LG 50PM4700-TA Schematic

Internal Use Only

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

PLASMA TV

SERVICE MANUAL

CHASSIS : PA22A

MODEL : 50PM4700 50PM4700-TA

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Printed in KoreaP/NO : MFL67341704 (1201-REV00)

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ........................................................................ 3

SPECIFICATION ....................................................................................... 4

ADJUSTMENT INSTRUCTION ................................................................ 6

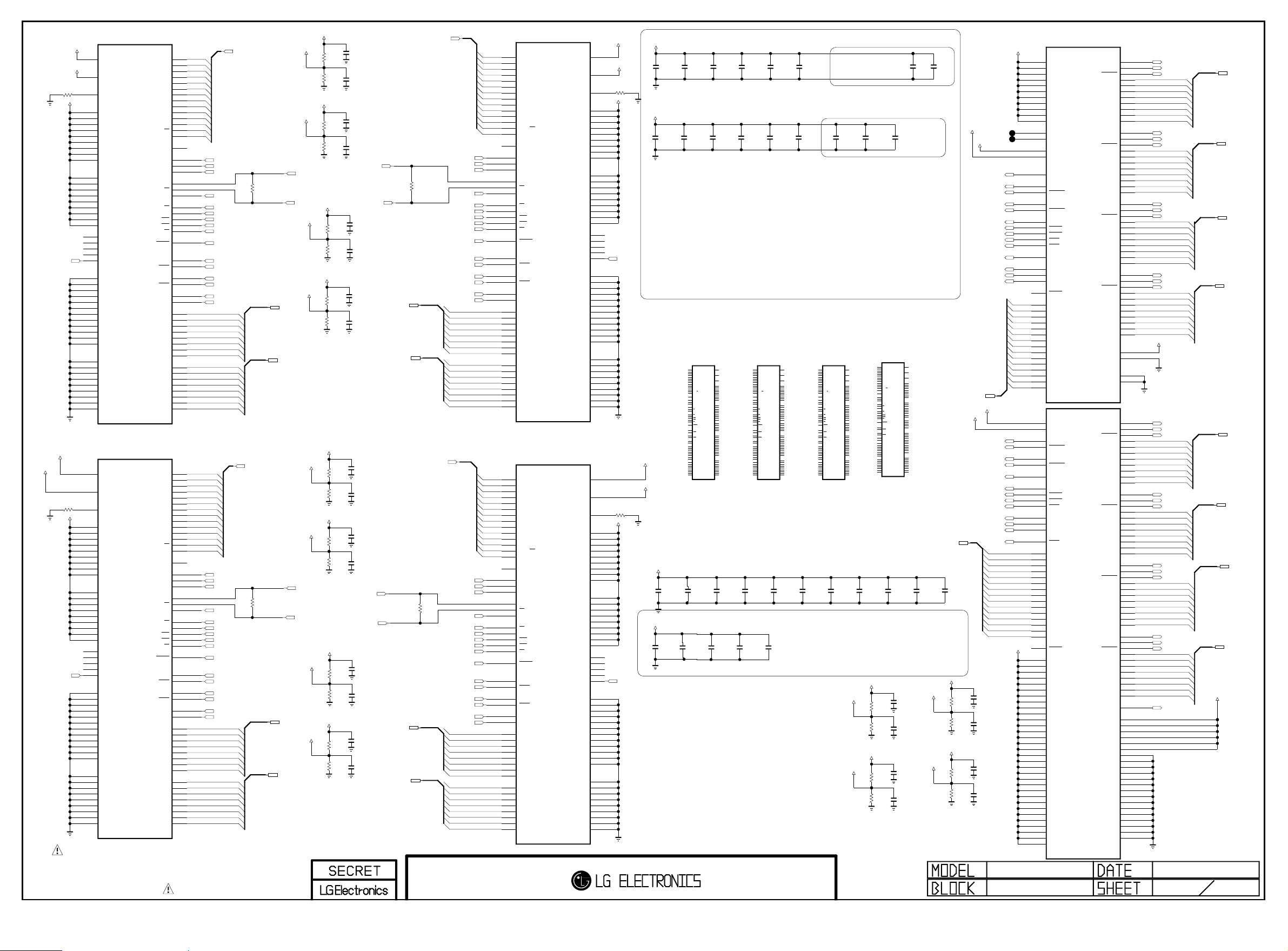

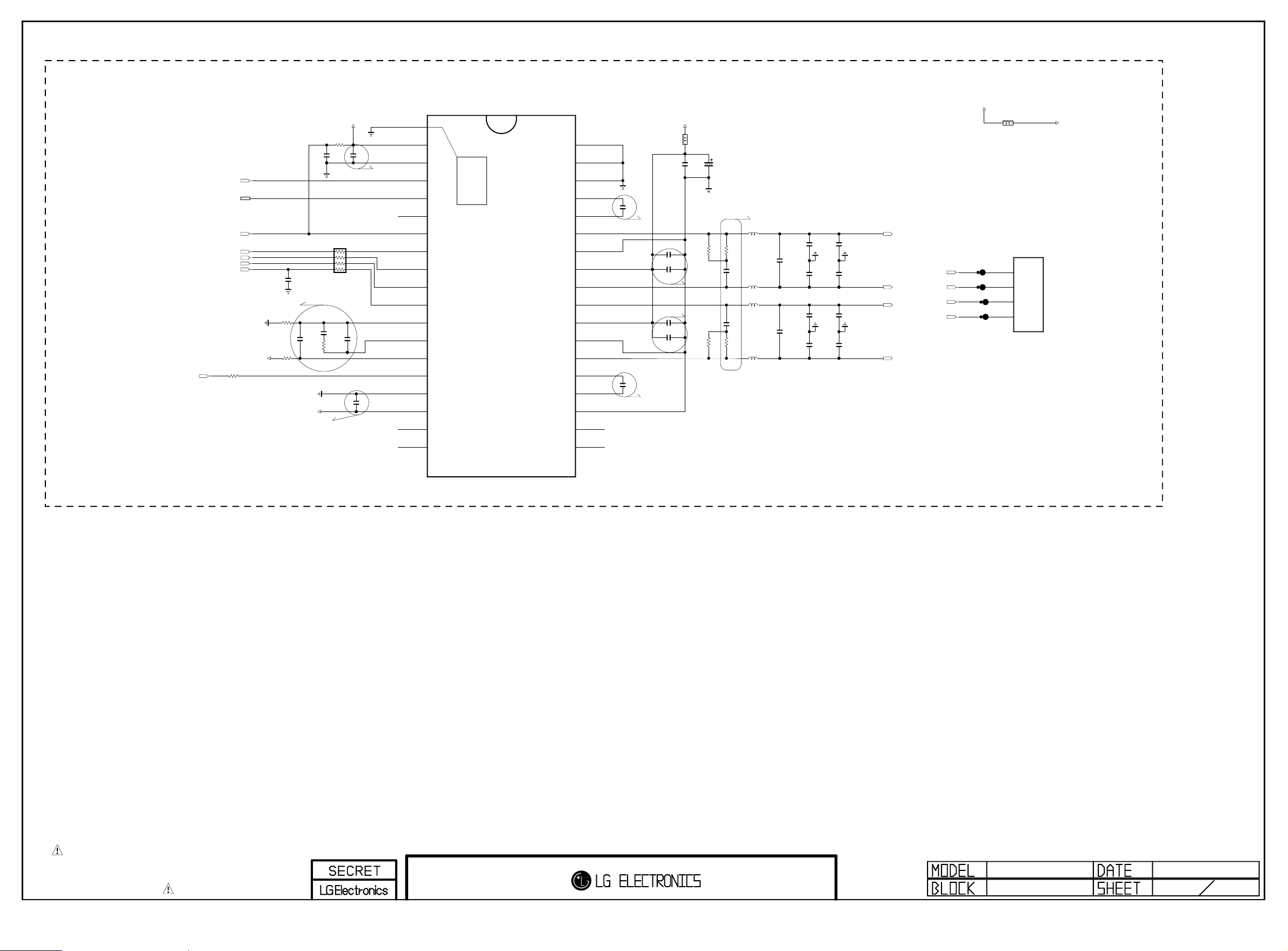

BLOCK DIAGRAM .................................................................................. 10

EXPLODED VIEW .................................................................................. 11

