LG 42PX4DV, 42PX4DV-AA Service Manual

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : DF-057A

MODEL : 42PX4DV

42PX4DV-AA

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

- 2 -

CONTENTS

SAFETY PRECAUTIONS ....................................................................................3

DESCRIPTION OF CONTROLS..........................................................................4

SPECIFICATIONS................................................................................................8

ADJUSTMENT INSTRUCTIONS .......................................................................10

TROUBLE SHOOTING GUIDE..........................................................................13

BLOCK DIAGRAM.............................................................................................21

EXPLODED VIEW..............................................................................................22

EXPLODED VIEW PARTS LIST........................................................................23

REPLACEMENT PARTS LIST...........................................................................24

SCHEMATIC DIAGRAM.........................................................................................

PRINTED CIRCUIT BOARD ..................................................................................

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on position, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

D/A TV INPUT

TV

DVD

VCR

SLEEP

GUIDE

INFO

MENU

TEXT

MUTE

LIST

SIZE UPDATE INDEX

STILL

TIME REVEAL MIX

I/II

PIP PR- PIP PR+ SWAP

PIP PSM SSM

PIP INPUT

Q.VIEW

FAV

OK

VOL PR

EXIT

POWER

ARC

?

INPUT

Selects the

Digital, Analogue, Video 1, Video

2, Component 1, Component 2, RGB-PC,

RGB-DTV or HDMI/DVI

modes.

switches the set on from standby.

VCR/DVD BUTTONS

Controls a LG video cassette recorder.

controls a LG DVD player.

POWER

switches the set on from standby or off to

standby.

ARC

Changes the picture format.

SSM

To select the sound appropriate to your

viewing programme.

EXIT

Clears all on-screen displays and returns to

TV viewing from any menu.

TEXT

These buttons are used for teletext.

For further details, see the ‘Teletext’ section.

COLOURED BUTTONS : These buttons are

used for teletext (only TELETEXT models) or

programme edit.

FAV

selects a favourite programme.

I/II

selects the sound output or the audio mode.

Q.VIEW

Returns to the previously viewed programme.

VOL +/- (Volume Up/Down)

Increases/decreases sound level.

PR +/- (Programme Up/Down)

Selects a programme.

SLEEP

Sets the sleep timer.

D/A TV

selects analogue or digital mode.

MODE

Selects another device.

GUIDE

shows a programme schedule.

(In Digital mode only)

MENU

Displays on screen menus one by one.

Exits the current menu.

Memorizes menu changes.

INFO

displays information on top of the screen

whilst watching the TV.

(In Digital mode only)

MUTE

Switches the sound on or off.

NUMBER buttons

LIST

Displays the programme table.

PSM

Adjusts the factory preset picture according

to the room.

PIP

Switches the sub picture on or off.

Selects PIP or DW modes.

PIP PR + /-

Selects a programme for the sub picture.

SWAP

Alternates between main and sub picture.

PIP INPUT

Selects the input mode for the sub picture.

OK

accepts your selection or displays the

current mode.

D/ E

or F / G

Adjusts menu settings.

Selects menu item.

