LG 505E Service Manual

COLOR MONITOR

SERVICE MANUAL

Website:http://biz.LGservice.com

E-mail:http://www.LGEservice.com/techsup.html

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MENU

SELECT

MODEL:

505E

(505EM-KL***L*)

CHASSIS NO. : CA-138

( ) **Same model for Service

1. PICTURE TUBE

Size : 15 inch (Flat Square Tube)

DefIection Angle : 90°

Neck Diameter : 29.4 mm

Dot Pitch : 0.28 mm

Face Treatment : AR-ASC (Anti-Reflection and

Anti-Static Coating)

AG(Anti-Glare)

Low Radiation : MPR-II, NON MPR II

2. SIGNAL

2-1. Horizontal & Vertical Sync

1) Input Voltage Level: Low= 0~1.2V, High= 2.5~5.5V

2) Sync Polarity : Positive or Negative

2-2. Video Input Signal

1) Voltage Level : 0 ~ 0.7 Vp-p

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.7 Vp-p

2) Input Impedance : 75 Ω

3) Video Color : R, G, B Analog

4) Signal Format : Refer to the Timing Chart

2-3. Signal Connector

15-pin D-Sub Connector (Attached Type)

2-4. Scanning Frequency

Horizontal : 30 ~ 54 kHz

Vertical : 50 ~ 120 Hz

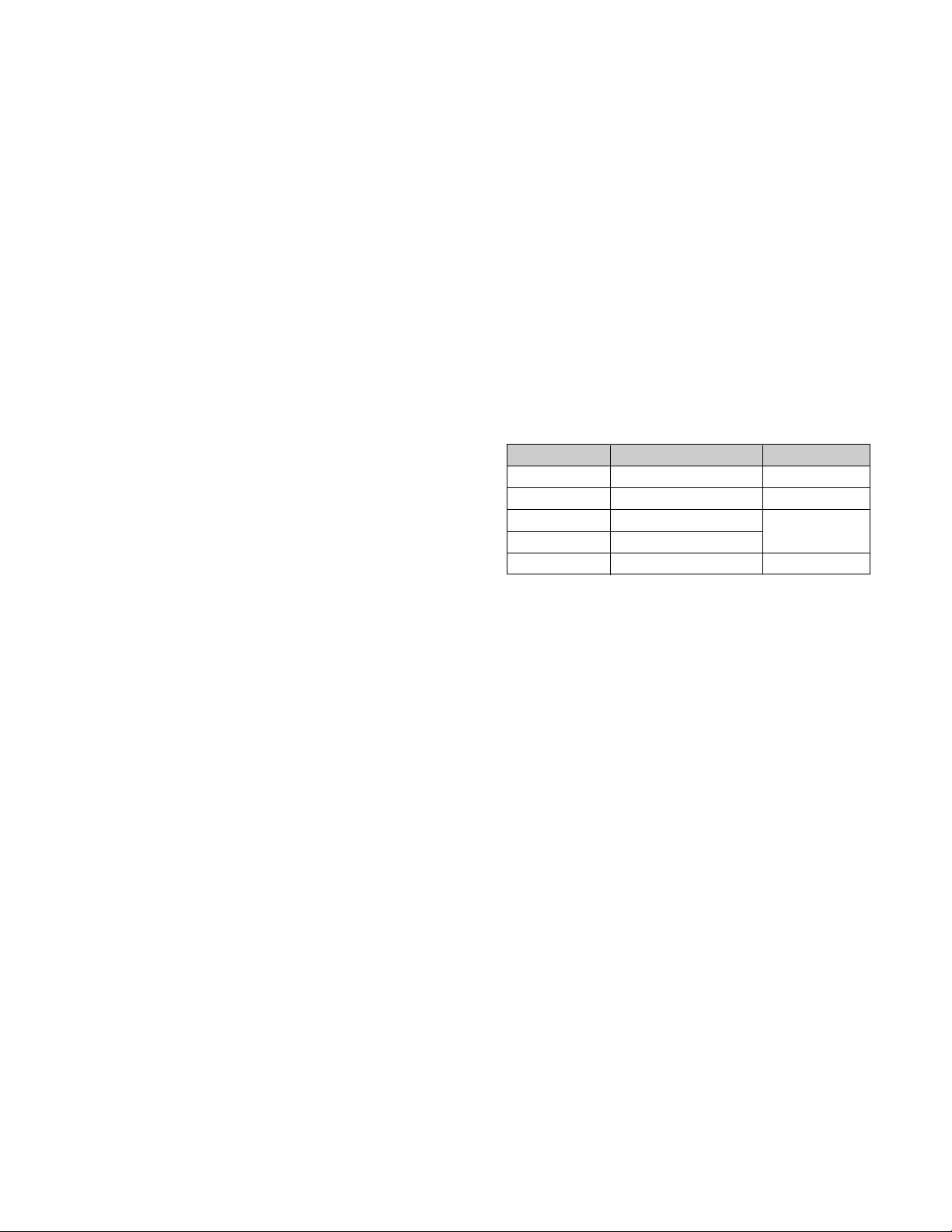

3. POWER SUPPLY

3-1. Power Range

AC 100~240V (Free Voltage), 50/60Hz, 1.0A Max.

