LG 500M, MB500F-NA Service Manual

W

ebsite:http://biz.LGservice.com

E-mail:http://www.LGEservice.com/techsup.html

COLOR MONITO R

S E RVICE MANUAL

CHASSIS NO. : CA-105

M O D E L : S t u d i o Works 500M

ID LABEL:MB500F-NA

C A U T I O N

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CONTENTS

SPECIFICATIONS ................................................... 2

SAFETY PRECAUTIONS ........................................ 3

TIMING CHART ....................................................... 4

OPERATING INSTRUCTIONS ................................ 5

CONTROL LOCATIONS ......................................... 8

WIRING DIAGRAM ................................................. 9

DISASSEMBLY .....................................................10

BLOCK DIAGRAM ................................................. 12

SPECIFICATIONS

1. PICTURE TUBE

Size : 15 inch

DefIection Angle : 90°

Neck Diameter : 29.1mm

Stripe Pitch : 0.28mm

Face Treatment : ARAS(Anti-Reflection and

Anti-Static Coating)

2. SIGNAL

2-1. Horizontal & Vertical Sync

1) Input Voltage Level: Low=0~1.2V, High=2.5~5.5V

2) Sync Polarity : Positive or Negative

2-2. Video Input Signal

1) Voltage Level : 0 ~ 0.7 Vp-p

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.7 Vp-p

2) Input Impedance : 75Ω

3) Video Color : R, G, B Analog

4) Signal Format : Refer to the Timing Chart

2-3. Signal Connector

15-pin Attached Connector

2-4. Scanning Frequency

Horizontal : 30 ~ 61 kHz

Vertical : 50 ~ 160 Hz

3.STEREO AUDIO

3-1. Input Voltage :0.707Vrms

3-2. Input Impedance :20kΩ min

3-3. Amp Output :1W+1W rms

3-4. Speaker Impedance :8Ω

DESCRIPTION OF BLOCK DIAGRAM...................13

ADJUSTMENT ...................................................... 15

TROUBLESHOOTING GUIDE .............................. 17

REPLACEMENT PARTS LIST.................................28

EXPLODED VIEW...................................................35

PIN CONFIGURATION........................................... 37

PACKING AND ACCESSORIES............................ 39

3. POWER SUPPLY

3-1. Power Range

AC 100~240V (Free Voltage), 50/60Hz, 1.5A

3-2. Power Consumption

MODE

NORMAL (ON)

STAND-BY

SUSPEND

OFF

4. DISPLAY AREA

4-1. Active Video Area :

• Max Image Size - 284 x 213mm (11.19" x 8.39")

• Preset Image Size - 270 x 200 mm (10.6" x 7.88")

4-2. Display Color : Full Colors

4-3. Display Resolution : 1024 x 768 / 75Hz

4-4. Video Bandwidth : 78MHz

5. ENVIRONMENT

5-1. Operating Temperature: 10°C ~ 40°C(Ambient)

5-2. Relative Humidity : 10% ~ 90%

5-3. Altitude : 5,000m

6. DIMENSIONS (with FLIP)

Width : 37.0cm (14.6 inch)

Depth : 37.5cm (14.8 inch)

Height : 41.5cm (16.3 inch)

7. WEIGHT (with FLIP )

Net Weight : 12.5kg (27.55lbs.)

H/V SYNC

ON/ON

OFF/ON

ON/OFF

OFF/OFF

POWER CONSUMPTION

less than 74W

less than 15W

less than 15W

less than 5W

(Non-Interlace)

(Non-condensing)

LED COLOR

GREEN

ORANGE

ORANGE

- 2 -

SAFETY PRECAUTIONS

SAFETY-RELATED COMPONENT WARNING!

There are special components used in this color monitor

which are important for safety. These parts are marked

on the schematic diagram and the replacement parts

list. It is essential that these critical parts should be

replaced with the manufacturer's specified parts to

prevent X-radiation, shock, fire, or other hazards. Do not

modify the original design without obtaining written

permission from LG or you will void the original parts and

labor guarantee.

CAUTION:

SAFETY CHECK

Care should be taken while servicing this color monitor

because of the high voltage used in the deflection circuits.

These voltages are exposed in such areas as the

associated flyback and yoke circuits.

FIRE & SHOCK HAZARD

An isolation transformer must be inserted between the

color monitor and AC power line before servicing the

chassis.

• In servicing, attention must be paid to the original lead

dress specially in the high voltage circuit. If a short

circuit is found, replace all parts which have been

overheated as a result of the short circuit.

• All the protective devices must be reinstalled per the

original design.

• Soldering must be inspected for the cold solder joints,

frayed leads, damaged insulation, solder splashes, or

the sharp points. Be sure to remove all foreign

materials.

No modification of any circuit should be

attempted.

Service work should be performed only after

you are thoroughly familiar with all of the

following safety checks and servicing

guidelines.

X-RADIATION

The only potential source of X-radiation is the picture tube.

However, when the high voltage circuitry is operating

properly there is no possibility of an X-radiation problem.

The basic precaution which must be exercised is keep the

high voltage at the factory recommended level; the normal

high voltage is about 29kV. The following steps describe

how to measure the high voltage and how to prevent Xradiation.

Note : It is important to use an accurate high voltage

meter calibrated periodically.

• To measure the high voltage, use a high impedance

high voltage meter, connect (–) to chassis and (+) to

the CDT anode cap.

• Set the brightness control to maximum point at full

white pattern.

• Measure the high voltage. The high voltage meter

should be indicated at the factory recommended level.

• If the meter indication exceeds the maximum level,

immediate service is required to prevent the possibility

of premature component failure.

• To prevent X-radiation possibility, it is essential to use

the specified picture tube.

CAUTION:

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

IMPLOSION PROTECTION

All used display tubes are equipped with an integral

implosion protection system, but care should be taken to

avoid damage and scratching during installation. Use only

same type display tubes.

