

normal?

Replace the connector.

Replace the

Y-Board.

After connecting each connector do

they operate normally?

Yes

No

Yes

Is the Ctrl Board

normal?

Replace the

X-Board.

Is the output voltage normal after

removing P1, 2, 4, 9, 10 connectors of

the Ctrl-B/D?

Yes

No

Yes

Is the Y-Board

normal?

Is the output voltage

normal after removing

P103 connector of

Y-B/D?

Is the appropriate Fuse(FS101,FS102)

on the Y-B/D normal?(Replace if open)

Yes

No

Yes Yes

Replace the

Z-Board.

Is the Z-Board

normal?

Is the output voltage

normal after removing

P1 connector of

Z-B/D?

Is the appropriate Fuse (FS1, FS2) on

Z-B/D? (replace if open)

Yes

No

Yes

Is the X- Board

normal?

Is the output voltage normal after

removing P1, 2, 3, 4, 5 connectors of

the X-B/D?

If the output voltage is normal after removing

the P1, P2, P3 : Replace the right X-B/D

If the output voltage is normal after removing

the P4, P5 : Replace the left X-B/D

Yes

No

Yes

Is the

VSC Board normal?

Is the output voltage normal after

removing P900, P901 of VSC Board?

After a COF crisis for each board, check the normal operation. For normal operation,

corresponding COF failure means the module should be relaced.

If it operates normally after removing the

P900, P901 : Replace the VSC Board

Yes

No

Is the COF of X, Y, Z

normal ?

No

Yes

Yes

Page 15

- 15 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Does minute discharge

At Module?

Is the LVDC cable

normal?

Is the VAVS on?

Check the PDP Module

Yes

No

YES

Yes

Reconnect the LVDS

cable in P800

No

Is the IC700(FLI8548)

Output normal?

Replace the VSC.

No

NO

Replace the Power

board

Is the Low/High output

voltage normal except for

stand-by 5V?

NO

4. No Raster

(1) Symptom

1) No OSD and image occur at screen.

2) It maintains the condition where the front LED is green.

(2) Procedure check

Page 16

- 16 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

5. In case of strange screen display in specific modes

5-1. In case of no OSD display

(1) Symptom

1) LED is green.

2) The minute discharge is continuously accomplished from the module.

(2) Procedure check

Is the LVDS cable

normal ?

Is the VSC Board

normal?

Is the LVDS cable

connected?

Re-insert the Cable.

Yes

No

No

Yes

Does the FIL8548

IC(IC700) operate?

Replace the FIL8548

IC(IC700)

No

Is the Ctrl Board of

Module normal?

Replace the Ctrl B/D.

No

No

Yes

Replace the VSC B/D

Replace the cable.

Yes

Page 17

- 17 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

5-2. In case there is no display on the screen in specific modes

(1) Symptom

1) There is no screen display from a specific input mode

(RF, AV, Component, RGB, DVI).

(2) Procedure check

1) Check the all input modes have normal display

.

2) Check the video(main)/ data(sub), video(main)/ video(sub) have normal

displays from the PIP mode or DW mode(re-check it/ swap).

(3) In case of an unusual display in RF mode

(4) In case of an unusual display in side S-video/ AV mode

Is the Tuner normal?

Is the CXA2069Q normal?

Is the Tuner Cable connected?

Re-insert the cable

Yes

No

No

Yes

Is the FIL8548 normal?

Replace the Tuner.

No

Are the Input voltage, IIC Communication

and CVBS output normal?

Yes

Are the Input voltage, IIC

Communication and HV sync normal?

No

Replace the IC.

No

Are the input voltage, IIC

Communication and HV sync normal?

No

Block A

Replace the IC.

No

Is the Video input of the AV

Jack(P1400) normal?

Yes

Is the CXA2069Q normal?

Check the input source

No

Are the Input voltage, IIC

Communication and HV sync normal?

No

Replace the IC.

No

Yes

Same as Block A

Page 18

- 18 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

(5) In case of an unusual display in Component, RGB mode

(6) In case of an unusual display in HDMI mode

(7) In case of an unusual display in SCART1 mode

(8) In case of an unusual display in SCART2 mode

Are the R,G,B input and H,V

Sync of the J1100 normal?

Check the input source

No

Is the HDMI002(IC1004)

normal?

Yes

Same as Block A

Are Input voltage, IIC Communication

and HV sync normal?

