Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PA02B

MODEL : 50PX950 50PX950-AA

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

Printed in Korea

P/NO : MFL63289209(1008-REV00)

Page 2

- 2 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

CONTENTS

CONTENTS ............................................................................................................................... 2

SAFETY PRECAUTIONS...........................................................................................................3

SPECIFICATION.........................................................................................................................4

ADJUSTMENT INSTRUCTION..................................................................................................6

BLOCK DIAGRAM....................................................................................................................11

EXPLODED VIEW ..................................................................................................................12

SVC. SHEET ................................................................................................................................

Page 3

- 3 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect

an electrical jumper across the two AC plug prongs. Place the

AC switch in the on position, connect one lead of ohm-meter to

the AC plug prongs tied together and touch other ohm-meter

lead in turn to each exposed metallic parts such as antenna

terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

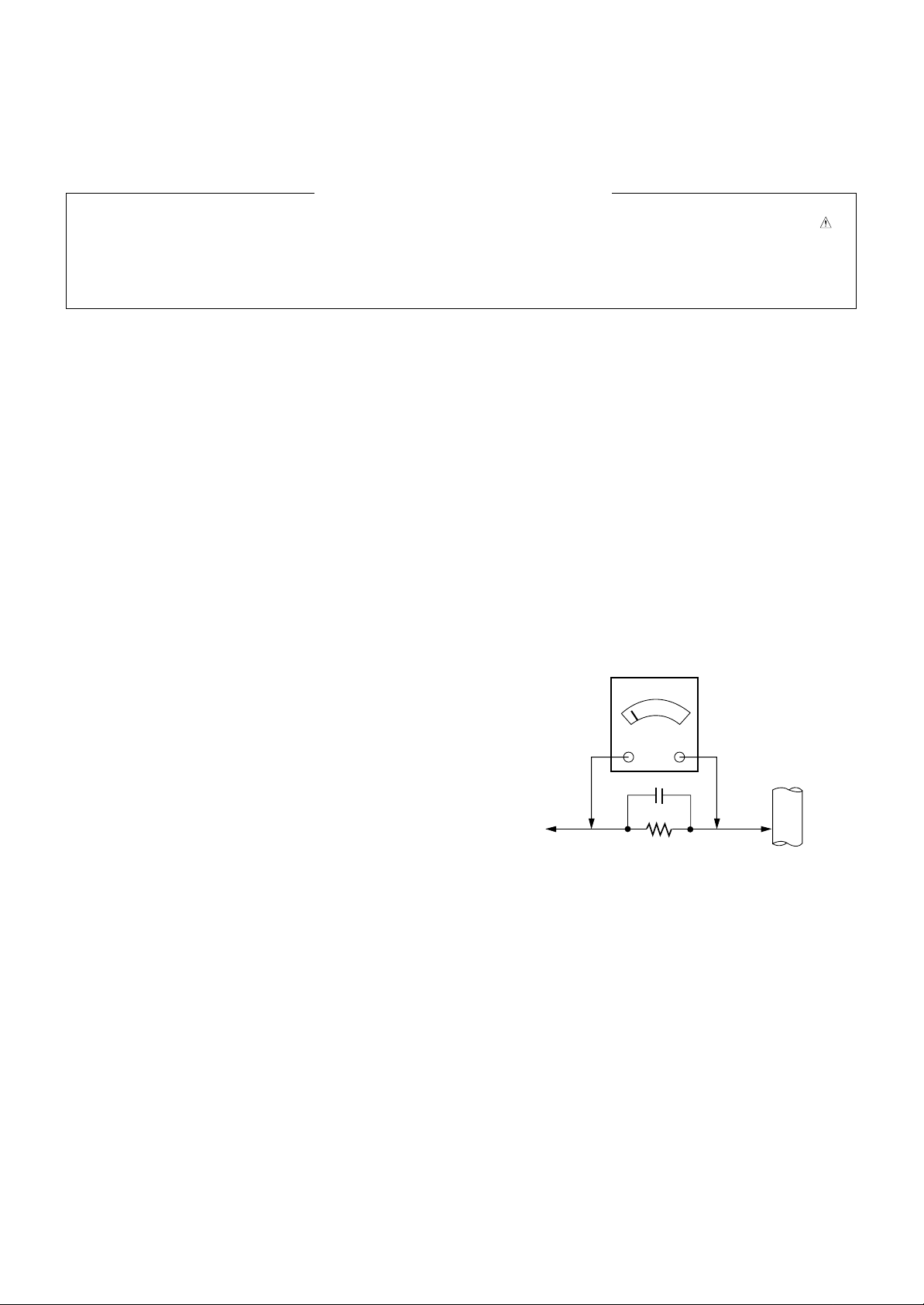

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to PDP TV used PA02B Chassis.

V Specification

Each part is tested as below without special appointment.

(1) Temperature : 25 °C ± 5 °C (77 °F ± 9 °F), CST : 40 ± 5

(2) Relative Humidity: 65 % ± 10 %

(3) Power Voltage: Standard Input voltage (100 V - 240 V ~, 50 / 60 Hz)

* Standard Voltage of each product is marked by models.

(4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with

SBOM.

(5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

(1) Performance : LGE TV test method followed.

(2) Demanded other specification

Safety: CE, IEC specification

EMC : CE, IEC

V Module Specification

(1) 50” 3D FHD

50PX950-AA Australia, New Zealand LG

Model Name Market Place Brand

Model Name

50PX950-AA

Remark

Safety : IEC/ EN60065, EMI : CISPR13

Market

Australia, New Zealand

No Item Specification Remark

1 Display Screen Device 127 cm (50 inch) wide Color Display Module PDP

2 Aspect Ratio 16:9

3 PDP Module PDP50R103##,

RGB Closed (Well) Type, Glass Filter (43%) 3D module

Pixel Format: 1920 horiz. By 1080 ver.

4 Operating Environment 1) Temp. : 0 deg ~ 40 deg

2) Humidity : 20 % ~ 80% LGE SPEC

5 Storage Environment 3) Temp. : -20 deg ~ 60 deg

4) Humidity : 10 % ~ 90 %

6 Input Voltage AC 100 V ~ 240 V, 50 / 60 Hz Maker LG

Page 5

- 5 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

V Model General Specification

No Item Specification Remark

1 Market 50/60PX950-AA New Zealand, Austrailia *DTV Region:

Australia/New Zealand(AU),

2 Broadcasting system 1) PAL/SECAM-B/G/D/K Australia, India : only PAL

2) PAL-I/II, Singapore : Except NTSC M

3) NTSC M ATV market : Except DVB-T

4) DVB-T

3 Receiving system Analog : Upper Heterodyne

Digital : COFDM

4 Video Input (2EA) PAL, SECAM, NTSC

5 Component Input (2EA) Y/Cb/Cr, Y/ Pb/Pr

6 RGB Input RGB-PC Analog (D-Sub 15Pin)

7 HDMI Input (4EA) HDMI-PC HDMI1/DVI 1,2,3,4

HDMI-DTV Upper 70 tool, But under 60 tool HDMI 3EA.

8 Audio Input (5 EA) RGB/DVI Audio, Component, AV L/R Input

9 SPDIF Out(1 EA) SPDIF Out

10 USB(2.0) For SVC, S/W Download, X-Studio, DivX

11 Bluetooth Bluetooth Phone(JPEG, MP3), Profile : A2DP,BIP,FTP,GAVDP,HSP, OPP

Bluetooth Headset(mono, stereo) Only 50/60PK*50R-TA

12 Ethernet LAN

Page 6

- 6 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Range

This spec sheet is applied to all of the PA02B chassis.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25 °C ± 5 °C of temperature and 65 % ± 10 % of relative

humidity if there is no specific designation.

(4) The input voltage of the receiver must keep 100 V ~ 240

V, 50 / 60 Hz.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment when module is in the circumstance of over

15 °C

- In case of keeping module is in the circumstance of 0 °C,

it should be placed in the circumstance of above 15 °C

for 2 hours

- In case of keeping module is in the circumstance of below

-20 °C, it should be placed in the circumstance of above

15 °C for 3 hours,.

O After RGB Full White in HEAT-RUN Mode, the receiver

must be operated prior to the adjustment.

O Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

- Set is activated HEAT run without signal generator in this

mode.

- Single color pattern ( WHITE ) of HEAT RUN MODE uses

to check panel.

- Caution : If you turn on a still screen more than 20

minutes (Especially digital pattern, cross hatch pattern),

an after image may be occur in the black level part of the

screen.

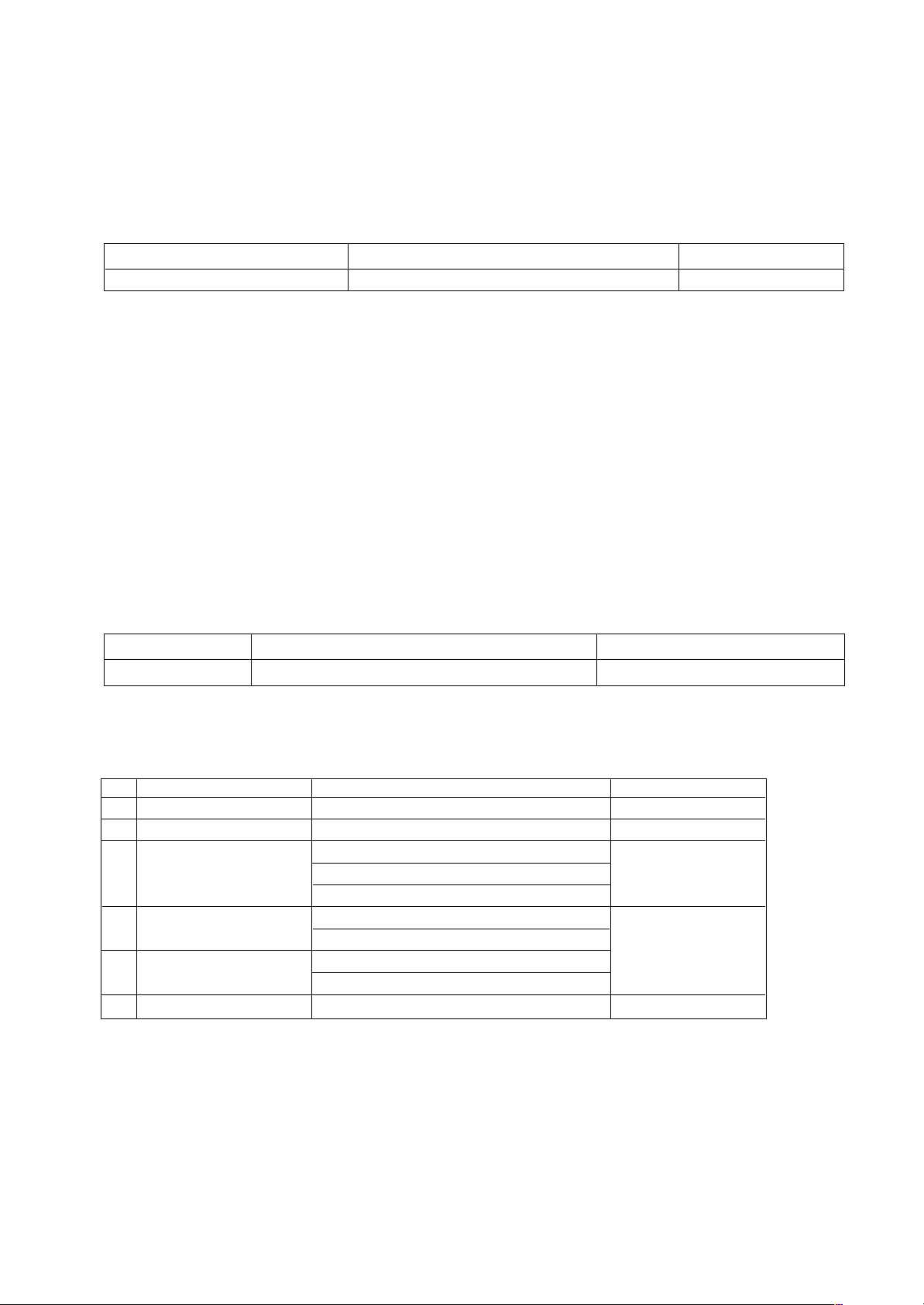

3. MAC Address.

* Connect TV SET and PC which download MAC Address

Writing program by RS232C-Cable

(1) Start “MAC+CIKeyl.exe”Program and Click (3) Button to

connect TV and PC.

(2) Click (4) to download MAC Address.

(3) When download succeed, you can see “OK” on (6)

* Each Chassis has it’ own MAC Address. Please be careful of

download.

3-2. Ping TEST

* This test is to check Network operation.