3-2. Power Consumption

4. DISPLAY AREA

4-1. Active Video Area :

• 285 x 215 mm (11.22" x8.46") - Max Image Size

• 270 x 200 mm (10.63"x 7.87") - Preset Image Size

4-2. Display Color : Full Colors

4-3. Display Resolution : 1024 x 768 / 60Hz

(Non-Interlace)

4-4. Video Bandwidth : 65 MHz

5. ENVIRONMENT

5-1. Operating Temperature: 10°C ~ 40°C

(Ambient)

5-2. Relative Humidity : 10%~ 80%

(Non-condensing)

5-3. Altitude : 3,000 m

6. DIMENSIONS (with TILT/SWIVEL)

Width : 356.0 mm (14.01")

Depth : 360.0 mm (13.10")

Height : 371.0 mm (14.61")

7. WEIGHT (with TILT/SWIVEL)

Net Weight : 12.5 kg (25.36 lbs)

Gross Weight : 13.7 kg (30.21 lbs)

CONTENTS

- 2 -

SPECIFICATIONS ................................................... 2

SAFETY PRECAUTIONS ........................................ 3

SERVICE PRECAUTION ........................................ 4

WIRING DIAGRAM ................................................. .7

BLOCK DIAGRAM ................................................... 8

DESCRIPTION OF BLOCK DIAGRAM.....................9

ADJUSTMENT ........................................................ 9

TROUBLESHOOTING GUIDE .............................. 16

EXPLODED VIEW................................................... 31

REPLACEMENT PARTS LIST ............................... 32

SCHEMATIC DIAGRAM......................................... 37

PRINTED CIRCUIT BOARD................................... 39

SPECIFICATIONS

MODE

MAX

NORMAL (ON)

STAND-BY

SUSPEND

OFF

POWER CONSUMPTION

75 W

63 W

less than 15 W

less than 15 W

less than 5 W

LED COLOR

GREEN

GREEN

FLASH

FLASH

SAFETY PRECAUTIONS

- 3 -

SAFETY-RELATED COMPONENT WARNING!

There are special components used in this color monitor

which are important for safety. These parts are marked

on the schematic diagram and the replacement

parts list. It is essential that these critical parts should be

replaced with the manufacturer's specified parts to prevent

X-radiation, shock, fire, or other hazards. Do not modify

the original design without obtaining written permission

from manufacturer or you will void the original parts and

labor guarantee.

CAUTION:

No modification of any circuit should be

attempted.

Service work should be performed only after

you are thoroughly familiar with all of the

following safety checks and servicing

guidelines.

SAFETY CHECK

Care should be taken while servicing this color monitor

because of the high voltage used in the deflection circuits.

These voltages are exposed in such areas as the

associated flyback and yoke circuits.

FIRE & SHOCK HAZARD

An isolation transformer must be inserted between the

color monitor and AC power line before servicing the

chassis.

• In servicing, attention must be paid to the original lead

dress specially in the high voltage circuit. If a short

circuit is found, replace all parts which have been

overheated as a result of the short circuit.

• All the protective devices must be reinstalled per the

original design.

• Soldering must be inspected for the cold solder joints,

frayed leads, damaged insulation, solder splashes, or

the sharp points. Be sure to remove all foreign

materials.

IMPLOSION PROTECTION

All used display tubes are equipped with an integral

implosion protection system, but care should be taken to

avoid damage and scratching during installation. Use only

same type display tubes.

X-RADIATION

The only potential source of X-radiation is the picture tube.

However, when the high voltage circuitry is operating

properly there is no possibility of an X-radiation problem.

The basic precaution which must be exercised is keep the

high voltage at the factory recommended level; the normal

high voltage is about 24.5kV. The following steps describe

how to measure the high voltage and how to prevent Xradiation.

Note : It is important to use an accurate high voltage

meter calibrated periodically.

• To measure the high voltage, use a high impedance

high voltage meter, connect (–) to chassis and (+) to

the CDT anode cap.

• Set the brightness control to maximum point at full

white pattern.

• Measure the high voltage. The high voltage meter

should be indicated at the factory recommended level.

• If the meter indication exceeds the maximum level,

immediate service is required to prevent the possibility

of premature component failure.

• To prevent X-radiation possibility, it is essential to use

the specified picture tube.