No

Is the Video input of the

A/V Jack(J1200) normal?

Yes

Same as Block A

Check the input source

No

Replace the IC.

No

Is the Video input of the

A/V Jack(J1201) normal?

Yes

Same as Block A

Check the input source

No

Yes

Same as Block A

Page 19

- 19 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

6. In case of no sound

(1) Symptom

1) LED is Green.

2) Screen display appears but there is no sound.

(2) Procedure check

All input(modes) have

no sound?

Is there no sound only

for HDMI?

No

Yes

Download

the EDID data

Check the signal after

CAX2069 refer to circuit diagram

No

Is there no sound only

for specific?

(except HDMI,DTV,RF)

Check the signal before

CAX2069 refer to circuit diagram

No

YES YES

Is there no sound only

for RF?

Check the Tuner IN/OUT

No

YES

YES

Is there no sound only

for AV/component/PC?

Is the output of

CXA2069 normal?

No

YES

Is the IC1300

operating normally?

Replace the IC1300

(MSP4450)

No

Is the IC1301

operating normally?

Replace the IC1300

(STA335BW)

No

YES

Replace the VSC B/D

YES

No

Replace the CXA2069

Is the speaker on?

Set speaker on in the

menu.

No

Is the speaker Cable

normal?

Check the Speaker

Cable.

