Page 1

LED LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : LA02R

MODEL : 55LX6500 55LX6500-UB

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

Printed in KoreaP/NO : MFL63727203 (1005-REV00)

Page 2

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 2 -

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ......................................................................... 3

SPECIFICATION....................................................................................... 6

ADJUSTMENT INSTRUCTION............................................................... 11

EXPLODED VIEW .................................................................................. 20

SVC. SHEET ...............................................................................................

Page 3

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument’s

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 4 -

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500°F to 600°F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500°F to 600°F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500°F to 600°F)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

SERVICING PRECAUTIONS

Page 5

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 5 -

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Page 6

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

1. Application range

This spec sheet is applied LCD TV with LA02R chassis.

2. Requirement for Test

Each part is tested as below without special appointment.

1) Temperature: 20±5ºC

2) Relative Humidity: 65±10%

3) Power Voltage : Standard input voltage(100-240V~, 50/60Hz)

* Standard Voltage of each product is marked by models

4) Specification and performance of each parts are followed

each drawing and specification by part number in

accordance with BOM.

5) The receiver must be operated for about 20 minutes prior to

the adjustment.

3. Test method

1) Performance: LGE TV test method followed

2) Demanded other specification

- Safety : UL, CSA, IEC specification

- EMC: FCC, ICES, IEC specification

- Wireless : WirelessHD Specification (Option)

Model Market Appliance

42/47/55LXLE6500-UB

North America Safety : UL1492, CSA C22.2.No.1,

47/55LX9500-UA EMC : FCC Class B, IEC Class B

- 6 -

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement.

4. General Specification(TV)

No Item Specification Remark

1 Receivable System 1) ATSC / NTSC-M

2 Available Channel VHF : 02 ~ 13

UHF : 14 ~ 69

DTV : 02 ~ 69

CATV : 01 ~ 135

CADTV : 01 ~ 135

3 Input Voltage 1) AC 100 ~ 240V 50/60Hz

4 Market North America

5 Aspect Ratio 16:9

6 Tuning System FS

7 LCD Module LC420EUS-SCA1 42LX6500-UB

LC470EUS-SCA1 47LX6500-UB

LC550EUC-SCA1 55LX6500-UB

LC470MUT-SCA1 47LX9500-UA

LC550MUT-SCA1 55LX9500-UA

8 Operating Environment Temp : 0 ~ 40 deg

Humidity : ~ 80 %

9 Storage Environment Temp : -20 ~ 50 deg

Humidity : -85 %

Page 7

- 7 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

5. Chrominance & Luminance

5.1. 42/47/55LX6500-UB

No Item Min Typ Max Unit Remark

1 Max Luminance 2D 350 430 cd/m

2

42LX6500-UB(2D)

(Center 1-point / 3D 48 61 cd/m

2

42LX6500-UB(3D)

Full White Pattern) 2D 350 430 cd/m

2

47LX6500-UB(2D)

3D 48 61 cd/m

2

47LX6500-UB(3D)

2D 350 430 cd/m

2

55LX6500-UB(2D)

3D 48 61 cd/m

2

55LX6500-UB(3D)

2 Color coordinate RED X Typ. 0.642 Typ. 42LX6500-UB

Y -0.03 0.335 +0.03

GREEN X 0.308

Y 0.602

BLUE X 0.156

Y 0.061

WHITE X 0.279

Y 0.292

RED X Typ. 0.642 Typ. 47LX6500-UB

Y -0.03 0.333 +0.03

GREEN X 0.307

Y 0.605

BLUE X 0.149

Y 0.058

WHITE X 0.279

Y 0.292

RED X Typ. 0.644 Typ. 55LX6500-UB

Y -0.03 0.333 +0.03

GREEN X 0.308

Y 0.605

BLUE X 0.149

Y 0.059

WHITE X 0.279

Y 0.292

3 Luminance Uniformity(2D) 77 % 5 point

4 3D Grosstalk 14 18 %

5 Contrast ratio 1000 1300 Only 2D

6 Response Time(Gray to Gray) 6 ms

Response Time(MPRT) 6 ms

Response Time(Uniformity MPRT) 1

Response Time(Uniformity G to G) 1

7 Dynamic CR 4,500,000 5,000,000

8 Color Temperature Cool Typ. 0.269 Typ. 42/47/55LX6500-UB

-0.015 0.273 +0.015 <Test Condition>

Medium Typ. 0.285 Typ. 85% Full white pattern

-0.015 0.293 +0.015 The W/B Tolerance is ±0.015 for

Warm Typ. 0.313 Typ. picture quality by DQA

-0.015 0.329 +0.015

Page 8

- 8 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

6. Component Video Input (Y, CB/PB, CR/PR)

No Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed

1. 720*480 15.73 60 13.5135 SDTV ,DVD 480I

2. 720*480 15.73 59.94 13.5 SDTV ,DVD 480I

3. 720*480 31.50 60 27.027 SDTV 480P

4. 720*480 31.47 59.94 27.0 SDTV 480P

5. 1280*720 45.00 60.00 74.25 HDTV 720P

6. 1280*720 44.96 59.94 74.176 HDTV 720P

7. 1920*1080 33.75 60.00 74.25 HDTV 1080I

8. 1920*1080 33.72 59.94 74.176 HDTV 1080I

9. 1920*1080 67.500 60 148.50 HDTV 1080P

10. 1920*1080 67.432 59.94 148.352 HDTV 1080P

11. 1920*1080 27.000 24.000 74.25 HDTV 1080P

12. 1920*1080 26.97 23.976 74.176 HDTV 1080P

13. 1920*1080 33.75 30.000 74.25 HDTV 1080P

14. 1920*1080 33.71 29.97 74.176 HDTV 1080P

7. RGB Input (PC)

No Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed

PC DDC

1. 640*350 31.468 70.09 25.17 EGA X

2. 720*400 31.469 70.08 28.32 DOS O

3. 640*480 31.469 59.94 25.17 VESA(VGA) O

4 . 800*600 37.879 60.31 40.00 VESA(SVGA) O

5. 1024*768 48.363 60.00 65.00 VESA(XGA) O

6. 1280*768 47.776 59.87 79.50 CVT(WXGA) X

7. 1360*768 47.712 60.015 85.50 VESA(WXGA) X

8. 1280*1024 63.981 60.020 108.00 VESA(SXGA) O

9. 1920*1080 66.587 59.934 148.5 HDTV 1080P O

Page 9

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 9 -

8. HDMI input (PC/DTV)

No Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed

PC DDC

1. 640*350 31.468 70.09 25.17 EGA X

2. 720*400 31.469 70.08 28.32 DOS O

3. 640*480 31.469 59.94 25.17 VESA(VGA) O

4 . 800*600 37.879 60.31 40.00 VESA(SVGA) O

5. 1024*768 48.363 60.00 65.00 VESA(XGA) O

6. 1280*768 47.776 59.870 79.50 CVT(WXGA) X

7. 1360*768 47.712 60.015 85.50 VESA(WXGA) X

8. 1280*1024 63.981 60.020 108.00 VESA(SXGA) O

9. 1920*1080 67.5 60 148.5 HDTV 1080P O

DTV

1 720*480 31.5 60 27.027 SDTV 480P

2 720*480 31.47 59.94 27.00 SDTV 480P

3 1280*720 45.00 60.00 74.25 HDTV 720P

4 1280*720 44.96 59.94 74.176 HDTV 720P

5 1920*1080 33.75 60.00 74.25 HDTV 1080I

6 1920*1080 33.72 59.94 74.176 HDTV 1080I

7 1920*1080 67.500 60 148.50 HDTV 1080P

8 1920*1080 67.432 59.939 148.352 HDTV 1080P

9 1920*1080 27.000 24.000 74.25 HDTV 1080P

10 1920*1080 26.97 23.976 74.176 HDTV 1080P

11 1920*1080 33.75 30.000 74.25 HDTV 1080P

12 1920*1080 33.71 29.97 74.176 HDTV 1080P

Page 10

- 10 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

9. 3D Mode

9.1. HDMI Input

No Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed Remark

1 1280x720 45.00 60.00 74.25 HDTV 720P Side by Side

Top&Bottom

HDMI1.4 Frame Packing

2 1920x1080 33.75 60.00 74.25 HDTV 1080I Side by Side

Top&Bottom

3 1920x1080 67.500 60 148.50 HDTV 1080P Side by Side

Top&Bottom

Checkerboard

Single Frame Sequential

HDMI1.4 Frame Packing

4 1920x1080 27.00 24.000 74.25 HDTV 1080P Side by Side

Top&Bottom

Checkerboard

HDMI1.4 Frame Packing

5 1920x1080 33.75 30.000 74.25 HDTV 1080P Side by Side

Top&Bottom

Checkerboard

9.2. USB Input

9.3. 3D Input mode

No Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed Remark

5 1920x1080 33.75 30.000 74.25 HDTV 1080P Side by Side

Top&Bottom

Checkerboard

No

1

Side by Side Top&Bottom Checkerboard Single Frame Sequential Frame Packing

Page 11

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 11 -

ADJUSTMENT INSTRUCTION

1. Application range

This spec sheet is applied to LA02R Chassis applied LCD TV

all models manufactured in TV factory

2. Specification

2.1 Because this is not a hot chassis, it is not necessary

to use an isolation transformer. However, the use of

isolation transformer will help protect test instrument.

2.2 Adjustment must be done in the correct order.

2.3 The adjustment must be performed in the

circumstance of 25±5°C of temperature and 65±10%

of relative humidity

2.4 The input voltage of the receiver must keep

100~240V, 50/60Hz.

