LG 42PC55, 42PC55-ZB, 50PC56, 50PC56-ZD Service Manual

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PD73A

MODEL : 42PC55 42PC55-ZB

website:http://biz.LGservice.com

- 2 -

CONTENTS

SAFETY PRECAUTIONS ....................................................................................3

SPECIFICATIONS ................................................................................................4

ADJUSTMENT INSTRUCTIONS .........................................................................6

TROUBLE SHOOTING GUIDE..........................................................................19

BLOCK DIAGRAM.............................................................................................28

EXPLODED VIEW..............................................................................................30

EXPLODED VIEW PARTS LIST ........................................................................31

REPLACEMENT PARTS LIST...........................................................................32

SCHEMATIC DIAGRAM.........................................................................................

PRINTED CIRCUIT DIAGRAM ..............................................................................

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

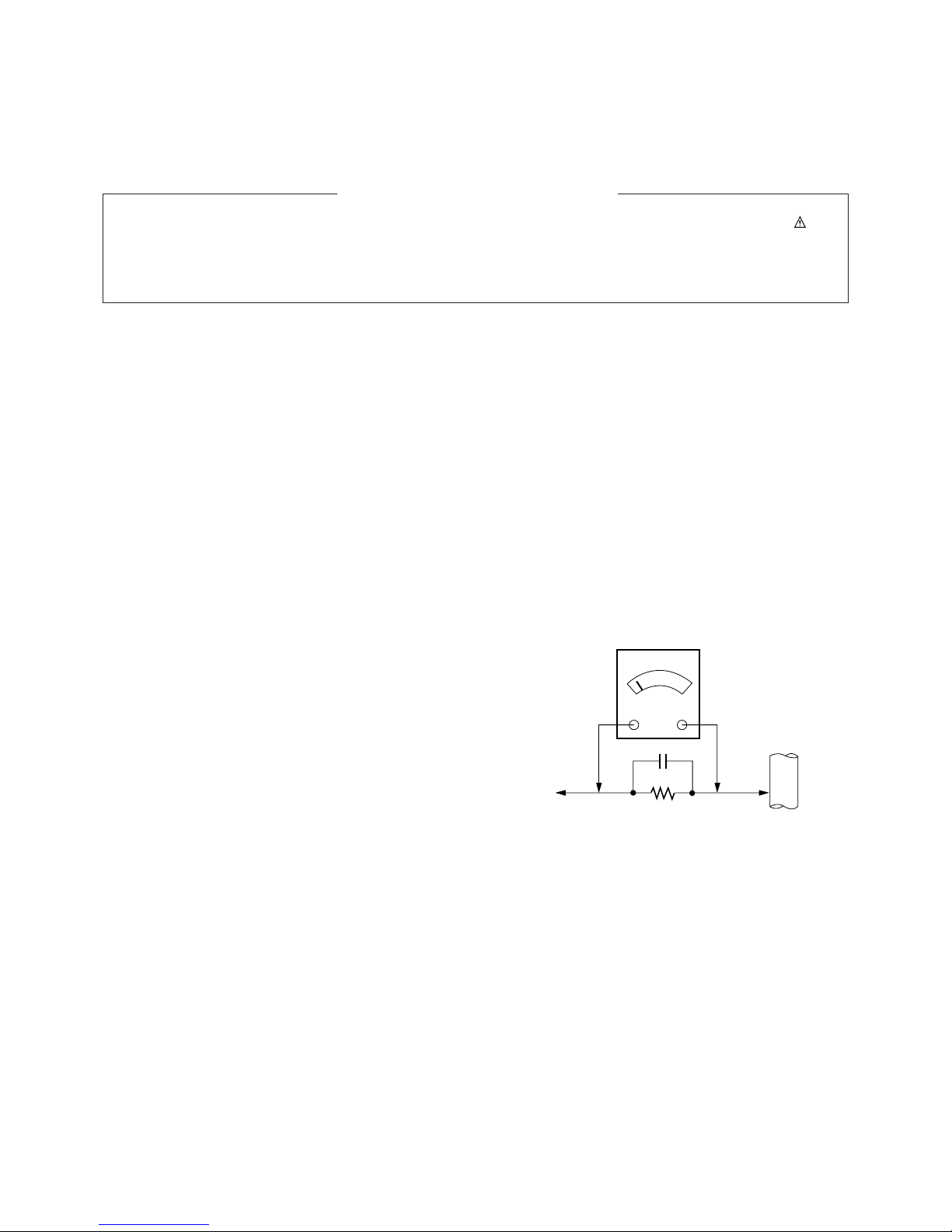

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to the 42” PLASMA TV used PD73A Chassis.

V Specification

Each part is tested as below without special appointment.

1) Temperature : 25±5°C (77±9°F), CST : 40±5

2) Relative Humidity: 65±10%

3) Power Voltage: Standard Input voltage (100-240V~, 50/60Hz)

* Standard Voltage of each product is marked by models.

4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with SBOM.

5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

1) Performance : LGE TV test method followed.

2) Demanded other specification

Safety : CE, IEC specification

EMC : CE, IEC

V General Specification

1. Module Specification ( 42” XGA MODULE )

- 4 -

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

No Item Specification Remark

42” Wide Color Display Module

16:9

PDP42X4,

RGB Closed Type, Film Filter

1)Temp. : 0~40deg

2)Humidity : 20~80%

3)Temp. : -20~60deg

4)Humidity : 10~90%

100-240V~, 50/60Hz

Plasma Display Panel

LGE SPEC.

Maker LG

Chassis

PD73A 42PC55-ZB UK, German, Italy, France, Sweden, Finland, Spain LG

Model Name Market Brand Remark

42PC55-ZB

Safety : IEC/EN60065

EMI : EN55013

EMS : EN55020

UK, German, Italy, France, Sweden, Finland, Spain

TEST

Model ApplianceMarket Remark

- 5 -

2. Model General Specification

Market

Broadcasting system

Receiving system

Scart Jack (2EA)

Video Input (1EA)

S-Video Input (1EA)

Component Input (1EA)

RGB Input(1EA)

HDMI Input(2EA)

Audio Input (3EA)

1

2

3

4

5

6

7

8

9

10

No Item Specification Remark

UK, German, Italy, France, Sweden, Finland, Spain

1) PAL-BG

2) PAL-DK

3) PAL-I,I’

4) DVB-T(ID TV)

5) SECAM-L/L’

Analog : Upper Heterodyne

Digital : COFDM

PAL, SECAM

PAL, SECAM, NTSC

PAL, SECAM, NTSC

Y/Cb/Cr, Y/Pb/Pr

RGB-PC

HDMI-DTV & SOUND

PC Audio, Component, AV

4 System : PAL, SECAM, NTSC, PAL60

4 System : PAL, SECAM, NTSC, PAL60

L/R Input

- 6 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions are applied to all of the 42” PLASMA TV,

PD73A Chassis.

2. Note

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100-240V~,

50/60Hz.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

O After RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

O Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

[ Set is activated HEAT-RUN without signal generator in

this mode.

[ Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses to check PANEL.

3. Channel memory Setting Method

: You can set channel memory by R/C for adjustment.

1) Press ADJ key on R/C for adjustment.

2) Press ENTER key on “System Control3”.

3) Press VOL + key on “Channel Recover”.

4. PCMCIA CARD Checking Method

: You must adjust DTV 29 Channel and insert PCMCIA CARD

to socket.

1) If PCMCIA CARD works normally, normal signals display

on screen.

But it works abnormally, “No CA module” words display on

screen.