- 3 -

MODE

MARK

MODE 1

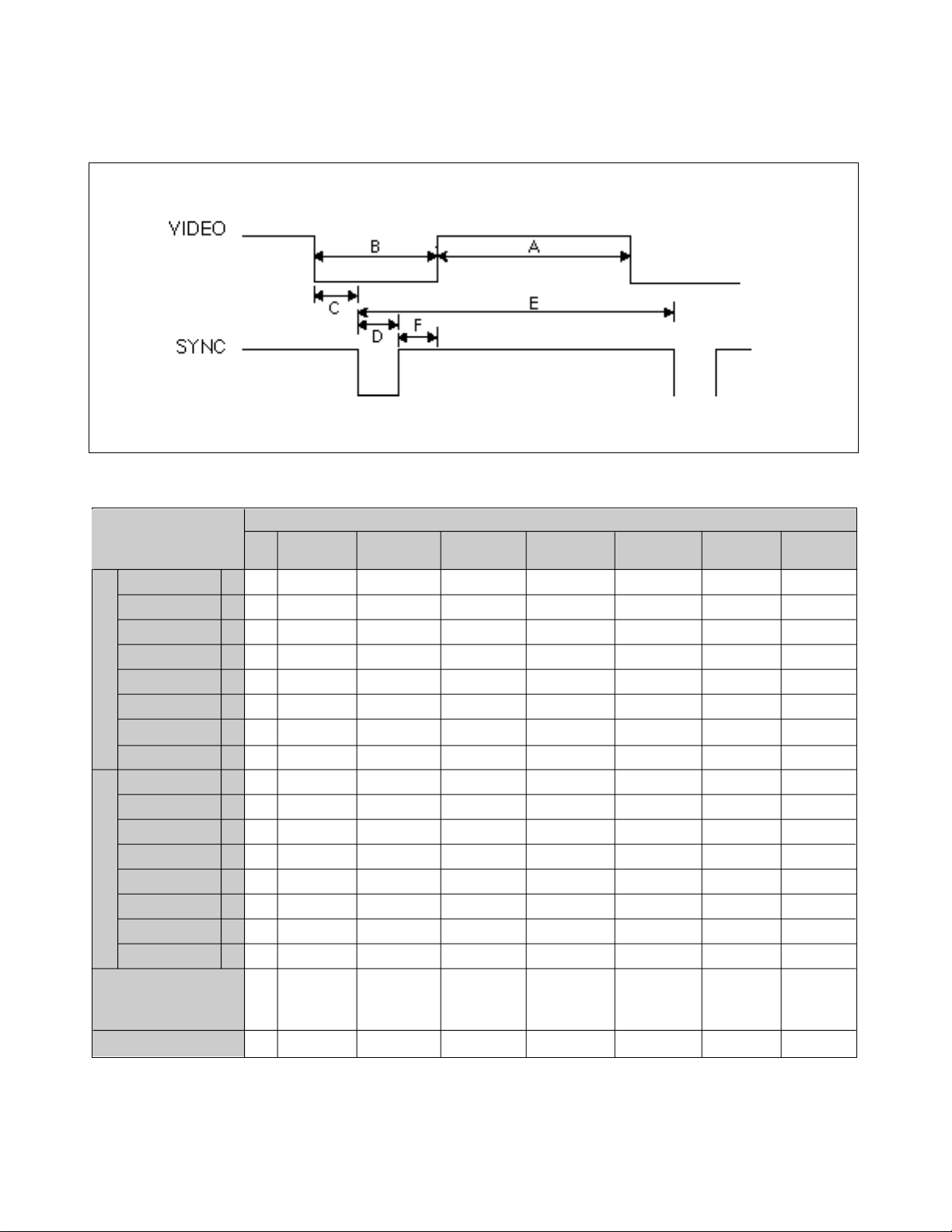

TIMING CHART

FACTORY PRESET MODE

MODE 2

MODE 3

MODE 4

MODE 5

MODE 6

MODE 7

Sync Polarity

H

O

Frequency

R

Total Period

I

Video Active Time

Z

O

Blanking Time

N

Front Porch

T

Sync Duration

A

L

Back Porch

Sync Polarity

V

Frequency

E

Total Period

R

T

Video Active Time

I

Blanking Time

C

Front Porch

A

L

Sync Duration

Back Porch

Resolution

Recall

kHz

µs

µs

µs

µs

µs

µs

Hz

ms

ms

ms

ms

ms

ms

-

31.69

E

31.778

A

25.422

B

6.356

C

1.907

D

3.813

F

0.636

-

59.940

E

16.683

A

15.253

B

1.430

C

1.048

D

0.064

F

0.318

640

x

480

60Hz

Yes

-

31.470

31.780

25.420

6.360

1.910

3.810

0.640

+

70.080

14.270

12.710

1.577

1.080

0.064

0.413

720

x

400

70Hz

Yes

-

37.500

26.670

20.320

6.350

3.810

2.030

0.510

-

74.990

13.335

12.802

0.533

0.427

0.080

0.026

640

x

480

75Hz

Yes

-

43.269

23.112

17.778

5.334

2.222

1.556

1.556

-

85.008

11.764

11.093

0.670

0.578

0.069

0.023

640

x

480

85Hz

Yes

+

46.880

21.330

16.160

5.170

3.230

1.620

0.320

+

75.010

13.331

12.796

0.533

0.448

0.064

0.021

800

x

600

75Hz

Yes

+

53.674

18.631

14.222

4.409

2.702

