Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PB61A

MODEL : 42PC1DV

42PC1DV-AA

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

- 2 -

CONTENTS

SAFETY PRECAUTIONS ....................................................................................3

DESCRIPTION OF CONTROLS ..........................................................................4

SPECIFICATIONS ..............................................................................................10

ADJUSTMENT INSTRUCTIONS .......................................................................12

TROUBLE SHOOTING GUIDE..........................................................................17

PRINTED CIRCUIT DIAGRAM ..........................................................................23

BLOCK DIAGRAM.............................................................................................27

EXPLODED VIEW..............................................................................................30

EXPLODED VIEW PARTS LIST ........................................................................31

REPLACEMENT PARTS LIST...........................................................................32

SCHEMATIC DIAGRAM.........................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on position, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

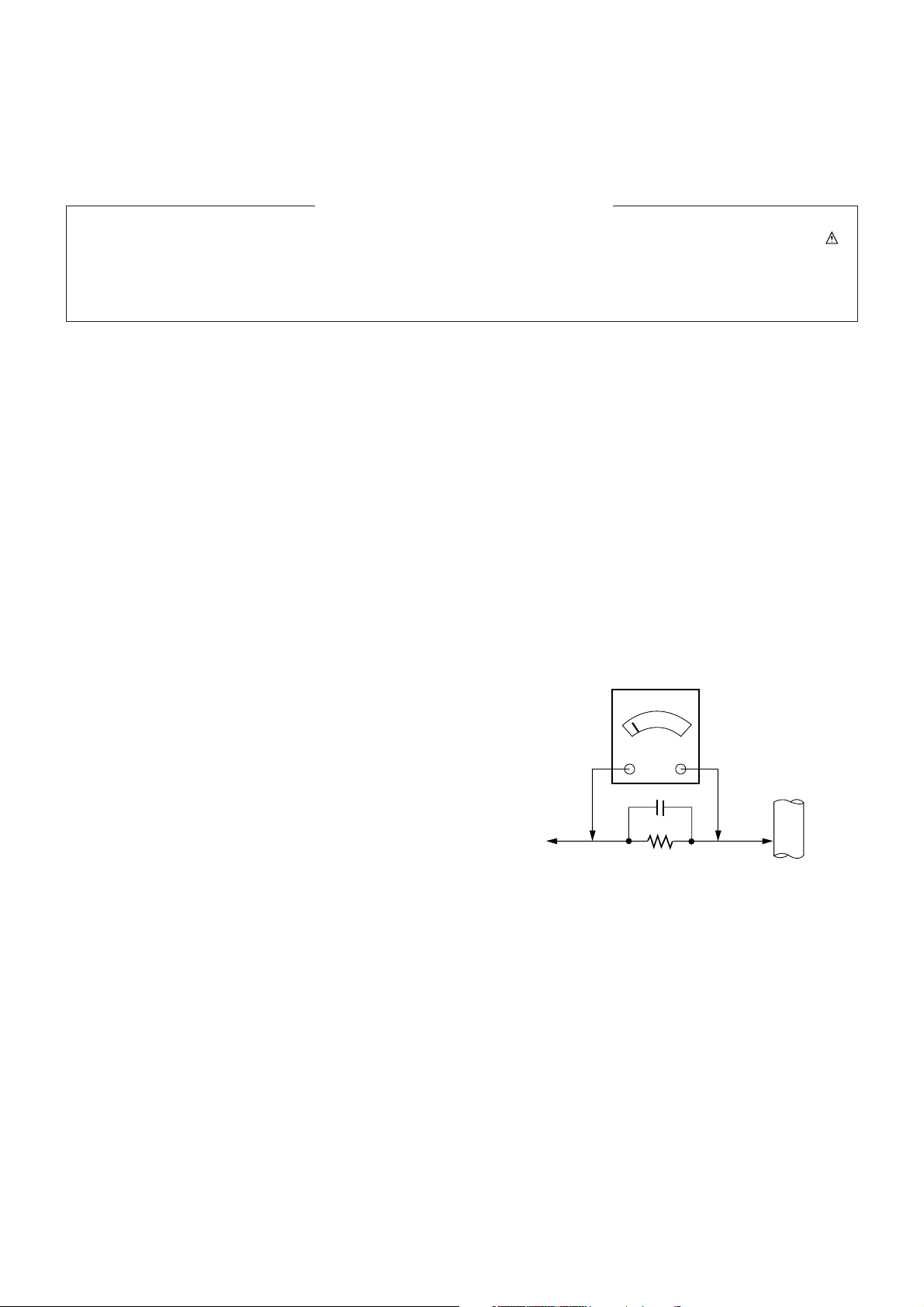

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

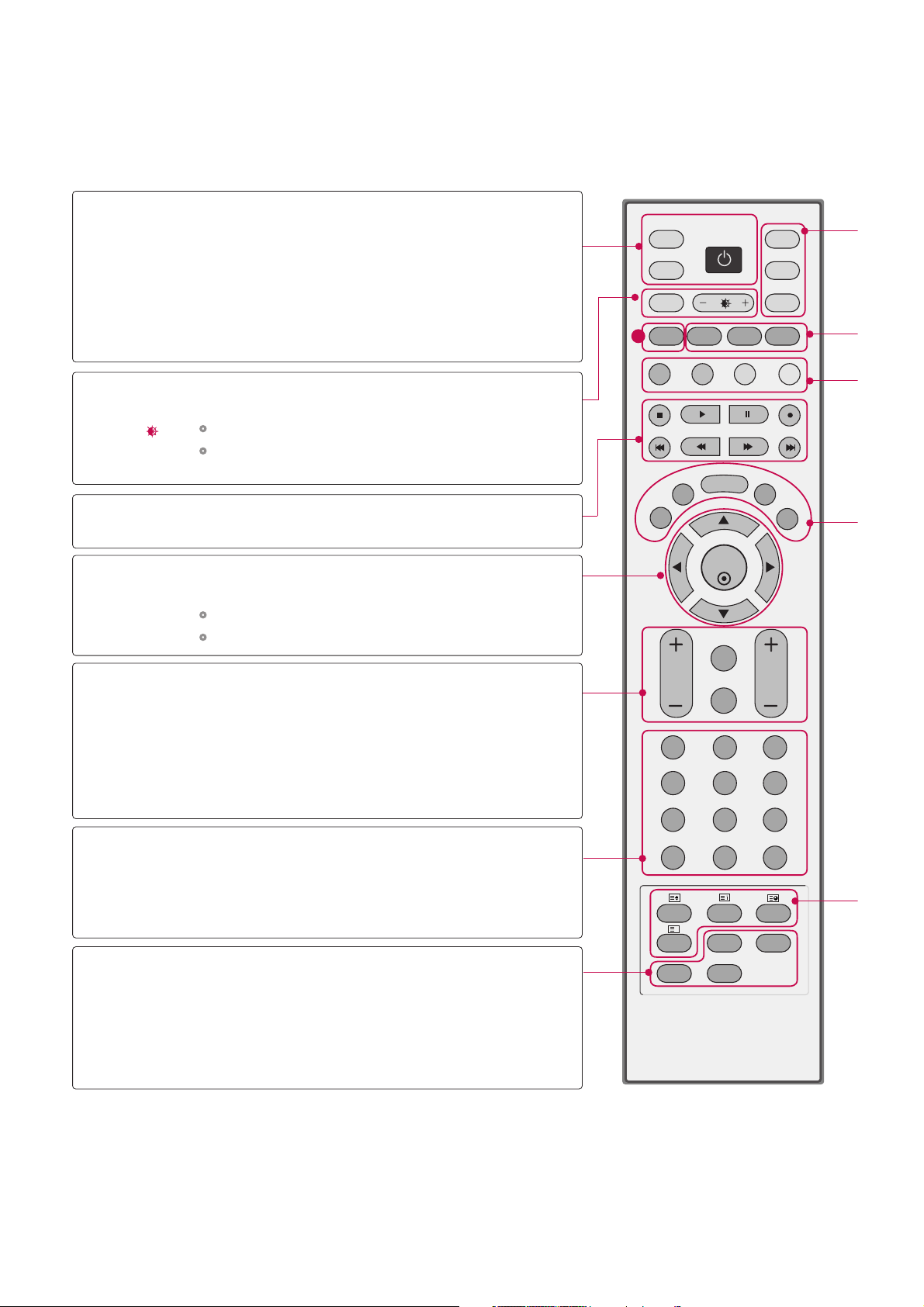

OK

TVD/A

INPUT

INPUT

DVD

ARC

EXIT

VOL

SIZE

INDEX

TIME

REVEAL PIP PR +

PIP INPUT

SWAP

PIP PR -

Q.VIEW

MUTE

PR

SLEEP

LIST

I/II

MENU

TEXT PIP

GUIDE

INFO

VCR

POWER

123

456

789

0

FAVAPM

?

D/A INPUT

(Digital TV /

Analogue TV)

INPUT

POWER

ARC

+/-

OK

THUMBSTICK

(Up/Down/Left

Right/OK)

VOLUME +/-

Q.VIEW

MUTE

Programme +/-

APM

FAV

(FAVOURITE)

PIP PR +/-

PIP INPUT

SWAP

Selects digital or analogue mode.

External input modes rotate in regular sequence:

Digital, Analogue, AV1-2, Component 1-2, RGBDTV (or RGB-PC), HDMI/DVI.

Switches the set between ON and STANDBY.

Selects your desired picture format.

Adjusts brightness on screen.

It returns to the default settings brightness by

changing mode source.

Control some video cassette recorders or DVD players

("RECORD" button is not available for DVD player).

Accepts your selection or displays the current

mode.

Adjusts menu settings.

Selects menu item.

Increase/decrease the sound level.

Returns to the previously viewed programme.

Switches the sound on or off.

Selects a programme.

Concurrently, compare with the Dynamic, Standard,

Mild, User1 and User2 on the screen.

Displays the selected favourite programmes.

Selects a programme for the sub picture.

Selects the input mode for the sub picture.

Alternates between main and sub picture in

PIP/Twin picture mode.

NUMBER button

VCR/DVD

control buttons

1

- 4 -

DESCRIPTION OF CONTROLS

Page 5

- 5 -

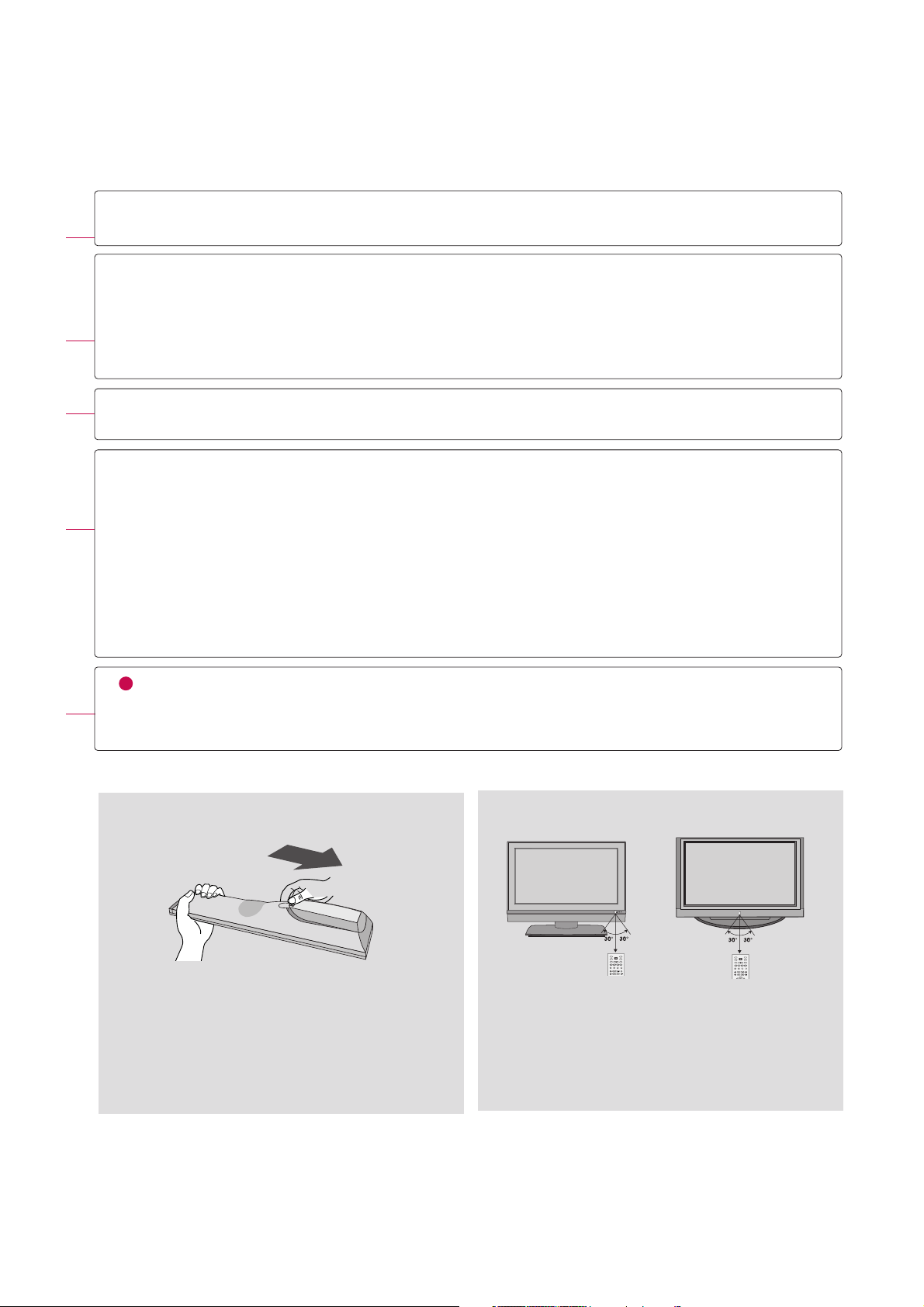

n

Open the battery compartment cover on the

back side and install the batteries matching

correct polarity (+with +,-with -).

n

Install two 1.5V AA batteries. Don’t mix old or

used batteries with new ones.

n

Close cover.

n

Use a remote control up to 7 meters distance

and 30 degree (left/right) within the receiving

unit scope.

n

Dispose of used batteries in a recycle bin

to preserve environment.

TVD/A

INPUT

INPUT

DVD

ARC

LIST

I/II

MENU

TEXT PIP

GUIDE

INFO

VCR

POWER

TVD/A

INPUT

INPUT

DVD

ARC

TEXT PIP

GUIDE

INFO

VCR

POWER

Installing Batteries Remote control effective range

TV, DVD,

VCR,

PIP

GUIDE

INFO

COLOURE

Button

EXIT

LIST

MENU

I/II

SLEEP

TELETEXT

BUTTONS

Selects the remote operating mode: TV, VCR, DVD. Select other operating modes,

for the remote to operate external devices.

Switches to PIP, POP and Twin picture modes or off mode.

