Page 1

Training Manual

50PQ30 Plasma Display

50PQ30 Plasma Display

Advanced Single Scan Troubleshooting

720p

720p

Published November 05

th

, 2009

Page 2

OUTLINE

OUTLINE

Section 1

Contact Information, Preliminary Matters, Specifications,

Plasma Overview, General Troubleshooting Steps,

Disassembly Instructions, Voltage and Signal Distribution

Section 2

Circuit Board Operation, Troubleshooting and Alignment of :

• Switch mode Power Supply

Overview of Topics to be Discussed

• Y-SUS Board

Delivers Logic Signals and FG5V to both upper and lower boards.

• Y-Drive Boards (2) Upper and Lower. Lower board delivers Scan to Upper

• Z-SUS Output Board (Also uses one Z-SUB board for bottom panel connector)

• Control Board

• X Drive Boards (3)

• Main Board

• Main Power Switch (Version 3). Shuts off stand by 5V.

2

November 2009 50PQ30 Plasma

Page 3

Overview of Topics to be Discussed

Overview of Topics to be Discussed

50PQ30 Plasma Display

Section 1

This Section will cover Contact Information and remind the Technician of

Important Safety Precautions for the Customers Safety as well as the Technician

and the Equipment.

Basic Troubleshooting Techniques which can save time and money sometimes

can be overlooked. These techniques will also be presented.

This Section will get the Technician familiar with the Disassembly, Identification and

Layout of the Plasma Display Panel.

At the end of this Section the Technician should be able to Identify the Circuit

Boards and have the ability and knowledge necessary to safely remove and

replace any Circuit Board or Assembly.

3

November 2009 50PQ30 Plasma

Page 4

Preliminary Matters (The Fine Print)

Preliminary Matters (The Fine Print)

IMPORTANT SAFETY NOTICE

IMPORTANT SAFETY NOTICE

The information in this training manual is intended for use by persons possessing an adequate

background in electrical equipment, electronic devices, and mechanical systems. In any attempt

to repair a major Product, personal injury and property damage can result. The manufacturer or

seller maintains no liability for the interpretation of this information, nor can it assume any

liability in conjunction with its use. When servicing this product, under no circumstances should

the original design be modified or altered without permission from LG Electronics. Unauthorized

modifications will not only void the warranty, but may lead to property damage or user injury.

If wires, screws, clips, straps, nuts, or washers used to complete a ground path are removed for

service, they must be returned to their original positions and properly fastened.

CAUTION

CAUTION

To avoid personal injury, disconnect the power before servicing this product. If electrical power

is required for diagnosis or test purposes, disconnect the power immediately after performing

the necessary checks. Also be aware that many household products present a weight hazard.

At least two people should be involved in the installation or servicing of such devices.

Failure to consider the weight of an product could result in physical injury.

4

November 2009 50PQ30 Plasma

Page 5

LG CONTACT INFORMATION

LG CONTACT INFORMATION

Customer Service (and Part Sales) (800) 243-0000

Technical Support (and Part Sales) (800) 847-7597

USA Website (GCSC) aic.lgservice.com

Customer Service Website us.lgservice.com

LG Web Training lge.webex.com

LG CS Academy lgcsacademy.com

LCD-DV:

PLASMA:

Also available on

Also available on

the Plasma page

the Plasma page

Published November 2009 by LG Technical Support and Training

http://136.166.4.200

LG Learning Academy

32LG40, 32LH30, 37LH55, 42LG60, 42LG70, 42LH20, 42LH40, 42LH50, 47LG90

42PG20, 42PQ20, 50PQ30, 50PG20, 50PS80, 50PS60

Plasma Panel

Alignment Handbook

LG Electronics Alabama, Inc.

201 James Record Road, Huntsville, AL, 35813.

New Training Materials on

New Training Materials on

the Learning Academy site

the Learning Academy site

Page 5

Page 5

Page 6

(Electrostatic Static Discharge)

ESD Notice

ESD Notice

Today’s sophisticated electronics are electrostatic discharge (ESD) sensitive. ESD can weaken or damage

the electronics in a manner that renders them inoperative or reduces the time until their next failure.

Connect an ESD wrist strap to a ground connection point or unpainted metal in the product. Alternatively,

you can touch your finger repeatedly to a ground connection point or unpainted metal in the product. Before

removing a replacement part from its package, touch the anti-static bag to a ground connection point or

unpainted metal in the product. Handle the electronic control

repackaging a failed electronic control assembly in an anti-static bag, observe these same precautions.

Regulatory Information

Regulatory Information

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy, and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures: Reorient or relocate

the receiving antenna; Increase the separation between the equipment and the receiver; Connect the

equipment to an outlet on a different circuit than that to which the receiver is connected; or consult the

dealer or an experienced radio/TV technician for help.

(Electrostatic Static Discharge)

assembly by its edges only. When

6

November 2009 50PQ30 Plasma

Page 7

Safety and Handling, Checking Points

Safety and Handling, Checking Points

Safety & Handling Regulations

1. Approximately 10 minute pre-run time is required before any adjustments are performed.

2. Refer to the Voltage Sticker inside the Panel when making adjustments on the Power Supply, Y-SUS and Z-SUS Boards.

3. Always adjust to the specified voltage level (+/- ½ volt) unless otherwise specified.

4. Be cautious of electric shock from the PDP module since the PDP module uses high voltage, check that the Power Supply

and Drive Circuits are completely discharged because of residual current stored before Circuit Board removal.

4. C-MOS circuits are used extensively for processing the Drive Signals and should be protected from static electricity.

5. The PDP Module must be carried by two people. Always carry vertical NOT horizontal.

6. The Plasma television should be transported vertically NOT horizontally.

7. Exercise care when making voltage and waveform checks to prevent costly short circuits from damaging the unit.

8. Be cautious of lost screws and other metal objects to prevent a possible short in the circuitry.

9. New Panels and Frames are much thinner than previous models. Be Careful with flexing these panels. Be careful

with lifting Panels from a horizontal position. Damage to the Frame mounts or panel can occur.

10. New Plasma models have much thinner cabinet assemblies and mounts.

Be extremely careful when moving the set around as damage can occur.

Checking Points to be Considered

1. Check the appearance of the Replacement Panel and Circuit Boards for both physical damage and part number accuracy.

2. Check the model label. Verify model names and board model matches.

3. Check details of defective condition and history. Example: Y Board Failure, Mal-discharge on screen, etc.

7

November 2009 50PQ30 Plasma

Page 8

Basic Troubleshooting Steps

Basic Troubleshooting Steps

Define, Localize, Isolate and Correct

• Define

failure. Use your senses Sight, Smell, Touch and Hearing. Look for burned parts and check

for possible overheated components. Capacitors will sometimes leak dielectric material and

give off a distinct odor. Frequency of power supplies will change with the load, or listen for

relay closing etc. Observation of the front Power LEDs may give some clues.

• Localize

and after giving a thorough examination using your senses the first check should always be

the DC Supply Voltages to those circuits under test. Always confirm the supplies are not

only the proper level but be sure they are noise free. If the supplies are missing check the

resistance for possible short circuits.

• Isolate

to make a final determination of the failure. Look for correct Amplitude Phasing and Timing

of the signals also check for the proper Duty Cycle of the signals. Sometimes “glitches” or

“road bumps” will be an indication of an imminent failure.

Look at the symptom carefully and determine what circuits could be causing the

After carefully checking the symptom and determining the circuits to be checked

To further isolate the failure, check for the proper waveforms with the Oscilloscope

• Correct

check the DC Supplies for proper levels. Make all necessary adjustments and lastly always

perform a Safety AC Leakage Test before returning the product back to the Customer.

The final step is to correct the problem. Be careful of ESD and make sure to

8

November 2009 50PQ30 Plasma

Page 9

50PQ30 PRODUCT INFORMATION SECTION

50PQ30 PRODUCT INFORMATION SECTION

This section of the manual will discuss the specifications of the

50PQ30 Advanced Single Scan Plasma Display Television.

9

November 2009 50PQ30 Plasma

Page 10

50PQ30 Specifications

50PQ30 Specifications

• 720p HD Resolution

• 600 Hz sub field driving

• 1,500 cd/m2 Brightness

• Dual XD Engine™

• 2000,000:1 Dynamic Contrast Ratio

• Smart Energy Saving

• 3x HDMI™ V.1.3 with Deep Color (2 Rear, 1 side).

720P PLASMA HDTV

50” Class (50” diagonal)

• AV Mode (Cinema, Sports, Game)

• Clear Voice

• LG SimpLink™ Connectivity

• Invisible Speaker System

• 100,000 Hours to Half Brightness (Typical)

• PC Input

10

November 2009 50PQ30 Plasma

Page 11

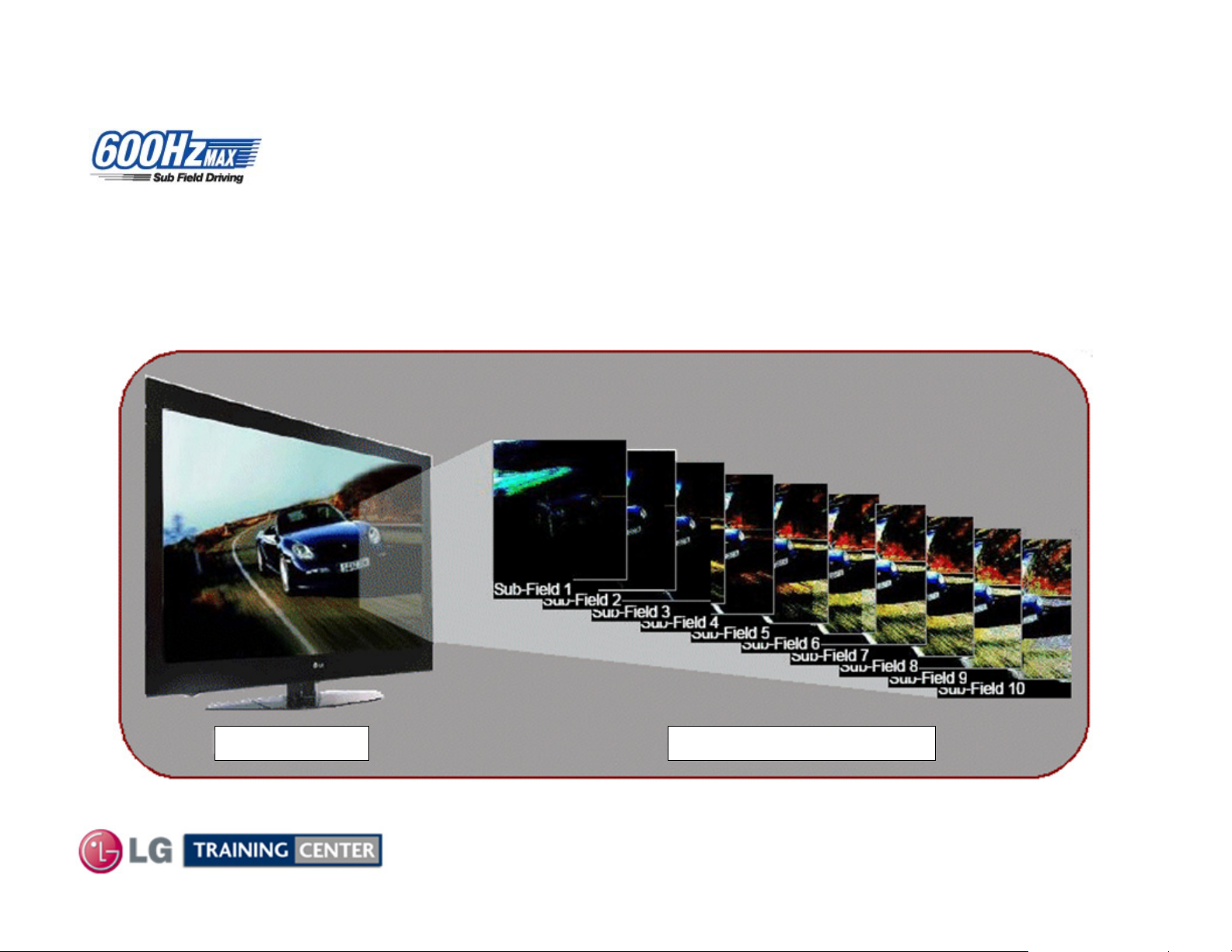

600Hz Sub Field Driving

600Hz Sub Field Driving

(600 Hz Sub Field Driving)

• 600 Hz Sub Field Driving is achieved by using 10 sub-fields per frame process

(vs. Comp. 8 sub-field/frame)

• No smeared images during fast motion scenes

Original Image 10 Sub Fields Per Frame

Sub Field firing occurs using wall charge and polarity differences between Y-SUS and Z-SUS signals.

11

November 2009 50PQ30 Plasma

Page 12

Specifications Logo Familiarization (Picture Wizard)

Specifications Logo Familiarization (Picture Wizard)

Picture Wizard

consumers through the

calibration process using

on-screen reference

points.

Customers can customize

picture performance

without the need for

additional expense.

easily guides

12

November 2009 50PQ30 Plasma

Page 13

50PQ30 Logo Familiarization Page 1 of 2

50PQ30 Logo Familiarization Page 1 of 2

HD RESOLUTION 720p HD Resolution Pixels: 1365 (H) × 768 (V)

High definition television is the highest performance segment of the

DTV system used in the US. It’s a wide screen, high-resolution video

image, coupled with multi-channel, compact-disc quality sound.