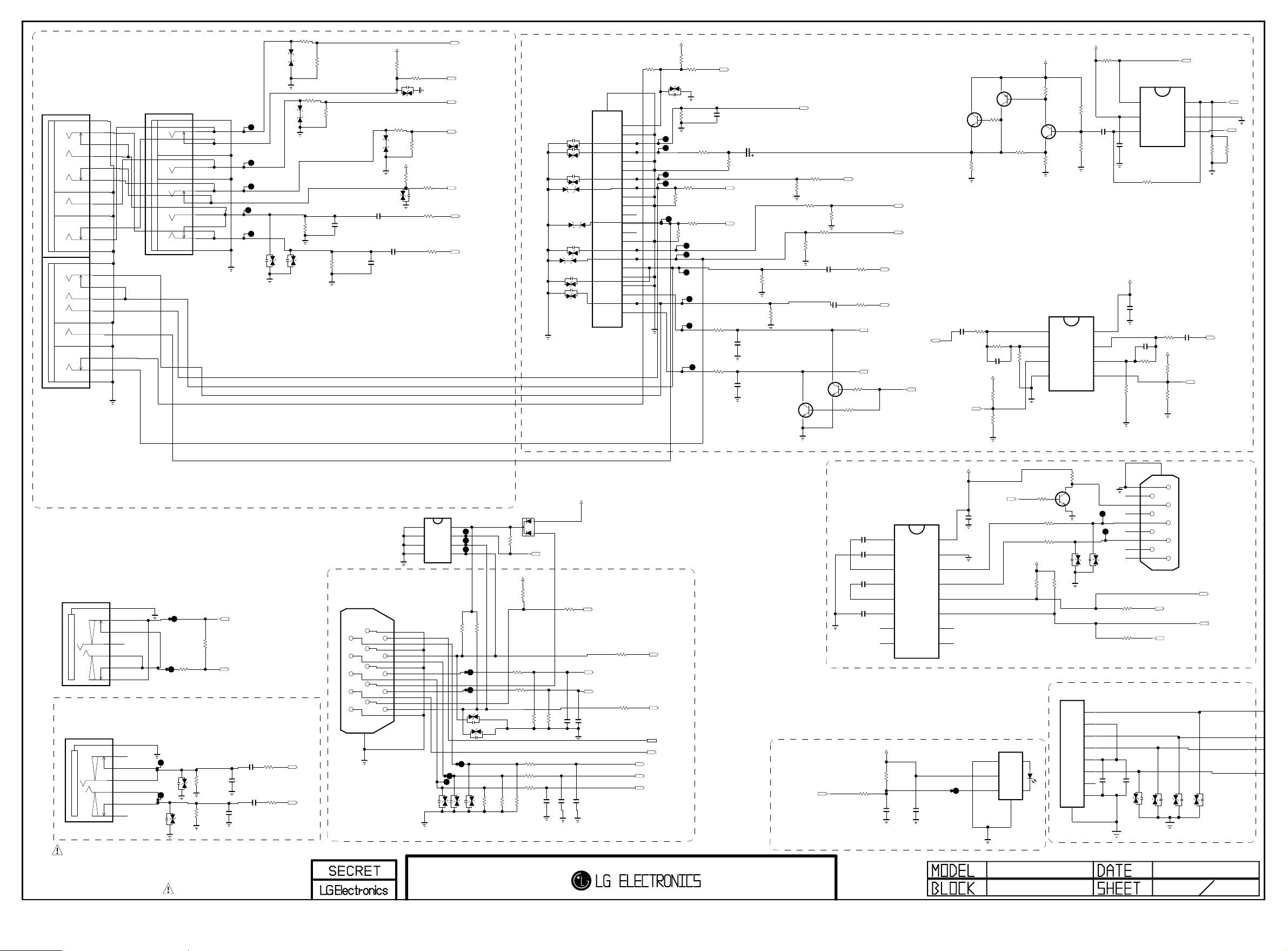

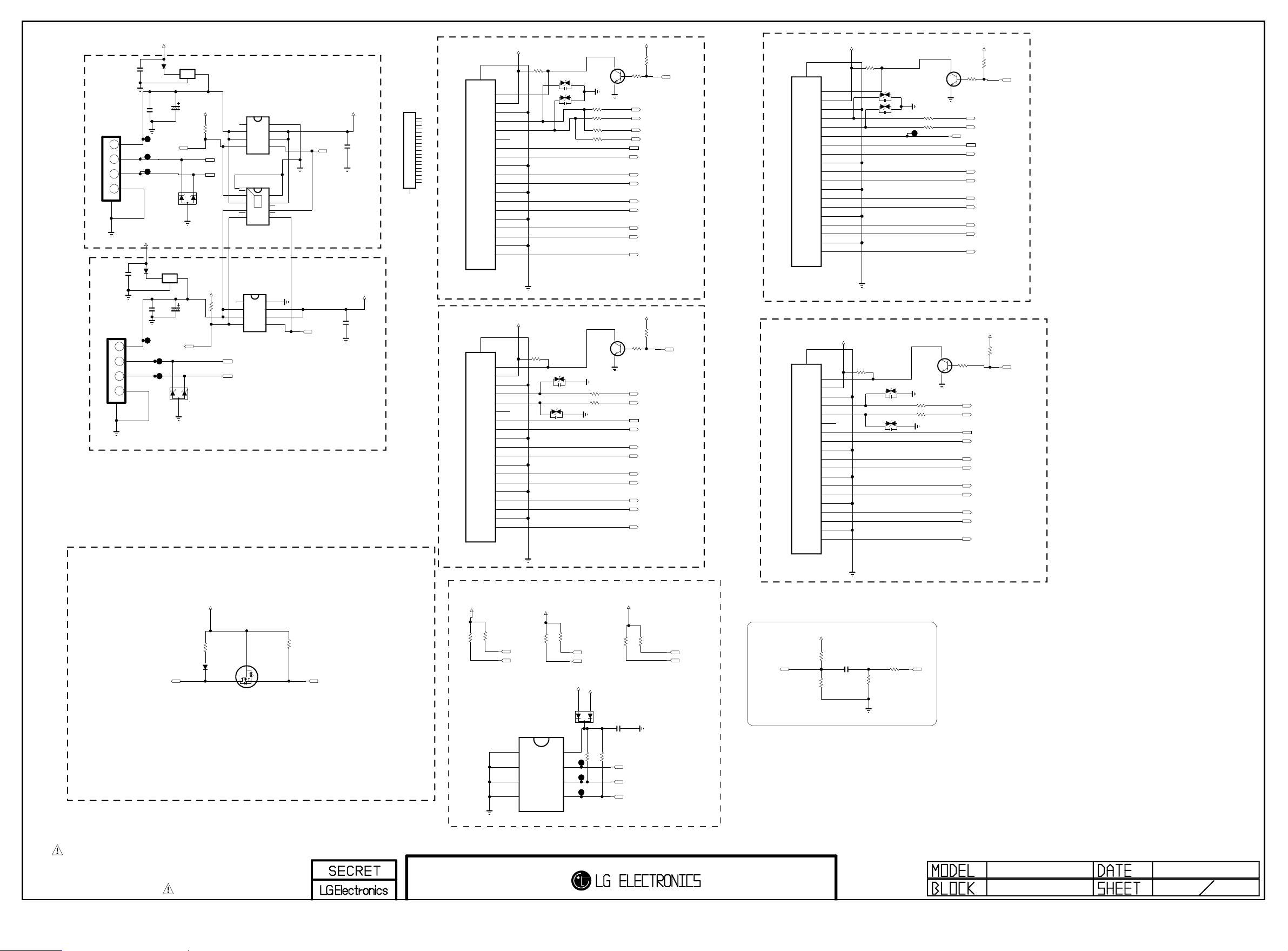

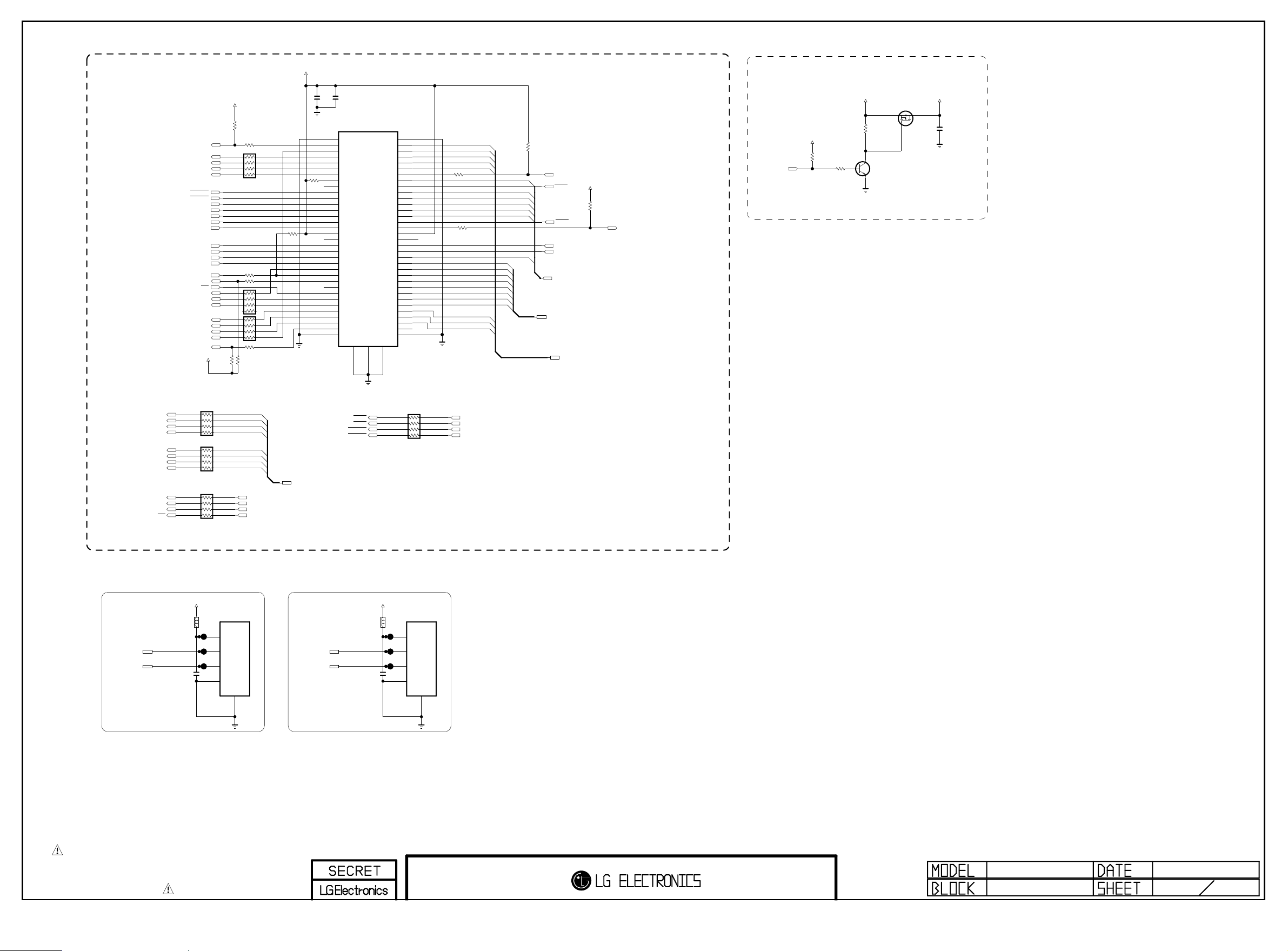

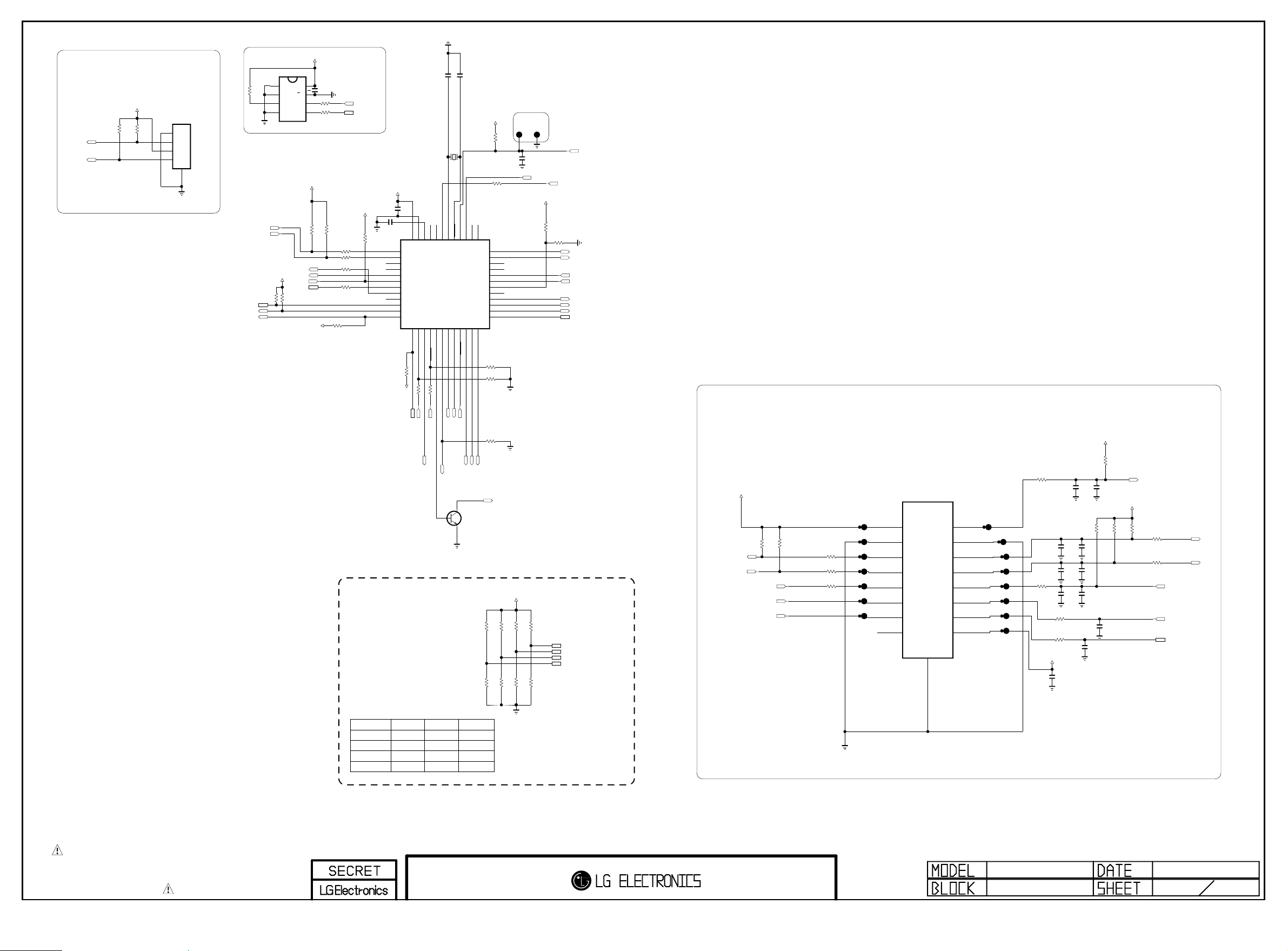

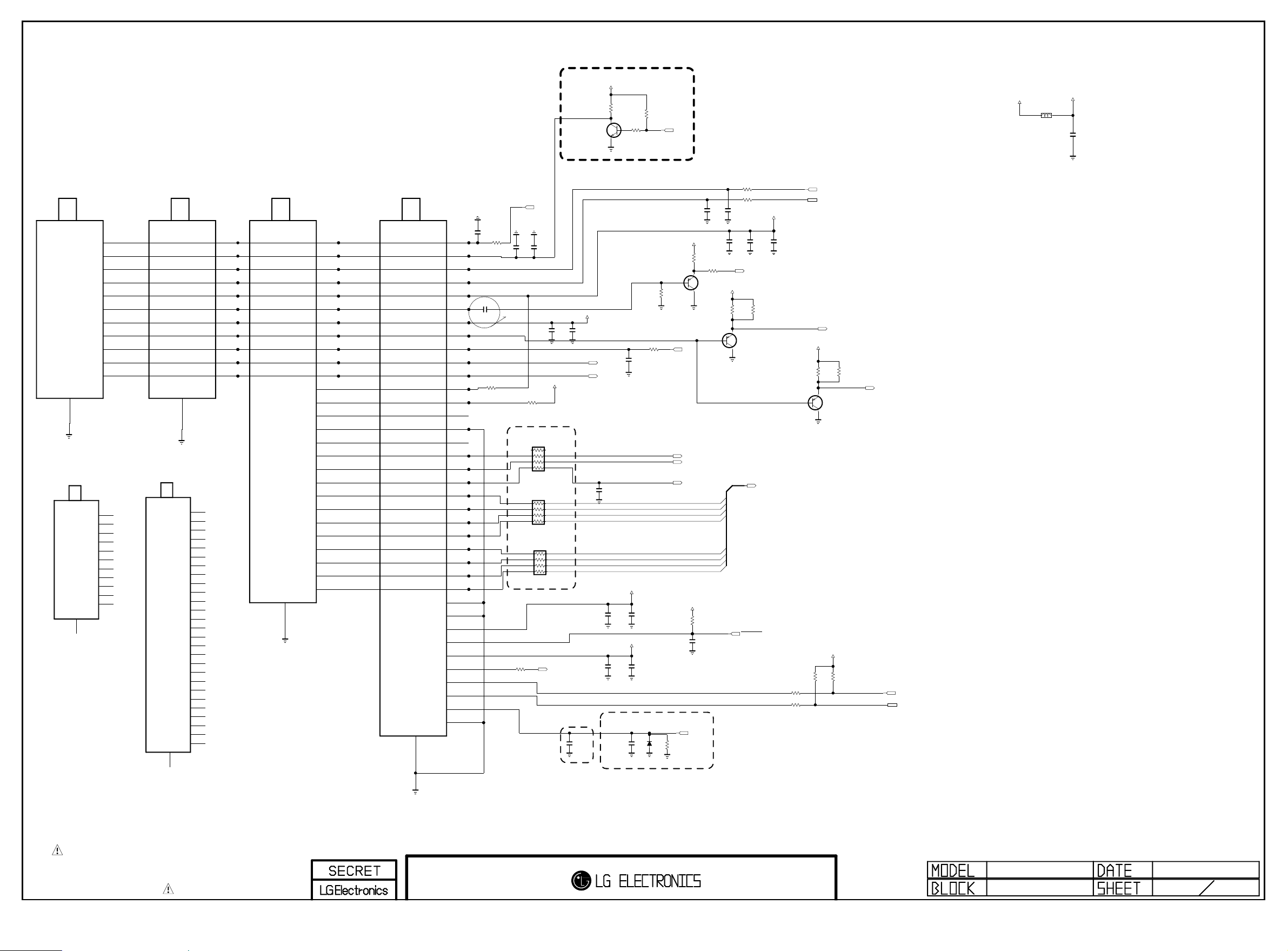

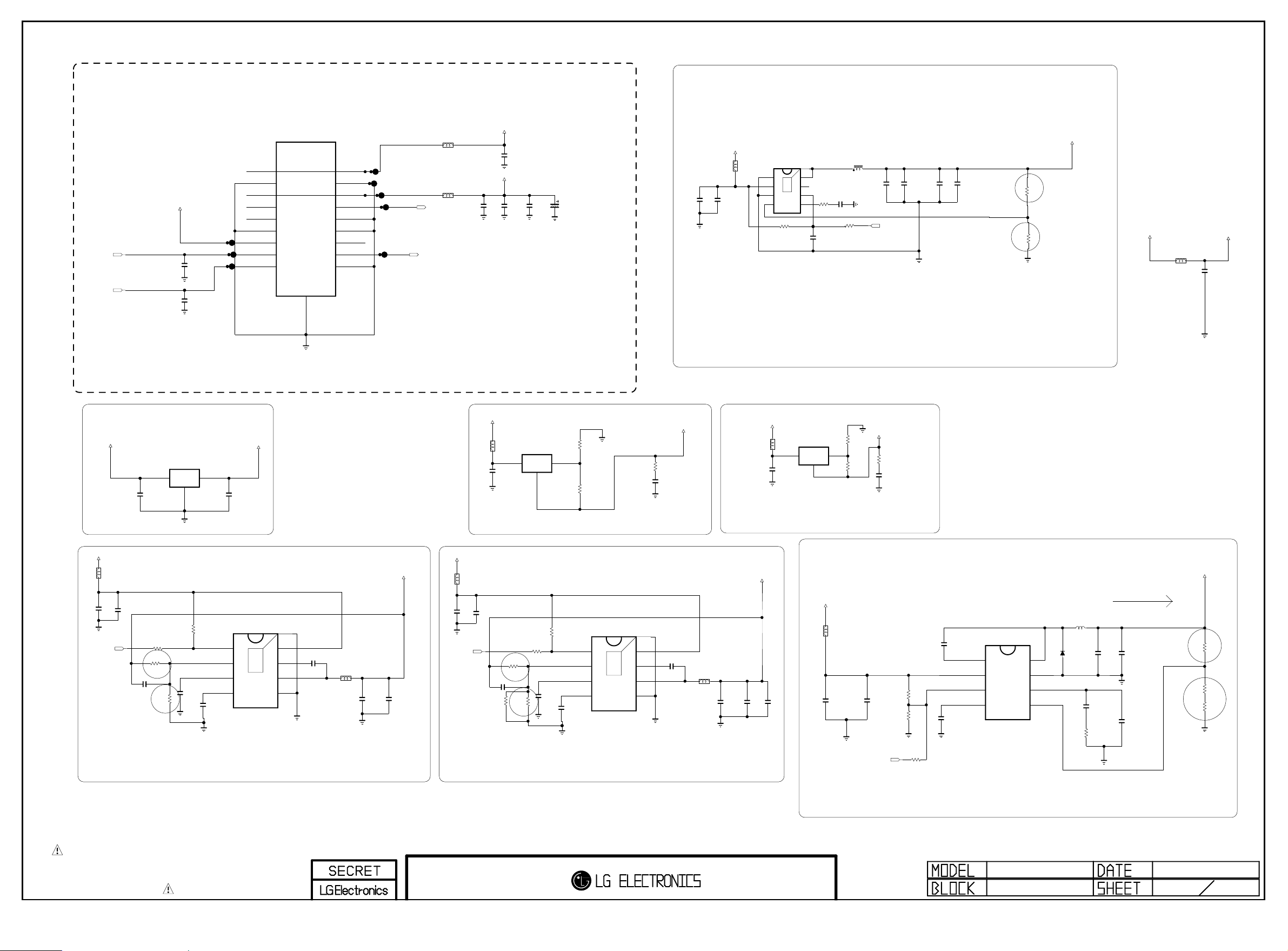

SCHEMATIC CIRCUIT DIAGRAM ..............................................................

Only for training and service purposes

- 2 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

AC Volt-meter

SAFETY PRECAUTIONS

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental sh orts of the cir cui try that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 M

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Ω and 5.2 MΩ.

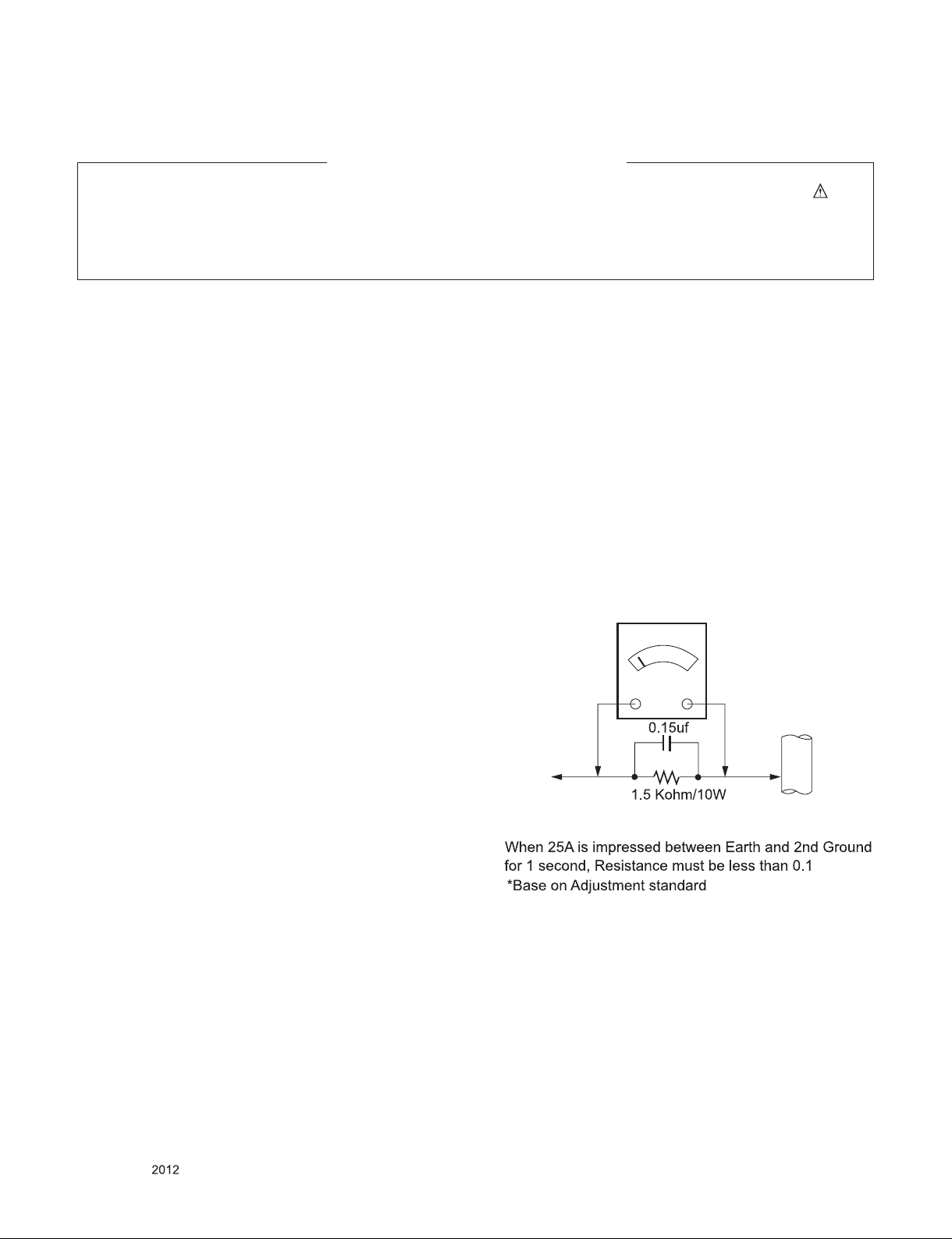

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

Good Earth Ground

such as WATER PIPE,

To Instrument's

exposed

METALLIC PARTS

CONDUIT etc.