Shows a programme schedule.

Shows the present screen information.

They are used as per the indications or functions displayed on the TV screen in

the case of Text displays (Teletext, EPG) and programme edit.

Returns to TV viewing from any menu.

Displays the programme table.

Selects a menu.

Selects the sound output or the audio mode.

Sets the sleep timer.

These buttons are used for teletext.

Text button is used to enable teletext services while other buttons are for teletext

functions.

* For further details, see the ‘Teletext’ section

1

R

Page 6

- 6 -

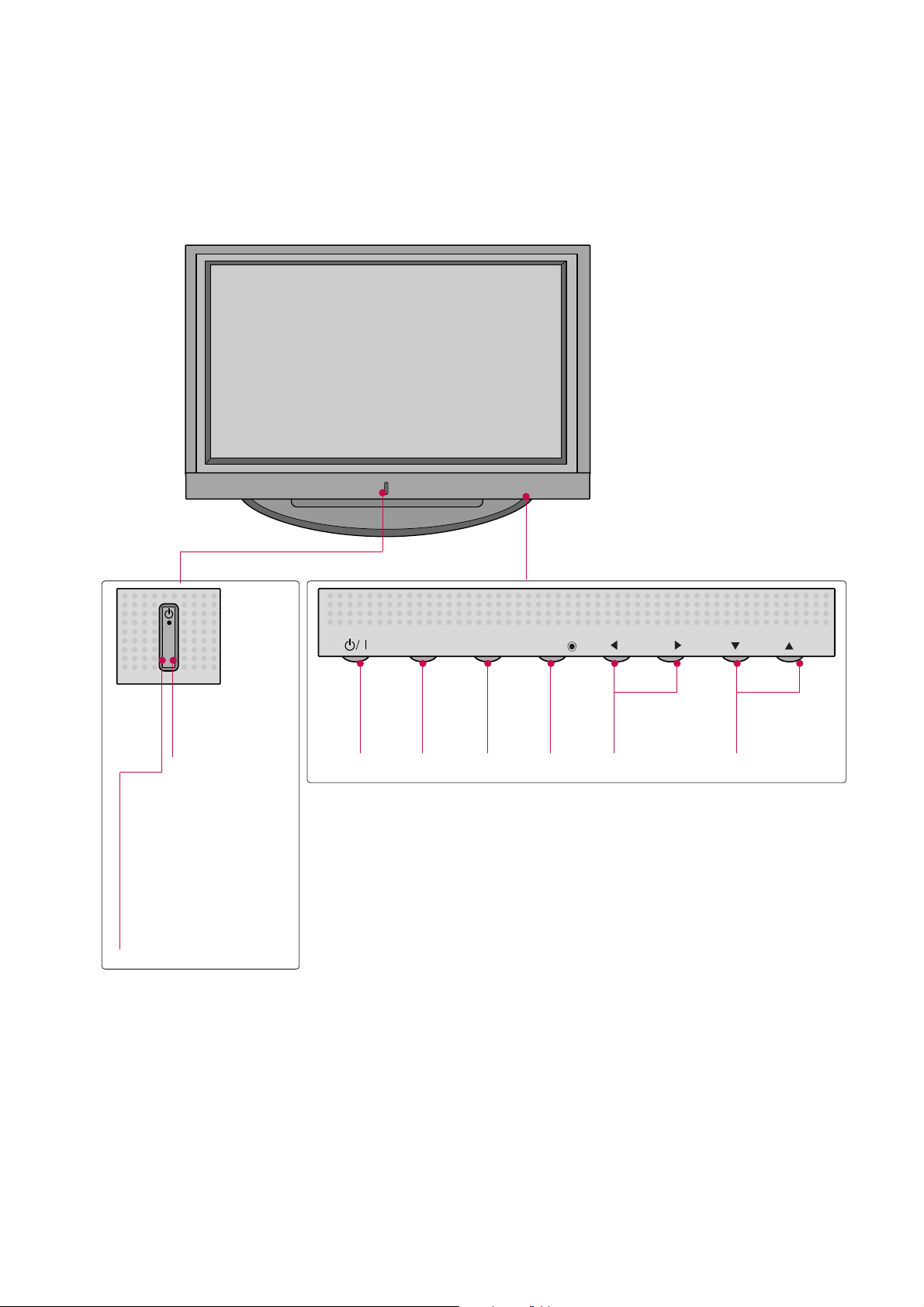

Front Panel Controls

PR

VOLOK

MENU

INPUT

Remote

Control

Sensor

POWER

Button

INPUT

Button

MENU

Button

OK

Button

VOLUME

(

FF,GG

)Buttons

PROGRAMME

(

EE,DD

)Buttons

Power Standby

Indicator

Illuminates red in

standby mode.

When the TV is turned

on, the indicator blinks

white and then illuminates white before the

picture is displayed.

Page 7

- 7 -

Back Connection Panel

Page 8

- 8 -

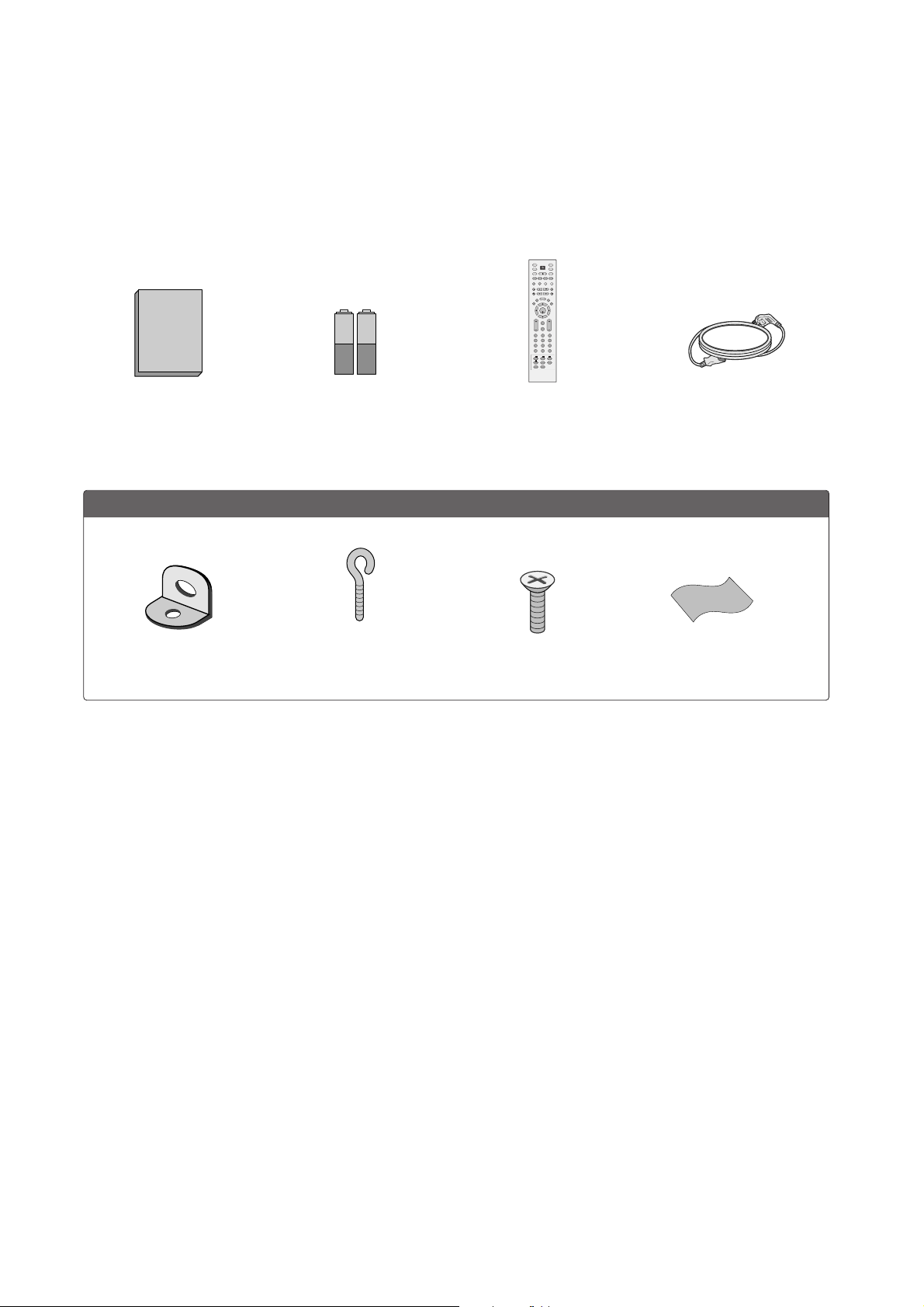

ACCESSORIES

Owner’s Manual

Owner’s Manual Batteries

OK

TVD/A

INPUT

INPUT

DVD

ARC

EXIT

VOL

SIZE

INDEX

TIME

REVEAL PIP PR +

PIP INPUT

SWAP

PIP PR -

Q.VIEW

MUTE

PR

SLEEP

LIST

I/II

MENU

TEXT PIP

GUIDE

INFO

VCR

POWER

123

456

789

0

FAVAPM

?

Remote Control Power Cord

For 42PC1D/42PC1DG/42PC1DV/50PC1D

2-Wall brackets

2- Bolts

42PC1DG

/42PC1DV only

42PC1DG

/50PC1D only

Polishing Cloth

Polish the screen with

the cloth.

2-eye-bolts

Page 9

- 9 -

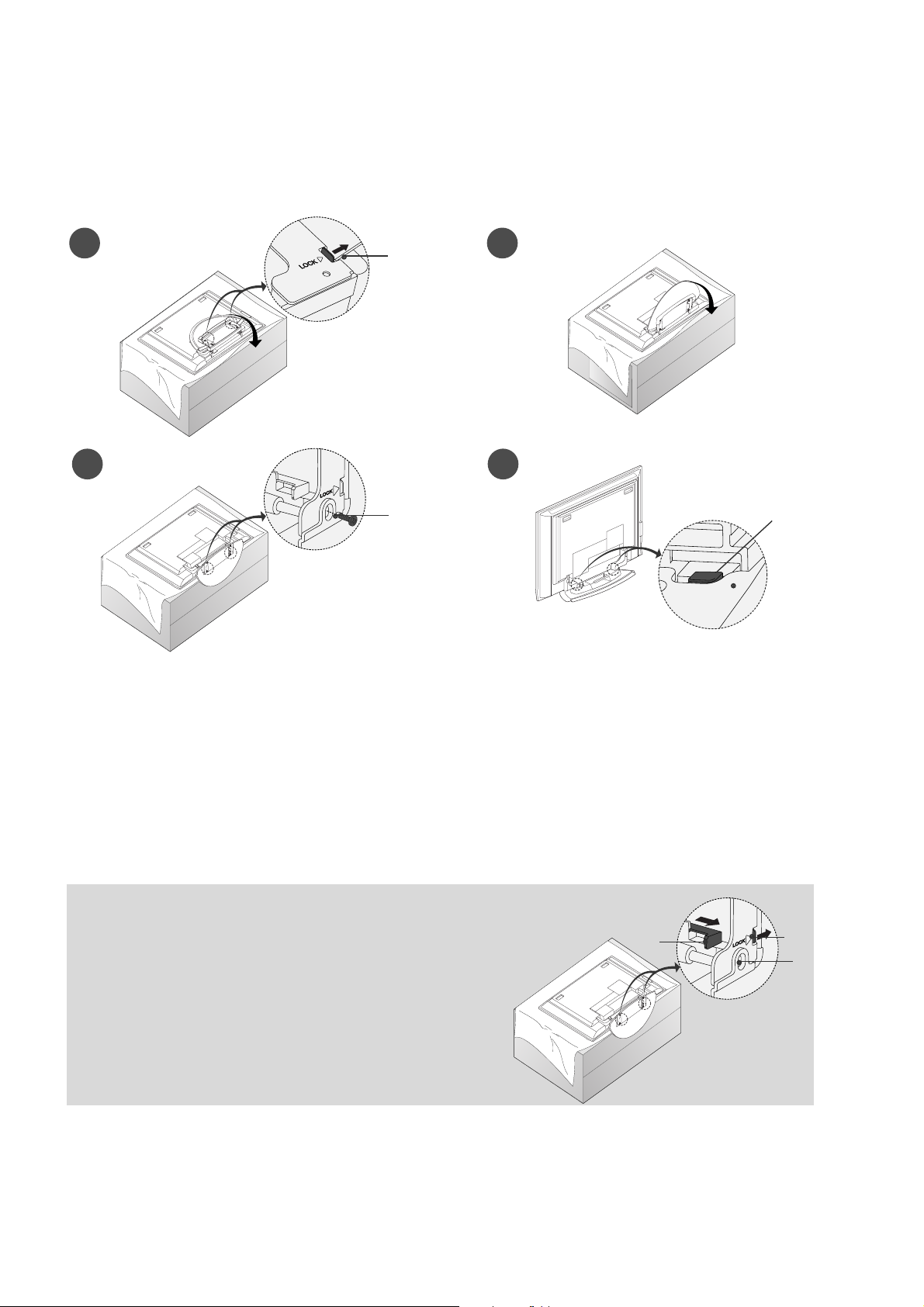

STAND INSTALLATION (OPTION)

Figures shown here may be slightly different from your set.

When closing the stand for storage

First remove the screws in the holes (B) on the bottom

of the stand. And then pull two Hooks (D) of the stand

bottom

and fold the stand into the back of the set.

After folding, push two Locks (A) of the stand bottom

outward.

O Place the set with the screen facing down on a cushion or soft cloth as shown in Figures 1.

Before unfolding the stand, please make sure two locks (A) on the bottom of the stand push outward.

O Pull the stand out as shown above in Figures 2 ~ 3.

After unfolding the stand, please insert and tighten the screws in the holes (B) on the bottom of the

stand.

O When connecting cables to the set, Do not disengage the lock (C).

This may cause the set to fall, causing serious bodily injury and serious damage to the set.

