LG 55LM960V-ZB User Manual

Internal Use Only

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

LED LCD TV

SERVICE MANUAL

CHASSIS : LD23E

MODEL : 55LM960V 55LM960V-ZB

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Printed in KoreaP/NO : MFL67361003 (1203-REV00)

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ........................................................................ 3

SERVICING PRECAUTIONS .................................................................... 4

SPECIFICATION ....................................................................................... 6

ADJUSTMENT INSTRUCTION .............................................................. 14

EXPLODED VIEW .................................................................................. 23

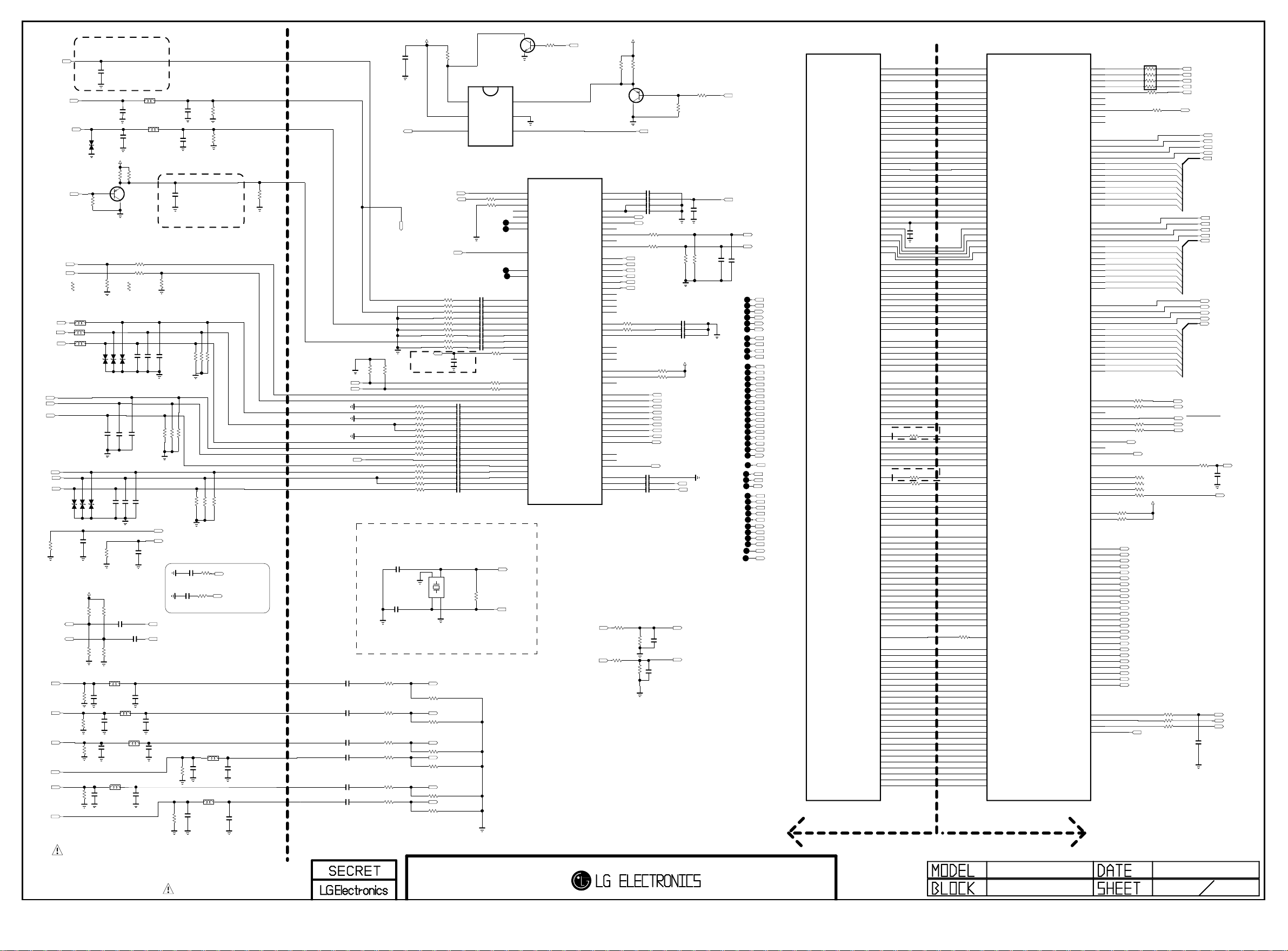

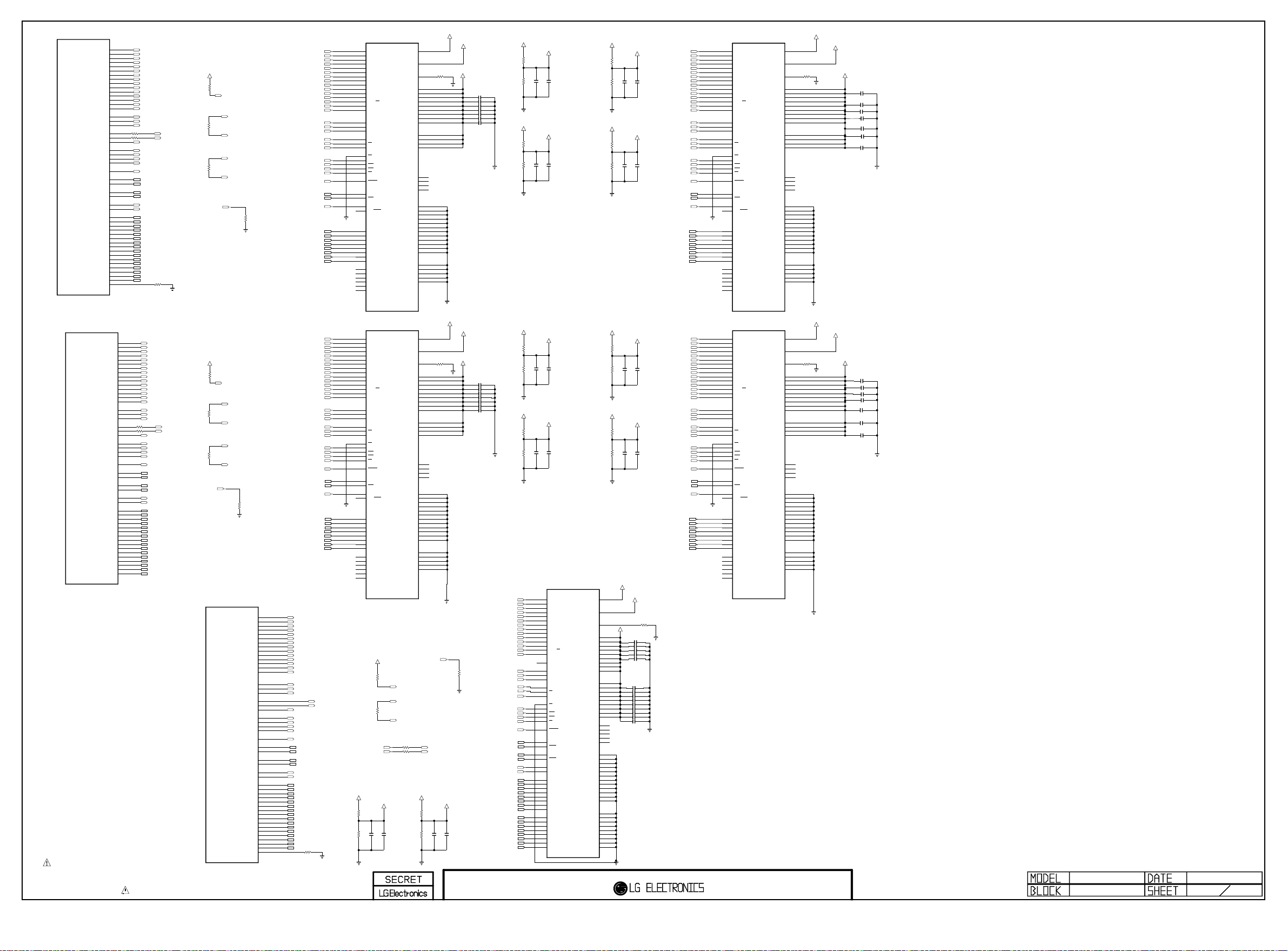

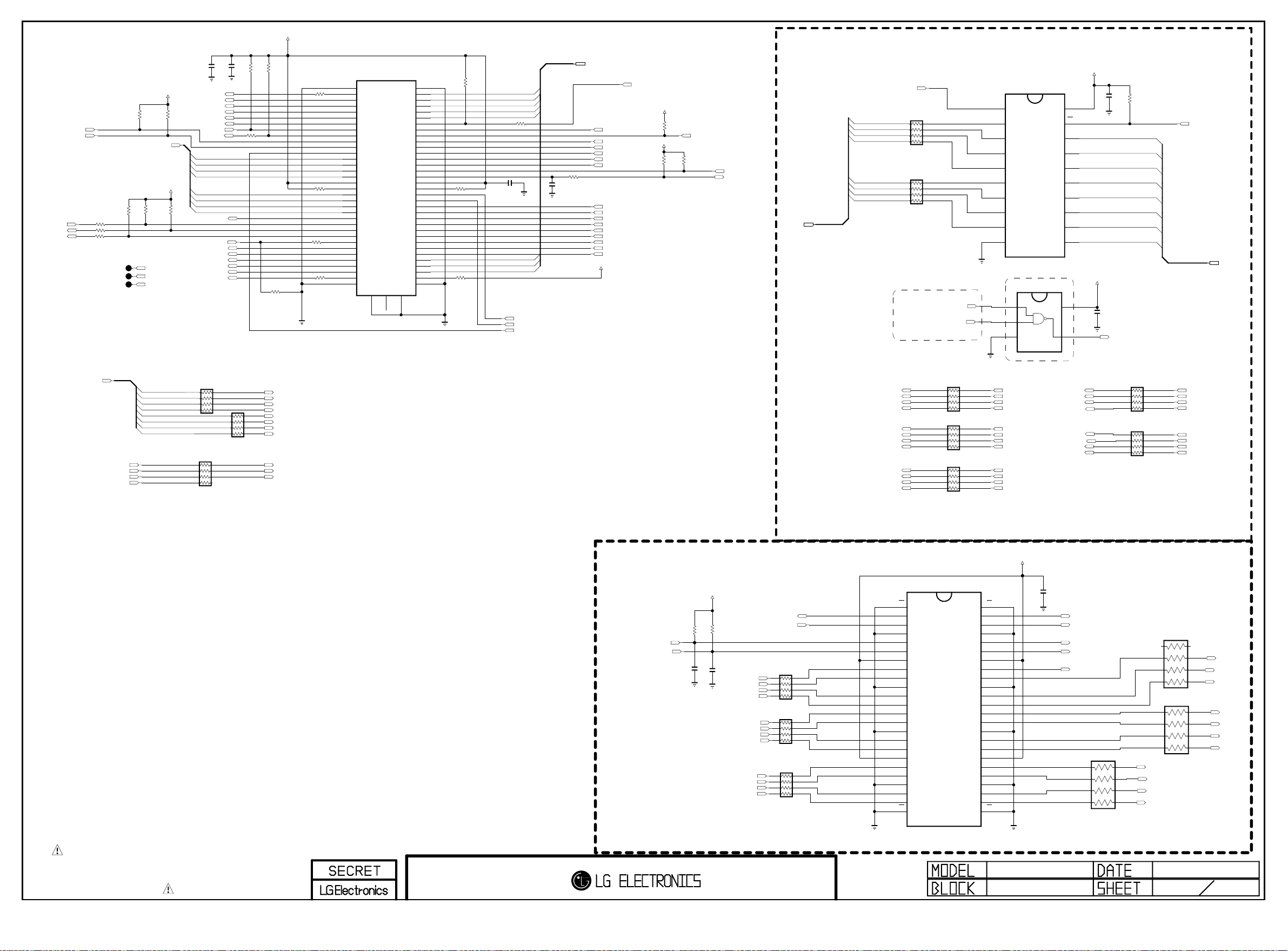

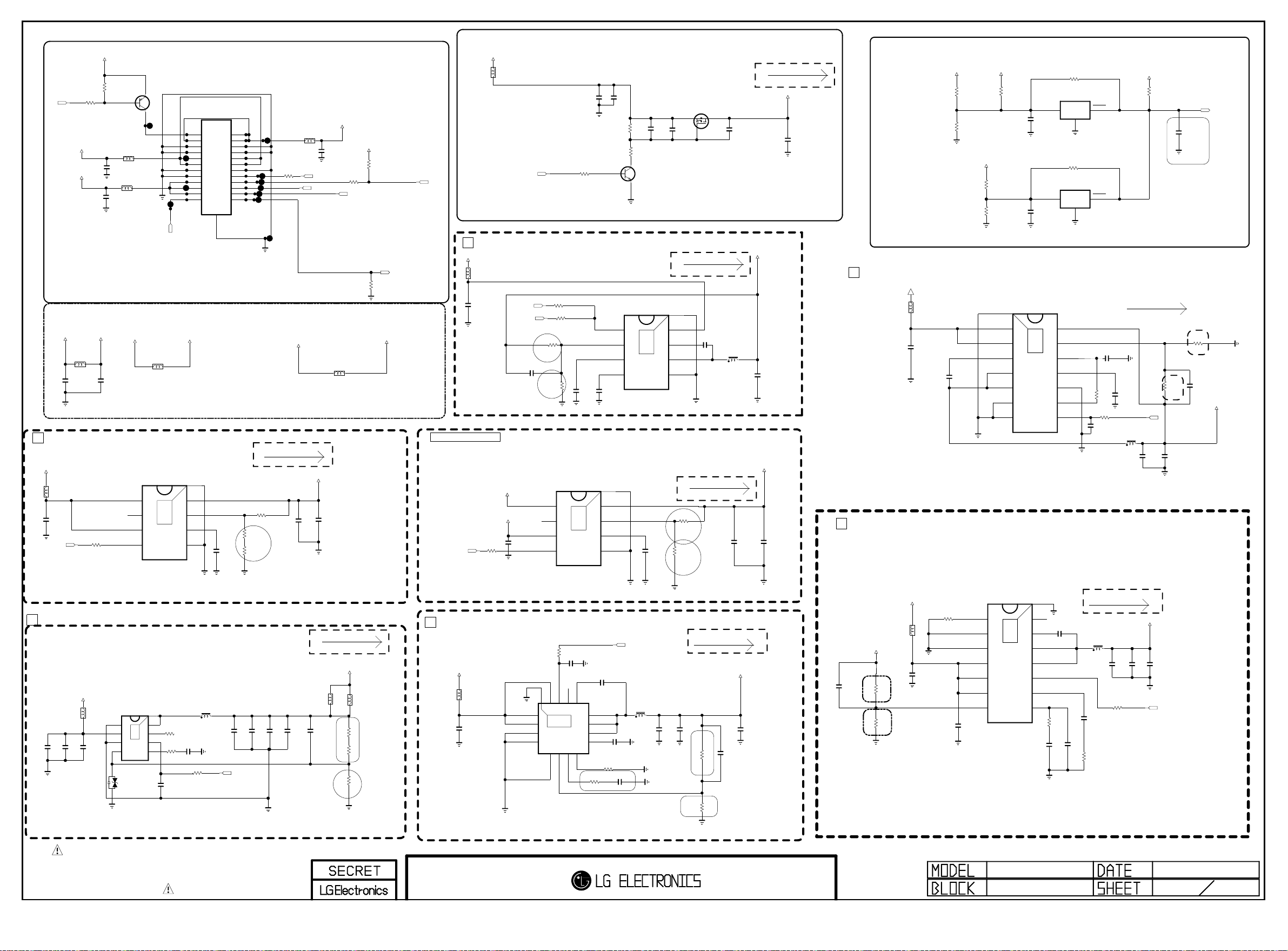

SCHEMATIC CIRCUIT DIAGRAM ..............................................................

