Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PD73A

MODEL : 50PC35 50PC35-ZC

website:http://biz.LGservice.com

Internal Use Only

Page 2

- 2 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

CONTENTS

SAFETY PRECAUTIONS ....................................................................................3

SPECIFICATIONS ................................................................................................4

ADJUSTMENT INSTRUCTIONS .........................................................................6

TROUBLE SHOOTING GUIDE..........................................................................19

BLOCK DIAGRAM.............................................................................................29

EXPLODED VIEW..............................................................................................30

EXPLODED VIEW PARTS LIST ........................................................................31

REPLACEMENT PARTS LIST...........................................................................32

SCHEMATIC DIAGRAM.........................................................................................

PRINTED CIRCUIT DIAGRAM ..............................................................................

Page 3

- 3 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

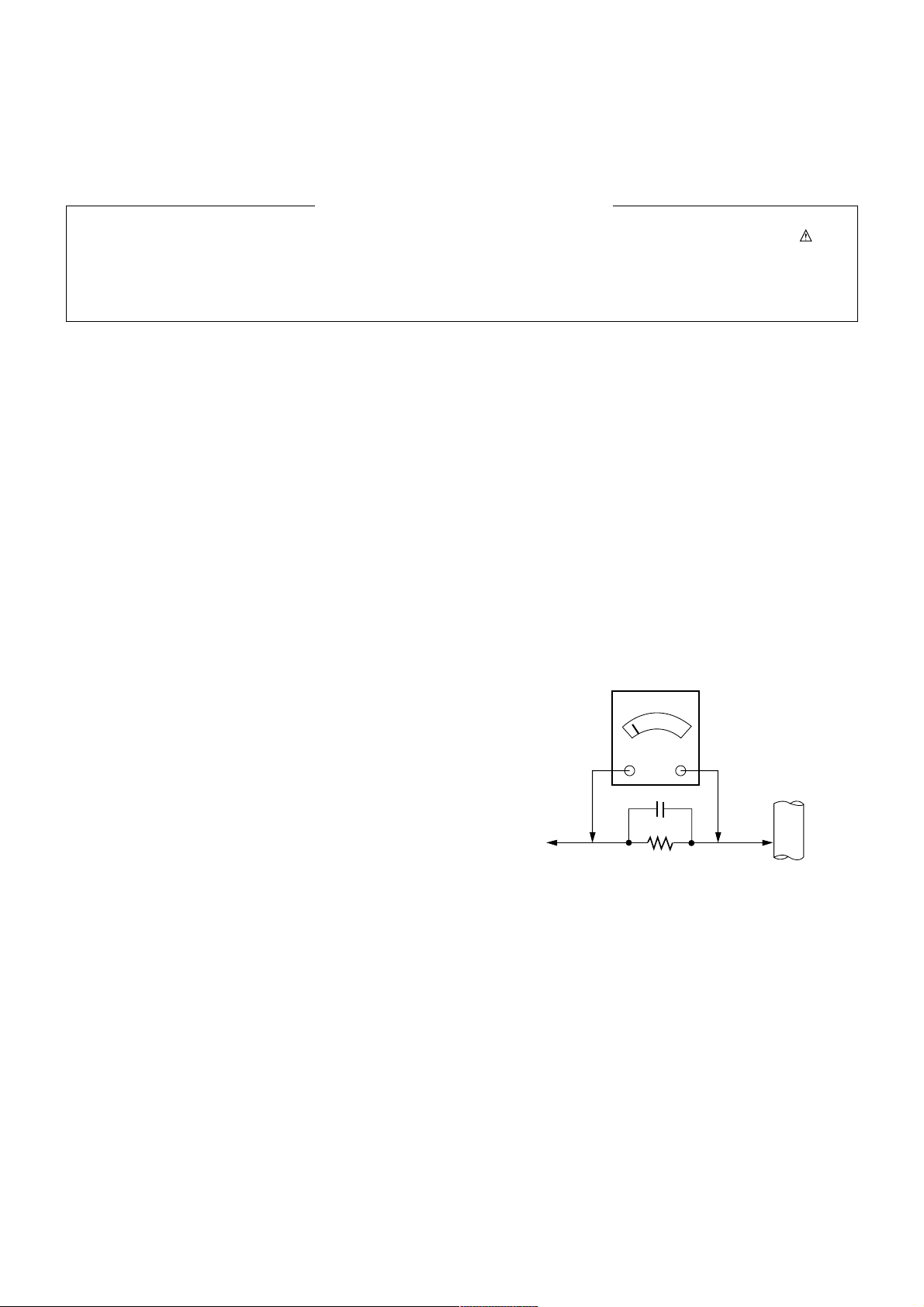

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to the 50” PLASMA TV used PD73A Chassis.

V Specification

Each part is tested as below without special appointment.

1) Temperature : 25±5°C (77±9°F), CST : 40±5

2) Relative Humidity: 65±10%

3) Power Voltage: Standard Input voltage (100-240V~, 50/60Hz)

* Standard Voltage of each product is marked by models.

4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with SBOM.

5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

1) Performance : LGE TV test method followed.

2) Demanded other specification

Safety : CE, IEC specification

EMC : CE, IEC

V General Specification

1. Module Specification ( 50” XGA MODULE )

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

No Item Specification Remark

50” Wide Color Display Module

16:9

PDP50X4A,

RGB Closed Type, Film Filter

1)Temp. : 0~40deg

2)Humidity : 20~80%

3)Temp. : -20~60deg

4)Humidity : 10~90%

100-240V~, 50/60Hz

Plasma Display Panel

LGE SPEC.

Maker LG

Chassis

PD73A 50PC35

UK, German, Italy, France, Sweden, Finland, Spain,

Netherlands, Belgium, Luxemburg, Greece, Denmark,

Czech, Austria, Poland, Portugal, Norway, Rumania,

Hungary , Bulgaria, Croatia, Serbia, Swiss, Slovenia, Russia

LG

Model Name Market Brand Remark

50PC35

Safety : IEC/EN60065

EMI : EN55013

EMS : EN55020

UK, German, Italy, France, Sweden, Finland,

Spain, Netherlands, Belgium, Luxemburg,

Greece, Denmark, Czech, Austria, Poland,

Portugal, Norway, Rumania, Hungary , Bulgaria,

Croatia, Serbia, Swiss, Slovenia, Russia

Model ApplianceMarket

TEST

Remark

Page 5

- 5 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2. Model General Specification

Market

Broadcasting system

Receiving system

Scart Jack (2EA)

Video Input (1EA)

S-Video Input (1EA)

Component Input (1EA)

RGB Input(1EA)

HDMI Input(2EA)

Audio Input (3EA)

1

2

3

4

5

6

7

8

9

10

No Item Specification Remark

UK, German, Italy, France, Sweden, Finland, Spain,

Netherlands, Belgium, Luxemburg, Greece,

Denmark, Czech, Austria

Poland, Portugal, Norway, Rumania, Hungary ,

Bulgaria, Croatia, Serbia, Swiss, Slovenia, Russia

1) PAL-BG

2) PAL-DK

3) PAL-I,I’

4) DVB-T(ID TV)

5) SECAM-L/L’

Analog : Upper Heterodyne

Digital : COFDM

PAL, SECAM

PAL, SECAM, NTSC

PAL, SECAM, NTSC

Y/Cb/Cr, Y/Pb/Pr

RGB-PC

HDMI-DTV & SOUND

PC Audio, Component, AV

Analog Only

4 System : PAL, SECAM, NTSC, PAL60

4 System : PAL, SECAM, NTSC, PAL60

L/R Input

Page 6

- 6 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions are applied to all of the 50” PLASMA TV,

PD73A Chassis.

2. Note

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100-240V~,

50/60Hz.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

O After RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

O Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

[ Set is activated HEAT-RUN without signal generator in

this mode.

[ Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses to check PANEL.

3. Channel memory Setting Method

: You can set channel memory by R/C for adjustment.

( Recovery the channel memory by adjust R/C)

1) Press ADJ key on R/C for adjustment.

2) Press VOL + key on “Channel Recover”.

4. PCMCIA CARD Checking Method

: You must adjust DTV 29 Channel and insert PCMCIA CARD

to socket.

1) If PCMCIA CARD works normally, normal signals display

on screen.

But it works abnormally, “No CA module” words display on

screen.

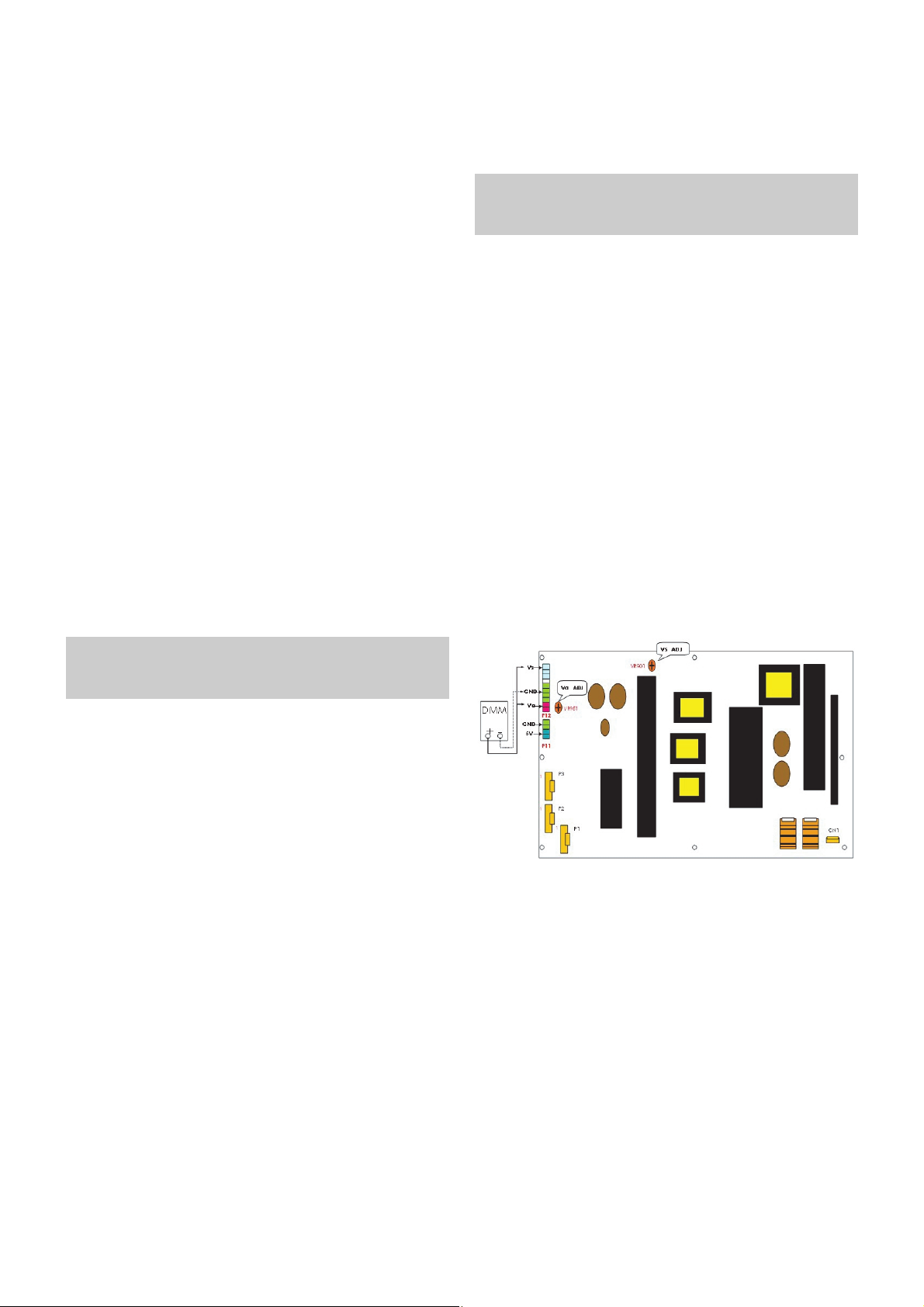

5. POWER PCB Assy Voltage

Adjustments (Va, Vs Voltage adjustments)

5-1. Test Equipment : D.M.M. 1EA

5-2.Connection Diagram for Measuring

: refer to Fig.1

5-3. Adjustment Method

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P12, connect terminal to GND pin of P12.