(1) Press "Po w e r on" butt o n of a s e rvice R/C.(Baud rate :

115200 bps)

(2) Connect RS232-C Signal Cable.

(3). Connect LAN cable to MAIN PCB Assembly.

(4) When network operates normally, you can see “OK”.

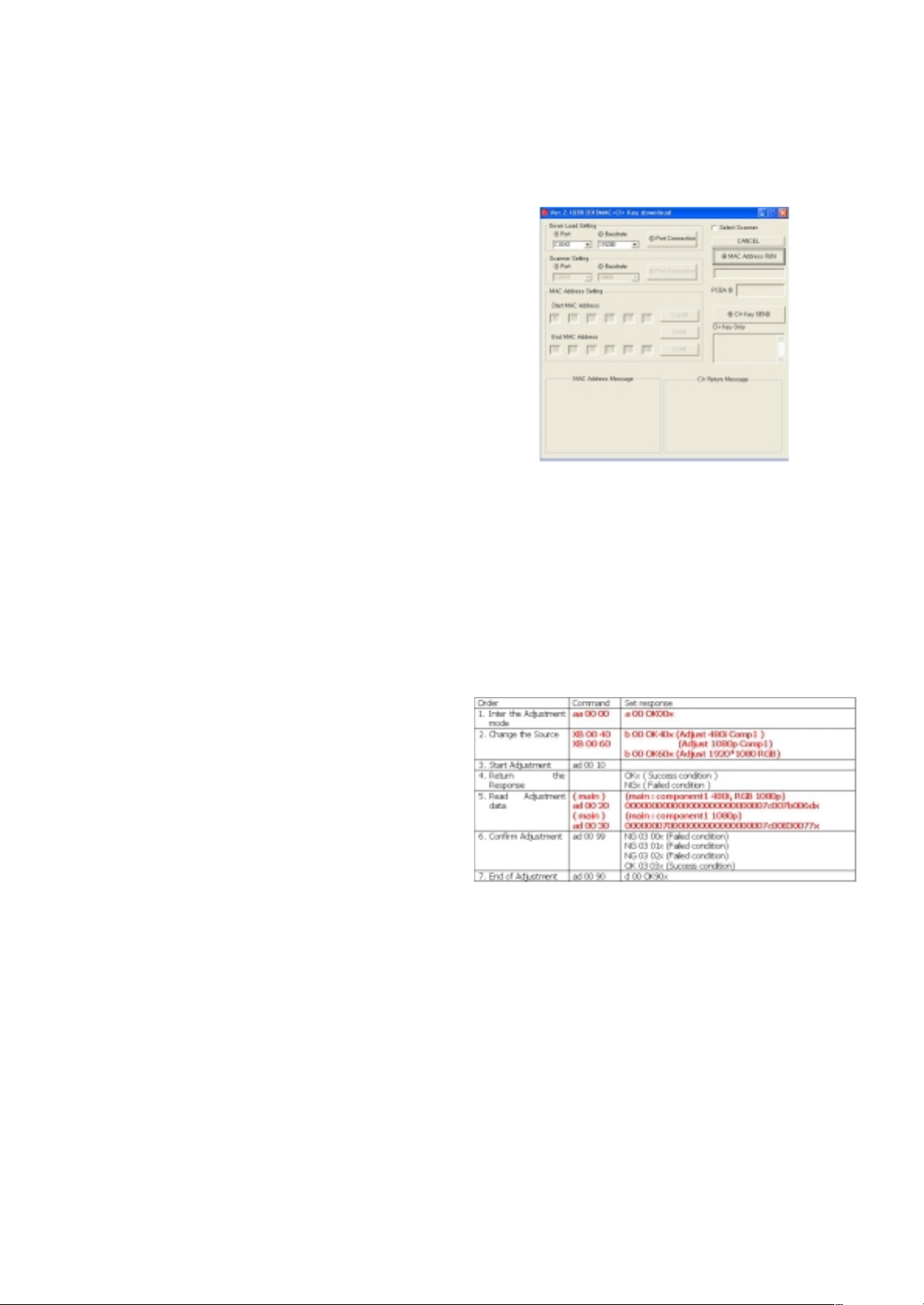

3-3. ADC Adjustment

O Auto-control adjustment protocol(RS-232C)

Page 7

(1) Adjustment of RGB

1) Convert to PC in Input-source.

2) Signal equipment displays

Output Voltage: 700 mVp-p

Impress Resolution XGA (1920 x 1080 @ 60Hz)

Model : 225 in Pattern Generator

Pattern : 65 in Pattern Generator

(MSPG-925 SERISE)

3) Adjust by commanding AUTO_COLOR_ADJUST

(2) COMPONENT input ADC

V Convert to Component in Input-source.

V Signal equipment displays

Impress Resolution 480i

MODEL: 209 in Pattern Generator(480i Mode)

PATTERN : 65 in Pattern Generator

(MSPG-925 SERISE)

Impress Resolution 1080i

MODEL: 225 in Pattern Generator(1080P Mode)

PATTERN: 65 in Pattern Generator

(MSPG-925 SERISE)

3-4. Insert Tool OPTION

and Model Name download.

(1) Press IN_START key on R/C to insert Tool OPTION

(2) On the “ Tool Option ”, Insert Tool Option by a number key

(3) Press the ENTER(

V)

(4) Press ENTER(

V) again.

(5) Select “OK to Download” by using

F/G(VOL +/-) and press

G(VOL +)

1) 50/60PX950-AA

3-5. EDID(The Extended Display

Identification Data) download

(1) Press the ADJ KEY on R/C and enter EZ ADJUST.

(2) Select “5.EDID D/L” by using

D/E(CH +/-) and press

ENTER(

V).

(3) Select “Start” and press navigation key(

G).

(4) EDID download is executed automatically.

(5) Press EXIT key on R/C

* Caution

- Never connect HDMI & D-sub Cable when the user

download EDID .

V Use the proper cables below for EDID Writing.

* Edid data and Model option download(RS232)

* EDID DATA

(1) Analog RGB

- 7 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

Model Tool Tool Tool Tool Tool

Name Value 1 Value 2 Value 3 Value 4 Value 5

50PX950-AA 37536 31831 54920 24940 2866

60PX950-AA 49824

Page 8

- 8 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

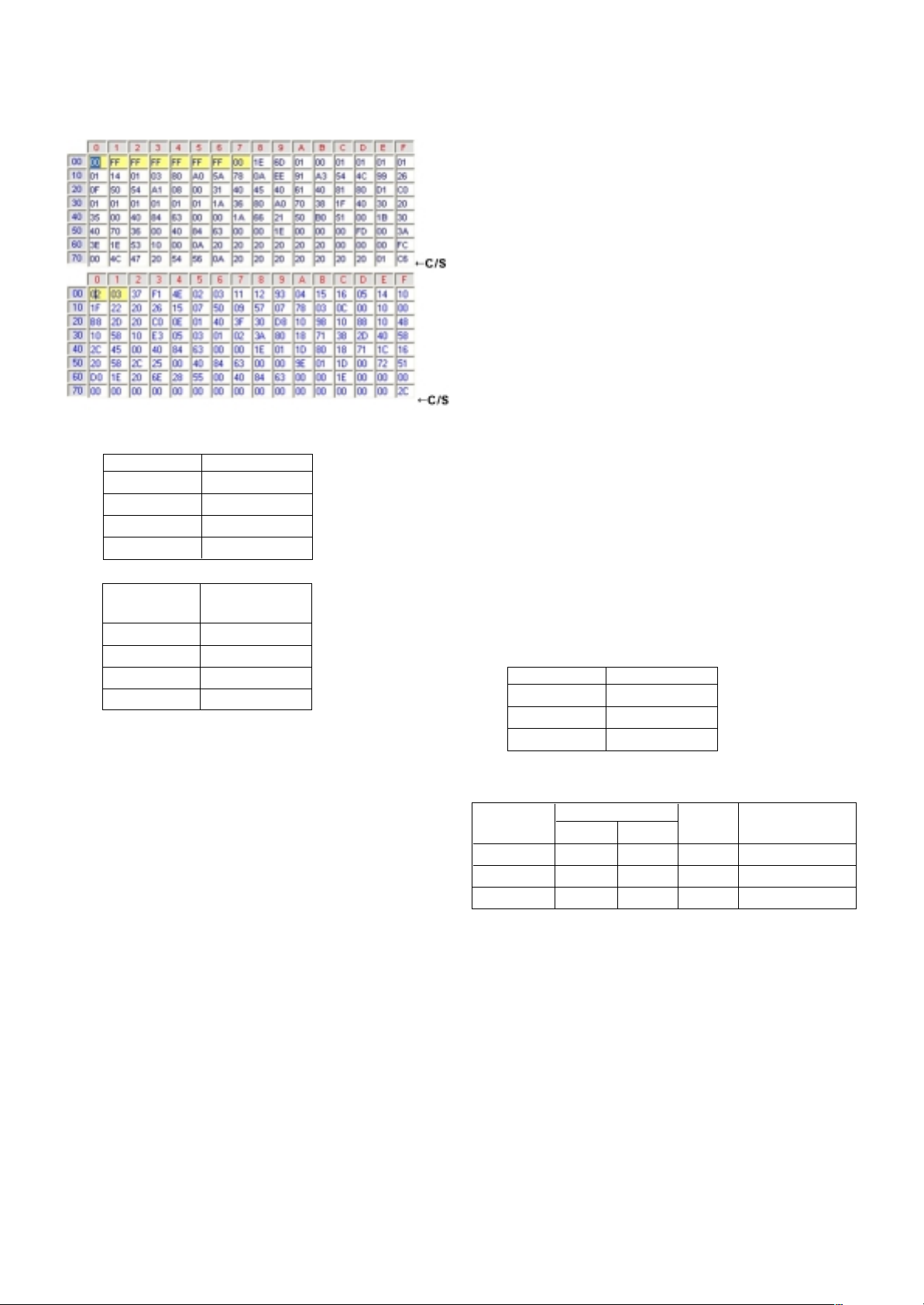

(2) HDMI 1

a. Vender ID

3-6. Confirmation

(1) Press ‘InStart’ Key on Factory SVC Remote Controller.

And MUST check ADC & EDID ADJ status is OK.

4. SET assembly adjustment method

* Caution : Each PCB assembly must be checked by check JIG

set. (Because power PCB Assembly damages to PDP

Module, especially be careful)

4-1.POWER PCB Assembly Voltage

adjustment (Va/Vs Voltage Adjustment)

Test equipment : D.M.M 1EA

Connection Diagram for Measuring : refer to fig.4

Adjustment method

(1) Va adjustment

1) Connect + terminal of D. M.M. to Va pin of P811,

connect -terminal to GND pin of P811.

2) After turning VR901,voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top

(deviation; ±0.5V)

(2) Vs adjustment

1) Connect + terminal of D. M..M. to Vs pin of P811,

connect -terminal to GND pin of P811.

2) After turning VR951, voltage of D.M.M adjustment as

same as Vs voltage which on label of panel right/top (

deviation ; ±0.5V)

4-2. Download Serial number (RS-232C)

V Press “Power on” key of service R/C.

(Baud rate : 115200 bps)

V Connect RS232 Signal Cable to RS-232 Jack.

V Write Serial number by use RS-232.

V Must check the serial number at the Diagnostics of SET UP

menu.

(Refer to below ‘6.SET INFORMATION’).

4-3. Adjustment of White Balance

Required Equipment

O Remote controller for adjustment

O Color Analyzer ( CS-1000, CA-100,100+,CA-210 or same

produc: CH 10 (PDP)

* Please adjust CA-210, CA-100+ by CS-1000 before

measuring

O Auto W/B adjustment instrument(only for Auto adjustment)

O 9 Pin D-Sub Jack(RS232C) is connected to the AUTO W/B

EQUIPMENT.

Before Adjust of White Balance, Please press POWER ONLY

key

Adjust Process will start by execute RS232C Command.

O Color temperature standards according to CSM and Module

O CS-1000/CA-100+/CA-210(CH 10) White balance

adjustment coordinates and color temperature.

* Manual W/B process (using adjusts Remote control)

Please Adjust in AV 1 MODE, Turn off Energy Saving Mode.

(1) Enter ‘PICTURE RESET’ on Picture Mode, then turn off

Fresh Contrast and Fresh colour in Advanced Control

(2) After enter Service Mode by pushing “ADJ” key,

(3) Enter White Pattern off of service mode, and change off ->

on.

(4) Enter “W/B ADJUST” by pushing “

G” key at “3. W/B

ADJUST”.

