Page 1

LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : LA73E

MODEL : 42LC7D

42LC7D-UB

R

Page 2

- 2 -

CONTENTS

CONTENTS .............................................................................................. 2

PRODUCT SAFETY ..................................................................................3

SPECIFICATION........................................................................................6

ADJUSTMENT INSTRUCTION................................................................11

TROUBLE SHOOTING & BLOCK DIAGRAM ........................................17

EXPLODED VIEW .................................................................................. 43

REPLACEMENT PARTS LIST ............................................................... 45

SVC. SHEET ...............................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

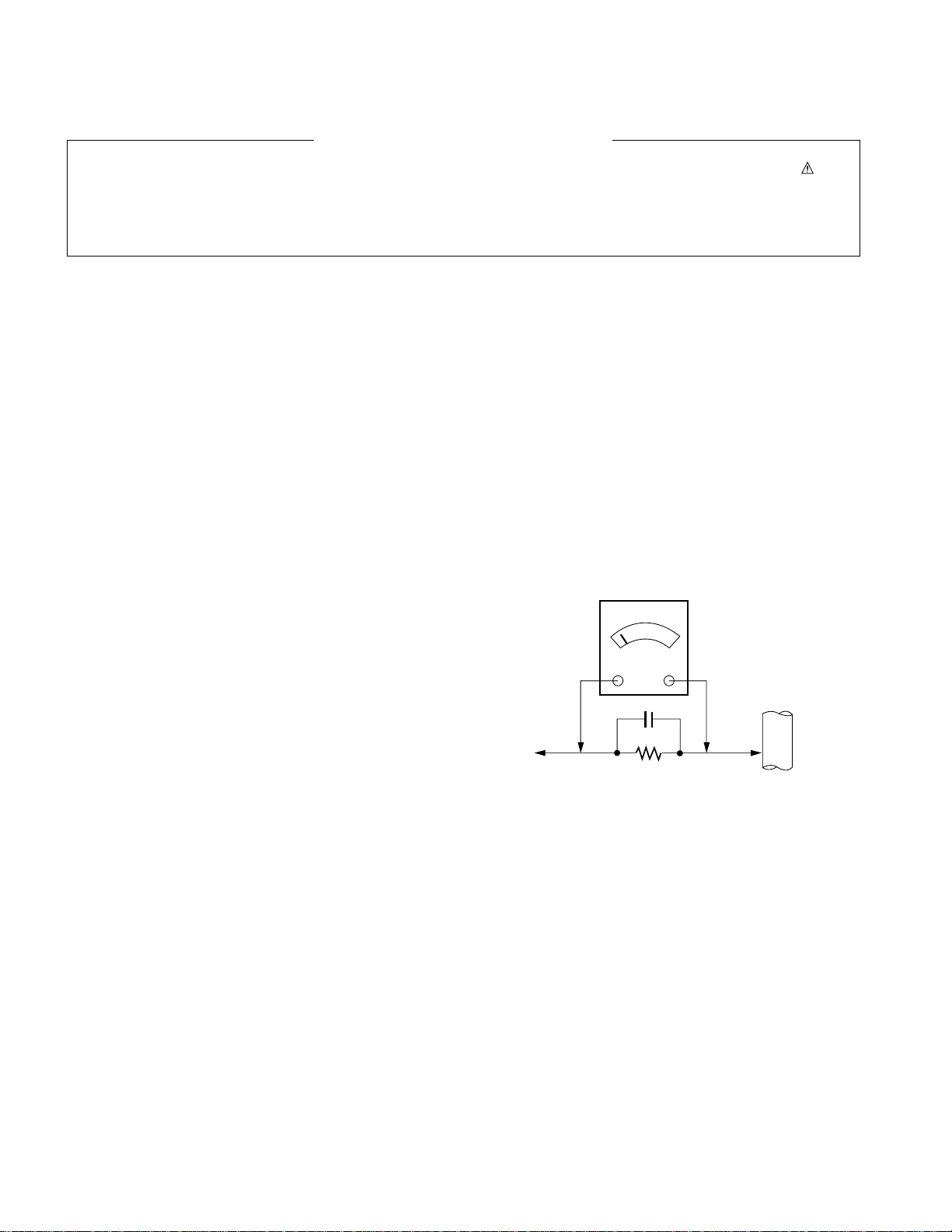

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

T

e

M

IMPORTANT SAFETY NOTICE

0.15uF

o Instrument's

xposed

ETALLIC PARTS

AC Volt-meter

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

1.5 Kohm/10W

Page 4

- 4 -

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500

F to 600 F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500

F to 600 F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500

F to 600 F)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

SERVICING PRECAUTIONS

Page 5

- 5 -

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Page 6

- 6 -

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

4. General Specification(TV)

No. Item Specification Remark

1. Receiving System ATSC/64 & 256 QAM/ NTSC-M

2. Available Channel 1) VHF : 02~13

2) UHF : 14~69

3) DTV : 02-69

4) CATV : 01~135

5) CADTV : 01~135

3. Input Voltage 1) AC 100 ~ 240V 50/60Hz

4. Market NORTH AMERICA

5. Screen Size 26 inch Wide – 26 inches(582.96mm) For 26LC7D-UB

32 inch Wide - 31.51inches(800.4mm) For 32LC7D-UB,32LC4D-UA

37 inch Wide – 32.02 inches(940.3mm) For 37LC7D-UB

42 inch Wide – 42.02 inches(1067.308mm) For 42LC7D-UB,42LC4D-UA

6. Aspect Ratio 16:9

7. Tuning System FS

8. LCD Module T260XW02-V5 For 26LC7D-UE

LC320WX4-SLA1 For 32LC7D-UB,32LC4D-UA

LC370WX3-SLA1 For 37LC7D-UB

LC420WX6-SLA1 For 42LC7D-UB,42LC4D-UA

9. Operating Environment 1) Temp : 0 ~ 40 deg

2) Humidity : ~ 80 %

10. Storage Environment 1) Temp : -20 ~ 60 deg

2) Humidity : 0 ~ 90 %

1. Application Range.

This spec sheet is applied to the 37"/42" LCD TV used LA73E

chassis.

2. Especificación

Each part is tested as below without special appointment

2.1 Temperature : 20 ±5°C

2.2 Relative Humidity : 65 ±10%

2.3 Power Voltage : Standard input voltage

(100~240V@ 50/60Hz)

• Standard Voltage of each products is marked by models

2.4 Specification and performance of each parts are followed

each drawing and specification by part number in

accordance with BOM .

2.5 The receiver must be operated for about 20 minutes prior

to the adjustment.

3. Test method

3.1 Performance : LGE TV test method followed.

3.2 Demanded other specification

Safety : UL, CSA, IEC specification

3.3 EMC : FCC, ICES, IEC specification

Page 7

- 7 -

5. Chroma & Brightness

5-1. 37LC7D-UB

CONDITION : EZ-Picture "Daylight"

5-2. 42LC7D-UB, 42LC4D-UA

CONDITION : EZ-Picture "Daylight"

No Item Min Typ Max Unit Remark

1. White peak brightness 360 450 cd/m

2

HDMI input, full white,

Video Black level=High

2. Contrast ratio 700:1 900:1 Non dimming mode

(PC Mode)

3000:1 4000:1 5000:1 Dimming mode

1. Input full black, wait 10 minute

,

measure black level

2. Input full white , wait 10 minute,

measure white level

3. Brightness uniformity 1.3 Refer to LCD SPEC.

4. Color coordinate RED X 0.633 +/- 0.03

Y 0.339 +/- 0.03

GREEN X 0.286 +/- 0.03

Y 0.610 +/- 0.03

BLUE X 0.147 +/- 0.03

Y 0.065 +/- 0.03

WHITE X 0.276 +/- 0.03

Y 0.283 +/- 0.03

5. Viewing angle 178 R/L, U/D

6. Color Temperature Standard 8,300 9,300 10,300 <Test Signal>

Cool 10,000 11,000 12,000

HDMI input, With 16-gray pattern

Warm 5,500 6,500 7,500 6thbar from right

No Item Min Typ Max Unit Remark

1. White peak brightness 360 450 cd/m

2

HDMI input, full white,

Video Black level=High

2. Contrast ratio 800:1 1000:1 Non dimming mode

(PC Mode)

3000:1 4000:1 5000:1 Dimming mode

1. Input full black, wait 10 minute

,

measure black level

2. Input full white , wait 10 minute,

measure white level

3. Brightness uniformity 1.3 Refer to LCD SPEC.

4. Color coordinate RED X 0.633 +/- 0.03

Y 0.339 +/- 0.03

GREEN X 0.286 +/- 0.03

Y 0.610 +/- 0.03

BLUE X 0.147 +/- 0.03

Y 0.065 +/- 0.03

WHITE X 0.276 +/- 0.03

Y 0.283 +/- 0.03

5. Viewing angle 178 R/L, U/D

6. Color Temperature Standard 8,300 9,300 10,300 <Test Signal>

Cool 10,000 11,000 12,000 HDMI input,

Warm 5,500 6,500 7,500 Daylight/Cool 85 IRE

Page 8

- 8 -

6. Component Video Input (Y, PB

, PR)

No.

