Page 1

COLOR MONIT OR

SER VICE MANUAL

Website:http://biz.LGservice.com

E-mail:http://www.LGEservice.com/techsup.html

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MENU

SELECT

MODEL: StudioWorks 500E

(500EJ-AL**M)

StudioWorks 500G

(500EJ-AL**A)

CHASSIS NO. : CA-133

( ) **

Same model for Service

*Same looking with new chassis.

Issue Date; 2003. 5.

F ACTORY MODEL: 500EJ

Page 2

1. PICTURE TUBE

Size : 15 inch (Flat Square Tube)

DefIection Angle : 90°

Neck Diameter : 29.1 mm

Dot Pitch : 0.28 mm

Face Treatment : AR-ASC (Anti-Reflection and

Anti-Static Coating)

AG(Anti-Glare)

Low Radiation : MPR-II, NON MPR II

2. SIGNAL

2-1. Horizontal & Vertical Sync

1) Input Voltage Level: Low= 0~1.2V, High= 2.5~5.5V

2) Sync Polarity : Positive or Negative

2-2. Video Input Signal

1) Voltage Level : 0 ~ 0.7 Vp-p

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.7 Vp-p

2) Input Impedance : 75 Ω

3) Video Color : R, G, B Analog

4) Signal Format : Refer to the Timing Chart

2-3. Signal Connector

15-pin D-Sub Connector (Attached Type)

2-4. Scanning Frequency

Horizontal : 30 ~ 54 kHz

Vertical : 50 ~ 120 Hz

3. POWER SUPPLY

3-1. Power Range

AC 100~240V (Free Voltage), 50/60Hz, 1.0A Max.

3-2. Power Consumption

4. DISPLAY AREA

4-1. Active Video Area :

• 285 x 215 mm (11.22" x8.46") - Max Image Size

• 270 x 200 mm (10.63"x 7.87") - Preset Image Size

4-2. Display Color : Full Colors

4-3. Display Resolution : 1024 x 768 / 60Hz

(Non-Interlace)

4-4. Video Bandwidth : 65 MHz

5. ENVIRONMENT

5-1. Operating Temperature: 10°C ~ 40°C

(Ambient)

5-2. Relative Humidity : 10%~ 90%

(Non-condensing)

5-3. Altitude : 3,000 m

6. DIMENSIONS (with TILT/SWIVEL)

Width : 356.0 mm (14.01")

Depth : 395.0 mm (14.37")

Height : 371.0 mm (14.61")

7. WEIGHT (with TILT/SWIVEL)

Net Weight : 11.5 kg (25.36 lbs)

Gross Weight : 13.7 kg (30.21 lbs)

CONTENTS

- 2 -

SPECIFICATIONS ................................................... 2

SAFETY PRECAUTIONS ........................................ 3

TIMING CHART ....................................................... 4

OPERATING INSTRUCTIONS ................................ 5

WIRING DIAGRAM ................................................. 6

BLOCK DIAGRAM ................................................... 7

DESCRIPTION OF BLOCK DIAGRAM.....................8

ADJUSTMENT ........................................................ 9

TROUBLESHOOTING GUIDE .............................. 11

EXPLODED VIEW...................................................21

REPLACEMENT PARTS LIST ............................... 23

PIN CONFIGURATION........................................... 28

SCHEMATIC DIAGRAM......................................... 30

PRINTED CIRCUIT BOARD................................... 32

SPECIFICATIONS

MODE

MAX

NORMAL (ON)

STAND-BY

SUSPEND

OFF

POWER CONSUMPTION

75 W

63 W

less than 15 W

less than 15 W

less than 5 W

LED COLOR

GREEN

GREEN

AMBER

AMBER

Page 3

SAFETY-RELATED COMPONENT WARNING!

There are special components used in this color monitor

which are important for safety. These parts are marked

on the schematic diagram and the replacement

parts list. It is essential that these critical parts should be

replaced with the manufacturer's specified parts to

prevent X-radiation, shock, fire, or other hazards. Do not

modify the original design without obtaining written

permission from manufacturer or you will void the original

parts and labor guarantee.

CAUTION:

No modification of any circuit should be

attempted.

Service work should be performed only after

you are thoroughly familiar with all of the

following safety checks and servicing

guidelines.

SAFETY CHECK

Care should be taken while servicing this color monitor

because of the high voltage used in the deflection circuits.

These voltages are exposed in such areas as the

associated flyback and yoke circuits.

FIRE & SHOCK HAZARD

An isolation transformer must be inserted between the

color monitor and AC power line before servicing the

chassis.

• In servicing, attention must be paid to the original lead

dress specially in the high voltage circuit. If a short

circuit is found, replace all parts which have been

overheated as a result of the short circuit.

• All the protective devices must be reinstalled per the

original design.

• Soldering must be inspected for the cold solder joints,

frayed leads, damaged insulation, solder splashes, or

the sharp points. Be sure to remove all foreign

materials.

IMPLOSION PROTECTION

All used display tubes are equipped with an integral

implosion protection system, but care should be taken to

avoid damage and scratching during installation. Use only

same type display tubes.

X-RADIATION

The only potential source of X-radiation is the picture tube.

However, when the high voltage circuitry is operating

properly there is no possibility of an X-radiation problem.

The basic precaution which must be exercised is keep the

high voltage at the factory recommended level; the normal

high voltage is about 24.5kV. The following steps describe

how to measure the high voltage and how to prevent Xradiation.

Note : It is important to use an accurate high voltage

meter calibrated periodically.

• To measure the high voltage, use a high impedance

high voltage meter, connect (–) to chassis and (+) to

the CDT anode cap.

• Set the brightness control to maximum point at full

white pattern.

• Measure the high voltage. The high voltage meter

should be indicated at the factory recommended level.

• If the meter indication exceeds the maximum level,

immediate service is required to prevent the possibility

of premature component failure.

• To prevent X-radiation possibility, it is essential to use

the specified picture tube.

CAUTION:

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

SAFETY PRECAUTIONS

- 3 -

Page 4

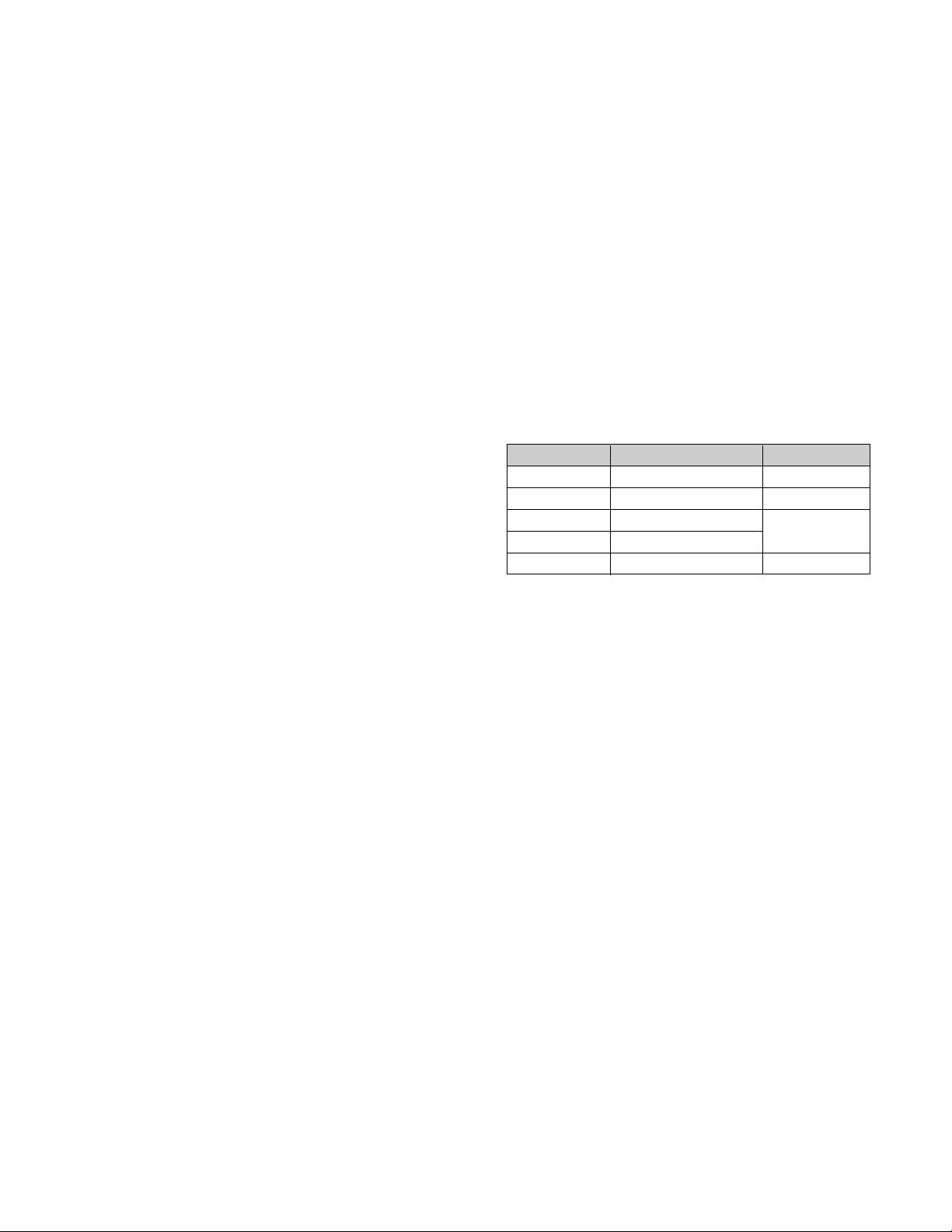

TIMING CHART

- 4 -

VIDEO

SYNC

C

E

D

F

A

B

H – 31.47 31.78 25.42 6.36 3.81 1.91 0.64

V – 59.94 16.684 15.254 1.430 0.063 1.049 0.318

H + 37.50 26.67 20.32 6.35 2.03 3.81 0.51

V + 74.99 13.335 12.802 0.533 0.080 0.427 0.026

H + 48.363 20.667 15.574 4.923 2.092 2.462 0.369

V + 60.004 16.666 15.880 0.786 0.124 0.600 0.062

H + 53.68 18.63 14.22 4.41 1.14 2.70 0.57

V + 85.07 11.755 11.178 0.577 0.056 0.503 0.018

Mode

H/V

Sort

1

2

3

4

640x480

60Hz

1024x768

60Hz

800x600

85Hz

640x480

75Hz

<< Dot Clock (MHz), Horizontal Frequency (kHz), Vertical Frequency (Hz), Horizontal etc... (µs), Vertical etc... (ms) >>

Sync

Polarity

Frequency

Total Period

(E)

Video Active

Time (A)

Sync Duration

(D)

Blanking Time

(B)

Back Porch

(C)

Front Porch

(F)