1.138

0.569

+

85.061

11.756

11.179

0.578

0.503

0.056

0.019

800

x

600

85Hz

Yes

+

60.020

16.660

13.000

3.666

2.240

1.220

0.200

+

75.030

13.328

12.795

0.533

0.466

0.050

0.017

1024

x

768

75Hz

Yes

- 4 -

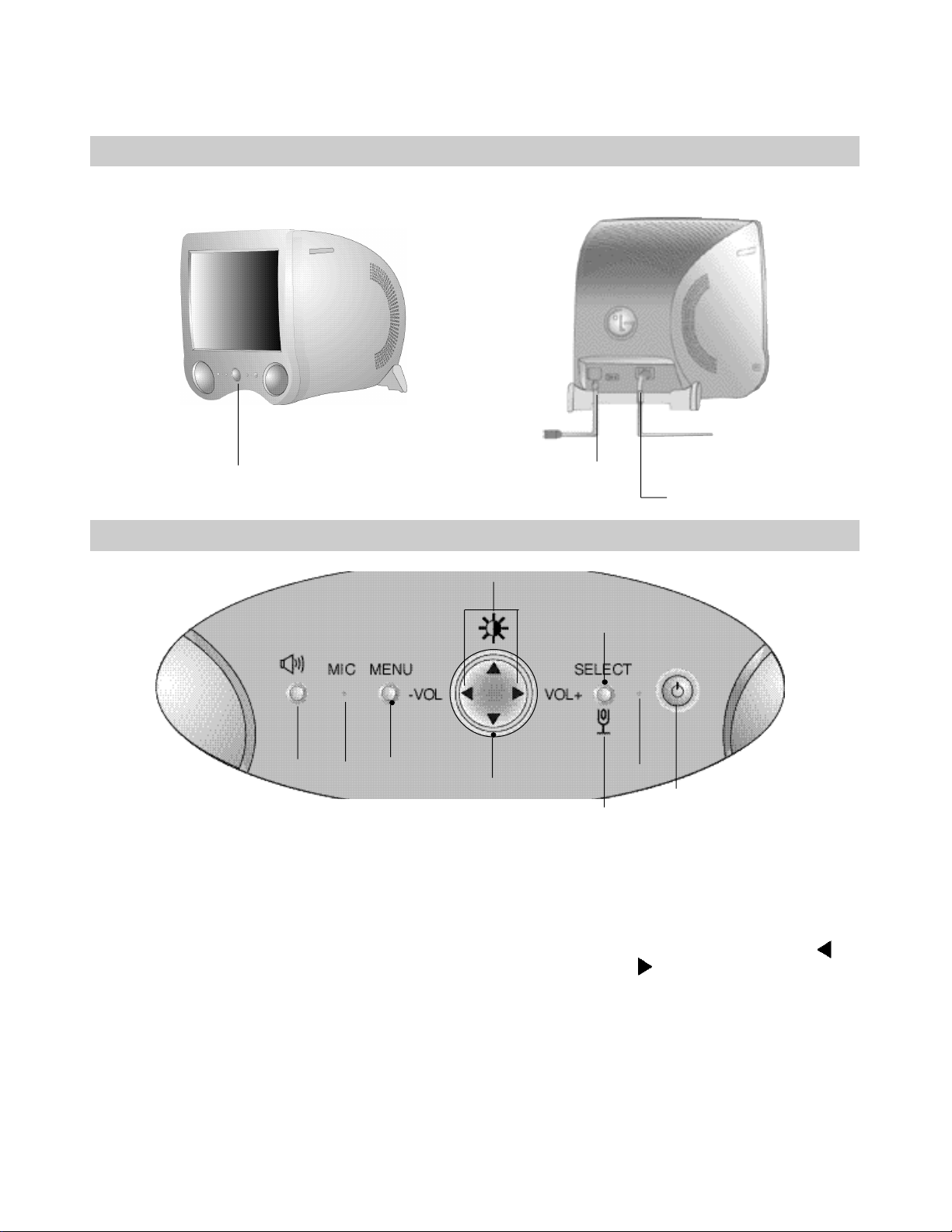

OPERATING INSTRUCTIONS

To adjust speaker volume in one step.Press to decrease

the volume and to increse the volume.To exit the volume

menu,just press the MENU button.

8. Built-in Mic

Built in microphone.

9. Sound Mute

Use the button to select sound on or off.

REAR VIEW FRONT VIEW

See Front Control Panel

Front Control Panel

9

8

1. Power ON/OFF Button

This button is used to turn the monitor ON and OFF.

2. Power Indicator

This indicator lights up green when the monitor operates

normally; in DPMS (Energy Saving) mode, stand-by, suspend,

or power off mode -its color changes to orange, and if abnormal

or damaging circuit turns out orange blink.

6

AC Power Socket

7

5

level of the selected menu.

6. MENU Button

This button to enter or exit the on screen display.

7. Volume Button

Signal Cable

3

2

1

4

3. SELECT Button

This button to enter a selection in the on screen display.

4. Mic ON/OFF Button

Use this button to select the MIc on or off.