5. POWER PCB Assy Voltage

Adjustments (Va, Vs Voltage adjustments)

5-1. Test Equipment : D.M.M. 1EA

5-2.Connection Diagram for Measuring

: refer to Fig.1

5-3. Adjustment Method

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P812, connect

- terminal to GND pin of P812.

3) After turning VR901, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P812, connect

– terminal to GND pin of P812.

2) After turning VR951, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

If you turn on a still screen more than 20 minutes (Especially

Digital pattern, Cross Hatch Pattern), an afterimage may occur

in the black level part of the screen.

Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

(Fig. 1) Connection diagram of power adjustment for measuring

<42” EAY32808901>

<42” 6709900019A>

- 7 -

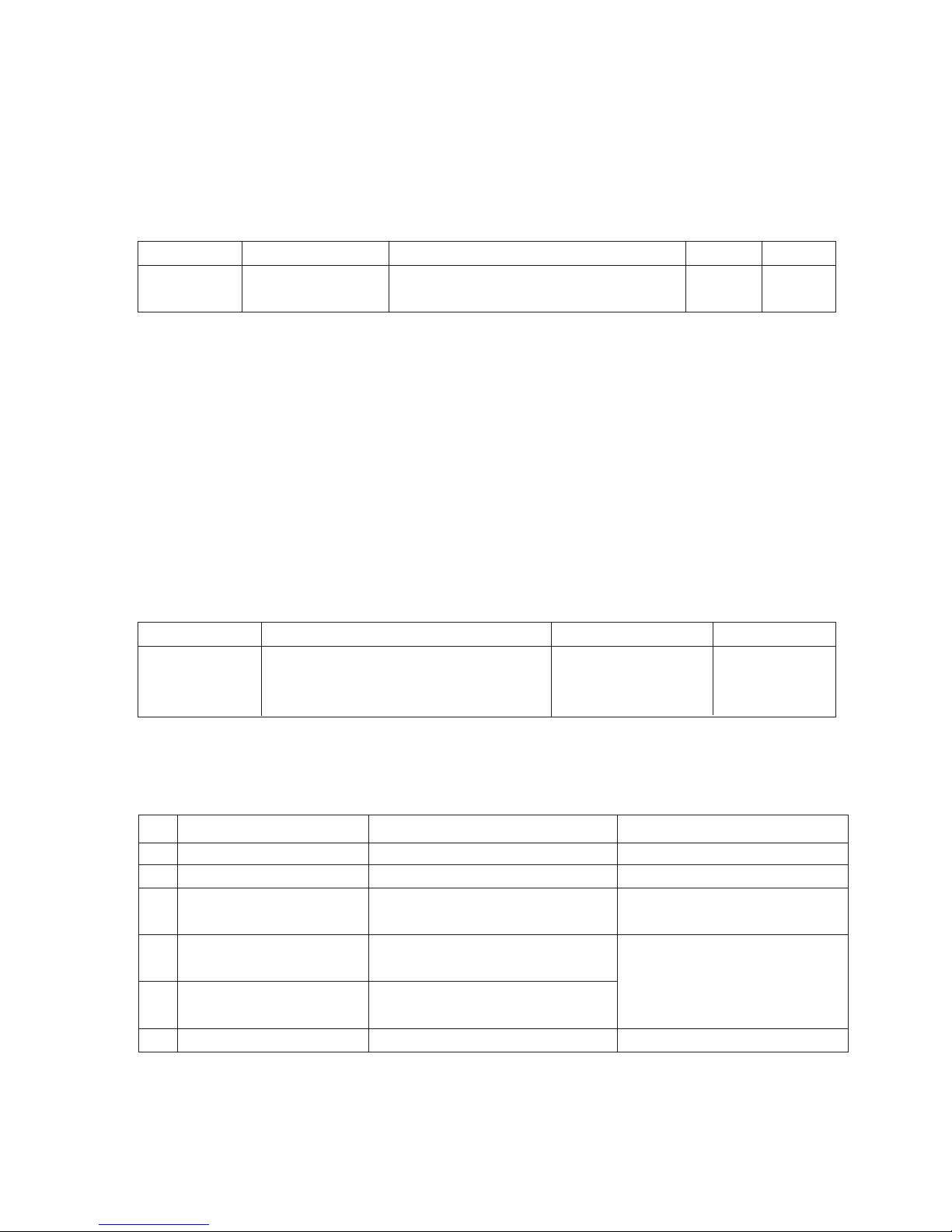

6. EDID (The Extended Display

Identification Data)/ DDC (Display

Data Channel) download

6-1. Required Test Equipment

1) Adjusting PC with S/W for writing EDID Data.(S/W : EDID

TESTER Ver.2.5)

2) A Jig for EDID Download

3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

15Pin cable, DVI to HDMI cable

6-2. Setting of device

6-3. Preparation for Adjustment

1) As above Fig. 2, Connect the Set, EDID Download Jig, PC

& Cable.

2) Turn on the PC & EDID Download Jig. And Execute the

S/W : EDID TESTER Ver,2.5.

3) Set up S/W option.

Repeat Number : 5

Device Address : A0

PageByte : 8

4) Power on the Set.

6-4. Sequence of Adjustment

- EDID Download

1) Init the data.

2) Load the EDID data.(Open File).

[Analog file] (for RGB)

[Digital file] (for HDMI)

3) Set the S/W as below.

4) Push the “Write Data & Verify”button. And confirm “Yes”.

5) If the writing is finished, you will see the “OK” message.

6) If TV has two HDMI, you must download two times for

each HDMI.

(Fig. 2) Connection Diagram of DDC download

Open FileOpen File

- 8 -

- EDID DATA

1) Analog RGB.

=> Detail EDID Options are below(1, 2, 3, 4, 5)

1. Product ID

2. Serial No : Controlled on production line

3. Month, Year : Controlled on production line

ex) Week : '03' => '03'

Year : '2006' => '10'

4. Model Name(Hex):

5. Checksum : Changeable by total EDID data

2) HDMI1.

=> Detail EDID Options are below(1, 2, 3, 4, 5)

1. Product ID

2. Serial No : Controlled on production line

3. Month, Year : Controlled on production line

ex) Week : '03' => '03'

Year : '2006' => '10'

4. Model Name(Hex):

5. Checksum : Changeable by total EDID data

3) HDMI2.

=> Detail EDID Options are below(1, 2, 3, 4, 5)