No

Yes

Page 20

- 20 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

BLOCK DIAGRAM

Page 21

- 21 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

MEMO

Page 22

- 22 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

EXPLODED VIEW

400

240

102

101

103

601

303

304

306

307

121

300

302

301

305

120

602

600

502

520

501

590

530

580

581

582

260

250

901

208

201

202

203

204

204

200

205

206

209

207

205

206

207

900

560

570

540

Page 23

- 23 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

101 EAL30846301 Fan Module, G6015S12b2 1.8KRPM DC 12V 840MA 12W 60HZ 200MM3 per MIN 60 x 60 x 15 DONG YANG ELE..

102 MJH32511701 Supporter, PRESS EGI 0.6 EGI FAN_SUPP

103 AJJ31606802 Supporter Assembly, 60PY30, SKD, FAN SUPPORTER ASSY

AJJ31606801 Supporter Assembly, 60PY30, FAN SUPPORTER ASSY LGERA

120 EAB33735401 Speaker Assembly, 50PY3 SLIM SPEAKER ASSY RIGHT

121 EAB33735402 Speaker Assembly, 50PY3 SLIM SPEAKER LEFT ASSY

200 EAJ32793601 PDP, Module-FullHD PDP60H10000.ASLGB FULLHD 60INCH 1920X1080 16/9 PDP DIVISION

EAJ32791701 PDP, Module-FullHD PDP60H10000.AKLGG FULLHD 60INCH 1920X1080 16/9 PDP DIVISION LGERA

201 EBR32922301 Hand Insert PCB Assembly, EBR32922301 CTRL ASS’Y HAND INSERT 60” H1 Full-HD CTRL PDP DIVISION

202 EBR32015901 Hand Insert PCB Assembly, EBR32015901 YDRV ASS’Y HAND INSERT 60” H1 Full-HD YDRV TOP PDP DIVISION

203 EBR32016101 Hand Insert PCB Assembly, EBR32016101 YDRV ASS’Y HAND INSERT 60” H1 Full-HD YDRV BOTTOM PDP DIVISION

204 EBR32003901 Hand Insert PCB Assembly, EBR32003901 XRLB ASSY HAND INSERT 60” H1 Full-HD XLB & XRT PDP DIVISION

205 EBR32004501 Hand Insert PCB Assembly, EBR32004501 XRCLBT ASSY’ HAND INSERT 60” H1 Full-HD XCLB & XCRT PDP DIVISION

206 EBR32004601 Hand Insert PCB Assembly, EBR32004601 XRCRBT ASSY’ HAND INSERT 60” H1 Full-HD XCRB & XCLT PDP DIVISION

207 EBR32004701 Hand Insert PCB Assembly, EBR32004701 XRRB ASSY HAND INSERT 60” H1 Full-HD XRB & XLT PDP DIVISION

208 EBR32324201 Hand Insert PCB Assembly, EBR32324201 YSUS ASS’Y HAND INSERT 60” H1 Full HD PDP DIVISION

209 EBR32324301 Hand Insert PCB Assembly, EBR32324301 ZSUS ASS’Y HAND INSERT 60” H1 Full HD PDP DIVISION

240 AJJ30996203 Supporter Assembly, 60PY30, SKD, Vertical Supporter Right Assy.

AJJ30996201 Supporter Assembly, 60PY30, Vertical Supporter Right Assy. LGERA

250 AJJ30996204 Supporter Assembly, 60PY30, SKD, Vertical Supporter Left Assy.

AJJ30996202 Supporter Assembly, 60PY30, Vertical Supporter Left Assy. LGERA

260 AJJ31606903 Supporter Assembly, 60PY30, MODULE SUPP_SIDE HOR.+ SUPP_SIDE. PANTON ASSY

AJJ31606902 Supporter Assembly, 60PY30, MODULE SUPP_SIDE HOR.+ SUPP_SIDE, Press LGERA

300 ABJ30995005 Cabinet Assembly, 60PY3DF-ZA PA71A 60” LG, C/SKD

ABJ30995003 Cabinet Assembly, 60PY3DF-ZA PA71A 60” LG LGERA

301 ADV31660202 Frame Assembly, 60py30 mf-056l 60” frame assy, LG

302 MBH32314201 Cabinet, MOLD ABS 60PY30 ABS E3, Cabinet, XCANVAS

303 AJJ30996402 Supporter Assembly, 60PY30, Filter Supporter Top, SKD

AJJ30996401 Supporter Assembly, 60PY30, Filter Supporter Top LGERA

304 AJJ30996502 Supporter Assembly, 60PY30, Filter Supporter Bottom Assy C/SKD

AJJ30996501 Supporter Assembly, 60PY30, Filter Supporter Bottom Assy LGERA

305 5230V00018B Filter, CUTTING ACRYL TOP 60PY2DR ø‹ 60inch PDP MITSUI 60” GLASS FILTER

306 AJJ30996603 Supporter Assembly, 60PY30, SKD, Filter Supporter Right Assy

AJJ30996601 Supporter Assembly, 60PY30, Filter Supporter Right Assy LGERA

307 AJJ30996703 Supporter Assembly, 60PY3, SKD, Filter Supporter Left Assy

AJJ30996701 Supporter Assembly, 60PY30, Filter Supporter Left Assy LGERA

400 ACQ30995608 Cover Assembly, Rear 60PY3DF-ZA PD75A 60” Back Cover Assy, SKD, Without DVR & Without Woofer

ACQ30995604 Cover Assembly, Rear 60PY3D PA71A 60” Back Cover Assy, Without DVR & Without Woofer LGERA

501 AGU31681111 Plate Assembly, ASSY PLATE TUNER BOT SMALL, 42PC5_EUROPASS FOR CKD

AGU31681103 Plate Assembly, ASSY PLATE TUNER BOT SMALL, EUROPASS LGERA

502 AGU31680926 Plate Assembly, ASSY 60PY3_FULL_HD_EU_C/SKD

AGU31680927 Plate Assembly, ASSY PLATE TUNER COVER SMALL, 60PY3_FULL_HD_WITHOUT CI CARD SLOT LGERA

520 EBR38413001 Hand Insert PCB Assembly, MAIN M.I PD75A 60PF95-ZA..KEKLLMP Main Manual Insert

EBR38580601 Hand Insert PCB Assembly, MAIN M.I PD75A 60PF95-ZA.KEULLMP Main Manual Insert

EBR37472212 Hand Insert PCB Assembly, MAIN M.I PD75A 60PF95-ZA.SEULJP Hand Insert PCB Assembly MAIN for MA_SKD

EBR37472211 Hand Insert PCB Assembly, MAIN M.I PD75A 60PF95-ZA.SEKLLJP Hand Insert PCB Assembly, MAIN for MA_SKD

EBR38150101 Hand Insert PCB Assembly, MAIN M.I PD75A 60PF95-ZA Full-HD Main Manual LGERA