2.5 The receiver must be operated for about 5 minutes

prior to the adjustment when module is in the

circumstance of over 15. In case of keeping module

is in the circumstance of 0°C, it should be placed in

the circumstance of above 15°C for 2 hours In case

of keeping module is in the circumstance of below 20°C, it should be placed in the circumstance of

above 15°C for 3 hours.

Caution) When still image is displayed for a period of 20

minutes or longer (especially where W/B scale is

strong. Digital pattern 13ch and/or Cross hatch

pattern 09ch), there can some afterimage in the

black level area.

3. Adjustment items

3.1. Main PCB check process

• Adjust 480i Comp1

Remark) Above adjustment items can be also performed in

Final Assembly if needed. Adjustment items in

both PCBA and final assembly stages can be

checked by using the INSTART Menu

1.ADJUST CHECK.

Component 1080p and RGB-PC Adjust will be

calculated by 480i adjust value.

3.2 Final assembly adjustment

•EDID/DDC download

•White Balance adjustment

•RS-232C functionality check

•Factory Option setting per destination

•Ship-out mode setting (In-Stop)

3.3 ETC

• Ship-out mode

• Tool option menu

• USB Download(S/W Update, Option, Service only)

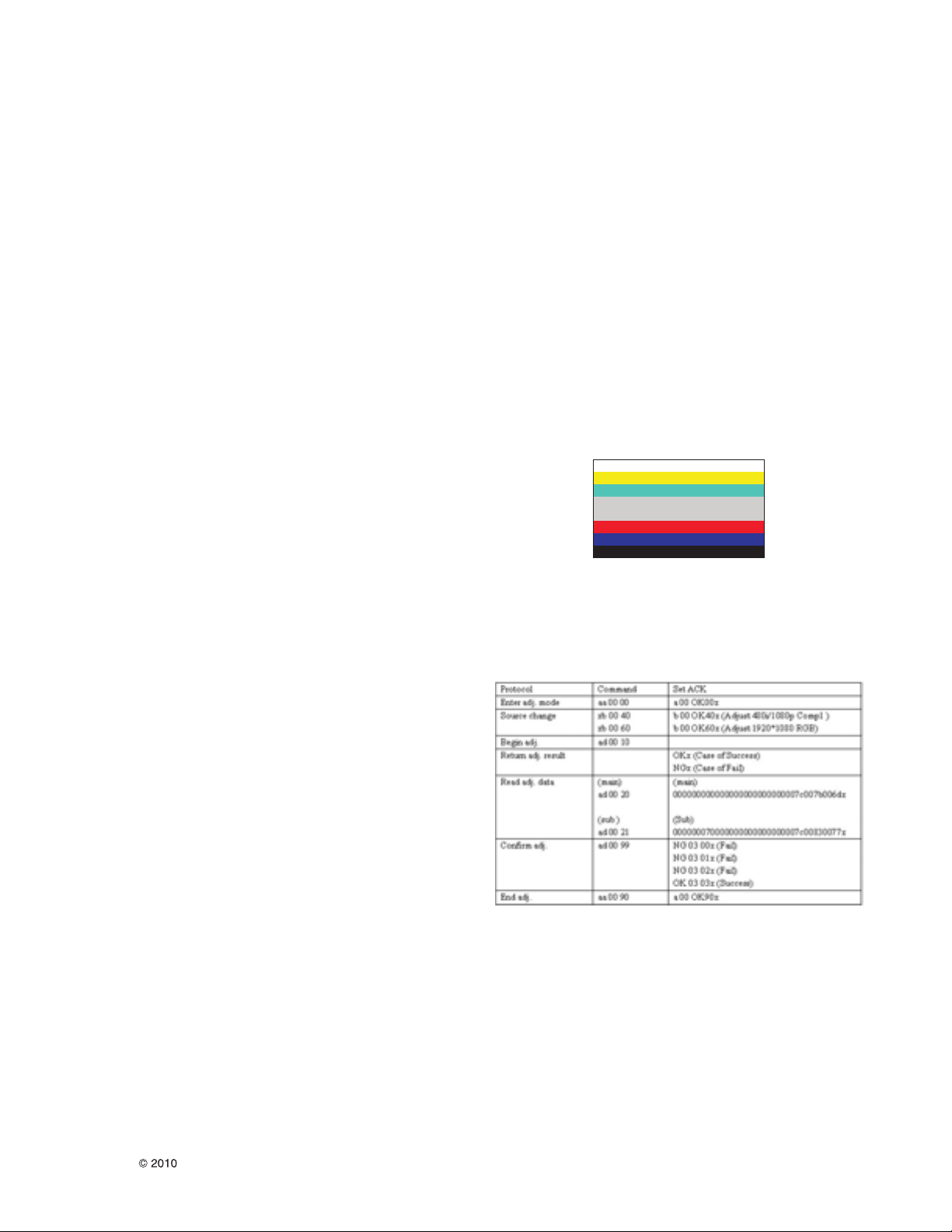

4. Automatic Adjustments

4.1. ADC Calibration(GP2 BCM3549)

(1) Overview

ADC adjustment is needed to find the optimum black level

and gain in Analog-to-Digital device and to compensate

RGB deviation.

(2) Equipment & Condition

1) Jig (RS-232C protocol)

2) MSPG-925 Series Pattern Generator(MSPG-925FA)

- Resolution : 480i Comp1 (MSPG-925FA: model-209,

pattern-65)

- Resolution : 1080p Comp1 (MSPG-925FA: model-225,

pattern-65)

- Resolution : 1920x1080 RGB (MSPG-925FA: model225, pattern-65)

- Pattern: Horizontal 100% Color Bar Pattern

- Pattern level: 0.7±0.1 Vp-p

- Image

(3) Adjustment

1) Adjustment method

- Using RS-232, adjust items listed in 3.1 in the other

shown in “4.1.3.3”

2) Adj. protocol

Ref.) ADC Adj. RS232C Protocol_Ver1.0

3) Adj. order

• aa 00 00 [Enter ADC adj. mode]

• xb 00 40 [Change input source to Component1

(480i/1080p)]

• ad 00 10 [Adjust 480i/1080p Comp1]

• ad 00 10 [Adjust 1080p Comp1]

• xb 00 60 [Change input source to RGB(1920x1080)]

• ad 00 10 [Adjust 1920x1080 RGB]

• ad 00 90 End adj.

Page 12

- 12 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

5. Manual Adjustments

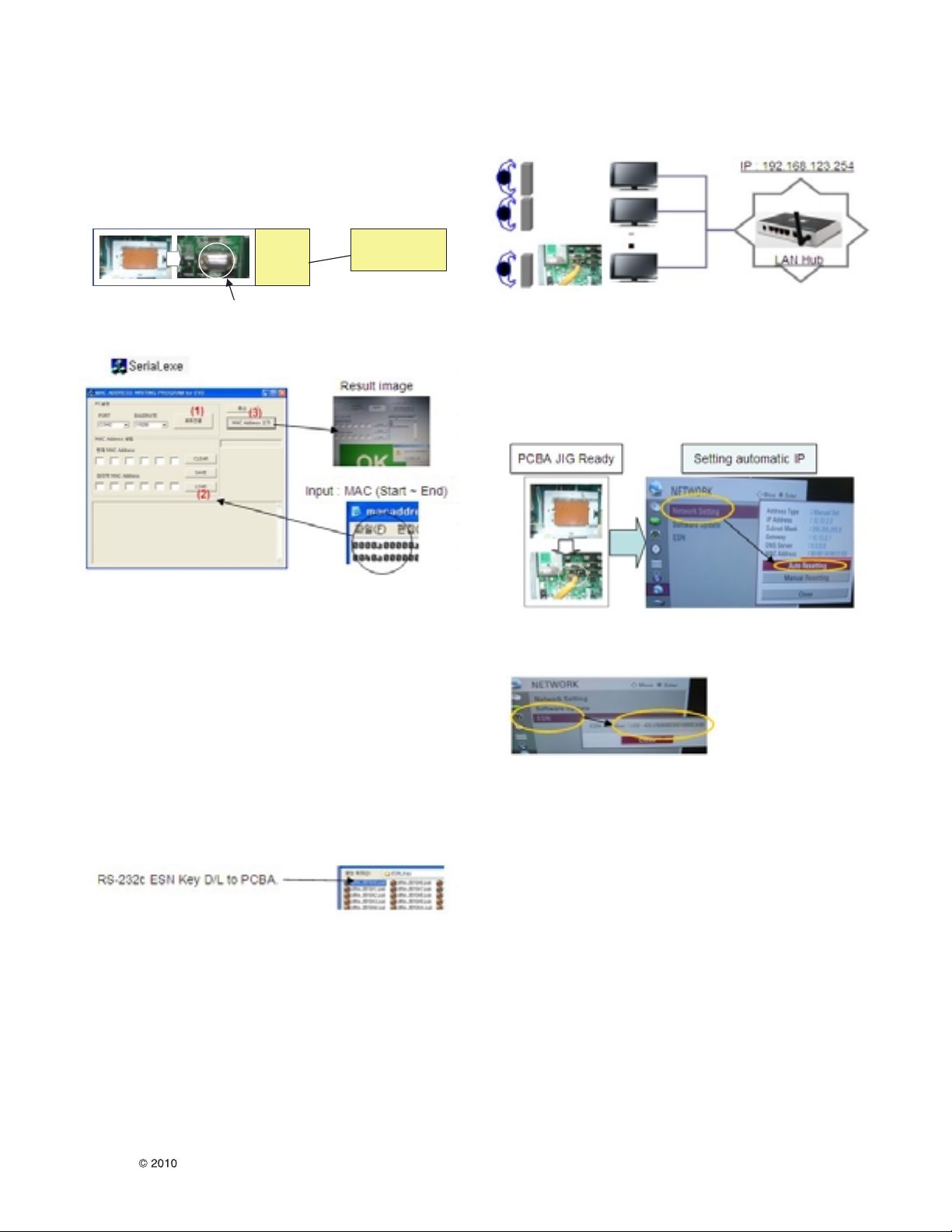

5.1. Download MAC address and ESN key

5.1.1 Communication Port connection

1 Connect : PCBA Jig-> RS-232C Port== PC-> RS-232C

Port

2 Mac Address Input

1) Equipment setting

- Play file : Serial.exe

- MAC Address edit

Srart / End MAC address input

- Communication port connection

- Com 1,2,3,4 and 115200(Baudrate)

- Port connection button click(1)

Load button click(2) for MAC Address write.