* Please refer HDMI1

Model

Name

42PC55-ZB

42PC56-ZD

50PC55-ZB

50PC56-ZD

50PB56-ZA

Product ID

Product ID

EDID table

B19C

B39C

5FC3

61C3

63C3

Hex

9CB1

9CB3

C35F

C361

C363

40013

40015

50015

50017

50019

Model Name

42PC55-ZB

42PC56-ZD

50PC55-ZB

50PC56-ZD

50PB56-ZA

Hex Data

00 00 00 FC 00 34 32 50 43 35 35 2D 5A 42 0A 20 20 20

00 00 00 FC 00 34 32 50 43 35 36 2D 5A 44 0A 20 20 20

00 00 00 FC 00 35 30 50 43 35 35 2D 5A 42 0A 20 20 20

00 00 00 FC 00 35 30 50 43 35 36 2D 5A 44 0A 20 20 20

00 00 00 FC 00 35 30 50 42 36 35 2D 5A 41 0A 20 20 20

1

2

3

4

5

1

2

3

4

5

5

Model

Name

42PC55-ZB

42PC56-ZD

50PC55-ZB

50PC56-ZD

50PB56-ZA

Product ID

Product ID

EDID table

B29C

B49C

60C3

62C3

64C3

Hex

9CB2

9CB4

C360

C362

C364

40114

40116

50016

50018

50020

Model Name

42PC55-ZB

42PC56-ZD

50PC55-ZB

50PC56-ZD

50PB56-ZA

Hex Data

00 00 00 FC 00 34 32 50 43 35 35 2D 5A 42 0A 20 20 20

00 00 00 FC 00 34 32 50 43 35 36 2D 5A 44 0A 20 20 20

00 00 00 FC 00 35 30 50 43 35 35 2D 5A 42 0A 20 20 20

00 00 00 FC 00 35 30 50 43 35 36 2D 5A 44 0A 20 20 20

00 00 00 FC 00 35 30 50 42 36 35 2D 5A 41 0A 20 20 20

1

2

3

4

5

5

- 9 -

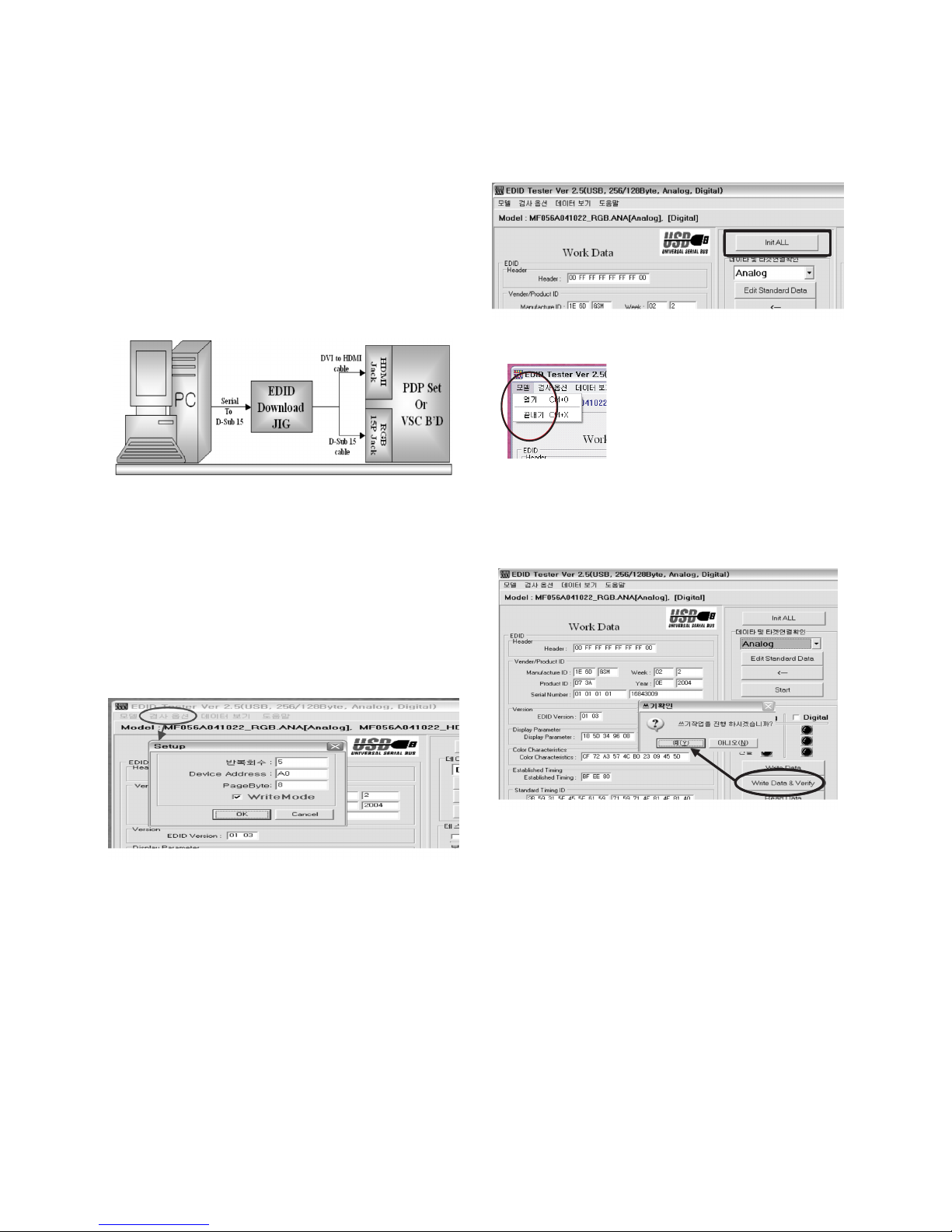

7. ADC Calibration

8. Auto AV(CVBS) Color Balance

8-1. Requirement

V This AV color balance adjustment should be performed

before white Balance Adjustment.

8-2. Required Equipment

1) Remote controller for adjustment.

2) MSPG-925FS Pattern Generator (Which has Video Signal:

7 Color Bar Pattern shown in Fig. 3).

- Model: 202 / Pattern: 65 EC and FC model use PALBGDHI. (composite signal)

8-3. Method of Auto AV(CVBS) Color Balance

1) Input the Video signal: 7 color Bar signal into AV3.

2) Set the PSM to Dynamic mode in the Picture menu.

3) Press IN-STAR key on R/C for adjustment.

4) Press the

G(Vol. +) key operate to set, then it becomes

automatically.

5) Auto-RGB OK means completed adjustment.

9. Adjustment of Component

9-1. Requirement

V This AV color balance adjustment should be performed

before white Balance Adjustment.

9-2. Required Equipment

1) Remote controller for adjustment.

2) MSPG-925FS Pattern Generator (Which has Video Signal:

7 Color Bar Pattern shown in Fig. 4).

- Model: 215 / Pattern: 65

9-3. Method of Auto Component Color Balance

1) Input the Component 720p/50Hz 7 Color Bar(MSPG-925FS

model:215, pattern:65) signal into Component.

2) Set the PSM to Dynamic mode in the Picture menu.

3) Press IN-STAR key on R/C for adjustment.

4) Press the

G(Vol. +) key operate to set, then it becomes

automatically.

5) Auto-RGB OK means completed adjustment.

10. Adjustment of RGB

10-1. Requirement

V This AV color balance adjustment should be performed

before white Balance Adjustment.

10-2. Required Equipment

1) Remote controller for adjustment.

2) MSPG-925FS Pattern Generator (Which has Video Signal:

7 Color Bar Pattern shown in Fig. 5).

- Model: 215 / Pattern: 65

10-3. Method of Auto RGB Color Balance

1) Input the PC 1024x768 @ 60Hz 7 color bar (MSPG-925FS,

Model:3, Pattern: 65) into RGB. (using D-sub to D-sub

cable)

2) Set the PSM to Dynamic mode in the Picture menu.

3) Press IN-STAR key on R/C for adjustment.

4) Press the

G(Vol. +) key operate to set, then it becomes

automatically.

5) Auto-RGB OK means completed adjustment.

MSPG925FS

Component RGB-PCRF/AV/S-VIDEOADC

Model : 3

(1024*768 60Hz)

Pattern : 65

7 Color Bar

Model:215(720P)

Pattern : 65

* 720/50Hz

7 Color Bar

PAL

INPUT SELECT AV3

Model : 202

(PAL-BGDHI)

Pattern : 65

* PAL 7 Color Bar

- System control RS-232 Host should be “PC“ for adjustment.

- Before AV ADC Calibration, execute the “Panel size selection“

(Fig. 4) Color bar Test Pattern

(Fig. 3) Color Balance signal

(Fig. 5) Color bar Test Pattern

- 10 -

11. Adjustment of White Balance

11-1. Requirement

V Before adjusting White-balance , the AV ADC should be

done.