Only for training and service purposes

- 2 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

SAFETY PRECAUTIONS

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of th e cir cuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 MΩ and 5.2 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

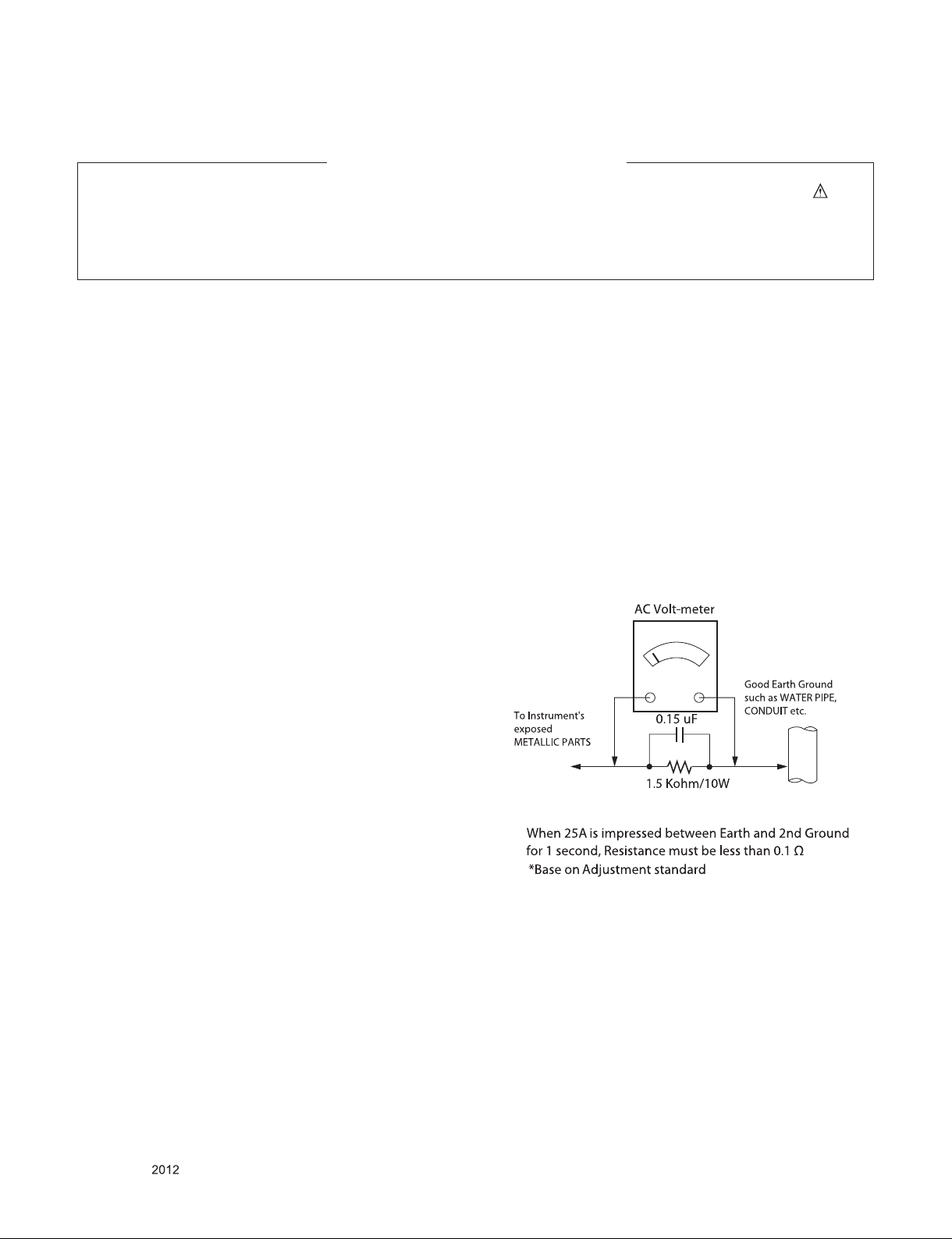

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exp ose d metallic par t. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

Only for training and service purposes

- 3 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conict between the

following servicing precautions and any of the safety precautions

on page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board mod-

ule or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specied otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10 % (by volume) Acetone and 90 %

(by volume) isopropyl alcohol (90 % - 99 % strength)

CAUTION: This is a ammable mixture.

Unless specied otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test xtures specied in this

service manual.

CAUTION: Do not connect the test xture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some eld-effect transistors

and semiconductor “chip” components. The following techniques

should be used to help reduce the incidence of component damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging

wrist strap device, which should be removed to prevent potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classied as “anti-static” can generate

electrical charges sufcient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufcient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your

foot from a carpeted oor can generate static electricity sufcient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500 °F to 600 °F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25 cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500 °F to 600 °F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500 °F to 600 °F)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder ows onto and around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

Only for training and service purposes

- 4 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent at against the circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing

the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close

as possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the

good copper pattern. Solder the overlapped area and clip off

any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

Only for training and service purposes

- 5 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application range

This specification is applied to the LCD TV used LD23E

chassis.

2. Requirement for Test

Each part is tested as below without special appointment.

1) Temperature: 25 °C ± 5 °C(77 °F ± 9 °F), CST: 40 °C ± 5 °C

2) Relative Humidity: 65 % ± 10 %

3) Power Voltage

: Standard input voltage (AC 100-240 V~, 50/60 Hz)

* Standard Voltage of each products is marked by models.

4) Specification and performance of each parts are followed

ea ch drawing and s pe cificatio n b y p art number in

accordance with BOM.

5) The receiver must be operated for about 20 minutes prior to

the adjustment.

3. Test method

1) Performance: LGE TV test method followed

2) Demanded other specification

- Safety : CE, IEC specification

- EMC : CE, IEC

- Wireless : Wireless HD Specification (Option)

4. Model General Specification

No. Item Specication Remarks

1 Market EU(PAL Market-36Countries) DTV & Analog (Total 37 countries)

DTV(MPEG2/4,DVB-T/T2/S)

Albania/Austria/Belarus/Belgium/Bosnia/Bulgaria/Croatia/

Czech/Estonia/France/Germany/Greece/Hungary/Ireland/

Italy/Kazakhstan/Latvia/Lithuania/Luxembourg/Morocco/

Netherlands/Poland/Portugal/Romania/Russia/Serbia/Slovenia/Spain/Slovakia/Switzerland/Turkey/UK/Ukraine/Denmark/Finland/Norway/Sweden

2 Broadcasting system 1) PAL-BG

2) PAL-DK

3) PAL-I/I’

4) SECAM L/L’, DK, BG, I

5) DVB-T

6) DVB-C

7) DVB-T2

8) DVB-S

9) DVB-S2

Supported satellite : 29 satellites

ABS1 75.0E/ AMOS 4.0W/ ASIASATS 105.5E/ ASTRA1LHMKR 19.2E/ ASTRA2ABD 28.2E/ ASTRA3AB 23.5E/

ASTRA4A 4.8E/ ATLANTICBIRD2 8.0W/ ATLANTICBIRD3

5.0W/ BADR 26.0E/ EUROBIRD3 33.0E/ EUROBIRD9A

9.0E/ EUTELSATW2A 10.E/ EUTELSATW3A 7.0E/ EUTELSATW4W7 36.0E/ EUTELSESAT 16.0E/ EXPRESSAM1

40.0E/ EXPRESAM3 140.0E/ EXPRESSAM33 96.5E/ HELLASAT2 39.0E/ HISPASAT1CDE 30.0W/ HOTBIRD 13.0E/

INTELSAT10&7 68.5E/ INTELSAT15 85.2E/ INTELSAT904

60.0E/ NILESAT 7.0W/ THOR 0.8W/ TURKSAT 42.0E/

YAMAL201 90.0E

DVB-S: Satellite

Only for training and service purposes

- 6 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

No. Item Specication Remarks

3 Receiving system Analog : Upper Heterodyne

Digital : COFDM, QAM

4 Input Voltage AC 100 ~ 240V 50/60Hz

5 Screen Size 46.96 inches 1046.68(H) x 594.02(V) x 1.5(D)mm (Typ.)

6 Aspect Ratio 16:9

7 Tuning System

8 Operating Environment 1) Temp : 0 ~ 40 deg

2) Humidity : ~ 80 %

9 Storage Environment 1) Temp : -20 ~ 60 deg

2) Humidity : ~ 85 %

► DVB-T

- Guard Interval(Bitrate_Mbit/s)

1/4, 1/8, 1/16, 1/32

- Modulation : Code Rate

QPSK : 1/2, 2/3, 3/4, 5/6, 7/8

16-QAM : 1/2, 2/3, 3/4, 5/6, 7/8

64-QAM : 1/2, 2/3, 3/4, 5/6, 7/8

► DVB-T2

- Guard Interval(Bitrate_Mbit/s)

1/4, 1/8, 1/16, 1/32, 1/128, 19/128, 19/256,

- Modulation : Code Rate

QPSK : 1/2, 2/5, 2/3, 3/4, 5/6

16-QAM : 1/2, 2/5, 2/3, 3/4, 5/6

64-QAM : 1/2, 2/5, 2/3, 3/4, 5/6

256-QAM : 1/2, 2/5, 2/3, 3/4, 5/6

► DVB-C

- Symbolrate :

4.0Msymbols/s to 7.2Msymbols/s

- Modulation :