HDMI (1.3 Deep Color) Digital multi-connectivity

HDMI (1.3 Deep color) provides a wider bandwidth (340MHz,

10.2Gbps) than that of HDMI 1.2, delivering a broader range of colors,

and also drastically improves the data-transmission speed.

Invisible Speaker

Personally tuned by Mr. Mark Levinson for LG

TAKE IT TO THE EDGE newly introduces ‘Invisible Speaker’ system,

guaranteeing first class audio quality personally tuned by Mr. Mark

Levinson, world renowned as an audio authority. It provides Full Sweet

Spot and realistic sound equal to that of theaters with its Invisible

Speaker.

Dual XD Engine

Realizing optimal quality for all images

One XD Engine optimizes the images from RF signals as another XD

Engine optimizes them from External inputs. Dual XD Engine presents

images with optimal quality two times higher than those of previous

models.

13

November 2009 50PQ30 Plasma

Page 14

50PQ30 Logo Familiarization Page 2 of 2

50PQ30 Logo Familiarization Page 2 of 2

AV Mode "One click" Cinema,

TAKE IT TO THE EDGE is a true multimedia TV with an AV Mode

which allows you to choose from 4 different modes of Cinema, Sports

and Game by a single click of a remote control.

Clear Voice Clearer dialogue sound

Automatically enhances and amplifies the sound of the human voice

frequency range to provide high-quality dialogue when background

noise swells.

Save Energy, Save Money

It reduces the plasma display’s power consumption.

The default factory setting complies with the Energy Star requirements

and is adjusted to the comfortable level to be viewed at home.

(Turns on Intelligent Sensor).

THX

Cinema, Sport, Game mode.

Save Energy, Save Money

Home electronic products use energy when they're off to power features like clock

displays and remote controls. Those that have earned the ENERGY STAR use as much

as 60% less energy to perform these functions, while providing the same performance at

the same price as less-efficient models. Less energy means you pay less on your energy

bill. Draws less than 1 Watt in stand by.

14

November 2009 50PQ30 Plasma

Page 15

50PQ30 Remote Control

50PQ30 Remote Control

TOP PORTION

BOTTOM PORTION

15

November 2009 50PQ30 Plasma

Page 16

50PQ30 Rear and Side Input Jacks

50PQ30 Rear and Side Input Jacks

AC In

REAR

INPUTS

Software

Upgrades

SIDE

INPUTS

Music and

Photos

USB

HDMI 3

16

November 2009 50PQ30 Plasma

Page 17

Power:

279W (Typical)

0.13W (Stand-By)

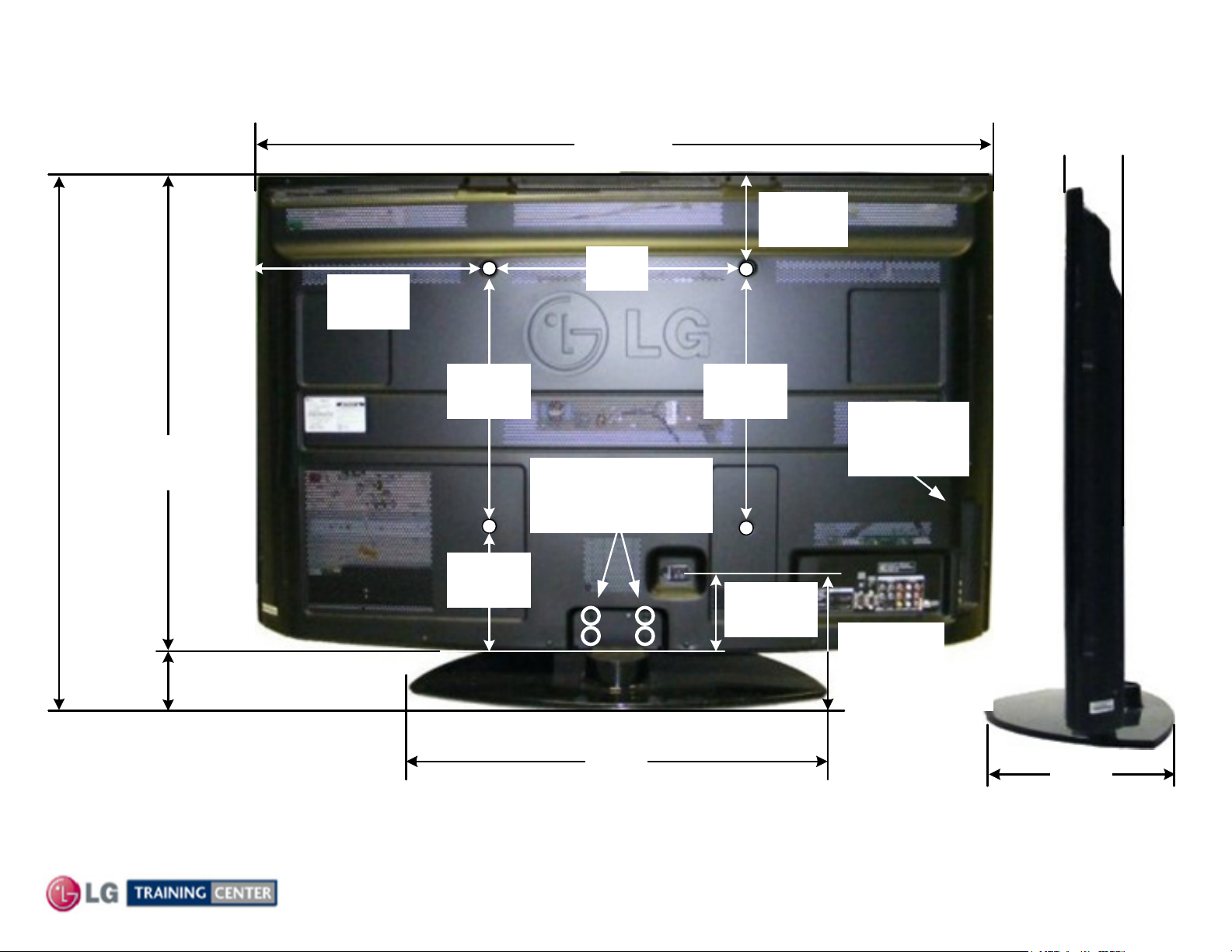

50PQ30 Dimensions

There must be at least 4 inches of Clearance on all sides

47-7/8"

1216.66mm

6-3/16"

157mm

15-3/4"

15-5/16"

405mm

400mm

3-5/16"

83.82mm

32-3/16"

817.9mm

759.46mm

Weight:

29-7/8"

2-5/16"

58.74mm

74.3 lbs with Stand

68.8 lbs without Stand

15-3/4"

400mm

7-7/8"

200mm

Remove 4 screws to

remove stand for

wall mount

25-5/8"

651mm

15-3/4"

400mm

Model No.

Serial No.

Label

4-15/16"

125mm

7-1/4"

183.74mm

13-7/8"

353mm

17 Published November 2009 50PQ30 Plasma

Page 18

DISASSEMBLY SECTION

DISASSEMBLY SECTION

This section of the manual will discuss Disassembly, Layout and Circuit

Board Identification, of the 50PQ30 Advanced Single Scan Plasma Display Panel.

Upon completion of this section the Technician will have a better

understanding of the disassembly procedures, the layout of the printed

circuit boards and be able to identify each board.

18

November 2009 50PQ30 Plasma

Page 19

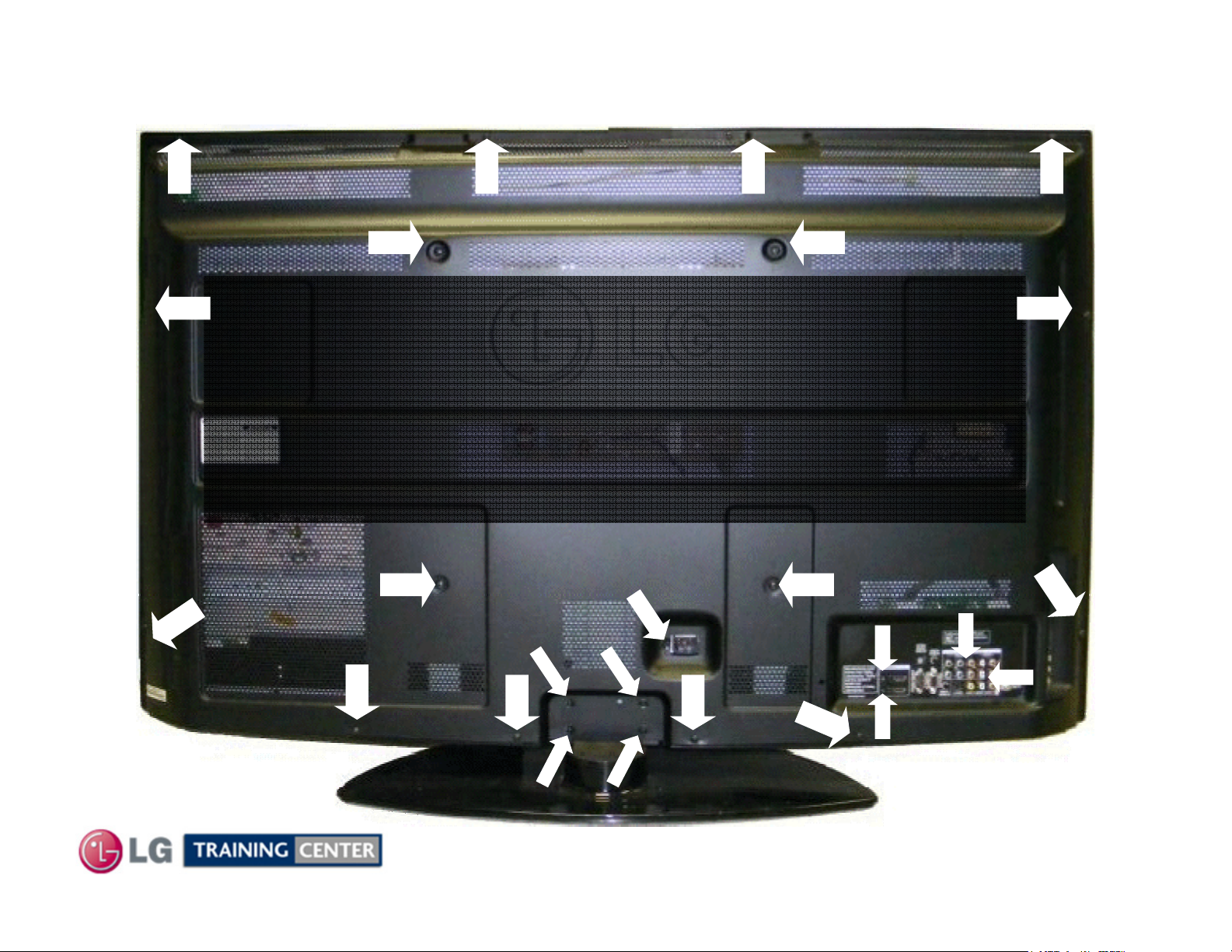

Removing the Back Cover

Removing the Back Cover

To remove the back cover, remove the 26 screws

(The Stand does not need to be removed).

PAY CLOSE ATTENTION TO THE TYPE, SIZE AND LENGTH

Of the screws when replacing the back cover.

Improper type can damage the front.

Indicated by the arrows.