A

D

A

C

B

B

1

3 4

2

* NOTE

Page 10

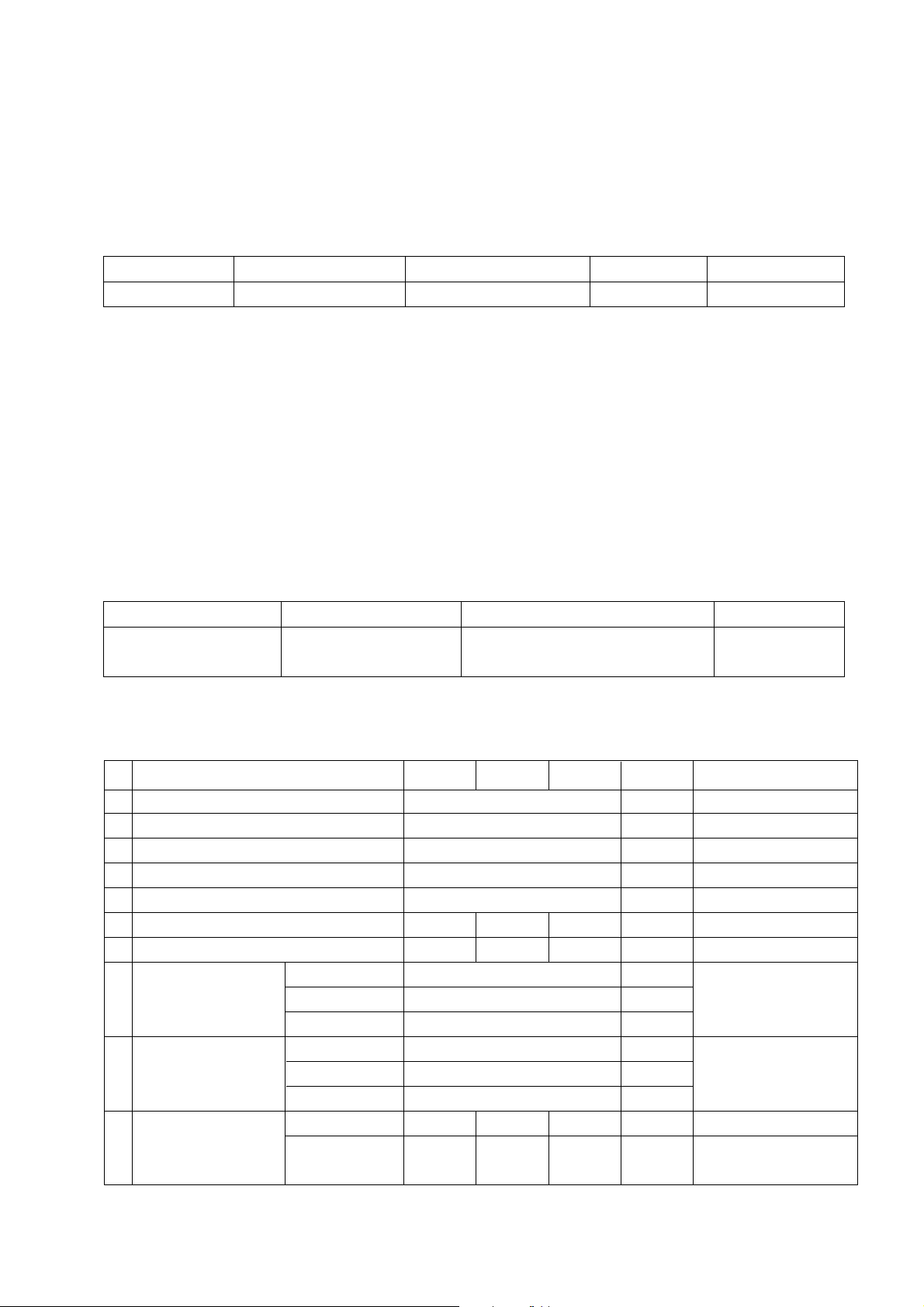

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to the 42” PLASMA TV used PB61A Chassis.

V Specification

Each part is tested as below without special appointment.

1) Temperature : 25±5°C (77±9°F), CST : 40±5

2) Relative Humidity: 65±10%

3) Power Voltage: Standard Input voltage (100-240V~, 50/60Hz)

* Standard Voltage of each product is marked by models.

4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with SBOM.

5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

1) Performance : LGE TV test method followed.

2) Demanded other specification

Safety : CB specification

EMC : CISPR 13 specification

V General Specification

1. Module Specification

- 10 -

Display area

Outline dimension

Number of Pixels

Cell pitch

Color arrangement

Weight(net)

Weight(gross)

Operation Environment Temperature

Humidity

Pressure

Storage Environmnet Temperature

Humidity

Pressure

I mage stick minimization Start time

mode Low Brightness

Arrival Time

920.1 (H) * 518.4(V) ± 0.5

1005(H) * 597(V) * 60.7(D) ±1

852(H) * 480(V)

320(H) * 1080(V)

RGB closed type

13.1 13.6 14.1

82.5 87.5 92.5

0 ~ 55

20 ~ 80

800 ~ 1100

-20 ~ 60

10 ~ 90

700 ~ 1100

4.5 5 5.5

14 15 16

1

2

3

4

5

6

7

8

9

10

No Item Remark

1Pixel=3RGB Cells

Green Cell basis

5EA 1 Box

Altitude : 0 to 2000M

Altitude : 0 to 3000M

Chassis

PB61A 42PC1DV-AA Australia LG

Model Name Market Brand Remark

42PC1DV-AA Safety : IEC60065,EN60065

EMC : CISPR 13 Class B

Australia

Model ApplianceMarket Remark

mm

mm

um

Kg

Kg

deg

%

hPa

deg

%

hPa

min

min

Min Typ Max Unit

Page 11

- 11 -

2. Model General Specification

Broadcasting system

Available Channel

Tuner IF

Input Voltage

PDP Module

Aspect ratio

Operating Temperature

Operating Humidity

Storage Temperature

Storage Humidity

PAL-B/G, DTV : DVB-T

1) VHF : 00 ~ 12

2) UHF : 20 ~ 75

3) CATV : 02 ~ 44

4) DTV : 06 ~12, 27 ~ 69

1) PAL : 38.90MHz(Picture),

34.40MHz(Sound)

2) DVB-T : 36.125MHz

240V~, 50Hz

PDP42V8

16:9 (wide)

0 40 deg

85 %

-20 60 deg

85 %

1

2

3

4

5

6

7

8

9

10

No

Item

Remark

Maker : LGE

RGB Closed Type

Specification

Min Typ Max Unit

Page 12

- 12 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions are applied to all of the 42” PLASMA TV,

PB61A

Chassis

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 220V~,

60Hz when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

O Preliminary action is applied to the test for afterimage

discharge detection, and 100% FULL WHITE PATTERN

must be operated automatically.

O Test for afterimage discharge detection

1) After pressing Power Only key(only operating by

pressing Power Only key), Full Test Pattern(2 min

30sec) --> Full Black Pattern(30sec) --> After this state,

Full White Pattern is displayed.

(but you must preset the program for Full White State

when you press the Main Power Off/On)

2) Pattern Mode is deselected by pressing CH +/-, Exit Key.

[ Set is activated HEAT-RUN without signal generator in

this mode.

If you turn on a still screen more than 20 minutes (Especially

Digital pattern, Cross Hatch Pattern), an afterimage may occur

in the black level part of the screen.

3. CPLD Download

(1) Test Equipment: PC, Jig for download

(2) Connect the power of VSC B/D.

(3) Execute download program of PC.

(4) After executing the hot key on the Programmer, click icon.

(5) End after confirming.

4. Sub-ucom(MTV) Download

(1) Test Equipment: PC, Jig for download

(2) Connect the power of VSC B/D.

(3) Execute download program of PC.

(4) After executing the hot key on the Programmer, click icon.

(5) End after confirming.

5. MST3362M-Set Adjustment

5-1. Synopsis

MST3362M-Set adjustment to set the black level and the Gain

of optimum with an automatic movement from the analog =>

digital converter.

5-2. Test Equipment

Service R/C, 801GF(802B,802F,802R),

MSPG-925 Pattern Generator.

( 480i, 1080i 60Hz Color Bar Pattern output will be possible

and the output level will accurately have to be revised with

0.7±0.1Vp-p)

5-3. Adjustment

(1) How to adjustment the Component1

1) Select Component1 as the input with Color Bar Pattern

in 480i 60Hz mode and select ‘Component1’ on screen.

2) After receiving signal for at least 1 second, press the

ADJ Key on the Service R/C to enter the ‘Ez - Adjust’

and select the ‘1. ADC 480i Comp1’. Pressing the Vol+

Key to adjust the component1.

3) When the adjustment is over, 'Component1 Adjustment

OK’ is displayed. If the adjustment has errors,

'Component1 Adjustment Failed! Try Again!’ is

displayed.

4) Readjust after confirming the case Pattern or adjustment

condition where the adjustment had errors.

5) After adjustment is complete, exit the adjustment mode

by pressing the ADJ KEY.

(2) How to adjustment the Component2, RGB

1) Select Component2, RGB-DTV as the input with Color

Bar Pattern in 1080i 60Hz mode and select

‘Component2’ on screen.

2) After receiving signal for at least 1 second, press the

ADJ Key on the Service R/C to enter the ‘Ez - Adjust’

and select the ‘2. ADC 1080i Comp2/RGB’. Pressing

the Vol+ Key to adjust the component2.

3) When the adjustment is over, 'Component2 Adjustment

OK’ is displayed. If the adjustment has errors,

'Component2 Adjustment Failed! Try Again!’ is

displayed. and If the adjustment has errors, 'RGB

Adjustment Failed! Try Again!’ is displayed.

4) Readjust after confirming the case Pattern or adjustment

condition where the adjustment had errors.

5) After adjustment is complete, exit the adjustment mode

by pressing the ADJ KEY.

PC

VSC

B/D

JIG cable(CPLD D/L )

<Fig. 1> Connection Diagram of CPLD Download

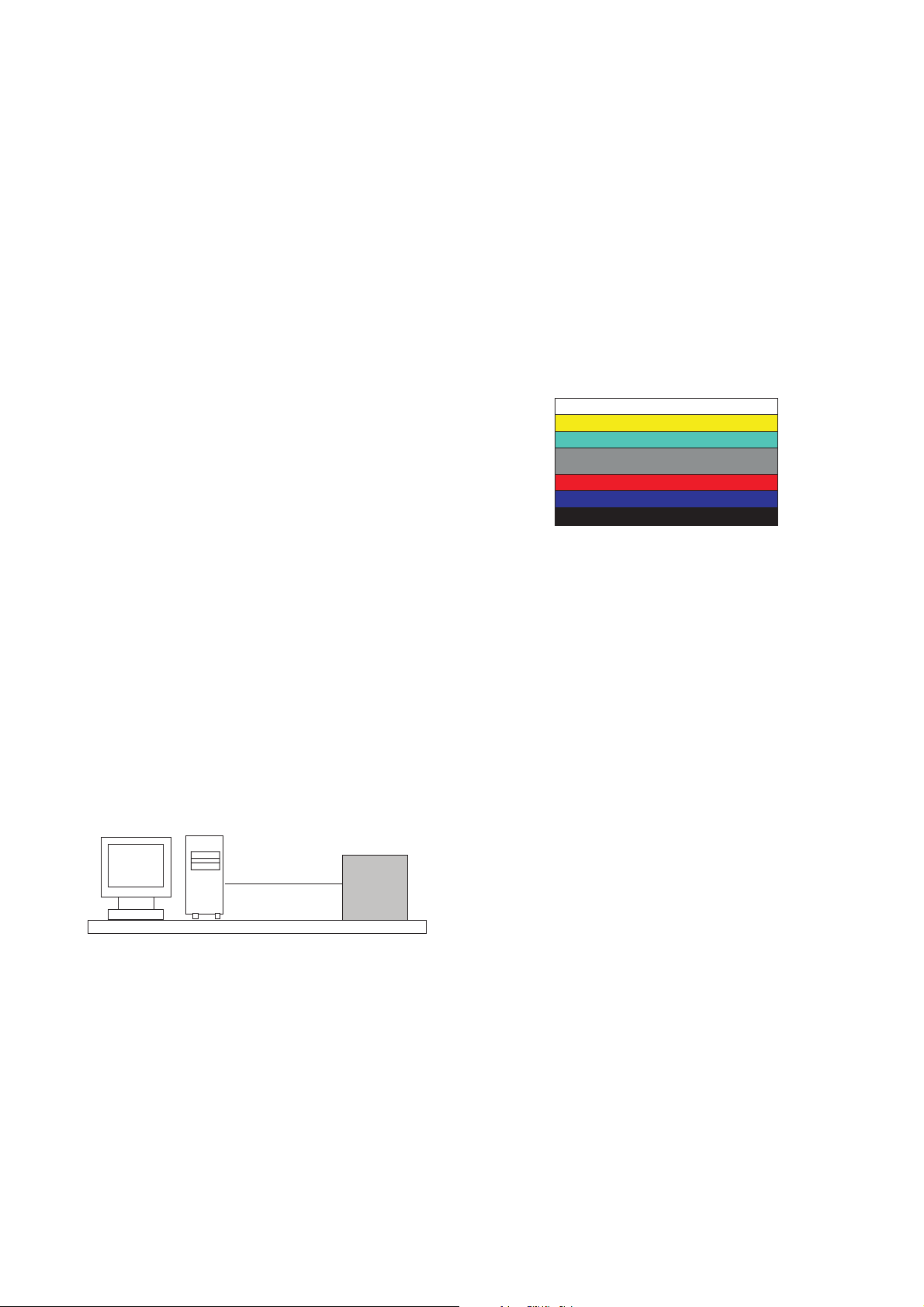

(Fig. 2) Adjust Pattern : 480i, 1080i 60Hz Color Bar Pattern

Page 13

- 13 -

6. Video(uPD)-Set

6-1. Synopsis

This is a adjustment to reduce the color difference of video

signal Main/Sub Display.

6-2. Required Equipment

Service R/C, MSPG-925 Pattern Generator.

(It’s available to output the Color Bar Pattern of the NTSC,PAL)

6-3. Adjustment

(1) How to adjustment the uPD PAL

1) Select AV1 as the input with 100% 8 Color Bar Pattern

in PAL mode and select ‘AV1’ on screen.

2) After receiving signal for at least 1 second, press the

ADJ Key on the Service R/C to enter the ‘Ez - Adjust’

and select the ‘3. uPD PAL(Main&Sub)-Set’. Pressing

the Vol+ Key to adjust the uPD PAL.

3) When the adjustment is over, 'uPD64015 PAL Main

Adjustment OK’ and ‘uPD64015 PAL Sub Adjustment

OK’ is displayed. If the adjustment has errors,

'uPD64015 PAL Main Error!’ or 'uPD64015 PAL Main

Error!’ is displayed.

4) Readjust after confirming the case Pattern or adjustment

condition where the adjustment had errors.

5) After adjustment is complete, exit the adjustment mode

by pressing the ADJ KEY.

(2) How to adjustment the uPD NTSC

1) Select AV1 as the input with 100% 8 Color Bar Pattern

in NTSC mode and select ‘AV1’ on screen.

2) After receiving signal for at least 1 second, press the

ADJ Key on the Service R/C to enter the ‘Ez - Adjust’

and select the ‘4. uPD NTSC(Main&Sub)-Set’. Pressing

the Vol+ Key to adjust the uPD NTSC.

3) When the adjustment is over, 'uPD64015 NTSC Main

Adjustment OK’ and ‘uPD64015 NTSC Sub Adjustment

OK’ is displayed. If the adjustment has errors,

'uPD64015 NTSC Main Error!’ or 'uPD64015 NTSC

Main Error!’ is displayed.

4) Readjust after confirming the case Pattern or adjustment

condition where the adjustment had errors.