5. OSD Select/Adjustment

Use for selecting (highlighting) an OSD icon and adjusting

- 5 -

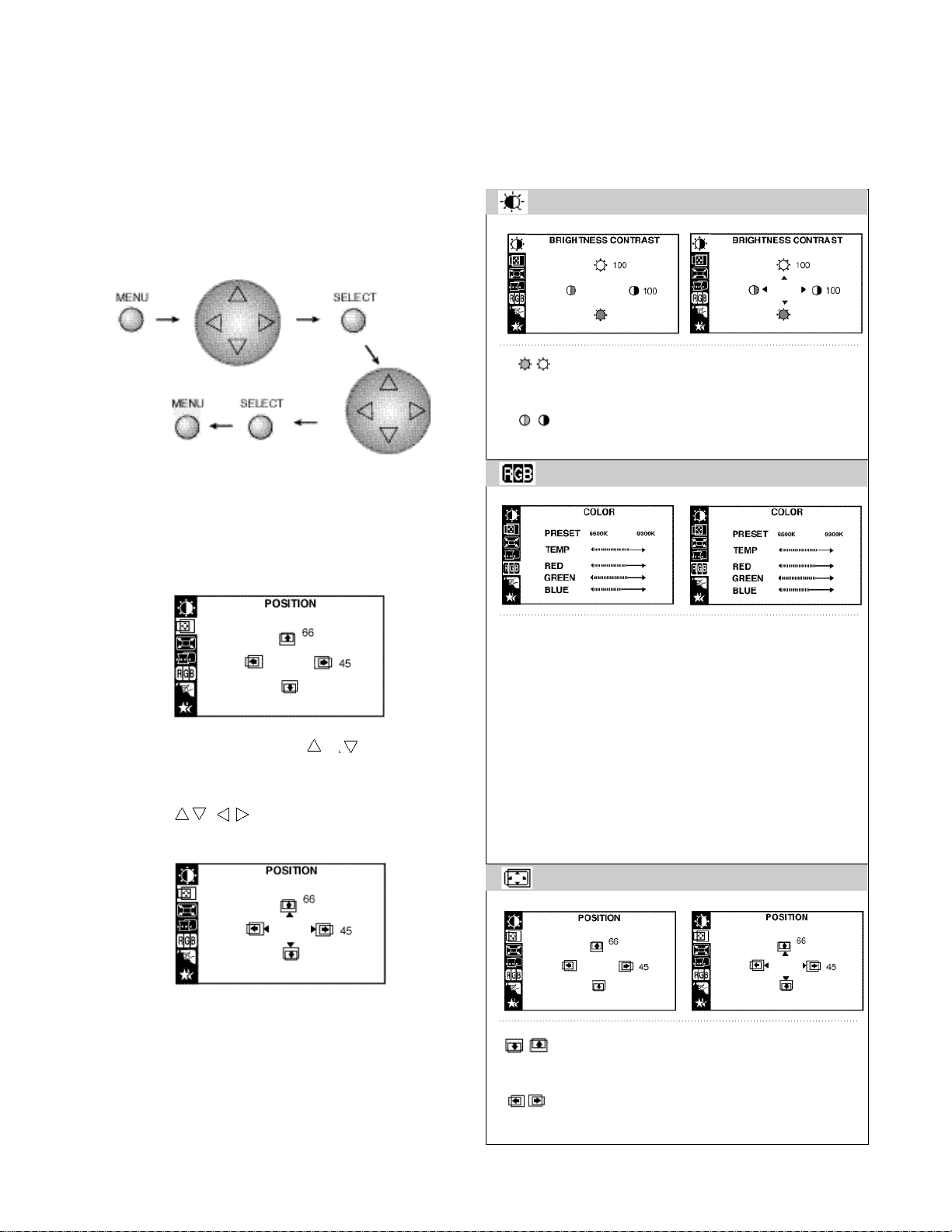

On-Screen-Display (OSD) Control

To adjust an image size, position, and operating

parameters are quick and easy with the On-ScreenDisplay control system, using the OSD button and the

Adjustment control button. A quick example is given below

to familiarize you with use of the controls.

Listed below are icons, icon names, and icon descriptions

of the OSD menu.

BRIGHTNESS CONTRAST

Birghtness

To adjust the screen brightness level.

Contrast

To adjust the image contrast level.

Example;

Note: (Monitor and PC’s power switch should be ON,

with an image or prompt on the screen).

1. Press the MENU Button, then the Main menu of the

OSD appears. Display will look like as below:

2. To access a control, use the or Buttons.

When the icon you want becomes highlighted, Press

the OSD SELECT Button.

3 . Use the / Buttons to adjust the item to the

desired level.

COLOR

6500K 9300K

To appear the display’s color temperature.

• 6500K : Slightly reddish white

• 9300K : Slightly Bluish white

TEMP

User easily color set without adjustment Red,

Green, Blue (R/ G/ B).

RED To set your own color levels.

GREEN To set your own color levels.

BLUE To set your own color levels.

POSITION

4 . Accept the changes by pressing the SELECT button.

5 . Exit the OSD by pressing the MENU Button.

Vertical Position

To move the image up or down.

Horizontal Position

To move the image left or right.

- 6 -

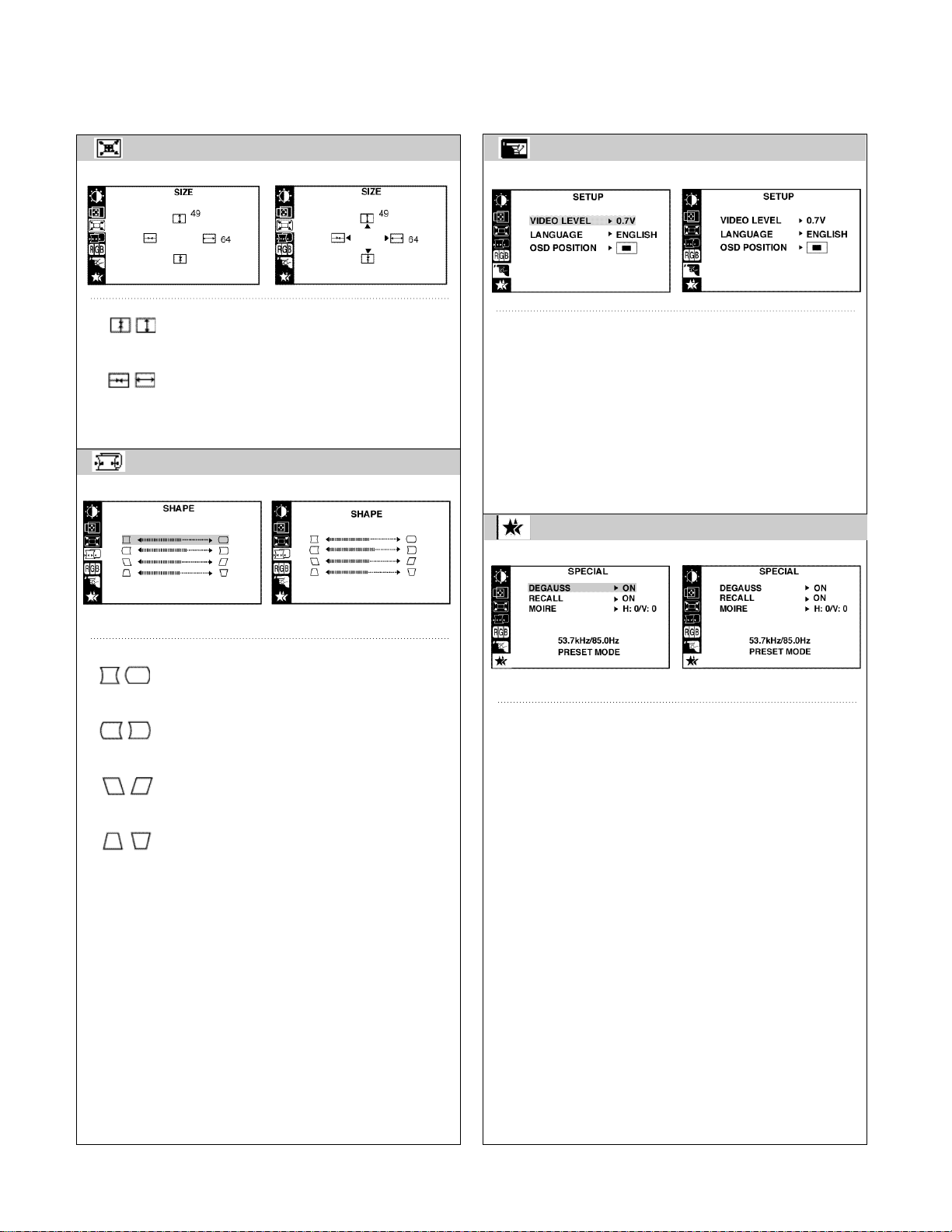

SIZE

SETUP

Vertical Size

To adjust the image height.