3) After turning VR901, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P12, connect –

terminal to GND pin of P12.

2) After turning VR951, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

If you turn on a still screen more than 20 minutes (Especially

Digital pattern, Cross Hatch Pattern), an afterimage may occur

in the black level part of the screen.

Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

(Fig. 1) Connection diagram of power adjustment for measuring

<50” EAY32929001 only for 50PB56>

Page 7

- 7 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

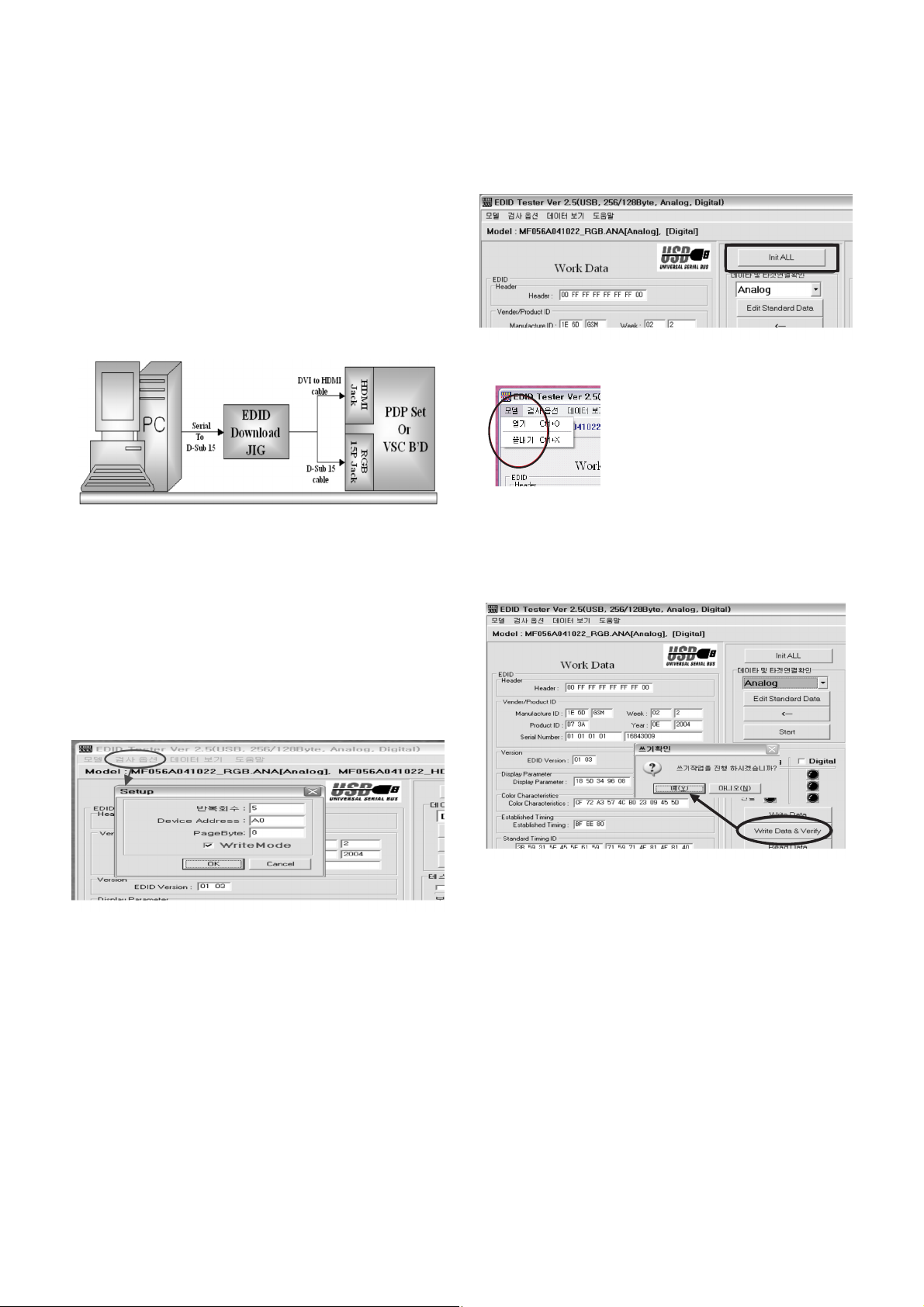

6. EDID (The Extended Display

Identification Data)/ DDC (Display

Data Channel) download

6-1. Required Test Equipment

1) Adjusting PC with S/W for writing EDID Data.(S/W : EDID

TESTER Ver.2.5)

2) A Jig for EDID Download

3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

15Pin cable, DVI to HDMI cable

6-2. Setting of device

6-3. Preparation for Adjustment

1) As above Fig. 2, Connect the Set, EDID Download Jig, PC

& Cable.

2) Turn on the PC & EDID Download Jig. And Execute the

S/W : EDID TESTER Ver,2.5.

3) Set up S/W option.

Repeat Number : 5

Device Address : A0

PageByte : 8

4) Power on the Set.

6-4. Sequence of Adjustment

- EDID Download

1) Init the data.

2) Load the EDID data.(Open File).

[Analog file] (for RGB)

[Digital file] (for HDMI)

3) Set the S/W as below.

4) Push the “Write Data & Verify”button. And confirm “Yes”.

5) If the writing is finished, you will see the “OK” message.

6) If TV has two HDMI, you must download two times for

each HDMI.

(Fig. 2) Connection Diagram of DDC download

Open FileOpen File

Page 8

- 8 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

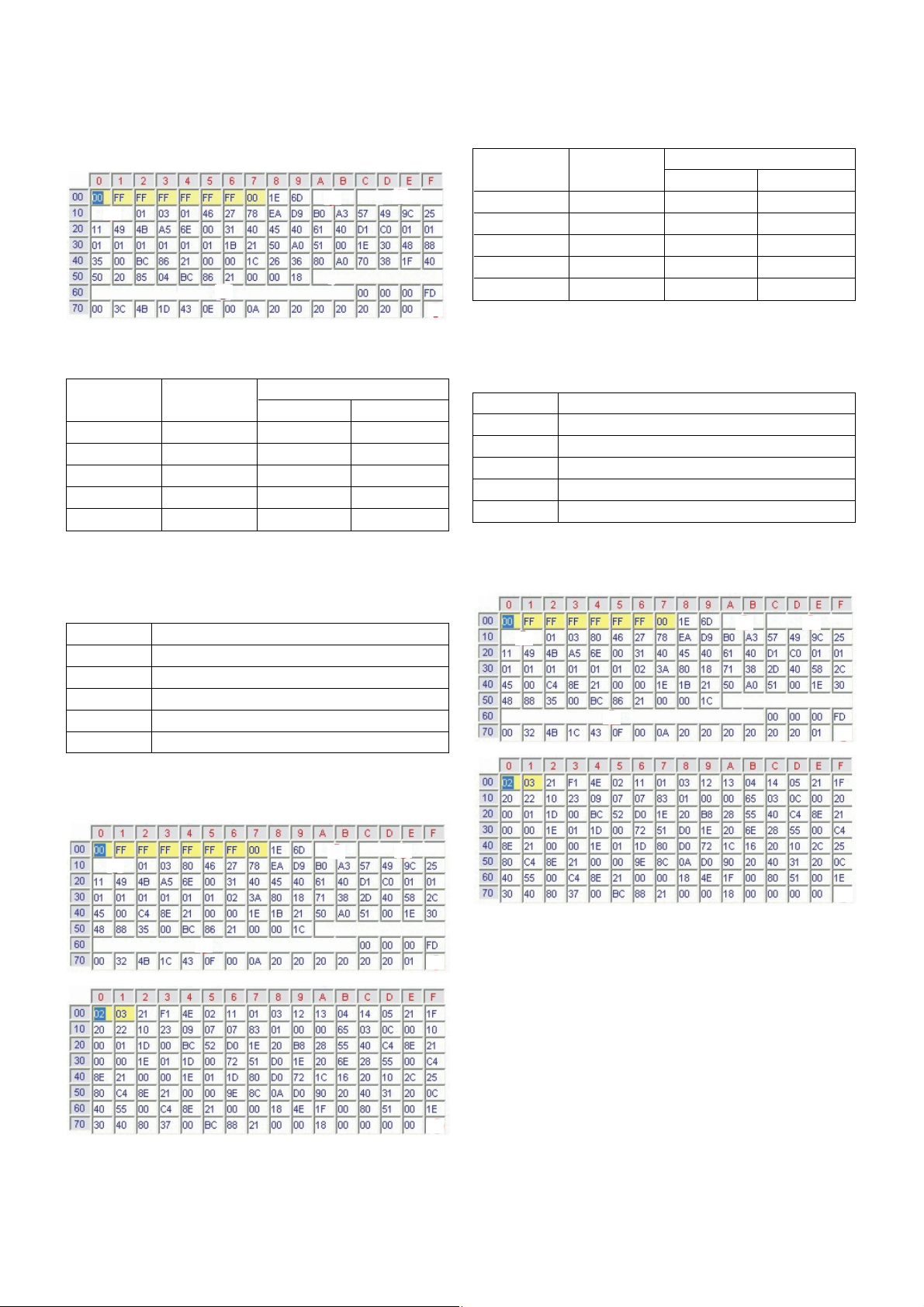

- EDID DATA

1) Analog RGB.

=> Detail EDID Options are below([1], [2], [3],[4], [5])

1. [1]-Product ID

2. [2]-Serial No : Controlled on production line

3. [3]-Month, Year : Controlled on production line

ex) Week : '03' => '03'

Year : '2006' => '10'

4. [4]-Model Name(Hex):

5. [5]-Checksum : Changeable by total EDID data

2) HDMI1.

=> Detail EDID Options are below([1], [2], [3],[4], [5])

1. [1]-Product ID

2. [2]-Serial No : Controlled on production line

3. [3]-Month, Year : Controlled on production line

ex) Week : '03' => '03'

Year : '2006' => '10'

4. [4]-Model Name(Hex):

5. [5]-Checksum : Changeable by total EDID data

3) HDMI2.

=> Detail EDID Options are below([1], [2], [3],[4], [5])

* Please refer HDMI1

Model

Name

50PC35

Product ID

Product ID

EDID table

77C3

Hex

C377

50039

Model Name

50PC35

Hex Data

00 00 00 FC 00 35 30 50 43 33 35 0A 20 20 20 20 20 20

1

2

3

4

5

1

2

3

4

5

5

Model

Name

50PC35

Product ID

Product ID

EDID table

78C3

Hex

C378

50040

Model Name

50PC35

Hex Data

00 00 00 FC 00 35 30 50 43 33 35 0A 20 20 20 20 20 20

1

2

3

4

5

5

Page 9

- 9 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

7. ADC Calibration

8. Auto AV(CVBS) Color Balance

8-1. Requirement

V This AV color balance adjustment should be performed

before white Balance Adjustment.

8-2. Required Equipment

1) Remote controller for adjustment.

2) MSPG-925FS Pattern Generator (Which has Video Signal:

7 Color Bar Pattern shown in Fig. 3).

- Model: 202 / Pattern: 65 EC and FC model use PALBGDHI. (composite signal)

8-3. Method of Auto AV(CVBS) Color Balance

1) Input the Video signal: 7 color Bar signal into AV3.

2) Set the PSM to Dynamic mode in the Picture menu.

3) Press IN-STAR key on R/C for adjustment.

4) Press the

G(Vol. +) key operate to set, then it becomes

automatically.