11-2. Required Equipment

1) Remote controller for adjustment.

2) Color Analyzer.( CA-1000,CA-100+,CA-200 or same

product ) : CH10(PDP)

* Please adjust CA-210, CA-100+ by CS-1000 before

measuring.

3) Auto W/B adjustment instrument.(only for Auto adjustment)

4) AV Pattern Generator.

W Synchronization relation between PSM and CSM.

W

CS-1000/CA-100+/CA-210 White balance adjustment coordinate

and color temperature.

11-3. Connection Picture of the Measuring

Instrument(On Automatic control)

V Inside PATTERN is used when W/B is controlled. Connect

to auto controller or push control R/C IN-START -> Enter

the mode of White-Balance, the pattern will come out.

V Auto-control interface and directions

1. Adjust in the place where the influx of light like floodlight

around is blocked.(illumination is less than 10ux)

2. Measure and adjust after sticking the Color Analyzer(CA-

100+, CA210) to the side of the module.

3. Aging time : keep white pattern using inside pattern.

W Auto adjustment Map(RS-232C)

12. Adjustment of White Balance

(Manual white Balance)

V One of R Gain/ G Gain/ B Gain should be kept on 80, and

others are controlled lowering from 80

(1) ‘power on’ of the control R/C, set heat run to white by

pressing and heat run over 15 minutes. (Set: RS-232 Host:

PC, Baud Rate: 115200bps, Download: Cortez)

(2) Zero Calibrate CA-100+, and stick the sensor to the center

of PDP module surface when you adjust.

(3) Double click In-start key on Controlling R/C and get in

‘white balance’.

(4) Set test-pattern on and display inside pattern. Control is

carried out on three color temperature, COOL, MEDIUM,

WARM. (Control is carried out three times.)

(5) When the R/G/B GAIN is 80 on OSD, it is the FULL

DYNAMIC Range of the Module. In order to control white

balance without the saturation of FULL DYNAMIC Range

and DATA, one of R Gain / G Gain / B Gain should be kept

on 80, and other two is controlled lowering from 80.

* Color Temperature: Cool, Medium, Warm

(1) When R GAIN is set to 80

- Control G GAIN and B GAIN by lowering from 80.

(2) When B GAIN is set to 80

- Control R GAIN and G GAIN by lowering from 80.

(3) When G GAIN is set to 80

- Control R GAIN and B GAIN by lowering from 80.

One of R Gain / G Gain / B Gain should be kept on 80, and

adjust other two lower than 80.

(When R/G/B GAIN are all 80, it is the FULL DYNAMIC

Range of Module)

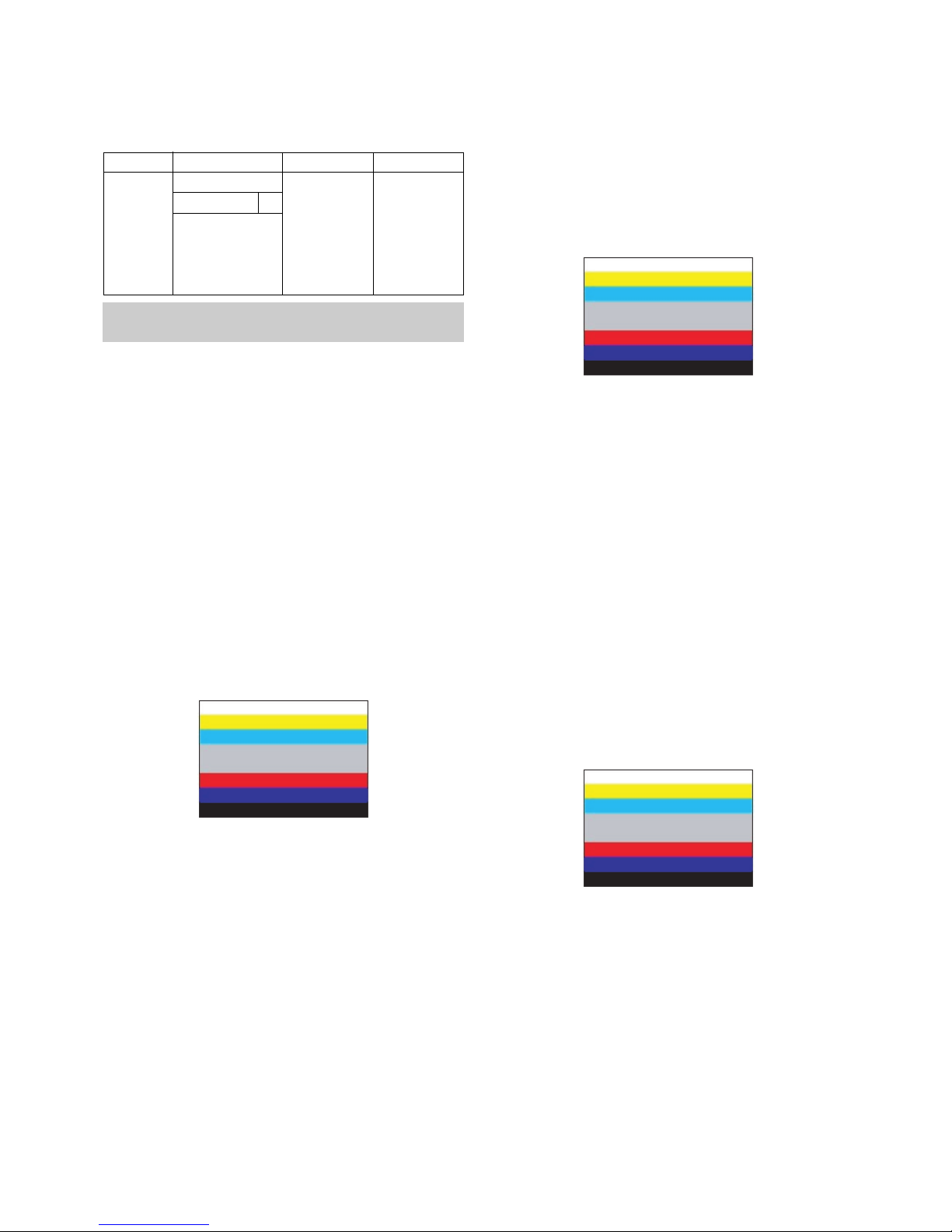

(Fig. 6) Auto AV(CVBS) Color Balance Test Pattern

Full White Pattern

RS-232C Communication

CA-210

Color

ANALYZER

TYPE : CA-210

Type

Baud Rate

115200

Index

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Data bit

8

Cmd1 Cmd2

ja

jb

jc

jd

je

jf

Stop bit

1

Parity

NONE

PD61A/C

Protocol

Setting

Data Min Value

00(00)

00(00)

00(00)

00(00)

00(00)

00(00)

Max Value

128(80)

128(80)

128(80)

128(80)

128(80)

128(80)

Color Coordinate

xy

0.283±0.002

0.293±0.002

0.329±0.00

2

11000K

9300K

6500K

0.000

0.000

0.003

0.276±0.002

0.285±0.002

0.313±0.00

2

COOL

MEDIUM

WARM

Mode Temp uv

PLASMA Remark

11000K

9300K

6500K

Cool

Normal

Warm

CSM

- 11 -

13.

