LG 520SI, CB550BN ADJUSTMENT

ADJUSTMENT

- 12 -

GENERAL INFORMATION

All adjustment are thoroughly checked and corrected

when the monitor leaves factory, but sometimes several

minor adjustment may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

• Alignment appliances and tools.

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- E(E)PROM with each mode data saved.

- Digital Voltmeter.

- White Balance Meter.

- Luminance Meter.

ADJUSTMENT PROCEDURE & METHOD

Set Contrast ( ) and Brightness ( ) volume to max

position.

1. Adjustment for B+Voltage

1) Display cross hatch pattern at Mode 1.

2)

Adjust VR901 to 14±0.2Vdc at D922 cathode voltage.

2. Adjustment for High Voltage

1) Display cross hatch pattern at Mode 1.

2)

Adjust D804 cathode voltage to 63±0.2Vdc with VR801.

3. Adjustment for Screen Image (Factory Mode)

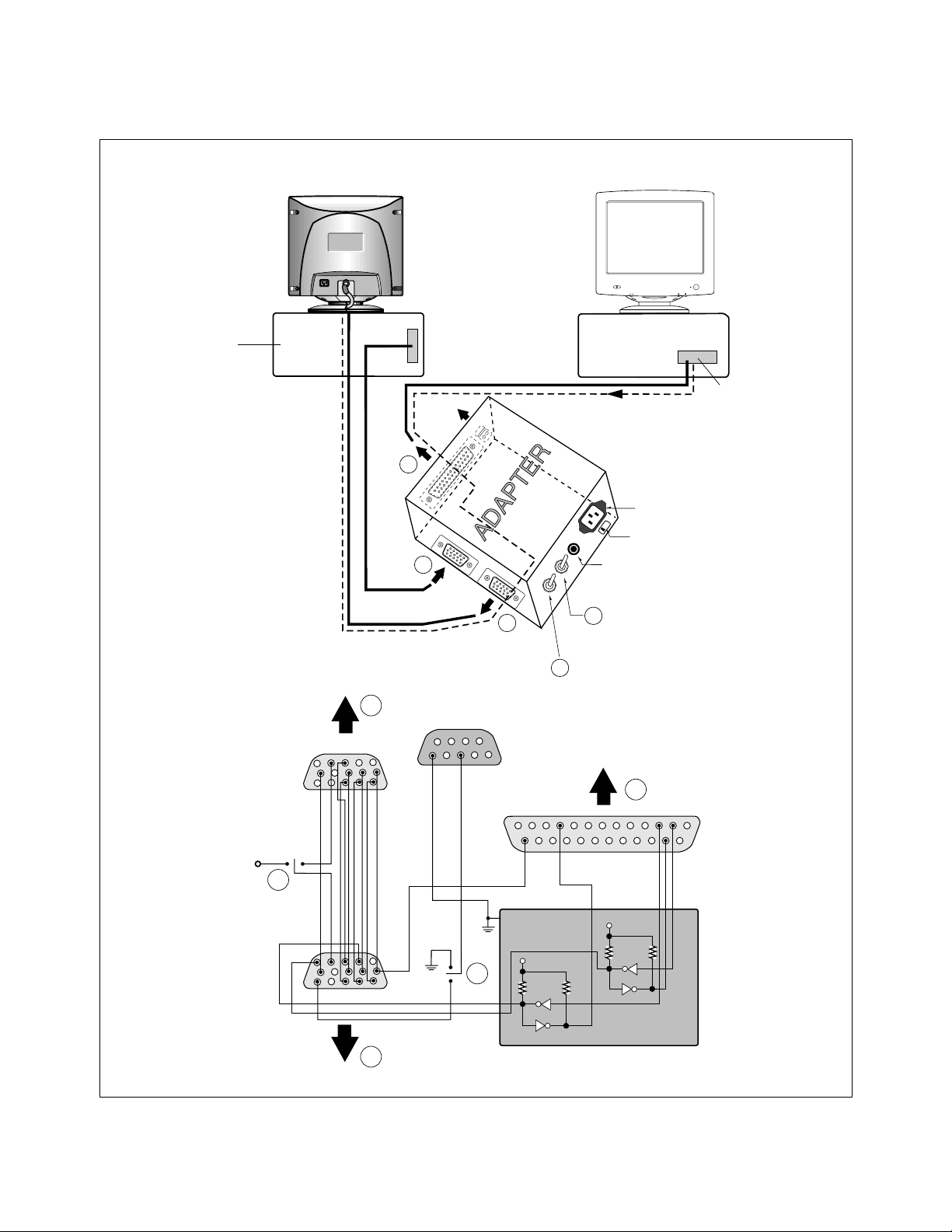

Install adaptor and cable for adjustment such as figure 1

and run alignment program on DOS for IBM compatible

PC.

1) Set ST Switch to OFF of the adaptor.

(Refer to see Figure 1.)

2) Display cross hatch pattern at Mode 1.

3) Adjust horizontal size ( ) with H-SIZE in the

alignment program or +, – buttons on the monitor to

270

±1mm.

4) Adjust horizontal position ( ) with H-POSI in the

alignment program or +, – buttons on the monitor to

center of the screen.

5) Adjust vertical size ( ) with V-SIZE in the

alignment program or +, – buttons on the monitor to

195

±1mm.

6) Adjust vertical position ( ) with V-POSI in the

alignment program or +, – buttons on the monitor to

center of the screen.

7) Adjust side-pincushion ( ) with S-PCC in the

alignment program or +, – buttons on the monitor to

be the best condition.

8) Adjust trapezoid ( ) with TRAPEZOID in the

alignment program or +, – buttons on the monitor to