5) Auto-RGB OK means completed adjustment.

9. Adjustment of Component

9-1. Requirement

V This AV color balance adjustment should be performed

before white Balance Adjustment.

9-2. Required Equipment

1) Remote controller for adjustment.

2) MSPG-925FS Pattern Generator (Which has Video Signal:

7 Color Bar Pattern shown in Fig. 4).

- Model: 215 / Pattern: 65

9-3. Method of Auto Component Color Balance

1) Input the Component 720p/50Hz 7 Color Bar(MSPG-925FS

model:215, pattern:65) signal into Component.

2) Set the PSM to Dynamic mode in the Picture menu.

3) Press IN-STAR key on R/C for adjustment.

4) Press the

G(Vol. +) key operate to set, then it becomes

automatically.

5) Auto-RGB OK means completed adjustment.

10. Adjustment of RGB

10-1. Requirement

V This AV color balance adjustment should be performed

before white Balance Adjustment.

10-2. Required Equipment

1) Remote controller for adjustment.

2) MSPG-925FS Pattern Generator (Which has Video Signal:

7 Color Bar Pattern shown in Fig. 5).

- Model: 215 / Pattern: 65

10-3. Method of Auto RGB Color Balance

1) Input the PC 1024x768 @ 60Hz 7 color bar (MSPG-925FS,

Model:3, Pattern: 65) into RGB. (using D-sub to D-sub

cable)

2) Set the PSM to Dynamic mode in the Picture menu.

3) Press IN-STAR key on R/C for adjustment.

4) Press the

G(Vol. +) key operate to set, then it becomes

automatically.

5) Auto-RGB OK means completed adjustment.

MSPG925FS

Component RGB-PCRF/AV/S-VIDEOADC

Model : 3

(1024*768 60Hz)

Pattern : 65

7 Color Bar

Model:215(720P)

Pattern : 65

* 720P/50Hz

7 Color Bar

PAL

INPUT SELECT AV3

Model : 202

(PAL-BGDHI)

Pattern : 65

* PAL 7 Color Bar

- System control RS-232 Host should be “PC“ for adjustment.

- Before AV ADC Calibration, execute the “Panel size selection“

(Fig. 4) Color bar Test Pattern

(Fig. 3) Color Balance signal

(Fig. 5) Color bar Test Pattern

Page 10

- 10 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

11. Adjustment of White Balance

11-1. Requirement

1) Before adjusting White-balance , the AV ADC should be

done.

2) If ADC status were “NG”, Need to ADC adjustment.

11-2. Required Equipment

1) Remote controller for adjustment.

2) Color Analyzer.( CA-1000,CA-100,100+,CA-210 or same

product ) : CH10(PDP)

* Please adjust CA-210, CA-100+ by CS-1000 before

measuring.

3) Auto W/B adjustment instrument.(only for Auto adjustment)

4) AV Pattern Generator.

W Color temperature standards according to CSM and Module.

W

CS-1000/CA-100+/CA-210(CH10) White balance adjustment

coordinate and color temperature.

11-3. Connection Picture of the Measuring

Instrument(On Automatic control)

V Inside PATTERN is used when W/B is controlled. Connect

to auto controller or push control R/C IN-START -> Enter

the mode of White-Balance, the pattern will come out.

V Auto-control interface and directions

1. Adjust in the place where the influx of light like floodlight

around is blocked.(illumination is less than 10ux)

2. Measure and adjust after sticking the Color Analyzer(CA-

100+, CA210) to the side of the module.

3. Aging time

1) After aging start, keep the power on(no suspension of

poewr supply) and heat-run over 15minutes.

2) Keep white pattern using inside pattern.

V Auto adjustment Map(RS-232C)

- Baud : 115200bps, RS232 Host : PC, Echo : none

12. Adjustment of White Balance

(Manual white Balance)

V One of R Gain/ G Gain/ B Gain should be kept on 80, and

others are controlled lowering from 80

(1) ‘power on’ of the control R/C, set heat run to white by

pressing and heat run over 15 minutes. (Set: RS-232 Host:

PC, Baud Rate: 115200bps, Download: Cortez)

(2) Zero Calibrate CA-100+, and stick the sensor to the center

of PDP module surface when you adjust.

(3) Double click In-start key on Controlling R/C and get in

‘white balance’.

(4) Set test-pattern on and display inside pattern. Control is

carried out on three color temperature, COOL, MEDIUM,

WARM. (Control is carried out three times.)

(5) When the R/G/B GAIN is 80 on OSD, it is the FULL

DYNAMIC Range of the Module. In order to control white

balance without the saturation of FULL DYNAMIC Range

and DATA, one of R Gain / G Gain / B Gain should be kept

on 80, and other two is controlled lowering from 80.

* Color Temperature: Cool, Medium, Warm

(1) When R GAIN is set to 80

- Control G GAIN and B GAIN by lowering from 80.

(2) When B GAIN is set to 80

- Control R GAIN and G GAIN by lowering from 80.

(3) When G GAIN is set to 80

- Control R GAIN and B GAIN by lowering from 80.

One of R Gain / G Gain / B Gain should be kept on 80, and

adjust other two lower than 80.

(When R/G/B GAIN are all 80, it is the FULL DYNAMIC

Range of Module)

(Fig. 6) Auto AV(CVBS) Color Balance Test Pattern

Full White Pattern

RS-232C Communication

CA-210

Color

ANALYZER

TYPE : CA-210

Color Coordinate

xy

0.283±0.002

0.293±0.002

0.329±0.00

2

11000K

9300K

6500K

0.000

0.000

0.003

0.276±0.002

0.285±0.002

0.313±0.00

2

COOL

MEDIUM

WARM

Mode Temp uv

PLASMA Remark

11000K

9300K

6500K

Cool

Normal

Warm

CSM

ADC adjust

Data Read

Default Write

Enter

Adjust Mode

ADC adjust

ADC Parameter

Digital Data

ADC Parameter

(Average)

Adjustment

Confirmation

Adjust ‘Mode In’

Adjust ‘Mode Off’

NO Item

Remark

CMD1 CMD2

Data 0

A

A

A

A

A

A

A

D

D

D

D

D

D

D

0

0

0

0

9

0

0

1

2

3

4

9

0

9

Transfer 18Byte

(Input resolution Data)

To check ADC Adjusment

on Assembly line

When transger the ‘Mode

In’, Carry the command.

- Caution : Using ‘power on’ button’ of the control R/C, power in TV.

Type

Baud Rate

115200

Index

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Data bit

8

Cmd1 Cmd2

ja

jb

jc

jd

je

jf

Stop bit

1

Parity

NONE

PD73A

Protocol

Setting

Data

Min Value

00(00)

00(00)

00(00)

00(00)

00(00)

00(00)

Max Value

128(80)

128(80)

128(80)

128(80)

128(80)

128(80)

Page 11

- 11 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

13.

Default Value in Adjustment mode

13-1. Auto Color Balance

13-2. Write Balance

14. EEPROM Data Write

(Serial No D/L)

14-1. Signal TABLE

CMD : A0h

LENGTH : 85~94h (1~16 bytes)

ADH : E

2

PROM Sub Address high (00~1F)

ADL : E

2

PROM Sub Address low (00~FF)

Data : Write data

CS :

CMD + LENGTH + ADH + ADL + Data_1 + ... + Data_n

Delay : 20ms

14-2. Command Set

* Description

FOS Default write : <7mode data> write

Vtotal, V_Frequency, Sync_Polarity, Htotal, Hstart, Vstart, 0, Phase

Data write : Model Name and Serial Number write in EEPROM,.

14-3. Method & Notice

(1) Serial number D/L is using of scan equipment.

(2) Setting of scan equipment operated by Manufacturing

Technology Group.

(3) Serial number D/L must be conformed when it is produced

in production line, because serial number D/L is mandatory

by D-book 4.0.

15. Set Information(Serial No& Model name)

15-1.

Setting up like bottom figure

(After setting white balance, this is set)

(Setting: Press ADJ Key in the Adjust remocon)

(1) Select “System Control 2” by using

D / E (CH+/-) key, and

press

V (ENTER) Using Adjust remocon, RS-232 Host &

Baud Rate & Download value change)

15-2. Push the menu button in DTV mode.

(1) Select the STATION-> Diagno stics -> To set.

CMD

LENGTH

ADH ADL

DATA_1 DATA_n

... CS DELAY

No

1

EEPROM WRITE

A0h 84h+n n-byted Write

(n=1~16)

Adjust mode CMD(hex) LENGTH(hex) Description

(Fig. 7) Default on OSD

<Component> <RGB>

<AV>

(Fig. 8) Default on OSD

Model

Name

50PC35

Tool

Option1

2180 1953 0 14 2 1 192

Tool

Option2

Area

Option

Option1 Option2 Option3 Option4

Page 12

- 12 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

(2) Check the Serial Number.

16. Input the Shipping Option Data

1) Push the IN-START key in a Adjust Remocon.

2) Input the Option Number that was specified in the BOM, into

the Shipping area.

3) The work is finished, Push

V Key.

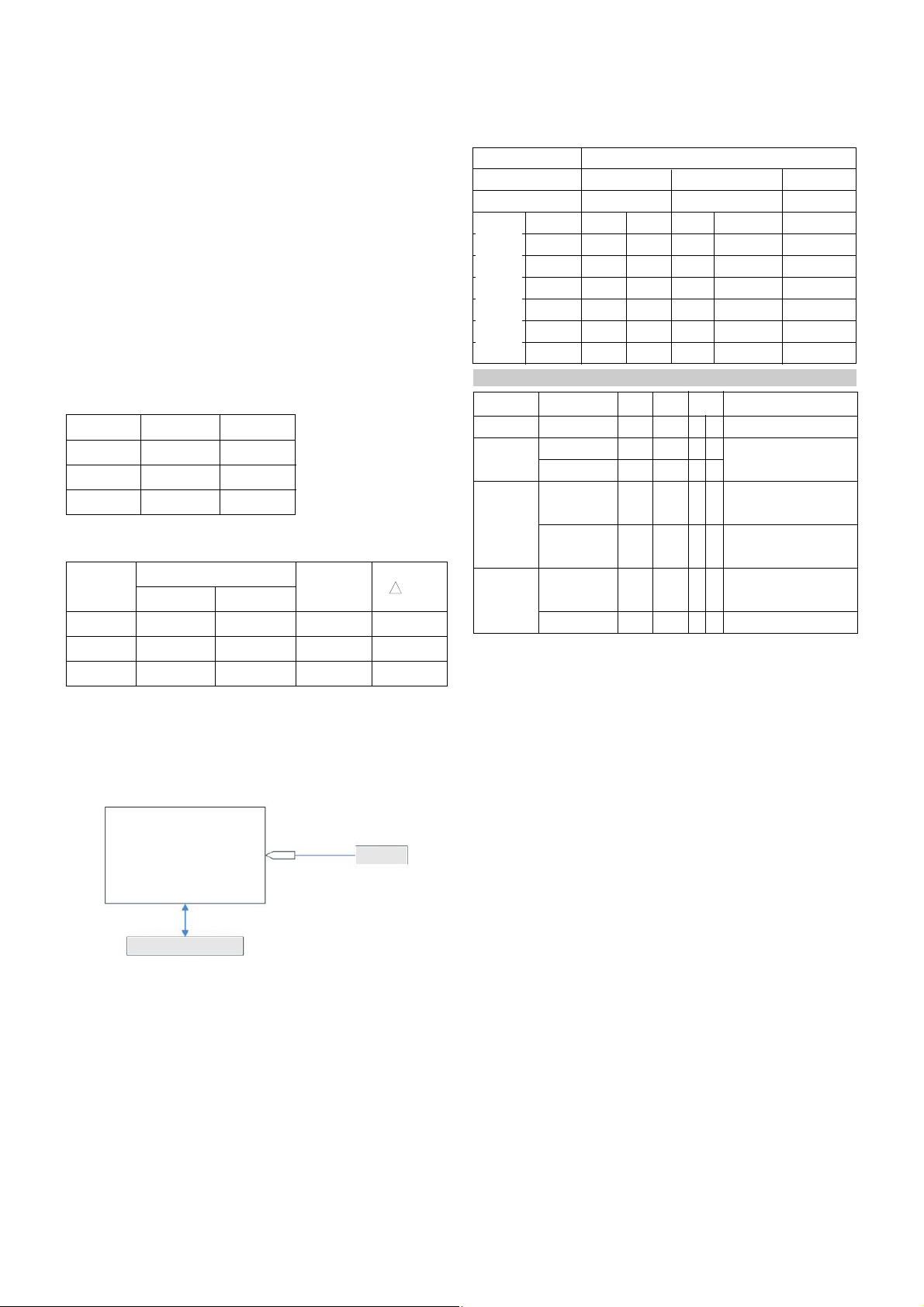

17. CORTEZ Download

17-1. CORTEZ Download By LGIDS

(1) Installation of the LGIDS

1) Extract to folder IDS_Setup.ZIP.

