Page 1

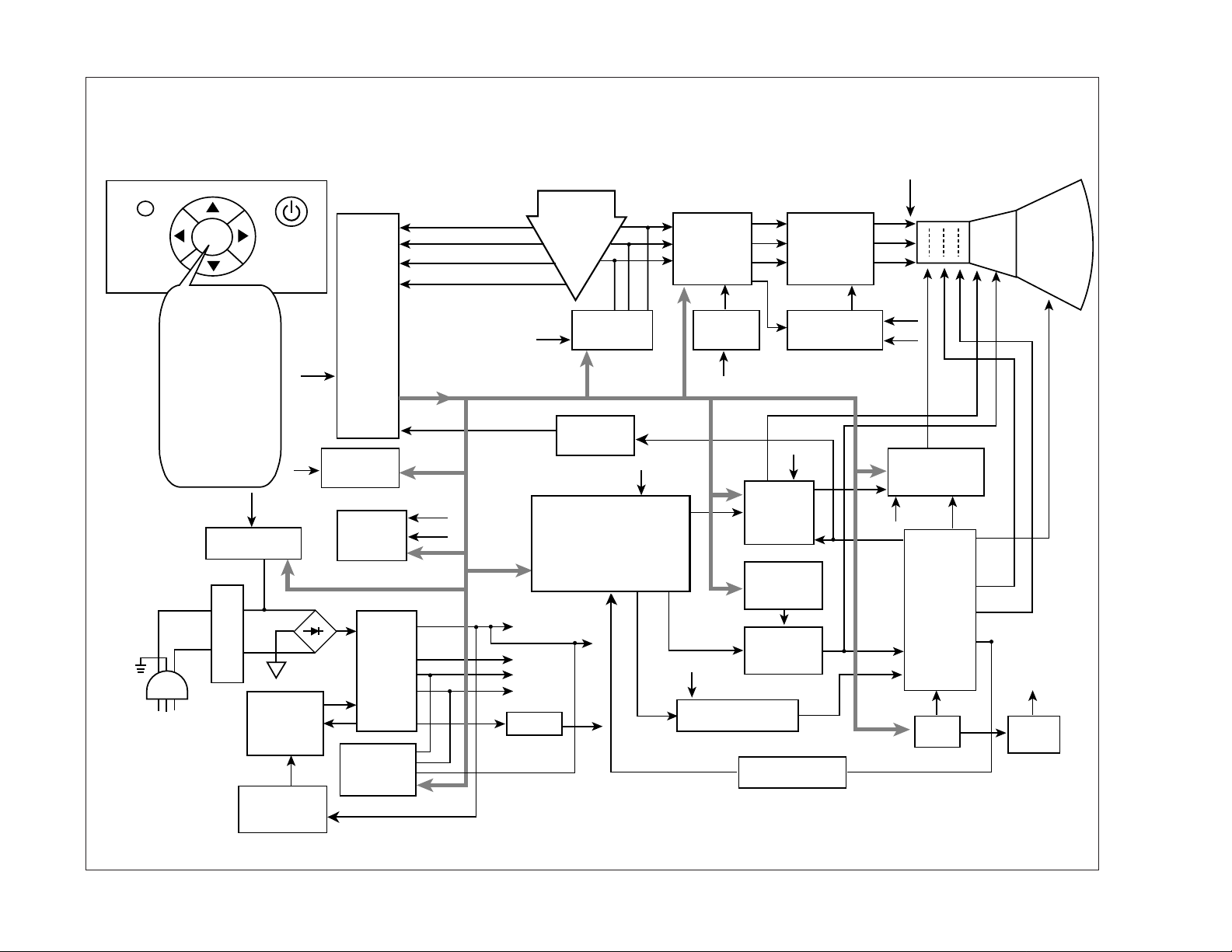

BLOCK DIAGRAM

- 12 -

POW ER INPUT

100~240VAC

(50/60Hz)

Line Filter

Degaussing

Circuit

OSD

ON/OFF

SET

[OSD Control]

SMPS

TRANS

(T901)

SMPS

CONTROL

(IC901)

DPM

CONTROL

194V

75V

15V

6.3V

TILT

Controlt

6.3V

6.3V

EEPROM

(IC402)

H / V POSITION

H / V SIZE

SPCC

TRAPIZODE

PIN BALANCE

PARALLELOGRAM

ROTATION

RECALL

DEGAUSSING

DDC OPTION

COLOR CURVE

MOIRE

LANGUAGE

RECALL

INFORMATION

5V

OSD IC

(IC301)

H-Sync

V-Sync

I

2

C DATA(SDA)

I2C CLOCK(SCL)