be the best condition.

9) Display from Mode 2 to Mode 5 and repeat above

adjustment.

4. Adjustment for White Balance and Luminance.

1) Set the White Balance Meter.

2) Demagnetize CDT with the demagnetizer. (external

degaussing coil).

3) Adjust H x V size to 270

±2mm x 195±2mm.

4) Display color 0,0 pattern at Mode 1.

5) Set Brightness ( ), Contrast ( ) volume to

max position.

6) Set VR302 (G-BIAS) and VR312 (R-BIAS) to min

and VR322 (B-BIAS) to center position.

7) Adjust Screen control on the FBT to 0.9~1FL of the

raster luminance.

8) Adjust VR302 (G-BIAS) and VR312(R-BIAS) to

x=0.283

±0.01 and y=0.298±0.01.

9) Adjust Screen control on the FBT to 0.3~0.4FL of the

raster luminance.

10)

Display color 15,0 box pattern (70 x 70mm) at Mode 1.

11)

Set Brightness ( ), Contrast ( ) volume to

max position.

12)

Adjust VR311 (G-DRIVE) to 55±1FL of the box

pattern luminance.

13)

Adjust VR301 (R-DRIVE) and VR321 (B-DRIVE) to

x=0.283

±0.003 and y=0.298±0.003.

14)

Set Brightness ( ), Contrast ( ) volume to

max position.

15)

Display color 15,0 full white patten at Mode 1.

16)

Adjust VR503 (ABL) to 33±1FL of the luminance.

5. Adjustment for Focus.

1) Display H character in the full screen at Mode 4.

2) Adjust two Focus control on the FBT that should be

the best condition.

E

- 13 -

Video

Figure 1. CABLE CONNECTION

Signal Generator

Monitor to be

adjusted

Control Line

C

PARALLEL

A

Not used

VGS

RS232C

MONITOR

ST

V-SYNC

IBM

Compatible PC

220

POWER

Power LED

Parallel Port

Power inlet (required)

Power Select Switch

(110V/220V)

5V

15

5

OFF ON

F

E

B

F

ST Switch

V-Sync On/Off Switch

(Switch must be ON.)

A

69

5

10

11

6

1

ON

OFF

1

C

13

25

5V

4.7K

E

5V

4.7K

74LS06

4.7K

74LS06

1

14

B

Loading...

Loading...