Resolution

Page 5

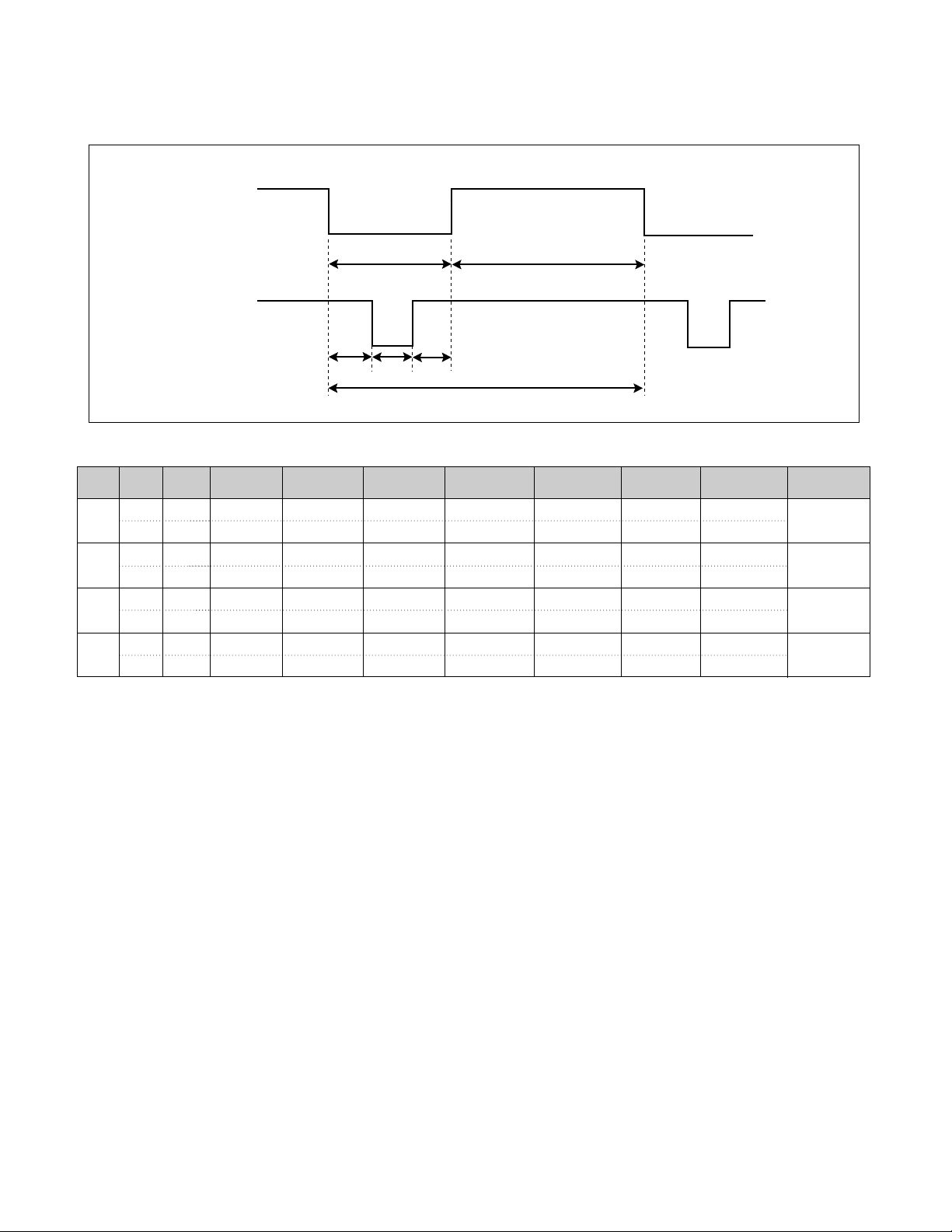

- 5 -

OPERATING INSTRUCTIONS

MENU

SELECT

FRONT VIEW REAR VIEW

AC Power Socket

Signal Connector

ID Label

Power ON/OFF Button

See Front Control Panel

Front Control Panel

1. Power ON/OFF Button

Use this button to turn the monitor on or off.

2. Power Indicator

This indicator lights up green when the monitor operates

normally; in DPMS (Energy Saving) mode, - stand-by,

suspend, or power off mode -its color changes to orange,

and if abnormal or damaging circuit turns out orange blink.

3. SELECT Button

Use this button to enter a selection in the on screen

display.

4. SET Button

Use these buttons to choose or adjust items in the on

screen display.

5. MENU Button

Use this button to enter or exit the on screen display.

1

3

4

5

2

MENU

SELECT

Page 6

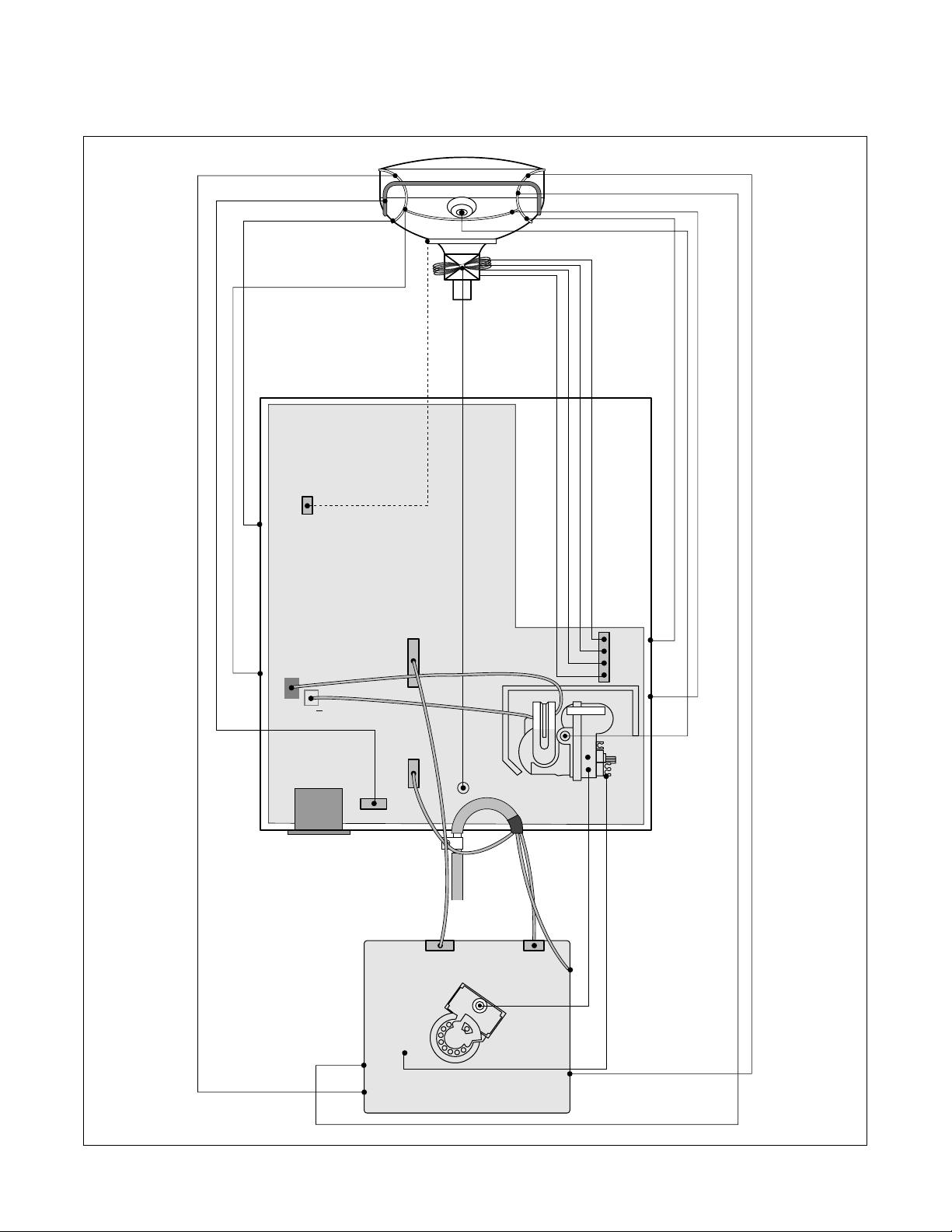

WIRING DIAGRAM

- 6 -

P501(option)

P301

P302

G2

P702

P701

T1

P402

P902

S

+

S

Signal

Cable

AC

Socket

FBT

Page 7

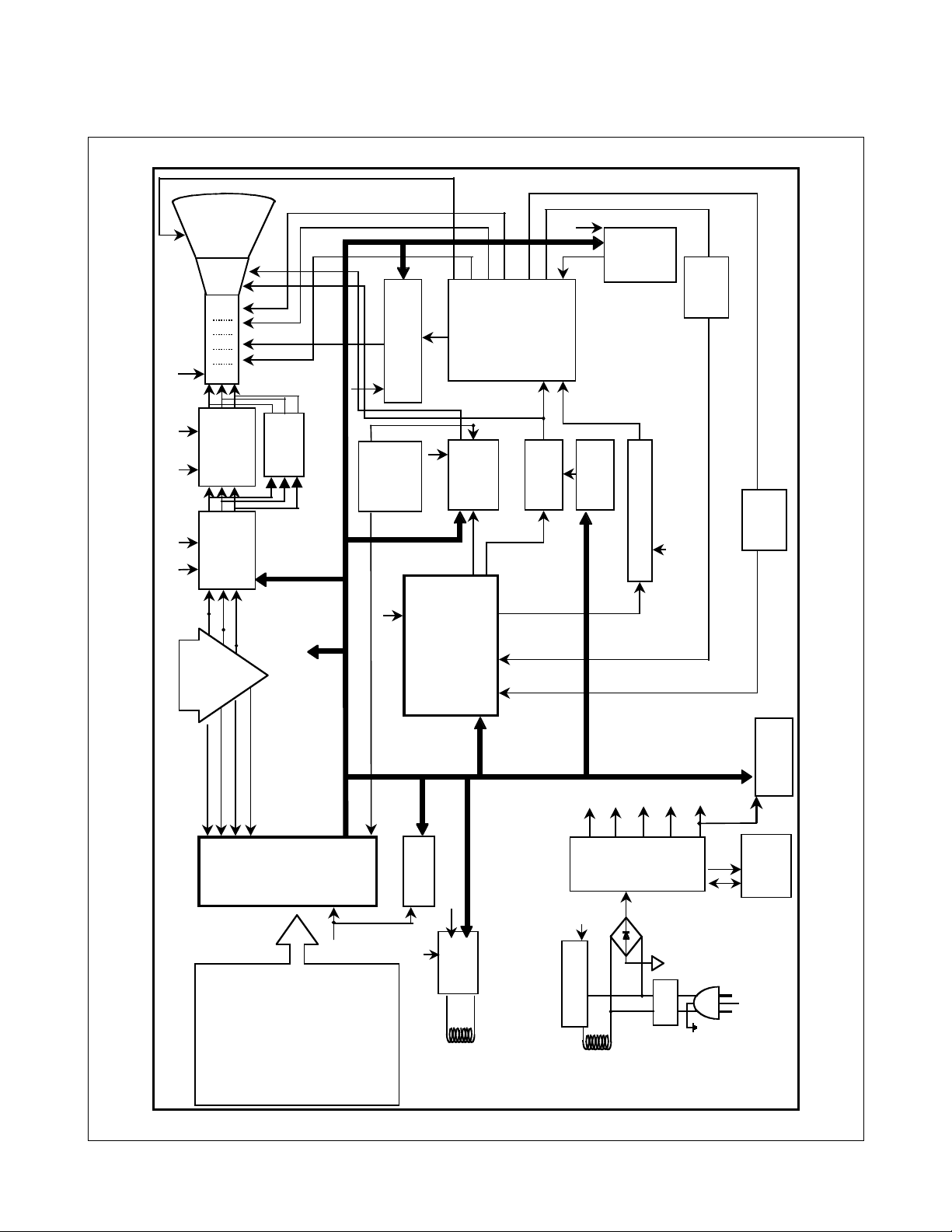

BLOCK DIAGRAM

- 7 -

Input_power

100~240VAC

(50/60Hz)