VIDEO

PRE-AMP

(IC302)

Signal

Cable

R

G

B

VIDEO

MAIN AMP

(IC303)

KA7808

(IC304)

8V

15V

CUT-OFF

CONTROL

150V

8V

5V

H/V Sync Processor

( IC701 )

TDA4856

V-OUT

( IC601)

TDA4866

H-OUT

( Q706)

H-Linearity

Correction

DC/DC Convert er

X-RAY

Protection

FBT

( T701 )

ABL

Beam

Limit

V-Blanking,

Brightness

Control

-120V

40V

30V

15V

MICOM

(IC401)

12V

15V

194V

DY CDT

Heater ( 6.3V

)

I

2

C

I2C

I2C

H/V

Sync

kD/D Feed Bac

G1Screen

Focus

H.V

R/G/B Drive

R/G/B Cut-off

R/G/B Bias

H-DRV

B-DRV

B+

IC302

15V

POWER

I2C

VOLTAG E

FEEDBACK

V-DY

H-DY

KA7805

5V

150V

5V

SCL/SDA

H/V SYNC,

PWM CONTROL

Page 2

DESCRIPTION OF BLOCK DIAGRAM

- 13 -

1. SMPS(Switching Mode Power Supply)

When you turn on the power switch, the operating procedure is as follows:

1) The AC line voltage is rectified by the bridge diodes

D901, D902, D903, D904

2) The control IC(IC901) starts switching and generates

switching pulses in the primary turn of the SMPS transformer (T901)

3) The switching pulses of the primary turns are induced

to the secondary turns of the transformer by the turn

ratio. This pulses are rectified by each diode(D922,

D923, D924, D926, D930)

4) Each rectified DC voltage(194V, 75V, 15V, 11V and

6.3V) is supplied to the main circuit.

2. Over Voltage Protection Circuit

When the input voltage of IC901 Vin(pin 4) is more

than 22V, all the secondary voltages of the SMPS

transformer (T901) down to low value.

3. Display Power Management Circuit

1) Stand-by and Suspend mode.

When no input of horizontal or vertical sync, Q922 and

Q923, Q924 are turned off and Q920, Q925 and Q926

are turned on. Then input power consumption is below

15 watts.

2) OFF mode

When no input of horizontal and vertical sync, Q922,

Q923, Q924, Q925, Q926 are turned off and Q920 is

turned on. Then input power consumption is below 5

watts.

4. X-ray Protection Circuit

When the high voltage reaches to 29kV in an abnormal

case, the high voltage detector circuit, R816, R818,

ZD801, C805, and Q807 start operation to shut down

high voltage circuit.

5. Microprocessor Control Circuit.

The operating procedure is as follows

1) Horizontal and Vertical sync signal are supplied to the

microcessor (IC401).

2) Microprocessor (IC401) discriminates the operating

mode from the sync polarity and resolution.

3) After microprocessor reads these adjusted mode data

stored at EEPROM, it controls operating mode data

through IIC.

4) Users can control screen condition by the OSD, SET,

UP, DOWN, RIGHT, LEFT buttons.

6. D/D Convert Circuit.

To obtain constant high voltage, this circuit supplies

controlled DC voltage for FBT and horizontal deflection

circuit according to the horizontal sync frequency.

7. Horizontal and Vertical Sync Processor Circuit.

The horizontal and vertical sync processor IC (IC701)

has a sync detector, a saw-tooth generator, and drive

function. And outputs horizontal and vertical drive signal to control screen distortions.

8. Horizontal S-correction Circuit.

This circuit corrects the horizontal linearity for each

horizontal sync frequency.

9. Horizontal drive and Output Circuit.

This circuit is a horizontal deflection amplifier for raster

scan.

10. ABL Circuit.

This circuit limits the beam-current for the reliability of

CDT.

11. Vertical Output Circuit.

This circuit takes the vertical ramp wave from the

TDA4856 (IC701) and performs the vertical deflection

by supplying the saw-tooth wave current to the vertical

deflection yoke.

12. Blanking and Brightness Control Circuit.

Blanking circuit eliminates the retrace line by supplying

a negative pulse wave to the G1 of the CDT.

Brightness control circuit is used for control of the

screen brightness by changing the DC level of G1.

13. Video Processor Circuit.

Video processor circuit consists of the video drive outputblock. The video drive IC(IC302) receives the video

signal from PC. The gain of each channel is controlled

by MICOM through IIC.

The cut-off circuit compensate different voltage of each

channel between the cathode and the G1 of the CDT.

14. OSD (On-Screen-Display) Circuit.

This circuit displays information of the montor’s status

on the screen.

Loading...

Loading...