- 4 -

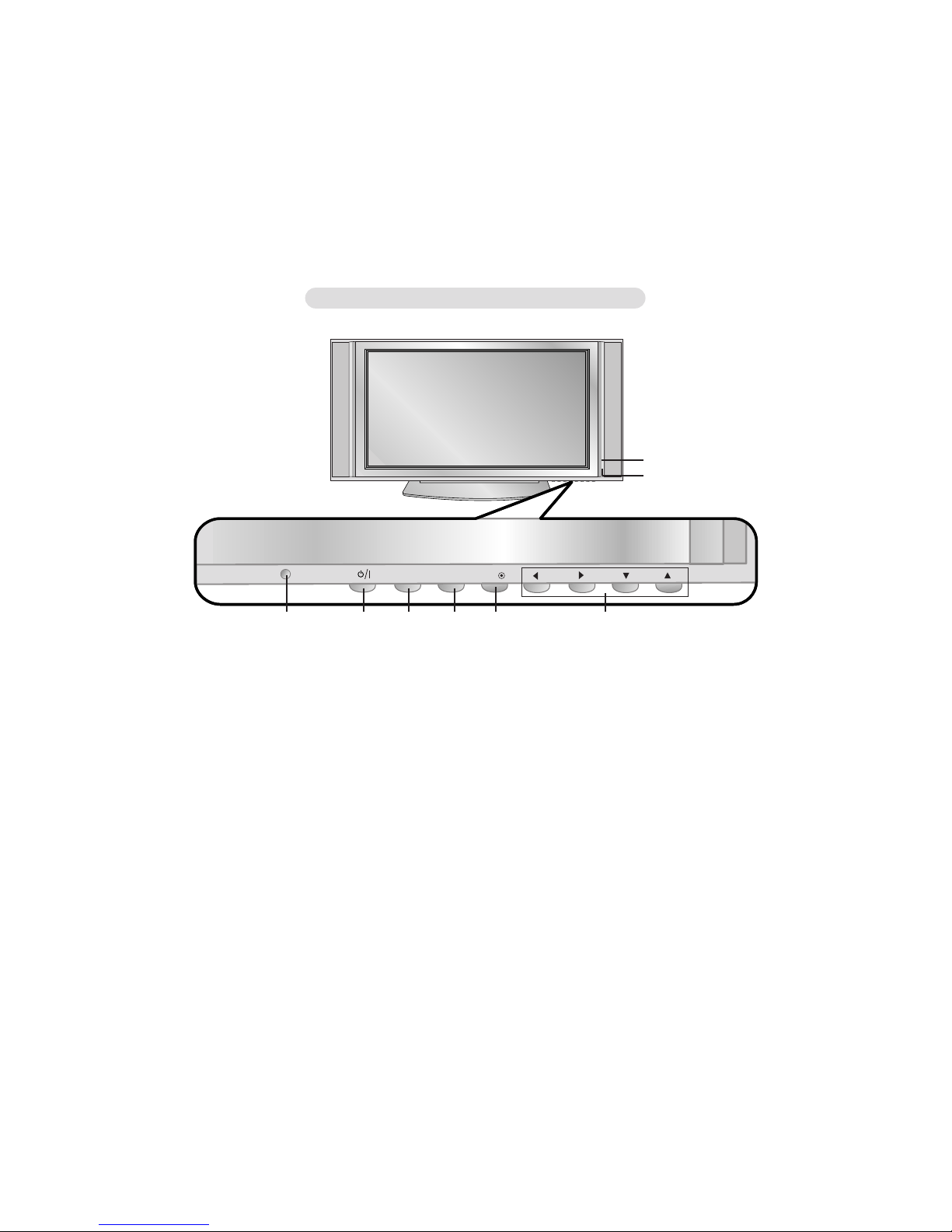

DESCRIPTION OF CONTROLS

- 5 -

PR

VOL

MENUTV/AV OK

2

1 3 4 5 6

7

8

1. Power Button

2. Remote Control Sensor

3. TV/AV Button

Selects the Digital, Analogue, Video 1, Video 2, Component

1, Component 2, RGB-PC, RGB-DTV or HDMI/DVI modes.

Switches the set on from standby.

4. MENU

Displays on screen menus one by one.

Exits the current menu.

Memorizes menu changes.

5. OK

Accepts your selection or displays the current mode.

6. DD / EE (Programme Up/Down)

Selects a programme or a menu item.

Switches the set on from standby.

FF / GG (Volume Up/Down)

Adjusts the volume.

Adjusts menu settings.

7. Power Standby Indicator

Illuminates red in standby mode, Illuminates green when

the set is turned on

8 . Intelligent Eye

Adjusts picture according to the surrounding conditions.