19

November 2009 50PQ30 Plasma

Page 20

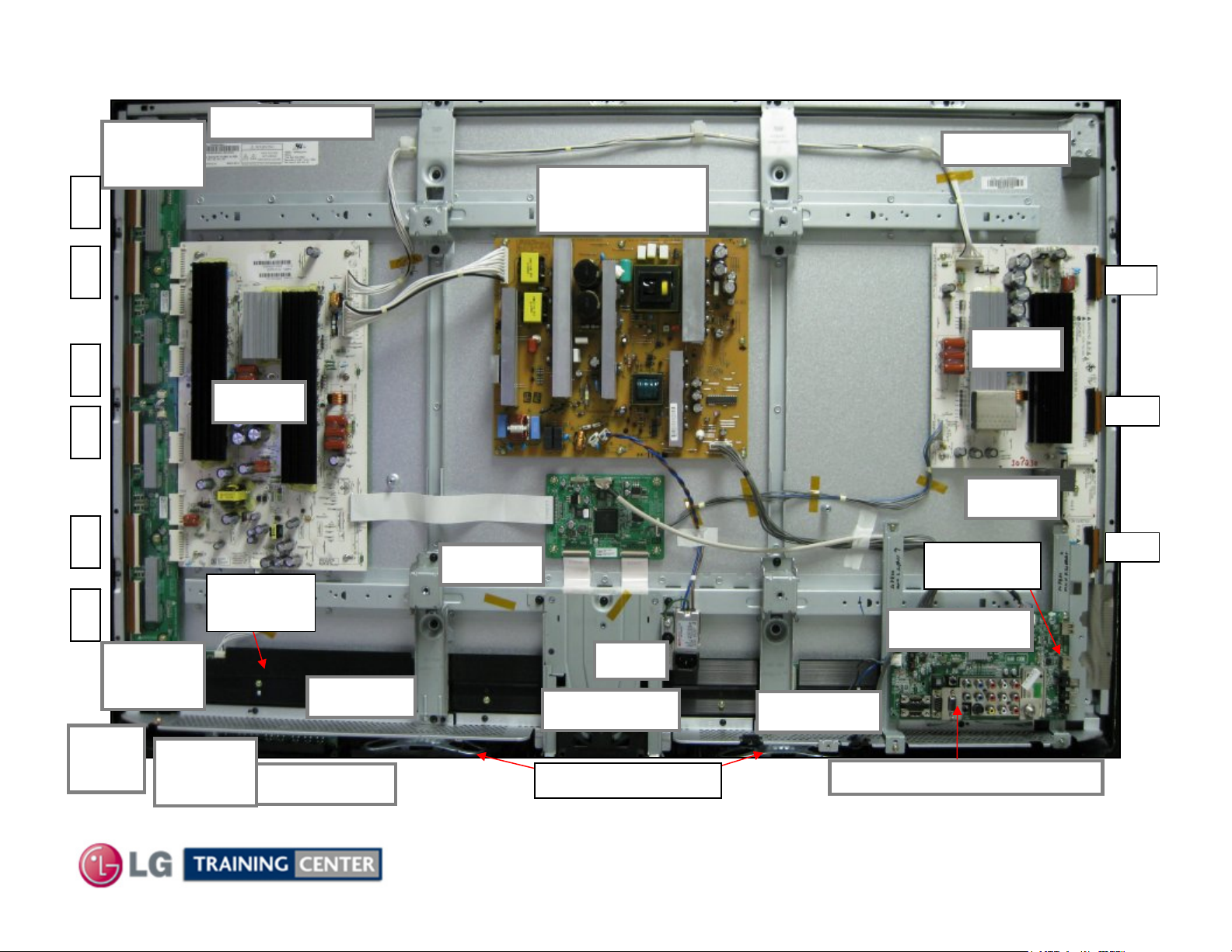

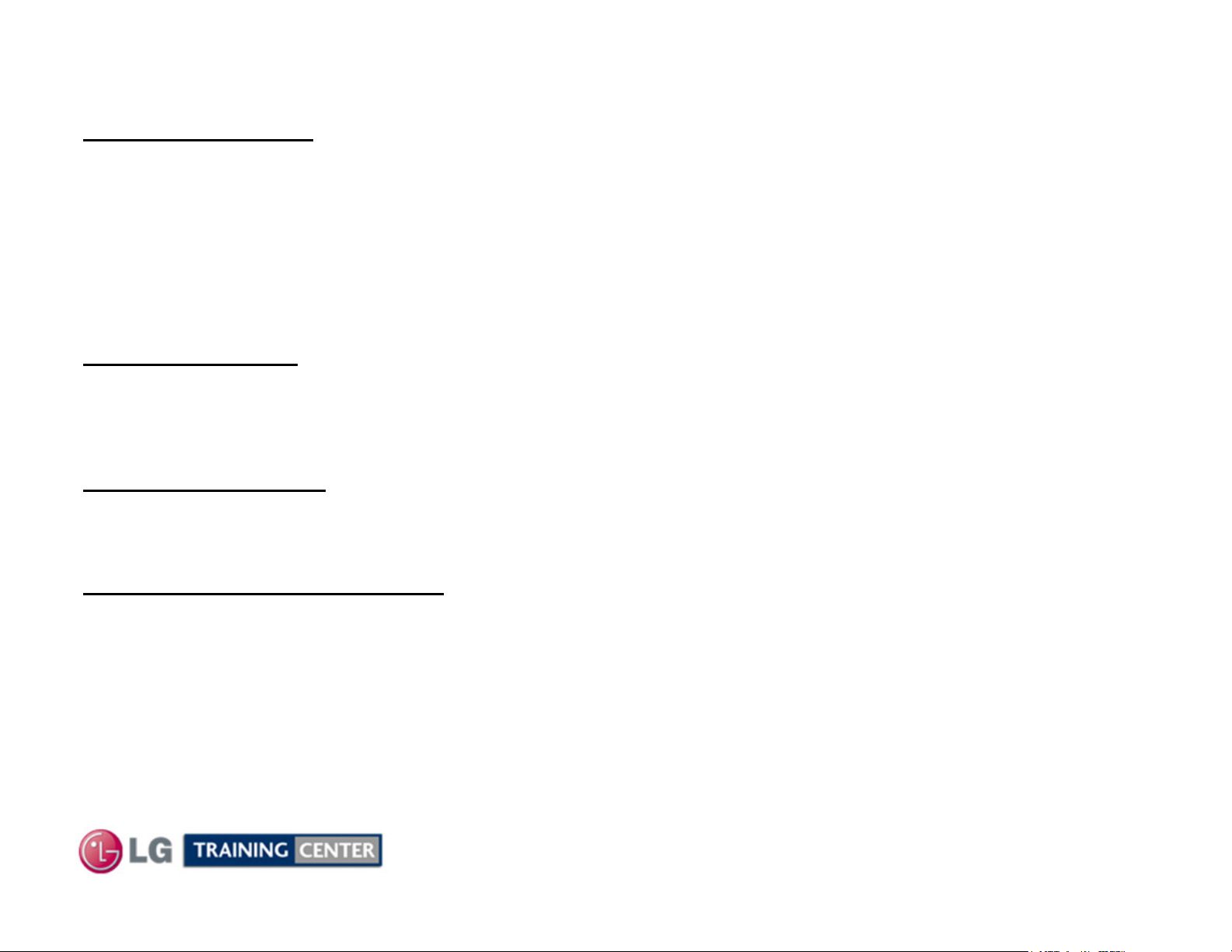

Circuit Board Layout

Circuit Board Layout

Panel Voltage Label

Y-Drive

Upper

FPC

FPC FPC FPC

Identify the Circuit Boards

Identify the Circuit Boards

Power Supply

(SMPS)

Panel ID Label

FPC

Z-SUS

FPC

FPC

IR/

LED

Y-Drive

Lower

Power

Main

Y-SUS

TCP

Heat Sink

Keyboard

Left “X”

Control

AC In

Center “X”

Invisible Speakers

Right “X”

Conductive Tape Under Main Board

Z-SUB

Side Input

(part of main)

Main Board

FPC

FPC

20

November 2009 50PQ30 Plasma

Page 21

Disassembly Procedure for Circuit Board Removal

Disassembly Procedure for Circuit Board Removal

Notes: 1) All Plugs listed are from left to right Pin 1,2, 3, ETC.

2) Remember to be cautious of ESD as some semiconductors are CMOS and prone to static failure.

Switch Mode Power Supply Board Removal

Disconnect the following connectors: P811, P813, SC101.

Remove the 8 screws holding the SMPS in place.

Remove the board.

When replacing, be sure to readjust the Va/Vs voltages in accordance with the Panel Label.

Also, re-confirm VSC, -Vy and Z-Bias as well.

After replacing the Y-Drive,

Y-SUS Board Removal

Disconnect the following connectors: P201, P206, P101, P202.

Remove the 8 screws holding the Y-SUS in place.

Remove the Y-SUS by lifting slightly to clear standoff and slid it to the right.

When replacing, be sure to readjust the Va/Vs voltages in accordance with the Panel Label.

Confirm VSC, -Vy and Z-bias as well.

After replacing the Y-Drive,

Y-Drive Boards Removal

check the connectors for solder breaks.

check the connectors for solder break.

Board Standoff

Disconnect the following Flexible Ribbon Connectors: P101~P103 and/or P201~P203.

Disconnect the following connectors: P209 and/or P108.

Remove the 3 screws holding either of the Y-Drive boards in place.

Remove the Y-Drive by lifting slightly and sliding the board to the left unseating P106,

P107, P109 and/or P205, P206 and P208 from the Y-SUS Board.

Note: Y, Z-SUS and Y-Drive boards are mounted on board stand-offs that have a small collar.

The board must be lifted slightly to clear these collars.

21

November 2009 50PQ30 Plasma

Collar

Page 22

Disassembly Procedure for Circuit Board Removal (2)

Disassembly Procedure for Circuit Board Removal (2)

Z-SUS Board Removal

Disconnect the following connectors: P100, P101.

Disconnect the following connectors: P104, P105 and P302. These are the FPC cables. Pull the locking

caps to the right. Lift carefully the Flexible Printed Circuits (FPCs) and slide them out to the right.

Remove the 5 screws holding the Z-SUS in place and the one holding the Z-SUB in place.

Lift the Z-SUS up and remove the board. Remove the Z-SUB by pulling it off the Z-SUS.

When replacing, be sure to readjust the Va/Vs voltages in accordance with the Panel Label.

Confirm VS, -Vy and Z-bias as well.

Main Board Removal

Disconnect the following connectors: P1001, P1003, P1005 and P1006.

Remove the 1screws holding on the decorative plastic piece on the right side.

Remove the 4 screws holding the Main board in place and Remove the board.

Control Board Removal

Disconnect the following connectors: P121 LVDS, P101, P161 Ribbon, P162 Ribbon by lifting up the

locking tab. Remove the 4 screws holding the Control board in place Remove the board.

Front Key and LED Board Removal

Remove the 2 screws holding the Key board in place. Remove the board by releasing the two black

tabs and lifting the board upward. Disconnect P101.

(Note: LED board is behind the Key board. Remove it’s 2 screws and remove.

Disconnect J1 and J2.

22

November 2009 50PQ30 Plasma

Page 23

X Drive Circuit Board Removal Continued

X Drive Circuit Board Removal Continued

Lay the Plasma down carefully on a padded surface.

Make sure AC is removed and remove the Back Cover and the Stand.

Carefully remove the LVDS Cable P121 from the Control Board by pressing the Locking Tabs together and

pull the connector straight back to remove the cable. (This prevents possible damage). See illustration below.

Press

Inward

LVDS Cable Connector

(A) Remove the Stand (4 Screws removed during back removal).

(B) Remove the Stand Metal Support Bracket (5 Screws).

(C) Remove connector P1001 to Front IR board and P1005 to the Speakers.

(D) Remove the 4 screws from the Main Board Mounting Bracket. Carefully reposition the Main Board and Mounting

Bracket up and off to the right side.

(E) Remove the metal support Braces marked “E”. Note: There is a Left and a Right brace. (3 Screws per/bracket).

(F) Remove the 9 screws holding the Heat Sink. (Warning: Never run the set with this heat sink removed).

X-DRIVE LEFT, CENTER AND RIGHT REMOVAL:

Disconnect all TCP ribbon cables from the defective X-Drive board. Remove the 3 screws in either the Left or Right X-Drive

board or the 4 screws holding the Center X-Drive in place.

Remove the board. Reassemble in reverse order. Recheck Va / Vs / VScan / -VY / Z-Drive.

Press

Inward

23

November 2009 50PQ30 Plasma

Page 24

Getting to the X Circuit Boards

Getting to the X Circuit Boards

Warning: Never run the TV with the TCP Heat Sink removed

A

LVDS Cable

B

Stand should have already be removed

F

Heat Sink

E

Left

B

A

Warning Shorting Hazard: Conductive Tape. Do not allow to touch energized circuits.

24

November 2009 50PQ30 Plasma

E

Right

C

D

Page 25

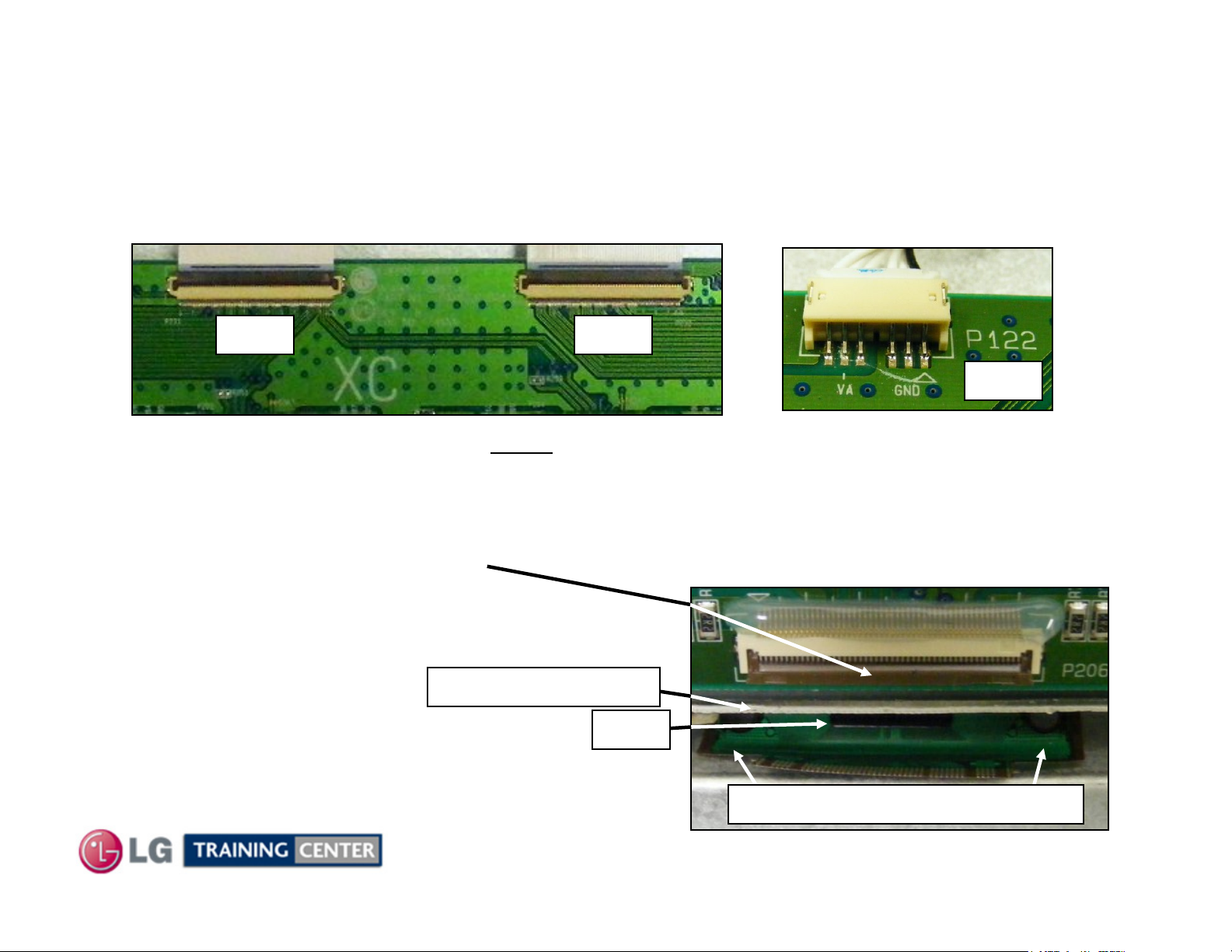

Left and Right X Drive Removal

Left and Right X Drive Removal

After removing the back cover, the Main board is lifted out of the way, the 9 screws removed from heat sink

covering the TCPs and connectors to the TCPs are removed, the X-Drive boards can be removed.