16QAM, 64-QAM, 128-QAM and 256-QAM

► DVB-S/S2

- symbolrate

DVB-S2 (8PSK / QPSK) : 2 ~ 45Msymbol/s

DVB-S (QPSK) : 2 ~ 45Msymbol/s

- viterbi

DVB-S mode : 1/2, 2/3, 3/4, 5/6, 7/8

DVB-S2 mode : 1/2, 2/3, 3/4, 3/5, 4/5, 5/6, 8/9, 9/10

FHD+240Hz

Only for training and service purposes

- 7 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

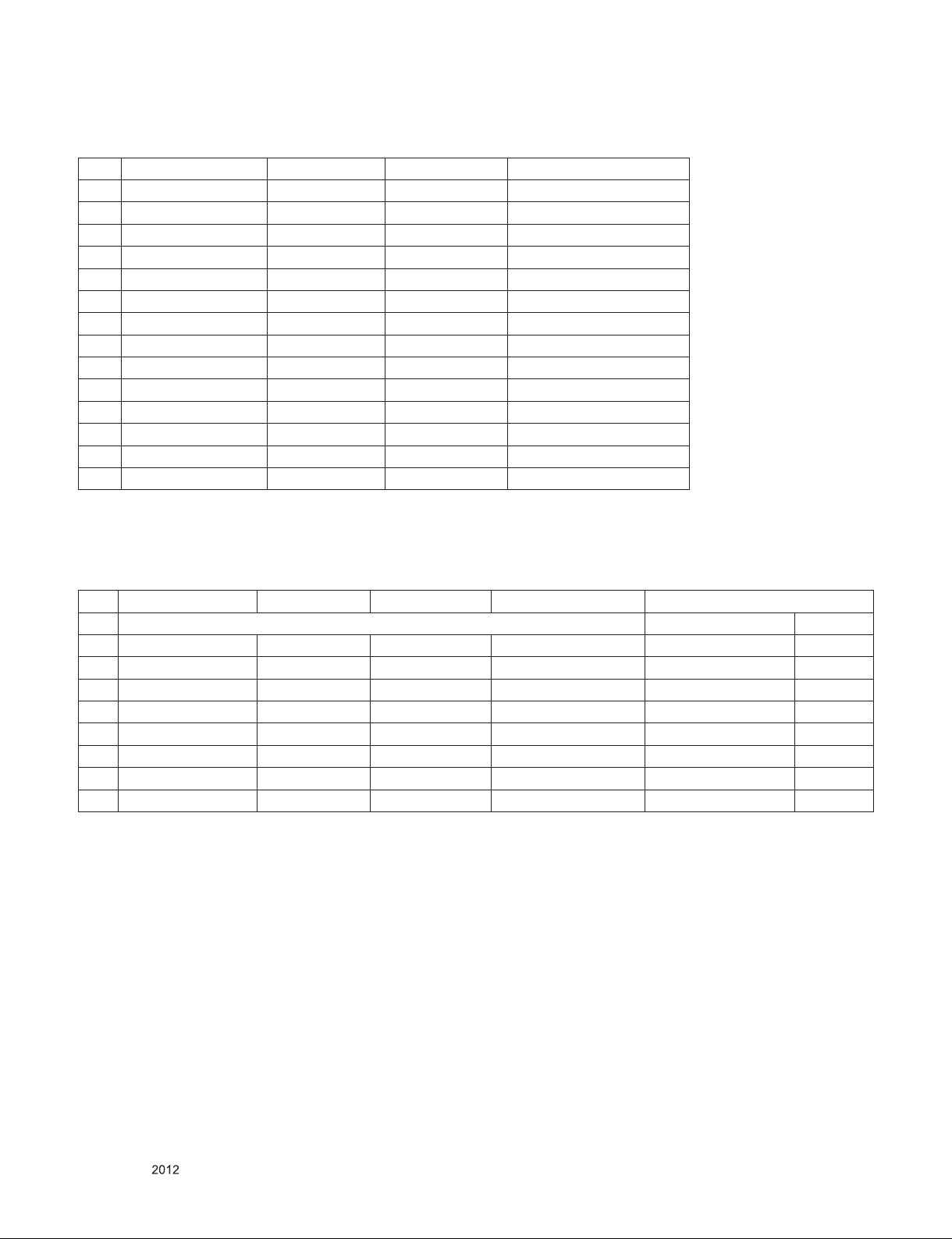

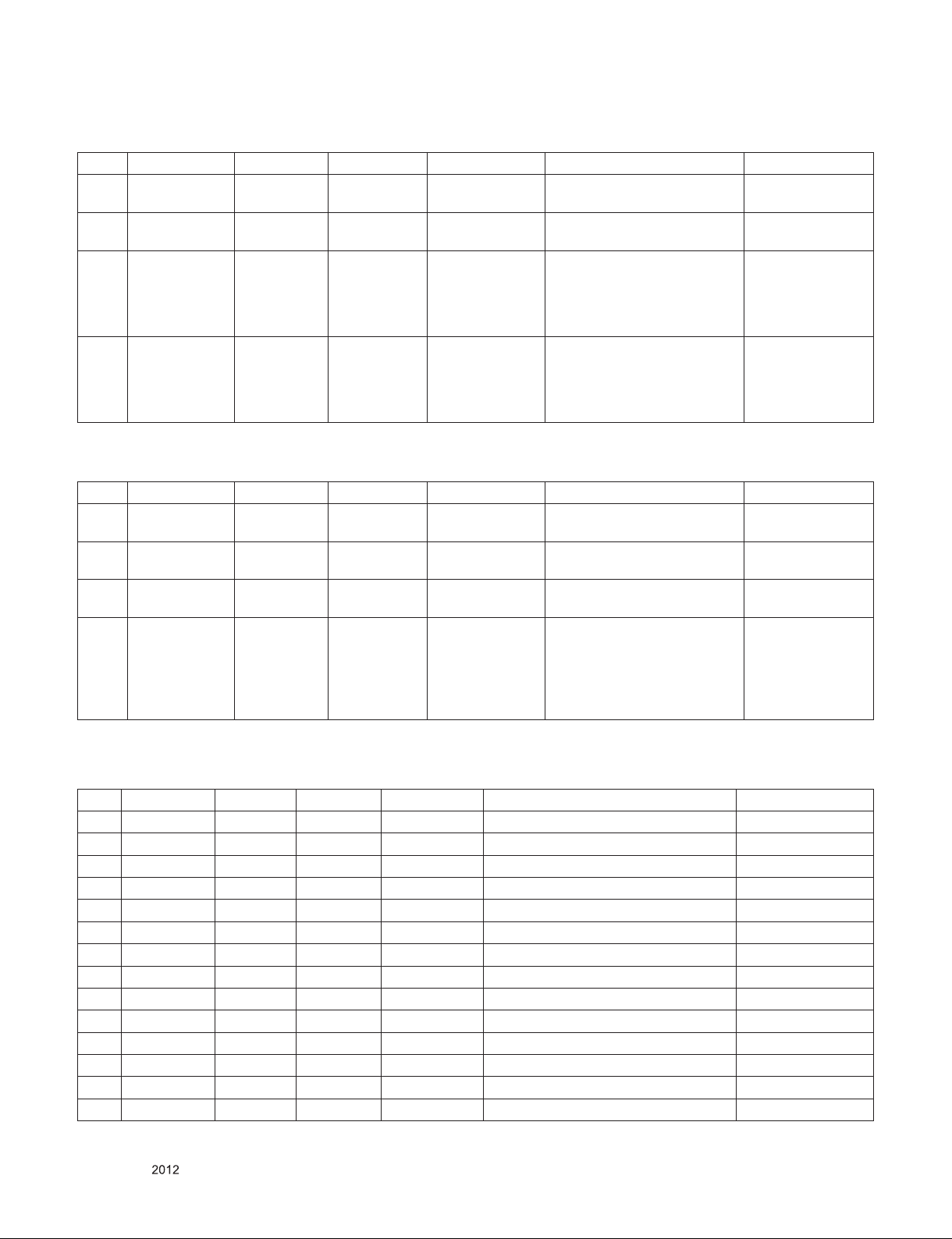

5. Component Video Input (Y, Cb/Pb, Cr/Pr)

No. Resolution H-freq(kHz) V-freq(Hz) Pixel clock

1. 720×480 15.73 60.00 SDTV, DVD 480i

2. 720×480 15.63 59.94 SDTV, DVD 480i

3. 720×480 31.47 59.94 480p

4. 720×480 31.50 60.00 480p

5. 720×576 15.625 50.00 SDTV 576i

6. 720×576 31.25 50.00 SDTV 576p

7. 1280×720 45.00 50.00 HDTV 720p

8. 1280×720 44.96 59.94 HDTV 720p

9. 1280×720 45.00 60.00 HDTV 720p

10. 1920×1080 31.25 50.00 HDTV 1080i

11. 1920×1080 33.75 60.00 HDTV 1080i

12. 1920×1080 33.72 59.94 HDTV 1080i

13. 1920×1080 56.250 50 HDTV 1080p

14. 1920×1080 67.5 60 HDTV 1080p

6. RGB input (PC)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed

PC DDC

1 640*350 31.468 70.09 25.17 EGA Х

2 720*400 31.469 70.08 28.32 DOS O

3 640*480 31.469 59.94 25.17 VESA(VGA) O

4 800*600 37.879 60.31 40.00 VESA(SVGA) O

5 1024*768 48.363 60.00 65.00 VESA(XGA) O

6 1152*864 54.348 60.053 80 VESA (WXGA) Х

7 1360*768 47.712 60.015 85.5 WUXGA O

8 1920*1080 67.5 60.00 148.5 WUXGA(CEA861D) O

Only for training and service purposes

- 8 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

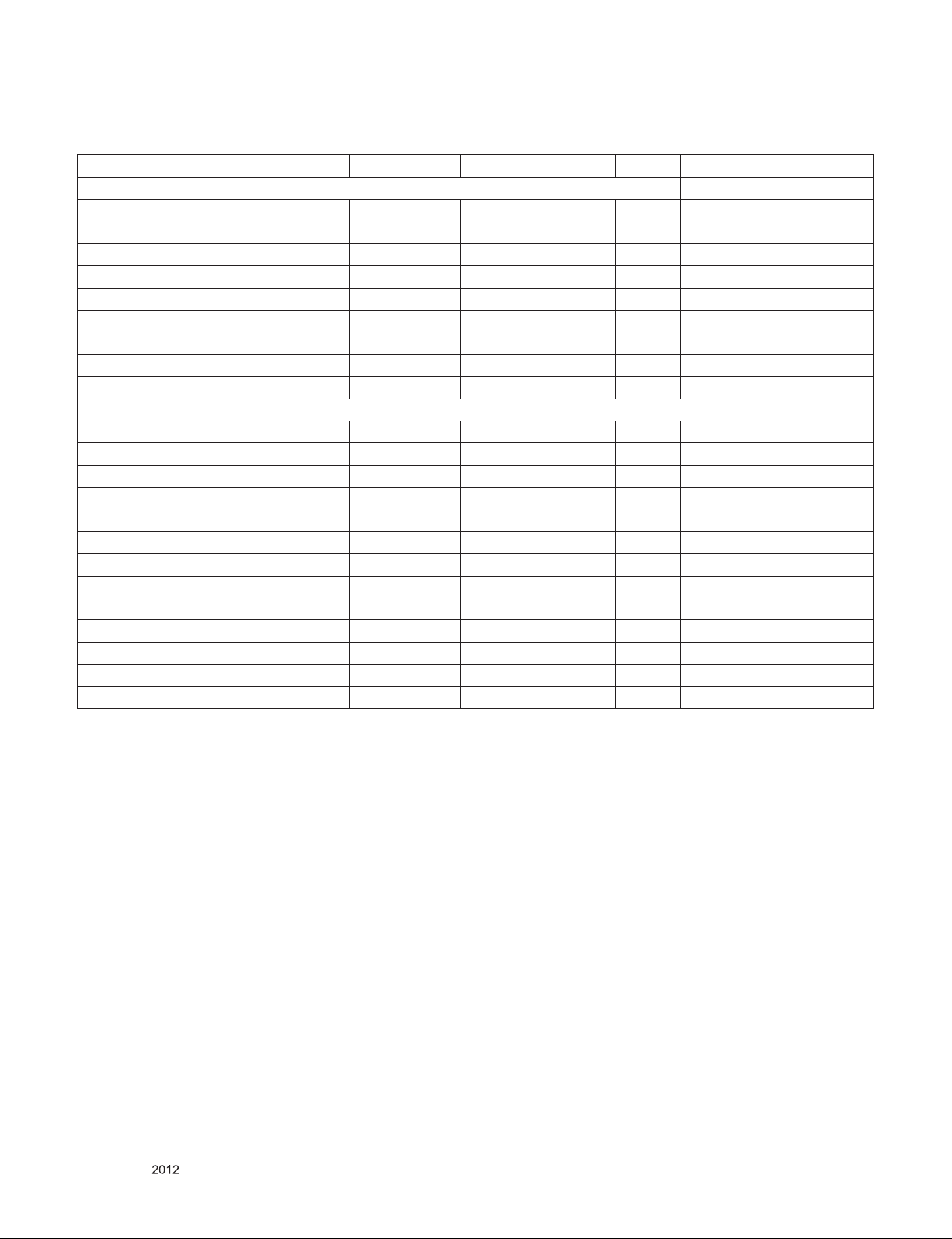

7. HDMI Input

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) VIC Proposed

HDMI-PC DDC

1 720*400 31.468 70.08 28.321 Х

2 640*480 31.469 59.94 25.17 VESA O

3 800*600 37.879 60.31 40.00 VESA O

4 1024*768 48.363 60.00 65.00 VESA(XGA) O

5 1360*768 47.72 59.8 84.75 WXGA O

6 1280*1024 63.595 60.0 108.875 SXGA O

7 1920*1080 67.5 60.00 148.5 WUXGA O

8 1360*768 47.712 60.015 85.5 VESA(WXGA) O

9 1920*1080 67.5 60.00 148.5 WUXGA(CEA861D) O

HDMI-DTV

1 640*480 31.469 / 31.5 59.94/ 60 25.125 1 SDTV 480P

2 720*480 31.469 / 31.5 59.94 / 60 27.00/27.03 2,3 SDTV 480P

3 720*576 31.25 50 27 17,18 SDTV 576P

4 720*576 15.625 50 27 21 SDTV 576I

5 1280*720 37.500 50 74.25 19 HDTV 720P

6 1280*720 44.96 / 45 59.94 / 60 74.17/74.25 4 HDTV 720P

7 1920*1080 33.72 / 33.75 59.94 / 60 74.17/74.25 5 HDTV 1080I

8 1920*1080 28.125 50.00 74.25 20 HDTV 1080I

9 1920*1080 26.97 / 27 23.97 / 24 74.17/74.25 32 HDTV 1080P

10 1920*1080 25 33 HDTV 1080P

11 1920*1080 33.716 / 33.75 29.976 / 30.00 74.25 34 HDTV 1080P

12 1920*1080 56.250 50 148.5 31 HDTV 1080P

13 1920*1080 67.43 / 67.5 59.94 / 60 148.35/148.50 16 HDTV 1080P

Only for training and service purposes

- 9 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

8. 3D Mode

8.1. RF Input(3D supported mode manually)

No. Resolution Proposed 3D input proposed mode

1 HD

2 SD

1080I

720P

576P

576I

8.2. RF Input(3D supported mode automatically)

No. Signal 3D input proposed mode

1 Frame Compatible

Side by Side(Half),

Top & Bottom

8.3. HDMI Input

8.3.1. HDMI 1.3 (3D supported mode manually)

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) Proposed 3D input proposed mode

1 1280*720 45.00 60.00 74.25 HDTV 720P

2 1280*720 37.500 50 74.25 HDTV 720P

3 1920*1080 33.75 60.00 74.25 HDTV 1080I

4 1920*1080 28.125 50.00 74.25 HDTV 1080I

5 1920*1080 27.00 24.00 74.25 HDTV 1080P

6 1920*1080 28.12 25 74.25 HDTV 1080P

7 1920*1080 33.75 30.00 74.25 HDTV 1080P

8 1920*1080 56.25 50 148.5 HDTV 1080P

9 1920*1080 67.50 60.00 148.5 HDTV 1080P

2D to 3D

Side by Side(Half)

Top & Bottom

2D to 3D

2D to 3D

Side by Side(half),

Top & Bottom,

Single Frame Sequential

2D to 3D

Side by Side(half),

Top & Bottom,

Single Frame Sequential

2D to 3D

Side by Side(half),

Top & Bottom

2D to 3D

Side by Side(half),

Top & Bottom

2D to 3D

Side by Side(half),

Top & Bottom

2D to 3D

Side by Side(half),

Top & Bottom,

Checkerboard

2D to 3D

Side by Side(half),

Top & Bottom,

Checkerboard

2D to 3D

Side by Side(half),

Top & Bottom,

Checkerboard,

Single Frame Sequential,

Row Interleaving,

Column Interleaving

2D to 3D

Side by Side(half),

Top & Bottom,

Checkerboard,

Single Frame Sequential,

Row Interleaving,

Column Interleaving

Only for training and service purposes

- 10 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

8.3.2. HDMI 1.4b (3D supported mode automatically)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) VIC 3D input proposed mode Proposed

1

640*480

2 62.938/63 59.94/ 60 50.35/50.4 1

3 31.469 / 31.5 59.94/ 60 50.35/50.4 1 Side-by-side(Full) (SDTV 480P)

4

720*480

5 62.938/63 59.94 / 60 54/54.06 2,3

6 31.469 / 31.5 59.94 / 60 54/54.06 2,3 Side-by-side(Full) (SDTV 480P)

7

720*576

8 62.5 50 54 17,18

9 31.25 50 54 17,18 Side-by-side(Full) (SDTV 576P)

10

720*576

11 31.25 50 54 21

12 15.625 50 54 21 Side-by-side(Full) (SDTV 576I)

13

14 75 50 148.5 19

15 37.500 50 148.5 19 Side-by-side(Full) (HDTV 720P)

1280*720

16 44.96 / 45 59.94 / 60 74.18/74.25 4

17 89.91/90 59.94 / 60 148.35/148.5 4

18 44.96 / 45 59.94 / 60 148.35/148.5 4 Side-by-side(Full) (HDTV 720P)

19

20 67.432/67.50 59.94 / 60 148.35/148.5 5

21 33.72 / 33.75 59.94 / 60 148.35/148.5 5 Side-by-side(Full) (HDTV 1080I)

1920*1080

22 28.125 50.00 74.25 20

23 56.25 50.00 148.5 20

24 28.125 50.00 74.25 20 Side-by-side(Full) (HDTV 1080I)

25

26 43.94/54 23.97 / 24 148.35/148.5 32

27 26.97 / 27 23.97 / 24 148.35/148.5 32 Side-by-side(Full) (HDTV 1080P)

28 28.12 25 74.25 33

29 56.24 25 148.5 33

1920*1080

30 28.12 25 148.5 33 Side-by-side(Full) (HDTV 1080P)

31 33.716 / 33.75 29.976 / 30.00 74.18/74.25 34

32 67.432 / 67.5 29.976 / 30.00 148.35/148.5 34

33 33.716 / 33.75 29.976 / 30.00 148.35/148.5 34 Side-by-side(Full) (HDTV 1080P)

34 56.250 50 148.5 31

35 67.43 / 67.5 59.94 / 60 148.35/148.50 16

31.469 / 31.5 59.94/ 60 25.125 1

31.469 / 31.5 59.94 / 60 27.00/27.03 2,3

31.25 50 27 17,18

15.625 50 27 21

37.500 50 74.25 19

33.72 / 33.75 59.94 / 60 74.17/74.25 5

26.97 / 27 23.97 / 24 74.18/74.25 32

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Field alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Field alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Field alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Top-and-Bottom

Side-by-side(half)

Secondary(SDTV 480P)

Secondary(SDTV 480P)

Secondary(SDTV 480P)

(SDTV 480P)

Secondary(SDTV 480P)

Secondary(SDTV 480P)

Secondary(SDTV 480P)

(SDTV 480P)

Secondary(SDTV 576P)

Secondary(SDTV 576P)

Secondary(SDTV 576P)

(SDTV 576P)

Secondary(SDTV 576I)

Secondary(SDTV 576I)

Secondary(SDTV 576I)

(SDTV 576I)

Primary(HDTV 720P)

Primary(HDTV 720P)

Primary(HDTV 720P)

(HDTV 720P)

Primary(HDTV 720P)

Primary(HDTV 720P)

Primary(HDTV 720P)

(HDTV 720P)

Secondary(HDTV 1080I)

Primary(HDTV 1080I)

Primary(HDTV 1080I)

(HDTV 1080I)

Secondary(HDTV 1080I)

Primary(HDTV 1080I)

Primary(HDTV 1080I)

(HDTV 1080I)

Primary(HDTV 1080P)

Primary(HDTV 1080P)

Primary(HDTV 1080P)

(HDTV 1080P)

Secondary(HDTV 1080P)

Secondary(HDTV 1080P)

Secondary(HDTV 1080P)

(HDTV 1080P)

Primary(HDTV 1080P)

Secondary(HDTV 1080P)

Primary(HDTV 1080P)

(HDTV 1080P)

Primary(HDTV 1080P)

Secondary(HDTV 1080P)

Primary(HDTV 1080P)

Secondary(HDTV 1080P)

Only for training and service purposes

- 11 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

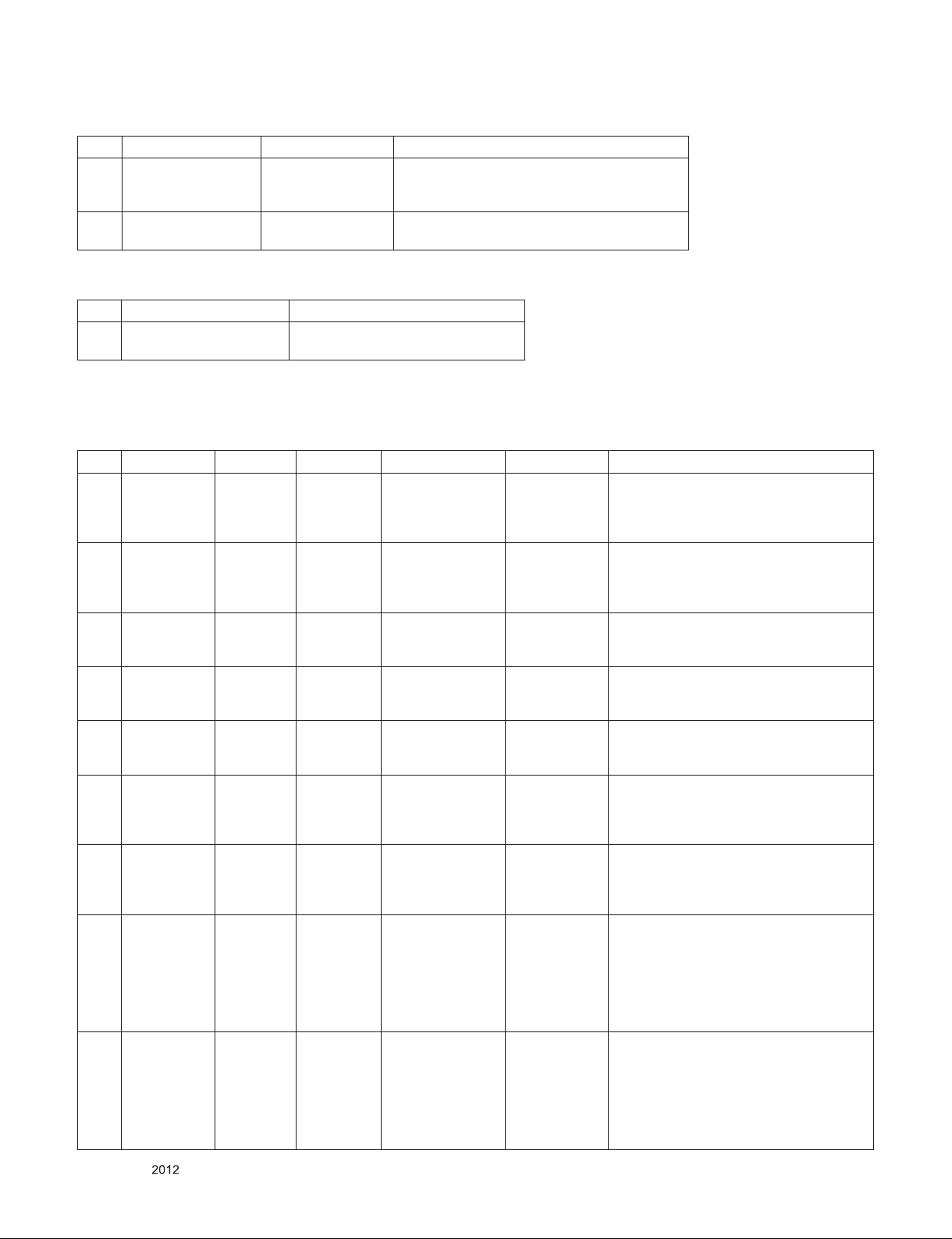

8.4. HDMI-PC Input (3D) (3D supported mode manually)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode Proposed

1 1024*768 48.36 60 65

2 1360*768 47.71 60 85.5

3 1920*1080 67.500 60 148.50

4 Others - - - 2D to 3D

2D to 3D, Side by Side(half)

Top & Bottom

2D to 3D, Side by Side(half)

Top & Bottom

2D to 3D, Side by Side(half)

Top & Bottom, Checker Board,

Single Frame Sequential,

Row Interleaving,

Column Interleaving

HDTV 768P

HDTV 768P

HDTV 1080P

640*350

720*400

640*480

800*600

1152*864

8.5. RGB-PC Input (3D) (3D supported mode manually)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode Proposed

1 1024*768 48.36 60 65

2 1360*768 47.71 60 85.5

3 1920*1080 67.500 60 148.50

4 Others - - - 2D to 3D

2D to 3D, Side by Side(half)

Top & Bottom

2D to 3D, Side by Side(half)

Top & Bottom

2D to 3D, Side by Side(half)

Top & Bottom,

HDTV 768P

HDTV 768P

HDTV 1080P

640*350

720*400

640*480

800*600

1152*864

1280*1024

8.6. Component Input(3D) (3D supported mode manually)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock 3D input proposed mode Proposed