Only for training and service purposes

- 3 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

1. Application range

This spec sheet is applied all of the PDP TV with PA22A chassis.

2. Requirement for Test

Each part is tested as below without special appointment.

(1) Temperature: 25 °C ± 5 °C(77 °F ± 9 °F), CST: 40 °C ± 5 °C

(2) Relative Humidity: 65 % ± 10 %

(3) Power Voltage

: Standard input voltage (AC 100-240 V~, 50/60 Hz)

* Standard Voltage of each products is marked by models.

(4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with

BOM.

(5) The receiver must be operated for about 5 minutes prior to the adjustment.

3. Test method

(1) Performance: LGE TV test method followed

(2) Demanded other specification

- Safety : CE, IEC specification

- EMC : CE, IEC

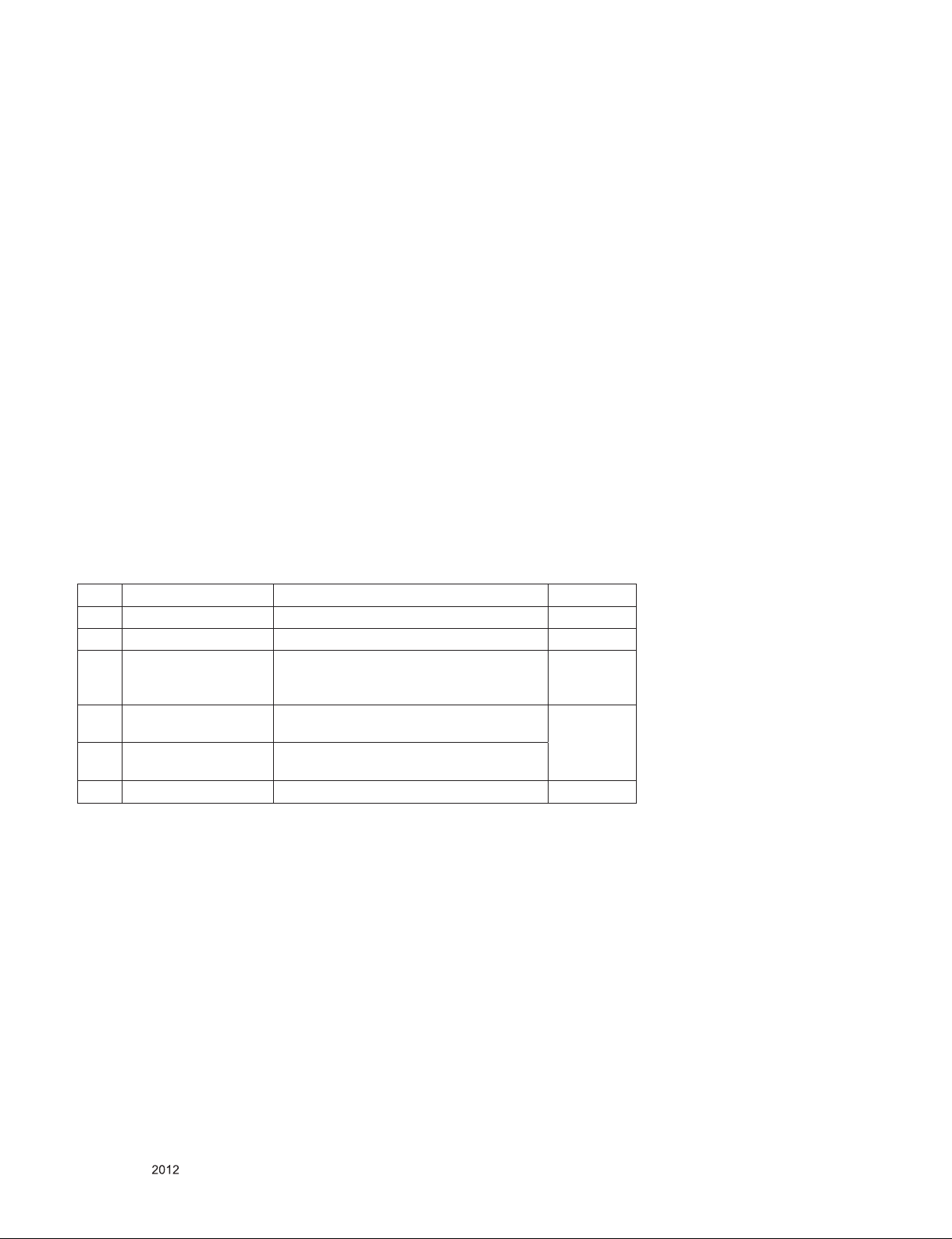

4. Module General Specification

- 50" 3D HD

No Item Specication Remark

1 Display Screen Device 127 cm (50 inch) wide Color Display Module PDP

2 Aspect Ratio 16:9

3 PDP Module PDP50T4####,

RGB Closed (Well) Type, Glass Filter (43%)

Pixel Format: 1024 horiz. By 768 ver.

4 Operating Environment 1) Temp. : 0 ~ 40 deg

2) Humidity : 20 ~ 80%

5 Storage Environment 1) Temp. : -20 ~ 60 deg

2) Humidity : 10 ~ 90 %

6 Input Voltage AC100 ~ 240V, 50/60Hz Maker LG

.

LGE SPEC

Only for training and service purposes

- 4 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

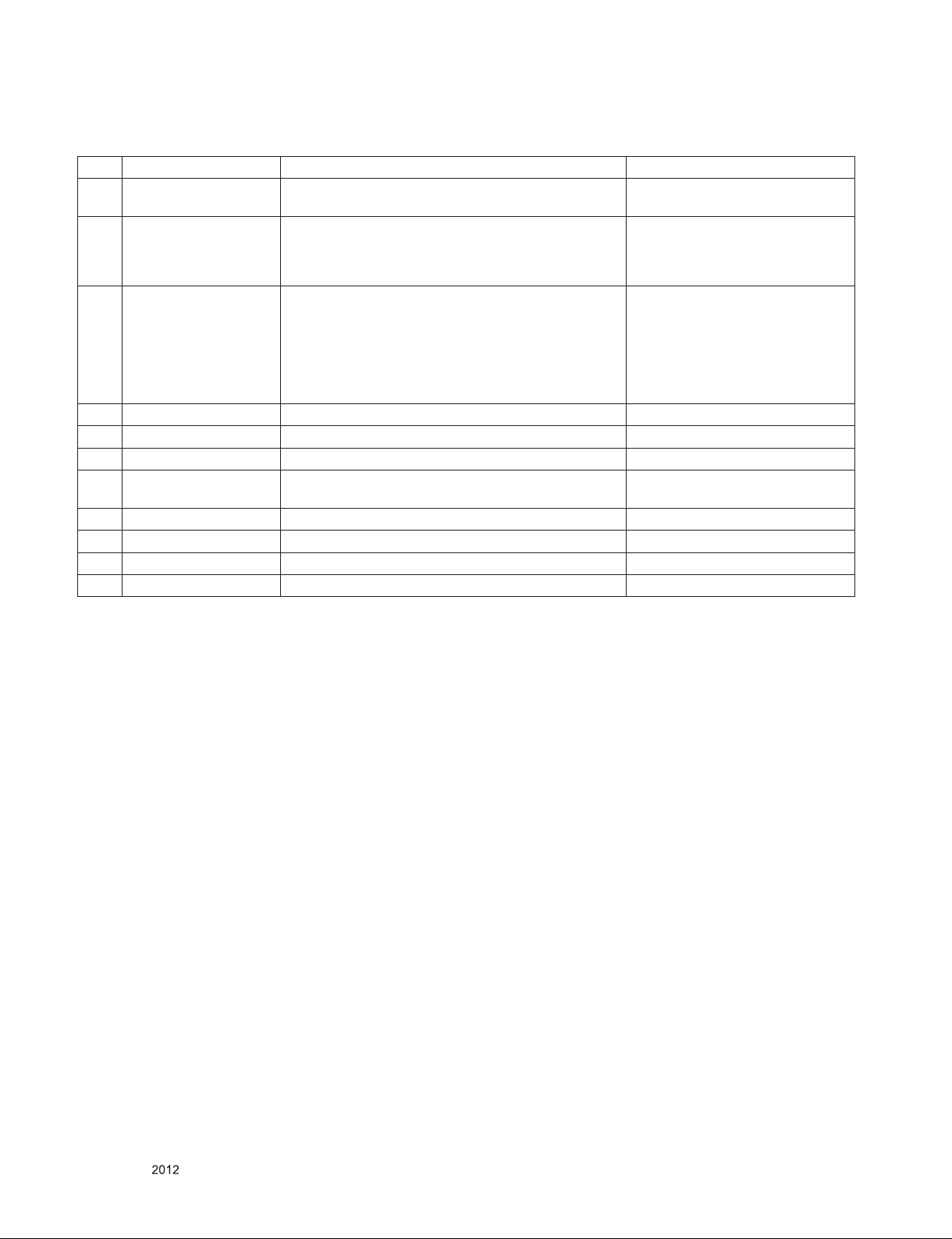

5. Model General Specification

No Item Specication Remark

1 Market Australia, New Zealand, Indonesia, Malaysia, Singapore,

Vietnam, South Africa, Iran, Kenya, Israel

2 Broadcasting system 1) PAL BG

2) PAL DK

3) PAL I / II

4) DVB T

3 Receiving system Analog : Upper Heterodyne

Digital : COFDM

4 AV (1EA) PAL

5 Component Input (1EA) Y/Cb/Cr, Y/Pb/Pr

6 RGB Input (1EA) RGB-PC Analog (D-Sub 15Pin)

7 HDMI Input (4EA) HDMI-PC

HDMI-DTV

8 Audio Input (2EA) RGB/DVI Audio, Component L/R Input

9 SPDIF Out (1 EA) SPDIF Out

10 USB (2EA) For SVC, S/W Download, X-Studio, DivX

11 Ethernet LAN(1EA)

► DVB-T

- Guard Interval(Bitrate_Mbit/s)

1/4, 1/8, 1/16, 1/32

- Modulation : Code Rate

QPSK : 1/2, 2/3, 3/4, 5/6, 7/8

16-QAM : 1/2, 2/3, 3/4, 5/6, 7/8

64-QAM : 1/2, 2/3, 3/4, 5/6, 7/8

HDMI1/DVI, HDMI2, HDMI3

Only for training and service purposes

- 5 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

ADJUSTMENT INSTRUCTION

1. Application Range

This spec. sheet applies to PA22A chassis applied PDP TV all

models manufactured in TV factory.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to

use an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25 °C ± 5 °C of temperature and 65±10% of relative

humidity if there is no specific designation.

(4) The input voltage of the receiver must keep 100~240V,

50/60Hz.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment when module is in the circumstance of over

15 °C

- In case of keeping module is in the circumstance of 0°C, it

should be placed in the circumstance of above 15°C for 2

hours

- In case of keeping module is in the circumstance of below

-20 °C, it should be placed in the circumstance of above 15

°C for 3 hours,.

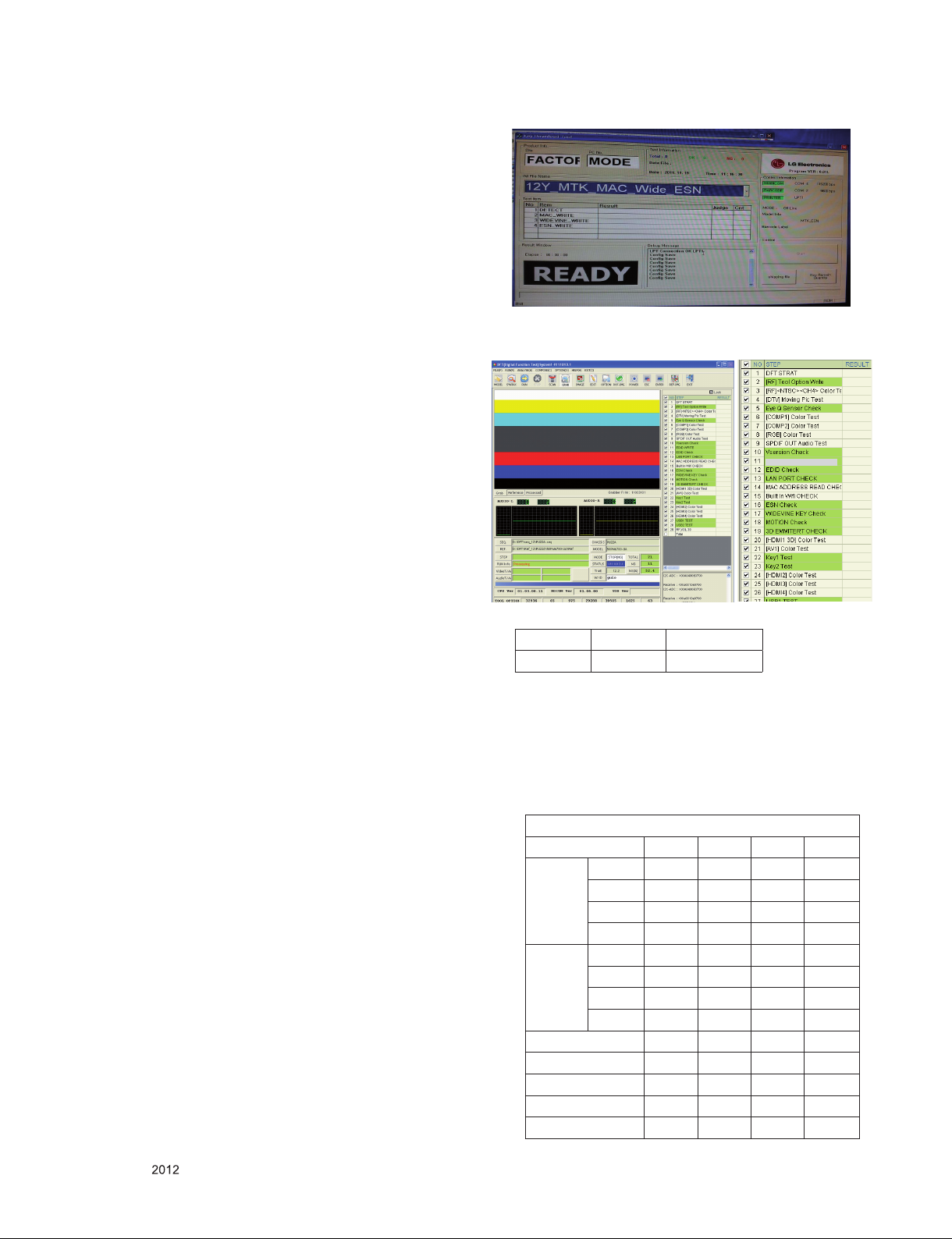

3.2. DFT Process

* Depend on situation, Step can be changed.

■ After RGB Full White in HEAT-RUN Mode, the receiver must

be operated prior to the adjustment.

■ Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

● Set is activated HEAT run without signal generator in this

mode.

● Single color pattern ( WHITE ) of HEAT RUN MODE uses to

check panel.

● Caution : If you turn on a still screen more than 20 minutes

(Especially digital pattern, cross hatch pattern), an

after image may be occur in the black level part of

the screen.

3. PCB Assembly adjustment

* Caution : Using ‘power on’ button of the control R/C power on

TV

3.1. MAC Address and ESN and Wide-vine

Key Download

* The CI+ Key download is need for only PD22A/B/C Models.

* Connect TV SET and PC which download keys Writing

program by RS232C-Cable

(1) Start Program and Click ‘start’ Button to connect TV and

PC.

(2) When download succeed, you can see “OK” on the

screen.

* Each Chassis has it’s own MAC Address/ESN/Wide-vine

key. Please be careful of download.

* Condition spec

Mode Volume Power Off

RF 0 DC On

3.3. Tool OPTION (MANUAL)

(1) Press ADJ key on R/C to insert Tool OPTION

(2) On the “ Tool Option ”, Insert Tool Option by a number key

(3) Press the ENTER(■)

(4) Press ENTER(■) again.