< Front Panel Controls >

< Front Panel Controls >

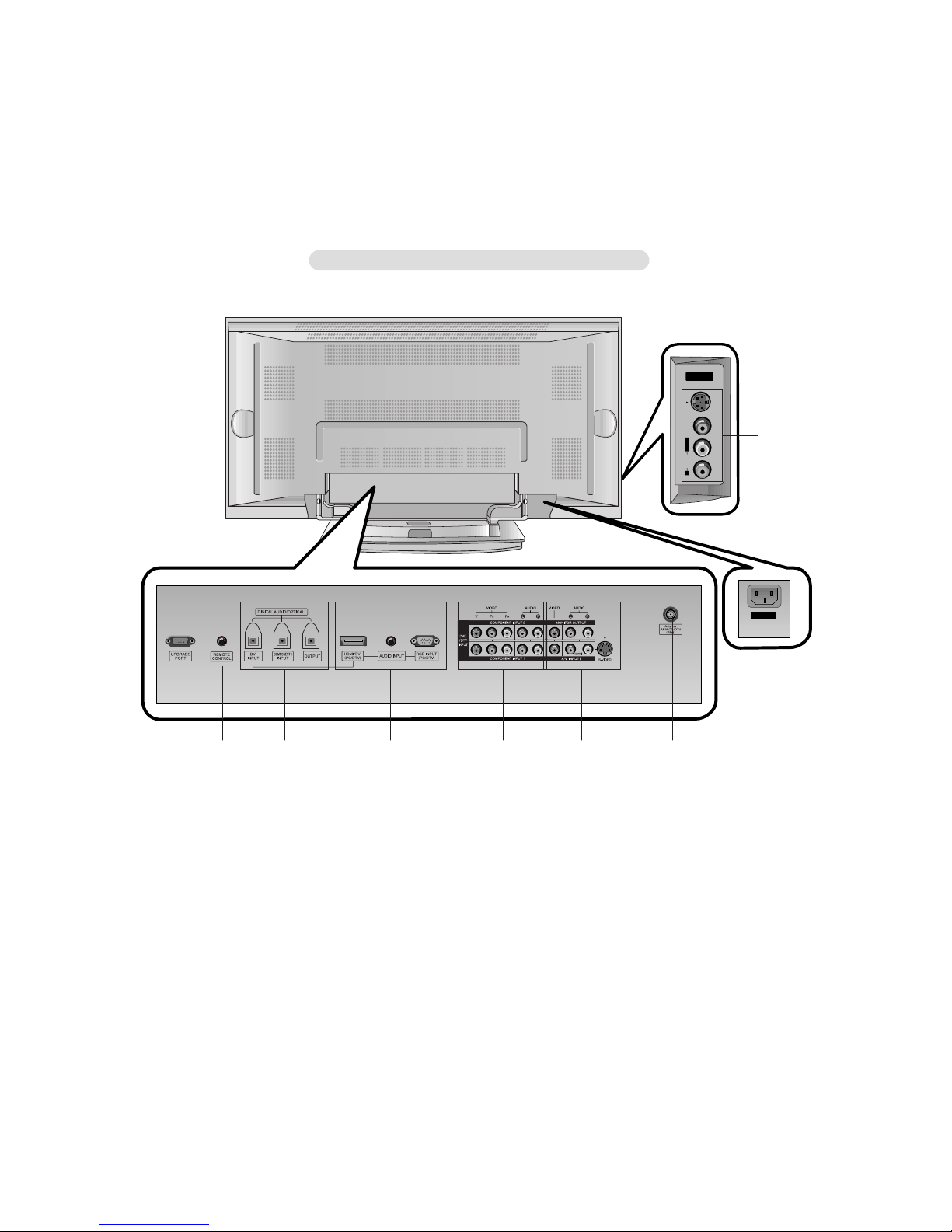

- 6 -

1. UPGRADE PORT

This port is used to upgrade the software version and debug

without changing the hardware.

Be careful not to use this port. Just contact your dealer or service centre.

