Page 1

LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : LA75A

MODEL : 42LC6DF

42LC6DF-UL

MODEL : 42LG20

42LG20-UM

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

Page 2

TABLE OF CONTENTS

Product Safety

Specification

Screw Torque

Test Procedure & Test Program

Guide for Trouble Shooting

Circuit Operation Theory

Exploded Diagram

Service Parts List

Page 3

Product Safety

Page 4

Page 5

Page 6

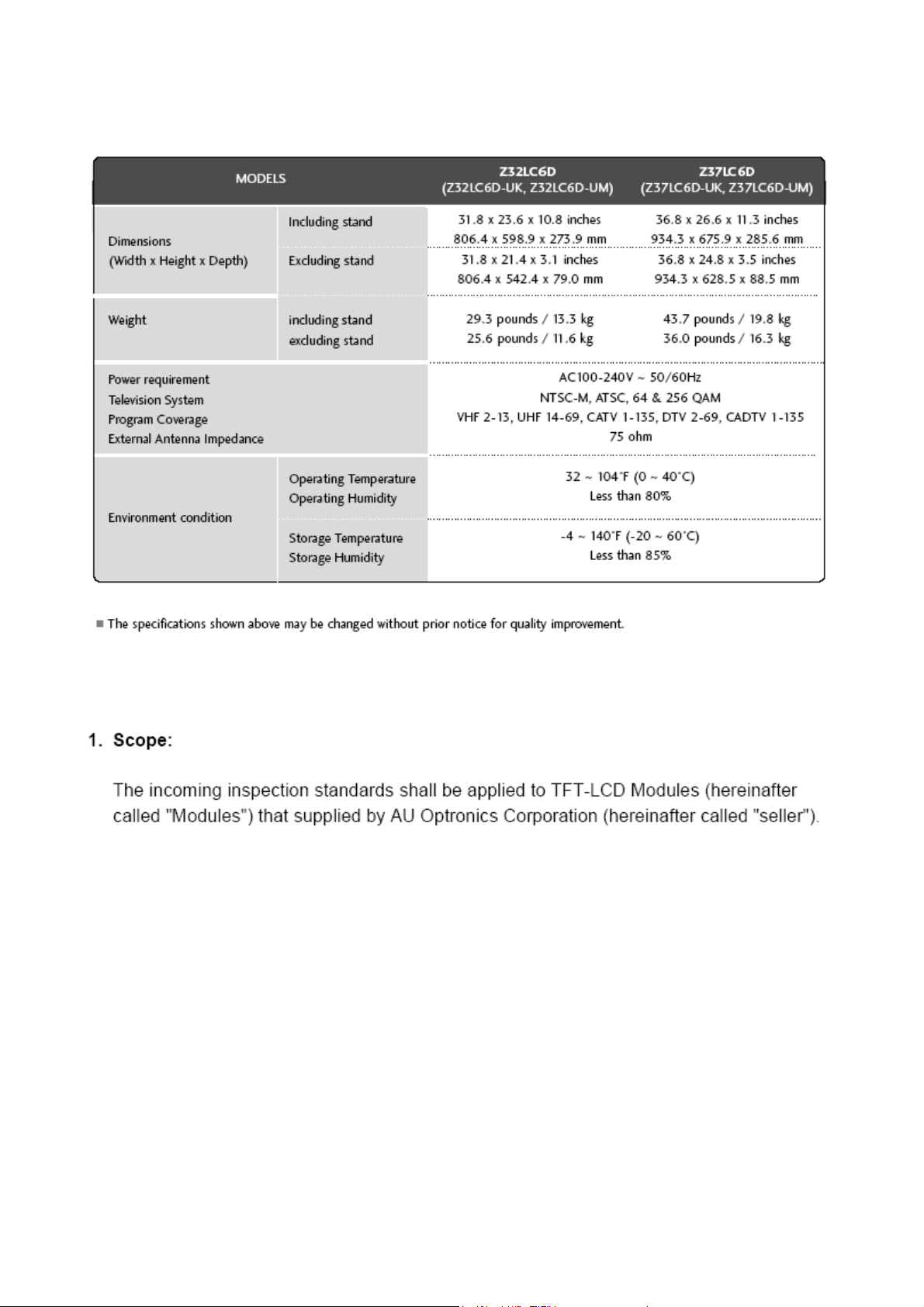

Specification

Penal Spec. for 32” model

Page 7

Page 8

Page 9

Page 10

Page 11

Penal Spec. for 37” model

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Z32LC6D

LG P/N :