Default Value in Adjustment mode

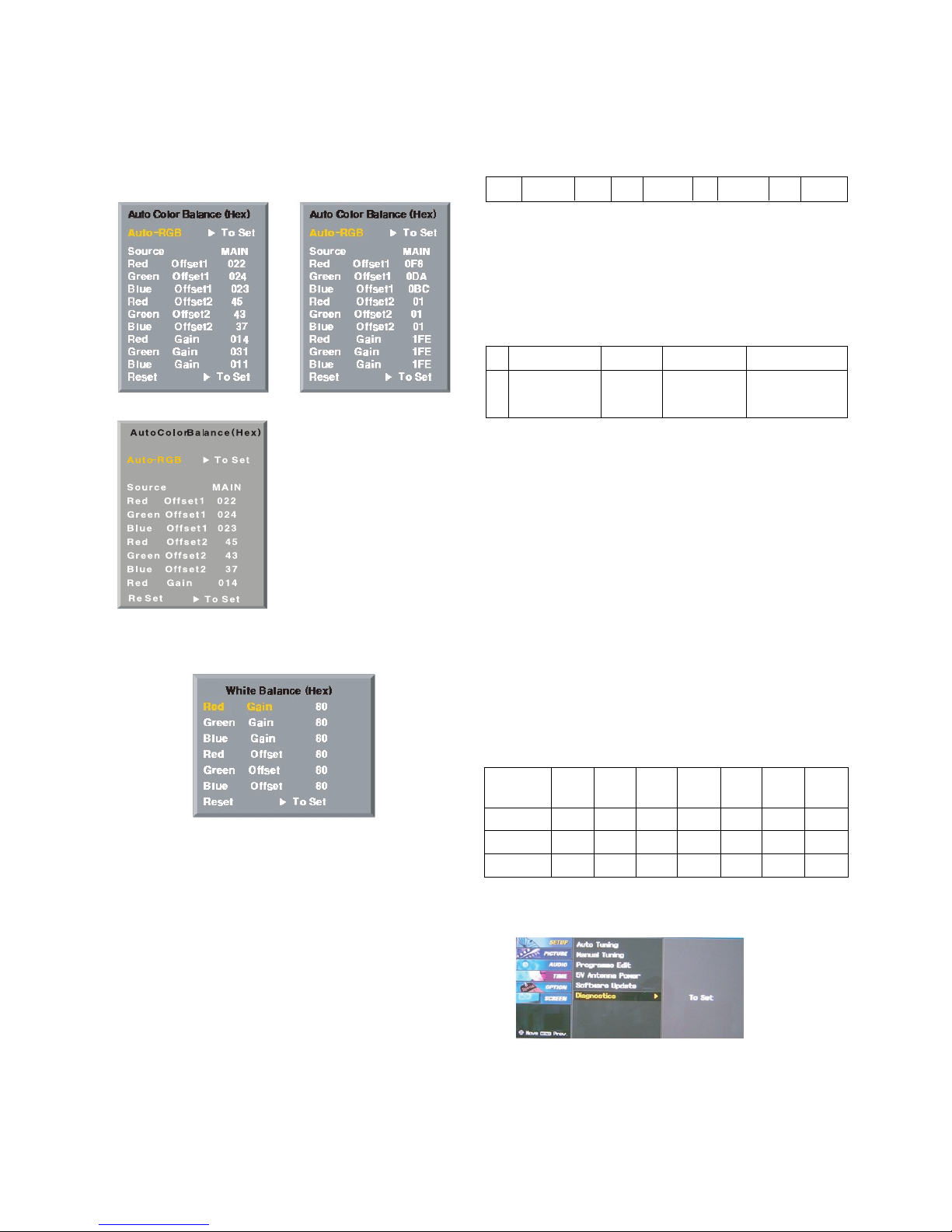

13-1. Auto Color Balance

13-2. Write Balance

14. EEPROM Data Write

(Serial No D/L)

14-1. Signal TABLE

CMD : A0h

LENGTH : 85~94h (1~16 bytes)

ADH : E

2

PROM Sub Address high (00~1F)

ADL : E

2

PROM Sub Address low (00~FF)

Data : Write data

CS :

CMD + LENGTH + ADH + ADL + Data_1 + ... + Data_n

Delay : 20ms

14-2. Command Set

* Description

FOS Default write : <7mode data> write

Vtotal, V_Frequency, Sync_Polarity, Htotal, Hstart, Vstart, 0, Phase

Data write : Model Name and Serial Number write in EEPROM,.

14-3. Method & Notice

(1) Serial number D/L is using of scan equipment.

(2) Setting of scan equipment operated by Manufacturing

Technology Group.

(3) Serial number D/L must be conformed when it is produced

in production line, because serial number D/L is mandatory

by D-book 4.0.

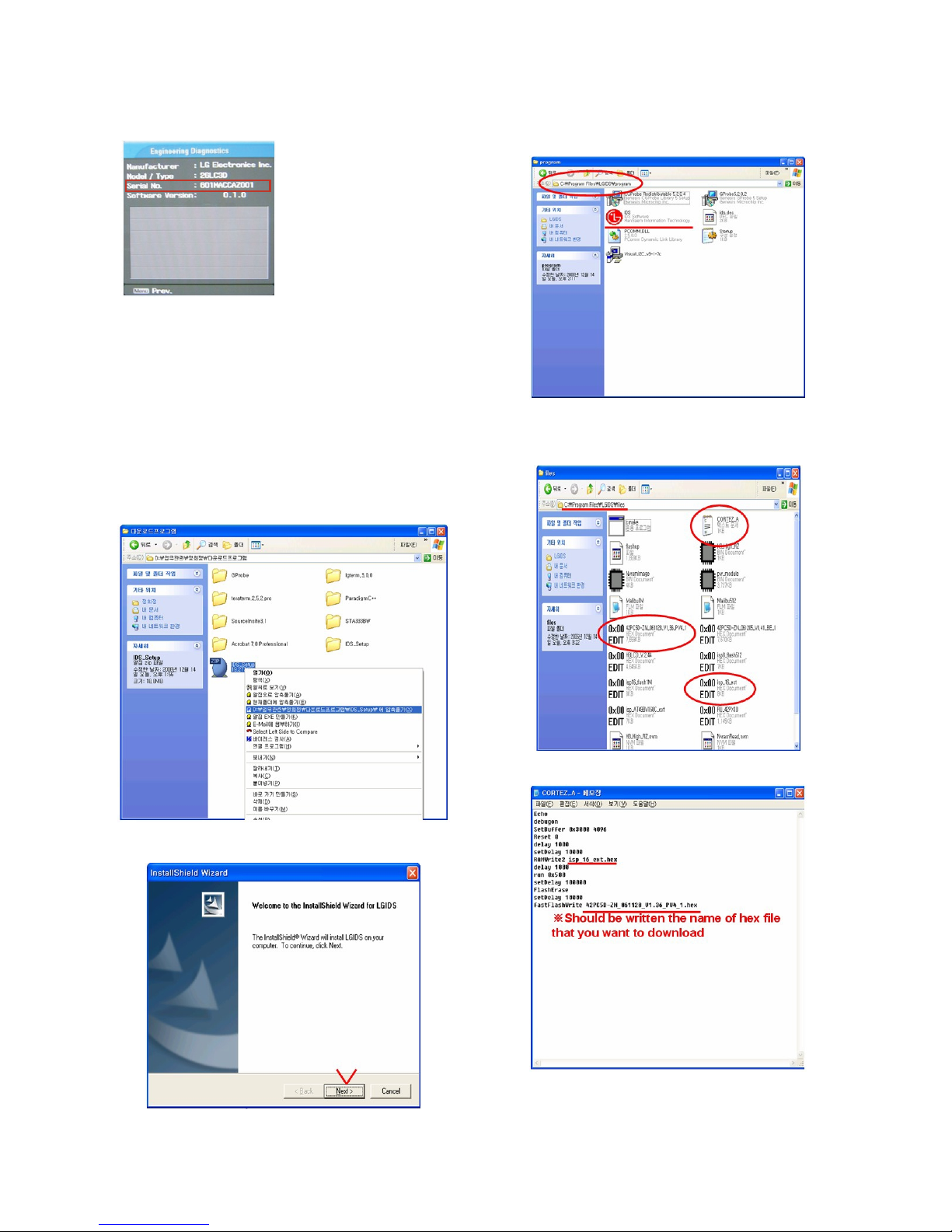

15. Set Information(Serial No& Model name)

15-1.