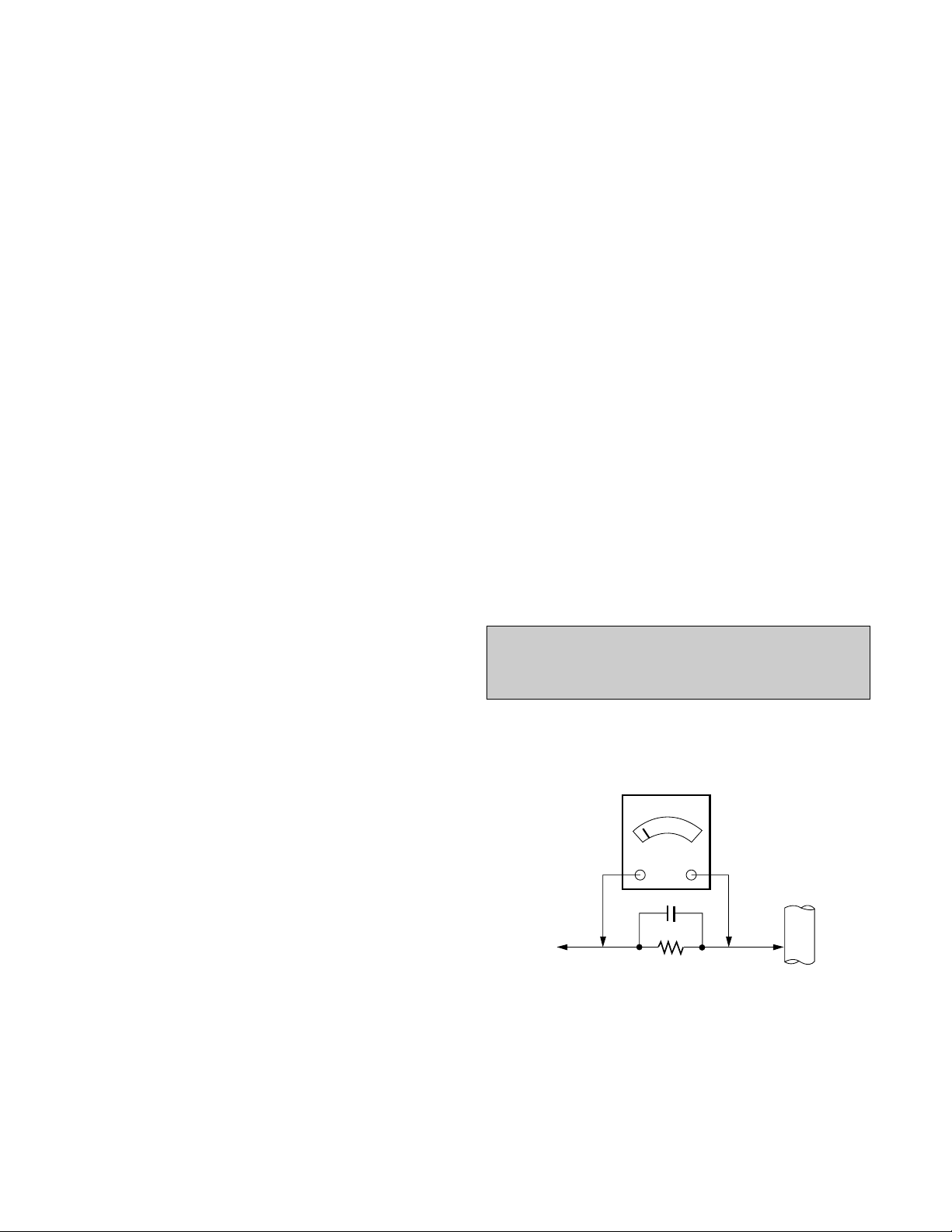

Leakage Current Hot Check Circuit

CAUTION:

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

- 4 -

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this

service manual and its supplements and addenda, read

and follow the SAFETY PRECAUTIONS on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict

between the following servicing precautions and any of the

safety precautions on page 3 of this publication, always

follow the safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC

power source before;

a. Removing or reinstalling any component, circuit

board module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical

plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may

result in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an

appropriate high voltage meter or other voltage

measuring device (DVM, FETVOM, etc) equipped with

a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield

at the point where the picture tube socket ground lead

is connected, and then (b) touch the other end of the

insulated clip lead to the picture tube anode button,

using an insulating handle to avoid personal contact

with high voltage.

4. Do not spray chemicals on or near this receiver or any

of its assemblies.

5. Unless specified otherwise in this service manual,

clean electrical contacts only by applying the following

mixture to the contacts with a pipe cleaner, cottontipped stick or comparable non-abrasive applicator;

10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual,

lubrication of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks

with which receivers covered by this service manual

might be equipped.

7. Do not apply AC power to this instrument and/or any of

its electrical assemblies unless all solid-state device

heat sinks are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test

receiver positive lead.

Always remove the test receiver ground lead last.

9. Use with this receiver only the test fixtures specified in

this service manual.

CAUTION: Do not connect the test fixture ground strap

to any heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be

damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES)

Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and

semiconductor "chip" components. The following

techniques should be used to help reduce the incidence of

component damage caused by static by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed to prevent potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with

ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static type solder removal device.

Some solder removal devices not classified as "antistatic" can generate electrical charges sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an ES

device.)

- 5 -

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range or 500

F to 600 F.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

mall wire-bristle (0.5 inch, or 1.25cm) brush with a

metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal

temperature.

(500

F to 600 F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder

braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500

F to 600 F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong)

through which the IC leads are inserted and then bent flat

against the circuit foil. When holes are the slotted type,

the following technique should be used to remove and

replace the IC. When working with boards using the

familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation

by gently prying up on the lead with the soldering iron

tip as the solder melts.

2. Draw away the melted solder with an anti-static

suction-type solder removal device (or with solder

braid) before removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle

brush. (It is not necessary to reapply acrylic coating to

the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board

and crimp the "U" with long nose pliers to insure metal

to metal contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close

as possible to diode body.

2. Bend the two remaining leads perpendicular y to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit

board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder

joints of the two "original" leads. If they are not shiny,

reheat them and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component

around notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent components and the

circuit board to prevent excessive component

temperatures.