(5) Select “OK to Download” by using ◄/►(VOL +/-) and

press ►(VOL +)

* PA22A

Model Name PM970 PM690 PM670 PM470

Tool

option 1

Tool

option 2

Tool option 3 973 973 973 845

Tool option 4 29294 29294 29294 29294

Tool option 5 47703 47703 47703 14933

Tool option 6 1561 1561 1561 1561

Tool option 7 8235 9259 8235 8235

42 HD 33062

50 HD 33064

50 FHD 32808 32904 32936

60 FHD 32810 32906 32938

42 HD 391

50 HD 391

50 FHD 390 390 390

60 FHD 390 390 390

Only for training and service purposes

- 6 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

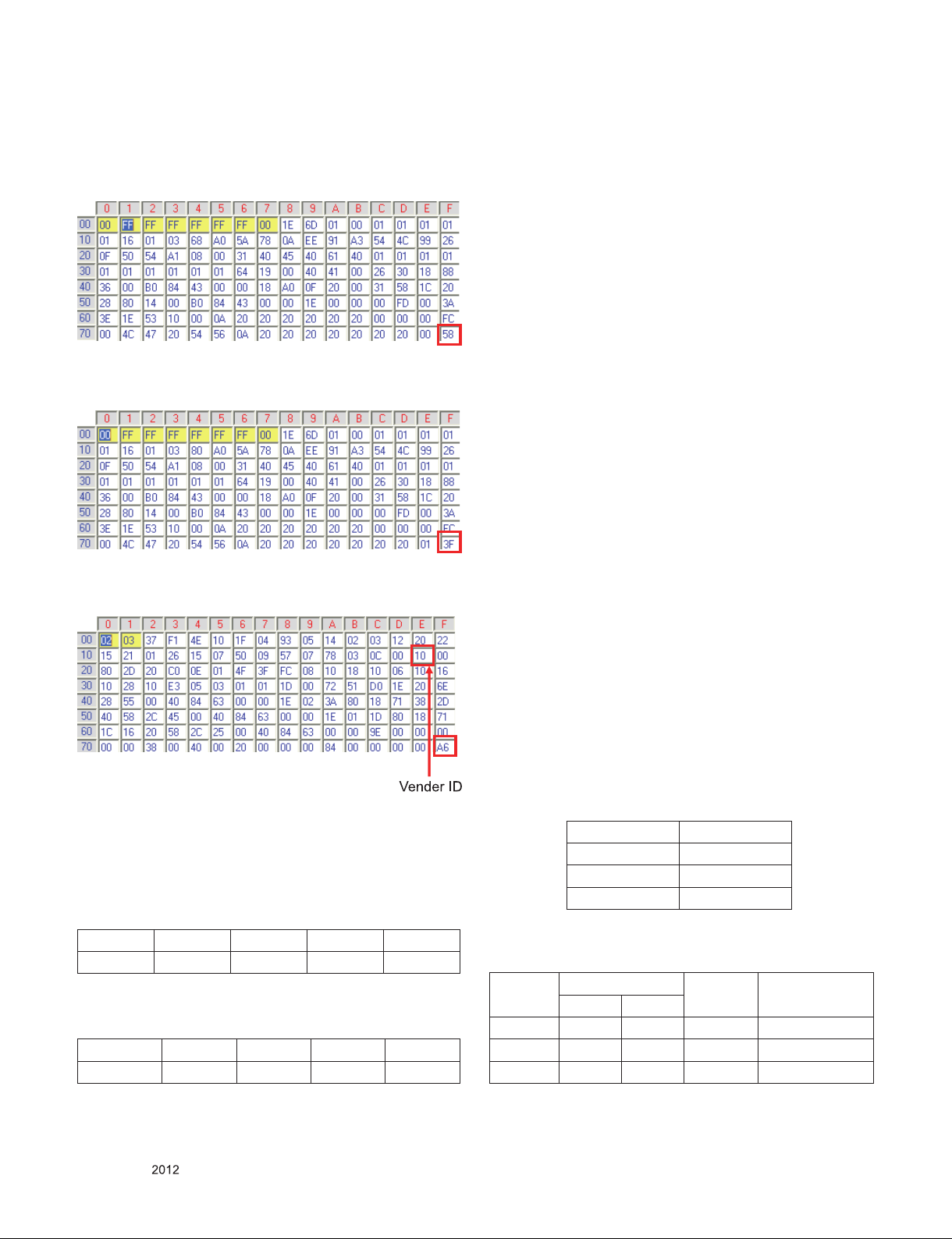

3.4. EDID (The Extended Display Identification Data)

■ RGB [C/S: 58] : For HD Models

EDID Block 0, Bytes 0-127 [00H-7FH]

Block Type: EDID 1.3

4. SET assembly adjustment method

* Caution: Each PCB assembly must be checked by check

JIG set. (Because power PCB Assembly damages

to PDP Module, especially be careful)

■ HDMI [C/S: 3F A6] : For HD Models

Block Type: EDID 1.3

EDID Block 1, Bytes 128-255 [80H-FFH]

Block Type: CEA EDID Timing Extension Version 3

4.1. POWER PCB Assembly Voltage adjustment

(Va, Vs voltage adjustment)

Test equipment : D.M.M 1EA

Connection Diagram for Measuring : refer to g.4

Adjustment method

4.1.1. Va adjustment

(1) Connect + terminal of D. M.M. to Va pin of P811, connect

-terminal to GND pin of P811.

(2) After turning VR502,voltage of D.M.M adjustment as same

as Va voltage which on label of panel right/top (deviation;

±0.5V)

4.1.2. Vs adjustment

(1) Connect + terminal of D. M..M. to Vs pin of P811, connect

-terminal to GND pin of P811.

(2) After turning VR901, voltage of D.M.M adjustment as

same as Vs voltage which on label of panel right/top (

deviation ; ±0.5V)

4.2. Adjustment of White Balance

- Required Equipment

● Remote controller for adjustment

● Color Analyzer ( CS-1000, CA-210 or same product

: CH 10 (PDP)

* Please adjust CA-210 by CS-1000 before measuring

● A uto W /B adjus tment in st rum en t(o nl y f or A ut o

G

adjustment)

● 9 Pin D-Sub Jack(RS232C) is connected to the AUTO

W/B EQUIPMENT

* CheckSum & Physical Address Table.

- Each HDMI Input has their own physical address(on

Address:9E). So, each HDMI Input has different C/S

value.

■ HDMI INPUT Physical Address Table

Address HDMI1 HDMI2 HDMI3 HDMI4

9E 10 20 30 40

■ HDMI INPUT C/S Table.

- HD

HDMI1 HDMI2 HDMI3 HDMI4

CheckSum 3FA6 3F96 3F86 3F76

Only for training and service purposes

Before Adjust of White Balance, Please press

POWER ONLY key

- Adjust Process will start by execute RS232C Command.

● Color temperature standards according to CSM and Module

CSM PLASMA

Cool 11000K

Medium 9300K

Warm 6500K

● CS-1000/CA-100+/CA-210(CH 10) White balance adjustment coordinates and color temperature.

CSM Color Coordination Temp ± Color

x y

COOL 0.276 0.283 11000K 0.002

MEDIUM 0.285 0.293 9300K 0.002

WARM 0.313 0.329 6500K 0.002

- 7 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Coordination

* Manual W/B process (using adjusts Remote control)

- Please Adjust in AV 1 MODE, Turn off Energy Saving Mode.

1) Enter ‘PICTURE RESET’ on Picture Mode, and then turn

off Fresh Contrast and Fresh colour in Advanced Control

2) After enter Service Mode by pushing “ADJ” key,

3) Enter White Pattern off of service mode, and change off

-> on.

4) Enter “W/B ADJUST” by pushing “►” key at “3. W/B

ADJUST”.

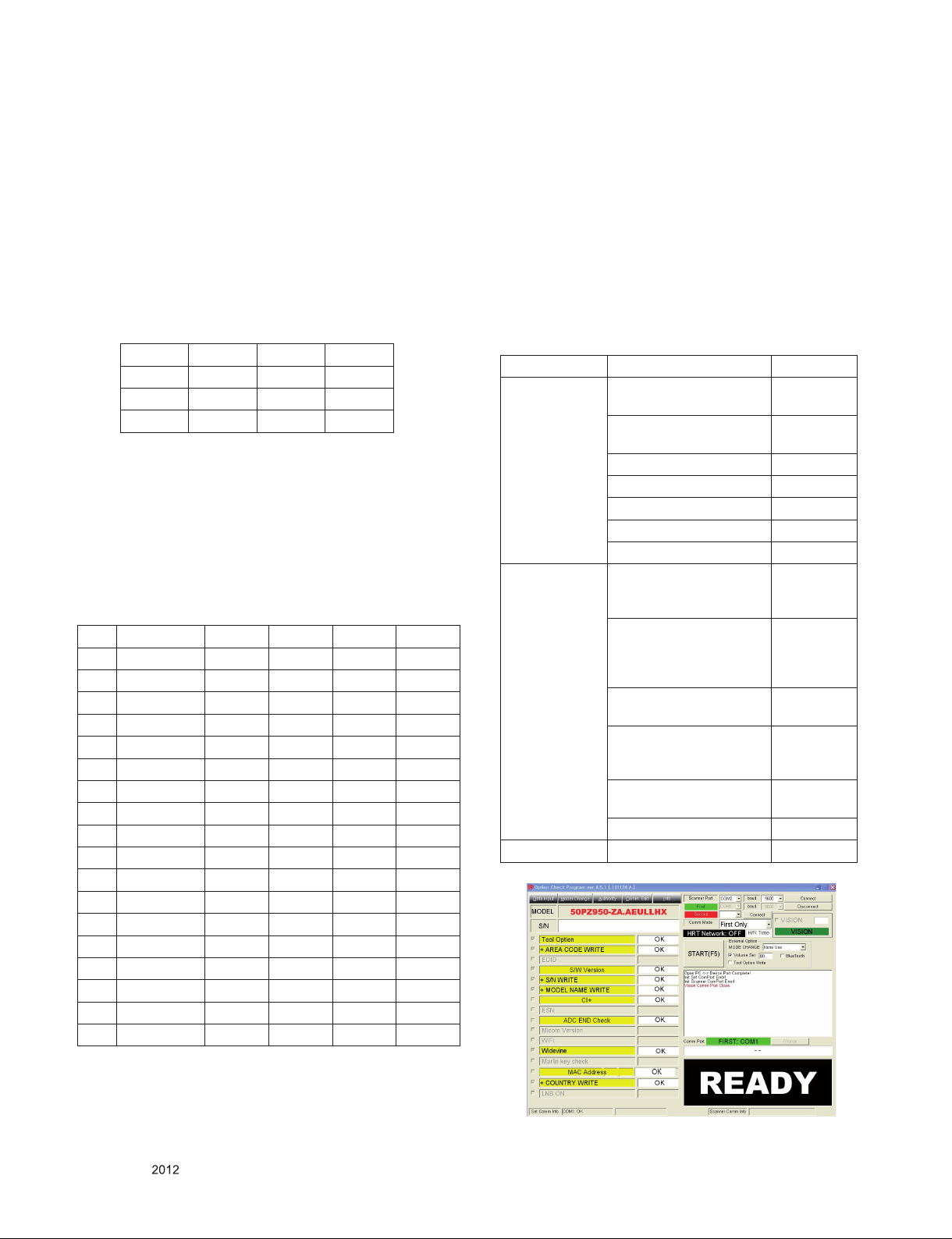

4.3. Serial number download & Model name D/L.

(1) Press "Power on" button of a service R/C.(Baud rate :

115200 bps)

(2) Connect RS232-C Signal Cable and start ‘Option Check

Program Ver3.8’

(3) Scan serial Number and press ‘F5’ button.

(4) Check ‘OK’ on program 1) program.

(5) Press ‘In start’ button on SVC R/C, check Serial Number

and Model Name.

* Gain Max Value is 192. So, Never make any Gain Value

over 192 and please x one Value on 192, between R, G

and B.

Min Typ Max

R-GAIN 0 192 192

G-GAIN 0 192 192

B-GAIN 0 192 192

* Auto-control interface and directions

(1) Adjust in the place where the inux of light like oodlight

around is blocked. (Illumination is less than 10ux).

(2) Measure and adjust after sticking the Color Analyzer (CA-

100+, CA210) to the side of the module.

(3) Aging time

- After aging start, keep the Power on (no suspension of

power supply) and heat-run over 5 minutes

* Auto adjustment Map (RS232C)

No Index CMD1 CMD2 Set ID Data

1 Start w b 0 00

2 Gain Start w b 0 10

3 Gain End w b 0 1F

4 Offset Start w b 0 20

5 Offset End w b 0 2F

6 End w b 0 FF

7 Medium R j a 0 00~FF

8 Medium G j b 0 00~FF

9 Medium B j c 0 00~FF

10 Warm R j d 0 00~FF

11 Warm G j e 0 00~FF

12 Warm B j f 0 00~FF

13 Cool R j g 0 00~FF

14 Cool G j h 0 00~FF

15 Cool B j i 0 00~FF

16 Cool R,G,B j j 0 00~FF

17 Medium j k 0 00~FF

18 Warm j l 0 00~FF

4.4. Check Tool Option and write Country

Group & Area Code(Option) D/L

- Refer to Table 3.4 insert tool option.

Country Group Market Area Option

AJ Myanmar

Etc.

Australia, New Zealand

Singapore, Malaysia

Indonesia 262

Vietnam 261

Thailand 16647

Sri Lanka 17671

India 18183

JA Irap, Lybia, Yemen,

Syria, Sudan, West Afria

Ect.

South Africa ,Alegeria,

Tunisia, Kuwait, Oman,

Kenya, Uganda

Palestine(SBITANY)

Qatar

Nigeria

U.A.E

Saudi Arabia

Barhrain

Egypt, Iran, Jordan

Lebanon

Pakistan 16642

IL Israel(H.Y.E) 259

257

263

257

259

260

261

263

Only for training and service purposes

- 8 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

4.5. Checking the EYE-Q Operation.

(1) Press the EYE Key on the adjustment remote controller.

(2) Check the Sensor DATA ( It must be under 10) and keep

the data longer than 1.5s

(3) Check ‘OK’

Green Eye-Check(Factory Mode)

Sensor Data 9

Power saving mode 1

OK

(Sensor DATA 0 ~ 4095, Power Saving Mode 0 ~ 12)

* IF you press IN-STAP Button, change Green Eye-check

OSD.

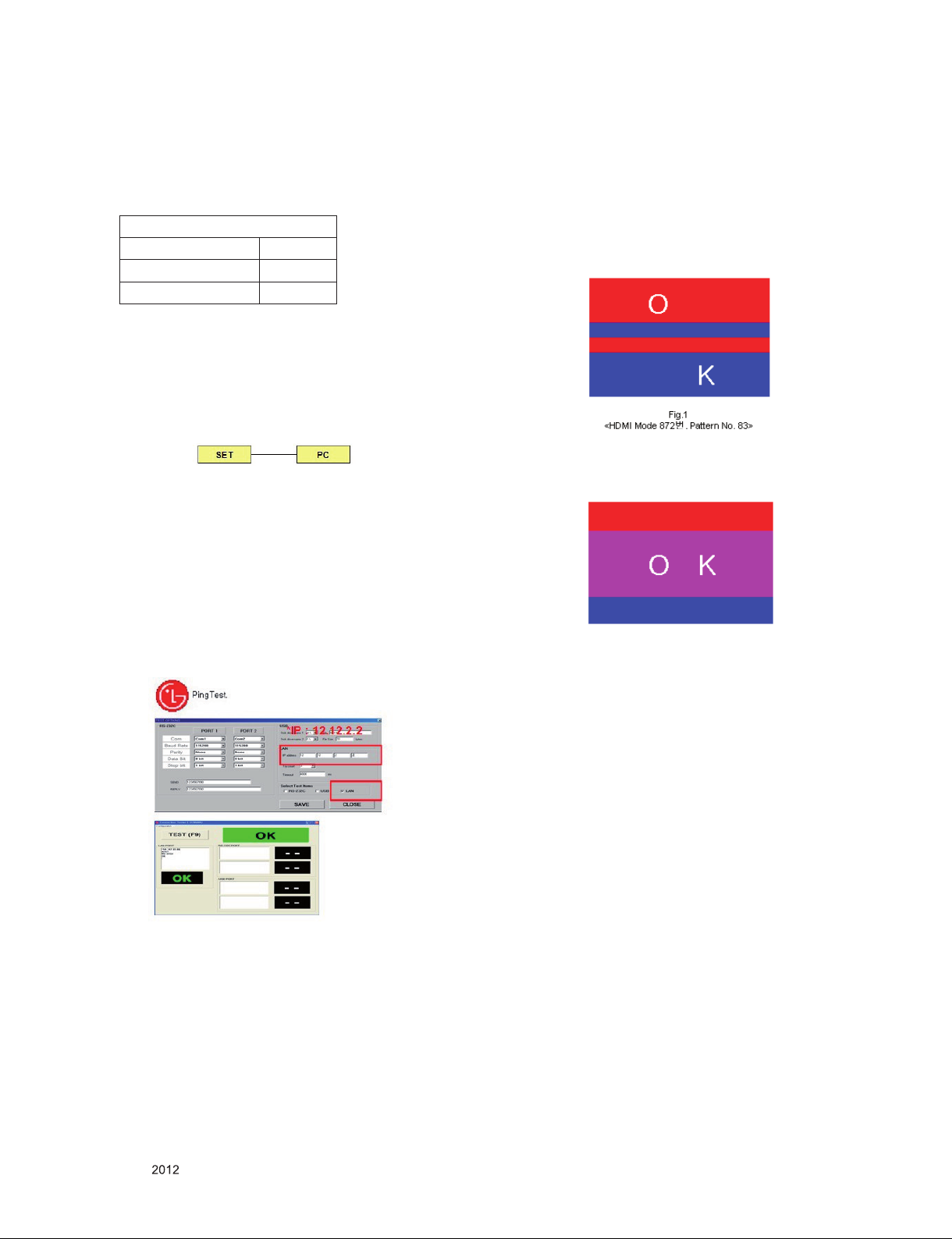

4.6. PING TEST

* In this case Network setting is on Manual Setting.