INOUT HEX

HDMI1 10

HDMI2 20

HDMI3 30

HDMI4 40

INOUT C/S

RGB 3E

HDMI1 C62C

HDMI2 C61C

HDMI3 C60C

HDM4 C6FC

CSM PLASMA

Cool 11000K

Medium 9300K

Warm 6500K

CSM

Color Coordinate

Temp ±Color Coordinate

xy

Cool 0.276 0.283 11000K 0.002

Medium 0.285 0.293 9300K 0.002

Warm 0.313 0.329 6500K 0.002

Page 9

- 9 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

* Gain Max Value is 192. So, Never make any Gain Value over

192 and please fix one Value on 192, between R, G and B.

* Auto-control interface and directions

(1) Adjust in the place where the influx of light like floodlight

around is blocked. (Illumination is less than 10ux).

(2) Measure and adjust after sticking the Color Analyzer (CA-

100+, CA210 ) to the side of the module.

(3) Aging time

After aging start, keep the Power on (no suspension of

power supply) and heat-run over 5 minutes

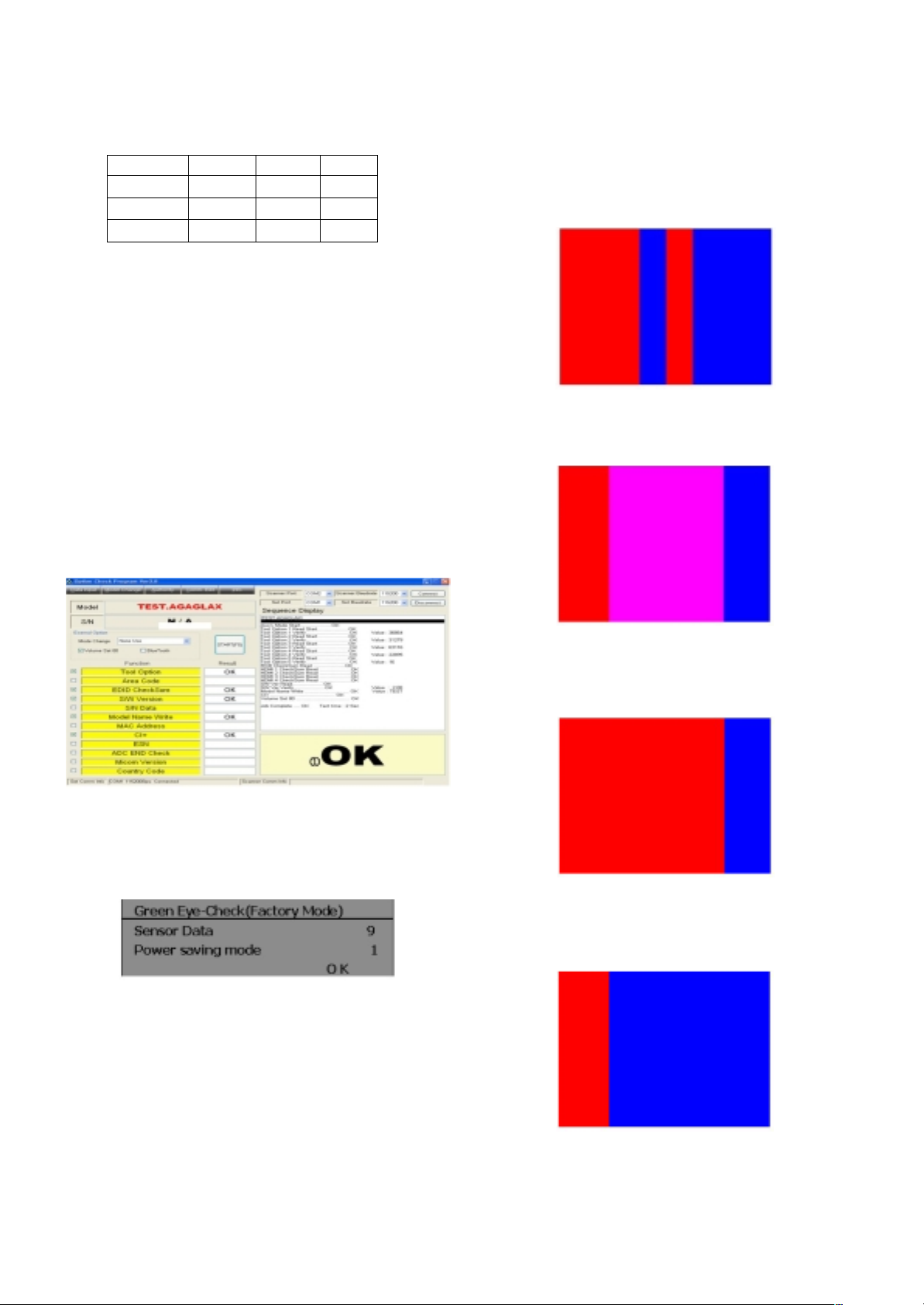

4-4. Serial number download & Model

name D/L and Check Tool Option.

(1) Press "Power on" button of a service R/C.(Baud rate :

115200 bps)

(2) Connect RS232-C Signal Cable and start ‘Option Check

Program Ver3.8’

(3) Scan serial Number and press ‘F5’ button.

(4) Check ‘OK’ on program (1) program.

(5) Press ‘In start’ button on SVC R/C, check Serial Number

and Model Name.

4-5. Checking the EYE-Q Operation.

(1) Press the EYE Key on the adjustment remote controller.

(2) Check the Sensor DATA ( It must be under 10) and keep

the data longer than 1.5s

(3) Check ‘OK’

(Sensor DATA 0 ~ 4095, Power Saving Mode 0 ~ 12)

* IF you press IN-STAP Button, change Green Eye-check OSD.

4-6. Ping TEST

* This test is to check Network operation.

(1) Connect LAN cable from Computer to TV Set

(2) When network operates normally, you can see “OK” on

Computer

5. 3D Function Test

(Pattern Generator MSPG-3233, HDMI mode NO. 371 ,

pattern No. 81)

(1) Please input 3D test pattern like below

(2) Enter 3D mode , then select side by side

(If you don’t wear a 3D Glasses, you will see the picture

like below)

(3) Put on the 3D Glasses, And block the right side of Glasses

(LEFT:OPEN[TEST], RIGHT:CLOSED)

And check the middle sides of picture , RED -> normal ,

others -> abnormal

(4) Put on the 3D Glasses, And block the right side of Glasses

(LEFT:CLOSED, RIGHT:OPEN[TEST])

And check the middle sides of picture , BLUE -> normal ,

others -> abnormal

Min Tpy Max

R-GAIN 0 192 192

G-GAIN 0 192 192

B-GAIN 0 192 192

Page 10

- 10 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

6. 2D to 3D convert inspection

(1) Input Combination Pattern like below in HDMI Input

(2) Enter the Swap Button(Yellow Color) like below.

* When you enter the swap button. Depth value is set to

Maximum value(20) automatically

Enter the ETC Key Before using the swap button

(3) Check the separated line in the SET

7. Set Information

(Serial No & Model name)

7-1. Check the serial number

& Model Name

(1) Push the menu button in DTV mode.

(2) Check the Serial Number

Select the STATION -> Diagnostics -> To set

8. SW Download Guide.

* Before put a *.epk to USB Stick make ‘LG_DTV’ folder in USB.

Then, put *.epk file to ‘LG_DTV’ folder and Turn on TV

(1) Put the USB Stick to the USB socket

(2) Automatically detecting update file in USB Stick

* If your downloaded program version in USB Stick is Low,

it didn’t work.

But your downloaded version is High, USB data is

automatically detecting.

(3) Show the message “Copying files from memory”

(4) Updating is staring.

(5) Updating Completed, The TV will restart automatically.

After turn on TV, Please press ‘IN-STOP’ button on ADJ

Remote-control.

* IF you don’t have ADJ R/C, enter ‘Factory Reset’ in

OPTION MENU.

(6) When TV turn on, check the Updated version on

Diagnostics MENU.