Setting up like bottom figure

(After setting white balance, this is set)

(Setting: Press ADJ Key in the Adjust remocon)

(1) Select “System Control 2” by using

D / E (CH+/-) key, and

press

V (ENTER) Using Adjust remocon, RS-232 Host &

Baud Rate & Download value change)

15-2. Push the menu button in DTV mode.

(1) Select the STATION-> Diagno stics -> To set.

CMD

LENGTH

ADH ADL

DATA_1 DATA_n

... CS DELAY

Model

Name

42PC55-ZB

50PC55-ZB

50PB65-ZA

Tool

Option1

2048

2052

2244

1697

1953

1977

0

0

0

14

14

14

2

2

2

1

1

1

192

192

192

Tool

Option2

Area

Option

Option1 Option2 Option3 Option3

No

1

EEPROM WRITE

A0h 84h+n n-byted Write

(n=1~16)

Adjust mode CMD(hex) LENGTH(hex) Description

(Fig. 7) Default on OSD

<Component> <RGB>

<AV>

(Fig. 8) Default on OSD

- 12 -

(2) Check the Serial Number.

16. Input the Shipping Option Data

1) Push the IN-START key in a Adjust Remocon.

2) Input the Option Number that was specified in the BOM, into

the Shipping area.

3) The work is finished, Push

V Key.

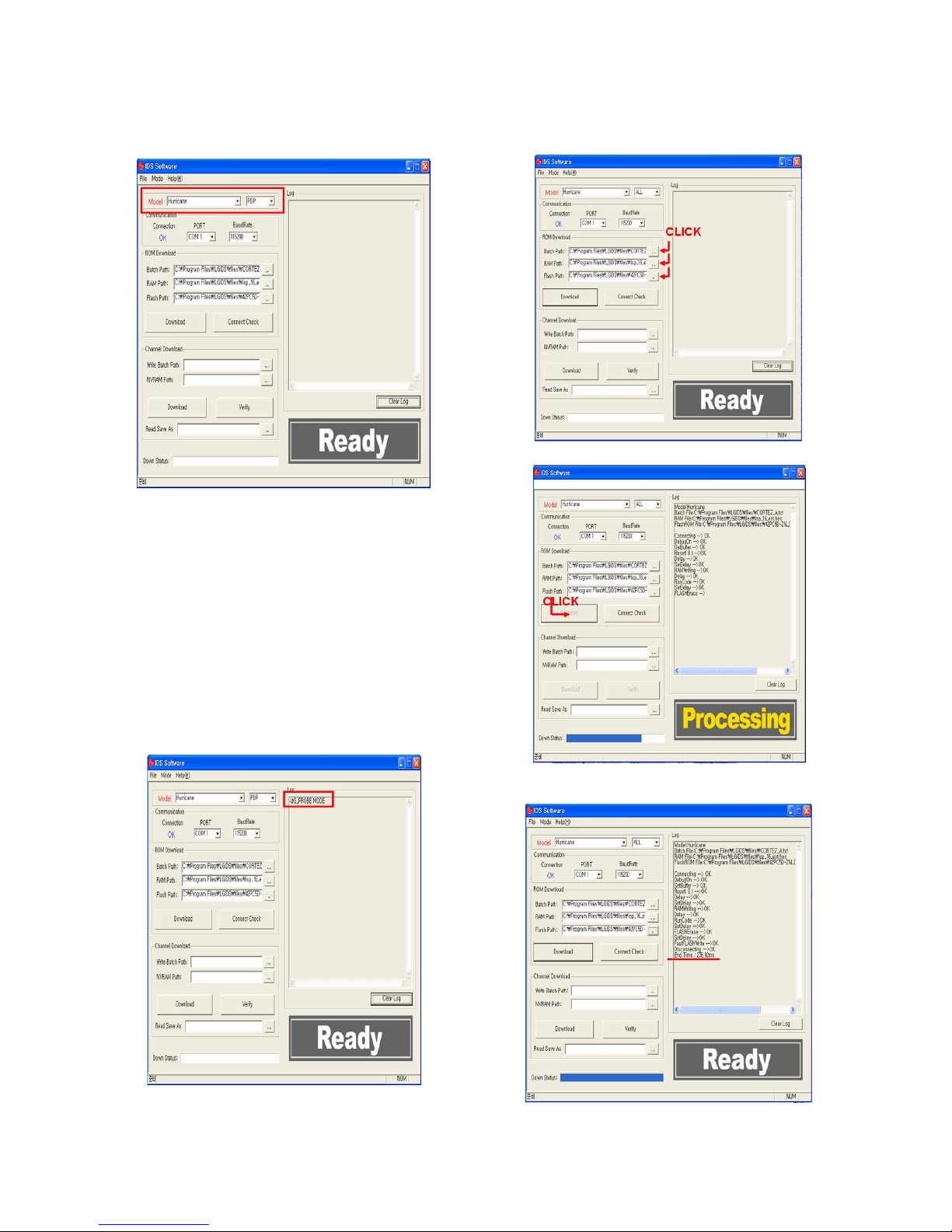

17. CORTEZ Download

17-1. CORTEZ Download By LGIDS

(1) Installation of the LGIDS

1) Extract to folder IDS_Setup.ZIP.

2) Install LGIDS-1

1. After Click the ‘NEXT’ icon, Installation is finished.

3) Install LGIDS-2

1. You can find the ICON on C:\Program Files\LGIDS.

(2) Download hex file

1) Prepare a Batch File(*.txt), RAM File(*.hex) on

C:\Program Files\LGIDS\files.

* In the TEXT FILE

2) Connect RS232 cable and turn on the power.

(Use the general RS-232C Serial Cable)

- 13 -

3) Execute the LGIDS Program - 1

1. Check a ‘PDP’ & ‘Hurricane’ on the ‘Model’ MENU

*

If your connection is ‘NG’, then set your PORT(COM1,2,3...)

correctly.

4) SVC MENU Setting for CORTEZ DOWNLOAD.

case 1. Press the ‘tilt’ button on the Adjustment Remote

Control.

case 2. Press the ‘ADJ’ button

1) Press the ‘System Control 2’ menu

2) Enter the ‘GProbe’ on the ‘RS-232Host menu’

3) Enter ‘115200bps’ on the ‘Baud Rate menu’

4) Enter the ‘Cortez’ on the ‘Download menu’

* If you don’t have a Adjustment Remote Control

‘Menu’ button on the Remote Control + ‘Menu’ button on

the Local Key during 7~8sec

After Change a mode, you can see ‘GPROBE MODE’

5) Execute the LGIDS Program - 2

1. Open a Batch file, RAM file and Flash file.

6) Execute the LGIDS Program - 3

7) Wait the final message.

1. After DOWNLOAD, Turn off the TV after download -> Turn

on.