Connect : SET->LAN Port == PC->LAN Port

4.6.1. Equipment Setting

(1) Play the LAN Port Test PROGRAM.

(2) Input IP set up for an inspection to Test

* IP Number : 12.12.2.2

4.6.2. LAN PORT inspection (PING TEST)

* In this case Network setting is on Manual Setting.

(1) Play the LAN Port Test Program.

(2) connect each other LAN Port Jack.

(3) Play Test (F9) button and confirm OK Message.

(4) remove LAN CABLE

4.8. 3D function test

- Required Equipment

● Pattern Generator :

MSHG-600, MSPG-6100 [SUPPORT HDMI1.4])

MODE : HDMI mode NO. 872

Pattern No.83

(1) Please input 3D test pattern like below (HDMI mode NO.

872 , pattern No.83)

(2) When 3D OSD appear automatically, then press OK button

on ADJ Remote Controller.

(3) Check the picture. The picture must be same as below.

(Don’t have to wear 3D glasses.)

4.7. Magic Motion Remote Controller test

(1) Equipment: RF R/C for test,

(2) You must confirm the battery power of RF-R/C before test

(Recommend that change the battery per every lot)

(3) Sequence (test)

1) if you select the ‘start key(Wheel Key)’ on the controller,

you can pairing with the TV SET.

2) You can check the cursor on the TV Screen, when select

the ‘Wheel Key’ on the controller

3) You must remove the pairing with the TV Set by select

‘Mute Key’ on the controller.

5. Set Information (Serial No & Model name)

5.1. Check the serial number & Model Name

(1) Push the menu button and press red button on R/C to

enter ‘Customer Support’menu.

(2) Move to ‘signal test’ menu. And check Serial No & Model

Name Select the STATION -> Diagnostics -> To set

6. SW Download Guide.

* Before put a *.epk to USB Stick make ‘LG_DTV’ folder in

USB. Then, put *.epk file to ‘LG_DTV’ folder and Turn on TV

(1) Put the USB Stick to the USB socket

(2) Automatically detecting update file in USB Stick

* If your downloaded program version in USB Stick is Low,

it didn’t work.

But your downloaded version is High, USB data is

automatically detecting.

(3) Show the message “Copying files from memory”

(4) Updating is staring.

(5) Updating Completed, The TV will restart automatically.

After turn on TV, Please press ‘IN-STOP’ button on ADJ

Remote-control.

* IF you don’t have ADJ R/C, enter ‘Factory Reset’ in

OPTION MENU.

(6) When TV turns on, check the Updated version on Product/

Service Info. MENU.

Only for training and service purposes

- 9 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

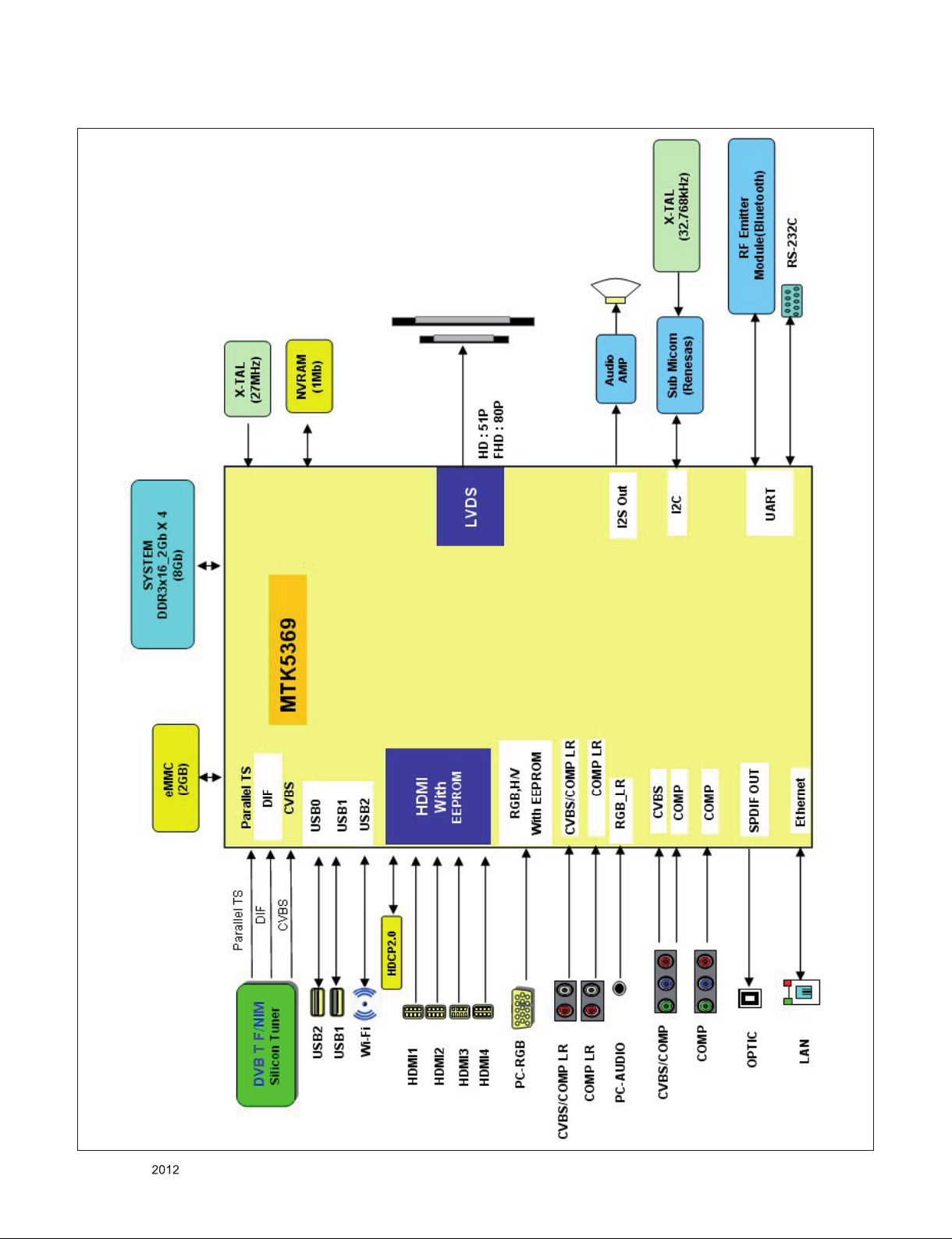

BLOCK DIAGRAM

Only for training and service purposes

- 10 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

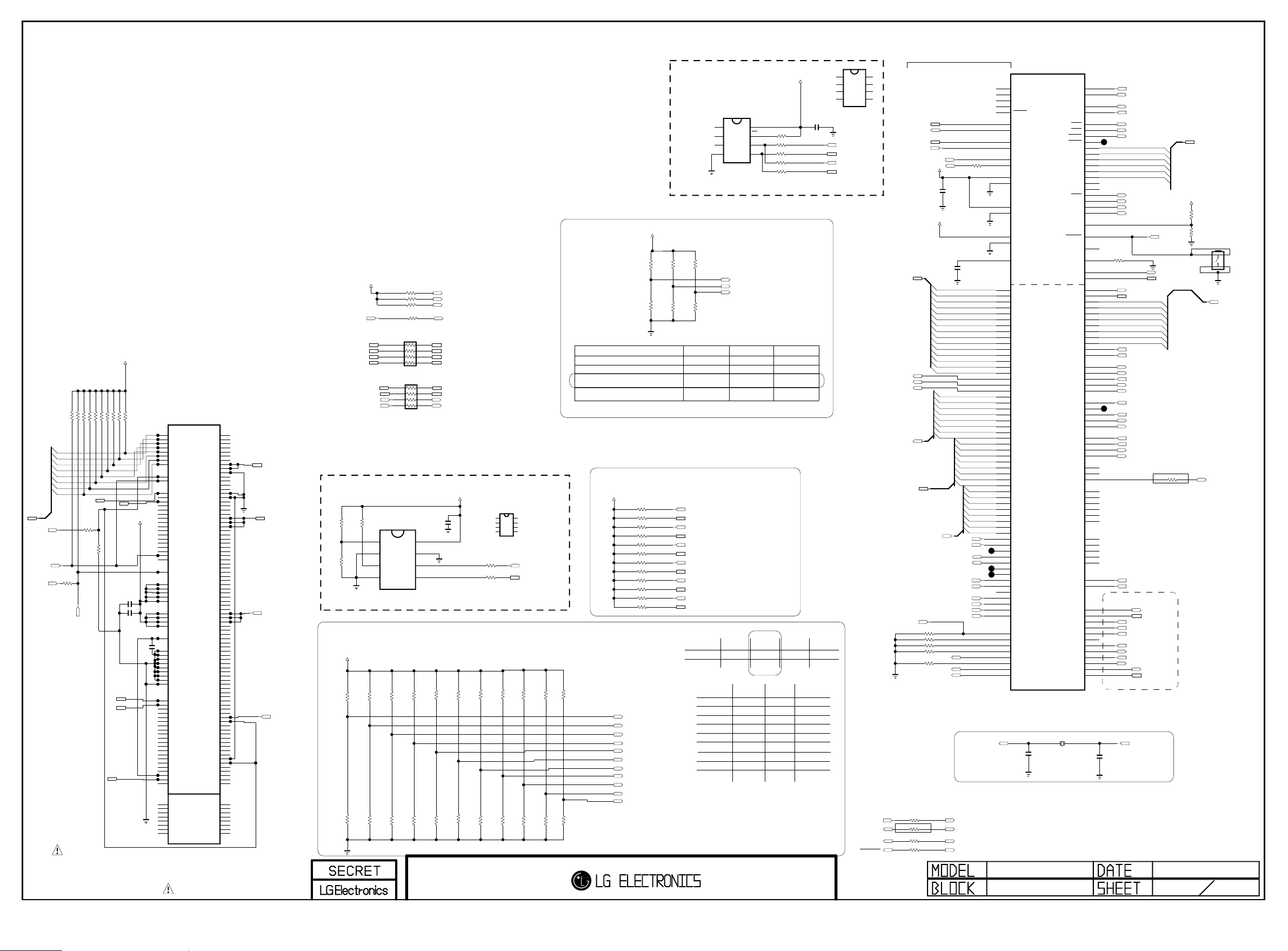

EXPLODED VIEW

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

310

305

301

300

200

302

580

207

208

202

303

209

203

304

204

205

206

560

201

601

520

540

501

A13

A12

A9

A10

LV1

400

Only for training and service purposes

240

- 11 -

590

120

A2

900

910

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

+3.3V_MULTI

Copyright © 2012 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

R108

R109 4.7K

R110 4.7K

EMMC_D[0-7]

EMMC_CLK

EMMC_CMD

EMMC_RST

R156 10K

EMMC_D[0]

EMMC_D[1]

EMMC_D[2]

EMMC_D[3]

EMMC_D[4]

EMMC_D[5]

EMMC_D[6]

EMMC_D[7]

R133

22

R172 10K

R173 10K

R174 10K

R155 10K

EMMC_D[7]

22

R157

EMMC_RST_BALL

EMMC_D[3]

EMMC_D[4]

EMMC_D[5]

+3.3V_MULTI

R175 10K

R176 10K

10K

R169

R177 10K

R178 10K

EMMC_D[6]

R179 10K

+3.3V_MULTI

C103

10uF

6.3V

C104

0.1uF

16V

C105

1uF

10V

SDIN5D2-4G-974L1

KLM2G1HE3F-B001

A3

A3

DAT0

A4

A4

DAT1

DAT1

A5

A5

DAT2

DAT2

B2

B2

DAT3

DAT3

B3

B3

DAT4

DAT4

B4

B4

DAT5

DAT5

B5

B5

DAT6

DAT6

B6

B6

DAT7

DAT7

M6

M6

CLK

CLK

M5

M5

CMD

CMD

A6

A6

NC_3

NC_3

A7

A7

NC_4

NC_4

C5

C5

NC_23

NC_23

E5

E5

NC_42

NC_42

E8

E8

NC_43

NC_43

E9

E9

NC_44

NC_44

E10

E10

NC_45

NC_45

F10

F10

NC_52

NC_52

G3

G3

NC_58

NC_58

G10

G10

NC_59

NC_59

H5

H5

NC_66

NC_66

J5

J5

NC_73

NC_73

K6

K6

NC_80

NC_80

K7

K7

NC_81

NC_81

K10

K10

NC_82

NC_82

P7

P7

NC_116

NC_116

P10

P10

NC_119

NC_119

K5

K5

RSTN

RESET

C6

C6

VDD_1

VCCQ_1

M4

M4

VDD_2

VCCQ_2

N4

N4

VDD_3

VCCQ_3

P3

P3

VDD_4

VCCQ_4

P5

P5

VDD_5

VCCQ_5

E6

E6

VDDF_1

VCC_1

F5

F5

VDDF_2

VCC_2

J10

J10

VDDF_3

VCC_3

K9

K9

VDDF_4

VCC_4

C2

C2

VDDI

VDDI

C4

E7

VSS_1

VSS_1

E7

G5

VSS_2

VSS_2

G5

H10

VSS_3

VSS_3

H10

K8

VSS_4

VSS_4

K8

C4

VSS_5

VSSQ_1

N2

N2

VSS_6

VSSQ_2

N5

N5

VSS_7

VSSQ_3

P4

P4

VSS_8

VSSQ_4

P6

P6

VSS_9

VSSQ_5

A1

A1

NC_1

NC_1

A2

A2

NC_2

NC_2

A8

A8

NC_5

NC_5

A9

A9

NC_6

NC_6

A10

A10

NC_7

NC_7

A11

A11

NC_8

NC_8

A12

A12

NC_9

NC_9

A13

A13

NC_10

NC_10

A14

A14

NC_11

NC_11

B1

B1

NC_12

NC_12

B7

B7

NC_13

NC_13

B8

B8

NC_14

NC_14

B9

B9

NC_15

NC_15

B10

B10

NC_16

NC_16

B11

B11

NC_17

NC_17

B12

B12

NC_18

NC_18

B13

B13

NC_19

NC_19

B14

B14

NC_20

NC_20

C1

C1

NC_21

NC_21

C3

C3

NC_22

NC_22

C7

C7

NC_24

NC_24

DU1

DUMMY_1

DU2

DUMMY_2

DU3

DUMMY_3

DU4

DUMMY_4

DU5

DUMMY_5

DU6

DUMMY_6

DU7

DUMMY_7

DU8

DUMMY_8

Sandisk_4GB

IC102

IC103

SS_2GBDAT0

NC_25

NC_25

NC_26

NC_26

NC_27

NC_27

NC_28

NC_28

NC_29

NC_29

NC_30

NC_30

NC_31

NC_31

NC_32

NC_32

NC_33

NC_33

NC_34

NC_34

NC_35

NC_35

NC_36

NC_36

NC_37

NC_37

NC_38

NC_38

NC_39

NC_39

NC_40

NC_40

NC_41

NC_41

NC_46

NC_46

NC_47

NC_47

NC_48

NC_48

NC_49

NC_49

NC_50

NC_50

NC_51

NC_51

NC_53

NC_53

NC_54

NC_54

NC_55

NC_55

NC_56

NC_56

NC_57

NC_57

NC_60

NC_60

NC_61

NC_61

NC_62

NC_62

NC_63

NC_63

NC_64

NC_64

NC_65

NC_65

NC_67

NC_67

NC_68

NC_68

NC_69

NC_69

NC_70

NC_70

NC_71

NC_71

NC_72

NC_72

NC_74

NC_74

NC_75

NC_75

NC_76

NC_76

NC_77

NC_77

NC_78

NC_78

NC_79

NC_79

NC_83

NC_83

NC_84

NC_84

NC_85

NC_85

NC_86

NC_86

NC_87

NC_87

NC_88

NC_88

NC_89

NC_89

NC_90

NC_90

NC_91

NC_91

NC_92

NC_92

NC_93

NC_93

NC_94

NC_94

NC_95

NC_95

NC_96

NC_96

NC_97

NC_97

NC_98

NC_98

NC_99

NC_99

NC_100

NC_100

NC_101

NC_101

NC_102

NC_102

NC_103

NC_103

NC_104

NC_104

NC_105

NC_105

NC_106

NC_106

NC_107

NC_107

NC_108

NC_108

NC_109

NC_109

NC_110

NC_110

NC_111

NC_111

NC_112

NC_112

NC_113

NC_113

NC_114

NC_114

NC_115

NC_115

NC_117

NC_117

NC_118

NC_118

NC_120

NC_120

NC_121

NC_121

NC_122

NC_122

NC_123

NC_123

DUMMY_9

DUMMY_10

DUMMY_11

DUMMY_12

DUMMY_13

DUMMY_14

DUMMY_15

DUMMY_16

/NAND_WE

NAND_D[7]