- 6 -

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil

to the circuit board causing the foil to separate from or

"lift-off" the board. The following guidelines and

procedures should be followed whenever this condition is

encountered.

At IC Connections

To repair a defective copper pattern at IC connections use

the following procedure to install a jumper wire on the

copper pattern side of the circuit board. (Use this

technique only on IC connections).

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as

absolutely necessary).

2. carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

3. Bend a small "U" in one end of a small gauge jumper

wire and carefully crimp it around the IC pin. Solder the

IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area and clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the

component side of the circuit board.

1. Remove the defective copper pattern with a sharp

knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire

opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead

of the nearest component on one side of the pattern

break to the lead of the nearest component on the

other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so the it does not touch components or sharp

edges.

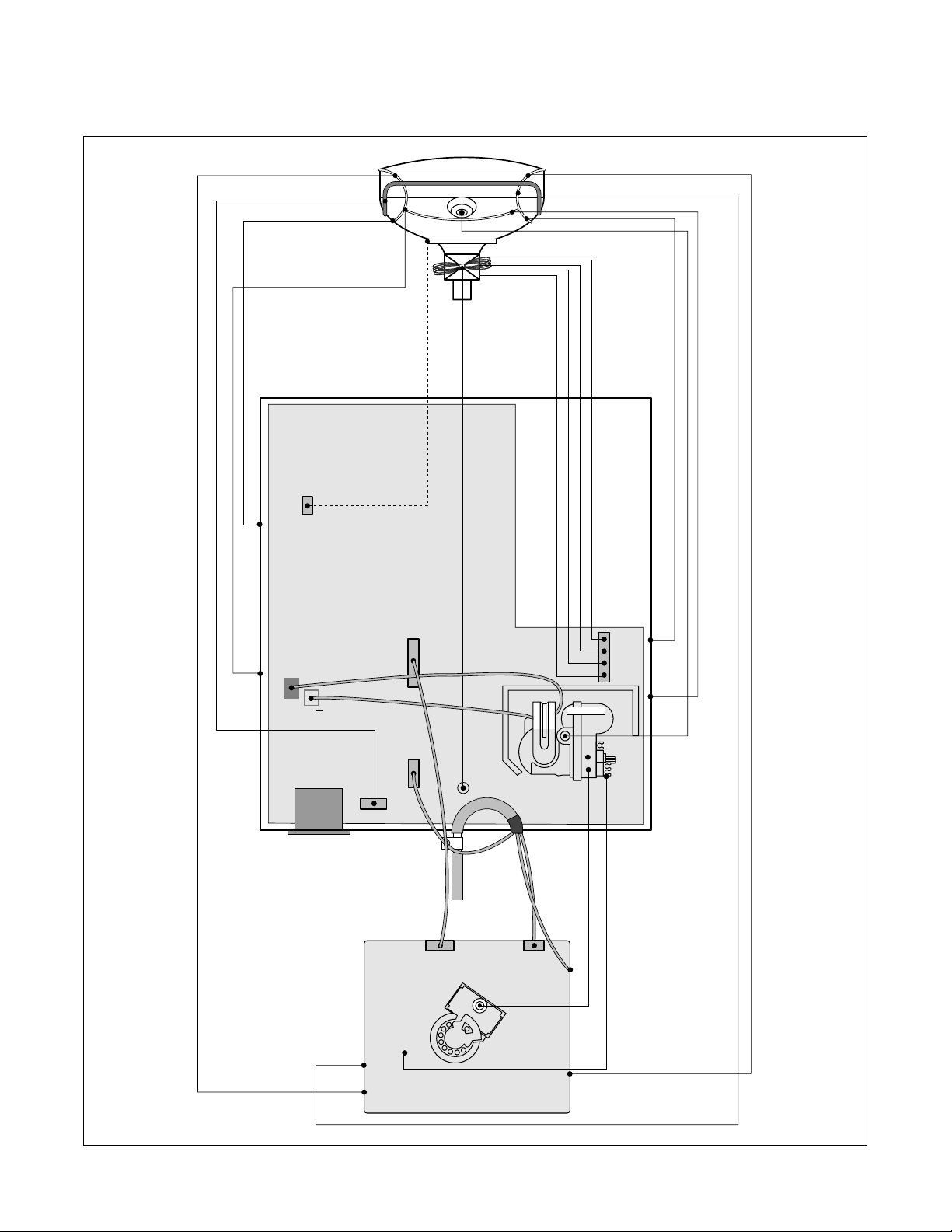

WIRING DIAGRAM

- 7 -

P501(option)