Specification

Remark

Resolution H-freq(kHz) V-freq(Hz)

1. 720*480 15.73 59.94 SDTV ,DVD 480I

2. 720*480 15.73 60.00 SDTV ,DVD 480I

3. 720*480 31.47 59.94 SDTV 480P

4. 720*480 31.50 60.00 SDTV 480P

5. 1280*720 44.96 59.94 HDTV 720P

6. 1280*720 45.00 60.00 HDTV 720P

7. 1920*1080 33.72 59.94 HDTV 1080I

8. 1920*1080 33.75 60.00 HDTV 1080I

9. 1920*1080 27 24 HDTV 1080P

10. 1920*1080 33.75 30 HDTV 1080P

No.

Specification

Remark

Resolution H-freq(kHz) V-freq(Hz)

Pixel clock(MHz)

PC DDC

1. 640*350 31.469 70.08 25.17 DOS

2. 720*400 31.469 70.08 28.32 DOS O

3. 640*480 31.469 59.94 25.17 VESA(VGA) O

4. 800*600 37.879 60.31 40.00 VESA(SVGA) O

5. 1024*768 48.363 60.00 65.00 VESA(XGA) O

6. 1280*768 47.776 59.87 79.50 CVT(WXGA) O

7. 1360*768 47.720 59.799 84.75 CVT(WXGA) O

8. 1366*768 47.13 59.65 72

7. RGB PC

- RGB PC INPUT Mode Table

- HDMI INPUT(PC/DTV)

No. Resolution H-freq(kHz) V-freq(Hz) Pixel clock(MHz) Remark

PC DDC

1. 640*480 31.469 59.94 25.17 VESA(VGA) O

2. 800*600 37.879 60.31 40.00 VESA(SVGA) O

3. 1024*768 48.363 60.00 65.00 VESA(XGA) O

4. 1280*768 47.776 59.87 79.50 CVT(WXGA) O

5. 1360*768 47.720 59.799 84.75 CVT(WXGA) O

6. 1366*768 47.13 59.65 72

DTV

7. 720*480 31.469 59.94 27.00 SDTV 480P

8. 720*480 31.500 60.00 27.03 SDTV 480P

9. 1280*720 44.96 59.94 74.17 HDTV 720P

10. 1280*720 45.00 60.00 74.25 HDTV 720P

11. 1920*1080 33.72 59.94 74.17 HDTV 1080I

12. 1920*1080 33.75 60.00 74.25 HDTV 1080I

13. 1920*1080 27 24.00 74.25 HDTV 1080P

14. 1920*1080 33.75 30.00 74.25 HDTV 1080P

Page 9

- 9 -

8. Mechanical specification

1) 37LC7D

No. Item Content Unit Remark

1. Product Widt(W) Length(D) Height(H) mm

Dimension Before Packing 927 280.5 692.8 mm With Stant

After Packing 999 264 874 mm

2. Product Only SET 20 Kg

With BOX 25 Kg

2) 42LC7D

No. Item Content Unit Remark

1. Product Widt(W) Length(D) Height(H) mm

Dimension Before Packing 1033.4 287.6 750 mm With Stant

After Packing 1119 374 858 mm

2. Product Only SET 24.9 Kg

With BOX 30.4 Kg

Page 10

- 10 -

9. Customer Menu Setup (Shipment Condition)

No Item Condition Remark

1. Input Mode TV02CH

2. Volume Level 30

3. Mute Off

4. Aspect Ratio 16:9

5. Video EZ Picture Daylight

Contrast 100

Brightness 40

Color 70

Sharpness 70

Tint 0

Color-temperature Cool

XD Auto(On)

Advanced Cinema3:2 Mode(Off)

Black Level(RF,HDMI=>Low),(AV=>High)( RGB-PC,Component=>Disable)

6. Audio Audio Language Off

EZ Sound Normal

Balance 0

Bass 50

Front Surround Off

TV Speaker On

7. Timer Auto clock Off

Manual Clock Off

Off Timer Off

On Timer Off

Sleep Timer Off

Auto Off Off

8. Option Aspect Ratio 16:9

Caption/Text Off

Caption Option Set By Program

Language English

Simplink On

9. Lock Lock System Off

Set password On

(Default:0000)

Block channel None

Movie Rating Off

TV Rating-Children None

TV Rating-General None

Input Block Off

10. Channel Memory RF : 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 30, 51, 63

CATV : 15, 16, 17

Page 11

- 11 -

ADJUSTMENT INSTRUCTION

1. Application Object

These instructions are applied to all of the LCD TV, LA73E.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

20±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 110V, 60Hz

when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

Perform preliminary operation after receiving 100% White

Pattern (06CH).

(Or 3. White Pattern status of Ez-Adjust)

White Pattern entry method

A) Enter into Ez-Adjust by pressing the ADJ key on the

adjustment R/C.

B) 100% FULL WHITE PATTERN appears if pressing the

OK (

) key after selecting the 3.WHITE PATTERN with

the CH + / - KEY.

* It is possible to heat run the set without a separate

signal generator in this mode.

Caution : Care must be taken as afterimage

phenomena may occur about the black level part of

screen If leaving pause image turned on for more

than 20 minutes (especially inner digital pattern (13

CH), Cross Hatch Pattern (09CH) with significant

black/white contrast).