530 EBR37489201 Hand Insert PCB Assembly, SUB M.I PD75A 60PY3DF-ZA - Fan Ass’y Hand Insert

540 EBT38269101 Chassis Assembly, SUB PD75A 60PY3DF-ZA VFD Assembly Total

EBT34195402 Chassis Assembly, SUB PD75A 60PY3DF FULL HD SUB VFD ASSY LGERA

560 EBR36865501 PCB Assembly, Audio BUZZER ASSEMBLY SOUND S.T PDP 50PB3,60PY3 PDP BUZZER B/D YANG WOO CO

570 EBR36845701 Hand Insert PCB Assembly, SUB M.I PD75A 60PY3DF-ZA - Pre_amp Hand Insert

580 EAY32929201 SMPS, AC/DC 1H391W 100VTO240V 800W 50 TO 60HZ UL/CE/TUV 60INCH PDP FULL HD SANKEN PSU MAIN DC/DC 1H391W

581 EAY32929401 SMPS, AC/DC 1H391W-PFC 100VTO240V 800W 50 TO 60HZ UL/CE/TUV 60INCH PDP FULL HD SANKEN PSU PFC BD 1H391W

582 EAY32929901 SMPS, AC/DC 1H391W-ACIN 100VTO240V 800W 50 TO 60HZ UL/CE/TUV 60INCH PDP FULL HD SANKEN PSU AC-IN 1H391W

590 EAM35012702 Filter, AC Line IF2-N10CEWL1 1.1mH 250VAC 10A 0.22uF 1000pF VDE/CSA/K/CCC HOUSING/RING BK DONG IL TECHNOLOGY

600 EBR37494701 Hand Insert PCB Assembly, SUB M.I PD75A 60PY3DF-ZA - Side_AV Ass’y Hand Insert

601 ABA30998702 Bracket Assembly, AV PY30 AB E3_SIDE AV BRACKET ASSY, EUROPASS, NON USB, WITH S-VIDEO

602 MGJ32323501 Plate, Shield PRESS AL 1.0 SHIELD AL E3 PY30 SHIELD,SIDE AV

900 AAN30997003 Base Assembly, STAND 60PY3 PA64F Stand Assy, SKD

AAN30997001 Base Assembly, STAND 60PY30 PA64F Stand Assy LGERA

901 MCK32693801 Cover, MOLD ABS 60PY3 ABS COVER CABLE

EXPLODED VIEW PARTS LIST

No. Part No.

Descriptions

The components identified by mark is

critical for safety.

Replace only with part number specified.

Page 24

- 24 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

C1 0CH3104K566 0805B104K500CT 100nF 10% 50V X7R

C100 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C100 0CC101CK41A C1608C0G1H101JT 100pF 5% 50V C0G

C100 0CC470CK41A C1608C0G1H470JT 47pF 5% 50V C0G -

C1003 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1004 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1005 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1006 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1007 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1008 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1009 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C101 0CE477WF6DC MVK10TP16VC470M 470uF 20% 16V 80M

C101 0CE1074F638 SRA5.0TP16VB100M 100uF 20% 16V 95

C101 0CC101CK41A C1608C0G1H101JT 100pF 5% 50V C0G

C101 0CK103BH56A C1005X7R1E103KT- 10nF 10% 25V X7R

C1010 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C102 0CE477WF6DC MVK10TP16VC470M 470uF 20% 16V 80M

C102 0CE106WFKDC MVK4.0TP16VC10M 10uF 20% 16V 16MA

C102 0CH3104K566 0805B104K500CT 100nF 10% 50V X7R

C103 0CE477WF6DC MVK10TP16VC470M 470uF 20% 16V 80M

C103 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C103 0CH4221K416 C2012C0G1H221JT 220pF 5% 50V C0G

C104 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C104 0CK105CD56A C1608X7R1A105KT 1uF 10% 10V X7R -

C105 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C105 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C106 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C106 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1068 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C107 0CK475DD56A C2012X7R1A475KT 4.7uF 10% 10V X7R

C107 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C108 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C109 0CK105CD56A C1608X7R1A105KT 1uF 10% 10V X7R -

C110 0CE106WFKDC MVK4.0TP16VC10M 10uF 20% 16V 16MA

C1104 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1105 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1106 0CC120CK41A C1608C0G1H120JT 12pF 5% 50V C0G -

C1108 0CC120CK41A C1608C0G1H120JT 12pF 5% 50V C0G -

C1109 0CK4R7CKFDA 0603N4R7J500LT 4.7pF 5% 50V C0G -

C111 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1110 0CK4R7CKFDA 0603N4R7J500LT 4.7pF 5% 50V C0G -

C1111 0CK4R7CKFDA 0603N4R7J500LT 4.7pF 5% 50V C0G -

C1116 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1119 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C112 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1120 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1121 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1123 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1125 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1128 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C113 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1132 0CC681CK41A C1608C0G1H681JT 680pF 5% 50V C0G