Line

Filter

Degaussing

Circuit

[ OSD Control ]

Power

Control

(IC901)

TILT

Control

Circuit

6.3V

15V

E

2

PROM

(IC402)

5V

H-sync Signal

V-sync Signal

I

2

C DATA(SDA)

I

2

C CLOCK(SCL)

VIDEO

OSD+pre_Amp

(IC302)

Signal

cable

RGB

VIDEO

Main_Amp

(IC303)

H/V Sync Processor

( IC701 )

TDA4841

V-out

( IC601)

TDA4867J

H-out

(Q706)

H-Linearity

Correction

Circuit

X-RAY

Protection

Circuit

Vertical Blanking,

- 160V

15V

D/D

Feed Back

30V

12V

MICOM

(IC401)

SCL / SDA

H/V sync

PWM control signal

15V

15V

50V

DY CDT

Heater ( 6.3V )

I

2

C

I

2

C

I

2

C

H/V

Sync

Screen

H.V

R/G/B

Bias

R/G/B

Contrast

H-Drive

B-Drive

B+

15V

BRIGHTNESS/CONTRAST

COLOR CURVE

H / V POSITION

H / V SIZE

SPCC

TRAPIZODE

PIN BALANCE

PARALLELOGRAM

ROTATION

TOP CORNER

BOTTOM CORNER

RECALL

DEGAUSSING

MOIRE

LANGUAGE

RESET

OSD TIME

DPM Control

Circuit

6.3V

15V 80V

Voltage

feedback

Voltage

feedback

Degaussing

Coil

Dynamic Focus

Static Focus

TILT

Coil

50V

80V

15V

G2

G1

DC/DC Converter

FBT

( T701 )

Regulation

Circuit

SMPS

(T901)

5V 15V

CUT-OFF IC

(IC304)

5V

Auto

Beam

Limit

(Option)

Page 8

DESCRIPTION OF BLOCK DIAGRAM

1. Line Filter & Associated Circuit

This is used for suppressing noise of power input line

flowing into the monitor and/or some noise generated in

the monitor flowing out through the power input line.

That is to say,this circuit prevents interference between

the monitor and other electric appliance.

2. Degaussing Circuit Coil.

The degaussing circuit consists of the degaussing coil,

the PTC(Positive Temperature Coefficient) thermistr

(TH901), and the relay(RL901). This circuit eliminate

abnormal color of the screen automatically by

degaussing the shadow mask in the CRT during turning

on the power switch.When you need to degaussing in

using the monitor,select DEGAUSS on the OSD menu.

3. SMPS(Switching Mode Power Supply).

This circuit is working of 90~264V AC(50/60Hz).

The operation procecedure is as below:

1)AC input voltage is rectified and smoothed by the

bridge diodes(D900) and the capacitor.

2)The rectified voltage(DC) is applied to the primary

coil of the transform(T901).

3)The control IC(IC901) generates switching pulse to

turn on and off the primary coil of the transformer

(T901) repeatedly.

4)Depending on turn ration of the transformer,the

secondary voltage appear at the secondary coils of

the transformer(T901).

5)These secondary voltage are rectified by each diode

(D941,D951,D961,D971,D942) and operate other

circuit.(horizontal and vertical deflection,video

amplifer,...etc.)

4. X-ray Protection Circuit

When the high voltage reaches to 29kV in an abnormal

state), voltage of IC401(MICOM) pin 35 come to about

2.5V.

Then MICOM control IC701 (Deflection controller)to

stophorizontal drive pulse and stop horizontal deflection.

5. Microprocessor Control Circuit

The operating procedure of MICOM(Microprocessor)

and its associating circuit is as fallow:

1) Horizontal and Vertical sync signals are supplied

from the signabl cable.

2) Microprocessor(IC401) discriminates the operating

mode from the sync polarity and resolution.

3) The Micom sets operating mode and offers the

controlled data.(H-Size,H-Position,V-Size,...)

4) The controlled data of each mode is stored in itself.

5) User can adjust screen condition by each OSD

function.the data of the adjusted condition is stored in

EEPROM(IC402).

6. Horizontal and Vertical Oscillation

This circuit generates the horizontal pulse and the

vertical pulse by taking the H and V sync signal.

This circuit consists of the H/V processor(IC701) and

the associate circuit.

7. D/D(DC to DC) Converter

This circuit supplies DC voltage to the horizontal

deflection output circuit by increasing DC 50V which is

the secdonary voltage of the SMPS in accordance with

the input horizontal sync signal.

8. Side-Pincushion & Trapezoid Correction Circuit

This circuit improve the side-pincushion and the

trapezoid distortion of the screen by mixing parabola

and saw-tooth wave to output of the horizontal

deflection D/D converter which is used for the supply

voltage (B + ) of the deflection circuit.

9. Horizontal Deflection Output Circuit

This circuit makes the horizontal deflection by supplying

the saw-tooth current to the horizontal deflection yoke.

10.

High Voltage Output & FBT(Flyback Transformer)

The high voltage output circuit is used for generating

pulse to the primry coil of the FBT(Flyback

Transformer(T701)). A boosted voltage about 24.5kV)

appears at the secondary of the FBT and it is suppliesd

to the anode, focus, and screen voltage of the CRT.

11.

H-Linearity Correction Circuit

This circuit corrects the horizontal linearity for each

horizontal sync frequency.

12.

Vertical Output Circuit

This circuit takes the vertical ramp wave from the IC701

and performs the vertical deflection by supplying the

saw-tooth current to the vertical deflection yoke.

13.

H & V Blanking and Brightness Control

Blanking circuit eliminate retrace line by supplying

negatinve pulse to the G1 of the CRT. And Brightness

control uses the R/G/B cut-off DC Level by IIC line.

14.

Image Rotation(Tilt)Circuit-Option

This circuit corrects the tilts of the screen by supplying

the image rotation signal to the tilt which is attached

near the deflection yoke of the CRT.

15.

Video Pre-AMP Circuit

This circuit amplifies the analog video signal from 0-

0.7V to 0-4V. It is operated by taking the clamp,R,G,B

drive and contrast signal from the MICOM(IC401).

16.

Video Output AMP Circuit

This the circuit amplifies the video signal which comes

from the video pre-amp circuit and amplifies it to applied

the CRT cathode.

- 8 -

Page 9

- 9 -

ADJUSTMENT

GENERAL INFORMATION

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several adjustments may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

• Alignment appliances and tools.

- IBM compatible PC.

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- EPROM or EEPROM with saved each mode data.

- Alignment Adaptor and Software.

- Digital Voltmeter.

- White Balance Meter.

- Luminance Meter.

- High-voltage Meter.

AUTOMATIC AND MANUAL DEGAUSSING

The degaussing coil is mounted around the CDT so that

automatic degaussing when turn on the monitor. But a

monitor is moved or faced in a different direction, become

poor color purity cause of CDT magnetized, then

press

DEGAUSS on the OSD menu.

ADJUSTMENT PROCEDURE & METHOD

-Install the cable for adjustment such as Figure 1and run

the alignment program on the DOS for IBM compatible PC.

-Set external Brightness and Contrast volume to max position.

1. Checked for B+ Voltage.

1) Display cross hatch pattern at Mode 4.

2) Check D961 voltage to 50V ± 1V with.

2. Adjustment for High-Voltage.

1) Display cross hatch pattern at Mode 4.

2) DIST.ADJ→CTRL PWM → High Voltage Command.

3) Adjust High Voltage to 24.5kV

±

0.1 kVdc.

4) Press Enter Key.

3. Adjustment for Factory Mode (Preset Mode).

1) Display cross hatch pattern at Mode 1.

2) Run alignment program for 500EJ on the IBM

compatible PC.

3) EEPROM → ALL CLEAR → Y(Yes) command.

<Caution> Do not run this procedure unless the

EEPROM is changed. All data in EEPROM (mode

data and color data) will be erased.

4) Power button of the monitor turn off → turn on.

5) COMMAND→PRESET START→Y(Yes) command.

6) DIST. ADJ→CTRLRWM→TILT Command.

7) DIST. ADJ. → BALANCE command.

8) Adjust parallelogram as arrow keys to be the best

condition.

9) Adjust balance of pin-balance as arrow keys to be

the best condition.

10)

DIST. ADJ. → FOS. ADJ command.

11)

Adjust V-SIZE as arrow keys to 200±2mm.

12)

Adjust V-POSITION as arrow keys to center of the

screen.

13)

Adjust H-SIZE as arrow keys to 270±2mm.

14)

Adjust H-POSITION as arrow keys to center of the

screen.

15)

Adjust S-PCC (Side-Pincushion) as arrow keys to be

the best condition.

16)

Adjust TRAPEZOID as arrow keys to be the best

condition.

17)

Save of the Mode 1.

18)

Display from Mode 2 to 4 and repeat above from

number 10) to 17)

19)

PRESET EXIT → Y (Yes) command.

4. Adjustment for White Balance and Luminance.

1) Set the White Balance Meter.

2) Press the DEGAUSS on the OSD menu for

demagnetization of the CDT.

3) COLOR ADJ. → LUMINANCE command of the

alignment program.

4) Set Brightness and Contrast to Max position.

5) Display color 0,0 pattern at Mode 4.

6) COLOR ADJ.→ BIAS ADJ.→ COLOR No. → 1

command of the alignment program.

7) Check whether green color or not at R-BIAS and GBIAS to min position and G-BIAS to 127(7F)

position. Sub-Brightness to 205(CD) position. Adjust

G2 (screen) command to 0.4

±

0.05FL of the raster

luminance.