2) Install LGIDS-1

1. After Click the ‘NEXT’ icon, Installation is finished.

3) Install LGIDS-2

1. You can find the ICON on C:\Program Files\LGIDS.

(2) Download hex file

1) Prepare a Batch File(*.txt), RAM File(*.hex) on

C:\Program Files\LGIDS\files.

* In the TEXT FILE

2) Connect RS232 cable and turn on the power.

(Use the general RS-232C Serial Cable)

Page 13

- 13 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3) Execute the LGIDS Program - 1

1. Check a ‘PDP’ & ‘Hurricane’ on the ‘Model’ MENU

*

If your connection is ‘NG’, then set your PORT(COM1,2,3...)

correctly.

4) SVC MENU Setting for CORTEZ DOWNLOAD.

case 1. Press the ‘tilt’ button on the Adjustment Remote

Control.

case 2. Press the ‘ADJ’ button

1) Press the ‘System Control 2’ menu

2) Enter the ‘GProbe’ on the ‘RS-232Host menu’

3) Enter ‘115200bps’ on the ‘Baud Rate menu’

4) Enter the ‘Cortez’ on the ‘Download menu’

* If you don’t have a Adjustment Remote Control

‘Menu’ button on the Remote Control + ‘Menu’ button on

the Local Key during 7~8sec

After Change a mode, you can see ‘GPROBE MODE’

5) Execute the LGIDS Program - 2

1. Open a Batch file, RAM file and Flash file.

6) Execute the LGIDS Program - 3

7) Wait the final message.

1. After DOWNLOAD, Turn off the TV after download -> Turn

on.

Page 14

- 14 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

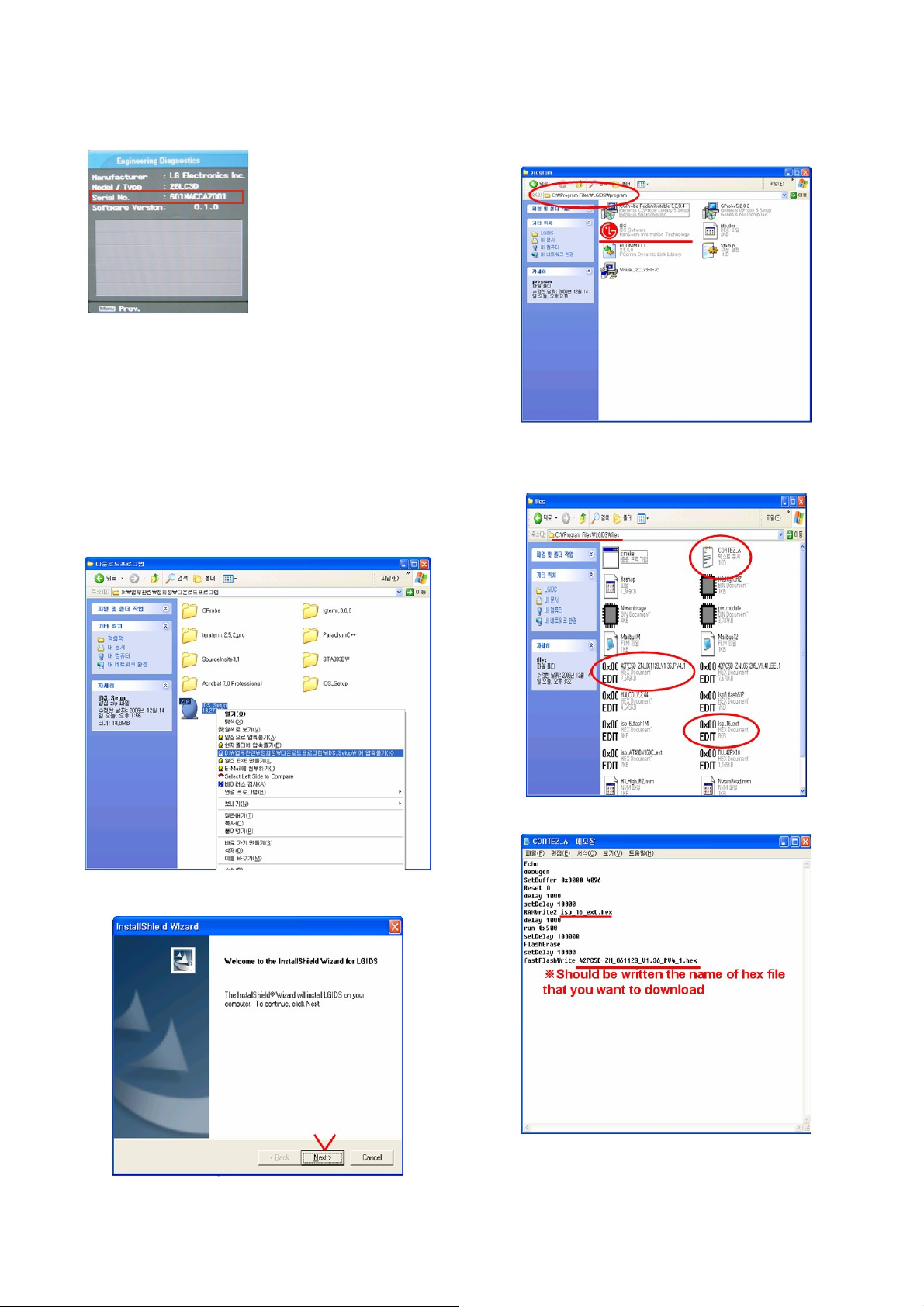

17-2. CORTEZ Download By GProbe 5

(1) Installation of the GProbe 5

1) Extract to folder GProbe5.0.0.15_S0006_EXE_09A.ZIP.

2) Install GProbe5.0.0.15.EXE - 1.

3) Install GProbe5.0.0.15.EXE - 2.

4) Install GProbe5.0.0.15.EXE - 3.

CLICK

CLICK

Page 15

- 15 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

5) Install GProbe5.0.0.15.EXE - 4.

(2) Download hex file using GProbe

1) Prepare a ‘*.hex‘, ‘isp_16_ext.hex‘, ‘*.txt‘ in the same folder.

* In the TEXT FILE

2) Connect TV set and PC by using RS232 cable.

3) SVC MENU Setting for CORTEZ DOWNLOAD.

case 1. Press the ‘tilt’ button on the Adjustment Remote Control.

case 2. Press the ‘ADJ’ button.

1) Press the ‘System Control 2’ menu

2) Enter the ‘GProbe’ on the ‘RS-232Host menu’

3) Enter ‘115200bps’ on the ‘Baud Rate menu’

4) Enter the ‘Cortez’ on the ‘Download menu’

* If you don’t have a Adjustment Remote Control ‘Menu’

button on the Remote Control + ‘Menu’ button on the

Local Key during 7~8sec.

4) Execute the GProbe Program.

5) Open the batch file - 1.

1. Click the ‘Commands’.

CLICK

Page 16

- 16 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

6) Open the batch file - 1.

1. Click the ‘Commands’.

7) Open the batch file - 2

1. Click ‘Bach’ in the ‘Commands’ menu & express the

‘...’ icon (It’s marked by the red check).

8) Open the batch file - 3.

1. Choose the text file.

9) It takes 300sec ~ 360sec, Wait the final message.

1. Turn off the TV after download -> Turn on.

18. Insert the ‘TOOL OPTION’ &

SERIAL NUMBER

V When you change a Main Ass’y, you should insert the TV

SET’s original Serial Number & MODEL NAME. It is the

way how to insert original number.

18-1. Insert the ‘Tool Option’

1) Insert ‘2180’ on ‘Tool Option1’, ‘1953’ on ‘Tool Option2’ for

50PC35 Press the ‘ENTER’ Button.

1. Before change the ‘Tool Option’, you should check

the White Balance Value.

2. Because change the ‘Tool Option’, the White Balance

Value is reset.

Page 17

- 17 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

18-2. Insert the ‘SERIAL NUMBER’ &

‘MODEL NAME’

1) Check the original serial number.

(Check the Label on the Back Cover)

2) After change the Main Ass’y, Press the ‘ADJ button on the

Adjustment Remote control.

1. Choose the ‘OPTION4’

2. Insert the ‘MODEL NAME’ by navigation key.

3. Insert the original serial number on the ‘SERIAL

NUMBER’ MENU by navigation key.

* After All Setting, Turn Off TV SET-> On

19. ST DOWN LOAD

19-1. ST ROM DOWN LOAD

(1) Installation the ‘LG Term’

1) Extract to folder lgterm.zip.

(2) Download biz file using LG Term

1) Prepare the ‘ *.biz ‘ that you want to download on ST.

2) Connect TV set and PC by using RS232 cable, Turn on

the TV.

3) SVC MENU Setting.

case 1. Press the ‘Turbo Sound’ button on the

Adjustment Remote Control.

case 2. Press the ‘ADJ’ button.

1) Press the ‘System Control 2’ menu

2) Enter the ‘GProbe’ on the ‘RS-232 Host’

3) Enter ‘115200bps’ on the ‘Baud Rate’

4) Enter the ‘STi 5100’ on the ‘Download’

* If you don’t have a Adjustment Remote Control.

‘Menu’ button on the Remote Control + ‘Menu’ button on

the Local Key during 7~8sec.

4) Execute ‘lgterm.exe’.

1. Select ‘Serial port’ on ‘Setup’ Menu.

2. Port’ should be connected with the TV SET by RS232.

5) TV SET DC Power OFF => ON.

1. Check the message like the Picture.

6) Insert ‘dn’ and Enter.

Page 18

- 18 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

7) When ‘Please Send the file’ appears, Press ‘ctrl’ + ‘s’.

8) When ‘Please Send the file’ appears, Press ‘ctrl’ + ‘s’.

9) Download takes 60sec ~ 120sec.

10) The End of DOWNLOAD

1. After Download successfully, you can see ‘EW EW

EW EW.

2. You can remove RS232 Cable and TV Power SET

OFF => ON

11) Change the mode.

1. Press the ‘ADJ’ button.

2. Press the ‘System Control 2’ menu.

3. Enter the ‘PC’ on the ‘RS-232 Host’.

4. Enter ‘115200bps’ on the ‘Baud Rate’.

5. Enter the ‘Cortez’ on the ‘Download.

Page 19

- 19 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

TROUBLE SHOOTING GUIDE

1. Power Board

1-1. The full flowchart for the voltage output

Start check

Manufacture’s model

passage

1. Check the Power Off

status.

Does the whole

screen appear?

Is it

identical to when the

power is off?

No

Yes

No

Yes

Yes

Yes

Yes

2. Check the Interface

signal status.

Is the Interface

signal operating?

Yes

3. Check the St-by 5V

signal circuit.

Does the

low pressure output

appear?

Does the

St-by 5V signal

appear?

No

No

Yes

4. Check the 5V Monitor

signal circuit.