Page 11

- 11 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

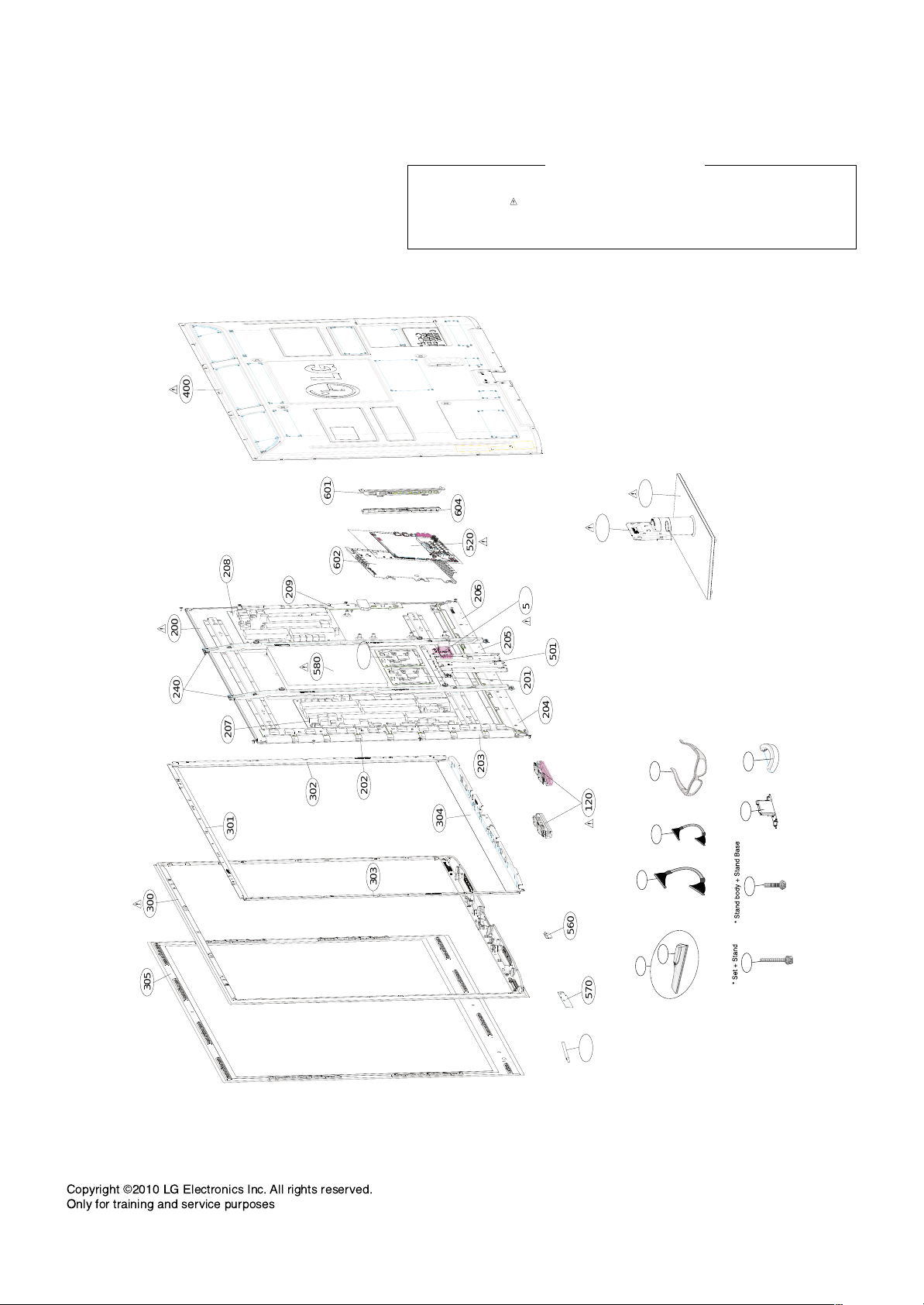

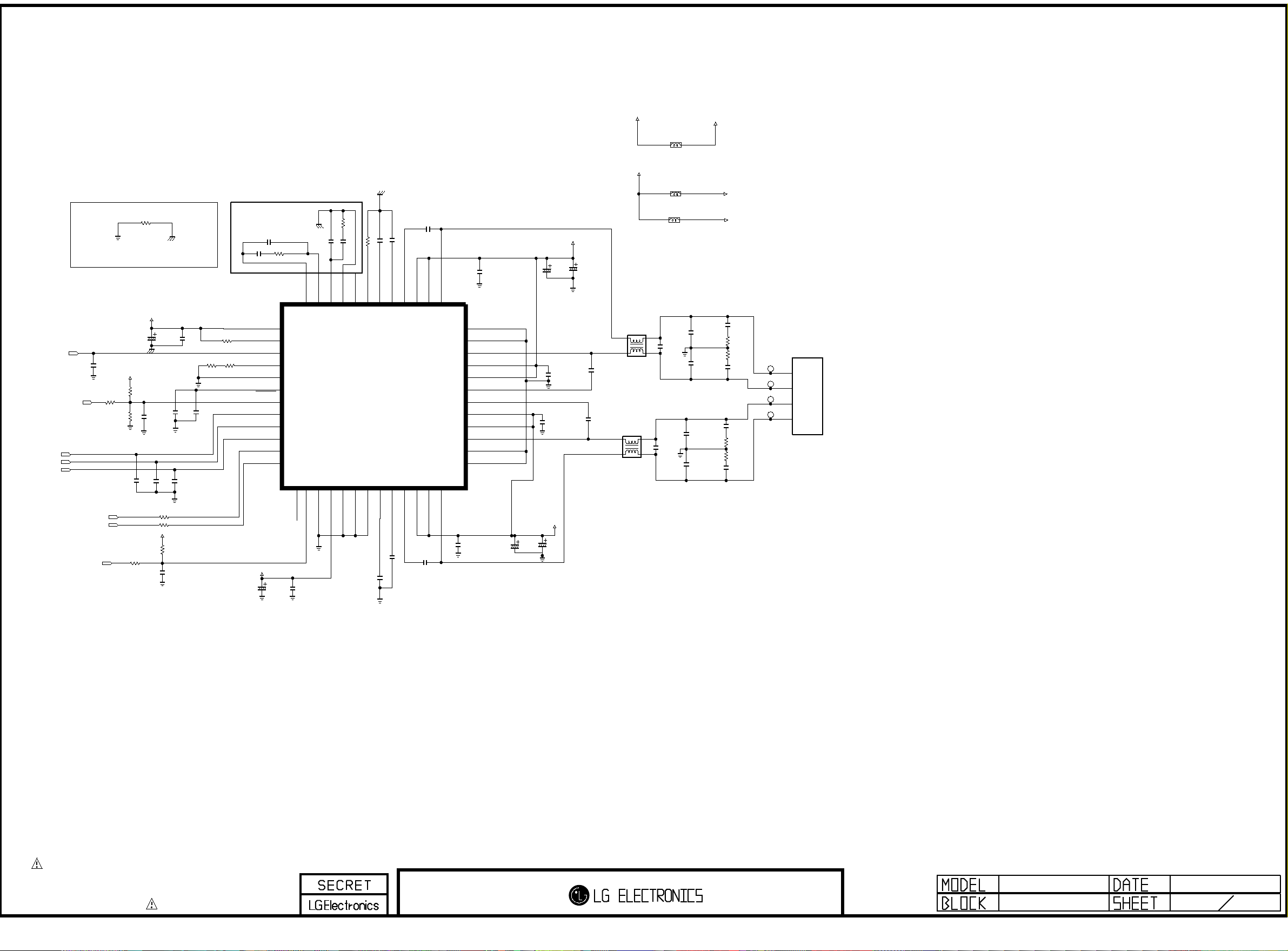

BLOCK DIAGRAM

Page 12

- 12 -

LGE Internal Use Only

EXPLODED VIEW

Copyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

305

570

207

203

202

303

602

501

560

400

208

580

300

120

200

209

601

520

604

204

201

206

205

240

301

302

304

590

521

900

910

310

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

LV1

A12

LV2

A10

A9

A13

A21

A2

A7

Page 13

NAND FLASH MEMORY 4G BIT FOR BBTV

Copyright © 2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

IC102-*1

TC58NVG2S3ETA00

NC_1

NC_29

1

C105

VCC

8

WP

7

SCL

6

SDA

5

NC_2

2

NC_3

3

NC_4

4

NC_5

5

NC_6

6

RY/BY

7

RE

8

CE

9

NC_7

10

NC_8

11

VCC_1

12

VSS_1

13

NC_9

14

NC_10

15

CLE

16

ALE

17

WE

18

WP

19

NC_11

20

NC_12

21

NC_13

22

NC_14

23

TOSHIBA_4G_NAND

48

NC_28

47

NC_27

46

NC_26

45

I/O8

44

I/O7

43

I/O6

42

I/O5

41

NC_25

40

NC_24

39

NC_23

38

VCC_2

37

VSS_2

36

NC_22

35

NC_21

34

NC_20

33

I/O4

32

I/O3

31

I/O2

30

I/O1

29

NC_19

28

NC_18

27

NC_17

26

NC_1624NC_15

25

NAND_DATA[0-7]

NAND_RB

NAND_RE

NAND_CE

NAND_CLE

NAND_ALE

NAND_WE

FLASH_WP

SYSTEM EEPROM

B

BCM REVIEW

2.7KR4

2.7KR5

C

Q100

KRC103S

E

4.7KR3

IC106

M24M01-HRMN6TP

NC

1

E1

2

STM_1M_EEPROM

E2

3

VSS

A8’h‘

4

D3.3V

10K

R8

Open Drain

C101

VCC

8

WP

7

SCL

6

SDA

5

0.1uF

D3.3V

VDD_1

VSS_1

NC_10

NC_11

NC_12

NC_13

NC_14

NC_15

+3.3V_MULTI

NC_1

NC_2

NC_3

NC_4

NC_5

NC_6

NC_7

NC_8

NC_9

RB

CL

AL

W

WP

R

E

NAND04GW3B2DN6E

1

NUMONYX_4G_NAND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

C102

0.1uF

22R18

22R19

IC102

READY

R20

0

R21

10K

SCL0_3.3V

SDA0_3.3V

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

FLASH_WP

NC_29

NC_28

NC_27

NC_26

I/O7

I/O6

I/O5

I/O4

NC_25

NC_24

NC_23

VDD_2

VSS_2

NC_22

NC_21

NC_20

I/O3

I/O2

I/O1

I/O0

NC_19

NC_18

NC_17

NC_16

NAND_DATA[7]

NAND_DATA[6]

NAND_DATA[5]

NAND_DATA[4]

D3.3V

C104

10uF 6.3V

0.1uF

NAND_DATA[3]

NAND_DATA[2]

NAND_DATA[1]

NAND_DATA[0]

GND

AT24C1024BN-SH-T

NC

1

A1

2

A2

3

4

IC106-*1

ATMEL_1M_EEPROM

RESET

+3.3V_MULTI

SW102

SKHMPWE010

12

FOR DEBUG

5

43

10K

R9

RESETB_BCM3556

0

R89

C103

0.1uF

READY

16V

RESET_OUTB

UART BYPASS(WIRED OR)

BCM_RX RS232C_RXD

NEC_RXD

BCM_TX RS232C_TXD

NEC_TXD

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

Boot Strap

22R73

22R72

NAND_DATA[0-7]

NAND_ALE

NAND_CLE

MODEL OPTION

IF_AGC_SEL

BT_ON/OFF

0R75

0R74

NAND_DATA[0]

NAND_DATA[1]NAND_DATA[1]

NAND_DATA[2]

NAND_DATA[3]

NAND_DATA[4]

NAND_DATA[5]

NAND_DATA[6]NAND_DATA[6]

NAND_DATA[7]

MODEL OPTION

PIN NAME

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_2

MODEL_OPT_3

MODEL_OPT_4

MODEL_OPT_5

PIN NO.

G19

C5

F7

B6

E18

D18

D3.3V

R46

2.7K

READY

R58

READY

READY

2.7K

R55

2.7K

R56

2.7K

R59

2.7K

R60

2.7K

R57

2.7K

R61

2.7K

R62

2.7K

R63

2.7K

R47

2.7K

READY

R50

2.7K

READY

R48

2.7K

R41

2.7K

READY

R42

2.7K

READY

R43

2.7K

R44

2.7K

READY

R45

2.7K

READY

R49

2.7K

D3.3V

1K

1K

1K

1K

FHD

AUS

R51

R53

READY

1K

AUS

R64

R66

R68

READY

100R37

100R40

1K

1K

1K

EU

READY

R65

R67

R69

READY

1K

1K

HD

READY

R52

R54

LOWHIGH

FRC

BRAZIL&AUS

NO FRC

EURO

NOT USE

FHD

XGA

EURO&AUS

HD

WXGA

BRAZIL

NAND_IO[0] : Flash Select (1)

0 : Boot From Serial Flash

1 : Boot From NAND Flash

NAND_IO[1] : NAND Block 0 Write (0)

NAND_IO[3:2] : NAND ECC (1,0)

NAND_IO[6:5] : Xtal Bias Control (1,0)

NAND_IO[7] : MIPS Frequency (0)

NAND_CLE

0 : Enable D2CDIFF AC (Dns)

1 : Disable D2CDIFF AC

0 : Enable Block 0 Write

1 : Disable Block 0 Write

00 : No ECC

01 : 1 ECC Bit

10 : 4 ECC Bit

11 : 8 ECC Bit

NAND_IO[4] : CPU Endian (0)

0 : Little Endian

1 : Big Endian

00 : 1.2mA

01 : 1.8mA

10 : 2.4mA (Recommand)

11 : 3.0mA

0 : 405MHz

1 : 378MHz

NAND_ALE : I2C Level (0)

0 : 3.3V Switching

1 : 5V Switching

1K

R70

READY

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_2

MODEL_OPT_3

MODEL_OPT_4

MODEL_OPT_5

1K

READY

R71

PDP CHASSIS OPTION

MODEL_OPT_1

MODEL_OPT_5 0

BRAZIL

D3.3V

4.7K

R82

NAND_DATA[0-7]

NAND_CE

NAND_ALE

NAND_RE

NAND_CLE

NAND_WE

NAND_RB

D3.3V

2.7KR78

NAND_DATA[0]

NAND_DATA[1]

NAND_DATA[2]

NAND_DATA[3]

2.7KR80

NAND_DATA[4]

NAND_DATA[5]

NAND_DATA[6]

NAND_DATA[7]

D3.3V

1.2KR83

1.2K

R84

1.2KR85

READY

1.2K

R86

EURO

AUSTRALIA

1

0

1

1

1

* I2C MAP

* I2C_1 : TUNER, NVRAM

* I2C_2 : NEC_SUBMICOM, (USB_HUB)

* I2C_3 : HDMISW, AMP, WIRELESS

* I2C_4 : MODULE

R88

1.2KR87

1.2K

READY

LGE3556CP (C0 3D PIP)

J23

J24

H25

H24

H23

J25

F26

H28

J26

H27

G26

J27

J28

F27

G24

H26

R96

G27

33

G28

K23

G25

U24

T26

T27

U26

U27

V26

V27

V28

T24

R23

T23

T25

R24

U25

W24

U23

V23

V24

SCL0_3.3V

SDA0_3.3V

SCL2_3.3V

SDA2_3.3V

SCL3_3.3V

SDA3_3.3V

NEC SUB MICOM

RESET_NEC

NEC_ISP_TXD

NEC_ISP_RXD

OCD1A

AT24C16BN-SH-B

NC_1

NC_2

NC_3

GND

ATMEL_16K_EEPROM

OCD1B

IC104-*1

1

2

3

4

R79

47K

ISP Port for SUB MICOM

+3.3V_NEC_ST

FOR DEBUG

10K

R11

FLMD0

FOR DEBUG

10K

R91

CHECK PIN!!