1 1280*720 37.5 50 74.25 2D to 3D, Side by Side, Top & Bottom HDTV 720P

2 1280*720 45.00 60.00 74.25 2D to 3D, Side by Side, Top & Bottom HDTV 720P

3 1280*720 44.96 59.94 74.176 2D to 3D, Side by Side, Top & Bottom HDTV 720P

4 1920*1080 33.75 60.00 74.25 2D to 3D, Side by Side, Top & Bottom HDTV 1080I

5 1920*1080 33.72 59.94 74.176 2D to 3D, Side by Side, Top & Bottom HDTV 1080I

6 1920*1080 28.12 50 74.25 2D to 3D, Side by Side, Top & Bottom HDTV 1080I

7 1920*1080 67.500 60 148.50 2D to 3D, Side by Side, Top & Bottom HDTV 1080P

8 1920*1080 67.432 59.94 148.352 2D to 3D, Side by Side, Top & Bottom HDTV 1080P

9 1920*1080 27.000 24.000 74.25 2D to 3D, Side by Side, Top & Bottom HDTV 1080P

10 1920*1080 28.12 25 74.25 2D to 3D, Side by Side, Top & Bottom HDTV 1080P

11 1920*1080 56.25 50 74.25 2D to 3D, Side by Side, Top & Bottom HDTV 1080P

12 1920*1080 26.97 23.976 74.176 2D to 3D, Side by Side, Top & Bottom HDTV 1080P

13 1920*1080 33.75 30.000 74.25 2D to 3D, Side by Side, Top & Bottom HDTV 1080P

14 1920*1080 33.71 29.97 74.176 2D to 3D, Side by Side, Top & Bottom HDTV 1080P

Only for training and service purposes

- 12 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

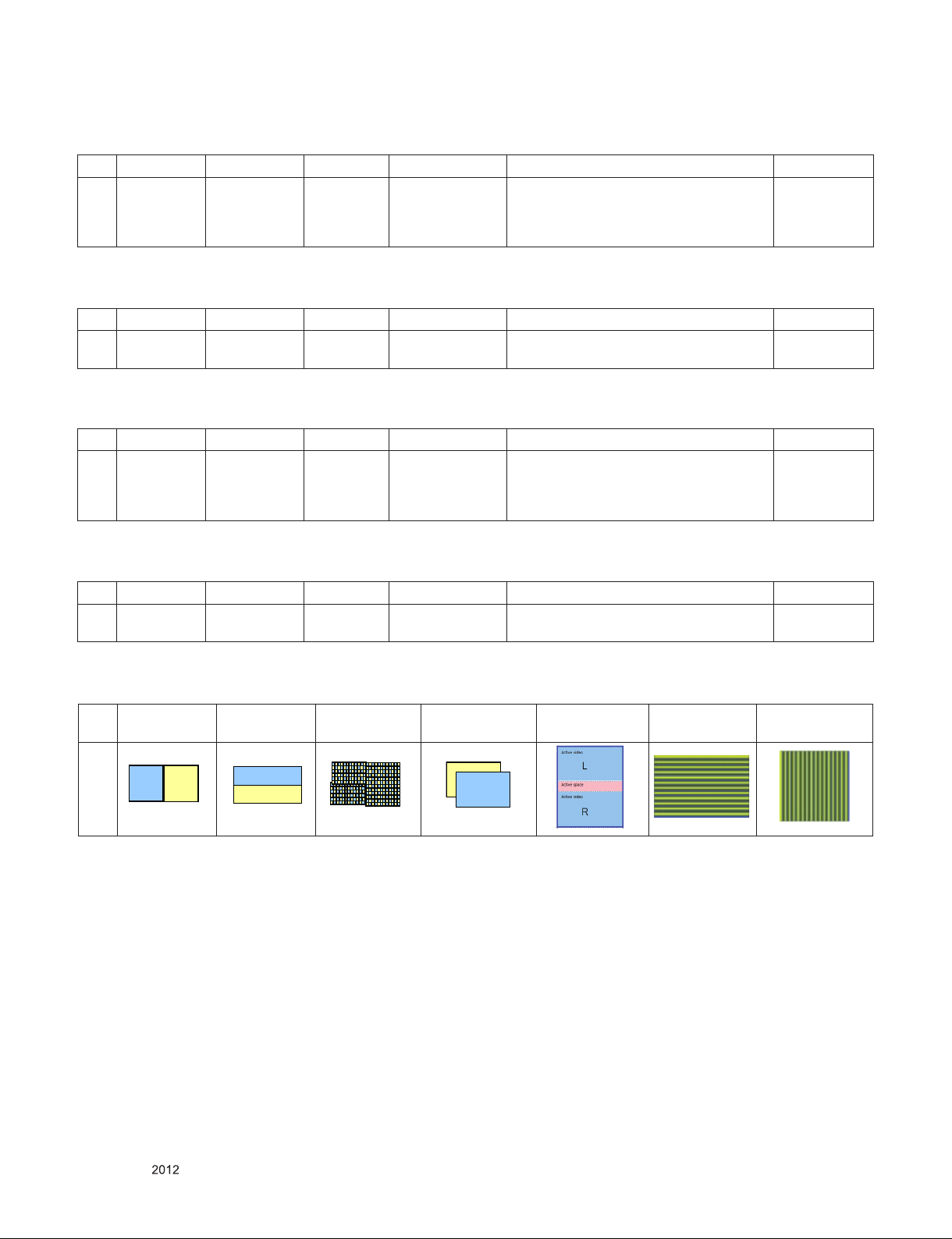

8.7. USB Input(3D) (3D supported mode manually)

R

L

R

L

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode Proposed

2D to 3D, Side by Side(Half),

1 1920*1080 33.75 30 74.25

Top & Bottom, Checkerboard,

Row Interleaving, Column Interleaving

(Photo : side by Side(half), Top & Bottom)

HDTV 1080P

8.8. USB Input(3D) (3D supported mode automatically)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode Proposed

1 1920*1080 33.75 30 74.25

Side by Side(Half), Top & Bottom,

Checkerboard, MPO(photo)

HDTV 1080P

8.9. DLNA Input (3D) (3D supported mode manually)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode Proposed

2D to 3D, Side by Side(Half),

1 1920*1080 33.75 30 74.25

Top & Bottom, Checkerboard,

Row Interleaving, Column Interleaving

(Photo : side by Side(half), Top & Bottom)

HDTV 1080P

8.10. DLNA Input (3D) (3D supported mode automatically)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode Proposed

1 1920*1080 33.75 30 74.25

■ Remark: 3D Input mode

No. Side by Side Top & Bottom Checker board

1

Single Frame

Sequential

Side by Side(Half), Top & Bottom,

Checkerboard, MPO(photo)

Frame Packing

Line

Interleaving

HDTV 1080P

Column

Interleaving

Only for training and service purposes

- 13 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

ADJUSTMENT INSTRUCTION

1. Application Range

This specification sheet is applied to all of the LED LCD TV

with LD23E chassis.

2. Designation

(1) Because this is not a hot chassis, it is not necessary to

use an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25 °C ± 5 °C of temperature and 65 % ± 10 % of relative

humidity if there is no specific designation.

(4) The input voltage of the receiver must keep AC 100-240

V~, 50/60 Hz.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment when module is in the circumstance of over

15.

In case of keeping module is in the circumstance of 0 °C, it

should be placed in the circumstance of above 15 °C for 2

hours.

In case of keeping module is in the circumstance of below

-20 °C, it should be placed in the circumstance of above 15

°C for 3 hours.

[Caution]

When still image is displayed for a period of 20 minutes or

longer (Especially where W/B scale is strong. Digital pattern

13ch and/or Cross hatch pattern 09ch), there can some

afterimage in the black level area.

3. Automatic Adjustment

3.1. ADC Adjustment

3.1.1. Overview

ADC adjustment is needed to find the optimum black level

and gain in Analog-to-Digital device and to compensate RGB

deviation.

3.1.3. Adjustment

(1) Adjustment method

- Using RS- 232, ad just items in the other shown in

"3.1.3.3)"

(2) Adj. protocol

Protocol Command Set ACK

Enter adj. mode aa 00 00 a 00 OK00x

Source change

Begin adj. ad 00 10

Return adj. result

Read adj. data

Conrm adj. ad 00 99

End adj. aa 00 90 a 00 OK90x

xb 00 04

xb 00 06

(main)

ad 00 20

(sub )

ad 00 21

b 00 OK04x (Adjust 480i, 1080p Comp1 )

b 00 OK06x (Adjust 1920*1080 RGB)

OKx (Case of Success)

NGx (Case of Fail)

(main)

000000000000000000000000007c007b006dx

(Sub)

000000070000000000000000007c00830077x

NG 03 00x (Fail)

NG 03 01x (Fail)

NG 03 02x (Fail)

OK 03 03x (Success)

Ref.) ADC Adj. RS232C Protocol_Ver1.0

(3) Adj. order

- aa 00 00 [Enter ADC adj. mode]

- xb 00 04 [Change input source to Component1 (480i&

1080p)]

- ad 00 10 [Adjust 480i&1080p Comp1]

- xb 00 06 [Change input source to RGB(1024*768)]

- ad 00 10 [Adjust 1920*1080 RGB]

- ad 00 90 End adj.

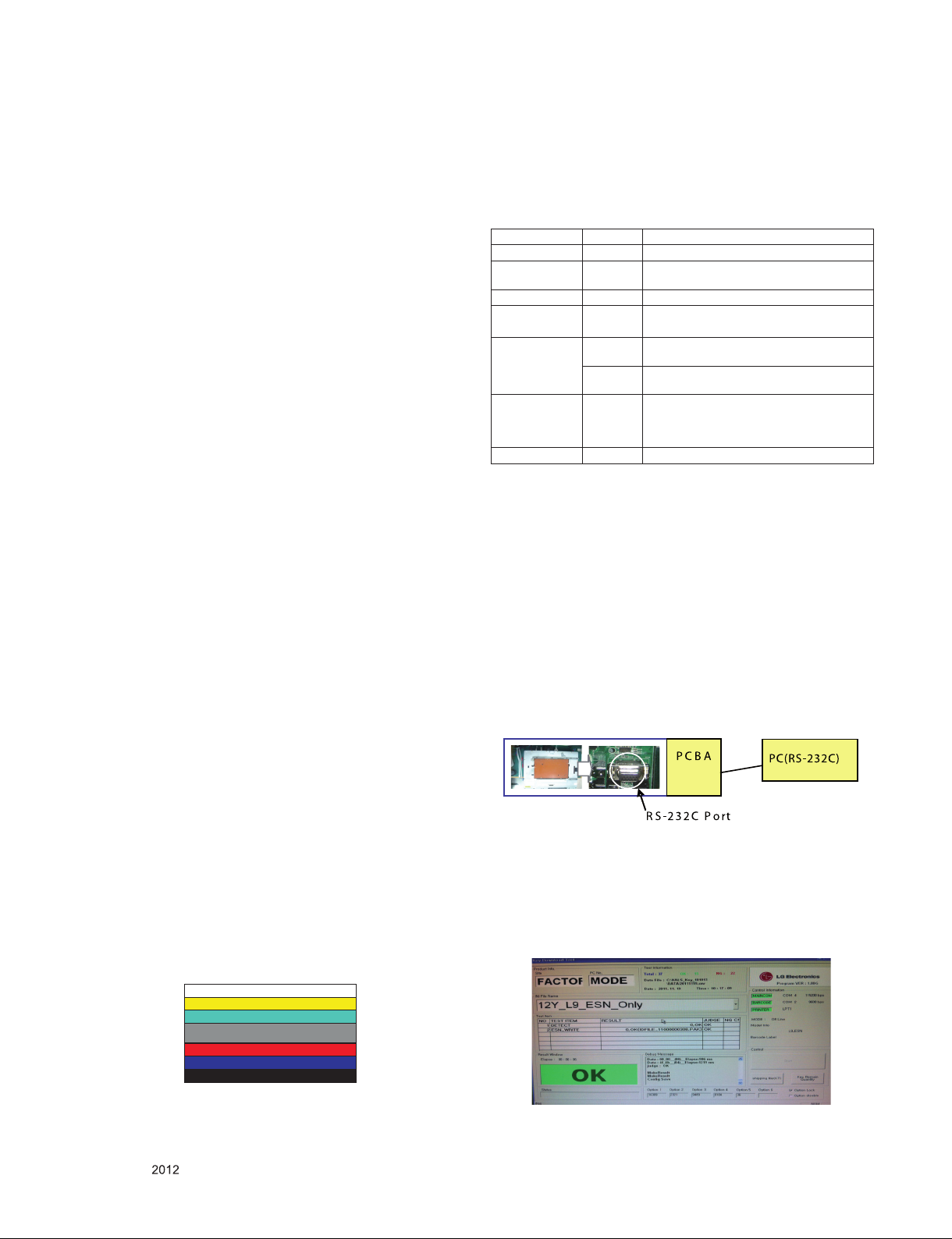

3.2. MAC address D/L, CI+ key D/L, Widevine

key D/L

Connect: PCBA Jig → RS-232C Port== PC → RS-232C Port

Communication Prot connection

3.1.2. Equipment & Condition

(1) USB to RS-232C Jig

(2) MSPG-92 5 Series Pattern Generat or(MSPG-925FA,

pattern - 65)

- Resolution : 480i Comp1

1080P Comp1

1920*1080 RGB

- Pattern : Horizontal 100% Color Bar Pattern

- Pattern level : 0.7 ± 0.1 Vp-p

- Image

Only for training and service purposes

- 14 -

▪ Com 1,2,3,4 and 115200(Baudrate)

Mode check: Online Only

▪ Check the test process: DETECT → MAC → CI → Widevine

→ ESN

▪ Play: START

▪ Result: Ready, Test, OK or NG

▪ Printer Out (MAC Address Label)

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

3.3. LAN Inspection

3.3.1. Equipment & Condition

▪ Each other connection to LAN Port of IP Hub and Jig

3.3.2. LAN inspection solution

▪ LAN Port connection with PCB

▪ Network setting at MENU Mode of TV

▪ Setting automatic IP

▪ Setting state confirmation

→ If automatic setting is finished, you confirm IP and MAC

Address.

3.4. LAN PORT INSPECTION(PING TEST)

Connect SET → LAN port == PC → LAN Port

SET PC

3.4.1. Equipment setting

(1) Play the LAN Port Test PROGRAM.

(2) Input IP set up for an inspection to Test Program.

*IP Number : 12.12.2.2

3.4.2. LAN PORT inspection(PING TEST)

(1) Play the LAN Port Test Program.

(2) Connect each other LAN Port Jack.

(3) Play Test (F9) button and confirm OK Message.

(4) Remove LAN cable.

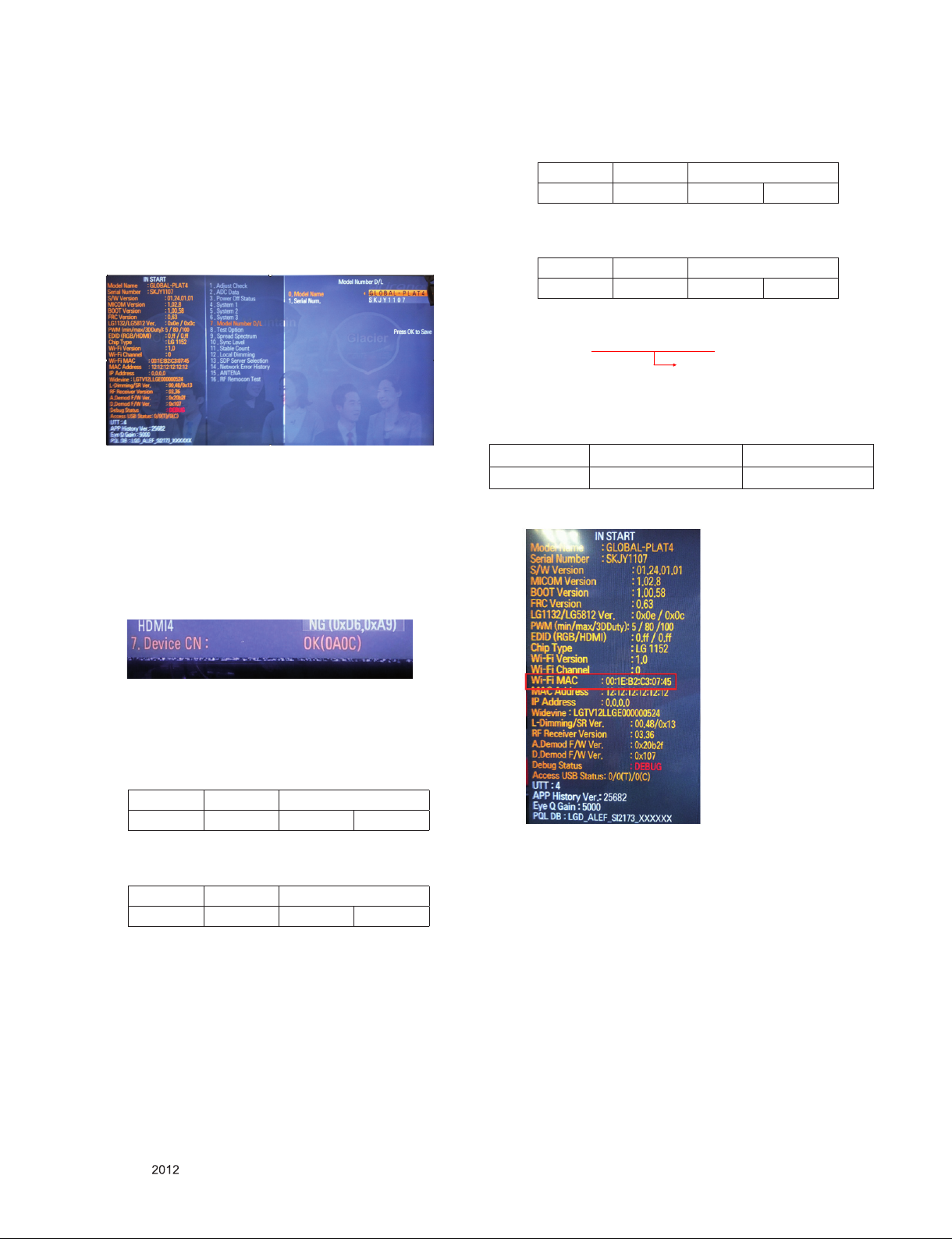

3.3.3. WIDEVINE key Inspection

- Confirm key input data at the "IN START" MENU Mode.

3.5. Model name & Serial number Download

3.5.1. Model name & Serial number D/L

▪ Press "Power on" key of service remote control.

(Baud rate : 115200 bps)

▪ Connect RS232 Signal Cable to RS-232 Jack.

▪ Write Serial number by use RS-232.

▪ Must check the serial number at Instart menu.

3.5.2. Method & notice

(1) Serial number D/L is using of scan equipment.

(2) Setting of scan equipment operated by Manufacturing

Technology Group.

(3) Serial number D/L must be conformed when it is produced

in production line, because serial number D/L is mandatory

by D-book 4.0.

Only for training and service purposes

- 15 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

* Manual Download (Model Name and Serial Number)

If the TV set is downloaded by OTA or service man, sometimes

model name or serial number is initialized.(Not always)

It is impossible to download by bar code scan, so It need

Manual download.

1) Press the "Instart" key of Adjustment remote control.

2) Go to the menu "7.Model Number D/L" like below photo.

3) Input the Factory model name(ex 42LD450-TA) or Serial

number like photo.

4) Check the model name Instart menu. → Factory name

displayed. (ex 47LM960V-ZB)

5) Check the Diagnost ics.(DTV country only) → Buyer

model displayed. (ex 47LM960V-ZB)

3.6. CI+ Key checking method

- Check the Section 4.2

Check whether the key was downloaded or not at ‘In Start’

menu. (Refer to below).