Does the

5V Monitor signal

appear?

No

7. Check the VSC Vs-ON

signal

Does the

high tension output

appear?

Does the

VSC signal Vs-ON

appear?

No

No

Does the

high tension

output voltage

occur?

When

removing the Y B/D

Module input connector,

does output voltage

drop?

When the

Y, Z B/D Module

input connector, does Power

Board high tension

output voltage drop?

No No No

9. Check the Power

Board Output high

tension circuit

Yes

10. Check the Z B/D

Module output circuit

Yes

When

removing the Z B/D

Module input connector,

does output voltage

drop?

11. Check the Y B/D

Module output circuit

Yes

Yes

8. Check the Vs, Va

voltage output circuit.

Does the

Vs, Va voltage output

appear?

No

Yes

Yes

5. Check the VSC RL-ON

signal.

Does the

VSC signal RL-ON

appear?

No

6. Check the VSC low

pressure output

Does the

VSC low pressure

output appear?

No

Page 20

- 20 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1-2. 50” Power Board Structure ( LGIT )

(1) Pin Layout

(2) Pin Spec

ANALOG & DIGITAL BOARD PDP MODULE

CN1

AC INLET

P1 P2 P3 P11 P12

AC

NC

AC

YH396-03V

AC Det

RL-ON

STB 5V

GND

Vs-ON

5V Det

M5V-ON

STB 5V

GND

NC

6V

GND

3.4V-ON

SMW250-013P

19V

19V

GND

GND

6V

GND

3.4V

GND

12V

GND

SMW250-010P

3.4V

3.4V

GND

GND

6V

6V

GND

GND

12V

12V

GND

GND

SMW250-012P

5V

5V

GND

GND

YH396-04V

Va

Va

GND

GND

GND

GND

NC

Vs

Vs

Vs

YH396-10V

1

2

3

4

5

6

7

8

9

10

11

12

13

DESCRIPTION

NO

Page 21

- 21 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1-3. 50” Power Board Structure ( Sanken )

(1) Pin Layout

(2) Pin Spec

ANALOG & DIGITAL BOARD PDP MODULE

CN1

AC INLET

P1 P2 P3 P11 P12

AC

NC

AC

YH396-03V

AC Det

RL-ON

STB 5V

GND

Vs-ON

5V Det

M5V-ON

STB 5V

GND

NC

6V

GND

3.4V-ON

SMW250-013P

19V

19V

GND

GND

6V

GND

3.4V

GND

12V

GND

SMW250-010P

3.4V

3.4V

GND

GND

6V

6V

GND

GND

12V

12V

GND

GND

SMW250-012P

5V

5V

GND

GND

YH396-04V

Va

Va

GND

GND

GND

GND

NC

Vs

Vs

Vs

YH396-10V

1

2

3

4

5

6

7

8

9

10

11

12

13

DESCRIPTION

NO

Page 22

- 22 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2. No Power

(1) Symptom

1) Does not minute discharge at module.

2) Non does not come into the front LED.

(2) Procedure check

Is the power cord plugged in? Plug in the power cord.

Yes

No

Is the Line Filter and Power

Board Cable connected?

Connect the Cable.

Yes

No

Is the appropriate Fuse(F101) on

the Power Board?

Replace the Fuse.

Yes

No

Is the Power Board and 13P of

VSC Board Cable connected?

Connect the Cable.

Yes

No

After removing the cables, connect them to the Power Board(except the

SC101 connection cable), and change the AC voltage marking to manual.

When ST-BY 5V does not operate, replace the Power Board.

Page 23

- 23 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3. Protect Mode

(1) Symptom

1) After lighting up once, it does not discharge

minutely from module.

2) The rely falls.(there is an audible “click”)

3) The color of the front LED turns from green to red.

(2) Procedure check

Is the Power Board

normal ?

Replace the Power Board.

Is the output Low/High voltage normal

except for Stand-by 5V?

Yes

No

No

Is the each connector

normal?

Replace the connector.

Replace the

Y-Board.

After connecting each connector do

they operate normally?

Yes

No

Yes

Is the Ctrl Board

normal?

Replace the

X-Board.

Is the output voltage normal after

removing P1, 2, 4, 9, 10 connectors of

the Ctrl-B/D?

Yes

No

Yes

Is the Y-Board

normal?

Is the output voltage

normal after removing

P103 connector of

Y-B/D?

Is the appropriate Fuse(FS101,FS102)

on the Y-B/D normal?(Replace if open)

Yes

No

Yes Yes

Replace the

Z-Board.

Is the Z-Board

normal?

Is the output voltage

normal after removing

P1 connector of

Z-B/D?

Is the appropriate Fuse (FS1, FS2) on

Z-B/D? (replace if open)

Yes

No

Yes

Is the X- Board

normal?

Is the output voltage normal after

removing P1, 2, 3, 4, 5 connectors of

the X-B/D?

If the output voltage is normal after removing

the P1, P2, P3 : Replace the right X-B/D

If the output voltage is normal after removing

the P4, P5 : Replace the left X-B/D

Yes

No

Yes

Is the

VSC Board normal?

Is the output voltage normal after

removing P900, P901 of VSC Board?

After a COF crisis for each board, check the normal operation. For normal operation,

corresponding COF failure means the module should be relaced.

If it operates normally after removing the

P900, P901 : Replace the VSC Board

Yes

No

Is the COF of X, Y, Z

normal ?

No

Yes

Yes

Page 24

- 24 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Does minute discharge

At Module?

Is the LVDC cable

normal?

Is the VAVS on?

Check the PDP Module

Yes

No

YES

Yes

Reconnect the LVDS

cable in P800

No

Is the IC700(FLI8548)

Output normal?

Replace the VSC.

No

NO

Replace the Power

board

Is the Low/High output

voltage normal except for

stand-by 5V?

NO

4. No Raster

(1) Symptom

1) No OSD and image occur at screen.

2) It maintains the condition where the front LED is green.

(2) Procedure check

Page 25

- 25 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

5. In case of strange screen display in specific modes

5-1. In case of no OSD display

(1) Symptom

1) LED is green.

2) The minute discharge is continuously accomplished from the module.

(2) Procedure check

Is the LVDS cable

normal ?

Is the VSC Board

normal?

Is the LVDS cable

connected?

Re-insert the Cable.

Yes

No

No

Yes

Does the FIL8548

IC(IC700) operate?

Replace the FIL8548

IC(IC700)

No

Is the Ctrl Board of

Module normal?

Replace the Ctrl B/D.

No

No

Yes

Replace the VSC B/D

Replace the cable.

Yes

Page 26

- 26 -

5-2. In case there is no display on the screen in specific modes

(1) Symptom

1) There is no screen display from a specific input mode

(RF, AV, Component, RGB, DVI).

(2) Procedure check

1) Check the all input modes have normal display

.

2) Check the video(main)/ data(sub), video(main)/ video(sub) have normal

displays from the PIP mode or DW mode(re-check it/ swap).

(3) In case of an unusual display in RF mode

(4) In case of an unusual display in side S-video/ AV mode

Is the Tuner normal?

Is the CXA2069Q normal?

Is the Tuner Cable connected?

Re-insert the cable

Yes

No

No

Yes

Is the FIL8548 normal?

Replace the Tuner.

No

Are the Input voltage, IIC Communication

and CVBS output normal?

Yes

Are the Input voltage, IIC

Communication and HV sync normal?

No

Replace the IC.

No

Are the input voltage, IIC

Communication and HV sync normal?

No

Block A

Replace the IC.

No

Is the Video input of the AV

Jack(P1400) normal?

Yes

Is the CXA2069Q normal?

Check the input source

No

Are the Input voltage, IIC

Communication and HV sync normal?

No

Replace the IC.

No

Yes

Same as Block A

Page 27

- 27 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

(5) In case of an unusual display in Component, RGB mode

(6) In case of an unusual display in HDMI mode

(7) In case of an unusual display in SCART1 mode

(8) In case of an unusual display in SCART2 mode

Are the R,G,B input and H,V

Sync of the J1100 normal?

Check the input source

No

Is the HDMI002(IC1004)

normal?

Yes

Same as Block A

Are Input voltage, IIC Communication

and HV sync normal?

No

Is the Video input of the

A/V Jack(J1200) normal?

Yes

Same as Block A

Check the input source

No

Replace the IC.

No

Is the Video input of the

A/V Jack(J1201) normal?

Yes

Same as Block A

Check the input source

No

Yes

Same as Block A

Page 28

- 28 -

6. In case of no sound

(1) Symptom

1) LED is Green.

2) Screen display appears but there is no sound.

(2) Procedure check

All input(modes) have

no sound?

Is there no sound only

for HDMI?

No

Yes

Download

the EDID data

Check the signal after

CAX2069 refer to circuit diagram

No

Is there no sound only

for specific?

(except HDMI,DTV,RF)

Check the signal before

CAX2069 refer to circuit diagram

No

YES YES

Is there no sound only

for RF?

Check the Tuner IN/OUT

No

YES

YES

Is there no sound only

for AV/component/PC?

Is the output of

CXA2069 normal?

No

YES

Is the IC1300

operating normally?

Replace the IC1300

(MSP4450)

No

Is the IC1301

operating normally?

Replace the IC1300

(STA335BW)

No

YES

Replace the VSC B/D

YES

No

Replace the CXA2069

Is the speaker on?

Set speaker on in the

menu.

No

Is the speaker Cable

normal?

Check the Speaker

Cable.

No

Yes

Page 29

- 29 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

BLOCK DIAGRAM

Integration

Page 30

- 30 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

EXPLODED VIEW

305

303

302

301

304

200

580

201

202

203

204

240

400

250

205

206

208

101

207

901

900

570

120

560

300

600

602

601

501

590

520

A2

A21

502

Page 31

- 31 -

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

101 5900904001A Fan Module, 1.7KRPM DC 12V 250UA 3W 50HZ 1.5M3 per MIN 396X60.2X108.3MM DONGYANG CHEMICAL

120 EAB30829601 Speaker, Woofer g2060102 ND 15W 8OHM 82DB 100HZ 240 X 57 X 49 LUG MACOM

200 EAJ38568901 PDP, Module-XGA PDP50X40A35.ASLGB XGA 50INCH 1365X768 16/9 PDP DIVISION

201 EBR35959201 Hand Insert PCB Assembly, CTRL ASS’Y HAND INSERT 50” X4A 4006W & 256CH CTRL PDP DIVISION

202 EBR37397801 Hand Insert PCB Assembly, YDRV ASS’Y HAND INSERT 50” X4A Reduce Size. (6.5mm) AU. YDRVT PDP DIVISION

203 EBR37398001 Hand Insert PCB Assembly, YDRV ASS’Y HAND INSERT 50” X4A Reduce Size (6.5mm). AU. YDRVB PDP DIVISION

204 EBR35855501 Hand Insert PCB Assembly, XRLT ASS’Y HAND INSERT 50” X4A 256CH PDP DIVISION

205 EBR35856701 Hand Insert PCB Assembly, XRCT ASS’Y HAND INSERT 50” X4A 256CH PDP DIVISION

206 EBR35856201 Hand Insert PCB Assembly, XRRT ASS’Y HAND INSERT 50” X4A 256CH PDP DIVISION

207 EBR37284101 Hand Insert PCB Assembly, YSUS ASS’Y HAND INSERT 50” X4A Change ER Coil. 2L. OSP PDP DIVISION

208 EBR37284601 Hand Insert PCB Assembly, ZSUS ASS’Y HAND INSERT 50” X4A Change ER Coil. 2L. OSP PDP DIVISION

240 4980900101C Supporter, ASSY AL SKD

250 4980900102C Supporter, ASSY AL VERTICAL L SKD

300 30919E0005G Cover Assembly, 50PC35-ZC PD74A 50” 50PC35-ZC LGEMA EUROPASS3 SKD