8) Adjust R-BIAS and G-BIAS command to x=0.283

±

0.005 and y=0.298±0.005 on the White Balance

Meter with PC arrow keys.

9)

Adjust SUB-Brightnesscommand to 0.4±0.1FL of the

raster luminance.

10)

Adjust repeat number 8).

11)

After push the “ENTER” key.

11-1)

COMMAND → PRESET START → Y(Yes) command.

12)

Display color 15,0 full white pattern at Mode 4.

13)

DRIVE ADJ.→ No 1. command.

14)

Set Brightness and Contrast to Max position.

15)

Set SUB-CONTRAST Max 127(7F) (decimal) position.

16)

Set B-DRIVE to 80(50) at DRIVE of the alignment

program.

Page 10

- 10 -

17-1)

Adjust R-DRIVE and B-DRIVE command to white

balance x=0.283

±

0.003 and y=0.298±0.003 on the

White Balance Meter with PC arrow keys.

17-2)

Display color 15,0 window pattern (70x70mm) at mode 4.

18)

Adjust SUB-CONTRAST command to 50±2FL .

19)

Display color 15,0 full white patten at Mode 4.

20)

Set Brightness and Contrast to Max position.

21)

COLOR ADJ. → LUMINANCE → ABL command.

22)

Adjust ABL to 32±1FL of the luminance.

23)

After push the “ENTER” key, and “COMMAND →

PRESET EXIT → Y(Yes)” command.

24)

Exit from the program.

5. Input EDID Data.

1) Display color 15,0 cross hatch pattern at Mode 4.

2) EEPROM → Write EDID command and confirm

“EDID Write OK!!” message of monitor.

3) Exit from the alignment program.

4) Power switch OFF/ON for EDID data save.

6. Adjustment for Focus.

1) Set the Brightness and Contrast to max position.

2) Display H character in full screen at Mode 4.

3) Adjust two Focus control on the FBT that focus

should be the best condition.

Page 11

- 11 -

TROUBLESHOOTING GUIDE

1. NO POWER

NO POWER

(POWER INDICATOR OFF)

TROUBLE IN

D900

TROUBLE IN FUSE

(F901)

TROUBLE IN

Q901

TROUBLE IN

D941, D942, D951,

D961, D971

TROUBLE IN

Q903, Q952,

Q951, Q942, Q941

CHECK

FUSE OK?

CHECK

C908 VOLTAGE?

(AC120V: 160VDC,

AC220V: 304VDC)

NO

YES

YES

YES

YES

NO

NO

NO

CHECK

IC901 PIN 6

WAVEFORM

?

CHECK

D941, D942,

D951, D961, D971

VOLTAGE?

Page 12

- 12 -

2. NO CHARACTER

NO CHARACTER

CHECK

IC302

PIN 18(5V) ?

CHECK

IC302 PIN 5, 6, 7?

CHECK

IC302 PIN 19, 20, 21 ?

CHECK

IC303

PIN 1, 2, 3 ?

CHECK

IC303 PIN 4 (80V)

PIN 8 (12V) ?

TROUBLE IN

P302 5V LINE

TROUBLE IN

PC SIGNAL,

P301 SIGNAL CABLE

TROUBLE IN

IC302

TROUBLE IN

P303 12V LINE/

80V LINE

TROUBLE IN IC303

NO

YES

NO

NO

YES

YES

YES

YES

NO

NO

CHECK

R, G, B CATHODE

VOLTAGE?

TROUBLE IN

R331~R333,

L311~L313,

D307~D312

TROUBLE IN

CRT SOCKET

YES

NO

Page 13

- 13 -

3. NO RASTER

NO VIDEO

(POWER INDICATOR ON)

CHECK

POWER INDICATOR

GREEN or AMBER?

CHECK

D712 ANODE

(-160V)?

CHECK

G1VOLTAGE?

(-55V~-15V)

TROUBLE IN

D712

TROUBLE IN

Q799

DPM MODE

(NO H and/or V SYNC)

AMBER

NO

GREEN

YES

NO

CHECK

CDT HEAT

VOLTAGE? (6.3V)

TROUBLE IN

D941, Q942, Q941

YES

NO

TROUBLE IN

CDT

YES

Page 14

- 14 -

4. NO HORIZONTAL DEFLECTION

NO H-DEFLECTION

(ONE VERTICAL LINE)

CHECK

Q706?

CHECK

B+ VOLTAGE

(50V)?

CHECK

T701(FBT) PIN 2

(31KHZ 60V,

69KHZ 140V) ?

CHECK

Q705 COLLECTOR

WAVEFORM?

TROUBLE IN

Q706

TROUBLE IN

50V LINE

TROUBLE IN

Q719, Q720, D710

TROUBLE IN

Q705

TROUBLE IN

T701, P701

NO

NO

YES

YES

YES

YES

NO

NO

0V

T

Page 15

- 15 -

5. TROUBLE IN H-LINEARITY

UNBALANCED OF H-LIN.

CHECK

IC401

PIN 6, 7, 8 ?

CHECK

Q711~Q716?

CHECK

L703?

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q711 ~ Q716

TROUBLE IN

L703

TROUBLE IN

C722, C723, C726, C729

NO

NO

NO

YES

YES

YES

Cs SIGNAL TABLE

HORIZONTAL

FREQUENCY(fH)

30K ~ 33.9K

34K ~ 38.9K

39K ~ 43.9K

44K ~ 48.9K

49K ~ 51.9K

52K ~ 57.9K

58K ~ 61.9K

62K ~ 65.9K

66K ~ 71K

Cs1

L

L

H

H

H

H

H

H

H

Cs2

L

H

L

L

H

H

H

H

H

Page 16

- 16 -

6. NO VERTICAL DEFLECTION

NO V-DEFLECTION

(ONE HORIZONTAL LINE)

CHECK

IC601 PIN 3

(15V+)?

CHECK

IC701 PIN 12, 13?

TROUBLE IN

D951 15V LINE

TROUBLE IN

IC701

TROUBLE IN

IC601, V-CIRCUIT

NO

YES

YES

NO

5V 12Pin

13Pin

Page 17

- 17 -

7. TROUBLE IN OSD

TROUBLE IN

OSD PERIPHERAL

CIRCUIT

NO OSD

TROUBLE IN

5V LINE

TROUBLE IN

IC401 PIN29 (V-FBP),

IC701 PIN 1 LINE (H-FBP)

NO

YES

DC 5V

YES

NO

Pin 24

5V

Pin 1

CHECK

IC302 B

+

(5V)

?

(ENTER BUTTON MUST BE PRESSED.)

CHECK

IC302 PIN 1, 24

WAVEFORM?

Page 18

- 18 -

8. TROUBLE IN DPM

CHECK

IC401 (MICOM)

PIN 30, 31 (H/V INPUT)

SIGNAL?

CHECK

IC401 PIN 13

WAVEFORM?

CHECK

IC401 (MICOM)

PIN 2, 3 ?

CHECK

B+LINE

(6.3V,15V+, 80V) ?

CHECK PC,

(PC IS NOT GOING INTO

DPM OFF MODE)

TROUBLE IN

X401

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q941, Q942, Q951, Q952,

TROUBLE IN PC

OFF MODE FAILURE

INPUT H/V SYNC SIGNAL

H/V SYNC

(NO OFF MODE.)

NO

NO

NO

NO (DPMF: 0V)

DPM TABLE

Mode

Item

NORMAL

STAND-BY

SUSPEND

OFF

DPMF

H

L

L

L

LED

GREEN

AMBER

AMBER

AMBER

DPMS

H

H

H

L

YES

YES

SEE DPM TABLE

YES

YES

5V

24MHz

Page 19

- 19 -

9. NO DEGAUSSING

CHECK

IC401 PIN 5

(0V)?

CHECK

Q953 COLLECTOR

VOLTAGE?

CHECK

P902 ?

CHECK

RL901?

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q953

TROUBLE IN

P902

TROUBLE IN

RL901

TROUBLE IN

TH901,

DEGAUSSING COIL

NO DEGAUSSING

DC 15V

NO

NO

NO

NO

YES

YES

YES

YES

(DEGAUSS ON THE OSD MENU MUST BE PRESSED.)

Page 20

- 20 -

10. NO TILT (NO ROTATION)

NO TILT (NO ROTATION)

TROUBLE IN

IC401 (

MICOM)

TROUBLE IN

15V LINE, 6.3V LINE

TROUBLE IN

Q501~Q503

TROUBLE IN

P501, TILT COIL

NO

YES

YES

YES

CHECK

15V LINE

AND 6.3V LINE ?

CHECK

Q503 EMITTER

VOLTAGE ?

NO

NO

CHECK

IC401 PIN21

WAVE FORM ?

Page 21

EXPLODED VIEW

- 21 -

10

A

MENU

SELECT

12

1

4

12

11

12

13

3

2

6

5

8

B

7

9

a

b

c

b

14

14

Page 22

EXPLODED VIEW PARTS LIST

- 22 -

Ref. No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

a

b

c

Part No.

3091TKB036V

3091TKB036Z

3091TKB036W

3091TKB036Y

2423GB0A81Z

2423GB0A59A

6318L15004A

2423GB0A8AW

2423GB0A58A

6318L15011A

3809TKB021A

3043TKK071B

3043TKK071A

339-002D

6140TC3006B

6174T11004B

6620TKB002A

or 6620TKB002B

6850TA9012A

4950TKS155K

4810TKK154A

332-102F

4810TKK204C

4930TKK031C

3313T15086C

3313T15086K

3313T15086D

3313T15086N

3313T15086E

3313T15086G

3313T15086H

3313T15086F

6871TMT412C

6871TMT412K

6871TMT412D

6871TMT412N

6871TMT412E

6871TMT412G

6871TMT412H

6871TMT412F

332-112F

4001TKK004E

332-095A

Description

CABINET ASSEMBLY, CB553H BRAND B031 MPR-II - For Europe, India(500E)

CABINET ASSEMBLY, CB553H BRAND B031 NON-MPR-II LG LOGO RED - For Chile, Mexico, Brazil, Panama(500G)

CABINET ASSEMBLY, CB553H BRAND B031 NON-MPR-II - For Australia, Indonesia, Southeast Asia, India, Europe(500G)

CABINET ASSEMBLY, CB553H BRAND B031 MPR-II LG LOGO RED - For Mexico(500E)

CDT(CIRC), M36LBL803X 00NLLW LG-PHILIPS DISPLAYS 70KHZ 29.1 MM - For Europe(500E)

CDT(CIRC), M36LBL503X 34RLLD LG-PHILIPS DISPLAYS 54KHZ 29.1 MM - For Brazil(500G)

CDT(CIRC), M36LBL503X00NLLW LG-PHILIPS 54KHZ 29.1MM FST GLARE - For Indonesia, Southeast Asia, Europe, panama(500G)