P301

P302

G2

P702

P701

T1

P402

P902

S

+

S

Signal

Cable

AC

Socket

FBT

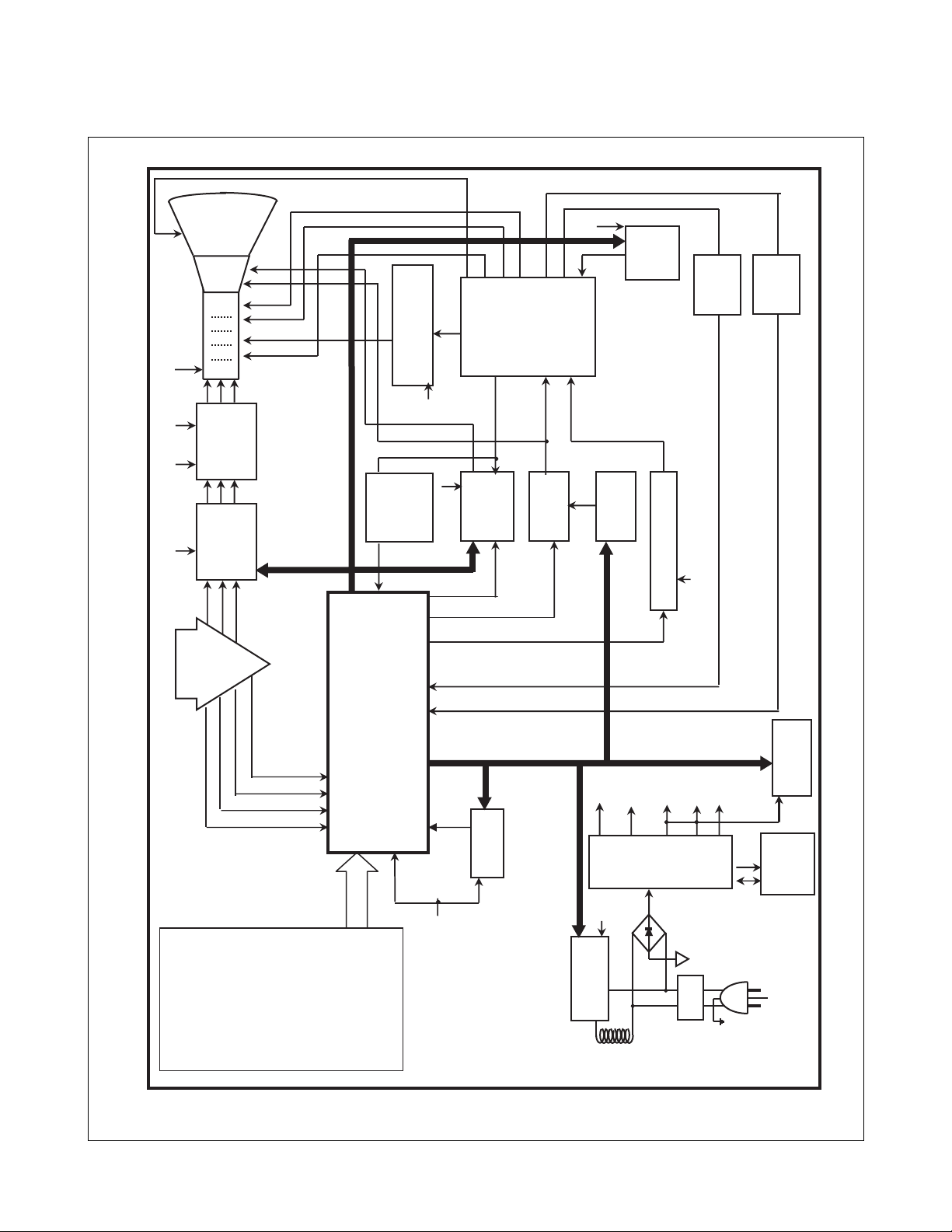

BLOCK DIAGRAM

- 8 -

H.V

Dyn ami c Foc us

Stat ic Foc us

DY CDT

Scr een

Heater ( 6.3V )

G1

G2

- 160V

Bri ght nes s Co ntrol

FBT

( T701 )

13V

Au to

Beam

Limi t

D/D

Feed B ack

Cir cu it

Regul atio n

8V 80V

5V

Video

H-Sync

IV OED

VIDEO

Pre-AMP /

RGB

Signa l

V-Sync

40V

13V

3

0

3

C

I

13V

X-RAY

Cir cu it

Prot ect ion

OSD

(IC302)

SCL / SDA

H-Sync /V-Syn c

PWM Cont rol Signal

( IC401 )

C CLOCK(SCL)

2

I

C DATA(SDA)

2

I

SAA4 849

MICOM & H/V Sync Pr ocess or

V-Out

( IC601)

TDA4867J

C

2

I

B+

H-Out

( Q706 )

H - Dri ve

80V

Cor rect ion

H-Linearit y

50V

DC/DC Converter

B-Drive

DPM

Contr ol

Cir cu it

50V

13V

6.3V

5V

PROM

2

E

(IC402)

5V

SPCC

MOIRE

CONTRAST

BRIGHTNESS

H / V SIZE

DEGAUSSING

H / V POSITION

TRAPEZOID

PIN BAL ANCE

PARALLE LOGRAM

COLOR

RECALL / RESET

INFORMATION

LANGUAGE

TOP/BOTTOM CORNER

VIDEO LEVEL

OSD CONTROL L OCK

[ OSD Contro l ]

13V

Cir cuit

Degaus sing

SMPS

(T901)

Degaussing

Coi l

Line

Volt age

feedba ck

SMPS

Contr ol

(IC901)

Filt er

(50/60Hz)

Power Input

100~240VAC

DESCRIPTION OF BLOCK DIAGRAM

- 9 -

1. SMPS(Switching Mode Power Supply)

When you turn on the power switch, the operating

procedure is as follows:

1) The AC line voltage is rectified by the bridge diode

D900.