301 4980900103B Supporter, FILTER AL 50PC3D-UD.SUSULLJR

302 4980900104B Supporter, FILTER AL 50PC3D-UD.SUSULLJR BOTTOM

303 4980900105B Supporter, FILTER AL 50PC3D-UD.SUSULLJR RIGHT

304 4980900106C Supporter, PRESS AL A5052-H34 1 Supporter AL -

305 5230V00017D Filter, CUTTING ACRYL TOP 50” PDP MITSUI 50” GLASS FILTER

400 3809900102P Cover Assembly, 50PC35-ZC PD74A 50” EUROPASS3 SKD

501 3301900089U Plate Assembly, AV 50PC35-ZC EUROPASS3 CKD

502 AGU34705202 Plate Assembly, REAR AV PLATE COVER ASSEMBLE 42PC35 & 50PC35 EU EUROPASS3 BASIC PRESS

520 EBR39671421 Hand Insert PCB Assembly, Main MAIN M.I PD73A 50PC35-ZC KEKLLMP Hand Insert PCB Assembly for MA CKD

560 68719SML96B Hand Insert PCB Assembly, Sub SUB M.I PD73A 50PC35-ZC AEULLHX -

570 EBR40208901 PCB Assembly, Sub SUB T.T PD73A 50PC35-ZC KEKYLMP SUB IR PCB Assembly for MA C/SKD

580 EAY32957901 SMPS, AC/DC YPSU-J017A 100VTO240V 530W 50 TO 60HZ UL/CE/TUV 50INCH PDP XPOWER LGIT PSU

590 6200J000115 Filter, AC Line IJ-N06CESL1 5.3mH 250VAC 6A 0.22uF 1000pF UL/VDE/CSA/TUV/CCC HOUSING/RING BK DONGJI

600 EBR39741801 Hand Insert PCB Assembly, Sub SUB M.I PD73A 42PC35 AEULLHX Hand Insert PCB Assembly SUB Side AV

601 4811900021M Bracket Assembly, SIDE AV 42PC35 & 50PC35-ZC PD74A EUROPASS3

602 48149V0003B Plate, PRESS SPTE T0.3 SIDE AV 50PC1R

900 3501900004D Base Assembly, STAND 50PC1DRA-UA PA61A SKD

901 35509K0101B Cover, 50PC1R-TA CABLE BK

A2 AKB33871401 Remote Controller Assembly, 19_22LS4D, EU(PAL), LD73B

A21 MCK36759201 Cover, MOLD ABS HF-380 MKJ339814 ABS, HF-380 TX BATTERY COVER

EXPLODED VIEW PARTS LIST

No. Part No. Descriptions

The components identified by mark is

critical for safety.

Replace only with part number specified.

Page 32

LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SCL_5V

FSCS0

CH0E+

0.1uF

C752

P_3.3V

22uF

16V

C701

FSDQM2

SDA_EEPR

0

R702

0.1uF

C702

0.1uF

C703

SCL_5V

500-ohm

L700

0.1uF

C704

SCL

22uF

16V

C705

0.1uF

C707

FLI8532_Top

(CORTEZ)

K10

CORE_1.8_1

U10

CORE_1.8_2

K11

CORE_1.8_3

L11

CORE_1.8_4

T11

CORE_1.8_5

U11

CORE_1.8_6

K16

CORE_1.8_7

L16

CORE_1.8_8

T16

CORE_1.8_9

U16

CORE_1.8_10

K17

CORE_1.8_11

T17

CORE_1.8_12

U17

CORE_1.8_13

E4

IO_3.3_1F4IO_3.3_2G4IO_3.3_3H4IO_3.3_4J4IO_3.3_5K4IO_3.3_6L4IO_3.3_7

AC14

IO_3.3_8

AC16

IO_3.3_9

AC18

IO_3.3_10

AC20

IO_3.3_11

AC22

IO_3.3_12

AB23

IO_3.3_13

Y23

IO_3.3_14

V23

IO_3.3_15

T23

IO_3.3_16

P23

IO_3.3_17

M23

IO_3.3_18

AC9

LBADC-33

D4

FS_2.5_1D6FS_2.5_2D7FS_2.5_3D8FS_2.5_4

D10

FS_2.5_5

D11

FS_2.5_6

D12

FS_2.5_7

D13

FS_2.5_8

D14

FS_2.5_9

D15

FS_2.5_10

D17

FS_2.5_11

D18

FS_2.5_12

D20

FS_2.5_13

D22

FS_2.5_14

D23

FS_2.5_15

C19

FSVREF1C9FSVREF2

H24

LVDS_PLL_3.3

E26

LVDS_3.3_1

H26

LVDS_3.3_2

J26

LVDS_3.3_3

M26

LVDS_3.3_4

AB4

ADC_1.8_1

AC4

ADC_1.8_2

AC5

ADC_1.8_3

A14

VDD18_DLL

C25

RPLL_1.8

D26

RPLL3.3

AD3

ADC_3.3

AD4

ADCA_3.3

AD5

ADCB_3.3

AD6

ADCC_3.3

AD7

ADCSC_3.3

FLI8532_

Right

B4

FSDATA0A4FSDATA1B5FSDATA2A5FSDATA3B7FSDATA4A7FSDATA5B8FSDATA6A8FSDATA7B9FSDATA8A9FSDATA9

B10

FSDATA10

A10

FSDATA11

B12

FSDATA12

A12

FSDATA13

B13

FSDATA14

A13

FSDATA15

B15

FSDATA16

A15

FSDATA17

B16

FSDATA18

A16

FSDATA19

B18

FSDATA20

A18

FSDATA21

B19

FSDATA22

A19

FSDATA23

B20

FSDATA24

A20

FSDATA25

B21

FSDATA26

A21

FSDATA27

B23

FSDATA28

A23

FSDATA29

B24

FSDATA30

A24

FSDATA31

C18

FSADDR0

C17

FSADDR1

C16

FSADDR2

C15

FSADDR3

C13

FSADDR4

C10

FSADDR5C8FSADDR6C7FSADDR7C6FSADDR8

C12

FSADDR9

D16

FSADDR10

C14

FSADDR11

C11

FSADDR12D5FSCLKPC5FSCLKN

D21

FSCS0

C22

FSCS1B6FSDQS0

B11

FSDQS1

A17

FSDQS2

A22

FSDQS3A6FSDQM0

A11

FSDQM1

B17

FSDQM2

B22

FSDQM3

C23

FSWE

D24

FSCAS

C24

FSRASC4FSCKE

C21

FSBKSEL0

C20

FSBKSEL1

L24

CH3E-/EBLU5

L23

CH3E+/EBLU4

L26

CKE-/EBLU7

L25

CKE+/EBLU6

K24

CH2E-/EGAN1

K23

CH2E+/EGAN0

K26

CH1E-/EGAN3

K25

CH1E+/EGAN2

J24

CH0E-/EGAN5

J23

CH0E+/EGAN4

G24

CH3O-/EGAN7

G23

CH3O+/EGAN6

G26

CKO-/ERED1

G25

CKO+ERED0

F24

CH2O-/ERED3

F23

CH2O+/ERED2

F26

CH1O-/ERED5

F25

CH1O+/ERED4

E24

CH0O-/ERED7

E23

CH0O+/ERED6

N23

EBLU0

N24

EBLU1

N25

EBLU2

N26

EBLU3

P24

DCLK

P25

DHS

R26

DVS

P26

DEN

AF15

OCMADDR21

AE15

OCMADDR20

AD15

OCMADDR19

AC15

OCMADDR18

AF16

OCMADDR17

AE16

OCMADDR16

AD16

OCMADDR15

AF17

OCMADDR14

AE17

OCMADDR13

AD17

OCMADDR12

AC17

OCMADDR11

AF18

OCMADDR10

AE18

OCMADDR9

AD18

OCMADDR8

AF19

OCMADDR7

AE19

OCMADDR6

AD19

OCMADDR5

AC19

OCMADDR4

AF20

OCMADDR3

AE20

OCMADDR2

AD20

OCMADDR1

AF21

OCMADDR0

AE21

OCMDATA15

AD21

OCMDATA14

AC21

OCMDATA13

AF22

OCMDATA12

AE22

OCMDATA11

AD22

OCMDATA10

AF23

OCMDATA9

AE23

OCMDATA8

AD23

OCMDATA7

AC23

OCMDATA6

AF24

OCMDATA5

AF25

OCMDATA4

AF26

OCMDATA3

AE24

OCMDATA2

AE25

OCMDATA1

AE26

OCMDATA0

AC25

OCM_RE

AC26

OCM_WE

AD24

ROM_CS

AD25

OCM_CS0

AD26

OCM_CS1

AC24

OCM_CS2

T24

GPIO_42

T25

GPIO_43

T26

GPIO_44

R23

GPIO_45

R24

GPIO_46

R25

GPIO_47

U25

PPWR

U26

PBIAS

0.1uF

C709

0.1uF

C710

VGA_B

100

R718

0.1uF

C711

FSDQS1

CH0E-

0.1uF

C712

COMP_Y

5.0V

0.1uF

C714

FSWE

3.3V_CTZ

0.1uF

C715

0.1uF

C716

0.1uF

C717

HDMI_SW

0.1uF

C718

KEY_1

SDA_5V

3.3V_ON

0.1uF

C721

0.1uF

C722

33

R724

22uF

16V

C723

0.1uF

C724

0.1uF

C726

22uF

16V

C727

4.7K

R729

0.1uF

C728

0.1uF

C729

0.1uF

C730

1.8V_HDMI

0.1uF

C732

MAIN_V/YOUT

0.1uF

C733

56R733

0.1uF

C734

FSDQS0

10K

R735

VGA_G

4.7K

R737

FSCAS

CH4E-

3_STATE_BUFFER

22

R740

KEY_2

SCL_EEPR

+3.3V_IO_CTZ

22uF

16V

C736

10K

R746

500-ohm

L701

0.1uF

C737

3.3V_HDMI

COMP_Pr

0.1uF

C738

FSDQS3

RL_ON/PWR_ONOFF_2

SCART1_R

56R754

FSRAS

MUTE_LINE_DTV

+2.5V_DDR_CTZ

56R759

SDA_EEPR

0.1uF

C739

22uF

16V

C740

0.1uF

C741

56R764

0.1uF

C742

22uF

16V

C743

22R769

0.1uF

C744

SDA_EEPR

0.1uF

C745

0.1uF

C746

0.1uF

C747

1uF

C748

Vbr_B_1 FOR LCD

0.1uF

C750

OPT

R773

0.1uF

C751

COMP_Pb

0.1uF

C700

FSDQS2

0.1uF

C753

0.1uF

C754

3.3V_CTZ

0.1uF

C755

3.3V_CTZ

MUTE_LINE

0.1uF

C756

0.1uF

C757

+3.3V_LVDS_CTZ

22uF

16V

C758

0.1uF

C759

0.1uF

C760

CH4E+

0.1uF

C761

0.1uF

C762

SCL

4.7K

R780

100

R781

SW_RESET

0.1uF

C763

SCL_EEPR

FAN_ALARM

YUV_PIXCLK

0.1uF

C764

0.1uF

C766

22R784

AGC_SPEED_CTL

10K

R785

MAIN_COUT

22R787

33

R788

FSDQM1

0.1uF

C767

19.6608MHZ

X700

4.7K

R791

MUTE_MAIN

0.1uF

C768

0.1uF

C769

0.1uF

C770

+3.3V_IO_CTZ

0.1uF

C771

0.01uF

C772

0.1uF

C773

0.1uF

C775

SDA

0.1uF

C776

9V_ON

0.1uF

C777

0.1uF

C778

0.1uF

C779

5V_ANN_CTL

FSCK+

VGA_R

SCART1_FB

4.7K

R799

8V_ON

+2.5V_DDR_CTZ

FSDQM0

0.1uF

C780

RESET

0.1uF

C781

0.1uF

C782

AI_ON_OFF

+3.3V_LVDS_CTZ

0.1uF

C783

5V_MNT

0.1uF

C784

V_SYNC_PC

33

R1708

0.1uF

C785

0.1uF

C786

10K

R1709

TUNER_3.3V_ON

0.1uF

C787

0.1uF

C788

0.1uF

C789

FLI8532_Bottom

(CORTEZ)