C1133 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C1134 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C1135 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1136 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C114 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C115 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C116 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C117 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C118 0CE106WFKDC MVK4.0TP16VC10M 10uF 20% 16V 16MA

C119 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C120 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1204 0CC221CK41A C1608C0G1H221JT 220pF 5% 50V C0G

C1205 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1206 0CK102CK56A 0603B102K500CT 1nF 10% 50V X7R -5

C1207 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1208 0CK102CK56A 0603B102K500CT 1nF 10% 50V X7R -5

C1209 0CC221CK41A C1608C0G1H221JT 220pF 5% 50V C0G

C121 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1210 0CC221CK41A C1608C0G1H221JT 220pF 5% 50V C0G

C1211 0CC331CK41A C1608C0G1H331JT 330pF 5% 50V C0G

C1215 0CC331CK41A C1608C0G1H331JT 330pF 5% 50V C0G

C1216 0CC331CK41A C1608C0G1H331JT 330pF 5% 50V C0G

C1217 0CE106WH6DC MVK5.0TP25VC10M 10uF 20% 25V 25MA

C122 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1225 0CE106WH6DC MVK5.0TP25VC10M 10uF 20% 25V 25MA

C123 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1232 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C1234 0CK102CK56A 0603B102K500CT 1nF 10% 50V X7R -5

C1235 0CK102CK56A 0603B102K500CT 1nF 10% 50V X7R -5

C1236 0CE106WH6DC MVK5.0TP25VC10M 10uF 20% 25V 25MA

C1237 0CE106WH6DC MVK5.0TP25VC10M 10uF 20% 25V 25MA

C1239 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C124 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1244 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1246 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1247 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C125 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C126 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C127 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C128 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C129 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C130 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1300 0CK105DH56A C2012X7R105KFT 1uF 10% 25V X7R -5

C1301 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1302 0CE108EH618 KMG5.0TP25VB1000M 1000uF 20% 25V

C1303 0CK105DH56A C2012X7R105KFT 1uF 10% 25V X7R -5

C1304 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

REPLACEMENT PARTS LIST

DATE: 2007. 05. 31.

CAPACITORs

Page 25

C1305 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1306 0CK222CK56A 0603B222K500CT 2.2nF 10% 50V X7R

C1307 0CK682CK51A C1608Y5P1H682KT 6.8nF 10% 50V Y5P

C1308 0CK682CK51A C1608Y5P1H682KT 6.8nF 10% 50V Y5P

C1309 0CE475WK6DC MVK5.0TP50VC4.7M 4.7uF 20% 50V 19

C131 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1310 0CE475WK6DC MVK5.0TP50VC4.7M 4.7uF 20% 50V 19

C1311 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1312 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1313 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C1314 0CC030CK01A 0603N3R0C500LT 3pF 0.25PF 50V C0G

C1315 0CC030CK01A 0603N3R0C500LT 3pF 0.25PF 50V C0G

C1316 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1317 0CC560CK41A C1608C0G1H560JT 56pF 5% 50V C0G -

C1318 0CC560CK41A C1608C0G1H560JT 56pF 5% 50V C0G -

C1319 0CE335WK6D8 MVK4.0TP50VC3.3M 3.3uF 20% 50V 14

C132 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1320 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1321 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1322 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1325 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C1326 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1327 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1329 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C133 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1330 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1332 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1333 0CC101CK41A C1608C0G1H101JT 100pF 5% 50V C0G

C1335 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1338 0CK471CK56A C1608X7R1H471KT 470pF 10% 50V X7R

C134 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1340 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1341 0CE335WK6D8 MVK4.0TP50VC3.3M 3.3uF 20% 50V 14

C1342 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1343 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C1344 0CE106WH6DC MVK5.0TP25VC10M 10uF 20% 25V 25MA

C1345 0CE106WH6DC MVK5.0TP25VC10M 10uF 20% 25V 25MA

C1346 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1347 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C135 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1350 0CE106WFKDC MVK4.0TP16VC10M 10uF 20% 16V 16MA

C1351 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1352 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1353 0CK222CK56A 0603B222K500CT 2.2nF 10% 50V X7R

C1354 0CC102CK41A C1608C0G1H102JT 1nF 5% 50V C0G -5

C1355 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1356 0CC101CK41A C1608C0G1H101JT 100pF 5% 50V C0G