NAND_D[6] EMMC_D[6]

NAND_D[2]

NAND_D[5]

NAND_D[3]

NAND_D[4]

NAND_ALE

C8

C8

C9

C9

C10

C10

C11

C11

C12

C12

C13

C13

C14

C14

D1

D1

D2

D2

D3

D3

D4

D4

D12

D12

D13

D13

D14

D14

E1

E1

E2

E2

E3

E3

E12

E12

E13

E13

E14

E14

F1

F1

F2

F2

F3

F3

F12

F12

F13

F13

F14

F14

G1

G1

G2

G2

G12

G12

G13

G13

G14

G14

H1

H1

H2

H2

H3

H3

H12

H12

H13

H13

H14

H14

J1

J1

J2

J2

J3

J3

J12

J12

J13

J13

J14

J14

K1

K1

K2

K2

K3

K3

K12

K12

K13

K13

K14

K14

L1

L1

L2

L2

L3

L3

L12

L12

L13

L13

L14

L14

M1

M1

M2

M2

M3

M3

M7

M7

M8

M8

M9

M9

M10

M10

M11

M11

M12

M12

M13

M13

M14

M14

N1

N1

N3

N3

N6

N6

N7

N7

N8

N8

N9

N9

N10

N10

N11

N11

N12

N12

N13

N13

N14

N14

P1

P1

P2

P2

P8

P8

P9

P9

P11

P11

P12

P12

P13

P13

P14

P14

DU9

DU10

DU11

DU12

DU13

DU14

DU15

DU16

EMMC_D[5]

EMMC_D[6]

EMMC_RST_BALL

EMMC_CMD

NVRAM

OPT

R103

R100

4.7K

4.7K

OPT

R111

4.7K

+3.3V_MULTI

R125

1K

OPT

OPT

R126

1K

R1EX24256BSAS0A

A0

1

A1

2

A2

3

VSS

4

FHD

R127

1K

HD

R128

1K

R101

IC105

NVRAM_Renesas

R129

1K

R130

1K

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

4.7K

/NAND_RE

/NAND_CE

/NAND_RB

22

EMMC_CMD

AR100

22

1/16W

AR101

22

1/16W

EMMC_D[7]

EMMC_D[2]

EMMC_D[5]

EMMC_D[3]

EMMC_D[4]

EMMC_D[0]

EMMC_D[1]NAND_CLE

+3.3V_MULTI

C108

0.1uF

16V

VCC

8

WP

7

SCL

6

SDA

5

Model Option

R158

1K

OPT

OPT

R159

R153

1K

R160

1K

OPT

1K

R131

R132

1K

1K

R106 22

R107 22

OPT

R161

1K

R162

1K

AT24C256C-SSHL-T

A0

A1

A2

GND

T2

R163

R164

NO_T2

IC104-*1

24LC16B

VCC

C112

0.1uF

16V

A0

1

HDCP_MICRO

A1

2

A2

3

VSS

4

I2C_SCL1

I2C_SDA1

I2C_SCL5

I2C_SDA5

8

WP

7

SCL

6

SDA

5

I2C_SDA5

I2C_SCL5

I2C_SDA3

I2C_SCL3

MT5369_XTAL_IN

MT5369_XTAL_OUT

DVDD3V3_STB

PCM_A[0-14]

STRAPPINGG

+3.3V_MULTI

R104

1K

OPT

R105

1K

HDCP EEPROM

HDCP_ST

IC104

M24C16-R

NC_1

1

NC_2

2

NC_3

3

VSS

4

R112

R114

1K

1K

R113

1K

R115

1K

OPT

LED_PWM0

LED_PWM1

OPCTRL3

8

7

6

5

VCC

WC

SCL

SDA

+3.3V_MULTI

R147 4.7K

R148 22

R149 22

R122

22

OPT

R123 22

OPT

OPT

STRAPPING LED_PWM0 LED_PWM1 OPCTRL3

ICE mode + 27M + Serial boot 0 0 0

ICE mode + 27M + ROM to Nand boot 0 0 1

ICE mode + 27M + Rom to eMMC boot 0 1 0

from eMMC pins (share pins w/s NAND)

ICE mode + 27M + ROM to eMMC boot 0 1 1

from SDIO pins

FE_TS_CLK_OUT

FE_TS_VAL_OUT

FE_TS_SYNC_OUT

FE_TS_D_OUT[0-7]

I2C

+3.3V_MULTI

IC105-*1

VCC

1

8

WP

7

2

NVRAM_ATMEL

SCL

6

3

SDA

5

4

I2C_SCL5

I2C_SDA5

S

OPT

1K

R165

1K

R1661KNO_S

OPT

1K

R150

1K

R167

1K

R151

1K

R168

1K

R141 2.7K

R142

R139 2.7K

R140

R143 2.7K

R144

R102 2.7K

R121

R145 2.7K

R146

R117 2.7K

R181

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_2

MODEL_OPT_3

MODEL_OPT_4

MODEL_OPT_5

MODEL_OPT_6

MODEL_OPT_7

MODEL_OPT_8

MODEL_OPT_9

MODEL_OPT_10

2.7K

2.7K

2.7K

2.7K

2.7K

2.7K

* I2C MAP

I2C_1 : AMP ,HDCP KEY

I2C_2 : Module

I2C_3 : MICOM

I2C_4 : S/Demod , LNB

I2C_5 : NVRAM

I2C_SCL1

I2C_6 : TUNER_MOPLL(T/C,ATV),

T2/Demod

I2C_SDA1

I2C_SCL2

I2C_SDA2

I2C_SCL3

I2C_SDA3

I2C_SCL4

I2C_SDA4

I2C_SCL5

I2C_SDA5

I2C_SCL6

I2C_SDA6

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_2

MODEL_OPT_3

MODEL_OPT_4 3D_DEPTH

MODEL_OPT_6

MODEL_OPT_7

MODEL_OPT_8

MODEL_OPT_9

MODEL_OPT_10

MODEL OPTION 6 is just for CP Box

It should not be appiled at MP

SoC

NO_FRC

0

0

internal

FRC

0

1

LG FRC2

1

0

HIGH

FHD

OPTIC

3D_Depth_IC

DDR_Default

DDRMODEL_OPT_5

CP BOX

S Tuner

Enable

Support

Support Not Support

T2 Tuner

C2 Tuner Support Not Support

EPI

Support Not Support

external

URSA5

1

1

LOW

HD

NON_OPTIC

NO_3D_Depth_IC

DDR_768MB

Disable

Not Support

3D_SYNC_RF

M_REMOTE_ISP

S2_RESET

PCM_D[0-7]

CI_TS_D[0-7]

SC_ID

R135

R118

R119

R120

R182

R116 0

R170 0

Place the P901

OPT

R180 0

R124 0

GPIO

AP14

JTCK

AM14

JTDI

AR14

JTDO

AR15

JTMS

AN14

JTRST

PCM_D[0]

PCM_D[1]

PCM_D[2]

PCM_D[3]

PCM_D[4]

PCM_D[5]

PCM_D[6]

PCM_D[7]

CI_TS_D[0]

CI_TS_D[1]

CI_TS_D[2]

CI_TS_D[3]

CI_TS_D[4]

CI_TS_D[5]

CI_TS_D[6]

CI_TS_D[7]

TP100

TP101

TP104

AP12

AN12

AP15

AN15

AT34

AU34

AK27

AH26

AK18

AK17

AK23

AM27

AJ20

AN23

AN24

AP23

AR23

AU23

AT23

AM24

AM23

H32

F37

F36

G37

G36

G35

G34

H34

L34

L32

K33

K32

H33

L35

K36

J32

J34

K34

K35

K37

J36

J37

J35

J33

G33

H35

H31

F34

E36

N33

P32

M35

M37

M33

F35

E35

E37

N32

M34

M36

M32

L33

E33

E32

F32

A29

D31

C31

E30

E31

F31

E29

AP9

AT9

AR9

AU9

OSDA0

OSCL0

OSDA1

OSCL1

XTALI

XTALO

AVDD33_XTAL_STB

AVSS33_XTAL_STB

AVDD33_VGA_STB

AVSS33_VGA_STB

AVDD33_PLLGP

AVSS33_PLLGP

AVDD10_LDO

GPIO0

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

GPIO8

GPIO9

GPIO10

GPIO11

GPIO12

GPIO13

GPIO14

GPIO15

GPIO16

GPIO17

GPIO18

GPIO19

GPIO20

GPIO21

GPIO22

GPIO23

GPIO24

GPIO25

GPIO26

GPIO27

GPIO28

GPIO29

GPIO30

GPIO31

GPIO32

GPIO33

GPIO34

GPIO35

GPIO36

GPIO37

GPIO38

GPIO39

GPIO40

GPIO41

GPIO42

GPIO43

GPIO44

GPIO45

GPIO46

GPIO47

GPIO48

GPIO49

GPIO50

GPIO51

GPIO52

GPIO53

GPIO54

GPIO55

ADIN0_SRV

ADIN1_SRV

ADIN2_SRV

ADIN3_SRV

ADIN4_SRV

ADIN5_SRV

ADIN6_SRV

ADIN7_SRV

NVRAM, HDCP KEY

MICOM

R183 0

C101

0.1uF

DVDD3V3

C109

85C

10V

4.7uF

PCM_A[0]

PCM_A[1]

PCM_A[2]

PCM_A[3]

PCM_A[4]

PCM_A[5]

PCM_A[6]

PCM_A[7]

PCM_A[8]

PCM_A[9]

PCM_A[10]

PCM_A[11]

PCM_A[12]

PCM_A[13]

PCM_A[14]

FE_TS_D_OUT[0]

FE_TS_D_OUT[1]

FE_TS_D_OUT[2]

FE_TS_D_OUT[3]

FE_TS_D_OUT[4]

FE_TS_D_OUT[5]

FE_TS_D_OUT[6]

FE_TS_D_OUT[7]

USB_OCD2

USB_OCD1

USB_CTL2

USB_CTL1

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_3

MODEL_OPT_7

MODEL_OPT_5

MODEL_OPT_6

NO_EU

10K

10K

10K

10K

M_REMOTE_RST

10K

TU_RST

MODEL_OPT_4

Crystal Matching Test result : 27pF -> 20pF -> 22pF

MT5369_XTAL_IN

MODEL_OPT_1AMP_RST

MODEL_OPT_5

MODEL_OPT_7

MODEL_OPT_4

IC100

LGE2112

JTAG

JTAG

JTAG

JTAG

JTAG

DEMOD_TSCLK

DEMOD_TSDATA0

DEMOD_TSDATA1

DEMOD_TSDATA2

DEMOD_TSDATA3

DEMOD_TSDATA4

DEMOD_TSDATA5

DEMOD_TSDATA6

DEMOD_TSDATA7

DEMOD_TSSYNC

DEMOD_TSVAL

PVR_TSDATA0

PVR_TSDATA1

U0TX

U0RX

U1RX

U1TX

POWE

POOE

POCE1

POCE0

PDD7

PDD6

PDD5

PDD4

PDD3

PDD2

PDD1

PDD0

PARB

PACLE

PAALE

EMMC_CLK

OPWRSB

ORESET

OIRI

FSRC_WR

STB_SCL

STB_SDA

DEMOD_RST

CI_INT

CI_TSCLK

CI_TSDATA0

CI_TSSYNC

CI_TSVAL

PVR_TSCLK

PVR_TSVAL

PVR_TSSYNC

SPI_CLK1

SPI_CLK

SPI_DATA

SPI_CLE

OPWM2

OPWM1

OPWM0

SD_D0

SD_D1

SD_D2

SD_D3

SD_CMD

SD_CLK

LDM_CS

LDM_CLK

LDM_VSYNC

LDM_DO

LDM_DI

LED_PWM1

LED_PWM0

AR18

AP18

AU16

AT16

A35

C33

B34

D33

D29

C30

D30

B31

A31

B32

A32

C32

D32

A34

C34

C29

AM20

AM22

AU21

D27

AT21

AR21

T34

T32

T36

U36

T33

T30

V33

V32

V31

V30

T35

T31

N36

T37

R35

R37

R36

R34

R32

R33

P33

P34

N37

P35

N34

N35

AU12

AT12

AR12

A37

C35

A36

B35

B36

B37

AT11

AU11

AR10

AM9

AP10

AN22

AP21

TP102

R134 4.7K

TP103

RS232_TXD

RS232_RXD

M_REMOTE_RX

M_REMOTE_TX

/NAND_WE

/NAND_RE

/NAND_CE

NAND_D[7]

NAND_D[6]

NAND_D[5]

NAND_D[4]

NAND_D[3]

NAND_D[2]

/NAND_RB

NAND_CLE

NAND_ALE

EMMC_CLK

PCM_RST

FE_TS_CLK

FE_TS_D[0]

FE_TS_D[1]

FE_TS_D[2]

FE_TS_D[3]

FE_TS_D[4]

FE_TS_D[5]

FE_TS_D[6]

FE_TS_D[7]

FE_TS_SYNC

FE_TS_VAL

/PCM_REG

/PCM_CE

CI_TS_SYNC

/PCM_WE

/PCM_OE

CI_TS_VAL

CI_TS_CLK

/PCM_IRQA

/PCM_WAIT

/CI_CD2

/CI_CD1

/PCM_IORD

/PCM_IOWR

Place the P901

LED_PWM1

LED_PWM0

SOC_RESET

I2C_SCL1

I2C_SDA1

Module

OPT

R171 0

NAND_D[2-7]

+3.3V_MULTI

R136

4.7K

OPT

R137

4.7K

OPT

AMP

SW100

JTP-1127WEM

1 2

FE_TS_D[0-7]