2. CONTROL LOCK / REMOTE CONTROL

3. DVI INPUT/COMPONENT 1 INPUT/OUTPUT (DIGITAL

AUDIO (OPTICAL))

Connect digital audio from various types of equipment.

Note: In standby mode, these ports will not work.

4. HDMI/DVI INPUT / AUDIO INPUT / RGB INPUT (PC/DTV)

Connect the monitor output socket of the PERSONAL COMPUTER to this socket.

Note: If you want to use RGB/DVI audio, we strongly recommend that you use the cable that has a core, or the EMI Filter

core along with separate cable.

5. COMPONENT INPUT

Connect DVD video outputs to Y, PB, PR of COMPONENT

INPUT and audio outputs to Audio sockets of AUDIO INPUT.

6. AUDIO/VIDEO IN SOCKETS (A/V INPUT1)

Connect the audio/video out sockets of external equipment to

these sockets.

S-VIDEO/AUDIO IN SOCKETS

Connect the S-VIDEO out socket of the VCR to the S-VIDEO

socket.

Connect the audio out sockets of the VCR to the audio sockets as in A/V INPUT1.

AUDIO/VIDEO OUT SOCKETS (MONITOR OUTPUT)

7. ANTENNA INPUT

8. POWER CORD SOCKET

This Monitor operates on AC power. The voltage is indicated

on the Specifications page. Never attempt to operate the

Monitor on DC power.

9. AUDIO/VIDEO IN SOCKETS (A/V INPUT2)

S-VIDEO/AUDIO IN SOCKETS

VIDEO

S-VIDEO

AUDIO

R

L/MONO

A/V INPUT2A/V INPUT2

AC INPUT

1

9

2 3 4 5 6 7 8

<Back Panel>

- 7 -

AS mark

LG TV

Owner’s Manual

1.5V

1.5V

Alkaline batteries

Power Cord

D/A TV INPUT

TV

DVD

VCR

SLEEP

GUIDE

INFO

MENU

TEXT

MUTE

LIST

SIZE UPDATE INDEX

STILL

TIME REVEAL MIX

I/II

PIP PR- PIP PR+ SWAP

PIP PSM SSM

PIP INPUT

Q.VIEW

FAV

OK

VOL PR

EXIT

POWER

ARC

?

Remote Control handset

- Optional extras can be changed or modified for quality improvement. Without any notification new optional extras can be

added.

- Contract your dealer for buying these items.

Optional Extras

Accessories

Tilt wall mounting bracket

Video cables Audio cables

Ceiling mounting bracket

40

42

50

42

40

- Secure the set assembly by fixing it to a wall by using the Eye Bolts/Wall brackets.

Fixing the set assembly to the wall to protect the set tumbling

• If the set is mounted on a desk top, insert the 2 Eye-Bolts and tighten them

securely in the upper holes as shown.

Install the wall brackets on the wall with 2 bolts*, (not supplied with the product),

as shown.

Match the height of the Eye-Bolts and the wall brackets.

Check to be sure the Eye-Bolts and the brackets are tightened securely.

• Secure the set assembly to the wall with strong strings or wound wire cables,

(not supplied with the product), as shown.