3.6.2. Check the method of CI+ key value(RS232)

1) Into the main ass’y mode(RS232: aa 00 00)

CMD 1 CMD 2 Data 0

A A 0 0

2) Check the mothed of CI+ key by command

(RS232: ci 00 20)

CMD 1 CMD 2 Data 0

C I 2 0

3) Result value

i 01 OK 1d1852d21c1ed5dcx

CI+ Key Value

3.7. WIFI MAC ADDRESS CHECK

(1) Using RS232 Command

H-freq(kHz) V-freq.(Hz)

Transmission [A][I][][Set ID][][20][Cr] [O][K][X] or [NG]

(2) Check the menu on in-start

=> Check the Download to CI+ Key value in LGset.

3.6.1. Check the method of CI+ Key value

(1) Check the method on Instart menu

(2) Check the method of RS232C Command

1) Into the main ass’y mode(RS232: aa 00 00)

CMD 1 CMD 2 Data 0

A A 0 0

2) Check the key download for transmitted command

(RS232: ci 00 10)

CMD 1 CMD 2 Data 0

C I 1 0

3) Result value

- Normally status for download : OKx

- Abnormally status for download : NGx

Only for training and service purposes

- 16 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

4. Manual Adjustment

* ADC adjustment is not needed because of OTP(Auto ADC

adjustment)

▪ Reference

- HDMI1 ~ HDMI4 / RGB

- In the data of EDID, bellows may be different by S/W or

Input mode.

4.1 EDID(The Extended Display Identification

Data)/DDC(Display Data Channel) download

4.1.1. Overview

It is a VESA regulation. A PC or a MNT will display an optimal

resolution through information sharing without any necessity

of user input. It is a realization of "Plug and Play".

4.1.2. Equipment

- Since embedded EDID data is used, EDID download JIG,

HDMI cable and D-sub cable are not need.

- Adjustment remote control

4.1.3. Download method

(1) Press "ADJ" key on the Adjustment remote control then

select "10.EDID D/L", By pressing "Enter" key, enter EDID

D/L menu.

(2) Select "Start" button by pressing "Enter" key, HDMI1/

HDMI2/ HDMI3/ HDMI4/ RGB are writing and display OK

or NG.

For Analog For HDMI EDID

D-sub to D-sub DVI-D to HDMI or HDMI to HDMI

4.1.4. EDID DATA

▪ HDMI(FHD 3D, HDMI 1.4a, 3D)

0x00 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09 0x0A 0x0B 0x0C 0x0D 0x0E 0x0F

0x00 00 FF FF FF FF FF FF 00 1E 6D

ⓒ

0x01

0x02 0F 50 54 A1 08 00 71 40 81 C0 81 00 81 80 95 00

0x03 90 40 A9 C0 B3 00 02 3A 80 18 71 38 2D 40 58 2C

0x04 45 00 A0 5A 00 00 00 1E 66 21 50 B0 51 00 1B 30

0x05 40 70 36 00 A0 5A 00 00 00 1E 00 00 00 FD 00 39

0x06 3F 1F 52 10 00 0A 20 20 20 20 20 20

0x07

0x00 02 03 37 F1 4E 90 1F 04 13 05 14 03 02 12 20 21

0x01 22 15 01 26 15 07 50 09 57 07

0x02

0x03

0x04 2C 45 00 A0 5A 00 00 00 1E 01 1D 80 18 71 1C 16

0x05 20 58 2C 25 00 A0 5A 00 00 00 9E 01 1D 00 72 51

0x06 D0 1E 20 6E 28 55 00 A0 5A 00 00 00 1E 00 00 00

0x07 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 ⓔ2

01 03 80 A0 5A 78 0A EE 91 A3 54 4C 99 26

ⓓ

ⓕ

E3 05 03 01 02 3A 80 18 71 1C 38 2D 40

ⓕ

▪ RGB

0x00 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09 0x0A 0x0B 0x0C 0x0D 0x0E 0x0F

0x00 00 FF FF FF FF FF FF 00 1E 6D

ⓒ

0x01

0x02 0F 50 54 A1 08 00 71 40 81 C0 81 00 81 80 95 00

0x03 90 40 A9 C0 B3 00 02 3A 80 18 71 38 2D 40 58 2C

0x04 45 00 A0 5A 00 00 00 1E 66 21 50 B0 51 00 1B 30

0x05 40 70 36 00 A0 5A 00 00 00 1E 00 00 00 FD 00 3A

0x06 3E 1E 53 10 00 0A 20 20 20 20 20 20

0x07

01 03 68 10 09 78 0A EE 91 A3 54 4C 99 26

ⓓ

ⓐⓓ ⓑ

ⓕ

ⓐ ⓑ

ⓓ

ⓓ

01 ⓔ1

ⓔ3

00

ⓐ Product ID

ⓑ Serial No: Controlled on production line.

ⓒ Month, Year: Controlled on production line:

ex) Monthly : ‘01’ → ‘01’

Year : ‘2012’ → ‘16’

ⓓ Model Name(Hex): LGTV

ⓔ Checksum(LG TV): Changeable by total EDID data.

ⓕ Vendor Specific(HDMI)

# HDMI 1(C/S : 9D BA)

EDID Block 0, Bytes 0-127 [00H-7FH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 01 16 01 03 8 0 A0 5A 78 0A EE 91 A3 54 4 C 99 26

20 0F 50 5 4 A1 08 00 31 40 45 4 0 61 40 71 4 0 81 80

30 01 01 01 01 01 01 0 2 3A 80 18 71 38 2D 40 58 2C

40 45 0 0 A0 5A 00 00 00 1E 66 21 50 B0 51 00 1B 30

50 40 70 36 0 0 A0 5 A 00 00 0 0 1E 00 00 00 FD 00 39

60 3F 1F 52 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 4 3

EDID Block 1, Bytes 128-255 [80H-FFH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 02 03 37 F1 4E 10 9F 04 13 05 14 03 02 12 20 21

10 22 15 01 26 15 07 50 09 57 07 78 03 0C 00 10 00

20 B8 2D 20 C0 0E 01 4F 3F FC 08 10 18 10 06 10 16

30 10 28 10 E3 05 03 01 02 3A 80 18 71 38 2D 40 58

40 2C 45 00 A0 5A 00 00 00 1E 01 1D 80 18 71 1C 16

50 20 58 2C 25 00 A0 5A 00 00 00 9E 01 1D 00 72 51

60 D0 1E 20 6E 28 55 00 A0 5A 00 00 00 1E 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 11

# HDMI 2(C/S : 9D AA)

EDID Block 0, Bytes 0-127 [00H-7FH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 01 16 01 03 80 A0 5A 78 0A EE 91 A3 54 4C 99 26

20 0F 50 54 A1 08 00 31 40 45 40 61 40 71 40 81 80

30 01 01 01 01 01 01 02 3A 80 18 71 38 2D 40 58 2C

40 45 00 A0 5A 00 00 00 1E 66 21 50 B0 51 00 1B 30

50 40 70 36 00 A0 5A 00 00 00 1E 00 00 00 FD 00 39

60 3F 1F 52 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 43

EDID Block 1, Bytes 128-255 [80H-FFH]

0 0 1 2 3 4 5 6 7 8 9 A B C D E F

00 02 03 37 F1 4E 10 9F 04 13 05 14 03 02 12 20 21

10 22 15 01 26 15 07 50 09 57 07 78 03 0C 00 20 00

20 B8 2D 20 C0 0E 01 4F 3F FC 08 10 18 10 06 10 16

30 10 28 10 E3 05 03 01 02 3A 80 18 71 38 2D 40 58

40 2C 45 00 A0 5A 00 00 00 1E 01 1D 80 18 71 1C 16

50 20 58 2C 25 00 A0 5A 00 00 00 9E 01 1D 00 72 51

60 D0 1E 20 6E 28 55 00 A0 5A 00 00 00 1E 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 01

Only for training and service purposes

- 17 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

# HDMI 3(C/S : 9D 9A)

EDID Block 0, Bytes 0-127 [00H-7FH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 01 16 01 03 80 A0 5A 78 0A EE 91 A3 54 4C 99 26

20 0F 50 54 A1 08 00 31 40 45 40 61 40 71 40 81 80

30 01 01 01 01 01 01 02 3A 80 18 71 38 2D 40 58 2C

40 45 00 A0 5A 00 00 00 1E 66 21 50 B0 51 00 1B 30

50 40 70 36 00 A0 5A 00 00 00 1E 00 00 00 FD 00 39

60 3F 1F 52 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 43

EDID Block 1, Bytes 128-255 [80H-FFH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 02 03 37 F1 4E 10 9F 04 13 05 14 03 02 12 20 21

10 22 15 01 26 15 07 50 09 57 07 78 03 0C 00 30 00

20 B8 2D 20 C0 0E 01 4F 3F FC 08 10 18 10 06 10 16

30 10 28 10 E3 05 03 01 02 3A 80 18 71 38 2D 40 58

40 2C 45 00 A0 5A 00 00 00 1E 01 1D 80 18 71 1C 16

50 20 58 2C 25 00 A0 5A 00 00 00 9E 01 1D 00 72 51

60 D0 1E 20 6E 28 55 00 A0 5A 00 00 00 1E 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 F1

# HDMI 4(C/S : 9D 8A)

EDID Block 0, Bytes 0-127 [00H-7FH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 01 16 01 03 80 A0 5A 78 0A EE 91 A3 54 4C 99 26

20 0F 50 54 A1 08 00 31 40 45 40 61 40 71 40 81 80

30 01 01 01 01 01 01 02 3A 80 18 71 38 2D 40 58 2C

40 45 00 A0 5A 00 00 00 1E 66 21 50 B0 51 00 1B 30

50 40 70 36 00 A0 5A 00 00 00 1E 00 00 00 FD 00 39

60 3F 1F 52 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 43

4.2. White Balance Adjustment

4.2.1. Overview

▪ W/B adj. Objective & How-it-works

(1) Objective: To reduce each Panel's W/B deviation

(2) How-it-works : When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic Range. In order to

prevent saturation of Full Dynamic range and data, one

of R/G/B is fixed at 192, and the other two is lowered to

find the desired value.

(3) Adjustment condition : normal temperature

1) Surrounding Temperature : 25 °C ± 5 °C

2) Warm-up time: About 5 Min

3) Surrounding Humidity : 20 % ~ 80 %

4.2.2. Equipment

(1) Color Analyzer: CA-210 (LED Module : CH 14)

(2) Adjustment Computer(During auto adj., RS-232C protocol

is needed)

(3) Adjustment Remote control

(4) Video Signal Generator MSPG-925F 720p/216-Gray

(Model: 217, Pattern: 78)

→ Only when internal pattern is not available

▪ Color Analyzer Matrix should be calibrated using CS-1000.

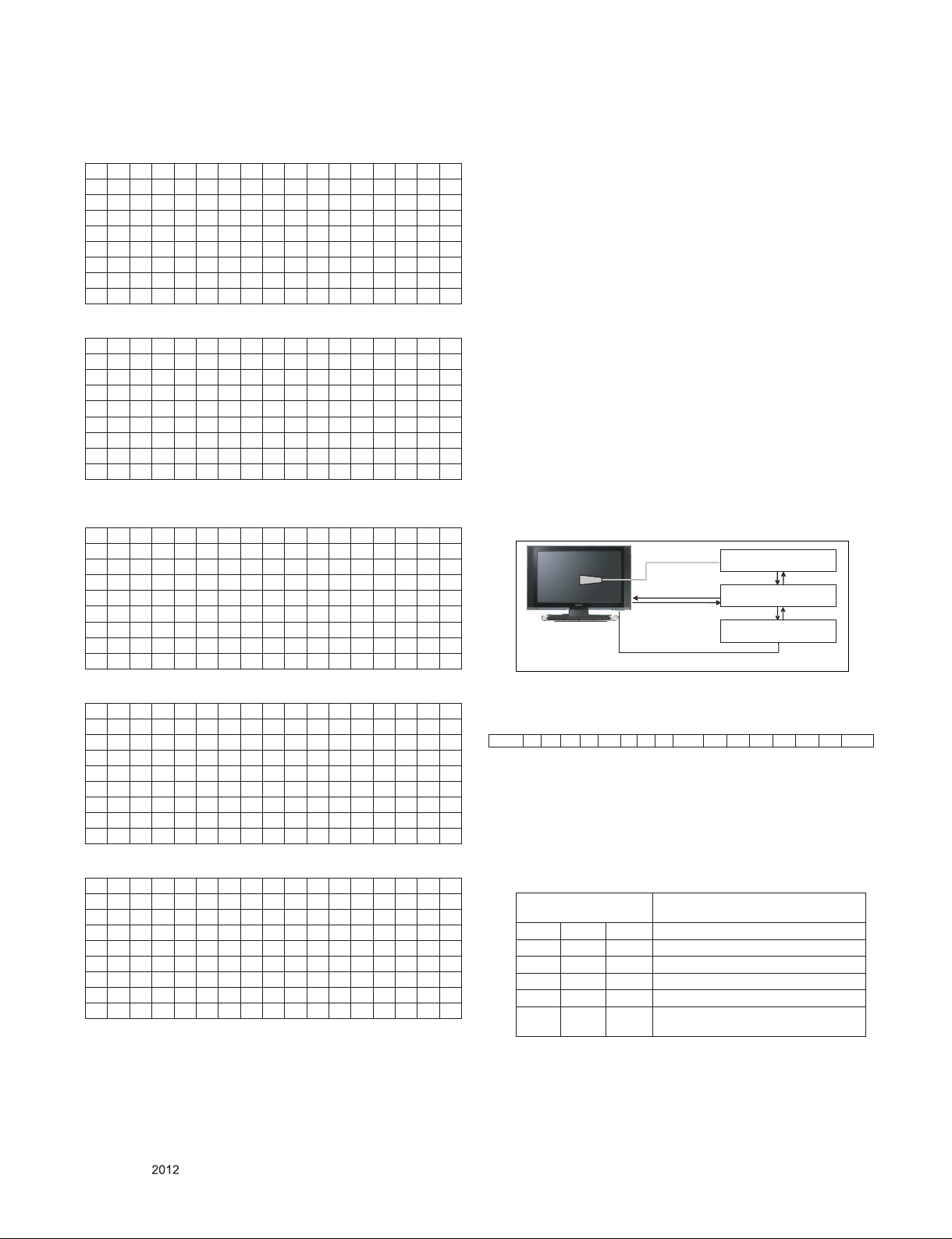

4.2.3. Equipment connection MAP

Co lor Anal yze r

Pro be

RS -232 C

Pattern Gen era to r

Sig nal Sou rce

* If TV internal pattern is used, not needed

RS- 232 C

Co mp ute r

RS- 232 C

EDID Block 1, Bytes 128-255 [80H-FFH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 02 03 37 F1 4E 10 9F 04 13 05 14 03 02 12 20 21

10 22 15 01 26 15 07 50 09 57 07 78 03 0C 00 40 00

20 B8 2D 20 C0 0E 01 4F 3F FC 08 10 18 10 06 10 16

30 10 28 10 E3 05 03 01 02 3A 80 18 71 38 2D 40 58

40 2C 45 00 A0 5A 00 00 00 1E 01 1D 80 18 71 1C 16

50 20 58 2C 25 00 A0 5A 00 00 00 9E 01 1D 00 72 51

60 D0 1E 20 6E 28 55 00 A0 5A 00 00 00 1E 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 E1

# RGB(C/S : 97)

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 01 16 01 03 68 A0 5A 78 0A EE 91 A3 54 4C 99 26

20 0F 50 54 A1 08 00 31 40 45 40 61 40 71 40 81 80

30 01 01 01 01 01 01 02 3A 80 18 71 38 2D 40 58 2C

40 45 00 A0 5A 00 00 00 1E 66 21 50 B0 51 00 1B 30

50 40 70 36 00 A0 5A 00 00 00 1E 00 00 00 FD 00 3A

60 3E 1E 53 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 00 5C

4.2.4. Adj. Command (Protocol)

<Command Format>

START 6E A 50 A LEN A 03 A CMD A 00 A VAL A CS STOP

- LEN: Number of Data Byte to be sent

- CMD: Command

- VAL: FOS Data value

- CS: Checksum of sent data

- A: Acknowledge

Ex) [Send: JA_00_DD] / [Ack: A_00_okDDX]

▪ RS-232C Command used during auto-adjustment.

RS-232C COMMAND

[CMD ID DATA]

wb 00 00 Begin White Balance adjustment

wb 00 10 Gain adjustment(internal white pattern)

wb 00 1f Gain adjustment completed

wb 00 20 Offset adjustment(internal white pattern)

wb 00 2f Offset adjustment completed

wb 00 ff

End White Balance adjustment

(internal pattern disappears )

Explantion

Only for training and service purposes

- 18 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Ex) wb 00 00 -> Begin white balance auto-adj.

wb 00 10 -> Gain adj.

ja 00 ff -> Adj. data

jb 00 c0

...

...

wb 00 1f → Gain adj. completed

*(wb 00 20(Start), wb 00 2f(end)) → Off-set adj.

wb 00 ff → End white balance auto-adj.