VCC

8

WP

7

SCL

6

SDA

5

IC104

M24C16-WMN6T

0IMMRSG036B

NC/E0

1

NC

NC/E1

2

E1

1/10W

5%

NC/E2

3

E2

VSS

4

GND

STM_16K_EEPROM

P102

12505WS-12A00

FOR DEBUG

1

2

3

4

5

6

7

8

9

10

11

12

SCL1_3.3V

SDA1_3.3V

NEC_EEPROM_SCL

NEC_EEPROM_SDA

+3.3V_NEC_ST

VCC

8

VCC

WC

WC

7

SCL

6

SCL

SDA

5

SDA

13

LED_WHITE

MODEL1_OPT_3

MODEL1_OPT_0

RESETB_BCM3556

FLASH_WP

MODEL1_OPT_1

C107

0.1uF

16V

R97

R98

NEC CONFIGURATION

+3.3V_NEC_ST

MICOM MODEL OPTION

AMP_RESET_N

DISP_EN

ERROR_DET

MODEL PWM OPTION

**PK50 : LED_RED

PK70 : LED_RED/LED_BLUE

PK90 : LED_RED/LED_BLUE/LED_BREADING

MODEL OPTION

PIN NAME

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_2

MODEL_OPT_3

R26

10K

READY

READY

R23

10K

R24

10K

READY

R25

10K

READY

+3.3V_NEC_ST

10K

R29

READY

LED_PK70

100R27

100R28

0

R77

10K

READY

R30

LED_PK50/LED_PK90

8

11

30

31

HIGH

PK90 PK50/PK70

NOT USE

NOT USE

PK70

PK50/PK90

PIN NO. LOW

10K

R31

10K

R32

NEC_ISP_TXD

NEC_ISP_RXD

OCD1A

OCD1B

10K

R33

READY

10K

READY

R34

10K

R35

LED_PK90

10K

R36

LED_PK50/LED_PK70

MODEL1_OPT_0

MODEL1_OPT_1

MODEL1_OPT_2

MODEL1_OPT_3

IC100

N26

EBI_ADDR3

EBI_ADDR4

EBI_ADDR2

EBI_ADDR1

EBI_ADDR0

EBI_ADDR5

EBI_ADDR6

EBI_ADDR8

EBI_ADDR9

EBI_ADDR13

EBI_ADDR12

EBI_ADDR11

EBI_ADDR10

EBI_ADDR7

EBI_TAB

EBI_WE1B

EBI_CLK_IN

EBI_CLK_OUT

EBI_RWB

EBI_CS0B

NAND_DATA0

NAND_DATA1

NAND_DATA2

NAND_DATA3

NAND_DATA4

NAND_DATA5

NAND_DATA6

NAND_DATA7

NAND_CS0B

NAND_ALE

NAND_REB

NAND_CLE

NAND_WEB

NAND_RBB

SF_MISO

SF_MOSI

SF_SCK

SF_CSB

GPIO_00

GPIO_01

GPIO_02

GPIO_03

GPIO_04

GPIO_05

GPIO_06

GPIO_07

GPIO_08

GPIO_09

GPIO_10

GPIO_11

GPIO_12

GPIO_13

GPIO_14

GPIO_15

GPIO_16

GPIO_17

GPIO_18

GPIO_19

GPIO_20

GPIO_21

GPIO_22

GPIO_23

GPIO_24

GPIO_25

GPIO_26

GPIO_27

GPIO_28

GPIO_29

GPIO_30

GPIO_31

GPIO_32

GPIO_33

GPIO_34

GPIO_35

GPIO_36

GPIO_37

GPIO_38

GPIO_39

GPIO_40

GPIO_41

GPIO_42

GPIO_43

GPIO_44

GPIO_45

GPIO_46

GPIO_47

GPIO_48

GPIO_49

GPIO_50

GPIO_51

GPIO_52

GPIO_53

GPIO_54

GPIO_55

GPIO_56

GPIO_57

SGPIO_00

SGPIO_01

SGPIO_02

SGPIO_03

SGPIO_04

SGPIO_05

SGPIO_06

SGPIO_07

C108

12pF

50V

C111

L26

N25

L25

K27

K28

K24

K26

K25

AA27

AA28

AA26

L1

L3

L2

Y25

Y26

M27

AA25

R25

N28

N27

AH18

P23

M23

AD19

AE19

M4

M5

L23

Y28

Y27

G2

G3

G5

G6

G4

L24

P25

L5

K4

K1

L27

M26

N23

R28

R27

R26

P28

P27

K6

K5

P26

M3

M2

M1

L4

L6

W27

W28

W26

W25

J2

J1

K3

K2

12pF

10MHz

50V

X100

FPGA_D/L

R132

R134

R135

R145

R180

100

R114

R136

0

100K

+3.3V_NEC_ST

C110

0.1uF

READY

C109

0.1uF

P60/SCL0

22

22

1

P61/SDA0

2

P62/EXSCL0

3

P63

4

P33/TI51/TO51/INTP4

5

P75

6

UPD78F0513AGA-GAM-AX

P74

7

P73/KR3

8

P72/KR2

9

P71/KR1

10

P70/KR0

11

12

13

REGC47VSS48VDD

46

14

15

P121/X1/OCD0A

45

16

5V_ON

OCD1B

R110

10K

10K

10K

R104

R101

10K

R109

R105

R106

P32/INTP3/OCD1B

P30/INTP1

P17/TI50/TO50

P16/TOH1/INTP5

P31/INTP2/OCD1A

NEC_EEPROM_SCL

22

NEC_EEPROM_SDA

22

OCD1A

IR_NEC

HDMI_CEC

LED_BREATHING

BCM GPIO & NEC MICOM & FLASH & SYS EEPROM

BCM GPIO/NEC MICOM/FLASH/SYS EEPROM

22

R160

R150

22

100R137

100R138

READY

R122

R123

22

0R179

READY

0

READY

0

0

READY

FLMD0

009:E3;009:F1

RTC_TXC

50V

22pF

C112

RTC_TXC

32.768KHz

X101

R10

4.7M

RTC_TXC

P123/XT1

FLMD044P122/X2/EXCLK/OCD0B

42

43

IC105

17

18

19

P15/TOH0

P13/TXD6

P14/RXD6

22R146

22R142

LED_RED

NEC_ISP_TXD

NEC_ISP_RXD

READY

READY

0R121

READY

IR_INT

IR_IN

0R178

100

100

COMP1_DET

USB2_CTL

SCL0_3.3V

SDA0_3.3V

SCL1_3.3V

SDA1_3.3V

SCL2_3.3V

SDA2_3.3V

SCL3_3.3V

SDA3_3.3V

RTC_TXC

50V

27pF

C113

20

21

22

P12/SO10

P10/SCK10/TXD0

P11/SL10/RXD0

AC_DET

NEC_RXD

0

0

R184

R185

IIC1<->2 SWAP

+3.3V_NEC_ST

RTC_KSD

X101-*1

32.768KHz

WIRELESS_DETECT

WIRELESS_PWR_EN

P120/INTP0/EXLVI

P4139P4040RESET41P124/XT2/EXCLKS

37

38

36

35

34

33

32

31

30

29

28

27

26

25

23

24

+3.3V_NEC_ST

AVSS

AVREF

C114

0.1uF

16V

4.7K

R163

4.7K

R164

NEC_TXD

USB1_OCD

MODEL_OPT_4

MODEL_OPT_5

SIDEAV_DET

HPD4

FLMD0

HPD3

USB2_OCD

MODEL_OPT_1

DSUB_DET

BT_RESET

/RST_HUB

BCM_RX

BCM_TX

MODEL_OPT_0

AUD_MASTER_CLK

HPD1

HPD2

USB1_CTL

EPHY_ACTIVE_Y

EPHY_LINK

MOD_ROM_TX

MOD_ROM_RX

VREG_CTR

TUNER_RESET

5V_HDMI_1

AV1_DET

MODEL_OPT_3

5V_HDMI_3

5V_HDMI_4

MODEL_OPT_2

COMP2_DET

FLASH_WP

DDC_SCL

DDC_SDA

USB_EN

LCD_HP_DET

10K

R165

RTC_KSD

50V

15pF

C112-*1

100K

R166

P140/PCL/INTP6

P00/TI000

P01/TI010/TO00

P130

P20/ANI0

ANI1/P21

ANI2/P22

ANI3/P23

ANI4/P24

ANI5/P25

ANI6/P26

ANI7/P27

READY

READY

SW100

12

JTP-1127WEM

FOR DEBUG

C1

0.1uF

50V

RTC_KSD

1%

LCD : ERROR OUT(PANEL)

For CI

LCD : MICOM_DOWNLOAD(FLMD0)

LCD : PWM_DIM

R103

0

/3D_FPGA_RESET

L/R_DETECT

R161

0

5V_HDMI_2

R107

0

E_TCK

LCD : AV_CVBS_DET

R112

0

E_TMS

READY

0R186

0R187

READY

R115

0

USB_OCP

LCD : FRC_RESET

43

RESET_NEC

50V

15pF

C113-*1

1%

009:E3;009:F1

120KR176

C

Q101EB

2SC3052

RL_ON

FLMD0

10KR170

SUB_SCL

SUB_SDA

MODEL1_OPT_2

INSTANT_BOOT

10KR174

22R168

KEY2

22R169

KEY1

08/10/28

E_TDO

WIRELESS_DL_RX

WIRELESS_DL_TX

E_TDI

KEY1

EDID_WP

1 13

+3.3V_MULTI

Page 14

BROAD BAND STUDIO

Copyright © 2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

FOR DEBUG

P200

TJC2508-4A

1

2

3

4

REAR_AV_L_IN

REAR_AV_R_IN

COMP2_L_IN

COMP2_R_IN

COMP1_L_IN

COMP1_R_IN

D3.3V

C200

FOR DEBUG

USB HUB

TP201

TP200

TP204

SIDE_LIN

SIDE_RIN

TP203

PC_L_IN

PC_R_IN

TP202

AUDIO INCM-TP

PLACE NEAR JACKS

4.7uF

A2.5V

BLM18PG121SN1D

R208

1.5K

A3.3V

USB_DM

USB_DP

1.5K

R226

L201

BLM18PG121SN1D

C202

100pF

BT_DM

BT_DP

L200

C201

4.7uF

51R220

51R221

5.1R222

51R209

51R210

5.1R211

51R212

51R213

5.1R223

51R214

51R215

5.1R224

51R216

51R217

5.1R218

A1.2V

0.015uFC213

0.015uFC214

0.15uFC215

0.015uFC206

0.015uFC220

0.15uFC222

0.015uFC207

0.015uFC208

0.15uFC225

0.015uFC209

0.015uFC210

0.15uFC227

0.015uFC211

0.015uFC212

0.15uFC216

C203

0.1uF

16V

A2.5V

BLM18PG121SN1D

R238:BCM recommened resistor 562 ohm

R227

3.9K

0.1uFC219

0.1uFC218

BLM18PG121SN1D

BLM18PG121SN1D

L203

0.047uF

0.047uF

0.47uFC238

C240

C242

C235

0.1uFC221

L204

0.047uF

0.47uFC244

0.47uFC230

R228

120

A1.2V

0.047uF

C232

L202

4.7uF

4.7uFC223

C224

0.1uF

0.047uF

C265

C231

C237

0.1uF

C233

0.01uF

0.1uFC226

0.047uF

0.47uFC267

C266

A3.3V

C228

0.1uF

4.7uF

EPHY_RDN

0.047uF

C268

A1.2V

0.1uF

C236

EPHY_RDP

EPHY_TDN

EPHY_TDP

0.047uF

0.47uFC270

C269

A2.5V

L210

BLM18PG121SN1D

0.1uF

C241

D3.3V

R235

R236

240

0.1uF

C234

0.047uF

0.047uF

C271

C272

L211

BLM18PG121SN1D

C243

R285

2.7K

2.7K

R237

1K

4.7uF

C239

C273

0.1uF

560R238

AC18

AF20

AG20

AG21

AF19

AD20

AE20

AH22

AH20

AG19

AH21

AA10

AB10

AA11

AB11

A2.5V

D23

C24

B26

A25

B25

A26

G23

D25

D24

C25

E27

E26

D28

D27

D26

E23

E24

F25

C27

C26

B28

B27

A27

F24

F23

E25

C28

A28

M25

M24

AE6

AD7

AF6

AH4

AG5

AG4

AG6

AF7

AE7

AH5

AG7

AH6

AD8

AF8

AE8

AH7

AH8

AG8

AF5

AB9

AC8

AE5

PKT0_CLK

PKT0_DATA

PKT0_SYNC

RMX0_CLK

RMX0_DATA

RMX0_SYNC

POD2CHIP_MCLKI

POD2CHIP_MDI0

POD2CHIP_MDI1

POD2CHIP_MDI2

POD2CHIP_MDI3

POD2CHIP_MDI4

POD2CHIP_MDI5

POD2CHIP_MDI6

POD2CHIP_MDI7

POD2CHIP_MISTRT

POD2CHIP_MIVAL

CHIP2POD_MCLKO

CHIP2POD_MDO0

CHIP2POD_MDO1

CHIP2POD_MDO2

CHIP2POD_MDO3

CHIP2POD_MDO4

CHIP2POD_MDO5

CHIP2POD_MDO6

CHIP2POD_MDO7

CHIP2POD_MOSTRT

CHIP2POD_MOVAL

VDAC_AVDD2P5

VDAC_AVDD1P2

VDAC_AVDD3P3_1

VDAC_AVDD3P3_2

VDAC_AVSS_1

VDAC_AVSS_2

VDAC_AVSS_3

VDAC_RBIAS

VDAC_1

VDAC_2

VDAC_VREG

BSC_S_SCL

BSC_S_SDA

R6

USB_AVSS_1

T6

USB_AVSS_2

R7

USB_AVSS_3

T7

USB_AVSS_4

T8

USB_AVSS_5

R3

USB_AVDD1P2

U3

USB_AVDD1P2PLL

T4

USB_AVDD2P5

T3

USB_AVDD2P5REF

R4

USB_AVDD3P3

U4

USB_RREF

V1

USB_DM1

V2

USB_DP1

U1

USB_DM2

U2

USB_DP2

T5

USB_MONCDR

R5

USB_MONPLL

R1

USB_PWRFLT_1

R2

USB_PWRFLT_2

T2

USB_PWRON_1

T1

USB_PWRON_2

P6

EPHY_VREF

P5

EPHY_RDAC

P3

EPHY_RDN

P2

EPHY_RDP

N3

EPHY_TDN

N2

EPHY_TDP

P1

EPHY_AVDD1P2

P4

EPHY_AVDD2P5

N4

EPHY_PLL_VDD1P2

N1

EPHY_AGND_1

N5

EPHY_AGND_2

P7

EPHY_AGND_3

AUDMX_LEFT1

AUDMX_RIGHT1

AUDMX_INCM1

AUDMX_LEFT2

AUDMX_RIGHT2

AUDMX_INCM2

AUDMX_LEFT3

AUDMX_RIGHT3

AUDMX_INCM3

AUDMX_LEFT4

AUDMX_RIGHT4

AUDMX_INCM4

AUDMX_LEFT5

AUDMX_RIGHT5

AUDMX_INCM5

AUDMX_LEFT6

AUDMX_RIGHT6

AUDMX_INCM6

AUDMX_AVSS_1

AUDMX_AVSS_2

AUDMX_AVSS_3

AUDMX_AVSS_4

AUDMX_AVSS_5

AUDMX_AVSS_6

AUDMX_LDO_CAP

AUDMX_AVDD2P5

LGE3556CP (C0 3D PIP)