There may be tape on the connectors P231 or P232

P231 P232

Peel the tape off the connectors

Remove tape (if present) and Gently

locking mechanism upward and remove the ribbon

cable from the connector.

Removing Connectors to the TCPs.

Gently lift the locking mechanism

upward on all TCP connectors

Left X: P101~105

Center X: P201~206

Right X: P301~305

Cushion (Chocolate)

pry the

Disconnect connector P122

P122

Va from the Y-SUS

Carefully lift the TCP ribbon up and off.

It may stick, be careful not to crack TCP.

(See next page for precautions)

TCP

25

Flexible ribbon cable connector

November 2009 50PQ30 Plasma

Page 26

TCP (Tape

TCP (Tape

Carrier

Carrier

Package) Generic Removal Precautions

Package) Generic Removal Precautions

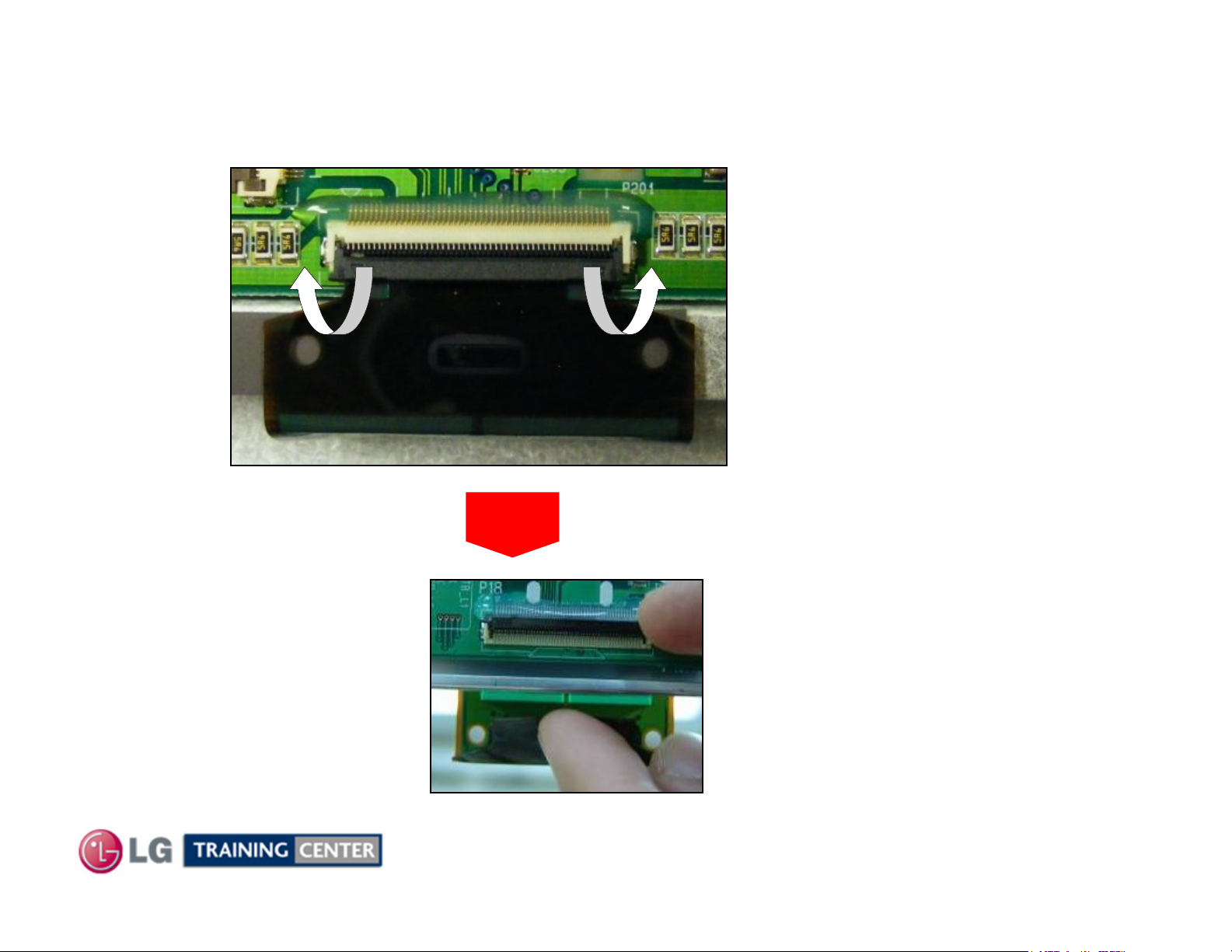

TCP Connector Removal

Lift up the lock as shown by arrows.

(The Lock can be easily broken.

It needs to be handled carefully.)

The TCP has two small tab on each

side which have to be lifted up

slightly to pull the connector out.

Note: TCP is usually stuck down

to the heat transfer material, be

Very careful when lifting up on

the TCP ribbon cable.

26

Pull TCP apart as shown by arrow.

(TCP Film can be easily damaged.

Handle with care.)

November 2009 50PQ30 Plasma

Page 27

Left and Right X Drive Removal

Left and Right X Drive Removal

Remove the 3 screws for either left or right board or 4 for the center. 8 total for all three.

(The screws between the boards, secures both boards)

The Left X Board drives the right side of the screen vertical electrodes

The Center X Board drives the Center of the screen vertical electrodes

The Right X Board drives the left side of the screen vertical electrodes

27

November 2009 50PQ30 Plasma

Page 28

CIRCUIT OPERATION, TROUBLESHOOTING AND CIRCUIT

CIRCUIT OPERATION, TROUBLESHOOTING AND CIRCUIT

ALIGNMENT SECTION

ALIGNMENT SECTION

50PQ30 Plasma Display

This Section will cover Circuit Operation, Troubleshooting and

Alignment of the Power Supply, Y-SUS Board, Y-Drive Boards, Z-SUS

Board, Control Board, Main Board and the X Drive Boards.

At the end of this Section the technician should understand the operation

of each circuit board and how to adjust the controls. The technician

should be able with confidence to troubleshoot a circuit board failure,

replace the defective circuit and perform all necessary adjustments.

28

November 2009 50PQ30 Plasma

Page 29

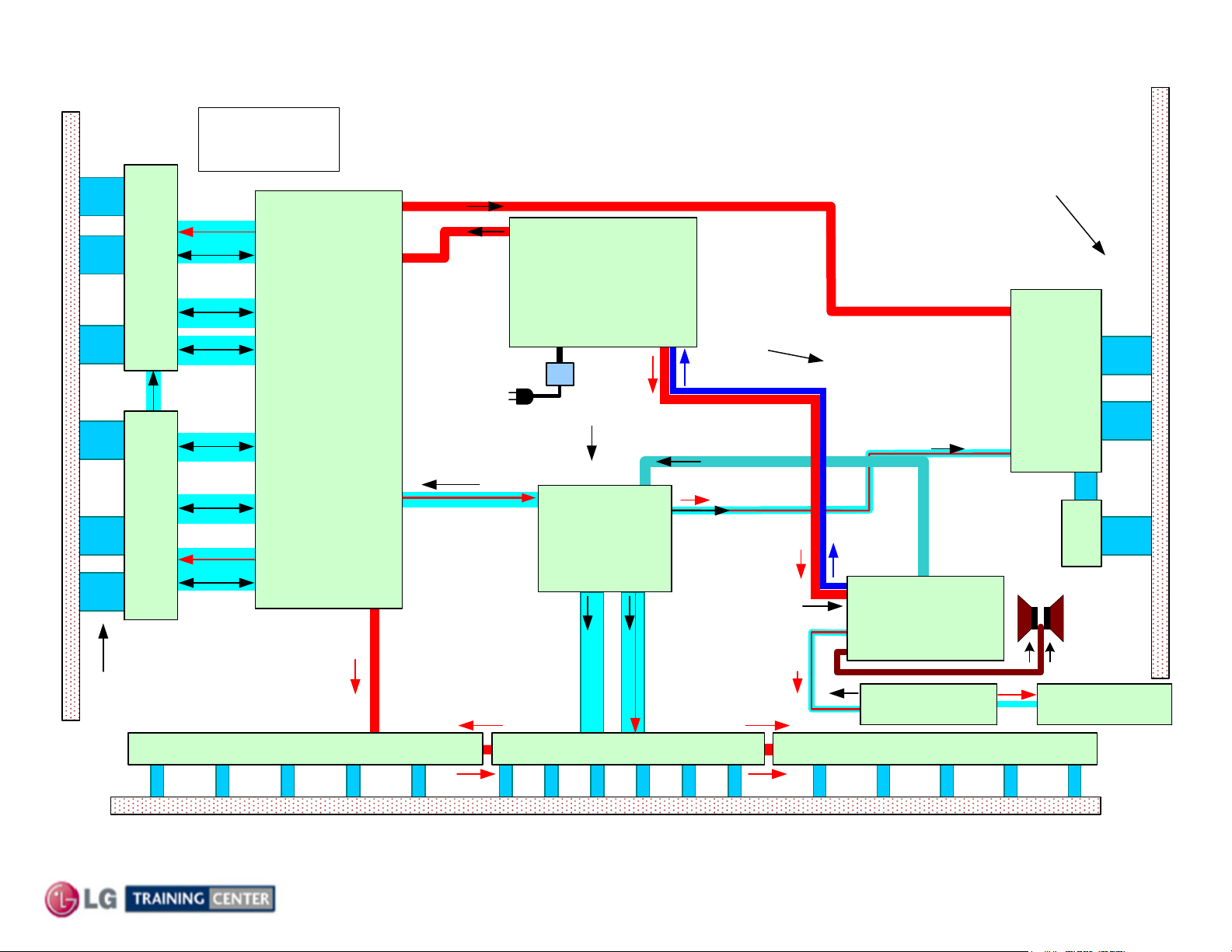

50PQ30 SIGNAL and VOLTAGE DISTRIBUTION DIAGRAM

Y Drive

FPCs

P101

P102

P103

FPCs

P201

P202

P203

Upper

P109

P101

P103

P106

P107

P106

(V Scan)

P209

P208

P206

P207

5VFG indicates

measured from

Floating Ground

Floating

Ground

5VFG

Drive Data

Clock (i2c)

5VFG

Drive Data

Clock (i2c)

Y Drive

Lower

Display Panel

Horizontal Electrodes

P209

(5VFG) (FG)

P204

(FG)

P203

(FG)

Y-SUS

Board

P208

(FG)

P208

(FG)

P207

(V Scan)

(5VFG) (FG)

VSC

DC/DC

-Vy

DC/DC

5VFG

DC/DC

P206

P201

P101

17V

DC/DC

P202

Va

P122

SMPS OUTPUT VOLTAGES IN STBY

STB +5V (also AC Voltage Det)

P811

Power

M5V, Vs, Va

Note:

Va not used

by Y-SUS

Drive Signals for

Y-SUS and Y-Drive

M5V, 17V

Note: 17V not used

by Control

Signals

3.3V

P121

P212

Supply

Board

SK101

AC

Input

Filter

M5V

P200

P111

3.3V

P121

P101

CONTROL

Board

P161

P162

RGB

Logic

P231

P232

P211 P311 P331

X-Board-Center

P813

Z Drive Signals

3.3V

RGB

Logic

Signals

3.3V

P232

SMPS OUTPUT VOLTAGES IN RUN

STB5V, +5V, 17V, 12V to Main PWB

Vs, Va and M5V to Y-SUS

SMPS

M5V, Vs, Error-Com

Turn On

Commands

Relay On

M5 On

VS On

+5V, 12V

M5V

Audio 17V,

Va, Vs

LVDS

Z Drive

17V

Set in

Signals

LVDS

Stand By:

STB +5

AC Voltage

Det

5V

STBY

P1006

P1001

P1005

P1003

MAIN Board

IR, Power LED,

3.3V

P211 P331

Intelligent Sensor

X-Board-RightX-Board-Left

Horizontal

Display Panel

Electrodes

P101

Z SUS

Board

17V

P100

Speakers

Control Keys

3.3V

Power Button

FPCs

P101

P102

P103

P302

P301

FPCs

3.3V

Key Board

Pull Up

Va

P101 P102 P103 P104 P105 P201 P301 P302 P304 P305

P202 P203 P204 P205 P206 P303

Va

Display Panel Vertical Address (RGB Cell Address)

29 Published November 2009 50PQ30 Plasma

Page 30

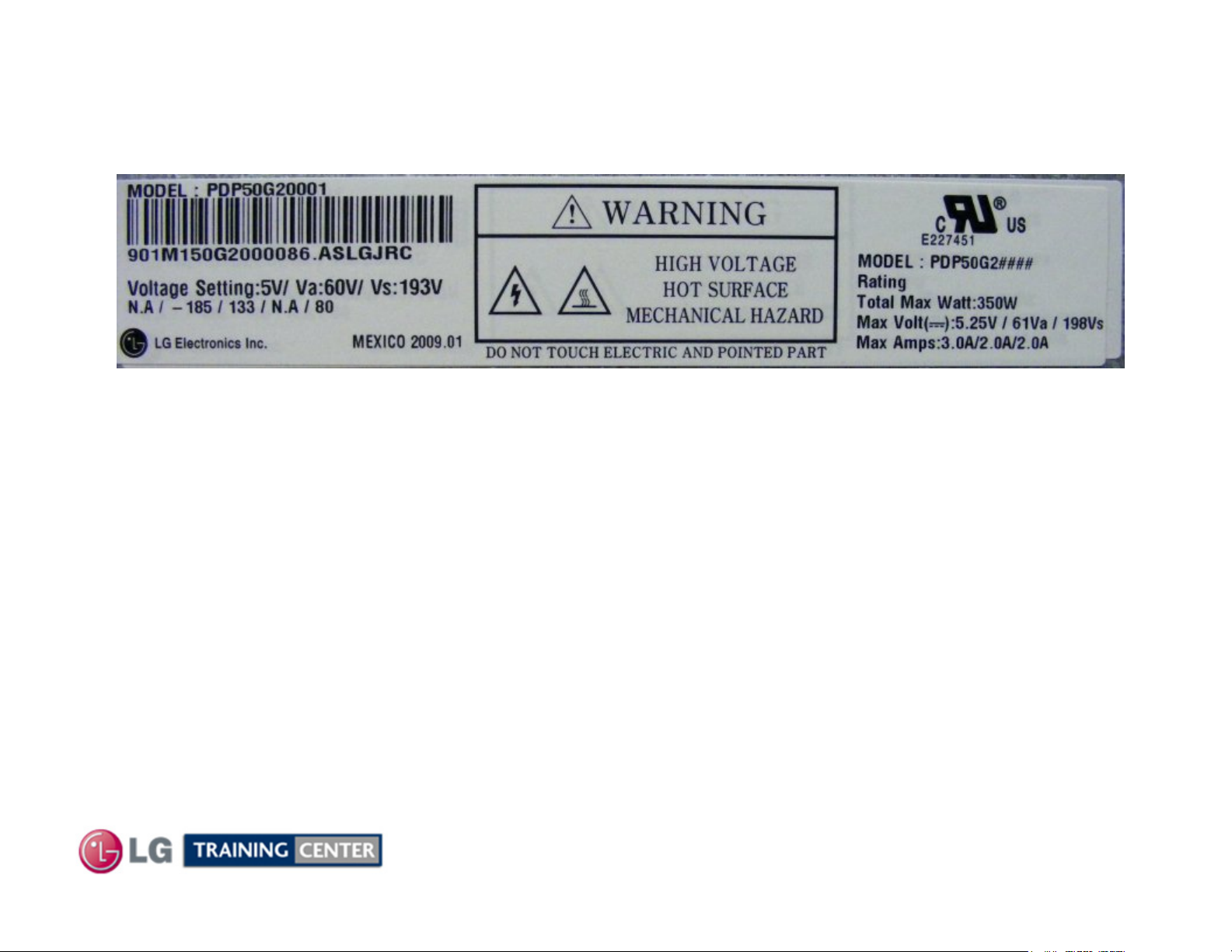

Panel Label Explanation

Panel Label Explanation

(1)

(2)

(3)

(4)

(5)

(6) (7)

(9) (10)

(8)

(11)

(12)

(13)

(14)

(15)

(1) Panel Model Name

(2) Bar Code

(3) Manufacture No.

(4) Adjusting Voltage DC, Va, Vs

(5) Adjusting Voltage (Set Up / -Vy / Vsc / Ve / Vzb)

(6) Trade name of LG Electronics

(7) Manufactured date (Year & Month)

(8) Warning

30

(9) TUV Approval Mark

(10) UL Approval Mark

(11) UL Approval No.

(12) Panel Model Name

(13) Max. Watt (Full White)

(14) Max. Volts

(15) Max. Amps

November 2009 50PQ30 Plasma

Page 31

Adjustment Notice

Adjustment Notice

All adjustments (DC or Waveform) are adjusted in WHITE WASH.

Customer’s Menu, Select “Options”, select “ISM” select “WHITE WASH”.

It is critical that the DC Voltage adjustments be checked when;

1) SMPS, Y-SUS or Z-SUS board is replaced.

2) Panel is replaced, Check Va/Vs since the SMPS does not come with new panel

3) A Picture issue is encountered

4) As a general rule of thumb when ever the back is removed

ADJUSTMENT ORDER “IMPORTANT”

DC VOLTAGE ADJUSTMENTS

1) POWER SUPPLY: Va Vs (Always do first)

2) Y-SUS: Adjust –Vy, Vscan,

Remember, the Voltage Label MUST be followed,

3) Z-SUS: Adjust Z-Bias (VZB)

it is specific to the panel’s needs.

WAVEFORM ADJUSTMENTS

1) Y-SUS: Set-Up, Set-Down

Manufacturer

Bar Code

The Waveform adjustment is only necessary

1) When the Y-SUS board is replaced

2) When a “Mal-Discharge” problem is encountered

3) When an abnormal picture issues is encountered

Set-

Up

31

-VY

Vscan

All label references are from a specific panel.

They are not the same for every panel encountered.

Ve

Z_BIAS

“Rear View”

November 2009 50PQ30 Plasma

Panel

Page 32

SWITCH MODE POWER SUPPLY SECTION

SWITCH MODE POWER SUPPLY SECTION

This Section of the Presentation will cover troubleshooting the Switch Mode Power Supply for

the Single Scan Plasma. Upon completion of the section the technician will have a

better understanding of the operation of the Power Supply Circuit and will be able to

locate voltage and test points needed for troubleshooting and alignments.

• DC Voltages developed on the SMPS

• Adjustments VA and VS.

• Always refer to the Voltage Sticker located on the back of the panel, in the upper Left

Hand side for the correct voltage levels for the VA, VS, -VY, Vscan, and Z Bias as these

voltages will vary from Panel to Panel even in the same size category.

• Set-Up and Ve are just for Label location identification and are not adjusted in this panel.

SMPS P/N EAY58316301

Check the silk screen label on the top center of the Power Supply board to identify the correct part

number. (It may vary in your specific model number).

On the following pages, we will examine the Operation of this Power Supply.

32

November 2009 50PQ30 Plasma

Page 33

50PQ30 50G2 (SMPS) POWER SUPPLY BOARD

50PQ30 50G2 (SMPS) POWER SUPPLY BOARD

P811

10

1

Hot Ground

C107

L102

L602L601

10) M5V

9) M5V

8) Gnd

7) VA

6) VA

5) Gnd

4) Gnd

3) N/C

2) VS

1) VS

C106

EXAMPLE: Voltage Label. Use the voltage

label off your specific panel for adjustments.

Hot Ground Symbol represents a SHOCK Hazard

T901

F801

4A/250V

VR502

Va

17V turns on

1

2

Hot Ground

RL101

RL103

STBY 123V

RUN 382V

F801

STBY 160V

RUN 382V

F302

1A/

250V

1

0

1

F

SC101

VR901

Hot Ground

F101

10A/250V

AC In

Vs

1,2) 17V

3,4) Gnd

5,6) 12V

7,8) Gnd

9,10,11) +5V

12) Stby 5V

13,14) Gnd

T301

15) n/c

16) Gnd

17) 5V Det

18) AC Det

19) RL_On

20) VS_On

21) M5_On

22) Auto Gnd

23) Stby 5V

24) Key_On

Model : PDP 50G2####

Voltage Setting:5V / Va:60V / Vs:193V

N.A. / -185 / 133 / N.A. / 80

Max Watt : 350 W (Full White)

with Vs On

command

IC701

P813

23

24

VA Adjust

VR502

17V

1

3

Gnd

5

12V

7

Gnd

9

5V

11

5V

13

Gnd

15

Gnd

17

5V Det

19

RL ON

M5 ON

21

Stby5V

23

VS Adjust

P813

2

4

6

8

10

12

14

16

18

20

22

24

VR901

17V

Gnd

12V

Gnd

5V

STBY 5V

Gnd

N/C

AC Det

VS ON

Auto Gnd

Key On

33

Published November 2009 50PQ30 Plasma

Page 34

Switch Mode Power Supply Overview

Switch Mode Power Supply Overview

The Switch Mode Power Supply Board Outputs to the :

Y-SUS Board

Main Board

Adjustments

VS

VA

M5V

STBY 5V Microprocessor Circuits

17V Audio B+ Supply

12V Tuner B+ Circuits

5V Signal Processing Circuits

There are 2 adjustments located on the Power Supply Board VA and VS. The

5V VCC is pre-adjusted and fixed. All adjustments are made with relation to

Chassis Ground. Use “Full White Raster” 100 IRE

Drives the Display Panel’s Horizontal Electrodes

Primarily responsible for Display Panel Vertical Electrodes

Used to develop Bias Voltages on the Y-SUS,

X Drive, and Control Boards

VA

VS

RV502

RV901

34

November 2009 50PQ30 Plasma

Page 35

Power Supply Circuit Layout

Power Supply Circuit Layout

P811

To Y-SUS

Main Bridge

Rectifier

123V Stby

382V Run

Fuse F801

4Amp/250V

160V Stby

382V Run

Fuse F302

1Amp/250V

Bridge

Rectifier

PFC

Circuit

Primary

Source

VS VR901

STBY 5V

5V, 12V

Source

VA Source

VS Source

17V Source

VA VR502

IC701

Sub Micon

Main Fuse

F101

10Amp/250V

35

AC Input

SC 101

P813

To MAIN

November 2009 50PQ30 Plasma

Page 36

Power Supply Basic Operation

Power Supply Basic Operation

AC Voltage is supplied to the SMPS Board at Connector SC101 from the AC Input assembly. Standby 5V is developed from

160V source supply (which during run measures 380V measured from the primary fuse F302).

This supply is also used to generate all other voltages on the SMPS.

The STBY5V (standby) is B+ for the Controller (IC701) on the SMPS and output at P813 pins 11 and 23 then sent to the

Main board for Microprocessor (IC1) operation. AC Detect is generated on the SMPS, by rectifying a small sample of the

A/C Line at D102 and associated circuitry and routed to the Controller (IC701) where it outputs at pin 15 and sent to P813

pin 18 to the Main Board where it is sensed and monitored by the Main Microprocessor (IC1). The AC Det in this set works

differently than most. If AC Det is missing the Microprocessor will turn off the television in about 10 seconds after turn on.

This will happen each time turn on is attempted.

A new feature included on the side keypad is called a Main Power Switch which opens a ground allowing the “Key On” line

of P813 Pin 24 to go high, turning off the 5V STB line defeating the Micro Processor (IC1) on the Main Board and Remote

Control Operation.

When the Microprocessor (IC1) on the Main Board receives an “ON“ Command from either the Power button or the

Remote IR Signal, it outputs a high called RL ON at Pin 19 of P813. This command causes the RelaY-Drive Circuit to

close both Relays RL102 and RL103 bringing the PFC source up to full power by increasing the 160V standby to 380V

run which can be read measuring voltage at Fuse F302 and F801 from “Hot” Ground. At this time the run voltages 12V,

and +5V sources become active and are sent to the Main Board via P813 (12V at pins 5 and 6 and 5V at pins 9,10, and

12). The 5V detect line from the SMPS Board to the Main Board can be measured at pin 17 of P813. It is not used.

The next step is for the Microprocessor (IC1) on the Main Board to output a high on M5V ON Line to the SMPS at P813 Pin

21 which is sensed by the Controller (IC701) turning on the M5V line and output at P811 pins 9 and 10 to the

Y-SUS board P201 pins 9, 10. Then it is routed to the Control and Z-SUS boards.