2) Start MAC Address write button(3)

3) Check the OK Or NG

5.1.2 Download ESN Key

1. Input the ESN Key

• Download Model sending Key file

• input by 1 by SET so as not to be duplicated

5.2 LAN PORT + ESN INSPECTION (Automatic IP)

5.2.1 Equipment & Condition

• Each other connection to LAN Port of IP Hub and Jig

5.2.2 LAN inspection solution

• LAN Port connection with PCB

• Network setting at MENU Mode of TV

• setting automatic IP

• Setting state confirmation

- If automatic setting is finished, you confirm IP and MAC

Address.

5.2.3 ESN Key confirmation

• confirm Key input Data at ESN MENU Mode

PCBA

PC(RS-232C)

RS-232C Port

Page 13

- 13 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

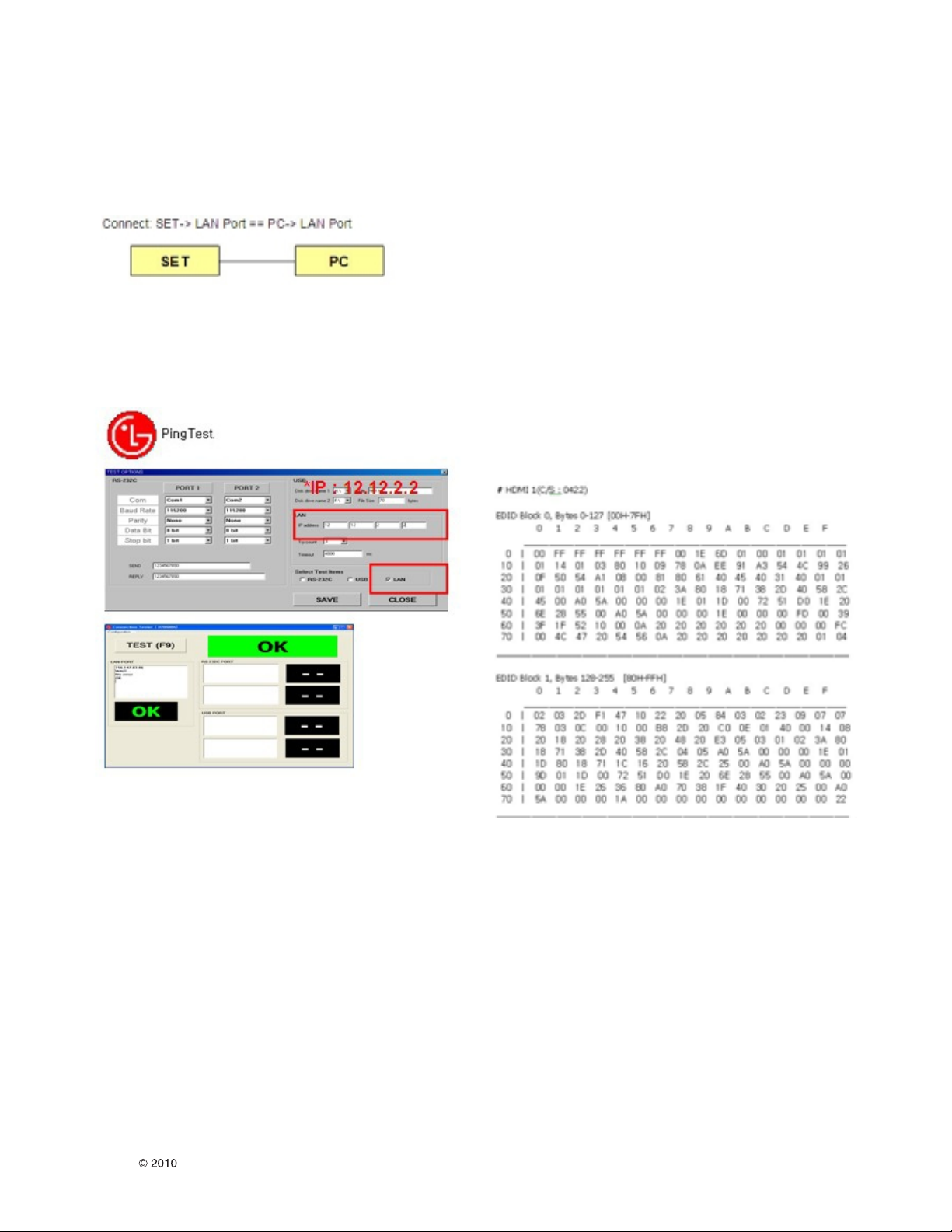

5.3 LAN PORT INSPECTION(PING TEST)

5.3.1. Equipment setting

1) Play the LAN Port Test PROGRAM.

2) Input IP set up for an inspection to Test

Program.

*IP Number : 12.12.2.2

5.3.2. LAN PORT inspection (PING TEST)

1) Play the LAN Port Test Program.

2) connect each other LAN Port Jack.

3) Play Test (F9) button and confirm OK Message.

4) remove LAN CABLE

5.4 EDID/DDC Download

(1) Overview

It is a VESA regulation. A PC or a MNT will display an

optimal resolution through information sharing without any

necessity of user input. It is a realization of “Plug and Play”.

(2) Equipment

• Since embedded EDID data is used, EDID download JIG,

HDMI cable and D-sub cable are not need.

• Adjust by using remote controller.

(3) Download method

1) Press Adj. key on the Adj. R/C,

2) Select EDID D/L menu.

3) By pressing Enter key, EDID download will begin

4) If Download is successful, OK is display, but If

Download is failure, NG is displayed.

5) If Download is failure, Re-try downloads.

Caution) When EDID Download, must remove RGB/HDMI

Cable.