IC100

LVDS_TX_0_DATA0_P

LVDS_TX_0_DATA0_N

LVDS_TX_0_DATA1_P

LVDS_TX_0_DATA1_N

LVDS_TX_0_DATA2_P

LVDS_TX_0_DATA2_N

LVDS_TX_0_DATA3_P

LVDS_TX_0_DATA3_N

LVDS_TX_0_DATA4_P

LVDS_TX_0_DATA4_N

LVDS_TX_0_CLK_P

LVDS_TX_0_CLK_N

LVDS_TX_1_DATA0_P

LVDS_TX_1_DATA0_N

LVDS_TX_1_DATA1_P

LVDS_TX_1_DATA1_N

LVDS_TX_1_DATA2_P

LVDS_TX_1_DATA2_N

LVDS_TX_1_DATA3_P

LVDS_TX_1_DATA3_N

LVDS_TX_1_DATA4_P

LVDS_TX_1_DATA4_N

LVDS_TX_1_CLK_P

LVDS_TX_1_CLK_N

LVDS_PLL_VREG

LVDS_TX_AVDDC1P2

LVDS_TX_AVDD2P5_1

LVDS_TX_AVDD2P5_2

LVDS_TX_AVSS_1

LVDS_TX_AVSS_2

LVDS_TX_AVSS_3

LVDS_TX_AVSS_4

LVDS_TX_AVSS_5

LVDS_TX_AVSS_6

LVDS_TX_AVSS_7

LVDS_TX_AVSS_8

LVDS_TX_AVSS_9

LVDS_TX_AVSS_10

LVDS_TX_AVSS_11

CLK54_AVDD1P2

CLK54_AVDD2P5

CLK54_XTAL_N

CLK54_XTAL_P

CLK54_MONITOR

VCXO_AGND_1

VCXO_AGND_2

VCXO_AGND_3

VCXO_AVDD1P2

VCXO_PLL_AUDIO_TESTOUT

POR_OTP_VDD2P5

PLL_MAIN_AVDD1P2

PLL_MAIN_MIPS_EREF_TESTOUT

PLL_MAIN_AGND

PLL_RAP_AVD_TESTOUT

PLL_RAP_AVD_AVDD1P2

PLL_RAP_AVD_AGND

BYP_SYS216_CLK

BYP_SYS175_CLK

CLK54_AVSS

PM_OVERRIDE

RESET_OUTB

TMODE_0

TMODE_1

TMODE_2

TMODE_3

SPI_S_MISO

POR_VDD1P2

EJTAG_TCK

EJTAG_TDI

EJTAG_TDO

EJTAG_TMS

EJTAG_TRSTB

EJTAG_CE0

EJTAG_CE1

BYP_CPU_CLK

BYP_DS_CLK

RESETB

NMIB

B4

A4

C6

B6

B3

A3

A1

A2

D5

D6

C5

B5

B1

B2

C2

C3

D1

D2

E1

E2

E3

E4

D3

D4

F5

F1

F4

F2

C1

F3

C4

A5

E5

E6

D7

E7

F7

G7

H7

AD27

AD28

AD26

AC26

AC27

AE25

Y23

AA23

AB24

AC24

AF25

AF24

P24

F6

N24

J5

J4

J6

J3

V25

AH3

AB8

H4

H3

H2

H1

G1

H6

H5

AB26

AC25

AB27

M6

N6

N7

AA24

Y24

AE24

AD25

C246

10uF

C247

D3.3V

4.7K

R240

READY

0.1uF

C248

R239

390

READY

10uF

1K

54MHz_XTAL_N

54MHz_XTAL_P

BLM18PG121SN1D

BLM18PG121SN1D

R281

C251

1K R241

1K R242

LVDS_TX_0_DATA0_P

LVDS_TX_0_DATA0_N

LVDS_TX_0_DATA1_P

LVDS_TX_0_DATA1_N

LVDS_TX_0_DATA2_P

LVDS_TX_0_DATA2_N

LVDS_TX_0_DATA3_P

LVDS_TX_0_DATA3_N

LVDS_TX_0_DATA4_P

LVDS_TX_0_DATA4_N

LVDS_TX_0_CLK_P

LVDS_TX_0_CLK_N

LVDS_TX_1_DATA0_P

LVDS_TX_1_DATA0_N

LVDS_TX_1_DATA1_P

LVDS_TX_1_DATA1_N

LVDS_TX_1_DATA2_P

LVDS_TX_1_DATA2_N

LVDS_TX_1_DATA3_P

LVDS_TX_1_DATA3_N

LVDS_TX_1_DATA4_P

LVDS_TX_1_DATA4_N

LVDS_TX_1_CLK_P

LVDS_TX_1_CLK_N

0.1uF

0.1uF

4.7uF

C252

C254

C257

L206

C250

4.7uF

RESET_OUTB

RESETB_BCM3556

A2.5V

L205

C249

0.1uF

C255

0.1uF

4.7uF

C258

C253

0.1uF

A1.2V

0.1uF

A1.2V

C259

C260

4.7uF

A1.2V

A2.5VA1.2V

0.1uF

C256

L207

BLM18PG121SN1D

L208

BLM18PG121SN1D

C261

0.1uF

4.7uF

A2.5V

A1.2V

A1.2V

READY

R243

2.7K

R244

2.7K

D3.3V

READY

R245

2.7K

R246

2.7K

LVDS

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

FHD

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

54MHz X-TAL

C262

54MHz_XTAL_N

54MHz_XTAL_P

+3.3V_MULTI

4.7K

R232

4.7K

R230

PC_SER_CLK

MDL_SCL

DISP_EN

MDL_SDA

+3.3V_MULTI

4.7K

R234

R250

4.7K

MOD_ROM_TX_MOD

MOD_ROM_RX_MOD

PC_SER_DATA

100

FHD

9

8

7

6

5

4

3

2

1

R253

FHD

R251

0

R252

0

R254

0

R280

0

0R294

0R289

L212

CB4532UK121E

R255

27K

LVDS_TX_1_DATA4_N

LVDS_TX_1_DATA4_P

LVDS_TX_1_DATA3_N

LVDS_TX_1_DATA3_P

LVDS_TX_1_DATA2_N

LVDS_TX_1_DATA2_P

LVDS_TX_1_CLK_N

LVDS_TX_1_CLK_P

LVDS_TX_1_DATA1_N

LVDS_TX_1_DATA1_P

LVDS_TX_1_DATA0_N

LVDS_TX_1_DATA0_P

LVDS_TX_0_DATA4_N

LVDS_TX_0_DATA4_P

LVDS_TX_0_DATA3_N

LVDS_TX_0_DATA3_P

LVDS_TX_0_DATA2_N

LVDS_TX_0_DATA2_P

LVDS_TX_0_CLK_N

LVDS_TX_0_CLK_P

LVDS_TX_0_DATA1_N

LVDS_TX_0_DATA1_P

LVDS_TX_0_DATA0_N

LVDS_TX_0_DATA0_P

L/R_DETECT

/3D_FPGA_RESET

+5V_MULTI

3D_SYNC_OUT

E_TDI

E_TMS

E_TDO

E_TCK

FPGA_D/L

R247

L209

604

CASE 1 : R = 0 ohm --> CL = 8 pF

CASE 2 : R = 22 Ohm --> CL = 22pF

22

R249

33pF

1008LS-272XJLC

22

R248

005:B6

005:B6

005:B6

005:B6

X200

54MHz

21

3

SCL3_3.3V

SDA3_3.3V

MOD_ROM_RX

MOD_ROM_TX

C263

12pF

12pF

C264

22 R283

22 R284

22 R259

22 R274

MDL_SCL

002:G4

MDL_SDA

MOD_ROM_RX_MOD

MOD_ROM_TX_MOD

002:G4

002:G4

002:G4

C245

10uF

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

TF05-51S

P201

BCM AUS DVR

BCM AUDIO/LVDS

08/10/27

2 13

Page 15

TU_IF_AGC_BCM

Copyright © 2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

A3.3V

3.9K

R394

R397

2K

R396

200

C3000

0.1uF

C3001

4.7uF

C3002

1000pF

C3003

0.01uF

C3004

0.1uF

C3005

10uF

C3006

10uF

D1.2V

C3007

33uF

C3009

1000pF

C3010

0.01uF

C3013

0.1uF

C3016

4.7uF

C3019

1000pF

C3022

0.01uF

C3025

0.1uF

C3028

4.7uF

C3031

1000pF

D1.2V

C3034

0.01uF

C3036

4.7uF

C3039

1000pF

C3042

0.01uF

C3045

0.1uF

C3048

4.7uF

C3051

1000pF

C3054

0.01uF

C3057

0.1uF

D3.3V

C3059

10uF

Place BCM IC Side

COMPONENT

COMP2_Y

COMP2_Pr

COMP2_Pb

COMP INCM-TP

PLACE NEAR JACKS

CVBS

IF FILTER OPTION

DSUB RGB INCM-TP

PLACE NEAR JACKS

DSUB

009:G4

009:G4

009:G5

R300

34

SC RGB INCM-TP

PLACE NEAR JACKS

CVBS INCM-TP

PLACE NEAR JACKS

TU_SIF

3.9K

0.01uF

R395

C397

DSUB_R

DSUB_G

DSUB_B

75

10pF

R301

C300

READY

SC1_RGB

CONNECT NEAR BCM CHIP

R303

0.1uF

C396

TU_IF_N_BCM

TU_IF_P_BCM

A1.2V

C306

0.1uF

R315

34

R316

34

R314

34

READY

READY

10pFC304

75

75

10pF

R317

C303

34

34

34

34

REAR_AV_IN

SIDEAV_CVBS_IN

A2.5V

R318

10K

R319

12K

R320

75

R32375R325

TU_CVBS

R321

10K

12K

R322

C305

75

75

R305

COMP1_Y

COMP1_Pr

COMP1_Pb

R307

34

R311

R312

R313

R310

A2.5V

0.1uF

C301

240

R306

C302

0.1uF

120

R304

A2.5V

A1.2V

BLM18PG121SN1D

C307

0.1uF

READY

75R324

10pF

C308

READY

10pF

0.01uF C315

0.01uF C316

BLM18PG121SN1D

L300

C309

0.1uF

L301

A2.5V

BLM18PG121SN1D

BLM18PG121SN1D

75

R330

R308

1%

18

12R309

R359

12

L303

L304

C312

1000pF

R326

751% R327

62

A1.2V

L302

BLM18PG121SN1D

C311

0.1uF

C317

C310

4.7uF

0.1uF

C318

1000pF

62 R328

C313

0.01uF

RGB_HSYNC

RGB_VSYNC

C324

C325

C327

C328

C329

C330

C331

C314

4.7uF

C332

C333

C334

C335

C336

C337

C338

C339

C340

C341

C342

C343

C344

C345

C347

0.1uF

C319

4.7uF

C320

0.01uF

+5V_MULTI

510 R333

A1.2V

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

READY

R332

LGE3556CP (C0 3D PIP)