3D_SYNC_RF

43

5V Tolerance

AU20

OPCTRL11

AT20

OPCTRL10

AN18

OPCTRL9

AP20

OPCTRL8

AM18

OPCTRL7

AN19

OPCTRL6

AP19

OPCTRL5

AR19

OPCTRL4

AN21

OPCTRL3

AM19

OPCTRL2

AN20

OPCTRL1

AR20

OPCTRL0

X100

27MHz

1

50V

C110

22pF

TUNER_MOPLL(T/C,ATV),T2 Demod

50V

C111

22pF

I2C_SCL2

I2C_SDA2

COMP1_DET

SC/COMP2_DET

DSUB_DET

COMP1_AV1_DET

DTV_ATV_SELECT

OPCTRL3

RF_SW_CTL

I2C_SCL6

I2C_SDA6

MT5369_XTAL_OUT

Module

+1.2V_MTK_CORE

Copyright © 2012 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

C200

0.1uF

DVDD3V3

C201

0.1uF

DVDD3V3

+1.2V_MTK_CORE DVDD3V3

DDC_SCL_2

DDC_SCL_3

DDC_SCL_4

DDC_SCL_1

DDC_SDA_2

DDC_SDA_3

DDC_SDA_4

DDC_SDA_1

5V_HDMI_2

5V_HDMI_3

5V_HDMI_4

5V_HDMI_1

WIFI_DP3

WIFI_DM3

HPD2

HPD3

HPD4

HPD1

USB_DP2

USB_DM2

USB_DP1

USB_DM1

USB_DP4

USB_DM4

C211

0.1uF

IC100

LGE2112

AA32

HDMI_CEC

AG33

HDMI_0_SCL

AE33

HDMI_1_SCL

AC33

HDMI_2_SCL

AH32

HDMI_3_SCL

AF33

HDMI_0_SDA

AD33

HDMI_1_SDA

AB33

HDMI_2_SDA

AH33

AG31

AE31

AC31

AH31

AG32

AE32

AC32

AJ32

AA24

AB24

AB29

AA29

AC29

AB30

AD30

AF31

AF32

AT13

AU13

AT14

AU14

AP13

AR13

Y24

W24

Y29

C36

C37

D36

D37

D35

D34

W35

W34

Y34

Y35

U24

V24

W30

W36

W37

HDMI_3_SDA

HDMI_0_PWR5V

HDMI_1_PWR5V

HDMI_2_PWR5V

HDMI_3_PWR5V

HDMI_0_HPD

HDMI_1_HPD

HDMI_2_HPD

HDMI_3_HPD

AVDD12_HDMI_0_RX

AVDD12_HDMI_1_RX

AVDD12_HDMI_2_RX

AVDD12_HDMI_3_RX

AVDD33_HDMI_0_RX

AVDD33_HDMI_1_RX

AVDD33_HDMI_2_RX

AVDD33_HDMI_3_RX

AVSS33_HDMI_RX_1

AVSS33_HDMI_RX_2

AVSS33_HDMI_RX_3

AVSS33_HDMI_RX_4

USB_DP_P0

USB_DM_P0

USB_DP_P1

USB_DM_P1

USB_DP_P2

USB_DM_P2

USB_DP_P3

USB_DM_P3

AVDD33_USB_P0P1

AVDD33_USB_P2P3

AVSS33_USB_P1

AVSS33_USB_P2

PCIE11_TXP

PCIE11_TXN

PCIE11_RXN

PCIE11_RXP

AVDD12_PCIE11

AVDD33_PCIE11

AVSS12_PCIE11

PCIE11_REFCKN

PCIE11_REFCKP

R2001K

R2011K

R2031K

R2041K

HDMI_0_RX_0

HDMI_0_RX_0B

HDMI_0_RX_1

HDMI_0_RX_1B

HDMI_0_RX_2

HDMI_0_RX_2B

HDMI_0_RX_C

HDMI_0_RX_CB

HDMI_1_RX_0

HDMI_1_RX_0B

HDMI_1_RX_1

HDMI_1_RX_1B

HDMI_1_RX_2

HDMI_1_RX_2B

HDMI_1_RX_C

HDMI_1_RX_CB

HDMI_2_RX_0

HDMI_2_RX_0B

HDMI_2_RX_1

HDMI_2_RX_1B

HDMI_2_RX_2

HDMI_2_RX_2B

HDMI_2_RX_C

HDMI_2_RX_CB

HDMI_3_RX_0

HDMI_3_RX_0B

HDMI_3_RX_1

HDMI_3_RX_1B

HDMI_3_RX_2

HDMI_3_RX_2B

HDMI_3_RX_C

HDMI_3_RX_CB

AVDD12_REC

AVDD33_COM

AVSS33_COM

AVSS12_REC

TXVP_0

TXVN_0

RXVN_1

RXVP_1

PHYLED1

PHYLED0

REXT

AVDD33_LD

AVSS33_LD

AG35

AG34

AG37

AG36

AF35

AF34

AH35

AH34

AE37

AE36

AD35

AD34

AC35

AC34

AE35

AE34

AB35

AB34

AA35

AA34

AA37

AA36

AC37

AC36

AK35

AK34

AJ35

AJ34

AJ37

AJ36

AJ33

AK33

AT18

AU18

AU17

AT17

AN16

AM16

AD15

AD14

AD16

AD17

AL16

AL15

AL14

D0+_HDMI2

D0-_HDMI2

D1+_HDMI2

D1-_HDMI2

D2+_HDMI2

D2-_HDMI2

CK+_HDMI2

CK-_HDMI2

D0+_HDMI3

D0-_HDMI3

D1+_HDMI3

D1-_HDMI3

D2+_HDMI3

D2-_HDMI3

CK+_HDMI3

CK-_HDMI3

D0+_HDMI4

D0-_HDMI4

D1+_HDMI4

D1-_HDMI4

D2+_HDMI4

D2-_HDMI4

CK+_HDMI4

CK-_HDMI4

D0+_HDMI1

D0-_HDMI1

D1+_HDMI1

D1-_HDMI1

D2+_HDMI1

D2-_HDMI1

CK+_HDMI1

CK-_HDMI1

EPHY_TDP

EPHY_TDN

EPHY_RDN

EPHY_RDP

R20524K

+1.2V_MTK_CORE

DVDD3V3

DIF_P

DIF_N

Close to Tuner

NO_T2_BR

C228 1uF

R214

2.2K

OPT

C2291uF

NO_T2_BR

IF_AGC

SC_CVBS_IN

COMP1_Y/AV1_CVBS

SC_B/COMP2_Y/AV2_CVBS

TU_CVBS

DVDD3V3

TU_SIF

Close to MT5395

C202

33pF

50V

NO_EU

DVDD3V3

C203

33pF

50V

NO_T2_BR

I2C_SCL4

I2C_SDA4

EU

+1.2V_MTK_CORE

MODEL_OPT_2

C245

0.1uF

SC/COMP2/AV2_R_IN

SC/COMP2/AV2_L_IN

COMP1/AV1_R_IN

COMP1/AV1_L_IN

DVDD3V3

C252

0.1uF

0 C241

R220

R221

2.2K

OPT

NO_T2_BR

R223

10K

NO_T2_BR

C232

0.047uF

25V

S/Demod , LNB

R232 100

R230 100

R229 100

R231 100

DVDD3V3

C253

0.1uF

MODEL_OPT_8

MODEL_OPT_9

MODEL_OPT_10

PCM_5V_CTL

EMMC_RST

C254

0.1uF

PC_R_IN

PC_L_IN

C242

0.01uF

50V

0.01uF

Close to MT5395

51

R225

NO_T2_BR

51

R233

+1.2V_MTK_CORE

Close to MT5395

C239 0.047uF

C227 0.047uF

C226 0.047uF

C238 0.047uF

C225 1uF

R235

C243

10V

F27

E27

F30

F29

B27

A27

B28

A28

C28

D28

E28

F28

B29

AG6

AJ6

AF6

AE6

AH7

AJ5

AG5

AF5

AE5

AH5

AG7

24K

1%

AU37

AU35

AT35

AT37

AU36

AP34

AT36

AR37

AR33

AP32

AR36

AP37

AR35

AP36

AL31

1uF

AJ28

AJ27

AN28

AU32

AT32

AD22

AL27

AM28

AJ26

U35

U34

TP207

AP31

TP201

AN30

TP202

V35

V34

AP28

AR29

AT30

EU

AR30

AR31

AN29

NO_EU

AP30

AK24

AK25

AL25

AM26

IC100

LGE2112

TCON0

TCON1

TCON2

TCON3

TCON4

TCON5

TCON6

TCON7

TCON8

TCON9

TCON10

TCON11

TCON12

AVDD12_LVDS_1

AVDD12_LVDS_2

AVDD12_VPLL

AVDD33_LVDSB

AVDD33_LVDSA

AVSS12_LVDS_2

AVSS12_LVDS_1

AVSS12_VPLL

AVSS33_LVDSB

AVSS33_LVDSA

REXT_VPLL

AIN0_R_AADC

AIN0_L_AADC

AIN1_R_AADC

AIN1_L_AADC

AIN2_R_AADC

AIN2_L_AADC

AIN3_R_AADC

AIN3_L_AADC

AIN4_R_AADC

AIN4_L_AADC

AIN5_R_AADC

AIN5_L_AADC

AIN6_R_AADC

AIN6_L_AADC

AVDD33_AADC

AVSS33_AADC

VMID_AADC

MPXP

ADCINP_DEMOD

ADCINN_DEMOD

AVDD33_DEMOD

AVDD12_DEMOD

AVSS33_DEMOD

AVSS12_DEMOD

IF_AGC

RF_AGC

LOUTN

LOUTP

OSCL2

OSDA2

SC0

SY0

CVBS3P

CVBS2P

CVBS1P

CVBS0P

CVBS_COM

AVDD33_CVBS_1

AVDD33_CVBS_2

AVSS33_CVBS_1

AVSS33_CVBS_2

AO3N

AO3P

AO4N

AO4P

AOCLKN

AOCLKP

AO2N

AO2P

AO1N

AO1P

AO0N

AO0P

AE4N

AE4P

AE3N

AE3P

AECLKN

AECLKP

AE2N

AE2P

AE1N

AE1P

AE0N

AE0P

BO4N

BO4P

BO3N

BO3P

BOCLKN

BOCLKP

BO2N

BO2P

BO1N

BO1P

BO0N

BO0P

BE4N

BE4P

BE3N

BE3P

BECLKN

BECLKP

BE2N

BE2P

BE1N

BE1P

BE0N

BE0P

AR0_ADAC

AL0_ADAC

AR1_ADAC

AL1_ADAC

AR2_ADAC

AL2_ADAC

AR3_ADAC

AL3_ADAC

AVDD33_DAC

AVDD33_DAC1

AVSS33_DAC

AVSS33_DAC1

ALIN

ASPDIF0

ASPDIF1

AOBCK

AOLRCK

AOMCLK

AOSDATA4

AOSDATA3

AOSDATA2

AOSDATA1

AOSDATA0

HSYNC

VSYNC

VGA_SDA

VGA_SCL

COM1

PB1P

PR1P

SOY1

COM0

PB0P

PR0P

SOY0

VDACX_OUT

VDACY_OUT

AVDD33_VDAC_BG

AVDD33_VDAC

AVDD12_RGB

AVSS33_VDAC_BG

AVSS12_RGB

AVSS33_VDAC

AG3

AG4

AG1

AG2

AF3

AF4

AE3

AE4

AE1

AE2

AD1

AD2

AL3

AL4

AL1

AL2

AK3

AK4

AJ3

AJ4

AJ1

AJ2

AH3

AH4

AT2

AU2

AT1

AU1

AR1

AR2

AP1

AP2

AN1

AN2

AM3

AM4

AT6

AU6

AP6

AR6

AP5

AR5

AT4

AU4

AP4

AR4

AP3

AR3

AN35

AN34

AM32

EU

AM34

EU

AM37

AM33

AM36

AM35

AG30

AF30

AK30

AE30

Y33

AR16

Y32

AR11

AP11

AM12

AM10

TP203

AM11

TP204

AN11

TP205

AN10

TP206

AN9

AN25

AM25

AR25

RP

AR24

GP

AU24

BP

AP24

COM

AT24

SOG

AR22

AP22

AT26

AR26

AP26

AU26

Y1P

AP25

AU28

AT28

AR28

AP27

Y0P

AR27

AU30

TP200

AP29

AD20

AD21

AD19

AJ22

AJ21

AL24

RXD0+

RXD0RXD1+

RXD1RXD2+

RXD2RXDCK+

RXDCKRXD3+

RXD3RXD4+

RXD4-

RXC0+

RXC0RXC1+

RXC1RXC2+

RXC2RXCCK+

RXCCKRXC3+

RXC3RXC4+

RXC4-

RXB0+

RXB0RXB1+

RXB1RXB2+

RXB2RXBCK+

RXBCKRXB3+

RXB3RXB4+

RXB4-

RXA0+

RXA0RXA1+

RXA1RXA2+

RXA2RXACK+

RXACKRXA3+

RXA3RXA4+

RXA4-

R23615K

R23715K

C204

330pF

50V

EU

Don’t use as GPIO

C2050.01uF

C2070.01uF

C2090.01uF

C2101500pF

C2230.01uF

C2190.01uF

C2210.01uF

C2241500pF

C2480.01uF R240100

C2120.01uF

C2140.01uF

EU

C2571500pF

SC_CVBS_OUT

NO_EU

C206

330pF

50V

EU

DAC_3V3

C250

0.1uF

R208100

R210100

R212100

R238100C2460.01uF

RGB_DDC_SDA

RGB_DDC_SCL

R239100C2470.01uF

R226100

R222100

R224100

R219100C2160.01uF

R215100

R217100

R2060

SC_ROUT

SC_LOUT

SPDIF_OUT

ARC

AUD_SCK

AUD_LRCK

AUD_MCLK

AUD_LRCH

DSUB_HSYNC

DSUB_VSYNC

DSUB_R

DSUB_G

DSUB_B

SC_G/COMP2_Pb

SC_R/COMP2_Pr

SC_B/COMP2_Y/AV2_CVBS

COMP1_Pb

COMP1_Pr

COMP1_Y/AV1_CVBS

SC_FB

DVDD3V3

+1.2V_MTK_CORE

JACK SIDE PLACE

R589

0

1/16W

5%

P200

TF05-51S

HD

52

LVDS

RXD4+

RXD4RXD3+

RXD3-

RXDCK+

RXDCK-

RXD2+

RXD2RXD1+

RXD1RXD0+

RXD0-

RXC4+

RXC4RXC3+

RXC3-

RXCCK+

RXCCK-

RXC2+

RXC2RXC1+

RXC1RXC0+

RXC0-

RXB4+

RXB4RXB3+

RXB3-

RXBCK+

RXBCK-

RXB2+

RXB2RXB1+

RXB1RXB0+

RXB0-

RXA4+

RXA4RXA3+

RXA3-

RXACK+

RXACK-

RXA2+

RXA2RXA1+

RXA1RXA0+

RXA0-

DISP_EN

I2C_SDA2

I2C_SCL2

+3.3V_MULTI

4.7K

R245

R202

2K

+3.3V_MULTI

R248

4.7K

R244

4.7K

A2CA1

D200

MMBD6100

+3.3V_MULTI

B

R211

47K

R249

4.7K

ROM_DW_DA

ROM_DW_CK

R213

4.7K

C

Q200

MMBT3904(NXP)

E

LD200

LTST-C150KGKT

P201

104060-8017

FHD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

RXB4+

RXB4RXB3+

RXB3-

RXBCK+

RXBCK-

RXB2+

RXB2RXB1+

RXB1RXB0+

RXB0-

RXA4+

RXA4RXA3+

RXA3-

RXACK+

RXACK-

RXA2+

RXA2RXA1+

RXA1RXA0+

RXA0-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

R250 0

R242100

R207

22

R209

22

R243

27K

OPT

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

CORE 1.2V : 6100mA

Copyright © 2012 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

MULTI 3.3V : XXXXmA

+1.2V_MTK_CORE

6.3V

C321

22uF

6.3V

C317

10uF

C319

10uF

6.3V

C324

22uF

6.3V

C322

0.1uF

C328

0.1uF

C325

0.1uF

C329

0.1uF

C340

0.1uF

C333

0.1uF

L300

BLM18PG121SN1D

L310

BLM18PG121SN1D

C316

0.1uF

AZ1117BH-ADJTRE1

INPUT

3

OUTPUT

DVDD3V3

60mA5600mA

L302

6.3V

C327

10uF

IC300

ADJ/GND

1

2

R1

R300

*V0=1.25(1+R2/R1)