2-Wall brackets

2-Eye Bolts

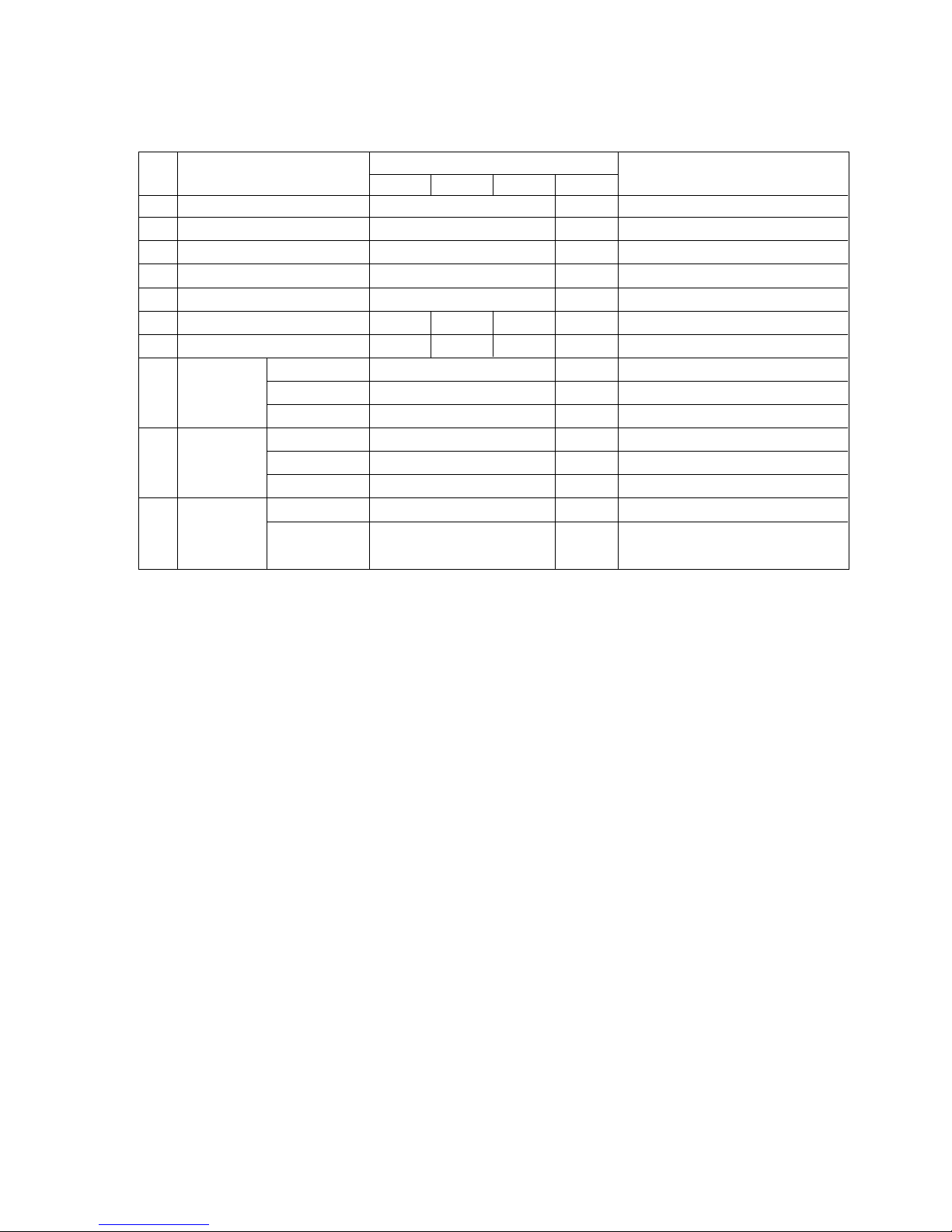

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

- 8 -

V Application Range

This spec is applied to the 42”/50”/60”PDP TV used DF-057A Chassis.

V Specification

Each part is tested as below without special appointment.

1) Temperature : 25±5°C (77±9°F), CST : 40±5

2) Relative Humidity: 65

±10%

3) Power Voltage: Standard Input voltage (100-240V~, 50/60Hz)

* Standard Voltage of each product is marked by models.

4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with BOM.

5)

The receiver must be operated for about 20 minutes prior to the adjustment

.

V Test Method

1) Performance : LGE TV test method followed.