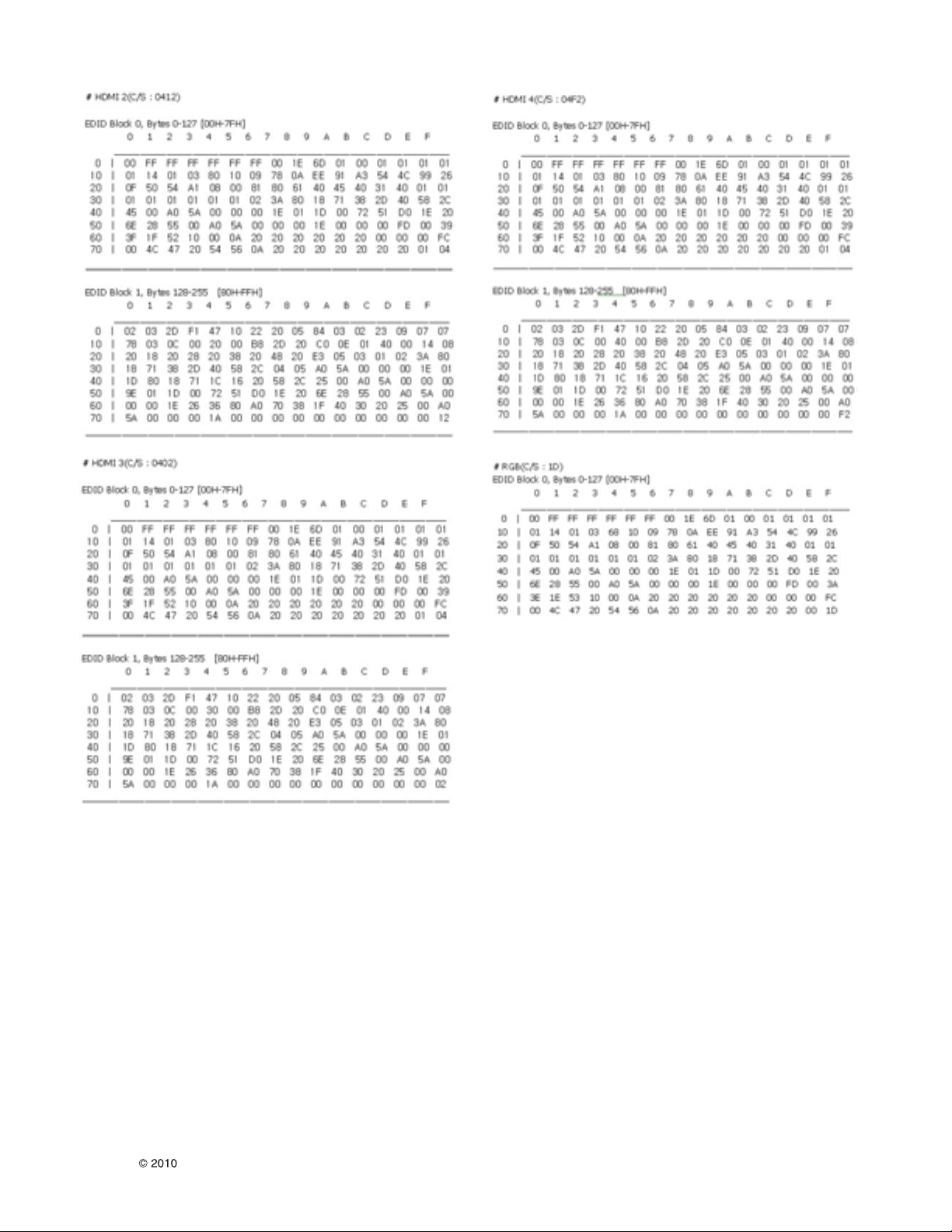

(4) EDID DATA

Page 14

- 14 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 15

- 15 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

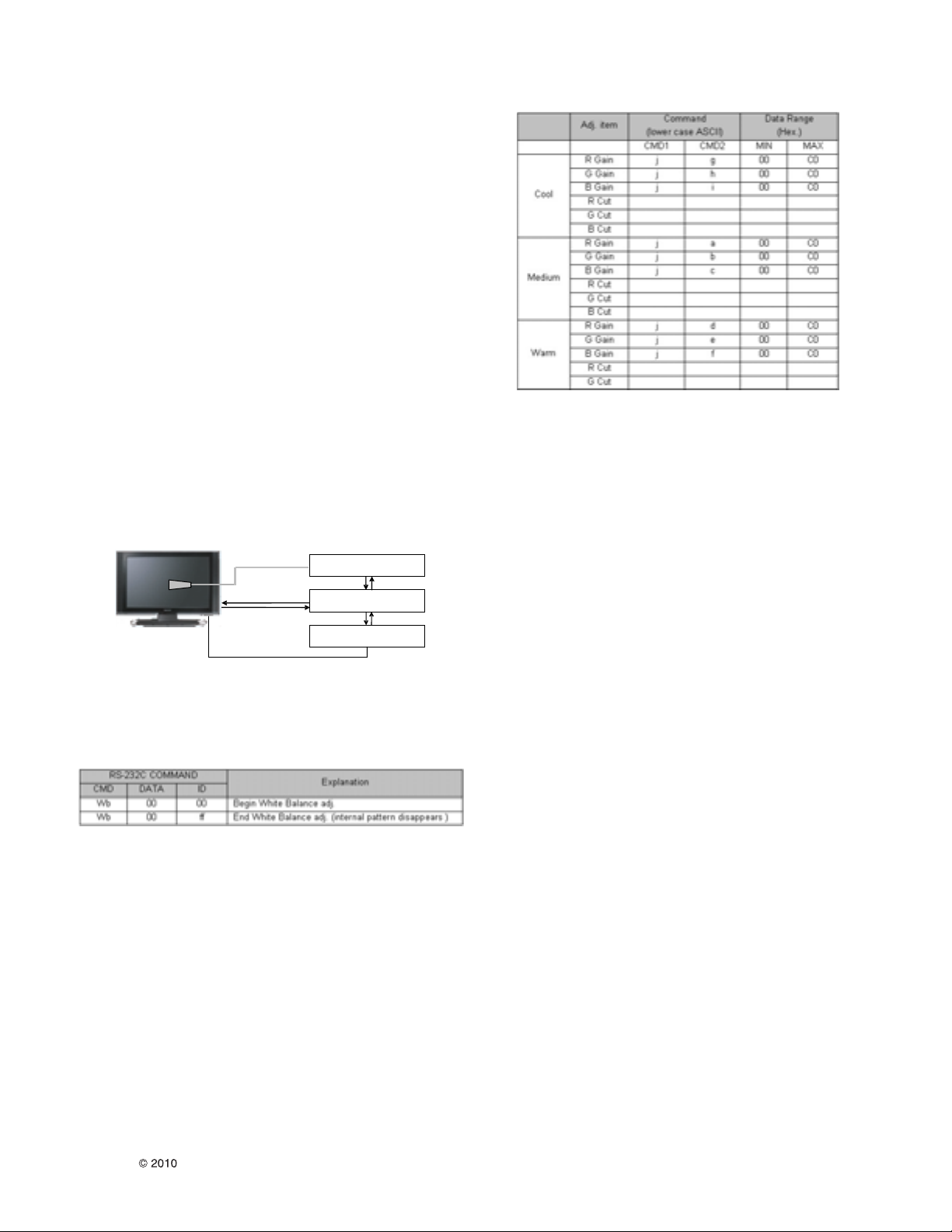

5.5. White Balance Adjustment

(1) Overview

• W/B adj. Objective & How-it-works

- Objective: To reduce each Panel’s W/B deviation

- How-it-works: When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic

Range. In order to prevent saturation of

Full Dynamic range and data, one of

R/G/B is fixed at 192, and the other two is

lowered to find the desired value.

- Adj. condition : normal temperature

1) Surrounding Temperature: 25±5ºC

2) Warm-up time: About 5 Min

3) Surrounding Humidity: 20% ~ 80%

(2) Equipment

1) Color Analyzer: CA-210 (NCG: CH 9 / WCG: CH12 /

LED : CH14)

2) Adj. Computer (During auto adj., RS-232C protocol is

needed)

3) Adjust Remocon

4) Video Signal Generator MSPG-925F 720p/216-Gray

(Model:217, Pattern:78)

-> Only when internal pattern is not available

• Color Analyzer Matrix should be calibrated using CS-1000

(3) Equipment connection MAP

(4) Adj. Command (Protocol)

•

RS-232C Command used during auto-adj.

Ex) wb 00 00 -> Begin White balance auto-adj.

wb 00 10 -> Gain adj.

ja 00 ff -> Adj. data

jb 00 c0

...

...

wb 00 1f -> Gain adj. complete

* (wb 00 20(start), wb 00 2f(endc)) -> Off-set adj.

wb 00 ff -> End white balance auto adj.

•

Adjustment Map

(5) Adj. method

• Auto adj. method

1) Set TV in adj. mode using POWER ON key

2) Zero calibrate probe then place it on the center of the

Display

3) Connect Cable(RS-232C)

4) Select mode in adj. Program and begin adj.

5) When adj. is complete (OK Sing), check adj. status pre

mode (Warm, Medium, Cool)

6) Remove probe and RS-232C cable to complete adj.

• W/B Adj. must begin as start command “wb 00 00”, and

finish as end command “wb 00 ff”. and Adj. offset if need

(6) Manual adj. method

1) Set TV IN Adj. mode using POWER ON

2) Zero Calibrate the probe of Color Analyzer, then place in

on the center of LCD module within 10cm of the surface.

3) Press ADJ KEY -> EZ adjust using adj. R/C -> 6. White

Balance then press the cursor th the right (KEY

G),

When Key(

G) is pressed 216 Gray internal pattern will

be displayed.

4) One of R Gain / G Gain / B Gain should be fixed at 192,

and the rest will be lowered to meet the desired value.

5) Adj. is performed in COOL, MEDIUM, WARM 3 modes

of color temperature.

• If internal pattern is not available, use RF input. In EZ Adj.

menu 6. White Balance, you can select one of 2 Testpattern. ON, OFF. Default is inner(ON). By selection OFF,

you can adjust using RF signal in 216 Gray pattern.

• Adj. condition and cautionary items

1) Lighting cndition in surrounding area.

Surrounding lighting should be lower 10 lux. Try to isolate

adj. area into dark surrounding.

2) Probe location : Color Snalyzer (CA-210) probe should be

within 10cm and perpendicular of the module surface

(80

º~100º)

3) Aging time

-After Aging Start, Keep the Power ON status during 5

Minutes.

- In case of LCD, Back-light on should be checked using

no signal or Full-white pattern.

Colo r Analyzer

Comp ut er

Pattern Ge n e r ator

RS-232C

RS-232C

RS-232C

Probe

Signal Source

* If TV internal pattern is used, not needed

Connection Diagram of Automatic Adjustment

Page 16

- 16 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

(7) Reference (White Balance Adj. coordinate and color

temperature)

• Luminance: 216 Gray

• Standard color coordinate and temperature using CS1000

• Standard color coordinate and temperature using CA-210

(CH 14)

• Standard color coordinate and temperature using CA210(CH 14) – by aging time

1) Edge/IOP LED models : 42/47/55LX6500-UB

2) IOP LED models : 47/55LX9500-UA

(8) THX Adjustment (THX certified model only)

Several THX certified model have to adjust White Balance

5 point at warm mode only.

1) Adjust 100 IRE White Balance

2) Adjust Max Brightness of Back Light Unit to approach

120cd.

3) Adjust Gamma 2.2 IRE(80,60,40,20) with Max Brightness.

4) Set R,G,B Gain at 10 IRE to 0,0,0

5) Complete 5 point Gamma and White Balance Adjustment.

5.6. Option selection per countries

(1) Overview

(2) Method

• Press ADJ key on the Adj. R/C, and then select Country

Group Menu

• Depending on destination, select KR or US, then on the

lower Country option, select US, CA, MX. Selection is

done using +, - KEY

(3) Tool Option Inspection

• Press Adj. key on the Adj. R/C, and then check Tool

option.

5.7. Local dimming inspection (Optional)

5.7.1. Edge LED models with local dimming

(1) Press ‘TILT” key of the Adj. R/C and check moving

patterns. The black bar patterns moves from left to right.

If local dimming function does not work, a whole screen

shows full white.

5.7.2. IOP LED models with local dimming

(1) Press ‘TILT” key of the Adj. R/C and check moving

patterns. The black cross-bar patterns moves from top-left to

Bottom-right. If local dimming function does not work, a whole

screen shows full white.