CDT(CIRC), M36LBL803X 31NLLA LG-PHILIPS DISPLAYS 54KHZ 29.1 MM - For Mexico(500E)

CDT(CIRC), M36LBL503X 34NLLD LG-PHILIPS DISPLAYS 54KHZ 29.1 MM - For Mexico(500G)

CDT(CIRC), M36LBL803X 34KLLM LG-PHILIPS 54KHZ 29.1MM FST NON-MPR SEMI-ITC - For India(500E)

BACK COVER ASSY, CB563 B024 ABS 85964

TILT SWIVEL ASSEMBLY, KCB563C B046, T051 HIPS 85964 SP LOCAL - For Europe(500E)

TILT SWIVEL ASSEMBLY, CB563 T051 B046 HIPS 85964 - For Australia, Chile(500G), India(500E)

SCREW ASSY, PHP+5*30BP(FZMY)+GW18

COIL,DEGAUSSING, 75D-437 KWANGSUNG CB563G NT

FBT (FLY BACK TRANSFORMER), 1056A,CB553J(54K) JUNGWOO 15”

SOCKET(CIRC),POWER, BAE EUN AC UNIVERSAL 3PIN BLACK

SOCKET(CIRC),POWER, SA-4S HUA JIE AC UNIVERSAL 3PIN BLACK

CABLE,D-SUB, UL20276-9C(5.8MM) AT 1560MM GRAY(85964) T710BJ DM

METAL, SHIELD BOTTOM “H”CHASSIS

BRACKET, CB773D SUPPORTER CDT(L)

SCREW, PTP+4*20BP(MSWR/FZMY)

BRACKET, H-CHASSIS HOLDER FBT, A-CKD

HOLDER, PCB FIX , PC+ABS

MAIN TOTAL ASSEMBLY, 500EJ BRAND LGEDI CA-133 - For Europe(500E)

MAIN TOTAL ASSEMBLY, 500EJ BRAND CA-132 - For Mexico(500G)

MAIN TOTAL ASSEMBLY, 500EJ BRAND CA-133 NON-MPR LGEDI - For Australia, Chile, panama(500G)

MAIN TOTAL ASSEMBLY, 500EJ BRAND CA-133 - For Indonesia, Southeast Asia, Europe(500G)

MAIN TOTAL ASSEMBLY, 500EJ BRAND CA-133 SKYWAY(MX) - For Mexico(500G)

MAIN TOTAL ASSEMBLY, 500EJ BRAND CA-133 NON-MPR(IL) - For India(500G)

MAIN TOTAL ASSEMBLY, 500EJ BRAND CA-133 MPR(IL) - For India(500E)

MAIN TOTAL ASSEMBLY, 500EJ BRAND CA-133 NON-MPR(SP) - For Brazil(500G)

PWB(PCB) ASSEMBLY,MAIN, 500EJ KLRDMD BRAND CA-133 TOTAL - For Europe(500E)

PWB(PCB) ASSEMBLY,MAIN, 500EK PLPAAA BRAND CA-132 TOTAL - For Mexico(500G)

PWB(PCB) ASSEMBLY,MAIN, 500EJ KLEUAD BRAND CA-133 TOTAL - For Australia, Chile, Panama(500G)

PWB(PCB) ASSEMBLY,MAIN, 500EJ KLIDAD BRAND CA-133 TOTAL - For Indonesia, Southeast Asia, Europe(500G)

PWB(PCB) ASSEMBLY,MAIN, 500EJ PLMXMA BRAND CA-133 TOTAL - For Mexico(500E)

PWB(PCB) ASSEMBLY,MAIN, 500EJ KLINAL BRAND CA-133 TOTAL - For India(500G)

PWB(PCB) ASSEMBLY,MAIN, 500EJ KLINML BRAND CA-133 TOTAL - For India(500E)

PWB(PCB) ASSEMBLY,MAIN, 500EJ KLBRAS BRAND CA-133 TOTAL - For Brazil(500G)

SCREW,DRAWING, D3.5 L10.0 MSWR/FZMY +SW3.5+RW3.5

SCREW ASSEMBLY, TAPTITE P TYPE D3.0 L10.0 MSWR/FZMY SW3+RW10

SCREW, PZP+3*8 (MSWR/FZMY)

Page 23

- 23 -

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C301 0CQ1021N419 1000P 100V J POLY NI TP

C302 0CE106CF638 10UF SHL,SD 16V M FM5 TP 5

C303 0CC5600K415 56P 50V J NP0 TP

C304 0CC5600K415 56P 50V J NP0 TP

C305 0CE476CF638 47UF SHL,SD 16V M FM5 TP 5

C306 0CZZTFT001M ECQB1H103JF3 MATSUSHITA 50V

C308 0CK1020K515 1000PF 50V K B TR

C309 0CK1040K945 0.1UF 50V Z F TR

C311 0CK1040K945 0.1UF 50V Z F TR

C312 0CK1040K945 0.1UF 50V Z F TR

C313 0CK1040K945 0.1UF 50V Z F TR

C314 0CC4700W405 47PF 500V J SL TP

C315 0CE476CF638 47UF SHL,SD 16V M FM5 TP 5

C317 0CK1040K945 0.1UF 50V Z F TR

C318 0CK1040K945 0.1UF 50V Z F TR

C319 0CK1040K945 0.1UF 50V Z F TR

C320 0CK10202515 1000PF D 2KV 10% TR B(Y5P)

C321 0CE225CK638 2.2UF SHL,SD 50V M FM5 TP 5

C323 0CE476CF638 47UF SHL,SD 16V M FM5 TP 5

C324 0CK1040K945 0.1UF 50V Z F TR

C325 181-288B MKT 100V 104JTR PHS26104

C326 0CC2200W415 22PF 500V J NP0 TR

C327 181-288B MKT 100V 104JTR PHS26104

C328 0CE226CN638 22UF SHL,SD 100V M FM5 TP 5

C329 181-288B MKT 100V 104JTR PHS26104

C330 181-288B MKT 100V 104JTR PHS26104

C331 181-288G MKT 100V 334JTR PHS26334

C332 181-288G MKT 100V 334JTR PHS26334

C333 181-288G MKT 100V 334JTR PHS26334

C334 181-288B MKT 100V 104JTR PHS26104

C335 181-288B MKT 100V 104JTR PHS26104

C339 0CK1520W515 1500P 500V K B TS

C340 181-288B MKT 100V 104JTR PHS26104

C341 0CK10202515 1000PF D 2KV 10% TR B(Y5P)

C344 181-288B MKT 100V 104JTR PHS26104

C346 0CK10302940 0.01M 2KV Z F S

C372 0CK1040K945 0.1UF 50V Z F TR

C401 0CK1040K945 0.1UF 50V Z F TR

C402 0CE476CF638 47UF SHL,SD 16V M FM5 TP 5

C403 0CK1040K945 0.1UF 50V Z F TR

C406 0CK1010K515 100PF 50V K B TR

C407 0CK1010K515 100PF 50V K B TR

C408 0CK1040K945 0.1UF 50V Z F TR

C410 0CK1010K515 100PF 50V K B TR

C412 0CK1040K945 0.1UF 50V Z F TR

C501 0CE106CF638

10UF SHL,SD 16V M FM5 TP 5

- For Indonesia, Southeast Asia, Europe(500G)

C599 0CE225CK638

2.2UF SHL,SD 50V M FM5 TP 5

- For Indonesia, Southeast Asia, Europe(500G)

C601 0CE477EH618 470UF KMG 25V M FL TP 5

C602 181-288B MKT 100V 104JTR PHS26104

C603 0CE476CK638 47UF SHL,SD 50V M FM5 TP 5

C604 0CZZTFT001V ECQB1H473JM3 473J 50V TP5.0

C605 0CK1020W515 1000P 500V K B TS

C701 0CQ5621N419 5600P 100V J POLY NI TP

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C702 0CZZTFT001M ECQB1H103JF3 MATSUSHITA 50V

C703 0CZZTFT001Z ECQB1H104JM3 104J 50V TP5.0

C704 0CQ8221N519 0.0082U 100V K POLY NI TP

C706 0CZZTFT001Z ECQB1H104JM3 104J 50V TP5.0

C707 0CZZTFT002B ECQV1H154JZ3 154J 50V TP5.0

C708 0CE227CH638 220UF SHL,SD 25V M FM5 TP 5

C709 0CZZTFT001P ECQB1H153JM3 153J 50V TP5.0

C711 0CQ5621N419 5600P 100V J POLY NI TP

C713 0CK2210K515 220P 50V K B TS

C714 0CE107CH638 100UF SHL,SD 25V M FM5 TP 5

C715 181-288N MKT 100V 103JTR PHS86103

C716 0CK2710K515 270P 50V K B TS

C717 0CZZTFT001R ECQB1H223JM3 223J 50V TP5.0

C718 0CZZTFT001V ECQB1H473JM3 473J 50V TP5.0

C719 0CZZTAB001F SHL-BP SYE / SWE 50V 3.3UF 2

C722 181-303H 394J 31.0*23.0*16.0*20.0 250

C724 0CN1040K949 0.1M 50V Z F TA52

C725 0CK6810W515 680P 500V K B TS

C726 181-482F 274JF 18.0*17.0*10.0*7.5 250

C728 0CQ5621N419 5600P 100V J POLY NI TP

C729 181-305V 514J 26.0*18.0*11.0*15.0 250

C730 0CN1040K949 0.1M 50V Z F TA52

C731 181-309X 542J 31.0*17.0*10.0*20.0 1.

C732 181-288N MKT 100V 103JTR PHS86103

C733 0CBZTBU003K 472J 20.0*13.0*8.0*10.0 800V

C734 0CE226CK638 22UF SHL,SD 50V M FM5 TP 5

C737 0CK10102515 100PF D 2KV 10% B(Y5P) TR

C739 0CE106CK638 10UF SHL,SD 50V M FM5 TP 5

C740 0CE227EL630 220UF KMG 63V M FM5 BULK

C741 0CZZTFT002B ECQV1H154JZ3 154J 50V TP5.0

C742 0CE106CK638 10UF SHL,SD 50V M FM5 TP 5

C743 0CZZTFT002B ECQV1H154JZ3 154J 50V TP5.0

C744 0CZZTAB005A SMSHR SYE / SWE 160V 47UF 20

C746 0CK3310W515 330P 500V K B TS

C747 0CK1040K945 0.1UF 50V Z F TR

C748 0CK1510W515 150PF 500V K B TR

C749 0CE105CQ638 1UF SHL,SD 200V M FM5 TP 5

C750 0CK1040K945 0.1UF 50V Z F TR

C751 181-288J MKT 100V 563JTR PHS26563

C752 0CQ4721N419 0.0047U 100V J POLY NI TP5

C753 0CK10301945 10000PF D 1KV Z F(Y5V) TR

C754 0CC4700W405 47PF 500V J SL TP

C754 0CC4700W405

47PF 500V J SL TP - For Mexico, India(500E)

C756 0CK1010K515 100PF 50V K B TR

C771 0CK10301945 10000PF D 1KV Z F(Y5V) TR

C774 0CZZTFT001Z ECQB1H104JM3 104J 50V TP5.0

C801 0CE105CK638 1UF SHL,SD 50V 20% FM5 TP 5

C805 0CE106CK638 10UF SHL,SD 50V M FM5 TP 5

C901 0CBZTBU002A BULK PCX2 335 224K

C902 0CBZTBU002C BULK PCX2 335 104M

C903 0CZZTCB003D BULK 7.5 CS E 102M 8.0 250V

C904 0CKZTBU003A SC E 222M 10.0BW7 250V BK7.5

C905 0CKZTBU003A SC E 222M 10.0BW7 250V BK7.5

C906 0CZZTCB003D BULK 7.5 CS E 102M 8.0 250V

REPLACEMENT PARTS LIST

CAUTION: BEFORE REPLACING ANY OF THESE COMPONENTS,

READ CAREFULLY THE SAFETY PRECAUTIONS IN THIS MANUAL.