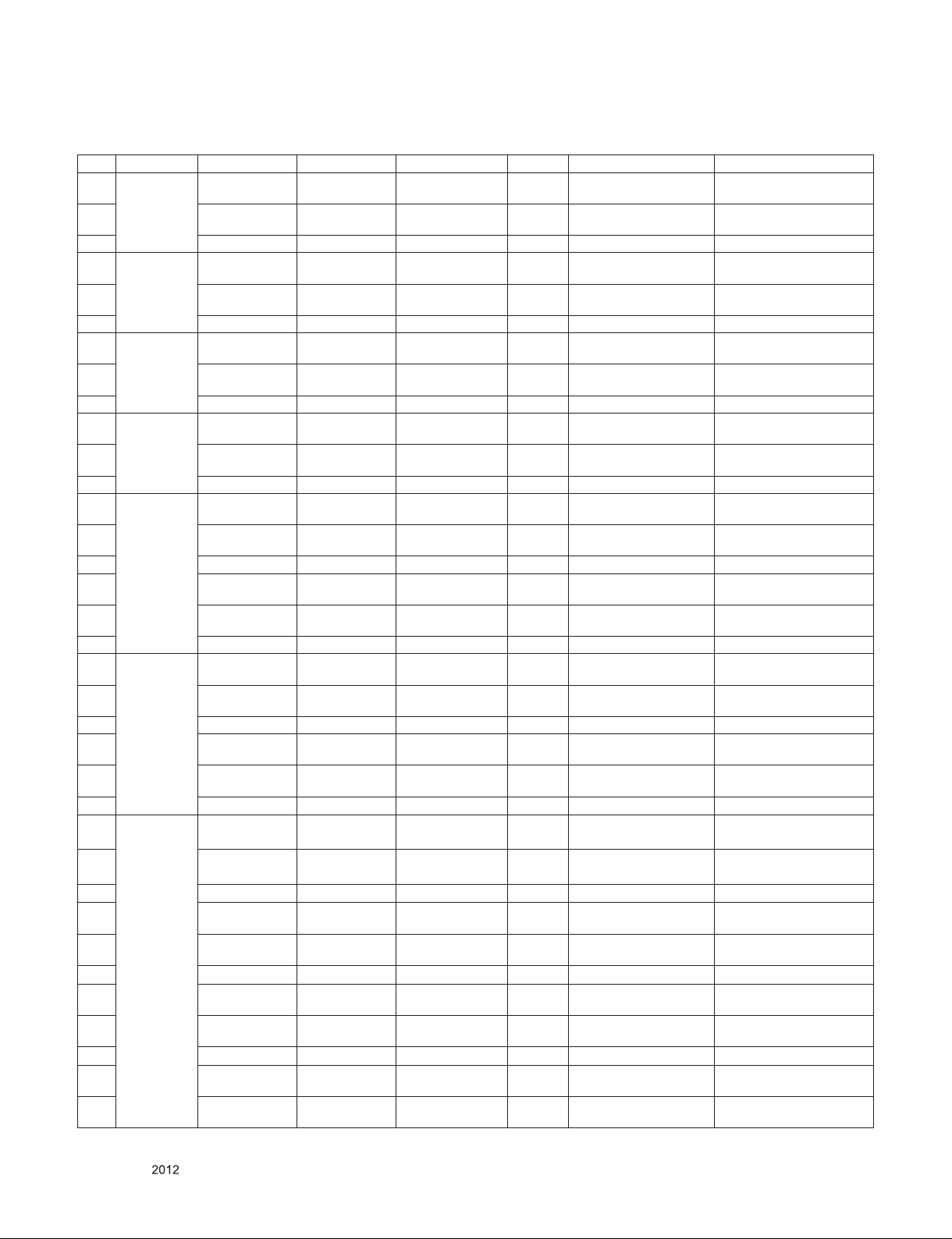

▪ Adj. Map

Cool

Medium

Warm

Adj. item

R Gain j g 00 C0

G Gain j h 00 C0

B Gain j i 00 C0

R Cut

G Cut

B Cut

R Gain j a 00 C0

G Gain j b 00 C0

B Gain j c 00 C0

R Cut

G Cut

B Cut

R Gain j d 00 C0

G Gain j e 00 C0

B Gain j f 00 C0

R Cut

G Cut

Command

(lower caseASCII)

CMD1 CMD2 MIN MAX

Data Range

(Hex.)

4.2.5. Adj. method

(1) Auto adj. method

1) Set TV in adj. mode using POWER ON key.

2) Zero calibrate probe then place it on the center of the

Display.

3) Connect Cable.(RS-232C to USB)

4) Select mode in adj. Program and begin adj.

5) When adj. is complete (OK Sign), check adj. status pre

mode. (Warm, Medium, Cool)

6) Remove probe and RS-232C cable to complete adj.

▪ W/B Adj. must begin as start command “wb 00 00” , and

finish as end command “wb 00 ff”, and Adj. offset if need.

(2) Manual adjustment. method

1) Set TV in Adj. mode using POWER ON.

2) Zero Calibrate the probe of Color Analyzer, then place it

on the center of LCD module within 10 cm of the

surface.

3) Press ADJ key → EZ adjust using adj. R/C → 7. WhiteBalance then press the cursor to the right(key ►).

(When right key(►) is pressed 216 Gray internal pattern

will be displayed)

4) One of R Gain / G Gain / B Gain should be fixed at 192,

and the rest will be lowered to meet the desired value.

5) Adjustment is performed in COOL, MEDIUM, WARM 3

modes of color temperature.

▪ If internal pattern is not available, use RF input. In EZ

Adj. menu 7.White Balance, you can select one of 2

Test-pattern: ON, OFF. Default is inner(ON). By selecting

OFF, you can adjust using RF signal in 216 Gray pattern.

Default

(Decimal)

▪ Adjustment condition and cautionary items

1) Lighting condition in surrounding area

Surrounding lighting should be lower 10 lux. Try to

isolate adj. area into dark surrounding.

2) Probe location

: Color Analyzer(CA-210) probe should be within 10 cm

and perpendicular of the module surface (80° ~ 100°)

3) Aging time

- After Aging Start, Keep the Power ON status during 5

Minutes.

- In case of LCD, Back-light on should be checked

using no signal or Full-white pattern.

4.2.6. Reference (White balance Adj. coordinate and

color temperature)

▪ Luminance : 216 Gray

▪ Standard color coordinate and temperature using CS-1000

(over 26 inch)

Mode

Coordinate

x y

Temp ∆uv

Cool 0.269 0.273 13000 K 0.0000

Medium 0.285 0.293 9300 K 0.0000

Warm 0.313 0.329 6500 K 0.0000

▪ Standard color coordinate and temperature using CA-210(CH 18)

Mode

Coordinate

x y

Temp ∆uv

Cool 0.269 ± 0.002 0.273 ± 0.002 13000 K 0.0000

Medium 0.285 ± 0.002 0.293 ± 0.002 9300 K 0.0000

Warm 0.313 ± 0.002 0.329 ± 0.002 6500K 0.0000

4.2.7. ALELF & EDGE LED White balance table

- EDGE LED module change color coordinate because of

aging time.

- Apply under the color coordinate table, for compensated

aging time.

- ALEF(55LM960*)

GP4

Aging

time

(Min)

1 20 282 298 298 318 319 344

2 21-25 280 296 296 316 317 342

3 26-30 279 294 295 314 316 340

4 31-35 277 292 293 312 314 338

5 36-40 276 290 292 310 313 336

6 41-50 275 288 291 308 312 334

7 51-80 272 284 288 304 309 330

8 81-119 271 282 287 302 308 328

9 Over 120 270 281 286 301 307 327

Cool Medium Warm

X y x y x y

269 273 285 293 313 329

Only for training and service purposes

- 19 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

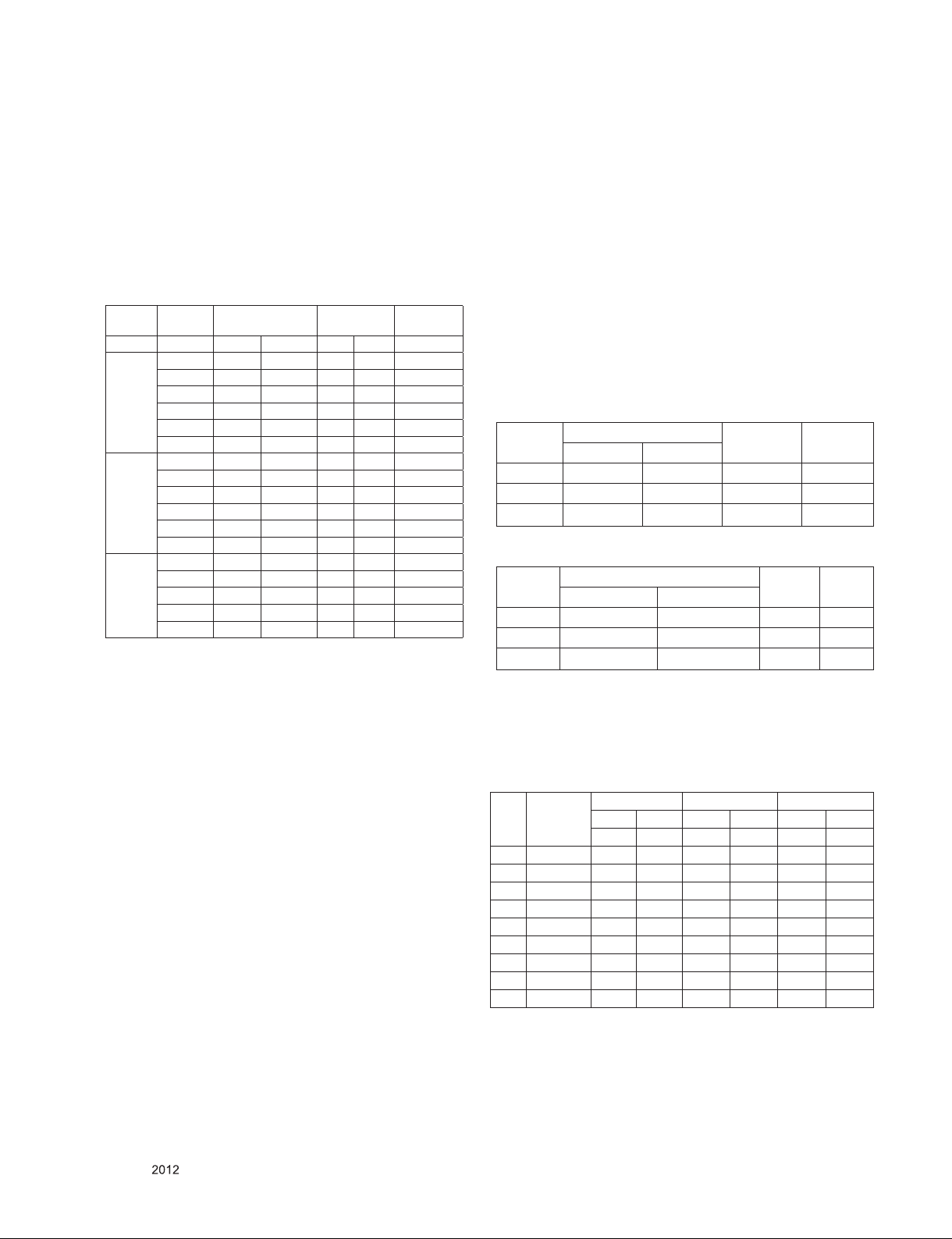

4.3. EYE-Q function check

(1) Turn on TV.

(2) Press EYE key of Adjustment remote control.

(3) Cover the Eye Q II sensor on the front of the using your

hand and wait for 6 seconds.

(4) Confirm that R/G/B value is lower than 10 of the "Raw

Data (Sensor data, Back light)". If after 6 seconds, R/G/B

value is not lower than 10, replace Eye Q II sensor.

G

(5) Remove your hand from the Eye Q II sensor and wait for 6

seconds.

4.4. Local Dimming Function Check

Step 1) Turn on TV.

Step 2) At the Local Dimming mode, module Edge Backlight

moving right to left Back light of IOP module moving.

Step 3) Confirm the Local Dimming mode.

Step 4) Press "exit" key.

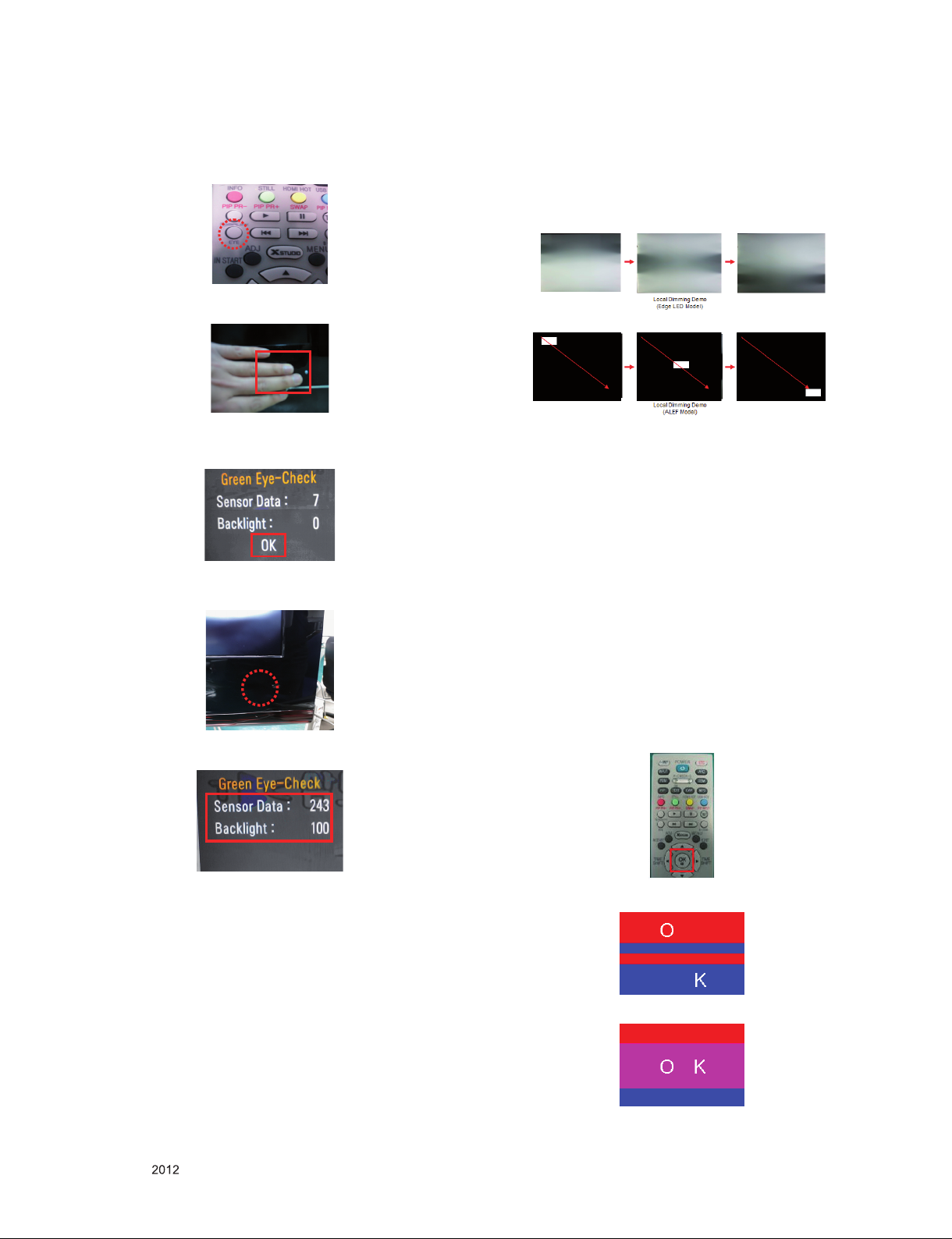

4.5. Magic Motion Remote control test

(1) Equipment : RF Remote control for test, IR-KEY-Code

Remote control for test

(2) You must confirm the battery power of RF-Remote control

before test(recommend that change the battery per every lot)

(3) Sequence (test)

1) if you select the "Start(Mute)" key on the Adjustment

remote control, you can pairing with the TV SET.

2) You can check the cursor on the TV Screen, when select

the "OK" key on the Adjustment remote control.

3) You must remove the pairing with the TV Set by select

"OK" key + "Mute" key on the Adjustment remote control

for 5 seconds.

(6) Confirm that "ok" pop up. If change is not seen, replace

Eye Q II sensor.

4.6. 3D function test

(Pattern Generator MSHG-600, MSPG-6100[Support HDMI1.4])

* HDMI mode NO. 872 , pattern No.83

(1) Please input 3D test pattern like below.

(2) When 3D OSD appear automatically, then select OK key.

(3) Don't wear a 3D Glasses, check the picture like below.

Only for training and service purposes

- 20 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

4.7. Wi-Fi Test

Step 1) Turn on TV

Step 2) Select Network Connection option in Network Menu.

Step 3) Select Start Connection button in Network Connection.

Step 4) If the system finds any AP like blow PIC, it is working

well.

4.9. Inspection of light scattering

▪ Test Method

(1) Push “Power only” key.

(2) Push “HDMI” hot key.

(3) Inspect whether light scattering is occurred in internal

black pattern or not.

(4) Push “Power only” key.

4.10. Option selection per country

4.10.1. Overview

- Option selection is only done for models in Non-EU

4.10.2. Method

(1) Press ADJ key on the Adj. R/C, then select Country Group

Meun

(2) Depending on destination, select Country Group Code 04

or Country Group EU then on the lower Country option,

select US, CA, MX. Selection is done using +, - or ►◄

key.

4.8. LNB voltage and 22KHz tone check

(only for DVB-S/S2 model)

▪ Test method

(1) Set TV in Adj. mode using POWER ON.

(2) Connect cable between satellite ANT and test JIG.

(3) Press Yellow key(ETC+SWAP) in Adj Remote control to

make LNB on.

(4) Check LED light ‘ON’ at 18 V menu.

(5) Check LED light ‘ON’ at 22 KHz tone menu.

(6) Press Blue key(ETC+PIP INPUT) in Adj Remote control

to make LNB off.

(7) Check LED light ‘OFF’ at 18 V menu.

(8) Check LED light ‘OFF’ at 22 KHz tone menu.

▪ Test result

(1) After press LNB On key, ‘18 V LED’ and ‘22 KHz tone

LED’ should be ON.