Horizontal Size

To adjust the image width.

SHAPE

Side Pincushion

To correct bowing in or out of the image.

Side Pincushion Balance

To correct the balance of both sides bowling.

Parallelogram

To correct the geometric distortion.

Trapezoid

To correct the geometric distortion.

Video Level

To select voltage level of the video card output - It is

input level of the monitor. Most video cards are 0.7V.

Language

To choose the language in which the control names are

displayed. OSD Menus are available in 9 languages.

OSD Position

This item lets you adjust the OSD position.

SPECIAL

Degaussing

Used to demagnetize the picture to give a more

accurate image and color.

Recall

To recall factory preset mode.

Moire

This item allows you to reduce the moire (Moire is

caused by interference Horizontal Scan Line with the

periodical dot screen), It is normally OFF (H:0/V:0)

The moire adjustments may affect the focus of the

screen. The screen image may moire reduction

function is on.

- 7 -

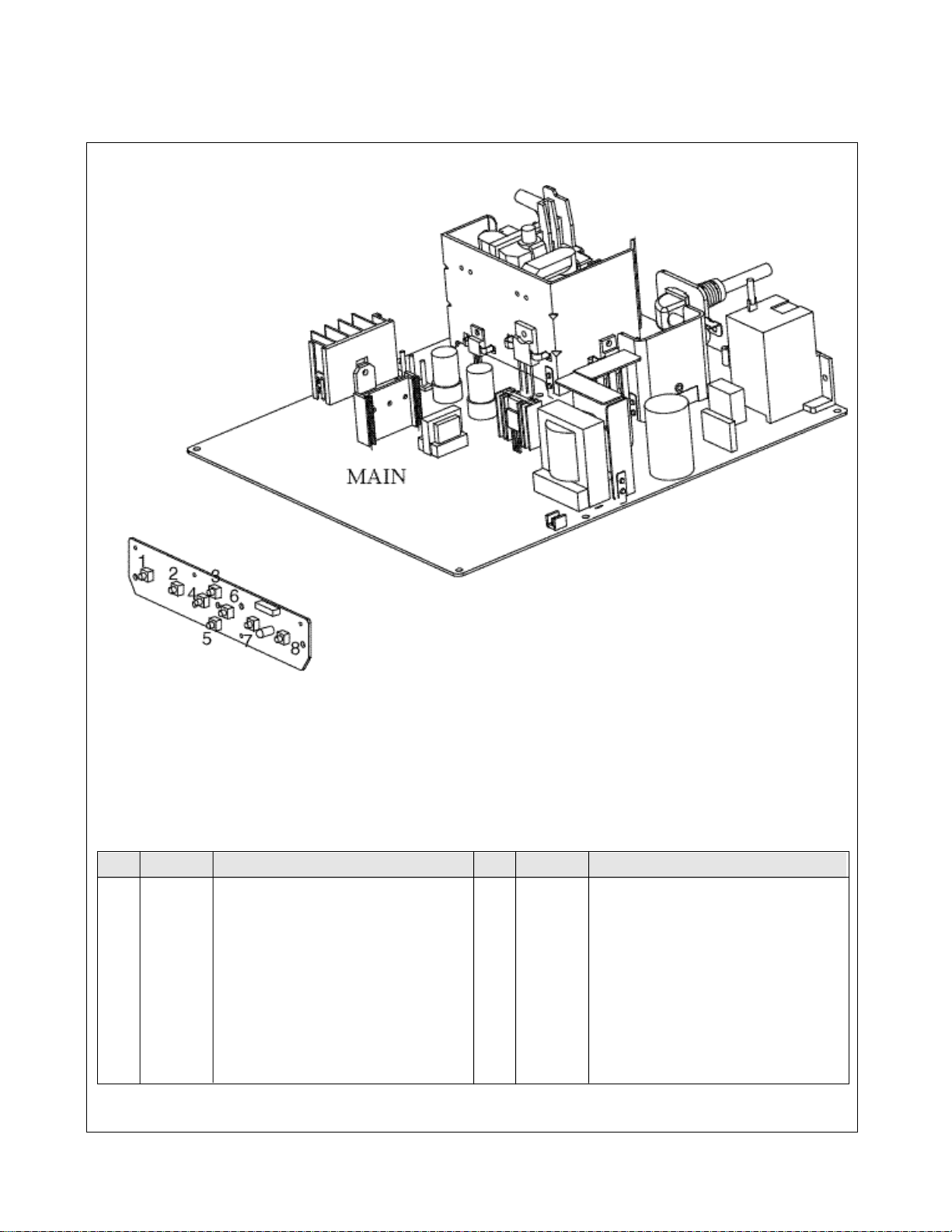

CONTROL LOCATIONS

No.

1

2

3

4

Ref. No.

SW207

SW204

SW205

SW206

Control Function

SOUND BUTTON

MENU BUTTON

OSD SELECT/ADJUSTMENT UP

OSD SELECT/ADJUSTMENT LEFT

- 8 -

No.

5

6

7

8

Ref. No.