* NOTE : S SAFETY Mark

AL ALTERNATIVE PARTS

CAPACITORS

Page 24

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C907 0CKZTBU003C SC E 472M 14.0BW7 250V BK7.5

C908 181-296K 150UF SMH,HC(25.4*30) 400V M

C909 0CK10301510 0.01M 1KV K B S

C910 0CK10101515 100PF 1KV K B TR

C911 0CE475CK638 4.7UF SHL,SD 50V M FM5 TP 5

C912 0CK3310K515 330P 50V K B TS

C913 0CE476CK638 47UF SHL,SD 50V M FM5 TP 5

C914 0CZZTFT001P ECQB1H153JM3 153J 50V TP5.0

C915 0CK6810K515 680P 50V K B TS

C917 0CK1020K515 1000PF 50V K B TR

C918 0CK1040K945 0.1UF 50V Z F TR

C941 0CE108CD618 1000UF SHL 10V M FL TP5

C942 0CE107CF638 100UF SHL,SD 16V M FM5 TP 5

C943 0CK56101515 560P 1KV K B TS

C944 0CKZTBU003C SC E 472M 14.0BW7 250V BK7.5

C946 0CK2710W515 270P 500V K B TS

C951 0CE108CH630 1000UF SHL 25V M FM5 BULK

C952 0CE227CH638 220UF SHL,SD 25V M FM5 TP 5

C953 0CE107CF638 100UF SHL,SD 16V M FM5 TP 5

C954 0CE108CF630 1000UF SHL 16V M FM5 BULK

C971 0CE476CN618 47UF SHL 100V M FL TP5

C999 0CE227CL630 220U SHL 63V M FM5

D201 0DLGP0010AB XIAMEN G&P GP32052ME/512-ZYD301 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D302 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D303 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D304 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D305 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D306 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D307 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D308 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D309 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D310 0DS124409AA 1SS244 TP ROHM KOREA

D311 0DS124409AA 1SS244 TP ROHM KOREA

D312 0DS124409AA 1SS244 TP ROHM KOREA

D313 0DS124409AA 1SS244 TP ROHM KOREA

D314 0DS124409AA 1SS244 TP ROHM KOREA

D315 0DS124409AA 1SS244 TP ROHM KOREA

D316 0DR140059DA 1N4005TB52 TP LITEON DO41 60

D402 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D404 971-0054 TIN 50MM TAPING

D512 0DSGF00019A

1N4148 GULF TP DO35 100V 0.1 - For Indonesia, Southeast Asia, Europe(500G)

D702 0DS124409AA 1SS244 TP ROHM KOREA

D703 0DRTW00050A MUR460L-1121 TIWAN SEMI BK D

D704 0DR150001AD DTV1500LFP SGS-THOMSON ST TO

D705 0DRTW00089A SRT14(1021) TIWAN SEMI TP NO

D706 0DR150001AD DTV1500LFP SGS-THOMSON ST TO

D709 971-0054 TIN 50MM TAPING

D710 0DR400409AC UF4004 GULF TP DO41 400V 1A

D711 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D712 0DR100009CD RGP10G-1021 TIWAN SEMI TP DO

D713 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D714 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D715 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D716 0DR140059DA 1N4005TB52 TP LITEON DO41 60

D717 0DR140059DA 1N4005TB52 TP LITEON DO41 60

D719 0DR100009DA RGP10J TP GULF SEMICONDUCTOR

D720 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D721 0DR100009CD RGP10G-1021 TIWAN SEMI TP DO

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

D722 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D723 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D724 0DR140059DA 1N4005TB52 TP LITEON DO41 60

D730 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D731 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D801 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D802 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D900 0DRTW00071A TS4B05G-1021 TIWAN SEMI ST N

D902 971-0054 TIN 50MM TAPING

D904 0DR100009CD RGP10G-1021 TIWAN SEMI TP DO

D905 0DD400709CB UF4007 TP G.I DO204AL 1000V

D906 0DR100009CD RGP10G-1021 TIWAN SEMI TP DO

D908 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D910 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D911 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D941 0DR100009LA UG1D TP G.I DO204AL 200V 1A

D942 0DR400409AC UF4004 GULF TP DO41 400V 1A

D951 0DRTW00044B UG2DL-1021 TIWAN SEMI BK DO1

D952 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D961 0DRGF00050A 31GF6 GULF BK DO201AD 600V 3

D971 0DD400709CB UF4007 TP G.I DO204AL 1000V

ZD402 0DZ560009AG GDZJ5.6B TP GRANDE DO-34 500

ZD403 0DZ560009AG GDZJ5.6B TP GRANDE DO-34 500

ZD404 0DZ560009AG GDZJ5.6B TP GRANDE DO-34 500

ZD405 0DZ560009AG GDZJ5.6B TP GRANDE DO-34 500

ZD407 0DZ560009AG GDZJ5.6B TP GRANDE DO-34 500

ZD410 0DZ560009AG GDZJ5.6B TP GRANDE DO-34 500

ZD701 0DZ120009BF GDZJ12B TP GRANDE DO34 0.5W

ZD902 0DZ510009BE GDZ5.1B TP GRANDE DO34 500MW

IC302 0IPRPNS025A LM1246DDA/NA NATIONAL SEMICO

IC303 0IPRPNS026A LM2445TA NATIONAL SEMICONDUC

IC304 0IPRPNS005A LM2480NA NATIONAL SEMICONDUC

IC401 0IZZTSZ262A SS 42PIN ST 4-KEY 500EJ

IC402 0ISG240860A M24C08-BN6 8DIP BK 8K SERIAL

IC601 0IPRPPH018A TDA4867J PHILIPS 9PIN,ST DIP

IC701 0IPRPPH005A TDA4841PS PHILIPS 32P,SDIP S

IC901 0ISS384200A KA3842B (PWM)

FB301 6210TCZ001J BAS3550T0(125-022J) BO SUNG

FB302 6210TCE003L BAS3580T BO SUNG 3580MM AXIA

FB303 6210TCZ001J BAS3550T0(125-022J) BO SUNG

FB304 6210TCZ001J BAS3550T0(125-022J) BO SUNG

FB305 6210TCE003P BRS2550B BO SUNG 2550MM RADI

FB306 6210TCE003L BAS3580T BO SUNG 3580MM AXIA

FB307 6210TCE003B BRS3580B BO SUNG 3580MM RADI

FB308 6210TCE003J BAS2550T BO SUNG 2550MM AXIA

FB309 6210TCE003J BAS2550T BO SUNG 2550MM AXIA

FB310 6210TCE003A BRD3510B BO SUNG 3510MM RADI

FB313 6210TCE003J BAS2550T BO SUNG 2550MM AXIA

FB402 971-0054 TIN 50MM TAPING

FB403 971-0054 TIN 50MM TAPING

FB701 6210TCE003L BAS3580T BO SUNG 3580MM AXIA

FB703 6210TCE003B BRS3580B BO SUNG 3580MM RADI

FB703 6210TCE003B

BRS3580B BO SUNG 3580MM RADI - For Mexico, India, Europe(500E)

FB705 971-0054 TIN 50MM TAPING

FB903 6210TCE003P BRS2550B BO SUNG 2550MM RADI

FB904 971-0054 TIN 50MM TAPING

- 24 -

DIODEs

ICs

COILs & COREs

Page 25

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

FB905 6210TCE003P BRS2550B BO SUNG 2550MM RADI

FB906 6210TCE003P BRS2550B BO SUNG 2550MM RADI

FB921 6210TCE003A BRD3510B BO SUNG 3510MM RADI

FB922 6210TCE003L BAS3580T BO SUNG 3580MM AXIA

FB952 6210TCE003G BRS3550B BO SUNG 3550MM RADI

L301 971-0054 TIN 50MM TAPING

L302 971-0054 TIN 50MM TAPING

L303 971-0054 TIN 50MM TAPING

L311 0LA0820K119 0.82UH K 2.3*3.4 TP

L312 0LA0820K119 0.82UH K 2.3*3.4 TP

L313 0LA0820K119 0.82UH K 2.3*3.4 TP

L702 6140TBZ025D - - H-SIZE,DR12*20-C6.0,150U

L703 6140TYZ010F LX31 GET DR14*15-C5.2,19.5T,

L705 6140TBZ026C DR15*18-C9.8 100UH 0.1*30MM

L901 6200TZZ004A SQE2626 NAMYANG BK L/FILTER

L903 6210TCE003G BRS3550B BO SUNG 3550MM RADI

Q501 0TR320209AA

KTC3202-Y(KTC1959) TP KEC TO - For Indonesia, Southeast Asia, Europe(500G)

Q502 0TR127009AA

KTA1270-Y(KTA562TM) TP KEC T - For Indonesia, Southeast Asia, Europe(500G)

Q503 0TR319809AA

KTC3198-Y(KTC1815) TP KEC TO - For Indonesia, Southeast Asia, Europe(500G)