Mode Color Coordination Temp ∆UV

xy

COOL 0.269 0.273 13000K 0.0000

MEDIUM 0.285 0.293 9300K 0.0000

WARM 0.313 0.329 6500K 0.0000

Mode Color Coordination Temp ∆UV

xy

COOL 0.269±0.002 0.273±0.002 13000K 0.0000

MEDIUM 0.285±0.002 0.293±0.002 9300K 0.0000

WARM 0.313+0.002 0.329±0.002 6500K 0.0000

Model Tool1 Tool2 Tool3 Tool4 Tool5

47LX9500-UA 33792 30291 56636 4588 1963

55LX9500-UA 46080 30291 56636 4588 1963

42LX6500-UB 25568 30291 56364 4524 1578

47LX6500-UB 33760 30291 56364 4524 1578

55LX6500-UB 46048 30291 56364 4524 1579

Page 17

- 17 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

5.8. Ship-out mode check (In-stop)

• After final inspection, press In-Stop key of the Adj. R/C and

check that the unit goes to Stand-by mode.

• After final inspection, Always turn on the Mechanical S/W.

6. GND and Hi-pot Test

6.1. Method

6.1.1. GND & HI-POT auto-check preparation

(1) Check the POWER CABLE and SIGNAL CABE

insertion condition (If loose, re-insert)

6.1.2. Perform GND & Internal Pressure auto-check

- Unit fully inserted POWER cord, Antenna cable and A/V

arrive to the auto-check process.

- Connect D-terinal to AV JACK TESTER

- Auto CONTROLLER(GWS103-4) ON

- Perform GND Test

- If NG, Buzzer will sound to inform the operator.

- If OK, change over to I/P check auto matically.

(Remove CORD, A/V form AV Jack Box)

- Perform I/P test

- If NG, Buzzer will sound to inform the operator.

- If OK, Good lamp will lit up and the stopper will allow the

pallet to move on to next process.

6.2. Checkpoint

• TEST voltage

- GND: 1.5KV/min at 100mA

- SIGNAL: 3KV/min at 100mA

• TEST time: 1 second

• TEST POINT

- GND TEST = POWER CORD GND & SIGNAL CABLE

METAL GND

- Internal Pressure TEST = POWER CORD GND & LIVE &

NEUTRAL

• LEAKAGE CURRENT: At 0.5mArms

7. EYE-Q function check

1) Turn on TV

2) Press EYE button on the adjustable R/C

3) Hide the Eye Q sensor on the front of the set for

approximately 6 seconds.

4) Check the “Sensor Data” whether it is under 10. If it is not

under 10, Eye Q sensor is faulty. And change a new

sensor.

5) Detach the hand from Eye Q II sensor for 6 seoconds.

6) Check the value of “Back Light(xxx)” on the display. If its

value does not increase after 6 senconds, Eye Q sensor is

faulty.

8. Check the R/C

- Required Equipments: RF-controller, IR-KEY-CODE

controller

- Check that AA Battery of RF-Remote controller is enough

before the test.

(Recommend that change the battery each LOT)

- Test Method

a) Press the START button on Controller for pairing with the

set

b) Check whether cursor is showed on a display of the set

after pressing the OK button.

c) Press the STOP button to pair off with the set.

<Step2> <Step3> <Step4>

<Step5> <Step6>

Page 18

- 18 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

9. Audio

Measurement condition:

1. RF input: Mono, 1KHz sine wave signal, 100% Modulation

2. CVBS, Component: 1KHz sine wave signal 0.4Vrms

3. RGB PC: 1KHz sine wave signal 0.7Vrms

10. 3D Performance Test

(Pattern Generator MSPG-3233, HDMI mode No.371, pattern

No. 81)

1) Input the below pattern for 3D test.

(HDMI mode No.371, Pattern No. 81)

2) Enter 3D mode, then select °∞side by side°±.

It is shown like the below example without wearing 3D

glasses.

3) It is a normal screen if the middle section is red checked by

the left side of 3D glass like the below example.

4) It is a normal screen if the middle section is blue checked

by the right side of 3D glass like the below example.

No Item Min Typ Max Unit

1. Audio practical max 4.5 5 6 W Measurement

Output, L/R 8.49 6.33 9.80 Vrms condition

(Distortion=10% EQ Off

max Output) AVL Off

Clear Voice Off

2. Speaker 5 7 W Measurement

(8Ω Impedance) condition

EQ On

AVL On

Clear Voice On

Page 19

- 19 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

11. USB S/W Download (option)

(1) Put the USB Stick to the USB socket

(2) Automatically detecting update file in USB Stick

- If your downloaded program version in USB Stick is Low,

it didn’t work.

But your downloaded version is High, USB data is

automatically detecting

(3) Show the message “Copying files from memory”

(4) Updating is staring.

(5) Updating Completed, The TV will restart automatically

(6) If your TV is turned on, check your updated version and

Tool option. (explain the Tool option, next stage)

* If downloading version is more high than your TV have,

TV can lost all channel data. In this case, you have to

channel recover. if all channel data is cleared, you didn’t

have a DTV/ATV test on production line.

* After downloading, have to adjust TOOL OPTION again.

1) Push "IN-START" key in service remote controller.

2) Select "Tool Option 1" and Push “OK” button.

3) Punch in the number. (Each model has their number

Page 20

300

EXPLODED VIEW

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is esse ntia l that t hese speci al safety parts shoul d be repla ced with the same compo nent s as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