SW203

SW202

SW201

SW208

Control Function

OSD SELECT/ADJUSTMENT DOWN

OSD SELECT/SDJUSTMENT

RIGHTSELECT BUTTON

POWER BUTTON

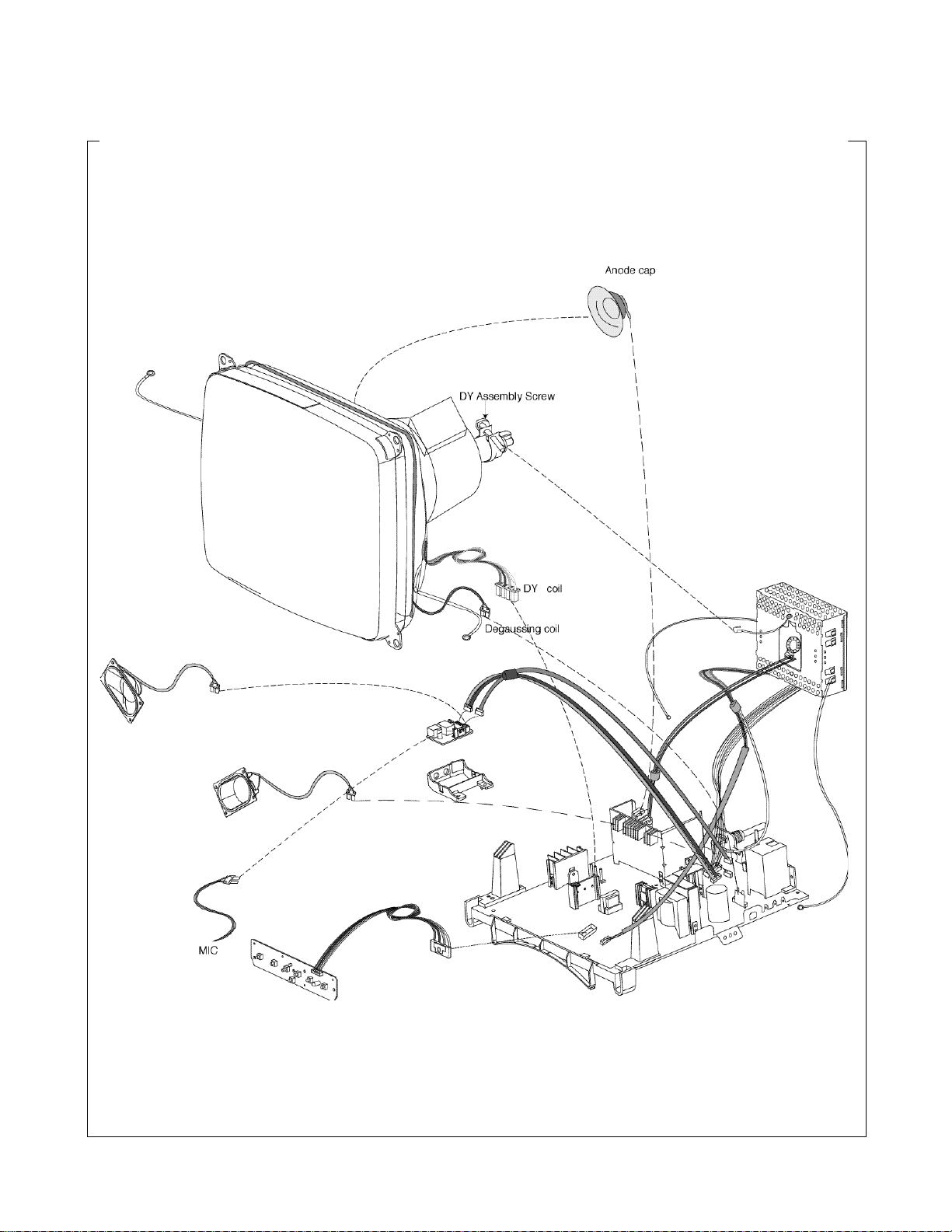

WIRING DIAGRAM

- 9 -

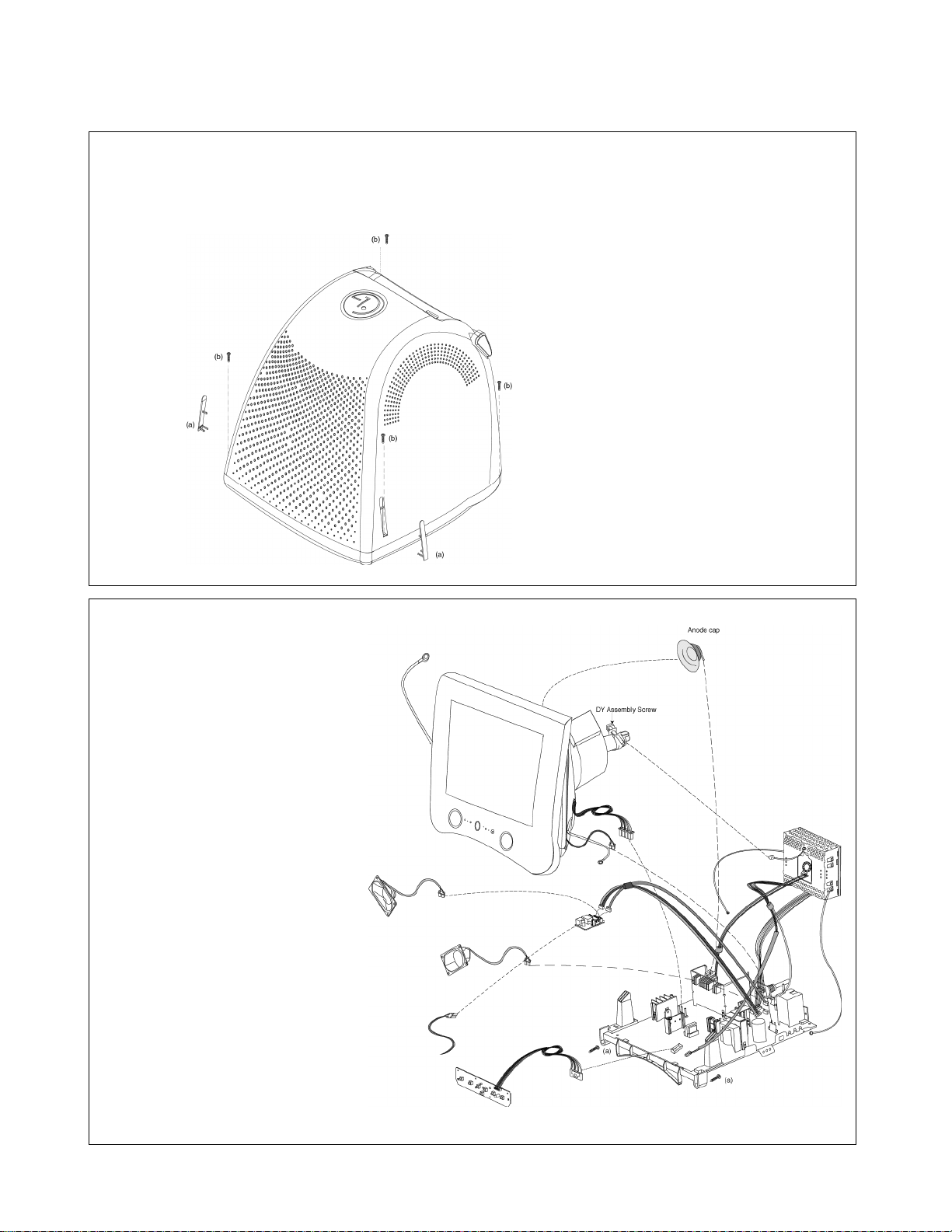

DISASSEMBLY

1. BACK COVER REMOVAL

1) Remove two screw cover (a).