510

AG28

DS_AGCI_CTL

AH28

DS_AGCT_CTL

AA21

EDSAFE_AVSS_1

AB22

EDSAFE_AVSS_2

AF26

EDSAFE_AVSS_3

AF27

EDSAFE_AVSS_4

AF28

EDSAFE_AVSS_5

AG27

EDSAFE_AVDD2P5

AE26

EDSAFE_DVDD1P2

AE28

EDSAFE_IF_N

AE27

EDSAFE_IF_P

AD24

PLL_DS_AGND

AB19

PLL_DS_AVDD1P2

AB25

PLL_DS_TESTOUT

AB18

SD_V5_AVDD1P2

AC17

SD_V5_AVDD2P5

AB17

SD_V5_AVSS

AD14

SD_V1_AVDD1P2

AD16

SD_V1_AVDD2P5

AB15

SD_V1_AVSS_1

AC15

SD_V1_AVSS_2

AD13

SD_V2_AVDD1P2

AE13

SD_V2_AVDD2P5

AC13

SD_V2_AVSS_1

AB14

SD_V2_AVSS_2

AC14

SD_V2_AVSS_3

AC12

SD_V3_AVDD1P2

AD12

SD_V3_AVDD2P5

AB13

SD_V3_AVSS_1

AA14

SD_V3_AVSS_2

AC11

SD_V4_AVDD1P2

AD11

SD_V4_AVDD2P5

AB12

SD_V4_AVSS

AD10

SD_R

AC10

SD_INCM_R

AE9

SD_G

AF9

SD_INCM_G

AH9

SD_B

AG9

SD_INCM_B

AG15

SD_Y1

AE15

SD_PR1

AF15

SD_PB1

AH15

SD_INCM_COMP1

AG16

SD_Y2

AF16

SD_PR2

AH17

SD_PB2

AH16

SD_INCM_COMP2

AG14

SD_Y3

AE14

SD_PR3

AF14

SD_PB3

AH14

SD_INCM_COMP3

AH10

SD_L1

AG10

SD_C1

AE10

SD_INCM_LC1

AE11

SD_L2

AF11

SD_C2

AH11

SD_INCM_LC2

AH13

SD_L3

AE12

SD_C3

AF12

SD_INCM_LC3

AD9

SD_CVBS1

AG11

SD_CVBS2

AG12

SD_CVBS3

AF13

SD_CVBS4

AC9

SD_INCM_CVBS1

AF10

SD_INCM_CVBS2

AH12

SD_INCM_CVBS3

AG13

SD_INCM_CVBS4

AF17

SD_SIF1

AG17

SD_INCM_SIF1

AD15

SD_FB

AE16

SD_FS

AE17

SD_FS2

AB16

PLL_VAFE_AVDD1P2

AA15

PLL_VAFE_AVSS

AC16

PLL_VAFE_TESTOUT

AG3

RGB_HSYNC

AF4

RGB_VSYNC

IC100

I2S_CLK_IN

I2S_CLK_OUT

I2S_DATA_IN

I2S_DATA_OUT

I2S_LR_OUT

AUD_LEFT0_N

AUD_LEFT0_P

AUD_AVDD2P5_0

AUD_AVSS_0_1

AUD_AVSS_0_2

AUD_AVSS_0_3

AUD_AVSS_0_4

AUD_AVSS_0_5

AUD_RIGHT0_N

AUD_RIGHT0_P

AUD_LEFT1_N

AUD_LEFT1_P

AUD_RIGHT1_N

AUD_RIGHT1_P

AUD_AVDD2P5_1

AUD_AVSS_1_1

AUD_AVSS_1_2

AUD_AVSS_1_3

AUD_LEFT2_N

AUD_LEFT2_P

AUD_RIGHT2_N

AUD_RIGHT2_P

AUD_AVDD2P5_2

AUD_AVSS_2_1

AUD_AVSS_2_2

AUD_SPDIF

SPDIF_AVDD2P5

SPDIF_AVSS

SPDIF_IN_N

SPDIF_IN_P

HDMI_RX_0_CEC_DAT

HDMI_RX_0_HTPLG_IN

HDMI_RX_0_HTPLG_OUT

HDMI_RX_0_DDC_SCL

HDMI_RX_0_DDC_SDA

HDMI_RX_0_RESREF

HDMI_RX_0_CLK_N

HDMI_RX_0_CLK_P

HDMI_RX_0_DATA0_N

HDMI_RX_0_DATA0_P

HDMI_RX_0_DATA1_N

HDMI_RX_0_DATA1_P

HDMI_RX_0_DATA2_N

HDMI_RX_0_DATA2_P

HDMI_RX_0_VDD3P3

HDMI_RX_0_VDD1P2

HDMI_RX_0_VDD2P5

HDMI_RX_0_AVSS_1

HDMI_RX_0_AVSS_2

HDMI_RX_0_AVSS_3

HDMI_RX_0_AVSS_4

HDMI_RX_0_AVSS_5

HDMI_RX_0_AVSS_6

HDMI_RX_0_PLL_AVSS

HDMI_RX_0_PLL_DVDD1P2

HDMI_RX_0_PLL_DVSS

HDMI_RX_1_CEC_DAT

HDMI_RX_1_HTPLG_IN

HDMI_RX_1_HTPLG_OUT

HDMI_RX_1_DDC_SCL

HDMI_RX_1_DDC_SDA

HDMI_RX_1_RESREF

HDMI_RX_1_CLK_N

HDMI_RX_1_CLK_P

HDMI_RX_1_DATA0_N

HDMI_RX_1_DATA0_P

HDMI_RX_1_DATA1_N

HDMI_RX_1_DATA1_P

HDMI_RX_1_DATA2_N

HDMI_RX_1_DATA2_P

HDMI_RX_1_VDD3P3

HDMI_RX_1_VDD1P2

HDMI_RX_1_VDD2P5

HDMI_RX_1_AVSS_1

HDMI_RX_1_AVSS_2

HDMI_RX_1_AVSS_3

HDMI_RX_1_AVSS_4

HDMI_RX_1_AVSS_5

HDMI_RX_1_AVSS_6

HDMI_RX_1_AVSS_7

HDMI_RX_1_AVSS_8

HDMI_RX_1_AVSS_9

HDMI_RX_1_PLL_AVSS

HDMI_RX_1_PLL_DVDD1P2

HDMI_RX_1_PLL_DVSS

I2S_LR_IN

AE18

AF18

AD17

AH19

AD18

AG18

AG26

AH26

AF23

AA20

AB21

AC22

AC23

AD23

AH25

AG25

AH23

AG23

AG24

AH24

AE22

AB20

AC21

AE23

AF21

AE21

AF22

AG22

AD21

AC20

AD22

AH2

AC6

AE4

AF3

AH1

AG1

AA6

AA5

AB3

Y6

AC4

AC1

AC2

AD1

AD2

AE1

AE2

AF1

AF2

AD3

AE3

AC3

AD4

AB5

AB6

AG2

AB4

AA7

Y8

AC5

W8

AA3

V4

U6

V5

V3

W4

W2

W3

Y1

Y2

AA2

AA1

AB2

AB1

Y3

Y4

W5

W1

U5

W6

U7

V7

W7

U8

V8

Y5

V6

AA4

Y7

R344

1K

R345

499 R346

499 R343

READY

C350

0.1uF

10K

C351

4.7uF

R350

SPDIF_OUT

+5V_MULTI

C352

1000pF

10K

10KR351

C354

0.1uF

10K

R353

A3.3V

BLM18PG121SN1D

C355

4.7uF

AUD_SCK

AUD_LRCH

AUD_LRCK

22 R355

22 R356

C356

0.01uF

D3.3V

10K

R354

L307

C357

1000pF

C360

0.01uF

C359

0.01uF

C361

0.01uF

HDMI0_RXC-_BCM

HDMI0_RXC+_BCM

HDMI0_RX0-_BCM

HDMI0_RX0+_BCM

HDMI0_RX1-_BCM

HDMI0_RX1+_BCM

HDMI0_RX2-_BCM

HDMI0_RX2+_BCM

C362

0.1uF

C364

10uF

C363

0.1uF

C365

0.01uF

C368

0.1uF

C367

0.1uF

C369

0.1uF

BLM18PG121SN1D

L305

C370

0.1uF

C372

10uF

C374

10uF

C373

10uF

C375

10uF

HDMI_SCL

HDMI_SDA

008:AA19

008:AB19

008:AB19

008:AB19

008:AC19

008:AC19

008:AC19

008:AD19

A1.2V

A3.3V

BLM18PG121SN1D

A2.5V

BLM18PG121SN1D

L306

L308

A1.2V

A2.5V

A2.5V

008:AA19

008:AA19

A2.5V

C378

0.1uF

16V

C3011

1000pF

C3012

0.1uF

C3014

1000pF

C389

R363

0.1uF

C3015

1000pF

A3.3V

20

C3018

0.01uF

C3020

C3017

1000pF

1000pF

D1.2V

LGE3556CP (C0 3D PIP)

H8

J8

K8

L8

M8

N8

P8

R8

AA8

H9

H10

H11

H12

H13

H14

H15

H16

H17

H18

H19

H21

J21

K21

L21

M21

N21

P21

R21

T21

U21

V21

W21

Y21

AH27

D3.3V

AA12

AA13

AA18

AA19

E28

L28

U28

AB28

D1.8V

A9

G9

G11

G13

A14

G15

G17

A19

G19

C3021

0.1uF

VDDC_1

VDDC_2

VDDC_3

VDDC_4

VDDC_5

VDDC_6

VDDC_7

VDDC_8

VDDC_9

VDDC_10

VDDC_11

VDDC_12

VDDC_13

VDDC_14

VDDC_15

VDDC_16

VDDC_17

VDDC_18

VDDC_19

VDDC_20

VDDC_21

VDDC_22

VDDC_23

VDDC_24

VDDC_25

VDDC_26

VDDC_27

VDDC_28

VDDC_29

VDDC_30

VDDC_31

VDDC_32

VDDC_33

AGC_VDDO

VDDO_1

VDDO_2

VDDO_3

VDDO_4

VDDO_5

VDDO_6

VDDO_7

VDDO_8

DDRV_1

DDRV_2

DDRV_3

DDRV_4

DDRV_5

DDRV_6

DDRV_7

DDRV_8

DDRV_9

C3024

4.7uF

C3023

0.01uF

IC100

C3027

1000pF

C3026

0.01uF

C3030

0.01uF

C3029

0.01uF

D3.3V

D1.8V

C3032

0.1uF

C3033

0.01uF

C3035

0.1uF

D1.8V

C3047

C3038

0.1uF

C3040

0.1uF

C3044

0.1uF

0.1uF

C3050

4.7uF

C3053

4.7uF

C3056

4.7uF

C3060

33uF

D1.8V

C3043

C3041

C3037

0.1uF

0.1uF

16V

16V

16V

AD5

AD6

J7

K7

L7

M7

AB7

AC7

G8

D9

AA9

G10

A11

L11

M11

N11

P11

R11

T11

U11

V11

D12

G12

L12

M12

N12

P12

R12

T12

U12

V12

L13

M13

N13

P13

R13

T13

U13

V13

G14

L14

M14

N14

P14

R14

T14

U14

V14

L15

M15

N15

P15

R15

T15

U15

V15

A16

G16

L16

M16

N16

C3046

10uF

0.1uF

10V

16V

IC100

LGE3556CP (C0 3D PIP)

DVSS_1

DVSS_2

DVSS_3

DVSS_4

DVSS_5

DVSS_6

DVSS_7

DVSS_8

DVSS_9

DVSS_10

DVSS_11

DVSS_12

DVSS_13

DVSS_14

DVSS_15

DVSS_16

DVSS_17

DVSS_18

DVSS_19

DVSS_20

DVSS_21

DVSS_22

DVSS_23

DVSS_24

DVSS_25

DVSS_26

DVSS_27

DVSS_28

DVSS_29

DVSS_30

DVSS_31

DVSS_32

DVSS_33

DVSS_34

DVSS_35

DVSS_36

DVSS_37

DVSS_38

DVSS_39

DVSS_40

DVSS_41

DVSS_42

DVSS_43

DVSS_44

DVSS_45

DVSS_46

DVSS_47

DVSS_48

DVSS_49

DVSS_50

DVSS_51

DVSS_52

DVSS_53

DVSS_54

DVSS_55

DVSS_56

DVSS_57

DVSS_58

DVSS_59

DVSS_60

DVSS_61

C3049

0.1uF

16V

DVSS_62

DVSS_63

DVSS_64

DVSS_65

DVSS_66

DVSS_67

DVSS_68

DVSS_69

DVSS_70

DVSS_71

DVSS_72

DVSS_73

DVSS_74

DVSS_75

DVSS_76

DVSS_77

DVSS_78

DVSS_79

DVSS_80

DVSS_81

DVSS_82

DVSS_83

DVSS_84

DVSS_85

DVSS_86

DVSS_87

DVSS_88

DVSS_89

DVSS_90

DVSS_91

DVSS_92

DVSS_93

DVSS_94

DVSS_95

DVSS_96

DVSS_97

DVSS_98

DVSS_99

DVSS_100

DVSS_101

DVSS_102

DVSS_103

DVSS_104

DVSS_105

DVSS_106

DVSS_107

DVSS_108

DVSS_109

DVSS_110

DVSS_111

DVSS_112

DVSS_113

DVSS_114

DVSS_115

DVSS_116

DVSS_117

C3052

0.1uF

P16

R16

T16

U16

V16

AA16

D17

L17

M17

N17

P17

R17

T17

U17

V17

AA17

AC19

G18

L18

M18

N18

P18

R18

T18

U18

V18

D20

G20

H20

A21

E21

F21

G21

E22

F22

G22

H22

J22

K22

L22

M22

N22

P22

R22

T22

U22

V22

W22

Y22

AA22

W23

AB23

F28

M28

T28

AC28

C3058

C3055

0.1uF

16V

16V

0.1uF

C3061

0.1uF

16V

16V

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

BCM VIDEO IN & MAIN POWER

08/10/xx

BCM VIDEO IN/BCM POWER 3 1 3

Page 16

IC100

Copyright © 2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

LGE3556CP (C0 3D PIP)