C1357 0CC221CK41A C1608C0G1H221JT 220pF 5% 50V C0G

C1358 0CH2122K516 0805B122K500CT 1.2nF 10% 50V Y5P

C1359 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C136 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1360 0CC331CK41A C1608C0G1H331JT 330pF 5% 50V C0G

C1361 0CC331CK41A C1608C0G1H331JT 330pF 5% 50V C0G

C1362 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1363 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1364 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1365 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1366 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1367 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1368 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1369 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C137 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1370 0CF4741L430 PCMT365 76474 470nF 5% 63V MPE -4

C1371 0CF4741L430 PCMT365 76474 470nF 5% 63V MPE -4

C1373 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C138 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C139 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C140 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1400 0CE475WK6DC MVK5.0TP50VC4.7M 4.7uF 20% 50V 19

C1401 0CE475WK6DC MVK5.0TP50VC4.7M 4.7uF 20% 50V 19

C1402 0CK682CK51A C1608Y5P1H682KT 6.8nF 10% 50V Y5P

C1403 0CK682CK51A C1608Y5P1H682KT 6.8nF 10% 50V Y5P

C1404 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1407 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C1408 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C1409 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C141 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1410 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C1411 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1412 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1413 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1418 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1419 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C142 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1420 0CK225DFK4A C2012Y5V1C225MT 2.2uF 20% 16V Y5V

C1421 0CC820CK41A C1608C0G1H820JT 82pF 5% 50V C0G -

C1422 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1423 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1426 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1428 0CK225DFK4A C2012Y5V1C225MT 2.2uF 20% 16V Y5V

C1429 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C143 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1439 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C144 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1440 0CK225DFK4A C2012Y5V1C225MT 2.2uF 20% 16V Y5V

C1441 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1442 0CK225DFK4A C2012Y5V1C225MT 2.2uF 20% 16V Y5V

C1444 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1445 0CK225DFK4A C2012Y5V1C225MT 2.2uF 20% 16V Y5V

C1447 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1448 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C1449 0CK225DFK4A C2012Y5V1C225MT 2.2uF 20% 16V Y5V

C145 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1450 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1451 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C1452 0CC150CK41A C1608C0G1H150JT 15pF 5% 50V C0G -

C1453 0CC150CK41A C1608C0G1H150JT 15pF 5% 50V C0G -

C146 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C147 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C148 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

- 25 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 26

C149 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C150 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C151 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C152 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C153 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C154 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C155 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C156 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C157 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C158 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C159 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C160 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C161 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C162 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C163 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C164 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C165 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C166 0CK106EF56A C3216X7R1C106KT 10uF 10% 16V X7R

C167 0CK106EF56A C3216X7R1C106KT 10uF 10% 16V X7R

C168 0CK106EF56A C3216X7R1C106KT 10uF 10% 16V X7R

C169 0CC100CK41A C1608C0G1H100JT 10pF 5% 50V C0G -

C170 0CC220CK41A C1608C0G1H220JT 22pF 5% 50V C0G -

C1700 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1701 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C1702 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1703 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1705 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1706 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1707 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C1708 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C1709 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C171 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C1710 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C172 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C173 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C174 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C175 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C176 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C177 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C178 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C179 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C180 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C181 0CE106WFKDC MVK4.0TP16VC10M 10uF 20% 16V 16MA

C182 0CK105CD56A C1608X7R1A105KT 1uF 10% 10V X7R -

C183 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C184 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C185 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C186 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C187 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C188 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C189 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C190 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C191 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C192 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C193 0CK822CK46A 0603B822J500CT 8.2nF 10% 50V X7R

C194 0CK822CK46A 0603B822J500CT 8.2nF 10% 50V X7R

C195 0CC220CK41A C1608C0G1H220JT 22pF 5% 50V C0G -

C196 0CC100CK41A C1608C0G1H100JT 10pF 5% 50V C0G -

C197 0CK475CC94A C1608Y5V0J475ZT 4.7uF -20TO+80% 6

C198 0CK475CC94A C1608Y5V0J475ZT 4.7uF -20TO+80% 6

C199 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C200 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C201 0CC470CK41A C1608C0G1H470JT 47pF 5% 50V C0G -