3. MICOM Download(Option)

3-1. Required Test Equipment

(1) JIG-LEVER TYPE for adjusting: 1EA

(2) PC & MONITOR: 2EA

(3) BOARD for INTERFACE: IIC & ISP BOARD: 2EA

(4) 15P D-SUB CABLE: 2EA

(5) Using the 12/15 line of D-SUB 15P

12-SDA/15-SCL

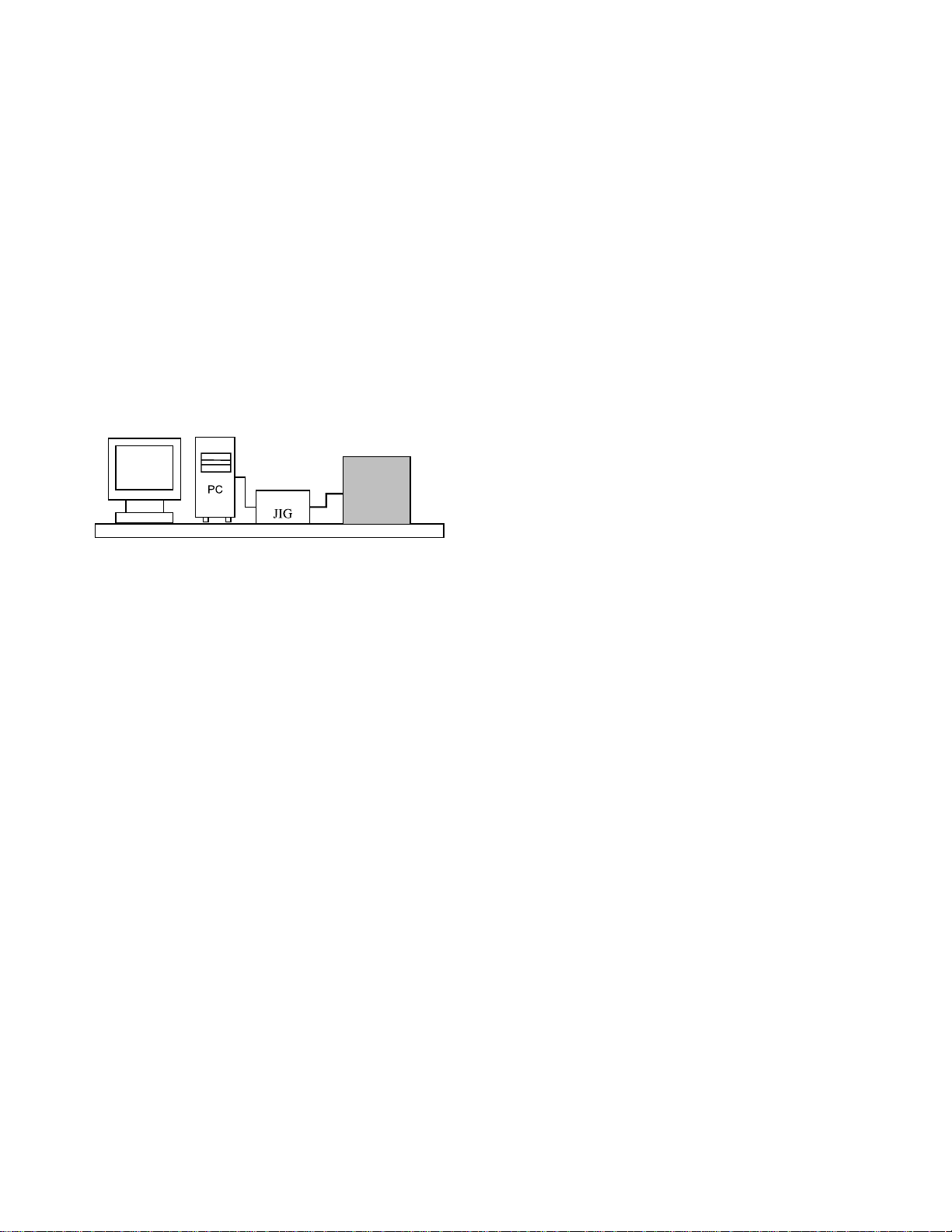

3-2. JIG Connection

3-3. Establishment Program

(1) Establish LGE Monitor Tools v1.1

(2) The program work and it is opened program window as

seen below.

connection

to PC

connection

to PC

Page 12

- 12 -

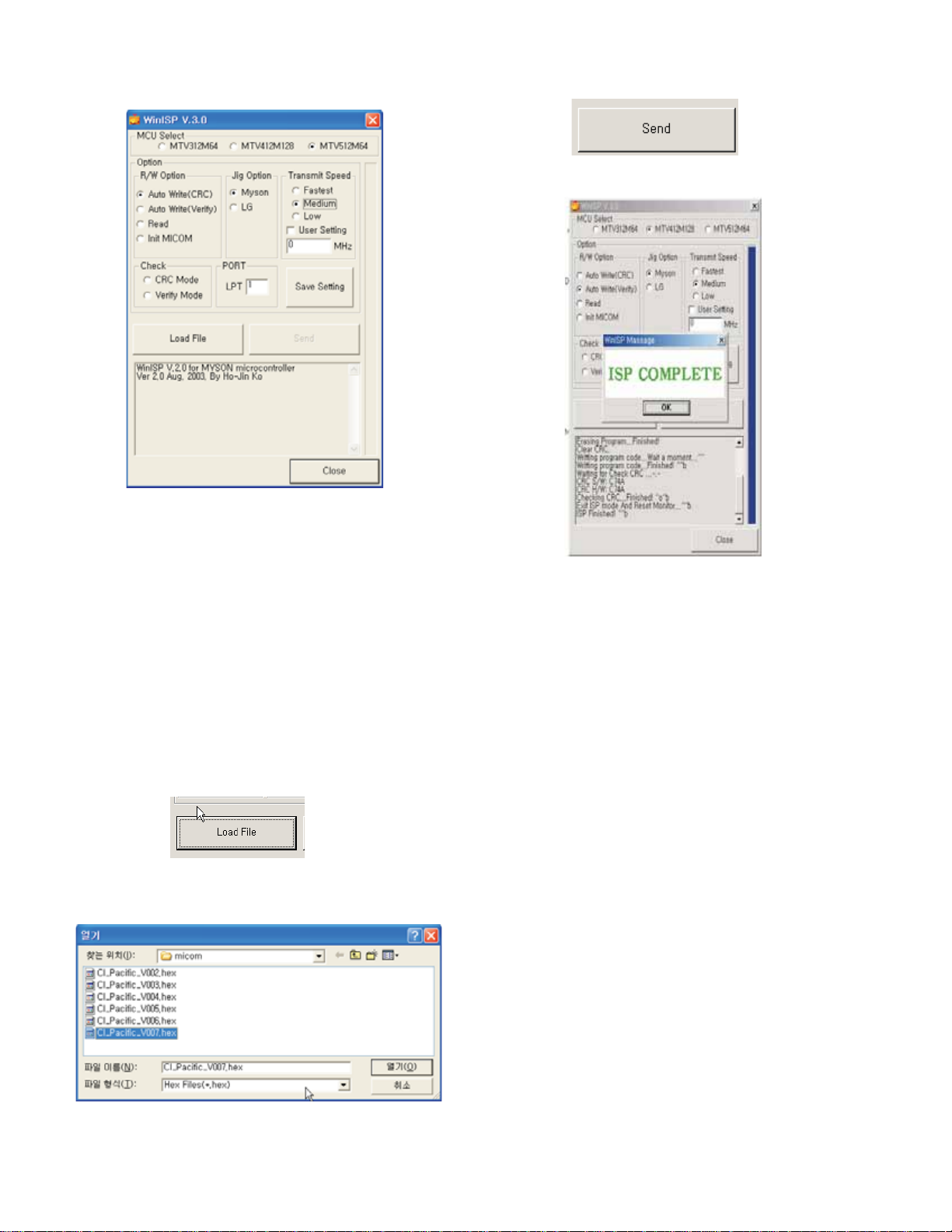

(3) Click the first icon shown in fig.9. The window seen in

fig.10 should appear.

3-4. Set Method

(1) MCU Select: MTV512M64

(2) Option

R/W Option: Auto Write(Verity)

Jig Option: Myson

Transmit Speed: Medium

(3) Check: Just do it with blank micom.

(4) PORT

Chose Parallel Port (normal LPT1)

Attention: You must chose EPP when select Rom BIAS at

LPT

3-5. Download Method

(1) Click the Load File.

(2) Locate and select the correct file from your computer.

(*.hex).

(3) Click the Send.

(4) When you see (ISP COMPLETE) the download is

complete.

Page 13

- 13 -

6. ADC-Set Adjustment

6-1. Synopsis

ADC-Set adjustment to set the black level and the Gain to

optimum.

6-2. Test Equipment

Service R/C, 801GF(802V, 802F, 802R) or MSPG925FA

Pattern Generator

(480i/1080i The Horizontal 100% Color Bar Pattern adjust to

within 0.7±0.1Vp-p)

[ADC adjustment (MSPG-925Fx series) Model No. & Pattern No.]

- Model No.: #209(480i adjustment), #223(1080i adjustment)

- Pattern No.: #65(7ColorBar Pattern)