(2) After press LNB OFF key, ‘18 V LED’ and ‘22 KHz tone

LED’ should be OFF.

Only for training and service purposes

4.11. MHL Test

(1) Turn on TV

(2) Select HDMI4 mode using input Menu.

(3) Set MHL Zig(M1S0D3617) using MHL input, output and

power cord.

(4) Connect HDMI cable between MHL Zig and HDMI4 port.

(5) Check LED light of Zig and Module of Set.

Result) If, The LED light is green and The Module shows

- 21 -

normal stream → OK, Else → NG

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

5. Tool Option selection

▪ Method : Press "ADJ" key on the Adjustment remote control,

then select Tool option.

6. Ship-out mode check(In-stop)

▪ After final inspection, press "IN-STOP" key of the Adjustment

remote control and check that the unit goes to Stand-by

mode.

7. GND and Internal Pressure check

7.1. Method

(1) GND & Internal Pressure auto-check preparation

- Check that Power cord is fully inserted to the SET.

(If loose, re-insert)

(2) Perform GND & Internal Pressure auto-check

- Unit fully inserted Power cord, Antenna cable and A/V

arrive to the auto-check process.

- Connect D-terminal to AV JACK TESTER

- Auto CONTROLLER(GWS103-4) ON

- Perform GND TEST

- If NG, Buzzer will sound to inform the operator.

- If OK, changeover to I/P check automatically.

(Remove CORD, A/V form AV JACK BOX.)

- Perform I/P test

- If NG, Buzzer will sound to inform the operator.

- If OK, Good lamp will lit up and the stopper will allow the

pallet to move on to next process.

7.2. Checkpoint

▪ TEST voltage

- GND: 1.5 KV / min at 100 mA

- SIGNAL: 3 KV / min at 100 mA

▪ TEST time: 1 second

▪ TEST POINT

- GND TEST = POWER CORD GND & SIGNAL CABLE

METAL GND

- Internal Pressure TEST = POWER CORD GND & LIVE &

NEUTRAL

▪ LEAKAGE CURRENT: At 0.5 mArms

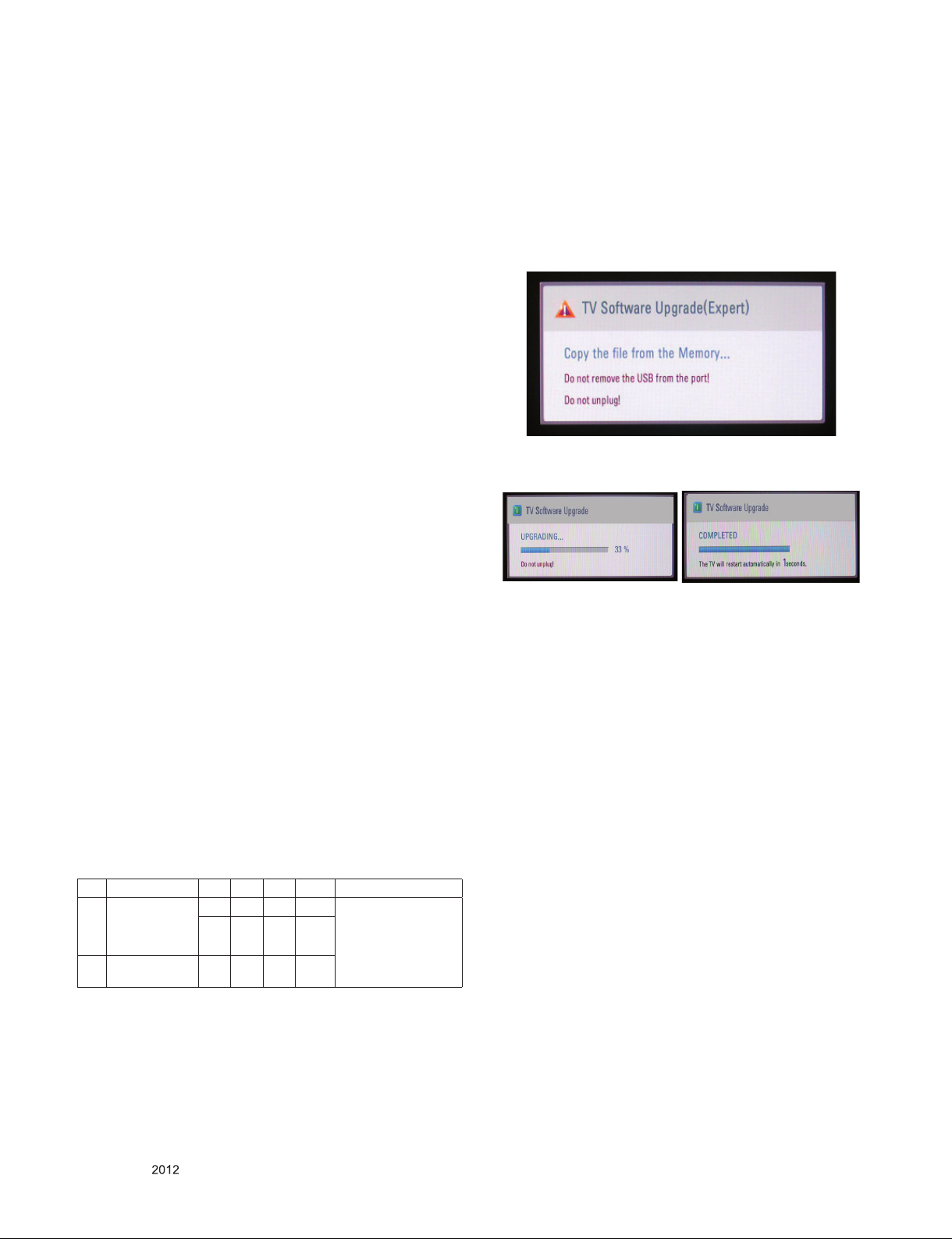

9. USB S/W Download(Service only)

(1) Put the USB Stick to the USB socket.

(2) Automatically detecting update file in USB Stick.

- If your downloaded program version in USB Stick is Low,

it didn't work. But your downloaded version is High, USB

data is automatically detecting.(Download Version High &

Power only mode, Set is automatically Download)

(3) Show the message "Copying files from memory".

(4) Updating is starting.

(5) Updating Completed, The TV will restart automatically.

(6) If your TV is turned on, check your updated version and

Tool option. (explain the Tool option, next stage)

* If downloading version is more high than your TV have, TV

can lost all channel data. In this case, you have to channel

recover. if all channel data is cleared, you didn’t have a DTV/

ATV test on production line.

* After downloading, have to adjust Tool Option again.

(1) Push "IN-START" key in service remote control.

(2) Select "Tool Option 1" and push "OK" key.

(3) Punch in the number. (Each model has their number)

8. Audio

No. Item Min Typ Max Unit Remark

Audio practical

max Output, L/R

1.

(Distortion=10%

max Output)

Speaker (8Ω

2.

Impedance)

Measurement condition:

(1) RF input: Mono, 1 KHz sine wave signal, 100 % Modulation

(2) CVBS, Component: 1 KHz sine wave signal 0.5 Vrms

(3) RGB PC: 1 KHz sine wave signal 0.7 Vrms

Only for training and service purposes

9.0 10.0 12.0 W

8.5 8.9 9.8 Vrms

10.0 15.0 W

Measurement condition

Auto Volume :Off

Audio EQ : Off

Clear Voice : Off

Virtual Surround:Off

- 22 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

400

EXPLODED VIEW

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essenti al that these special safet y parts shoul d be replac ed with the same compo nents as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

700

710

570

920

860

830

820

910

521

540

LV1

560

510

900

122

530

121

810

120

500

200D

850

501

541

840

AG2

AG1

Dual Play

200

300

Only for training and service purposes

- 23 -

A10

A2

A5

A22

* Set + Stand

A21

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

* Stand Base + Body

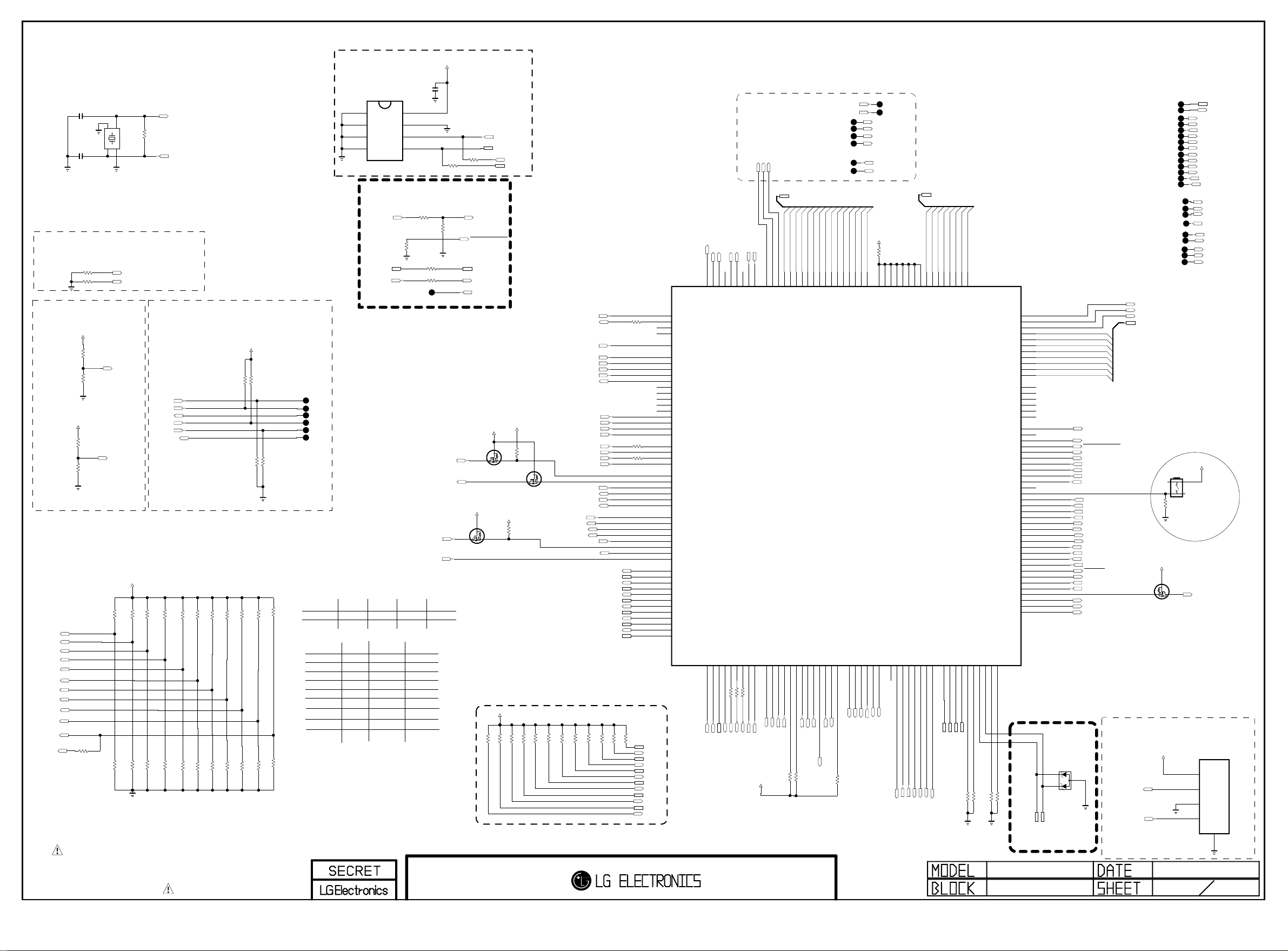

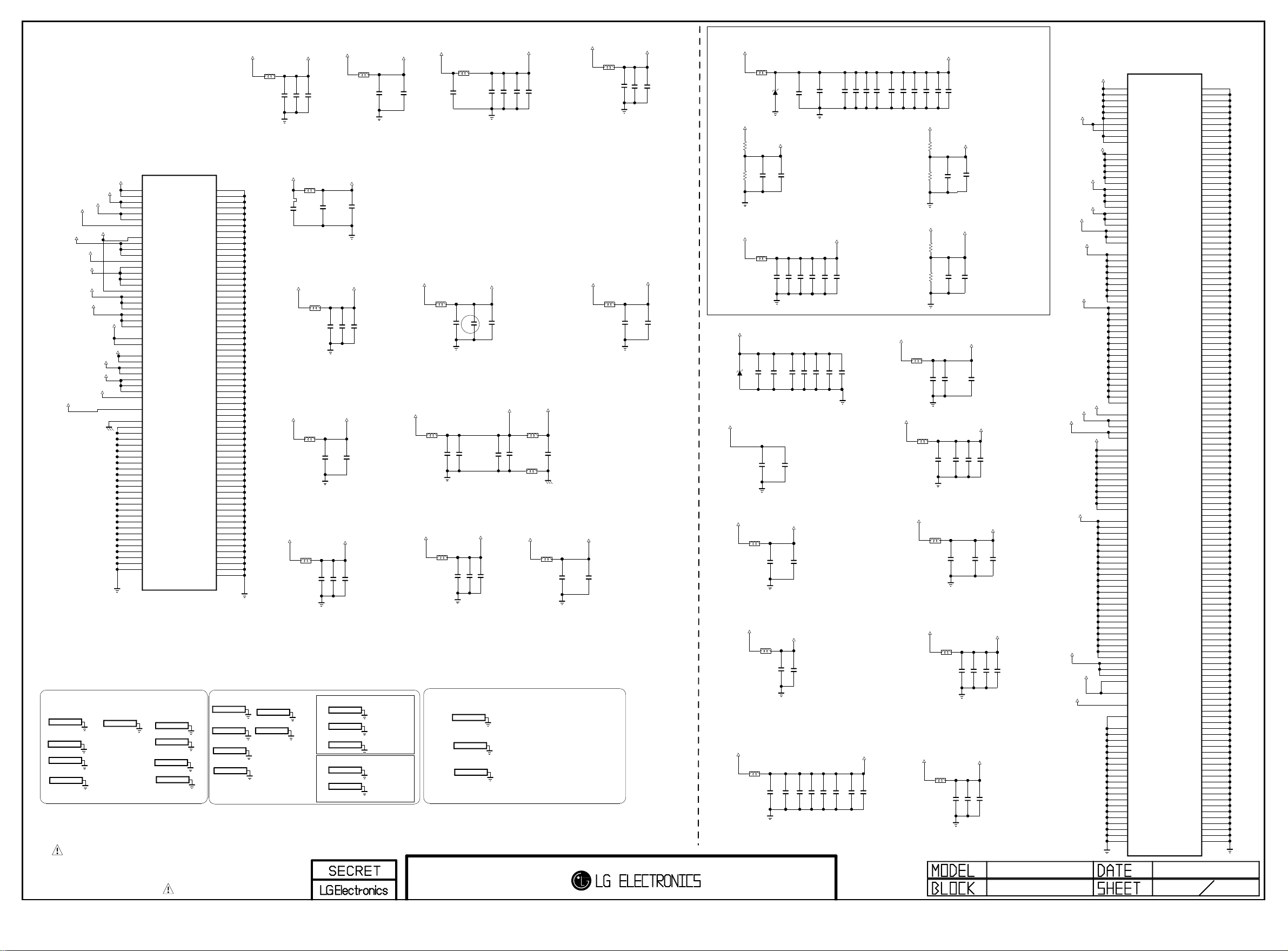

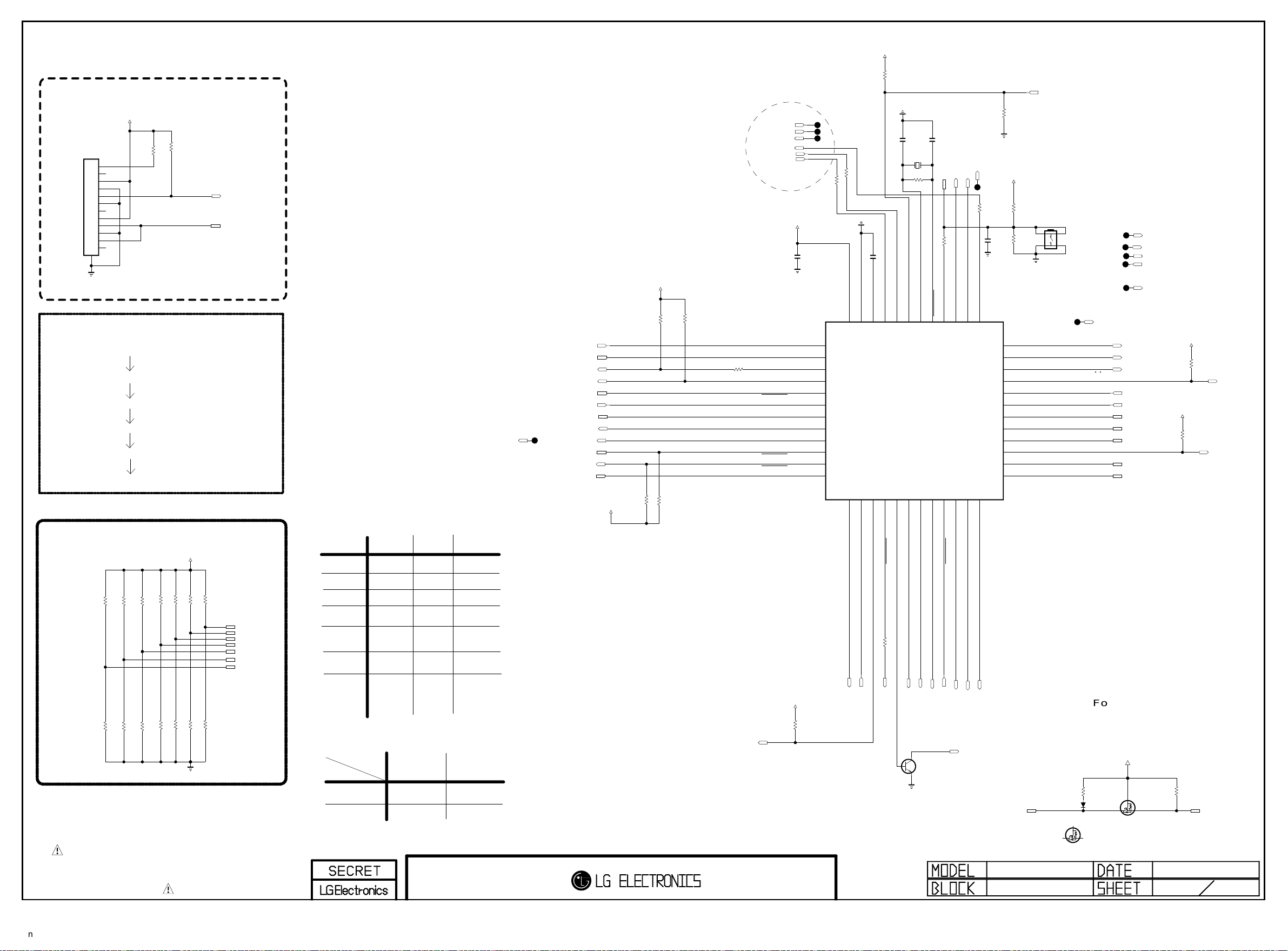

System Configuration

Copyright © 2012 LG Electronics. Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