FAB30009502

LG P/N :

FAB30012602

LG P/N :

FAB30016403

LG P/N :

FAB30012001

LG P/N :

FAB30018405

LG P/N :

FAB30123502

LG P/N :

FAB30013614

Page 18

LG P/N :

FAB30013210

LG P/N :

FAB30007701

LG P/N : FAB30013210

LG P/N : FAB30016415

Z37LC6D

LG P/N :

FAB30013614

LG P/N :

FAB30013210

LG P/N :FAB30012602

Page 19

LG P/N :

FAB30016415

LG P/N :

FAB30012001

LG P/N :

FAB30007507

LG P/N :

FAB30006308

LG P/N :

FAB30123502

LG P/N :

FAB30018405

Page 20

LG P/N :

FAB30009502

LG P/N :

FAB30016403

LG P/N :

FAB30013210

LG P/N :

FAB30007701

Page 21

ADJUSTMENT INSTRUCTION

1. Application Range

These instructions are applied to all of the LCD TV, LA75C

Chassis.

2. Notice

1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

2) Adjustment must be done in the correct order. But it is

flexible when its factory local problem occurs.

3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

2.4 The input voltage of the receiver must keep 100~220V,

50/60Hz.

2.5 Before adjustment, execute Heat-Run for 30 minutes.

O After Receive 100% Full white pattern (06CH) then

process Heat-run

(Or 6. White Pattern condition of Ez – Adjust)

O How to make set white pattern

A. Press Power ON button of Service Remocon

B. Press ADJ button of Service remocon to enter “Ez-

Adjust”. Select "6. WHITE PATTERN" and press

A

key. And 100% Full White pattern appear.

In this status you can maintain Heat-Run useless any

pattern generator.

Notice) If you maintain one picture over 20 minutes

(Especially sharp distinction black with white pattern

– 13Ch, or Cross hatch pattern – 09Ch) then it can

appear image stick near black level

3. MICOM Download(Option)

3-1. Required Test Equipment

(1) JIG-LEVER TYPE for adjusting: 1EA

(2) PC & MONITOR: 2EA

(3) BOARD for INTERFACE: IIC & ISP BOARD: 2EA

(4) 15P D-SUB CABLE: 2EA

(5) Using the 12/15 line of D-SUB 15P

12-SDA/15-SCL

3-2. JIG Connection

3-3. Establishment Program

(1) Establish LGE Monitor Tools v1.1

(2) The program work and it is opened program window as

seen below.

(3) Click the first icon shown in fig.9. The window seen in

fig.10 should appear.

connection

to PC

connection

to PC

Page 22

3-4. Set Method

(1) MCU Select: MTV412M128

(2) Option

R/W Option: Auto Write(Verity)

Jig Option: Myson

Transmit Speed: Medium

(3) Check: Just do it with blank micom.

(4) PORT

Chose Parallel Port (normal LPT1)

Attention: You must chose EPP when select Rom BIAS at

LPT

3-5. Download Method

(1) Click the Load File.

(2) Locate and select the correct file from your computer.

(*.hex).

(3) Click the Send.

(4) When you see (ISP COMPLETE) the download is

complete.

4. Using RS-232C

(1) Necessary items before Adjustment items

- Pattern Generator : (MSPG-925FA)

- Adjust 480i Comp1 (MSPG-925FA:model :209 , pattern :65)

- Adjust 1080p Comp1/RGB (MSPG-925FA : model : 225,

pattern :65)

(2) Adjustment sequence

- ad 00 00 : Enter the ADC Adjustment mode.