C202 0CC101CK41A C1608C0G1H101JT 100pF 5% 50V C0G

C203 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C204 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C206 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C207 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C209 0CK106EF56A C3216X7R1C106KT 10uF 10% 16V X7R

C212 0CK106EF56A C3216X7R1C106KT 10uF 10% 16V X7R

C213 0CK106EF56A C3216X7R1C106KT 10uF 10% 16V X7R

C216 0CK106EF56A C3216X7R1C106KT 10uF 10% 16V X7R

C218 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C219 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C220 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C221 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C222 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C224 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C226 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C227 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C228 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C229 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C230 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C231 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C232 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C233 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C234 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C235 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C236 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C237 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C238 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C239 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C240 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C241 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C242 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C243 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C301 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C302 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C303 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C306 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C307 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C308 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C309 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C310 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C311 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C312 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C313 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C314 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C409 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C410 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

- 26 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 27

C411 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C412 0CE106WFKDC MVK4.0TP16VC10M 10uF 20% 16V 16MA

C413 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C414 0CE106WFKDC MVK4.0TP16VC10M 10uF 20% 16V 16MA

C415 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C416 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C417 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C418 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C419 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C422 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C423 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C424 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C425 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C427 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C429 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C430 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C439 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C515 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C516 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C517 0CE227WF6DC MVK8.0TP16VC220M 220uF 20% 16V 80

C518 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C519 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C520 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C521 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C522 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C523 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C524 0CE477WF6DC MVK10TP16VC470M 470uF 20% 16V 80M

C525 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C526 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C527 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C528 0CE227WF6DC MVK8.0TP16VC220M 220uF 20% 16V 80

C529 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C530 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C531 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C532 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C533 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C534 0CE227WF6DC MVK8.0TP16VC220M 220uF 20% 16V 80

C535 0CK105CD56A C1608X7R1A105KT 1uF 10% 10V X7R -

C537 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C539 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C540 0CK105CD56A C1608X7R1A105KT 1uF 10% 10V X7R -

C541 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C542 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C543 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C544 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C548 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C549 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C550 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C551 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C553 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C554 0CK105CD56A C1608X7R1A105KT 1uF 10% 10V X7R -

C555 0CK105CD56A C1608X7R1A105KT 1uF 10% 10V X7R -

C601 0CC101CK41A C1608C0G1H101JT 100pF 5% 50V C0G

C602 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C603 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C604 0CC470CK41A C1608C0G1H470JT 47pF 5% 50V C0G -

C605 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C606 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C608 0CC101CK41A C1608C0G1H101JT 100pF 5% 50V C0G

C609 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C610 0CC271CK41A C1608C0G1H271JT 270pF 5% 50V C0G

C611 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C612 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C613 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C615 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C616 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C623 0CC470CK41A C1608C0G1H470JT 47pF 5% 50V C0G -

C624 0CC470CK41A C1608C0G1H470JT 47pF 5% 50V C0G -

C625 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C626 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C627 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C630 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C633 0CK106CC67A C1608X5R0J106MT 10uF 20% 6.3V X5R

C633 0CK475CC94A C1608Y5V0J475ZT 4.7uF -20TO+80% 6

C635 0CK472CK56A 0603B472K500CT 4.7nF 10% 50V X7R

C636 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C637 0CK472CK56A 0603B472K500CT 4.7nF 10% 50V X7R

C638 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C639 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C640 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C641 0CC470CK41A C1608C0G1H470JT 47pF 5% 50V C0G -

C642 0CC470CK41A C1608C0G1H470JT 47pF 5% 50V C0G -

C700 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C701 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C702 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C703 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C704 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C705 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C706 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C707 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C708 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C709 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C710 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C711 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C712 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C713 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C714 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C715 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C716 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C717 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C718 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C721 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C722 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C723 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C724 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C725 0CC200CK41A C1608C0G1H200JT 20pF 5% 50V C0G -

C726 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C727 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C728 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C729 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

- 27 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 28

C730 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C732 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C733 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C734 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C736 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C737 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C738 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C739 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C740 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C741 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C742 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C743 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C744 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C745 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C746 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C747 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C749 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C750 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C751 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C752 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C753 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C754 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C755 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C756 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C757 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C758 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C759 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C760 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C761 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C762 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C763 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C764 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C765 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C766 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C767 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C768 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C769 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C770 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C771 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C772 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C773 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C774 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C775 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C776 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C777 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C778 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C779 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C780 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C781 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C782 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C783 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C784 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C785 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C786 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C787 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C788 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C789 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C790 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C791 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C792 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C793 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C794 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C795 0CC220CK41A C1608C0G1H220JT 22pF 5% 50V C0G -