Full Power occurs when the Microprocessor (IC1) on the Main Board brings the VS-ON line high at Pin 20 of P813 of the

SMPS Board. VS-ON is routed to the Controller (IC701) which turns on the 17V Audio, VA, and the VS supplies. VA and

VS output at P811 to the Y-SUS board. (VA pins 6 and 7 and VS pins 1 and 2). The 17V Audio supply outputs to the Main

board at P814 pins 1 and 2 and used for Audio processing and amplification.

AUTO GND Pin 22 of P813: This pin is grounded on the Main board. When it is grounded, the Controller IC701 works in

the normal mode, meaning it turns on the power supply via commands sent from the Main board. When this pin is floated

(opened), it pulls up and turns the Controller IC701 on in the Auto mode. In this state, the Controller turns on the power

supply in stages automatically. A load is necessary to perform a good test of the SMPS if the Main board is suspect.

36

November 2009 50PQ30 Plasma

Page 37

50PQ30 POWER SUPPLY START UP SEQUENCE

50PQ30 POWER SUPPLY START UP SEQUENCE

1

Standby 5V will not

be output if the Main

Power Switch is off.

AC In

Stand

By 5V Reg

AC

Det.

Stand

By 5V

3

AC Det.

If missing,

the set

will turn

off in 10

seconds.

3.3V Reg

IC301

3

5V Mnt.

2

+5V

HDMI

EDID

AC-Det

6

Relay

5V

Mnt

2

6

Microprocessor

(BCM)

In Stand-By Primary side is 160V/123V

In Run (Relay On) Primary side is 386V

POWER SUPPLY

8

(SMPS)

5V/12V

Regulators

5

17V

RL

Reg

On

5V

12V

14

17V

M5V

On

7

On

5

8

17V Audio

PWR

On

Relay

On

5

IC1

Power On

12V Tuner

B+ stepped

down to 5V

Video

Processing

At point TV is in

Stand-By state.

It is Energy Star

Less than 1 Watt

3

Compliant.

M5-On

8

Vs/Va-On

13

4

Power On IR

13

On

13

Vs

MAIN

Board

M5V

Reg

Vs

Reg

Va

Reg

8

16

Vs

Va

15

Va

Y-SUS

Va

15

15

STBY 5V

Vs

M5V

16 8

Va

2

4

5VFG

10

M5V

17V

9

X PWB

Left

FG5V

Floating Gnd 5V

10

16

Vs

1615

Vs

16

Z-SUS

17V

11

12

3.3V

15 15

Va Va

Front IR

Board

Remote

Or Key

11

3.3V

X PWB

Center

Y DRIVE

Upper

Y DRIVE

Lower

CONTROL

11

9

17V M5V 3.3V

12

12

3.3V

X PWB

Right

Power Button

Off

On

12

37 Published November 2009 50PQ30 Plasma

Page 38

Power Supply Va and Vs Adjustments

Power Supply Va and Vs Adjustments

Important: Use the Panel Label

Example Voltage Label

Va TP

P811

Pin 6 or 7

Vs TP

P811

Pin 1 or 2

Not this book for all voltage adjustments.

Use Full White Raster “White Wash”

Vs Adjust:

Place voltmeter on pin 1 or 2

of P811. Adjust VR901 until

the reading matches your

label.

38

Va Adjust:

Place voltmeter on pin 6 or 7

of P811. Adjust VR502 until

the reading matches your

label.

November 2009 50PQ30 Plasma

Page 39

50PQ30 SMPS STATIC TEST UNDER LOAD

Using two 100 Watt light bulbs, attach one end to Vs and the other end to ground. Apply AC to SC101. If the light bulbs

turn on and VS is the correct voltage, allow the SMPS to run for several minutes to be sure it will operate under load. If

this test is successful and all other voltages are generated, you can be fairly assured the power supply is OK.

Note: To be 100% sure, you would need to read the current handling capabilities of each power supply listed on the silk

screen on the SMPS and place each supply voltage under the appropriate load.

or

4

100W

or

5

8

Gnd

100W

Vs

Pins

Check Pins 1 or 2

for Vs voltage

Check Pins 6 or 7

for Va voltage

You can even pre-

align the Vs and Va

voltage to the

panel’s label.

But you must

recheck when you

can get a white

Check Pins 1~4

For M5V

or

1 2

P811

raster.

P811

1

4A/250V

Hot Ground

C107

L102

L602L601

F801

C106

Hot Ground

RL101

RL103

STBY 123V

RUN 382V

F801

STBY 160V

RUN 382V

F302

1A/

250V

1

0

1

F

SC101

Hot Ground

10A/250V

AC In

T901

VR901

Vs

T301

F101

1,2) 17V

3,4) Gnd

5,6) 12V

7,8) Gnd

9,10,11) +5V

12) Stby 5V

13,14) Gnd

15) n/c

16) Gnd

17) 5V Det

18) AC Det

19) RL_On

20) VS_On

21) M5_On

22) Auto Gnd

23) Stby 5V

24) Key_On

VR502

Va

17V turns on

with Vs On

command

IC701

P813

1

2

23

24

Provided the Power Button is

closed, any time AC is applied to

the SMPS, STBY 5V and AC DET

should be present.

If AC Det is missing,

the TV will come on then shut

off within 10 Sec.

This will happen each time the

TV is turned on.

P813

Check Pins 11 or 23 for

5V SBY

Check Pin 18 for

AC Det (5V)

Check Pin 9,10,12 for

(+5V)

Check Pins 1 or 2 for

17V

Check Pins 5 or 6 for

12V

Note: This SMPS will run without a load, however if the Vs is not loaded,

the 17V may pulsate up and down.

It is always best to test the SMPS under a load using the 2 light bulbs.

39 Published November 2009 50PQ30 Plasma

Page 40

Power Supply Static Test (Forcing on the SMPS in stages)

Power Supply Static Test (Forcing on the SMPS in stages)

WARNING: Remove AC when

adding or removing any

plug or resistor.

(A) Ground the Auto Ground (Pin 22) on P813.

(B) When AC Power is applied, Check AC_Det (Pin 18) and 5V Stand-By (Pins 12 and 23) are 5V.

P811 disconnected from

the Y-SUS or the SMPS.

P1006 disconnected from

the Main board.

Use the holes in the

connector P1006 side to

insert the resistor or

jumper leads.

(C) 100Ω ¼ watt resistor added from STBY 5V (Pins 12 or 23) (Note pins 9~11 are not on yet).

to RL_ON (Pin 19) closes relay RL101 and RL103 turning on the 5V and 12V Supplies.

(D) 100Ω ¼ watt resistor added from 5V (Pins 9 ~ 11) to M5 ON (Pin 21) brings the M5V (P811 pins 9,

10) line high.

(E) 100Ω ¼ watt resistor added from STBY 5V (Pins 9 ~ 11) to VS ON (Pin 20) brings the

• 17V (P813 pins 1 and 2) lines high.

• VA and VS (P811 pins 1 and 2 Vs and Pins 6 and 7 Va) lines high.

40

November 2009 50PQ30 Plasma

Page 41

Connector P813 Identification, Voltages and Diode Check

Connector P813 Identification, Voltages and Diode Check

P813 CONNECTOR “SMPS" to “Main" P1006

Diode ModeRun STBYLabelPin

a

17V1

2.2V17.3V0V

a

17V2

GndGndGndGnd3

b

12V5

Open12V0V

b

12V6

GndGndGndGnd7

b

5V9

b

5V11

1.1V5V5V

1.1V5V5V

b

5V10

GndGndGndGnd13

GndGndGndGnd15

Open5V.15V5V Det17

Open3.73V0VRL On19

Open3.24V0VM5 ON21

22

Open5V5VStby 5V23

Auto Gnd

c

Key On24

Diode ModeRun STBYLabelPin

2.2V17.3V0V

GndGndGndGnd4

Open12V0V

GndGndGndGnd8

1.1V5V5V

1.13V5V5VStby 5V12

GndGndGndGnd14

Not UsedGndGndGnd16

Open5V5VAC Det18

Open3.2V0VVS On20

OpenGndGnd

Open0V0V

a

Note: The 17V turns on when the

VS On command arrives.

b

Note: The 5V/12V turns on when the

RL On command arrives.

Diode Mode Readings taken with all connectors Disconnected. DVM in Diode Mode.

41

c

Note: If the Key On line is 4.39V, the

Main Power Switch is open.

Stand-By 5V will shut off.

November 2009 50PQ30 Plasma

Page 42

Connector SC101 and P811 Identification, Voltages and Diode Checkk

Connector SC101 and P811 Identification, Voltages and Diode Chec

SC101 AC INPUT

Standby Run Diode ModeConnector Pin Number

SC101 120VAC 120VAC Open

P811 CONNECTOR "Power Supply“ to Y-SUS “P201”

* Note: This voltage will vary in accordance with Panel Label

1 and 3

Diode ModeRun STBYLabelPin

Open*194V0VVs1, 2

n/cn/cn/cn/c3

Gnd0V0VGnd4, 5

Open*60V0VVa6, 7

Gnd0V0VGnd8

0.86V5V0VM5V9, 10

Diode Mode Readings taken with all connectors Disconnected. DVM in Diode Mode.

42

November 2009 50PQ30 Plasma

Page 43

SUS BOARD SECTION

YY--SUS BOARD SECTION

(Overview)

(Overview)

Y-SUS Board develops the V-Scan drive signal to the Y-Drive boards.

This Section of the Presentation will cover troubleshooting the Y-SUS Board for the Single

Scan Plasma. Upon completion of the Section the technician will have a better

understanding of the operation of the circuit and will be able to locate voltage and

Diode mode test points needed for troubleshooting and alignments.

• Adjustments

• DC Voltage and Waveform Checks

• Diode Mode Measurements

Operating

Operating

SMPS Supplied VA

Y-SUS Developed -VY VR502

Floating Ground FG 5V

Voltages

Voltages

VS

M5V

VSC VR501

V SET UP VR601

V SET DN VR602

15V

FG 15V

VA supplies the Panel Vertical Electrodes (Routed to the Left X-Board)

VS Supplies the Panel Horizontal Electrodes (Also routed to the Z-SUS board)

5V Supplies Bias to Y-SUS (Then Routed to the Control board and Z-SUS board)

-VY Sets the Negative excursion of the Y-SUS Drive Waveform

VSC Set the amplitude of the complex waveform.

SET UP sets amplitude of the Top Ramp of the Drive Waveform

SET DOWN sets the Pitch of the Bottom Ramp of the Drive Waveform

To the Control Board then routed to the Z-SUS board

Used on the Y-Drive boards (Measured from Floating Gnd)

Used in the Development of the V-Scan signal (Measured from Floating Gnd)

43

November 2009 50PQ30 Plasma

Page 44

SUS Block Diagram

YY--SUS Block Diagram

Distributes Vs and M5V

Power Supply Board - SMPS

Z-SUS Board

Left X Board

Simplified Block Diagram of

Y-Sustain Board

Distributes VA

Circuits generate

Y-Sustain Waveform

Receive M5V, Va, Vs

FETs amplify Y-Sustain

Waveform

Distributes Vs, Va and M5V

from SMPS

from M5V by DC/DC Converters

Distributes 15V

Distributes 15V and 5V

Control Board

Generates Vsc and -Vy

Also controls Set Up/Down

Generates Floating Ground

5V by DC/DC Converters

Logic signals needed to scan the panel

Y-Drive Boards

Receive Scan Waveform

Logic signals needed to generate drive waveform

44

November 2009 50PQ30 Plasma

Display Panel

Page 45

SUS Board Layout

YY--SUS Board Layout

P209

Pins 8 ~12 Logic (Drive)

Signals to the Y-Drive

Upper board

Floating Gnd 5V

Pins 4 and 5

P204, P203, P205 and

P208 All Pins are

Floating Ground

P204

SET UP

VR 601

FS202 (Vs)

4A 250V

P206

P201

VS to and Error

Com from Z-SUS

VS, VA and M5V

Input from the

SMPS

P209, P204 and P203

Plugs into Y-Drive upper

P205, P208 and P207

Plugs into Y-Drive lower

P207 Pins 11 and 12

Y-Drive signal (V Scan)

Floating Gnd 5V

Pins 8 and 9

Pins 2 ~5 Logic (Drive)

Signals to the Y-Drive

Lower board

P203

P205

P208

P207

VSC ADJ

VR501

c

VSC TP

R202

P202

-VY TP

R201

V SET DN

VR 401

-VY ADJ

VR502

FS501 (17V)

4A/125V

P101

FS201 (Va)

10A/125V

FS201 (M5V)

10A/125V

M5V and 17V

Ribbon

Logic Signals from

the Control Board

P202

Va to Left X Board

Pins 5~7

45

November 2009 50PQ30 Plasma

Page 46

VSC and --

VSC and

VY Adjustments

VY Adjustments

These are DC level Voltage Adjustments

VSC TP

R202

-

+

Voltage Reads

Positive

-

+

-Vy TP R201

VR502

VR501

Set should run for 15 minutes, this is the “Heat Run” mode.

Set screen to “White Wash”.

Adjust –Vy to Panel Label voltage (+/- 1V)

Adjust VSC to Panel Label voltage (+/- 1V)

46

Lower Center of board

Just below Heat Sinks

November 2009 50PQ30 Plasma

Page 47

Y-Drive Upper Test Point

(Bottom of Board)

VR108

VR209

c Overall signal observed 4mS/div

There are several other test points on either the

Upper or Lower Y-Drive boards that can be used.