=3.37

6.3V

C300

10uF

AVDD3V3_MEMPLL

DVDD3V3_STB

1%

330

C335

0.1uF

R2

R302

560

OPT

1%

C307

0.1uF

C310

0.1uF

C311

0.1uF

R303

AA15

AB15

AA16

AB16

AA17

AB17

R2

R3

J4

R4

Y4

F5

J5

R5

Y5

W5

L7

M7

R7

AA5

AB5

K7

U7

W7

E9

E8

F9

G14

J6

R15

T15

U15

V15

W15

Y15

H11

R16

T16

U16

V16

W16

Y16

R17

T17

U17

V17

Y17

T18

V18

Y18

T19

V19

Y19

W17

R18

AB6

H19

H22

J11

J12

J22

VCCK_43

VCCK_45

VCCK_47

VCCK_42

VCCK_44

VCCK_46

VCCK_48

VCCK_37

VCCK_39

VCCK_41

VCCK_38

VCCK_40

VCCK_1

VCCK_9

VCCK_11

VCCK_13

VCCK_14

VCCK_16

VCCK_18

VCCK_20

VCCK_22

VCCK_23

VCCK_28

VCCK_2

VCCK_24

VCCK_3

VCCK_25

VCCK_15

VCCK_17

VCCK_19

VCCK_21

DVSS_51

DVSS_52

DVSS_37

DVSS_53

DVSS_107

DVSS_20

DVSS_38

DVSS_54

DVSS_108

DVSS_95

DVSS_44

DVSS_46

DVSS_56

DVSS_120

DVSS_130

DVSS_43

DVSS_77

DVSS_97

DVSS_13

DVSS_12

DVSS_22

DVSS_28

DVSS_39

DVSS_57

DVSS_68

DVSS_78

DVSS_87

DVSS_99

DVSS_112

DVSS_122

DVSS_132

DVSS_34

DVSS_58

DVSS_69

DVSS_79

DVSS_88

DVSS_100

DVSS_113

DVSS_123

DVSS_133

DVSS_59

DVSS_70

DVSS_80

DVSS_89

DVSS_114

DVSS_71

DVSS_90

DVSS_115

DVSS_72

DVSS_91

DVSS_116

DVSS_101

DVSS_124

DVSS_134

DVSS_60

DVSS_131

DVSS_35

DVSS_36

DVSS_40

DVSS_41

DVSS_42

IC100

LGE2112

IC100

LGE2112

VCCK_31

VCCK_32

VCCK_36

VCCK_8

VCCK_10

VCCK_12

VCCK_33

VCCK_30

VCCK_7

VCCK_29

VCCK_6

VCCK_27

VCCK_5

VCCK_26

VCCK_4

VCCK_34

VCCK_35

VCC3IO_B_4

VCC3IO_B_2

VCC3IO_B_1

VCC3IO_B_3

VCC3IO_A_5

VCC3IO_A_7

VCC3IO_A_6

VCC3IO_A_8

VCC3IO_A_3

VCC3IO_A_4

VCC3IO_A_2

VCC3IO_A_1

DVSS_104

DVSS_117

DVSS_127

DVSS_137

DVSS_105

DVSS_118

DVSS_128

DVSS_138

DVSS_106

DVSS_119

DVSS_129

DVSS_139

DVSS_140

DVSS_109

DVSS_136

DVSS_126

DVSS_103

DVSS_110

DVSS_135

DVSS_125

DVSS_102

DVSS_121

DVSS_111

DVSS_55

DVSS_62

DVSS_73

DVSS_83

DVSS_92

DVSS_29

DVSS_63

DVSS_74

DVSS_84

DVSS_93

DVSS_64

DVSS_75

DVSS_85

DVSS_94

DVSS_65

DVSS_76

DVSS_86

DVSS_96

DVSS_30

DVSS_27

DVSS_17

DVSS_25

DVSS_45

DVSS_66

DVSS_7

DVSS_14

DVSS_8

DVSS_18

DVSS_26

DVSS_33

DVSS_49

DVSS_82

DVSS_61

DVSS_81

DVSS_47

DVSS_67

DVSS_98

DVSS_11

DVSS_21

C313

0.1uF

0.1uF

DAC_3V3

1

C354

10uF

6.3V

0.1uF

C315

0.1uF

C308

0.1uF

OPT

C312

C306

+1.2V_MTK_CORE

AA14

AB14

AC14

AC19

AC15

AC16

AA23

AR7

AT7

AU7

AP8

AR8

AT8

AU8

AM7

AN7

AP7

AM8

AN8

P14

R14

T14

U14

V14

W14

Y14

P15

P16

V23

W23

Y23

AC22

AC23

AD24

P23

R24

T24

AC24

AC21

P20

AC20

P19

AC18

P18

AC17

P17

AD18

AD23

AL9

AK10

AK9

AK11

H29

J29

H30

J30

G31

G32

F33

E34

R6

R20

T20

U20

V20

W20

Y20

AA20

AB20

G16

R21

T21

U21

V21

W21

Y21

AA21

AB21

R22

T22

U22

V22

W22

Y22

AA22

AB22

R23

T23

U23

AB23

W6

G17

F25

Y6

E21

F21

L8

T7

D11

E11

D12

E22

F22

G25

AB19

AA19

P22

W19

U19

R19

Y7

AB18

AA18

W18

U18

AA7

N22

T8

W8

Y8

E7

F8

+1.2V_MTK_CORE

DVDD3V3

INNER CAP

C336

0.1uF

P_+5V

+3.3V_MULTI

C305

10uF

6.3V

C352

10uF

10V

BLM18PG121SN1D

OPT

OPT

C304

0.1uF

INNER CAP

C301

0.1uF

On the Main chip

OPT

C309

0.1uF

INNER CAP

C303

0.1uF

C343

0.1uF

OPT

C337

C341

0.1uF

0.1uF

C302

0.1uF

BOTTOM PCB FOR REWORKING

C350

C347

0.1uF

0.1uF

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

B_RVREF5

Copyright © 2012 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

R409

ARA[14]

B_RVREF6

R408

BRA[14]

A_RVREF4

A_RVREF1

+1.5V_DDR

+1.5V_DDR

M8

H1

1%

240

L8

B2

D9

G7

K2

K8

N1

N9

R1

R9

A1

A8

C1

C9

D2

E9

F1

H2

H9

J1

J9

L1

L9

T7

A9

B3

E1

G8

J2

J8

M1

M9

P1

P9

T1

T9

B1

B9

D1

D8

E2

E8

F9

G1

G9

M8

H1

1%

240

L8

B2

D9

G7

K2

K8

N1

N9

R1

R9

A1

A8

C1

C9

D2

E9

F1

H2

H9

J1

J9

L1

L9

T7

A9

B3

E1

G8

J2

J8

M1

M9

P1

P9

T1

T9

B1

B9

D1

D8

E2

E8

F9

G1

G9

IC401

H5TQ2G63BFR-PBC

HYNIX

VREFCA

VREFDQ

ZQ

VDD_1

VDD_2

VDD_3

VDD_4

VDD_5

VDD_6

VDD_7

VDD_8

VDD_9

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDDQ_6

VDDQ_7

VDDQ_8

VDDQ_9

NC_1

NC_2

NC_3

NC_4

NC_6

VSS_1

VSS_2

VSS_3

VSS_4

VSS_5

VSS_6

VSS_7

VSS_8

VSS_9

VSS_10

VSS_11

VSS_12

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSSQ_6

VSSQ_7

VSSQ_8

VSSQ_9

IC400

H5TQ2G63BFR-PBC

HYNIX

VREFCA

VREFDQ

ZQ

VDD_1

VDD_2

VDD_3

VDD_4

VDD_5

VDD_6

VDD_7

VDD_8

VDD_9

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDDQ_6

VDDQ_7

VDDQ_8

VDDQ_9

NC_1

NC_2

NC_3

NC_4

NC_6

VSS_1

VSS_2

VSS_3

VSS_4

VSS_5

VSS_6

VSS_7

VSS_8

VSS_9

VSS_10

VSS_11

VSS_12

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSSQ_6

VSSQ_7

VSSQ_8

VSSQ_9

A10/AP

A12/BC

RESET

DQSL

DQSL

DQSU

DQSU

DQL0

DQL1

DQL2

DQL3

DQL4

DQL5

DQL6

DQL7

DQU0

DQU1

DQU2

DQU3

DQU4

DQU5

DQU6

DQU7

A10/AP

A12/BC

RESET

DQSL

DQSL

DQSU

DQSU

DQL0

DQL1

DQL2

DQL3

DQL4

DQL5

DQL6

DQL7

DQU0

DQU1

DQU2

DQU3

DQU4

DQU5

DQU6

DQU7

ARBA0

ARBA1

ARBA2

ARCKE

/ARCS

ARODT

/ARRAS

/ARCAS

/ARWE

ARREST

ARDQS0

/ARDQS0

ARDQS1

/ARDQS1

ARDQM0

ARDQM1

BRBA0

BRBA1

BRBA2

BRCKE

/BRCS

BRODT

/BRRAS

/BRCAS

/BRWE

BRREST

BRDQS0

/BRDQS0

BRDQS1

/BRDQS1

BRDQM0

BRDQM1

ARA[0-13]

BRA[0-13]

R421

100

5%

R422

100

5%

ARDQ[8-15]

BRDQ[8-15]

ARA[0]

N3

A0

ARA[1]

P7

A1

ARA[2]

P3

A2

ARA[3]

N2

A3

ARA[4]

P8

A4

ARA[5]

P2

A5

ARA[6]

R8

A6

ARA[7]

R2

A7

ARA[8]

T8

A8

ARA[9]

R3

A9

ARA[10]

L7

ARA[11]

R7

A11

ARA[12]

N7

ARA[13]

T3

A13

M7

A15

M2

BA0

N8

BA1

M3

BA2

J7

CK

K7

CK

K9

CKE

L2

CS

K1

ODT

J3

RAS

K3

CAS

L3

WE

T2

F3

G3

C7

B7

E7

DML

D3

DMU

E3

F7

F2

F8

H3

H8

G2

H7

D7

C3

C8

C2

A7

A2

B8

A3

BRA[0]

N3

A0

BRA[1]

P7

A1

BRA[2]

P3

A2

BRA[3]

N2

A3

BRA[4]

P8

A4

BRA[5]

P2

A5

BRA[6]

R8

A6

BRA[7]

R2

A7

BRA[8]

T8

A8

BRA[9]

R3

A9

BRA[10]

L7

BRA[11]

R7

A11

BRA[12]

N7

BRA[13]

T3

A13

M7

A15

M2

BA0

N8

BA1

M3

BA2

J7

CK

K7

CK

K9

CKE

L2

CS

K1

ODT

J3

RAS

K3

CAS

L3

WE

T2

F3

G3

C7

B7

E7

DML

D3

DMU

E3

F7

F2

F8

H3

H8

G2

H7

D7

C3

C8

C2

A7

A2

B8

A3

A_RVREF1

A_RVREF4

A_RVREF2

A_RVREF3

ARDQ[0-7]

BRDQ[0-7]

ARCLK0

/ARCLK0

B_RVREF5

B_RVREF6

BRCLK0

/BRCLK0

B_RVREF7

B_RVREF8

+1.5V_DDR

+1.5V_DDR

+1.5V_DDR

+1.5V_DDR

+1.5V_DDR

+1.5V_DDR

+1.5V_DDR

+1.5V_DDR

R400

1K

1%

R401

1K

1%

R402

1K

1%

R403

1K

1%

R432

1K

1%

R433

1K

1%

R430

1K

1%

R431

1K

1%

R404

1K

1%

R405

1K

1%

R406

1K

1%

R407

1K

1%

R428

1K

1%

R429

1K

1%

R426

1K

1%

R427

1K

1%

C402

0.01uF

C403

0.01uF

C404

0.01uF

C405

0.01uF

C461

0.01uF

C462

0.01uF

C459

0.01uF

C460

0.01uF

C408

0.01uF

C409

0.01uF

C410

0.01uF

C411

0.01uF

C457

0.01uF

C458

0.01uF

C455

0.01uF

C456

0.01uF

ARCLK1

/ARCLK1

ARDQ[16-23]

ARDQ[24-31]

BRCLK1

R423

/BRCLK1

BRDQ[16-23]

BRDQ[24-31]

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

100

R420

100

5%

5%

ARA[0-13]

BRA[0-13]

ARBA0

ARBA1

ARBA2

ARCKE

/ARCS

ARODT

/ARRAS

/ARCAS

/ARWE

ARREST

ARDQS2

/ARDQS2

ARDQS3

/ARDQS3

ARDQM2

ARDQM3

ARDQ[16]

ARDQ[17]

ARDQ[18]

ARDQ[19]

ARDQ[20]

ARDQ[21]

ARDQ[22]

ARDQ[23]

ARDQ[24]

ARDQ[25]

ARDQ[26]

ARDQ[27]

ARDQ[28]

ARDQ[29]

ARDQ[30]

ARDQ[31]

BRBA0

BRBA1

BRBA2

BRCKE

/BRCS

BRODT

/BRRAS

/BRCAS

/BRWE

BRREST

BRDQS2

/BRDQS2

BRDQS3

/BRDQS3

BRDQM2

BRDQM3

BRDQ[16]

BRDQ[17]

BRDQ[18]

BRDQ[19]

BRDQ[20]

BRDQ[21]

BRDQ[22]

BRDQ[23]

BRDQ[24]

BRDQ[25]

BRDQ[26]

BRDQ[27]

BRDQ[28]

BRDQ[29]

BRDQ[30]

BRDQ[31]

ARA[0]

ARA[1]

ARA[2]

ARA[3]

ARA[4]

ARA[5]

ARA[6]

ARA[7]

ARA[8]

ARA[9]

ARA[10]

ARA[11]

ARA[12]

ARA[13]

BRA[0]

BRA[1]

BRA[2]

BRA[3]

BRA[4]

BRA[5]

BRA[6]

BRA[7]

BRA[8]

BRA[9]

BRA[10]

BRA[11]

BRA[12]

BRA[13]

IC402

H5TQ2G63BFR-PBC

N3

P7

P3

N2

P8

P2

R8

R2

T8

R3

L7

R7

N7

T3

M7

M2

N8

M3

J7

K7

K9

L2

K1

J3

K3

L3

T2

F3

G3

C7

B7

E7

D3

E3

F7

F2

F8

H3

H8

G2

H7

D7

C3

C8

C2

A7

A2

B8

A3

N3

P7

P3

N2

P8

P2

R8

R2

T8

R3

L7

R7

N7

T3

M7

M2

N8

M3

J7

K7

K9

L2

K1

J3

K3

L3

T2

F3

G3

C7

B7

E7

D3

E3

F7

F2

F8

H3

H8

G2

H7

D7

C3

C8

C2

A7

A2

B8

A3

HYNIX

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10/AP

A11

A12/BC

A13

A15

BA0

BA1

BA2

CK

CK

CKE

CS

ODT

RAS

CAS

WE

RESET

DQSL

DQSL

DQSU

DQSU

DML

DMU

DQL0

DQL1

DQL2

DQL3

DQL4

DQL5

DQL6

DQL7

DQU0

DQU1

DQU2

DQU3

DQU4

DQU5

DQU6

DQU7

IC403

H5TQ2G63BFR-PBC

HYNIX

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10/AP

A11

A12/BC

A13

A15

BA0

BA1

BA2

CK

CK

CKE

CS

ODT

RAS

CAS

WE

RESET

DQSL

DQSL

DQSU

DQSU

DML

DMU

DQL0

DQL1

DQL2

DQL3

DQL4

DQL5

DQL6

DQL7

DQU0

DQU1

DQU2

DQU3

DQU4

DQU5

DQU6

DQU7

VREFCA

VREFDQ

VDD_1

VDD_2

VDD_3

VDD_4

VDD_5

VDD_6

VDD_7

VDD_8

VDD_9

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDDQ_6

VDDQ_7

VDDQ_8

VDDQ_9

NC_1

NC_2

NC_3

NC_4

NC_6

VSS_1

VSS_2

VSS_3

VSS_4

VSS_5

VSS_6

VSS_7

VSS_8

VSS_9

VSS_10

VSS_11

VSS_12

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSSQ_6

VSSQ_7

VSSQ_8

VSSQ_9

VREFCA

VREFDQ

VDD_1

VDD_2

VDD_3

VDD_4

VDD_5

VDD_6

VDD_7

VDD_8

VDD_9

VDDQ_1

VDDQ_2

VDDQ_3

VDDQ_4

VDDQ_5

VDDQ_6

VDDQ_7

VDDQ_8

VDDQ_9

NC_1

NC_2

NC_3

NC_4

NC_6

VSS_1

VSS_2

VSS_3

VSS_4

VSS_5

VSS_6

VSS_7

VSS_8

VSS_9

VSS_10

VSS_11

VSS_12

VSSQ_1

VSSQ_2

VSSQ_3

VSSQ_4

VSSQ_5

VSSQ_6

VSSQ_7

VSSQ_8

VSSQ_9

IC100

A_RVREF2

M8

A_RVREF3

H1

L8

ZQ

+1.5V_DDR

B2

D9

G7

K2

K8

N1

N9

R1

R9

A1

A8

C1

C9

D2

E9

F1

H2

H9

J1

J9

L1

L9

T7

A9

B3

E1

G8

J2

J8

M1

M9

P1

P9

T1

T9

B1

B9

D1

D8

E2

E8

F9

G1

G9

M8

H1

L8

ZQ

+1.5V_DDR

B2

D9

G7

K2

K8

N1

N9

R1

R9

A1

A8

C1

C9

D2

E9

F1

H2

H9

J1

J9

L1

L9

T7

A9

B3

E1

G8

J2

J8

M1

M9

P1

P9

T1

T9

B1

B9

D1

D8

E2

E8

F9

G1

G9

R424

R425

1%

240

ARA[14]

1%

240

BRA[14]

B_RVREF8

B_RVREF7

+1.5V_DDR

+1.5V_DDR

+1.5V_DDR

+1.5V_DDR

C401

0.1uF

C400

0.1uF

C467

0.1uF

C468

0.1uF

C407

0.1uF

C406

0.1uF

C474

0.1uF

K4B2G1646C-HCK0

SS

N3

A0

P7

A1

P3

A2

N2

A3

P8

A4

P2

A5

R8

A6

R2

A7

T8

A8

R3

A9

L7

A10/AP

R7

A11

N7

A12/BC

T3

A13

M7

NC_5

M2

BA0

N8

BA1

M3

BA2

J7

CK

K7

CK

K9

CKE

L2

CS

K1

ODT

J3

RAS

K3

CAS

L3

WE

T2

RESET

F3

DQSL

G3

DQSL

C7

DQSU

B7

DQSU

E7

DML

D3

DMU

E3

DQL0

F7

DQL1

F2

DQL2

F8

DQL3

H3

DQL4

H8

DQL5

G2

DQL6

H7

DQL7

D7

DQU0

C3

DQU1

C8

DQU2

C2

DQU3

A7

DQU4

A2

DQU5

B8

DQU6

A3

DQU7

C473

0.1uF

IC400-*1

INNER CAP

INNER CAP

C420

C413

1uF

C415

1uF

C417

1uF

C419

0.1uF

C423

0.1uF

0.1uF

On the Main chip

+1.5V_DDR

C412

0.1uF

C414

0.1uF

C416

0.1uF

C418

0.1uF

C421

0.1uF

OPT

OPT

C424

0.1uF

OPT

C422

0.1uF

RVREF_A

RVREF_B

TP1

TP2

BOTTOM PCB FOR REWORKING

ARCKE

ARCLK1

/ARCLK1

ARCLK0

/ARCLK0

ARODT

/ARRAS

/ARCAS

/ARCS

/ARWE

ARREST

ARBA0

ARBA1

ARBA2

ARA[14]

ARA[13]

ARA[12]

ARA[11]

ARA[10]

ARA[9]

ARA[8]

ARA[7]

ARA[6]

BRCLK0

BRCLK1

BRCKE

BRODT

/BRRAS

/BRCAS

/BRCS

BRBA0

BRBA1

BRBA2

/BRWE

BRA[14]

BRA[13]

BRA[12]

BRA[11]

BRA[10]

BRA[9]

BRA[8]

BRA[7]

BRA[6]

BRA[5]

BRA[4]

BRA[3]

BRA[2]

BRA[1]

BRA[0]

ARA[5]