- 14 -

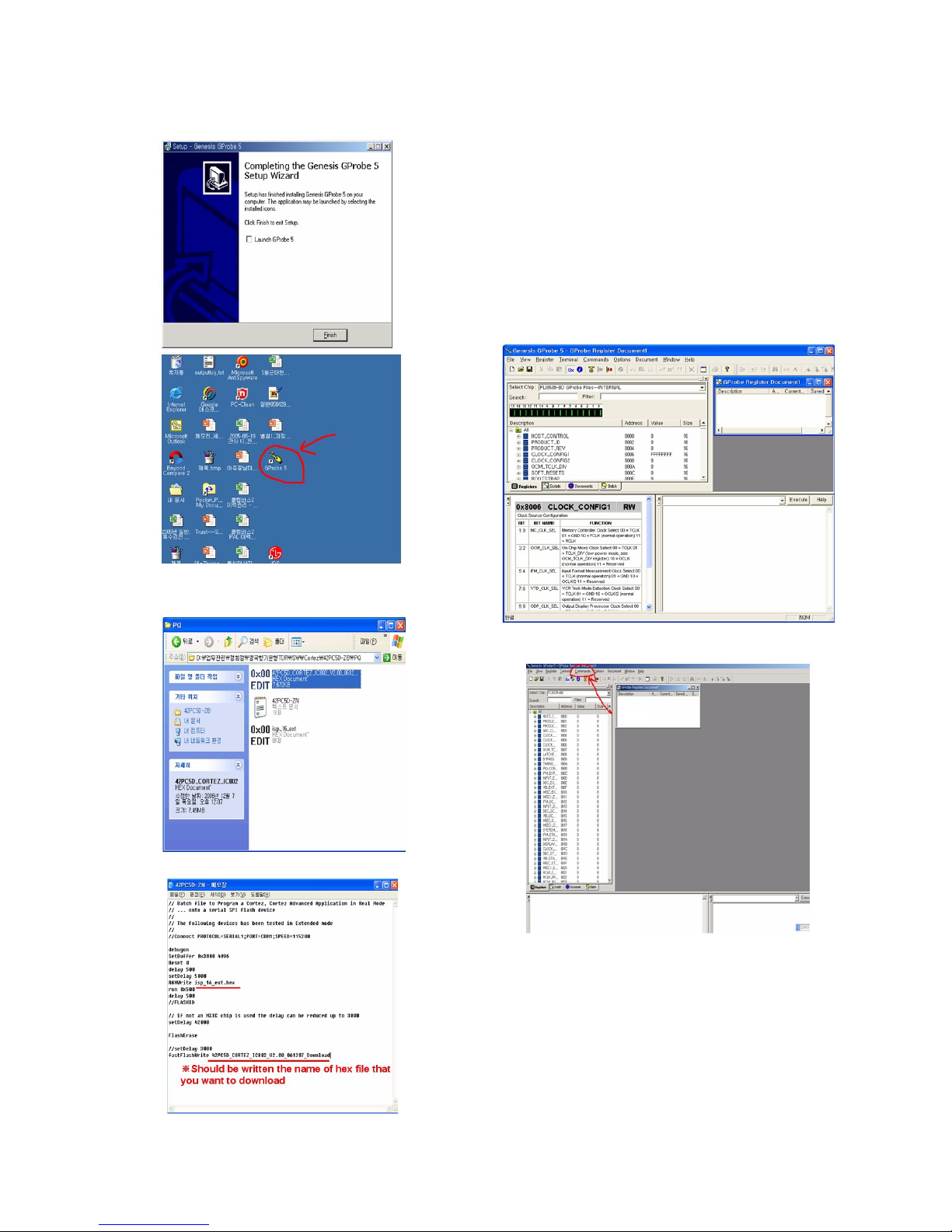

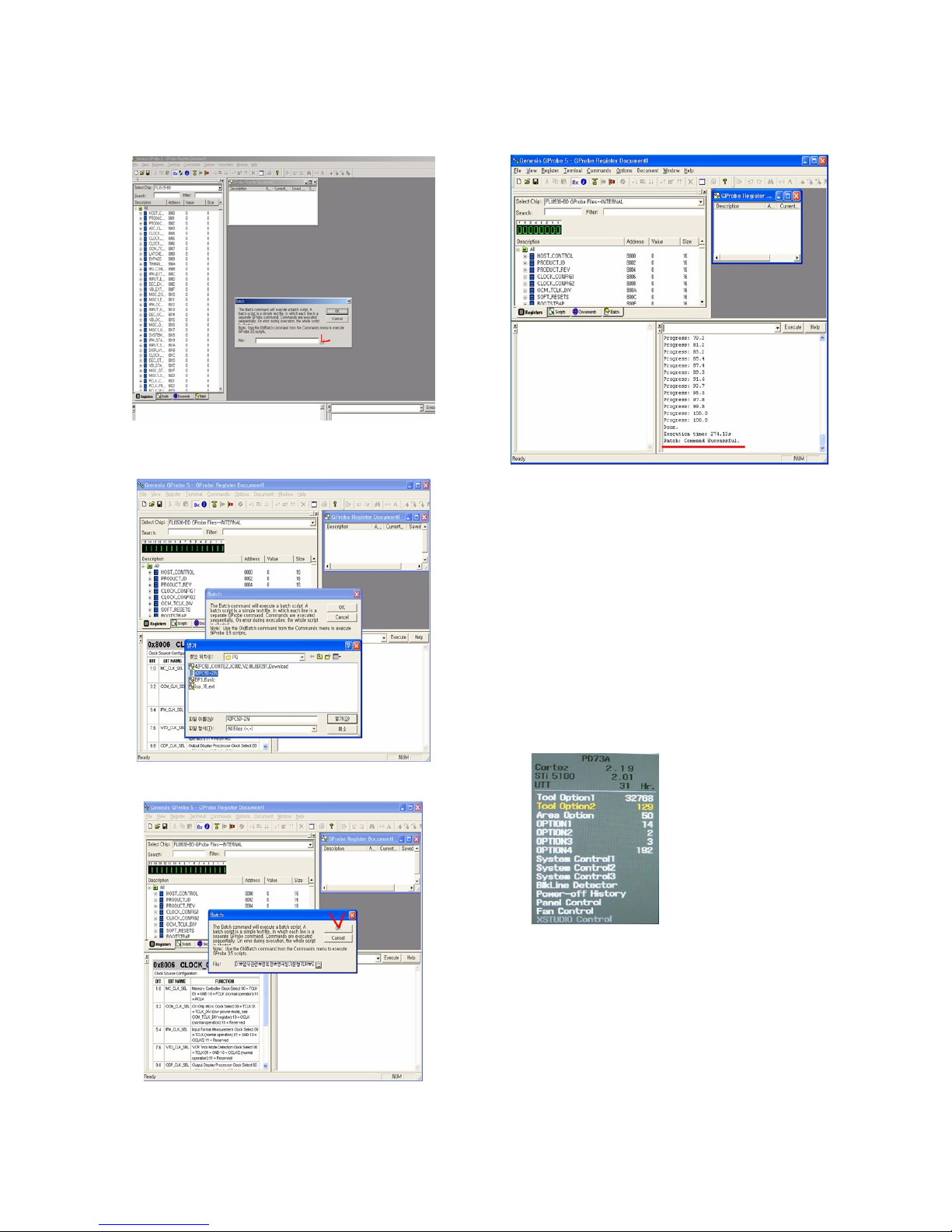

17-2. CORTEZ Download By GProbe 5

(1) Installation of the GProbe 5

1) Extract to folder GProbe5.0.0.15_S0006_EXE_09A.ZIP.

2) Install GProbe5.0.0.15.EXE - 1.

3) Install GProbe5.0.0.15.EXE - 2.

4) Install GProbe5.0.0.15.EXE - 3.

CLICKCLICK

CLICKCLICK

- 15 -

5) Install GProbe5.0.0.15.EXE - 4.