5) After adjustment is complete, exit the adjustment mode

by pressing the ADJ KEY.

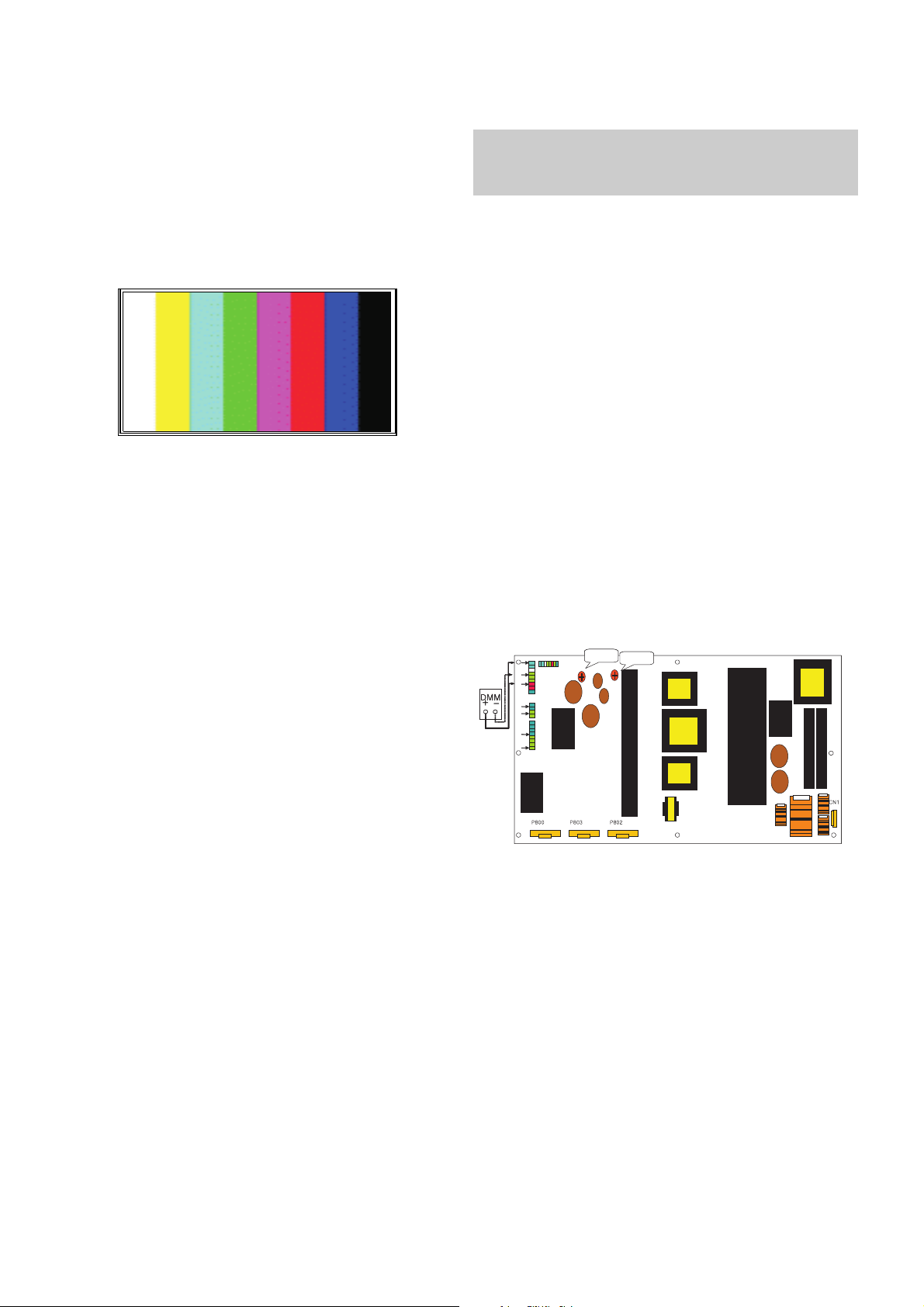

7. POWER PCB Assy Voltage

Adjustment (Va, Vs Voltage Adjustment)

7-1. Test equipment: D.M.M 1EA

7-2. Connection Diagram for Measuring

Refer to Fig.5

7-3. Adjustment Method

Adjustment Method for Power Board( P/No: 6709900019A)

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P812, connect

- terminal to GND pin of P812.

3) After turning VR0901, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P812, connect

– terminal to GND pin of P812.

2) After turning VR951, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(Fig. 3) Adjust Pattern :100% 8 Color Bar Pattern

Each PCB Assy must be checked by Check JIG Set before

assembly. (Especially, be careful Power PCB Assy which can

cause Damage to the PDP Module.)

11

1

Vs AD J

VR951

Va A DJ

VR901

GND

Va

5V

Vs

GND

P821

GND

5V

P822

P811

P812

11

1

Vs AD J

VR951

Va A DJ

VR901

GND

Va

5V

Vs

GND

P821

GND

5V

P822

P811

P812

(Fig. 5) Connection Diagram of Power Adjustment for Measuring

Page 14

- 14 -

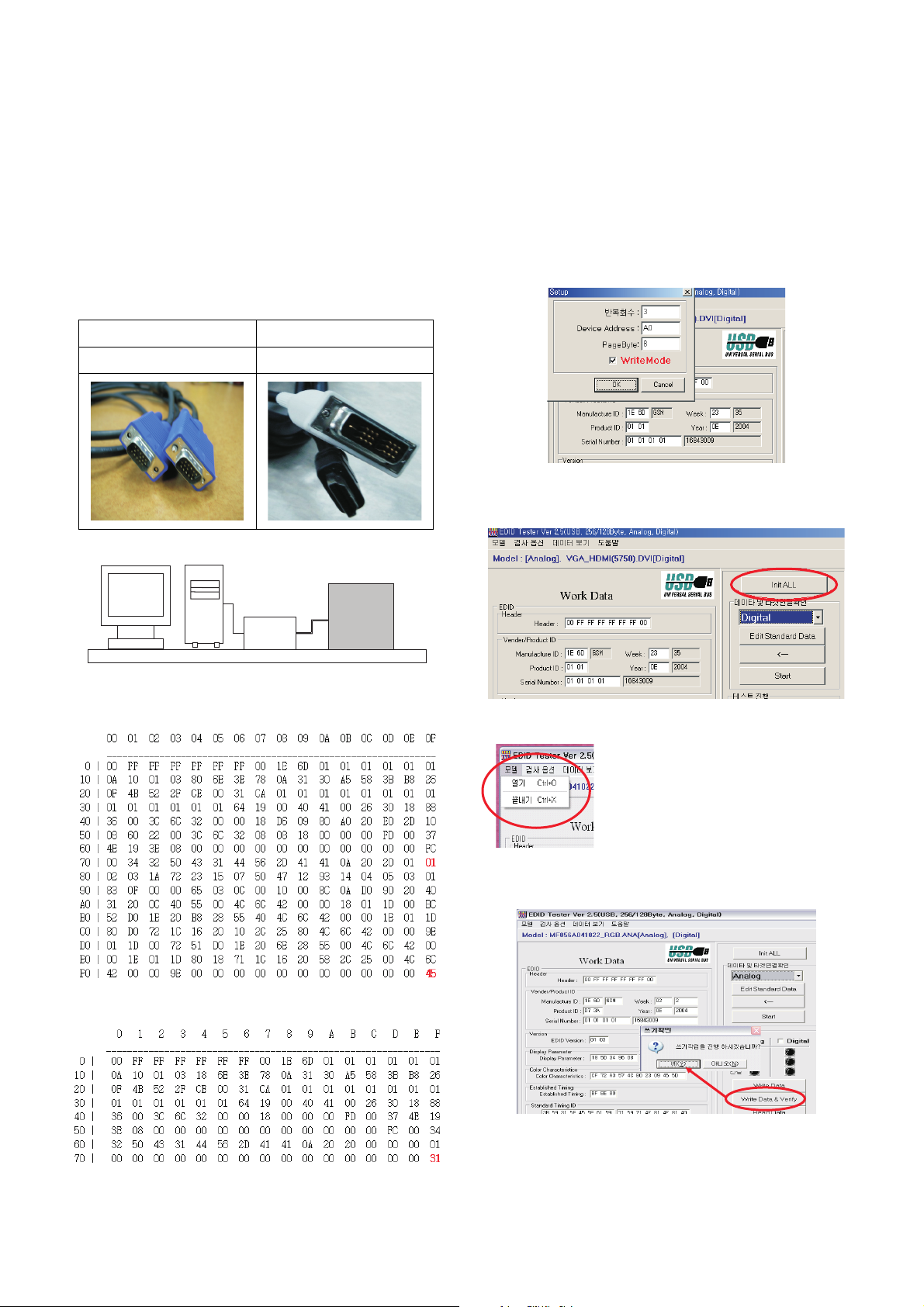

8. EDID(The Extended Display

Identification Data)/DDC

(Display Data Channel) Download

This is the function that enables “Plug and Play".

8-1. Required Test Equipment

(1) PC, Jig for adjusting DDC.

(PC serial to D-sub Connection equipment)

(2) DVI to HDMI Connector.

8-2. Setting of Device

8-3. EDID DATA

(1) HDMI EDID DATA.

(2) HDMI EDID DATA.

8-4. Act or set the EDID S/W

1) As above Fig. 6, Connect the Set, EDID Download Jig, PC

& Cable.

2) Turn on the PC & EDID Download Jig. And Execute the

S/W : EDID TESTER Ver,2.5.

3) Set up S/W option.

Repeat Number : 3

Device Address : A0

PageByte : 8

8-5. How to use the EDID S/W

1) Init the data.

2) Load the EDID data.(Open File)

42PC1DV_AA_HDMI(0145).DVI

42PC1DV_AA_RGB(31).ana

3) Press the “Write Data & Verify”button. and input the

data.

4) If the writing is finished, you will see the “OK” message.

Analog EDID

D-sub to D-sub

HDMI EDID

DVI-D to HDMI

PC

JIG

PDP

SET

Page 15

- 15 -

9. Adjustment of White Balance

9-1. Required Equipment

(1) Color analyzer (CA-210 or similar product)

(2) Automatic adjustor (with automatic adjustment hour

necessity and the RS-232C communication being possible)

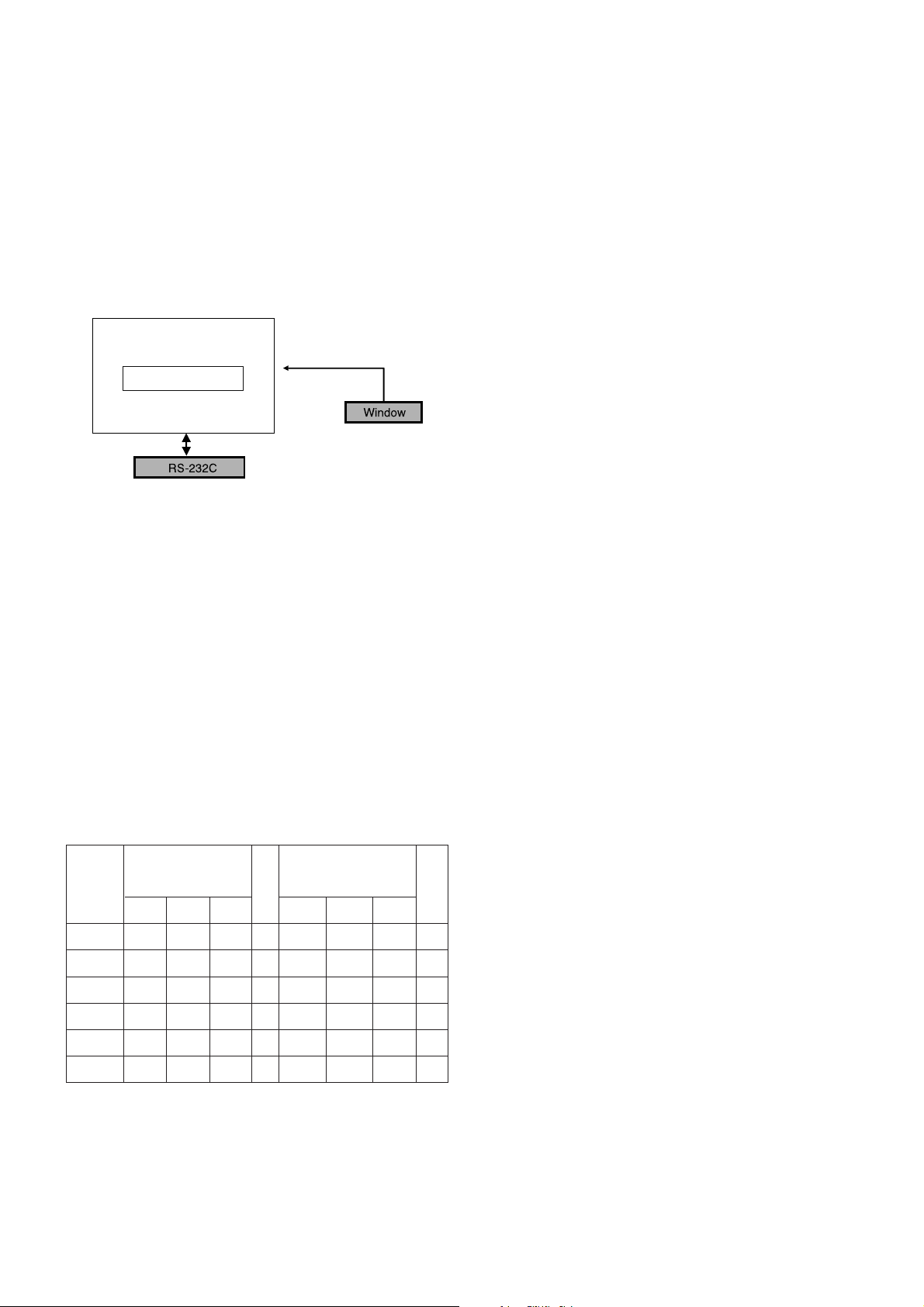

9-2. Connection Diagram of Equipment

for Measuring (Automatic Adjustment)

9-3. Process of automatic adjustment

(1) As using the white pattern for adjustment the inner part,

HDMI connection need not. But as lower part, the RS-232C

Command is used.

Wb 00 00 start of automatic adjustment the white balance.

Wb 00 10 Start of gain adjustment.(inside pattern)

Ja 00 ff Adjustment Date.

Jb 00 c0

...

Wb 00 1f Ending gain adjustment.

As occasion demands , adjust the offset.

( Wb 00 20(Start) , Wb 00 2f(end))

Caution) When you adjust, automatically, RS-232C

Command is used.