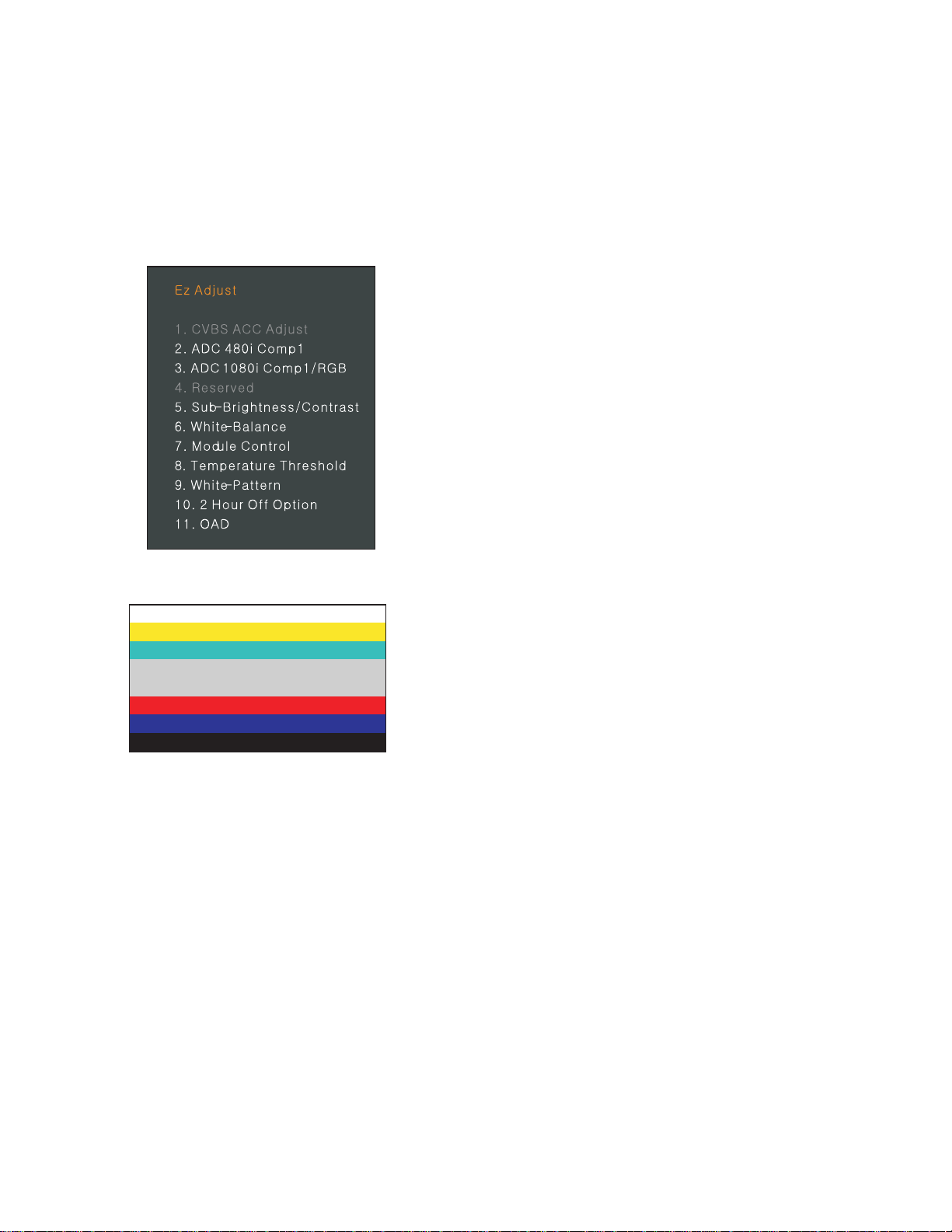

6-3. Adjustment

(1) Select Component1 as the input with 100% Horizontal

Color Bar Pattern(HozTV31Bar) in 480i Mode

(2) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and select

the ‘2. ADC 480i Comp1’.

Pressing the Enter Key to adjust automatically.

(3) When the adjustment is over, 'MST3361 Component

Success’ is displayed. If the adjustment has errors,

'MST3361 Configuration Error’ is displayed.

(4) Select Component1 as the input with 100% Horizontal

Color Bar Pattern(HozTV31Bar) in 1080i Mode.

(5) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and select

the ‘3. ADC 1080i Comp1/RGB’.

Pressing the Enter Key to adjust automatically.

(6) When the adjustment is over, 'MST3361 Component

Success’ is displayed. If the adjustment has errors,

'MST3361 Configuration Error’ is displayed.

(7) After the Component MST3361 adjustment is over, convert

the RGB-DTV Mode and display Pattern.

When the adjustment is over, 'MST3361 RGB_DTV

Success’ is displayed.

(8) Readjust after confirming the case Pattern or adjustment

condition where the adjustment errors.

(9) After adjustment is complete, exit the adjustment mode by

pressing the ADJ KEY.

<Fig. 2> Adjustment Mode

<Fig. 3> Adjustment Pattern: 480i/1080i 60Hz HozTV30 Bar

Pattern

Page 14

- 14 -

7. EDID(The Extended Display

Identification Data)/DDC

(Display Data Channel) Download

This is the function that enables “Plug and Play".

7-1. HDMI EDID Data Input

(1) Required Test Equipment

1) PC, Jig for adjusting DDC. (PC serial to D-sub

Connection equipment)

2) S/W for writing DDC(EDID data write & read)

3) D-Sub cable

4) Jig for HDMI Cable connection

(2) Preparation for Adjustments &

Setting of Device

1) Set devices as below and turn on the PC and JIG.

2) Open S/W for writing DDC (EDID data write & read).

(operated in DOS mode)

7-2. EDID DATA for LA73E

:EDID for HDMI-1 (DDC (Display Data Channel) Data)

EDID Block 0 table =

EDID Block 1 table =

:EDID for HDMI-2 (DDC (Display Data Channel) Data)

EDID Block 0 table =

EDID Block 1 table =

:EDID for RGB-PC

EDID Block 0 table =

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C 2F CE 00 31 40 45 40 61 40 01 01 01 01

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 C4 8E 21 00 00 1E 0E 1F 00 80 51 00 1E 30

50 | 40 80 37 00 C4 8E 21 00 00 1C 00 00 00 FD 00 38

60 | 4B 1F 3C 09 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 98

0 | 02 03 16 F1 46 84 05 03 02 20 22 23 15 07 50 66

10 | 03 0C 00 10 00 80 01 1D 00 72 51 D0 1E 20 6E 28

20 | 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 | 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 | 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 | 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 00 00

60 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 25

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C 2F CE 00 31 40 45 40 61 40 01 01 01 01

30 | 01 01 01 01 01 01 01 1D 00 72 51 D0 1E 20 6E 28

40 | 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

50 | 58 2C 25 00 C4 8E 21 00 00 9E 00 00 00 FC 00 4C

60 | 47 20 54 56 0A 20 20 20 20 20 20 20 00 00 00 FD

70 | 00 38 4B 1F 3C 09 00 0A 20 20 20 20 20 20 01 66

0 | 02 03 16 F1 46 84 05 03 02 20 22 23 15 07 50 66

10 | 03 0C 00 20 00 80 8C 0A D0 8A 20 E0 2D 10 10 3E

20 | 96 00 C4 8E 21 00 00 18 8C 0A D0 8A 20 E0 2D 10

30 | 10 3E 96 00 13 8E 21 00 00 18 00 00 00 00 00 00

40 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

50 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

60 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 B3

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 11 01 03 68 73 41 96 0A CF 30 A3 57 4C B0 23

20 | 09 50 4E A1 08 00 01 01 01 01 01 01 01 01 01 01

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 C4 8E 21 00 00 1E 0E 1F 00 80 51 00 1E 30

50 | 40 80 37 00 C4 8E 21 00 00 1C 00 00 00 FD 00 38

60 | 4B 1F 3C 09 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 00 D0

LCD TV SET

(or Digital Board)

Page 15

- 15 -

8. Adjustment of White Balance

8-1. The Purpose and Principal of Color

Temperature Adjustment

(1) Purpose: to reduce the difference in color temperature

among modules

(2) Principal: A module is in full dynamic range when RGB

Gain on OSD is 192. To adjust the white balance without

causing full dynamic range and full data, fix one of RGB

Gains at 192 and control the other two by reducing them

from 192.

8-2. Required Equipment

(1) Color Analyzer : CA-110 or CA-210

(2) Automatic adjustor (with automatic adjustment necessity

and the RS-232C communication being possible)

8-3. Connection Diagram of Equipment

for Measuring

(Automatic Adjustment)

Use the internal pattern to adjust White Balance. The pattern

is automatically given when the automatic adjustment device

is connected or when a user presses ADJ on the remote

controller to start Ez Adjust and then selects 6.White-Balance.

[ Requirements for Automatic Adjustment

(1) The illuminance of surroundings

10 lux or less; preventing light in surroundings as much as

possible

(2) The location of the Probe

1) For PDP: place the color analyzer (CA-110, CA-210)

close to the surface of a module and start the

adjustment.

2) For LCD: place the color analyzer (CA-110, CA-210)

close to the surface of a module within 10 cm and keep

the probe of the color analyzer at 80° to 100° angle from

the surface of a module.

(3) Aging time

1) Once Aging is started, keep the power on without power

supply interruption for at least 15 minutes for heat run.

2) For PDP, use the internal pattern to adjust White

Pattern.

3) For LCD, use NO SIGNAL or Full White Pattern to

ensure the backlight is turned on.

8-4. Adjustment of White Balance

(Automatic Adjustment)

(1) Turn on the POWER ON( ) of the remote controller to set

the adjustment and then start the automatic adjustment or

set the Baud Rate to 115200.Â) of the remote controller to

(2) Start the adjustment from “wb 00 00” and complete it at

“wb 00 ff”. (Adjust the offset if necessary)

wb 00 00 the automatic adjustment of White Balance is

started.

wb 00 10 adjusting gain (internal pattern appears) is

started.

ja 00 ff adjusting data

jb 00 c0

...

wb 00 1f adjusting gain is completed.

Adjust the offset (from wb 00 20 to wb 00 2f) if necessary.

wb 00 ff the automatic adjustment of White Balance

(internal pattern disappears) is completed.

Connection Diagram of Automatic Adjustment

Full W hite Pattern

RS-232C

CA-100+

COL OR

ANALYZER

TYPE; CA-100+

Page 16

- 16 -

[[

RS-232C Command

(Automatic Adjustment)

LA73E Chassis Model All]

8-5. Adjustment of White Balance

(Manual Adjustment)

Required Equipment : CA-210

(1) Enter ‘Ez - Adjust’ by pressing ADJ KEY on the Service

Remote Control.

(2) Select "9. TEST PATTERN" using CH +/- Key and HEAT

RUN at least 30 minutes by pressing the ENTER Key.

(3) Zero Calibrate of the Color Analyzer, then attach sensor to

LCD module surface when you adjust.