2) Demanded other specification

Safety: CE, IEC specification

EMC : CE, IEC

V General Specification

1. SET(42PX4DV-AA)

Remark

Safety : IEC60065, EN60065

EMC : CISPR 13 Class B

Model Name

42PX4DV

Market

Australia

Broadcasting system

Available Channel

Tuner IF

Input Voltage

PDP Module

Aspect ratio

Operating Temperature

Operating Humidity

Storage Temperature

Storage Humidity

1

2

3

4

5

6

7

8

9

10

No Item

Specification

Remark

Min Typ Max Unit

PAL-B/G, DTV : DVB-T

VHF : 00~12

UHF : 28~69

CATV : 02~44

DTV : 06~12, 27~69

PAL : 38.90 MHz

DVB-T : 36.167 MHz

240V~, 50Hz

PDP42V7xxxx,

RGB Closed Type, Film Filter

16:9(wide)

0 40 deg

85 %

-20 60 deg

85 %

Maker : Sanken

2. PDP Module(PDP42V7xxxx)(film Filter)

- 9 -

Display area

Outline dimension

Number of Pixels

Cell Pitch

Color arrngement

Weight(net)

weight(gross)

Operating Temperature

Environment Humidity

Pressure

Storage Temperature

Environment Humidity

Pressure

Image stick Start time

minimization Low Brightness

mode Arrival Time

1

2

3

4

5

6

7

8

9

10

No Item

Specification

Remark

Min Typ Max Unit

920.1(H) * 518.4(V) ± 0.54.8 mm

1005(H) * 597(V) * 61.2(D) ± 1 mm

852(H) *480(V)

320(H) * 1080(V)

U

m

RGB closed type

14.3 14.8 15.3 Kg

106.0 111.0 116.0 Kg

0 ~ 40 deg

20 ~ 80 %

800 ~ 1100 hPa

-20 ~ 60 deg

10 ~ 90 %

700 ~ 1100 hPa

4.5 5 5.5 min

14 15 16 min

Maker : Sanken

- 10 -

1. Application Object

These instructions are applied to all of the PDP TV, DF-057A.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 220V, 60Hz

when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

O After receiving 100% white pattern, the receiver must be

operate prior to adjustment.(Or white condition in HEATRUN mode)

O Enter into HEAT-RUN MODE

- Press the POWER ON KEY on R/C for adjustment.

OSD display and screen display 100% full WHITE

PATTERN.

[ Set is activated HEAT-RUN without signal generator in

this mode.

If you turn on a still screen more than 20 minutes (Especially

Digital pattern, Cross Hatch Pattern), an afterimage may occur

in the black level part of the screen.

3. EPLD Download

(1) Test Equipment: PC, Jig for download

(2) Connect the power of VSC B/D.

(3) Execute download program of PC.

(4) After executing the hot key on the Programmer, click

Program icon

(5) End after confirming.

4. POWER PCB Assy Voltage

Adjustment

(Va, Vs Voltage Adjustment)

4-1. Test Equipment :D.M.M 1EA

4-2. Adjustment Method (3501V00220A)

(1) Connection Diagram for Measuring : fig. 4-1

(2) Va Adjustment

1) After receiving 100% Full White Pattern by Video/RGB

or selecting White Mode of Heat-Run Mode, Execute

HEAT RUN over 10 minutes.

2) Connect + terminal of D.M.M to Va pin of P807, and

connect - terminal to GND pin of P807.

3) After turning RV501, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(3) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P807, connect

– terminal to GND pin of P807.

2) After turning RV401, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

4-3. Adjustment Method (3501V00221A)

(1) Connection Diagram for Measuring : fig. 4-2

(2) Va Adjustment

1) After receiving 100% Full White Pattern by Video/RGB

or selecting White Mode of Heat-Run Mode, Execute

HEAT RUN over 10 minutes.

2) Connect + terminal of D.M.M to Va pin of P805 and

connect – terminal to GND pin of P805.

3) After turning RV601, adjust voltage of D.M.M as same

as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

ADJUSTMENT INSTRUCTIONS

PC

VSC

B/D

<Fig 1> Connection Diagram of EPLD Download

Each PCB Assy must be checked by Check JIG Set before

assembly. (Especially, be careful Power PCB Assy which can

cause Damage to the PDP Module.)

<Fig. 4-1> Connection diagram of power adjustment for measuring

- 11 -

(3) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805 and

connect – terminal to GND pin of P805.