NVRAM

Clock for LG1152

MAIN Clock(24Mhz)

C100

8pF

50V

X-TAL_1

GND_1

1

2

X101

24MHz

4

3

C101

8pF

50V

GND_2

X-TAL_2

PLL SET[1:0] ==> Internal Pull-UP. N.C is high

00 : CPU clock(1056Mhz), Main0,1/2 DDR (792/792 Mhz)

01 : CPU clock(792Mhz), Main0,1/2 DDR (672/792 Mhz)

10 : CPU clock(1152Mhz), Main0,1/2 DDR (792/672 Mhz)

11 : CPU clock(984Mhz), Main0,1/2 DDR (792/792 Mhz)

BOOT MODE

"11" or "01" : NOR

"10" : eMMC

"00" : NAND

OPT

R102 22

R103 22

OPT

+3.3V_NORMAL

4.7K

R187

4.7K

R185

OPT

PLLSET1

PLLSET0

BOOT_MODE1

BOOT_MODE1

+3.3V_NORMAL

4.7K

R188

OPT

R186

BOOT_MODE0

4.7K

R112

1M

TRST_N0

SOC_RESET

TDI0

TDO0

TMS0

TCK0

XIN_MAIN

XO_MAIN

JTAG I/F FOR MAIN

+3.3V_NORMAL

OPT

OPT

R131 10K

R132 10K

OPT

R133 10K

OPT

R134 10K

BOOT_MODE0

+3.3V_NORMAL

HW_OPT_0

HW_OPT_1

HW_OPT_2

HW_OPT_3

HW_OPT_4

HW_OPT_5

HW_OPT_6

HW_OPT_7

HW_OPT_8

HW_OPT_9

HW_OPT_10

HP_AMP_MUTE

BackEnd 1

BackEnd 2

Pannel Resol

OPTIC I/F

3D Depth IC

DDR Size

CP BOX

FrontEnd 1

FrontEnd 2

OPT

22

R117

10K

URSA5

R110

FRC_EXTERNAL

R100 10K

10K

FRC3

FRC_INTERNAL

R107 10K

R111

FHD

R124 10K

UD

R125 10K

OPTIC

R138 10K

NON_OPTIC

R139 10K

OPT

3D_DEPTH

R140 10K

R145 10K

1GByte

R141 10K

R146 10K

NON_3D DEPTH

CP_BOX

R152 10K

R147 10K

DVB_T2_TUNER

NON_CP_BOX

R153 10K

R148 10K

NON_DVB_T2_TUNER

DVB_S_TUNER

R156 10K

R154 10K

DVB_C2_TUNER

R158 10K

R155 10K

NON_DVB_S_TUNER

NON_DVB_C2_TUNER

ZORAN_FRC

R121 10K

NOT_ZORAN_FRC

R126 10K

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_2

MODEL_OPT_3

MODEL_OPT_4

MODEL_OPT_5

MODEL_OPT_6

MODEL_OPT_7

MODEL_OPT_8

MODEL_OPT_9

MODEL_OPT_10

Zoran FRC

MODEL OPTION 8 is just for CP Box

It should not be appiled at MP

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

IC102

R1EX24256BSAS0A

A0

1

2

3

4

A0’h

8

7

6

5

A1

A2

VSS

Place to LVDS Wafer

FRC_RESET

I2C_SCL1

SoC

internal

NO_FRC

FRC

0

0 1

1

HIGH

FHD

OPTIC

3D DEPTH

3D_Depth_IC

DDR Reserved

CP BOX

Enable

T2 Tuner

Support

S Tuner

Support

Support

C2 Tuner

Support

(For UD)

C111

0.1uF

VCC

WP

SCL

SDA

R151 22

4.7K

R113

R160 22

R162 22

MHL_DET

HDMI_INT

LG FRC3

10

0

LOW

UD

NON_OPTIC

NON_3D_Depth_IC

DDR_Default

Disable

Not Support

Not Support

Not Support

Not Support

+3.3V_NORMAL

Write Protection

- Low : Normal Operation

- High : Write Protection

R143

OPT

22

10K

R170

SOC_RX

SOC_TX

2N7002K

URSA5

1

R142

OPT

22

FRC3_RESET

3D_DEPTH_RESET

I2C_BE_SDA1I2C_SDA1

I2C_BE_SCL1

LOCAL_DIM_EN

+5V_NORMAL

G

D

Q100

2N7002K

+5V_NORMAL

G

S

D

Q105

OPT

+3.3V_NORMAL

R178

2.2K

I2C_SCL5

I2C_SDA5

I2C_SCL3

I2C_SDA3

+3.3V_NORMAL

S

+3.3V_NORMAL

R203

100K

R180

3.3K

R179

2.2K

OPT

R181

100K

2N7002K

3.3K

R202

G

S

D

Q103

I2C PULL UP

R182

2.2K

R195

2.2K

SOC_RESET

BOOT_MODE1

BOOT_MODE0

ERROR_OUT

/USB_OCD2

/USB_OCD3

M_REMOTE_RX

M_REMOTE_TX

IRB_SPI_MISO

IRB_SPI_MOSI

IRB_SPI_CK

IRB_SPI_SS

AV1_CVBS_DET

DTV_ATV_SELECT

R196

3.3K

R197

3.3K

XIN_MAIN

XO_MAIN

TRST_N0

TMS0

TCK0

TDI0

TDO0

PLLSET1

PLLSET0

EPHY_INT

UART1_RX

UART1_TX

R198

3.3K

I2C_SCL1

I2C_SDA1

I2C_SCL2

I2C_SDA2

I2C_SCL3

I2C_SDA3

I2C_SCL4

I2C_SDA4

I2C_SCL5

I2C_SDA5

I2C_SCL6

I2C_SDA6

R199

3.3K

R150 22

R101

R184

R183

1.2K

R104 560

1%

BOOT_MODE1

BOOT_MODE0

1.2K

22

I2C_SDA1

I2C_SCL1

I2C_SDA2

I2C_SCL2

I2C_SDA3

I2C_SCL3

I2C_SDA4

I2C_SCL4

I2C_SDA5

I2C_SCL5

I2C_SDA6

I2C_SCL6

A22

XIN_MAIN

B22

XO_MAIN

AB16

OPM1

AB17

OPM0

AE3

PORES_N

V23

TRST_N0

U25

TMS0

V25

TCK0

V24

TDI0

U24

TDO0

Y22

TRST_N1

AA22

TMS1

AB20

TCK1

AB21

TDI1

W22

TDO1

AB9

PLLSET1

AB8

PLLSET0

AB15

BOOT_MODE1

AB14

BOOT_MODE0

Y23

EXT_INTR3/GPIO48

W25

EXT_INTR2/GPIO63

W24

EXT_INTR1/GPIO62

W23

EXT_INTR0/GPIO61

Y5

UART0_RX/GPIO49

W6

UART0_TX/GPIO50

AA6

UART1_RX

Y6

UART1_TX

AB5

UART2_RX

AA5

UART2_TX

AB23

SPI_DI0/GPIO39

AB24

SPI_DO0/GPIO38

AA25

SPI_SCLK0/GPIO37

AB25

SPI_CS0/GPIO36

Y25

SPI_DI1/GPIO35

AA23

SPI_DO1/GPIO34

Y24

SPI_SCLK1/GPIO33

AA24

SPI_CS1/GPIO32

AB6

SCL0/GPIO60

AB4

SDA0/GPIO59

AC5

SCL1/GPIO58

AC4

SDA1/GPIO57

AD4

SCL2/GPIO56

AE4

SDA2/GPIO71

AE5

SCL3/GPIO70

AD5

SDA3/GPIO69

AE6

SCL4/GPIO68

AD6

SDA4/GPIO67

AC6

SCL5/GPIO66

AC7

SDA5/GPIO65

FPGA_LVDS_INFO

USB_CTL3

DiiVA_POD_CTL

M25

M24

M23

N23

T27

EB_CS3/GPIO64

EB_CS2/GPIO79

EB_CS1/GPIO78

EB_CS0/GPIO77

RMII_REF_CLK

RMII_CRS_DV

RMII_MDIO

RMII_MDC

AD2

AB1

AB2

AB3

AC2

R105 22

EPHY_MDC

EPHY_MDIO

EPHY_REFCLK

EPHY_CRS_DV

for DiiVA(China)

SEL_USB3

SEL_USB2

SEL_USB1

EB_OE_N

EB_BE_N1

EB_BE_N0

EB_WE_N

T28

U27

U26

U28

J22

K22

EB_OE_N

EB_WE_N

EB_WAIT

EB_BE_N1

EB_BE_N0

EB_ADDR17/GPIO84

EB_ADDR16/GPIO83

LG1152D-B1

RMII_TXEN

RMII_TXD1

RMII_TXD0

RMII_RXD1

RMII_RXD0

CAM_CE1_N

CAM_CE2_N

AC3

AE1

AD3

AD1

W26

V28

R108 22

R106 22

/PCM_CE2

EPHY_TXD1

EPHY_TXD0

EPHY_RXD1

+3.3V_NORMAL

/PCM_CE1

EPHY_RXD0

EPHY_EN

EB_ADDR[0-14]

EB_ADDR[11]

EB_ADDR[12]

EB_ADDR[13]

EB_ADDR[14]

J23

L26

L27

L25

N26

N27

EB_ADDR14

EB_ADDR13

EB_ADDR12

EB_ADDR11

EB_ADDR15/GPIO82

CAM_CD1_N

CAM_CD2_N

CAM_VS1_N

CAM_VS2_N

CAM_IREQ_N

Y27

Y26

W28

W27

AA28

AB26

CAM_CD2_N

CAM_CD1_N

CAM_IREQ_N

CI

CI

10K

R166

R167 10K

EB_ADDR[9]

EB_ADDR[7]

EB_ADDR[8]

EB_ADDR[6]

EB_ADDR[10]

M26

L28

L24

L23

K28

EB_ADDR9

EB_ADDR8

EB_ADDR7

EB_ADDR6

EB_ADDR10

IC100

CAM_RESET

CAM_INPACK_N

CAM_VCCEN_N

CAM_WAIT_N

CAM_REG_N

Y28

V27

V26

AA27

AA26

PCM_RST

CAM_REG_N

CAM_WAIT_N

CAM_INPACK_N

PCM_5V_CTL

HP_DET

EPHY_INT

EB_ADDR[3]

EB_ADDR[2]

EB_ADDR[5]

EB_ADDR[4]

K27

K26

K25

EB_ADDR5

EB_ADDR4

EB_ADDR3

CAM_IOIS16_N

SC_CLK/GPIO90

R25

U23

SMARTCARD_CLK

CI

10K

R168

SEL_USB1

SEL_USB2

SEL_USB3

/RST_PHY

SC_DET

DiiVA_POD_CTL

+3.3V_NORMAL

EB_ADDR[1]

EB_ADDR[0]

10K

R109

K24

K23

V22

U22

T22

EB_ADDR2

EB_ADDR1

EB_ADDR0

EB_DATA15

EB_DATA14

SC_DETECT/GPIO93

SC_VCCEN/GPIO89

SC_VCC_SEL/GPIO88

SC_RST/GPIO91

SC_DATA/GPIO92

T25

T24

T23

R24

C22

SMARTCARD_RST

SMARTCARD_VCC

SMARTCARD_DET

SMARTCARD_DATA

SMARTCARD_PWR_SEL

R22

P22

N22

M22

L22

EB_DATA9

EB_DATA8

EB_DATA13

EB_DATA12

EB_DATA11

EB_DATA10

SD_CLK/GPIO76

SD_CMD/GPIO73

SD_CD_N/GPIO75

SD_WP_N/GPIO74

SD_DATA3/GPIO72

SD_DATA2/GPIO87

C23

A23

B23

A24

B24

MOTOR_CW

MOTOR_CCW

MOTOR_CLOSE_SW

MO_SENS_TO_MAIN_UP

MO_SENS_TO_MAIN_DOWN

EB_DATA[0-7]

EB_DATA[0]

EB_DATA[1]

EB_DATA[3]

EB_DATA[2]

EB_DATA[4]

EB_DATA[5]

EB_DATA[6]

EB_DATA[7]

T26

R28

R27

R26

P28

P27

P26

N28

EB_DATA7

EB_DATA6

EB_DATA5

EB_DATA4

EB_DATA3

EB_DATA2

EB_DATA1

EB_DATA0

EMMC_RST

EMMC_CLK

EMMC_CMD

EMMC_DATA7

EMMC_DATA6

EMMC_DATA5

EMMC_DATA4

EMMC_DATA3

EMMC_DATA2

EMMC_DATA1

EMMC_DATA0

NAND_CS1

NAND_CS0

NAND_ALE

NAND_CLE

NAND_REN

NAND_WEN

GPIO31

GPIO30

GPIO29

GPIO28

GPIO27

GPIO26

GPIO25

GPIO24

GPIO23

GPIO22

GPIO21

GPIO20

GPIO19

GPIO18

GPIO17

GPIO16

GPIO15

GPIO14

GPIO13

GPIO12

GPIO11

GPIO10

GPIO9

GPIO8

GPIO7

GPIO6

GPIO5

GPIO4

GPIO3

GPIO2

GPIO1

GPIO0

SD_DATA1/GPIO86

SD_DATA0/GPIO85

USB_DP1

USB_DM1

USB_DP2

USB_DM2

USB_TXR_RKL

USB_ANALOGTEST

BT_USB_DP

BT_USB_DM

BT_TXR_RKL

BT_ANALOGTEST

R173

Y4

C25

B25

AA1

AA2

AA4

22

22

OPT

OPT

R175

R176

R174

C24

A25

B27

USB_HUB_IC_IN_DP

IR_B_RESET

MOTOR_OPEN_SW

A27

A26

B26

USB_DM3

USB_DP3

USB_HUB_IC_IN_DM

Place near Jack side

LG1152 B1

E28

F27

F26

C26

EMMC_DATA[7]

E27

EMMC_DATA[6]

E26

EMMC_DATA[5]

D27

EMMC_DATA[4]

D28

EMMC_DATA[3]

C27

EMMC_DATA[2]

C28

EMMC_DATA[1]

D26

EMMC_DATA[0]

R23

P24

N25

P23

N24

P25

AC1

V7

W5

W4

V6

V5

V4

U6

U5

U4

T6

T5

T4

R6

R5

R4

P6

P5

P4

N6

N5

N4

N3

M6

AC23

AC24

AE24

AD23

AE23

AC22

AD22

AE22

WIFI_DP

WIFI_DM

MAIN & GPIO

OPT

RCLAMP0502BA

D100

OPTIC_FPGA_RESET

OPTIC_SERDES_RESET

3D_DEPTH_RESET

/RST_PHY

OLED_TCON_RESET

HW_OPT_9

HW_OPT_7

HW_OPT_8

DSUB_DET

SC_DET

COMP1_DET

HW_OPT_5

HW_OPT_6

M_RFModule_ISP

HW_OPT_10

M_RFModule_RESET

FRC_RESET

HW_OPT_2

HW_OPT_1

HW_OPT_0

HW_OPT_4

FLASH_WP

/RST_HUB

HW_OPT_3

HP_DET

RF_SWITCH_CTL

/TU_RESET

/S2_RESET

UART1_RX

UART1_TX

EMMC_RST

EMMC_CLK

EMMC_CMD

EMMC_DATA[0-7]

JTP-1127WEM

1/16W

5%

+5V_NORMAL

S

Q104

2N7002K

Debug

+3.3V_NORMAL

+3.3V_NORMAL

SW1

4 3

R201

2.7K

G

D

1

SMARTCARD_DATA

SMARTCARD_RST

SMARTCARD_PWR_SEL

SMARTCARD_VCC

SMARTCARD_DET

SMARTCARD_CLK

MOTOR_CLOSE_SW

MOTOR_OPEN_SW

MOTOR_CW

MOTOR_CCW

MO_SENS_TO_MAIN_UP

MO_SENS_TO_MAIN_DOWN

12

For ISP

Delete PV

DEBUG

HDMI_S/W_RESET

12507WS-04L

I2C_SDA2

I2C_SCL2

OPTIC_FPGA_RESET

OPTIC_SERDES_RESET

OLED_TCON_RESET

FPGA_LVDS_INFO

IRB_SPI_MISO

IRB_SPI_MOSI

IRB_SPI_CK

IRB_SPI_SS

IR_B_RESET

P100

1

DEBUG

2

3

4

5

+1.0V_VDD