Basically any output pin on any of the FPC

to the panel are OK to use.

d Highlighted signal from waveform

above observed 400uS/div

e Highlighted signal from

Y-Drive Lower Test Point

(Top of Board)

NOTE: The Waveform Test Points are fragile. If by

accident the land is torn and the run lifted, make sure

there are no lines left to right in the screen picture.

waveforms above observed

100uS/div

47

80VRms

100uS

516V p/p

November 2009 50PQ30 Plasma

Page 48

Observing (Capturing) the Y--

Observing (Capturing) the Y

Drive Signal for Set Up Adjustment

Drive Signal for Set Up Adjustment

Set must be in “WHITE WASH”

All other DC Voltage adjustments should have already been made.

Fig 1:

As an example of how to lock in to the Y-Drive Waveform.

Fig 1 shows the signal locked in at 4ms per/div.

Note the 2 blanking sections.

The signal for SET-UP is outlined within the Waveform

Fig 2:

At 2mSec per/division, the waveform to use for

SET-UP Is now becoming clear.

Now, the two blanking signal are still present.

Fig 3:

At 400us per/div. the signal for SET-UP is now easier to

recognize. It is outlined within the Waveform.

Remember, this is the first large signal to the right of blanking.

Outlined

Area

Area to

be adjusted

Area to

be adjusted

Blanking

Blanking

Blanking

Blanking

FIG1

4mS

FIG2

2mS

FIG3

400uS

Fig 4:

At 40uSec per/division, the adjustment for SET-UP

can be made.

It will make this adjustment easier if you use

the “Expanded” mode of your scope.

48

Area to

be adjusted

FIG4

40uS

November 2009 50PQ30 Plasma

Page 49

Observing (Capturing) the Y--

Observing (Capturing) the Y

Drive Signal for Set Up Adjustment

Drive Signal for Set Up Adjustment

Set must be in “WHITE WASH”

All other DC Voltage adjustments should have already been made.

Fig 1:

As an example of how to lock in to the Y-Drive Waveform.

Fig 1 shows the signal locked in at 4ms per/div.

Note the 2 blanking sections.

The signal for SET-DN is outlined within the Waveform

Fig 2:

At 2mSec per/division, the waveform to use for

SET-DN is now becoming clear.

Now the two blanking signals are still present.

Fig 3:

At 400us per/div. the signal for SET-DN is now easier to

recognize. It is outlined within the Waveform.

Remember, this is the first large signal to the right of blanking.

Outlined

Area

Area to

be adjusted

Area to

be adjusted

Blanking

Blanking

Blanking

Blanking

FIG1

4mS

FIG2

2mS

FIG3

400uS

Fig 4:

At 20uSec per/division, the adjustment for

SET-DN can be made.

It will make this adjustment easier if you use the

“Expanded” mode of your scope.

49

Area to

be adjusted

FIG4

20uS

November 2009 50PQ30 Plasma

Page 50

Set Up and Set Down Adjustments

Set Up and Set Down Adjustments

Observe the Picture while making these adjustments. Normally, they do not have to be done.

Y-Drive Test Point

Set must be in “WHITE WASH”

All other DC Voltage adjustments should have already been made.

ADJUSTMENT LOCATIONS:

Top Left and Center Right

50

SET-UP ADJUST:

1) Adjust VR601 and set the (A) portion of the

signal to match the waveform above. (150V ± 5V)

SET-DN ADJUST:

2) Adjust VR401 and set the (B) time of the

signal to match the waveform above. (100uSec 5uSec)

November 2009 50PQ30 Plasma

Page 51

Set Up Adjustment Too High or Low

Set Up Adjustment Too High or Low

Set Up swing is Minimum 80V Max 200V

Ramp (SET UP) Too High (200V)

Full Counter Clock Wise

Panel Waveform Adjustment

The center begins to wash out and arc due to SET UP

Ramp (SET UP) Too Low (80V)

Full Clock Wise

Very little alteration to the picture, the wave form indicates a

distorted SET UP. The peek widens due to the SET UP

peeking too quickly.

51

November 2009 50PQ30 Plasma

Page 52

Set Down Adjustment Too High or Low

Set Down Adjustment Too High or Low

Set Dn swing is Minimum 73uS Max 166uS+

(SET DN) Too High 166uSec

Full Clock Wise

100V off

the Floor

Floor

Panel Waveform Adjustment

NOTE: If Set DN too high, this set

may go excessive bright,

then shutdown.

If this happens, remove the LVDS

from Control board and make

necessary adjustments. Then

reconnect LVDS select White Wash

and adjust correctly.

All of the center washes out due to increased SET_DN time.

(SET DN) Too Low

Counter Clock Wise

The center begins to wash out and arc due to decreased

SET DN time.

52

November 2009 50PQ30 Plasma

Page 53

SUS How to Check the Output FETs (1 of 2)

YY--SUS How to Check the Output FETs (1 of 2)

Name is printed on the components. Readings “In Circuit”.

45F122

Q34

RJP4584

Q32

K3667

*Q18

Q31

Shown: 0.6V

Reverse: 1.64V

Shown: 0.69V

Reverse: 0.67V

Shown: 0.59V~0.6V

Reverse: Open

*Reversed: 2.18V

Shown: 0.38V

Reverse: Open

Blk RedBlk Red BlkRed

Shown: 0.483V

Reverse: Open

Blk RedBlk Red

Shown: 0.5V

Reverse: Open

Blk RedBlk Red

Shown: 2.02V

Reverse: Open

Shown: 1.09V

Reverse: Open

BlkRed

Shown: Open

*Shown: 2.2V

Reverse: Open

BlkRed

RF2001

D31

D32

D33

D34

D36

D717

Blk Red

Shown: Shorted

Reverse: Shorted

0.3 Ohms

Blk Red

Shown: 0.37V~0.38V

Reverse: Open

53

November 2009 50PQ30 Plasma

Shown: 0.37~0.38V

Reverse: Open

BlkRed

Page 54

SUS How to Check the Output FETs (2 of 2)

YY--SUS How to Check the Output FETs (2 of 2)

Name is printed on the components. Readings “In Circuit”.

I4F14229

Q16

Q17

30J124

Q11

Q12

Q13

RF020

D11

Shown: 0.876V

Reverse: 1.56V

Shown: 0.668V

Reverse: 0.6V

Shown: Shorted

Reverse: Shorted

(0.3 Ohm)

Shown: 0.46V

Reverse: Open

Blk RedBlk Red BlkRed

Shown: 0.392V

Reverse: Open

Blk RedBlk Red BlkRed

Shown: 0.392V

Reverse: Open

Shown: 1.95V

Reverse: Open

Shown: 0.998V

Reverse: Open

Shown: 0.392V

Reverse: Open

Blk RedBlk Red BlkRed

54

November 2009 50PQ30 Plasma

Page 55

SUS Board P207 (Bottom Connector) Explained

YY--SUS Board P207 (Bottom Connector) Explained

TIP: Use P207 pins 1 or 2 or the Right Side of C213 to test

for Y Scan signal if the Y-Drive boards are removed

C213

FL201

11) V Scan

10) V Scan

9) n/c

8) 5V VF

P205

c

Y-Drive Lower

Board

Bottom Connector P207

P207

Y-SUS Board

7) 5V VF

6) Ground (F)

5) STB

4) OC1

3) DATA

2) OC2

1) Ground (F)

P207 Pins 1 and 2

Y Scan signal

400V p/p (No Y-Drives)

440V p/p (With Y-Drives)

FG5V measured from

Pins 7 or 8

Floating Gnd

Pins 1 or 6

P207 Pins 2, 3, 4, and 5 are

Logic (Drive) Signals to the

Y-Drive lower.

P209 carries the Y-Drive signals

to the upper via P108.

55

November 2009 50PQ30 Plasma

Page 56

SUS P207 (Drive Output Plug) Diode Mode Testing

YY--SUS P207 (Drive Output Plug) Diode Mode Testing

P205 of the

Y-Drive

Lower Board

c

P207 of the

Y-SUS Board

C213

P207

Checking the Y--

Checking the Y

NOTE: Disconnected from the Y--

NOTE: Disconnected from the Y

SUS Board P207

SUS Board P207

Readings from Floating Ground (Pin 1)

RED LEAD

Blk Lead FG

Y-Drive Sig

Y-Drive Sig

Floating Gnd

Floating Gnd

12) V Scan

11) V Scan

10) n/c

9) 5V VF

8) 5V VF

7) Ground (F)

6) CLK

5) STB

4) OC1

3) DATA

2) OC2

1) Ground (F)

Open

Open

Open

1.9V

1.9V

0V

1.43V

1.43V

1.43V

1.53V

1.53V

0V

DRIVE boards

DRIVE boards

BLACK LEAD

Red Lead FG

Open

Open

Open

0.557V

0.557V

0V

0.66V

0.66V

0.68V

0.66V

0.68V

0V

Y-Drive Board should be

disconnected for this test.

56

Meter in the Diode Mode

November 2009 50PQ30 Plasma

Page 57

SUS Board P209 (Top Connector) Explained

YY--SUS Board P209 (Top Connector) Explained

Y-Drive Upper

Board

P109

FL101

c

Y-SUS Board

P209

Top Connector P209

P209 Pins 7, 8, 9, and 10 are Logic Signals

from the Control board routed through the

Y-SUS to the Y-Drive upper.

Between the Y-Drive upper and lower is

P209, P108 which carries the Y-Drive (Scan)

signals from the lower to the upper.

11) Ground (F)

10) DATA

9) OC1

8) STB

7) CLK

6) Ground (F)

5) 5V VF

4) 5V Vf

3) Ground (F)

2) Ground (F)

1) Ground (F)

FG5V (+5V F) measured

from Pins 4 or 5 to

Floating Gnd

Pins 1~3, 6 or 11

57

November 2009 50PQ30 Plasma

Page 58

SUS P209 Diode Mode Testing

YY--SUS P209 Diode Mode Testing

P109 of the

Y-Drive

Upper Board

c

P209 of the

Y-SUS Board

Checking the Y--

Checking the Y

NOTE: Disconnected from the Y--

NOTE: Disconnected from the Y

SUS Board P209

SUS Board P209

Readings from Floating Ground (Pin 1~3)

RED LEAD

Blk Lead FG

Floating Gnd

Floating Gnd

Floating Gnd

Floating Gnd

Floating Gnd

12) Ground (F)

11) DATA

10) OC1

9) STB

8) CLK

7) STB

6) Ground (F)

5) 5V VF

4) 5V VF

3) Ground (F)

2) Ground (F)

1) Ground (F)

0

1.53V

1.43V

1.53V

1.43V

1.43V

0V

1.94V

1.94V

0V

0V

0V

DRIVE boards

DRIVE boards

BLACK LEAD

Red Lead FG

0V

0.68V

0.66V

0.68V

0.66V

0.66V

0V

0.68V

0.68V

0V

0V

0V

P209

Y-Drive Board should be

disconnected for this test.

Meter in the Diode Mode

58

November 2009 50PQ30 Plasma

Page 59

SUS P201 to SMPS P812 Plug Information

YY––SUS P201 to SMPS P812 Plug Information

Voltage and Diode Mode Measurement

P201 CONNECTOR "Y-SUS" to "Power Supply" P811

Diode ModeRun STBYLabelPin

Open*193V0VVs1

Open*193V0VVs2

NCNCNCNC3

GndGndGndGnd4

GndGndGndGnd5

Open*60V0VVa6

* Note: This voltage will vary in accordance with Panel Label

Diode Mode Readings taken with all connectors Disconnected. DVM in Diode Mode.

59

November 2009 50PQ30 Plasma

Open*60V0VVa7

GndGndGndGnd8

0.86V5V0VM5V9

0.86V5V0VM5V10

Page 60

SUS P202 to X Drive P122 Plug Information

YY--SUS P202 to X Drive P122 Plug Information

Voltage and Diode Mode Measurements for the Y-SUS Board

P202 CONNECTOR "Y-SUS" to "X-Drive” Left P122

Diode ModeRun STBYLabelPin

GndGndGndGnd1

GndGndGndGnd2

GndGndGndGnd3

ncncncnc4

Open*60V0VVA5

Open*60V0VVA6

* Note: This voltage will vary in accordance with Panel Label

Diode Mode Readings taken with all connectors Disconnected. DVM in Diode Mode.

60

November 2009 50PQ30 Plasma

Open*60V0VVA7

Page 61

SUS P206 to Z Drive P101 Plug Information

YY--SUS P206 to Z Drive P101 Plug Information

Voltage and Diode Mode Measurements for the Y-SUS Board

P206 Connector Y-SUS to Z Drive P101 Plug Information

Diode ModeRun STBYLabelPin

0.86V5V0VM5V1, 2

GndGndGndGnd3~6

ncncncnc7

Gnd*89V0VEr Com8, 9

ncncncnc10

Open*193V0VVS11, 12

* Note: This voltage will vary in accordance with Panel Label

Diode Mode Readings taken with all connectors Disconnected. DVM in Diode Mode.