(2) Download hex file using GProbe

1) Prepare a ‘*.hex‘, ‘isp_16_ext.hex‘, ‘*.txt‘ in the same folder.

* In the TEXT FILE

2) Connect TV set and PC by using RS232 cable.

3) SVC MENU Setting for CORTEZ DOWNLOAD.

case 1. Press the ‘tilt’ button on the Adjustment Remote Control.

case 2. Press the ‘ADJ’ button.

1) Press the ‘System Control 2’ menu

2) Enter the ‘GProbe’ on the ‘RS-232Host menu’

3) Enter ‘115200bps’ on the ‘Baud Rate menu’

4) Enter the ‘Cortez’ on the ‘Download menu’

* If you don’t have a Adjustment Remote Control ‘Menu’

button on the Remote Control + ‘Menu’ button on the

Local Key during 7~8sec.

4) Execute the GProbe Program.

5) Open the batch file - 1.

1. Click the ‘Commands’.

CLICK

- 16 -

6) Open the batch file - 1.

1. Click the ‘Commands’.

7) Open the batch file - 2

1. Click ‘Bach’ in the ‘Commands’ menu & express the

‘...’ icon (It’s marked by the red check).

8) Open the batch file - 3.

1. Choose the text file.

9) It takes 300sec ~ 360sec, Wait the final message.

1. Turn off the TV after download -> Turn on.

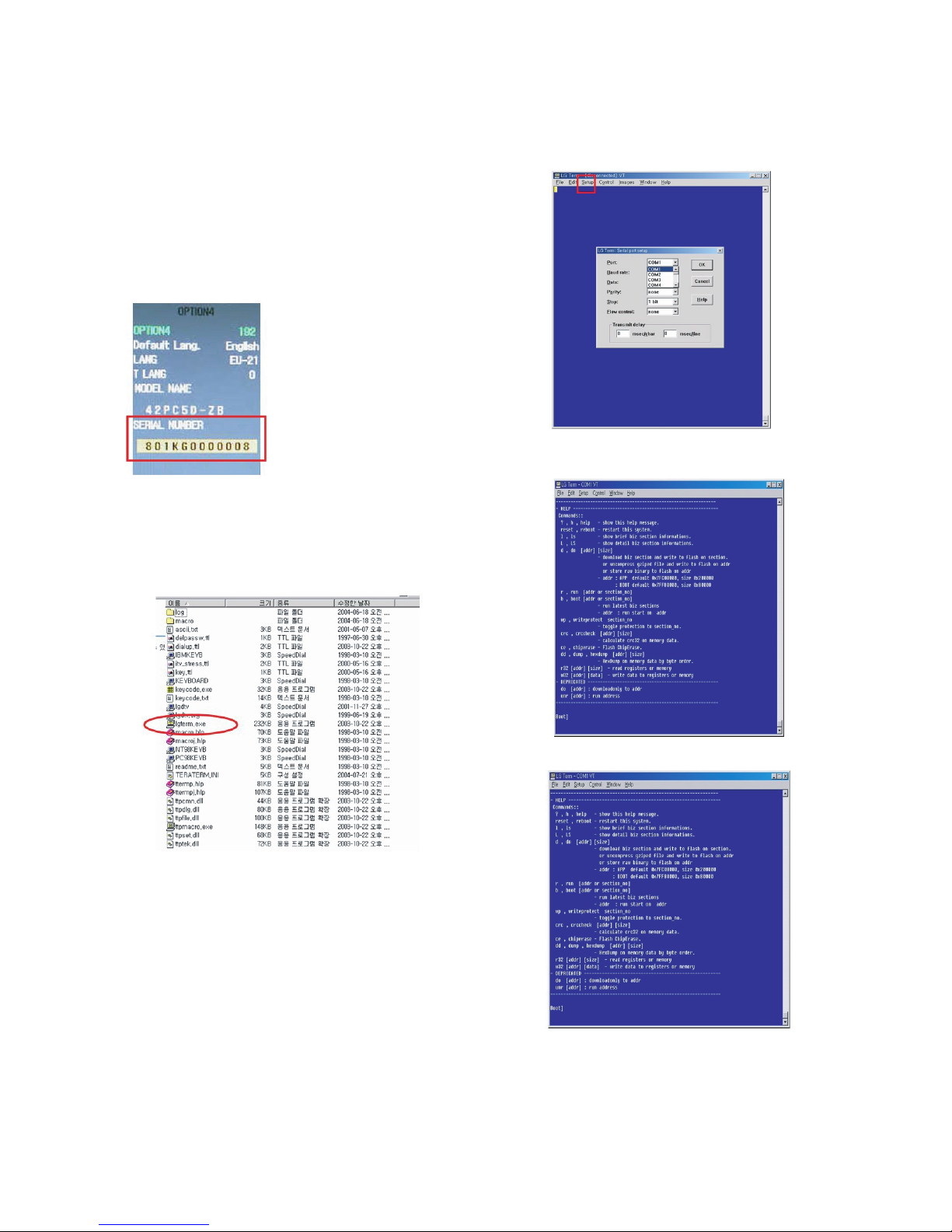

18. Insert the ‘TOOL OPTION’ &

SERIAL NUMBER

V When you change a Main Ass’y, you should insert the TV

SET’s original Serial Number & MODEL NAME. It is the

way how to insert original number.

18-1. Insert the ‘Tool Option’

1) Insert ‘2048’ on ‘Tool Option1’, ‘1697’ on ‘Tool Option2’ for

42PC55-ZB Press the ‘ENTER’ Button.

2) Insert ‘2052’ on ‘Tool Option1’, ‘1953’ on ‘Tool Option2’ for

50PC55-ZB Press the ‘ENTER’ Button.

1. Before change the ‘Tool Option’, you should check

the White Balance Value.

2. Because change the ‘Tool Option’, the White Balance

Value is reset.

- 17 -

18-2. Insert the ‘SERIAL NUMBER’ &

‘MODEL NAME’

1) Check the original serial number.

(Check the Label on the Back Cover)

2) After change the Main Ass’y, Press the ‘ADJ button on the

Adjustment Remote control.

1. Choose the ‘OPTION4’

2. Insert the ‘MODEL NAME’ by navigation key.

3. Insert the original serial number on the ‘SERIAL

NUMBER’ MENU by navigation key.

* After All Setting, Turn Off TV SET-> On

19. ST DOWN LOAD

19-1. ST ROM DOWN LOAD

(1) Installation the ‘LG Term’

1) Extract to folder lgterm.zip.

(2) Download biz file using LG Term

1) Prepare the ‘ *.biz ‘ that you want to download on ST.

2) Connect TV set and PC by using RS232 cable, Turn on

the TV.

3) SVC MENU Setting.

case 1. Press the ‘Turbo Sound’ button on the

Adjustment Remote Control.

case 2. Press the ‘ADJ’ button.

1) Press the ‘System Control 2’ menu

2) Enter the ‘GProbe’ on the ‘RS-232 Host’

3) Enter ‘115200bps’ on the ‘Baud Rate’

4) Enter the ‘STi 5100’ on the ‘Download’

* If you don’t have a Adjustment Remote Control.

‘Menu’ button on the Remote Control + ‘Menu’ button on

the Local Key during 7~8sec.

4) Execute ‘lgterm.exe’.

1. Select ‘Serial port’ on ‘Setup’ Menu.

2. Port’ should be connected with the TV SET by RS232.

5) TV SET DC Power OFF => ON.

1. Check the message like the Picture.

6) Insert ‘dn’ and Enter.

Loading...

Loading...