(4) Select ‘6. White-Balance’ of ‘Ez - Adjust’ by pressing the

ADJ KEY on the Service R/C. Then enter adjustment mode

by pressing the Right KEY (

G

) .

(The internal pattern of full white appears by pressing

G

)

(5) The adjustment is conducted in three levels of color

temperature; COOL, MEDIUM, and WARM.

[ Color temperature: Cool, Medium, Warm

(1) When R Gain is fixed at 192,

Control G Gain and B Gain by reducing them from 192.

(2) When B Gain is fixed at 192,

Control R Gain and G Gain by reducing them from 192.

(3) When G Gain is fixed to 192,

Control R Gain and B Gain by reducing them from 192.

Fix one of three Gains (R Gain, G Gain, and B Gain) at 192

and control the other two by reducing values from 192 to

prevent it from increasing.

(When RGB Gains are all 192, the module is in full dynamic

range.)

R Gain

G Gain

B Gain

R Cut

G Cut

B Cut

jg

jh

ji

Cool

ja

jb

jc

Mid

RS-232C COMMAND

[CMD ID DATA]

CENTER

(DEFAULT)(Decimal)

jd

je

jf

00

00

00

192

192

192

Warm

Min

Max

(Deci

mal)

64

64

64

Cool

64

64

64

Mid

64

64

64

Warm

9. USB S/W Download (Option)

9-1. Overview

USB Download enables quick response to S/W upgrading

and helps to configure the panel to the latest updates.

9-2. How to Download

(1) Before starting USB download, ensure that the power is

turned off and the display is turned on.

(2) Once the USB memory stick containing the upgraded file

is connected to the USB port on the main board, the

following picture appears on the screen.

(3) Check the current version at [Current TV Software Version

Information] and the target version at [New Found TV

Software Version Information]. Press Enter on the remote

controller to confirm the upgrade.

(4) The following picture shows the downloading in progress.

Once the download is completed, the power is

automatically turned on and off. (Otherwise, please turn

the power on and off)

(5) Once the download is completed, remove the USB

memory stick from the USB port. Press IN-START on the

remote controller to check the upgraded S/W version at

the top of the screen while the display is turned on.

<S/W Upgrade Screen>

<Downloading in progress Screen>

Do not plug off.

Press EXIT to cancel the upgrade.

The software upgrade is now in progress.

Until the whole process if completed, please.

- Do not remove the memory card from the slot.

- Do not plug off.

Reading the file---Done

Upgrading---Done

The TV will restart automatically in 0 seconds.

Page 17

- 17 -

TROUBLESHOOTING & BLOCK DIAGRAM

- Prouct Brief spec

RGB In (15 Pin)

Others

1 RF(Air /Cable)RF

O(PSIP)Program Guide Type

YesXD Engine

Yes(2D)Enhanced Noise Reduction

YesAdaptive Picture Mode

YesSRS Trusurround TX

YesBBE

YesAuto Navigation (Link)

NoRGB DTV

DOS70,VGA60,S

VGA60,

XGA60,WXGA60,

SXGA60

¥Audio Output

10W*2

¥Freeze No

RemarkBroadcomFeature

1 RF

Use Brief Info

USE scalier On/Off OSD Menu

Phase, SizeAdjust

Page 18

- Block diagram for CI DTV

- 18 -

12

EEP

Audio

ROM

X-tal

54MHz

256Mbit

SDRAM

256Mbit

SDRAM

RS-232C

64-Bit I/F

USB for upgrade S/W

BCM3560

VSB/QAM/NTSC/SIF

LVDS

Trans

Digital Output.

VDEC_CVBS/S_Y

SPDIF Out

SPDIF_OUT

I2S Audio Input

Audio

PWM L/R

I2S Output

DVI Input

16MB

Flash Memory

LR

MNT_Out

(MTV416)

(MTV416)

Sub Micom

Sub Micom

IIC

AUDIO DAC

IIS

HDMI/DVI

Tuner

CableANT.

SIF for NTSC

ATSC/NT

SC Tuner

Reset IC

S

B

V

C

CXA2069(AV S/W)

SIF for NTSC

V, LR

Rear AV

IF P/N for DTV

IN5

IN1

YC, LR

Rear S

IN1

V,LR

Side AV

Y,C

CVBS

OUT1

IN4

YC, LR

Side S

IN4

I2S

Audio R/L

IN4

IN3

OUT3

LR

LR

LR

MNT_V_Out

RGB(Phone)

Comp_1

Comp_2

SPDIF

Data [24]

Hsync/Vsync/DE/Clk

AUDIO ADC

HDMI & Component

HDCP

RGB-PC

MST3361

H/V Sync

2X1

S/W

R/G/B

2X1

S/W

YCbCr

YCbCr

Comp_1

Comp_2

TMDS

TMDS

DDS

DDS

Page 19

- 19 -

- Powr flow diagram

5V_PANEL

CMO, AUO

CMO, AUO

MP1593

MP1593

MST3361

MST3361

BCM3560

M62320FP

M62320FP

LM75CIMX

LM75CIMX

MM1732

MM1732

+2.5V_MST

SC1566-2.5

SC1566-2.5

BCM3560

A1.2V_BCM, D1.2V_BCM

DDC

DDC

SI4925DY

SI4925DY

FAN4

FAN4

KIA78R09

KIA78R09

FAN1,2,3

FAN1,2,3

MC3307

MC3307

+5.0V

CS5331A

CS5331A

CS4344

CS4344

AT24C02N

AT24C02N

AT24C512W

AT24C512W

74F08D

74F08D

TPS2042

TPS2042

FMS6400

FMS6400

FMS6407

FMS6407

+5V_TU

D3.3V_BCM

FSA1156

FSA1156

TUNER

TUNER

BCM3560

BCM3560

3.3VST_MICOM

BCM3560

BCM3560

3.3V_MST

MST3361

MST3361

A2.6V_BCM

SC1566-2.5

SC1566-2.5

74LVC14A

74LVC14A

HYDU561622

HYDU561622

THC63LVD

THC63LVD

MTV416GMF

MTV416GMF

BCM3560

BCM3560

D2.6V_BCM

S29GL128M

S29GL128M

P_+19V

P_+19V

TPA3100

TPA3100

+12.0V

+12.0V

KIA78R09

KIA78R09

PQ05DZ1U

PQ05DZ1U

CXA2069

CXA2069

+9.0V

+9.0V

+6.0V

+6.0V

AZ1117H-3.3

AZ1117H-3.3

ST_5V

ST_5V

BA033FP

BA033FP

A3.3V_BCM

A3.3V_BCM

BCM3560

BCM3560

BCM3560

SC1566-2.5

SC1566-2.5

+3.3V

+3.3V

BCM3560

Page 20

- 20 -

- 12C Control block diagram

0x90

0xA6

I2C Address

0xC2

0x74

0x9C

0x1C

0x50

M62320

AV S/W(CXA2069)

5.0V

4.7K J

Main EEPROM

5.0V

ATSC/NTSC Tuner

I2C1_3.3

V

4.7K J

3.3V

2.7K J

MST3361

PDP Module

Sub-Micom

3.3V

2.7K J

I2C0_5V

I2C_Channel 0

BCM3560

I2C1_5V

I2C_Channel 1

I2C2_3.3

V

I2C_Channel 2

I2C3_3.3

V

I2C_Channel 3

Page 21

- 21 -

- Video signal path for Composite/S-Video/IF

BCM3550

IF_P

IF_N

LPF for

IF_N from TUNER for DTV

IF_P from TUNER for DTV

SD_CVBS

SD_CVBS

M_CVBS

CVBS

SD_Y

Y

Y/CVBS

FMS6400

M_CVBS/Y

SD_C

C

C

C

TUNER

ANT/ Cable

CVBS from TUNER

TV IN

CXA2069

IN1

IN1

V, LR

Rear AV

V,LR

YC, LR

Rear S

Side AV

OUT1/Y

IN4

IN4

YC, LR

Side S

OUT1/C

LR

Comp_1

IN4

IN3

LR

LR

RGB(Phone)

Comp_2

OUT3

MNT_V_Out

Page 22

- 22 -

- Video signal path for Composite

GPIO for Component 2

6(Out3) Y/G to LPF

5(Out2) Pb/B to LPF

3(Out1) Pr/R to LPF

IC1001

BCM3550

HD-DVI

GPIO

GPIO

H,V Sync/Clock

GPIO

8(3A)

L

11(2A)

16(1A)

IC5002

MM1731

RGB_G 9(3B)

H

RGB_B 14(2B)

RGB_R 1(1B)

2 12 7

SW1 SW2 SW3

Data [24]