2) The control IC(IC901) starts switching and generates

switch pulse in the primary turn of the SMPS

transformer(T901)

3) The switching pulses of the primary turns are induced

to the secondary turns of the transformer by the turn

ratio. This pulses are rectified by each diode(D971,

D961(D962),D951,D942,D941)

4) Each rectified DC voltage(80V, 50V, 13V, 6.3V

and 5V)

2. Over Voltage Protection Circuit

When the input of IC901 Vin (pin 4) is more than

22V, all the secondary voltages of the SMPS

transformer (T901) down to low value

3. Display Power Management Circuit(DPM)

1) STAND-BY & SUSPEND Mode

When no input of horizontal or vertical sync Q951,

Q941 are turned off and Q952,Q942 are turned off.

Then input power consumption is below 5 watts.

2) OFF Mode

When no input of horizontal and vertical sync Q951,

Q941 are turned off and Q952, Q942 are turned off.

Then input power consumption is below 5 watts.

5. D/D Converter Circuit.

To obtain constant high voltage, this circuit supplies

controlled DC voltage for FBT and horizontal deflection

circuit according to the horizontal sync frequency.

6. X-RAY Protection Circuit

When the high Voltage reaches to 29kV in an abnormal

case, the high voltage detector circuit, R818,D721,C739-1

R416, C409 start operation to shut down high voltage

circuit.

7. Horizontal S-correction Circuit.

This circuit corrects the horizontal linearity for each

horizontal sync frequency.

8. Horizontal drive and Output Circuit.

This circuit is a horizontal deflection amplifier for raster

scan.

9. ABL Circuit

This circuit limits the beam-current for the reliability of

CDT

10. Vertical Output Circuit

This circuit takes the vertical ramp wave from the

TDA4867J (IC601) and perform the vertical deflection

by supplying the saw-tooth wave current to the vertical

deflection yoke.

4. Microprocessor Control & Horizontal and

Vertical Sync Processor Circuit

The operating procedure is as follows ;

1) There is Horizontal & Vertical process function in

Microprocessor.(IC401)

2) Microprocessor (IC401) discriminates the operating

mode from the sync polarity and resolution.

3) After microprocessor reads these adjusted mode data

stored at EEPROM, it controls operating mode data

through IIC

4) Users can control screen condition by the OSD Select,

Up, Down, Left, Right, Exit.

5) The horizontal and vertical sync processor IC (IC401)

has a sync detector, a saw-tooth generator, and drive

function, And outputs horizontal and vertical drive

signal to control screen distortions

11. Blanking and Brightness Control Circuit.

Blanking circuit eliminates the retrace line by

supplying a negative pulse wave to the G1 of the CDT.

Brightness control circuit is used for control of the

screen brightness by changing the DC level G1.

12. Image Rotation (Tilt) Circuit.

This circuit corrects the tilt of the screen by

supplying the image rotation signal to the tilt coil

which is attached near the deflection yoke of the

CDT

13. OSD (On Screen Display) Circuit.

This circuit displays information of the monitor`s status

on the screen.

DESCRIPTION OF BLOCK DIAGRAM

- 10 -

14. Video Processor Circuit.

Video processor circuit consists of the video drive

output block. The video drive IC(IC302) receives the

video signal from PC. The gain of each channel is

controlled by MICOM through IIC.

The cut-off circuit compensate different voltage of

each channel between the cathode and the G1 of the

CDT

15. Video Pre-Amp Circuit.

This circuit amplifies the analog video signal from

0~0.7 V to 0~4 V. It is operated by taking the clamp,

R,G,B drive and contrast signal from the MICOM

(IC401)

16. Video Output Amp Circuit.

This circuit amplifies the video signal which comes

from the video pre-amp circuit and amplified it to

applied the CDT cathode

1. Preparation for Service Adjustment

GENERAL INFORMATION

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several adjustments may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

• Alignment appliances and tools.

- IBM compatible PC.

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- EPROM or EEPROM with saved each mode data.

- Alignment Adaptor and Software.

- Digital Voltmeter.

- White Balance Meter.

- Luminance Meter.

- High-voltage Meter.

AUTOMATIC AND MANUAL DEGAUSSING

The degaussing coil is mounted around the CDT so that

automatic degaussing when turn on the monitor. But a

monitor is moved or faced in a different direction, become

poor color purity cause of CDT magnetized, then press

DEGAUSSING on the OSD menu.

ADJUSTMENT PROCEDURE & METHOD

- Install the cable for adjustment such as Figure 1and run

the alignment program on the DOS for IBM

compatible PC.

- Set external Brightness and Contrast volume to max

position.

1. Adjustment for B+ Voltage.

1) Display cross hatch pattern at Mode 4.

2) Check D961 cathode voltage within 50V ± 1V .

2. Adjustment for High-Voltage.

1) Display cross hatch pattern at Mode 4.

2) Enter the SVC SUB menu as the following instruction.

3) Adjust H/Voltage to 24.5kV±0.1 kV by adjust 1-P value.

2. Adjustment by Service Hot key

How to enter SVC HOT KEY

1. Press Menu and OSD window will appear.

2. While OSD window is displayed,

is seen on the

left bottom of OSD window.

3. Press + power switch simultaneously and the

screen will immediately refresh.