DDR_BVDD0

DDR_BVDD1

DDR_BVSS0

DDR_BVSS1

DDR_PLL_TEST

DDR_PLL_LDO

DDR01_CKE

DDR01_ODT

DDR_EXT_CLK

DDR0_CLKB

DDR1_CLKB

DDR01_CASB

DDR0_DQS0

DDR0_DQS0B

DDR0_DQS1

DDR0_DQS1B

DDR1_DQS0

DDR1_DQS0B

DDR1_DQS1

DDR1_DQS1B

DDR01_RASB

DDR_VREF0

DDR_VREF1

DDR01_WEB

DDR_VDDP1P8_1

DDR_VDDP1P8_2

* DDR_VTT

C402

C485

100uF

100uF

16V

16V

DDR0_VREF0

C400

0.1uF

16V

DDR_COMP

DDR0_CLK

DDR1_CLK

DDR01_A00

DDR01_A01

DDR01_A02

DDR01_A03

DDR0_A04

DDR0_A05

DDR0_A06

DDR01_A07

DDR01_A08

DDR01_A09

DDR01_A10

DDR01_A11

DDR01_A12

DDR01_A13

DDR1_A04

DDR1_A05

DDR1_A06

DDR01_BA0

DDR01_BA1

DDR01_BA2

DDR0_DQ00

DDR0_DQ01

DDR0_DQ02

DDR0_DQ03

DDR0_DQ04

DDR0_DQ05

DDR0_DQ06

DDR0_DQ07

DDR0_DQ08

DDR0_DQ09

DDR0_DQ10

DDR0_DQ11

DDR0_DQ12

DDR0_DQ13

DDR0_DQ14

DDR0_DQ15

DDR1_DQ00

DDR1_DQ01

DDR1_DQ02

DDR1_DQ03

DDR1_DQ04

DDR1_DQ05

DDR1_DQ06

DDR1_DQ07

DDR1_DQ08

DDR1_DQ09

DDR1_DQ10

DDR1_DQ11

DDR1_DQ12

DDR1_DQ13

DDR1_DQ14

DDR1_DQ15

DDR0_DM0

DDR0_DM1

DDR1_DM0

DDR1_DM1

DDR_VTT

DDR1_VREF0

C401

0.1uF

16V

R400

0

R401

0

A6

A24

B7

B24

F20

B23

B17

C22

E16

C23

B12

C12

A13

A12

B15

E14

A15

D15

E13

E12

F13

C14

F14

B14

D14

C13

D13

B13

F15

C15

D16

F16

B16

E15

A17

A8

B11

B8

D11

E11

C8

C11

C9

D8

E10

E9

F11

F12

E8

D10

F8

C18

C20

A18

B21

C21

B18

B20

D18

E18

D21

F18

E20

A22

F17

B22

E17

A10

C10

A20

F19

B10

B9

F10

F9

B19

C19

E19

D19

C16

A7

A23

C17

C7

D22

C403

10uF

10V

C404

0.1uF

A1.2V

READY

DDR0_DQ[10]

DDR0_DQ[11]

DDR0_DQ[12]

DDR0_DQ[13]

DDR0_DQ[14]

DDR0_DQ[15]

DDR1_DQ[10]

DDR1_DQ[11]

DDR1_DQ[12]

DDR1_DQ[13]

DDR1_DQ[14]

DDR1_DQ[15]

D1.8V

0.1uF C408

0.1uF C409

0

R403

R406

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR0_A[4]

DDR0_A[5]

DDR0_A[6]

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

DDR1_A[4]

DDR1_A[5]

DDR1_A[6]

DDR0_DQ[0]

DDR0_DQ[1]

DDR0_DQ[2]

DDR0_DQ[3]

DDR0_DQ[4]

DDR0_DQ[5]

DDR0_DQ[6]

DDR0_DQ[7]

DDR0_DQ[8]

DDR0_DQ[9]

DDR1_DQ[0]

DDR1_DQ[1]

DDR1_DQ[2]

DDR1_DQ[3]

DDR1_DQ[4]

DDR1_DQ[5]

DDR1_DQ[6]

DDR1_DQ[7]

DDR1_DQ[8]

DDR1_DQ[9]

READY

C406

0.1uF

C407

0.1uF

16V

C405

10uF

10V

C486

0.1uF

16V

C416

D1.8V

D1.8V

C423

C422

C424

470pF

IC401

0.047uF

0.1uF

DM/RDQS

NU/RDQS

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDD_1

VDD_2

VDD_3

VDD_4

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSSDL

VSS_1

VSS_2

VSS_3

VSS_4

VREF

VDDL

10uF

C8

DQ0

C2

DQ1

D7

DQ2

D3

DQ3

D1

DQ4

D9

DQ5

B1

DQ6

B9

DQ7

B7

DQS

A8

DQS

B3

A2

A9

C1

C3

C7

C9

A1

L1

E9

H9

A7

B2

B8

D2

D8

A3

E3

J1

K9

E2

E1

E7

C421

240

1%

DDR01_CKE

DDR01_ODT

DDR0_CLK

DDR0_CLKb

DDR1_CLK

DDR1_CLKb

DDR01_BA0

DDR01_BA1

DDR01_BA2

DDR01_CASb

004:C7;004:C4

004:C7;004:C4

004:F7;004:F4

004:F7;004:F4

DDR01_A[0-3]

DDR0_A[4-6]

DDR01_A[7-13]

DDR1_A[4-6]

DDR0_DQ[0-15]

004:A7;004:C4

004:A7;004:C4

DDR0_CLK

DDR0_CLKb

DDR01_CKE

DDR01_RASb

DDR01_CASb

DDR01_WEb

DDR01_BA0

DDR01_BA1

DDR01_BA2

DDR01_A[0-3,7-13]

DDR0_A[4-6]

DDR01_ODT

R410

NT5TU128M8DE_BD

NANYA_1G_DDR2

1%

100

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR0_A[4]

DDR0_A[5]

DDR0_A[6]

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

E8

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

F3

WE

G8

CS

G2

BA0

G3

BA1

G1

NC_1/BA2

H8

A0

H3

A1

H7

A2

J2

A3

J8

A4

J3

A5

J7

A6

K2

A7

K8

A8

K3

A9

H2

A10/AP

K7

A11

L2

A12

L8

A13

L3

NC_2/A14

L7

NC_3/A15

F9

ODT

C425

470pF

DDR0_DQ[0]

DDR0_DQ[1]

DDR0_DQ[2]

DDR0_DQ[3]

DDR0_DQ[4]

DDR0_DQ[5]

DDR0_DQ[6]

DDR0_DQ[7]

C426

0.047uF

C427

0.1uF

D1.8V

DDR0_VREF0

C430

0.1uF

C428

22uF

DDR0_DQS0

DDR0_DQS0b

DDR0_DM0

470pF

C433

C429

10uF

C432

10uF

22uF

DDR0_DQ[0-7]

004:A4

004:A4

004:A4

004:B6;004:F3;004:I7

0.1uF

004:A7;004:F4

004:A7;004:F4

DDR01_A[0-3,7-13]

C435

C436

Close to IC

DDR1_DQ[0-15]

DDR0_DM0

READY

0.1uF 16V

C488

0.1uF

16V

1uF

GND

EN

VTTS

VREF

DDR01_RASb

READY

C410

C411

C412

470pF

470pF

IC400

BD35331F-E2

1

2

3

4

DDR0_DM1

DDR1_DM0

DDR1_DM1

DDR0_DQS0

DDR0_DQS0b

DDR0_DQS1

DDR0_DQS1b

DDR1_DQS0

DDR1_DQS0b

DDR1_DQS1

DDR1_DQS1b

C413

1uF

R402

10K

004:E6

004:E3

004:H6

004:H3

004:E6

004:E6

004:E3

004:E3

004:H6

004:H6

004:H3

004:H3

DDR01_WEb

VTT

8

VTT_IN

7

VCC

6

VDDQ

5

1uF

C419

2.2uF

10V

R412

220

C414

470pF

+3.3V_ST

C415

470pF

C420

10uF

10V

DDR0_VREF0

C417

1uF

C478

0.1uF

16V

C418

DDR1_VREF0

D1.8V

C477

10uF

10V

004:A7;004:C7

004:A7;004:C7

004:A7;004:C7;004:F7;004:F4

DDR0_CLK

DDR0_CLKb

DDR01_CKE

DDR01_RASb

DDR01_CASb

DDR01_WEb

DDR01_BA0

DDR01_BA1

DDR01_BA2

DDR01_A[0-3,7-13]

DDR0_A[4-6]

DDR01_ODT

C479

0.1uF

16V

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR0_A[4]

DDR0_A[5]

DDR0_A[6]

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

E8

F8

F2

F7

G7

F3

G8

G2

G3

G1

H8

H3

H7

J2

J8

J3

J7

K2

K8

K3

H2

K7

L2

L8

L3

L7

F9

IC403

NT5TU128M8DE_BD

NANYA_1G_DDR2

CK

CK

CKE

RAS

CAS

WE

CS

BA0

BA1

NC_1/BA2

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10/AP

A11

A12

A13

NC_2/A14

NC_3/A15

ODT

DM/RDQS

NU/RDQS

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDD_1

VDD_2

VDD_3

VDD_4

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSSDL

VSS_1

VSS_2

VSS_3

VSS_4

VREF

VDDL

DDR0_DQ[8-15]

C8

DDR0_DQ[9]

DQ0

C2

DDR0_DQ[8]

DQ1

D7

DDR0_DQ[12]

DQ2

D3

DDR0_DQ[13]

DQ3

D1

DDR0_DQ[15]

DQ4

D9

DDR0_DQ[11]

DQ5

B1

DDR0_DQ[10]

DQ6

B9

DDR0_DQ[14]

DQ7

B7

DQS

A8

DQS

B3

A2

A9

C1

C3

C7

C9

A1

L1

E9

H9

A7

B2

B8

D2

D8

A3

E3

J1

K9

E2

E1

E7

D1.8V

DDR0_DQS1

DDR0_DQS1b

DDR0_DM1

DDR0_VREF0

C431

0.1uF

C434

470pF

004:A4

004:A4

004:A4

DDR01_A[0-3,7-13]

Close to IC

C439

C438

C437

004:B6

0.047uF

470pF

DDR1_CLK

DDR1_CLKb

DDR01_CKE

DDR01_RASb

DDR01_CASb

DDR01_WEb

DDR01_BA0

DDR01_BA1

10uF

DDR01_BA2

DDR1_A[4-6]

004:A7;004:C5;004:C2;004:F2;004:I4;004:I6

DDR01_ODT

DDR1_CLK

DDR1_CLKb

DDR01_CKE

DDR01_RASb

DDR01_CASb

DDR01_WEb

DDR01_BA0

DDR01_BA1 DDR1_DQS1

DDR01_BA2

DDR1_A[4-6]

004:B6;004:F6;004:I7

DDR01_ODT

C440

0.1uF

R411

C441

100

0.047uF

C442

470pF

1%

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR1_A[4]

DDR1_A[5]

DDR1_A[6]

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

DDR01_A[0]

DDR01_A[1]

DDR01_A[2]

DDR01_A[3]

DDR1_A[4]

DDR1_A[5]

DDR1_A[6]

DDR01_A[7]

DDR01_A[8]

DDR01_A[9]

DDR01_A[10]

DDR01_A[11]

DDR01_A[12]

DDR01_A[13]

IC402

NT5TU128M8DE_BD

NANYA_1G_DDR2

E8

CK

F8

CK

F2

CKE

F7

RAS

G7

CAS

F3

WE

G8

CS

G2

BA0

G3

BA1

G1

NC_1/BA2

H8

A0

H3

A1