[[

RS-232C Command (Automatic Adjustment)

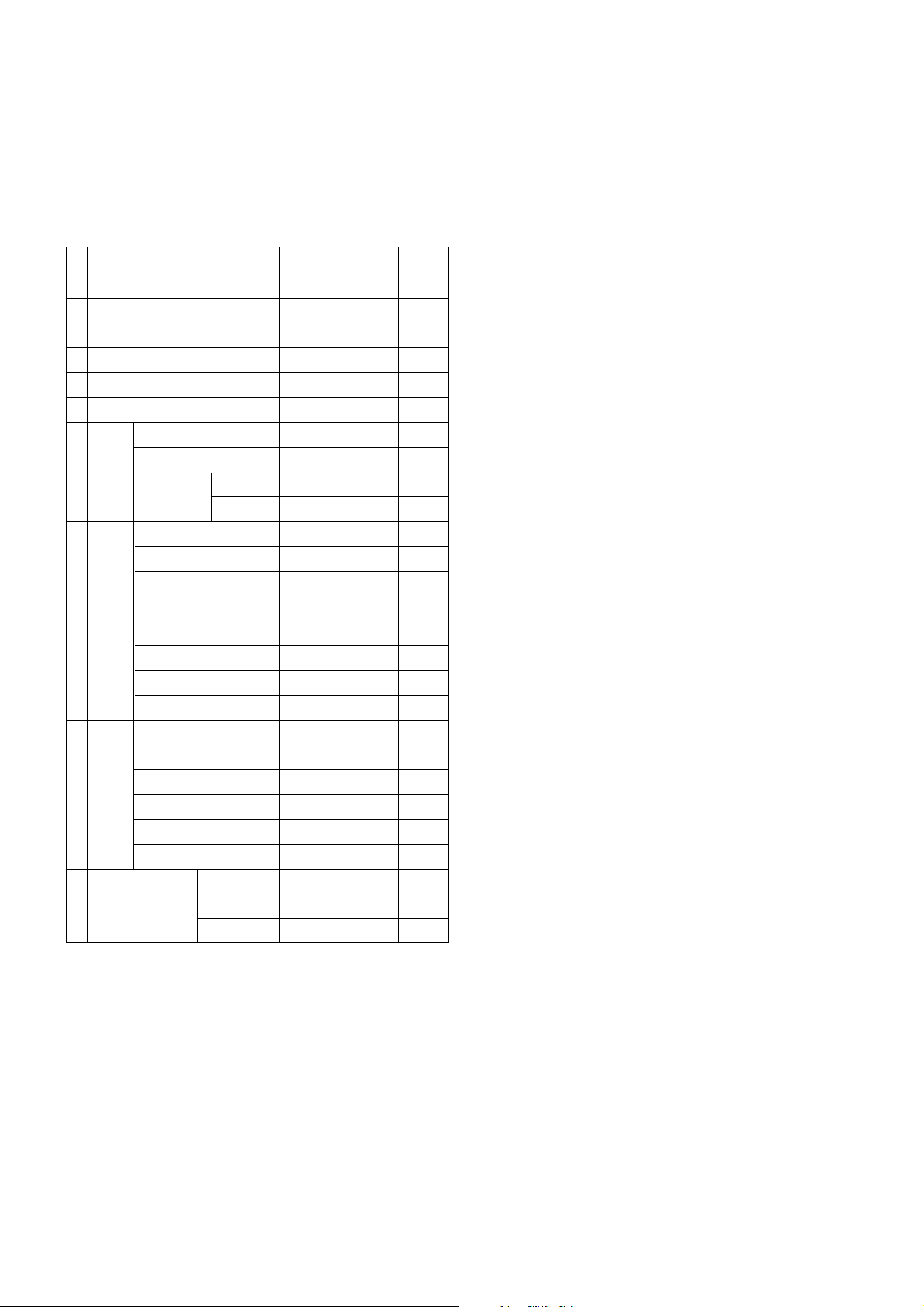

9-4. Adjustment of White Balance

(Automatic Adjustment)

O

Calibrate of the CA-210, then attach sensor to PDP module

surface when you adjust.

O

Manual adjustment is also possible by the following sequence.

(1) HEAT RUN at least 30 minutes by pressing the Power only

Key on the Service Remote Control and adjust. and use

power only or tint key and establish BaudRate to 115200.

(2) It must start “ 00 00”, complete “wb 00 ff”.

(3) Adjust offset.

9-5. Adjustment of White Balance

(Passivity Adjustment)

(1) HEAT RUN at least 30 minutes by pressing the ‘7. White-

Pattern’ on the Service Remote Control and adjust.

(2) After attaching sensor to center of screen, select ‘7. White-

Balance’ of ‘Ez - Adjust’ by pressing the ADJ KEY on the

Service R/C. Then enter adjustment mode by pressing the

Right KEY (

G

). This time white pattern is displayed.

(3) Adjust the High Light using B Gain/G Gain - [Cool].

(B Gain 192, R-Cut/G-Cut/B-Cut: 64/62/65 Fix.)

Adjust the High Light using B Gain/R Gain - [Medium].

(B Gain 192, R-Cut/G-Cut/B-Cut: 65/62/66 Fix.)

Adjust the High Light using G Gain/B Gain - [Warm].

(B Gain 192, R-Cut/G-Cut/B-Cut: 62/62/65 Fix.)

(4) Adjust using Volume +/- KEY.

Value of bright : High Level -> 216gray

[Cool]

X; 0.278±0.0015 Y; 0.279±0.0015

Color temperature: 11000°K ±1000°K

dUV: -3dUV

[Medium]

X; 0.287±0.0015 Y; 0.289±0.0015

Color temperature: 9300°K±1000°K

dUV: -3dUV

[Warm]

X; 0.314±0.0015 Y; 0.318±0.0015

Color temperature: 6500°K±1000°K

dUV: -3dUV

(5) After adjustment is complete, exit the adjustment mode by

pressing the ADJ KEY.

216 FULL WHITE

CVBS Part

PDP MONITOR

COLOR

ANALYZER

TYPE; CA-100

<Fig. 6> Connection Diagram of Automatic Adjustment

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

CENTER

(DEFAULT)(Hex)

00

00

00

D0

D0

D0

7f

7f

7f

Min

Max

(Hex)

C0

C0

C0(Fix)

40

3E

41

Cool

C0

C0(Fix)

C0

41

3E

42

Mid

C0(Fix)

C0

C0

3E

3E

40

Warm

RS-232C COMMAND

[CMD ID DATA]

Jg

Jh

Ji

lp

lq

lr

Cool

Ja

Jb

Jc

lj

lk

ll

Mid

Jd

Je

Jf

lm

ln

lo

Warm

Page 16

- 16 -

10. Check the adjustment of the plant

shipping mode

: This adjustment is checking the set state after take a

adjustment of examination, check state of this model as

shown below pressing the IN_STOP button on the

adjustment Remote Controller.

1

2

3

4

5

6

7

8

9

10

Digital

30

Off

16:9

1

Dynamic

Cool

Off

Auto

Standard

Off

0

On

On

--

Off

Off

Off

16:9

Off

Normal

Off

C0, C5, C6, S11,

C20, C35, C52, C68

C43

Item ConditionNo

Remark

Input Mode

Volume Level

Mute

Aspect Ratio

SET ID

Picture PSM

Color Temp.

Advanced Cinema

Black level

Sound SSM

AVL

Balance

TV Speaker

Time Auto Clock

Manual Clock

Off Timer / On Timer

Sleep Timer / Auto Off

Option Sub title

Child Lock

ARC

Demo

ISM Method

Low Power

Channel Memory Analog

Digital

Page 17

- 17 -

TROUBLE SHOOTING GUIDE

1. Power Board

1-1. The whole flowchart which it follows in voltage output state

Start check

Manufacture enterprise

meaning of a passage

1. Check the Power Off

condition.

Doesn't the

screen whole come

out?

Is it identical

with Power Off

condition?

Yes

Yes

No

No

No

No

No

2. Check the Interface

signal condition.

Is the Interface

signal operated?

Yes

3. Check the St-by 5V

signal circuit.

Doesn't the

low pressure output

come out?

Doesn't the

St-by 5V signal

come out?

Yes

Yes

No

4. Check the 5V Monitor

signal circuit.

Doesn't the

5V Monitor signal

come out?

Yes

7. Check the VSC Vs-ON

signal

Doesn't the

high tension output

come out?

Doesn't the

VSC signal Vs-ON

come out?

Yes

Yes

Does

high tension

output voltage Drop

occur?

When the

Y B/D Module

input connector is

removed, does output

voltage drop

occur?

When the

Y, Z B/D Module

input connector is remove,

does Power Board hightension

output voltage Drop

occur?

Yes No No

9. Check the Power

Board Output high

tension circuit

Yes

10. Check the Z B/D

Module output circuit

Yes

When the

Z B/D Module

input connector is

removed, does output

voltage Drop

occurs?

11. Check the Y B/D

Module output circuit

Yes

No

8. Check the Vs, Va

voltage output circuit.

Doesn't the

Vs, Va voltage output

come out?

Yes

No

No

5. Check the VSC RL-ON

signal.

Doesn't the

VSC signal RL-ON

come out?

Yes

6. Check the VSC low

pressure output

Doesn't the

VSC low pressure

output come out?

Yes

Page 18

- 18 -

1-2. 42” Power Board Structure

T801: Vs Trans

T901: Va Trans

T112: Low Voltage Trans

T501: ST-BY Trans

T601: PFC Inductor

Page 19

- 19 -

2. In case of occurring strange screen into specific mode

2-1. In case the OSD does not displayed

(1) Symptom

1) LED is white.

2) Some discharge on Panel becomes accomplished continuously.

(2) Check follow

Is the LVDS cable

normal ?

Is the VSC Board

normal?

Is the LVDS cable

connected well?

Cable inserts well.

Yes

No

No

Yes

Does the Thine IC

(IC900) Operates ?

Replace Thine

(IC900).

No

Is the Ctrl Board of

Module normal?

Replace Ctrl B/D.

No

No

Replace Scaler

(IC401).

No

Does the Scaler

(IC401) Operates ?

Replace VSC

Digital B/D.

Replace the cable.

Yes

Yes Yes

Page 20

- 20 -

2-2. In case of does’t display the screen into specific mode

(1) Symptom

1) The screen does not become the display from specific input mode.

(RF, AV, Component, RGB, DVI)

(2) Check following

1) Check the all input mode should become normality display

.

2) Check the Video(Main)/Data(Sub), Video(Main)/Video(Sub) should become

normality display from the PIP mode or DW mode.

(Re-Check using Swap function)

Check the NEC64015(IC701) if the main picture is abnormal, and

Check the NEC64015(IC801) If the sub picture is abnormal.

(3) When Analog TV mode is abnormal

(4) When AV mode is abnormal

Is the Splitter normal?

Is the Flat Cables

normal?

Replace Flat Cables.

Is the Tuner Cable

connected well?

Cable inserts well.

Yes

No

No

Yes

Is the CXA2069Q(IC100)

normal?

Replace the Tuner.

No

Is the Input voltage, IIC Communication

and CVBS output normal?

No

Is normal the Input voltage, IIC

Communication and HV sync?

No

Replace the IC.

No

Yes

Is the uPD64015

normal?

Is normal the Input voltage, IIC

Communication and HV sync?

Is normal the Input voltage, IIC

Communication and HV sync?

Is normal the Input voltage, IIC

Communication and HV sync?

No

Replace the IC.

No

Is the CXA2069Q

normal?

Yes

Is the uPD64015

normal?

No

Replace the IC.

No

No

Replace the IC.

No

Is normal the Input voltage, IIC

Communication and HV sync?

Yes

Is the Scaler normal?

No

Replace the IC.

No

Yes

Page 21

- 21 -

(5) When Component or RGB-DTV/ PC mode is abnormal

(6) When HDMI/DVI mode is abnormal

(7) When DVI-PC mode is abnormal

(8) When Digital TV mode is abnormal

Is normal the Input voltage, IIC

Communication and HV sync?

Is normal the Input voltage, IIC

Communication and HV sync?

Is the CXA2151Q(IC500)

normal?

Yes

Is the MST3362(IC604)

normal?

Is the MST3362(IC604)

normal?

No

Replace the IC.

No

No

Replace the IC.

No

Is normal the Input voltage, IIC

Communication and HV sync?

Yes

Is the Scaler normal?

No

Replace the IC.

No

Is normal the Input voltage, IIC

Communication and HV sync?

Is the EDID correct?

Yes

Is the latest version the Graphic card

driver of the PC?

Update the Graphic card driver with the

latest version.

No

No

Is normal the Input voltage, IIC

Communication and HV sync?

Yes

Is the Scaler normal?

No

Replace the IC.

Cable connected well.

No

Is the Tuner Cable connected

well?

No

Is normal the Input voltage, IIC

Communication and output of the tuner?

Is the Splitter normal?

Yes

Replace the Tuner.

Is the Flat Cables

normal?

No

Is normal the Input voltage, IIC

Communication and HV sync?

Replace the IC.

No

Is normal the Input voltage, IIC

Communication and HV sync?

Yes

Is the Scaler normal?

No

Replace the IC.

No

No

Replace the Tuner.

No

Yes

Page 22

- 22 -

3. When sound is abnormal

(1) Symptom

1) LED is green.

2) Screen display but sound is not output.

(2) Check following

Is the SPK cable

normal?

Is the SPK cable

connected well?

Cable inserts well.

No

No

Is the Flat cable

connected well?

Is the RF(Digital)

sound normal?

Cable inserts well.

No

No

Replace the IC200.

Replace SPK cable.

Yes

Yes

Yes

Is the RF(Analog) / AV/

Component L-R sound

normal?

Is the CS5330A(IC1000),

MC33078(IC1001),

Scaler(IC401) normal?

No

No

Is the MSP4450K

(IC200) normal?

Replace the IC400.

Yes

Is the NSP2100

(IC400) normal?

Replace the IC402.

Yes

Is the TAS5122

(IC402) normal?

Replace the IC400.

Yes

Yes

No No No

No

Is the Scaler

(IC401) normal?

Replace

VSC Digital B/D.

Yes

Yes

Replace the IC.

No

Is the SPDIF sound

normal?

Is the XC95288(IC300),

CS8415A(IC1003),

Scaler(IC401) normal?

No

Replace the IC.