2) After turning RV401, adjust voltage of D.M.M as same as

Va voltage which on label of panel right/top. (Deviation;

±0.5V)

5. EDID(The Extended Display Idetification Data)

/ DDC(Display Data Channel) Download

This is the function that enables “Plug and Play".

5-1. Required Test Equipment

1) PC, Jig for adjusting DDC (PC serial to D-sub.

Connection equipment)

2) DVI to HDMI Connector

5-2. Composition of Device

5-3. EDID DATA

- Download only EDID for HDMI.

6. AD9883A-Set Adjustment

6-1. Synopsis

AD9883A-Set adjustment to set the black level and the Gain

of optimum with an automatic movement from the analog =>

digital converter.

6-2. Test Equipment

Service R/C, MSPG925 Series Pattern Generator

(720P 60Hz 100% Color Bar Pattern output will be possible

and the output level will accurately have to be revised with

0.7±0.1Vp-p)

6-3. Adjustment

(1) Input the color Bar Pattern of the 720P 60Hz Mode what is

supportable to Component or RGB INPUT and the select

the Input Mode as Component2.

(2) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and then

select the ‘1. AD9883A-Set’.

Pressing the Vol + Key to adjust with automatic movement.

(3) If Component adjustment is completed normality,

'Component Adjustment OK' is displayed and if RGB

adjustment is completed normality, 'RGB Adjustment OK' is

displayed. If the adjustment has errors, 'AD9883A-Failed!

Try Again' is displayed.

(4) Readjust after confirming the case Pattern or adjustment

condition where the adjustment errors.

(5) After adjustment is complete, exit the adjustment mode by

pressing the ADJ KEY.

7. Adjustment of White Balance

7-1. Required Equipment

(1) Color analyzer (CA-100 or similar product)

(2) Automatic adjustor (with automatic adjustment hour

necessity and the RS-232C communication being possible)

(3) AV Pattern Generator

Va ADJ

RV601

P806

P805

P807

Va

GND

NC

VS

DMM

+ -

P804

P801

P802

Vs ADJ

V401

P803

<Fig. 4-2> Connection diagram of power adjustment for measuring

PDP

SET

00 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

A0 |

B0 |

C0 |

D0 |

E0 |

F0 |

00

00

23

0F

01

13

3E

47

00

02

83

16

72

00

8C

00

21

01

FF

0E

4B

01

00

08

20

00

03

01

20

1C

BC

0A

18

00

02

FF

01

52

01

4C

00

54

00

1A

00

58

16

52

D0

01

00

03

FF

03

EF

01

6C

00

56

00

72

00

2C

20

D0

90

1D

1E

04

FF

80

CE

01

42

00

0A

00

23

65

25

10

1E

20

00

00

05

FF

6E

00

01

00

00

20

00

09

03

00

2C

20

40

72

00

06

FF

3E

31

C3

00

00

20

00

07

0C

C4

25

B8

31

51

00

07

00

78

CA

1E

18

00

20

00

02

00

8E

80

28

20

D0

00

08

1E

0A

01

00

00

00

20

00

47

10

21

C4

55

0C

1E

00

09

6D

31

01

20

00

00

20

00

81

00

00

8E

40

40

20

00

0A

01

30

01

41

00

00

20

00

03

01

00

21

C4

55

6E

00

0B

01

A5

01

00

FD

00

20

00

05

1D

9E

00

8E

00

28

00

0C

01

58

01

20

00

00

00

00

14

80

01

00

21

C4

55

00

0D

01

3B

01

30

37

FC

00

00

13

18

1D

9E

00

8E

00

00

0E

01

B8

01

10

4E

00

00

01

12

71

80

01

00

21

C4

00

0F

01

26

01

60

1E

4C

01

57

04

1C

D0

1D

1E

00

8E

50

<Fig. 6> Adjustment Pattern : 720P 60Hz Color Bar Pattern

Loading...

Loading...