570

LV1

200

IMPORTANT SAFETY NOTICE

830

500

120

A2

A9

800

A10

530

840

810

850

540

520

880

541

400

920

710

A5

Only for training and service purposes

- 20 -

910

900

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Page 21

COMPONENT/AV

REAR JACK

REAR AV

COMPONENT2

COMPONENT1

REAR AV

COMPONENT2

COMPONENT1

JK100

PPJ237-01

DEV

[RD1]E-LUG

6C

[RD1]O-SPRING

5C

[RD1]CONTACT

4C

[WH1]O-SPRING

5B

[YL1]CONTACT

4A

[YL1]O-SPRING

5A

[YL1]E-LUG

6A

[RD2]E-LUG

6H

[RD2]O-SPRING_2

5H

[RD2]CONTACT

4H

[WH2]O-SPRING

5G

[RD2]O-SPRING_1

5F

[RD2]E-LUG-S

7F

[BL2]O-SPRING

5E

[BL2]E-LUG-S

7E

[GN2]CONTACT

4D

[GN2]O-SPRING

5D

[GN2]E-LUG

6D

[RD3]E-LUG

6N

[RD3]O-SPRING_2

5N

[RD3]CONTACT

4N

[WH3]O-SPRING

5M

[RD3]O-SPRING_1

5L

[RD3]E-LUG-S

7L

[BL3]O-SPRING

5K

[BL3]E-LUG-S

7K

[GN3]CONTACT

4J

[GN3]O-SPRING

5J

[GN3]E-LUG

6J

D104

5.6V

D105

5.6V

D106

5.6V

D107

5.5V

D3.3V

C104

R104

470K

C101

R108

2.7K

C105

100pF

50V

R103

470K

AV

COMPONENT2

R119

1K

C123

100pF

C124

100pF

R100

0

R101

0

R102

10

COMPONENT1

R129

1K

C137

100pF

C136

100pF

R106

0

R107

0

COMP2_DET

009:G5

COMP2_R_IN

010:B5

COMP2_L_IN

010:B5

COMP2_Pr

011:D3

COMP2_Pb

011:D3

COMP2_Y

011:D3

COMP1_DET

009:G5

COMP1_R_IN

010:B5

COMP1_L_IN

010:B5

COMP1_Pr

011:D4

COMP1_Pb

011:D4

D108

5.6V

D109

5.6V

D110

5.5V

D111

5.5V

D112

5.5V

D114

5.6V

D119

5.6V

D115

5.6V

D116

5.5V

D117

5.5V

D113

5.6V

D3.3V

R114

470K

R115

470K

C114

27pF

50V

C112

27pF

50V

C113

27pF

50V

R124

470K

R123

470K

R116

2.7K

C127

27pF

50V

C128

27pF

50V

C115

100pF

50V

C116

1uF

25V

C117

1uF

25V

D3.3V

C132

1uF

25V

1uF

25V

L103

270nH

L104

270nH

L102

270nH

L100

270nH

L101

270nH

C131

R125

2.7K

C130

100pF

50V

R117

0

R118

0

R127

0

R126

0

C122

27pF

50V

C120

27pF

50V

C121

27pF

50V

C133

27pF

50V

C134

27pF

50V

R113

1K

1uF

25V

1uF

25V

R110

0

R109

0

R105

0

C109

100pF

50V

C108

100pF

50V

C106

47pF

50V

REAR_AV_DET

009:G3

REAR_AV_R_IN

010:B5

REAR_AV_L_IN

010:B5

REAR_AV_CVBS

011:C4

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

D118

5.5V

C129

27pF

50V

GP2_BCM_ATSC

COMPONENT / AV REAR

L105

270nH

C135

27pF

50V

R131

10

COMP1_Y

011:D4

09/10/xx

1 100

Page 22

HDMI SWITCH 1.8V POWER

1.8V FOR HDMI SW

R202

+1.8V_HDMI

OPT

C201

10K

4.7uF

POWER_ON/OFF2_1

D1.8V

R200

120K

OPT

C200

4.7uF

10V

OPT

DEV

Q200

AO3438

EBK60752601

D

S

G

R201

0

Seperated from Common sheet83

N.America & Korea only use 1.8V control

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

GP2_BCM_ATSC

HDMI_POWER

09/10/xx

2 100

Page 23

EARPHONE BLOCK

USB BLOCK

EARPHONE AMP

HP/BT_LOUT_N

011:F2

HP/BT_LOUT_P

011:F2

HP/BT_ROUT_N

011:F2

HP/BT_ROUT_P

011:F2

EARPHONE JACK SIDE

HP_L_OUT

003:Q26

HP_R_OUT

003:Q21

R300

R301

4.7K

OPT

C307

1uF

+3.3V_NORMAL

L302

10uH

C317

C315

0.1uF

10uF

16V

10V

SGND

15

IC300

TPA6132A2

EAN60724701

C308

1uF

10V

EN13VDD

14

8

HPVSS

12

11

10

C316

2.2uF

10V

C318

2.2uF

10V

HPVDD

CPP

C319

2.2uF

PGND

10V

CPN

9

R306

100K

OPT

Close to the IC

4.7K

INR+

INL+

INR-

INL-

OUTL

16

1

2

3

4

5G06G17

OUTR

C304

1uF

10V

C305

1uF

10V

C306

1uF

10V

10V

R302

OPT

R303

R308

0

1/16W

R307

0

1/16W

EMS_KOREA

BG2012B080TF

C321

22000pF

50V

EMS_Default

+3.3V_NORMAL

Q308EB

2SC3052

BG2012B080TF

C320

22000pF

50V

EMS_Default

C321-*1

0.22uF

16V

C

R309

4.7K

L304

L303

EMS_KOREA

OPT

R310

0

R311

1K

C320-*1

0.22uF

16V

HP_L_OUT

SIDE_HP_MUTE

HP_R_OUT

USB2

+5V_USB

010:D4

C313

0.1uF

USB_PWRFLT2

C311

10uF

+3.3V_NORMAL

IC301

AP2191SG-13

USB_DM2

USB_DP2

GND

IN_1

IN_2

EN

0 R318

1

2

3

4

EAN60921001

DEV

CDS3C05HDMI1

R320

4.7K

OPT

10V

USB_PWRON2

R321

010:D4

2.7K

010:D4

010:D4

NC

8

OUT_2

7

OUT_1

6

FLG

5

ESD_USB

D303

5.6V

L301

MLB-201209-0120P-N2

120-ohm

C310

100uF

16V

CDS3C05HDMI1

ESD_USB

D301

5.6V

JK302

KJA-UB-4-0004

USB DOWN STREAM

1234

EAG41945401

5

USB

USB(DVR Ready)

CHANGE USB_PWRFLT PULL-UP FROM 5V TO 3.3V

USB1 (DVR Ready)

+3.3V_NORMAL

GND

IN_1

IN_2

EN

IC302

AP2191SG-13

1

2

3

4

EAN60921001

DEV

NC

8

OUT_2

7

OUT_1

6

FLG

5

0 R317

CDS3C05HDMI1

ESD_USB

L300

MLB-201209-0120P-N2

120-ohm

D302

CDS3C05HDMI1

5.6V

C309

100uF

16V

ESD_USB

D300

5.6V

JK301

KJA-UB-4-0004

USB DOWN STREAM

1234

EAG41945401

5

MMBT3904-(F)

MMBT3904-(F)

Q300

Q301

+5V_USB

C

B

OPT

E

C

B

OPT

E

009:G3

B

SIDE_HP_DET

B

E

Q303

MMBT3904-(F)

OPT

C

E

Q302

MMBT3904-(F)

OPT

C

JK300

KJA-PH-0-0177

5GND

R314

120

+3.5V_ST

E

C

Q306

ISA1530AC1

OPT

B

R315

C

150

OPT

Q307

2SC3052

OPT

E

4L

3DETECT

DEV

1R

EAG61030001

B

SIDE_HP_MUTE

003:Q23;081:I4

010:D4

C314

0.1uF

USB_PWRFLT1

C312

10uF

10V

010:D4

010:D4

R322

2.7K

USB_DM1

USB_DP1

USB_PWRON1

R319

4.7K

OPT

010:D4

WIRELESS I2C LEVEL SHIFTER

LEVEL SHIFTER

+3.3V_NORMAL

R324

10K

OPT

Q304

G

FDV301N

WIRELESS_SCL

WIRELESS_SDA

OPT

S

D

D

Q305

FDV301N

OPT

G

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

SCL3_3.3V

SDA3_3.3V

S

GP2_BCM_ATSC

USB/EAR-PHONE

09/10/xx

3 100

Page 24

SIDE COMPONENT LINE

086:M25

086:M21

086:M22

SIDE_COMP_Y

SIDE_COMP_Pr

SIDE_COMP_Pb

CLOSE TO MAIN IC

0.1uFC400

0.1uFC401

0.1uFC402

R401-*1

82

75

75

82

R400

R401

KOREA_ESD

R402

KOREA_ESD

US_ESD

R402-*1

82

US_ESD

SIDE_COMP-Y

SIDE_COMP-Pr

SIDE_COMP-Pb

011:C4;011:D4

011:C4;011:D4

011:C4;011:D4

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

SIDE GENDER LINE

09/10/xx

SIDE_GENDER_LINE 4 1 0 0

Page 25

SMD GASKET FOR EMI (8*6*5.5 FOR LE5400/5500/7500)

SMD GASKET FOR EMI (8*6*12.5T)

GASKET on the Bottom

DEV

GAS1

GAS2

GAS3

GAS4

GAS5

GAS6

GAS7

GAS8

GAS9

GAS10

GAS11

GAS12

SMD GASKET FOR EMI (8*6*7.5 FOR LE8500)

GASKET on the Bottom

DEV

GAS1-*1

GAS2-*1

GAS3-*1

GAS4-*1

GAS5-*1

GAS6-*1

GAS7-*1

GAS8-*1

GAS9-*1

GAS10-*1

GAS11-*1

GAS12-*1

Draw bottom location when make a new pcb

GAS11

GASKET_12.5T

GAS3-*2

GAS5-*2

GAS1-*2

MDS61887708

MDS61887708

GAS2-*2

MDS61887708

MDS61887708

GAS4-*2

MDS61887708

MDS61887708

GAS6-*2

GAS7-*2

MDS61887708

MDS61887708

GAS8-*2

GAS9-*2

MDS61887708

MDS61887708

GAS10-*2

MDS61887708

GAS11-*2

MDS61887708

GAS12-*2

SMD GASKET FOR EMI (8*6* 9.5T)

GASKET_9.5T

GAS1-*3

MDS61887710

MDS61887710

GAS2-*3

GAS3-*3

MDS61887710

MDS61887710

GAS4-*3

MDS61887710

GAS5-*3

MDS61887710

GAS6-*3

GAS7-*3

MDS61887710

MDS61887710

GAS8-*3

GAS9-*3

MDS61887710

MDS61887710

GAS10-*3

MDS61887710

GAS11-*3

MDS61887710

GAS12-*3

SMD GASKET FOR EMI (8*6*6.5 FOR 32LE7500)

GASKET_6.5T

GAS5

GAS3

GAS6

GAS8

GAS2

GAS1

EAX61538101

GAS12

GAS4

GAS9

GAS10

GAS7

GAS5

GAS11

GAS3

GAS6

GAS8

GAS1

EAX61746401

GAS12

GAS2

GAS4

GAS9

GAS10

GAS7

GAS1-*4

MDS62110206

GAS2-*4

MDS62110206

GAS3-*4

MDS62110206

GAS4-*4

MDS62110206

GAS5-*4

MDS62110206

GAS6-*4

MDS62110206

GAS7-*4

MDS62110206

GAS8-*4

MDS62110206

GAS9-*4

MDS62110206

GAS10-*4

MDS62110206

GAS11-*4

MDS62110206

GAS12-*4

MDS62110206

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

GP2_BCM_ATSC

SMD_GASKET

09/10/xx

5 100

Page 26

BCM-DDR

DEV

IC900

EAN60345904

C619

0.1uF

LGE3549XQ (B2 VERSION)

DDR VTT

DDR0_VREF0

DDR_BVDD0

DDR_BVDD1

DDR_BVSS0

DDR_BVSS1

DDR_PLL_TEST

DDR_PLL_LDO

DDR01_CKE

DDR_COMP

DDR01_ODT

DDR_EXT_CLK

DDR0_CLK

DDR0_CLKB

DDR1_CLK

DDR1_CLKB

DDR01_A00

DDR01_A01

DDR01_A02

DDR01_A03

DDR0_A04

DDR0_A05

DDR0_A06

DDR01_A07

DDR01_A08

DDR01_A09

DDR01_A10

DDR01_A11

DDR01_A12

DDR01_A13

DDR1_A04

DDR1_A05

DDR1_A06

DDR01_BA0

DDR01_BA1

DDR01_BA2

DDR01_CASB

DDR0_DQ00

DDR0_DQ01

DDR0_DQ02

DDR0_DQ03

DDR0_DQ04

DDR0_DQ05

DDR0_DQ06

DDR0_DQ07

DDR0_DQ08

DDR0_DQ09

DDR0_DQ10

DDR0_DQ11

DDR0_DQ12

DDR0_DQ13

DDR0_DQ14

DDR0_DQ15

DDR1_DQ00

DDR1_DQ01

DDR1_DQ02

DDR1_DQ03

DDR1_DQ04

DDR1_DQ05

DDR1_DQ06

DDR1_DQ07

DDR1_DQ08

DDR1_DQ09

DDR1_DQ10

DDR1_DQ11

DDR1_DQ12

DDR1_DQ13

DDR1_DQ14

DDR1_DQ15

DDR0_DM0

DDR0_DM1

DDR1_DM0

DDR1_DM1

DDR0_DQS0

DDR0_DQS0B

DDR0_DQS1

DDR0_DQS1B

DDR1_DQS0

DDR1_DQS0B

DDR1_DQS1

DDR1_DQS1B

DDR01_RASB

DDR_VREF0

DDR_VREF1

DDR01_WEB

DDR_VDDP1P8_1

DDR_VDDP1P8_2

C621

0.1uF

A1.2V

A6

0.1uF C656

A24

0.1uF C657

B7

B24

F20

B23

B17

C22

E16

C23

B12

C12

A13

A12

B15

E14

A15

D15

E13

E12

F13

C14

F14

B14

D14

C13

D13

B13

F15

C15

D16

F16

B16

E15

A17

A8

B11

B8

D11

E11

C8

C11

C9

D8

E10

E9

F11

F12

E8

D10

F8

C18

C20

A18

B21

C21

B18

B20

D18

E18

D21

F18

E20

A22

F17

B22

E17

A10

C10

A20

F19

B10

B9

F10

F9

B19

C19

E19

D19

C16

A7

A23

C17

C7

006:C3;006:E5;006:F3;006:H5;006:I4;006:I2

D22

UBW3216-121

C623

100uF

16V

DDR1_VREF0

C622

0.1uF

120-ohm

C625

10uF

16V

C624

0.1uF

R615

D1.8V

R616

0

L600

OPT

DDR1_A[4]