Page 23

- 23 -

PRINTED CIRCUIT BOARD

MAIN(TOP)

Page 24

- 24 -

MAIN(BOTTOM)

Page 25

- 25 -

TUNER (TOP)

TUNER (BOTTOM)

Page 26

- 26 -

CONTROL

PRE-AMP

SIDE A/V

Page 27

- 27 -

BLOCK DIAGRAM

Page 28

- 28 -

Page 29

MEMO

- 29 -

Page 30

- 30 -

EXPLODED VIEW

600

602

601

121

120

570

203

204

206

200

580

205

201

202

400

240

250

430

530

501

301

304

303

302

560

502

520

300

Page 31

- 31 -

120 6400WMCX03A Speaker, Woofer G1560102 ND35 15W 8OHM 82DB 100HZ 193X57mM LUG

121 6400DTTX02C Speaker, Tweeter EN15D-6659-1 N35 15W 8OHM 81DB - 38.3X88mM LUG

200 6348Q-E113H PDP, Module-VGA PDP42V80201.AKLGG VGA 42INCH 852X480 16/9

201 6871QCH074A PCB Assembly, Display CTRL ASSY HAND INSERT 42” 42V8 4005 ASIC LVDS

202 6871QDH118A PCB Assembly, Display YDRV ASSY HAND INSERT 42” 42V8 80PIN SCAN IC APLICATION

203 6871QLH057A PCB Assembly, Display XRLT ASSY HAND INSERT 42” 42V8 XL 4004 ASIC LVDS

204 6871QRH067A PCB Assembly, Display XRRT ASSY HAND INSERT 42” 42V8 XR 4004 ASIC LVDS

205 6871QYH048A PCB Assembly,Display YSUS ASSY HAND INSERT 42” 42V8 Y SUS B/D

206 6871QZH053A PCB Assembly,Display ZSUS ASSY HAND INSERT 42” 42V8

240 4980900109A Supporter, COMPLEX ASSY AL 42PC1R-TA, VERTICAL RIGHT

250 4980900109B Supporter, COMPLEX ASSY AL 42PC1R-TA, VERTICAL LEFT

300 30919E0006E Cover Assembly, 42PC1V-AA BRAND 30909E0001A NON

301 4980900113A Supporter, COMPLEX ASSY AL FILTER TOP 42PC1R-TA

302 4980900114A Supporter, COMPLEX ASSY AL FILTER BOTTOM 42PC1R-TA

303 4980900115A Supporter, COMPLEX ASSY AL FILTER RIGHT 42PC1R-TA

304 4980900116A Supporter, COMPLEX ASSY AL FILTER LEFT 42PC1-TA

400 3809900103B Cover Assembly, 42PC1D NON DIGITAL

430 3501900014A Base Assembly, D/T SPK STAND AP-42DC11 MF056A FOLDING STAND

501 3301900095H Plate Assembly, AV 42PC I-DTV

502 3301900092A Plate Assembly, ASSY DIGITAL COVER ASSY (PB61A)

520 68719MMV65A PCB Assembly, Main MAIN1 M.I PB61A 42PC1DV-AA AAULLHX AUSTRAILIA DTV DIGITAL MANUAL

530 68719SMK96A PCB Assembly, Sub SUB M.I PB61A 42PC1DV-AA AAULLHX AUSTRAILIA DTV TUNER MANUAL

560 68719SMK74A PCB Assembly, Sub SUB M.I PB61A 42PC1DV-AA AAULLHX AUSTRAILIA DTV LOCAL ASSY MANUAL

570 68719SMJ64A PCB Assembly, Sub SUB M.I PP61A 42PC3RV Z PREAMP+LED

580 68719PT299A PCB Assembly, Power POWER T.T PA61A 42INCH PDP UNIFICATION PSU ALL GUMI

600 68719SML57A PCB Assembly,Sub SUB M.I PB61A 42PC1DV-AA AAULLHX AUS DTV SIDE AV MANUAL

611 4811900021D Bracket Assembly, SIDE AV 42PC1RV-TH PP62A CORTEZ, NON EU

612 48149V0003A Plate, PRESS SPTE T0.3 SIDE AV 42PC1R

EXPLODED VIEW PARTS LIST

No. Part No. Descriptions

The components identified by mark is

critical for safety.

Replace only with part number specified.

Page 32

0IMCR02273A 0IMCR02273A PHILIPS DIP

CXA2069Q 8.5TO9.5V1300MW QFP

S3C44BOX01-EDRO 3TO3.6V 60MA 66MHZ

CS5331A-KSR 4.75TO5.25V 48KHZ 18BIT

MC33078DR2G +-5TO+-18V 2mV

KIA78R09F 10TO25V 9V 8W DPAK

CS8415A-CZR 4.5TO5.5,2.85TO5.5

AT24C512W-10SU-2.7 512KBIT

AZ1117H-2.5TR/E1 15V 2.5V - SOT223

PQ05DZ1U 6TO16V 5V 8W D2PAK

AZ1117H-1.8TRE1(EH13A),LF 3.2TO10V

AZ1117H-3.3 4.75TO10V 3.3V SOT223

SDA6001 2.5VTO3.3V- MQFP TR 128P

KIA7027AF -0.3TO15V 2.7V 500MW SOT89

24LC16BT-I/SNG 16KBIT 256X8X8BIT

M12L64164A-5TG 64MBIT 16BIT 3.3V

AZ1117H-2.5TR/E1 15V 2.5V - SOT223

PQ05DZ1U 6TO16V 5V 8W D2PAK

KIA7029AF -0.3TO15V 2.9V 500MW

24LC16BT-I/SNG 16KBIT 256X8X8BIT 2.5

AZ1117H-3.3 4.75TO10V 3.3V - SOT223

MSP4450K-QA-D6 7.6TO8.7V_4.75

M12L64164A-5TG 64MBIT 16BIT 3.3V

M12L64164A-5TG 64MBIT 16BIT 3.3V

XC95288XL-10TQG144C 3TO3.6V 2.3

PQ05DZ1U 6TO16V 5V 8W D2PAK R/TP 5P

AZ1117H-1.8TRE1(EH13A),LF 3.2TO10V

KIA7029AF -0.3TO15V 2.9V 500MW

PA9516APW 0.5TO7.00W 300MW

ST3232CDR 3.0TO5.5 - SOP R/TP 16P

KA7809R 11.5TO24V 9V 150W DPAK

74HC14D 2TO6V 0.002mA

PA9516APW 0.5TO7.00W 300MW - 5

NSP-2100A 1.8VTO3.3V-2 TQFP R/TP 64P

AZ1117H-1.8TRE1(EH13A),LF 3.2TO10V

TAS5122DCARG4,LF 3TO3.6V_16TO25.5V

LGDT1102F HD2.4 0.5TO4.6 0A 27MHZ

TAS5122DCARG4,LF 3TO3.6V_16TO25.5V

AZ1117H-3.3 4.75TO10V 3.3V

AZ1117H-1.8TRE1(EH13A),LF 3.2TO10V

AZ1117H-1.8TRE1(EH13A),LF 3.2TO10V

M12L64164A-5TG 64MBIT 16BIT 3.3V

CXA2181Q 4.75VTO5.25V - 1.645W

M12L64164A-5TG 64MBIT 16BIT 3.3V

M12L64164A-5TG 64MBIT 16BIT 3.3V

M12L64164A-5TG 64MBIT 16BIT 3.3V

LGDT1901B 3.6VTO3.0V,0.0VTO0.0V

CAT24WC02J-TE13 2KBIT 256X8BIT 2.5V

24LC02BT-I/SNG 2KBIT 256X8BIT

FMS6407MTF20X-NL 4.75VTO5.25V

74F08D 4.5TO5.5V 12.9mA AND GATE

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC602

IC603

IC604

IC605

IC701

IC703

IC704

IC705

IC706

IC801

IC802

IC803

IC804

IC900

IC901

U131

U132

U151

U201

U221

U261

U271

U281

U501

U601

U701

U801

U851

U901

U951

Q151

Q201

Q262

Q281

Q601

Q601

Q602

Q603

Q604

Q952

Q100

Q101

Q101

Q102

Q102

Q102

Q103

Q103

Q104

Q105

Q1101

0IPMGA0010A

0IMMRCS012B

0IPRP00697A

0IPMG00107A

0IPRPNE011B

0IPMG00028A

0IMMR00229A

0IPMGA0010A

0ISA721700C

0IPRPNE011B

0IMMR00229A

0IPMGA0010A

0IPMG00028A

0IMCRTH002A

0IPMGA0010A

0IKE431000B

0IKE431000B

0IPMGFA073A

0IKE431000B

0IPMG78442A

0IMCRKE014A

0IKE431000B

0IKE431000B

0IPMG78398A

0IPMG78441A

0IMCR02273A

0IPMG78439A

0IPMG78440A

0IKE431000B

0IKE431000B

0TFST10002A

0TFTH50001A

0TFFC10028A

0TFFC10027A

0TFFN10010A

0TR830009BA

0TFFN10010A

0TR830009BA

0TR830009BA

0TFFC10020A

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

AZ1117H-3.3 4.75TO10V 3.3V - SOT223

CAT24WC08W-T(MST3000) 8KBIT

MST3362M-LF-110 MSTAR 128P

AZ1117H-2.5TR/E1 15V 2.5V

UPD64015AGM-UEU-A,LF 3.0V

AZ1117H-1.5TRE1 3TO10V 1.5V

M12L16161A-5TG 16MBIT 16BIT

AZ1117H-3.3 4.75TO10V 3.3V

LA7217M 4.5VTO5.5V 16.1KHZ 150MW

UPD64015AGM-UEU-A,LF 3.0VTO3.6V

M12L16161A-5TG 16MBIT 16BIT 3.3V

AZ1117H-3.3 4.75TO10V 3.3V

AZ1117H-1.5TRE1 3TO10V 1.5V

THC63LVD103 3.0TO3.6 1W TQFP TR 64P

AZ1117H-3.3 4.75TO10V 3.3V

KIA431 36V 36V 700MW TO92 TP 3P

KIA431 36V 36V 700MW TO92 TP 3P

KA7552A 10TO30V 16.5V 800MW DIP ST 8P

KIA431 36V 36V 700MW TO92 TP 3P

NJM2374AD 2.5TO40V 40V 875MW DIP ST 8P

KIA278R12PI 13TO29V 12V 1.5W TO220IS

KIA431 36V 36V 700MW TO92 TP 3P

KIA431 36V 36V 700MW TO92 TP 3P

STR-W6251 SANKEN 6PIN,TO-220F-6L

ICE1PCS02 -0.3TO22VDIP ST 8P

S3F9498 3TO5.5V - 8MHZ 2BYTE

MR4040 11TO18V - 10W TO-220F ST 7P

MR5060 16V - 20W TO-220F ST 7P

KIA431 36V 36V 700MW TO92 TP 3P

KIA431 36V 36V 700MW TO92 TP 3P

FET, STP6NK90ZFP(FORMING) N-CHANNEL

FET, 2SK2961 N-CHANNEL MOSFET 60V

FET, FQPF27P06 P-CHANNEL MOSFET

FET, FQPF13N06L N-CHANNEL MOSFET

FET, SD20N60 N-CHANNEL MOSFET 650V

FET, BSS83 N-CHANNEL MOSFET 10V - 50MA

FET, SD20N60 N-CHANNEL MOSFET 650V

FET, BSS83 N-CHANNEL MOSFET 10V - 50MA

FET, BSS83 N-CHANNEL MOSFET 10V - 50MA

FET, FQPF16N25C N-CHANNEL MOSFET 250V

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

LOCA. NO PART NO DESCRIPTION

I1

IC100

IC100

IC1000

IC1001

IC1002

IC1003

IC101

IC102

IC1101

IC1102

IC1103

IC1200

IC1201

IC1202

IC1203

IC1205

IC1303

IC1500

IC1501

IC1503

IC200

IC202

IC203

IC300

IC300

IC301

IC301

IC302

IC303

IC303

IC304

IC305

IC400

IC400

IC401

IC401

IC402

IC402

IC403

IC404

IC500

IC500

IC501

IC502

IC503

IC505

IC600

IC600

IC601

IC601

0IZZ9H9009A

0ISO206900A

0IMCRSS016A

0ICB533100A

0ISTL00029A

0IPMGKE032A

0ICB841500B

0IMCRAL021A

0IPMG00107A

0IMCRSH001A

0IPMG00049A

0IPMGA0010A

0IMCRMN023A

0IKE702700D

0IMMR00022A

0IMMR00230A

0IPMG00107A

0IMCRSH001A

0IKE702900G

0IMMR00022A

0IPMGA0010A

0IMCRMN028C

0IMMR00230A

0IMMR00230A

0IMCRXL004A

0IMCRSH001A

0IPMG00049A

0IKE702900G

0IMCRPH026B

0IMCRSG010A

0IMCRFA010A

0IPH741400E

0IMCRPH026B

0ILNR00015A

0IPMG00049A

0IMCRTI028C

0ICTMLG009E

0IMCRTI028C

0IPMGA0010A

0IPMG00049A

0IPMG00049A

0IMMR00230A

0IMCRSO025A

0IMMR00230A

0IMMR00230A

0IMMR00230A

0ICTMLG013B

0ICS240213A

0IMMR00018A

0IPRPFA016B

0IPH740800H

IC

TRANSISTOR & FET

- 32 -

Page 33

- 33 -

LOCA. NO PART NO DESCRIPTION

Q1102

Q1103

Q1104

Q1105

Q1107

Q1200

Q121

Q1300

Q1301

Q1302

Q1303

Q1304

Q1305

Q1503

Q152

Q200

Q200

Q201

Q202

Q202

Q203

Q204

Q205

Q205

Q206

Q207

Q223

Q251

Q253

Q271

Q300

Q500

Q501

Q600

Q600

Q602

Q603

Q603

Q604

Q604

Q605

Q605

Q605

Q606

Q701

Q702

Q705

Q706

Q801

Q851

Q951

0TR150400BA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR319809AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR103009AD

0TR102009AM

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR102009AJ

0TR150400BA

0TR150400BA

0TR387500AA

0TRSK10001A

0TR126609AA

0TR320000AB

0TR103009AG

0TR102009AJ

0TR150400BA

0TRKE50004A

0TR102009AJ

0TR102009AJ

0TR102009AJ

0TR387500AA

0TRRH80083A

0TR150400BA

0TRRH80082A

0TR387500AA

0TR387500AA

0TRKE50004A

0TR150400BA

0TRRH80052A

0TRRH80052A

0TR150400BA

0TR150400BA

0TR319809AA

0TR319809AA

0TR387500AA

2SA1504S(ASY) PNP 5V 50V 50V

2SA1504S(ASY) PNP 5V 50V 50V

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SA1504S(ASY) PNP 5V 50V 50V

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

KTC3198(KTC1815) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

KRC103M NPN 40V - 50V 100MA 500NA

KRA102S PNP 30V 50V 0.1A

2SA1504S(ASY) PNP 5V 50V 50V

2SA1504S(ASY) PNP 5V 50V 50V

2SA1504S(ASY) PNP 5V 50V 50V

2SA1504S(ASY) PNP 5V 50V 50V

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

KRC102S NPN 30V - 50V 100MA 500NA

2SA1504S(ASY) PNP 5V 50V 50V

2SA1504S(ASY) PNP 5V 50V 50V

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SA1568 PNP -6V -60V -60V 12A

KTA1266-Y(KTA1015) PNP -5V -50V -50V

KTC3200-BL (KTC2240) BK KEC - -

KRC103S NPN 40V - 50V 100MA 500NA

KRC102S NPN 30V - 50V 100MA 500NA

2SA1504S(ASY) PNP 5V 50V 50V

KTC3209 NPN 5V 50V 50V 2A 100NA

KRC102S NPN 30V - 50V 100MA 500NA

KRC102S NPN 30V - 50V 100MA 500NA

KRC102S NPN 30V - 50V 100MA 500NA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC5826TV2Q NPN 6V 60V 60V 3A 1UA