4. Press Menu and make sure that is changed to

1 2.

5. Follow the menu on the left of OSD window to find 12

and OSD will change as shown in the figure.

6. Select Degauss in the above figure and then press

Select and

to enter the screen of the SUB menu.

(Back Raster for Pattern)

FOS SPEC

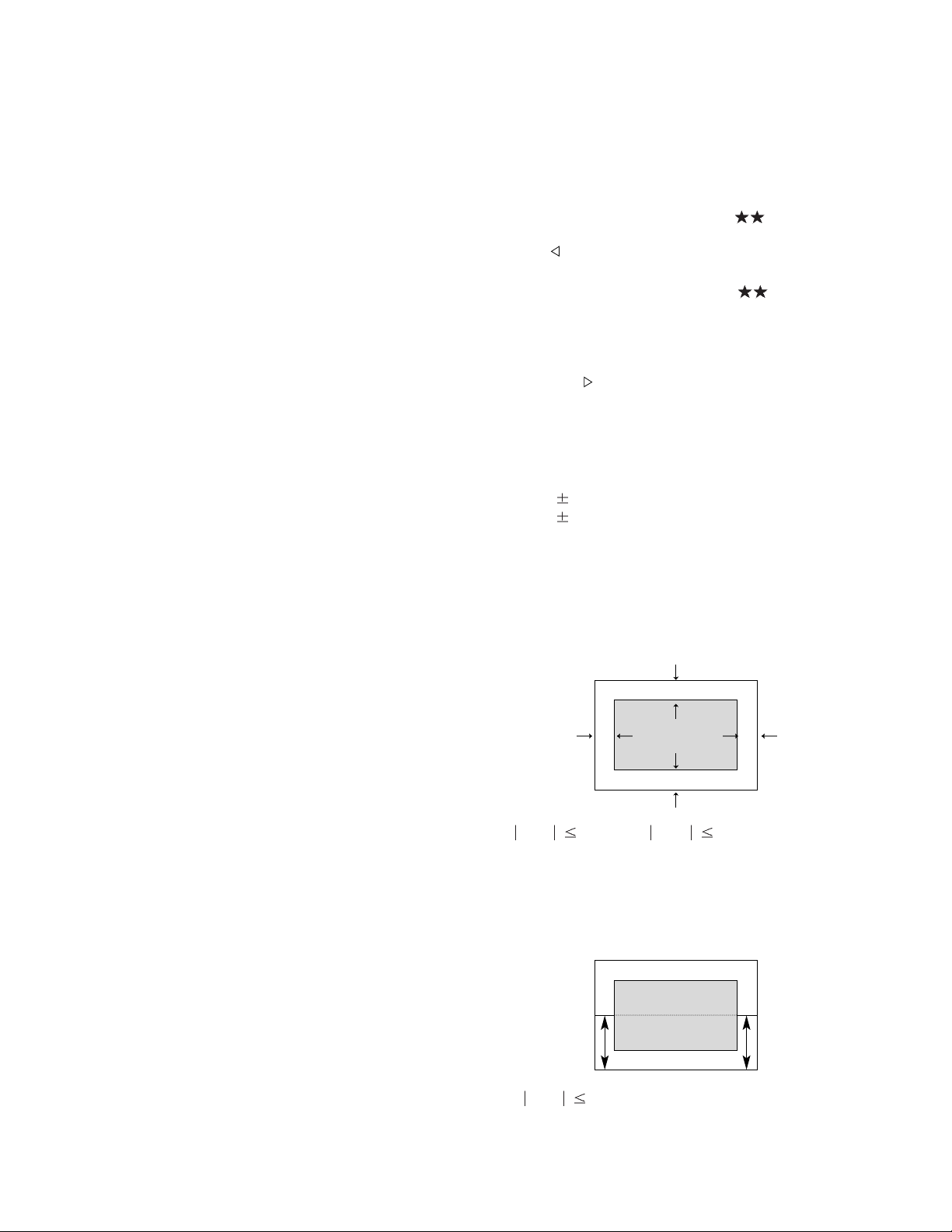

1. Size

H : 270

4mm

V : 200

4mm

Scanning frequency : All Mode (Mode 1~4)

Display image : Cross hatch pattern

2. Centering

Scanning frequency : All Mode (Mode 1~4)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

H :

L-R 4mm, V : U-D 4mm

3. Tilt

Scanning frequency : All Mode (Mode 1~4)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

Tilt :