IC700

L10

D_GND1

M10

D_GND2

N10

D_GND3

P10

D_GND4

R10

D_GND5

T10

D_GND6

M11

D_GND7

N11

D_GND8

P11

D_GND9

R11

D_GND10

K12

D_GND11

L12

D_GND12

M12

D_GND13

N12

D_GND14

P12

D_GND15

R12

D_GND16

T12

D_GND17

U12

D_GND18

K13

D_GND19

L13

D_GND20

M13

D_GND21

N13

D_GND22

P13

D_GND23

R13

D_GND24

T13

D_GND25

U13

D_GND26

K14

D_GND27

L14

D_GND28

M14

D_GND29

N14

D_GND30

P14

D_GND31

R14

D_GND32

T14

D_GND33

U14

D_GND34

K15

D_GND35

L15

D_GND36

M15

D_GND37

N15

D_GND38

P15

D_GND39

R15

D_GND40

T15

D_GND41

U15

D_GND42

M16

D_GND43

N16

D_GND44

P16

D_GND45

R16

D_GND46

L17

D_GND47

M17

D_GND48

N17

D_GND49

P17

D_GND50

R17

D_GND51

AA2

D_GND_ADC1

AA3

D_GND_ADC2

AA4

D_GND_ADC3

E25

LVDS_GND1

H25

LVDS_GND2

J25

LVDS_GND3

M25

LVDS_GND4

H23

LVDS_PLL_GND

AB3

ADC_AGND1

AC3

ADC_AGND2

AD2

ADC_AGND3

AE3

ADC_AGND4

AC6

ADC_AGND5

AE6

ADC_AGND6

AC8

ADC_AGND7

AD8

ADC_DGND

AE9

ADC_AGND8

AC11

LBADC_GND

B14

VSSA18_DLL

A25

PPLL_AGND1

A26

PPLL_AGND2

B25

PPLL_DGND

D19

FSVREFVSS1D9FSVREFVSS2

SDA_5V

4.7K

R1713

5V_ANN_MNT

0.1uF

C790

SCART1_B

100

R1715

FSCK-

SCART1_FB

SCL_EEPR

0.1uF

C792

22uF

16V

C793

0.01uF

C794

FSDQM3

RESET

33

R1719

+3.3V_IO_CTZ

SDA

IR

4.7K

R1721

22uF

16V

C796

0.1uF

C798

10K

R1722

H_SYNC_PC

0.1uF

C799

0.1uF

C1700

100

R1726

0.1uF

C1702

SCART1_G

0.1uF

C1703

33

R172733R172833R1729

33R1730

33

R1731

33R1732

33R1733

33R1734

33R1735

33

R173633R1737

33R1738

33

R1739

33R1740

33

R1741

33

R1742

RX4-

RX4+

RX0-,RX0+,RX1-,RX1+,RX2-,RX2+,RX3-,RX3+,RXCLK-,RXCLK+

OCMDATA[0-15]

FSDATA[0-31]

OCMADDR[0-21]

FSCKE

FSBKSEL0

FSBKSEL1

656_D[0-7]

FSVREF

FSVREF

3.3V_CTZ

3.3V_ADC_CTZ

3.3V_ADC_CTZ

3.3V_ADC_CTZ

1.8V_PLL_CTZ

1.8V_PLL_CTZ

1.8V_CORE_CTZ

1.8V_CORE_CTZ

1.8V_HDMI

3.3V_HDMI

1001%R1743

1501%R1744

TX2-

TX2+

TX1-

TX1+

TX0+

TX0-

TXCLK+

TXCLK-

HDMI_SCK

HDMI_LRCK

HDMI_LRCH

100

R1747

100

R1748

100

R1749

SCL_HDMI

SDA_HDMI

22

R751

22

R712

1uF

C1704

5000:1 FOR LCD

OCM_RE

OCM_WE

ROM_CS

FSADDR[0-12]

0

R1771

COR_STI_SWITCH

AC_DET

0.1uF

C1709

0.1uF

C1705

0.1uF

C1706

0.1uF

C1707

3.3V_CTZ

CEC_0

10K

R732

READY

10K

R701

10K

R1717

10K

R745

10K

R753

READY

10K

R786

10K

R728

10K

R722

10K

R747

10K

R768

READY

1.8V_CTZ

1.8V_CTZ

22uF

16V

C1708

22

R1761

22

R1762

22R1765

22

R1766

22

R1768

22

R1769

100R1758

1.8V_ADC_CTZ

1.8V_ADC_CTZ

47uF

16V

C797

47uF

16V

C765

INV_CTL/VAVS_ON

100 R767

PANEL_CTL/DISP_EN

100 R782

LED_G

LED_R

0

READY

R1772

3.3V_HDMI

SCL_EEPR

SDA_EEPR

0.1uF

C1711

READY

CH1E-

CH1E+

CH2E-

CH2E+

CKE-

CKE+

CH3E+

CH3E-

22R1773

22R1774

0.1uF

C1710

DTV_RESET

3.3V_CTZ

24LC256-I/SM

IC701

3A22A14

VSS

1

A0

5

SDA6SCL7WP8VCC

22pF

C795

SW_TU_SCL

SW_TU_SDA

SW_TU_SCL

SW_TU_SDA

4.7K

R1780

4.7K

R1778

BOOSTER

5V_ON

SCL_HDMI

SDA_HDMI

OAD_CONT

UART0_TX

UART1_TX

UART1_RX

UART0_RX

4.7K

R1752

4.7K

R1753

+5VST

0

AR711

123

45

6

7

8

0

AR704

1

2

3

45

678

0

FULL_HD

AR705

123

45

678

0

FULL_HD

AR703

123

45

6

7

8

0R704

0

FULL_HD

R1725

0

FULL_HD

R736

0R1714

FOR PDP,FULL_HD

0R743

0

FULL_HD

R700

0R798

FOR PDP,FULL_HD

0

FAN

R1712

0

FAN

R765

100

R775

100

R748

22R792

100

R779

100

R757

100

R1703

22R708

100

R705

100

R727

0

FAN

R721

100

R710

100

R796

22R795

100

R1716

100

R1704

100

R709

100

R741

100 R734

0

R744

100

R1720

100

R717

100

R797

100

R1718

100

R739

22

R771

22

R1770

22R1759

22

R1767

22

R1763

22

R1764

22

R1760

0.1uF

C749

0.1uF

C1701

0.1uF

C713

0.1uF

C774

0.1uF

C706

0.1uF

C708

0.1uF

C791

10K

R793

10K

R794

10KR720

10K

R778

10K

R711

10K

R707

10K

R783

10K

R755

10K

R762

22R756

100

R772

100

R725

22R1710

GIL-G-02P

CON700

OPT

1

2

0

FULL_HD

R749

33

AR702

123

45

678

33

AR707

123

45

678

33

AR701

123

45

678

33

AR709

123

45

678

33

AR700

123

45

678

33

AR710

123

45

678

33

AR706

123

45

678

33

AR708

123

45

678

33R1724

33

R71333R777

33

R1706

33

R715

33R731

33

R750

33R752

VFD_CS

R706

60"_FULL_HD

HDMI2_5V_DET

HDMI1_5V_DET

EEPROM_WP

2.2K

R1777

Cortez_RESET

TP700

TP701

TP702

TP703

TP704

TP705

TP706

TP707

TP708

TP709

TP710

TP711

TP713

TP714

TP715

VFD_SCK

VFD_SDA

60"_FULL_HD

R1785

60"_FULL_HD

R1786

TP716

HH-1M3216-501

L706

HH-1M3216-501

L703

HH-1M3216-501

L707

HH-1M3216-501

L704

HH-1M3216-501

L705

22

R1751

22

R1750

10K

R1788

FOR LCD,FULL_HD_LCD

10K

R1787

FOR PDP,FULL_HD_PDP

+3.3V_IO_CTZ

5V_TU

FLI8532_Left

(CORTEZ)

AB1

A1P

AF1

A2P

AF4

A3P

AF7

A4P

AD1

AN

AC2

B1P

AE2

B2P

AE5

B3P

AE8

B4P

AF3

BN

AC1

C1P

AF2

C2P

AF5

C3P

AF8

C4P

AF6

CN

AB2

SV1P

AE1

SV2P

AE4

SV3P

AE7

SV4P

AF9

SVN

AA1 ADC_TEST

AC7

VOUT2

AF12

AIP_RAW_HS_CS

AE12

AIP_RAW_VS

AD13

EXT_OSD_VS

AC13

EXT_OSD_HS

AF13

EX_OSD_CLKP3ADATA0P2ADATA1P1ADATA2R4ADATA3R3ADATA4R2ADATA5R1ADATA6T4ADATA7T3ADATA8T2ADATA9T1ADATA10

U4 ADATA11

U3 ADATA12

U2

ADATA13

U1

ADATA14

V4 ADATA15

V3

ADATA16

V2 ADATA17

V1 ADATA18

W4

ADATA19W3ADATA20W2ADATA21W1ADATA22

Y4 ADATA23

N3

AODDY1AVSY2AHSY3AHREF_DE

N1 IPCLK0

P4

IPCLK1M4IPCLK2

L1 IPCLK3

N2 DIP_RAW_HS_CS

M2

DIP_EXT_CLAMPM3DIP_EXT_COASTM1DIP_CLEAN_HS_OUT

B1

BDATA0/DOBLU0

C3 BDATA1/DOBLU1

C2

BDATA2/DOBLU2C1BDATA3/DOBLU3D3BDATA4/DOBLU4D2BDATA5/DOBLU5

D1 BDATA6/DOBLU6

E3

BDATA7/DOBLU7E2BDATA8/DOGRN0E1BDATA9/DOGRN1F3BDATA10/DOGRN2

F2 BDATA11/DOGRN3

F1

BDATA12/DOGRN4

G3 BDATA13/DOGRN5

G2 BDATA14/DOGRN6

G1 BDATA15/DOGRN7

H3 BDATA16/DORED0

H2 BDATA17/DORED1

H1 BDATA18/DORED2

J3 BDATA19/DORED3

J2 BDATA20/DORED4

J1

BDATA21/DORED5

K3 BDATA22/DORED6

K2

BDATA23/DORED7N4BODD

L2 BVS

L3 BHS

K1

BHREF_DE

B26 XTAL

C26 TCLK

V24

PWM0

U23

PWM1

U24

PWM2

AB24

IR0

AE11

LBADC_IN6

AF11

LBADC_IN5

AC10

LBADC_IN4

AD10

LBADC_IN3

AE10

LBADC_IN2

AF10

LBADC_IN1

AD11

LBADC_RETURN

W26

OCM_UDO_0

W25

OCM_UDI_0B2OCM_UDO_1B3OCM_UDI_1

AD9

RESET

AA24

MSTR0_SCL

AA23

MSTR0_SDAA3MSTR1_SCLA2MSTR1_SDA

AB26

MSTR2_SCL

AB25

MSTR2_SDA

AA26

VGA0_SCL

AA25

VGA0_SDA

Y26

VGA1_SCL

Y25

VGA1_SDA

AF14

AVS_IN_SCL/JTAG_CLK

AD12

AVS_IN_WS/JTAG_MODE

AC12

AVS_IN_DATA/JTAG_TDI

AD14

AVS_OUT_DATA

AE13

AVS_OUT_SCL/JTAG_TDO

AE14

AVS_OUT_WS/JTAG_RST

M24

VCO_LV

D25

OBUFC_CLKA1SCAN_EN

W24

OCM_TIMER1

Y24

OCM_INT2

W23

OCM_INT1

V26

SLAVE_SCL

V25

SLAVE_SDA

FLI8548H-LF-AB

IC700-*1

A1P

AB1

A2P

AF1

A3P

AF4

A4P

AF7

AN

AD1

B1P

AC2

B2P

AE2

B3P

AE5

B4P

AE8

BN

AF3

C1P

AC1

C2P

AF2

C3P

AF5

C4P

AF8CNAF6

SV1P

AB2

SV2P

AE1

SV3P

AE4

SV4P

AE7

SVN

AF9

VOUT2

AC7

AIP_RAW_HS_CS

AF12

AIP_RAW_VS

AE12

EXT_OSD_VS

AD13

EXT_OSD_HS

AC13

EX_OSD_CLK

AF13

I2S_DOUT_1/GPIOP3I2S_DOUT_2/GPIOP2I2S_DOUT_3/GPIOP1DVI_RX0-V1DVI_RX0+V2DVI_RX1-U1DVI_RX1+U2DVI_RX2-T1DVI_RX2+T2DVI_RXC-Y1DVI_RXC+Y2DVI_REXTR1IPCLK0N1IPCLK1P4IPCLK2M4IPCLK3L1DIP_RAW_HS_CSN2DIP_EXT_CLAMPM2DIP_EXT_COASTM3DIP_CLEAN_HS_OUTM1BDATA0B1BDATA1C3BDATA2C2BDATA3C1BDATA4D3BDATA5D2BDATA6D1BDATA7E3BDATA8E2BDATA9E1BDATA10F3BDATA11F2BDATA12F1BDATA13G3BDATA14G2BDATA15G1BDATA16H3BDATA17H2BDATA18H1BDATA19J3BDATA20J2BDATA21J1BDATA22K3BDATA23K2DIP_BODDN4BVSL2BHSL3BHREF_DEK1XTAL