2) Remove four screws(b).

3) Slide the Back Cover away from the Front Cabinet of the monitor.

2. TOTAL CHASSIS ASSEMBLY

REMOVAL

1) Remove two screws (a).

2) Disconnect P701(DY pin),

P902(Degaussing coil),

P405,P3 from the Main PCB.

3) Disconnect the CDT earth

from the Video PCB.

4) Carefully separate the Video

Board Assembly from

the CDT neck.

5) Discharge the remaining

static electricity by shorting

between the Anode Cap

and the CDT ground.

6) Disconnect the Anode Cap

from the CDT.

7) Disconnect P42,P44 from

Audio Board.

8) Remove the Total Chassis

Assembly from the Main

Frame.

- 10 -

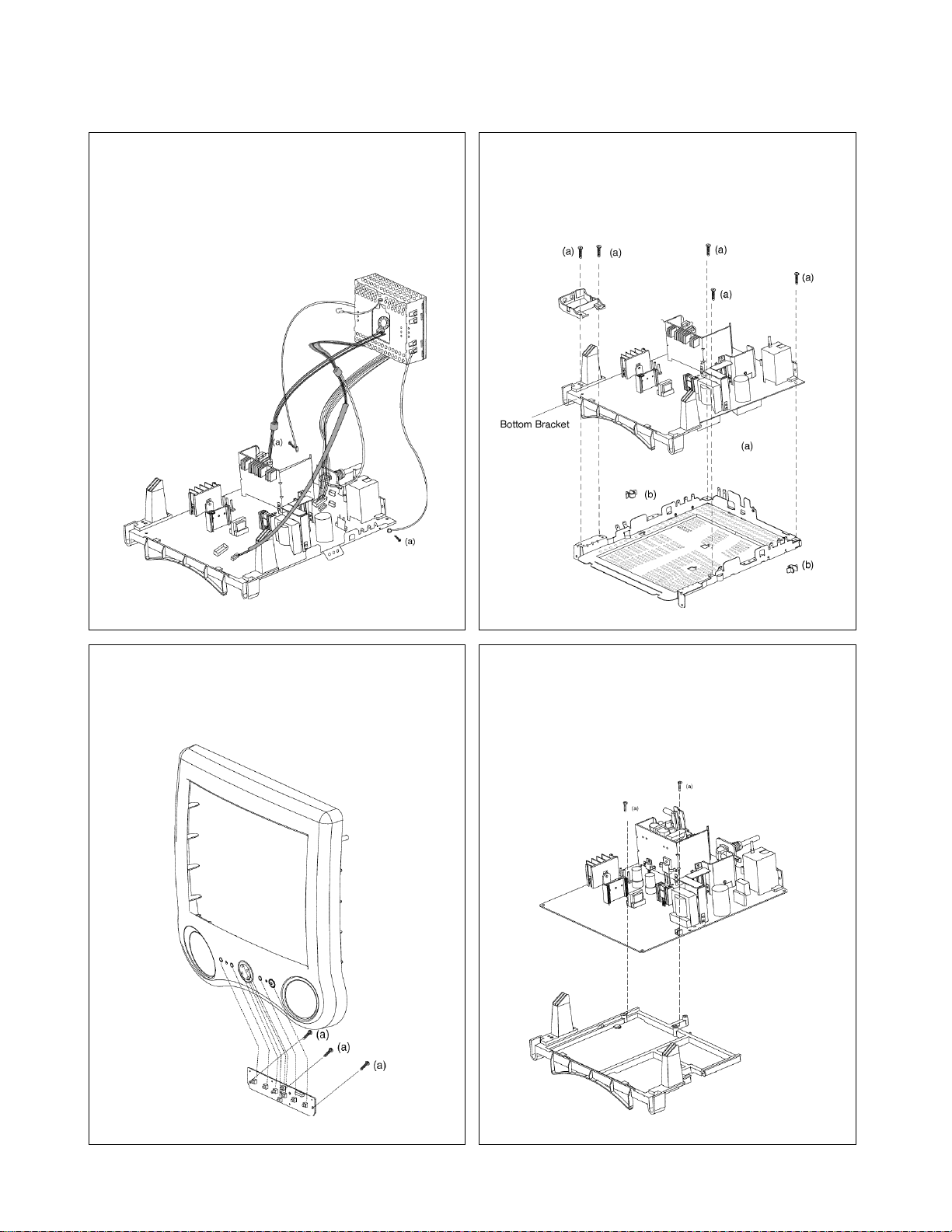

3. VIDEO PCB ASSEMBLY REMOVAL

1) Remove two screws (a).

2) Disconnect P402,P702 .

3) Remove the Video PCB Assembly.

5. BOTTOM SHIELD REMOVAL

1) Remove five screws (a).

2) Remove two latches(b).

3) Remove the Bottom Bracket.

4. CONTROL PCB ASSEMBLY REMOVAL

1) Remove three screws (a).

2) Remove the Control PCB Assembly

from the Front Cabinet.

6. MAIN BRACKET REMOVAL

1) Remove two screws (a).

2) Remove the main bracket.