- kb 00 04 : Change the mode to Component1 (No actions)

- ad 00 10 : Adjust 480i Comp1(Change the mode and

adjustment action)

- kb 00 06 : Change to RGB-DTV mode(No action)

- ad 00 10 : Adjust 1080p Comp1/RGB(Change the mode and

adjustment action)

- ad 00 90 : End of the adjustment

(3) Adjustment protocol

Order Command Set response

1. Inter the Adjustment mode ad 00 00 d 00 OK00x

2. Change the Source kb 00 04 b 00 OK04x (Adjust 480i Comp1)

kb 00 06 b 00 OK06x (Adjust 1080p Comp1/RGB)

3. Start Adjustment ad 00 10

4. Return the Response OKx ( Success condition )

NGx ( Failed condition )

5. Read Adjustment data (main) (main)

ad 00 20 000000000000000000000000007c007b006dx

(sub) (Sub)

ad 00 21 000000070000000000000000007c00830077x

6. Confirm Adjustment ad 00 99 NG 03 00x (Failed condition)

NG 03 01x (Failed condition)

NG 03 02x (Failed condition)

OK 03 03x (Success condition)

7. End of Adjustment ad 00 90 d 00 OK90x

Page 23

5. ADC-Set adjustment

5-1. Synopsis

ADC-set is Gain and Black level setting at Analog to Digital

converter, and compensate the RGB deviation

5-2. Test Equipment

Service R/C, 801GF(802V, 802F, 802R) or MSPG925FA

Pattern Generator (It can output 480i/1080i horizontal 100%

color bar pattern signal, and its output level must setting

0.7V±0.1V p-p correctly)’

5-3. Adjustment

(1) ADC 480i Component1 adjustment

1) Set Component 480i mode and 100% Horizontal Color

Bar Pattern(HozTV31Bar), then set TV set to

Component1 mode and its screen to "NORMAL"

2) After get the signal, wait more a second and enter the

"Ez-Adjust" with press ADJ key of Service remocon.

After then select "2.ADC 480i Comp1" with navigator

button and press "Enter". It is automatically adjustment

3) You can see "ADC Component1 Success" message

after Adjustment success

Error Messages: When its adjustment is not correct,

"ADC Component1 480i Fail" message displayed. If

component is not connection "Component1 Not

Connected", its format is not 480i then "Not Valid

Format", its signal don’t out then "Check Signal Status"

message displayed. These messages will be displayed

just a second.

(2) ADC 1080p Component1 / RGB adjustment

- Check connection both of Component1 and RGB

- MSPG-925FA -> Model: 225, Pattern 65

1) Set Component 1080p mode and 100% Horizontal Color

Bar Pattern(HozTV31Bar), then set TV set to

Component1 mode and its screen to "NORMAL"

2) After get the signal, wait more a second and enter the

"Ez-Adjust" with press ADJ key of Service remocon.

After then select "4.ADC 1080p Comp1/RGB" with

navigator button and press "Enter". First, it is

automatically adjustment Component1.

3) If adjustment is correctly finished, "ADC Component1

Success" message will be displayed. But adjustment is

not correctly finished, "ADC Component1 1080p Fail"

message will be displayed.

4) After adjustment Component1 mode, move to RGB-DTV

mode automatically and RGB adjustment start. After

RGB Adjustment successfully finished, "ADC RGB

1080P Success" message will be displayed.

5) If Adjustment doesn’t success, check conditions all of

the adjustment condition and adjustment again. See

"Error Messages" sentence.

6) After adjustment finished, press "ADJ" key and exit from

Adjustment mode.

6. EDID

(The Extended Display Identification Data)

/

DDC

(Display Data Channel)

Download

6-1. Summary

It is established in VESA, for communication between PC and

Monitor without order from user for building user condition. It

helps to make easily use realize "Plug and Play" function.

6-2. Write HDMI EDID data

(1) Using instruments

1) Jig. (PC Serial to D-Sub connection) for PC, DDC

adjustment.

2) S/W for DDC recording (EDID data write and read)

3) D-sub jack

4) Additional HDMI cable connection Jig.

(2) Preparing and setting.

1) Set instruments and Jig. Like fig.4), then turn on PC and

Jig.

2) Operate DDC write S/W (EDID write & read)

3) It will operate in the DOS mode.

<Fig. 1> Adjustment Mode

<Fig. 2> Adjustment Pattern: 480i/1080P 60Hz HozTV30 Bar Pattern

<Fig. 3> Device configuration diagram for HDMI EDID Data input

LCD TV SET

(or Digital Board)

Page 24

6-3. EDID DATA for LA75C

(1) EDID data for LA75A Chassis

- HDMI1 EDID (DDC (Display Data Channel) Data

* 128byte

* 256byte

- HDMI2 EDID (DDC (Display Data Channel) Data

* 128byte

* 256byte

- Analog (RGB) EDID table - 128byte

* See Working Guide if you want more information about EDID

communication.