Q705 0TR200009AB KTC200-Y TP KEC TO92 NPN

Q706 0TRTH10005A 2SC5855 TOSHIBA ST TO3P 1500

Q707 0TR127009AA KTA1270-Y(KTA562TM) TP KEC T

Q708 0TR127009AA KTA1270-Y(KTA562TM) TP KEC T

Q709 0TR141300AB KTD1413 BK KEC TO220I S NPN

Q711 0TF630000AC IRF630M BK SGS-THOMSON 200V

Q713 0TF630000AC IRF630M BK SGS-THOMSON 200V

Q715 0TR319809AA KTC3198-Y(KTC1815) TP KEC TO

Q716 0TR319809AA KTC3198-Y(KTC1815) TP KEC TO

Q719 0TF630000CA IRFS630A BK SAMSUNG 200V 6.5

Q720 0TR390409CA FAIRCHILD 2N3904(TA) TP TO-9

Q799 0TRKE90019A MPSA92 KEC TP TO92 -300V -50

Q901 0TF760000AD SSS7N60B FAIRCHILD ST TO220F

Q903 0TR100809AA KSC1008C-Y TP SAMSUNG TO92

Q941 0TR319809AA KTC3198-Y(KTC1815) TP KEC TO

Q942 0TR127309AA KTA1273-Y(KTA966A) TP KEC TO

Q951 0TR319809AA KTC3198-Y(KTC1815) TP KEC TO

Q952 0TR127309AA KTA1273-Y(KTA966A) TP KEC TO

Q953 0TR319809AA KTC3198-Y(KTC1815) TP KEC TO

R301 0RD0752Q609 75 1/4W(3 5% TA52

R302 0RD0752Q609 75 1/4W(3 5% TA52

R303 0RD0752Q609 75 1/4W(3 5% TA52

R305 0RN6201F409 6.20K 1/6W 1% TA52

R314 0RD1000Q609 100 1/4W(3 5% TA52

R315 0RD1000Q609 100 1/4W(3 5% TA52

R319 0RD4701Q609 4.70K 1/4W(3 5% TA52

R320 0RD4701Q609 4.70K 1/4W(3 5% TA52

R326 0RD2201Q609 2.20K 1/4W(3 5% TA52

R327 0RD1001Q609 1K 1/4W(3 5% TA52

R328 0RD1001Q609 1K 1/4W(3 5% TA52

R329 0RD1001Q609 1K 1/4W(3 5% TA52

R330 0RD1001Q609 1K 1/4W(3 5% TA52

R331 0RD2200Q609 220 1/4W(3 5% TA52

R332 0RD2200Q609 220 1/4W(3 5% TA52

R333 0RD2200Q609 220 1/4W(3 5% TA52

R334 0RD3303Q609 330K 1/4W(3 5% TA52

R335 0RD3303Q609 330K 1/4W(3 5% TA52

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R336 0RD3303Q609 330K 1/4W(3 5% TA52

R337 0RD1000Q609 100 1/4W(3 5% TA52

R338 0RD0471Q609 4.70 1/4W(3 5% TA52

R340 0RN1002F409 10K 1/6W 1 TA52

R341 0RD0332A609 33 OHM 1/2 W (7.0) 5% TA52

R342 0RD0332A609 33 OHM 1/2 W (7.0) 5% TA52

R343 0RD0332A609 33 OHM 1/2 W (7.0) 5% TA52

R344 0RD0332Q609 33 1/4W(3 5% TA52

R345 0RD0332Q609 33 1/4W(3 5% TA52

R346 0RD0332Q609 33 1/4W(3 5% TA52

R347 0RD1200Q609 120 1/4W(3 5% TA52

R401 0RD1000Q609 100 1/4W(3 5% TA52

R402 0RD5600Q609 560 1/4W(3 5% TA52

R403 0RD1002Q609 10K 1/4W(3 5% TA52

R405 0RD2001Q609 2K 1/4W(3 5% TA52

R406 0RD2001Q609 2K 1/4W(3 5% TA52

R407 0RD1300Q609 130 1/4W(3 5% TA52

R408 0RD1300Q609 130 1/4W(3 5% TA52

R409 0RD1000Q609 100 1/4W(3 5% TA52

R411 0RD3901Q609 3.90K 1/4W(3 5% TA52

R412 0RD1004Q609 1M OHM 1/4 W (3.4) 5% TA52

R415 0RD1801Q609 1.80K 1/4W(3 5% TA52

R416 0RD4701Q609 4.70K 1/4W(3 5% TA52

R417 0RD1000Q609 100 1/4W(3 5% TA52

R418 0RD1002Q609 10K 1/4W(3 5% TA52

R419 0RD1004Q609 1M OHM 1/4 W (3.4) 5% TA52

R420 0RD2001Q609 2K 1/4W(3 5% TA52

R424 0RD2200Q609 220 1/4W(3 5% TA52

R425 0RD4701Q609 4.70K 1/4W(3 5% TA52

R426 0RD4701Q609 4.70K 1/4W(3 5% TA52

R429 0RD1000Q609 100 1/4W(3 5% TA52

R430 0RD1000Q609 100 1/4W(3 5% TA52

R431 0RD1000Q609 100 1/4W(3 5% TA52

R432 0RD1000Q609 100 1/4W(3 5% TA52

R433 0RD1000Q609 100 1/4W(3 5% TA52

R434 0RD1000Q609 100 1/4W(3 5% TA52

R438 0RD1001Q609 1K 1/4W(3 5% TA52

R439 0CN1010K519 100P 50V K B TA52

R441 0RD2200Q609 220 1/4W(3 5% TA52

R442 0RD2200Q609 220 1/4W(3 5% TA52

R443 0RD0912Q609 91 OHM 1/4 W (3.4) 5% TA52

R445 0RD5101Q609 5.10K 1/4W(3 5% TA52

R445 0RD2201Q609

2.20K 1/4W(3 5% TA52 - For Indonesia, Southeast Asia, Europe(500G)

R446 0RD1002Q609 10K 1/4W(3 5% TA52

R447 0RD1001Q609 1K 1/4W(3 5% TA52

R490 0RD9100Q609 910 1/4W(3 5% TA52

R491 0RD2200Q609 220 1/4W(3 5% TA52

R492 0RD4300Q609 430 OHM 1/4 W(3.4) 5.00% TA5

R493 0RD7500Q609 750 OHM 1/4 W (3.4) 5% TA52

R494 0RD1001Q609 1K 1/4W(3 5% TA52

R495 0RD1001Q609 1K 1/4W(3 5% TA52

R501 0RD0102A609

10 OHM 1/2 W (7.0) 5% TA52 - For Indonesia, Southeast Asia, Europe(500G)

R508 0RD4702Q609

47K 1/4W(3 5% TA52 - For Indonesia, Southeast Asia, Europe(500G)

R515 0RD1502Q609

15K 1/4W(3 5% TA52 - For Indonesia, Southeast Asia, Europe(500G)

R597 0RD3902Q609

39K 1/4W(3 5% TA52 - For Indonesia, Southeast Asia, Europe(500G)

R598 0RD5601Q609

5.60K 1/4W(3 5% TA52 - For Indonesia, Southeast Asia, Europe(500G)

R599 0RD0202Q609

20 1/4W(3 5% TA52 - For Indonesia, Southeast Asia, Europe(500G)

R601 0RD1000Q609 100 1/4W(3 5% TA52

R602 0RD1000Q609 100 1/4W(3 5% TA52

R603 0RN0390H609 0.39 1/2W 5 TA52

R604 0RD0101A609 1 OHM 1/2 W (7.0) 5% TA52

R605 0RD1500A609 150 OHM 1/2 W (7.0) 5% TA52

- 25 -

TRANSISTOR

RESISTORs

Page 26

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R606 0RD1000A609 100 OHM 1/2 W (7.0) 5% TA52

R607 0RN4701F409 4.70K 1/6W 1% TA52

R607 0RN5101F409

5.10K 1/6W 1% TA52 - For Word Wied(500G), Mexico, India(500E)

R608 0RD2200A609 220 OHM 1/2 W (7.0) 5% TA52

R700 971-0054 TIN 50MM TAPING

R701 0RN3301F409 3.30K 1/6W 1% TA52

R702 0RN6800F409 680 1/6W 1% TA52

R703 0RD1001Q609 1K 1/4W(3 5% TA52

R704 0RD3601Q509 3.6K OHM 1/4 W(3.4) 2% TA52

R706 0RN2701F409 2.7K OHM 1/6 W 1.00% TA52

R709 0RD2202Q609 22K 1/4W(3 5% TA52

R710 0RD1000Q609 100 1/4W(3 5% TA52

R711 0RD1000Q609 100 1/4W(3 5% TA52

R712 0RD1500A609 150 OHM 1/2 W (7.0) 5% TA52

R713 0RD1000Q609 100 1/4W(3 5% TA52

R714 0RD5601Q609 5.60K 1/4W(3 5% TA52

R714-1 0RN3001F409 3K 1/6W 1% TA52

R714-2 0RN6200F409 620 1/6W 1% TA52

R715 0RD6202Q609 62K OHM 1/4 W (3.4) 5% TA52

R717 0RD2702Q609 27K 1/4W(3 5% TA52

R717 0RD3302Q609

33K 1/4W(3 5% TA52 - For Word Wied(500G), Mexico, India(500E)

R718 0RD1602Q609 16K 1/4W(3 5% TA52

R719 971-0054 TIN 50MM TAPING

R721 0RD1001Q609 1K 1/4W(3 5% TA52

R722 0RD2402Q609 24K 1/4W(3 5% TA52

R723 0RD1001Q609 1K 1/4W(3 5% TA52

R722 0RD2702Q609

27K 1/4W(3 5% TA52 - For Word Wied(500G), Mexico, India(500E)

R724 0RD1001Q609 1K 1/4W(3 5% TA52

R725 0RN1501F409 1.5K 1/6W 1 TA52

R726 0RD5102A609 51K OHM 1/2 W (7.0) 5% TA52

R727 0RX0472K665 47 OHM 2 W 5% SF

R728 0RD1001Q609 1K 1/4W(3 5% TA52

R729 0RD1002Q609 10K 1/4W(3 5% TA52

R731 0RD1002Q609 10K 1/4W(3 5% TA52

R732 0RD1003Q609 100K 1/4W(3 5% TA52

R733 0RD1002Q609 10K 1/4W(3 5% TA52

R735 0RD1001Q609 1K 1/4W(3 5% TA52

R736 0RX2201J609 2.2KOHM 1 W 5% TA52

R737 0RN0560H609 0.56 1/2W 5 TA52

R738 0RN0560H609 0.56 1/2W 5 TA52

R739 0RD6800Q609 680 1/4W(3 5% TA52

R740 0RD0271A609 2.7 OHM 1/2 W (7.0) 5% TA52

R741 0RD1000Q609 100 1/4W(3 5% TA52

R743 0RD2702Q509 27K OHM 1/4 W(3.4) 2% TA52

R744 0RD2200A609 220 OHM 1/2 W (7.0) 5% TA52

R747 0RD3001Q609 3K 1/4W(3 5% TA52

R748 0RD4702Q609 47K 1/4W(3 5% TA52

R749 0RD2201Q609 2.20K 1/4W(3 5% TA52

R750 0RD3001Q609 3K 1/4W(3 5% TA52

R751 0RD0222A609 22 OHM 1/2 W (7.0) 5% TA52

R752 0RD2201Q609 2.20K 1/4W(3 5% TA52

R754 0RX4300K607 430 OHM 2 W 5% TA62

R755 0RD0471Q609 4.70 1/4W(3 5% TA52

R756 0RD2202A609 22K OHM 1/2 W (7.0) 5% TA52

R757 971-0054 TIN 50MM TAPING

R758 0RN1303F409 130K 1/6W 1% TA52

R759 0RD1302Q509 13K OHM 1/4 W (3.4) 2% TA52

R760 0RD5103Q609 510K 1/4W(3 5% TA52

R761 0RD3001Q609 3K 1/4W(3 5% TA52

R762 0RD3001Q609 3K 1/4W(3 5% TA52

R764 971-0054 TIN 50MM TAPING

R765 0RD3000A609 300 OHM 1/2 W (7.0) 5% TA52

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R766 0RD1501Q609 1.50K 1/4W(3 5% TA52