DDR1_A[5]

DDR1_A[6]

DDR1_DQ[0]

DDR1_DQ[1]

DDR1_DQ[2]

DDR1_DQ[3]

DDR1_DQ[4]

DDR1_DQ[5]

DDR1_DQ[6]

DDR1_DQ[7]

DDR1_DQ[8]

DDR1_DQ[9]

DDR1_DQ[10]

DDR1_DQ[11]

DDR1_DQ[12]

DDR1_DQ[13]

DDR1_DQ[14]

DDR1_DQ[15]

DDR01_RASb

DDR01_WEb

C658

0.1uF

DDR_VTT

VREF_ORIGINAL

BLM18PG121SN1D

VREF_ORIGINAL

BLM18PG121SN1D

0

0R618

R614

240

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR0_A[4]

DDR0_A[5]

DDR0_A[6]

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

DDR01_BA0

DDR01_BA1

DDR01_BA2

DDR01_CASb

DDR0_DQ[0]

DDR0_DQ[1]

DDR0_DQ[2]

DDR0_DQ[3]

DDR0_DQ[4]

DDR0_DQ[5]

DDR0_DQ[6]

DDR0_DQ[7]

DDR0_DQ[8]

DDR0_DQ[9]

DDR0_DQ[10]

DDR0_DQ[11]

DDR0_DQ[12]

DDR0_DQ[13]

DDR0_DQ[14]

DDR0_DQ[15]

DDR0_DM0

DDR0_DM1

DDR1_DM0

DDR1_DM1

DDR0_DQS0

DDR0_DQS0b

DDR0_DQS1

DDR0_DQS1b

DDR1_DQS0

DDR1_DQS0b

DDR1_DQS1

DDR1_DQS1b

C626

0.1uF

120-ohm

L601

L602

120-ohm

C698

0.1uF

C627

0.1uF

C628

0.1uF

DDR01_CKE

DDR01_ODT

DDR0_CLK

DDR0_CLKb

DDR1_CLK

DDR1_CLKb

DDR01_A[0-3]

DDR0_A[4-6]

DDR01_A[7-13]

DDR1_A[4-6]

006:B1;006:E5;006:F3;006:H5;006:I4;006:I2

DDR0_DQ[0-15]

DDR1_DQ[0-15]

C654

470pF

GND

EN

VTTS

VREF

C652

1uF C653

470pF

POWER_ON/OFF1

IC602

BD35331F-E2

1

2

3

4

EAN52430901

C655

1uF

0.1uF C699

10KR612

K4T1G084QE-HCF8

E8

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

F3

SS DDR

WE

G8

CS

G2

BA0

G3

BA1

G1

BA2

H8

A0

H3

A1

H7

A2

J2

A3

J8

A4

J3

A5

J7

A6

K2

A7

K8

A8

K3

A9

H2

A10/AP

K7

A11

L2

A12

L8

A13

L3

NC_1

L7

NC_2

F9

ODT0

006:B1;006:E5

DDR0_CLK

006:B2;006:E5

DDR0_CLKb

DDR01_CKE

006:B5;006:E5;006:F3;006:H5;006:I3;006:I2

006:B3;006:E5;006:F3;006:H5;006:I2

006:B5;006:E5;006:F3;006:H5;006:I4;006:I2

DDR01_BA0

DDR01_BA1

DDR01_A[0-3]

DDR0_A[4-6]

DDR01_A[7-13]

DDR01_BA2

006:B2;006:E6;006:F4;006:H6;006:I4;006:I2

DDR01_ODT

006:B1;006:E6;006:F4;006:H6;006:I4;006:I3

C650

C648

C651

470pF

470pF

1uF C649

1uF

+3.5V_ST

VTT

8

VTT_IN

7

VCC

6

R613

VDDQ

5

220

C645

10uF

16V

D1.8V

VREF_TEST

VREF_ORIGINAL

VREF_TEST

D1.8V

R619

DDR01_RASb

DDR01_CASb

DDR01_WEb

1K

DDR0_VREF0

R665

R667

1K

R666

L603

CIS21J121

120

C646

2.2uF

100

IC603-*1

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR0_A[4]

DDR0_A[5]

DDR0_A[6]

0

C647

0.1uF

DM/RDQS

NU/RDQS

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

VREF_TEST

VREF_TEST

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQS

DQS

VDD_1

VDD_2

VDD_3

VDD_4

VSS_1

VSS_2

VSS_3

VSS_4

VREF

VDDL

VSSDL

DDR1_VREF0

1K

R668

R670

VREF_ORIGINAL

1K

R669

C8

C2

D7

D3

D1

D9

B1

B9

B7

A8

B3

A2

A9

C1

C3

C7

C9

A1

L1

E9

H9

A7

B2

B8

D2

D8

A3

E3

J1

K9

E2

E1

E7

E8

F8

F2

F7

G7

F3

G8

G2

G3

H8

H3

H7

J2

J8

J3

J7

K2

K8

K3

H2

K7

L2

G1

L3

L7

L8

F9

IC603

NT5TU128M8DE_BD

NANYA DDR

CK

CK

CKE

RAS

CAS

WE

CS

BA0

BA1

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10/AP

A11

A12

NC_1/BA2

NC_2/A14

NC_3/A15

A13

ODT

EAN60992101

Place Caps close to DRAM pin

0

DDR1_VREF0

DDR0_VREF0

DM/RDQS

NU/RDQS

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

D1.8V

D1.8V

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQS

DQS

VDD_1

VDD_2

VDD_3

VDD_4

VSS_1

VSS_2

VSS_3

VSS_4

VREF

VDDL

VSSDL

VREF_TEST

VREF_TEST

VREF_TEST

VREF_TEST

K4T1G084QE-HCF8

E8

IC604-*1

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

SS DDR

F3

WE

G8

CS

G2

BA0

G3

BA1

G1

BA2

H8

A0

H3

A1

H7

A2

J2

A3

J8

A4

J3

A5

J7

A6

K2

A7

K8

A8

K3

A9

H2

A10/AP

K7

A11

L2

A12

L8

A13

L3

NC_1

L7

NC_2

F9

ODT0

C8

DDR0_DQ[0]

C2

DDR0_DQ[1]

D7

DDR0_DQ[2]

D3

DDR0_DQ[3]

D1

DDR0_DQ[4]

D9

DDR0_DQ[5]

B1

DDR0_DQ[6]

B9

DDR0_DQ[7]

B7

A8

B3

A2

A9

C1

C3

C7

C9

A1

L1

E9

H9

A7

B2

B8

D2

D8

A3

E3

J1

K9

E2

E1

E7

1K

R661

1K

R662

1K

R663

1K

R664

D1.8V

DDR0_VREF0

C641

0.1uF

006:B1;006:C3;006:F3;006:H5;006:I4;006:I2

006:B5;006:C3;006:F3;006:H5;006:I3;006:I2

006:B3;006:C3;006:F3;006:H5;006:I2

006:B5;006:C3;006:F3;006:H5;006:I4;006:I2

006:B2;006:C3;006:F3;006:H5;006:I4;006:I2

006:B2;006:C3;006:F3;006:H5;006:I3;006:I2

006:B2;006:C4;006:F4;006:H6;006:I4;006:I2

006:B1;006:C4;006:F4;006:H6;006:I4;006:I3

C8

DQ0

C2

DQ1

D7

DQ2

D3

DQ3

D1

DQ4

D9

DQ5

B1

DQ6

B9

DQ7

B7

DQS

A8

DQS

B3

DM/RDQS

A2

NU/RDQS

A9

VDDQ_1

C1

VDDQ_2

C3

VDDQ_3

C7

VDDQ_4

C9

VDDQ_5

A1

VDD_1

L1

VDD_2

E9

VDD_3

H9

VDD_4

A7

VSSQ_1

B2

VSSQ_2

B8

VSSQ_3

D2

VSSQ_4

D8

VSSQ_5

A3

VSS_1

E3

VSS_2

J1

VSS_3

K9

VSS_4

E2

VREF

E1

VDDL

E7

VSSDL

DDR0_DQ[0-15]

006:B1;006:C3;006:E5;006:H5;006:I4;006:I2

006:B5;006:C3;006:E5;006:H5;006:I3;006:I2

006:B3;006:C3;006:E5;006:H5;006:I2

006:B4

006:B5;006:C3;006:E5;006:H5;006:I4;006:I2

DDR0_DQS0

DDR0_DQS0b

006:B4

DDR0_DM0

006:B4

006:B2;006:C3;006:E5;006:H5;006:I4;006:I2

006:B2;006:C3;006:E5;006:H5;006:I3;006:I2

006:B2;006:C4;006:E6;006:H6;006:I4;006:I2

C640

470pF

006:B1;006:C4;006:E6;006:H6;006:I4;006:I3

DDR0_CLK

006:B1;006:C3

DDR0_CLKb

006:B2;006:C3

DDR01_CKE

DDR01_RASb

DDR01_CASb

DDR01_WEb

DDR01_BA0

DDR01_BA1

DDR01_A[0-3]

DDR0_A[4-6]

DDR01_A[7-13]