DATA_OUT

H/V/DE/CLK

/DE/Clock

H sync/V sync

GPIO for sync selection

LPF_CTRL1

GPIO for Component 1

LPF_CTRL0

GPIO for Component 2

IC704

MST3361

44(GIN+)

43(SOGIN)

41(BIN+)

46(RIN+)

RGB_HS

RGB_VS

6(Out3) Comp_Y

5(Out2) Comp_Pb

3(Out1) Comp_Pr

RGB_HS

RGB_VS

IC5001

L

MM1732

Comp1_Y 8(3A)

Comp1_Pb 11(2A)

Comp1_Pr 16(1A)

Comp2_Y 9(3B)

H

Comp2_Pb 14(2B)

Comp2_Pr 1(1B)

2 12 7

SW1 SW2 SW3

RGB_B

RGB_G

GPIO for Component 1

RGB_R

16 Comp_Y

15 Comp_Pb

14 Comp_Pr

7404

V Sync

H Sync

IC4009

FMS6407

Y/G 3(YIN)

Pb/B 5(PBIN)

Pr/R 7(PBIN)

RGB_HS

1(EXT_SYNC)

GPIO for sync selection

18(SYNC_IN)

LPF_CTRL0

LPF_CTRL1

Page 23

- 23 -

- Video signal path for HDMI

IC1001

BCM3550

IC704

MST3361

DDC1

INPUT

HD-DVI

Data [0: 23]

H sync/V sync

DATA_OUT

TMDS1

INPUT

H,V Sync/Clock

/DE/Clock

/Clock

H,V Sync/DE

GPIO for Interrupt

GPIO

INT

GPIO for Hot plug detection 1

DDC2

GPIO

GPIO for Power detection 1

INPUT

GPIO

GPIO

GPIO for Power detection 2

GPIO for Hot plug detection 2

TMDS2

INPUT

GPIO

NDA

NCL

DDC SDA1

DDC SCL1

HDMI 1

TMDS1 RX2+/-

TMDS1 RX0+/-

TMDS1 RX3+/-

TMDS1 RX1+/-

DDC SDA1

EEPROM

DDC SCL1

DDC SDA2

DDC SCL2

HDCP SDA

EEPROM

HDCP SCL

For HDCP

For EDID

TMDS2 RX2+/-

TMDS2 RX0+/-

TMDS2 RX1+/-

GPIO for Power detection 1

GPIO for Hot plug detection 1

EEPROM

For EDID

TMDS2 RX3+/-

GPIO for Hot plug detection 2

DDC SDA2

DDC SCL2

GPIO for Power detection 2

HDMI 2

Page 24

- 24 -

- Audio signal path for all

BCM3550

IF_P

IF_N

SIF from TUNER

IF_N from TUNER for DTV

IF_P from TUNER for DTV

SIF

I2S_SCK_IN

I2S_SCK_IN

I2S_LRCH_IN

AUDIO ADC

Audio R

OUT1/R

CXA2069

I2S_LRCK_IN

I2S_LRCH_IN

I2S_LRCK_IN

(CS5331)

Audio L

OUT1/L

SPDIF_IN_P

SPDIF from MST3361

I2S_SCK_OUT

I2S_SCK_OUT

I2S_LRCK_OUT

I2S_LRCH_OUT

I2S_LRCK_OUT

I2S_LRCH_OUT

(CS4344)

AUDIO DAC

MC3307

(OP-AMP)

AUD_LEFT_P

SPDIF_OUT_P

SPK_L_P

SPDIF Out

AUD_LEFT_N

SPK_L_N

Audio

AUD_RIGHT_P

SPK_R_P

AMP

AUD_RIGHT_N

SPK_R_N

(TPA3100)

TUNER

ANT/ Cable

IN1

V, LR

Rear AV

IN1

V,LR

YC, LR

Rear S

Side AV

IN4

YC, LR

Side S

IN4

IN4

LR

LR

Comp_1

Comp_2

IN3

RGB(Phone) LR

_L

_R

MNT_Out

MNT_Out

Analog L_OUT

Analog R_OUT

Page 25

- 25 -

- Audio Link system

P7007

P7008

5(GND)

P7004

10k

HDMI_POWER_1

2.7k

(R5128)

0(R3072)

AD24

AC4

22(R3126)

0(R3075)

5V_HIGH

BCM3550

5V_HIGH

+5V

HDMI_POWER_2

22(R3052)

5V_HIGH

AC22

AE1

22(R3125)

5V_HIGH

/RGB-PC

¥RGB-PC ‰d, H/W †˛ B\L.

1k

0V_HIGH

Y23

¥Plug-IN (LOW), Plug-OUT (HIGH)

+9V

6(S2-1)

100k

(R5027)

CXA2069

9V_HIGH

+9V

13(S2-2)

100k

(R5069)

9V_HIGH

+5V

4.7k(R5097)

J5005

4.7k

+5V

J5004

COMP2_SW

J5007

AV1_SW

COMP1_SW

P5001

0(R5088) 100(R5079)

AV2_SW

Page 26

- 26 -

- Audio Input level for RF/AV

PALNTSC and PALNTSC and PALSystem

SCART-CVBSAVRFInput signal

700mV700mVInput

700mV700mV

* Measurement data for RF/AV amplitude at the point of BCM3550 input pin

IC spec

Measurement

data

waveform

Measurement

Page 27

- 27 -

- Video Input level for S-Video/Component

ComponentS-Video

500mV~1V700mV

480i@60Hz,576i@50Hz

NTSC and PAL

800mV700mV

Input

* Measurement data for S-video/Component input amplitude at the point of

BCM3550 input pin

System

Input signal

IC spec

Measurement

data

waveform

Measurement

Page 28

- 28 -

- Main feature of BCM3550

Page 29

- 29 -

- Main feature of BCM3550

Page 30

- 30 -

- Whole chip internal block

Page 31

- 31 -

- Brief diagram for our system

VEC

CRC

CRC

Lbox

Lbox

Detect

Detect

Capture 0

Capture 0

Capture 1

Capture 1

Capture 2

Capture 2

2D HD Scaler

2D HD Scaler

2D HD Scaler

PEP

TNT/

PEP

TNT/

Video

Netw

2D HD Scaler

Compositor

VBP

VBP

ork

Swith

Back

DNR

DNR

2D SD Scaler

2D SD Scaler

NULL

NULL

MAD

MAD

Feed Back

Feed Back

NULL

NULL

UpScaler

UpScaler

Graphic

Graphic

MPEG Feeder

MPEG Feeder

Video

ITU 656

ITU 656

Video Feeder

Video Feeder

Video Feeder

Video Feeder

Video Feeder

Video Feeder

Digital

Input

Network Swith

HD-DVI

HD-DVI

Front

HDMI-RX

HDMI-RX

VDEC 0

VDEC 0

VDEC 1

VDEC 1

Feed Back

Feed Back

Page 32

- 32 -

- ADC/IF Demodulator

Input Band

Input Band

Input Band

Input Band

Video Output

Video Output

BCM3560 DATA

BCM3560 DATA

Transport Module

Transport Module

Input Band

Input Band

Audio Output

Audio Output

MPEG-2 Transport

MPEG-2 Transport

Band

Input

Band

Input

MUX

MUX

Demux w/DVB,DES

Demux w/DVB,DES

HSX1 Serial

HSX1 Serial

Memory Controller

Memory Controller

Input Band

Input Band

Inband

Inband

FEC

FEC

ATSC

ATSC

Receiver

Receiver

Advanced

ATSC VSB

Advanced

ATSC VSB

12Bit A/D

12Bit A/D

Inband AFE

Inband AFE

AGC Control

Output

Output

Interface

Interface

ITU-T J.83

ITU-T J.83

QAM VSB

QAM VSB

Annex

Annex

A/B/C FEC

A/B/C FEC

Receiver

Receiver

Advanced

Advanced

NTSC IF

NTSC IF

Demodulator

Demodulator

OOB

OOB

Output

Output

DVS-167 FEC

DVS-167 FEC

OOB QPSK

OOB QPSK

6Bit A/D

6Bit A/D

OOB AFE

OOB AFE

Interface

Interface

DVS-178 FEC

DVS-178 FEC

Receiver

Receiver

AGC Control

Page 33

- 33 -

- Before Video network

Lbox

Lbox

Detect

Detect

BVB

BVB

Interface

Interface

De-Inter

De-Inter

Buffer

Frame

Buffer

Frame

MPEG Feeder

Horizon

Horizon

Pan Scan

Pan Scan

Croma

Croma

Conversion

Conversion

SCB

BUS

SCB

BUS

TAB

TAB

2D - Scaler

2D - Scaler

BVB

BVB

Interface

Interface

De-Inter

De-Inter

Buffer

Frame

Buffer

Frame

Video Feeder

Horizon

Horizon

Pan Scan

Pan Scan

Croma

Croma

Conversion

Conversion

SCB

BUS

SCB

BUS

2D - Scaler

2D - Scaler

DVI-Primary

BVB

BVB

Input

Input

Timing

RGB

RGB

???