R769 971-0054 TIN 50MM TAPING

R770 971-0054 TIN 50MM TAPING

R771 0RD1501Q609 1.50K 1/4W(3 5% TA52

R772 0RD1302Q509 13K OHM 1/4 W (3.4) 2% TA52

R773 0RD3302A609 33K OHM 1/2 W (7.0) 5% TA52

R778 0RD2001Q609 2K 1/4W(3 5% TA52

R793 0RD4702Q609 47K 1/4W(3 5% TA52

R797 0RD1501Q609 1.50K 1/4W(3 5% TA52

R797 0RD1501Q609

1.50K 1/4W(3 5% TA52 - For Mexico, India(500E)

R798 0RD2001Q609 2K 1/4W(3 5% TA52

R799 0RD1502Q609 15K 1/4W(3 5% TA52

R801 0RD3002Q609 30K 1/4W(3 5% TA52

R802 0RD1502Q609 15K 1/4W(3 5% TA52

R803 0RD1001Q609 1K 1/4W(3 5% TA52

R808 971-0054 TIN 50MM TAPING

R809 0RX0101K665 1 OHM 2 W 5% SF

R813 0RD4302Q609 43K 1/4W(3 5% TA52

R814 0RD1002Q609 10K 1/4W(3 5% TA52

R816 0RN3301F409 3.30K 1/6W 1% TA52

R818 0RN5602F409 56K 1/6W 1% TA52

R819 0RN1203F409 120K 1/6W 1% TA52

R901 0RD4703A609 470K OHM 1/2 W (7.0) 5% TA52

R902 0RD0332Q609 33 1/4W(3 5% TA52

R903 0RN1800F409 180 OHM 1/6 W 1.00% TA52

R904 0RX3902K665 39K OHM 2 W 5% SF

R906 0RD6200Q609 620 1/4W(3 5% TA52

R907 0RD3902Q609 39K 1/4W(3 5% TA52

R908 971-0054 TIN 50MM TAPING

R910 0RX4702J609 47K OHM 1 W 5% TA52

R911 0RD0202Q609 20 1/4W(3 5% TA52

R912 0RN1802F409 18K 1/6W 1% TA52

R913 0RN2701F409 2.7K OHM 1/6 W 1.00% TA52

R915 0RD0622Q609 62 OHM 1/4 W(3.4) 5.00% TA52

R916 0RD1002Q609 10K 1/4W(3 5% TA52

R918 0RD1001Q609 1K 1/4W(3 5% TA52

R923 0RD1003Q609 100K 1/4W(3 5% TA52

R925 0RB0180K607 0.18OHM 2 W 5% TA62

R926 0RD4301Q609 4.30K 1/4W(3 5% TA52

R927 0RD2002Q609 20K 1/4W(3 5% TA52

R928 0RD1800Q609 180 1/4W(3 5% TA52

R929 0RD0332Q609 33 1/4W(3 5% TA52

R941 0RN0220H609 0.22 1/2W 5% TA52

R944 0RD4700A609 470 OHM 1/2 W (7.0) 5% TA52

R945 0RD4701Q609 4.70K 1/4W(3 5% TA52

R951 971-0054 TIN 50MM TAPING

R952 0RD1202A609 12K OHM 1/2 W(7.0) 5.00% TA5

R953 0RD1001A609 1K OHM 1/2 W (7.0) 5% TA52

R954 0RD4701Q609 4.70K 1/4W(3 5% TA52

R955 0RD4701Q609 4.70K 1/4W(3 5% TA52

R956 0RD6802A609 68K OHM 1/2 W (7.0) 5% TA52

R957 0RD0472A609 47 OHM 1/2 W (7.0) 5% TA52

R960 0RD6200A609 620 OHM 1/2 W(7.0) 5.00% TA5

R962 0RD0332Q609 33 1/4W(3 5% TA52

F1 430-858C AFC-520 BAE EUN TA

F2 430-858C AFC-520 BAE EUN TA

F901 0FZZTTH004B TIME LAG HBC TSC 5A/250V,WAL

RL901 6920TBA004A G5PA-1-M OMRON 250VAC 5A 12V

SC301 6620TBC002A PCS629-01B PARK ELEC. 8PIN 1

- 26 -

OTHERs

Page 27

DATE: 2003. 05. 24.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

SC901 6620TKB002A BAE EUN AC UNIVERSAL 3PIN BL

SG305 6918TRT005A SSG-102-A0,1KV SMART RADIAL

SW1 140-058B EVQ PB2 05K MATUSHITA NON 12

SW2 140-058B EVQ PB2 05K MATUSHITA NON 12

SW3 140-058B EVQ PB2 05K MATUSHITA NON 12

SW4 140-058B EVQ PB2 05K MATUSHITA NON 12

SW5 140-058B EVQ PB2 05K MATUSHITA NON 12

T1 5240T0B002A W-T 480MM UL1007 AWG 24 TWI

T1 5240T0B002A

W-T 480MM UL1007 AWG 24 TWI - For Mexico, India(500E)

T2 5240T0B002A W-T 480MM UL1007 AWG 24 TWI

T2 5240T0B002A

W-T 480MM UL1007 AWG 24 TWI - For Mexico, India(500E)

T701 6174T11004B 1056A,CB553J(54K) JUNGWOO 15

T703 6170TCZ015A EI-19 4.45MH H-DRIVE,700BJ

T901 6170TMZ147A EER3541 300UH V-16PIN J-CHAS

TH901 163-053D J502P62C090Q290 JAHWA +/-20

TH902 6322A00003C 8 D2 10 SEMITEC 8OHM 15% D(1

X401 6212AA2004A HC-49U TXC 12.0MHZ +/- 30 PP

- 27 -

Page 28

PIN CONFIGURATION

- 28 -

M24C08 Serial I2C BUS EEPROM

SYMBOL

E0-E2

SDA

SCL

WC

Vcc

Vss

DESCRIPTION

Chip Enable Input

Serial Data Address Input/Output

Serial Clock

Write Control

Supply Voltage

Ground

1

PSDIP8 (BN)

0.25mm Frame

8

1

1

SO8 (MN)

150mil Width

TSSOP8 (DW)

169mil Width

8

8

Logic Dirgram

TDA4867J PHILIPS 32P, SDIP

AMPLIFIER A

FLYBACK

GENERATOR

GUARD

CIRCUIT

INPUT STAGE

from e.g TDA485X

or SAA4856

INP

INN

IPROTECTION

AMPLIFIER B

4

9

6

8

1

2

357

OUTA

GUARO output/

power save mode

GND

FEEDB

OUTB

vertical

deflection

coil

R

p

V

p

V

FB

R

m

R

ref

I

defl

Block Diagram

SYMBOL

INP

INN

V

P

OUTB

GND

OUTA

V

FB

GUARD

FEEDB

DESCRIPTION

non-inverted input

inverted input

supply voltage

output B

ground

output A

flyback supply voltage

guard output

feedback inprt

PIN

1

2

3

4

5

6

7

8

9

INP

INN

V

P

OUTB

GND

OUTA

V

FB

GUARD

FEEDB

1

2

3

4

5

6

7

8

9

TDA4867J

Pin Configuration

Page 29

- 29 -

TDA4841PS PHLIPS 32P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

FOCUS

HSMOD

HPLL2

HCAP

HREF

HBUF

HPLL1

SGND

VCAP

VREF

VAGC

VSMOD

ASCOR

SDA

SCL

HUNLOCK

HFLB

XRAY

BOP

BSENS

BIN

BDRV

PGND

HDRV

XSEL

Vcc

EWDRV

VOUT2

VOUT1

VSYNC

HSYBC

CLBL

TDA4841PS

Pin Configuration

V-sync

(TTL level)

(TTL level)

(video)

15

25

10

18

19

2

17

16

14

7

H/C-SYNC INPUT

AND POLARITY

CORRECTION

(1) See calculation of f range.

(2) See Figs 22 and 23.

SUPPLY

AND

REFERENCE

HUNLOCK

OUTPUT

VIDEO

CLAMPING

AND V-BLANK

V-SYNC INPUT

AND POLARITY

CORRECTION

V-SYNC

INTEGRATOR

VERTICAL

OSCILLATOR

AND AGC

EHT COMPENSATION

H-SIZE AND V-SIZE

EW-OUTPUT

V-OUTPUT

V-LINEARITY

V-LINEARITY BALANCE

H-PINCUSHION

H-CORNER

H-TRAPEZIUM

H-SIZE

OUTPUT

ASYMMETRIC

EW-CORRECTION

FOCUS

HORIZONTAL

AND VERTICAL

B+

CONTROL

B+ CONTROL

APPLICATION

H-OUTPUT

STAGE

X-RAY

PROTECTION

PLL2, PARALLELOGRAM,

PIN UNBALANCE AND

SOFT START

V-POSITION

V-SIZE, VOVSCN

TDA4841PS

I C-BUS

RECEIVER

2

I C-BUS REGISTERS

HUNLOCK

SDA

SCL

9.2 to 16V

H/C-sync

V+

clamping

blanking

PROTECTION

AND SOFT START

COINCIDENCE DETECTOR

FREQUENCY DETECTOR

PLL1 AND

H-POSITION

HORIZONTAL

OSCILLATOR

12

13

Vout2

Vout1

20 or

32

8

9

XSELX-RAYHFLB

213029

12

2%

1%

nF

10 nF

8.2

3.3

nF

100

nF

282726

(1)

R

HBUF

R

HREF

6

4

3

5

(2)

HDRV

23 24 22 21

VSMOD HSMOD

31 11

7V

1.2V

22

1%

5%

100 150

nF

nF

EHT compensaton

EHT compensation

via vertical size

via horizontal size

EWDRV

H

Block Diagram

Page 30

IIC-SDA

IIC-SCL

DDC-SDA

DDC-SCL

- 30 -

- 31 -

SCHEMATIC DIAGRAM

Page 31

- 32 -

- 33 -

PRINTED CIRCUIT BOARD

1. MAIN BOARD (Component Side)

2. MAIN BOARD (Solder Side)

Page 32

May . 2003

P/NO : 3828TSL092B Printed in Korea

Loading...

Loading...