DDR01_BA2

DDR01_ODT

006:B2;006:H5

006:B2;006:H5

DDR01_A[0-3]

DDR1_A[4-6]

DDR01_A[7-13]

DDR1_CLK

DDR1_CLKb

DDR01_CKE

DDR01_RASb

DDR01_CASb

DDR01_WEb

DDR01_BA0

DDR01_BA1

DDR01_BA2

DDR01_ODT

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR0_A[4]

DDR0_A[5]

DDR0_A[6]

K4T1G084QE-HCF8

E8

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

SS DDR

F3

WE

G8

CS

G2

BA0

G3

BA1

G1

BA2

H8

A0

H3

A1

H7

A2

J2

A3

J8

A4

J3

A5

J7

A6

K2

A7

K8

A8

K3

A9

H2

A10/AP

K7

A11

L2

A12

L8

A13

L3

NC_1

L7

NC_2

F9

ODT0

R617

100

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

IC605-*1

DM/RDQS

NU/RDQS

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDD_1

VDD_2

VDD_3

VDD_4

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSS_1

VSS_2

VSS_3

VSS_4

VREF

VDDL

VSSDL

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR1_A[4]

DDR1_A[5]

DDR1_A[6]

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

Place Caps close to DRAM pin

NT5TU128M8DE_BD

NANYA DDR

E8

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

F3

WE

G8

CS

G2

BA0

G3

BA1

H8

A0

H3

A1

H7

A2

J2

A3

J8

A4

J3

A5

J7

A6

K2

A7

K8

A8

K3

A9

H2

A10/AP

K7

A11

L2

A12

G1

NC_1/BA2

L3

NC_2/A14

L7

NC_3/A15

L8

A13

F9

ODT

EAN60992101

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQS

DQS

IC604

C8

C2

D7

D3

D1

D9

B1

B9

B7

A8

B3

A2

A9

C1

C3

C7

C9

A1

L1

E9

H9

A7

B2

B8

D2

D8

A3

E3

J1

K9

E2

E1

E7

IC605

NT5TU128M8DE_BD

NANYA DDR

E8

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

F3

WE

G8

CS

G2

BA0

G3

BA1

H8

A0

H3

A1

H7

A2

J2

A3

J8

A4

J3

A5

J7

A6

K2

A7

K8

A8

K3

A9

H2

A10/AP

K7

A11

L2

A12

G1

NC_1/BA2

L3

NC_2/A14

L7

NC_3/A15

L8

A13

F9

ODT

EAN60992101

C8

DQ0

C2

DQ1

D7

DQ2

D3

DQ3

D1

DQ4

D9

DQ5

B1

DQ6

B9

DQ7

B7

DQS

A8

DQS

B3

DM/RDQS

A2

NU/RDQS

A9

VDDQ_1

C1

VDDQ_2

C3

VDDQ_3

C7

VDDQ_4

C9

VDDQ_5

A1

VDD_1

L1

VDD_2

E9

VDD_3

H9

VDD_4

A7

VSSQ_1

B2

VSSQ_2

B8

VSSQ_3

D2

VSSQ_4

D8

VSSQ_5

A3

VSS_1

E3

VSS_2

J1

VSS_3

K9

VSS_4

E2

VREF

E1

VDDL

E7

VSSDL

DM/RDQS

NU/RDQS

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

DDR0_DQ[9]

DDR0_DQ[8]

DDR0_DQ[12]

DDR0_DQ[13]

DDR0_DQ[15]

DDR0_DQ[11]

DDR0_DQ[10]

DDR0_DQ[14]

K4T1G084QE-HCF8

E8

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

F3

WE

G8

CS

G2

BA0

G3

BA1

G1

BA2

H8

A0

H3

A1

H7

A2

J2

A3

J8

A4

J3

A5

J7

A6

K2

A7

K8

A8

K3

A9

H2

A10/AP

K7

A11

L2

A12

L8

A13

L3

NC_1

L7

NC_2

F9

ODT0

C8

DQ0

C2

DQ1

D7

DQ2

D3

DQ3

D1

DQ4

D9

DQ5

B1

DQ6

B9

DQ7

B7

DQS

A8

DQS

B3

A2

A9

C1

C3

C7

C9

A1

VDD_1

L1

VDD_2

E9

VDD_3

H9

VDD_4

A7

VSSQ_1

B2

VSSQ_2

B8

VSSQ_3

D2

VSSQ_4

D8

VSSQ_5

A3

VSS_1

E3

VSS_2

J1

VSS_3

K9

VSS_4

E2

VREF

E1

VDDL

E7

VSSDL

DDR0_DQS1

DDR0_DQS1b

DDR0_DM1

D1.8V

DDR0_VREF0

C662

0.1uF

IC606-*1

SS DDR

DDR1_DQ[0]

DDR1_DQ[1]

DDR1_DQ[5]

DDR1_DQ[3]

DDR1_DQ[4]

DDR1_DQ[2]

DDR1_DQ[6]

DDR1_DQ[7]

006:B1;006:C3;006:E5;006:F3;006:I4;006:I2

006:B5;006:C3;006:E5;006:F3;006:I3;006:I2

006:B5;006:C3;006:E5;006:F3;006:I4;006:I2

006:B2;006:C3;006:E5;006:F3;006:I4;006:I2

006:B2;006:C3;006:E5;006:F3;006:I3;006:I2

006:B4

006:B4

006:B4

006:B2;006:C4;006:E6;006:F4;006:I4;006:I2

006:B1;006:C4;006:E6;006:F4;006:I4;006:I3

C663

470pF

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQS

DQS

DM/RDQS

NU/RDQS

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDD_1

VDD_2

VDD_3

VDD_4

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSS_1

VSS_2

VSS_3

VSS_4

VREF

VDDL

VSSDL

DDR1_DQS0

DDR1_DQS0b

DDR1_DM0

D1.8V

DDR1_VREF0

C673

470pF

0.1uF

DDR0_DQ[0-15]

006:B2;006:F3

006:B2;006:F3

006:B3;006:C3;006:E5;006:F3;006:I2

C8

C2

D7

D3

D1

D9

B1

B9

B7

A8

B3

A2

A9

C1

C3

C7

C9

A1

L1

E9

H9

A7

B2

B8

D2

D8

A3

E3

J1

K9

E2

E1

E7

006:B4

006:B4

006:B4

C674

C620

470pF

DDR1_CLKb

DDR01_CKE

DDR01_RASb

DDR01_CASb

DDR01_WEb

DDR01_BA0

DDR01_BA1

DDR01_A[0-3]

DDR1_A[4-6]

DDR01_A[7-13]

DDR01_BA2

DDR01_ODT

DDR1_DQ[0-15]

C629

0.047uF

DDR1_CLK

* DDR2 1.8V By CAP - Place these Caps near Memory

C664

470pF

C665

0.047uF

C666

0.1uF

DDR01_A[7-13]

DDR01_A[7-13]

C667

C668

DDR01_A[0-3]

DDR1_A[4-6]

DDR01_A[0-3]

DDR0_A[4-6]

470pF

C671

C670

C669

10uF

0.1uF

0.047uF

006:B1;006:C3;006:E5;006:F3;006:H5;006:I4

SI

006:B1;006:C3;006:E5;006:F3;006:H5;006:I2

10uF

* DDR2 1.8V By CAP - Place these Caps near Memory

D1.8V

C630

0.1uF

C631

10uF

C632

470pF

C633

0.047uF

C634

0.1uF

C635

10uF

C636

10uF

C637

22uF

NT5TU128M8DE_BD

NANYA DDR

E8

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

F3

WE

G8

CS

G2

BA0

G3

BA1

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR1_A[4]

DDR1_A[5]

DDR1_A[6]

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

H8

A0

H3

A1

H7

A2

J2

A3

J8

A4

J3

A5

J7

A6

K2

A7

K8

A8

K3

A9

H2

A10/AP

K7

A11

L2

A12

G1

NC_1/BA2

L3

NC_2/A14

L7

NC_3/A15

L8

A13

F9

ODT

D1.8V

C672

22uF

SI

C638

IC606

EAN60992101

10uF

C675

10uF

DDR01_A[2]

DDR01_A[0]

DDR1_A[6]

DDR01_A[12]

DDR01_A[9]

DDR01_A[7]

DDR1_A[5]

DDR1_A[4]

DDR01_A[11]

DDR01_A[8]

DDR01_A[13]

DDR01_A[3]

DDR01_A[1]

DDR01_A[10]

DDR01_A[2]

DDR01_A[0]

DDR0_A[6]

DDR01_A[3]

DDR01_A[1]

DDR01_A[10]

DDR01_A[12]

DDR01_A[9]

DDR01_A[7]

DDR0_A[5]

DDR0_A[4]

DDR01_A[11]

DDR01_A[8]

DDR01_A[13]

C639

0.1uF

C676

10uF

DDR01_RASb

DDR01_CASb

DDR01_BA1

DDR01_BA0

DDR01_BA2

DDR01_WEb

DDR01_CKE

DDR01_ODT

DDR01_RASb

DDR01_BA1

DDR01_BA0

DDR01_BA2

DDR01_WEb

DDR01_CKE

DDR01_ODT

C642

0.047uF

DM/RDQS

NU/RDQS

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDD_1

VDD_2

VDD_3

VDD_4

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSS_1

VSS_2

VSS_3

VSS_4

VREF

VDDL

VSSDL

C678

0.047uF

C679

470pF

C680

10uF

C681

0.1uF

C682

0.047uF

C697

470pF

C677

0.1uF

DDR_VTT

SI

C683

75R620

75R611

75

75R621

75R625

470pF

C695

470pF

0.1uF

C684

0.1uF

C685

0.1uF

C686

0.1uF

C687

0.1uF