Interface

Timing

Converter

???

Interface

Adjust

Adjust

Converter

MAD-IT

MAD-IT

Video

Netwo

rk

Input

DVI-Secondary

HDMI Block

HDMI

Swith

BVB

BVB

Input

Timing

Timing

RGB

RGB

???

???

HDCP

HDCP

HDMI

Receive

Receive

Interface

Interface

Converter

Converter

Decrypt

Decrypt

Front

Adjust

Adjust

Decode

Decode

BVB

BVB

Interface

Interface

End

Back

End

Back

Demo

Demo

Chroma

Chroma

Y/C

Y/C

VDEC Block

Separation

Separation

End

End

Front

Front

NULL

NULL

BVB

BVB

Interface

Interface

Color

Color

Convertor

Convertor

Coef Table

Coef Table

Gamma

Gamma

Correction

Correction

Scaler

Scaler

Horizon

Horizon

Pre-

Pre-

Alpha

Multipl

Alpha

Multipl

Memory Interface (SCB)

Memory Interface (SCB)

Graphic Feeder Block

Feed Back

Feed Back

Key

Key

Color

Color

Color

Color

Expansion

Expansion

Pixel

Pixel

Cropping

Cropping

CLUT

CLUT

DVI

DVI

Pins

Pins

HDMI

HDMI

HDMI

HDMI

Pins

Pins

TMDS

TMDS

Pins

Pins

AFE

AFE

Pins

Pins

ANALOG

ANALOG

SCB

SCB

DATA

DATA

Buffer

Buffer

Page 34

- 34 -

- Scaler and MAD

CRC

CRC

Capture 0

Capture 0

Capture 1

Capture 1

Capture 2

Capture 2

Video

Netwo

Compositor

Compositor

PEP

PEP

rk

Swith

Back

VBP

VBP

NULL

NULL

Feed Back

Feed Back

Lbox

Lbox

Detect

Detect

TAB

TAB

Scaler

Scaler

Vertical

Vertical

MUX

MUX

TAB 2D-Scaler

MUX

MUX

BVB

BVB

Receiver

Hoarizonal

Receiver

Hoarizonal

MUX

MUX

MUX

MUX

SCB

SCB

Vertical

2D-Scaler

Vertical

MUX

MUX

Scaler

BVB

BVB

Receiver

Hoarizonal

Receiver

Hoarizonal

MUX

MUX

Scaler

Scaler

Scaler

MAD

Scaler

Scaler

Output

Output

Pixel

Pixel

Pixel

Pixel

Distribution

Distribution

Processing

Processing

Block

Block

BVB

BVB

BVB

BVB

Block

Block

Receiver

Receiver

Interface

Interface

Field Control Block

Field Control Block

NULL

NULL

Video

Netwo

Graphic Feeder Block

rk

Swith

Front

Page 35

- 35 -

- PEP and Compositor

BVB

BVB

Interface

Interface

CRC

CRC

Fore

Ground

Fore

Ground

Fore

Ground

Blend2

Blend2

Blend1

Blend1

Back

Ground

Back

Ground

Blend0

Blend0

Back

Ground

PEP COMPOSITOR

MUX

MUX

Surfaces

Surfaces

Screen

Screen

Compositer

Compositer

BVB

BVB

Interface

Interface

SCB

BUS

SCB

BUS

LAB

DMA

DMA

Burst

FIFO

Burst

LAB

422 TO 444

Conversion

422 TO 444

FIFO

Conversion

Cropping

Cropping

Luma

Luma

Keying

Keying

Video Intra-Surface (With PEP)

Capture Block

Packing&

Packing&

RDMA Trig

RDMA Trig

BVB

BVB

Receiver

Receiver

CAB

CAB

BVB

BVB

Adjust

(Matrix)

Adjust

(Matrix)

Color Bright

Color Bright

CLIP

Color

CLIP

Color

Reciever

Reciever

BVB

BVB

Interface

Interface

Cropping

Cropping

Luma

Luma

Keying

Keying

BVB

BVB

Interface

Interface

Y/Cb/Cr Register

Y/Cb/Cr Register

Cropping

Cropping

BackGround Color

Graphics Intra-Surface

Adjust

(Matrix)

Adjust

(Matrix)

Color Bright

Color Bright

Video Intra-Surface (Without PEP)

422 TO 444

Conversion

422 TO 444

Conversion

BVB

BVB

Reciever

Reciever

BVB

BVB

VBP

VBP

Reciever

Reciever

(Video Bypass)

(Video Bypass)

NULL

NULL

Feed Back

Feed Back

Video

Netwo

Video

Netwo

Graphic Feeder Block

rk

Swith

Front

rk

Swith

Front

Page 36

- 36 -

- Back end(Digital and Analog)

656

DVI

DAC3

DAC2

DAC1

DAC0

MISC_ITU656_IN_MUX.SELECT

Digital

Digital

CSC

CSC

(Matrix)

Mux

Mux

(Matrix)

656

656

Video

Video

Formatter

Formatter

Digital

Timing

Digital

Timing

DVI

DVI

Interface

Interface

Video

Digital

Video

Digital

Formatter

Formatter

CSC

CSC

(Matrix)

(Matrix)

Mux

Mux

MISC_DVI_IN_MUX.SELECT

Digital

Timing

Digital

Generator

Generator

Timing

Generator

Generator

Cross

Cross

CSC

CSC

(Matrix)

Bar

Bar

Modulator

Modulator

SUB-Carrier

SUB-Carrier

Video

Video

Formatter

Formatter

(Matrix)

Input

Input

Timing

Timing

VIDEO_ENC_BYPASS_CONTROL.SELECT

Mux

Mux

Video

Video

Compositor

Compositor

Digital

Timing

Digital

Timing

RAM

RAM

VIDEO_ENC_PRIM_CONTROL.SELECT

Mux

Mux

VBP

VBP

(Video Bypass)

(Video Bypass)

Page 37

- 37 -

- Explanation

VDEC Detail Block

BVB

BVB

Interface

Interface

End

Back

End

Back

Demo

Demo

Chroma

Chroma

Y/C

Y/C

Separation

Separation

End

End

Front

Front

AFE

AFE

Mpeg Feeder And Video Feeder (MFD and VFD)

-Mpeg Feeder is a data path of VSB or QAM decoded signal. These signals go to the Minititan of BCM3550.

-In the minititan block do processing the MPEG and video.

Explanation

VDEC ( Video Display Decoder)

color decoding, auto gain control, etc.

-This block has several detailed block. It can handle the input composite signal for example, Y/C separation,

Digital Input

are decoded. So this path is very important block in our system.

-Digital input can handle digital video signal. In our system th rough this path, component,RGB PC, HDMI/DVI signals

Page 38

- 38 -

- TV/CATV doesn't display

& IIC lines.

You should check power line

NO

IIC lines?

YES

Are they all normal?

Could you measure voltage of TU4001 &

NO

YES

Can you see the normal signal?

Check TU4001 Pin9(Video output)

You should replace TUNER.

should decide to replace AV switch or not.

After checking the Power of AV switch you

NO

switch(IC5003).

Check the input(Pin63) of AV

Can you see the normal waveform?

YES

should decide to replace AV switch or not.

After checking the Power of AV switch you

NO

switch(IC5003).

Check the output(Pin56) of AV

Can you see the normal waveform?

decide to replace LPF or not.

decide to replace LPF or not.

chip(BCM3550) have some troubles.

After checking the Power of LPF you should

NO

YES

After checking the Power of LPF you should

NO

YES

This board has big problem because Main

YEX

YES

BCM3550(IC4006).

After checking thoroughly all path once again,

You should decide to replace BCM3550 or not.

more easy to check.

Check the input(PinH26) of

Can you see the normal waveform?

Check the input(Pin1) of LPF(IC4006).

Can you see the normal waveform?

Check the output(Pin8) of LPF(IC4006).

Can you see the normal waveform?

Measure waveform at C1010 because its

Page 39

- 39 -

- Video doesn't display

Jack.

J5007 may have problem. Replace this

NO

YES

NO

Check J5007 Pin3C

Can you see the normal waveform?

Check the input(Pin1 or Pin8) of AV

switch(IC5003). Pin1 is for video1,Pin8 is

After checking the Power of AV switch you

should decide to replace AV switch or not.

for video 2.

Can you see the normal waveform?