61

November 2009 50PQ30 Plasma

Page 62

P101 Y--

P101 Y

SUS 15V and 5V to Control board P111 Information

SUS 15V and 5V to Control board P111 Information

Voltage Measurements for the Y-SUS Board

Y-SUS Board B+ checks for the P101 connector.

FS201

5V to run the Control Board.

Leaves the Control Board on P101

pins 4~7.

Can also be checked at J843 M5V TP.

Run: 5VStandby: 0V

Diode Check: 0.86V

FS501 and 15V Test Point

15V to run the Z-SUS Board.

Routed out P101 to the Control

Board.

Leaves the Control Board on

P101 pins 11 and 12.

Can also be checked at J642 15V TP.

Location: Just below P201

Location

Run: 15VStandby: 0V

Diode Check: Open

Location: Bottom Center Right

62

November 2009 50PQ30 Plasma

Page 63

SUS Floating Ground (15V) and (5V) Checks

YY--SUS Floating Ground (15V) and (5V) Checks

Voltage Measurements for the Y-SUS Board

Floating Ground checks must be made from Floating

Ground. Use any pin on P204, P203, P205 or P208.

FG5V Test Point

Floating Ground referenced 5V. Used for low

voltage signal processing on the Y-Drive

board. Leaves the Y-SUS board on P207 pins 8

and 9. AND P209 pins 5 and 5.

Checked at J795 (+5V (F) Test Point.

Run: 5VStandby: 0V Diode Check: 1.94V

FG15V Test Point

FG15V to develop the Y-Drive signal.

Location

Location: Bottom Left

Checked at J644 (+15V (F) Test Point.

Run: 15.2VStandby: 0V Diode Check: 1.5V

Floating Ground J643

Location: Bottom Center of the

two large black heat sinks.

63

November 2009 50PQ30 Plasma

Page 64

SUS P101 to Control P111 Plug Information (Tip)

YY--SUS P101 to Control P111 Plug Information (Tip)

“Y-SUS" P101 CONNECTOR to “Control board" P111

(30 Pin Connector)

See next page

For Voltage readings

Pin 1

Only Odd pins

are easily

accessible with

Ribbon Cable

inserted

With Ribbon Cable Without Ribbon Cable

TIP:

For Voltage

readings,

Check Odd pins on

Y-SUS board

Check Even pins on

Control board

P101

Connector Label

Pin 29

Diode Mode Readings taken with all connectors Disconnected. DVM in Diode Mode.

64

November 2009 50PQ30 Plasma

Page 65

SUS P101 to Control P111 Plug Voltage Checks

YY--SUS P101 to Control P111 Plug Voltage Checks

“Y-SUS" P101 CONNECTOR to “Control" P111

TIP: For Voltage readings,

Check Odd pins on Y-SUS board

Check Even pins on Control board

Run LabelPin

Diode

Mode

1.37V17.04V15V1

1.37V17.04V15V3

2V5V5V5

2V5V5V7

1.30.1VCTRL_OE9

1.78V0VGnd (Y Enable)11

GndGndGnd13

0.9V1.99VDelta VY Det15

0.9V0.5VSet On17

0.9V1.29VDet Level Sel19

0.9V0.17VSlope Rate Sel21

0.9V0.114VER DN23

Run LabelPin

Diode

Mode

1.37V17.04V15V2

2V4.95V5V4

2V4.95V5V6

GndGndGnd8

GndGndOE10

GndGndGnd12

0.9V1.82VOC214

0.9V0VData16

0.9V1.44VOC118

0.9V1.45VSTB20

0.9V0.6VCLK22

0.9V024VSET UP24

0.9V2.6VSUS DN25

0.9V0.14VER UP27

0.9V0.11VYSUS UP29

There are No Stand By Voltages on this Connector

Diode Mode Readings taken with all connectors Disconnected. DVM in Diode Mode.

65

November 2009 50PQ30 Plasma

0.9V3.12VRamp Slope OPT 126

0.9V1.1VBlocking28

GndGndGnd30

Page 66

DRIVE BOARD SECTION

YY--DRIVE BOARD SECTION

Y-Drive Boards work as a path supplying the Sustain and Reset waveforms which are

made in the Y-Sustain board and sent to the Panel through Scan Driver IC’s.

The Y-Drive Boards supply a waveform which selects the horizontal electrodes

sequentially starting at the top and scanning down the panel.

* 50PQ30 uses 8 Driver ICs on 2 Y-Drive Boards

Drive Explained)

(Y(Y--Drive Explained)

TIP:

See additional Service Tips

beginning on page 131.

Y-Drive (V Scan) WAVEFORM

Y-Drive WAVEFORM TEST POINTS

Warning: To facilitate scope attachment, solder a small wire (Stand Off) at this point.

Be very careful, these are fragile and can peal off with excessive heat or stress.

66

November 2009 50PQ30 Plasma

Page 67

Upper Y--

Upper Y

Drive Layout

Drive Layout

TIP:

The connectors

to the Y-SUS

board are very

easy to

misalign and

plugged in.

The Connector

will be below

the actual pins

on the Y-SUS.

Look carefully.

See Tip section

page 133-134.

FG5V Volts from the

Y-SUS board and Logic

Signals from the Control

through the Y-SUS

board are supplied to

the Upper Y-Drive

Board on Connector

P109.

Y-Drive signal (VSC)

from the Y-SUS board

through the Y-Drive

lower is supplied to the

Upper Y-Drive Board on

Connector P108.

PANEL

SIDE

Y-SUS

SIDE

67

November 2009 50PQ30 Plasma

Page 68

Upper Y--

Upper Y

P109 Pins 7, 8, 9, and 10 are Logic Signals

from the Control board routed through the

Between the Y-Drive upper and lower is

P108/P209 which carries the Y-Drive (Scan)

FG5V (+5V F) measured

from Pins 4 or 5 to

Floating Gnd

Pins 1~3, 6 or 11

Drive P109 (Top Connector) Explained

Drive P109 (Top Connector) Explained

Y-SUS to the Y-Drive upper.

signal from the lower to the upper.

11) Ground (F)

10) DATA

9) OC1

8) STB

7) CLK

6) Ground (F)

5) 5V VF

4) 5V VF

3) Ground (F)

2) Ground (F)

1) Ground (F)

Y-Drive Upper

Board

Y-SUS

Board

c

FL101

68

P109

Top Connector P109

November 2009 50PQ30 Plasma

P209

Page 69

Upper Y--

Upper Y

Checking the Upper Y--

Checking the Upper Y

NOTE: Disconnected from the Y--

NOTE: Disconnected from the Y

All Readings from Floating Ground (Pin 1~3, 6 or 12)

Drive Upper P109 Diode Mode Testing

Drive Upper P109 Diode Mode Testing

Drive BOARD P109

Drive BOARD P109

SUS Board

SUS Board

TIP: This test will check “All”

scan buffers Low Voltage input

side on the Y-Drive Upper board.

Y-Drive

Upper

Board

Y-SUS

Board

Floating Gnd

Floating Gnd

Floating Gnd

Floating Gnd

Floating Gnd

12) Ground (F)

11) OC2

10) DATA

9) OC1

8) STB

7) CLK

6) Ground (F)

5) 5V VF

4) 5V VF

3) Ground (F)

2) Ground (F)

1) Ground (F)

Meter in the Diode Mode

RED LEAD

Blk Lead FG

0V

Open

Open

Open

Open

Open

0V

1.94V

1.94V

0V

0V

0V

BLACK LEAD

Red Lead FG

0V

0.52V

0.67V

0.54V

0.54V

0.54V

0V

0.43V

0.43V

0V

0V

0V

FL101

c

P109

Y-SUS Board should be

disconnected for this test.

P209

69

November 2009 50PQ30 Plasma

Page 70

Drive Lower Layout

YY--Drive Lower Layout

PANEL

SIDE

TIP:

The connectors

to the Y-SUS

board are very

easy to

misalign and

plugged in.

The Connector

will be below

the actual pins

on the Y-SUS.

Look carefully.

See Tip section

page 133-134.

Y-SUS

SIDE

FG5V Volts from the

Y-SUS board and Logic

Signals from the Control

through the Y-SUS

board are supplied to

the Lower Y-Drive

Board on connector

P205.

Y-Drive signal (VSC)

from the Y-SUS board is

supplied to the Lower

Y-Drive Board on

connector P205 pins 11

and 12. Then the Lower

Y-Drive delivers the

V-Scan signal to the

upper via P209 to P108.

70

November 2009 50PQ30 Plasma

Page 71

Drive Lower P205 (Bottom Connector) Explained

YY--Drive Lower P205 (Bottom Connector) Explained

TIP: Use P207 pins 1 or 2 or the Right Side of C213 to test

for Y Scan signal if the Y-Drive boards are removed

Blanking

Reset

FL201

c

P205

Y-Drive Board

P207

C213

Y-SUS Board

11) V Scan

10) V Scan

9) n/c

8) 5V VF

7) 5V VF

6) Ground (F)

5) STB

4) OC1

3) DATA

2) OC2

1) Ground (F)

P207 Pins 1 and 2

Y Scan signal

516V p/p

FG5V measured from

Pins 7 or 8

Floating Gnd

Pins 1 or 6

P207 Pins 2, 3, 4, and 5 are

Logic (Drive) Signals to the

Y-Drive lower P209 carries the

Y-Drive signals to the Upper

Y-Drive board

Sustain

Bottom Connector P205

71

November 2009 50PQ30 Plasma

Page 72

Lower Y--

Lower Y

Drive P205 Diode Mode Testing

Drive P205 Diode Mode Testing

TIP: This test will check “All”

scan buffers Low Voltage input

side on the Y-Drive lower board.

Checking the Lower Y--

Checking the Lower Y

NOTE: Disconnected from the Y--

NOTE: Disconnected from the Y

All Readings from Floating Ground (Pin 1 or 7)

Y-Drive Sig

Y-Drive Sig

Floating Gnd

Floating Gnd

12) V Scan

11) V Scan

10) n/c

9) 5V VF

8) 5V VF

7) Ground (F)

6) CLK

5) STB

4) OC1

3) DATA

2) OC2

1) Ground (F)

Drive Board P205

Drive Board P205

RED LEAD

Blk Lead FG

Open

Open

Open

Open

Open

0V

Open

Open

Open

Open

Open

Open

SUS board

SUS board

BLACK LEAD

Red Lead FG

1.0V

1.0V

Open

0.425V

0.425V

0V

0.538V

0.538V

0.538V

Open

0.521V

0V

P205 of the

Y-DRIVE Lower

FL201

P205

c

P207 of the

Y-SUS Board

C213

P207

Meter in the Diode Mode

72

Y-SUS Board should be

disconnected for this test.

November 2009 50PQ30 Plasma

Page 73

Drive P108 and P209 Voltage and Diode Mode Check

YY--Drive P108 and P209 Voltage and Diode Mode Check

TIP: This test will check “All” scan buffers Input side on the board.

Voltage and Diode Mode Measurements (Taken from Floating Ground)

P108 CONNECTOR “Y-Drive Upper to Lower”

Y-Drive Upper

P108

P209

Y-Drive Lower

Run LabelPin

P209 CONNECTOR “Y-Drive Lower to Upper”

Run LabelPin

Diode Mode

Diode Mode

Red Lead

0V0VFGnd1

0V0VFGnd2

Open*134VY Scan3

Open*134VY Scan4

Open*134VY Scan5

Red Lead

0V0VFGnd1

0V0VFGnd2

Open*134VY Scan3

Diode Mode

Black Lead

0V

0V

1.2V

1.2V

1.2V

Diode Mode

Black Lead

0V

0V

1.0V

Diode Mode Readings taken with all

connectors Disconnected. DVM in Diode

Mode.

Open*134VY Scan4

Open*134VY Scan5

Note: This voltage will vary in accordance with Panel Label

73

November 2009 50PQ30 Plasma

1.0V

1.0V

Page 74

Removing (Panel) Flexible Ribbon Cables from Y--

Removing (Panel) Flexible Ribbon Cables from Y

Drive Upper or Lower

Drive Upper or Lower

Flexible Ribbon Cables shown are from a different model, but pro

Flexible Ribbon Cables shown are from a different model, but pro

To remove the Ribbon Cable from the connector first carefully lift the Locking Tab from

the back and tilt it forward ( lift from under the tab as shown in Fig 1).

The locking tab must be standing straight up as shown in Fig 2.

Lift up the entire Ribbon Cable gently to release the Tabs on each end. (See Fig 3)

Gently slide the Ribbon Cable free from the connector.

Be sure ribbon tab is released

By lifting the ribbon up slightly,

Gently Pry

Up Here

Locking tab in

upright position

cess is the same.

cess is the same.

before removing ribbon.

Fig 1

To reinstall the Ribbon Cable, carefully slide it back into the slot see ( Fig 3 ), be sure the Tab is seated

securely and press the Locking Tab back to the locked position see ( Fig 2 then Fig 1).

Fig 2

74

November 2009 50PQ30 Plasma

Fig 3

Page 75

Incorrectly Seated Y--

Incorrectly Seated Y

The Ribbon Cable is clearly improperly seated

into the connector. You can tell by observing the

line of the connector compared to the FPC, they

should be parallel.

The Locking Tab will offer a greater resistance to

closing in the case.

Note the cable is crooked. In this case the Tab on

the Ribbon cable was improperly seated at the

Drive Flexible Ribbon Cables