C796 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C797 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C798 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C799 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C800 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C801 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C802 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C803 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C806 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C807 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C810 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C812 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C813 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C815 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C817 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C818 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C822 0CE226WF6DC MVK5.0TP16VC22M 22uF 20% 16V 30MA

C824 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C826 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C828 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C830 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C831 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C834 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C836 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C840 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C841 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C844 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C846 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C847 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C850 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C851 0CK225DFK4A C2012Y5V1C225MT 2.2uF 20% 16V Y5V

C852 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C853 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C854 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C855 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C856 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C857 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C858 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C859 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C860 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C861 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C862 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C863 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C864 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C865 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C866 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C867 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

LOC. NO. PART NO. DESCRIPTION / SPECIFICATION LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

- 28 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 29

C868 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C869 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C870 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C871 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C872 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C873 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C874 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C875 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C876 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C877 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C878 0CK104BF56A C1005X7R104KET 100nF 10% 16V X7R

C900 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C901 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C903 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C905 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C907 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C908 0CK104CF56A 0603B104K160CT 100nF 10% 16V X7R

C909 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C910 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C911 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C912 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

C914 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C915 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C917 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C924 0CE107WH6DC MVK8.0TP25VC100M 100uF 20% 25V 18

C925 0CE227WF6DC MVK8.0TP16VC220M 220uF 20% 16V 80

C928 0CE227WF6DC MVK8.0TP16VC220M 220uF 20% 16V 80

C929 0CE227WF6DC MVK8.0TP16VC220M 220uF 20% 16V 80

C931 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C932 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C933 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C934 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C935 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C937 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C954 0CE477WF6DC MVK10TP16VC470M 470uF 20% 16V 80M

C955 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C956 0CK474CH94A 0603F474Z250CT 470nF -20TO+80% 25

C957 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C958 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C959 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C960 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C961 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C962 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C969 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C970 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C971 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C972 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C973 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C974 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C975 0CE107WF6DC MVK6.3TP16VC100M 100uF 20% 16V 80

C977 0CK104CK56A 0603B104K500CT 100nF 10% 50V X7R

C980 0CK103CK56A 0603B103K500CT 10nF 10% 50V X7R -

C981 0CE476WF6DC MVK6.3TP16VC47M 47uF 20% 16V 80MA

D100 EAH33945901 CDS3C30GTH 30V 50V 120V 1.9A 1W S

D1000 0DD184009AA KDS184 KDS184 TP KEC - 85V - - -

D1001 0DD184009AA KDS184 KDS184 TP KEC - 85V - - -

D101 EAH33946001 CDS3C05GTA 5.6V 6.4V 19V 1.9A 1W

D102 EAH33946001 CDS3C05GTA 5.6V 6.4V 19V 1.9A 1W

D103 EAH33945901 CDS3C30GTH 30V 50V 120V 1.9A 1W S

D104 EAH33945901 CDS3C30GTH 30V 50V 120V 1.9A 1W S

D401 0DD100009AM EU1ZV(1) 200V 2.5V 10UA 15A 400NS

D900 0DS226009AA KDS226 1.2V 85V 300MA 2A 4NSEC 15

D902 0DS226009AA KDS226 1.2V 85V 300MA 2A 4NSEC 15

D903 0DS226009AA KDS226 1.2V 85V 300MA 2A 4NSEC 15

D904 0DS226009AA KDS226 1.2V 85V 300MA 2A 4NSEC 15

D905 0DS226009AA KDS226 1.2V 85V 300MA 2A 4NSEC 15

D906 0DD100009AM EU1ZV(1) 200V 2.5V 10UA 15A 400NS

ZD1100 EAH33946001 CDS3C05GTA 5.6V 6.4V 19V 1.9A 1W

ZD1101 EAH33946001 CDS3C05GTA 5.6V 6.4V 19V 1.9A 1W

ZD1104 EAH33945901 CDS3C30GTH 30V 50V 120V 1.9A 1W S

ZD1105 EAH33945901 CDS3C30GTH 30V 50V 120V 1.9A 1W S

ZD1106 EAH33945901 CDS3C30GTH 30V 50V 120V 1.9A 1W S