After checking the Power of AV switch you

NO

YES

Check the output(Pin56) of AV

should decide to replace AV switch or not.

YES

switch(IC5003).

Can you see the normal waveform?

decide to replace LPF or not.

After checking the Power of LPF you should

NO

YES

Can you see the normal waveform?

Check the input(Pin1) of LPF(IC4006).

decide to replace LPF or not.

After checking the Power of LPF you should

NO

Can you see the normal waveform?

Check the output(Pin8) of LPF(IC4006).

chip(BCM3550) have some troubles.

This board has big problem because Main

After checking thoroughly all path once again,

You should decide to replace BCM3550 or not.

YEX

YES

BCM3550(IC4006).

more easy to check.

Check the input(PinH26) of

Can you see the normal waveform?

Measure waveform at C1010 because its

Page 40

- 40 -

- Component doesn't display

Jack.

J5004,J5005 may have problem. Replace this

After checking the input TR of component, you

not.

should decide to replace component switch or

After checking the Power of component switch

you should decide to replace component switch

or not.

should decide to replace MST3361 or not.

After checking the Power of MST3361 you

should decide to replace MST3361 or not.

After checking the Power of MST3361 you

chip(BCM3550) have some troubles.

This board has big problem because Main

After checking thoroughly all path once again,

You should decide to replace BCM3550 or not.

NO

Check J5004,J5005.

Can you see the normal waveform?

NO

YES

NO

YES

switch(IC5001,IC5002).

Check the input of Component

Can you see the normal waveform?

NO

YES

switch(IC5001,IC5002).

Check the output of Component

Can you see the normal waveform?

Check the input of MST3361(IC7004

YES

Pin41,44,46).

Can you see the normal waveform?

NO

YEX

YES

Check the input and output of

Can you see the normal waveform?

Check the output of MST3361(IC7004 ).

check

The H,V sync and clock.

Can you see the normal waveform?

BCM3550(IC4006). Especially you should

Page 41

- 41 -

- RGB_PC doesn't display

not.

After checking the input TR of RGBHV, you

P7004 may have problem. Replace this Jack.

should decide to replace these components or

After checking the Power of RGB switch you

not.

should decide to replace component switch or

should decide to replace MST3361 or not.

After checking the Power of MST3361 you

should decide to replace MST3361 or not.

After checking the Power of MST3361 you

chip(BCM3550) have some troubles.

This board has big problem because Main

After checking thoroughly all path once again,

You should decide to replace BCM3550 or not.

NO

Check input connect P7004.

Can you see the normal waveform?

NO

YES

NO

YES

switch(IC5002).

Check the input of Component

Can you see the normal waveform?

switch(IC5002).

Check the output of Component

Can you see the normal waveform?

YES

NO

Pin41,44,46).

Can you see the normal waveform?

Check the input of MST3361(IC7004

NO

YES

Can you see the normal waveform?

Check the output of MST3361(IC7004 ).

YEX

YES

check

The H,V sync and clock.

Check the input and output of

Can you see the normal waveform?

BCM3550(IC4006). Especially you should

Page 42

- 42 -

- HDMI doesn't display

not.

should decide to replace this or not.

After checking the Power of this chip, you

P7007 may have problem. Replace this Jack.

NO

NO

YES

Pin5,6)

Check input connect P7007.

Can you see the normal waveform?

Check DDC communication lines(IC7013

should decide to replace this or not.

After checking the Power of this chip, you

should decide to replace MST3361 or not.

MST3361, you should decide to replace MST3361 or

After checking the trace of TMDS lines and power of

NO

YES

NO

YES

After checking the Power of MST3361 you

NO

YES

YES

Pin5,6)

This signal is TMDS.

chip(BCM3550) have some troubles.

This board has big problem because Main

After checking thoroughly all path once again,

You should decide to replace BCM3550 or not.

YEX

check

The H,V sync and clock.

Check the input and output of

Can you see the normal waveform?

Check HDCP communication lines(IC7005

Check the input of MST3361(IC7004)

Can you see the normal waveform?

Check the output of MST3361(IC7004 ).

BCM3550(IC4006). Especially you should

Can you see the normal waveform?

Page 43

- 43 -

300

200

310

500

510

120

820

801

802

803

800

804

600

610

530

520

400

810

840

900

807

830

805

806

EXPLODED VIEW

Page 44

- 44 -

EXPLODED VIEW PARTS LIST

No.

PART NO.

DESCRIPTION

120 EAB33775101

"Speaker,Full Range", EN1562C-6712 ND 10W 8OHM 82DB 100HZ 193.5 X 42 X 39.9 LUG KOREA TOPTONE

200 EAJ33852601

"LCD,Module-TFT", LC420WX6-SLA1 WXGA 42INCH 1366X768 450CD COLOR 72% 16/9 1000:1(Basic) DCR(5000:1) Inverterless Narrow A-TW Pol. 10000K LG PHILIPS LCD

300 ABJ32403509 Cabinet Assembly, "42LC7D-UB PACIFIC2 BCM FOR SKD 42"" CABINET ASSY"

310 ABA32548801 Bracket Assembly, GRILLE 42LB7 - SPEAKER GRILLE ASSY

400 ACQ32247911 Cover Assembly, "42LC7D-UB BCM 42"" BACK COVER ASSY_BCM"

500 EBR35527601 PCB Assembly, "SUB T.T LA63E 42LC2D-UA V668, BCM PRE AMP TOTAL ASSY"

510 EBR35527701 PCB Assembly, "SUB T.T LA73E 42LC7D-UB V668,BCM CONTROL TOTAL ASSY"

520 AGF33004001 Package Assembly, "SUB 42LC7D-UB V668,ACINLET,PACKING ASSY"

530 EBR35527001 PCB Assembly, "SUB T.T LA73E 42LC7D-UB V668, BCM SIDE A/V TOTAL ASSY"

600 EAY34797001

Power Supply Assembly, "Tornado 42inch 42INCH Tornado 42inch LCD LGIT LCD Tornado 42inch (Power+Inverter) ¥Î«¸ PSU LG INNOTEK.,LTD."

610 EBT35526501 Chassis Assembly, "MAIN LA63E 42LC7D-UA,V668,MAIN TOTAL ASSY"

800 MGJ32902303

Plate, "PRESS EGI 1.2 FRAME SBHG-A 42LC7R METAL BAR TOP FOR LPL MODULE (C/SKD OF P/NO ""01"")"

801 MGJ32902406

Plate, PRESS EGI 1.6 FRAME SBHG-A 42LC7 METAL BAR BOTTOM ('c'∫Œ pem-nut 'NO') FOR LPL MODULE (C/SKD OF P/NO 05)

802 MGJ32902504 Plate, "PRESS EGI 1.2 FRAME SBHG-A 42LC7 METAL BAR RIGHT C/SKD OF P/NO ""02"""

803 MGJ32902705

Plate, "PRESS EGI 1.2 FRAME SBHG-A 42LC7 METAL BAR CENTER('c'∫Œ pem nut 'NO') V668 module C/SKD OF P/NO""04"""

804 MJH34248204

Supporter, "PRESS EGI 1.2 GUIDE EGI 42LC7 METAL BAR LEFT FOR V668 MODULE C/SKD OF P/NO""01"""

805 MGJ32902808

Plate, "PRESS EGI 1.2 FRAME SBHG-A 42LC7D_UB (BCM) METAL BAR SIDE TOP C/SKD OF P/NO ""04"""

806 MGJ32902907

Plate, "PRESS EGI 1.2 FRAME SBHG-A 42LC7D-UB(BCM) METAL BAR SIDE BOTTOM C/SKD OF P/NO ""04"""

807 MJH34000502

Supporter, "PRESS EGI 2 GUIDE EGI 42LC4 METAL STAND SUPPORTER C/SKD OF P/NO ""01"""

810 MGJ32918108 "Plate,Shield", "PRESS SPTE 0.5 SHIELD SPTE 37"" upper for pacific2 chassis ""02"" C/SKD"

820 MCK32929601 Cover, "MOLD ABS HF-380 42LC4 ABS, HF-380 CABLE MANAGEMENT"

830 EAM35501401

"Filter,AC Line", IF3-N06CEWL1 5.3mH 250VAC 6A 0.22uF 1000pF UL/CSA/VDE/K HOUSING/RING BK DONG IL TECHNOLOGY LTD.

840 MAZ34241801 Bracket MOLD ABS STAND 42LC5 - ABS GUIDE

900 AAN32937104 Base Assembly, STAND 42LC7D-UB LA73E STAND ASSY_NO PRINT_CSKD(HIGH GLOSSY)

Page 45

Page 46

Page 47

Feb., 2007

Printed in KoreaP/NO : MFL36768812

Loading...

Loading...