7. Adjustment of White Balance

- Purpose: to reduce the difference in color temperature

among modules

- Principal: A module is in full dynamic range when RGB Gain

on OSD is 192. To adjust the white balance without causing

full dynamic range and full data, fix one of RGB Gains at 192

and control the other two by reducing them from 192.

7-1. Required Equipment

(1) Color Analyzer : CA-110 or CA-210

(2) Automatic adjustor (with automatic adjustment necessity

and the RS-232C communication being possible)

7-2. Connection Diagram of Equipment

for Measuring

(Automatic Adjustment)

Use the internal pattern to adjust White Balance. The pattern

is automatically given when the automatic adjustment device

is connected or when a user presses ADJ on the remote

controller to start Ez Adjust and then selects 6.White-Balance.

*

When you adjust LCD color temperature, on color analyzer

(CA-210), you should use Channel 9 which is Matrix

compensated (White, Red, Green, Blue revised) by CS-1000

and adjust in accordance with White balance adjustment

coordinate which is specified on the next.

7-3. Adjustment of White Balance

(Automatic Adjustment)

(1) Turn on the POWER ON(

Â) of the remote controller to set

the adjustment and then start the automatic adjustment or

set the Baud Rate to 115200.

(2) Start the adjustment from “wb 00 00” and complete it at

“wb 00 ff”. (Adjust the offset if necessary)

- wb 00 00 the automatic adjustment of White Balance is

started.

- wb 00 10 adjusting gain (internal pattern appears) is

started.

- ja 00 ff adjusting data

- jb 00 c0

- ...

- wb 00 1f adjusting gain is completed.

- Adjust the offset (from wb 00 20 to wb 00 2f) if necessary.

- wb 00 ff the automatic adjustment of White Balance

(internal pattern disappears) is completed.

CA-100+

COLOR

ANALYZER

TYPE; CA-100+

Full W hite Patter n

RS-232C

Connection Diagram of Automatic Adjustment

Page 25

* RS-232C Command (Automatic Adjustment)

- LA75C Chassis Model All

7-4. White Balance Adjustment(Manual)

(1) Test Equipment: CA-210

(2) Manual adjustment sequence is like bellowed one.

1)Turn to "Ez-Adjust" mode with press ADJ button of

service remocon.

2) Select "9.Test Pattern" with CH+/- button and press

enter. Then set will go on Heat-run mode. Over 30

minutes set let on Heat-run mode.

3) Let CA-210 to zero calibration and must has gap more

10cm from center of LCD module when adjustment.

4) Press "ADJ" button of service remocon and select

"6.White-Balance" in "Ez-Adjust" then press "

G" button

of navigation key. (When press "

G" button then set will

go to full white mode)

5) Adjust at three mode (Cool, Medium, Warm)

- When R Gain is fixed at 192

:

Control G Gain and B Gain by reducing them from 192.

- When B Gain is fixed at 192,

:

Control R Gain and G Gain by reducing them from 192.

- When G Gain is fixed to 192,

: Control R Gain and B Gain by reducing them from 192.

Fix one of three Gains (R Gain, G Gain, and B Gain) at 192

and control the other two by reducing values from 192 to

prevent it from increasing.

(When RGB Gains are all 192, the module is in full dynamic

range.)

R Gain

G Gain

B Gain

R Cut

G Cut

B Cut

jg

jh

ji

Cool

ja

jb

jc

Mid

RS-232C COMMAND

[CMD ID DATA]

CENTER

(DEFAULT)(Decimal)

jd

je

jf

00

00

00

192

192

192

Warm

Min

Max

(Deci

mal)

64

64

64

Cool

64

64

64

Mid

64

64

64

Warm

Page 26

UL Vertical Force Stability Warning

Page 27

Guide for Trouble Shooting

Page 28

Page 29

Page 30

Circuit Operation Theory

Page 31

EXPLODED VIEW

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

EXPLODED VIEW

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

300

200

800

804

520

400

820

401

540

530

900

807

806

801

802

120

500

121

510

810

805

803

Page 32

Mar., 2008

Printed in KoreaP/NO : MFL39941411

Loading...

Loading...