- 11 -

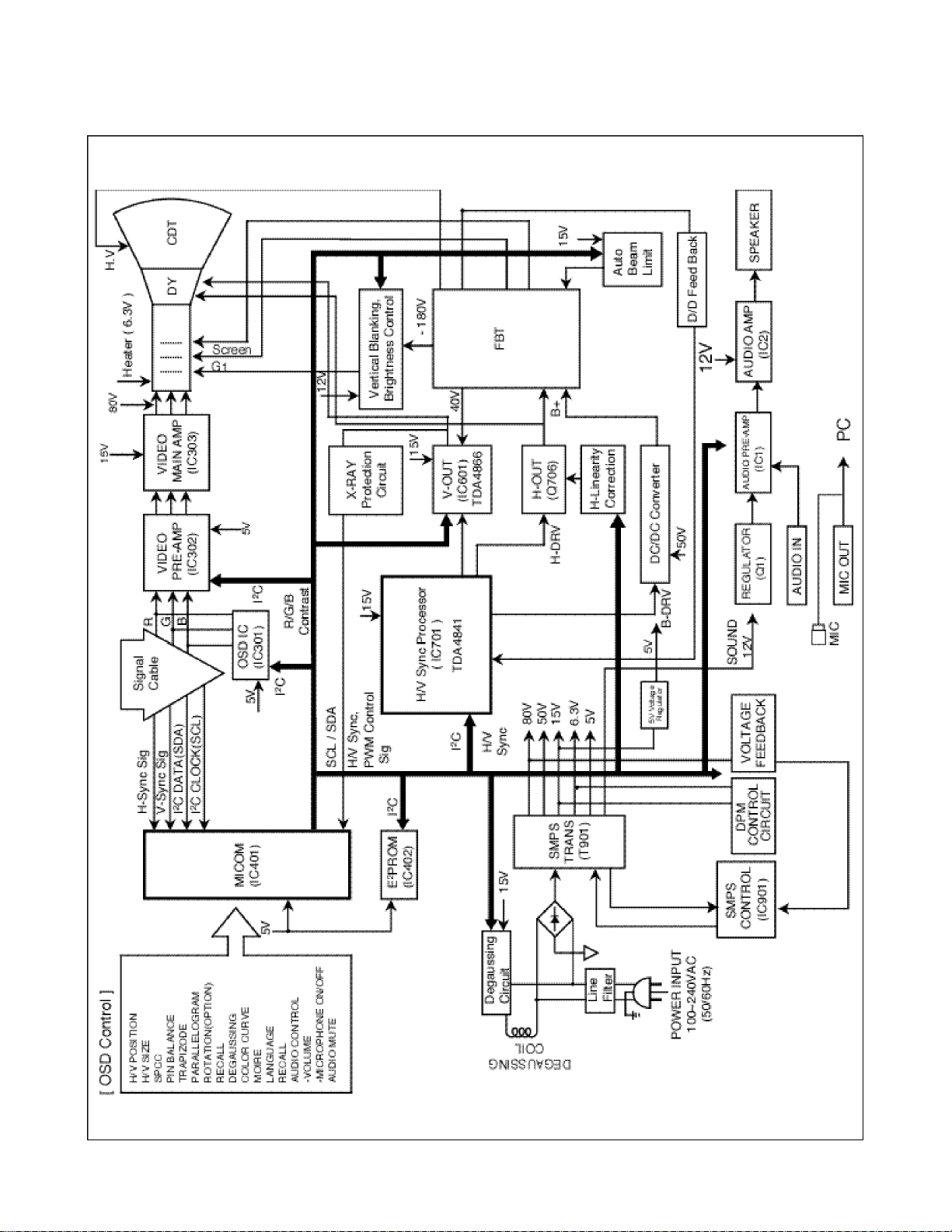

BLOCK DIAGRAM

- 12 -

DESCRIPTION OF BLOCK DIAGRAM

1. Line Filter & Associate Circuit

This is used for suppressing noise of power input line

flowing into the monitor and/or some noise generate in

this monitor flowing out through the power input line.

That is to say,this circuit prevents interference between

the monitor and other electric appliance.

2. Degaussing Circuit & Coil

The degaussing circuit consists of the degaussing coil,

the PTC (Positive Temperature Coefficent) thermistor

(TH901),and the relay(RL901).This circuit eliminates

abnormal color of the screen automatically by

degaussing the shadow mask in the CRTduring turning

on the power switch.When you need to degauss in

using the monitor,select DEGAUSS on the MENU

menu.

3. SMPS(Switching Mode Power Supply)

This circuit is working of 90~264V AC(50/60Hz).

The operation procedure is as follows:

1)The AC line voltage is rectified by the bridge diodes

D900 and the capacitor(C908).

2)The reectified voltage(DC) is supplied to the primary

coil of the transformer(T901)

3)Thecontrol IC(IC901) generates switching pulse to turn

on and off the primary coil of the transformer (T901)

repeatedly.

4) Depending on turn ratio of the transformer,the

secondary voltage appear at the secondary coils of the

transformer (T901).

5) These secondary voltages are rectified by each

diode(D941,D942,D951,D961,D962,D971) and operate

other circuit.(horizontal and vertical deflection,video

amplifier,...etc.)

4. X-ray Protection

If the high voltage of the FBT reaches up to

29kV(abnormal state),Q807 operates and IC401(MICOM)

pin 19 come to low level.Then MICOM control

IC701(Deflection controller) to stop Horizontal drive pulse

and stop Horizontal Deflection.

5. MICOM Circuit

The operating procedure of MICOM(Microprocessor)

and its associated circuit is as follows:

1)H and V sync signal is supplied from the signal cable.

2)The Micom(IC401) distinguishes polarity and frequency

of H and V sync.

3)The Micom sets operating mode and offer the controller

data.(H-size,H-position,V-size,...etc.)

4)The controller data of each mode is stored in itself.

5)User can adjust screen condition by each OSD

function.The data of the adjusted condition is stored

in EEPROM(IC402)

6. Horizontal and Vertical Oscillation

This circuit generates the horizontal pulse and the vertical

pulse by taking the H and V sync signal.

7. D/D Convert Circuit.

This circuit supplies DC voltage to the horizontal

defelection output circuit by increasing DC 50V which is

the secondary voltage of the SMPS in accordance with

the input horizontal sync signal.

8. Horizontal Deflection Output Circuit

This circuit makes the horizontal deflection by supplying

the saw-tooth current to the horizontal deflection yoke.

9. High Voltage Output & FBT (Flyback Transformer)

The high voltage output circuit is used for generating

pulse to the primary coil of the FBT(Flyback Transformer

(T701)).A boosted voltage (about 24.5kV) appears at the

secondary of the FBT and it is supplied to the anode,

focus,and screen voltage of the CRT.

1 0 .Horizontal linearity Circuit.

This circuit corrects the horizontal linearity for each

horizontal sync frequency.

11. Vertical Output Circuit

This circuit input the vertical ramp wave from the IC701

(TDA4841) to the IC601(TDA4866) and amplifies,supplies

the saw-tooth current to the vertical deflection yoke(V-DY)

12. H & V Blanking and Brightness Control

Blanking circuit eliminates retrace line by supplying

negative pulse to the G1of the CRT.And Brightness

circuit is used for control of the screen brightness by

changing DC level of the G1.

- 13 -

Loading...

Loading...