2SA1504S(ASY) PNP 5V 50V 50V

2SA2073TV2Q PNP -4V -60V -40V -3A

2SC3875S(ALY) NPN 5V 60V 50V 150MA

2SC3875S(ALY) NPN 5V 60V 50V 150MA

KTC3209 NPN 5V 50V 50V 2A 100NA

2SA1504S(ASY) PNP 5V 50V 50V

2SD2114K NPN 12V 25V 20V 500MA

2SD2114K NPN 12V 25V 20V 500MA

2SA1504S(ASY) PNP 5V 50V 50V

2SA1504S(ASY) PNP 5V 50V 50V

KTC3198(KTC1815) NPN 5V 60V 50V

KTC3198(KTC1815) NPN 5V 60V 50V

2SC3875S(ALY) NPN 5V 60V 50V 150MA

LOCA. NO PART NO DESCRIPTION

D100

D101

D101

D1101

D1102

D1200

D1201

D1202

D121

D122

D123

D124

D125

D1305

D151

D152

D154

D202

D221

D251

D252

D261

D262

D271

D300

D301

D501

D502

D503

D504

D505

D506

D600

D601

D601

D602

D602

D603

D604

D605

D606

D607

D611

D700

D703

D704

D801

D803

D804

D805

0DD184009AA

0DD184009AA

0DRSD00241A

0DS226009AA

0DS226009AA

0DS226009AA

0DS226009AA

0DS226009AA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DRFJ00115A

0DD184009AA

0DRSA00119A

0DRFJ00135A

0DD140009AA

0DR306000AA

0DRSA00020A

0DRSA00251A

0DS113379BA

0DRSA00251A

0DS113379BA

0DR306000AA

0DD184009AA

0DD184009AA

0DRFJ00125A

0DRFJ00115A

0DRFJ00135A

0DRFJ00135A

0DRSA00119A

0DRFJ00125A

0DRSE00048A

0DD184009AA

0DRNH00160A

0DRSD00281A

0DRSE00048A

0DRFJ00115A

0DS113379BA

0DD400509BB

0DS113379BA

0DD400509BB

0DRSD00281A

0DD184009AA

0DS113379BA

0DS113379BA

0DD100009AY

0DD400709CC

0DS141489AB

0DD400709CC

KDS184 KDS184 TP KEC - 85V- 300MA

KDS184 KDS184 TP KEC - 85V- 300MA

D15XB60-7000 600V 1.1V 10UA 200A

KDS226 1.2V 85V 300MA 2A 4NSEC

KDS226 1.2V 85V 300MA 2A 4NSEC

KDS226 1.2V 85V 300MA 2A 4NSEC

KDS226 1.2V 85V 300MA 2A 4NSEC

KDS226 1.2V 85V 300MA 2A 4NSEC

1SS133 1200MV 90V 400MA 600MA

1SS133 1200MV 90V 400MA 600MA

1SS133 1200MV 90V 400MA 600MA

1SS133 1200MV 90V 400MA 600MA

ERA15-06 600V 1.1V 10A 40A

KDS184 KDS184 TP KEC - 85V- 300MA

SARS01 800V 1200MV 10UA 110A 18USEC

ERA38-06 600V 2500MV 50UA 10A 50NSEC

EK14 550MV 40V 1.5A-

SF30SC6 60V 630MV 10MA 250A

FMB-G24H 550MV 40V 10A- TO220 ST 2P 1

FMX-G12S 200V 980MV 100UA 65A 30NSEC

1SS133 1200MV 90V 400MA 600MA

FMX-G12S 200V 980MV 100UA 65A 30NSEC

1SS133 1200MV 90V 400MA 600MA

SF30SC6 60V 630MV 10MA 250A

KDS184 KDS184 TP KEC - 85V- 300MA

KDS184 KDS184 TP KEC - 85V- 300MA

ERA15-10 1KV 1100MV 10UA 40A

ERA15-06 600V 1.1V 10A 40A

ERA38-06 600V 2500MV 50UA 10A 50NSEC

ERA38-06 600V 2500MV 50UA 10A 50NSEC

SARS01 800V 1200MV 10UA 110A 18USEC

ERA15-10 1KV 1100MV 10UA 40A

RLCAMP0504M 1.2V 6V 25V 12A 300W

KDS184 KDS184 TP KEC - 85V- 300MA

30PDA60 600V 1V 10UA 100A - DO201AD

SF10L60U 600V 3V 25UA 120A - FTO220

RLCAMP0504M 1.2V 6V 25V 12A 300W

ERA15-06 600V 1.1V 10A 40A

1SS133 1200MV 90V 400MA 600MA

UF4005(52MM) 600V 1.7V 10UA 30A

1SS133 1200MV 90V 400MA 600MA

UF4005(52MM) 600V 1.7V 10UA 30A

SF10L60U 600V 3V 25UA 120A

KDS184 KDS184 TP KEC - 85V

1SS133 1200MV 90V 400MA 600MA

1SS133 1200MV 90V 400MA 600MA

RG1C 1KV 3.3V 20UA 10A 100NSEC

UF4007-1021 1KV 1700MV 10UA 30A

1N4148 1V 100V 150MA 500MA 4NSEC

UF4007-1021 1KV 1700MV 10UA 30A

DIODE

Page 34

- 34 -

LOCA. NO PART NO DESCRIPTION

D807

D851

D852

D854

D855

D856

D901

D951

D952

D953

ZD121

ZD151

ZD200

ZD252

ZD300

ZD301

ZD501

ZD502

ZD503

ZD601

ZD606

ZD607

ZD608

ZD609

ZD802

ZD852

C100

C100

C1000

C1001

C1002

C1003

C1004

C1005

C1006

C1007

C1008

C1009

C101

C101

C101

C1010

C1011

C1012

C1013

C1014

C1015

C1016

C1017

C1018

0DRFJ00115A

0DRFC00345A

0DD100009AY

0DS141489AB

0DRFC00345A

0DRFJ00115A

0DRNH00151A

0DRSA00081A

0DRFJ00115A

0DRFJ00115A

0DZ110009AD

0DZ200009AD

0DZRM00248A

0DZ680009BB

0DR050008AA

0DR050008AA

0DZ110009AD

0DZ200009AF

0DZ200009AD

0DZ200009AD

0DZRM00178A

0DZRM00178A

0DZRM00178A

0DZRM00178A

0DZ150009AD

0DZ150009AD

0CE105WK6DC

0CK104CK56A

0CK103CK56A

0CE226WF6DC

0CE226WF6DC

0CC470CK41A

0CK104CK56A

0CE107WF6DC

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CE107WF6DC

0CK104CK56A

0CK474CH94A

0CZZVSB015A

0CC470CK41A

0CE226WF6DC

0CE226WF6DC

0CK103CK56A

0CK104CK56A

0CE476WF6DC

0CK104CK56A

0CE476WF6DC

0CK104CK56A

ERA15-06 600V 1.1V 10A 40A

1N5408 1KV 1200MV 5UA 200A

RG1C 1KV 3.3V 20UA 10A 100NSEC

1N4148 1V 100V 150MA 500MA 4NSEC

1N5408 1KV 1200MV 5UA 200A

ERA15-06 600V 1.1V 10A 40A

FSF10A60 600V 1800MV 30UA 120A

FMC-G28SL 800V 3V 200UA 60A

ERA15-06 600V 1.1V 10A 40A

ERA15-06 600V 1.1V 10A 40A

MTZJ11B 11V 10.5TO11.05V 20OHM

MTZJ20B 20V 18.63TO19.59V 30OHM

RLZ8.2B 8200MV 7.78TO8.19V 8OHM

MTZJ6.8B 6800MV 6.49TO6.83V 20OHM

SD05.TC - 6V 14.5V 24A 350W SOD323

SD05.TC - 6V 14.5V 24A 350W SOD323

MTZJ11B 11V 10.5TO11.05V 20OHM

MTZJ22B 22V 20.64TO21.71V 30OHM

MTZJ20B 20V 18.63TO19.59V 30OHM

MTZJ20B 20V 18.63TO19.59V 30OHM

UDZS5.1B 5.1V 4.98TO5.2V 80OHM

UDZS5.1B 5.1V 4.98TO5.2V 80OHM

UDZS5.1B 5.1V 4.98TO5.2V 80OHM

UDZS5.1B 5.1V 4.98TO5.2V 80OHM

MTZJ15B 15V 13.89TO14.62V 25OHM

MTZJ15B 15V 13.89TO14.62V 25OHM

MVK4.0TP50VC1M 1uF 20% 50V 5.6MA

0603B104K500CT 100nF 10% 50V X7R

0603B103K500CT 10nF 10% 50V X7R

MVK5.0TP16VC22M 22uF 20% 16V 30MA

MVK5.0TP16VC22M 22uF 20% 16V 30MA

C1608C0G1H470JT 47pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC100M 100uF 20% 16V

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC100M 100uF 20% 16V

0603B104K500CT 100nF 10% 50V X7R

0603F474Z250CT 470nF -20TO+80%

PCX2 337 11105 1uF 10% 275V MPP

C1608C0G1H470JT 47pF 5% 50V C0G

MVK5.0TP16VC22M 22uF 20% 16V 30MA

MVK5.0TP16VC22M 22uF 20% 16V 30MA

0603B103K500CT 10nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

LOCA. NO PART NO DESCRIPTION

C1019

C102

C102

C1020

C1021

C1022

C1023

C1024

C1025

C103

C103

C103

C103

C104

C104

C104

C104

C105

C105

C105

C105

C106

C106

C107

C107

C108

C108

C109

C109

C110

C110

C1100

C1101

C1103

C1104

C1108

C1109

C111

C111

C111

C1111

C1112

C1113

C1114

C1115

C1116

C1117

C1118

C1119

C112

C112

C112

0CK472CK56A

0CC101CK41A

0CK104CK56A

0CE106WFKDC

0CK103CK56A

0CK104CK56A

0CK104CK56A

0CK103CK56A

0CK104CK56A

0CE4763F618

0CC101CK41A

0CK104CK56A

0CKZTBU004E

0CE226WF6DC

0CE4763F618

0CK104CK56A

0CKZTBU004E

0CE226WF6DC

0CE4763F618

0CK104CK56A

0CBZTBU002B

0CE476WF6DC

0CK104CK56A

0CK103CK56A

0CK104CK56A

0CE225WK6DC

0CK103CK56A

0CE105WK6DC

0CK103CK56A

0CE225WK6DC

0CK103CK56A

0CE476WF6DC

0CK104CK56A

0CE476WF6DC

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CC101CK41A

0CC101CK41A

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CE476WF6DC

0CK104CK56A

0CE476WF6DC

0CK104CK56A

0CC270CK41A

0CE476WF6DC

0CE476WF6DC

0CK104CK56A

0CK104CK56A

0CK104CK56A

0603B472K500CT 4.7nF 10% 50V X7R

C1608C0G1H101JT 100pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP16VC10M 10uF 20% 16V 16MA

0603B103K500CT 10nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B103K500CT 10nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

ESF476M016T1A5E05G 47uF 20% 16V

C1608C0G1H101JT 100pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

DE2E3KX102MA5A 1nF 20% 250V Y5U

MVK5.0TP16VC22M 22uF 20% 16V 30MA

ESF476M016T1A5E05G 47uF 20% 16V

0603B104K500CT 100nF 10% 50V X7R

DE2E3KX102MA5A 1nF 20% 250V Y5U

MVK5.0TP16VC22M 22uF 20% 16V 30MA

ESF476M016T1A5E05G 47uF 20% 16V

0603B104K500CT 100nF 10% 50V X7R

PCX2 335 91645 0.47uF 20% 275V MPP

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

0603B103K500CT 10nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP50VC2.2M 2.2uF 20% 50V 10MA

0603B103K500CT 10nF 10% 50V X7R

MVK4.0TP50VC1M 1uF 20% 50V 5.6MA

0603B103K500CT 10nF 10% 50V X7R

MVK4.0TP50VC2.2M 2.2uF 20% 50V 10MA

0603B103K500CT 10nF 10% 50V X7R

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

C1608C0G1H101JT 100pF 5% 50V C0G

C1608C0G1H101JT 100pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

C1608C0G1H270JT 27pF 5% 50V C0G

MVK6.3TP16VC47M 47uF 20% 16V 80MA

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

CAPACITOR

Page 35

- 35 -

LOCA. NO PART NO DESCRIPTION

C1121

C1122

C1123

C1124

C1125

C1126

C1128

C113

C113

C113

C1130

C1131

C1131

C1132

C1134

C1135

C1135

C1138

C1139

C114

C114

C1140

C1142

C1143

C1144

C1145

C1146

C1147

C1148

C1149

C115

C115

C116

C116

C116

C117

C117

C117

C118

C118

C119

C119

C120

C120

C1203

C1208

C1209

C121

C121

C121

C121

C1210

0CC270CK41A

0CK103CK56A

0CK103CK56A

0CK104CK56A

0CE475WK6DC

0CE476WF6DC

0CC101CK41A

0CE476WF6DC

0CC101CK41A

0CC101CK41A

0CC102CK41A

0CK475CC94A

0CK475CC94A

0CC102CK41A

0CE227SF6DC

0CC102CK41A

0CK475CC94A

0CE227SF6DC

0CC102CK41A

0CE105WK6DC

0CK104CK56A

0CK475CC94A

0CE227SF6DC

0CK475CC94A

0CE227SF6DC

0CK103CK56A

0CC271CK41A

0CE475WK6DC

0CE476WF6DC

0CK104CK56A

0CE227SF6DC

0CK103CK56A

0CC101CK41A

0CC101CK41A

0CC220CK41A

0CC101CK41A

0CC101CK41A

0CK104CK56A

0CE225WK6DC

0CC220CK41A

0CE225WK6DC

0CC271CK41A

0CC821CK41A

0CK104CK56A

0CC151CK41A

0CC330CK41A

0CK475CC94A

0CE476WF6DC

0CC101CK41A

0CC101CK41A

0CK224DK56A

0CC330CK41A

C1608C0G1H270JT 27pF 5% 50V C0G

0603B103K500CT 10nF 10% 50V X7R

0603B103K500CT 10nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK5.0TP50VC4.7M 4.7uF 20% 50V 19MA