E-F 2.0mm

- 11 -

ADJUSTMENT

U

D

L

R

EF

- 12 -

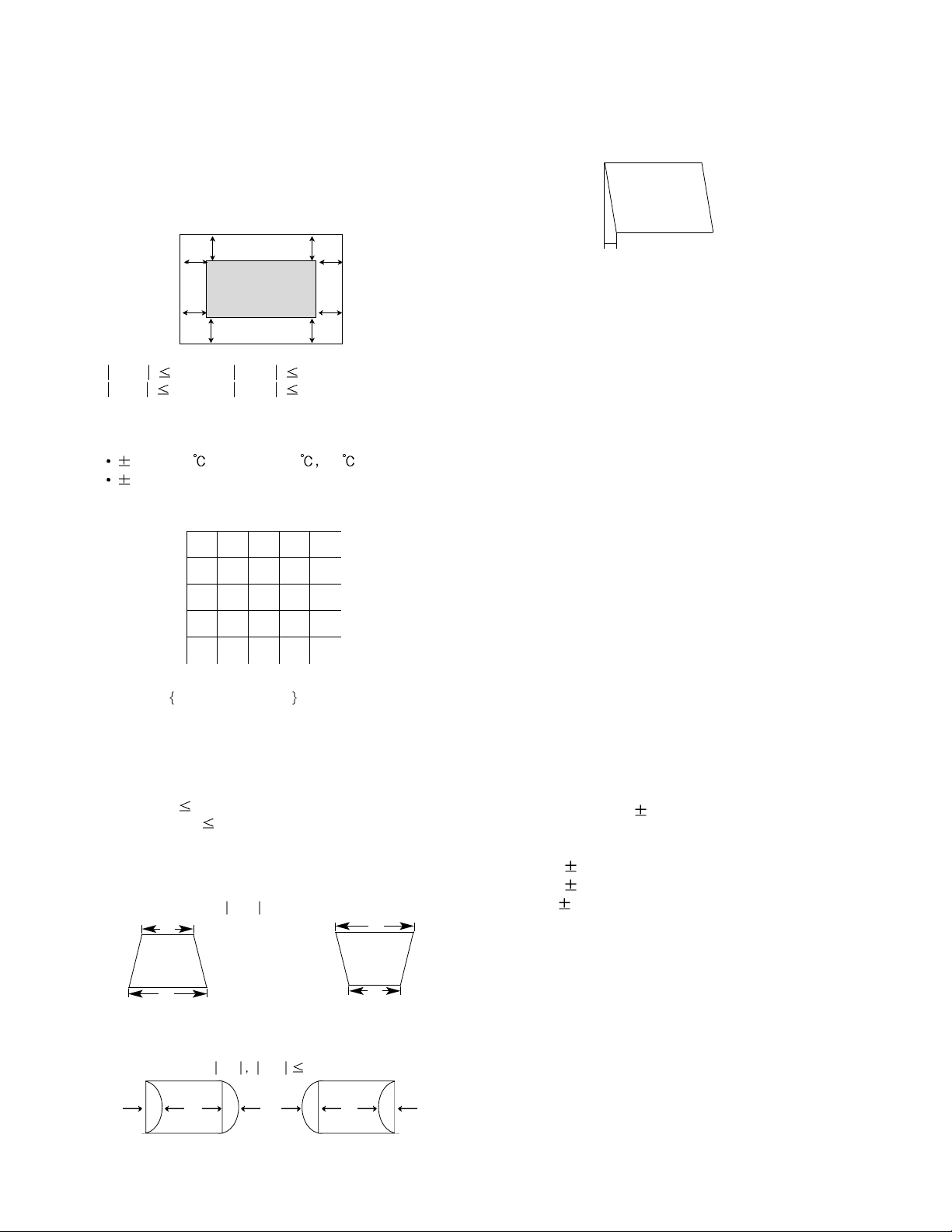

4. Distortion

Scanning frequency : All Mode (Mode 1~4)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

A-B 2.0mm, C-D 2.0mm

E-F 2.0mm, G-H

2.0mm

5. Displa Size drift

4mm : 25 Standard, 10 35

0.5mm : 180V ~ 264V

6. Linearity

Formula :

(Max - Min) / Max

x 100(%)

Criteria : H - 10% Max. (Upper 40kHz)

14% Max. (Less 40kHz)

V - 8% Max.

7. Regulation

Luminance

2mm

Dynamic(lode) 2mm

Scanning frequency : All Mode (Mode 1~4)

8. Trapezoid

9. Pin Balance

10.Parallelogram

11. Adjustment of white balance (Adjustment of

chromaticity diagram)

*(Adjustment of white balance must be made after

entering Hot Key Mode and DEGAUSS.)

CONDITIONS

Signal: 54 kHz / 85 Hz

Display image: Back raster (Color 0,0)

Contrast: Maximum

Brightness: Maximum

Color temperature: 9300K

11-1. Adjustment of cut off (Adjustment of back raster)

11-1(a). Before adjustment, press Menu and Degauss

to remove.

=> Enter hot key mode.

Adjust Brightness and Contrast to Max in OSD

window.

(1)Adjust cut off (back raster) first. Enter DEGAUSS in

the Menu and modify the following data.

Modify RCUT to Min ,

Modify GCUT To Min ,

Adjust to BCUT Data = 127 (7F (h)) ,

Adjust to SBRT Data = 205 ( CD (h)).

(2)Turn FBT screen volume on "CRT COLOR

ANALYZER CA-100" equipment to adjust

Brightness to 0.4

0.05FL.

(3)Adjust RCUT, GCUT, and SBRT to set chromaticity

diagram at :

x: 0.283

0.005

y: 0.298 0.005

Y: 0.40

0.05FL

* If color values would not be matched desirable values,

repeat sequence 1 and 2 after readjusting “GREEN

CUTOFF” control a little different.

U

D

D

U

U-D

< 4mm

L1 R1

2.0mm

L1

R1 L1

R1

Y1

Y2

Y3

Y4

X1 X2 X3 X4

4mm

A B

DC

EG

FH

Loading...

Loading...