B26

TCLK

C26

PWM0

V24

PWM1

U23

PWM2[SPDIF]

U24

IR0

AB24

LBADC_IN6

AE11

LBADC_IN5

AF11

LBADC_IN4

AC10

LBADC_IN3

AD10

LBADC_IN2

AE10

LBADC_IN1

AF10

LBADC_RETURN

AD11

OCM_UDO_0

W26

OCM_UDI_0

W25

OCM_UDO_1B2OCM_UDI_1B3OCM_INT1

W23

OCM_INT2

Y24

OCM_TIMER1

W24

RESET

AD9

MSTR0_SCL

AA24

MSTR0_SDA

AA23

MSTR1_SCLA3MSTR1_SDAA2MSTR2_SCL

AB26

MSTR2_SDA

AB25

VGA0_SCL

AA26

VGA0_SDA

AA25

VGA1_SCL

Y26

VGA1_SDA

Y25

AVS_IN_SCL

AF14

AVS_IN_WORD_SEL

AD12

AVS_IN_DATA

AC12

AVS_OUT_DATA

AD14

AVS_OUT_SCL

AE13

AVS_OUT_WS

AE14

NC

M24

OBUFC_CLK

D25

TEST_ENA1SLAVE_SCL

V26

SLAVE_SDA

V25

JTAG_BS_EN

AC20

2.7K

FOR LCD

R1722-*1

CEC_0

22

R1745

22

R723

Vbr_A

Vbr_B_1

33

R79033R770

20pF

C725

M2404HEPROM

IC702

3

A22A1

4

VSS

1

A0

5

SDA6SCL7WP8VCC

TMUE312GAB

SW700

12

43

5

SYNC_DE

HP_DET_S/W_0

100

R703

HP_DET_S/W_1

EYE

100

R1784

390R726

Vbr_B_1 FOR LCD

1.2KR1754

5000:1 FOR LCD

4.7uF

C1704-*1

4.7uF

C748-*1

200

R1754-*1

200

R726-*1

FSDATAU[2]

FSDATA[0]

FSCKEU

OCMADDR[20]

OCMADDR[2]

OCMADDR[19]

OCMADDR[10]

FSDATA[1]

OCMADDR[6]

RX1-

OCMADDR[18]

FSDATAU[28]

FSDATA[2]

FSDATAU[4]

OCMADDR[4]

RX1+

FSDATA[3]

FSDATAU[23]

FSADDRU[5]

FSDATAU[9]

FSDATAU[15]

FSDATAU[6]

FSDATAU[25]

FSDATA[4]

OCMADDR[13]

RX2-

FSDATA[5]

FSBKSELU[0]

RX2+

FSDATA[6]

OCMADDR[19]

FSADDRU[0]

RX0-

OCMADDR[21]

FSDATAU[11]

FSADDRU[12]

FSDATA[7]

OCMADDR[8]

OCMADDR[3]

RX0+

OCMADDR[7]

OCMADDR[16]

FSDATA[8]

FSDATAU[31]

FSADDRU[9]

FSDATA[9]

FSDATAU[20]

FSDATAU[5]

656_D[7]

OCMADDR[11]

FSDATA[10]

OCMADDR[12]

FSDATAU[3]

FSDATAU[30]

FSADDRU[2]

FSADDR[0-12]

OCMADDR[0]

OCMADDR[0-21]

OCMADDR[12]

FSDATA[11]

656_D[6]

FSDATAU[29]

FSDATAU[24]

FSADDRU[8]

FSDATA[12]

OCMADDR[18]

FSDATA[16]

656_D[5]

OCMADDR[7]

OCMADDR[5]

FSDATA[13]

FSDATAU[17]

FSDATAU[14]

FSDATA[17]

OCMADDR[9]

656_D[4]

FSDATA[14]

OCMADDR[5]

FSADDRU[3]

FSDATA[18]

OCMADDR[8]

OCMADDR[2]

FSDATA[15]

656_D[3]

FSDATAU[22]

FSDATA[19]

FSDATA[20]

656_D[2]

OCMADDR[0]

OCMADDR[4]

FSDATA[21]

FSADDRU[7]

656_D[1]

FSADDRU[1]

FSDATA[22]

FSDATAU[10]

FSDATA[23]

FSDATAU[0]

FSADDRU[4]

OCMADDR[9]

FSDATAU[26]

FSDATA[24]

FSDATAU[18]

FSDATAU[21]

FSDATA[25]

OCMADDR[6]

OCMADDR[15]

OCMADDR[11]

FSDATAU[13]

FSDATA[26]

OCMADDR[13]

FSDATAU[16]

FSADDRU[10]

FSDATAU[12]

OCMADDR[14]

FSDATAU[27]

FSDATAU[8]

FSBKSELU[1]

FSDATA[27]

OCMADDR[1]

OCMADDR[15]

FSADDRU[6]

FSDATA[28]

OCMADDR[17]

OCMADDR[3]

FSDATA[29]

OCMADDR[14]

OCMADDR[17]

FSDATAU[1]

OCMADDR[1]

FSDATA[30]

OCMADDR[16]

FSDATAU[19]

OCMADDR[10]

FSDATA[31]

FSDATAU[7]

FSADDRU[11]

FSADDRU[11]

FSADDRU[4]

FSADDRU[9]

FSADDRU[12]

FSADDRU[5]

FSADDRU[6]

FSADDRU[7]

FSADDRU[8]

FSCKEU

FSBKSELU[0]

FSBKSELU[1]

FSADDRU[0]

FSADDRU[1]

FSADDRU[2]

FSADDRU[10]

FSADDRU[3]

OCMDATA[15]

OCMDATA[14]

OCMDATA[13]

OCMDATA[12]

OCMDATA[11]

OCMDATA[10]

OCMDATA[9]

OCMDATA[8]

OCMDATA[7]

OCMDATA[6]

OCMDATA[5]

OCMDATA[4]

OCMDATA[3]

OCMDATA[2]

OCMDATA[1]

OCMDATA[0]

FSADDR[4]

FSADDR[9]

FSADDR[12]

FSADDR[5]

FSADDR[8]

FSADDR[7]

FSADDR[6]

FSADDR[0]

FSADDR[1]

FSADDR[2]

FSADDR[10]

FSADDR[3]

FSADDR[11]

RXCLK+

RX3+

RX3-

RXCLK-

656_D[0]

7. CORTEZ_PLUS

NC

Bootstrap

This is for

NC

NC

T24~R25(6pins):Used for 100/120Hz in case of LCD(10Bits TTL)

if else(Plasma), T24,25,26 is used for FAN

EEPROM

I2C FULL-UP

AF14~AE14(6pins)

For AVS Function

(8K bits)

1

2

3

4

241

3

3

4

241

312

Stand_by power

Not stand_by power

IC 702, C1710

R1773, R1774

Option for remote control

To be one hex file for LCD or PDP(Plasma)

R1788 or R1787 can’t be used together

if defined, R1788 for LCD

R1787 for PDP(Plasma)

Must be confirmed before PQ

CORTEZ-PLUS

HDCP

Vbr_B_1 FOR FULL_HD

5000:1 FOR FULL_HD

3V3

3.3V

1.2V

1V2

1V2

1.2V

1.2V

1.2VA

2V5

3V3

2V5

3V3

3V3

1V2

1.2VA

3.3V

1.2VA

3V3

3V3

1V25

1.2VA

3V3

3V3

2.5V

I2C_SDA0

004:C5

FMI_D[0-15]

I2C_SDA1

003:I1

LDD[0-15]

002:K3

PIO2B6004:A7

I2C_SCL1

003:I1

LDCAS

002:K4

PIO2B7004:A8

I2C_SCL0

004:C5

FMILBA

003:J4

OUT_LEFT

005:H8

LDDQM0

002:K4

FMIBE1

003:K5

TS_SEL

003:B4;004:F4

LDCLKN

002:K5

CPU_RST

001:F3

LDCLKE

002:K5

CVBS

005:D7

LDDQM1

002:K4

LDA[0-12]

002:K2

LDCLK

002:K5

LDBA0

002:K4

LDCS

002:K4

FMI_A[1-25]

COMM_UART_TX

005:I5

FMICS1

003:E8

LDRAS

002:K4

LDDQS1

002:K4

SYS_RST

002:A7

CI_RST

003:E6

FMIREQ

003:J3

FMIOE

002:D8;003:J4

CPU_RST_OUT001:A5

DEBUG_UART_TX

004:F7;005:I5

LDDQS0

002:K4

YUV_PIXCLK

005:I4

FMIWE

002:A7

FE_RESET

003:K1

LDBA1

002:K4

FMICS3

002:D8

OUT_RIGHT

005:H9

FMIGNT

003:J3

LDWE

002:K4

CPU_RST

001:C4

TS_DATA_CLK

003:B7;003:C7;003:E4

TS_DATA[3]

003:C5;003:C8;003:E3

CPU_WAIT

004:F4

TS_DATA[1]

003:C6;003:C8;003:E3

TS_DATA[0]

003:C6;003:C8;003:E3

TS_DATA[4]

003:C5;003:C8;003:E3

TS_DATA_VAL

003:B6;003:C6;003:E3

IRQ2

004:E2

TS_DATA[5]

003:C5;003:C8;003:E3

TS_DATA_SYN

003:B6;003:C6;003:E3

TS_DATA[2]

003:C5;003:C8;003:E3

TS_DATA[6]

003:C5;003:C8;003:E3

TS_DATA[7]

003:C5;003:C8;003:E3

CPU_RST_OUT

001:F3

DEBUG_UART_RX

004:F6;005:I5

IRQ1

003:F8

COMM_UART_RX

005:I5

4.7uF

C198

6.3V

4.7uF

C197

6.3V

8.2nF

C194

8.2nF

C193

0.1uF

C111

0.1uF

C129

0.1uF

C185

0.1uF

C163

0.1uF

C124

0.1uF

C138

0.1uF

C157

0.1uF

C179

0.1uF

C174

0.1uF

C134

0.1uF

C159

0.1uF

C164

0.1uF

C156

0.1uF

C160

0.1uF

C112

0.1uF

C106

0.1uF

C143

0.1uF

C135

0.1uF

C161

0.1uF

C119

0.1uF

C148

0.1uF

C173