MVK6.3TP16VC47M 47uF 20% 16V 80MA

C1608C0G1H101JT 100pF 5% 50V C0G

MVK6.3TP16VC47M 47uF 20% 16V 80MA

C1608C0G1H101JT 100pF 5% 50V C0G

C1608C0G1H101JT 100pF 5% 50V C0G

C1608C0G1H102JT 1nF 5% 50V C0G

C1608Y5V0J475ZT 4.7uF -20TO+80%

C1608Y5V0J475ZT 4.7uF -20TO+80%

C1608C0G1H102JT 1nF 5% 50V C0G

MVG6.3TP16VC220M 220uF 20% 16V

C1608C0G1H102JT 1nF 5% 50V C0G

C1608Y5V0J475ZT 4.7uF -20TO+80%

MVG6.3TP16VC220M 220uF 20% 16V

C1608C0G1H102JT 1nF 5% 50V C0G

MVK4.0TP50VC1M 1uF 20% 50V 5.6MA

0603B104K500CT 100nF 10% 50V X7R

C1608Y5V0J475ZT 4.7uF -20TO+80%

MVG6.3TP16VC220M 220uF 20% 16V

C1608Y5V0J475ZT 4.7uF -20TO+80%

MVG6.3TP16VC220M 220uF 20% 16V

0603B103K500CT 10nF 10% 50V X7R

C1608C0G1H271JT 270pF 5% 50V C0G

MVK5.0TP50VC4.7M 4.7uF 20% 50V 19MA

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

MVG6.3TP16VC220M 220uF 20% 16V

0603B103K500CT 10nF 10% 50V X7R

C1608C0G1H101JT 100pF 5% 50V C0G

C1608C0G1H101JT 100pF 5% 50V C0G

C1608C0G1H220JT 22pF 5% 50V C0G

C1608C0G1H101JT 100pF 5% 50V C0G

C1608C0G1H101JT 100pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP50VC2.2M 2.2uF 20% 50V 10MA

C1608C0G1H220JT 22pF 5% 50V C0G

MVK4.0TP50VC2.2M 2.2uF 20% 50V 10MA

C1608C0G1H271JT 270pF 5% 50V C0G

0603N821J500LT 820pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

C1608C0G1H151JT 150pF 5% 50V C0G

C1608C0G1H330JT 33pF 5% 50V C0G

C1608Y5V0J475ZT 4.7uF -20TO+80%

MVK6.3TP16VC47M 47uF 20% 16V 80MA

C1608C0G1H101JT 100pF 5% 50V C0G

C1608C0G1H101JT 100pF 5% 50V C0G

CS2012X7R224K500NR 220nF 10% 50V

C1608C0G1H330JT 33pF 5% 50V C0G

LOCA. NO PART NO DESCRIPTION

C1211

C1212

C1213

C1214

C1215

C1216

C1217

C1218

C1219

C122

C122

C122

C1220

C1221

C1222

C1223

C1224

C1225

C1226

C1227

C1228

C1229

C123

C123

C123

C1230

C1231

C1232

C1233

C1234

C1235

C1236

C1237

C1238

C1239

C124

C124

C124

C1240

C1241

C1242

C1243

C1244

C1245

C1247

C1248

C125

C125

C126

C126

C127

C127

0CE106WFKDC

0CE106WFKDC

0CE106WFKDC

0CE106WFKDC

0CE106WFKDC

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CC101CK41A

0CC101CK41A

0CK224DK56A

0CK104CK56A

0CE106WFKDC

0CK104CK56A

0CK104CK56A

0CE106WFKDC

0CK104CK56A

0CE106WFKDC

0CE106SK6DC

0CE106WFKDC

0CK104CK56A

0CE105WK6DC

0CK104CK56A

0CK224DK56A

0CK104CK56A

0CK104CK56A

0CE106WFKDC

0CE476WF6DC

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CK103CK56A

0CE106WFKDC

0CK103CK56A

0CE105WK6DC

0CK103CK56A

0CK334DK56A

0CE226WF6DC

0CK104CK56A

0CE476WF6DC

0CK104CK56A

0CK104CK56A

0CE476WH6DC

0CE106WFKDC

0CK475CC94A

0CE226WJ6DC

0CK224DK56A

0CK104CK56A

0CK473DK56A

0CK104CK56A

0CK334DK56A

MVK4.0TP16VC10M 10uF 20% 16V 16MA

MVK4.0TP16VC10M 10uF 20% 16V 16MA

MVK4.0TP16VC10M 10uF 20% 16V 16MA

MVK4.0TP16VC10M 10uF 20% 16V 16MA

MVK4.0TP16VC10M 10uF 20% 16V 16MA

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

C1608C0G1H101JT 100pF 5% 50V C0G

C1608C0G1H101JT 100pF 5% 50V C0G

CS2012X7R224K500NR 220nF 10% 50V

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP16VC10M 10uF 20% 16V 16MA

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP16VC10M 10uF 20% 16V 16MA

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP16VC10M 10uF 20% 16V 16MA

VMV106M050S0ANC010 10uF 20% 50V

MVK4.0TP16VC10M 10uF 20% 16V 16MA

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP50VC1M 1uF 20% 50V 5.6MA

0603B104K500CT 100nF 10% 50V X7R

CS2012X7R224K500NR 220nF 10% 50V

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP16VC10M 10uF 20% 16V 16MA

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B103K500CT 10nF 10% 50V X7R

MVK4.0TP16VC10M 10uF 20% 16V 16MA

0603B103K500CT 10nF 10% 50V X7R

MVK4.0TP50VC1M 1uF 20% 50V 5.6MA

0603B103K500CT 10nF 10% 50V X7R

330nF 10% 50V

MVK5.0TP16VC22M 22uF 20% 16V 30MA

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK8.0TP25VC47M 47uF 20% 25V 80MA

MVK4.0TP16VC10M 10uF 20% 16V 16MA

C1608Y5V0J475ZT 4.7uF -20TO+80%

MVK6.3TP35VC22M 22uF 20% 35V 40MA

CS2012X7R224K500NR 220nF 10% 50V

0603B104K500CT 100nF 10% 50V X7R

C2012X7R1H473KT 47nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

330nF 10% 50V

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 36

- 36 -

LOCA. NO PART NO DESCRIPTION

C128

C129

C129

C130

C130

C1300

C1301

C1302

C1303

C1305

C1306

C1307

C1308

C1309

C131

C1310

C1311

C1312

C1313

C1314

C1315

C1316

C1317

C1318

C1319

C1321

C1324

C1331

C1332

C1341

C1344

C1345

C1346

C1347

C1348

C1349

C1350

C1353

C1354

C1402

C1406

C1500

C1501

C1502

C1503

C1505

C1506

C1507

C1509

C151

C1510

C1511

0CE476WH6DC

0CK474CH94A

0CK474CH94A

0CK474CH94A

0CK474CH94A

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CE105WK6DC

0CK104CK56A

0CE477WF6DC

0CE477WF6DC

0CE477WF6DC

0CE477WF6DC

0CE225WK6DC

0CE476WF6DC

0CK104CK56A

0CE477WF6DC

0CE477WF6DC

0CE477WF6DC

0CE476WF6DC

0CE477WF6DC

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CE477WF6DC

0CK104CK56A

0CE477WF6DC

0CK104CK56A

0CK474CH94A

0CK104CK56A

0CK471CK56A

0CK104CK56A

0CK104CK56A

0CK471CK56A

0CK104CK56A

0CK471CK56A

0CK471CK56A

0CK471CK56A

0CK103CK56A

0CK103CK56A

0CE106WFKDC

0CE106WFKDC

0CE105WK6DC

0CC221CK41A

0CE106WFKDC

0CC220CK41A

0CC220CK41A

0CK104CK56A

0CF1021Y45A

0CK104CK56A

0CE107WF6DC

MVK8.0TP25VC47M 47uF 20% 25V 80MA

0603F474Z250CT 470nF -20TO+80%

0603F474Z250CT 470nF -20TO+80%

0603F474Z250CT 470nF -20TO+80%

0603F474Z250CT 470nF -20TO+80%

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP50VC1M 1uF 20% 50V 5.6MA

0603B104K500CT 100nF 10% 50V X7R

MVK10TP16VC470M 470uF 20% 16V 80MA

MVK10TP16VC470M 470uF 20% 16V 80MA

MVK10TP16VC470M 470uF 20% 16V 80MA

MVK10TP16VC470M 470uF 20% 16V 80MA

MVK4.0TP50VC2.2M 2.2uF 20% 50V 10MA

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

MVK10TP16VC470M 470uF 20% 16V 80MA

MVK10TP16VC470M 470uF 20% 16V 80MA

MVK10TP16VC470M 470uF 20% 16V 80MA

MVK6.3TP16VC47M 47uF 20% 16V 80MA

MVK10TP16VC470M 470uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK10TP16VC470M 470uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

MVK10TP16VC470M 470uF 20% 16V 80MA

0603B104K500CT 100nF 10% 50V X7R

0603F474Z250CT 470nF -20TO+80%

0603B104K500CT 100nF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

0603B103K500CT 10nF 10% 50V X7R

0603B103K500CT 10nF 10% 50V X7R

MVK4.0TP16VC10M 10uF 20% 16V 16MA

MVK4.0TP16VC10M 10uF 20% 16V 16MA

MVK4.0TP50VC1M 1uF 20% 50V 5.6MA

C1608C0G1H221JT 220pF 5% 50V C0G

MVK4.0TP16VC10M 10uF 20% 16V 16MA

C1608C0G1H220JT 22pF 5% 50V C0G

C1608C0G1H220JT 22pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

PUX63Y102JCFS03 1n 5% 630V PP

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC100M 100uF 20% 16V

LOCA. NO PART NO DESCRIPTION

C1513

C1514

C1515

C1516

C1517

C1518

C1519

C152

C1520

C1521

C1524

C1526

C1527

C153

C1535

C1536

C1539

C1540

C1541

C1543

C155

C156

C157

C200

C200

C201

C201

C201

C202

C202

C202

C203

C203

C203

C204

C204

C204

C205

C205

C205

C206

C206

C207

C207

C208

C209

C210

C210

C210

C211

C211

C212

0CK104CK56A

0CE226WF6DC

0CK104CK56A

0CK104CK56A

0CE226WJ6DC

0CE226WJ6DC

0CE476WF6DC

181-288X

0CK103CK56A

0CK104CK56A

0CK471CK56A

0CK471CK56A

0CK471CK56A

0CE2262K638

0CK471CK56A

0CK471CK56A

0CE226WF6DC

0CK471CK56A

0CK471CK56A

0CK471CK56A

0CK333DK56A

0CK222DK56A

181-288N

0CK104CK56A

0CK104CK56A

0CE226WF6DC

0CZZTAB003D

0CK104CK56A

0CZZTAB003D

0CC020CK01A

0CK104CK56A

0CZZTAB003D

0CC020CK01A

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CK474DK56A

0CE1072D638

0CC560CK41A

0CK104CK56A

0CC560CK41A

0CK104CK56A

0CC560CK41A

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CE335WK6D8

0CK104CK56A

181-091R

0CK103CK56A

0CK104CK56A

0CE226WF6DC

0603B104K500CT 100nF 10% 50V X7R

MVK5.0TP16VC22M 22uF 20% 16V 30MA

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP35VC22M 22uF 20% 35V 40MA

MVK6.3TP35VC22M 22uF 20% 35V 40MA

MVK6.3TP16VC47M 47uF 20% 16V 80MA

PCMT 365 76684 680nF 5% 63V MPE

0603B103K500CT 10nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

WL1H226M05011PA 22uF 20% 50V 150MA

C1608X7R1H471KT 470pF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

MVK5.0TP16VC22M 22uF 20% 16V 30MA

C1608X7R1H471KT 470pF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

C1608X7R1H471KT 470pF 10% 50V X7R

C2012X7R1H333KT 33nF 10% 50V X7R

CS2012X7R222K500NR 2.2nF 10% 50V

PCMT 365 86103 10nF 5% 100V MPE

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK5.0TP16VC22M 22uF 20% 16V 30MA

NXB10VB3300M 3300uF 20% 10V 2.77A

0603B104K500CT 100nF 10% 50V X7R

NXB10VB3300M 3300uF 20% 10V 2.77A

C1608C0G1H020CT 2pF 0.25PF 50V C0G

0603B104K500CT 100nF 10% 50V X7R

NXB10VB3300M 3300uF 20% 10V 2.77A

C1608C0G1H020CT 2pF 0.25PF 50V C0G

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

UMK212BJ474KG-T 470nF 10% 50V X7R

WL1A107M05011PA 100uF 20% 10V

C1608C0G1H560JT 56pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

C1608C0G1H560JT 56pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

C1608C0G1H560JT 56pF 5% 50V C0G

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK4.0TP50VC3.3M 3.3uF 20% 50V 14MA

0603B104K500CT 100nF 10% 50V X7R

LRYM7102KHA 1nF 10% 1000V Y5R

0603B103K500CT 10nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK5.0TP16VC22M 22uF 20% 16V 30MA

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 37

- 37 -

LOCA. NO PART NO DESCRIPTION

C212

C213

C213

C214

C214

C215

C215

C216

C216

C217

C217

C218

C218

C219

C219

C220

C220

C221

C221

C222

C222

C223

C223

C223

C224

C224

C225

C226

C227

C227

C228

C229

C230

C231

C232

C233

C234

C235

C236

C237

C238

C239

C240

C241

C242

C251

C252

C255

C256

C261

C262

C263

0CK104CK56A

0CK104CK56A

0CK474CH94A

0CK104CK56A

0CK222CK51A

0CK104CK56A

0CK474CH94A

0CK104CK56A

0CK222CK51A

0CK104CK56A

0CK104CK56A

0CE476WF6DC

0CK222CK51A

0CE476WF6DC

0CK103CK56A

0CK104CK56A

0CK222CK51A

0CK104CK56A

0CK222CK51A

0CC101CK41A

0CK103CK56A

0CE1072K638

0CK103CK56A

0CK222CK51A

0CK222CK51A

0CK222DK56A

0CK222CK51A

0CK103CK56A

0CZZTAB003D

0CC471CK41A

0CE335WK6D8

0CK104CK56A

0CE107WF6DC

0CE106WFKDC

0CK474CH94A

0CK474CH94A

0CK474CH94A

0CK474CH94A

0CE106WFKDC

0CE475WK6DC

0CE475WK6DC

0CK104CK56A

0CE476WF6DC

0CK104CK56A

0CK104CK56A

0CZZTAB003Q

0CK222DK56A

0CZZTAB003T

181-091R

0CZZTAB003R

0CE1072H638

181-091R

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603F474Z250CT 470nF -20TO+80%

0603B104K500CT 100nF 10% 50V X7R

0603B222K500CT 2.2nF 10% 50V Y5P

0603B104K500CT 100nF 10% 50V X7R

0603F474Z250CT 470nF -20TO+80%

0603B104K500CT 100nF 10% 50V X7R

0603B222K500CT 2.2nF 10% 50V Y5P

0603B104K500CT 100nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B222K500CT 2.2nF 10% 50V Y5P

MVK6.3TP16VC47M 47uF 20% 16V 80MA

0603B103K500CT 10nF 10% 50V X7R

0603B104K500CT 100nF 10% 50V X7R

0603B222K500CT 2.2nF 10% 50V Y5P

0603B104K500CT 100nF 10% 50V X7R

0603B222K500CT 2.2nF 10% 50V Y5P

C1608C0G1H101JT 100pF 5% 50V C0G

0603B103K500CT 10nF 10% 50V X7R